Patents

Literature

379results about "Crossheads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

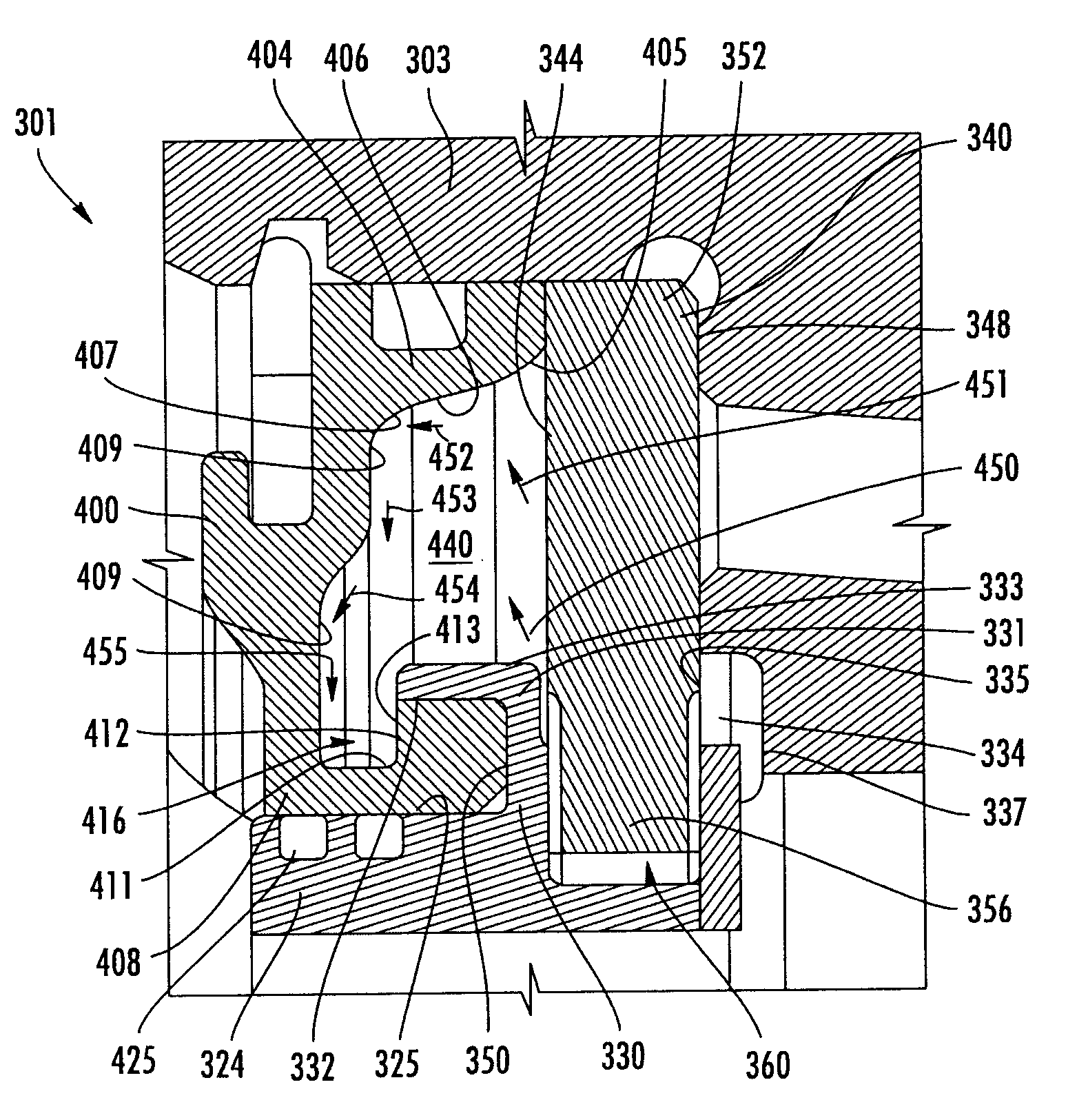

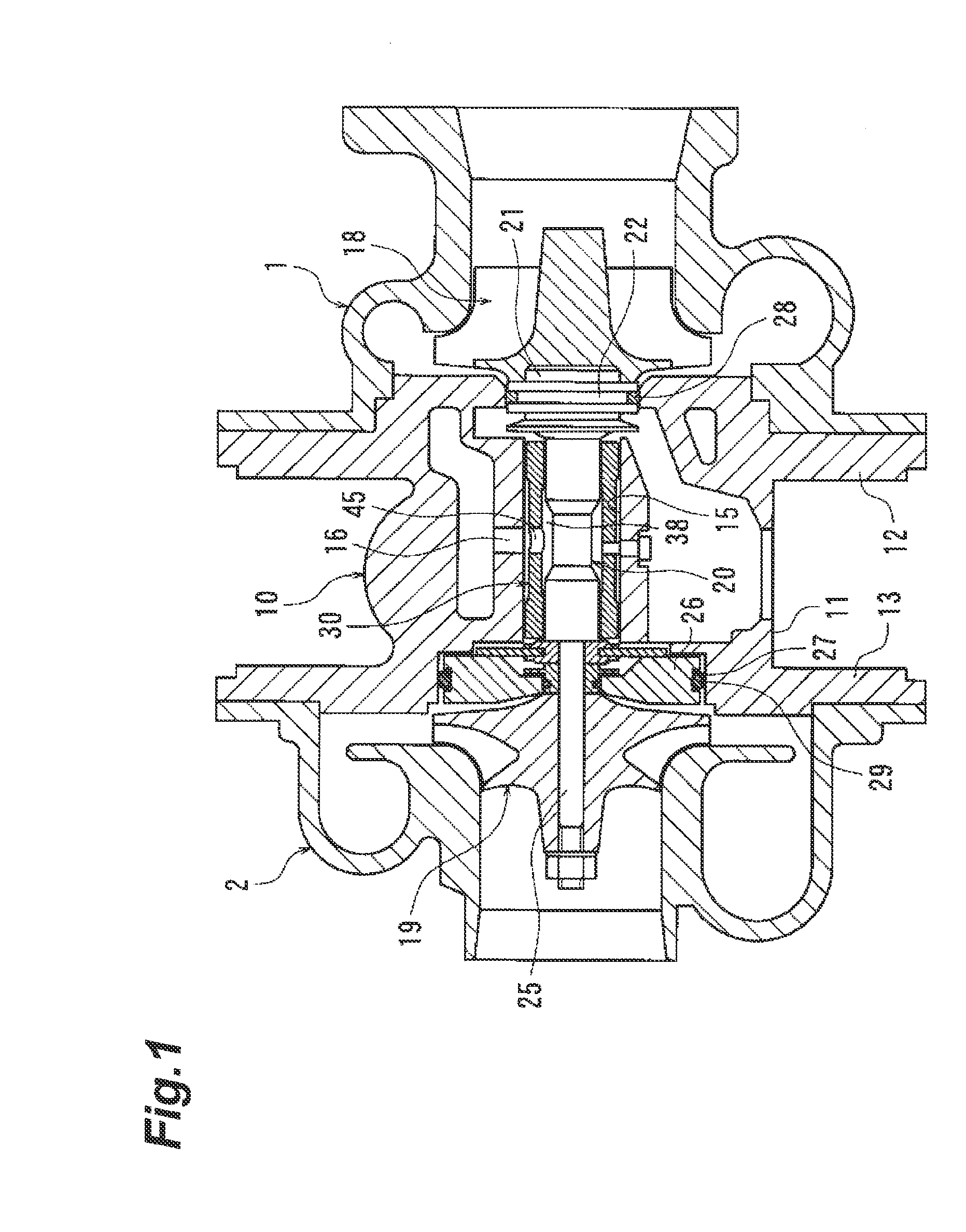

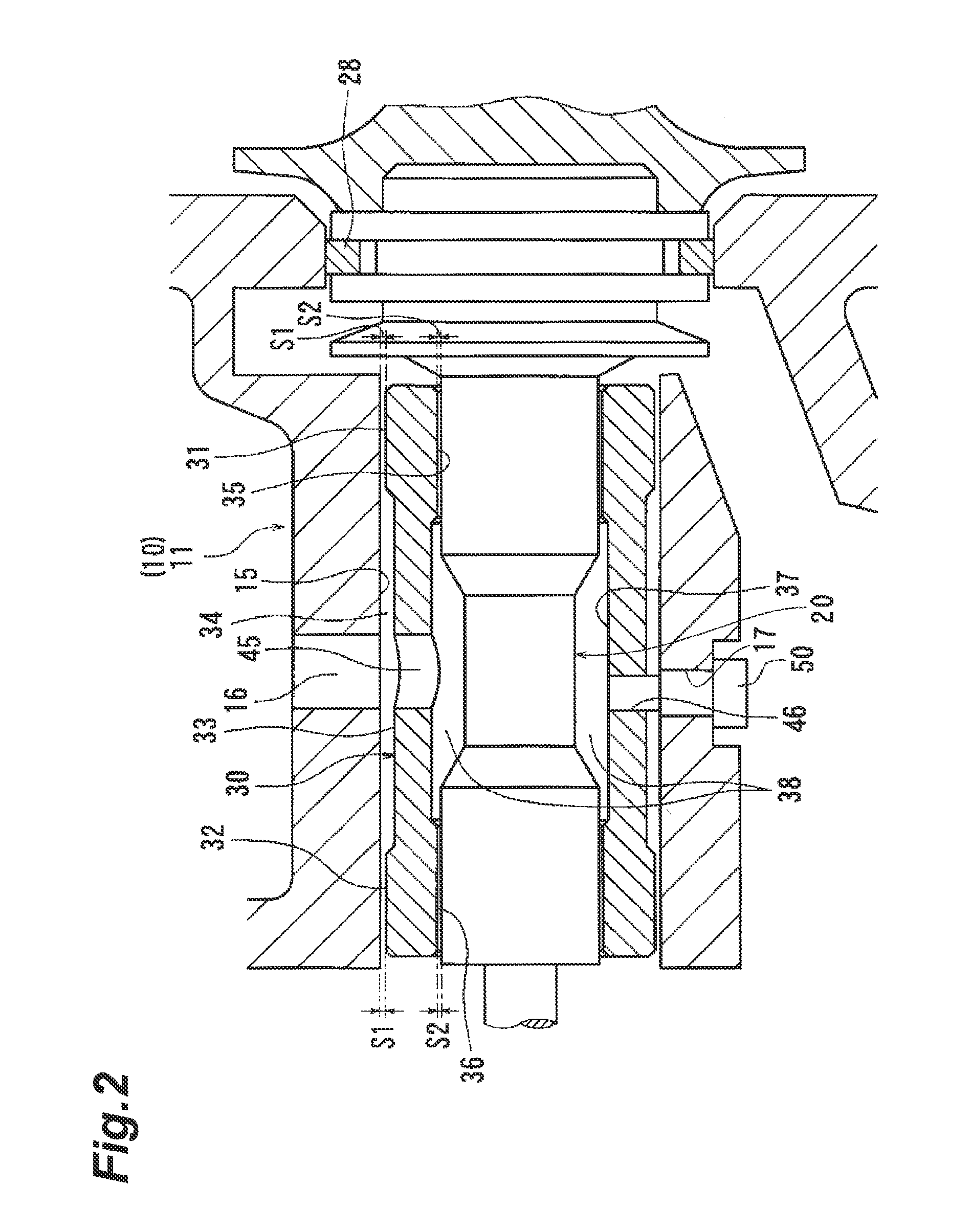

Sealing system between bearing and compressor housing

ActiveUS20100139270A1Efficient and cost-effectiveExtend your lifeCrankshaftsPump componentsTurbochargerThrust bearing

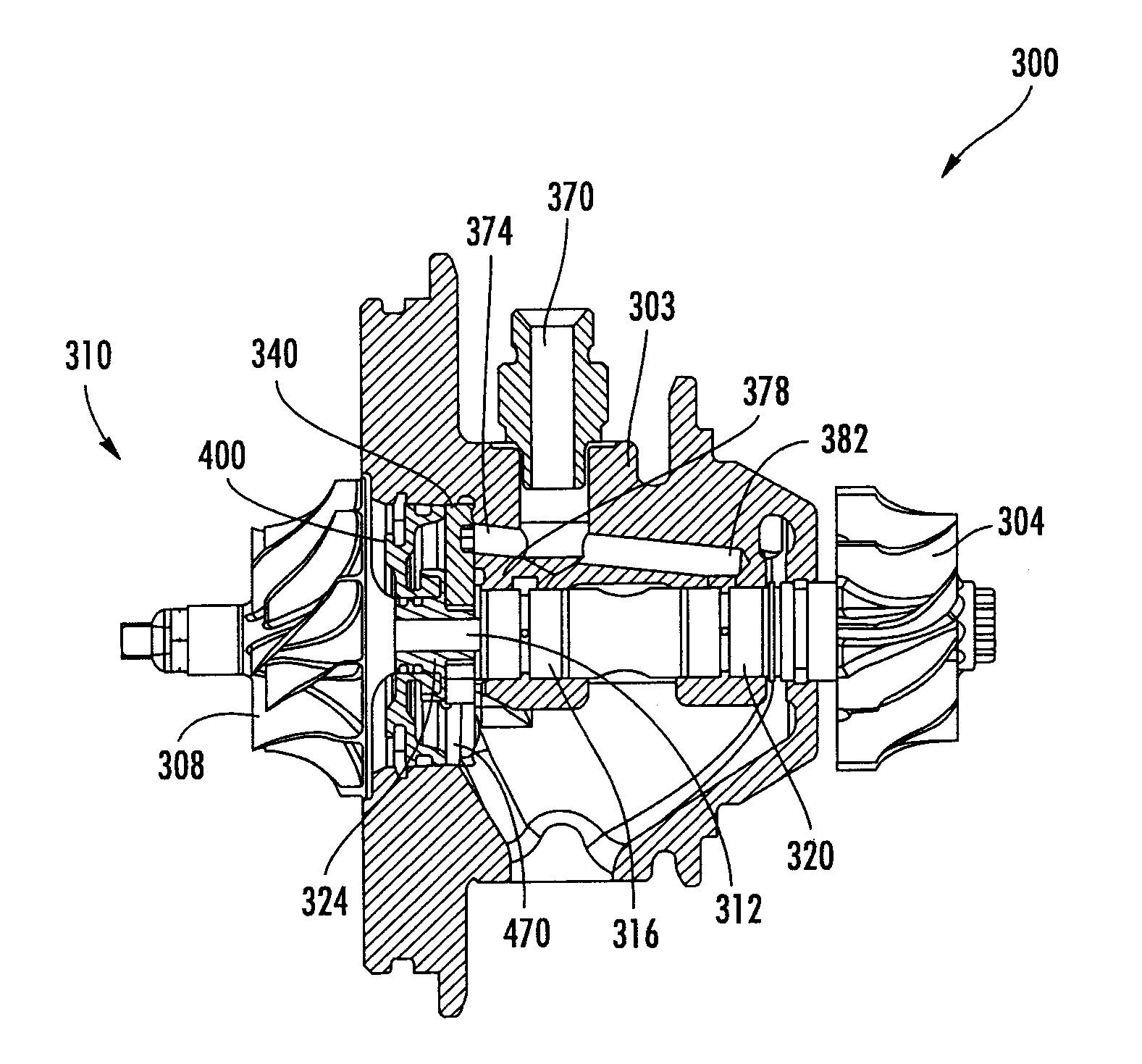

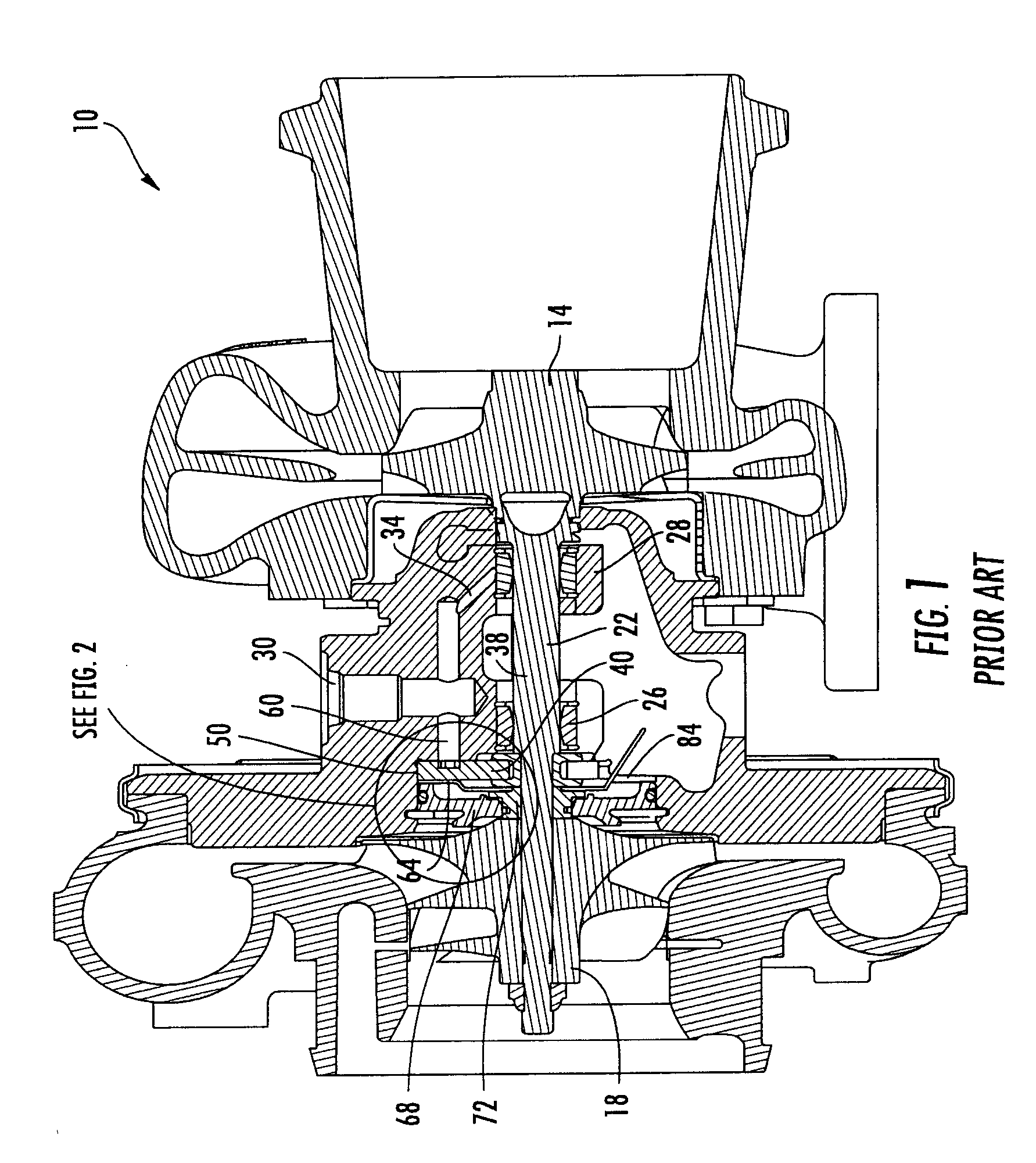

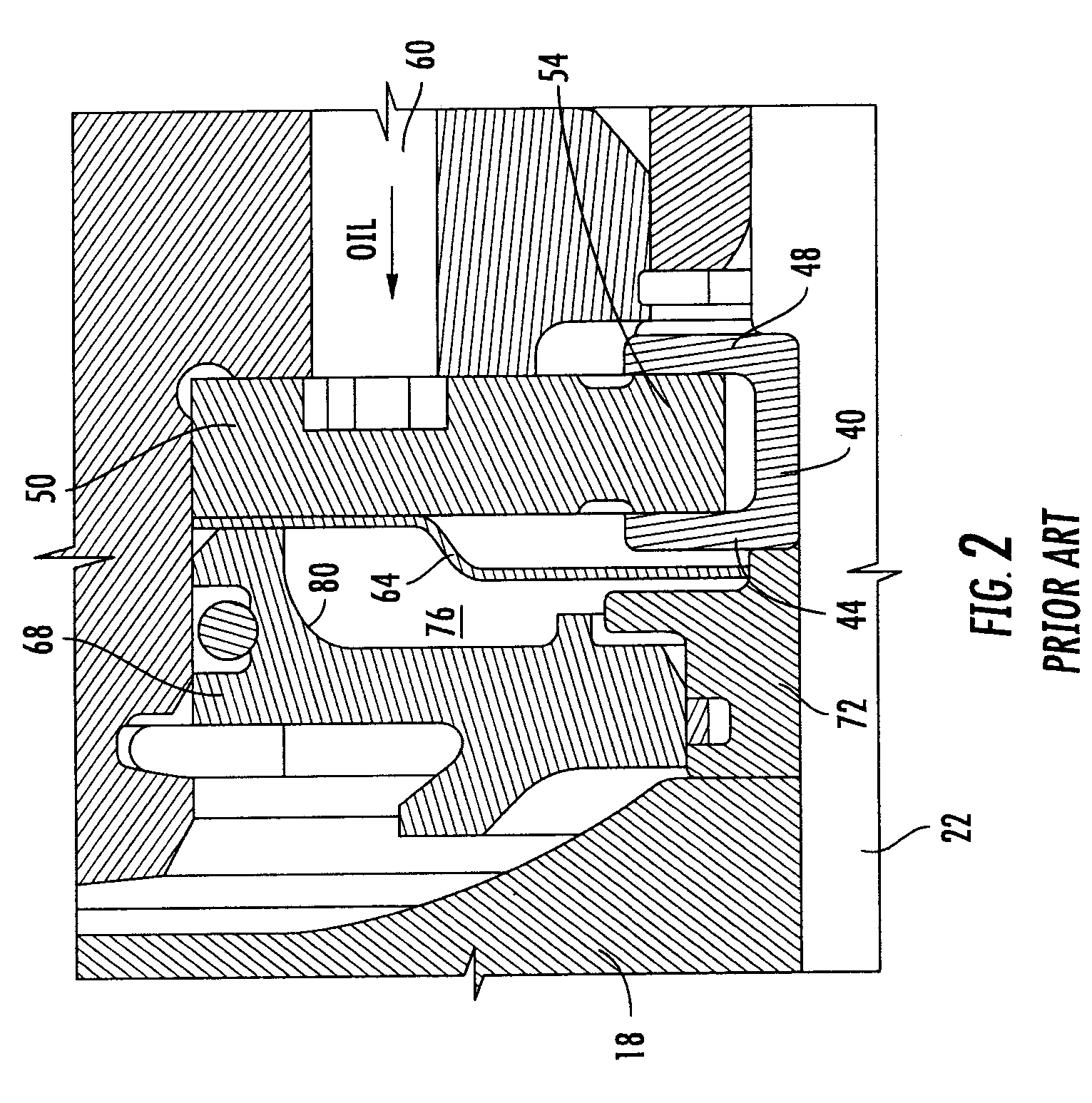

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

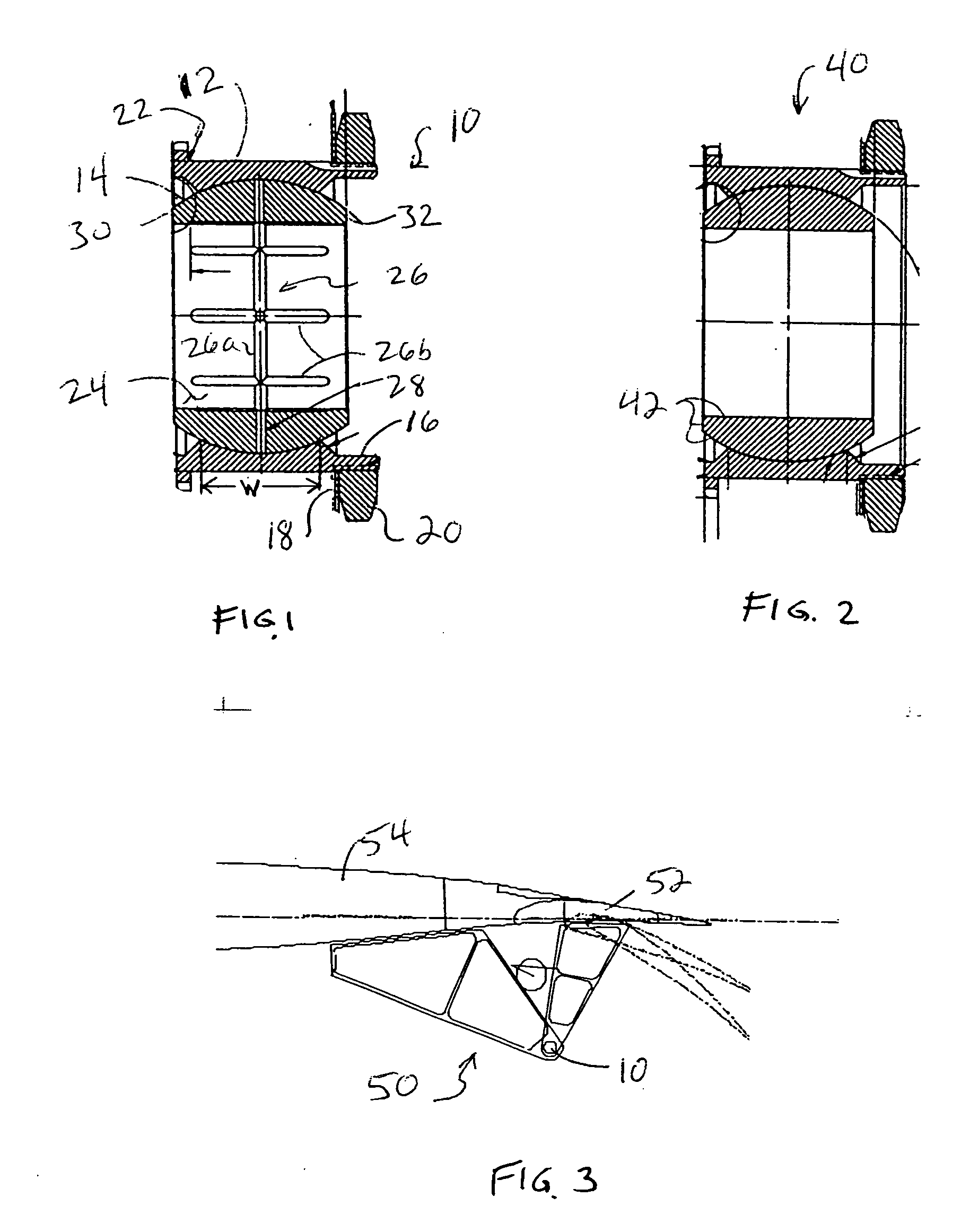

Bearing and hinge mechanism

A spherical plain bearing has an outer ring having a concave first bearing surface and an inner ring having a convex second bearing surface slidably disposed to the first bearing surface. The inner ring member also has a third bearing surface for engaging a pin to be mounted in the bearing. At least one bearing surface has a lubrication groove, and one of the outer ring and the inner ring is made from 440 stainless steel while the other is made from a precipitation-hardened martensitic stainless steel. Alternatively, the outer ring and the inner ring may be made from steel and a copper-beryllium alloy. In yet another alternative, the bearing need not have a lubrication groove, but may have a lubrication liner on the third bearing surface. A dropped hinge mechanism for a flap on a fixed wing aircraft has a hinge that includes such a bearing.

Owner:ROLLER BEARING OF AMERICA

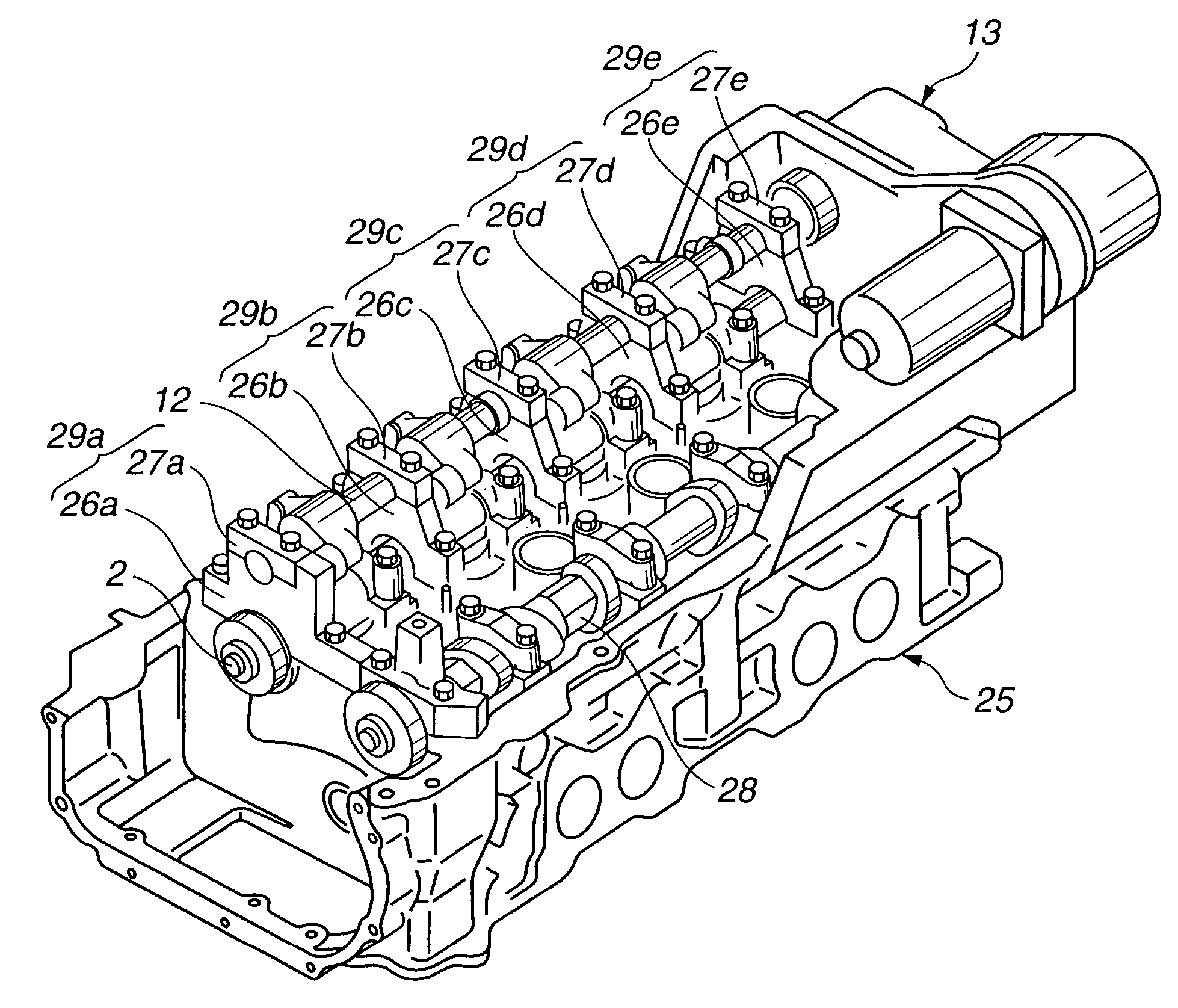

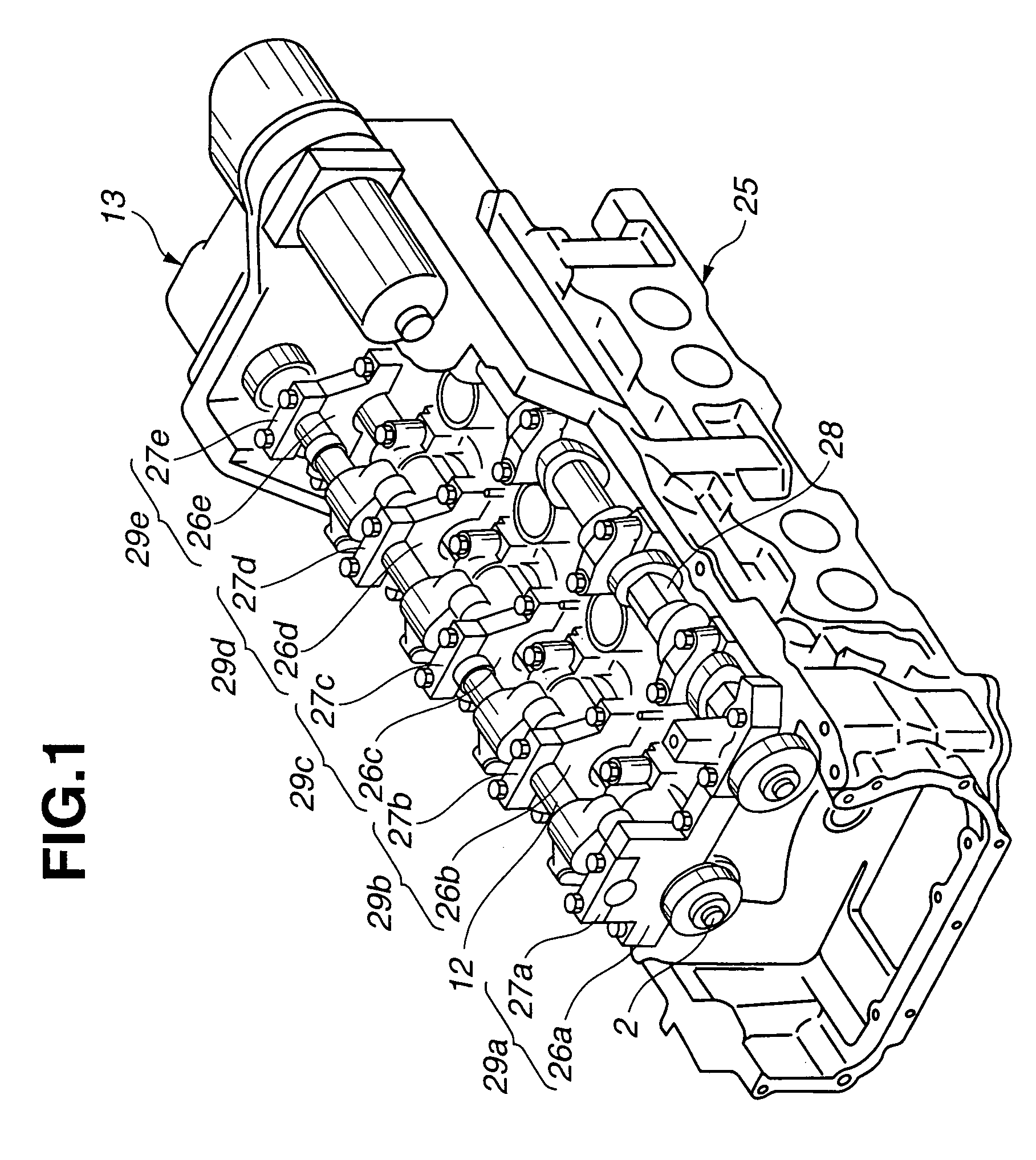

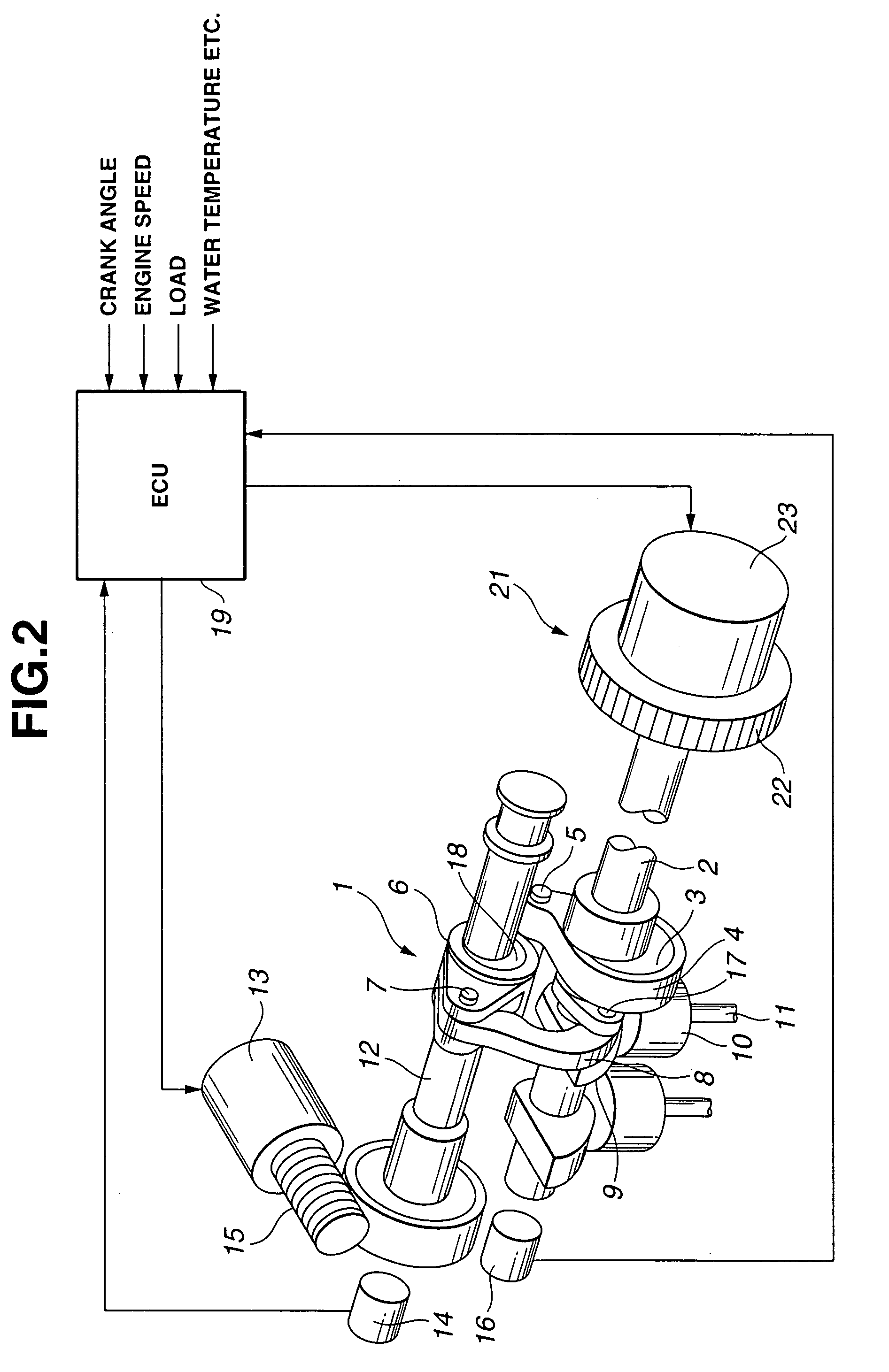

Variable valve actuating mechanism for internal combustion engine

ActiveUS7107950B2Reduce temperature non-uniformityReduce unevennessClutchesCrankshaftsExternal combustion engineInlet valve

A lift and operating angle varying mechanism is arranged to vary an intake valve operation angle and an intake valve lift of the engine continuously by rotating a control shaft with an actuator disposed at an end of the control shaft which is rotatably supported by a plurality of bearings. A lubricating oil is supplied to the bearings so as to reduce nonuniformity in temperature distribution of the control shaft in the longitudinal direction.

