Aluminum diamond composite material coated with aluminum silicon carbide layer on surface and preparation method and application thereof

A technology of silicon carbide layer and composite materials, which is applied in the preparation of aluminum-diamond composite materials and the field of aluminum-diamond composite materials, which can solve the problems of easy exposure of diamond particles and limit the use range of aluminum-diamond products, so as to reduce consumption and energy consumption, Reduce the difficulty of machining and reduce the effect of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

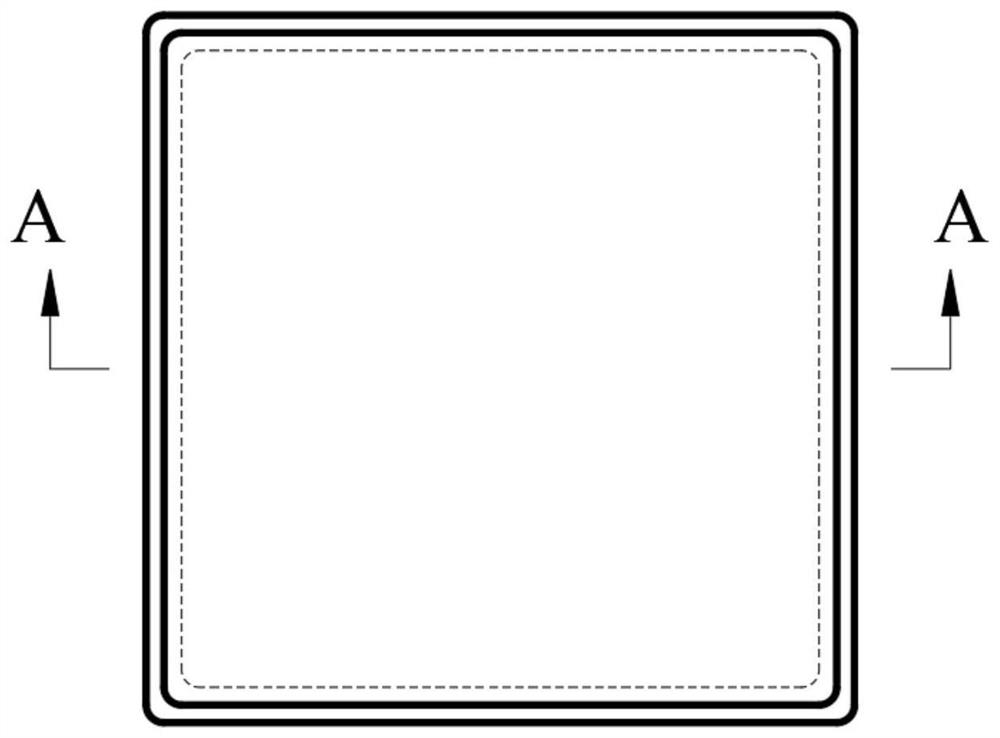

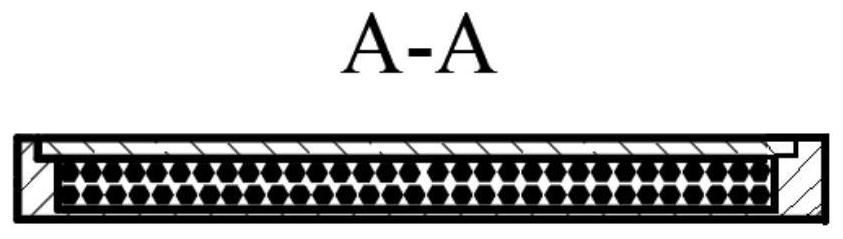

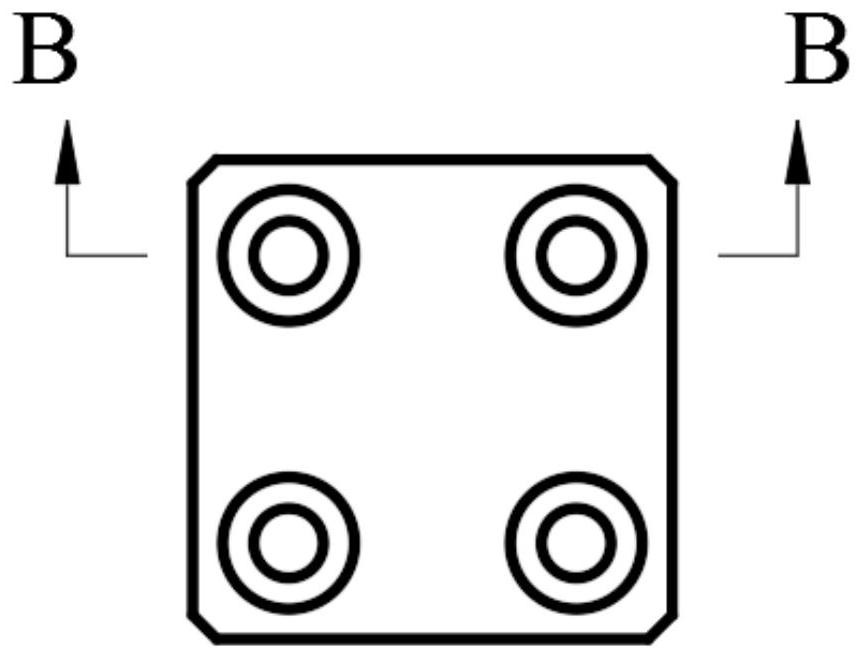

[0041] figure 1 It is a schematic structural view of the aluminum-diamond composite material with an aluminum-silicon carbide layer on the surface prepared in preferred embodiment 1 of the present invention; figure 2 It is the A-A sectional view of the preferred embodiment 1 of the present invention; image 3 It is a front view of the structure of the aluminum-diamond component of the surface aluminum-silicon carbide layer prepared in preferred embodiment 2 of the present invention; Figure 4 It is the B-B sectional view of the preferred embodiment 2 of the present invention; Figure 5 It is a front view of the structure of the aluminum diamond part of the surface aluminum silicon carbide layer prepared in the preferred embodiment 3 of the present invention; Figure 6 It is a structural view of preferred embodiment 3 of the present invention; Figure 7 It is a front view of the structure of the aluminum-diamond component of the surface aluminum-silicon carbide layer prepar...

Embodiment 1

