Patents

Literature

39 results about "Central belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Central Belt of Scotland is the area of highest population density within Scotland. It has a population of about 3.5 million covering an area of approximately 10,000 km 2, including Greater Glasgow, Ayrshire, Falkirk, Edinburgh, Lothian and Fife.

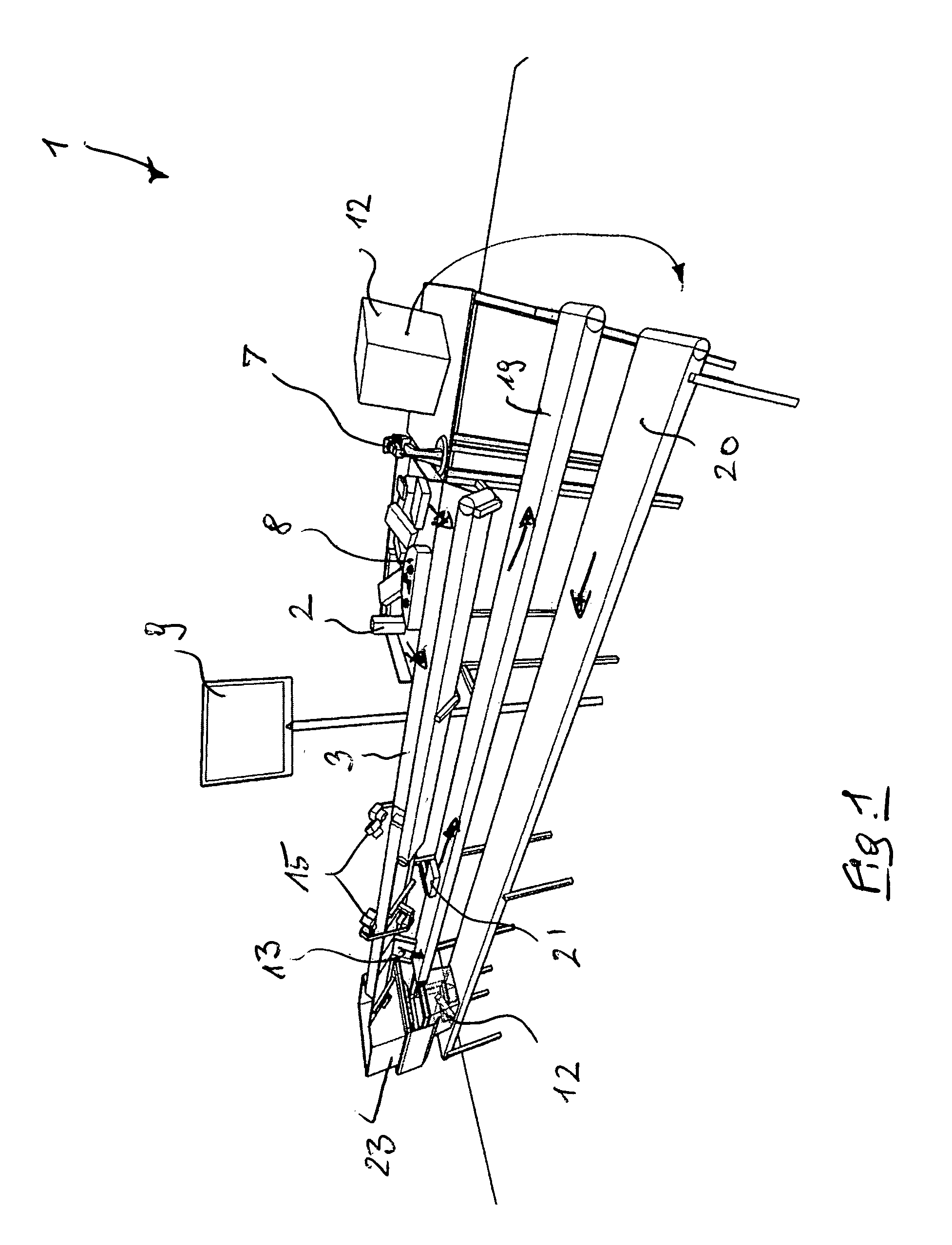

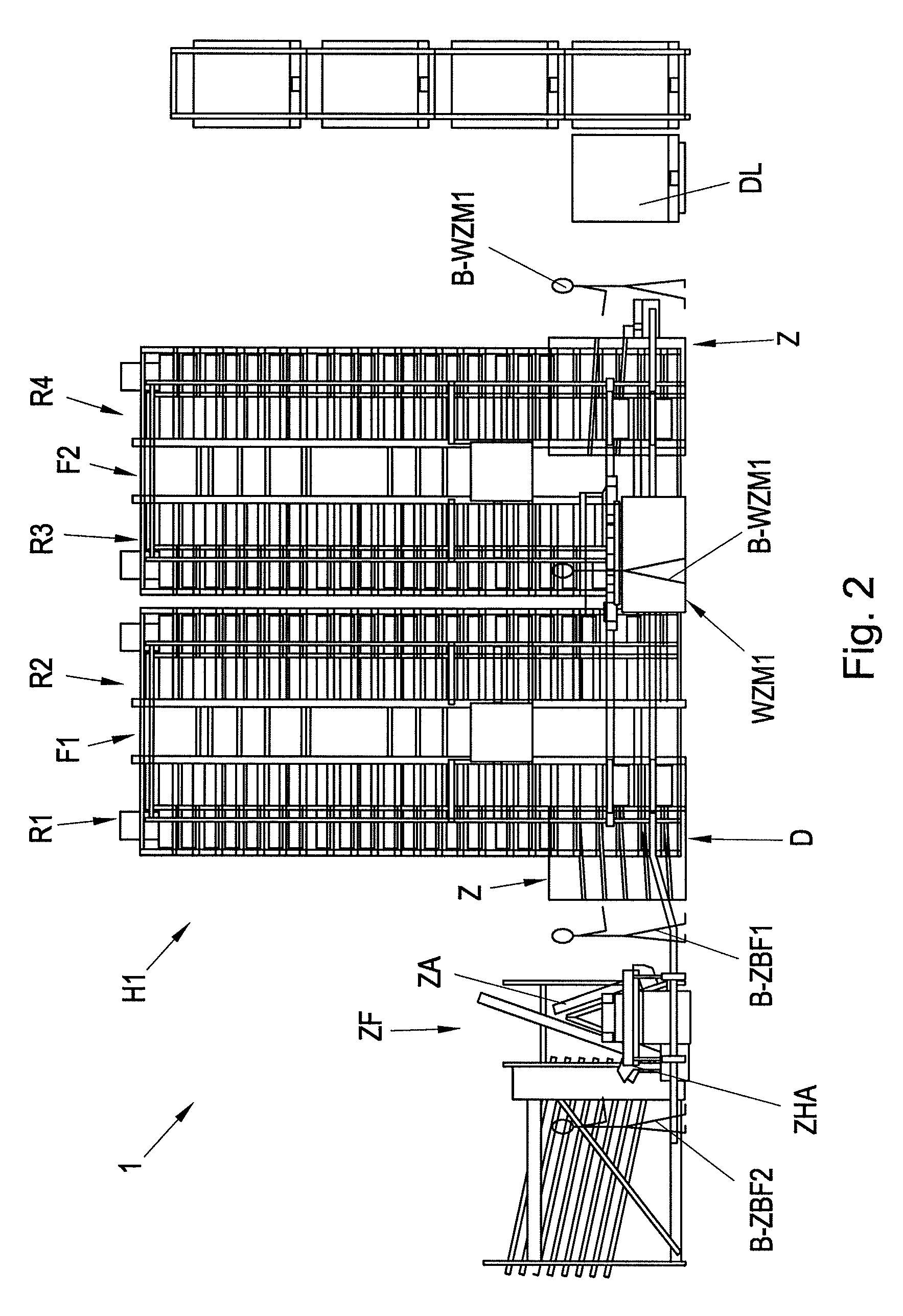

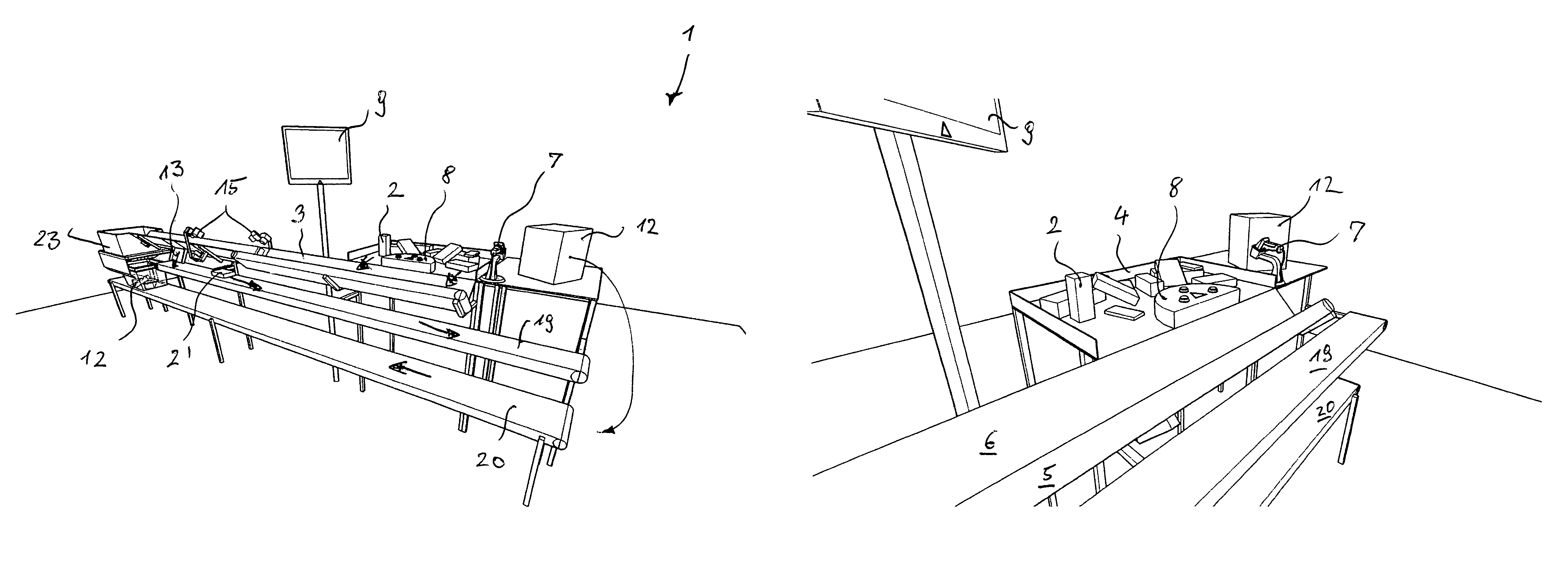

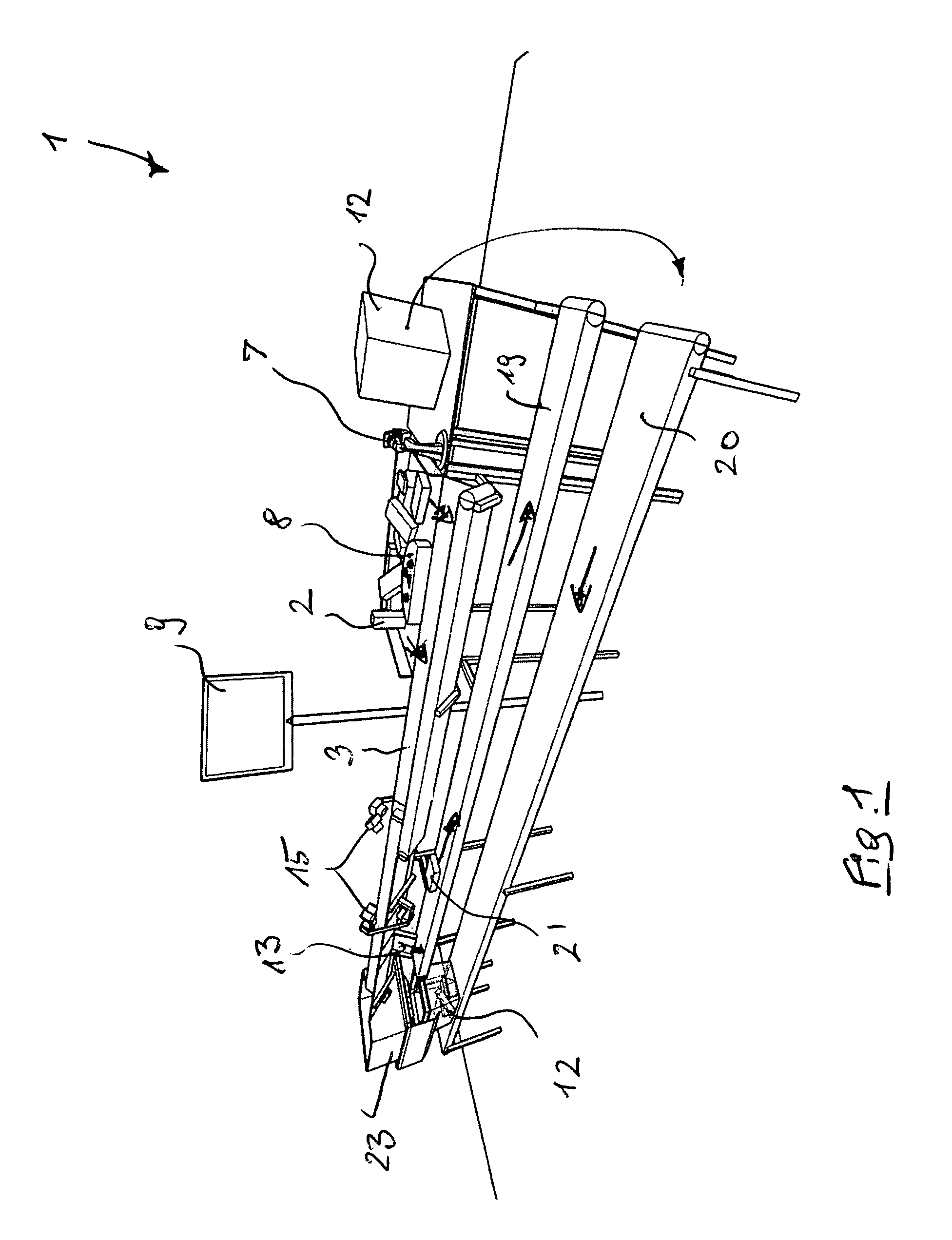

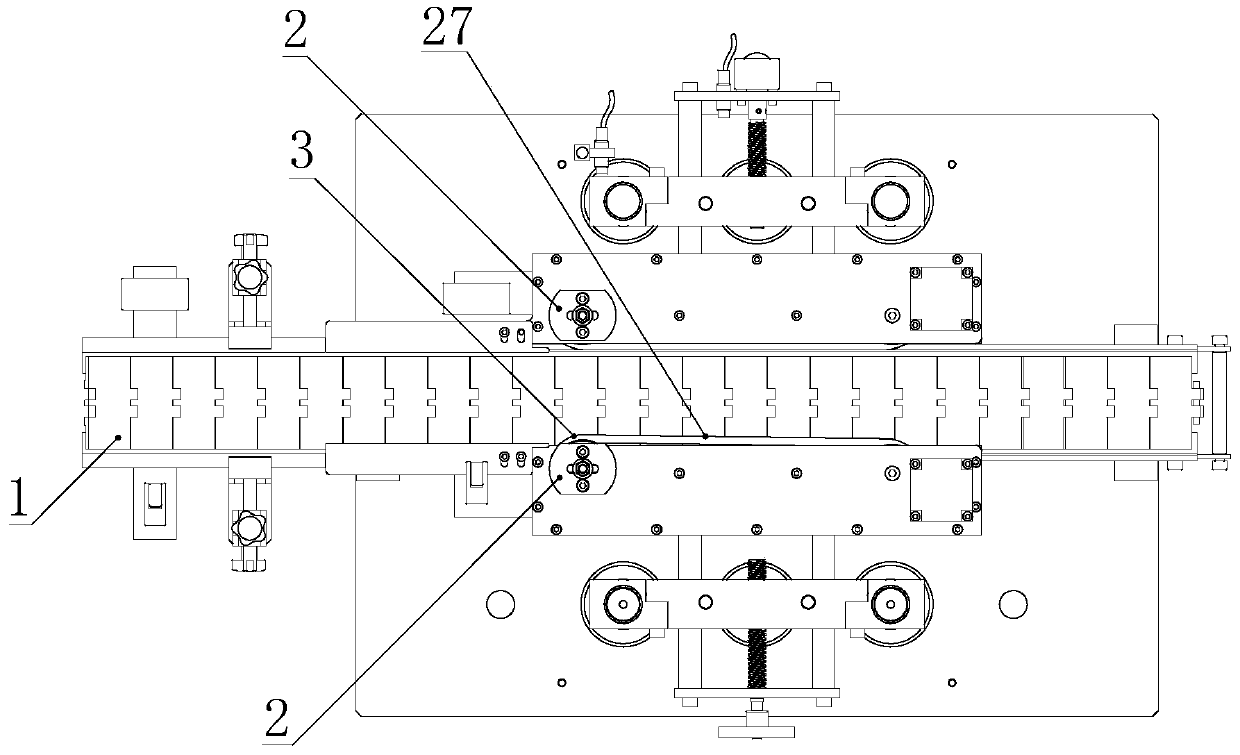

Device and process for recognizing and guiding individually packaged products with a code

ActiveUS20110320036A1Faster throughputImprove reliabilityDigital data processing detailsConveyor partsCentral beltEngineering

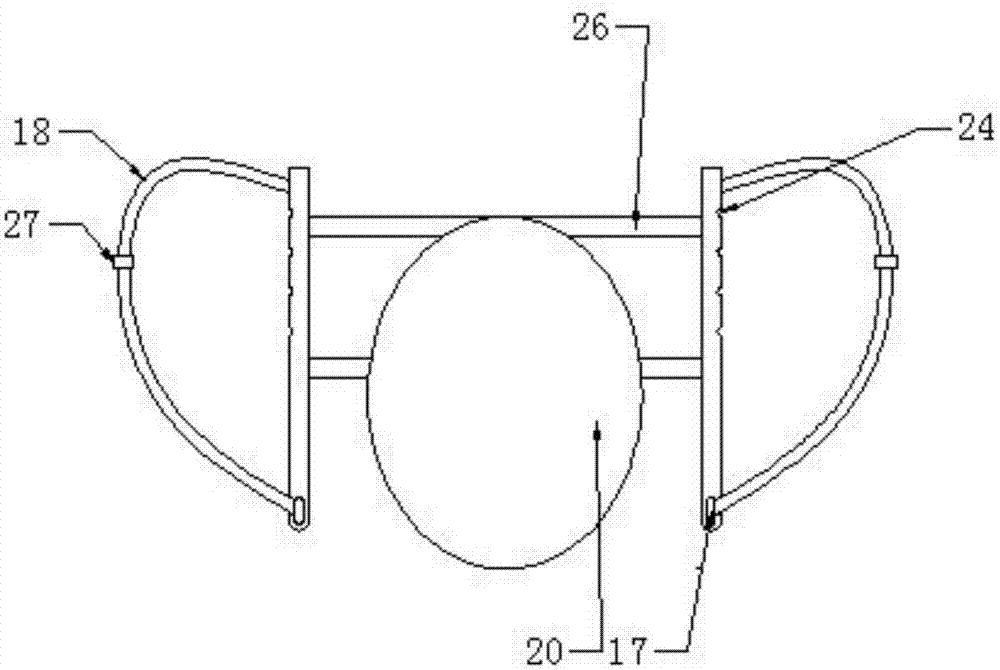

An arrangement (1) and to a method is for detecting and controlling piece goods (2), having a code, in a commissioning system. The piece goods are fed on a conveyor line (3) through a scanning device (15), and are identified as actual data and are compared or captured to target data of the piece goods quantity stored in a central computer. The piece goods are separated out if the target data do not match the actual data. The invention proposes that a plurality of ejection devices (13) are provided. Each of the ejection devices (13) fills a positioned order container (25) of a particular commissioning order with piece goods, and piece goods that are not detected or sorted out are discharged to the longitudinal end of the conveyor line (3). The piece goods of various commissioning orders are randomly distributed on the central belt (27) of an automated commissioning machine and fed to the arrangement (1).

Owner:KNAPP AG

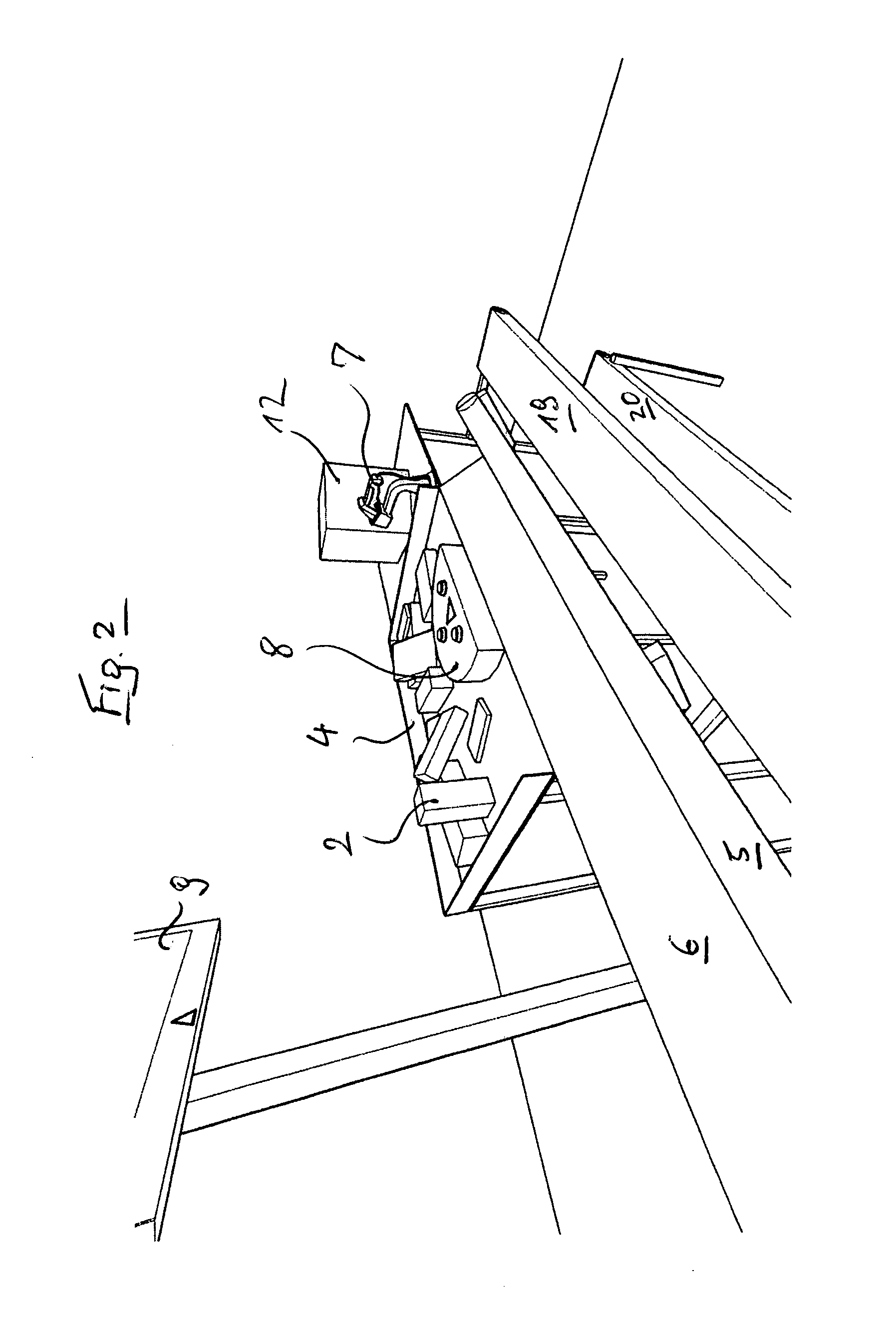

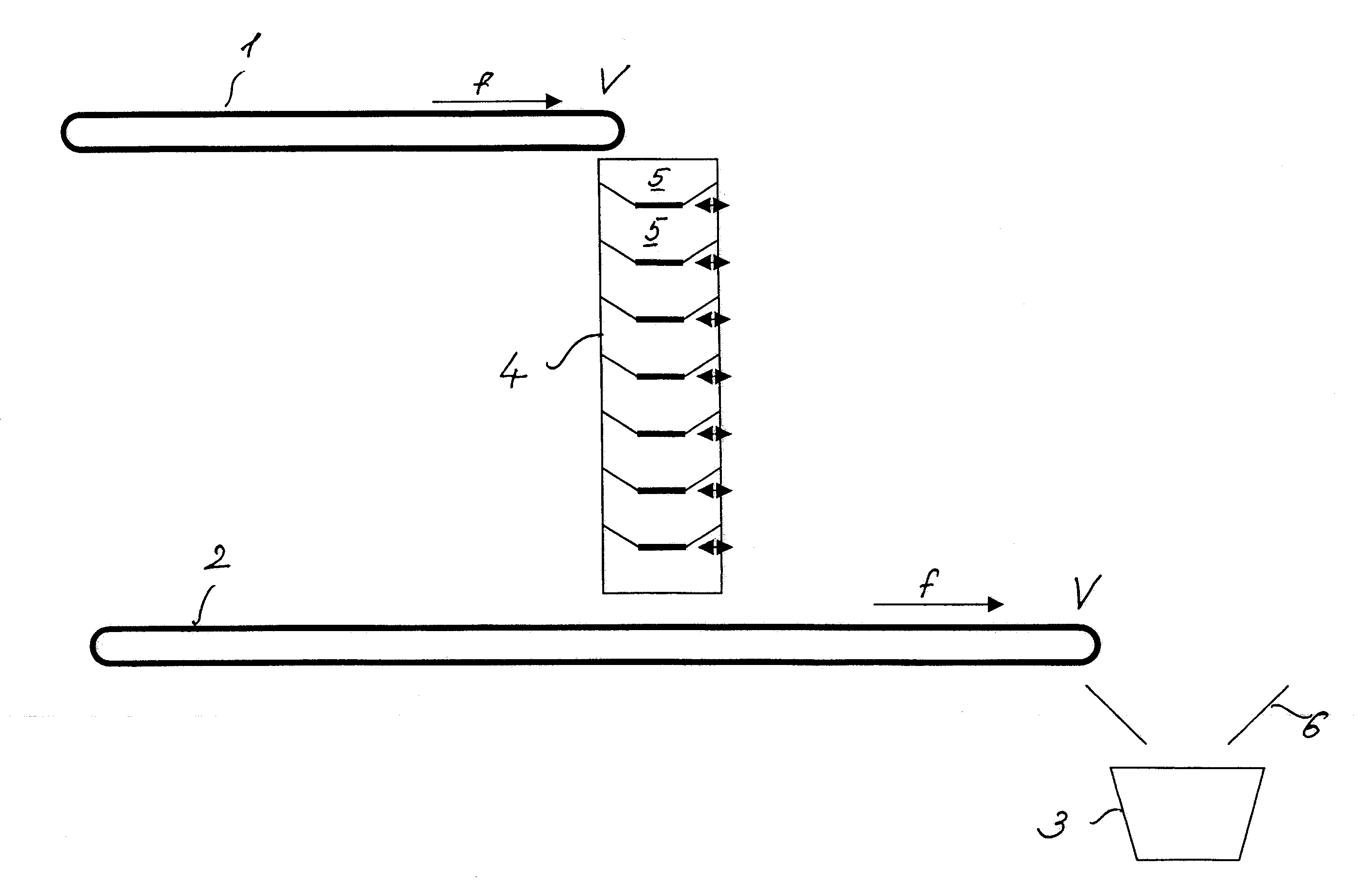

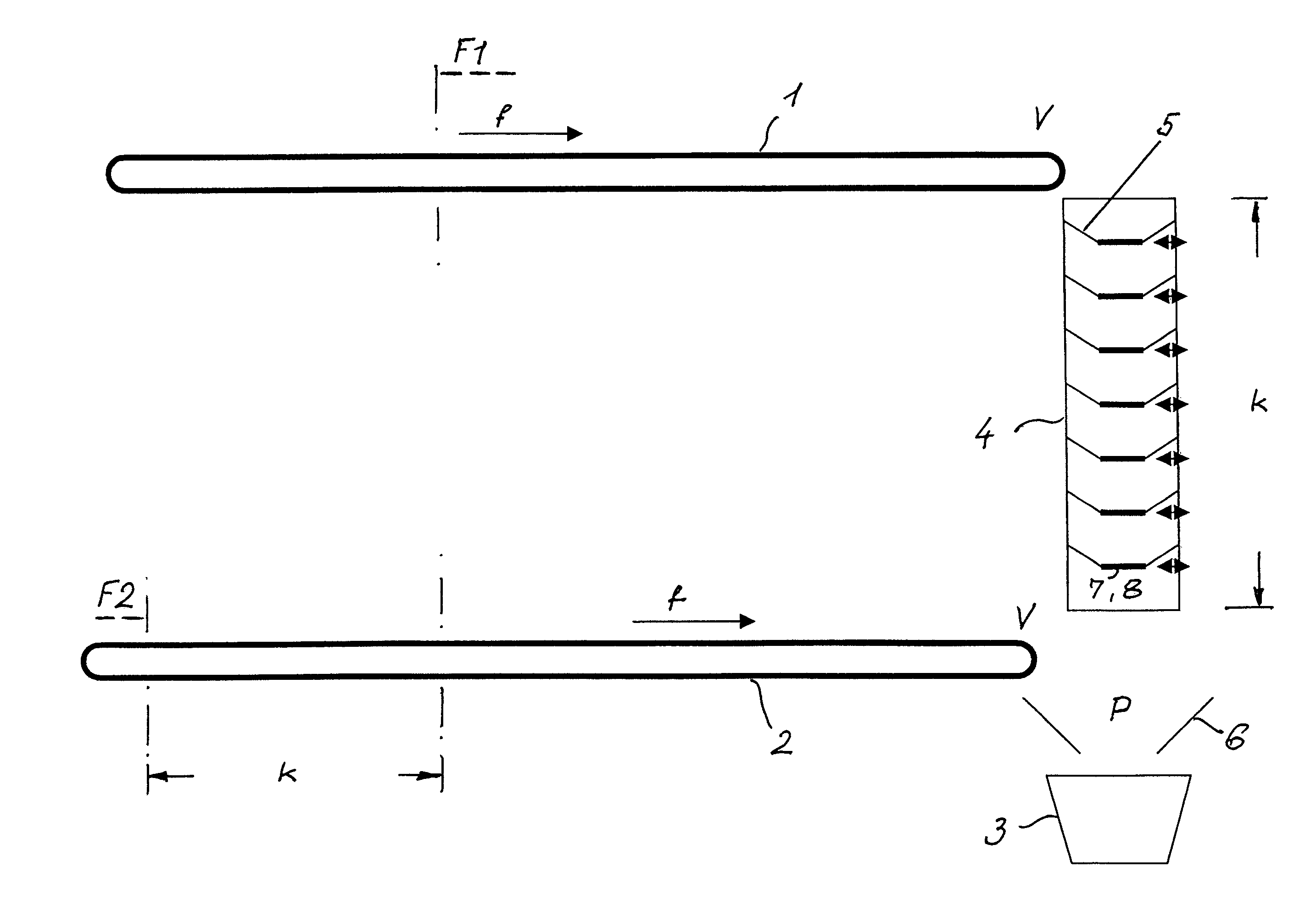

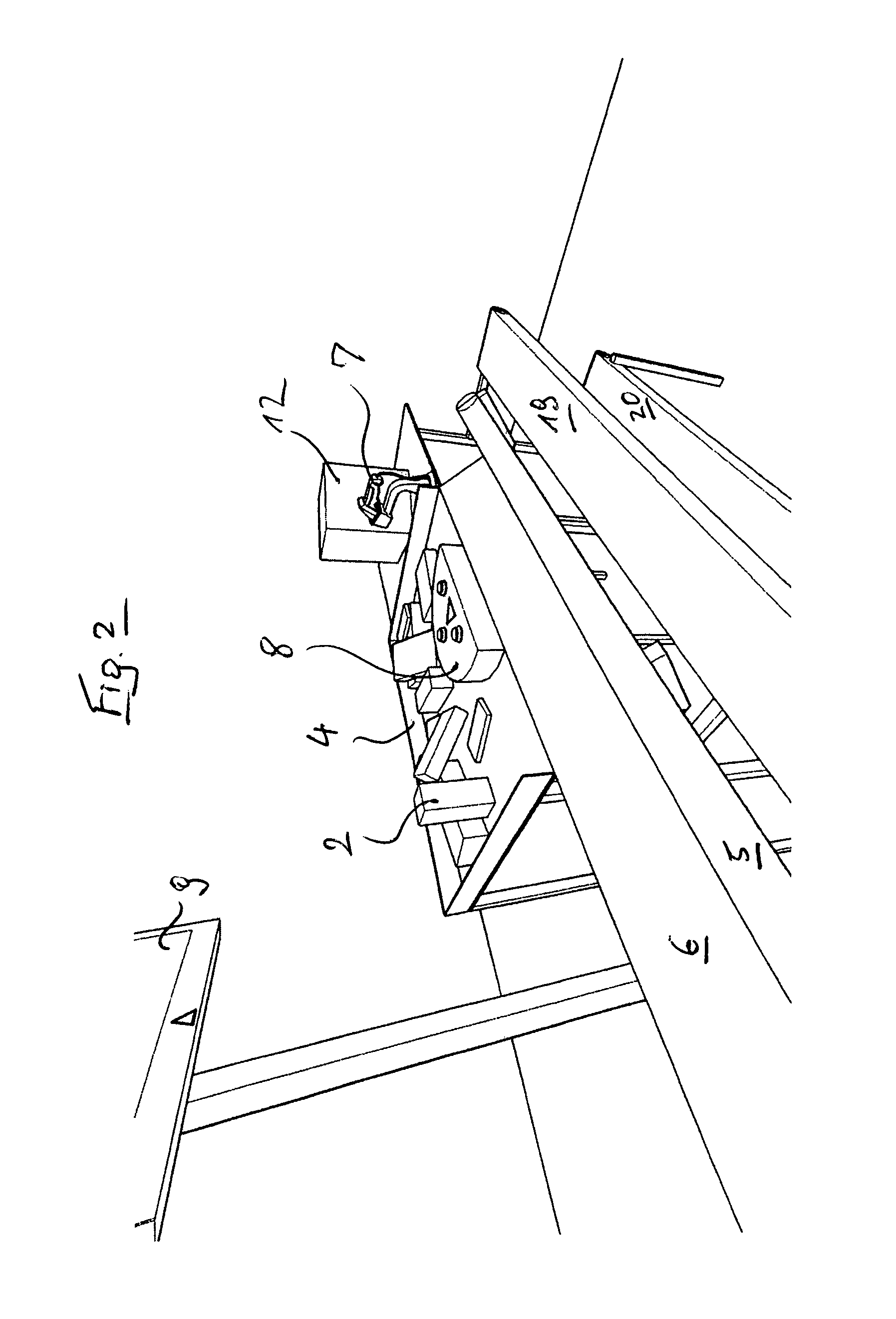

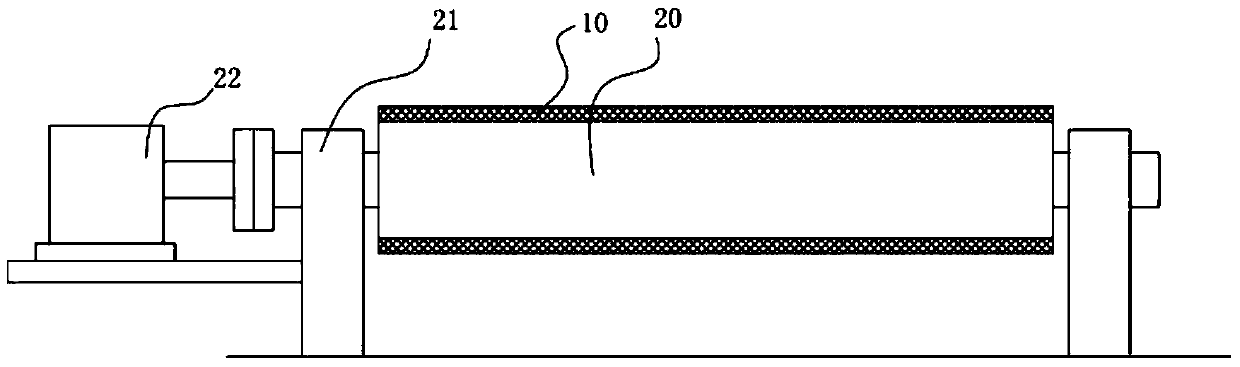

Process and central belt automatic unit for filling an order container in a commissioning system

