Patents

Literature

42results about "Intermittent wound-up machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

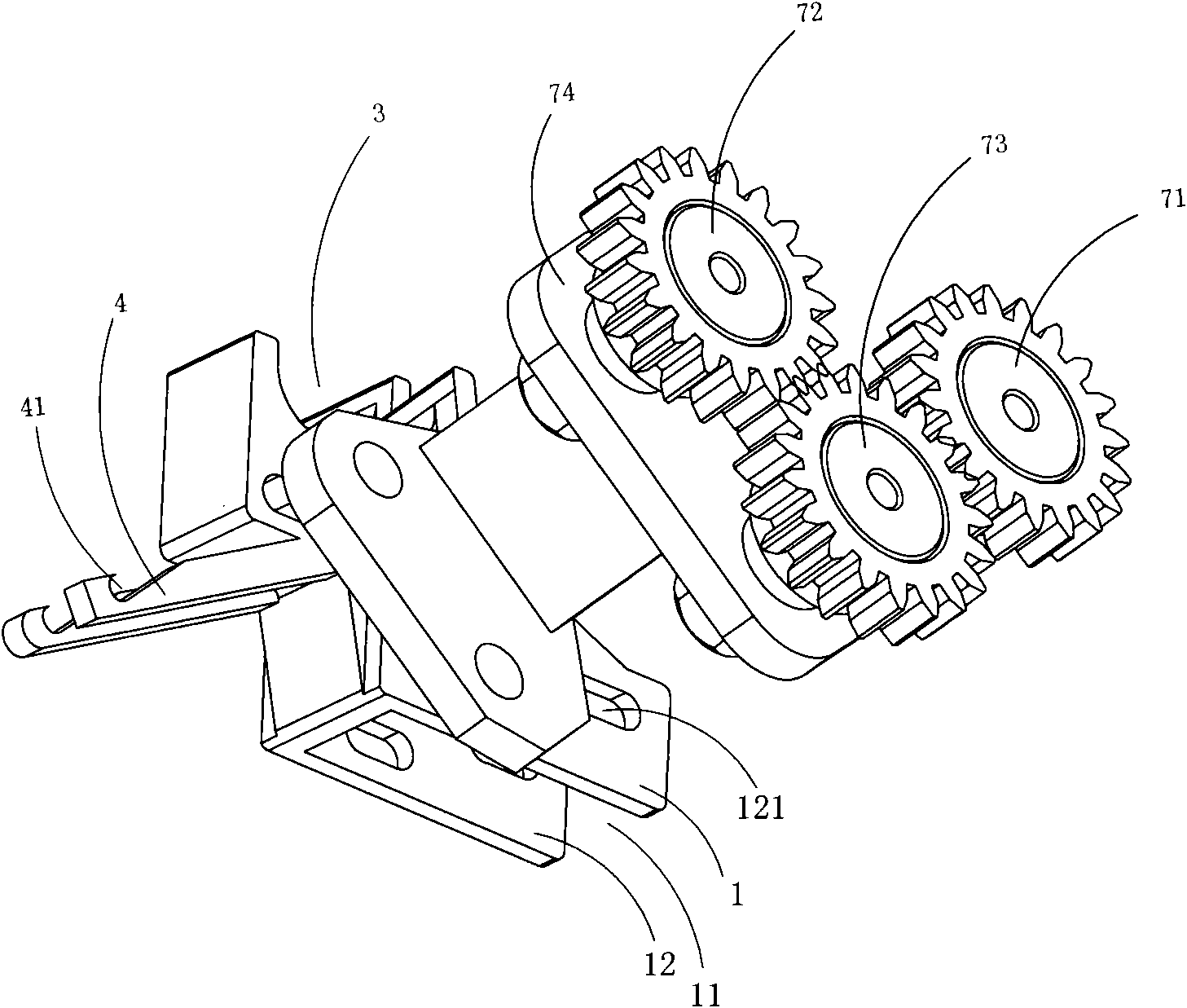

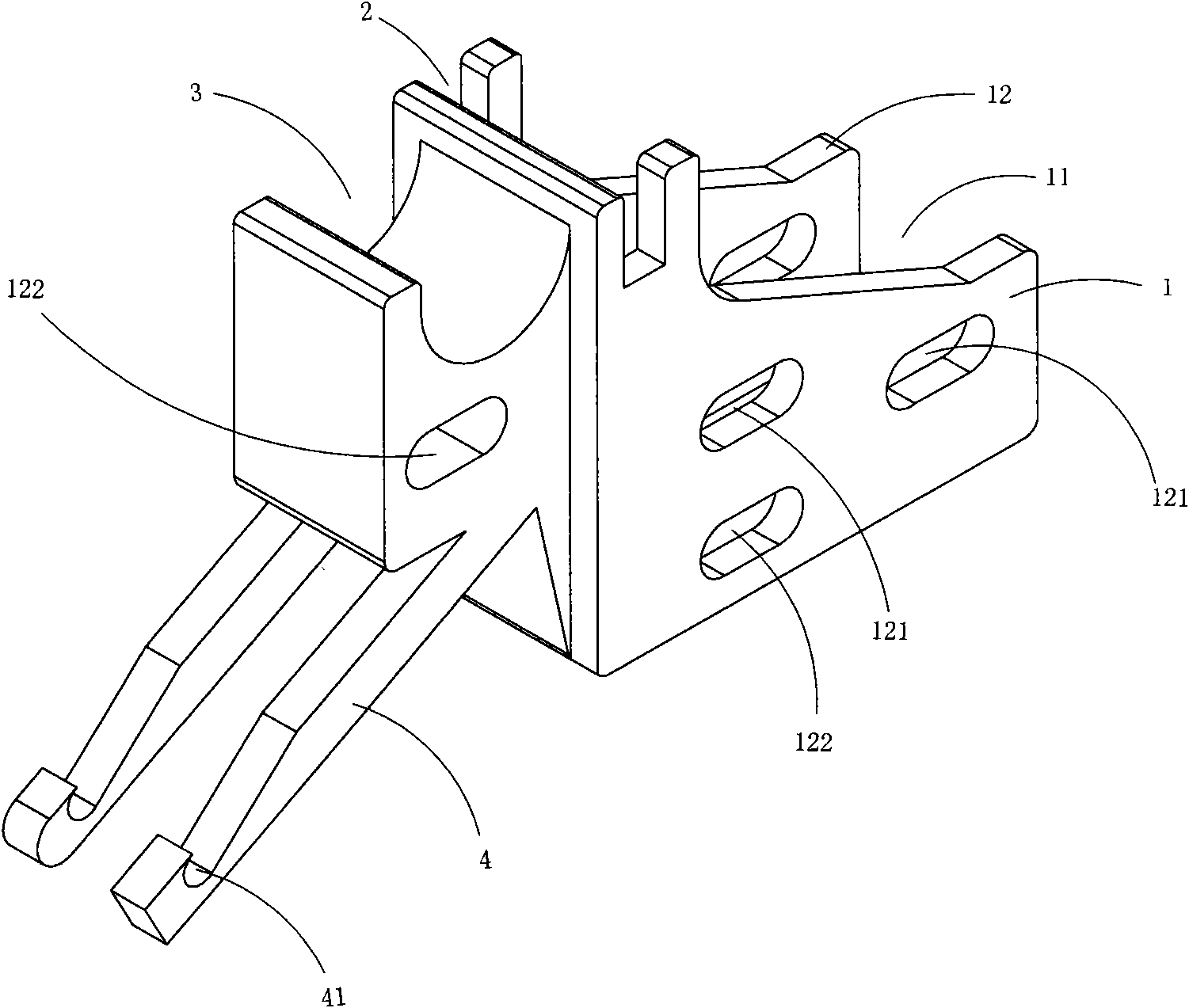

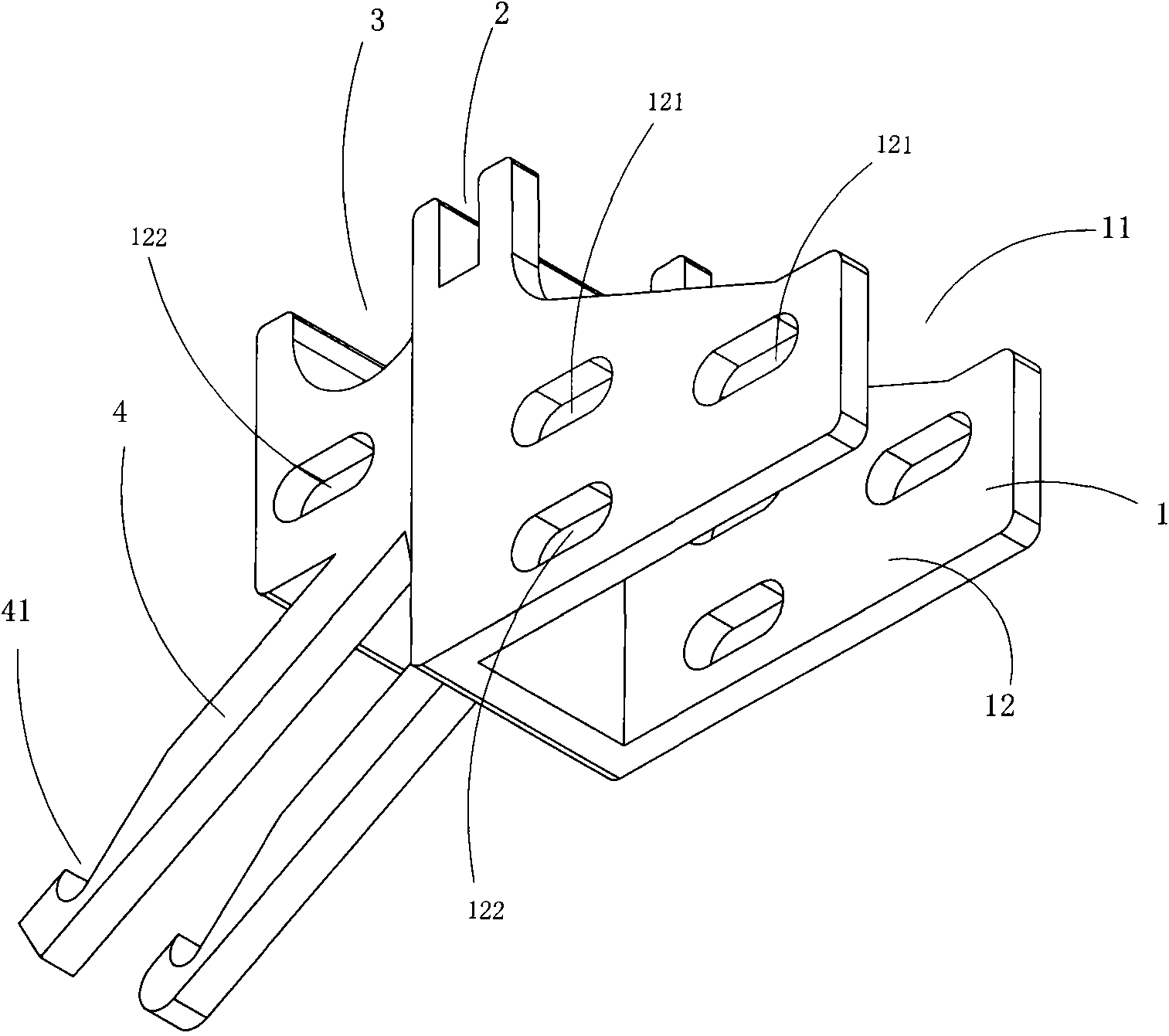

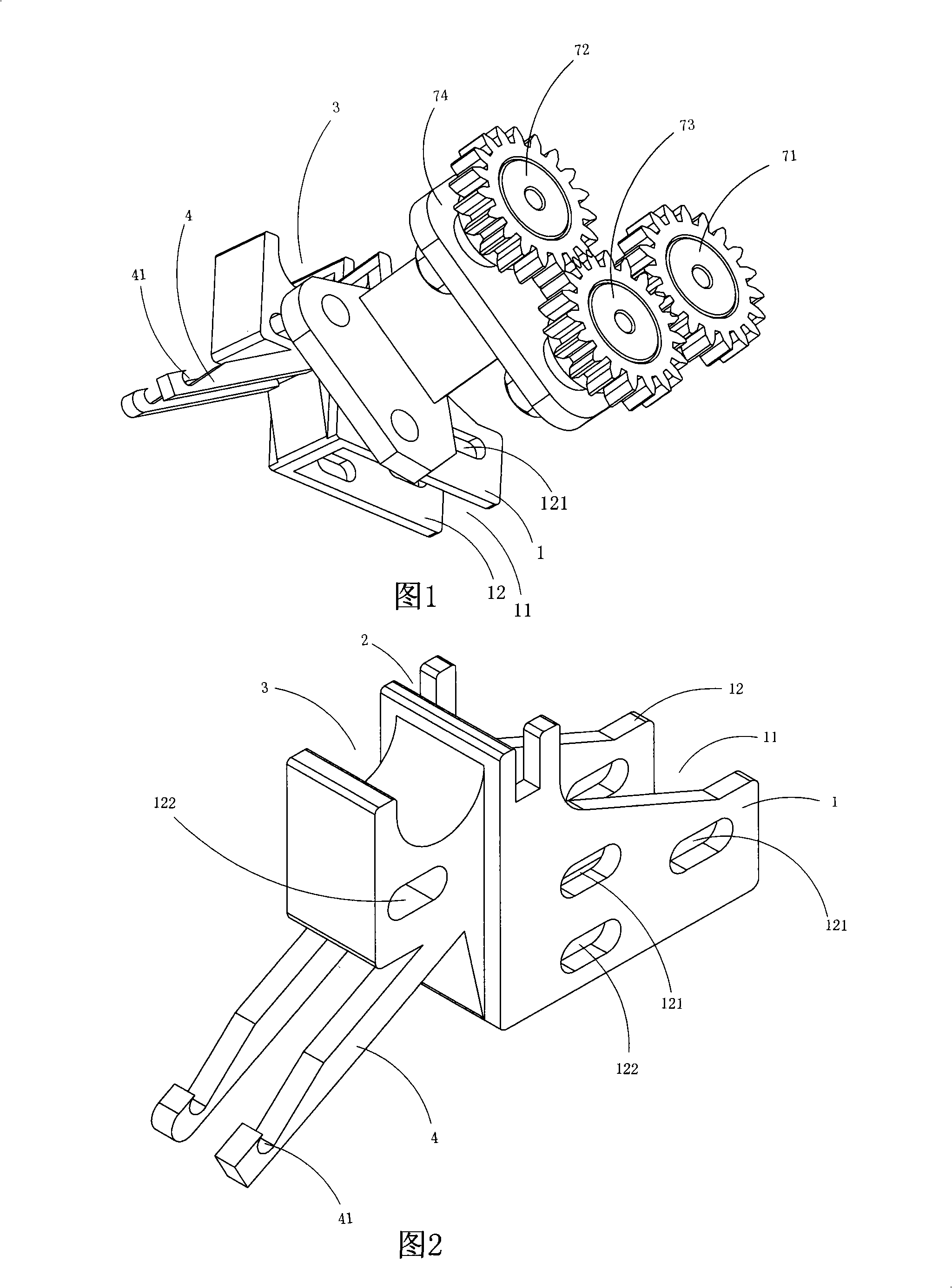

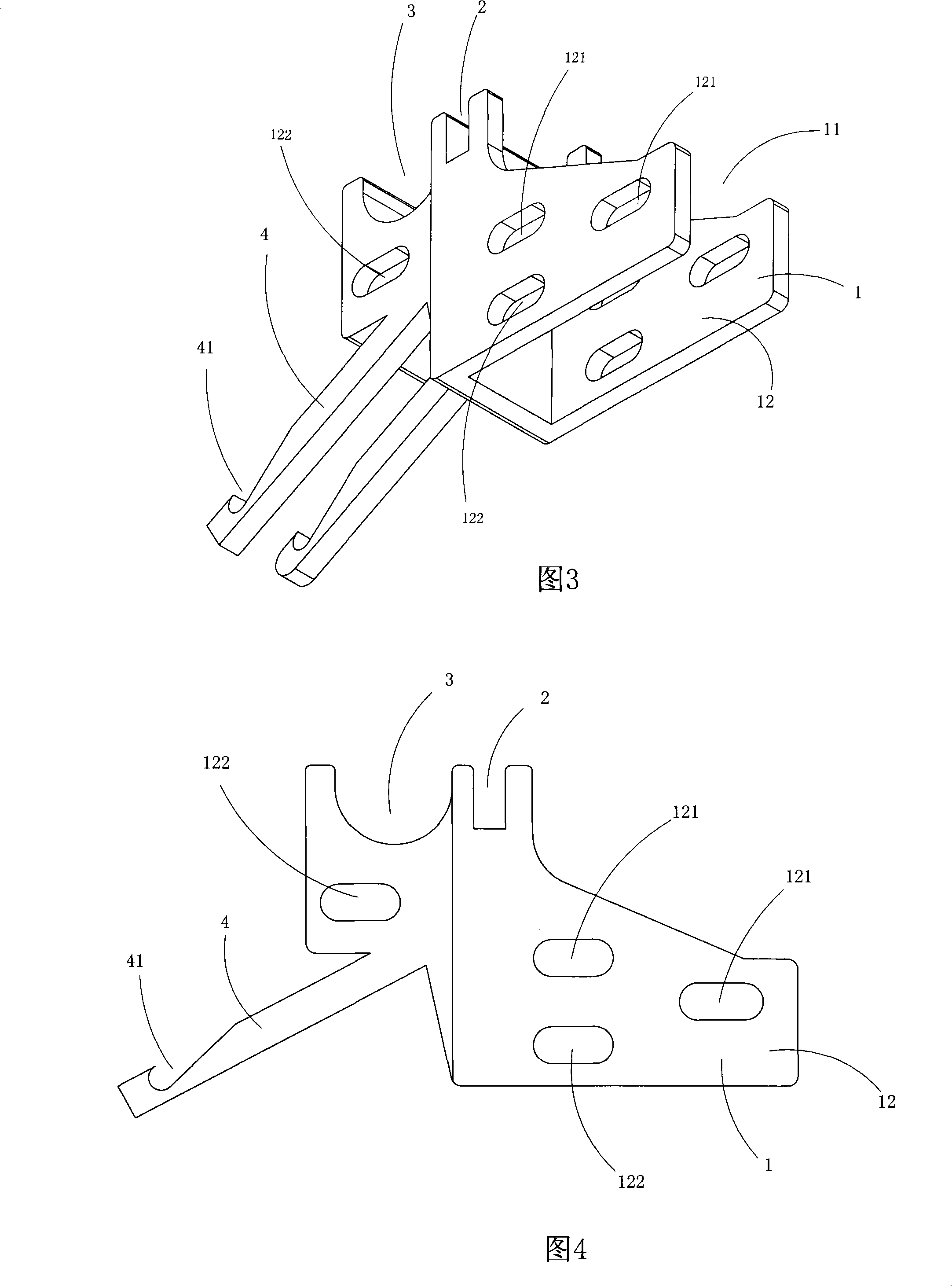

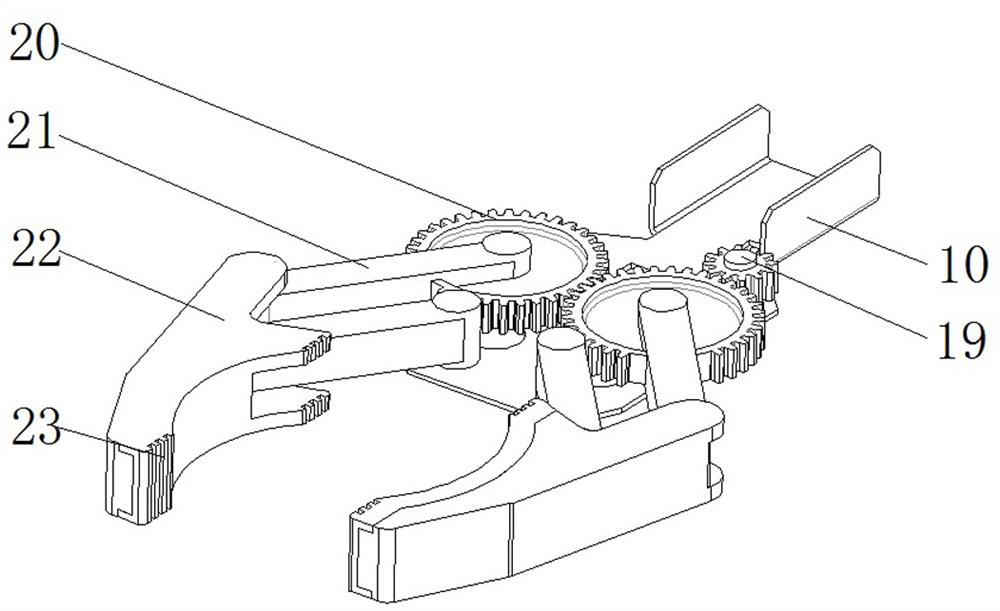

Special idle gear system for four-roller compact spinning machine

InactiveCN101613896AReasonable structureWon't affect placementDrafting machinesContinuous wound-up machinesGear wheelGear system

The invention discloses a special idle gear system for a four-roller compact spinning machine. The system comprises an idle gear assembly for driving; the idle gear assembly comprises a maser idle gear, a first auxiliary idle gear and a second auxiliary idle gear which are arranged on either side of the maser idle gear respectively. The system has the advantages of rational and compact structure and low renovation cost, and can help improve spinning effect.

Owner:张忠宝

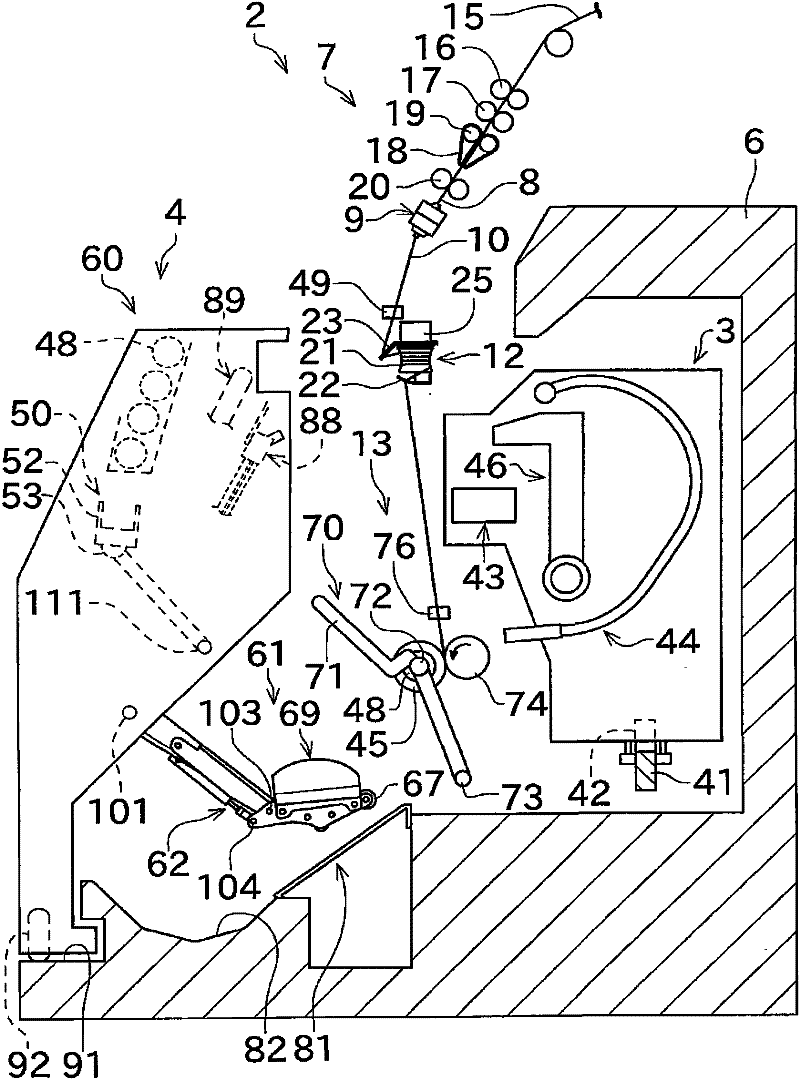

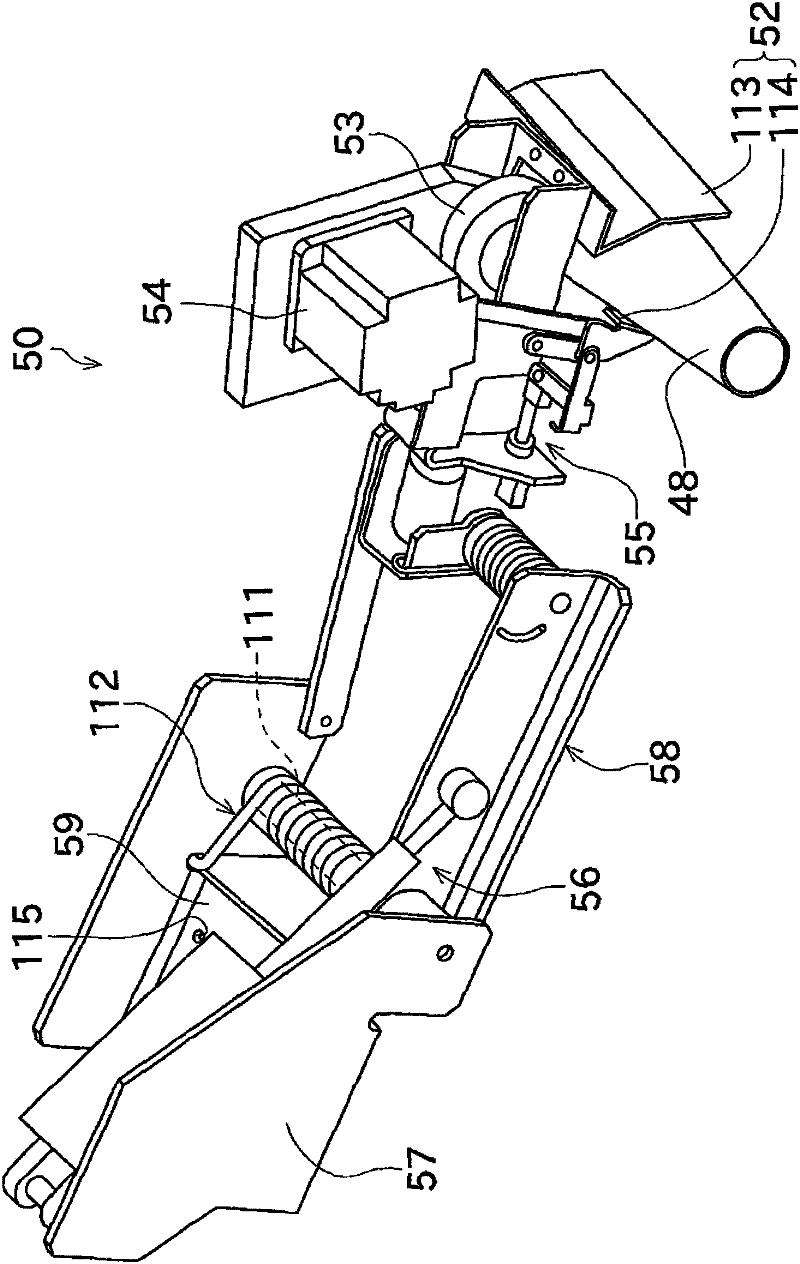

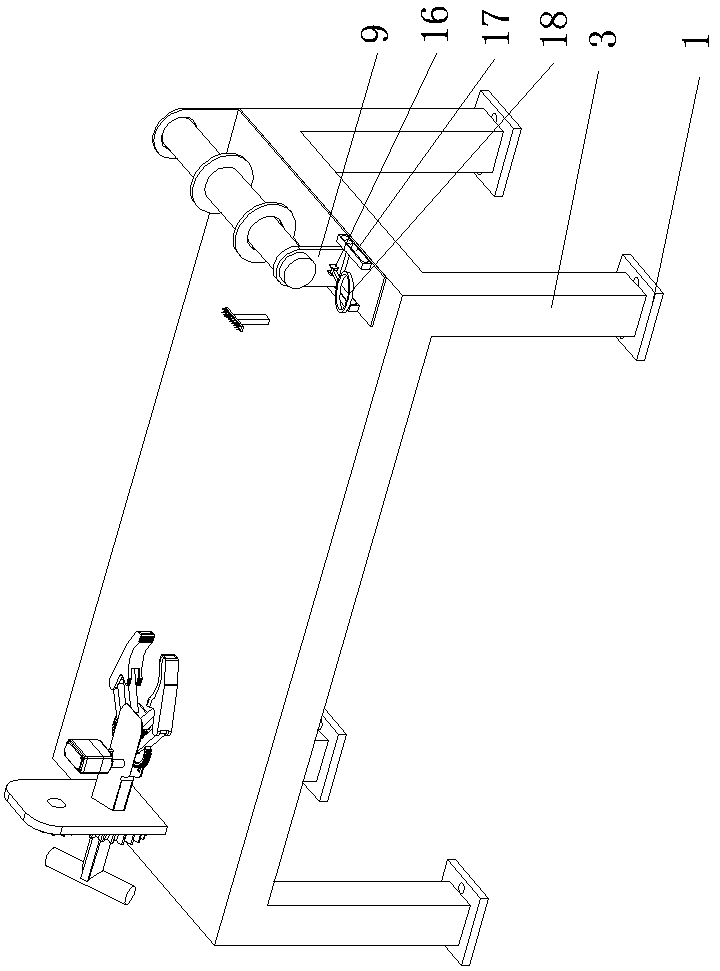

Yarn winding apparatus

ActiveCN102453987AReduce the number of installationsLow costFilament handlingIntermittent wound-up machinesYarnBobbin

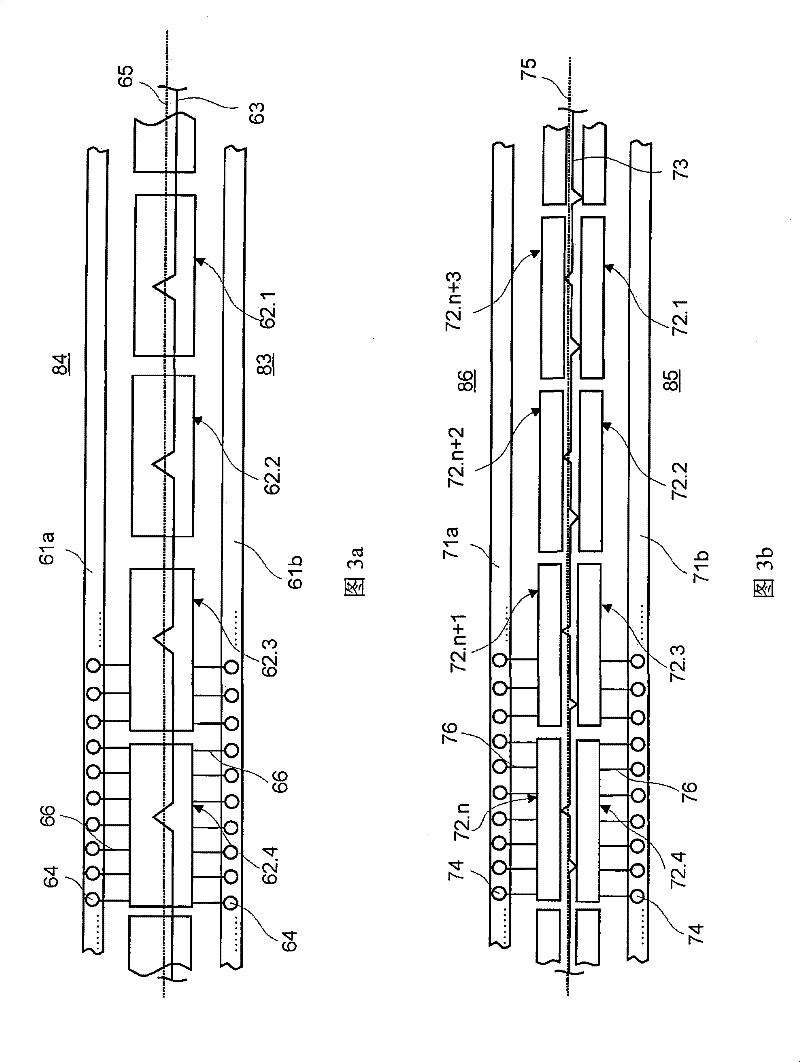

A bobbin installation device (60) includes a bobbin gripping section (52) and a path adjusting plate (59). A pivot arm (58) is attached to a rocker shaft (111) and swings by pivoting about the rocker shaft (111). The bobbin gripping section (52) grips a bobbin, onto which a yarn is to be wound, and supplies the bobbin in between a pair of bobbin holders (72) that define a target position of the bobbin. The path adjusting plate (59) can adjust a path (bobbin supplying path) along which the bobbin is supplied by the bobbin gripping section (52) to the target position.

