Water-based UV touch oil and preparation method thereof

A water-based, tactile technology, applied in the field of tactile oil, can solve the problems of alcohol resistance, anti-adhesion, non-biodegradable, poor wear resistance, etc., and achieve the effects of low cost, enhanced curing degree, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

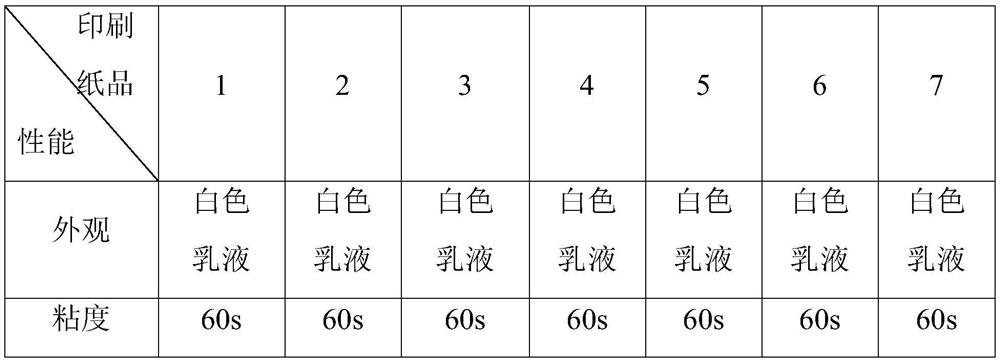

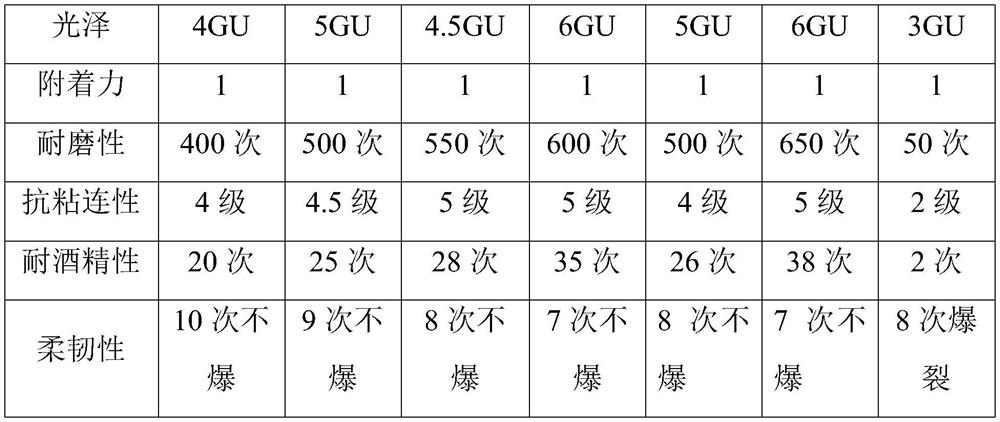

Examples

Embodiment 1

[0031] The present embodiment provides a kind of aqueous UV tactile oil, and its preparation method is as follows:

[0032] Raw materials (by mass percentage): 580g of self-dulling water-based polyurethane emulsion, 200g of water-based polyurethane diacrylate, (9) 100g of ethoxylated trimethylol triacrylate, 15g of photoinitiator (Irgacure2959), fluff powder hand feel agent (RHU -5070D) 60g, wetting agent (TEGO Twin4100) 15g, defoamer (DC-62) 5g, anti-scratch agent (DC-51) 5g, deionized water 20g.

[0033] The preparation steps of this water-based UV tactile oil are as follows:

[0034] Under normal temperature conditions, (9) ethoxylated trimethylol triacrylate and photoinitiator (Irgacure2959) were stirred, the stirring speed was 400r / min, and the dispersion time was 3h to obtain a UV semi-finished product.

[0035] Mix and stir the water-based self-dulling polyurethane and water-based polyurethane diacrylate, the stirring speed is 100r / min, and the dispersion time is 20 mi...

Embodiment 2

[0038] Raw materials (by mass percentage): 500g of water-based self-dulling polyurethane emulsion, 150g of water-based polyurethane triacrylate, (9) 130g of ethoxylated trimethylol triacrylate, 10g of photoinitiator (Irgacure2959), silky hand feeling agent (GL -1702) 40g, wetting agent (TEGO Twin4100) 10g, defoamer (DC-62) 3g, anti-scratch agent (DC-51) 7g, deionized water 10g, thickener 1g, film-forming agent 1g, water-based Wax emulsion 7g.

[0039] The preparation steps of this water-based UV tactile oil are as follows:

[0040] Under normal temperature conditions, (9) ethoxylated trimethylol triacrylate and photoinitiator (Irgacure2959) were stirred, the stirring speed was 600r / min, and the dispersion time was 2h to obtain a UV semi-finished product.

[0041] Mix and stir the water-based self-dulling polyurethane and water-based polyurethane triacrylate, the stirring speed is 200r / min, and the dispersion time is 10 minutes; then add the UV semi-finished product, and the d...

Embodiment 3

[0044] Raw materials (by mass percentage): 550g of water-based self-dulling polyurethane emulsion, 130g of water-based polyurethane triacrylate, (6) 110g of ethoxylated trimethylol triacrylate, 20g of photoinitiator (Irgacure2959), fluffy powder feel agent (RHU -5070D) 50g, wetting agent (TEGO Twin4100) 20g, defoamer (DC-62) 7g, anti-scratch agent (DC-51) 10g, deionized water 30g, thickener 5g, film-forming agent 3g, water-based Wax emulsion 5g.

[0045] The preparation steps of this water-based UV tactile oil are as follows:

[0046] Under normal temperature conditions, (6) ethoxylated trimethylol triacrylate and photoinitiator (Irgacure2959) were stirred, the stirring speed was 500r / min, and the dispersion time was 2.5h to obtain a UV semi-finished product.

[0047] Mix and stir the water-based self-dulling polyurethane and water-based polyurethane triacrylate, the stirring speed is 150r / min, and the dispersion time is 18 minutes; then add the UV semi-finished product, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com