Patents

Literature

212results about How to "Increase the relative molecular mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of instant ultra-high molecular weight polyacrylamide dry powder

InactiveCN103304714AIncrease the relative molecular massGood water solubilityWater/sewage treatment by flocculation/precipitationSolventAmmonia

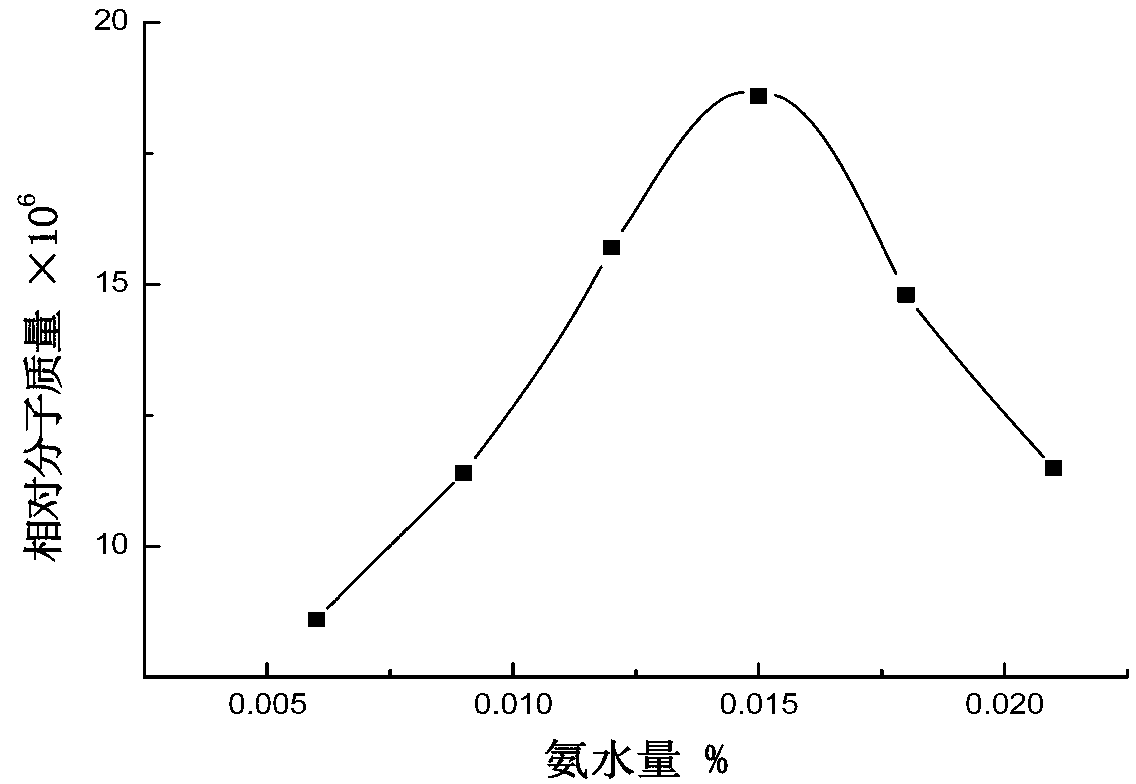

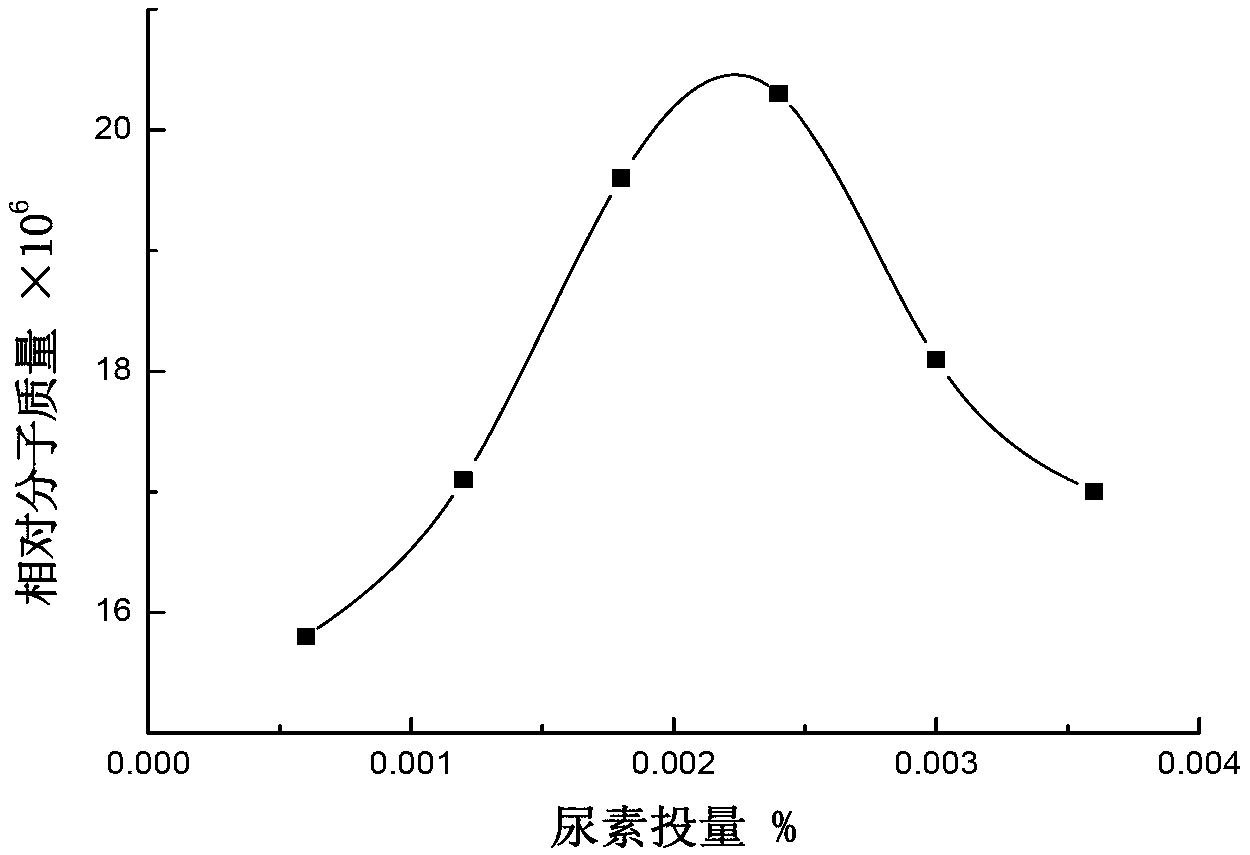

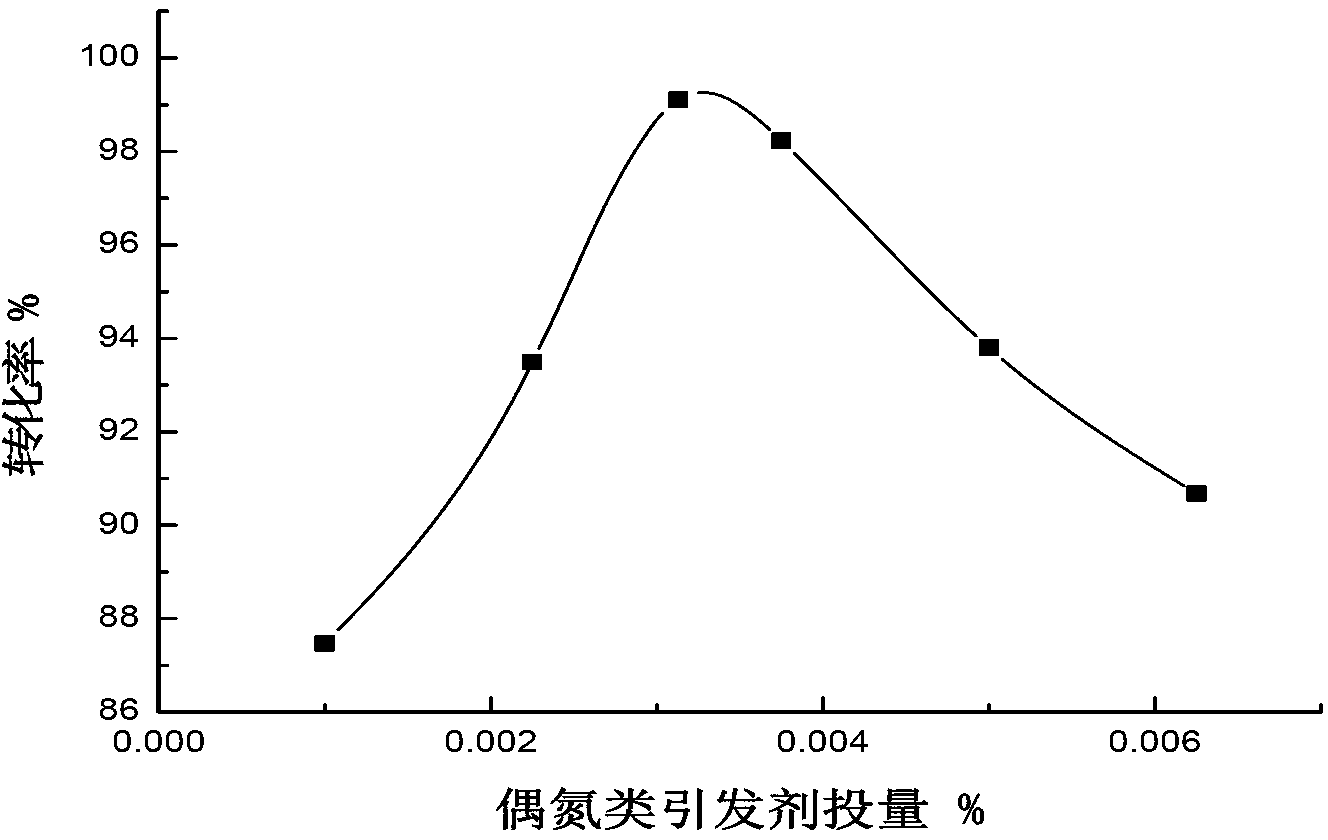

The invention relates to a preparation method of instant ultra-high molecular weight polyacrylamide dry powder. The method comprises the following steps of: taking acrylic amide AM as a monomer, adopting a low-temperature composite initiation system taking NTP and K2S2O8 as main initiators, and an azo compound as an auxiliary initiator; adopting ammonia water and urea as cosolvents; and adding the initiator in batches and controlling the concentration of the cosolvent and the pH value of the medium, so as to obtain the instant ultra-high molecular weight polyacrylamide dry powder. The relative molecular weight range of the ultra-high molecular weight polyacrylamide PAM is that Mw is smaller than or equal to 25000000 and greater than or equal to 5000000. The optimal production technology is determined by discussing the influence factors such as the initiation system, the cosolvent concentration, and the pH value of the medium; the obtained polyacrylamide is rapidly dissolved, and is high in relative molecular weight, high in percent conversion, low in monomer content, high in production efficiency, low in cost and suitable for industrial production.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

