Patents

Literature

80results about How to "Little change in shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

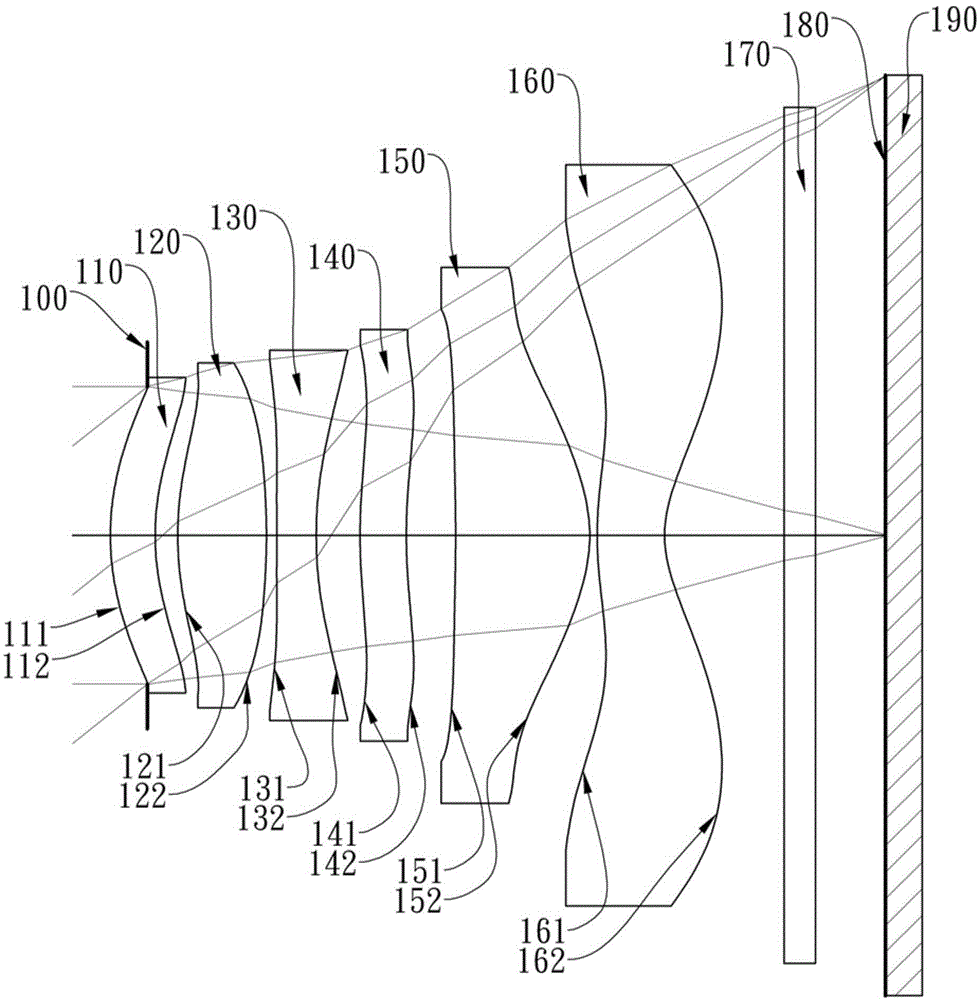

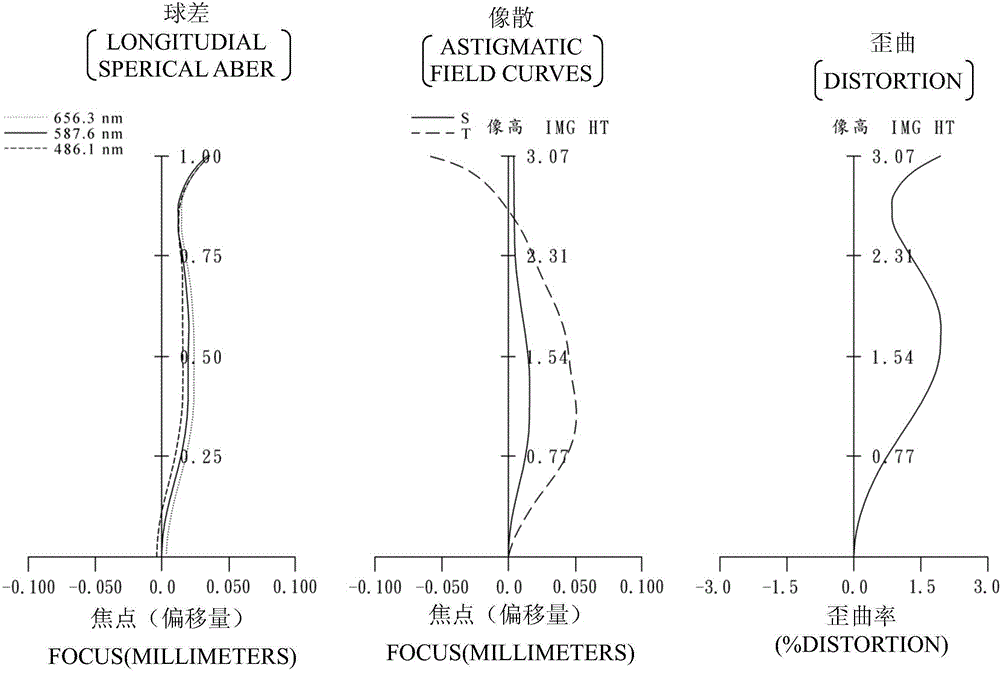

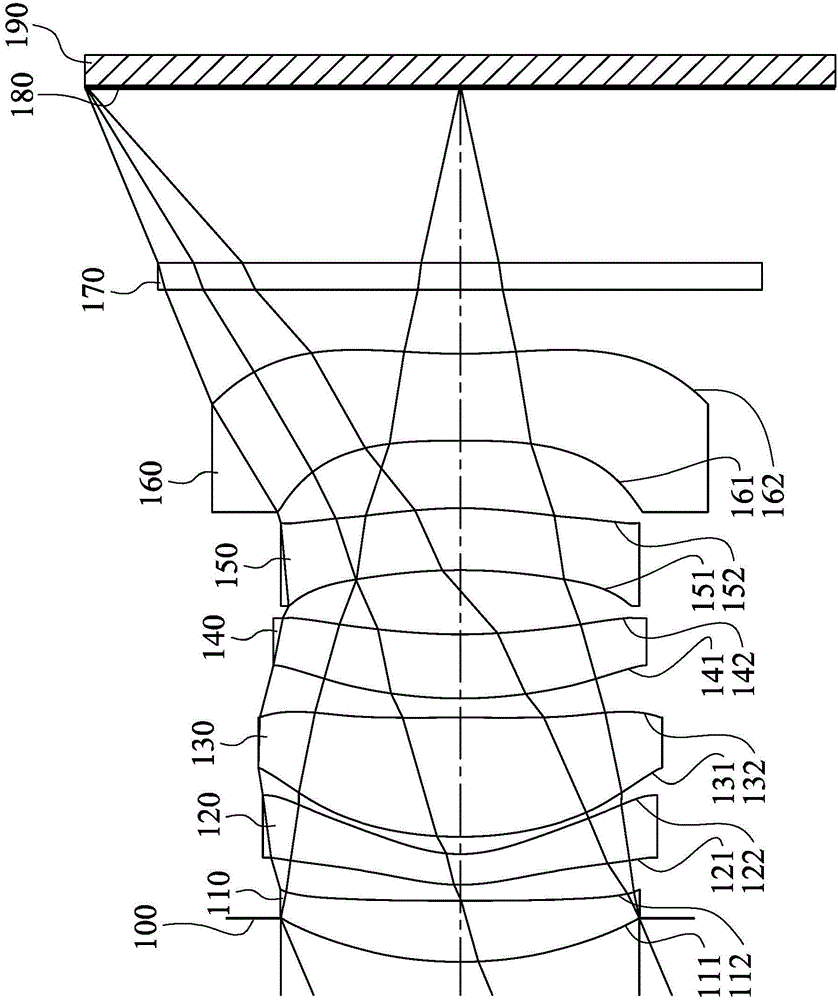

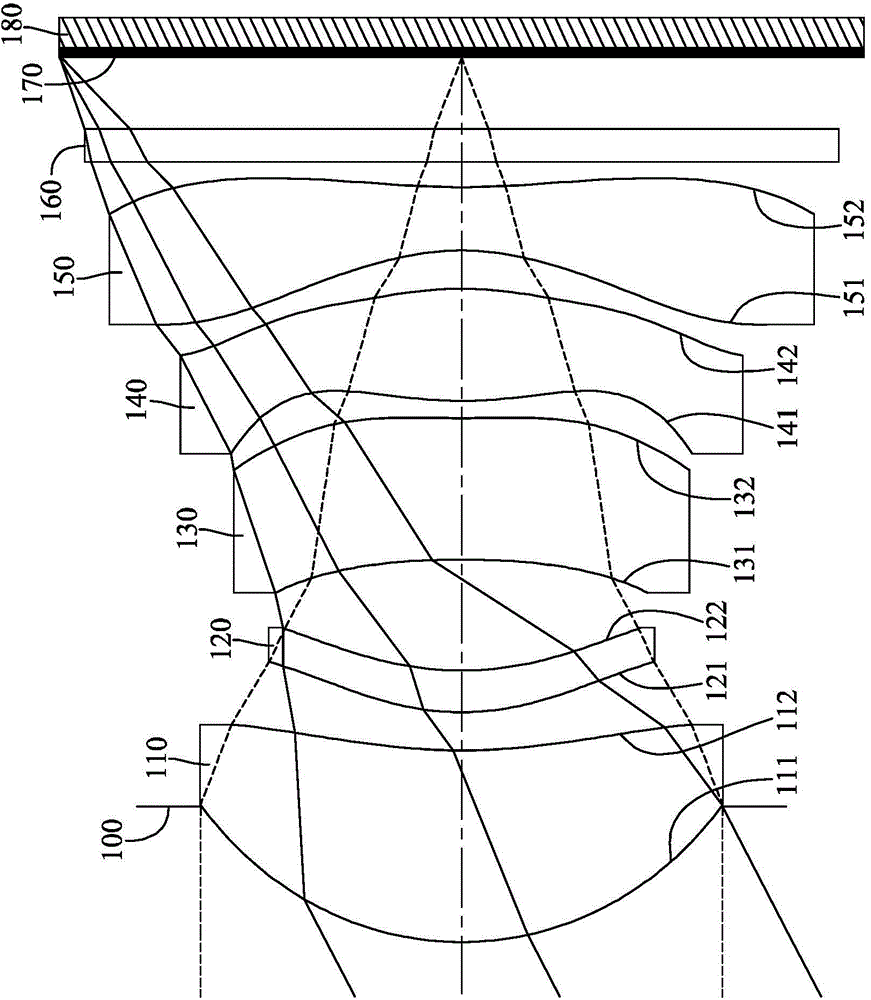

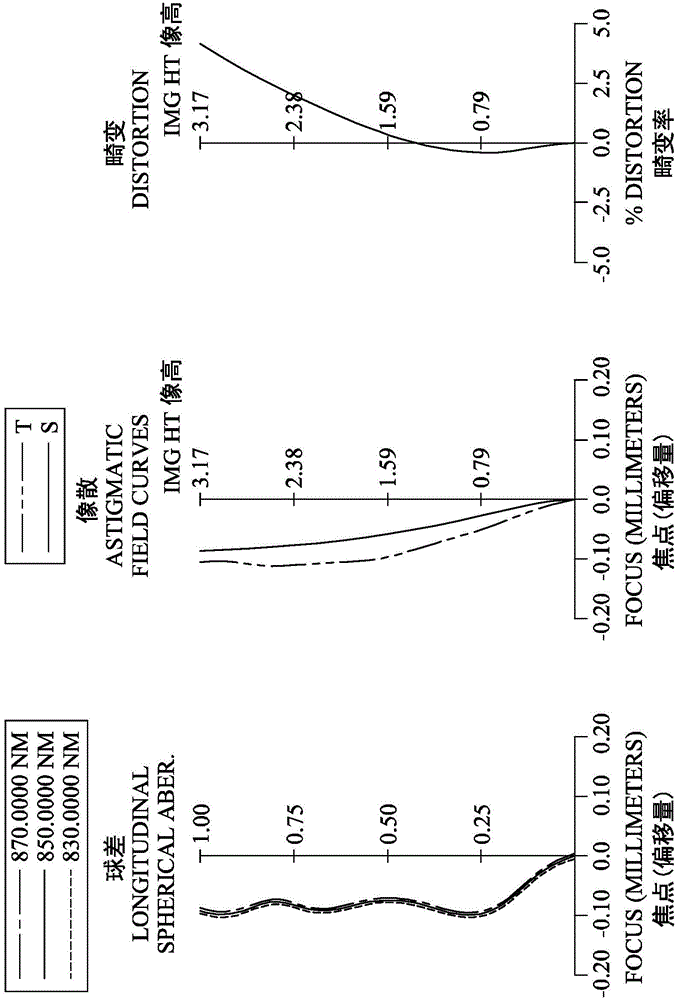

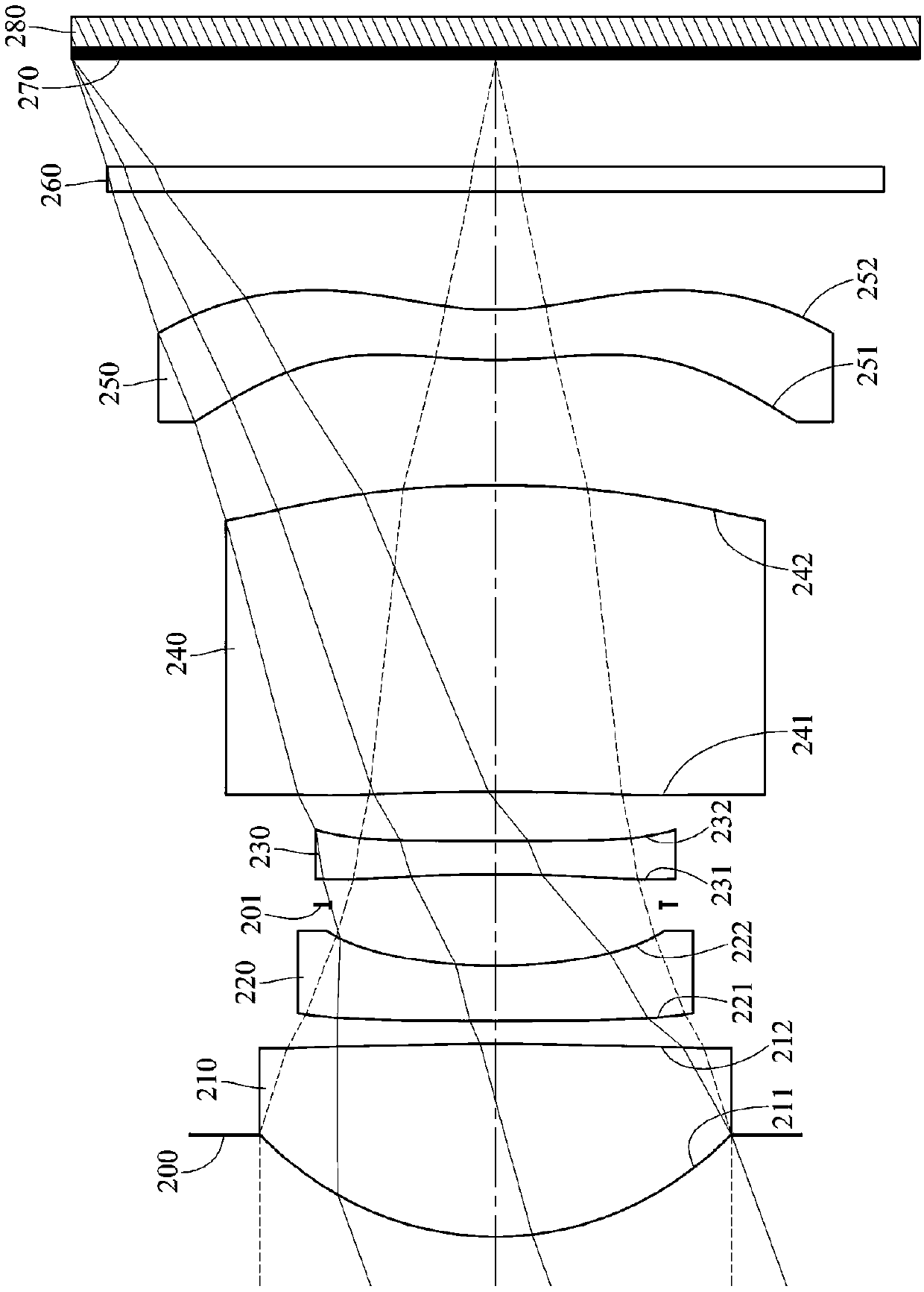

Optical image capture battery of lens, image capture apparatus and electronic apparatus

ActiveCN105717609AReduce sensitivityEnhance photosensitivityOptical elementsOptical axisImage capture

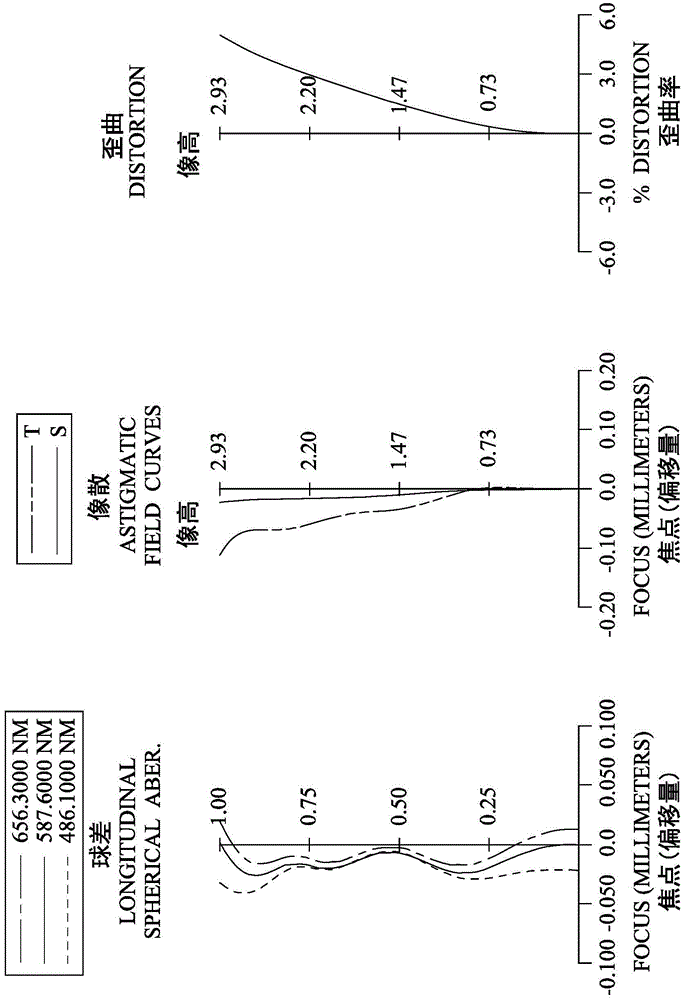

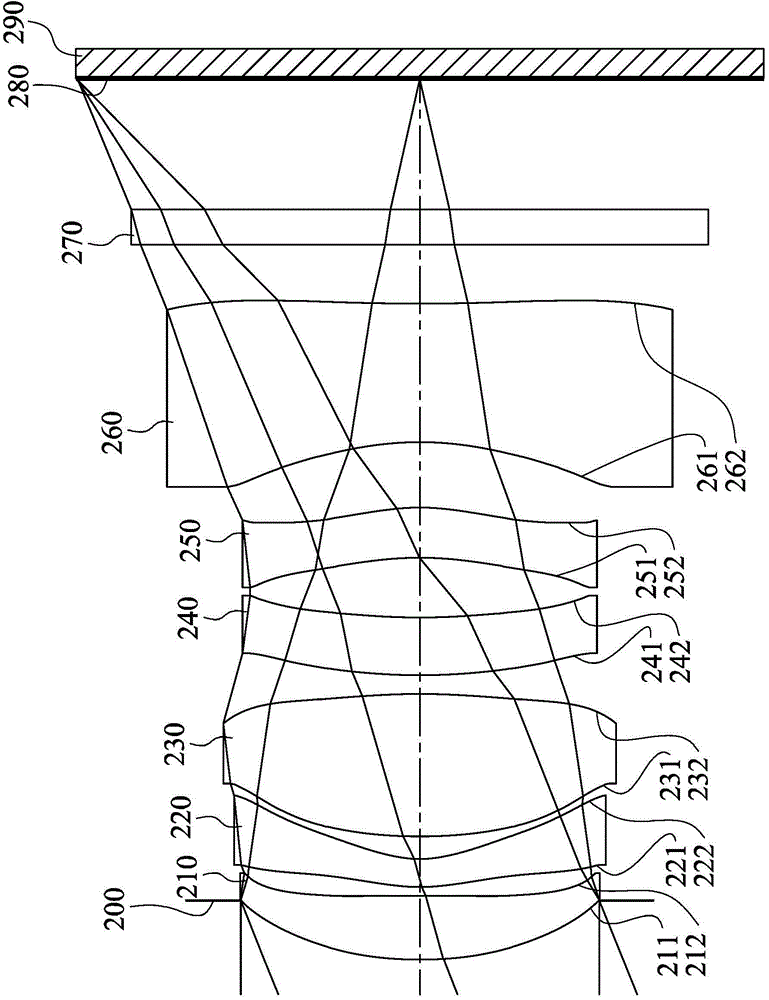

The invention discloses an optical image capture battery of lens, an image capture apparatus and an electronic apparatus. The optical image capture battery of lens includes, from the object side to the image side: a first lens with refraction power, a second lens with positive refraction power, a third lens with refraction power, a fourth lens with refraction power, a fifth lens with refraction power, and a sixth lens with refraction power, wherein the object side surface of the first lens is a convex surface at the position being close to an optical axis, wherein the object side surface; the image side surface of the third lens is a concave surface at the position being close to the optical axis; the image side surface of the fourth lens is a concave surface at the position being close to the optical axis, and both the object side surface and the image side surface of the fourth lens are aspheric surfaces; the object side surface of the fifth lens is a concave surface at the position being close to the optical axis; and the image side surface of the sixth lens is a concave surface at the position being close to the optical axis, both the object side surface and the image side surface of the sixth lens are aspheric surfaces, and the image side surface is provided with at least one convex surface at the position of an off axis. The invention also discloses an image capture apparatus with the optical image capture battery of lens and an electronic apparatus with the image capture apparatus. Through the above configuration, the optical image capture battery of lens, the image capture apparatus and the electronic apparatus can alleviate the situation of deflection of light ray when initial incidence of the light ray into the battery of lens so as to control generation of aberrations and reduce the sensitivity of the optical image capture battery of lens and further improve the yield rate for production.

Owner:LARGAN PRECISION

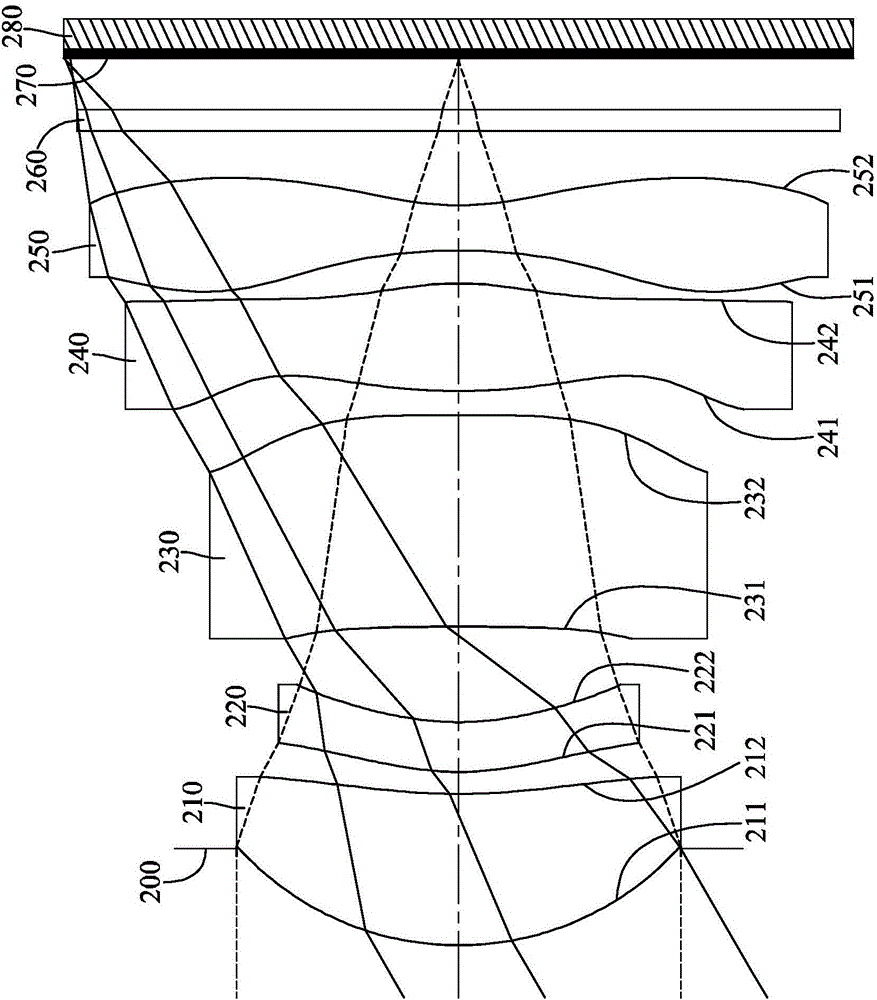

Optical shooting lens set, image capture device and electronic device

The invention discloses an optical shooting lens set, an image capture device and an electronic device. The optical shooting lens set comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens in sequence from an object side to an image side. The first lens has positive refractive power, and the object side surface thereof near an optic axis is a convex surface. The second lens has refractive power. The third lens has refractive power. The fourth lens has refractive power. The fifth lens has refractive power, the image side surface thereof near the optic axis is a convex surface, and the object side surface and the image side surface thereof are aspheric surfaces. The sixth lens has refractive power, and the object side surface and the image side surface thereof are aspheric surfaces. The invention further discloses an image capture device with the optical shooting lens set and an electronic device with the image capture device. When satisfying a specific condition, the optical shooting lens set has good telephoto capability.