Owner:NISSAN MOTOR CO LTD

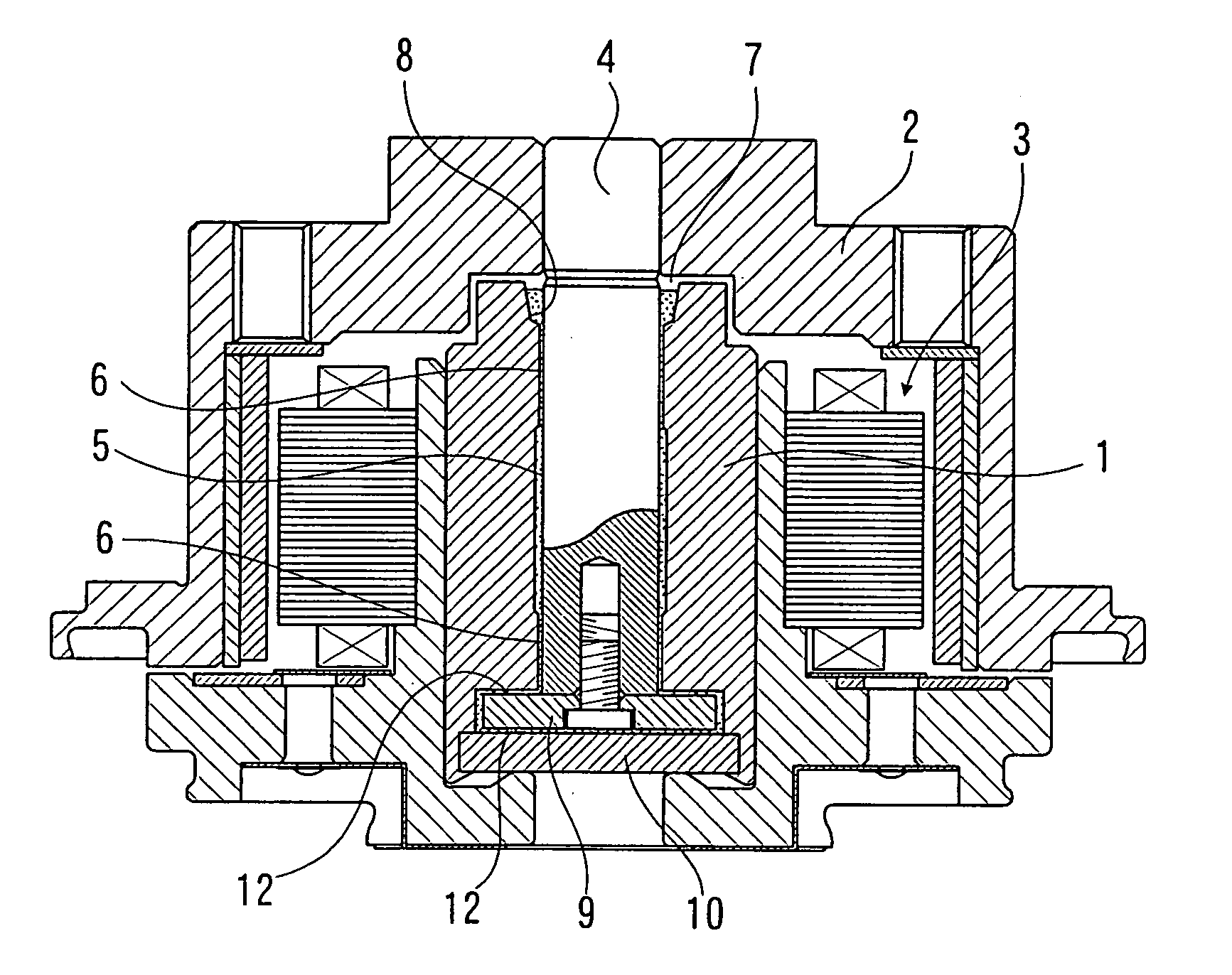

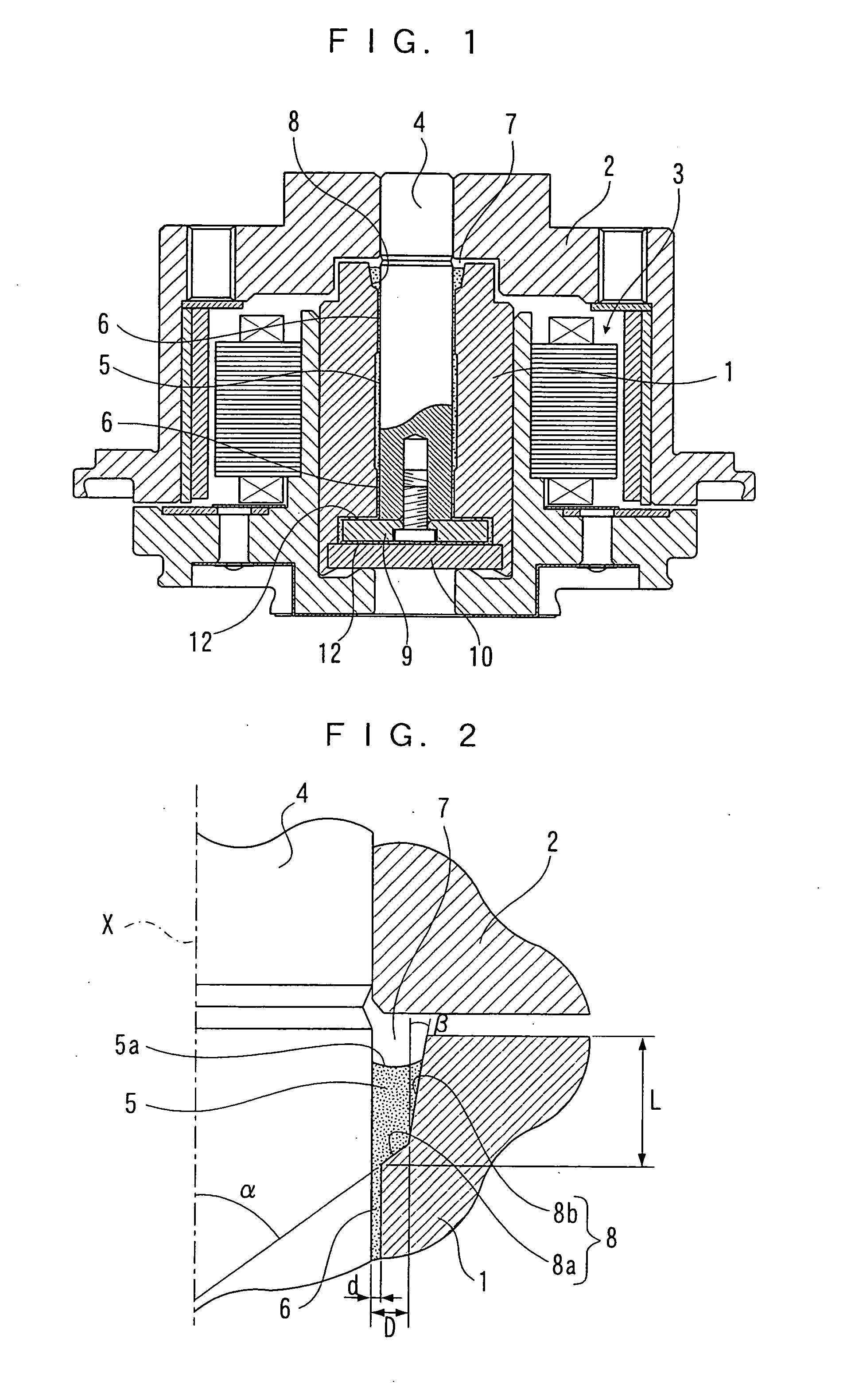

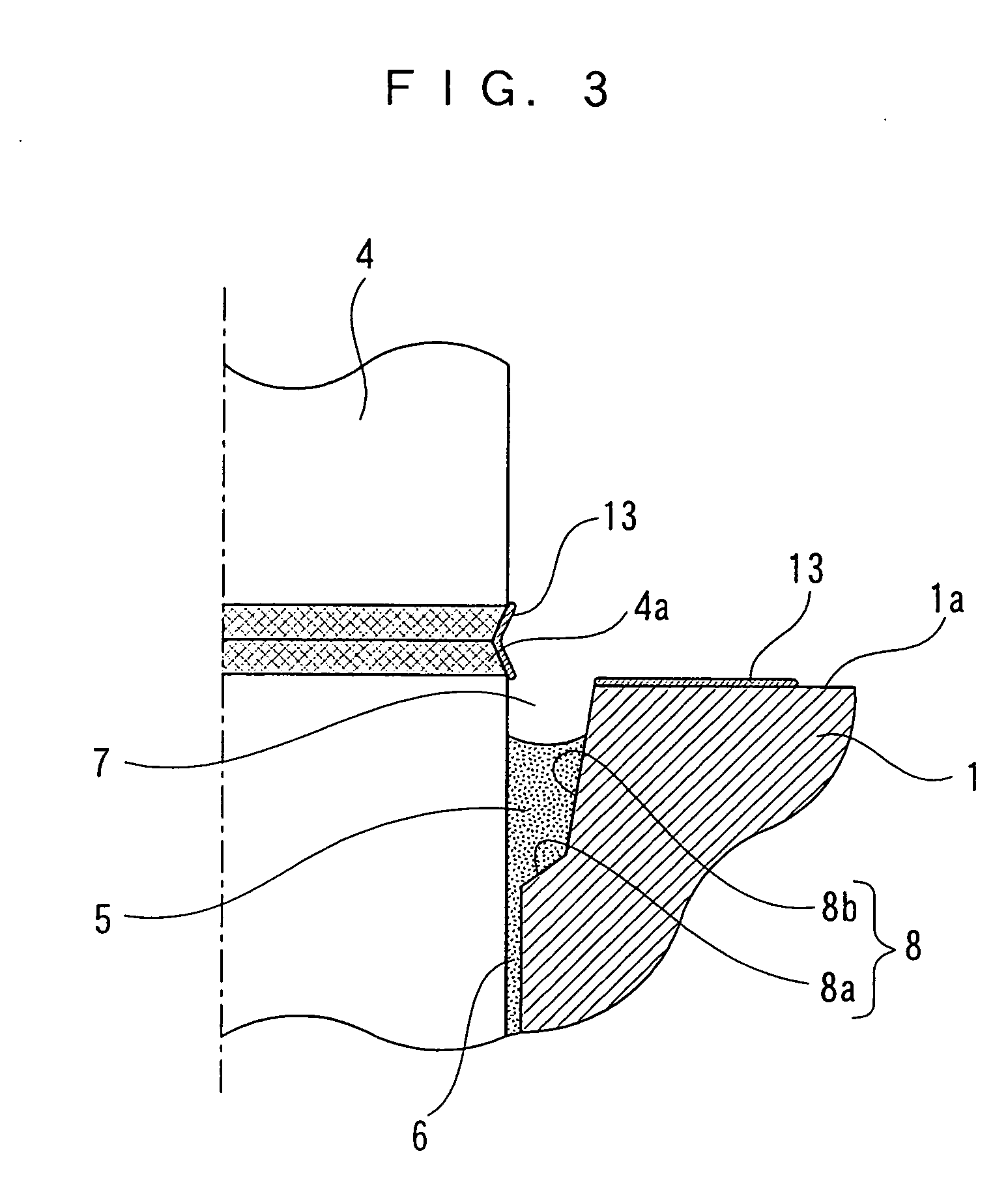

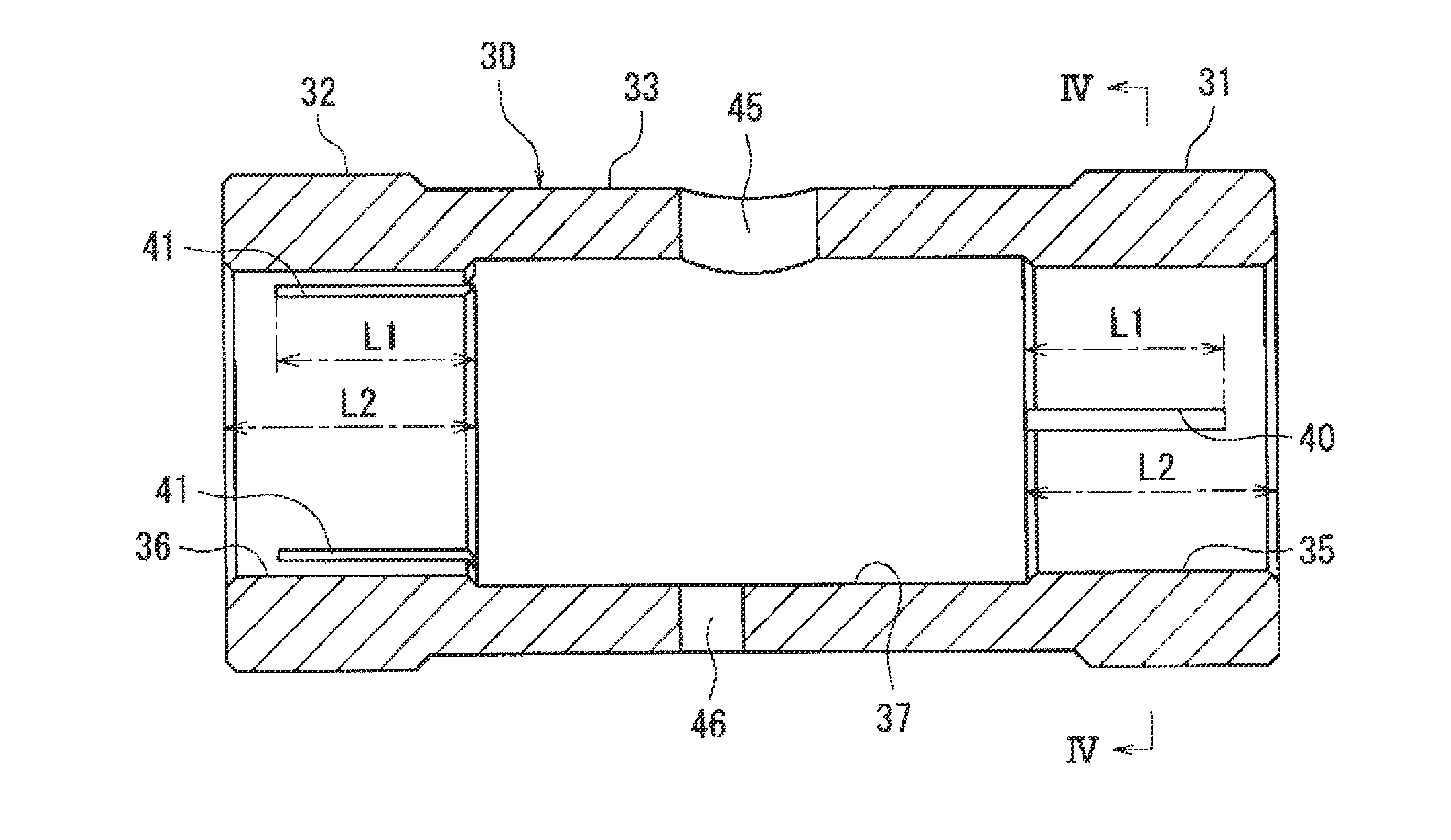

Fluid bearing device

ActiveUS20050111769A1Sufficient length dimensionSmall depthCrankshaftsRecord information storageEngineeringFluid bearing

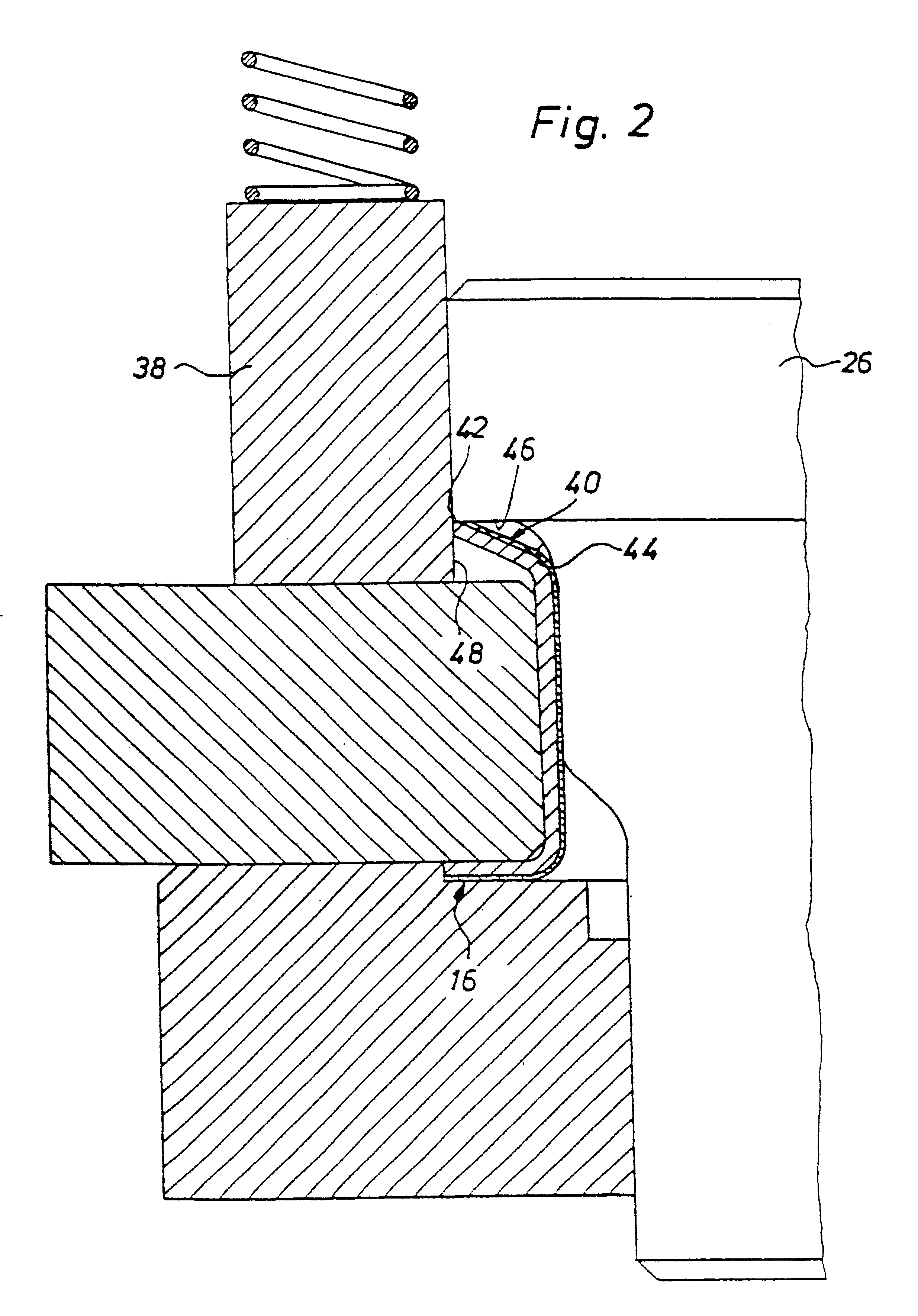

A fluid bearing device capable of preventing a lubricant from scattering outward even during rotation thereof, while holding a relatively large amount of lubricant at a seal surface portion. A lubricant is filled between a sleeve and a shaft, a seal surface portion is formed on the sleeve in a location facing an open end thereof, the seal surface portion has a sectional shape defined by a plurality of inclined surfaces, and an inclination angle α of the inclined surface of the seal surface portion adjacent a radial bearing portion with respect to a shaft axis is formed to be larger than an inclination angle β of the inclined surface of the seal surface portion distant away from the radial bearing portion with respect to the shaft axis.

Owner:PHC HLDG CORP

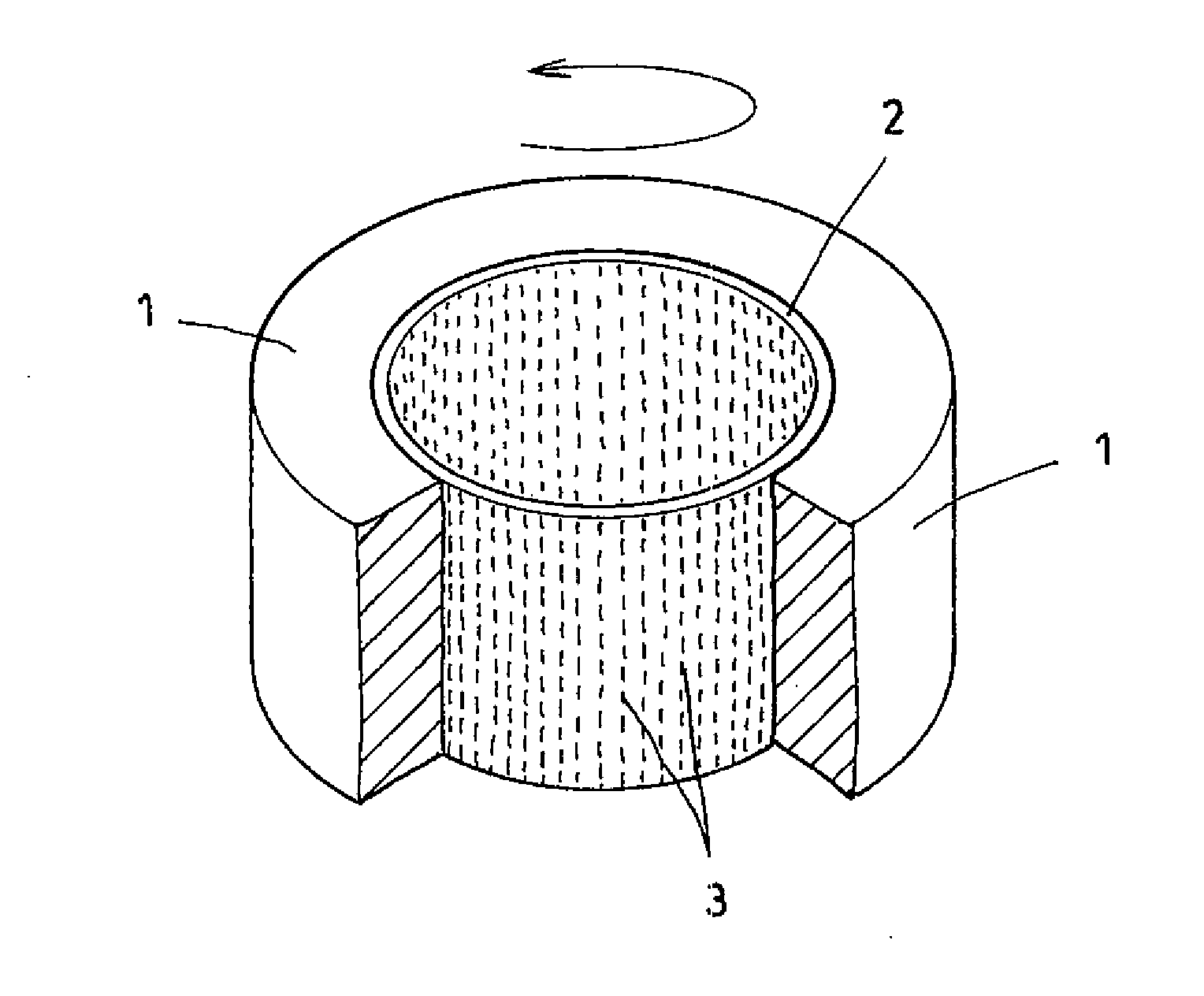

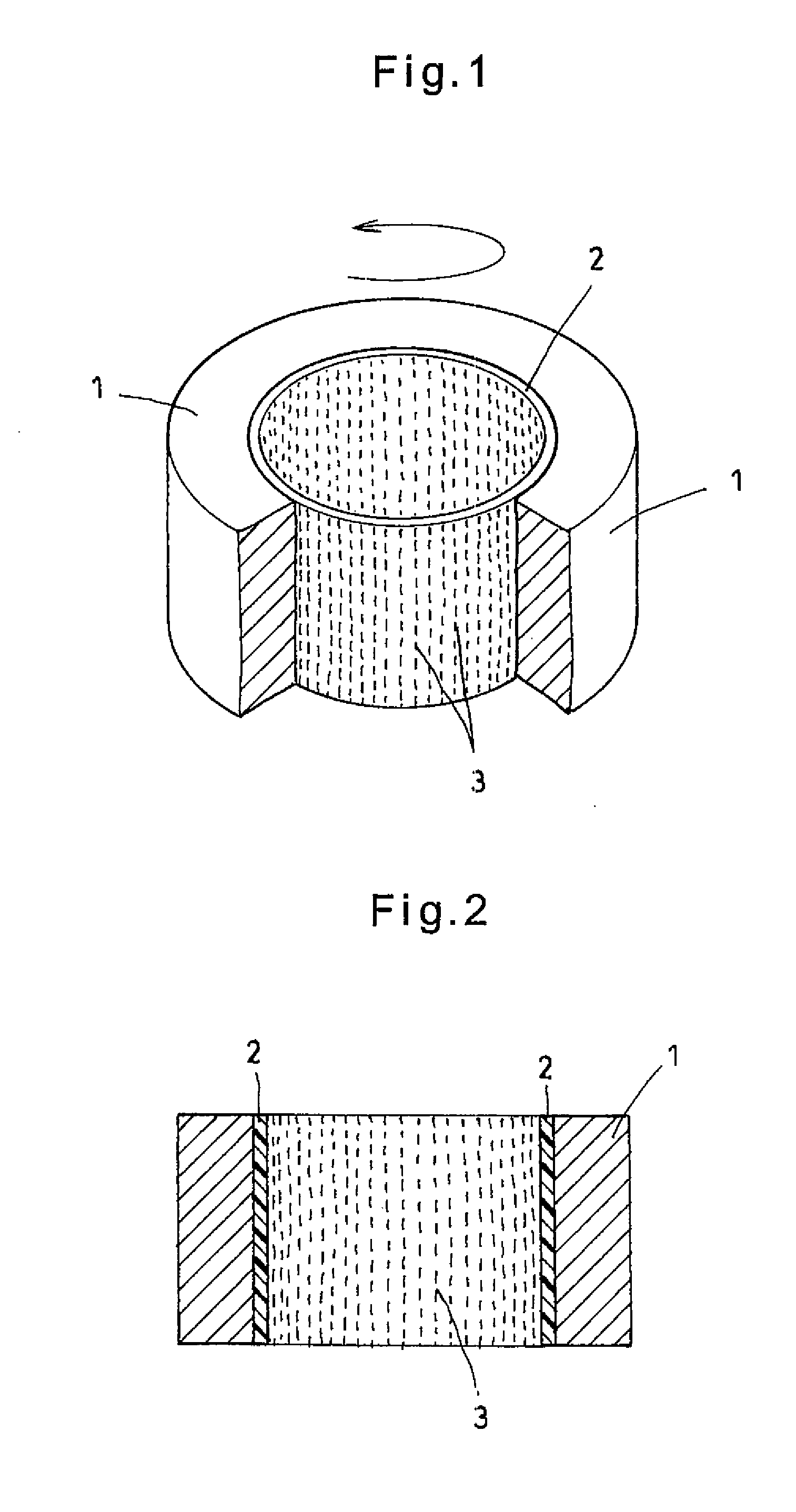

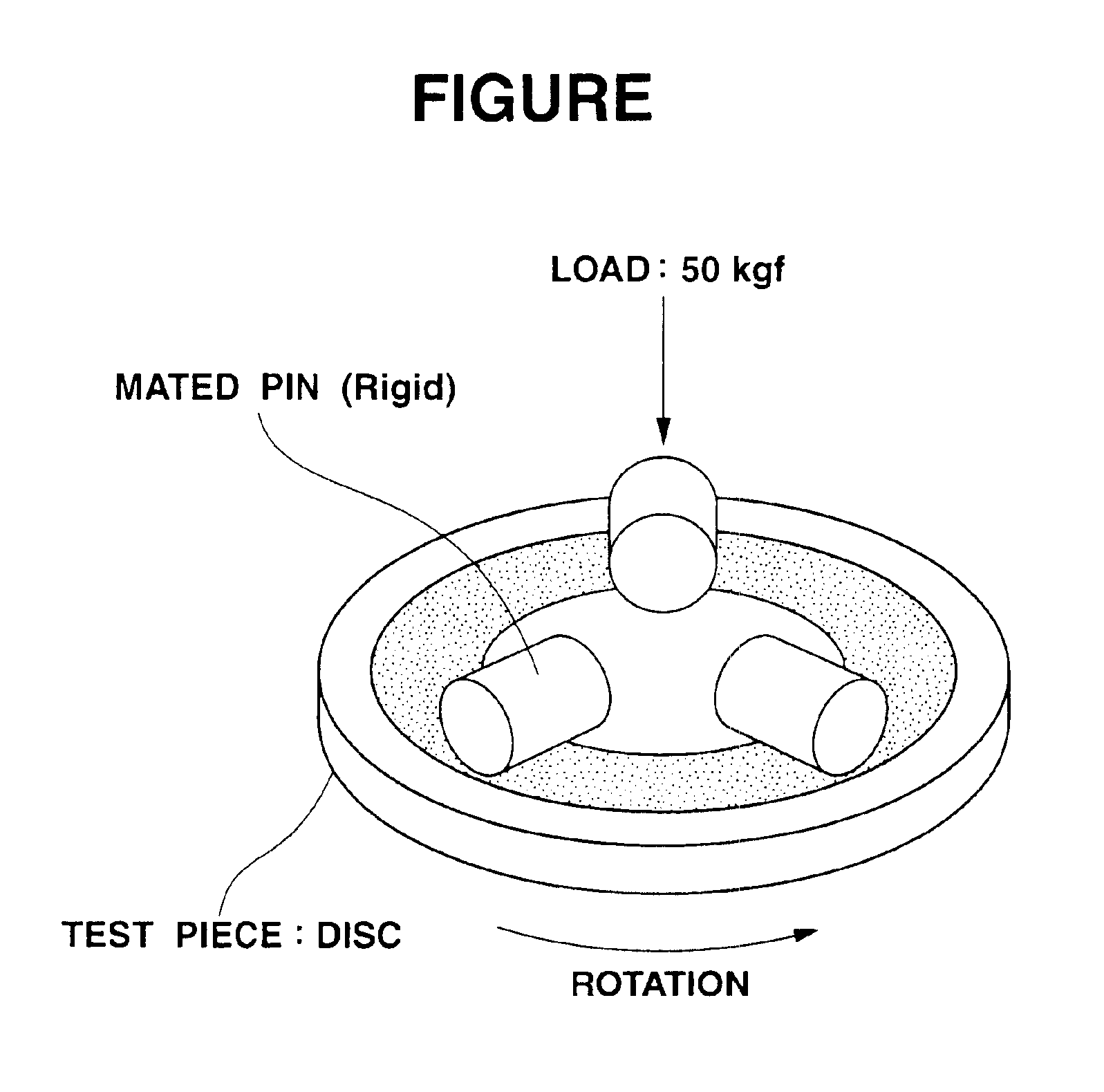

Composite slide bearing

A high-precision slide bearing is provided which includes a substrate of sintered metal and a synthetic resin layer. This bearing can be used e.g. for rotary shafts in compressors of room air-conditioners or in transmissions of motor vehicles and construction machines to support relatively large radial and axial loads. The resin layer is integrally superposed on the radially inner surface of the sintered metal substrate of the slide bearing, which is a cylindrical member. The resin layer is made of a resin composition of an aromatic polyetherketone resin containing a fibrous filler. The fibrous filler are made up of fibers dispersed in the resin layer and oriented such that their length directions intersect the rotational direction of the bearing at angles of 45 to 90 degrees. The resin layer has a thickness of 0.1 to 0.7 mm.

Owner:NTN CORP

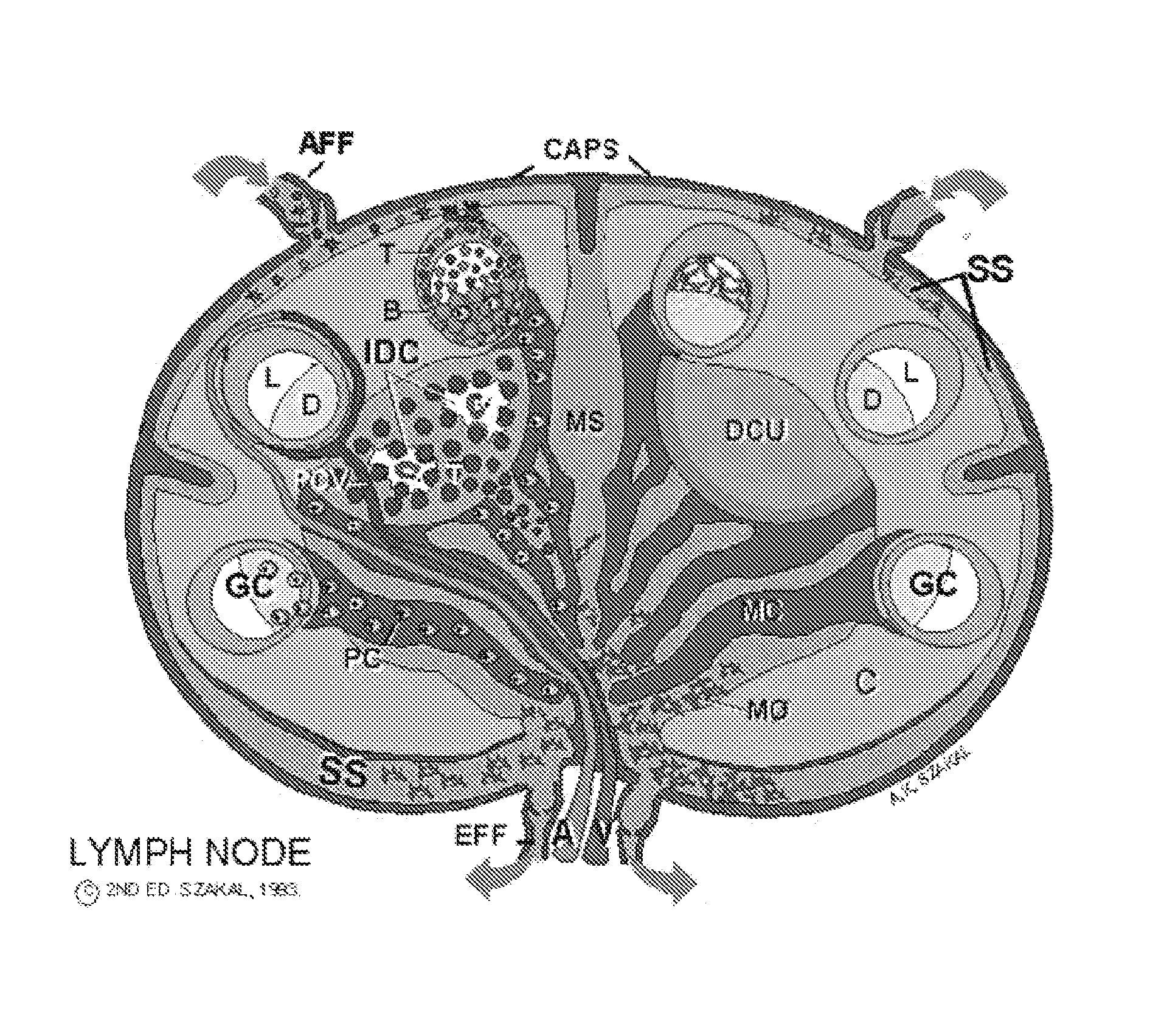

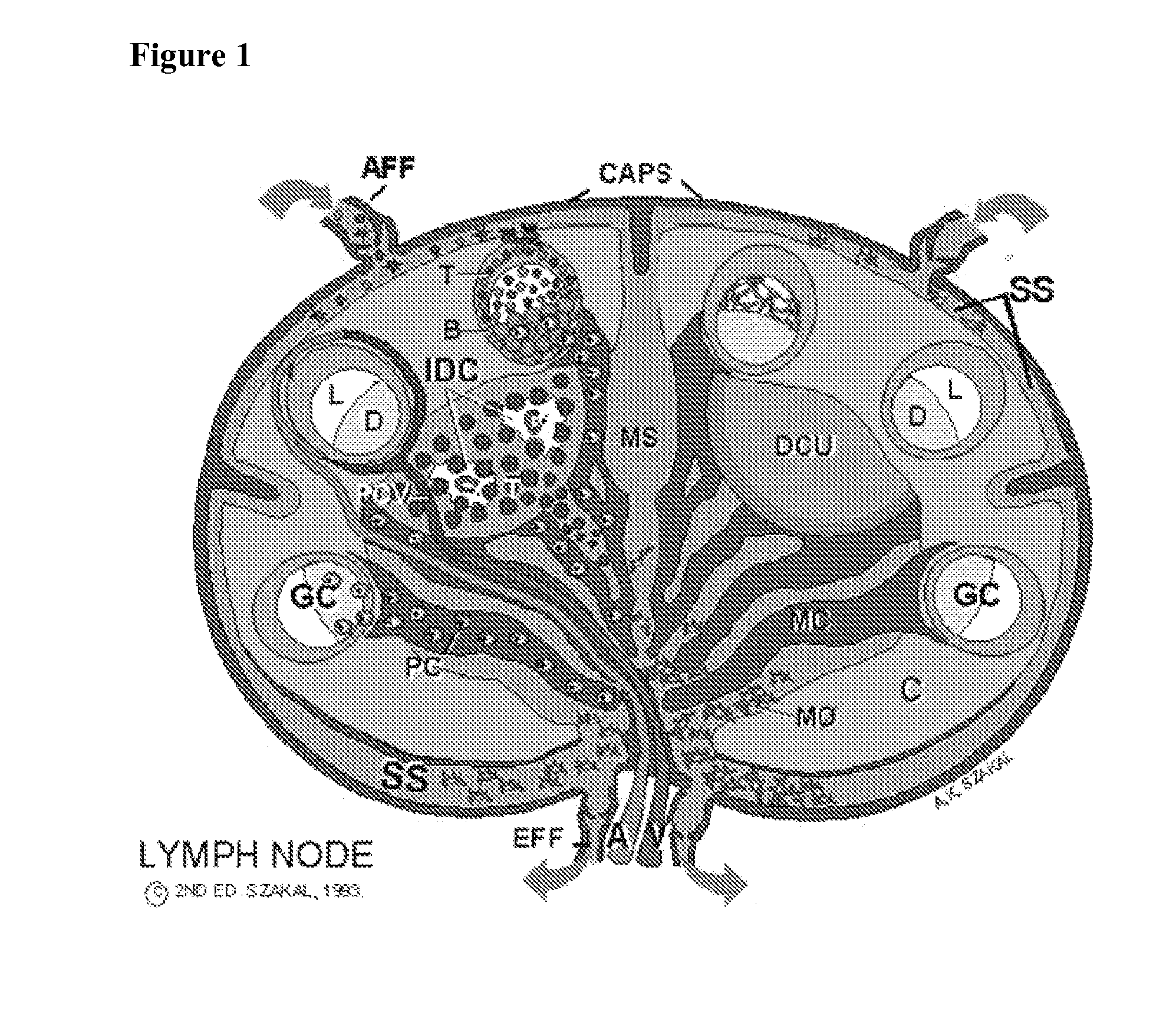

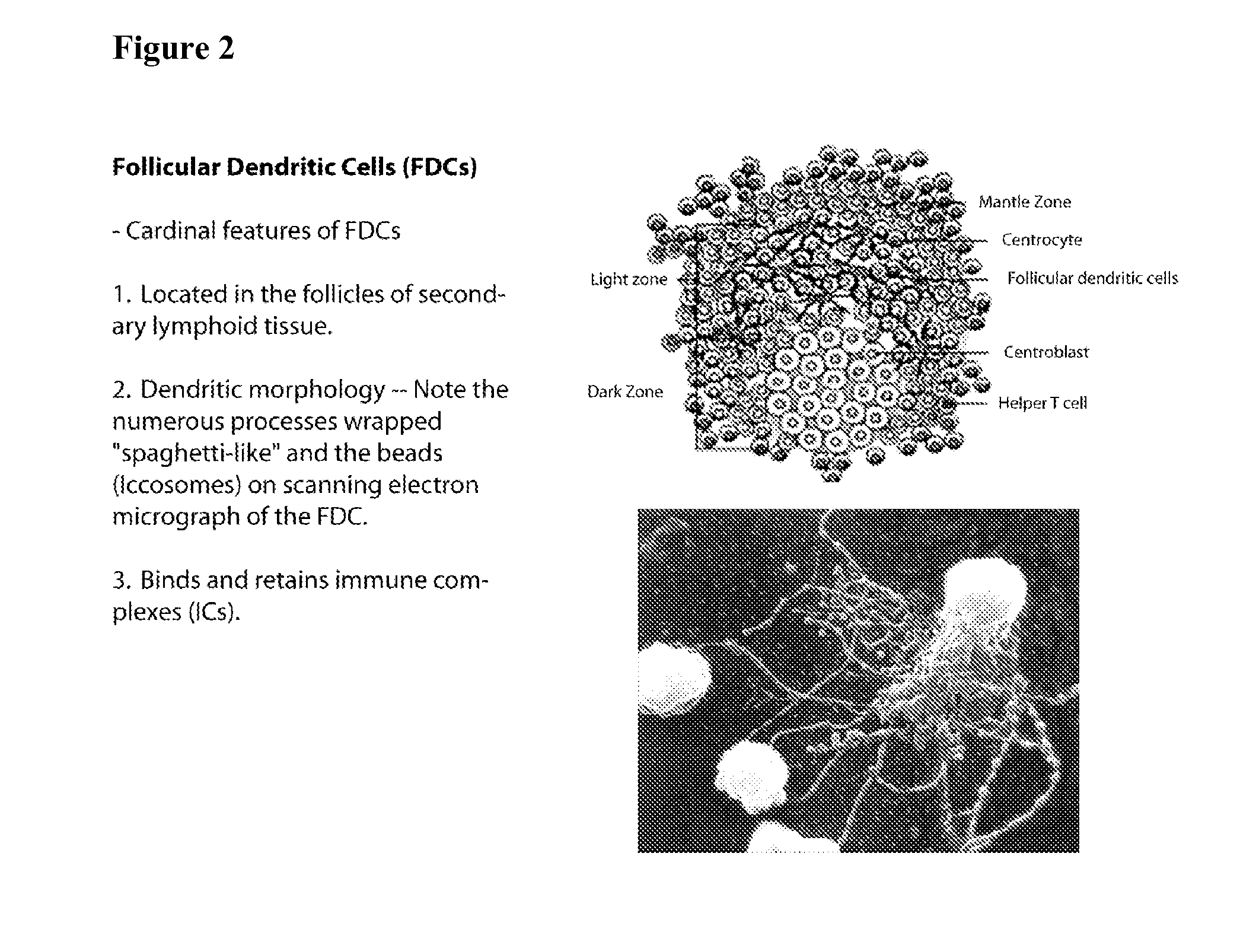

Models for vaccine assessment

ActiveUS20080008653A1Improve accuracyImprove predictabilityCompounds screening/testingCrankshaftsAdjuvantBiological Immunotherapy

The present invention is directed to methods for constructing and using in vivo and in vitro models of aspects of human immunity and, in particular, construction of a human immune system model for the testing of, for example, vaccines, adjuvants, immunotherapy candidates, cosmetics, drugs, biologics and other chemicals. The present invention comprises both in vivo and in vitro models of aspects of human immunity that are useful for assessing the interaction of substances with the immune system, and thus can be used to accelerate and improve the accuracy and predictability of, for example, vaccine, drug, biologic, immunotherapy, cosmetic and chemical development. The invention is also useful for the generation of human monoclonal and polyclonal antibodies.

