Patents

Literature

32 results about "Edta treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EDTA chelation, or chelation therapy, is primarily known as a treatment for heavy metal poisoning. The letters "EDTA" stand for the chemical solution ethylenediamine tetraacetic acid.

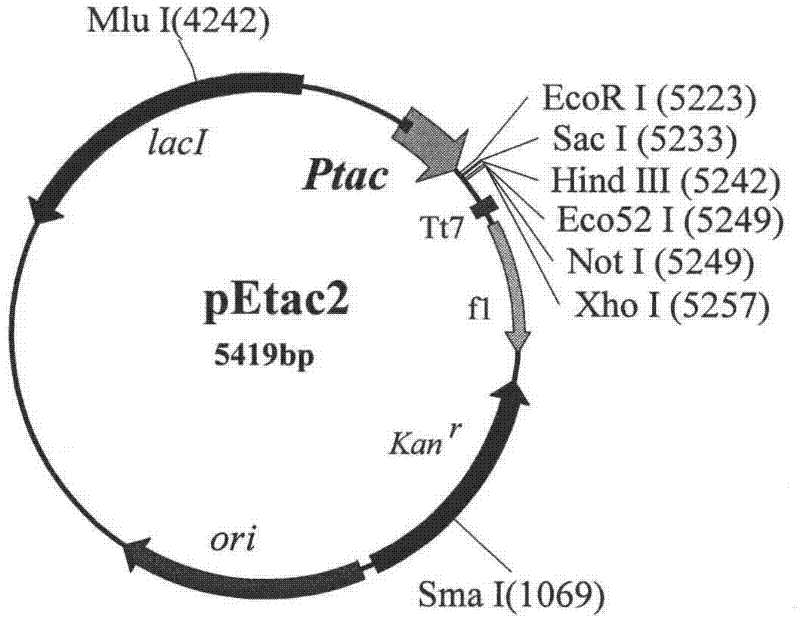

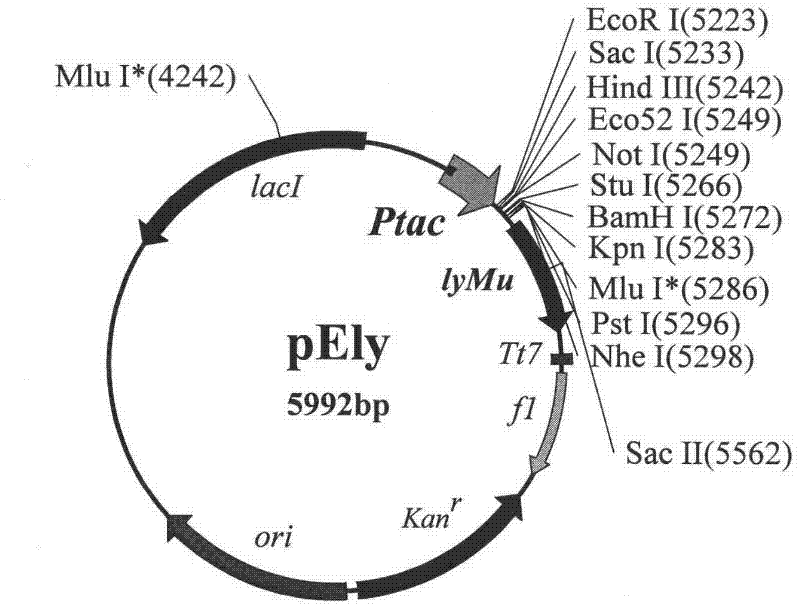

Escherichia coli expression vector capable of controlling self-cracking of host bacterium

InactiveCN102286519AEasy constructionEasy to recycleBacteriaMicroorganism based processesEscherichia coliBiology

The invention discloses an Escherichia coli expression vector capable of controlling the self-cracking of a host bacterium, which belongs to the technical field of microbes and gene engineering. In the invention, the composition of the codon of a lysozyme gene in a T4 phage and a restriction endonuclease identification site are optimized, and the optimized T4 lysozyme gene mutation lyMu and a modified Escherichia coli expression vector are recombined to form a recombinant expression vector pEly. The expression vector pEly can be used for inducing expression of an exogenous gene, and when the exogenous gene is induced to express, T4 lysozyme is expressed. The cell undergoing induction expression is treated by ethylene diamine tetraacetic acid (EDTA) solution and then self-cracks, so that the product of expression in the cell is released. The expression vector obtained by implementing the invention can realize the express of various exogenous proteins in Escherichia coli hosts, the host bacteria release the products of expression after undergoing EDTA treatment, and thus, the recovery of the products of the expression can be promoted. The expression vector has an application prospect in fields of enzymic preparation production, polypeptide medicine production and the like.

Owner:JIANGNAN UNIV

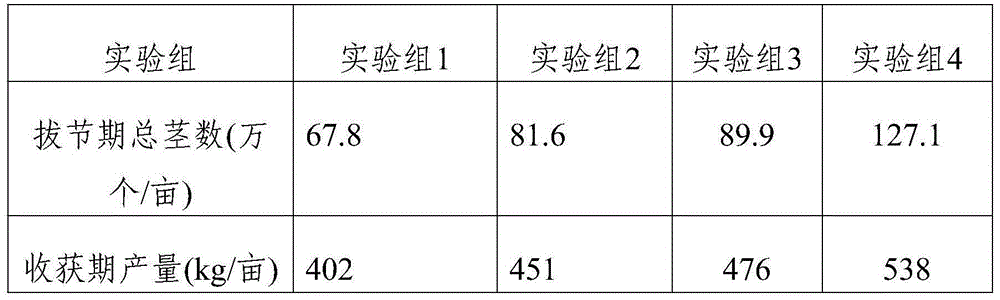

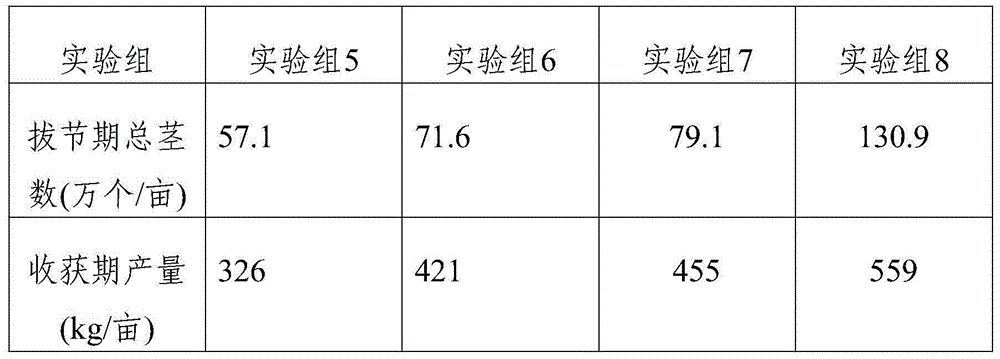

Method for improving saline-alkali soil through ardealite, slow-release binder, EDTA, straw and biological bacteria

InactiveCN105123012ALower pHLight weightSoil-working methodsFertilizer mixturesAlkalinityAlkali soil

The invention provides a method for improving saline-alkali soil through ardealite, a slow-release binder, EDTA, straw and biological bacteria. The method includes the steps that first, the ardealite is used for treatment; then the slow-release binder is used for treatment; afterwards, the EDTA is used for treatment; finally, a mixed material of the straw and the biological bacteria is used for treatment. By the adoption of the method for improving the saline-alkali soil, the saline-alkali soil can be improved quickly and is made to be suitable for growth of crops; besides, the application range of the modifying agent is wide, the modifying agent is suitable for improvement of soil alkalization in different areas and for different reasons, the modifying agent is applied to the soil reasonably, and the soil structure can be improved; the soil alkalinity is lowered, the salt elimination rate of the soil is increased, the soil fertility is improved, the growth of the crops is promoted, and agricultural economy is improved.

Owner:GUIZHOU KAILIN GRP CO LTD +1

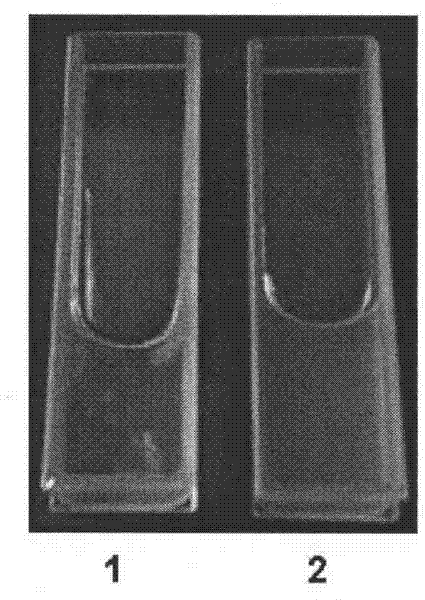

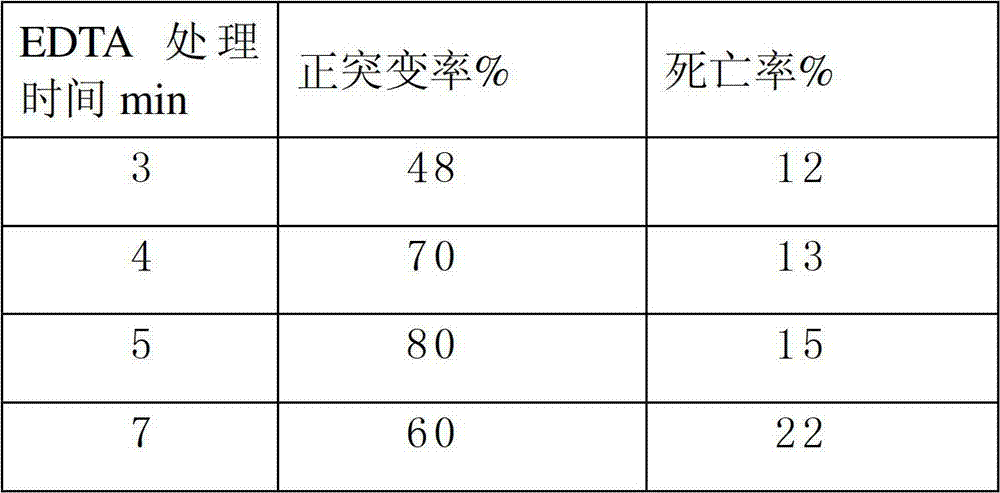

Breeding method of high-yielding strain of tetracycline

InactiveCN102851274AHigh positive variabilityLittle change in shapeMutant preparationMicroorganism based processesUltravioletMortality rate

The invention relates to a method for breeding high-yielding strain of tetracycline. The method is characterized by comprising the steps of: adding water into cultured Streptomyces aureus strains to prepare a spore suspension; shaking the flask for cultivation; filtrating; diluting; filling the suspension in four test tubes; adding a same amount of an EDTA solution and acting for respectively 3, 4, 5 and 7min; adding lysozyme and acting for 3 min; conducting gradient dilution to 10<-5>; and coating 0.1, 0.3 and 0.5ml spore liquid from each dilution on plates for cultivation; calculating a forward-mutation rate and a mortality rate; selecting an acting time with high forward-mutation rate; conducting further flask shaking screening; and selecting strains with high increase rate. The invention adopts a method, which first uses lysozyme to remove cell wall and then conducts EDTA treatment, thus breeding high-quality and high-yielding strain of tetracycline; and compared with an ultraviolet method and an ion implantation method, the method provided by the invention has advantages of simple operation, low cost, high safety, little environmental pollution, high mutation rate of strains, and high shake flask titer of the produced strain.

Owner:NINGXIA QIYUAN PHARMA

Peptidoglycan immunopotentiator and its production process

InactiveCN1739790AIncrease productionReduce manufacturing costPeptide/protein ingredientsAnimal feeding stuffBiotechnologyNitrogen gas

The peptidoglycan immunopotentiator is light brown, has viscosity of 3.2-5.0 and specific weight of 1.021-1.042, and contains peptidoglycan as active component in 1.5-2.0 wt%, protein in 5-8 wt%, fat in 0.3-0.5 wt%, RNA in 0.01-0.02 wt% and total solids in 8-10 wt% except water. The production process of the immunopotentiator includes the following steps: culturing strain, the first seed culturing and the second stage of seed tank culturing; fermentation in the primary fermenting tank while introducing nitrogen; terminating fermentation after reaching OD value 1.0-1.4; expanding fermentation in n fermenting tanks to obtain target fermented liquid; separation and post-treatment via adding digestive buffering liquid, lysozyime, cysteine, EDTA and papain; and obtaining the required liquid peptidoglycan preparation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

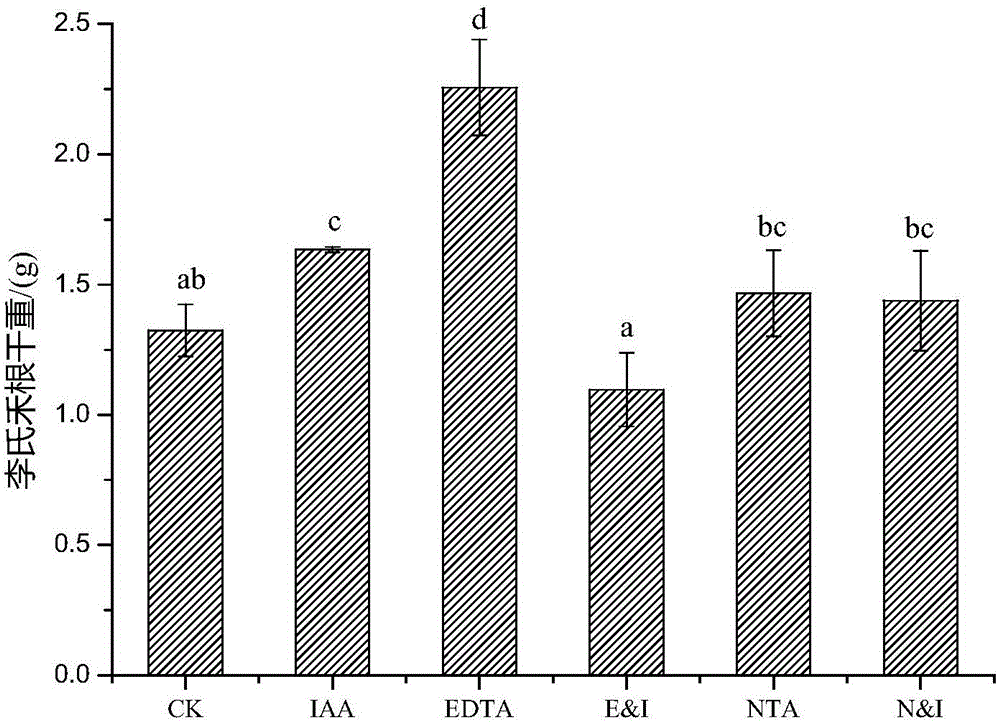

Method for remedying heavy metal Cu contaminated soil

InactiveCN106734128AIncrease contentPromote growthContaminated soil reclamationSoil remediationEdta treatment