Owner:LARGAN PRECISION

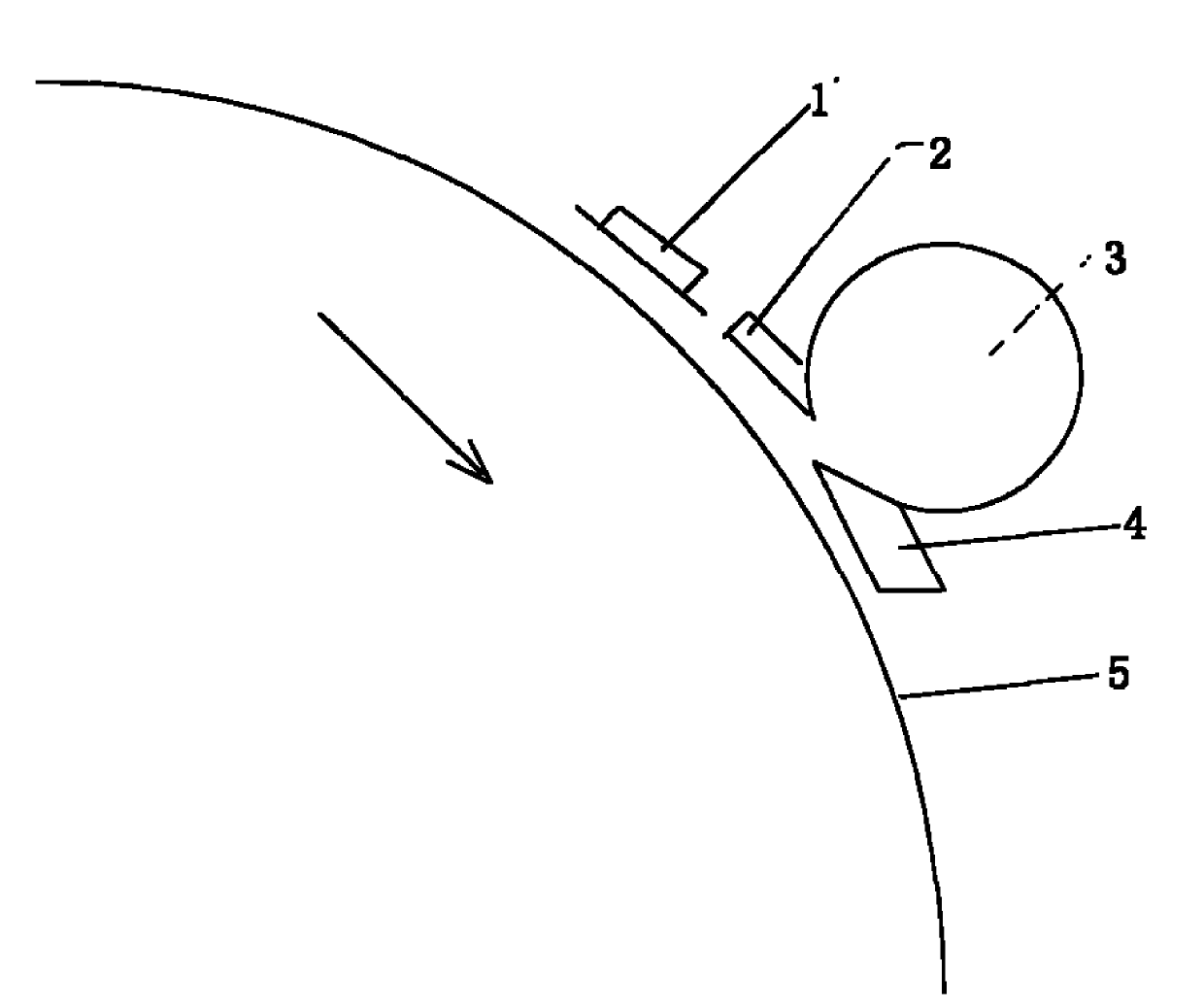

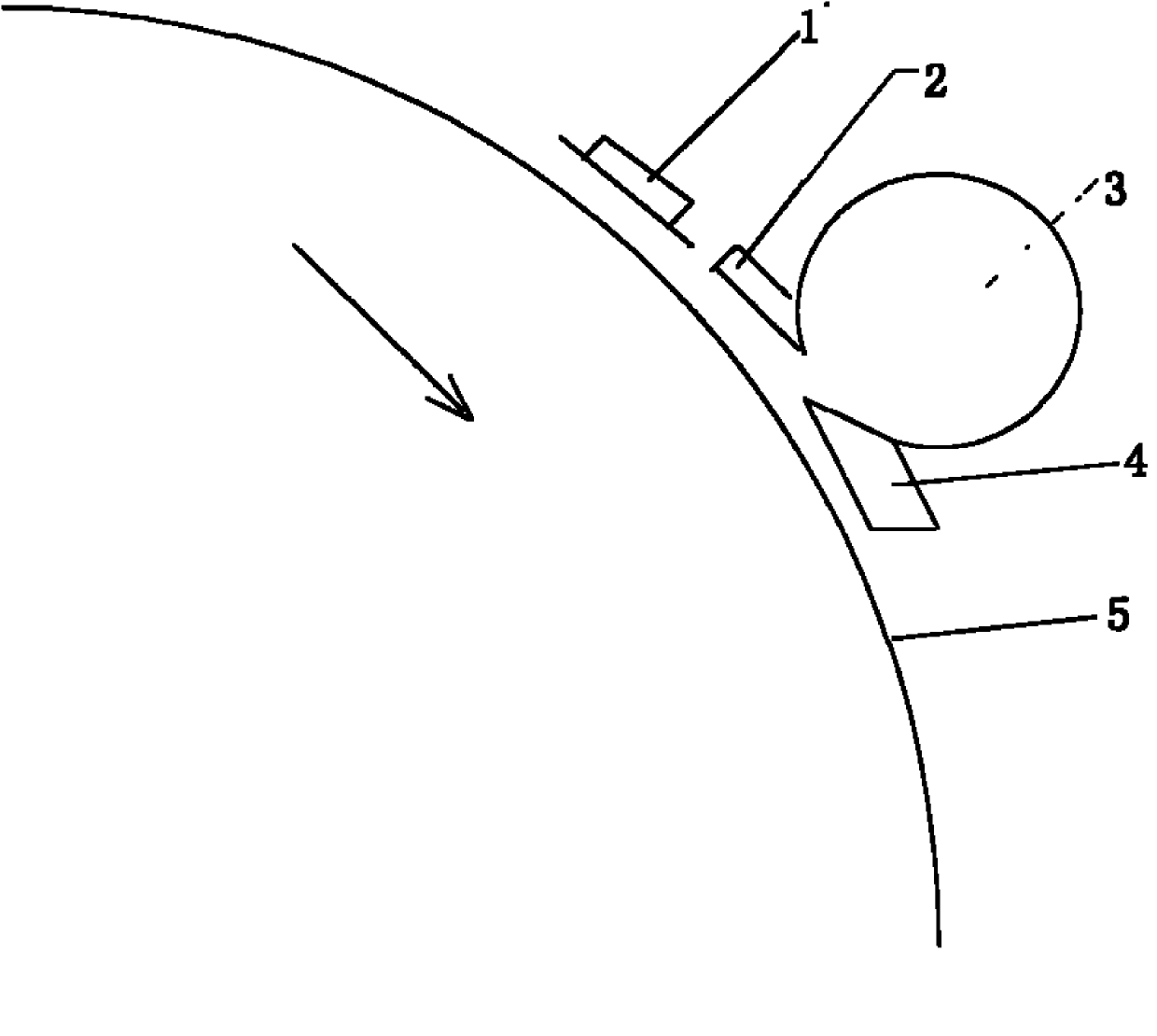

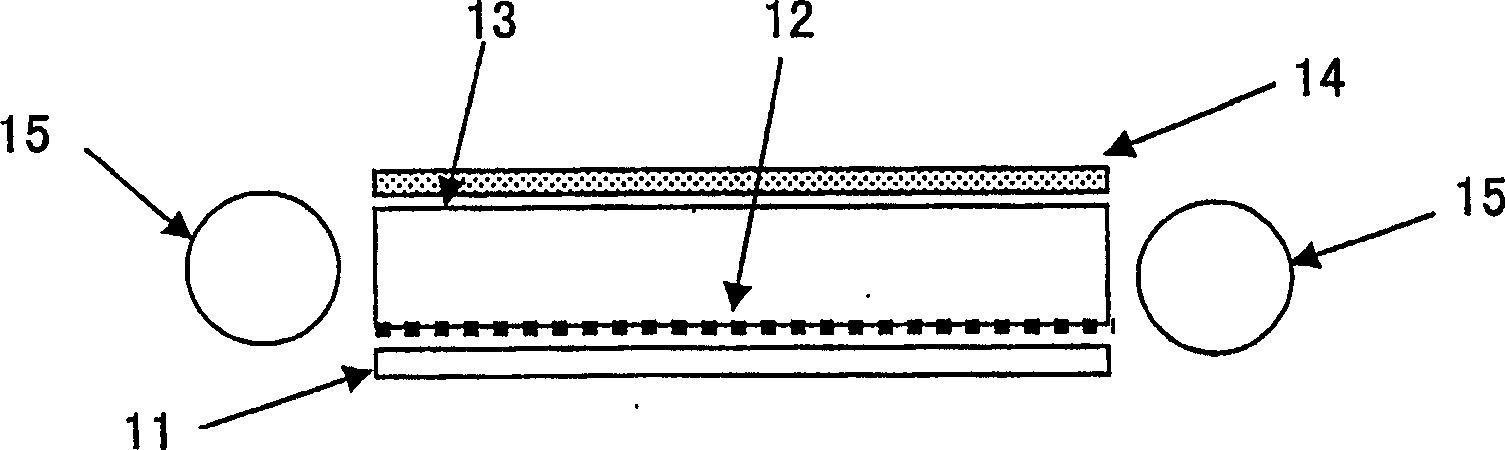

Electrostatic type crosrol web cleaner for carding machine

InactiveCN101906680AImprove sliver qualityThe index of impurity content has not been improvedCarding machinesBiochemical engineeringDissemination

The invention provides an electrostatic type crosol web cleaner for a carding machine, relating to the technical filed of textile, taking gauge adjustment of electrostatic plates and voltage adjustment as the key technology, and providing the installation form and the use effect of the electrostatic type crosol web cleaner for the carding machine. In the invention, a guide plate type crosrol web cleaner with the electrostatic plate is loaded at the position of a front knife plate of the carding machine; under the normal production condition, the different gauges between the electrostatic plate and cylinder as well as the different voltages are adjusted to influence the quality of a carded sliver; a Uster AFIS filament tester is used for carrying out quality testing on the carded sliver produced under the condition of the different gauges of the static electric plates and the voltages, a statistical analysis technique is used for analyzing the testing result which shows that under the condition of the appropriate dereferencing of the voltages and the gauges of the static electric plates, when the electrostatic type crosol web cleaner for the carding machine is loaded to the position of the front knife plate of the carding machine, the quality of the carded sliver can be improved. In the process of utilization, the loaded electrostatic plates have simple structure and small change on the traditional crosol web cleaner form, are convenient to manufacture and install and are favor of wide application and dissemination.

Owner:EASTERN LIAONING UNIV

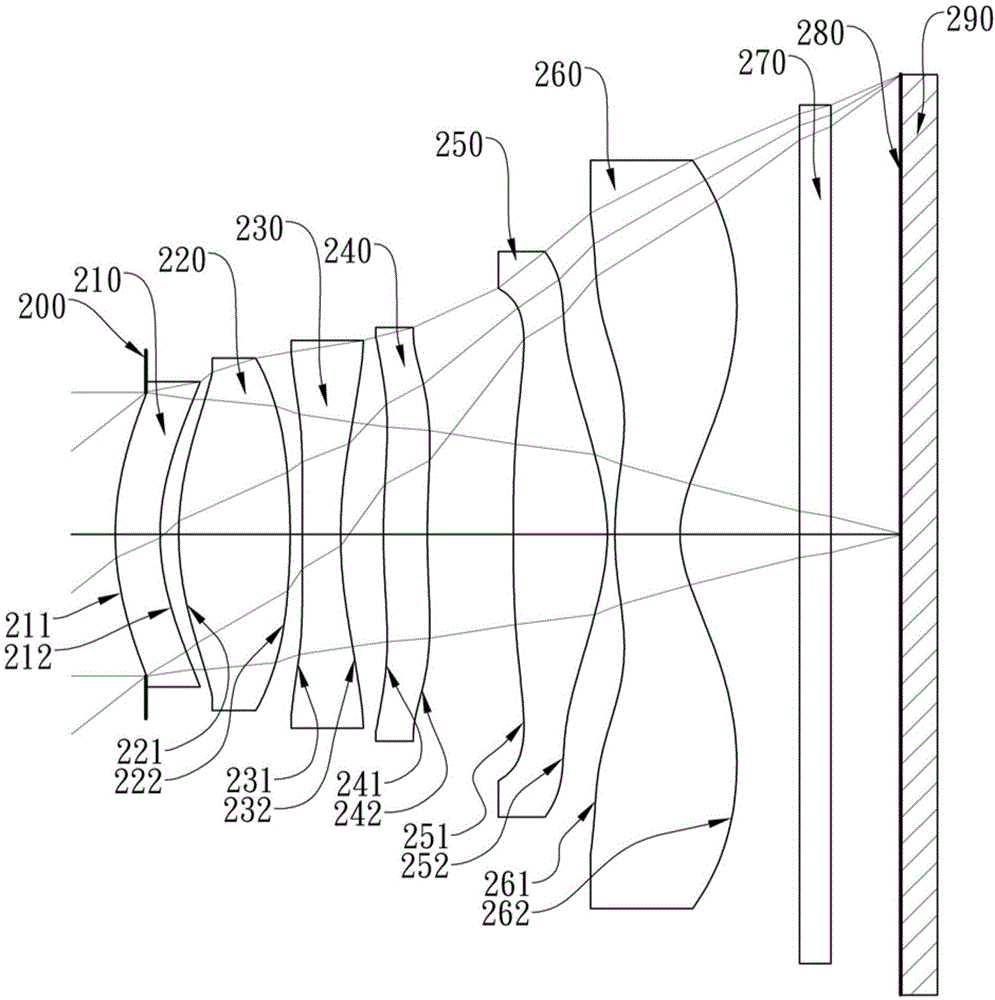

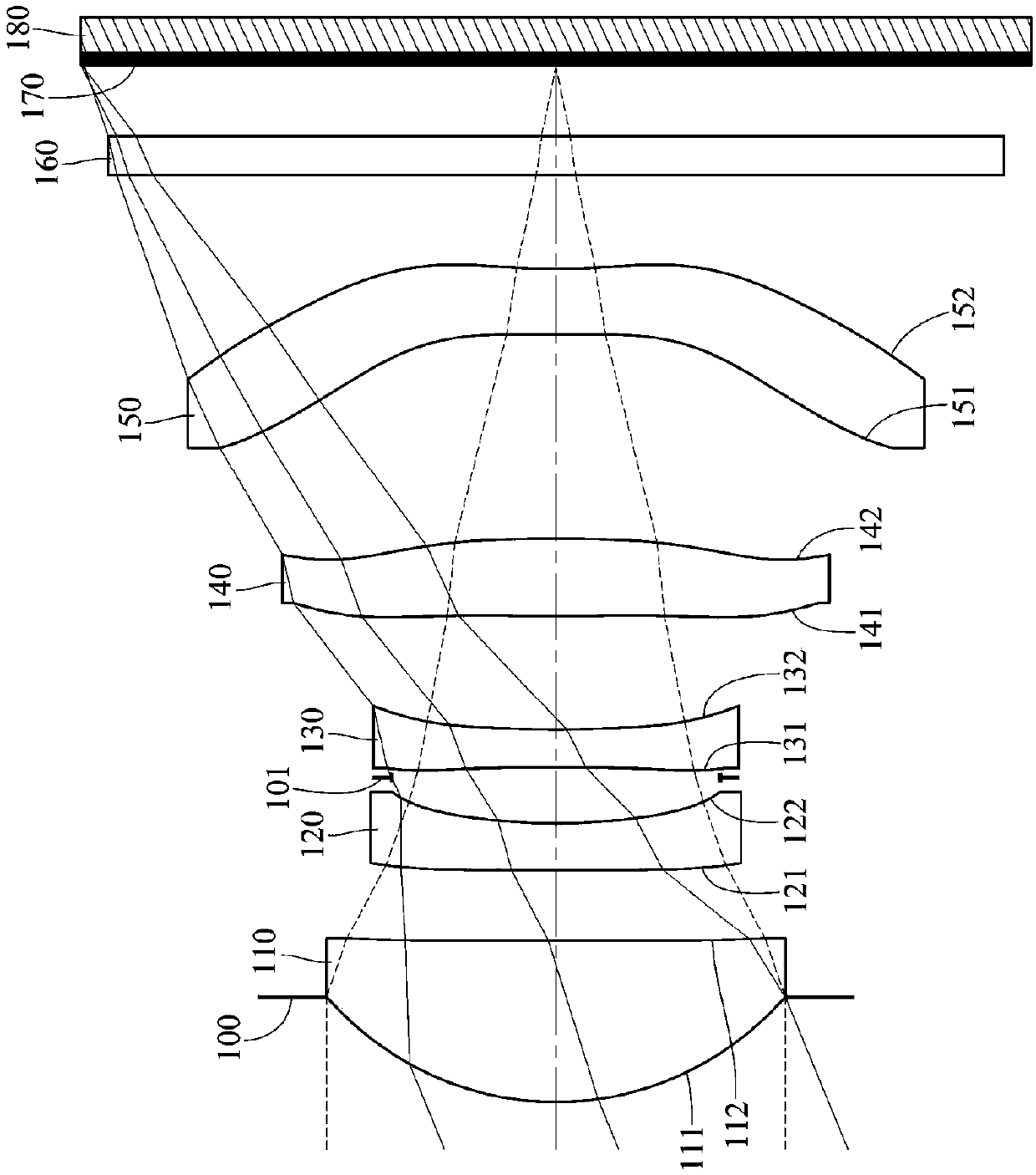

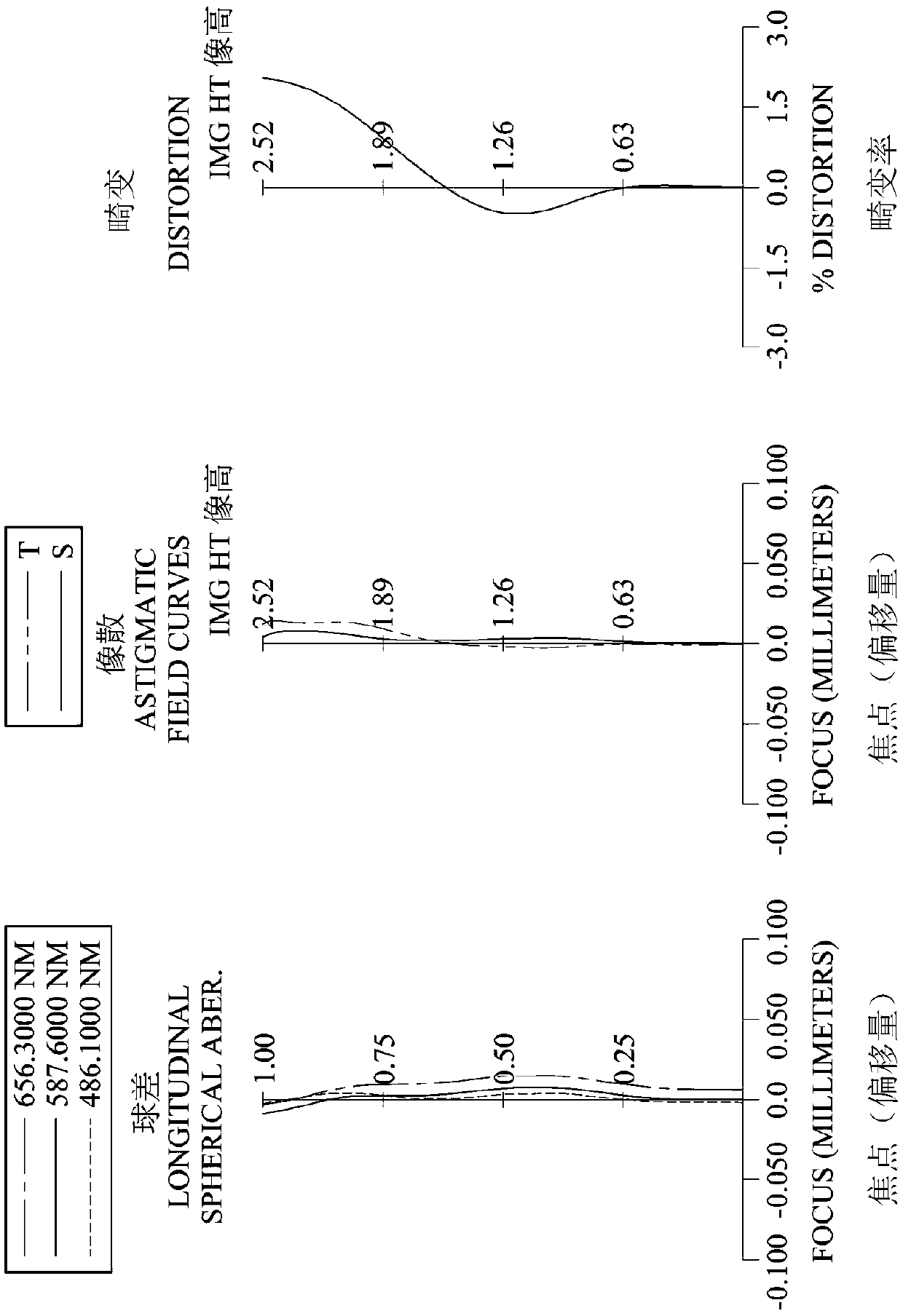

Optical imaging lens group, image capturing device and electronic device

ActiveCN105739060ALittle change in shapeAvoid Surface Reflection IssuesOptical elementsImage captureNegative refraction

The invention discloses an optical imaging lens group, an image capturing device and an electronic device. The optical imaging lens group comprises, from the object side to the image side, a first lens, a second lens, a third lens, a fourth lens and a fifth lens which have refraction power. The first lens has positive refraction power and an object side surface, close to an optical axis, of the first lens is a convex surface. The second lens has positive refraction power and an object side surface, close to an optical axis, of the second lens is a convex surface. The third lens has refraction power. The fourth lens has positive refraction power; an object side surface, close to an optical axis, of the fourth lens is a convex surface; an image side surface close to the optical axis is a convex surface; and the object side surface and image side surface are both aspheric surfaces. The fifth lens has negative refraction power; an object side surface, close to an optical axis, of the fifth lens is a concave surface; an image side surface close to the optical axis is a concave surface; the image side surface, away from the axis, is provided with a convex surface; the object side surface and the image side surface are both aspheric surfaces. Any two of the above adjacent lenses are spaced by air. The invention also discloses an image capturing device provided with the optical imaging lens group and an electronic device provided with the image capturing device.