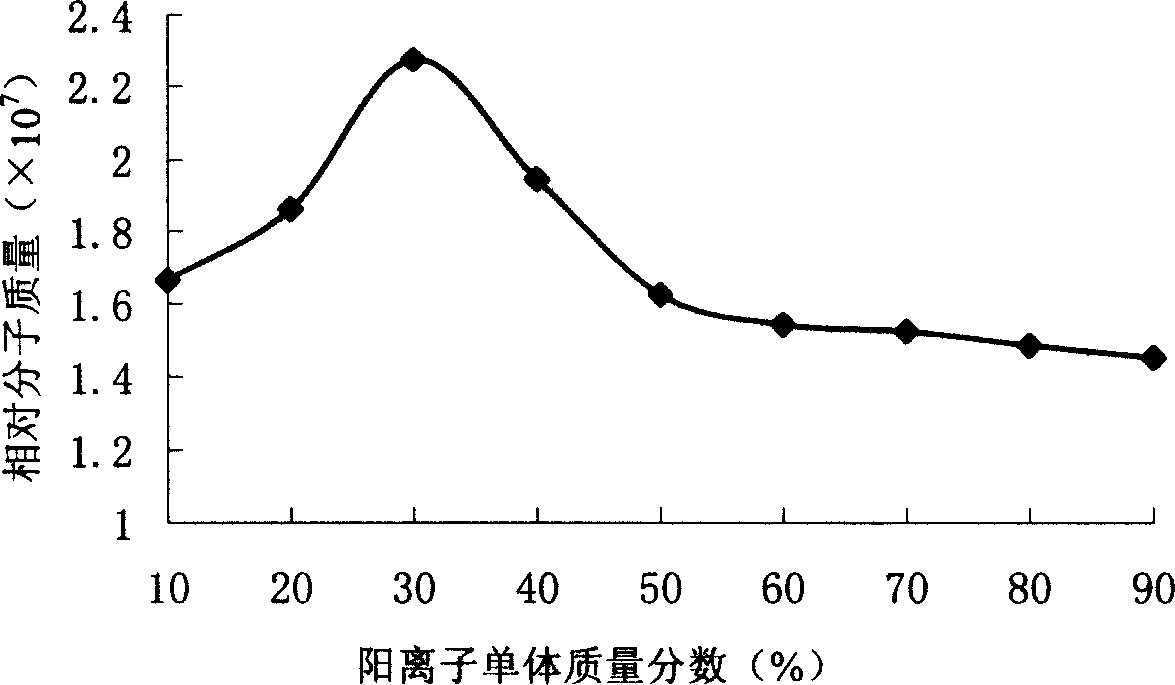

Method for preparing high molecular weight cation type polyacrylamide

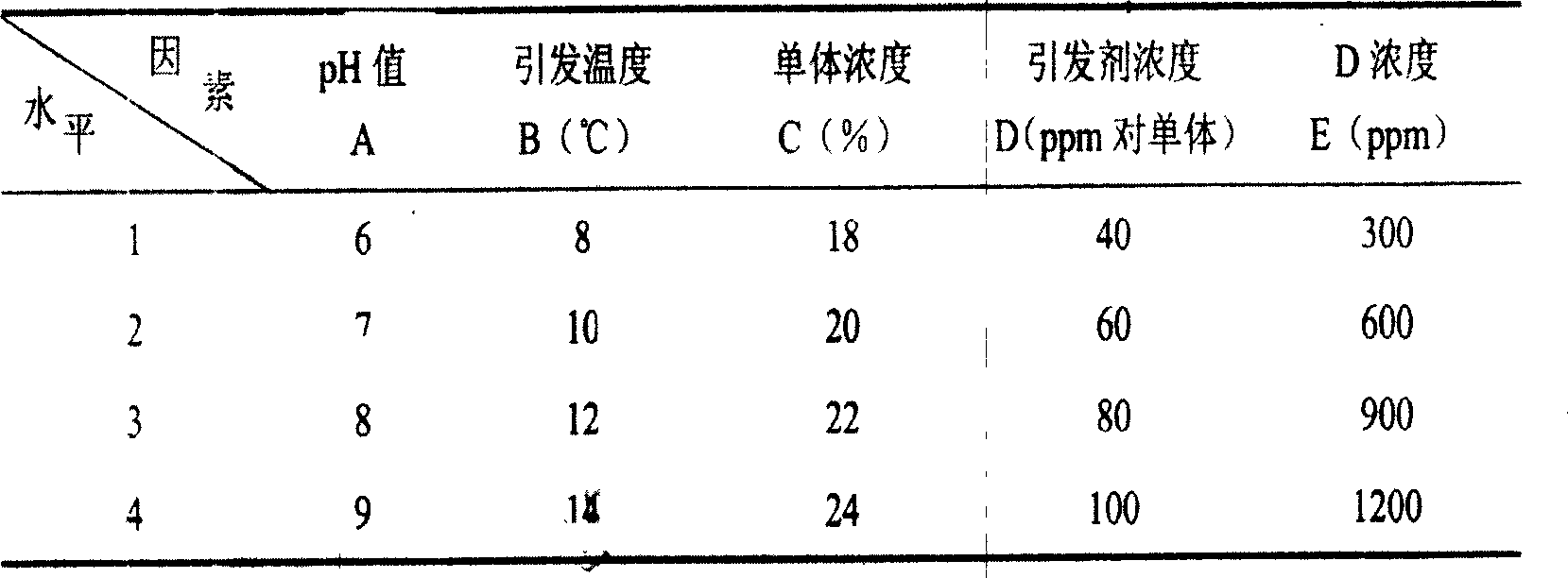

The present invention relates to preparation process of high molecular weight cation type polyacrylamide. The preparation process includes: mixing acrylamide and acrylyl oxyethyl trimethyl ammonium chloride in weight ratio of 1 / 99-99 in reactor and dissolving with added deionized water to total monomer concentration of 18-30 %; regulating system pH with ammonia water to 6-9; adding successively chain extender, reductant, disodium editate, urea, Span-20 and AIBN into the reactor with initiating temperature of 8-14 deg.c via stirring; introducing N2 to eliminate O2 for 30 min, adding oxidant ammonium persulfate and introducing for other 10 min; sealing for adiabatic polymerization; taking out the colloid block after the reaction system temperature is lowered to room temperature; pelletizing, stoving, crushing and sieving to obtain the powdered cation type polyacrylamide product.

Owner:大庆东昊投资有限公司

Oil-displacing agent composition used for improving recovery ratio of high-temperature reservoir and preparation method of composition

ActiveCN103666433AHigh molecular weightIncrease the relative molecular massDrilling compositionActive agentCarboxylic acid

The invention relates to an oil-displacing agent composition for improving a recovery ratio of a high-temperature reservoir and a preparation method of the composition, mainly solving the problems that a polymer-containing oil-displacing agent in the prior art is poor in temperature resistance, salt resistance and thermal stability resistance, and low in displacement efficiency. In order to solve the problems better, a following technical scheme is adopted as follows: the oil-displacing agent composition comprises the following components in percentage by weight: 0.005%-8.0% of high-temperature-resistant and oil-displacing acrylamide polymers, 0.005%-5.0% of a fatty alcohol polyoxyethylene ether carboxylate surfactant and 87.0%-99.99% of injected water. The preparation method of the oil-displacing agent composition comprises the following steps: regulating a pH value; ventilating a nitrogen gas and removing an oxygen gas; carrying out hydrolysis reaction; drying, crushing and sieving to obtain acrylamide polymers; stirring the acrylamide polymers, the fatty alcohol polyoxyethylene ether carboxylate and the injected water for 0.5 hour-5 hours at 5 DEG C-45 DEG C, and uniformly mixing to obtain the oil-displacing agent composition. And therefore, the oil-displacing agent composition can be used for tertiary oil recovery production of the high-temperature reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of secondary-post-chain-extension waterborne polyurethane and dispersing liquid prepared from waterborne polyurethane

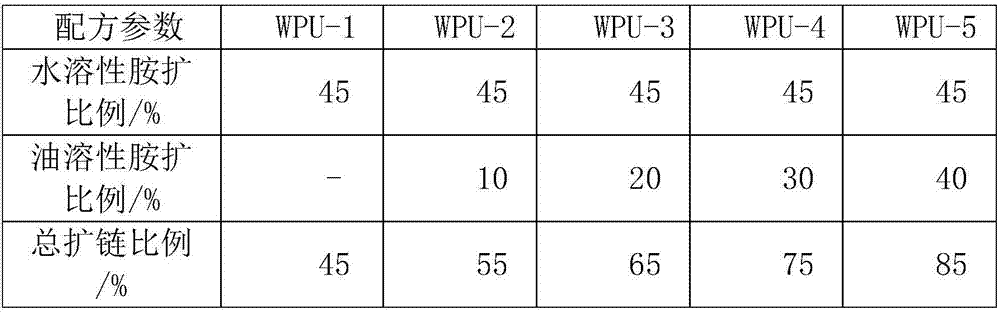

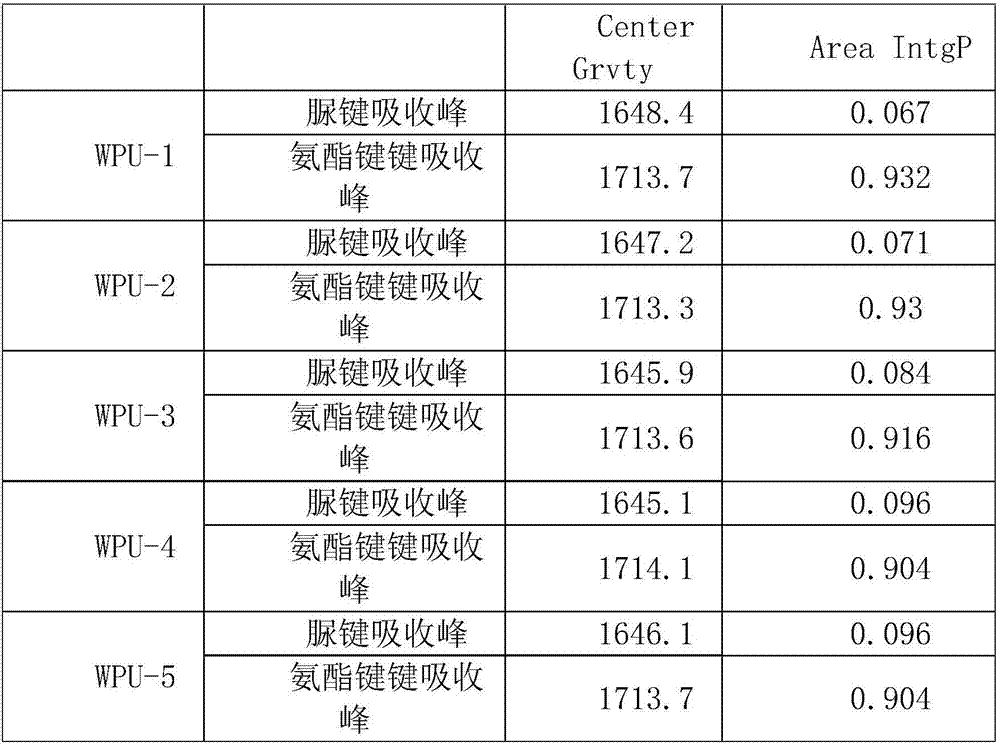

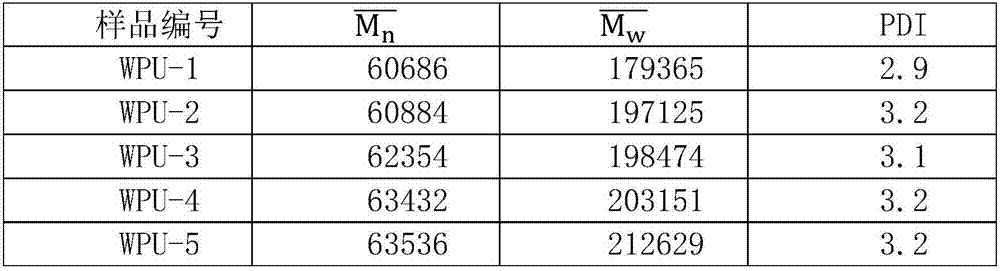

The invention discloses a preparation method of secondary-post-chain-extension waterborne polyurethane and a dispersing liquid prepared from waterborne polyurethane. According to the preparation method, the problems that the post-chain-extension reaction of water-soluble diamine is only limited on the hydrophilic surfaces of polyurethane emulsion particles at present, therefore, no effective chain extension is caused to oleophilic isocyanate groups remained in the polyurethane emulsion particles, and the relative molecular mass of waterborne polyurethane is difficult to be adequately increased are solved. The preparation method comprises the steps of reacting polymeric polylol with diisocyanate, a hydrophilic chain extender and a small molecule chain extender in the presence of a catalyst, adjusting the viscosity by virtue of a solvent so as to obtain a prepolymer, adding a neutralizer for neutralization, carrying out chain extension by virtue of a water-soluble chain extender, carrying out secondary post chain extension by virtue of an oil-soluble post chain extender, and decompressing to remove the solvent, so as to obtain the secondary-post-chain-extension waterborne polyurethane dispersing liquid. By virtue of a secondary-post-chain-extension method, the adequate reaction between the remained isocyanate groups of polyurethane and a post chain extender is realized, and the relative molecular mass of the waterborne polyurethane is rapidly and effectively increased.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

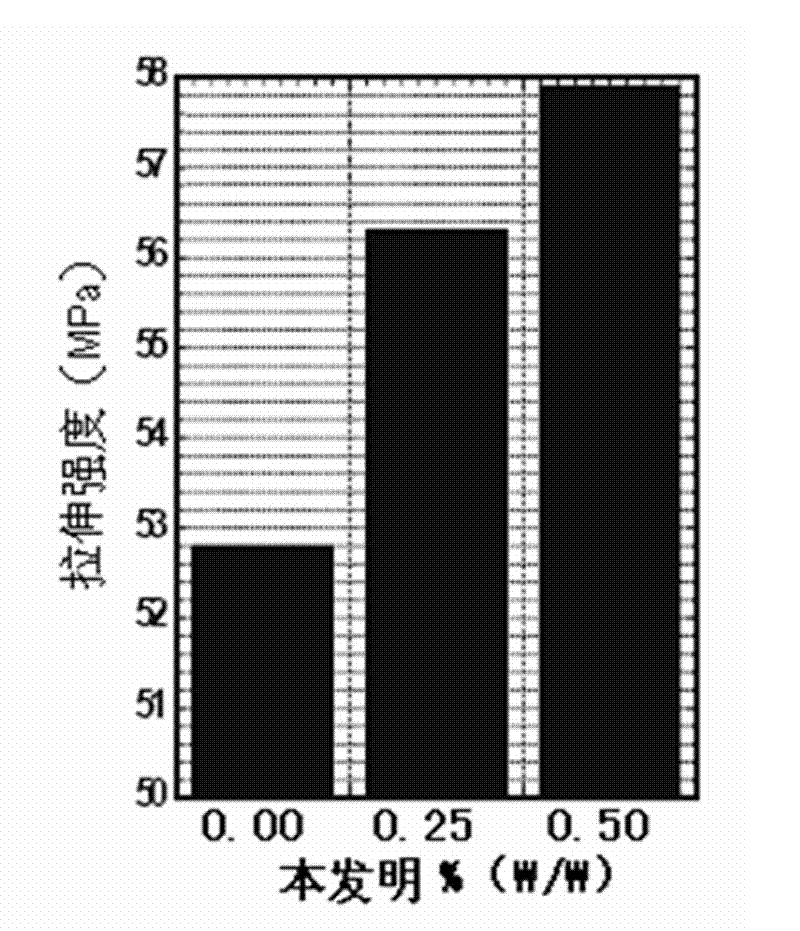

High-performance flame-retardant PLA (polylactic acid)/graphene nano-sheet composite material and preparation method thereof

The invention discloses a method for preparing a high-performance flame-retardant PLA (polylactic acid) / graphene nano-sheet composite material. The composite material comprises the following components in parts by weight: 30-100 parts of PLA, 10-30 parts of flame retardant, 5-10 parts of a flame retardant synergist, 1-5 parts of a nucleation accelerant, 2-6 parts of a flexibilizer, 1-6 parts of a graphene nano-sheet, 5-15 parts of carbon fibers, 10-20 parts of glass fiber, and 5-25 parts of talc powder. According to the preparation method, the mechanical performance of PLC can be improved by adopting the graphene nano-sheet which is subjected to surface treatment by a silane coupling agent. The composite material has the advantages that the compatibility of the graphene nano-sheet and PLA can be improved, the graphene nano-sheet can be well dispersed in matrix resin to play the effect of synergetic flame retardance.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

Method of initiating acrylamide polymerization by composite initiation system

The invention discloses a triggering method of acrylamide through two-segment composite low-temperature and high-temperature system, which comprises the following steps: adding acrylamide monomer into water with density at 20-40% without removing oxygen; cooling to 0 deg.c; adding oxidant-reducer-catalyst and azo-compound into composite system; sealing the reactor; insulating to react for 4-6h to finish polymerizing; fetching gel-shaped material; purifying through anhydrous alcohol; drying in the vacuum under 50-60 deg.c to constant weight; obtaining the product with molecule at 20000000-28000000; simplifying the reaction without removing oxygen.