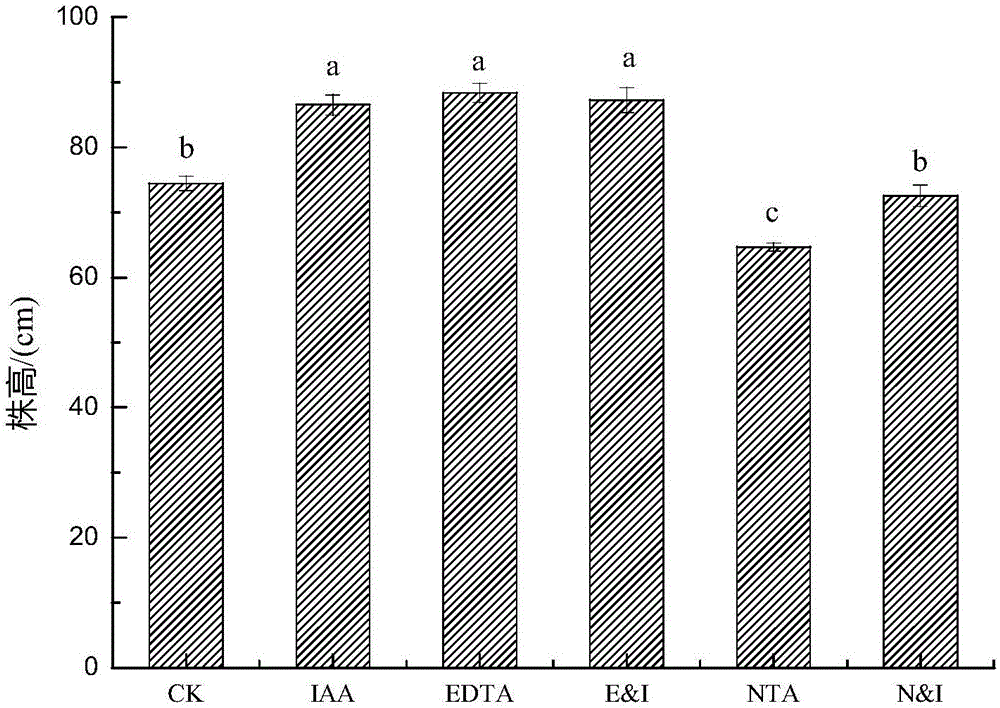

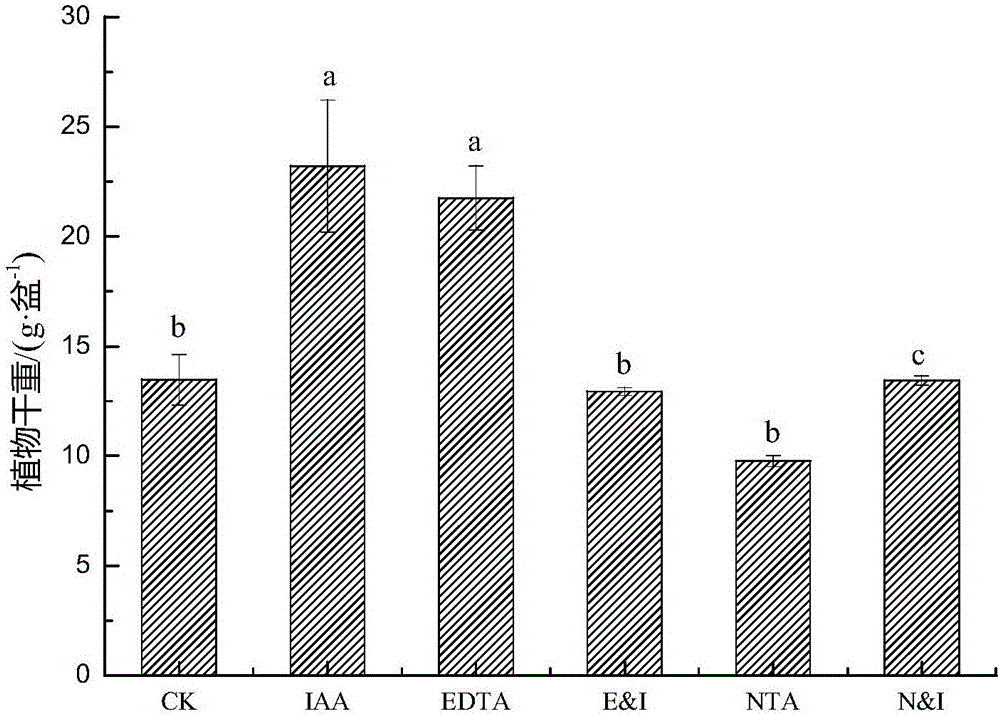

The invention relates to the technical field of soil remediation, in particular to a method for remedying heavy metal Cu contaminated soil. Heavy metal Cu in the soil is removed in a plant remediation mode by adding a chelating agent EDTA and plant hormones IAA. Treatment with the IAA and the EDTA can remarkably prompt growth and development of plants, effectively relieve the stress effect of Cu in soil to the plants, and remarkably increase the Cu content of the overground parts of the plants, specifically, the Cu content is increased by 29.47% averagely compared with check treatment, and therefore, as exogenous additives, the IAA and the EDTA can effectively improve the efficiency of remediation of Leersia hexandra to the Cu contaminated soil.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