Owner:LARGAN PRECISION

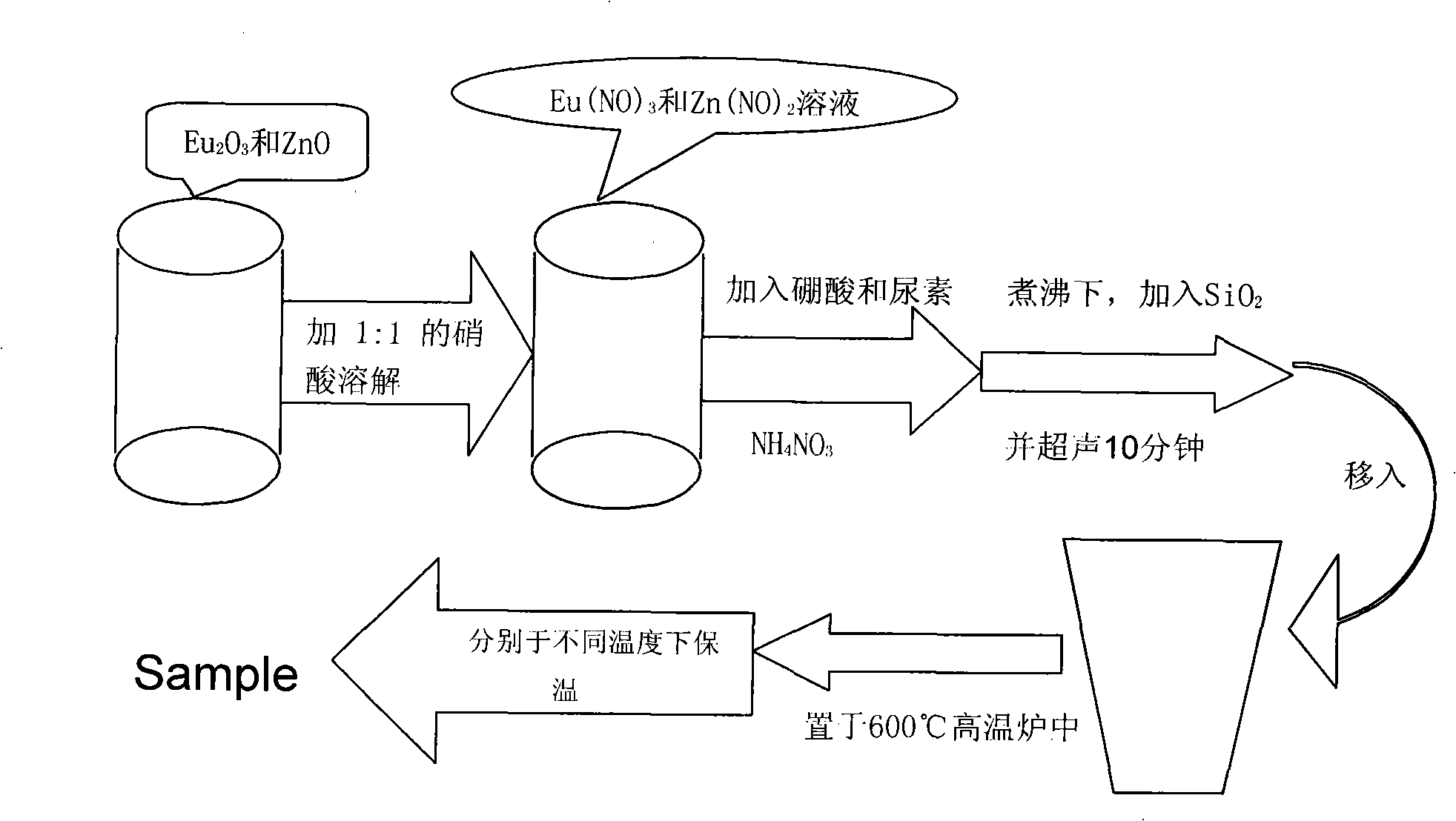

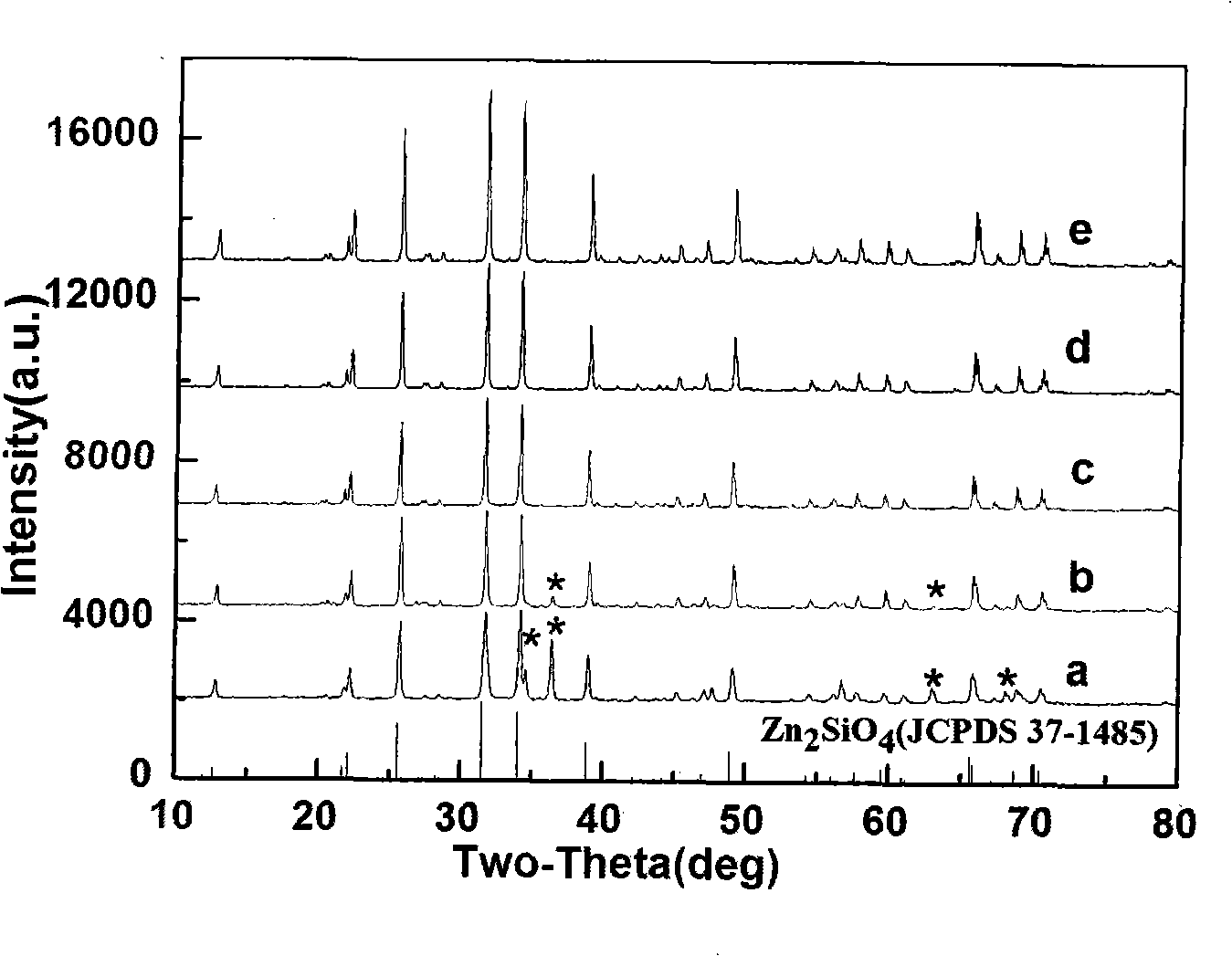

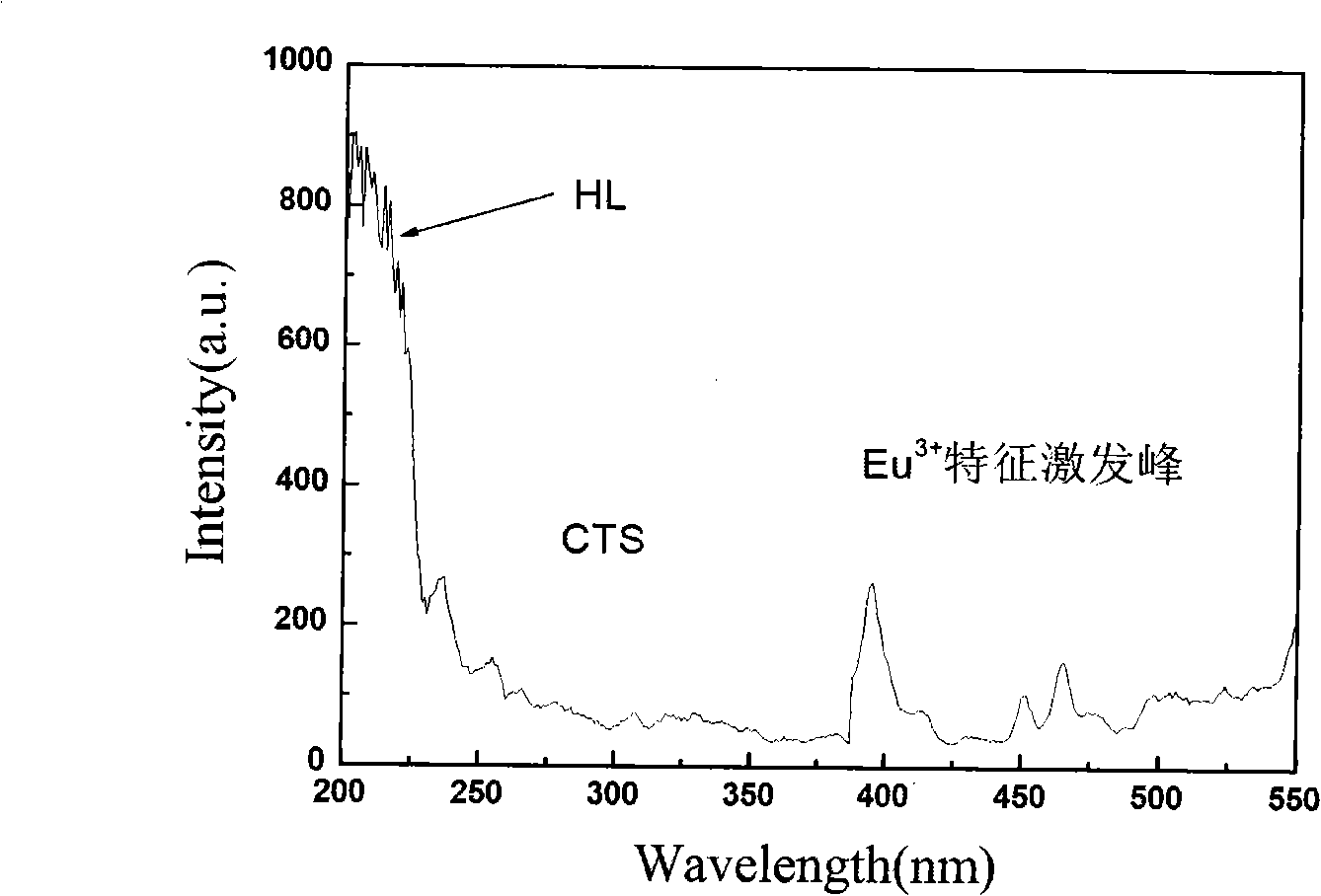

Preparation of red fluorescent powder Zn2SiO4:Eu3+

InactiveCN101280189AIncrease the heat of combustionGood crystal shapeLuminescent compositionsPhosphorBiological activation

The invention discloses the preparation method of red phosphor Zn2SiO4:Eu3+, which adopts the combustion method as the novel preparation method; Urea is used as the incendiary agent to synthesize the red phosphor Zn2SiO4:Eu3+ successfully; the combustion thermal discharge is improved and excessive combustion gas is generated through the addition of a small quantity of combustion auxiliary agent ammonium nitrate so that the combustion product is ensured to be looser; the combustion auxiliary agent is combusted in the interior of the mixture to catalyze the whole combustion reaction, facilitating the system to overcome high reaction activation potential barrier; the raw product is combusted within the temperature range of the experiment; after the continuous heat preservation; the product has small morphological changes; the crystal formation of the product is good, avoiding the decreasing of the luminescent property caused by the damage of the crystal lattice after grinding and crushing.

Owner:SHANGHAI NORMAL UNIVERSITY

Cell cryopreservation fluid and application thereof

InactiveCN109221092AAvoid pollutionImprove survival rateDead animal preservationAntigenHydroxyethyl starch

The invention relates to the technical field of biomedicine, in particular to cell cryopreservation fluid and application thereof. The cell cryopreservation fluid disclosed by the invention is prepared from the following components: dimethyl sulfoxide, human albumin, low-molecular dextran, a human mesenchymal stem cell exosome, hydroxyethyl starch and a basal culture medium. Cells cryopreserved and revived by using the cell cryopreservation fluid are high in viability, the morphologic change is not large, differentiation cannot be caused during culture, and surface antigen detection accords with the standard; in addition, by optimizing a cell cryopreservation scheme, death of a large amount of cells caused by ice crystal formation during a cryopreservation process of the cells can be avoided as much as possible, a cryopreservation system is optimized, revived cells can be directly fed back to a human body, and animal derived serum is not added, animal derived virus infection is avoided; the cell cryopreservation fluid is wide in application, and the technical problem that the cell viability after the reviving of the cells which are cryopreserved by an existing cell cryopreservationsystem is not high is solved.

Owner:GUANGDONG CHINAHEALTH LIFE SCI CO LTD

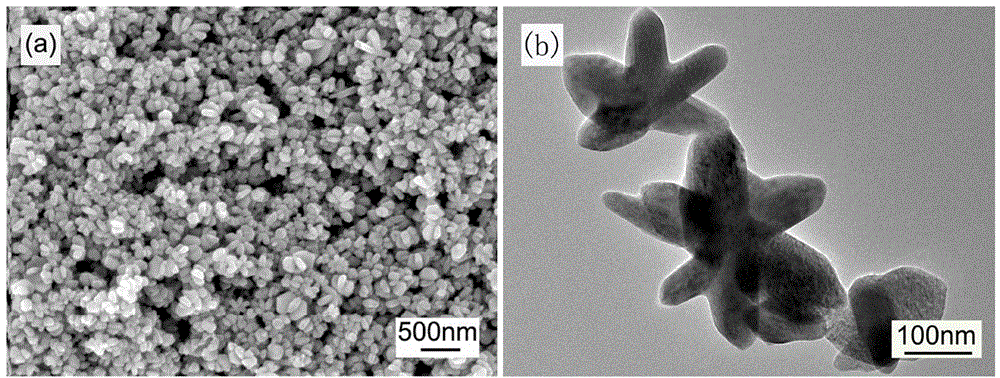

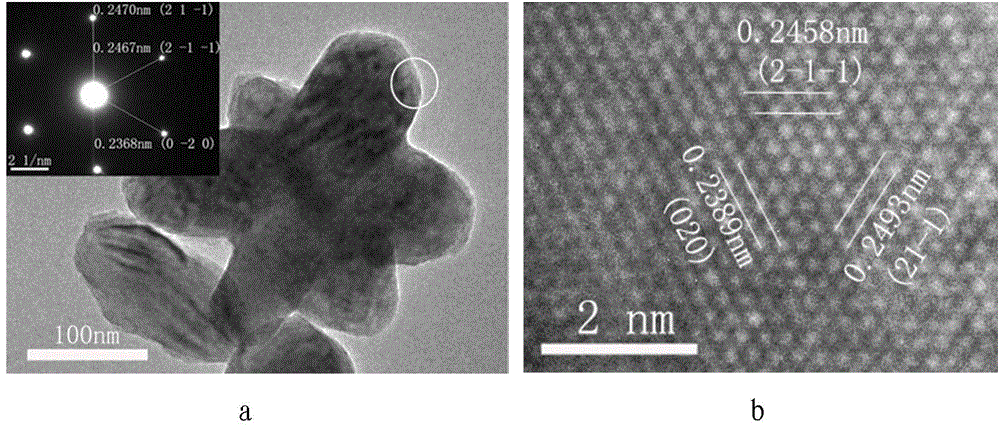

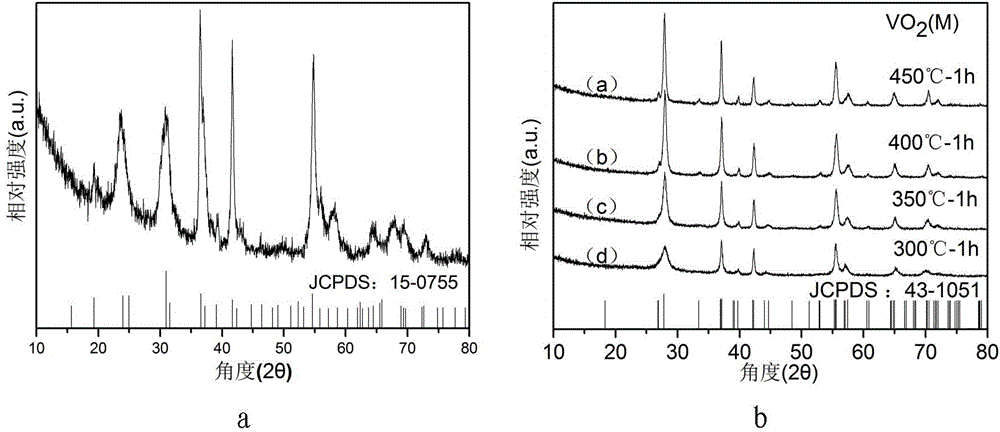

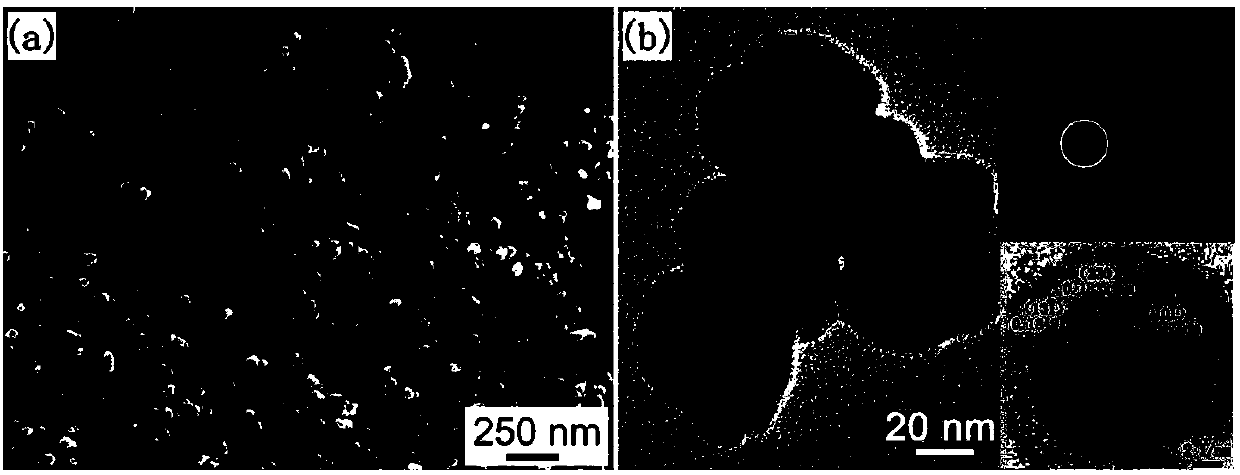

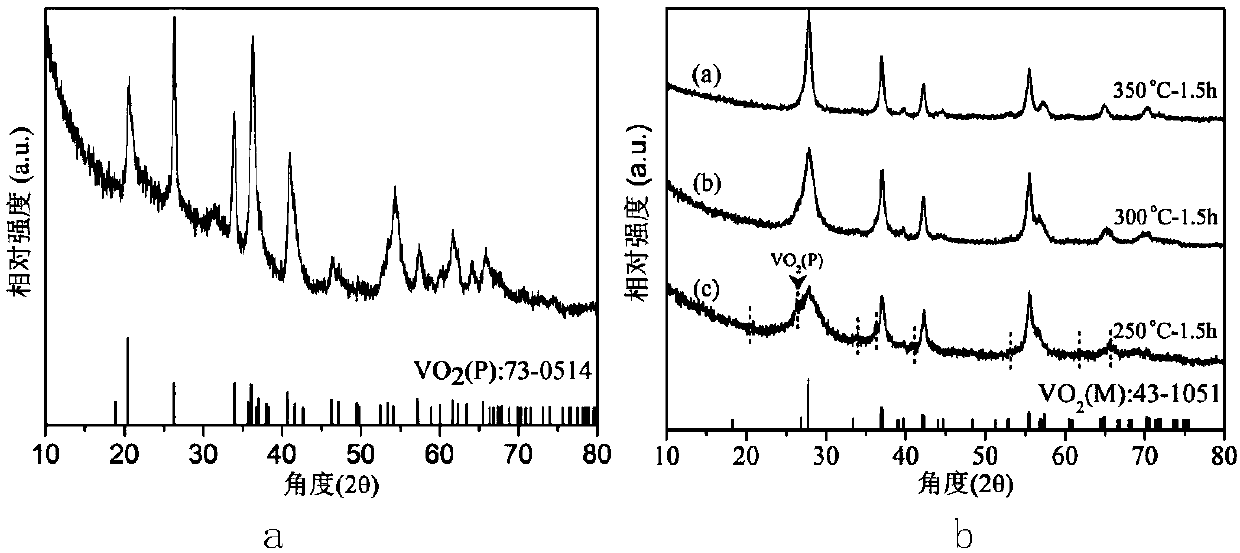

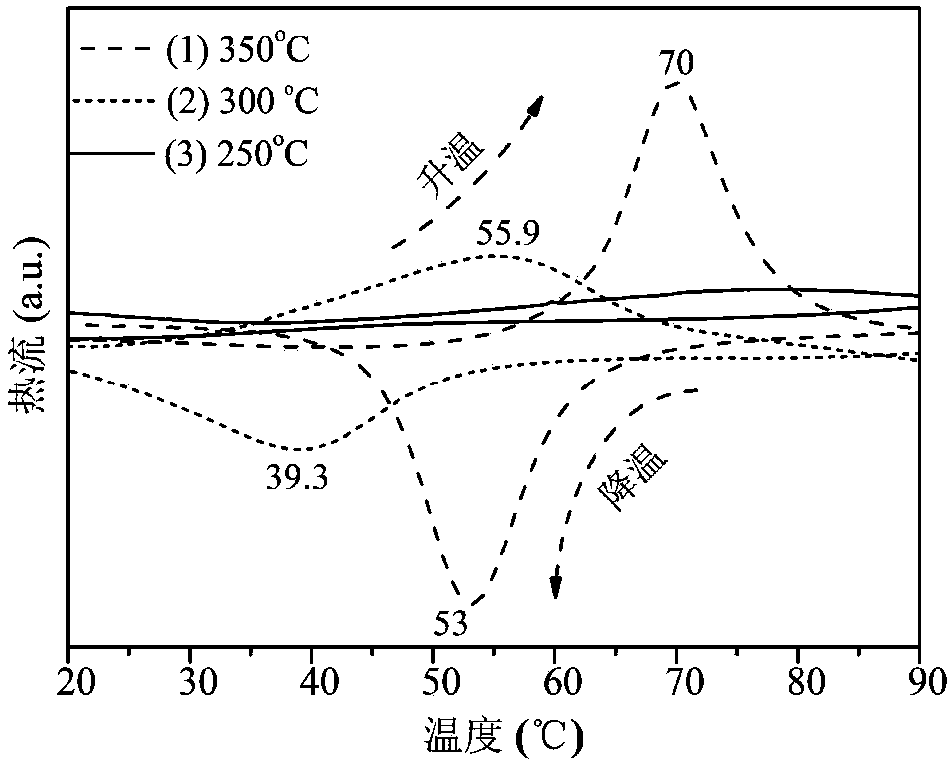

D-phase vanadium dioxide nano-star powder and preparation method thereof

ActiveCN104402050AImprove playbackGood dispersionMaterial nanotechnologyVanadium oxidesVanadium dioxideTemperature control

The invention relates to D-phase vanadium dioxide nano-star powder and a preparation method thereof. The powder is D-phase vanadium dioxide nano-star powder with a shape of pentagram or hexagram flat particles with the flat thickness of 30-60nm and the flat diameter of 60-100nm. Conical star point base thickness of the pentagram or hexagram particle is same with the flat thickness, conical star point base width is 30-60nm, and star point length is 70-100nm. The preparation method comprises the following steps: ammonium metavanadate is dissolved in deionized water, and the mixture is stirred, such that an ammonium metavanadate water solution is obtained; a formic acid solution is dropped into the ammonium metavanadate water solution being stirred, such that a mixed liquid with a pH value of 1-3 is obtained; the mixed liquid is set in a sealed state, and is allowed to react for 1-3d under a temperature of 180-220 DEG C, such that a reaction liquid is obtained; and the reaction liquid is sequentially subjected to solid-liquid separation, washing and drying, such that a target product is obtained. With subsequent heat treatment, obtained VO2(M) nano-star powder can be widely applied in the fields of intelligent temperature-control films, thermistor materials, photoelectric switch materials, infrared detection materials, gas sensors, storage materials, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