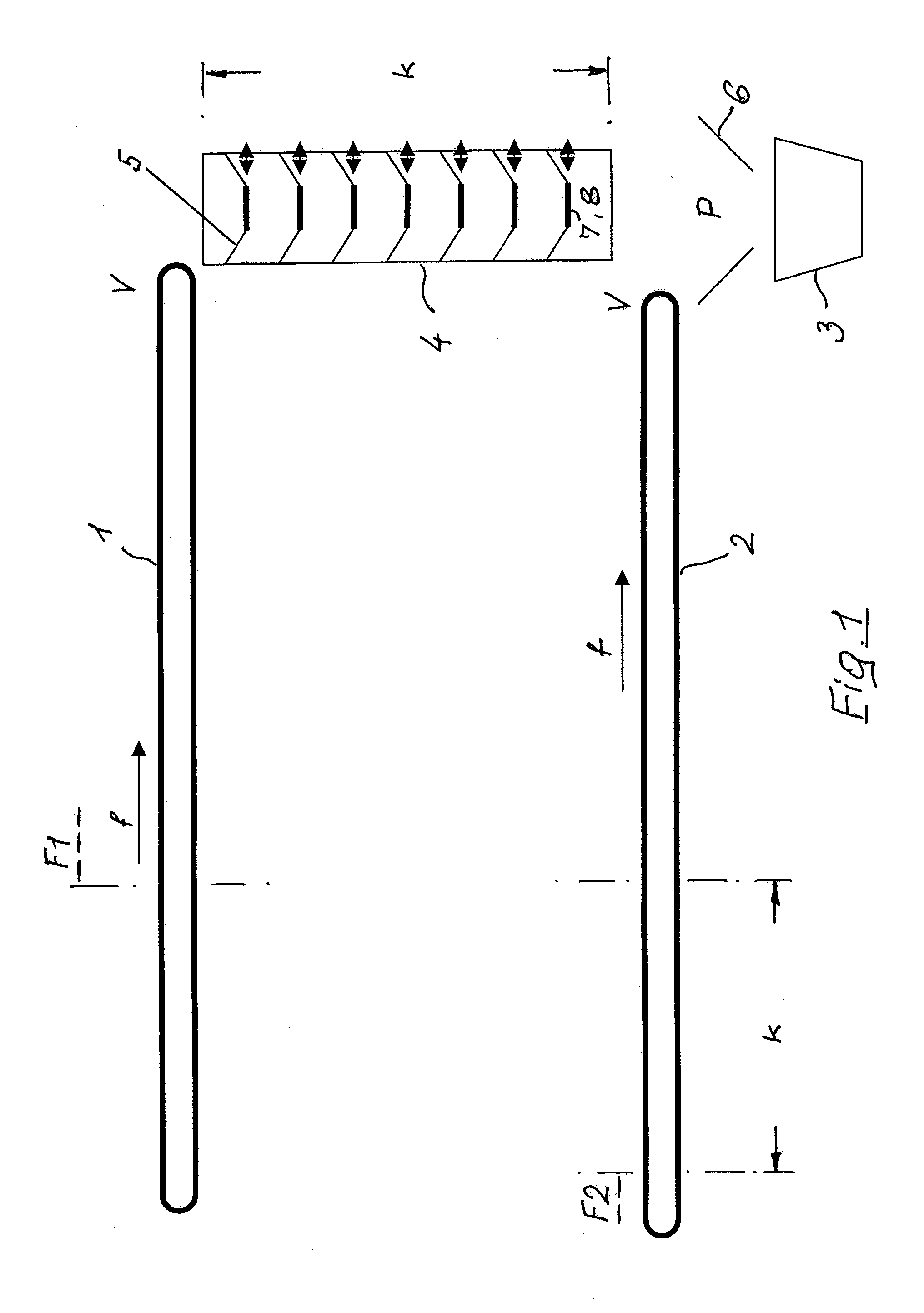

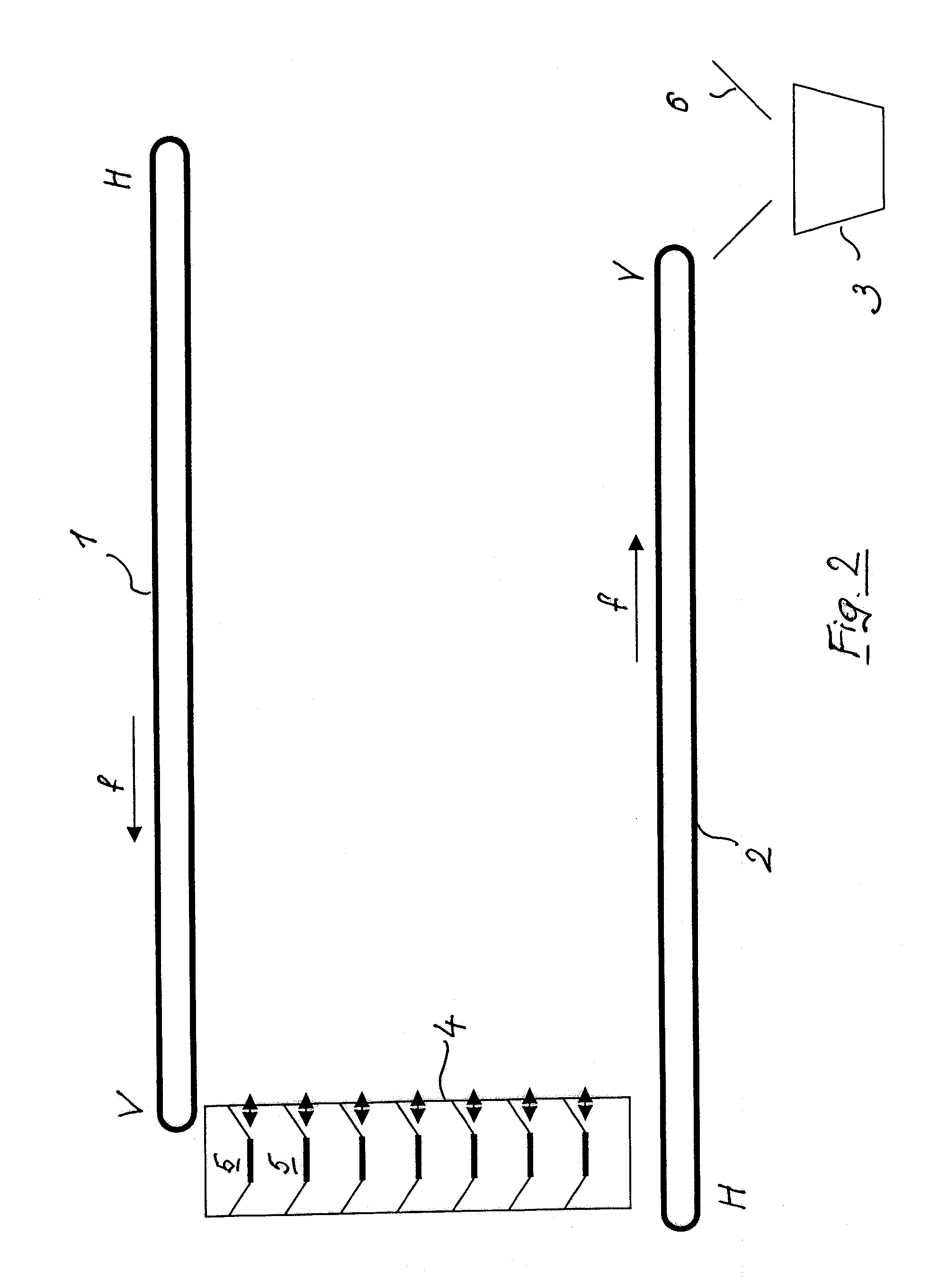

InactiveUS20090026017A1Convenient lengthSpace minimizationDigital data processing detailsBaby linensCentral beltOrder form

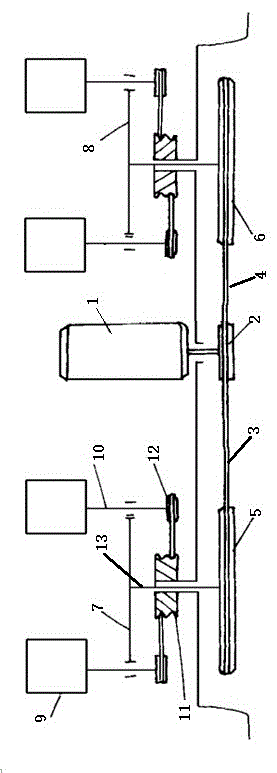

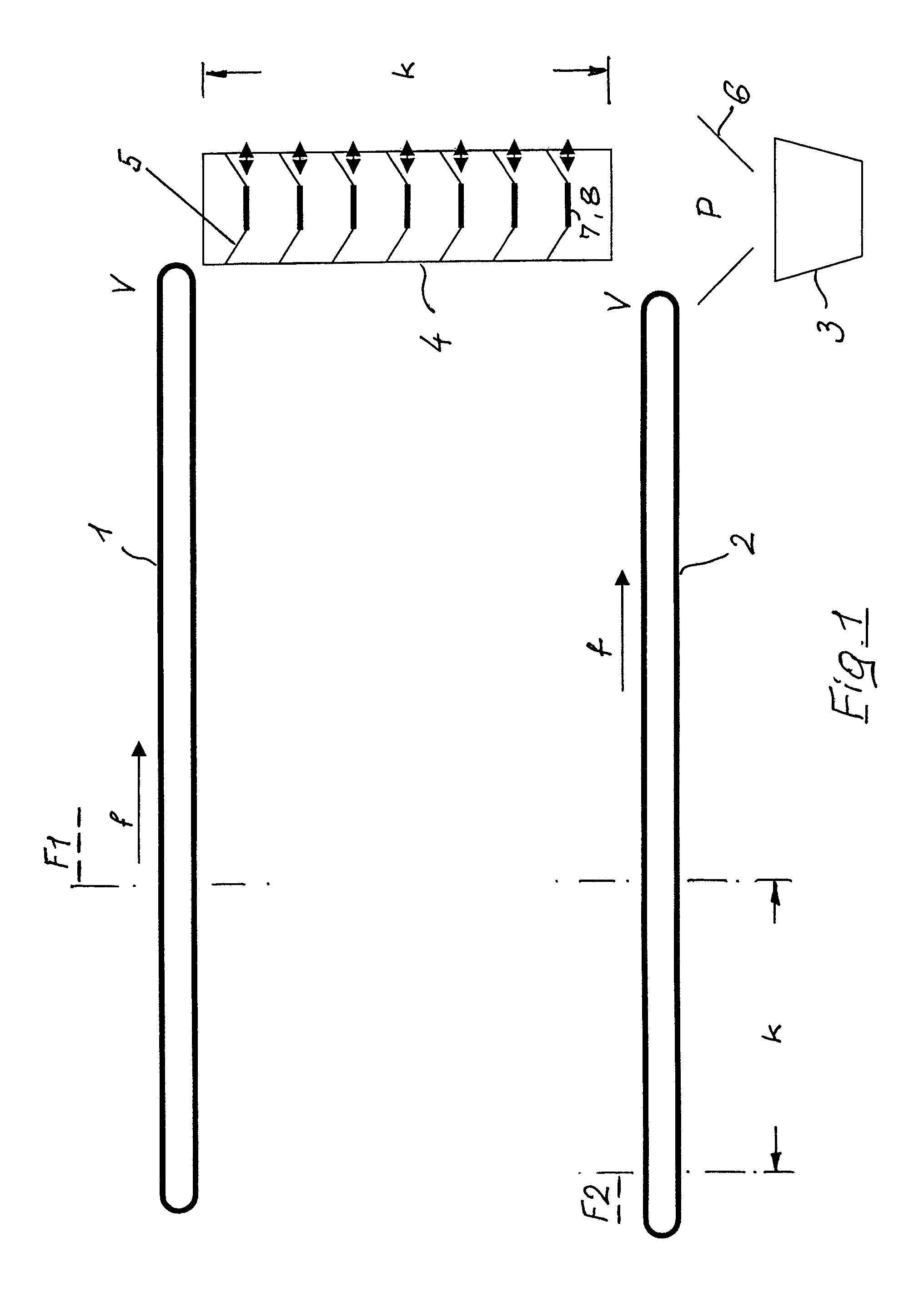

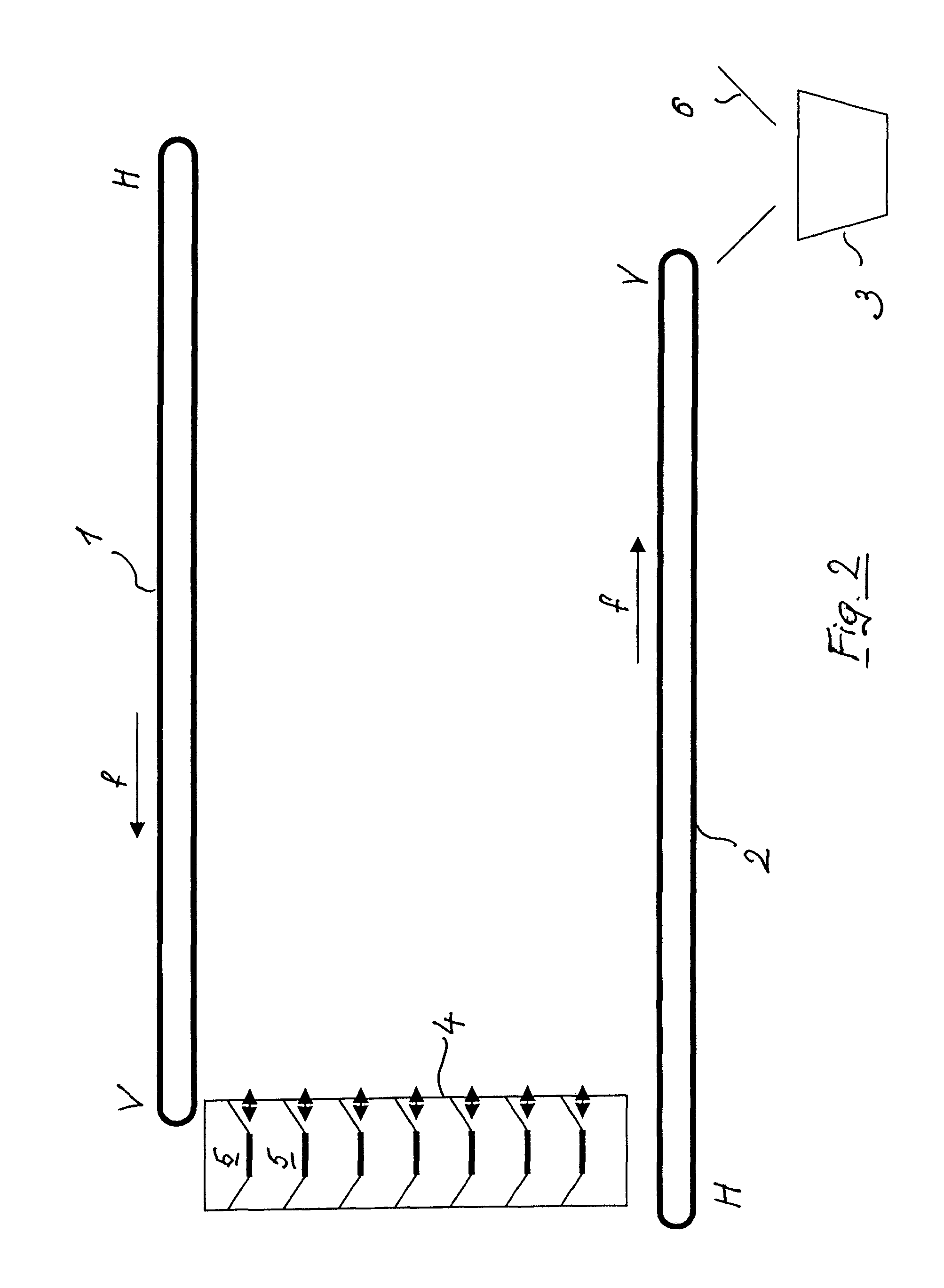

A method and a central-belt machine are provided for filling an order container. The central-belt machine includes two central belt provided with articles along a virtual window of an order, and the articles being discharged to the order container at a filling point at the front longitudinal end (V) of the central belt. The two central belts (1, 2) of the central-belt machine, are arranged vertically one above the other, to fill the order container (3), for an order, by at least one interposed vertical conveyor (4) at a single filling point (P) of the lower central belt (2).

Owner:KNAPP LOGISTIK AUTOMATION GES

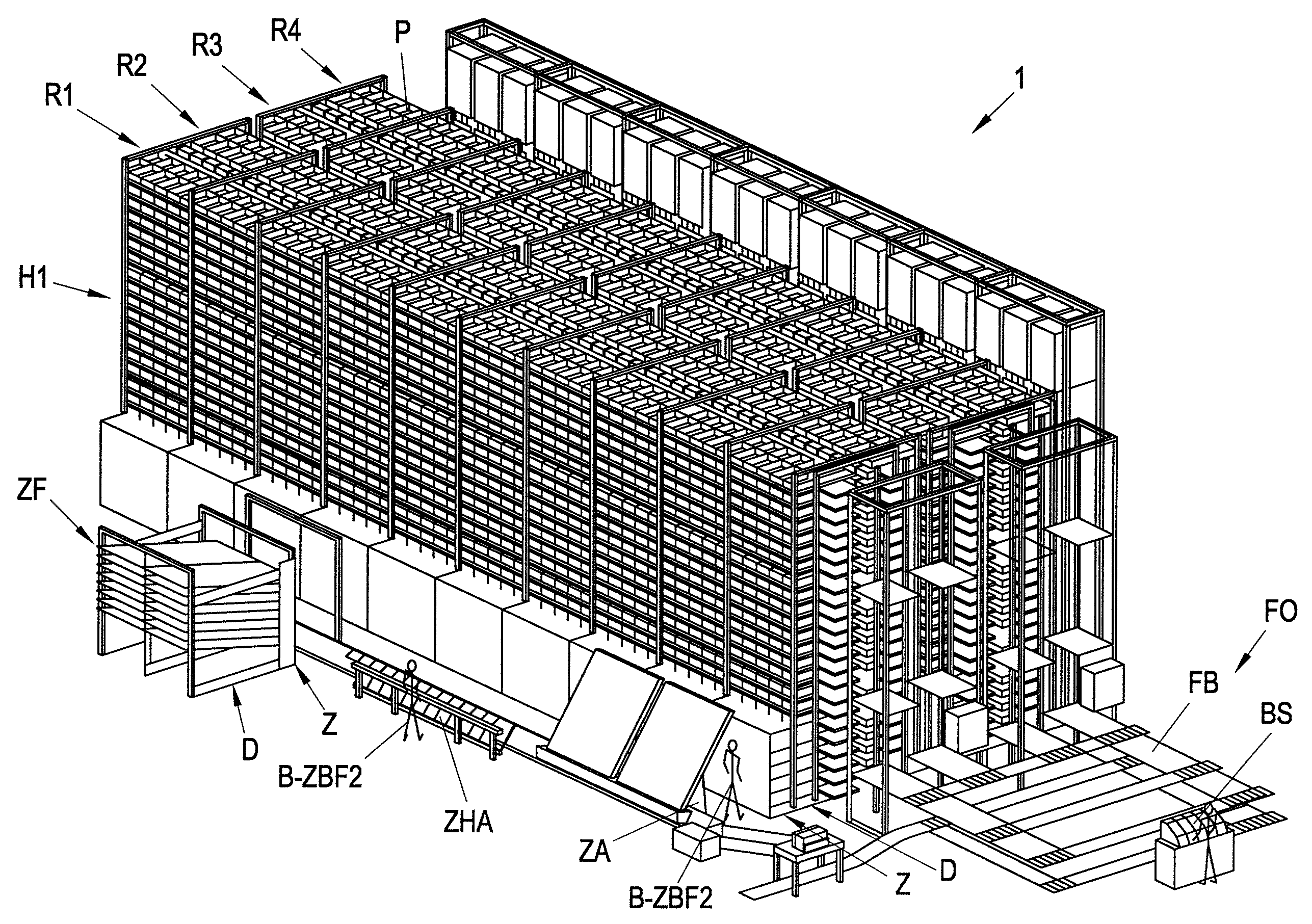

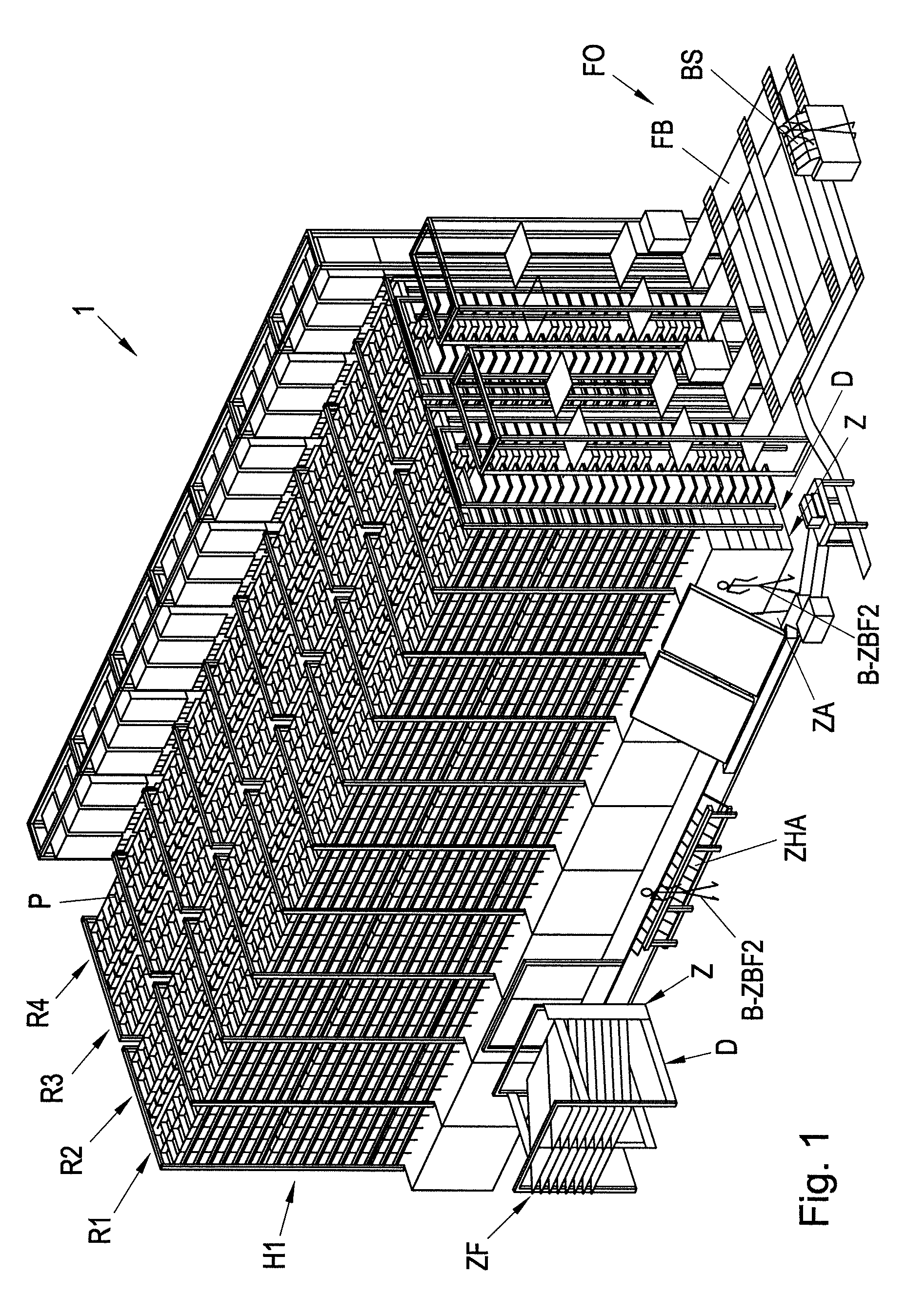

Storage and picking system

ActiveUS8965560B2Avoid less flexibilityImprove performanceDigital data processing detailsStorage devicesProduct typeTransport system

A method for order picking products in an order picking facility having at least one rack for storing products and an assigned warehouse transport system for collecting and storing the products and for transferring the collected products to a transport system, by means of which the collected products are transported to a good-to-picker order picking station, at which the quantity of the collected products that is determined in a picking order is order-picked manually or automatically by a robot, into one order transport unit for each picking order. Product types corresponding to the picking order are collected, order-picked at the good-to-picker order picking station, one after the other, and the remaining products of the product type are stored via the transport system again in the rack. The warehouse transport system further transfers collected products via at least one through-channel to an intermediate storage site of a order picking station, from where collected products are manually or automatically by robot, supplied to a central belt assembly on a central belt. Irrespective of whether a product is to be order picked at the good-to-picker order picking station or at the order picking station, the product is collected from the same storage site of the rack.