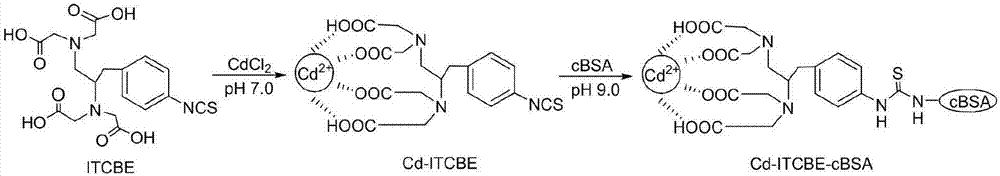

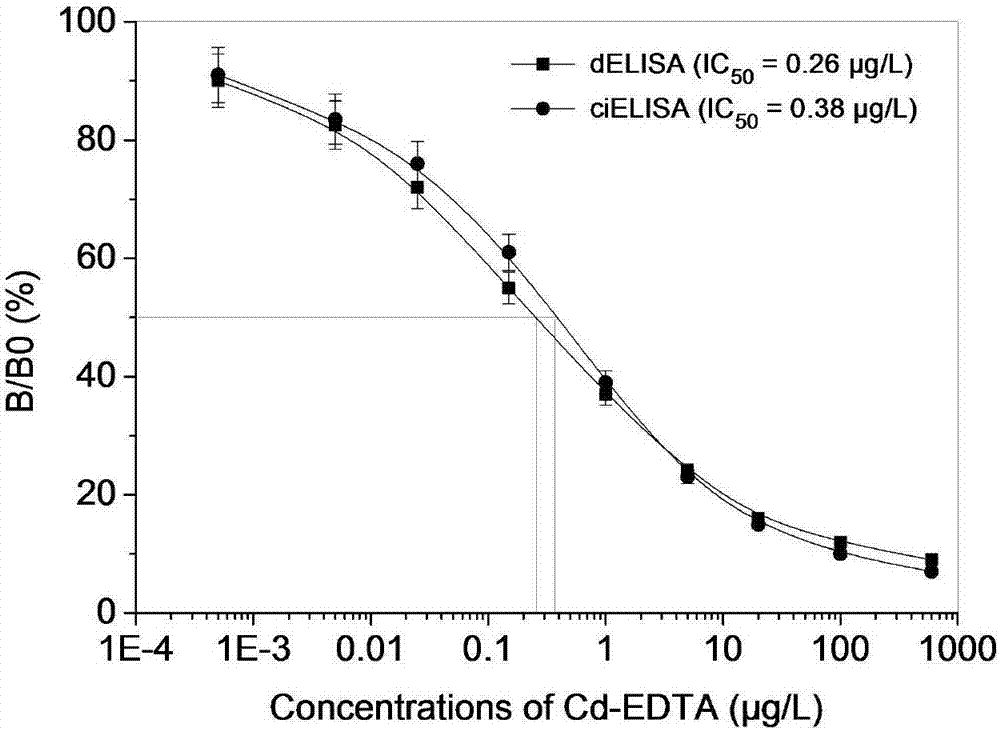

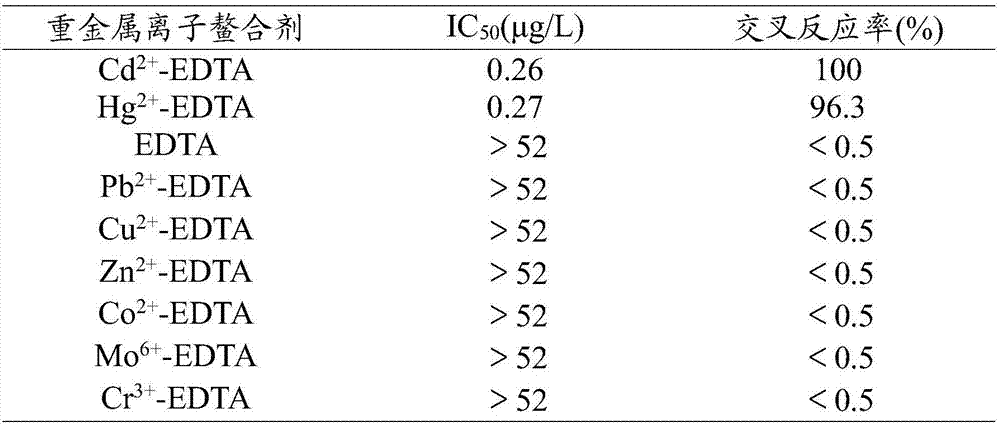

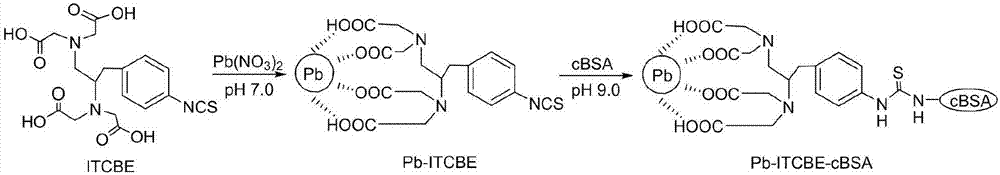

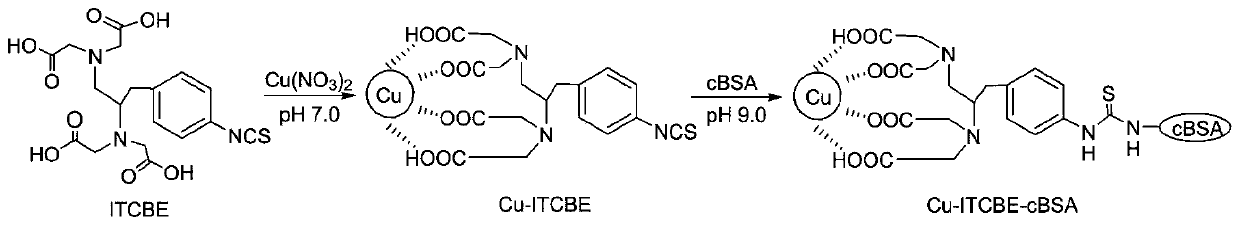

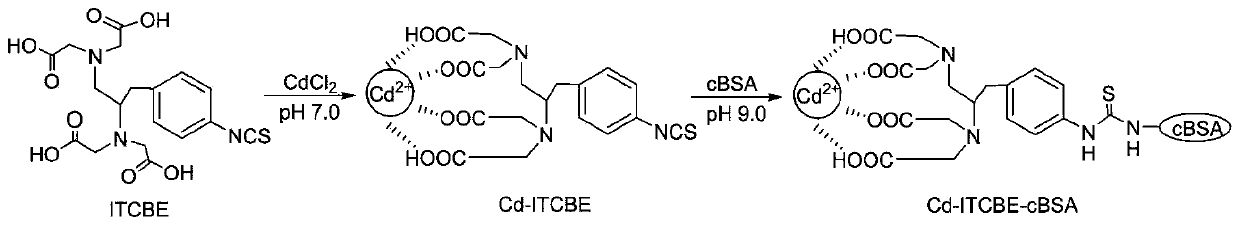

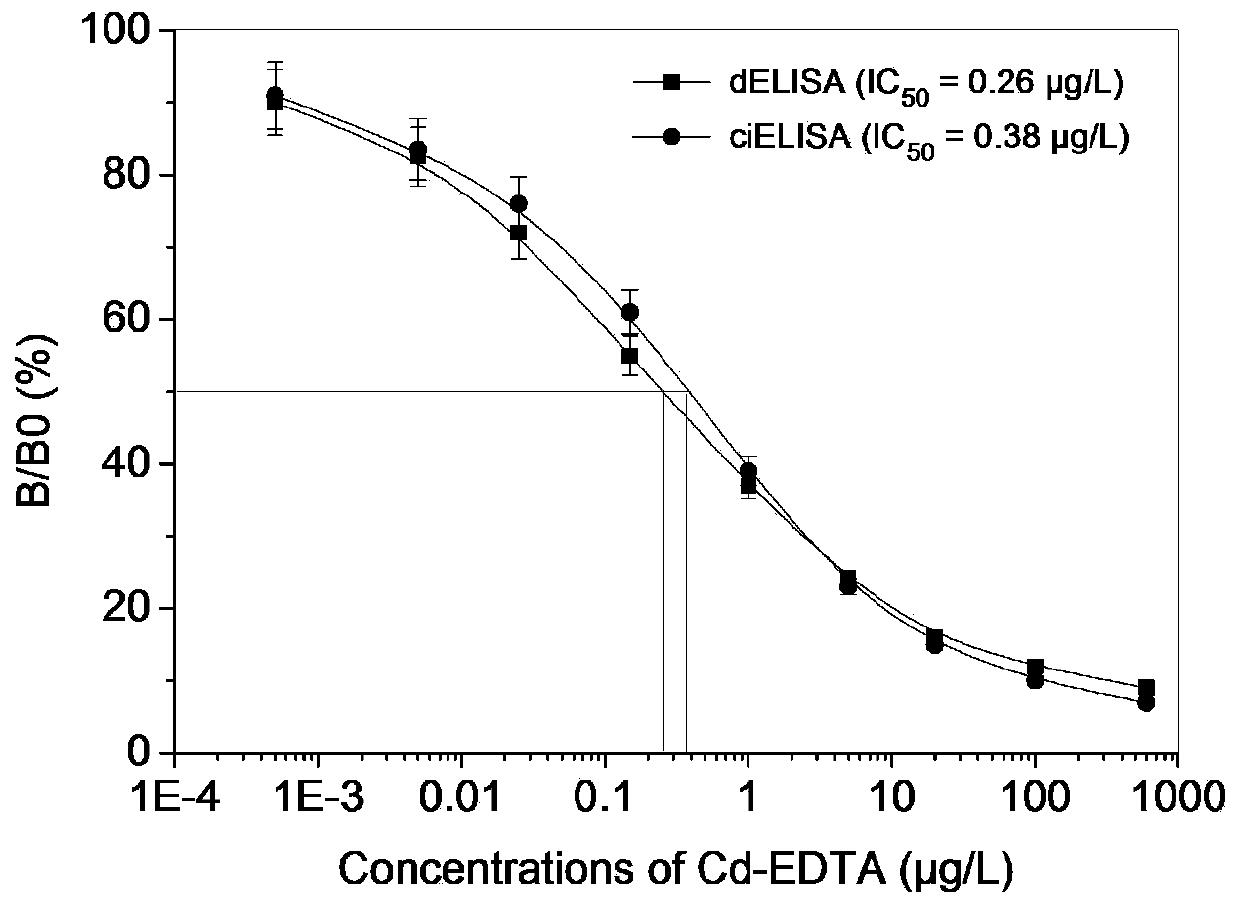

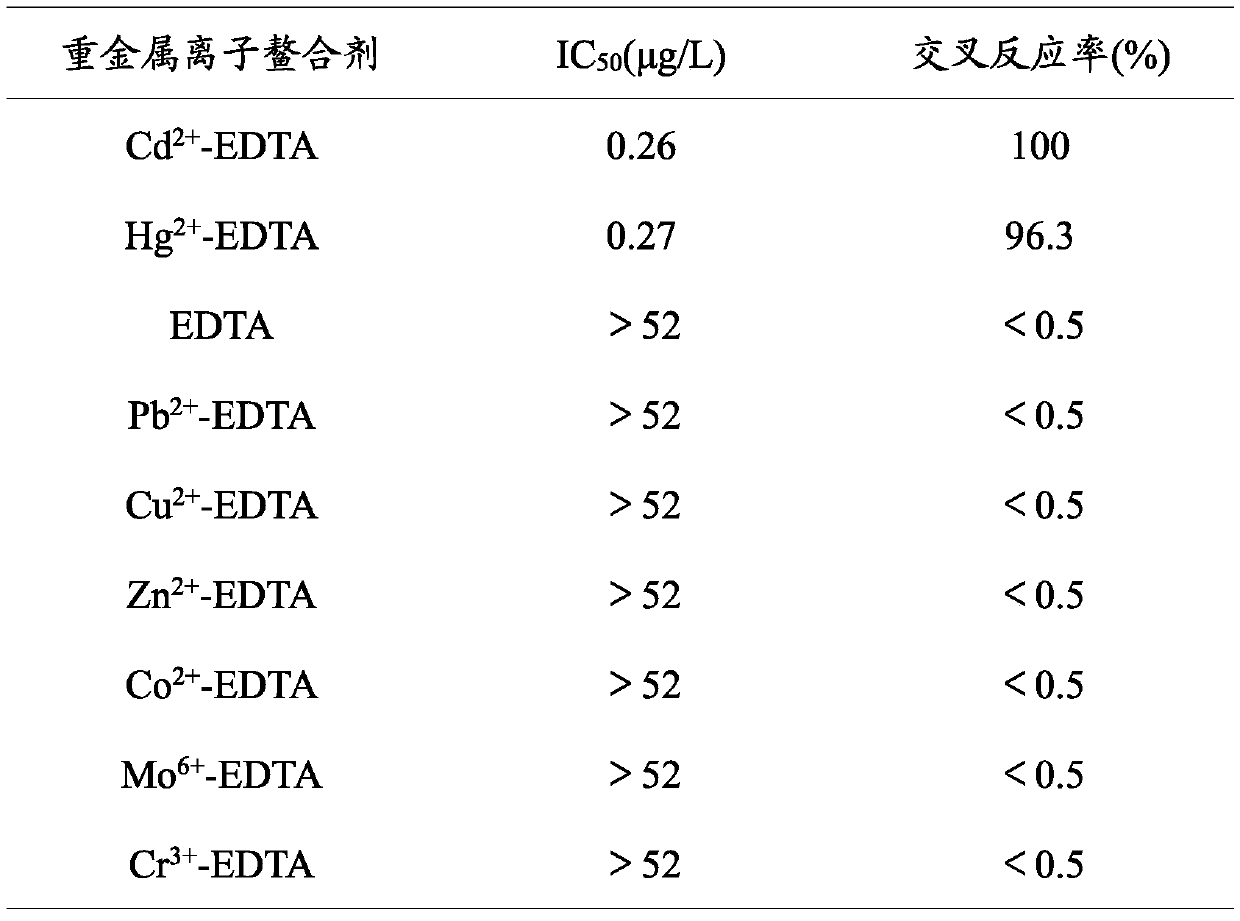

Kit for detecting cadmium ions based on direct competition enzyme-linked immunoadsordent assay and application thereof

InactiveCN106872709AReduce the number of washesShorten the timeBiological testingBALB/cEthylene diamine

The invention provides a kit for detecting cadmium ions based on a direct competition enzyme-linked immunoadsordent assay. The kit comprises a detection plate coated with a goat anti-mouse IgG secondary antibody, a Cd-ITCBE chelate hapten with the mass concentration of 20mu g / mL to 50mu g / mL, an anti-cadmium ion monoclonal antibody solution with the mass concentration of 10mu g / mL to 20mu g / mL, 1.0mol / L to 3.0mol / L of a stopping solution, a sample diluting solution, a substrate color developing solution, a washing solution, a cadmium ion standard product solution and an EDTA (Ethylene Diamine Tetraacetic Acid) treatment solution with the mass concentration of 10mg / mL to 20mg / mL, wherein the detection plate is sealed and packaged in vacuum; the coating concentration of the goat anti-mouse IgG secondary antibody is 50mu g / mL to 200mu g / mL; the anti-cadmium ion monoclonal antibody solution is prepared from Cd-ITCBE-cBSA immunogen immunized Balb / C mice. The kit provided by the invention has the characteristics of high sensitivity and high specificity and also has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH

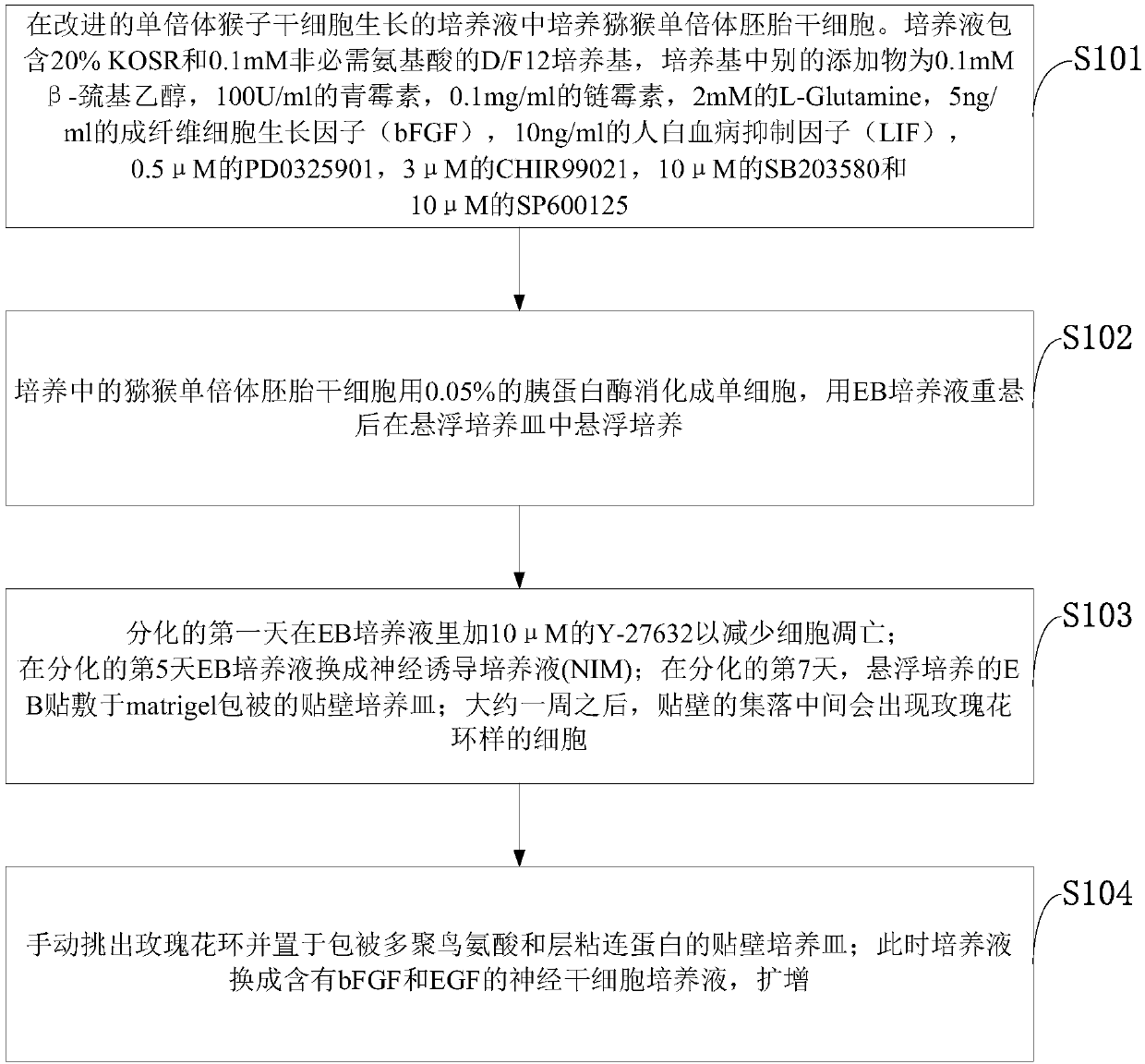

Method for acquiring monkey haploid neural stem cells

The invention belongs to the technical field of bioengineering and discloses a method for acquiring monkey haploid neural stem cells. The method includes: performing optimization culture on the basisof an original common monkey stem cell culture medium, using 0.05% of trypsin / EDTA to treat haploid embryonic stem cells, cloning to a unicellular cell, and using an EB culture medium for suspension culture to form embryoid body balls; starting from the first day of differentiation, adding ROCK inhibitor Y-27632 into the culture medium to inhibit cell apoptosis; on the fifth day, replacing the EBculture medium with a neural induced culture medium; planting EB balls with neuroderm formed preliminarily in a culture dish with base glue paved at the bottom, and adding the neural induced culture medium for differentiation; picking neural garland, and planting in a culture dish with 30ug / ml polyornithine and 3ug / ml laminin paved at the bottom; after culturing for 14 days, performing flow cytometry, and separating haploid cells. By the method, the monkey haploid neural stem cells are acquired in vitro for the first time and have ability of differentiation in a neural downstream direction.

Owner:NANKAI UNIV

Method for improving saline and alkaline land through ardealite, DMTU, EDTA and biological bacteria

InactiveCN105144898ALower pHLight weightOther chemical processesOrganic fertilisersAlkalinityAlkali soil

The invention provides a method for improving saline and alkaline land through ardealite, DMTU, EDTA and biological bacteria. The method includes the steps that first, the land is treated with ardealite; then, the land is treated with a mixture of DMTU, a curing agent and an improver; then, the land is treated with EDTA; finally, the land is treated with a material obtained after mixed treatment of straw and biological bacteria. By the adoption of the method for improving the saline and alkaline land, saline and alkaline soil can be rapidly improved to be suitable for crop growth; besides, the improver is wide in application range and suitable for soil improvement on soil salinization and alkalinization caused by different reasons in different areas and can improve the soil structure, lower soil alkalinity, increase the soil salt rejection ratio, improve soil fertility, promote crop growth and improve agricultural economy when reasonably applied into soil.

Owner:GUIZHOU KAILIN GRP CO LTD +1

Method for improving saline-alkali soil by using phosphogypsum, trimethylenetetraurea, EDTA (ethylene diamine tetraacetic acid) and biological bacteria

InactiveCN105112058ALower pHLight weightAgriculture tools and machinesOrganic fertilisersAlkali soilPolyethylene glycol

The invention provides a method for improving saline-alkali soil by using phosphogypsum, trimethylenetetraurea, EDTA (ethylene diamine tetraacetic acid) and biological bacteria. The method comprises the steps of treating the saline-alkali soil with phosphogypsum, then treating the saline-alkali soil with trimethylenetetraurea, phthalic acid and polyethylene glycol and finally treating the saline-alkali soil with EDTA. The saline-alkali soil can be quickly improved by adopting the saline-alkali soil improvement method and is suitable for crop growth. The improvers have a wider range of application, are suitable for improving the soil salinized and alkalized due to different reasons in different regions and can achieve the effects of improving the soil structure, reducing the soil alkalinity, increasing the salt elimination rate of the soil, improving the soil fertility, promoting growth of crops and increasing the agricultural economy by being reasonably applied to the soil.

Owner:GUIZHOU KAILIN GRP CO LTD +1

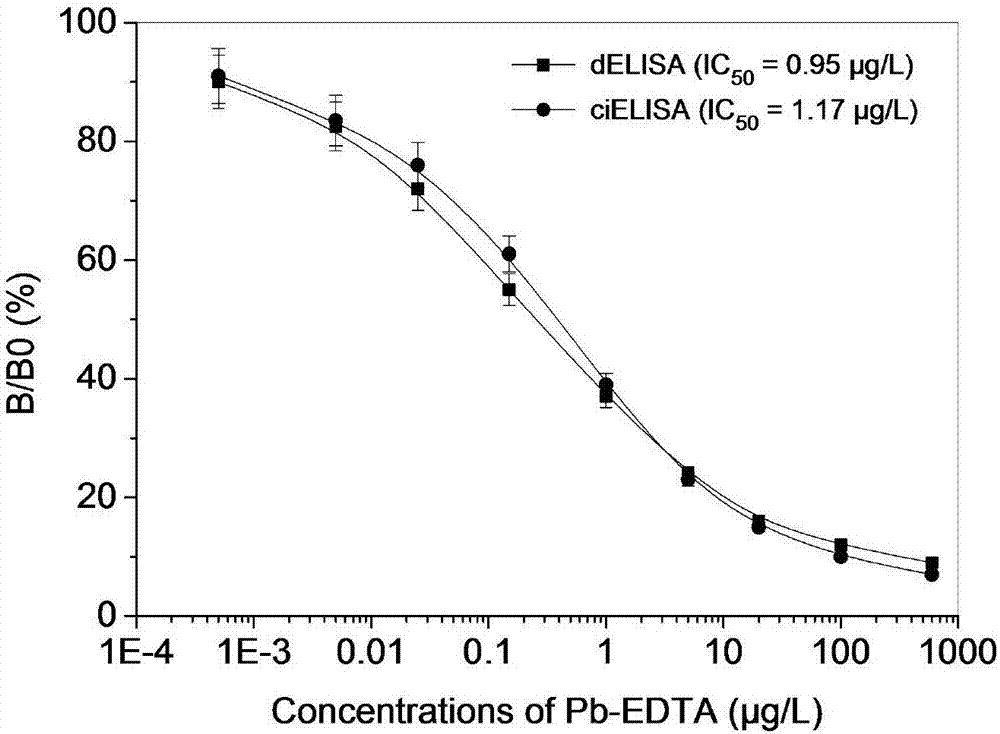

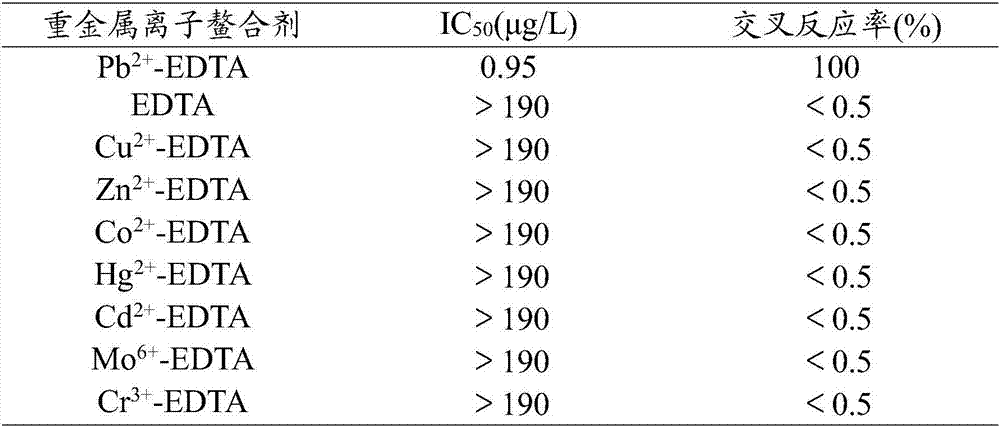

Kit for detecting lead ions based on direct competition enzyme-linked immunoadsordent assay and application thereof

