Patents

Literature

559results about How to "Improve engine performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

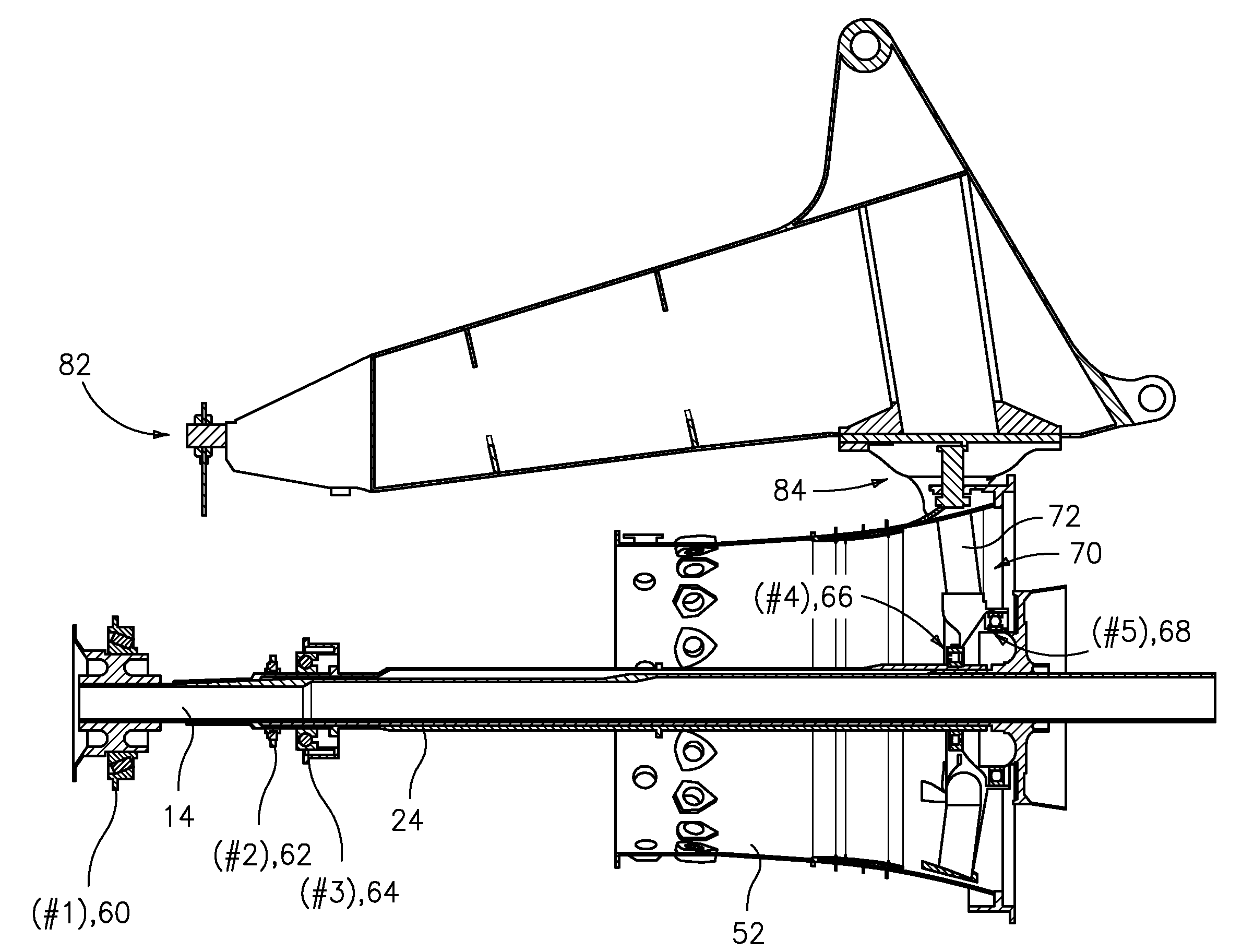

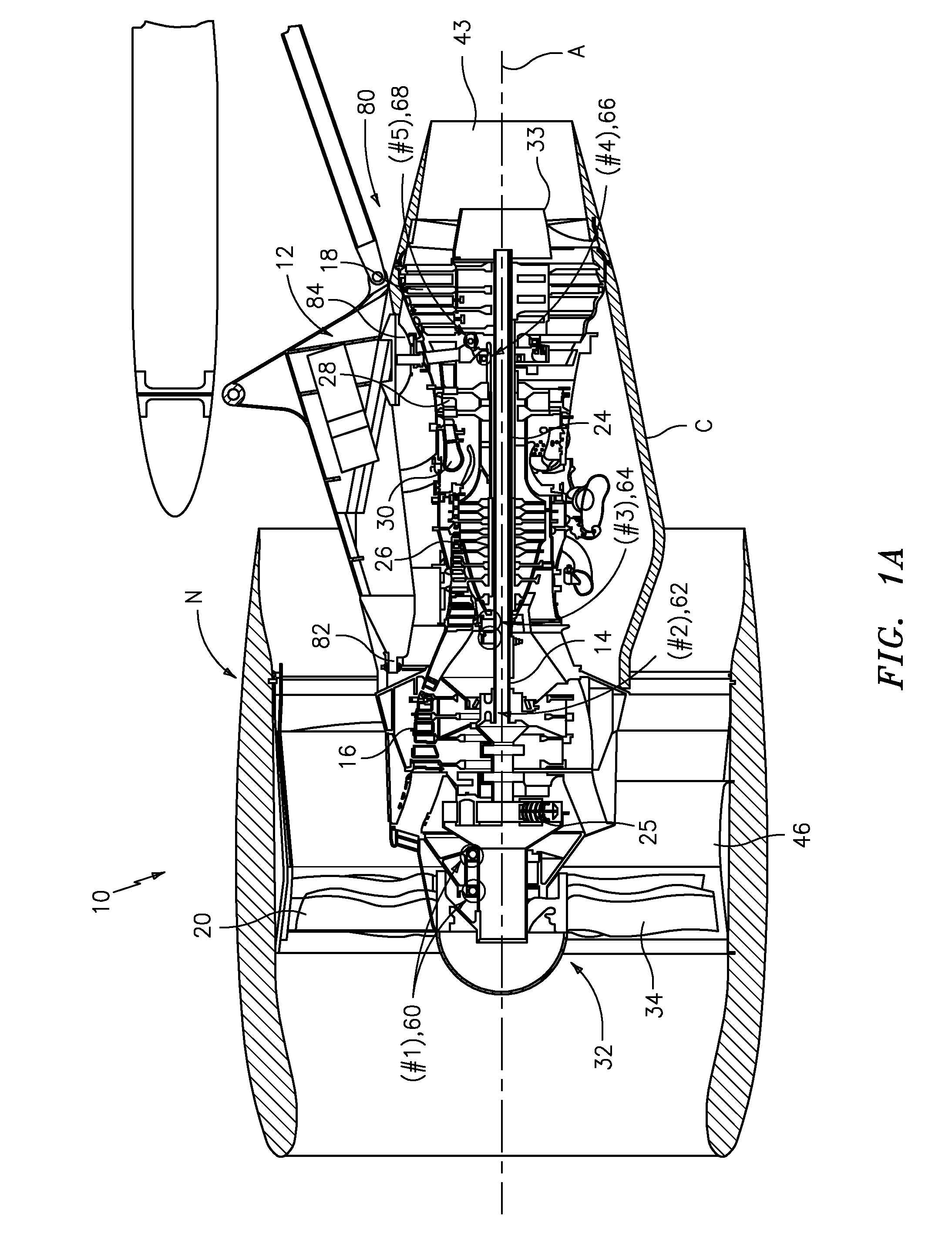

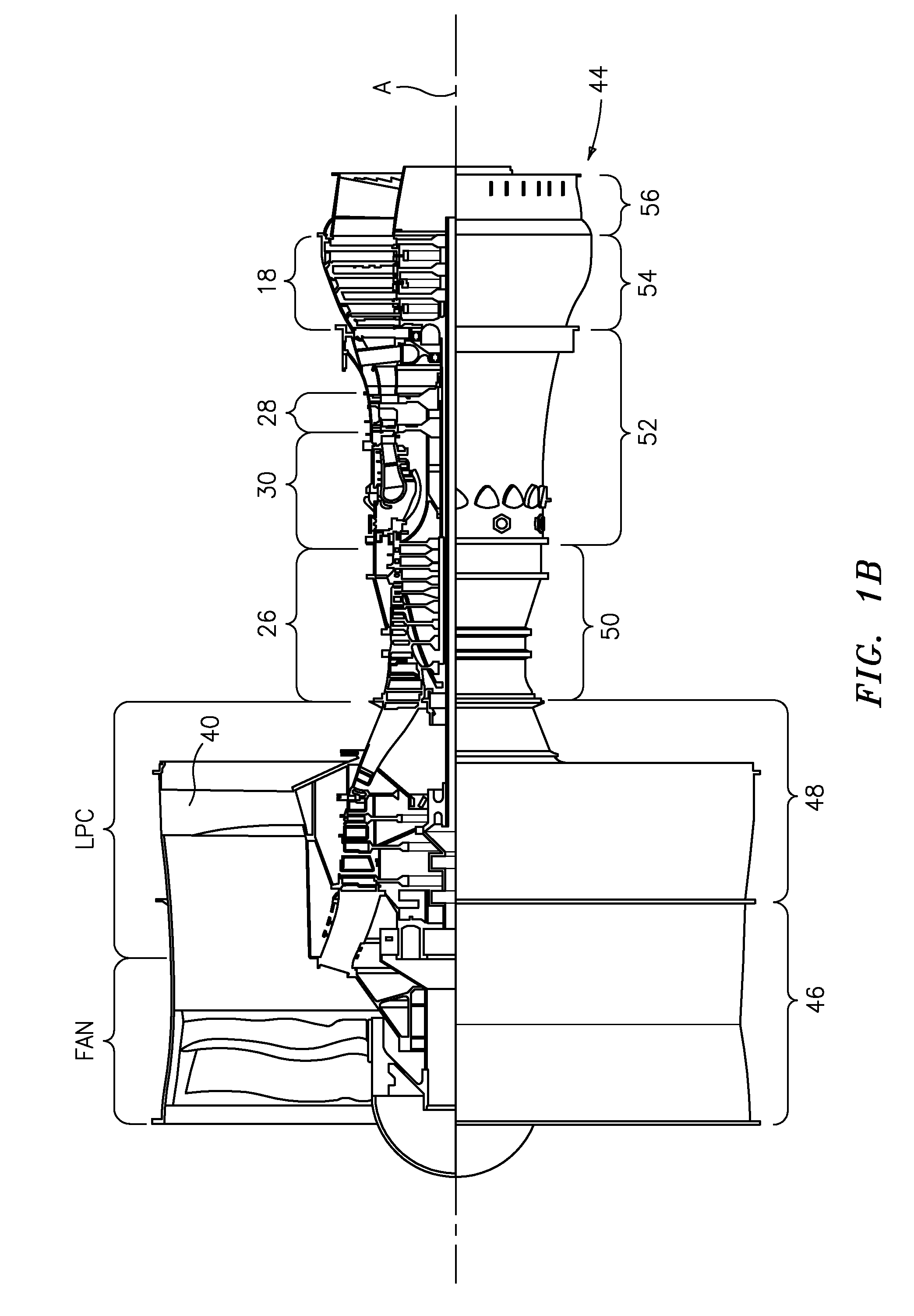

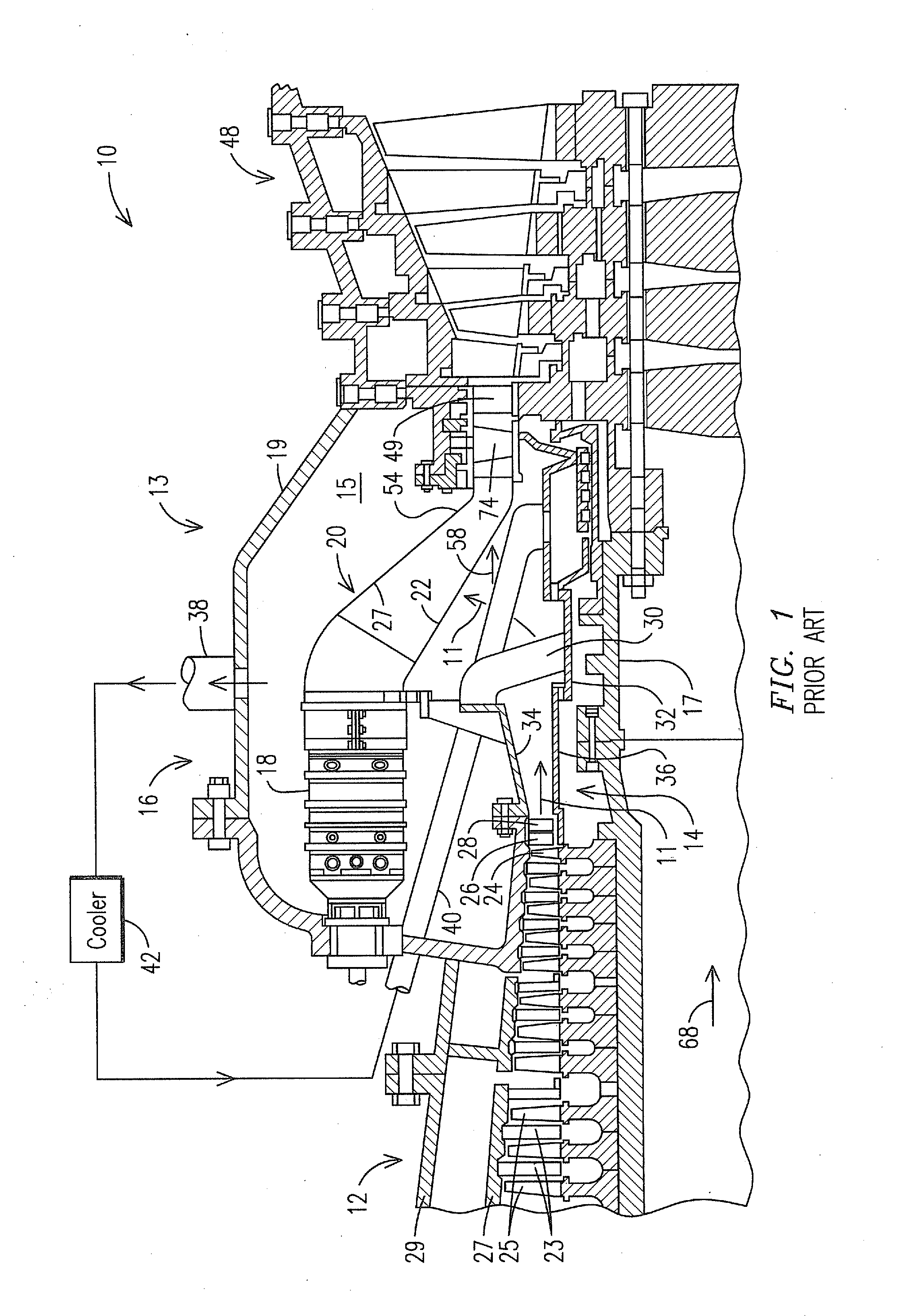

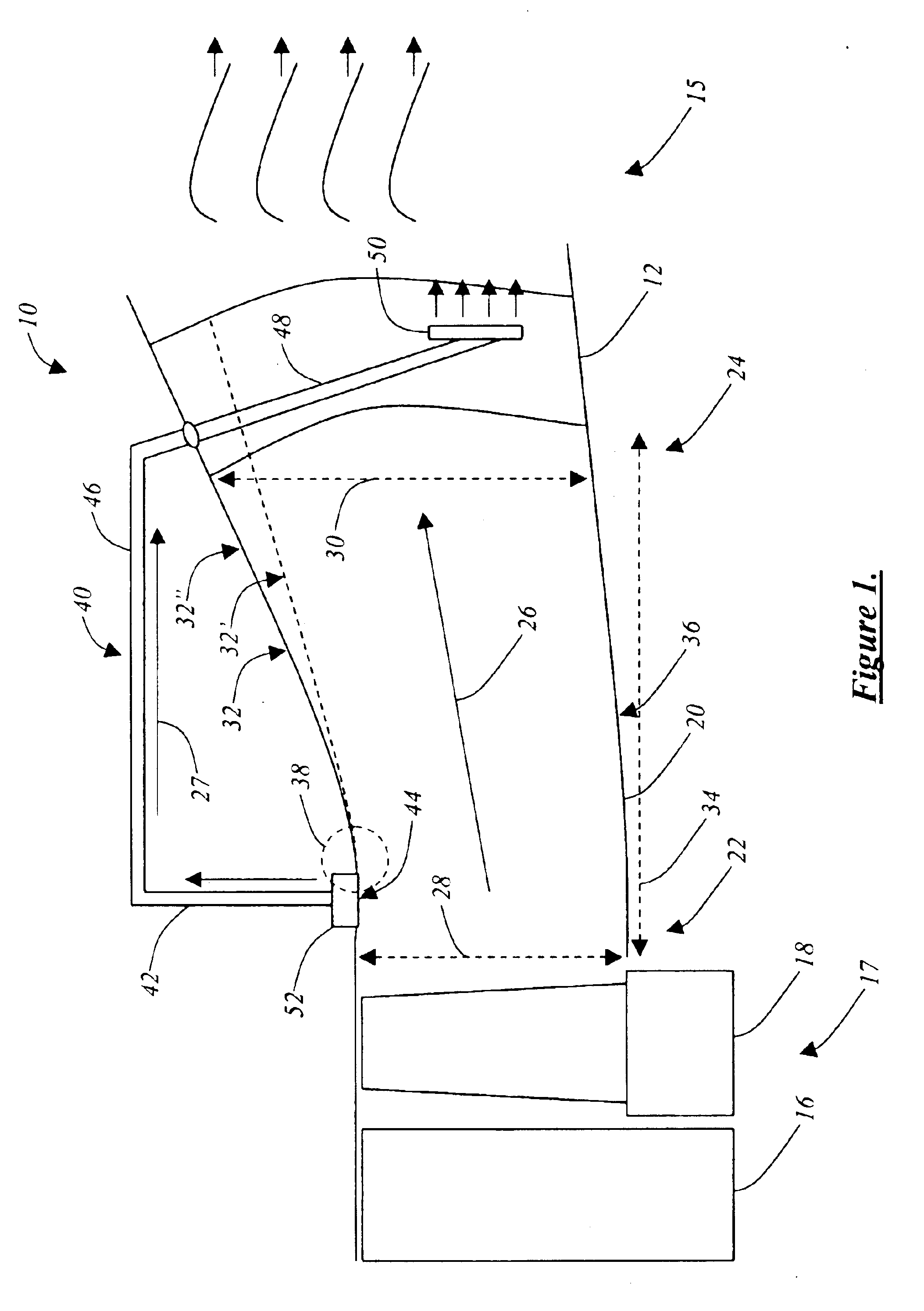

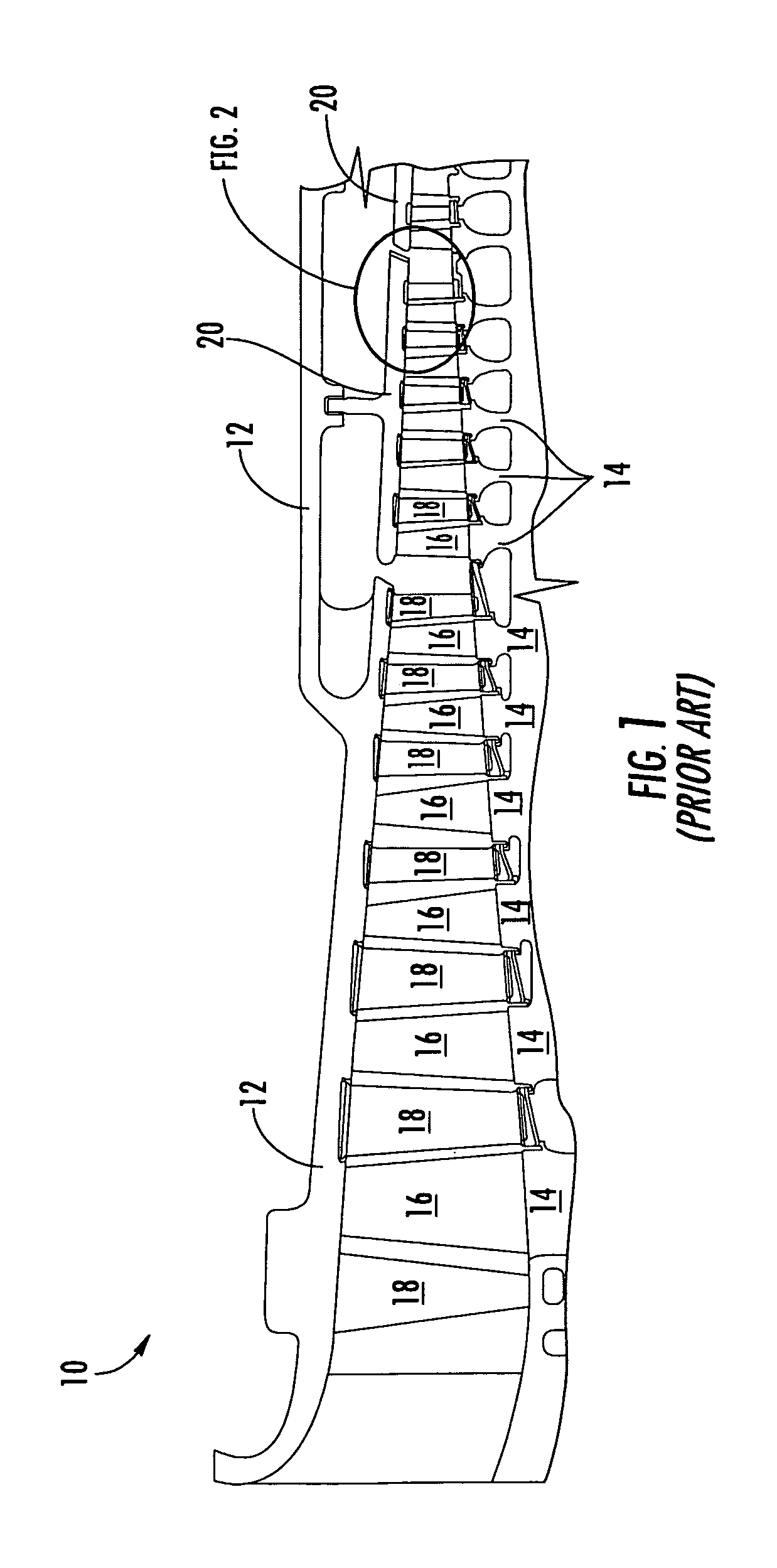

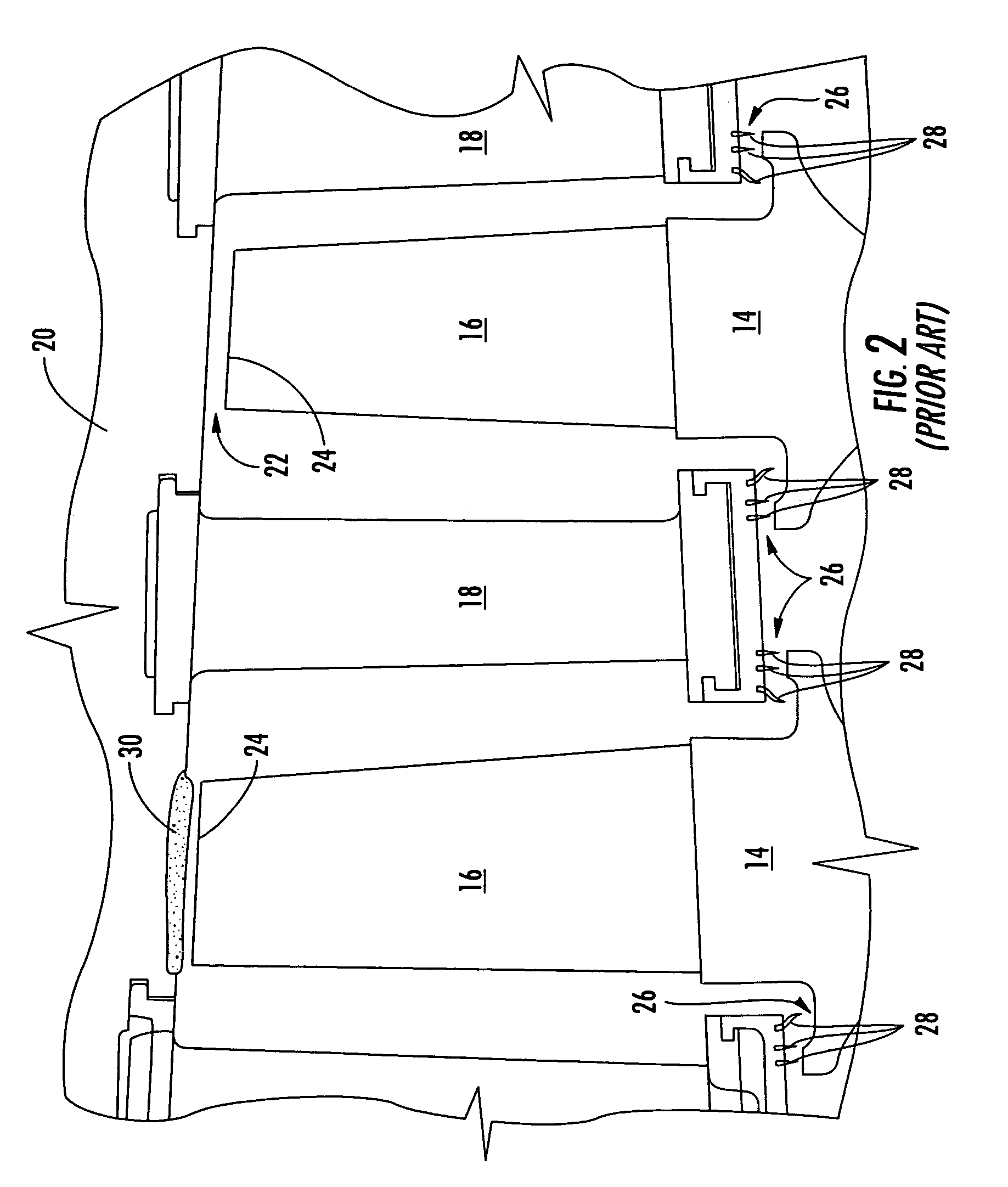

Engine mounting configuration for a turbofan gas turbine engine

ActiveUS20090056343A1Minimizes backbone bendingMinimizes engine case distortionPower plant constructionJet type power plantsNacelleEngine mount

An engine mounting configuration reacts engine thrust at an aft mount. The engine mounting configuration reduces backbone bending of the engine, intermediate case distortion and frees-up space within the core nacelle.