Owner:SICHUAN GUANGYA POLYMER CHEM

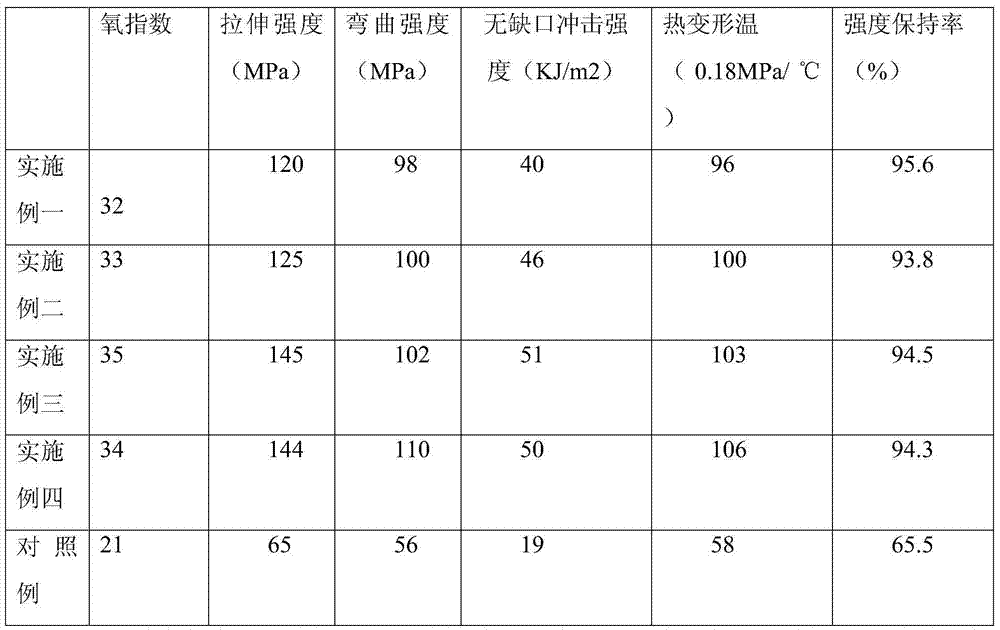

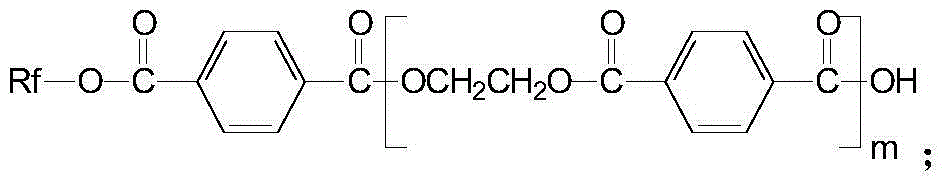

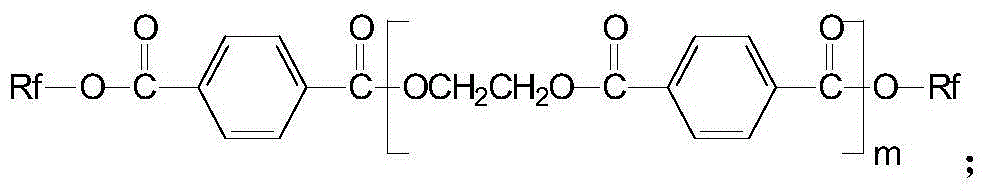

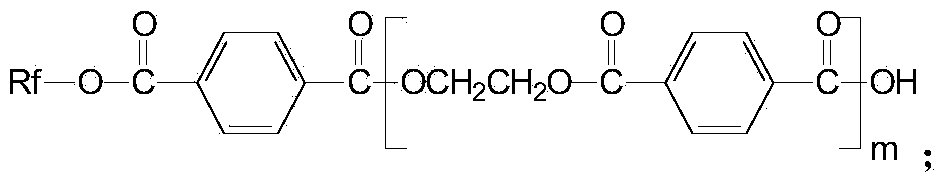

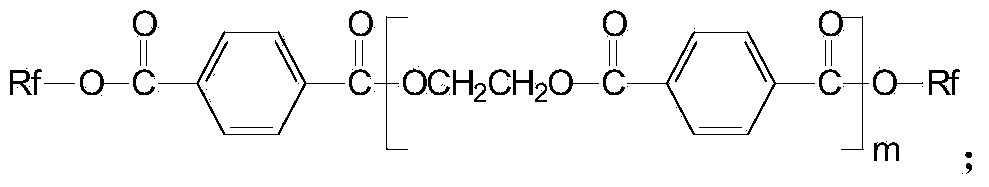

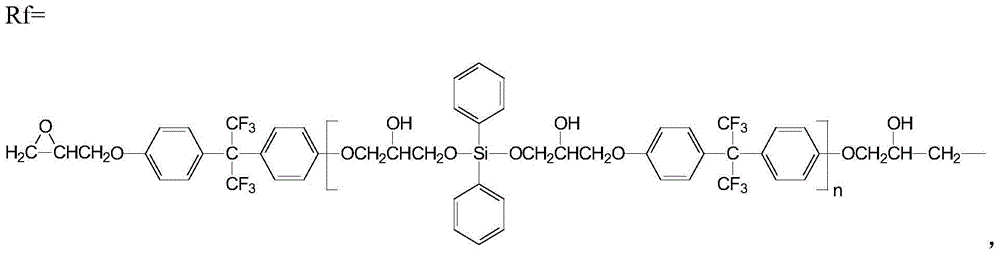

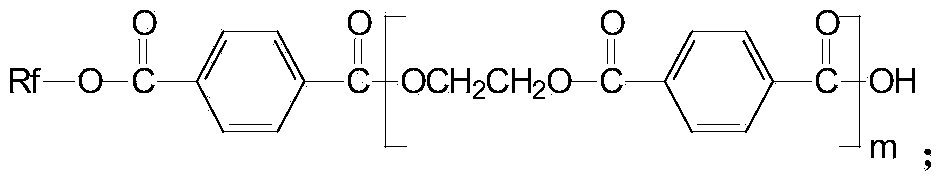

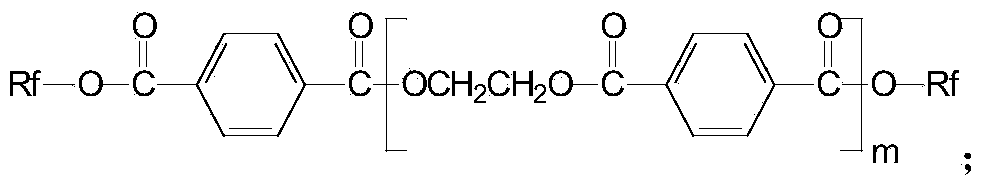

Marine creep-resistant polyester high-strength low-elongation industrial yarn and its preparation method

ActiveCN103556293AIncrease forcePlay the role of creep resistanceNew-spun product collectionMelt spinning methodsPolyesterYarn

The invention relates to a marine creep-resistant polyester high-strength low-elongation industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a marine creep-resistant polyester high-strength low-elongation industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound and a carbodiimide stabilizer to react so as to obtain the creep-resistant polyester hyperviscous slice; and the marine creep-resistant polyester high-strength low-elongation industrial yarn is prepared from the creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The marine creep-resistant polyester high-strength low-elongation industrial yarn provided by the invention has a certain creep resistance, hydrolysis resistance and stability, can be applied in a hot and humid environment for a long time, and has a huge application prospect in the fields of marine mooring ropes, fishing nets and the like.

