Patents

Literature

1175 results about "Slider bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

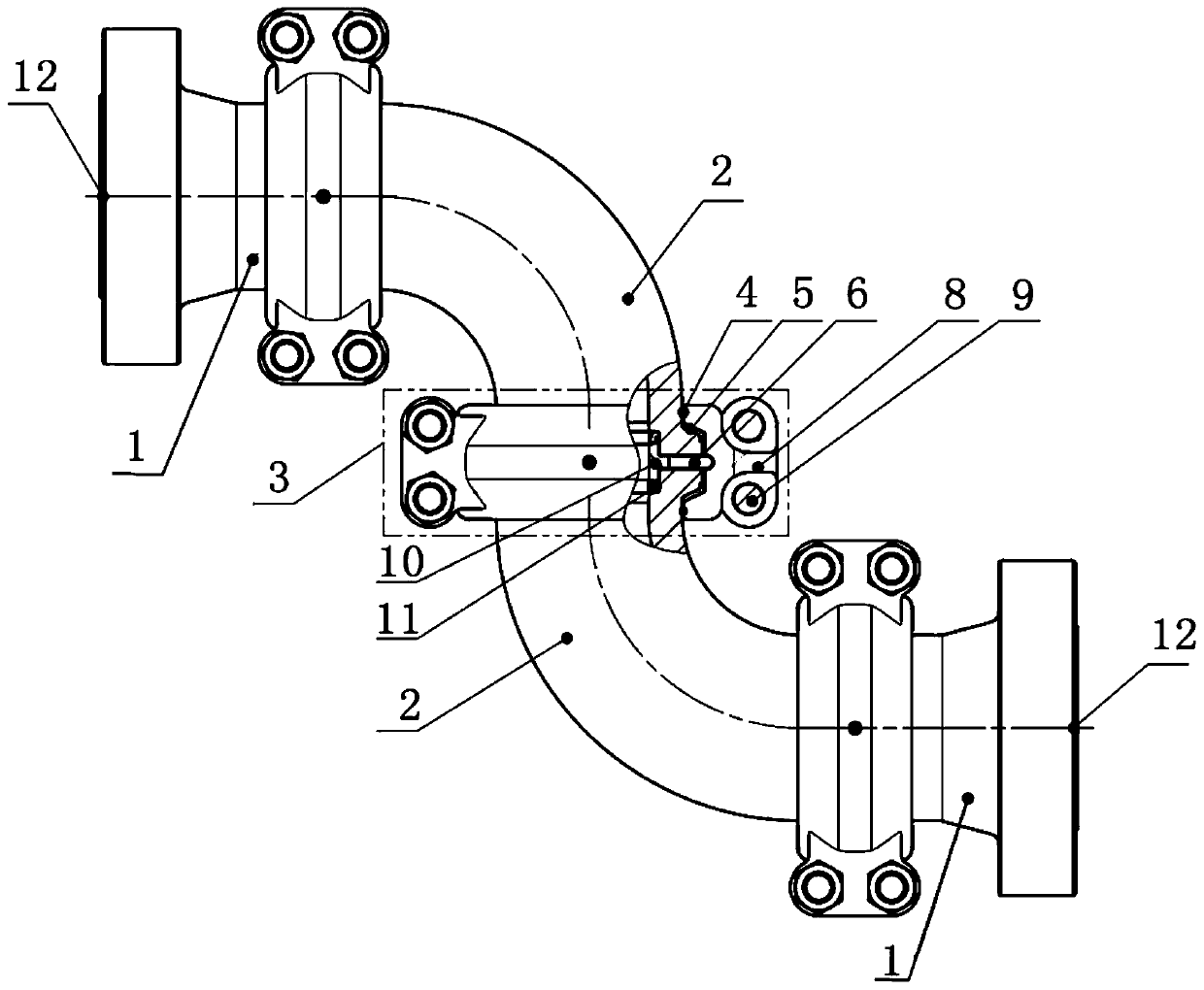

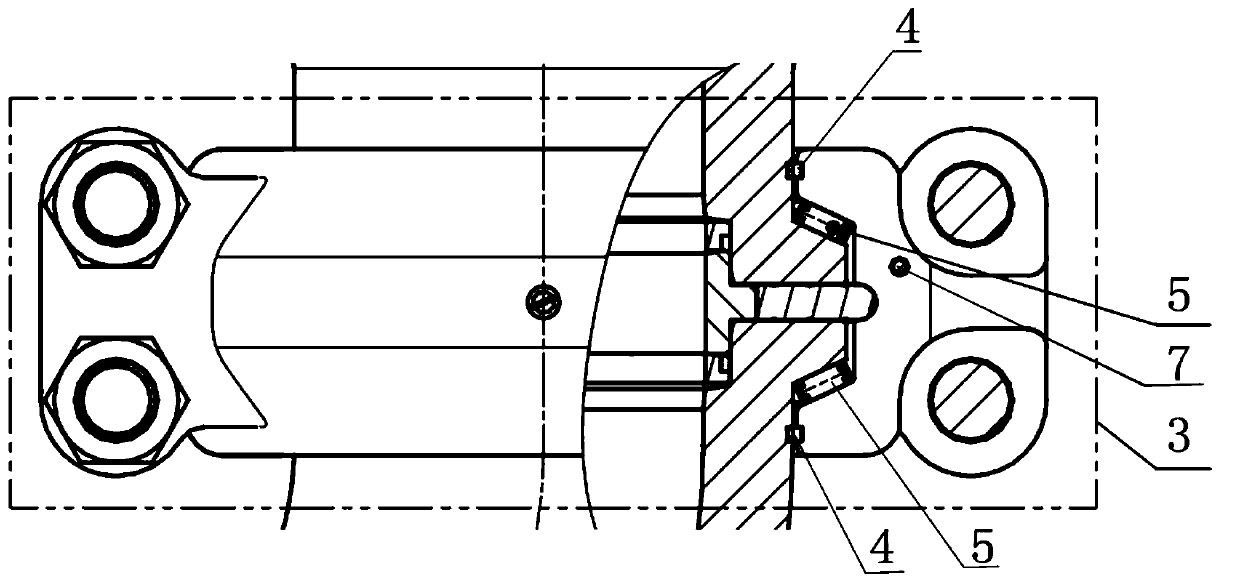

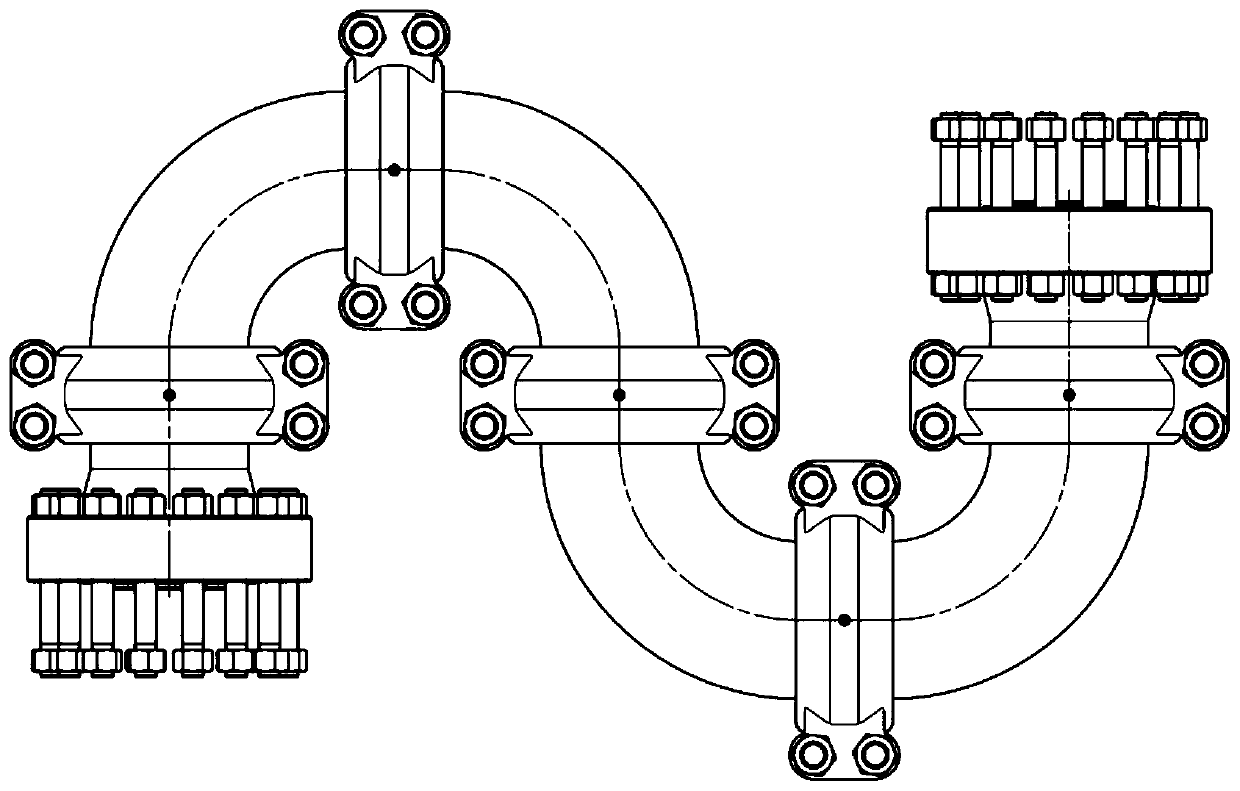

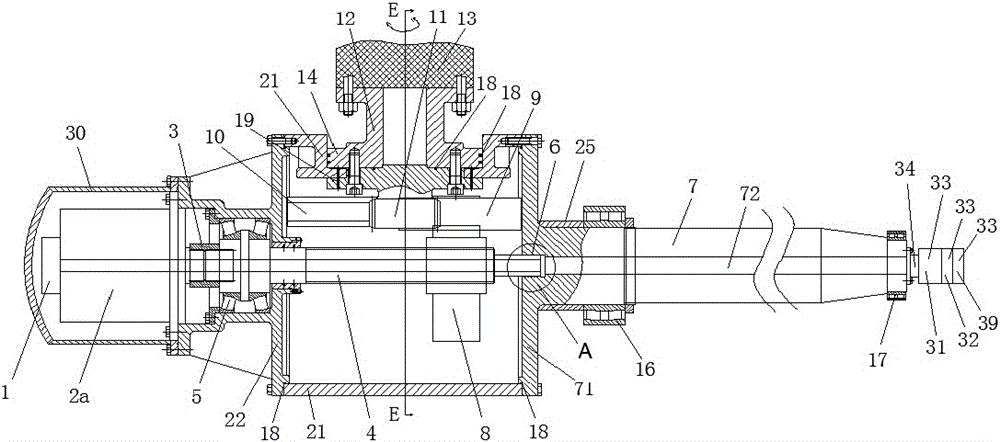

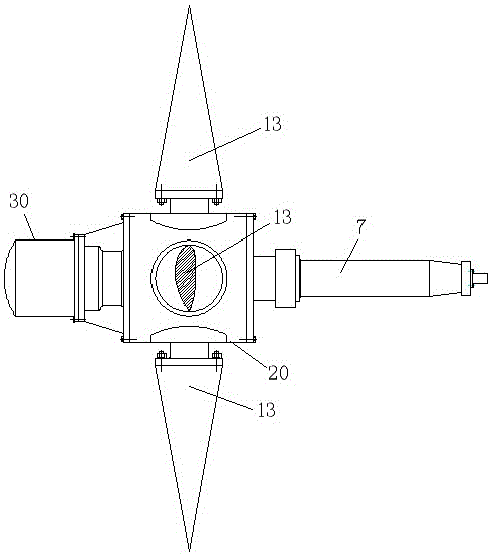

Large-sized high-pressure movable bend structure

PendingCN111594062ASmall structureVarious molding methodsDrilling rodsDrilling casingsSlider bearingRolling-element bearing

The invention discloses a large-sized high-pressure movable bend structure which comprises a connector, bends and hinging assemblies. The connector and the bend, and the bends are connected by the hinging assemblies. The connector is connected to upstream and downstream equipment. Each hinging assembly comprises a sealing mechanism, a rotating part and a hoop. The sealing mechanism is used for hermetically connecting the connector and the bend, and the bends. The hoop is used for connecting and fixing the connector and the bend, and the bends. The hoop and the connector or the hoop and the bend are connected by the rotating part. The rotating part is a rolling bearing or a sliding bearing. The large-sized high pressure movable bend structure has the beneficial effects that the structure islarger in diameter, flexible to connect, small in size, light in weight and diversified in forming mode, meets the operation demand of high pressure and large displacement of shale gas, lowers the input cost of operation equipment greatly, optimizes the site layout and is connected to the upstream and downstream equipment flexibly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

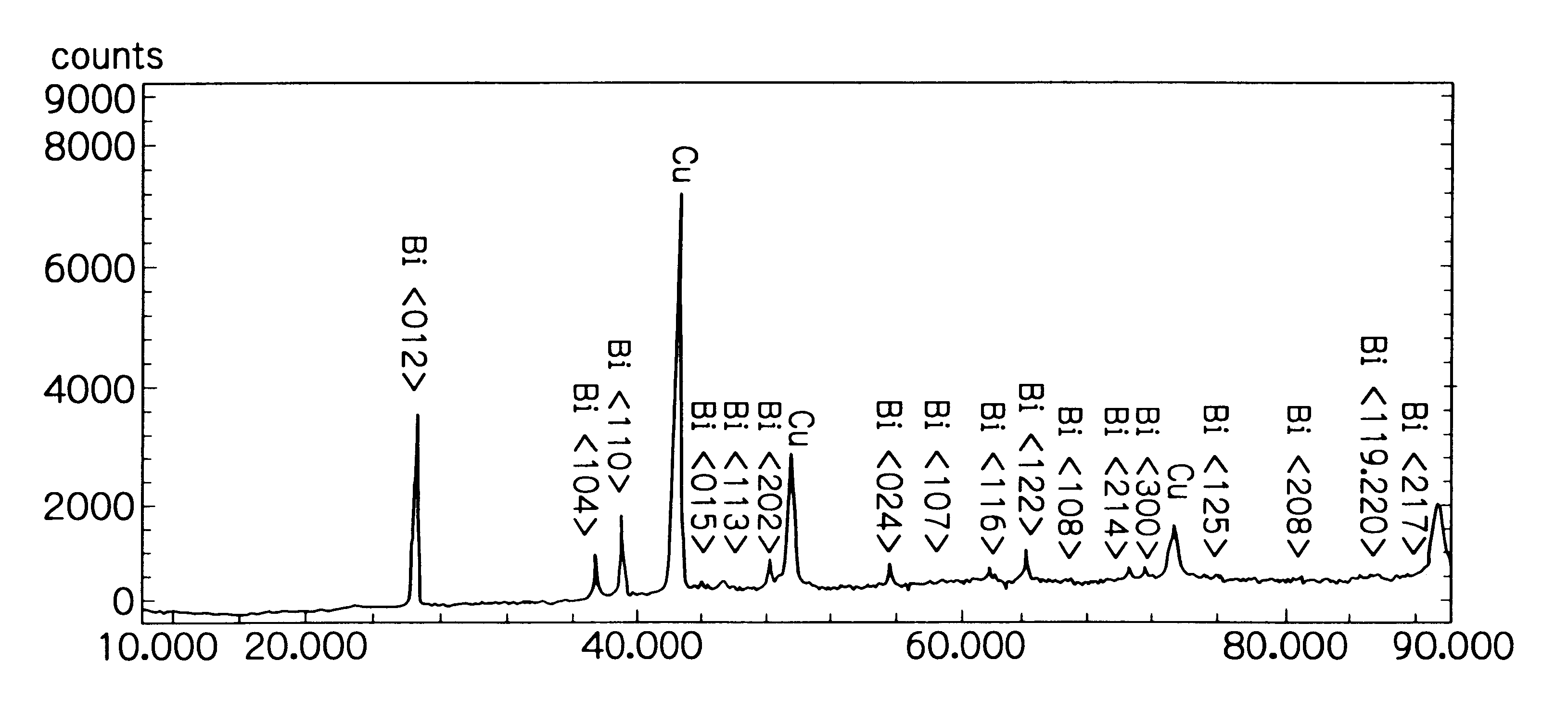

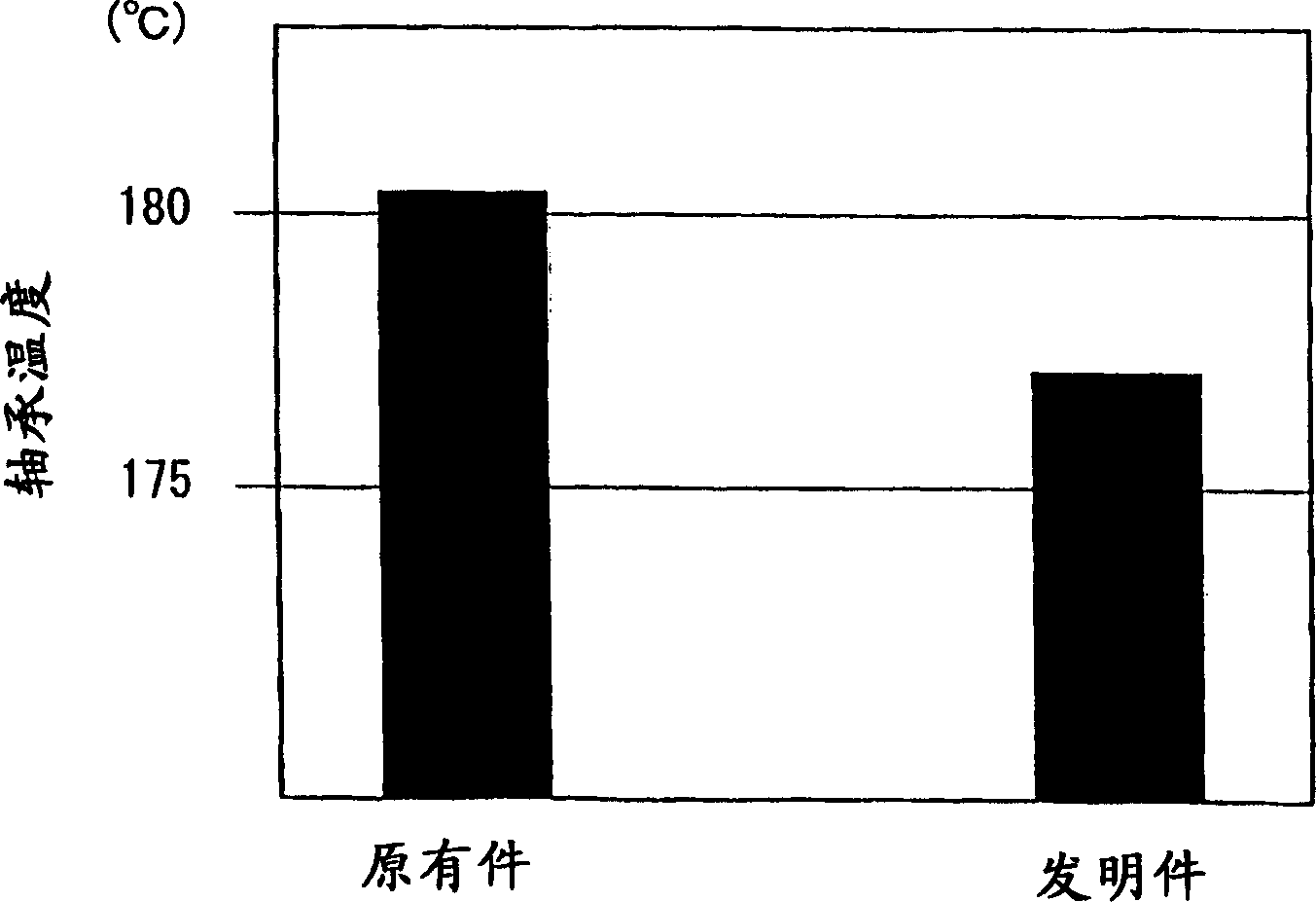

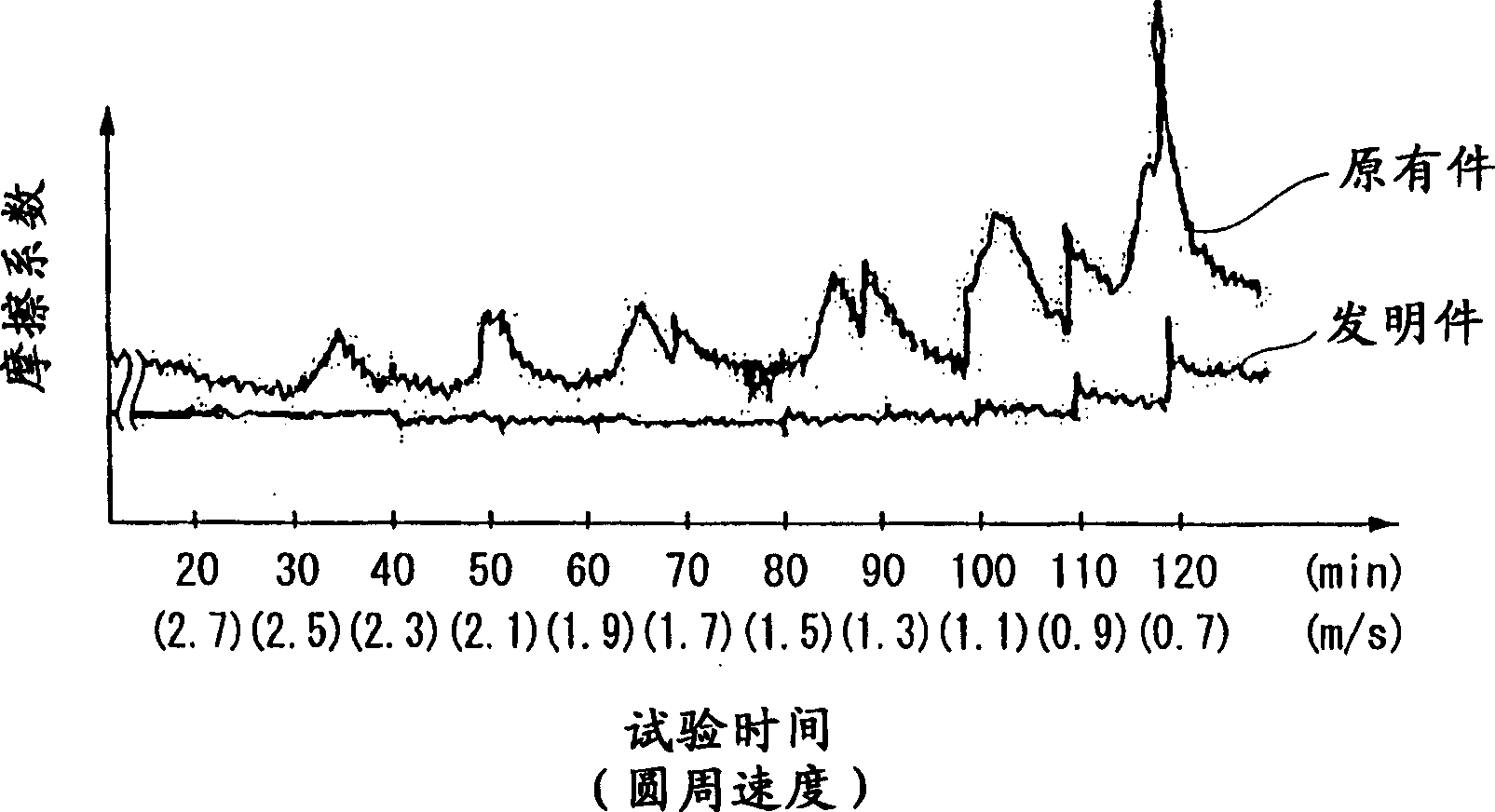

Sliding bearing and its production method

A sliding bearing, which comprises a lining and a bismuth or bismuth-alloy overlay having improved compatibility and fatigue resistance is provided. The overlay is characterized by the following orientation. The relative ratio of the X-ray diffraction intensity I[hkl] of the bismuth or bismuth-alloy overlay defined below satisfies the following conditions (a) and (b):(a) the relative ratio of the X-ray diffraction intensity I[hkl] of planes other than the {012} planes is from 0.2 to 5 times as high as the ratio of the X-ray diffraction intensity I[012], namely, 0.2I[012]<=I[hkl]<=5I[012](b) the relative ratio of the X-ray diffraction intensity I[hkl] of three or more planes other than {012} planes ranges from 0.5 to 2 times as high as the ratio of the X-ray diffraction intensity I[012], namely, 0.5I[012]<=2I[012].

Owner:TAIHO INDUSTRIES CO LTD +2

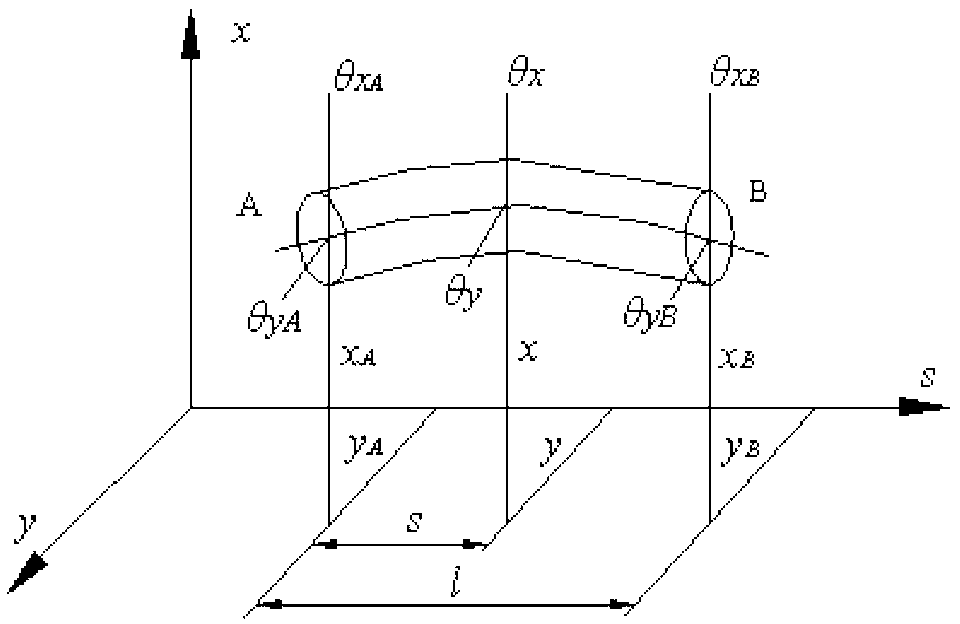

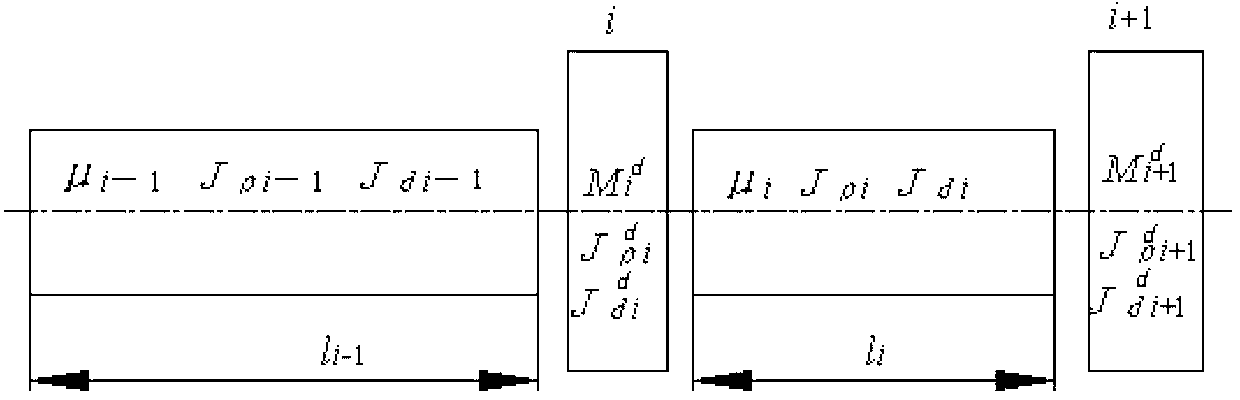

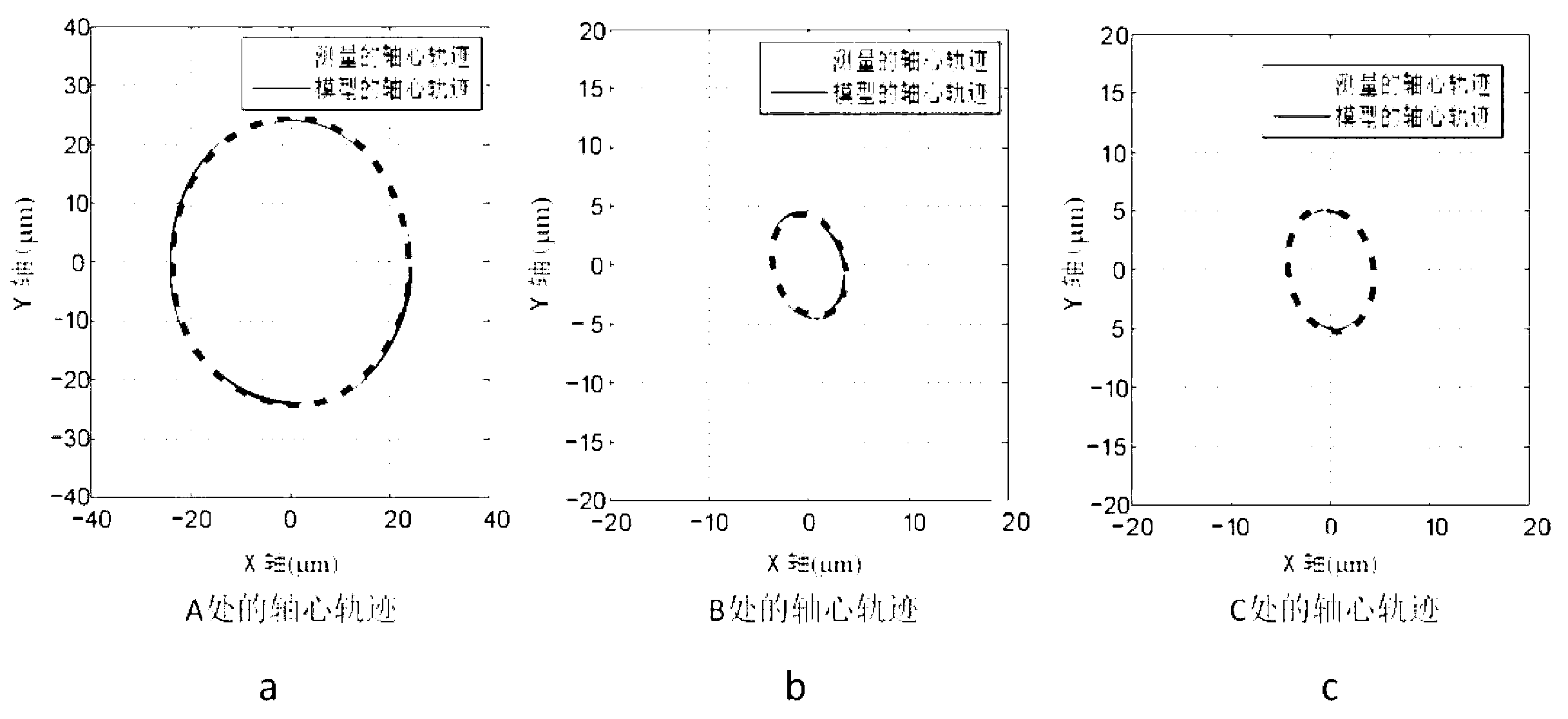

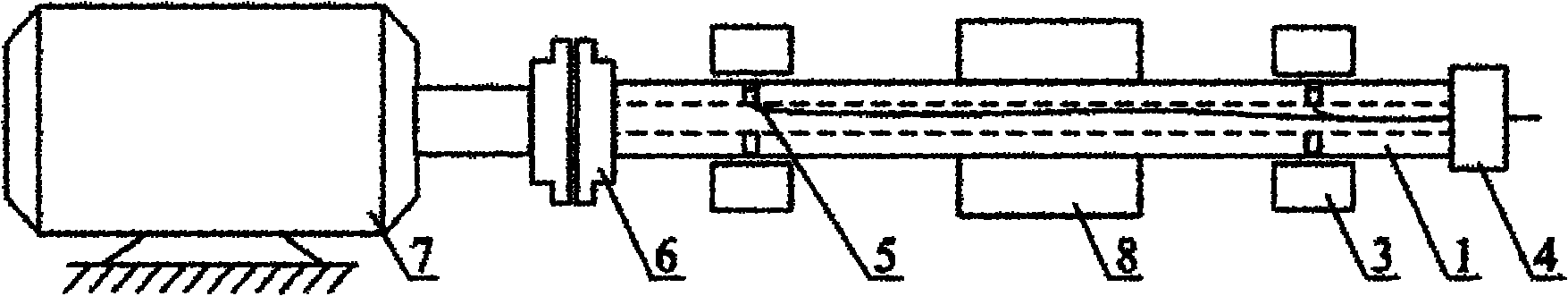

Online test method for characteristic parameter of bearing-rotor system

ActiveCN103076163AOnline test operation method is simple and reliableStrong practical valueMachine bearings testingSlider bearingOnline test

The invention discloses an online test method for a characteristic parameter of a bearing-rotor system. The online test method comprises the steps of: installing a signal acquisition system on the bearing-rotor system supported by a sliding bearing; regulating the rotation speed of a main shaft, and starting a drive motor and a signal acquisition instrument; acquiring vibration signals of specific positions in real time by an eddy current displacement sensor, and storing the vibration signals by the signal acquisition system; establishing a bearing-rotor system model by adopting a finite element method; and applying a characteristic parameter optimization method of the bearing-rotor system based on combination of machinery dynamics modeling with a genetic algorithm to ensure that a theoretical vibration state obtained through the simulation model is close to an actual measurement value, thereby realizing online solving of the rigidity and damping coefficient of the sliding bearing, the off set of a rotor and the like of the bearing-rotor system. Compared with the traditional method, the online test method disclosed by the invention has the obvious advantages that external excitation or multiple machine start / stop does not need to be performed on the bearing-rotor system, and the online test method is simple and reliable and has the characteristics of high efficiency, high stability and high precision.

