Patents

Literature

80results about How to "Reduce the difficulty of machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

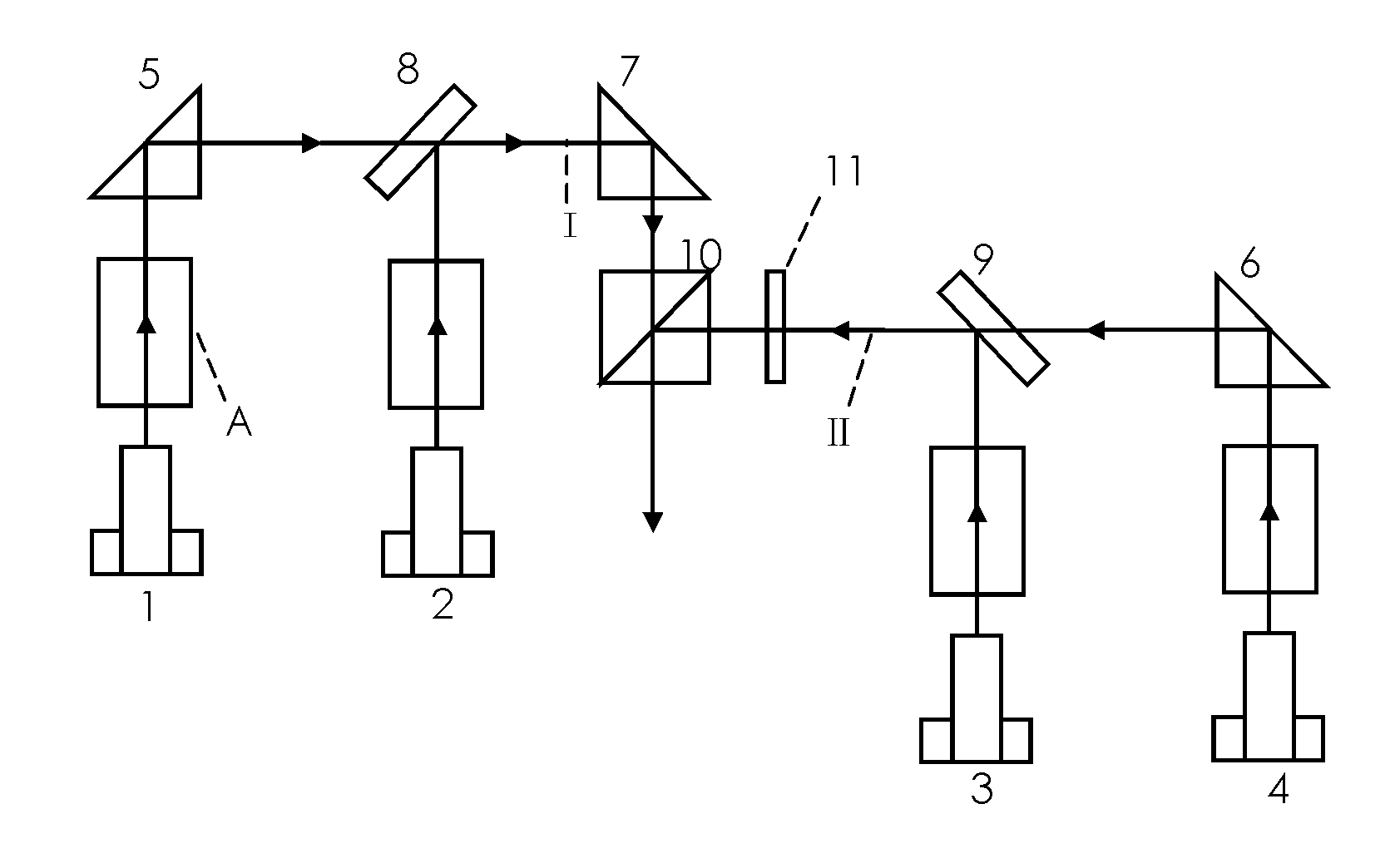

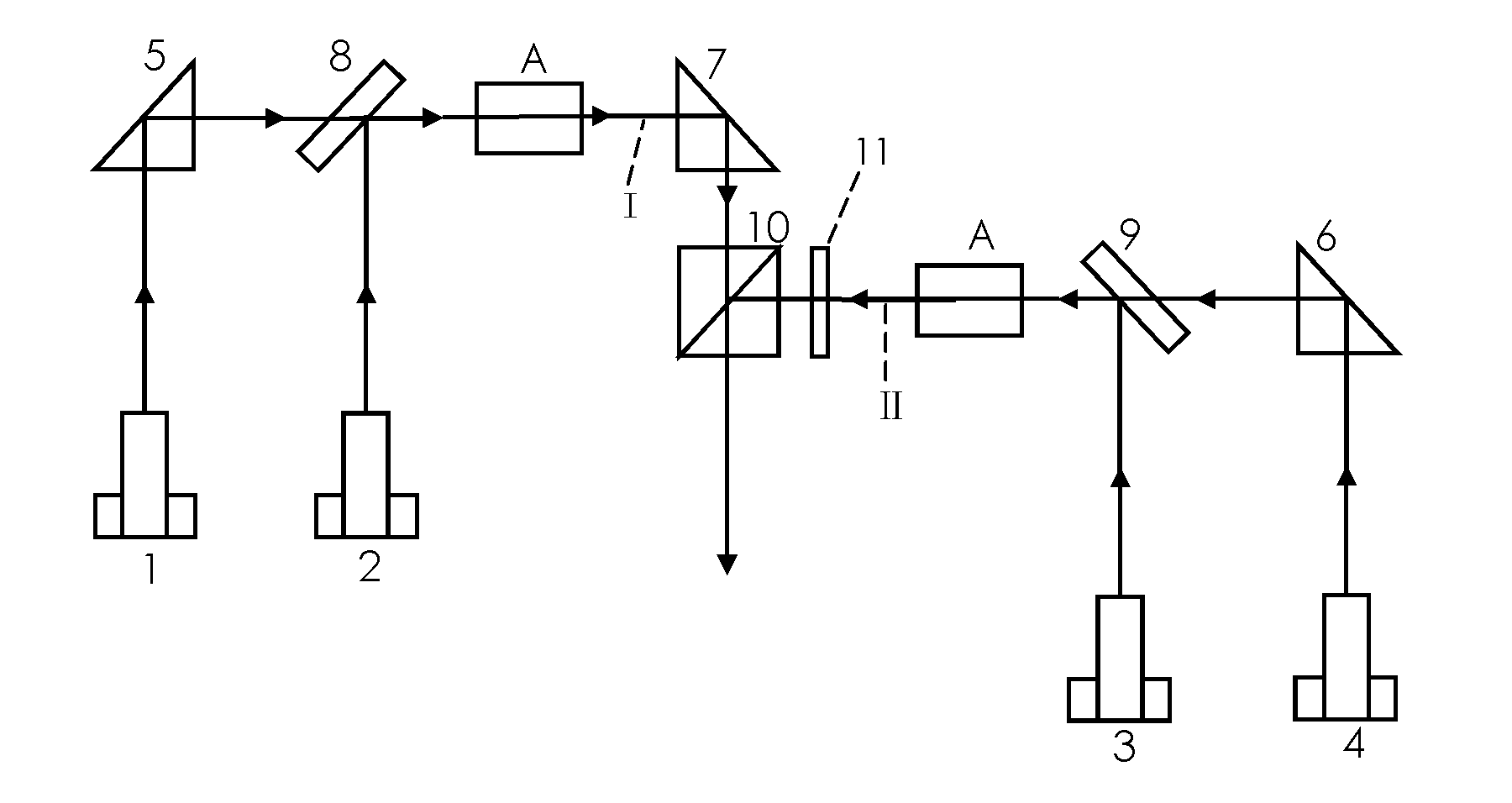

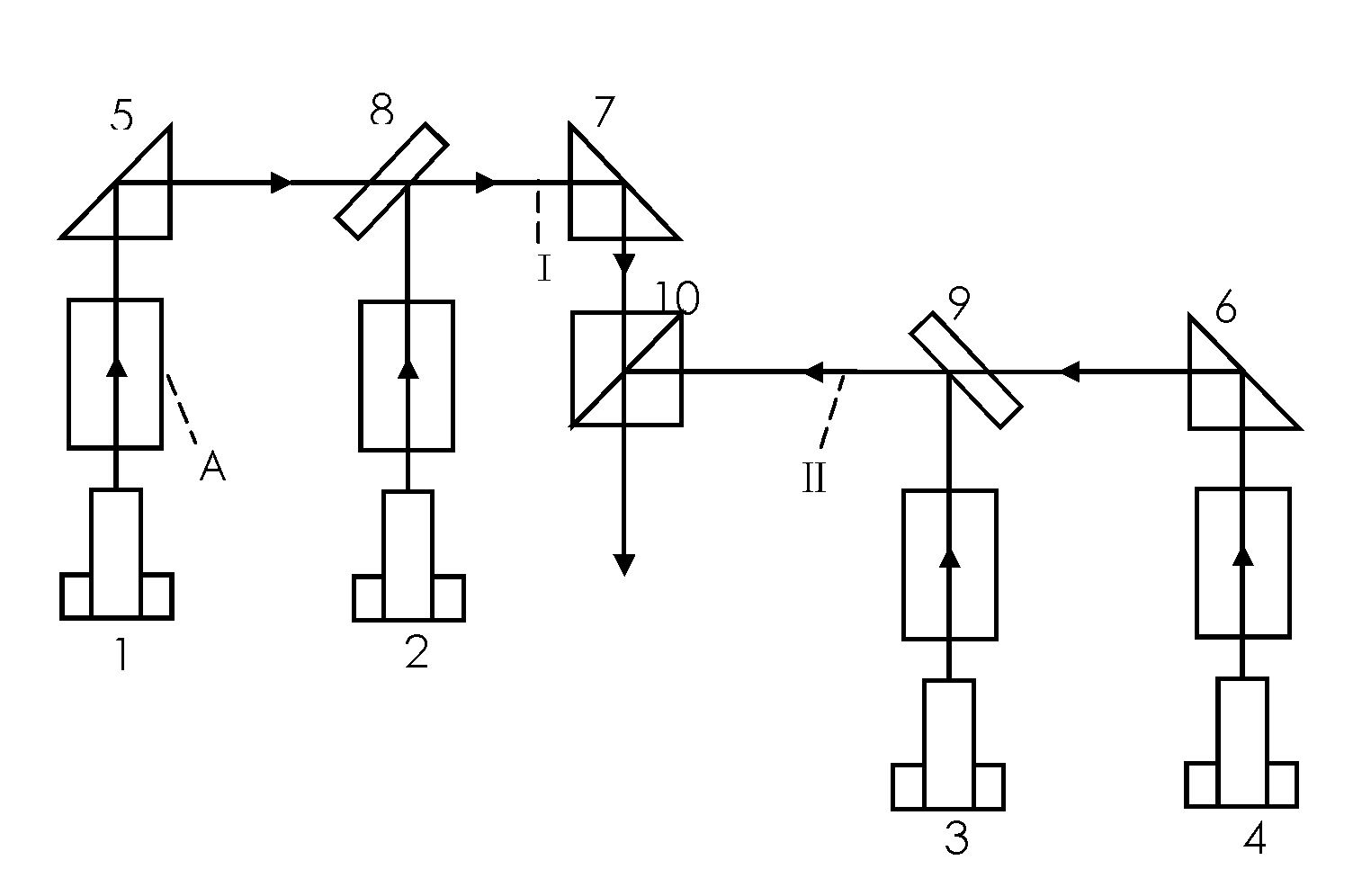

Laser beam coupling output device for high-power semiconductor

InactiveCN102012567AReasonable structureReduce the difficulty of machiningPolarising elementsSemiconductor laser theoryPower semiconductor device

The invention relates to a multi-beam coupling output device for a high-power semiconductor laser system, belonging to the technical field of laser. With respect to the device, light with two wavelengths, which is respectively emitted by a first semiconductor laser array and a second semiconductor laser array, is subject to wavelength coupling by using a wavelength coupler, thus obtaining a beam with two wavelengths; light with two wavelengths, which is respectively emitted by a third semiconductor laser array and a fourth semiconductor laser array, is subject to wavelength coupling by using the wavelength coupler, thus obtaining a beam comprising two wavelengths; and the two beams respectively with two wavelengths are combined by a polarization coupler to finally obtain a combined beam, and the combined beam is output. The coupling output device has more reasonable structure, smaller volume, good controllability and lower cost, and is easy to process.