Owner:JIANGSU HENGLI CHEM FIBER

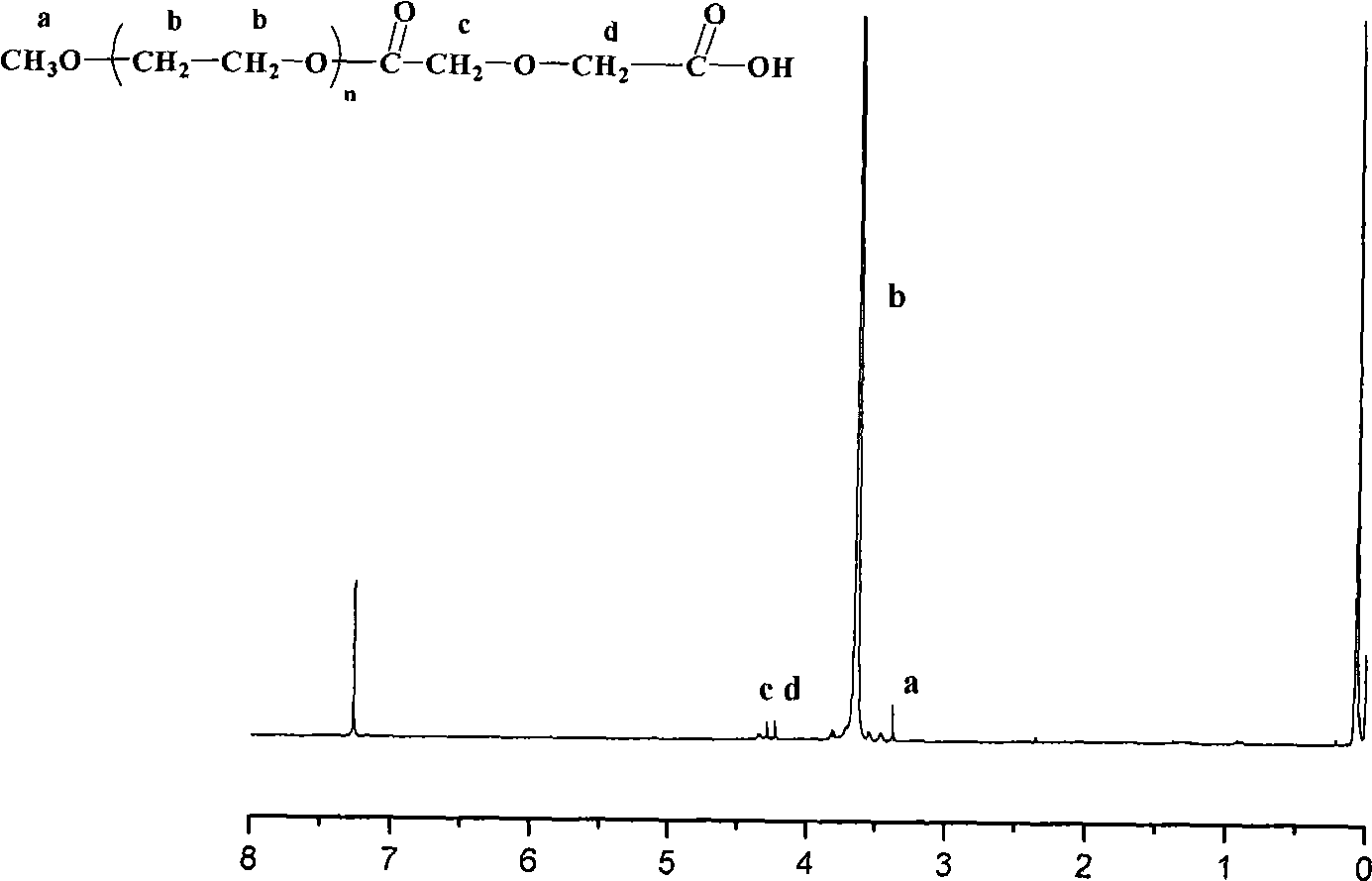

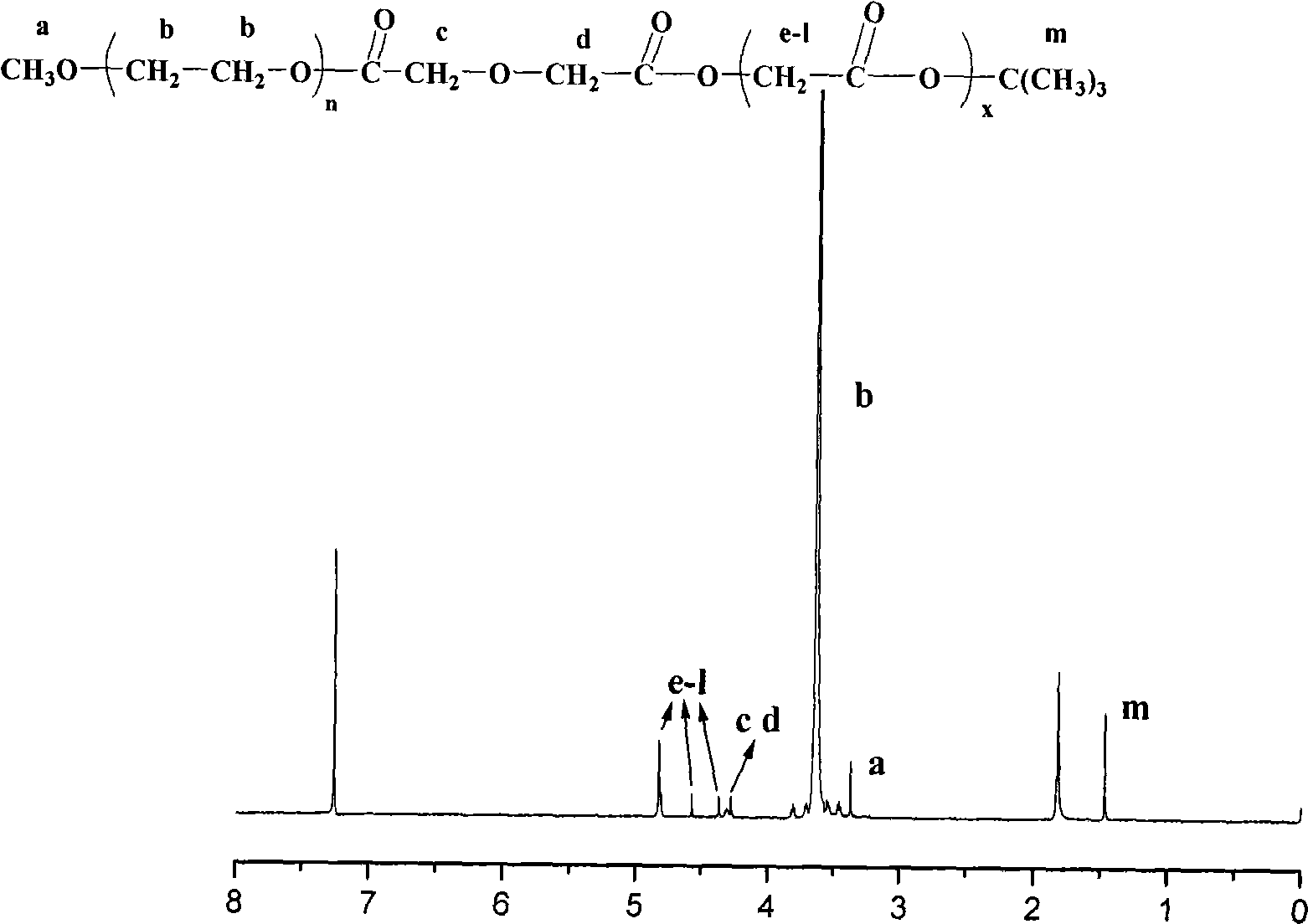

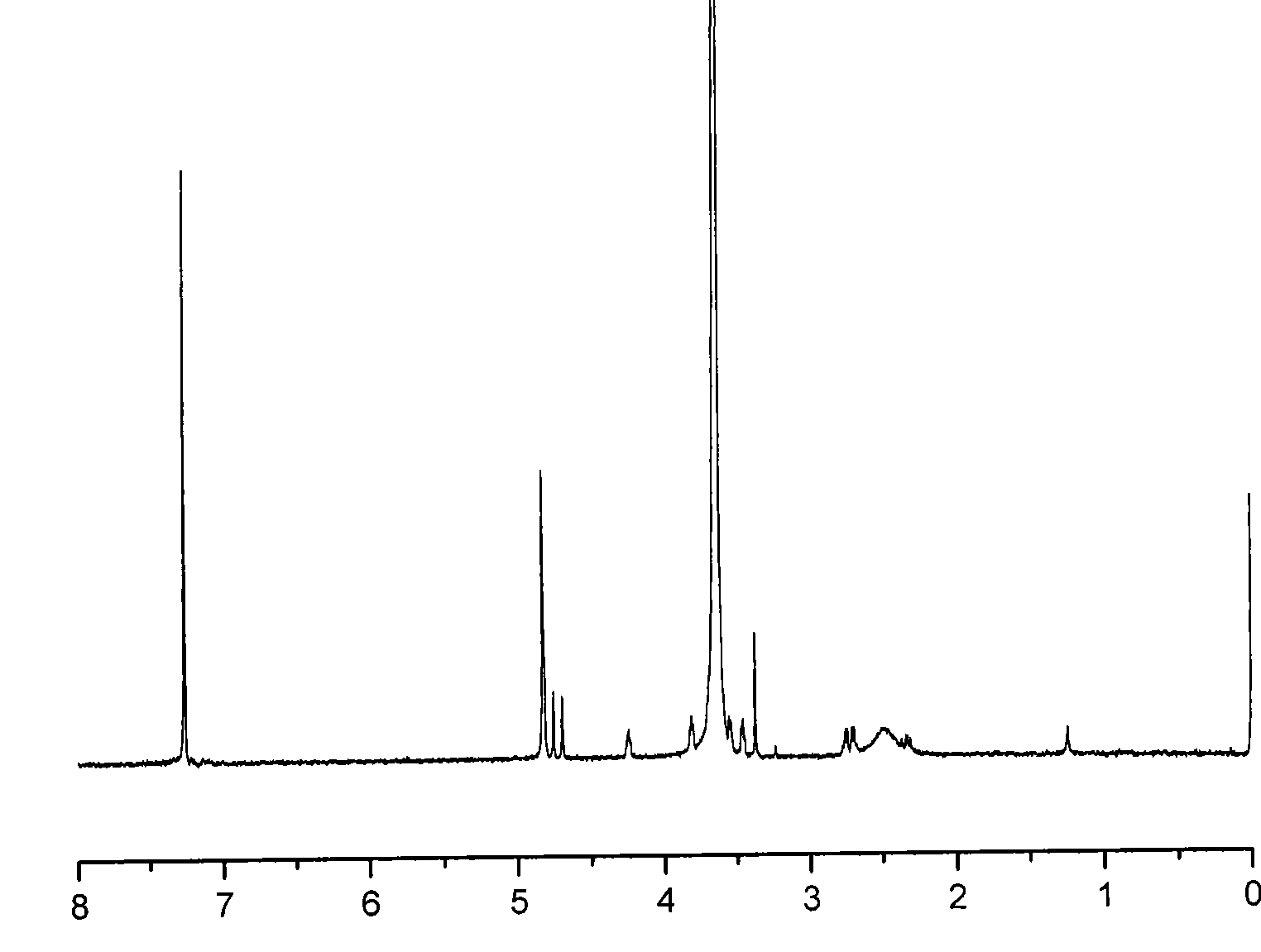

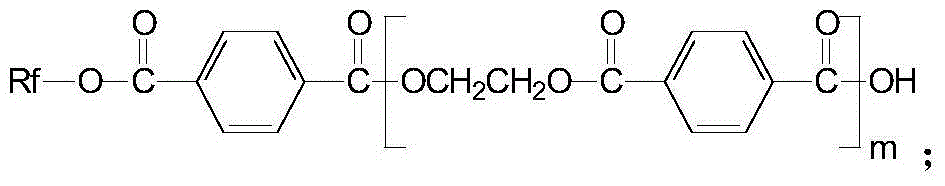

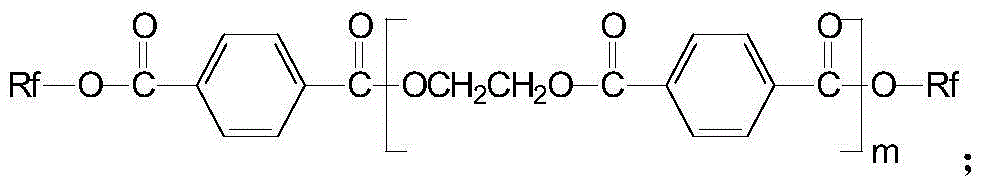

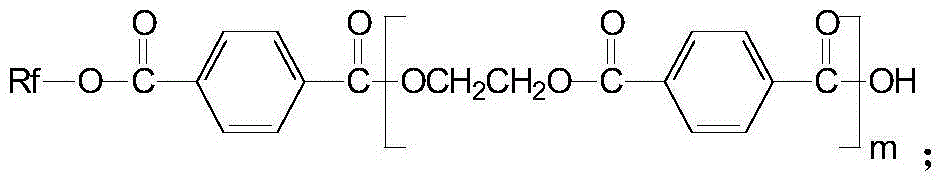

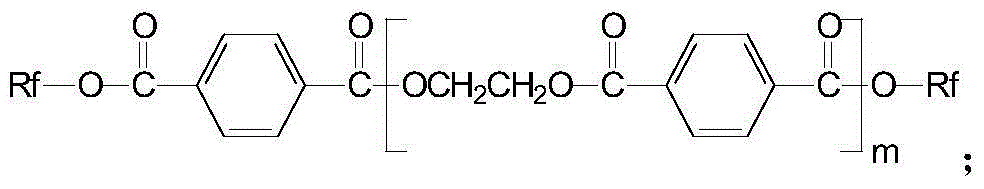

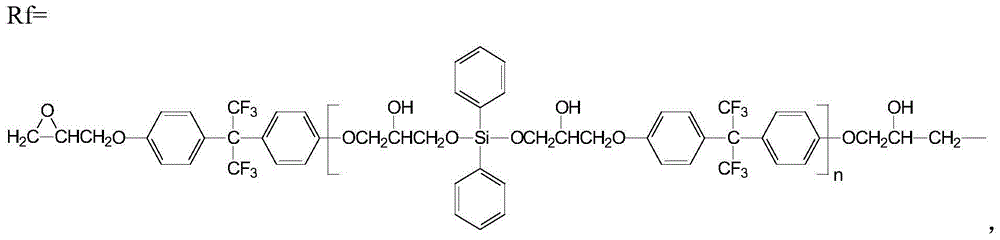

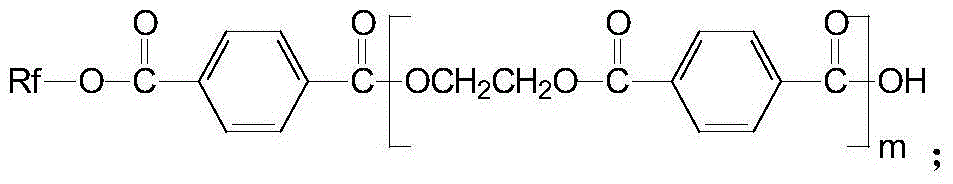

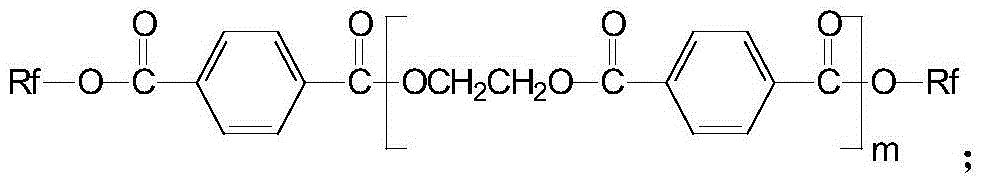

Anti-tumor prodrug having accurate structure and taking novel amphipathic polymer as carrier and synthetic method thereof

InactiveCN101543632ASolve the problem of insoluble in waterFacilitate dissociationOrganic active ingredientsPharmaceutical non-active ingredientsSide effectAdditive ingredient

The invention discloses a prodrug system prepared by connecting a series of oligopolymers synthesized by a group protection and deprotection method and polyethyleneglycol to be used as a drug carrier, belonging to the technical field of chemical drugs. Laden drugs are water-insoluble anti-tumor drugs such as taxol, or other cancer therapy drugs such as doxorubicine and camptothecin. A research discovers that drug compositions prepared by the method greatly improve the hydrophobic nature of the anti-tumor drugs and can accurately control the gather time of the oligopolymers on focus parts and the hydrolyzation rupture time of ester bonds by accurately controlling the lengths of segmers of the oligopolymers so as to control the drug release time so that drugs are stably released, thereby the method prevents burst release causing toxic side effect on normal cells, reduces the drug dosage to enhance the curative effect and sufficiently plays a sustained and controlled release role; and in addition, the structure of the oligopolymers is accurate, and the molecular weight of synthesized amphipathic block polymers which are uniformly distributed is accurate, thereby the method can ensure synthesized drug ingredients to be definite and stable and the pharmacokinetics and the treatment effect (activity and toxicity) of the synthesized drugs to have good reproduction quality and be accurately defined.

Owner:XIANGTAN UNIV

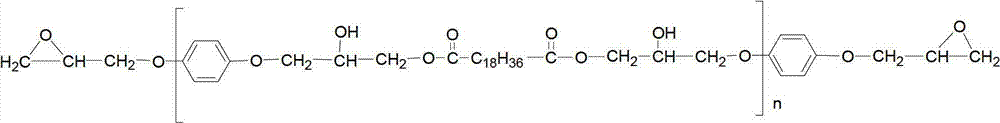

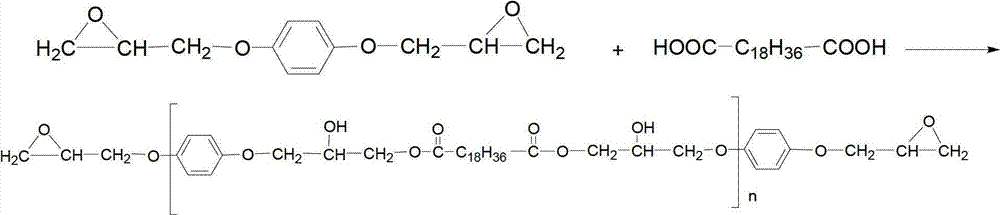

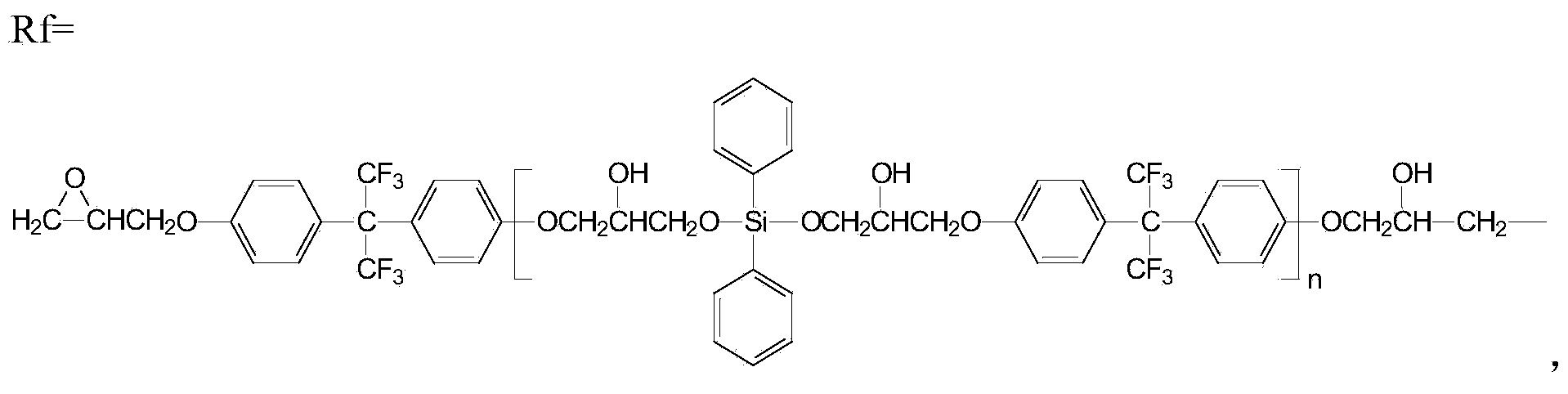

Modified bisphenol A-type epoxy resin and preparation method thereof

InactiveCN102827105ALow reaction temperatureFast responseOrganic chemistryEpoxy resin coatingsBisphenol SAddition reaction

The invention relates to modified bisphenol A-type epoxy resin and a preparation method thereof; the modified bisphenol A-type epoxy resin disclosed by the invention is a product obtained by reacting bisphenol epoxy resin and octadecanedicarboxylic acid under the effect of special catalyst; a carbon chain in a special structure is led into an epoxy resin molecule structure through the addition reaction of the modified bisphenol A-type epoxy resin and an epoxy group; the preparation method comprises the following steps: mixing epoxy resin and the octadecanedicarboxylic acid evenly; then, stirring a mixture under the protection of nitrogen while heating the mixture to 95-100 degrees centigrade; adding catalyst; keeping the reaction time of a reactant within 1.5-5 hours at a temperature when the temperature of the reactant reaches to 130-170 degrees centigrade; cooling the reactant; and discharging the reactant. According to the invention, the modified bisphenol A-type epoxy resin and the preparation method thereof have advantages of low reaction temperature, fast reaction speed, high yield, light color of the modified bisphenol A-type epoxy resin and good rigidity, toughness and chemistry resistance of modified curing epoxy resin.

Owner:SUZHOU SIRGEL RESINS SPECIALTIES CO LTD

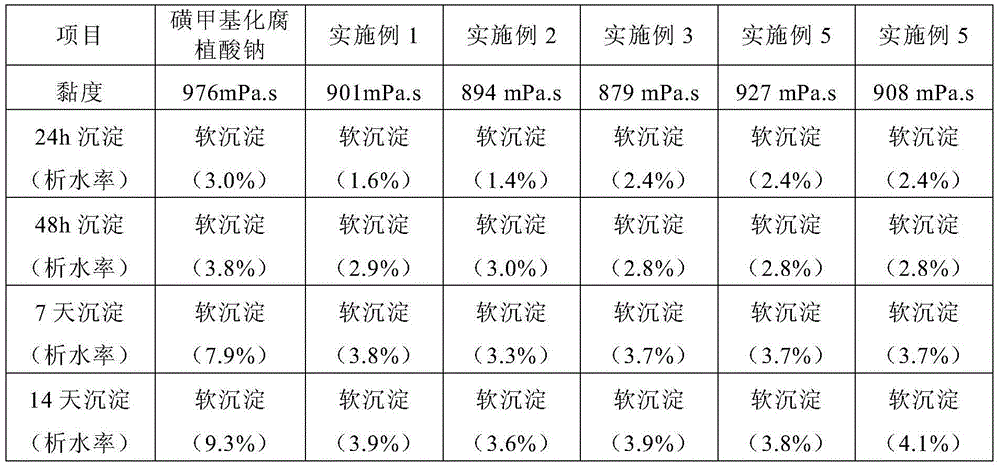

Amphoteric humate coal water slurry dispersant as well as preparation and application thereof

InactiveCN104152195APossesses both yin and yang characteristicsEvenly dispersedLiquid carbonaceous fuelsCoal waterCross linker

The invention discloses a preparation method of an amphoteric humate coal water slurry dispersant. The preparation method comprises the following steps: preparing sulfomethylated humic acid by reaction of humic acid, formaldehyde and a sulfonating agent; then further performing cationization reaction on sulfomethylated humic acid and a cationic etherifying agent and finally dropping a cross-linking agent to perform cross-linking reaction so as to obtain the novel amphoteric humate coal water slurry dispersant. The method for preparing the coal water slurry dispersant comprises three steps of sulfomethylation, cationization and cross-linking reaction, and anionic and cationic groups are introduced on a matrix of the humic acid, so that the relative molecular weight of the dispersant is also increased; by using the novel dispersant, the apparent viscosity of the coal water slurry can be effectively reduced and the stability of the coal water slurry can be also obviously improved.