InactiveCN106872708AReduce the number of washesShorten the timeBiological testingBALB/cEthylene diamine

The invention provides a kit for detecting lead ions based on a direct competition enzyme-linked immunoadsordent assay. The kit comprises a detection plate coated with a goat anti-mouse IgG secondary antibody, a Pb-ITCBE chelate hapten with the mass concentration of 20mu g / mL to 50mu g / mL, an anti-lead ion monoclonal antibody solution with the mass concentration of 10mu g / mL to 20mu g / mL, 1.0mol / L to 3.0mol / L of a stopping solution, a sample diluting solution, a substrate color developing solution, a washing solution, a lead ion standard product solution and an EDTA (Ethylene Diamine Tetraacetic Acid) treatment solution with the mass concentration of 10mg / mL to 20mg / mL, wherein the detection plate is sealed and packaged in vacuum; the coating concentration of the goat anti-mouse IgG secondary antibody is 50mu g / mL to 200mu g / mL; the anti-lead ion monoclonal antibody solution is prepared from Pb-ITCBE-cBSA immunogen immunized Balb / C mice. The kit provided by the invention has the characteristics of high sensitivity and high specificity and also has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH

Method for amending saline-alkaline land by using ardealite, methylene diurea, EDTA (Ethylene Diamine Tetraacetic Acid) and biological bacteria

InactiveCN105131958ALower pHReduce solubilityOther chemical processesOrganic fertilisersAlkali soilMixed materials

The invention provides a method for amending saline-alkaline land by using ardealite, methylene diurea, EDTA (Ethylene Diamine Tetraacetic Acid) and biological bacteria. The method comprises the steps of firstly carrying out treating with ardealite, then, carrying out treating with a mixture of methylene diurea, diethyl oxalate and hydroxymethyl cellulose, then, carrying out treating with EDTA, and finally, carrying out treating with a mixed material of straws and the biological bacteria. By adopting the method to amend the saline-alkaline land, saline-alkali soil can be amended rapidly so as to be suitable for crop growing; and the amendment is relatively wide in scope of application and is applicable to the soil amendment of soil salinization caused by different regions and different reasons, by reasonably applying the amendment to soil, the structure of the soil can be improved, the alkalinity of the soil is lowered, the salt draining ratio of the soil is increased, the fertility of the soil is increased, the growth of crops is promoted, and agricultural economy is improved.

Owner:GUIZHOU KAILIN GRP CO LTD +1

Method for improving saline and alkaline land through ardealite, dimethylolurea and EDTA

InactiveCN105144900ALight weightGood water permeabilityOther chemical processesOrganic fertilisersAlkalinityAlkali soil

The invention provides a method for improving saline and alkaline land through ardealite, dimethylolurea and EDTA. The method includes the steps of ardealite and humic acid treatment, dimethylolurea treatment and EDTA treatment. By the adoption of the method for improving the saline and alkaline land, saline and alkaline soil can be rapidly improved to be suitable for crop growth; besides, an improver is wide in application range and suitable for soil improvement on soil salinization and alkalinization caused by different reasons in different areas and can improve the soil structure, lower soil alkalinity, increase the soil salt rejection ratio, improve soil fertility, promote crop growth and improve agricultural economy when reasonably applied into soil.

Owner:GUIZHOU KAILIN GRP CO LTD +1

Method for improving saline and alkaline land through ardealite, TMPU and EDTA

InactiveCN105144901ALower pHLight weightOther chemical processesOrganic fertilisersAlkali soilChemistry

The invention provides a method for improving saline and alkaline land through ardealite, TMPU and EDTA. The method includes the steps that first, the land is treated with ardealite and fulvic acid calcium; then, the land is treated with a mixture of TMPU, oxalic acid and hydroxymethyl cellulose; finally, the land is treated with EDTA. By the adoption of the method for improving the saline and alkaline land, saline and alkaline soil can be rapidly improved to be suitable for crop growth; besides, an improver is wide in application range and suitable for soil improvement on soil salinization and alkalinization caused by different reasons in different areas and can improve the soil structure, lower soil alkalinity, increase the soil salt rejection ratio, improve soil fertility, promote crop growth and improve agricultural economy when reasonably applied into soil.

Owner:GUIZHOU KAILIN GRP CO LTD +1

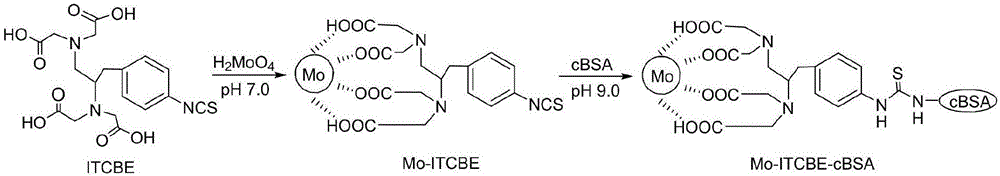

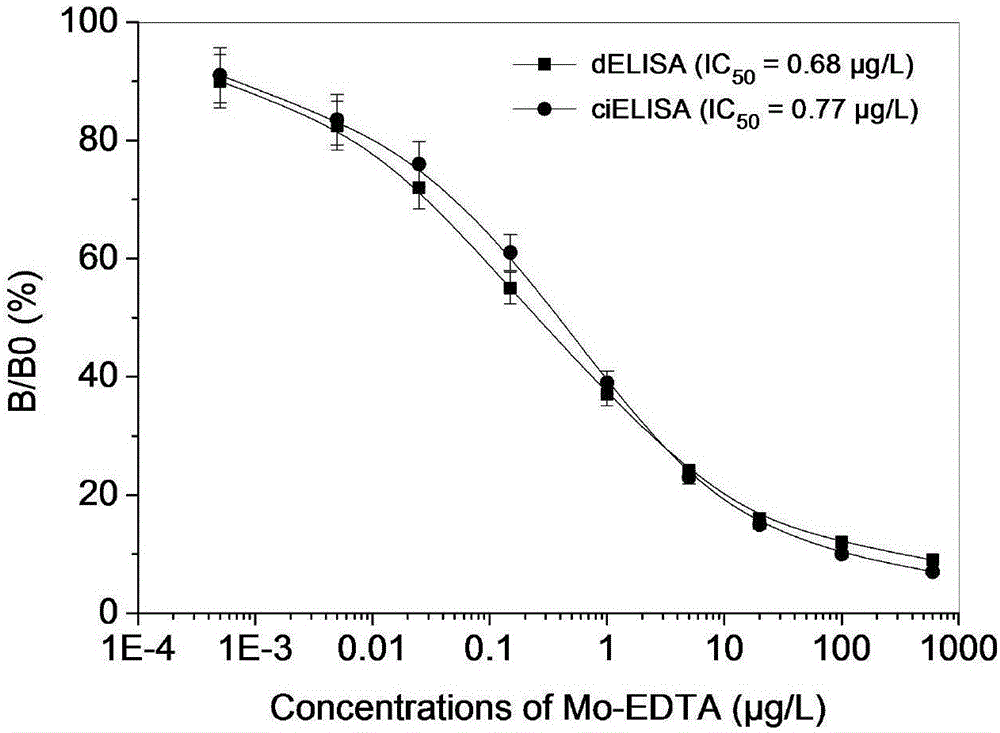

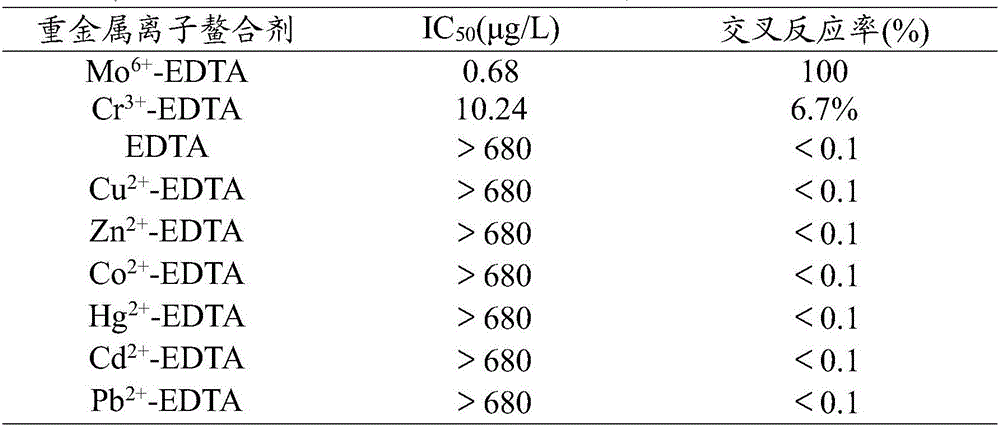

Molybdenum ion detection kit based on direct competitive ELISA (enzyme-linked immunosorbent assay) and application of kit

ActiveCN106841627AThe test result is simpleReduce the number of washesMaterial analysisBALB/cChemistry

The invention provides a molybdenum ion detection kit based on direct competitive ELISA (enzyme-linked immunosorbent assay). The kit comprises a detection plate coated with a goat anti-mouse IgG secondary antibody, an enzyme-labeled Mo-ITCBE chelate hapten with the mass concentration being 20-50 mu g / mL, an anti-molybdenum-ion monoclonal antibody solution with the mass concentration being 10-20 mu g / mL, 1.0-3.0 mol / L of a stop buffer, a sample diluent, a substrate color developing solution, a scrubbing solution, a molybdenum ion standard solution and an EDTA (ethylene diamine tetraacetic acid) treatment solution with the mass concentration being 10-20 mg / mL, wherein the detection plate is subjected to vacuum sealed packaging; the coating concentration of the goat anti-mouse IgG secondary antibody is 50-200 mu g / mL; the anti-molybdenum-ion monoclonal antibody solution is prepared from a Mo-ITCBE-cBSA immunogen immune Balb / C mouse. The kit has the characteristics of high sensitivity and high specificity and has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH

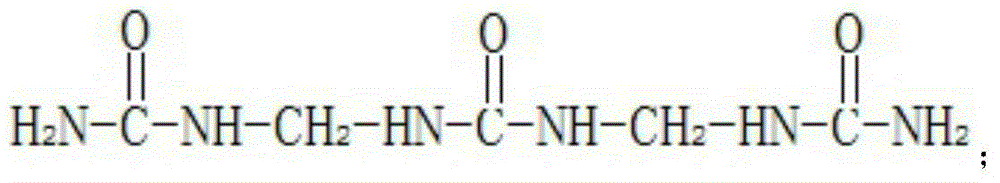

Method for improving saline-alkali soil through ardealite, N'N-(methylenedi-4,1-phenylene)bis[N'-phenyl-Urea] and EDTA

InactiveCN105103694ALower pHLight weightOther chemical processesOrganic fertilisersAlkali soilDiethyl oxalate

The invention provides a method for improving saline-alkali soil through ardealite, N'N-(methylenedi-4,1-phenylene)bis[N'-phenyl-Urea] and EDTA. The method includes the steps of firstly, processing the saline-alkali soil through ardealite and fulvic acid; secondly, processing the saline-alkali soil through N'N-(methylenedi-4,1-phenylene)bis[N'-phenyl-Urea], diethyl oxalate and hydroxymethyl cellulose; thirdly, processing the saline-alkali soil through EDTA. By means of the method, the saline-alkali soil can be rapidly improved to be suitable for growth of crops, the application range of a modifying agent is wide, and the modifying agent is suitable for improving saline-alkali soil generated due to different reasons in different regions; after the modifying agent is reasonably applied into the soil, the structure of the soil can be improved, the soil alkalinity can be lowered, the salt elimination rate of the soil can be improved, the fertility of the soil can be increased, growth of crops can be promoted, and agricultural economy can be improved.