Owner:XI AN JIAOTONG UNIV

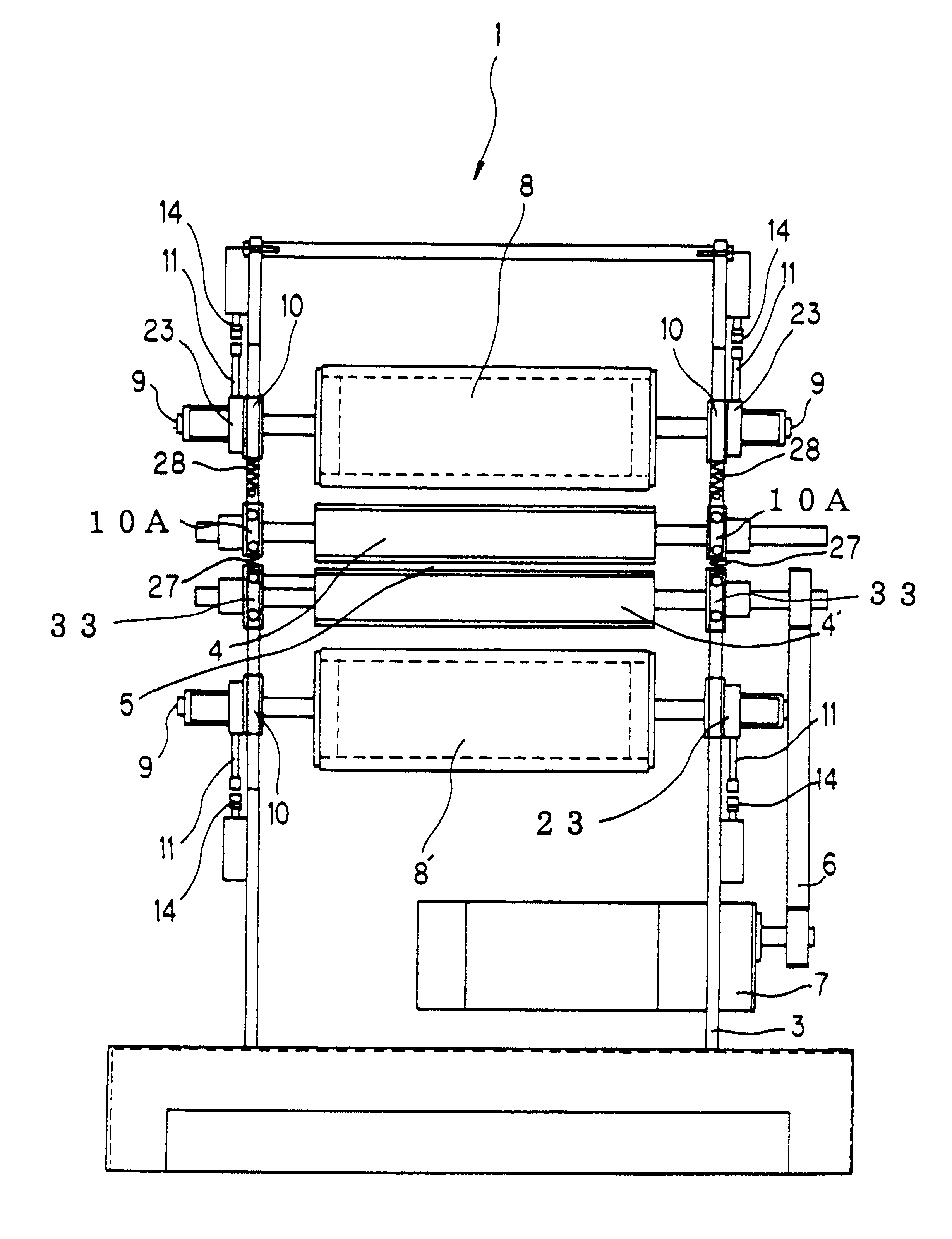

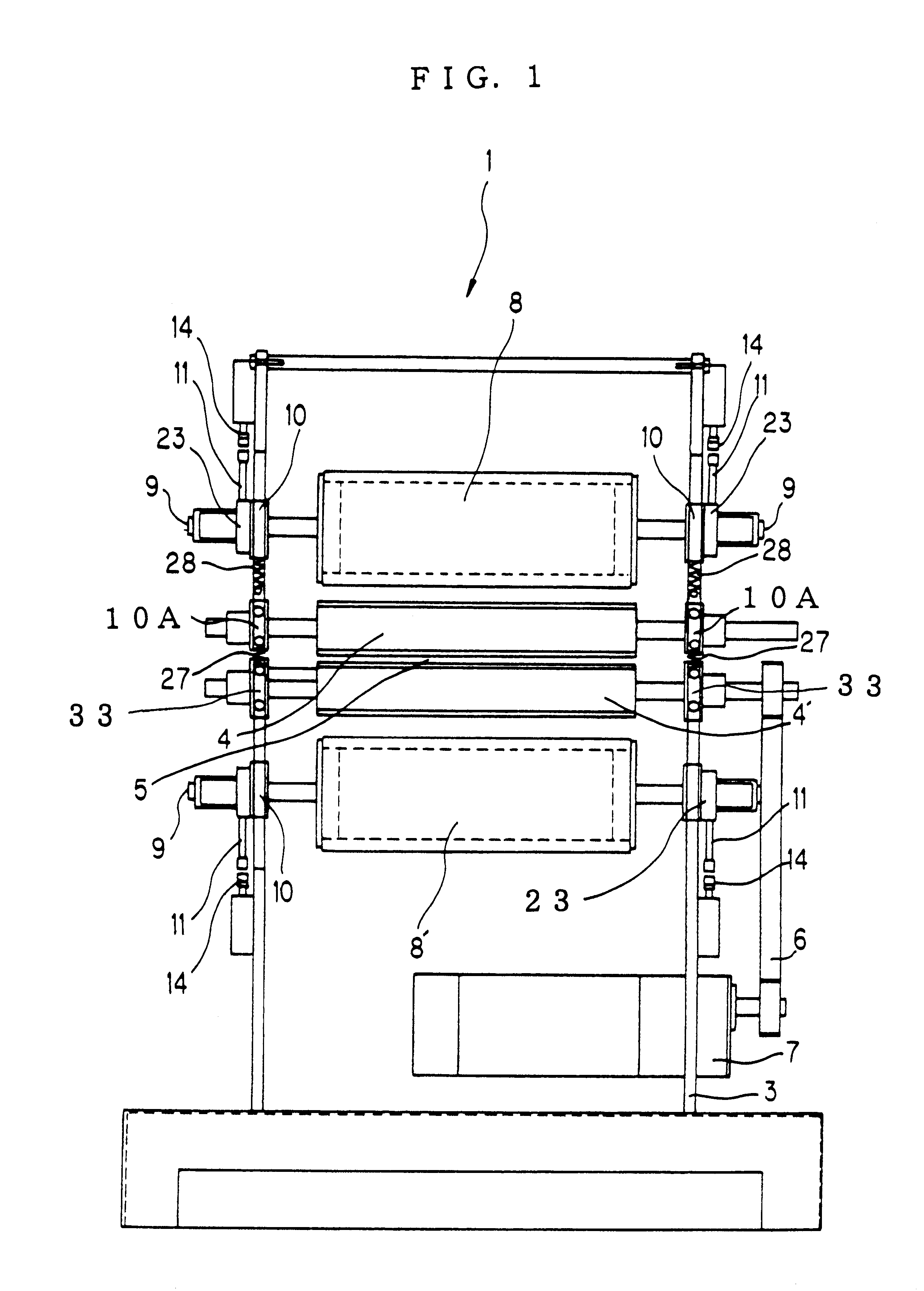

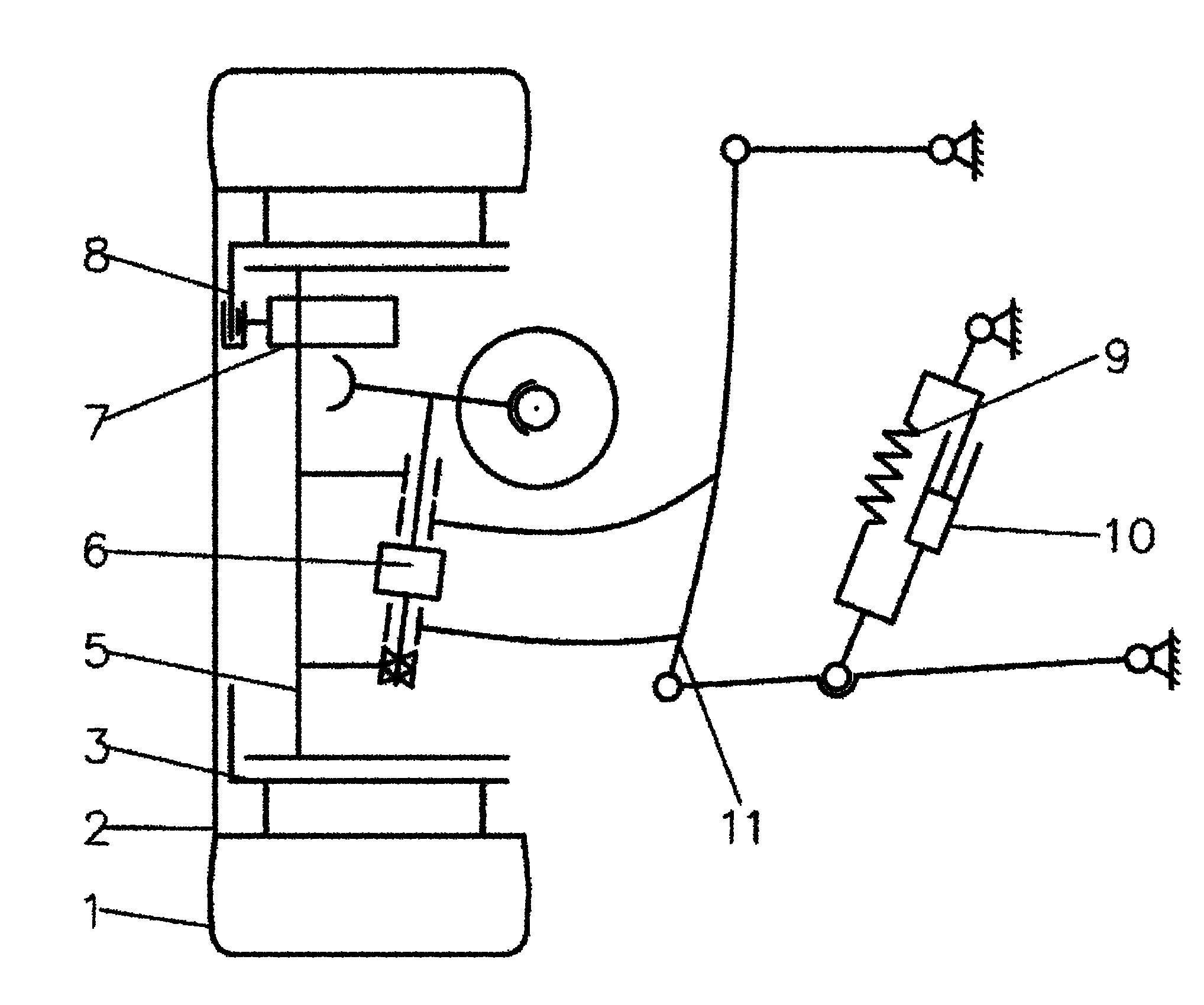

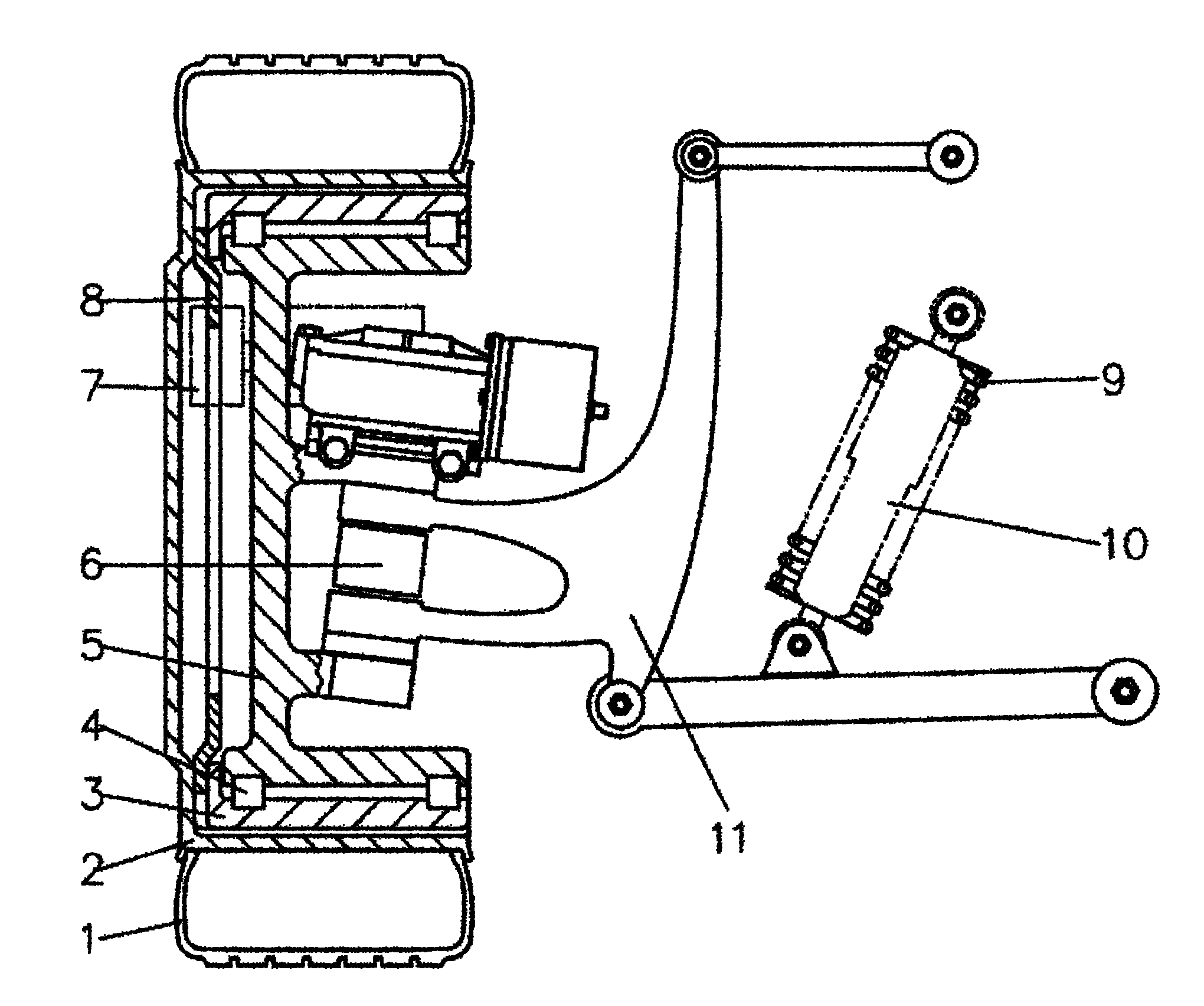

Substrate or sheet surface cleaning apparatus

InactiveUS6237176B1Efficient captureEfficient removalLiquid processingCarpet cleanersFixed bearingSurface cleaning

A substrate or sheet surface cleaning apparatus is provided with at least one tacky rubber roller and at least one adhesive tape roll which is brought into close contact with the tacky rubber roller. The roller and roll are rotatably supported at opposite ends of their shafts by bearings which are slidable in a vertical direction. Pressed rods are arranged integrally on the slidable bearings for the roll. By urging the pressed rods with pressing rods driven by d.c. motors via gear trains while controlling the d.c. motors by a position sensor, the pressure between the roll and the roller and the pressure between the roller and the substrate or sheet are optimized so that dirt or particles can be efficiently removed from an opposing surface of the substrate or sheet. Another substrate or sheet surface cleaning apparatus is provided two tacky rubber rollers arranged in an up-and-down parallel relationship and two adhesive tape rolls arranged above the upper roller and below the lower roller, respectively. Position adjusters with one or more springs disposed therein are arranged between slidable bearings supporting the upper roller and fixed bearings supporting the lower roller to correct tilting, if any, of the upper roller.

Owner:RAYON IND

Composite slide bearing

A high-precision slide bearing is provided which includes a substrate of sintered metal and a synthetic resin layer. This bearing can be used e.g. for rotary shafts in compressors of room air-conditioners or in transmissions of motor vehicles and construction machines to support relatively large radial and axial loads. The resin layer is integrally superposed on the radially inner surface of the sintered metal substrate of the slide bearing, which is a cylindrical member. The resin layer is made of a resin composition of an aromatic polyetherketone resin containing a fibrous filler. The fibrous filler are made up of fibers dispersed in the resin layer and oriented such that their length directions intersect the rotational direction of the bearing at angles of 45 to 90 degrees. The resin layer has a thickness of 0.1 to 0.7 mm.

Owner:NTN CORP

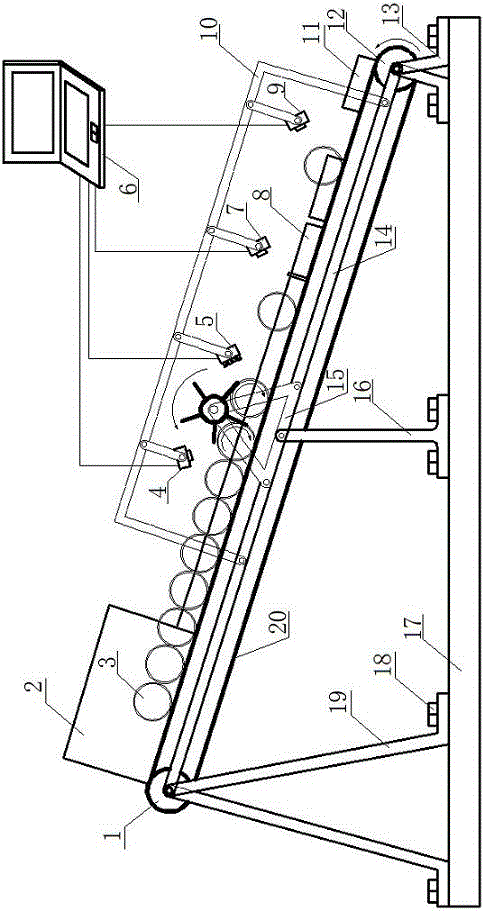

Multi-index high-speed dynamic detection and material dividing method and device of annular sliding bearing

ActiveCN104567677AShorten the timeImprove detection efficiencyOptically investigating flaws/contaminationUsing optical meansMachine visionSlider bearing

The invention discloses a multi-index high-speed dynamic detection and material dividing method and device of an annular sliding bearing. According to the method, multiple indexes of the outer surface size and the inner surface coating defects of the sliding bearing are dynamically detected through machine vision, material division is carried out on workpieces according to the detection result through the color recognition technology of machine vision, and the method has the advantages of being high in detection efficiency, accurate in recognition, high in automation degree and the like. The device comprises a roller, a conveying belt, a high-definition camera, a digital control spraying device, an electric switch, a computer system and the like, wherein the high-definition camera is used for carrying out multi-index dynamic detection on the sliding bearing rotating in a fixed-axis mode, whether defects exist is recognized and material division is carried out through the high-definition camera and a limiting switch, the detecting speed is as high as 120-180 per second, the recognition accuracy is as high as 100 percent, automatic production is fully realized, and the detection cost is largely reduced.

Owner:JIANGSU UNIV +1

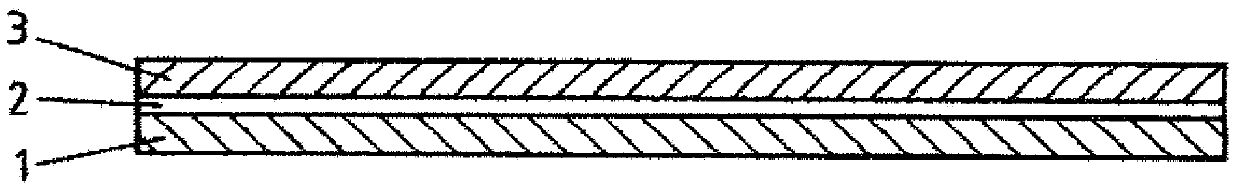

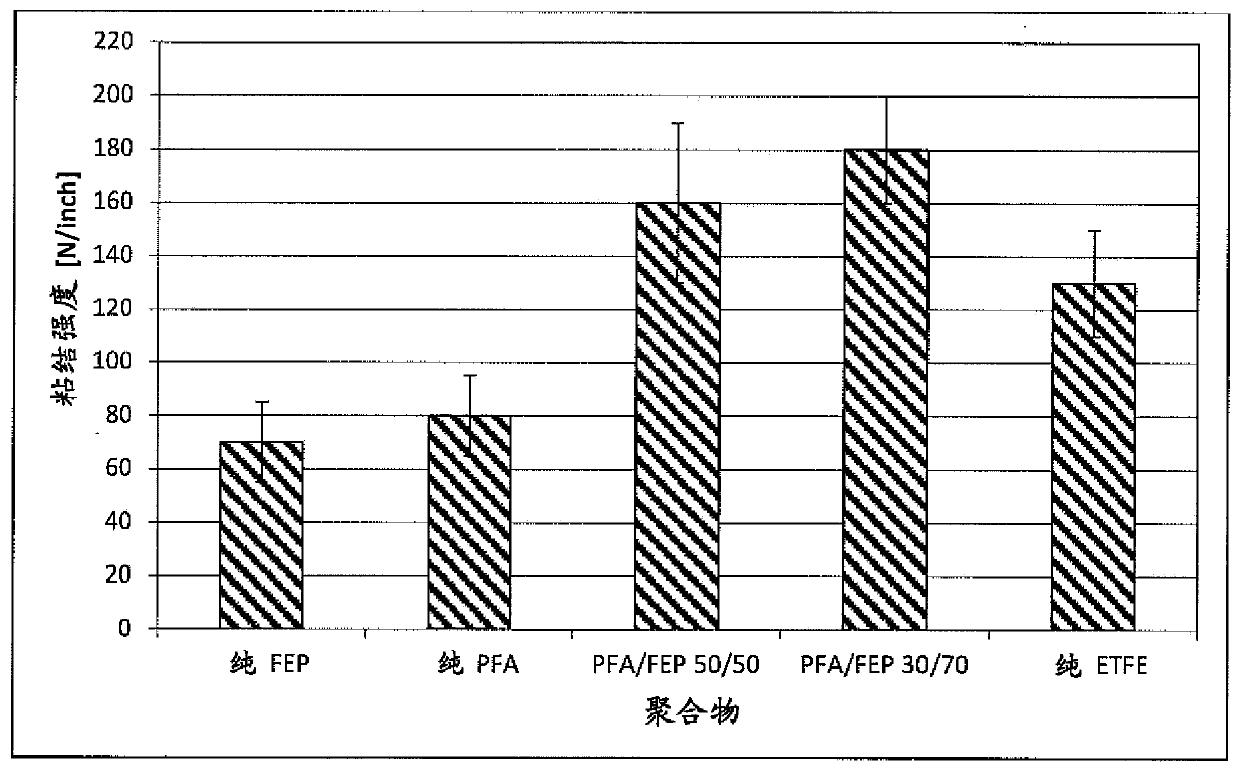

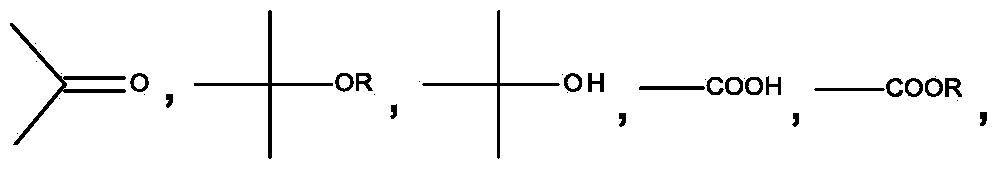

Maintenance-free slide bearing with FEP or PFA in the adhesive layer

Slide bearings and methods of producing slide bearings are disclosed. The slide bearing has a metal support, an adhesive layer and a sliding layer. The adhesive layer is applied directly to the metal support. The adhesive layer comprises a blend of at least two fluoropolymers P1 and P2, wherein P1 is selected from perfluoroalkoxyethylene (PFA) or tetrafluoroethylene-hexafluoropropylene (FEP). P2 is different from P1 and can be a fluoropolymer.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

