Method for preparing high relative molecular mass chitin and chitosan, and comprehensive utilization

A technology of relative molecular mass and chitin, which is applied in the preparation of chitosan and the field of high relative molecular mass chitin, can solve the problems of high energy consumption and serious environmental pollution of waste, achieve low energy consumption, improve economic benefits, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

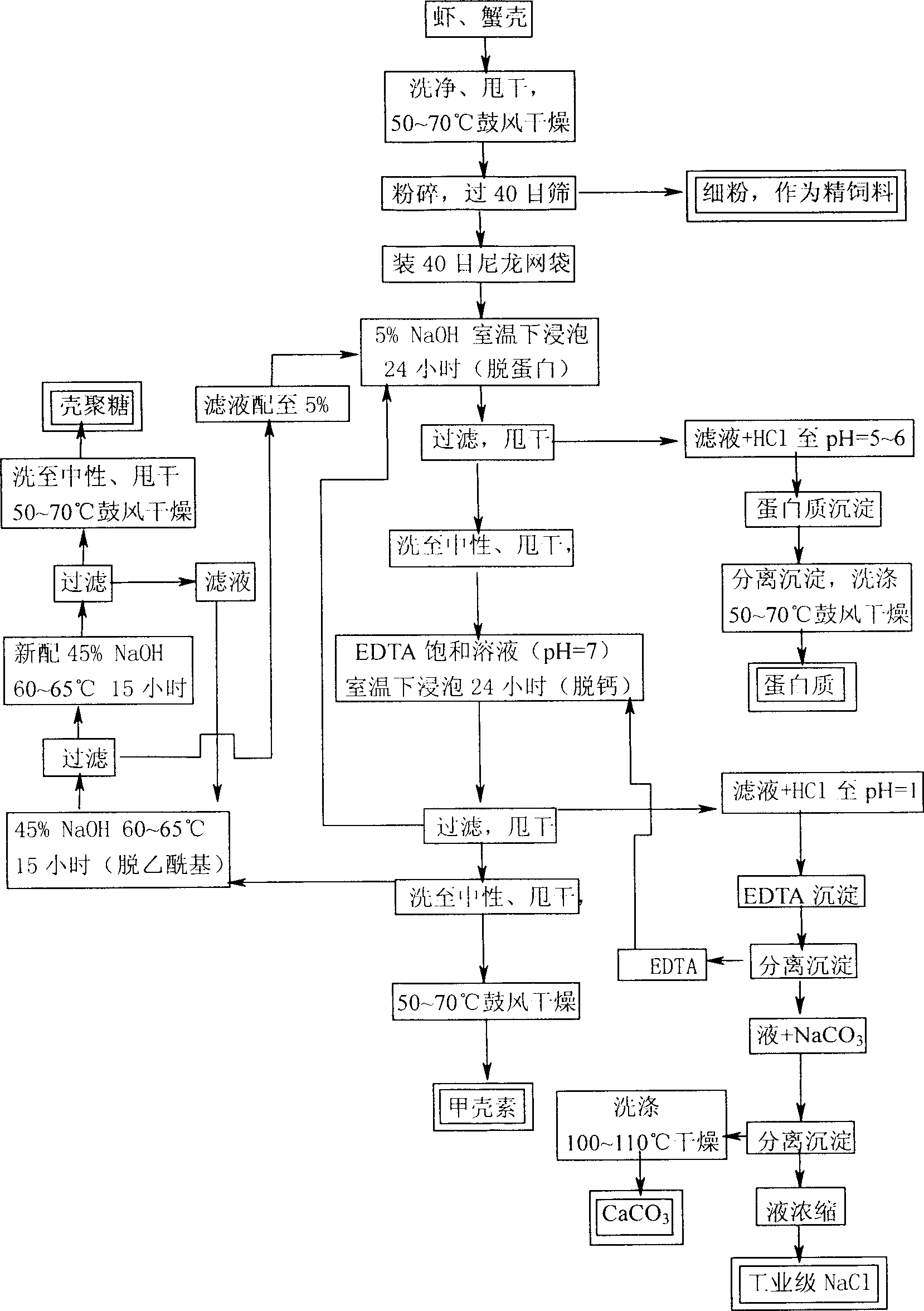

[0032] Example 1: Preparation and Comprehensive Utilization of High Relative Molecular Mass Chitin