Owner:MURATA MASCH LTD

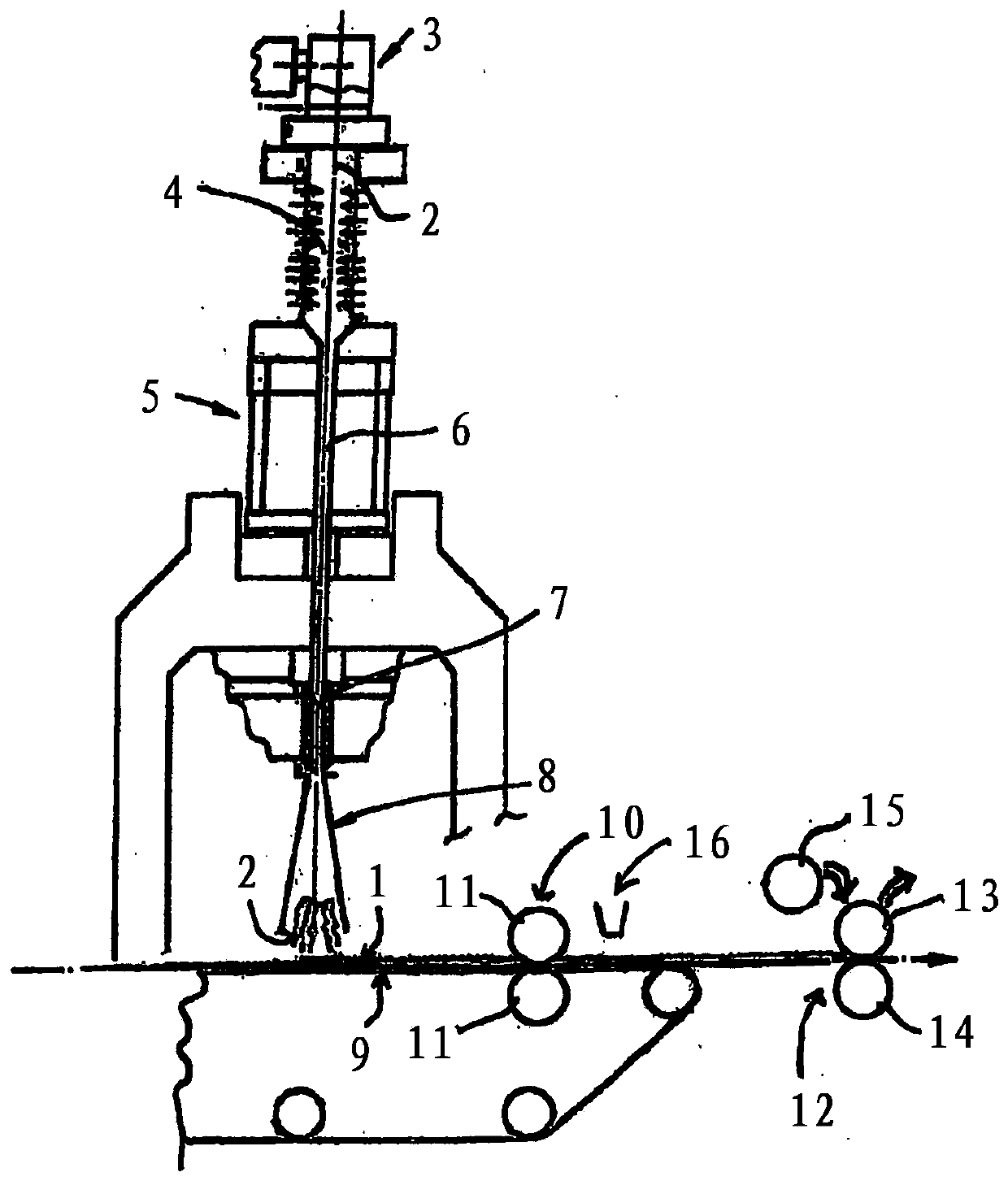

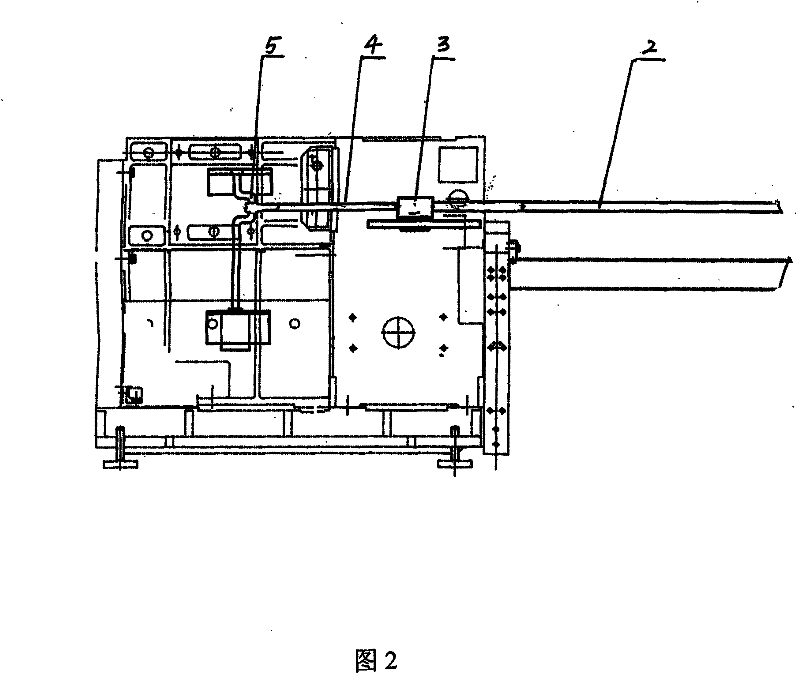

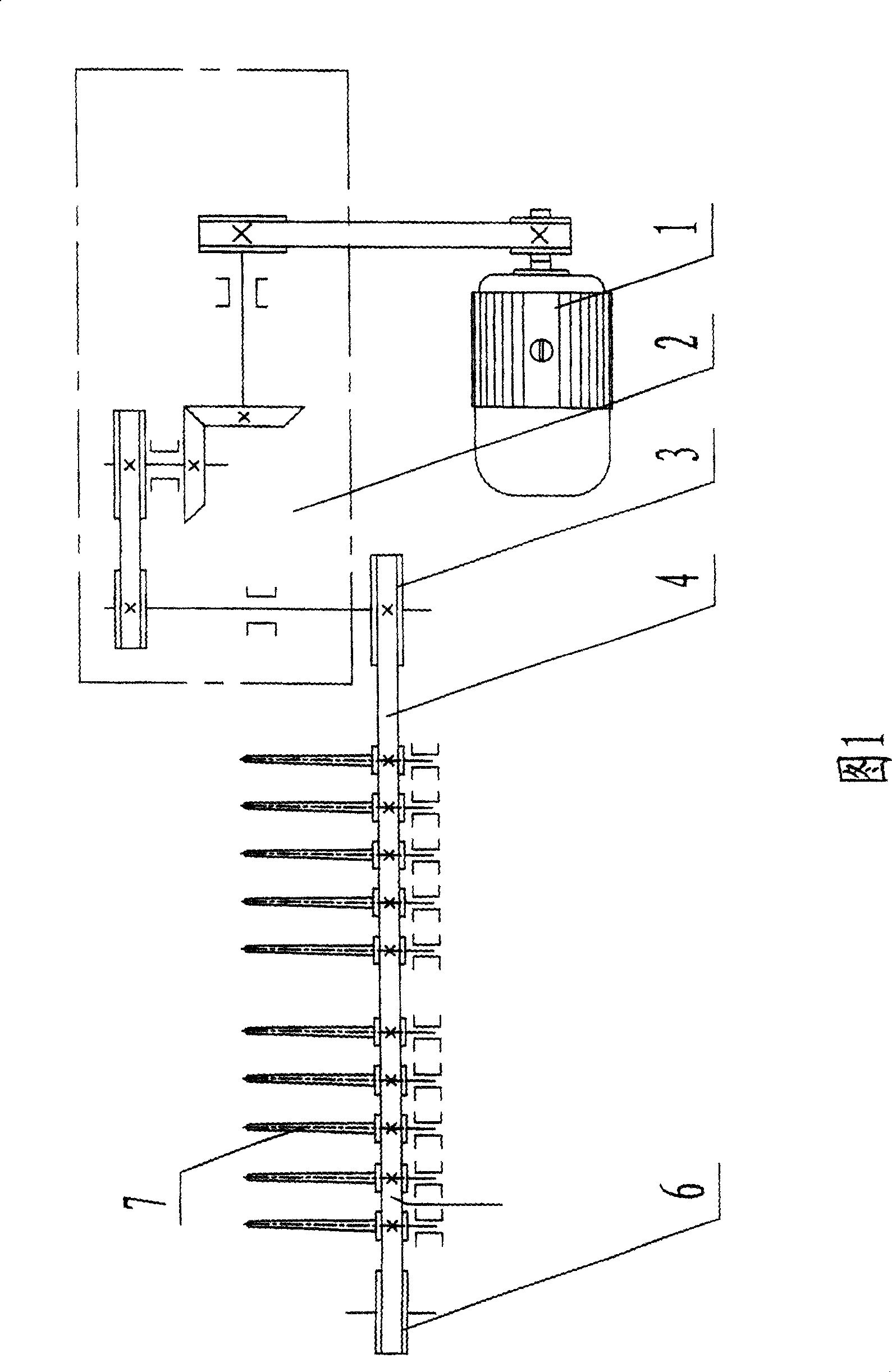

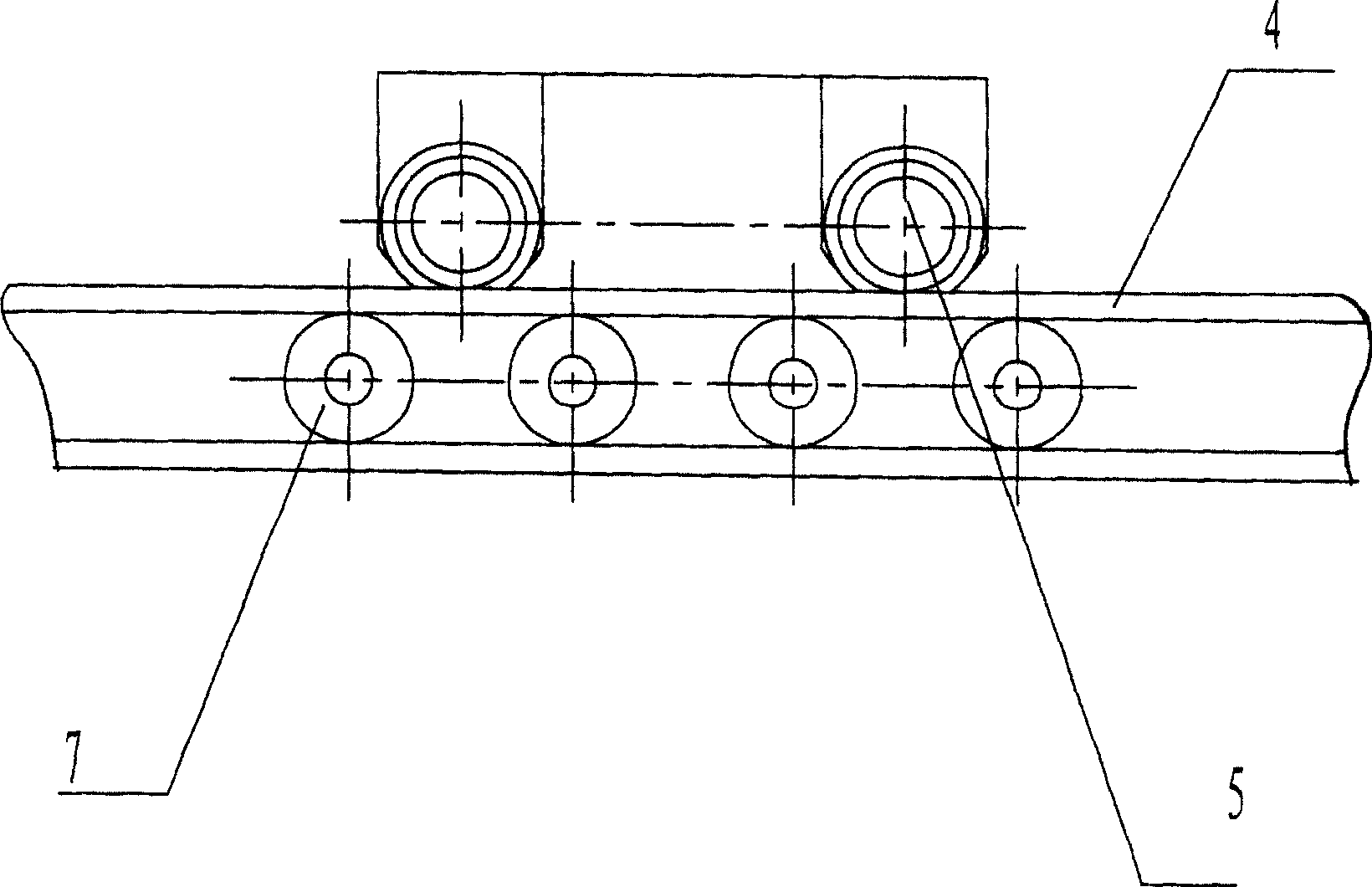

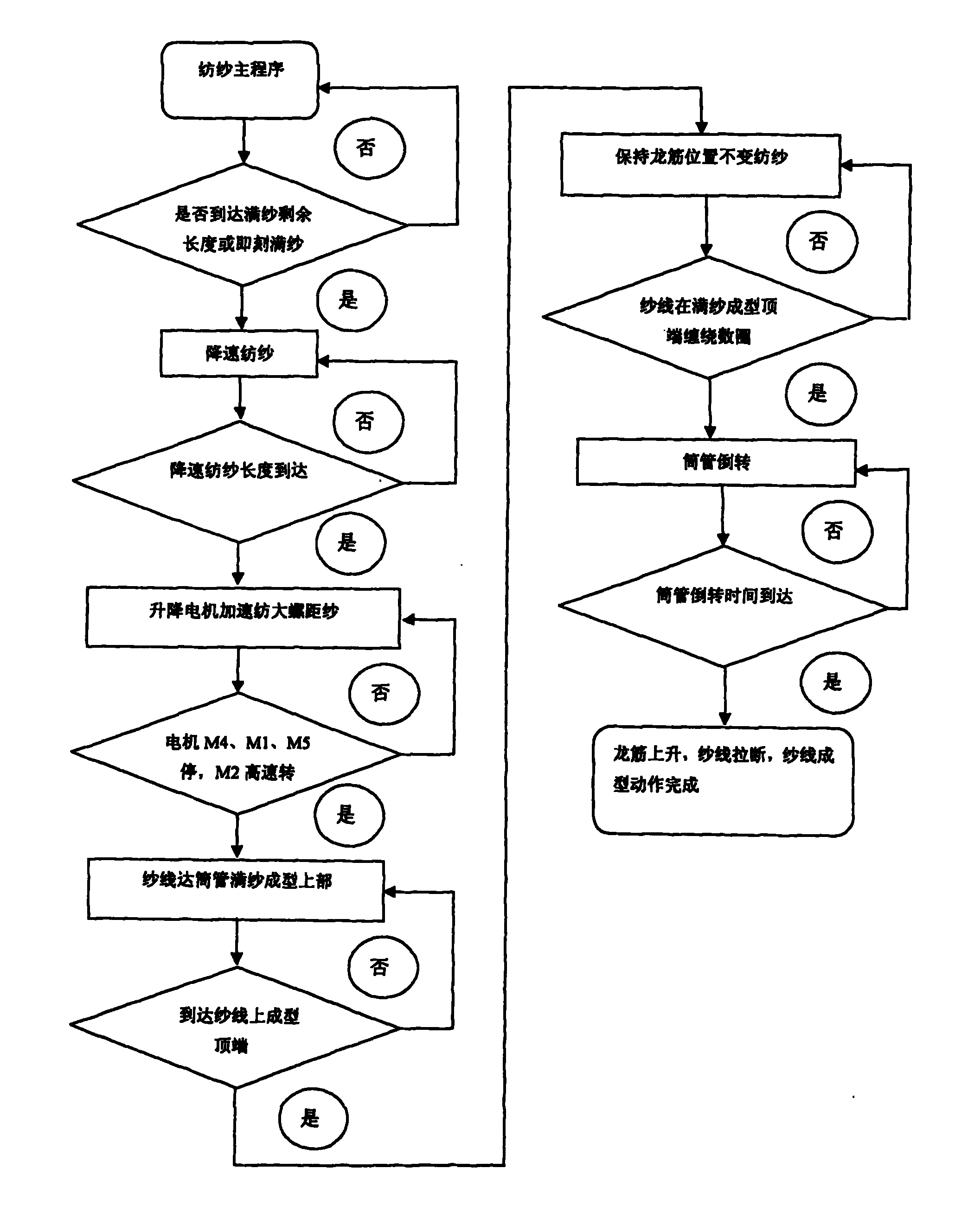

Method and device for winding and forming rough yarn after bobbiner is full of yarn

ActiveCN101634062ANot easy to fall offInhibit sheddingFilament handlingTextile/flexible product manufactureYarnBobbin

The invention discloses a method and a device for winding and forming a rough yarn after a bobbiner is full of yarn. The method comprises that: if the length of a residual rough yarn is in accordance with a preset value, controlling the bobbiner to spinning at a reduced speed; if the length of a yarn spun at a low speed is in accordance with a preset value, controlling a flier motor, a drafter motor and a bobbin rotating body motor to rotate at a low speed, a lower keel motor to rotate at a high speed and the yarn to be distributed at a thread pitch; when the yarn reaches a full-yarn forming upper part of the bobbin, stopping the flier motor, the drafter motor and the bobbin rotating body motor and controlling the lower keel motor to rotate at a high speed; when the yarn reaches the full-yarn forming top end of the bobbin, stopping the lower keel motor, keeping the position of the lower keel, controlling the flier motor the drafter motor and the bobbin rotating body motor to rotate at a low speed, winding the yarn on the full-yarn forming top end of the bobbin and stopping all motors; and controlling the bobbin rotating body motor to rotate reversely, the lower keel motor to rotate and move upward, and breaking the yarn to complete the winding and forming of rough yarn after the bobbiner is full of yarn. The device comprises a draft detection part, a main control unit, a programmable controller, a variable speed controller, a filer, the lower keel and a detection device, wherein the lower keel is provided with bobbin rotating body and the bobbin; and the effect of rough yarn winding and forming after the bobbiner is full of yarn is ideal and free from falling.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

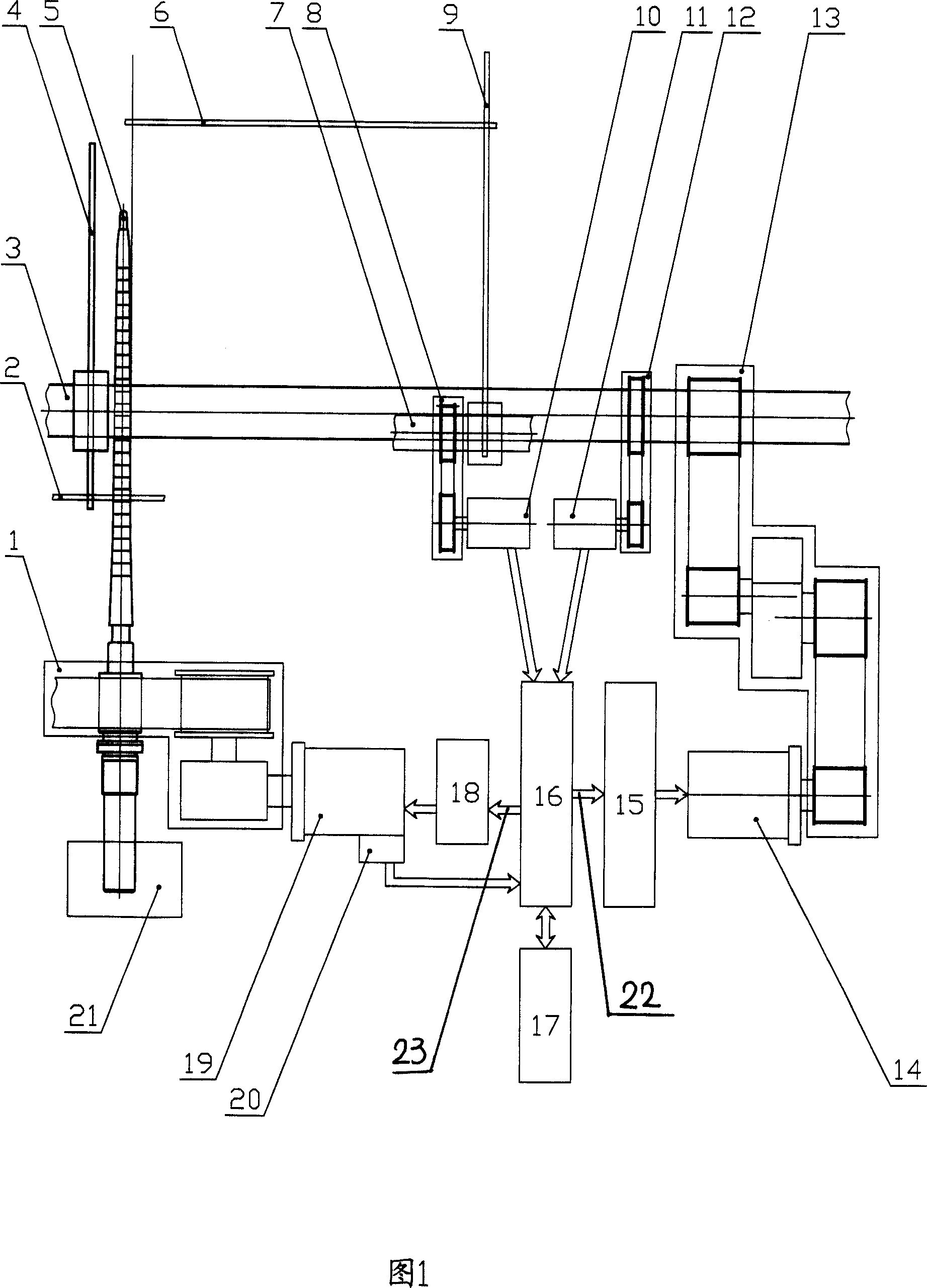

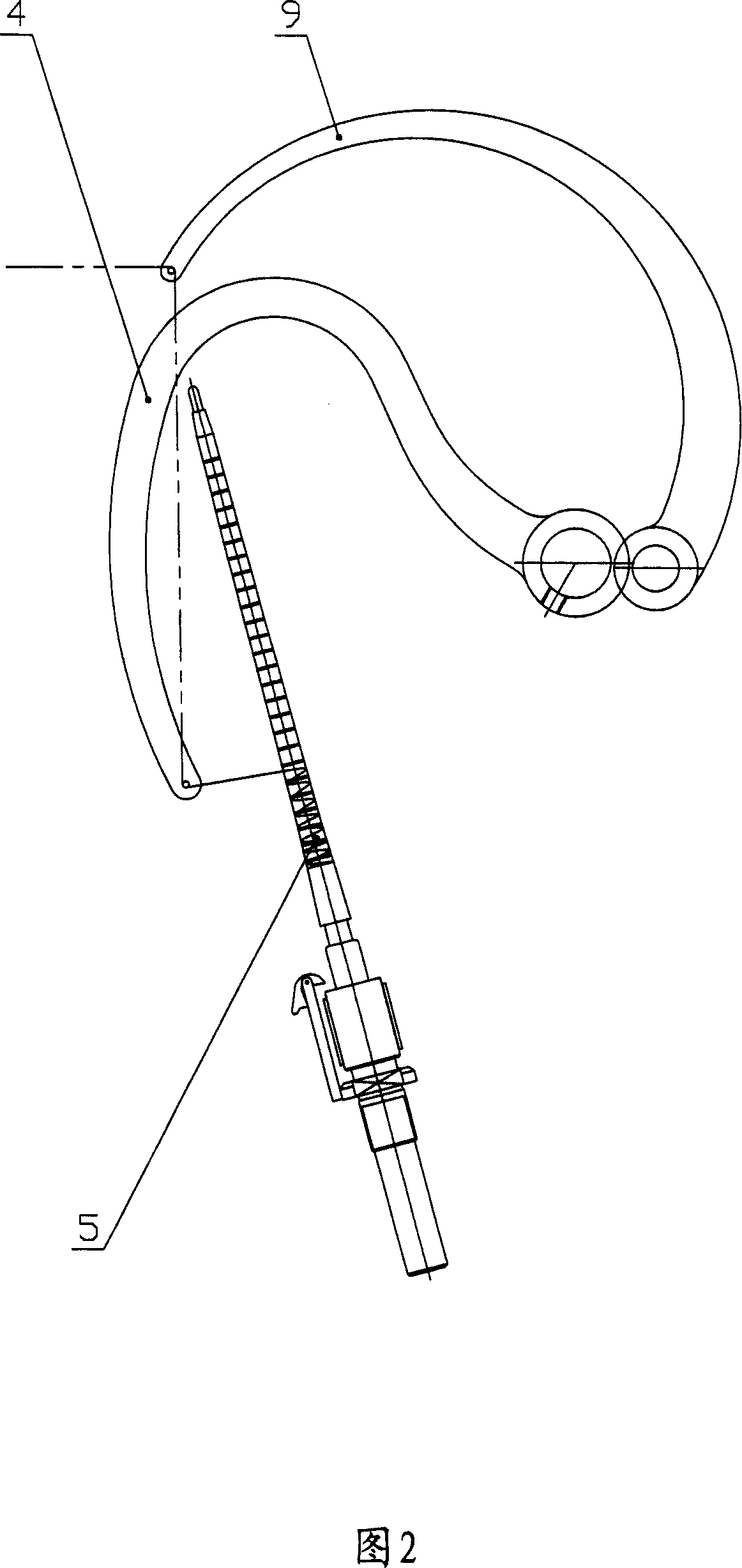

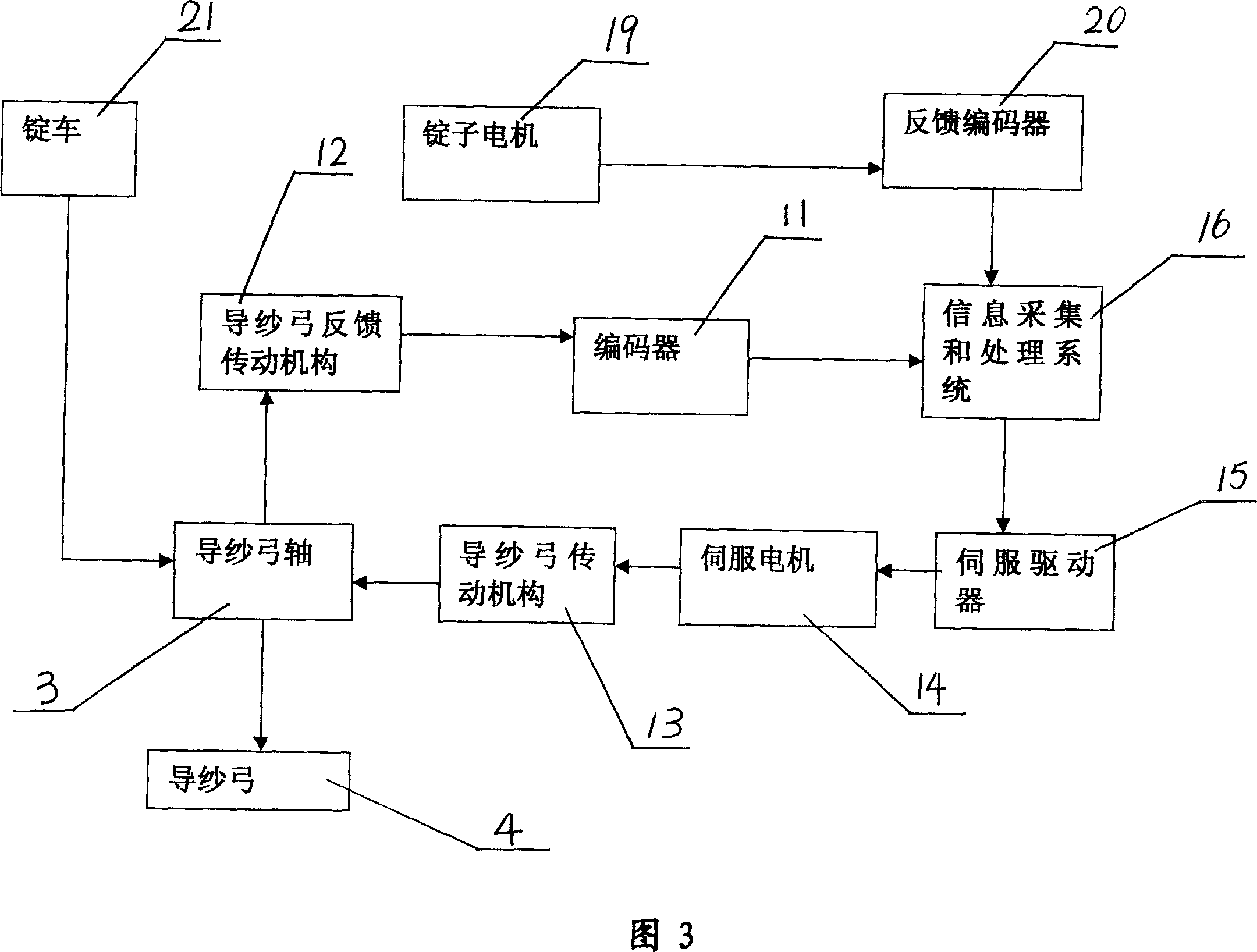

Yarn ear forming mechanism of mule spinning machine

ActiveCN1920135AMeet the requirements of formingIntuitive adjustmentIntermittent wound-up machinesYarnAutomatic control

The invention relates to a yarn ear shaping device of mule spinning machine, wherein it comprises: an information collecting treating system, a yarn guide arc transmitter, a spindle transmitter, a spindle cart, a tension arc, a feedback control circuit of spindle rotation, a servo motor control unit, and a yarn guide arc transmission feedback control circuit; the feedback control circuit of spindle rotation can shape the yarn better; the servo motor control unit can make the rotation speed of yarn guide arc supplied by servo motor meet the demand of yarn ear shape; the yarn guide arc transmission feedback control circuit can detect the transmission efficiency of whole yarn guide arc transmitter, to compensate the control signal sent from the servo driver to the servo motor in time, to meet the demand of rotation speed of yarn guide arc. And since it uses automatic control and feedback control yarn ear shaping device, the shape of yarn ear is better and accurate.