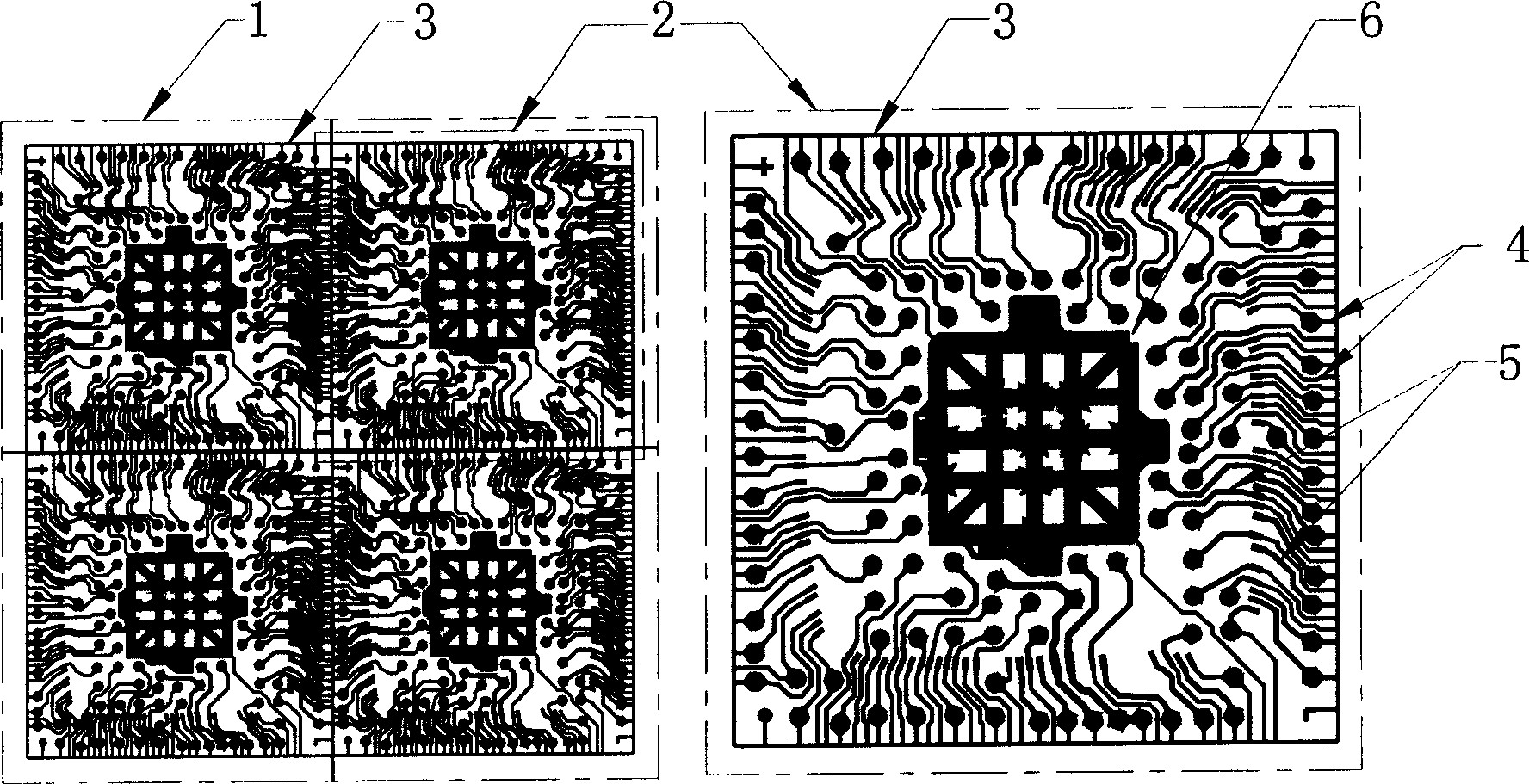

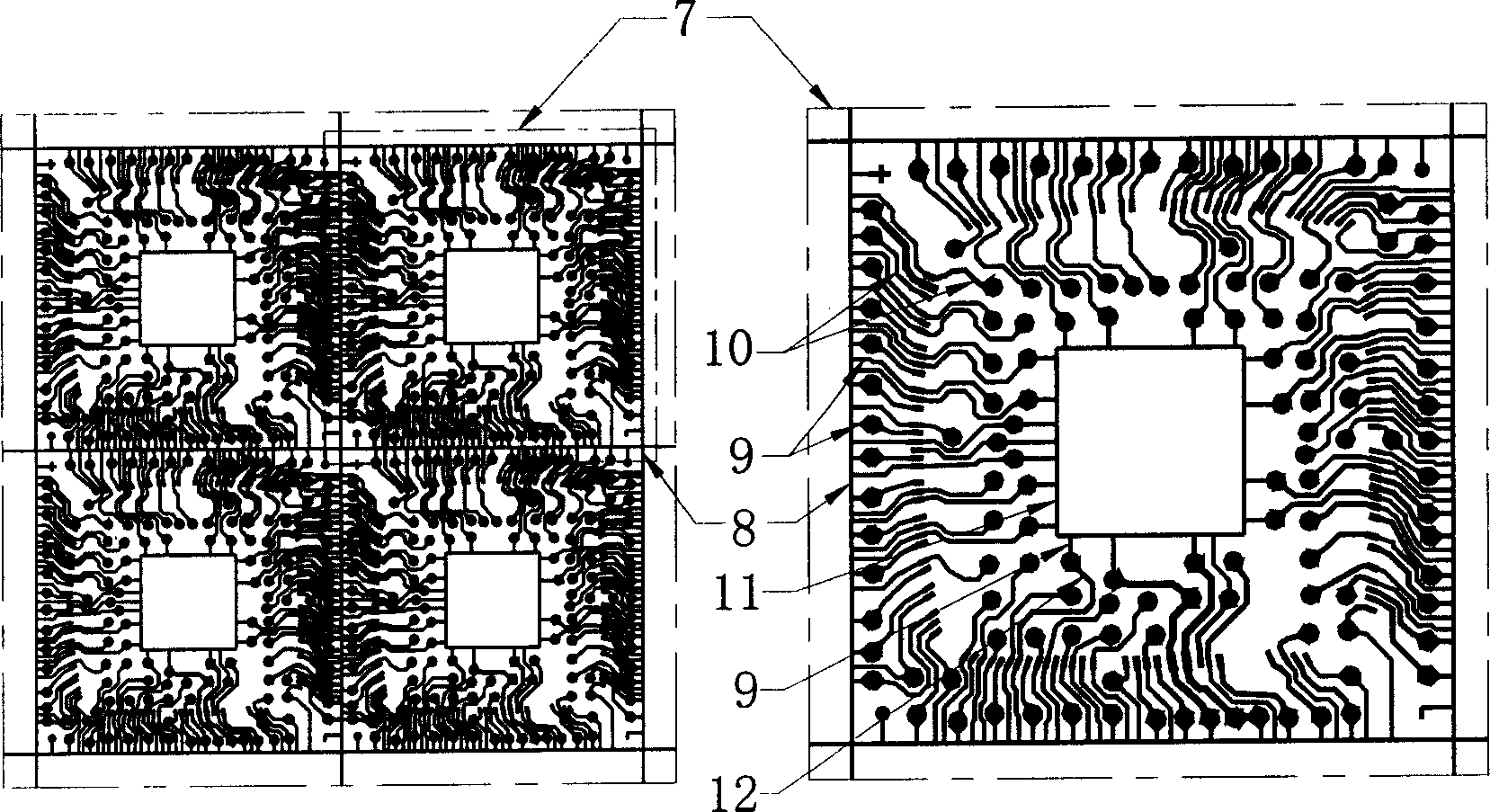

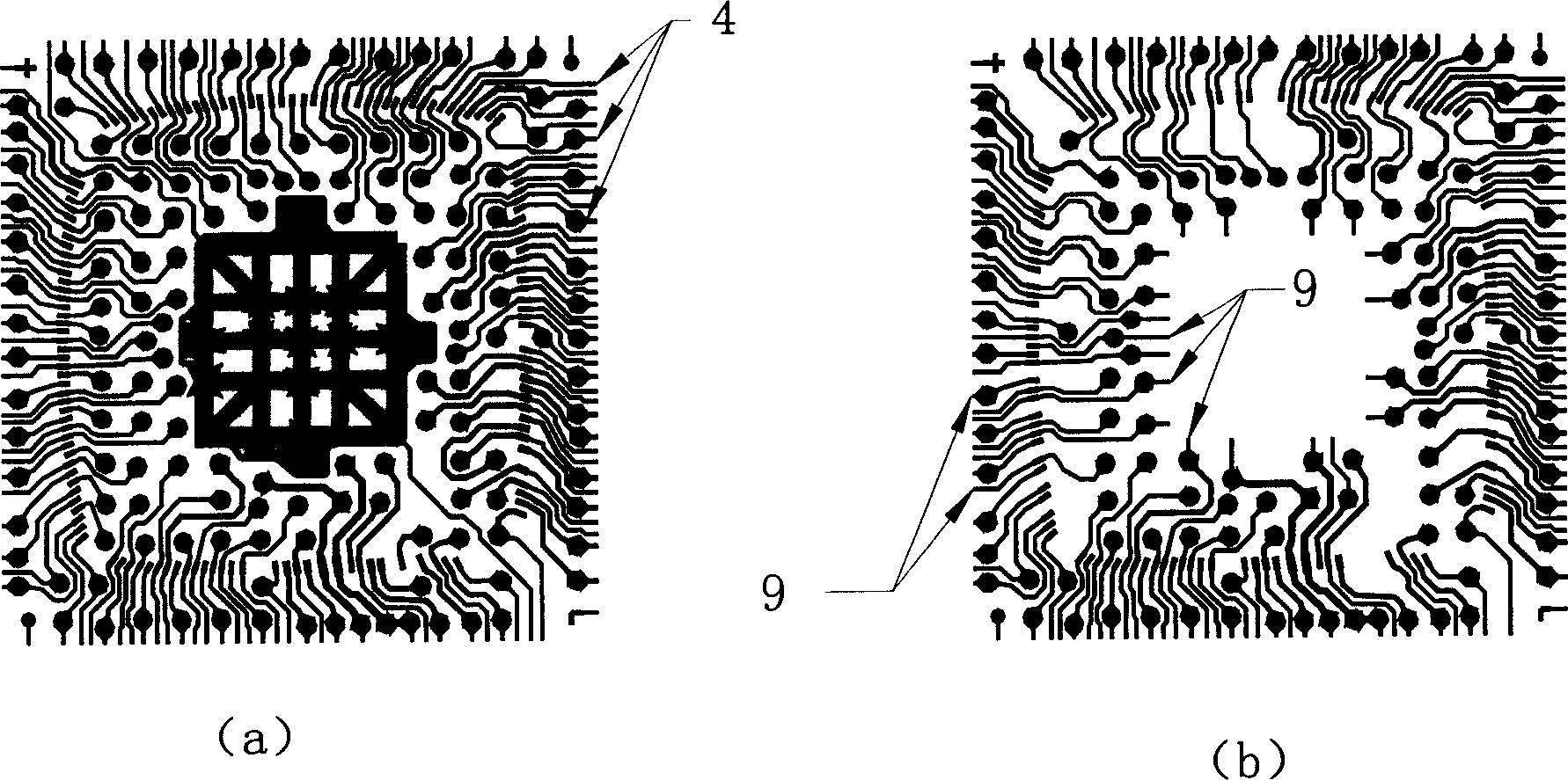

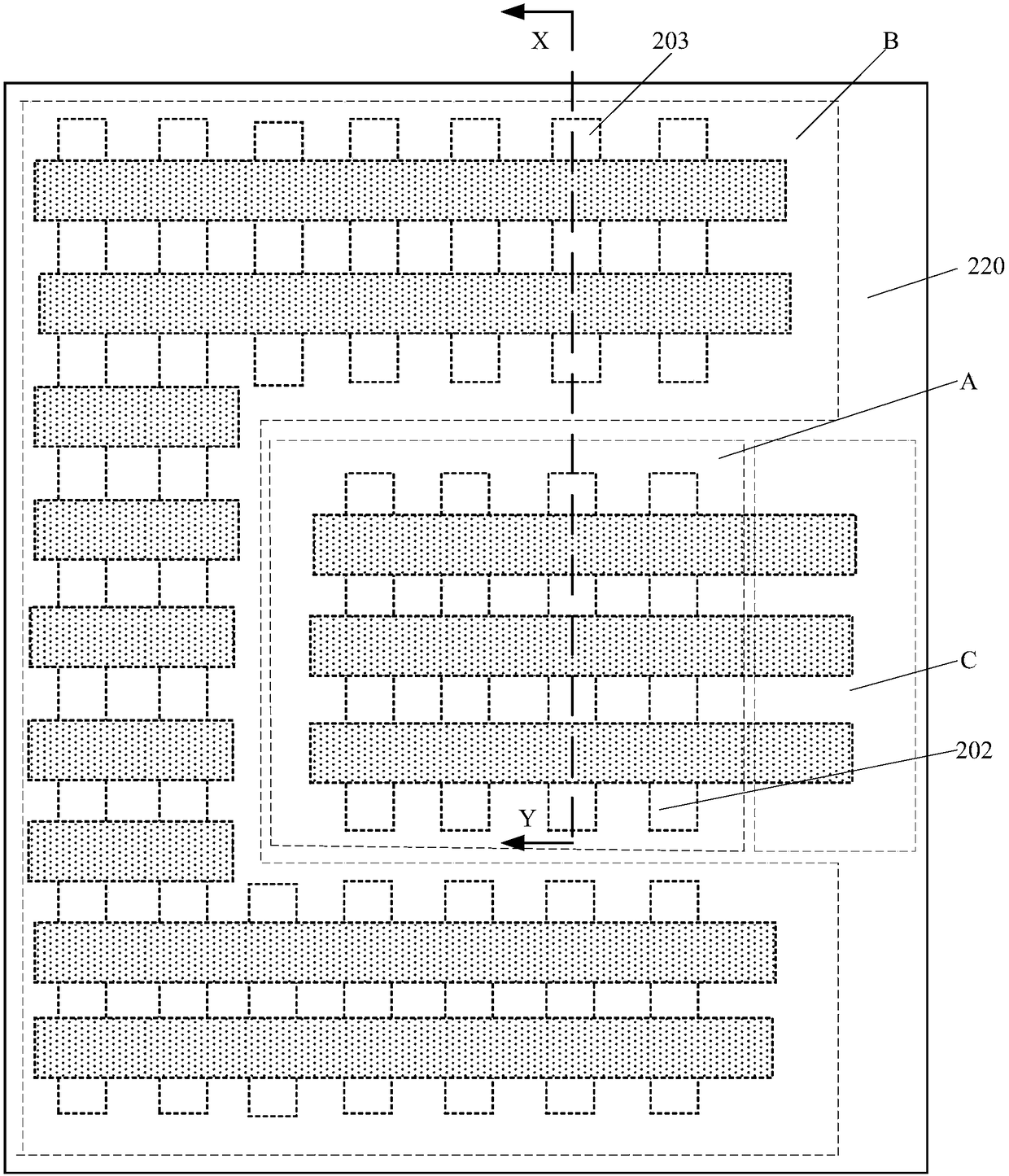

Method for handling electroplating lead layout of IC packaging base plate and electroplating lead structure

InactiveCN1567552AImprove electrical performanceLittle change in shapeSemiconductor/solid-state device detailsSolid-state devicesShape changeProcess conditions

The invention relates to a processing method of plating wire distribution of IC packing substrate, including: a. arranging plating wires between wire patterns in packing substrate units to make all the wires of the wire patterns connect mutually by plating wires, where the plating wires or wire patterns connect with metal power supply layers in packing substrates; b. making plating treatment on the packing substrates and eliminating the plating wires by chemically etching process. The invention public plating wires between wire patterns in the packing substrates units, where the plating public wires are thinner than the wire patterns and narrower than the narrowest wire pattern, and eliminates the public wires by etching process, can make the shape change of the wire patterns minimum by controlling etching process conditions, thus beneficial to the improvement of electric performance of the substrate, assuring the integrity of signals and able to reduce wiring area, especially applied to make high-frequency high-speed IC packing substrates.

Owner:美龙翔微电子科技(深圳)有限公司

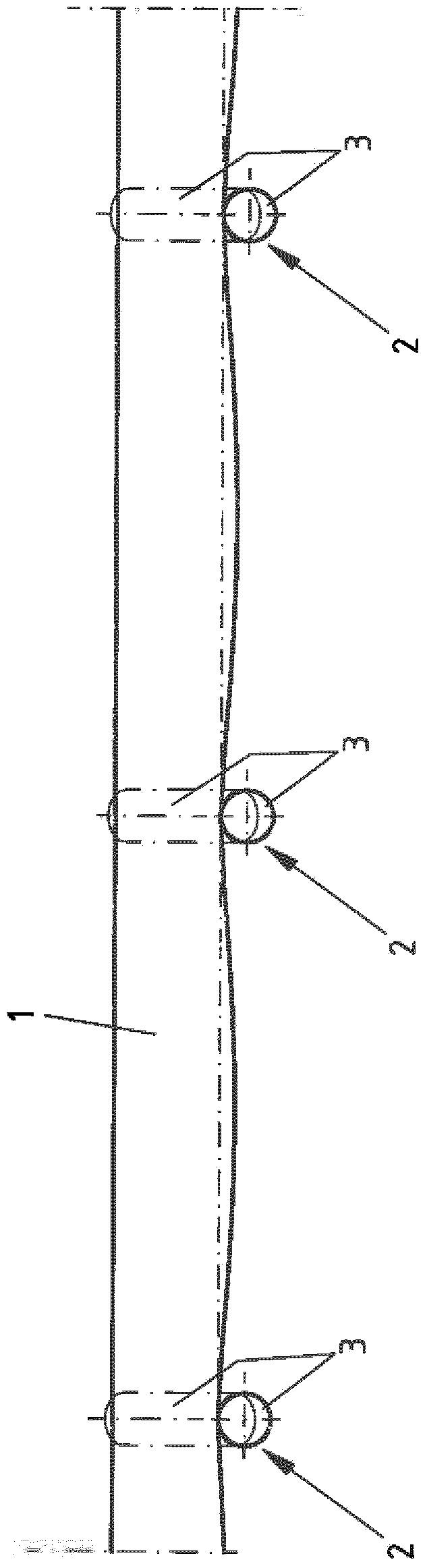

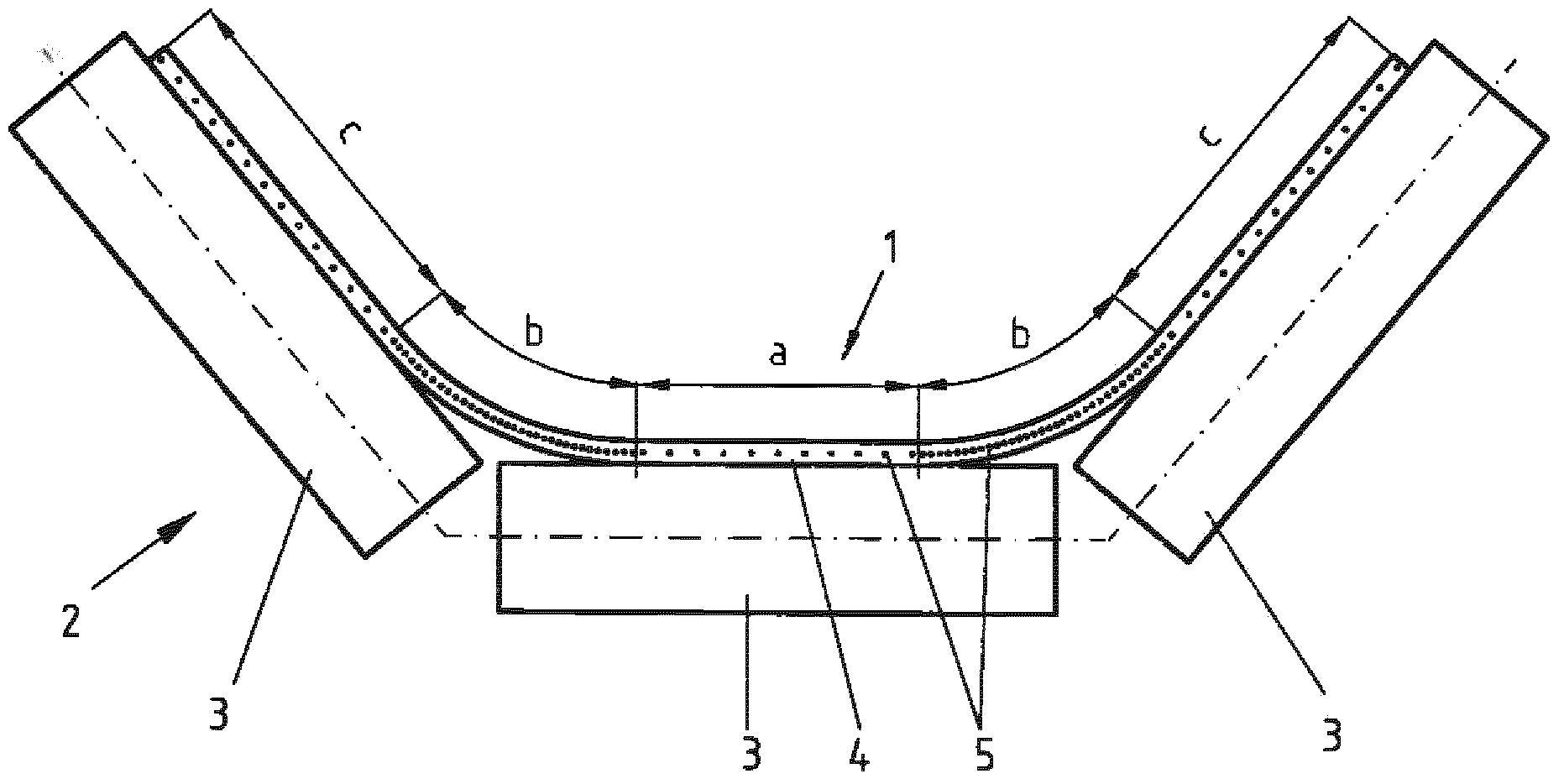

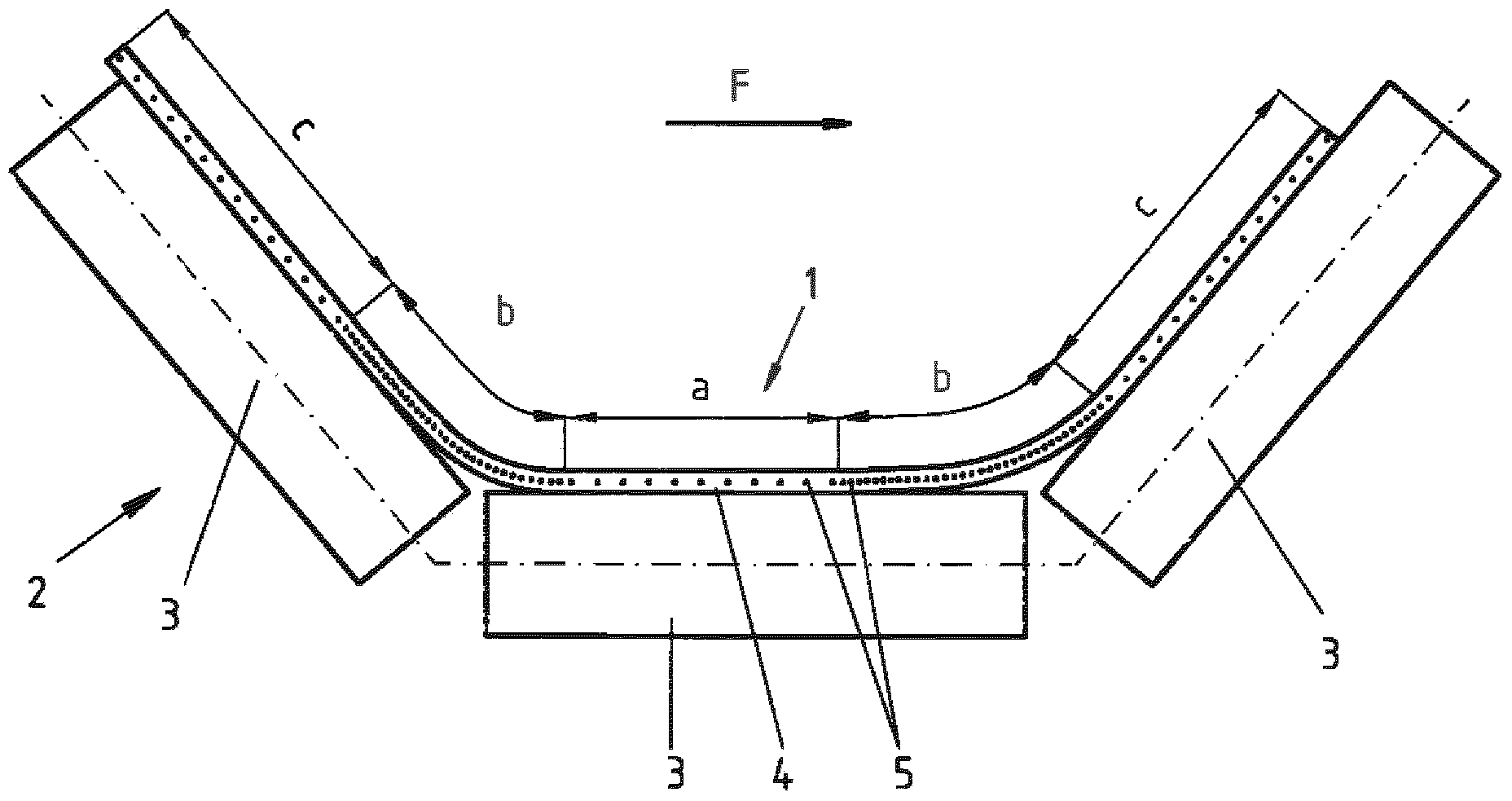

Conveyor belt system and conveyor belt

The invention relates to a conveyor belt system comprising a conveyor belt (1) extending in the longitudinal direction and a plurality of support roller stations (2) arranged at a distance from each other in the longitudinal direction and on which the conveyor belt (1) is supported by support rollers (3), said conveyor belt (1) being formed from a flexible base material (4) and a plurality of unconnected traction means (5) which determine the tensile strength of the conveyor belt (1) and which extend in the longitudinal direction. According to the invention, in the cross-section of the conveyor belt (1) and with respect to a desired position on a central belt section (a) supported on a support roller (3) of the support roller station (2), the tensile strength relative to the belt width is less than on the laterally adjoining belt sections (b) which are not supported in the desired position by a support roller (3). The invention also relates to the conveyor belt (1) itself.

Owner:THYSSENKRUPP RESOURSE TECH GMBH

Preparation method of alumina

The invention discloses a preparation method of alumina. The method is as below: merging an aluminum salt solution and a precipitating agent, and adding the mixture into a water solution containing polyethylene glycol to conduct a co-precipitation reaction; aging, filtering and drying the obtained pseudo-boehmite dry glue; and roasting the pseudo-boehmite dry glue to obtain gamma-Al2O3 powder. The method has the advantages of simple process and low production cost; the prepared alumina has regular layered structure, less aggregation of powder particles, large pore volume, large aperture, high specific surface area and little pollution to environment, and is easy for realization of industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

