Graphene-containing silicone rubber composite material with high thermal conductivity and preparation method thereof

A composite material and graphene technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of cumbersome graphite treatment process, etc., and achieve the effect of easy industrial scale production, industrial scale production, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The high thermal conductivity silicone rubber composite material provided by the present invention and its preparation method comprise the following steps:

[0031] (1) Knead the matrix, thermally conductive filler and vulcanizing agent at room temperature (20°C-30°C) to obtain the compounded rubber;

[0032] (2) Place the obtained mixed rubber in a vacuum drying oven, and at a certain temperature, use a vacuum method to remove internal air bubbles.

[0033] (3) The mixed rubber obtained in step (2) is hot-pressed and vulcanized by a flat vulcanizer, and then subjected to two-stage vulcanization in a vacuum drying oven to obtain a high thermal conductivity silicone rubber composite material.

[0034] Wherein, the matrix is silicone rubber raw rubber, and the silicone rubber raw rubber is polysiloxane containing vinyl with a molecular weight of 200,000 to 1,000,000 (such as: methyl vinyl silicone rubber, methyl silicone rubber, methyl vinyl benzene base silicone rubbe...

Embodiment 1

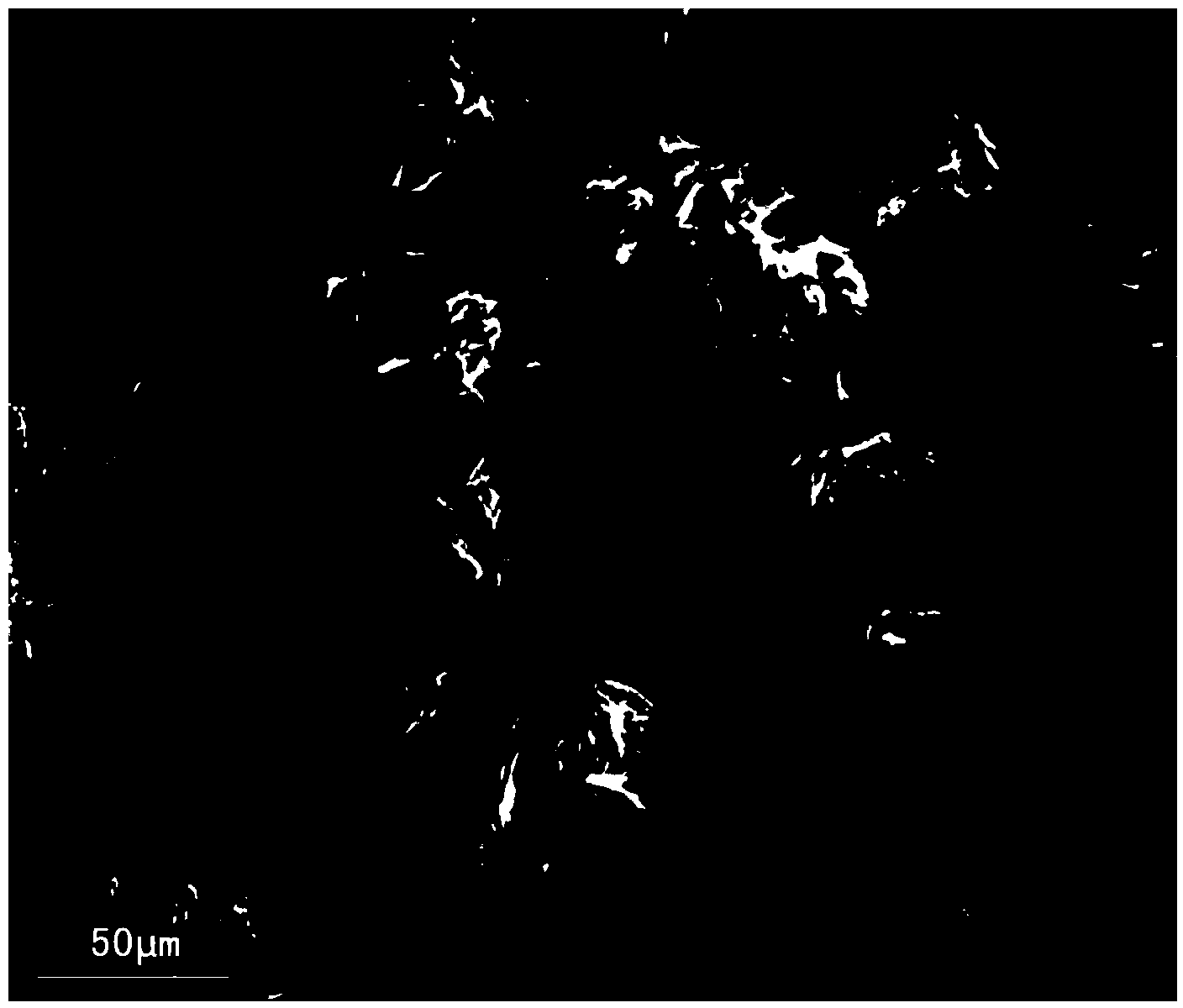

[0037] (1) Weigh 100g of methyl vinyl silicone rubber, put it into a two-roll mill, the processing temperature is 24°C, and then add 25g of graphene ( figure 1 ), and 0.7g of vulcanizing agent (2,5-dimethyl-2,5-di-tert-butylperoxyhexane DHBP), after mixing evenly, thin pass 5 times, and the next tablet.