Owner:RAYTHEON TECH CORP

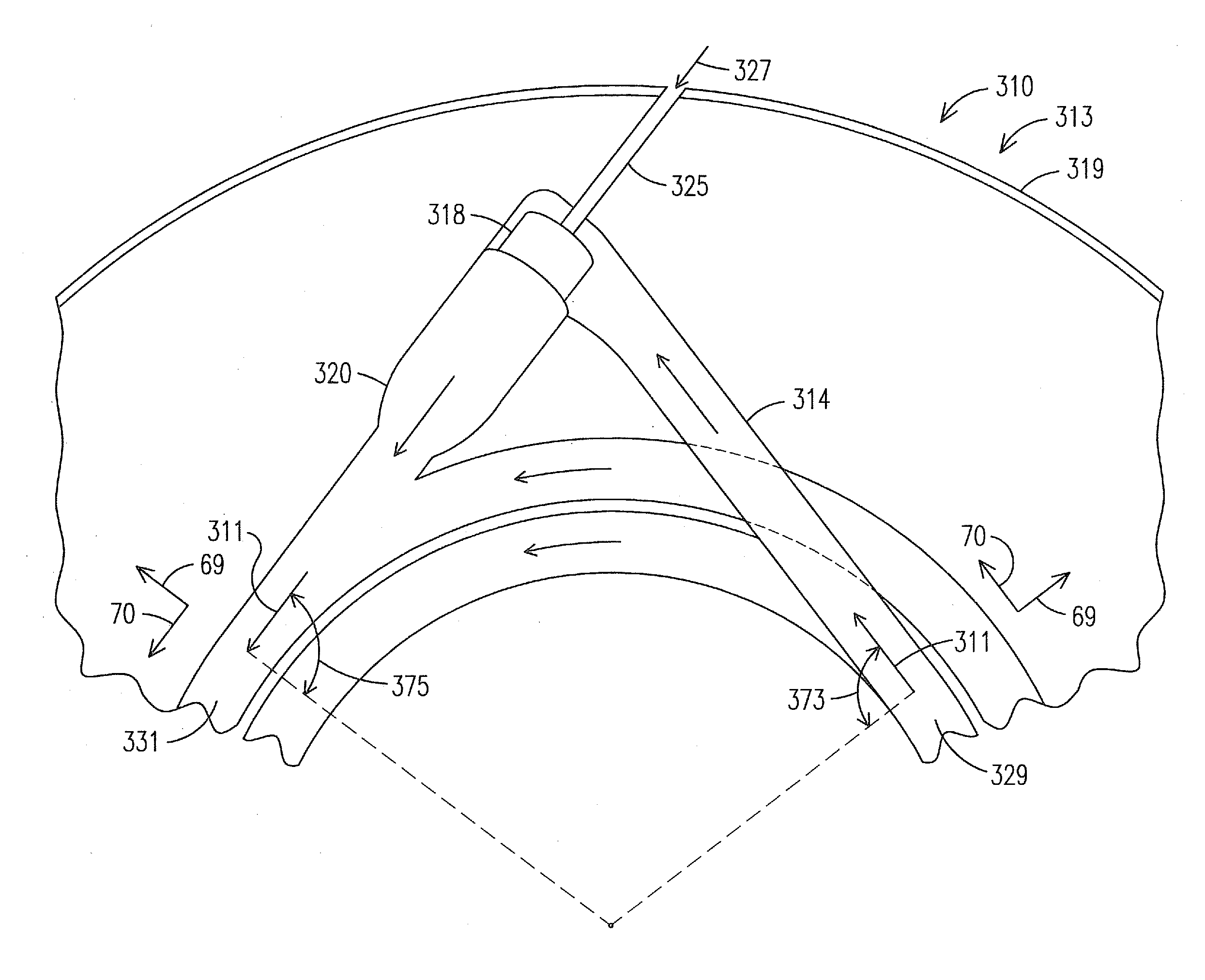

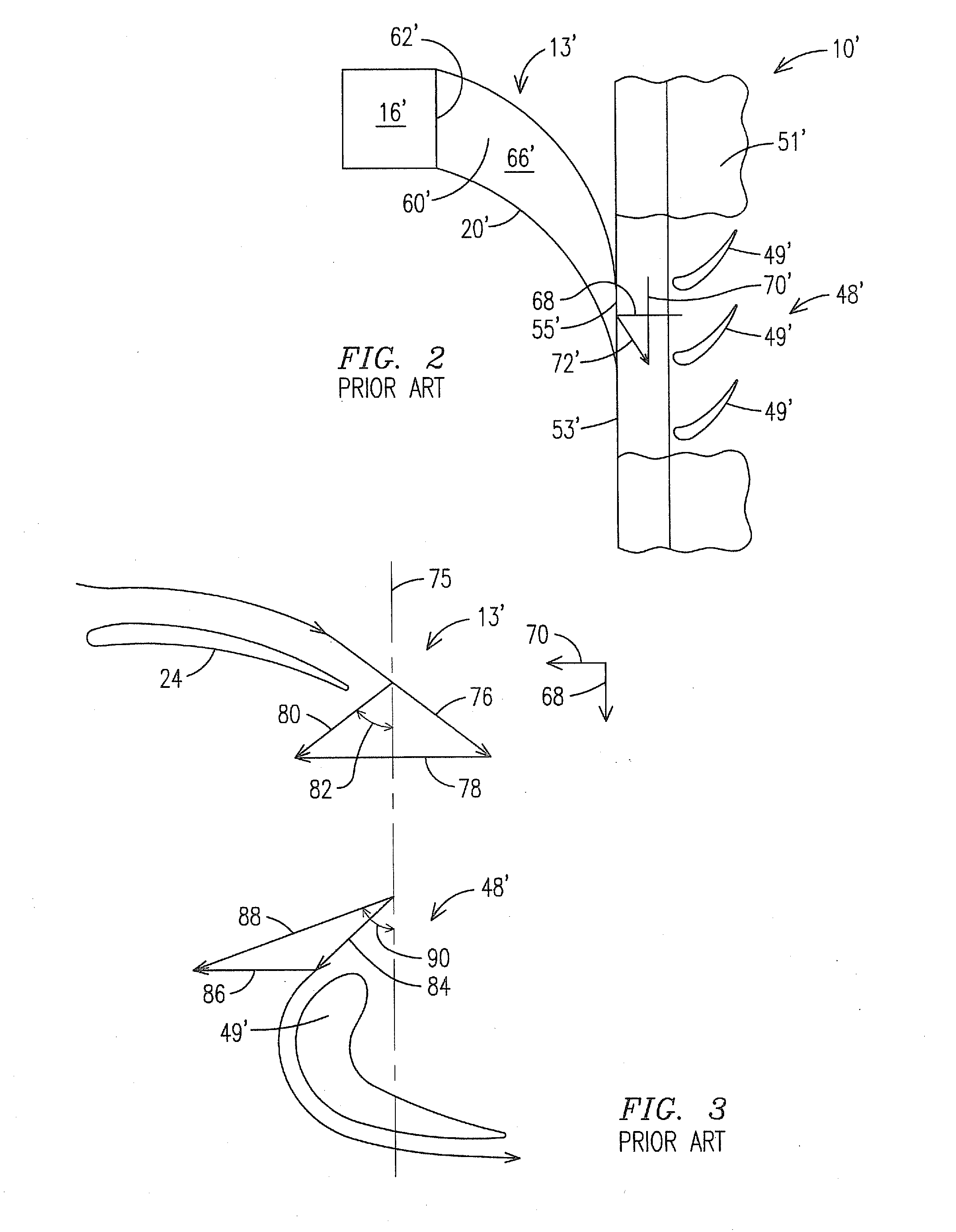

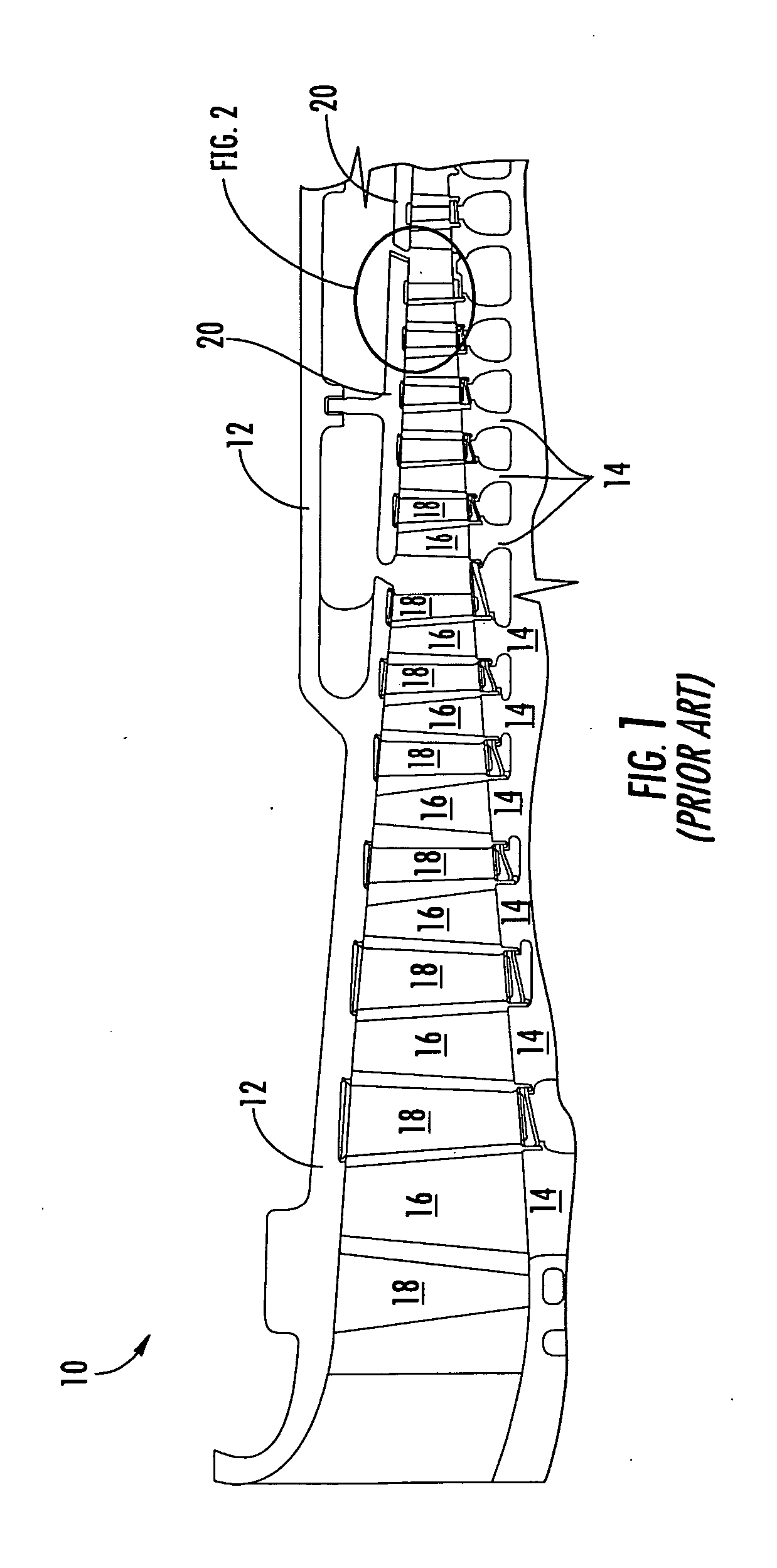

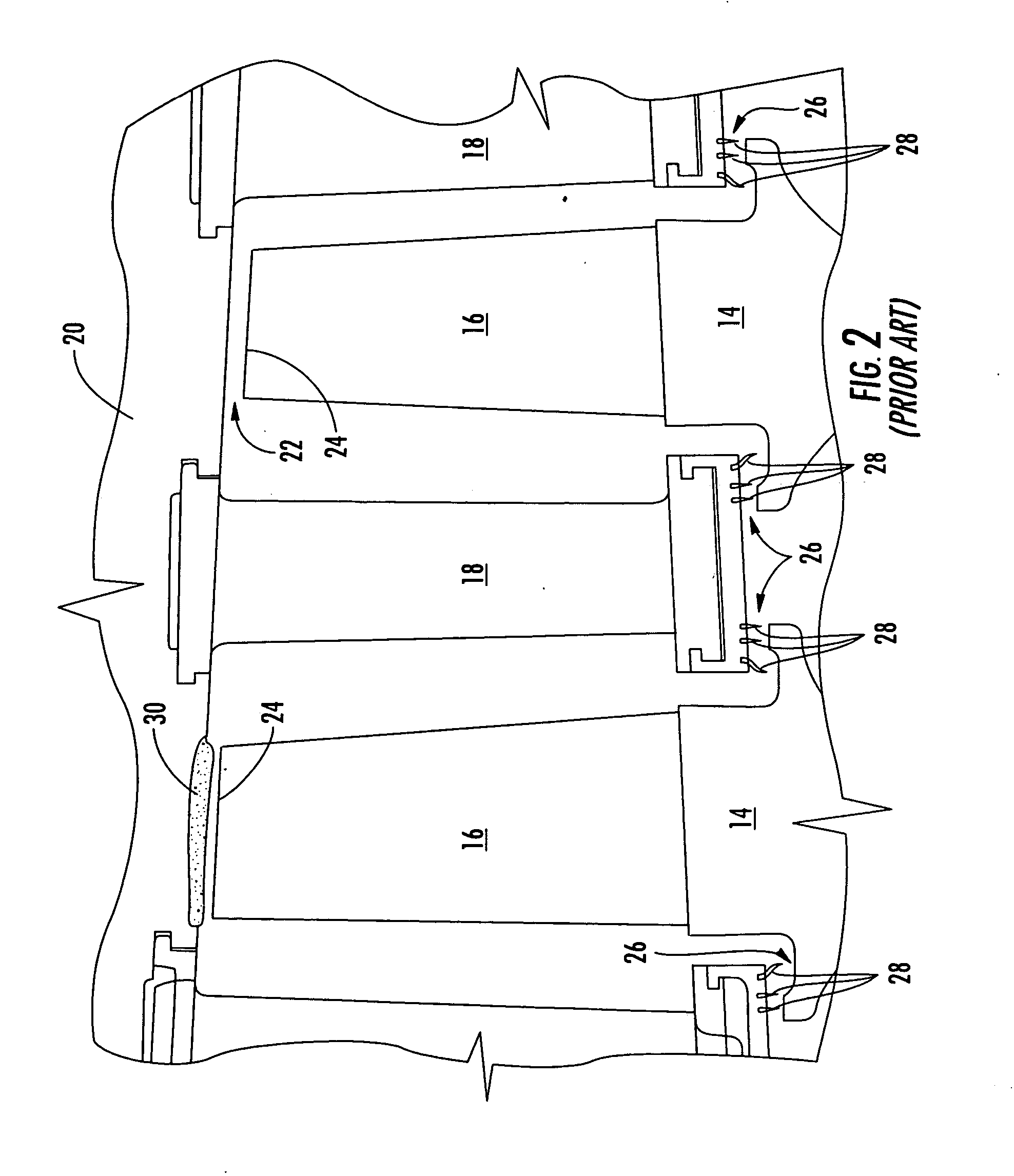

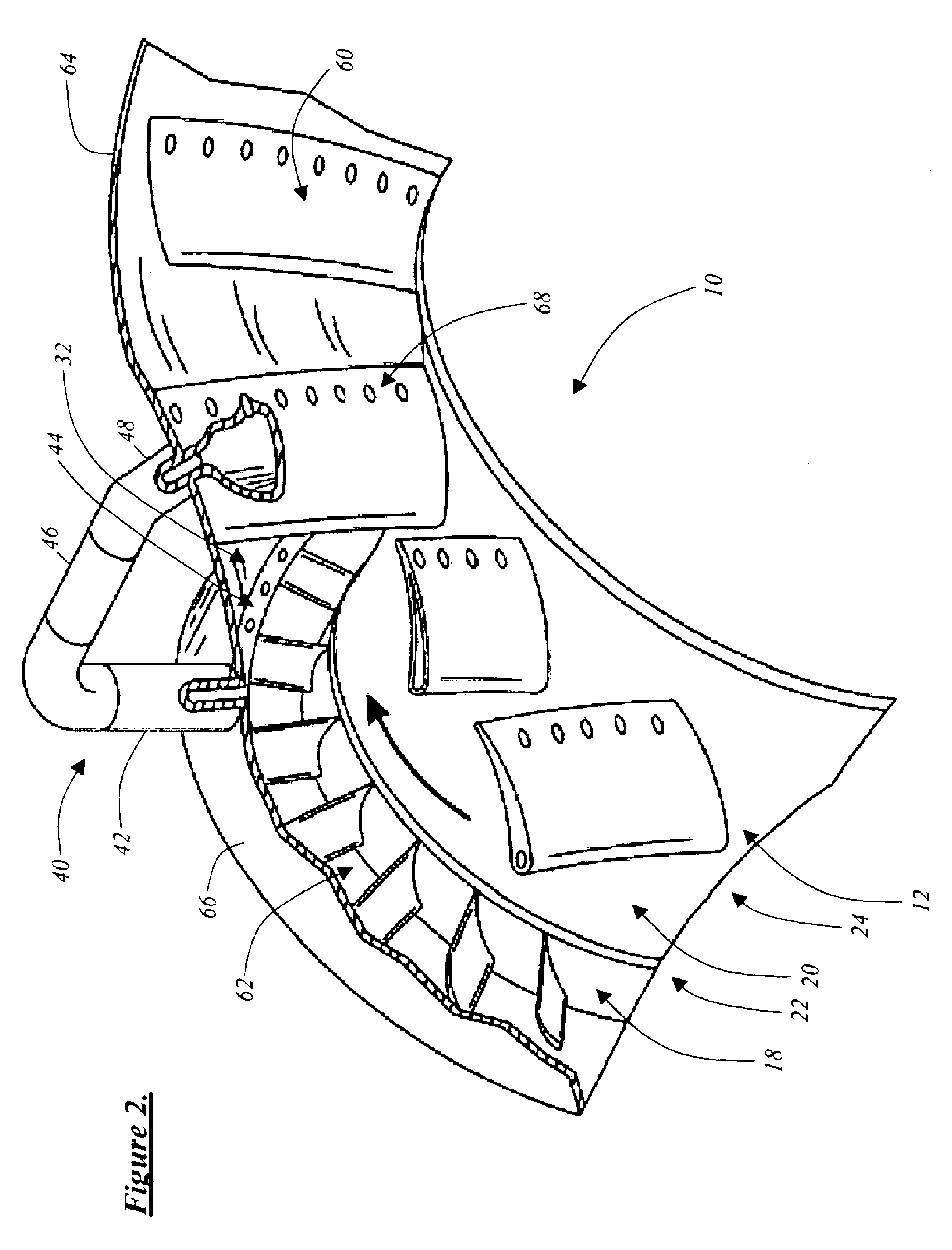

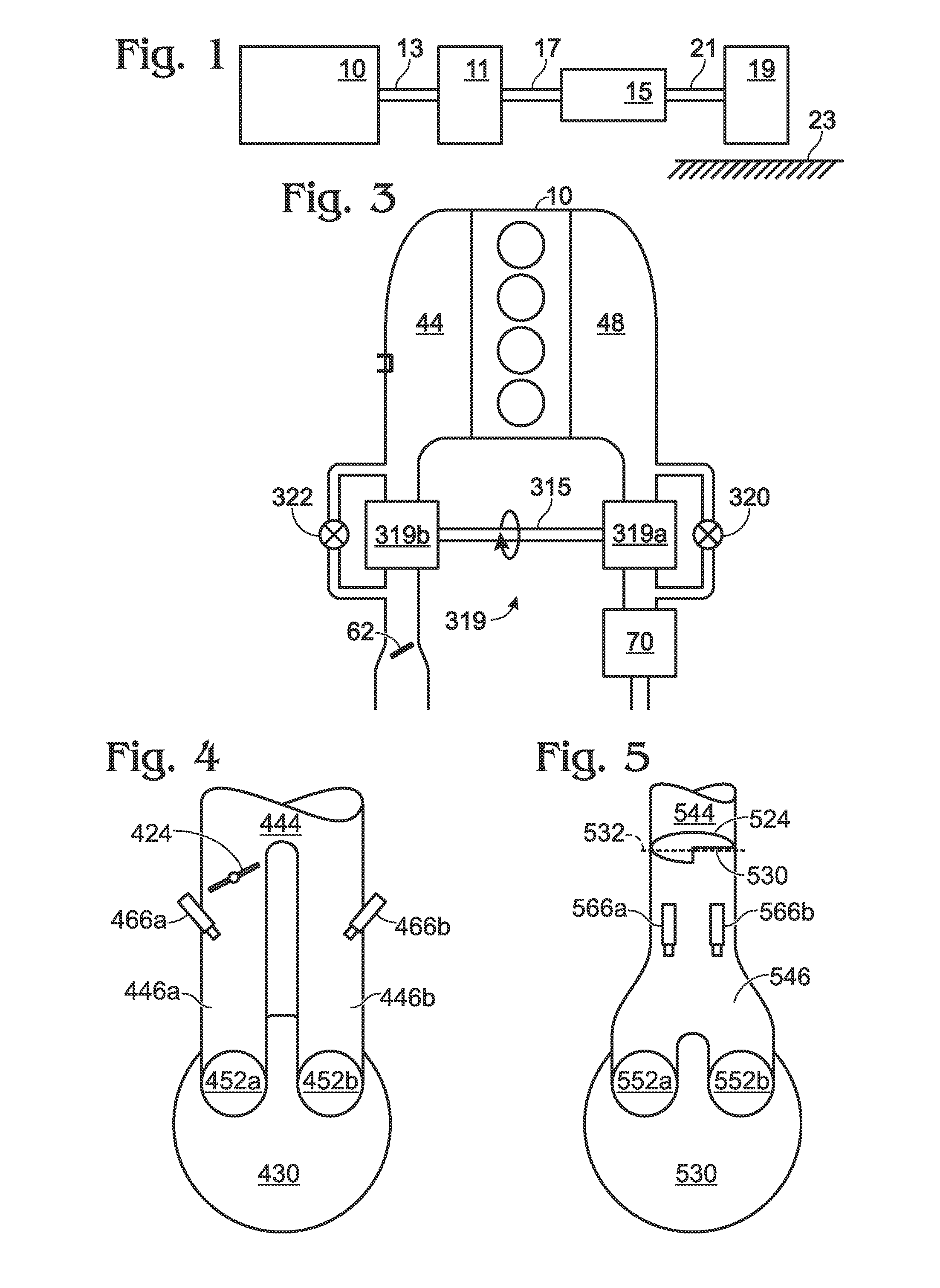

Mid-section of a can-annular gas turbine engine with an improved rotation of air flow from the compressor to the turbine

InactiveUS20130219853A1Easy to operateReduce lossesContinuous combustion chamberGas turbine plantsCombustorTurbine

A midframe portion (313) of a gas turbine engine (310) is presented and includes a compressor section with a last stage blade to orient an air flow (311) at a first angle (372). The midframe portion (313) further includes a turbine section with a first stage blade to receive the air flow (311) oriented at a second angle (374). The midframe portion (313) further includes a manifold (314) to directly couple the air flow (311) from the compressor section to a combustor head (318) upstream of the turbine section. The combustor head (318) introduces an offset angle in the air flow (311) from the first angle (372) to the second angle (374) to discharge the air flow (311) from the combustor head (318) at the second angle (374). While introducing the offset angle, the combustor head (318) at least maintains or augments the first angle (372).