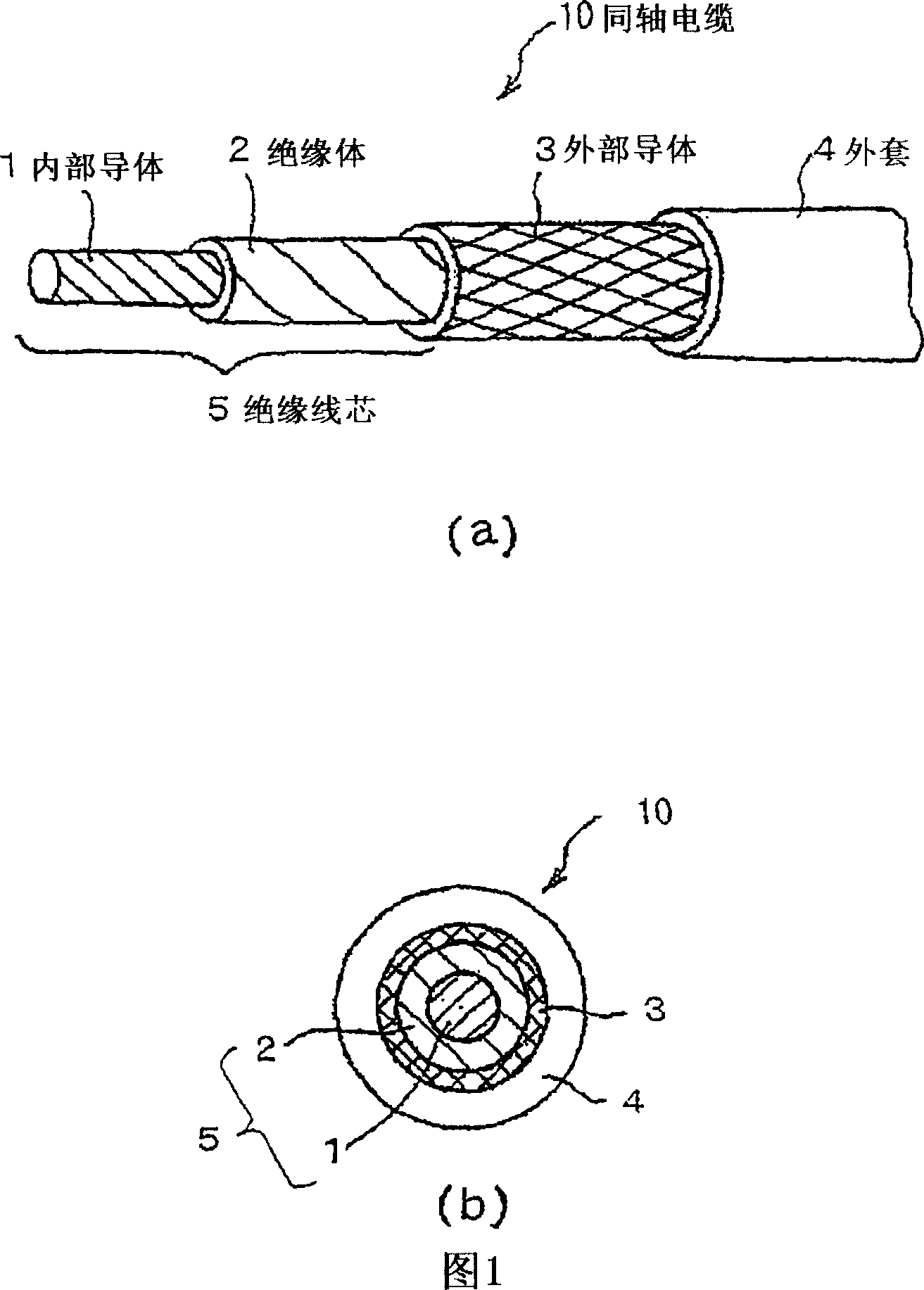

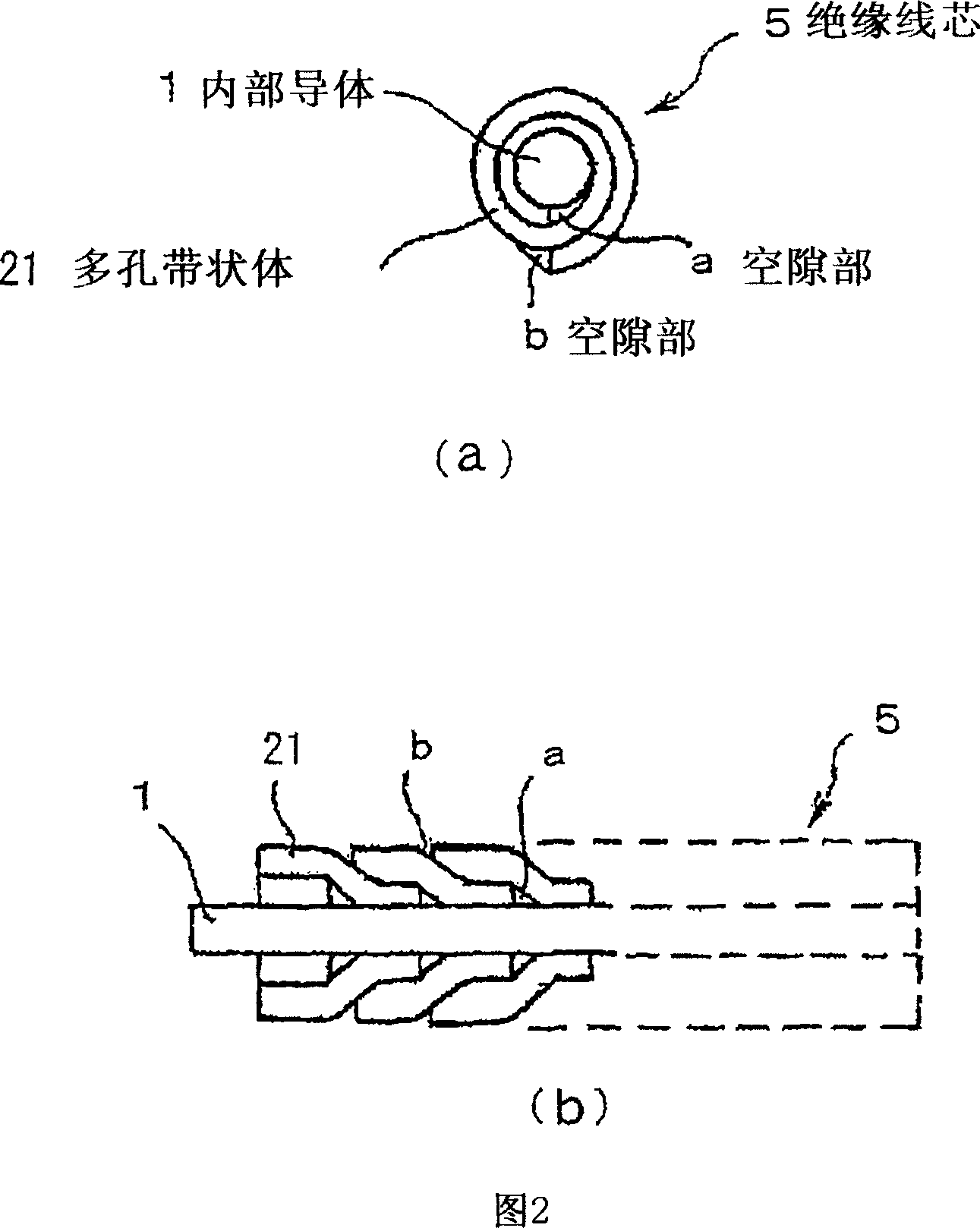

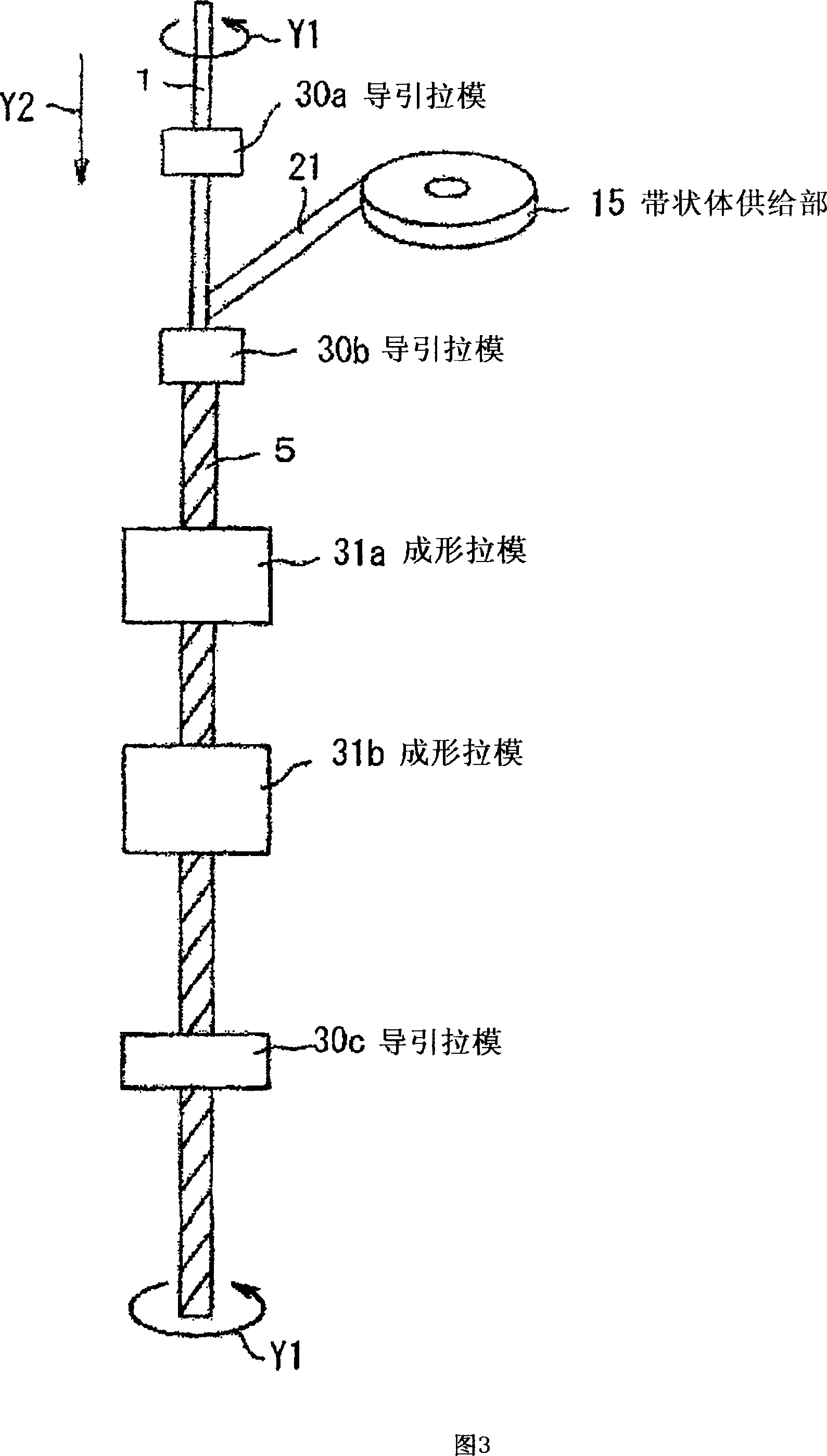

High-precision foamed coaxial cable

InactiveCN1957427ALittle change in shapeCable insulation constructionReduction rateElectrical conductor

A high-precision foamed coaxial cable in which, even if a mechanical stress such as bend, torsion, or slide is applied to a cable, variation in shape of an insulator and an outer conductor is less and as a result, the external shape and the outside diameter of the cable can be maintained and variation in characteristic impedance can be reduced. In a high-precision foamed coaxial cable (10) comprising an inner conductor (1) constructed by stranding conductors, an insulator (2) constructed by winding a porous tape (21) around the outer circumference of the inner conductor (1), and an external conductor (3) constructed by braiding thin conductor wires around the outer circumference of the insulator (2), the insulator (2) is formed to have right circle external shape, the outside diameter of the insulator (2) is formed smaller at a reduction rate of 3-5% than the outside diameter, immediately after the winding, of the insulator (2), the external conductor (3) is formed to have right circle external shape, the outside diameter of the external conductor (3) is formed smaller at a reduction rate of 2-4% than the outside diameter, immediately after the braiding, of the external conductor (3) and the precision of its characteristic impedance is set at +-1 Omega.

Owner:HIRAKAWA HEWTECH +1

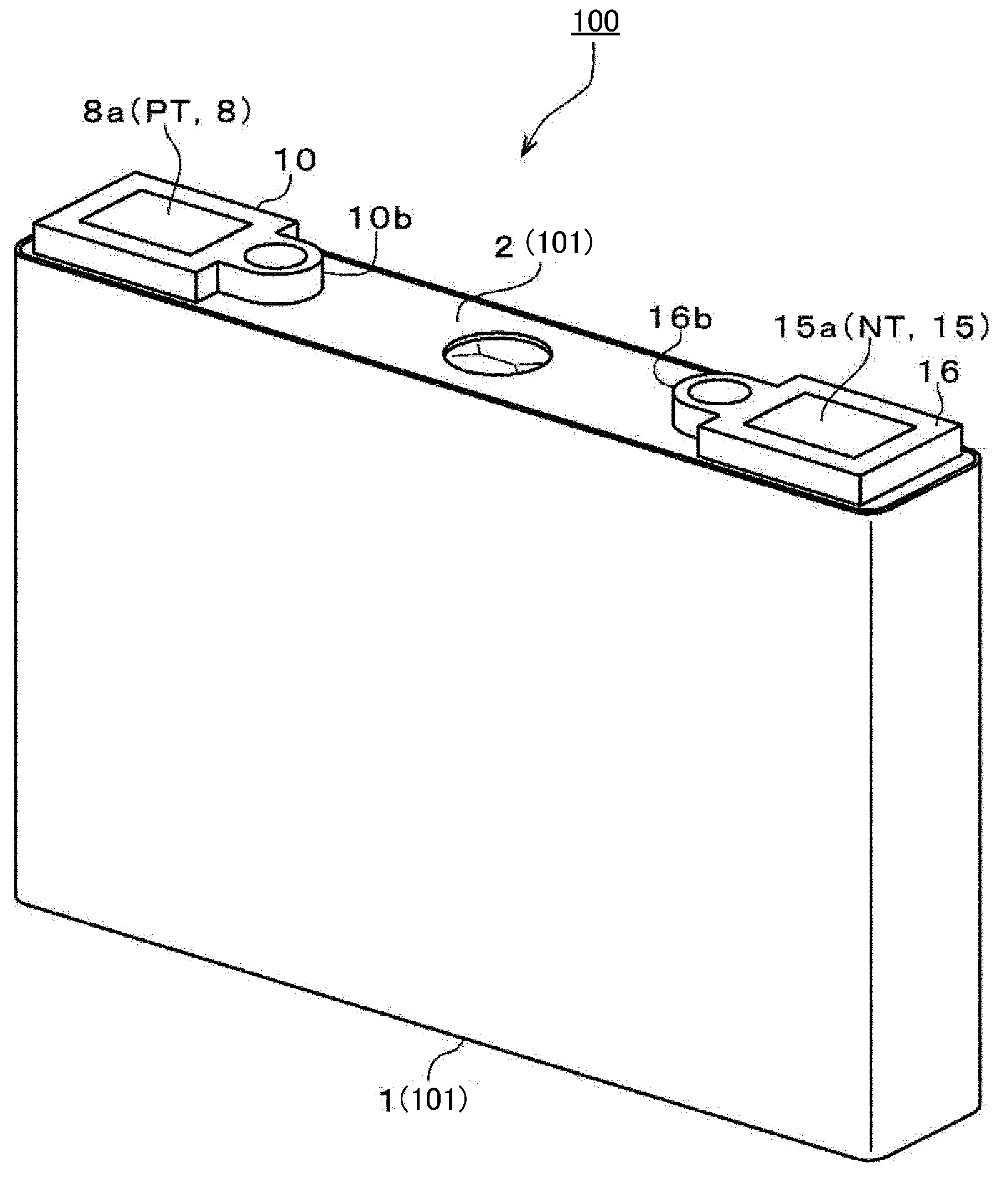

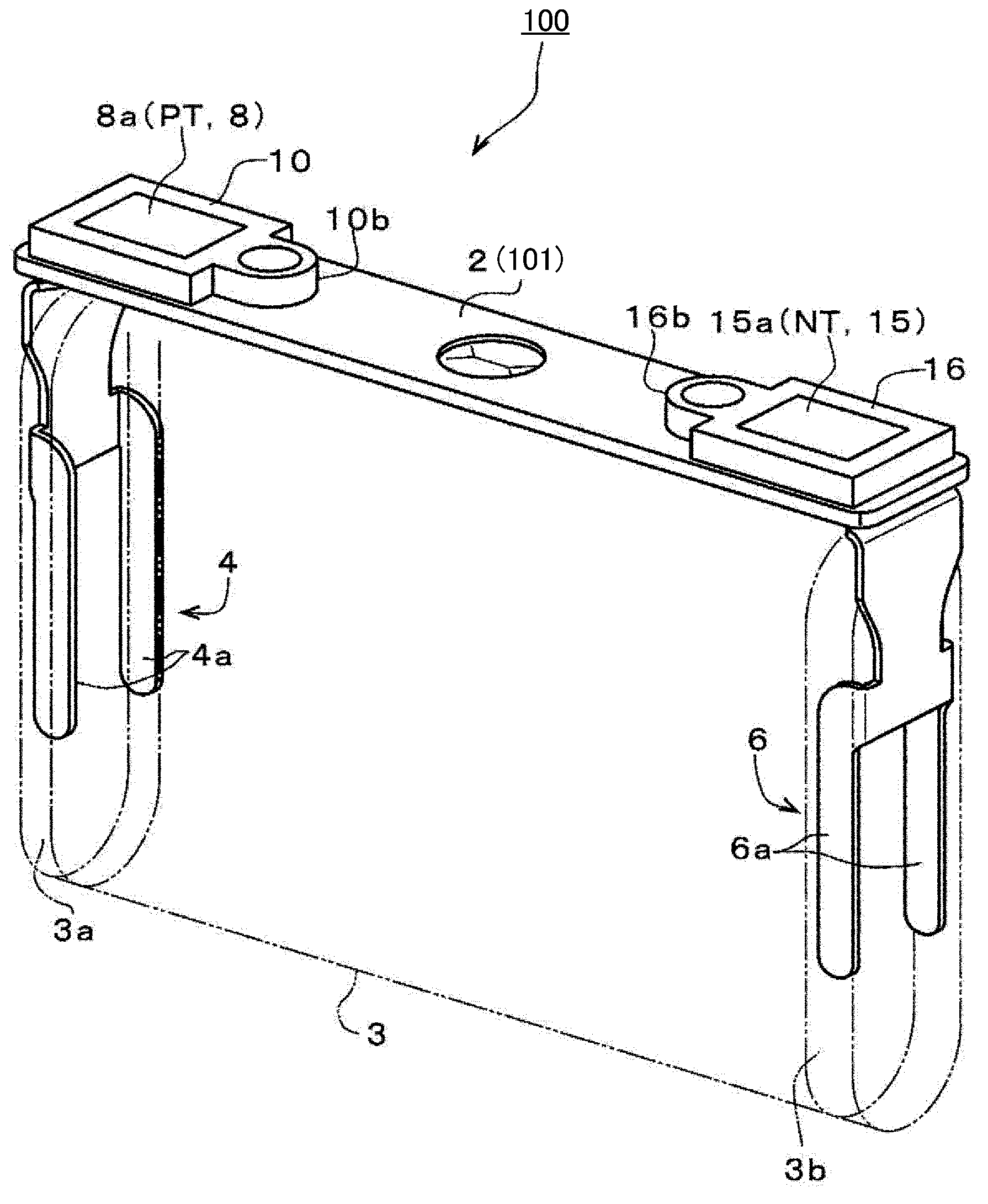

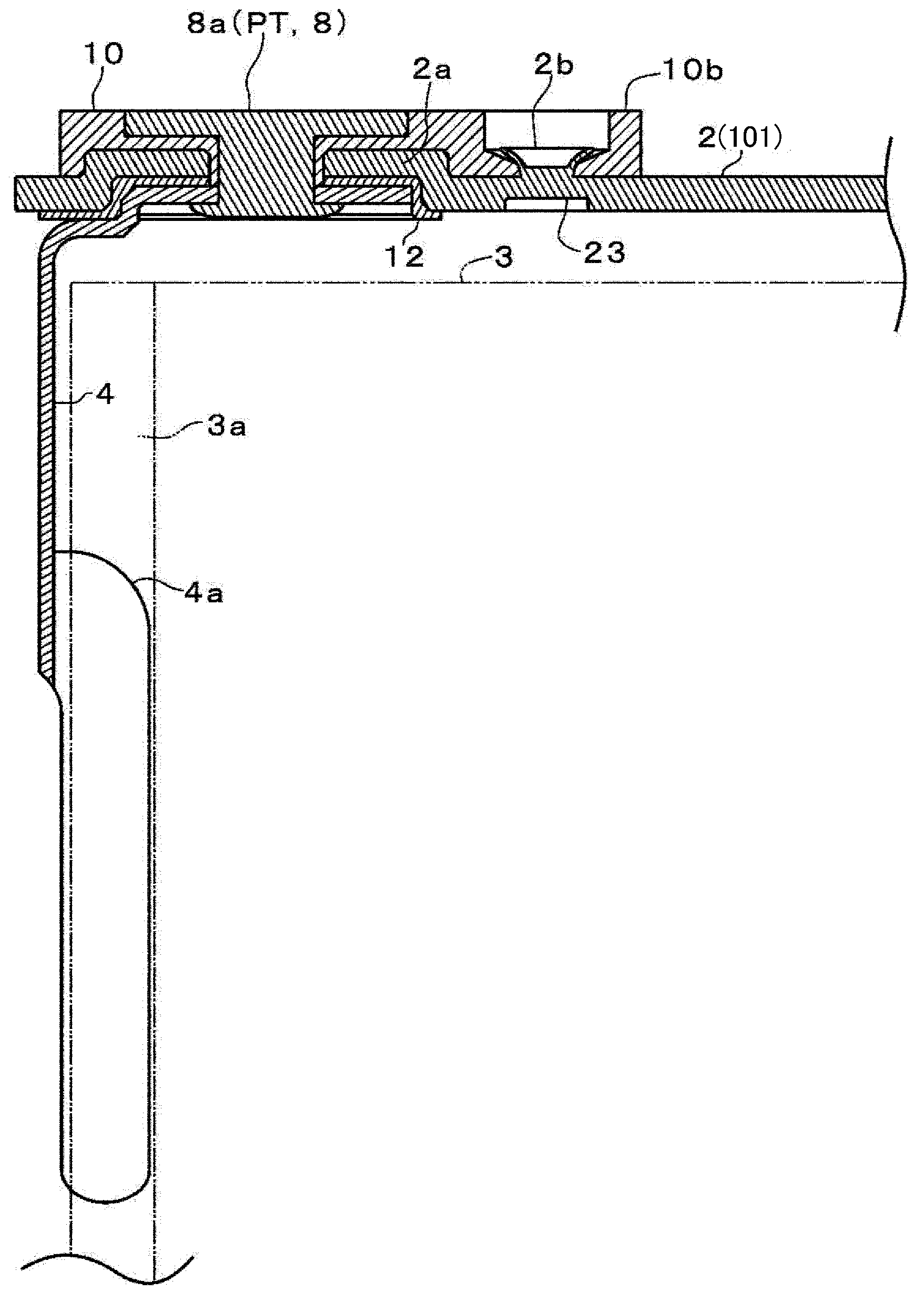

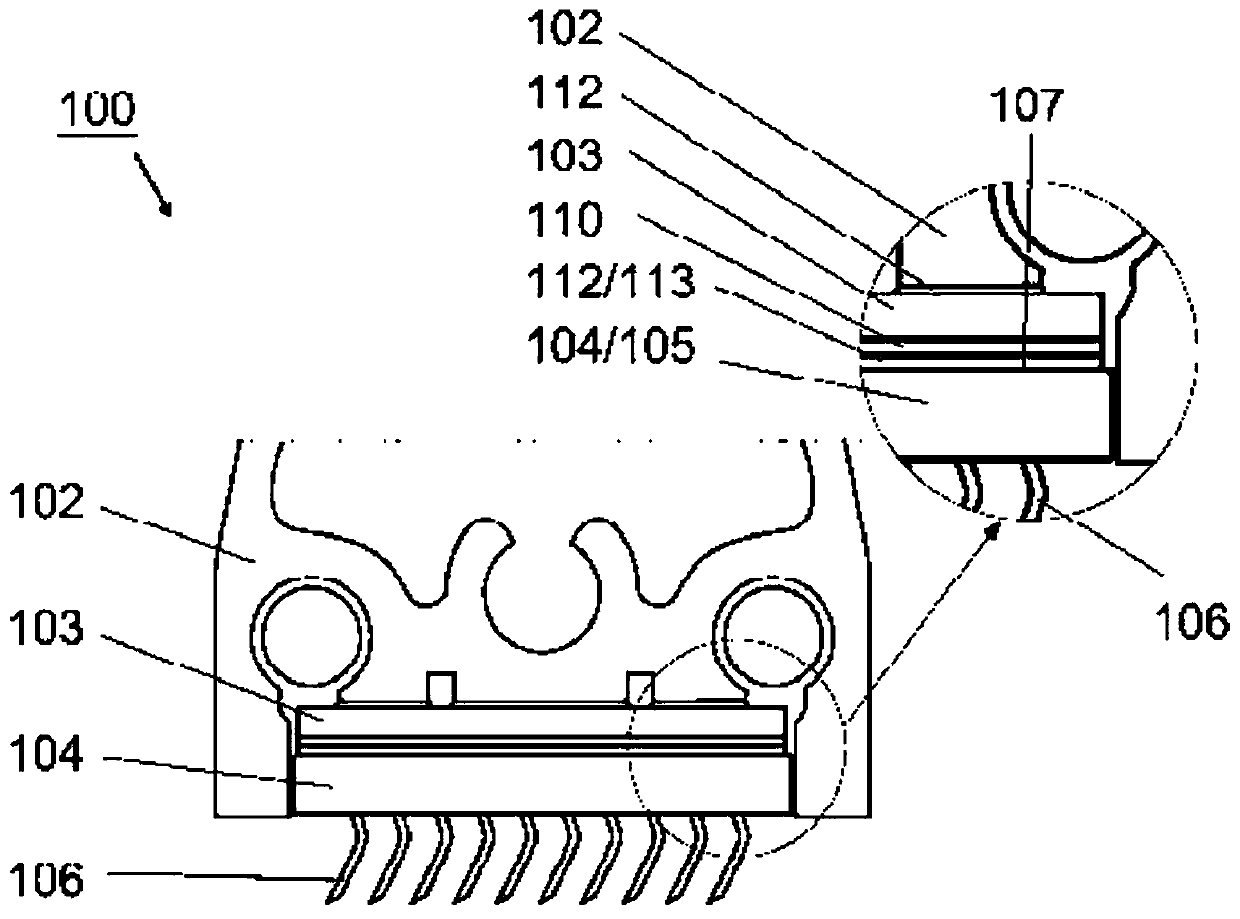

Energy storage element, metal component, and energy storage element manufacturing method

ActiveCN103227295ALittle change in shapeHigh mechanical strengthFinal product manufactureCapacitor terminalsEngineeringEnergy storage

The present invention is provides an energy storage element, in which a metal component is formed by forming a protrusion on a plate shaped member while ensuring the mechanical strength of and in the vicinity of the protrusion. An energy storage element (100) includes: a metal component (2) that is a metal plate member that includes a protrusion (2b)extending from a surface of the metal plate member, and is provided as a portion of a container (101). The protrusion (2b) includes: a tubular portion (22) provided at a tip end of the protrusion in an extending direction, and a base portion (21) that is solid and extends from the surface of the metal component (2) to the tubular portion (22) in the extending direction.

Owner:GS YUASA INT LTD

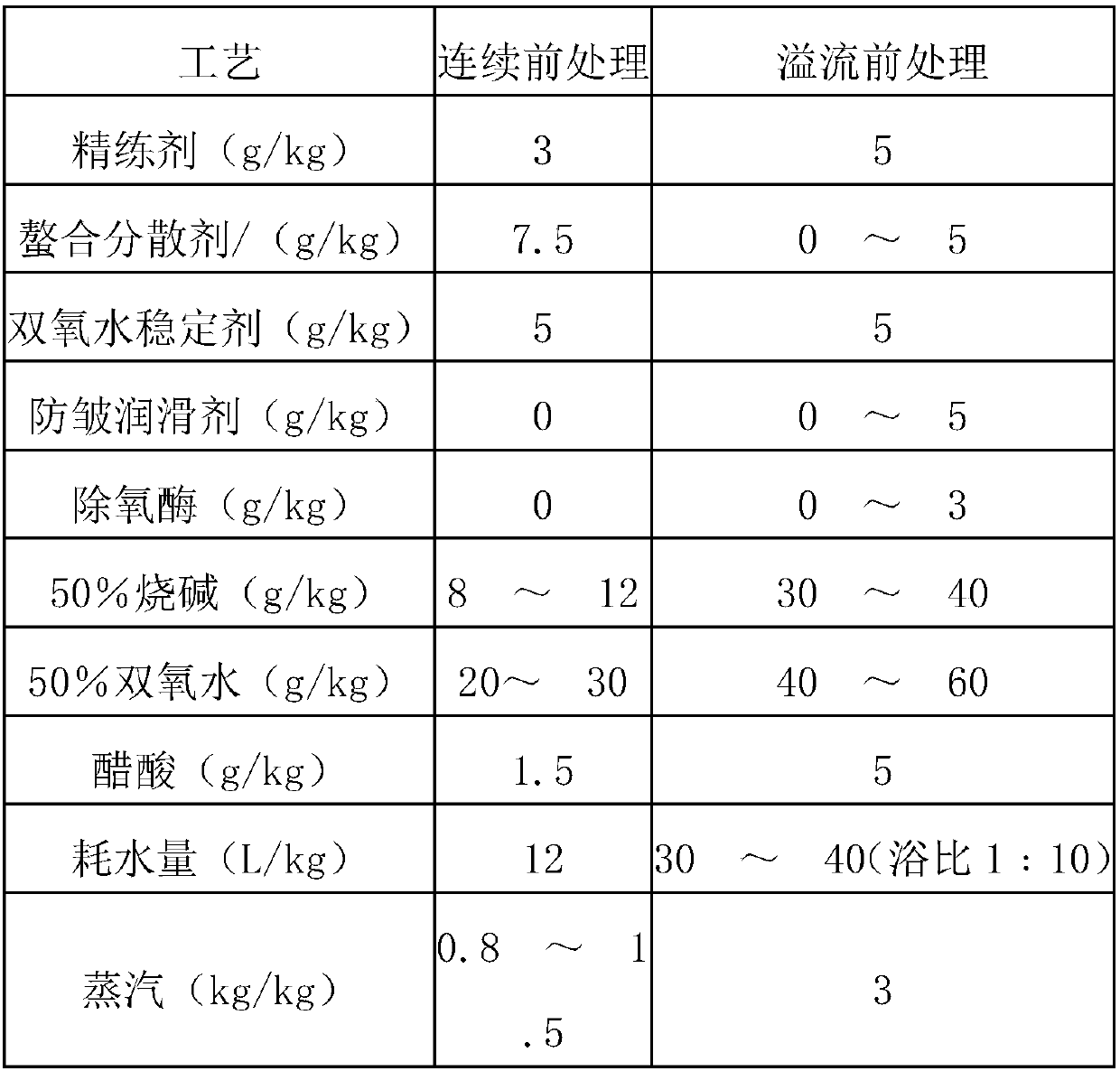

Technique of full width continuous pretreatment cleaning production of knitted fabrics

InactiveCN107938221AReduce labor intensityGuaranteed freshSucessive textile treatmentsWeft knittingDyeingEngineering

The invention discloses a technique method, and especially relates to a technique of full width continuous pretreatment cleaning production of knitted fabrics. The technique is carried out according to steps of use of degreaser and bleaching liquid assistant and formula design-design of very technical parameter of full width continuous pretreatment-intelligent control production of full width continuous pretreatment-dyeing of gas-liquid dyeing machine-post finishing-finished product inspection. A technique of full width continuous pretreatment cleaning production of knitted fabrics can replacean overflow dyeing machine and its similar wet processing technique method, and has obvious effects of energy-saving and emission reduction; the technique has the advantages of improving the production efficiency, reducing resource, energy source, materials and human resources while improving the quality of the of knitted and dyed product and the product grade, further promoting the market competitiveness of enterprises and products, and creating preconditions. Moreover, the technique solves the problems widely concerned by the industry that the production efficiency of the existing wet treatment techniques and technical equipment for bleaching, dyeing, washing knitted fabrics is low; consumptions of resource, energy source, material and human source are huge; the emission amount of bleaching and dyeing waste water and pollutants is big.