Owner:VIRGINIA COMMONWEALTH UNIV +1

Sealing system between bearing and compressor housing

ActiveUS8348595B2Extend your lifeEfficient and cost-effective structureCrankshaftsPump componentsTurbochargerThrust bearing

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

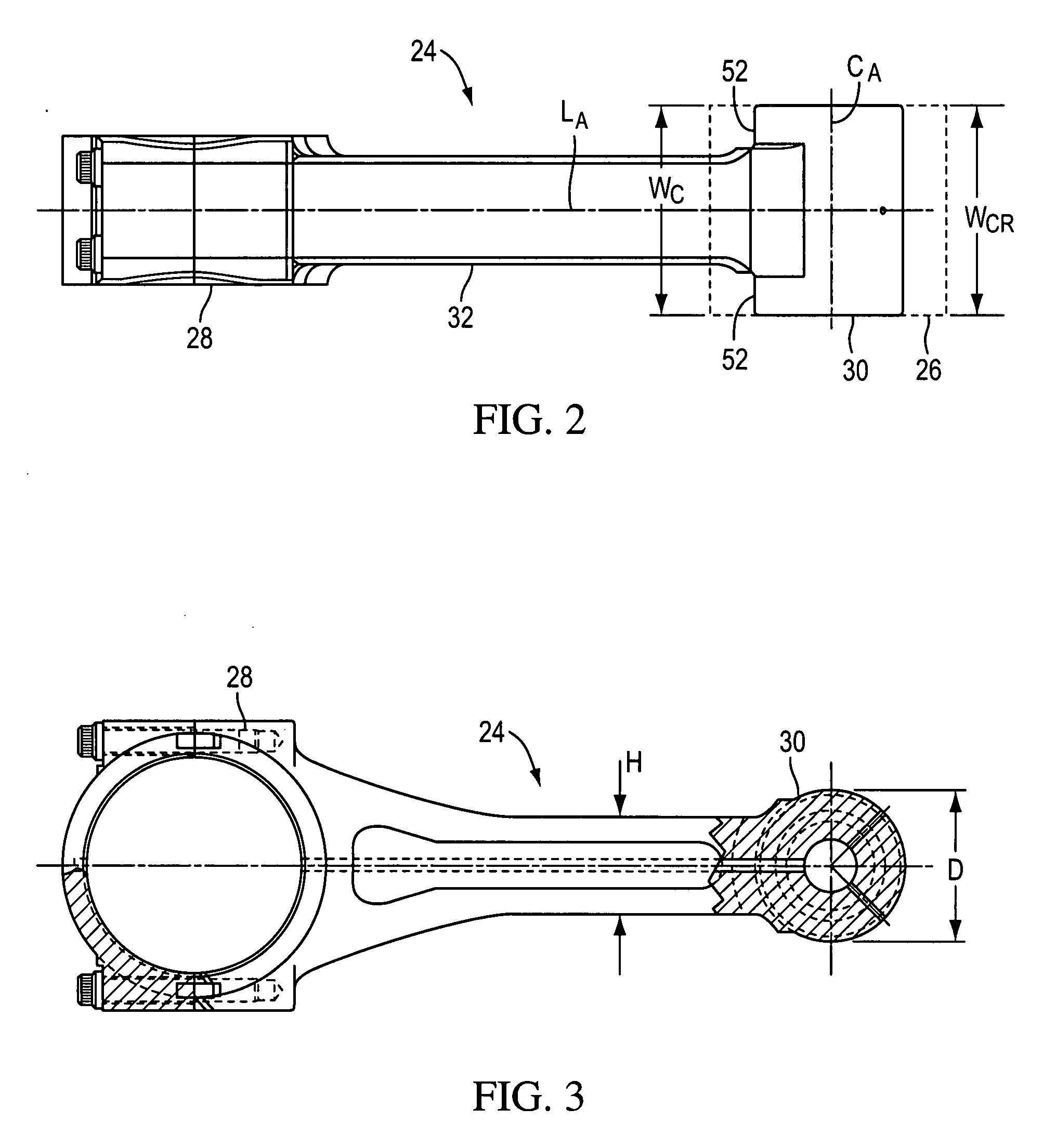

Connecting rod without wrist pin

InactiveUS8376723B2Reduce weightEliminate needConnecting rod bearingsPositive displacement pump componentsEngineeringCrankshaft

Owner:WEIR SPM

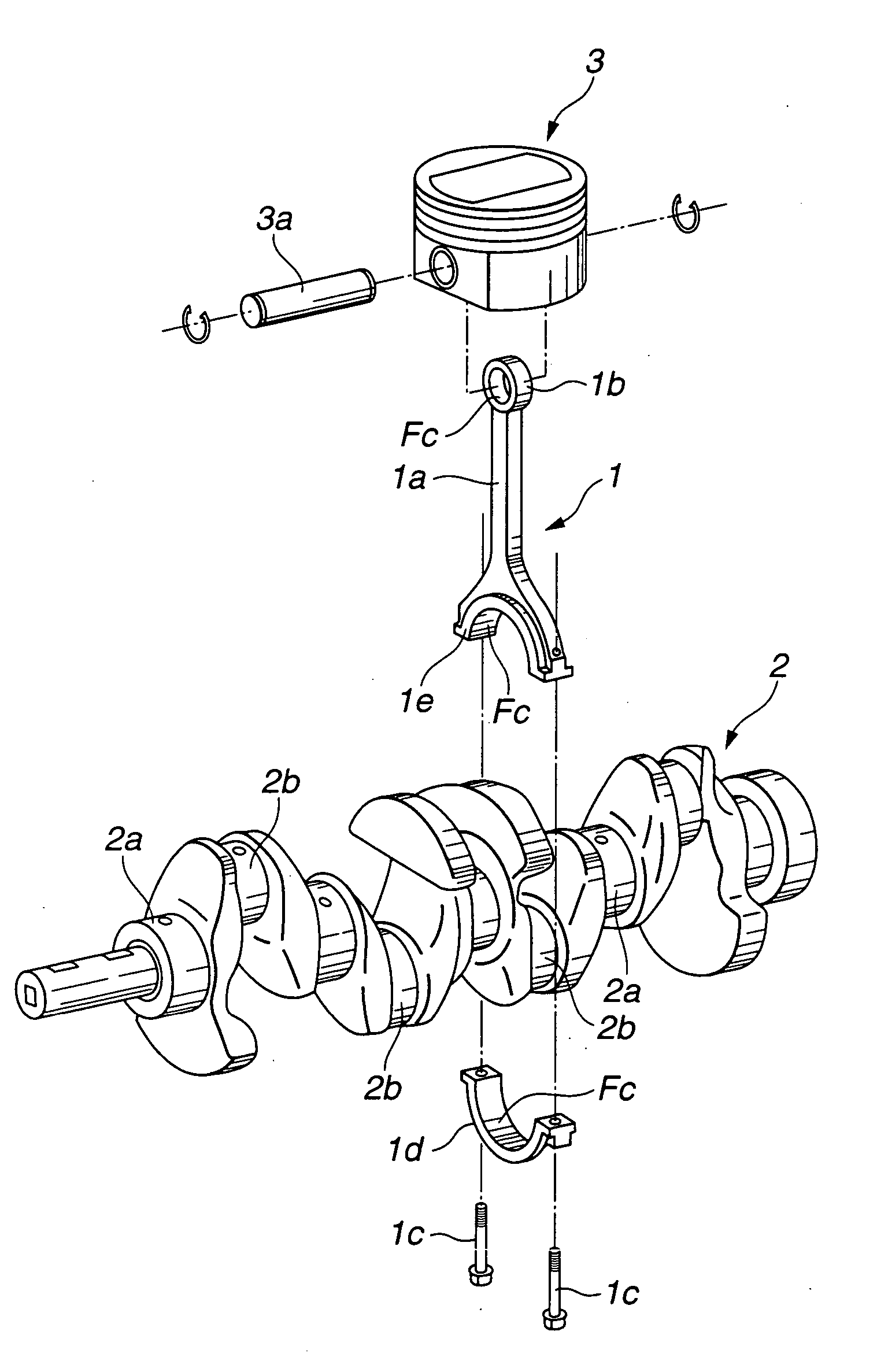

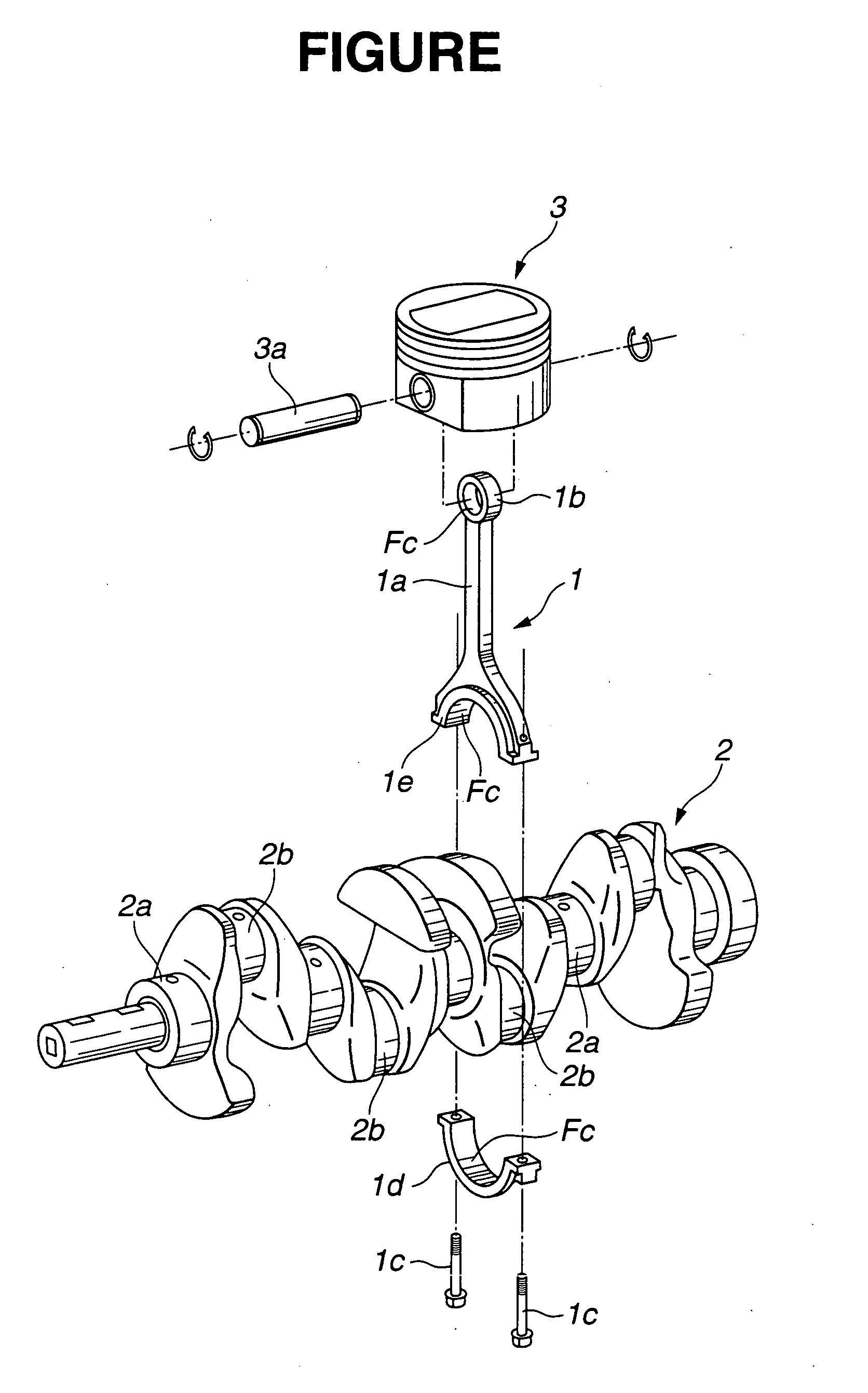

Structure for connecting piston to crankshaft

InactiveUS20050061291A1Reduce sliding frictionImprove engine performanceCrankshaftsConnecting rodsCarbon coatingHydrogen content

There is provided a structure for connecting a piston to a crankshaft in an internal combustion engine, including a piston pin fitted into the piston, a crankpin integral with the crankshaft and a connecting rod having a piston pin bearing portion slidably engaged with an outer cylindrical portion of the piston pin and a crankpin bearing portion slidably engaged with an outer cylindrical portion of the crankpin. At least one of the piston pin bearing portion of the connecting rod and the outer cylindrical portion of the piston pin and at least one of the crankpin bearing portion of the connecting rod and the outer cylindrical portion of the crankpin have hard carbon coatings formed thereon with a hydrogen content of 20 atomic % or less.

Owner:NISSAN MOTOR CO LTD

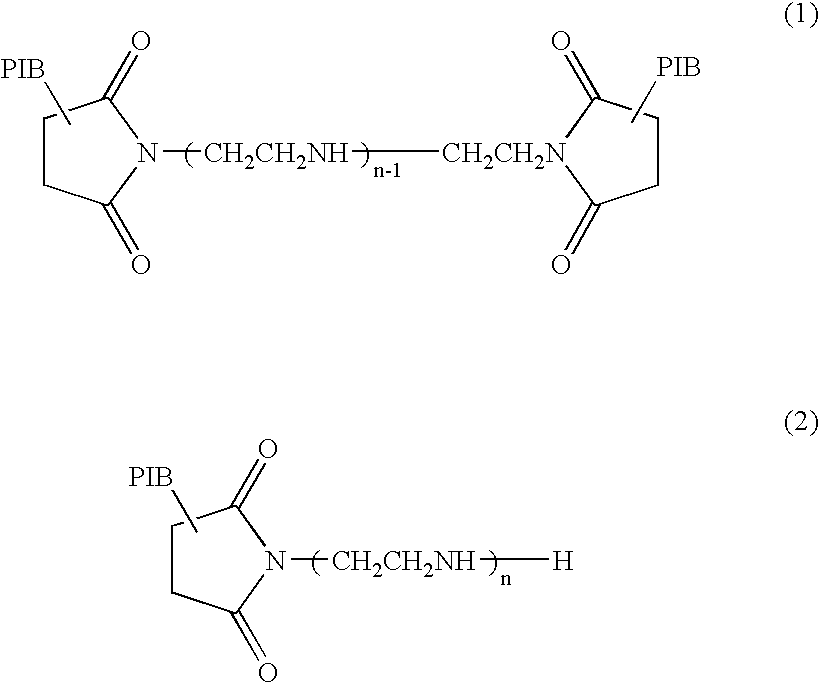

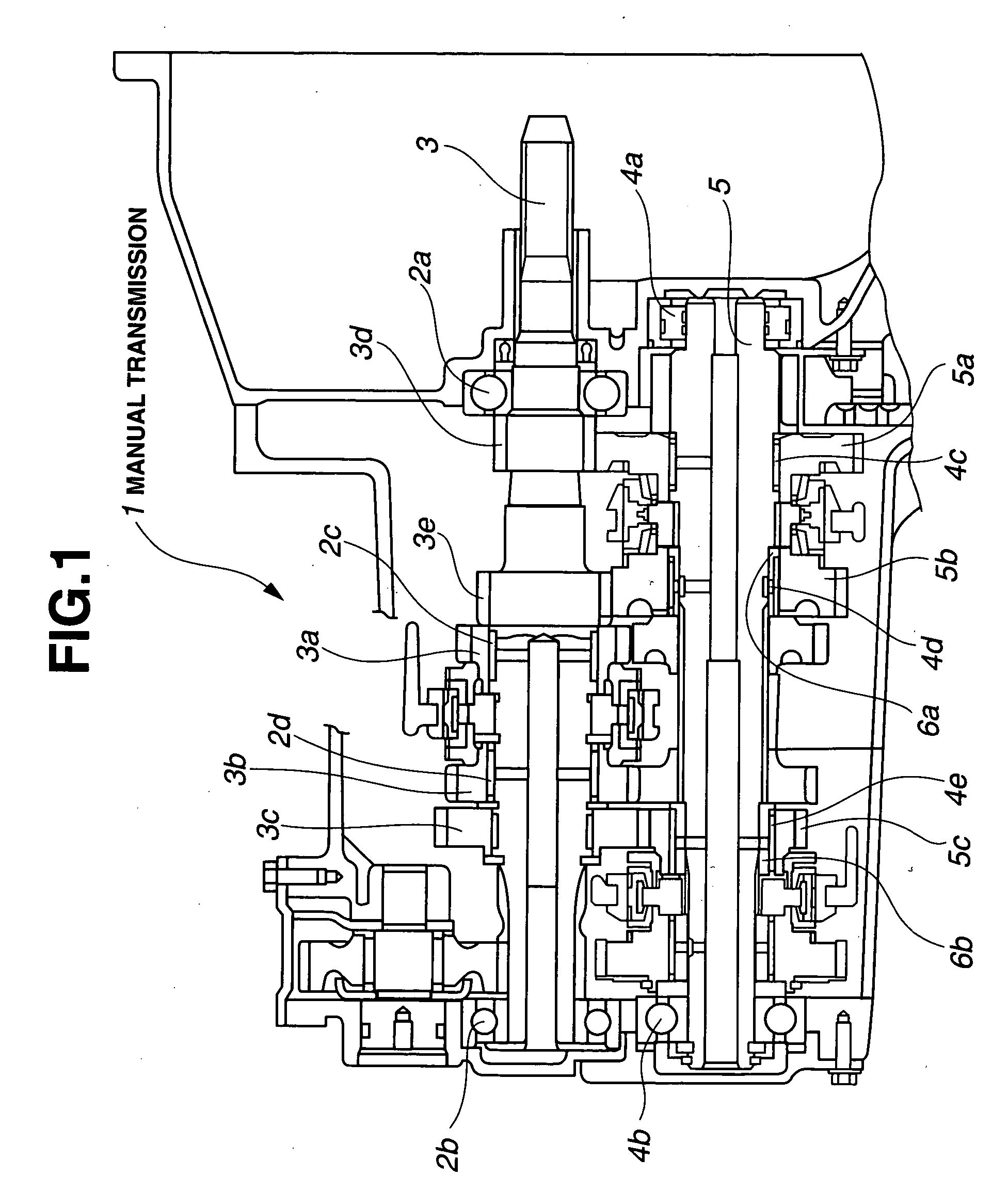

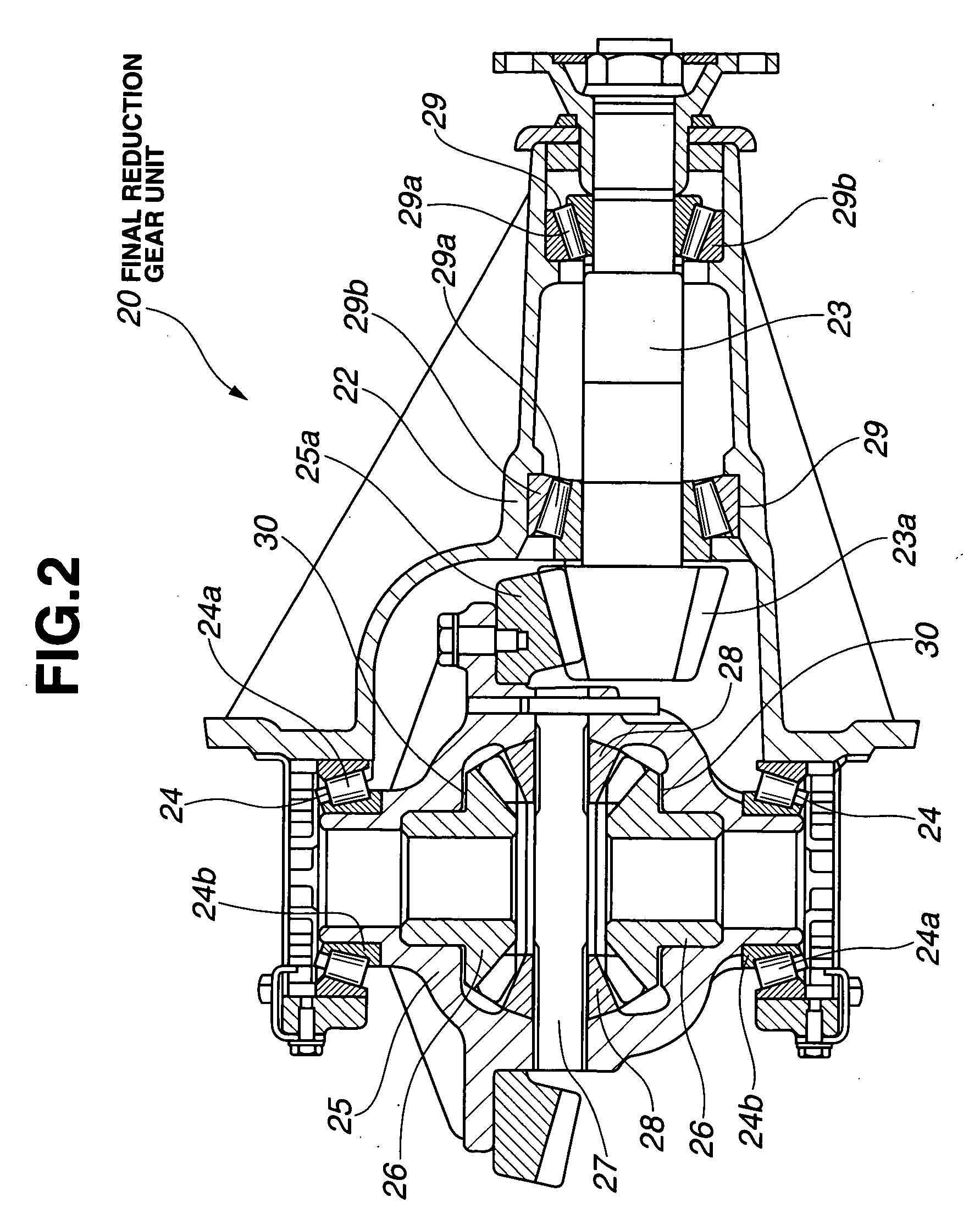

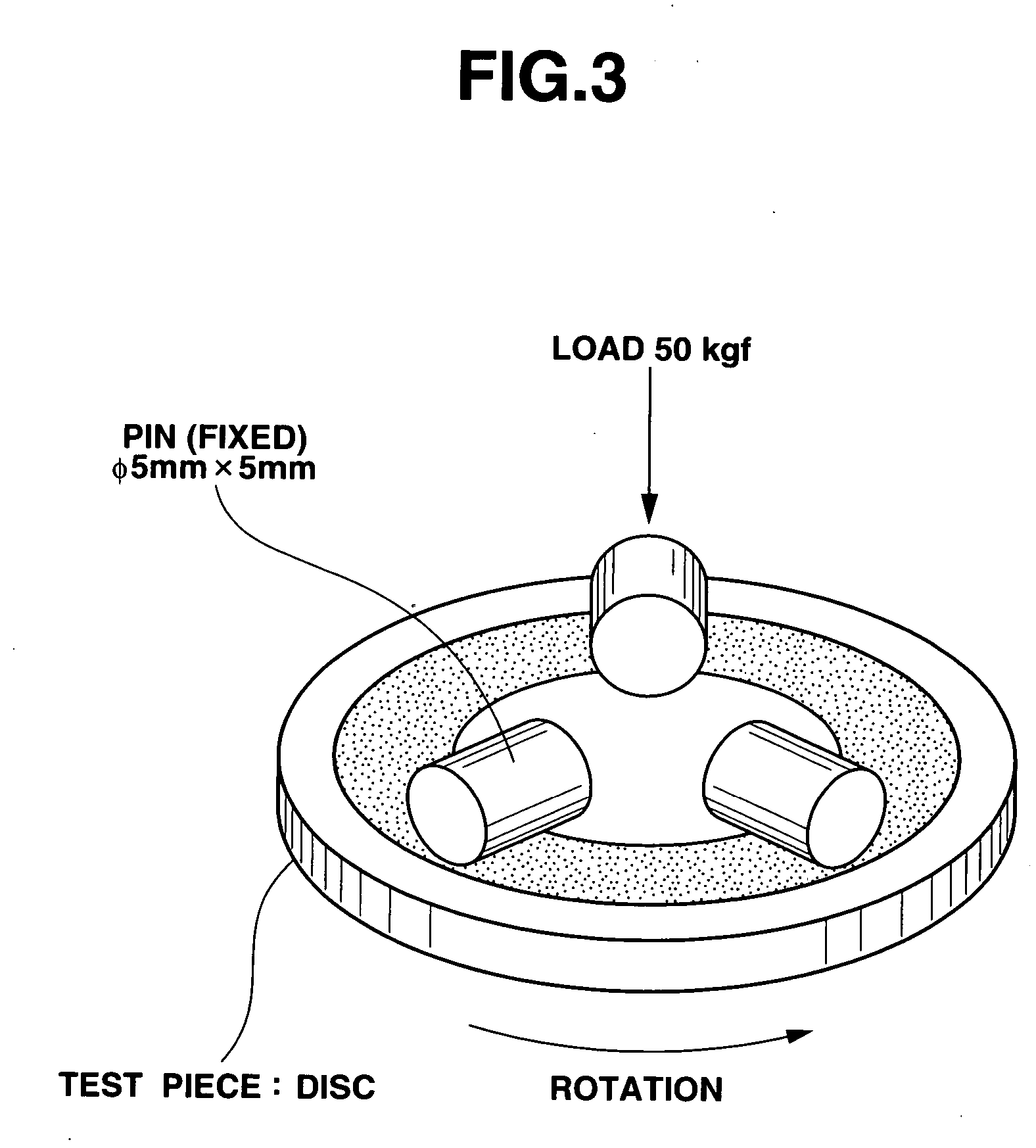

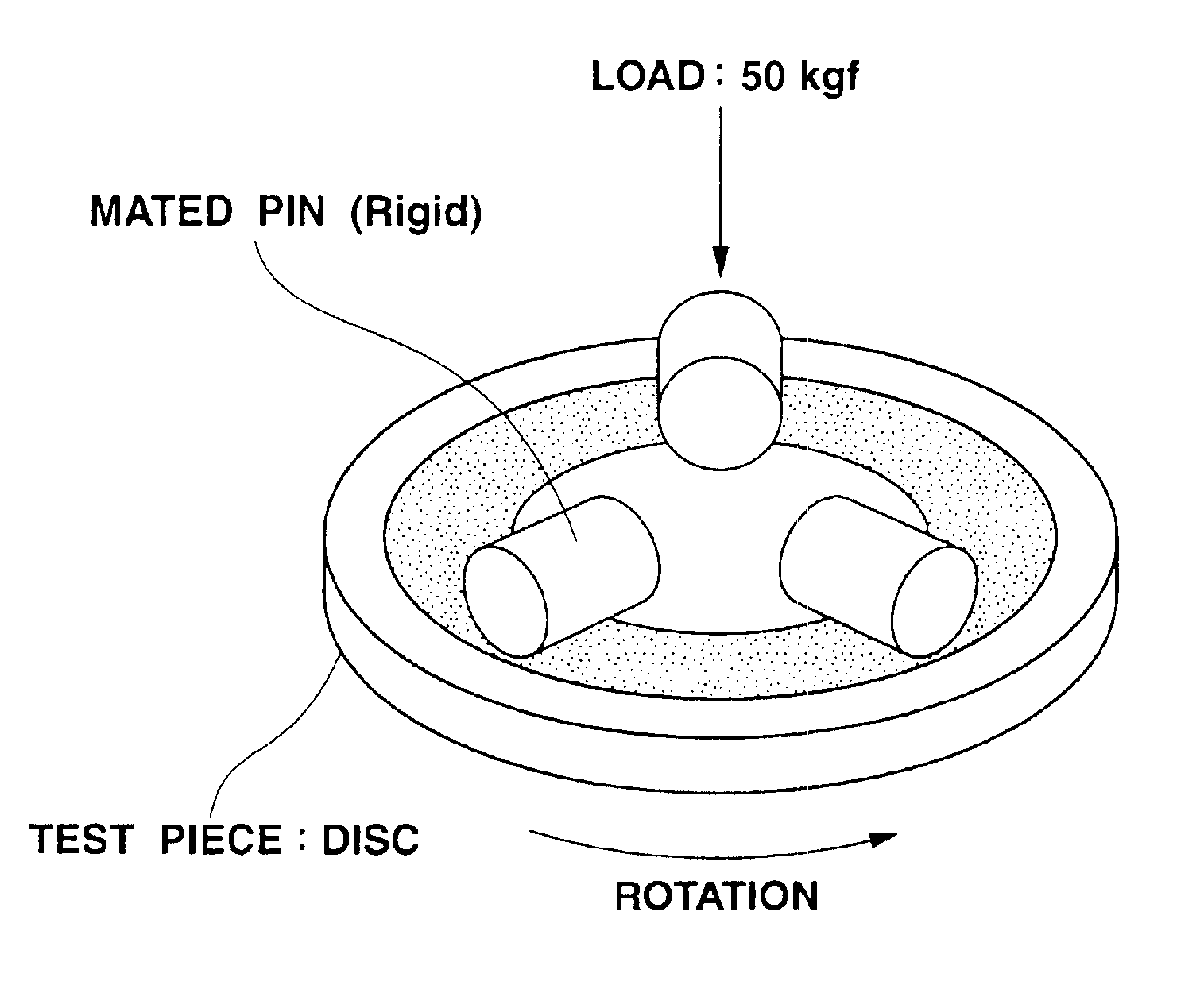

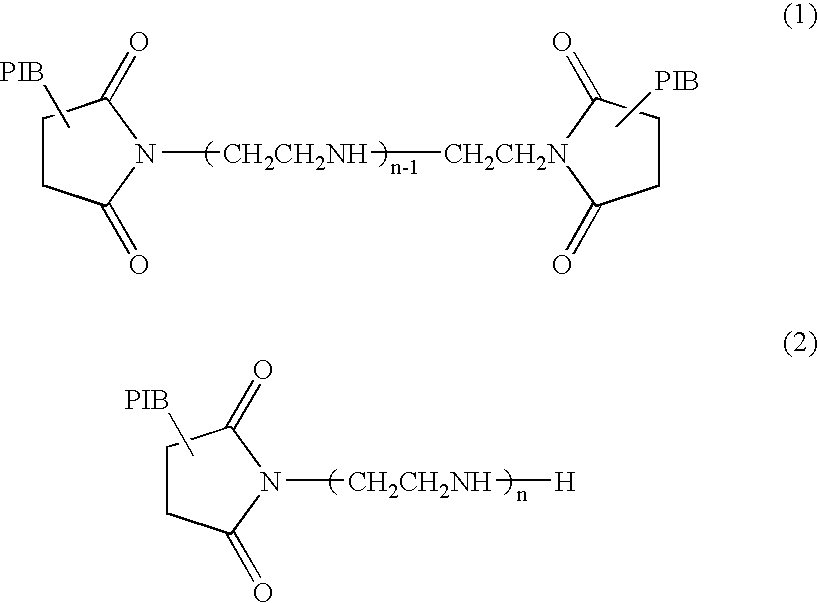

Low-friction sliding mechanism, low-friction agent composition and method of friction reduction

ActiveUS20060263604A1Reduce coefficient of frictionImprove fuel efficiencyCrankshaftsGear lubrication/coolingSimple Organic CompoundsFriction reduction

The invention provides a low-friction sliding mechanism, a low-friction agent composition, a friction reduction method, a manual transmission and a final reduction gear unit that can exert very excellent low friction characteristics to sliding surfaces present under various applications, and, in particular, that have more excellent low friction characteristics than that of a combination of an existing steel material and an organic Mo compound. The low-friction sliding mechanism has an oxygen-containing organic compound or an aliphatic amine compound interposed between sliding surfaces that a DLC coated sliding member and a sliding member form. The low-friction agent composition contains an oxygen-containing organic compound or an aliphatic amine compound. The friction reduction method includes supplying the low-friction agent composition between sliding surfaces that a DLC coated sliding member and a sliding member form. The manual transmission includes, as at least one of sliding members, a DLC coated sliding section. The final reduction gear unit includes, as at least one of sliding members, a DLC coated sliding section.