Owner:SUZHOU YOULIAN TEXTILE EQUIP TECH

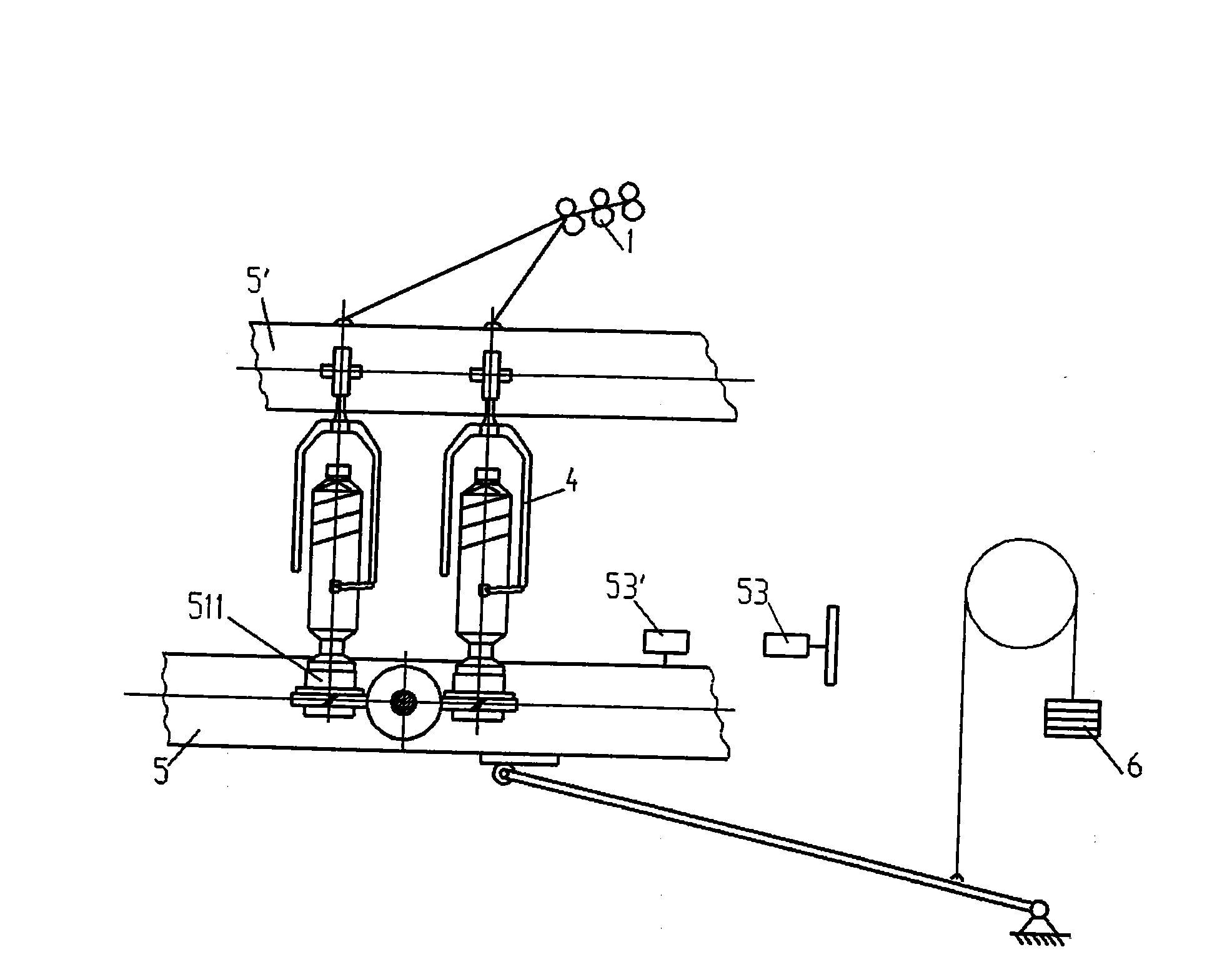

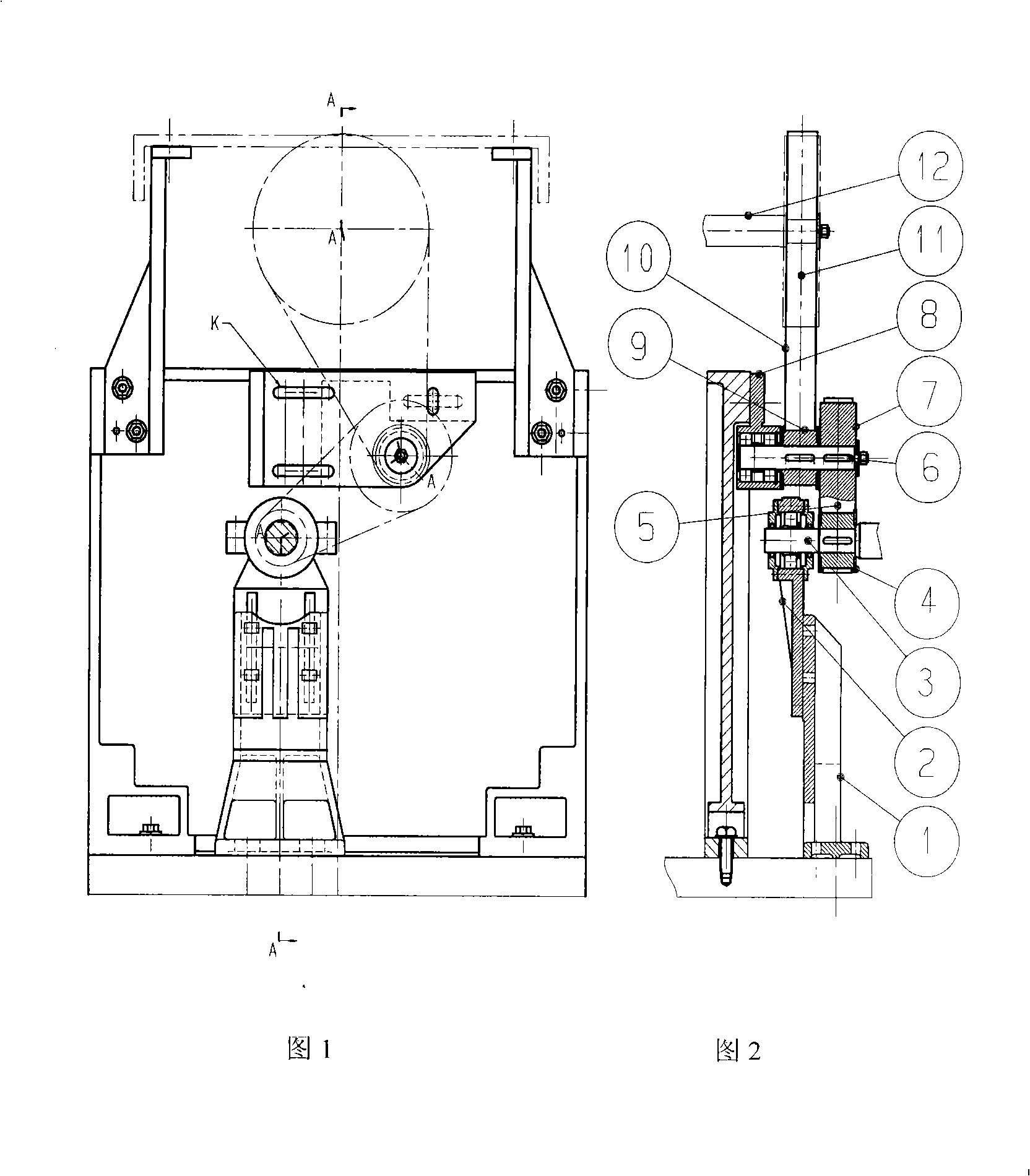

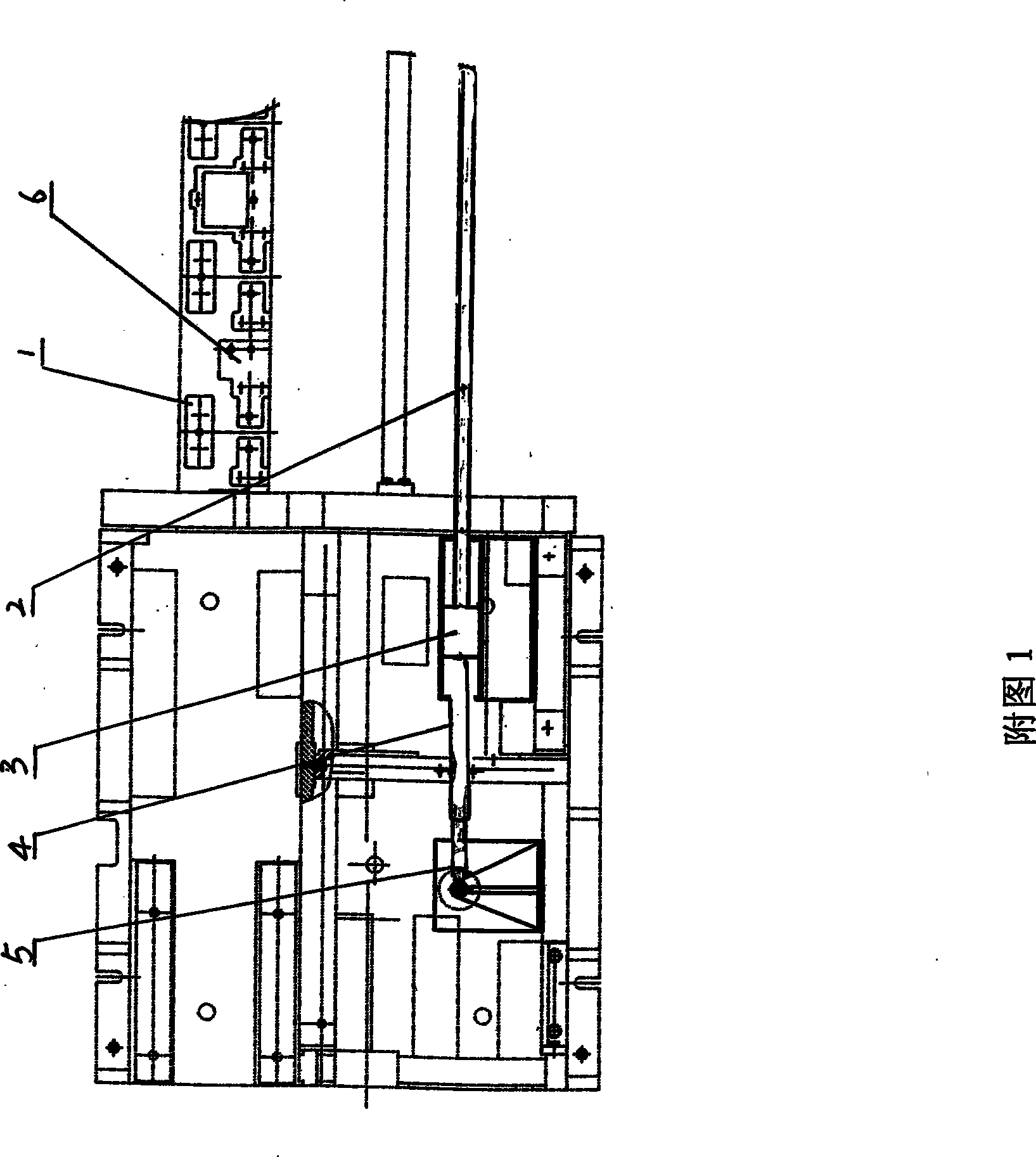

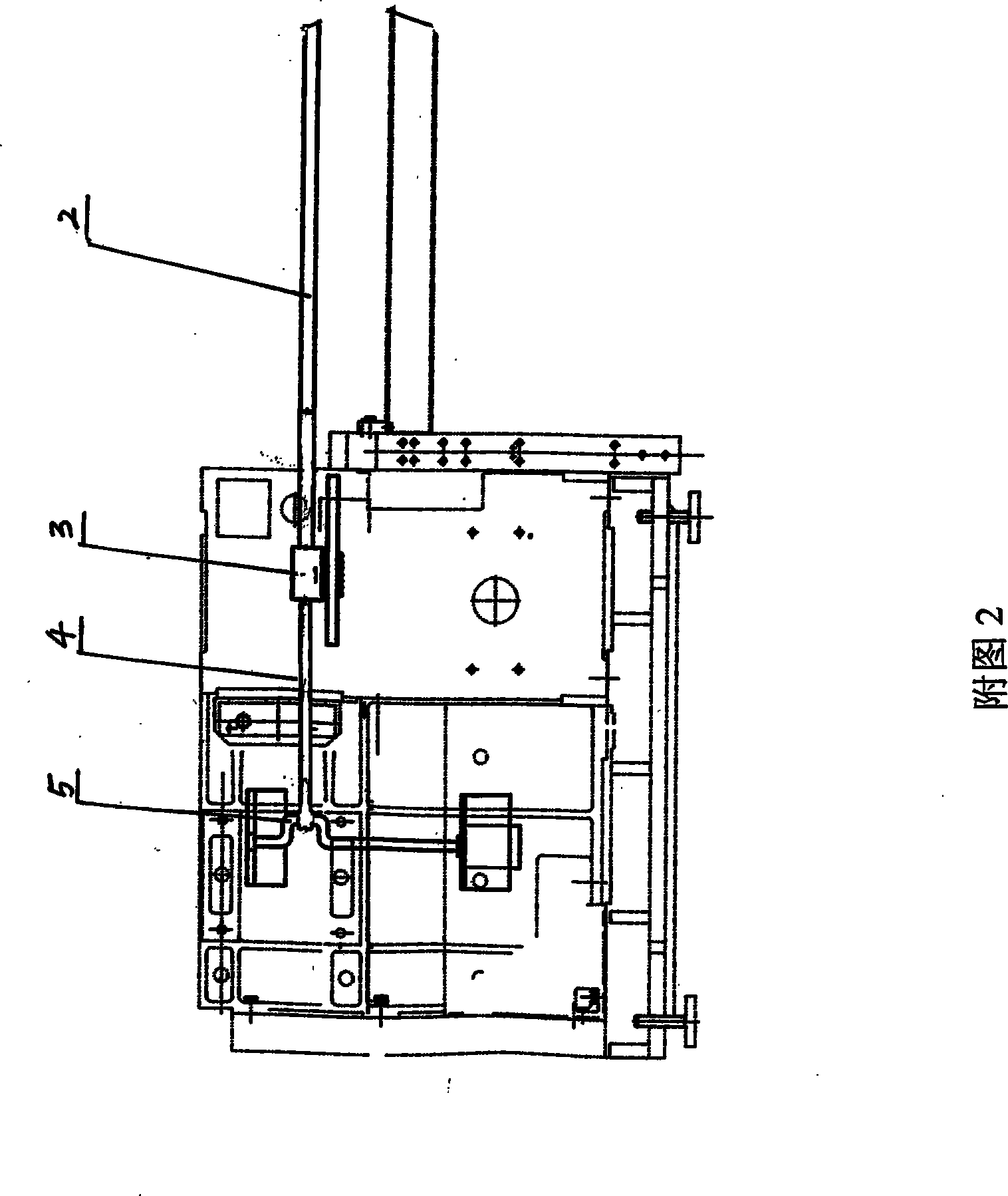

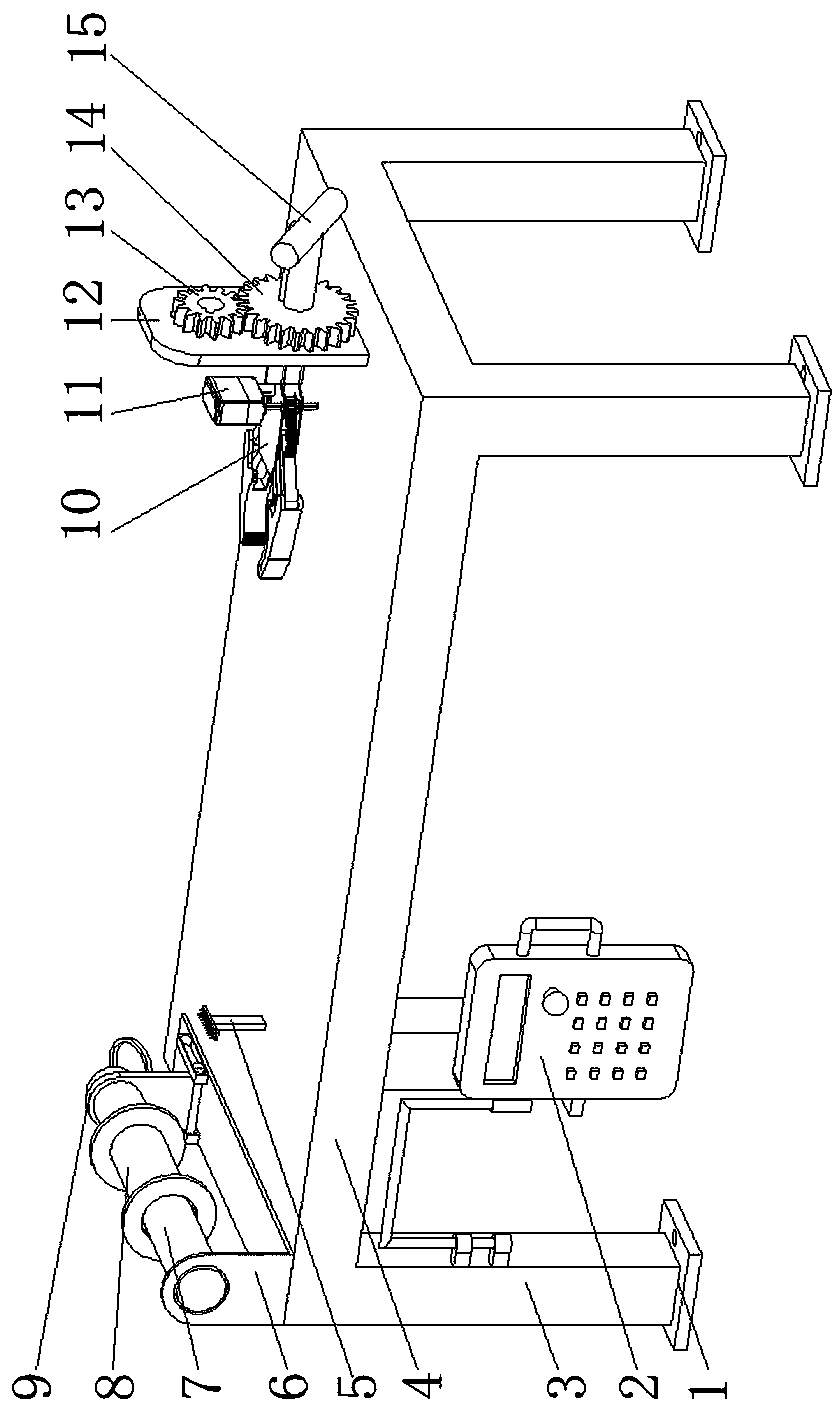

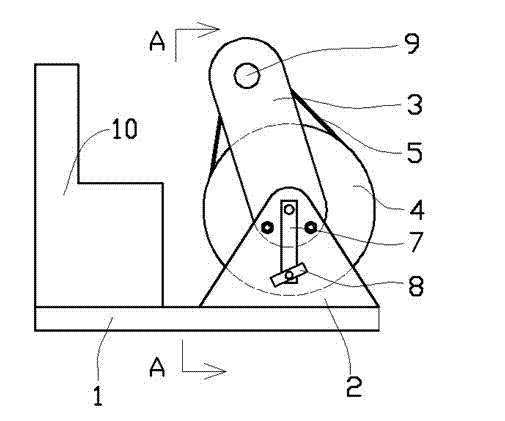

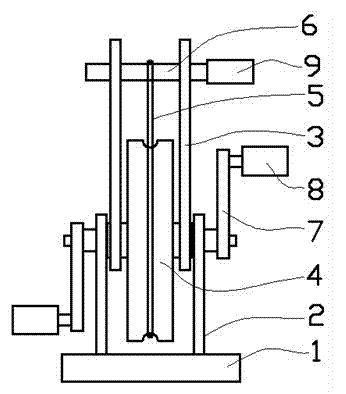

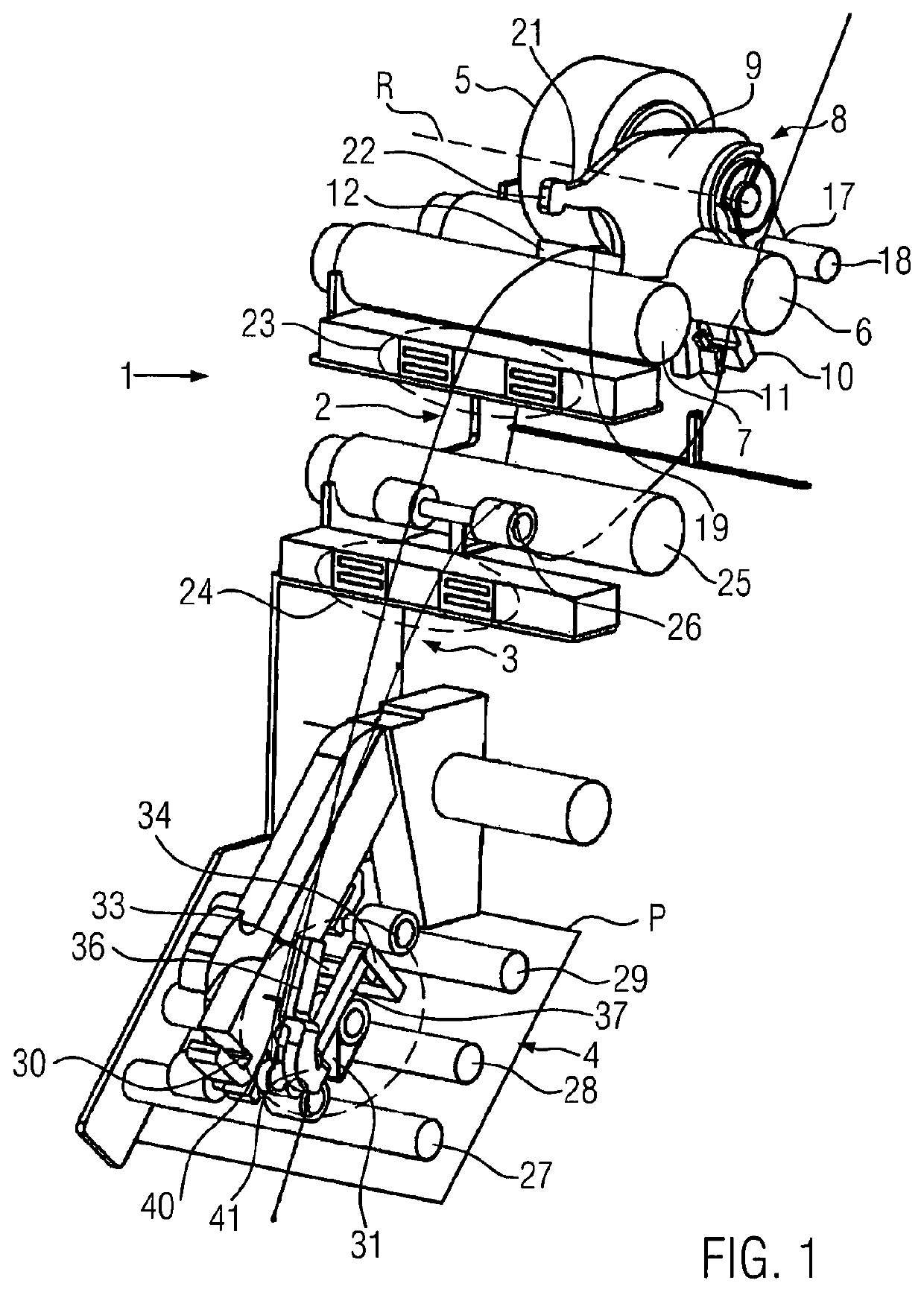

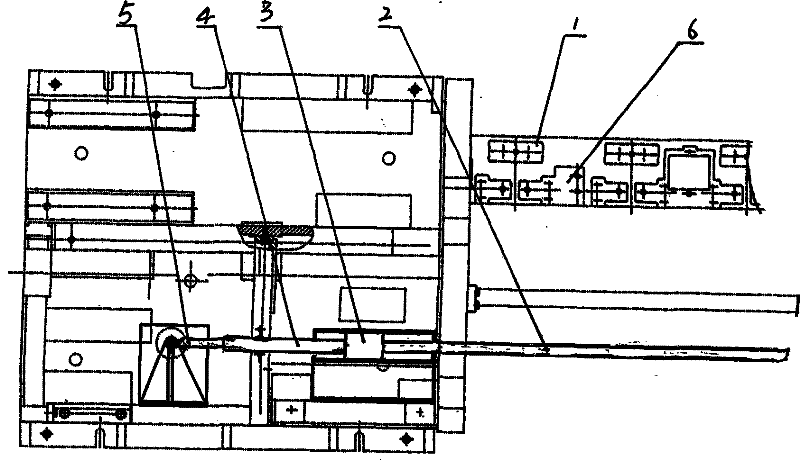

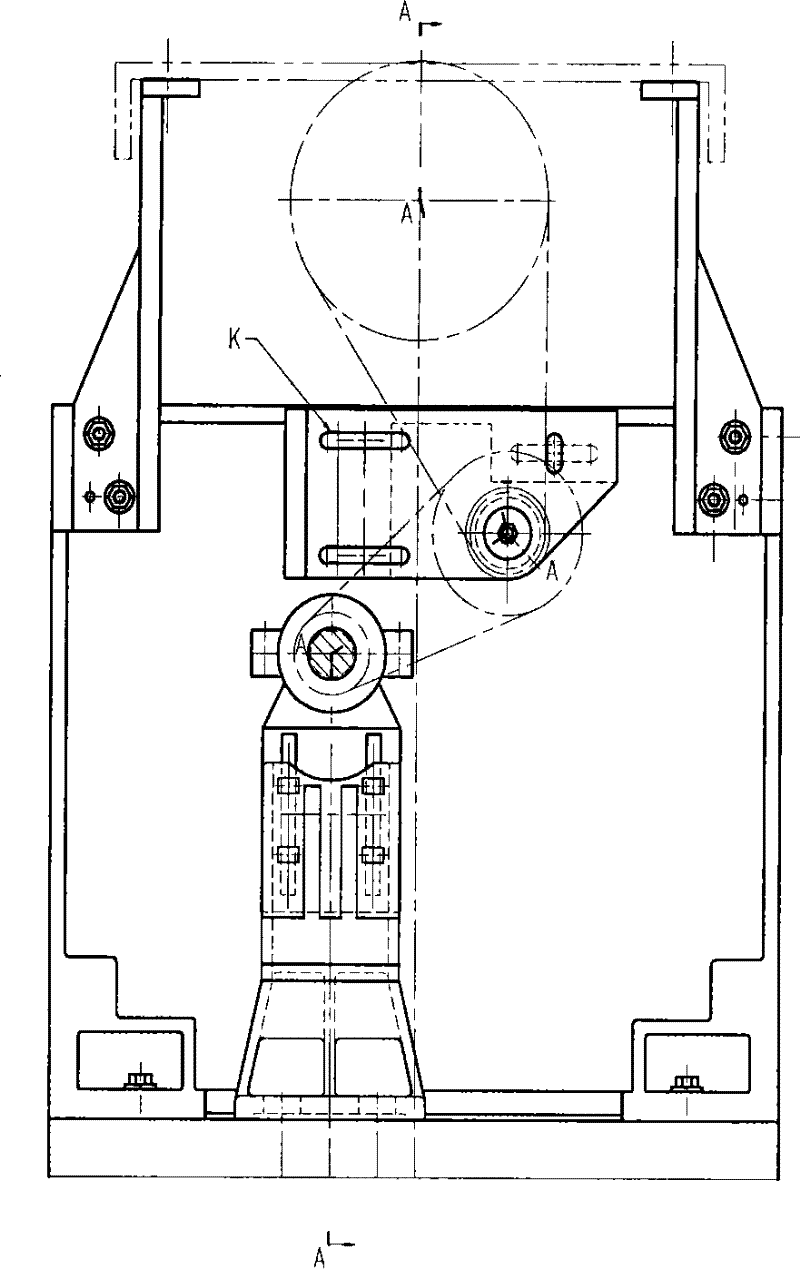

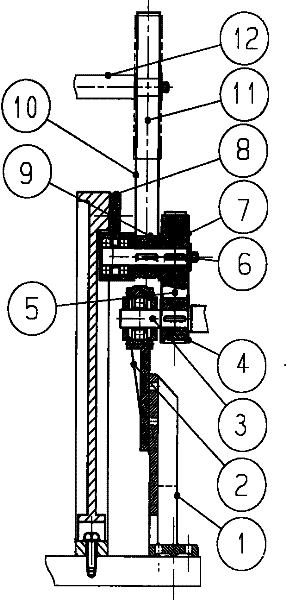

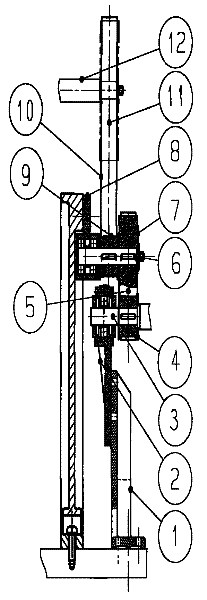

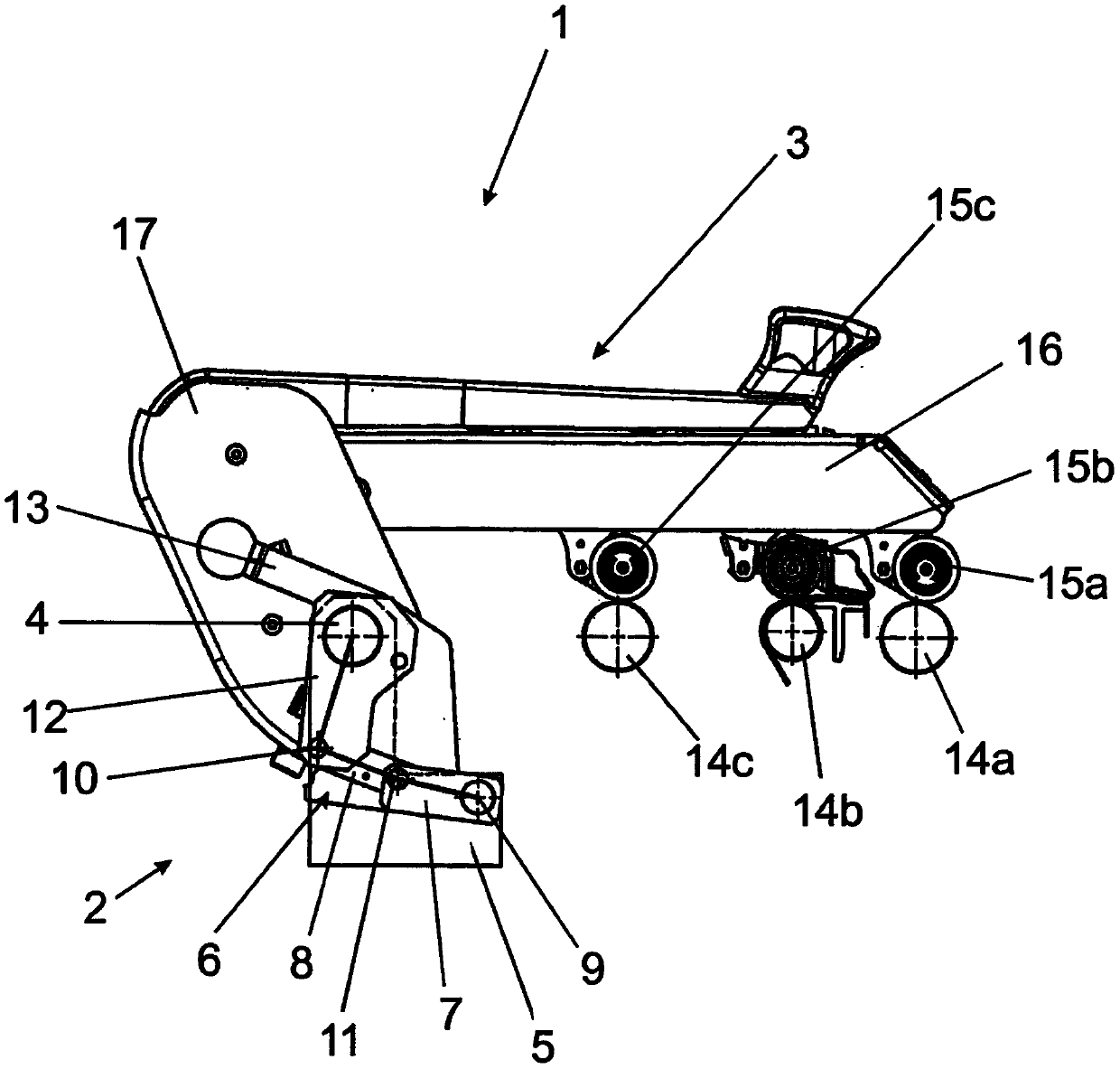

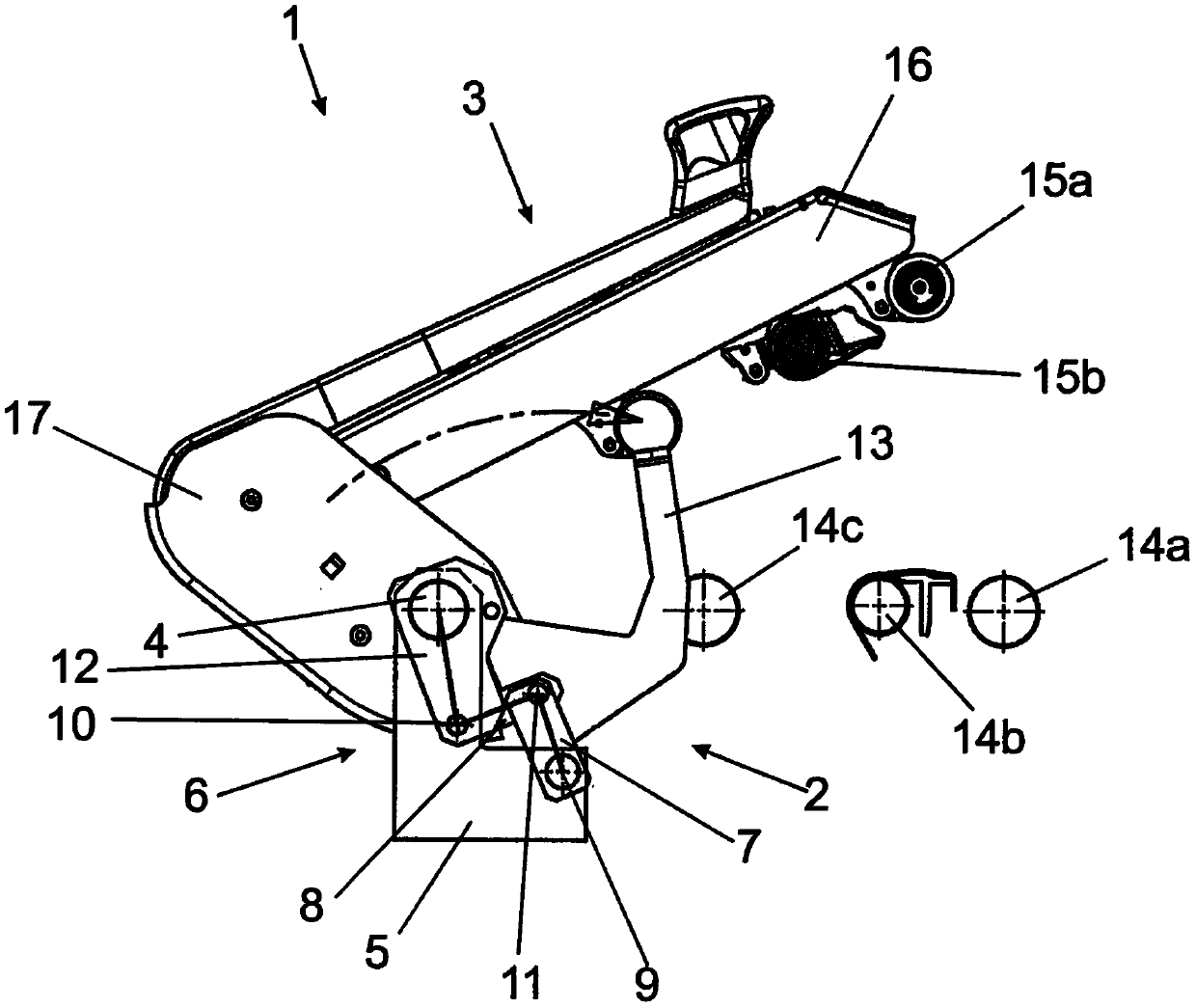

Apparatus for extending twist number range of spinning frame

InactiveCN101343786AReasonable layoutCompact structureContinuous wound-up machinesOpen-end spinning machinesEngineeringMechanical engineering

The invention relates to a device which can expand the twisting degree scope of a spinning machine. The device comprises a base (1), a bearing seat (2), a main axle (3), a tooth-shaped belt wheel (4), a tooth-shaped belt (5), a small axle (6), a tooth-shaped belt wheel (7), a belt wheel seat (8), a tooth-shaped belt wheel (9), a tooth-shaped belt (10) and a tooth-shaped belt wheel (11). The base (1) is provided with the bearing seat (2), the bearing seat (2) is arranged on a bottom plate of the machine head, the main axle (3) is arranged on the bearing seat (2), the tooth-shaped belt wheel (4) is arranged on the main axle (3) and is connected with the tooth-shaped belt wheel (7) through the tooth-shaped belt (5), the belt wheel seat (8) is disposed on a head wall plate, the small axle (6) is arranged in the belt wheel seat (8), the tooth-shaped belt wheel (7) and the tooth-shaped belt wheel (9) are arranged on the small axle (6), the tooth-shaped belt wheel (9) is connected with the tooth-shaped belt wheel (11) through the tooth-shaped belt (10), and the tooth-shaped belt wheel (11) is arranged on an upper input axle (12) of a lathe head. The device has the function of expanding the twisting degree scope.