Owner:KNAPP AG +1

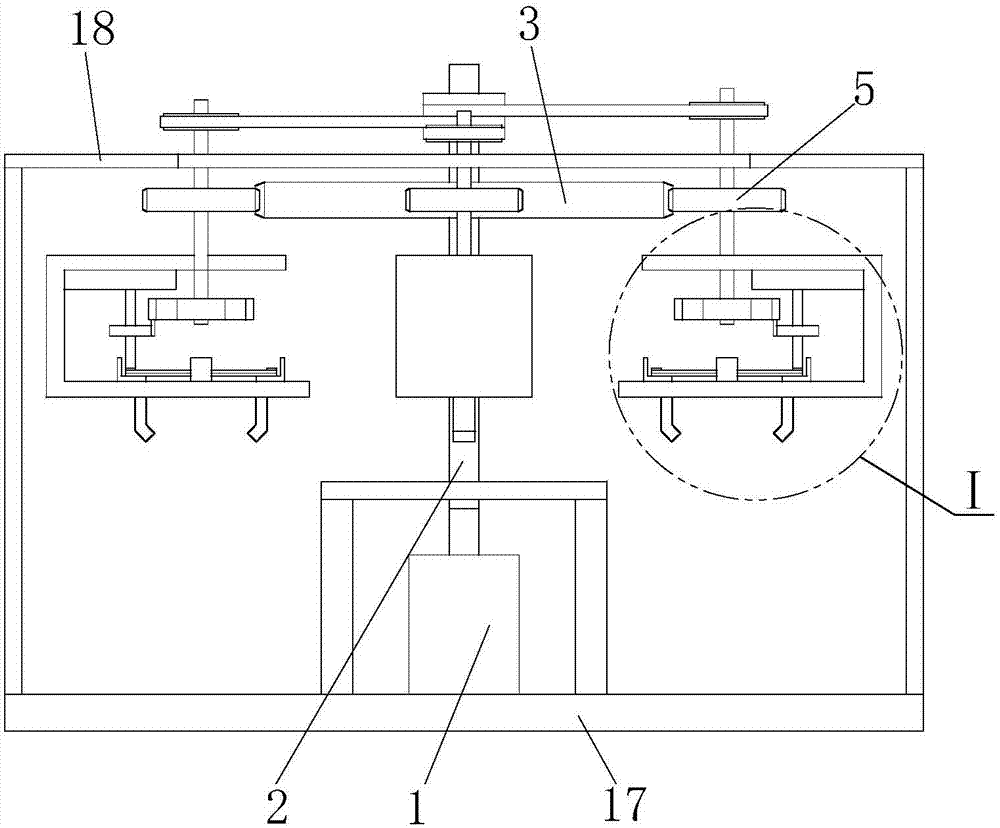

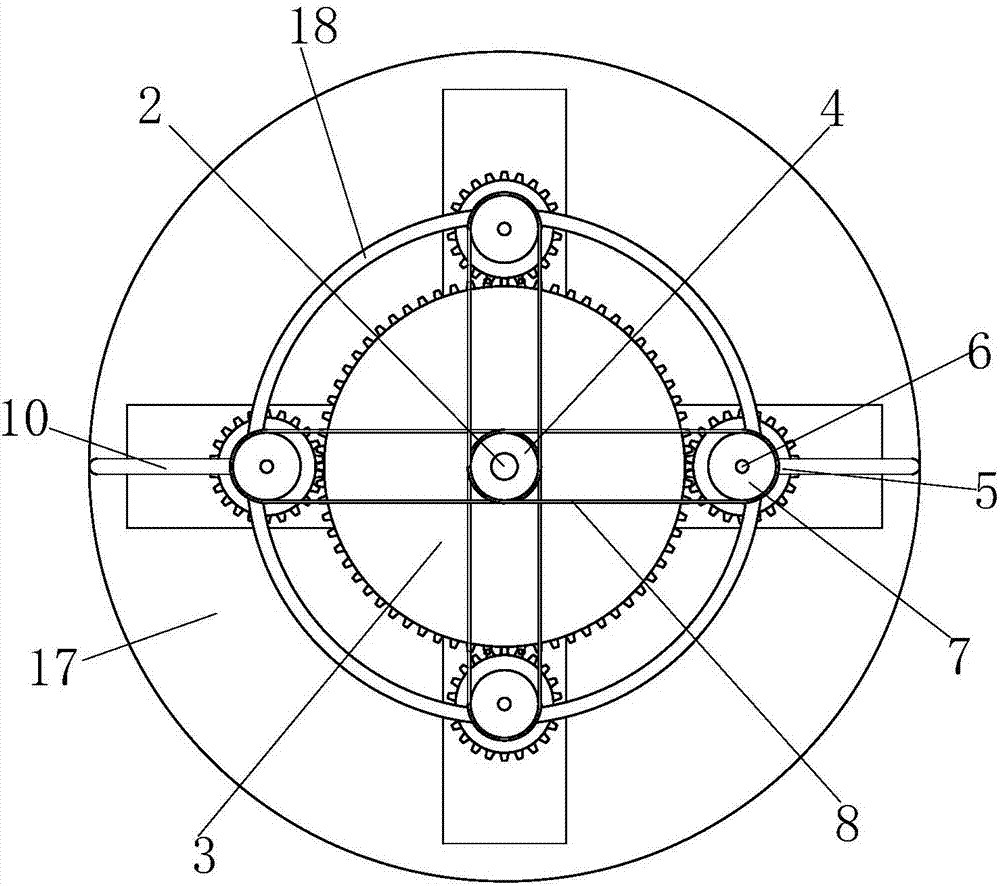

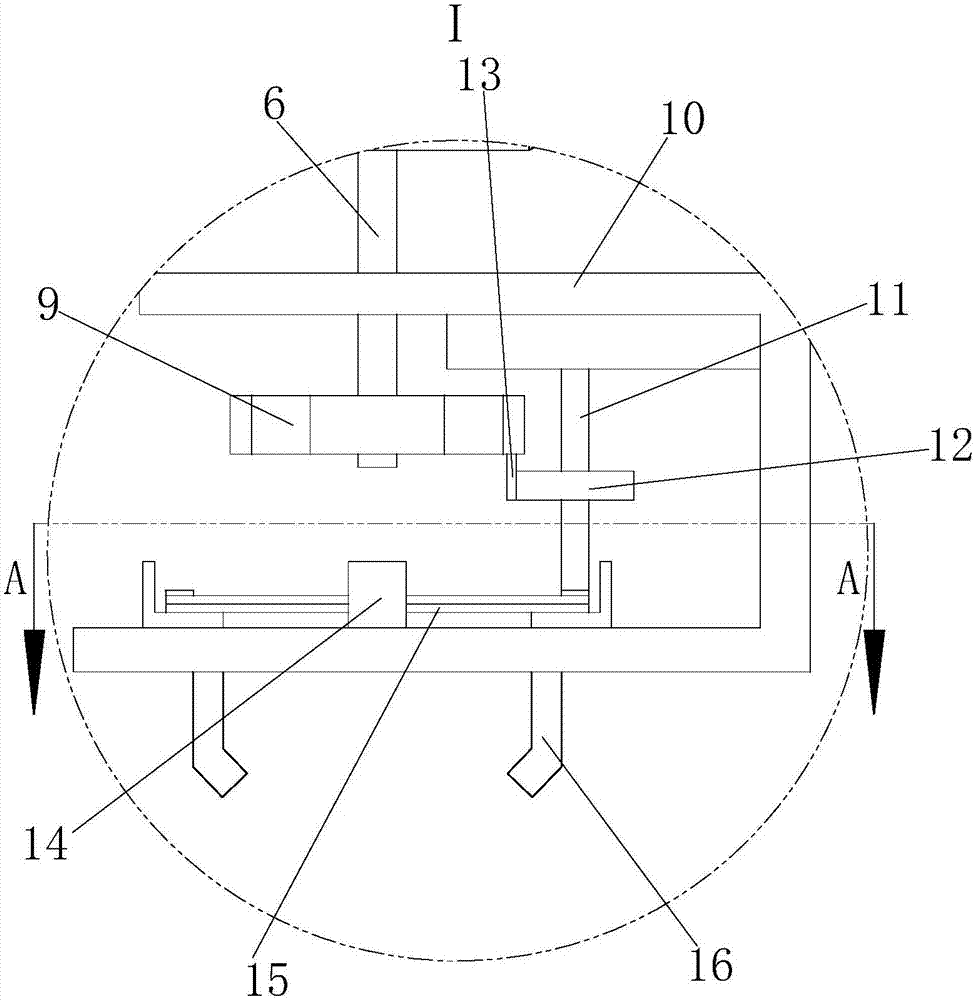

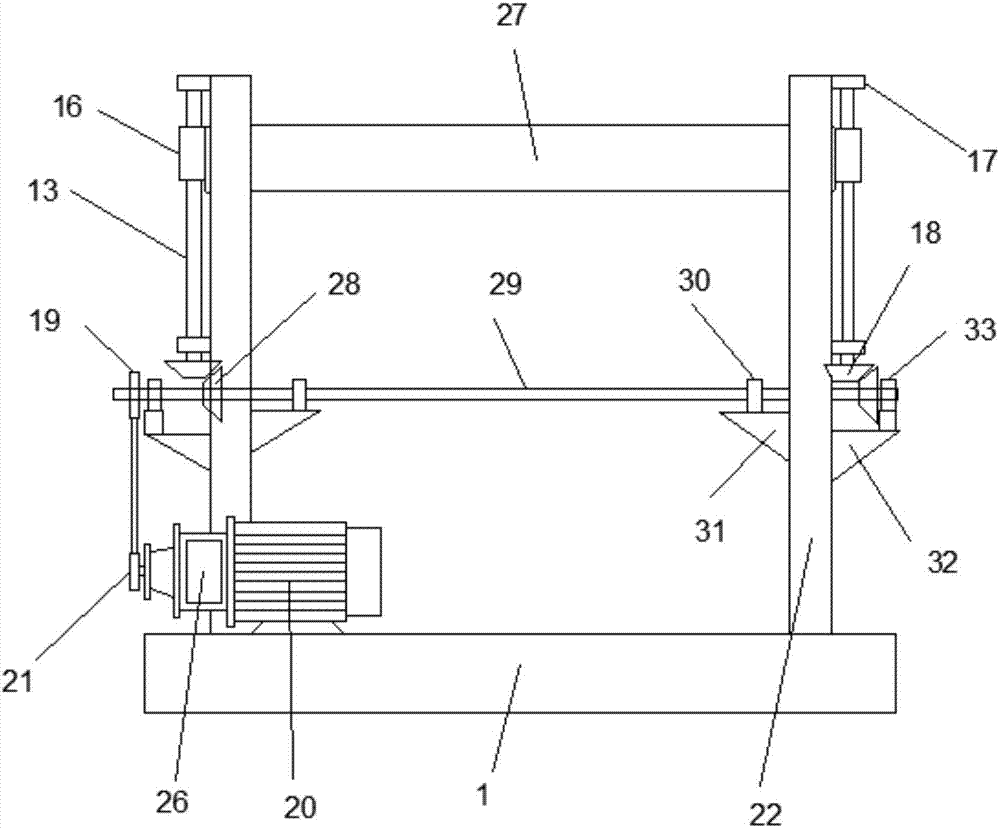

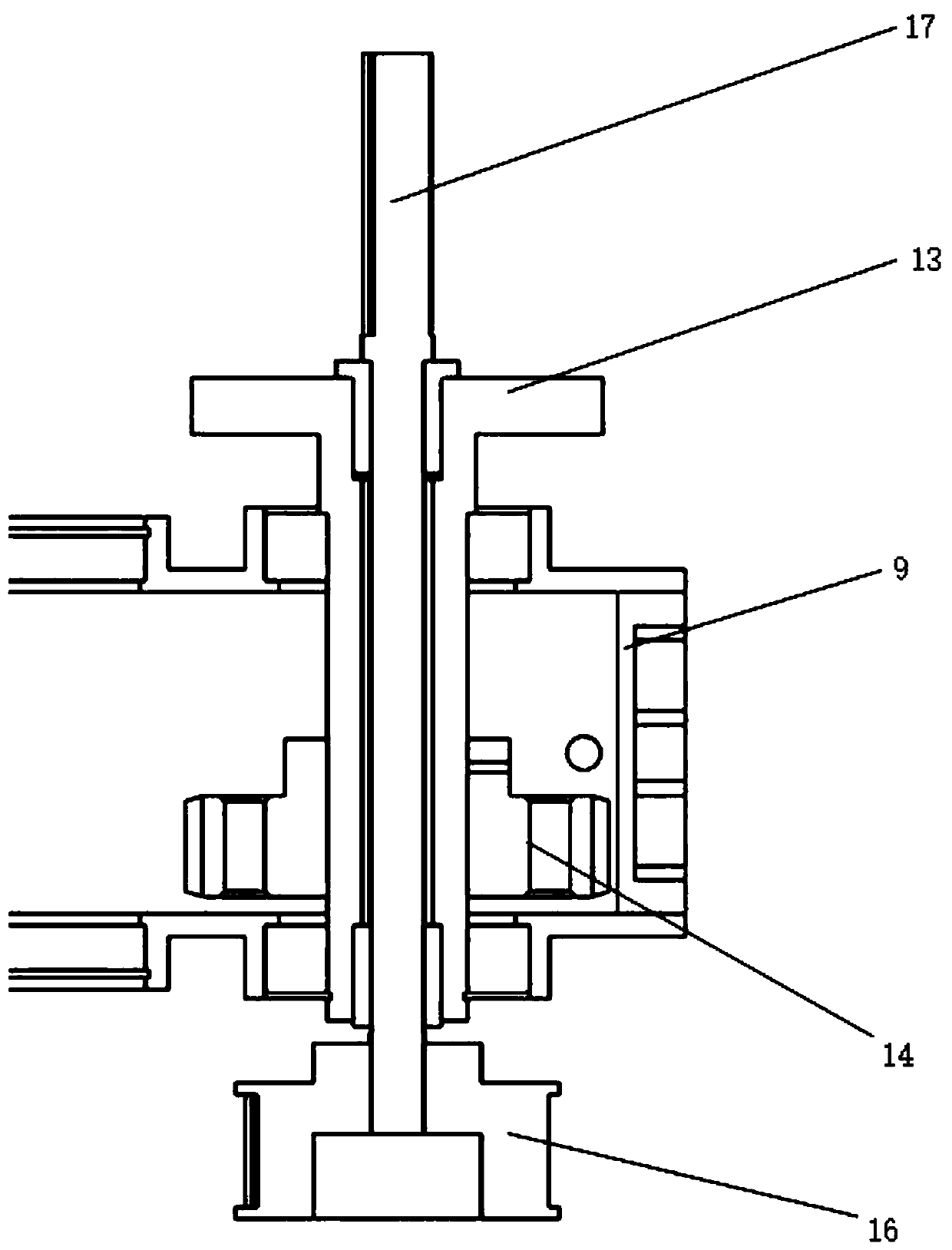

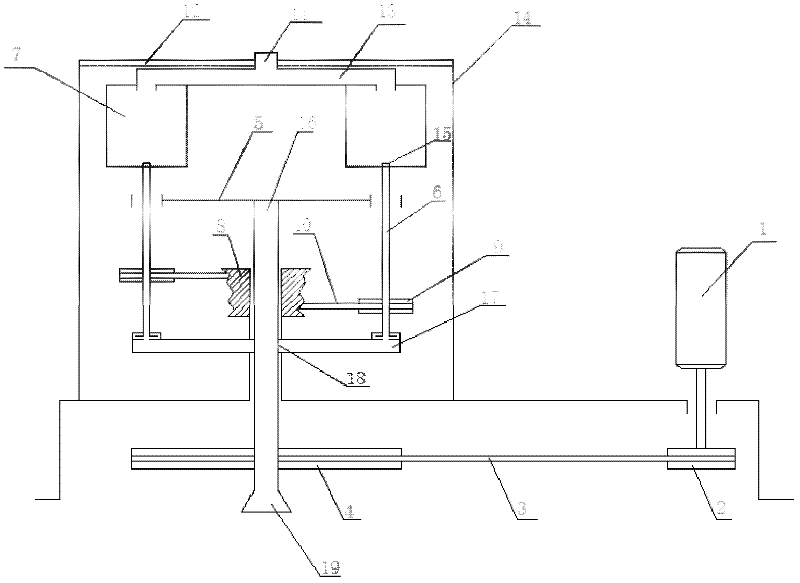

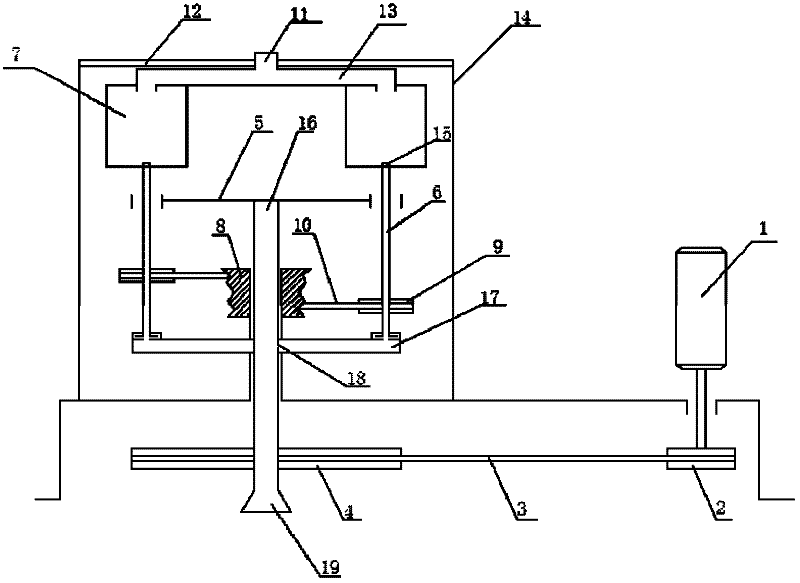

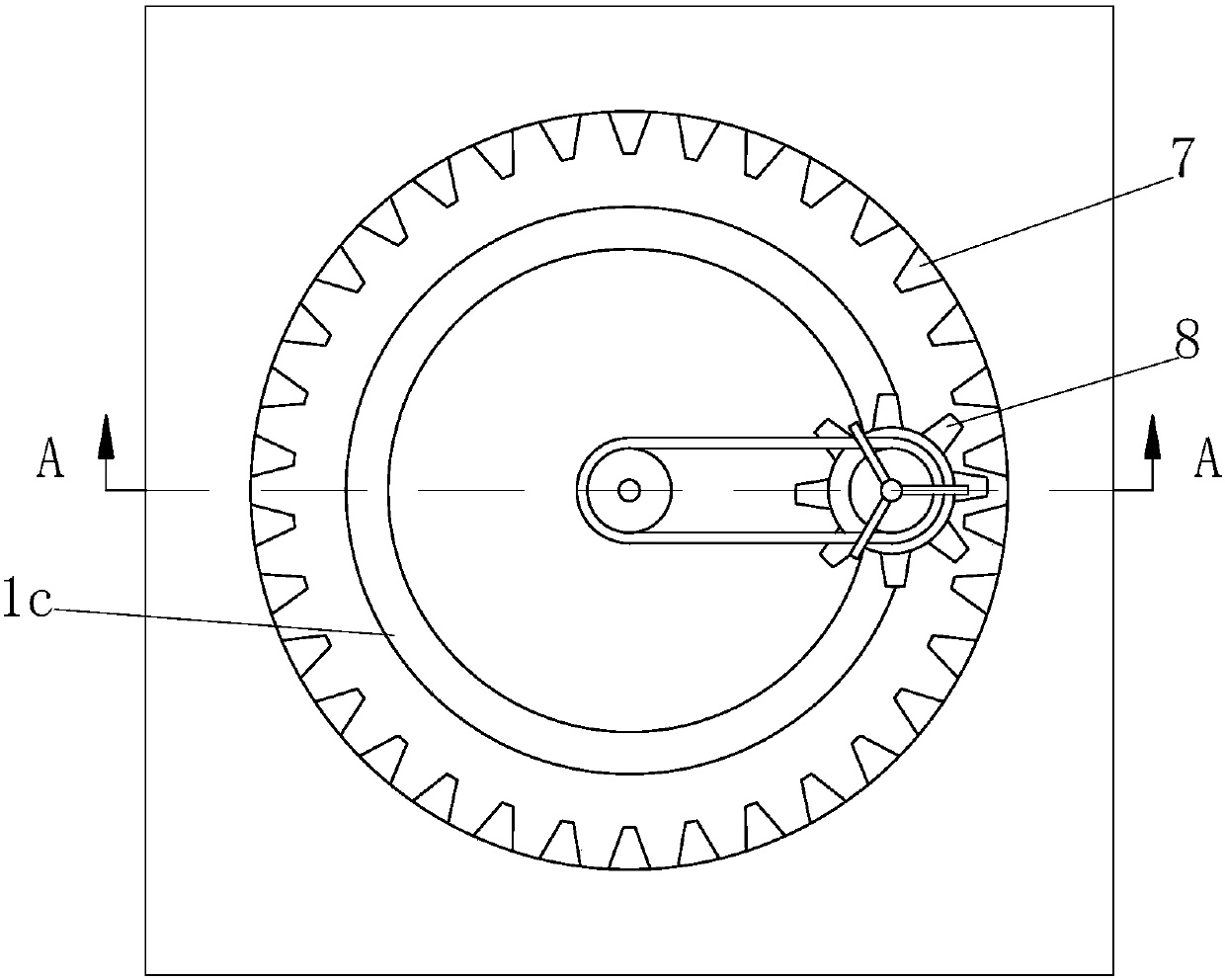

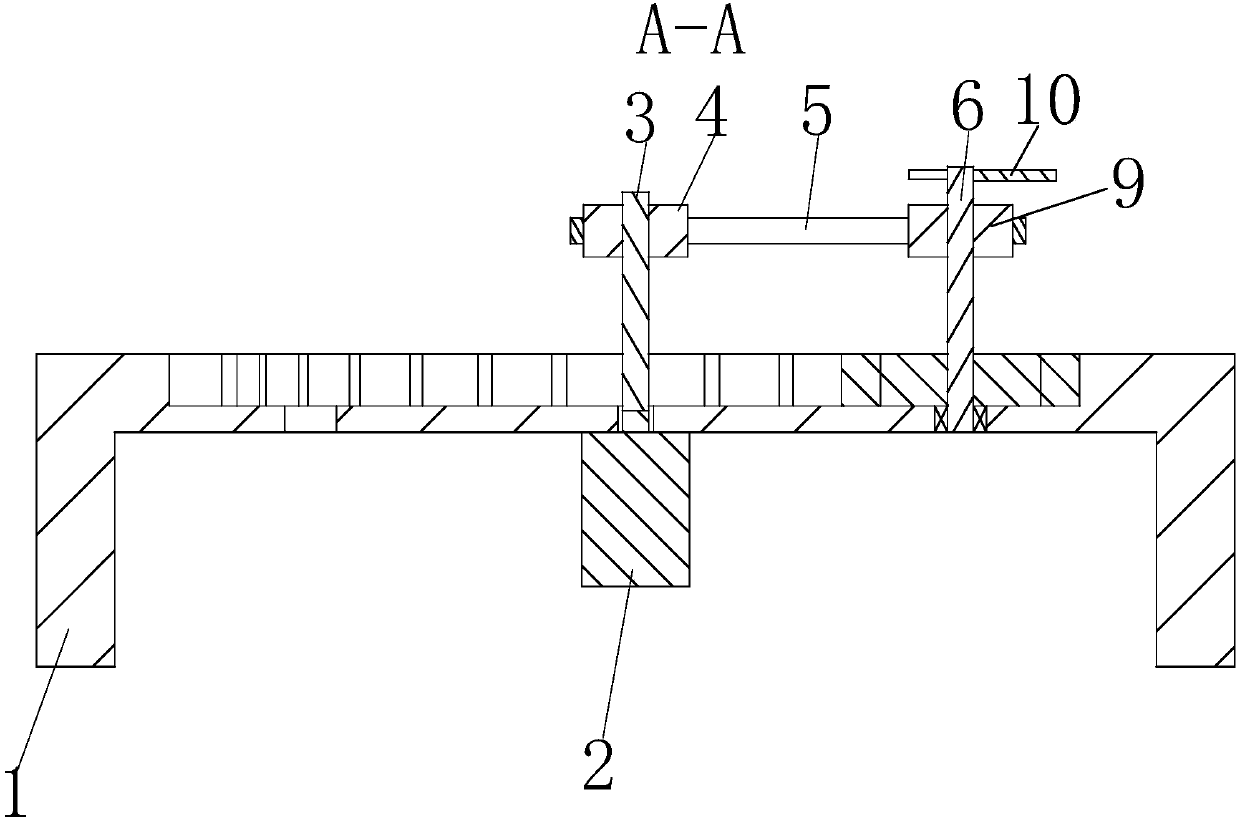

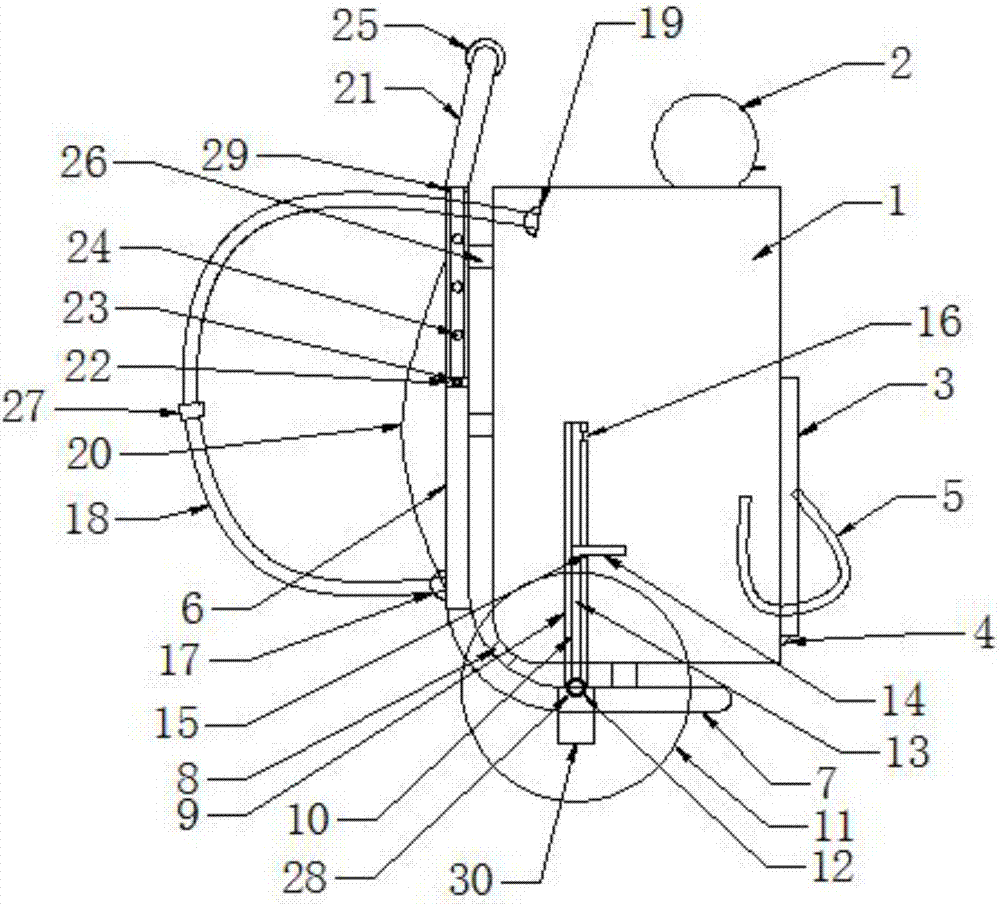

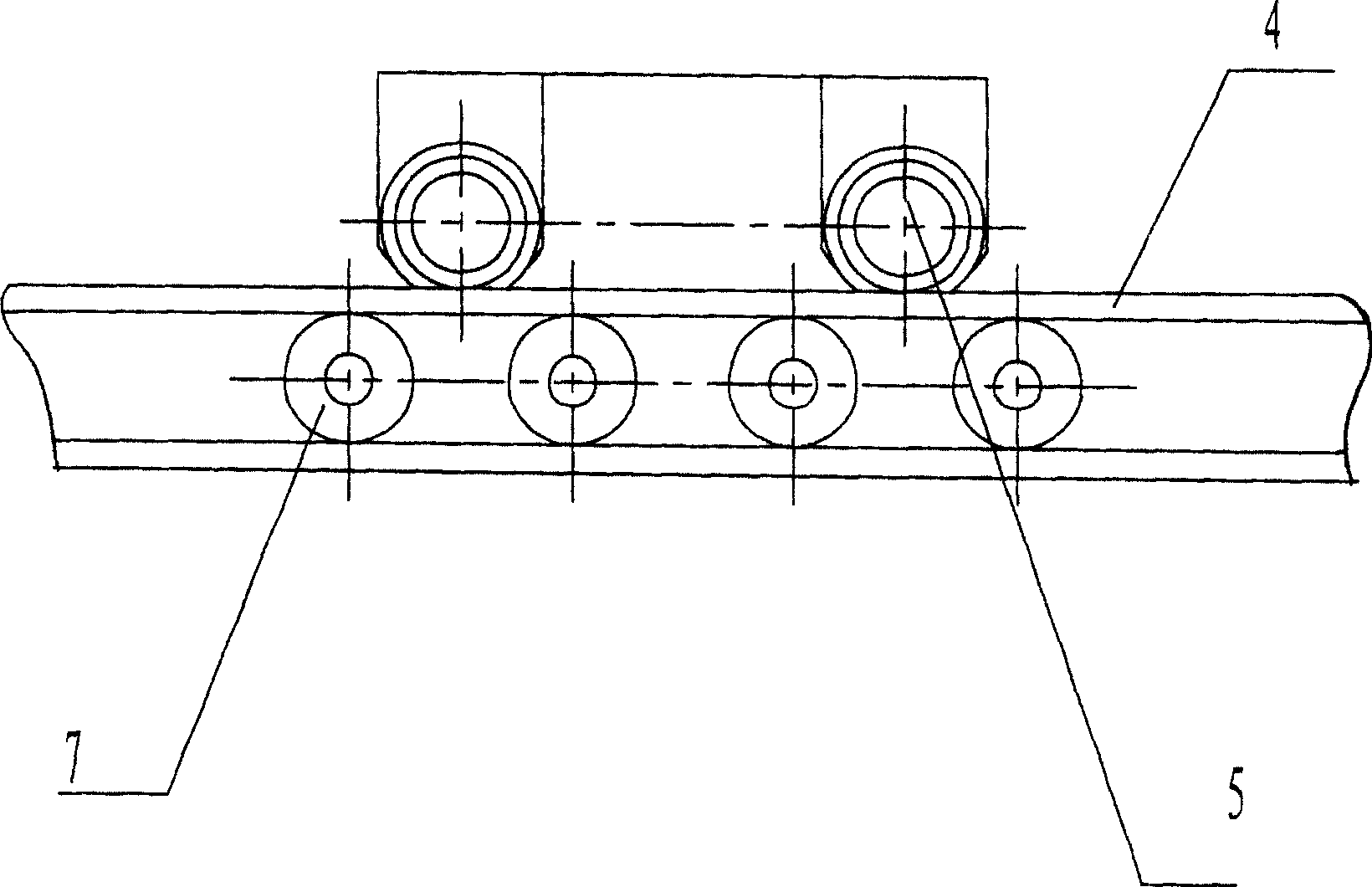

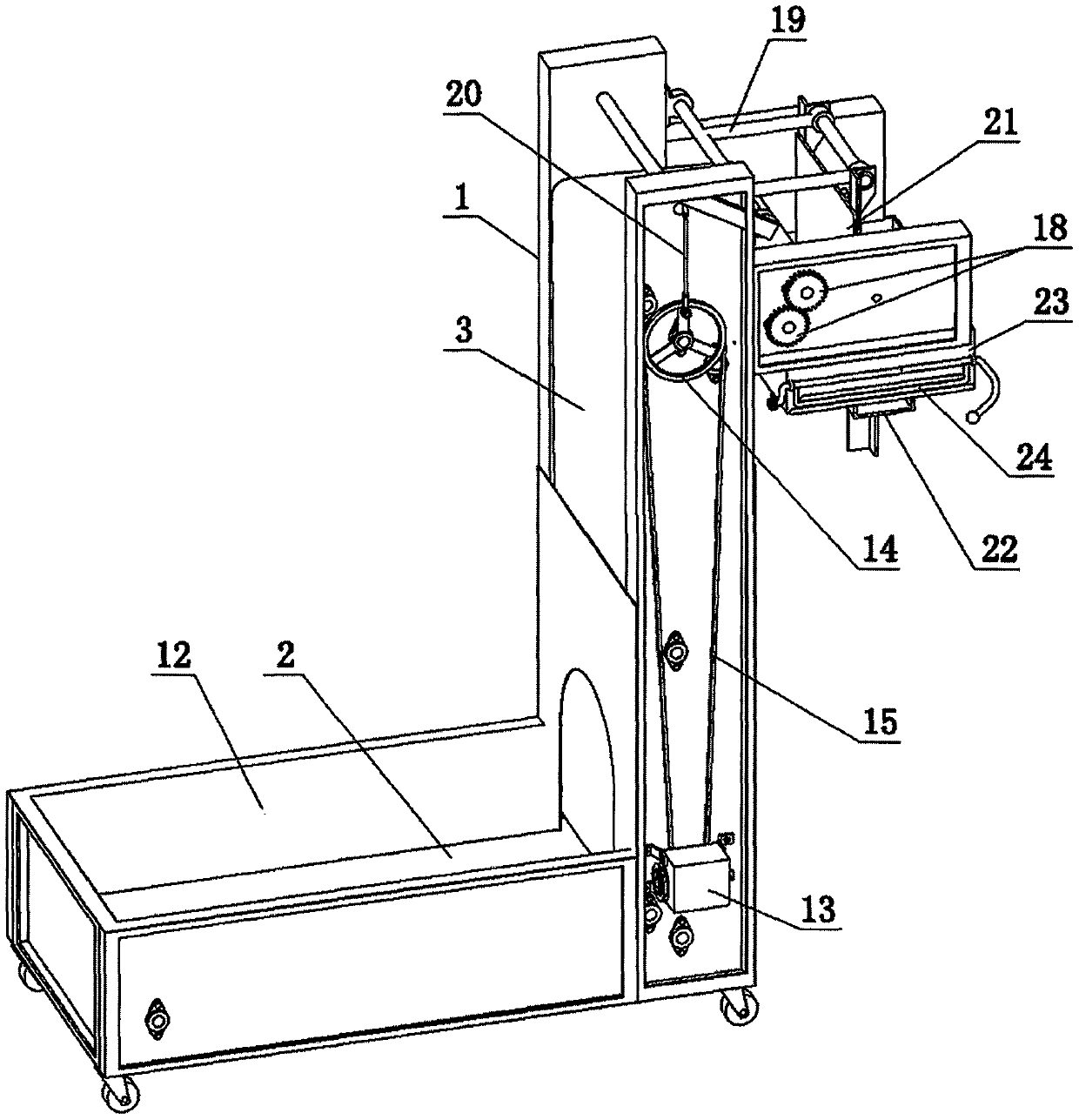

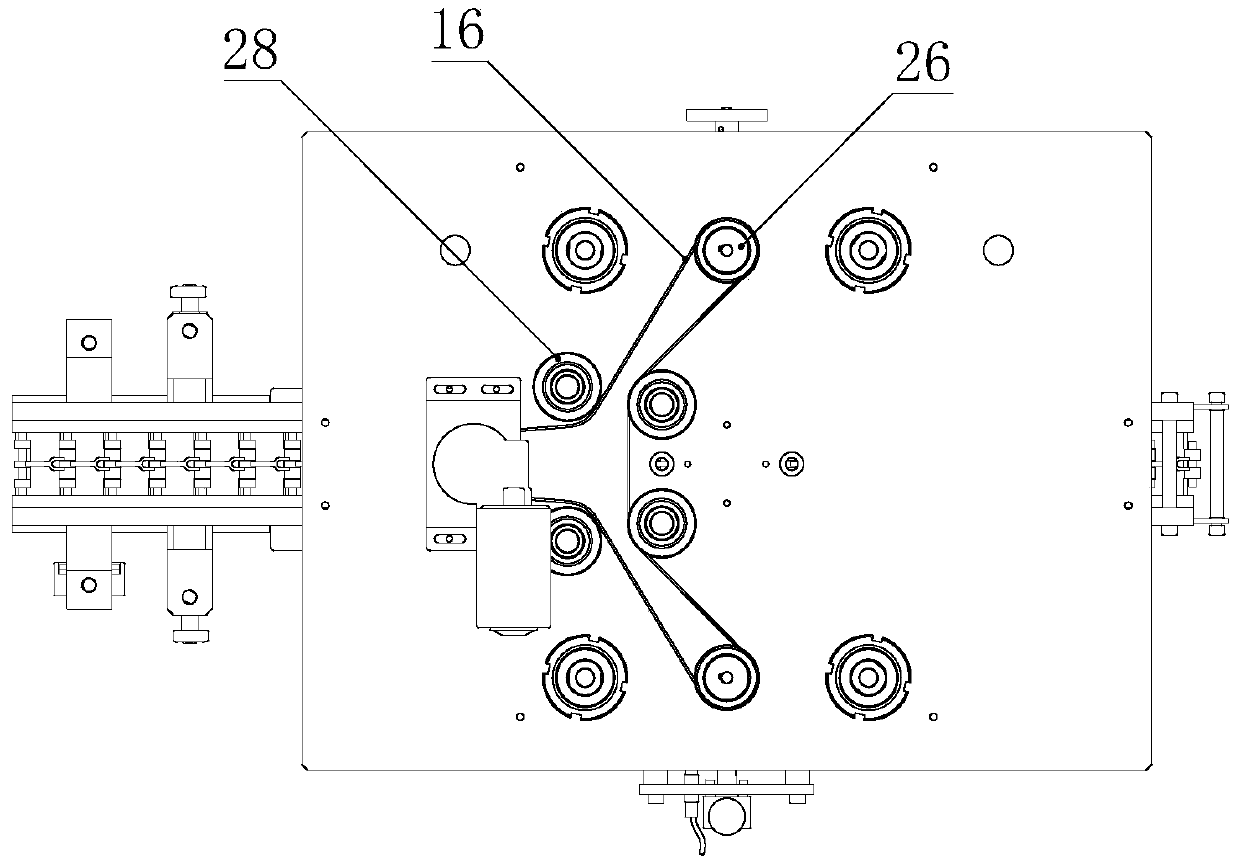

Power delivery device applied to annular processing line

The invention relates to a power delivery device applied to an annular processing line. The power delivery device comprises a bottom plate and a motor, wherein the motor is connected with a central shaft, a large gear and a central belt wheel are connected to the upper end of the central shaft, four pinions are uniformly distributed around the large gear, each pinion is connected with a secondary shaft, each secondary shaft is connected with a secondary belt wheel, and a belt is arranged between each secondary belt wheel and the central belt wheel; and an auxiliary frame is arranged on the bottom plate. According to the power delivery device disclosed by the invention, the effect of carrying out one-by-one stopping conveying processing on raw materials subjected to batch processing in the form of a flow line is achieved through controlling a plurality of pairs of clamping blocks to carry out clamping release and stopping in the clamping release on the basis of controlling a follow-up frame to rotate at a constant speed to transport, so that the processing efficiency can be effectively increased.