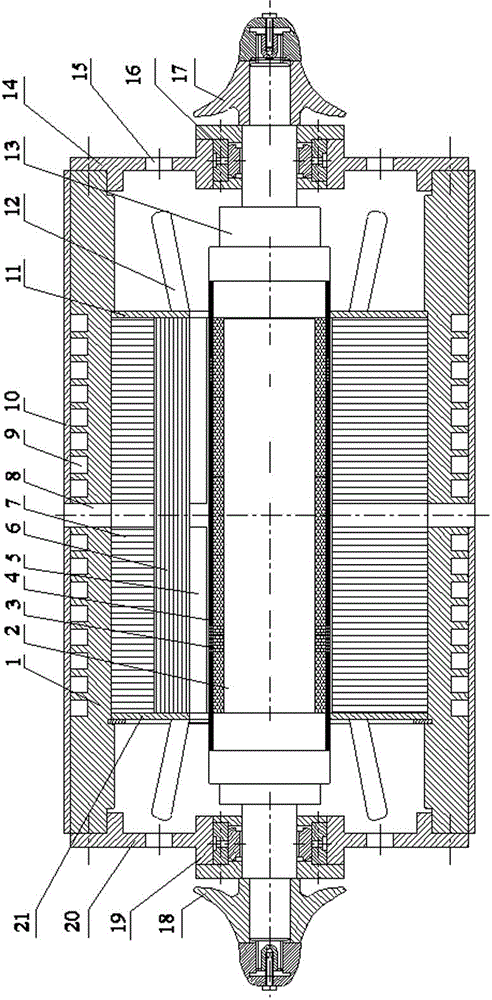

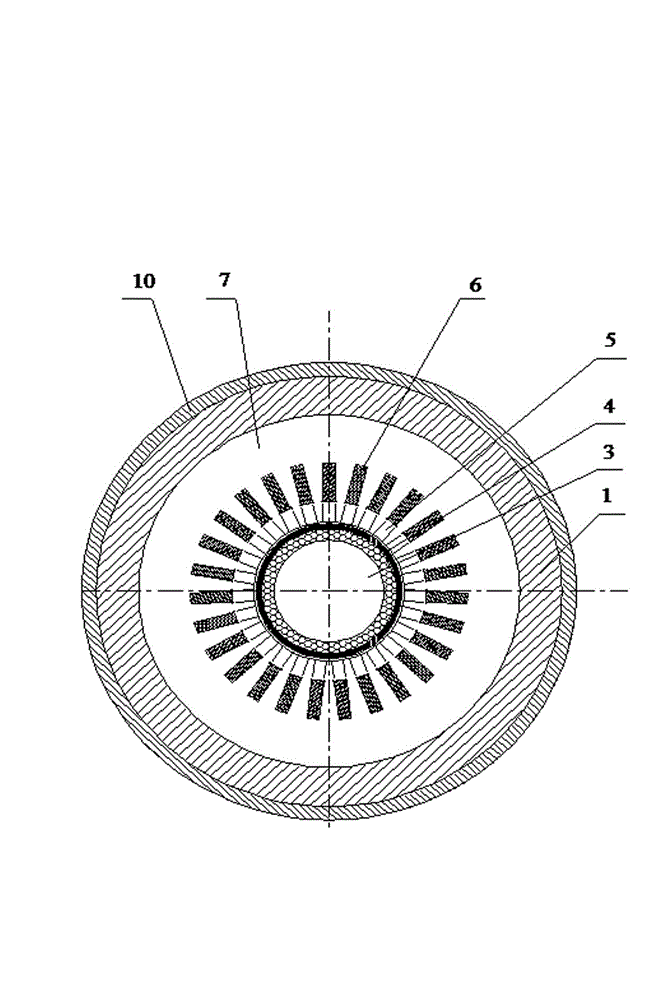

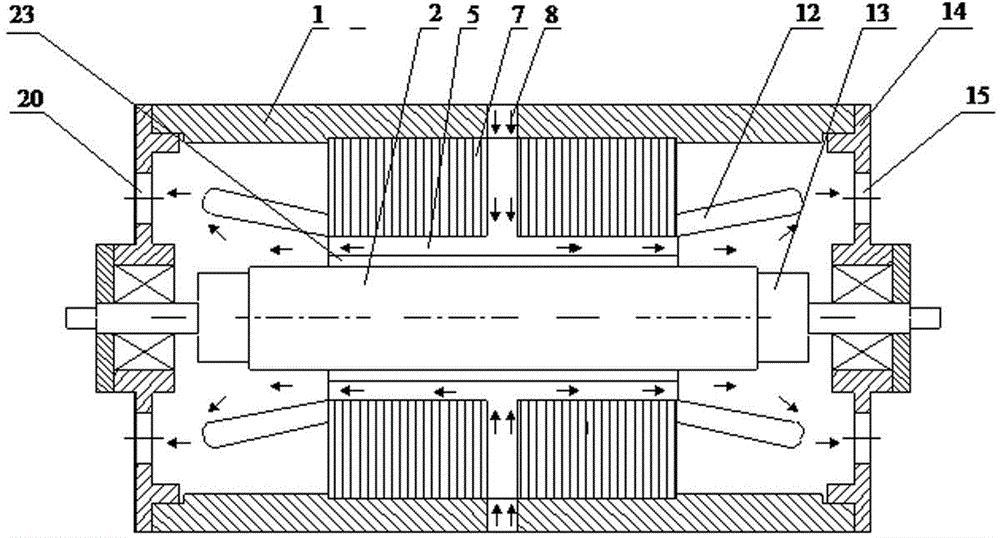

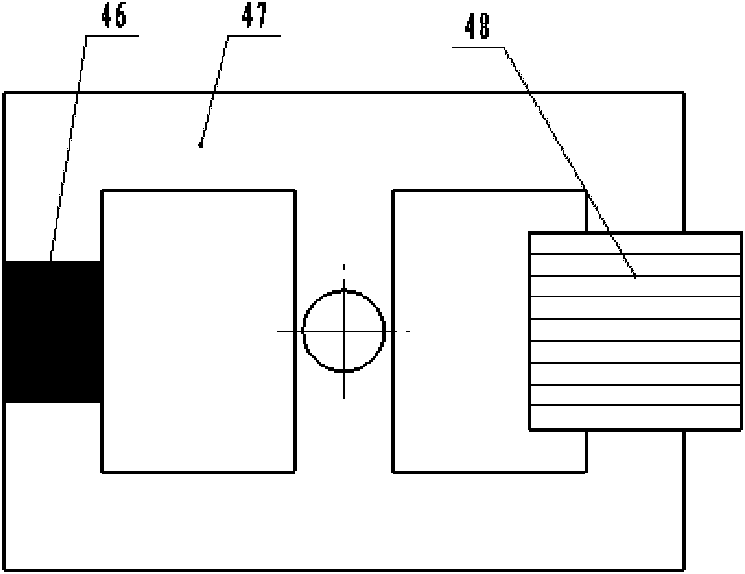

In-slot self-cooling high-speed permanent magnetic motor system for compressor

InactiveCN102983679AAvoid additional lossSafe and effective protectionMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorImpeller

The invention relates to an in-slot self-cooling high-speed permanent magnetic motor system for a compressor and belongs to the technical field of motors. The megawatt high-speed variable-frequency motor comprises a cooling water jacket, a stator core, a stator winding, a stator radial air channel, an inner stator air channel, a permanent magnet rotor, two sliding bearings and two compressor impellers. The system has the advantages that the problems of severe heat and uneven temperatures of a high-speed motor rotor can be solved effectively; the problems of the over-temperature and overlarge axial temperature gradient of the stator core are solved; and not only the strength problem of a permanent magnet under a condition of high-speed rotation of the rotor can be solved mechanically, but also higher harmonics can be effectively prevented from entering the permanent magnet and generating added losses electromagnetically.

Owner:SHENYANG POLYTECHNIC UNIV

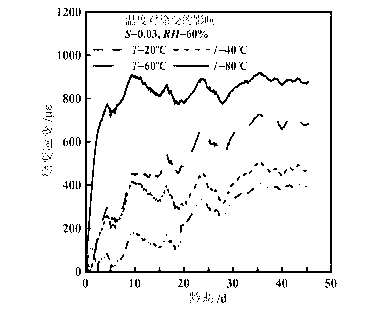

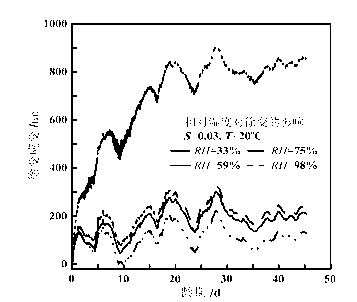

Device and method for testing material creep under coupling action of tensile stress and environment

InactiveCN103267682AUniform stressUniform stress distributionMaterial strength using tensile/compressive forcesTemperature controlInorganic salts

The invention discloses a device for testing material creep under the coupling action of tensile stress and the environment. The device comprises a support, a weight, a heating jacket, a container containing a saturated inorganic salt solution, a strain demodulator, a power supply, a temperature controller, a strain sensor and a test piece, wherein the support comprises a positioning plate, an upper spherical hinge, an upper clamping head, a supporting rod, a bearing plate, a base plate, a lower clamping head and a lower spherical hinge; the supporting rod is connected with the bearing plate through a sliding bearing; the test piece is embedded in a groove in the upper clamping head and a groove in the lower clamping head; the weight is positioned on the bearing plate; the heating jacket covers on the outer side of the support; the container is positioned between the support and the heating jacket; the strain sensor is adhered to the outer wall surface of the test piece; and the temperature controller is connected with the ring-shaped heating jacket. By adopting the device, the reliability of the test process can be improved, and the accuracy of results is ensured. Meanwhile, the invention also discloses a test method for the test device. The method is simple and easy to operate, and can keep that the test piece does not generate stress relaxation in the process of long-term load application, and the stress is uniformly distributed.

Owner:SOUTHEAST UNIV

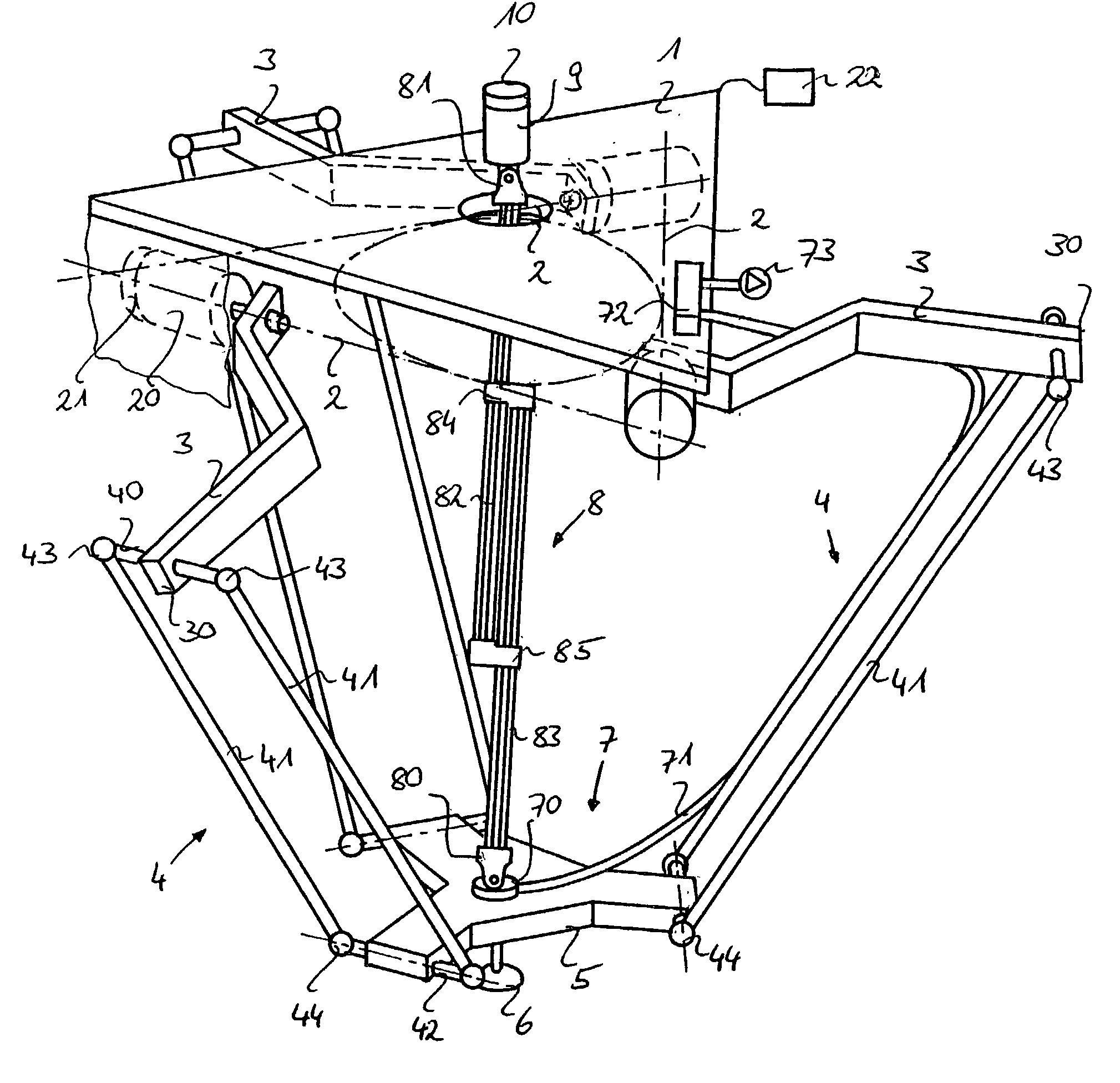

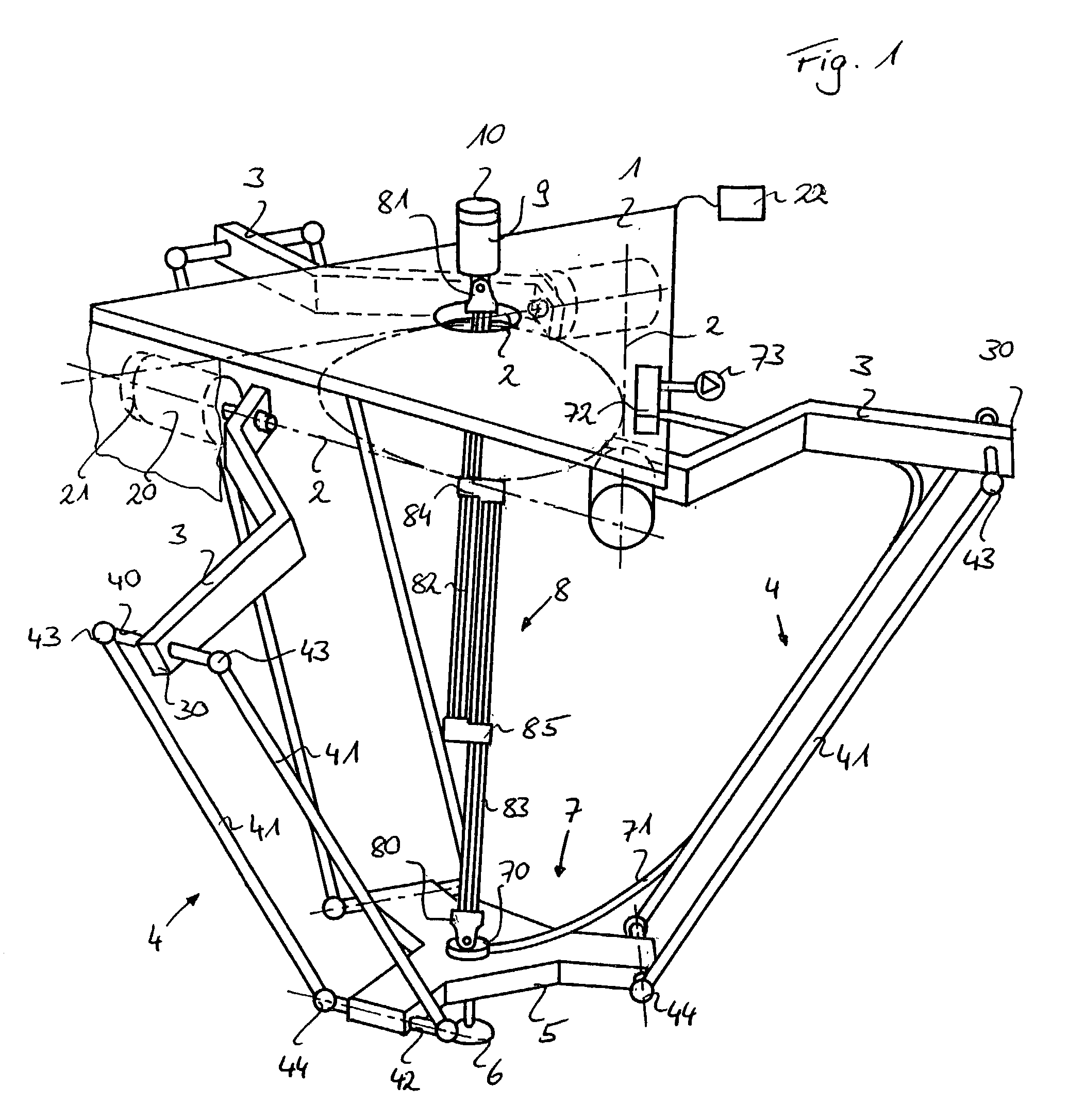

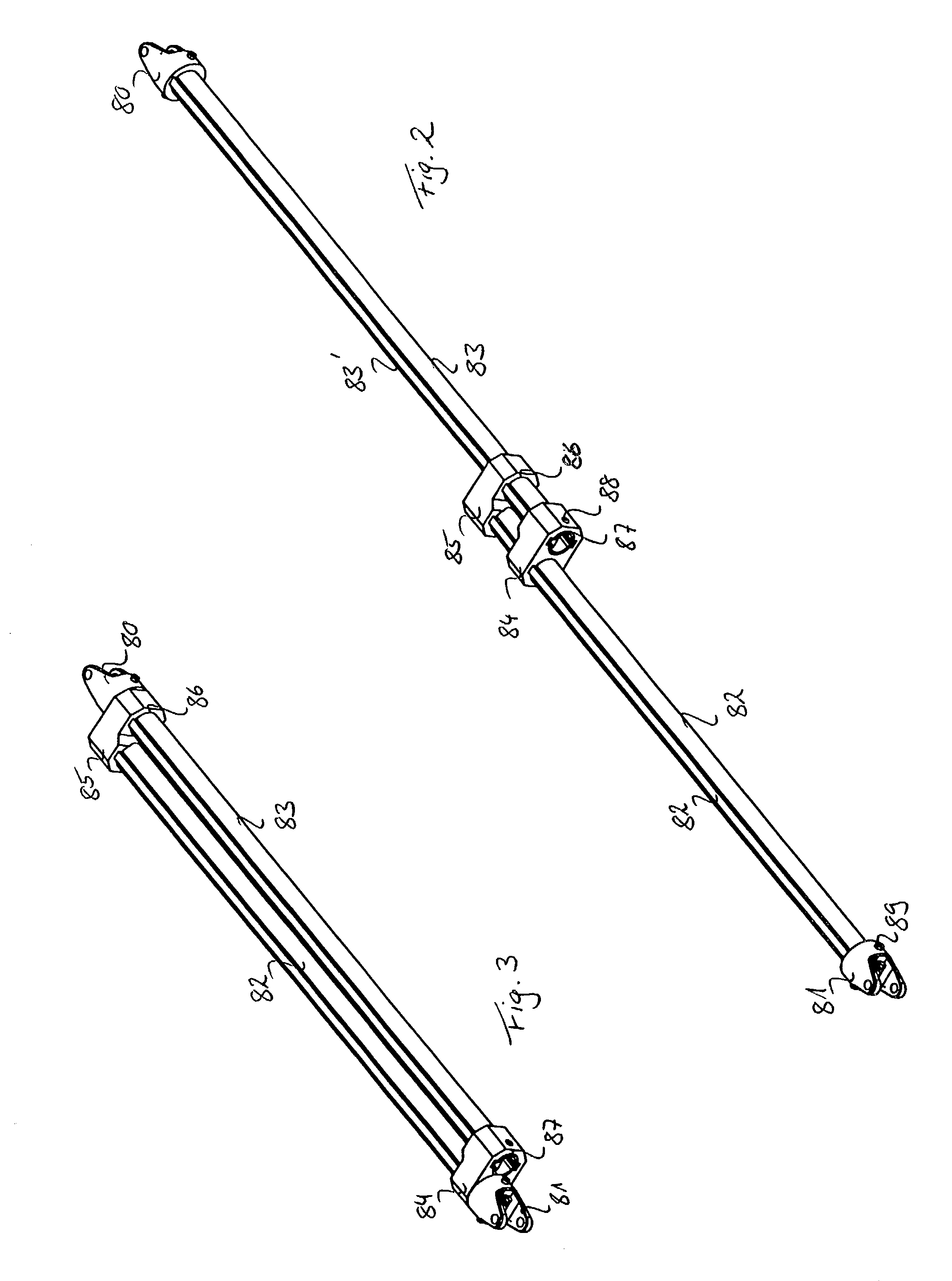

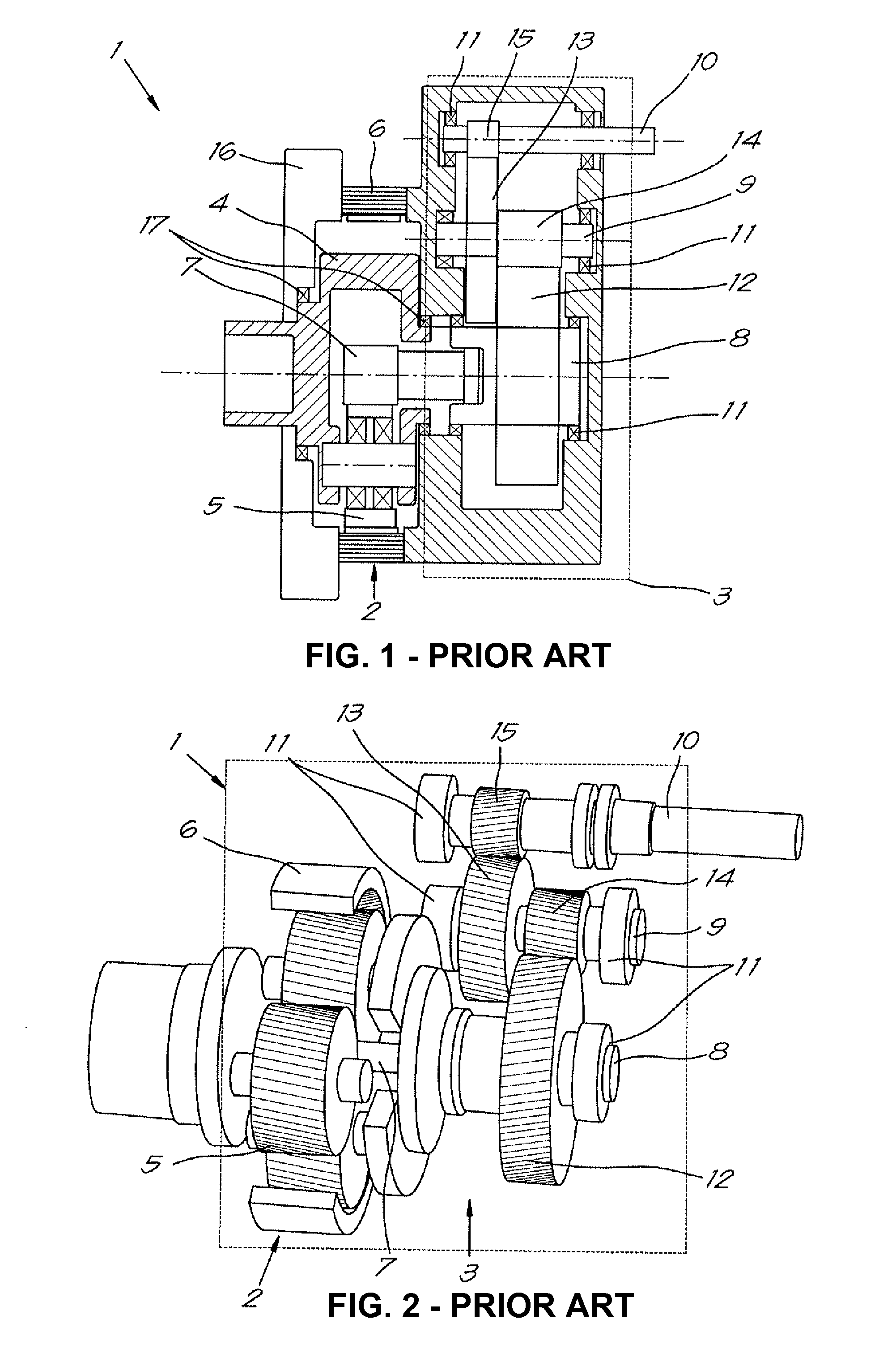

Device for transmitting torques

InactiveUS20030064816A1Easy to cleanSpace minimizationProgramme-controlled manipulatorScaffold connectionsFlexural strengthTorque transmission

A changeable-length fourth axis of a delta robot has a first bar (82) and a second bar (83), which can be displaced parallel to one another in a slide bearing (84, 85). They are connected to articulation heads (80, 81) for leading in an incoming torque and for leading out an outgoing torque. The first and second bars (82, 83) are arranged here such that the incoming torque runs in a direction which is parallel to, but offset from, the direction of the outgoing torque. This fourth axis allows precise torque transmission, but is nevertheless of straightforward construction, has a high bending strength and relatively low weight and can easily be cleaned by being washed down.

Owner:ROBERT BOSCH GMBH

All-around lubricating film pressure wireless monitoring method of liquid sliding bearing

InactiveCN102095548AAvoid interference and loss of signal accuracyEasy to installTransmission systemsMachine bearings testingLubricationDistribution characteristic

The invention discloses a method for measuring the pressure of a lubricating liquid film of a liquid sliding bearing to achieve the real-time measurement of the all-around lubricating liquid film pressure of a liquid sliding journal bearing and a thrust bearing with different rotation speeds. A pressure sensor is mounted on a revolving shaft by different methods according to different shaft diameters; the sensor is connected with a wireless emission device mounted in the shaft or on the tail end of the shaft; the wireless emission device transmits the liquid film pressure signal of the bearing to the outside of a bearing rotor system while rotating together with the shaft; an external wireless receiving device receives the pressure signals so as to monitor the pressure distribution characteristics and the lubrication state of the lubricating film of the bearing in real time.

Owner:XI AN JIAOTONG UNIV

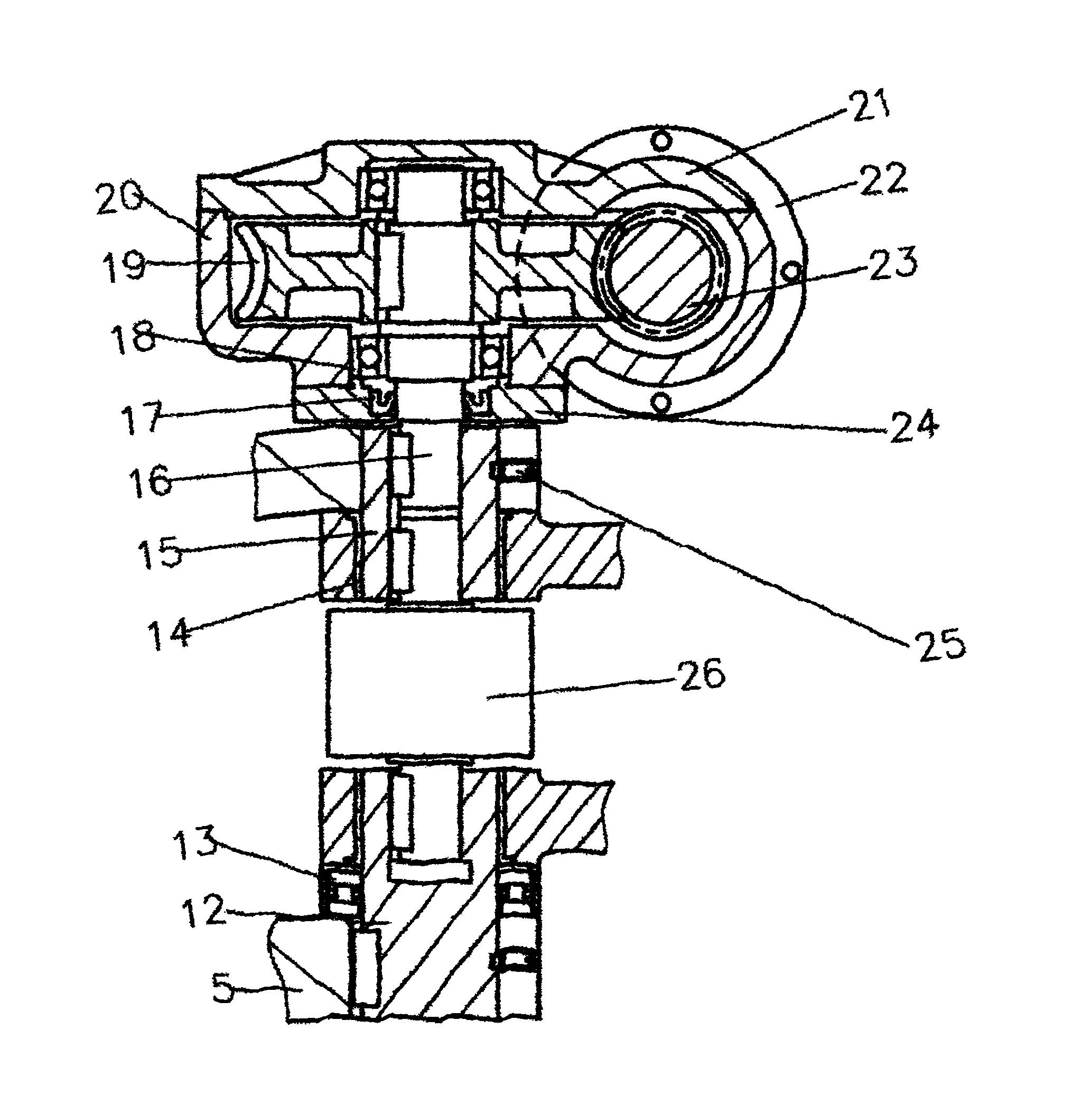

Wire controlled wheel independent steering execution mechanism and wheel assembly

InactiveCN102069843ASimple structureOptimize layoutSteering linkagesMechanical steering gearsCouplingThrust bearing

The invention discloses a wire controlled wheel independent steering execution mechanism and a wheel assembly. The wire controlled wheel independent steering execution mechanism comprises a steering gear, a lower master pin, a master pin thrust bearing, two master pin sliding bearings with the same structure, an upper master pin, a steering motor and photoelectric encoder combined unit, and a torque sensor. The output shaft of the steering motor is connected with the input shaft of the steering gear by a coupler, the output shaft of the steering gear is in key connection with one end of the torque sensor through the upper master pin, the other end of the torque sensor is in key connection with the other end of the torque sensor, the lower end of the upper master pin is sleeved with the master pin sliding bearing and is in dynamic fit with the master pin sliding bearing, and the lower master pin is sleeved with the master pin sliding bearing and the master pin thrust bearing, which have the same structure, in turn from top down, and is in dynamic fit with the master pin sliding bearing and the master thrust bearing. The wheel assembly comprises a tire, a hub, an annual hub motor, a brake, an annular brake disc and the line controlled wheel independent steering executing mechanism. The annular hub motor consists of an annular hub motor outer rotor, a large-diameter cone roller bearing, a steering joint and a motor inner stator component.