Owner:SHAANXI UNIV OF SCI & TECH

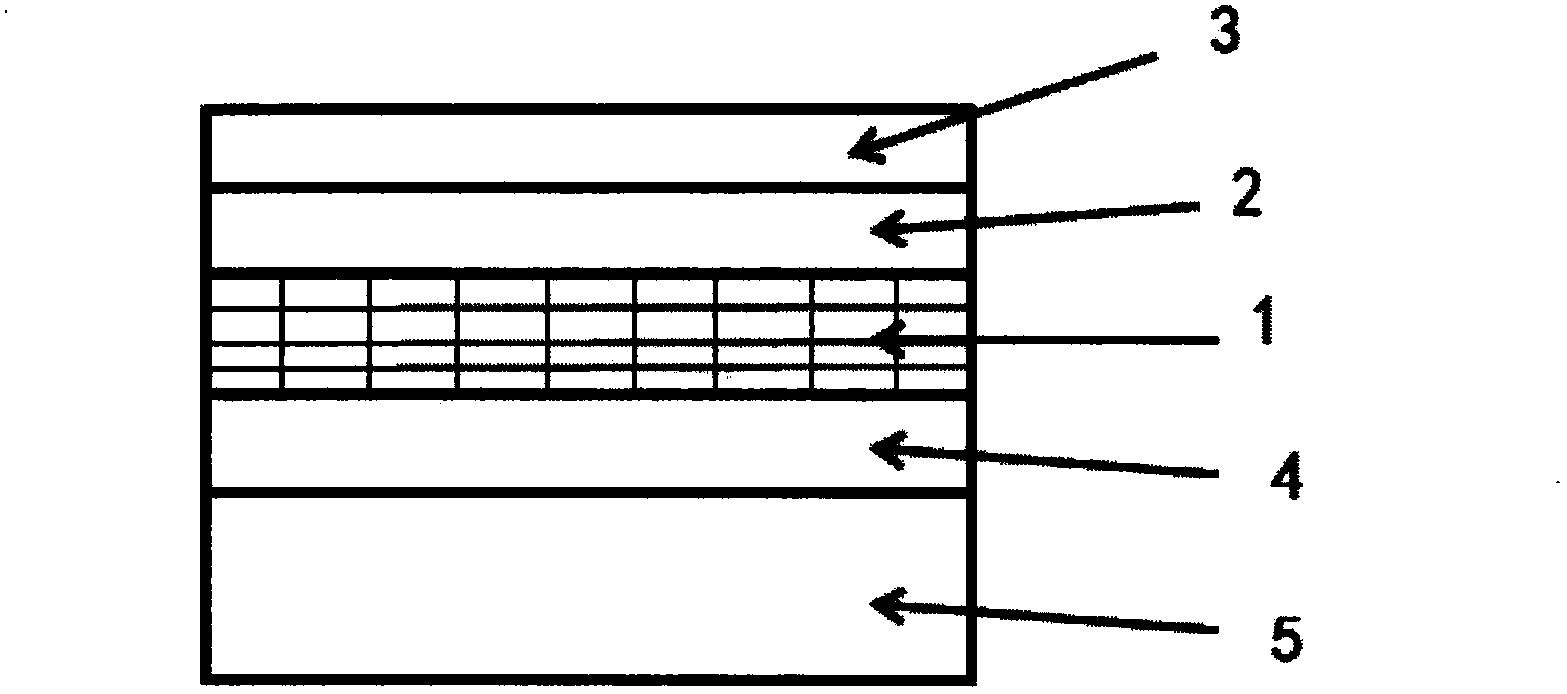

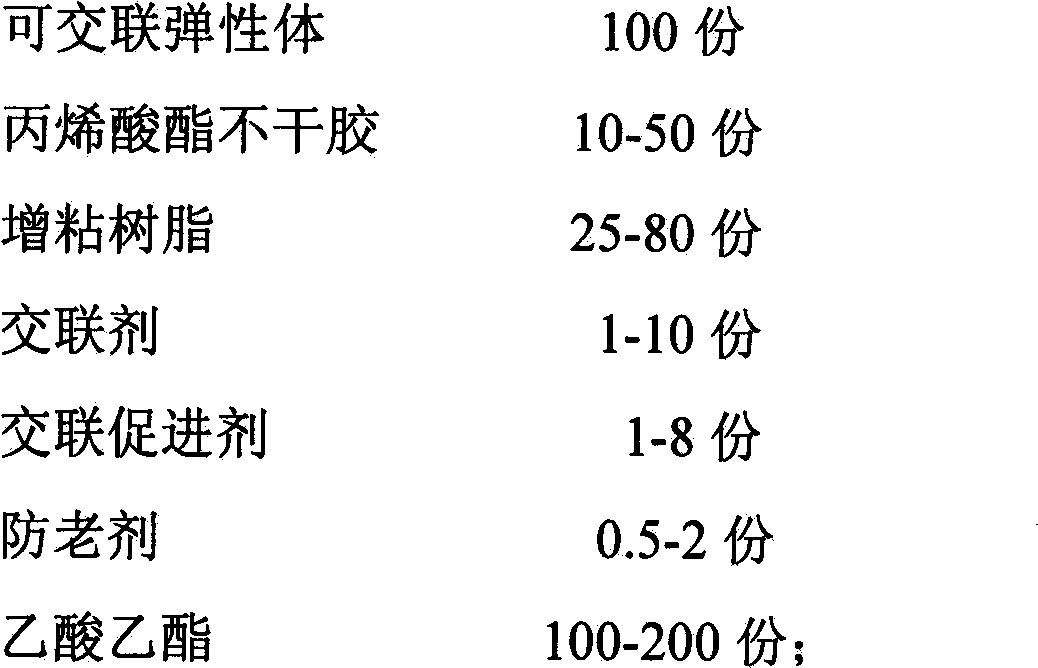

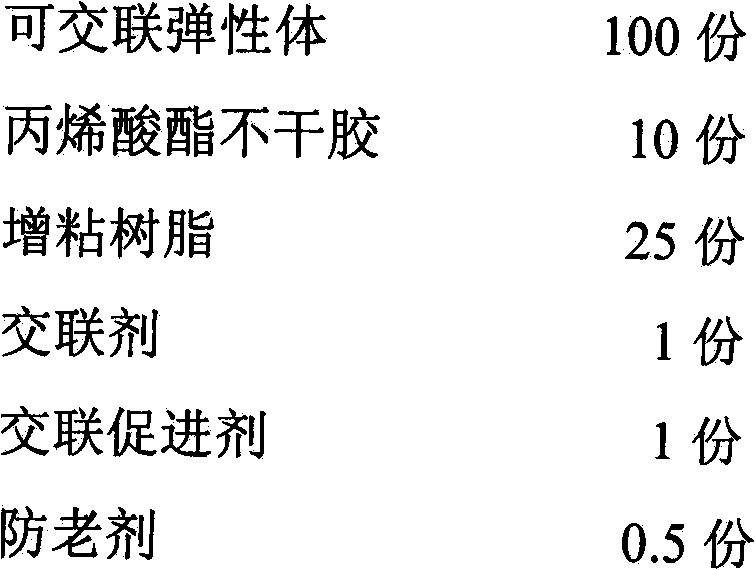

Pressure sensitive adhesive tape for high-temperature resistant masking and preparation method thereof

InactiveCN103571369AEliminate high temperature residual glueHigh peel strengthNatural rubber adhesivesFilm/foil adhesivesHot TemperaturePressure sensitive

The invention relates to a pressure sensitive adhesive tape for high-temperature resistant masking and a preparation method thereof. The pressure sensitive adhesive tape consists of a substrate layer, an isolator layer, a release agent layer, a primer layer and an adhesive layer, wherein the isolator layer and the release agent layer sequentially cover the upper surface of the substrate layer, and the primer layer and the adhesive layer sequentially cover the lower surface of the substrate layer. The pressure sensitive adhesive tape prepared by the invention, compared with the prior art, can avoid crack and residue when being peeled off after being roasted for 60 minutes at high temperature of 180 DEG C, and the adhesive property has strong adhesive property and can avoid a wrapping phenomenon when being used.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Epoxy resin flame-retardation composition and preparation method thereof

InactiveCN106243630AIncrease the relative molecular massImprove thermal stabilityAmmonium polyphosphateSmoke

The invention discloses an epoxy resin flame-retardation composition and a preparation method thereof, belonging to the field of flame-retardation substances. The composition comprises, by mass, 75 to 90 parts of epoxy resin, 5 to 15 parts of a curing agent and 5 to 10 parts of a fire retardant, summing to 100 parts, wherein the fire retardant is a rational compound of poly(bisphenoxy)biphenol phosphorate (PBPP) and ammonium polyphosphate (APP). The fire retardant in the composition is high-efficiency halogen-free compound intumescent flame retardant, and overcomes the disadvantages of generation of heavy smoke and a great number of droplets in combustion of halogen fire retardants and the problem that a great addition amount of an inorganic fire retardant leads to changing of the mechanical properties of a material; the epoxy resin flame-retardation composition overcomes the problems of low heat stability, proneness to hydrolysis, difficulty in processing and proneness to migration in a matrix of conventional phosphorus-containing fire retardants, realizes synergistic flame retardation of multiple elements such as elemental nitrogen and elemental phosphorus, and has high flame retardation efficiency; and the preparation method for the epoxy resin flame-retardation composition is simple.

Owner:GUIZHOU NORMAL UNIVERSITY

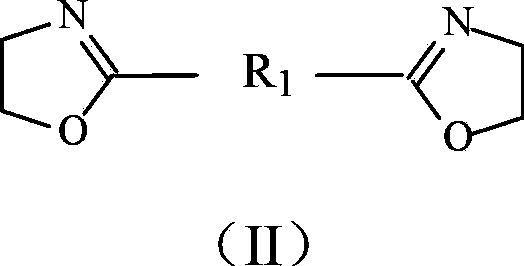

Chain extender for polyamide preparation through chain extending

The invention relates to a chain extender for polyamide preparation through chain extending. The chain extender is prepared by the step of: reacting polymethyl methacrylate with styrene in a stainless steel reaction vessel equipped with a mixer, a condenser and a temperature control device as well as nitrogen atmosphere for 2-3h at a temperature of 108DEG C-112DEG C, thus obtaining a copolymer with a number-average molecular weight of 6000-7500 and a glass transition temperature of 50DEG C-60DEG C, with the styrene of 0.05 wt%-2 wt% in content. The invention also relates to application of the chain extender in a direct polymerization technology of polycaprolactam. Polycaprolactam slices obtained by a direct polymerization technology employing the chain extender have stable amino end group content, and high dyeing uniformity in a post processing process as well as good spinnability, thus being suitable for polyamide high-speed spinning and fine denier yarn production.