Owner:BEIJING UNIV OF TECH

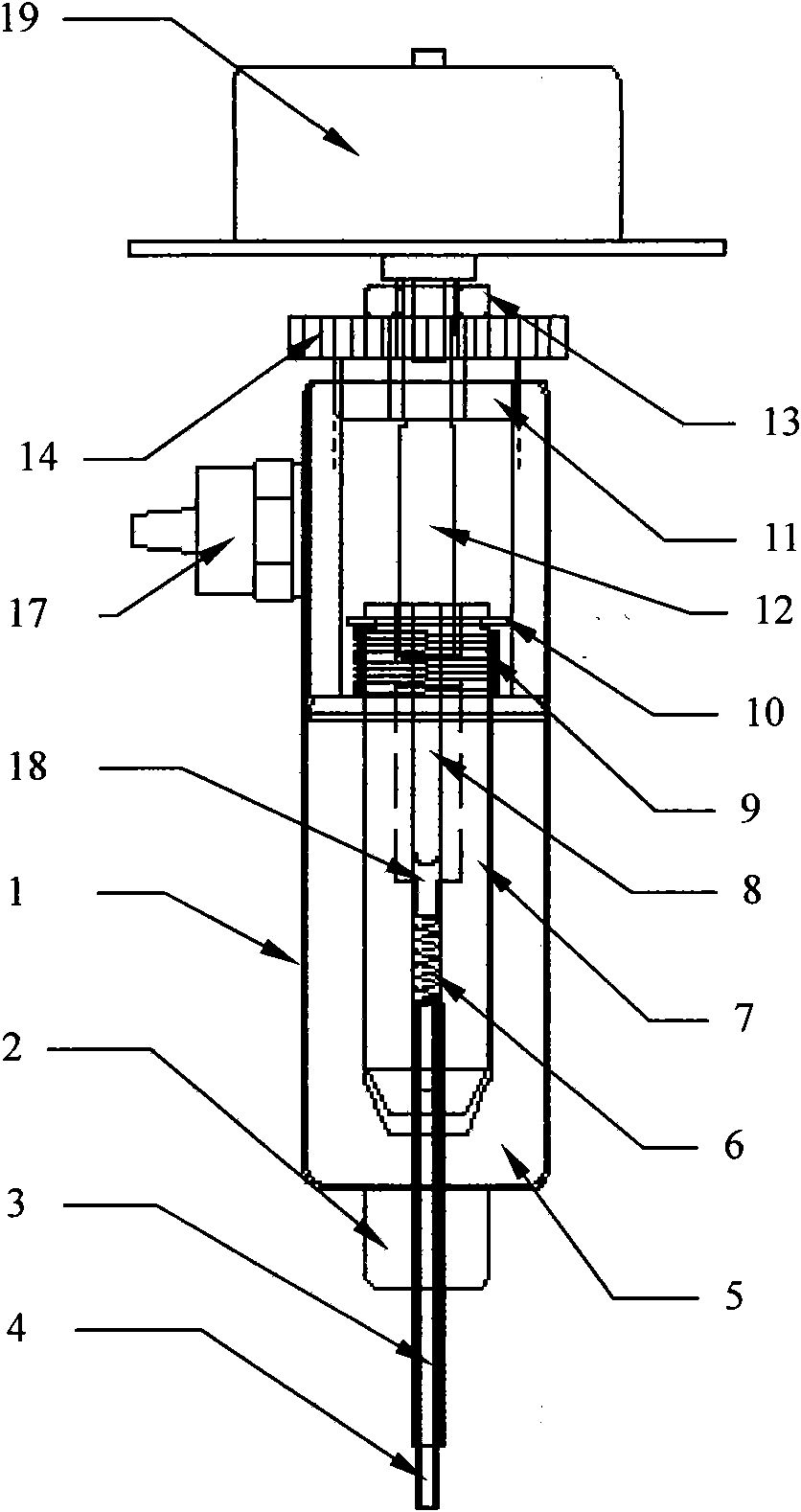

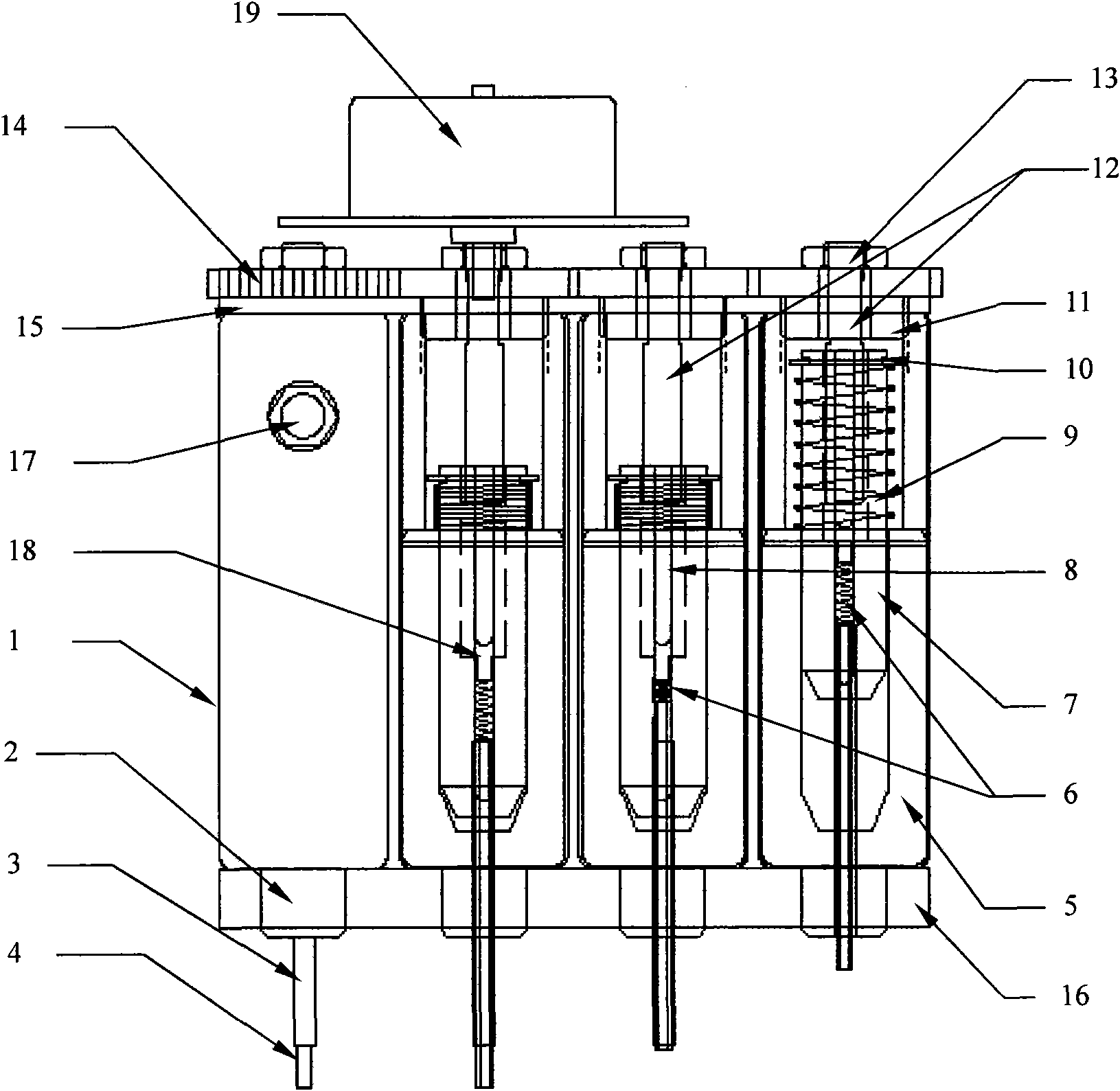

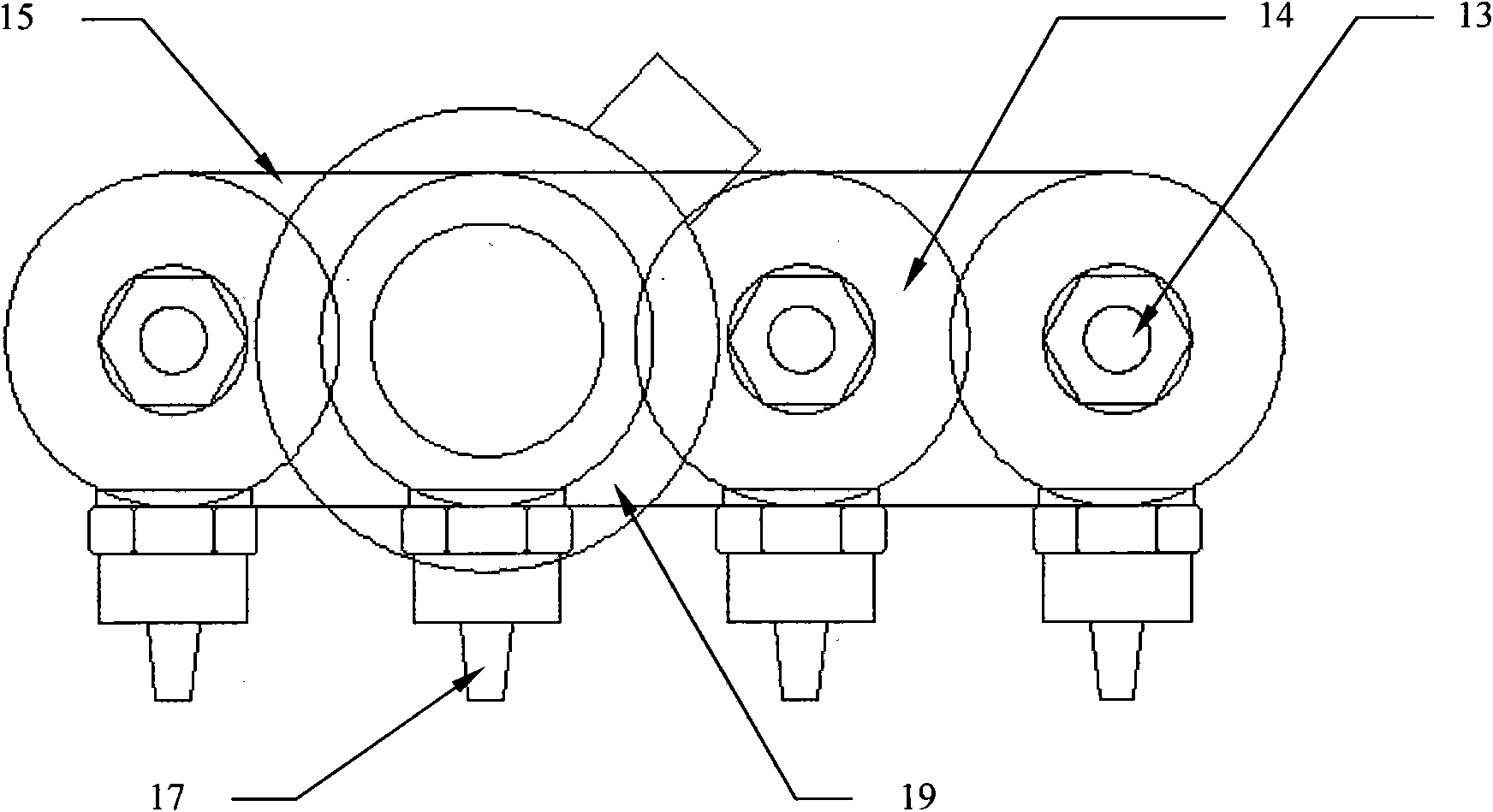

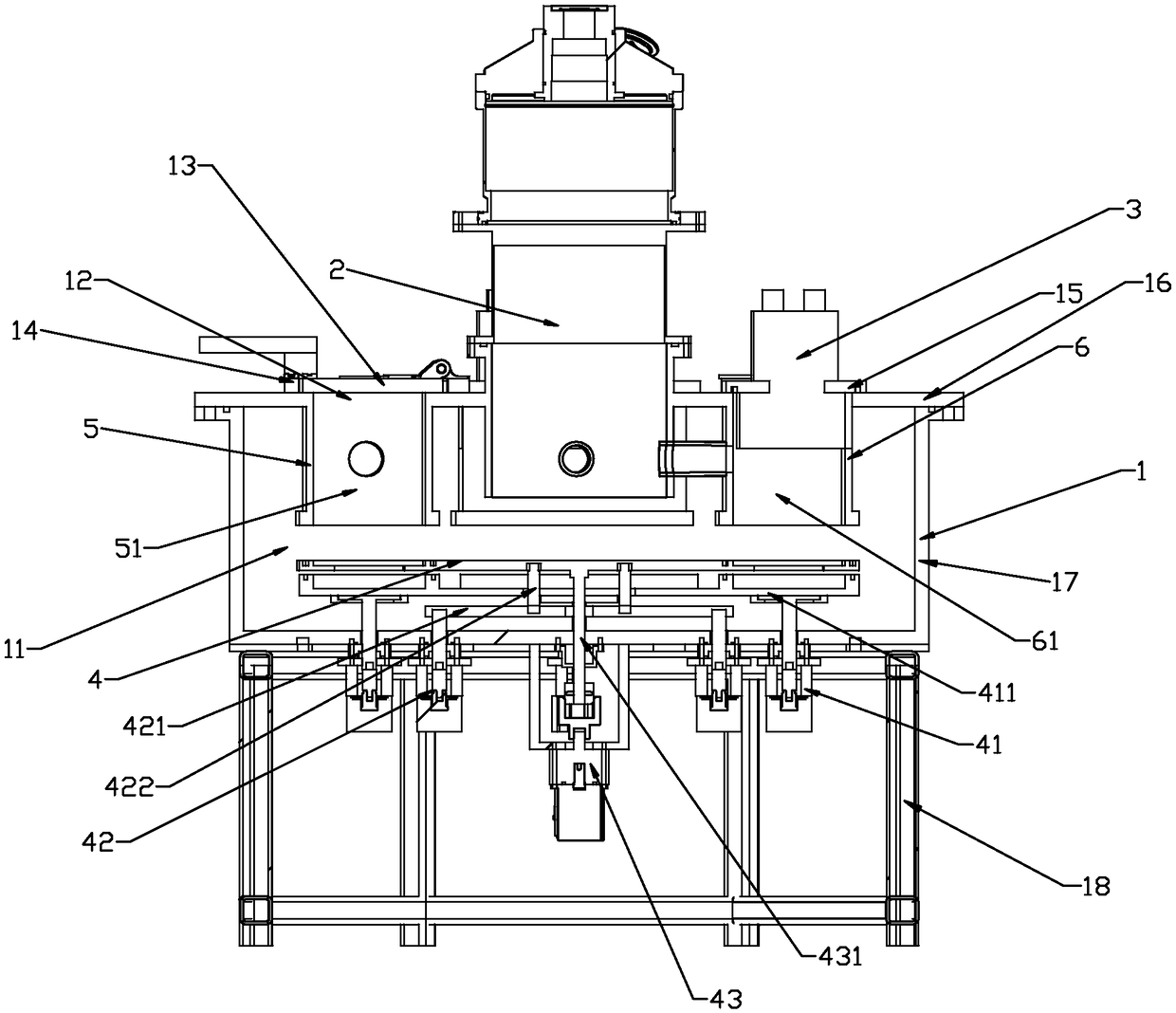

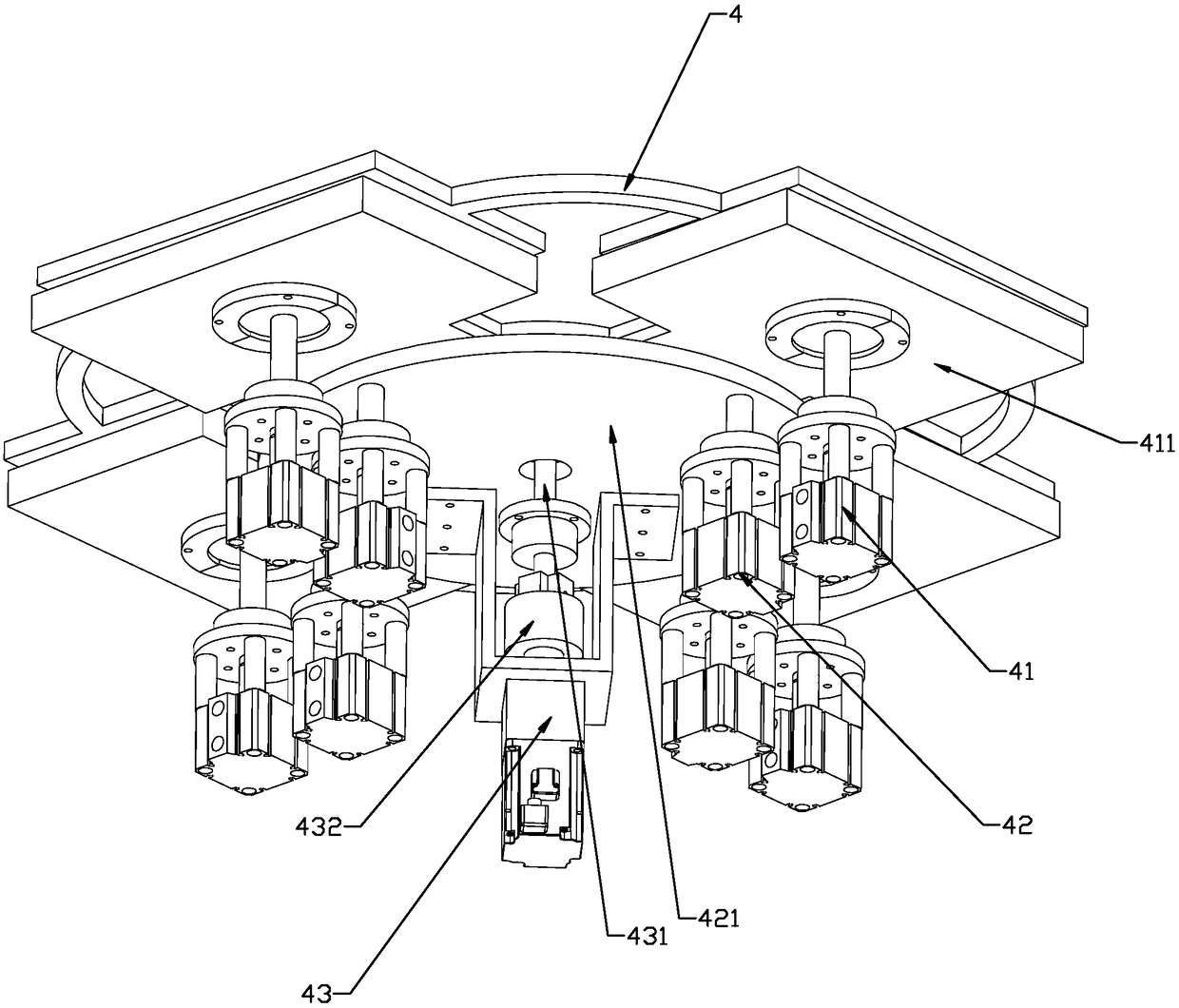

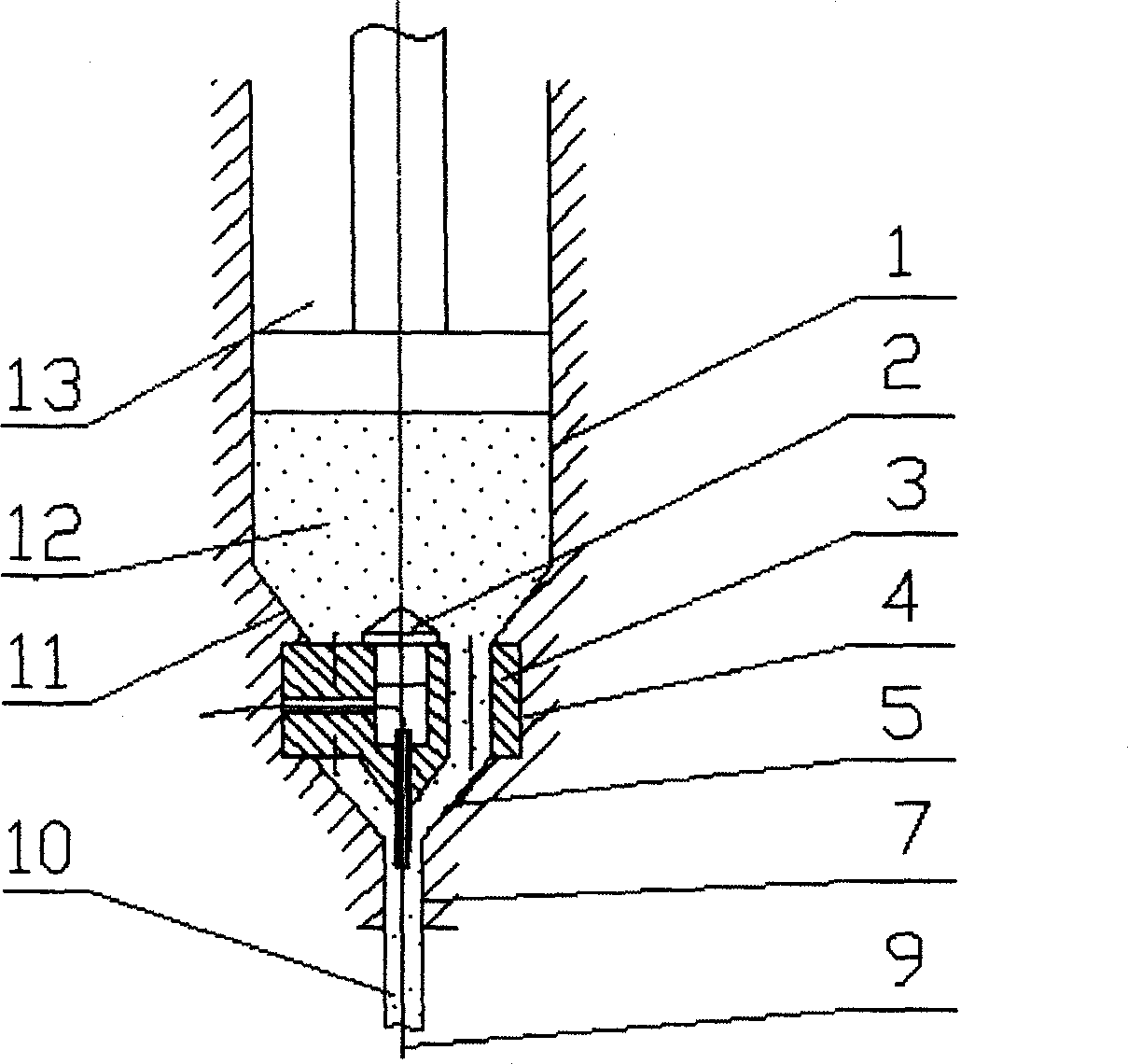

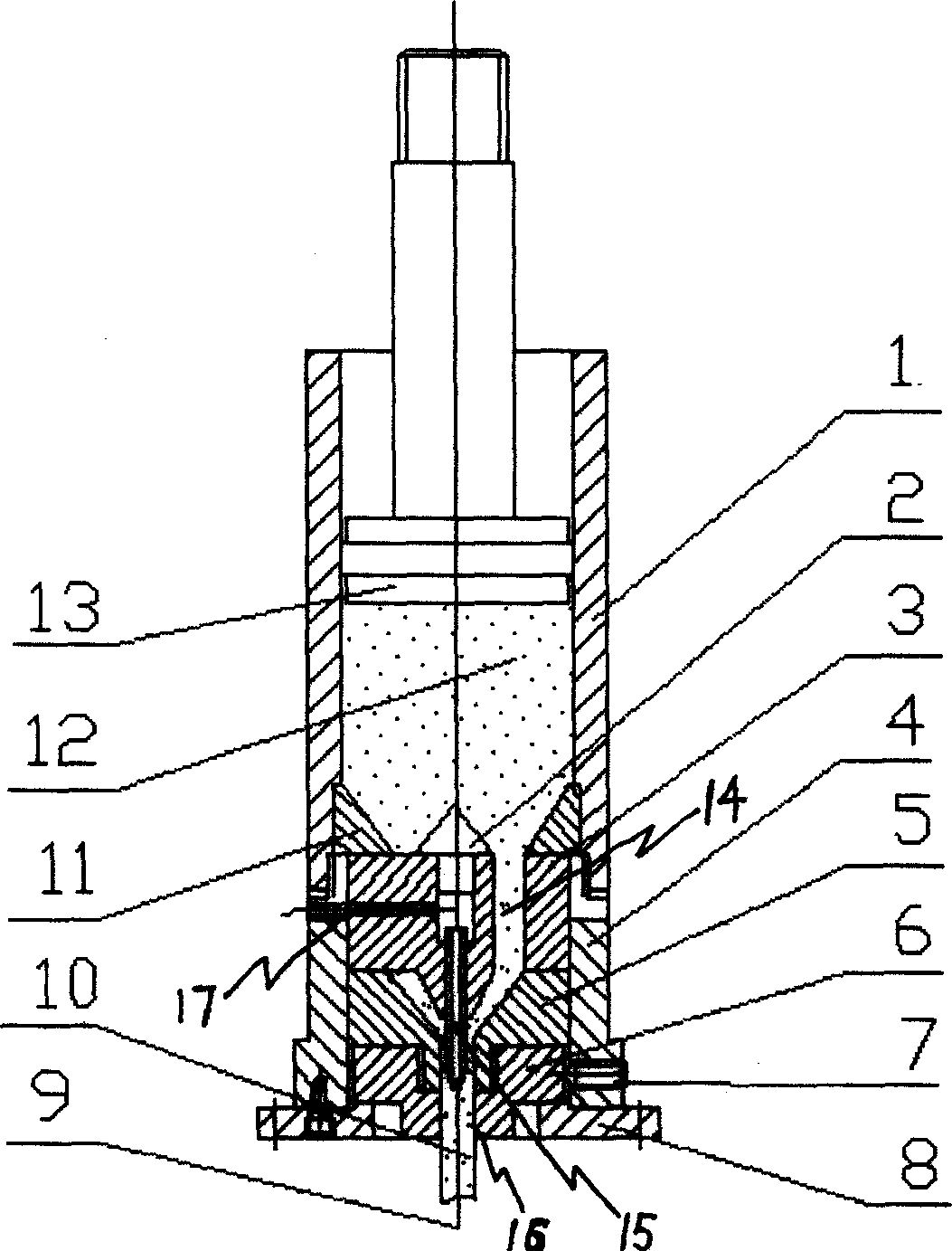

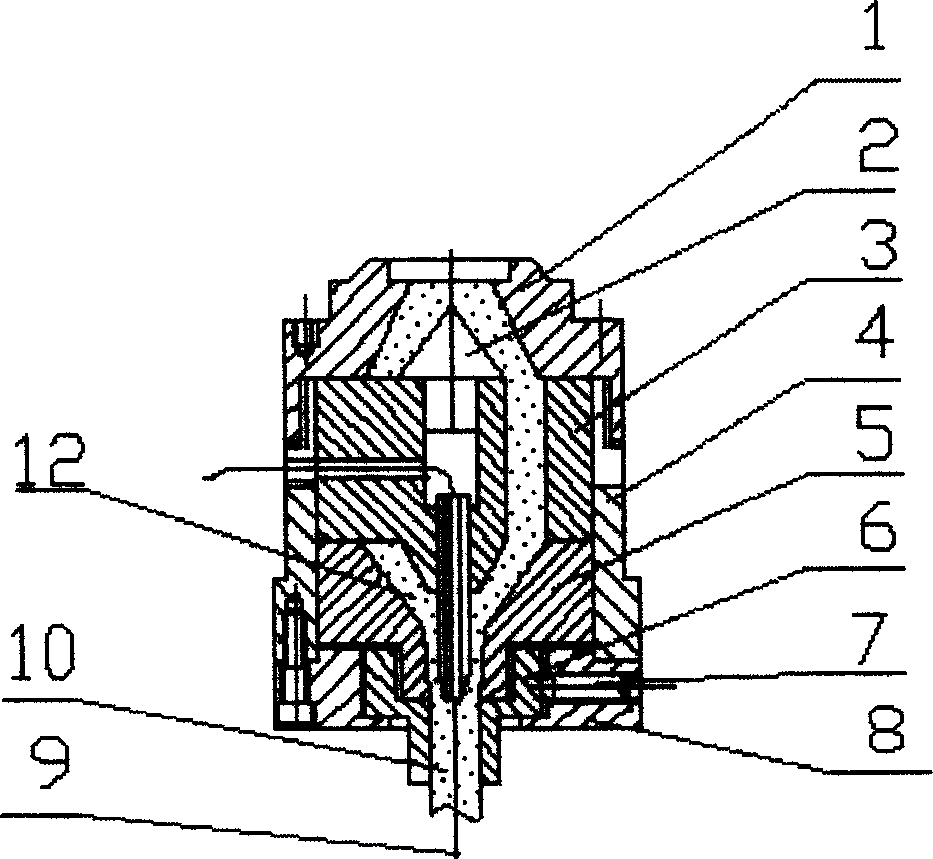

Miniature array electromagnet mounting assembly

InactiveCN101674721AReasonable structure layoutReduce volumePrinted circuit assemblingElectrical componentsEngineeringElectromagnet

The invention relates to the technical field of chip mounters, in particular to a mounting structure of the chip mounter, and discloses a miniature array electromagnet mounting assembly which is assembled by a plurality of mounting heads capable of independently working in rows and arrays. A suction nozzle is moved up and down by the mounting head adopting an electromagnet; the direction positioning of all the suction nozzles of the mounting heads is controlled by a stepper motor; a shell, the lifting of the suction nozzle and a rotation mechanism are kept in a same axial lead; and the suctionnozzle is provided with a retractable damping device, thus effectively releasing the impact on a component, and simultaneously compensating the component mounting with unequal thickness. The mountingassembly is neatly integrated, has reasonable structure, simple and direct transmission link, small volume, light weight and effective response speed and facilitates flexible integration.

Owner:李建

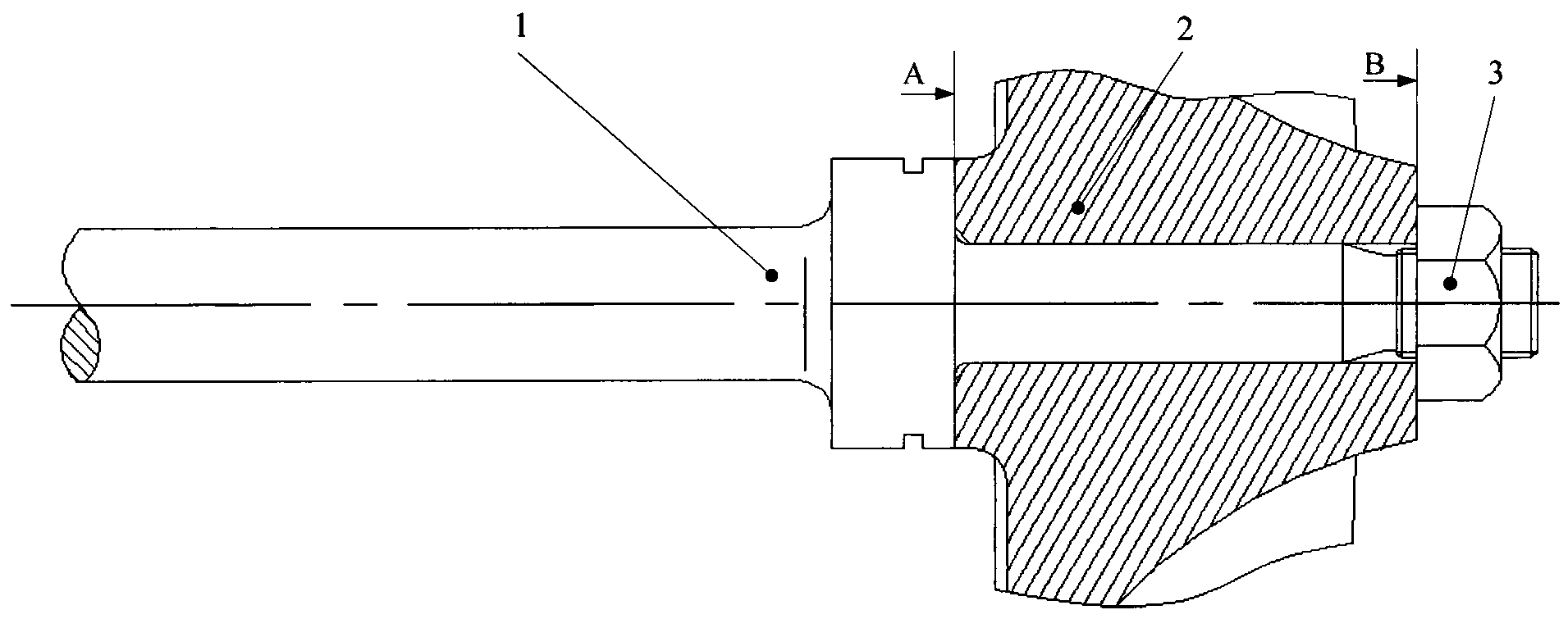

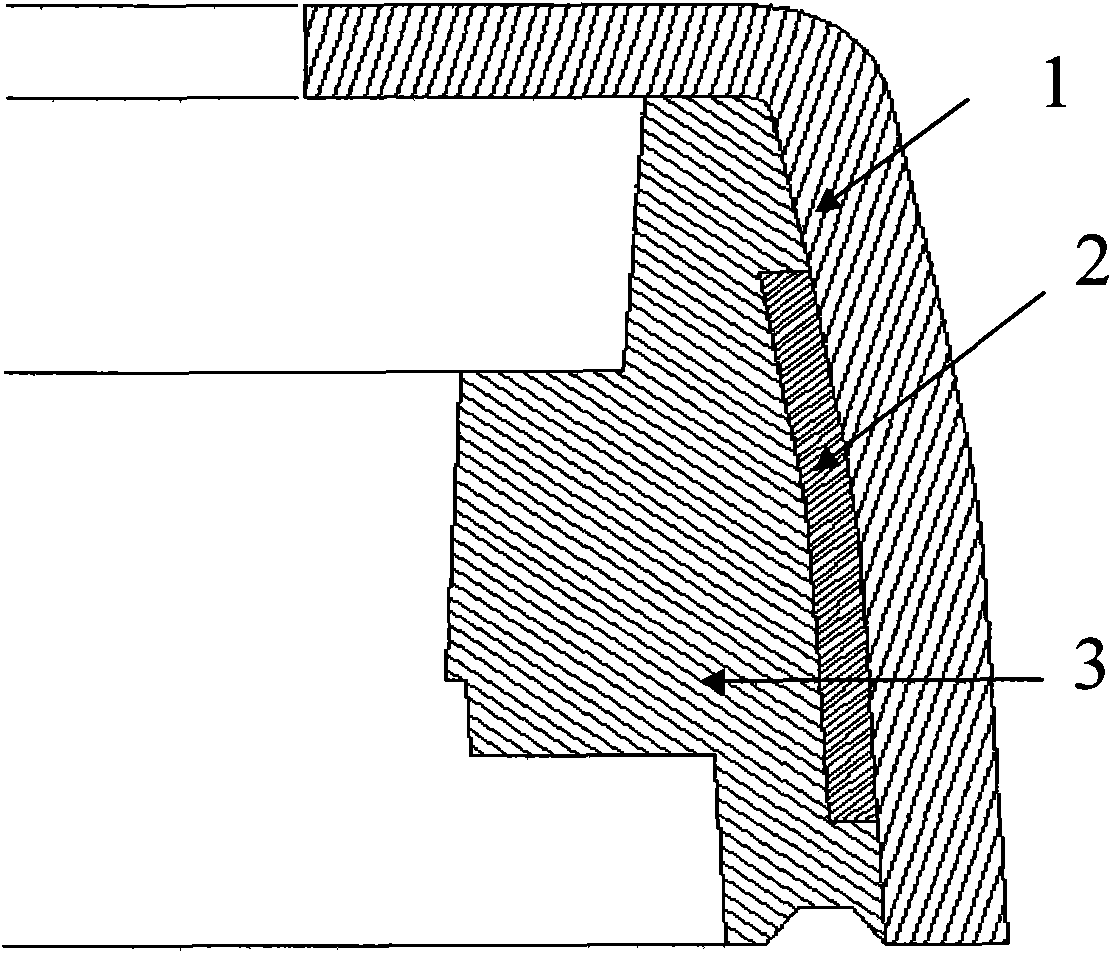

Through-hole connection method and connection structure of titanium aluminum turbine impeller and rotating shaft

ActiveCN103321685AMeet the needs of engineering applicationsGuaranteed connection strengthBlade accessoriesMachines/enginesInterference fitImpeller

The invention relates to a through-hole connection structure and connection method of a titanium aluminum supercharger turbine impeller and a rotating shaft. The connection structure comprises the rotating shaft, the titanium aluminum turbine impeller and a shaft end locking nut. A through hole is formed in the center of the titanium aluminum turbine impeller. A thread is arranged at the end portion of the rotating shaft. Seen from the end of a turbine, the rotating direction of the thread is the same as the rotating direction of the turbine rotating shaft during working. The lower portion of the thread is the rotating shaft connection portion. The rotating shaft connection portion penetrates through the through hole of the turbine impeller. The rotating shaft connection portion and the turbine impeller through hole are in transition fit or interference fit. The shaft end locking nut is installed on the thread of the end portion of the rotating shaft. As for the connection problem of the titanium aluminum turbine impeller and the rotating shaft, the through-hole connection and threaded locking structure are adopted, the durable and reliable connection between the titanium aluminum turbine impeller and the 42CrMo rotating shaft can be achieved, the requirements for the connection strength of the supercharger turbine impeller and the rotating shaft are met, and meanwhile the connection structure has the advantages of being simple in structure, easy to machine and the like.

Owner:CHINA NORTH ENGINE INST TIANJIN

Forming method and product thereof

The invention provides a forming method for manufacturing plastic products with metal pieces; the method comprises the following steps: a. an adhesive layer is arranged on the surface of the metal piece. b. plastic raw material and the metal piece are integrated into one body. The invention also provides a product manufactured by the method; by adopting the method, the plastics are formed while the metal piece and the plastics are integrated into one body, so as to lead the plastics and the metal piece to be adhered together by surface contact under a no buckling condition, that is, the plastics are not needed to be embedded in a metal structure, the metal structure is not needed to be embedded in a plastic structure; the structure of the metal piece is simplified, the mechanical processing difficulty in design is reduced, and the product quality is ensured at the same time.

Owner:BYD CO LTD

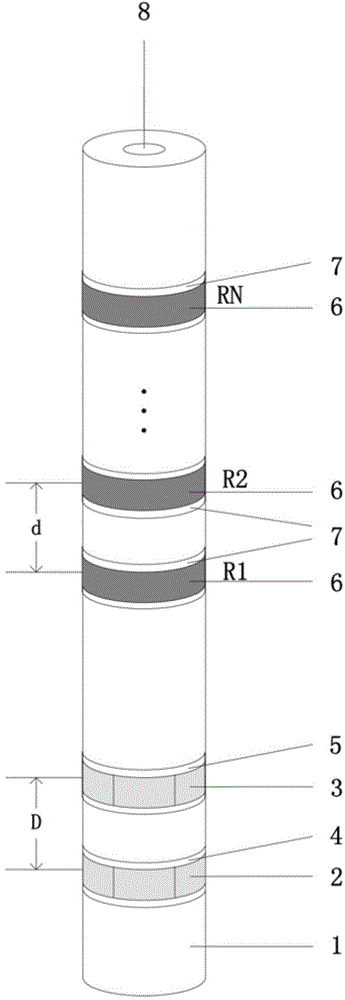

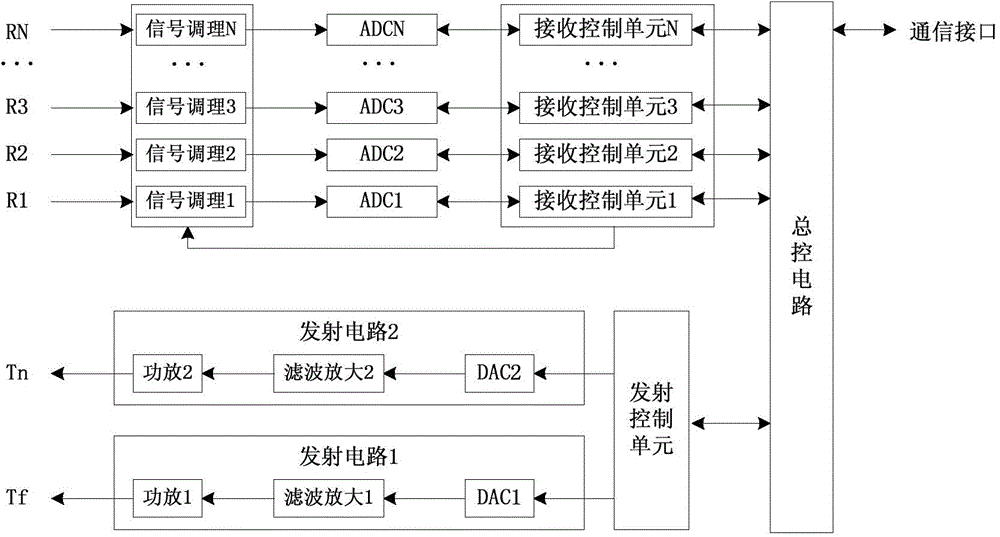

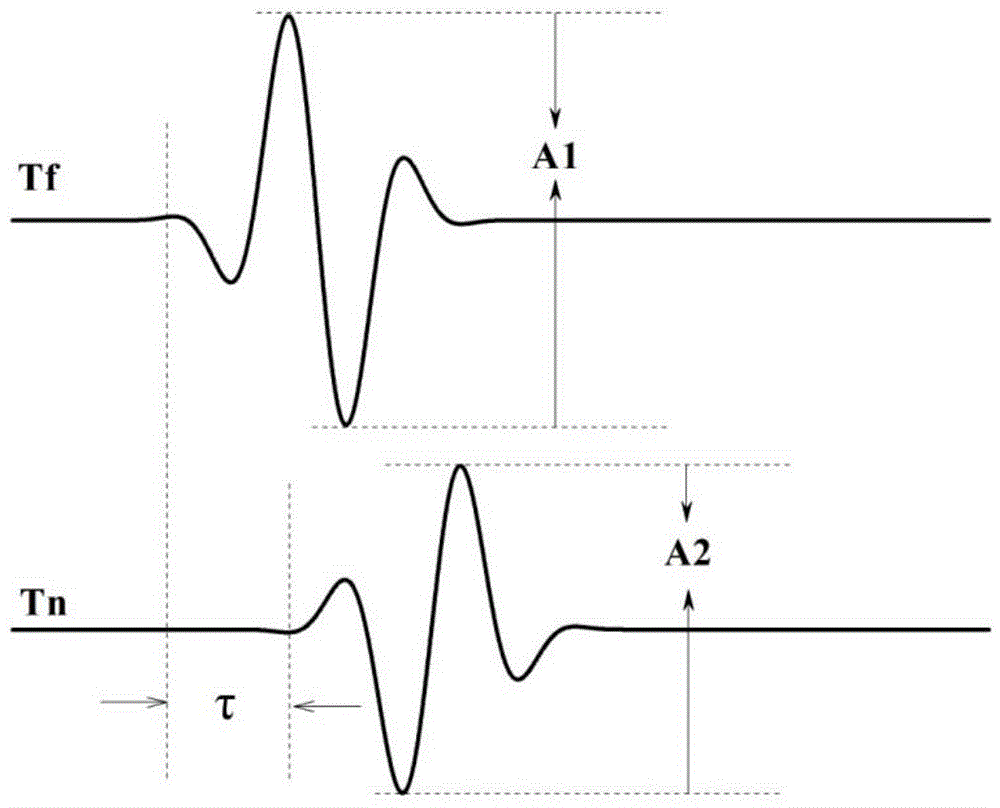

Acoustic logging while drilling method and device based on double-source flyback technology