Owner:山东爱舒乐卫生用品有限责任公司

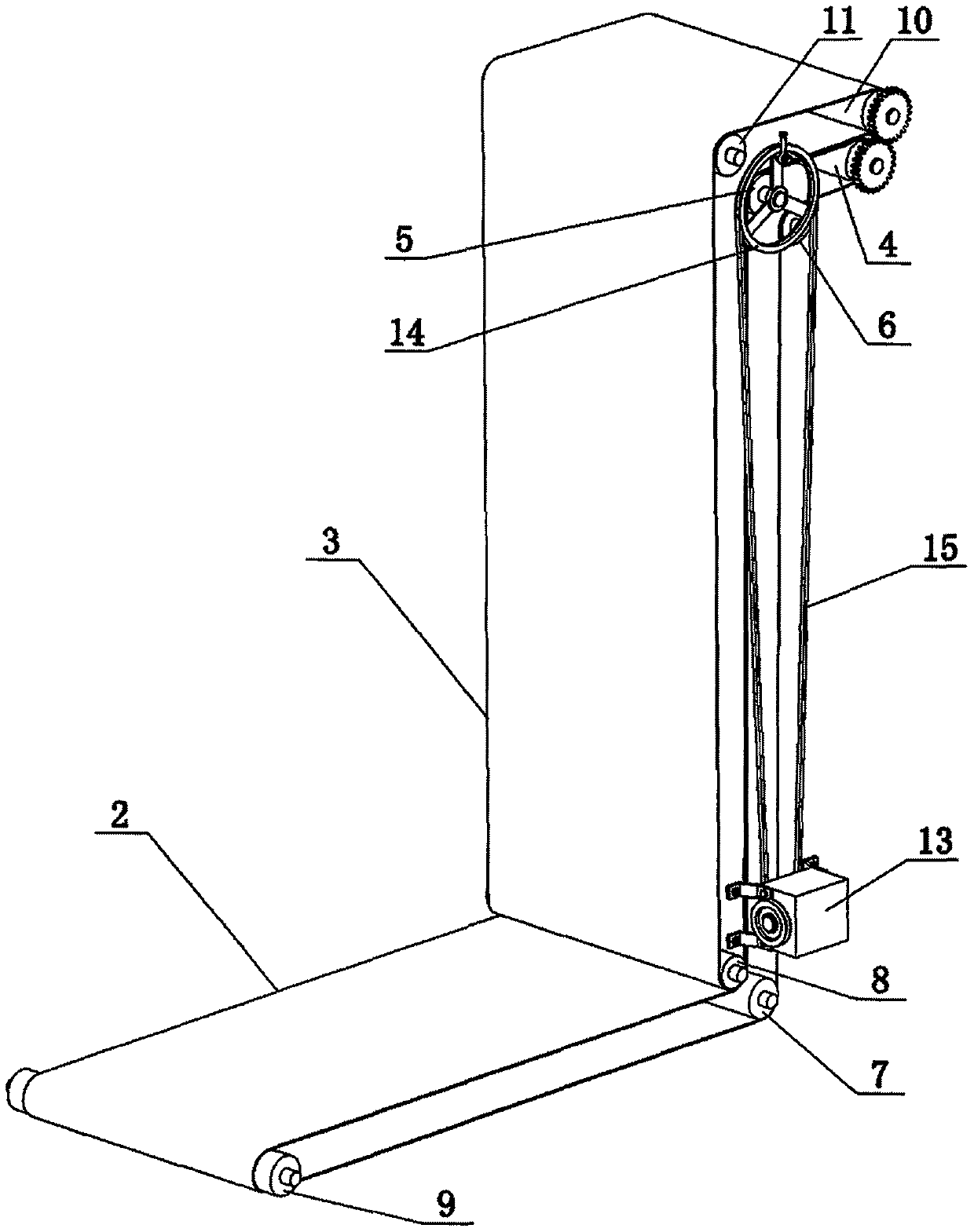

Quick cleaning device for building French window

The invention discloses a quick cleaning device for floor-to-ceiling windows of a building, which comprises a support seat, a water storage tank is connected to the middle part of the upper end of the support seat, a water diversion chamber is arranged at the right end inside the water storage tank, a water diversion pump is arranged inside the water diversion chamber, and the upper end of the support seat is connected to the right side. There is a support frame, the bottom of the front support frame is provided with a drive motor, the front end of the drive motor is connected to a reducer, the reducer is connected to a driving pulley, the upper end of the drive pulley is connected to a driven belt through a belt, and the middle part of the driven belt is connected to a rotating belt. Rod, the middle part of both ends of the rotating rod is connected with a rotating gear, the upper end of the rotating gear is meshed with a driving gear, the middle part of the upper end of the driving gear is connected with a driving screw, the middle part of the driving screw is connected with a slider, the sliders are connected with a lifting plate, and the right end of the lifting plate is connected There is a cleaning rod, and the right end of the cleaning rod is connected with a cleaning device. The present invention realizes the up and down movement of the cleaning device, increases the cleaning efficiency of the floor-to-ceiling windows of buildings, and makes it unnecessary to spray water additionally when cleaning the floor-to-ceiling windows.

Owner:李群珍

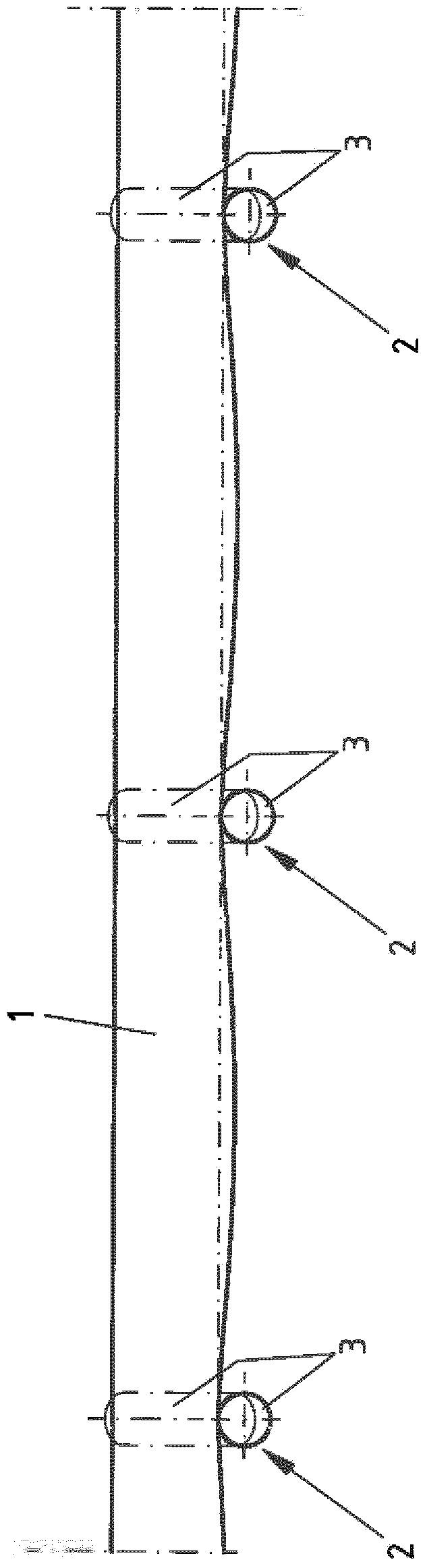

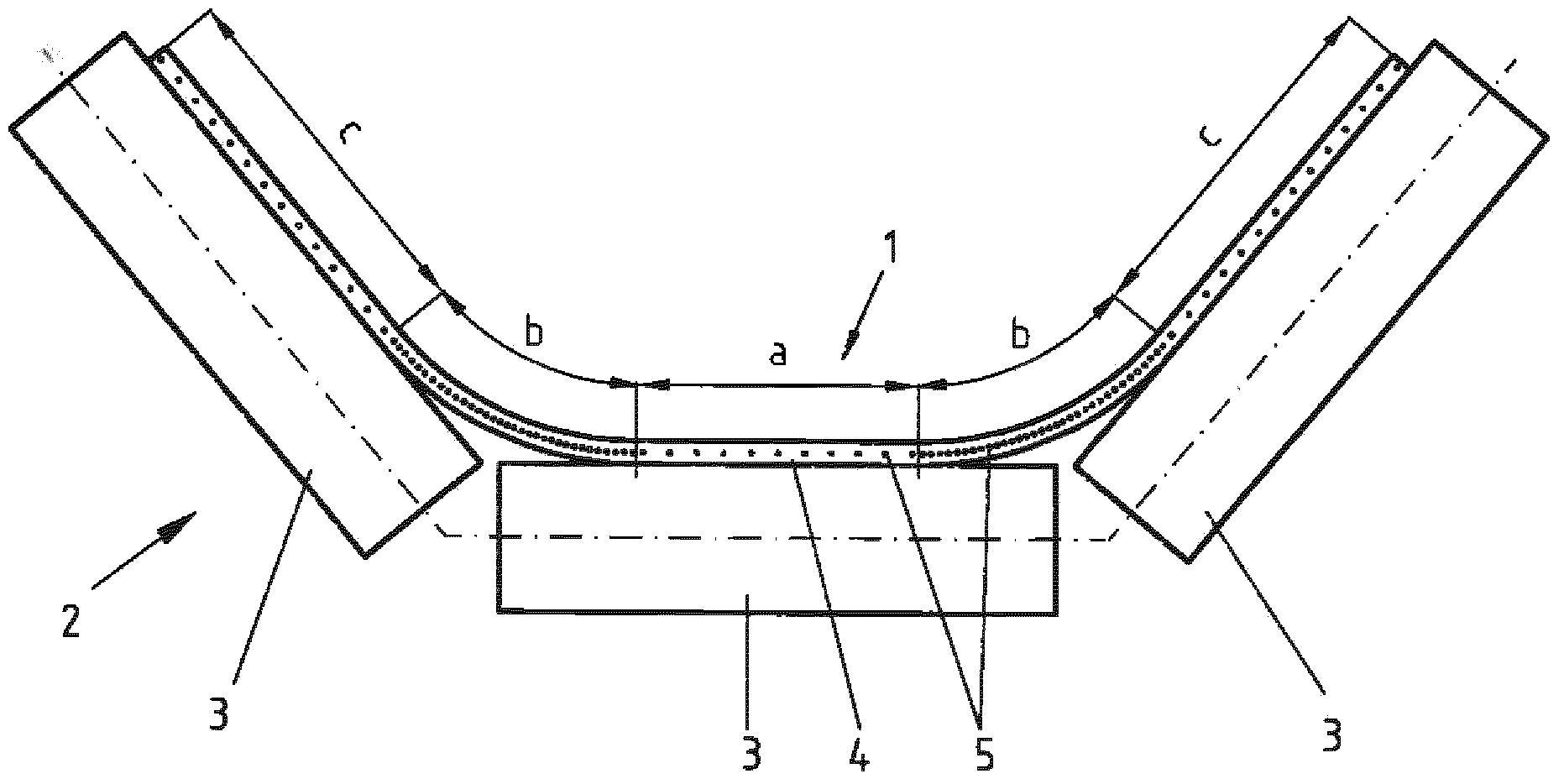

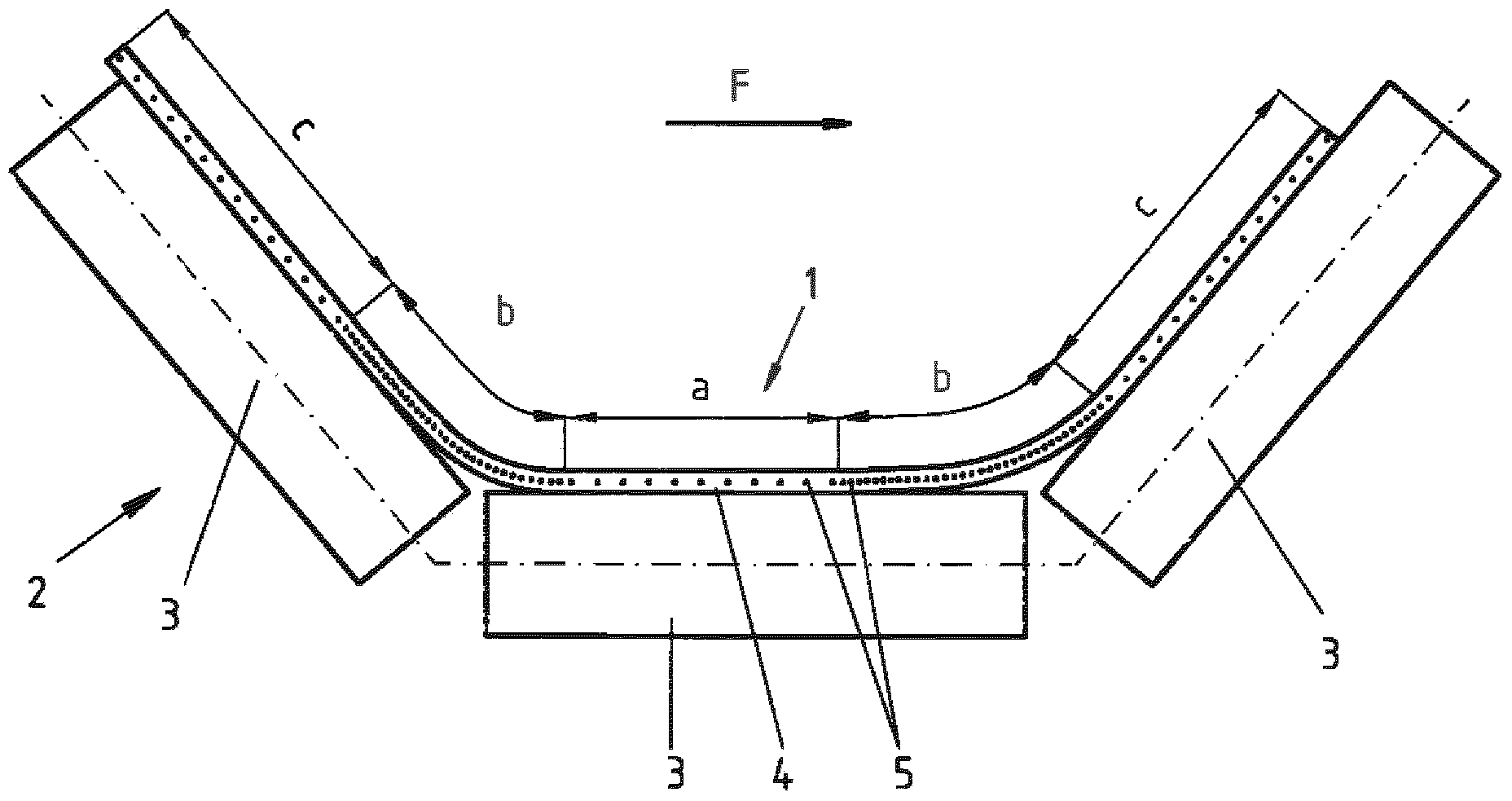

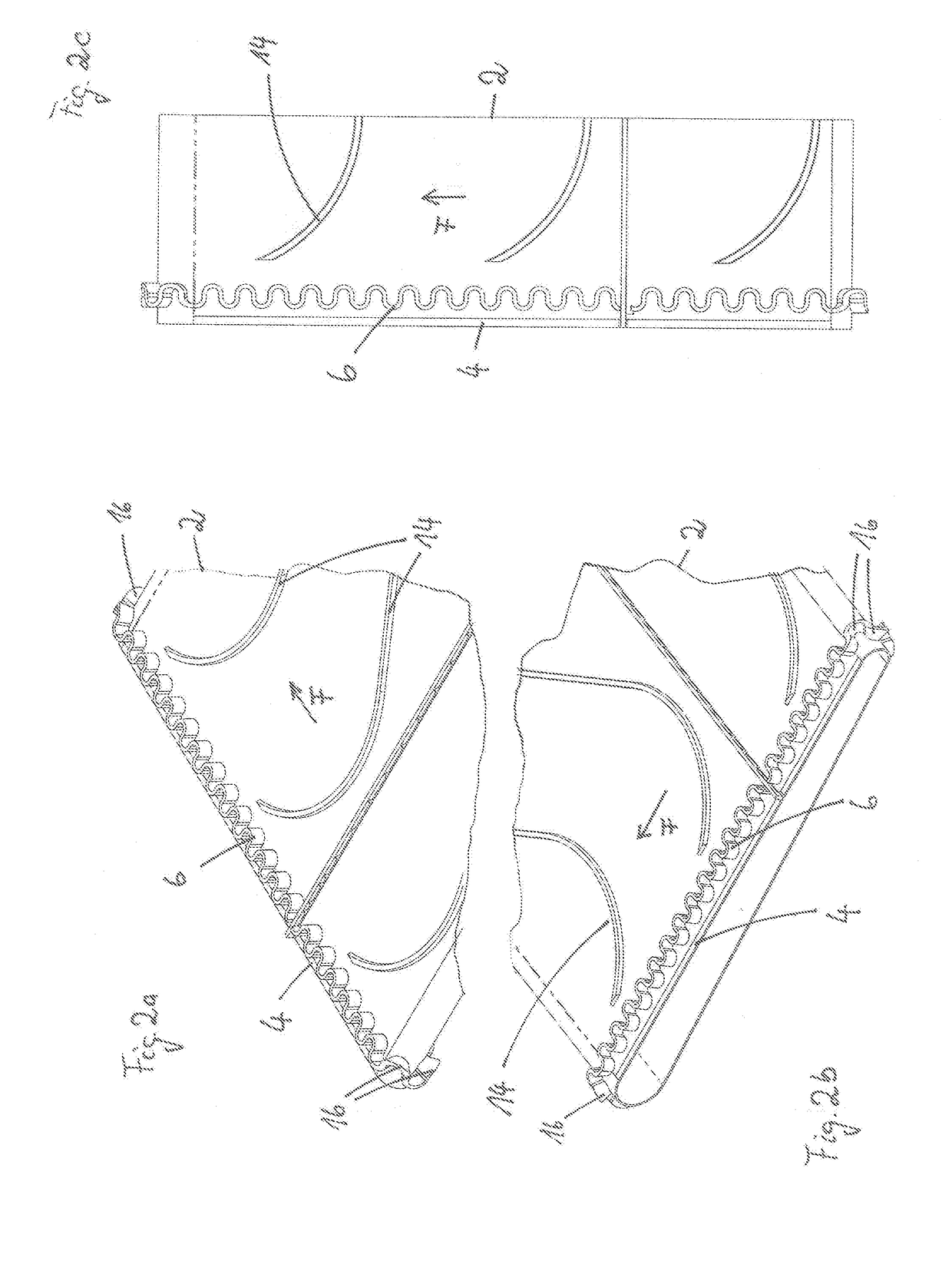

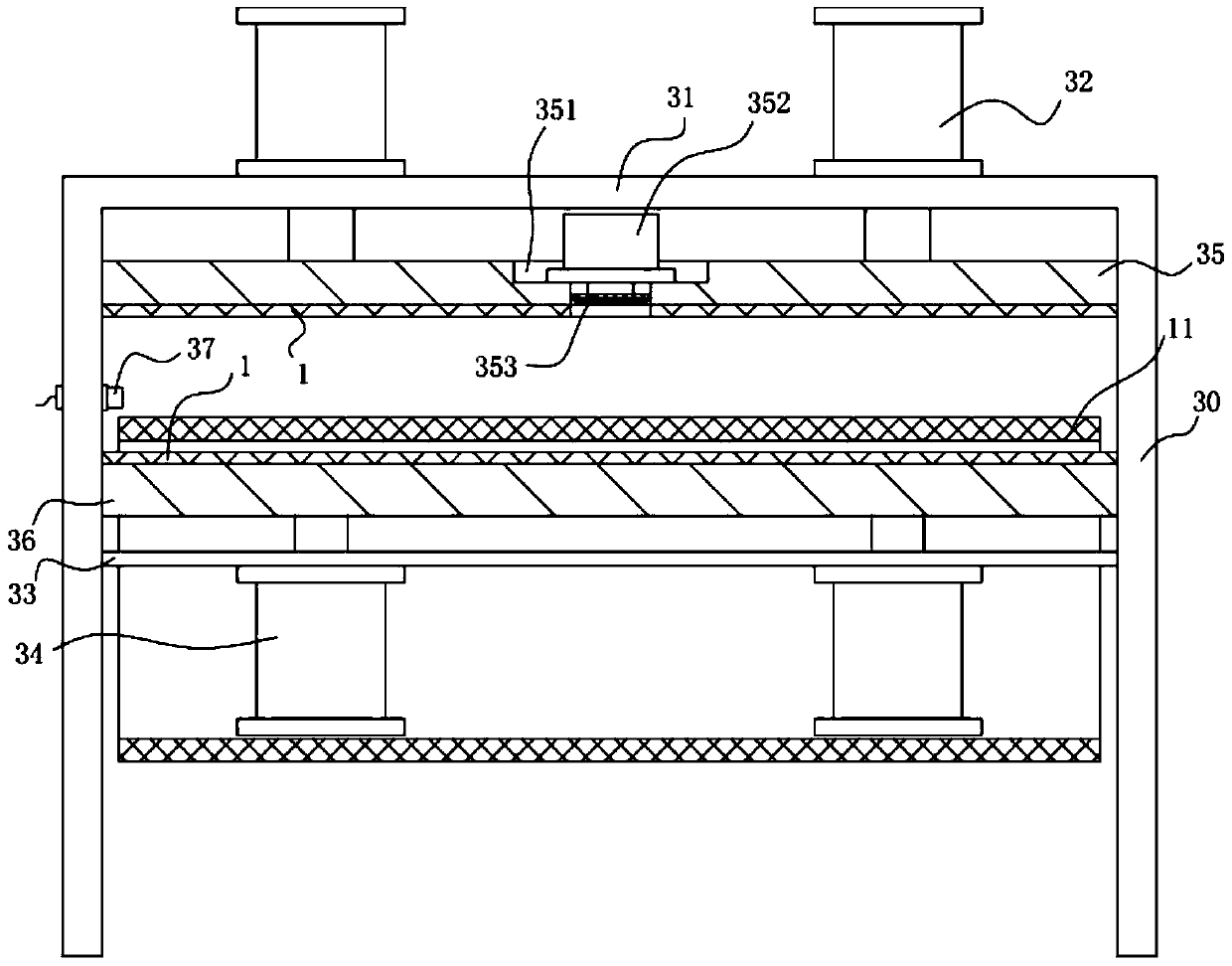

Conveyor belt system and conveyor belt

The invention relates to a conveyor belt system comprising a conveyor belt (1) extending in the longitudinal direction and a plurality of support roller stations (2) arranged at a distance from each other in the longitudinal direction and on which the conveyor belt (1) is supported by support rollers (3), said conveyor belt (1) being formed from a flexible base material (4) and a plurality of unconnected traction means (5) which determine the tensile strength of the conveyor belt (1) and which extend in the longitudinal direction. According to the invention, in the cross-section of the conveyor belt (1) and with respect to a desired position on a central belt section (a) supported on a support roller (3) of the support roller station (2), the tensile strength relative to the belt width is less than on the laterally adjoining belt sections (b) which are not supported in the desired position by a support roller (3). The invention also relates to the conveyor belt (1) itself.

Owner:THYSSENKRUPP RESOURSE TECH GMBH

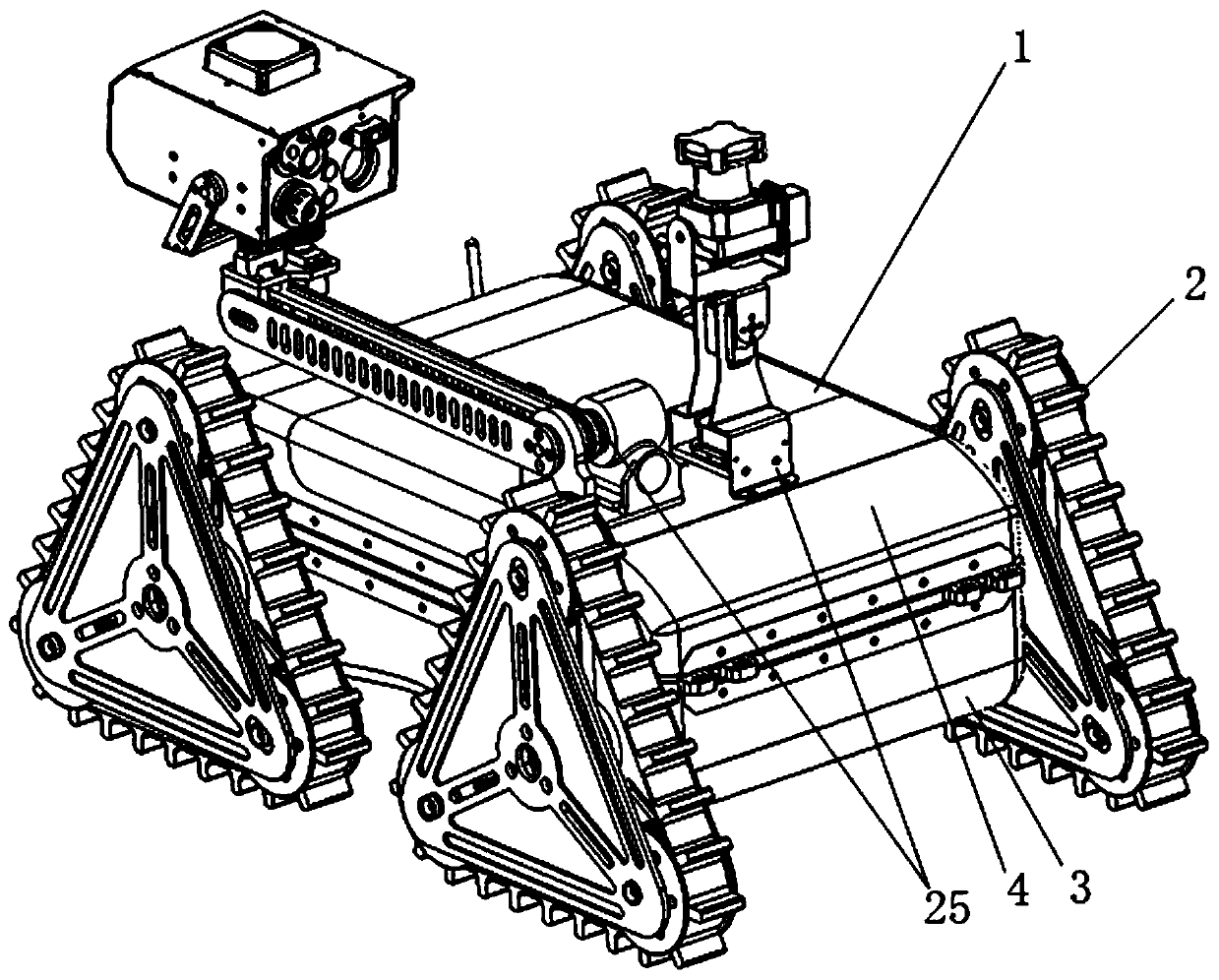

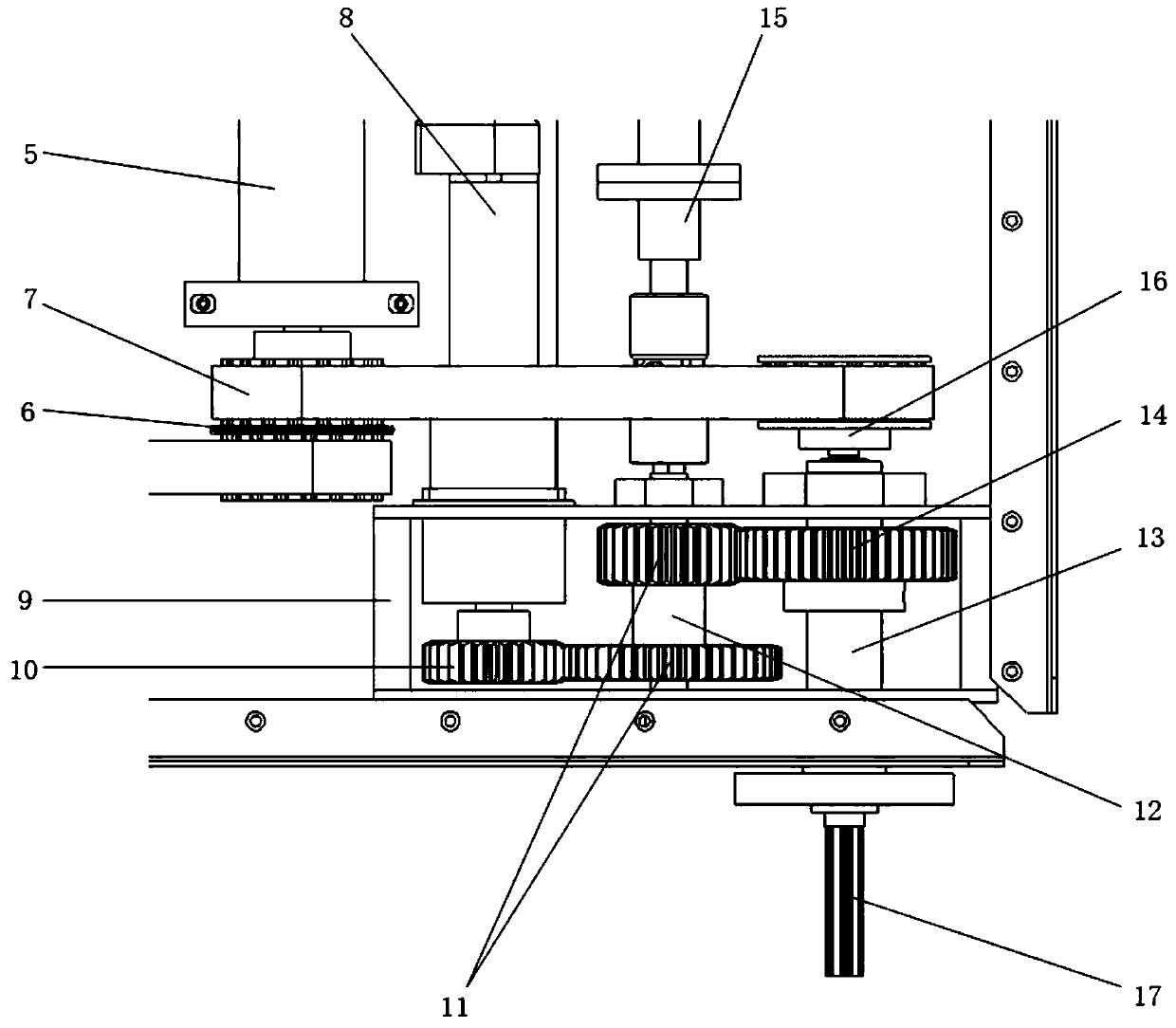

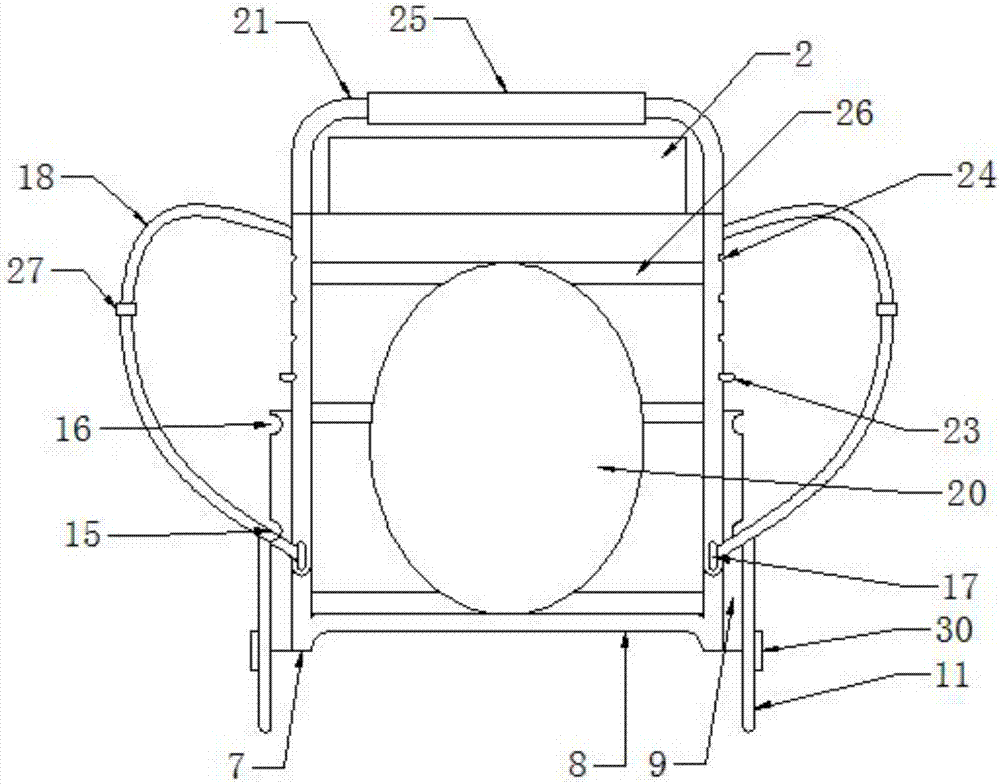

Planetary triangular crawler-type travelling mechanism

InactiveCN110466631ARealize profiling obstacle surmountingFlip over obstaclesEndless track vehiclesCentral beltRoad surface

The invention discloses a planetary triangular crawler-type travelling mechanism, and belongs to the field of agricultural autonomous mobile equipment. The planetary triangular crawler-type travellingmechanism comprises a trolley platform, planetary triangular crawler wheel mechanisms, an identification detection unit and a rocker arm, each of the planetary triangular crawler wheel mechanisms (2)is provided with a belt transmission mechanism, two driven crawler wheels (19) and an external grounding crawler belt (20), the belt transmission mechanisms are composed of central belt wheels (21),internal transmission crawler belts (22) and driving crawler wheels (23) so as to achieve the transmission action, various sensors are involved in the identification detection unit (25), and can be used for collecting various information so as to perform comprehensive detection on the environment, the use of the rocker arm (26) widens the range of identification detection, crawler-type moving andprofiling obstacle crossing are adopted when a flat road surface and a lower obstacle are encountered, and wheel-type moving is carried out for obstacle crossing when a higher obstacle is encountered.The planetary triangular crawler-type travelling mechanism has the characteristics of being simple in structure and light and convenient to operate, and meanwhile has higher travelling speed and excellent obstacle crossing capability.

