Patents

Literature

98 results about "Micro roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

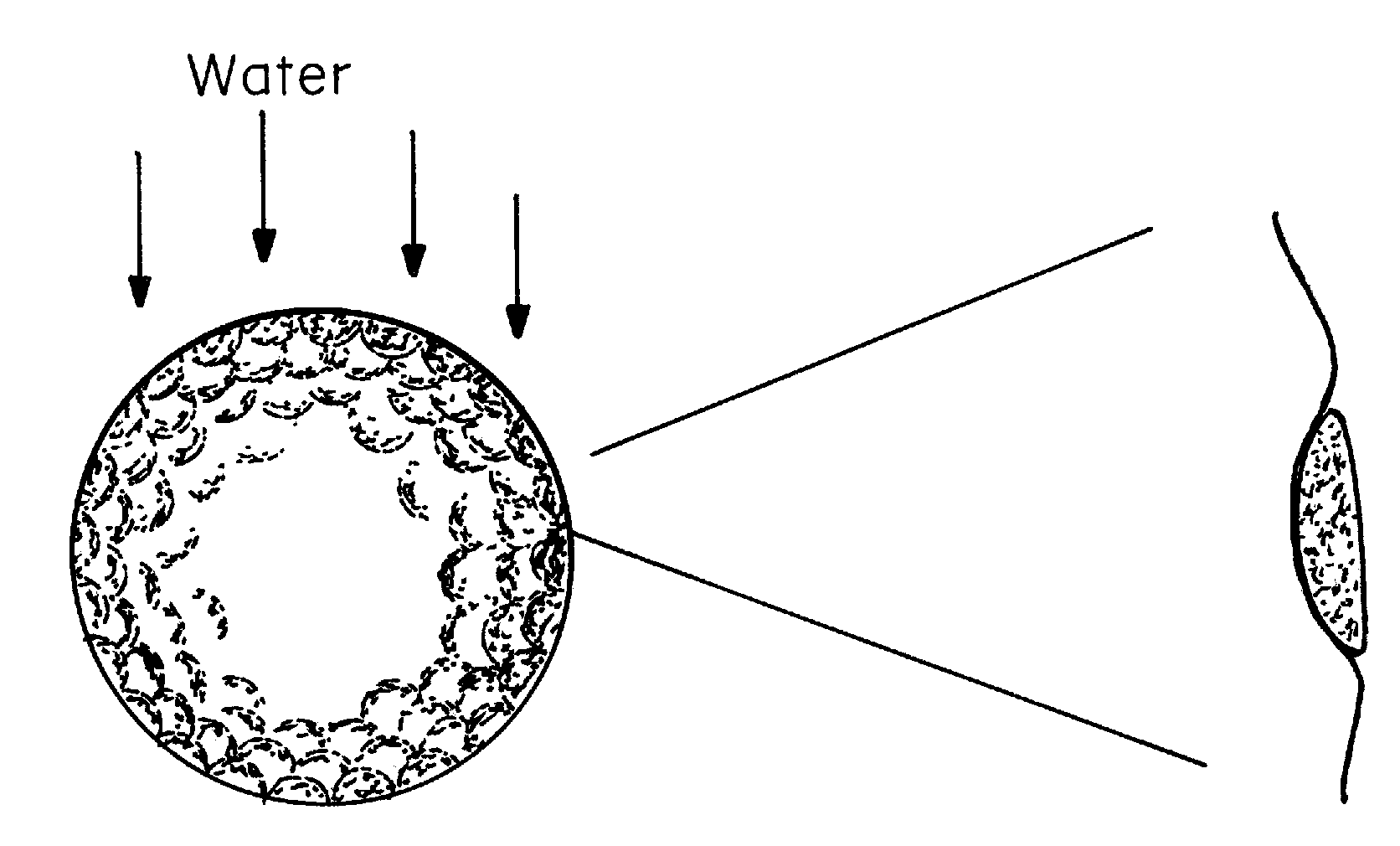

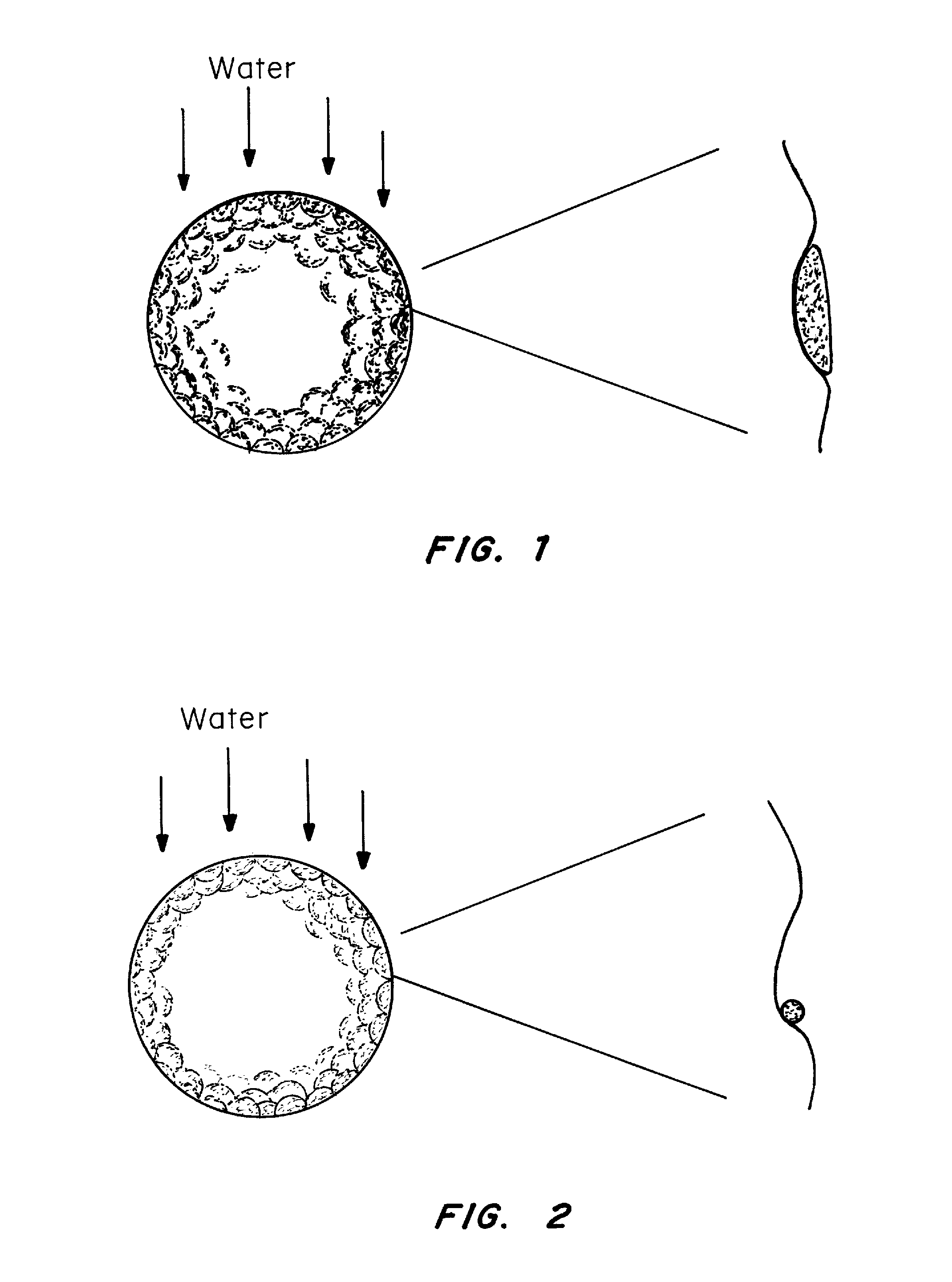

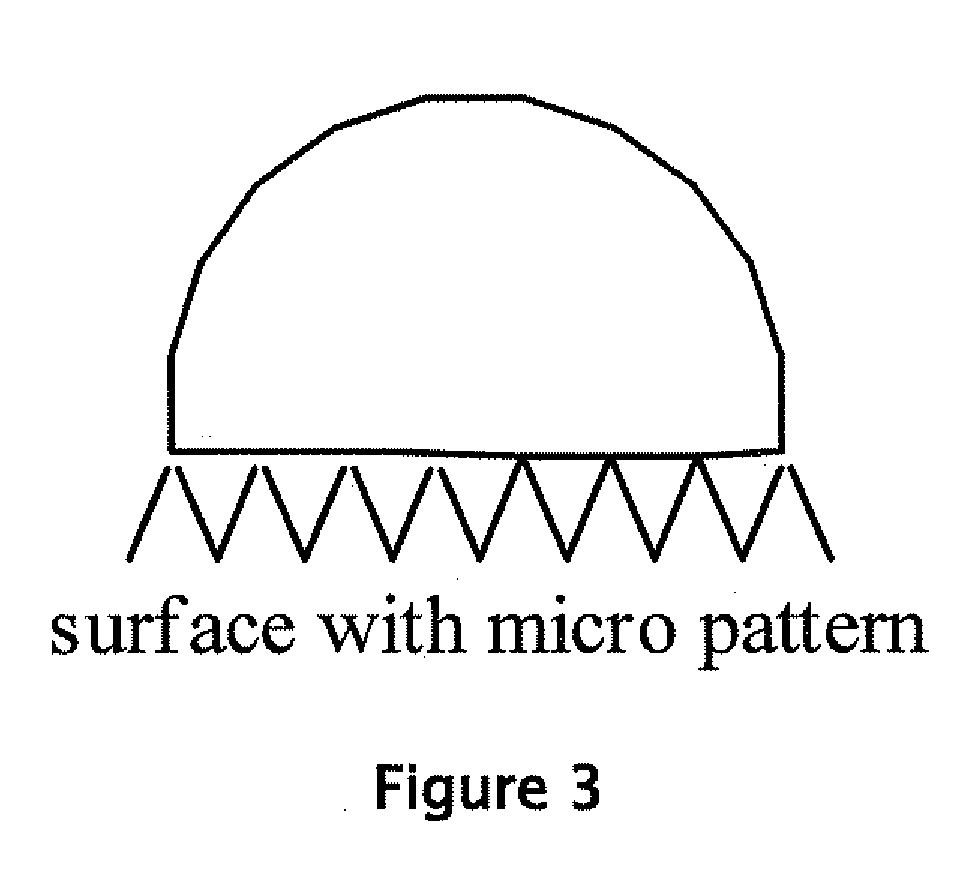

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

Slurry Composition for Final Polishing of Silicon Wafers and Method for Final Polishing of Silicon Wafers Using the Same

InactiveUS20080127573A1Reduce hazeIncrease productionPigmenting treatmentOther chemical processesWaferingSlurry

Disclosed is a slurry composition for final polishing of silicon wafers to achieve mirror surfaces of the wafers. The slurry composition can include deionized water, abrasive particles, a pH-adjusting agent, a water-soluble thickener, an acetylene surfactant, and a heterocyclic amine. The particle diameter of the abrasive particles and the contents of the components can be selected so that the slurry composition can markedly reduce the number of LLS defects having a size larger than about 50 nm formed on the surface of wafers, and greatly reduce the haze and microroughness of wafer surfaces.

Owner:CHEIL IND INC

Footwear safety apparatus, device, and method

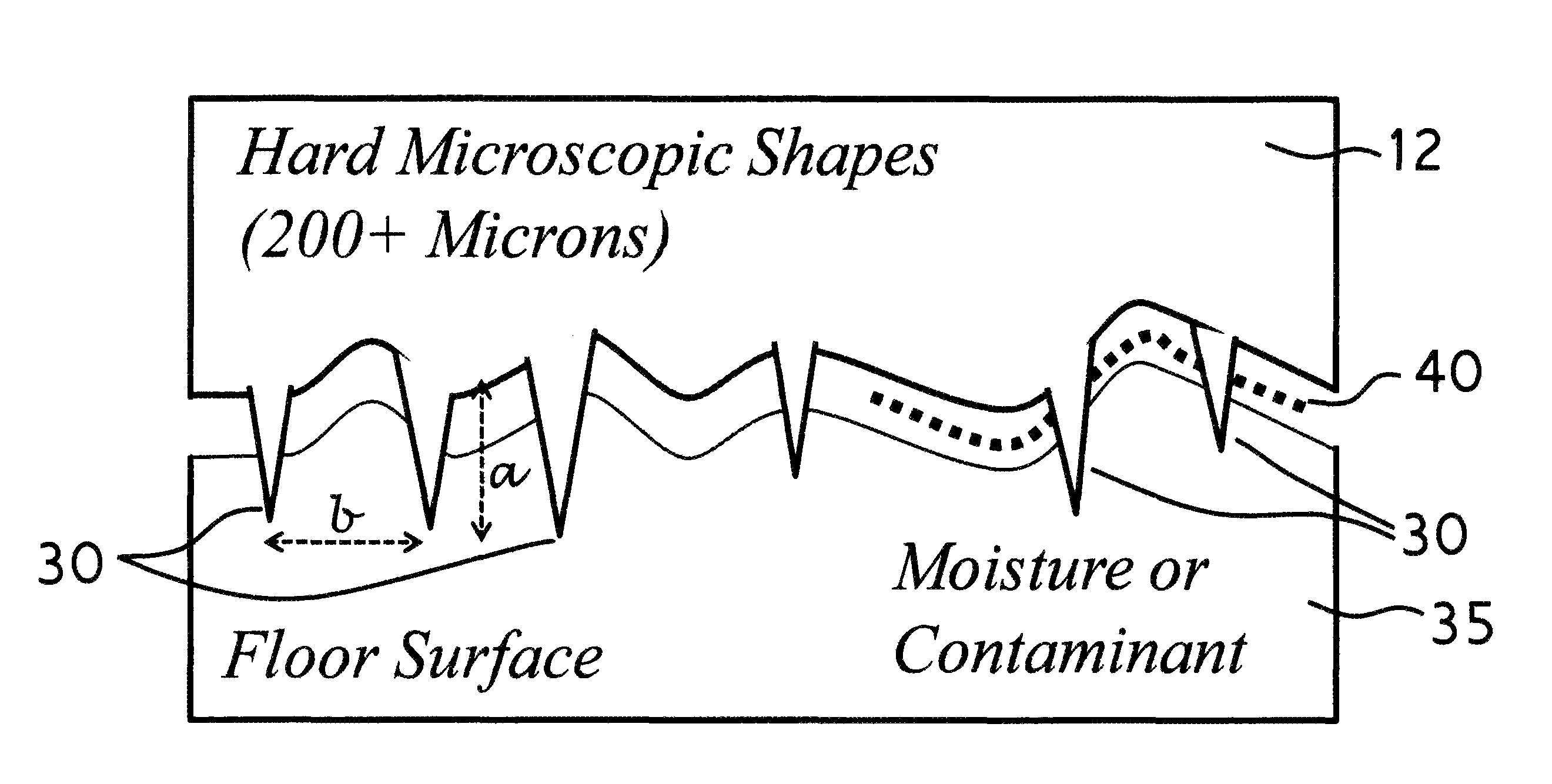

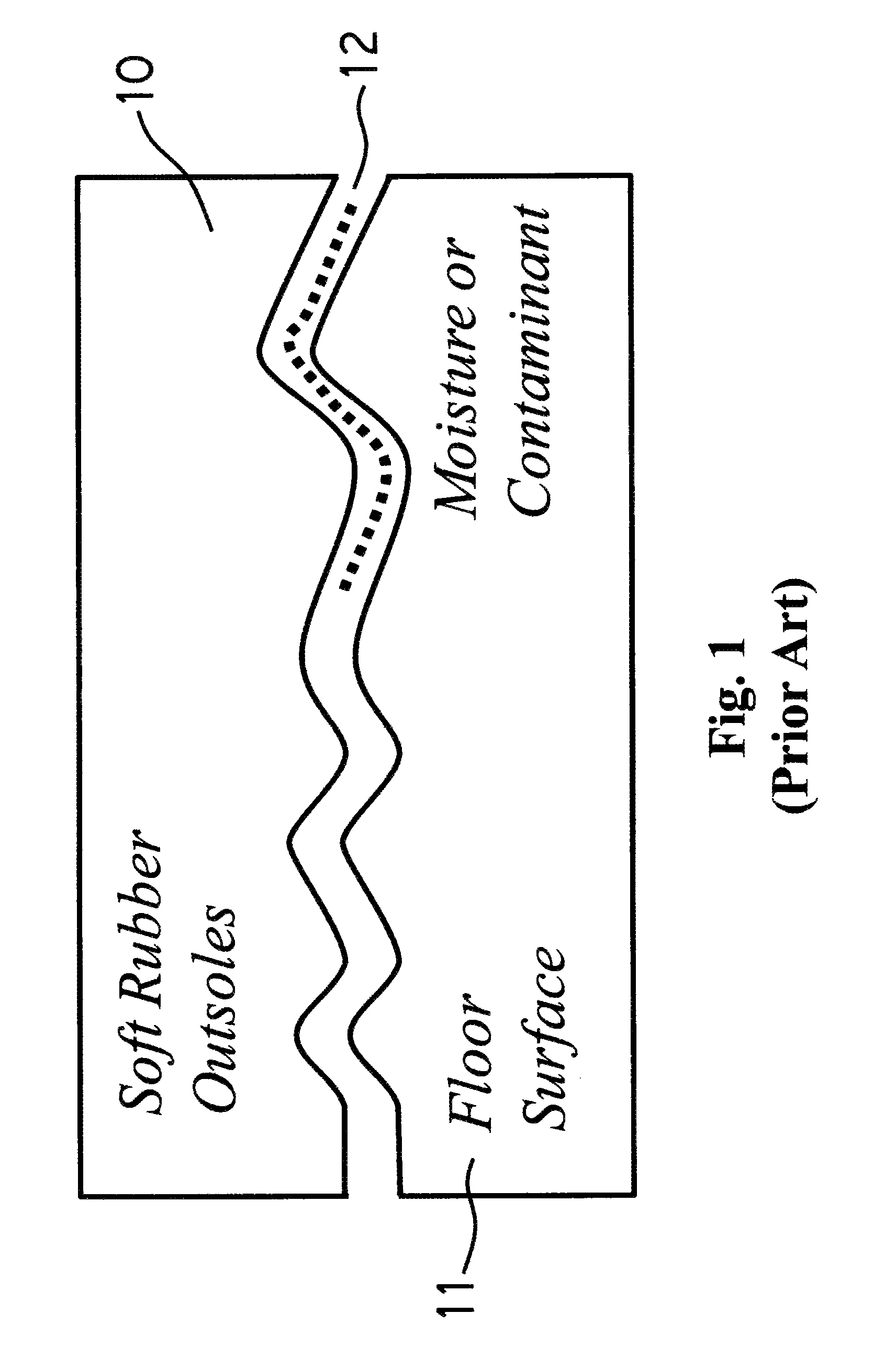

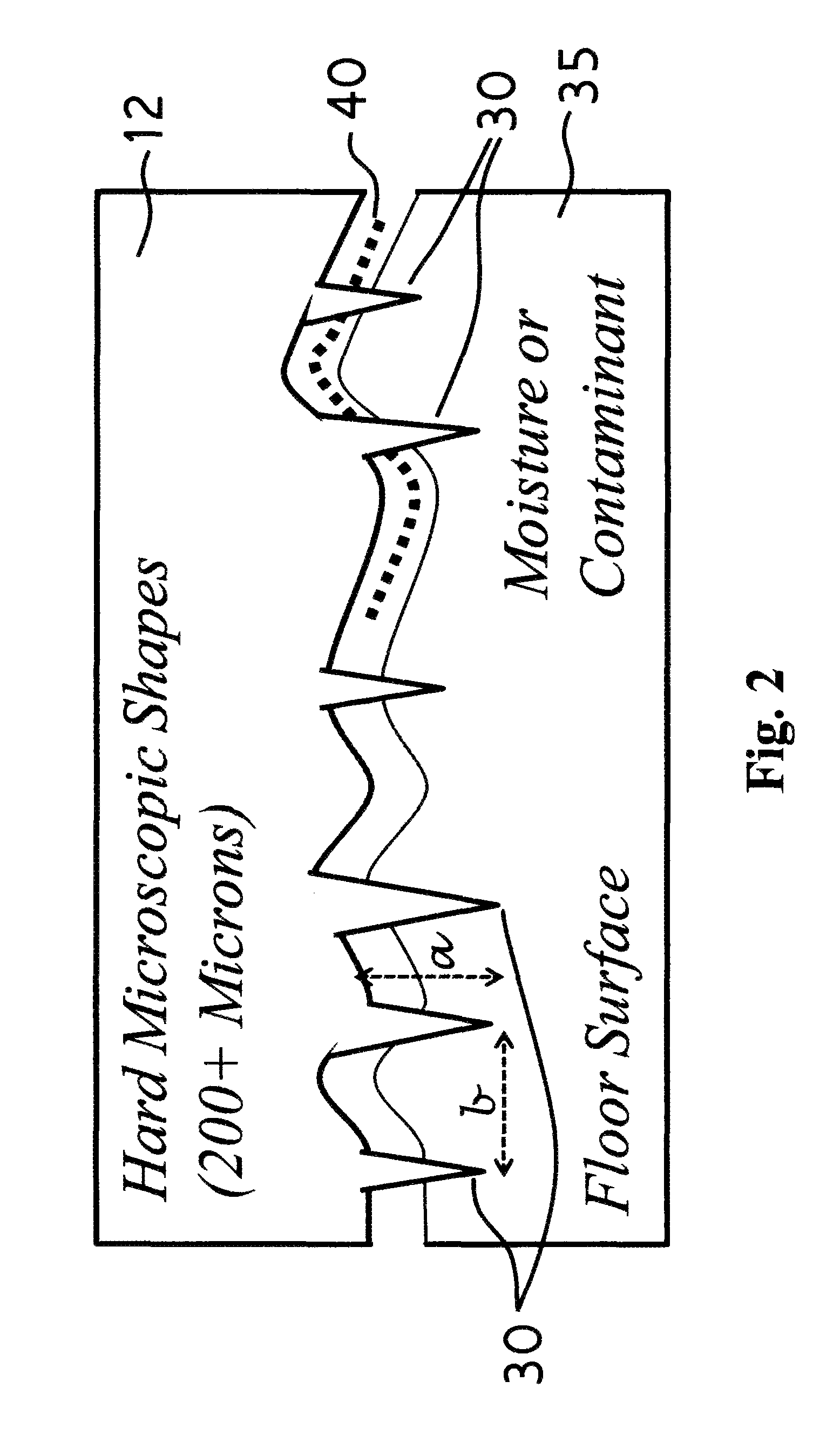

A footwear traction device is disclosed that enhances regular or slip-resistant shoes during a slip-in-progress. The traction device includes an adhesive layer embedded with microscopic friction additives, natural or engineered, and partially covered with an epoxy resin in a design that pierces and grips the microscopic roughness of a surface and any contaminants thereon, providing emergency traction during a slip. The footwear traction device provides more than one opportunity to recover from a slip and regain traction. In the event that a fall is unavoidable, the footwear traction device provides a first and a second push back force, spreading the force of the fall over a larger area, minimizing the absolute force of the fall and providing a safer trajectory during the fall. The slip recovery method and system of the present invention offers an economical solution that reduces the financial and human toll caused by slip-and-fall accidents and deaths.

Owner:WOODRUFF MICHAEL J

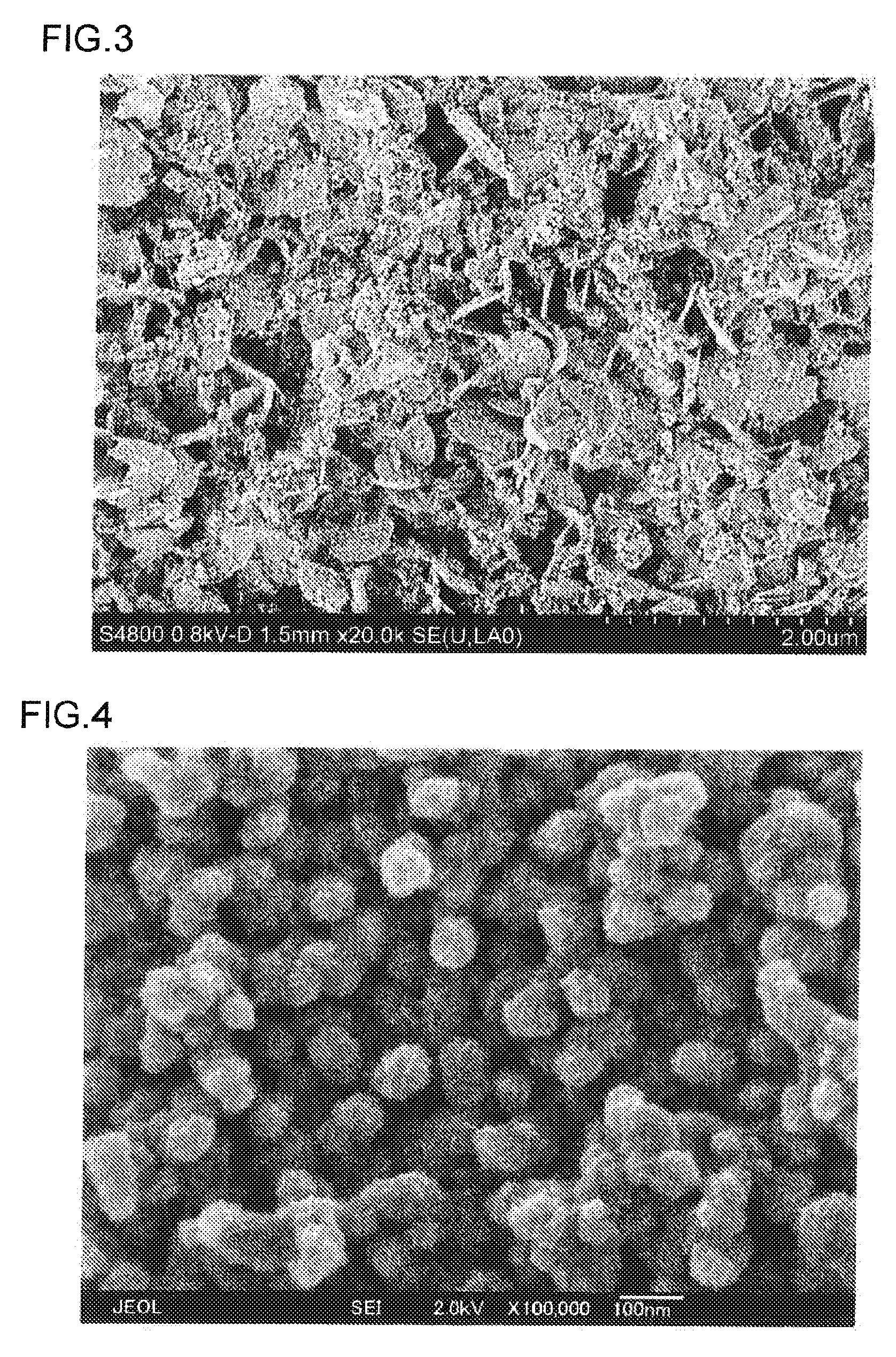

Composite of metal and resin and method for manufacturing same

ActiveUS20090280296A1Little effect resin strength of resinEfficient productionSynthetic resin layered productsRecord information storageSurface layerPhosphate

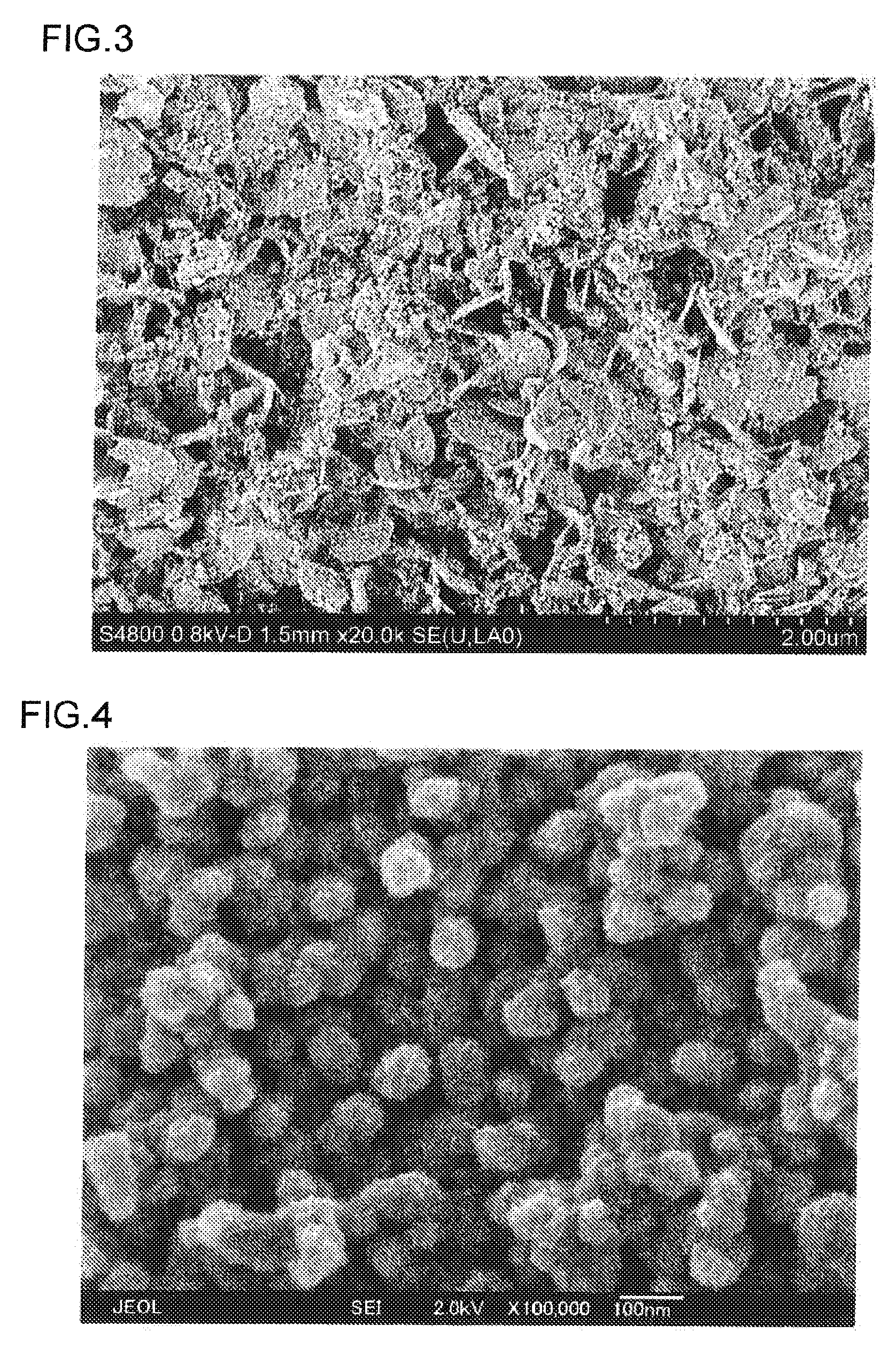

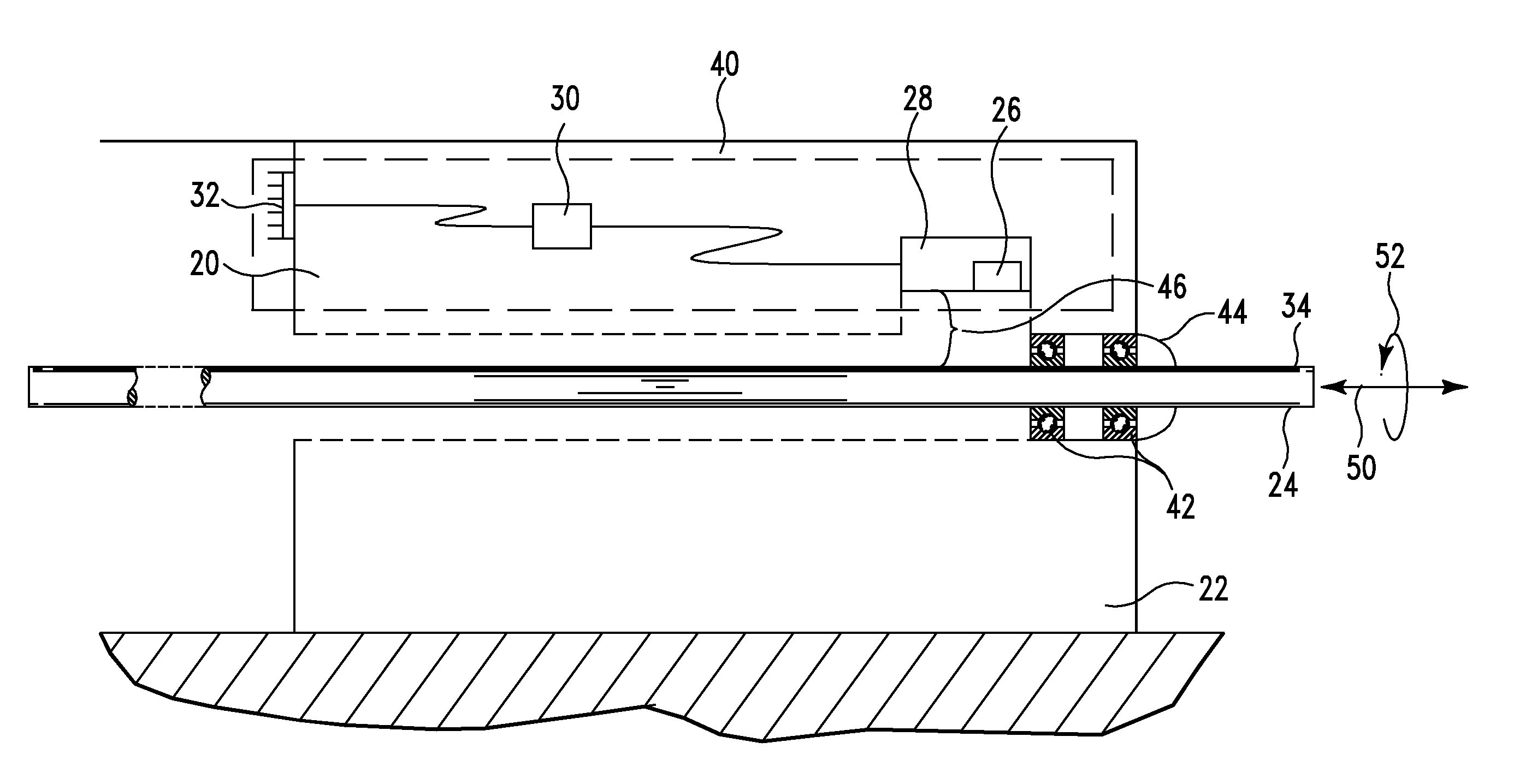

[Problem] A composite of a metal part and a resin composition part that is improved so that the metal and resin are integrally joined to have strong bonding properties, and a method for manufacturing the composite.[Solution] A magnesium alloy part is inserted into a mold, a resin composition is injected and joined to the part, and a composite is obtained. A part having, formed thereon, a surface layer of a metal oxide, a metal carbonate, or a metal phosphate in use of a usual conversion treatment or a modification method thereof can be used for the magnesium alloy plate 1. The surface that has a larger amount of crystal-like objects of a nanolevel on the surface layer composed of the metal oxide, metal carbonate, or metal phosphate has a higher level of hardness, microscopic roughness, and good injection joining force, and these parameters can be controlled by a conversion treatment method. A resin composition 4, containing PBT or PPS as the main component, is used as the resin composition part.