ActiveCN104453854AAvoid notched designsReduce machining difficulty and manufacturing costSurveySignal onData processing

The invention discloses an acoustic logging while drilling method and device based on the double-source flyback technology. The method includes: a far transmitter and a near transmitter are used, during logging, the far transmitter Tf is stimulated first, the transmitting amplitude of the far transmitter Tf is A1, the near transmitter Tn is stimulated after a time delay tau, the transmitting polarity of Tn is opposite to that of Tf, and the transmitting amplitude of the near transmitter Tn is A2; during sound source stimulation, signals on N receivers are collected and recorded; the drill collar waves stimulated by the far transmitter and the near transmitter reach the positions of the receivers at the same time, the polarities of the drill collar waves of the far transmitter and the near transmitter are different, the amplitude of the drill collar waves of the far transmitter and the near transmitter are the same, the drill collar waves of the far transmitter and the near transmitter are overlaid and balanced off, and drill collar wave compression is achieved; a sound wave interference method is used to compress the influence of the residual drill collar waves in subsequent data processing, the speed of stratum waves is extracted, and the acoustic logging while drilling technology which needs no sound insulation devices is formed. The acoustic logging while drilling method has the advantages that the drill collar wave interference during single pole longitudinal wave logging while drilling is solved, drill strength destroying caused by grooving is avoided, and instrument machining difficulty and manufacturing cost are lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

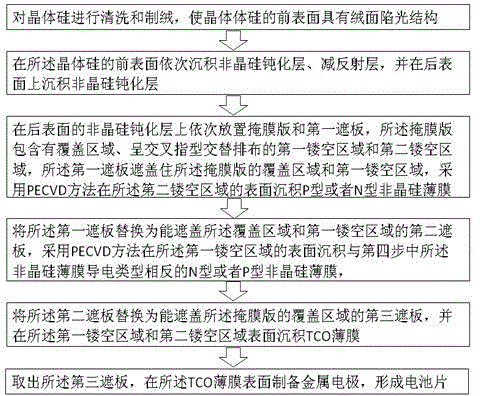

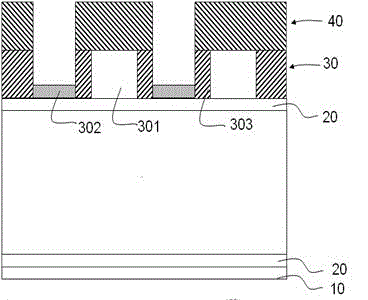

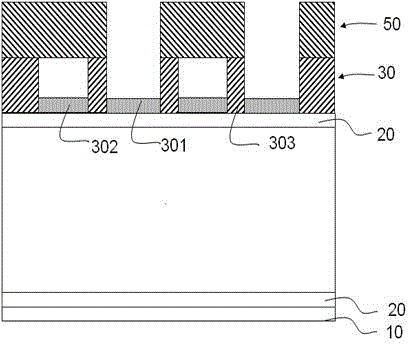

Process for preparing heterojunction solar cell without grid electrode on front surface at low temperature

ActiveCN104425651ASimplified binding stepsAvoid damageFinal product manufacturePhotovoltaic energy generationState of artHeterojunction

The invention provides a process for preparing a heterojunction solar cell without a grid electrode on the front surface at a low temperature. P type and N type amorphous silicon membranes which are alternately distributed in a cross finger form are deposited by a PECVD (Plasma Enhanced Chemical Vapor Deposition) method at a relatively low temperature, and the P type and N type amorphous silicon membranes are respectively deposited by combining a mask plate and different shielding plates, so that damage caused by an etching step in the prior art is avoided; meanwhile, the mask plate and the shielding plates are not required to be frequently cleaned, so that the step of combining an HIT (Heterojunction with Intrinsic Thin film) cell and an IBC (Interdigitated back contact) cell is also simplified, and the process is suitable for industrial production.

Owner:IDEAL ENERGY (SHANGHAI) SUNFLOWER THIN FILM EQUIPMENT LTD

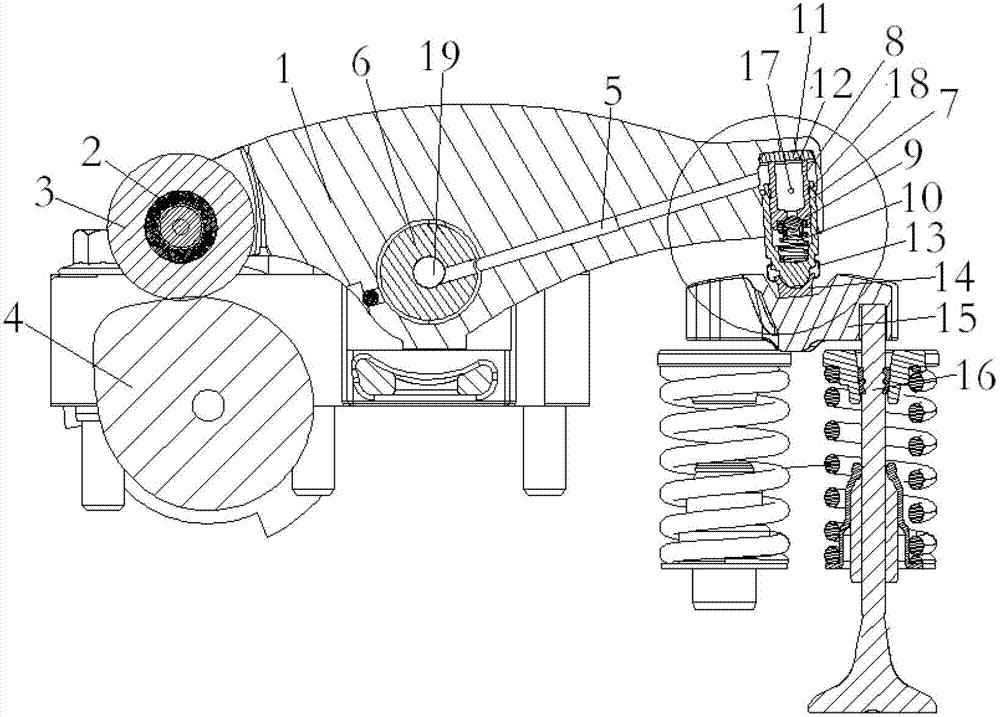

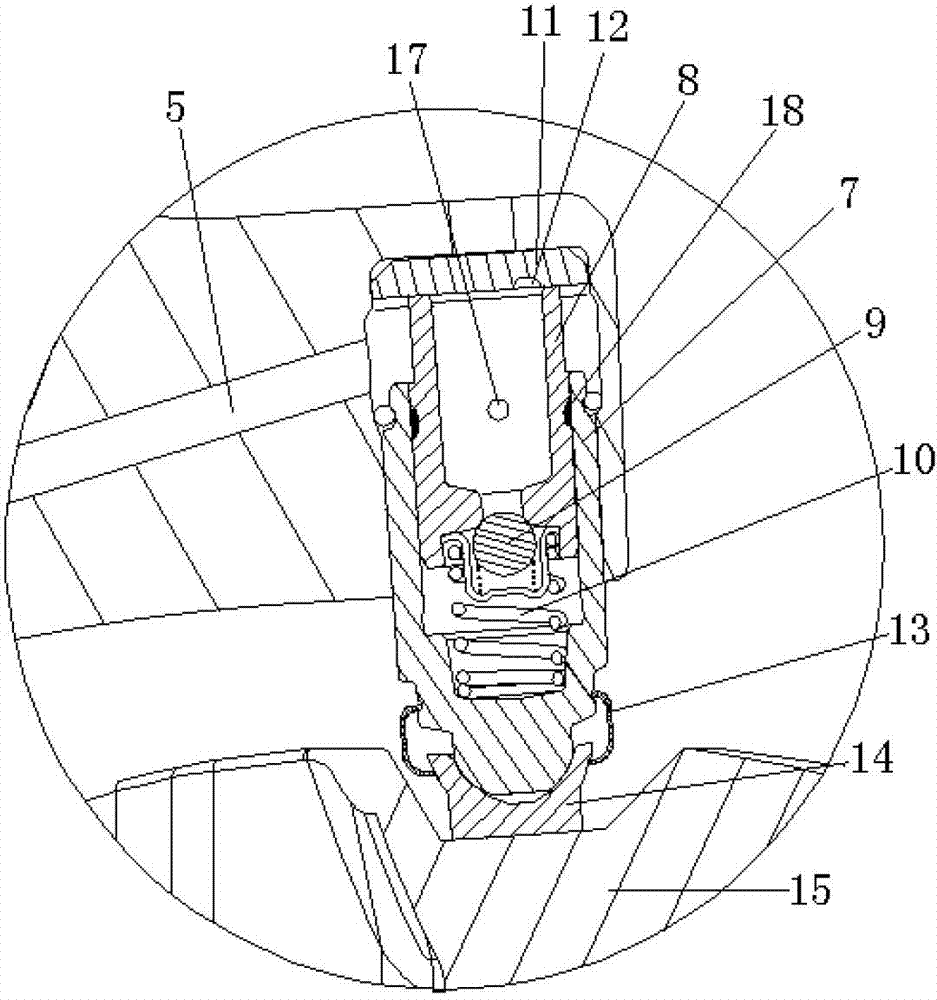

Roller-type hydraulic rocking arm component

InactiveCN102733875ARealize air intakeRealize exhaust functionValve arrangementsLubrication of auxillariesEngineeringCam

The invention discloses a roller-type hydraulic rocking arm component. The structure is as follows: one end of a rocking arm is provided with a short shaft, a bearing is embedded outside the short shaft and into the roller, and the roller and a camshaft form a transmission pair; an oil duct is arranged in the rocking arm, the middle part of the rocking arm is provided with a rocking arm shaft, the other end of the rocking arm is provided with a plunger bushing, and a plunger, a check valve and a return spring are sequentially arranged in the plunger bushing; the upper end of the plunger bushing is provided with a plunger cover plate, and the plunger cover plate is provided with an oil return channel; and the plunger bushing is connected with a slider through a cutting sleeve, the slider closely contacts a valve bridge, and the valve bridge contacts a valve push rod mechanism. The invention is suitable for an overhead camshaft mechanism, and the structure is simplified since the valve support column, the push rod and other parts connected with the cam are reduced. The rocking arm forms a zero-clearance fit with the camshaft and the valve push rod, thereby lowering the noise. On the premise of enhancing the strength of the engine block, cylinder head and the like, the volume of the engine is reduced, so that the structure is more compact reasonable, and the economical efficiency and power performance of the engine are enhanced.

Owner:东风朝阳朝柴动力有限公司

Sinusoidal pressure generation chamber with filter characteristics

ActiveCN101979980AEliminate the effects of higher harmonicsReduce the difficulty of machiningFluid pressure measurementDistortionMechanical filter

The invention relates to a dynamic pressure calibration device, and provides a sinusoidal pressure generation chamber with filter characteristics, which comprises a sinusoidal pressure chamber body with a main-assisted structure, wherein the two sides of the sinusoidal pressure chamber body are provided with an auxiliary sinusoidal pressure chamber and a main sinusoidal pressure chamber respectively; a mechanical filter is arranged in a communicated channel between the auxiliary sinusoidal pressure chamber and the main sinusoidal pressure chamber; the top and bottom of the auxiliary sinusoidal pressure chamber are grooved to form a first sensor mounting position and a second sensor mounting position respectively; the top and bottom of the main sinusoidal pressure chamber are provided with through holes to form an air inlet and an air outlet respectively; and the main sinusoidal pressure chamber part of the sinusoidal pressure chamber body with the main-assisted structure is fixed in a middle hole reserved on the middle part of a chamber support of which the top is provided with the air inlet and the bottom is provided with two first square holes and a second square hole. The device of the invention can eliminate the influence of higher harmonics, simultaneously reduce difficulties in mechanical machining, improve the accuracy of the mechanical machining and greatly improve the degree of distortion and dynamic-static amplitude ratio of sinusoidal pressure waveforms generated by a sinusoidal pressure generator.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

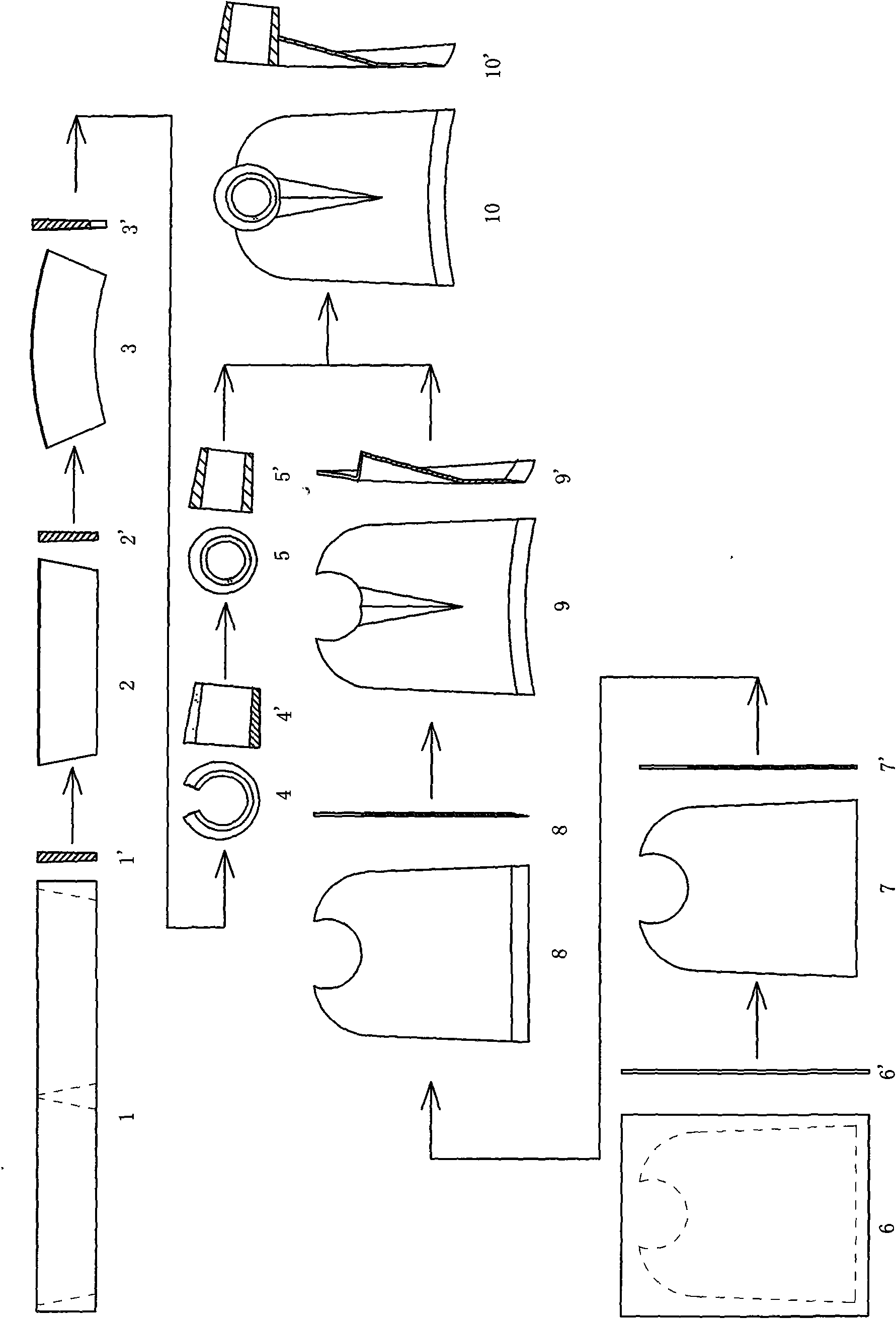

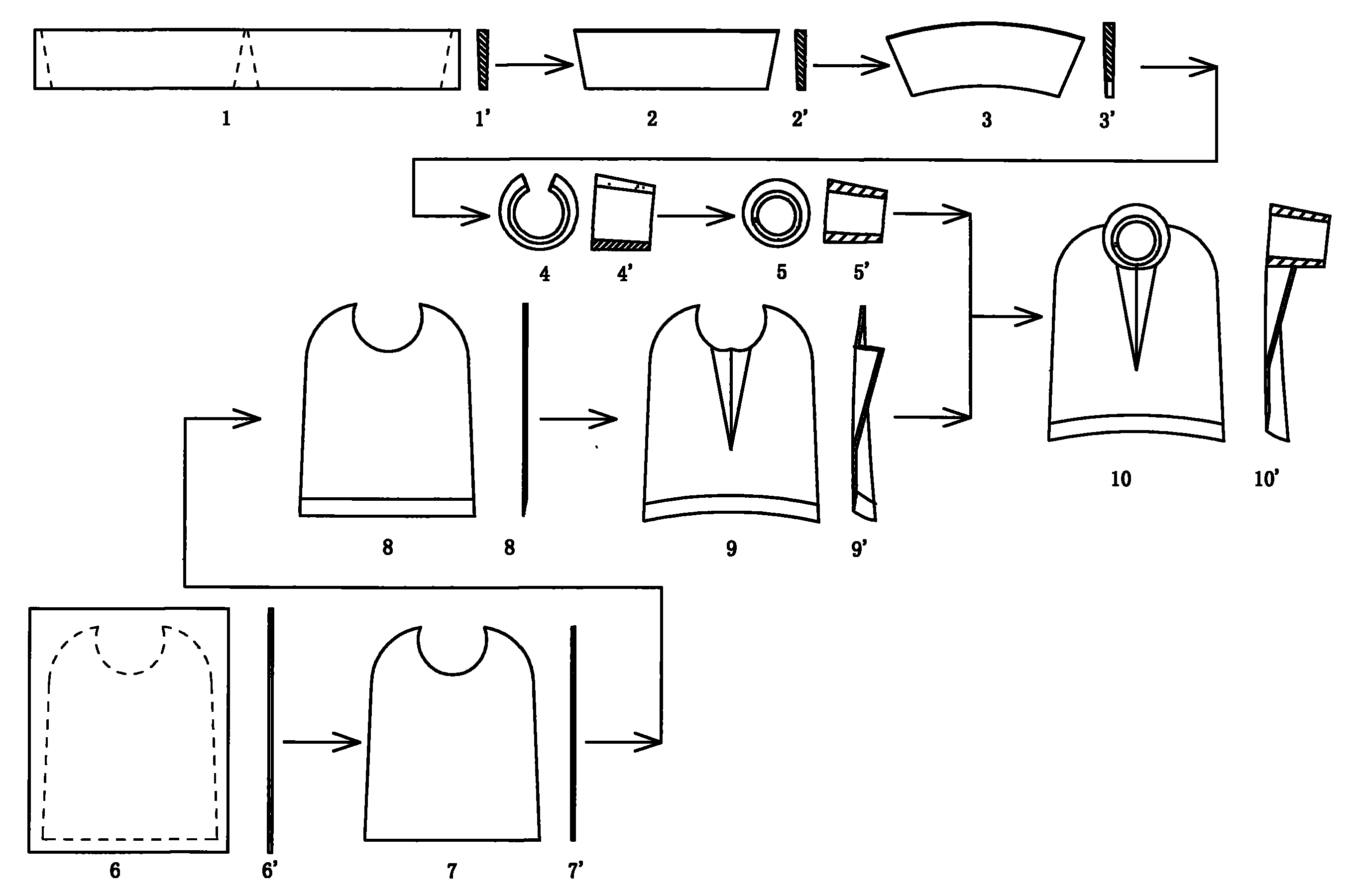

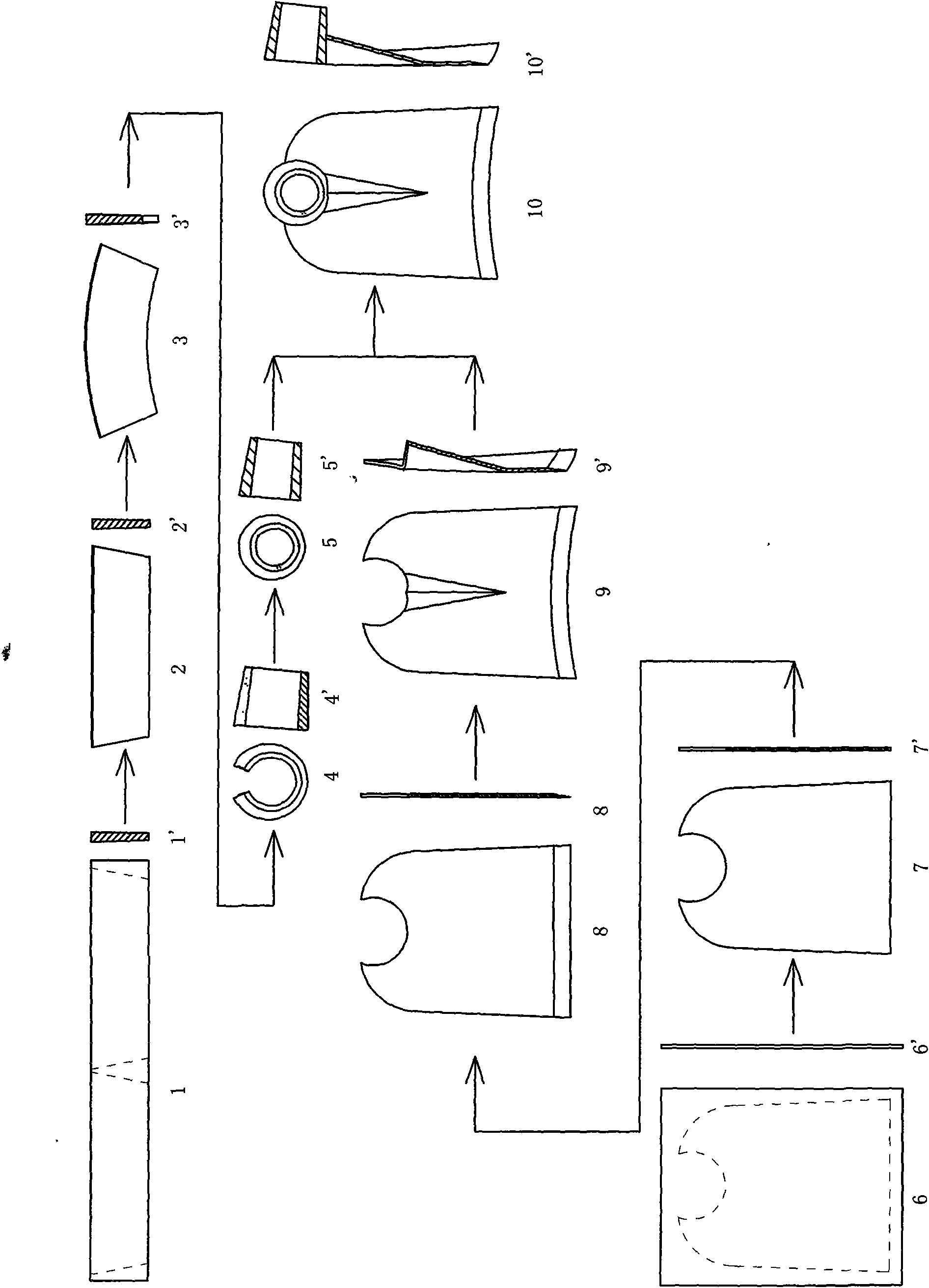

Processing technique of new steel plate hoe

InactiveCN101584265AReduce utilizationIncrease profitHoesSaving energy measuresSheet steelEngineering

The invention relates to a processing technique of a new steel plate hoe, belonging to the field of the general agricultural mechanism or agricultural tool technology. The producing technique uses belt steel and strip steel to mechanically mold a hoe plate and a hoe wedge via mechanical blanking; the hoe plate and hoe are jointed via welded connection with a high automation; the hoe is wearable with a great appearance, energy and fuel saving without smoke and dust pollution and noise pollution, which is especially suitable for the industrial production.

Owner:湖南省嘉禾县中兴工具有限公司

Method for preparing C-shaped arm

InactiveCN1970217ALow costImprove manufacturing precisionExtrusion diesOther manufacturing equipments/toolsCurve shapeEngineering

It relates to mechanical parts manufacturing and processing. The proposed C arm is made by compressing the mold to make the direct bar like material, bending the bar to curving shape, and applying timely treatment, mechanical processing and surface processing. It reduces mold cost and processing cost, improved product quality and efficiency, with less continuous processing difficulty.