Owner:JINGWEI TEXTILE MASCH CO LTD

Production method for woolen yarns in count of 56Nm

The invention relates to a production method for woolen yarns in count of 56Nm. The method includes steps: A, carding, to be specific, processing wool rolls through a carding machine, wherein the weight of a single rough yarn wool roll processed by the carding machine is controlled to be 0.044g / m; B, doubling, to be specific, adopting a doubling machine for doubling the rough yarn wool rolls processed by the carding machine, wherein the weight of a doubled stranded rough yarn wool roll is controlled to be 0.088g / m; C, roving, to be specific, subjecting the doubled rough yarn wool rolls to drafting twisting by a spinning roving machine, wherein the weight of a single rough yarn is controlled to be 0.022g / m after roving; D, mule spinning, to be specific, subjecting rough yarns to mule spinning on a mule spinning machine after roving, wherein the spun yarn weight is controlled to be 0.0178g / m after mule spinning, and the count is 56Nm; E, spooling. By adding of doubling and roving processes between carding machine and mule spinning processes, transition distribution is realized through the roving machine to further change the rough yarn weight, and yarn thinning is realized.

Owner:JIANGSU LIANHONG TEXTILE

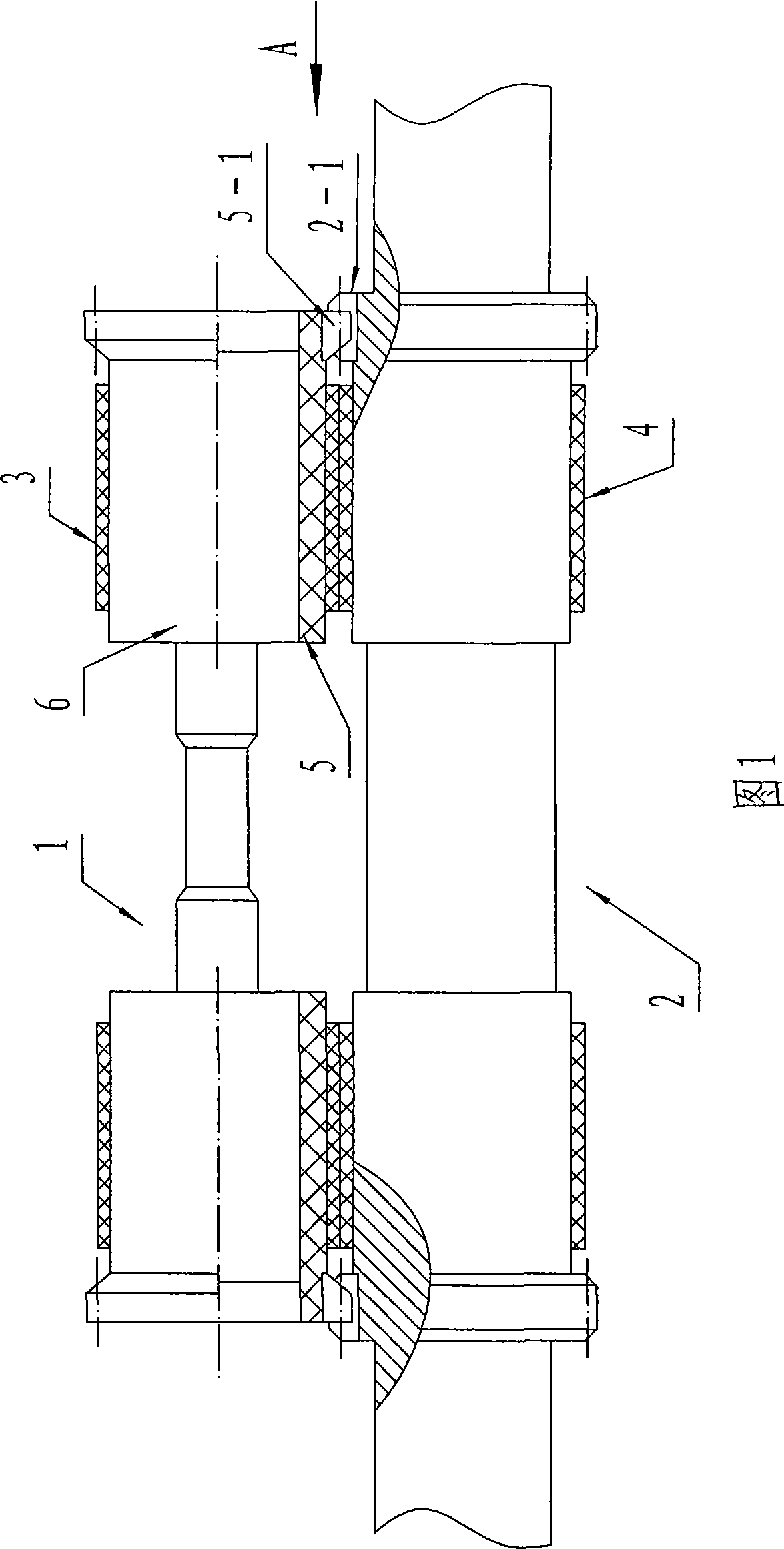

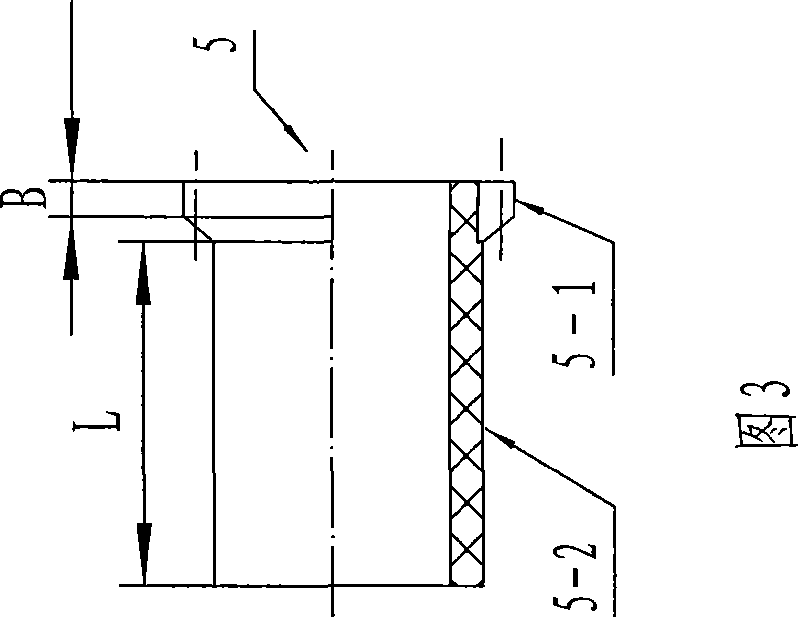

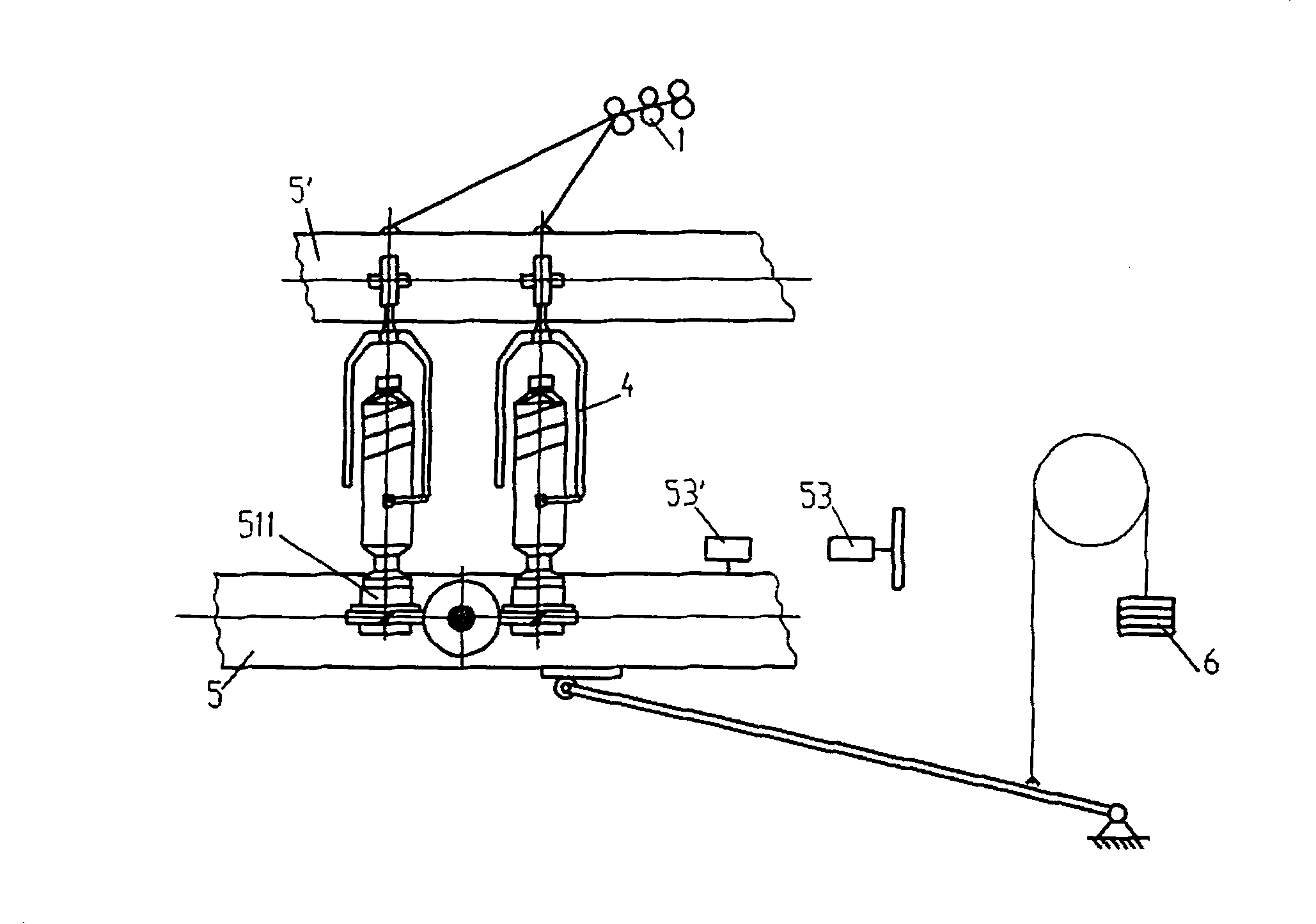

Roller transmission mechanism for drafting assembly of spinning frame

InactiveCN101418481ASlippery rate reductionReduce wearDrafting machinesContinuous wound-up machinesRubber ringYarn

The invention relates to a roller transmission mechanism for a drafting system of a spinning machine, which is used for solving the problem that the slip of a rubber ring is high so as to influence the yarn forming quality. The technical proposal of the roller transmission mechanism is as follows: the roller transmission mechanism comprises an upper-middle roller and a lower-middle roller which are in transmission connection, an upper rubber ring arranged on the upper-middle roller and a lower rubber ring arranged on the lower-middle roller, wherein the lower-middle roller is a driving part, and the improved upper-middle roller and lower-middle roller are in transmission connection through a pair of gears with the same tooth number. The machine has the advantages as follows: 1. the roller transmission mechanism can ensure that the upper and lower rollers synchronously rotate, greatly reduce the slip between the upper rubber ring and the lower rubber ring, is favorable for feeding strands to a front roller jaw, improve the yarn forming quality, and reduce bunchy yarn; and 2. under the condition of ensuring enough gripping power to the strands, the cradle pressure and the power to drive the drafting system to work are properly reduced, thereby reducing energy consumption and abrasion of related parts, saving production cost and reducing material consumption.

Owner:SHIJIAZHUANG CHANGSHAN BEIMING TECH CO LTD

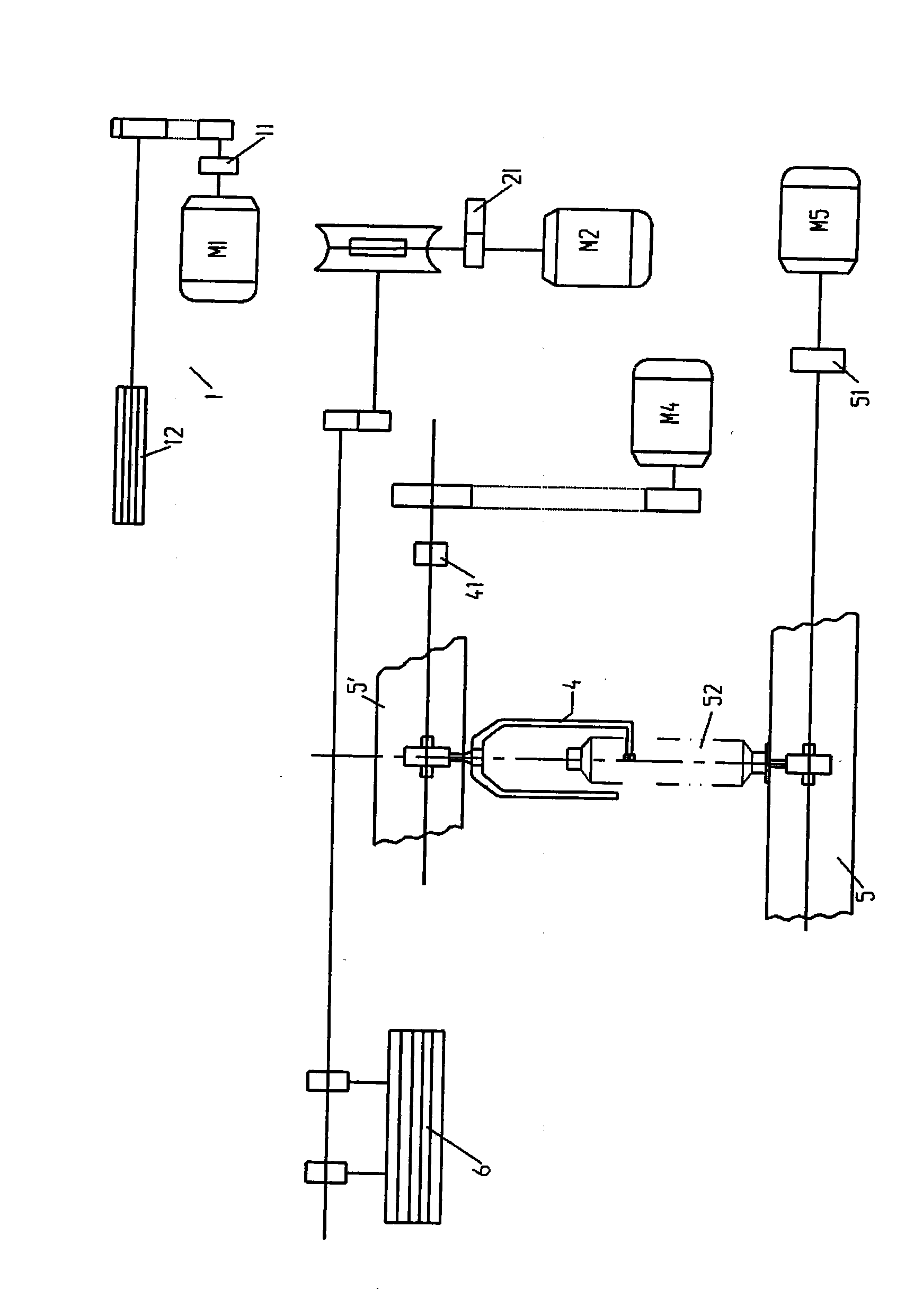

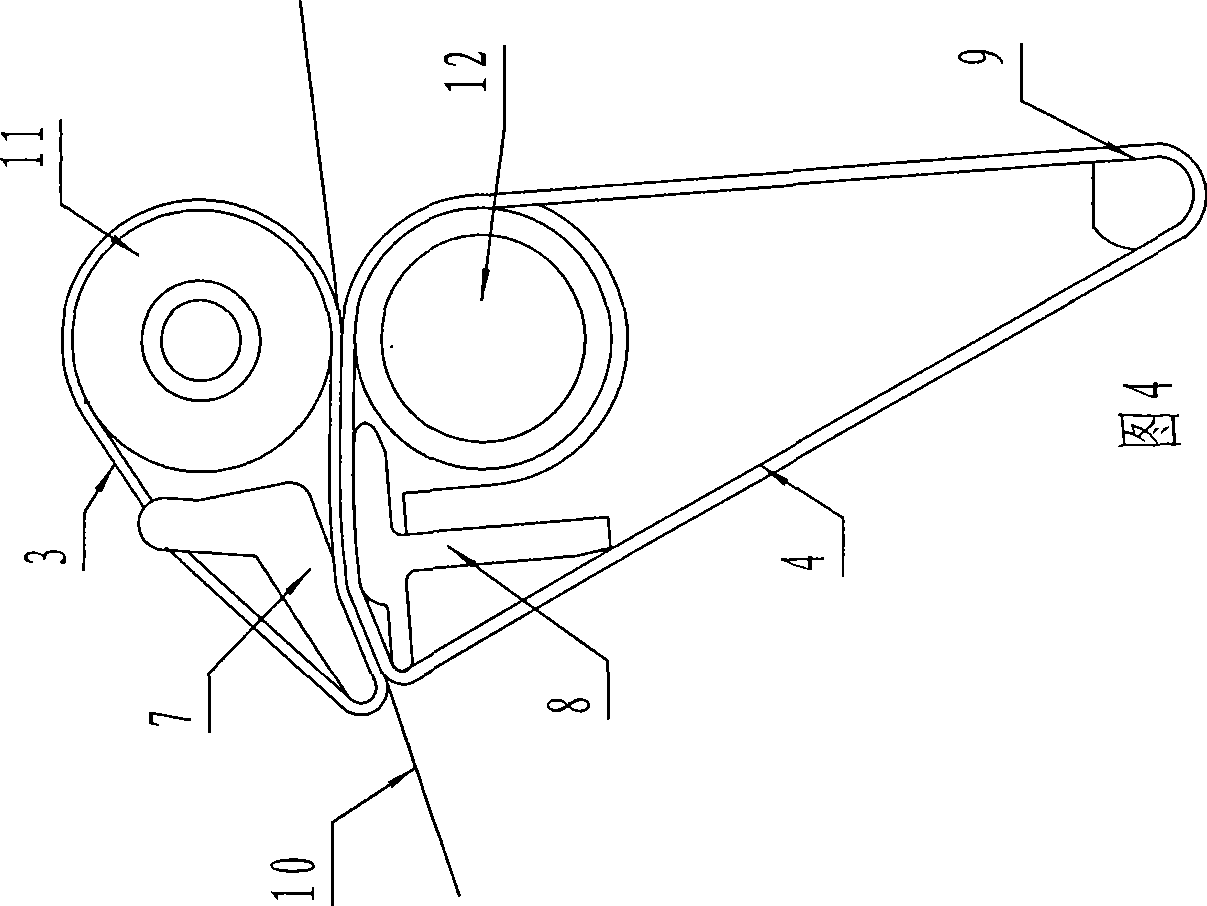

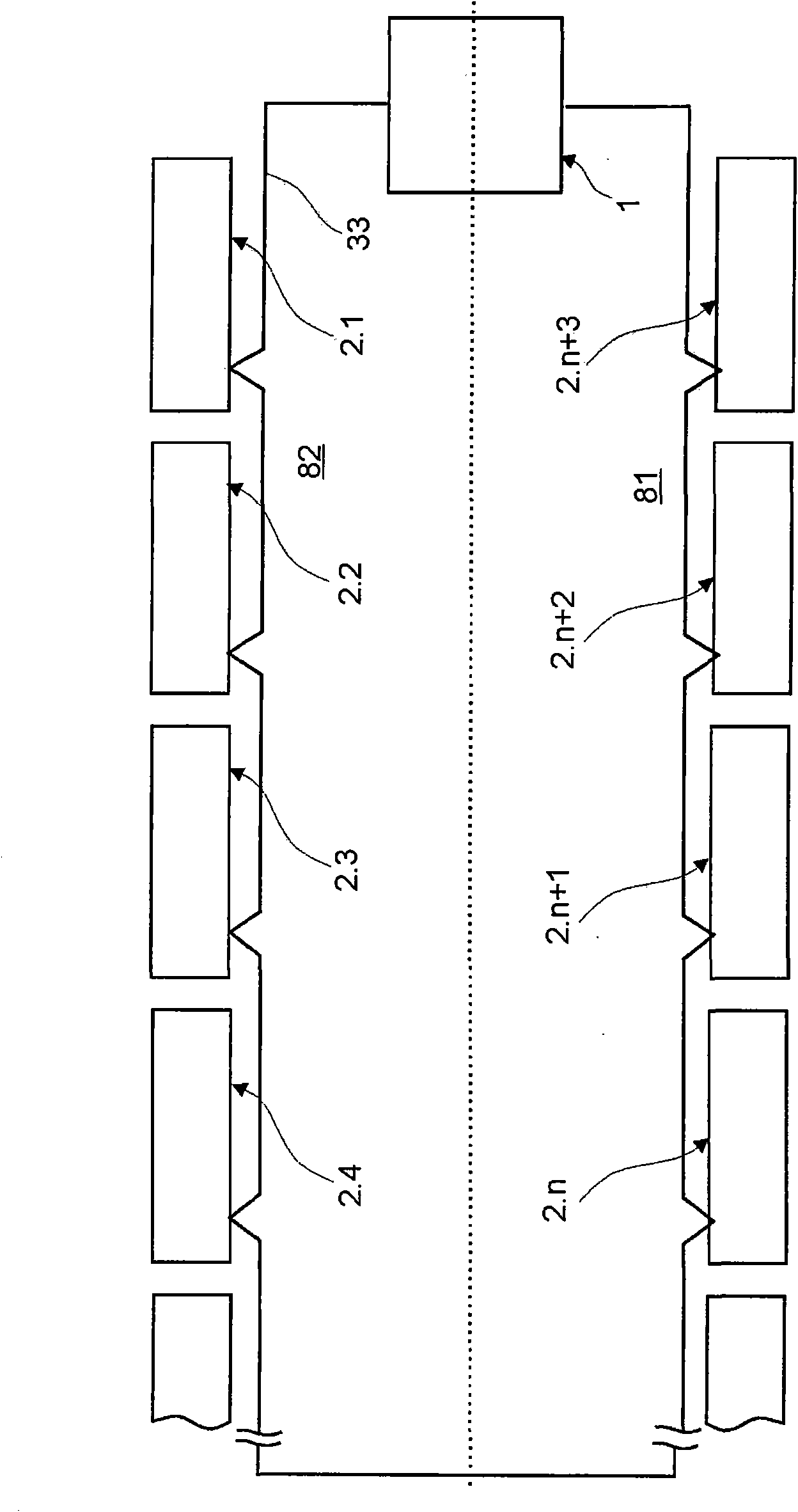

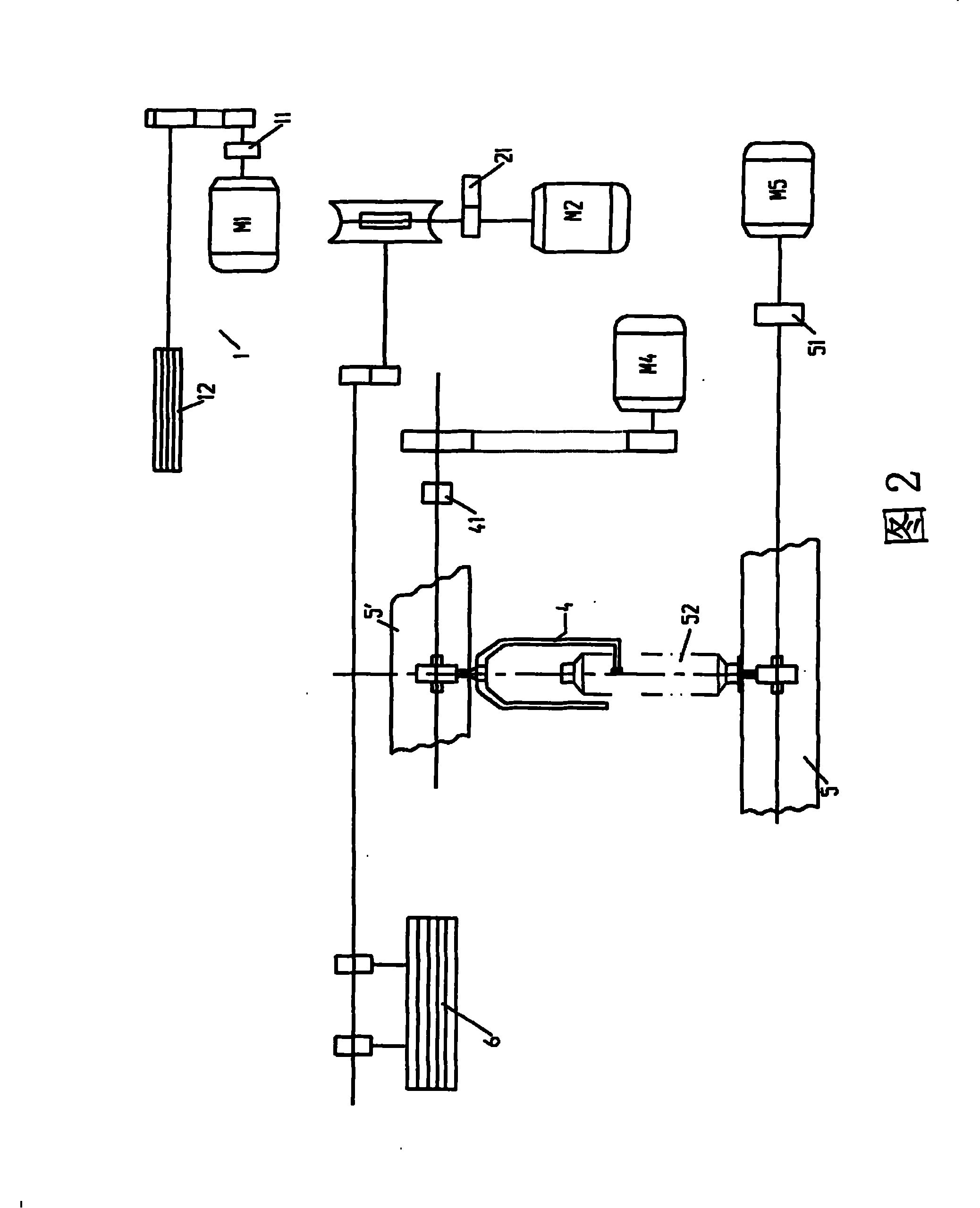

Linkage device for realizing synchronous and same-phase running of all flyers or bobbins of roving frame

InactiveCN101748519AThe effect is positive and obviousRealize synchronous and same-phase operationContinuous wound-up machinesIntermittent wound-up machinesBobbinMotor drive

The invention relates to a linkage device for realizing the synchronous and same-phase running of all flyers or bobbins of a roving frame, which comprises more than two driving units and an electric mechanism, wherein any one driving unit consists of 2 to 48 first synchronous pulleys, a second synchronous pulley, a synchronous belt and a motor, and any one first synchronous pulley is arranged on a keel; any one first synchronous pulley is connected by the synchronous belt, and any one motor is connected with a second synchronous pulley; tension pulleys can be arranged in the driving units, and any one first synchronous pulley is respectively connected with a flyer or a bobbin; the motor drives the synchronous pulley through the second synchronous pulley, and all second synchronous pulleys synchronously run in phase; and the synchronous belts drive the first synchronous pulleys in all driving units to synchronously run in phase, thereby realizing the synchronous and same-phase running, stop and state keeping of all the flyers or bobbins of the whole roving frame in any states including the state of complete loss of power.