Owner:TAISEI PLAS CO LTD

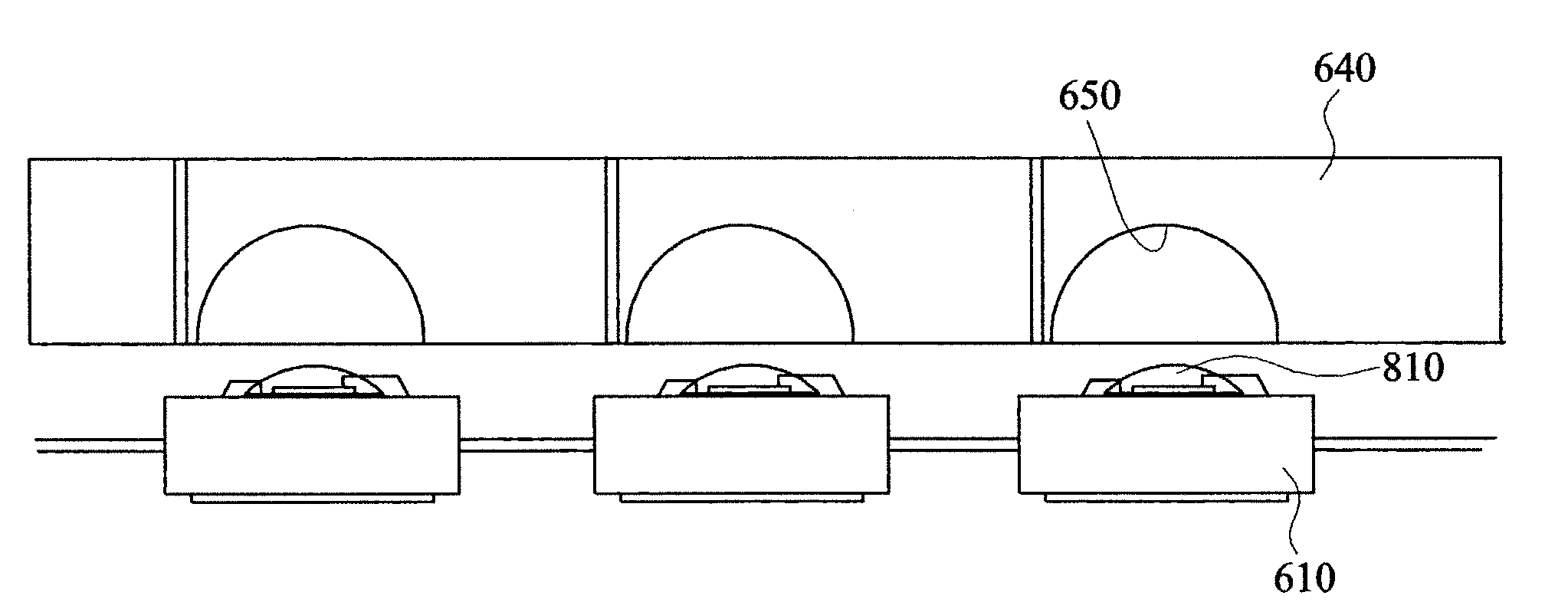

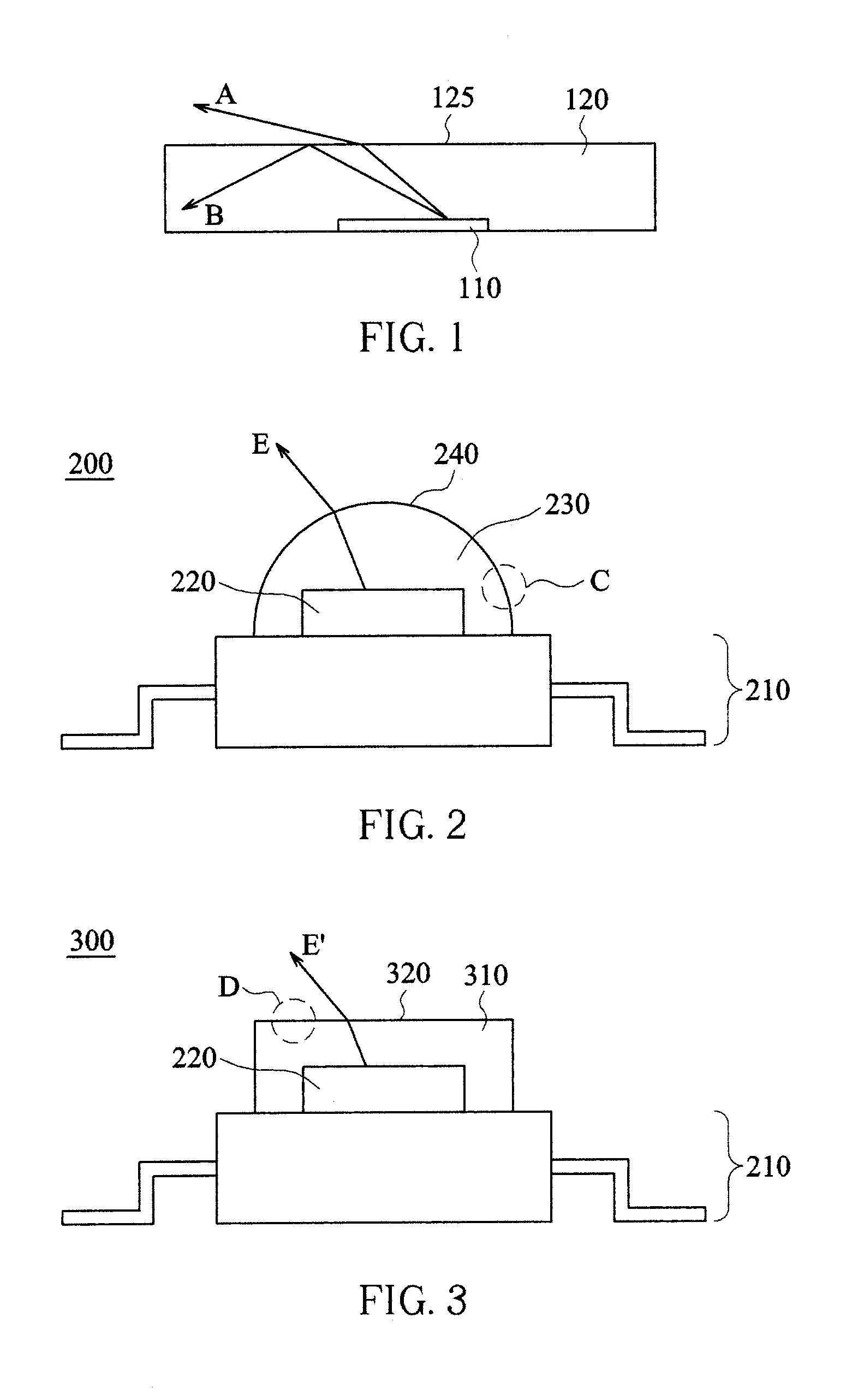

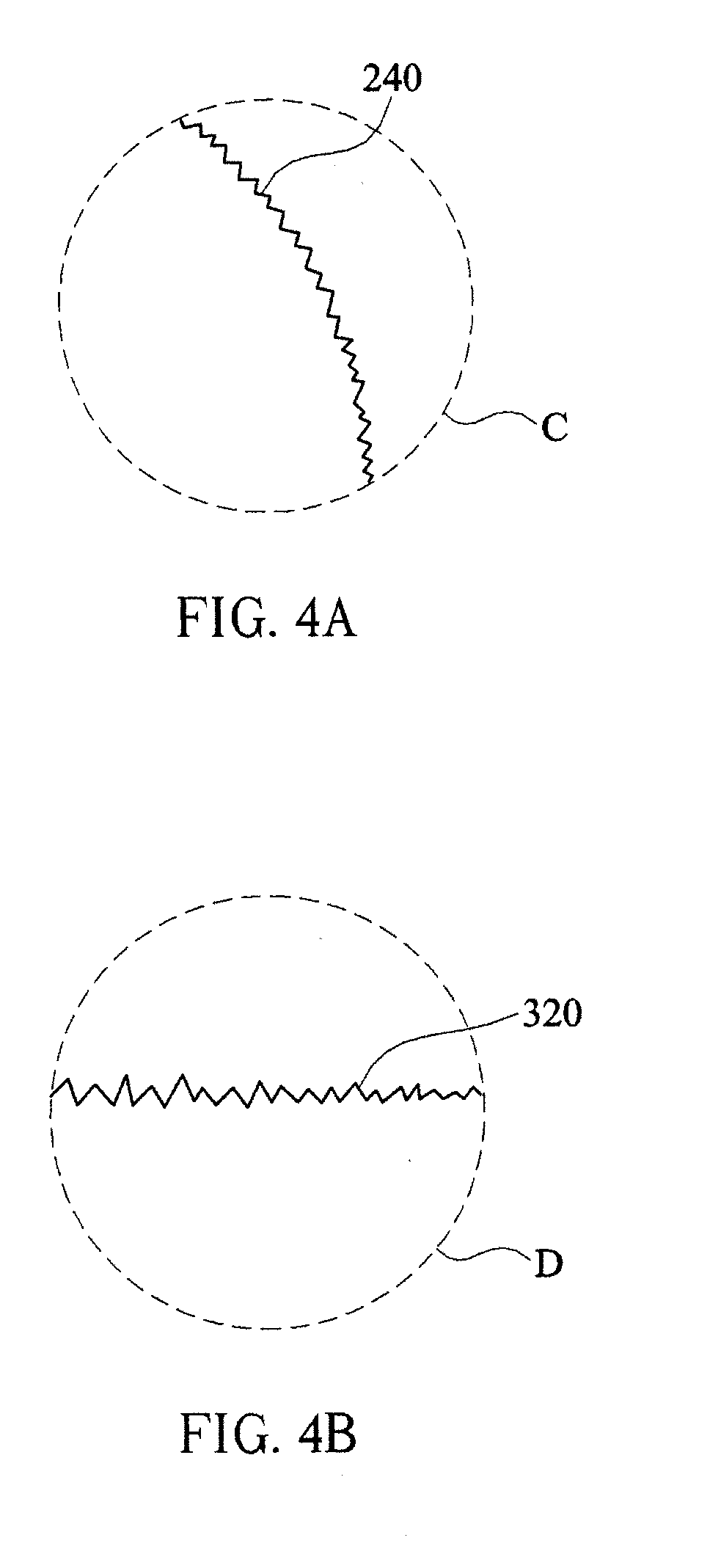

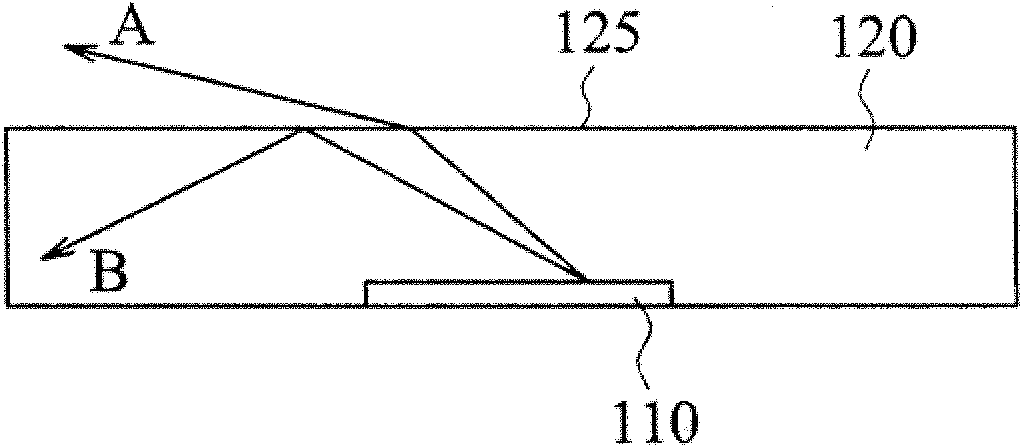

LED device with a light extracting rough structure and manufacturing methods thereof

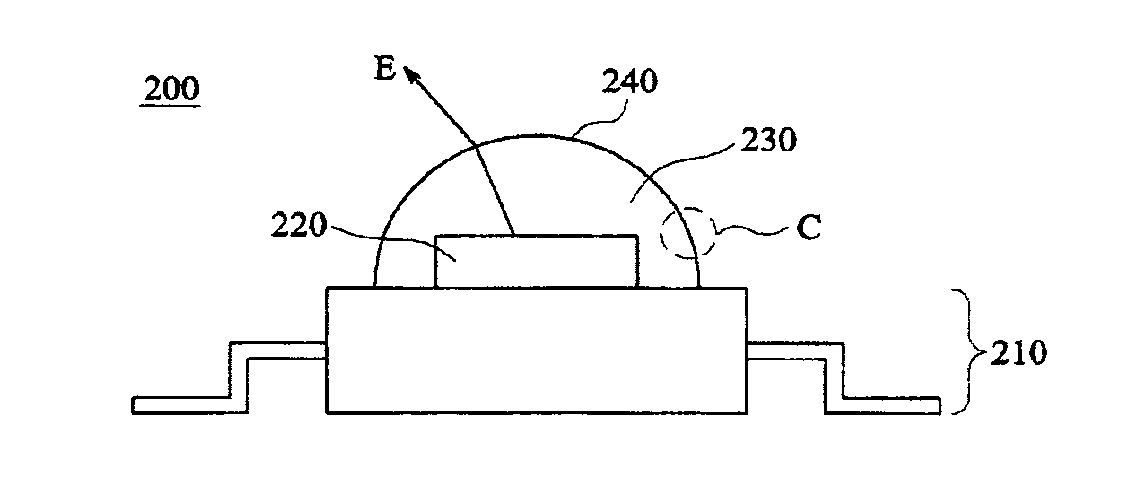

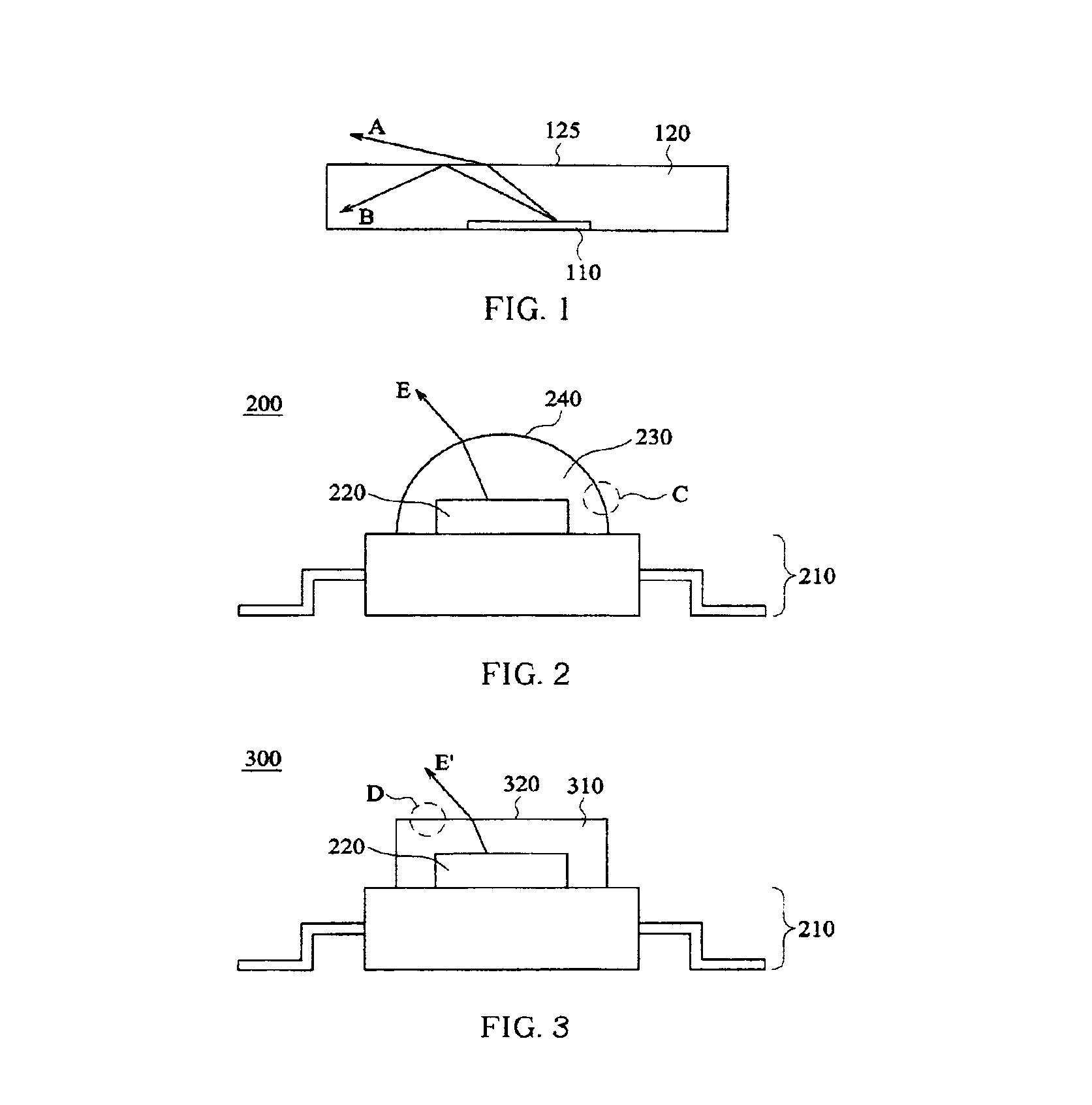

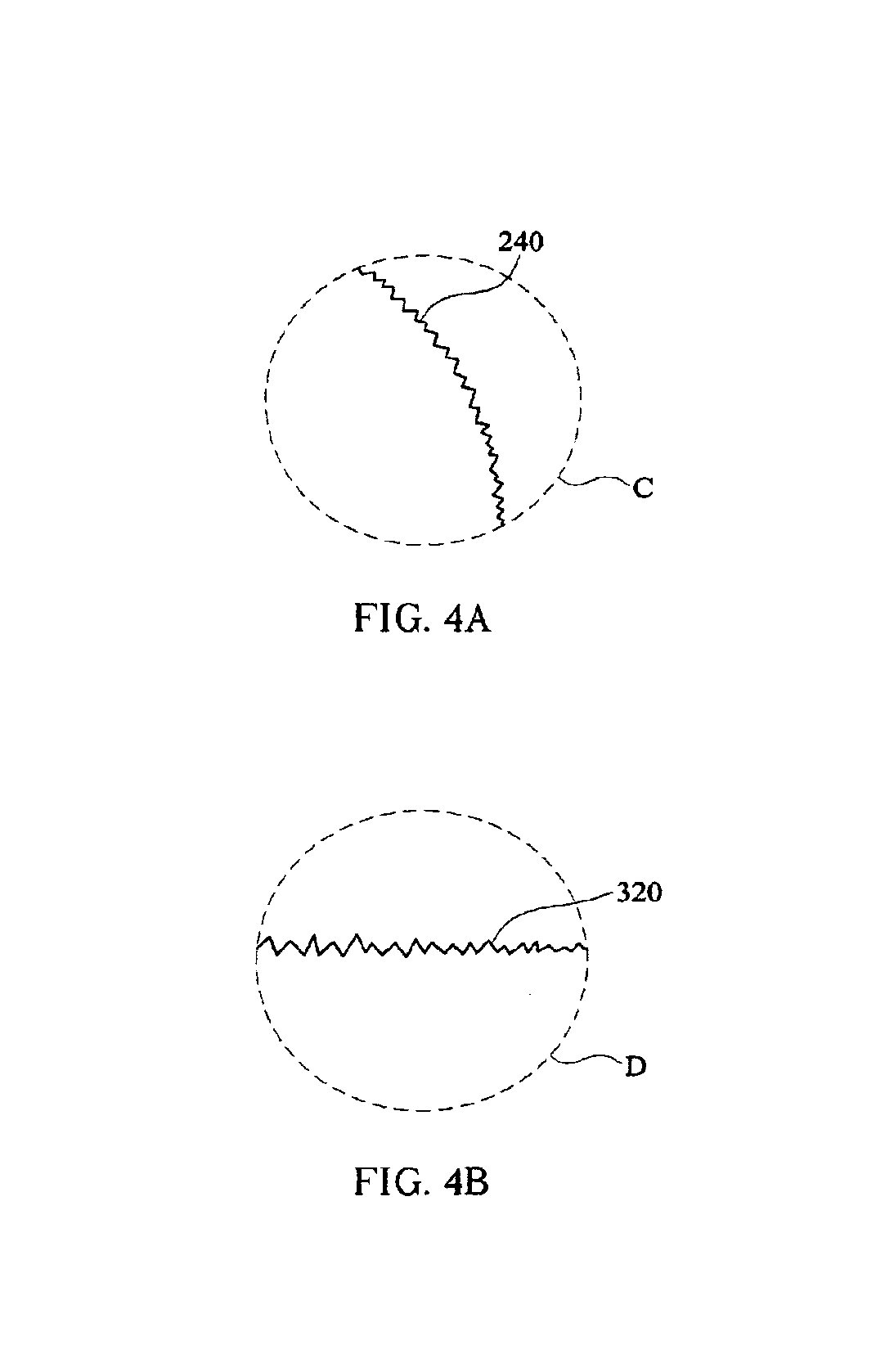

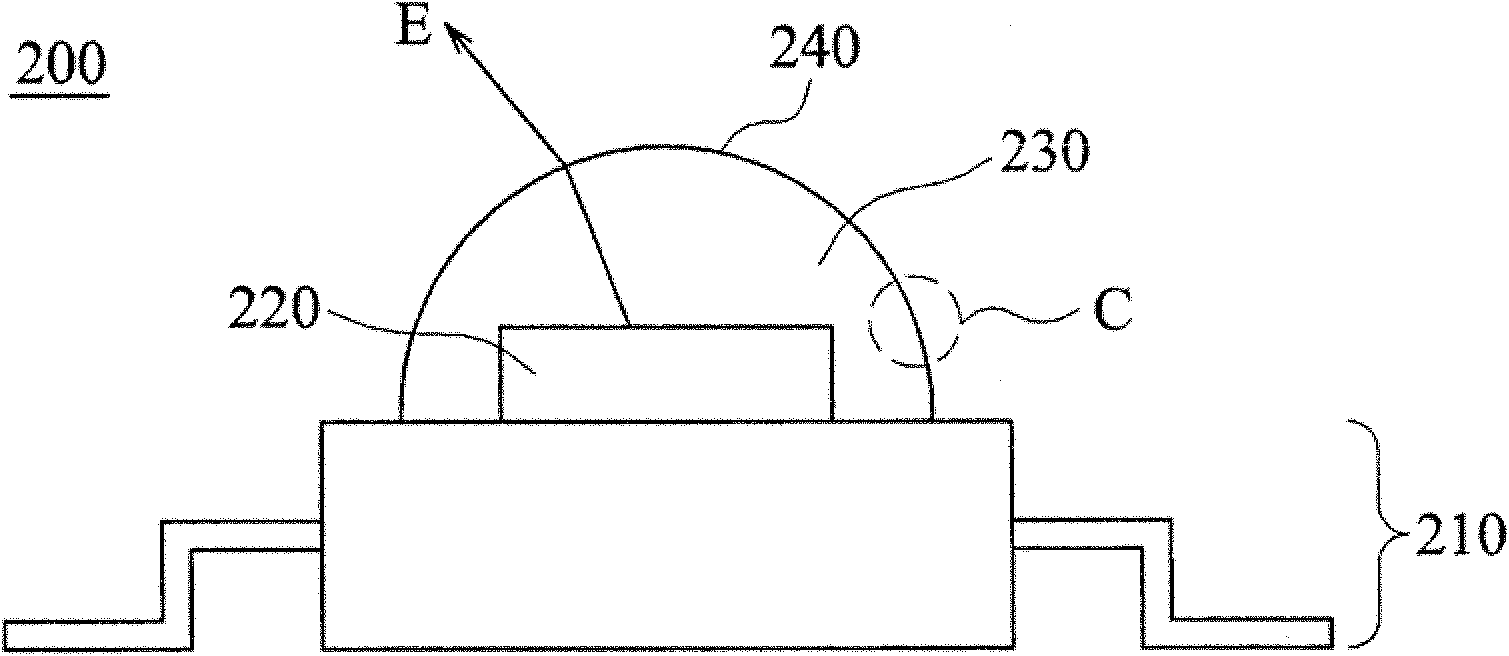

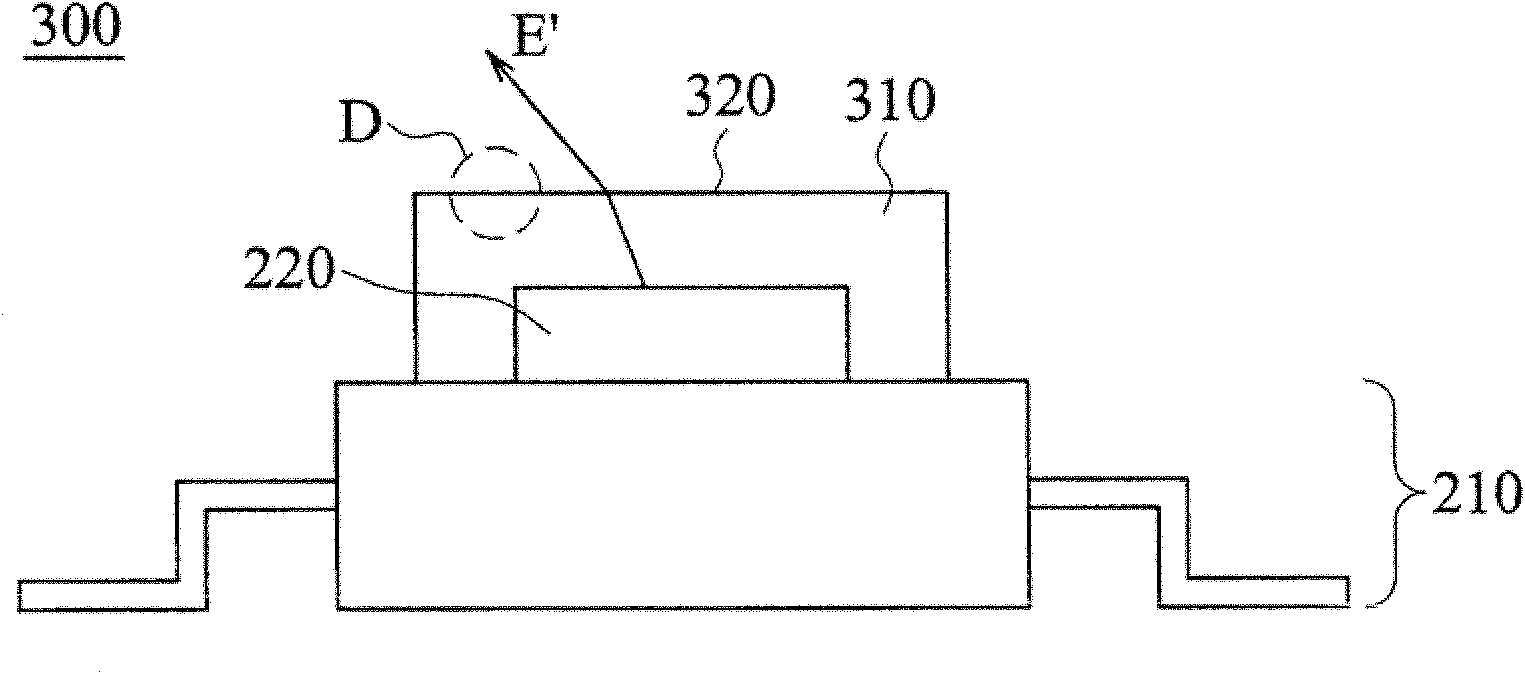

InactiveUS20100283065A1Micro-roughness structureSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeMicro roughness

The invention relates to a light emitting diode device having a light extracting rough structure. The device includes a leadframe, one or more light emitting diode chips provided on and electrically connected to the leadframe, and a lens configured to encapsulate the one or more light emitting diode chips, the lens having a surface including a micro-roughness structure. The micro-roughness structure of the lens has a roughness between 0.1 μm and 50 μm. The invention also relates to a method of manufacturing a light emitting diode device having a light extracting rough structure.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

Pasta machine for domestic use with improved cover

ActiveUS8162653B2Guaranteed uptimeInhibition releaseDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

The item in subject is a pasta machine for domestic use, in which the surfaces of the various parts of the housing are composed of a microporous layer of aluminum oxide and completed with sealing of the micropores for hydration thus obtaining a micro-roughness with nonstick properties enabling the working of moist pasta.