Owner:JIANGSU UNIV

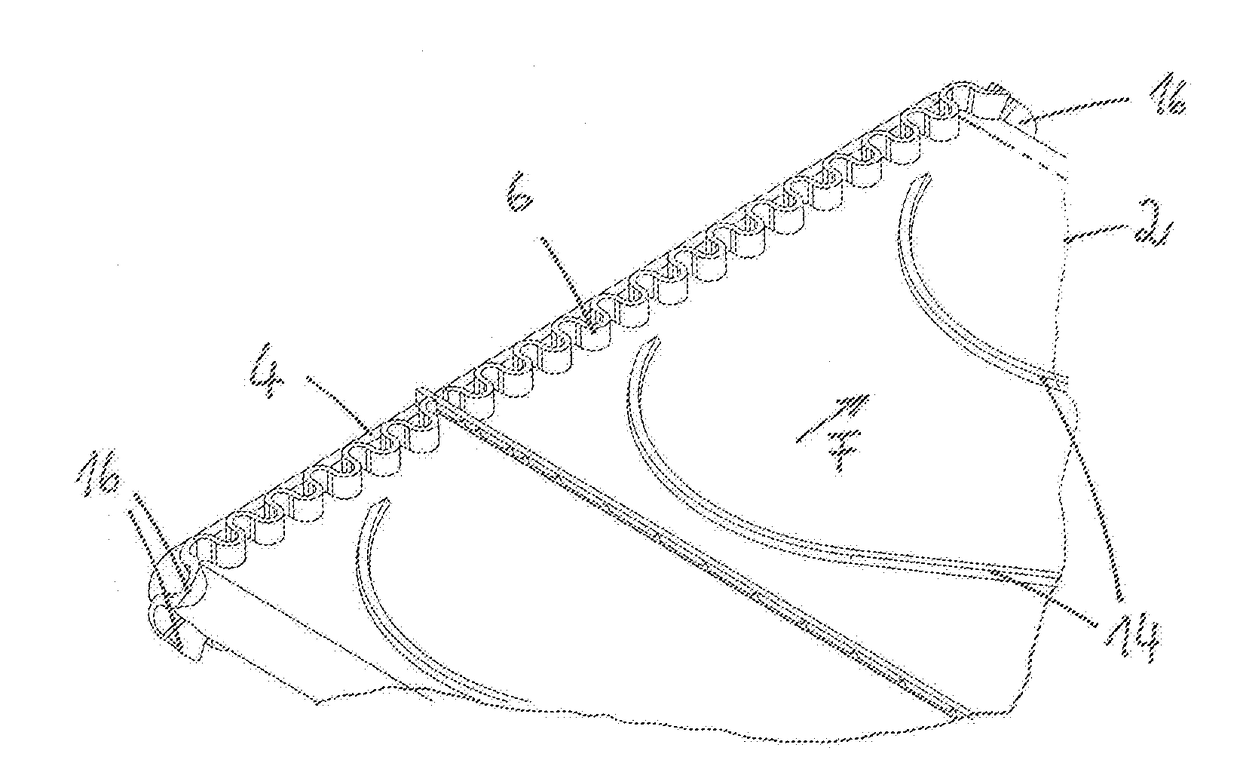

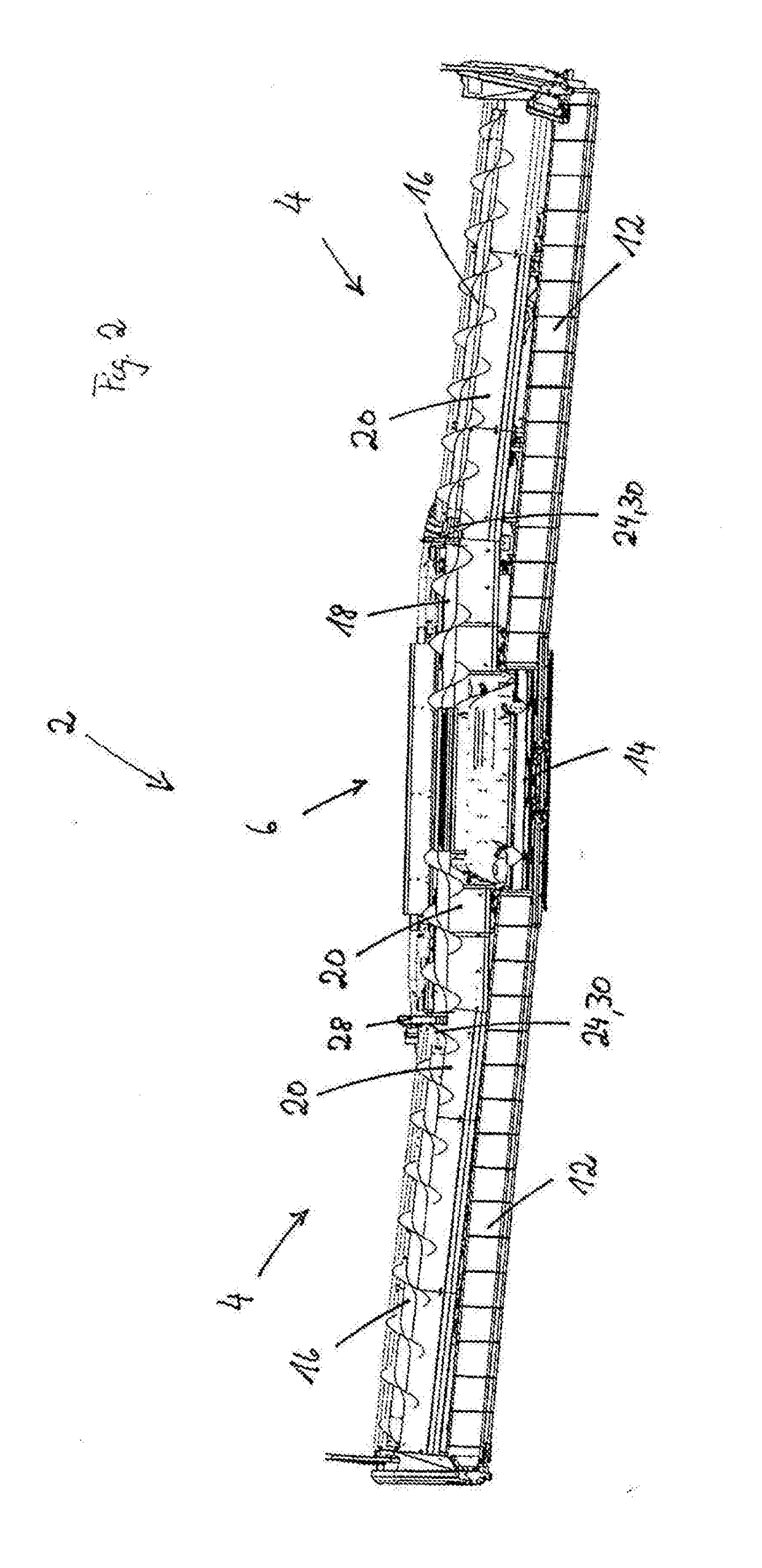

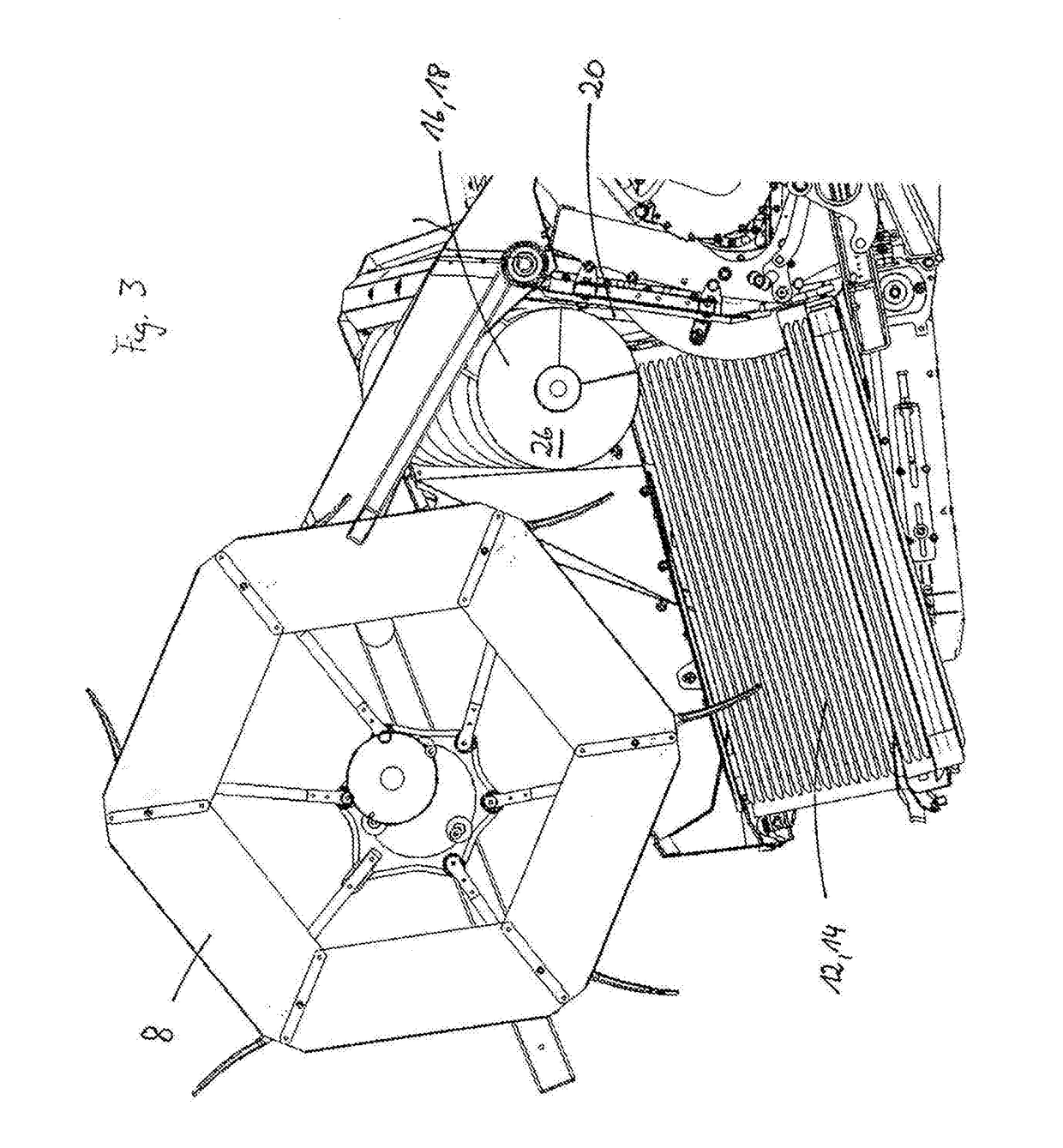

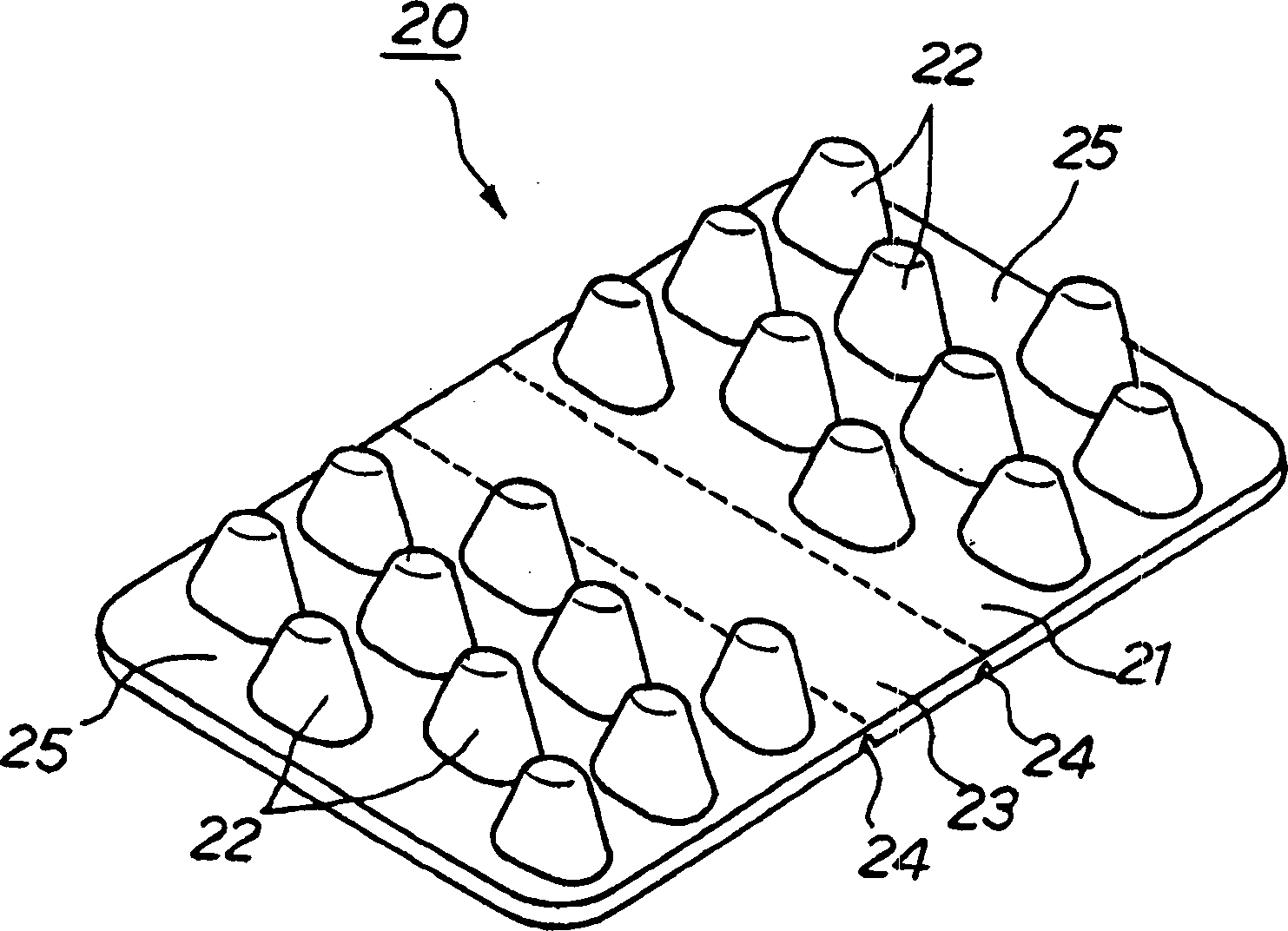

Header with Middle Belt and Additional Grain Loss Prevention Means

InactiveUS20170094899A1Satisfactory service lifeReduce tensile loadConveyorsLawn-mowersCentral beltEngineering

A header for harvesting agricultural crop is designed to be mounted on a harvesting machine and has a support frame with a cutter bar arranged on the front side and blades fastened thereto. Conveying elements for transporting away the cut stalk material include at least two belt conveyors conveying the crop transversely relative to the travel direction and a central belt conveyor as a middle belt that conveys counter to the travel direction. A drive drives the cutter bar and the conveying elements. In order to better protect the middle belt against grain losses over the lateral edge of the revolving belt, the middle belt has, at lateral edges on its outwardly pointing surface, a grain-blocking elevation, respectively.

Owner:CARL GERINGHOFF GMBH & CO KG

Ball mill

InactiveCN102407181AImprove continuityKeep the planetary ball millGrain treatmentsCentral beltBall mill

The invention discloses a ball mill which comprises transmission mechanisms and turning pairs, wherein a first belt transmission mechanism is composed of a small belt pulley (connected with a speed regulating motor) and a large belt pulley by a first belt; a plurality of ball-milling jars are symmetrically arranged on a rotating disc which is connected with the large belt pulley by a central principal shaft and coaxially runs with the large belt pulley; a turning pair is composed of a rotating shaft of each ball-milling jar and the rotating disc, and the lower part of the rotating shaft is connected with a planet belt pulley; a second belt transmission mechanism is composed of the planet belt pulley and a central belt pulley (connected with a base) by a second belt; and the central principal shaft and the rotating shafts are hollow shafts, the ball-milling jars are communicated with the respective rotating shafts, the rotating shafts are connected and communicated with the central principal shaft, and the lower end of the central principal shaft is provided with a material outlet.

Owner:ZHONGKAI UNIV OF AGRI & ENG

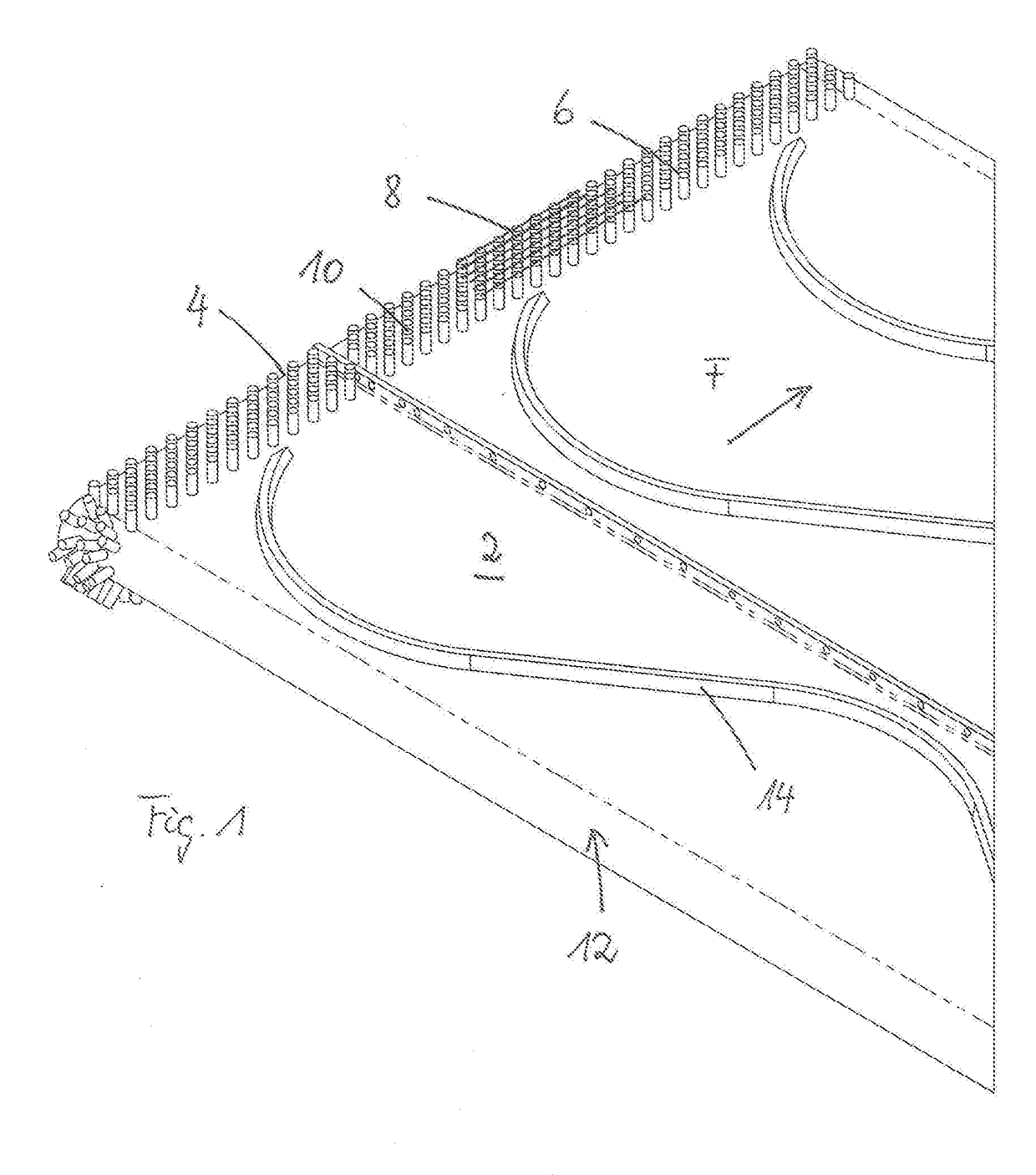

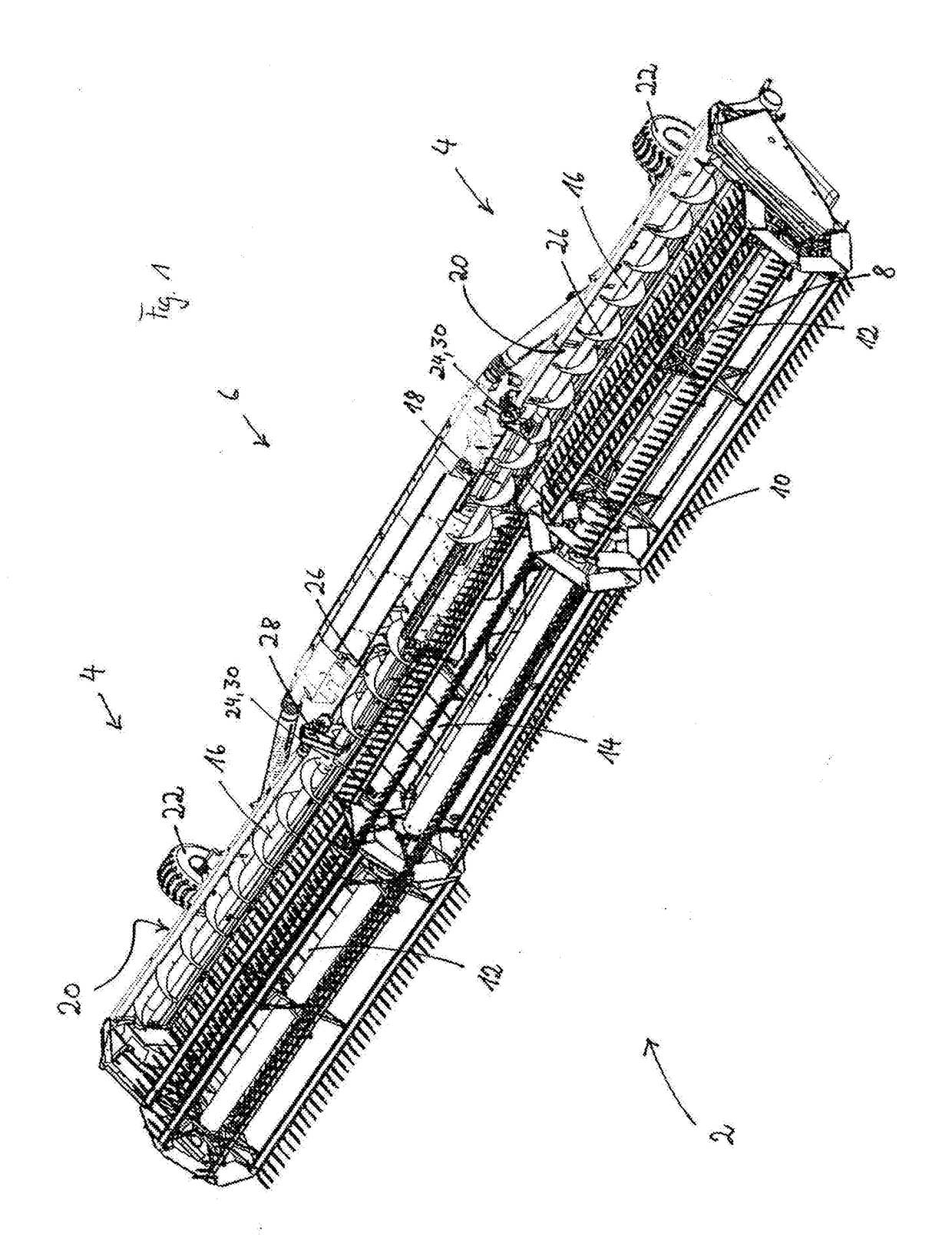

Draper Head with Multipart Screw Conveyor

A cutting system for a combine harvester has a three-part frame with frame parts articulately joined with each other. A cutter bar, a reel, a central belt conveyor system, and lateral belt conveyor systems for discharging the cut stalk material are supported by the frame. The lateral belt conveyor systems move transversely to the travel direction towards the central belt conveyor system. The central belt conveyor system moves contrary to the travel direction. To prevent accumulation of crop material near the rear wall of the lateral belt conveyor systems, a three-part screw conveyor is arranged near the rear wall and extends across the operating width of the cutting system such that the length of the screw conveyor parts corresponds at least approximately to the width of the frame parts. The screw conveyor parts are powered by a joint drive. Adjacent screw conveyor parts are mutually connected by universal joints.