Owner:ZHANGJIAGANG CHAINENG BIOLOGICAL TECH

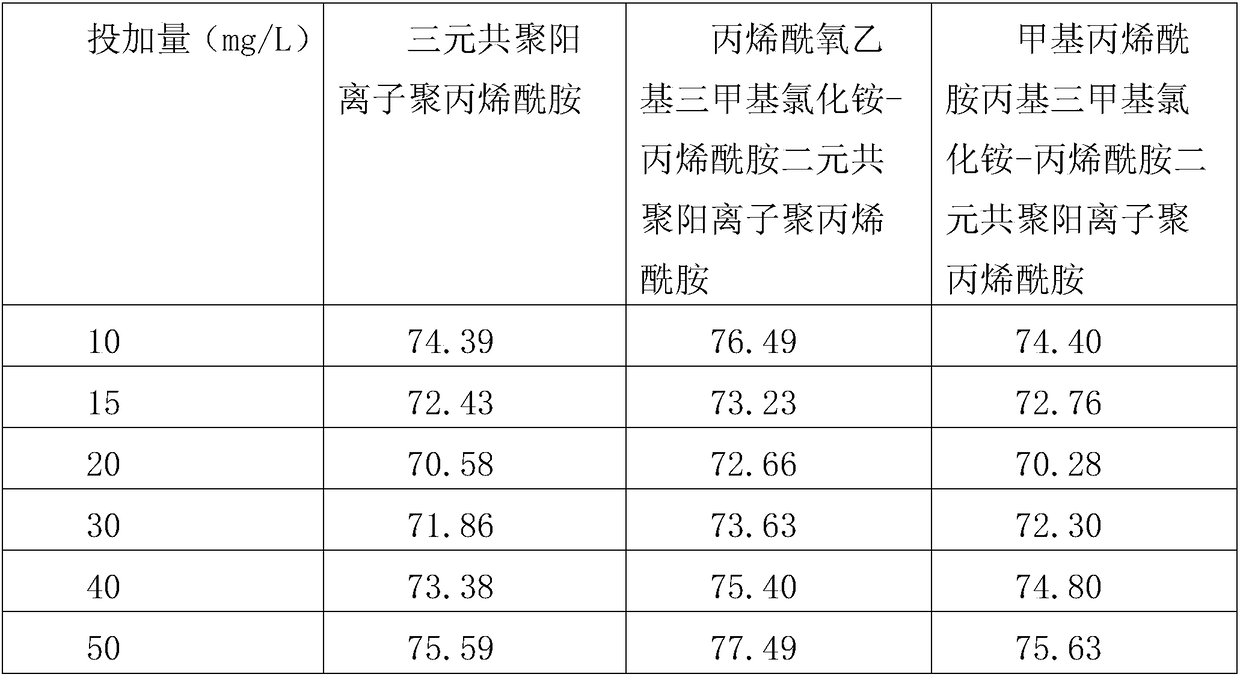

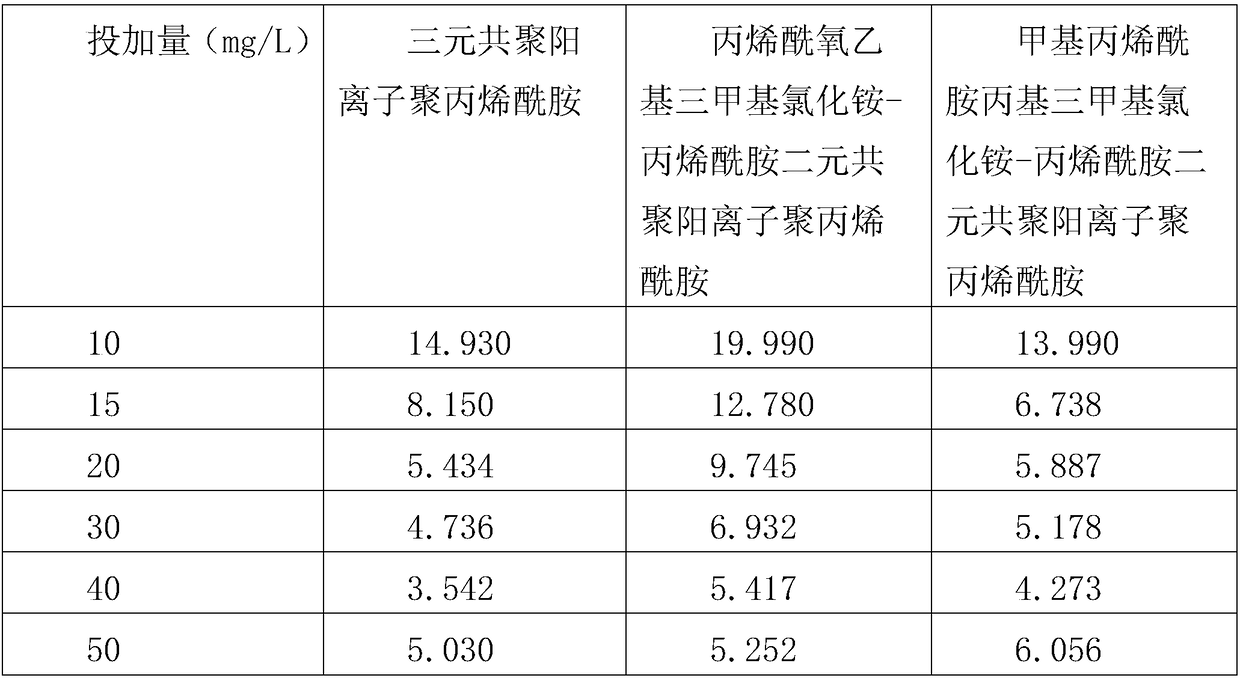

Preparation method of ternary copolymerized cationic polyacrylamide

The invention discloses a preparation method of ternary copolymerized cationic polyacrylamide, including the following steps: stirring to dissolve cationic monomer diallyl dimethyl ammonium chloride,methacrylamide, propyl trimethylammonium chloride, nonionic monomer acrylamide, a metal ion chelating agent, and a chaotropic agent in water, adding a chain transfer agent and an initiating agent in turn after injecting nitrogen for removing oxygen, which evenly mixes the chain transfer agent and initiating agent and reaction liquid by effect of the nitrogen flow to obtain the ternary copolymerized cationic polyacrylamide colloid product, obtaining the colloidal particles by prilling the colloid product, adding anti-crosslinking agent solution into the colloidal particles for mixing, drying and milling the colloidal particles into powder, after sieving, obtaining powder product of the ternary copolymerized cationic polyacrylamide. The ternary copolymerized cationic polyacrylamide has significant hydrolysis resistance property, flocculent property is maintained and improved, the product economy is optimized relative to copolymerized products of MAPTAC and acrylamide. The method is applicable to large kettle production, which is easy to implement industrialization.

Owner:中科乐美科技集团有限公司

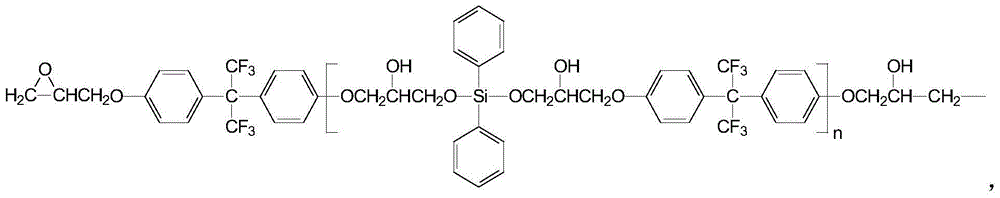

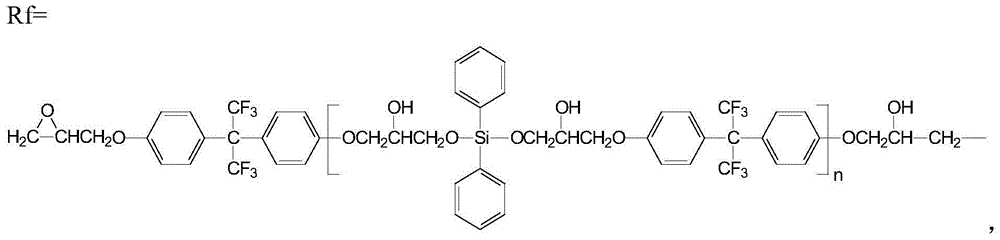

Synthetic-leather-used UV solidifying and flame-retarding polyurethane and preparation method thereof

ActiveCN105131227AHigh flame retardant efficiencyEasy to control performanceEnvironmental resistanceSide chain

The invention discloses synthetic-leather-used UV solidifying and flame-retarding polyurethane and a preparation method thereof. The method is characterized by comprising the steps that low-viscosity liquid dihydric alcohol and diisocyanate serve as raw materials, side-group phosphorus / nitrogen-containing dihidroxy acrylate is introduced into the polyurethane structure in the form of chain extender, and then side-group phosphorus-containing monohydroxy acrylate is used for sealing the end. Both a main chain and a side chain of the obtained UV solidifying polyurethane contain photosensitive perssad, through the UV solidification, the crosslinking degree and relative molecular mass of resin can be improved, the contradiction between the fact that photosensitive perssad in traditional UV solidifying polyurethane is low in content and the fact that the molecular weight of coating polymer is high in requirement is reconciled, and meanwhile the comprehensive performance of the polyurethane such as wear resistance, scratch resistance, waterproofness, heat resistance and solvent resistance is improved; phosphorus / nitrogen flame-retarding ingredients are 'suspended'on the macromolecular side chain of the polyurethane, the flame-retarding effect is good, and fire retardant is not migrated or separated out and is resistant to hydrolysis in the storage and using processes; in addition, no organic solvent is used in the preparation process of the polyurethane, and the synthetic-leather-used UV solidifying and flame-retarding polyurethane has the advantages of being prominent in greenness, environment-friendliness, health, safety and the like and can be used in synthetic leather manufacturing and coating materials such as leather and textiles.

Owner:SICHUAN UNIV

Water-repellent creep-resistant polyester fully drawn yarn (FDY) fiber and preparation method thereof

ActiveCN103526325AIncrease forcePlay the role of creep resistanceFibre typesMonocomponent copolyesters artificial filamentPolyesterYarn

The invention relates to a water-repellent creep-resistant polyester fully drawn yarn (FDY) fiber and a preparation method thereof. The preparation method comprises the preparation of a creep-resistant polyester melt and the preparation of the water-repellent creep-resistant polyester FDY fiber; polyester is blended or added with a fluorine-containing epoxy compound during polyester synthesizing to obtain the creep-resistant polyester melt; then the creep-resistant polyester melt is subjected to metering, extruding, cooling, oiling, stretching and winding to obtain the water-repellent creep-resistant polyester FDY fiber, wherein the oiling operation refers to the operation of coating the surface of the water-repellent creep-resistant polyester FDY fiber with water repellents. The water-repellent creep-resistant polyester FDY fiber has certain creep resistance, hydrolysis resistance and performance stability, can be used in a humid field environment or a high-temperature high-humidity environment for a long time, and has great prospect in the fields of plastic packaging, waterproof fabrics, ropes, mooring ropes, marine fibers and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Octadecanoyl tributyl citrate plasticizer and preparation thereof

InactiveCN101255240AIncrease the relative molecular massHigh plasticizing efficiencyCarbonyl chlorideStearic acid

The invention provides octade carbonyl tributyl citrate plasticizer and preparation method thereof. The composition of octade carbonyl tributyl citrate plasticizer (in mass percent): tributyl citrate 43.5-53.8%, octade carbonyl chloride 45.2-55.0%, catalyst 1.0-1.5%. The preparation method comprises: (1) adding citric acid, butylalcohol, water-carrying agent and catalyst into reaction kettle, stirring, heating up until reflowing to obtain tributyl citrate; (2) adding stearic acid into reaction kettle, stirring, heating up to 50 degree and then adding phosphorous trichloride and heating up to 75 degree to perform thermal insulating reaction for 3 hours and layering to obtain octade carbonyl chloride; (3) adding tributyl citrate and catalyst in the reaction kettle, stirring, heating up to 70 degree and then adding octade carbonyl chloride to obtain chlorine hydride and the chlorine hydride being absorbed in water containing soda in drier, when the pH of the water containing soda is constant, the reaction being stopped and the product being subjected to neutralizing, cleaning, pump filtering under reduced pressure to obtain octade carbonyl tributyl citrate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