Owner:GUIZHOU KAILIN GRP CO LTD +1

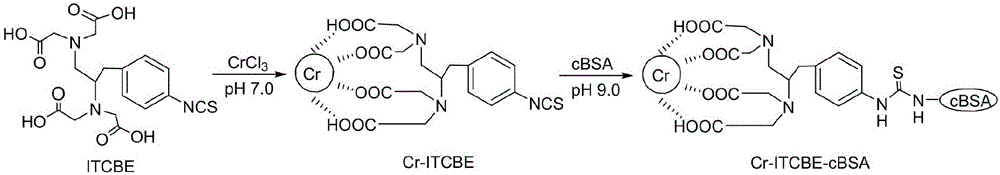

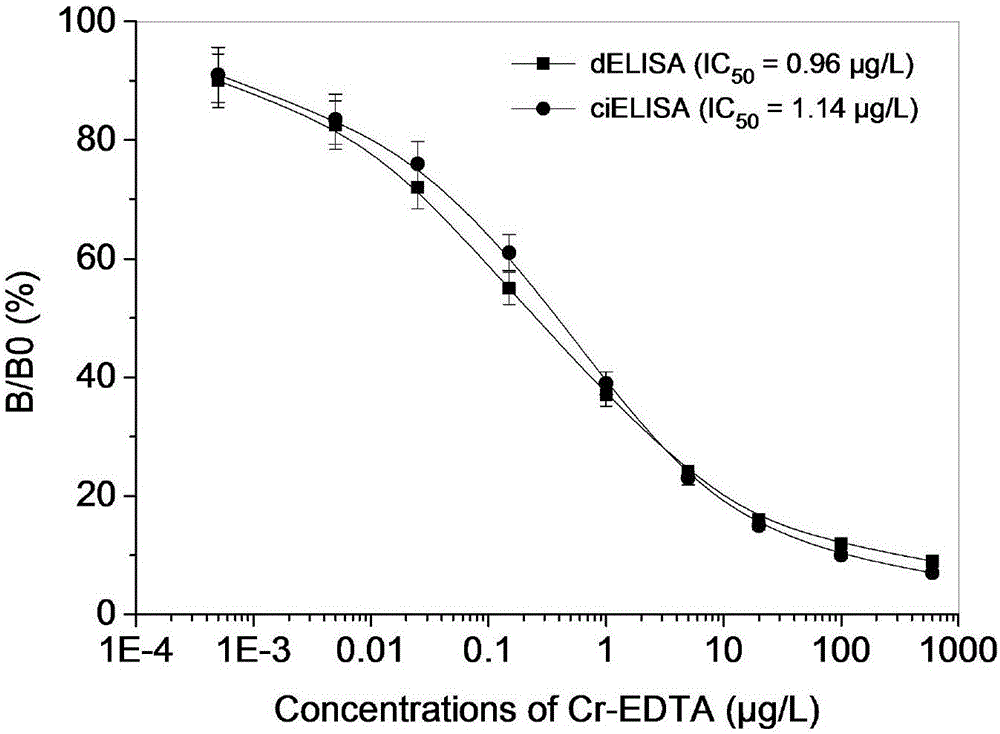

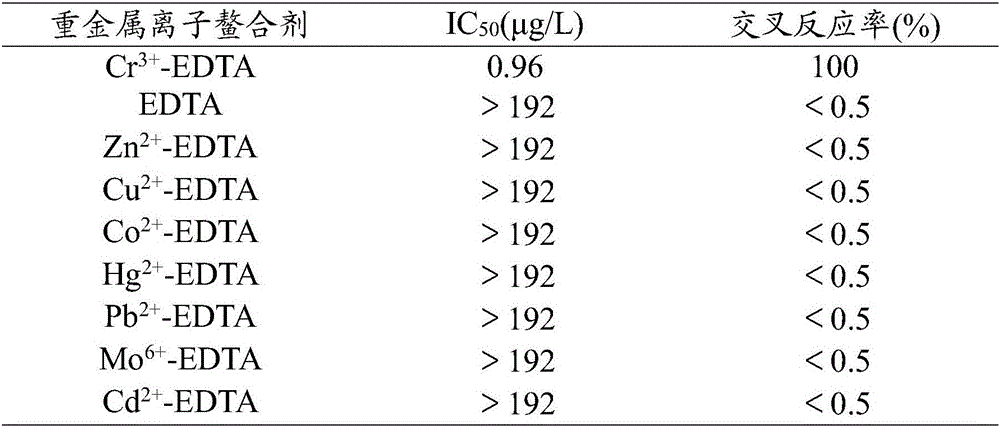

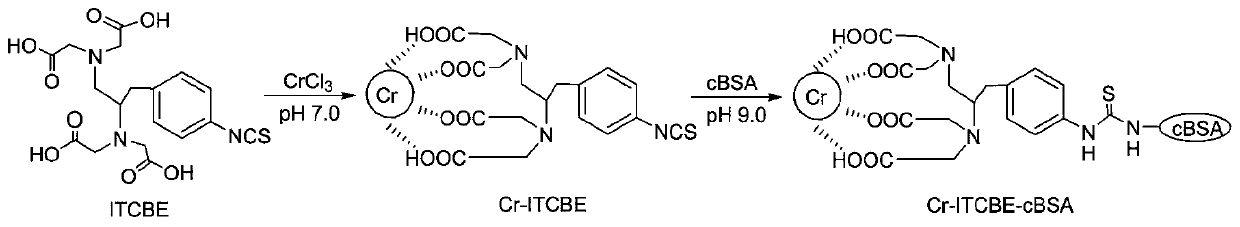

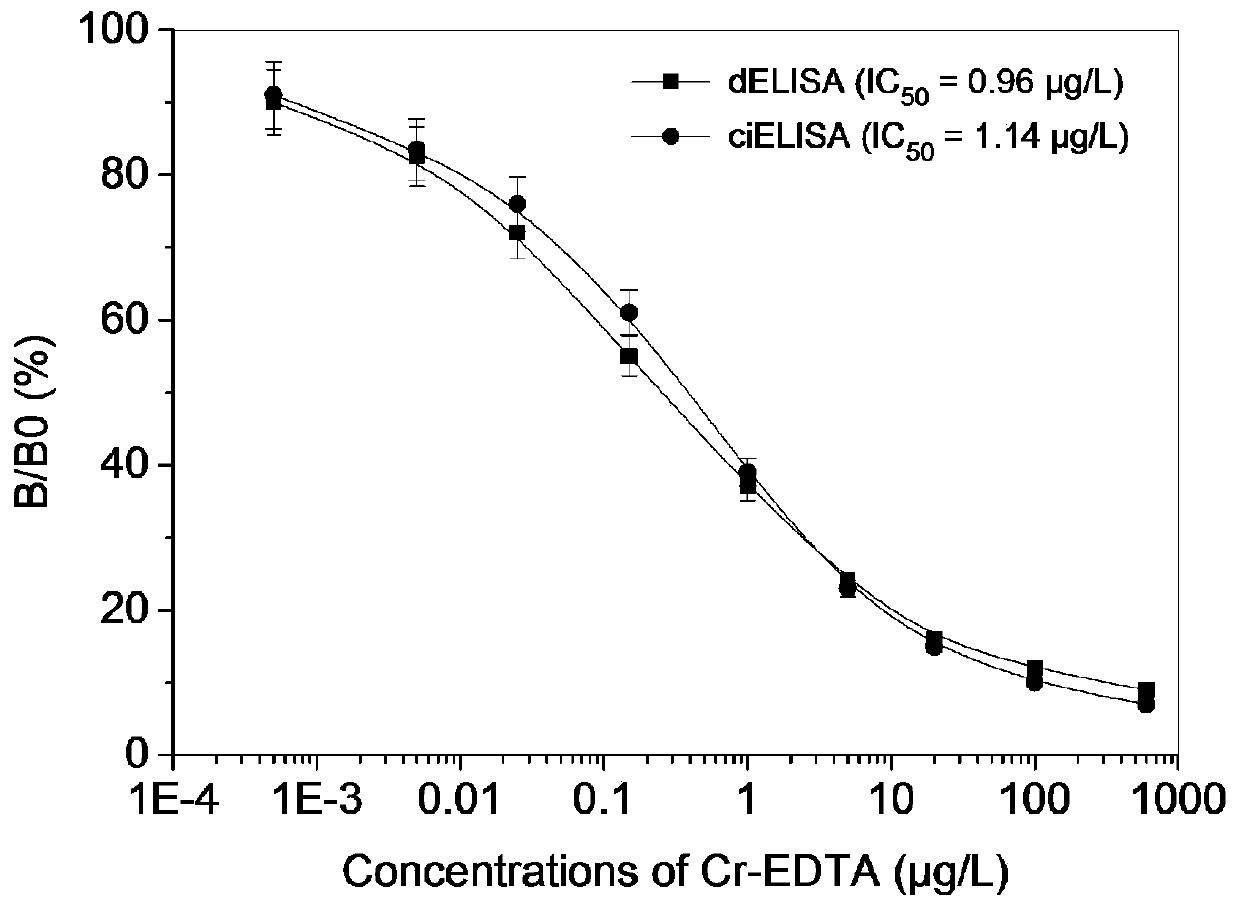

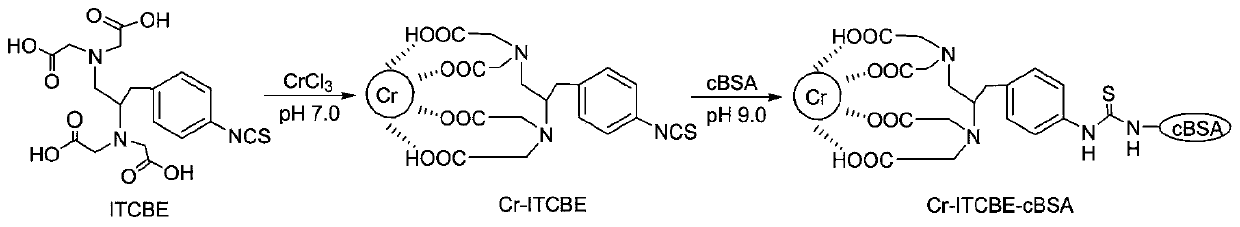

Kit for detecting chromium ions on basis of direct competitive enzyme linked immunosorbent assay and application thereof

The invention provides a kit for detecting chromium ions on the basis of a direct competitive enzyme linked immunosorbent assay. The kit comprises a detection plate coated with a goat-anti-mouse IgG secondary antibody, an enzyme-labeled Cr-ITCBE chelate hapten with mass concentration of 20 to 50mu g / mL, chromium ion resistant monoclonal antibody solution with mass concentration of 10 to 20mu g / mL, 1.0 to 3.0mol / L of stop buffer, sample diluent, substrate developing solution, cleaning solution, chromium ion standard substance solution, and EDTA conditioning fluid with mass concentration of 10 to 20mg / mL, wherein the detection plate is packaged in a vacuum sealed mode; coating concentration of the goat-anti-mouse IgG secondary antibody is 50 to 200mu g / mL; the chromium ion resistant monoclonal antibody solution is prepared from Cr-ITCBE-cBSA immunogen immunized Balb / C mice. The kit provided by the invention has the characteristics of high sensitivity and high specificity, and meanwhile, has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH

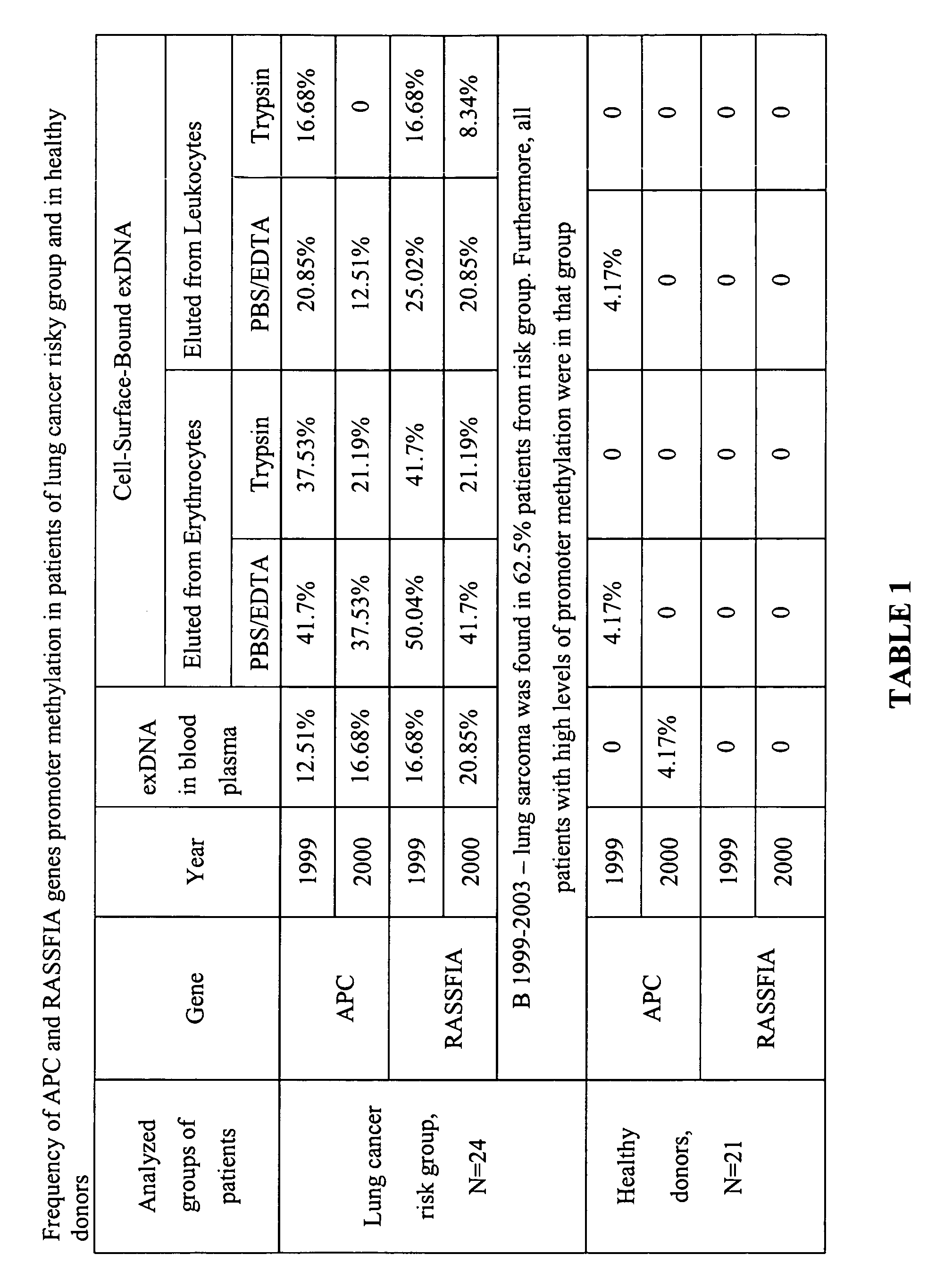

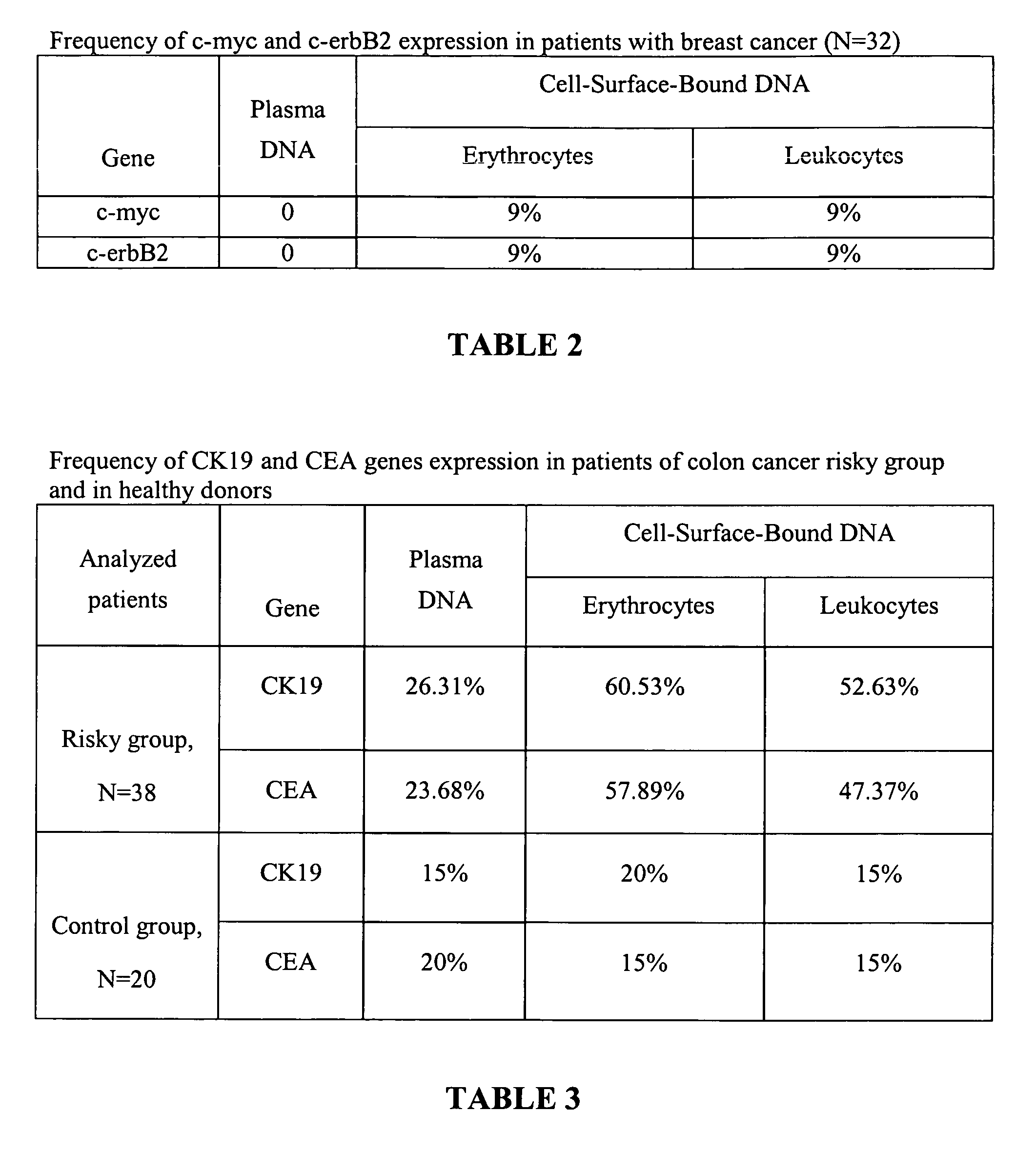

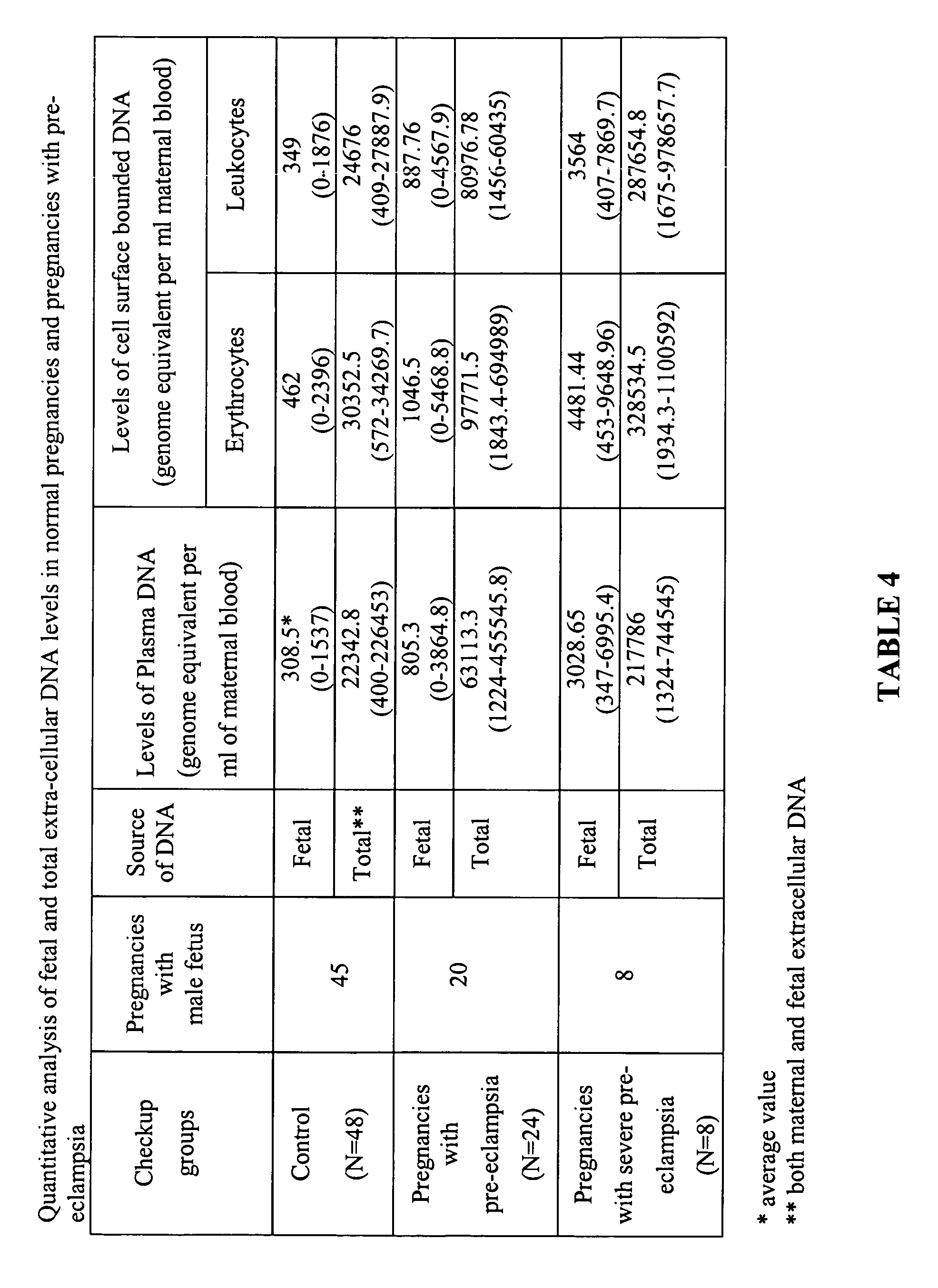

Method for early detection and monitoring of diseases by analysis of cell-surface-bound nucleic acids

InactiveUS20070020636A1Microbiological testing/measurementBiological testingWhite blood cellBlood plasma

This invention relates to noninvasive methods of early detection of different sicknesses, like precancerous state or early stages of cancer development, pathologies of pregnancy, and monitoring of efficacy of anticancer therapy. The method is based on cell-surface extra-cellular nucleic acids from human blood which is divided into plasma and cellular fractions, and further divided into Leukocytes and erythrocytes. Cell-Surface-bound extra-cellular nucleic acids are eluted form cell surface with PBS-EDTA treatment or treatment of cells with trypsin solution. Eluted nucleic acids are isolated with convenient method and analyzed for presence of at least two specific sequences of nucleic acids such as PCR analysis, multiplex PCR, hybridization assay or other methods, thereby increasing the reliability of early detection of the diseases with abnormal functioning of genetic apparatus of cells due to increase of sensitivity of detection of specific DNA and RNA sequences.

Owner:UNIVSKLINIKUM SCHLESWIG HOLSTEIN

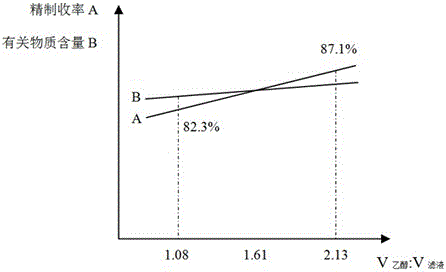

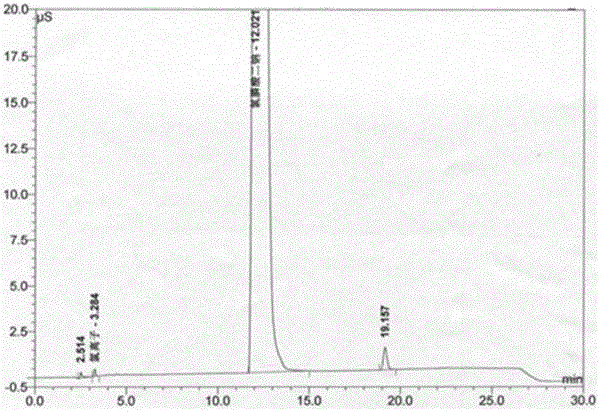

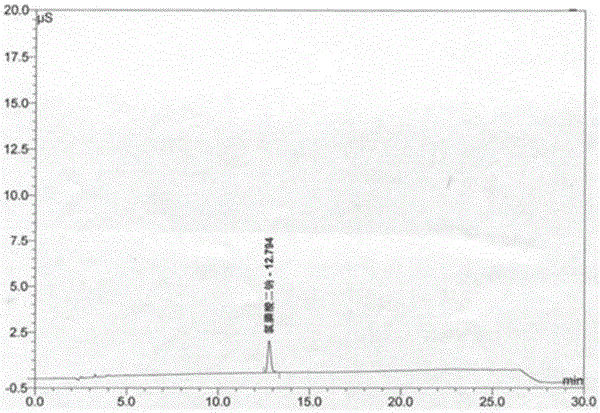

Method for refining and purifying disodium clodronate

ActiveCN106317110ALow content of related substancesHigh clarityGroup 5/15 element organic compoundsFiltrationBiological activation

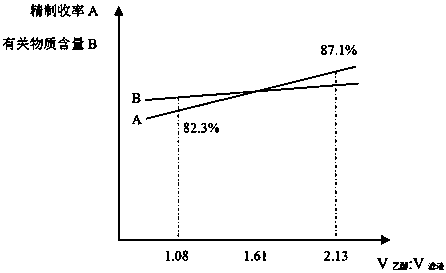

The invention relates to a method for refining and purifying disodium clodronate. The method comprises the following steps: S1, treatment of activated carbon by EDTA: adding the activated carbon in an EDTA solution, stirring and enabling EDTA to be in full contact with the activated carbon, and then washing the activated carbon until chloride cannot be detected; S2, activation of the activated carbon: drying the activated carbon in S1 and activating the activated carbon; S3, impurity removal of the activated carbon: treating a coarse product solution of the disodium clodronate by using the activated carbon in S2, filtering, washing and controlling pH of filtrate not to exceed 3.65; and S4, crystallization and drying: adding ethanol in the filtrate of S3 while stirring, and after white crystals are separated out, standing, carrying out suction filtration and drying to obtain refined disodium clodronate. In the step S1, the mass ratio of EDTA to the activated carbon is 1:800-1,200; and in the step S4, the volume ratio of the ethanol to the filtrate is 1.08:1-2.13:1. The contents of related substances in the product refined and purified by the method provided by the invention are remarkably reduced on the premise of guaranteeing high yield, and the product has high purity and solution clarity and good stability.