Owner:PACIFIC MECHATRONIC GRP

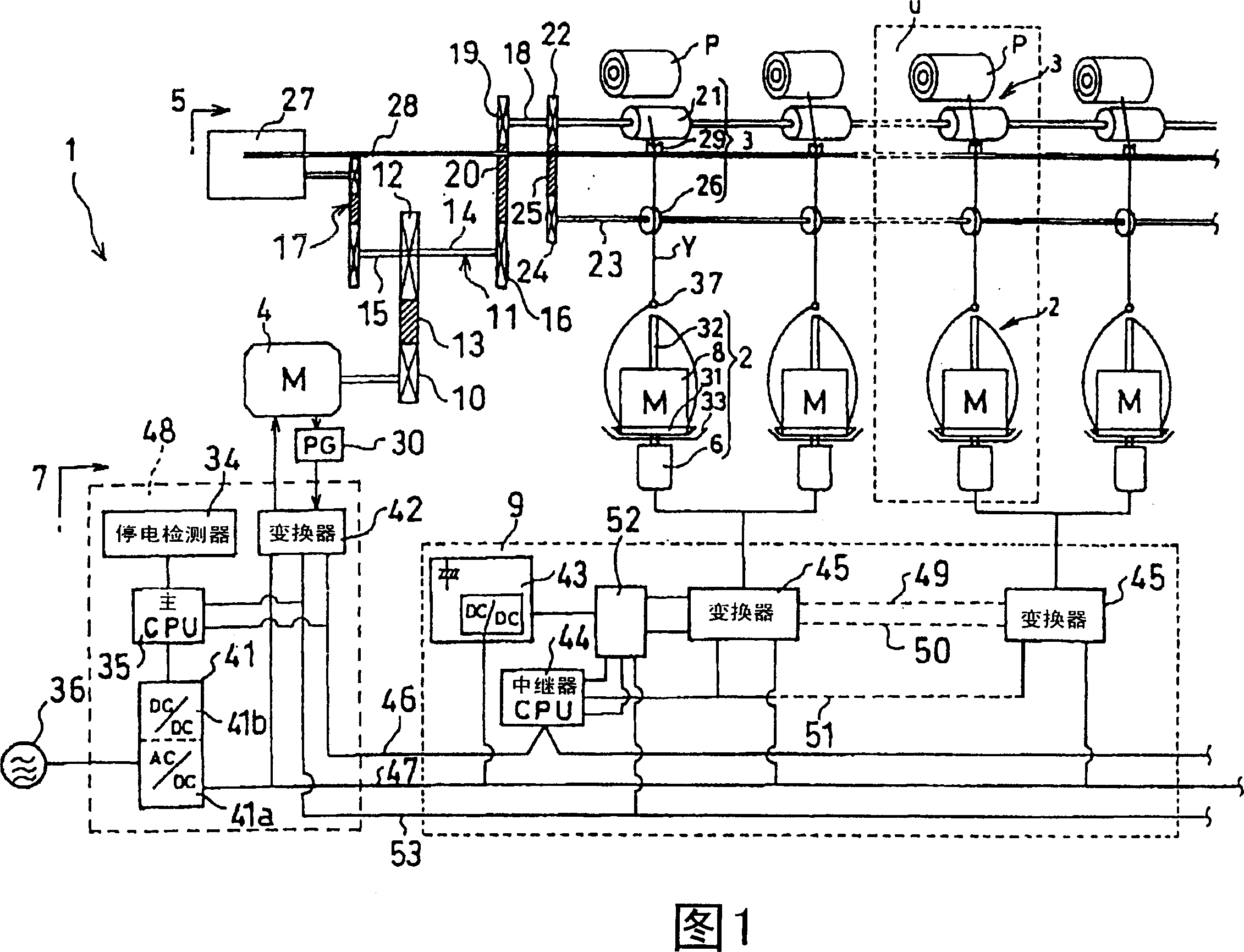

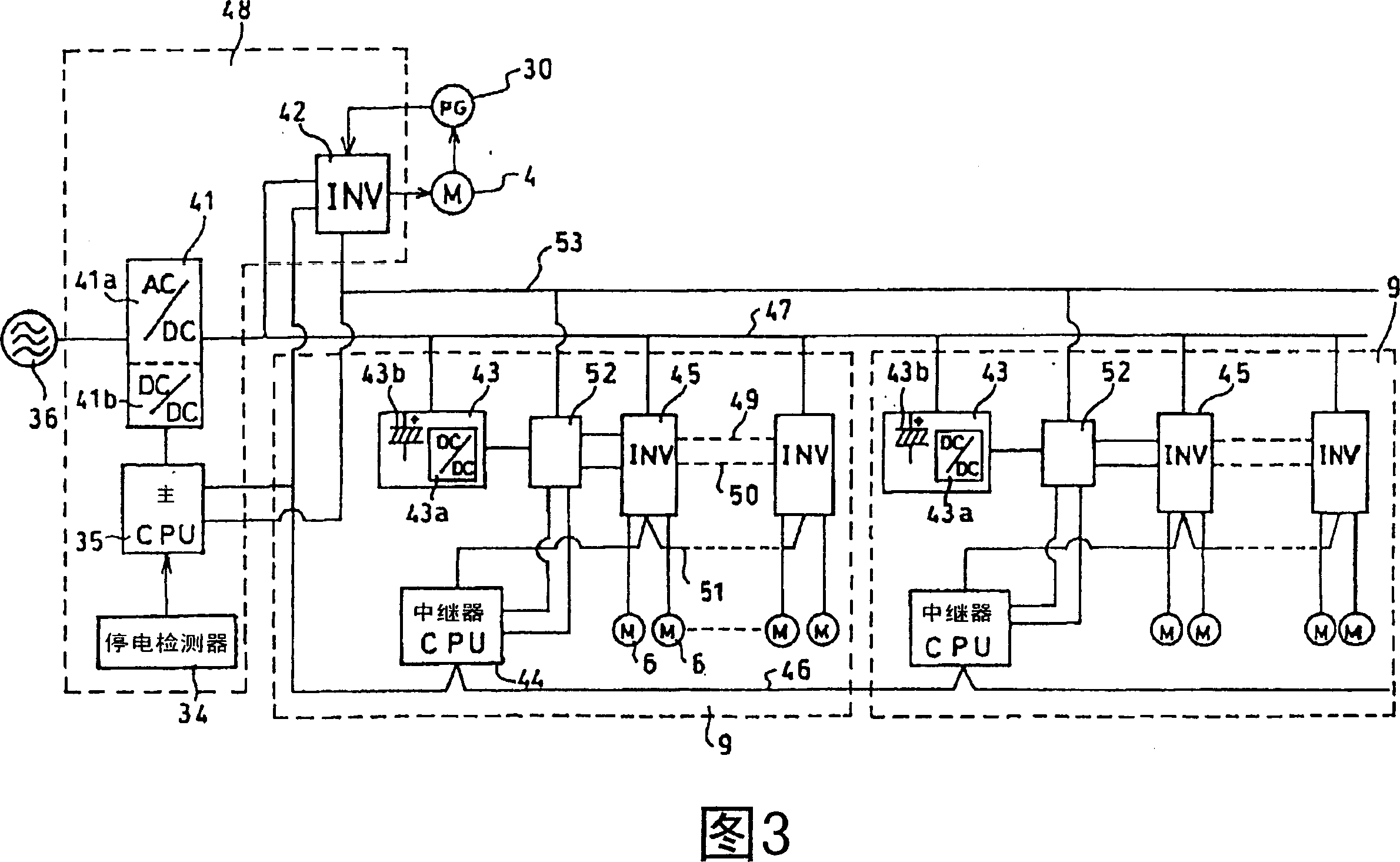

Individual-spindle-drive type textile machine

InactiveCN1970858AAvoid voltage dropMotor/generator/converter stoppersMultiple motor speed/torque controlFiberStop time

This invention provides an apparatus for treating power failure capable of decelerating and stopping spindle driving system motors and drum driving system motors while synchonizing both with simple control at the time of the power failure. This apparatus for treating power failure of a multiple twister drives the plural spindle driving motors installed for each spindle and the winding drum driving motors common to the plural spindles with inverters, respectively. The apparatus is equipped with a power failure detecting means for detecting the power failure when the voltage is reduced by a prescribed value or above, stop commanding means for outputting stop commands to respective inverters when detecting the power failure and the stopping means for performing feedback control so as to stop each of motors at a predetermined stopping time based on the stop commands.

Owner:MURATA MASCH LTD

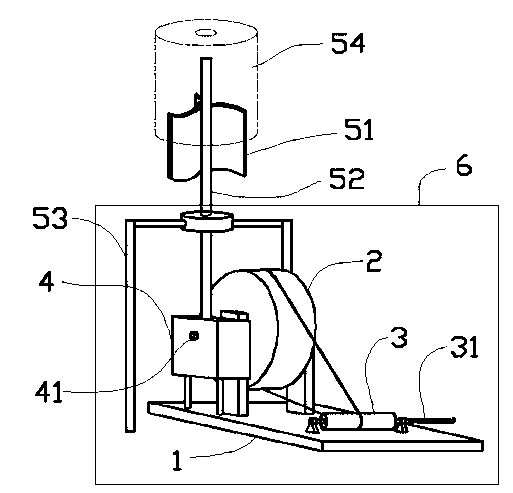

Wind-driven reeling machine

The invention discloses a wind-driven reeling machine. The wind-driven reeling machine comprises a fixed base plate, a power wheel, a reeling shaft, a reversing device and a wind-driven device, wherein the power wheel and the reeling shaft are arranged on the fixed base plate and are linked with each other; a frame is arranged in the axial direction of the reeling shaft; the wind-driven device is driven by wind and comprises a blade and a main shaft; and the main shaft drives the power wheel in a reversing way through the reversing device. The wind-driven reeling machine is driven by the wind and is green and pollution-free; during use, the blade is arranged under the wind; and the wind-driven reeling machine is easy to use and operate and can be operated by a single hand, thus strength is saved.

Owner:WUJIANG JIANGXU TEXTILE

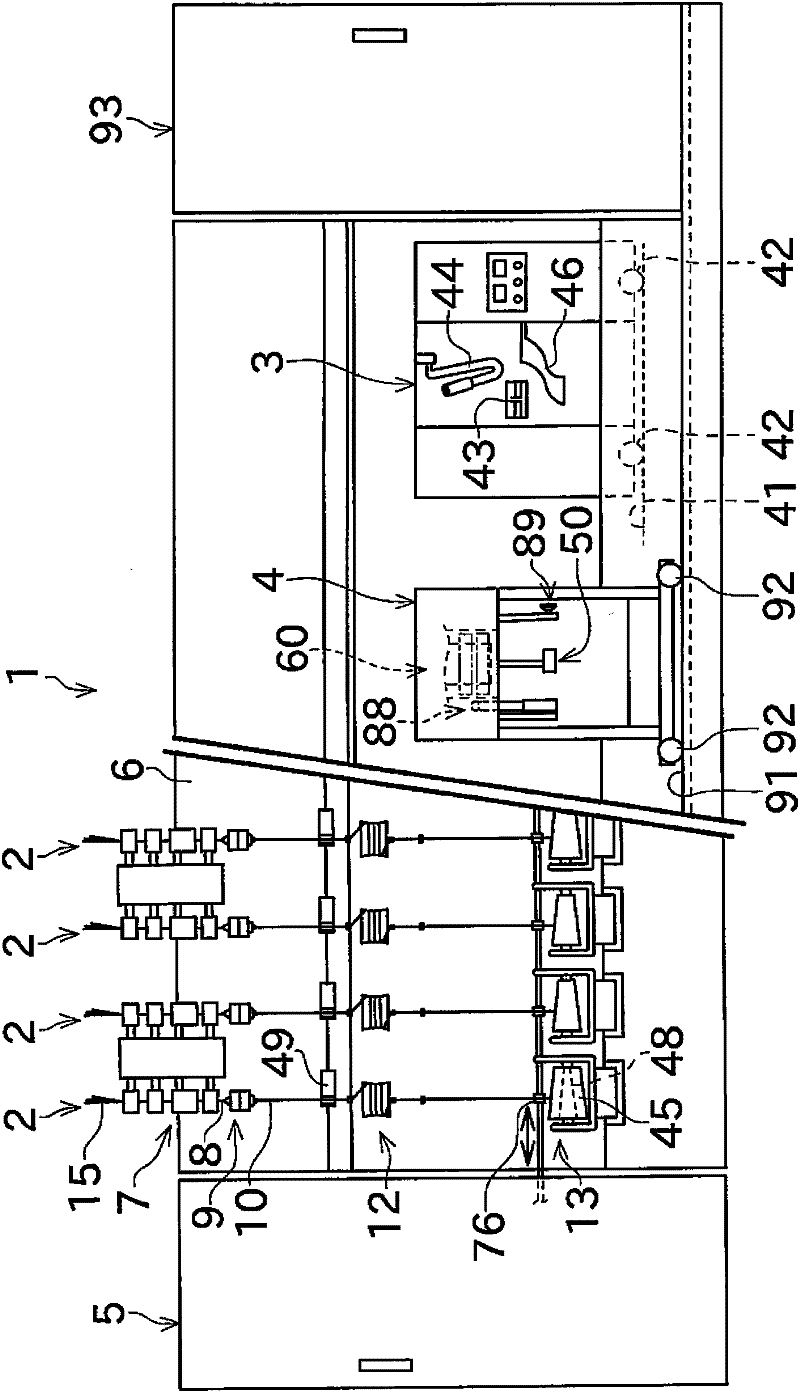

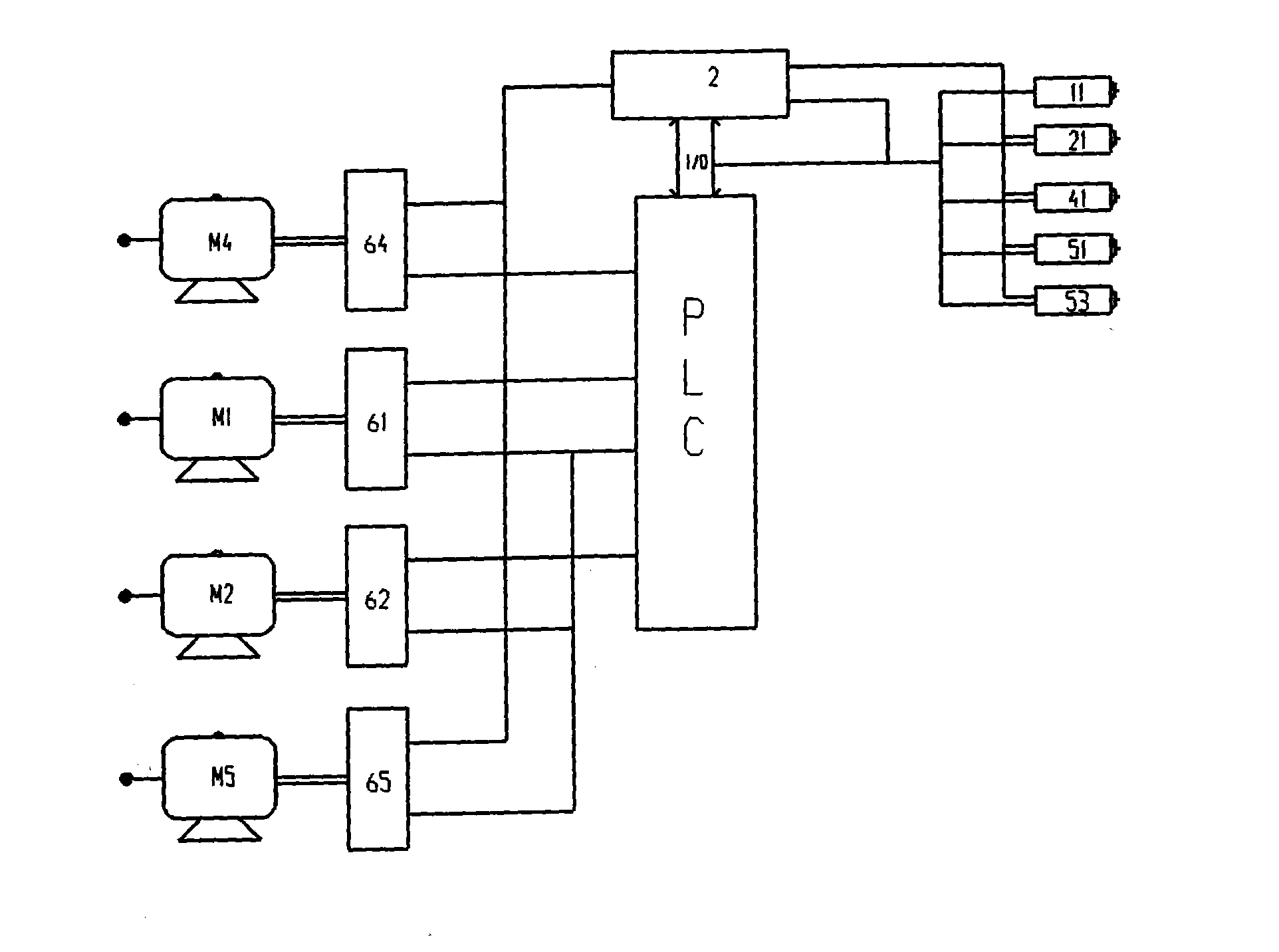

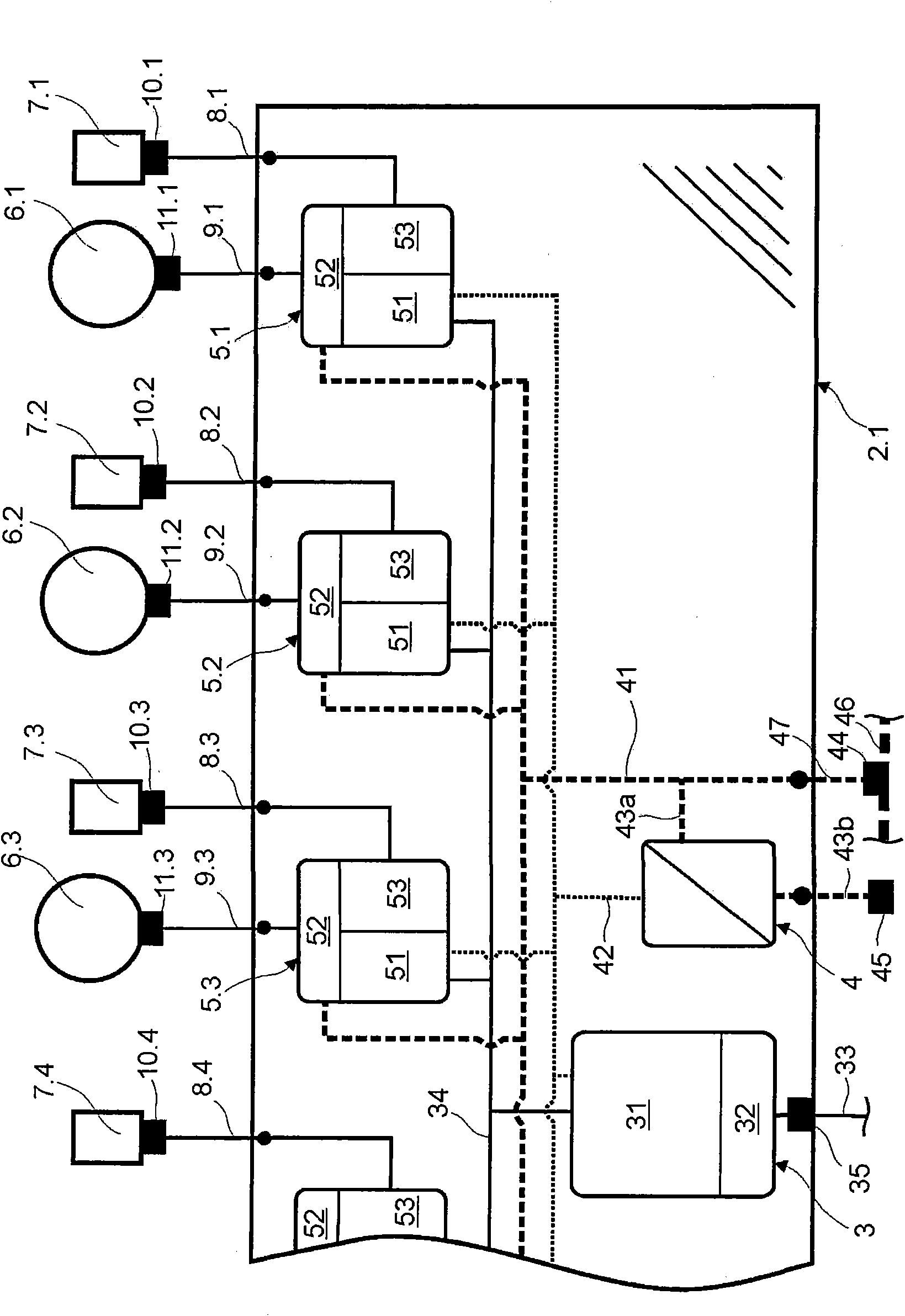

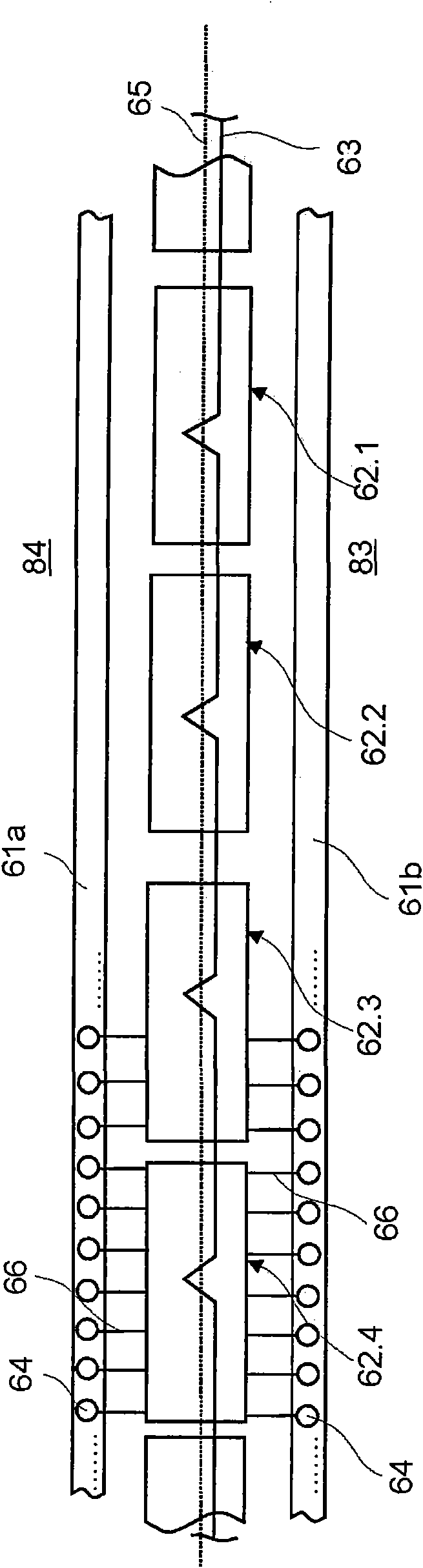

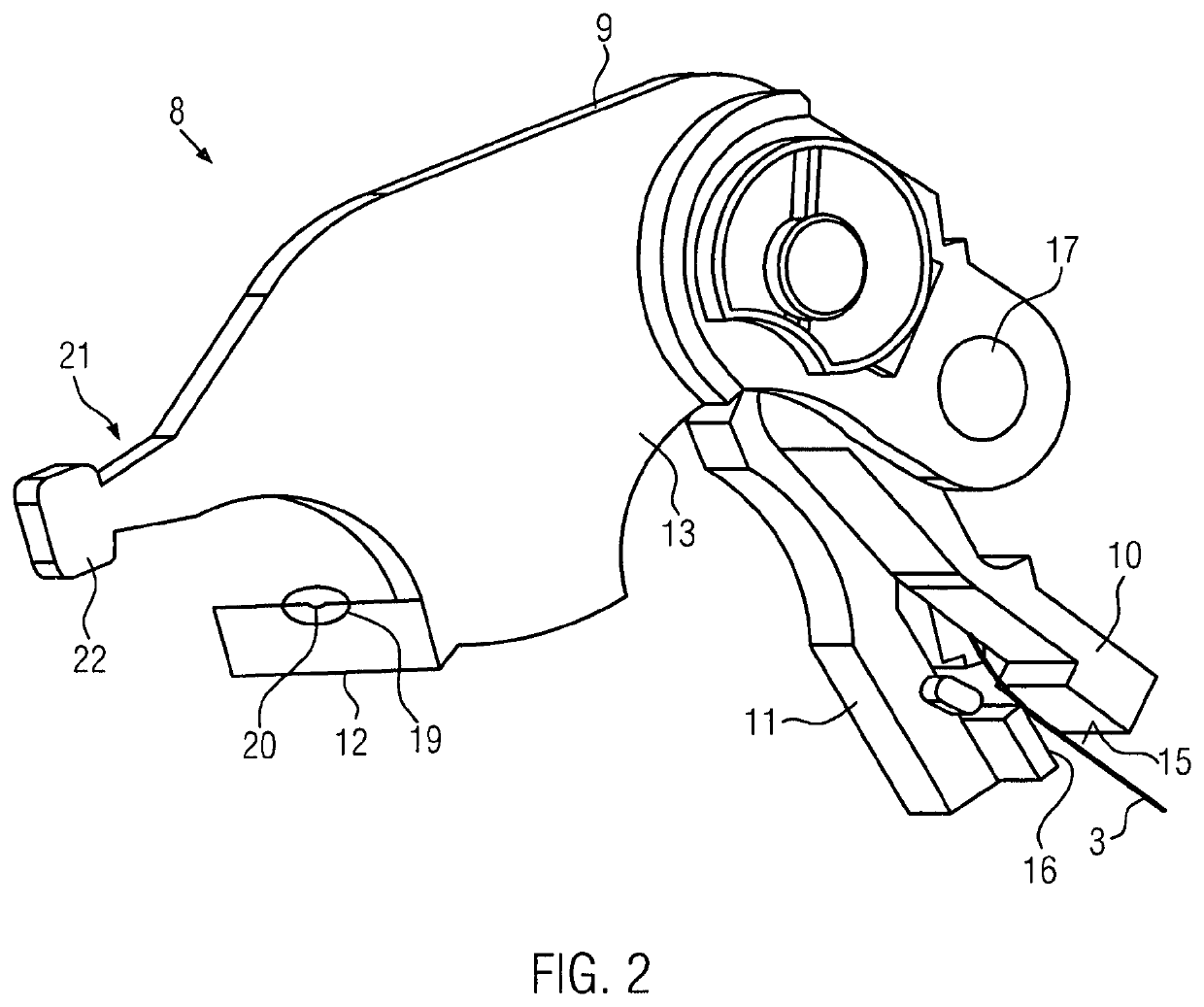

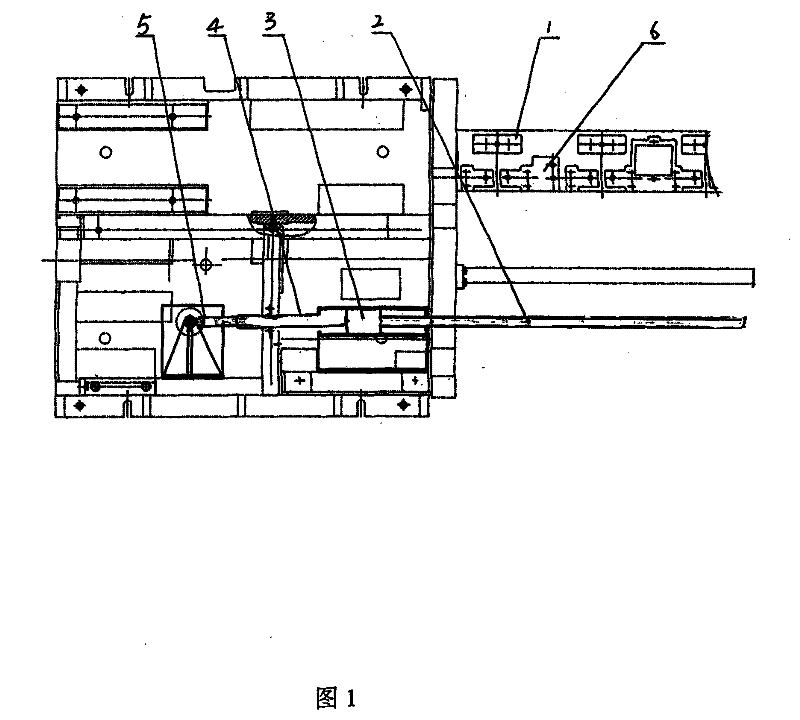

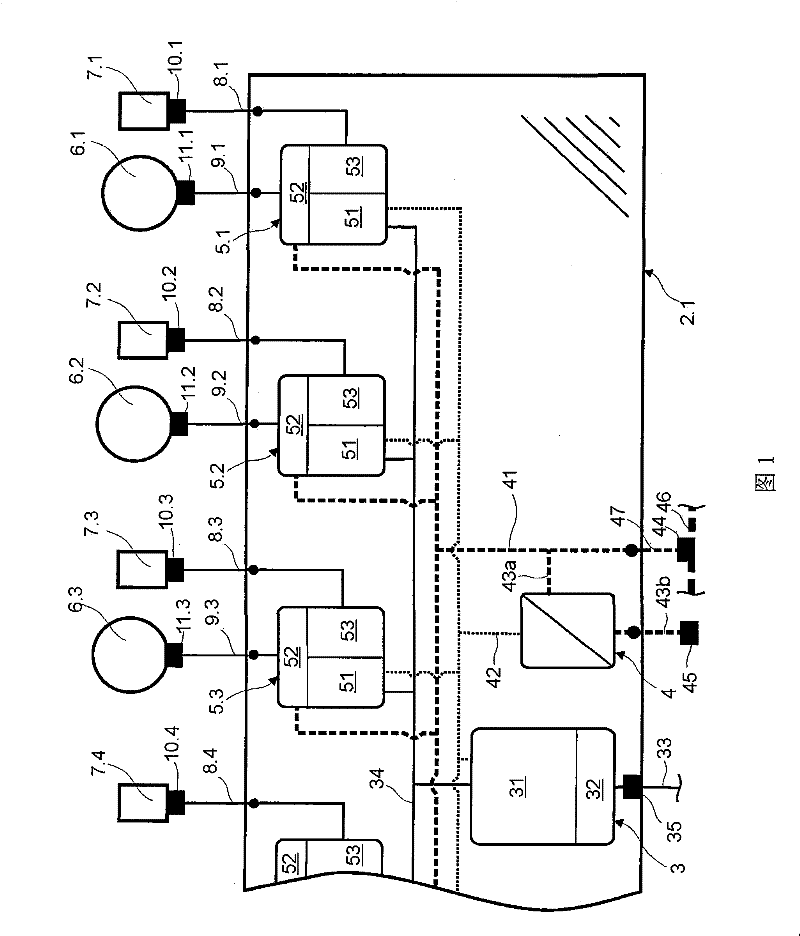

Spinning machine with individual spindle drive

InactiveCN101560709AEasy to set upQuick installationContinuous wound-up machinesOpen-end spinning machinesMachine controlEngineering

The present invention relates to a spinning machine with individual spindle drive, having a plurality of working benches, which are divided into a plurality of sections, each section has a plurality of working benches. Each working bench has a spindle device comprising a spindle and a spindle drive unit (6). Further, the spinning machine includes a machine control unit for driving spindles of each section and a section electronic unit (3), the spindles and the section electronic unit (3) are connected to the machine control unit by data line (33), the spindle drive units (6) are separately connected to the section electronic unit (3) and are driven by the section electronic unit (3) arranged on the same. Each spindle device has spindle drive electronic units (5). The spindle drive electronic units (5) and section electronic units (3) of same section are arranged on a same circuit board (2). The spindle drive electronic units (5) are connected to the section electronic units (3) over data line in manner of conductive tapes (34). The data line (33) is guided into the machine control unit from the section electronic units (3). A power supply line (9) is guided into the spindle drive units (6) arranged on the spindle drive electronic units (5) from the spindle drive electronic units (5).