Owner:MARCATO

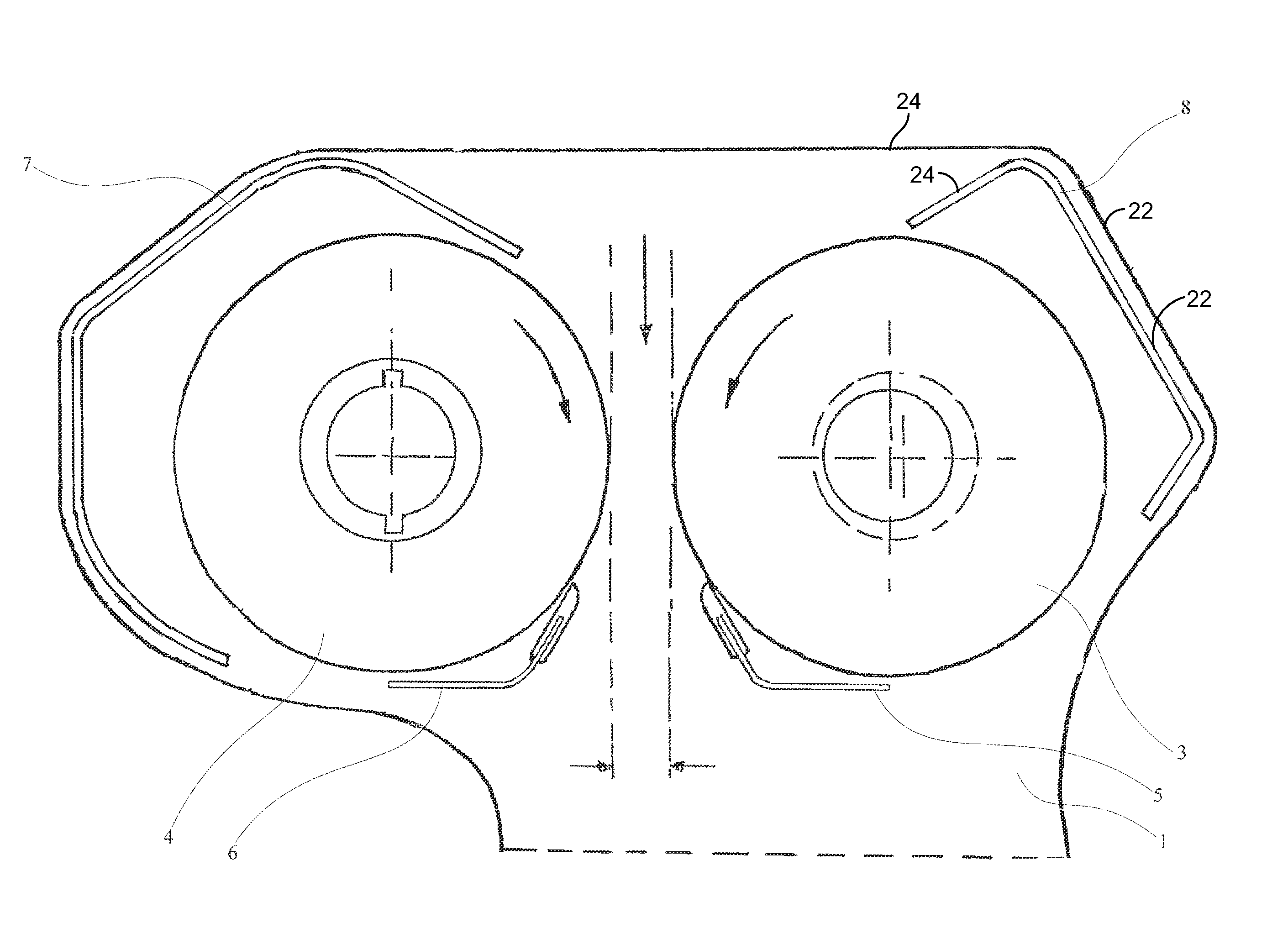

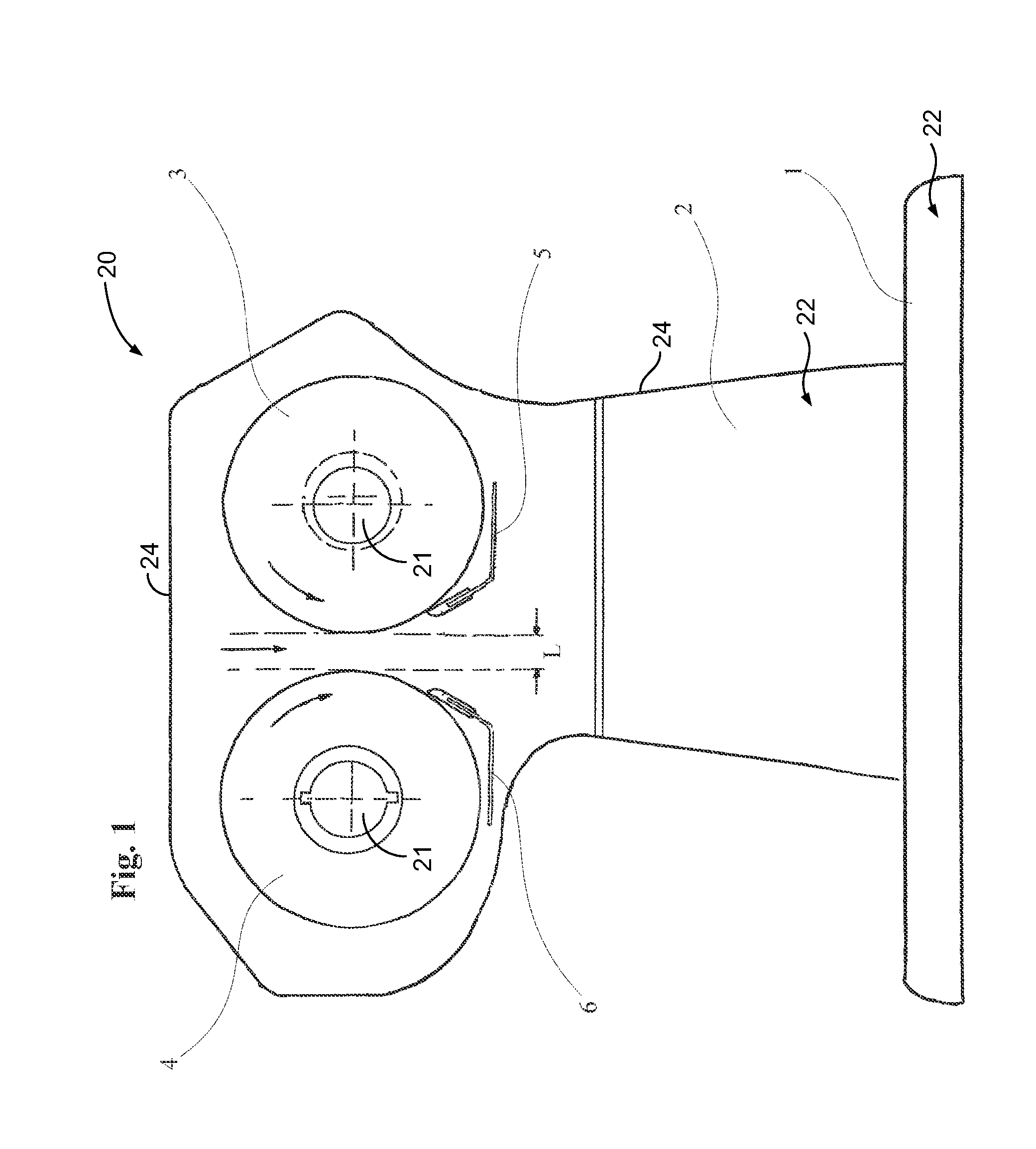

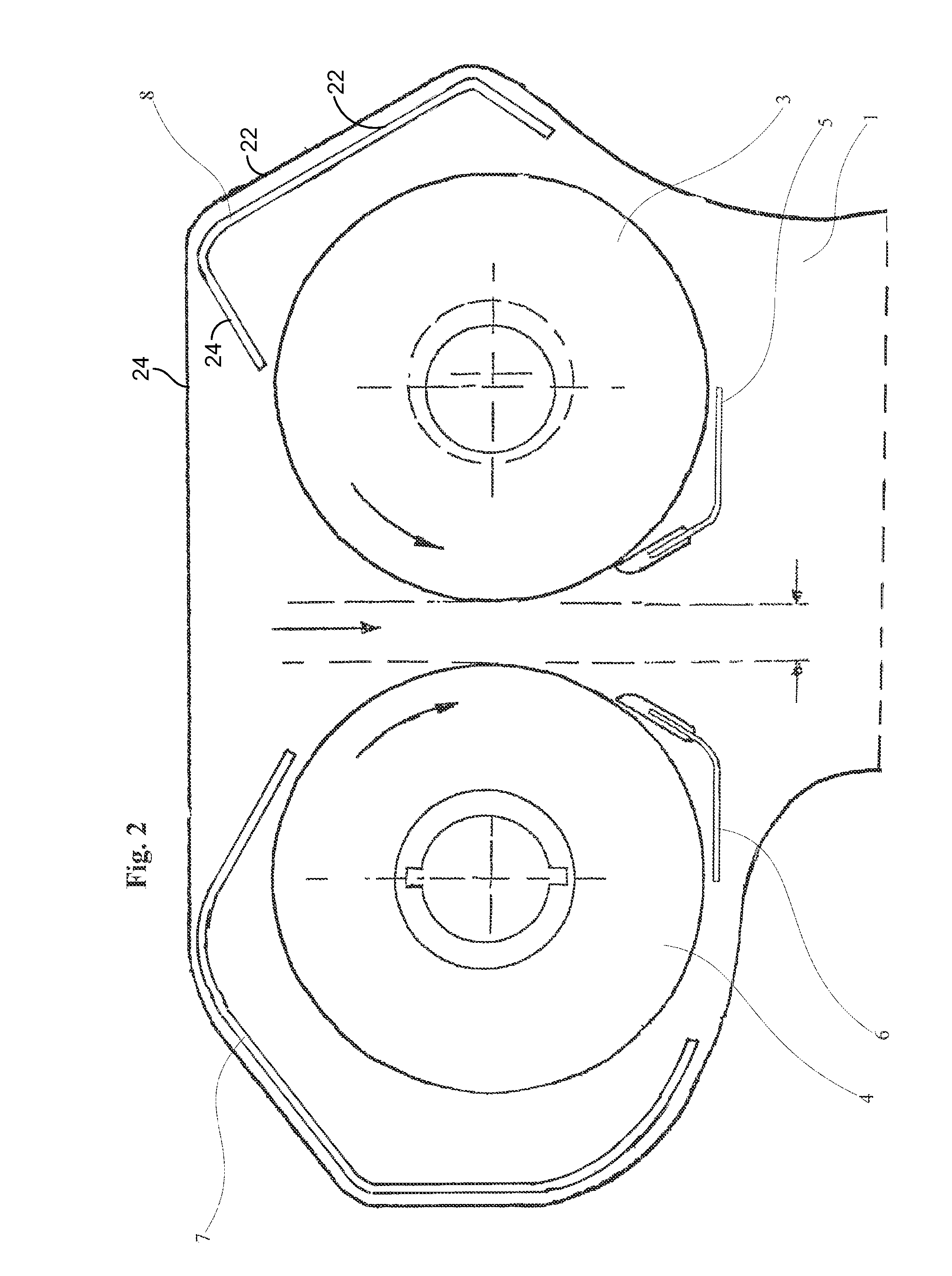

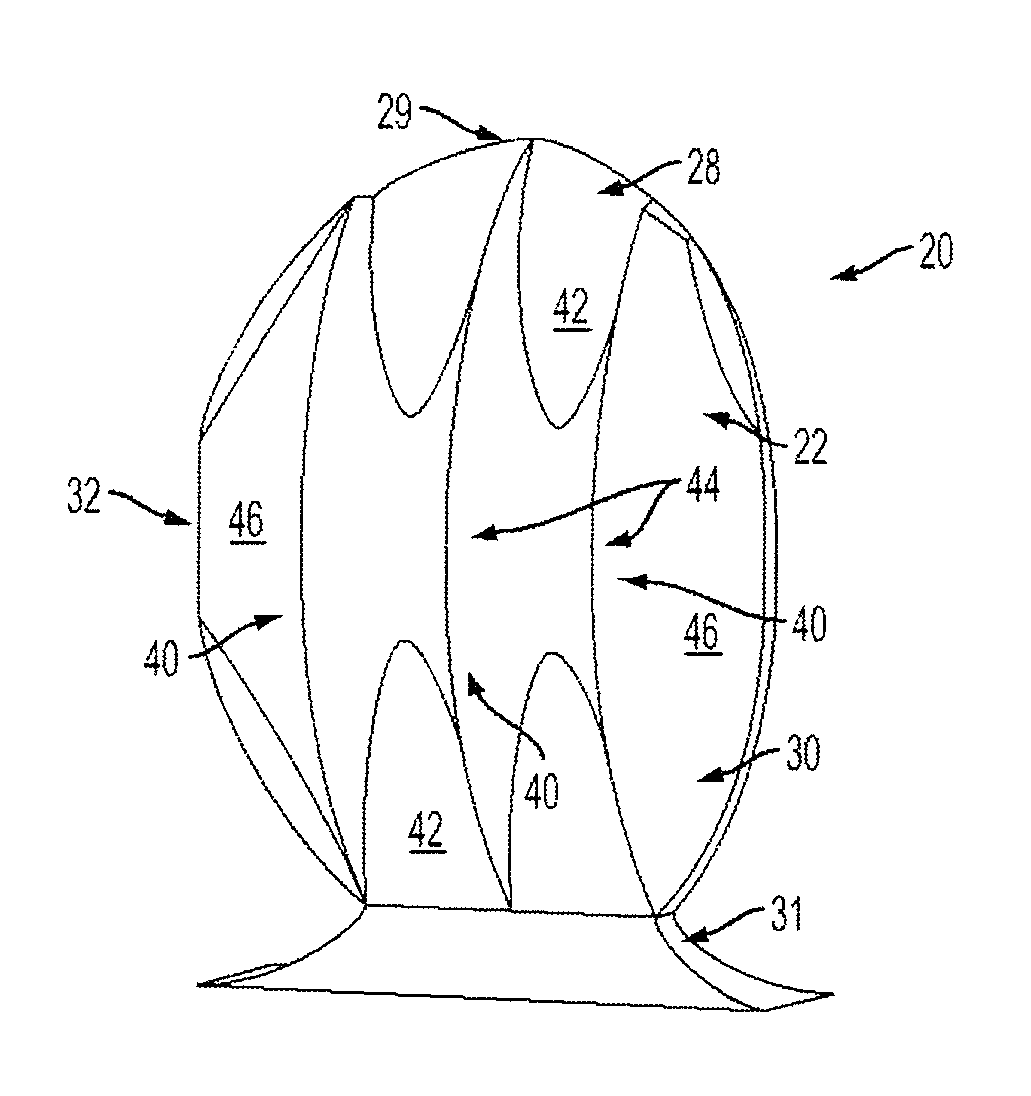

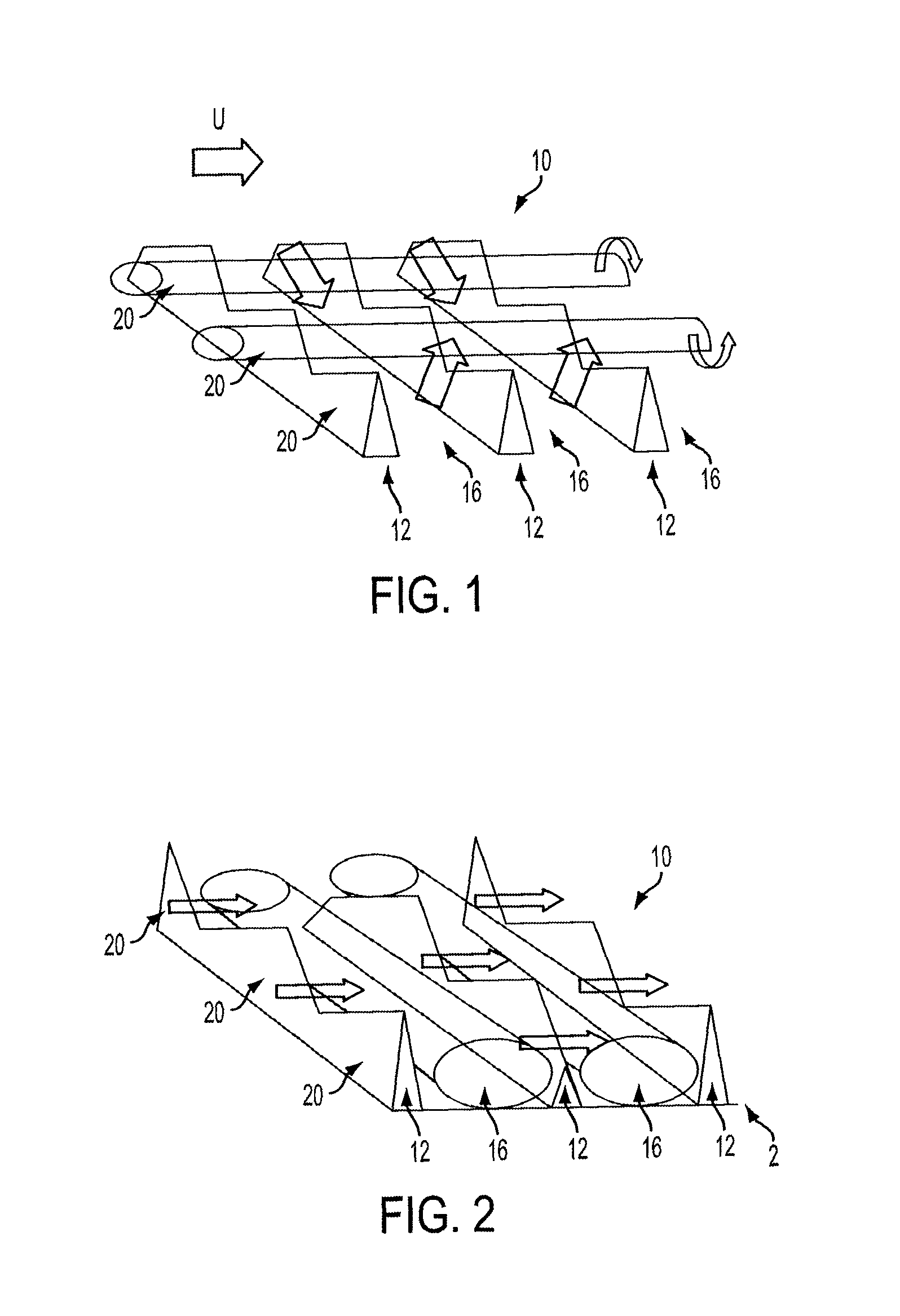

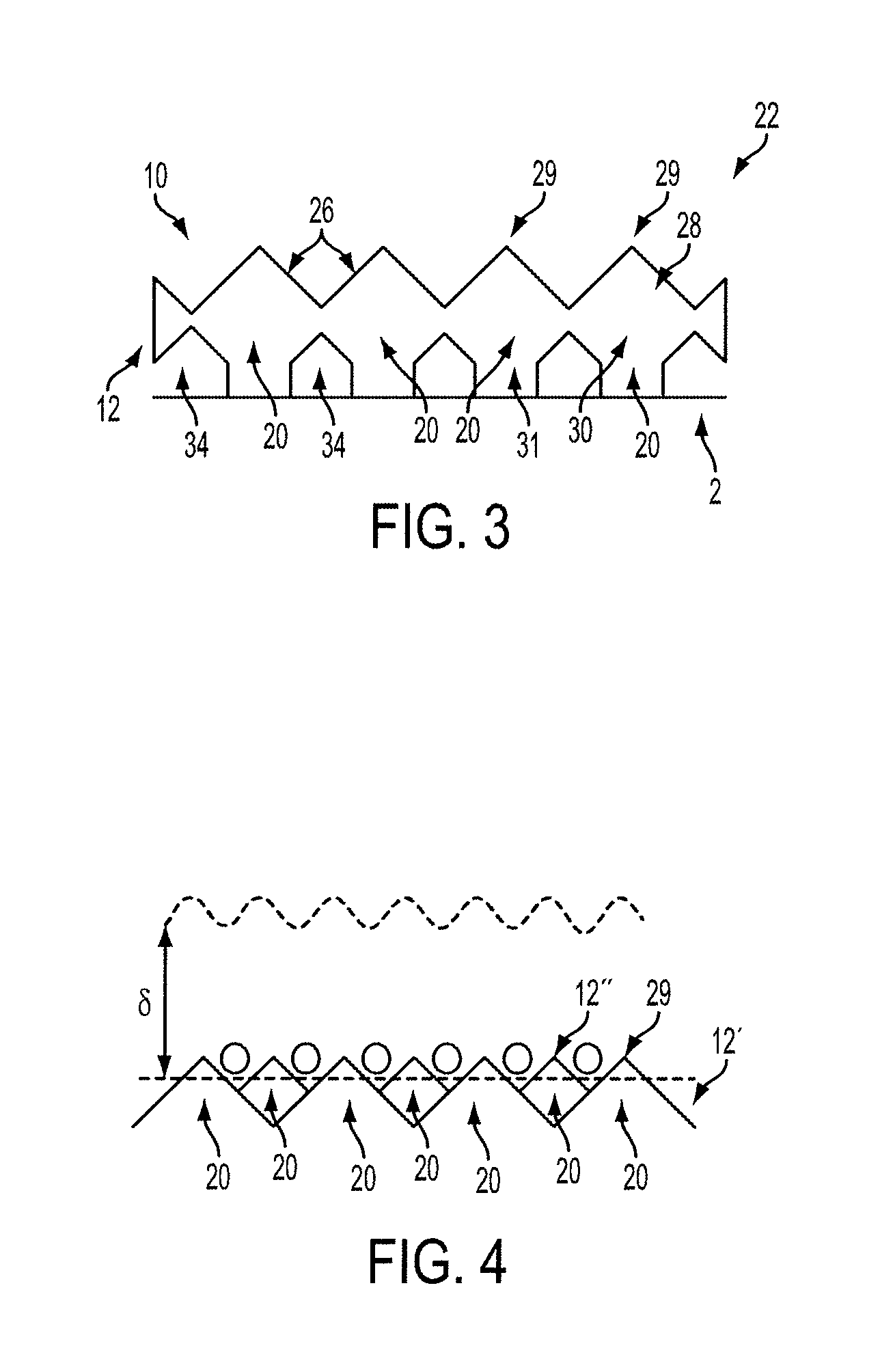

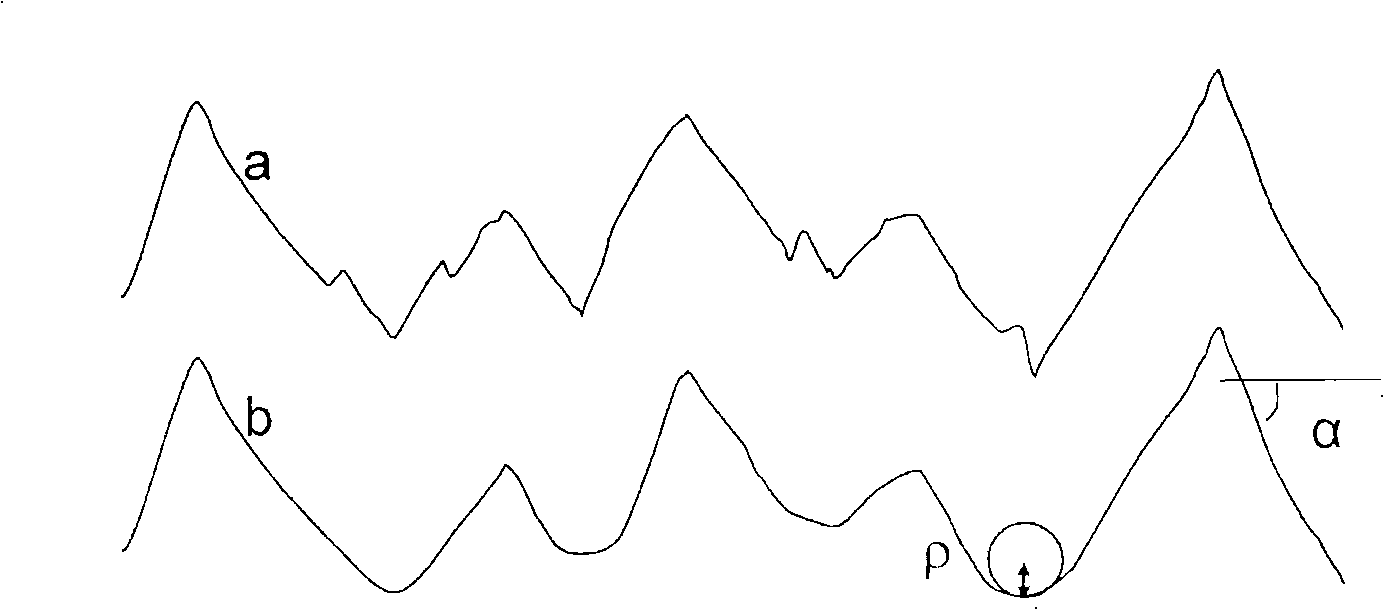

Passive micro-roughness array for drag modification

ActiveUS8113469B2Reduce skin friction drag coefficientDelay transitionAircraft stabilisationBoundary layer controlsEngineeringMicro roughness

The present invention is directed to a micro-array surface that provides for either drag reduction or enhancement. In one aspect, an aerodynamic or hydrodynamic wall surface that is configured to modify a fluid boundary layer on the surface comprises at least one array of roughness elements disposed on and extending therefrom the surface. In one example, the interaction of the roughness elements with a turbulent boundary layer of the fluid reduces the skin friction drag coefficient of the surface over an identical smooth surface without the roughness elements.