Owner:CARL GERINGHOFF GMBH & CO KG

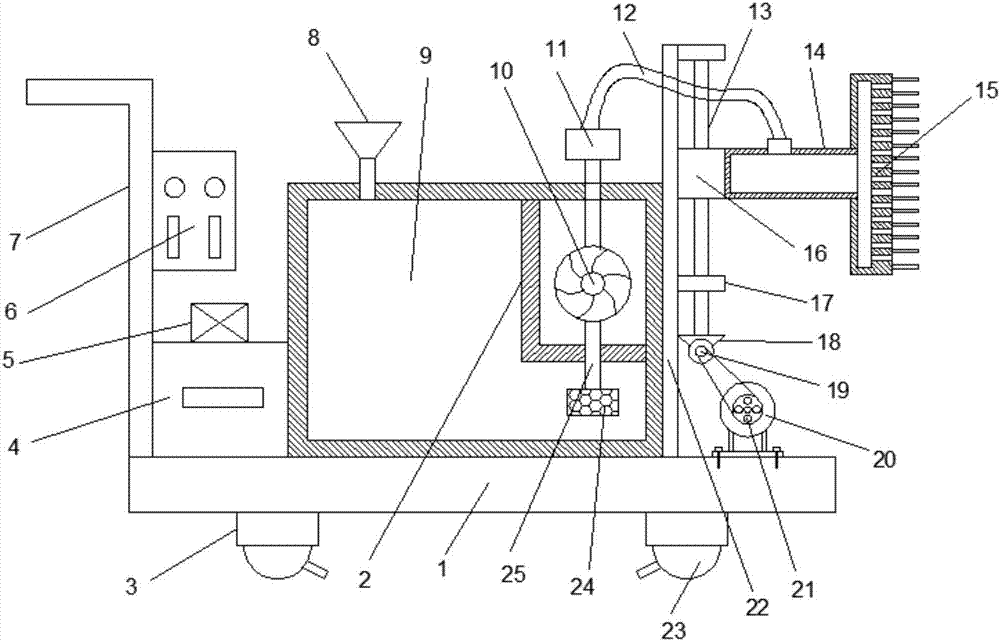

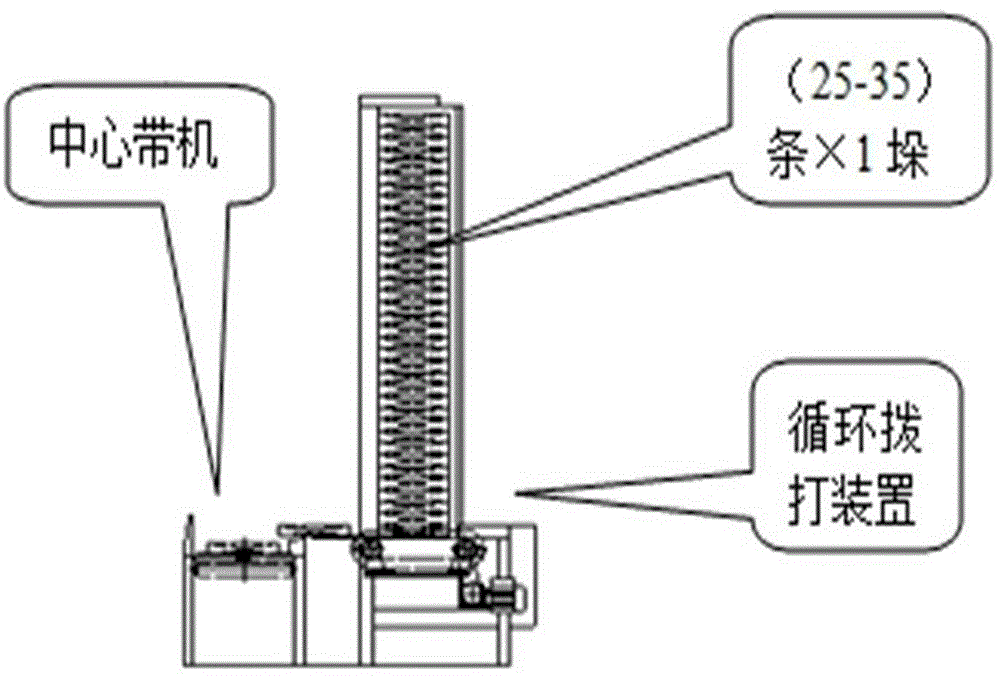

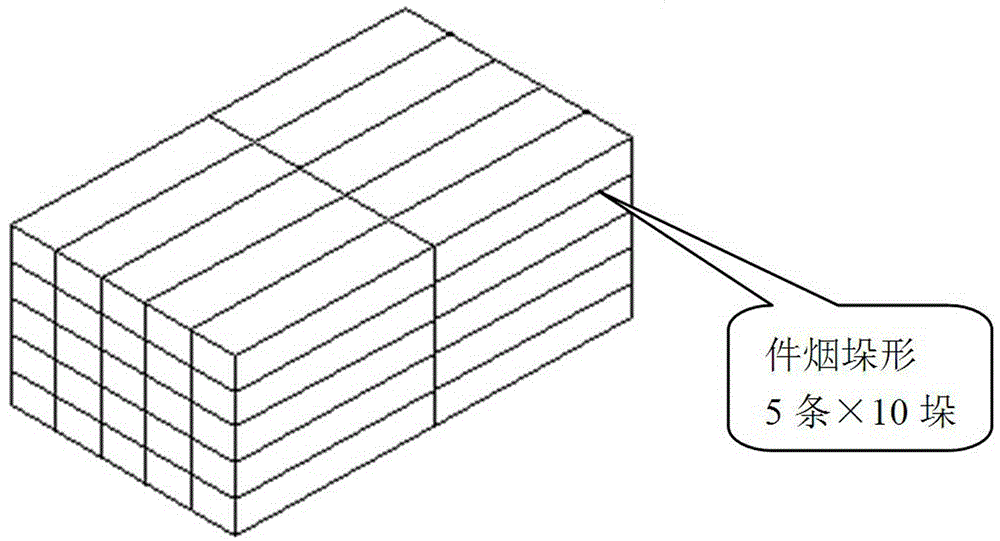

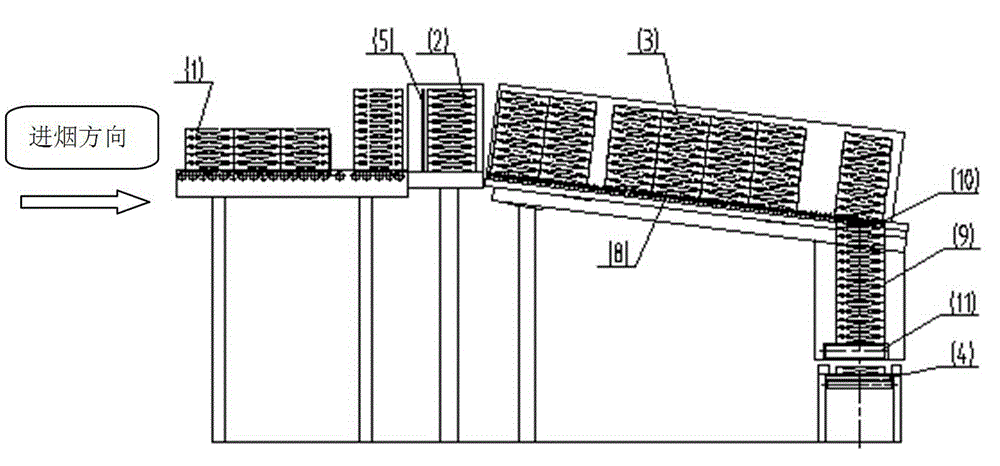

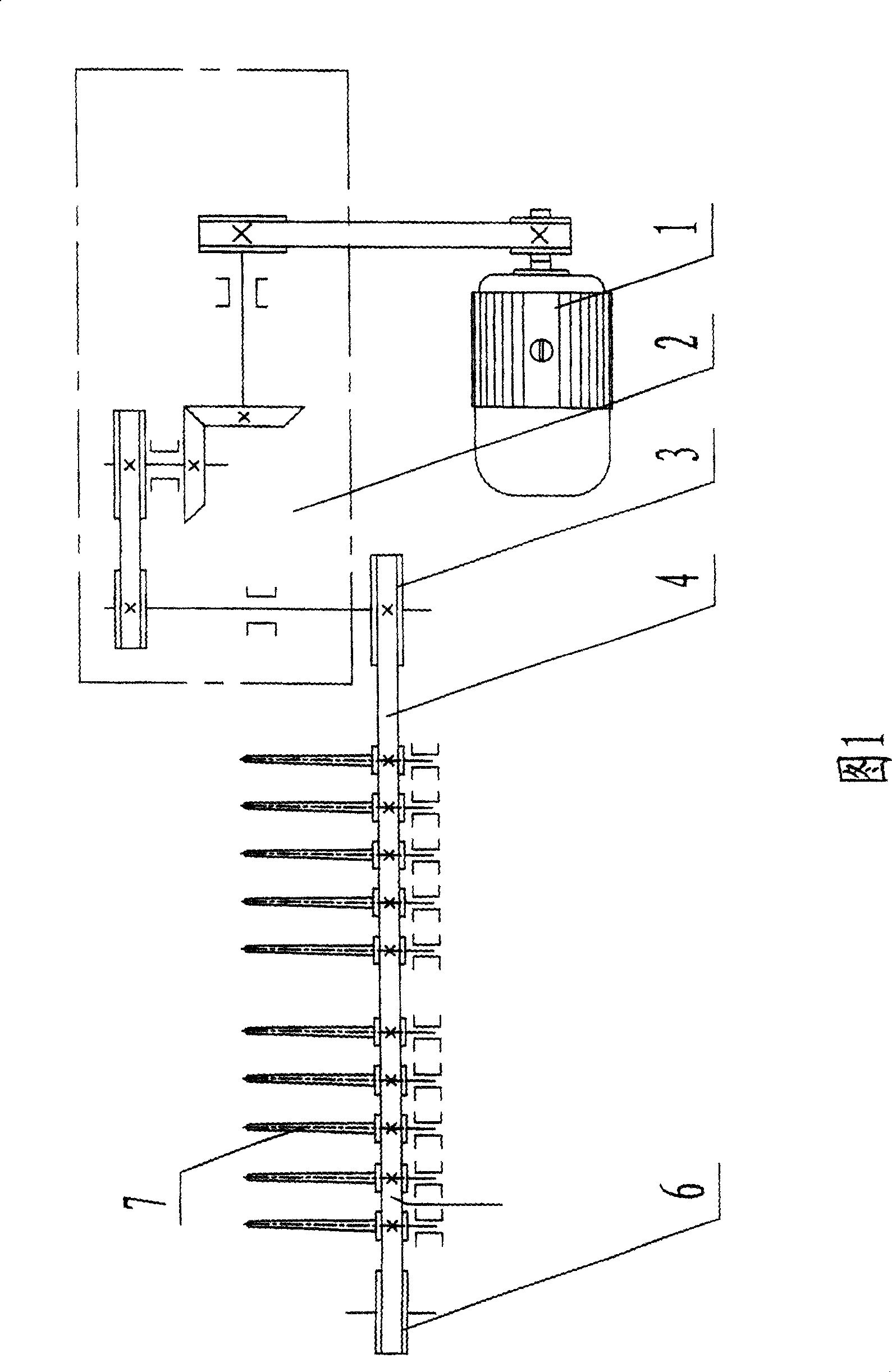

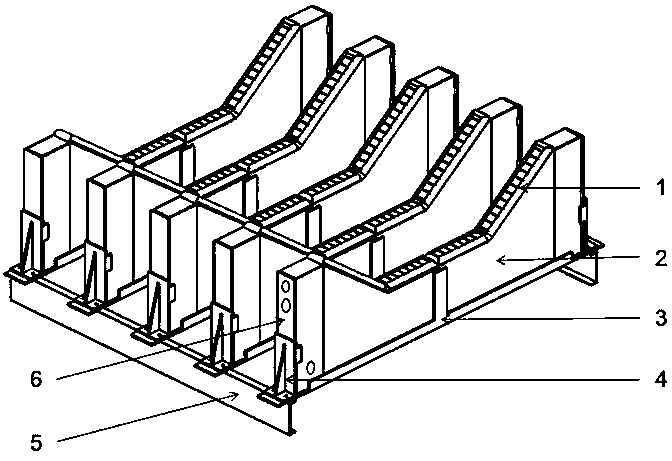

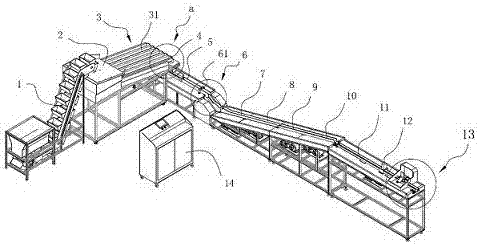

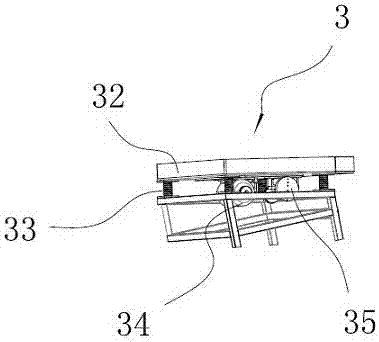

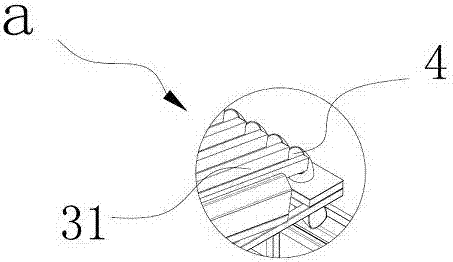

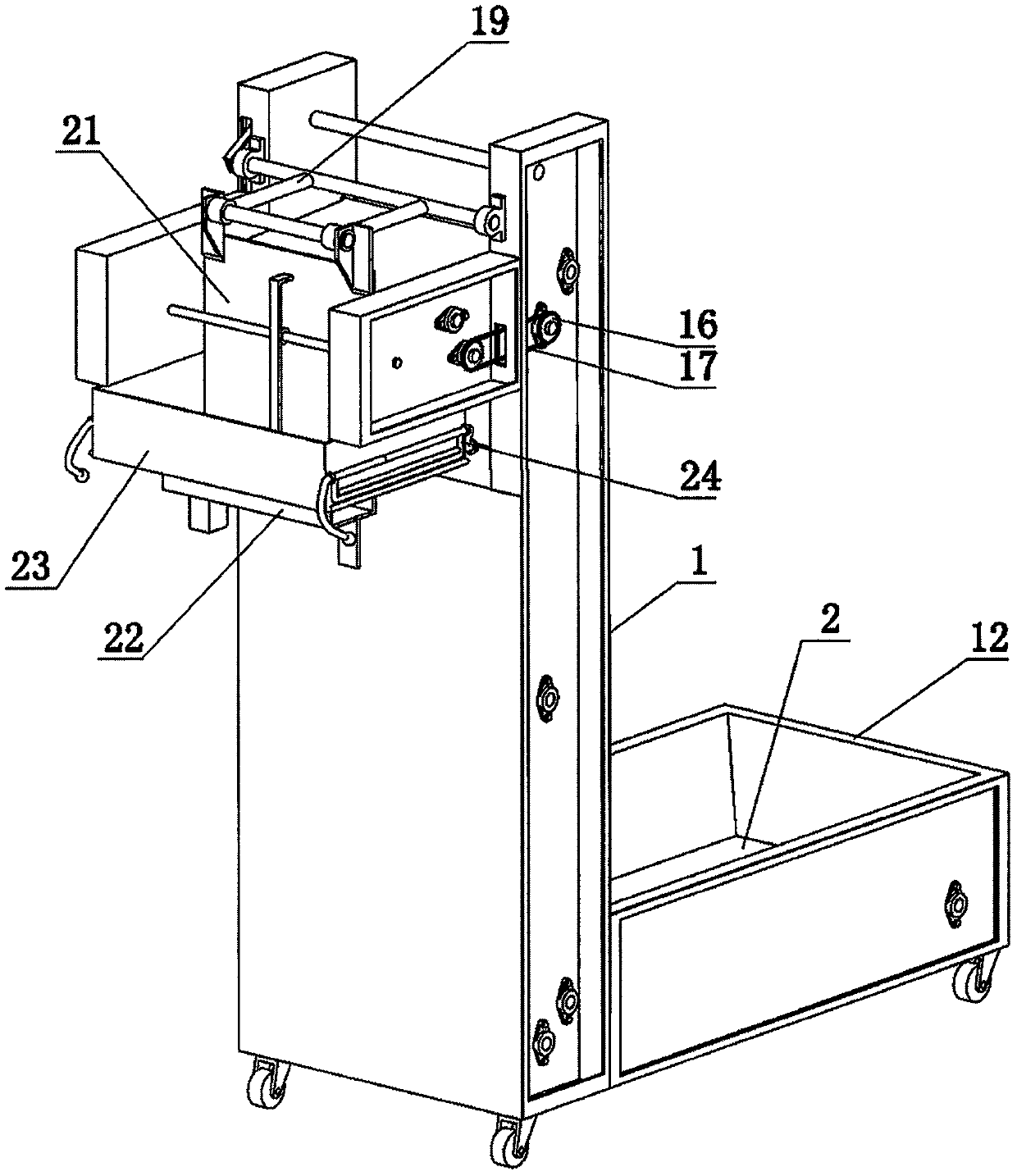

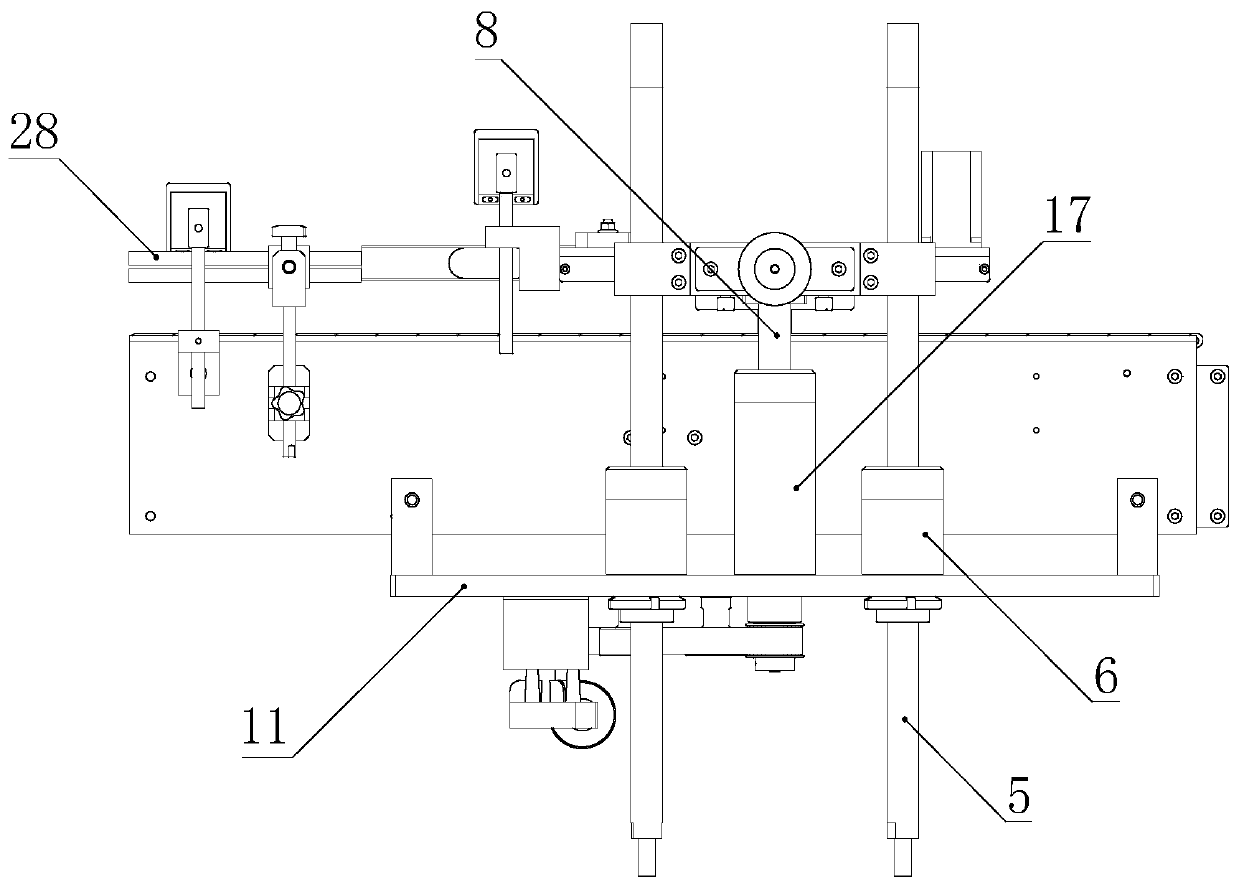

High-speed cigarette sorting unit

ActiveCN104590900AAchieve continuous supplyRealize stack conversionStacking articlesDe-stacking articlesCentral beltClockwise

The invention discloses a high-speed cigarette sorting unit. The high-speed cigarette sorting unit is characterized in that the upstream connecting opening is unpacking equipment and comprises a stack-shaped conversion device (1), a replenishment car (2), a dispensing machine (3), a central belt machine (4), and the like; the stack-shaped conversion device (1), the replenishment car (2) and the dispensing machine (3) are successively arranged in a clockwise direction, the central belt machine (4) is located under the end section of the dispensing machine (3); an unstacking mechanism (5) is arranged in the replenishment car (2), and the unstacking mechanism (5) reciprocates along a track (6) between the stack-shaped conversion device (1) and the sorting channel (7). The high-speed cigarette sorting unit has the beneficial effects that the sorting capacity is high, a stack shape is easily converted, goods can be automatically replenished, and the high-speed cigarette sorting unit has the compatibility of a plurality of brands, and is stable in performance and lower in cost.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

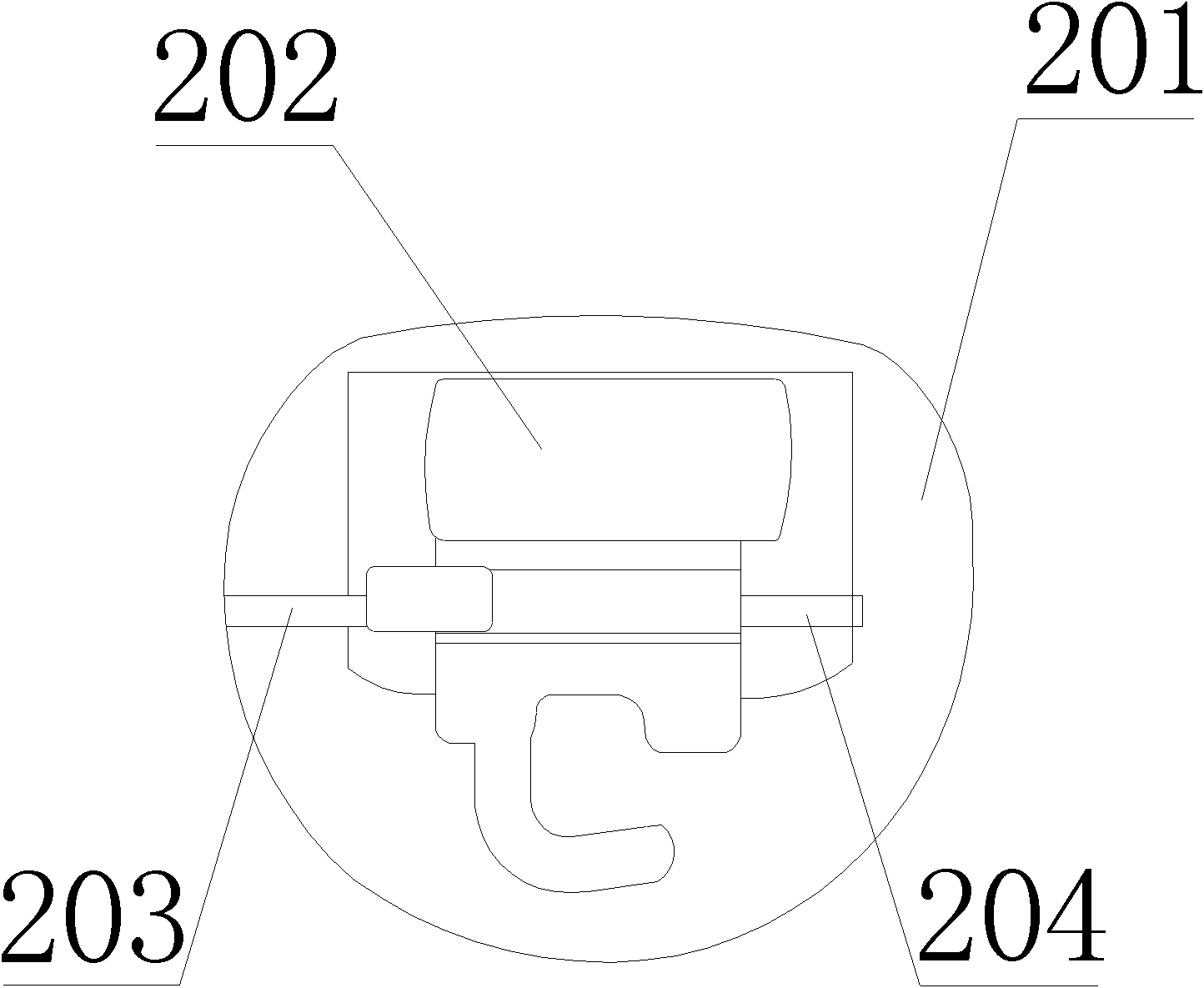

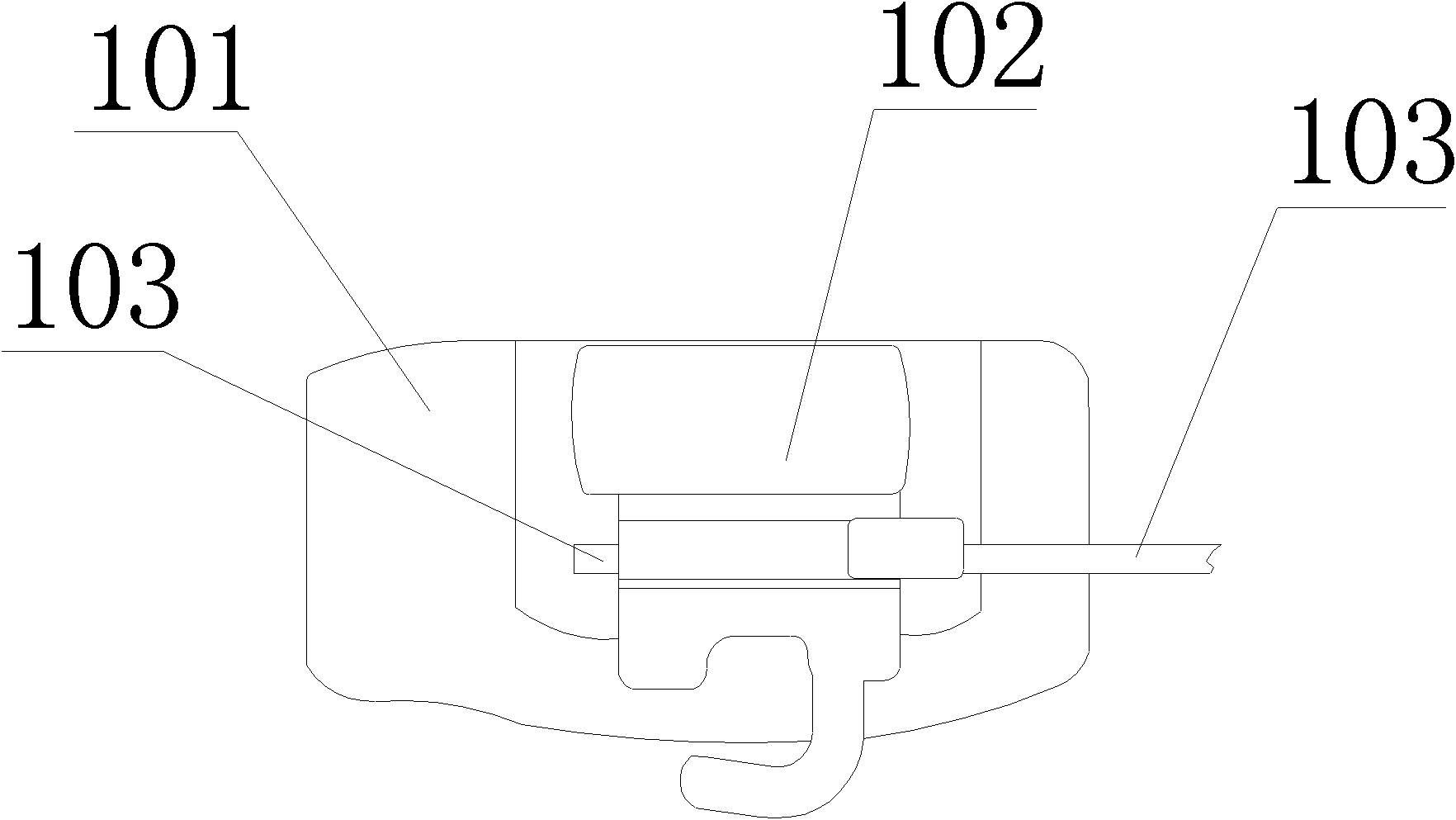

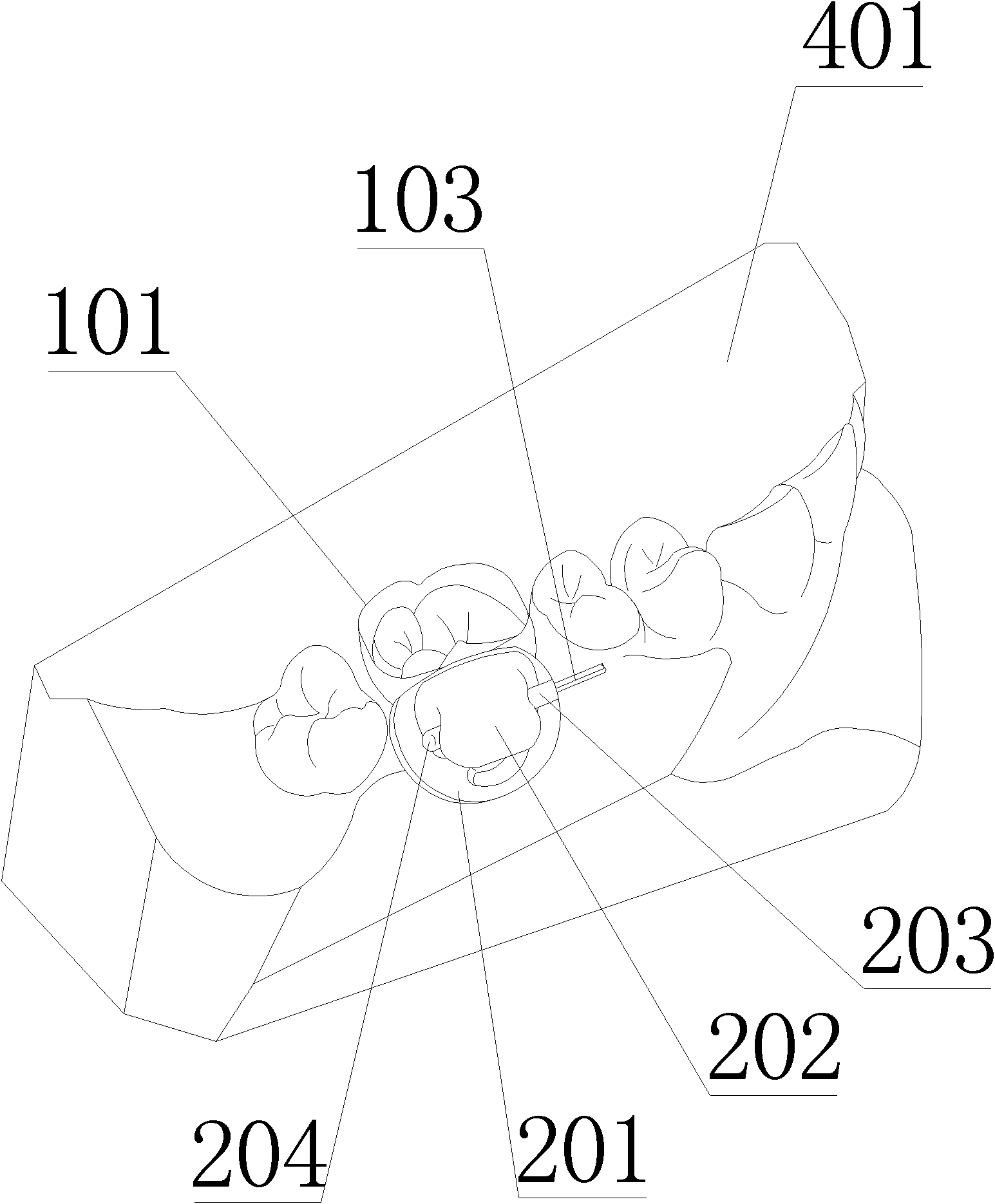

Fixed appliance end protection device

The invention provides a protective device for the end of a fixed appliance, comprising a protective film (201), a concave platform (202) matching the shape of the buccal tube (102) with a ring is provided in the center of the protective film (201), and the concave platform ( 202) is provided with an arch wire groove (203) relative to the position of the arch wire (103), and the arch wire groove (203) is provided with an arch wire margin groove (204) relative to the end of the arch wire (103), and the margin groove ( 204) is closed at the end. The end protection device of the fixed appliance of the present invention can prevent the buccal tube from contacting the oral mucosa, and prevent the end of the archwire from protruding, being too long and warping up, thereby reducing the irritation and scratching of the oral mucosa, and preventing traumatic stomatitis and mucous membrane Symptoms such as ulcers occur. Moreover, the end protection device of the fixed appliance of the present invention is detachable, which is convenient for oral cavity cleaning and repeated use.