Owner:BEIJING ORIENTAL E T MEDICAL EQUIP

Propelling-stable cannonball support for air cannon and design method of cannonball support

ActiveCN109668478AReduce lossReduce the difficulty of design and machiningSustainable transportationLaunching weaponsTechnical supportStructural engineering

The invention discloses a propelling-stable cannonball support for an air cannon and a design method of the cannonball support. Grooves with different numbers and sizes are machined in the outer sideof the cylindrical cannonball support, the gap leakage amount generated when the cannonball support moves in a cannon barrel is reduced, the gap between the cannonball support and the cannon barrel can be increased under the same gap leakage amount, and therefore unstable movement caused by the interference such as machining and impurities of the outer wall of the cannonball support and the innerwall of a cannon bore can be reduced, loss generated during launching of the cannonball support under the same launching pressure is reduced, the design and machining difficulty are reduced, and stable launching of the cannonball support is guaranteed; and the two-dimensional cannonball support profile curve is subjected to iteration and calculation through the mode of making the gap leakage amount index objective function, the cannonball support two-dimensional profile of the corresponding design gap leakage amount rate index parameter is obtained, and therefore the geometrical shape of thepropelling-stable cannonball support is designed. The cannonball support and the related design method can provide an efficient and stable propelling test technical support for various air cannon tests.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

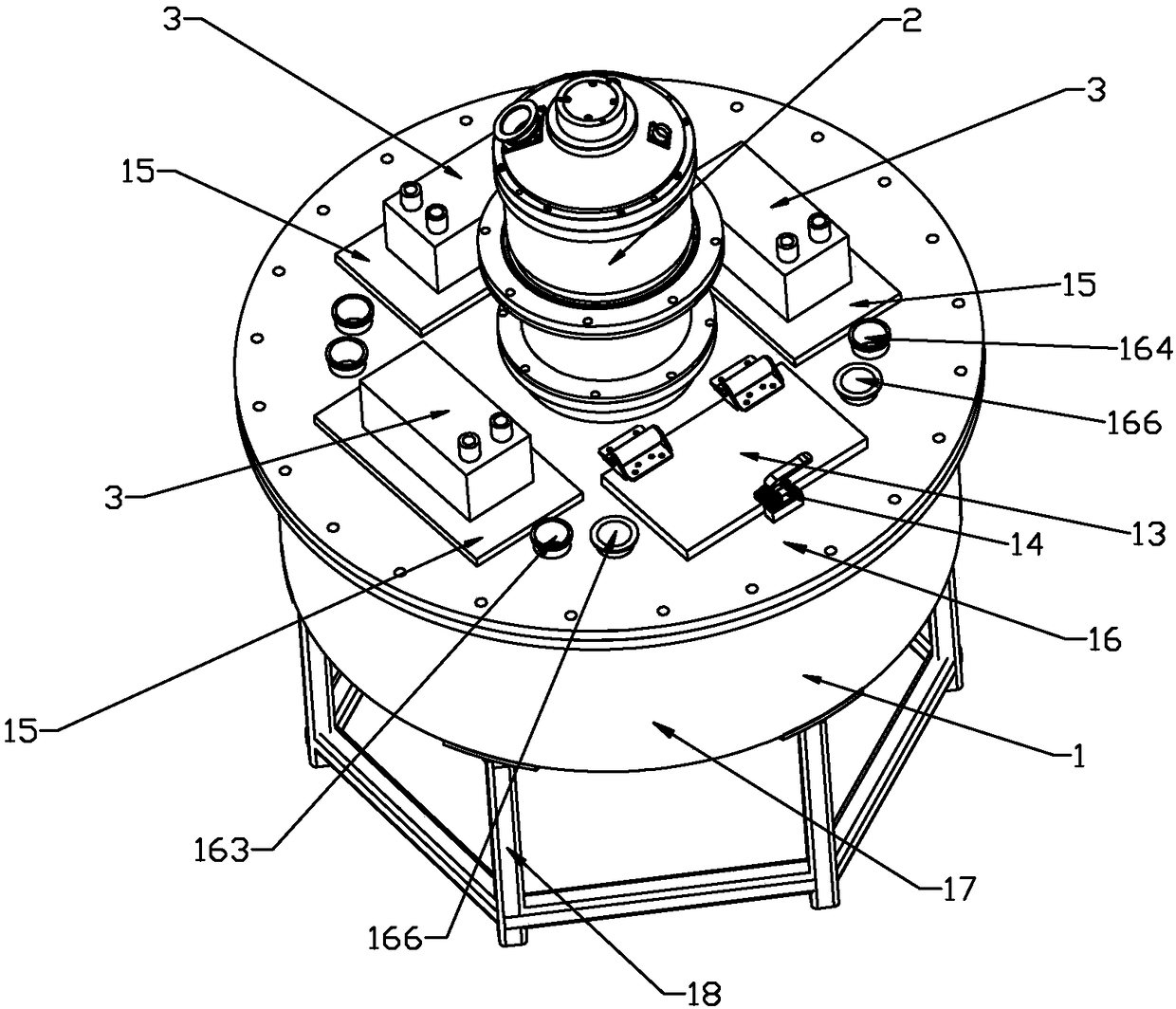

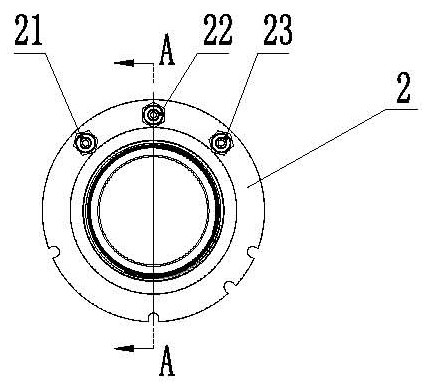

Annular circulation continuous vacuum coating device

ActiveCN108179396ASimple equipmentReduce the difficulty of machiningVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention relates to an annular circulation continuous vacuum coating device which comprises a main cavity, a main vacuum system and coating technology assemblies, wherein the main cavity is provided with a main chamber and a feeding hole capable of being opened and closed; the annular circulation continuous vacuum coating device further comprises a rotary disc, a rotary disc lifting mechanism, a rotary disc rotating mechanism, a feeding chamber, a plurality of technological chambers and a feeding sub chamber vacuum system; the rotary disc rotating mechanism drives the rotary disc to rotate horizontally to transmit a to-be-coated workpiece among the feeding chamber and all technological chambers; the rotary disc lifting mechanism drives the rotary disc to go up and down to switch overthe feeding chamber and the technological chambers between the communicating state of the main chamber and the state of an independent vacuum chamber; the main vacuum system carries out vacuum treatment on the main chamber and all technological chambers; the feeding sub chamber vacuum system carries out vacuum treatment on the feeding chamber separately; and different coating technology assembliesare mounted on all technological sub cavities to realize different coating functions. The annular circulation continuous vacuum coating device can realize annular circulation continuous and low-costcoating production in the vacuum cavity.

Owner:WENZHOU POLYTECHNIC

Extrusion molding method for ceramic pin blank tube with core and extrusion head thereof

InactiveCN1631634AMeet the precision requirementsEasy to disassemble and replaceCeramic extrusion diesCoupling light guidesEngineeringMachining

The invention is a contact pin perform tube core containing ejecting shaping method and its ejecting head of which the feature is that eject the clay from the ejector with an ejecting head to form a contact pin material with a core filament inside which is processed with machine after the stretching and baking to obtain the contact pin perform which can obtain the contact pin perform tube by defatting and high temperature agglomeration. The perform tube of the invention is easily processing and of high accuracy.

Owner:李元科

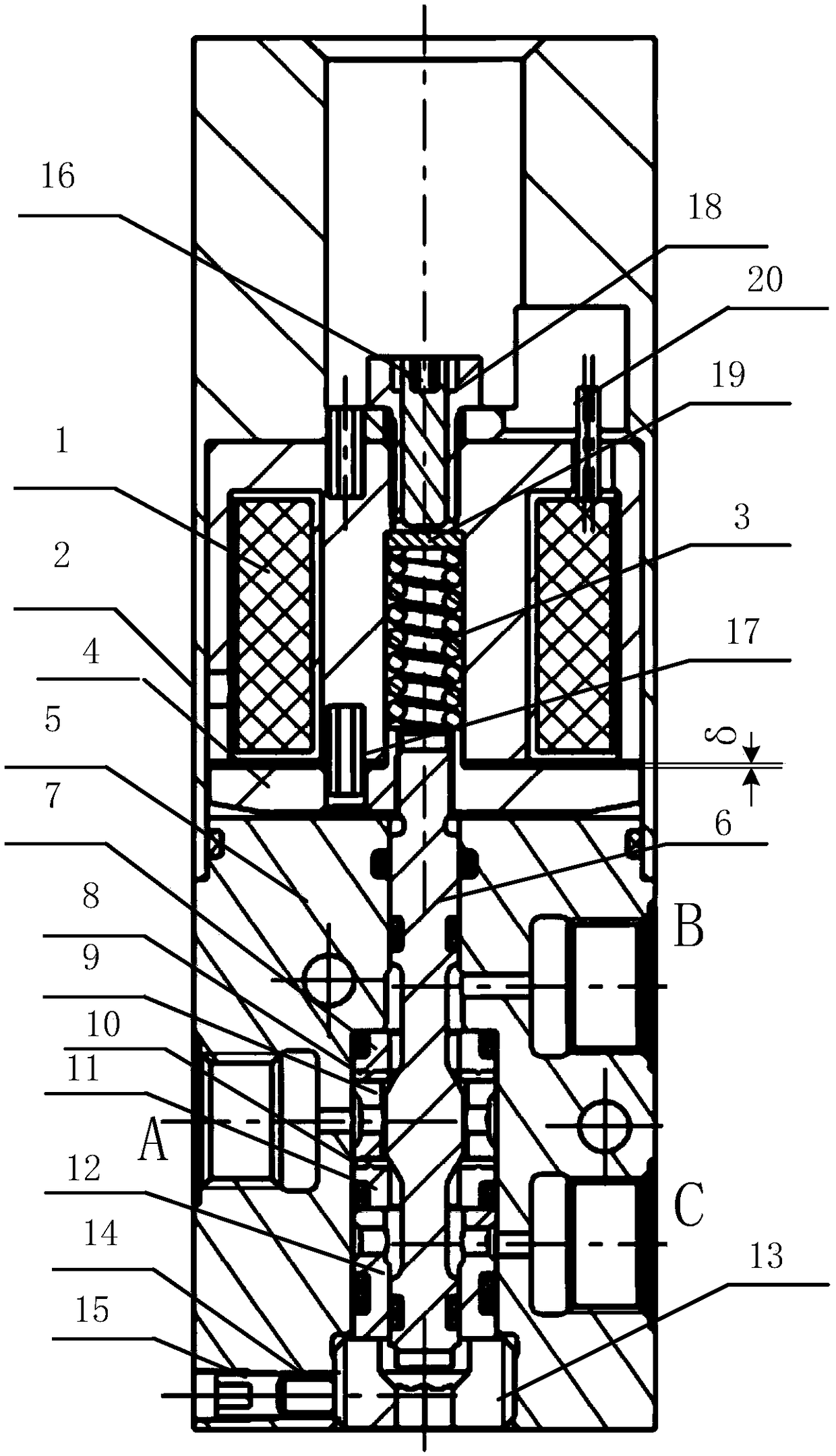

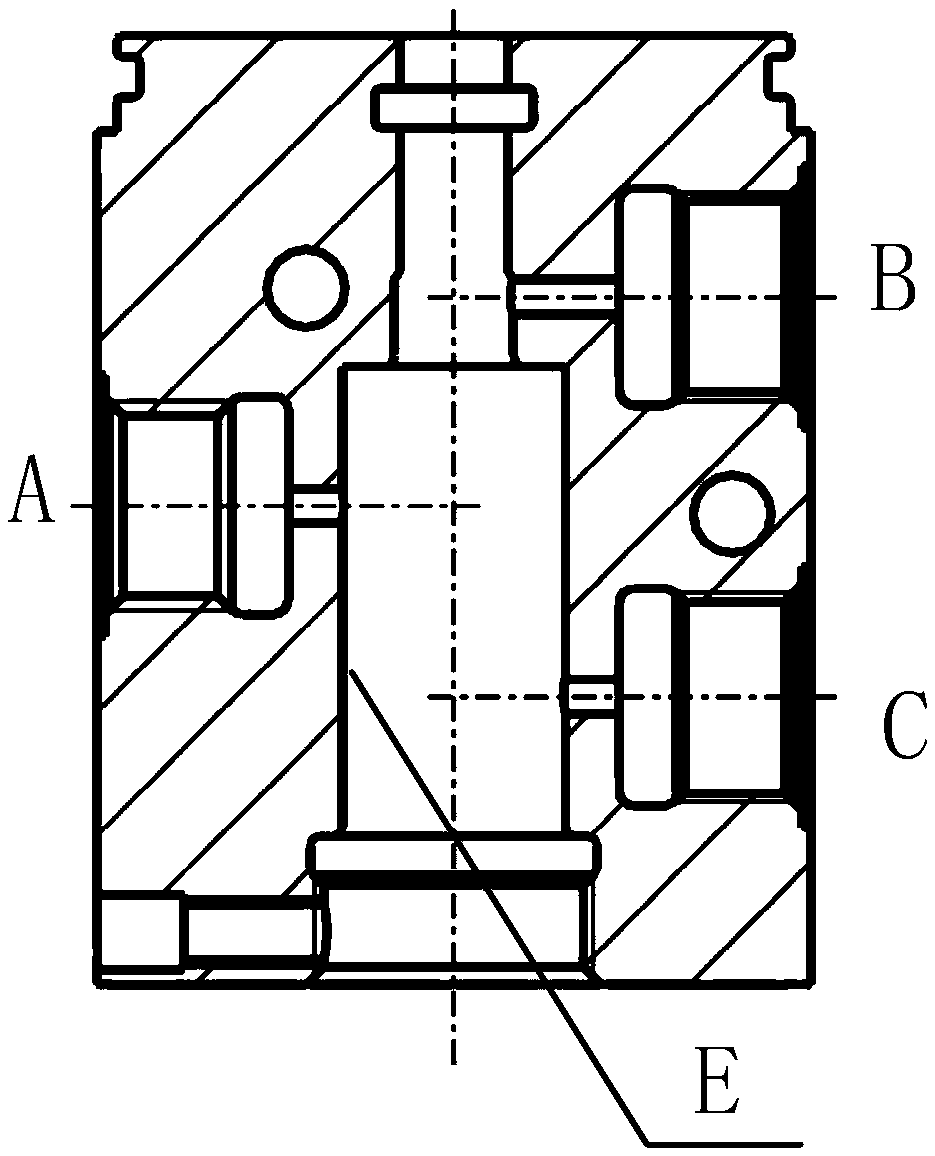

High-voltage multifunctional two-position three-way solenoid valve

ActiveCN108916419ARealize high pressure and even ultra high pressureSame cross-sectional areaOperating means/releasing devices for valvesMultiple way valvesSolenoid valveEngineering

A high-voltage multifunctional two-position three-way solenoid valve comprises an electromagnet (1), an electromagnet housing (2), a return spring (3), an armature (4), a valve body (5), a valve stem(6), an upper valve seat (7) and a lower valve seat (11). Three vent holes formed in the valve body (5) can be used as fluid inlet holes or fluid outlet holes. The valve stem (6) is mounted in an inner cavity E of the valve body (5) through the upper valve seat (7), an upper valve seat sealing gasket (8), a middle valve sleeve (9), a lower valve port sealing gasket (10), the lower valve seat (11)and a bottom valve sleeve (12). The diameter of the sealing portion of the valve stem (6) and the valve body (5), the diameter of the contact portion of the valve stem (6) and the upper valve seat sealing gasket (8) or the lower valve port sealing gasket (10) and the diameter of the sealing portion of the valve stem (6) and the bottom valve sleeve (12) are identical. One hole A is communicated with a circumferential hole formed in the middle valve sleeve (9). When the valve stem (6) and the upper valve seat sealing gasket (8) or the lower valve port sealing gasket (10) is sealed, the vent holeA is communicated with the other vent holes.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

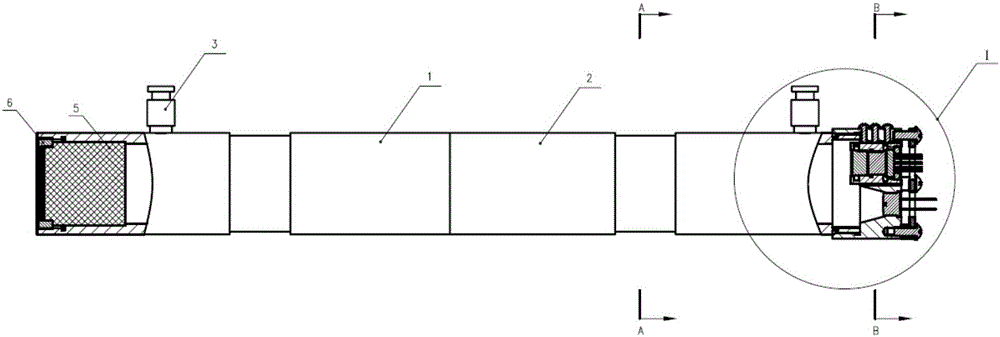

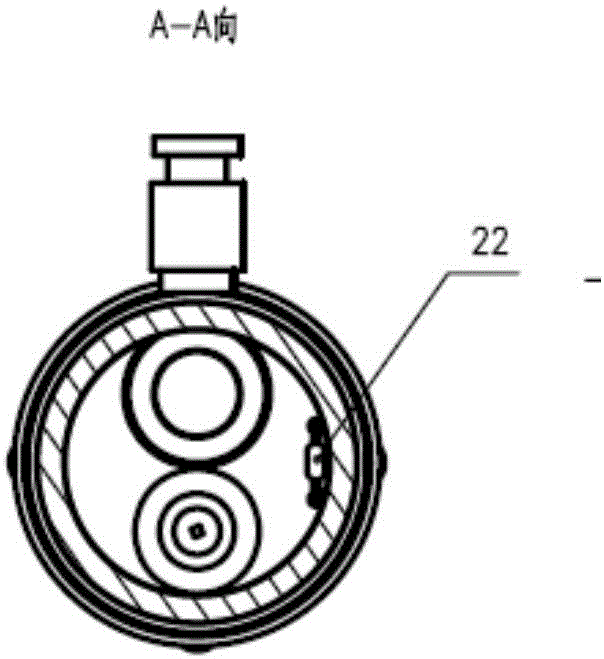

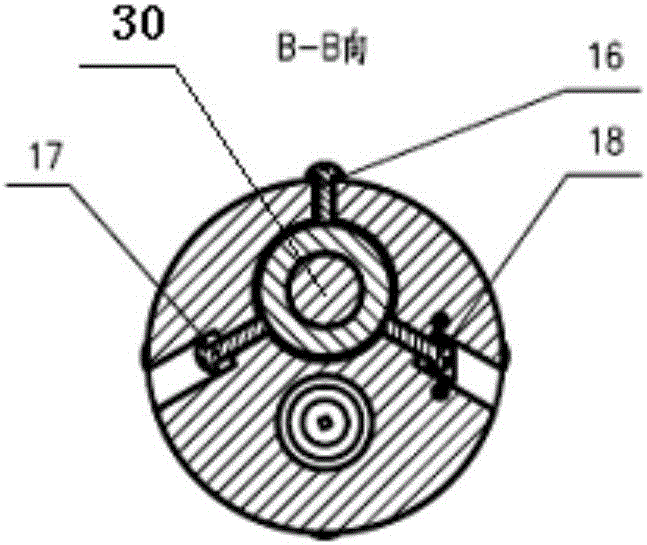

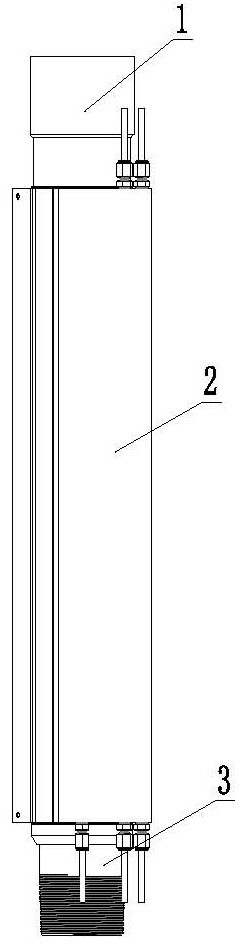

Spatial light reflection type gas pool used for detecting gas spectral absorption

InactiveCN106770021AHigh detection sensitivityHigh beam qualityColor/spectral properties measurementsLight spotLight reflection

The invention relates to a spatial light reflection type gas pool used for detecting gas spectral absorption. The spatial light reflection type gas pool comprises a front sleeve, a rear sleeve, an gas inlet nozzle and an gas outlet nozzle, wherein the gas inlet nozzle and the gas outlet nozzle are arranged on the front sleeve and the rear sleeve respectively; the tail end of the front sleeve is connected with a sleeve head, a light emission assembly is arranged on the sleeve head, a temperature sensor is arranged on the sleeve head and used for temperature compensation, a photovoltaic conversion pre-amplification electric circuit is put on the sleeve head, and a light receiving element is arranged on the photovoltaic conversion pre-amplification circuit; a cube-corner prism and a prism pressing ring are arranged at the tail end of the rear sleeve, the cube-corner prism is used for reflecting laser so that the absorption optical path of gas can be double increased, and the detection sensitivity of a gas measurement system can be improved. The light emission assembly of the gas pool is easy to adjust, the output laser is small in light spot and high in collimation, and the gas pool is high in stability and can be applied to an optical gas detecting devices and instruments.