Owner:GUANGZHOU BAIYUNSHAN MINGXING PHARM CO LTD

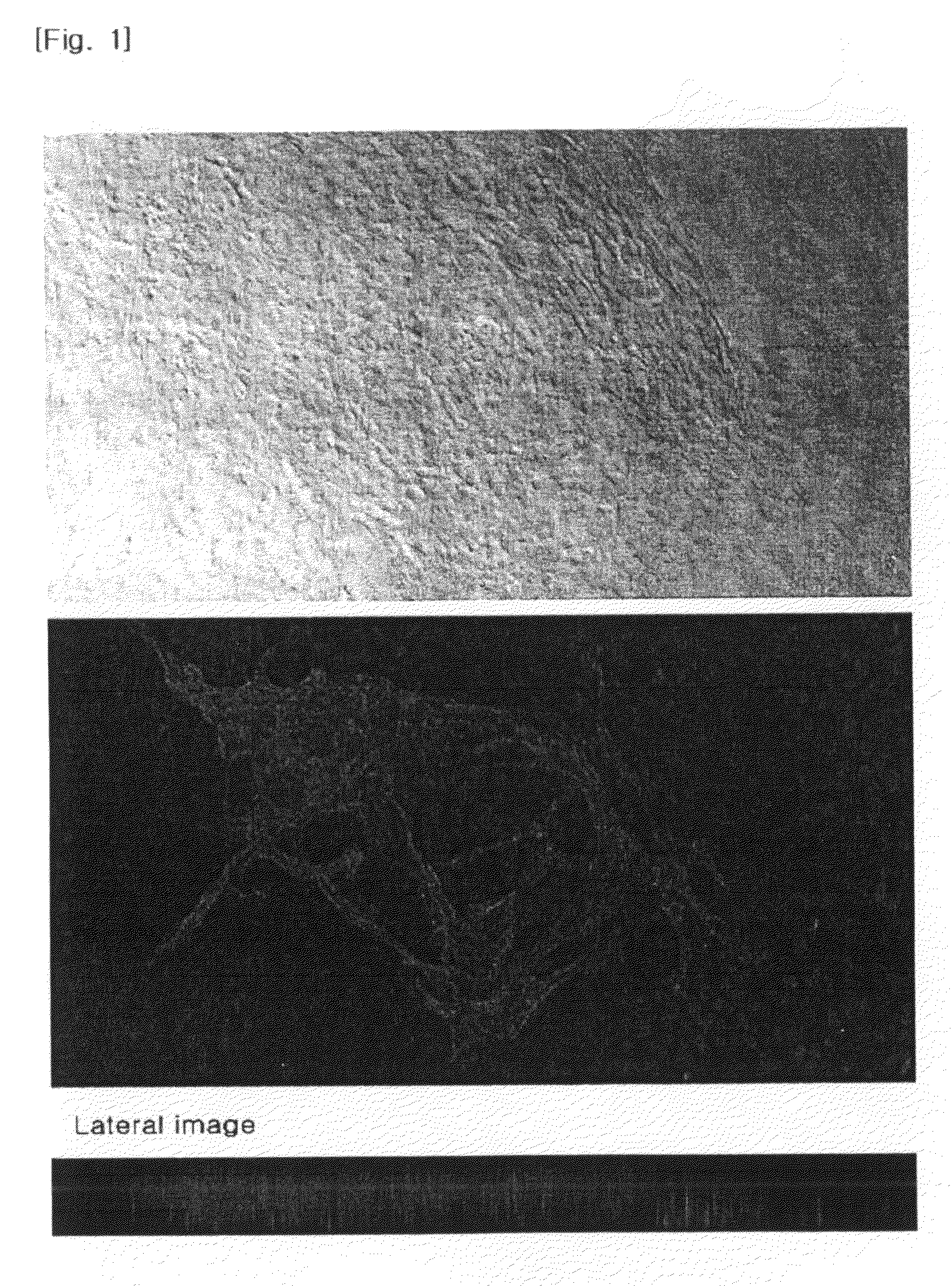

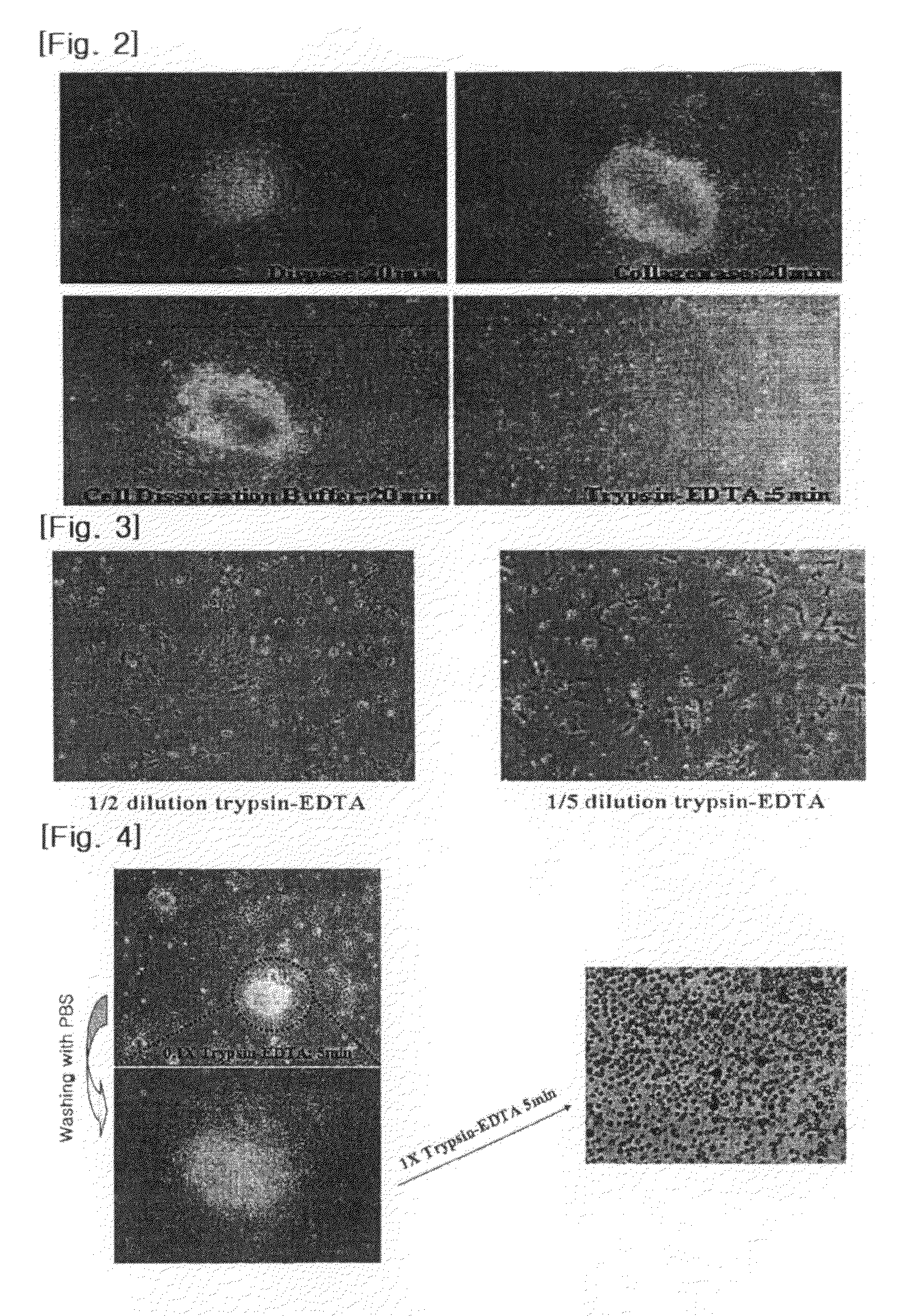

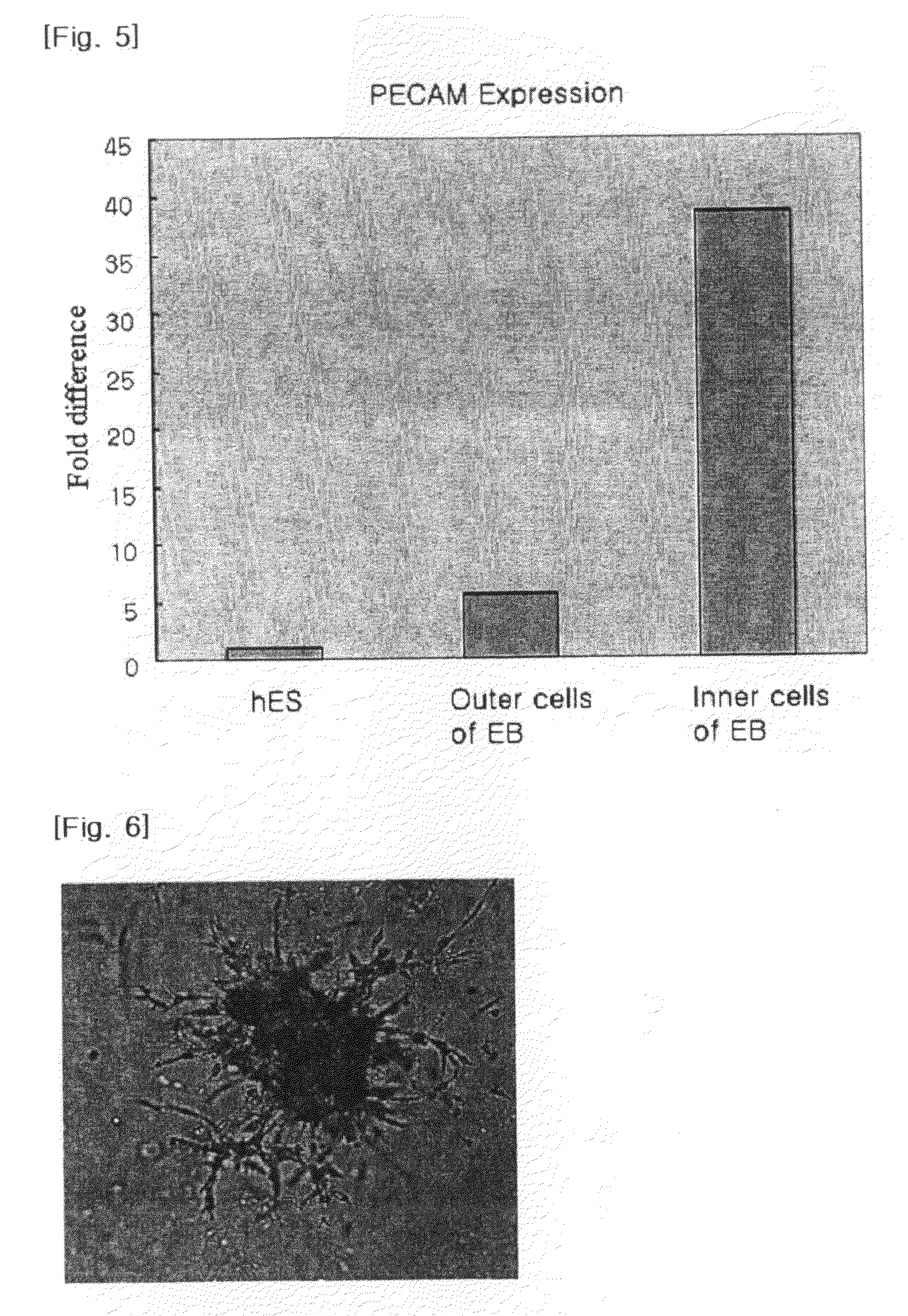

Process for isolating vascular endothelial cells from embryoid bodies differentiated from embryonc stem cells

ActiveUS7919318B2High yieldEasily and rapidly removedCell dissociation methodsArtificial cell constructsVascular endotheliumEdta treatment

Owner:CHA BIOTECH +1

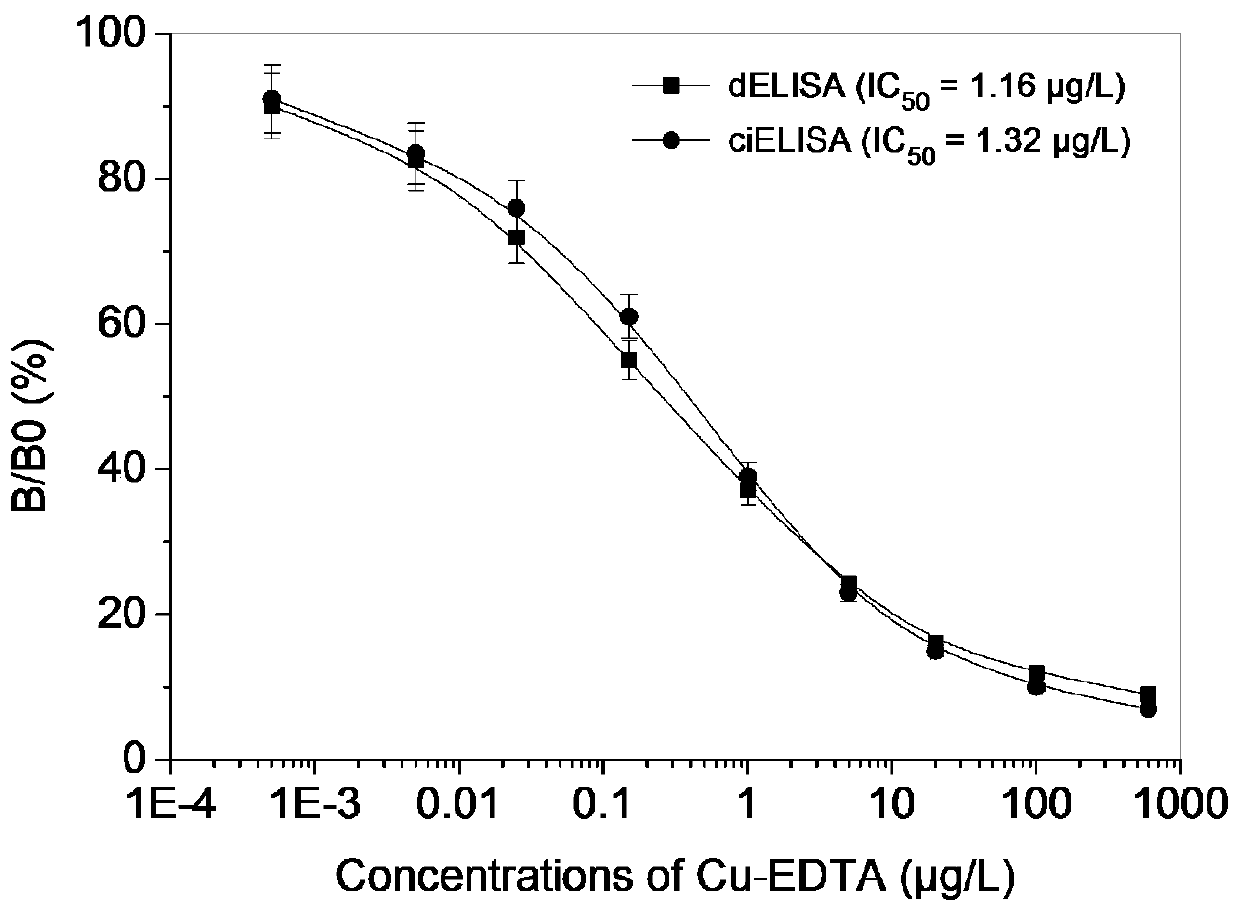

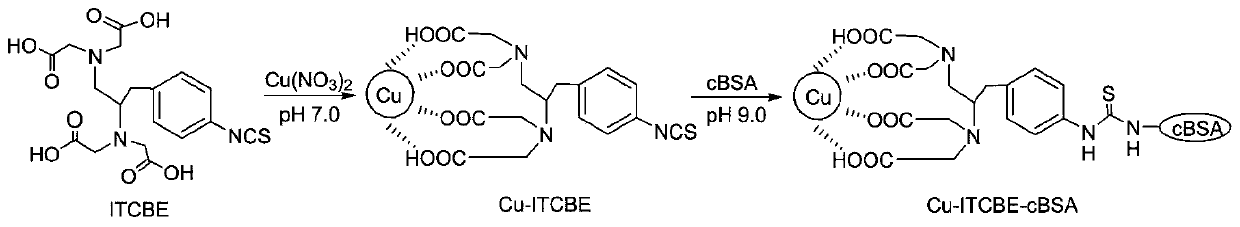

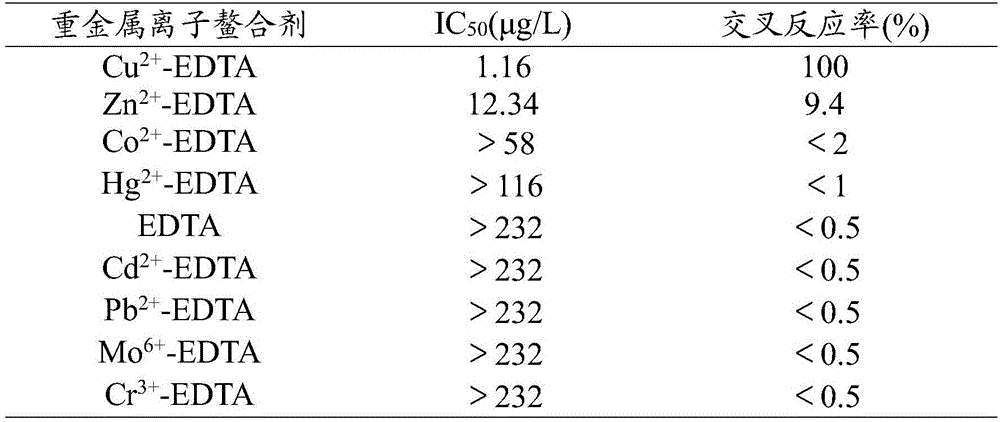

Copper ion direct competition enzyme-linked immunoassay kit and its application in environmental pollution

ActiveCN106841626BReduce the number of washesShorten the timeMaterial analysisBALB/cEthylene diamine

The invention provides a copper ion detection kit based on direct competitive ELISA (enzyme-linked immunosorbent assay). The kit comprises a detection plate coated with a goat anti-mouse IgG secondary antibody, an enzyme-labeled Cu-ITCBE chelate hapten with the mass concentration being 20-50 mu g / mL, an anti-copper-ion monoclonal antibody solution with the mass concentration being 10-20 mu g / mL, 1.0-3.0 mol / L of a stop buffer, a sample diluent, a substrate color developing solution, a scrubbing solution, a copper ion standard solution and an EDTA (ethylene diamine tetraacetic acid) treatment solution with the mass concentration being 10-20 mg / mL, wherein the detection plate is subjected to vacuum sealed packaging; the coating concentration of the goat anti-mouse IgG secondary antibody is 50-200 mu g / mL; the anti-copper-ion monoclonal antibody solution is prepared from a Cu-ITCBE-cBSA immunogen immune Balb / C mouse. The kit has the characteristics of high sensitivity and high specificity and has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH +1

Copper ion detection kit based on direct competitive ELISA (enzyme-linked immunosorbent assay) and application of kit

ActiveCN106841626AReduce the number of washesShorten the timeMaterial analysisBALB/cEthylene diamine

The invention provides a copper ion detection kit based on direct competitive ELISA (enzyme-linked immunosorbent assay). The kit comprises a detection plate coated with a goat anti-mouse IgG secondary antibody, an enzyme-labeled Cu-ITCBE chelate hapten with the mass concentration being 20-50 mu g / mL, an anti-copper-ion monoclonal antibody solution with the mass concentration being 10-20 mu g / mL, 1.0-3.0 mol / L of a stop buffer, a sample diluent, a substrate color developing solution, a scrubbing solution, a copper ion standard solution and an EDTA (ethylene diamine tetraacetic acid) treatment solution with the mass concentration being 10-20 mg / mL, wherein the detection plate is subjected to vacuum sealed packaging; the coating concentration of the goat anti-mouse IgG secondary antibody is 50-200 mu g / mL; the anti-copper-ion monoclonal antibody solution is prepared from a Cu-ITCBE-cBSA immunogen immune Balb / C mouse. The kit has the characteristics of high sensitivity and high specificity and has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH +1

