Automobile exhaust waste heat recycling and charging device based on pulse tube generator

A technology for vehicle exhaust and waste heat recovery, applied in electric vehicle charging technology, electric vehicles, exhaust devices, etc., can solve the problems of vehicle exhaust emission, difficult assembly, huge size, etc., to improve system reliability and process manufacturing. Feasibility, low machining difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

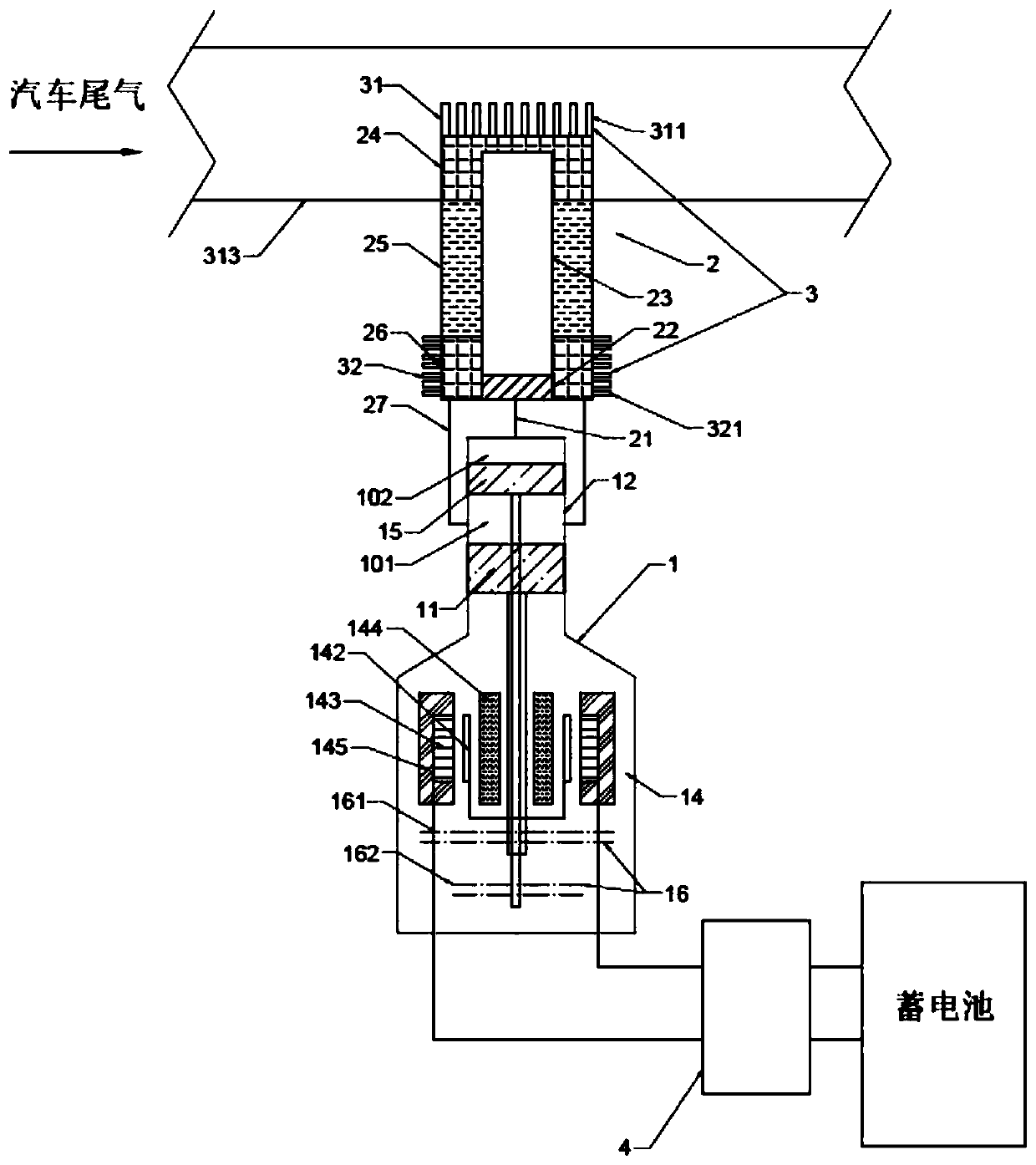

[0026] A charging device for recovering waste heat from automobile exhaust based on a pulse tube generator, such as figure 1 As shown, it includes a single expander 1 with work recovery capability, a heat head 2 of a pulse tube generator, a heat exchange system 3 and a rectification system 4 .

[0027] The expander expansion cavity 101 is formed between the expansion piston 11 and the work recovery piston 15 in the expander cylinder 12, and the expander work recovery cavity 102 is formed by the back cavity formed by the cylinder 12 and the work recovery piston 15;

[0028] The thermal head 2 of the pulse tube generator consists of a connecting pipe 21 at the room temperature end of the pulse tube, a gas homogenizer 22 at the room temperature end of the pulse tube, a pulse tube 23, a heat exchanger 24 at the high temperature end of the thermal head, a regenerator 25, and a heat exchanger at the room temperature end of the thermal head 26 and the connecting pipe 27 at the room t...