Owner:BEIJING RES INST OF TELEMETRY +1

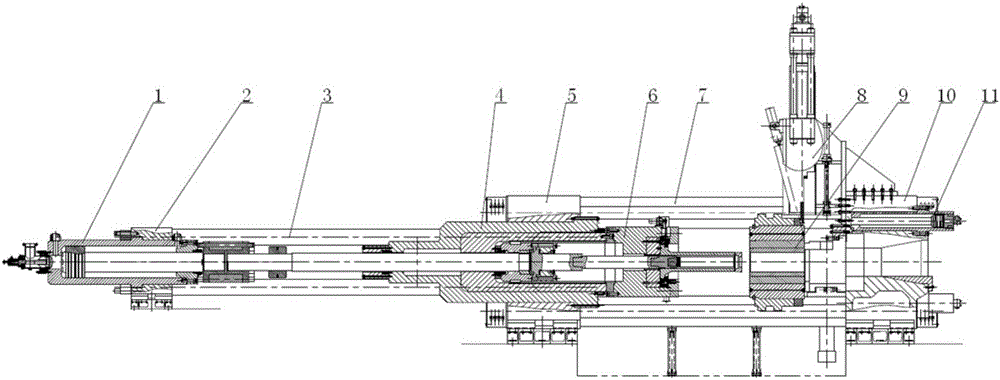

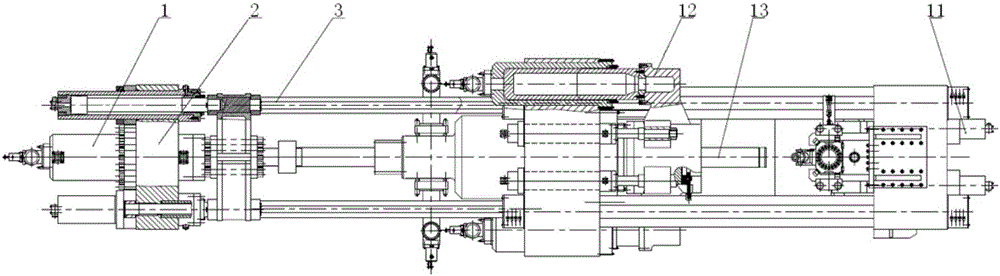

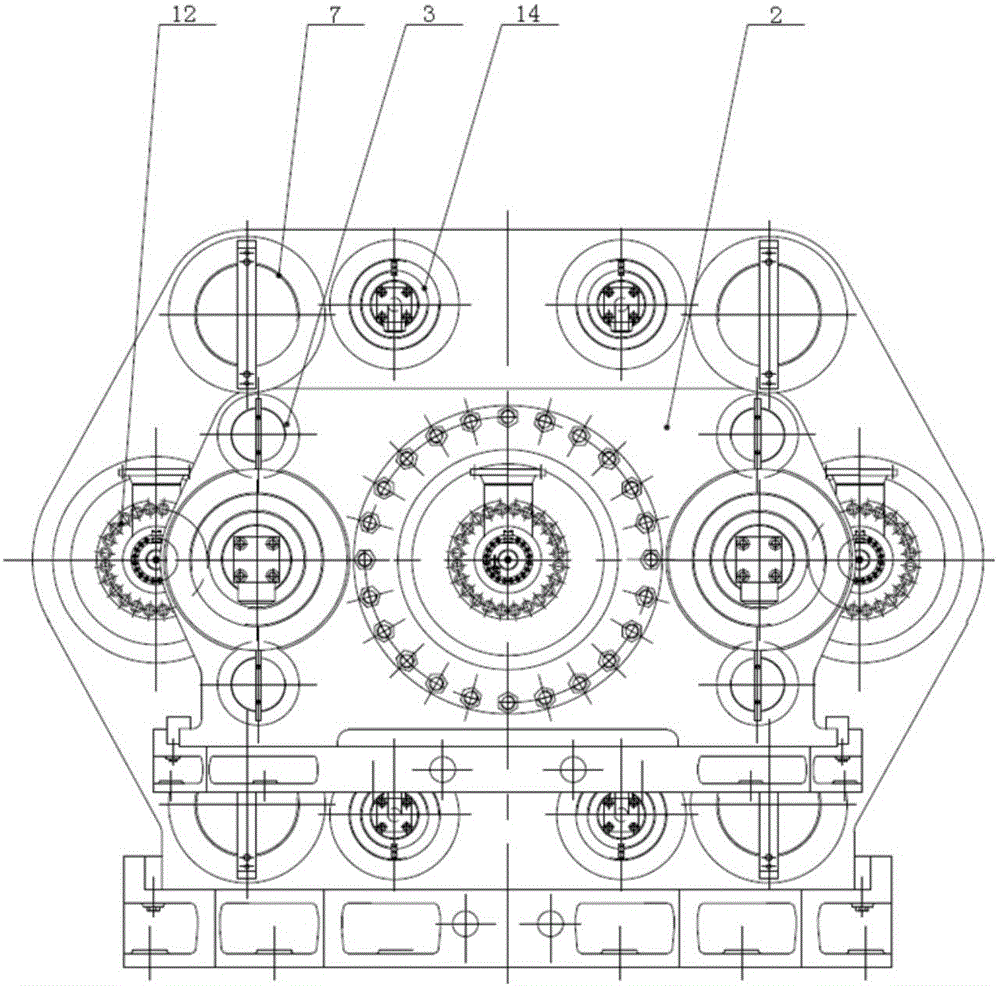

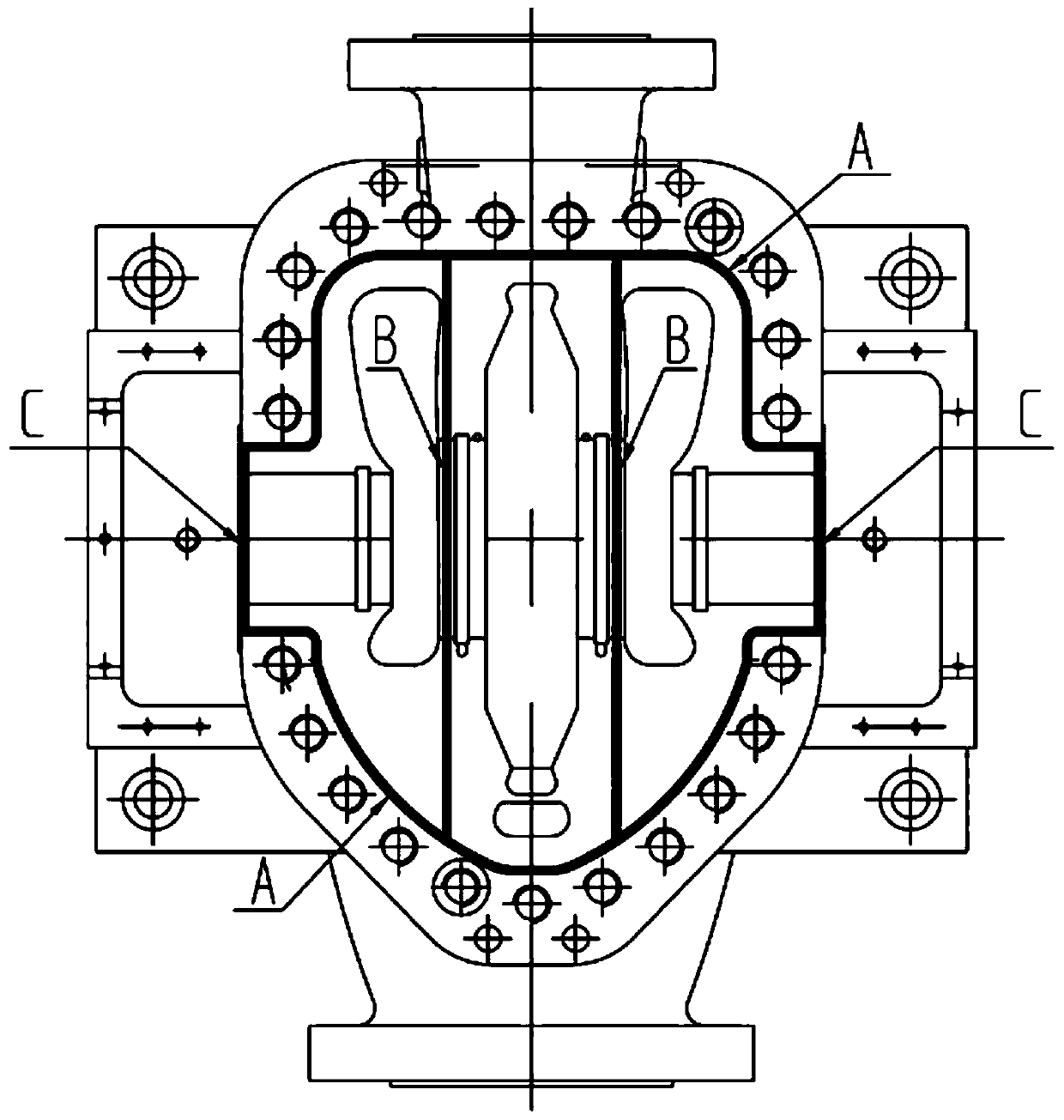

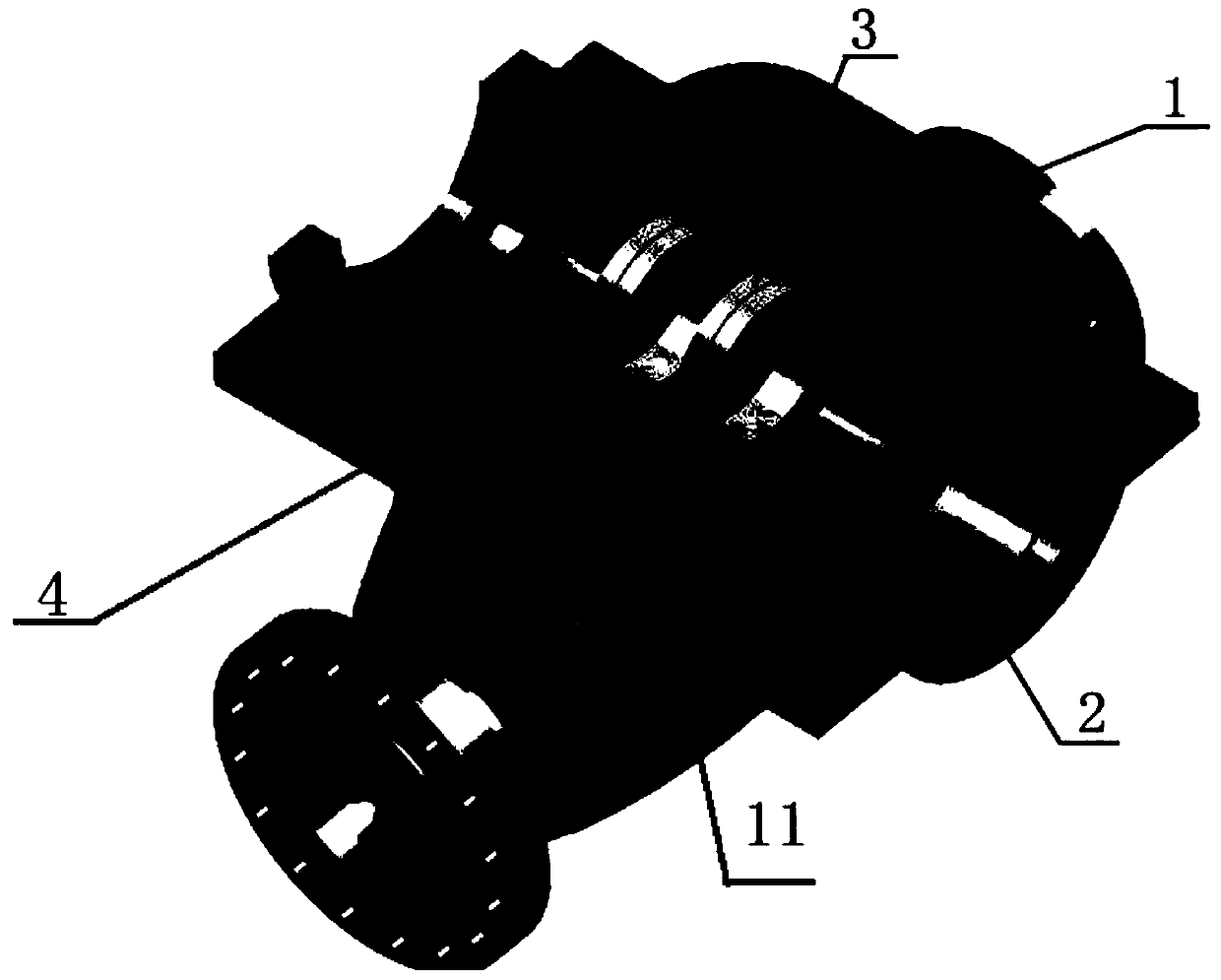

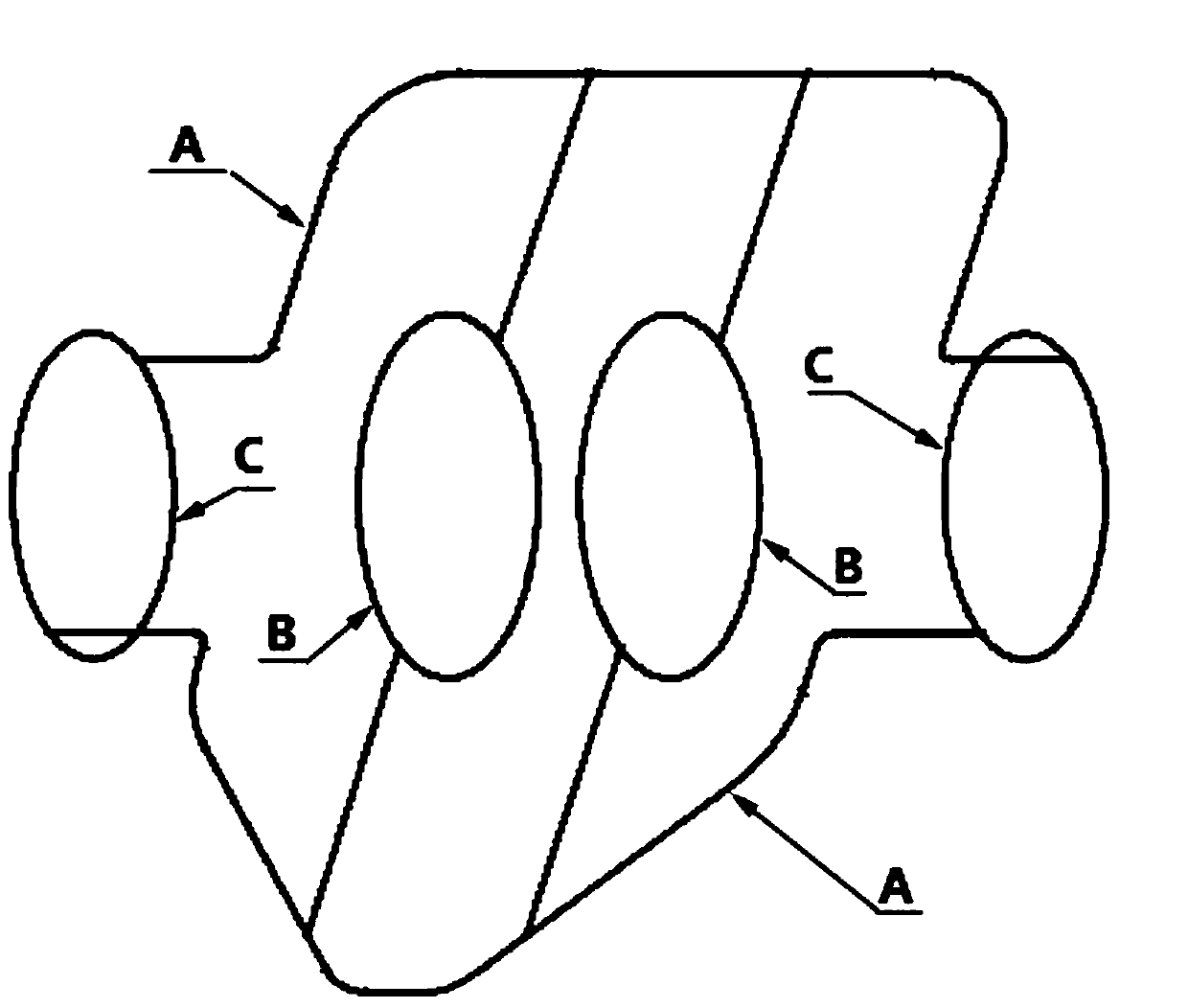

Main machine structure of super-heavy double-action extruding machine

ActiveCN105880305ASmall diameterReduce processing difficultyExtrusion mandrelsUltimate tensile strengthMechanical engineering

The invention belongs to the field of metallurgical equipment and particularly relates to a new structure of super-heavy extruding equipment. The new structure comprises a rear beam, pull rod pressing sleeves and a front beam which are used for forming an extruding machine prestressed rack, wherein an external perforation system is connected with the rear end of the rear beam and comprises a perforation rear beam provided with a fixed perforation cylinder and perforation pull rod pressing sleeves; two ends of each perforation pull rod pressing sleeve are connected with the extruding machine rear beam and the perforation rear beam respectively; a large main working cylinder is fixed on the extruding machine rear beam, small main working cylinders are symmetrically arranged on the left side and the right side of the large main working cylinder, and four side cylinders are symmetrically arranged on the upper side and the lower side of the large main working cylinder; a main plunger of the large main working cylinder is connected with a moving cross beam; an extruding tool is mounted on the moving cross beam; a pair of main scissors is fixed on the extruding machine front beam; and an extruding barrel is arranged between the extruding machine front beam and the moving cross beam. The main machine structure manner is designed for the structure of an extruding machine with the largest tonnage in the industry, the overall performance of the super-heavy extruding machine can be improved, and the strength and extruding precision of super-heavy backward extruding equipment can be improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

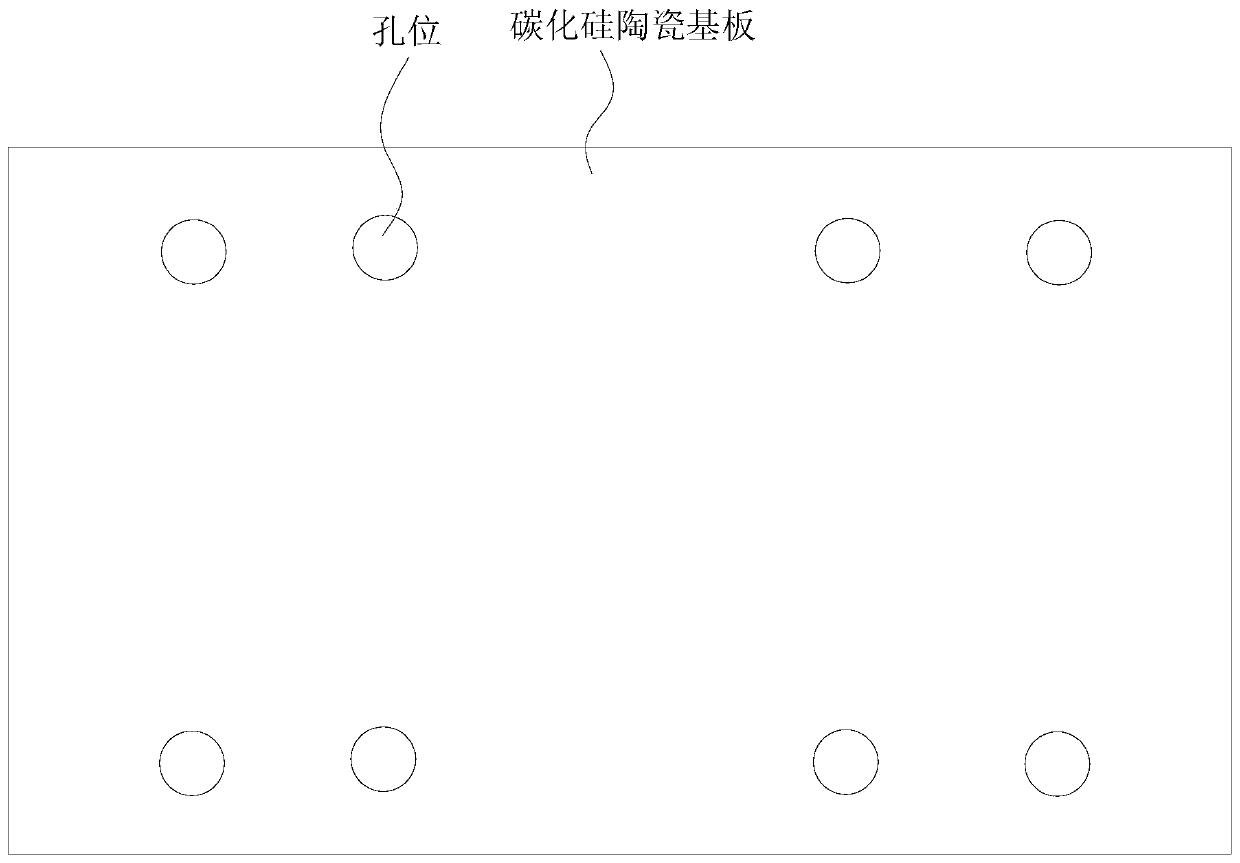

Ceramic matrix composite satellite lightweight structural member surface flatness treatment method and structural member

PendingCN112495735AImprove flatnessEasy to meet the design and use requirementsPretreated surfacesEpoxy resin coatingsEpoxySuperfinishing

The invention relates to a ceramic matrix composite satellite lightweight structural member surface flatness treatment method and a ceramic matrix composite satellite lightweight structural member, and aims to solve the problems that the flatness requirement is difficult to meet by general machining and high-precision scraping cannot be performed due to relatively high material hardness of the ceramic matrix composite satellite lightweight structural member, the processing difficulty is increased, and the product quality is difficult to guarantee. The ceramic matrix composite satellite lightweight structural member surface flatness treatment method comprises the following steps: carrying out preliminary machining, cleaning and drying on the surface of the ceramic matrix composite satellitelightweight structural member; smearing a glue solution prepared from epoxy resin glue on the surface of the ceramic matrix composite satellite lightweight structural member; carrying out super-finish machining on the surface of a glue layer after the glue solution is cured to form the glue layer; and finally, scraping to enable the surface flatness of the structural member to meet the requirement. The structural member manufactured through the ceramic matrix composite satellite lightweight structural member surface flatness treatment method has the advantages that the surface flatness meetsthe design and use requirements, and the performance is good.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

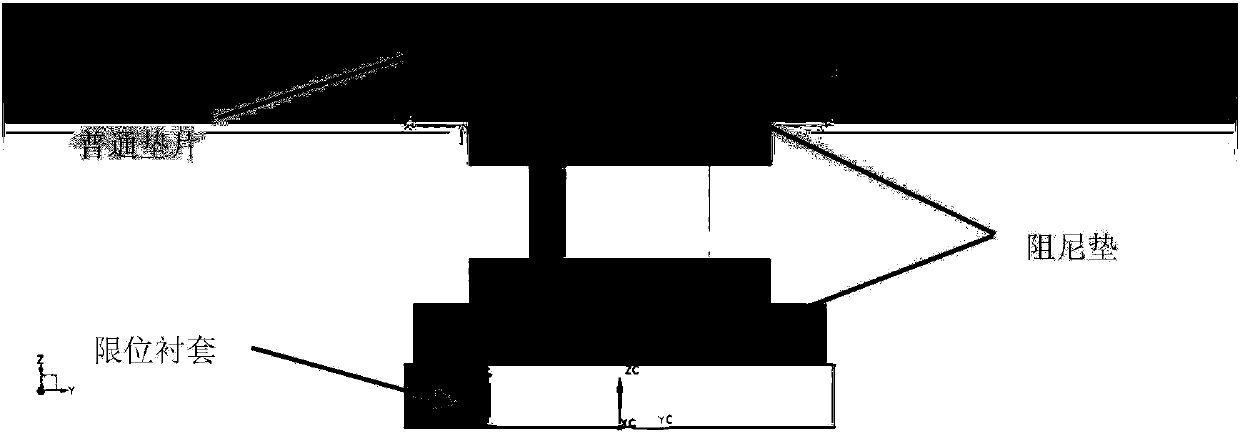

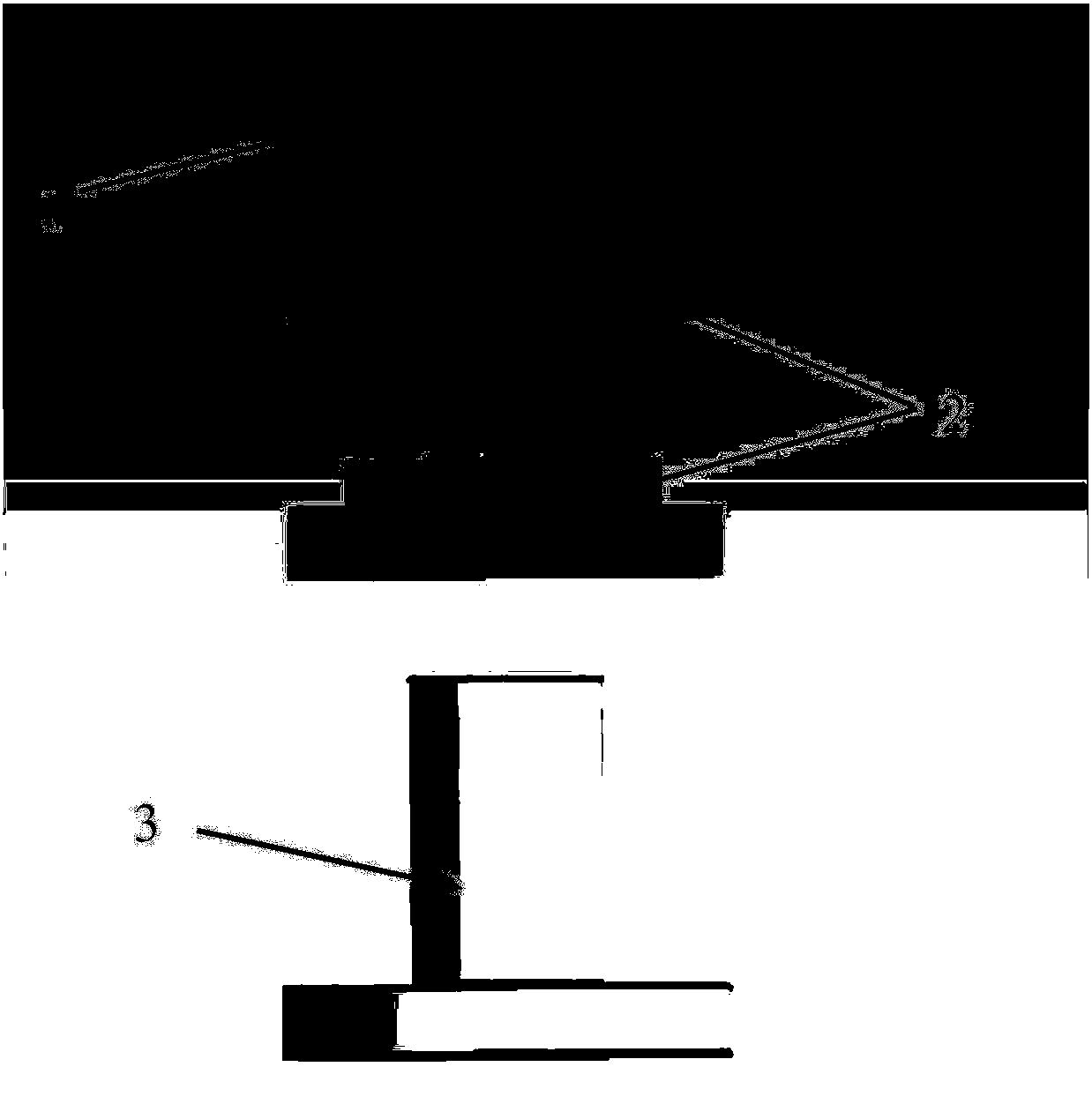

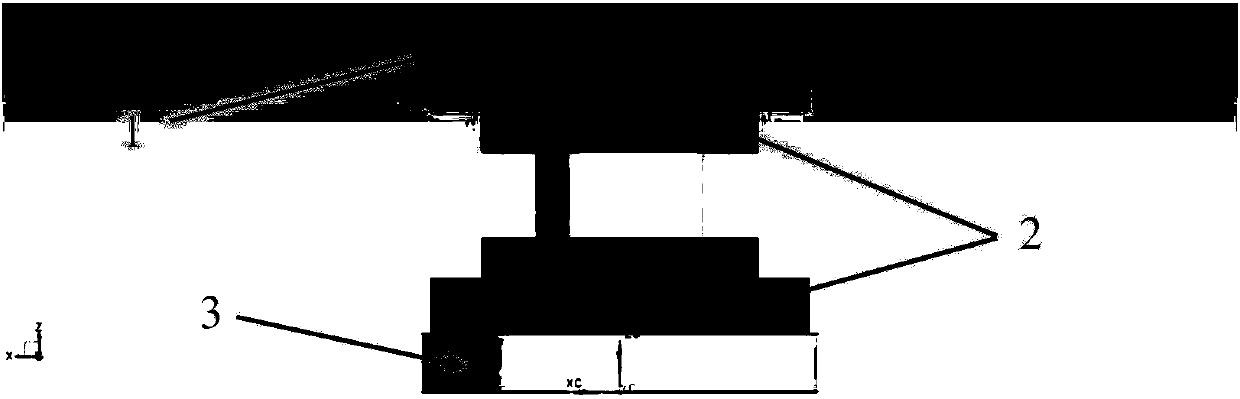

Electronic product shock absorber assembly structure using fall prevention measure

InactiveCN107630960AReduce the difficulty of machiningReduce processing difficultyShock absorbersEngineeringVibration isolation

The invention relates to an electronic product shock absorber assembly structure using a fall prevention measure, and belongs to the technical field of structures and strength. Compared with the priorart, the electronic product shock absorber assembly structure has the advantages that an anti-fall gasket design is adopted, ordinary gaskets in the prior art are replaced, friction force between a damping gasket and an anti-fall gasket is increased, so that parts of a shock absorber assembly cannot fall off due to accidental bump brought a small assembly space, and the purpose of fall preventionis achieved; the shock absorber assembly does not need to change the dimensions and structural shapes of other parts, the changing amount of the anti-fall gasket is small, processing difficulty is low, so that the purpose that the shock absorber assembly is simple in structure and easy to realize is achieved; and the amount of compression of the damping gasket is consistent with the structure ofan existing shock absorber, and the purpose of no obvious weakening of the vibration isolation efficiency of an electronic product is achieved.