Owner:MASCHINENFABRIK RIETER AG

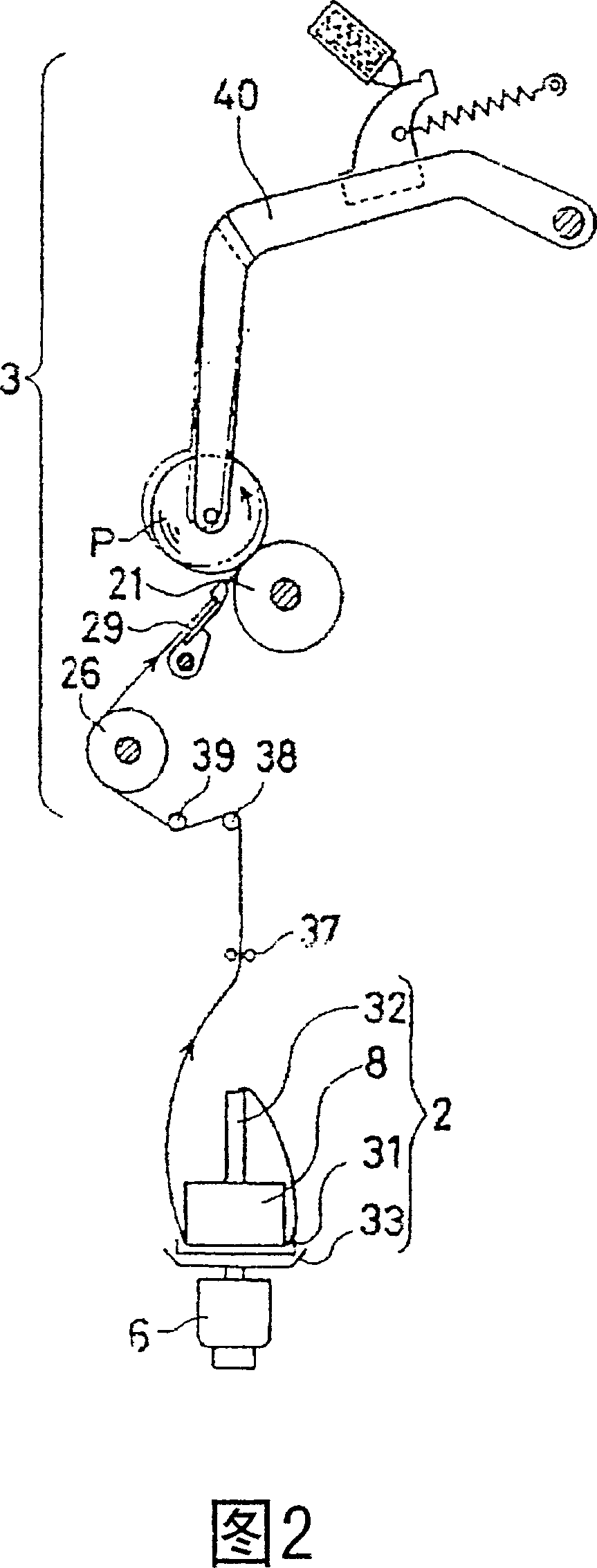

Electronic type hair bulb winding-shaping apparatus

InactiveCN101450757AAdjust forming angleReduce the difficulty of machiningFilament handlingContinuous wound-up machinesFrequency changerSimple machine

The invention discloses a hair bulb winding and shaping device for a roving machine, which comprises a front roller, a traverse bar, and a sliding block fixed with the traverse bar. A hinge of the sliding block is at one end of a connecting rod, a crank link mechanism is connected with a servo motor which is driven by a servo controller driver, the servo controller driver is connected with a frequency converter of a main motor, a shaft of a rotary encoder is concentrically and mechanically connected with the front roller, and the rotary encoder detects change signals of revolution speed of the front big roller and feeds back the change signals to a PLC programmable controller which controls a servo driver and the frequency converter. The device can adjust shaping angles of wool tops through replacing a synchronous pulley in the state of no stopping, has simple machine work, and reduces processing cycle.

Owner:ZHANGJIAGANG DA CHENG TEXTILE MACHINERY

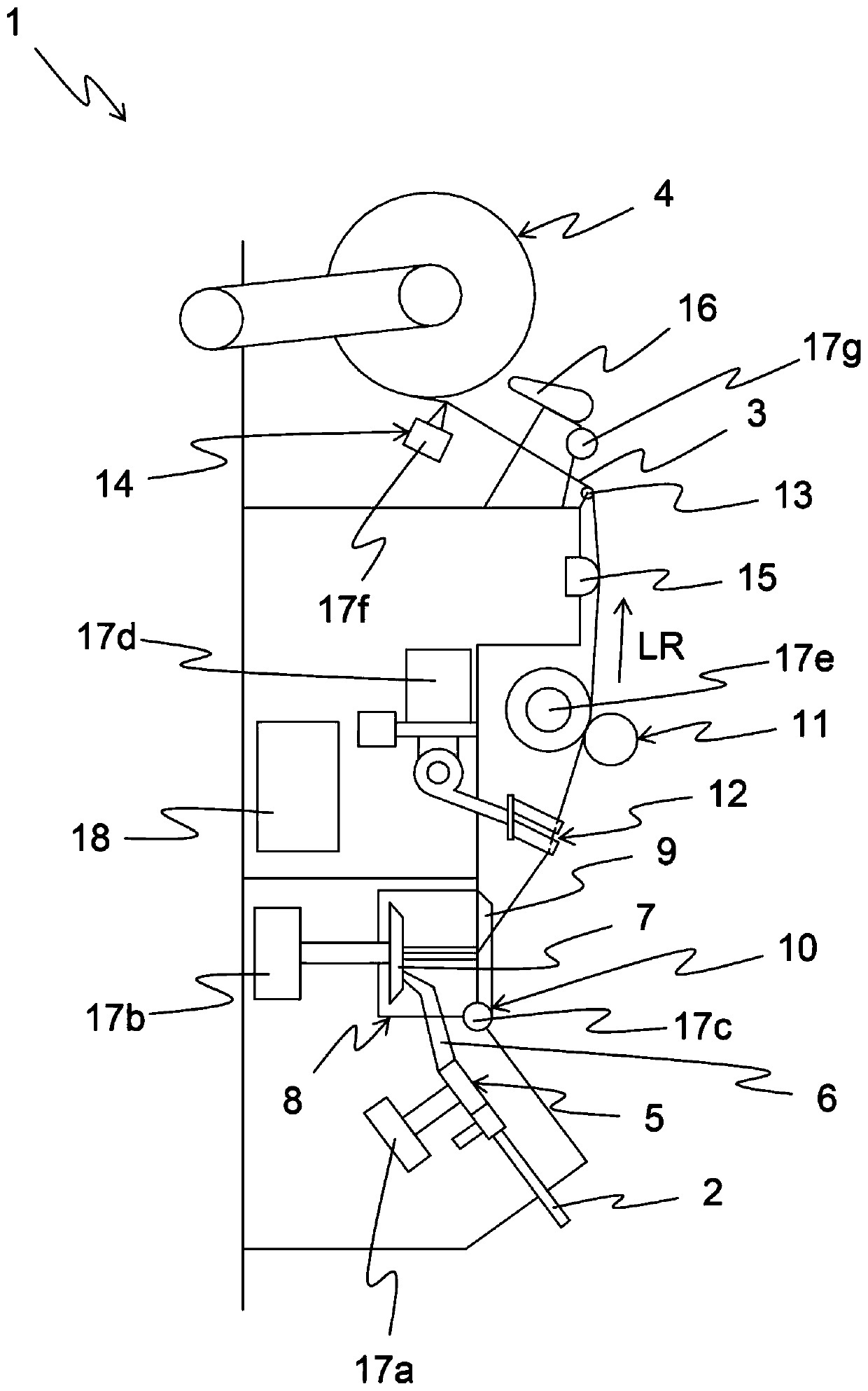

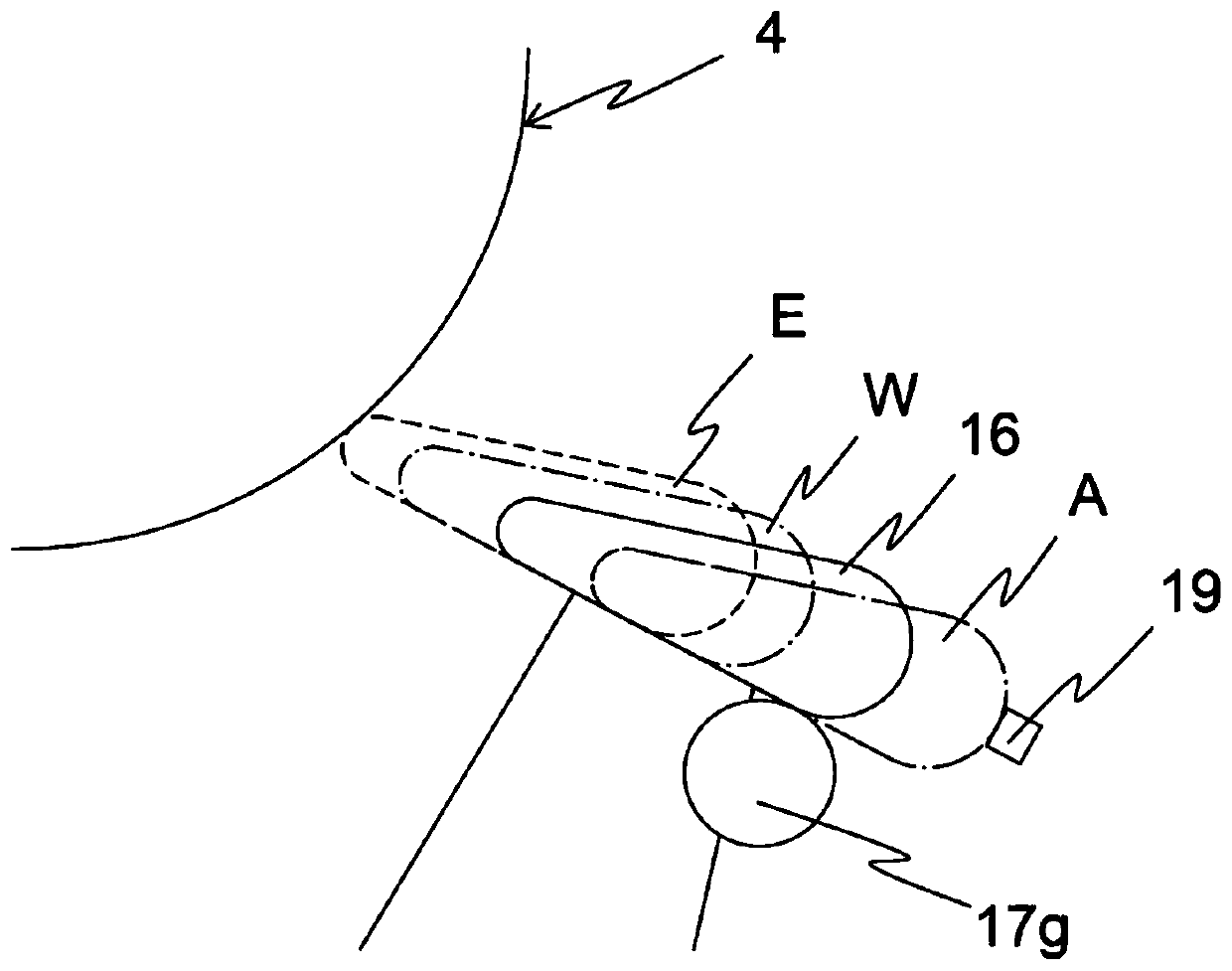

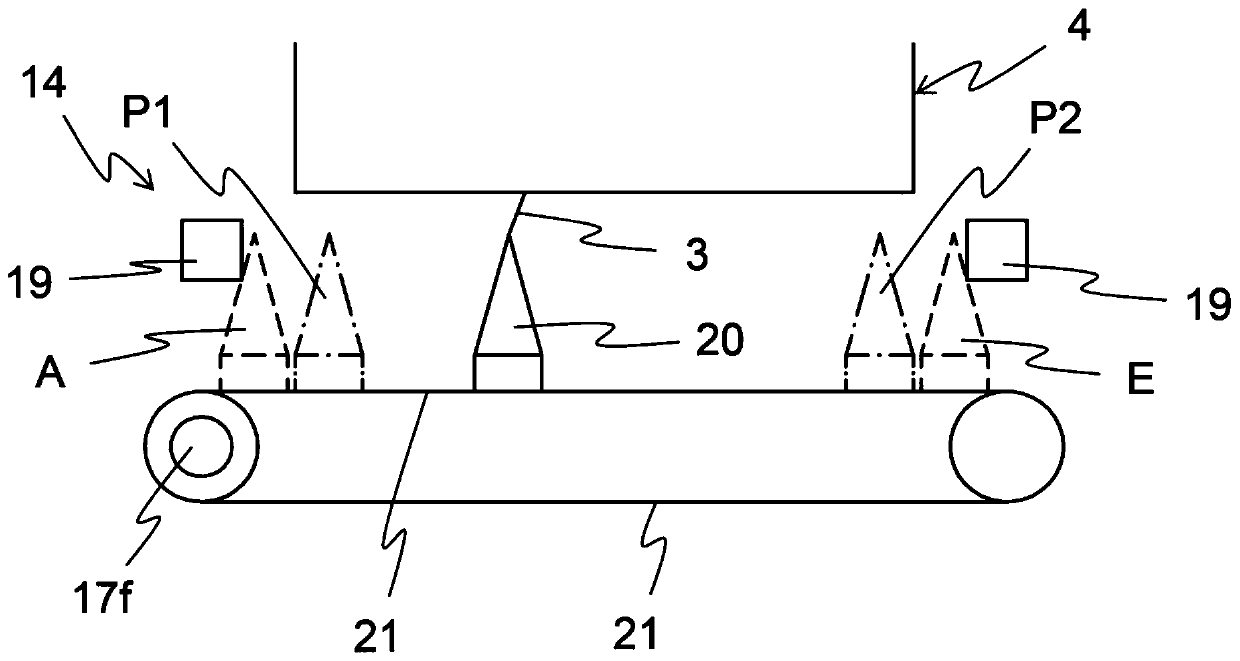

Method for operating a textile machine and textile machine

ActiveCN110540109AReasonable operationControls are simple but very efficientFilament handlingDynamo-electric converter controlSpinningControl engineering

The invention relates to a method of operating a textile machine, in particular a free end spinning machine or an air jet spinning machine, wherein the textile machine comprises a plurality of stations (1) driven at least partially by a single motor, wherein the stations (1) are associated with at least one stepping motor (17). According to the invention, the load variable, in particular the loadangle, of the stepping motor (17) is measured, and based on the change of the load variable, in particular the increase of the load angle, the elements driven by the stepping motor (17) are identified, (5, 7, 9, 11, 12, 14, 16) approaching the final position (E). The invention also relates to a textile machine, particularly a free end spinning machine or an air jet spinning machine, which comprises a plurality of stations (1) driven at least partially by a single motor, wherein the station (1) is associated with at least one stepping motor (17), and wherein each station (1) comprises means formeasuring a load variable of the stepping motor (17), in particular a load angle, and a controller (18) for operating the stepping motor (17) according to the foregoing operation.

Owner:MASCHINENFABRIK RIETER AG

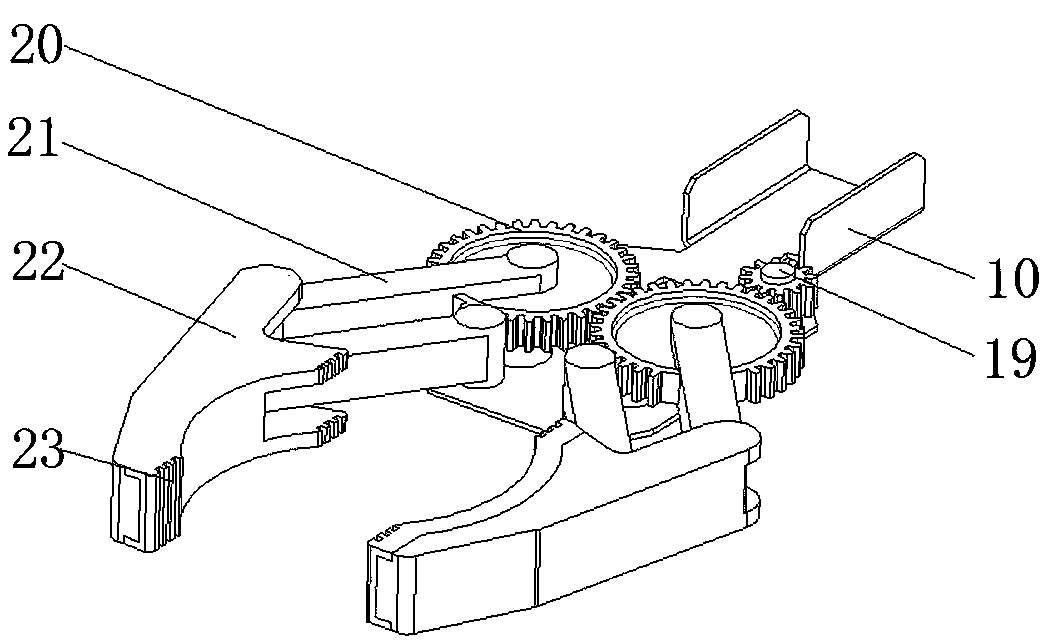

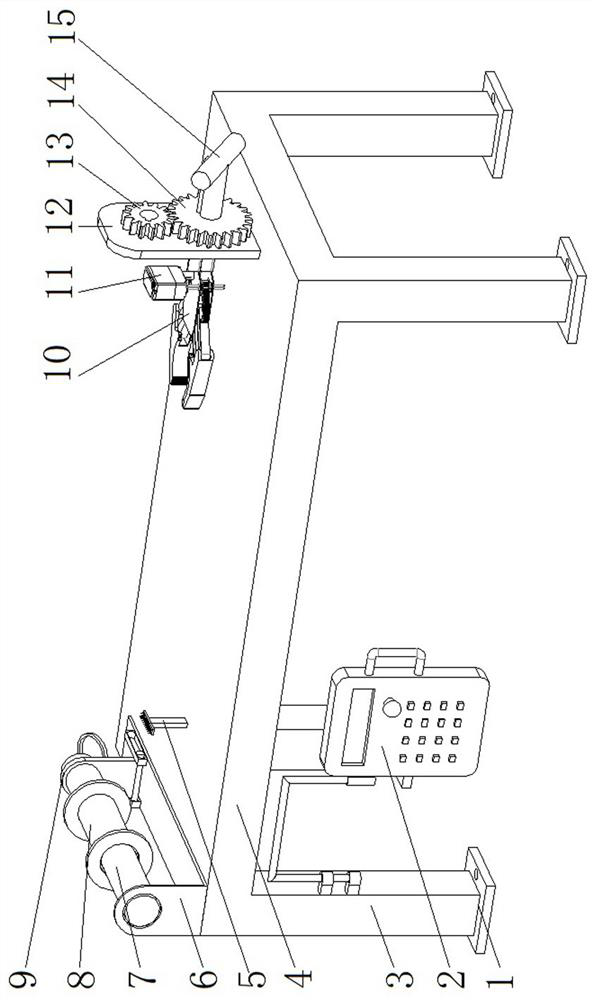

Novel multifunctional twisting machine for cotton combing

ActiveCN110592743ARealize the clamping functionEasy clampingIntermittent wound-up machinesCombingEngineering

The invention discloses a novel multifunctional twisting machine for cotton combing. The twisting machine comprises supporting legs, a top plate and a load bearing plate. The supporting legs are installed at the four corners of the bottom end of the top plate, anti-skid pads are installed at the bottom ends of the supporting legs, a fixing plate is installed at the top end of the top plate, a fixing shaft is mounted at the top end of the fixing plate, and a take-up reel is installed on the outer side of the fixing shaft. A movable plate is installed on one side of the take-up reel, a hinge block is installed on one side of the movable plate, a motor is installed at the top of a clamping plate, a small gear is installed on one side of the load bearing plate, a large gear is installed at thebottom end of the small gear, and a crank is installed on the inner side of the large gear. One side of one supporting leg is provided with a controller, and the output end of the controller is electrically connected with the input end of the motor through a wire. According to the twisting machine, by installing the supporting legs, the top plate and the load bearing plate, the gears with different diameters are mounted on one side of the load bearing plate so that the torque for twisting cotton threads can be changed, and the efficiency is greatly improved.

Owner:徐州久源纺织有限公司

Method and device for producing nonwoven web made of fibers

ActiveCN110965205AIncrease amplitude speedEasy to replaceCalendersMelt spinning methodsFiberPolymer science

The invention relates to a method for producing a nonwoven web made of fibers, in which the fibers are spun out and cooled and laid on a laying belt as a fiber laying layer. According to the invention, at least one pre-consolidation device for pre-consolidating a nonwoven web is provided, and at least one first calendering roller for consolidating the nonwoven web, which is connected downstream ofthe pre-consolidation device, is provided. The first calendering roller is replaced with a second calendering roller in a continuous process operation. Here, the first calendering roller is removed from the nonwoven web and the pre-consolidation of the nonwoven web is reinforced during the replacement of the calendering roller. The pre-consolidation of the nonwoven web is again reduced after introduction of the second calendering roller.

Owner:REIFENHAEUSER GMBH& CO KG MASCHFAB

Pedaled spinning wheel

InactiveCN103243419APlay a fitness effectIntermittent wound-up machinesEngineeringMechanical engineering

The invention provides a pedaled spinning wheel and belongs to the technical field of spinning machinery. The pedaled spinning wheel comprises a base, support plates, connecting plates, a power wheel, a transmission wire, a rotating rod, pedal bars, pedals, and a spinning wheel. The support plates are pairwise fixed on the base. The power wheel is rotatably fitted between the two support plates. The connecting plates are connected with the support plates respectively. The rotating rod is rotatably fitted on the connecting plates. One end of the rotating rod penetrates the connecting plates to be connected with the spinning wheel. The power wheel is connected with the transmission wire through the rotating rod. The parts of two shaft ends of the power wheel, penetrating the support plates, are fixedly connected with the pedal bars. The rotatable pedals are connected to the pedal bars. The pedaled spinning wheel is driven by means of pedaling, is more convenient to use, and has the effect of body building.

Owner:WUJIANG JIANGXU TEXTILE

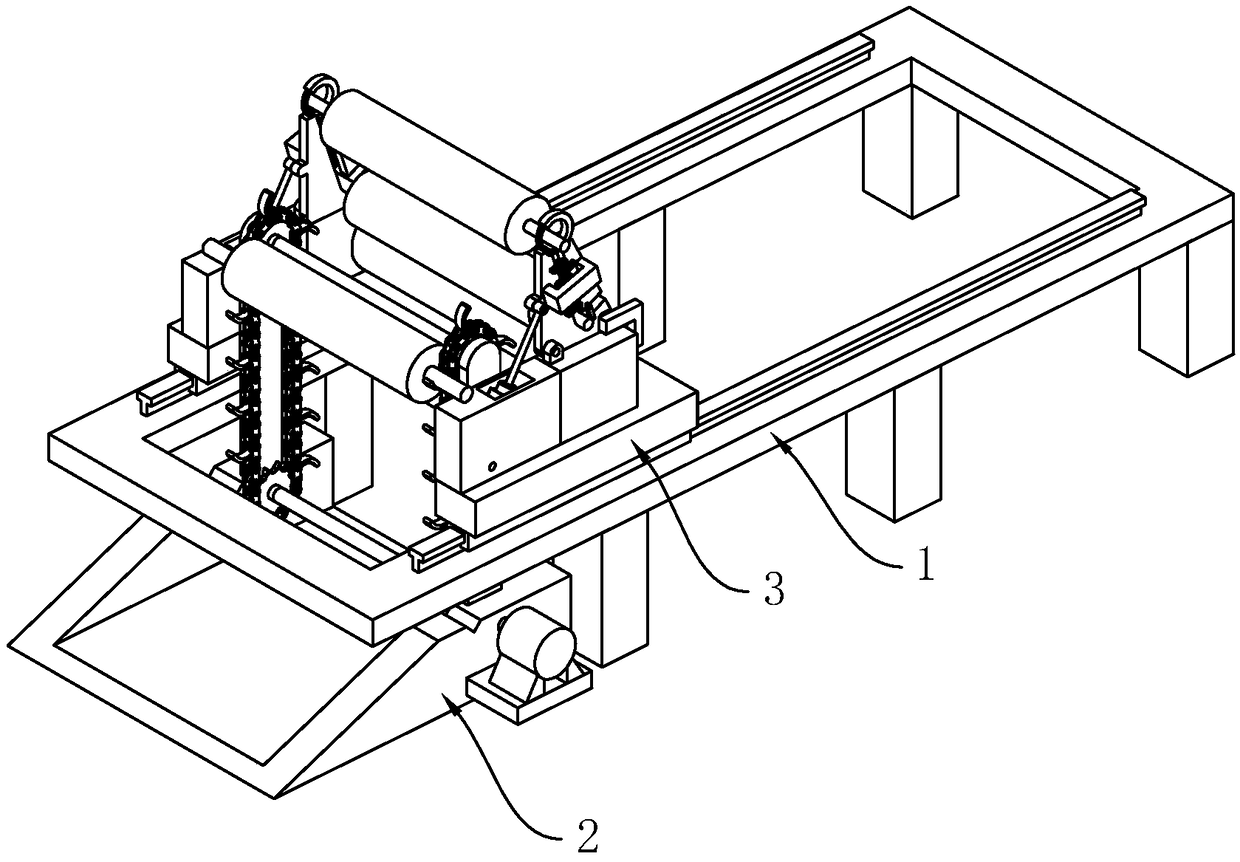

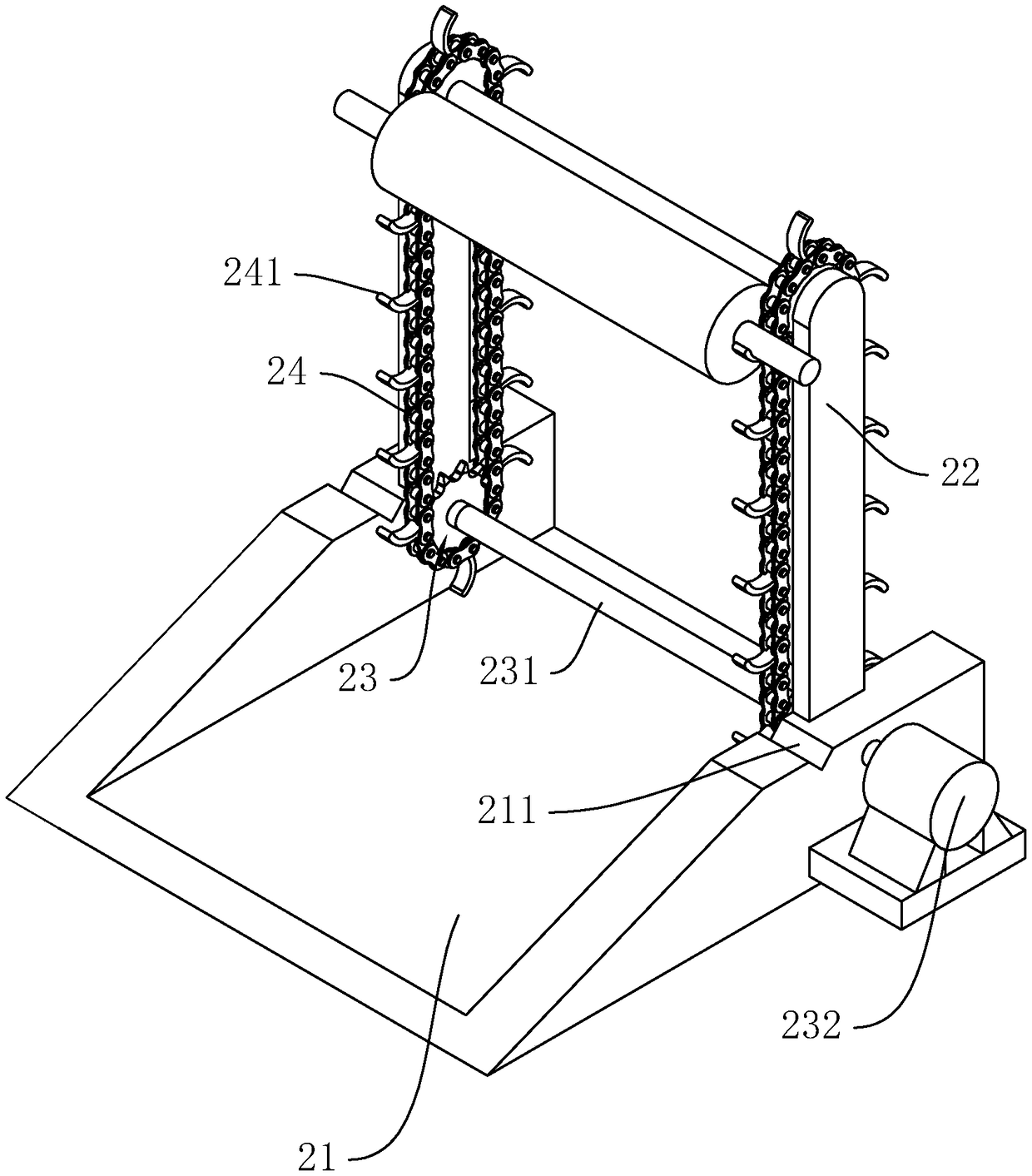

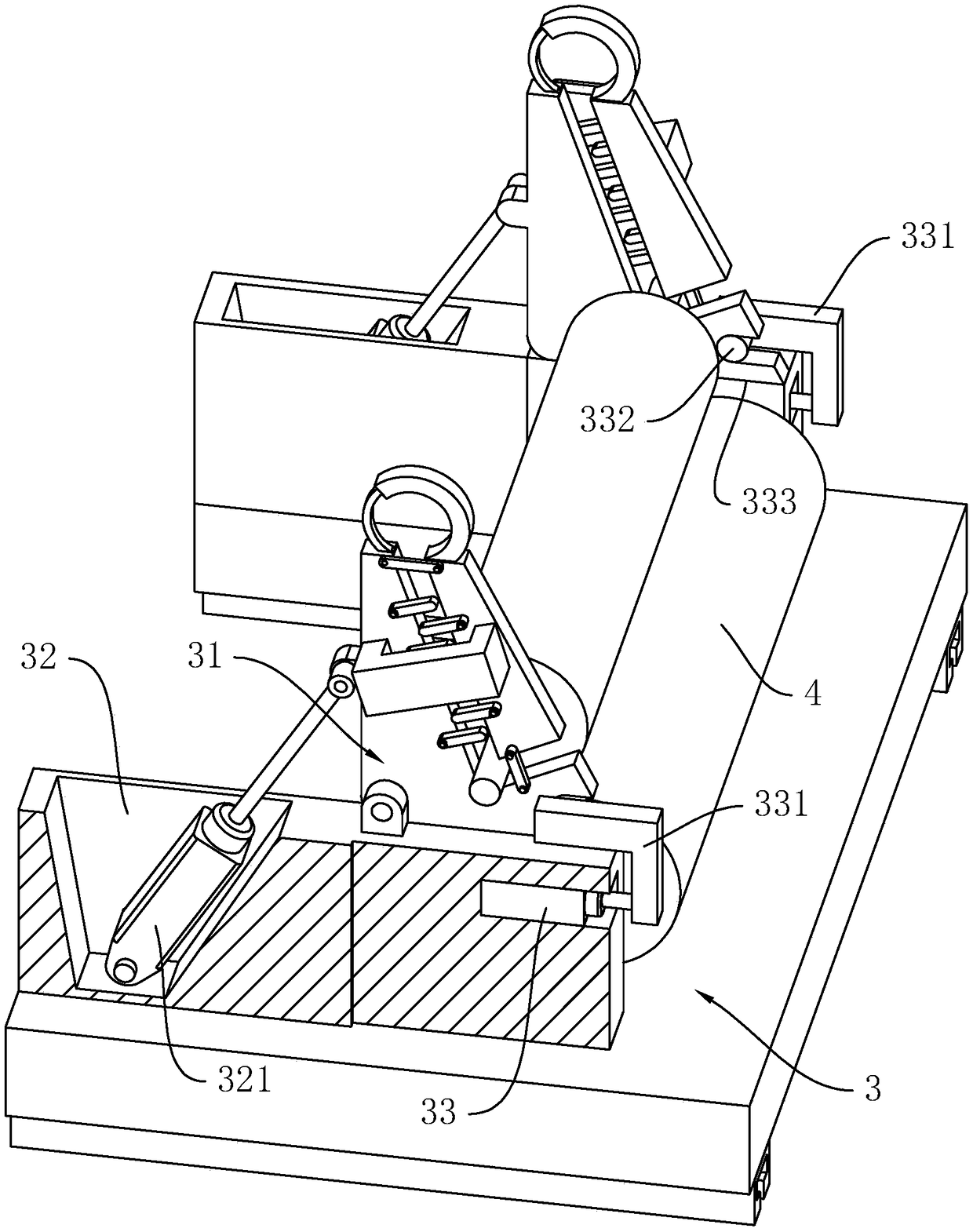

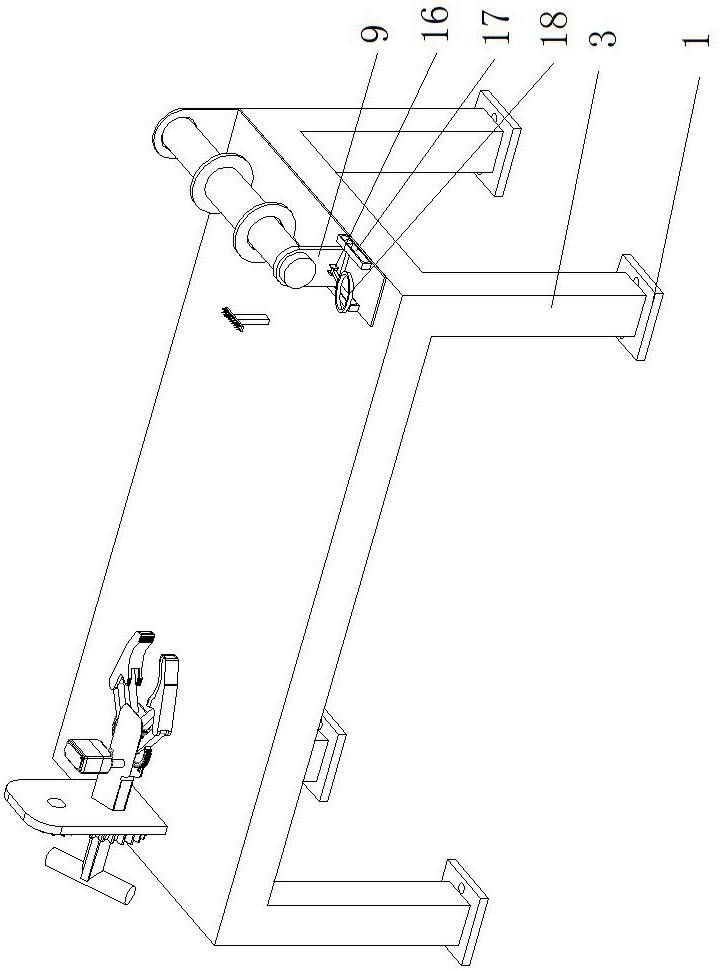

Mule spinning machine

PendingCN108950759AReduce labor intensityEasy to operateIntermittent wound-up machinesYarnPulp and paper industry

The invention discloses a mule spinning machine, and relates to the field of spinning machines. The mule spinning machine comprises a machine frame and a mule slidingly connected to the machine frame,two yarn roller racks are rotatably connected to the two ends of the mule respectively, fixing arms are fixedly connected to the upper ends of the two yarn roller racks respectively and slidingly connected with movable arms, inserting grooves are formed in the upper ends of the yarn roller racks, pushing springs are further arranged on the fixing arms and can push the movable arms to be insertedinto the inserting grooves, a lifting assembly is arranged at one end of the machine frame, a first driving mechanism capable of driving the two yarn roller racks to rotate is arranged on the mule, and arc surfaces are further arranged on the outer sides of the movable arms, and can slide the movable arms when the movable arms abut against the ends of yarn rollers, so that the ends of the yarn rollers are inserted into supporting rings. The problems are solved that in the prior art, when yarn rollers are carried onto a reel rack, operation is difficult, and labor intensity is high, and the mule spinning machine has the advantages that the yarn rollers can be conveniently placed on the reel rack, operation is simple, and the labor intensity is lowered.