[0064] Aluminum-diamond composite material coated with aluminum-silicon carbide layer on the surface, including: aluminum-diamond core material and surface aluminum-silicon carbide layer coated on the outside of the aluminum-diamond core material; the aluminum-diamond core material includes pure aluminum and surface-modified diamond particles; the surface The aluminum silicon carbide layer is pure aluminum and silicon carbide particles, and the volume fraction of silicon carbide particles is 65%.

[0065] Such as figure 1 and figure 2 Shown, the preparation method of the aluminum-diamond composite material of surface coating aluminum-silicon carbide layer, comprises the following steps:

[0066] Preparation of silicon carbide preforms: The mixed granulated silicon carbide powder with a particle size of 45 μm and a particle size of 100 μm is molded at 150 MPa into a frame of 40 mm × 40 mm × 2 mm to prepare a silicon carbide preform blank, which is kept at a constant temperatu...

Embodiment 2

[0071] Aluminum diamond parts with aluminum silicon carbide layer on the surface, including: aluminum diamond core material and surface aluminum silicon carbide layer coated on the aluminum diamond core material; aluminum diamond core material includes 6063 aluminum alloy and surface modified diamond particles; surface The aluminum silicon carbide layer includes 6063 aluminum alloy and silicon carbide particles, and the volume fraction of silicon carbide particles is 70%.

[0072] Such as image 3 and Figure 4 Shown, the preparation method of the aluminum diamond component of surface aluminum silicon carbide layer, comprises the following steps:

[0073] Preparation of silicon carbide preform: gel injection molding of silicon carbide particles with a particle size of 45 μm into a frame of 23mm×23mm×6mm to prepare a silicon carbide preform blank, sintering at a constant temperature of 1000°C for 1 hour under vacuum conditions to obtain a porosity of 40% SiC preforms;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com