Embodiment 2

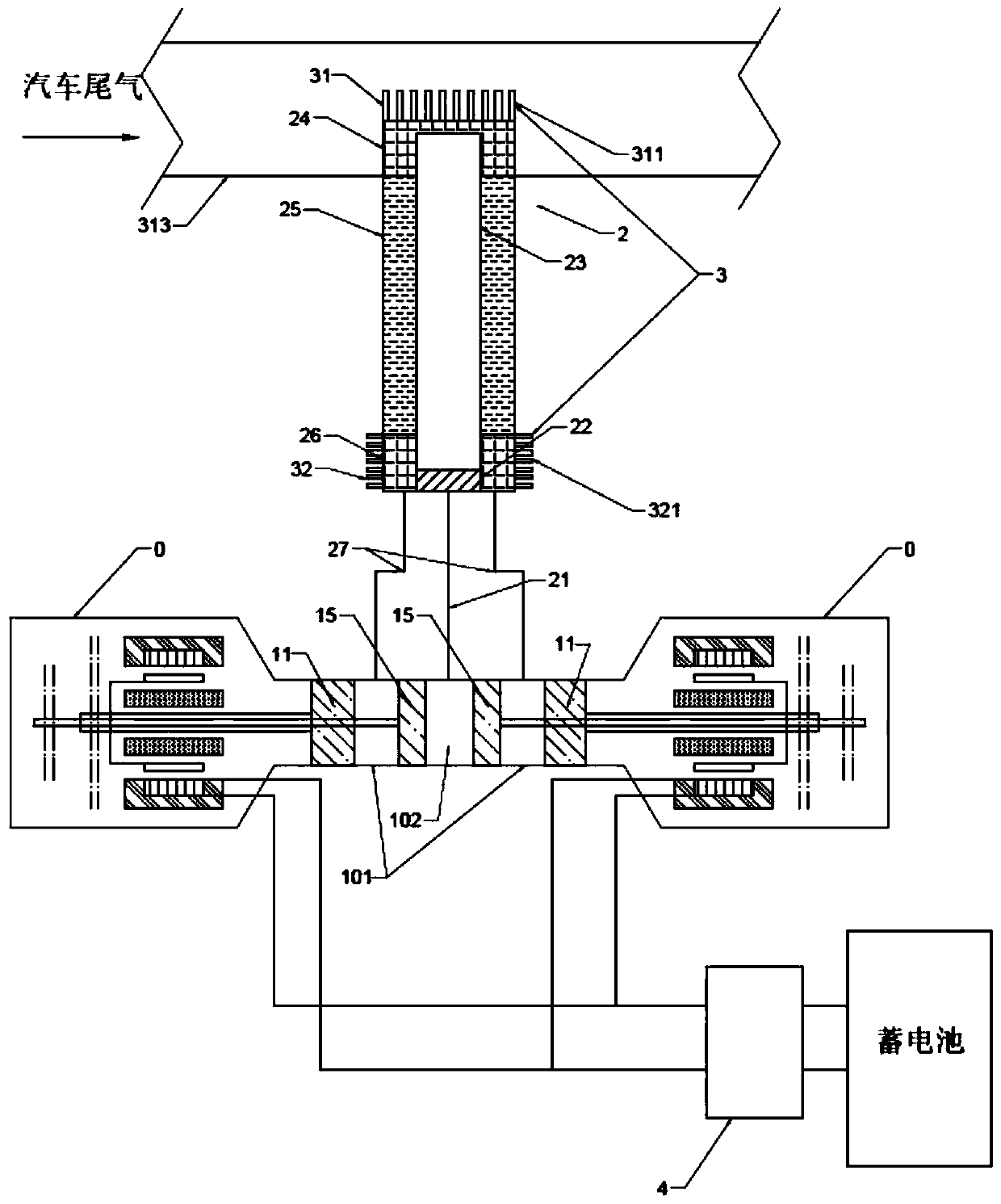

[0039] A car exhaust waste heat recovery charging device based on a pulse tube generator, the difference from Embodiment 1 is that the expansion machine 1 with work recovery capability is changed from one to two, and it is a double-headed symmetrical expansion machine 0, such as figure 2 As shown, two linear motors 14, two expansion pistons 11 and two work recovery pistons 15 are symmetrically arranged, and the two expanders face each other and share one expander cylinder 12. Two expander expansion chambers 101 are formed, and the work back chambers of the two work recovery pistons are connected to form an expander work recovery chamber 102 . The connecting pipe 27 at the room temperature end of the regenerator connects the expansion chambers 101 of the two expanders with the room temperature end of the regenerator, and the connecting pipe 21 at the room temperature end of the vessel connects the work recovery chamber 102 of the expander with the room temperature end of the ve...