Owner:NISSAN MOTOR CO LTD +2

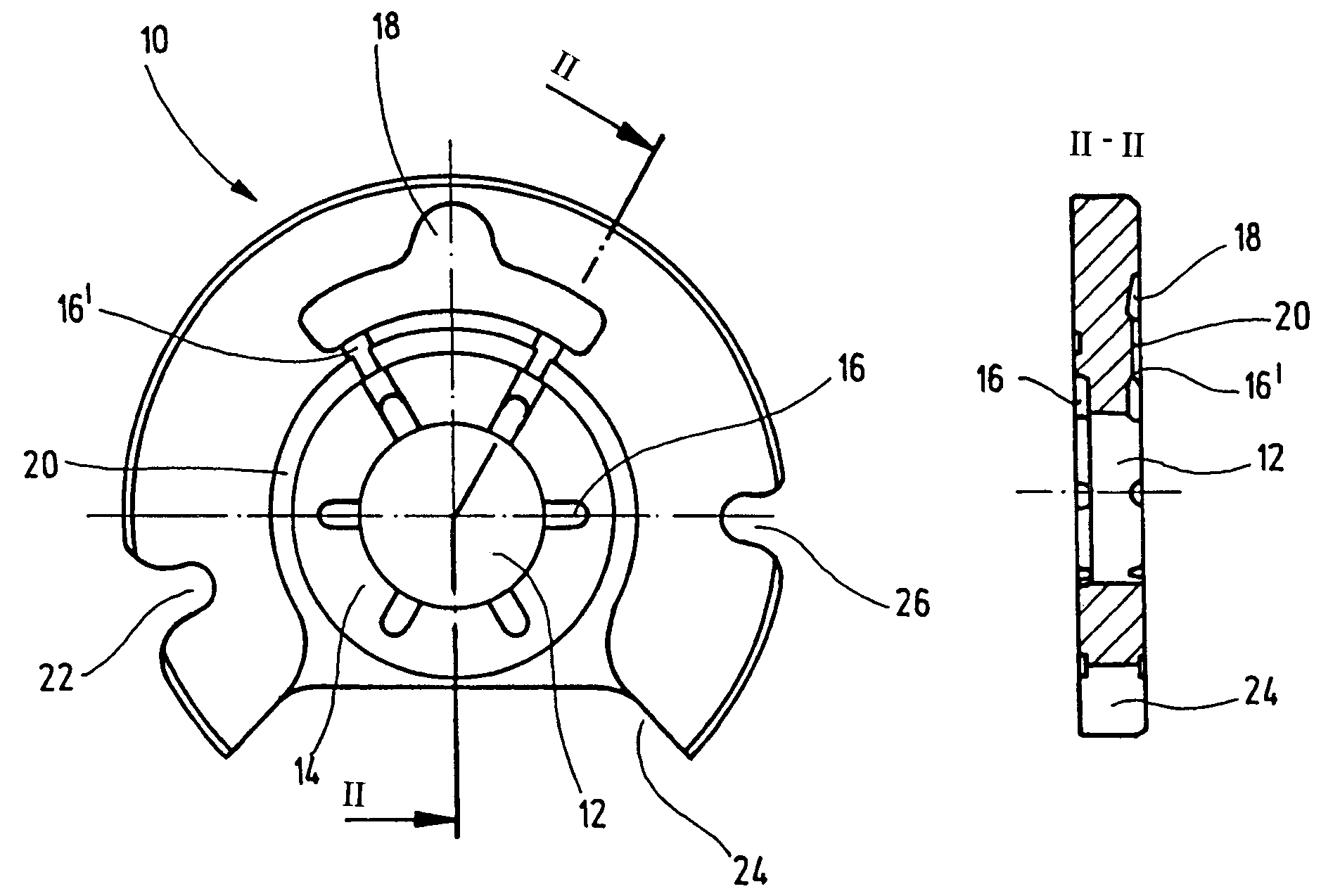

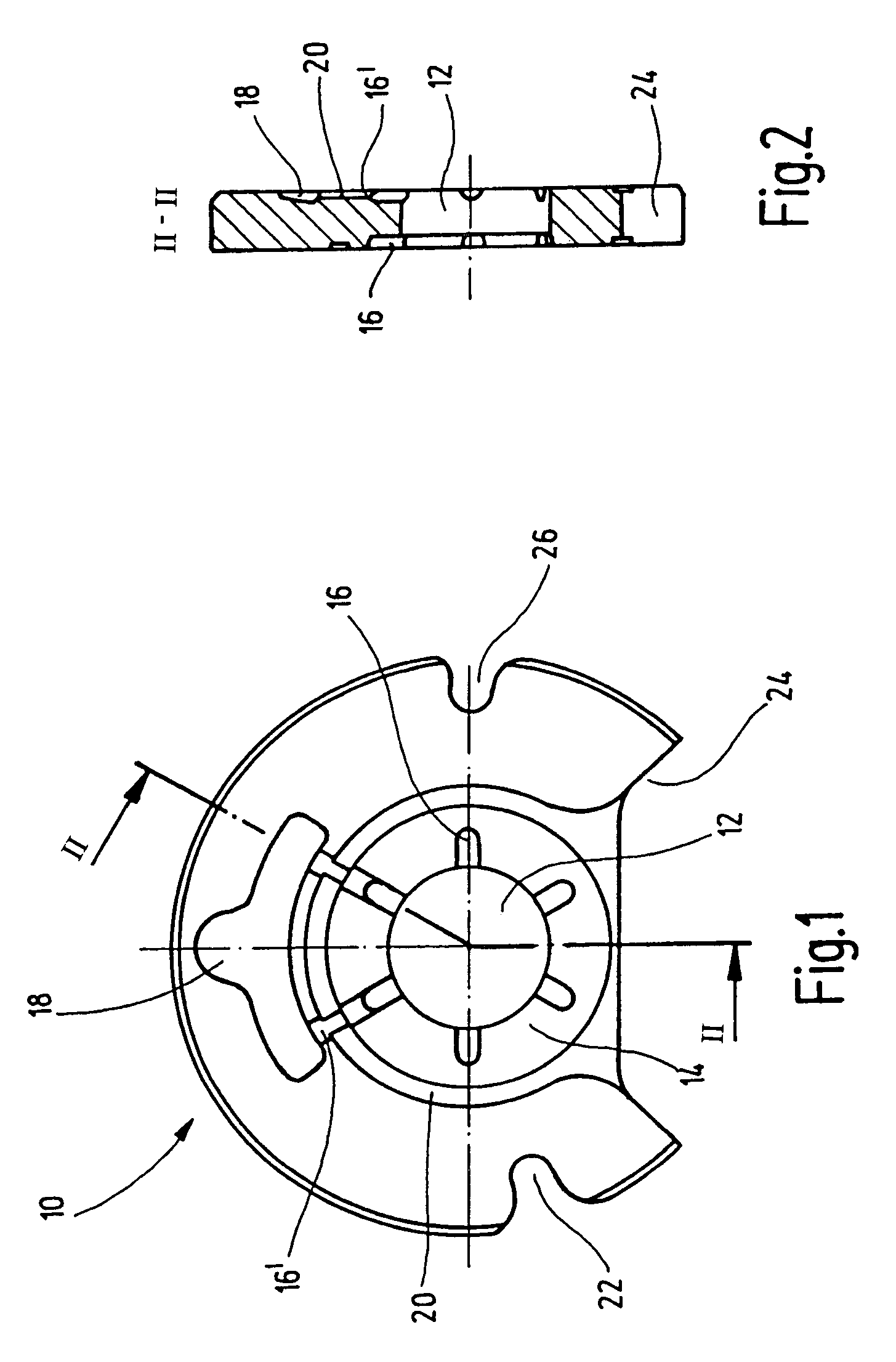

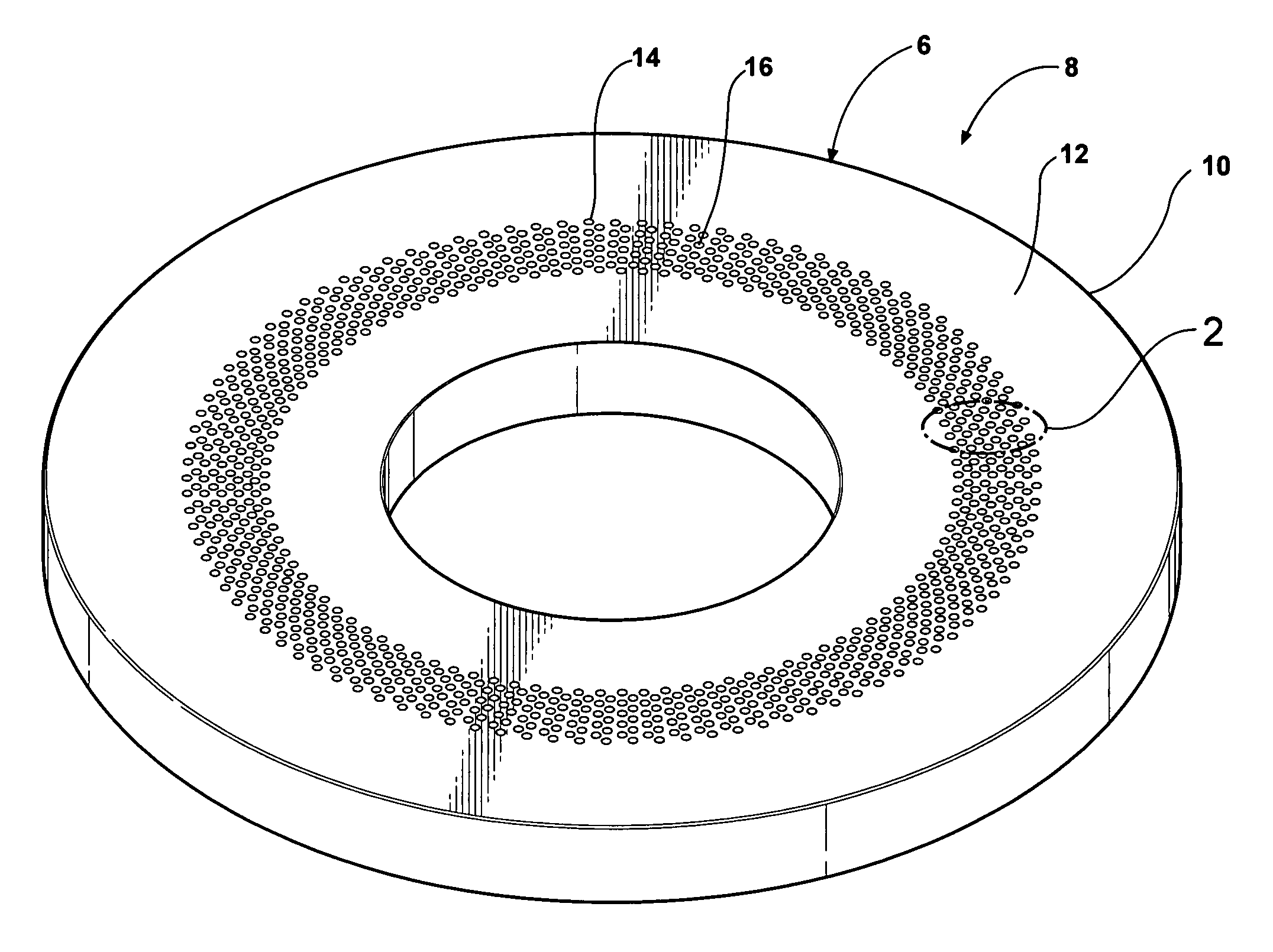

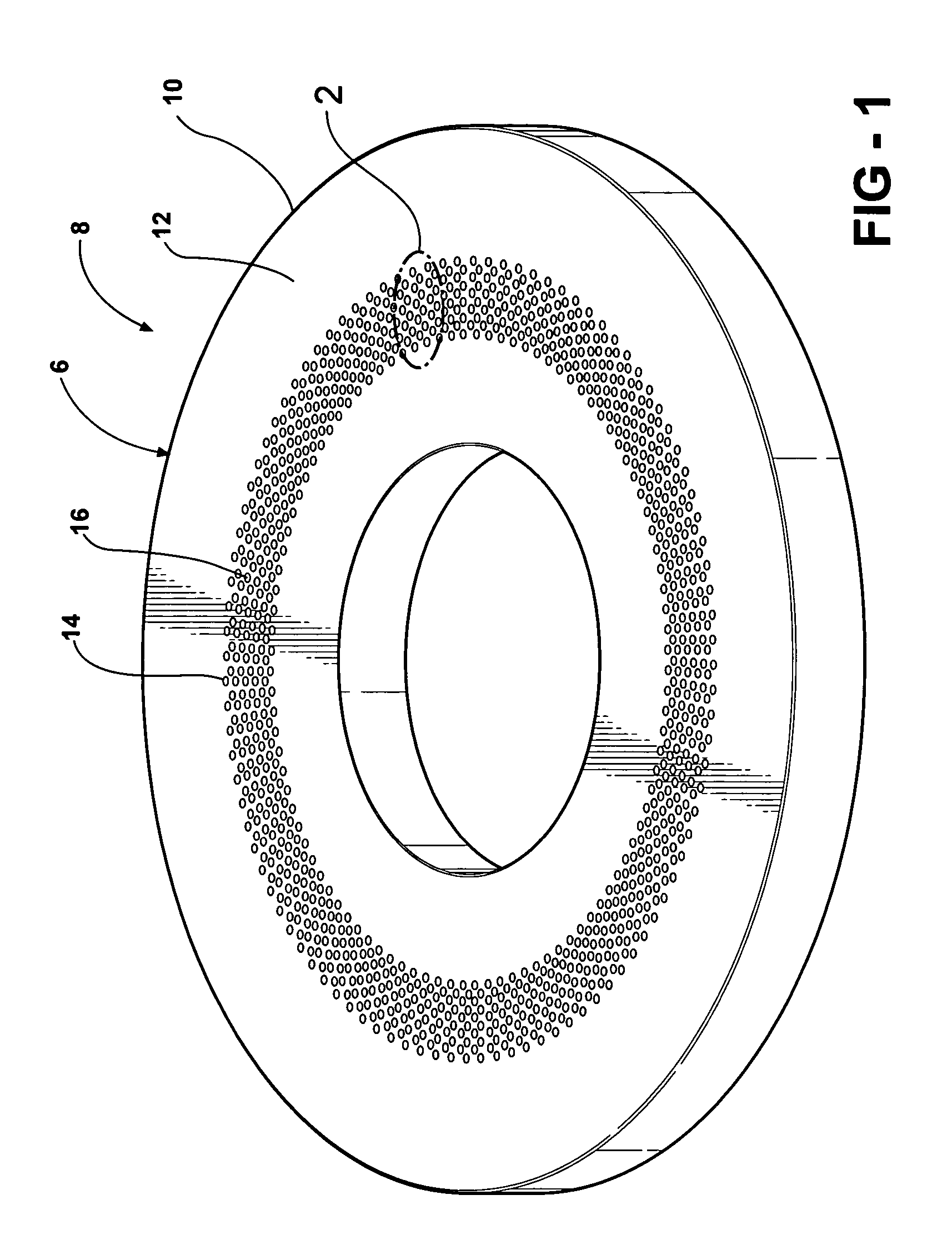

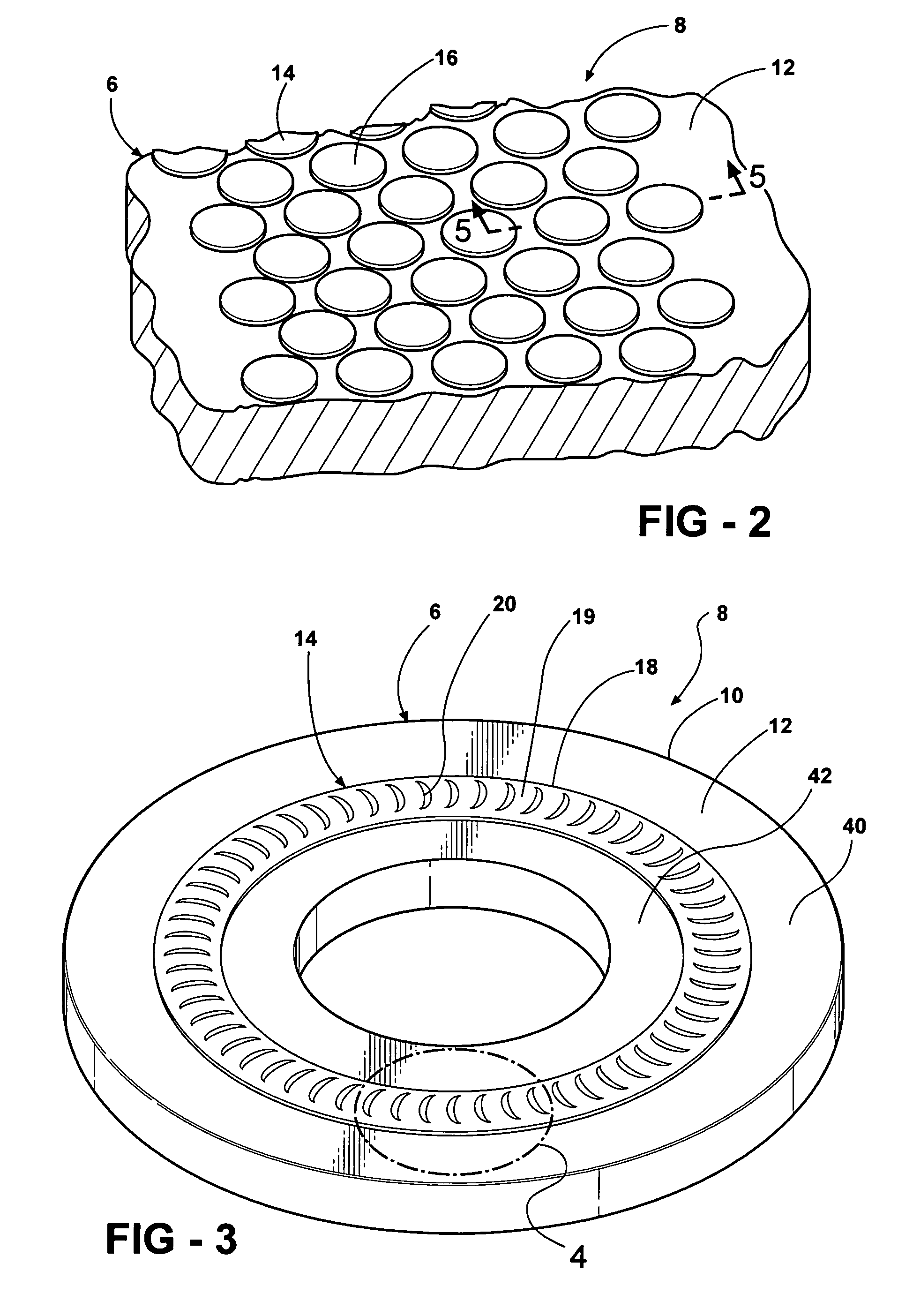

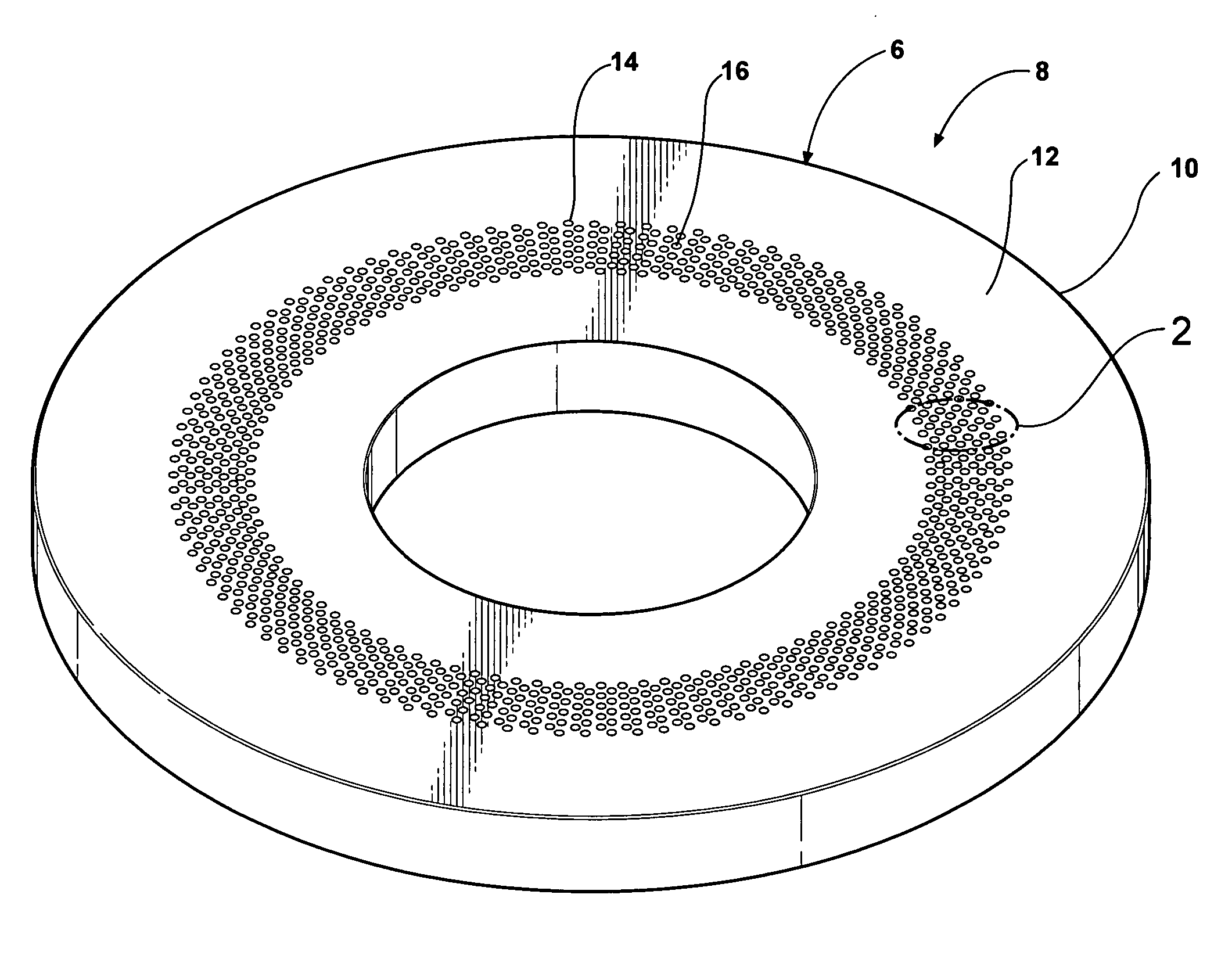

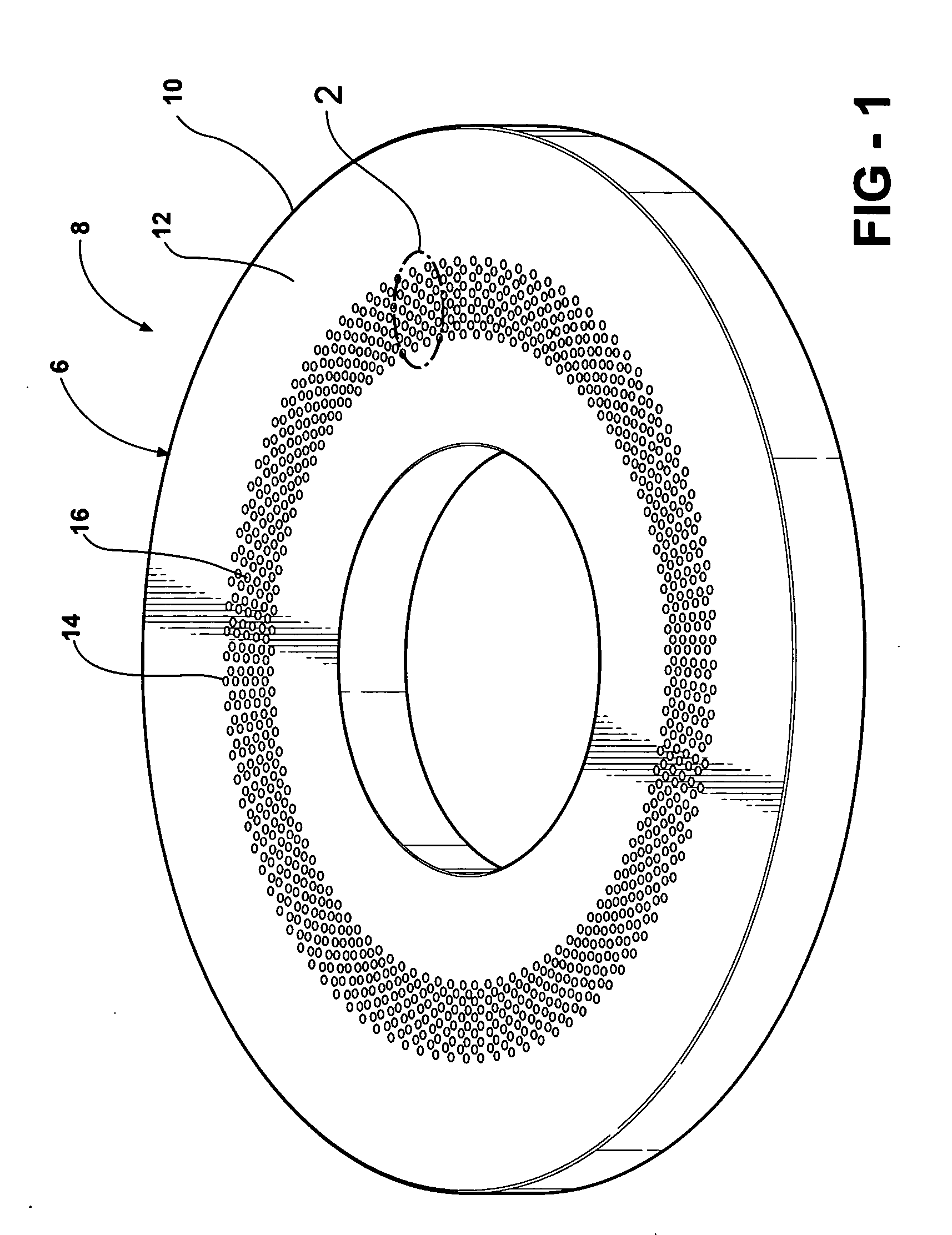

Axial bearing

ActiveUS7401980B2Safe and cost-effectiveReduce manufacturing costCrankshaftsCrossheadsTurbochargerThrust bearing

A thrust bearing, in particular for a turbo charger, has an essentially disc shaped bearing body (10) with a central through opening (12) for a shaft, at least one bearing surface (14) surrounding the through opening (12) for a collar which is placed on the shaft, and at least one oil supply channel which leads from a radially outer region of the bearing body to the through opening (12). In order to realize a cost effective manufacture of the thrust bearing it is proposed according to the invention that the at least one oil supply channel is designed to be a groove (16′).

Owner:BORGWARNER INC

Low-friction sliding mechanism

ActiveUS6969198B2Increase resistanceReduce coefficient of frictionCrankshaftsCrossheadsDiamond-like carbonAliphatic amine

A low-friction sliding mechanism includes first and second sliding members having respective sliding surfaces slidable relative to each other and a lubricant applied to the sliding surfaces of the first and second sliding members. At least the sliding surface of the first sliding member is made of a diamond-like carbon material, and at least the sliding surface of the second sliding member is made of either an aluminum-based alloy material, a magnesium-based alloy material or a diamond-like carbon material. The lubricant contains a base oil and at least one of an ashless fatty-ester friction modifier and an ashless aliphatic-amine friction modifier.

Owner:NISSAN MOTOR CO LTD +1

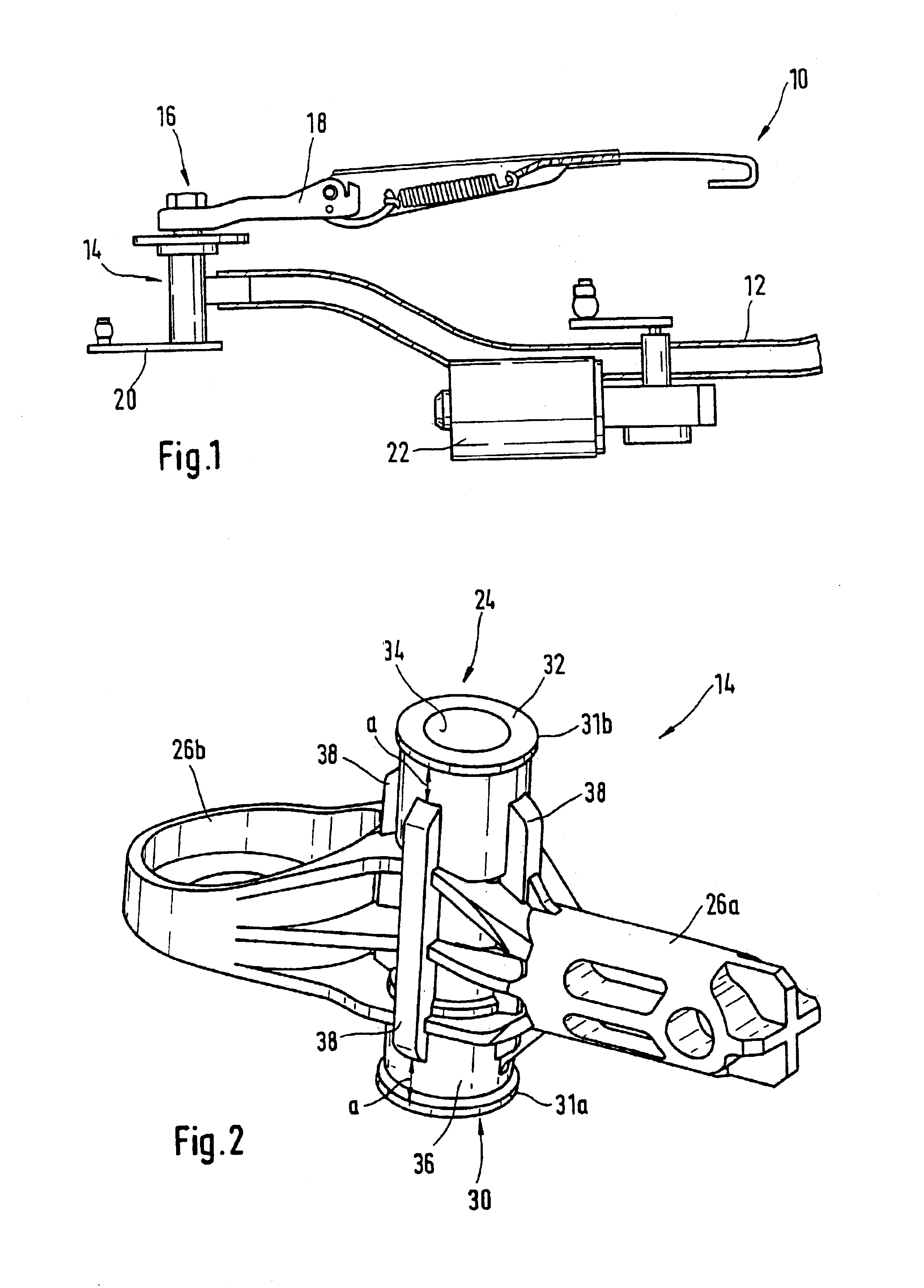

Windshield wiper, especially for motor vehicles and method for production of said windshield wiper

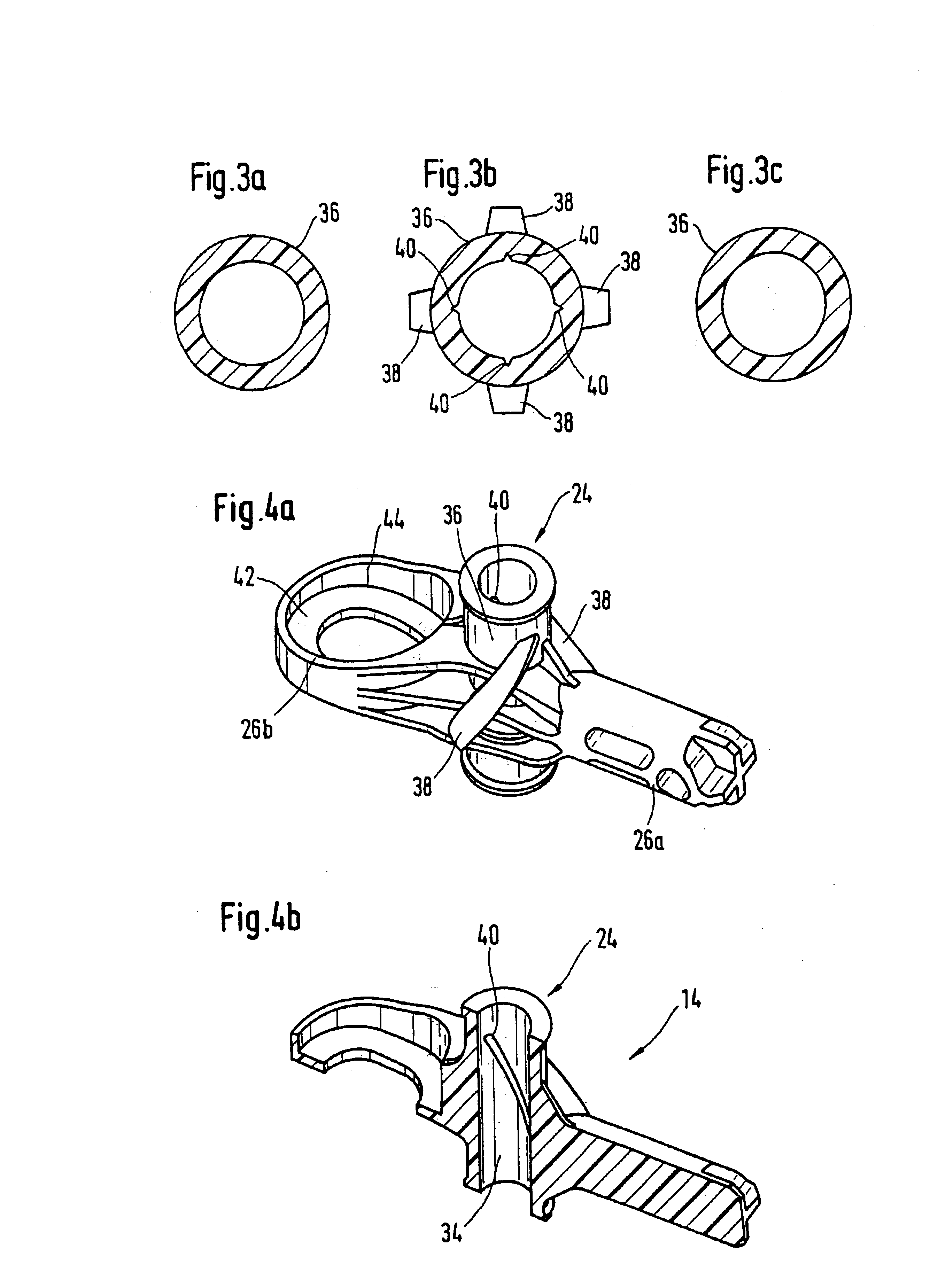

InactiveUS6883966B2Reduce tooling costsSmall diameterCrankshaftsCrossheadsMobile vehicleMotor vehicle part

A windshield wiper system, and a method for producing such a system, in particular for a motor vehicle, having at least one wiper bearing (14) substantially comprising an injection-moldable material, in particular plastic, in which a wiper shaft (16) is supported at least in such a way that it can swing back and forth, and in the region of the wiper shaft (16), the wiper bearing (14) has a substantially hollow-cylindrical segment (24) on whose inner surface (34) at least one groove (40) is provided; at least one, in particular riblike, accumulation of material (38) is provided on the outer surfaces of the hollow-cylindrical segment (24), which accumulation is disposed in the radially outward direction of the groove (40) relative to the axis of rotation of the wiper shaft (16).

Owner:ROBERT BOSCH GMBH

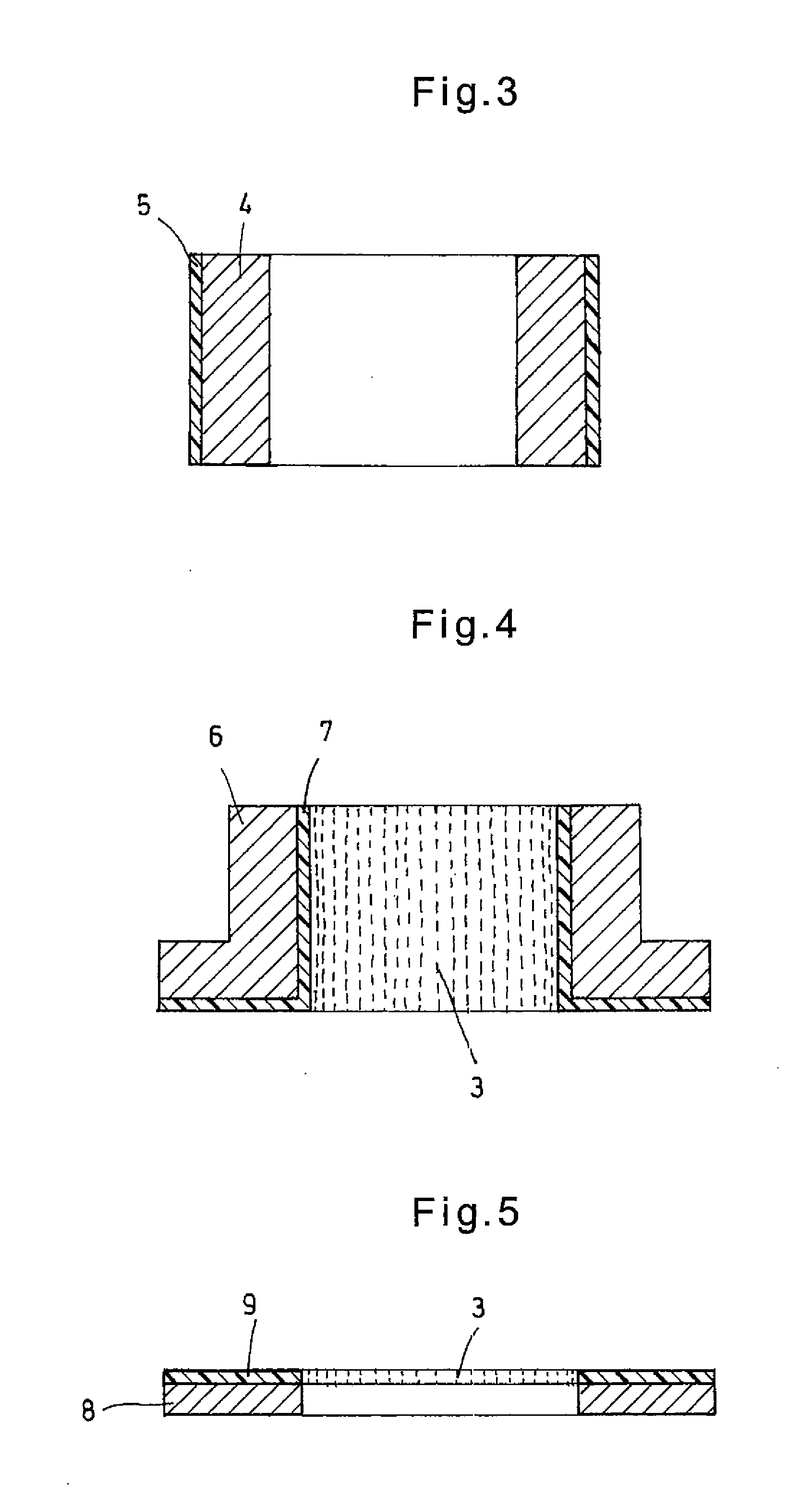

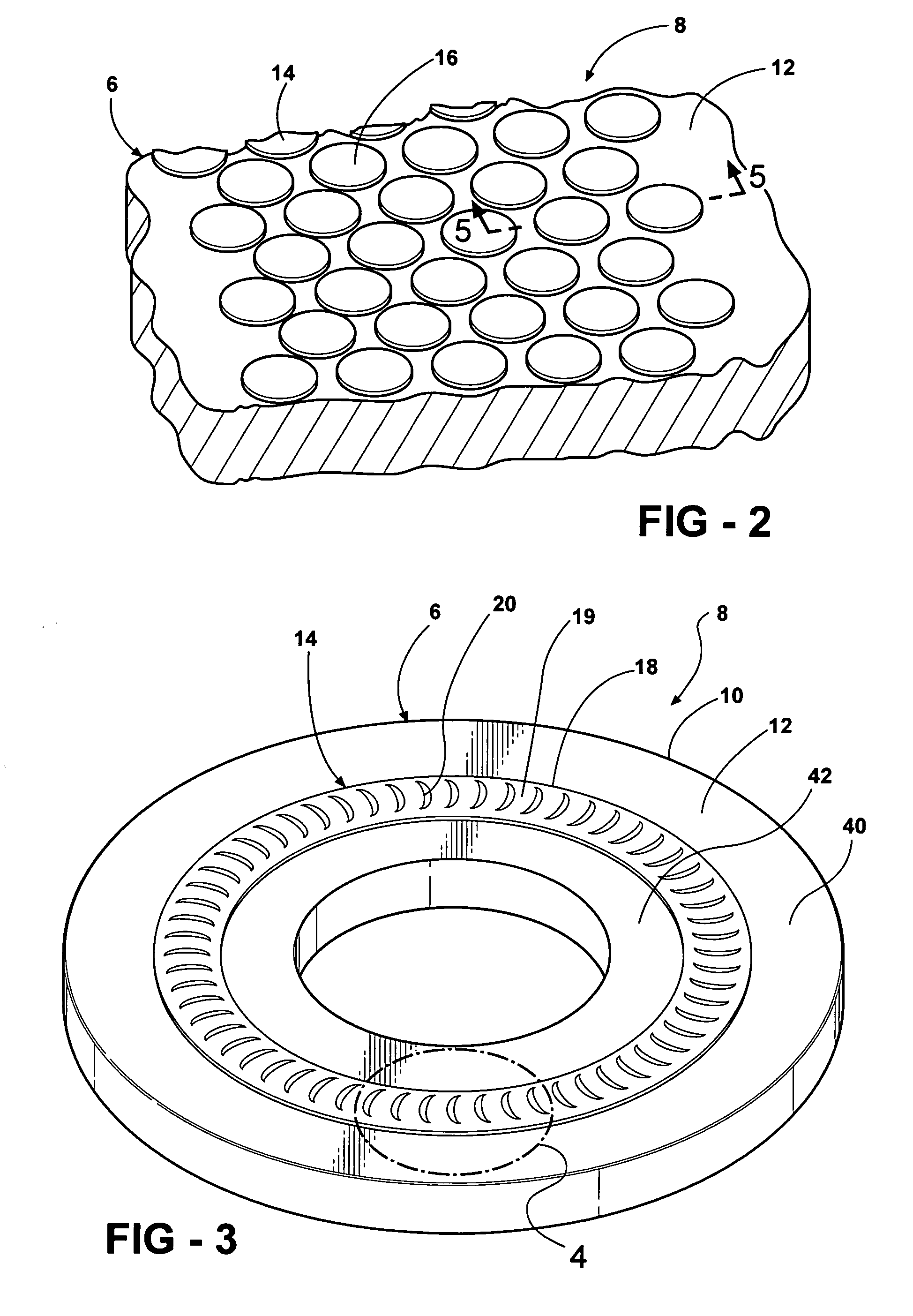

Method of making a sliding bearing

InactiveUS7458158B2Improve performanceCompromising performanceCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

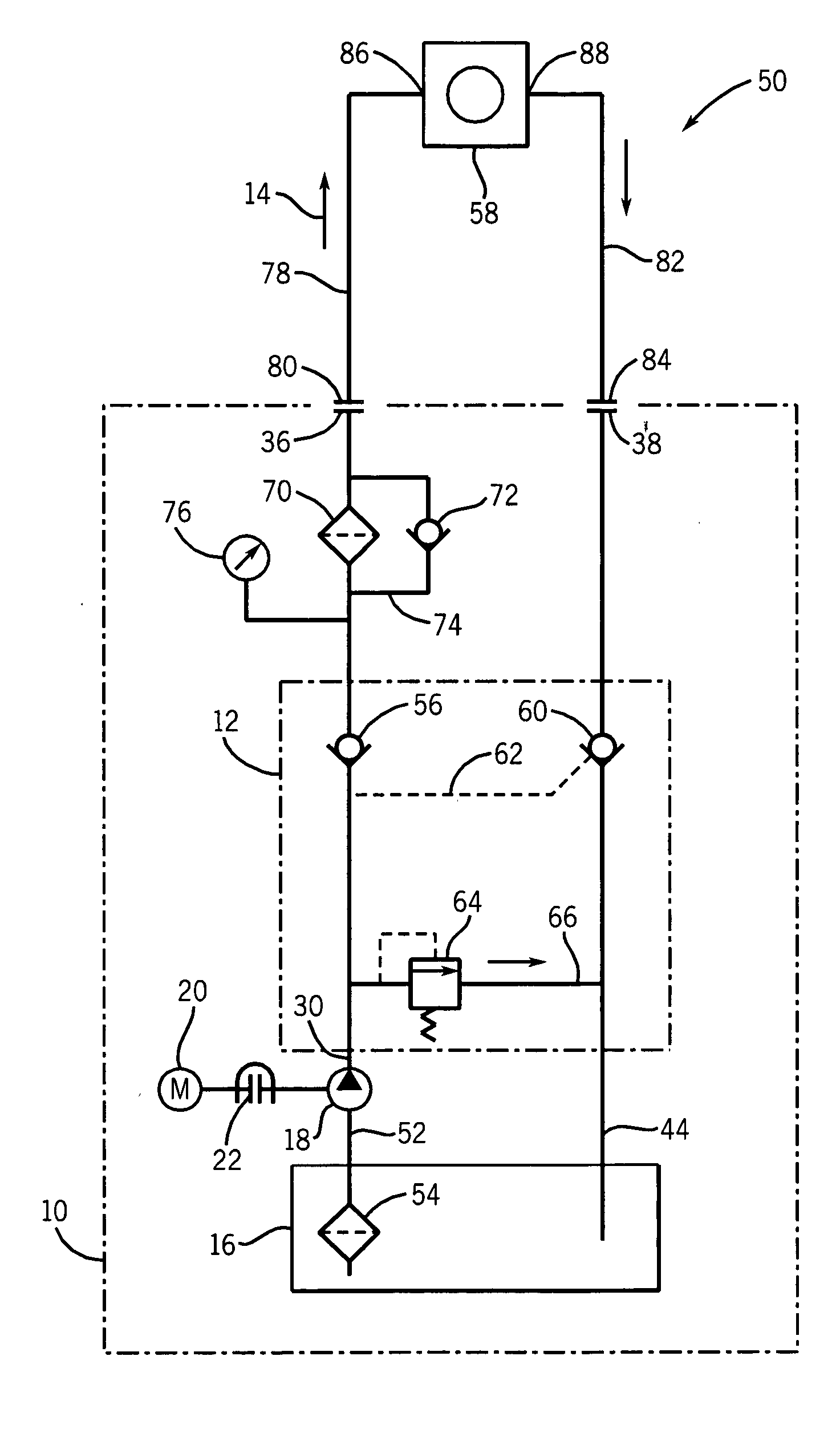

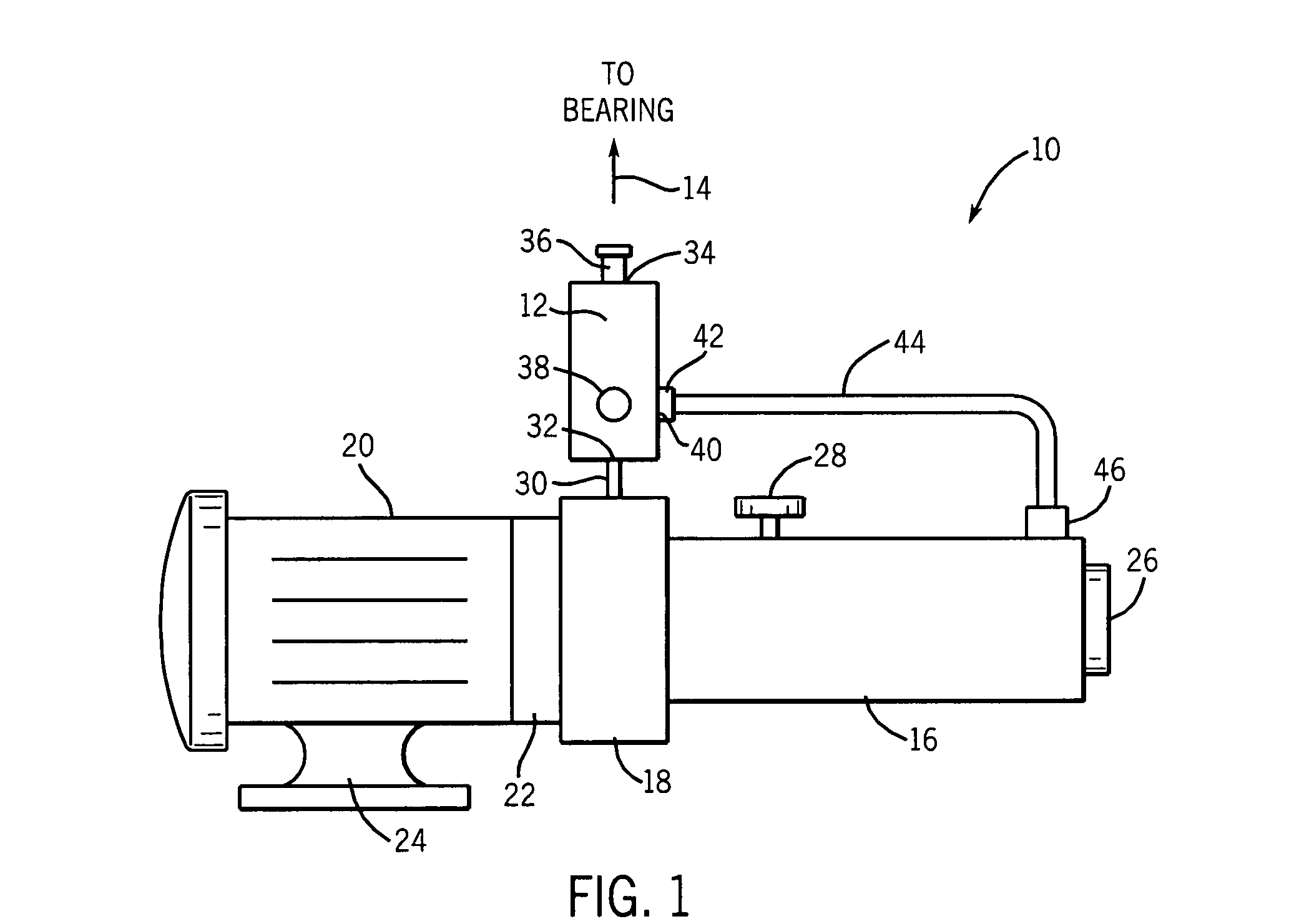

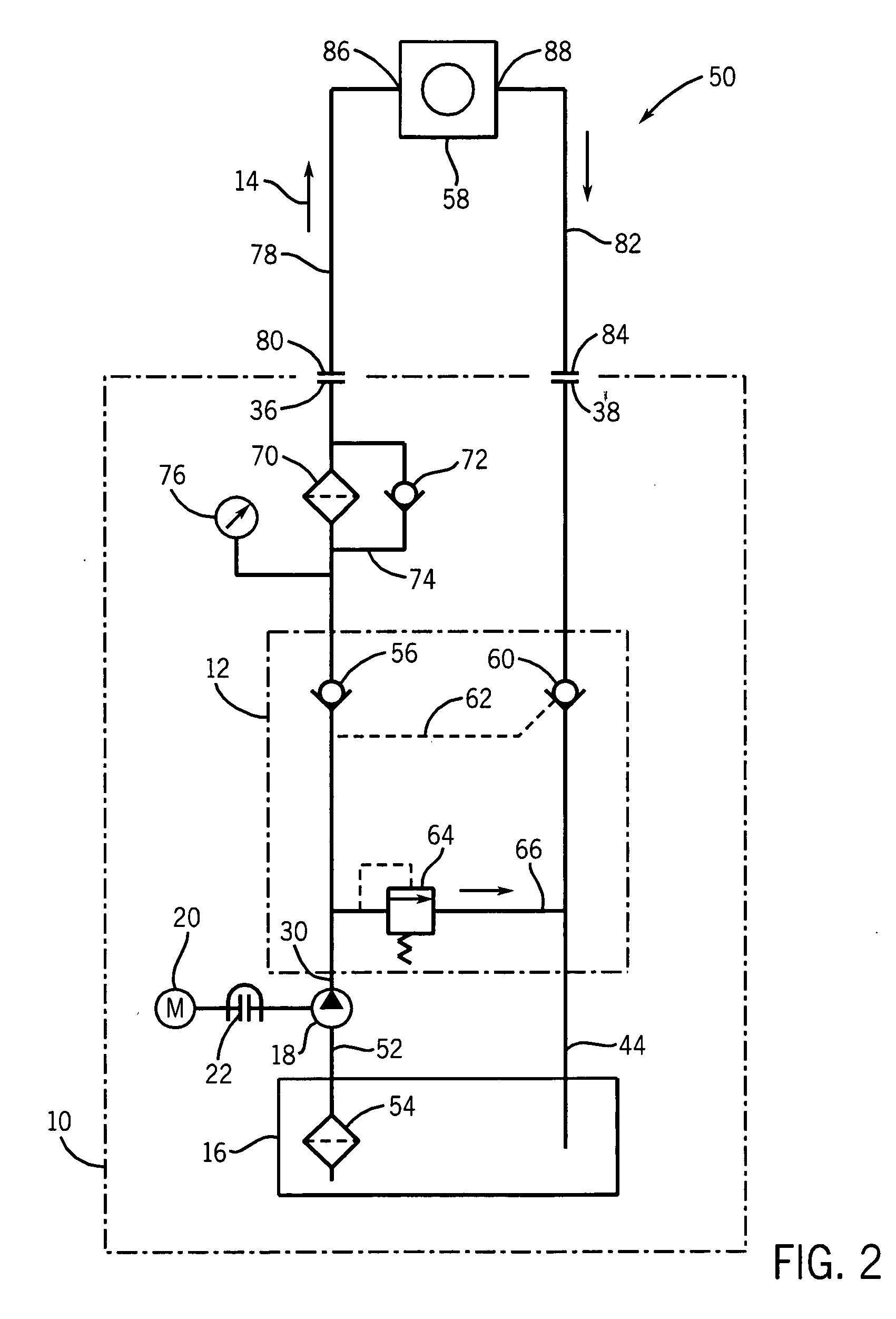

Oil circulation retention system and method

ActiveUS20060054404A1Prevent overflowPrevent drainageCrankshaftsCrossheadsCirculator pumpCheck valve

A bearing lubrication (oil circulation) system having a check valve configuration for preventing overflow of an oil reservoir or tank. The pressurized oil circulation system may comprise a pump that pressurizes oil from the tank and circulates the oil through a supply conduit to a bearing, and returns the oil to the tank through a return conduit. The system may include a check valve disposed in the supply conduit and a pilot-operated check valve disposed in the return conduit. The pilot may be taken from the supply conduit upstream of the check valve disposed on the supply conduit. When pressure is discharged from the oil circulation, such as with shutdown of a circulation pump, the check valves automatically close and thus prevent oil contained in the supply and return conduits from draining (i.e., by gravity) to the oil tank. Therefore, flooding of the oil tank with excessive oil is prevented. Furthermore, loss of oil from the bearing sump is also prevented.