Owner:UNIVERSITY OF ALABAMA

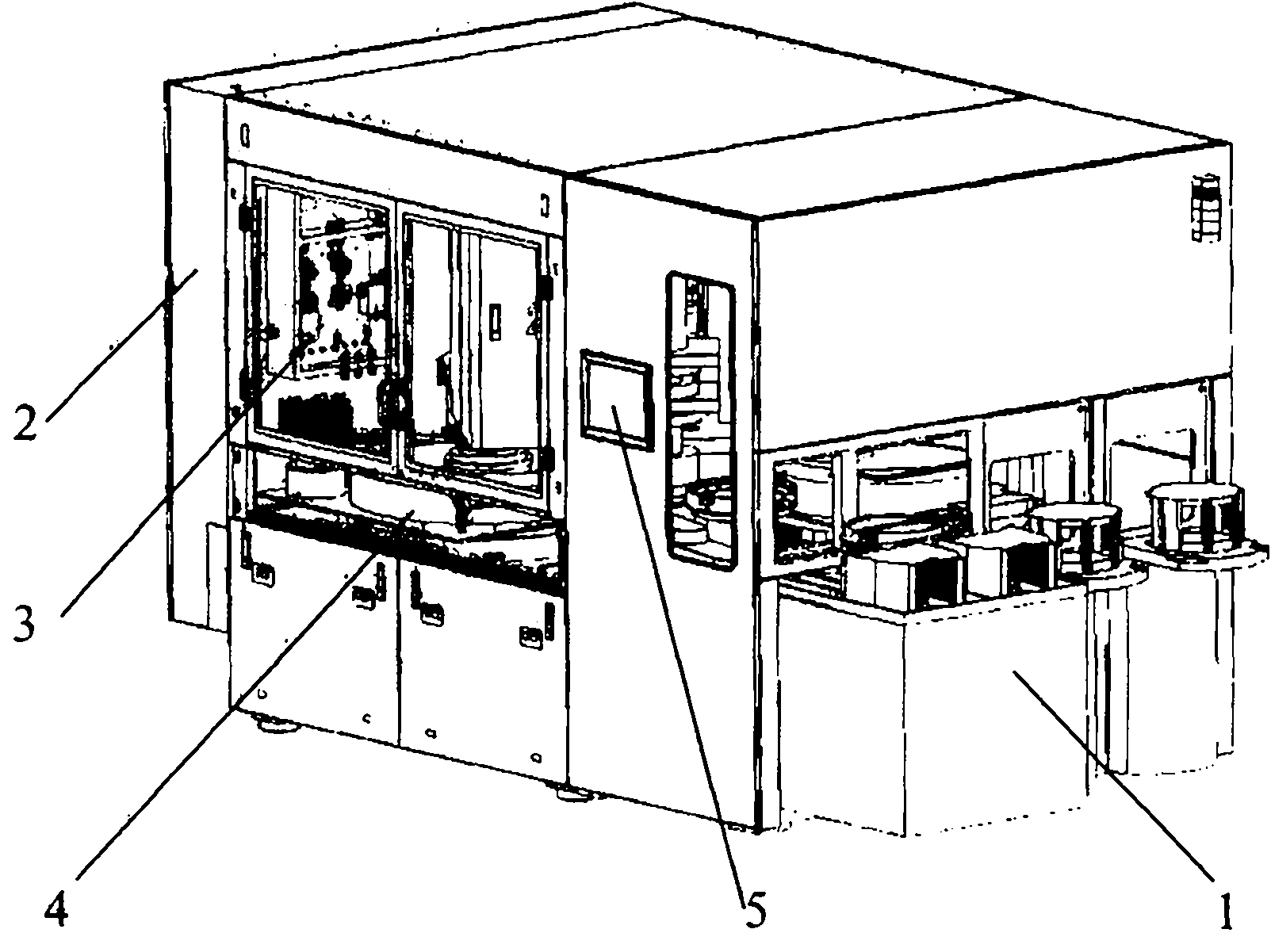

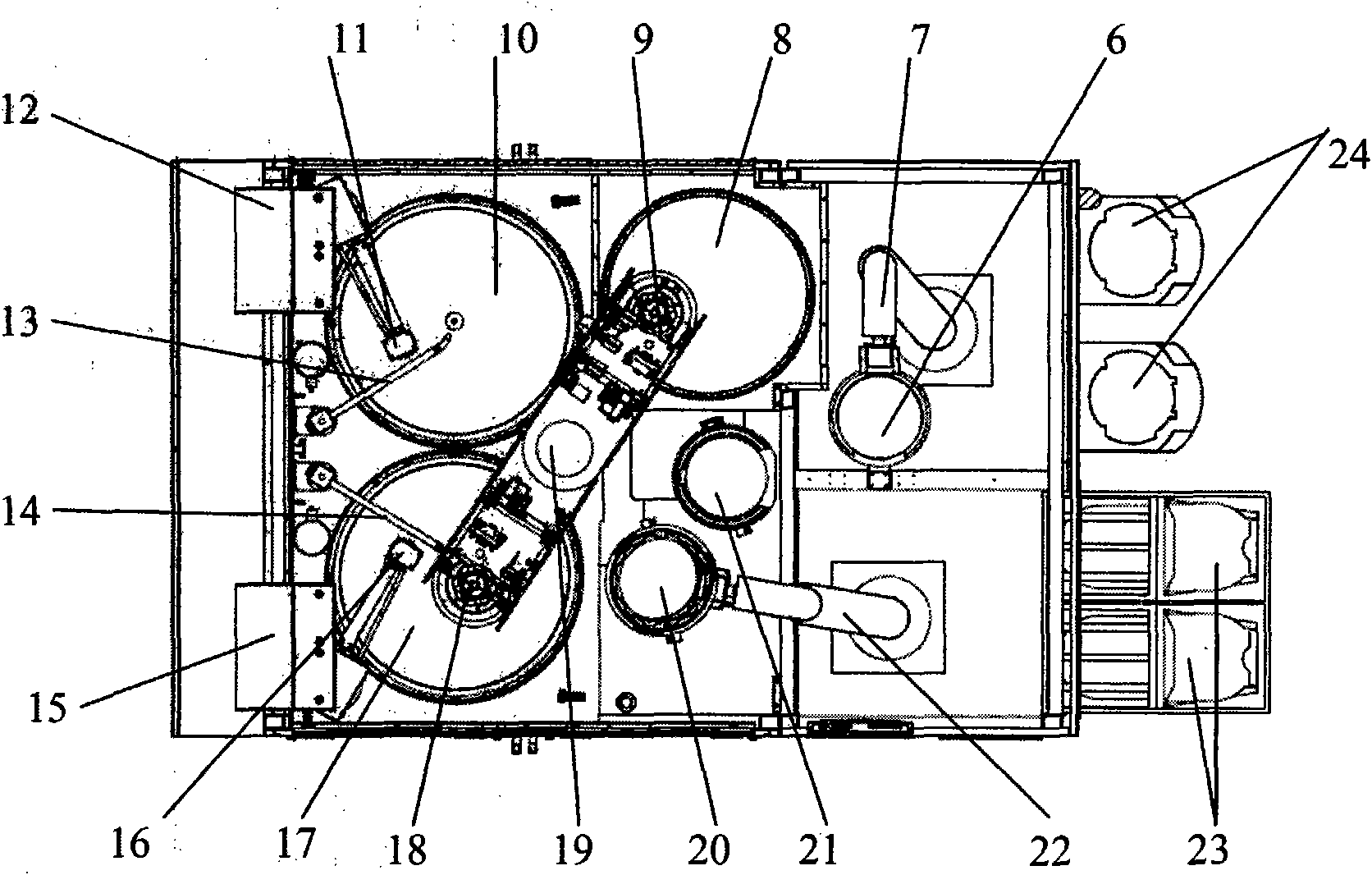

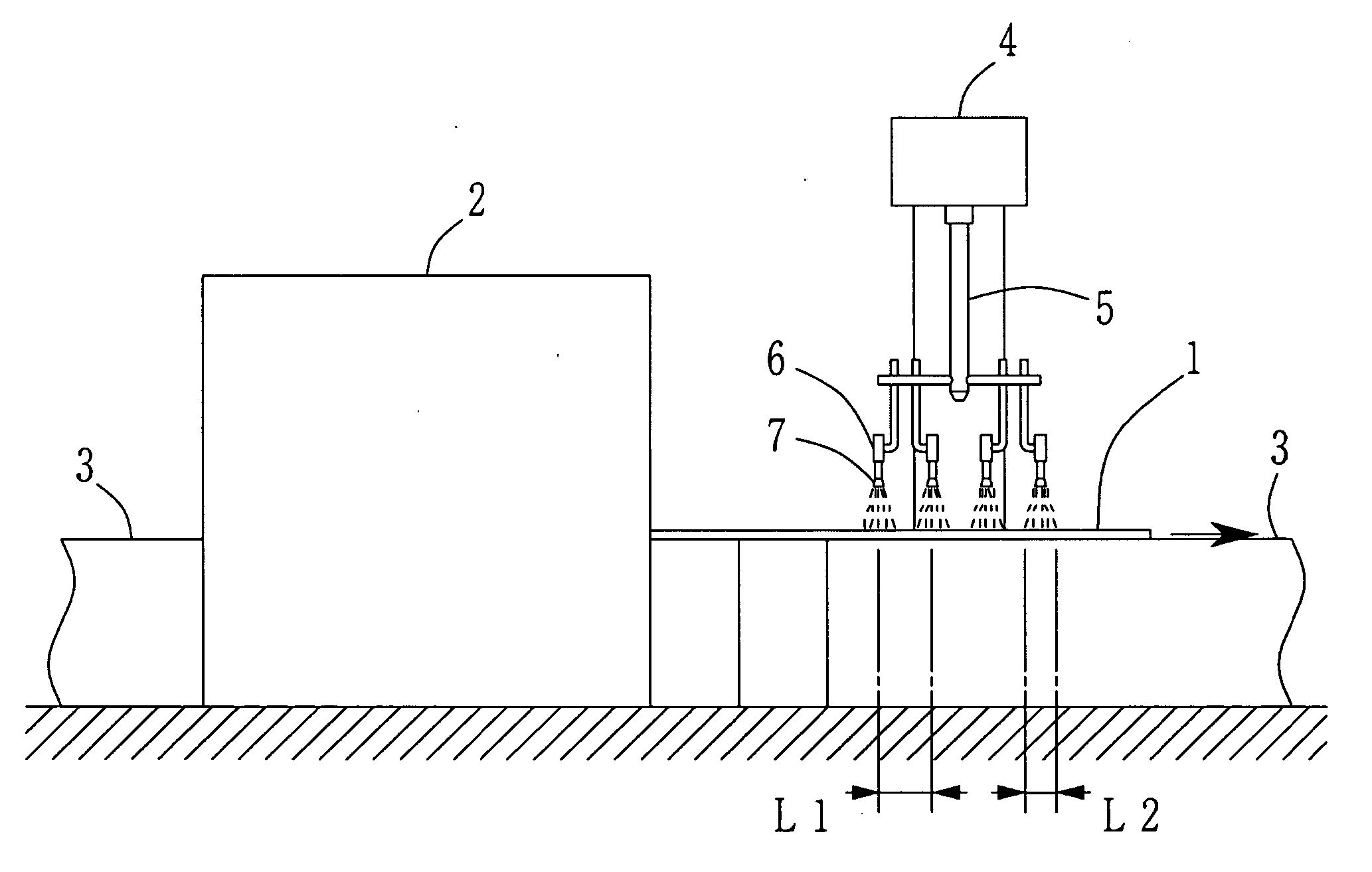

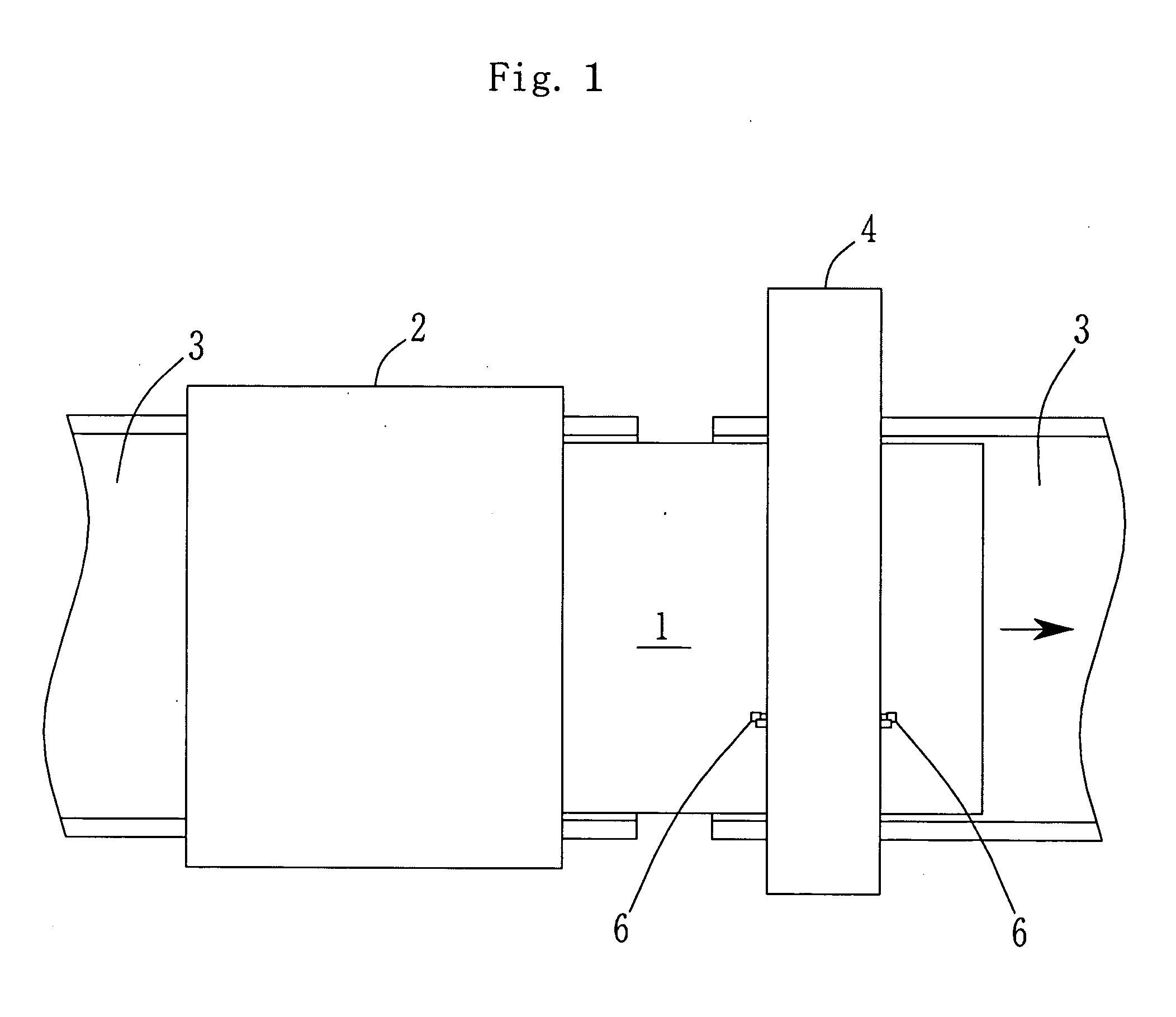

Single-sided chemically mechanical polishing method and device of silicon chip

InactiveCN101934497AReduce or eliminate residueImprove single-sided polishing qualityLapping machinesSilicon chipMaterials science

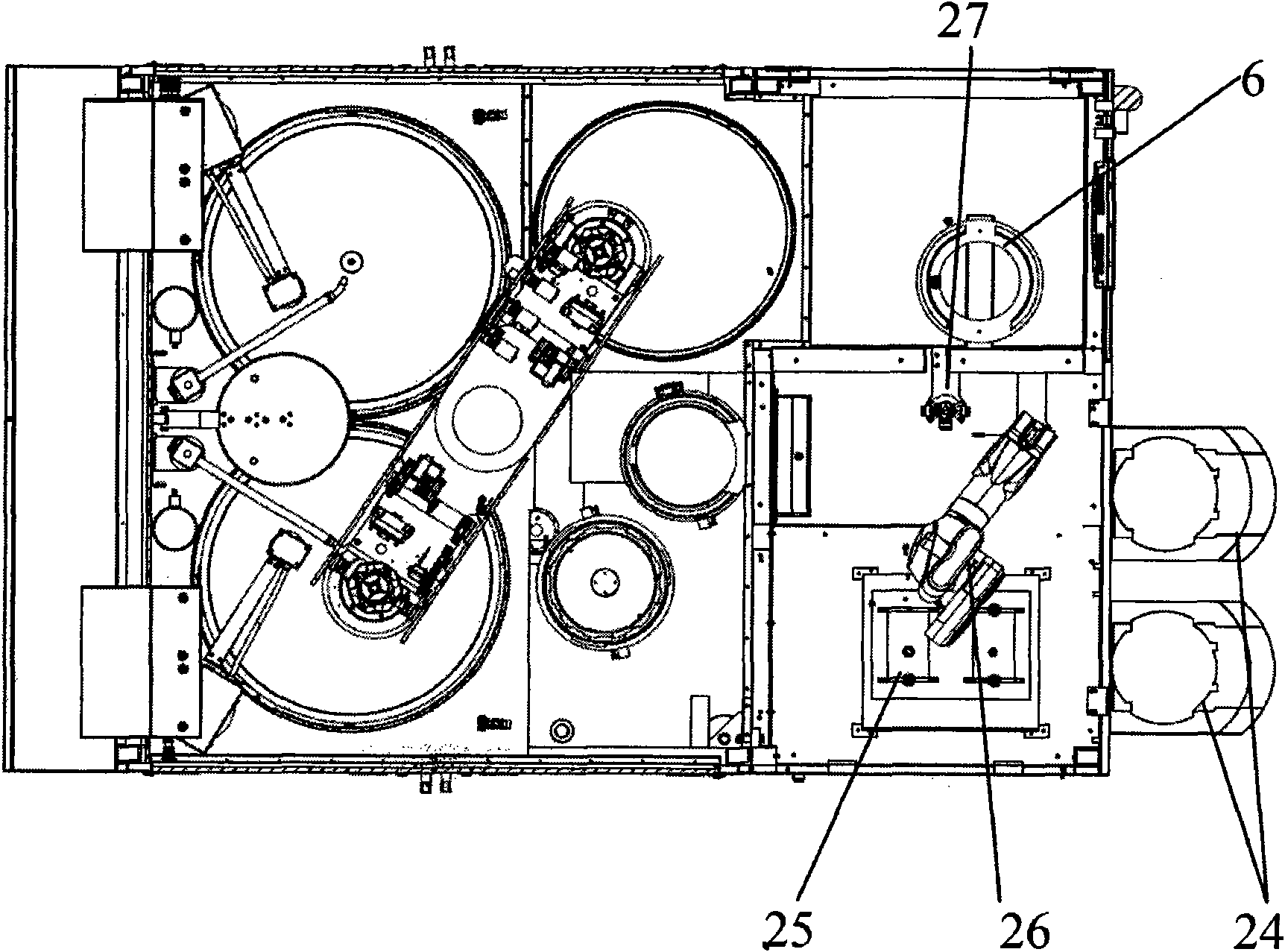

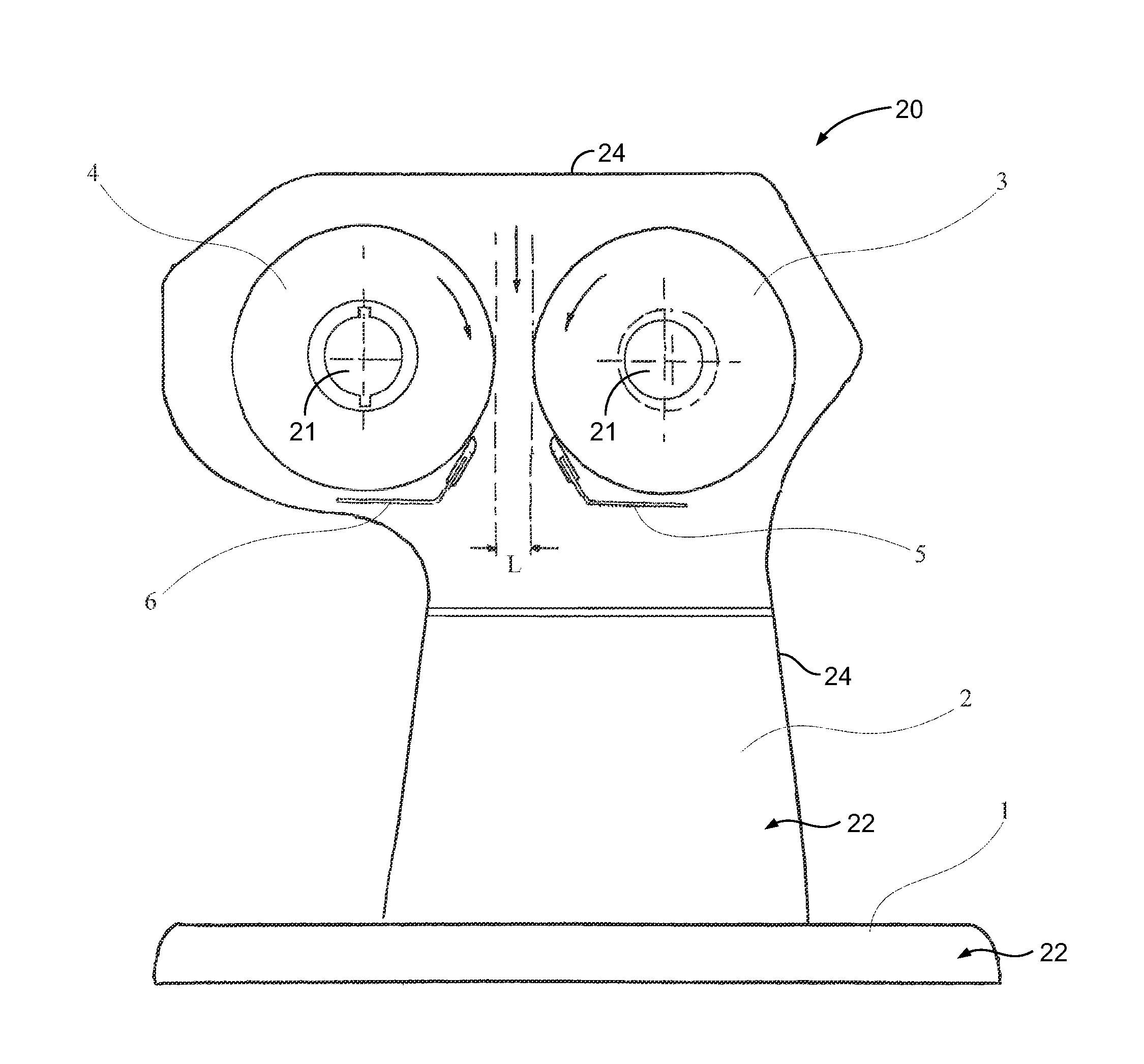

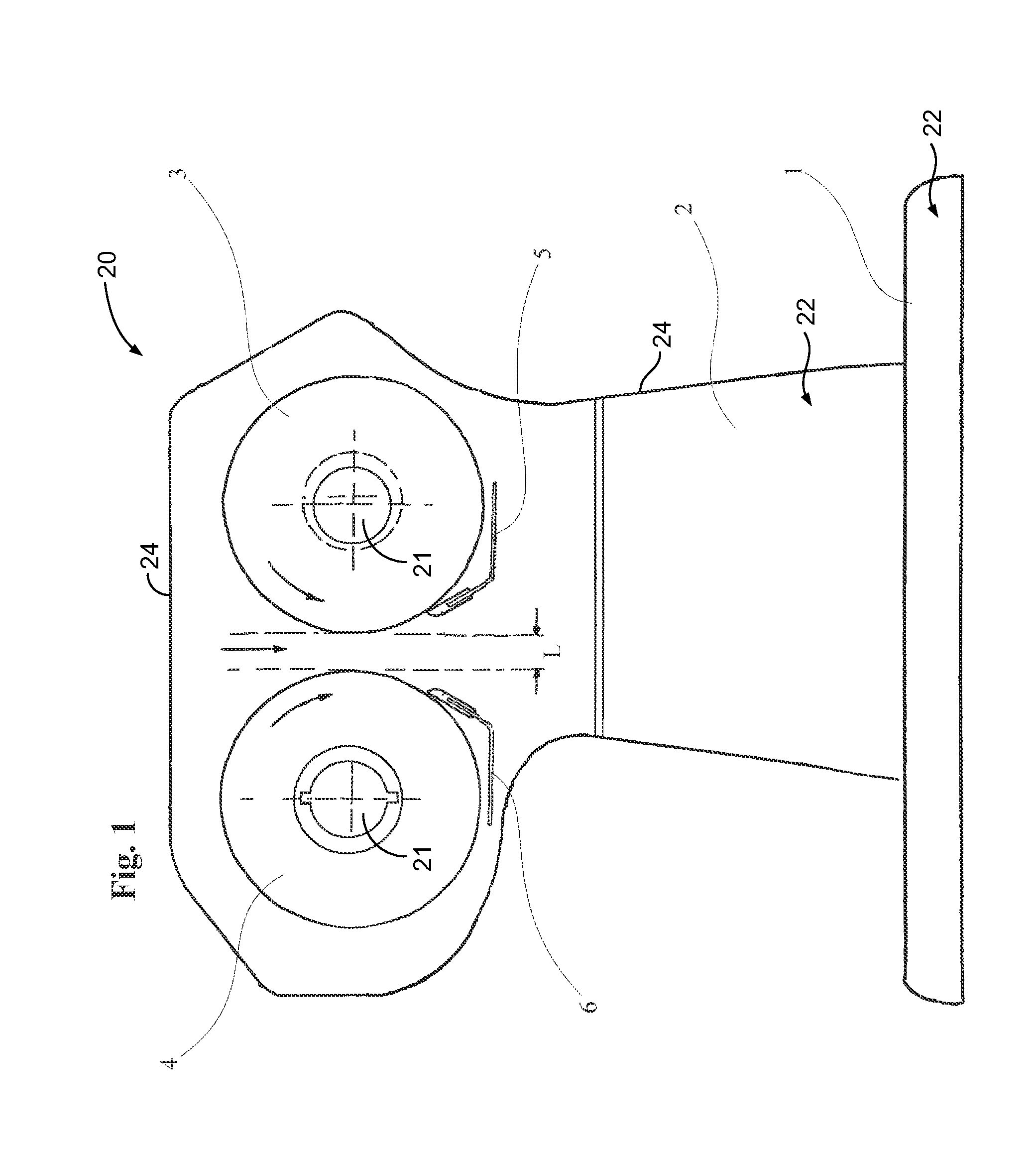

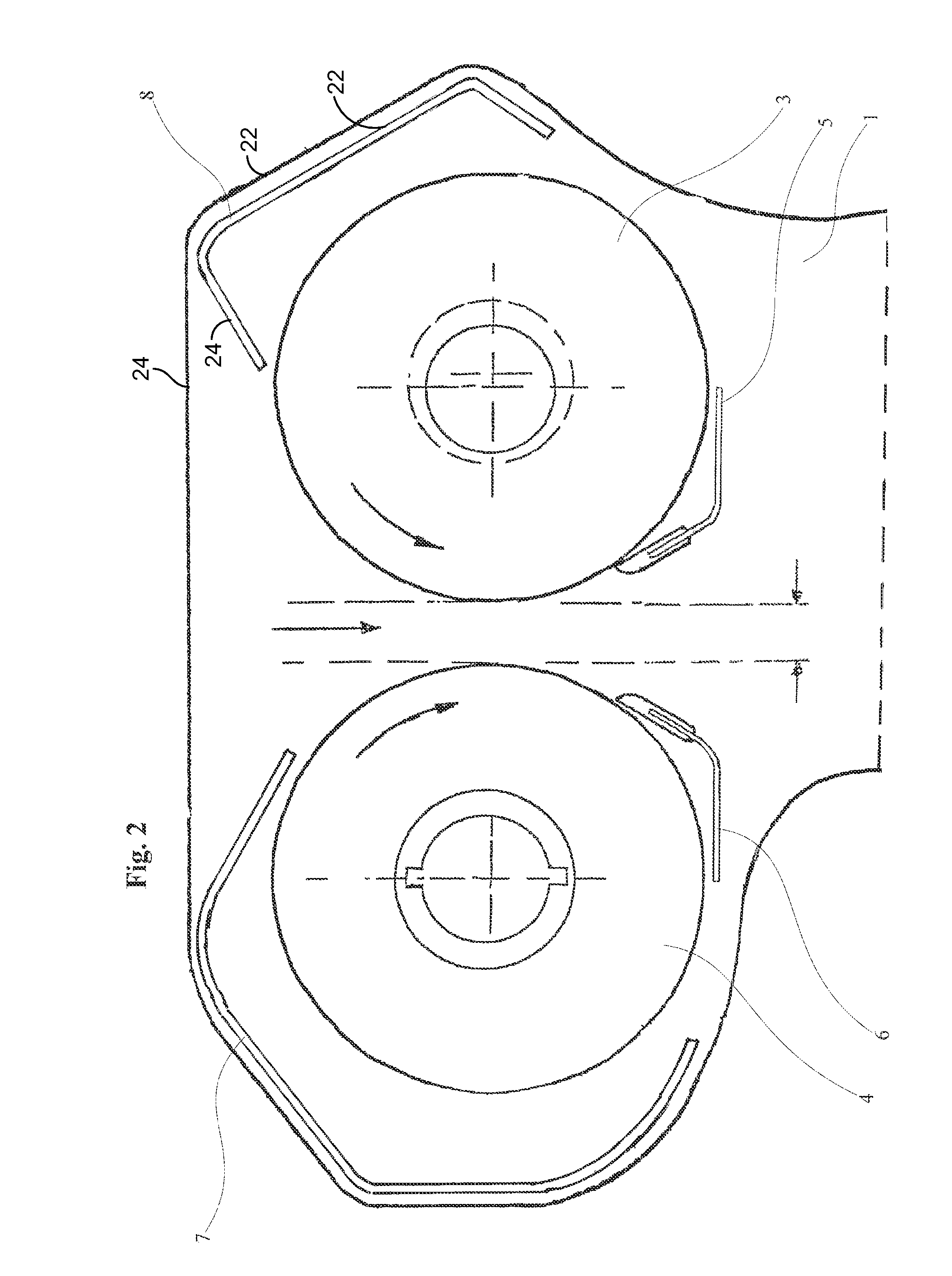

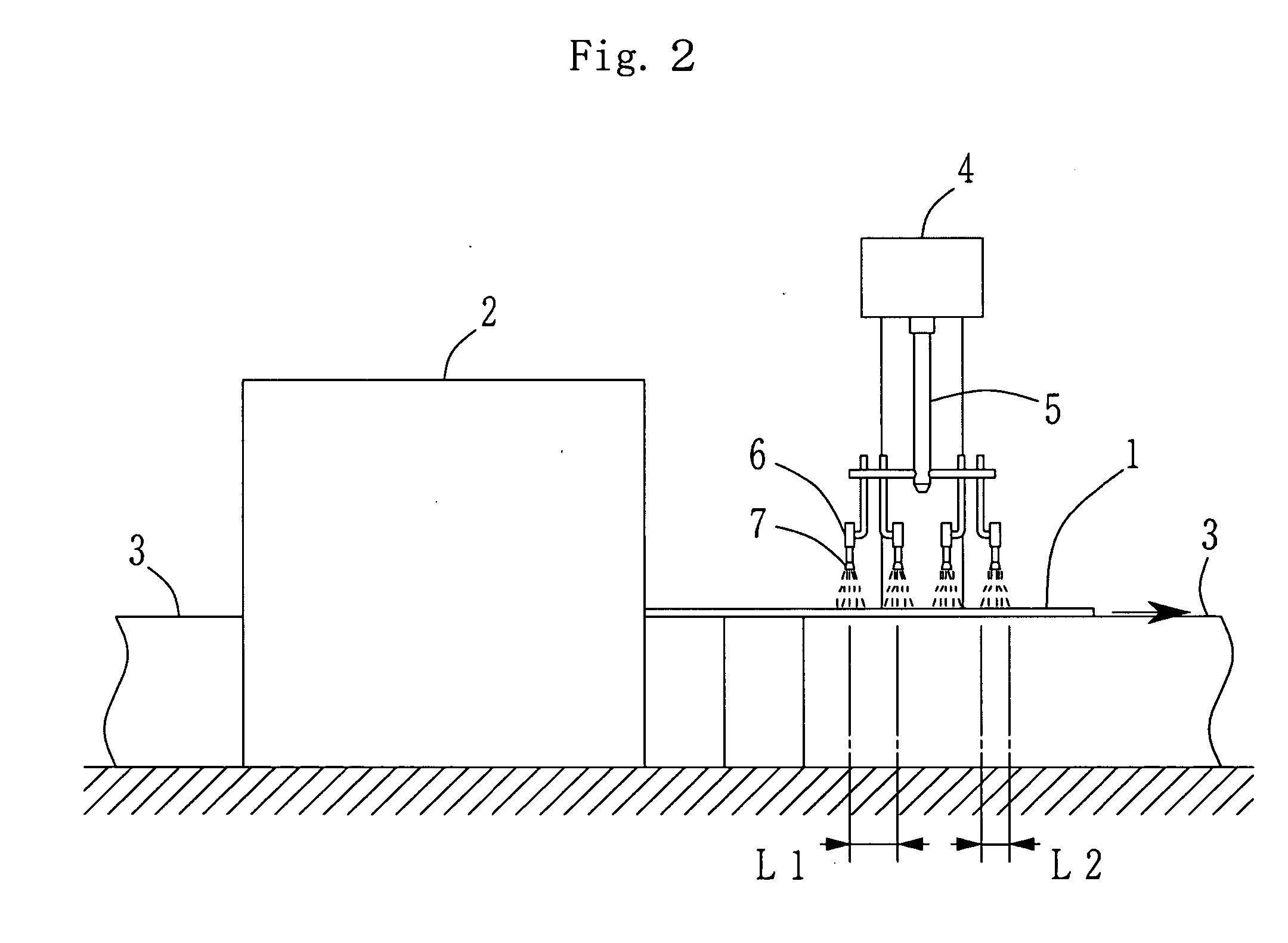

The invention provides single-sided chemically mechanical polishing method and device of a silicon chip, belonging to the technical field of single-sided chemically mechanical polishing methods and apparatuses of the silicon chip. The method comprises the following steps of: carrying out primary polishing and / or fine polishing according to surface quality requirements of single-sided polishing of the silicon chip and then carrying out rinsing polishing on a silicon chip. The device mainly comprises a primary polishing table and / or a fine polishing table and a rinsing polishing table. The invention can effectively reduce or eliminate residues of a polishing solution on a silicon chip surface after the silicon chip is primarily polished or finely polished, can greatly improve the single-sided polishing quality of the silicon chip, has wide application and can particularly satisfy higher precision requirements of the silicon chip with a diameter of 300 mm and above on overall and partial flatness and micro-roughness, and the like; the method is reasonable, unique in principle and favorable in processibility; the device has simple structure, reasonable configuration and high and stable single-sided polishing quality and is beneficial to enhancing production efficiency, reducing costs and realizing automation in the production process.

Owner:THE 45TH RES INST OF CETC

Pasta machine for domestic use with improved cover

ActiveUS20100196529A1Minimizes problemMinimize releaseDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

The item in subject is a pasta machine for domestic use, in which the surfaces of the various parts of the housing are composed of a microporous layer of aluminum oxide and completed with sealing of the micropores for hydration thus obtaining a micro-roughness with nonstick properties enabling the working of moist pasta.