Embodiment 3

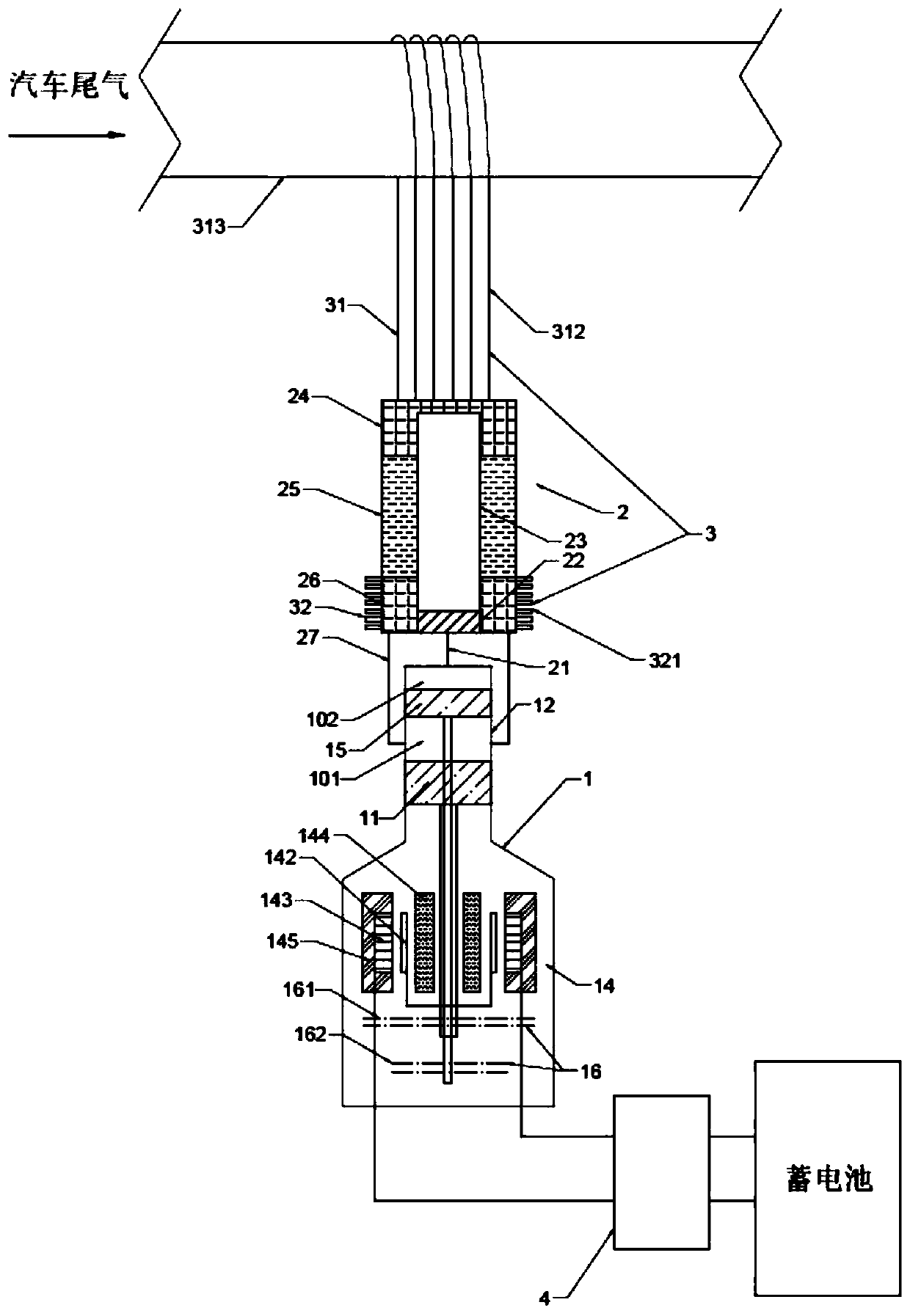

[0041] A charging device for recovering waste heat from automobile exhaust based on a pulse tube generator, such as image 3 As shown, the difference from Embodiment 1 is that the high-temperature end heat exchange system 31 uses one or more high-temperature heat pipes 312, and the evaporation section of the high-temperature heat pipes 312 is wound around the automobile exhaust main pipe 313, and is in thermal contact with the pipe wall. The condensing section of the heat pipe 312 is riveted with the high temperature heat exchanger 24 of the heat head, and the heat conduction between the high temperature heat exchanger 24 of the heat head and the exhaust gas of the automobile is completed through the phase conversion heat in the high temperature heat pipe 312 . The linear motor 14 adopted in this embodiment is a moving magnet type, including a magnet 142, a coil 143, an inner iron core 144, and an outer iron core 145; the magnet 142 and the expansion piston 11 move together, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com