Owner:佛山市顺德金纺集团有限公司

Crispy durian cake and preparing method thereof

InactiveCN107006562ACrispy tasteThe entrance is crispy and deliciousReady-for-oven doughsFood preservationFood additiveGluten

The invention discloses a crisp durian cake. The crisp durian cake is prepared from, by weight, 25-50 parts of high-gluten flour, 8-30 parts of low-gluten flour, 8-20 parts of butter, 3-8 parts of white granulated sugar, 15-36 parts of ghee, 80-160 parts of stuffing, 0.01-0.04 part of food additive and 2-10 parts of water, and the stuffing is composed of durian pulp, granular stuffing, corn starch and Daifuku wrappers. The invention further provides a preparing method of the crisp durian cake, and the technological process mainly comprises the steps of weighing raw materials, preparing the stuffing, preparing dough, wrapping the ghee, pressing the dough, making crisp wrappers, filling the stuffing, forming, brushing egg liquid, baking, cooling and packaging. According to the crisp durian cake, the raw materials are simple and easy to obtain, the prepared crisp durian cake contains multiple layers of stuffing with obvious layers, the wrappers are compact and crisp, the stuffing is soft, tender and not too sweet and too greasy, and the crisp cake is pure in taste, aromatic but not greasy; meanwhile, through the adoption of semi-mechanized production, the work intensity is relieved, and the production efficiency is improved, so that the crisp durian cake is likely to keep uniform.

Owner:广西朗盛食品科技有限公司

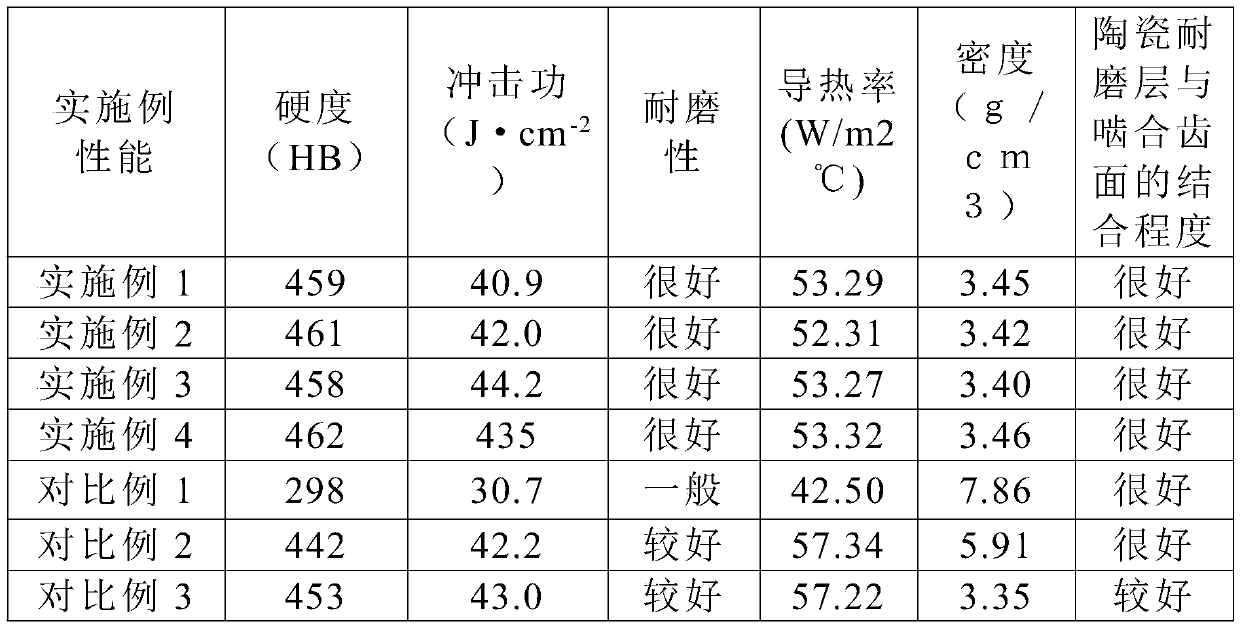

Lightweight abrasion-resistant automobile gear and preparation method thereof

InactiveCN105499554AHigh strengthIncrease stiffnessMetal-working apparatusPortable liftingFoaming agentResin adhesive

The invention relates to a lightweight abrasion-resistant automobile gear and belongs to the technical field of processing of automobile gears. The automobile gear comprises a core body and an outer layer arranged on the surface of the core body, wherein the core body is made of a porous alloy steel ceramic material. The porous alloy steel ceramic material comprises alloy steel powder, ceramic powder, a pore-foaming agent and a resin adhesive according to a mass ratio of 100 to (50.1-145.2) to (0.6-1.2) to (9-12). The outer layer is made of an alloy steel ceramic material; the alloy steel ceramic material comprises the alloy steel powder, the ceramic powder and the resin adhesive according to a mass ratio of 100 to (50.1-145.2) to (7-10). The lightweight abrasion-resistant automobile gear is excellent in mechanical property and high in sound-absorbing and vibration-damping effects, and can work for a long time under the harsh conditions.

Owner:NINGBO QUNXING POWDER METALLURGY

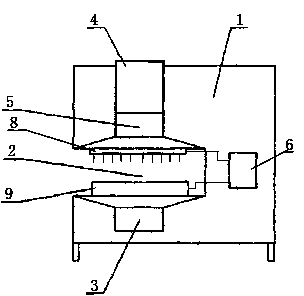

Tea leaf high-voltage electrostatic field dryer

InactiveCN103859069AProtective ingredientsReduce broken ratePre-extraction tea treatmentAgricultural engineeringTea leaf

The invention relates to tea leaf dryers, and specifically relates to a tea leaf high-voltage electrostatic field dryer. Drying technology brings direct influence for output and quality of tea leaf, present drying technology usually employs flat type, tunnel type or hot-air circulating type dryers for drying, and the flat type, tunnel type or hot-air circulating type dryers respectively have problems of influencing quality, appearance and output of tea leaf. The high-voltage electrostatic field dryer comprise a baking oven, an evaporating chamber, an air inlet, an air outlet, an air exhaust device and a high-voltage electrostatic field generating assembly; and the high-voltage electrostatic field generating assembly mainly consists of a power supply, a pressure regulating rectifier, an upper pole plate, a lower pole plate and a controller. The tea leaf drying process is performed at a normal temperature when the high-voltage electrostatic field dryer is employed, so that the compositions of tea leaf are effectively protected, and dried tea leaf is small in color and shape variation; the broken rate of tea leaf is low, the quality and the beauty of tea leaf are effectively guaranteed, the output is improved, and especially quality guarantee is provided for production of high-grade tea leaf.

Owner:高松

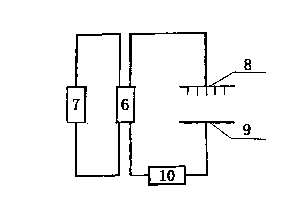

Carbon nanotube conductive paste and preparation method and application thereof

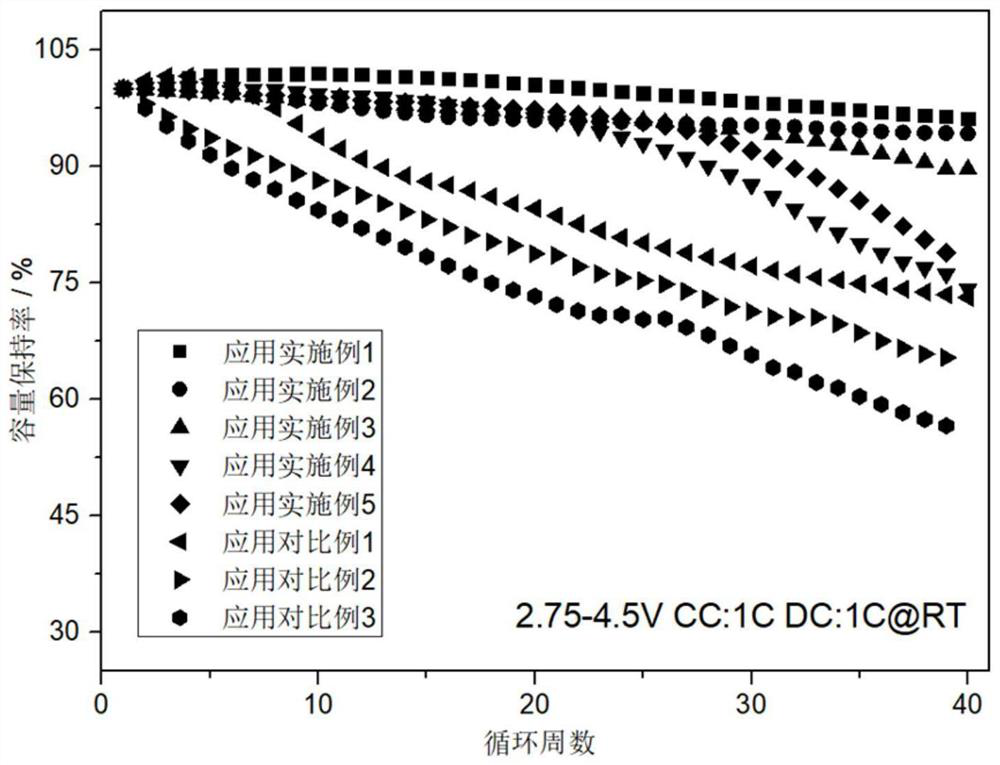

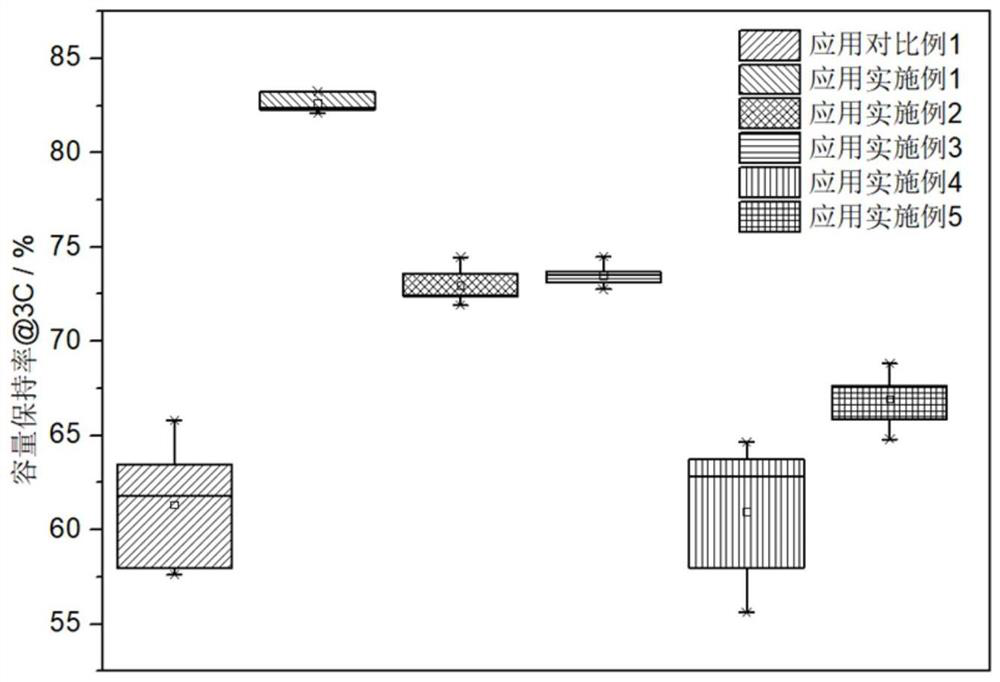

ActiveCN113036146AAvoid direct contactImprove cycle performanceMaterial nanotechnologySecondary cellsConductive pasteElectrolytic agent

The invention relates to carbon nanotube conductive paste and a preparation method and application thereof. The carbon nanotube conductive paste comprises carbon nanotubes, a dispersant, a solvent and a stabilizer, wherein the stabilizer comprises an anhydride compound. In the carbon nanotube conductive paste, the stabilizer can be preferentially decomposed under a high-voltage condition (2.75-4.5 V). In addition, the conductive paste can be uniformly distributed in a homogenizing process, so that a stable CEI film is formed on the surface of a positive electrode material, the positive electrode material is prevented from being in direct contact with an electrolyte under a high-voltage charging and discharging condition, and the cycle performance and the rate capability of the battery are improved.

Owner:哈尔滨万鑫石墨谷科技有限公司

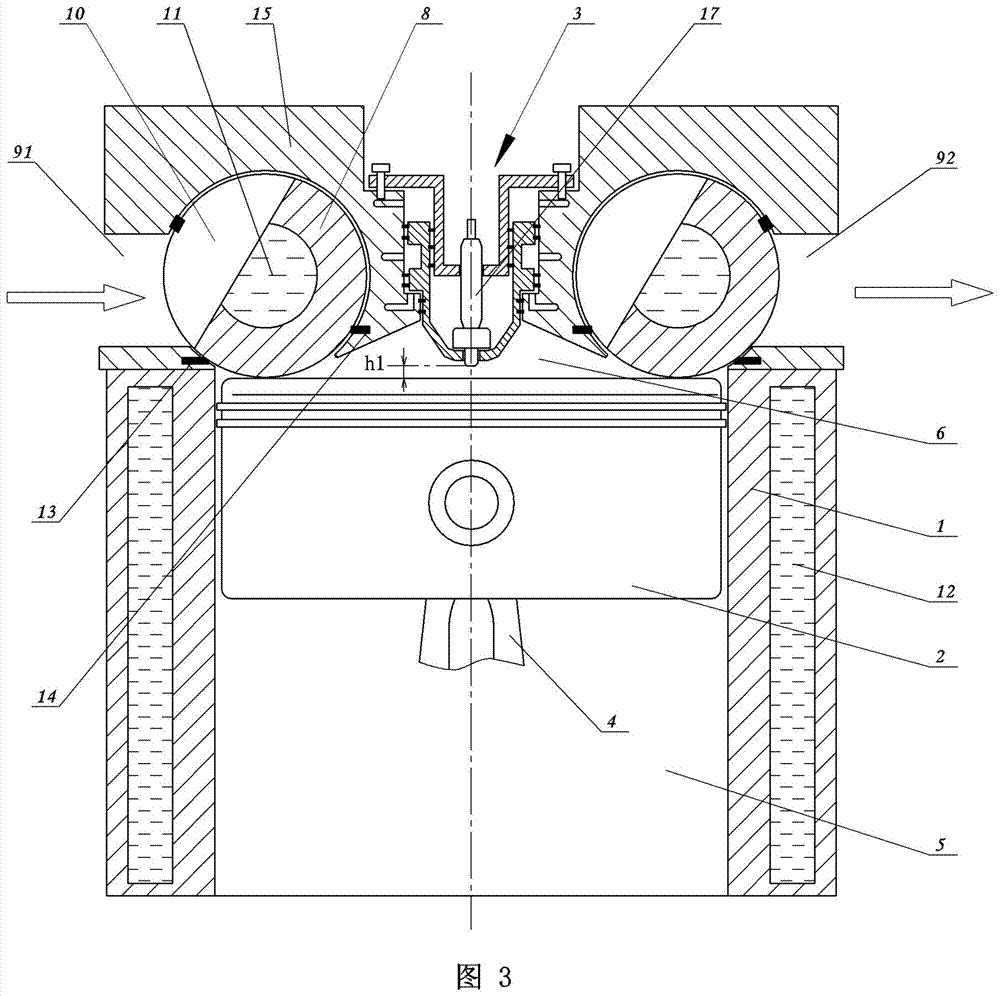

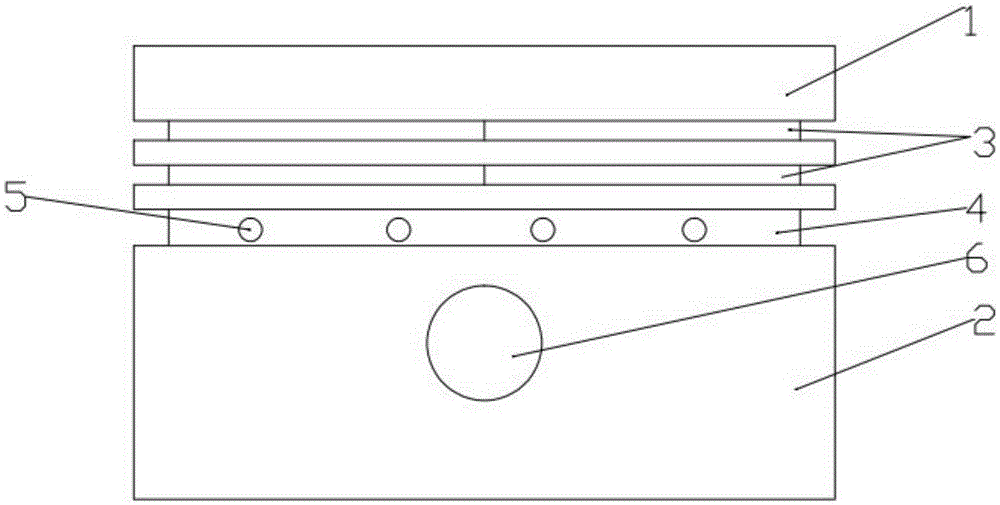

Variable-compression-ratio mechanism of engine and air distribution system matched with variable-compression-ratio mechanism

PendingCN106870052AEmission reductionImprove running stabilityLiquid coolingMechanical controlDistribution systemEngineering

The invention discloses a variable-compression-ratio mechanism of an engine and an air distribution system matched with variable-compression-ratio mechanism. An inner cavity is formed in the center position of the top of an air cylinder cover to serve as a hydraulic cylinder barrel. A piston cover is fixed to the top of the hydraulic cylinder barrel, and a hydraulic cylinder inner sleeve is arranged at the bottom of the center of the piston cover. An annular piston body is arranged in the hydraulic cylinder barrel in a sealed and sleeved manner. An upper oil cavity and a lower oil cavity are formed in the upper end and the lower end of the piston body correspondingly and communicate with an oil inlet pipe and an oil outlet pipe correspondingly. A spark plug installation head is arranged at the bottom of the annular piston body and is fixedly connected with a spark head. The compression ratio of the variable-compression-ratio mechanism can be adjusted in a stepless manner; the engine adopting the variable-compression-ratio mechanism is suitable for multi-fuel driving; emission can be better reduced; running stability is improved; torque is improved; implementation is simple, convenient and feasible; and the construction cost is low.

Owner:牛清锋

Preparation method of P-phase VO2 nano-powder

ActiveCN106698514ASmall sizeGood dispersionNanotechnologyVanadium oxidesVanadium dioxideDocusate Sodium

The invention discloses a preparation method of P-phase VO2 nano-powder. The method adopts a hydrothermal method and specifically comprises the following steps: firstly, ammonium metavanadate and docusate sodium are added to water and stirred, a mixed solution is obtained, a formic acid solution is added dropwise to the mixed solution under stirring, and a reaction precursor solution is obtained; then the reaction precursor solution is placed at 180-250 DEG C for closed reaction, a reaction liquid is obtained and subjected to solid-liquid separation, washing and drying, and a granular target product with particle size being 50-90 nm, namely, the P-phase VO2 nano-powder, is obtained. The preparation method has the characteristics that environmental protection is realized and nitrogen protection is not needed for follow-up annealing treatment of the target product, conversion of VO2(P) to VO2(M) can be realized easily through low temperature thermal treatment, and accordingly, the final product VO2(M) is applied to the fields of energy-saving windows, sensors, storage devices and the like commercially and widely quite easily.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

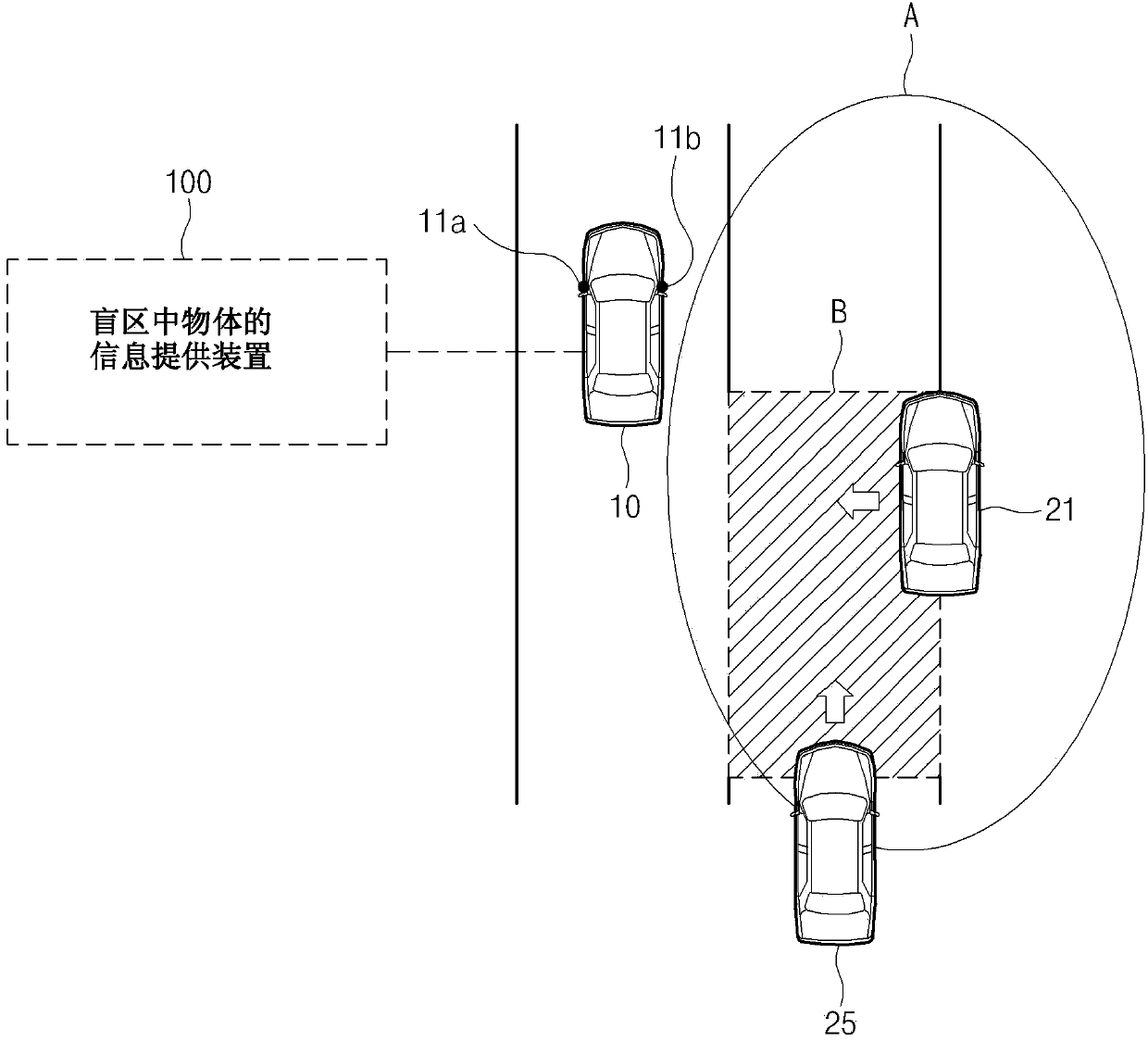

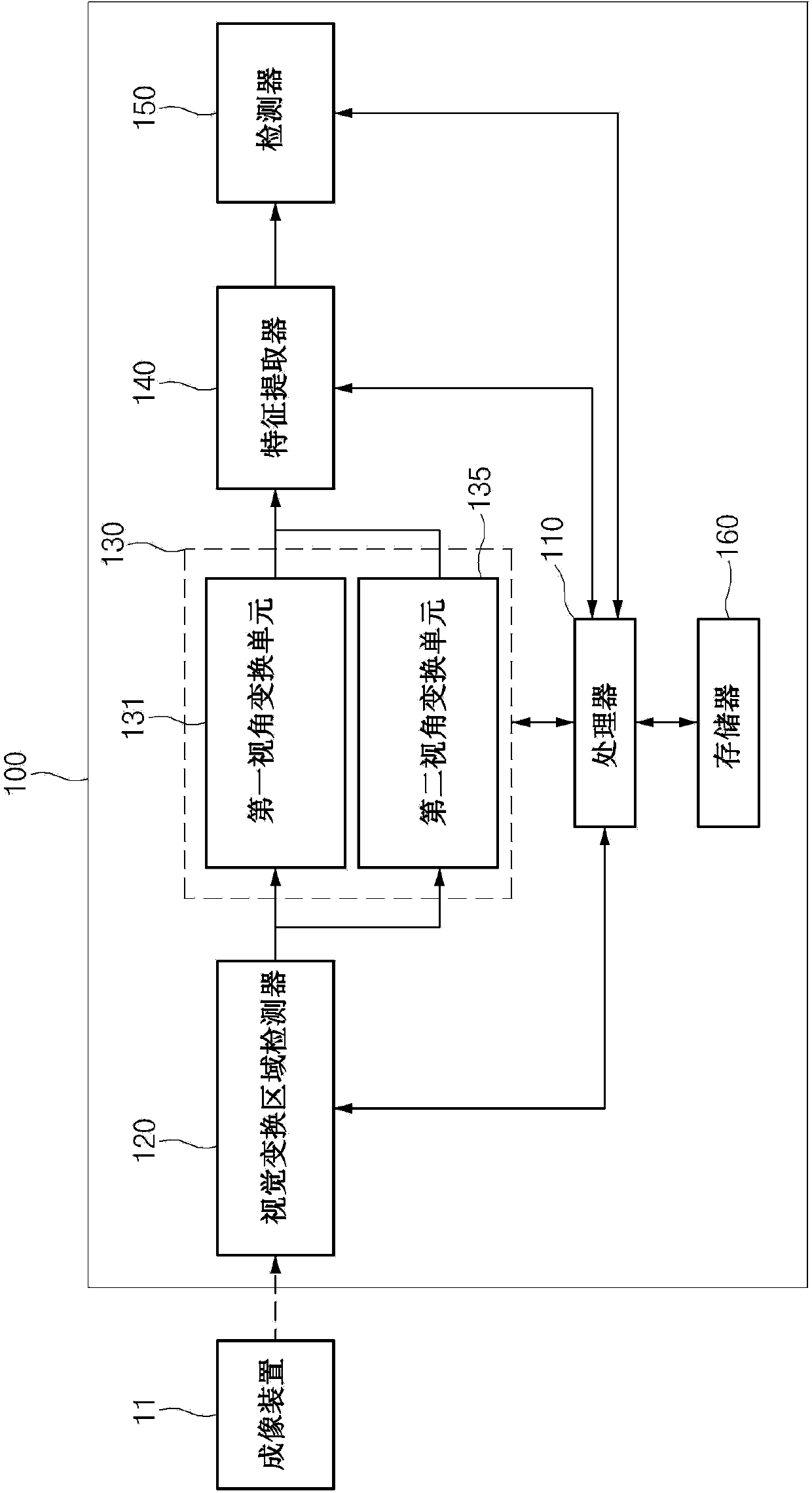

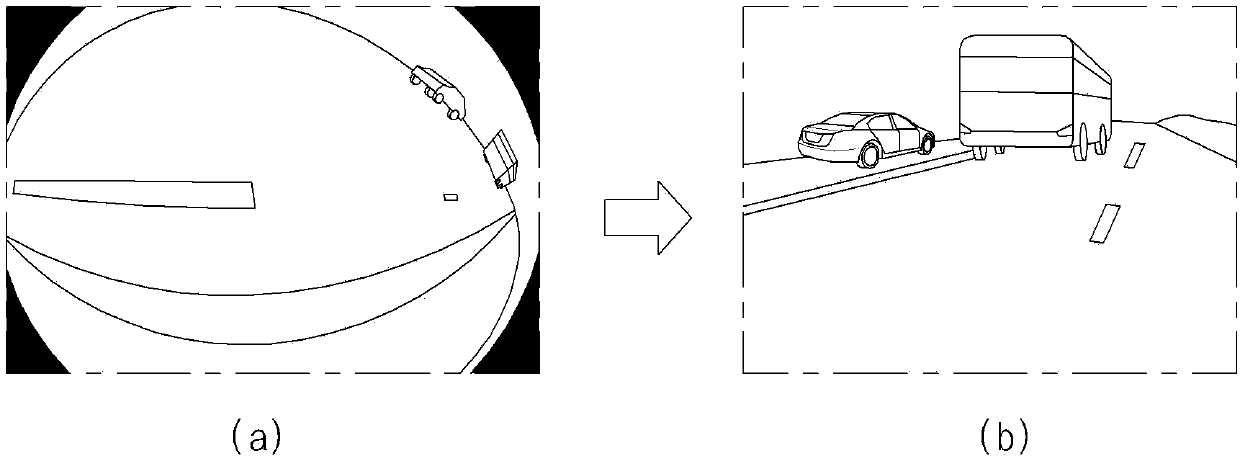

Apparatus and method for providing information of blind spot

InactiveCN103863190AImprove detection accuracyLittle change in shapePedestrian/occupant safety arrangementScene recognitionTransformerTransformation parameter

Disclosed is an apparatus and method for providing information regarding a blind spot in a vehicle. The apparatus includes a view transforming area detector that is configured to detect a predefined side area and rear side area from a captured image input from a side imaging device. The imaging device is configured to capture the image including the blind spot of the vehicle. Additionally, the apparatus includes a view transformer that is configured to view transform an image of the side area and an image of the rear side area based on a pre-set view transformation parameter and generate view transformed images corresponding to the images of the side area and the rear side area.