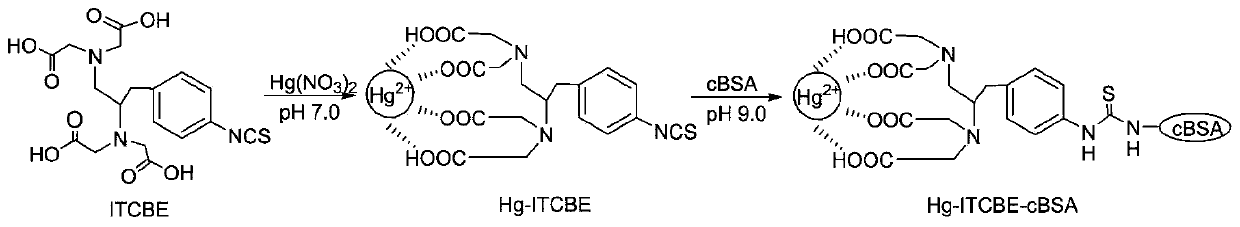

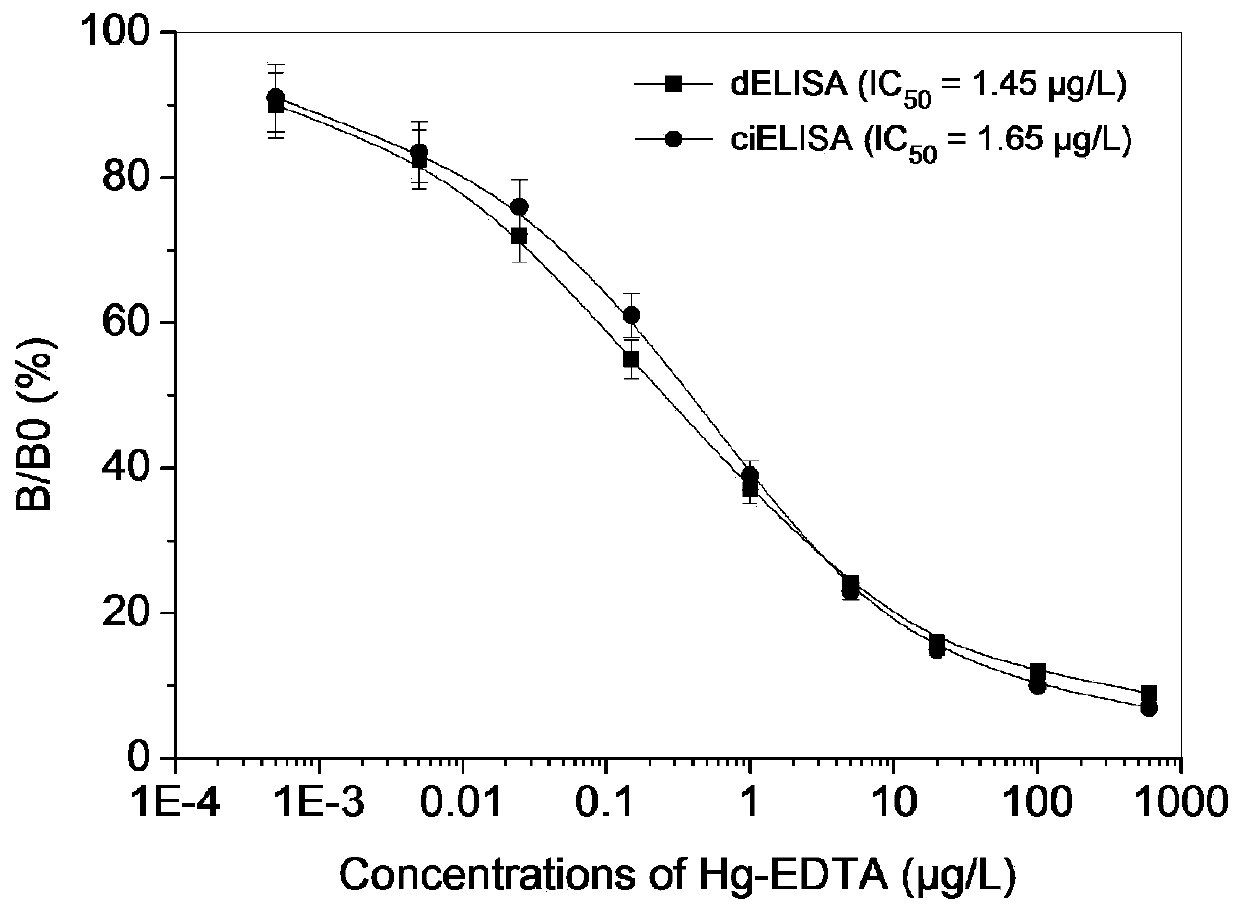

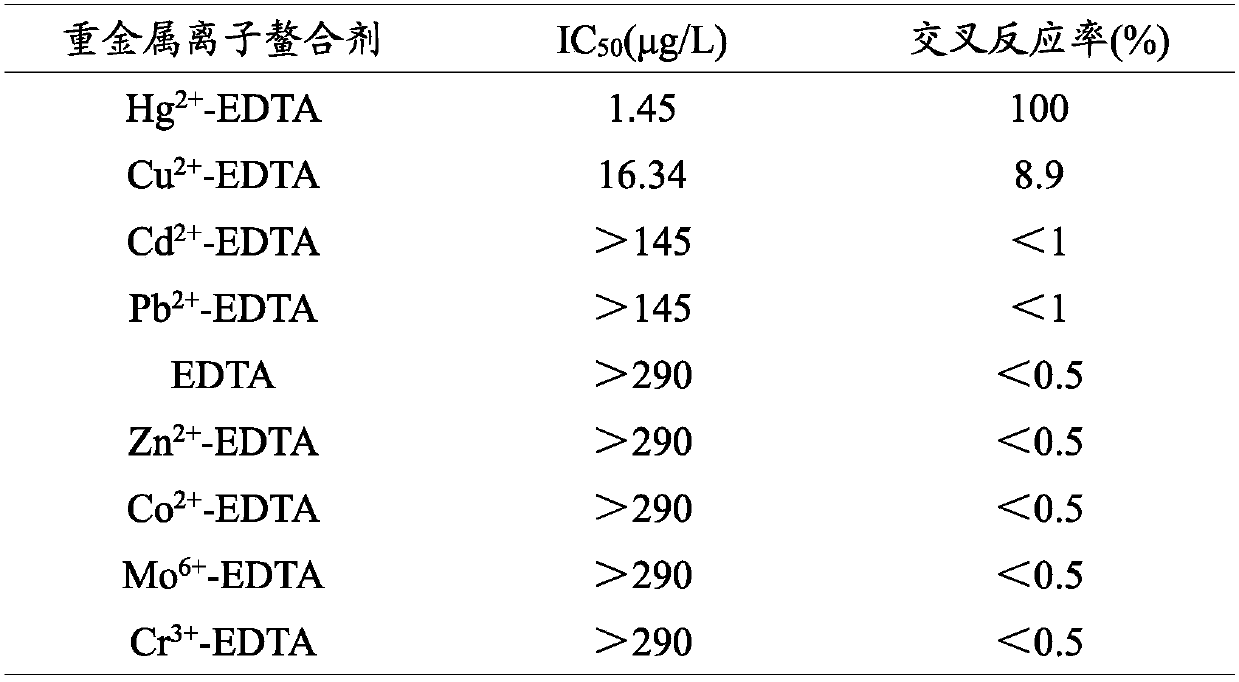

Direct Competitive ELISA Kit and Its Application in Mercury Ion Food Contamination

ActiveCN106872692BThe test result is simpleReduce the number of washesMaterial analysisBALB/cEthylene diamine

The invention provides a kit for detecting mercury ions based on a direct competition enzyme-linked immunoadsordent assay. The kit comprises a detection plate coated with a goat anti-mouse IgG secondary antibody, an Hg-ITCBE chelate hapten with the mass concentration of 20mu g / mL to 50mu g / mL, an anti-mercury ion monoclonal antibody solution with the mass concentration of 10mu g / mL to 20mu g / mL, 1.0mol / L to 3.0mol / L of a stopping solution, a sample diluting solution, a substrate color developing solution, a washing solution, a mercury ion standard product solution and an EDTA (Ethylene Diamine Tetraacetic Acid) treatment solution with the mass concentration of 10mg / mL to 20mg / mL, wherein the detection plate is sealed and packaged in vacuum; the coating concentration of the goat anti-mouse IgG secondary antibody is 50mu g / mL to 200mu g / mL; the anti-mercury ion monoclonal antibody solution is prepared from Hg-ITCBE-cBSA immunogen immunized Balb / C mice. The kit provided by the invention has the characteristics of high sensitivity and high specificity and also has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH +1

Method for improving saline-alkali soil by using phosphogypsum, slow release binder and EDTA (ethylene diamine tetraacetic acid)

InactiveCN105112066ALower pHLight weightAgriculture tools and machinesOther chemical processesAlkali soilPhosphogypsum

The invention provides a method for improving saline-alkali soil by using phosphogypsum, a slow release binder and EDTA (ethylene diamine tetraacetic acid). The method comprises the steps of firstly treating the saline-alkali soil with phosphogypsum and humic acid, then treating the saline-alkali soil with the slow release binder and finally treating the saline-alkali soil with EDTA. The saline-alkali soil can be quickly improved by adopting the saline-alkali soil improvement method and is suitable for crop growth. The improvers have a wider range of application, are suitable for improving the soil salinized and alkalized due to different reasons in different regions and can achieve the effects of improving the soil structure, reducing the soil alkalinity, increasing the salt elimination rate of the soil, improving the soil fertility, promoting growth of crops and increasing the agricultural economy by being reasonably applied to the soil.

Owner:GUIZHOU KAILIN GRP CO LTD +1

Peptidoglycan immunopotentiator and its production process

InactiveCN1321685CGood effectEasy to usePeptide/protein ingredientsAnimal feeding stuffBiotechnologyNitrogen gas

The peptidoglycan immunopotentiator is light brown, has viscosity of 3.2-5.0 and specific weight of 1.021-1.042, and contains peptidoglycan as active component in 1.5-2.0 wt%, protein in 5-8 wt%, fat in 0.3-0.5 wt%, RNA in 0.01-0.02 wt% and total solids in 8-10 wt% except water. The production process of the immunopotentiator includes the following steps: culturing strain, the first seed culturing and the second stage of seed tank culturing; fermentation in the primary fermenting tank while introducing nitrogen; terminating fermentation after reaching OD value 1.0-1.4; expanding fermentation in n fermenting tanks to obtain target fermented liquid; separation and post-treatment via adding digestive buffering liquid, lysozyime, cysteine, EDTA and papain; and obtaining the required liquid peptidoglycan preparation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Process for isolating vascular endothelial cells from embryoid bodies differentiated from embryonc stem cells

ActiveUS20100144032A1High yieldEasily and rapidly removedCell dissociation methodsArtificial cell constructsVascular endotheliumEmbryo

The present invention provides a process for isolating vascular endothelial cells from embryoid bodies differentiated from embryonic stem cells, which comprises: (a) treating embryoid bodies differentiated from embryonic stem cells with 0.005-0.015% trypsin and 0.05-0.15 mM ethylenediaminetetraacetate (EDTA) to obtain vascular endothelial cell clusters; and (b) treating the vascular endothelial cell clusters with 0.1-0.5% trypsin and 0.5-2 mM EDTA so as to separate the vascular endothelial cell clusters into single cells.

Owner:CHA BIOTECH +1

A kind of cadmium ion direct competition ELISA kit and its application

Owner:HENAN INST OF SCI & TECH

Method for improving saline-alkali soil by using phosphogypsum, trimethylene tetraurea and EDTA

InactiveCN105107836ALower pHReduce solubilityAgriculture tools and machinesOther chemical processesAlkalinityAlkali soil

The invention provides a method for improving saline-alkali soil by using phosphogypsum, trimethylene tetraurea and EDTA. The method comprises the following steps: firstly treating the saline-alkali soil by using phosphogypsum and humilic acid, then treating the saline-alkali soil by using trimethylene tetraurea, phthalic acid and polyethylene glycol, and finally treating the saline-alkali soil by using EDTA. Through the adoption of the method for improving the saline-alkali soil, the saline-alkali soil can be quickly improved to be suitable for growth of crops; the improver is relatively wide in application range and is suitable for improving the saline-alkali soil caused by different reasons in different regions; when the improver is reasonably applied to the soil, the soil structure can be improved, the alkalinity of the soil can be reduced, the salt rejection ratio of the soil can be increased, the fertility of the soil can be improved, the growth of the crops can be accelerated, and the agricultural economy can be improved.

Owner:GUIZHOU KAILIN GRP CO LTD +1

A method for refining and purifying disodium clodronate

ActiveCN106317110BHigh clarityLow content of related substancesGroup 5/15 element organic compoundsFiltrationBiological activation

The invention relates to a method for refining and purifying disodium clodronate. The method comprises the following steps: S1, treatment of activated carbon by EDTA: adding the activated carbon in an EDTA solution, stirring and enabling EDTA to be in full contact with the activated carbon, and then washing the activated carbon until chloride cannot be detected; S2, activation of the activated carbon: drying the activated carbon in S1 and activating the activated carbon; S3, impurity removal of the activated carbon: treating a coarse product solution of the disodium clodronate by using the activated carbon in S2, filtering, washing and controlling pH of filtrate not to exceed 3.65; and S4, crystallization and drying: adding ethanol in the filtrate of S3 while stirring, and after white crystals are separated out, standing, carrying out suction filtration and drying to obtain refined disodium clodronate. In the step S1, the mass ratio of EDTA to the activated carbon is 1:800-1,200; and in the step S4, the volume ratio of the ethanol to the filtrate is 1.08:1-2.13:1. The contents of related substances in the product refined and purified by the method provided by the invention are remarkably reduced on the premise of guaranteeing high yield, and the product has high purity and solution clarity and good stability.

Owner:GUANGZHOU BAIYUNSHAN MINGXING PHARM CO LTD

Method for improving saline-alkali soil through ardealite, DMTU and EDTA

InactiveCN105123009ALower pHWill not cause secondary pollutionSoil-working methodsFertilizer mixturesAlkalinityAlkali soil

The invention provides a method for improving saline-alkali soil through ardealite, DMTU and EDTA. The method includes the steps that first, the ardealite and fulvic acid are used for treatment; then the DMTU, oxalic acid and hydroxymethyl cellulose are used for treatment; finally, the EDTA is used for treatment. By the adoption of the method for improving the saline-alkali soil, the saline-alkali soil can be improved quickly and is suitable for growth of crops; moreover, the application range of the modifying agent is wide, the modifying agent is suitable for improvement of soil alkalization in different areas and for different reasons, the modifying agent can be applied to the soil reasonably, and the soil structure can be improved; the soil alkalinity is lowered, the salt elimination rate of the soil is increased, the soil fertility is improved, the growth of the crops is promoted, and agricultural economy is improved.

Owner:GUIZHOU KAILIN GRP CO LTD +1

A kind of kit for detecting chromium ion based on direct competitive ELISA and its application

The invention provides a kit for detecting chromium ions on the basis of a direct competitive enzyme linked immunosorbent assay. The kit comprises a detection plate coated with a goat-anti-mouse IgG secondary antibody, an enzyme-labeled Cr-ITCBE chelate hapten with mass concentration of 20 to 50mu g / mL, chromium ion resistant monoclonal antibody solution with mass concentration of 10 to 20mu g / mL, 1.0 to 3.0mol / L of stop buffer, sample diluent, substrate developing solution, cleaning solution, chromium ion standard substance solution, and EDTA conditioning fluid with mass concentration of 10 to 20mg / mL, wherein the detection plate is packaged in a vacuum sealed mode; coating concentration of the goat-anti-mouse IgG secondary antibody is 50 to 200mu g / mL; the chromium ion resistant monoclonal antibody solution is prepared from Cr-ITCBE-cBSA immunogen immunized Balb / C mice. The kit provided by the invention has the characteristics of high sensitivity and high specificity, and meanwhile, has the advantage of short detection time.

Owner:HENAN INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com