[0033] Use fresh shrimp and crab shells as raw materials, wash them, shake them dry, blow dry them at about 60°C for 5-8 hours, and then crush them into about 5×5mm 2 Fragments of different sizes are passed through a 40-mesh sieve. The sieved shrimp and crab shells are put into a 40-mesh nylon mesh bag, soaked in 5% NaOH solution at room temperature for 24 hours, filtered, dried, rinsed with water until neutral, and then dried to complete the alkali treatment deproteinization process . The sieved fine powder is used as concentrate feed, which is the first by-product of this process. The filtrate was adjusted to pH = 5-6 with concentrated HCl to precipitate the protein, the precipitate was separated, washed, and dried by air at about 60°C to obtain the protein. This is the second by-product.

[0034] Dissolve EDTA in NaOH solution to obtain a saturated solution (pH = 7), imm...

Embodiment 2

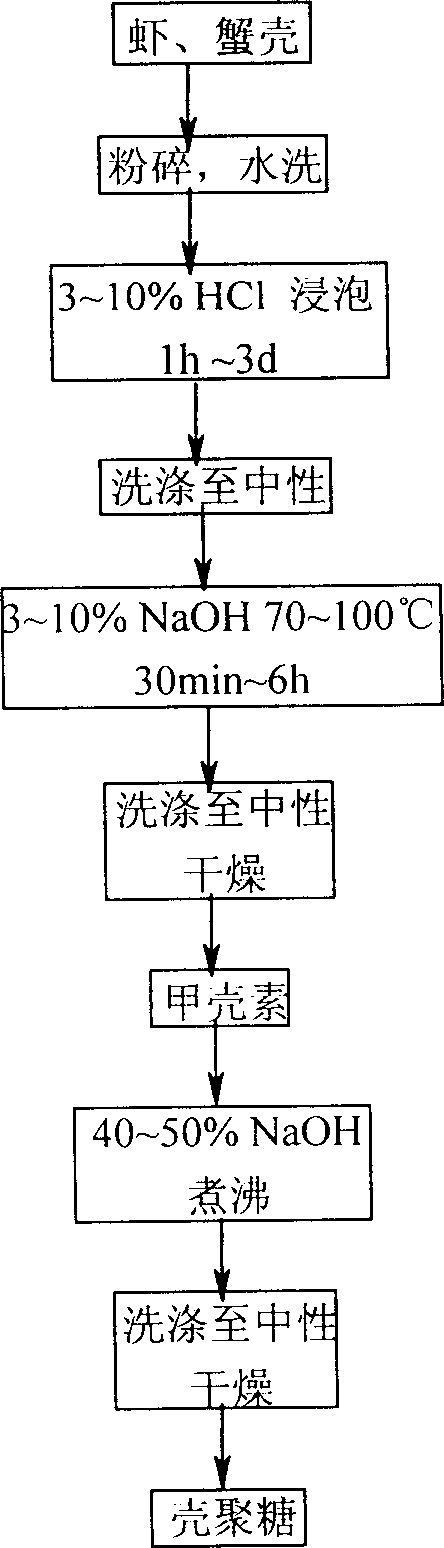

[0037] Embodiment two: the preparation of high relative molecular mass chitosan:

[0038] Utilize the chitin that the technique described in embodiment one makes for the production of chitosan, after finishing the alkali treatment deproteinization operation of embodiment one and the EDTA treatment decalcification operation, without drying this operation, as figure 1 As shown, add 45% NaOH solution to the wet material, treat it at about 62°C for 15 hours, then filter, then use a new 45% NaOH solution, treat it at about 62°C for 15 hours, filter, wash with water until it is neutral, and dry it. Blow drying at about 60°C to obtain a white chitosan product with a degree of deacetylation DD > 85%.

[0039] The filtrate is used for recycling, and the filtrate filtered for the first time is recycled for 3-4 times, and then prepared into a concentration of 5% for deproteinization treatment in the process of preparing chitin. The filtrate filtered for the second time is recycled twice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com