Owner:HYUNDAI MOTOR CO LTD

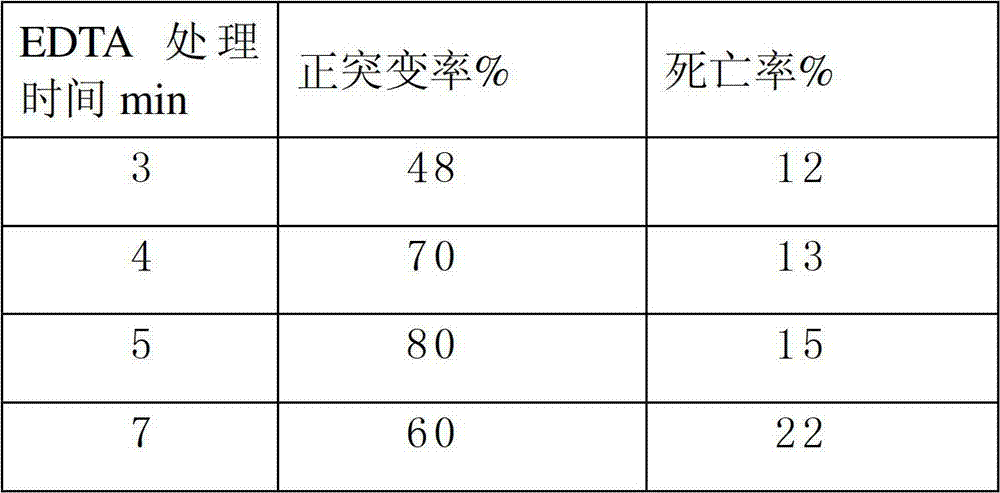

Breeding method of high-yielding strain of tetracycline

InactiveCN102851274AHigh positive variabilityLittle change in shapeMutant preparationMicroorganism based processesUltravioletMortality rate

The invention relates to a method for breeding high-yielding strain of tetracycline. The method is characterized by comprising the steps of: adding water into cultured Streptomyces aureus strains to prepare a spore suspension; shaking the flask for cultivation; filtrating; diluting; filling the suspension in four test tubes; adding a same amount of an EDTA solution and acting for respectively 3, 4, 5 and 7min; adding lysozyme and acting for 3 min; conducting gradient dilution to 10<-5>; and coating 0.1, 0.3 and 0.5ml spore liquid from each dilution on plates for cultivation; calculating a forward-mutation rate and a mortality rate; selecting an acting time with high forward-mutation rate; conducting further flask shaking screening; and selecting strains with high increase rate. The invention adopts a method, which first uses lysozyme to remove cell wall and then conducts EDTA treatment, thus breeding high-quality and high-yielding strain of tetracycline; and compared with an ultraviolet method and an ion implantation method, the method provided by the invention has advantages of simple operation, low cost, high safety, little environmental pollution, high mutation rate of strains, and high shake flask titer of the produced strain.

Owner:NINGXIA QIYUAN PHARMA

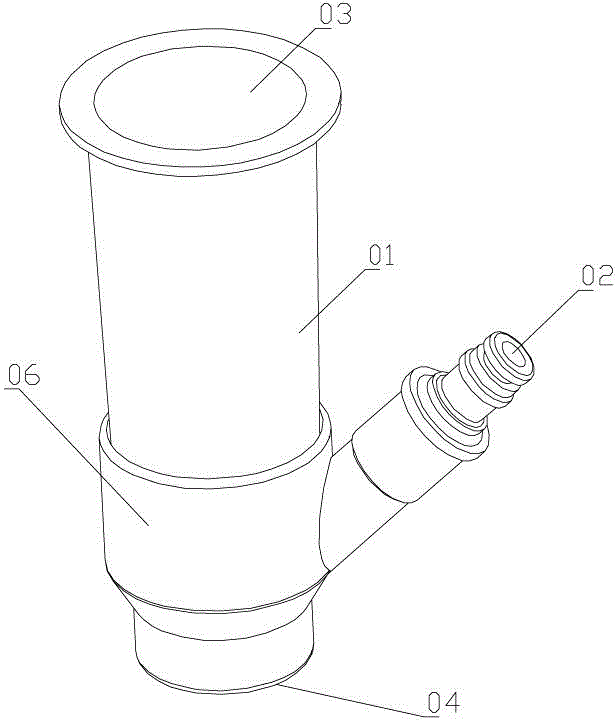

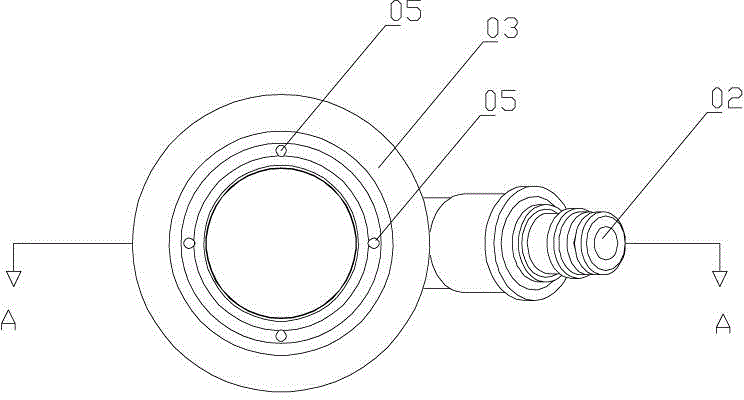

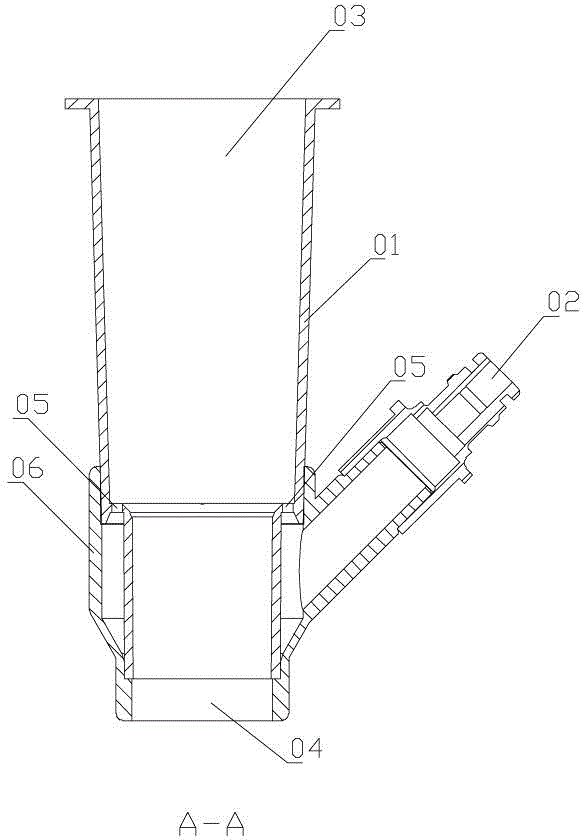

Siphon head for cleaning swimming pool

ActiveCN103334600ADoes not reduce flow rateFlow rate is not easy to generateGymnasiumSwimming poolsSiphonSewage

The invention provides a siphon head which is larger in siphon force and used for cleaning a swimming pool. The siphon head for cleaning the swimming pool comprises a cylinder body (1), wherein a sewage outlet (3) is formed in the upper end of the cylinder body (1), a sewage suction mouth (4) is formed in the lower end of the cylinder body (1), a water inlet (2) is formed in the side wall of the cylinder body (1), the water inlet (2) is communicated with a water outlet hole (6), the water outlet hole (6) is formed in the inner wall of the cylinder body (1), and the water outlet direction faces towards the sewage outlet (3). The siphon head for cleaning the swimming pool is characterized in that the number of the water outlet hole (6) is one, the sewage outlet (3) is connected with a cover (5), a gap is reserved in the position, over the water outlet hole (6), of the cover (5), and the size of the gap is from one fourths to one seconds of the area of the cover.

Owner:NINGBO DONGCHUAN SWIMMING POOL EQUIP

Optical reflector and surface light source device

ActiveCN1791811ALittle change in shapeGuaranteed brightnessMechanical apparatusMirrorsPolyolefinOptoelectronics

Provided is a light reflector formed of a white polyolefin film; the white polyolefin film contains a polyolefin resin and a filler, is stretched at least along one axis, and has an area stretching ratio of 1.3 to 80 times, and The total light reflectance is greater than or equal to 95%, the size change rate after standing at 70°C for 300 hours is less than or equal to 1.5%, and the melting initiation temperature is greater than or equal to 70°C. If this light reflection body is attached to a surface light source device, even if this surface light source device is used for a long time, unevenness in brightness of a surface light source will not generate|occur|produce easily.

Owner:MITSUBISHI CHEM CORP

Optical imaging lens assembly, image capturing unit and electronic device

Owner:LARGAN PRECISION

Medical device including anionic drug

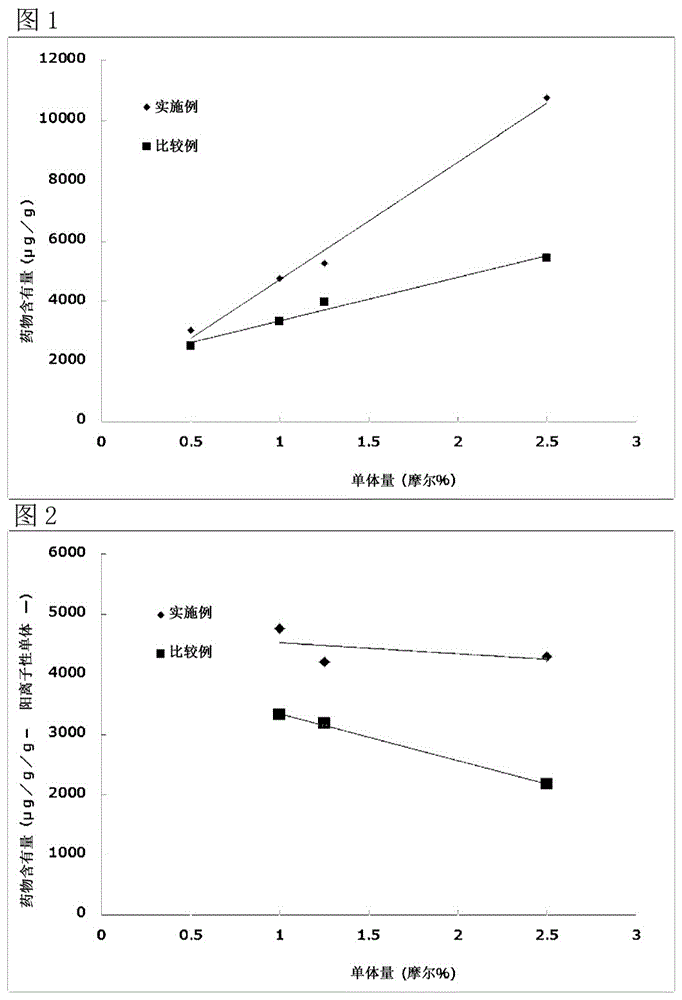

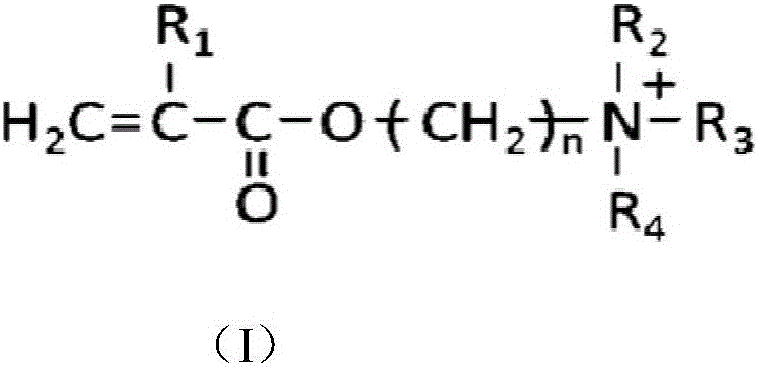

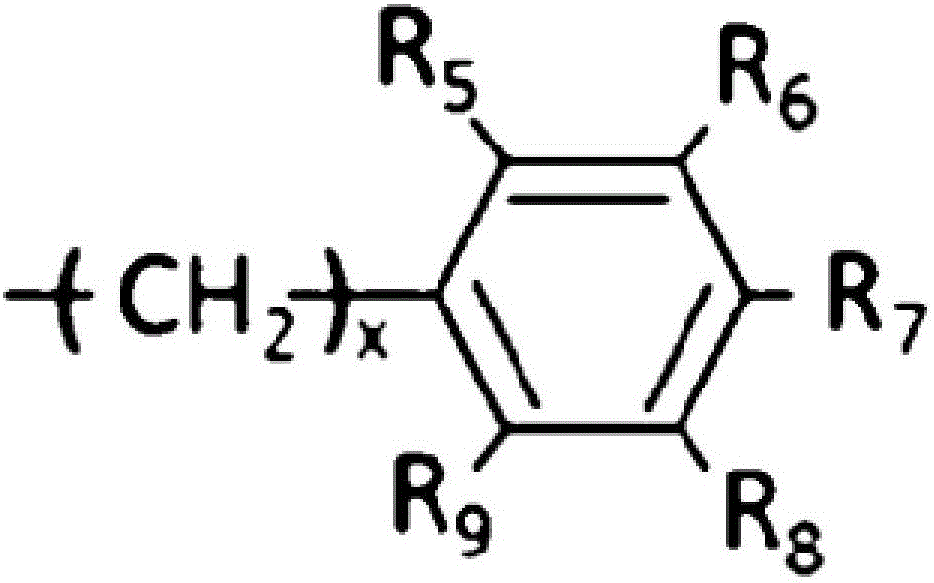

ActiveCN106413755ANot in bad shapeImproved shape stabilityOrganic active ingredientsSenses disorderMeth-Ammonium compounds

The purpose of the present invention is to provide a medical device including a drug, which is manufactured using a polymer gel that enables the increase in the amount of the drug to be included in the medical device compared with the conventional techniques, and which has reduced influence on gel strength and shape stability after the release of the drug. The purpose can be achieved by a medical device including an anionic drug, said medical device comprising: (1) an anionic drug; and (2) a copolymer which contains, as constituent components, a cationic monomer comprising a condensation product of an alkyl quaternary ammonium compound having a substituted or unsubstituted aralkyl group and (meth)acrylic acid or a salt of the condensation product and a monomer capable of copolymerizing with the condensation product or the salt of the condensation product.

Owner:SEED CO LTD +1

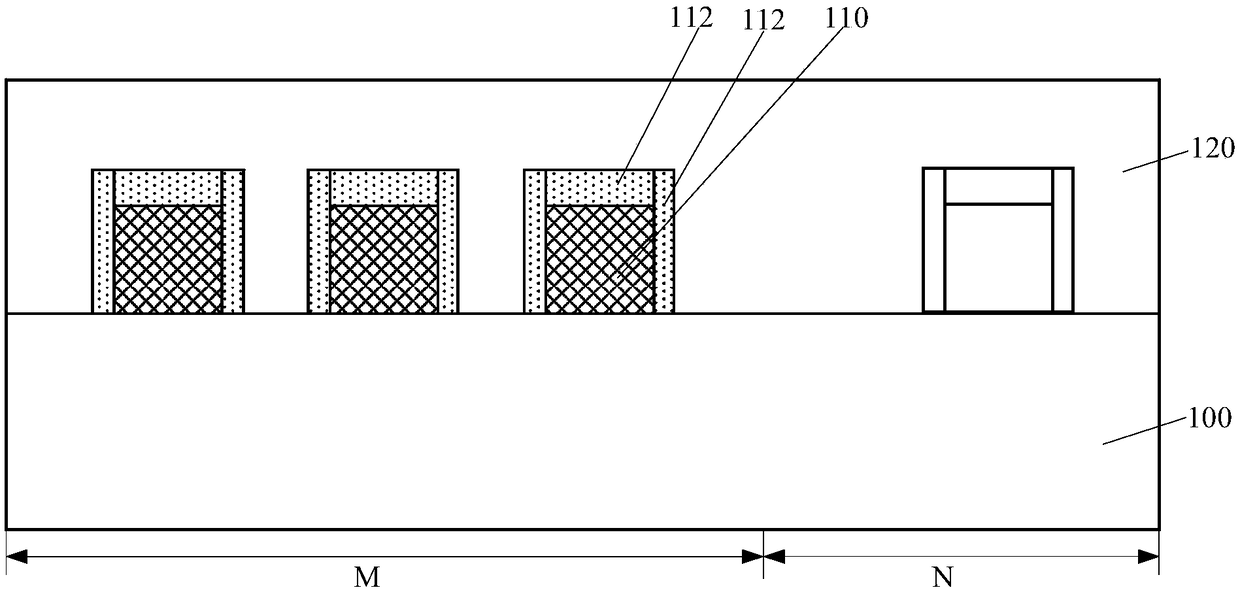

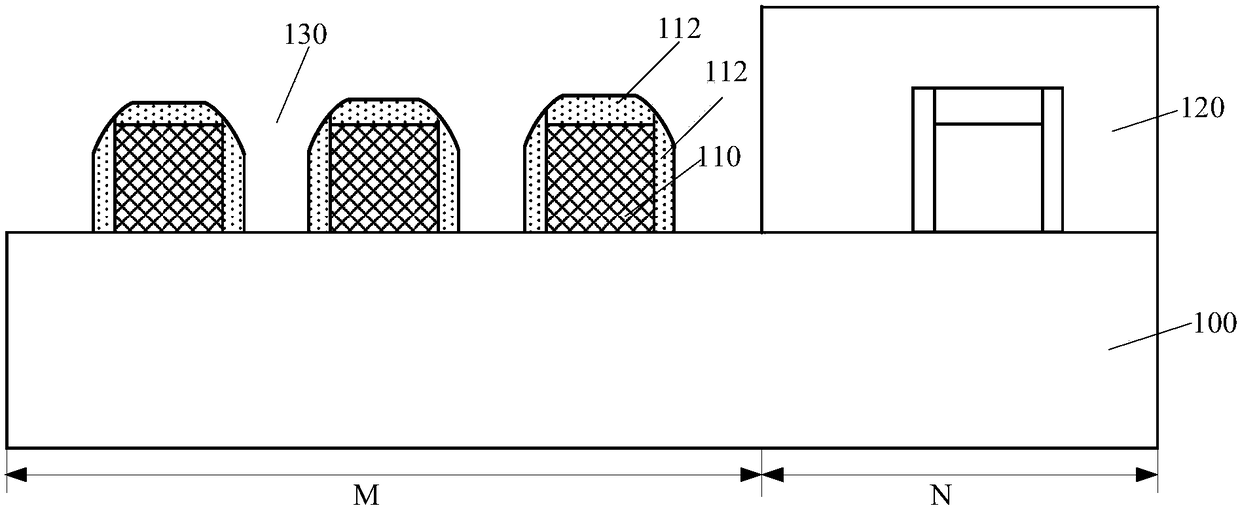

Semiconductor device and formation method thereof

ActiveCN109427583ALittle change in shapeLow costSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorProtection layer

The invention discloses a semiconductor device and a formation method thereof. The method comprises the following steps that: forming first grid electrode structure bodies on the first area of a substrate, first initial protection layers and first dielectric layers, wherein the first initial protection layers are positioned on the surfaces of the side walls and the top wall of each first grid electrode structure body, and each first dielectric layer covers each first initial protection layer; etching to remove parts of each first dielectric layer of the first area to enable a second dielectriclayer to be formed on each first dielectric layer of the first area, and enabling the first initial protection layer on the top of each first grid electrode structure body and parts of the first initial protection layer on the side walls of each grid electrode structure body to be exposed; carrying out an intermediate processing technology for at least one time until the second dielectric layer is removed, and enabling the first initial protection layers to form first protection layers positioned on the surfaces of the side walls and the top of the first grid electrode structure body, whereinthe intermediate processing technology comprises the following step of carrying out back etching on parts of the second dielectric layer of the first area after parts of the first initial protectionlayer on the top of the first grid electrode structure body are planarized. By use of the method, the performance of the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