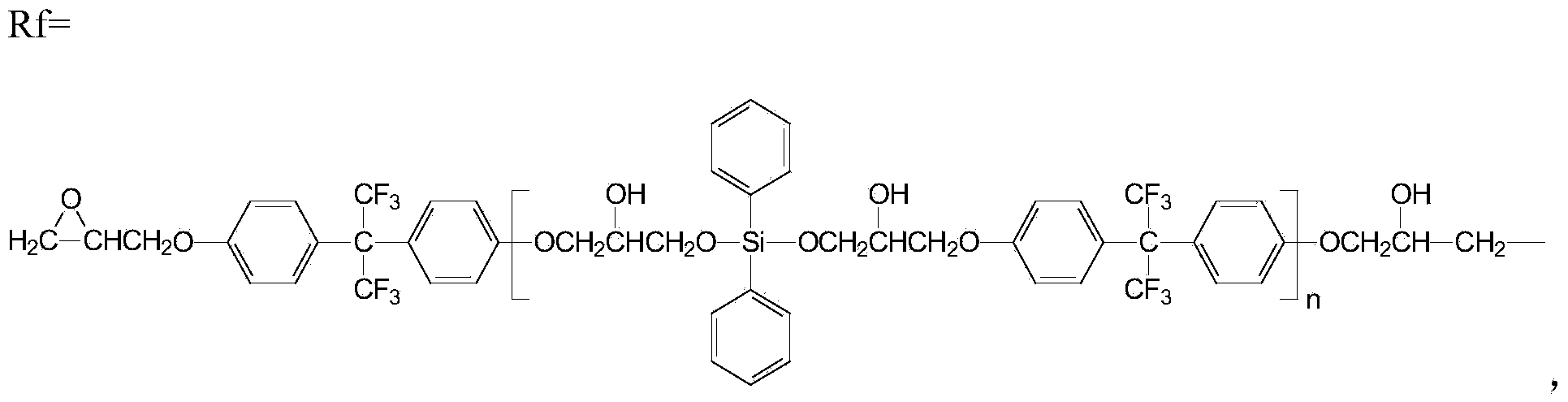

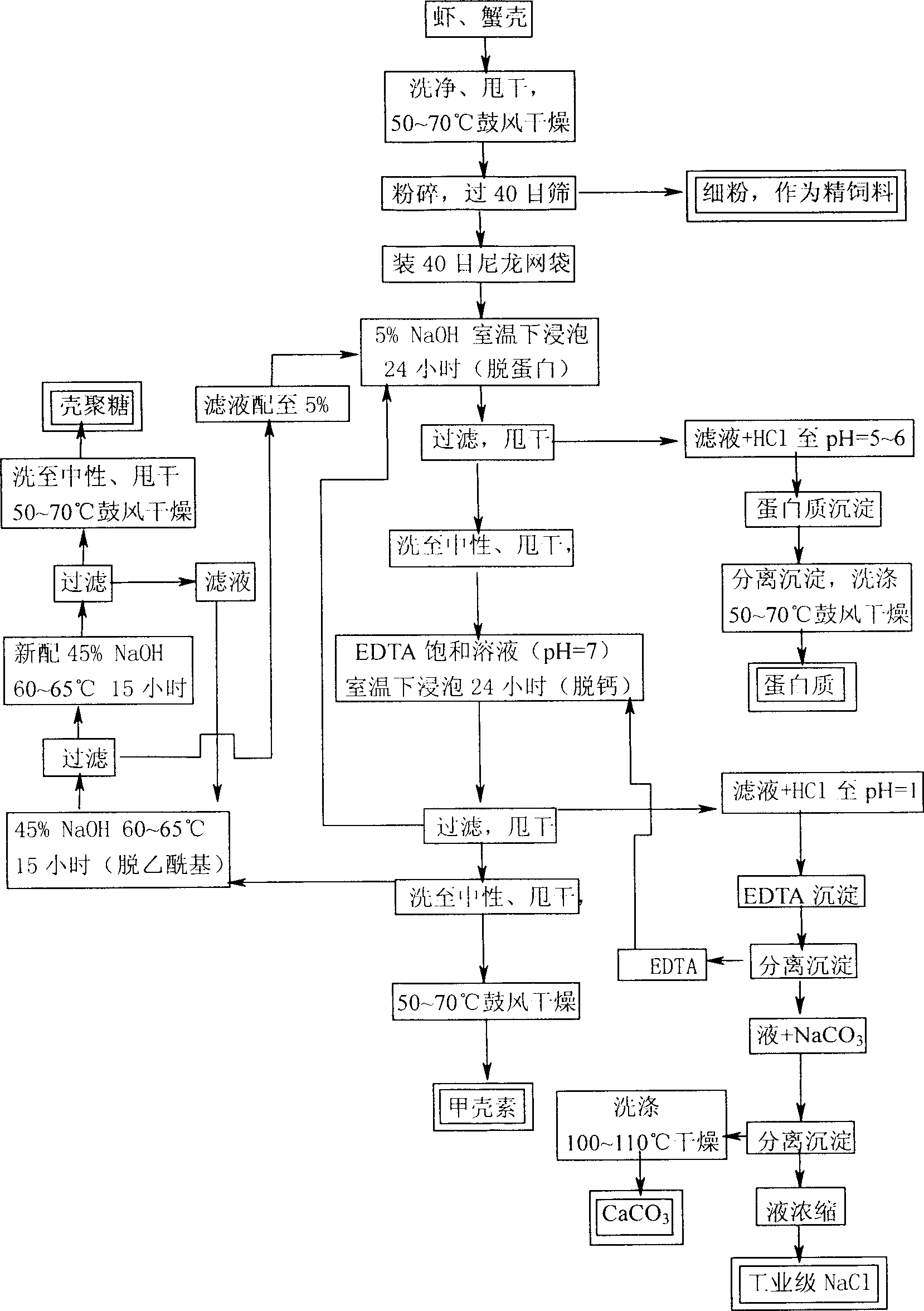

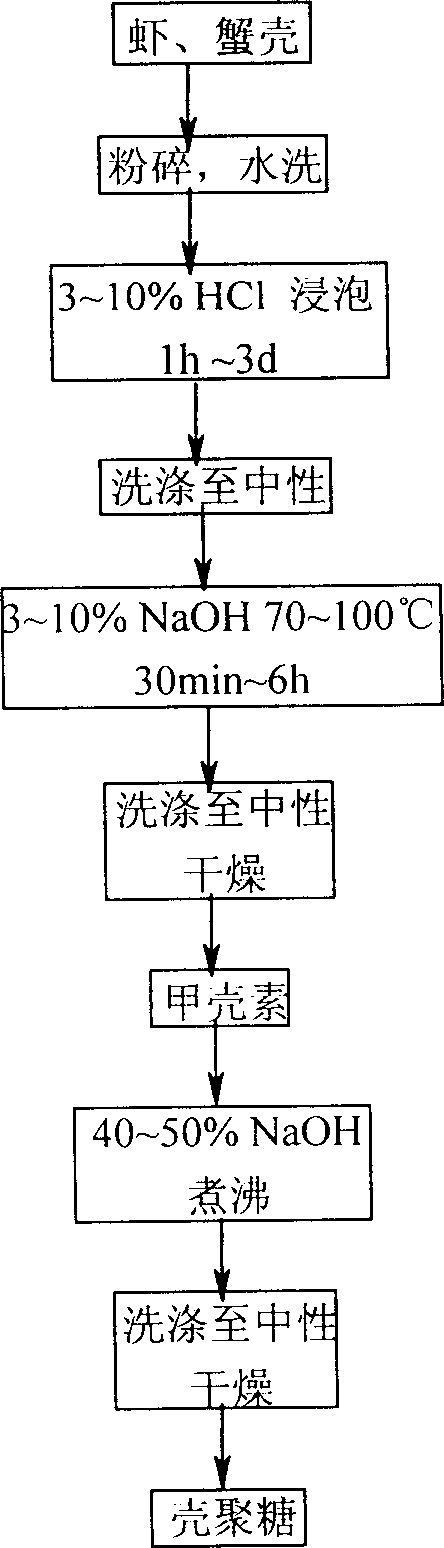

Method for preparing high relative molecular mass chitin and chitosan, and comprehensive utilization

A process for preparing the chitin or chitosan with high relative molecular mass is characterized by that EDTA instead of HCl is used for decalficiation, resulting in no damage to molecular chain and higher yield increased by 10% or more. Its by-products and rejected substance are all recovered for lower cost.

Owner:GUANGDONG OCEAN UNIVERSITY

Method for extracting pectin from waste sisal residues

The invention belongs to the technical field of plant component extraction, and discloses a method for extracting pectin from waste sisal residues. The method includes the steps of smashing sisal residues, killing enzyme with hot water, conducting extracting through a cellulose compound enzyme solution after degreasing to obtain a sisal residue pectin solution extracted through an enzyme method and solid residues, adding solid residues to an ammonium oxalate solution, conducting ultrasonic extracting to obtain a sisal residue pectin solution extracted through an ultrasonic method, combining and concentrating the sisal residue pectin solution, adding absolute ethyl alcohol for sedimentation, and making sediment sequentially subjected to decoloring through an acid alcohol solution and washing through an ethyl alcohol water solution and vacuum drying to obtain sisal residue pectin. The enzyme method and the ultrasonic extracting method are put forward first so that sisal residue pectin can be extracted; compared with an acid extracting method, an oxalic acid and ammonium oxalate extracting method, a fermentation method and the like in the prior art, the pectin extracting rate is increased to be 30-40% from 10-15%.

Owner:SOUTH CHINA UNIV OF TECH

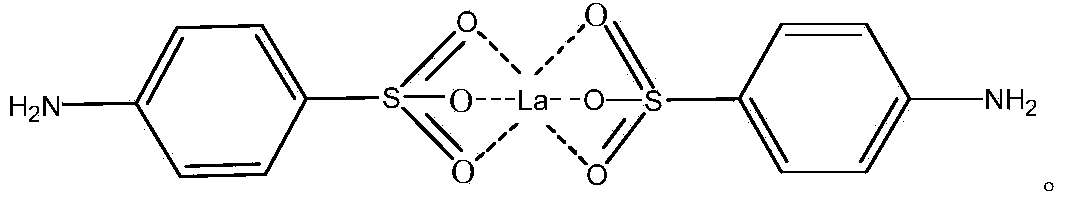

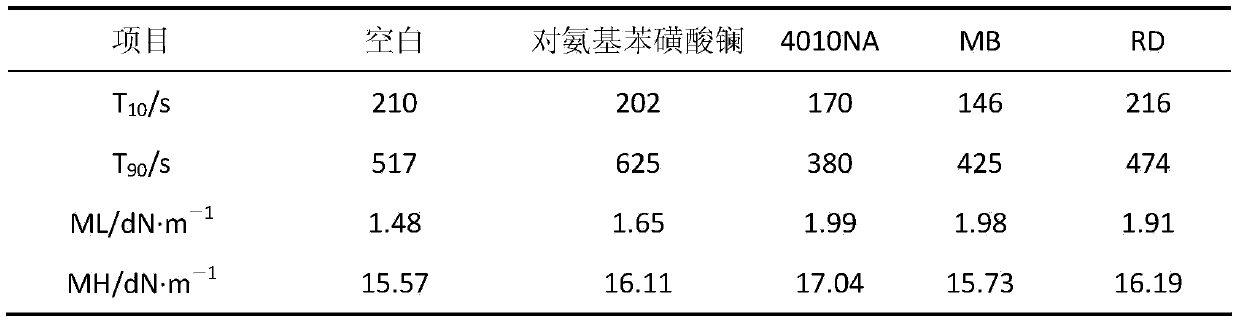

Rare-earth complex rubber anti-aging agent, and preparation method and application thereof

InactiveCN104004224AThe synthesis method is simpleGood oxidation protection performanceSulfonic acid preparationRubber materialPolymer science

The invention discloses a rare-earth complex rubber anti-aging agent, and a preparation method and application thereof. The preparation method of the rare-earth complex comprises the following steps: dissolving sodium sulfanilate in water to prepare a solution having a concentration of 5-60%; adding rare-earth salts of which the mole number is equivalent to 10-100% of the mole number of the sodium sulfanilate, and then performing stirring reaction at 40-95 DEG C for 2-24 hours; and filtering the obtained product, washing, and drying to obtain a powdered target product lanthanum sulfanilate. The rare-earth complex rubber anti-aging agent is applied in rubber preparation. According to the invention, the preparation method of the rare-earth complex rubber anti-aging agent is simple and easy to implement; and the rare-earth complex rubber anti-aging agent can obviously decelerate aging of rubber, can be singly used or compounded with other anti-aging agents for use, and has the advantages of causing no pollution to a rubber product, prolonging the scorching time of a rubber material, lowering the viscosity of the rubber material and the like.

Owner:SOUTH CHINA UNIV OF TECH

Creep-resistant polyester ultralow-shrinkage industrial yarn and its preparation method

ActiveCN103556285AIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentPolyesterEpoxy

The invention relates to a creep-resistant polyester ultralow-shrinkage industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester ultralow-shrinkage industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester ultralow-shrinkage industrial yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The obtained creep-resistant polyester ultralow-shrinkage industrial yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Synthetic method of anionic polyacrylamide

The invention relates to a synthetic method of anionic polyacrylamide, which comprises the steps of adding distilled water, an acrylamide monomer, an acrylic monomer and sodium hydroxide powder to a reaction device in sequence, stirring uniformly until completely dissolving to form a monomer aqueous solution, adding appropriate solubilizer, chelating agent and initiator to the monomer aqueous solution, stirring uniformly, filling high-purity nitrogen into the reaction device, exhausting air in the reaction device, sealing the reaction device, placing in an ultraviolet light reaction device, initiating a polymerization reaction under the irradiation of ultraviolet light with certain wavelength, generating an anionic polyacrylamide colloid, purifying, washing and refining the colloid, drying in a vacuum drying oven, grinding, and obtaining anionic polyacrylamide. The method is simple in process, short in production cycle and few in procedure; the polymerization reaction is more stable, and easy to control; prepared polyacrylamide is large in molecular weight, high in conversion rate and solid content, good in dissolvability, and stable; and anionic polyacrylamide is high in DEHP (Di-2-Ethyl Hexyl Phthalate) removal rate.

Owner:江苏源通新材料有限公司

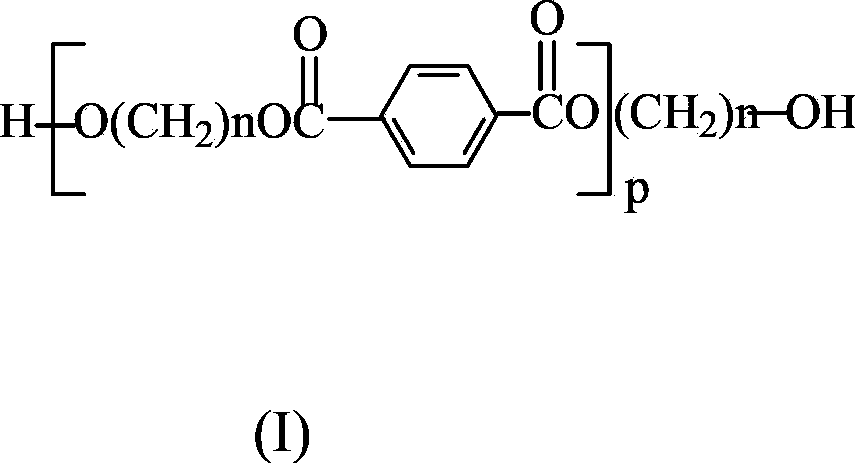

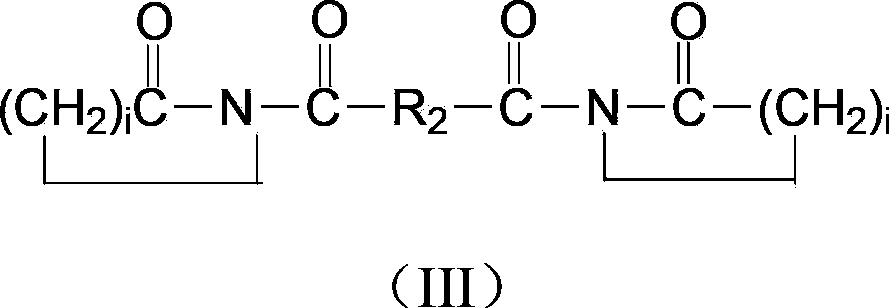

Biodegradable aliphatic-aromatic block mixed polyester preparation method

The invention relates to a biodegradable aliphatic-aromatic block mixed polyester preparation method, and belongs to the technical field of mixed polyesters. The preparation method comprises that: dimethyl terephthalate and excess aliphatic diol are subjected to ester exchange to obtain a poly terephthalate diester oligomer having terminal hydroxyl, the poly terephthalate diester oligomer having the terminal hydroxyl reacts with an aliphatic dicarboxylic acid to obtain an aliphatic-aromatic block mixed polyester prepolymer, and chain extenders such as diacyl di-lactam and bisoxazoline are adopted to carry out chain extension to prepare the biodegradable aliphatic-aromatic block mixed polyester with the 30 DEG C intrinsic viscosity of 0.48-0.78 dL / g. According to the method, the polymerization temperature is moderate and is 180-240 DEG C so as to avoid side reaction intensifying at the later stage of the high temperature reaction, and the obtained polymer has characteristics of high melting point, excellent thermal stability and excellent mechanical property.