Owner:MARCATO

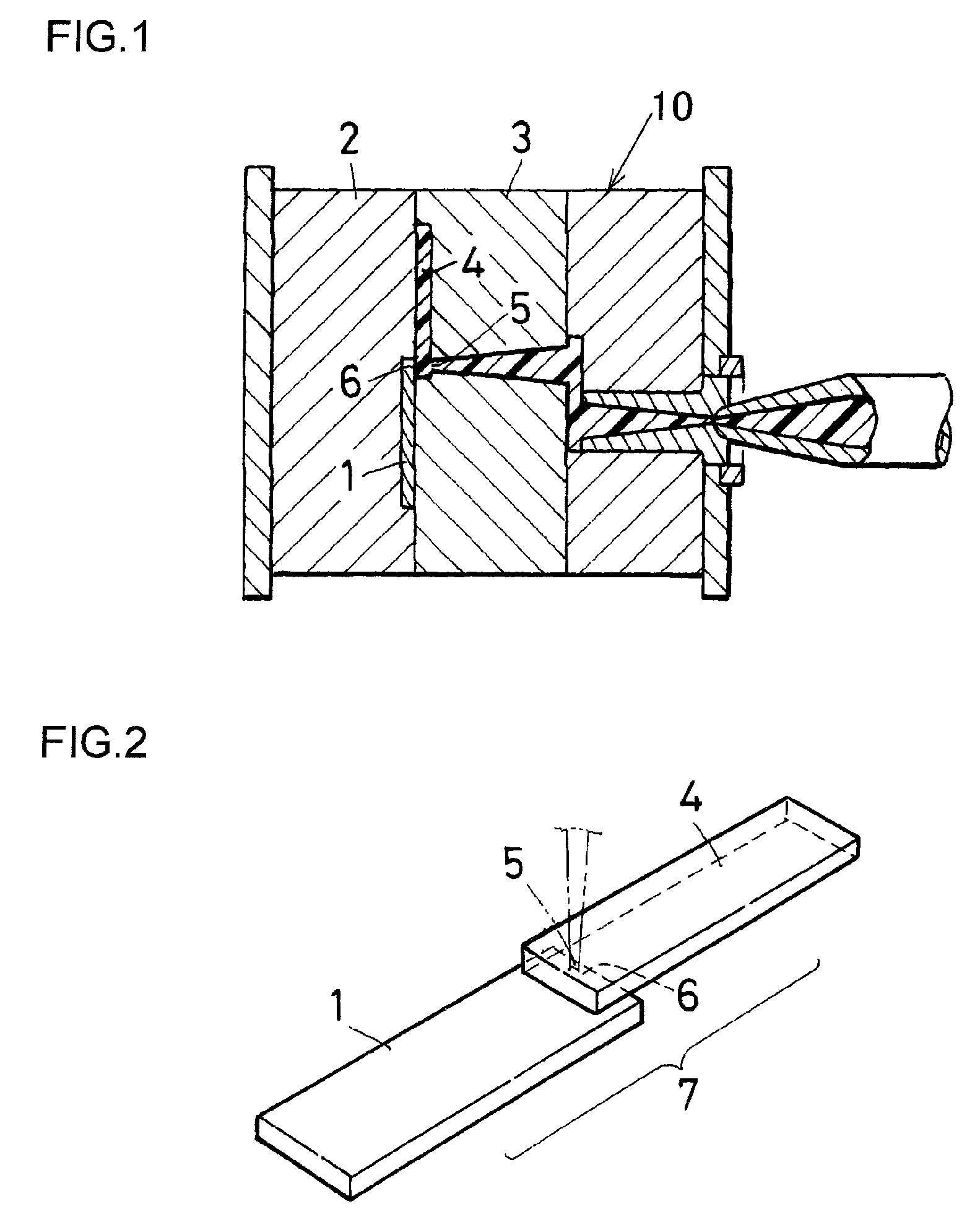

Method of fabricating implant with improved surface properties and implant fabricated by the same method

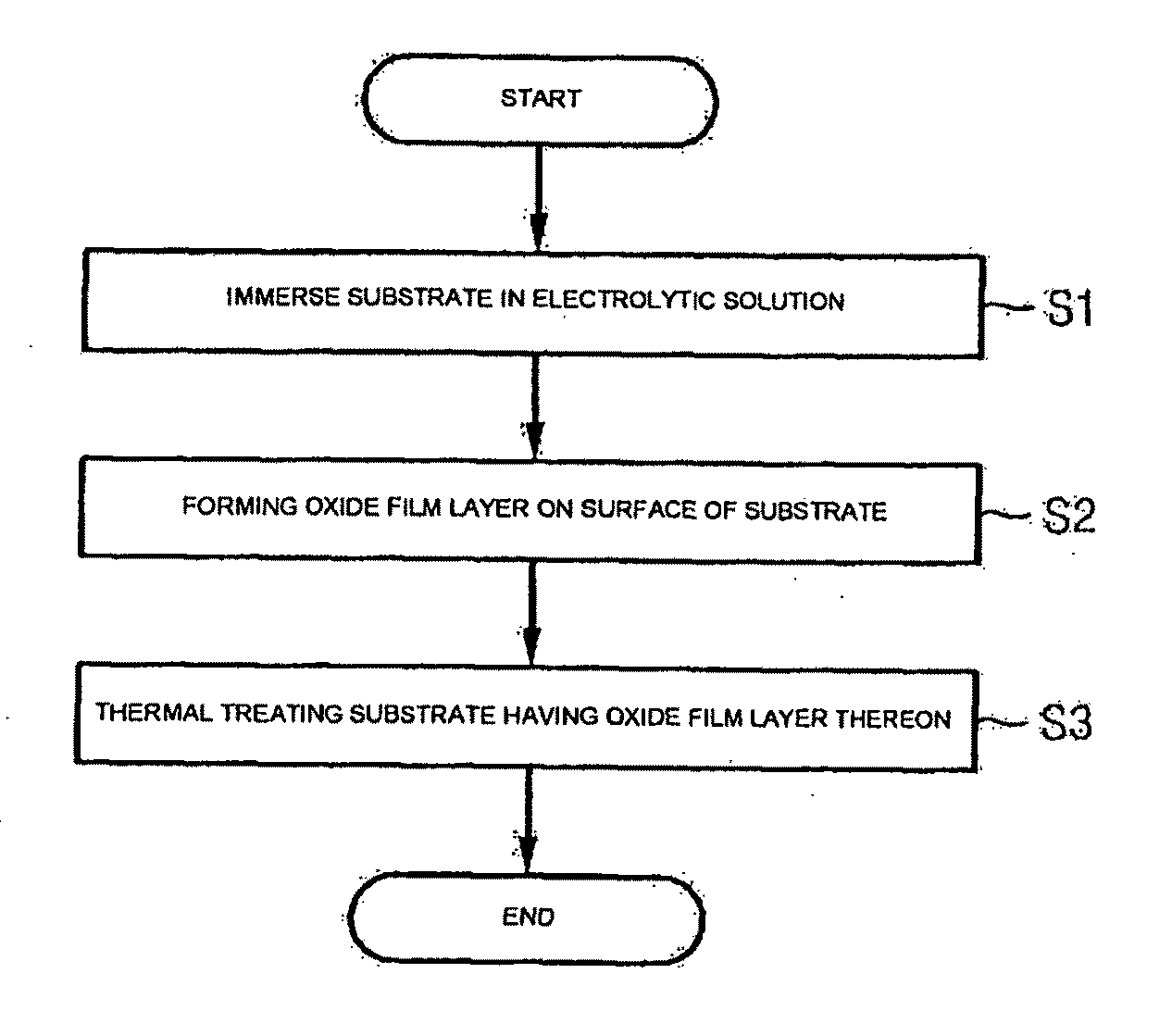

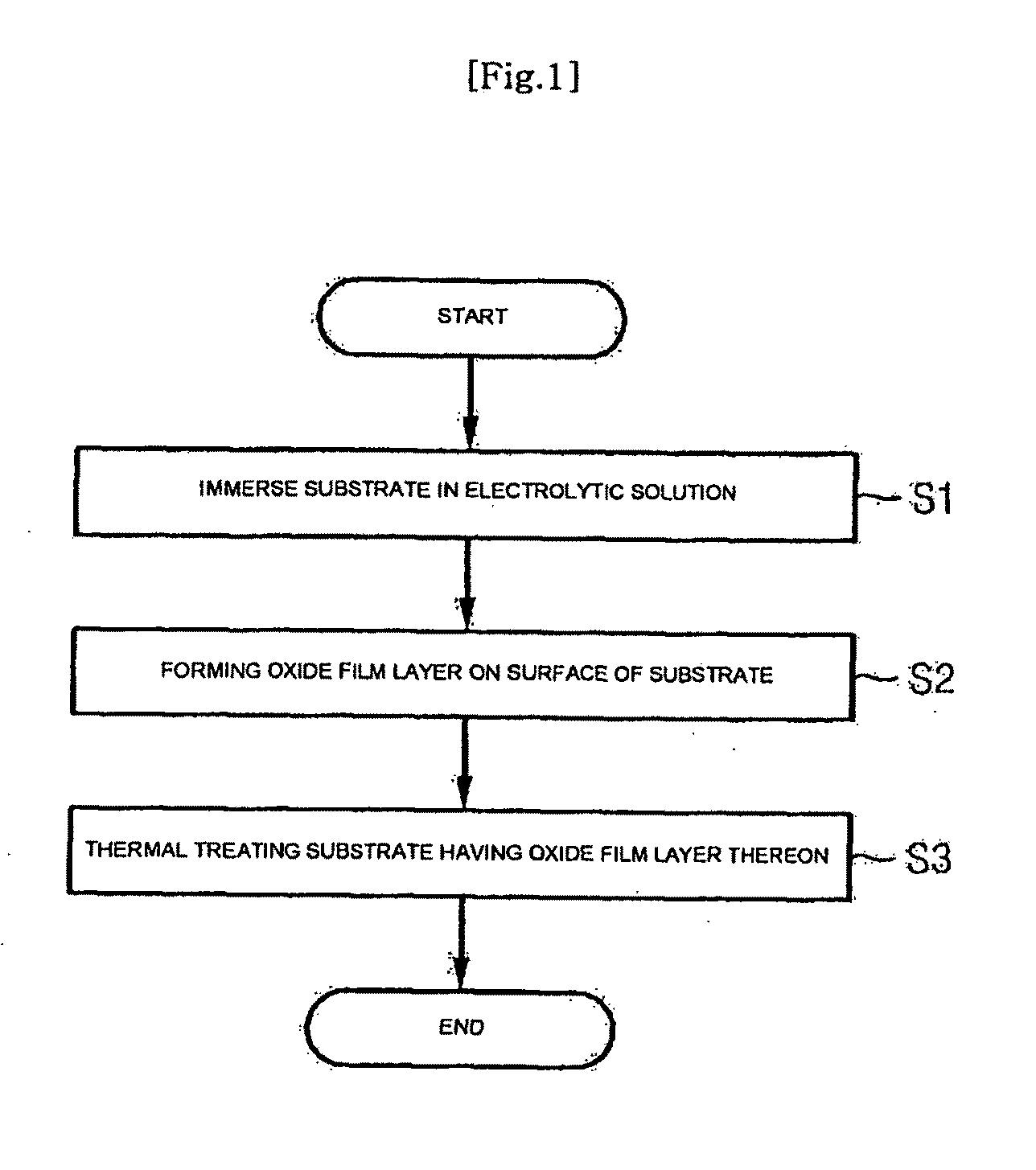

ActiveUS20100136506A1Well formedGood biocompatibilityDental implantsPretreated surfacesTime conditionPhosphate

A method of fabricating an implant with improved surface properties and an implant fabricated using the same are provided. The method includes immersing a substrate that has titanium or titanium alloy in electrolytic solution including at least one of the group consisting of phosphate or fluoride ion and strontium ion, and forming an oxide film layer with a surface structure having a fine roughness of a micro scale by making at least one of phosphate or fluoride ion and strontium ion react to the titanium or the titanium alloy of the substrate on a surface of the immersed substrate using hydrothermal reaction associated with temperature, pressure and time conditions.

Owner:OSTEOPHIL

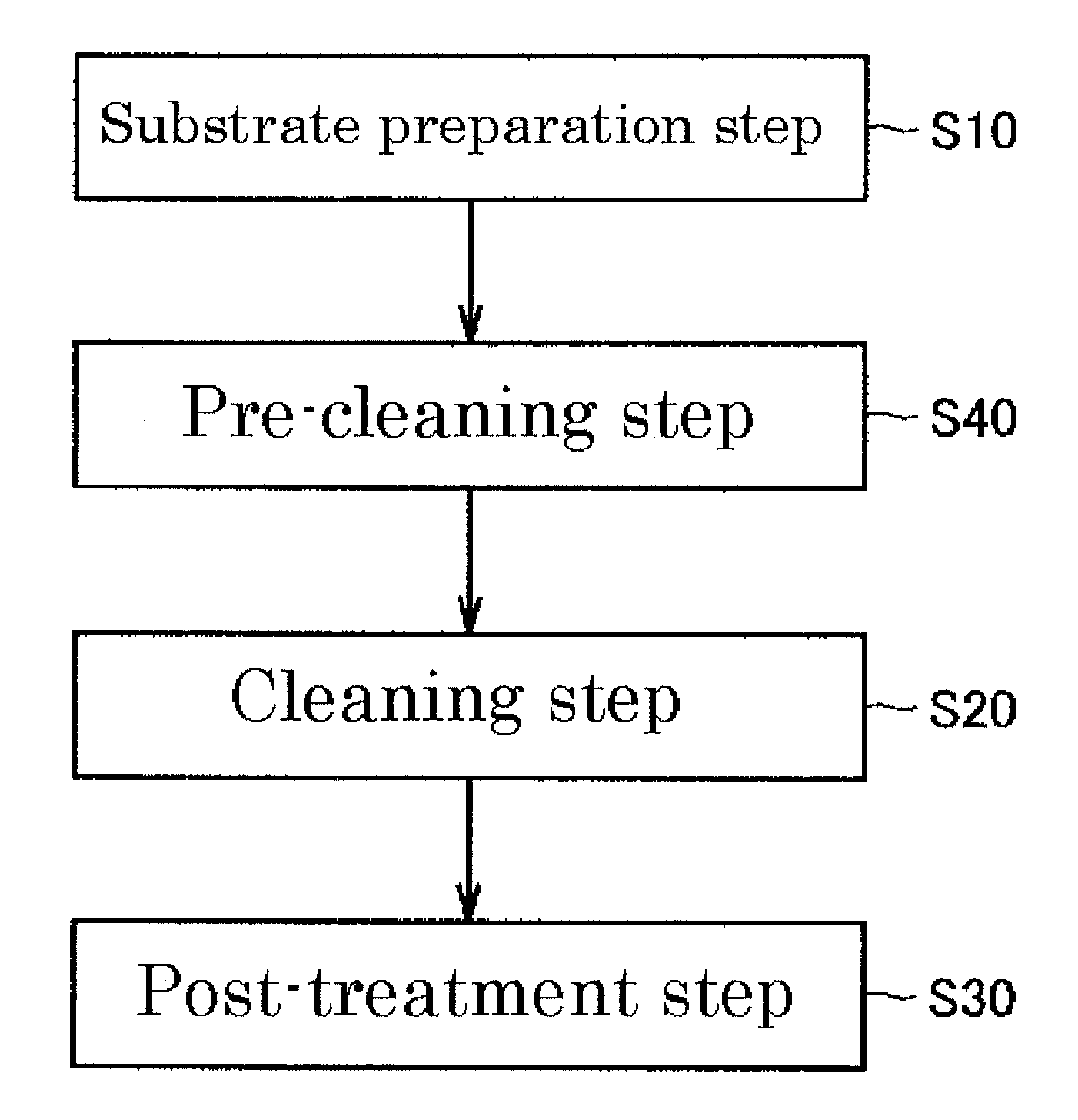

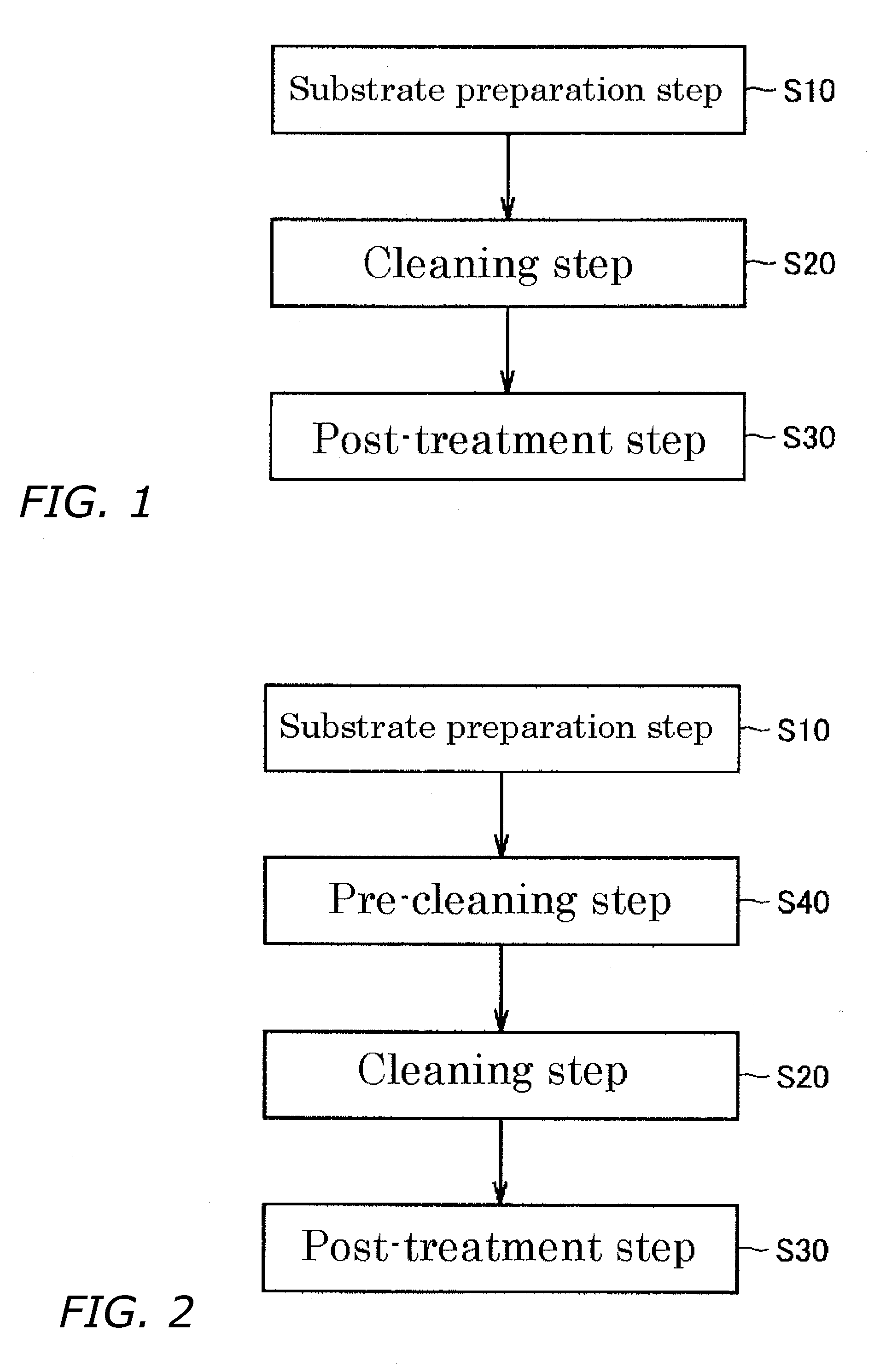

Method of Surface Treating Substrates and Method of Manufacturing III-V Compound Semiconductors

InactiveUS20070014915A1Reduce surface roughnessReduce roughnessPharmaceutical containersPretreated surfacesChemical compoundOxidizing agent

Affords methods of surface treating a substrate and of manufacturing Group III-V compound semiconductors, in which a substrate made of a Group III-V semiconductor compound is rendered stoichiometric, and microscopic roughness on the surface following epitaxial growth is reduced. The methods include preparing a substrate made of a Group III-V semiconductor compound (S10), and cleaning the substrate with a cleaning solution whose pH has been adjusted to an acidity of 2 to 6.3 inclusive, and to which an oxidizing agent has been added (S20).