Owner:SIEMENS ENERGY INC

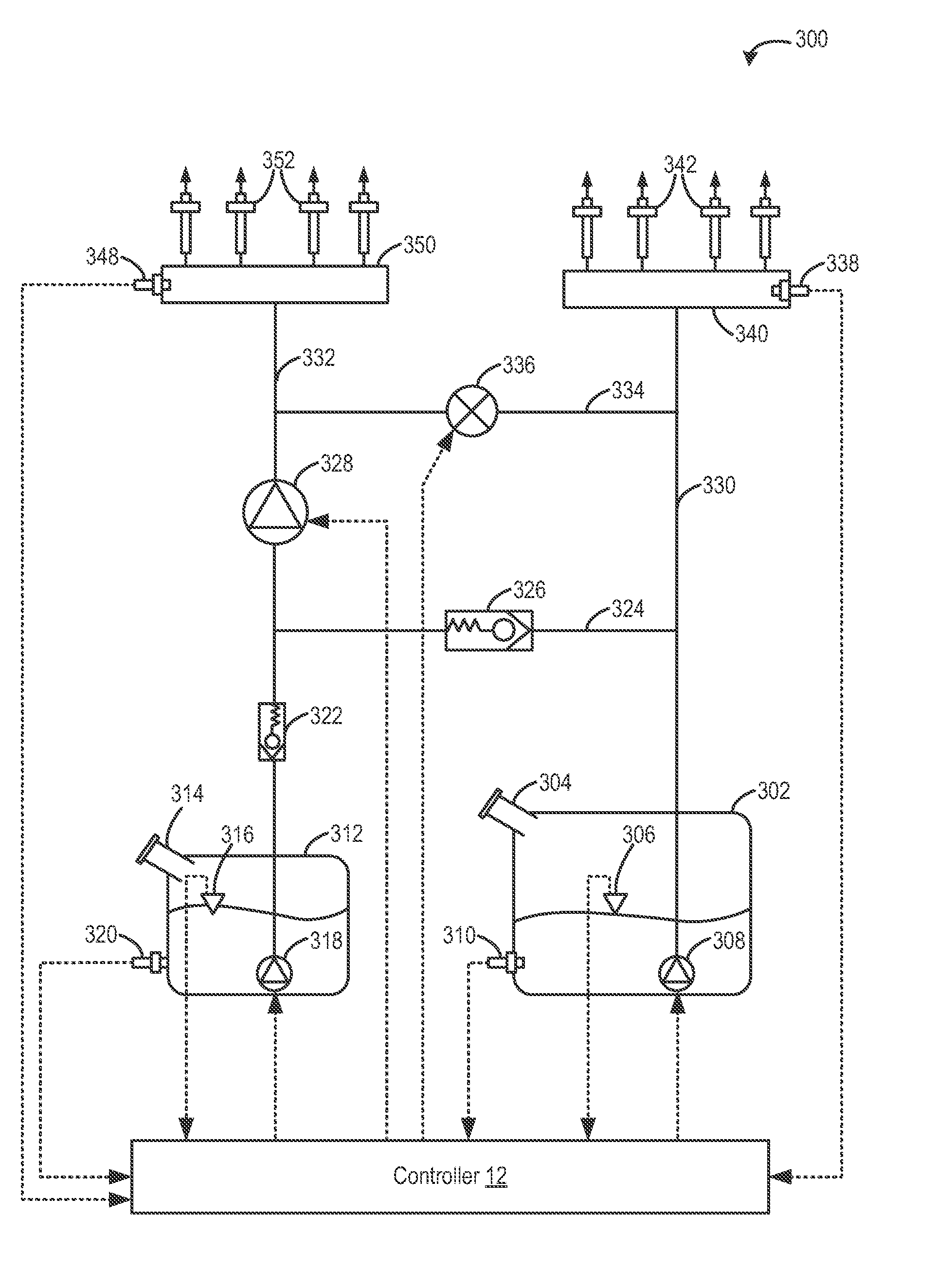

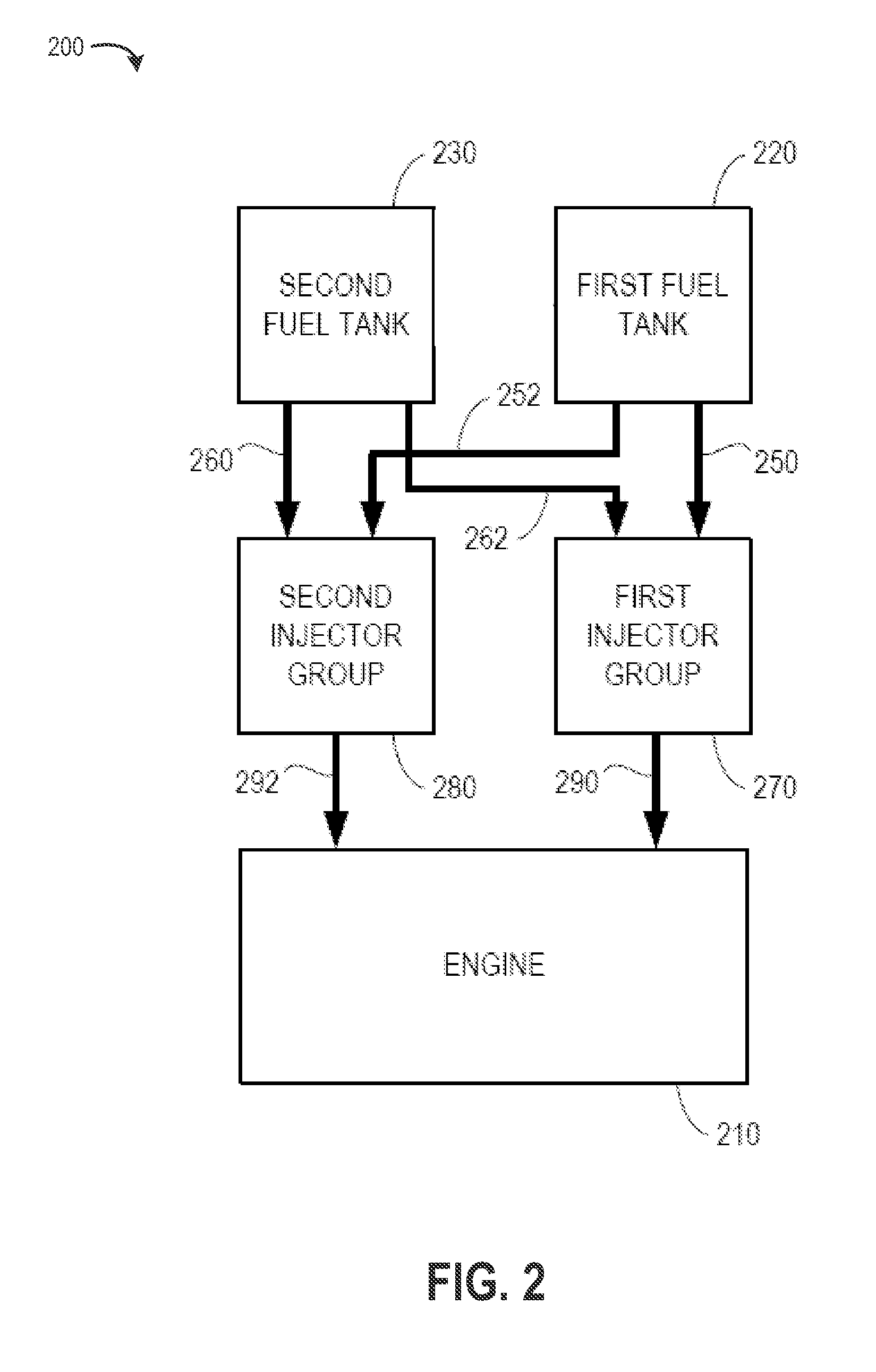

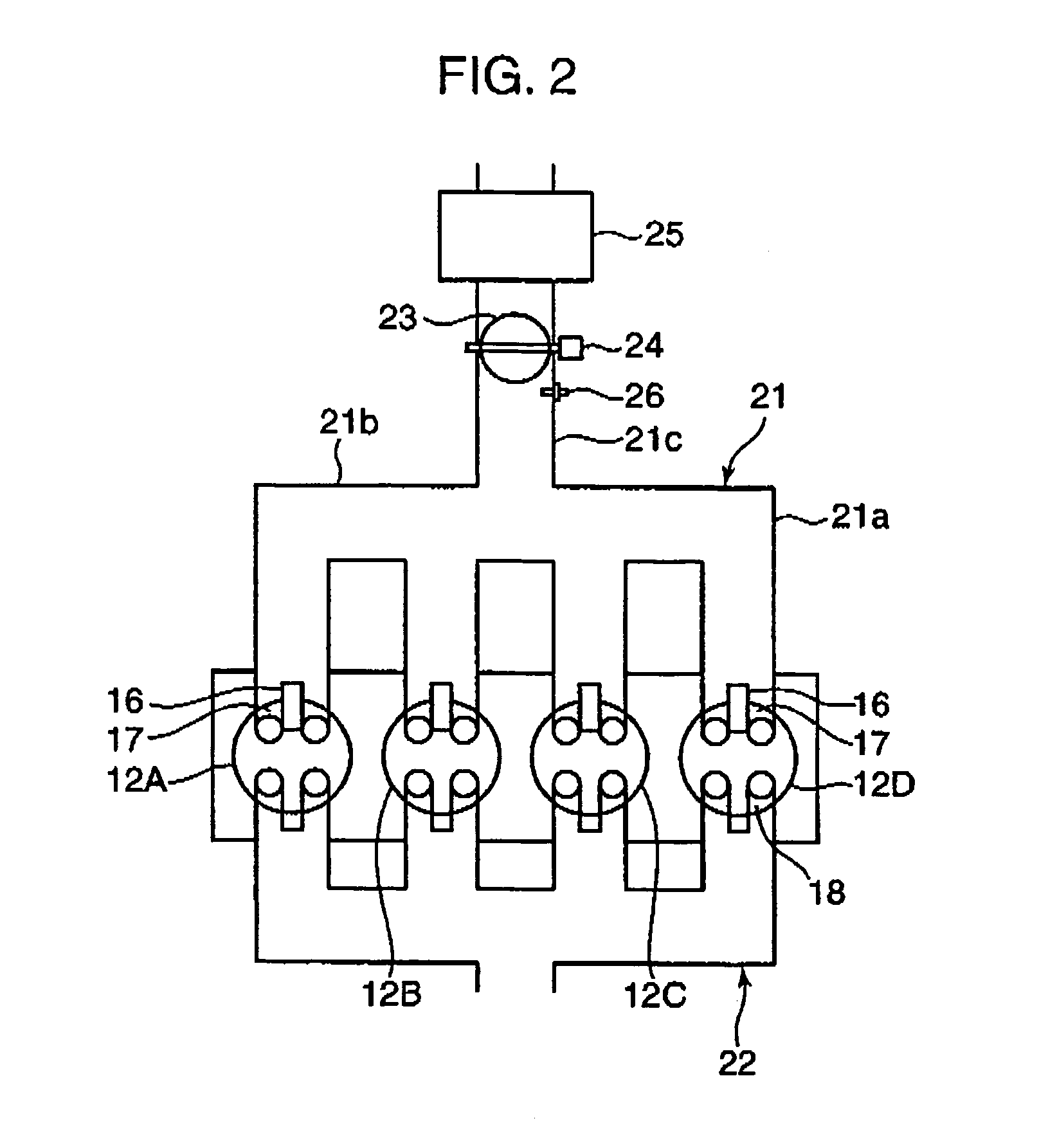

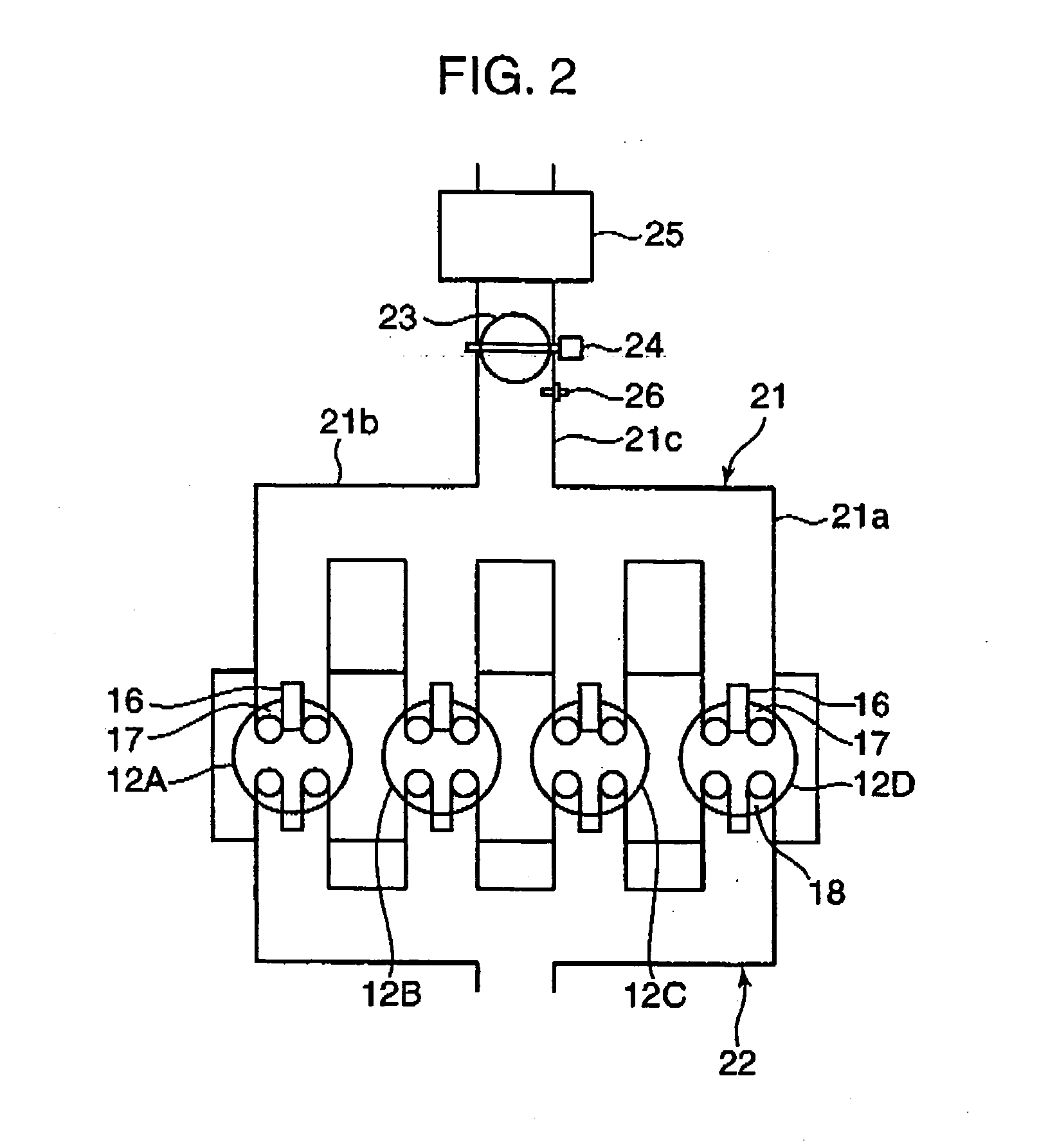

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

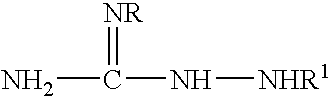

Fuel additives to maintain optimum injector performance

ActiveUS20090282731A1Maximize driveabilityMaximize fuel economyLiquid carbonaceous fuelsFuel additivesHydrogenCarboxylic acid

A diesel fuel, diesel fuel additive concentrate and method for improving the performance of fuel injectors for a diesel engine are provided. The diesel fuel includes a major amount of middle distillate fuel; and a reaction product of a hydrocarbyl substituted dicarboxylic acid or anhydride and an amine compound or salt. The amine compound has the formulawherein R is selected from the group consisting of a hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product contains at least one amino triazole group and is present in the fuel in an amount sufficient to improve the performance of diesel fuel injectors.

Owner:AFTON CHEMICAL

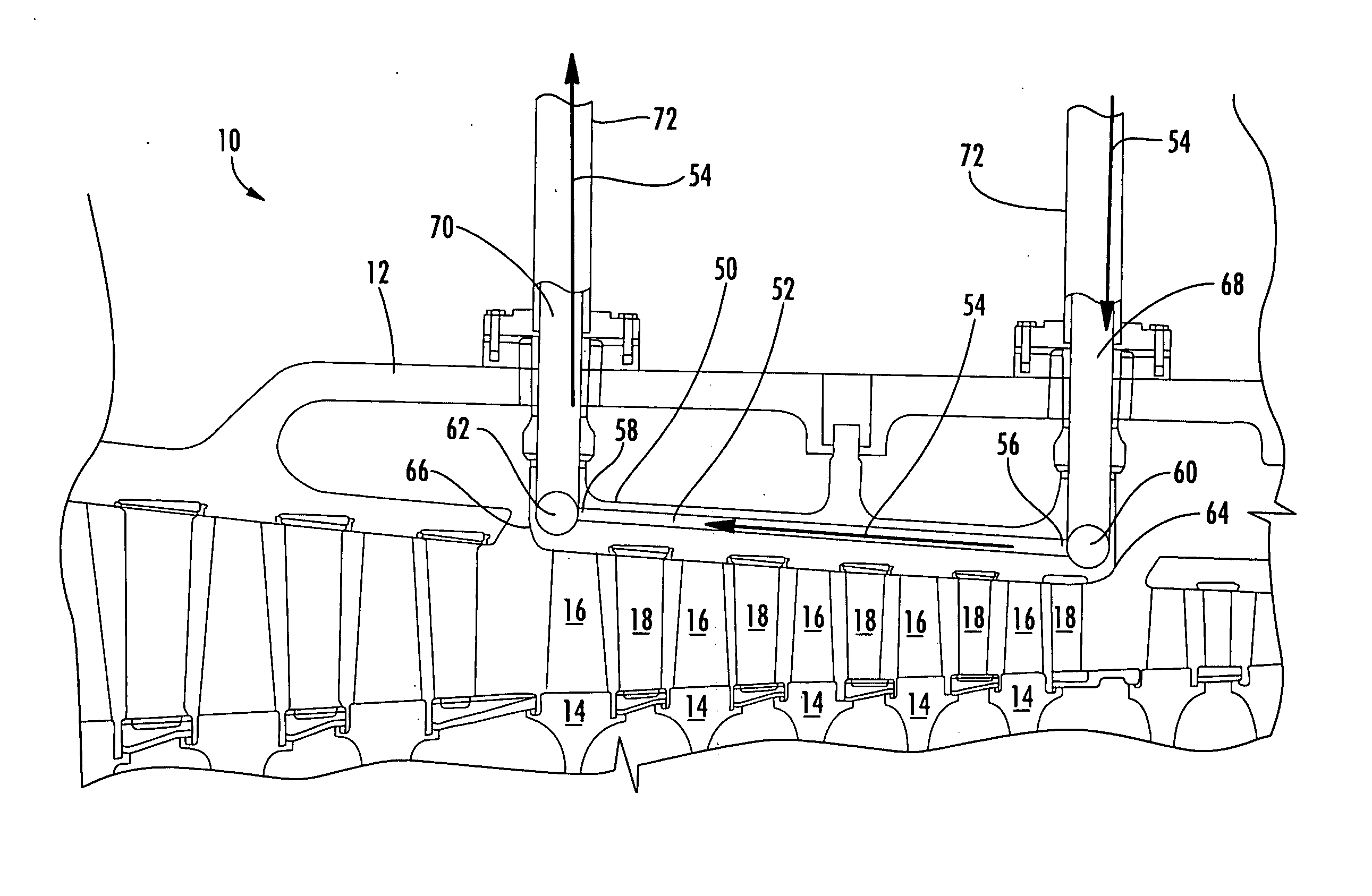

System for actively controlling compressor clearances

InactiveUS20060225430A1Reduce the temperatureMinimize radial expansionPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

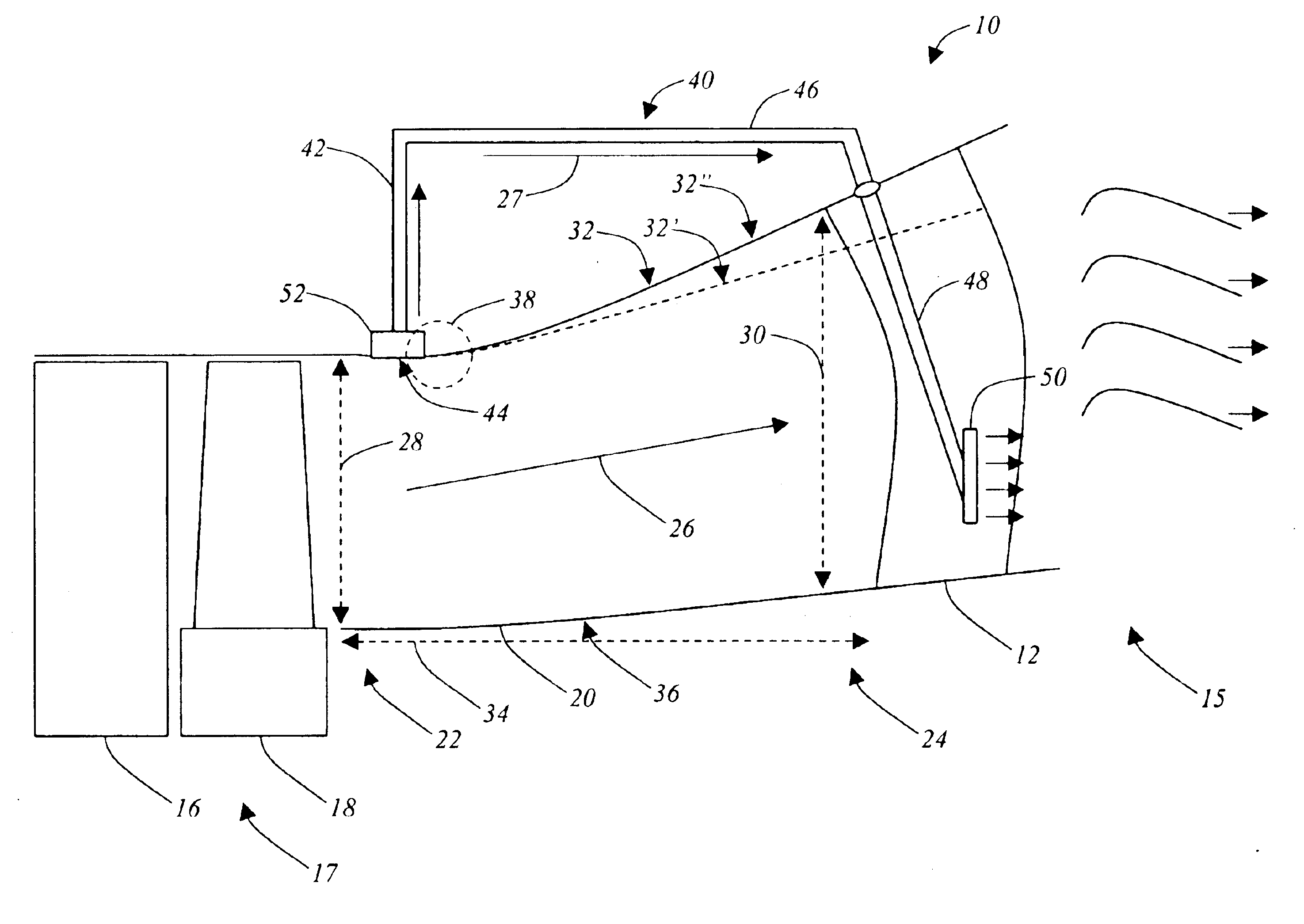

Self-aspirating high-area-ratio inter-turbine duct assembly for use in a gas turbine engine

InactiveUS6851264B2Improve performanceEnhanced aerodynamic benefitWind motor controlCombination enginesPressure differenceHigh pressure