Owner:BEIJING UNIV OF CHEM TECH

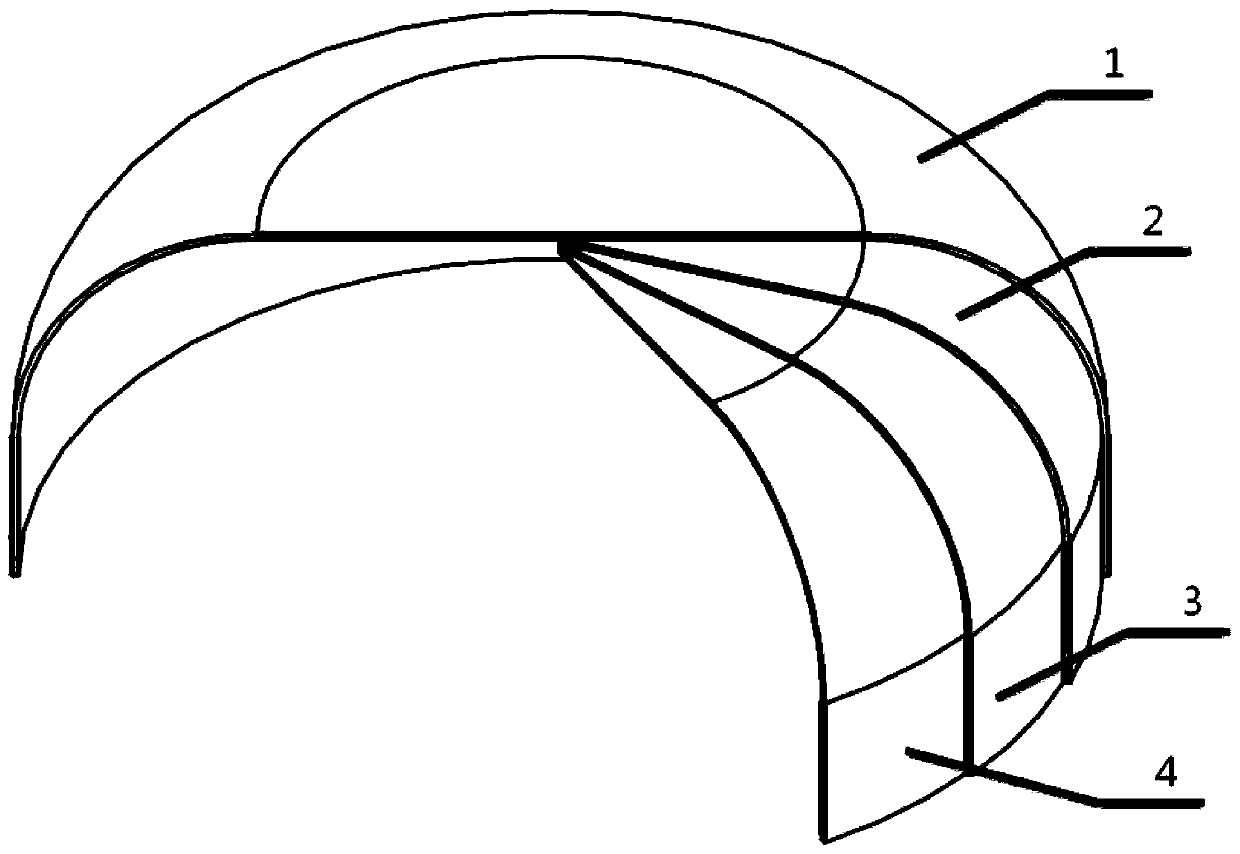

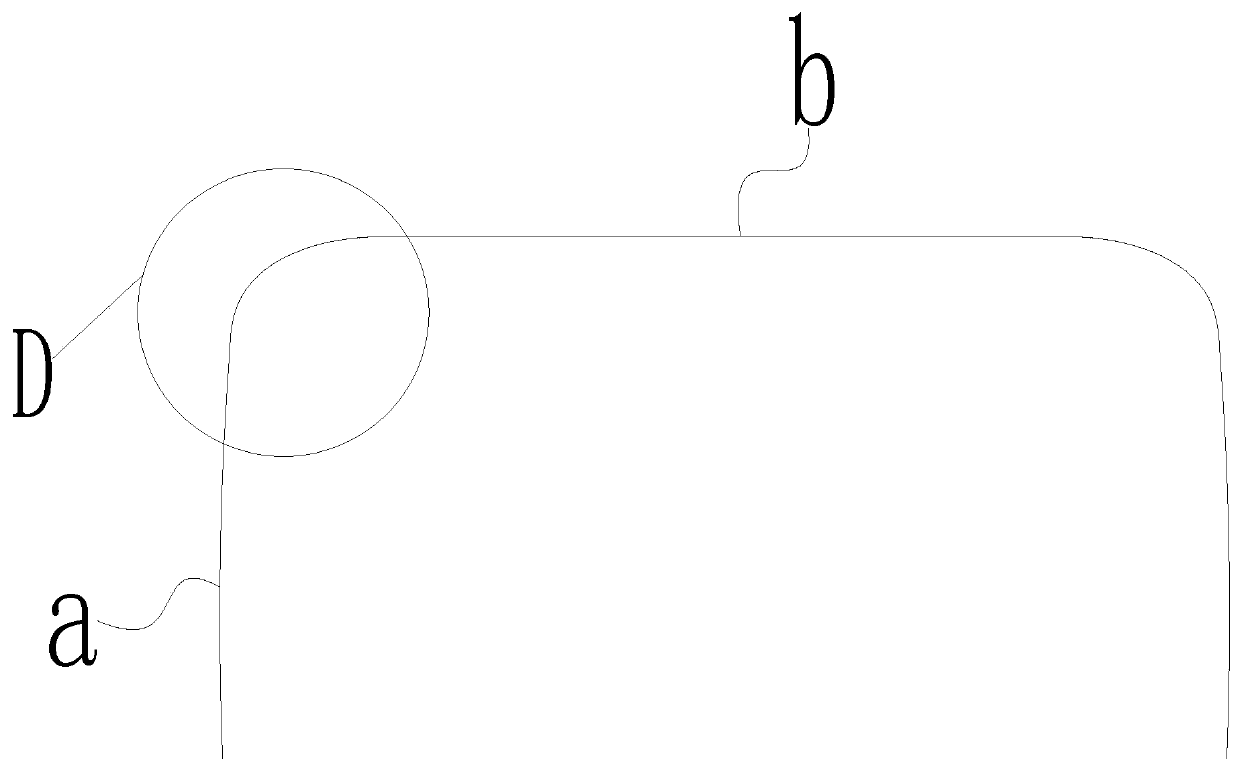

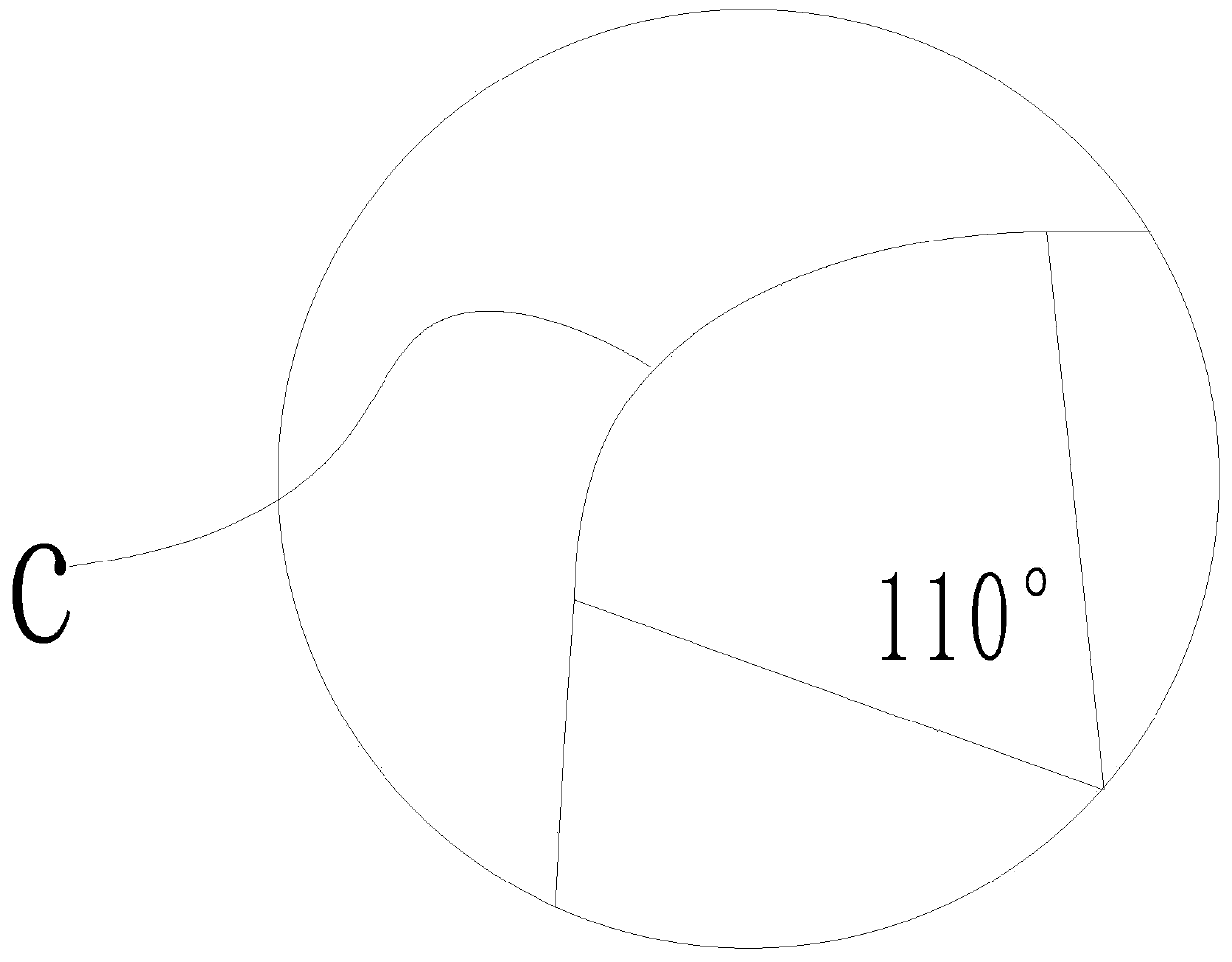

High-wave-transparent light honeycomb sandwich bulletproof radome

PendingCN110416724AIncrease the relative molecular massThe main chain is well combinedRadiating element housingsFiber layerWave transmission

The invention discloses a high-wave-transparent light honeycomb sandwich bulletproof radome which comprises a radome main body. A concave cover body is in the radome main body, an inner core of the radome main body is a honeycomb layer for supporting, and an ultrahigh molecular weight polyethylene fiber layer for ballistic protection with a matched shape is outside the honeycomb layer. The radomemain body is cylindrical and comprises a side surface portion as a side surface and a bottom surface portion as a bottom surface, the side surface portion has an arc shape which is contracted at two ends of a middle ridge, the bottom surface portion is planar, the bottom surface portion and the side surface portion are connected by arc bending unit, the angle between the bottom surface portion andthe side surface portion is larger than or equal to 90 degrees and smaller than 120 degrees, and the bulletproof radome is made of ultrahigh molecular weight polyethylene as a raw material and has high wave transmission performance and bulletproof performance.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP +1

Creep-resistant polyester color yarn and its preparation method

ActiveCN103556287AIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentYarnEpoxy

The invention relates to a creep-resistant polyester color yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester color yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester color yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, mixing with a black masterbatch, extrusion, cooling, oiling, stretching and coiling. The creep-resistant polyester color yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of automobile safety belts, bags fabric for military use, lifting belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Water-borne wood paint and preparation method of water-borne wood paint

InactiveCN102850886ASolve defects such as easy saggingSolve water problemsPolyurea/polyurethane coatingsAssociation typeDefoaming Agents

The invention provides water-borne wood paint, which comprises the following ingredients in percentage by weight: 10 to 20 parts of deionized water, 1 to 5 parts of propylene glycol, 1 to 3 parts of base association type thickening agents, 0.05 to 0.5 parts of dimethylethanolamine, 0.01 to 0.5 parts of non-silicone mineral oil system defoaming agents, 0.05 to 0.3 parts of water-borne carboxymethyl cellulose, 0.2 to 1.2 parts of ethanol, 60 to 80 parts of water-borne nanometer core-case crylic acid polymer dispersoid, 3 to 10 parts of water-borne fluorine-containing polyurethane nanometer dispersoid, 1 to 5 parts of alcohol ester twelve coalescing agents, 0.01 to 0.05 parts of fluorine flatting agents and 0.1 to 0.3 parts of anticorrosive and bacterium prevention agents. The water-borne wood paint has the advantages that the water-borne fluorine-containing polyurethane nanometer dispersoid is used as the core technology and is organically combined with water-borne auxiliaries such as the fluorine flatting agents, the problem that the wood surface cannot be easily moistened by the water-borne wood paint because the water surface tension is strong is solved, and the problems of poor paint film adhesion force, poor boiled water resistance and the like of the ordinary water-borne wood paint are solved. The invention also provides a preparation method of the water-borne wood paint at the same time.

Owner:WENZHOU BANGXUAN TECH

Composting method used for increasing humic acid content through phased adding of humic acid precusor substances

ActiveCN110156499AIncrease contentIncrease productionBio-organic fraction processingExcrement fertilisersFiberSugar

The invention discloses a composting method used for increasing humic acid content through phased adding of humic acid precusor substances. The composting method is used for solving a problem in the prior art that humic acid content is not high. The composting method comprises following steps: 1, protein organic waste and fiber organic waste are subjected to composting, at composting temperature increasing period, MnO2 is added, and a low concentration polyphenol waste is added; 2, before composting high temperature period, in each time of overturning of the protein organic waste, a sugar containing waste, a polyphenol waste, and a carboxyl waste are added, in each time of overturning of the fiber organic waste, the protein organic waste and the carboxyl waste are added; 3, at composting high temperature period, a humic acid containing precursor waste is packaged with textile bags, and is embedded in high temperature period compost; and 4, at composting temperature reduction period, ahumic acid containing precursor waste processed through harmless treatment is added into compost for at least one time. The composting method is used in the field of composting.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Creep-resistant polyester and its preparation method

ActiveCN103556289AIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberEpoxy

The invention relates to creep-resistant polyester and its preparation method. According to the preparation method, polyester is mixed with a fluorine-containing epoxy compound or a fluorine-containing epoxy compound is added during the synthesis process of polyester. Then, the creep-resistant polyester can be obtained. By the use of the fluorine-containing epoxy compound for blocking modification of the polyester, creep-resistant performance of the polyester can be improved to some extent, and hydrolysis resistance and performance stability of the polyester can be raised. Fiber prepared from the creep-resistant polyester can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Starch-based composite seed coating agent and preparation method thereof

InactiveCN104529629AStrong water absorptionImprove adhesionMagnesium fertilisersAlkali orthophosphate fertiliserInsect pestBiology

The invention discloses a starch-based composite seed coating agent and a preparation method thereof and aims to solve the problems that common starch is poor in film formation property and easily lost through dissolution when being applied to a film forming agent; the requirements on the film formation property and the cohesiveness cannot be satisfied simultaneously when certain high-molecular film forming substance is used independently. The composite seed coating agent is divided into an inner layer and an outer layer, wherein the inner layer takes etherified starch as a base material, contains a bactericide, an insecticide, a plant growth inhibitor, a fertilizer and the like, and can be used for preventing diseases and insect pests of seeds to a certain extent; the outer layer takes the starch base a substrate; graft copolymerization of an acrylic acid monomer is triggered by free radicals to prepare a film layer and a water retaining layer; the film layer and the water retaining layer are good in cohesiveness and film formation property, can be used for protecting components of the inner layer from loss and also have water retention property and moisture retention property, so that the germination rate and planting percent of the seeds are increased. The starch-based composite seed coating agent disclosed by the invention is broad-spectrum and suitable for seed coatings of crops such as vegetables, flowers and grains.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

High-modulus low-shrinkage creep-resistant polyester industrial yarn and preparation method thereof

ActiveCN103526327AIncrease the relative molecular massImproved creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsSolid phasesChemistry

The invention relates to a high-modulus low-shrinkage creep-resistant polyester industrial yarn and a preparation method thereof. The preparation method comprises the preparation of a high-viscosity creep-resistant polyester chip and the preparation of the high-modulus low-shrinkage creep-resistant polyester industrial yarn; polyester is subjected to solid phase polycondensation for viscosifying and then is blended and reacted with a fluorine-containing epoxy compound to obtain the high-viscosity creep-resistant polyester chip; then the high-viscosity creep-resistant polyester chip is subjected to metering, extruding, cooling, oiling, stretching, heat setting and winding to obtain the high-modulus low-shrinkage creep-resistant polyester industrial yarn. The high-modulus low-shrinkage creep-resistant polyester industrial yarn has certain creep resistance, hydrolysis resistance and performance stability, can be used in a high-temperature high-humidity environment for a long time, and has great prospect in the fields of plastic packaging, waterproof fabrics, ropes, mooring ropes, marine fibers and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com