Owner:JILIN UNIV

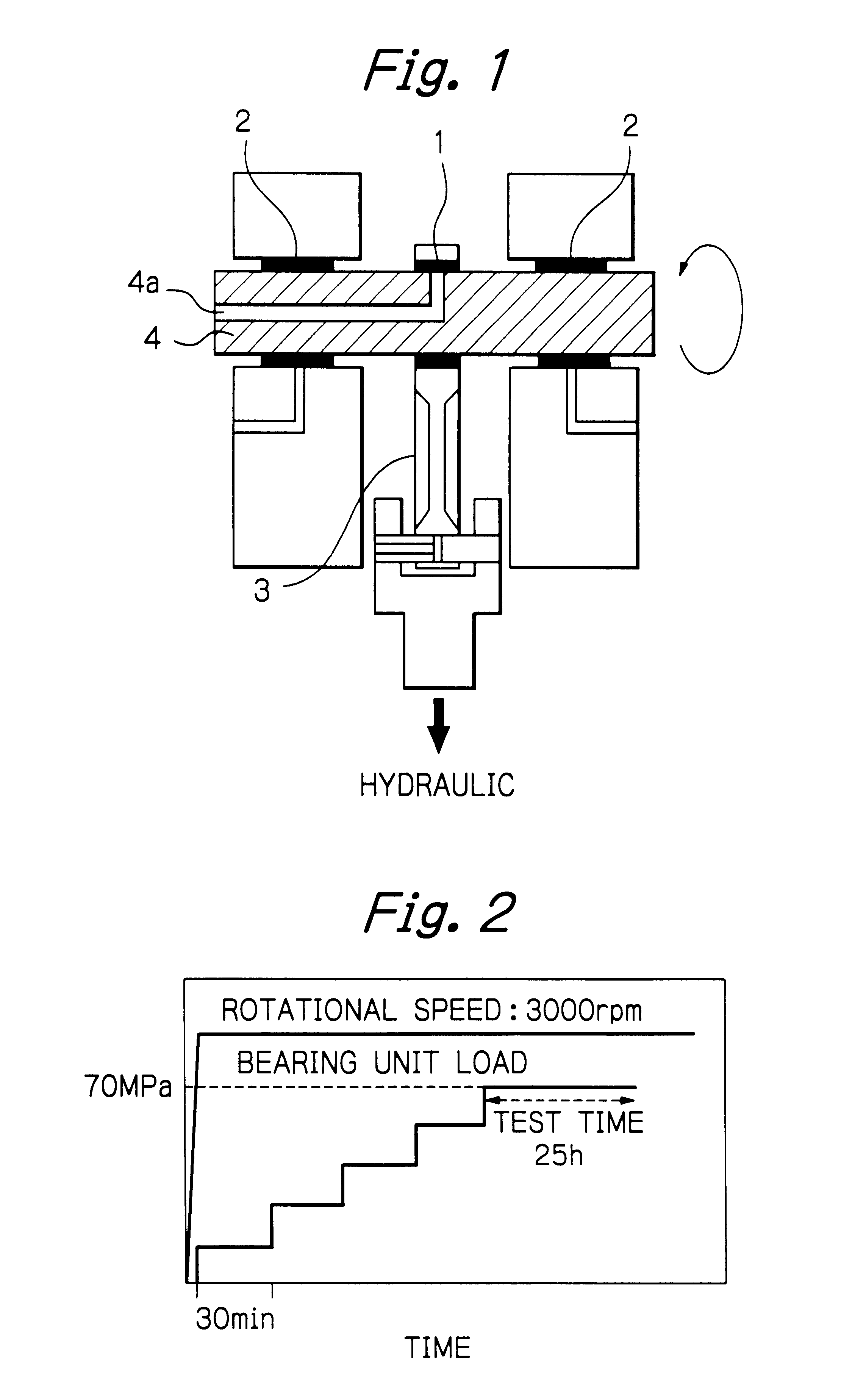

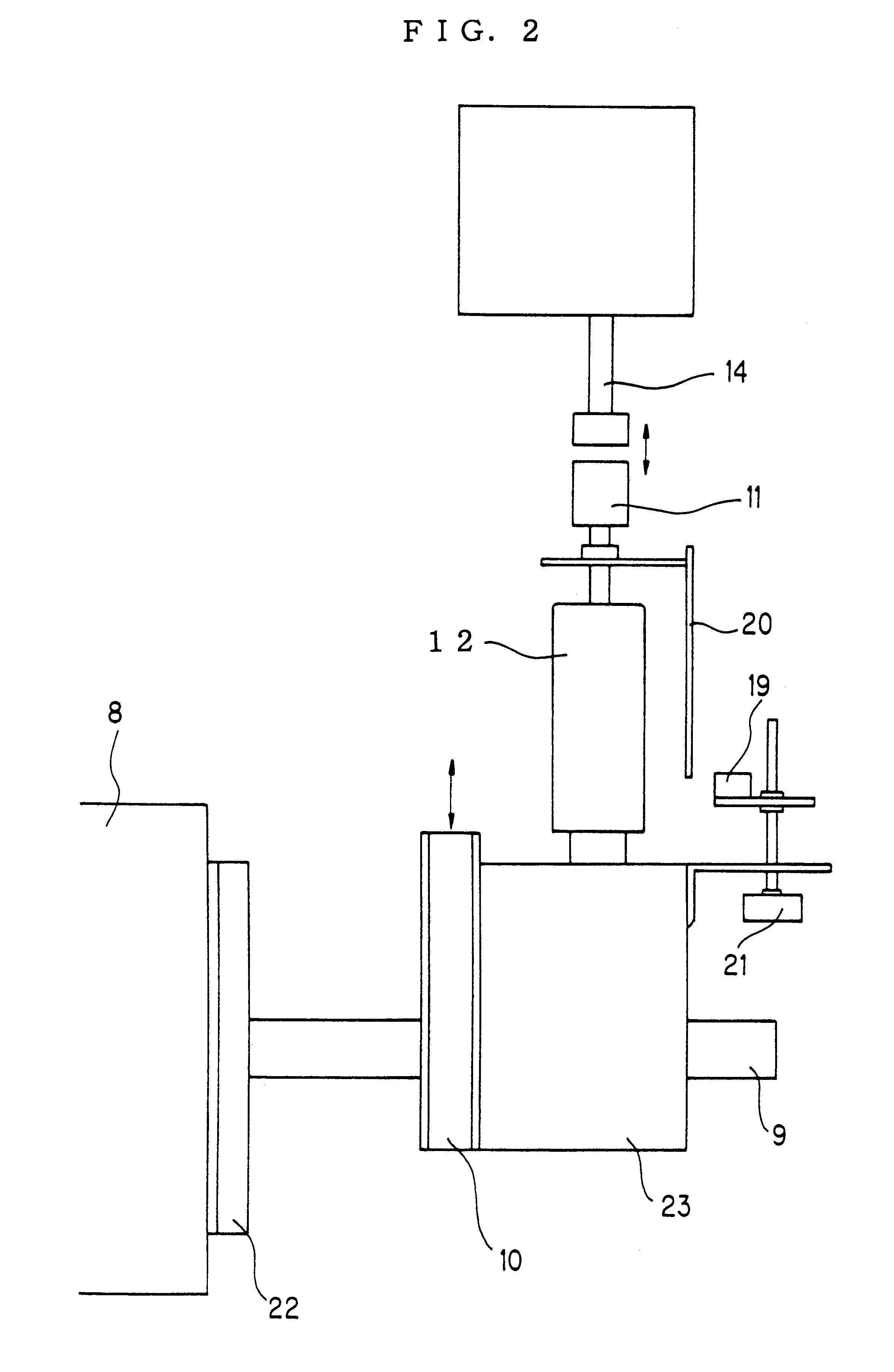

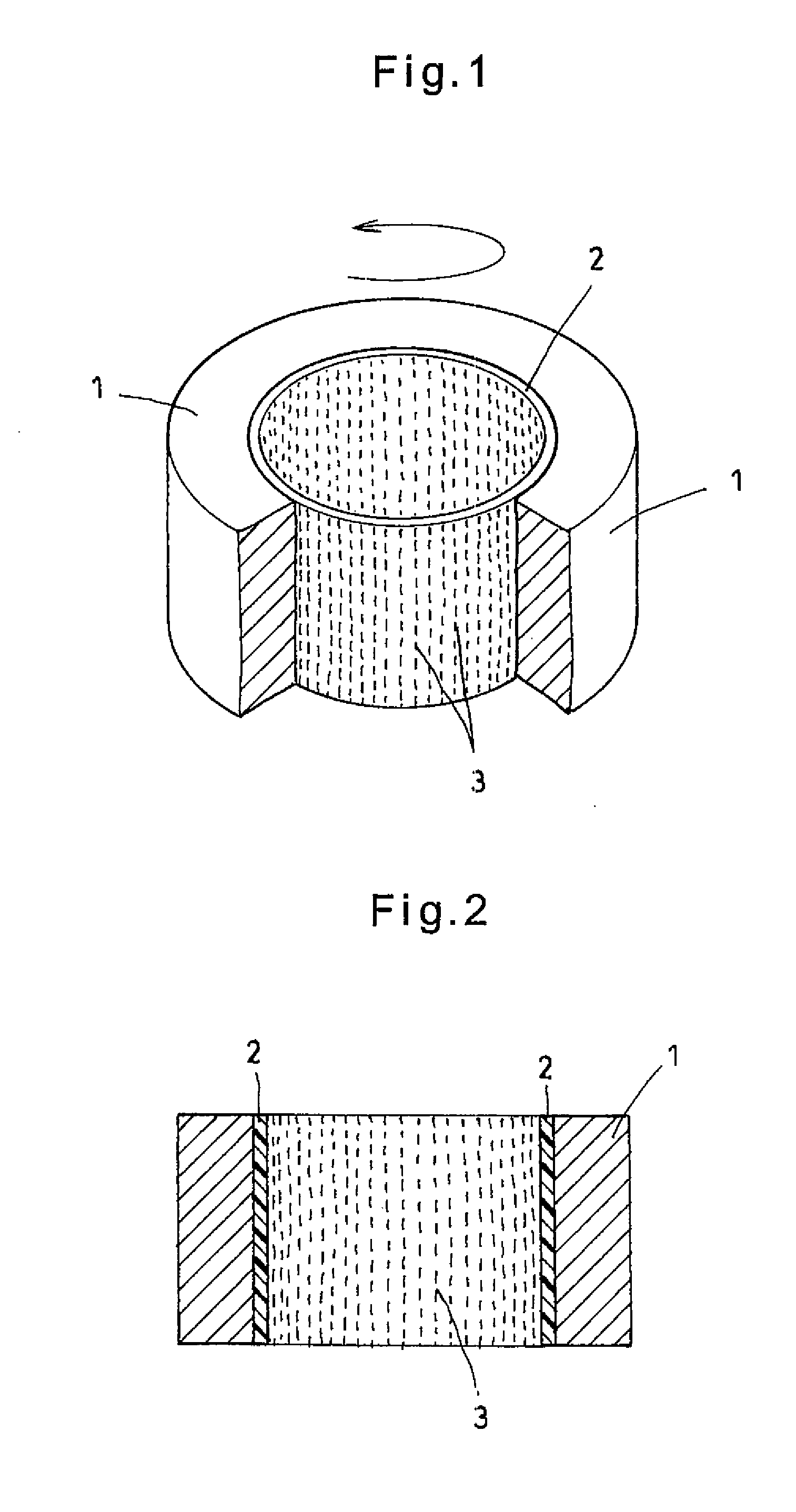

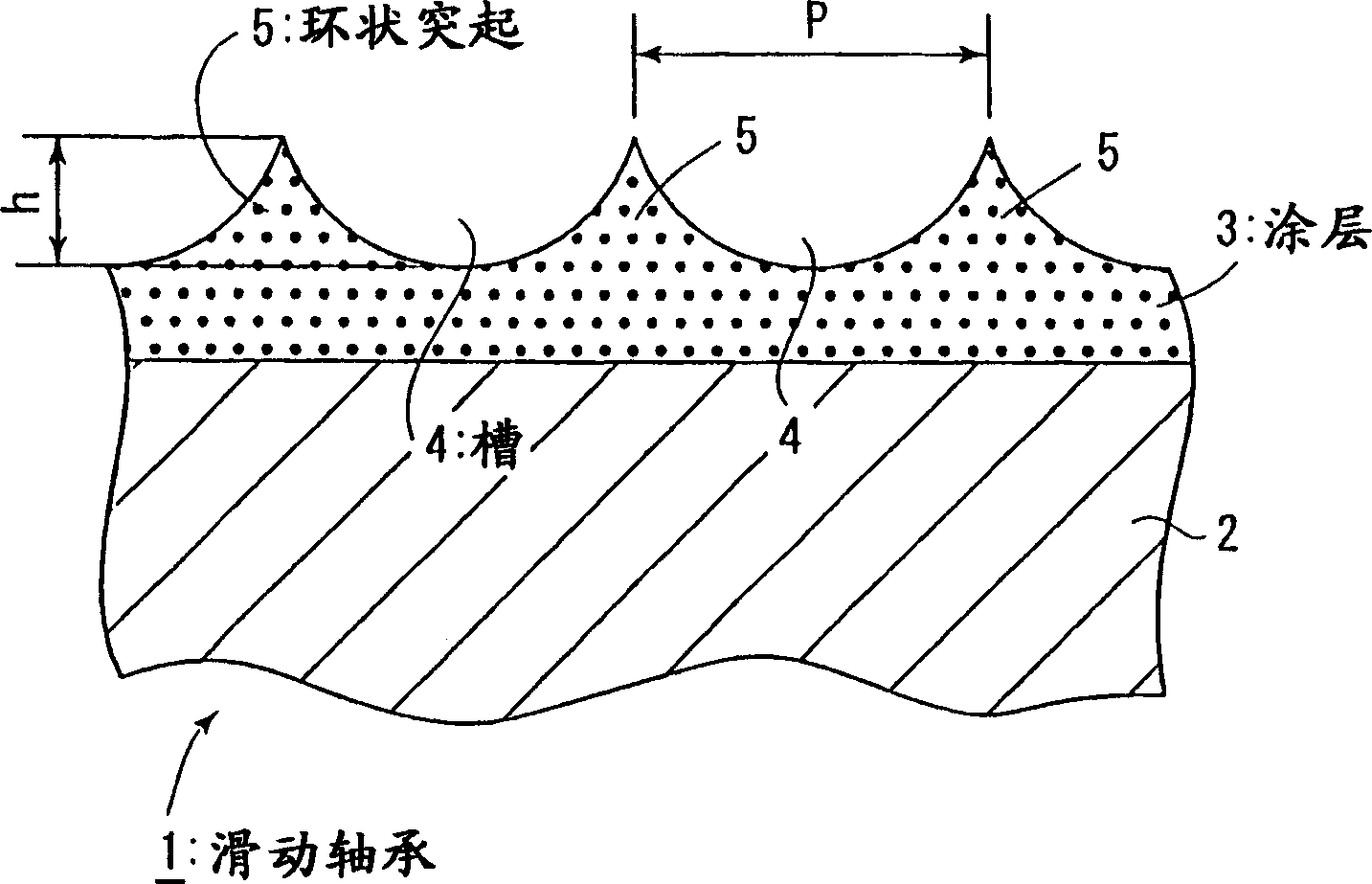

Sliding bearing

An overlay layer 3 comprising MoS2 as a solid lubricant and PAI resin as a binder resin is formed on a flattened surface of a bearing alloy layer 2, and a helical groove 4 and annular projections 5 are formed as an uneven configuration in and on the surface of the overlay layer. In accordance with the invention, a regular uneven configuration is formed on the surface of the overlay layer to allow a lubricant oil to be secured in recesses of the uneven configuration, allowing a seizure resistance to be improved. The bearing alloy layer is machined to have a flat surface having a fine roughness on its surface which represents a boundary with an overlay layer, whereby individual convex areas of the overlay layer are evenly subject to a plastic deformation, allowing the fitting property response of the sliding bearing to be improved.

Owner:TAIHO INDUSTRIES CO LTD

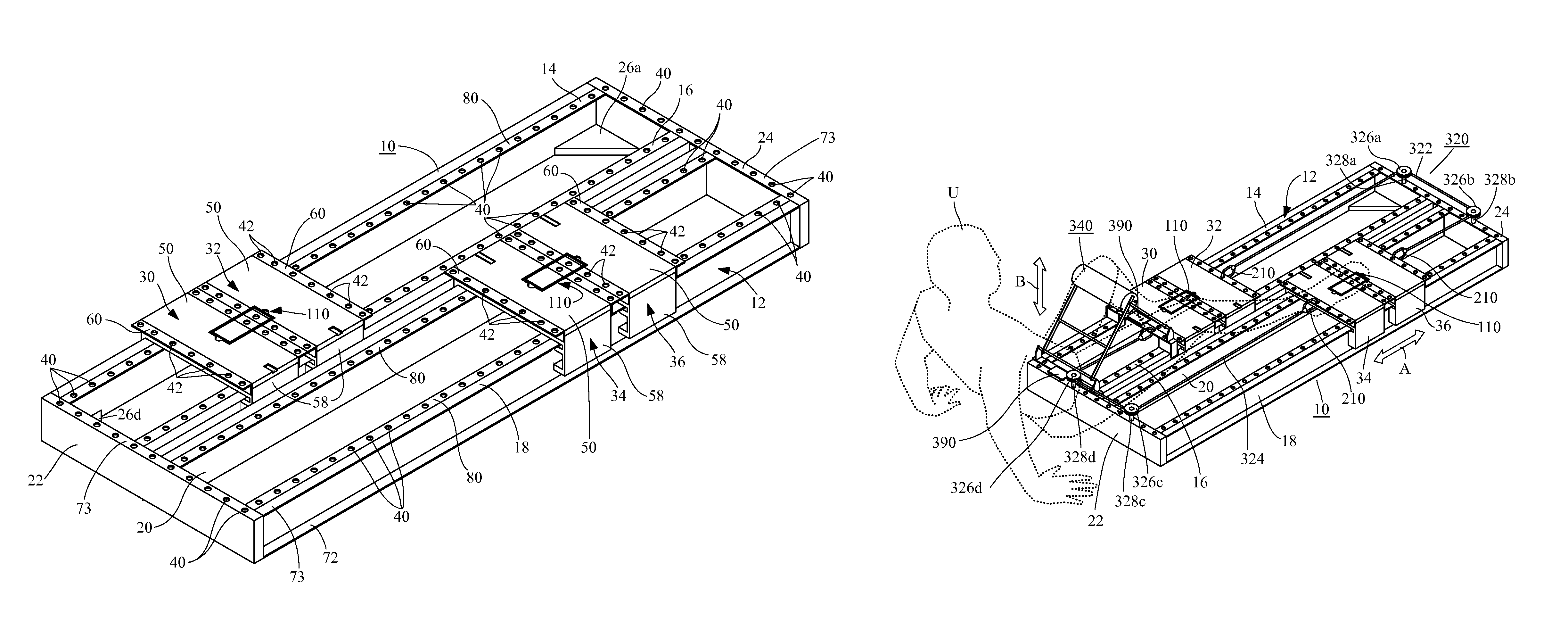

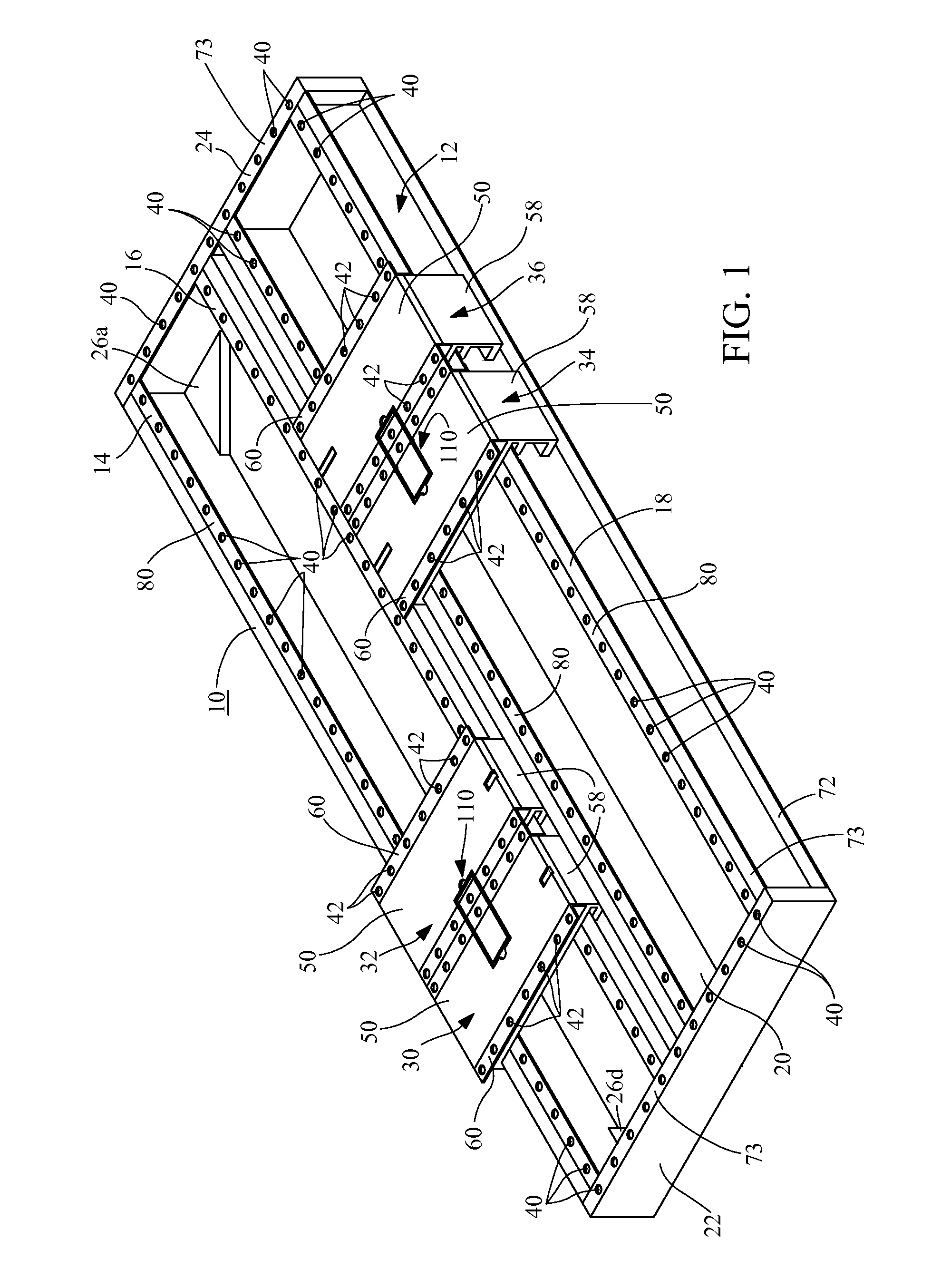

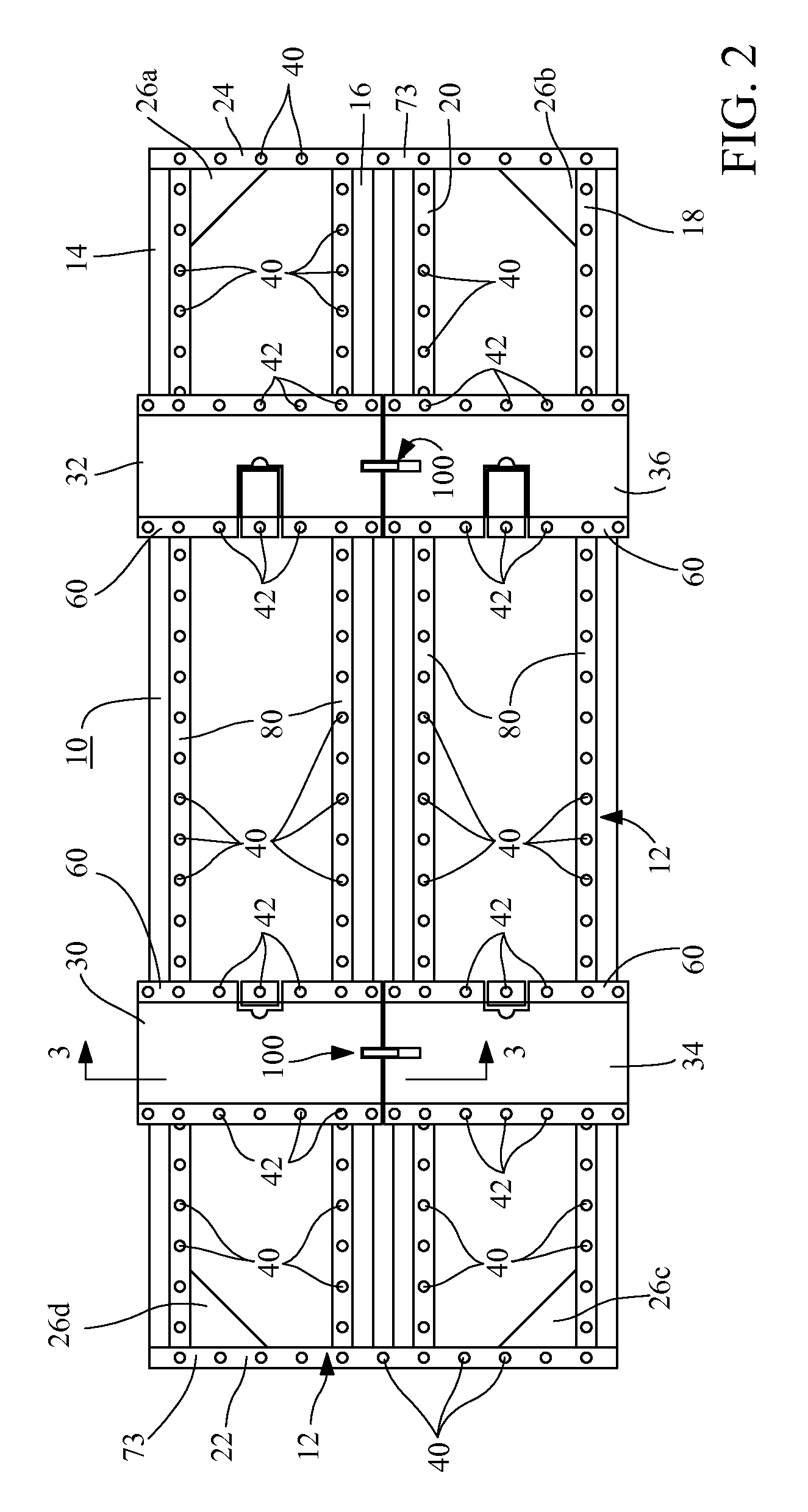

Therapeutic exercise apparatus with multiple selectively interlockable sliding platforms

InactiveUS9011296B2Quickly and easily reconfiguredImprove versatilityResilient force resistorsChiropractic devicesTherapeutic exerciseEngineering

An exercise apparatus comprises a frame having two parallel tracks, two platforms mounted on the first track by a sliding bearing, and two platforms mounted on the second track by a sliding bearing. The tracks are spaced apart a sufficient distance to permit the platforms on different tracks to move freely past each other. A transverse interlock allows selective connection of platforms on different tracks for movement together and a longitudinal interlock allows selective connection of platforms on the same track for movement together. The frame includes cross braces connecting the rails at their ends, and the rails, cross braces, and platforms all include connecting points for permitting the user to selectively connect to and between the frame and the platforms a variety of exercise accessories or appliances. The accessories can include elastic resistance bands, cord and pulley assemblies, handles, weights, and appliances for administering physical therapy.

Owner:PERALO CHARLES A

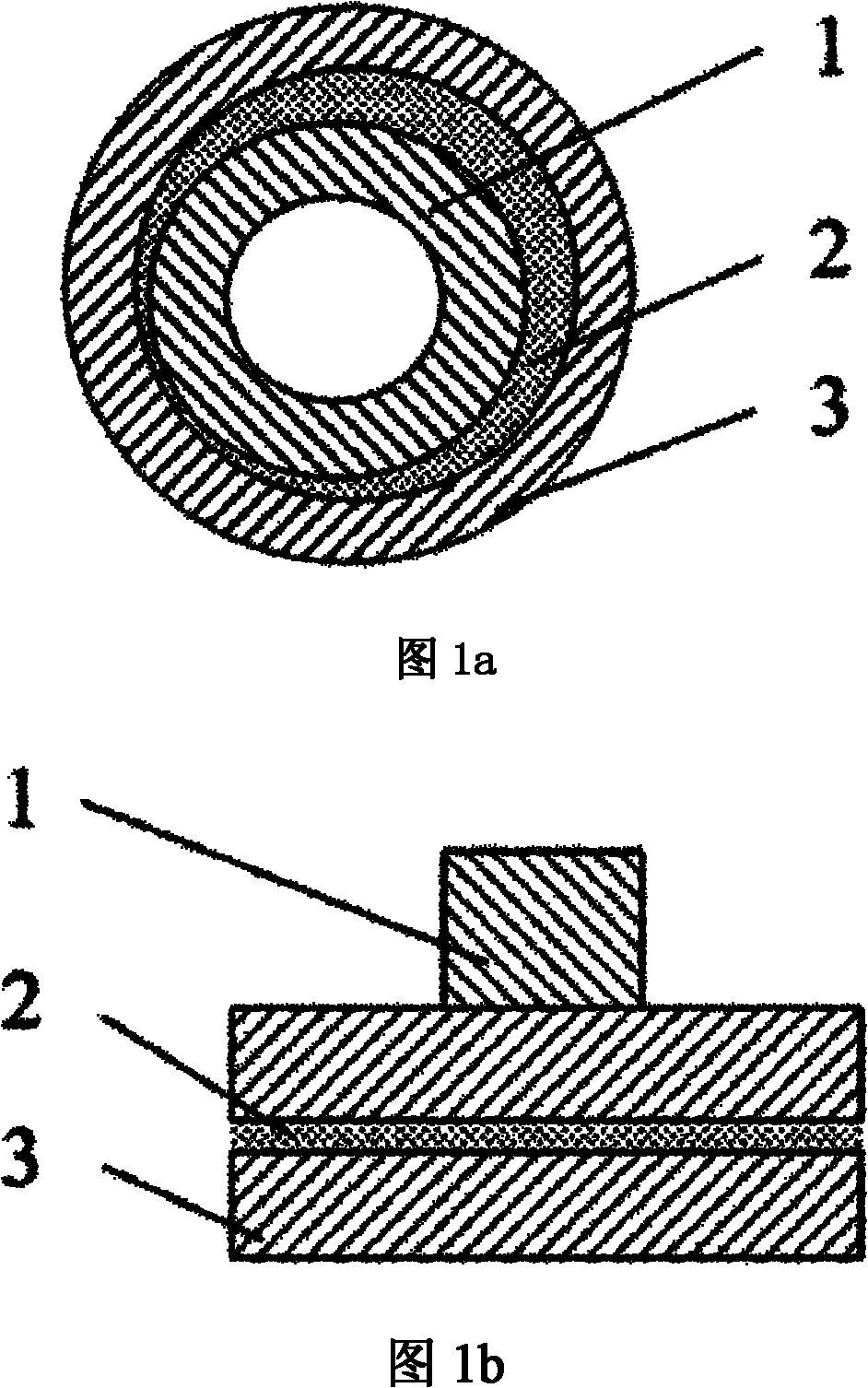

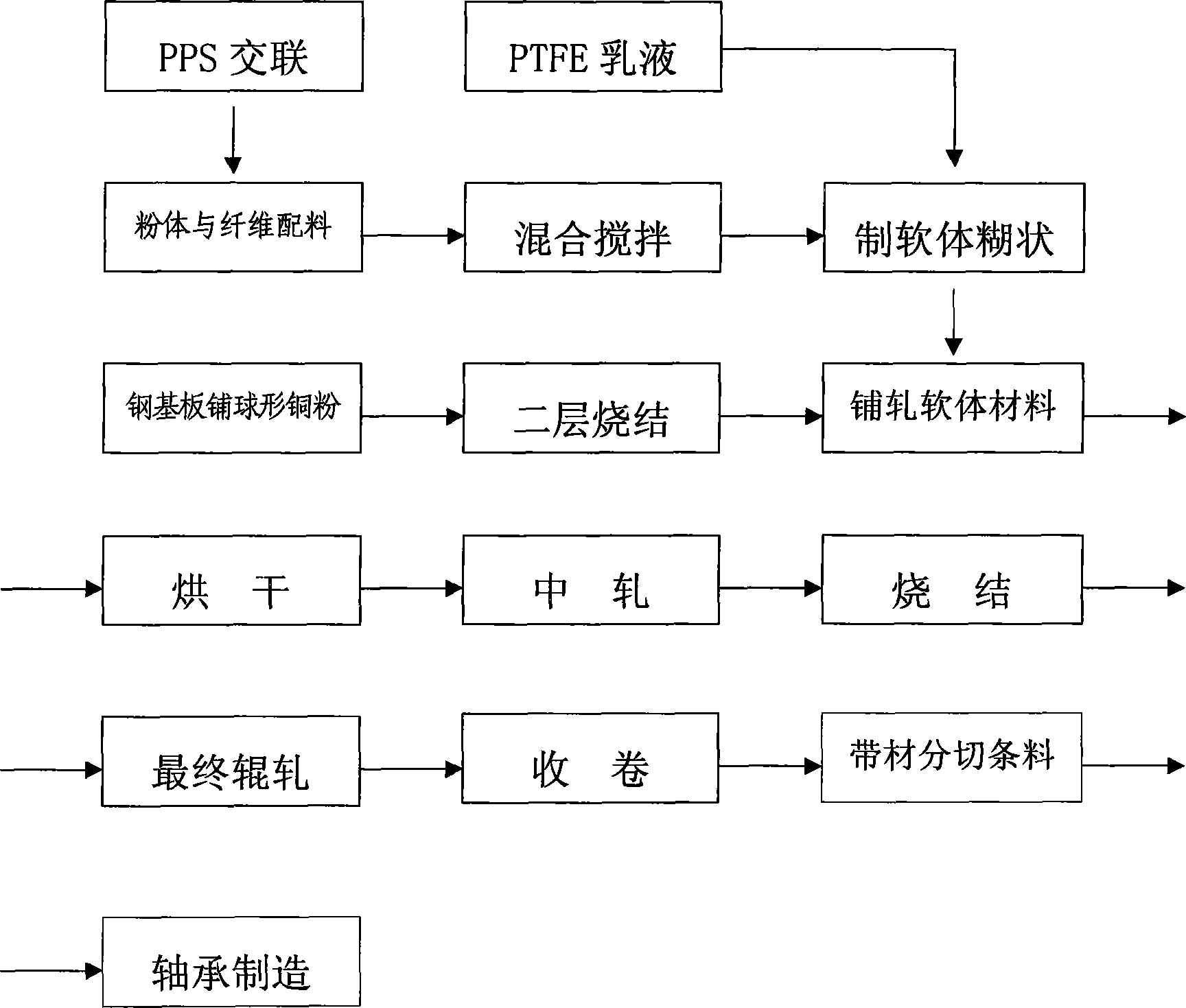

Dry friction self-lubricating slide bearing

InactiveCN101413543AReduce coefficient of frictionImprove performanceBearing componentsPolytetrafluoroethyleneCopper

The invention discloses a dry friction self-lubricating sliding bearing which is obtained by rolling three layers of composite materials. The three layers of composite materials comprise a metal substrate; a spherical porous copper powder layer which is sintered on one surface of the metal substrate; and an anti-friction wear resistant material layer which permeates and covers the copper powder layer, wherein, the copper powder layer consists of the following components by weight percentages: 8% of tin powder, 3% of zinc powder and copper powder; the anti-friction wear resistant material layer consists of the following components by weight percentages: 40-60% of polytetrafluoroethylene, 10-15% of polyimide, 3-6% of molybdenum disulfide and tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer (PFA). The dry friction self-lubricating sliding bearing has the advantages of small initial friction coefficient, less heat production, easy formation of a transfer membrane, minimal damage to a grinding shaft and the like; meanwhile, the application of the bearing can be expanded to fields of food, pharmacy, beverage, hydrotechnics, medical machinery and the like as manufacturing raw materials do not contain hazardous substances such as lead, toluene and the like.

