Electronic type hair bulb winding-shaping apparatus

A ball-rolling and traversing technology, applied in electric speed/acceleration control, continuous winding spinning machine, intermittent winding spinning machine, etc., can solve the problem of large number of parts, affecting production progress and cumbersome assembly and other problems, to achieve the effect of simple machining, reducing the difficulty of machining, and reducing the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

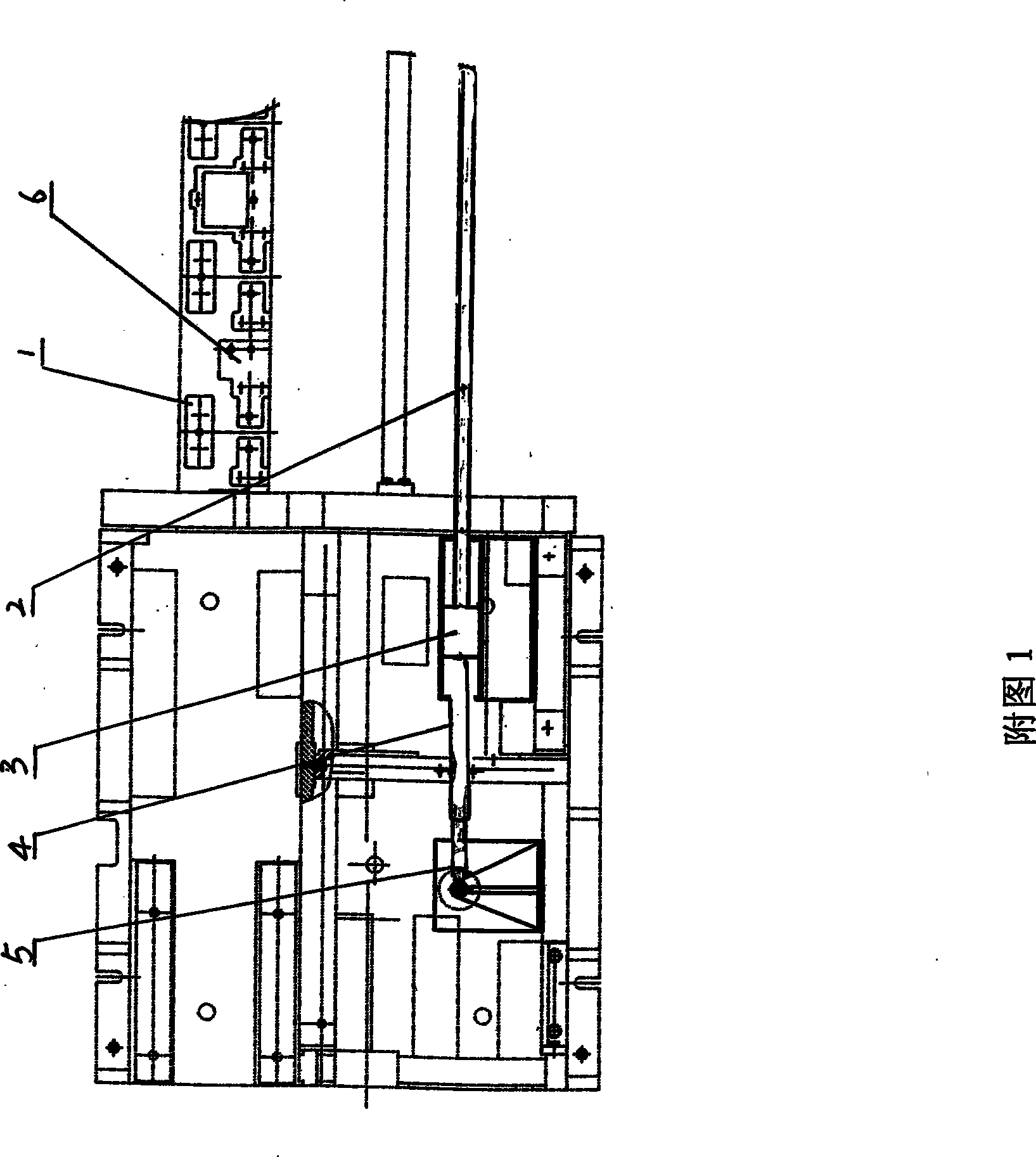

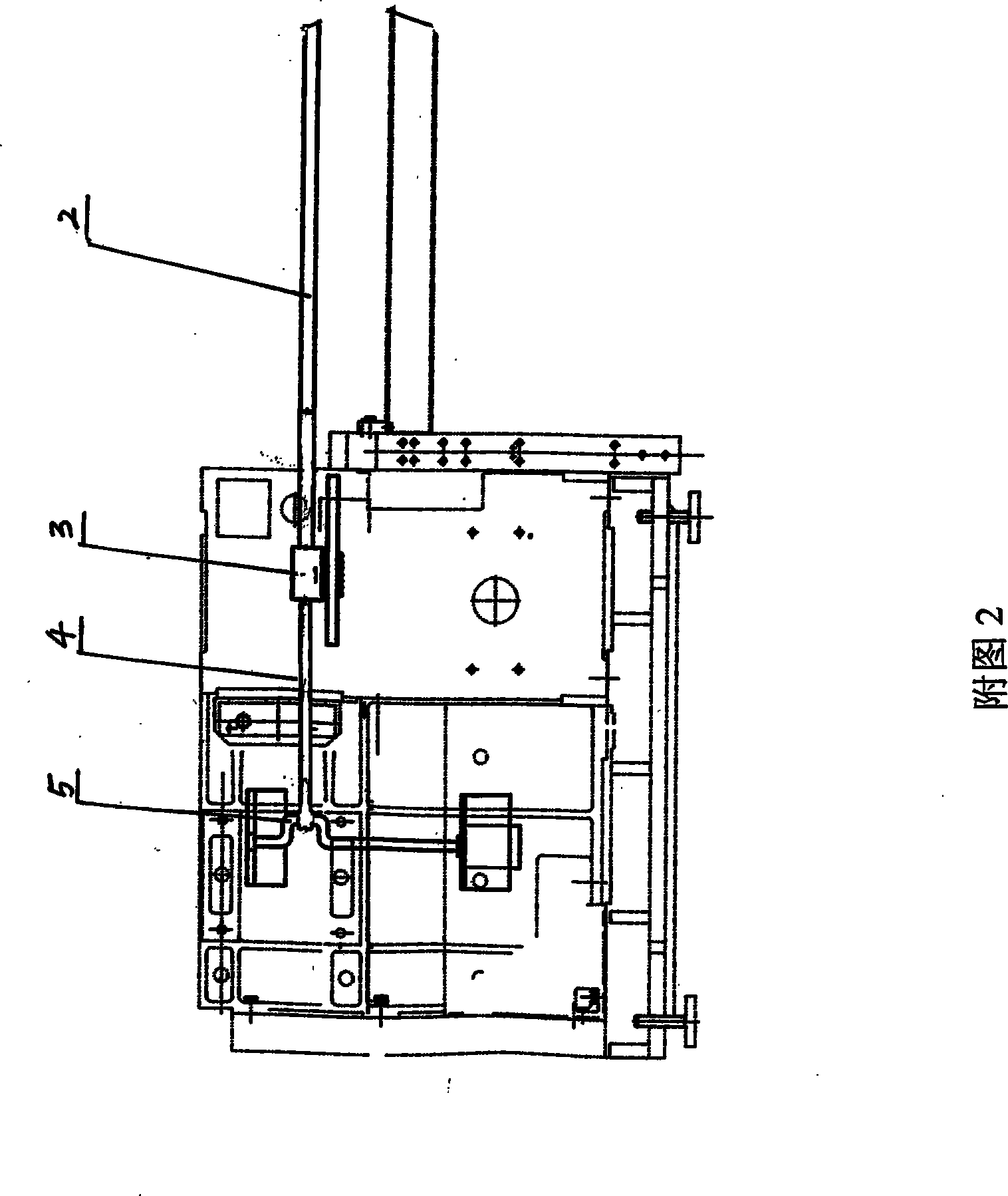

[0010] A hair ball winding and forming device of a roving frame includes a front roller 1, a traverse rod 2, and a slider 3 fixed to the traverse rod 2. The hinge of the slider 3 is at one end of the connecting rod 4, and the crank 5 connecting rod 4 mechanism Connected to the servo motor, the crank connecting rod mechanism drives the slider to move linearly, so that the traverse rod maintains a uniform speed of reciprocating linear motion. The servo motor is driven by the servo controller, which is connected to the frequency converter of the main motor, and the rotary encoder 6 The shaft is concentrically mechanically connected with the front roller 1. The rotary encoder detects the speed change signal of the front big roller and feeds it back to the PLC programmable controller. The PLC programmable controller controls the servo drive and the frequency converter, and is controlled by the PLC The controller processes the collected signals, controls the running speed of the servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com