Owner:SUMITOMO ELECTRIC IND LTD

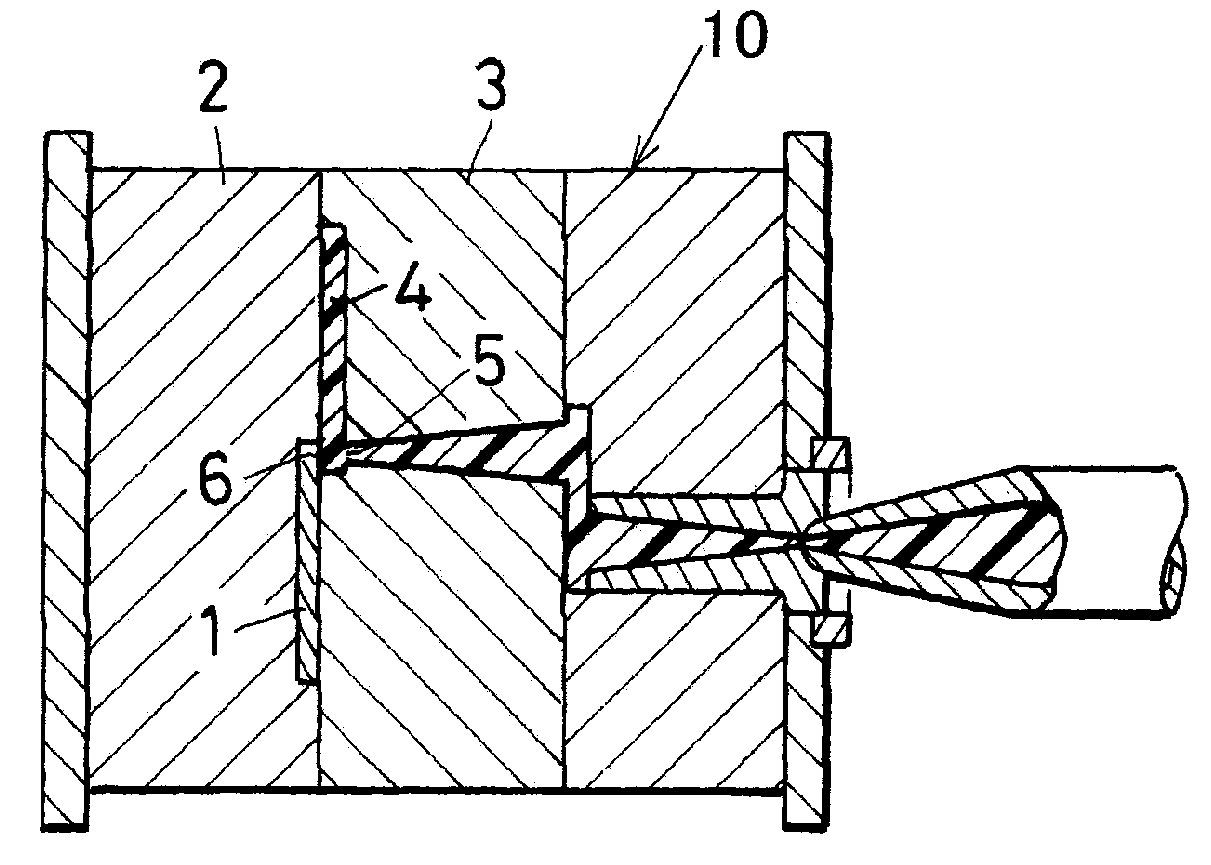

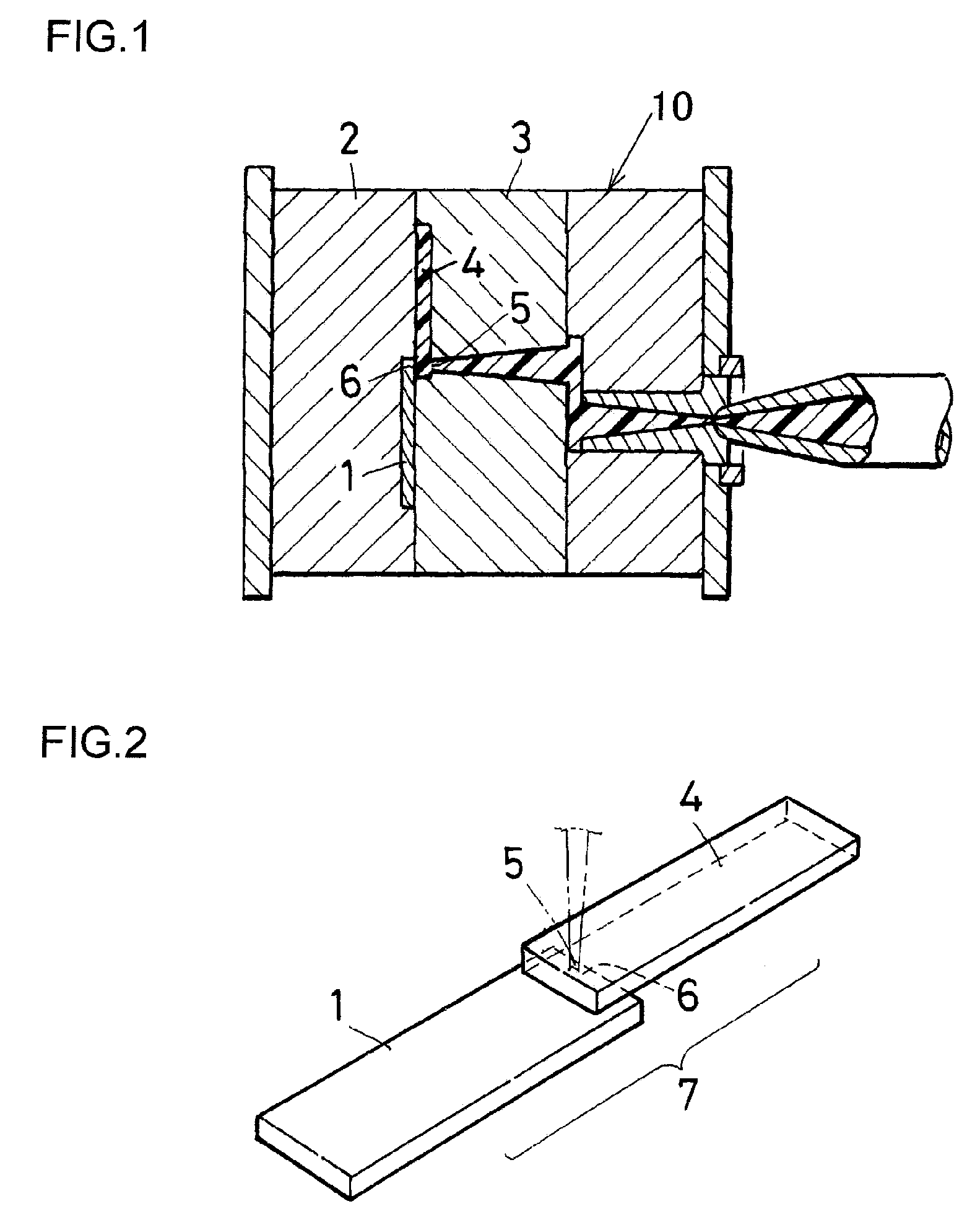

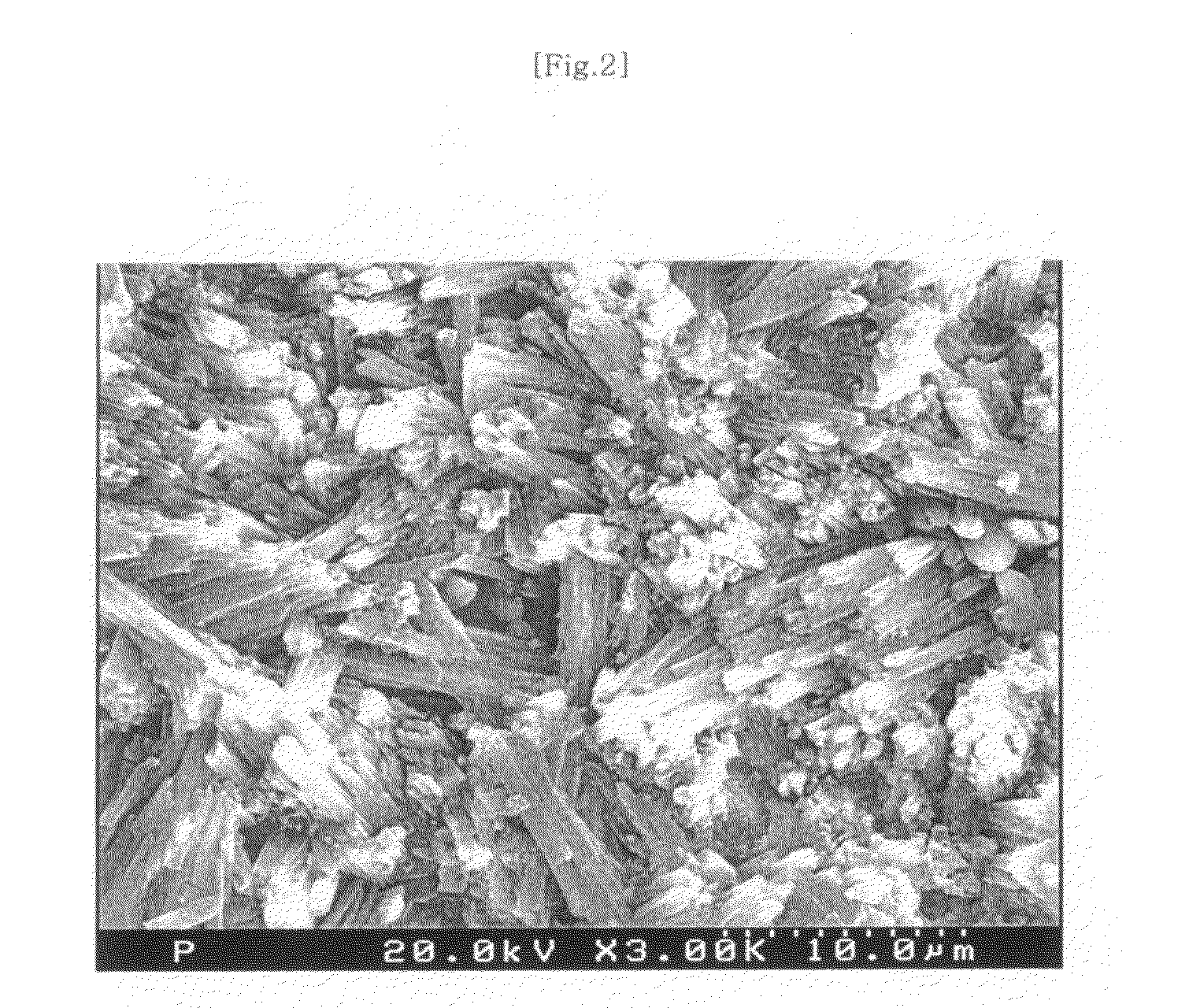

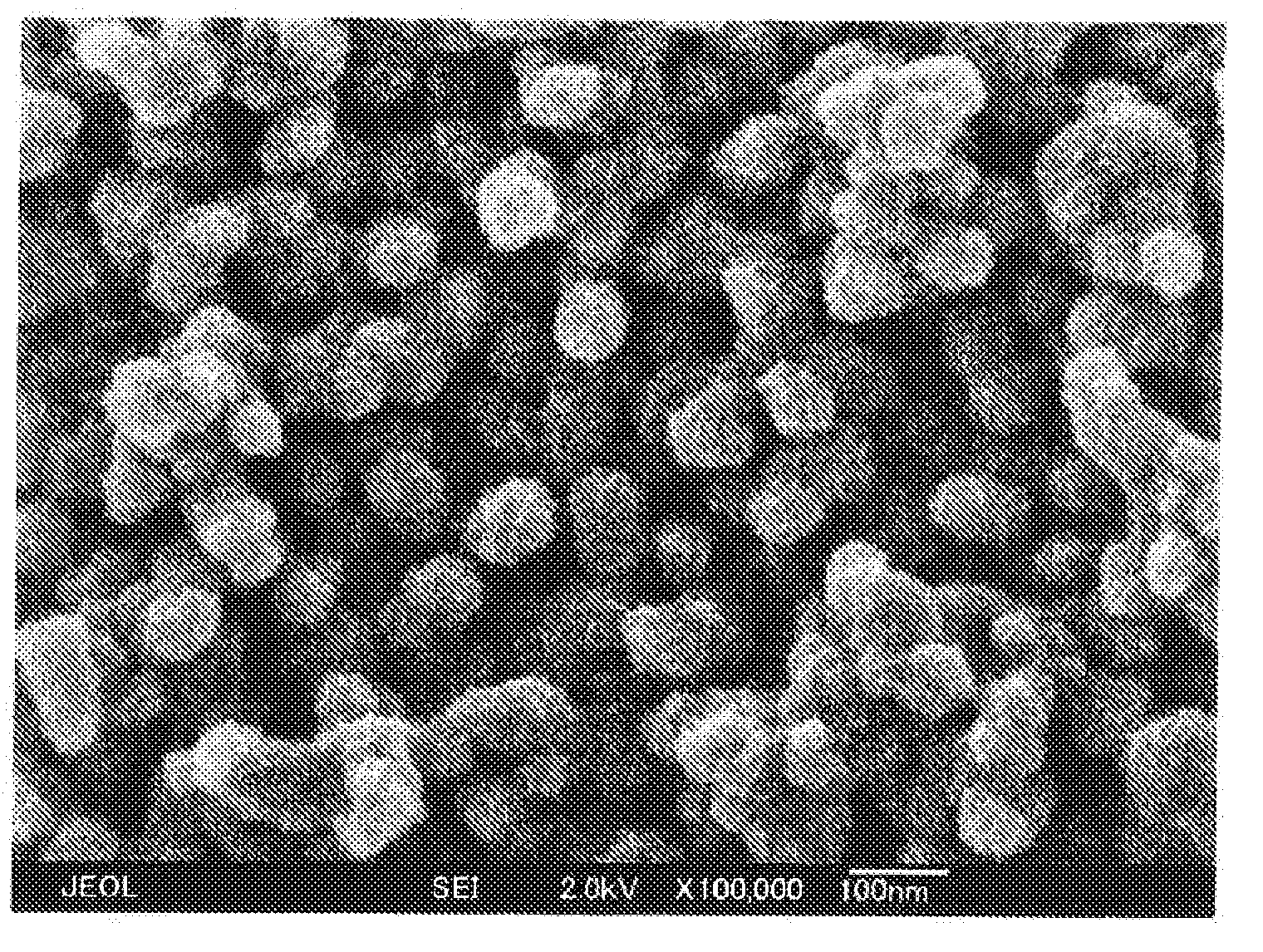

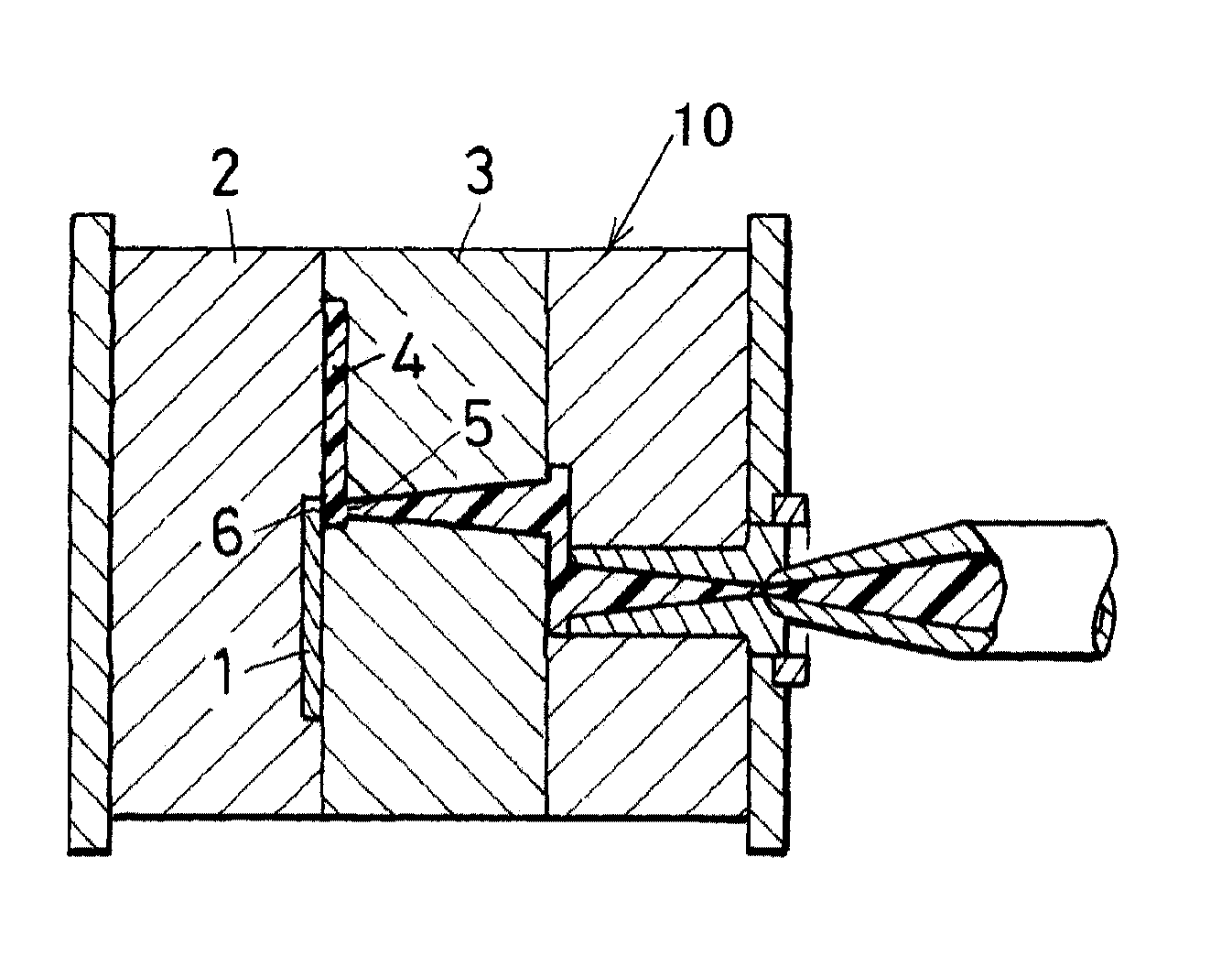

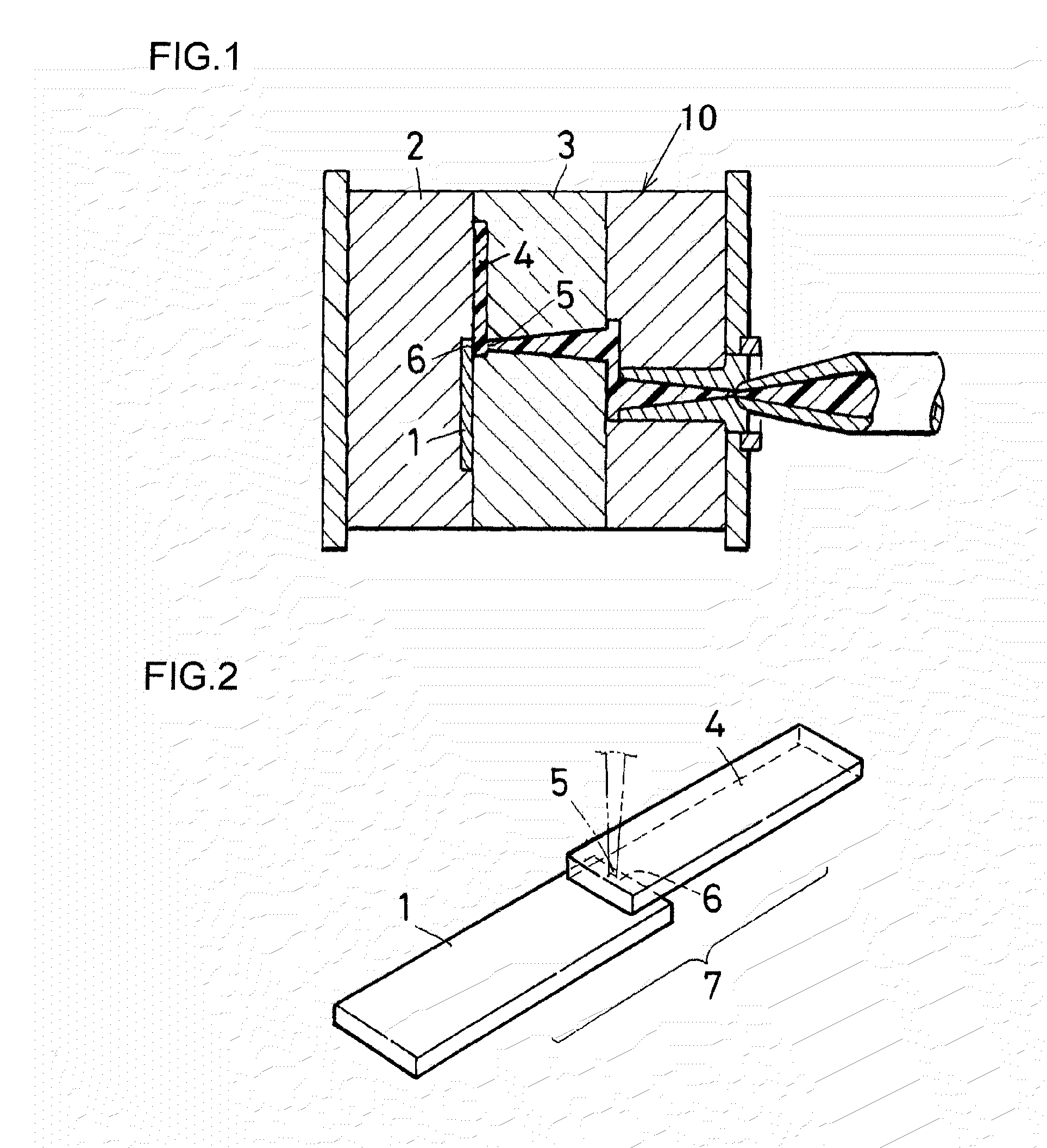

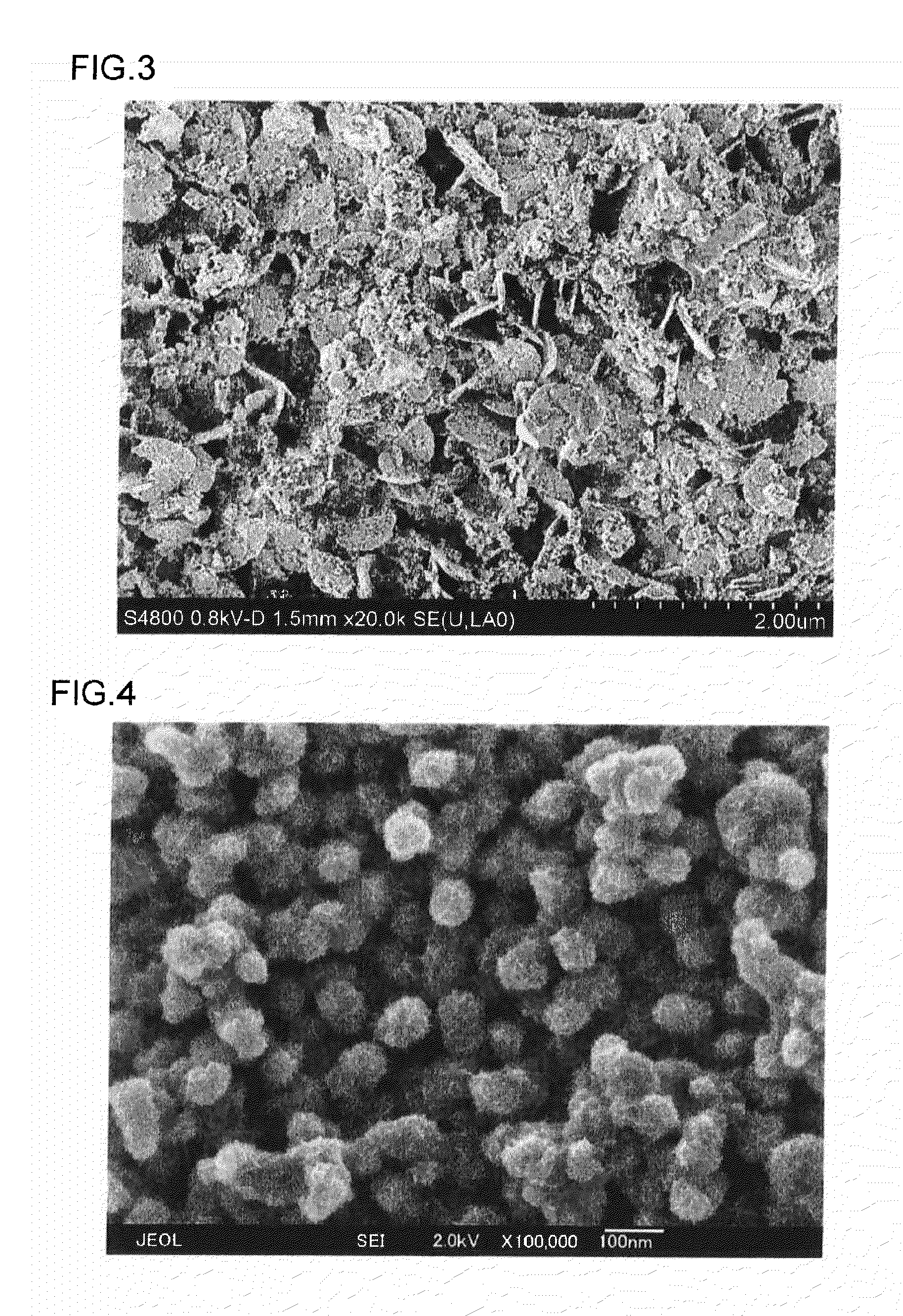

Composite of metal and resin and method for manufacturing same

ActiveUS8703272B2High hardnessEasy to peelSynthetic resin layered productsRecord information storageSurface layerPhosphate

A composite of a metal part and a resin composition part that is improved so that the metal and resin are integrally joined to have strong bonding properties, and a method for manufacturing the composite. A magnesium alloy part is inserted into a mold, a resin composition is injected and joined to the part, and a composite is obtained. A part having, formed thereon, a surface layer of a metal oxide, a metal carbonate, or a metal phosphate in use of a usual conversion treatment or a modification method thereof can be used for the magnesium alloy plate 1. The surface that has a larger amount of crystal-like objects of a nanolevel on the surface layer composed of the metal oxide, metal carbonate, or metal phosphate has a higher level of hardness, microscopic roughness, and good injection joining force, and these parameters can be controlled by a conversion treatment method. A resin composition 4, containing PBT or PPS as the main component, is used as the resin composition part.

Owner:TAISEI PLAS CO LTD

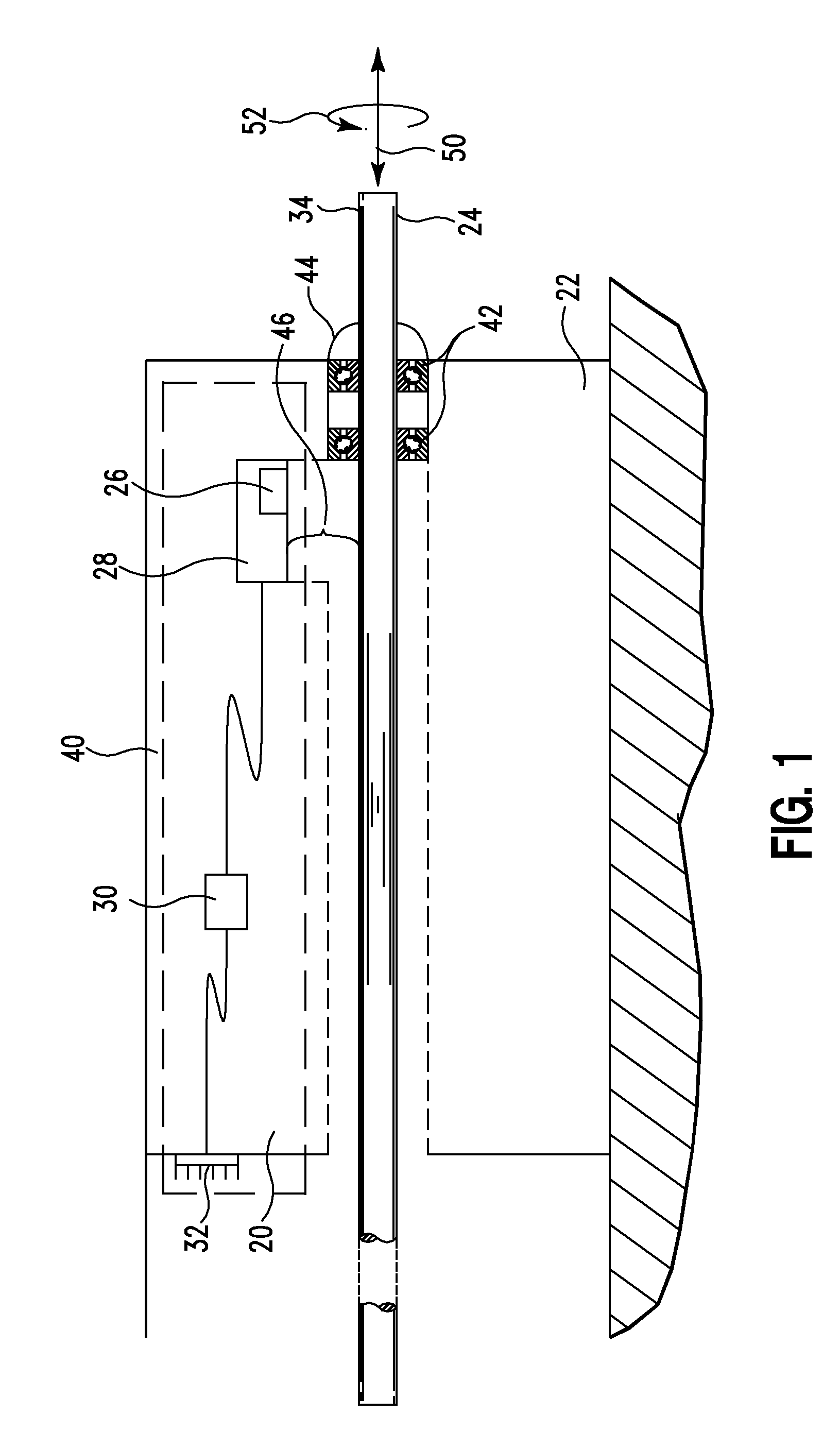

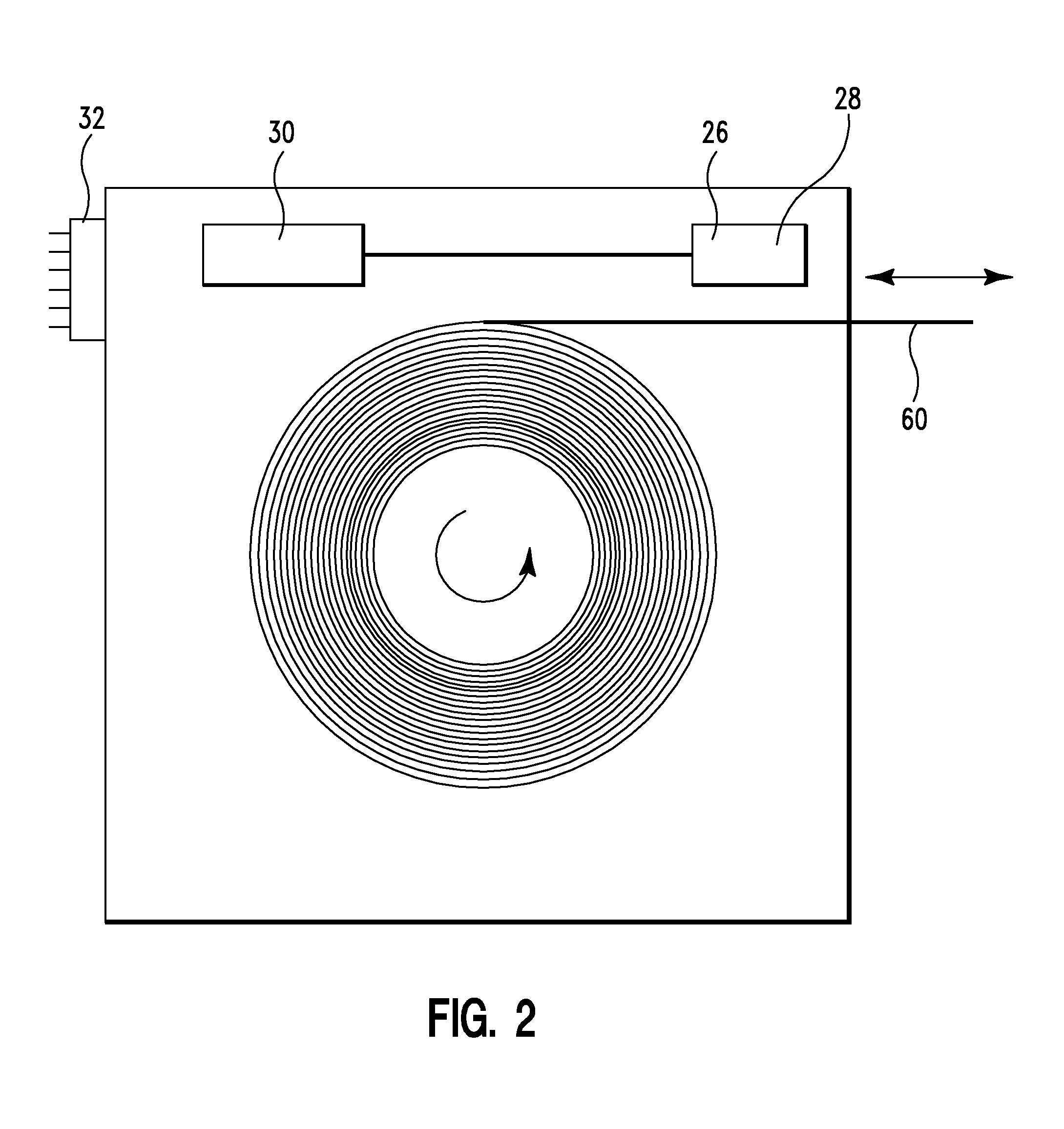

Optical Linear and Rotation Displacement Sensor

A system includes a measuring tool, a fixture, and a rotatable target. The measuring tool includes a light source, an imaging device, and an electronic circuit. The fixture allows the rotatable target to rotate about an axis. The rotatable target includes a surface having microscopic asperities. The imaging device is mounted to provide a sequence of images derived from said microscopic asperities. The electronic circuit is connected to the imaging device for measuring rotation of the rotatable target from the sequence of images.

Owner:LORD CORP

LED Device With A Light Extracting Rough Structure And Manufacturing Methods Thereof

InactiveUS20120086035A1Solid-state devicesSemiconductor/solid-state device manufacturingStructure functionElectromagnetic radiation

A light emitting diode device includes a substrate, one or more light emitting diode chips on the substrate configured to emit electromagnetic radiation, and a lens configured to encapsulate the light emitting diode chips having a surface with a micro-roughness structure. The micro-roughness structure functions to improve the light extraction of the electromagnetic radiation and to direct the electromagnetic radiation outward from the lens.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

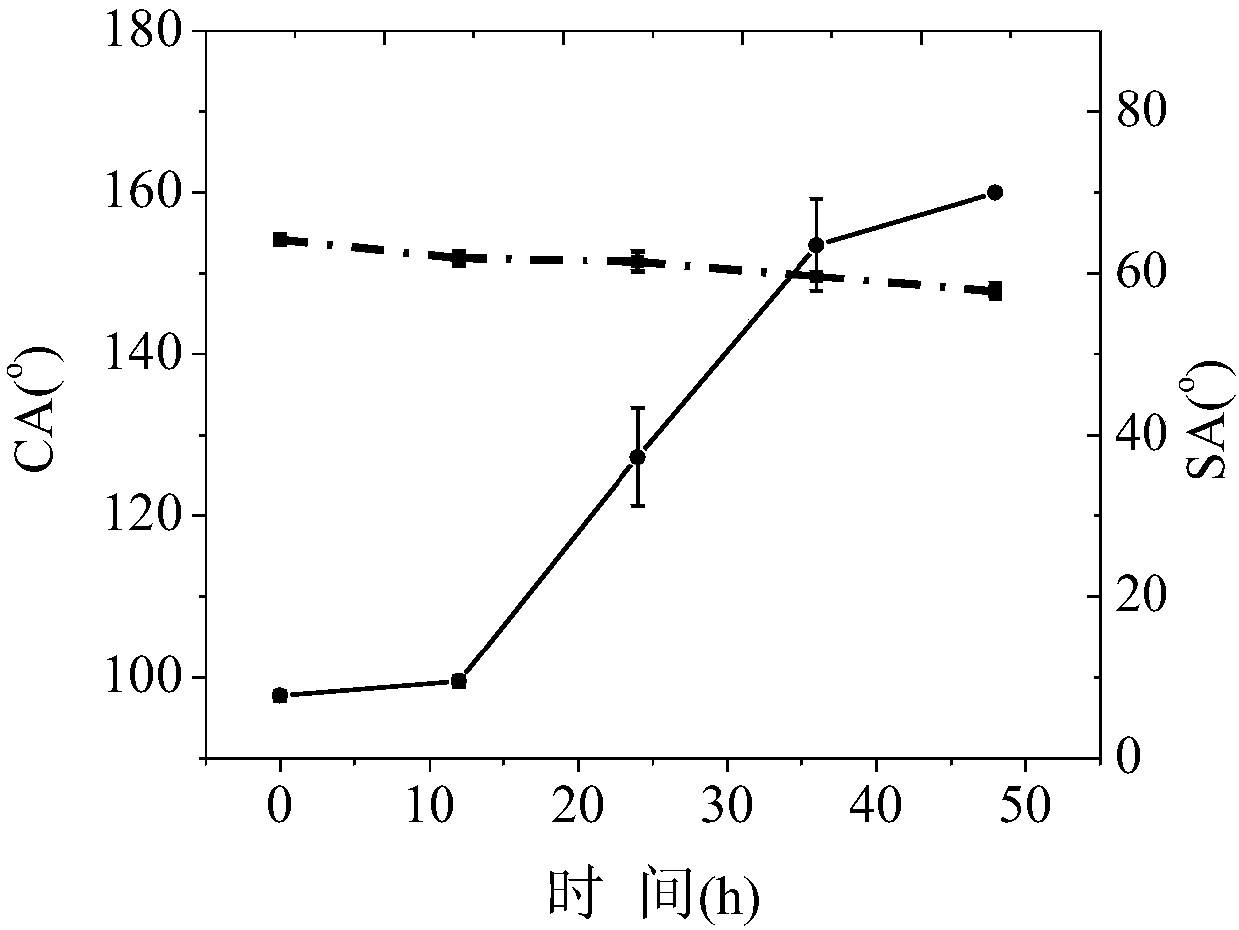

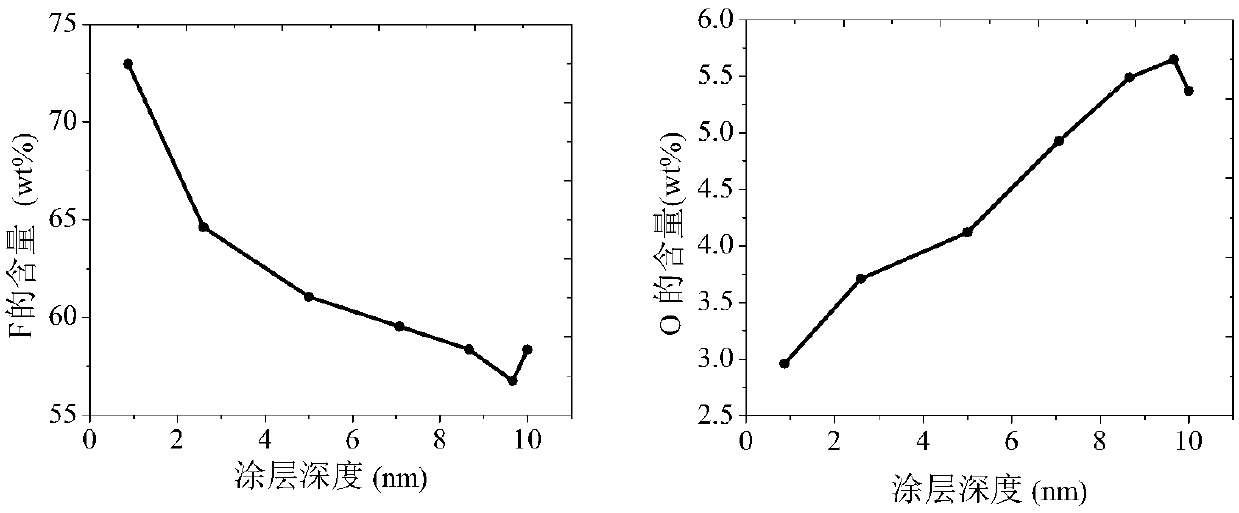

Waterborne superhydrophobic coating for building exterior walls, and preparation method and application thereof

InactiveCN107779084AExcellent superhydrophobic propertiesSimple preparation processAntifouling/underwater paintsPaints with biocidesAcrylic resinSilicon oxide

The invention discloses a waterborne superhydrophobic coating for building exterior walls. The coating is characterized by being prepared according to the following method: mixing deionized water andinorganic micron-nano-sized particles, carrying out uniform mixing by stirring at a room temperature, then adding a building exterior wall coating emulsion and fluorine-containing acrylic resin, and carrying out uniform stirring so as to obtain the waterborne superhydrophobic coating for building exterior walls, wherein the building exterior wall coating emulsion is one or a mixture of two or moreselected from the group consisting of a silicone-acrylate emulsion, a styrene-acrylic emulsion, a pure acrylic emulsion or an organosilicon emulsion in an arbitrary proportion; and the inorganic micron-nano-sized particles are one or a combination of two or more selected from the group consisting of silicon oxide, calcium carbonate and titanium dioxide. The preparation process provided by the invention is simple and has simple and convenient operations; the building exterior wall coating emulsion is utilized to provide a base bonding force; the fluorine-containing acrylic resin is self-migrated to the surface to form low surface energy; the micron-nano-sized particles provide micro roughness; thus, the coating has excellent superhydrophobicity.

Owner:ZHEJIANG UNIV OF TECH

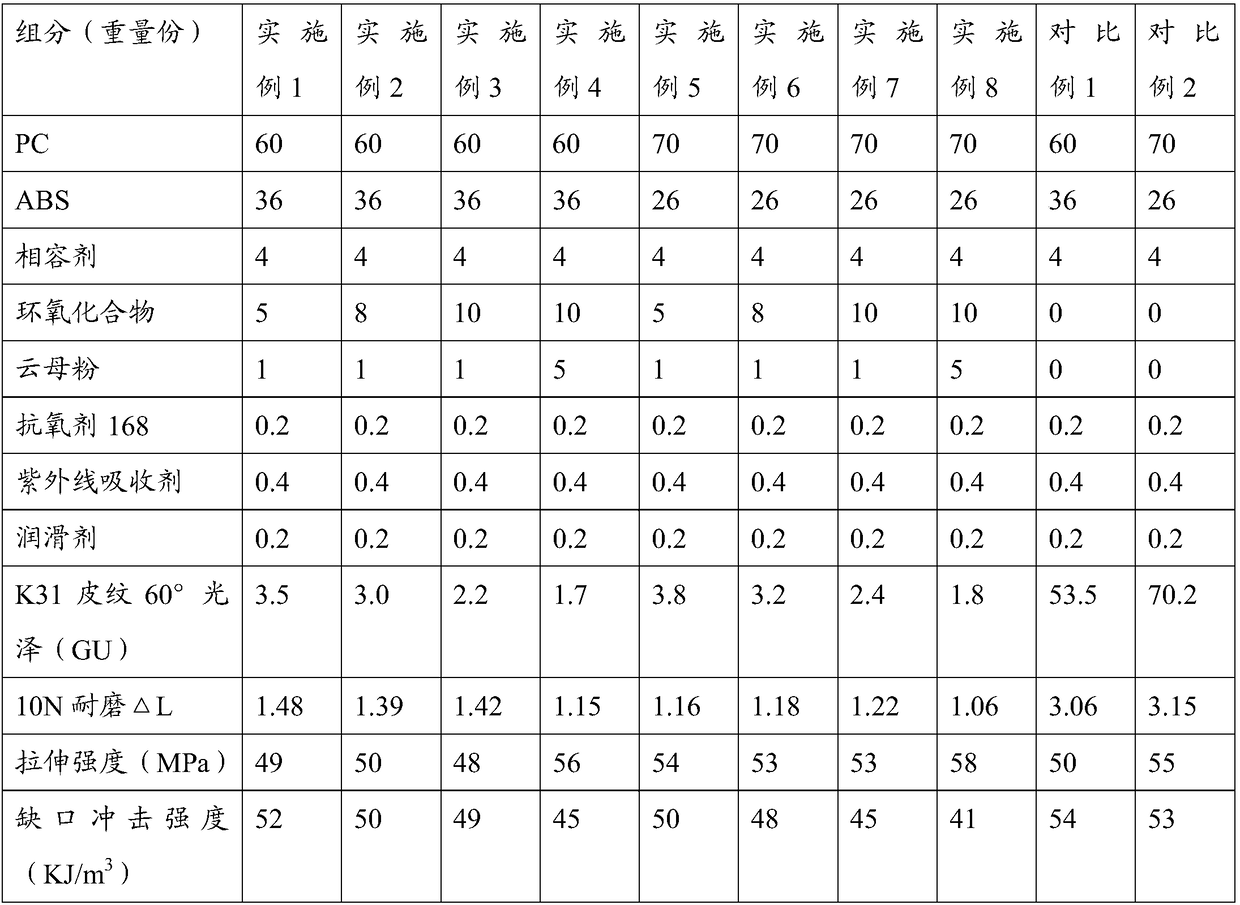

Spray-free matte PC-ABS alloy material and preparation method thereof

ActiveCN108587106AIncrease the relative molecular massWith wear-resistant propertiesFiberCarbon fibers

The application discloses a spray-free matte PC-ABS alloy material and a preparation method thereof. The spray-free matte PC-ABS alloy material is prepared from the following raw materials: PC, an epoxy compound, ABS, PMI, mica powder, an ultraviolet light absorber, a compatilizer, an antioxidant, a lubricant, calcium carbonate, carbon fibers, titanium oxide fibers, glass fibers, polyethylene glycol, EBS, MBS, HDPE, a flame retardant, PTT fibers and EVA; an epoxy functional group reacts with a terminal hydroxyl group of PC, so that the PC is branched or partially crosslinked, the relative molecular quality is improved, the concentration of the terminal group is reduced and the compatibility between the PC and ABS interface is also decreased before branching; macromolecular chain segments of the material begin to curl by adding mica powder for compounding, a free space is filled with inorganic mineral powder while the macromolecular chain segments curl, so that uneven convex micro-roughness of extrusion lines and extrusion particles of the material is realized; parts obtained by injection molding show low gloss characteristics, while inorganic minerals enable the material to have wear resistance.