Owner:JIANGSU CCVI BEARING

Composite high-efficiency high-flow servo valve

InactiveCN102213243ASmall excitation powerHigh frequency responseOperating means/releasing devices for valvesServomotor componentsControl engineeringAlloy

The invention relates to a composite high-efficiency high-flow servo valve. The technical scheme is as follows: the servo valve consists of a composite flow valve and a composite magnetic control motor, two ends of the composite flow valve are respectively connected with a left haft part and a right half part of the composite magnetic control motor. A first electromagnetic converter [2] and a displacement sensor [44] are concentrically arranged in a left shell [3] from left to right in sequence; a valve core [5] is movably arranged in a valve sleeve [11] that is fixed in a valve body [8]; an angle displacement sensor [37], a second electromagnetic converter [19], a left sliding bearing [35], a gear shaft [28] and a right sliding bearing [29] are concentrically arranged in a right shell [17] from left to right in sequence; one side of the gearing shaft [28] is provided with a rack [31] that is meshed with the gear shaft [28]; and one end of the valve core [5] of the composite flow valve is in contact with an end surface of a first electromagnetic memorial alloy [45], and the other end of the valve core [5] is fixedly connected with a second magnetic control memorial alloy [36]. The servo valve has the characteristics of high frequency response, high reliability, high flow, small volume, small leakage, compact structure and high precision.

Owner:WUHAN UNIV OF SCI & TECH

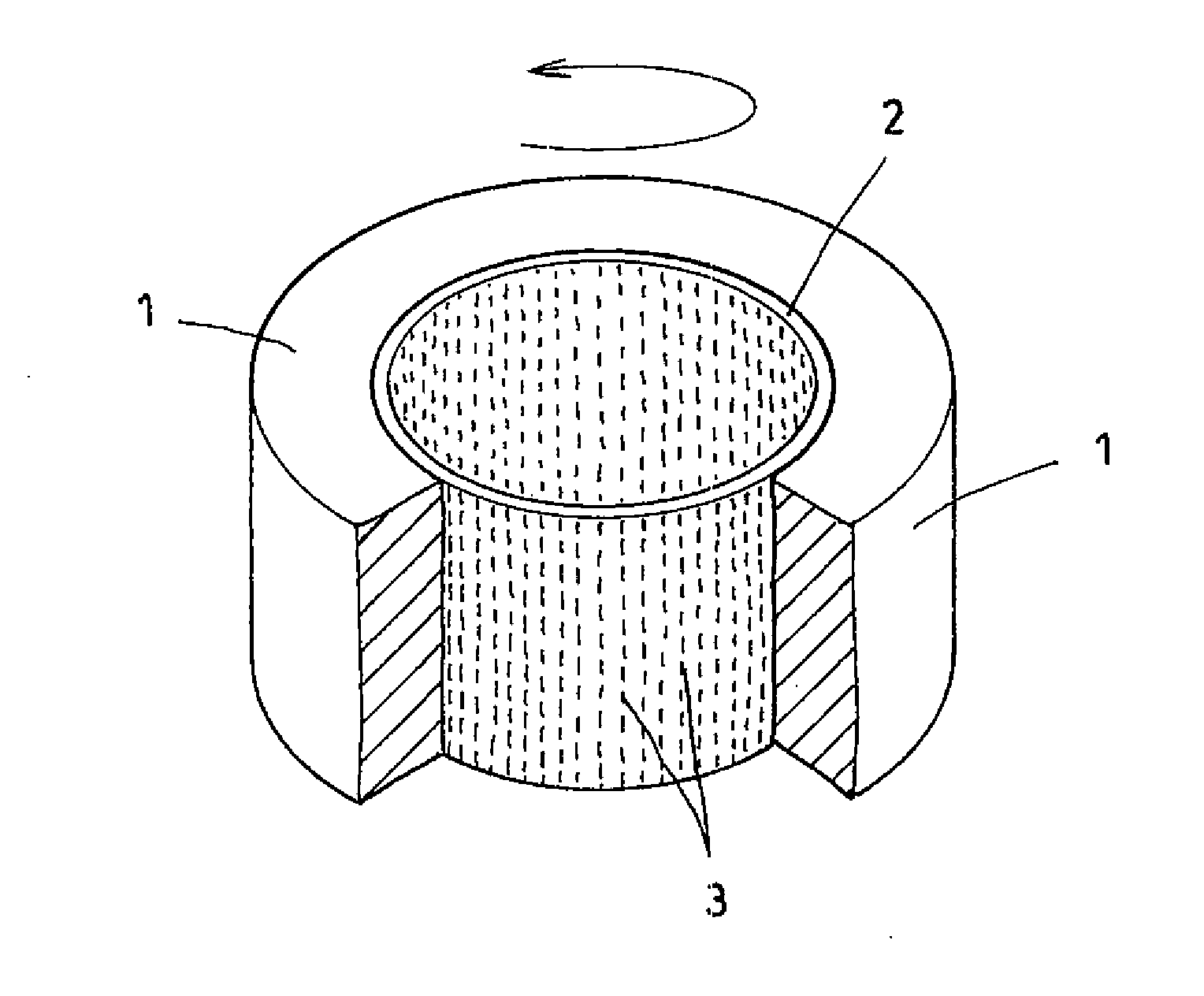

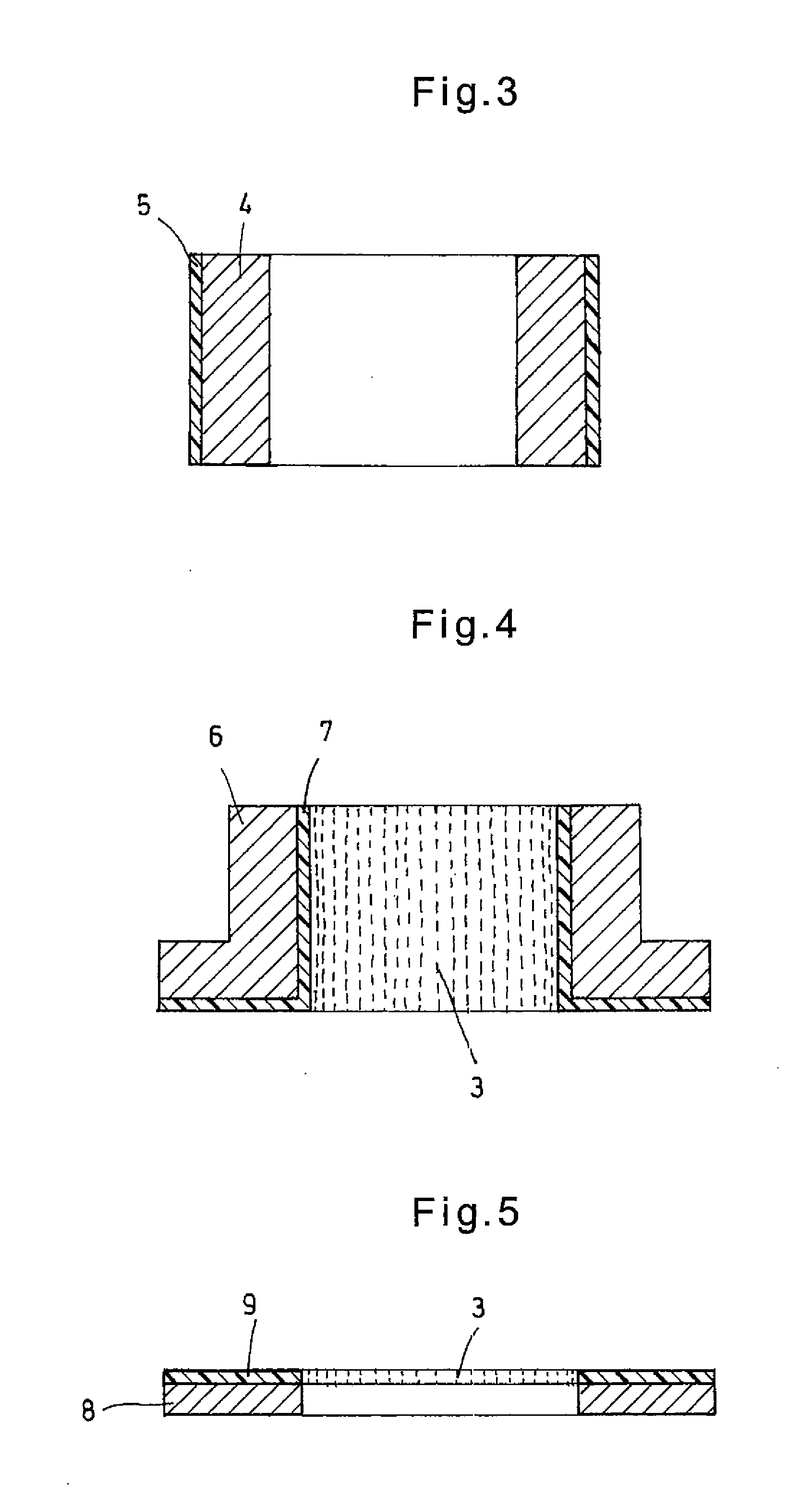

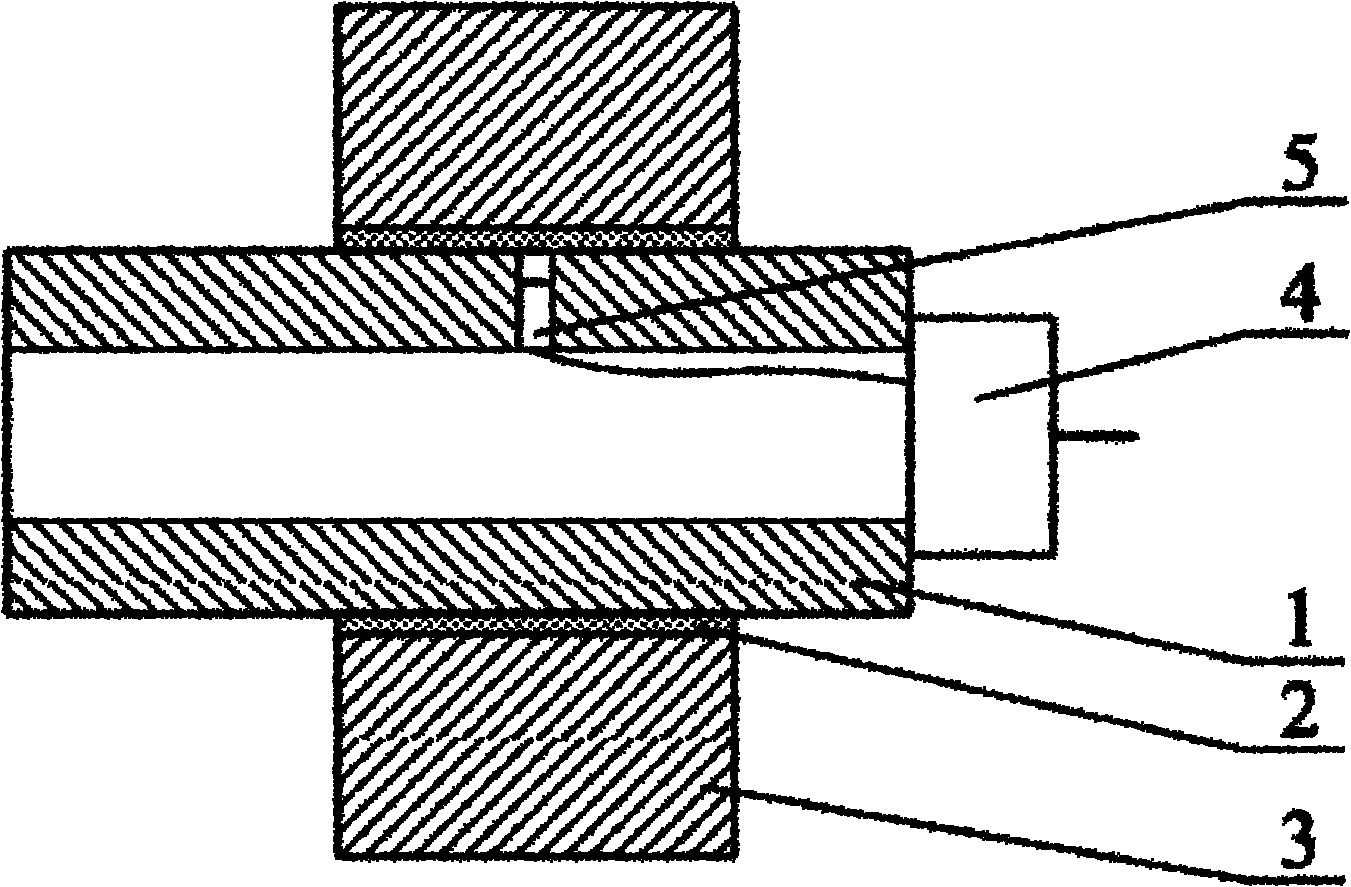

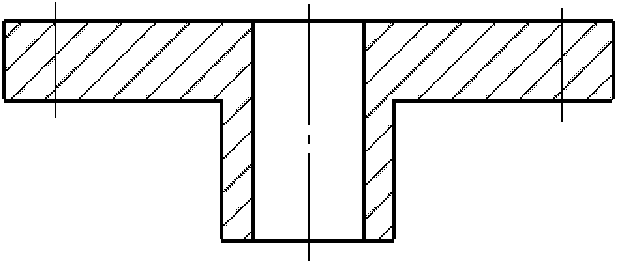

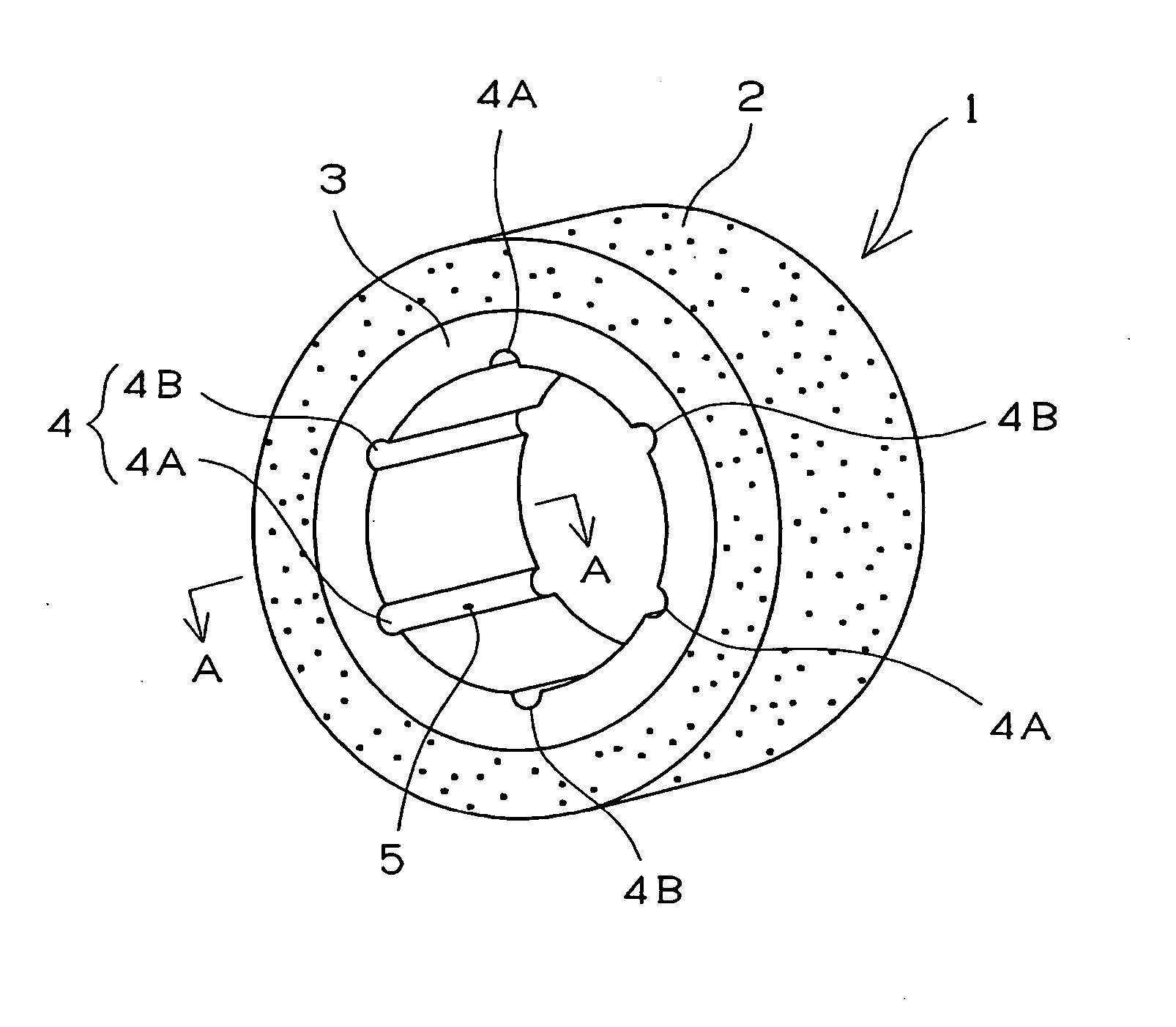

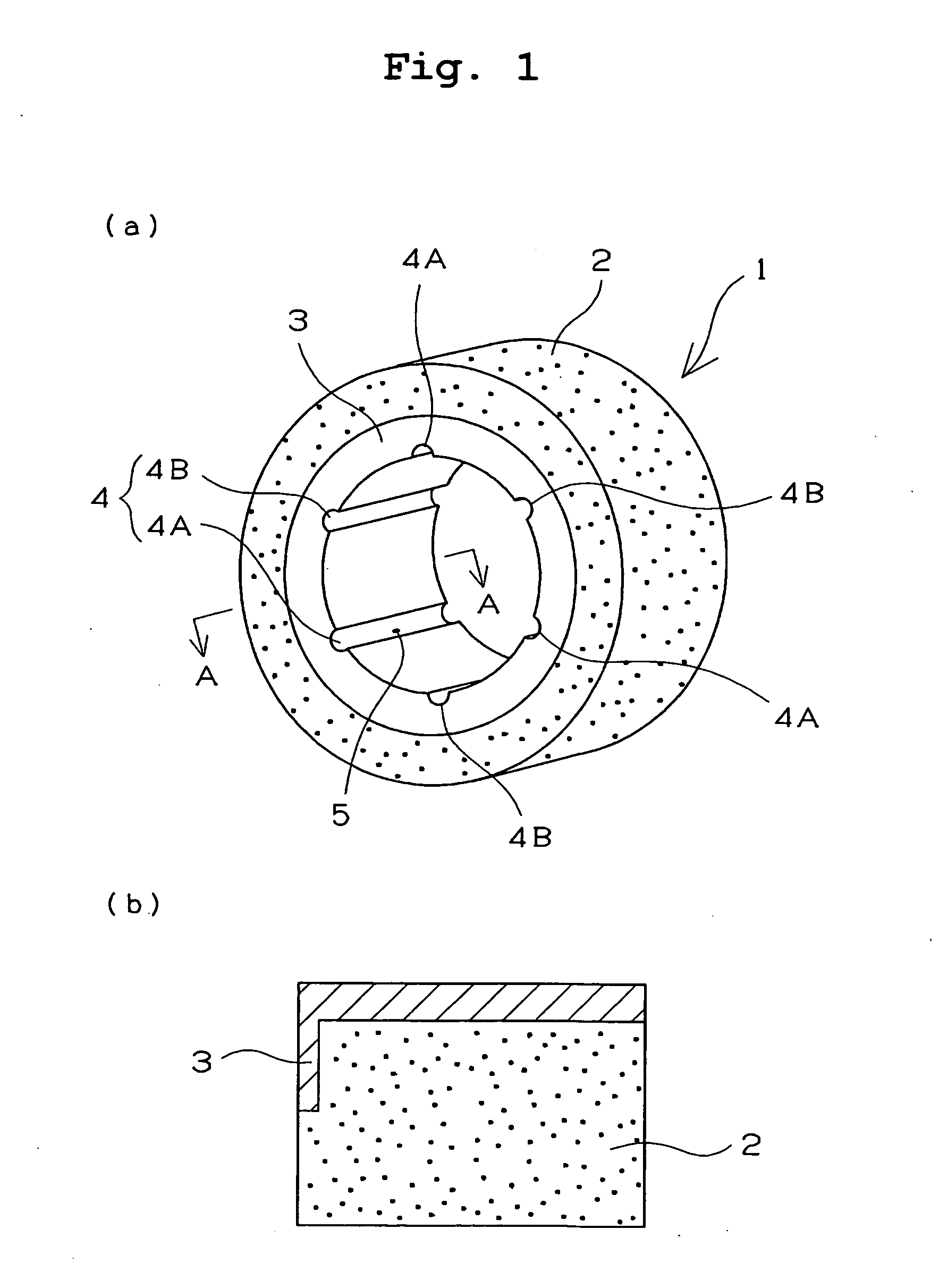

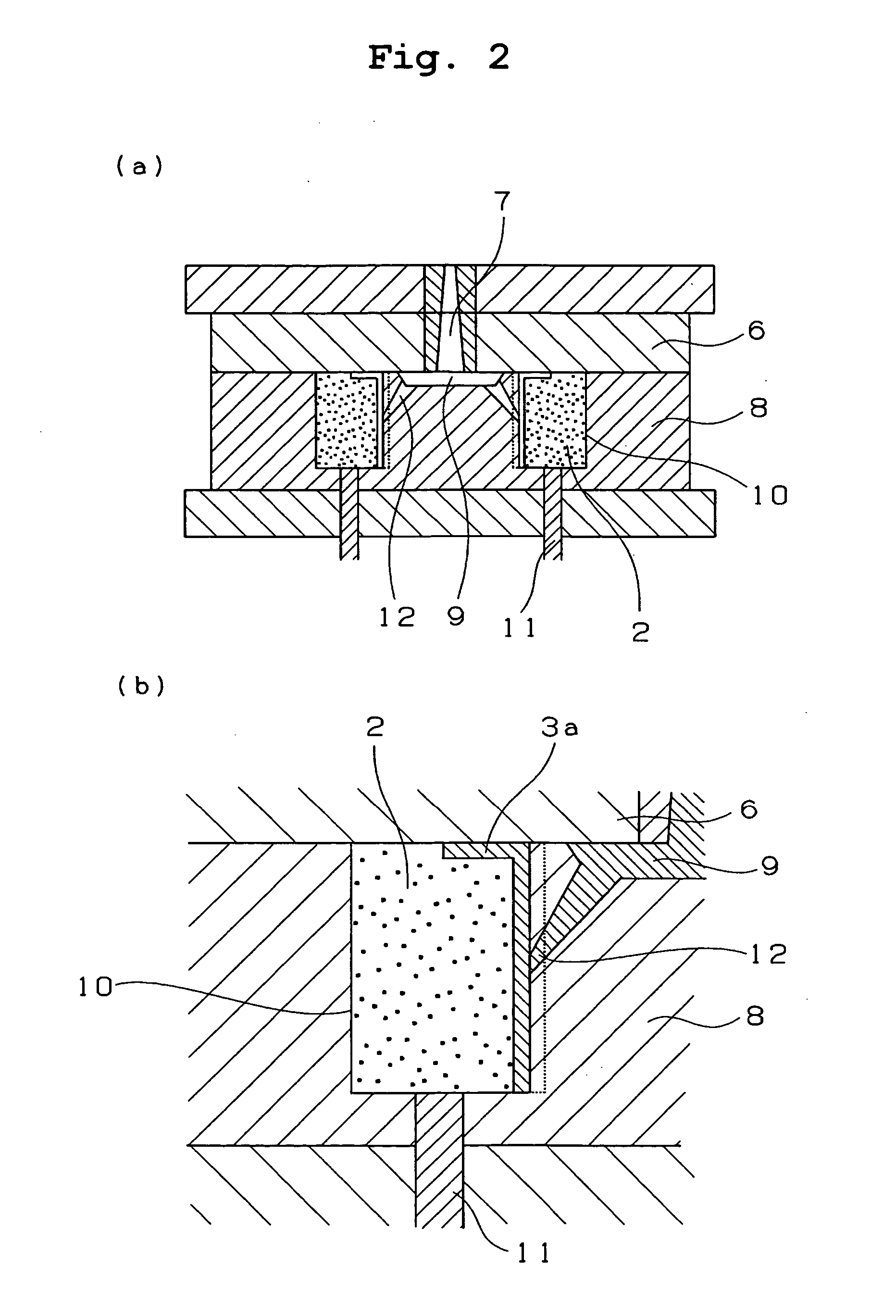

High-accuracy sliding bearing

InactiveUS20070177833A1Improve productivityImprove accuracyBearing componentsSliding contact bearingsProduction rateSlider bearing

The present invention provides a high-accuracy sliding bearing which eliminates the need for treating a gate mark, has a high accuracy, is excellent in its mechanical strength, and is in its productivity. A sintered metal (2) is used as a bearing peripheral part. A resin material is molded at a sliding portion of the bearing peripheral part to form a resin layer (3). In the resin layer (3), a product of a coefficient of linear thermal expansion of the resin material and a thickness of the resin layer is not more than 0.15. The resin layer (3) is molded through tunnel gates. The resin layer comprises a plurality of axial grooves (4A) and (4B) on a bearing sliding surface thereof, and the tunnel gate marks (5) are alternately formed on a bottom of each of the grooves.

Owner:NTN CORP +1

Novel parallel mechanism having reconfigurable characteristic

InactiveCN105437216AAchieve foldingAchieve expansionProgramme-controlled manipulatorSlider bearingMedial axis

The invention discloses a parallel mechanism having a reconfigurable characteristic. The parallel mechanism comprises a base component, first, second and third branch chain components, lower shafts of the first, second and third branch chains, middle shafts of the first, second and third branch chains, a middle platform component and a tail end platform component, wherein a bearing seat at the rear end of the lower part of the first branch chain is connected with a first base slider bearing seat on the base component through the lower shaft of the first branch chain; the bearing seat at the front end of the lower part of the first branch chain is connected with a first middle platform bearing seat of the middle platform component through the middle shaft of the first branch chain; an end cover of the upper part of a first spherical hinge of the first branch chain component is connected with a first tail end platform connecting part of the tail end platform component; the second and third branch chain components are totally the same as the first branch chain component; a bevel gear of a base rotates to drive a wing plate screw to rotate so that a rectilinearly-moving slider of the base performs rectilinear motion along linear guide rails of the base; a screw motor rotates to drive a middle rectilinearly-moving screw to rotate, so that a middle rectilinearly-moving slider can move along middle rectilinearly-moving guide rails.