In various embodiments, the present invention provides a means for improving gas turbine engine performance by applying fluid flow control to the inter-turbine duct joining a high-pressure turbine spool and an associated low-pressure turbine spool, allowing the low-pressure turbine spool to have a relatively larger diameter than the high-pressure turbine spool. One or more unobstructed fluid flow paths between one or more boundary layer suction ports disposed within the upstream end of the outer-body surface of the inter-turbine duct and the suction side of the associated low-pressure turbine nozzle are provided. Advantageously, the natural static pressure difference between these points results in a self-aspirating assembly. The fluid flow control provided by the respective suction and blowing forces generated allows for a relatively larger diameter low-pressure turbine spool and / or relatively fewer low-pressure turbine nozzles to be used than is possible with conventional systems, assemblies, and methods. Thus, a gas turbine engine weight savings and optimized performance may be achieved.

Owner:GENERAL ELECTRIC CO

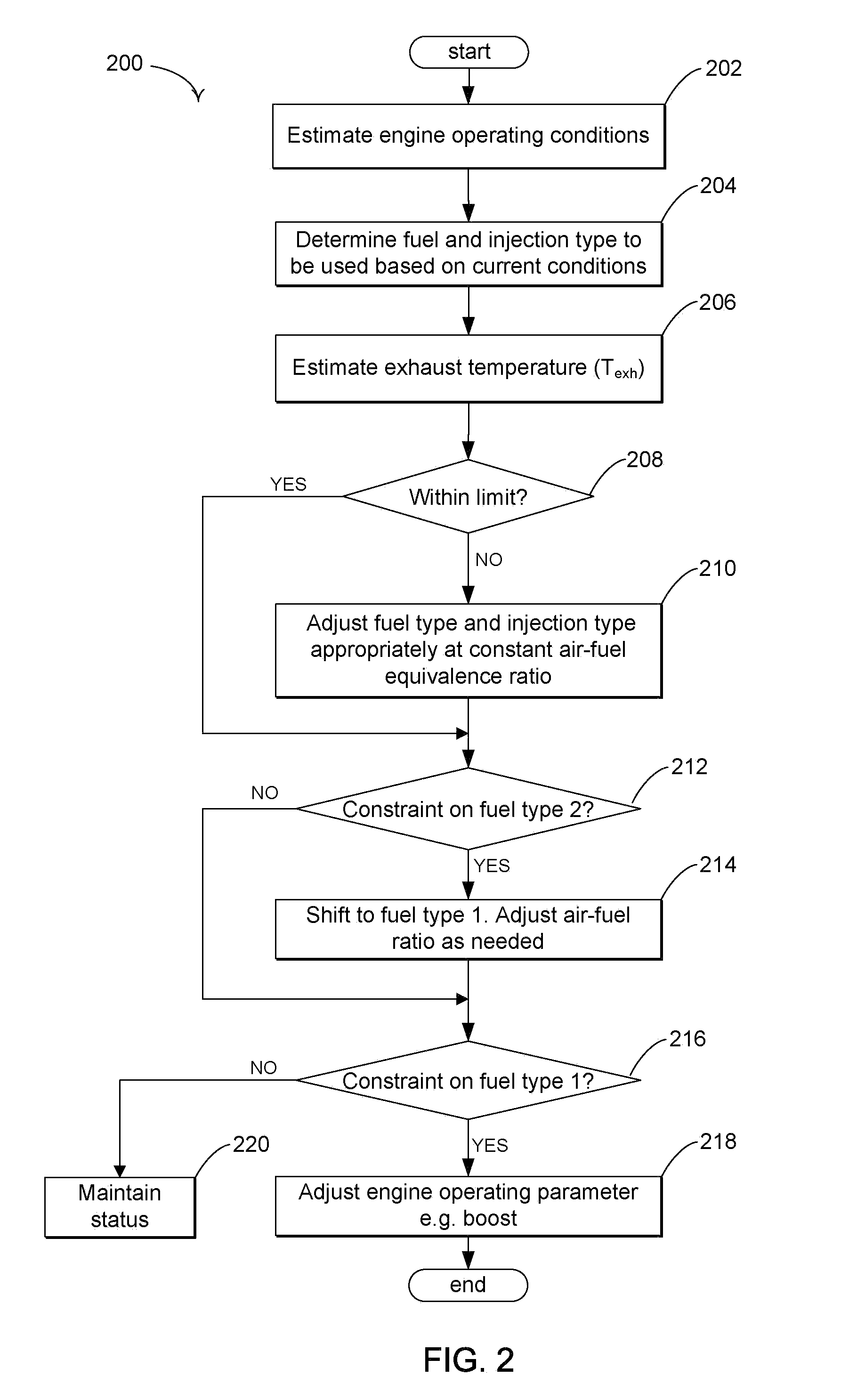

Engine exhaust temperature regulation

ActiveUS20090282810A1Improve engine performanceEasy to chargeElectrical controlInternal combustion piston enginesVaporizationInjector

In one example, a method of operating an engine in a vehicle is described. The method comprises delivering a first substance to a cylinder of the engine from a first injector; delivering a second substance to the cylinder of the engine from a second injector, where the second substance has a greater heat of vaporization than the first substance; and increasing injection of the second substance responsive to an exhaust over-temperature condition.