Owner:浙江绿洲纺织股份有限公司

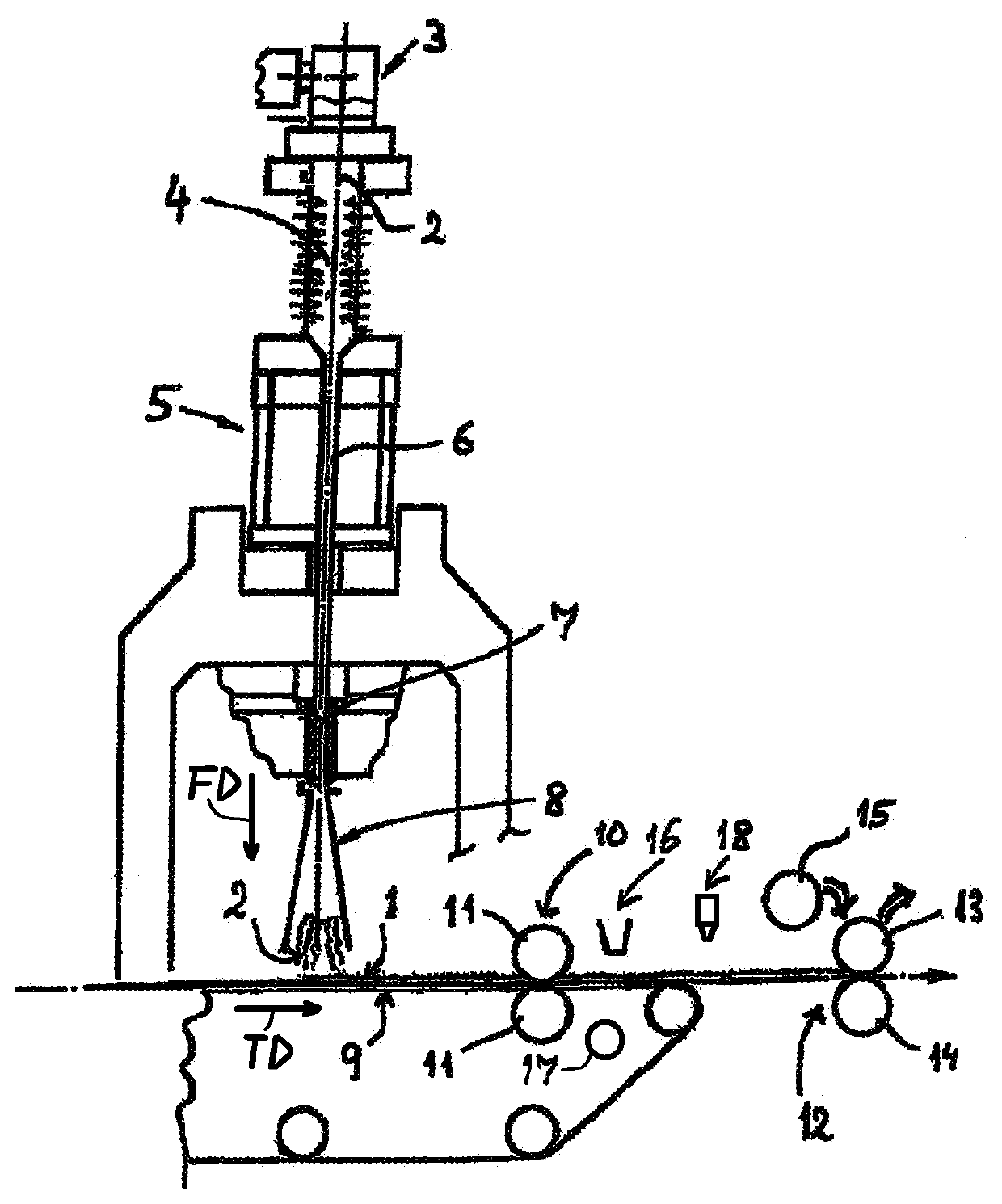

Ringspinning system for producing a yarn and method for stopping the supply of filaments to a drafting stage of a ringspinning system

The present disclosure provides a ringspinning system for producing a yarn. It is provided a the ringspinning system comprising a bobbin holder for holding a bobbin from which a first filament is supplied, a drafting stage for drafting the first filament together with a second filament, which is fed to the drafting stage, and a spindle, the ringspinning system further contains at least one sensor for detecting a breakage of the first and / or second filament and / or a roving comprising the first and second filament, which roving comes out of the drafting stage, and a clamp assembly comprising a clamp for fixing the second filament in the case that the sensor detects the breakage, wherein the clamp is provided adjacent the bobbin holder. It is further provided a method for stopping the supply of filaments to a drafting stage of a ring spinning system.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

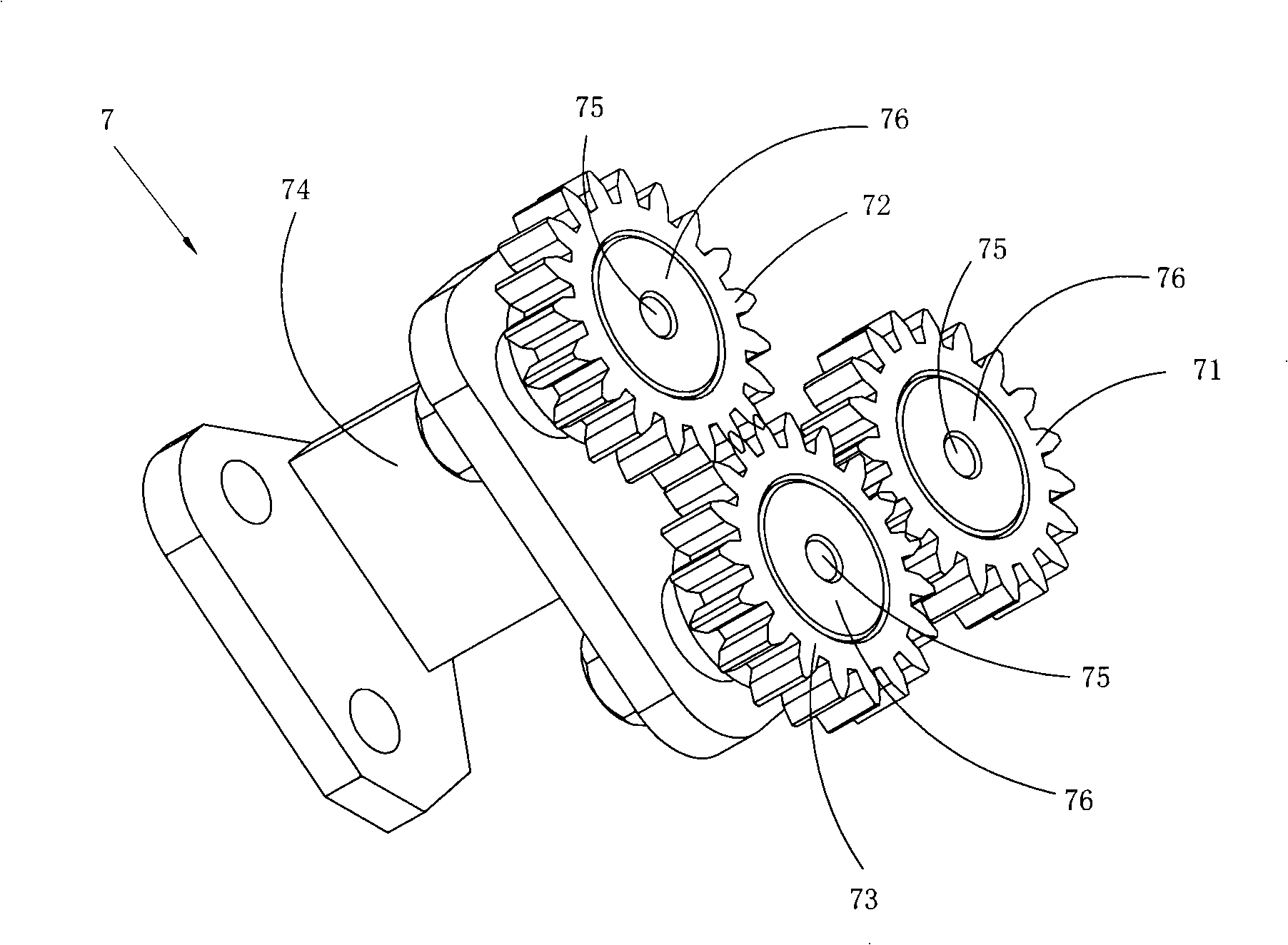

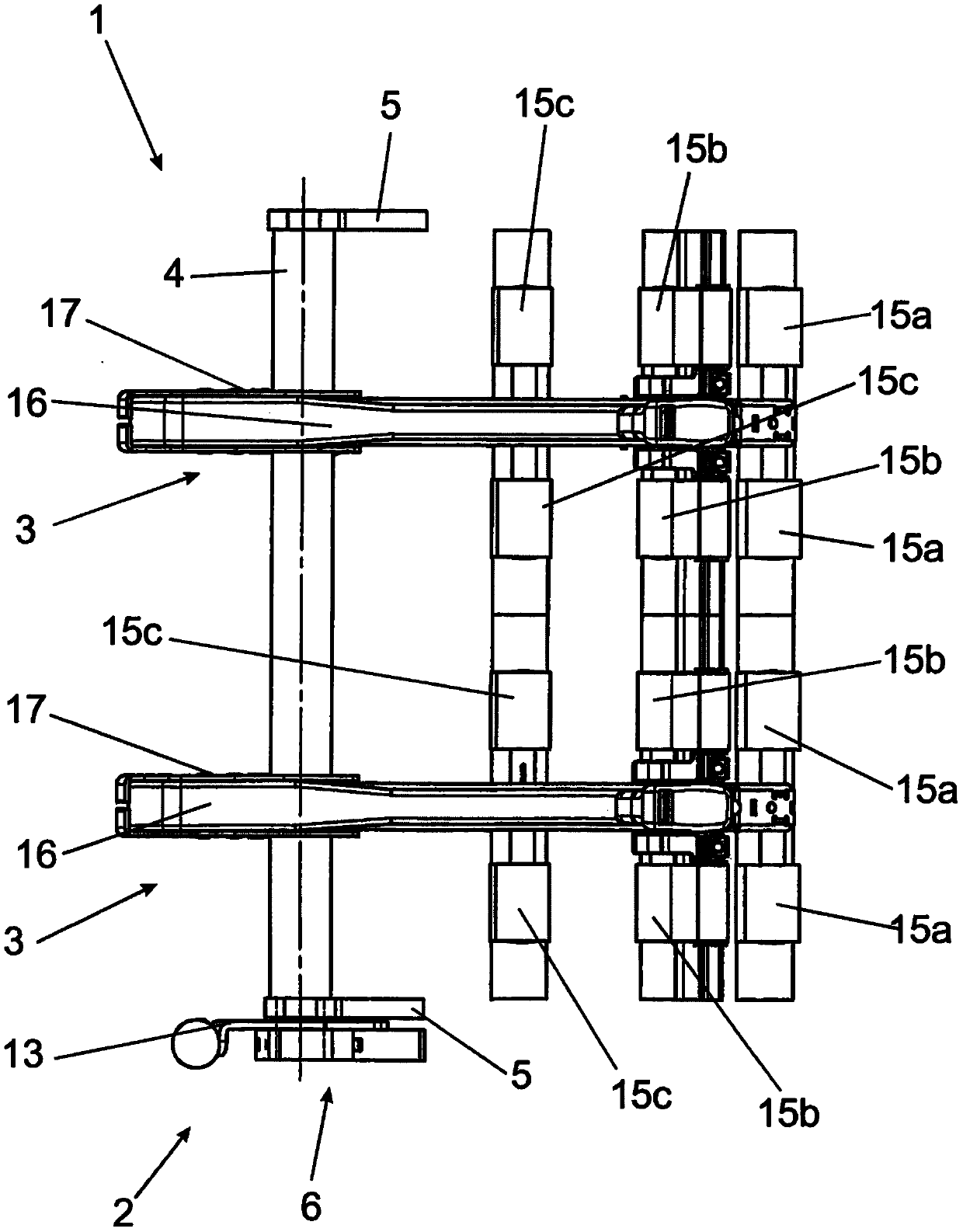

Special carrier gear system for four-roller compact spinning machine

InactiveCN101613896BDraft Ratio AdjustmentEasy to operateDrafting machinesContinuous wound-up machinesGear wheelGear system

The invention discloses a special idle gear system for a four-roller compact spinning machine. The system comprises an idle gear assembly for driving; the idle gear assembly comprises a maser idle gear, a first auxiliary idle gear and a second auxiliary idle gear which are arranged on either side of the maser idle gear respectively. The system has the advantages of rational and compact structure and low renovation cost, and can help improve spinning effect.

Owner:张忠宝

Nonwoven web and method of making same

ActiveUS20200157715A1Simple methodSimple and efficient and reliable procedureCalendersMelt spinning methodsFiberEngineering

A nonwoven web is made by first depositing fibers as a nonwoven web in a deposition area, then conveying the web away from the deposition area in a web-travel direction, preconsolidating the web in the path, and passing the preconsolidated web between a pair of rollers that compress and final consolidate the preconsolidated web. One of the rollers is separated from the web such that final consolidation of the web at a starting level is stopped and at the same time or immediately beforehand upstream preconsolidation of the web increased. After separating the one roller from the web, another roller is engaged with the web at the consolidation station and then final consolidation is recommenced, whereupon upstream preconsolidation of the web is reduced back to the starting level.

Owner:REIFENHAUSER GMBH & CO

Electronic type hair bulb winding-shaping apparatus

InactiveCN101450757BEasy to unwindAvoid accidental relocationFilament handlingContinuous wound-up machinesFrequency changerEngineering

The invention discloses a hair bulb winding and shaping device for a roving machine, which comprises a front roller, a traverse bar, and a sliding block fixed with the traverse bar. A hinge of the sliding block is at one end of a connecting rod, a crank link mechanism is connected with a servo motor which is driven by a servo controller driver, the servo controller driver is connected with a frequency converter of a main motor, a shaft of a rotary encoder is concentrically and mechanically connected with the front roller, and the rotary encoder detects change signals of revolution speed of the front big roller and feeds back the change signals to a PLC programmable controller which controls a servo driver and the frequency converter. The device can adjust shaping angles of wool tops through replacing a synchronous pulley in the state of no stopping, has simple machine work, and reduces processing cycle.

Owner:ZHANGJIAGANG DA CHENG TEXTILE MACHINERY

A multifunctional twisting machine for combing cotton

ActiveCN110592743BRealize the clamping functionEasy clampingIntermittent wound-up machinesCardingGear wheel

The invention discloses a multifunctional twisting machine for cotton carding. A fixed plate is installed on the top of the top plate, and a fixed shaft is installed on the top of the fixed plate. A wire take-up reel is installed on the outer side of the fixed shaft, and a movable plate is installed on one side of the take-up reel, and one side of the movable plate is installed There is a hinge block, a motor is installed on the top of the splint, a pinion is installed on one side of the load-bearing plate, and a large gear is installed at the bottom end of the pinion. A controller is installed on one side, and the output end of the controller is electrically connected with the input end of the motor through wires. The invention can change the torque of twisting the cotton thread by installing the supporting feet, the top plate and the load-bearing plate, and install gears with different diameters on one side of the load-bearing plate, thereby greatly improving the efficiency.

Owner:徐州久源纺织有限公司

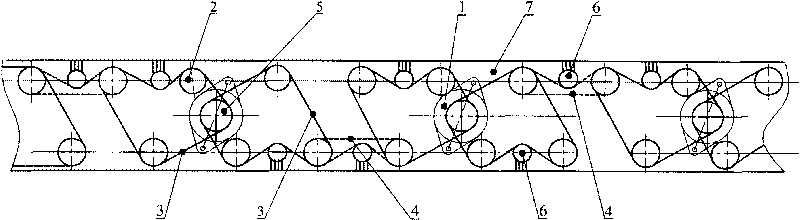

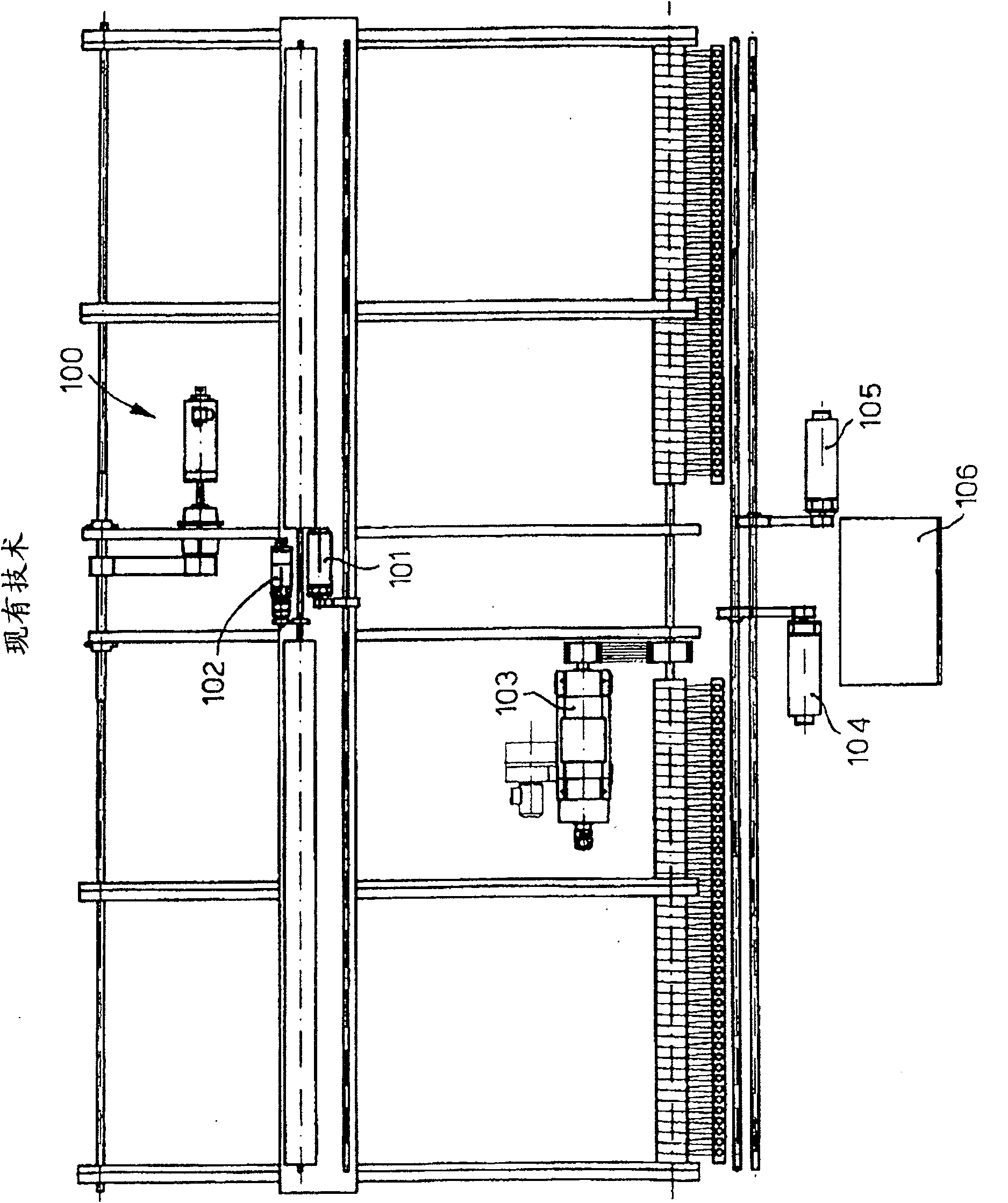

Spindle transmission mechanism of trestle-conveying-type spinning machine

InactiveCN100464012CIncrease contact areaSlippery small and evenIntermittent wound-up machinesDrive wheelCentral belt

The invention relates to a spindle transmitter of walking spinning machine, which comprises several spindles whose axles are parallel in same plane, a central belt, a driving wheel, and a tension wheel, wherein the axle of driving wheel and the axle of tension wheel are parallel with the axles of spindles; said central belt is tensioned on the driving wheel and the tension wheel; said central belt compacts the circumference of each spindle tightly, to gear the spindle; since the central belt is wide and it uses compression roller, the compact area between spindle and belt is increase, and it uses tension wheel to adjust the tension of central belt, it can realize stepless adjustment of tension, to adjust the compact stress between central belt and spindle stepless, to adjust the spindle transmission torque; therefore, the twisting difference is controlled, and the product has high quality.

Owner:SUZHOU YOULIAN TEXTILE EQUIP TECH

Method for winding and forming rough yarn after bobbiner is full of yarn

ActiveCN101634062BNot easy to fall offInhibit sheddingFilament handlingTextile/flexible product manufactureYarnBobbin

The invention discloses a method for winding and forming a rough yarn after a bobbiner is full of yarn, the method comprises the steps: calculating whether the length of a residual rough yarn accords with a preset value, controlling the bobbiner to spinning at a reduced speed; calculating whether the length of a yarn spun at a low speed accords with a preset value; the method also comprises: a flier motor, a drafter motor and a bobbin rotating body motor rotate at a low speed, a lower keel motor rotates at a high speed and the yarn is distributed at a thread pitch; if the yarn reaches a full-yarn forming upper part of the bobbin, then the flier motor stops, the drafter motor and the bobbin rotating body motor stop, the lower keel motor rotates at a high speed; if the yarn reaches the full-yarn forming top end of the bobbin, then the lower keel motor stops, keeps the position of the lower keel, the flier motor and the drafter motor and the bobbin rotating body motor rotate at a low speed, the yarn is winded on the full-yarn forming top end of the bobbin, all motors stop; the bobbin rotating body motor rotates reversely, the lower keel motor rotates and moves upward, breaks the yarn, completes the winding and forming of rough yarn after the bobbiner is full of yarn. According to the invention, the effect of rough yarn winding and forming after the bobbiner is full of yarn is ideal and free from falling.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Spinning machine with individual spindle drive

InactiveCN101560709BQuick installationQuick connectionContinuous wound-up machinesOpen-end spinning machinesMachine controlEngineering

The present invention relates to a spinning machine with individual spindle drive, having a plurality of working benches, which are divided into a plurality of sections, each section has a plurality of working benches. Each working bench has a spindle device comprising a spindle and a spindle drive unit (6). Further, the spinning machine includes a machine control unit for driving spindles of each section and a section electronic unit (3), the spindles and the section electronic unit (3) are connected to the machine control unit by data line (33), the spindle drive units (6) are separately connected to the section electronic unit (3) and are driven by the section electronic unit (3) arranged on the same. Each spindle device has spindle drive electronic units (5). The spindle drive electronic units (5) and section electronic units (3) of same section are arranged on a same circuit board (2). The spindle drive electronic units (5) are connected to the section electronic units (3) over data line in manner of conductive tapes (34). The data line (33) is guided into the machine control unit from the section electronic units (3). A power supply line (9) is guided into the spindle drive units (6) arranged on the spindle drive electronic units (5) from the spindle drive electronic units (5).

Owner:MASCHINENFABRIK RIETER AG

A device for enlarging the twist range of spinning frame

InactiveCN101343786BReasonable layoutCompact structureContinuous wound-up machinesOpen-end spinning machinesSprocketEngineering

The invention relates to a device for expanding the twist range of a spinning frame. A bearing seat (2) is arranged on the base (1), the bearing seat (2) is arranged on the bottom plate of the headstock, and the main shaft (3) is arranged on the bearing seat (2). The main shaft (3) is provided with a first toothed pulley (4), the first toothed pulley (4) is connected with the second toothed pulley (7) through the first toothed belt (5), and the pulley seat (8) be arranged on the head wallboard, the small shaft (6) is arranged in the pulley seat (8), and the second toothed pulley (7) and the third toothed pulley (9) are all arranged on the small shaft ( 6), the third toothed pulley (9) is connected with the fourth toothed pulley (11) through the second toothed belt (10), and the fourth toothed pulley (11) is set on the input shaft on the head box (12) on. The device has the function of expanding the twist range.