Owner:DODGE ACQUISITION CO +1

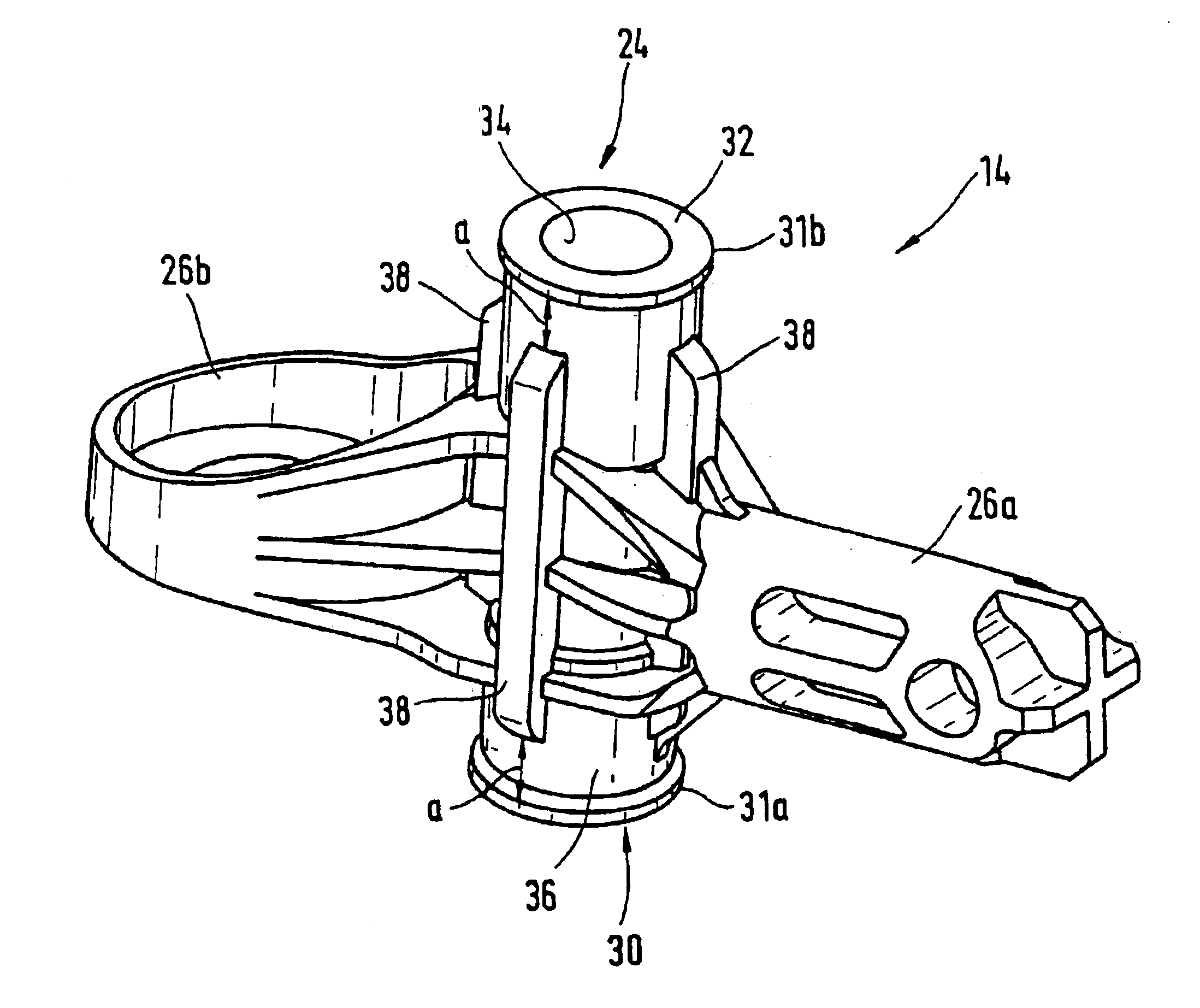

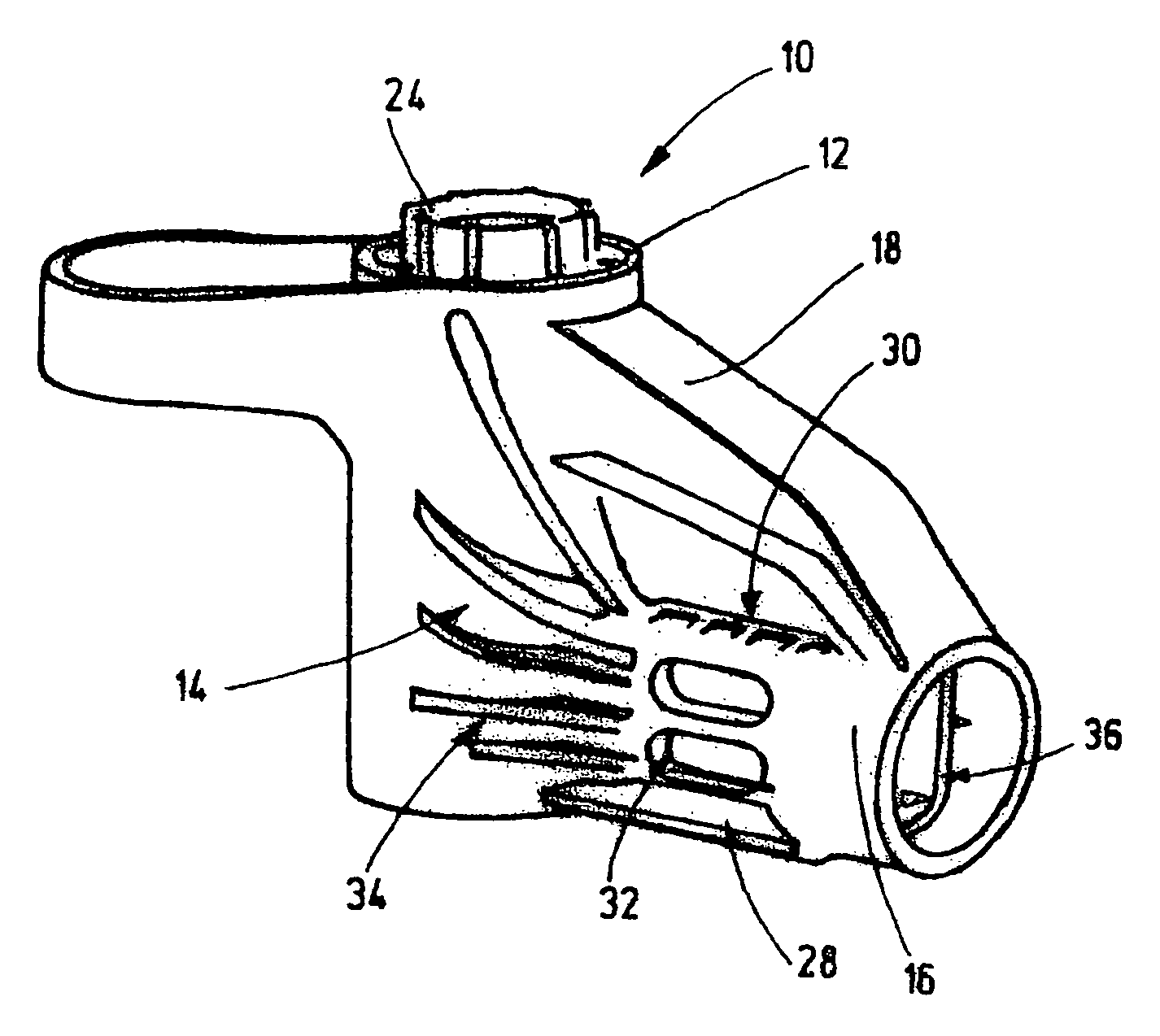

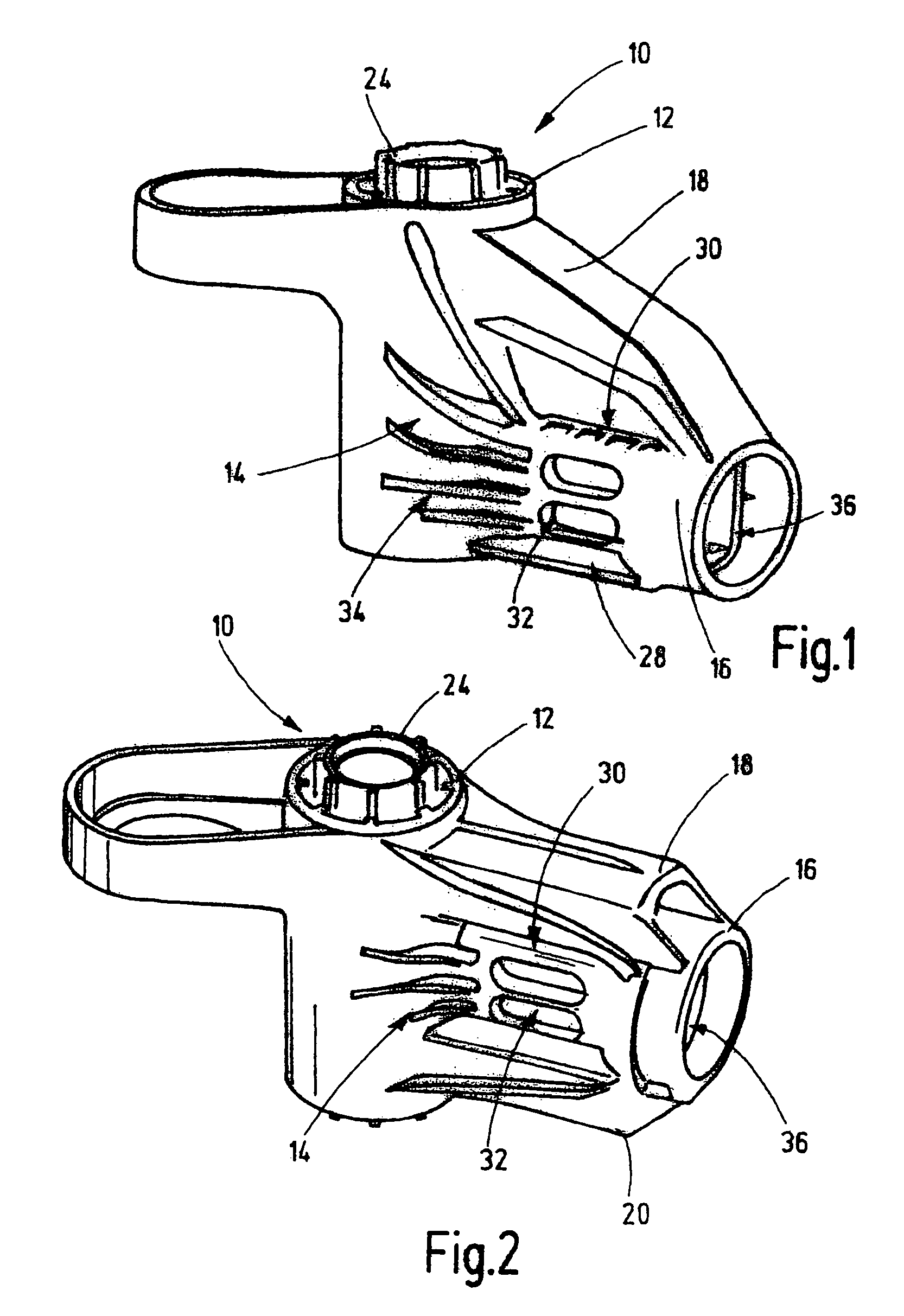

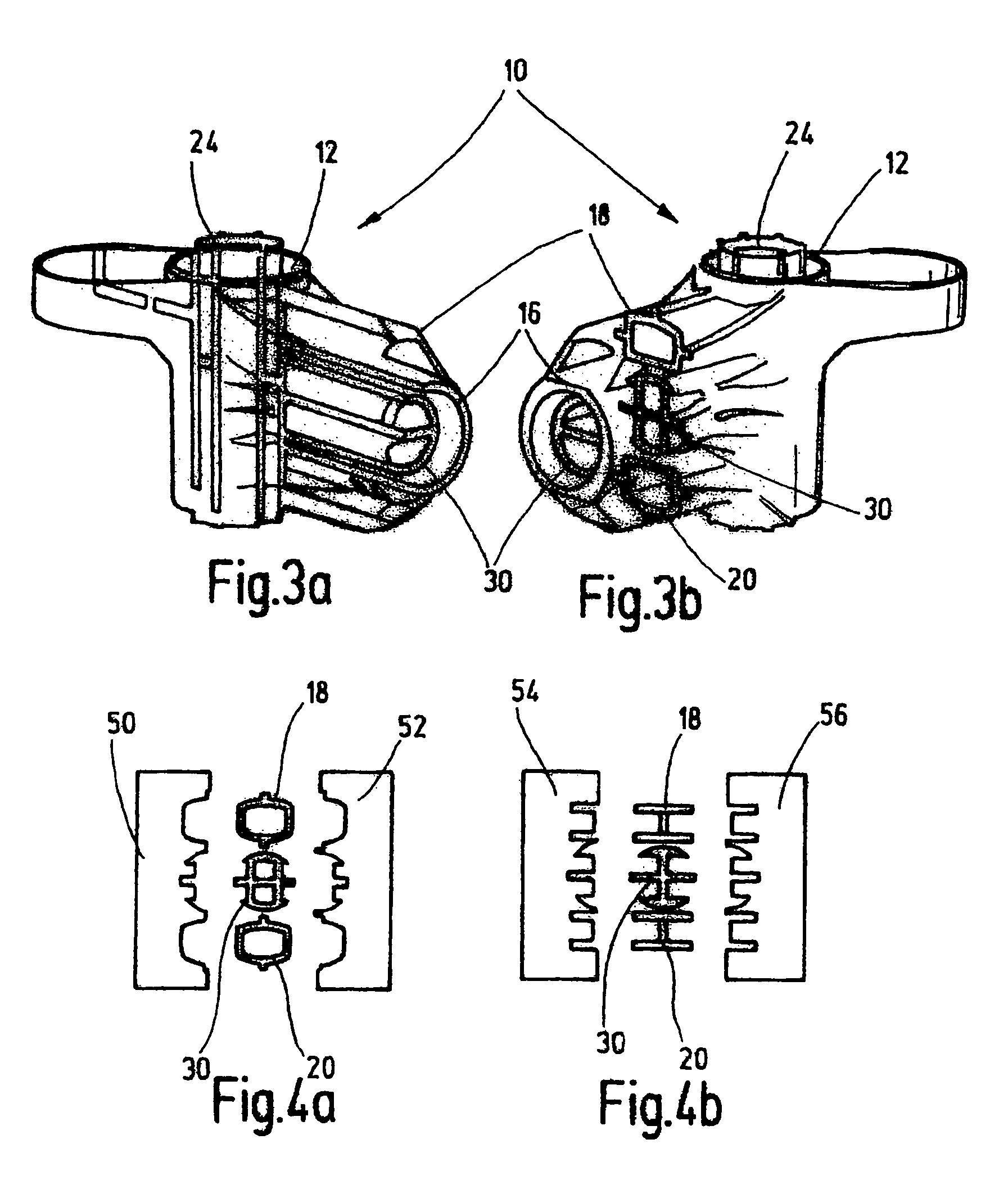

Wiper bearing

InactiveUS7581887B2Improve stabilityGuaranteed ease of connectionCrankshaftsCrossheadsEngineeringTube forming

The invention relates to a wiper bearing for a windshield wiper system comprising a bearing housing (12) provided with an outer tube forming the bearing housing (12) and an inner tube (24) arranged in a concentric manner in relation thereto and a journal (30) arranged on a bearing area (14) on the bearing housing (12) for receiving a tubular plate (40). It is proposed that an annular element (16), which is arranged in a coaxial manner on the journal (30), be provided outside the journal (30) in the region of the front side thereof (36).

Owner:ROBERT BOSCH GMBH

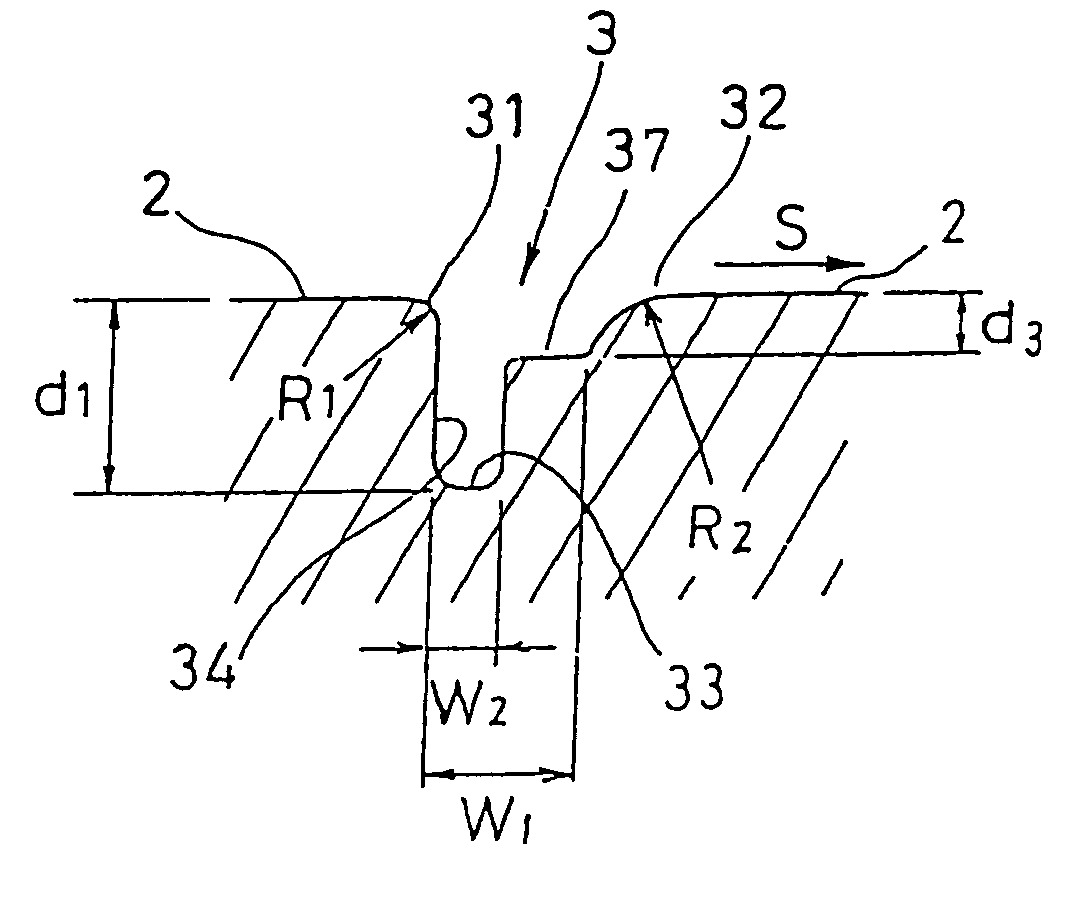

Thrust bearing

In a thrust bearing supporting a load in a thrust direction in a rotary portion, a size of a curved surface in the forward side of a lubricating groove with respect to a relative rotating direction of an opposing sliding member is set to be larger than a size of a curved surface in the rearward side of the lubricating groove with respect to the relative rotating direction, and a depth of the lubricating groove is set to be deeper than a starting point in the side of a groove bottom of the curved surface formed in the groove shoulder in the forward side of the lubricating groove with respect to the rotating direction, so that a lubricating effect and a cooling effect are increased.