Owner:BEIJING JIAOTONG UNIV

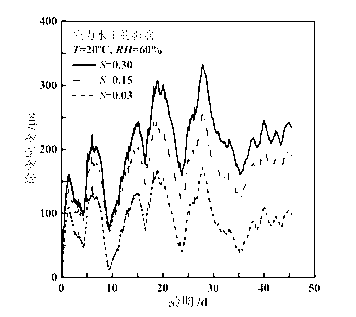

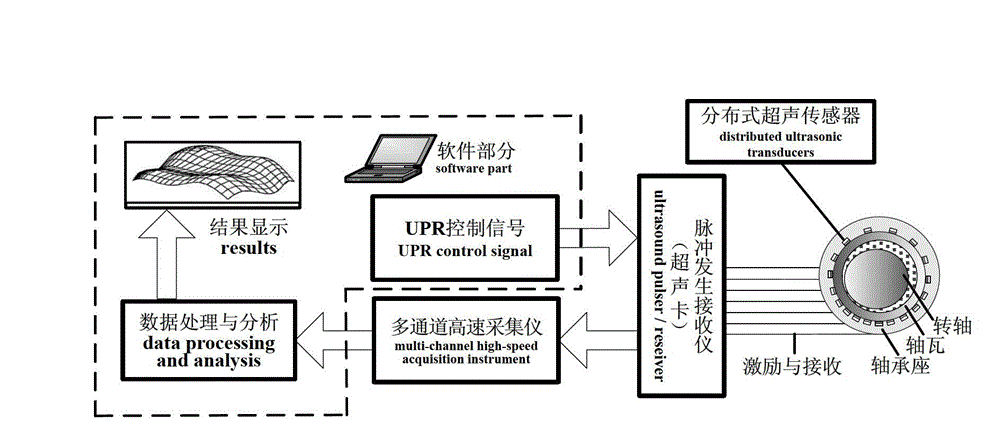

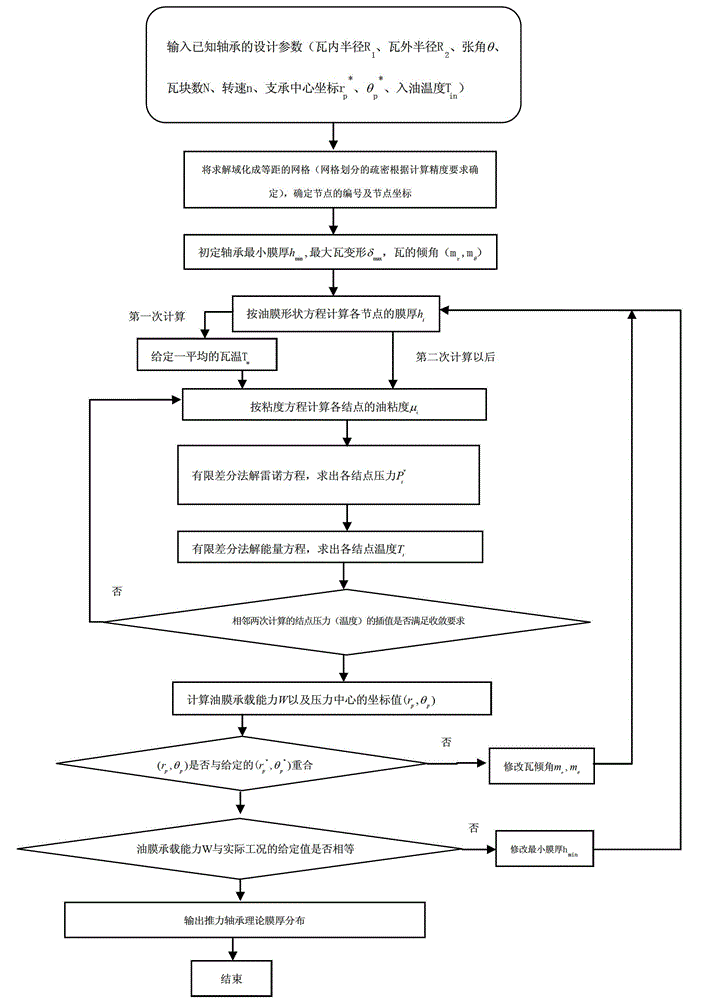

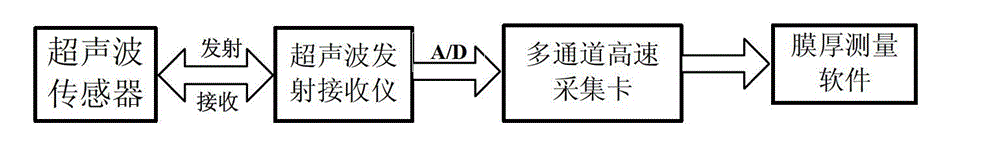

Sliding bearing universe lubricant film thickness distribution detection method

ActiveCN103335616AReal-time detection of lubrication statusTimely detection of local lubrication failure or even frictionUsing subsonic/sonic/ultrasonic vibration meansUltrasonic sensorSlider bearing

The invention discloses a sliding bearing universe lubricant film thickness distribution detection method to realize real-time detection of the sliding bearing universe lubricant film thickness distribution under an actual working condition. The method comprises the following steps: through the finite difference method, iterating to solve the lubricant basic equation of the sliding bearing to acquire the theoretical distribution of the lubricant film thickness of the sliding bearing, then, according to the theoretical distribution of the lubricant film thickness of the sliding bearing, determining the positions of distributed measure points of the sliding bearing, at the selected positions of the measure points, mounting circular sheet ultrasonic sensors in an embedded manner, and acquiring the real-time film thickness values of all measure points by adopting the ultrasonic film thickness measurement technology, and finally, performing interpolation on the measured lubricant film thickness values at all distributed measure points to acquire the distribution of the lubricant film thicknesses of the sliding bearing under the actual working condition.

Owner:XI AN JIAOTONG UNIV

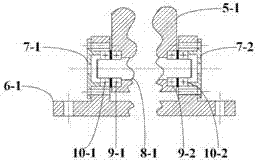

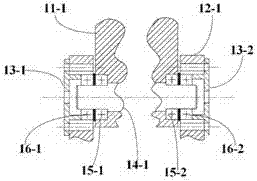

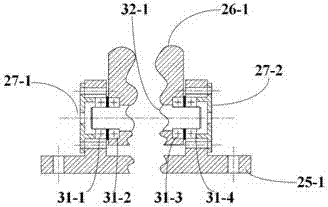

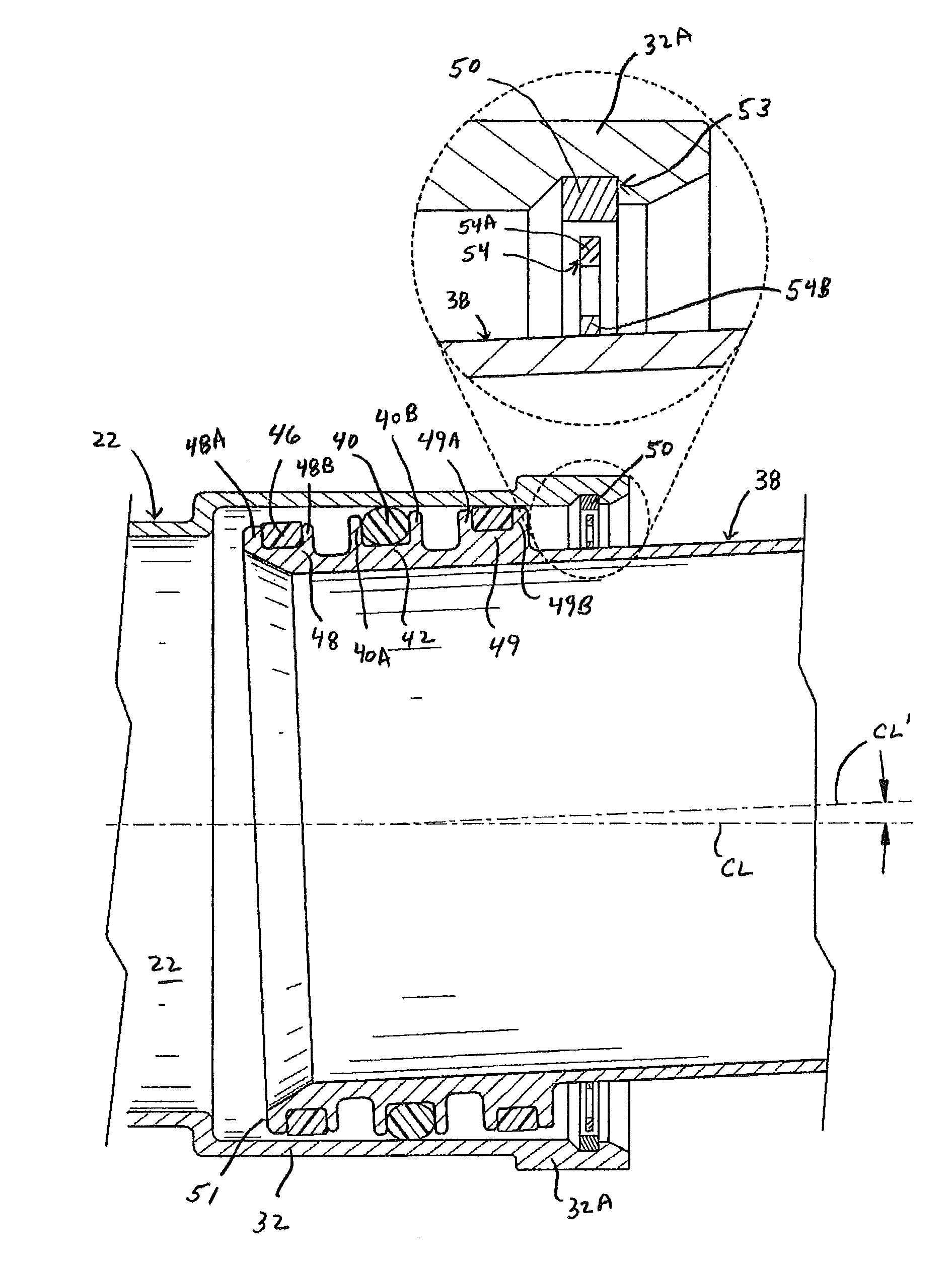

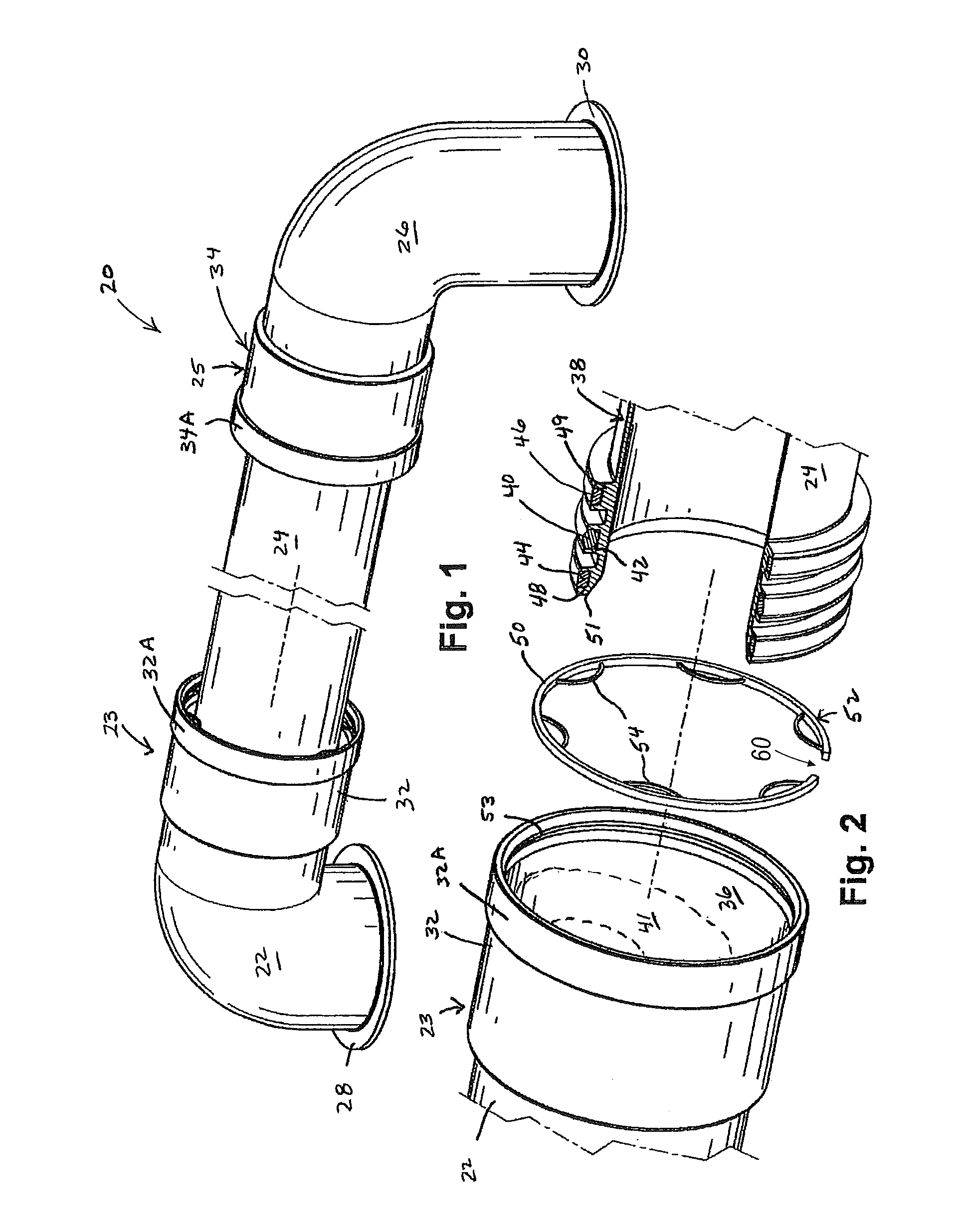

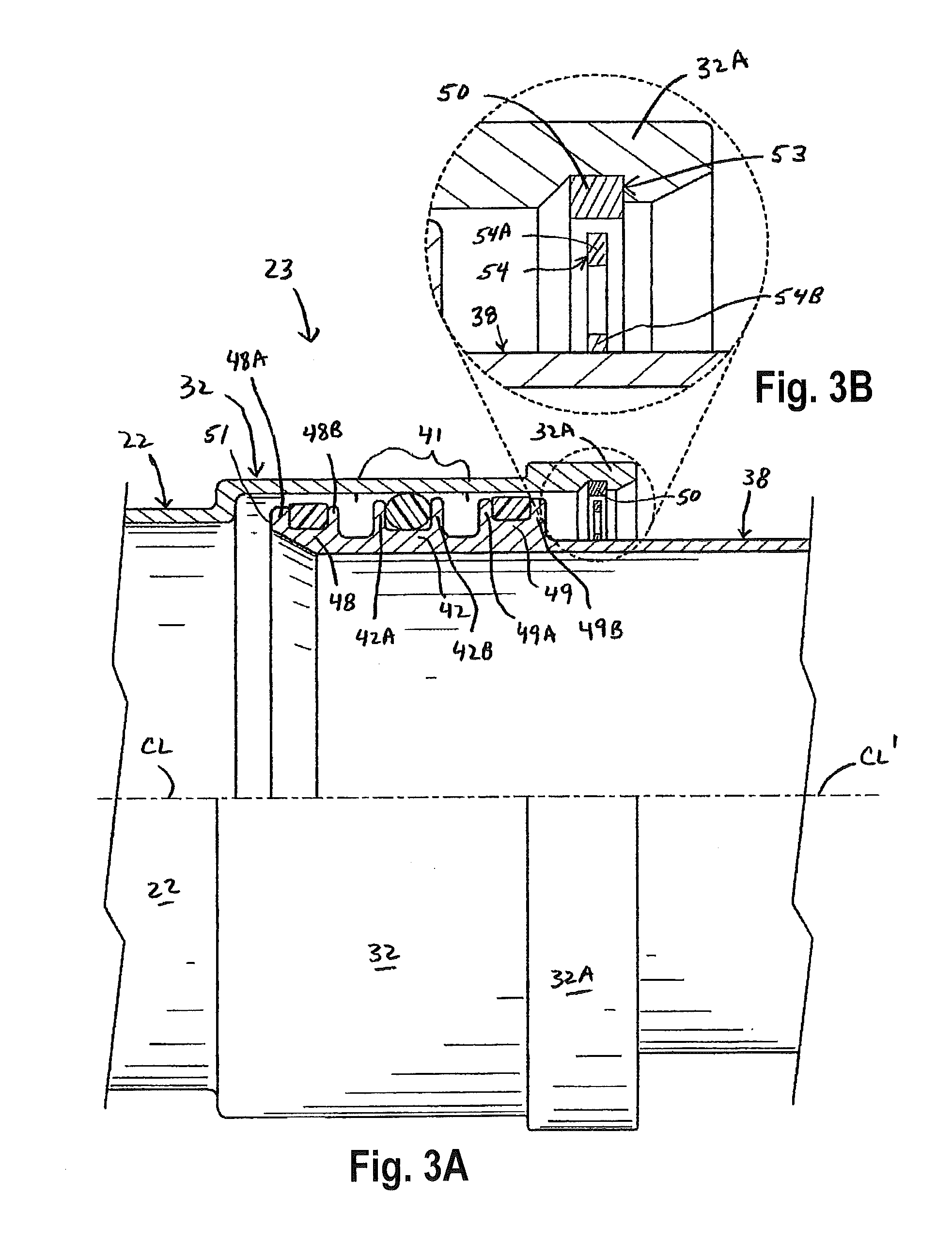

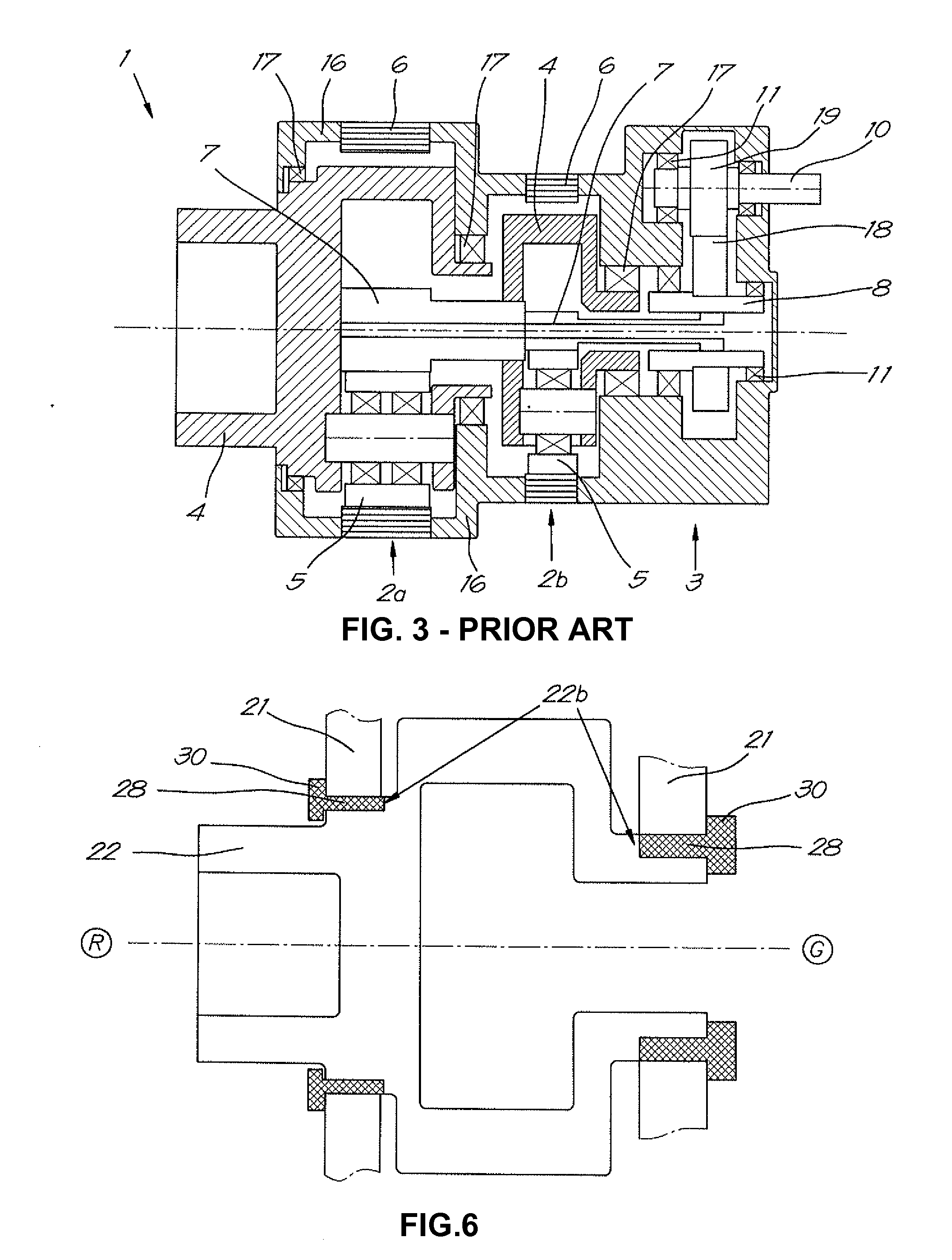

Compliant conduit connector

ActiveUS8360477B2Prevents wear and gallingImprove sealingSleeve/socket jointsJoints with sealing surfacesElectrical conductorSlider bearing

A compliant conduit connector system for the sealed joining of two fluid conduits having two or more slip bearings to maintain mechanical connection between the two fluid conduits and a sealing o-ring to maintain a fluid seal between the two fluid conduits is disclosed. A socket having an inner surface including a sealing surface is formed on an end of a first fluid conduit. A plurality of slip bearings are held in position on the outer surface of a second fluid conduit by respective bearing channels attached to an outer surface of the second fluid conduit where the slip bearings are in mechanical contact with an inner surface of the socket formed in the first fluid conduit. The o-Ring makes sealing contact with a sealing surface defined as part of the inner surface of the first fluid conduit. To assure electrical conductivity a conductor assembly contacts both the first fluid conduit and the second fluid conduit.

Owner:EATON INTELLIGENT POWER LTD

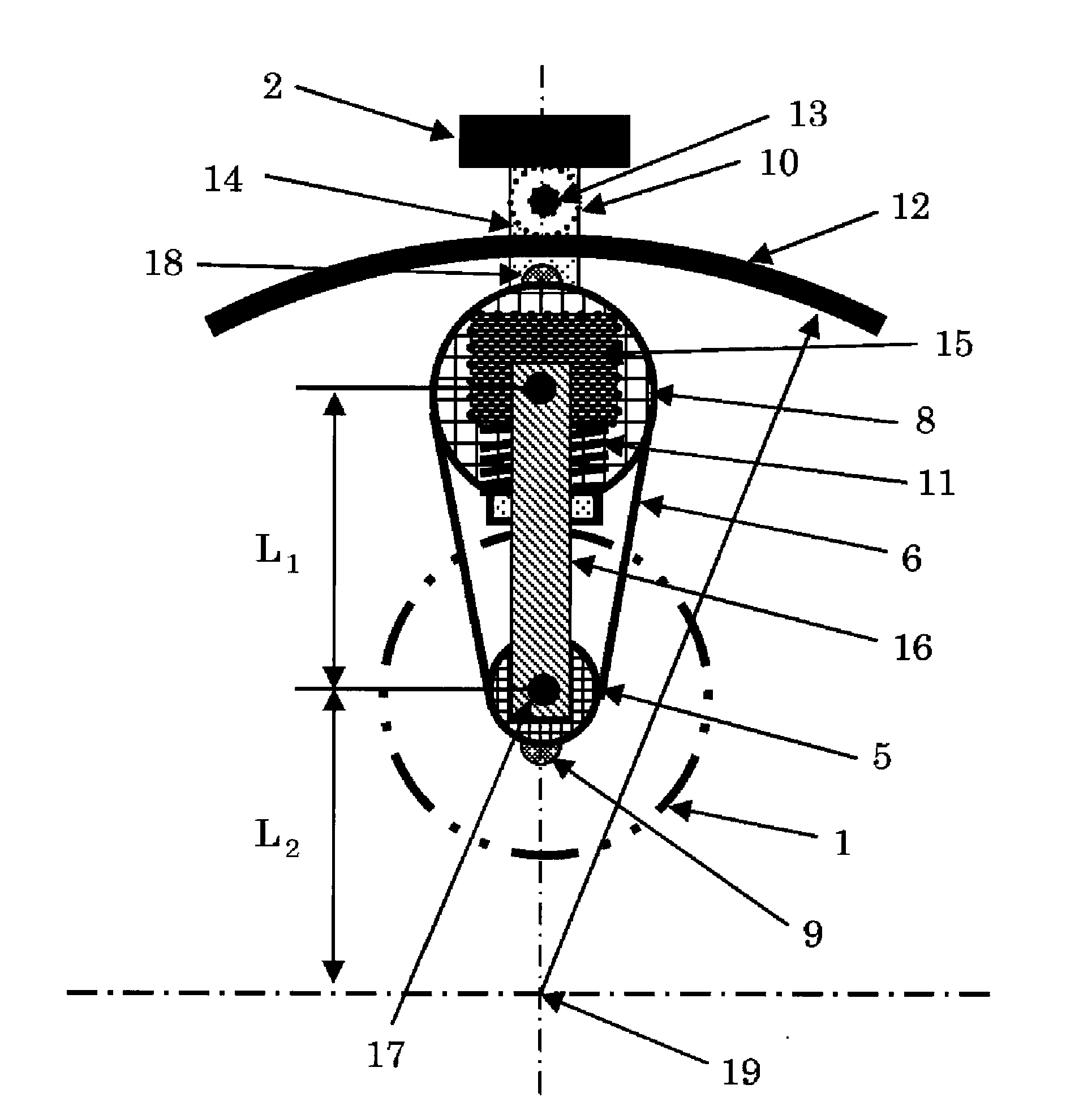

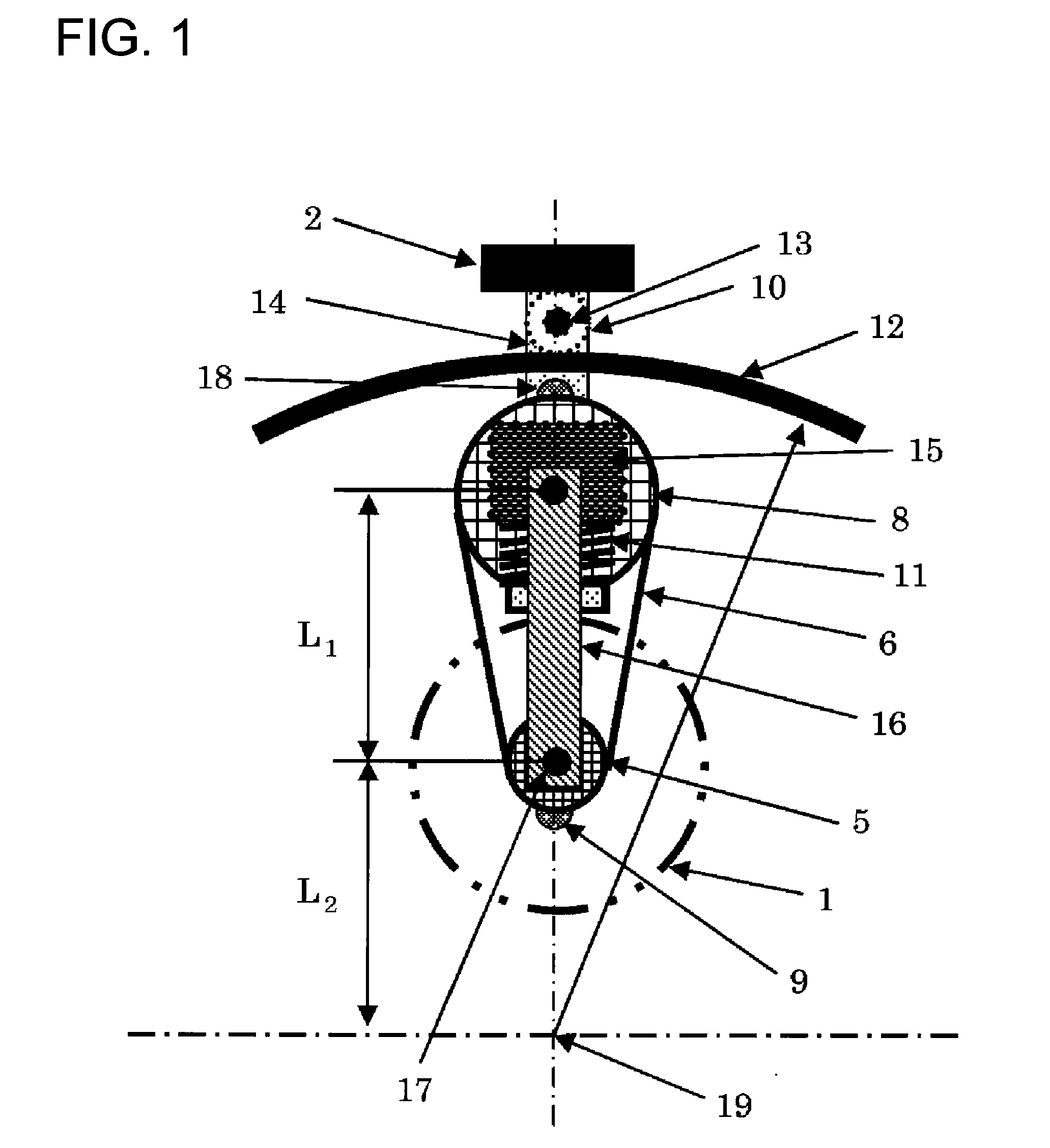

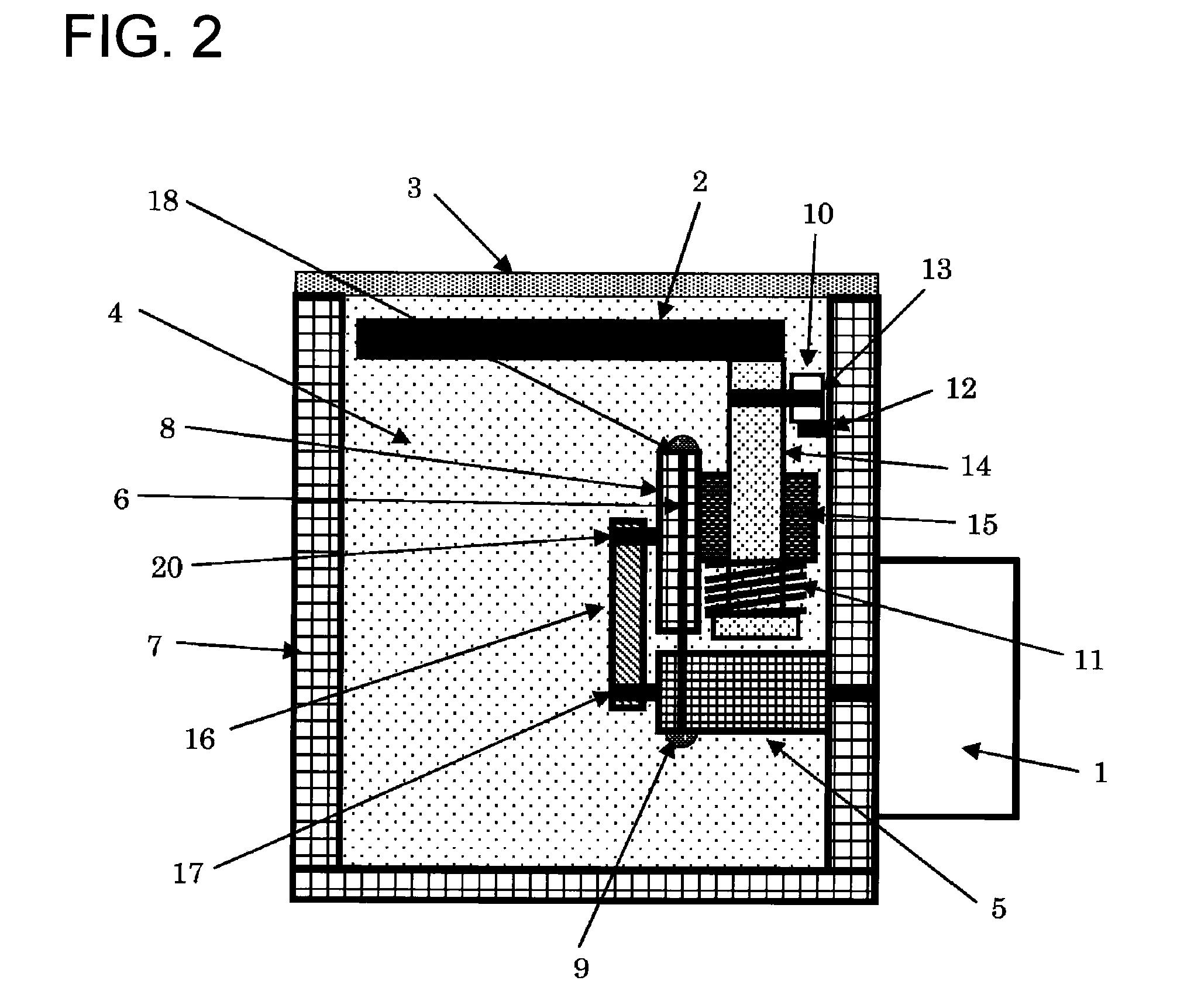

Ultrasonic probe

InactiveUS20090275836A1Avoid obstaclesUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesBiological bodySlider bearing

Disclosed is an ultrasonic probe having an organism contact portion that is shaped for use along a comparatively large curvature and can easily be used while closely contacting an organism, and that has an adequately reduced size. According to the technique of the invention, a first cylinder pulley 5, secured to a probe casing 7, an arm 16, secured to a motor spindle 17 that is extended through a first pulley, and a second cylinder pulley 8, rotatably arranged on the opposite side, are coupled together by a wire 6. The second pulley is equipped with a slider shaft 14 that is arranged, in an extensible manner, by a slider bearing 15. The slider shaft is quipped with a roller 10 that contacts a guide rail 12 of the probe casing, and an ultrasonic element 2 is attached to the distal end of the slider shaft to provide the telescopic structure for the slider shaft. In this manner, the size of a scanning mechanism, for oscillating the ultrasonic element along a large curvature, is reduced.