Owner:FORD GLOBAL TECH LLC

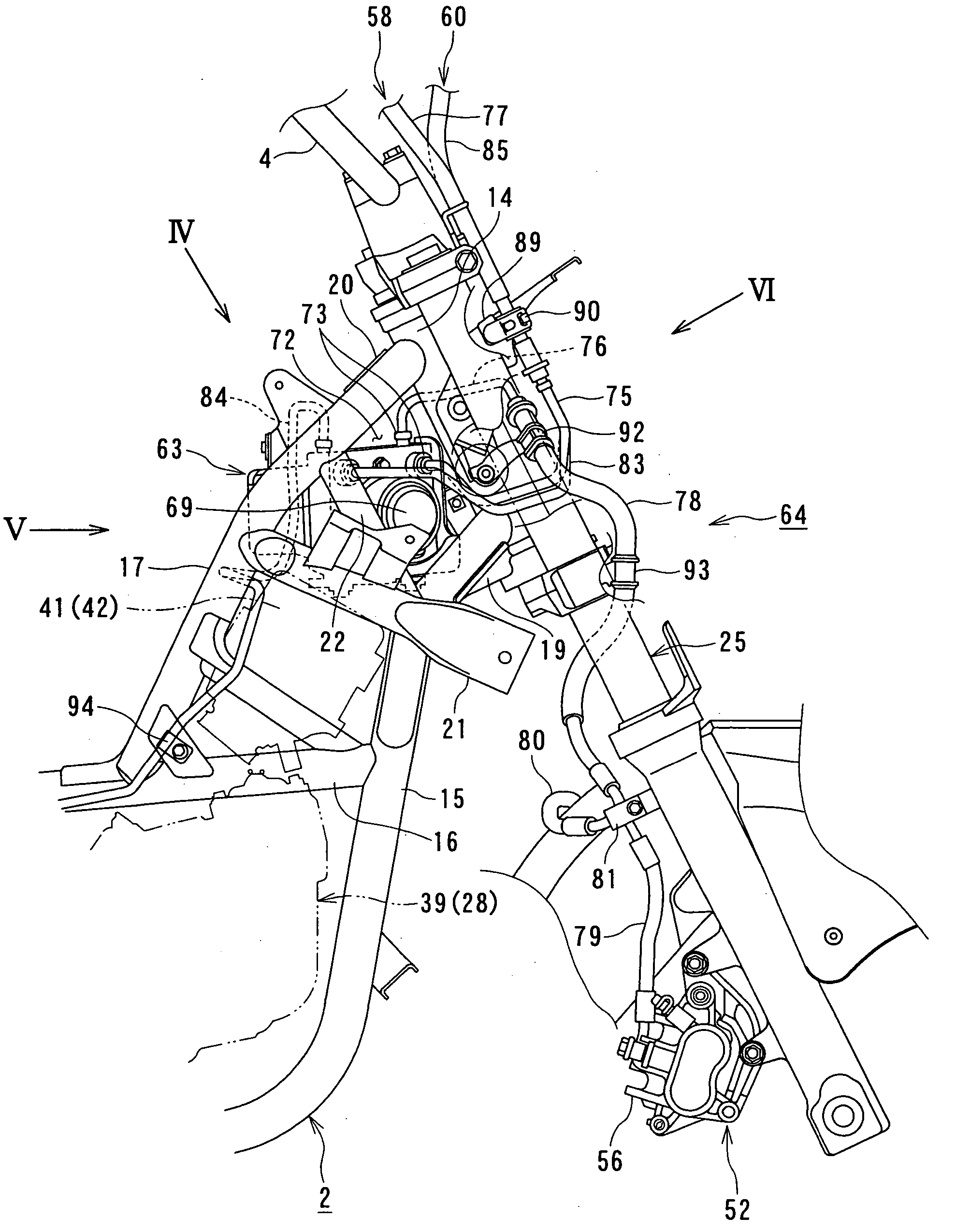

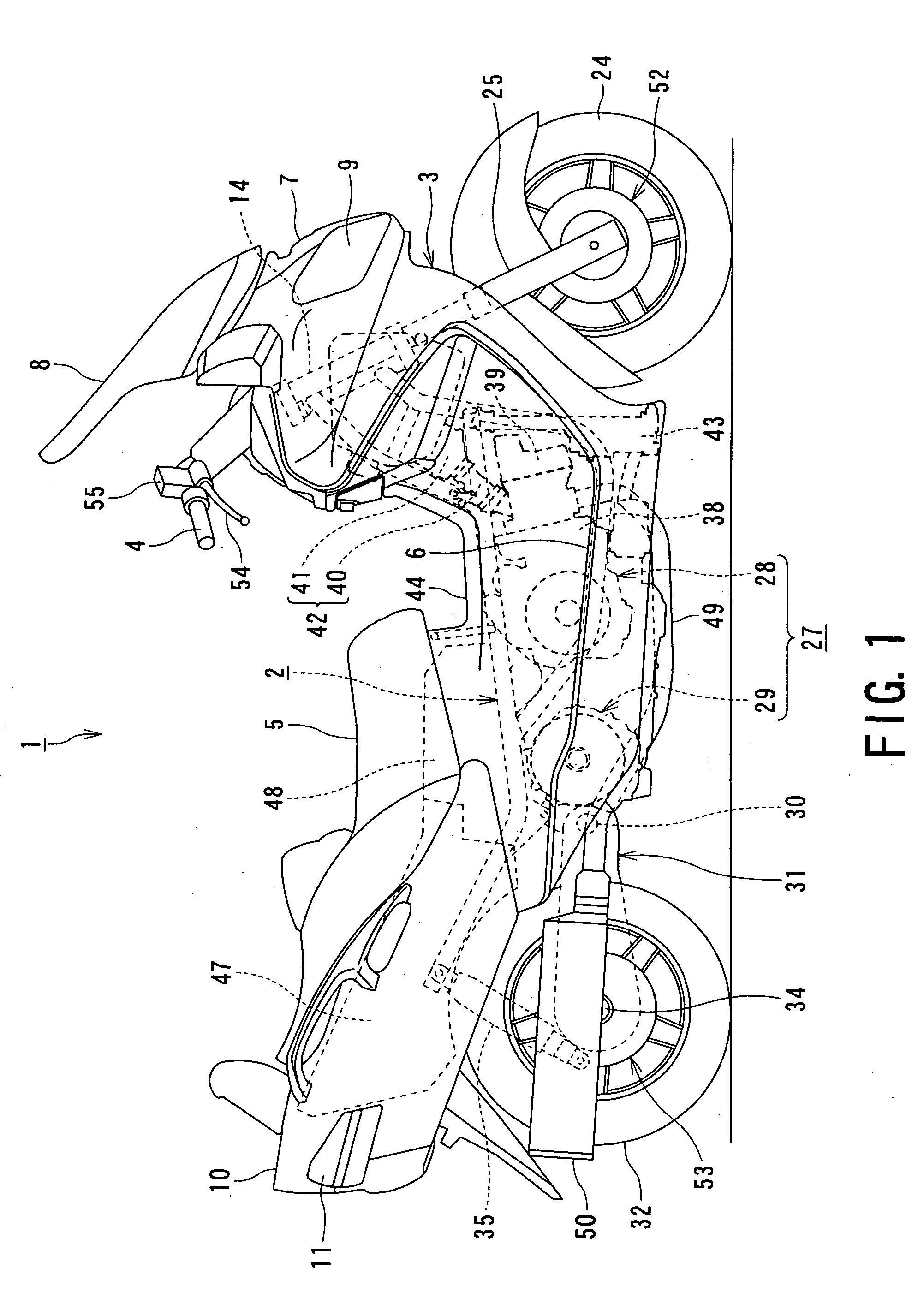

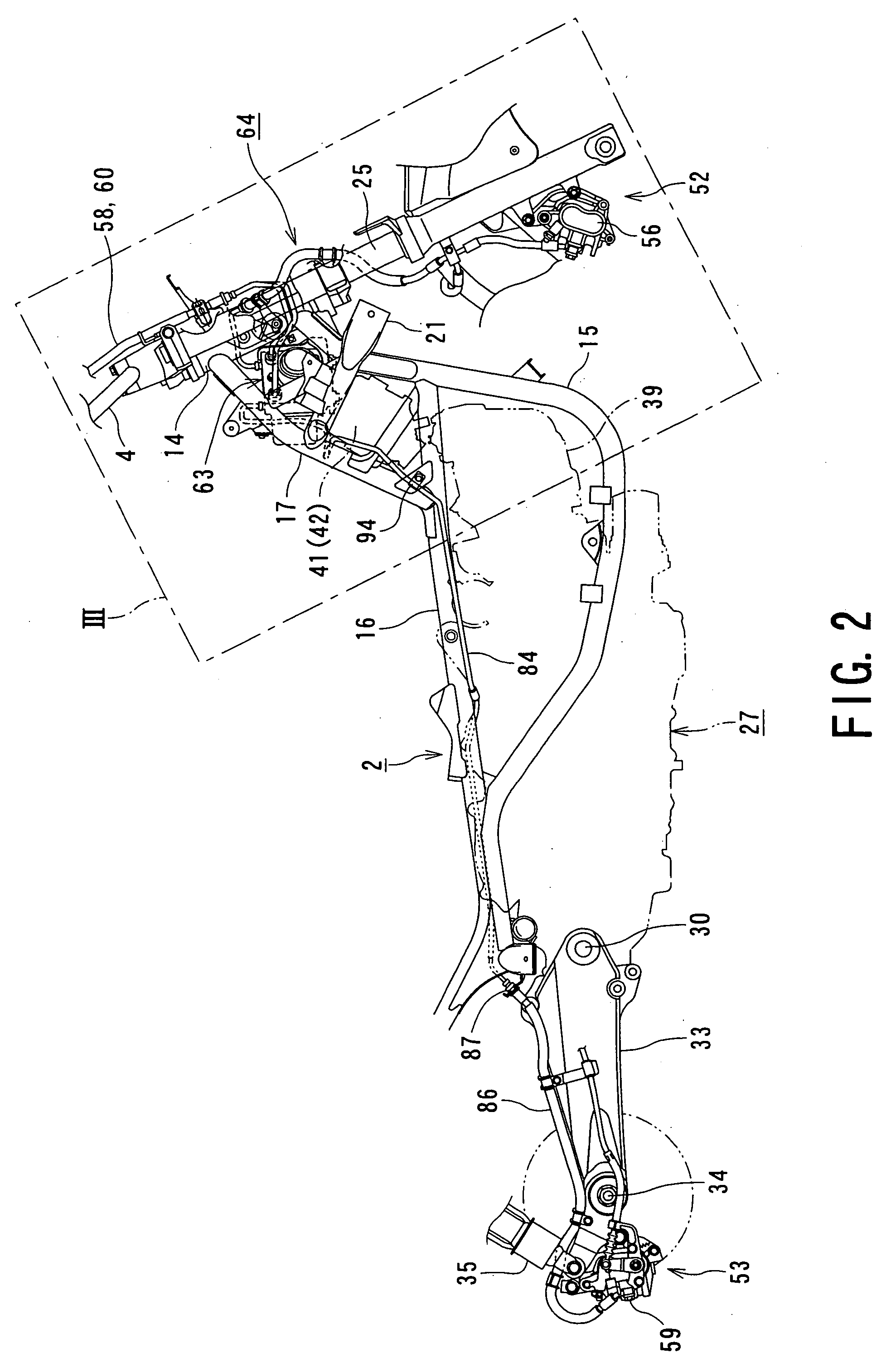

Motorcycle with antilock brake system

ActiveUS20050134114A1Improve braking performanceImprove engine performanceElectric propulsion mountingGas pressure propulsion mountingMaster cylinderEngineering

In a motorcycle provided with an antilock brake system, a front fork supporting a front wheel of a motorcycle is supported to be rotatable by a head pipe which is located at the front end portion of a body frame of a motorcycle, a handle-bar is secured to an upper end portion of the head pipe, master cylinders attached to the handle-bar are connected to hydraulic wheel brakes, respectively, via brake pipes. An antilock brake system includes an ABS-unit for antilock control disposed in an intermediate portion of the brake pipes. The ABS-unit is disposed immediately behind the head pipe and between a pair of body frame components disposed on both lateral sides of the motorcycle body and extending, from the head pipe, obliquely downward and backward, while extending outward in directions opposite to each other in the width direction of the motorcycle body.

Owner:SUZUKI MOTOR CORP

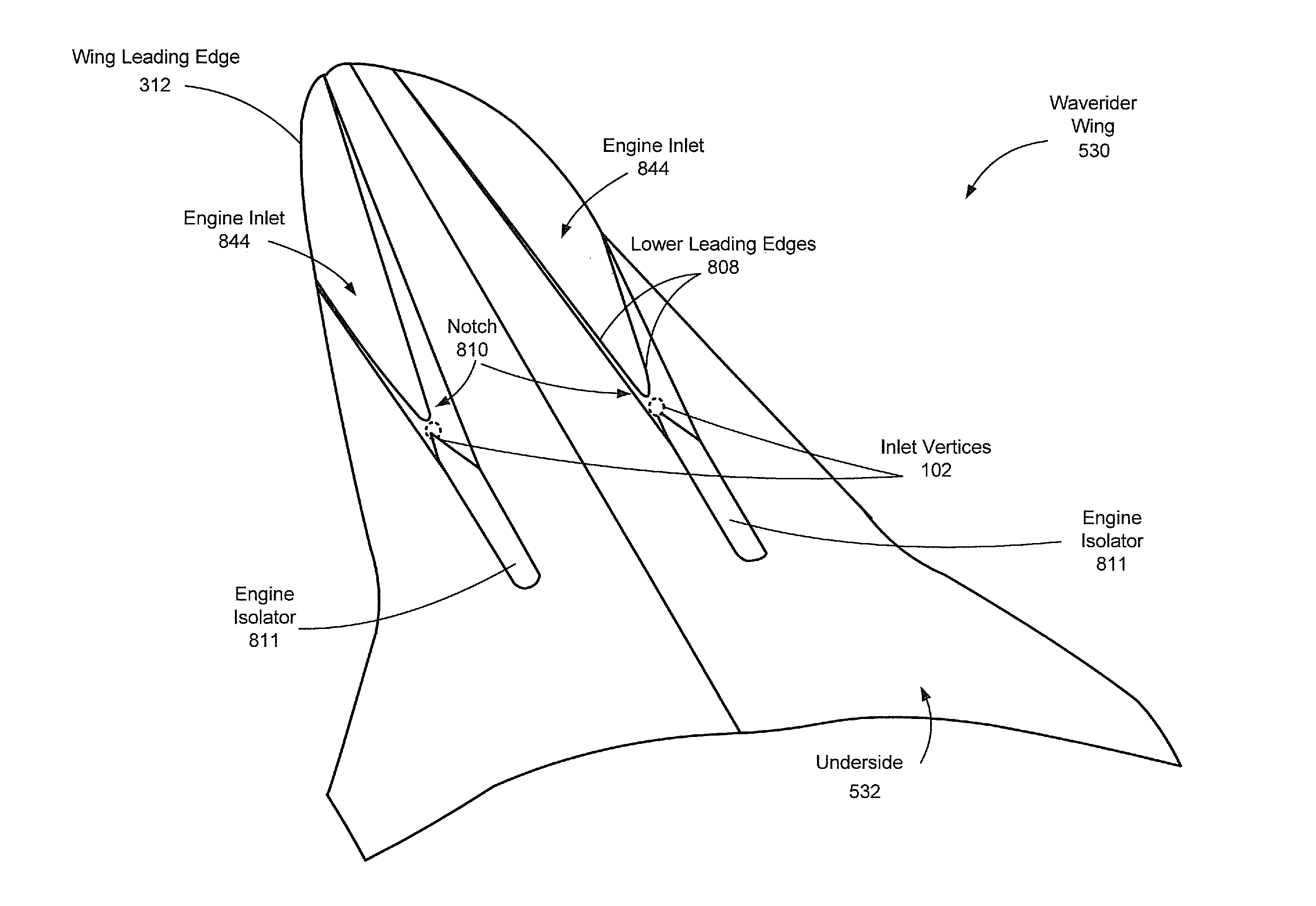

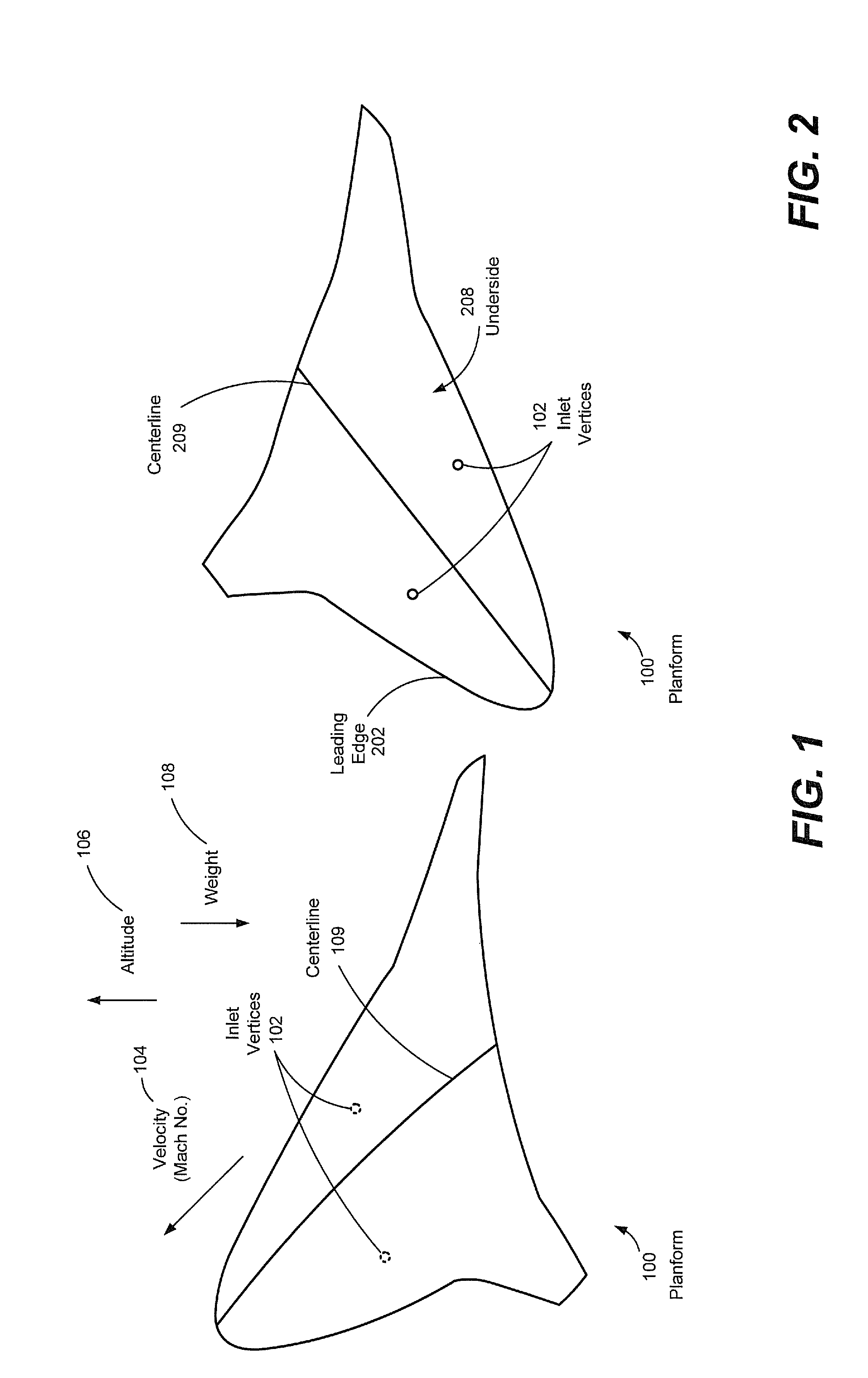

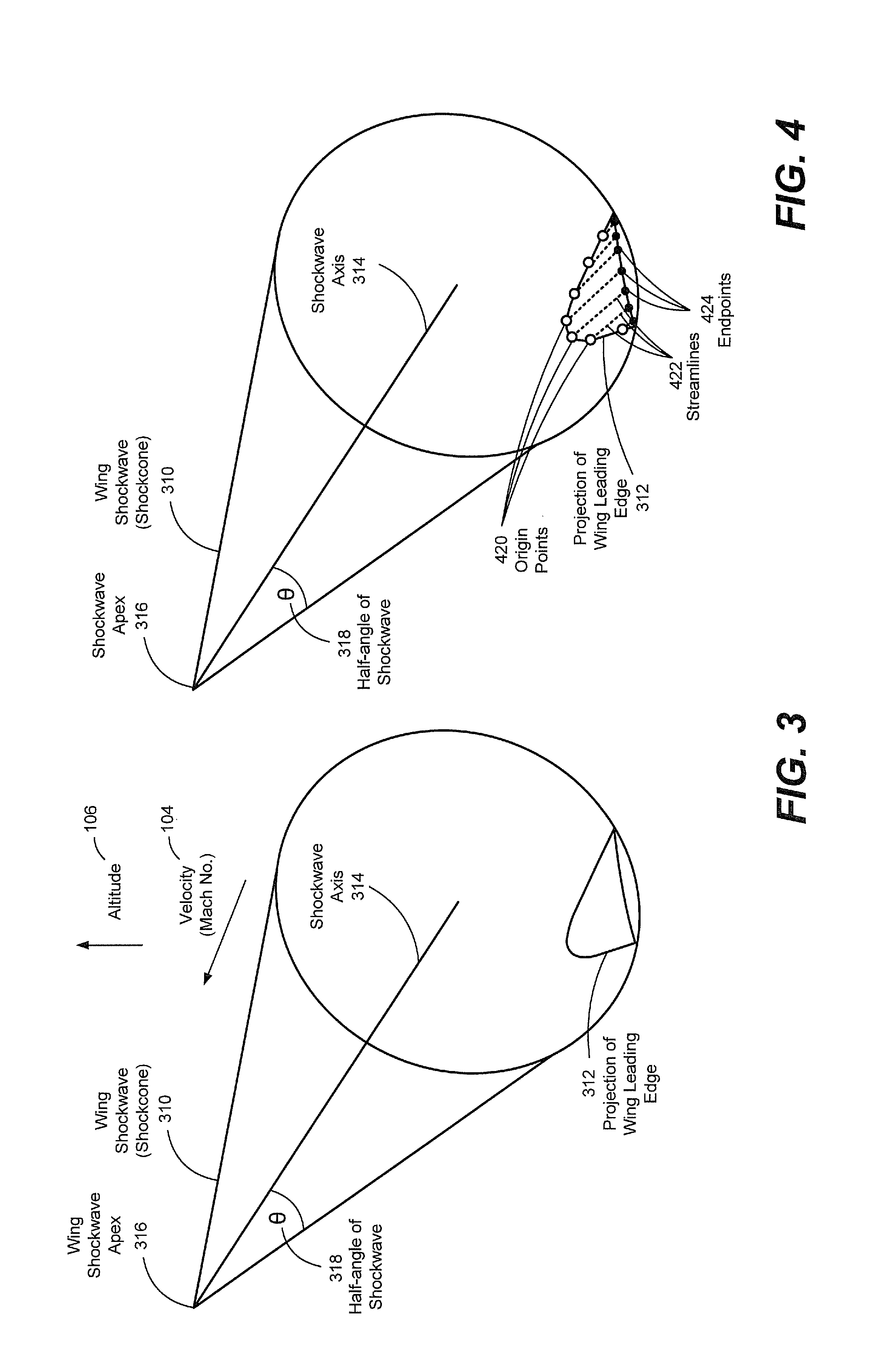

Integrated hypersonic inlet design

ActiveUS8256706B1Improve efficiencyImprove engine performanceAircraft navigation controlCombustion enginesLeading edgeNacelle

Methods, aircraft, and engine nacelles are disclosed. A wing leading edge of a planform is superimposed on a wing shockwave that extends in a first direction from a shockwave apex toward the wing leading edge. A waverider shape is streamline traced between the wing leading edge and a trailing edge of the planform to form a waverider wing. A position of an engine inlet vertex relative to the waverider wing is identified. An inlet shockwave is projected from the inlet vertex in a second direction generally opposed to the first direction. The inlet shockwave intersects the wing shockwave. An inlet leading edge of an engine inlet includes a lower leading edge including a plurality of points where the inlet shockwave intersects the wing shockwave.