Owner:NOK CORP

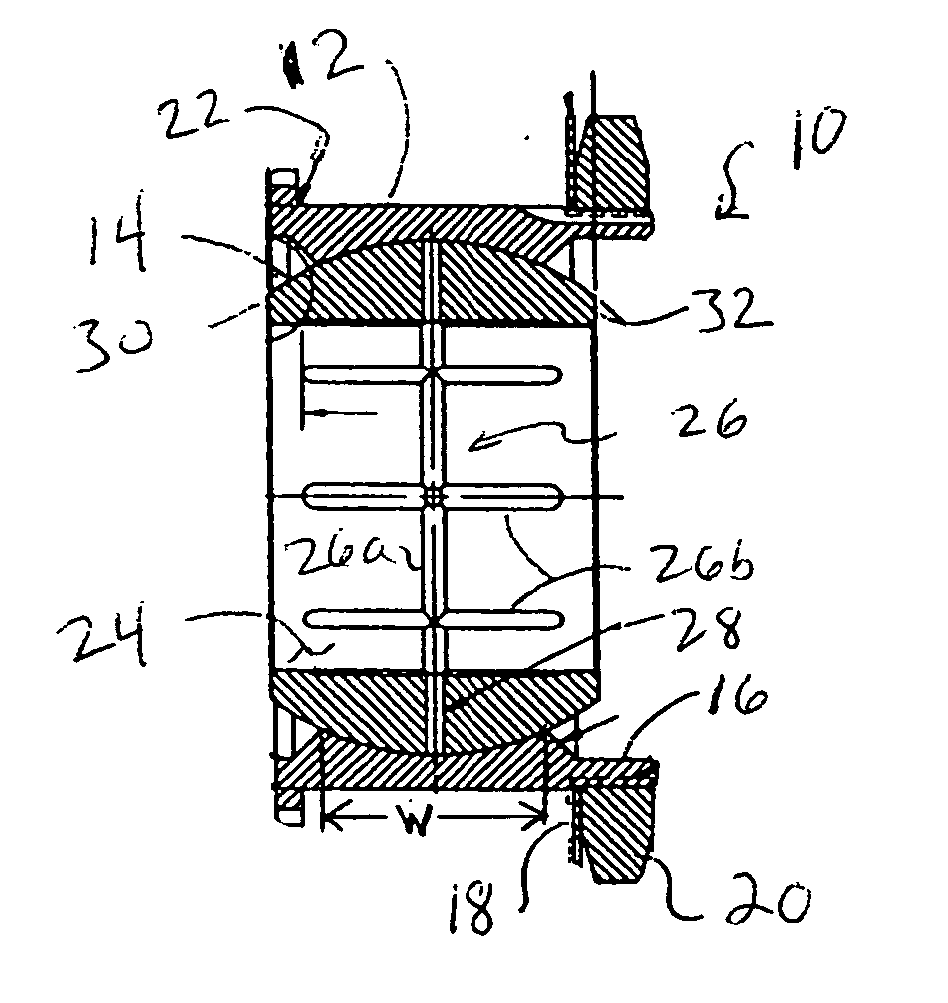

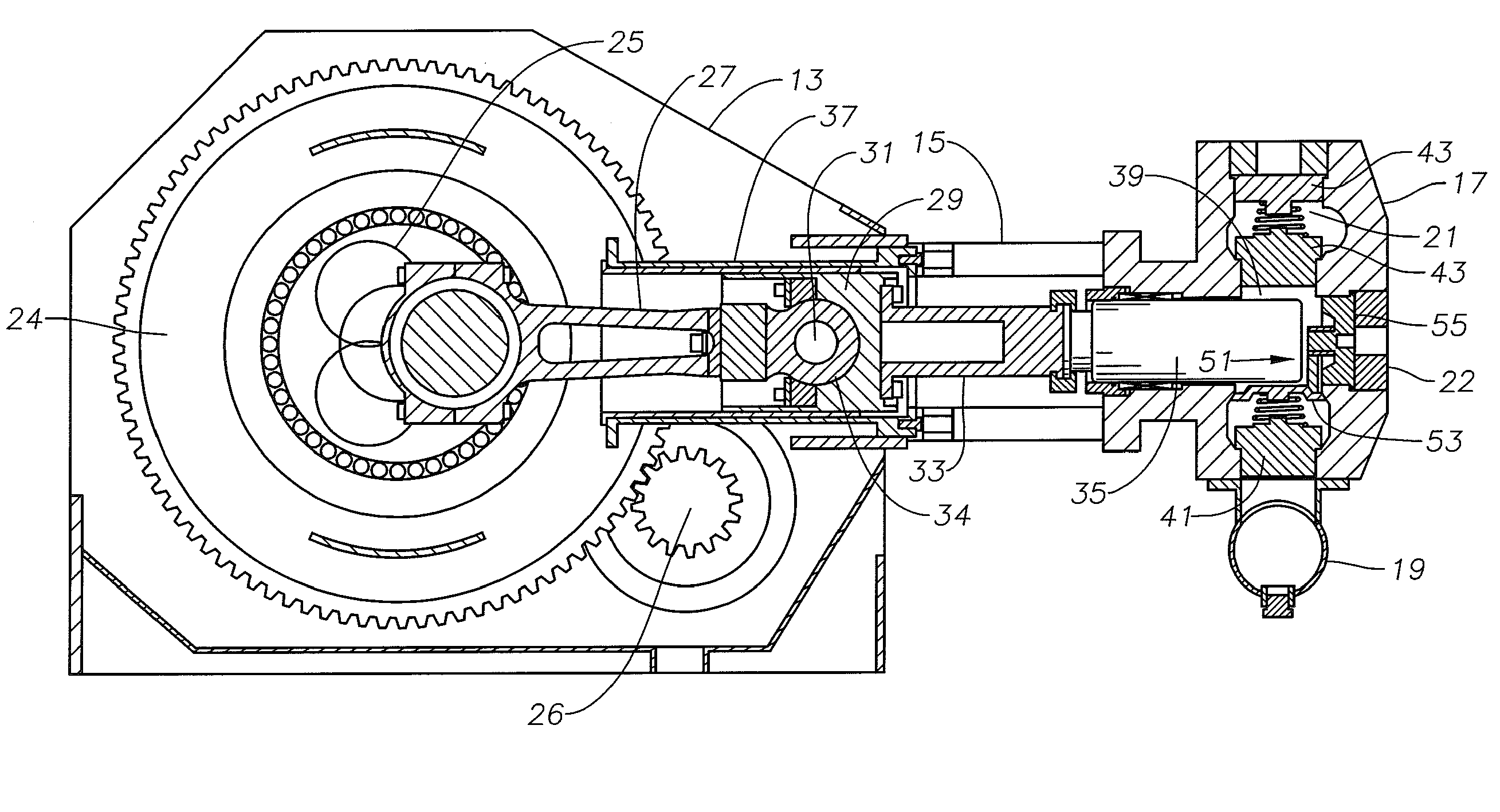

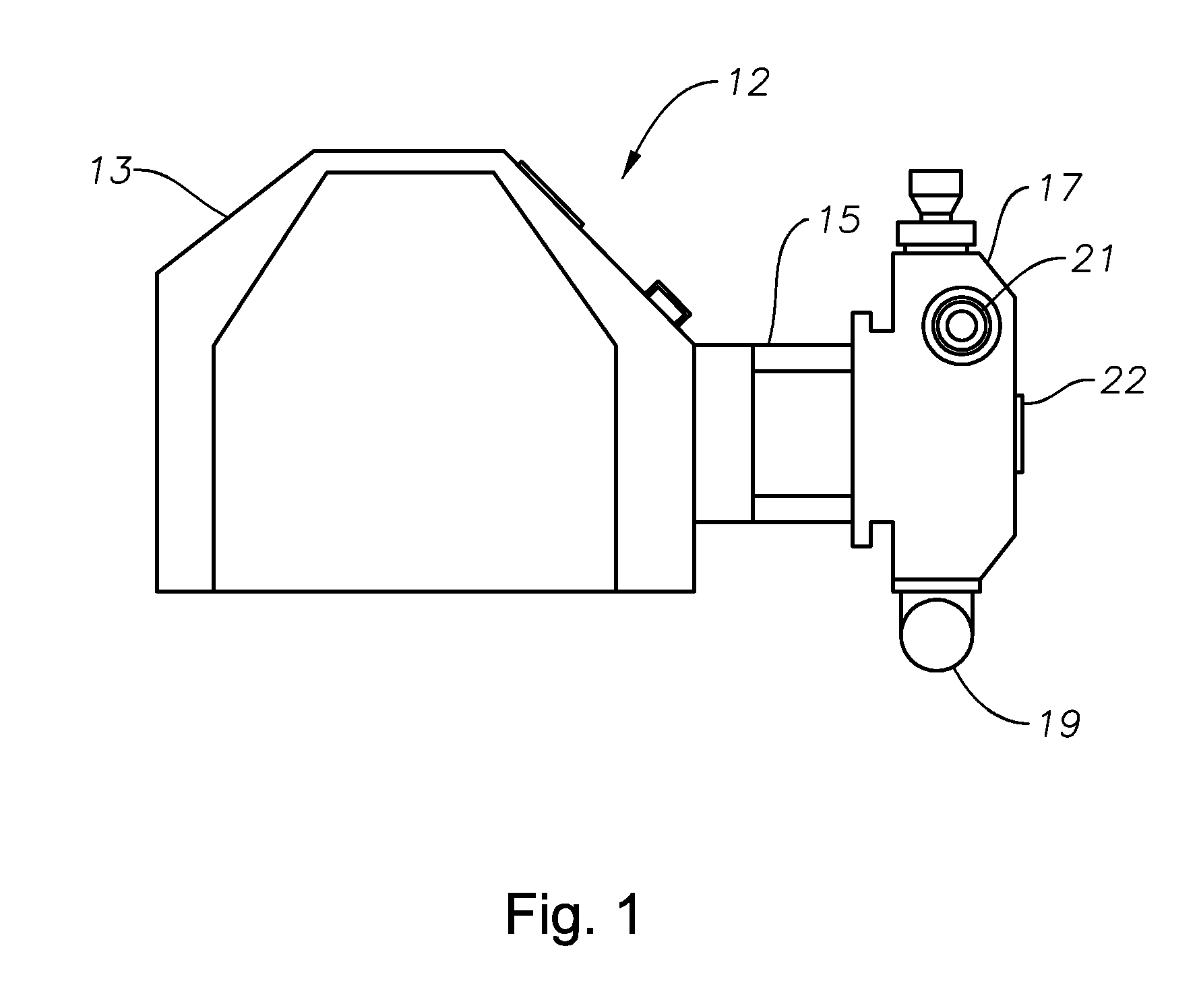

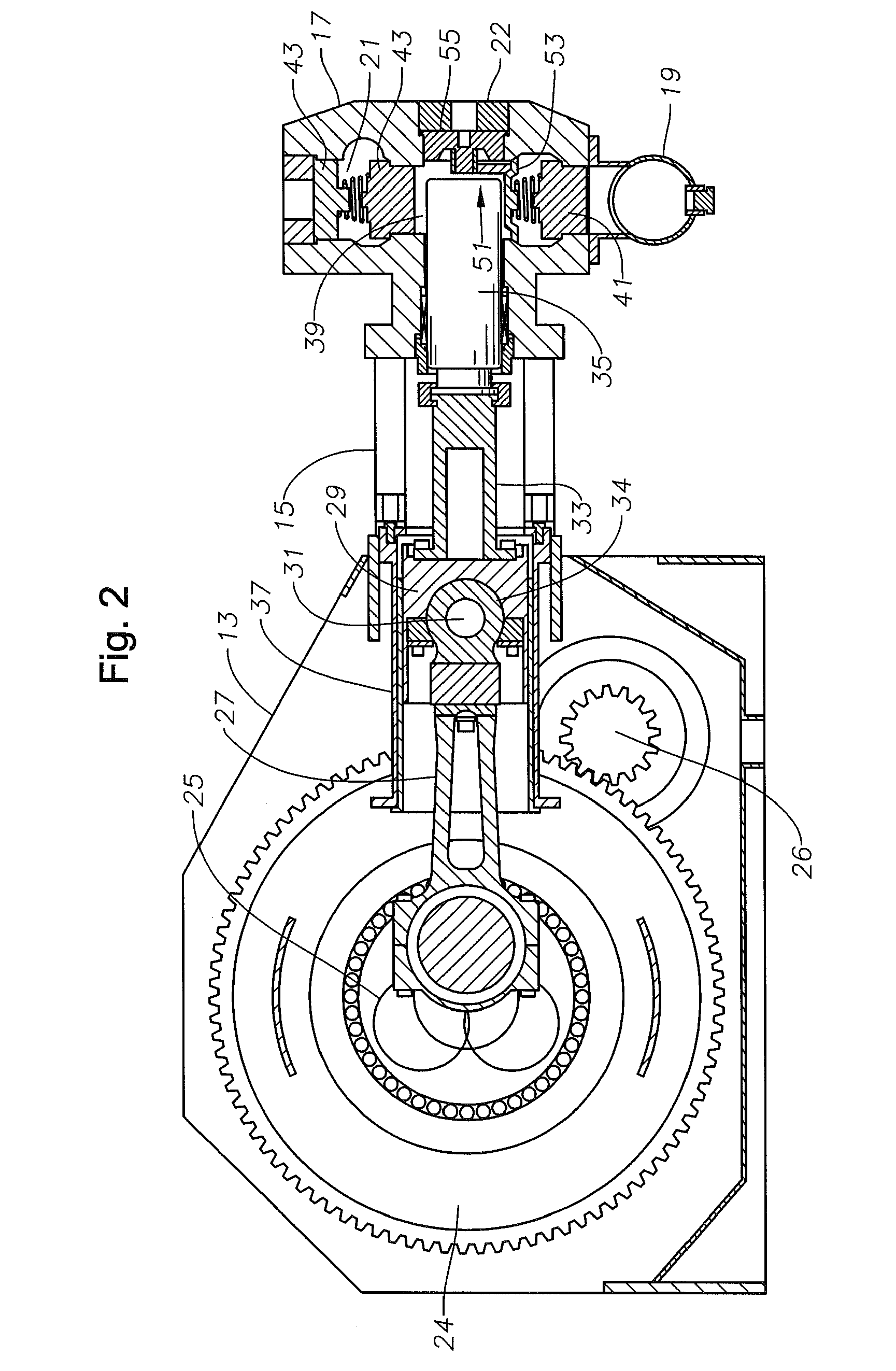

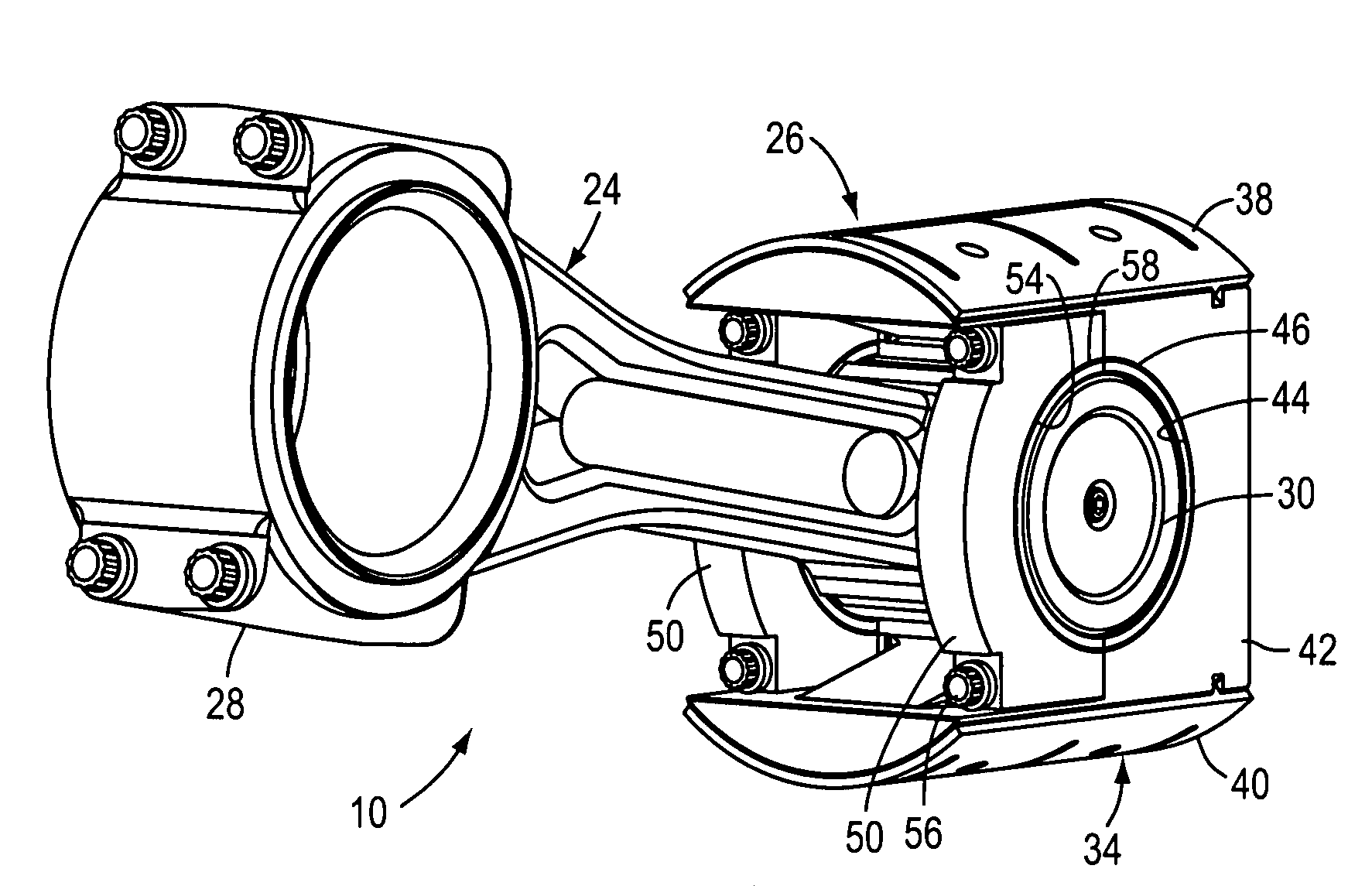

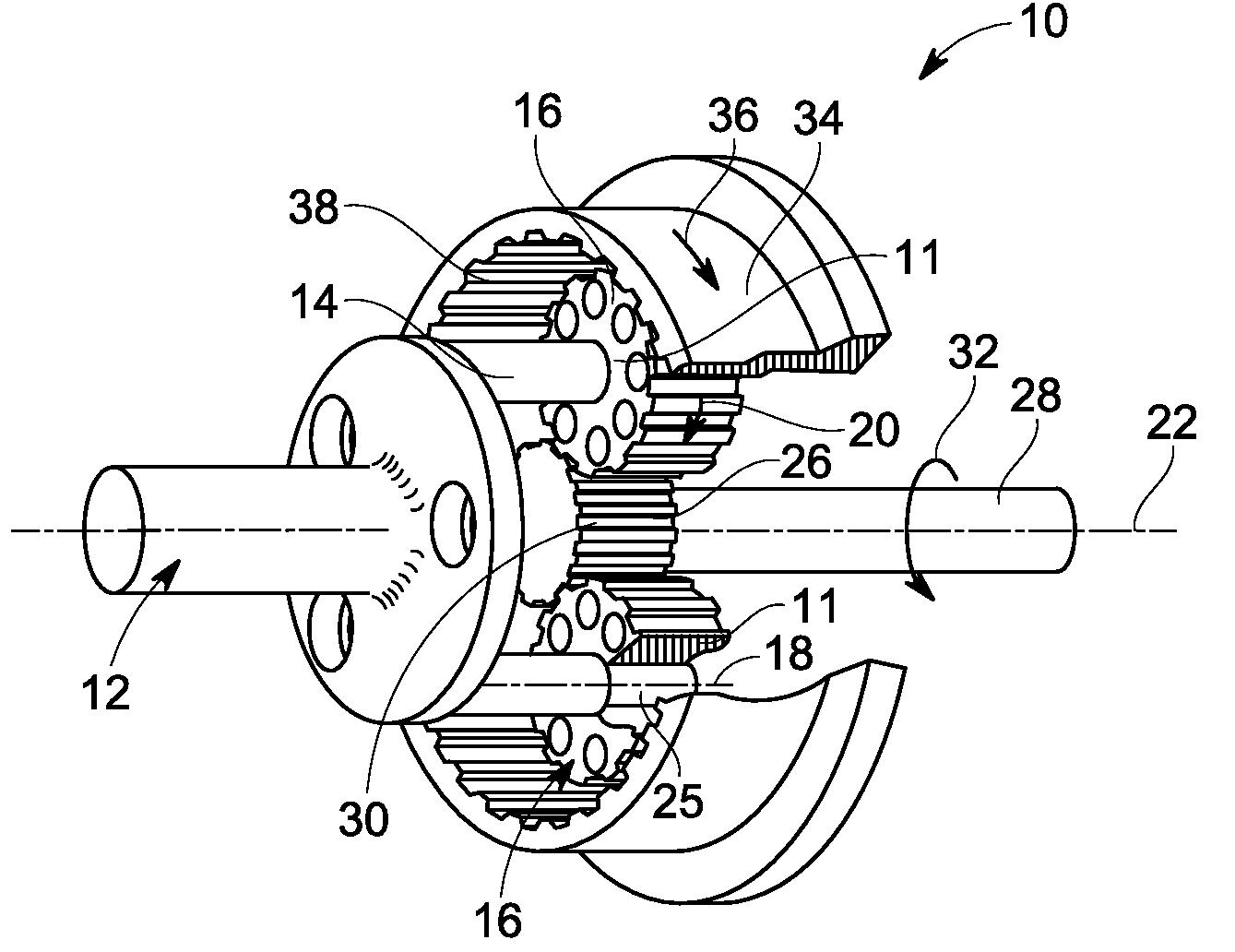

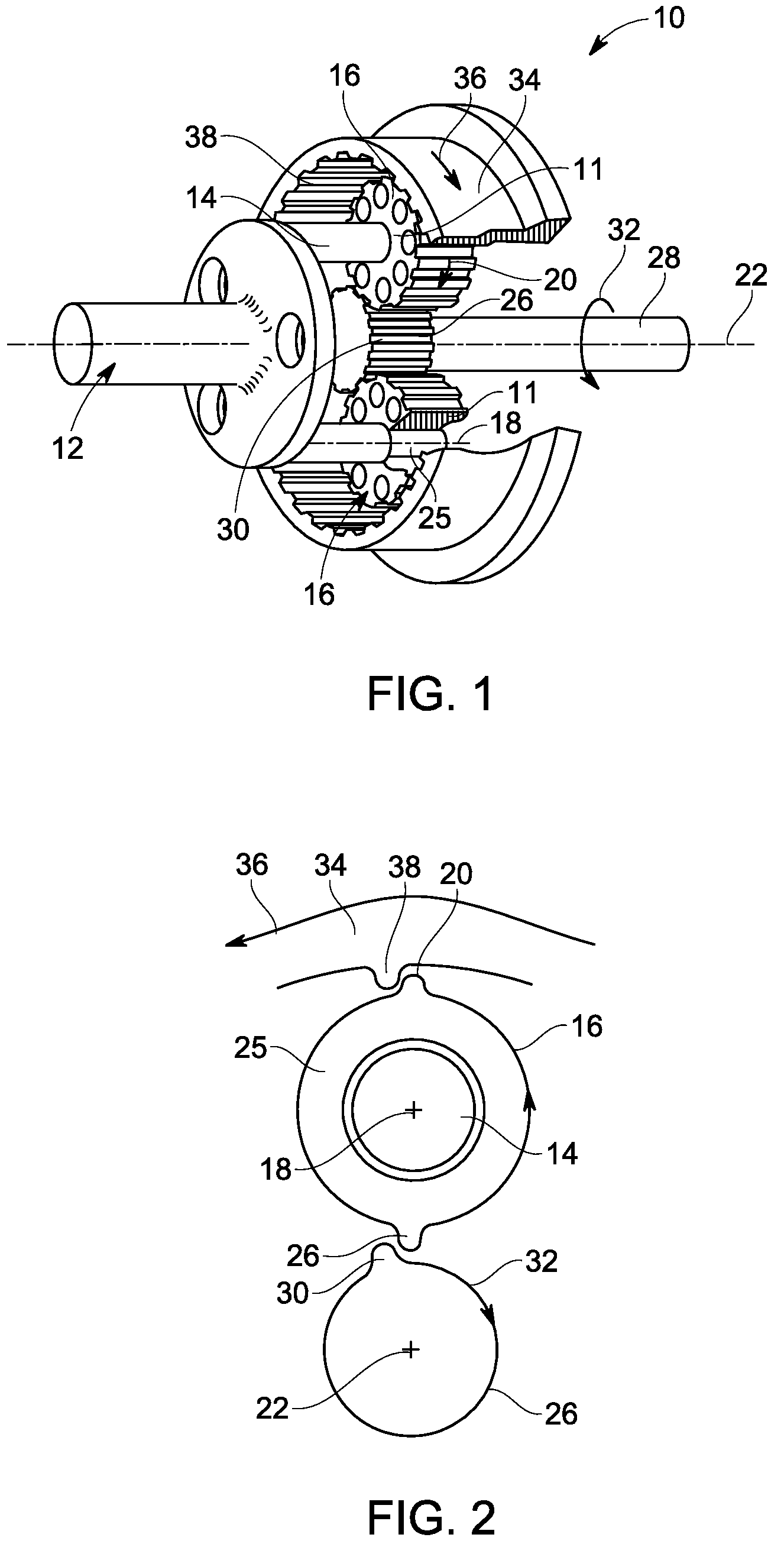

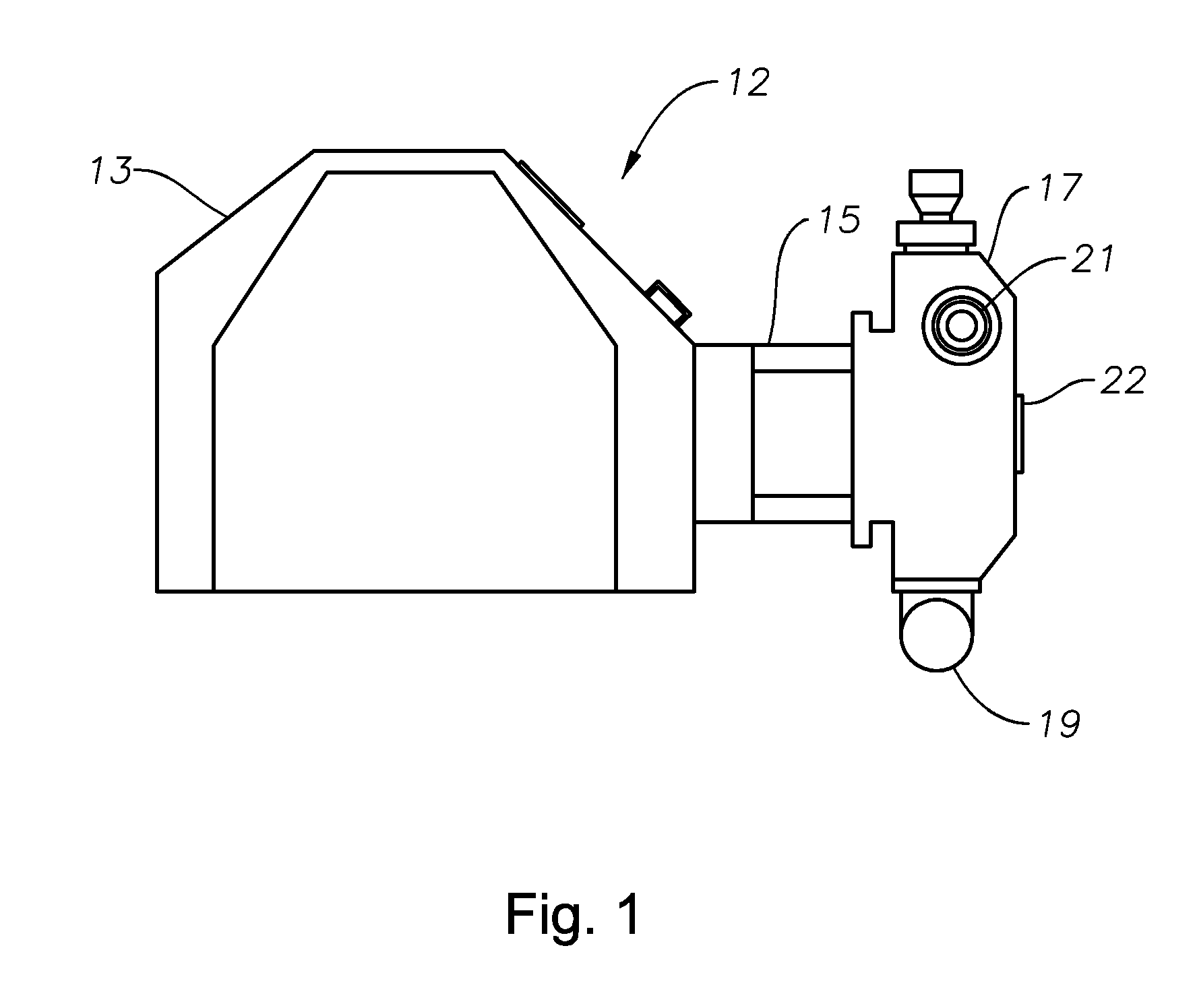

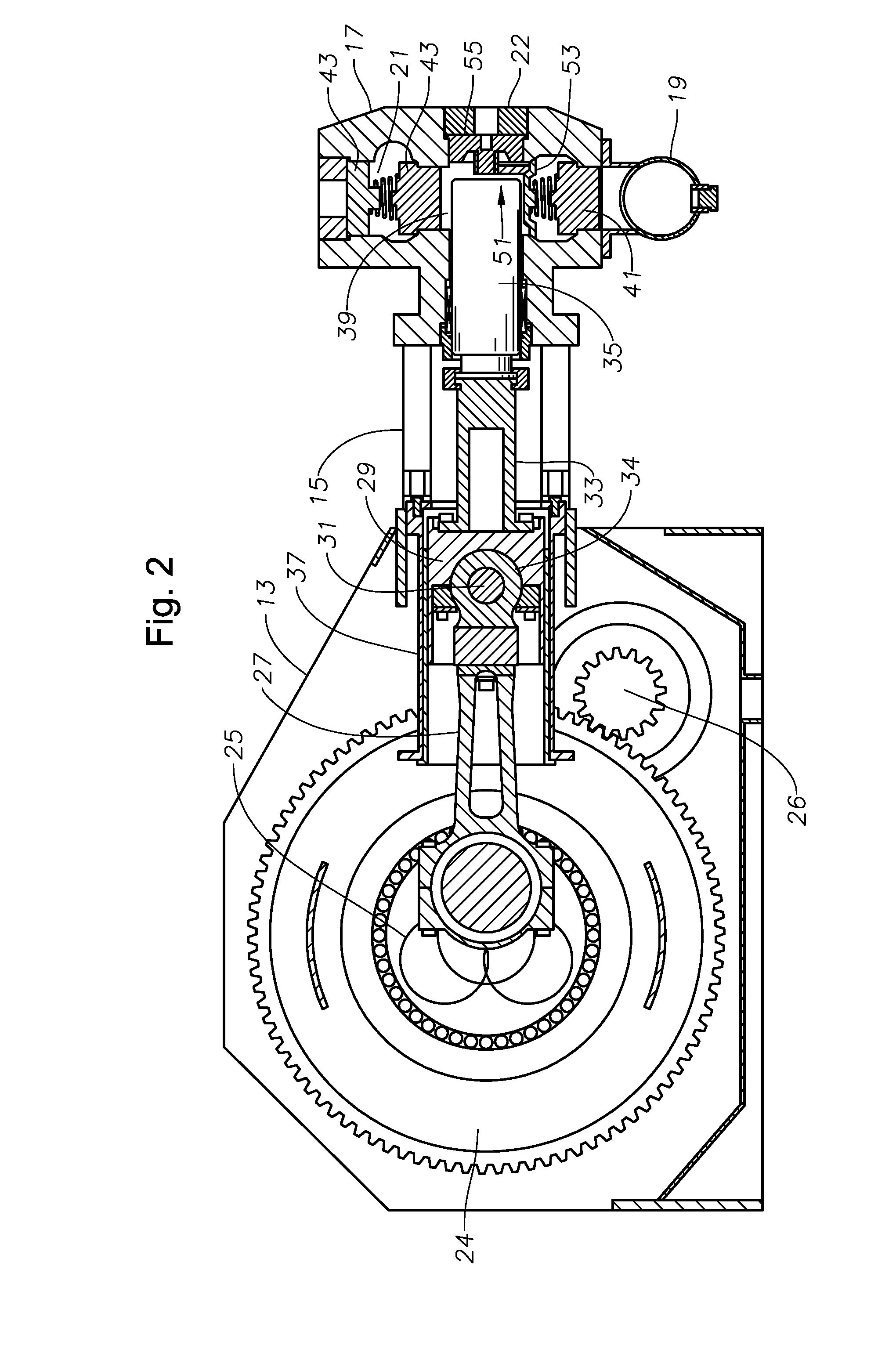

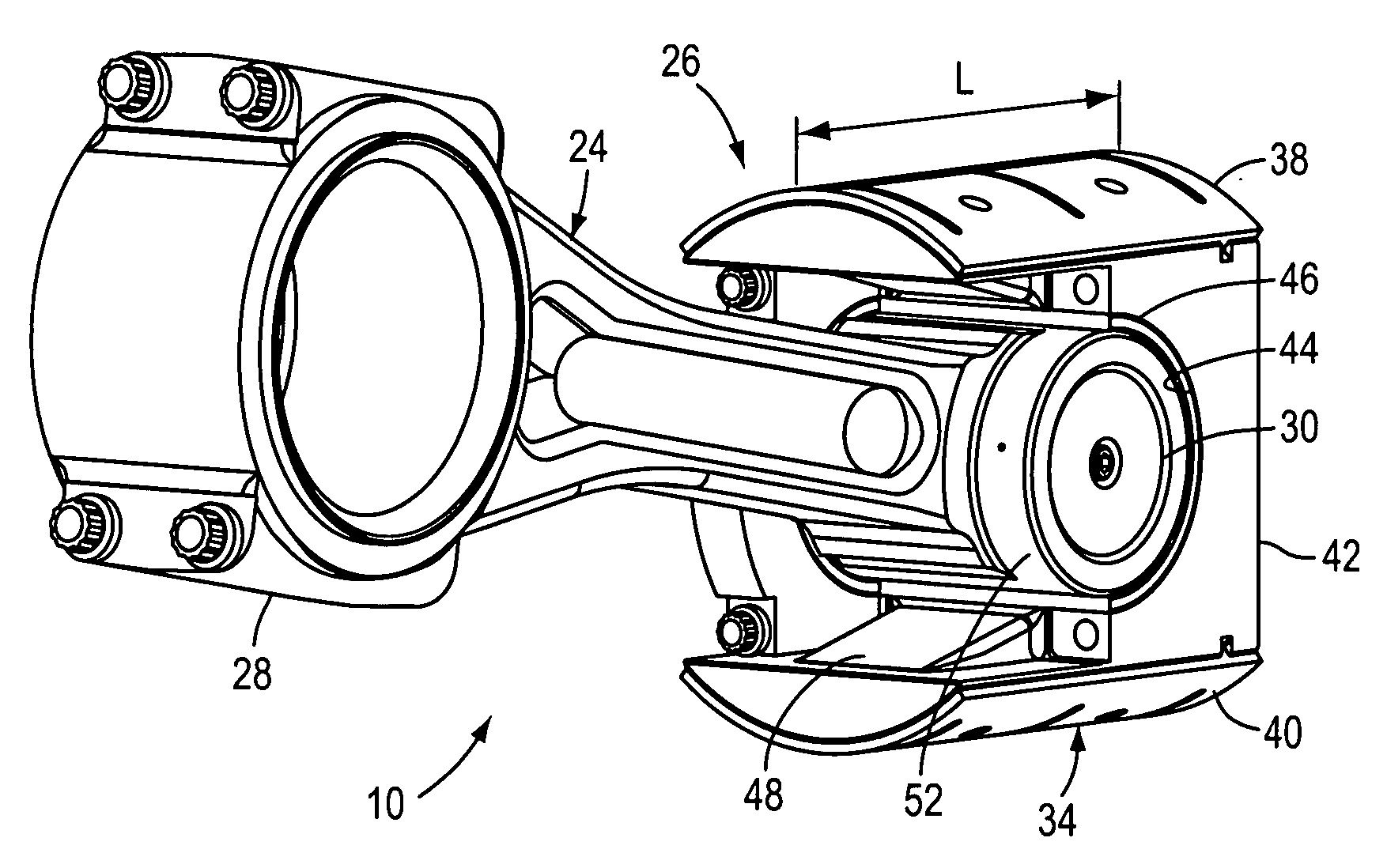

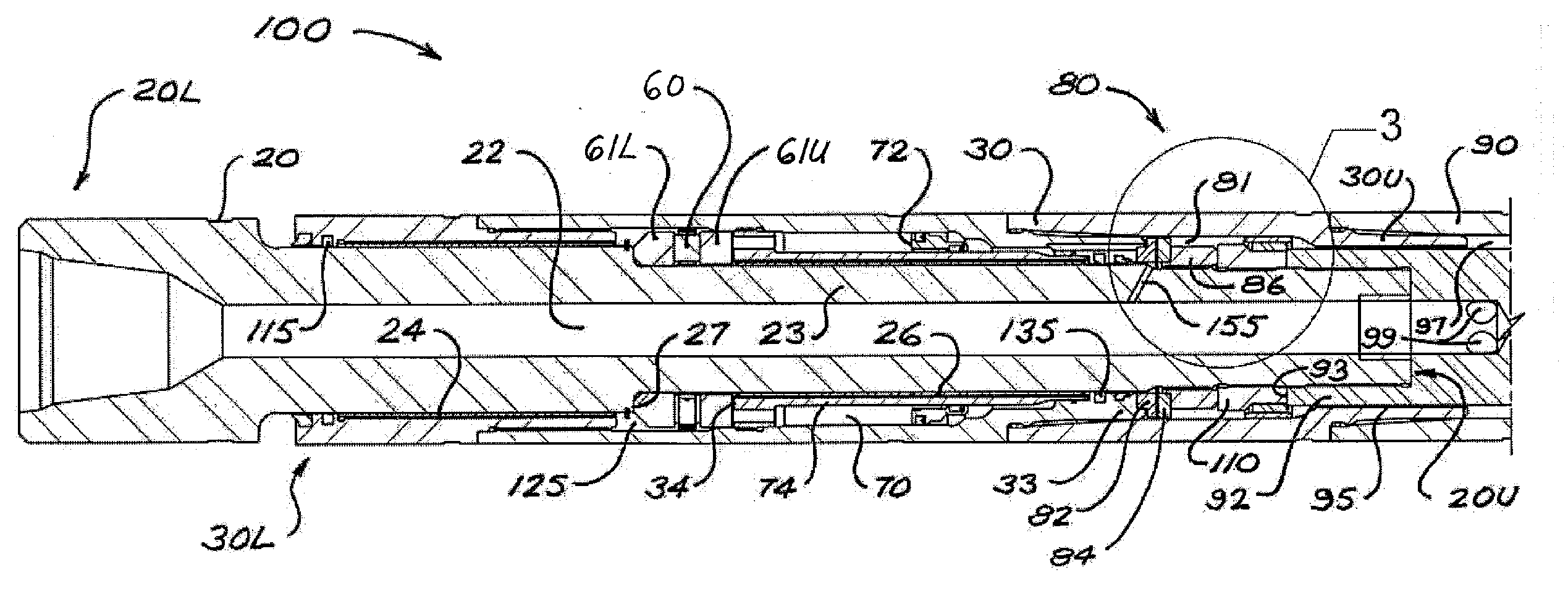

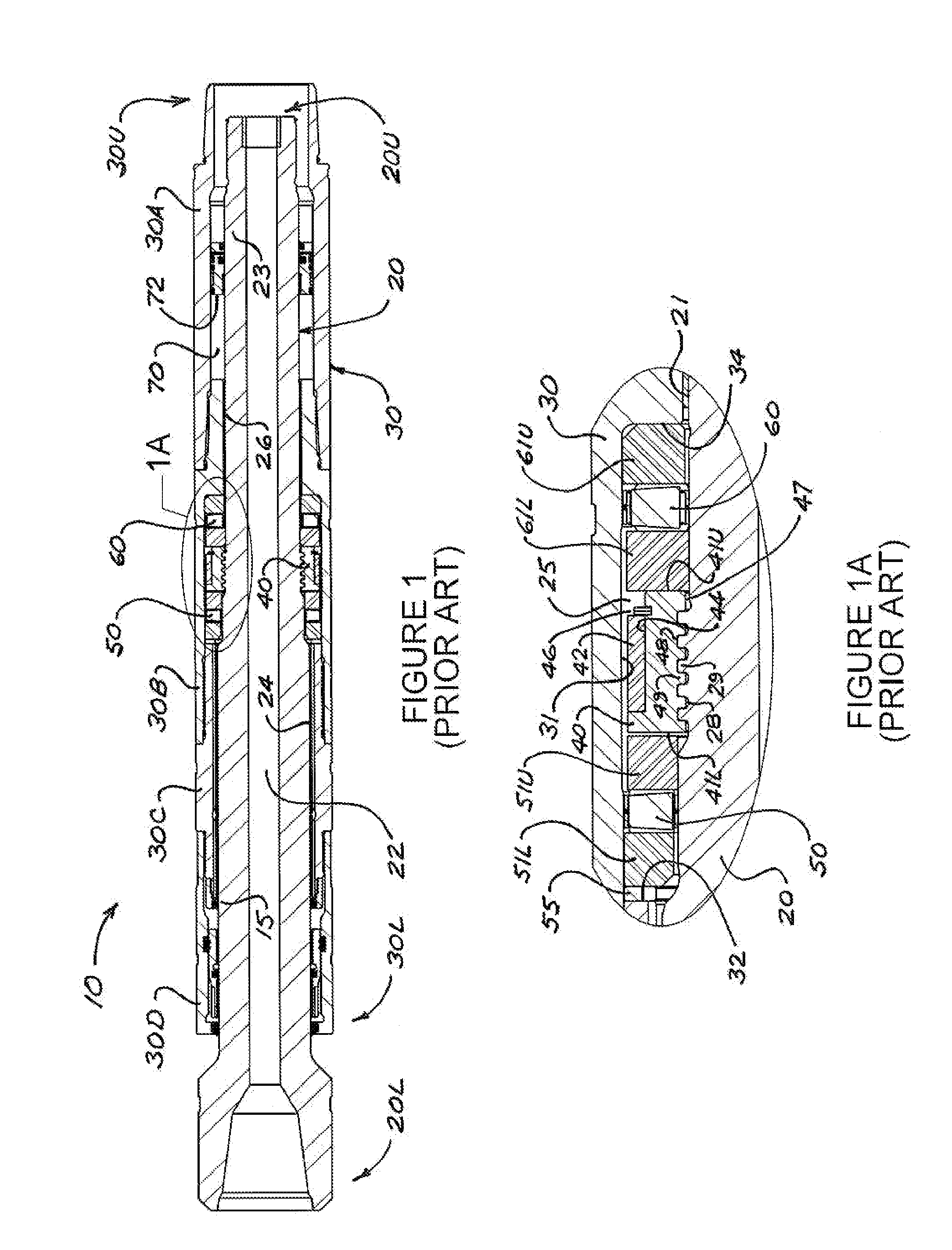

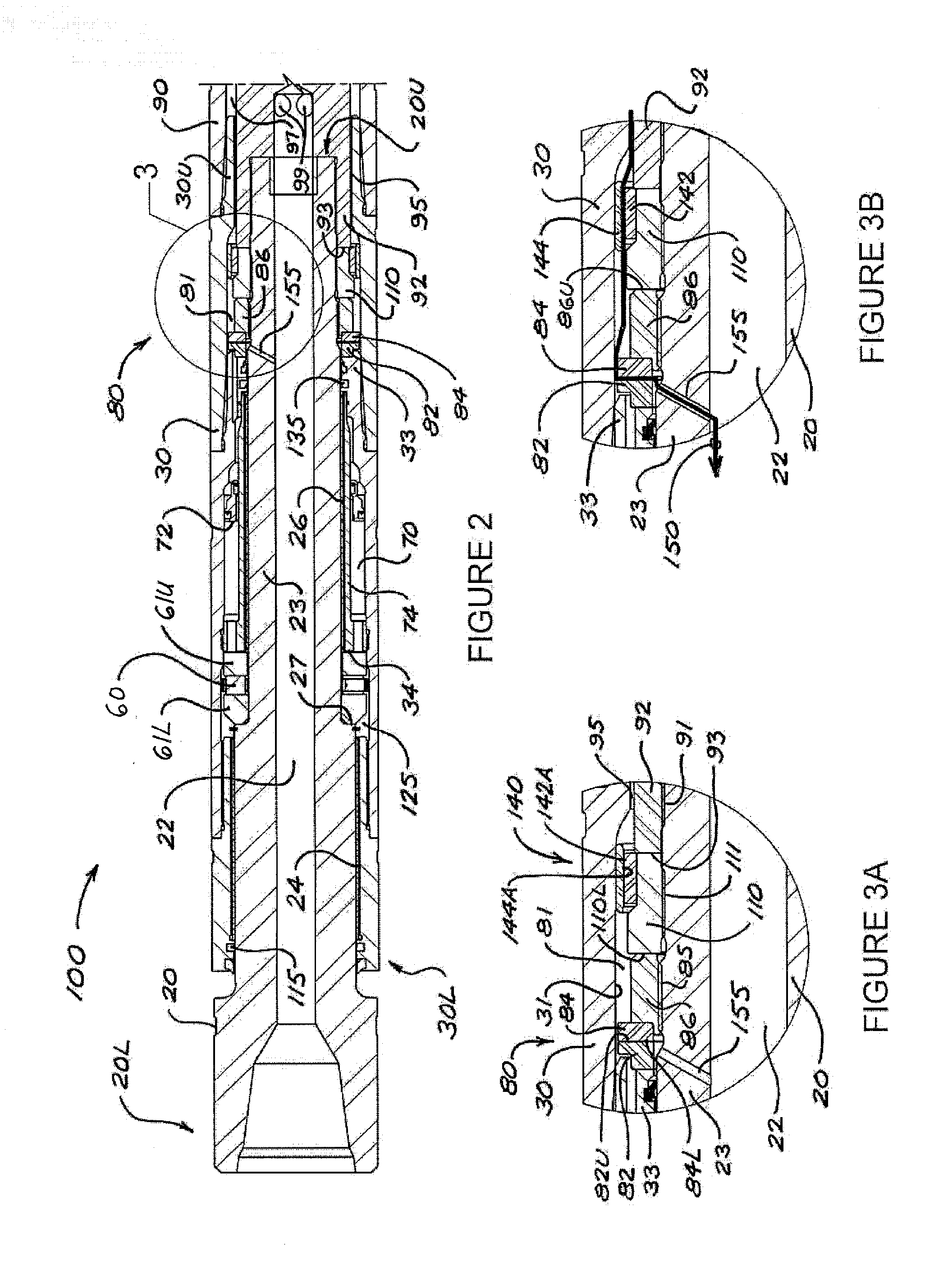

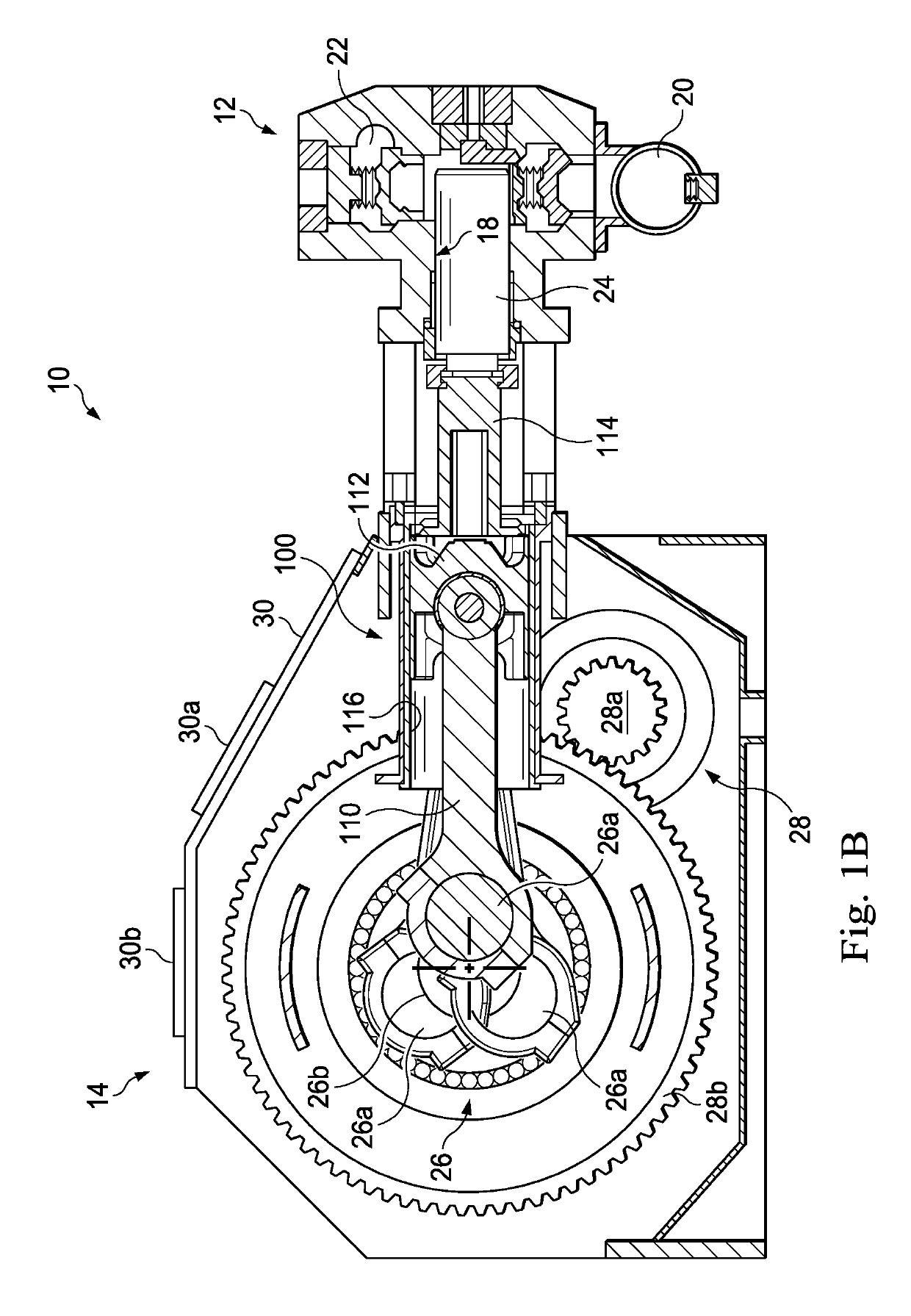

Pump crosshead and connecting rod assembly

ActiveUS7610847B2Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

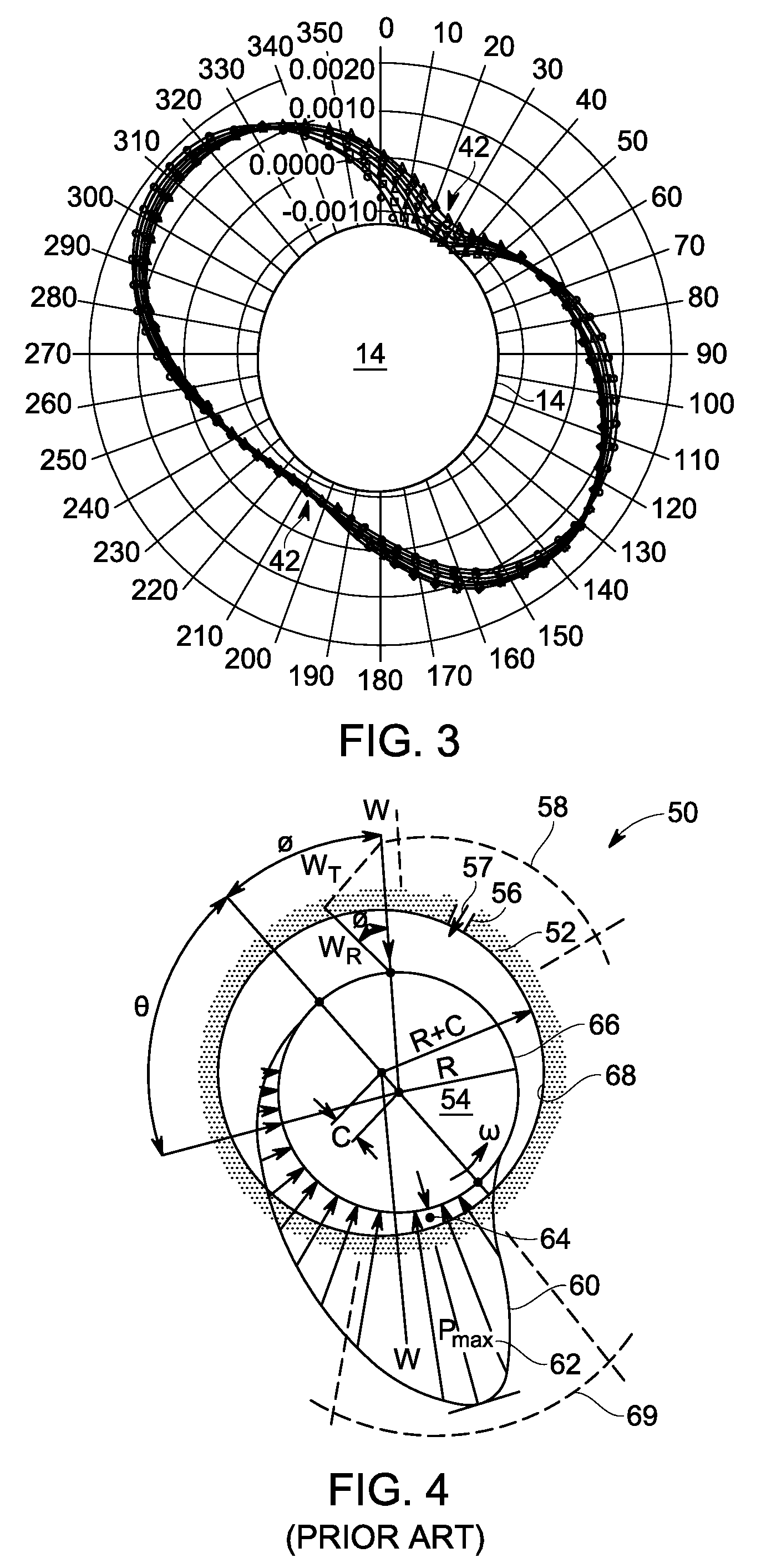

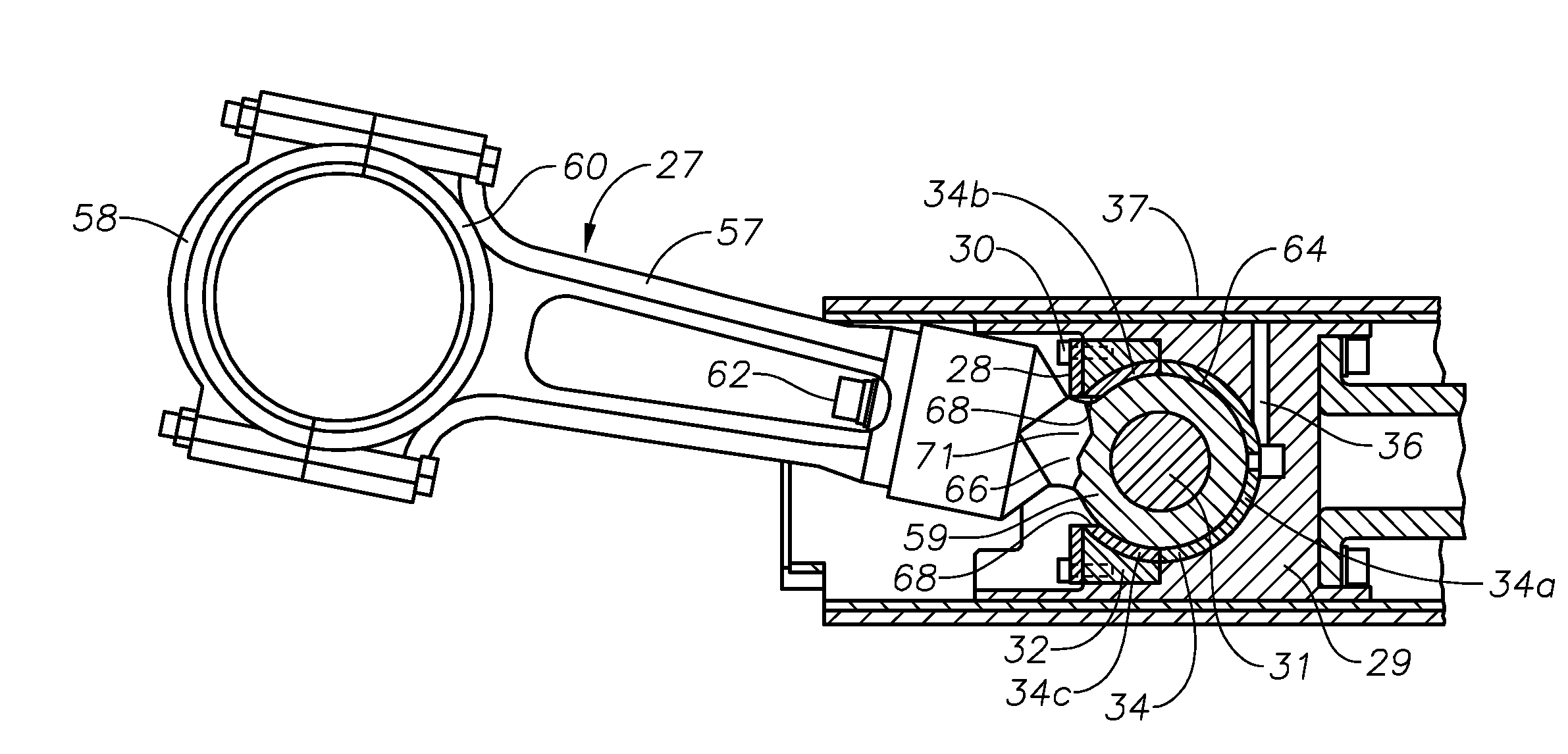

Journal bearing and method of facilitating hydrodynamic oil flow, load capacity and optimization of bearing performance

A journal bearing for use in an epicyclical gearbox including a journal pin, a journal bearing body into which the journal pin is disposed and at least one lubricating fluid inlet. The lubricating fluid inlet is configured to provide for an input of a lubricating fluid in a loaded arc portion proximate at least one high pressure point exerted upon the journal bearing body during a high pressure event, thereby permitting a free flow of a lubricating fluid there between the journal pin and the journal bearing body during the high pressure event. In an embodiment, the journal pin is configured to mimic the shape of the journal bearing body at least at a high pressure point exerted upon the journal bearing body during a high pressure event. An epicyclical gearbox including the journal bearing and method of facilitating a hydrodynamic oil flow in the planet gear journal bearing.