Owner:BEIJING POWER MACHINERY INST

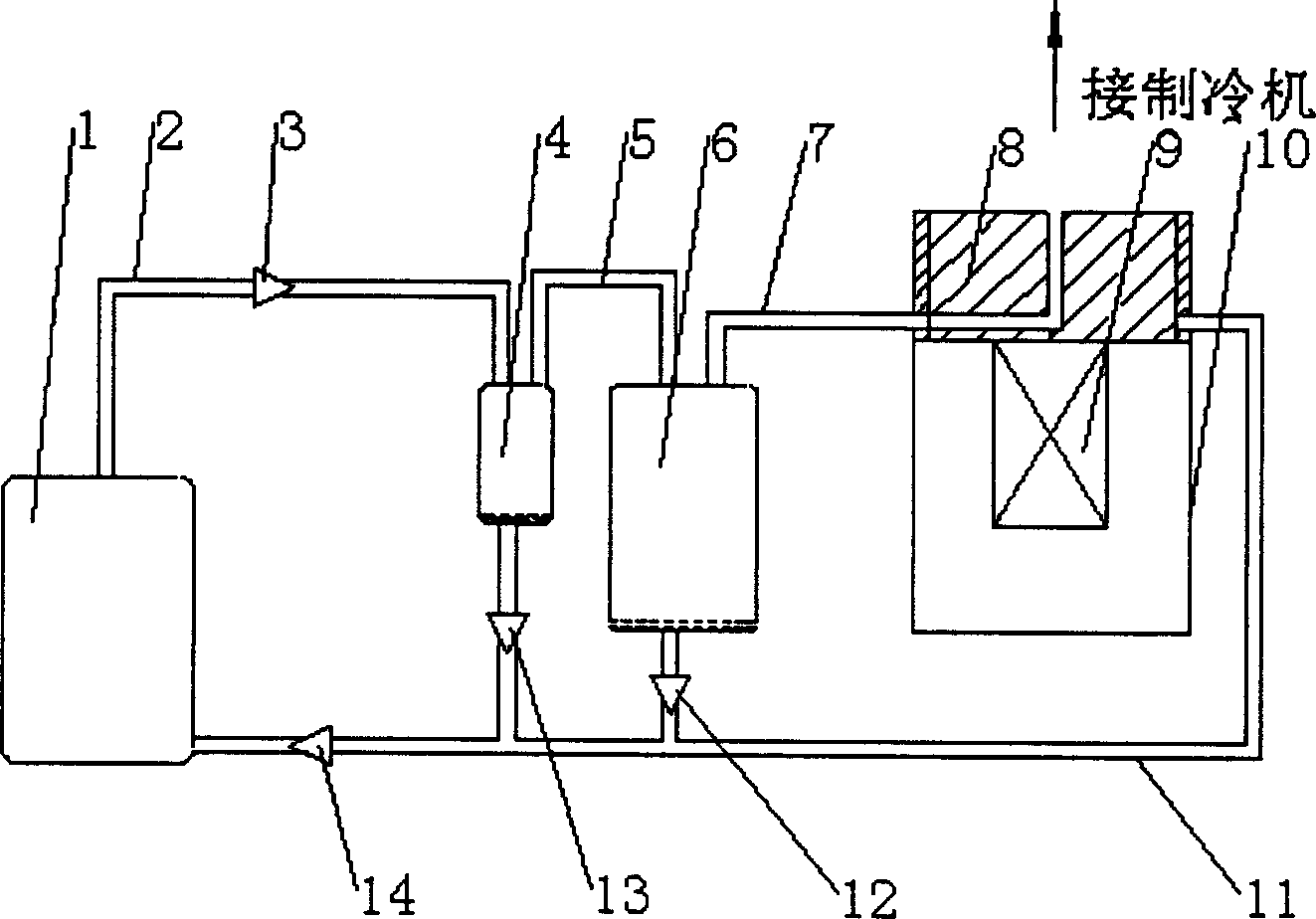

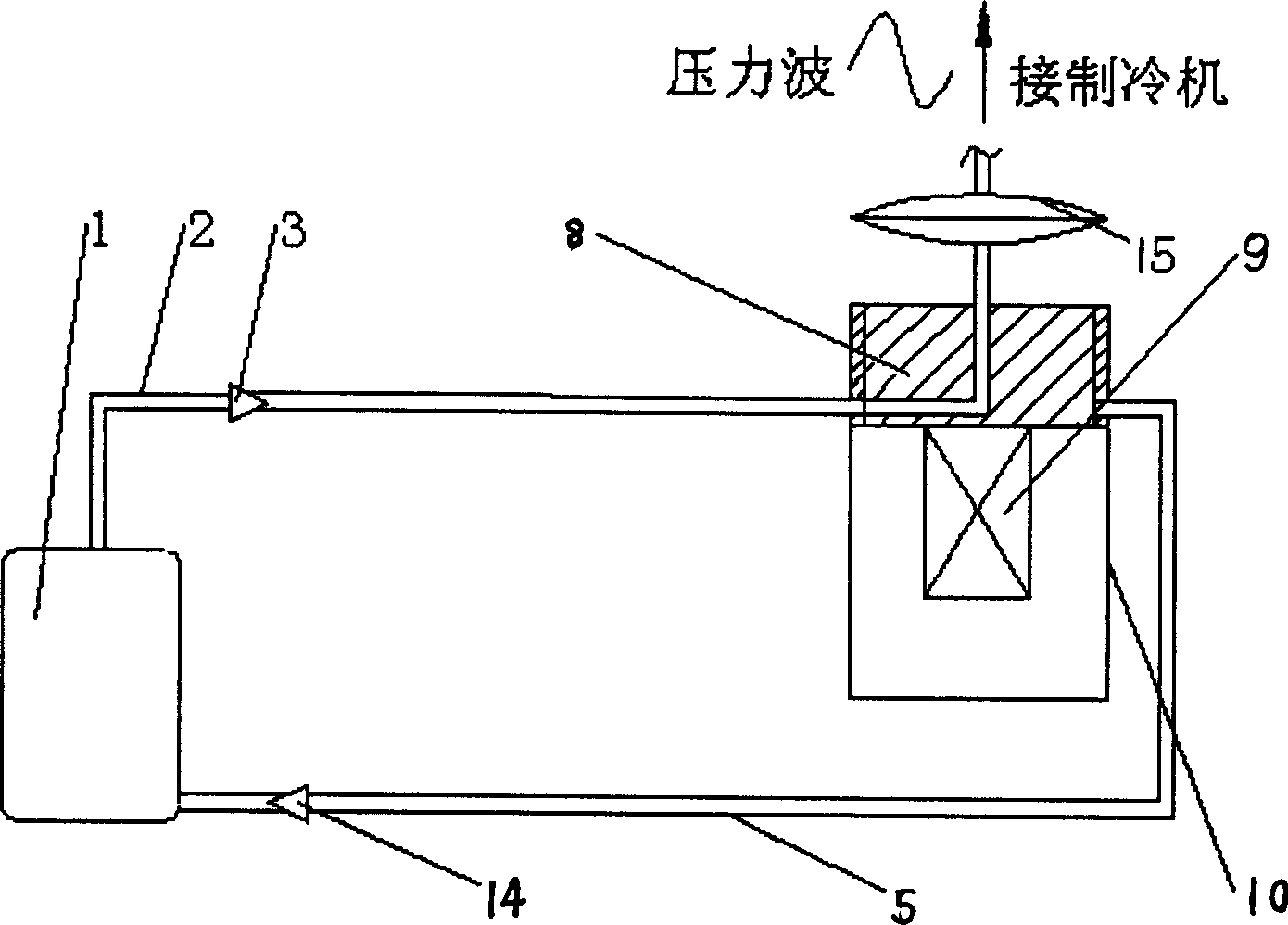

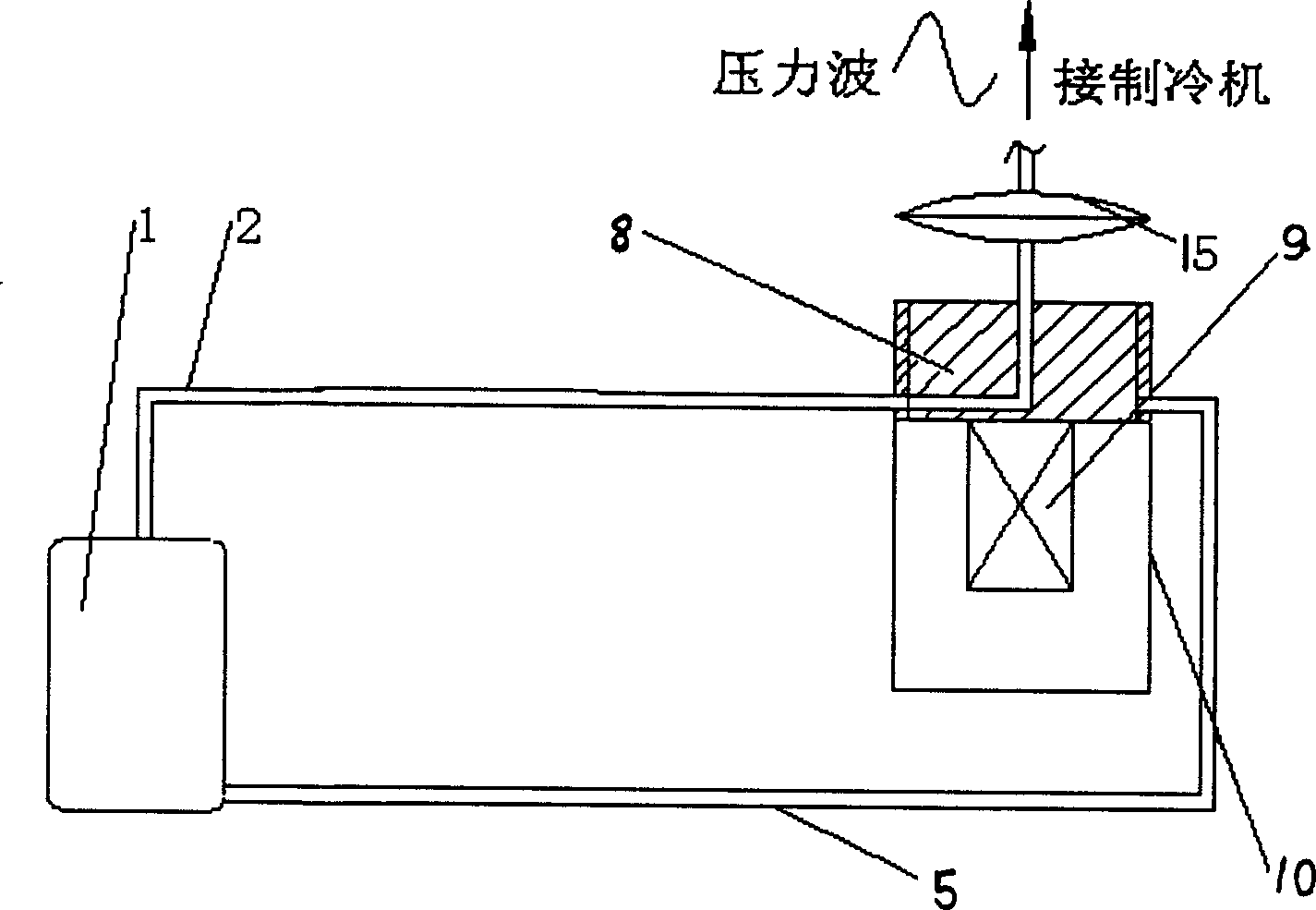

Compression wave generation system of cooling machine with compressor of constant oil lubricating flow

InactiveCN1687674AAvoid enteringExtended service lifeCompression machinesElectric machineMetallic materials

The invention relates to the pressure wave producing system of the oil-lubricating stable flowing compressor refrigerator. It comprises the compressor orderly connected and forming the loop, the oil conveying pipeline, the plane revolving valve between the revolving electric machine and the refrigerator. Its characteristics are: it also includes the elastic film equipped between the plane revolving valve and the refrigerator; the said plane revolving valve is lubricated by oil. The said elastic film is the organic or metal material film with high elasticity. Compared with the prior art, the key technology of the invention is that it adopts the high-elasticity film that can effectively convey the mechanic power to the refrigerating system in sound wave pattern and prevent the lubricating oil in the pressure wave producing system going into the refrigerating system. It makes the GM refrigerator maintain the high efficiency and improve the reliability and greatly reduces the cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

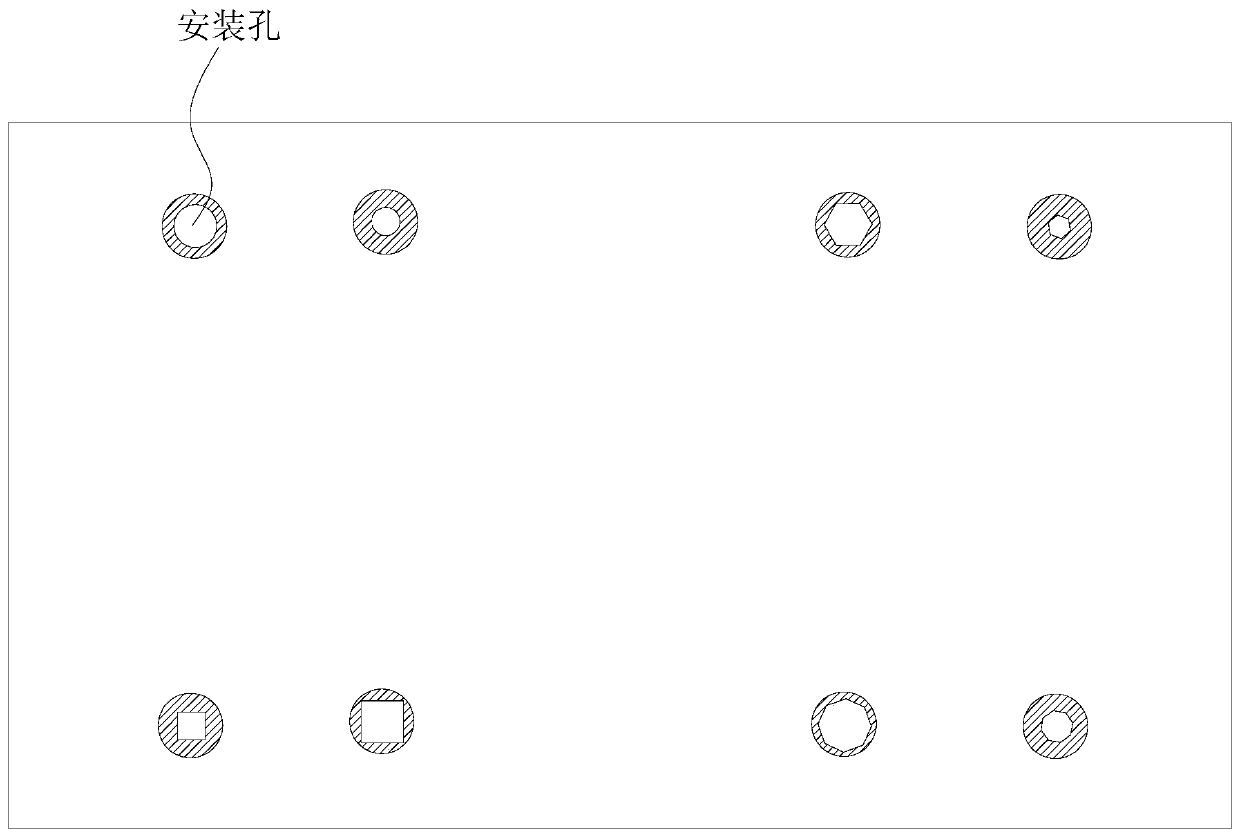

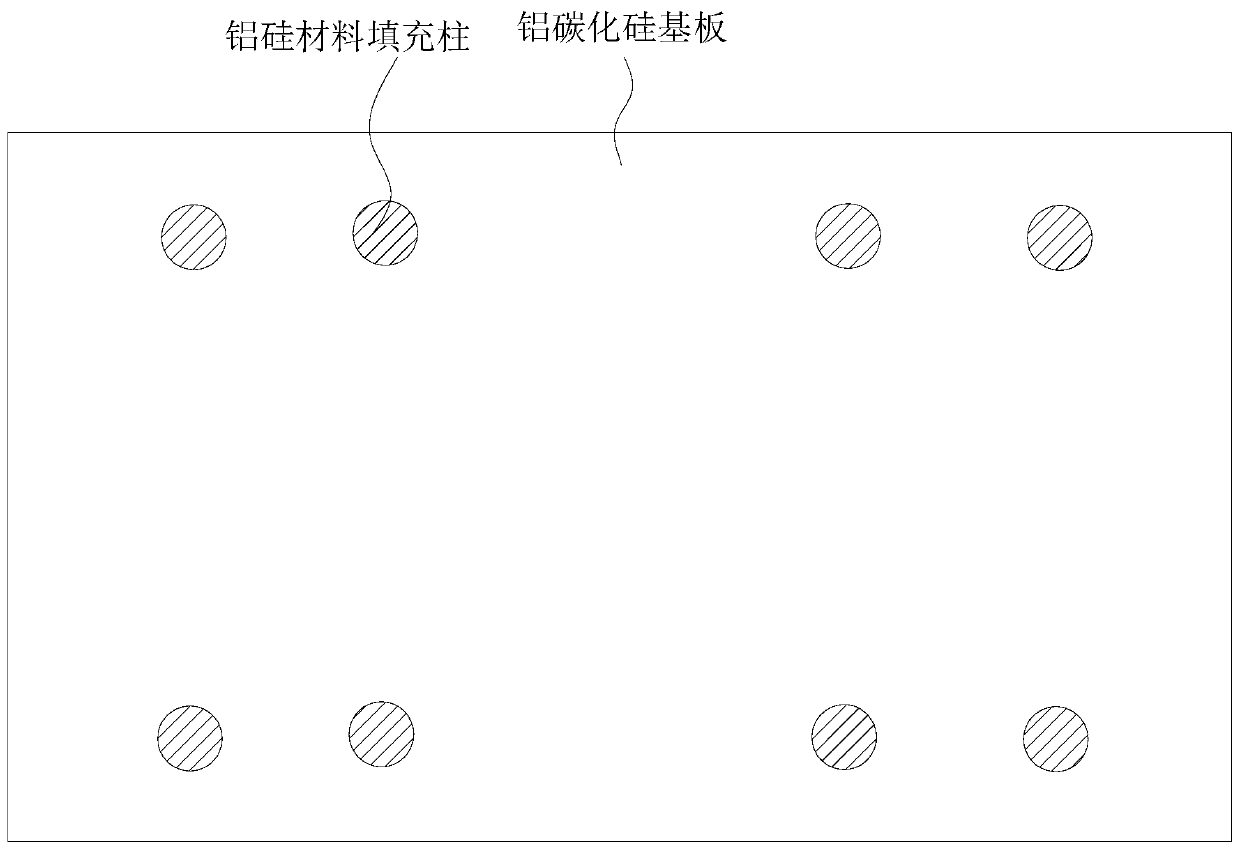

Aluminum silicon carbide packaging substrate and preparation method thereof

InactiveCN110277318AImprove performanceImprove and guarantee comprehensive performanceSemiconductor/solid-state device detailsSolid-state devicesSilicon chipCeramic substrate

The invention relates to the technical field of packaging substrates, and specifically relates to an aluminum silicon carbide packaging substrate and a preparation method thereof. The preparation method comprises the steps of firstly preparing and forming a silicon carbide ceramic substrate with hole positions and a silicon wafer matched with the hole positions, then inlaying the silicon wafer in the hole positions to form an integral ceramic substrate, and aluminizing the integral ceramic substrate to form an aluminum silicon carbide substrate with aluminum silicon carbide and an aluminum silicon bi-phase material. Installation holes with various shapes and sizes can be easily manufactured by machining on the aluminum silicon material at the hole positions, not only screw holes can be manufactured, and the screw holes are not easy get loosened, thereby solving a problem that the installation holes on the aluminum silicon carbide packaging substrate are difficult to be processed and manufactured. According to the manufacturing method, the aluminum silicon material at the hole positions is firmly combined with the aluminum silicon carbide material and not easy to crack and fall off, thereby enabling the installation holes manufactured on the aluminum silicon material to be high in reliability.

Owner:西安明科微电子材料有限公司

Saturated fatty acid sterile pipeline transportation device

ActiveCN111350942AEasy to operateReliable sterilization effectPipeline systemsProcess engineeringElectrical and Electronics engineering

The invention relates to a saturated fatty acid sterile pipeline transportation device which solves the technical problems that it is hard to transform and mount an existing transportation pipeline, it is needed to stop pipeline transportation during maintenance, a pipeline heating function and a sterilizing function at the connection of the transportation pipeline and a reaction kettle are not available, the heating efficiency is low and the like. The saturated fatty acid sterile pipeline transportation device is provided with the transportation pipeline, wherein a supplementary port heater is arranged at the tail end of the transportation pipeline, the supplementary port heater is provided with a sleeve, a water return valve of the supplementary port heater and a water inlet valve of thesupplementary port heater, the sleeve separately communicates to the water return valve of the supplementary port heater and the water inlet valve of the supplementary port heater, separately, and the upstream end of the sleeve communicates to the transportation pipeline. The transportation pipeline is further provided with a pipeline heater and a sterilizing device. The invention can be widely applied to the saturated fatty acid sterile pipeline transportation device.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

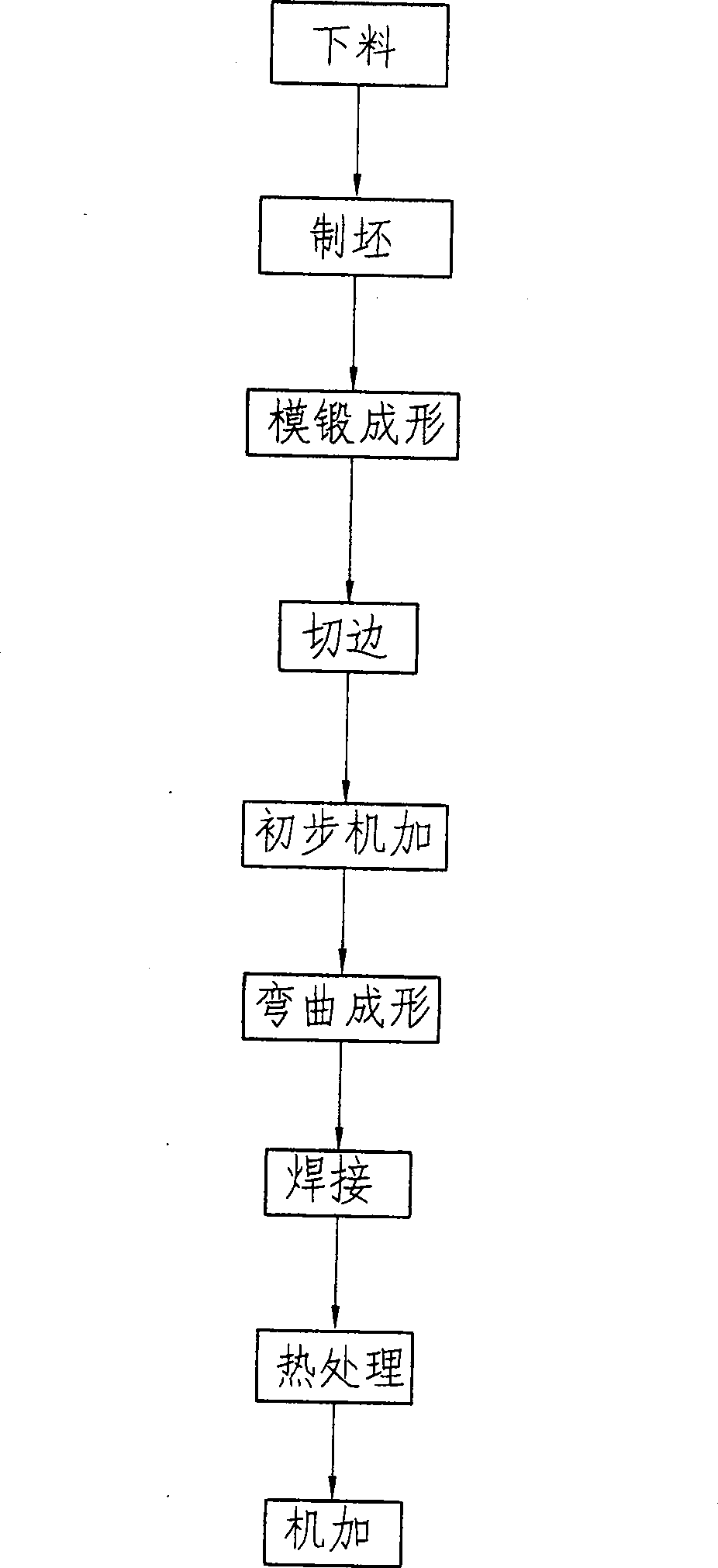

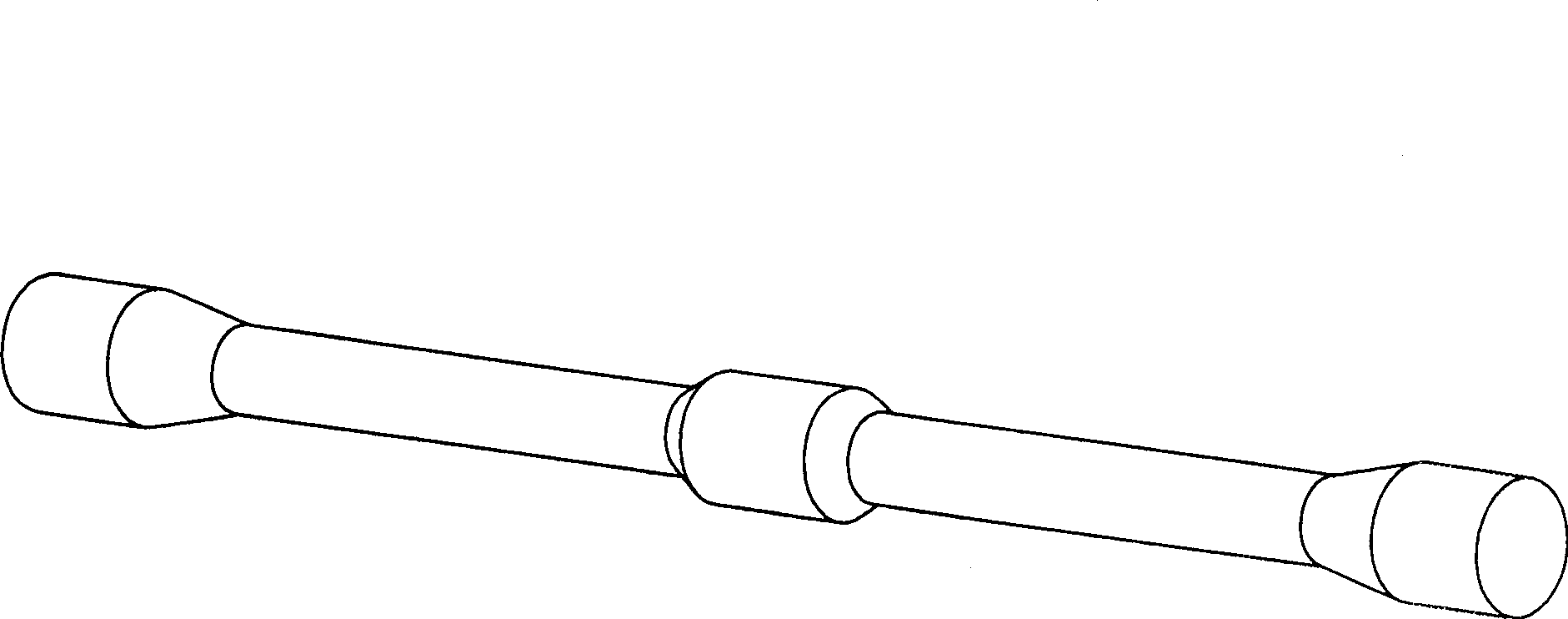

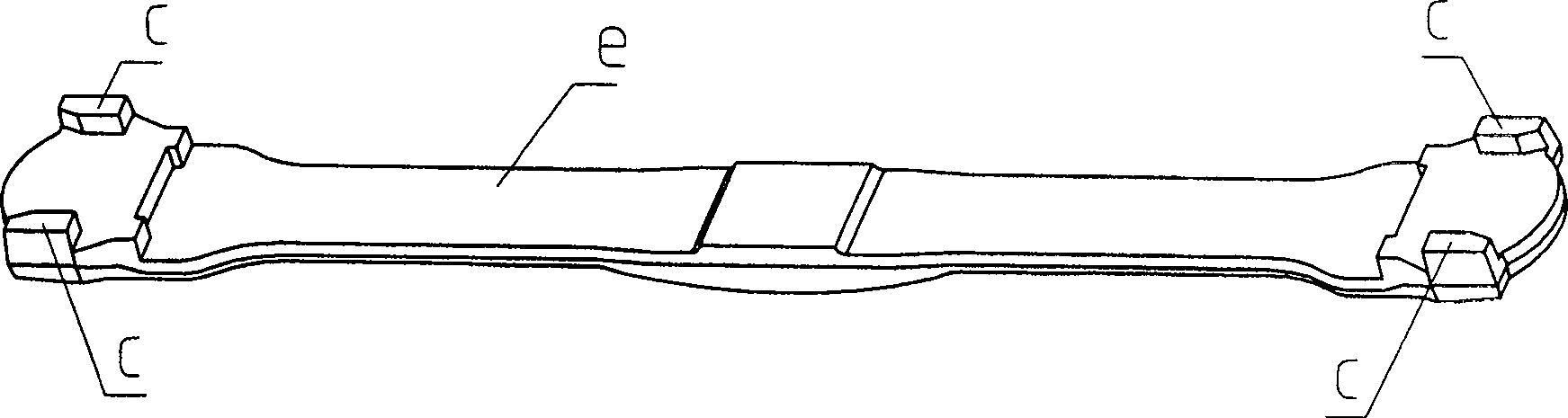

Method for forging combined forged steel coupler yoke for railway vehicles

ActiveCN100486760CSmall machining allowanceReduce workloadMetal-working apparatusOther manufacturing equipments/toolsHigh volume manufacturingMetal fibers

The invention relates the forging method of composite steel-forged coupler yoke frame, comprising blanking, making flan, die forging forming, cutting edge, preprocessing, bending forming, welding, heat treatment and machining. Making flan is that the blank is forged to get the explosion blank whose shape and size are close to coupler yoke frame; die forging forming is that the blank is putted in final forging mold cavity to get the explosion rough; bending forming is that the explosion rough is bended to U-shaped; welding is combination welding to form butt plate of coupler yoke frame. The invention possesses the following characters: metal fiber current direction is good, forging forming is easy, the die lifetime is long, forging and machining difficulty are reduced, material utilization is high, and the cost is low.

