Spindle transmission mechanism of trestle-conveying-type spinning machine

A technology of transmission mechanism and spinning frame, which is applied in spinning frame, intermittently wound spinning frame, textile and paper making, etc. And the effect of easy maintenance, low maintenance cost and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

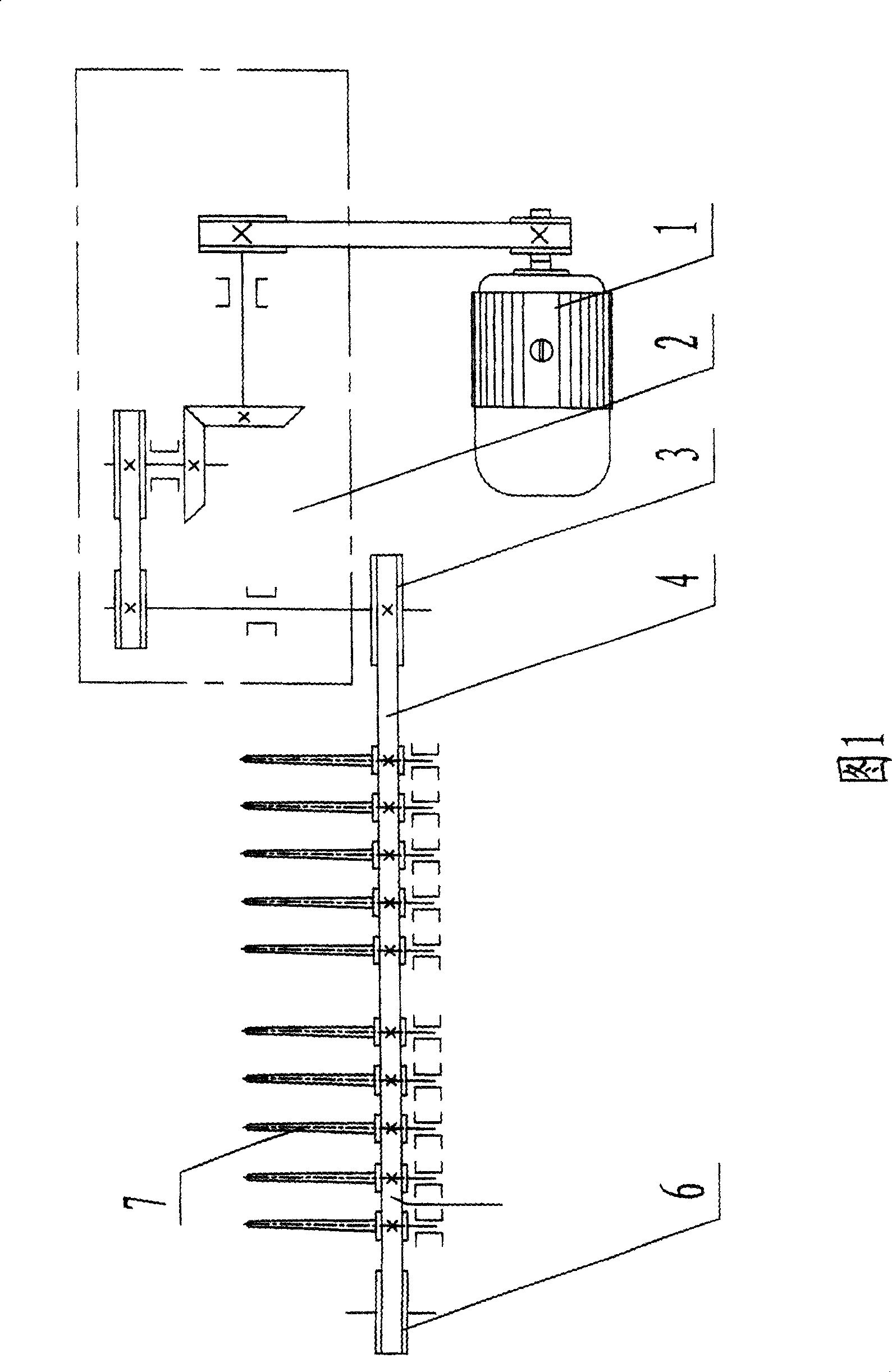

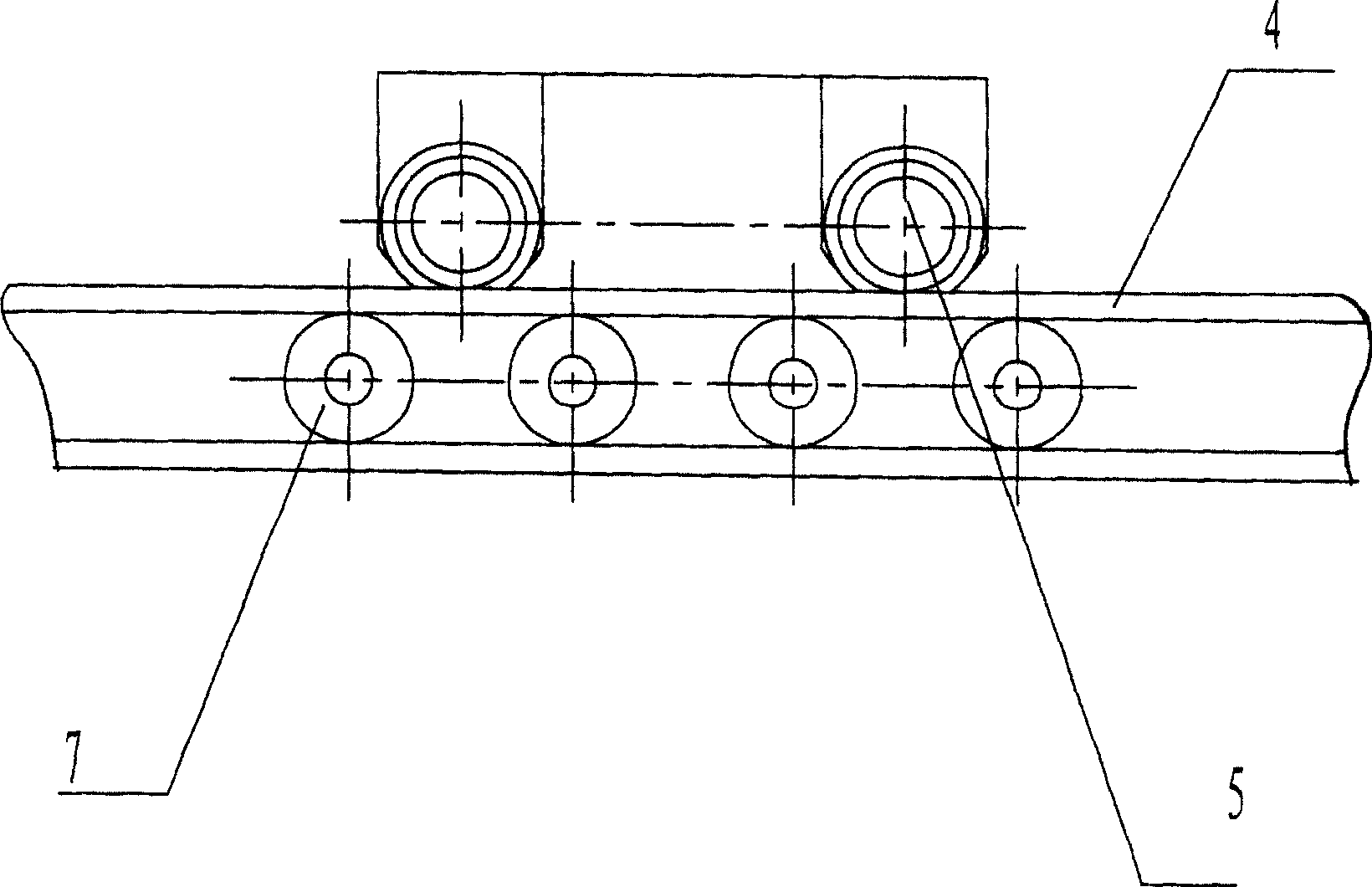

[0011] Figure 1~ figure 2 The spindle transmission mechanism of a frame-type spinning frame shown includes a plurality of spindles 7, a dragon belt 4, a driving wheel 3, and a tension pulley 6, wherein the axis lines of the plurality of spindles 7 are parallel to each other and the plurality of spindles The axis lines of 7 are located on the same plane, the axis lines of the driving pulley 3, the axis lines of the tension pulley 6 and the axis lines of each spindle 7 are also parallel to each other, and the dragon belt 4 is tensioned on the above-mentioned On the driving pulley 3 and the tension pulley 6, the dragon belt 4 is attached to the part of the outer circumferential surface of each of the spindles 7.

[0012] The inner surface of the dragon belt 4 is attached to the part of the outer peripheral surface of each spindle 7. In order to make the dragon belt 4 better adhere to the part of the outer peripheral surface of each spindle 7, according to figure 2 In the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com