Owner:南京跃贝新材料科技有限公司

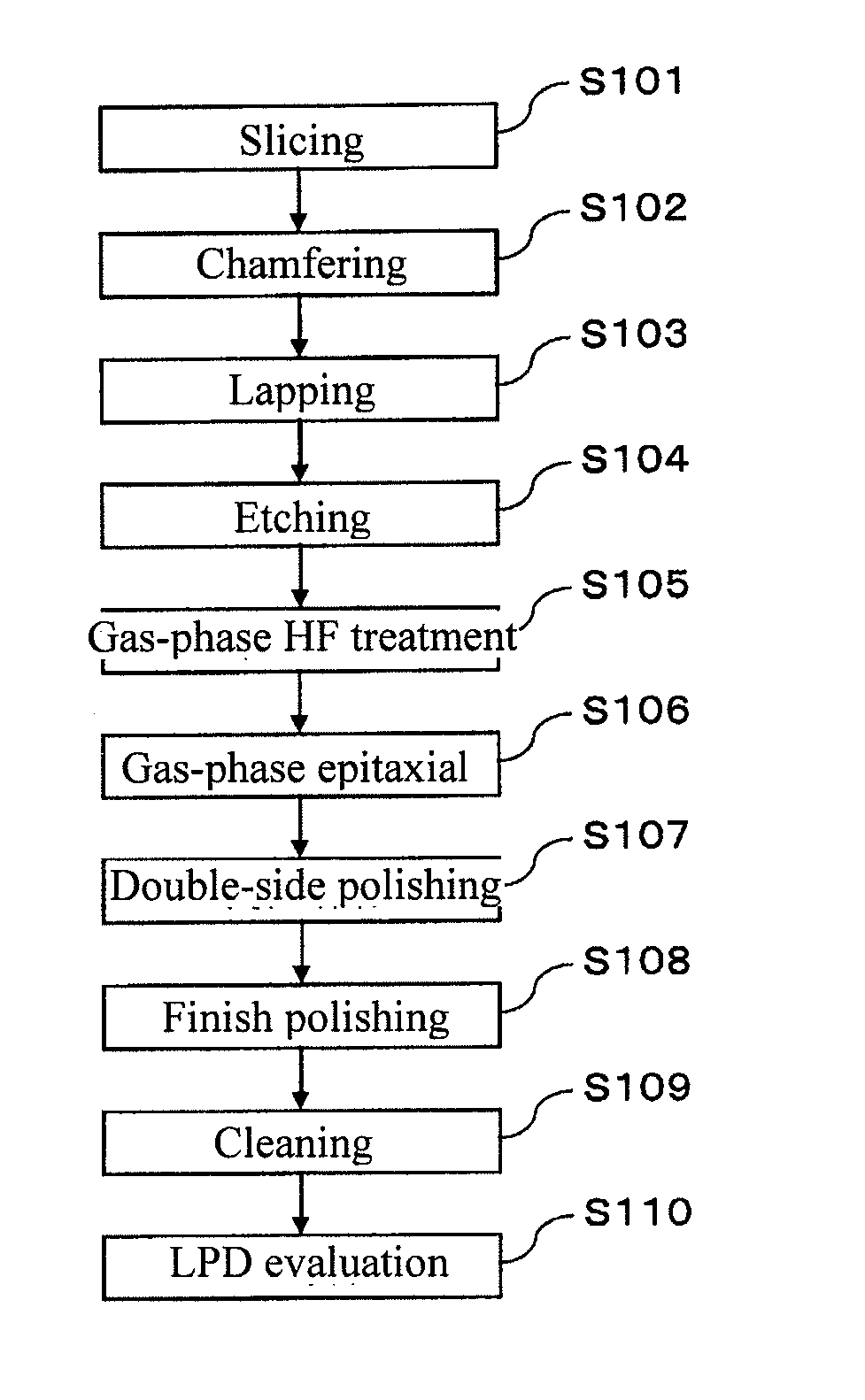

Silicon wafer cleaning process

ActiveCN102486994AImprove surface conditionSurface micro-roughness guaranteeSemiconductor/solid-state device manufacturingCleaning using liquidsHydrofluoric acidSilicon chip

The invention relates to a silicon wafer cleaning process. According to the invention, multiple cleaning steps are adopted in the silicon wafer cleaning process, and hydrofluoric acid and hydrogen peroxide which are chemical reagents are used in each step, wherein the volume ratio of HF to H2O2 to H2O is 1: 1: 20 - 1: 1: 300. The silicon wafer cleaning process has the advantages of effectively improving particle removing efficiency, reducing surface micro-roughness level and increasing the product percent of pass.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

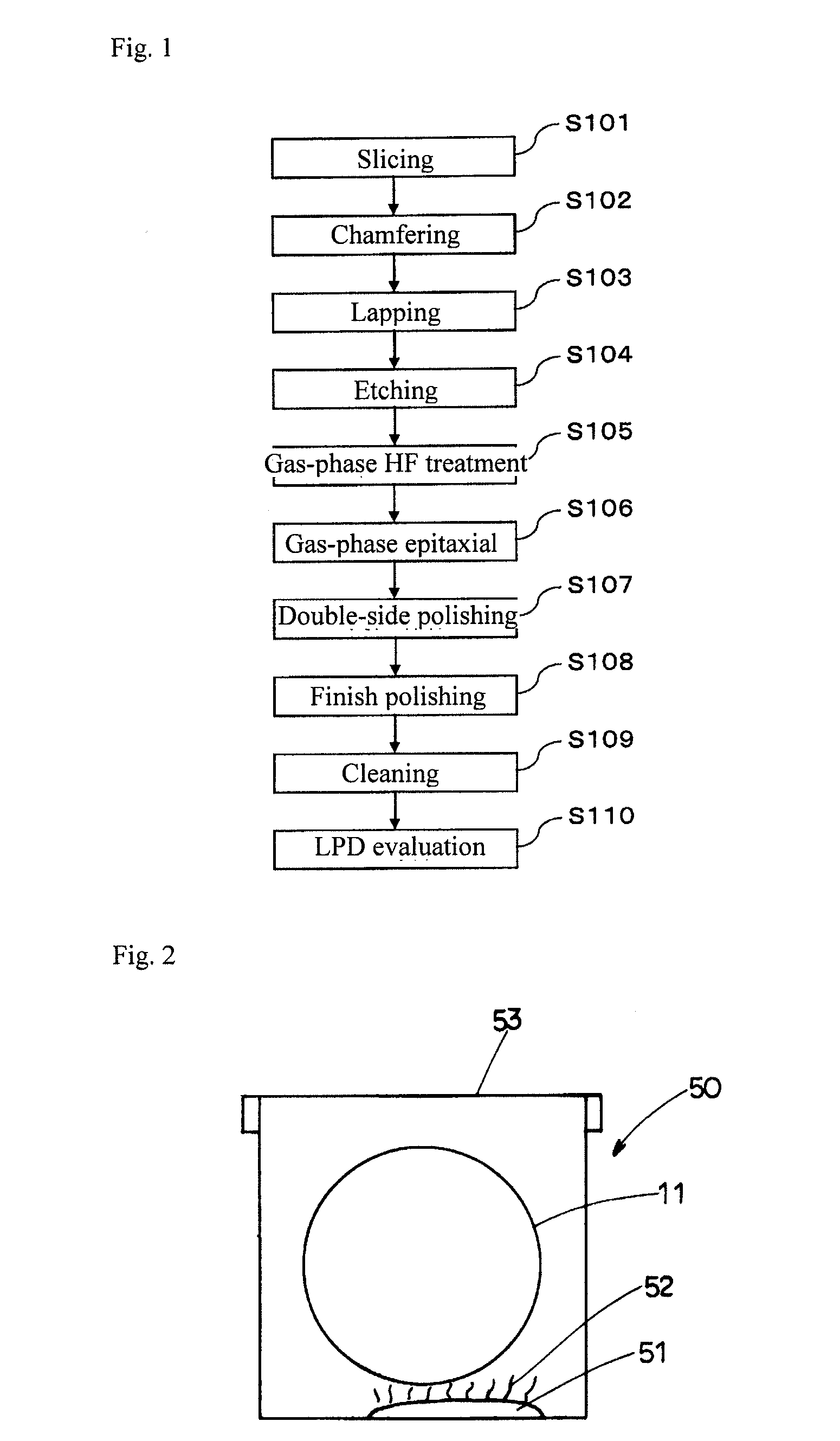

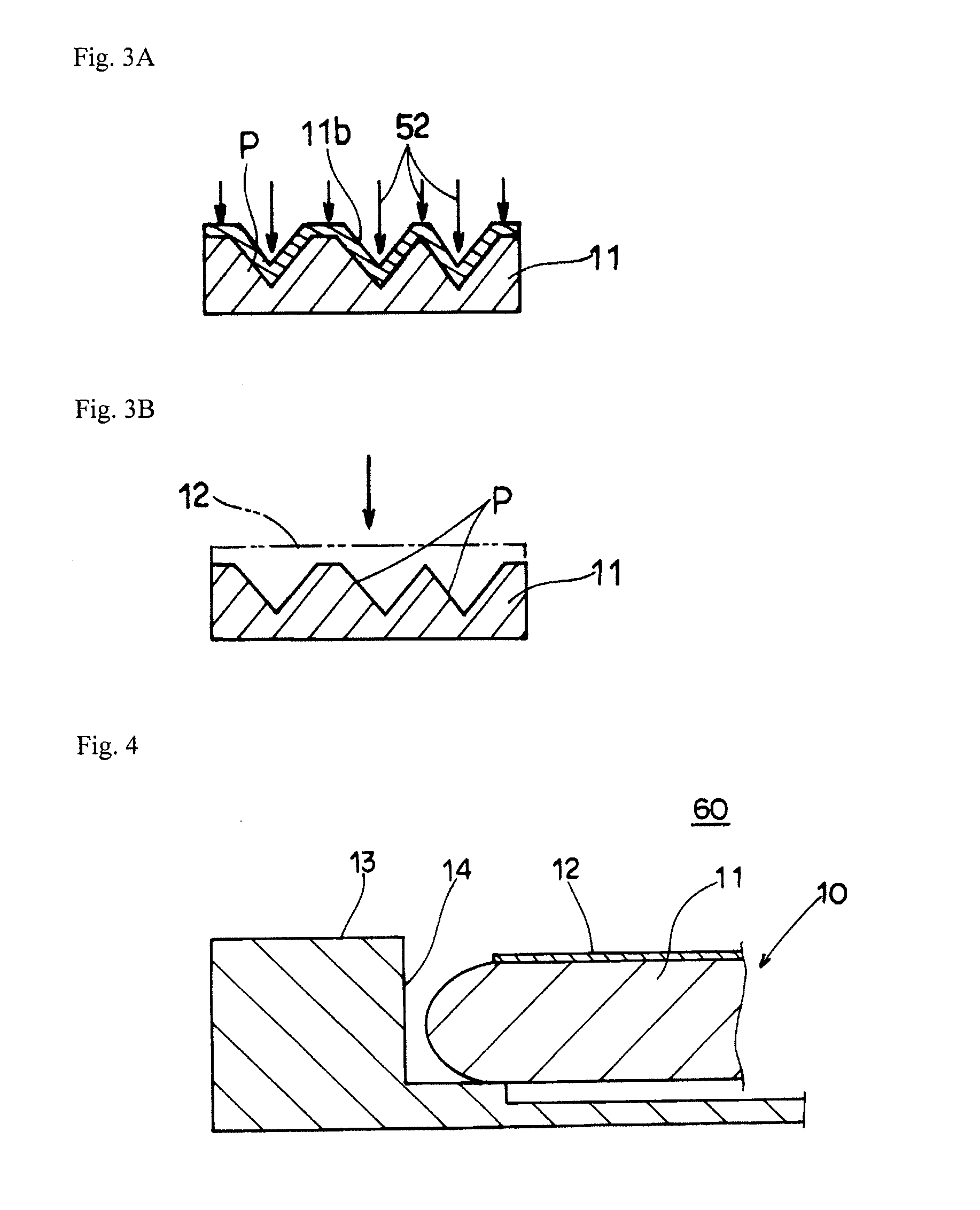

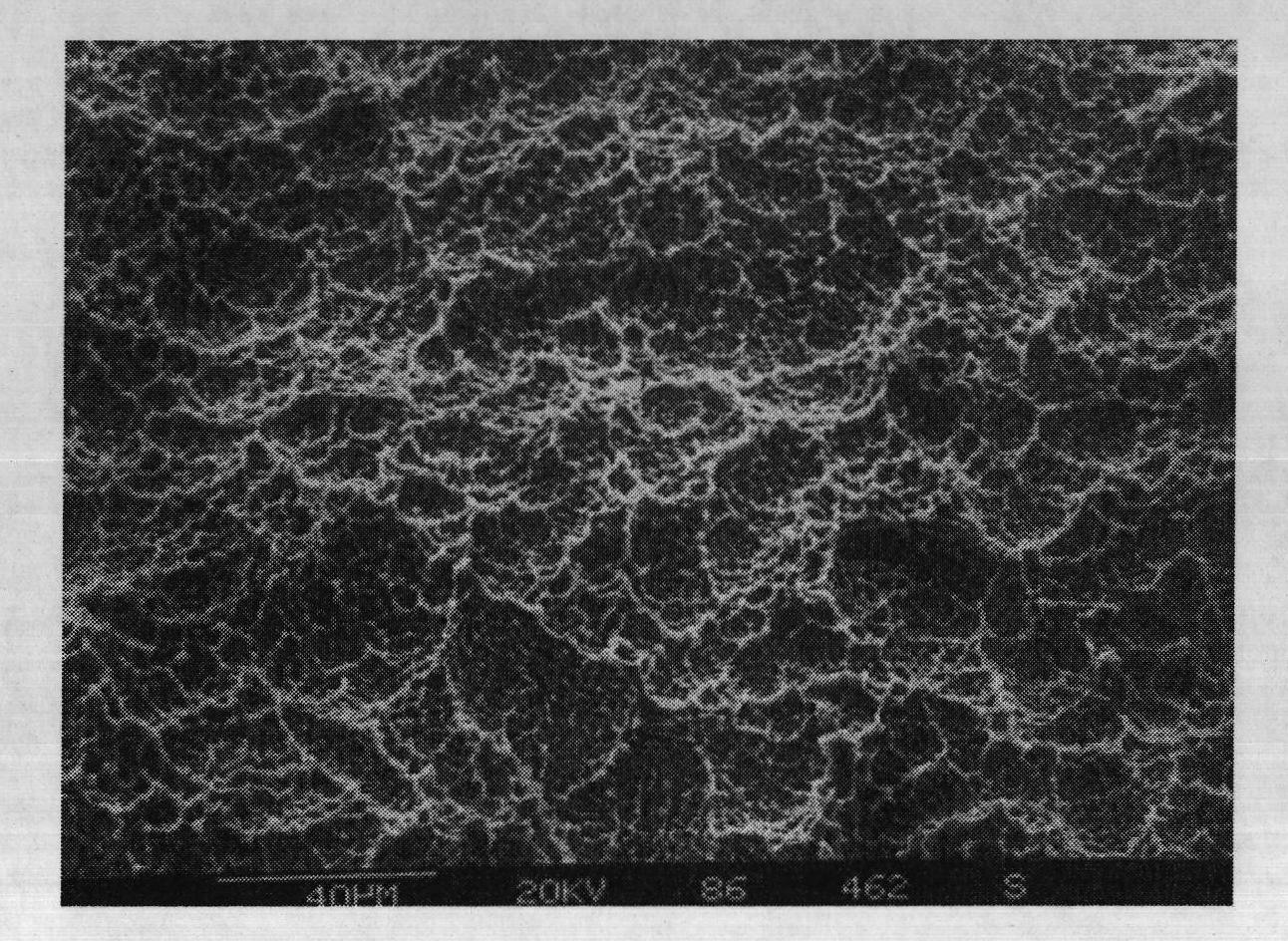

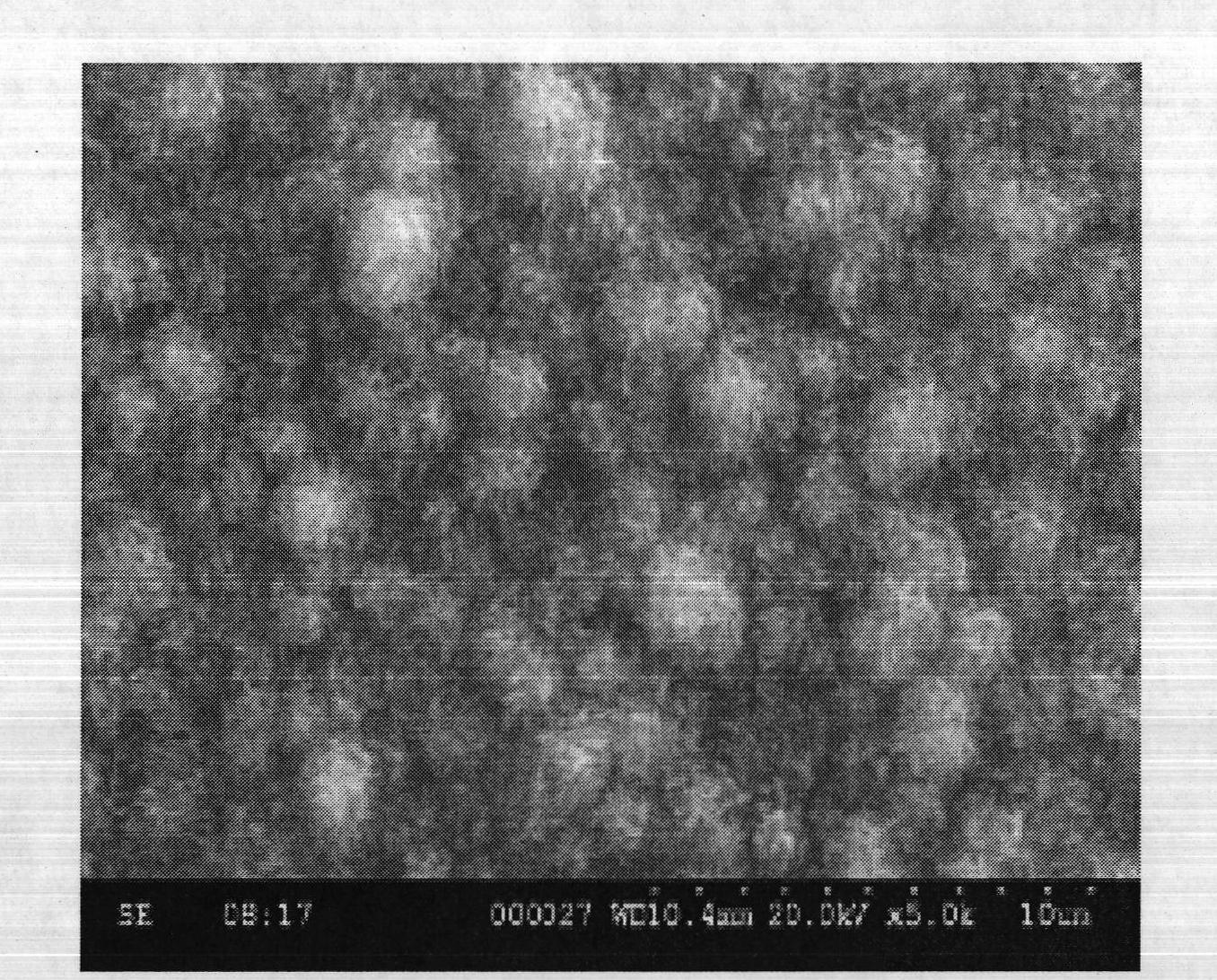

Method for manufacturing epitaxial silicon wafer

InactiveUS20100288192A1Enhancing wafer flatnessWithout reducing productivityPolycrystalline material growthAfter-treatment detailsProduction rateHydrogen fluoride

A silicon oxide film on a wafer front surface, including on internal surfaces of pits, is removed by hydrogen fluoride gas. The pits are thus completely filled with a film growth component at a time of epitaxial film growth. Thereby, productivity is not reduced; wafer flatness is enhanced; and micro-roughness of the wafer front surface is improved.

Owner:SUMCO CORP

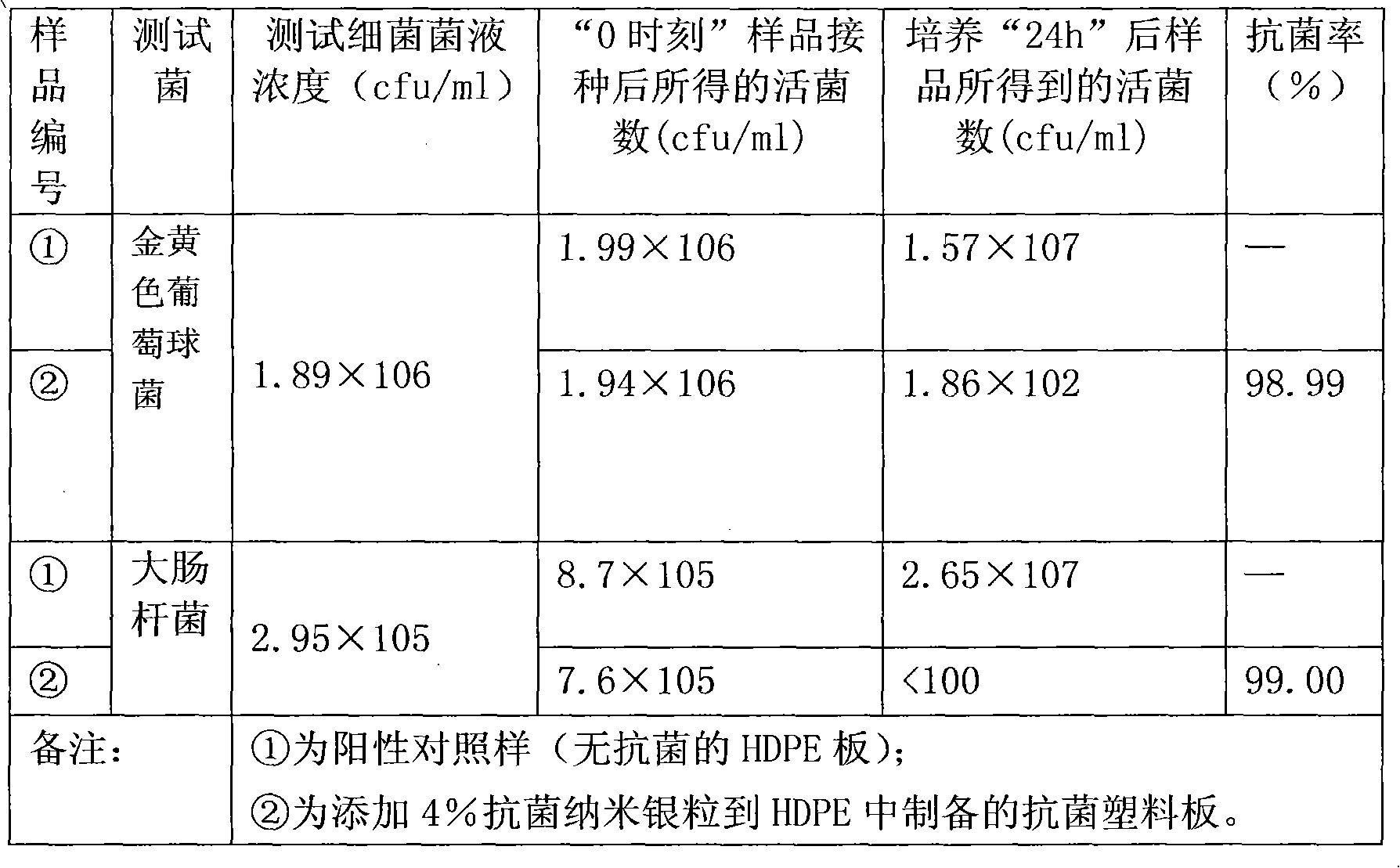

Preparation of nano-coating micropore surface implant having regeneration activity and antibacterial property

InactiveCN101862269APromote regenerationImprove biological activityImpression capsDentistry preparationsMicro nanoTissue repair

The invention relates to the preparation of a nano-coating micropore surface implant having a regeneration activity and an antibacterial property. The preparation is characterized in that the implant is a dental implant taking pure titanium or titanium alloy as a matrix and an artificial joint medicinal hard tissue implant material; and the surface of a matrix material is subjected to micro-roughness treatment, improved biomimetic liquid treatment and nano silver grain coating technology treatment to form a nano biomimetic coating structure having the regeneration activity and the antibacterial property, wherein the nano silver grain is a metallic silver elementary substance which is attached to the surface of the implant and has the antibacterial property and a tissue repairing function, and has the grain diameter of 6 to 50nm; and a nano coating crystal grain formed on the surface of the implant through treatment and induction is a bone-like hydroxyapatite material rich in calcium and phosphor. The micro-nano biomimetic coating implant has a bone-promoting regeneration activity and a high affinity; compared with an un-coating material, the coating implant is improved in the bonding force with bones by several times so as to effectively avoid the phenomena of loosening and shedding and to be a novel medicinal implant material having both the antibacterial property and the regeneration activity.

Owner:杭州伟智生物医药科技有限公司

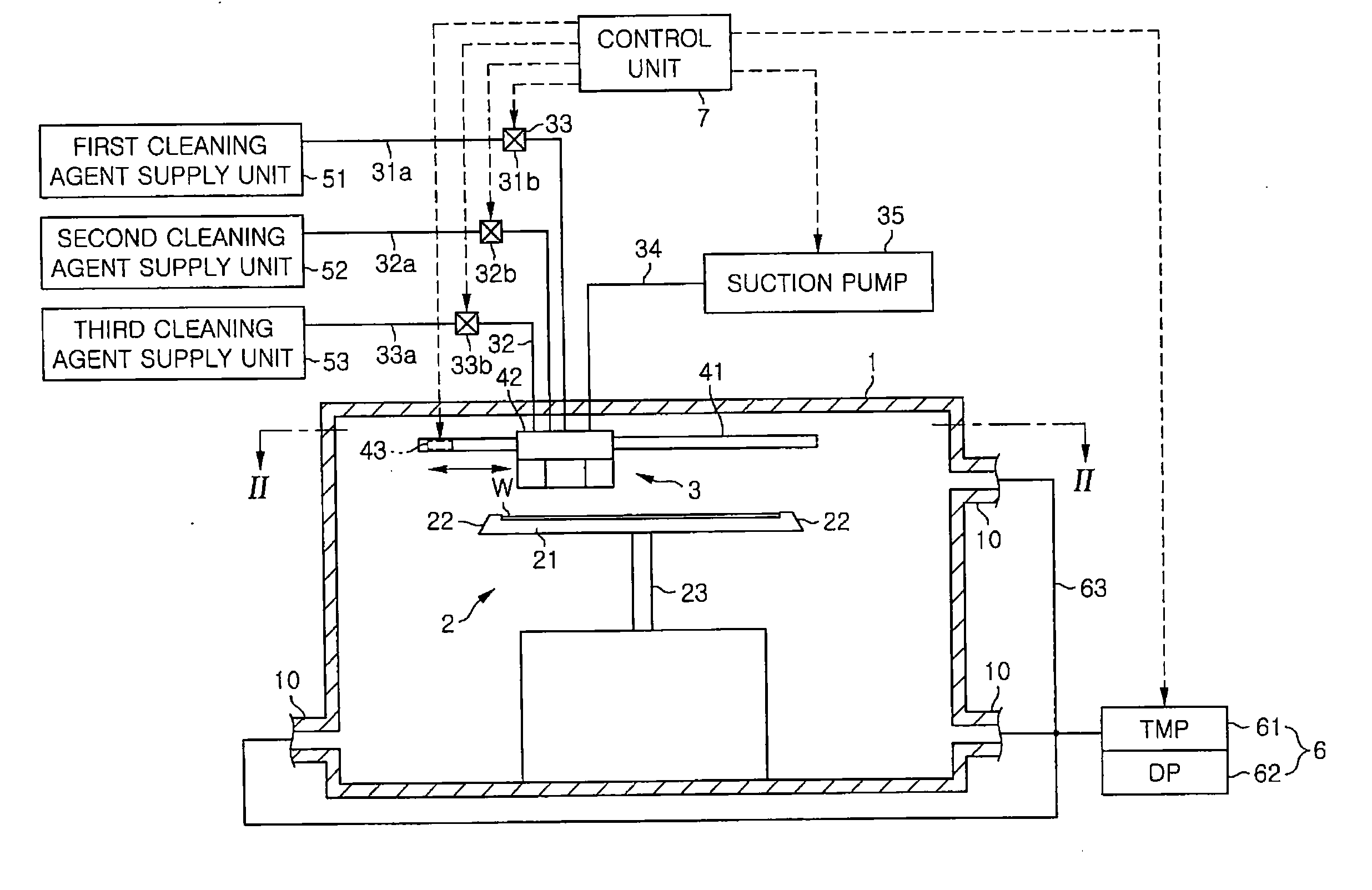

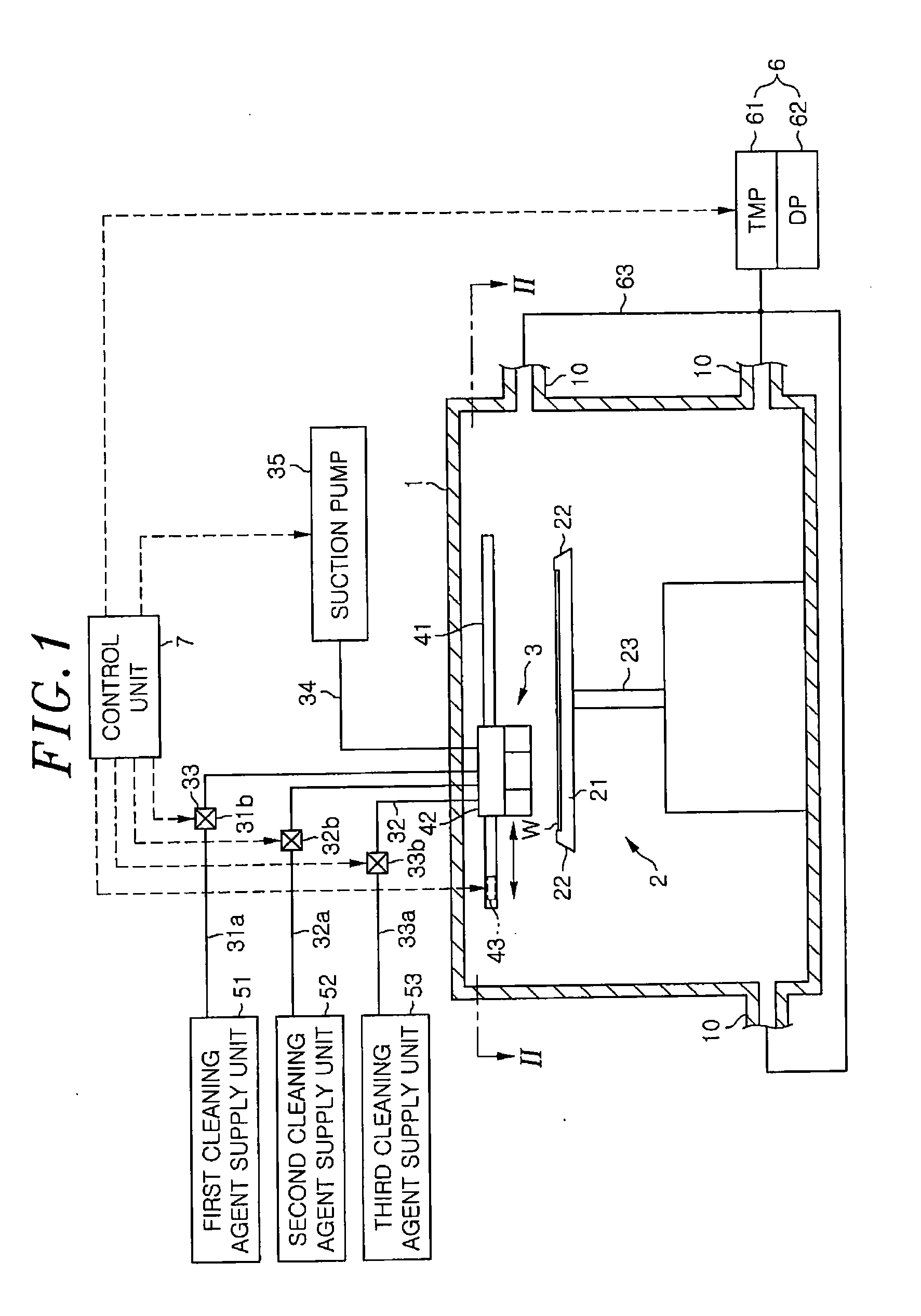

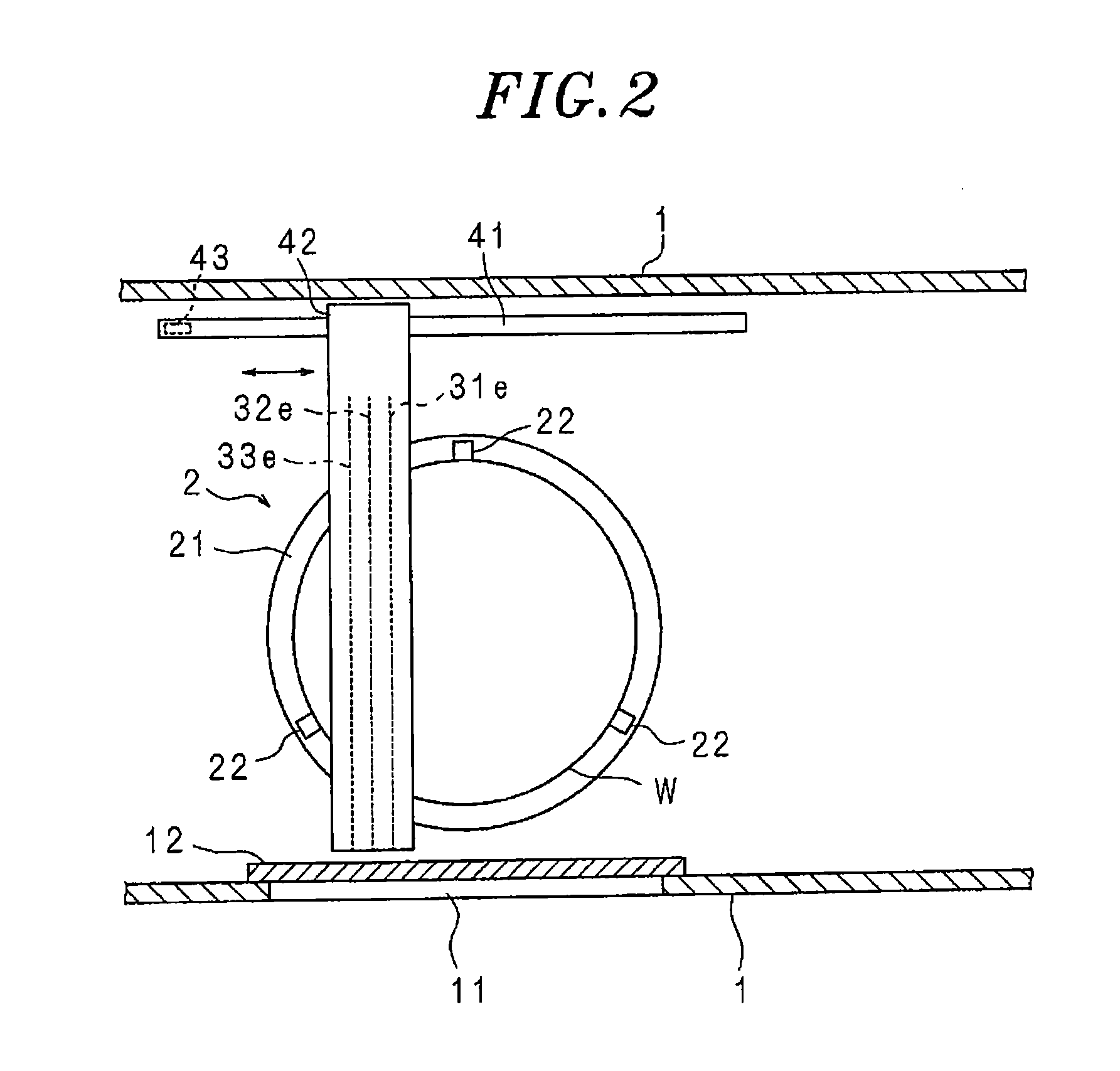

Substrate cleaning apparatus and substrate cleaning method

ActiveUS20130008470A1Suction cleanersSemiconductor/solid-state device manufacturingEngineeringCleansing Agents

A substrate cleaning device is capable of removing more diverse contaminants from substrates than ultra-low temperature aerosol ejection, while avoiding technical problems inherent to wet cleaning, such as micro-roughness, watermarks, loss of substrate material and destruction of the device structure. A substrate cleaning device for cleaning wafers to which cleaning target objects have adhered includes a cluster spraying unit which sprays the wafer with one or more types of clusters formed of cleaning preparation molecules agglomerated together, a suction unit which sucks the cleaning target objects separated by spraying the clusters of the cleaning agent molecules; and a unit for moving the wafer and the cluster spraying unit relative to the one another along the surface of the wafer W to which the cleaning target objects have adhered.