Owner:CHONGQING CHANGZHENG HEAVY IND

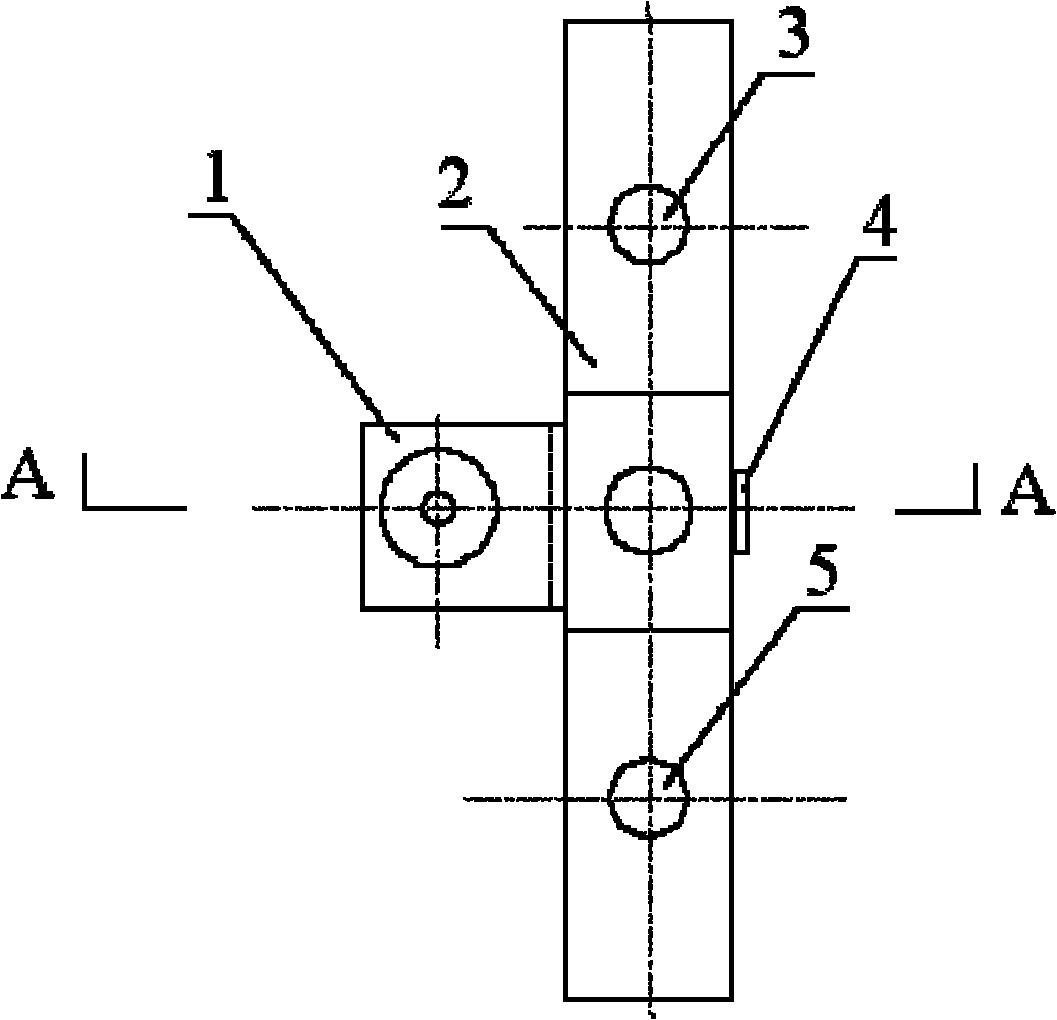

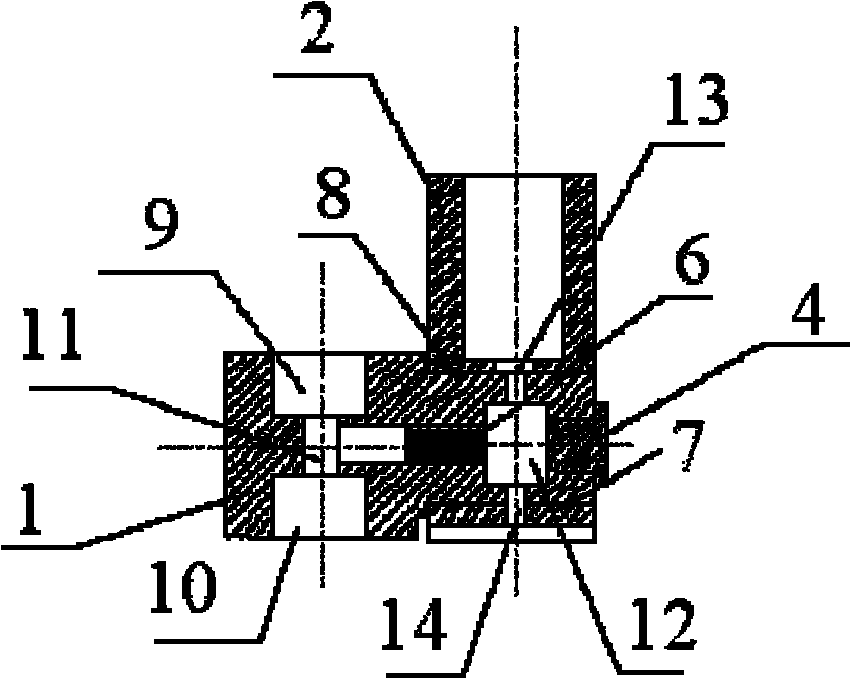

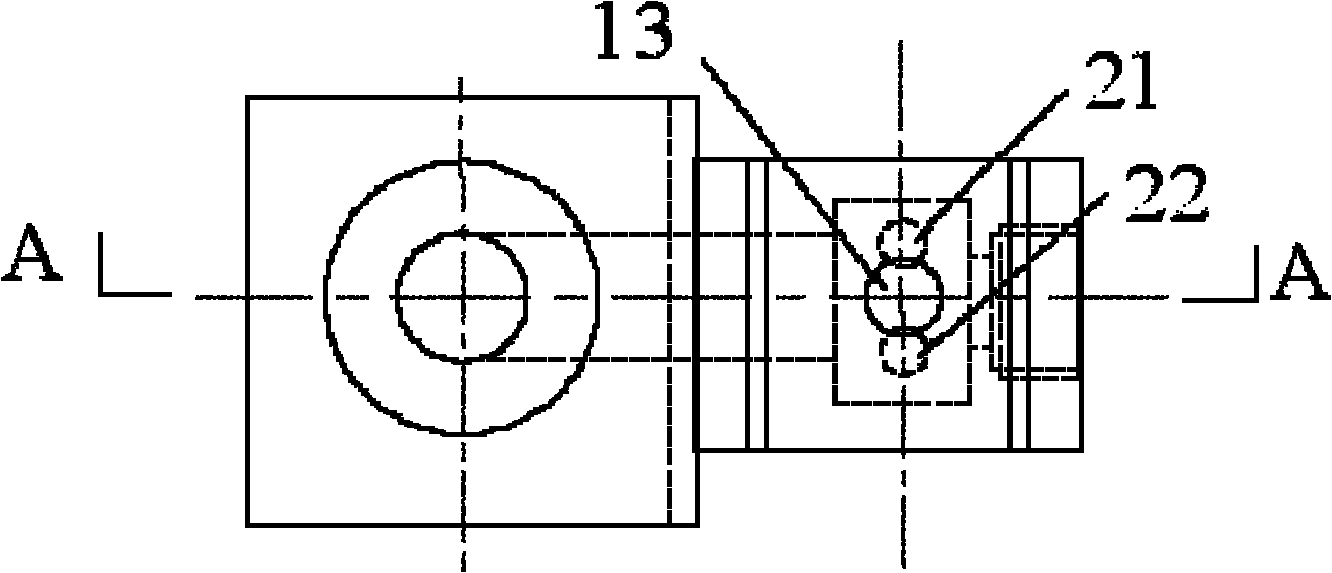

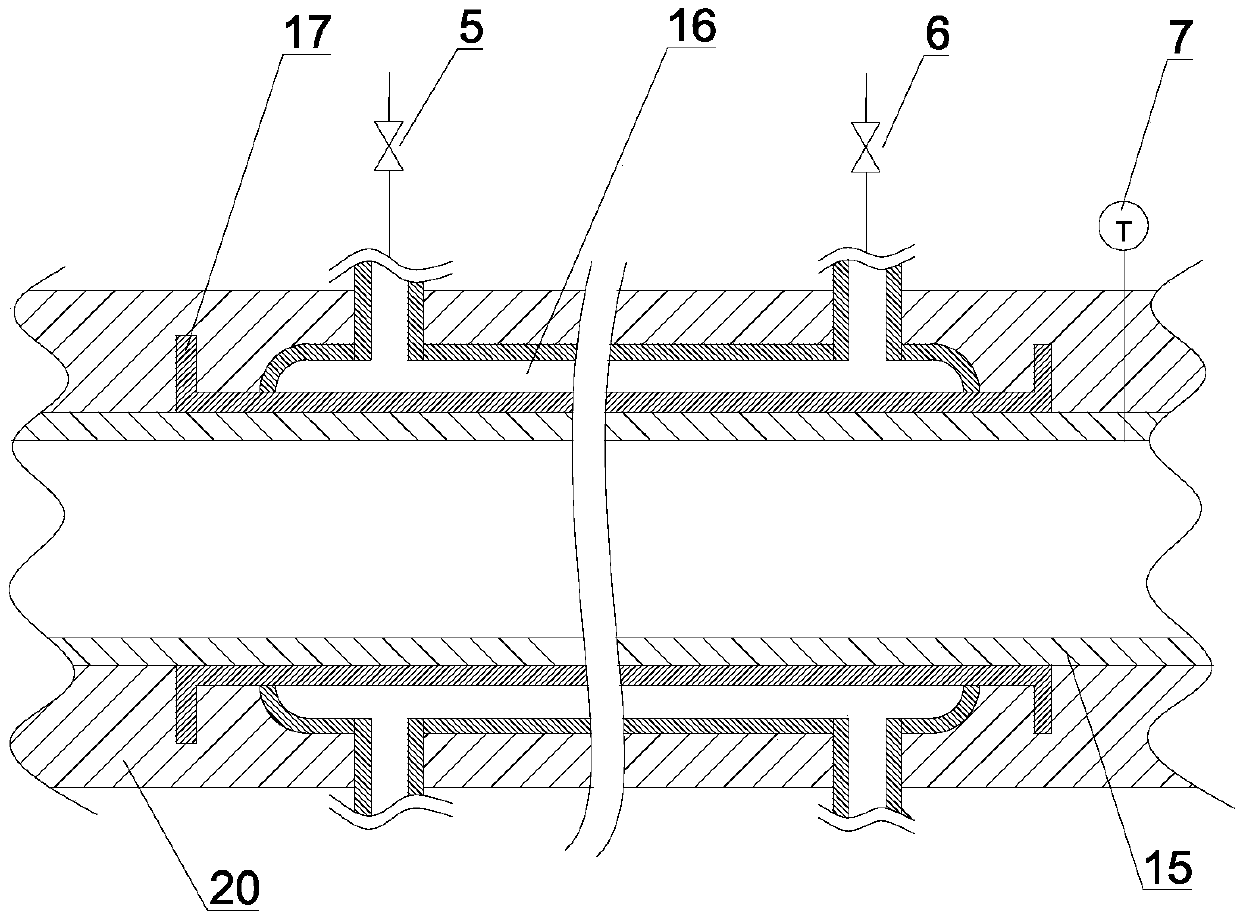

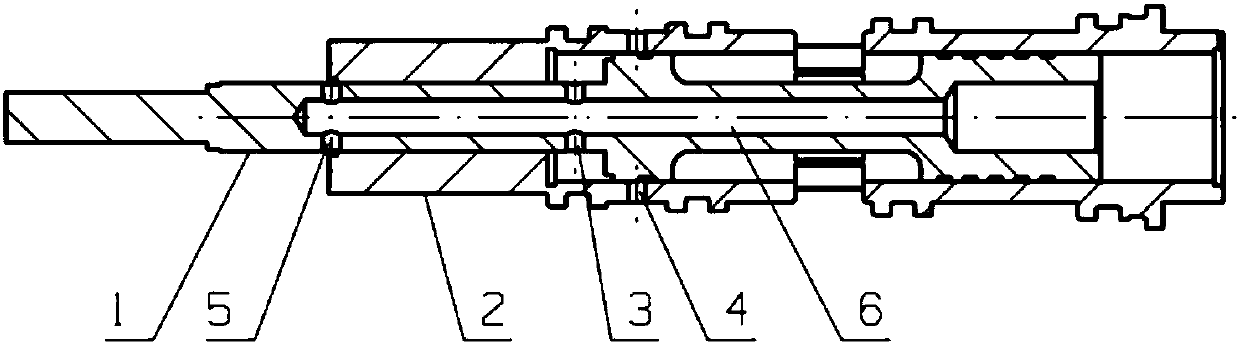

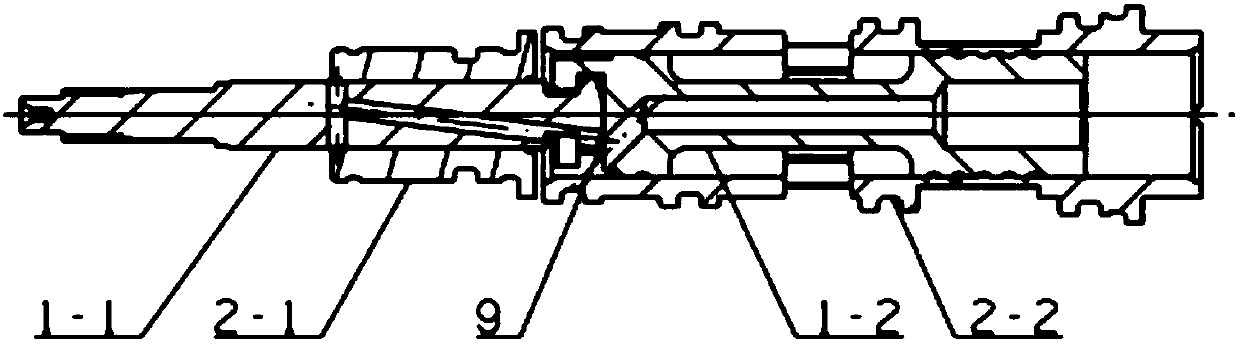

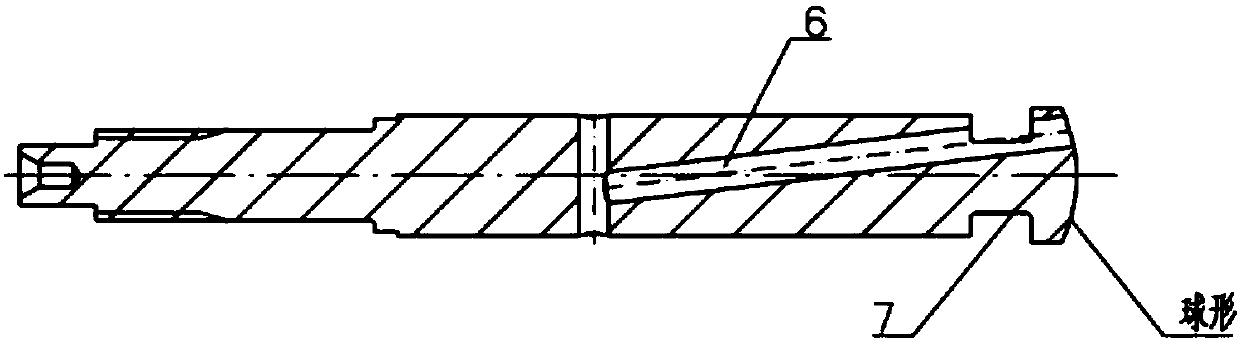

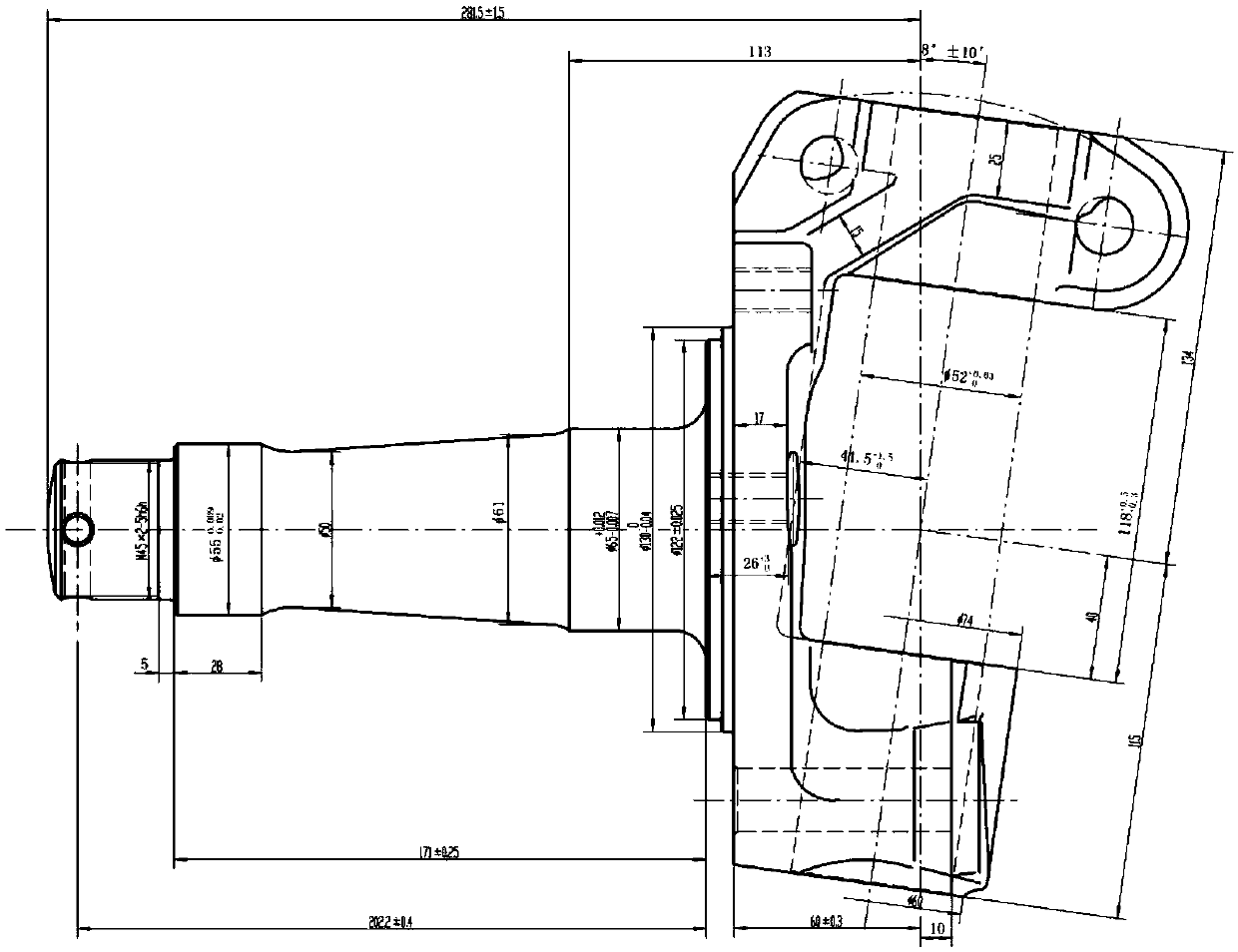

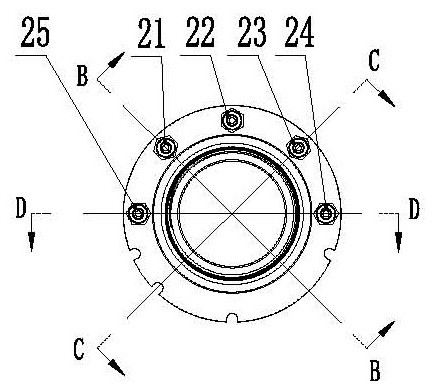

Split metering valve

ActiveCN109653878AReduce processing difficultyReduce the difficulty of machiningTurbine/propulsion fuel controlValve housingsFuel oilEngineering

The invention belongs to the technical field of mechanical hydraulic control, and relates to a split metering valve. The metering valve comprises a valve body (1) and a bush (2), and the bush (2) sleeves the valve body (1). A servo fuel oil inlet hole (3) and a servo fuel oil inlet hole (4) are formed in the valve body (1) and the bush (2) correspondingly. A throttling hole (5) and a servo oil path (6) are formed in the valve body (1). The split metering valve is characterized in that the valve body (1) and the bush (2) are split, the valve body (1) is divided into a valve (1-1) and a valve (1-2), and the valve body (1) is divided into two portions by the servo fuel oil inlet hole (3). The bush (2) is divided into an instruction control section (2-1) and a fuel oil metering section (2-2) according to a function section. The machining difficulty is reduced, the series connection manner is adopted for connection in the assembling process, all the portions can be aligned by themselves, the cooperation difficulty is reduced, and assembling efficiency is improved.

Owner:XIAN AERO ENGINE CONTROLS

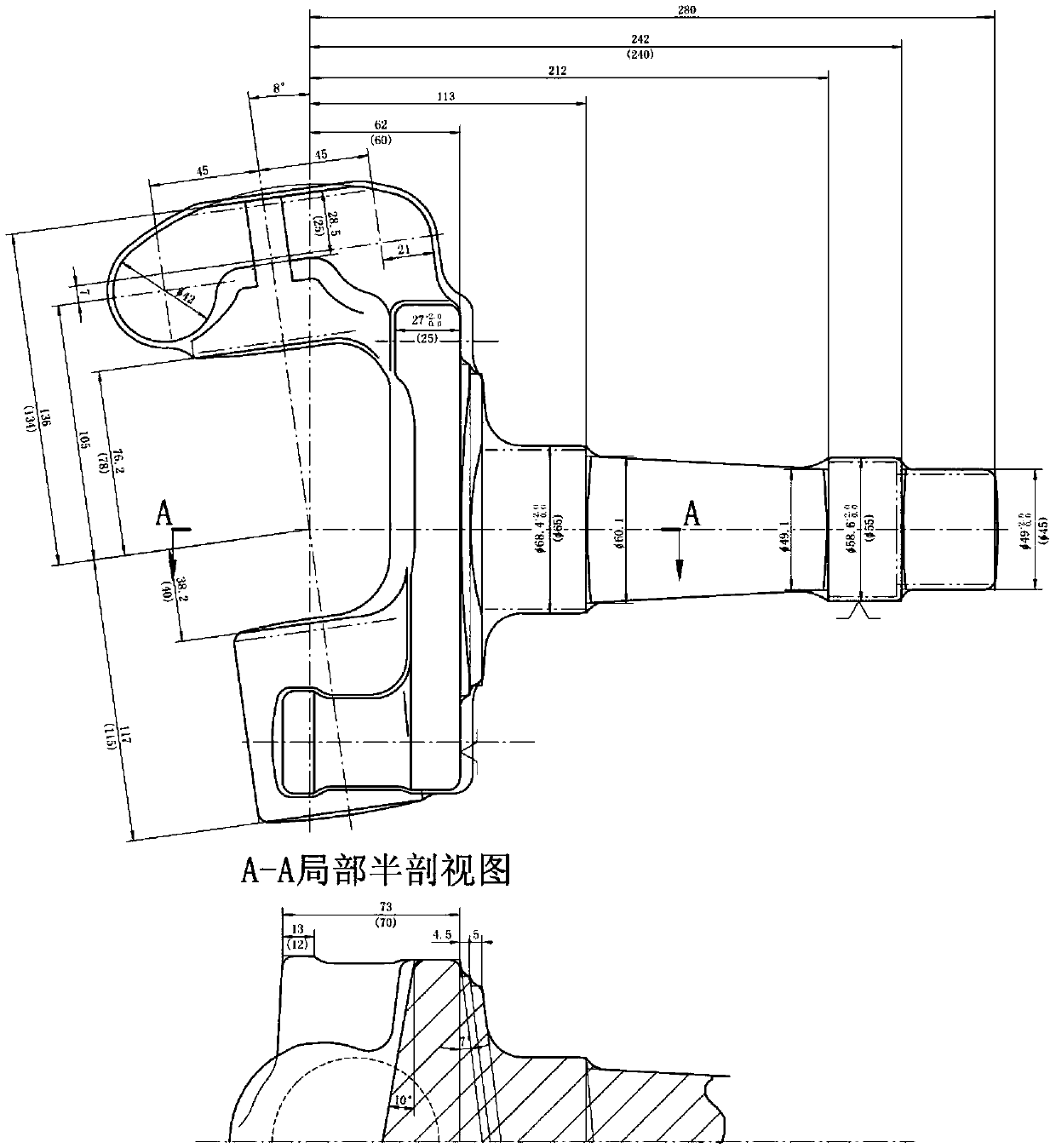

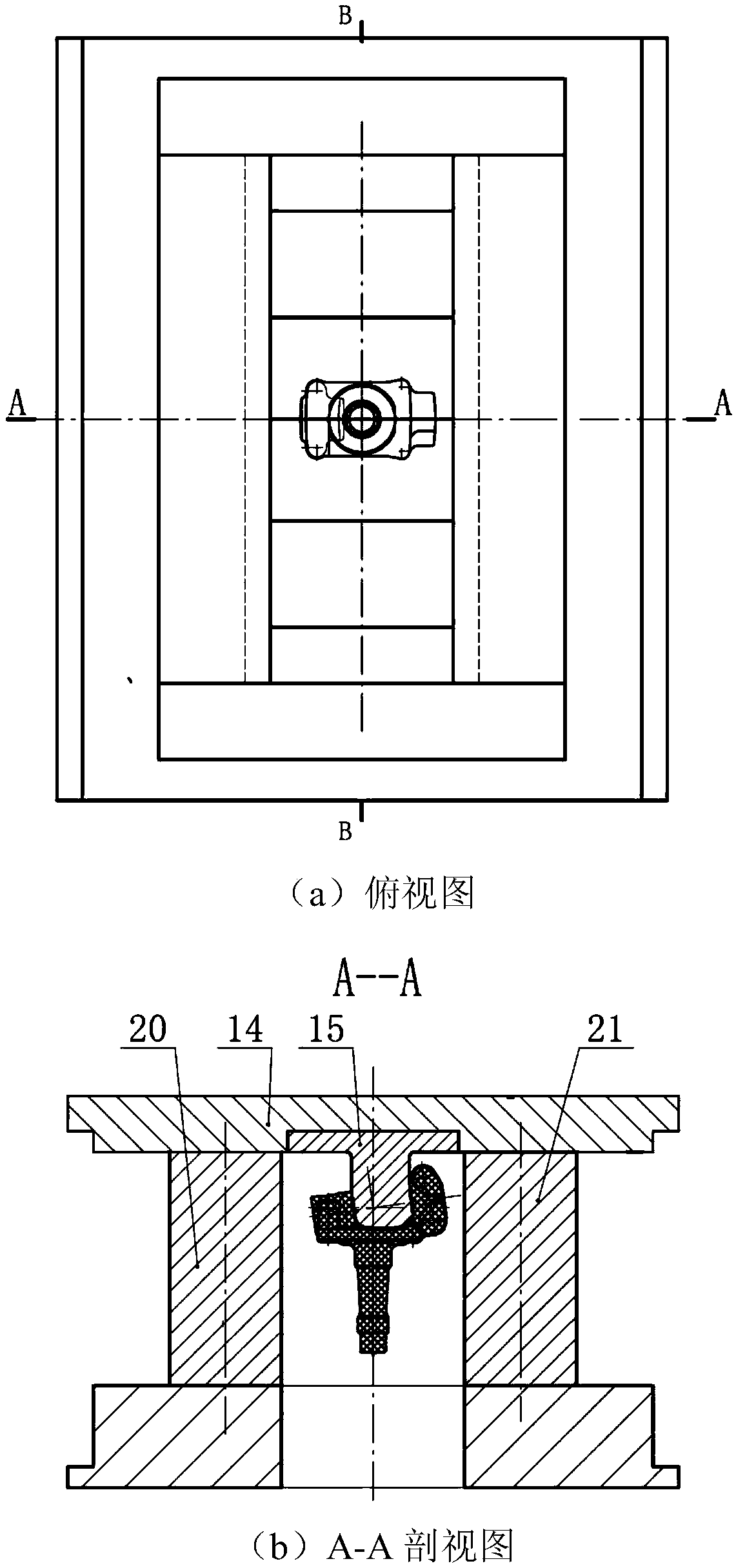

Technology and mold for pressure sizing and net shaping of drum-type knuckle flange

InactiveCN109676071AIncrease profitReduced processing performanceForging/hammering/pressing machinesReciprocating motionEngineering

The invention provides a technology and mold for pressure sizing and net shaping of a drum-type knuckle flange, wherein a drum-type knuckle forge piece produced with a horizontal-parting and horizontal-mold-forging technology is used on hammer equipment; the forging piece is put at a vertical state by a vertically divisible concave mold after edge cutting; and acting force is applied with a convexmold, so the flange with a large draft angle can satisfy the size required form a drum-type steering part flange after pressure sizing and net shaping. The invention also provides the mold used to implement the above method. The mold comprises a concave mold frame, a combined convex mold, a divisible concave mold and a divisible concave mold openable mechanism, wherein the concave mold is openedand closed under reciprocating motion of an ejection oil cylinder piston rod and motion of a rotatable hinge and a T-shaped guide device on the divisible concave mold, so the vertical pressure sizingand net shaping of the complicated knuckle forging piece can be realized. The technology and mold provided by the invention have the advantages that the amount and difficulty of subsequent machining are reduced and the material utilization rate is increased.

Owner:HUBEI TRI RING FORGING

Aluminum diamond composite material coated with aluminum silicon carbide layer on surface and preparation method and application thereof

PendingCN113149714AHigh thermal conductivityImprove thermal conductivityCarbide siliconAluminium matrix

The invention discloses an aluminum diamond composite material coated with an aluminum silicon carbide layer on the surface and a preparation method and application thereof. The aluminum diamond composite material comprises an aluminum diamond core material and the surface aluminum silicon carbide layer coated outside the aluminum diamond core material; the aluminum diamond core material comprises an aluminum matrix and surface-modified diamond particles; the surface aluminum silicon carbide layer comprises an aluminum substrate and silicon carbide particles, the volume fraction of the silicon carbide particles is 60%-75%, and the aluminum substrate in the surface aluminum silicon carbide layer and the aluminum substrate in the aluminum diamond core material are continuous distribution phases. According to the aluminum diamond composite material coated with the aluminum silicon carbide layer on the surface, the surface aluminum silicon carbide layer can prevent the diamond particles in the aluminum diamond core material from being exposed, and the machining difficulty and the surface roughness of the aluminum diamond composite material coated with the aluminum silicon carbide layer on the surface are reduced. The surface aluminum silicon carbide layer is high in heat conductivity and expansion coefficient and is matched with the aluminum diamond core material, and the interface stress between the aluminum silicon carbide layer and the aluminum diamond core material is low, so that the application in the aerospace field with high temperature cycle requirements is met.