Owner:李强 +2

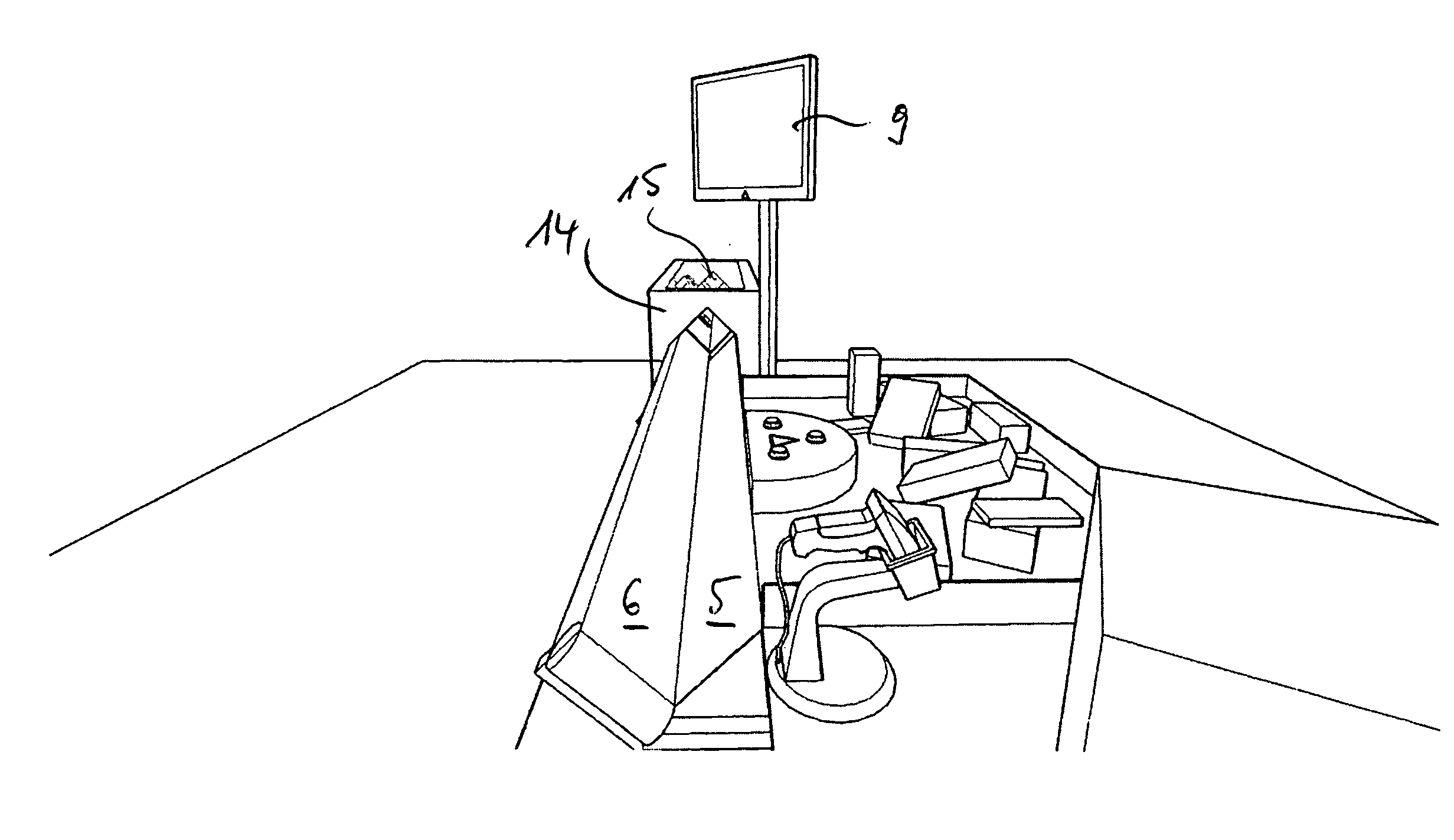

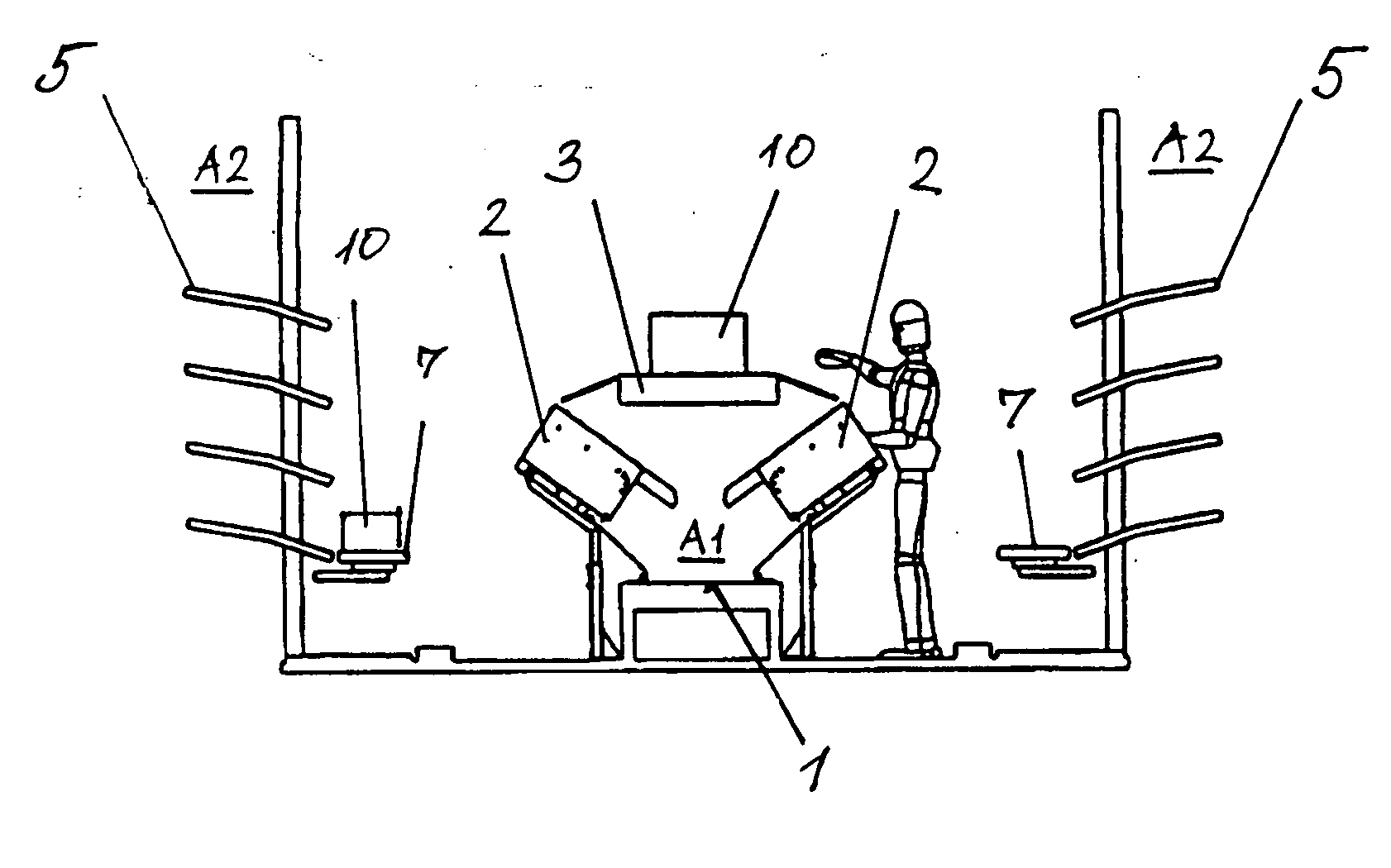

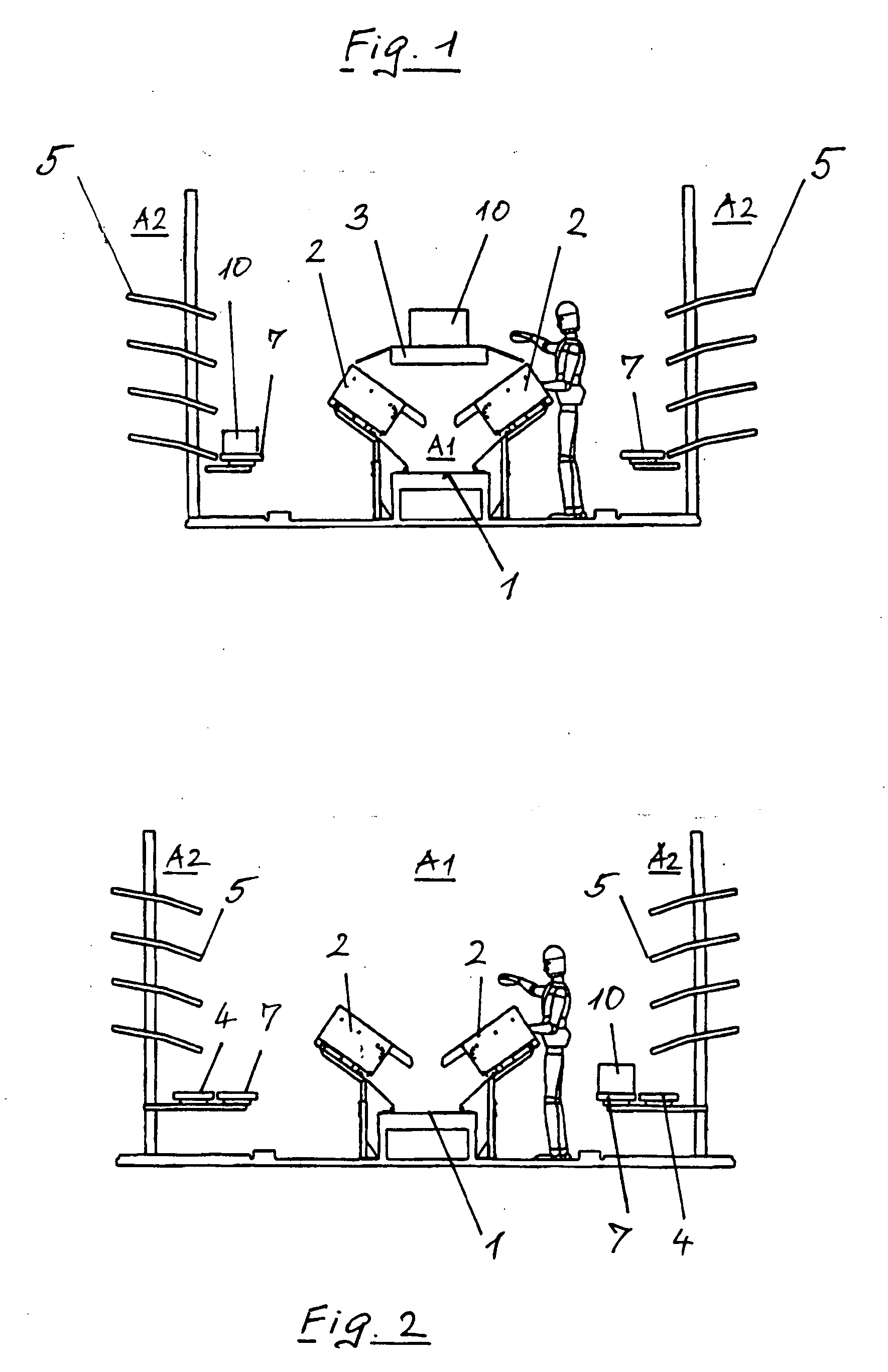

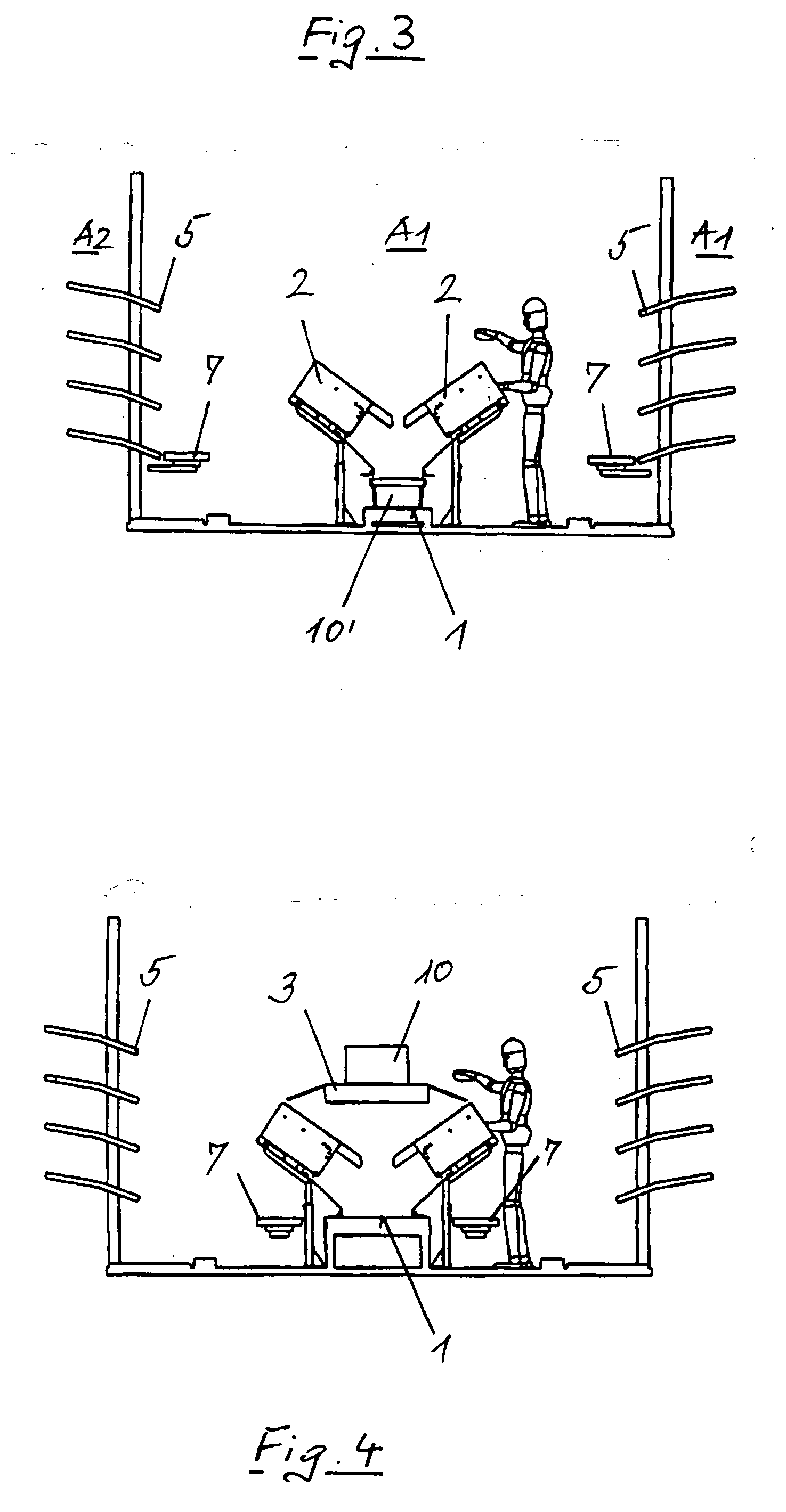

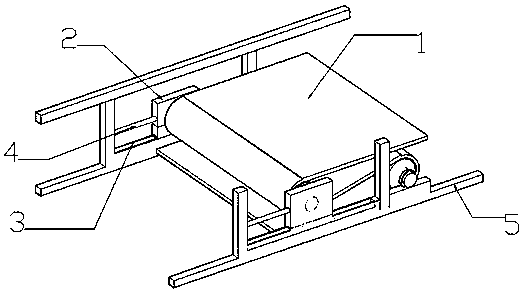

Method and system for commissioning articles which are suitable for a central belt and articles which are not suitable for a central belt

InactiveUS20060177290A1Simple and efficientEliminate processingOral administration deviceStorage devicesCentral beltEngineering

A method and a commissioning system are provided for commissioning articles (A1) which are suitable for a central belt in a central belt commissioning system and articles (A2) which are not suitable for a central belt, preferably manually from an article warehouse or shelf (5), wherein articles which are suitable for a central belt (1) are commissioned and automatically fall directly onto the driven central belt (1) in a targeted manner, and at the end of the central belt they fall into a stationary container or immediately into a container (10) arranged on the driven central belt. The articles (A2) which are not suitable for a central belt are commissioned manually in containers (10) in a commissioning path to the right and / or left of the central belt (1) of the central belt commissioning device and are directly fed to a dispatching station or preferably to the central belt commissioning device for commissioning with articles (A1) which are suitable for a central belt.

Owner:KNAPP LOGISTIK AUTOMATION GES

Planetary ball mill

The invention provides a planetary ball mill which comprises a speed regulating motor (1), a small belt pulley (2) connected with the speed regulating motor (1), a first belt (3) connected with the small belt pulley (2), a second belt (4) connected with the small belt pulley, a first large belt pulley (5) connected with the first belt (3), a second large belt pulley (6) connected with the second belt (4), a first rotary disk (7) connected with the first large belt pulley (5) and a second rotary disk (8) connected with the second large belt pulley (6). Two ball milling barrels (9) are symmetrically arranged above the first rotary disk (7) and the second rotary disk (8), a rotating shaft (13) is connected under the first rotary disk (7) and the second rotary disk (8), a central belt pulley (11) is arranged on the rotating shaft (13), and a central rotating shaft (10) is connected under the ball milling barrels (9). By means of two sets of belt transmitting mechanisms, a plurality of groups of powder can be ball milled at the same time. Thus, the using efficiency of the planetary ball mill is improved.

Owner:HAIAN TIANPENG MACHINERY MFG

Process and central belt automatic unit for filling an order container in a commissioning system

InactiveUS7882933B2Convenient lengthSpace minimizationDigital data processing detailsBaby linensCentral beltEngineering

Owner:KNAPP LOGISTIK AUTOMATION GES

Ring-shaped air-cooling device for conveyor working

InactiveCN107939702AHigh degree of automationEasy to usePump componentsPump installationsCentral beltIn degree

The invention relates to a ring-shaped air-cooling device for conveyor working. The ring-shaped air-cooling device comprises a mounting base table, wherein a motor is mounted on the middle part of themounting base table; the motor is connected with a central shaft; a central belt wheel is mounted on the central shaft; a gear ring and a ring-shaped slide slot are sequentially arranged on the mounting base table; a bearing base is mounted in the slide slot in a sliding mode; a sub shaft is mounted on the bearing base; the lower part of the sub shaft is equipped with a sub gear engaged with thegear ring; a sub belt wheel is mounted on the upper part of the sub shaft; and a belt for connecting the sub belt wheel to the central belt wheel in a transmission mode is arranged between the sub belt wheel and the central belt wheel. The ring-shaped air-cooling device is high in degree of automation, can effectively control a fan to travel along a ring-shaped track through wheel-tooth transmission and guide as well as belt transmission, can automatically rotate for automatically blowing air and cooling apparatuses which are arranged in a ring-shaped mode in a conveyor, and is convenient to use.

Owner:安徽芜湖宝丰输送机械有限公司

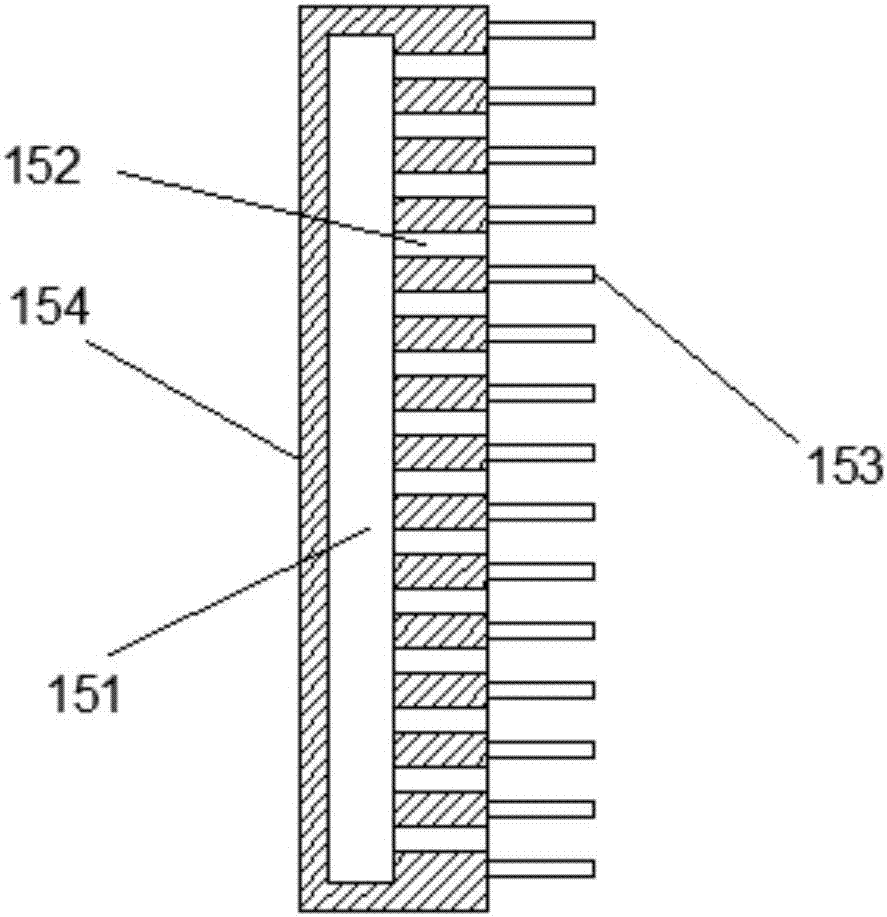

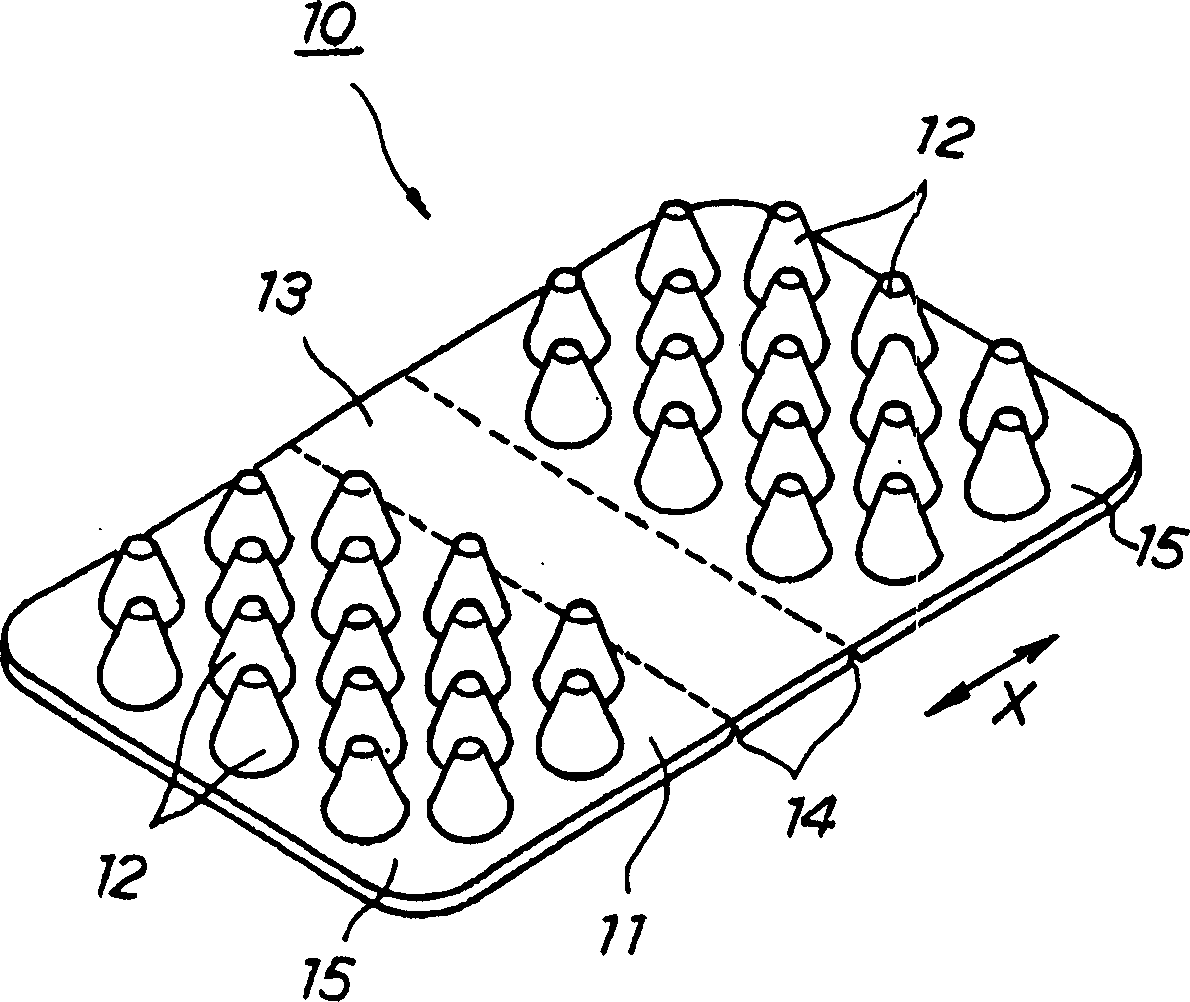

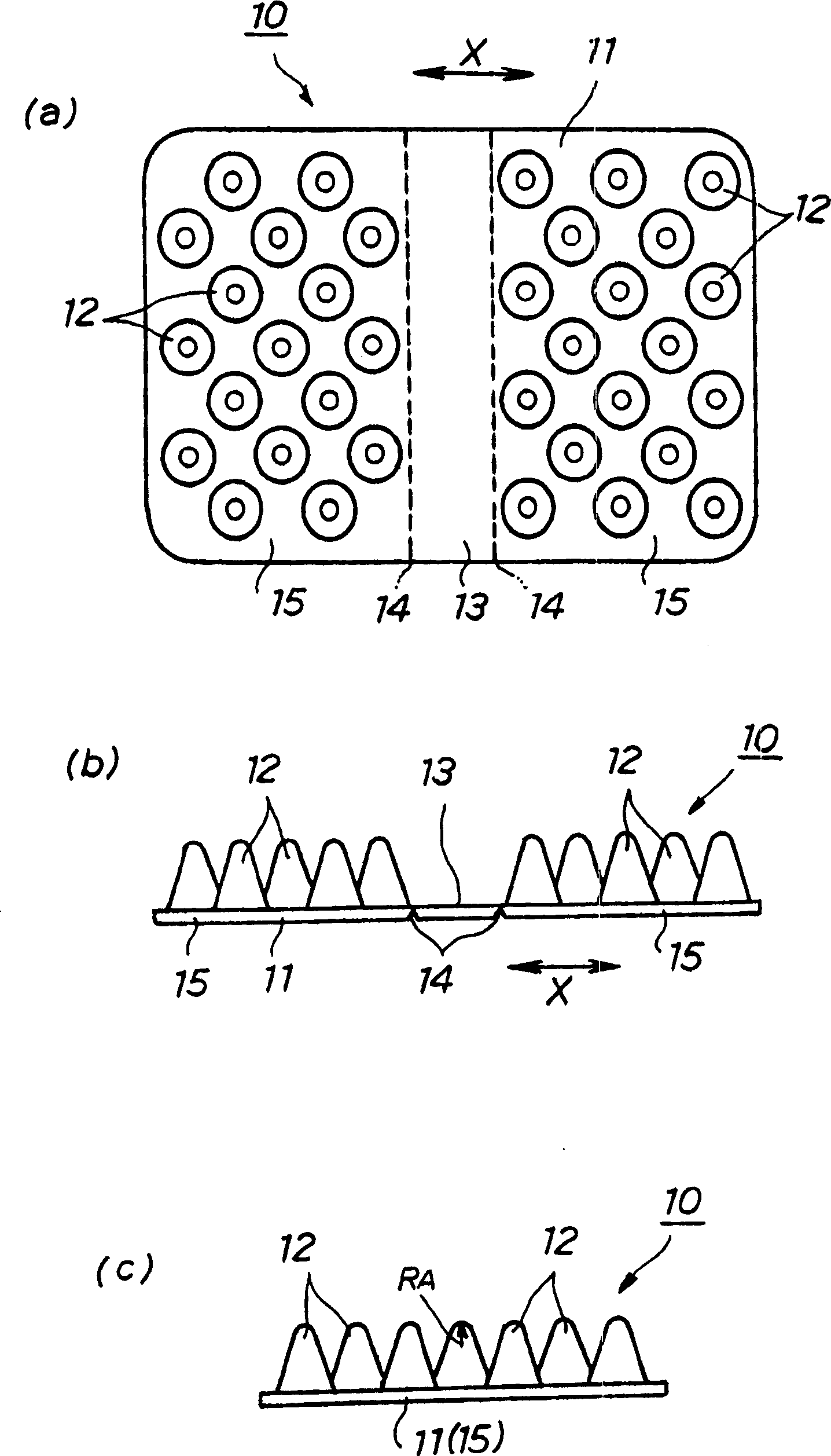

Hair scrubbing brush

The patent provides a sheet brush for hair which can improve convenience as a brush for conditioning and mending hair by using projections to permit easy combing of the hair. The sheet brush 10 for hair is dispersedly arranged with a plurality of the projections 12 on one surface of a substrate sheet 11, in which the substrate sheet 11 is made two-foldable at its central belt-like segment 13 and a plurality of the projections 12 are decreased in their sectional areas toward their front ends, are respectively protruded to circular cone shapes and are arranged alternately from each other with the segment 13 in-between in such a manner that the projections 12 in one lateral segment 15 of the substrate sheet 11 holding the segment 13 in-between are packed into valley parts between the adjacent projections 12 of the other lateral segment 16 so as not to interfere to each other when the substrate sheet 11 is doubly folded. The sheet brush for hair is used by being impregnated with various kinds of cosmetics for hair, such as odor eliminating bases, deodorant bases, water absorptive bases, antimicrobial agents, and UV absorbents.

Owner:KAO CORP

Device and process for recognizing and guiding individually packaged products with a code

ActiveUS8682480B2Faster throughputImprove reliabilityDigital data processing detailsControl devices for conveyorsCentral beltEngineering

An arrangement (1) and to a method is for detecting and controlling piece goods (2), having a code, in a commissioning system. The piece goods are fed on a conveyor line (3) through a scanning device (15), and are identified as actual data and are compared or captured to target data of the piece goods quantity stored in a central computer. The piece goods are separated out if the target data do not match the actual data. The invention proposes that a plurality of ejection devices (13) are provided. Each of the ejection devices (13) fills a positioned order container (25) of a particular commissioning order with piece goods, and piece goods that are not detected or sorted out are discharged to the longitudinal end of the conveyor line (3). The piece goods of various commissioning orders are randomly distributed on the central belt (27) of an automated commissioning machine and fed to the arrangement (1).

Owner:KNAPP AG

Automobile travel first-aid case

The invention discloses a first-aid kit for automobile travel, which comprises a first-aid kit body, a waterproof bag is arranged on the top of the first-aid kit body, an operation panel is arranged on one side of the first-aid kit body, and the bottom of the operation panel is connected to the bottom of the operation panel through a hinge. The first aid kit body is fixedly connected, both sides of the operation panel are provided with fixing straps, the other end of the fixing strap is fixedly connected with the middle part of the first aid kit body, and the other side of the first aid kit body is provided with Carrying rack, the bottom of the carrying rack is provided with a bracket, and several struts are arranged between the top of the bracket and the bottom of the first aid box body, and the top middle of the bracket is provided with a guide column, and the guide column A guide groove is arranged on the column, a wheel is arranged at the lower part of the guide column, and a rotating shaft is arranged inside the wheel. Beneficial effects: the problem that the walking distance is too far and unsuitable for rescue is solved, the safety of travel is improved, and the travel is more joyful and reassuring.

Owner:HUAIAN JUNRUI CHUANGZHI IND DESIGN CO LTD

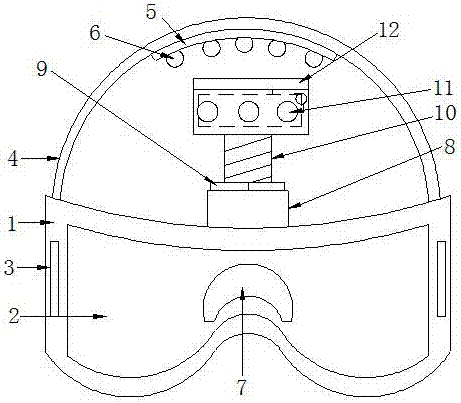

Eyewear with illumination function

InactiveCN107329282AEasy to wear for pressure reliefQuick installationGogglesNon-optical adjunctsCentral beltNose

The invention discloses a goggle with lighting, which relates to the technical field of outdoor equipment; lenses are installed inside the picture frame, a nose support air bag is installed in the middle of the inner side of the picture frame, and both ends of the picture frame are installed There is a threading groove frame, and the two ends of the sleeve are respectively connected in the threading groove frame, and a shock-absorbing airbag is installed on the inner wall of the middle part of the sleeve, and several shock-absorbing airbags are installed on the inner wall of the shock-absorbing airbag. Decompression ball, the middle and upper end of the picture frame is equipped with a threaded sleeve, the inside of the threaded sleeve is equipped with a screw, the screw is locked in the threaded sleeve through a lock nut, and the upper end of the screw is equipped with a lamp body. The upper surface of the lamp body is provided with a photovoltaic battery panel; the invention is convenient for fast decompression wearing, can realize lighting, is convenient for quick installation and disassembly, and is convenient to use and easy to operate.

Owner:SUZHOU GUIGUO ELECTRONICS

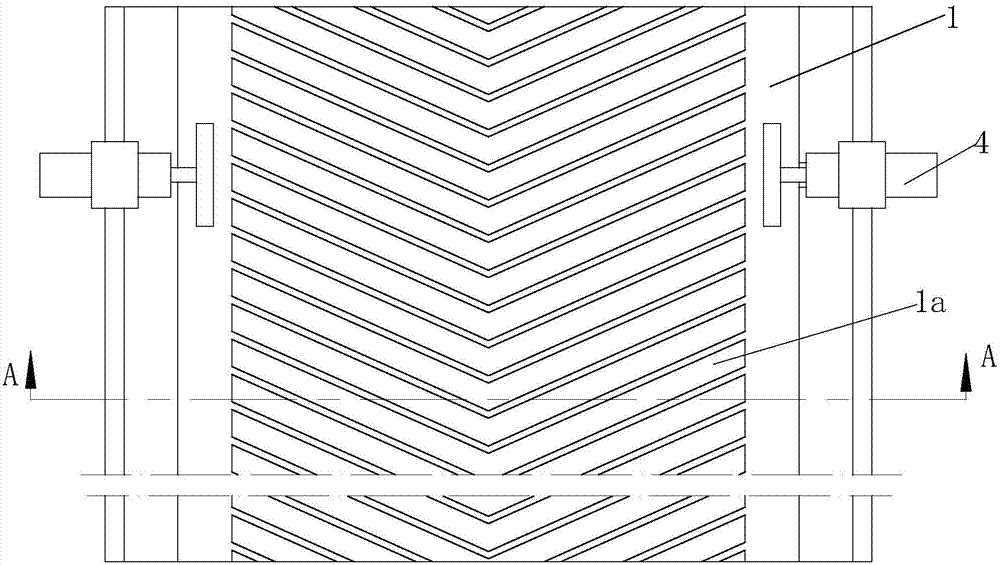

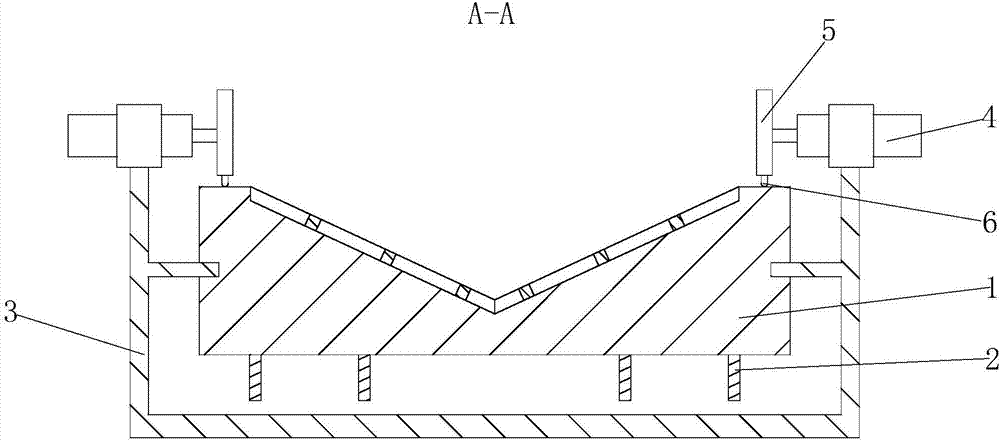

Bearing hard belt for conveying fine straws

InactiveCN107323947AGuarantee stabilityGuaranteed shockproof effectConveyorsCentral beltConveyor belt

The invention relates to a load-bearing hard belt for transporting fine straws, comprising a bearing frame, on which a belt body is slidably installed along the front and rear directions, the upper end of the belt body has a V-shaped cross section, and is used for transporting fine straws. At the same time, the fine straw is always located in the upper middle of the belt body, which ensures that it is difficult to fall off due to vibration during transportation. The upper end of the belt body is arranged with V-shaped slots along the front and rear direction, and the effect of the slots is to increase the friction between the hard belt and the tiny straws on the hard belt. The lower end of the belt body is a plane, and two groups of blocks are welded at the lower end of the belt body. The invention is easy to use, and can ensure the stable bearing of the straw through the belt body and the V-shaped slot, and on this basis, can also effectively ensure the stability and stability of the straw transportation through the setting of the push plate and the extension plate. Shockproof effect.