Owner:JINGWEI TEXTILE MASCH CO LTD

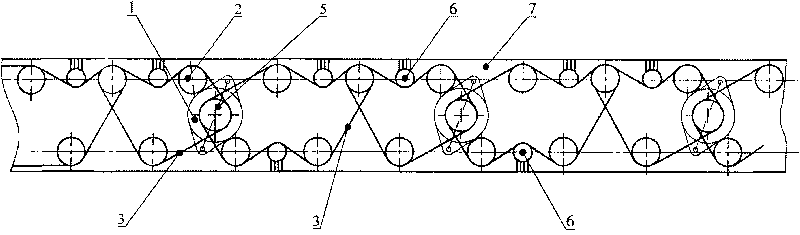

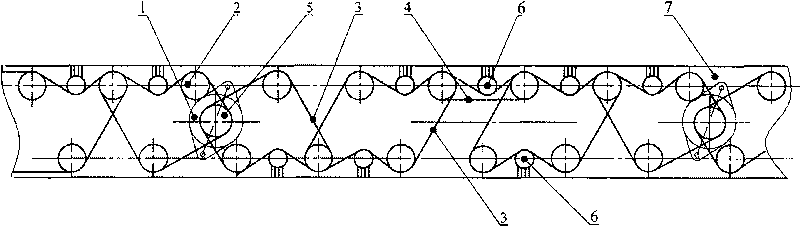

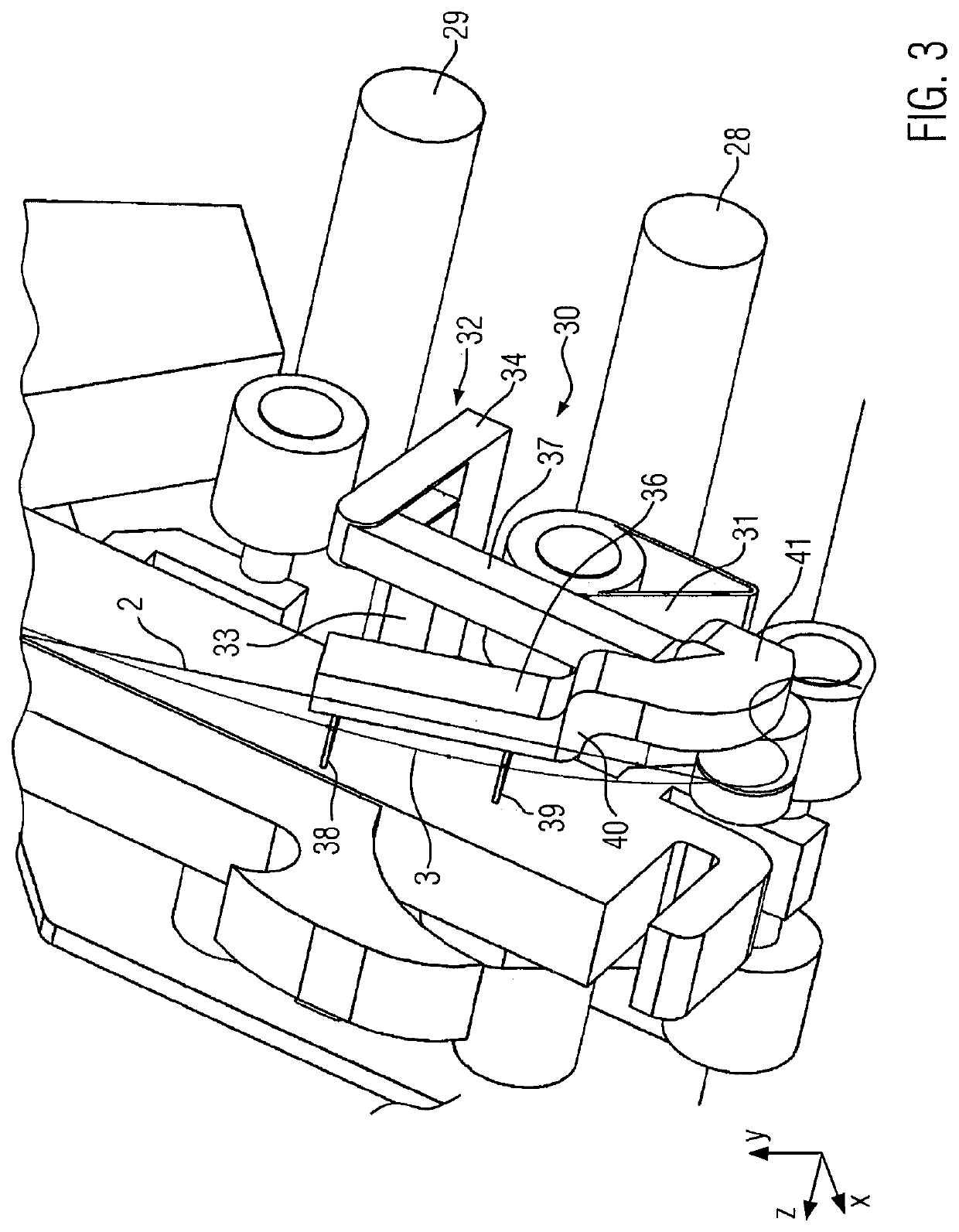

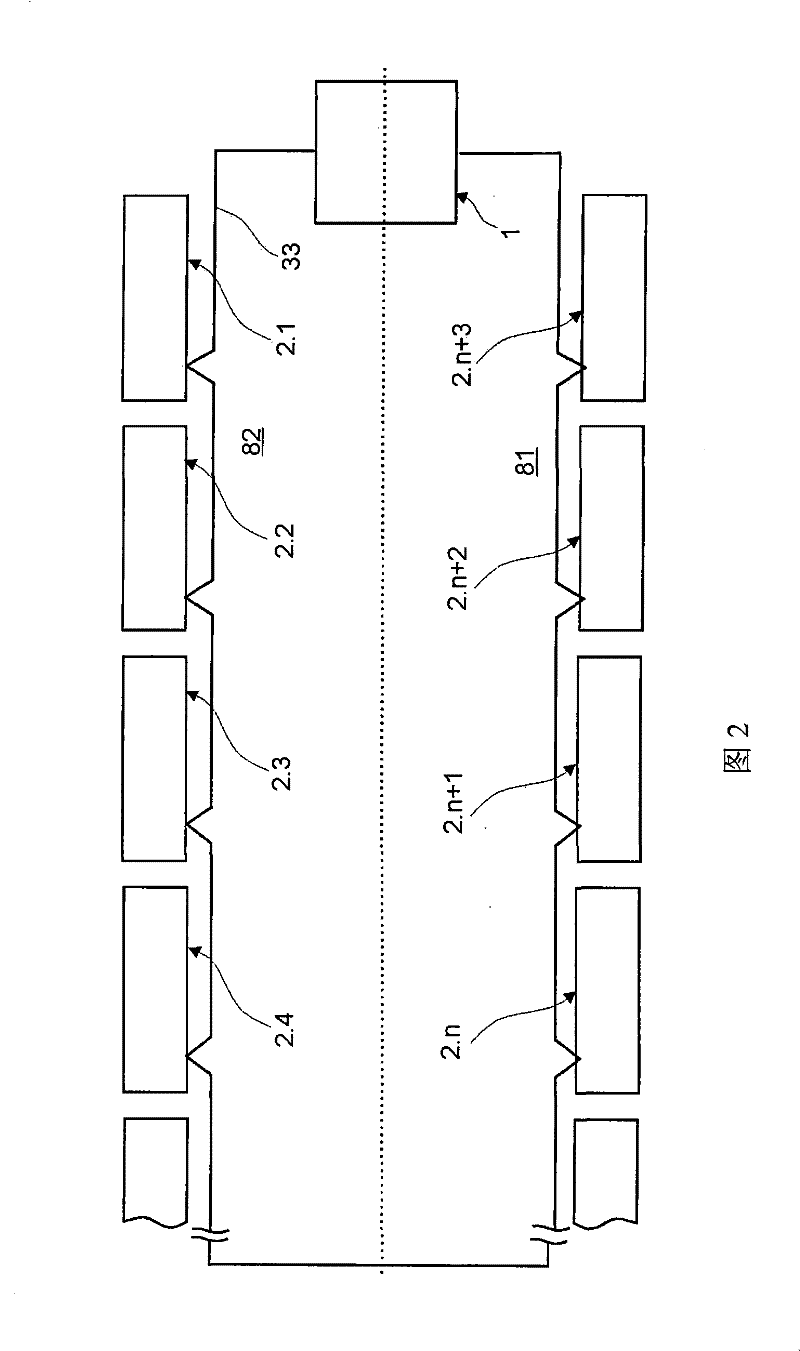

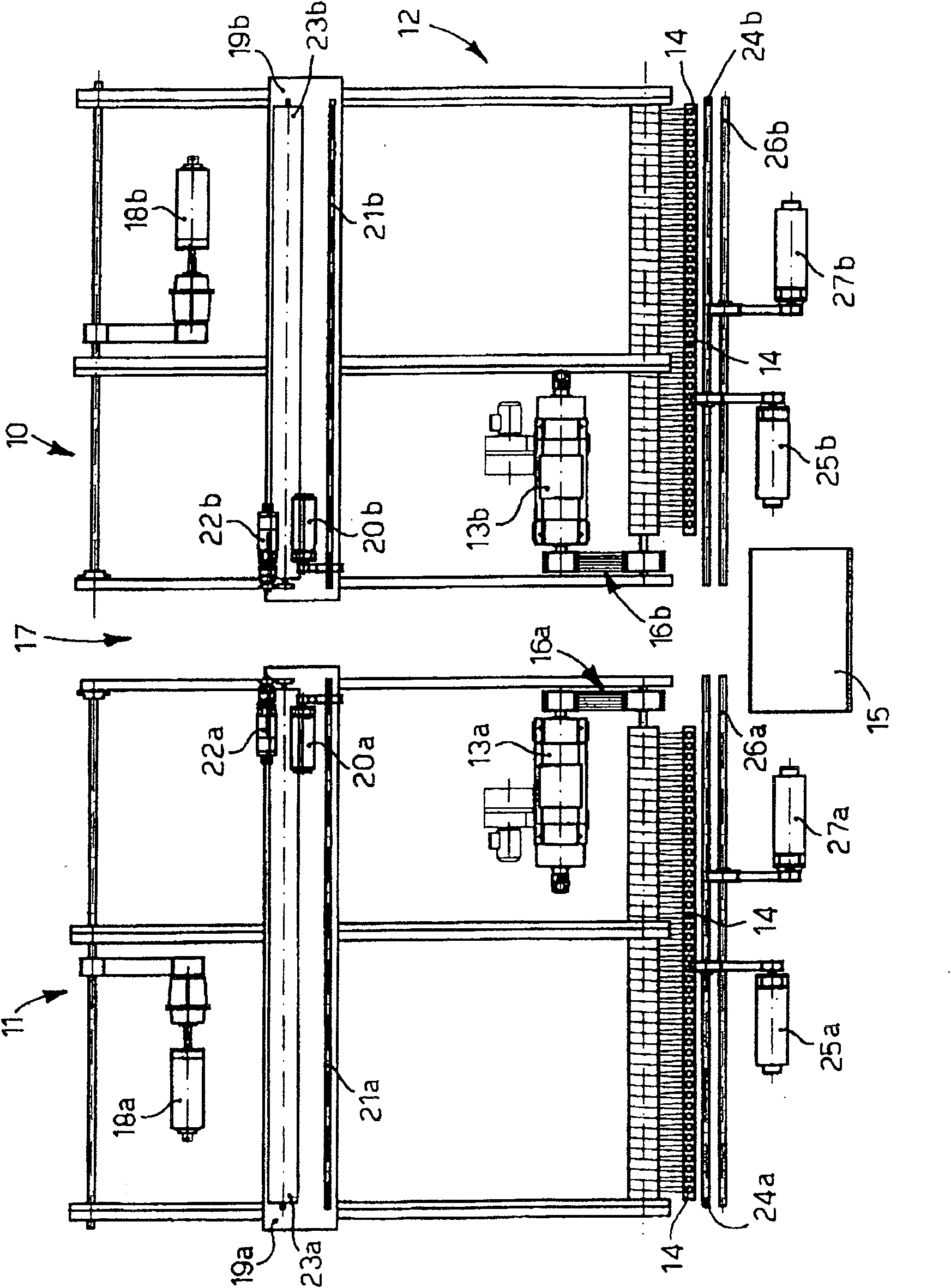

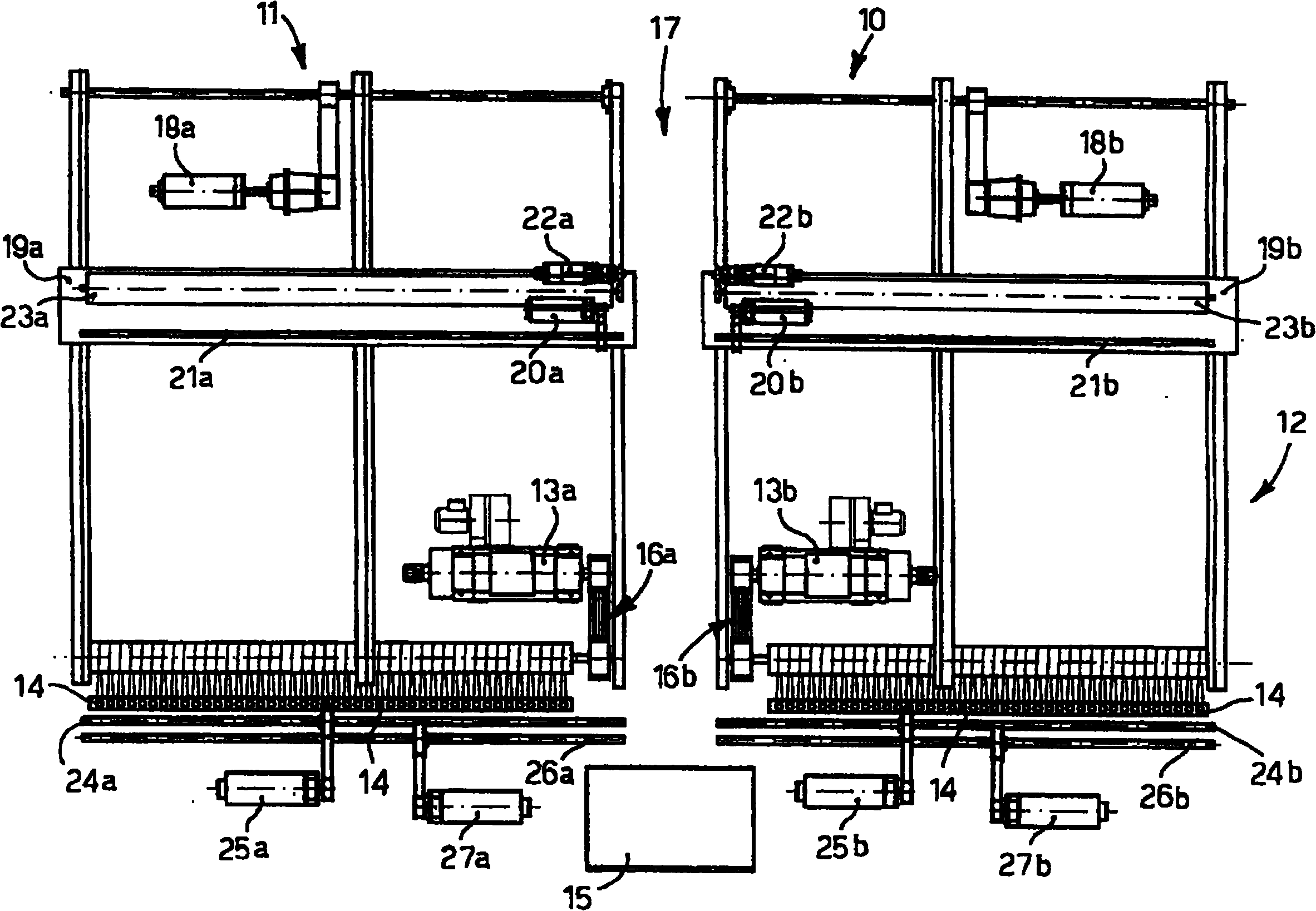

Self-acting mule

ActiveCN1873066BReduced power ratingIncrease savingsContinuous wound-up machinesIntermittent wound-up machinesYarnEngineering

Self-acting mule used to produce yarns in general, and particularly for the production of quality yarns in weaving and knitwear. The self-acting mule (10) consists of at least two sections of machine, respectively left (11) and right (12), independent from each other from the mechanical point of view, and each comprising at least a relative spool-bearing carriage (19a, 19b), relative spindles (14), relative cylinders (21a, 21b), relative fallers (24a, 24b), relative counter-fallers (26a, 26b), and relative drums for unwinding the spools (23a, 23b).

Owner:PROXIMA CORP

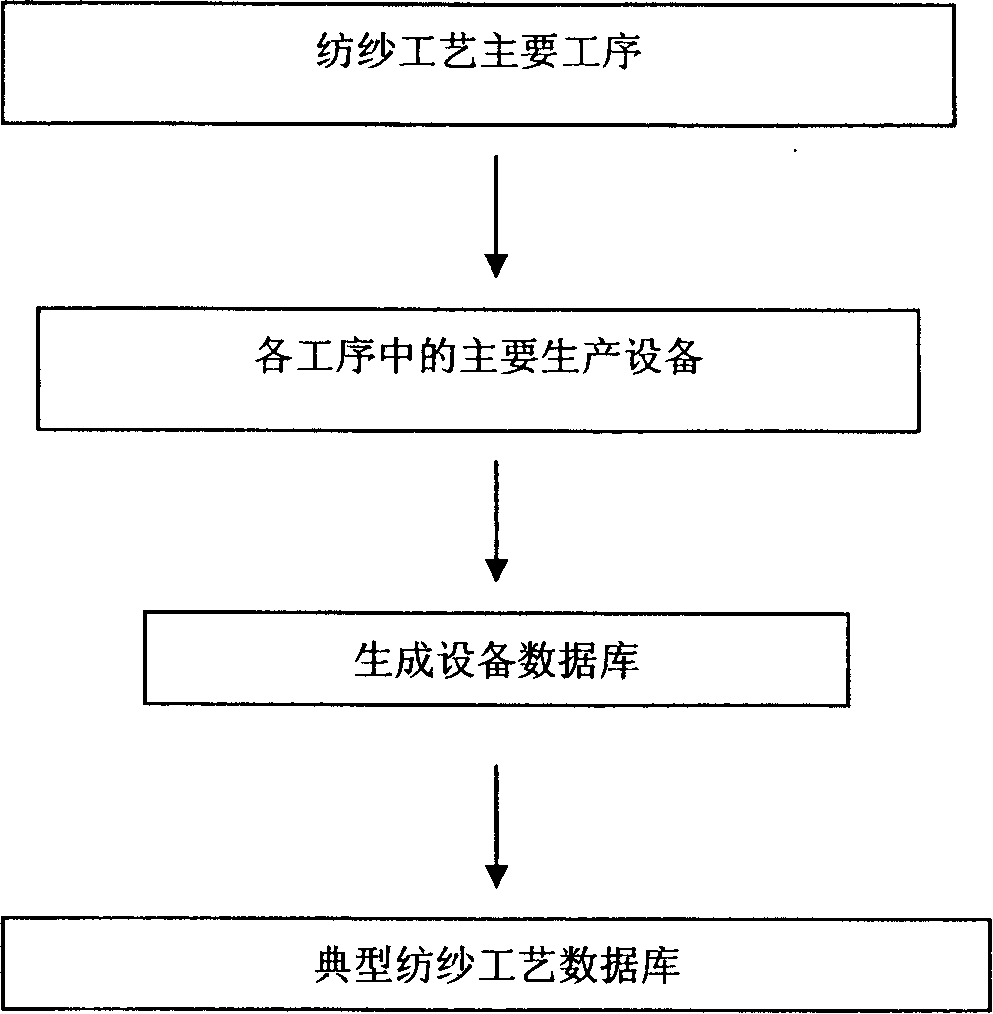

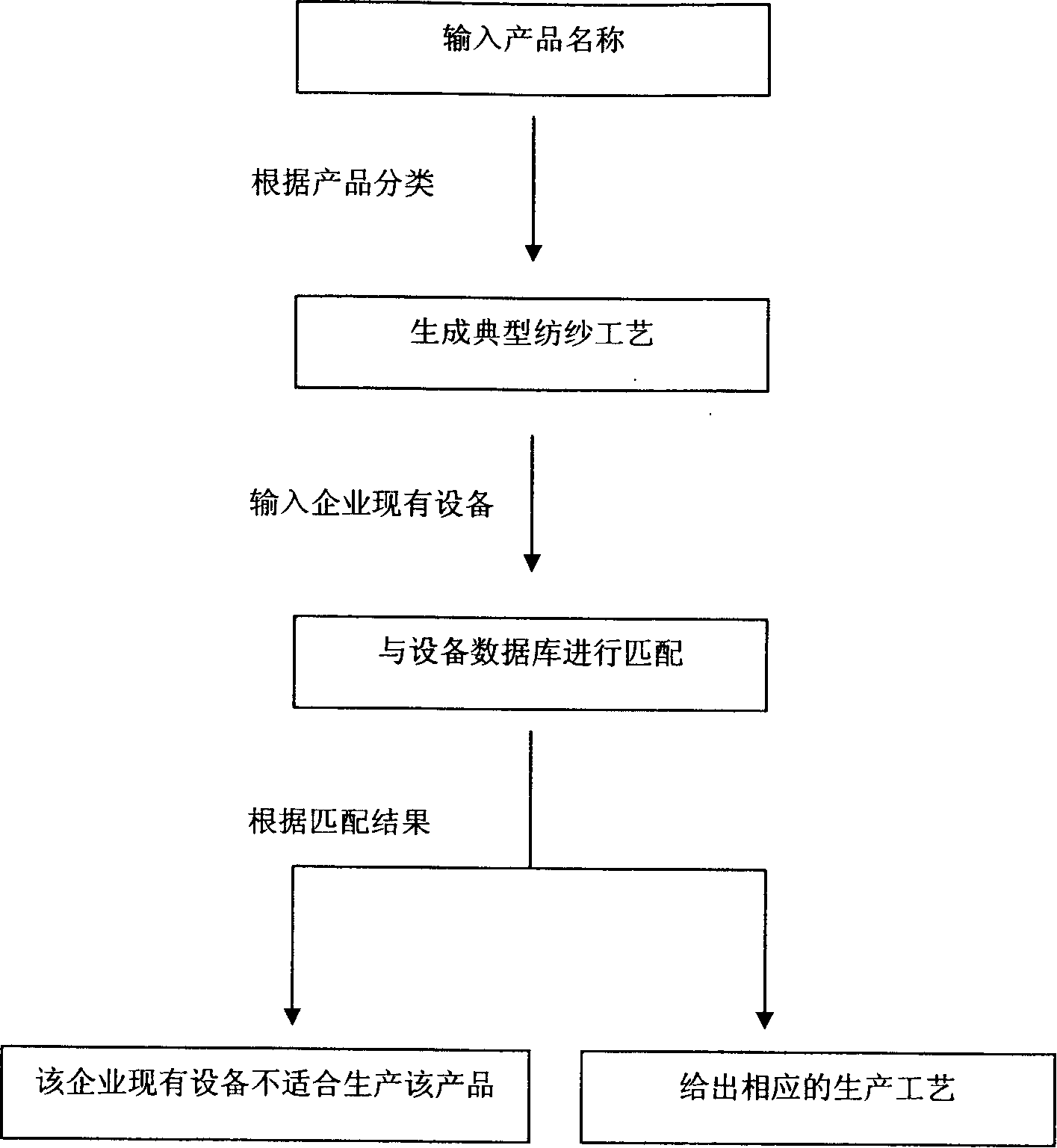

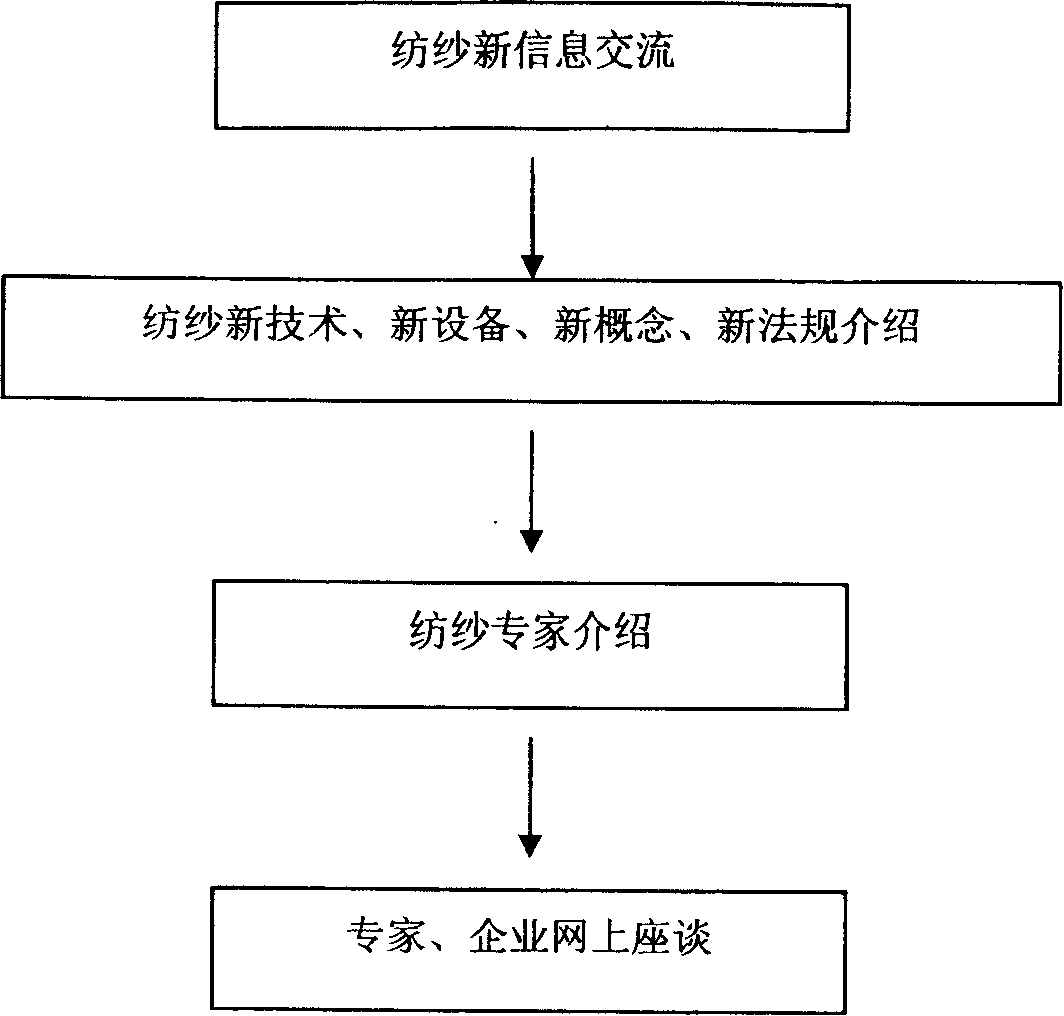

Textile technology interactive design method

InactiveCN1851074ATimely technical supportComprehensive technical supportContinuous processingContinuous wound-up machinesTextile technologyYarn

The invention discloses the spin art mutual design method combined with the computer technique. The spin process includes the a few working procedures, the main producing facility of the several working procedures are gathered and settled to form the facility database; then sorting according to the yam, the model spin craftwork database is based. Finally, the flat roof is based to intercourse with the enterpriser with the spin process. The method can provide the timely and trend art sustain to the spinning enterprise.

Owner:DONGHUA UNIV

Drafting system and drafting system unit for a spinning machine

ActiveCN110528126AReliable regulation of movementComfortable shiftingDrafting machinesIntermittent wound-up machinesEngineeringMechanical engineering

The invention relates to a drafting system and a drafting system unit for a spinning machine. The drafting system unit has at least one weighting arm, which can be pivoted between an operating position and an open position by a repositioning device. In order to provide a drafting system and a drafting system unit for a drafting system for a spinning machine, the drafting system unit having a particularly simple design and permitting user-friendly operation, it is provided that the at least one weighting arm is connected to a retaining rod for conjoint rotation, which retaining rod is mounted on a retaining rod holder for rotation about the longitudinal axis of the retaining rod by the repositioning device.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

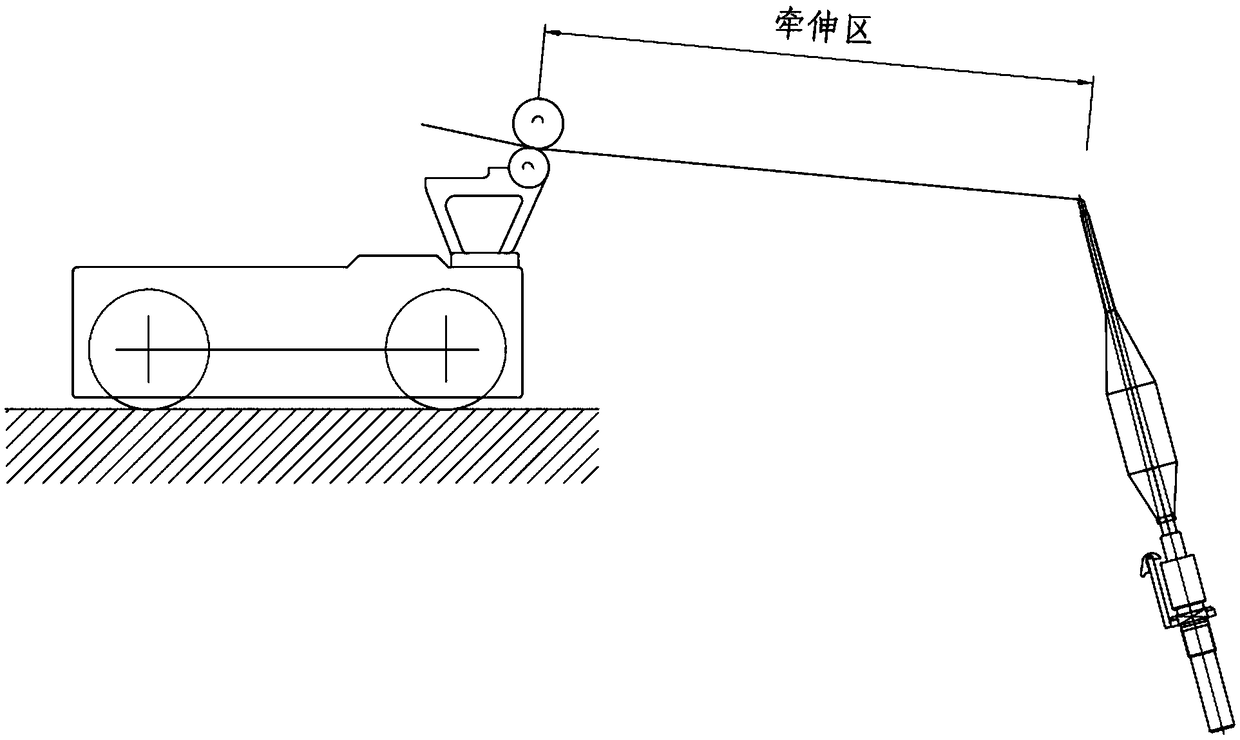

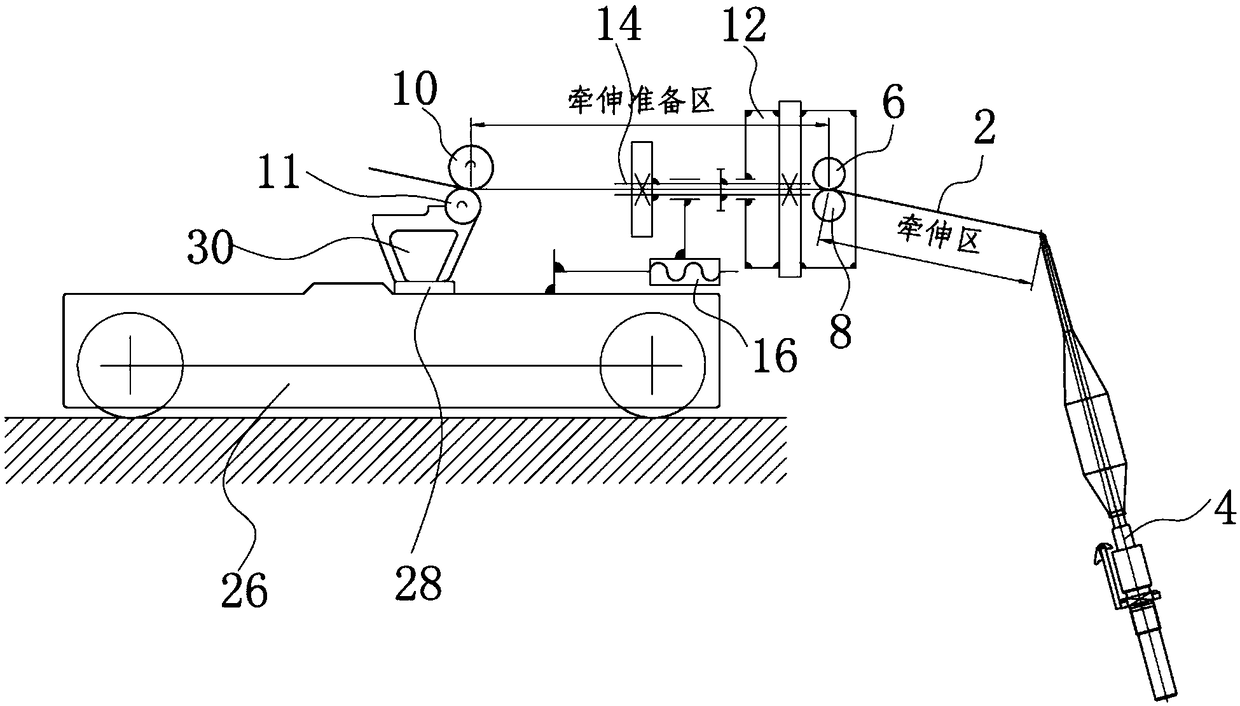

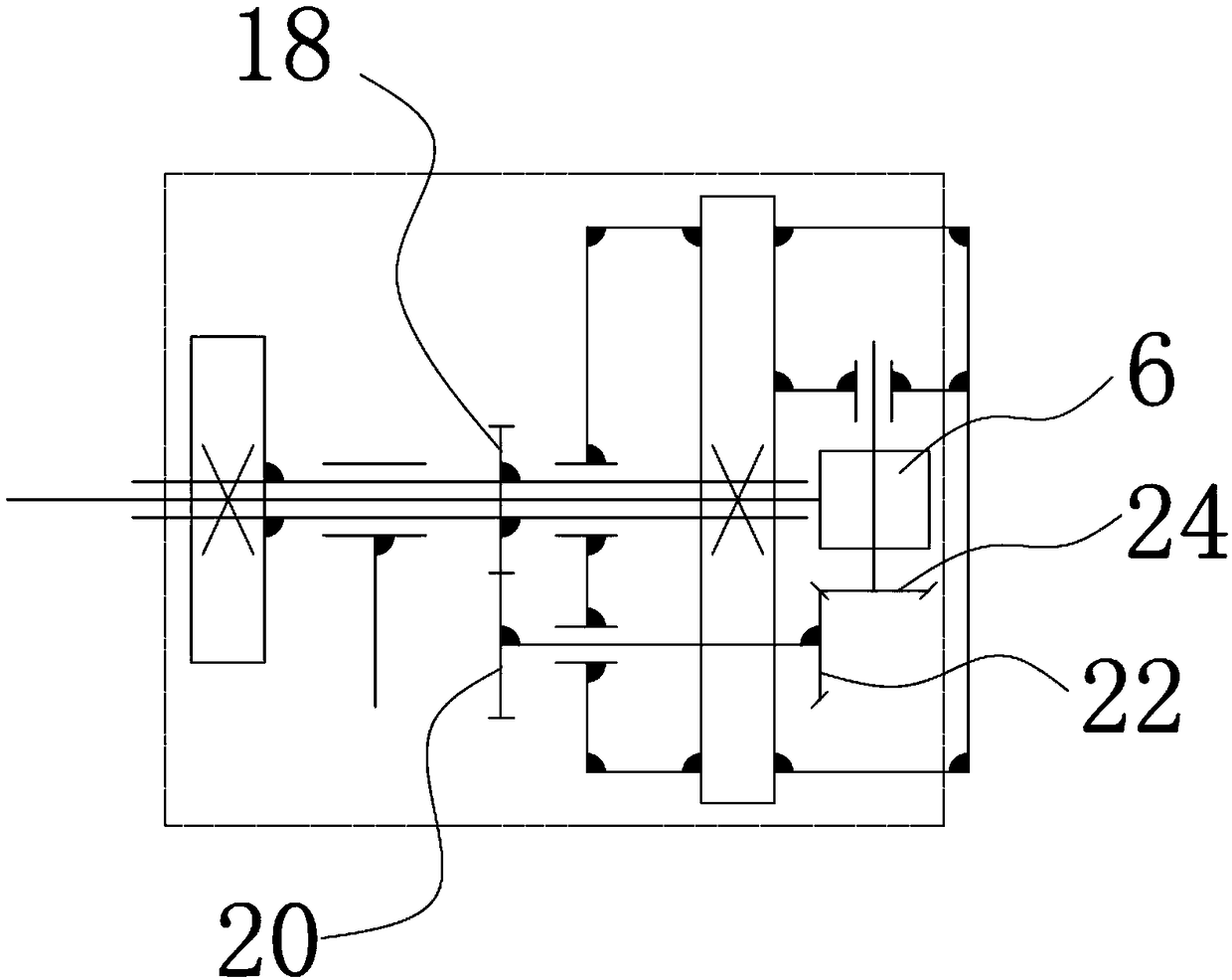

Spindle pivot drafting device for spinning frame

PendingCN109082735AImprove qualityAchieving segmental draftingIntermittent wound-up machinesYarnEngineering

The invention discloses a spindle pivot drafting device for a spinning frame. The device comprises a draft preparation area and a draft area arranged in turn in the direction of yarn movement; a firstroller and a second roller are arranged between the draft preparation area and the draft area, the first roller and the second roller are paired, and the first roller is driven to rotate by a power source; the draft preparation area is provided with a third roller, a fourth roller and a rotary drum, and the third roller and the fourth roller are paired; the rotary drum is driven to rotate by thepower source, and the rotary drum, the first roller, the second roller, the third roller and the fourth roller are cooperated to send yarns and conduct twisting, so that the yarns sent by the first roller and the second roller into the draft area have a target twist. According to the spindle pivot drafting device for the spinning frame, the draft preparation area is added, the yarns are physicallyisolated, by pre-twisting the yarns which need to be drafted, the adverse effect of uneven yarn twist distribution caused by the lag of twist transfer on the drafting is effectively reduced, the quality of the yarns is improved, and the spinnability is expanded.

Owner:SUZHOU YOULIAN TEXTILE EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com