Owner:TOKYO ELECTRON LTD +1

Method for locally forming smooth surface on frosted glass

InactiveUS20130236645A1Avoid image blurImage can be preventedPretreated surfacesCoatingsSealantMaterials science

A method for locally forming a smooth surface on frosted glass includes steps of: a) preparing a piece of frosted glass; b) locally coating the frosted glass with a sealant; and c) such forming the sealant that has a smooth surface. The smooth surface of the frosted glass allows a video camera to capture clear images therethrough so as to prevent blurred images caused by micro-roughness on a surface of the frosted glass.

Owner:LIEFCO OPTICAL

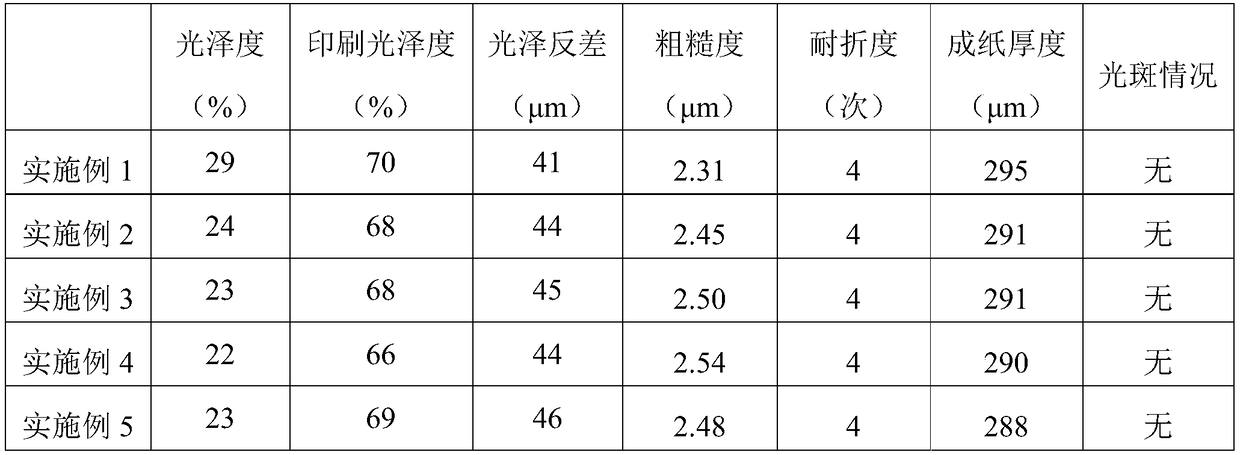

Preparation method of semigloss art paper

InactiveCN108867146AImprove qualityReasonable micro roughnessSpecial paperWater-repelling agents additionFolding enduranceSoftwood

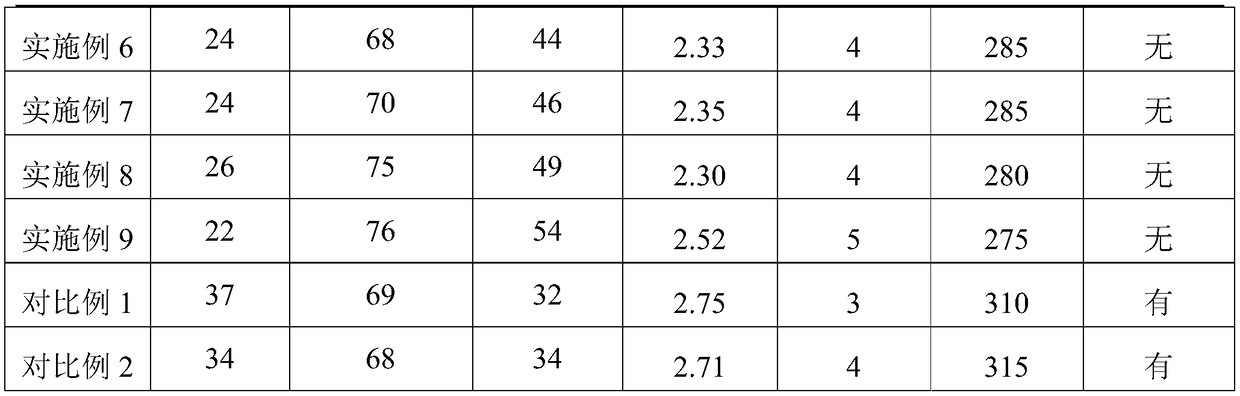

The invention discloses a preparation method of semigloss art paper. Sulfate softwood pulp, bleached sulfate hardwood pulp, bleached chemical hot-grinding mechanical pulp, ground calcium carbonate andpositive starch are used for raw paper, the reasonable proportion and properties, such as formation and surface structure, of the raw paper are strictly controlled, and the basis is provided for production of high-quality semigloss art paper. According to the method, different raw material proportions are adopted for bottom coating, middle coating and face coating, three glue application technologies are reasonably controlled, the paper face keeps the reasonable microcosmic roughness, and the reasonable luster contrast is achieved. By further strictly controlling the production technology, through the scheme, the operation loss and cost of a paper machine are reduced, edge floating paper breaking does not occur to a papermaking net part of 300 gsm, after paper formation and press, the thickness is 275-295 microns, the folding endurance (time) MD is larger than and equal to 4, the roughness is smaller than or equal to 2.54, the lustrousness is 22-29%, the lustrousness after printing is66-76%, the lustrousness contrast is 41-49%, and light spots do not occur.

Owner:HAINAN JINHAI PULP & PAPER

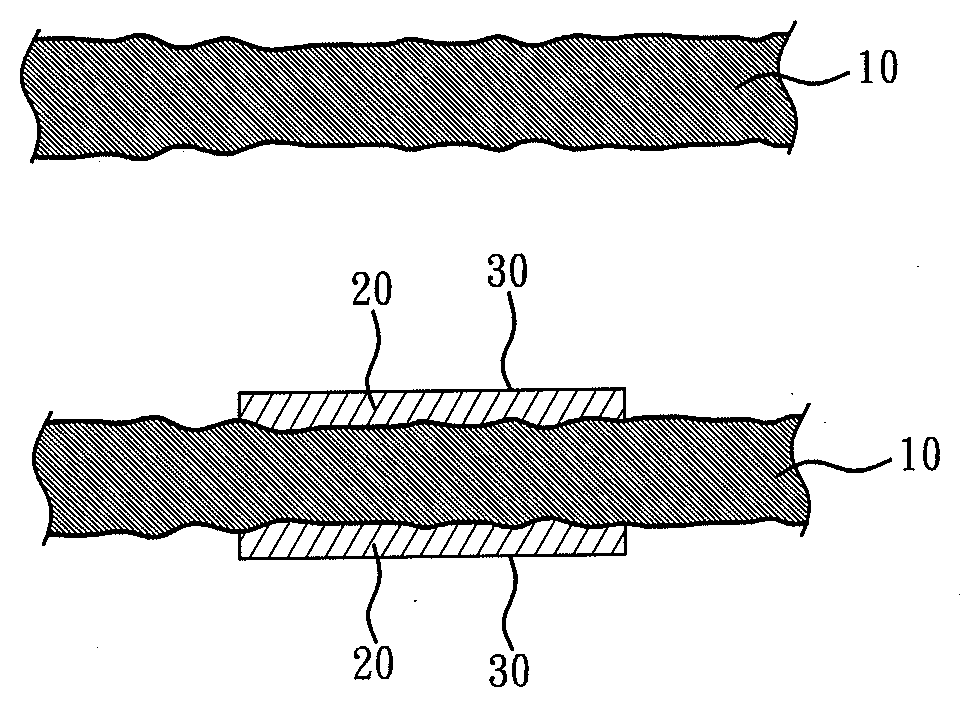

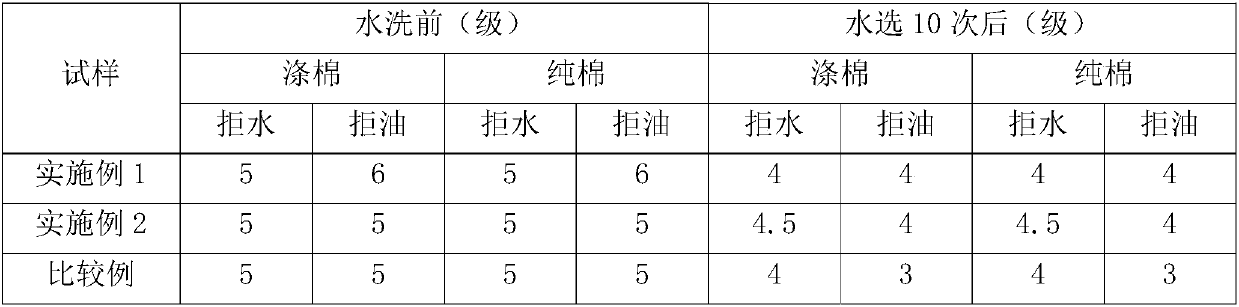

Preparation method of nano-modified fluorine-containing textile finishing agent

The invention discloses a preparation method of a nano-modified fluorine-containing textile finishing agent, comprising the following steps: preparing an organic fluorine and epoxy modified nano-SiO2aqueous dispersion and preparing a short-carbon-chain low-content organic fluorine modified acrylate copolymer emulsion, and then compounding the two components according to a certain ratio to obtainthe nano-modified fluorine-containing textile finishing agent. The preparation method has the following advantages: as the organic fluorine and epoxy modified nano-SiO2 aqueous dispersion simultaneously provides micro-roughness and low surface tension in the finishing agent and the short-carbon-chain low-content organic fluorine modified acrylate copolymer emulsion provides good adhesion to a substrate, the nano-modified fluorine-containing textile finishing agent maintains water and oil repellency required by textiles, the total amount of organic fluorine is reduced, the cost of raw materialsis lowered, fluorine resources are saved, and durability is improved.

Owner:ANHUI LINGDA CHEM TECH

Method for producing glass sheet coated with titanium oxide thin film

InactiveUS20060201202A1Increase the surface compressive stressImprove adhesionCoatingsCoated surfaceInterference color

Mist of titanium element-containing liquid particles is adhered to the surface of a glass substrate having a surface compressive stress of at most 10 MPa so as to coat the surface of the glass substrate with the liquid. Next, the liquid-coated surface is heated up to a maximum temperature of from 550 to 700° C. and then cooled under a specific condition, thereby making the resulting glass sheet have a surface compressive stress of from 20 to 250 MPa. The process gives a glass sheet coated with a titanium oxide thin film having a photocatalytic function. The resulting titanium oxide thin filmhad good adhesiveness andabrasion resistance. Since its surface has a micro-roughness, the glass sheet has neither interference color nor interference fringes and has good transparency.

Owner:NAKAJIMA GLASS

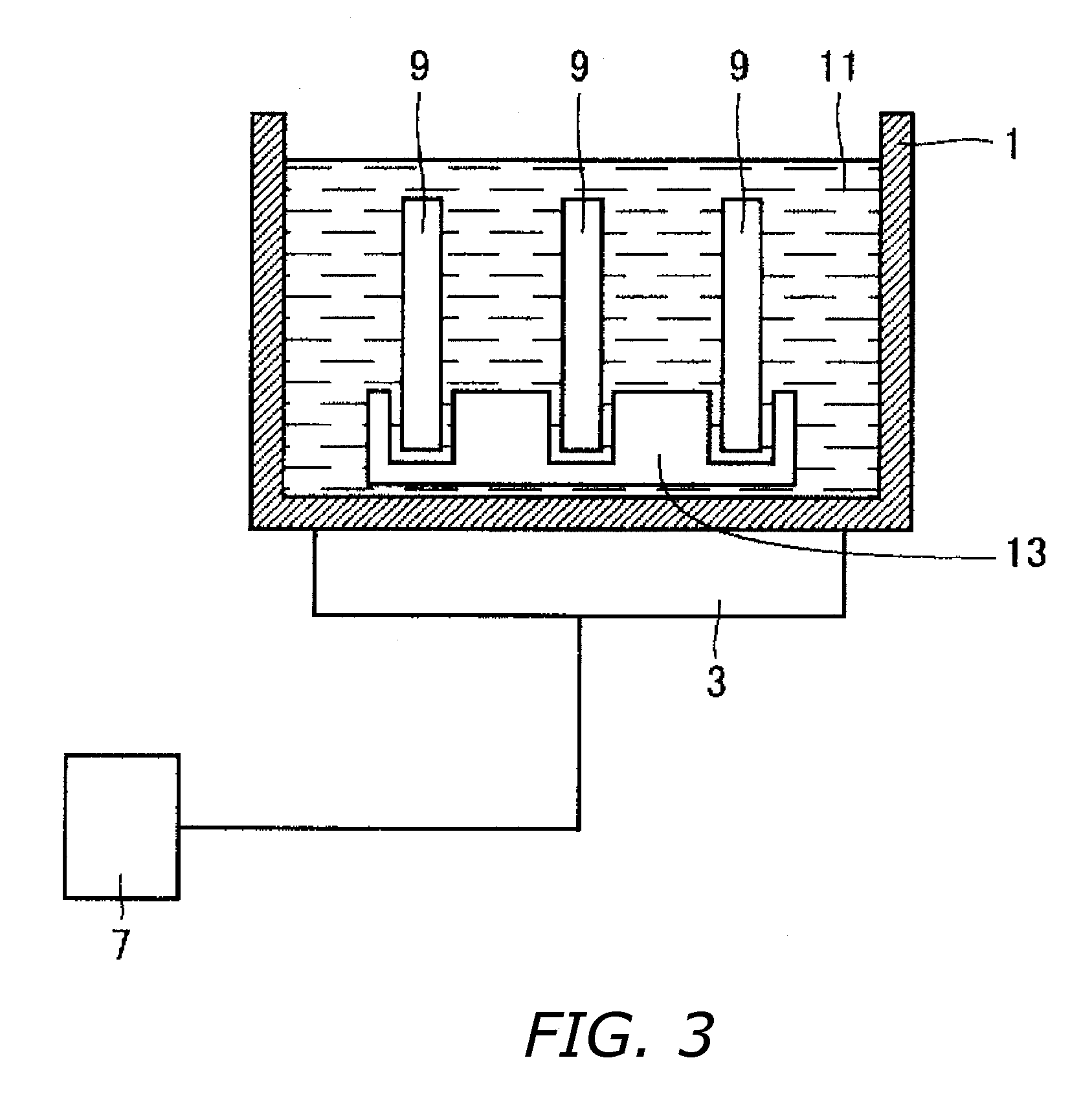

Electrode characterized by highly adhering superficial catalytic layer and method for its production

InactiveUS6589406B2High surface developmentReduce mechanical stressMachining electrodesPhotography auxillary processesProduct gasOperant conditioning

The invention is relative to an electrode for gas evolution in electrolytic and electrometallurgical industrial applications, made of a metal substrate having a surface morphology characterized by a combination of micro-roughness and macro-roughness which favors high adherence of a superficial catalytic layer in order to prevent detachment of the same and passivation of the substrate even under critical operating conditions.

Owner:DE NORA ELETTRODI SPA

Composite of metal and resin and method for manufacturing same

ActiveUS20140186641A1High hardnessEasy to peelMetal rolling stand detailsSynthetic resin layered productsSurface layerPhosphate

A magnesium alloy part is inserted into a mold, a resin composition is injected and joined to the part, and a composite is obtained. A part having, formed thereon, a surface layer of a metal oxide, a metal carbonate, or a metal phosphate in use of a usual conversion treatment or a modification method thereof can be used for the magnesium alloy plate 1. The surface that has a larger amount of crystal-like objects of a nanolevel on the surface layer composed of the metal oxide, metal carbonate, or metal phosphate has a higher level of hardness, microscopic roughness, and good injection joining force, and these parameters can be controlled by a conversion treatment method. A resin composition 4, containing PBT or PPS as the main component, is used as the resin composition part.

Owner:TAISEI PLAS CO LTD

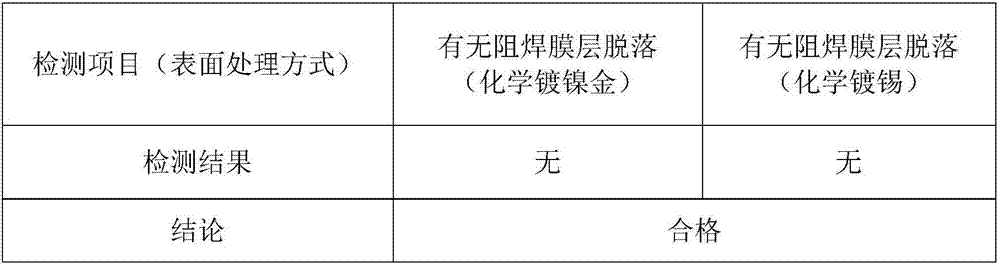

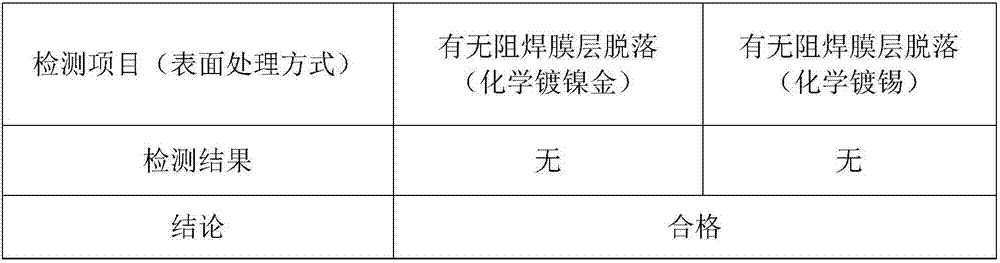

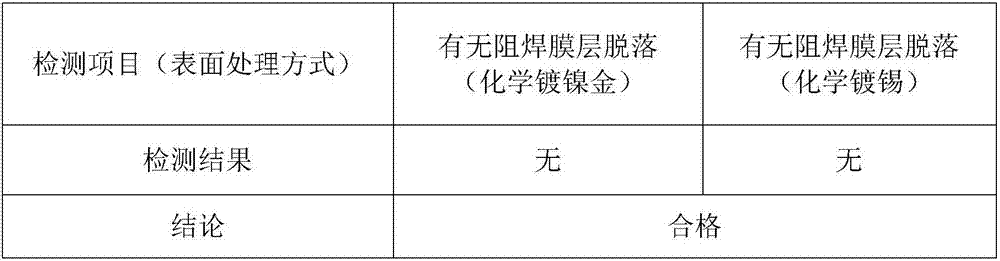

Organic acid super roughening process for pretreatment of printed circuit board resistance welding film layer

InactiveCN107267986AInhibit sheddingImprove bindingInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOrganic acidScreen printing

The invention provides an organic acid super roughening process for pretreatment of a printed circuit board resistance welding film layer. The organic acid super roughening process comprises the following steps that after a working solution of a printed circuit board resistance welding film layer pretreatment slot is completely discharged, the pretreatment slot is washed with tap water completely; circulating washing is performed with deionized water; an organic acid super roughening water solution is added and heated to 25-35 DEG C; a circulating filtering pump is started; a circuit board to be subjected to resistance welding film layer silk-screen printing is placed into the organic acid super roughening water solution to be soaked; the circuit board is taken out and is washed with the tap water; the circuit board is dried at the temperature of 70-80 DEG C; and the dried circuit board is transferred to the resistance welding film layer silk-screen printing process. According to the resistance welding film layer pretreatment organic acid super roughening process, through the manner of organic acid chemical super roughening, a copper surface of ultra high micro-roughness is formed, the quality defect that the resistance welding film layer falls in the subsequent surface treatment process of the circuit board is prevented, the production process is free of pollution, and the organic acid super roughening process is suitable for industrialized production.

Owner:东莞市斯坦得电子材料有限公司

Led device with light extracting rough structure and manufacturing methods thereof

The invention discloses a light emitting diode device with a light extracting rough structure. The device includes a lead frame, one or more light emitting diode chips provided on and electrically connected to the lead frame, and a lens configured to encapsulate the one or more light emitting diode chips. The lens has a surface with a micro-roughness structure. The micro-roughness structure of the lens has a roughness between 0.1 [mu] m and 50 [mu] m. The invention also discloses methods for manufacturing a light emitting diode device with a light extracting rough structure.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

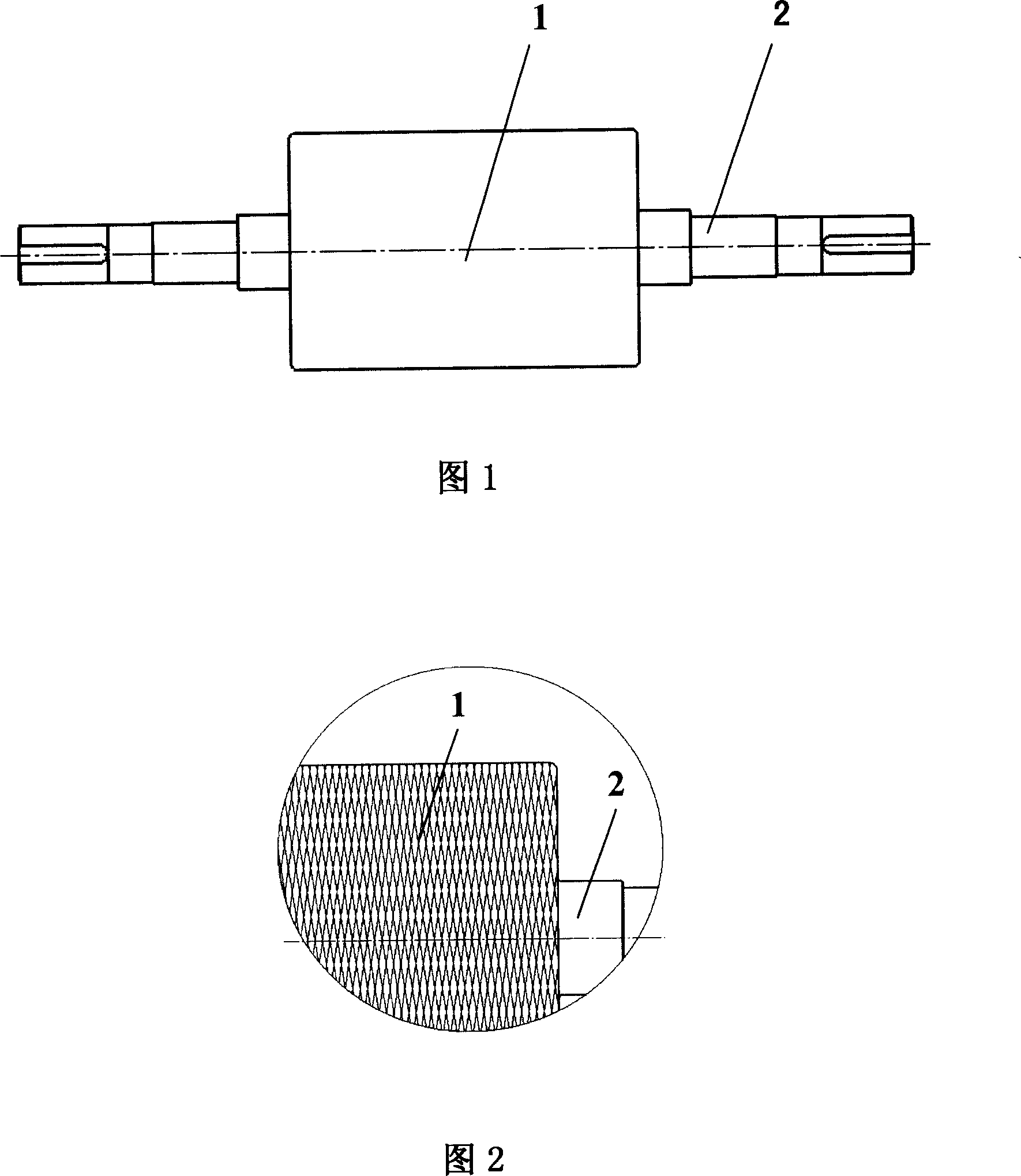

Texiuring mill roller and its production process

InactiveCN1935381ADefects to Avoid CollisionsImprove efficiencyOther manufacturing equipments/toolsGrain treatmentsMicrometerHardness

The present invention relates to a frosted grinding roller and its production process. It is characterized by that said invention adopts grinding roller smooth roller, and utilizes high-temperature nozzle to make close right-rotary and left-rotary bidirectional or unidirectional scanning machining along roller body surface so as to produce contour micro roughness, and the mean height can be represented by roughness value Ra and can be 3.5-9.5 micrometer. Said frosted grinding roller has high surface hardness and can greatly raise working efficiency.

Owner:HENAN ZHONGYUAN ROLLER CO LTD

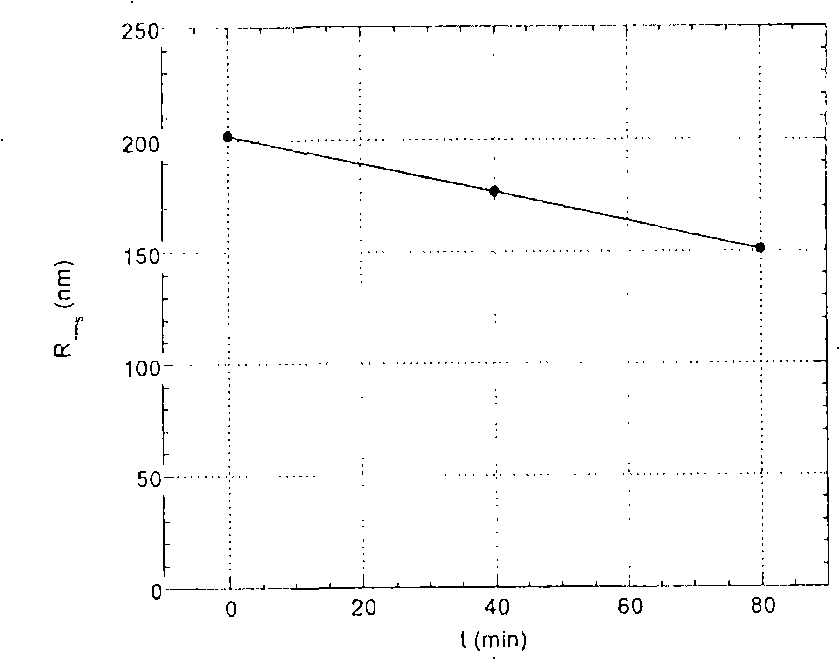

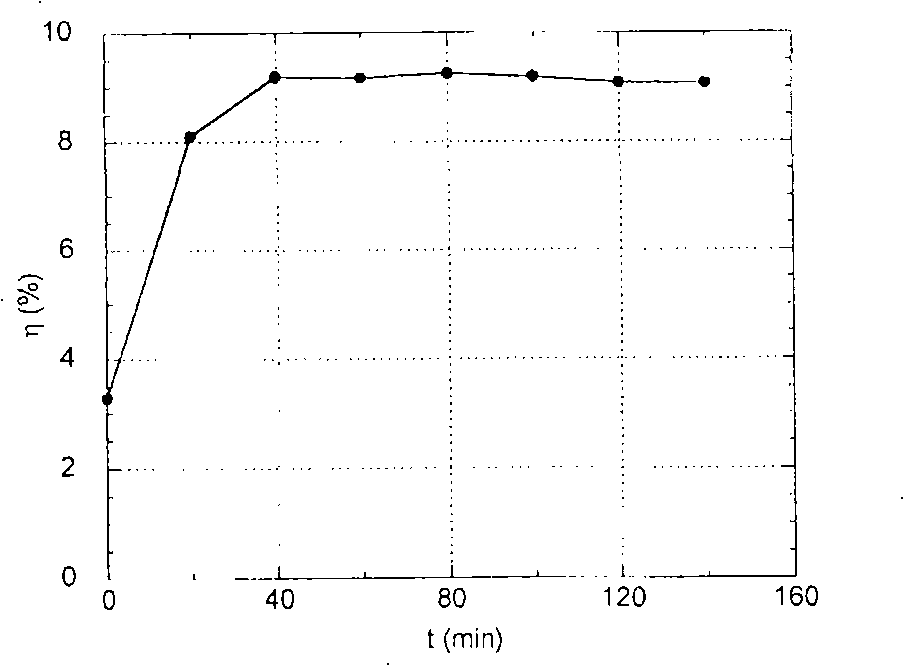

Transparent, conducting and textured layer and method of fabrication

InactiveCN101410980APromote late growthReduce scatterDiodeEnergy conversion devicesOptoelectronicsMicro roughness

Owner:UNIV DE NEUCHATEL NEUCHATEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com