Owner:GENERAL ELECTRIC CO

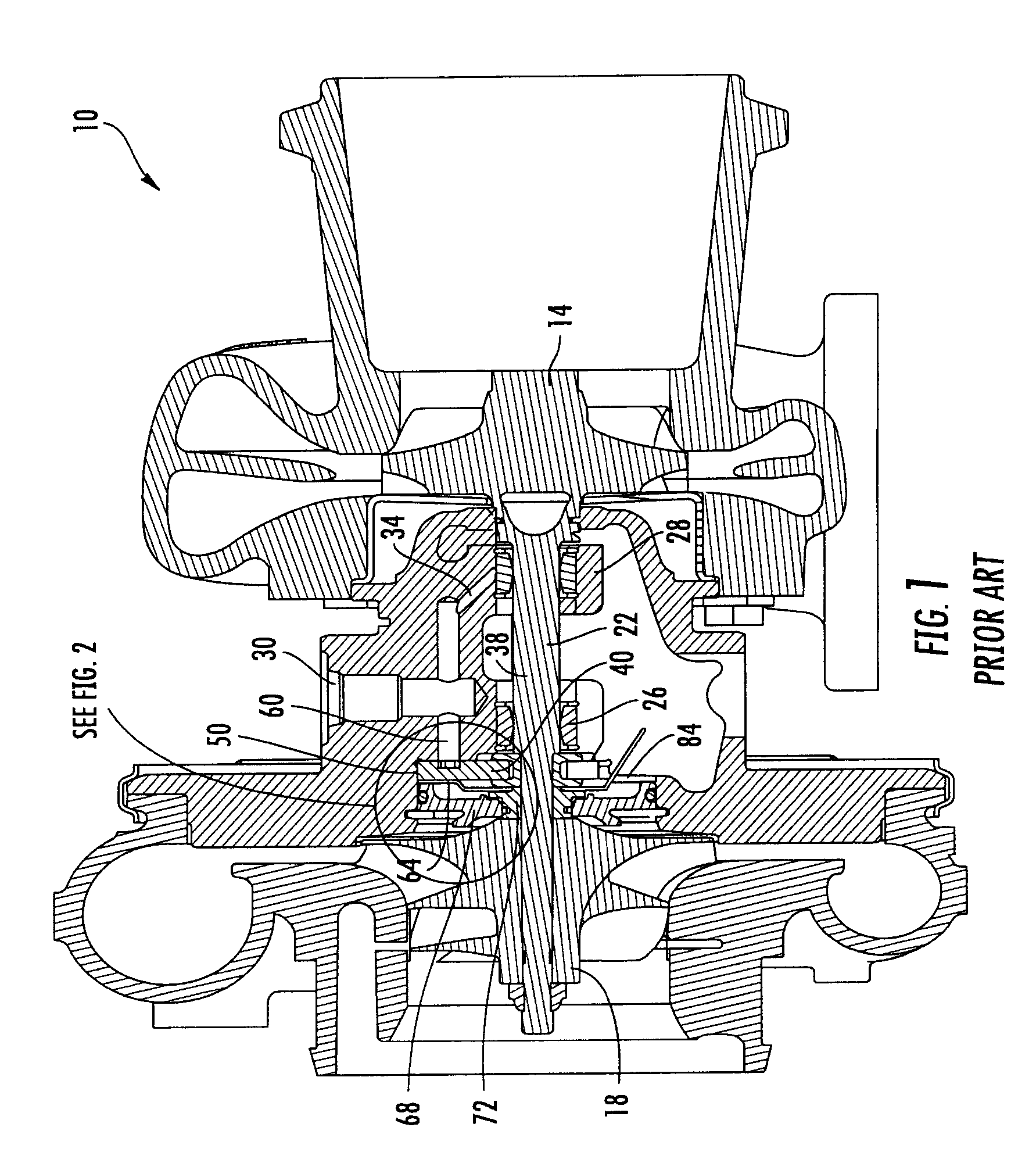

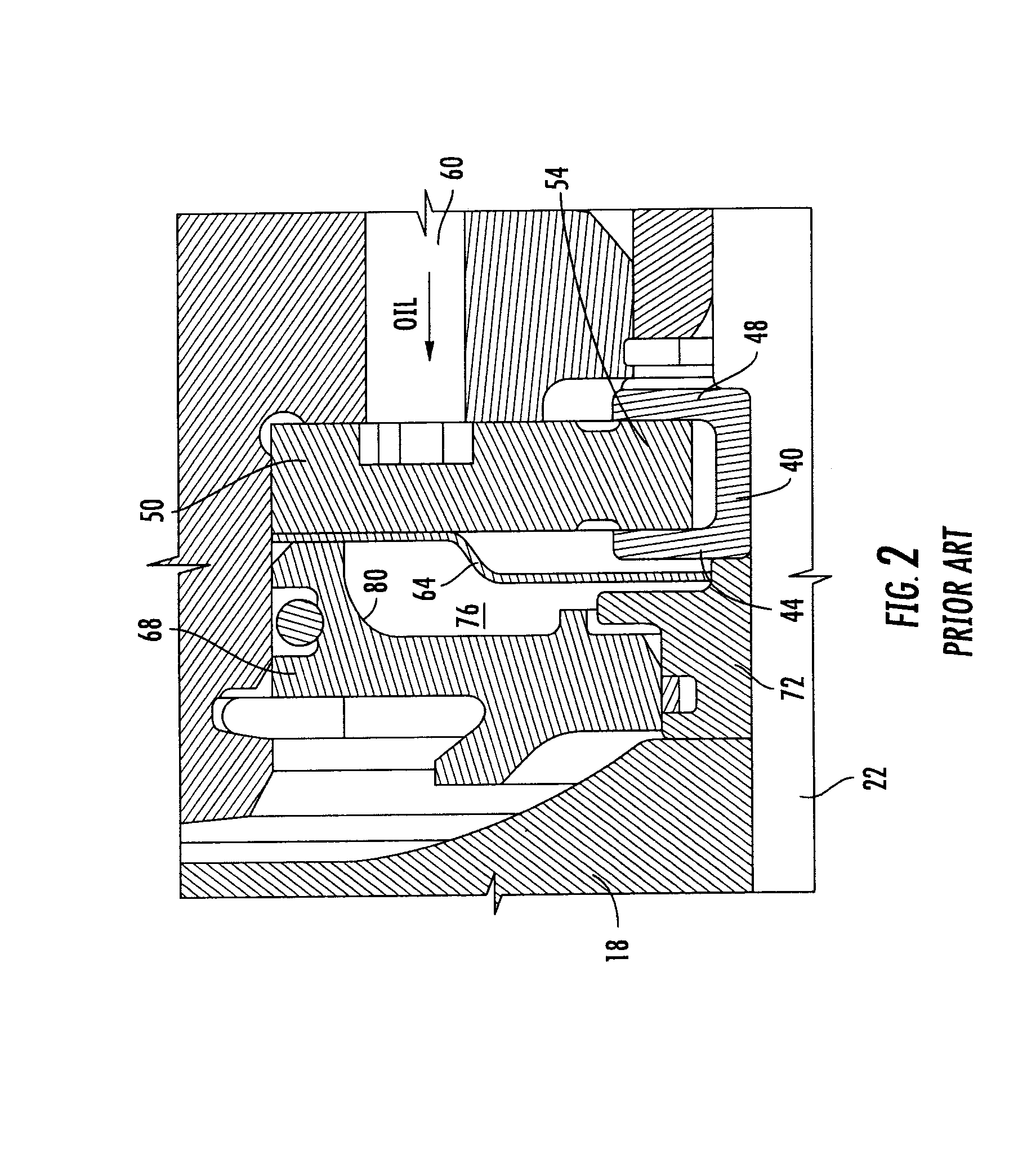

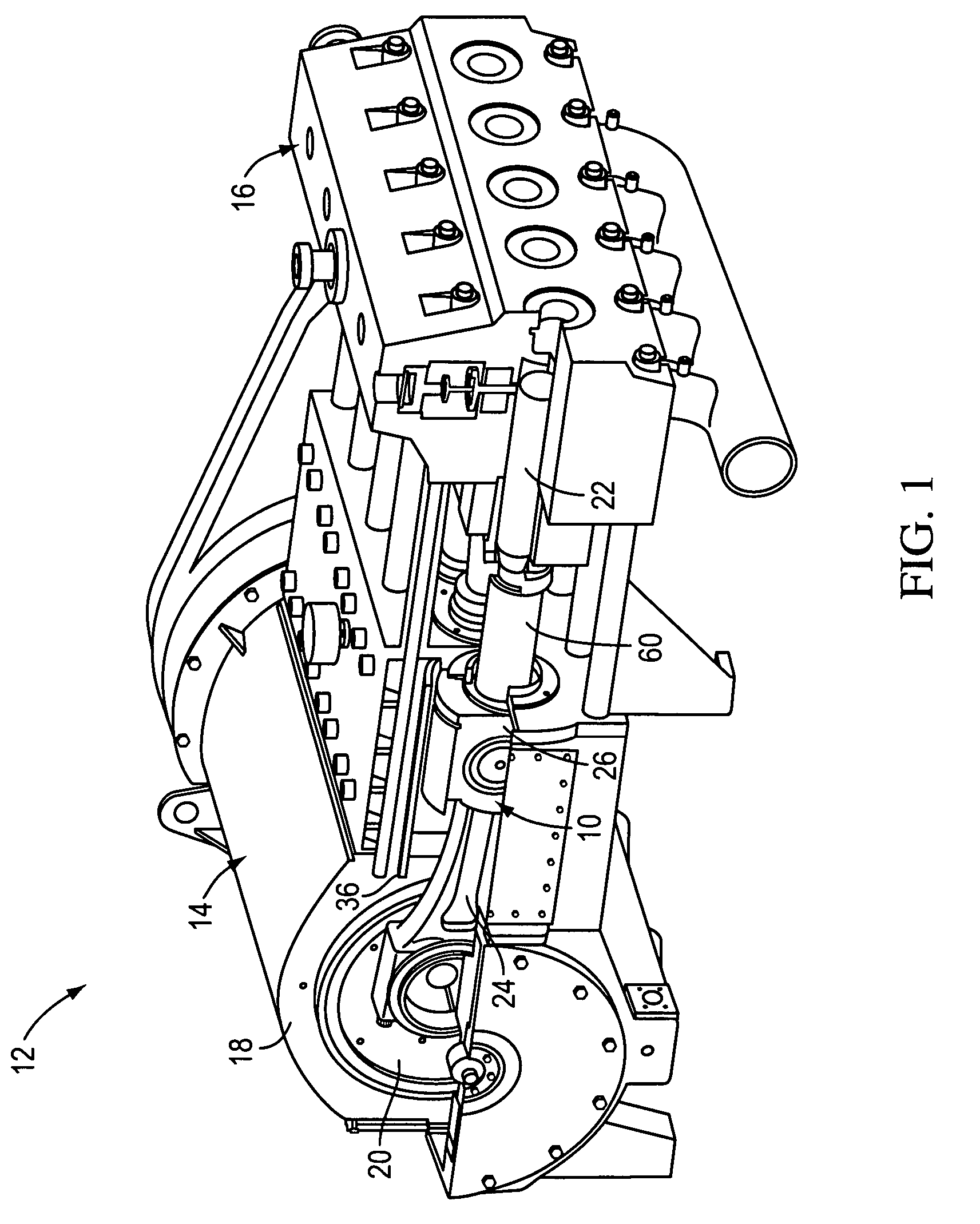

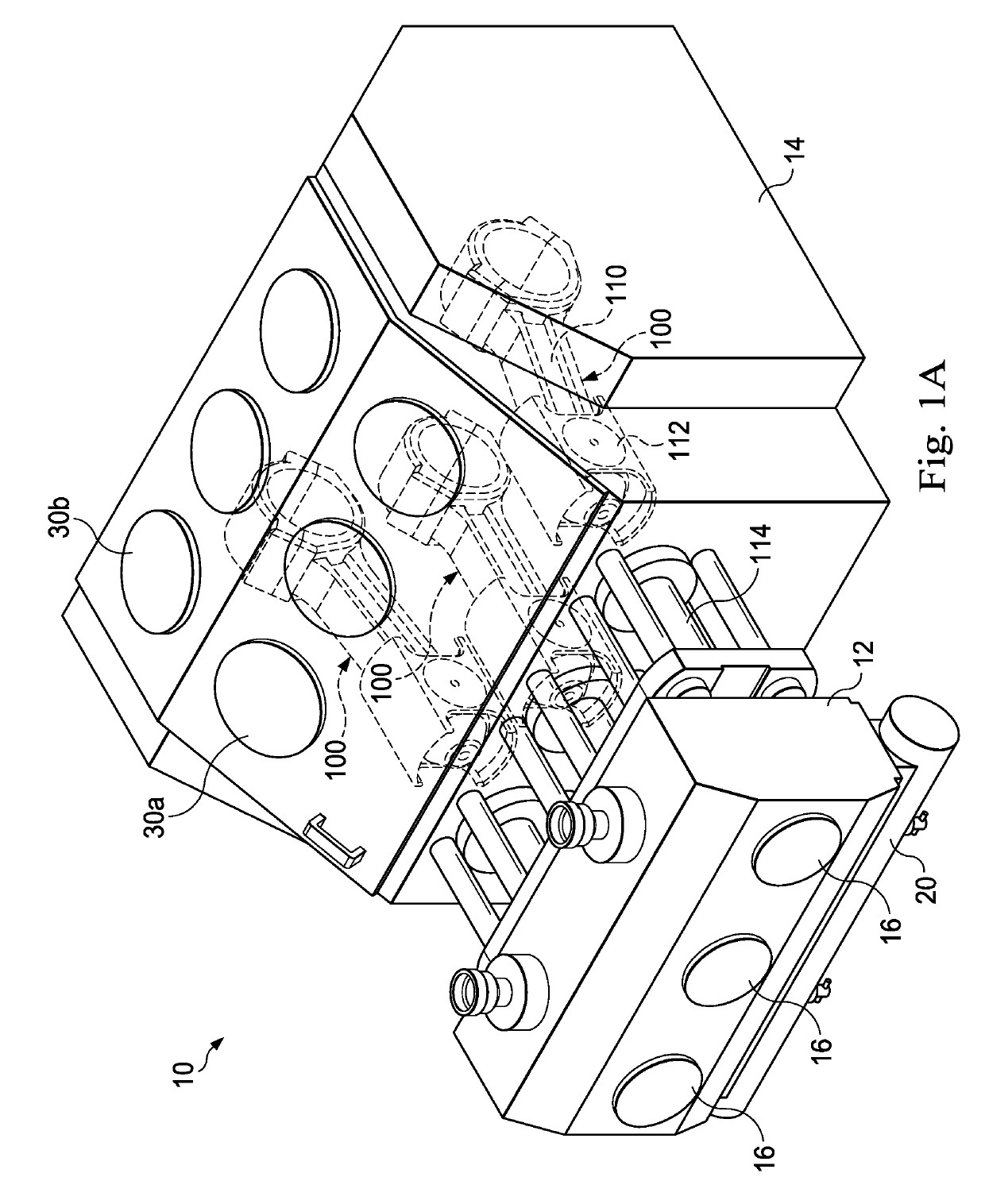

Connecting rod without wrist pin

InactiveUS20100172778A1Reduce weightEliminate needConnecting rod bearingsPositive displacement pump componentsLinear motionEngineering

A reciprocating pump assembly has a pump within a housing. The pump has a crankshaft that rotates and a crosshead that is connected to a plunger via a pony rod. The plunger pumps fluid through cylinders in the pump. A connecting rod connects at one end to the crankshaft and at another end to the crosshead to translate the crankshaft's rotational movement into linear movement of the crosshead and thereby the plunger. The end connected to the crosshead is secured to the crosshead by a bushing located within the crosshead that allows the connecting rod end to pivot during operation. The bushing extends more than 180 degrees, retaining the connecting rod with the crosshead without the need for a wrist pin. The end secured by the bushing can be retained within the bushing by a lock plate, and retainers without the need for a wrist pin.

Owner:WEIR SPM

Pump crosshead and connecting rod assembly

ActiveUS20080006148A1Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

Method of making a sliding bearing

InactiveUS20060288579A1Improve performanceImprove structural strengthCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

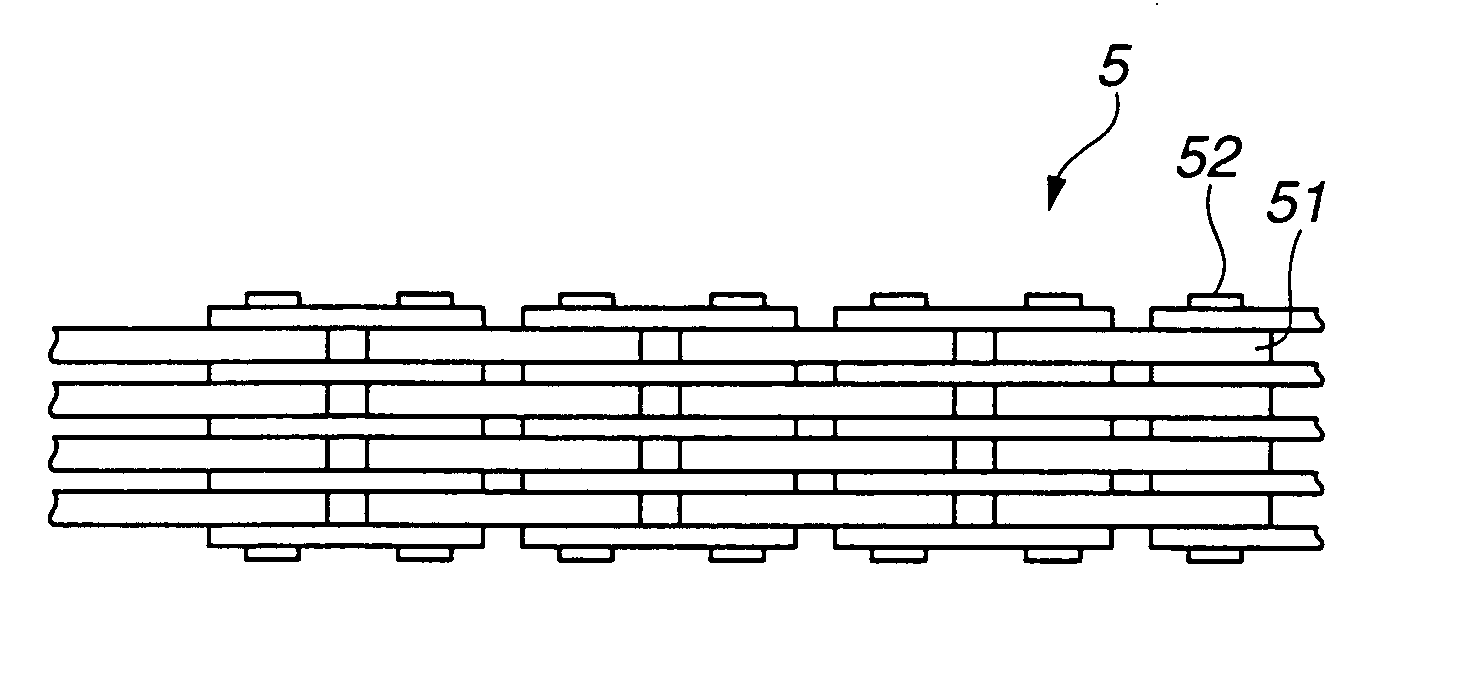

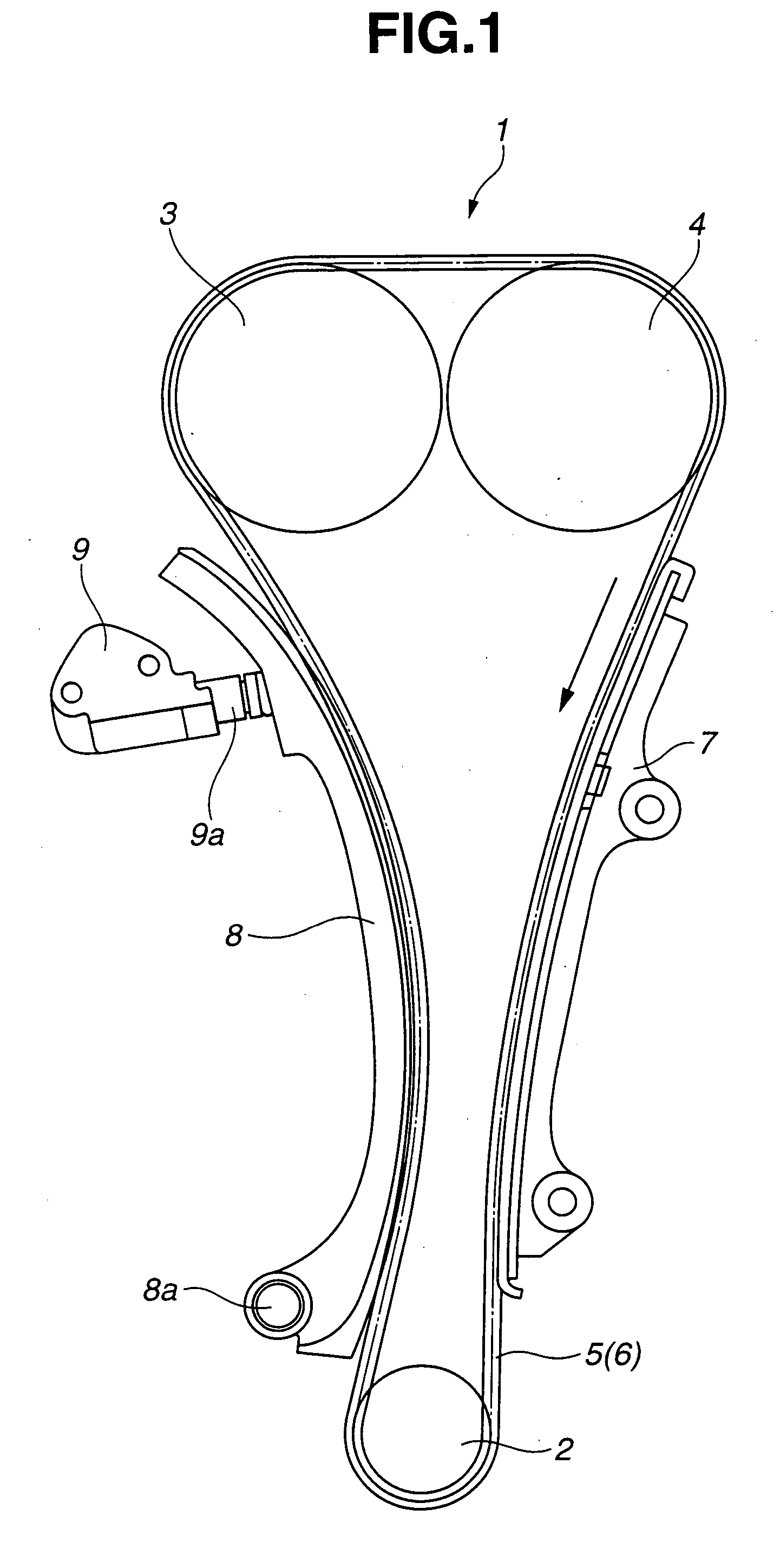

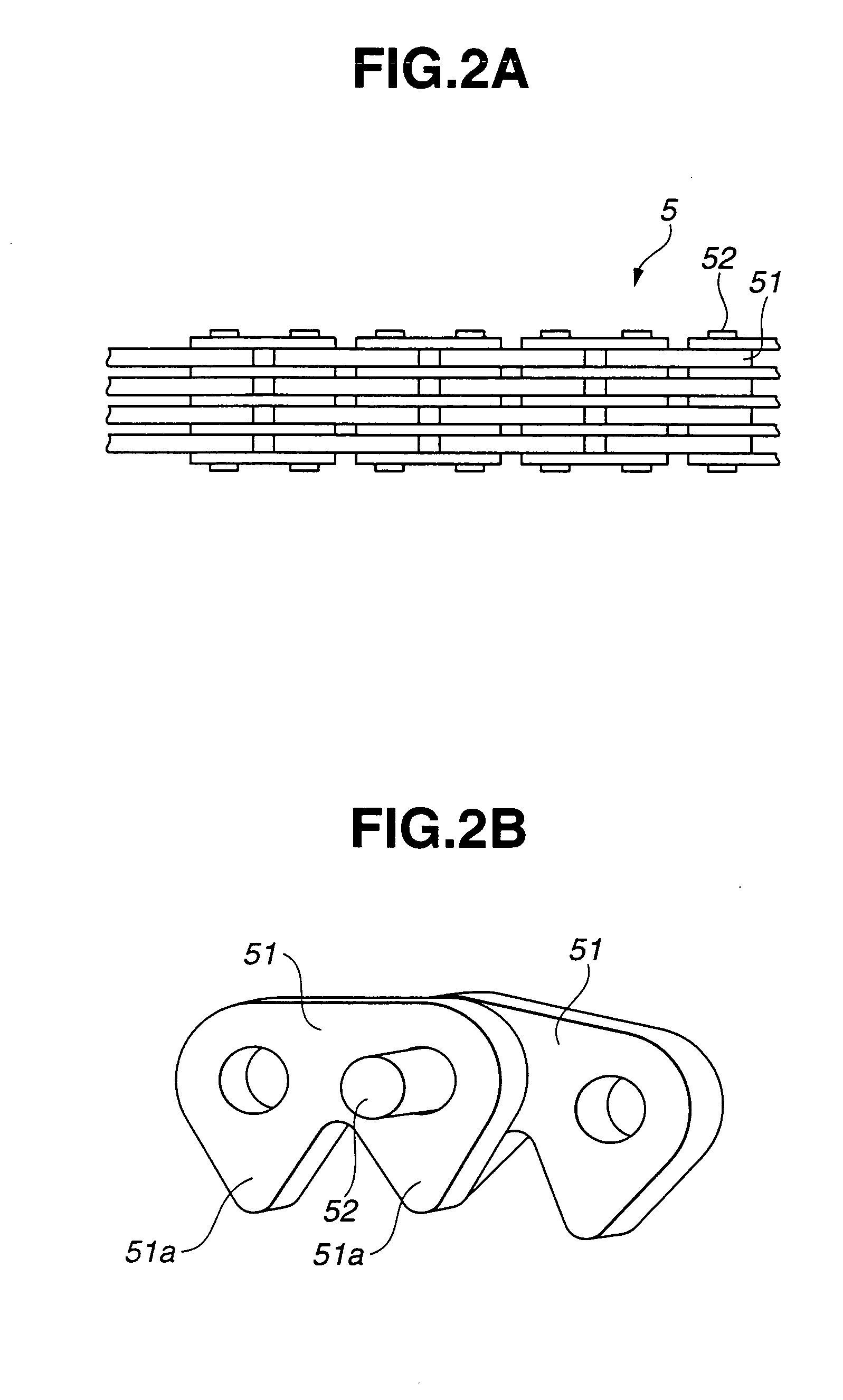

Chain drive system

InactiveUS20050037879A1Avoid excessive frictional resistanceAvoid excessive wearConnecting rod bearingsV-beltsCarbon coatingHydrogen content

A chain drive system includes a drive sprocket, a driven sprocket and a chain looped over the drive sprocket and the driven sprocket. The chain and the sprocket having respective sliding surfaces slidable relative to each other in the presence of lubricating oil, and any adjacent chain components of the chain having respective sliding surfaces slidable relative to each other in the presence of lubricating oil. At least one of the sliding surfaces between the chain and the sprocket and at least one of the sliding surfaces between any adjacent chain components have hard carbon coatings formed on base portions thereof. Each of the hard carbon coatings has a hydrogen content of 10 atomic % or less.

Owner:NISSAN MOTOR CO LTD

Bearing structure of turbocharger

InactiveUS8628247B2Reduce rotation speedReduce vibrationCrankshaftsBearing assemblyTurbochargerMechanical engineering

Owner:TOYOTA IND CORP

Oil-Sealed Mud Motor Bearing Assembly With Mud-Lubricated Off-Bottom Thrust Bearing

ActiveUS20120195542A1Shorten the lengthControl loadCrankshaftsRoller bearingsDrive shaftThrust bearing

A bearing assembly for a mud motor has a mandrel rotatably disposed within a cylindrical housing, with a rolling-element thrust bearing disposed within an oil-sealed annular chamber between the mandrel and the housing, for resisting on-bottom axial thrust loads. Off-bottom axial thrust loads are resisted by a mud-lubricated thrust bearing assembly located above the oil-sealed chamber. The lower end of a drive shaft adapter coupled to the mandrel is used to provide an upper load-transferring shoulder for the off-bottom thrust bearing, with a lower load-transferring shoulder being provided in association with the housing. The upper and lower shoulders come into mating contact under off-bottom thrust loading, with the upper shoulder rotatable (with the mandrel) relative to the lower shoulder.

Owner:NAT OILWELL VARCO LP

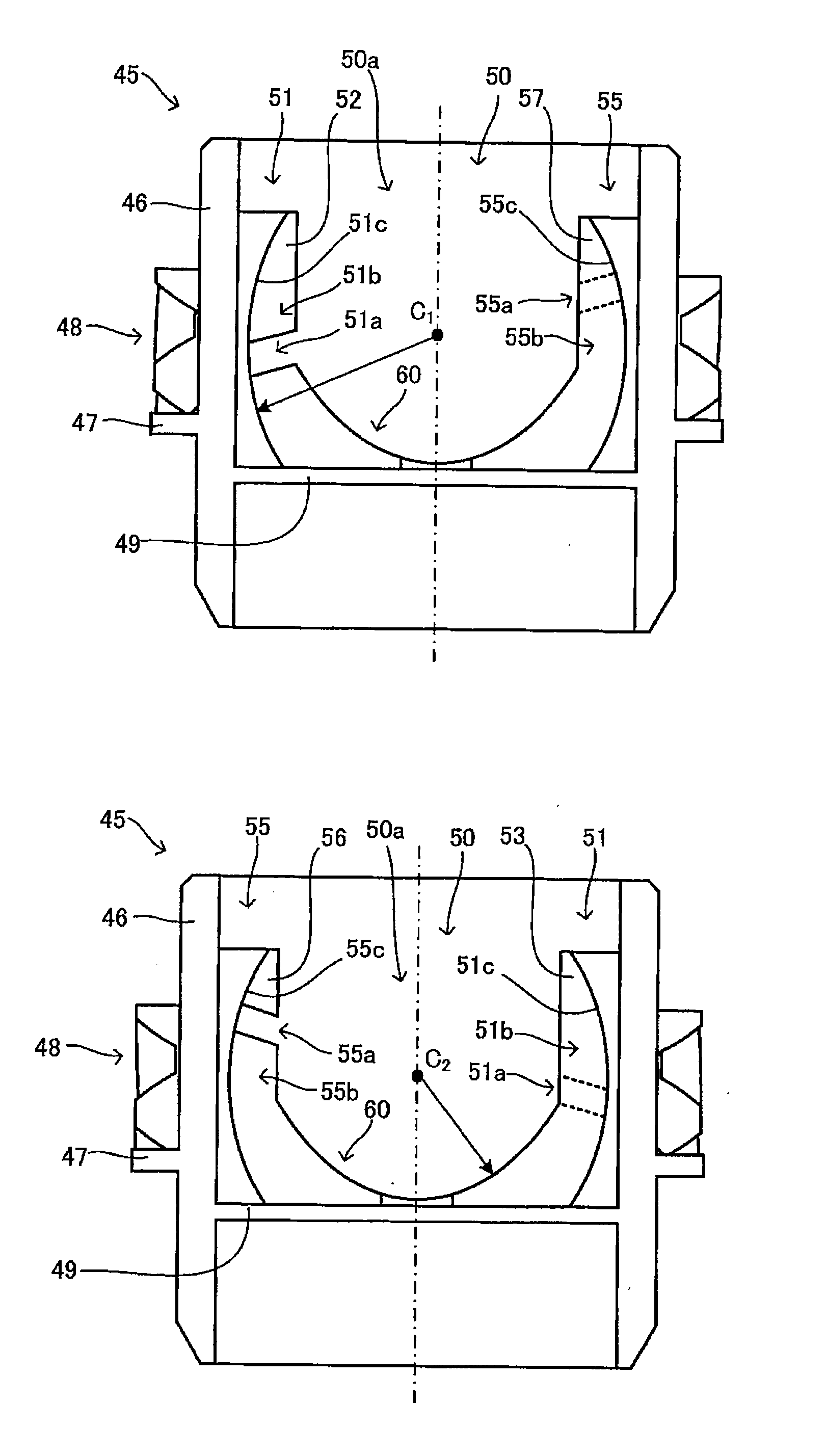

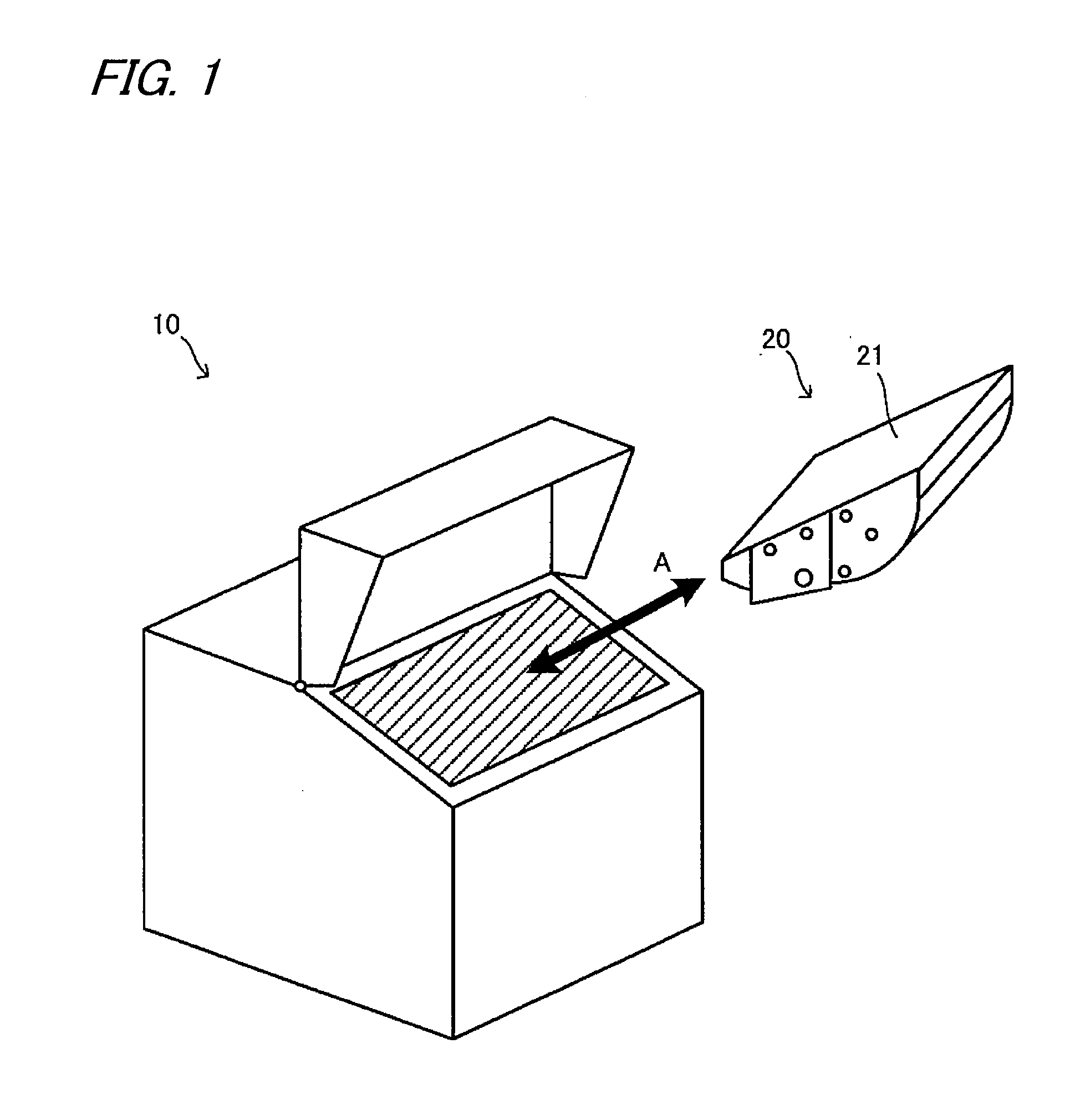

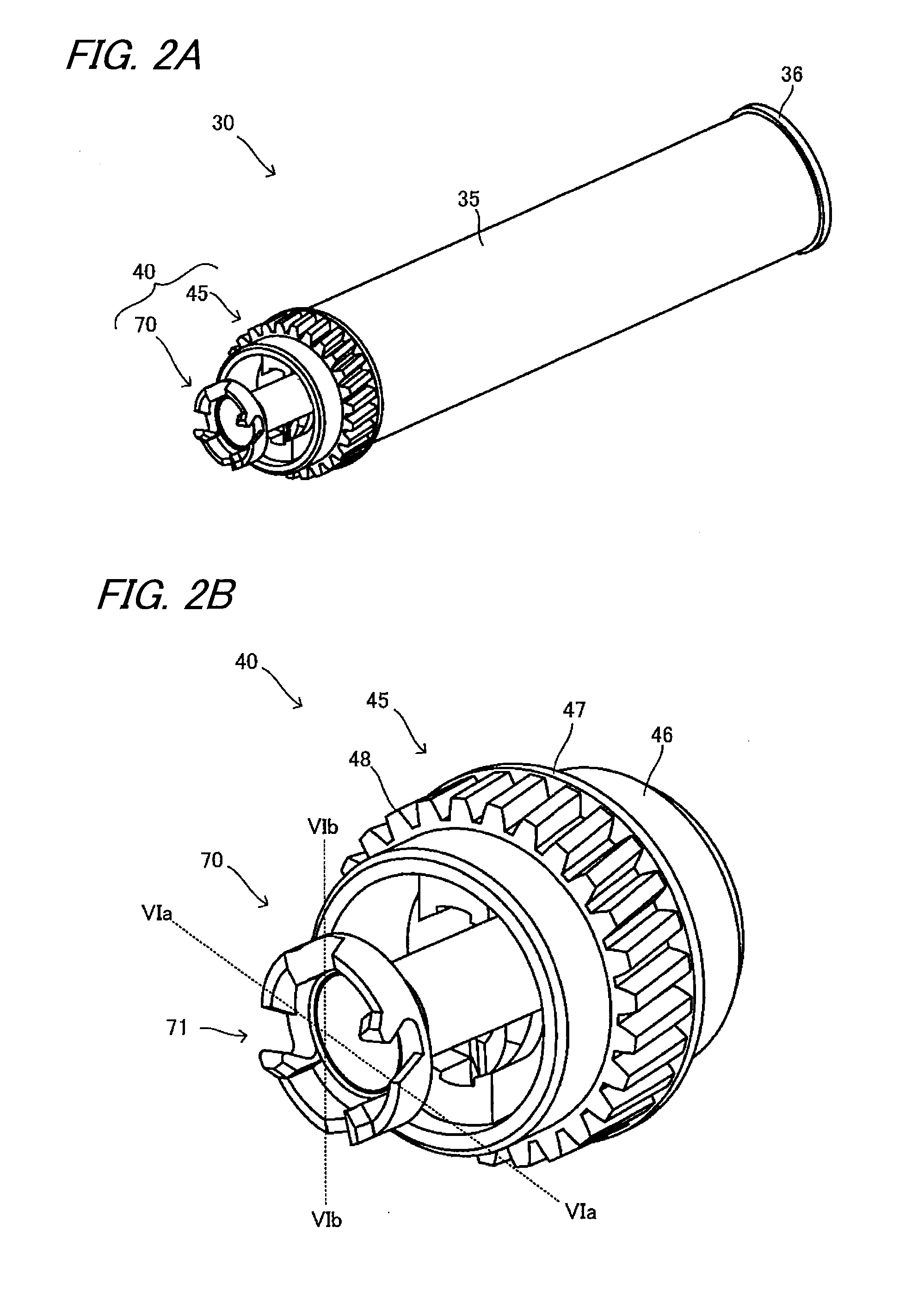

Bearing member, end member, photosensitive drum unit, process cartridge, and method for manufacturing bearing member

ActiveUS20130322923A1Realize the combinationGuaranteed uptimeCrankshaftsYielding couplingTorque transmissionMechanical engineering

A bearing member placed at an end of a photosensitive drum, and a shaft member is attached thereto. The bearing member has a cylindrical body and a retaining portion placed in the cylindrical body, retaining a torque transmission pin provided in the shaft member, and removably provided. The retaining portion is provided with swaying grooves at least two grooves extending in an axial direction of the cylindrical body, placed opposite each other, and whose bottoms have each a curved surface exhibiting a bow with respect to the axial direction; inlet grooves at one end thereof connected to the respective swaying grooves and at the other end thereof connected to outside of the retaining portion and placed at an upstream position with respect to the swaying grooves along a direction of rotation of the cylindrical body; and a pedestal interposed, at one end, between the two swaying grooves.

Owner:MITSUBISHI CHEM CORP

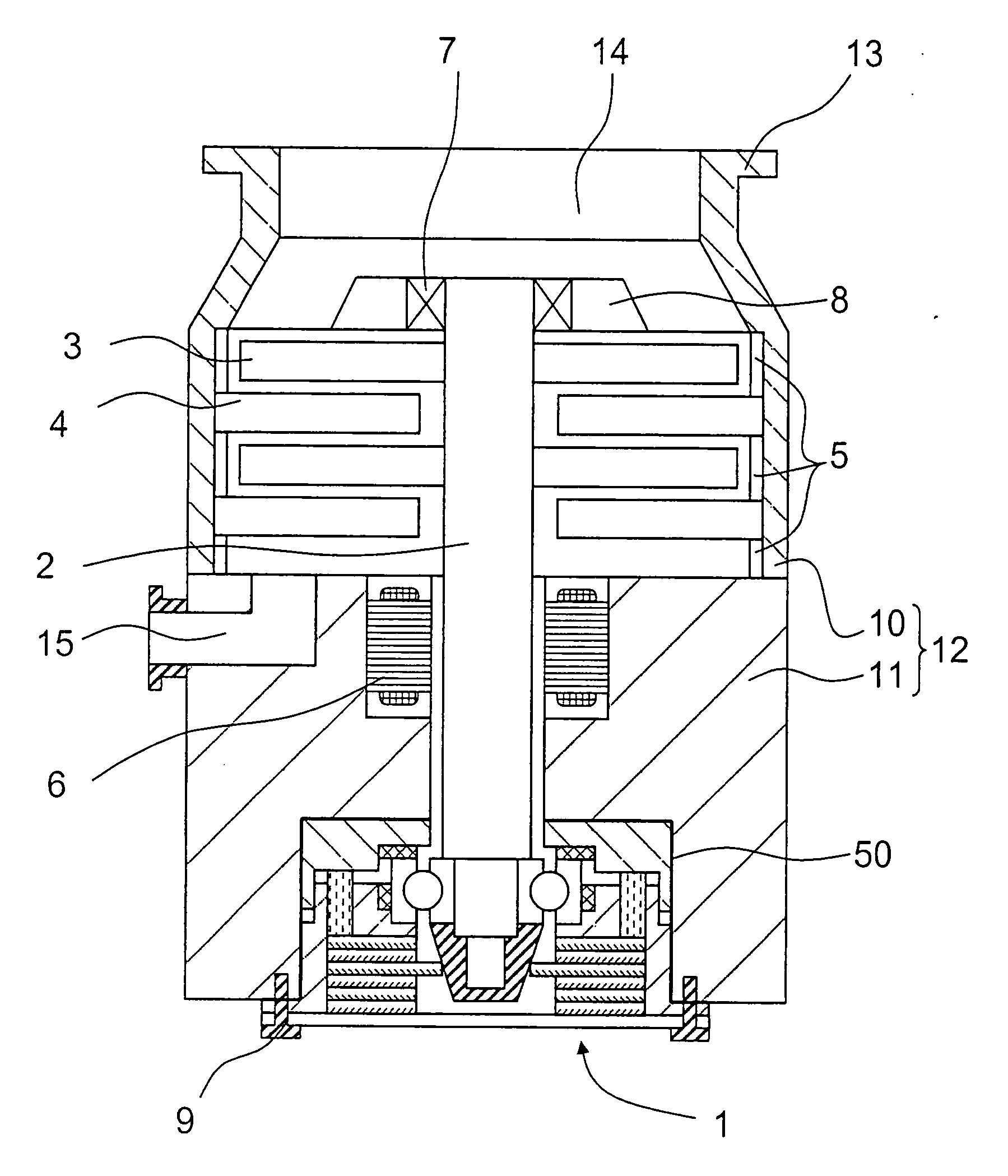

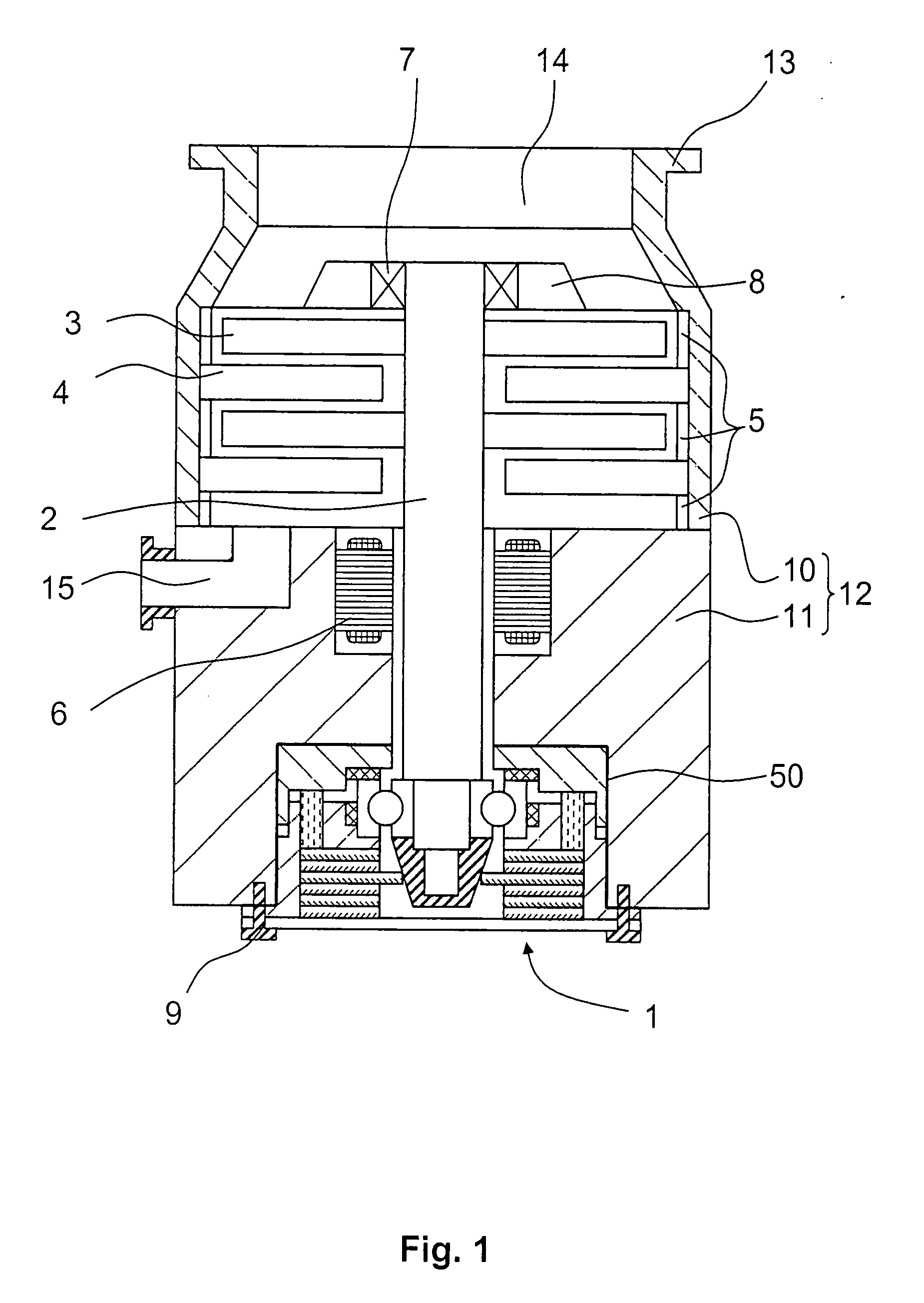

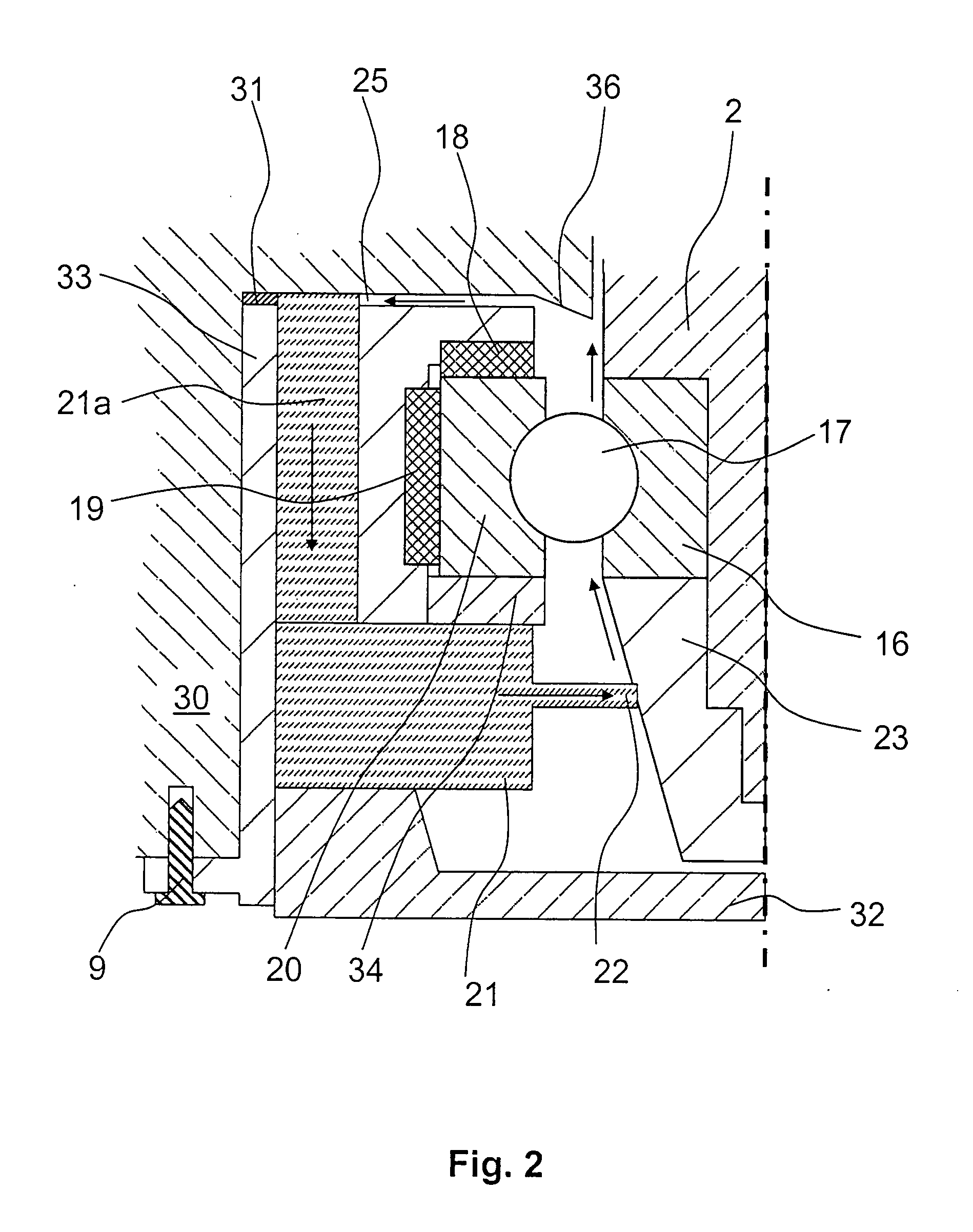

Bearing module for a vacuum pump

InactiveUS20080112660A1Satisfactory circulationMulti-layered capabilityCrankshaftsPump componentsRolling-element bearingCentrifugal force

A bearing module for supporting a rapidly rotatable shaft of a vacuum pump includes a rolling bearing for supporting rotatably the shaft, a reservoir for a lubricant having an element forming a sliding contact with a delivery structure supported on the shaft for delivery of the lubricant in the rolling bearing under action of centrifugal forces generated during rotation of the shaft, and a radial delivery element provided on a side of the rolling bearing opposite a side of the bearing at which the delivery structure is located, for returning the lubricant to the reservoir.