Owner:KONICA MINOLTA INC

Lead-free self-lubricating bearing and its production

The invention relates to a mechanical components industry regulation hole coaxial between the methodology and regulation components, in particular the aviation, aerospace, civil and other mechanical structure of the multi-hinge assembly point. Double eccentric bushing from the eccentric bushing and the eccentric bushing composition, the eccentric bushing diameter and the outer diameter of a round circle of eccentric and the eccentric bushing diameter and the outer diameter of a round of the same circle of eccentric, and, Bushing end of the shaft is the first shoulder. Double eccentric bushing used in the eccentric bushing and the eccentric bushing with a certain amount of tolerance, through the inner and outer sleeve of repeated eccentric rotation adjustment can be realized coaxial connection points more than the match, and for each hub Heart of the biggest angle adjustment of not more than 360 degrees, adjust volume small. This greatly reduces the difficulty of assembling and because of the internal and external sleeve with tolerance, as well as components and assembly hub between the matching hole in the machining tolerances can be very good at that in the assembly, so there is no need to conduct a follow-up processing, reducing assembly time.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

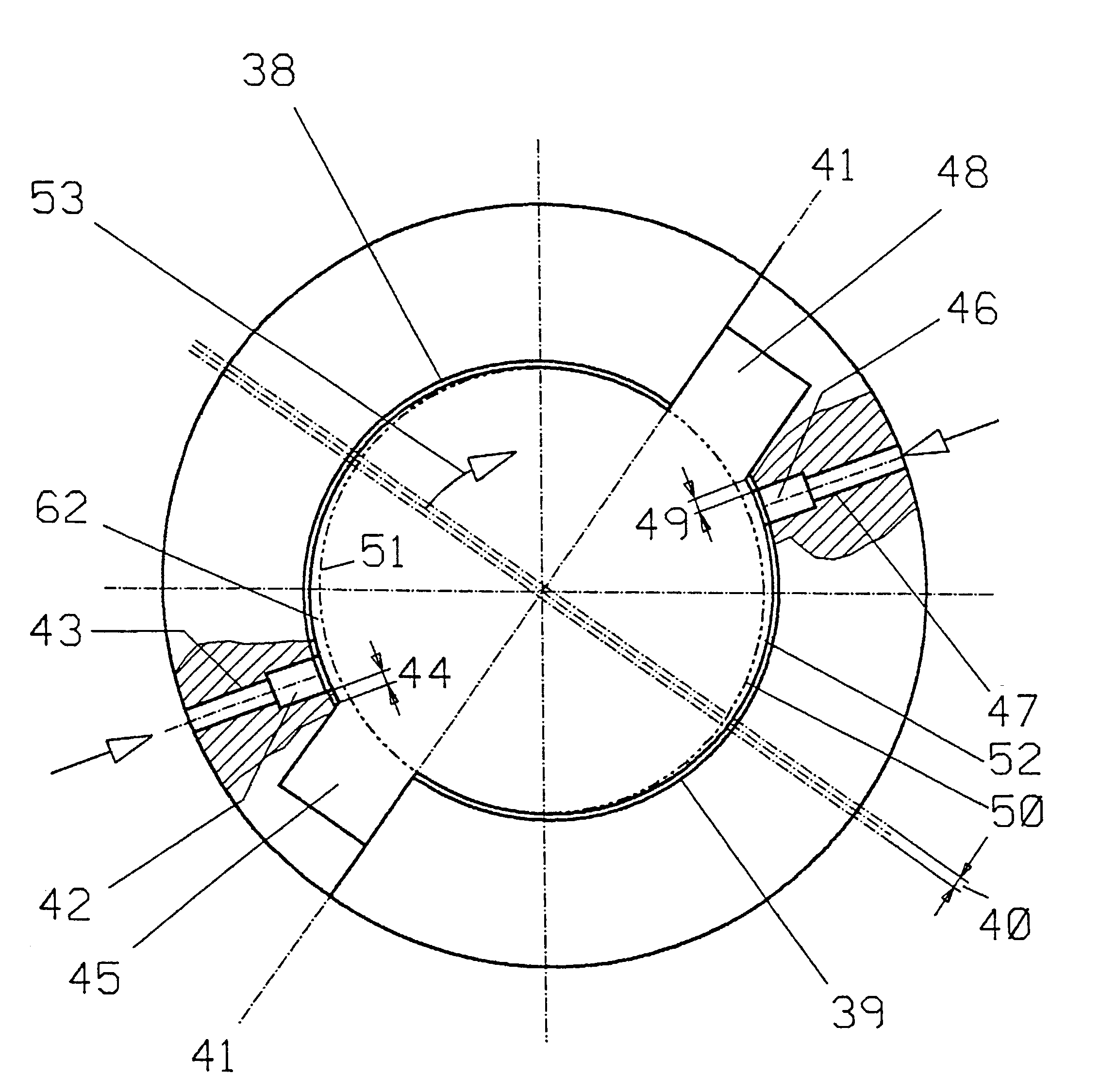

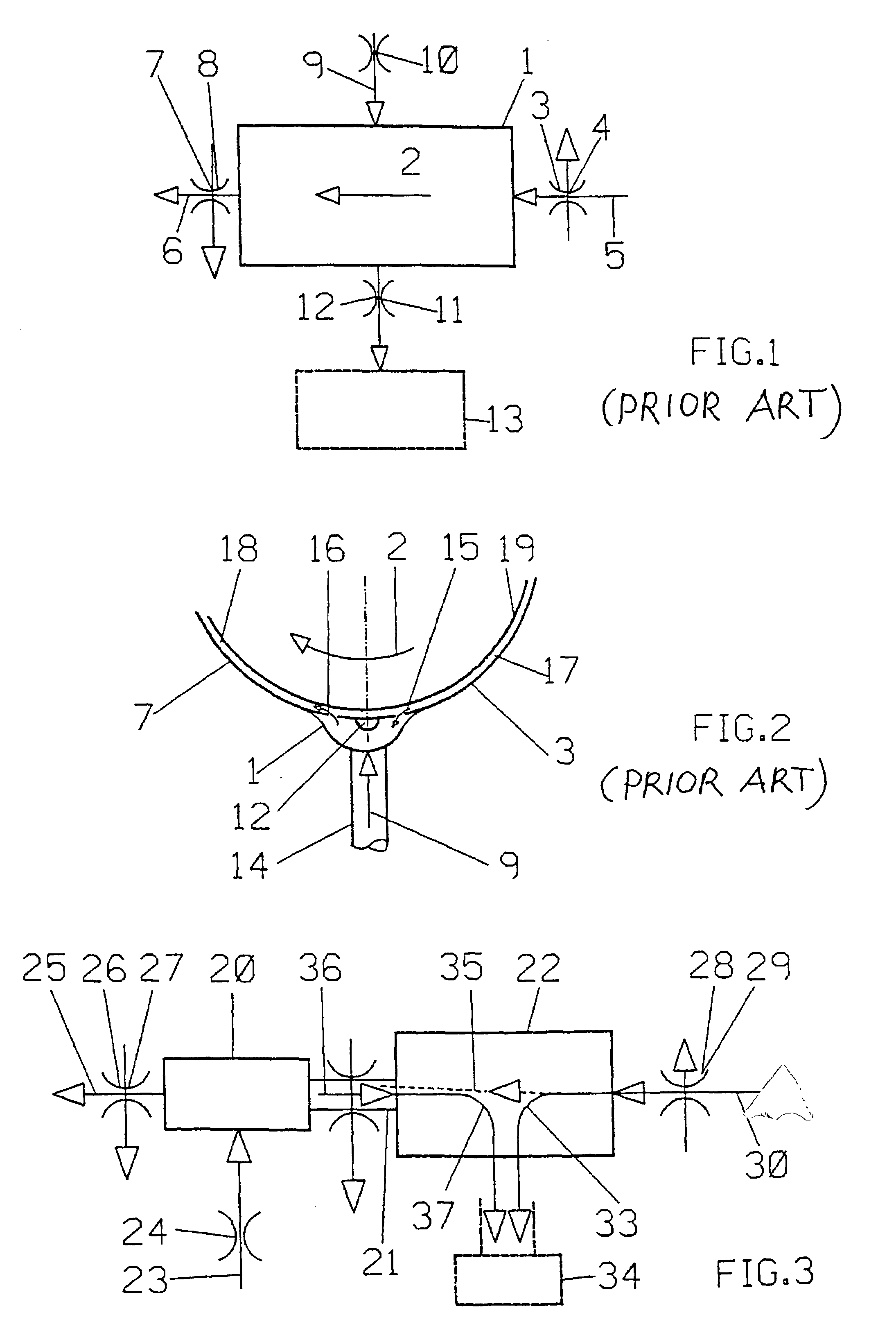

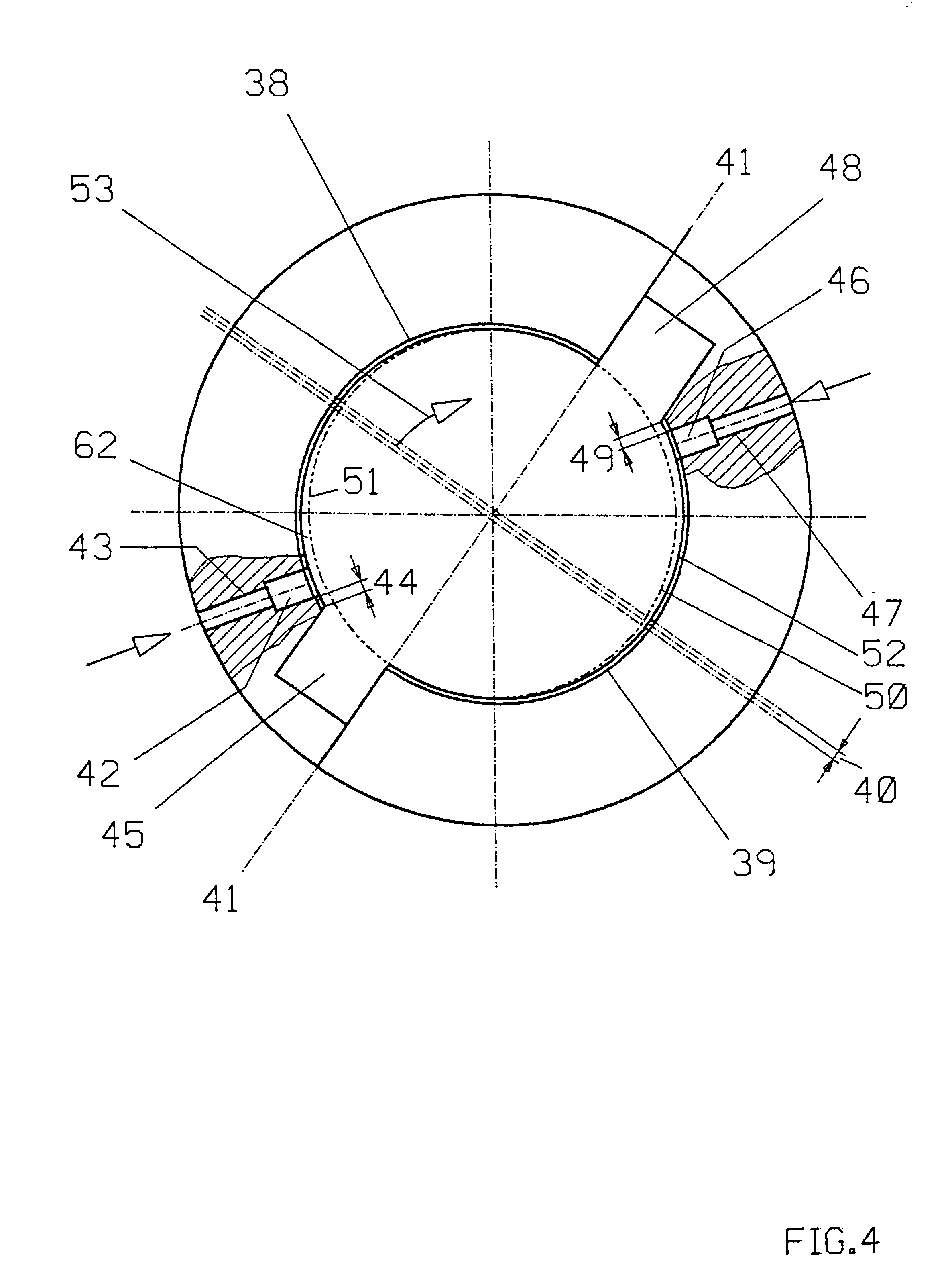

Hydrodynamic plain bearing and method of lubricating and cooling the bearing

InactiveUS6966700B2Reduce lossReduce consumptionCrankshaftsCrossheadsSlider bearingDecompression chamber

A method of lubricating and cooling a hydrodynamic plain bearing for a rotating element comprises the steps of supplying fresh, cold lubricant under pressure from a pressure chamber arranged upstream of a fixed gliding plane to a lubricating gap between the fixed gliding plane and the rotating element, the supply of fresh, cold lubricant being so controlled that an effective lubricating wedge is formed between the rotating element and the fixed gliding plane. The pressure chamber is connected to a decompression chamber predominantly filled with gas and arranged upstream of the pressure chamber by a mixing conduit, used, hot lubricant adhering to the rotating element is moved to the decompression chamber, and a portion of the used, hot lubricant is removed from the decompression chamber while the remaining portion of the used, hot lubricant flows from the decompression chamber into the mixing conduit and is mixed with fresh, cold lubricant flowing countercurrently in the mixing conduit whence the mixture is pressed into the decompression chamber.

Owner:GLEITLAGERTECHN WEISSBACHER

Unleaded Cu-based sliding bearing material and preparation method thereof

InactiveCN101576118AAchieve lead-freeImprove mechanical propertiesLiquid/solution decomposition chemical coatingSliding contact bearingsGraphiteHigh intensity

The invention relates to an unleaded Cu-based sliding bearing material and a preparation method thereof and the invention has the characteristics that: the material is composed of nickel, tin, zinc, iron, graphite, bismuth, copper and assistants, the substrate of the material is unleaded copper alloy, and the antifriction and antisticking constituent element is bismuth and graphite. The Cu-based bearing material features high intensity, and good antifriction and antisticking, thus realizing an unleaded Cu-based bearing material. The lead is cancelled in an original bearing material with lead and copper, and a synergistic effect of bismuth and graphite can replace the use of lead, thus completely overcoming the defect of lead pollution; moreover, the service performance of the bearing remains nearly the same, therefore the unleaded Cu-based sliding bearing material can completely replace the bearing material with lead and copper. The material of the invention can be applied in food machinery, drugs machinery, construction machinery, automobile and other products, and has advantages of good antifriction and antisticking, good heat dissipation effect, oxidation resistance and corrosive resistance.

Owner:HEFEI UNIV OF TECH

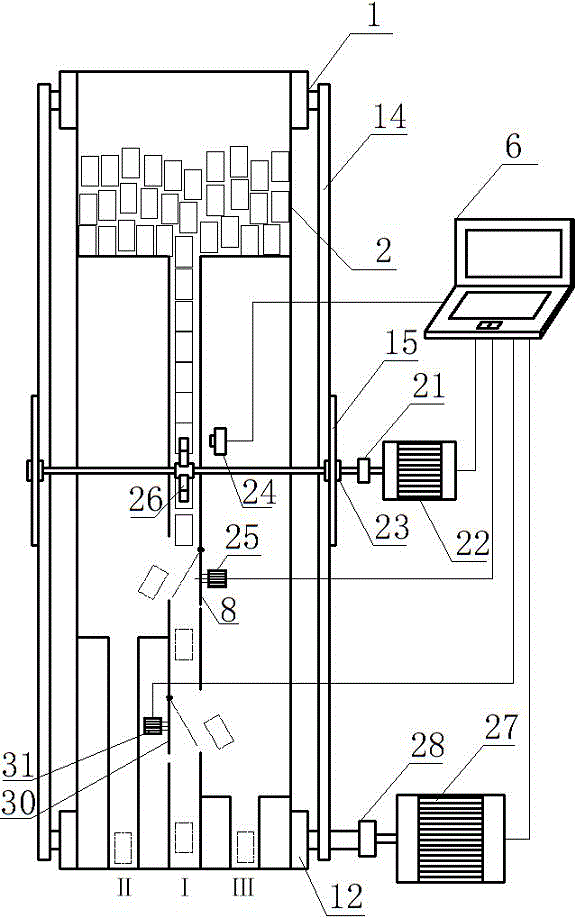

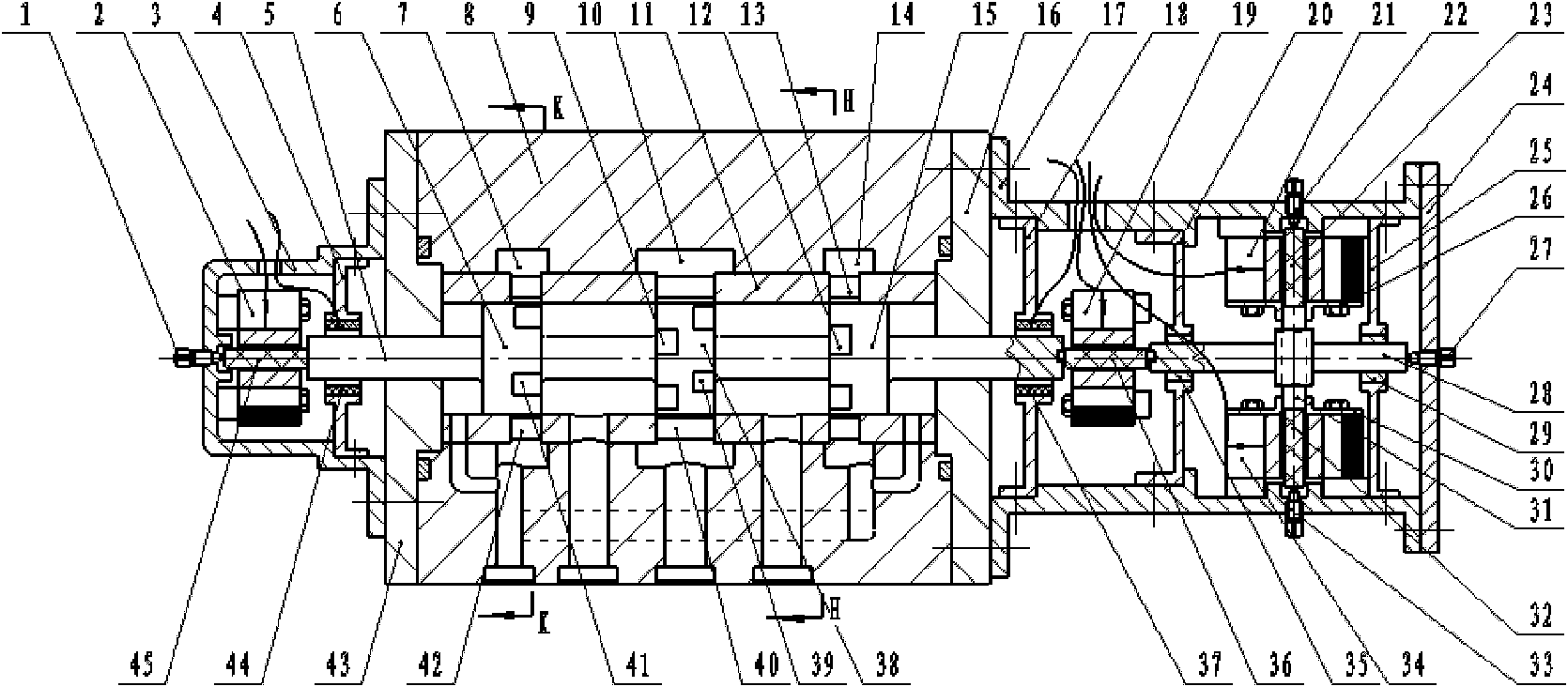

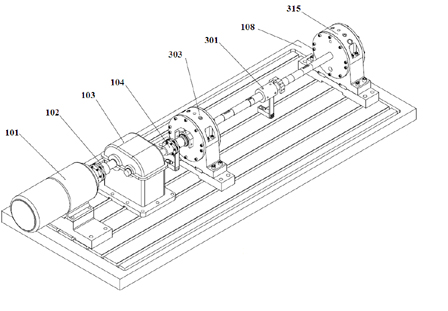

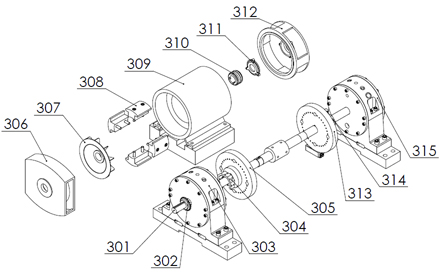

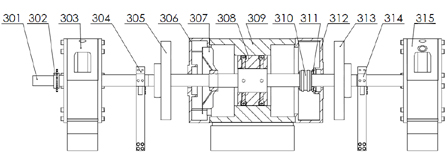

Generator rotor unbalance magnetic tension testing bench supported by sliding bearings

InactiveCN102507120AMeasurable pressure distributionTest dynamic response characteristicsVibration testingMultiple fluid pressure valves simultaneous measurementSlider bearingGear wheel

The invention discloses a generator rotor unbalance magnetic tension testing bench supported by sliding bearings, which includes a variable magnetic pole logarithmic generator rotor main shaft system and a testing bench basic framework. The rotor main shaft system includes a generator rotor, a front sliding bearing support subsystem, a sensor bracket, a stator front end cover, a generator rotor core and a magnet exciting coil, a generator stator, a collecting ring, a carbon brush bracket, a carbon brush, a stator rear end cover, and a rear sliding bearing support subsystem. The generator rotor core and the colleting ring are both mounted on the generator rotor, front and rear ends of the generator rotor are supported by the front and the rear sliding bearing support subsystems, and the generator stator is mounted outside the generator rotor. The testing bench basic framework includes an electromotor, a low-speed coupler, a speed-changing gear box and a high-speed coupler, wherein the electromotor is connected with a low-speed shaft of the speed-changing gear box through the low-speed coupler, and a high-speed shaft of the speed-changing gear box is connected with the generator rotor through the high-speed coupler.