Owner:HUNAN HARVEST TECH DEV

Sealing structure of horizontal axially split pump and mounting method of sealing structure

ActiveCN110671356AReduce in quantityReduced processing performancePump componentsPumpsImpellerEngineering

The invention provides a sealing structure of a horizontal axially split pump and a mounting method of the sealing structure. The problems that the process requirement of head-to-head metal sealing adopted for an existing horizontal axially split pump is high, the cost of flat gasket sealing is high, the reliability of gumming sealing is poor, and interstage sealing is lacked are solved. The sealing structure comprises a stereoscopic sealing groove and an integrated sealing element matched with the stereoscopic sealing groove. The stereoscopic sealing groove is formed by sealing ring sealing grooves located in the peripheries of N shell body sealing rings separately and a sealing groove in an upper pump body and a lower pump body. The sealing groove in the upper pump body and the lower pump body comprises two pump body sealing grooves in the axially split surface of the lower pump body and two pump shaft end sealing grooves. The two ends of the two pump body sealing grooves are connected with the two pump shaft end sealing grooves separately, and each sealing ring sealing groove is connected with the two pump body sealing grooves. N is determined by the stage number of the horizontal axially split pump, the impeller form and the impeller arrangement position.

Owner:西安航天泵业有限公司

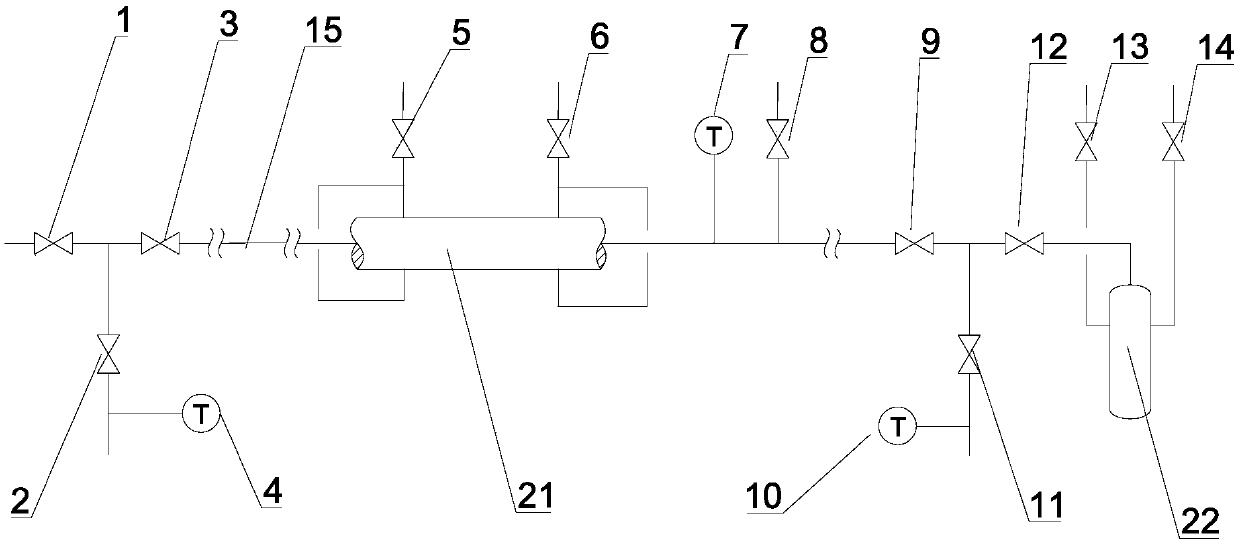

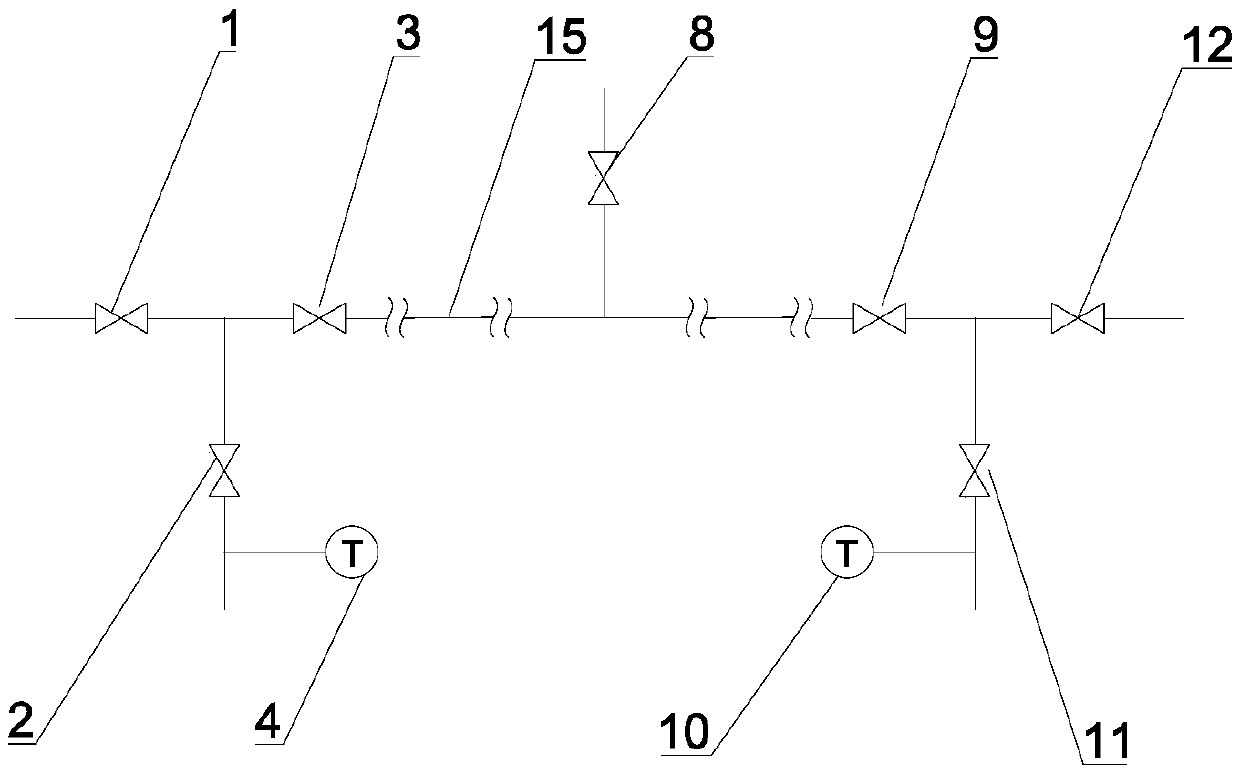

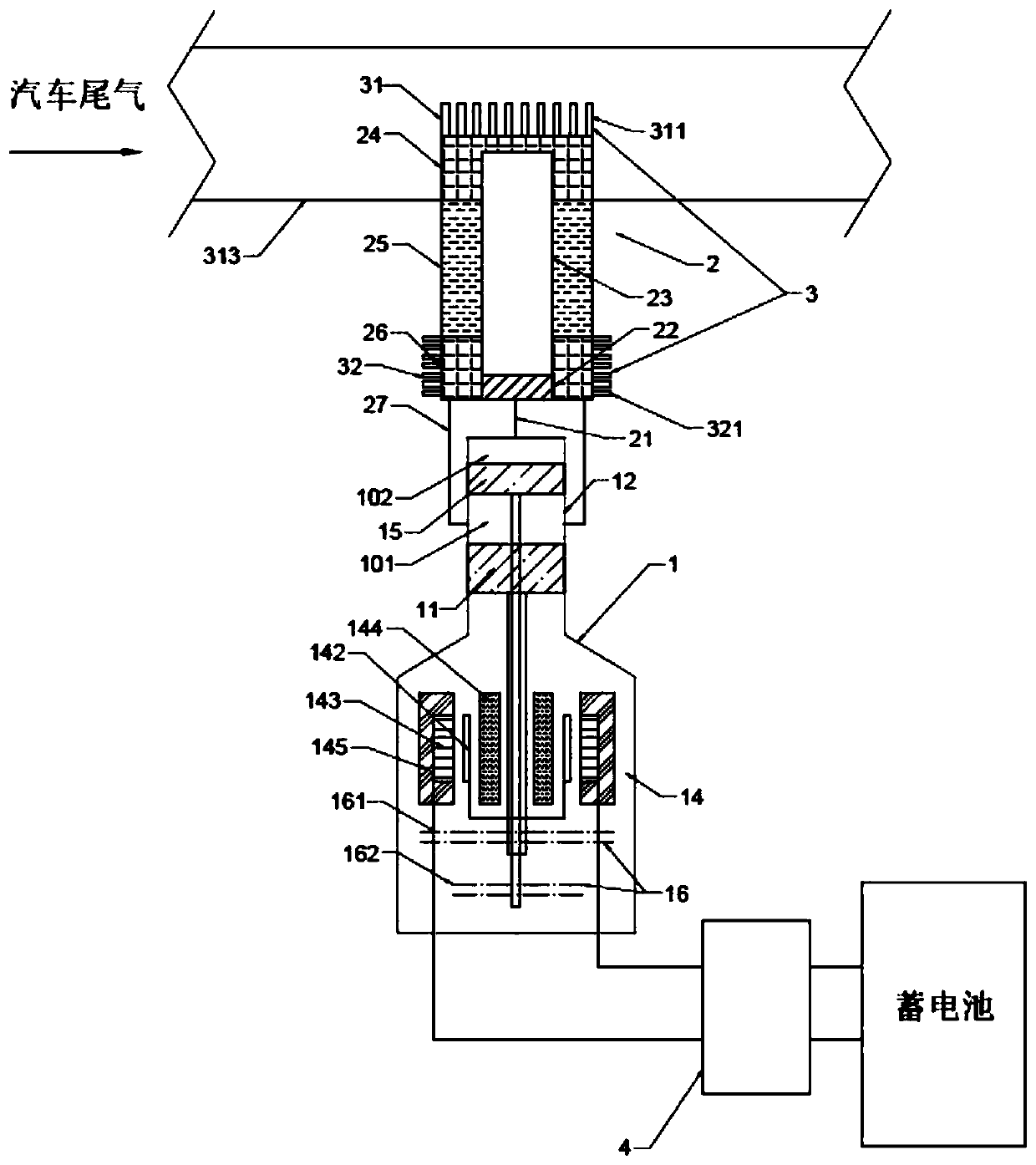

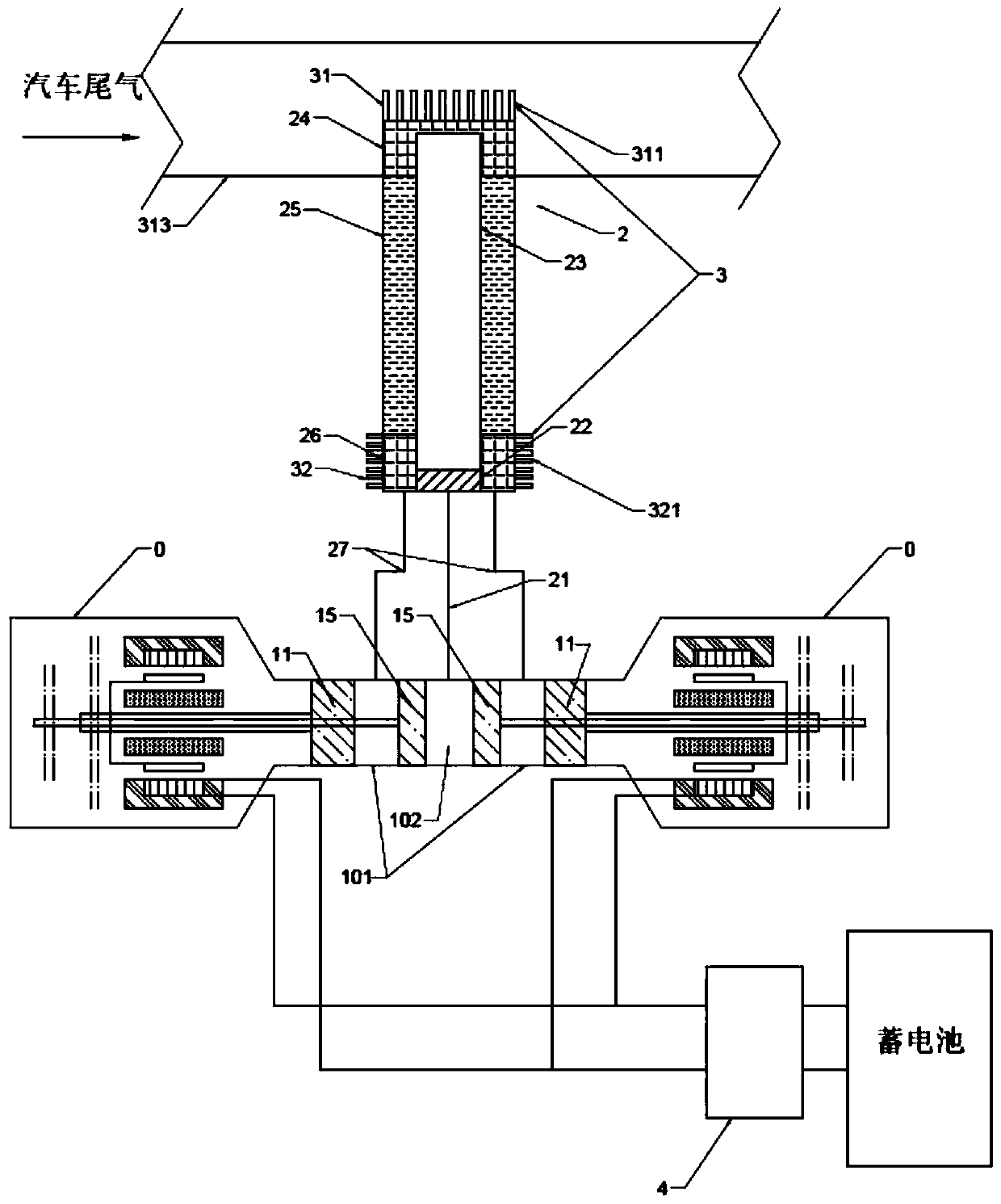

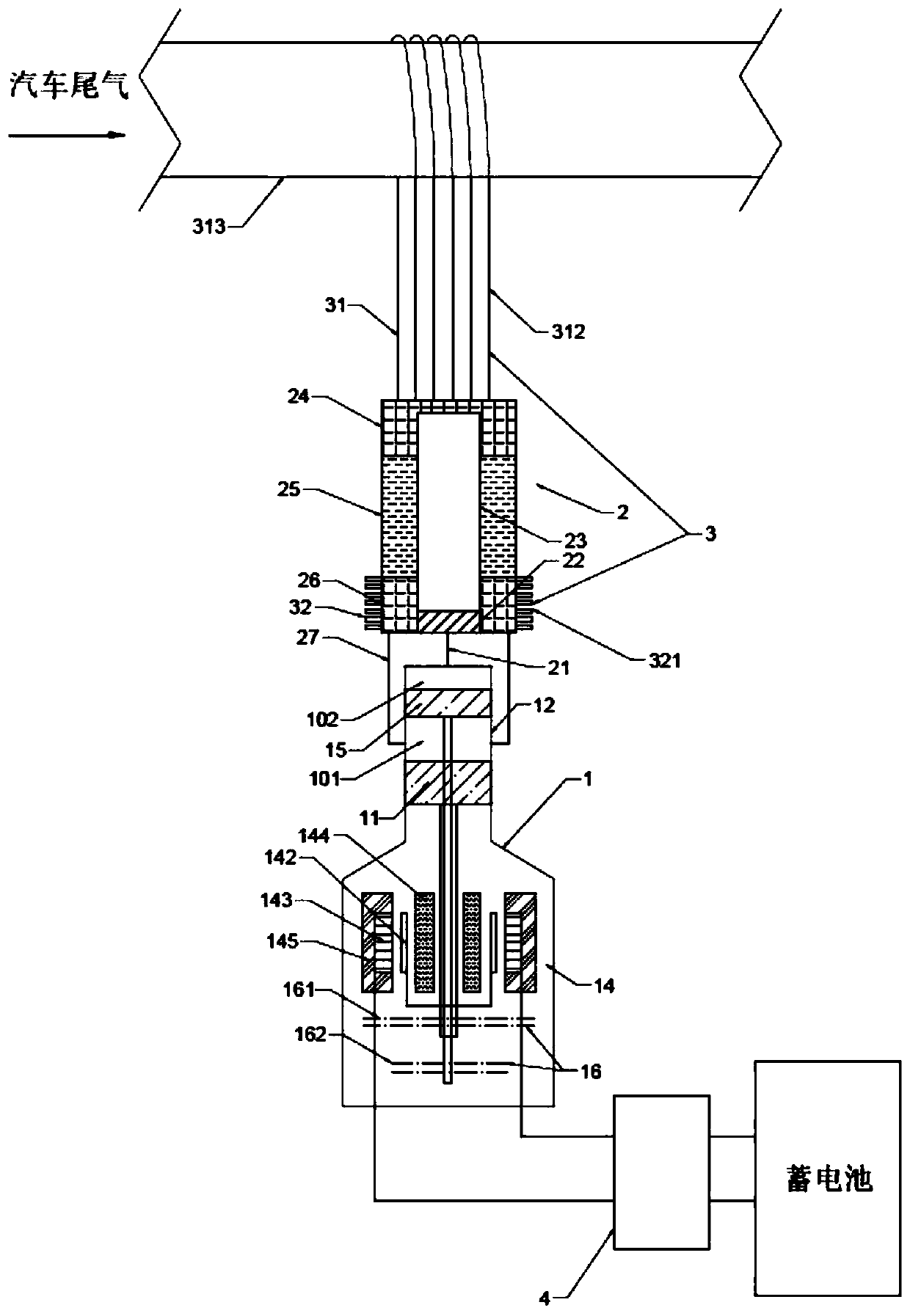

Automobile exhaust waste heat recycling and charging device based on pulse tube generator

ActiveCN110307066AReduce the difficulty of machiningImprove system reliability and manufacturing feasibilityCharging stationsInternal combustion piston enginesElectric generatorThermal energy

The invention relates to an automobile exhaust waste heat recycling and charging device based on a pulse tube generator. The device comprises an expansion machine (1) capable of recovering work, a pulse tube generator thermal head (2), a heat exchange system (3) and a rectifying system (4), wherein the heat exchange system (3) takes heat from high-temperature exhaust gas and then release heat at the room temperature end; through the simple harmonic motion of a piston of the expansion machine (1) capable of recovering work, the transmission of acoustical power from one high-temperature end to another high-temperature end and the recycling process of a working medium in the expansion machine (1) and the pulse tube generator thermal head (2) is completed, so that electricity power is generated by the piston motion of the expansion machine (1) to complete the process of electricity generation, thus being capable of charging automobile storage batteries though the rectifying system (4). Compared with the prior art, the automobile exhaust waste heat recycling and charging device based on the pulse tube generator has the advantages that thermal energy is recycled to provide power to an automobile while thermal pollution of the automobile is reduced, so that a positive circulation of energy saving and emission reduction inside the automobile is realized; in addition, no movement component is arranged at the high-temperance, no high-precision matching requirement is imposed, and the machining difficulty is low, thus being capable of improving reliability of a system and feasibilityof processing and manufacturing.

Owner:TONGJI UNIV

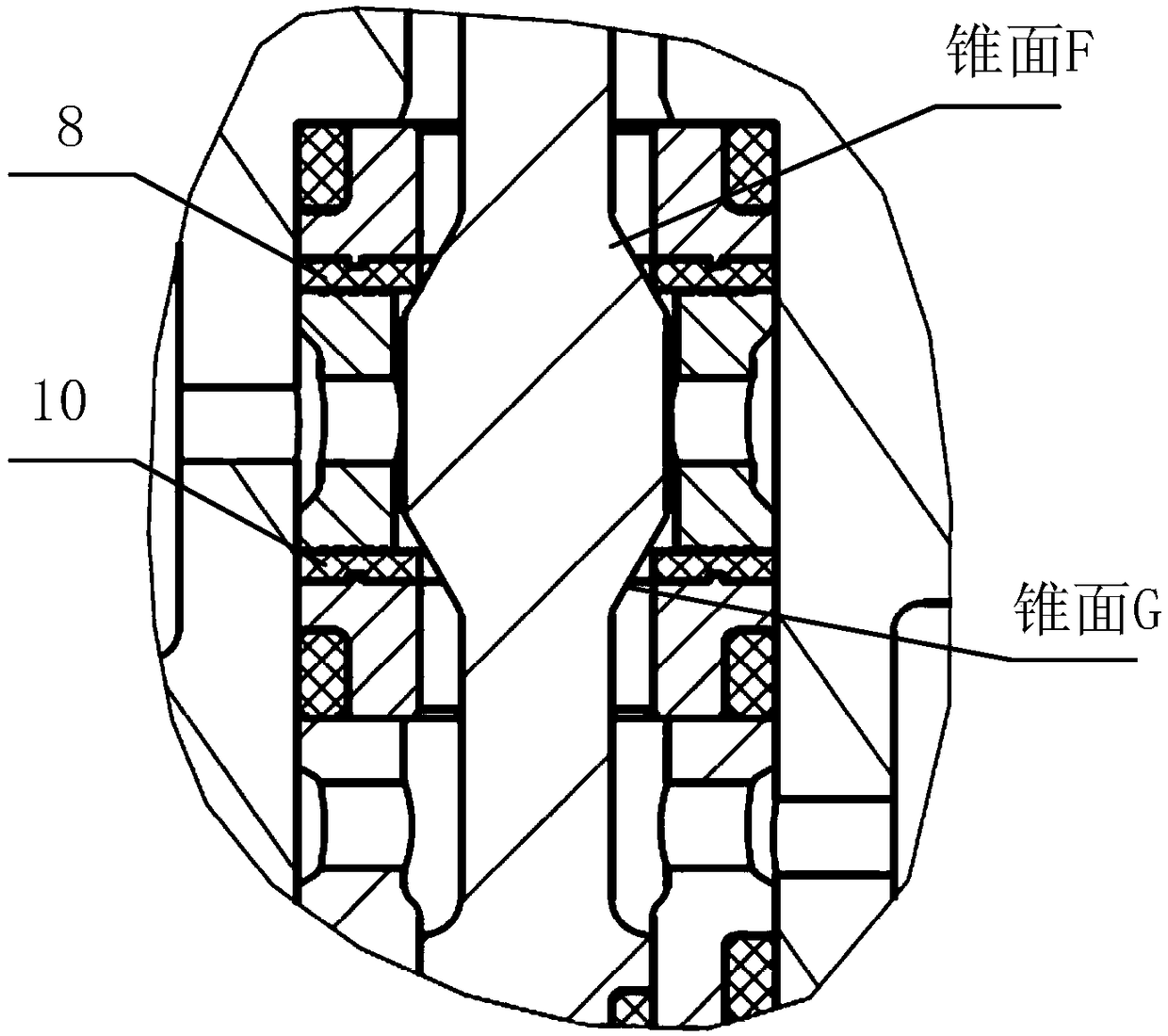

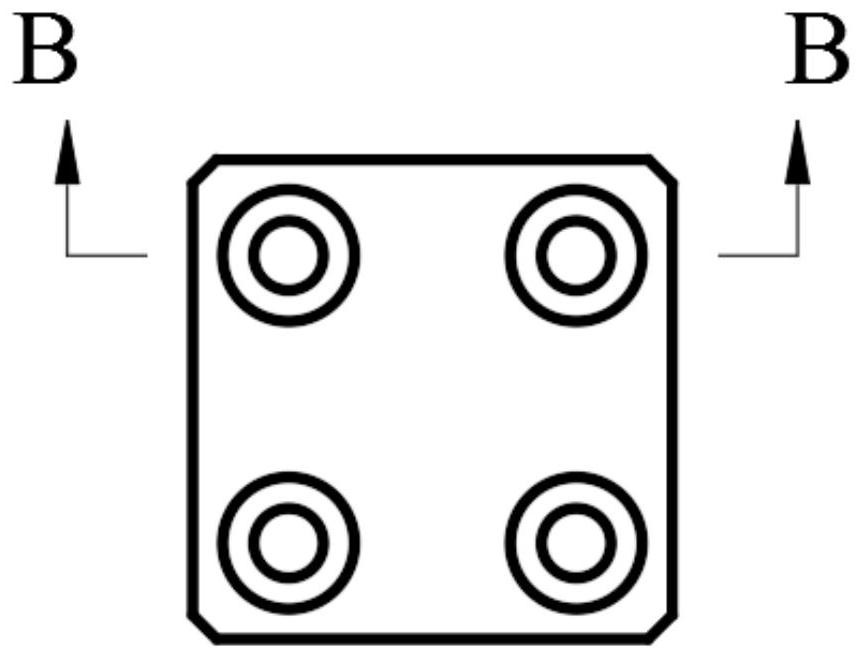

Assembling tool and assembling method for single-slit self-lubricating joint bearing

PendingCN112045393AEasy to processFlexible and convenient assembly operationMetal working apparatusSlider bearingStructural engineering

The invention relates to an assembling tool and assembling method for a single-slit self-lubricating joint bearing, and belong to the field of sliding bearing assembling. The tool and method involve the assembling tool and a support, the upper portion of the assembling tool is conical, the taper angle is 20-30 degrees, the size of the minimum position of the taper angle is smaller than that of theminimum position of the inner diameter of the end surface of the bearing, and the size of the maximum position is 5-8 mm larger than a spherical diameter of the joint bearing; a long-strip-shaped through groove is machined in the radial direction of the taper of the assembling tool, the assembling tool is made of 45 # or 42CrMo, and the hardness of a surface hardening layer of the assembling toolexceeds the hardness of a bearing outer ring and reaches HRC 60 or above; and the assembling tool needs to be used in cooperation with the cuboid support, and the cuboid support is placed right abovethe outer ring in the assembling process. According to the assembling tool, die machining is is simple, in the assembling process, the operation is flexible and convenient, hours of work are saved, no damage exists during joint bearing assembling, the product quality is greatly improved, and the using reliability of the bearing is guaranteed.

Owner:大连精一工业科技有限公司

Processing technique of new steel plate hoe

InactiveCN101584265BIncrease profitReduce labor intensityHoesSaving energy measuresSheet steelEngineering

The invention relates to a processing technique of a new steel plate hoe, belonging to the field of the general agricultural mechanism or agricultural tool technology. The producing technique uses belt steel and strip steel to mechanically mold a hoe plate and a hoe wedge via mechanical blanking; the hoe plate and hoe are jointed via welded connection with a high automation; the hoe is wearable with a great appearance, energy and fuel saving without smoke and dust pollution and noise pollution, which is especially suitable for the industrial production.

Owner:湖南省嘉禾县中兴工具有限公司

Intelligent well completion underground digital hydraulic communication controller

ActiveCN114704224AImprove reliabilityImprove stabilityConstructionsGeothermal energy generationMechanical engineeringPiston

An intelligent well completion underground digital hydraulic communication controller is characterized in that an upper connector is arranged at one end of a valve body, a lower connector is arranged at the other end of the valve body, a piston is arranged in the valve body, the two ends of the piston extend into the upper connector and the lower connector respectively, piston stop structures are arranged in the upper connector and the lower connector respectively, and a lock sleeve is arranged between the piston and the valve body; a first reset elastic structure body is sleeved on the piston in a seventh hydraulic cavity formed between the upper part of the lock sleeve and the piston; a sixth hydraulic cavity formed by a first radial groove and the lock sleeve, a fifth hydraulic cavity formed by a second radial groove and the lock sleeve, a fourth hydraulic cavity formed by a third radial groove and the lock sleeve and a second hydraulic cavity formed by a fourth radial groove and the lock sleeve are sequentially machined in the outer side wall of the valve body. A fifth radial groove is machined in the position, located on the inner side of the fourth hydraulic cavity, of the lock sleeve and forms a third hydraulic cavity with the piston, a first hydraulic cavity is formed between the piston below the lock sleeve in the axial direction and the valve body, a lock sleeve locking structure is arranged on the valve body in the first hydraulic cavity, and the piston is sleeved with a second reset elastic structure body.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com