[0038] Such as figure 1 Shown, the morphology characteristic and technical parameter of graphene of the present invention are as follows:

[0039] From figure 1 It can be seen from the figure that graphene has a very good sheet structure. Because it has a very large aspect ratio (greater than 1000), its diameter is 0.5-5μm, and its thickness is 1-5nm. It shows a curled shape as shown in the figure macroscopically. , appearing as fluffy clusters.

[0040] (2) Put the mixed rubber in a vacuum drying oven at a temperature of 50°C, and vacuum 5 times to remove internal air bubbles.

[0041] (3) Put the mixed rubber with air bubbles removed in a suitable mold, cover the steel ...

Embodiment 2

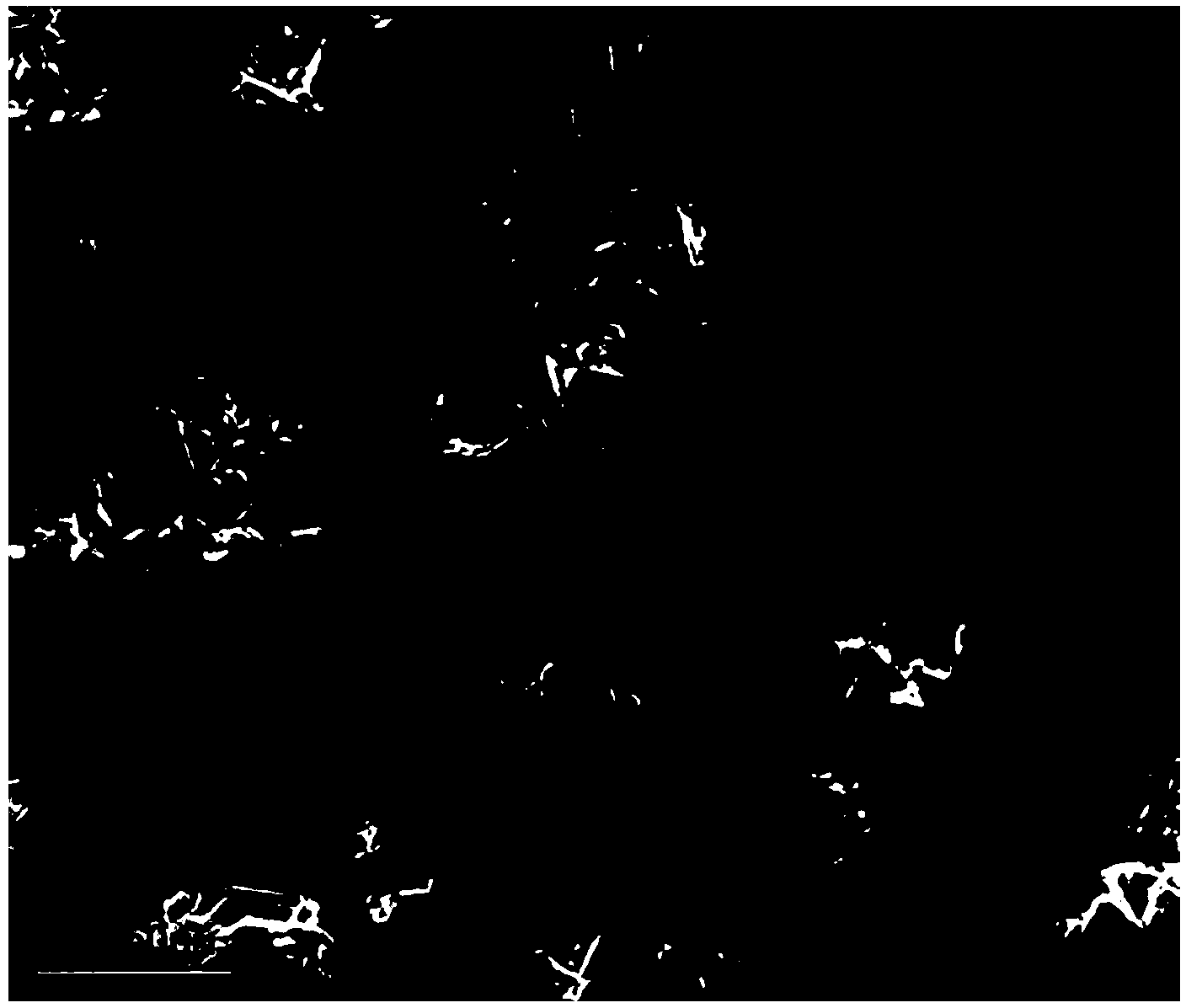

[0043] (1) Weigh 100g of methyl vinyl silicone rubber, put it into a two-roll mill, the processing temperature is 24°C, and then add 25g of graphene ( figure 1 ) and 44g of alumina ( figure 2 ), and 0.7g of vulcanizing agent (2,5-dimethyl-2,5-di-tert-butylperoxyhexane), after mixing evenly, thin pass 8 times, and the next tablet.

[0044] Such as figure 2 Shown, the morphology characteristics and technical parameter of aluminum oxide of the present invention are as follows: from figure 2 Visible in Al2 o 3 It is a dense spherical particle with a particle size ranging from 20 to 100 μm.

[0045] (2) Put the mixed rubber in a vacuum drying oven at a temperature of 50°C, and vacuum 5 times to remove internal air bubbles.

[0046] (3) Put the mixed rubber with air bubbles removed in a suitable mold, cover the steel plate up and down, place it in a flat vulcanizer for high-temperature vulcanization, cross-linking and hot-press molding. The conditions are 170°C, 10MPa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com