Owner:THE BOEING CO

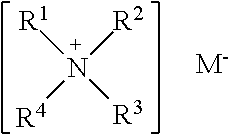

Fuel additive for improved performance of direct fuel injected engines

ActiveUS20130118062A1Reduce amount of depositImprove power recoveryCationic surface-active compoundsLiquid carbonaceous fuelsDiesel engineThermogravimetric analysis

A fuel composition for a direct fuel injected diesel engine, a method for improving performance of fuel injectors and a method for cleaning fuel injectors for a diesel engine. The fuel composition includes a major amount of fuel and a minor, effective amount of a quaternary ammonium salt having a thermogravimetric analysis (TGA) weight loss of greater than 50 wt. % at 350° C. The amount of quaternary ammonium salt present in the fuel is sufficient to improve performance of the direct fuel injected diesel engine having combusted the composition compared to the performance of such engine having combusted a fuel composition that does not contain the quaternary ammonium salt.

Owner:AFTON CHEMICAL

Engine starting system

ActiveUS7079941B2Improve engine performanceImprove rendering capabilitiesAnalogue computers for vehiclesPower operated startersAlternatorElectric power

Owner:MAZDA MOTOR CORP

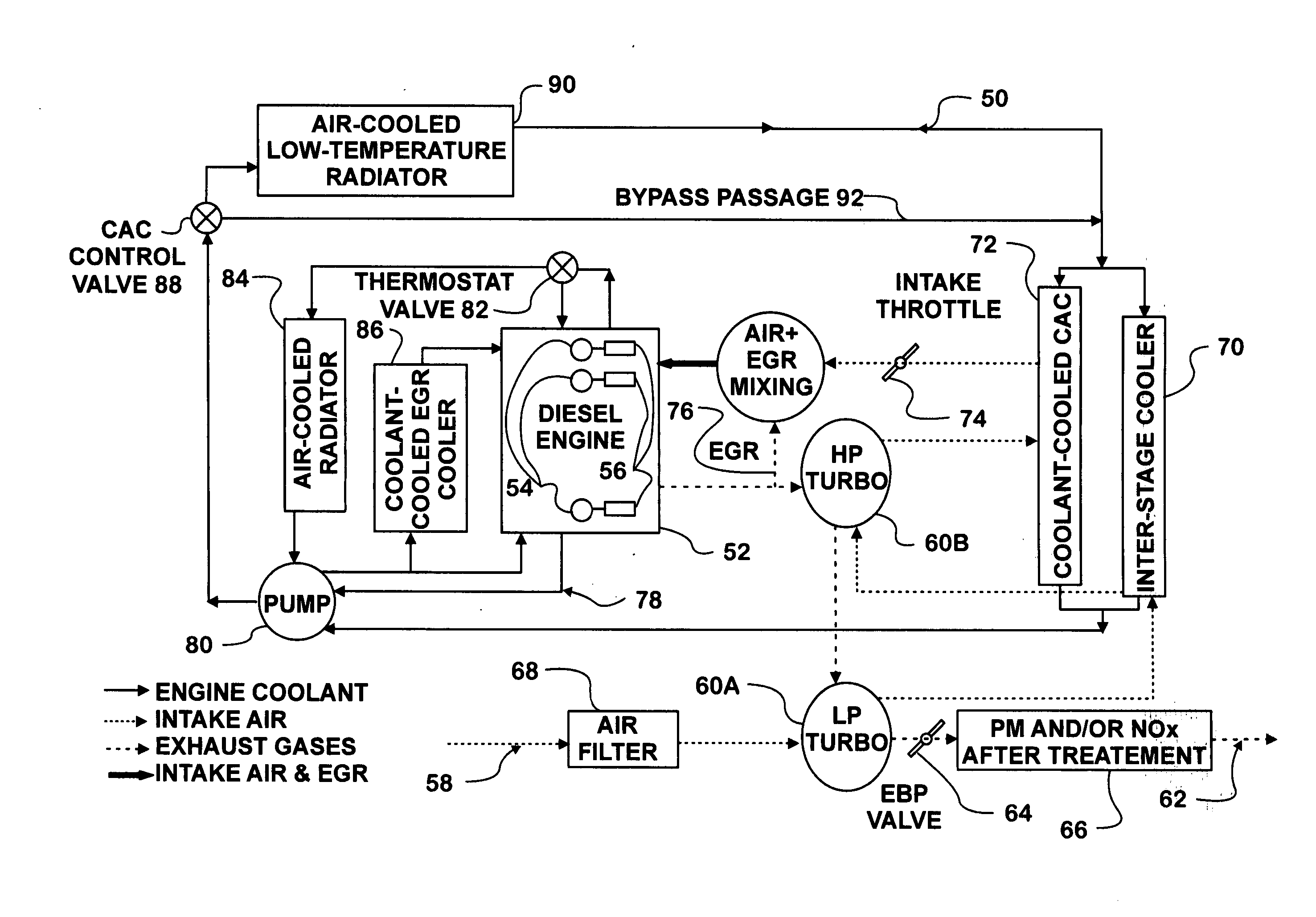

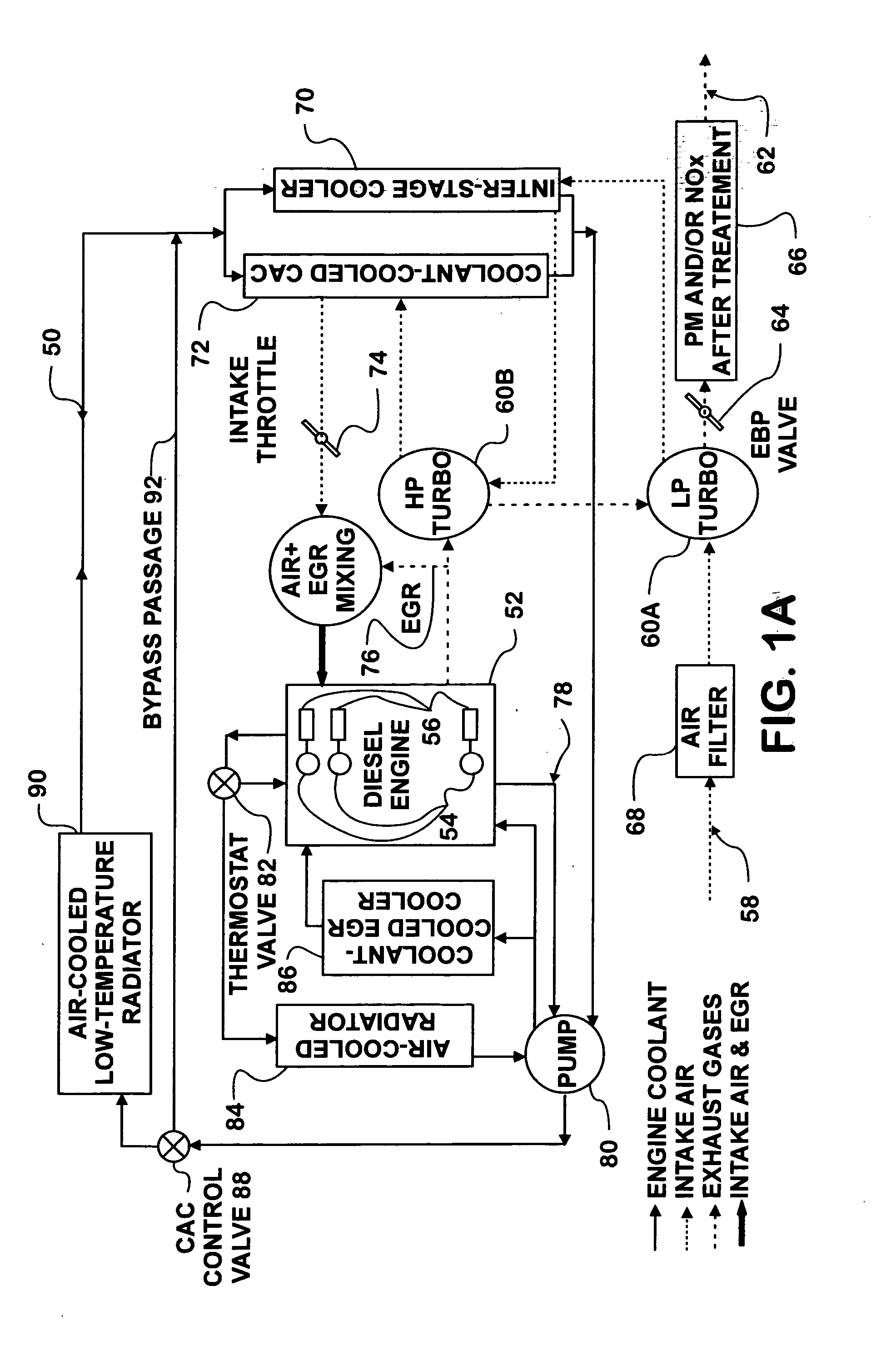

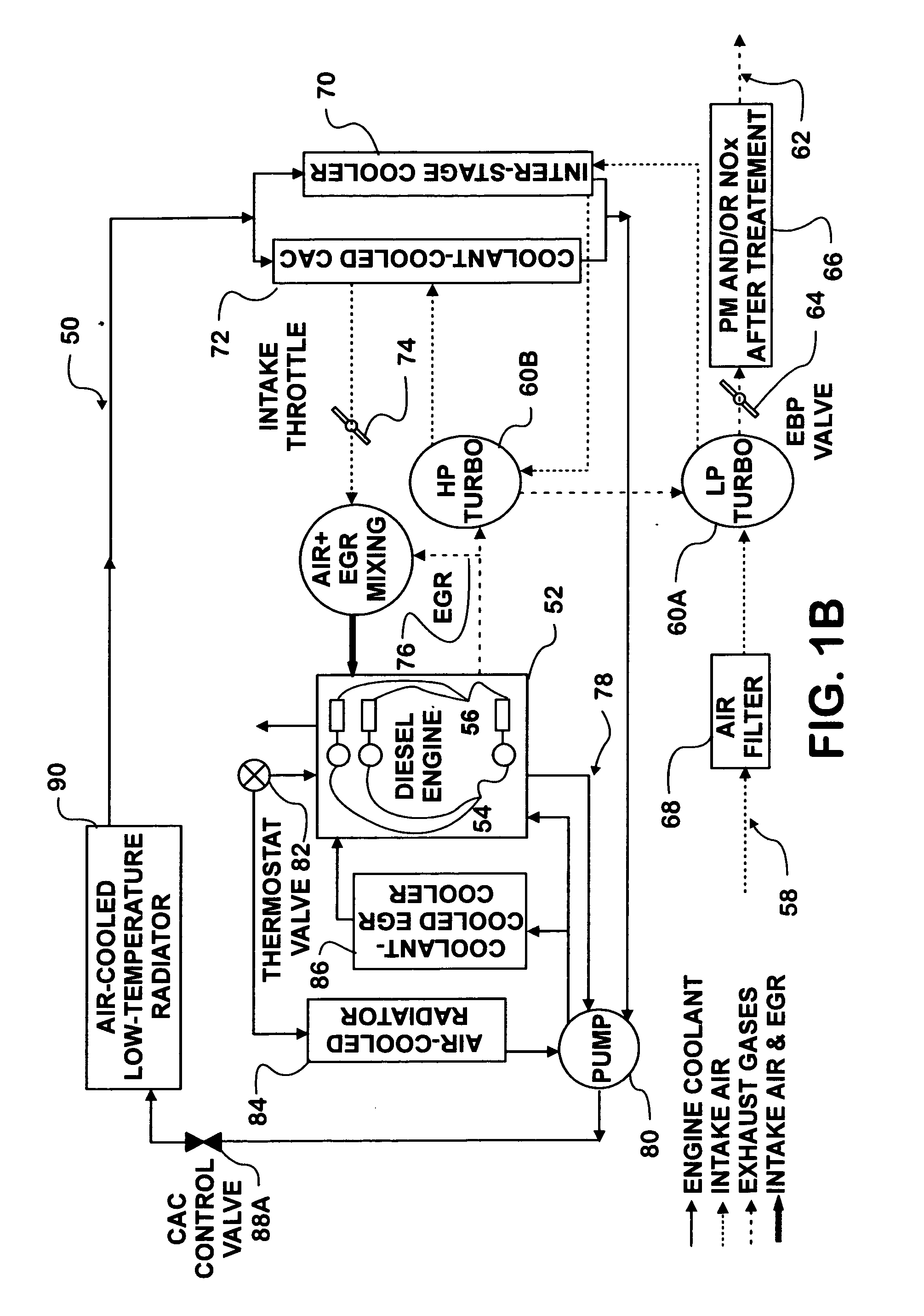

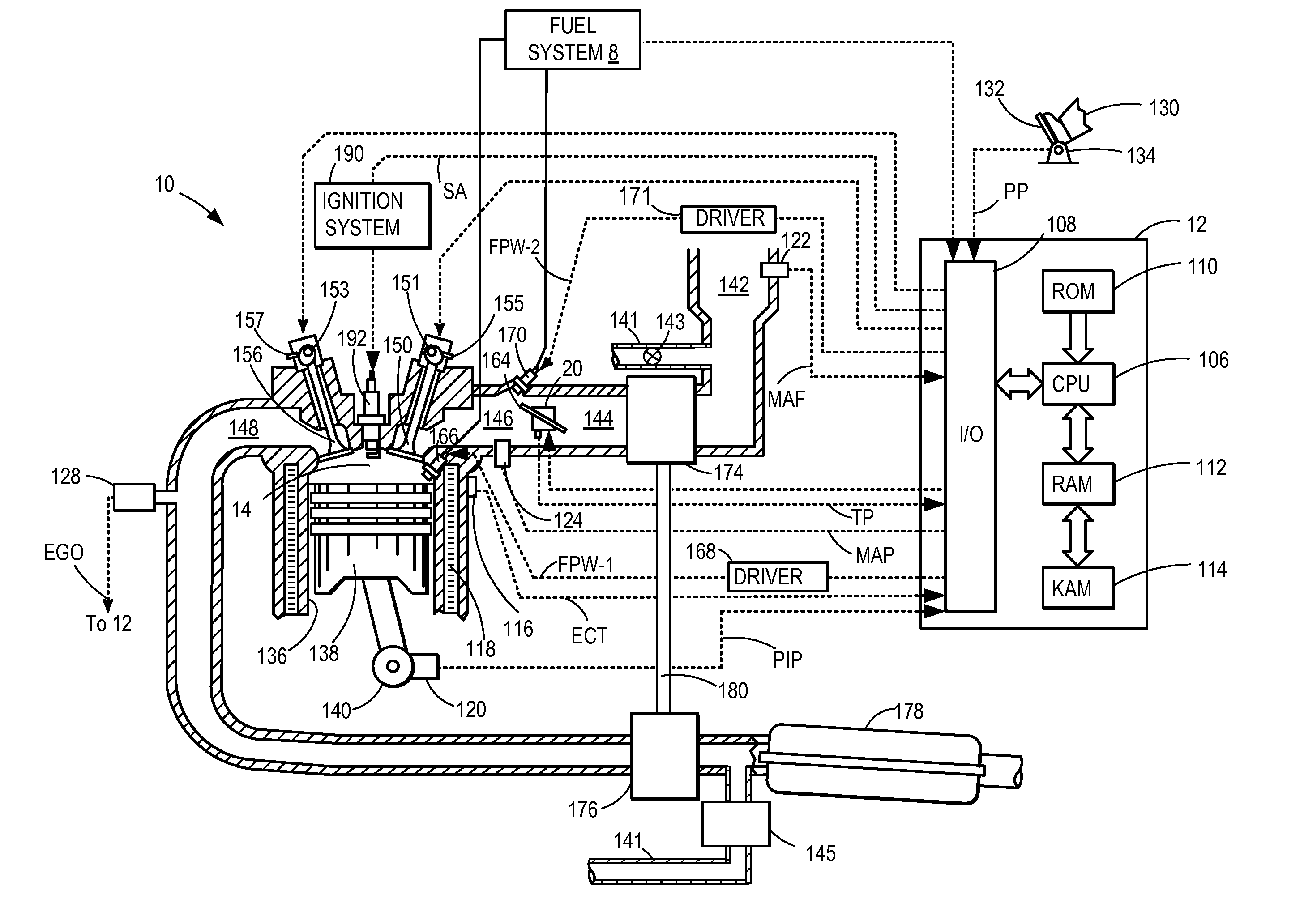

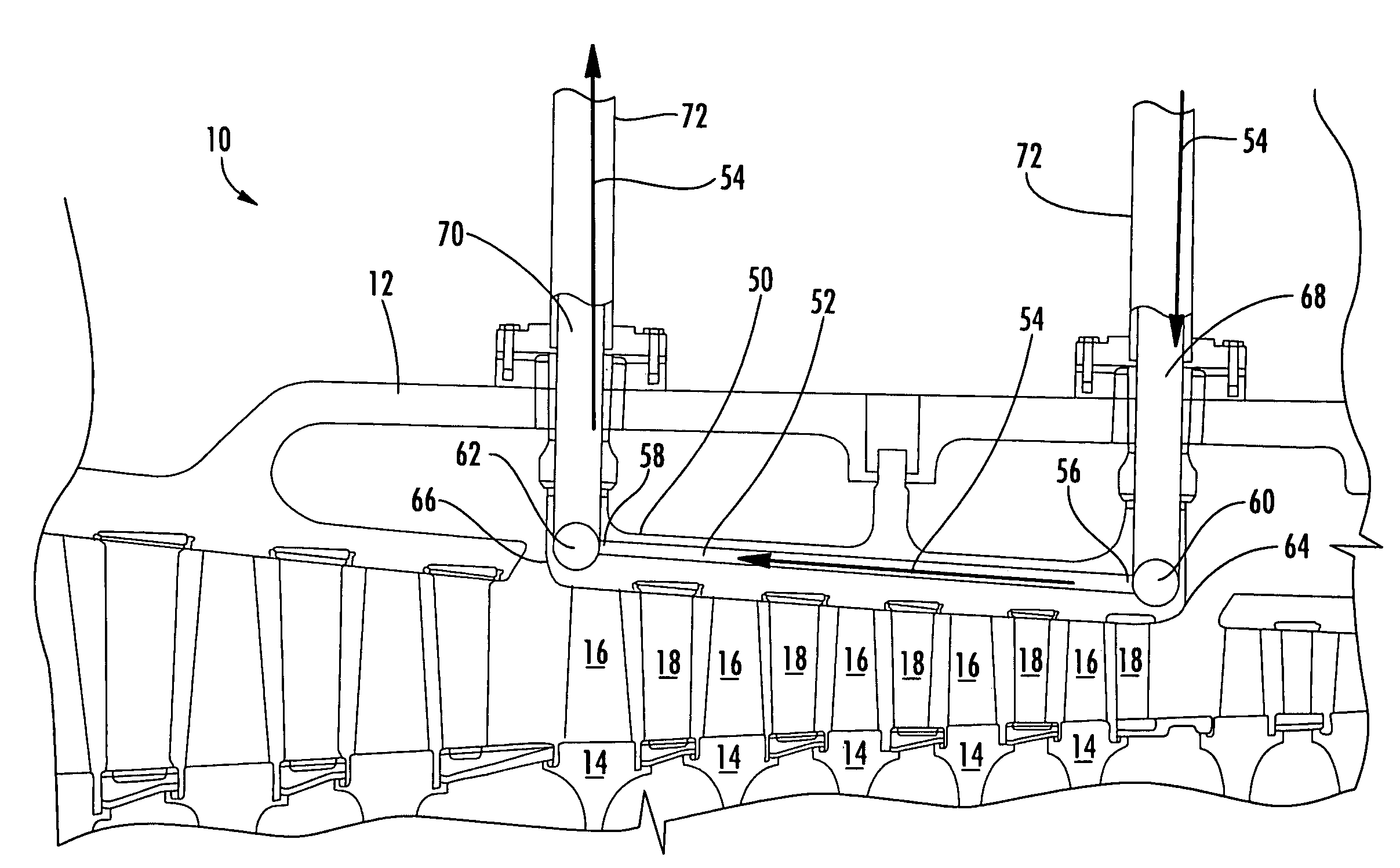

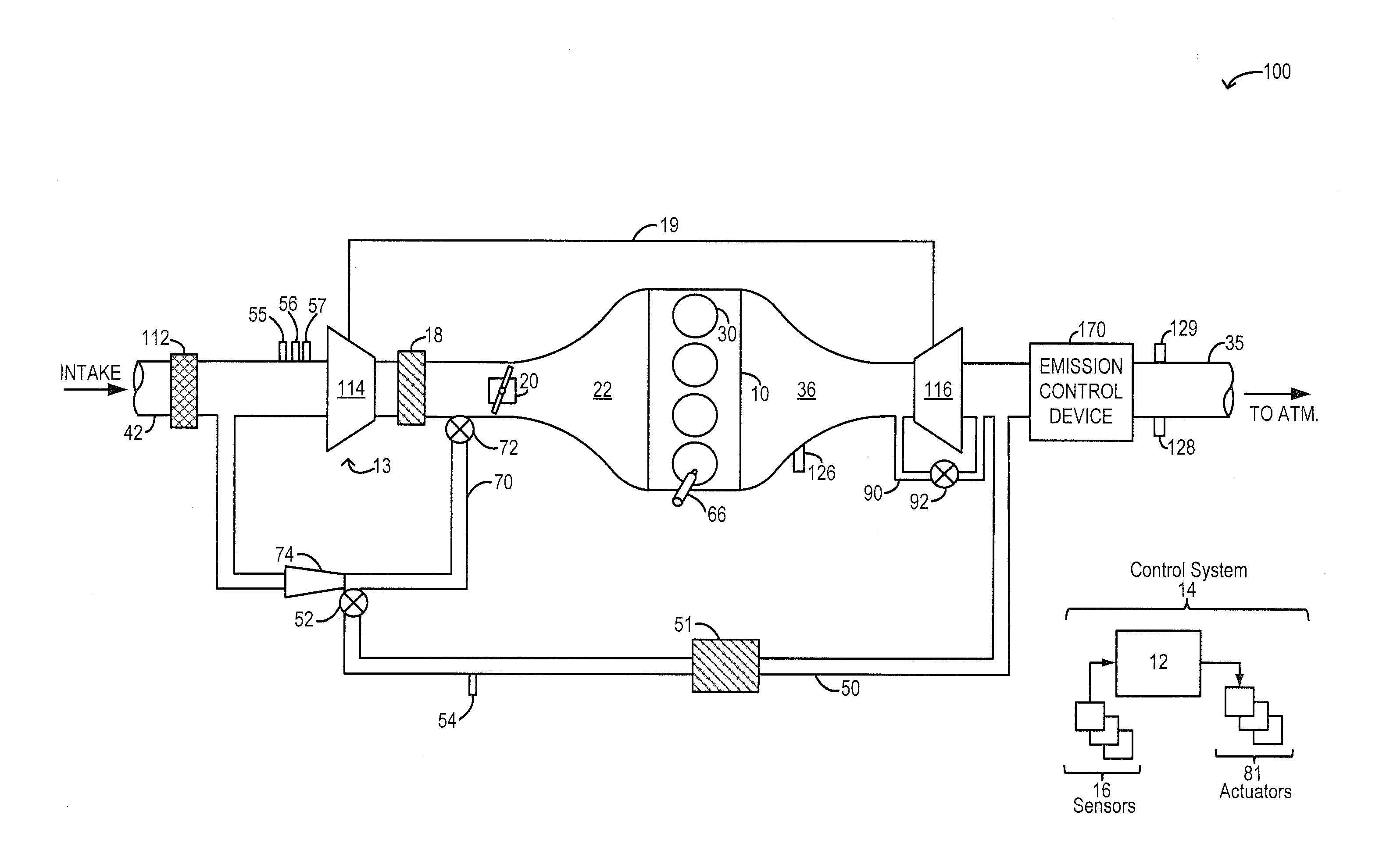

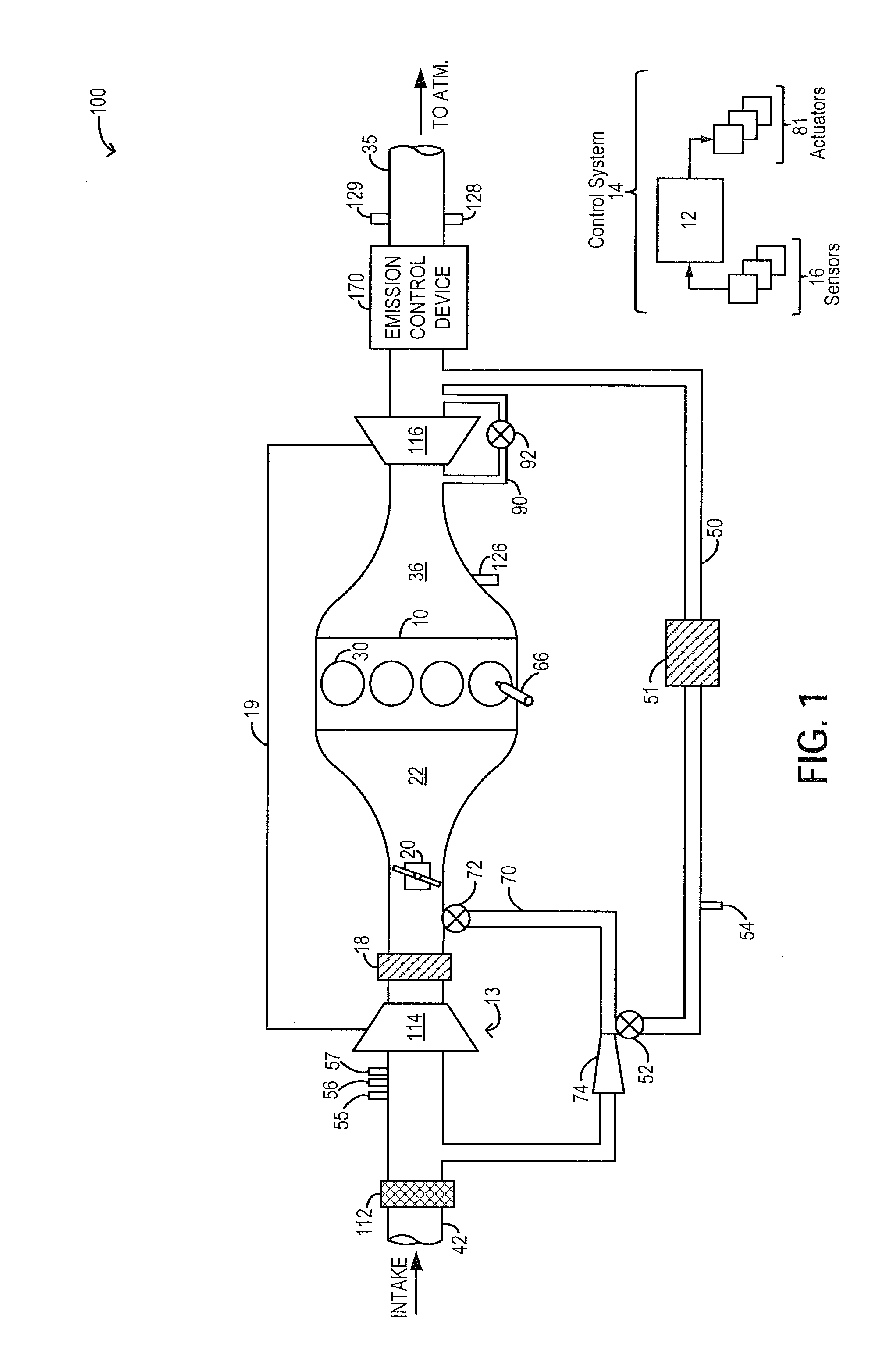

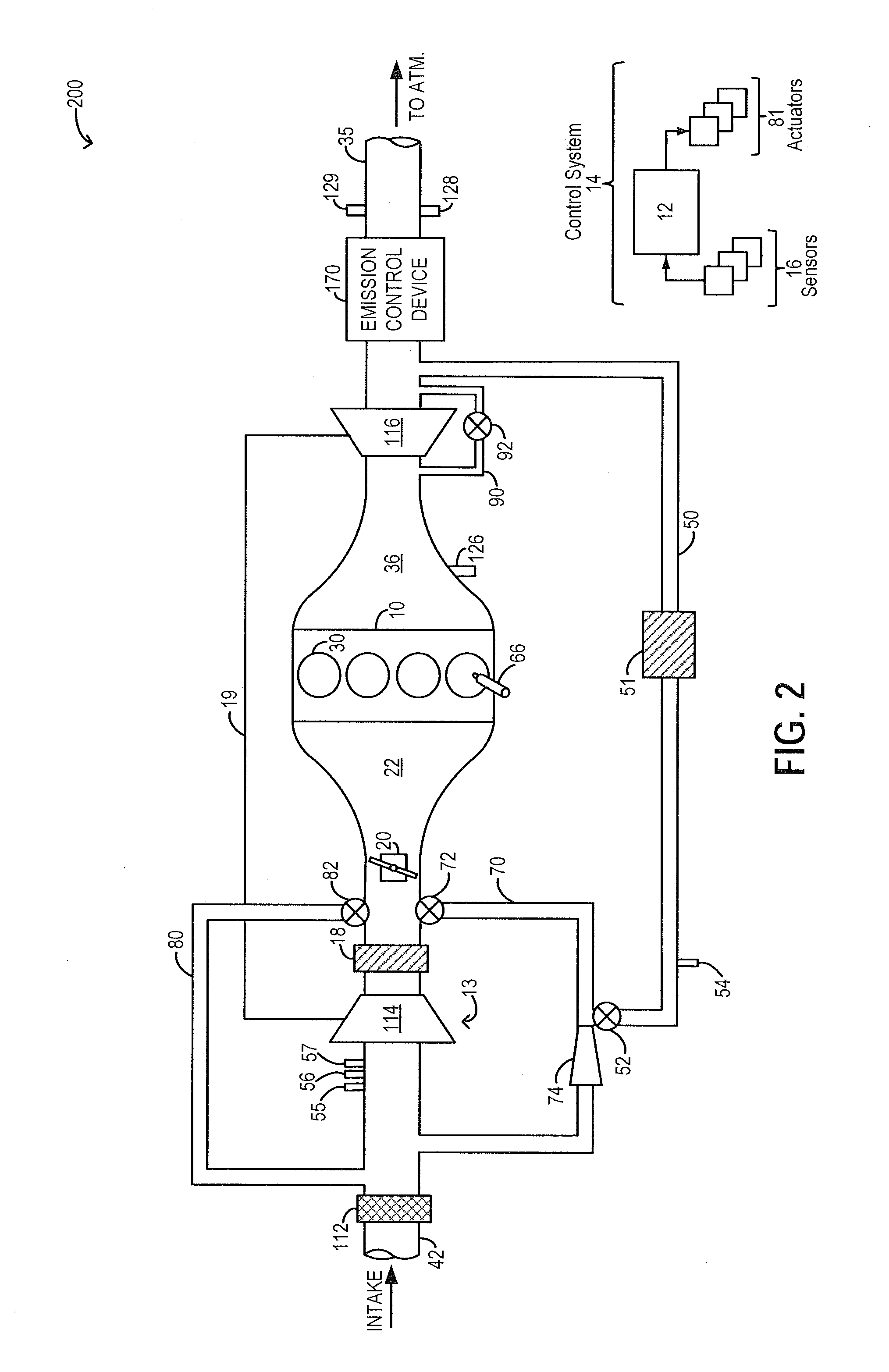

Flexible engine cooling and exhaust gas temperature controls for diesel after-treatment regeneration and engine performance improvement

InactiveUS20070199320A1Avoidance of added installationReduce Warranty CostsElectrical controlInternal combustion piston enginesTemperature controlAfter treatment

System, methods, and strategies for regulating charge air temperature in an intake manifold of an internal combustion engine (50) by controlling the flow rate and temperature of liquid engine coolant flowing through a liquid flow path of a charge air cooler (72) that is in heat exchange relationship with charge air entering the intake manifold over a range that provides for the charge air to be selectively heated and cooled by liquid engine coolant. The invention provides flexible control that is useful in controlling exhaust gas temperature for regeneration and / or efficiency restoration of exhaust after-treatment devices (66) as well as improved engine performance.

Owner:INT ENGINE INTPROP CO LLC

Methods and systems for turbocharger control

ActiveUS20110041493A1Improve engine performanceEliminates the potential disturbances from the throttleElectrical controlInternal combustion piston enginesTurbochargerControl theory

Methods are provided for controlling a turbocharged engine having a throttle and a turbocharger. One example method comprises, moving the throttle during boosted conditions, separating out effects on the throttle inlet pressure into a first portion corresponding to disturbances caused by the movement of the throttle, and a second, remaining, portion. The method further comprises adjusting the turbocharger based on the second portion and not the first portion.