Owner:SHANGHAI JIAO TONG UNIV

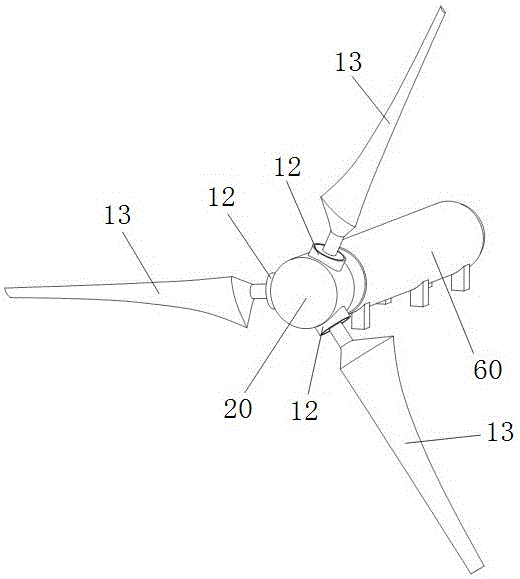

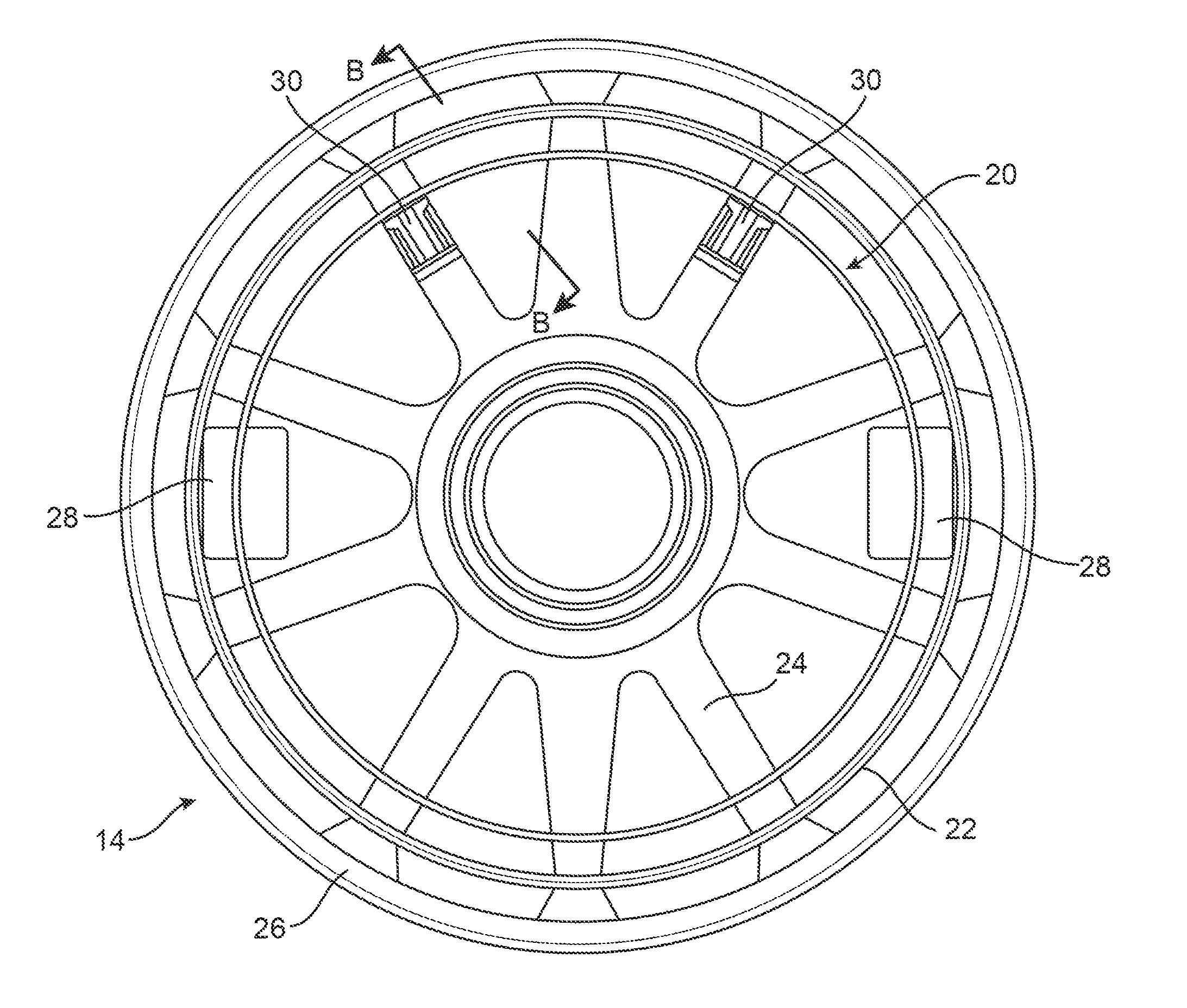

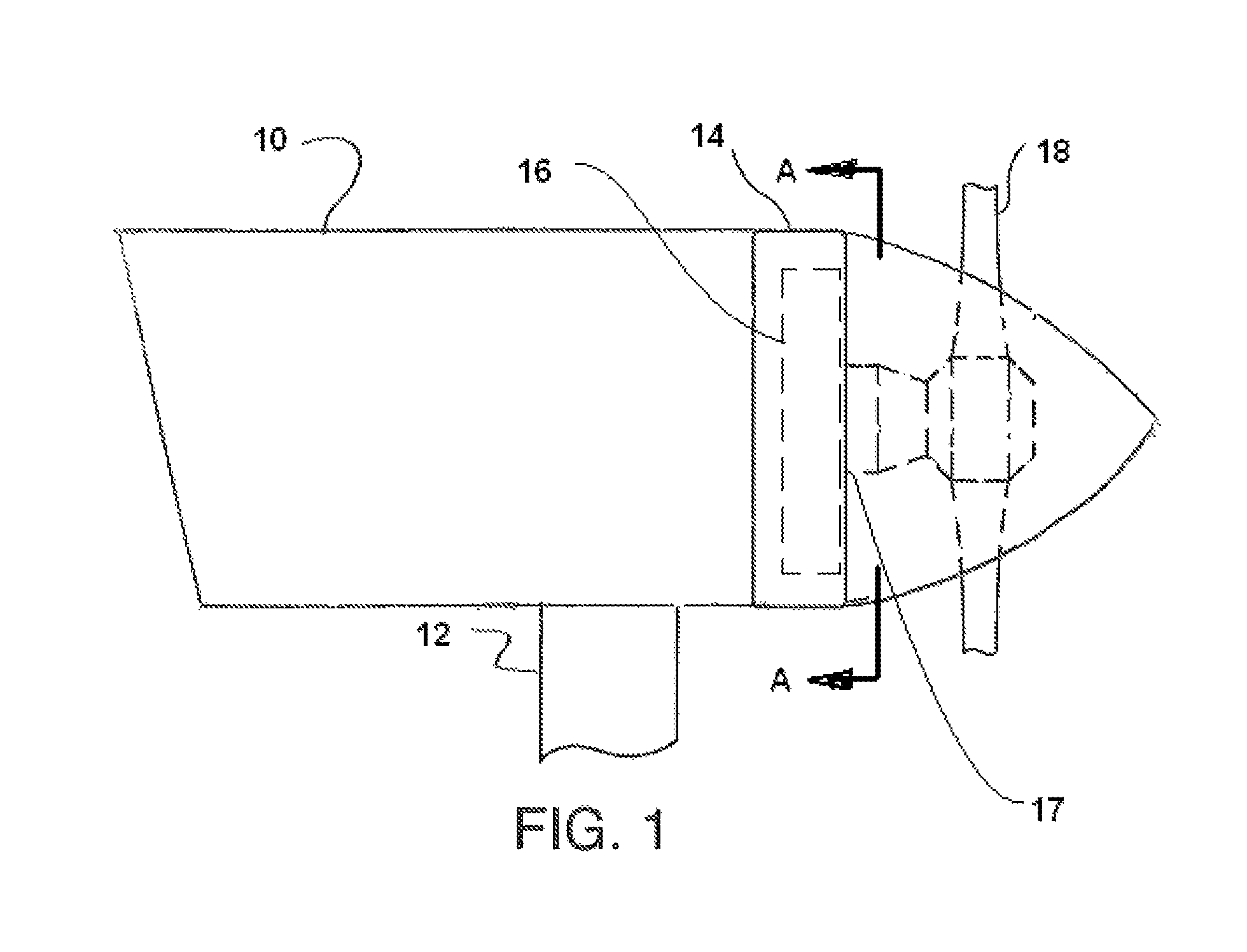

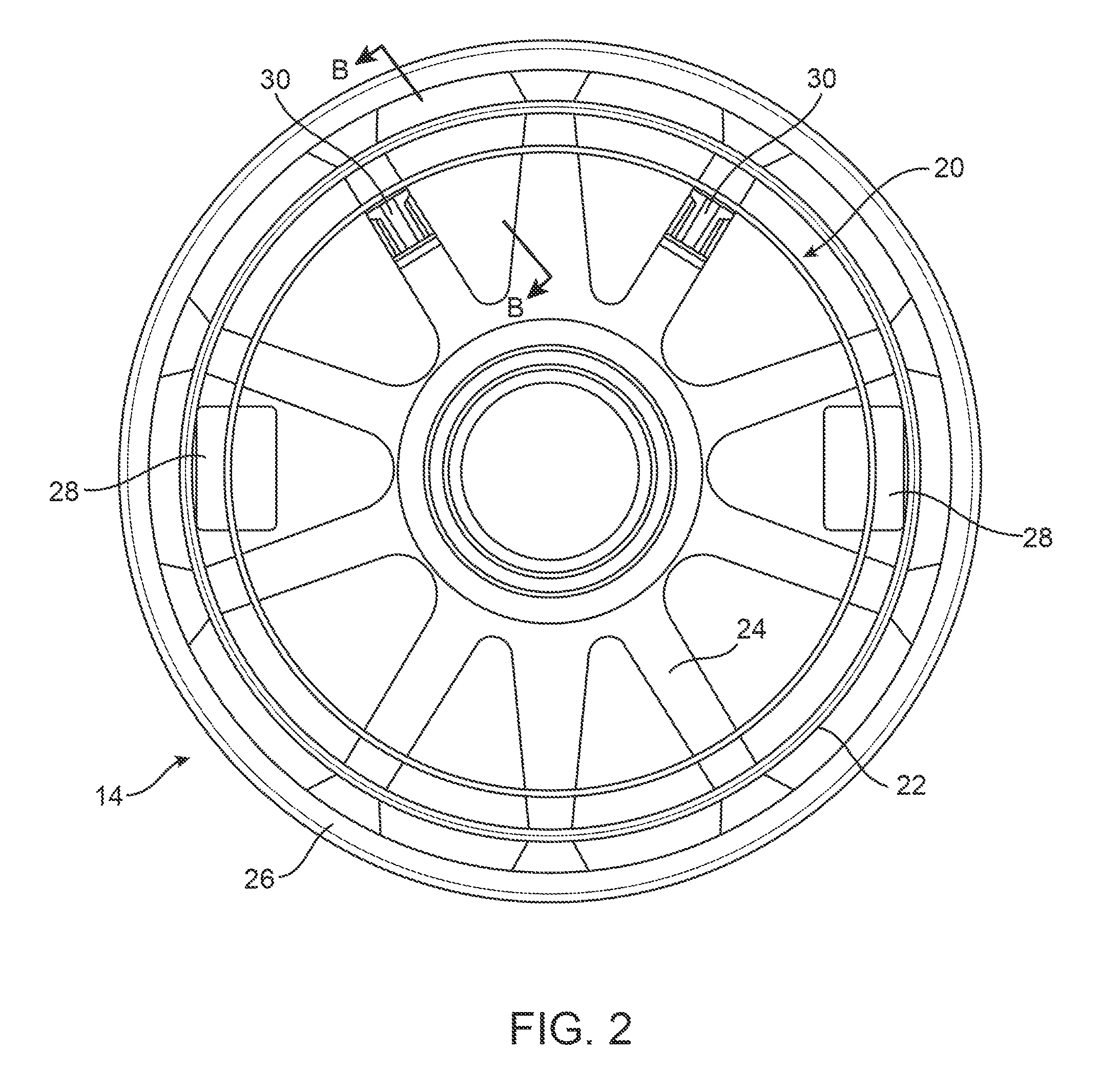

Horizontal axis ocean current energy electric generator variable-pitch device and horizontal axis ocean current energy electric generator

ActiveCN105840411AEasy to captureHigh transmission powerHydro energy generationReaction enginesGear wheelHorizontal axis

The invention discloses a horizontal axis ocean current energy electric generator variable-pitch device and a horizontal axis ocean current energy electric generator. The variable-pitch device comprises a driving part which is a motor or a hydraulic motor, a screw rod which is fixedly connected with an output shaft of the driving part through a coupler and a push plate which is arranged on the screw rod in a sleeving mode and is in threaded connection with the screw rod. The left end of the screw rod is supported through a pair of centripetal thrust bearings. The right end of the screw rod extends into the left end of a central hole of a spindle flange and a spindle. A first sliding bearing is formed between the screw rod and the left end of the central hole of the spindle flange and the spindle. Electric slip rings or a hydraulic slip ring are / is mounted at the right end of the spindle. One gear rack is fixed to each side surface of the push plate, each gear rack is engaged with a gear wheel, all the gear wheels are fixedly connected with the roots of corresponding blades through variable-pitch flanges, and second sliding bearings are formed between the variable-pitch flanges and the wheel hub wall. An angle transducer is installed at the left end of the driving part. By means of the horizontal axis ocean current energy electric generator variable-pitch device and the horizontal axis ocean current energy electric generator, the variable-pitch angle larger than 180 degrees can be achieved, therefore, double-way electricity generation is achieved, unified pitch variation can be achieved, and operation is stable.

Owner:ZHEJIANG UNIV

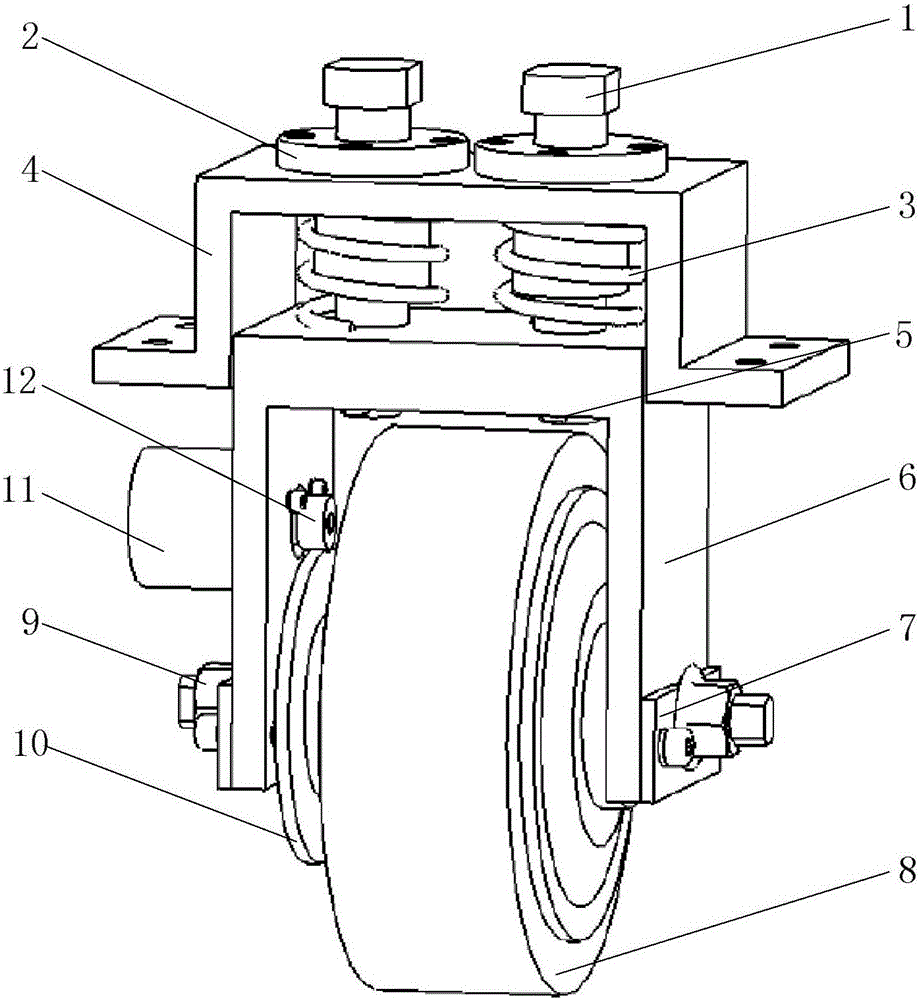

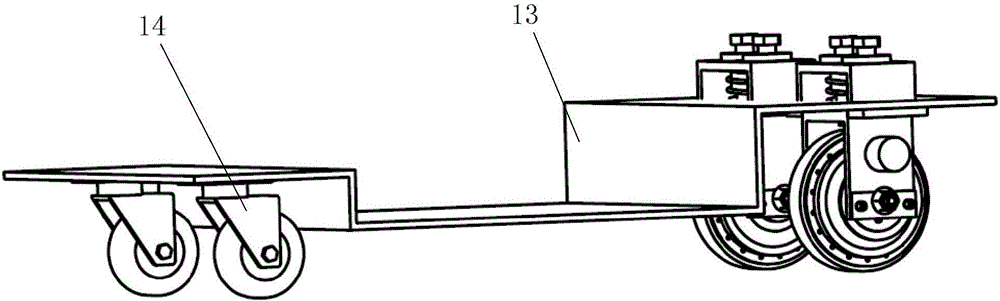

AGV (automatic guided vehicle) elastic support driving device using hub motor and AGV

InactiveCN106004298AReduce vibrationSmall sizeMotor depositionResilient suspensionsDrive wheelSlider bearing

The invention discloses an AGV (automatic guided vehicle) elastic support driving device using a hub motor. The AGV elastic support driving device comprises a support fixing frame, a driving wheel bracket, a guide rod, a linear sliding bearing with a flange, a cylindrical spiral spring, the hub motor, a photoelectrical rotary encoder, an encoding small gear, and an encoding large gear, wherein the linear sliding bearing with the flange is fixedly arranged on the support fixing frame, and forms a vertical sliding pair together with the guide rod, the guide rod is fixedly connected with the driving wheel bracket through thread connection, and the cylindrical spiral spring is arranged on the lower part of the guide rod to realize elastic support; the two ends of a main shaft of the hub motor are sheathed on U-shaped grooves of the driving wheel bracket. The invention also discloses an AGV. The AGV elastic support driving device has the advantages that by adopting the elastic support, a driving wheel can compress the ground when the ground is not flat, so that the slipping and idle running are avoided, the vibration of the vehicle body is reduced, and the driving accuracy and stability are improved; the adverse factors caused by the installation of speed reducers are avoided, the running reliability is improved, the structure of the driving device is simplified, and the size of the vehicle body is further reduced.

Owner:SOUTH CHINA UNIV OF TECH

Apparatus for maintaining air-gap spacing in large diameter, low-speed motors and generators

InactiveUS8786151B1Maintaining clearanceWeight increaseDynamo-electric brakes/clutchesMagnetic circuitBearing surfaceStator

A rotor-stator structure including plural bumper elements that may employ synthetic sliding bearing surfaces, mounted to the stator, and designed to contact a machined surface on the rotor if generator structural deflection occurs during operation. During normal operation, the bearing surface is not in contact with the machine rotor. If extreme loads are imposed on the rotor or stator structures, or other issue like bearing failure, causes the air gap to close, the bumper elements will “touch down” on a machined surface on the rotor to maintain a minimum air gap.

Owner:WEG ELECTRIC CORP

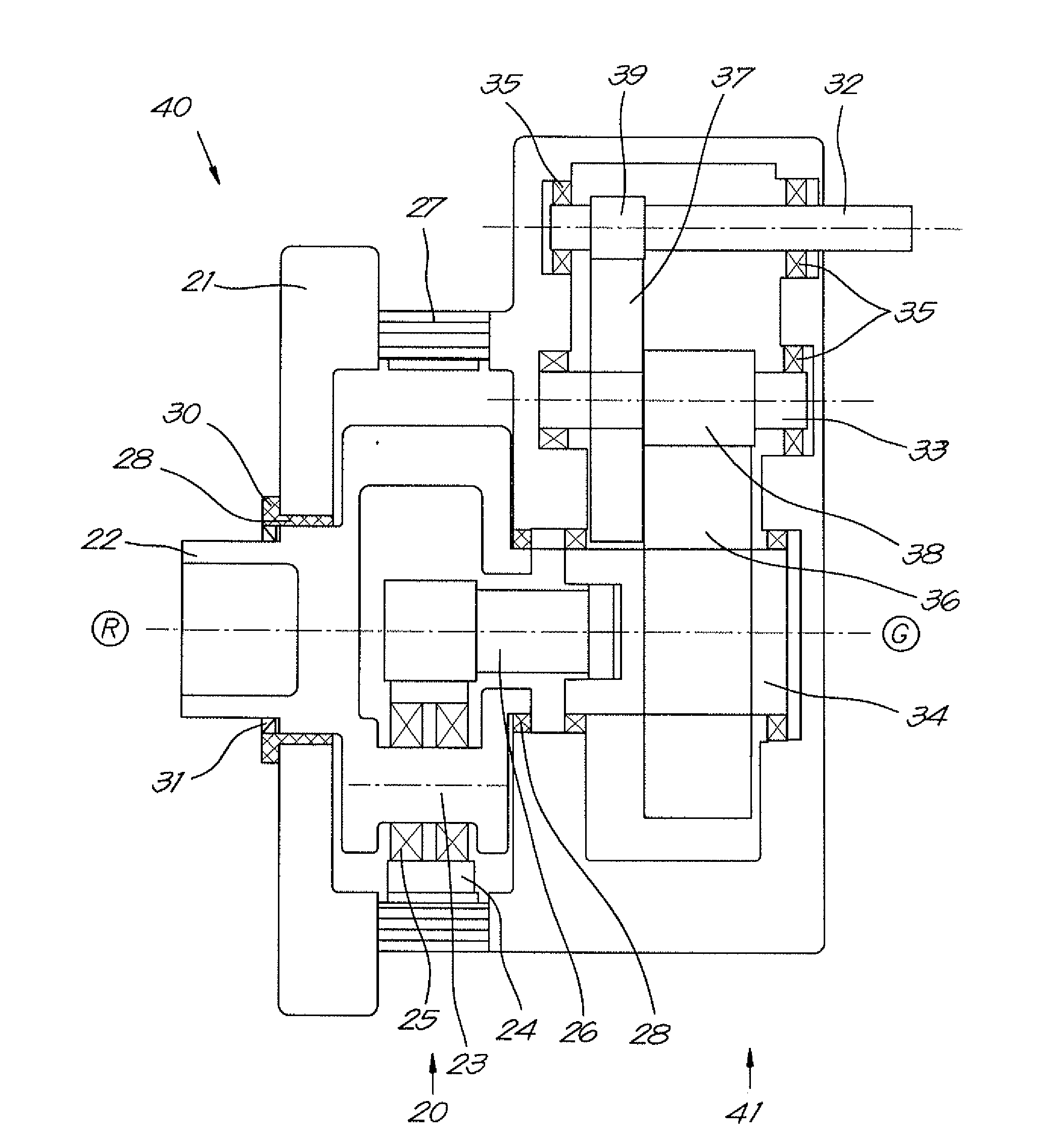

Planetary gear unit for a gearbox for a wind turbine

InactiveUS20110077120A1Cost of manufactureReduce manufacturing costEngine fuctionsToothed gearingsRolling-element bearingGear wheel

A planetary gear unit (20) for a gearbox (40) for a wind turbine includes a housing (21) and a planet carrier (22) provided with planet shafts (23) distributed uniformly around a planet carrier's axis for rotatably supporting planet gears (24) which are mounted between a sun gear (26) and a ring gear (27) for mutual interaction and which are supported by rolling bearings (25). The planet carrier is rotatably mounted in the housing with sliding bearings (28). By using sliding bearings which are different from existing classical sliding bearings which are currently used for rotatably mounting the planet carrier in the housing in combination with the use of rolling bearings for supporting other parts of the planetary gear unit, costs of the planetary gear unit may significantly be reduced. A gearbox including such a planetary gear unit and a wind turbine including such a gearbox are also described.

Owner:HANSEN TRANSMISSIONS INT NV

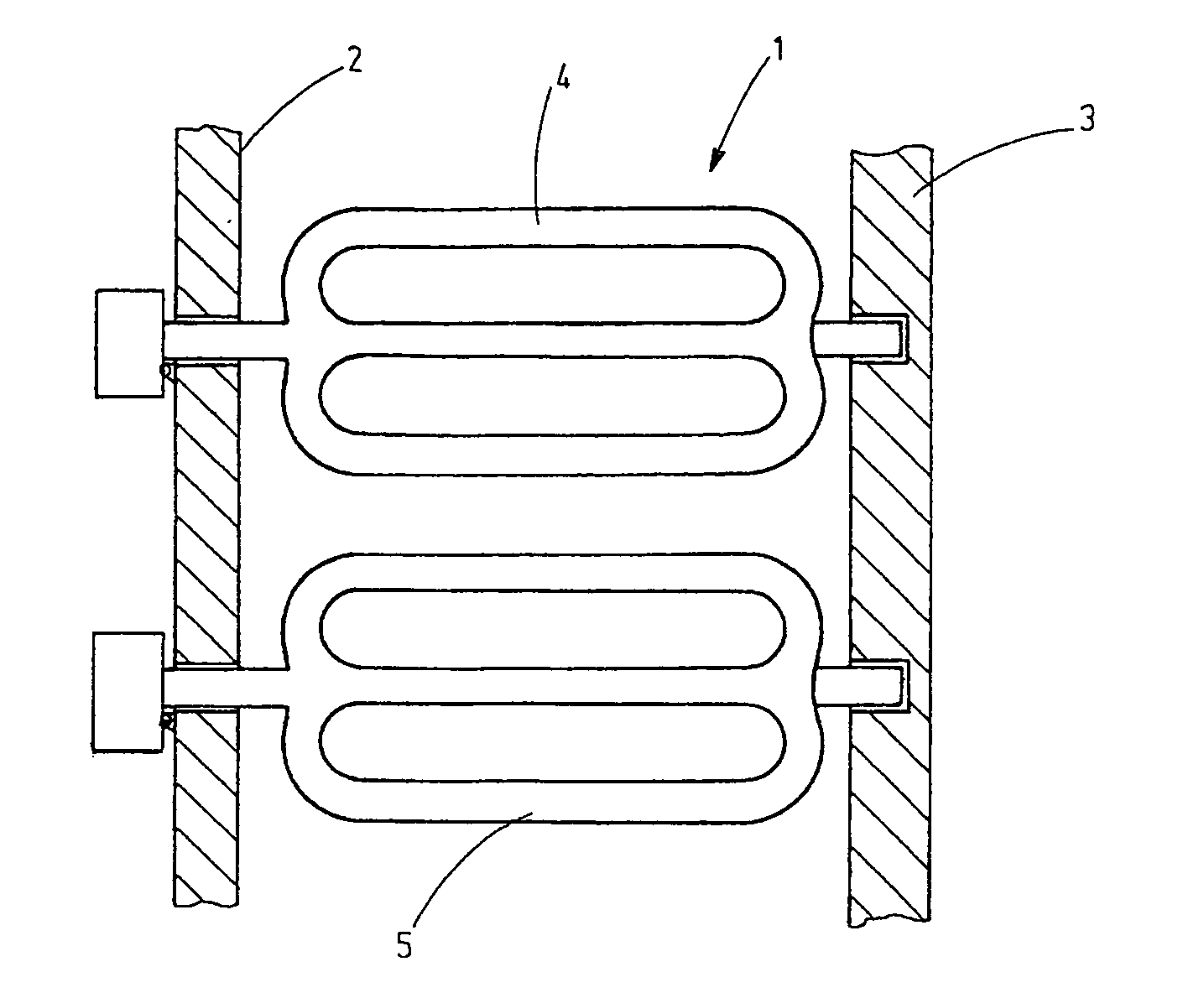

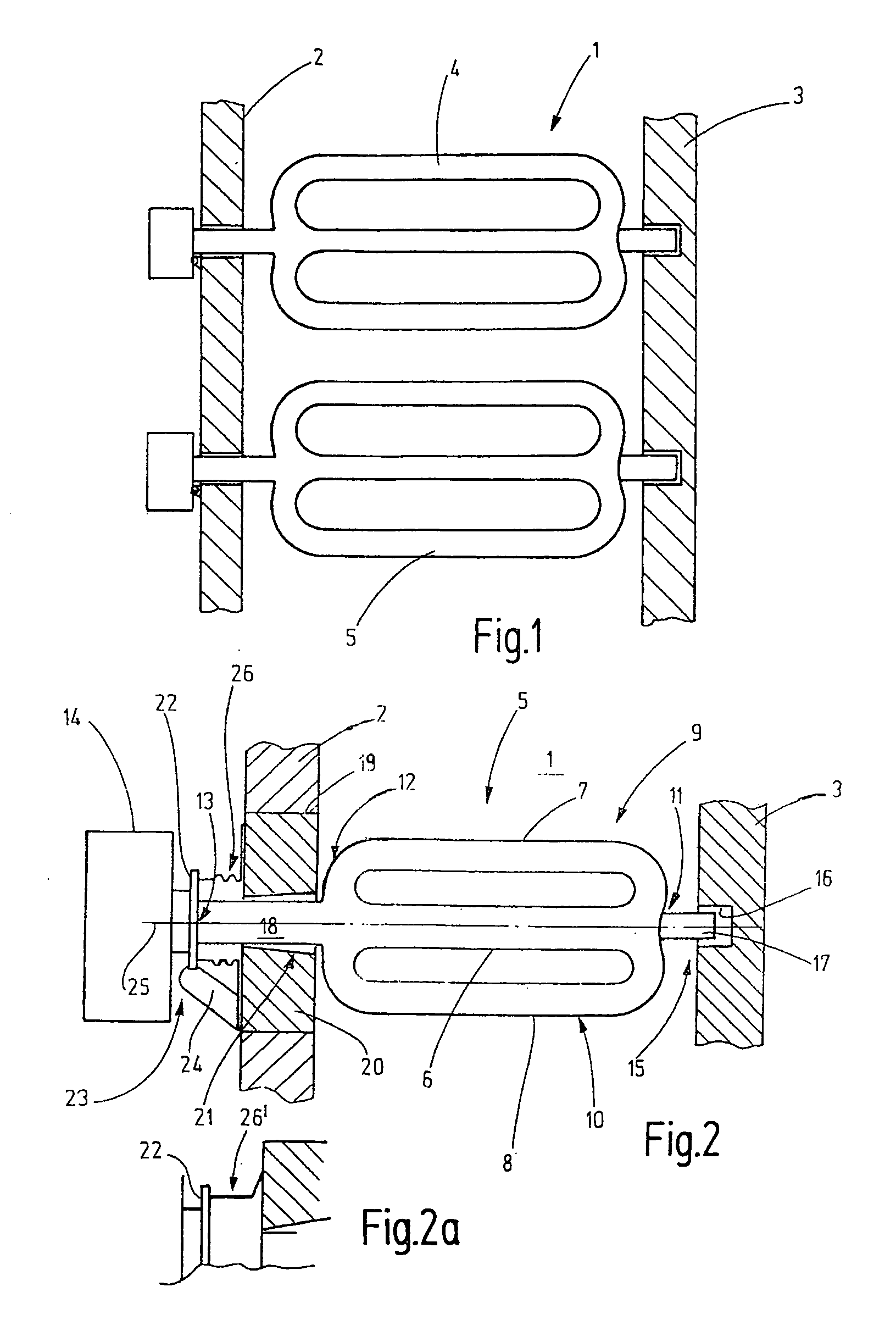

Radiant heating arrangement with distortion compensation

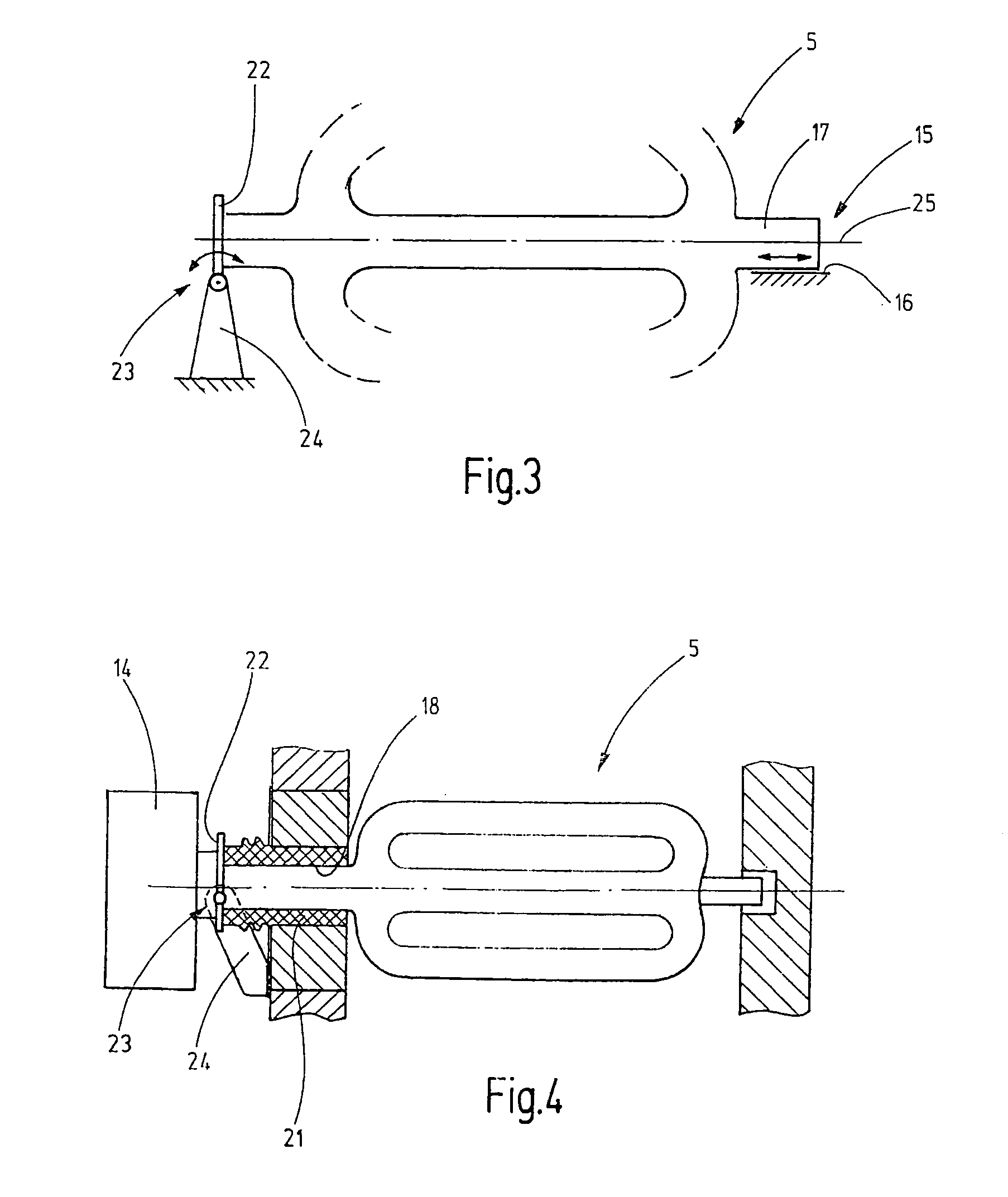

ActiveUS20110120453A1Force can be appliedFurnace componentsDomestic stoves or rangesDistortionEngineering

A radiant heat tube (5) comprises a tube body having a center section (6) and at least one recirculating section (7, 8) arranged next to the center section, said recirculating section forming a loop (9, 10) with said center section. A pivot joint bearing (23) is arranged on one end (12) of the radiant heat tube, while a sliding bearing (15) is arranged on the other end (11) of the radiant heat tube, said sliding bearing (15) being arranged opposite said pivot joint bearing (23). A burner (14) is disposed to heat the radiant heat tube (5).

Owner:WS WARMEPROZESSTECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com