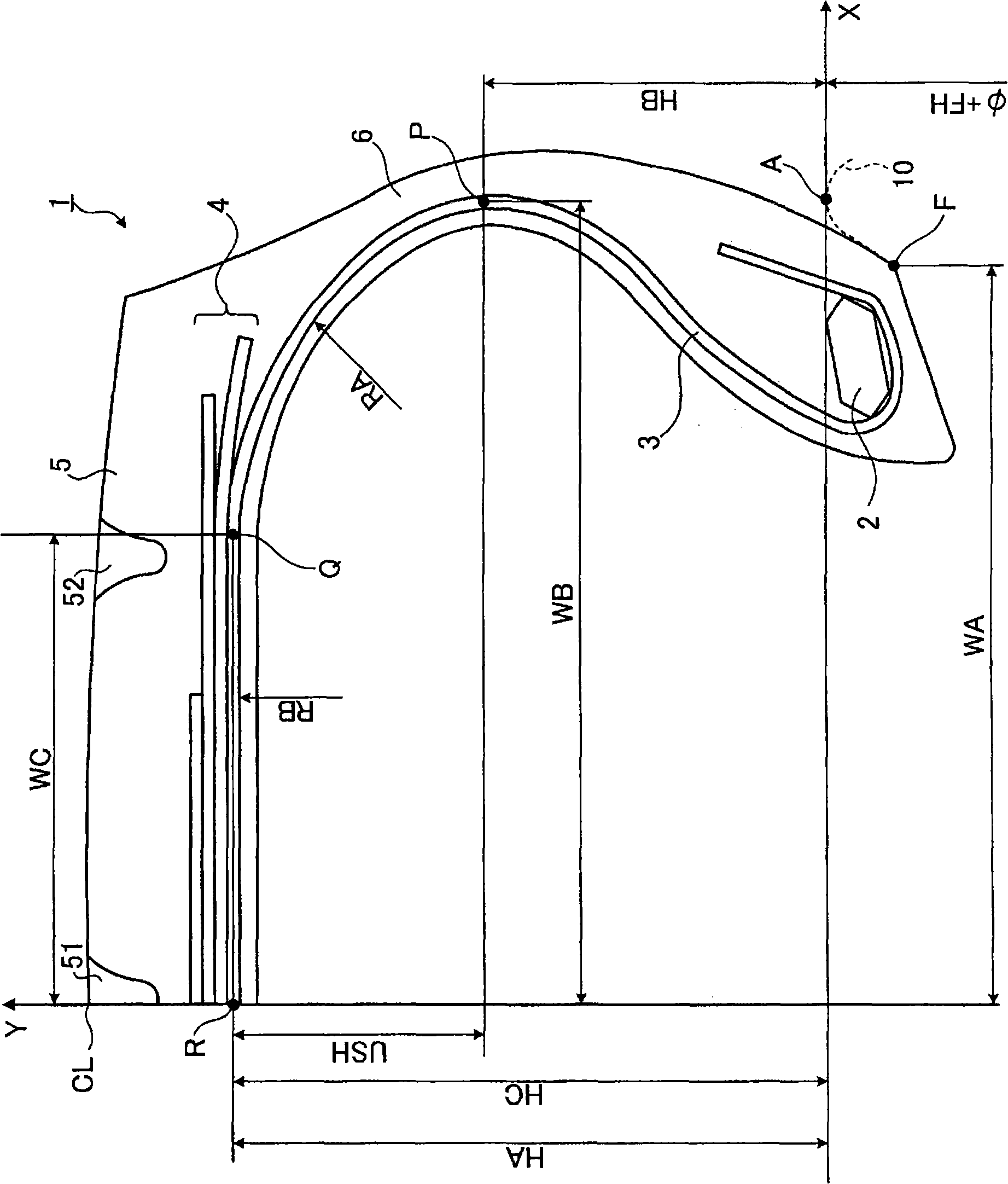

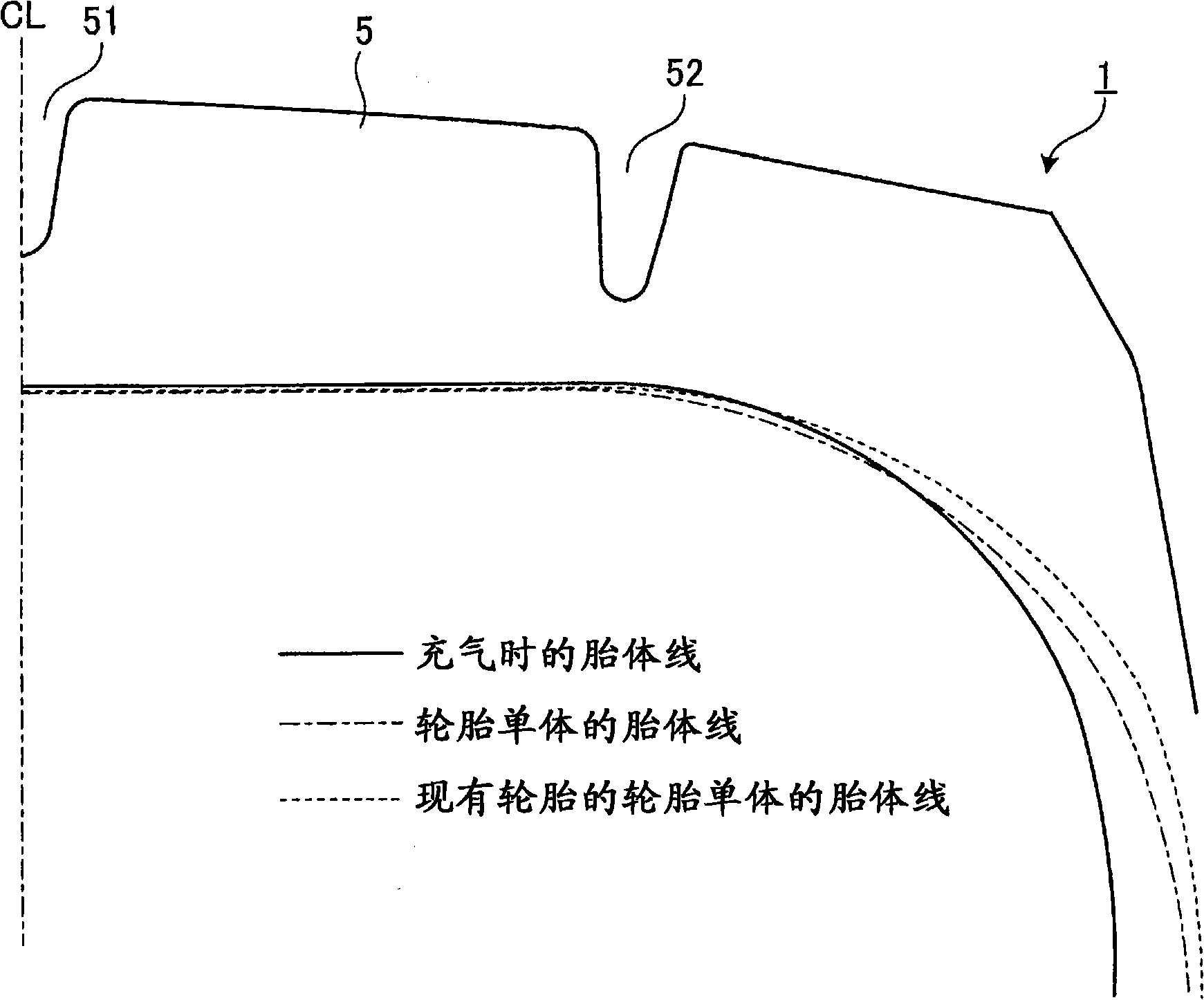

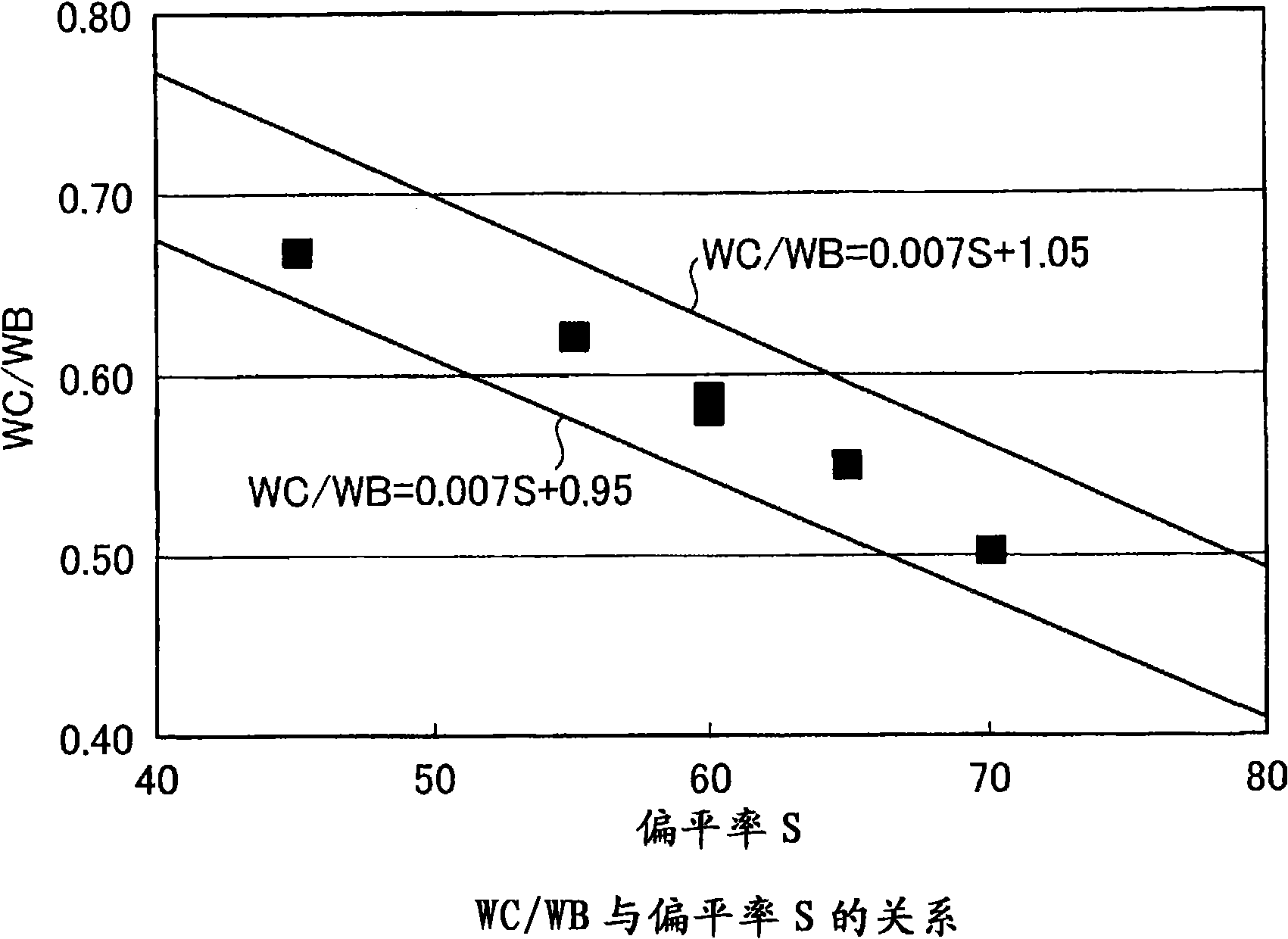

Pneumatic tire

InactiveCN101541562AAvoid crackingLittle change in shapeHeavy duty tyresHeavy duty vehicleMeridional directionMechanical engineering

A pneumatic tire (1) satisfying relationships of 48[%]<=HB / HA<=52[%], 98[%]<=HC / HA<=100[%], 108[%]<=WB / WA<=115[%], and 55[%]<=WC / WA<=75[%] in a cross-section in the meridional direction of the tire when it is held as a single unit such that the width of a tire base is not less than 100% and not more than 120% of the width of an applicable rim, with WA the width half the width of the tire base, WB the distance from the Y-axis to the maximum width point P of a carcass layer (3), WC the distance from the Y-axis to an inflection point Q of the carcass layer (3), HA the distance from the X-axis to the top point R of that portion of the carcass layer (3) which is at a center crown CL, HB is the distance from the X-axis to the maximum width point P of the carcass layer (3), and HC the distance from the X-axis to the inflection point Q of the carcass layer (3).

Owner:THE YOKOHAMA RUBBER CO LTD

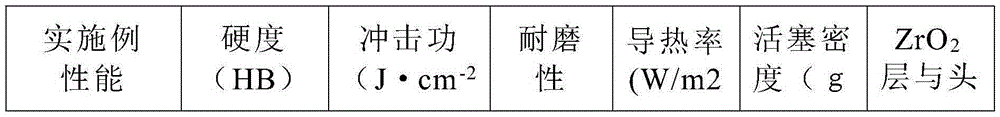

Light and wear-resistant automobile engine piston and preparing method thereof

InactiveCN105422307AHigh mechanical strengthIncrease stiffnessMachines/enginesPistonsWear resistantEngineering

The invention relates to a light and wear-resistant automobile engine piston and a preparing method thereof and belongs to the technical field of piston machining. A head and a skirt part connected to the lower end of the head are reserved on the automobile engine piston. The head is provided with an oil ring groove and a gas ring groove in sequence from bottom to top. A radial small hole is formed in the bottom face of the oil ring groove. Two opposite pin holes are formed in the two sides of the skirt part. The engine piston is made of an aluminum alloy ceramic porous material which includes aluminum alloy powder, ceramic powder, a pore-forming agent and a binding agent with the mass ratio of 100:(55.1-165.2):(0.4-0.9):(9-12). The piston prepared through the method is good in mechanical property, good in thermal shock resisting property, low in noise, small in specific gravity and convenient o use and transport.

Owner:NINGBO QUNXING POWDER METALLURGY

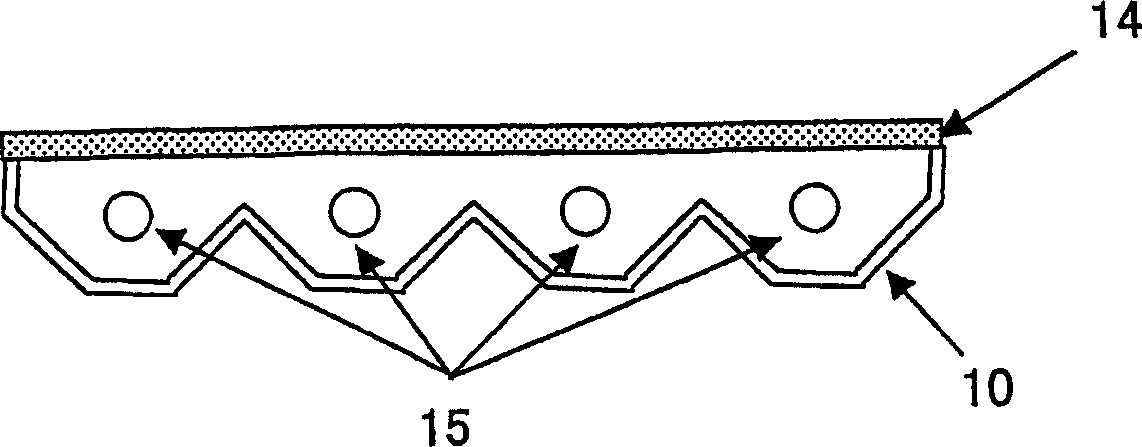

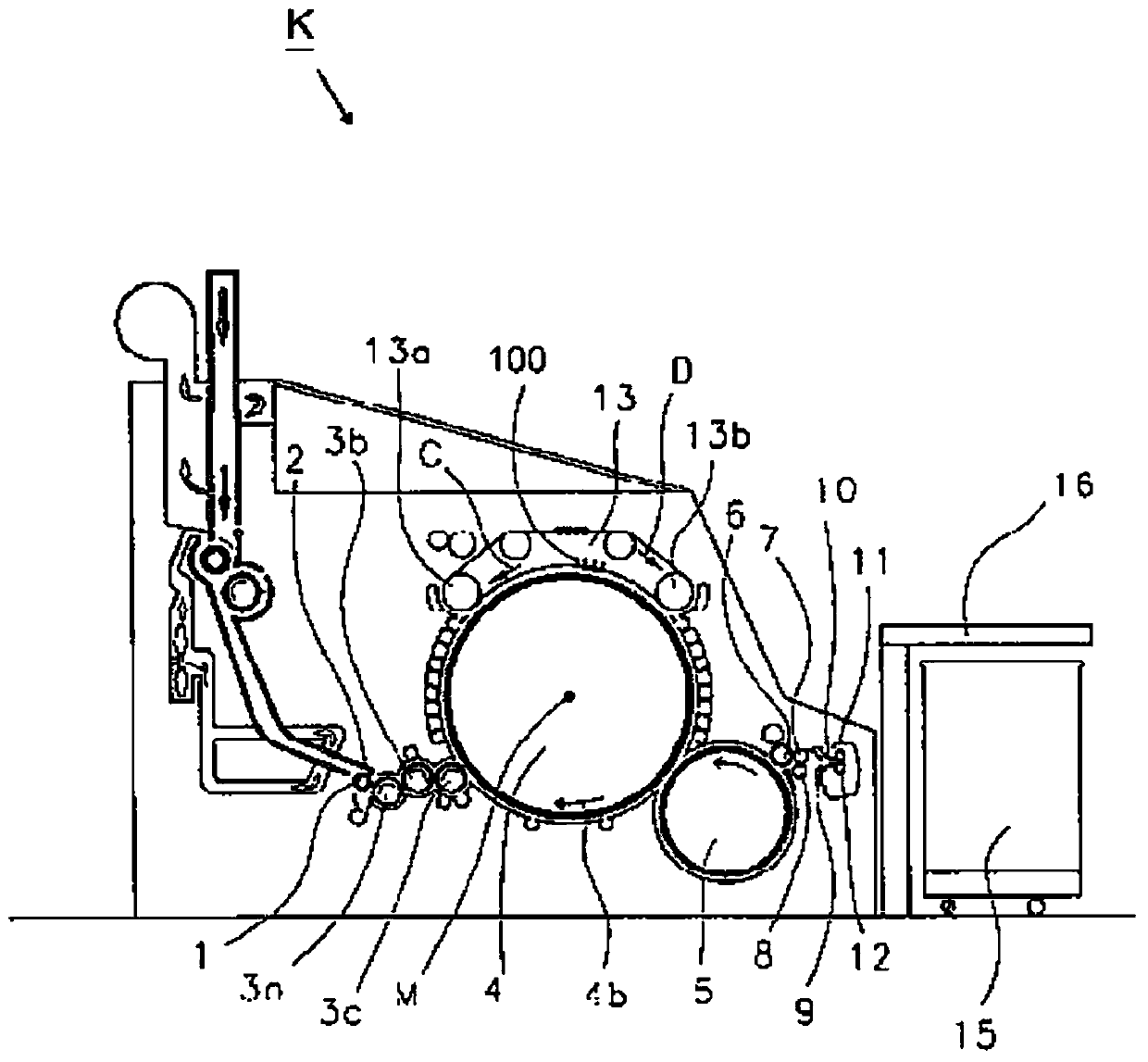

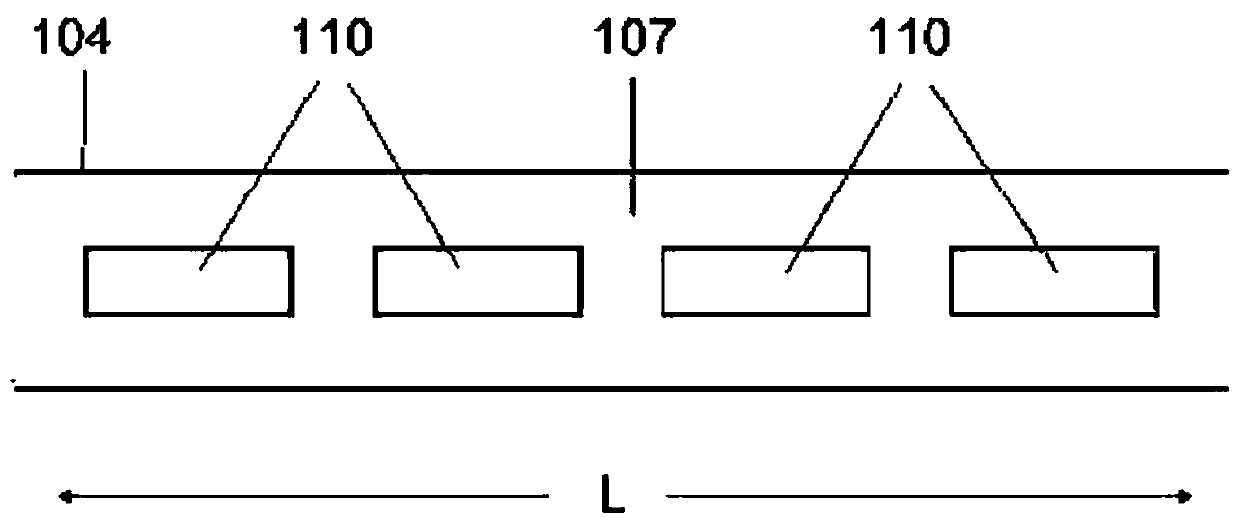

Flat bar system

The invention relates to a flat bar system (100) for use on a carding machine (K) for cotton, man-made fibers or such like. The flat bar system comprises an elongated flat bar (102) to which a magnetic element (103) is fastened, and an elongated flat top strip (104) which on its rear side (107) facing the flat bar (102) has a rear layer containing a ferrous material. The flat top strip (104) can therefore be detachably fastened to the magnetic element (103) of the flat bar (102) by its rear layer (108), using magnetic force. The rear layer (108) comprises a plurality of segments (110), which each contain a ferrous material, and the segments (110) are spaced apart and uncoupled from each other in the longitudinal direction (L) of the flat top strip (104).

Owner:TRUETZSCHLER GRP SE

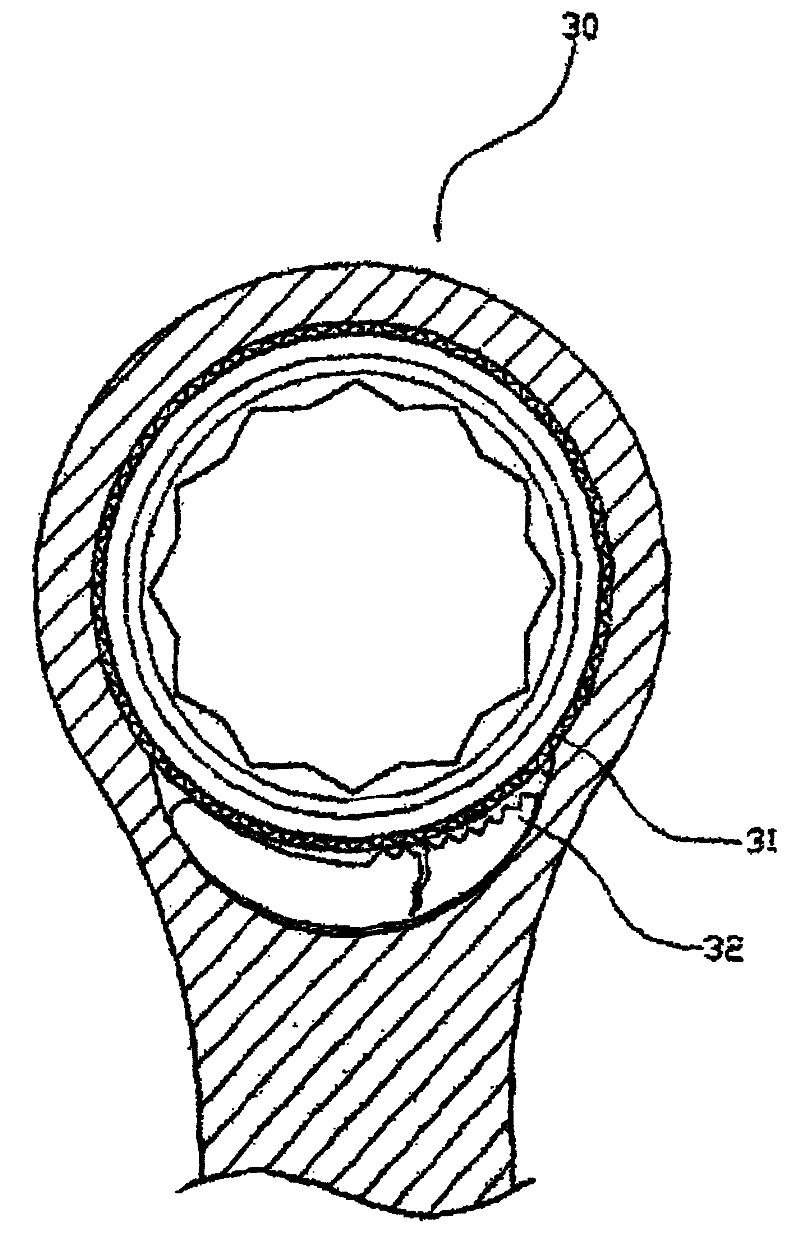

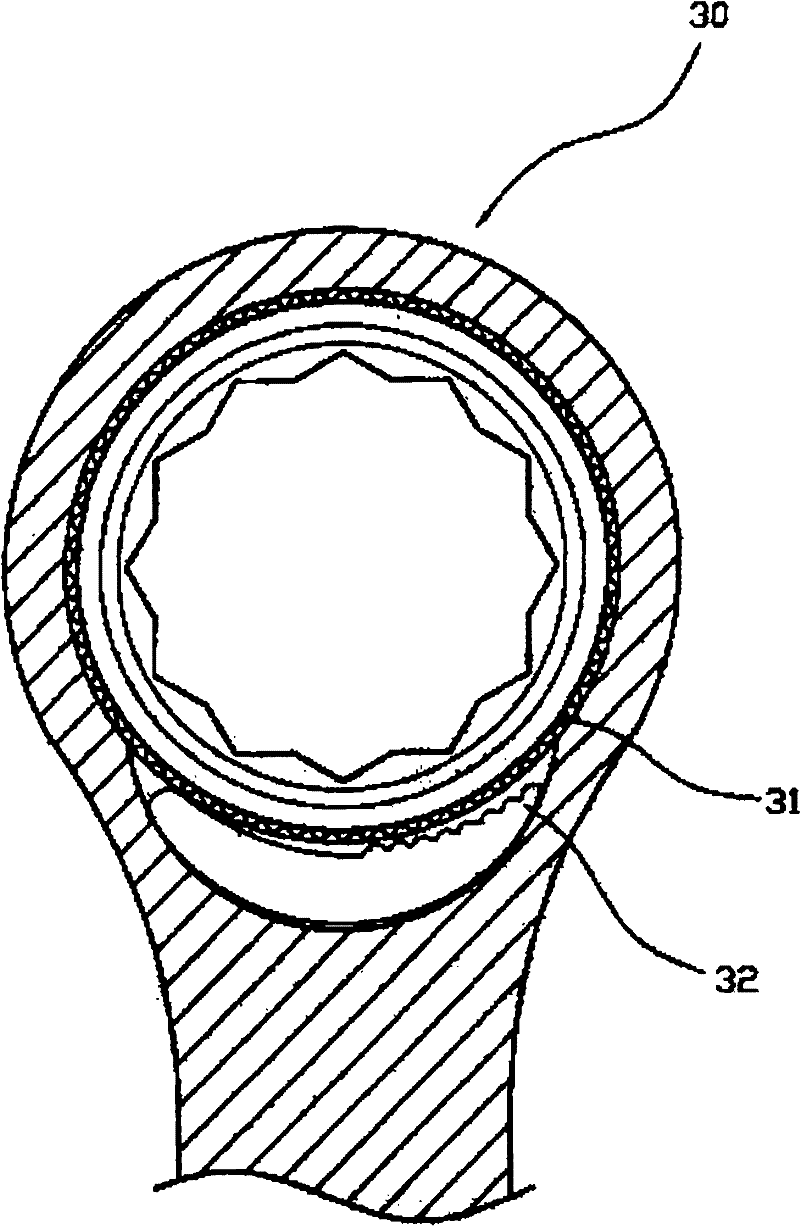

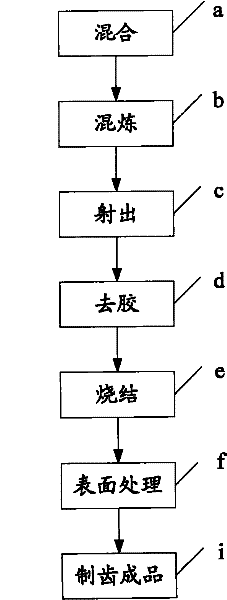

Molding method of ratchet wrench braking teeth

InactiveCN102125979AImprove structural strengthImprove mechanical propertiesMetal-working apparatusPunchingSand blasting

The invention discloses a molding method of ratchet wrench braking teeth, which sequentially comprises the following steps of: firstly, primary blank cutting: cutting the primary blank into a plurality of plate-shaped primary materials with preset sizes through continuously punching and cutting; secondly, appearance molding: carrying out primary cold forging and punching on the continuously cut plate-shaped primary materials, extruding the primary materials by an upper mould and a lower mould, extending the primary materials on two side ends to form a bent arc shape, and sinking one side of the primary material to form an arc-shaped surface; thirdly, external teeth pressing: carrying out secondary cold forging and punching, pressing down the arc-shaped surface by a toothed mould to form external teeth; fourthly, blur removal: carrying out triple cold forging and punching on the primary materials with the external teeth, and removing residual blurs resulting from a continuous punching process on the surfaces of the primary materials to form semi-finished products; fifthly, thermal treatment: thermally treating the semi-finished products to eliminate internal residual stress and increase hardness and tensile strength of the semi-finished products; finally, surface treatment: carrying out sand-blasting and rust-preventing treatment on the thermally treated semi-finished product to prepare a finished ratchet wrench braking tooth.

Owner:彭桔星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com