Owner:无为飞翔秸秆综合利用有限公司

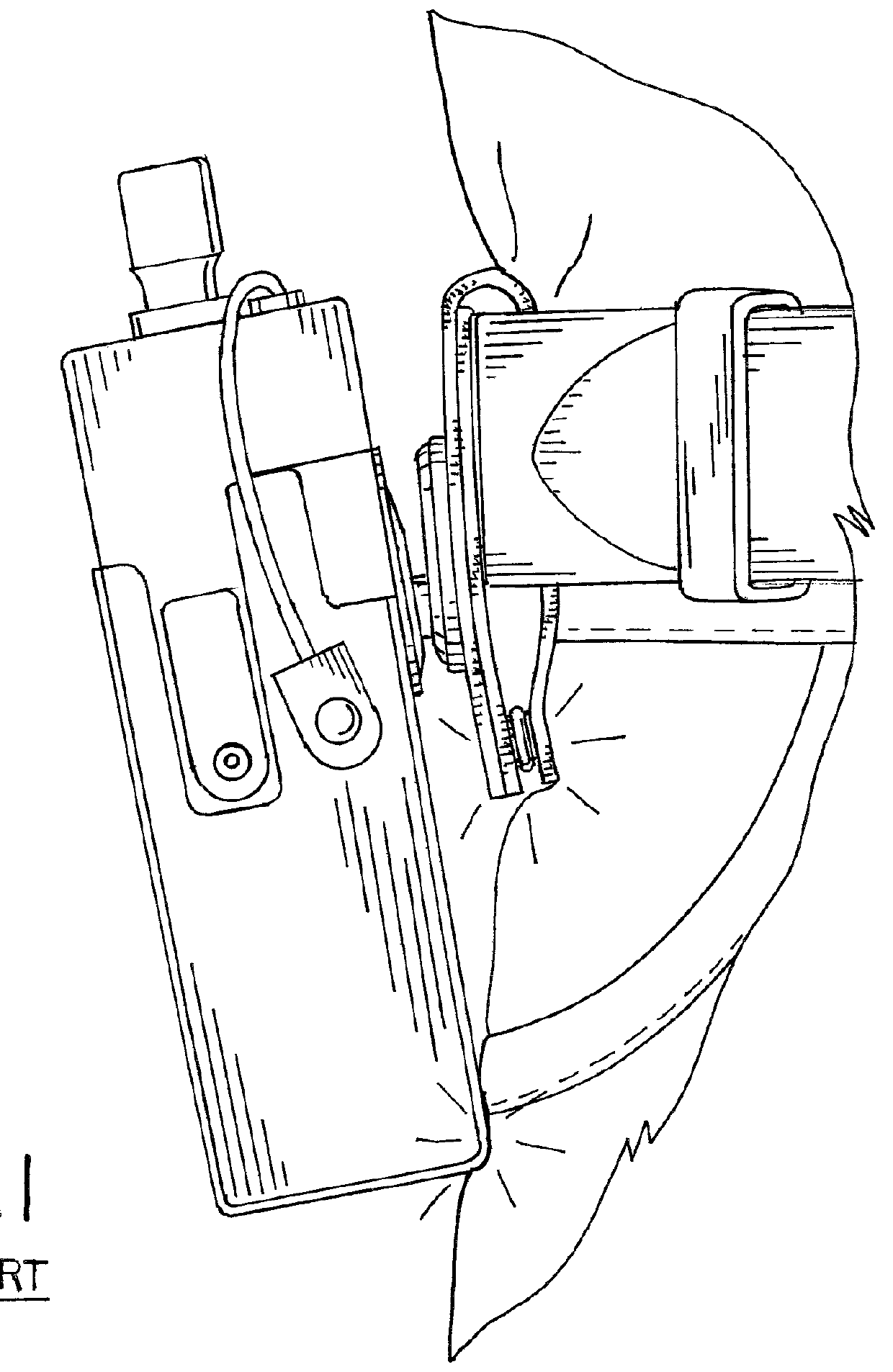

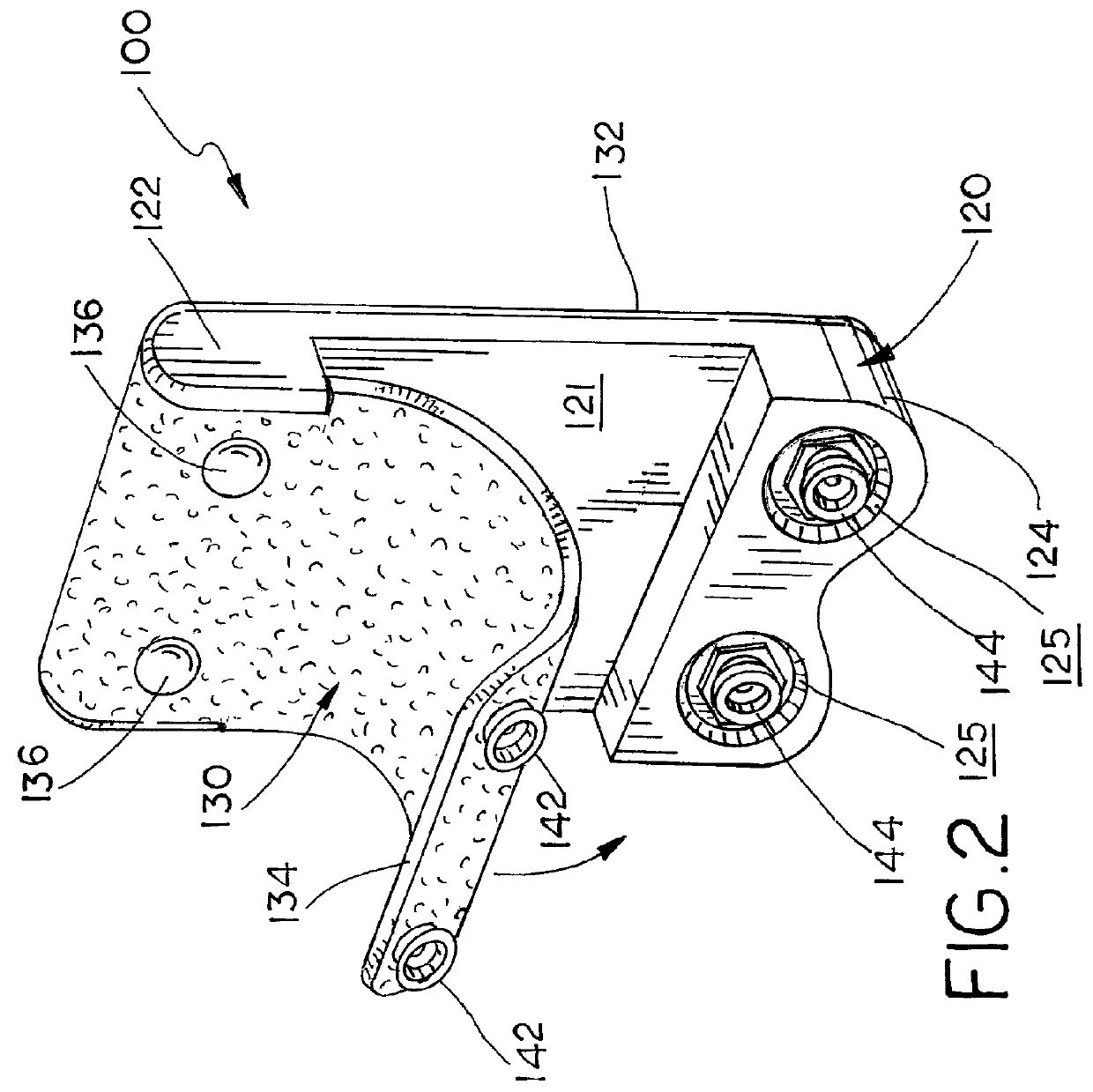

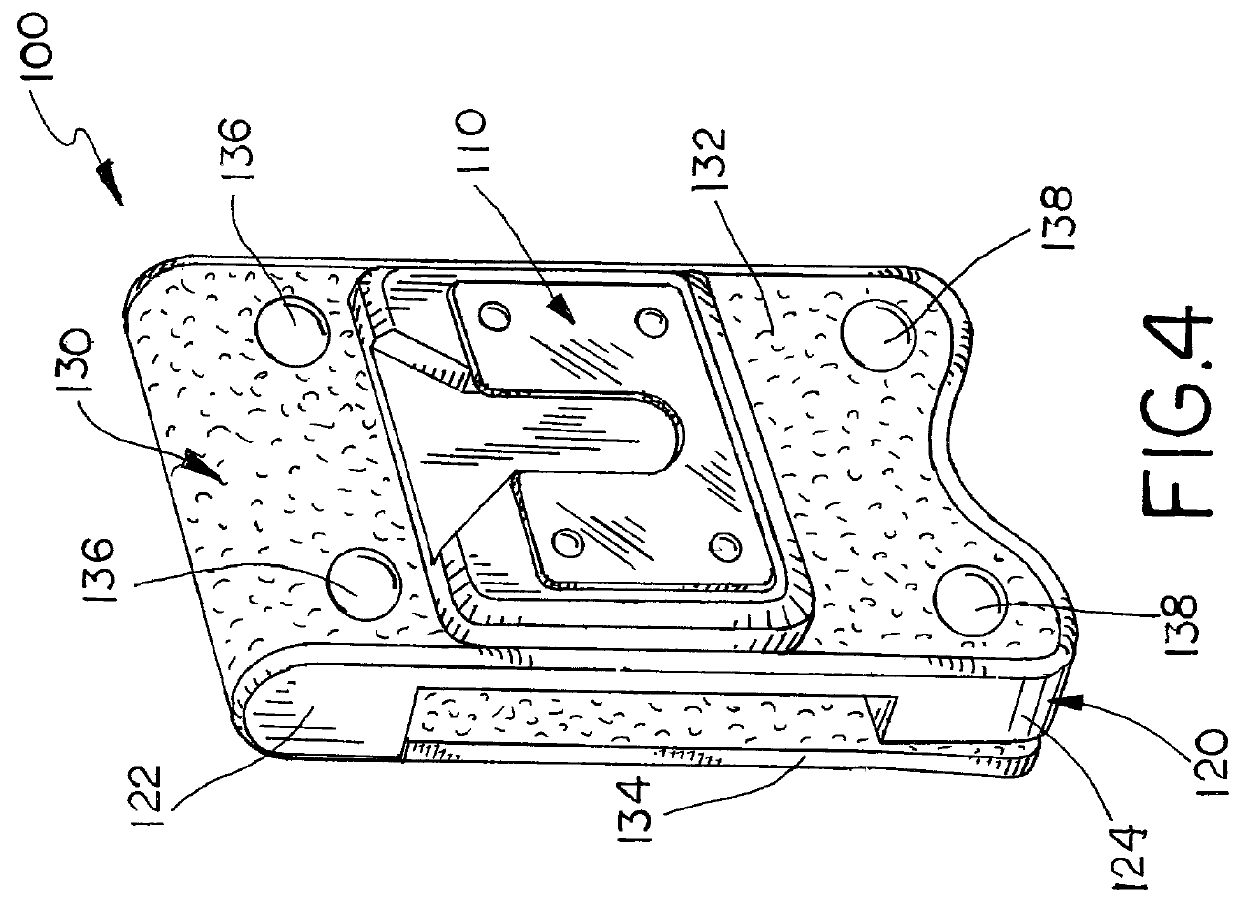

Belt hanger for handheld device

A belt hanger detachably supports the handheld device, whether or not carried in a pouch or holster, to a wearer's waist belt to comfortably and securely carry the device while preventing the device from sagging and hanging outward from the wearer's body. The belt hanger includes a rigid hanger body, a flexible strap cover and a quick connector part, which couples directly to the handheld device or its carry pouch or holster. The hanger body has a rectangular shape and a central belt channel for receiving the user's waist belt. The cover strap is bonded to the hanger body and wraps over the hanger body so that one end covers one its faces and the opposite loose end extends over the belt channel and its other face to act as the closure strap for belt hanger. The opposite loose end of the cover strap is secured to the hanger body by a pair of snaps.

Owner:MERZON RICHARD H

Spindle transmission mechanism of trestle-conveying-type spinning machine

InactiveCN100464012CIncrease contact areaSlippery small and evenIntermittent wound-up machinesDrive wheelCentral belt

The invention relates to a spindle transmitter of walking spinning machine, which comprises several spindles whose axles are parallel in same plane, a central belt, a driving wheel, and a tension wheel, wherein the axle of driving wheel and the axle of tension wheel are parallel with the axles of spindles; said central belt is tensioned on the driving wheel and the tension wheel; said central belt compacts the circumference of each spindle tightly, to gear the spindle; since the central belt is wide and it uses compression roller, the compact area between spindle and belt is increase, and it uses tension wheel to adjust the tension of central belt, it can realize stepless adjustment of tension, to adjust the compact stress between central belt and spindle stepless, to adjust the spindle transmission torque; therefore, the twisting difference is controlled, and the product has high quality.

Owner:SUZHOU YOULIAN TEXTILE EQUIP TECH

Transmissive belt damage detecting device and method

ActiveCN107673030AAvoid damageReduce tearingConveyorsControl devices for conveyorsFace detectionCentral belt

The invention discloses a transmissive belt damage detecting device and method; and the transmissive belt damage detecting device is a device for detecting large-area belt tearing accident caused by aspike penetrating through a belt, and belongs to the field of belt conveyor belt tearing detection. The transmissive belt damage detecting device and method are used for detecting transmissive belt damage, and meanwhile, prevent economical loss caused by secondary belt tearing. Multiple sets of transmissive belt damage detecting devices are matched and mounted in parallel; monomers penetrate through the belt damage detecting devices; an air pressure surface detecting mode is adopted; and two airbag cover devices are symmetrically designed to realize full-coverage detection of non-working surfaces of conveying belts. According to scene working conditions, a detachable design is adopted to satisfy actual installation demands. The transmissive belt damage detecting device can effectively detect transmissive belt damage faults, and meanwhile, is matched with a belt machine central processing system to finish the equipment stalling at the first time, so that the equipment property safety can be effectively protected, the maintenance cost is reduced, and the equipment damage loss is reduced.

Owner:国投中煤同煤京唐港口有限公司

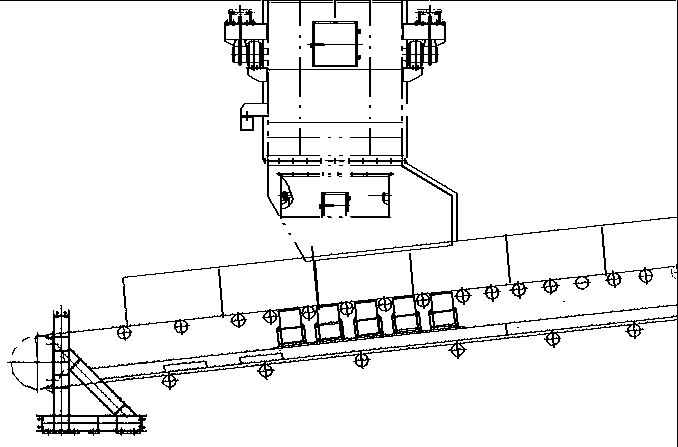

A vacuum packaging inkjet coding line

InactiveCN104444293BReduce processing timeExtended shelf lifePackagingConveyor partsCentral beltEngineering

A vacuum packaging coding and sorting line, characterized in that it includes a quantitative hoist for conveying and lifting bagged materials, a transitional inclined platform for receiving bagged materials under the quantitative hoist, and a transitional inclined platform that exits the transitional inclined platform The feeding port is connected with a vibration sorting device for vibrating and loosening the bagged materials. One end of the discharge port of the vibration sorting device is connected with a plurality of bagged material turning slides, and a bag is arranged under the bagged material turning slides. The material sending out belt, the end of the bagged material sending out belt away from the bagged material turning slider is sequentially connected with the first climbing material belt, the second climbing material belt, the third climbing material belt, and the second Four climbing material belts, the end of the fourth climbing material belt is connected with a coding conveyor belt, the middle part of the coding conveyor belt is provided with an inkjet printer, and the end of the coding conveyor belt is also equipped with defective products separation device. The vacuum packaging material sorting line of the present invention has a high degree of automation of the coding operation and saves a lot of labor costs.

Owner:陈嘉荣

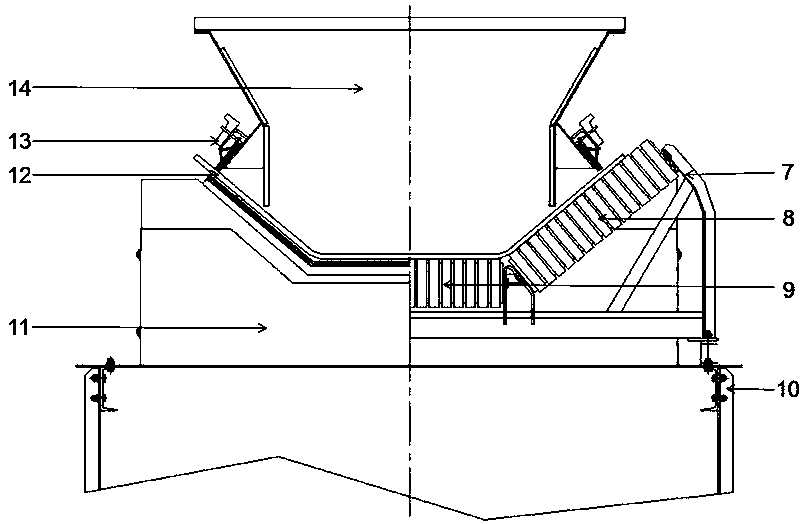

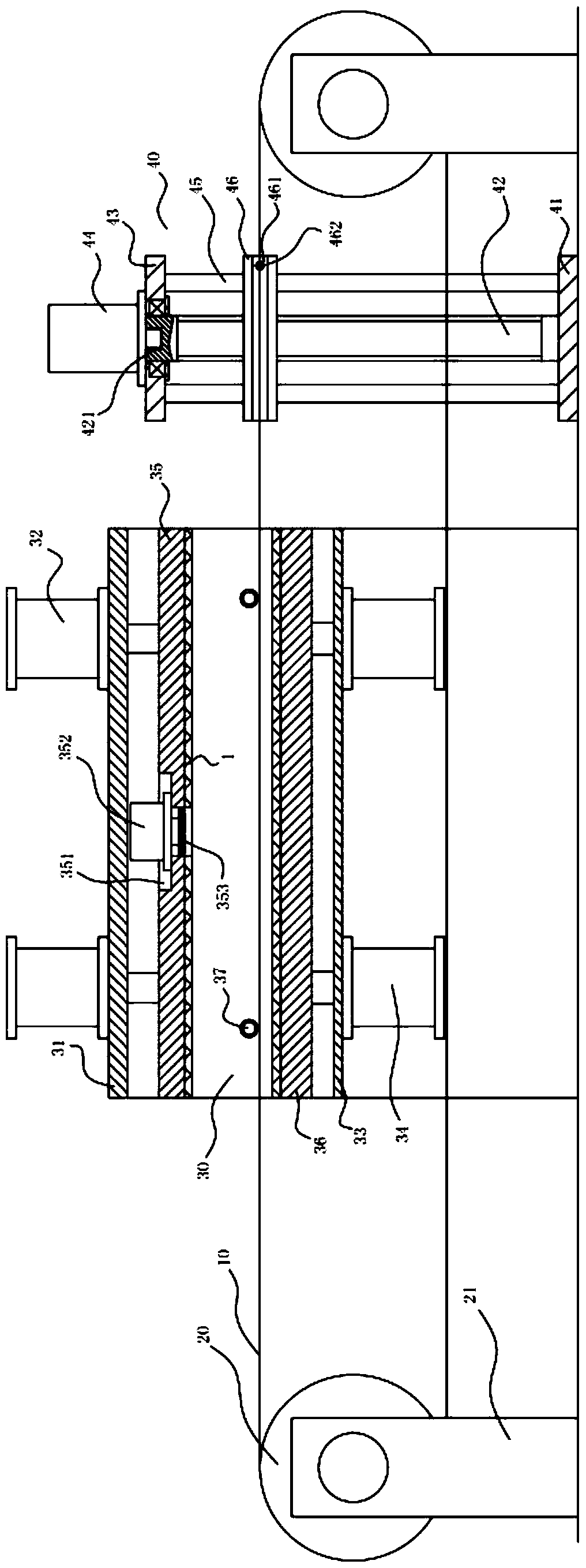

Cashmere full-automatic bagging machine

PendingCN107934038ASimple mechanical structureReduce manufacturing costPackagingFailure rateCentral belt

The invention discloses a cashmere full-automatic bagging machine which comprises a rack, a conveying device, a compaction device and an opening device. The conveying device comprises a conveying drive mechanism, a conveying belt A and a conveying belt B. The conveying belt A is composed of a lower horizontal conveying segment, a middle vertical conveying segment and an upper horizontal conveyingsegment. The conveying belt B is composed of a middle vertical conveying segment and an upper horizontal conveying segment. The conveying belt A and the conveying belt B are each supported and drivenby multiple roll wheels. A cashmere collection hopper is arranged on the lower horizontal conveying segment of the conveying belt A. The opening device is arranged on the lower sides of the ends of the upper horizontal conveying segments of the conveying belt A and the conveying belt B, and the compaction device is arranged on the upper portion of the opening device. The cashmere full-automatic bagging machine is simple in structure, low in manufacturing cost, low in failure rate and convenient to use and operate, and cashmere cannot fall off.

Owner:赤峰圣伦绒毛制品有限公司

A kind of corrugated carton knocking printing and picking device

The invention discloses a corrugated carton knocking and printing pick-up device, which comprises a conveyor belt, a drive roller and a frame. Material rack; the frame is a portal frame, and a plurality of upward push cylinders are fixed on the top plate of the frame, and a plurality of lower push cylinders are fixed on the middle support plate of the frame, and the middle support plate is conveyed on the upper and lower sides of the conveyor belt. Between the parts, the reclaiming frame includes a reclaiming base plate, two lifting screws are hinged on both sides of the retrieving base plate, the upper ends of the lifting screws are hinged on the upper reclaiming plate, and a lifting motor is fixed on the upper reclaiming plate , the output shaft of the lifting motor is connected to the upper end of the lifting screw, one end of the support rod is fixed on the reclaiming bottom plate, and the other end of the support rod is fixed on the upper reclaiming plate. Printing, and automatically lift the printed corrugated boxes, convenient for the operator to take directly.

Owner:汕头市源纳纸制品有限公司

Novel multi-functional conveyor belt tension control device

The present invention relates to a novel belt tension control device for a multifunctional conveyor, which comprises a belt, a moving plate, a sliding track, a support rod and a bottom bar; wherein, the belt is located in the center of the device, and the moving plate has two pieces, respectively On both sides of the device, the sliding track is located under the moving plate, the support rod is located on the left side of the moving plate, and the bottom bar is located at the bottom of the device. The novel belt tension control device of the present invention has the advantages of convenient operation, adjustable looseness, good operability and the like.

Owner:浙江省柯桥中学

A mechanism for a filling machine with synchronous bottle feeding and positioning functions

ActiveCN105439063BImprove adaptabilityReduce time consumptionLiquid bottlingConveyor partsSolenoid valveCentral belt

Owner:SHANGHAI CHENG XING MACHINERY & ELECTRONICS

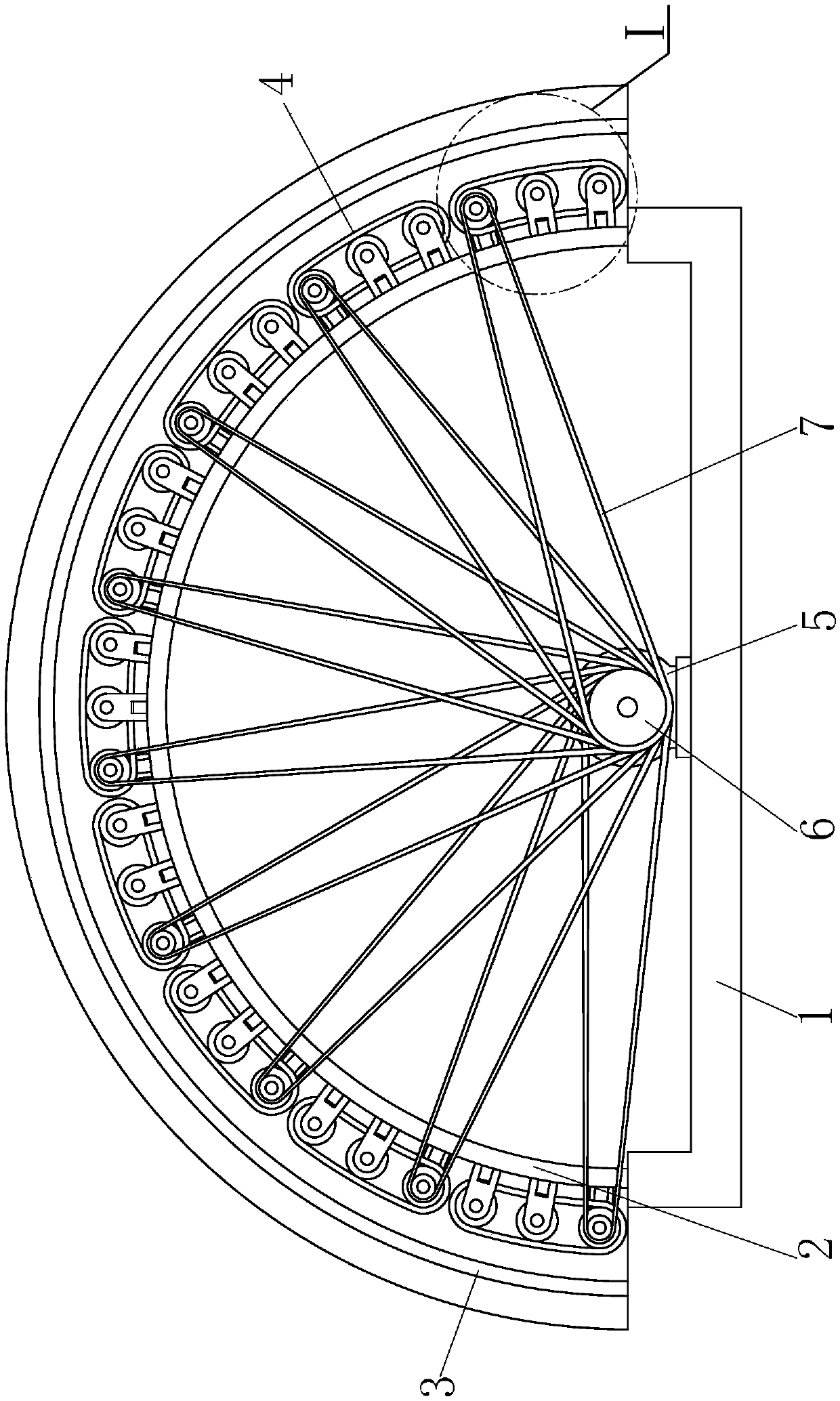

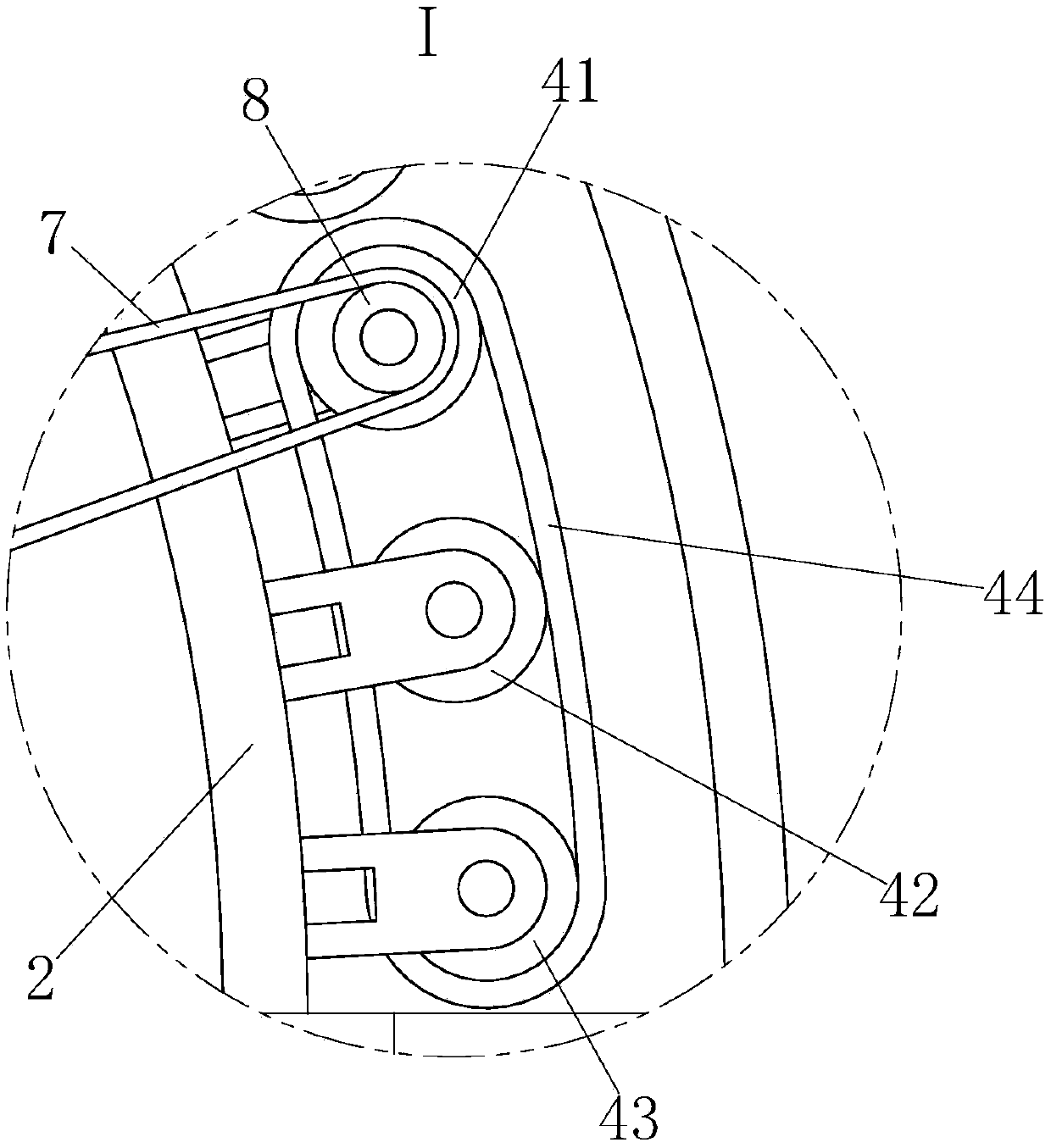

A cruise ship rack

ActiveCN107115676BStrong gaming experienceIntense gaming experienceHelter-skeltersCentral beltTransmission belt

The invention relates to a rowboat action frame comprising an underframe, wherein a semicircular rail frame is arranged on the underframe, and a semicircular guide rail is arranged on the back end of the rail frame; a belt conveyor device is installed on an arc surface of the upper end of the rail frame from left to right; a total driving motor is installed at the center of the underframe, the total driving motor is connected with a central belt pulley, transmission belts are installed on the central belt pulley from front to back, each transmission belt is connected with a branch belt pulley coaxially connected with the left belt pulley on the end deviating from the central belt pulley. The rowboat action frame has relatively high swimming ability, the tourists can also be guided to experience the pleasant sensation of automatically climbing slopes and experiencing weight loss on the basis that the rowboat travels by the belt transmission, thereby bringing intensive nervous and irritative game experience for the tourists.

Owner:芜湖思科生产力促进中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com