Owner:PFEIFFER VACUUM GMBH

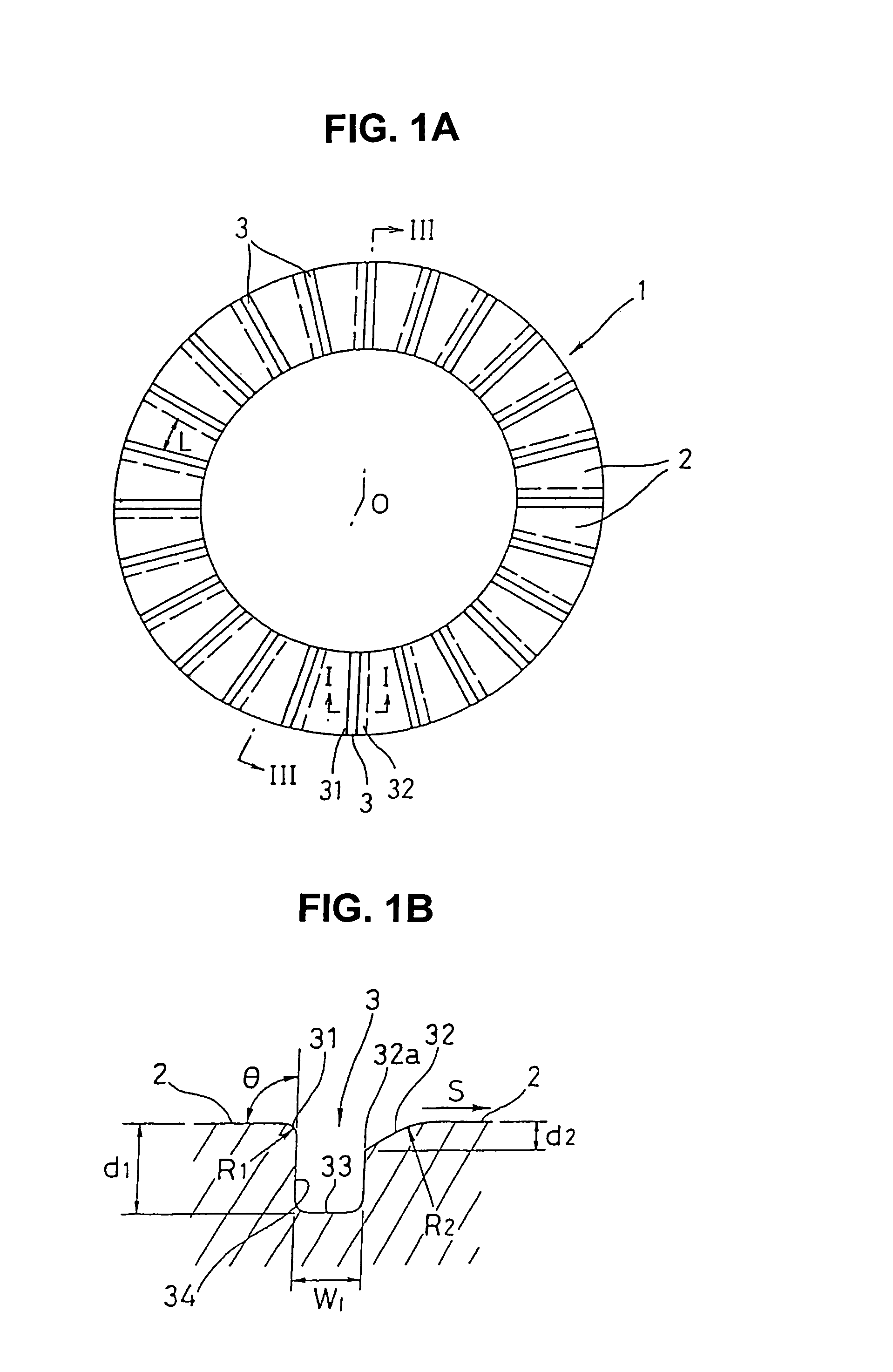

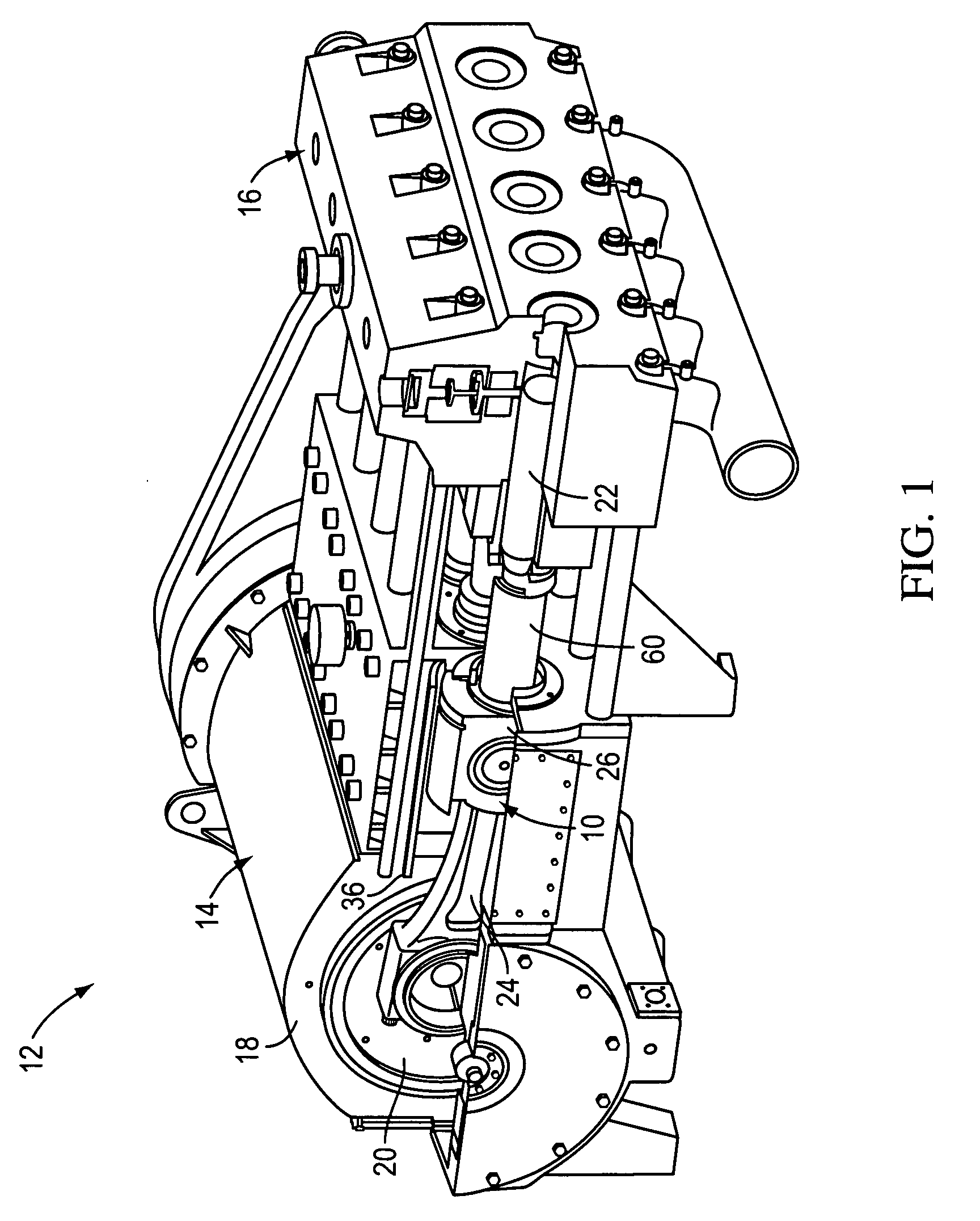

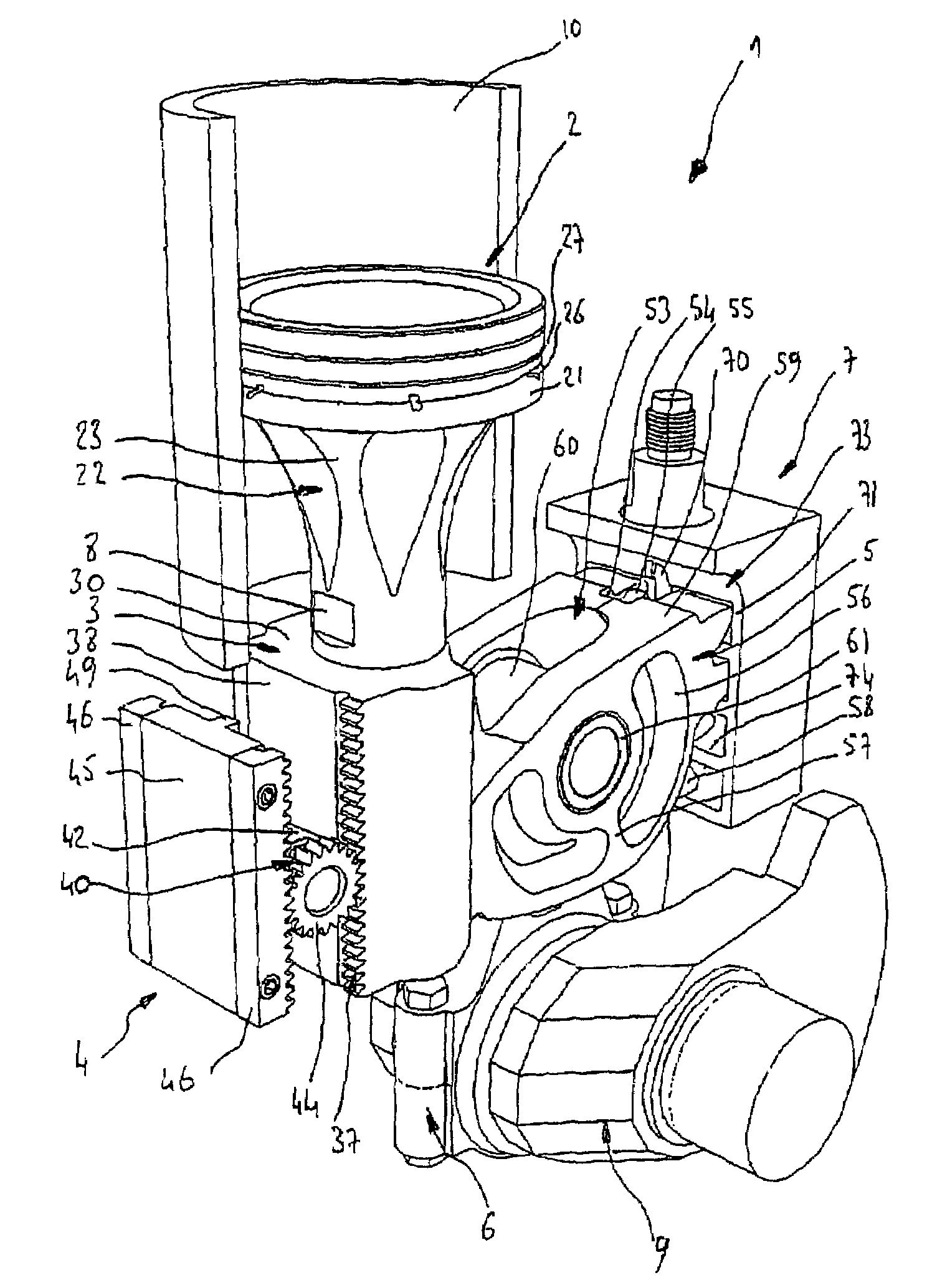

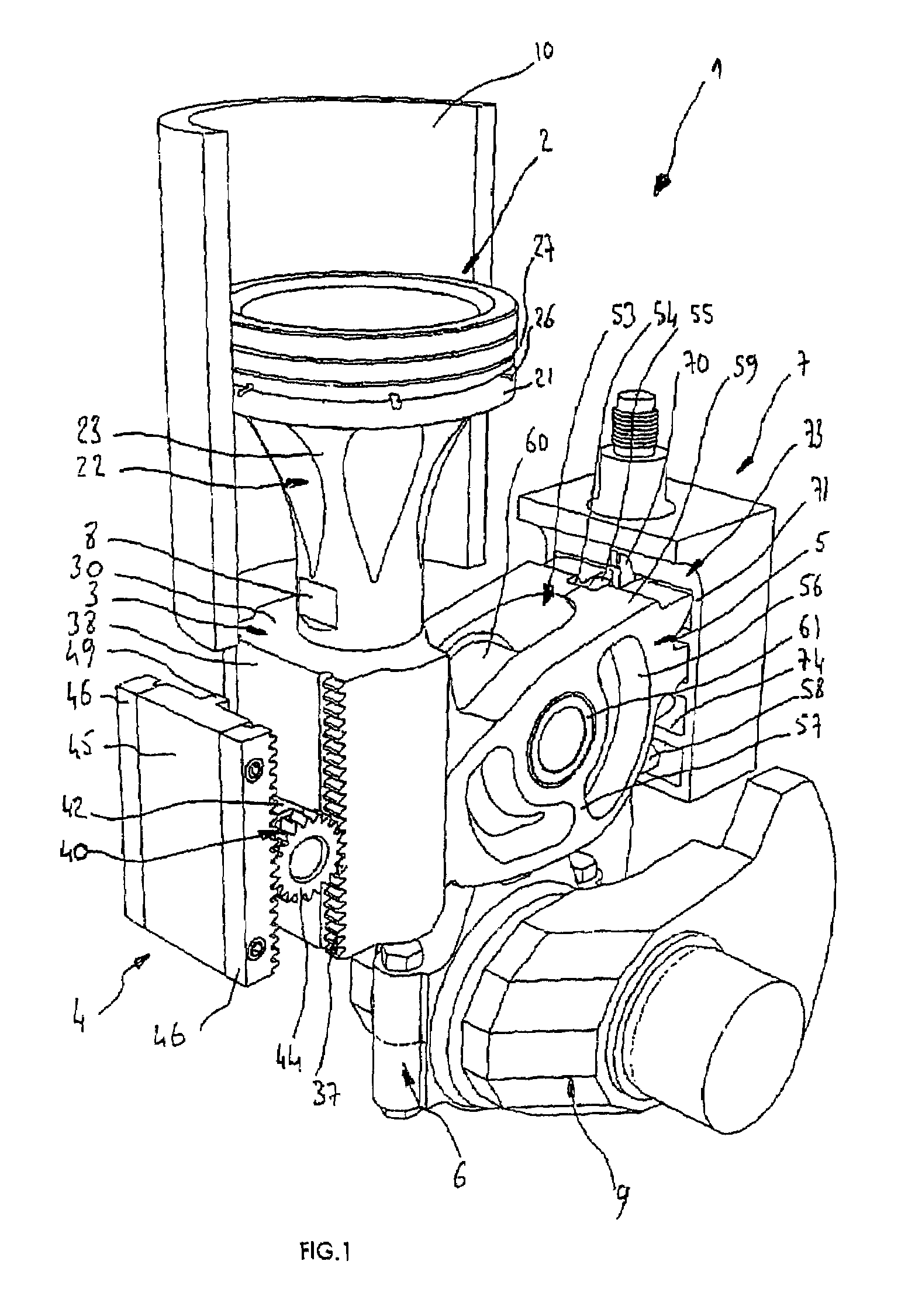

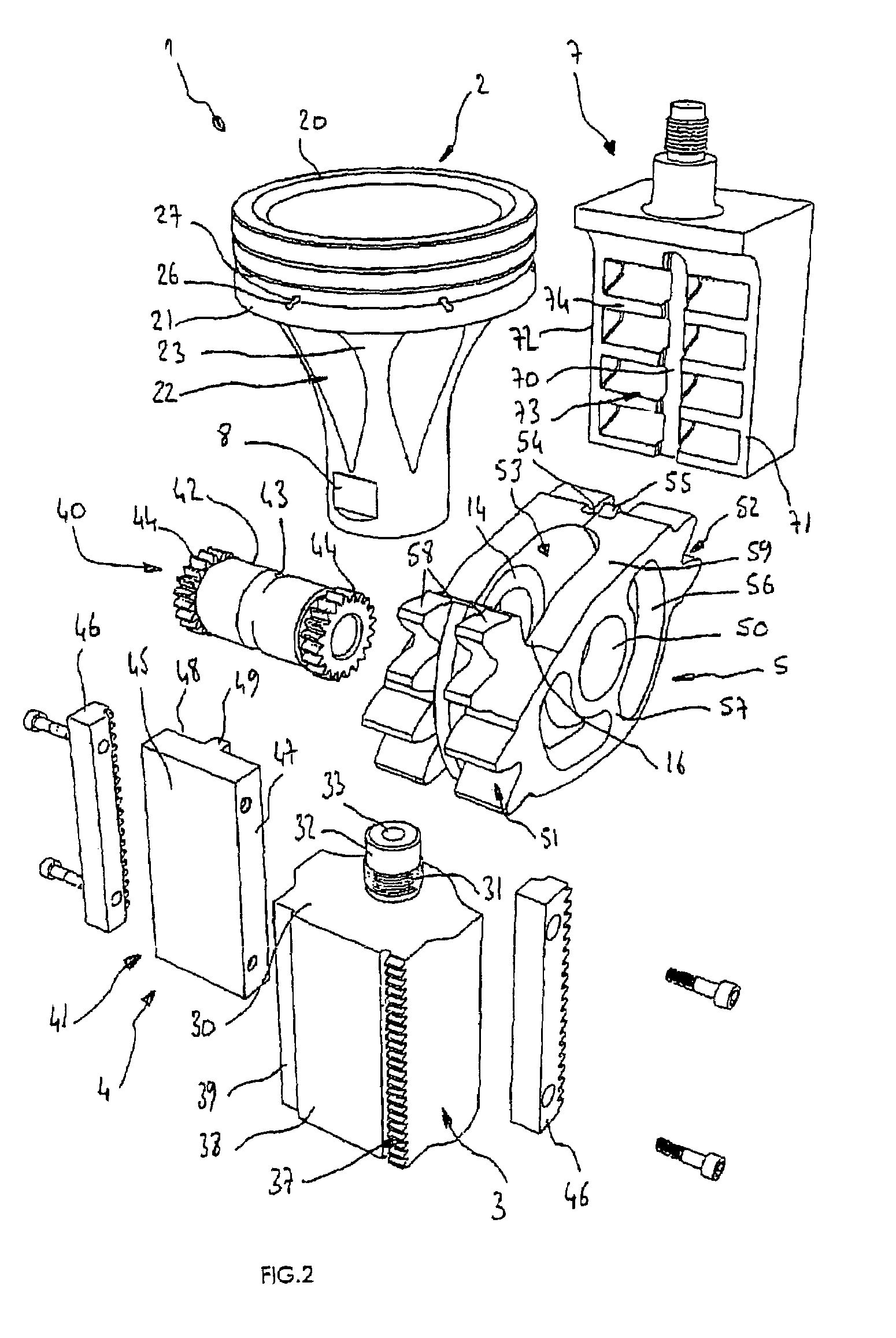

Variable cylinder capacity engine

InactiveUS7013849B2Improve guidanceStrengthen the relative fixedConnecting rodsCrossheadsFlexural strengthSprocket

A mechanical transmission device for a variable cylinder capacity engine includes at least a cylinder (10) wherein moves a piston (2), which is integral in its lower portion with a transmission member (3) co-operating through a small-sized rack (37) with a roller bearing guide device (4) and through another large-sized rack (35) with a sprocket wheel (5) linked to a connecting rod (6), a control member (7) having a large-sized rack (73) co-operating with the sprocket wheel (5), elements for fixing (24, 31) the piston (2) on the transmission member (3) which provide a preload for clamping it and ensure its centring, linking elements (11, 12; 71, 72) for rigidifying the transmission (3) and control (7) members and for increasing the flexural strength of the teeth of the large-sized racks (35, 73) and elements for lightening (56) the sprocket wheel (5) which maintain its rigidity and load capacity.

Owner:MCE 5 DEV 72 PART INTEREST

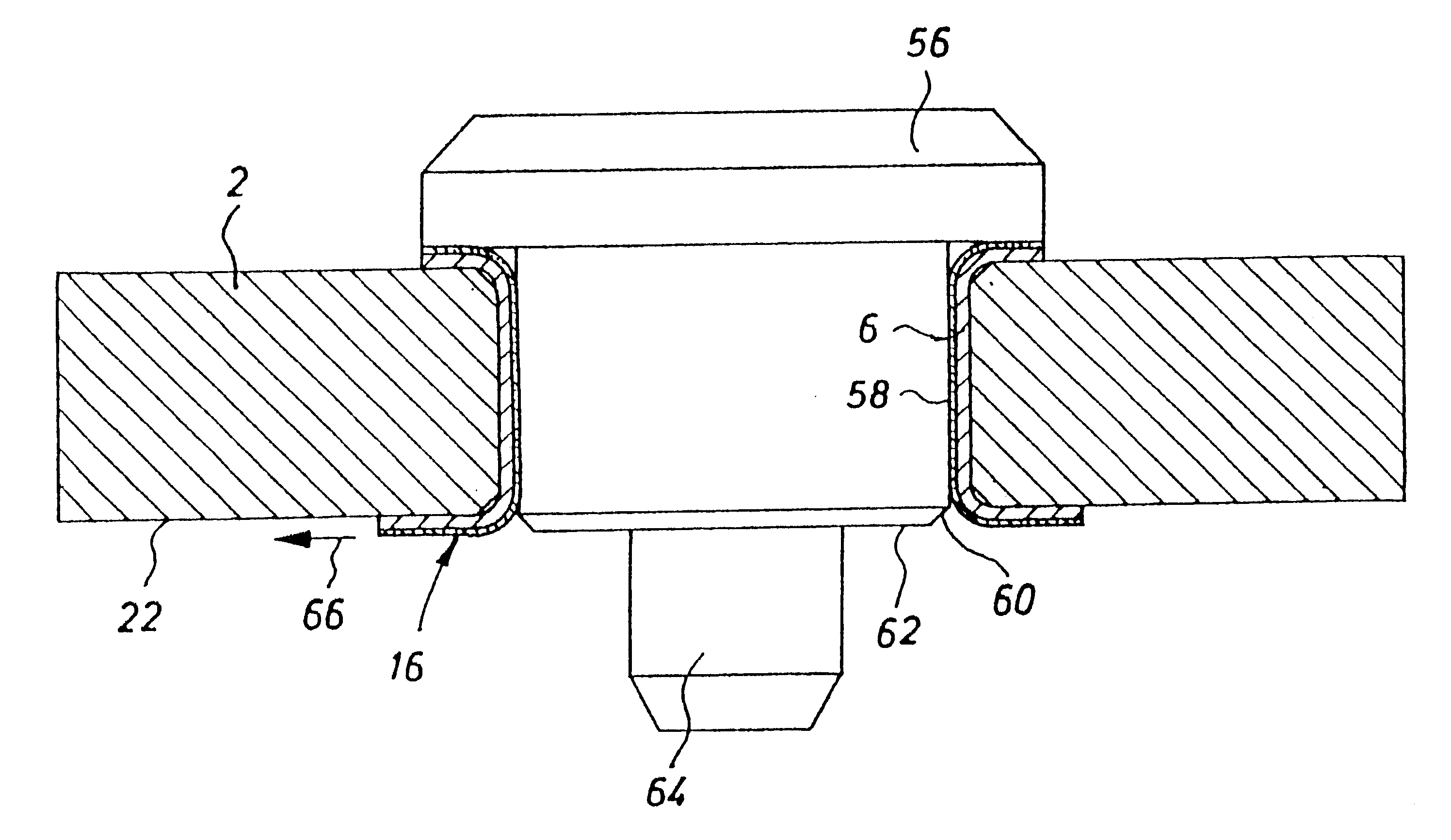

Slide bearing and method for the production thereof

InactiveUS6648512B1Considerably efficientConsiderable costCrankshaftsCrossheadsEngineeringPlain bearing

The invention relates to a slide bearing comprising with a bearing opening (4) pertaining to a hinge-housing component (2) and a flange bearing box (6) pressed into said bearing opening (4), whereby a bearing pin (26) can be inserted and rotated therein. Said flange bearing box (6) has a crimped projection (50) which projects radially inwards in the direction of the periphery. In order to create a slide bearing which can be preassembled, said slide-bearing is formed such that said crimped projection (50), when viewed from a longitudinal section of the box forms as a curved region (52) in the wall of said flange bearing box (6) in the vicinity of the axial end of the bearing opening (4) and said curved region (52) projects into the flange (16) of the box (6) in such a way that a space (h) is created between the opening (4) and of the bearing outer side which faces the flange bearing box (6) in the region of the curved profile prior to insertion of the bearing pins (26). The curved region (52) of the flange bearing box (6) can be radially deformed radially in an outward direction.

Owner:GLEITLAGER

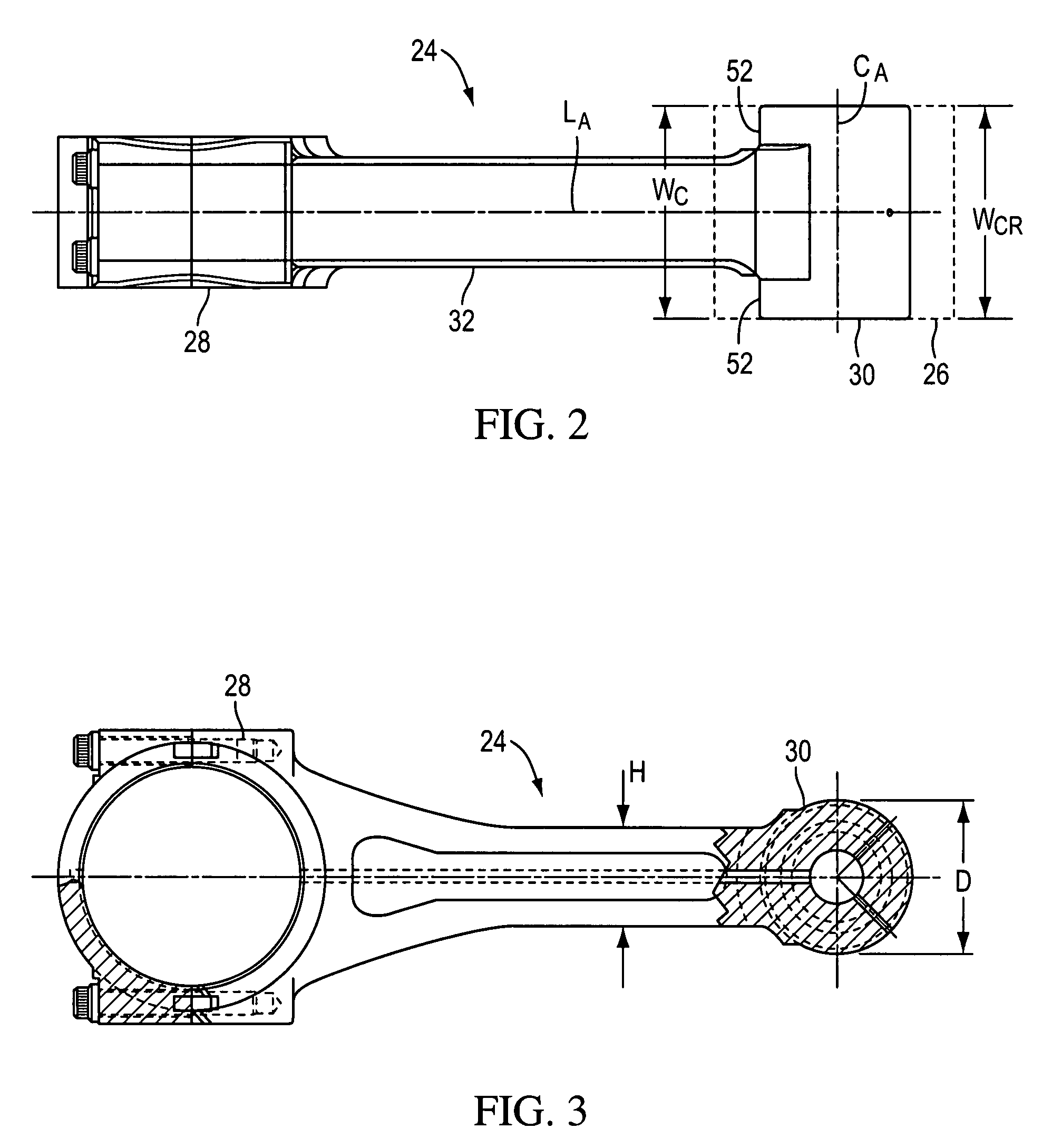

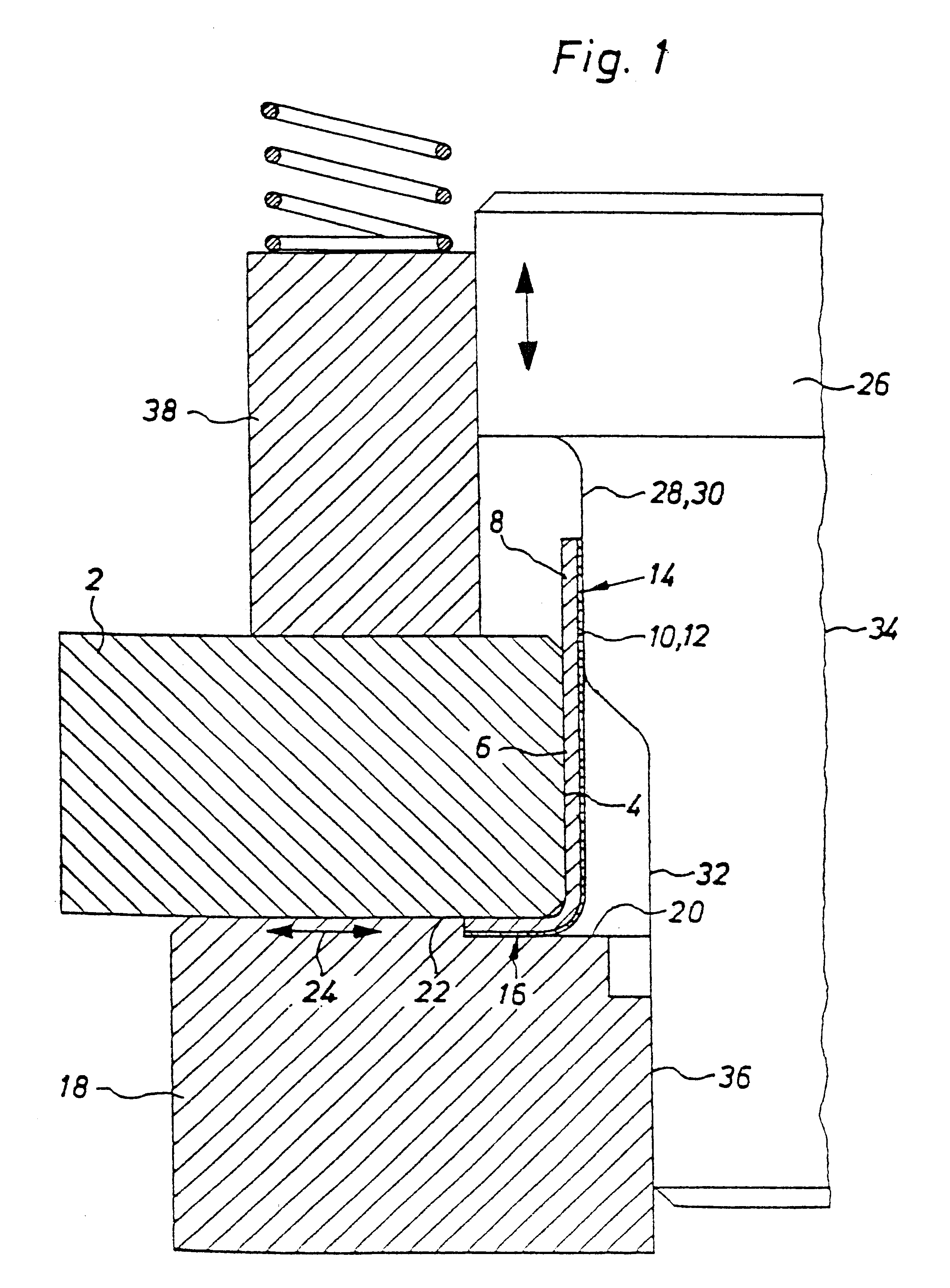

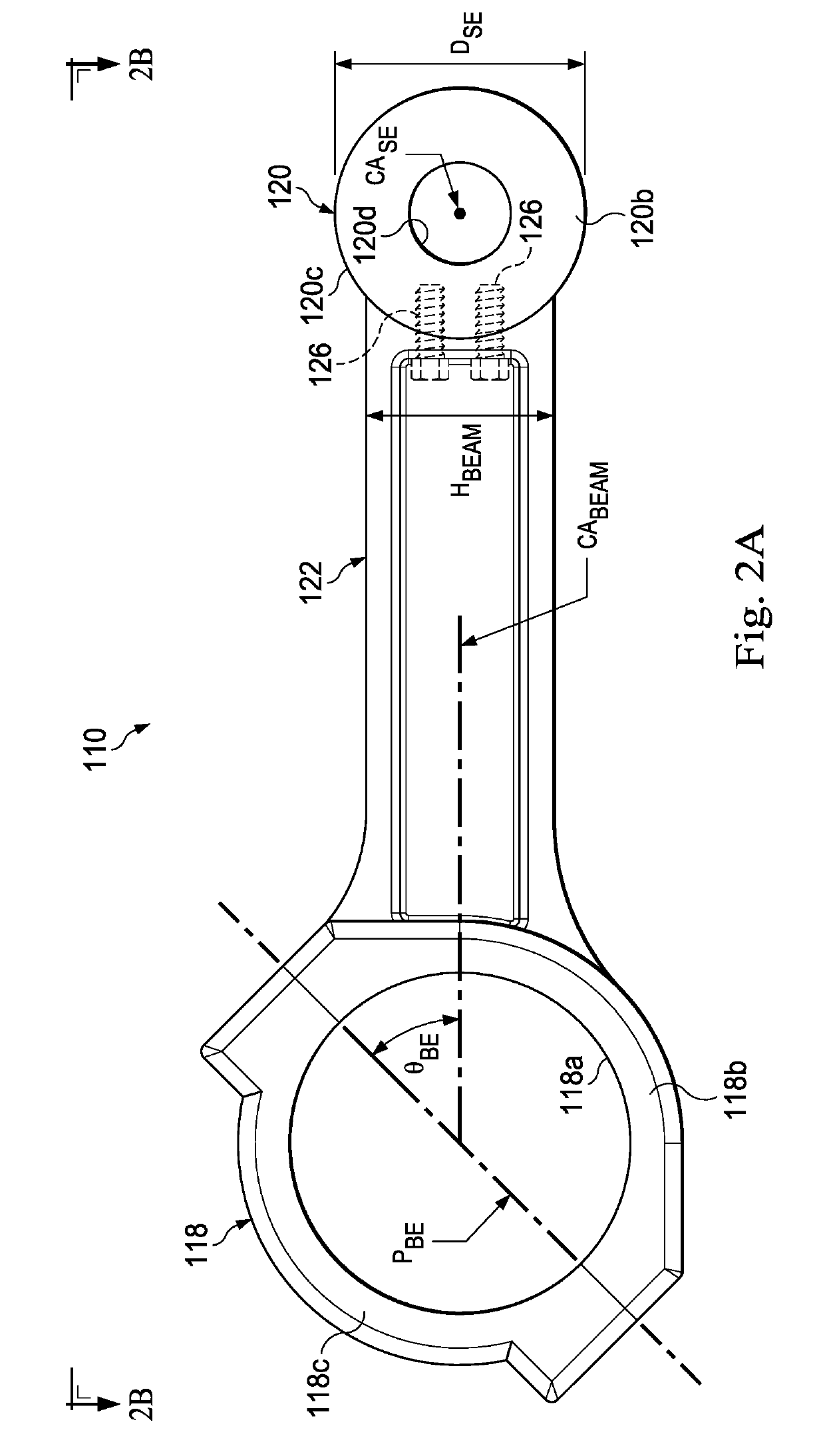

Connecting rod and crosshead assembly for enhancing the performance of a reciprocating pump

ActiveUS10393113B2Reduce displacementPositive displacement pump componentsCrossheadsAxial displacementEngineering

A method and apparatus for a reciprocating pump assembly, including a crosshead and a connecting rod. The crosshead includes a main body having a cylindrical bore formed therethrough and defining a bearing surface, and a window formed through the main body and into the cylindrical bore. The connecting rod includes a small end disposed within the cylindrical bore and a beam portion extending through the window and being connected to the small end. In an exemplary embodiment, a bearing including a tubular body and a cutout is disposed within the cylindrical bore. In another exemplary embodiment, a clamp engages both the main body of the crosshead and the respective opposing end portions of the small end, thus reducing axial displacement of the small end relative to the crosshead.

Owner:SPM OIL & GAS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com