Owner:FORD GLOBAL TECH LLC

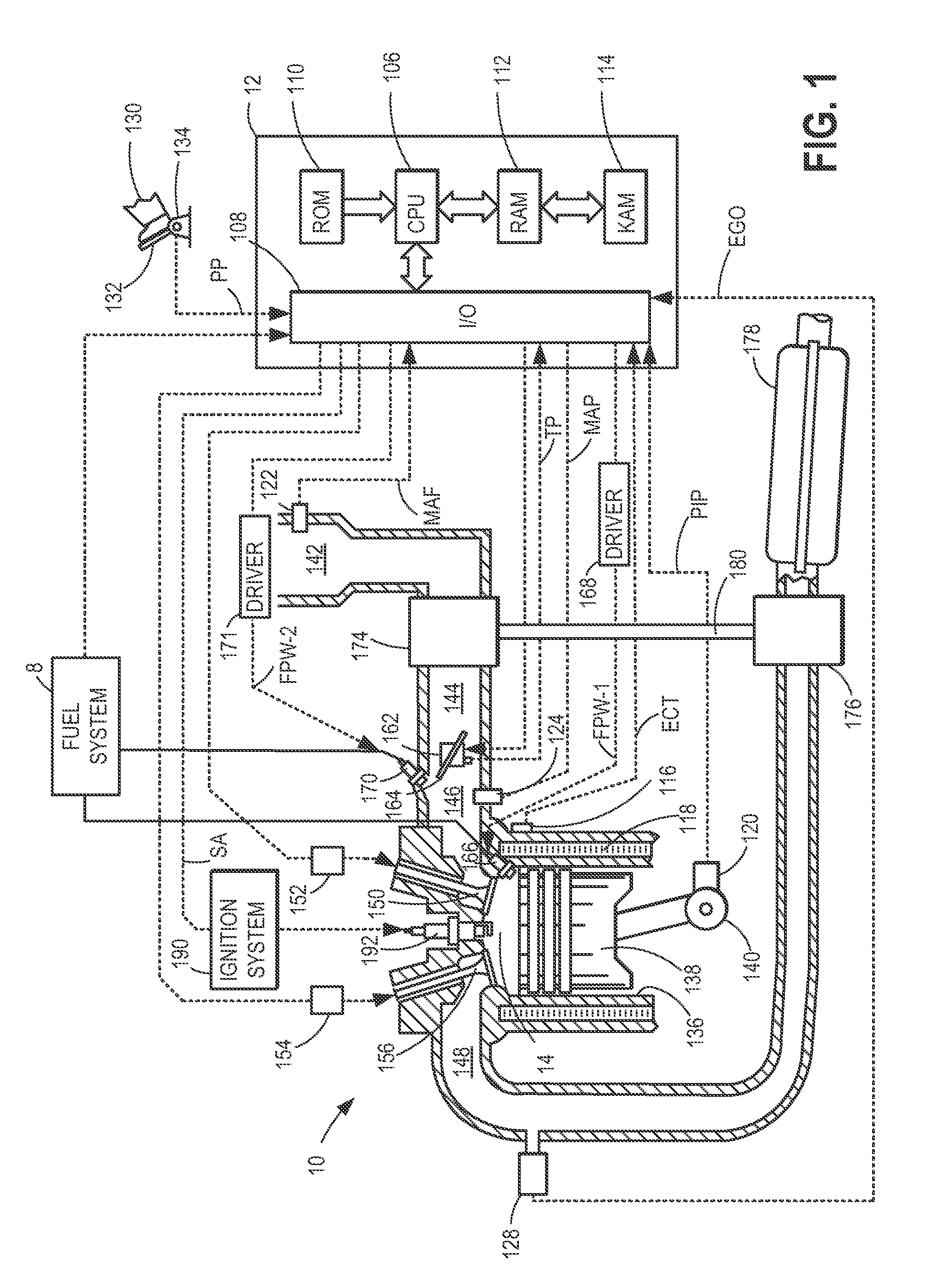

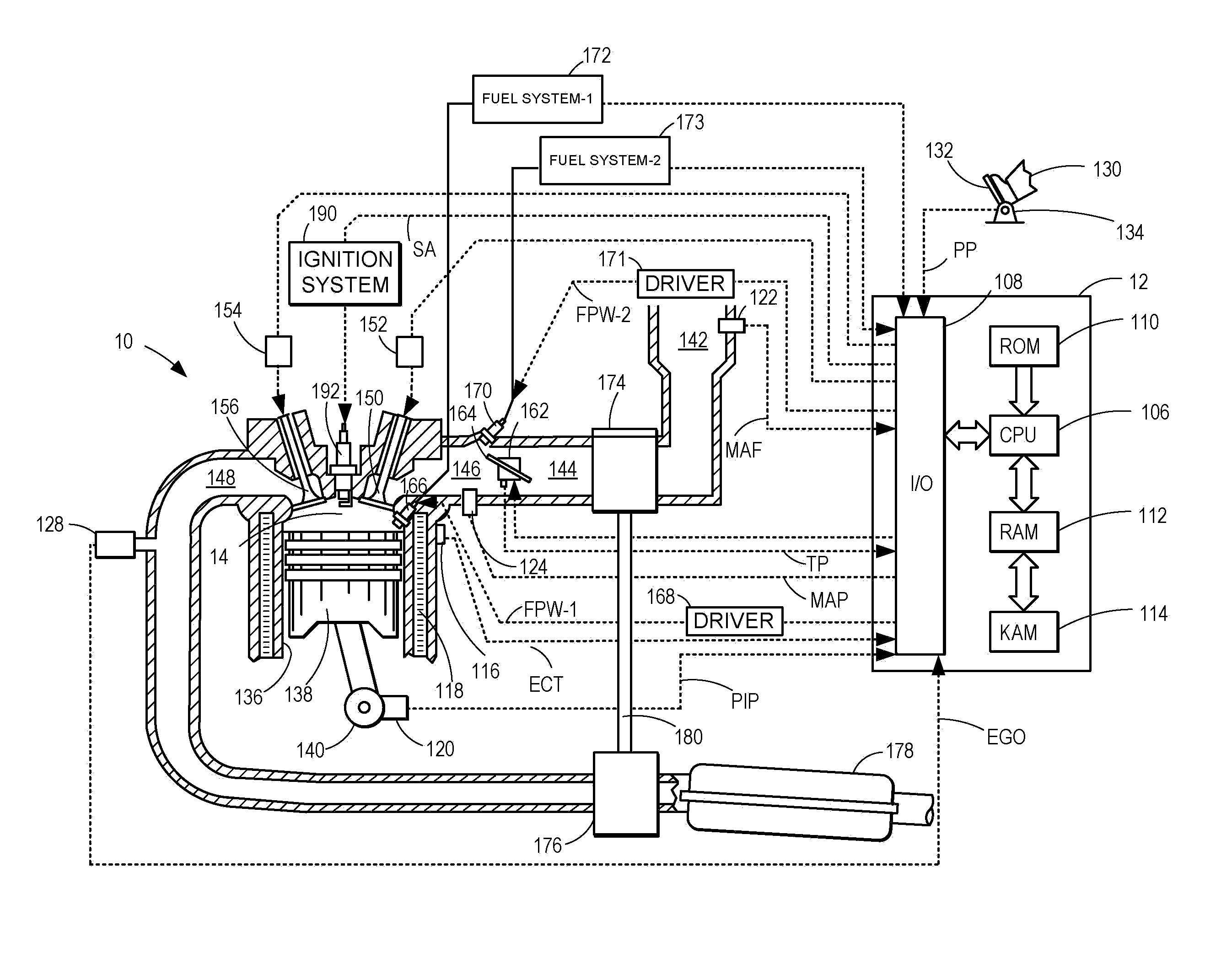

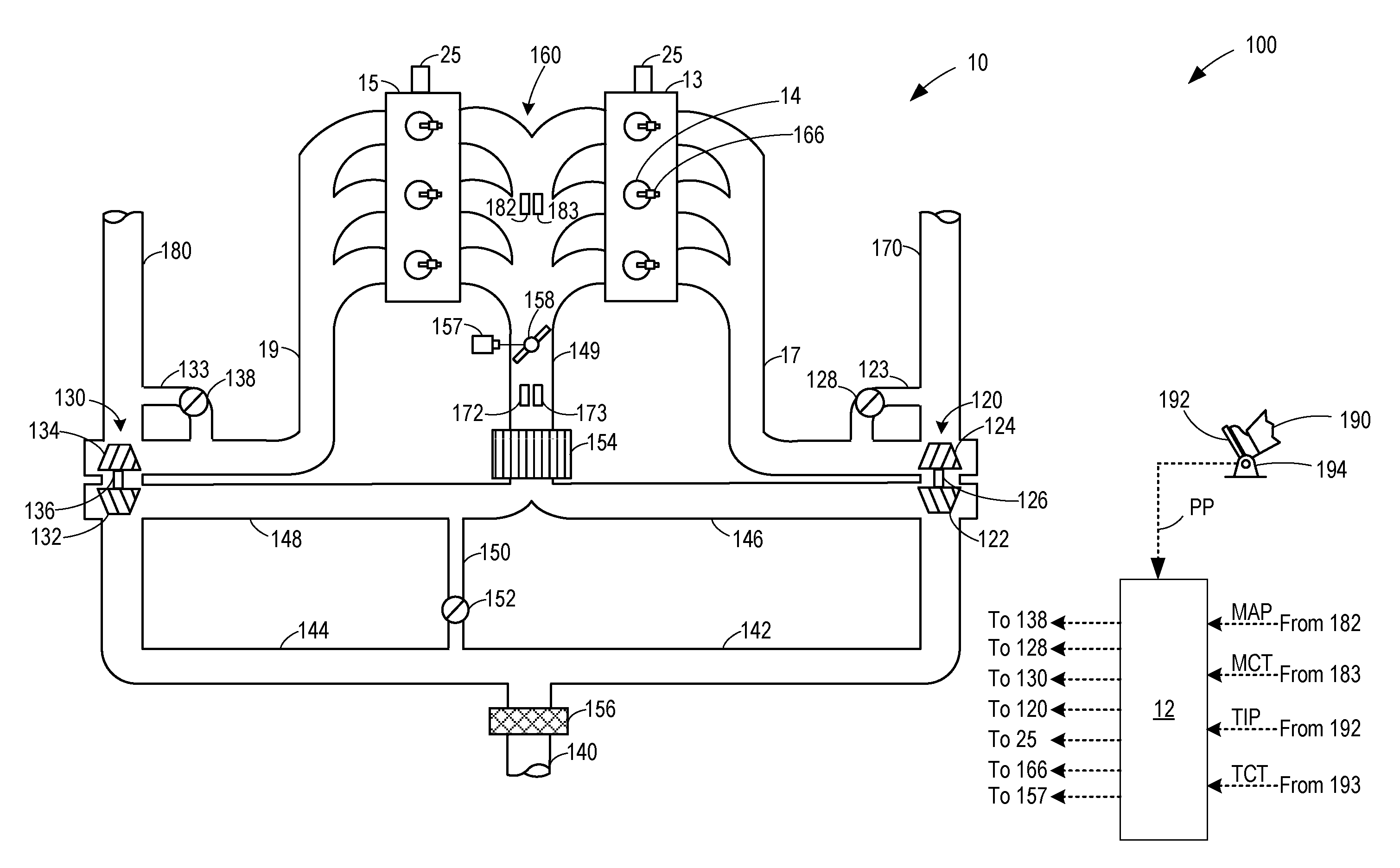

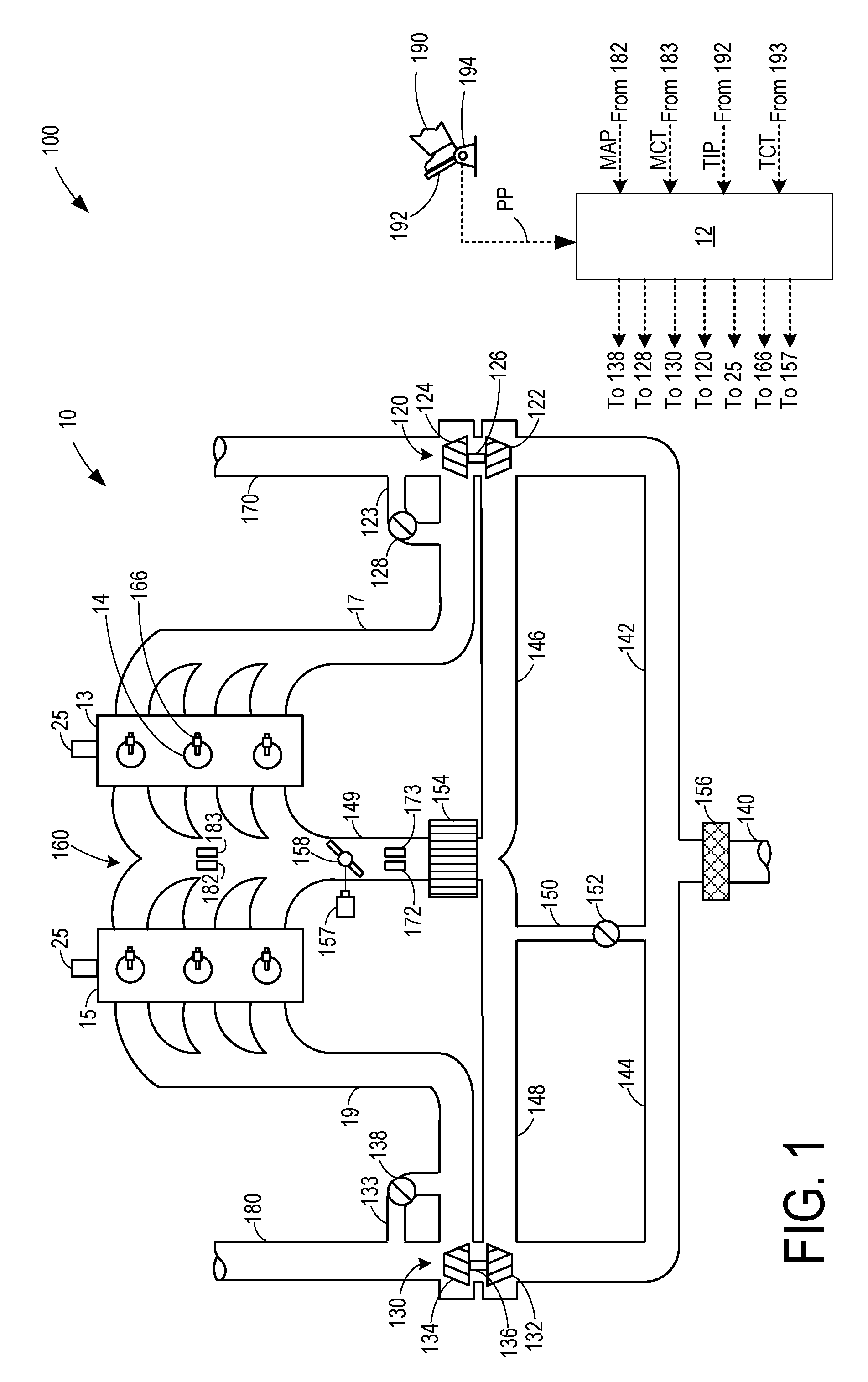

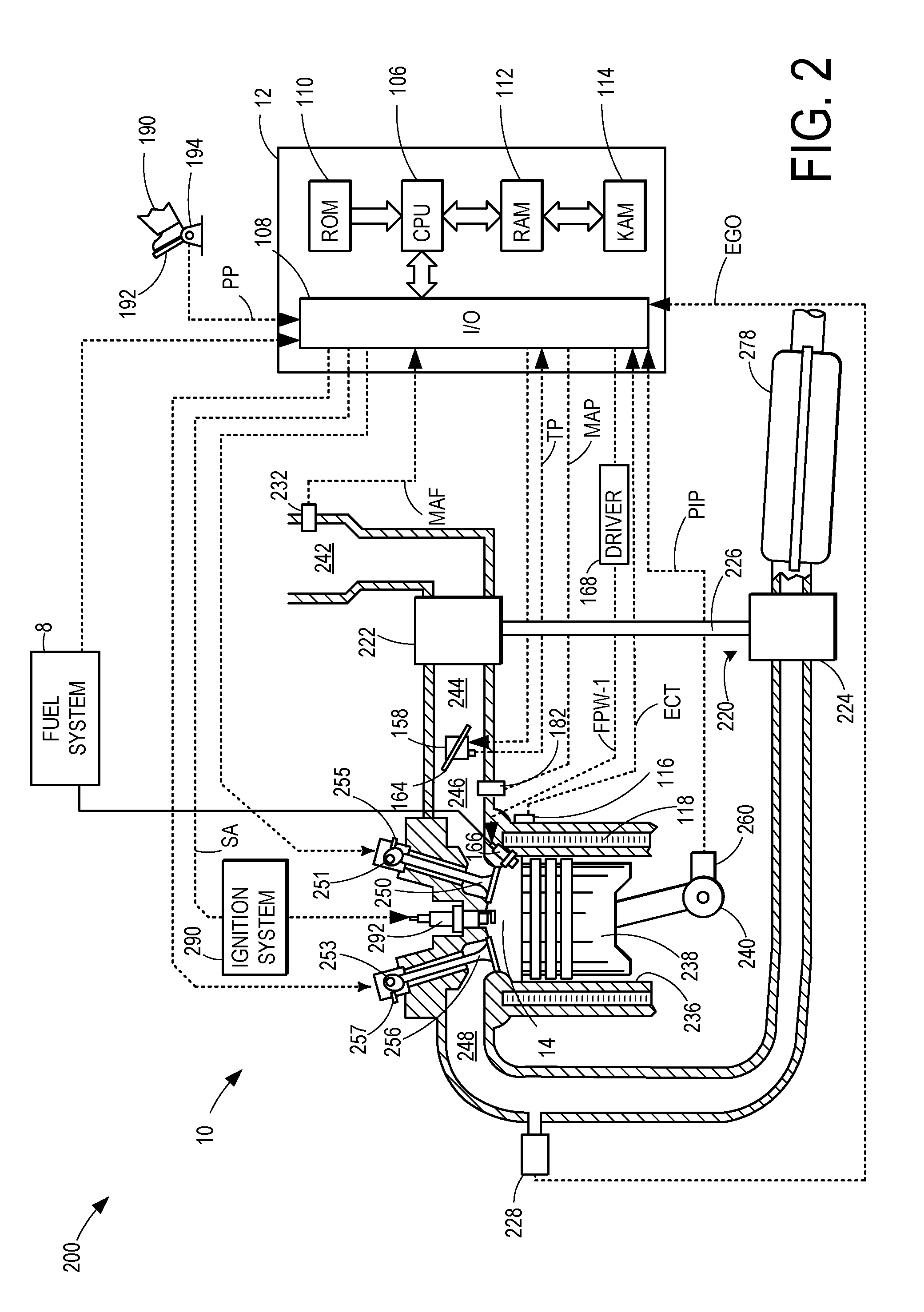

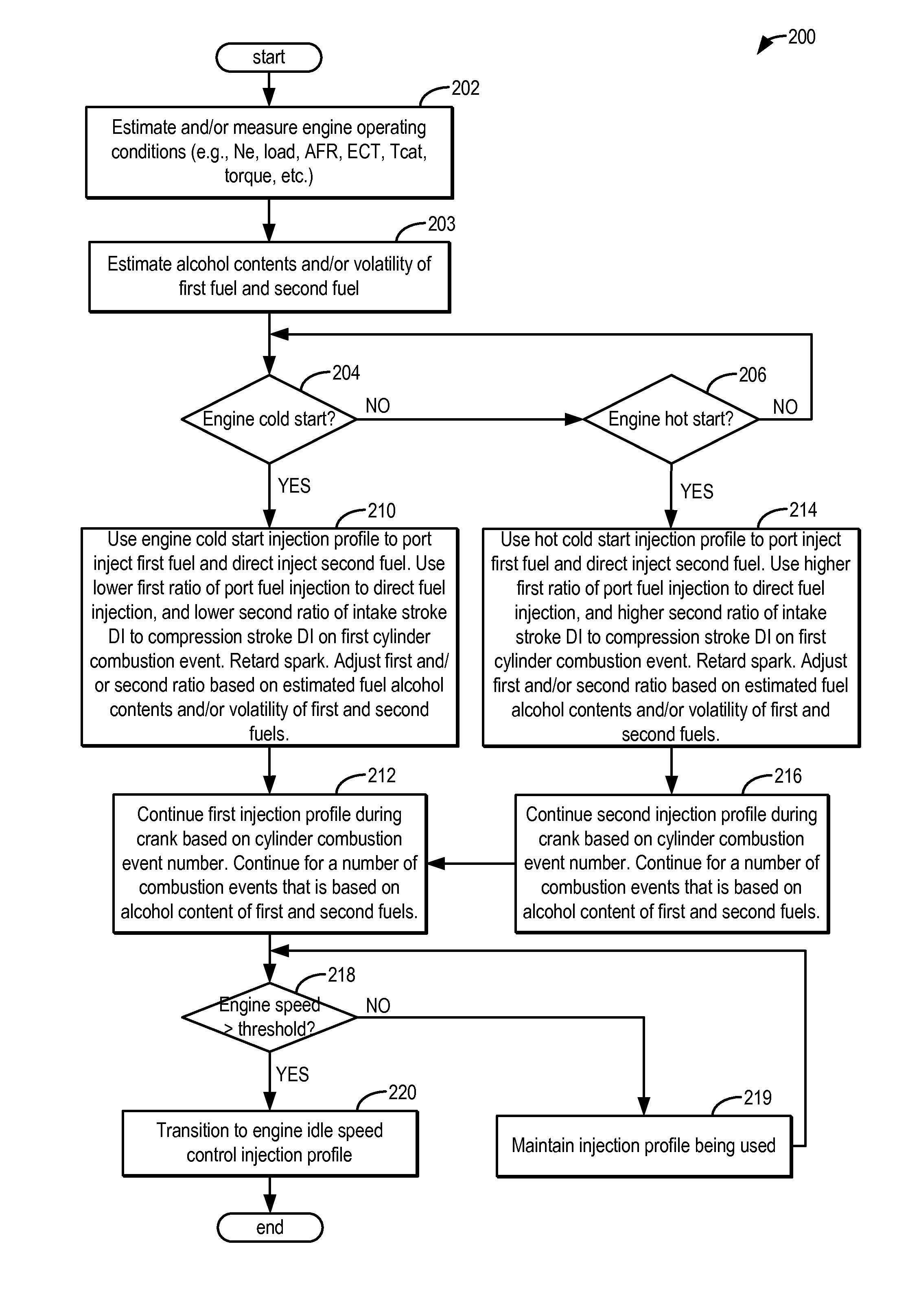

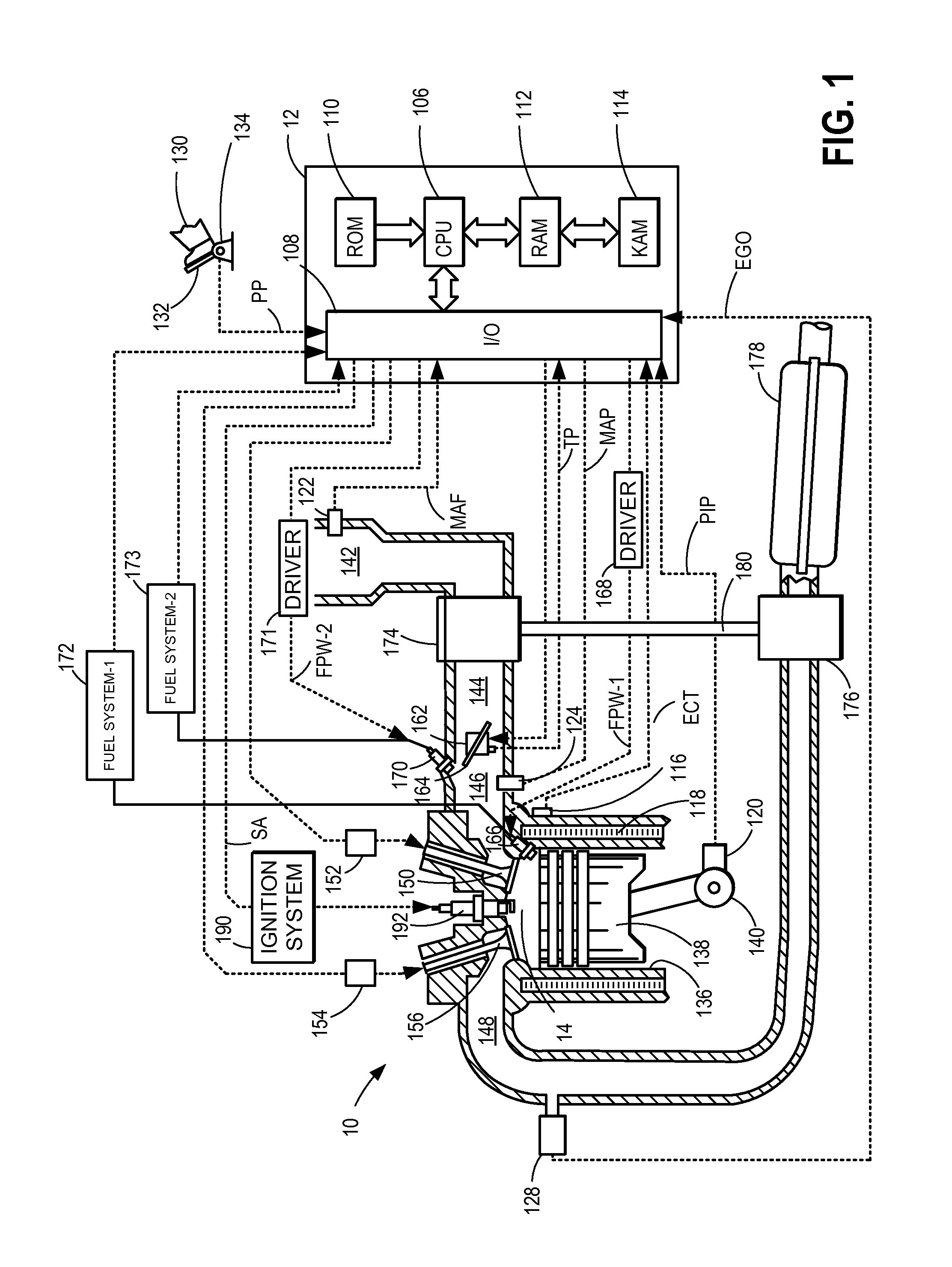

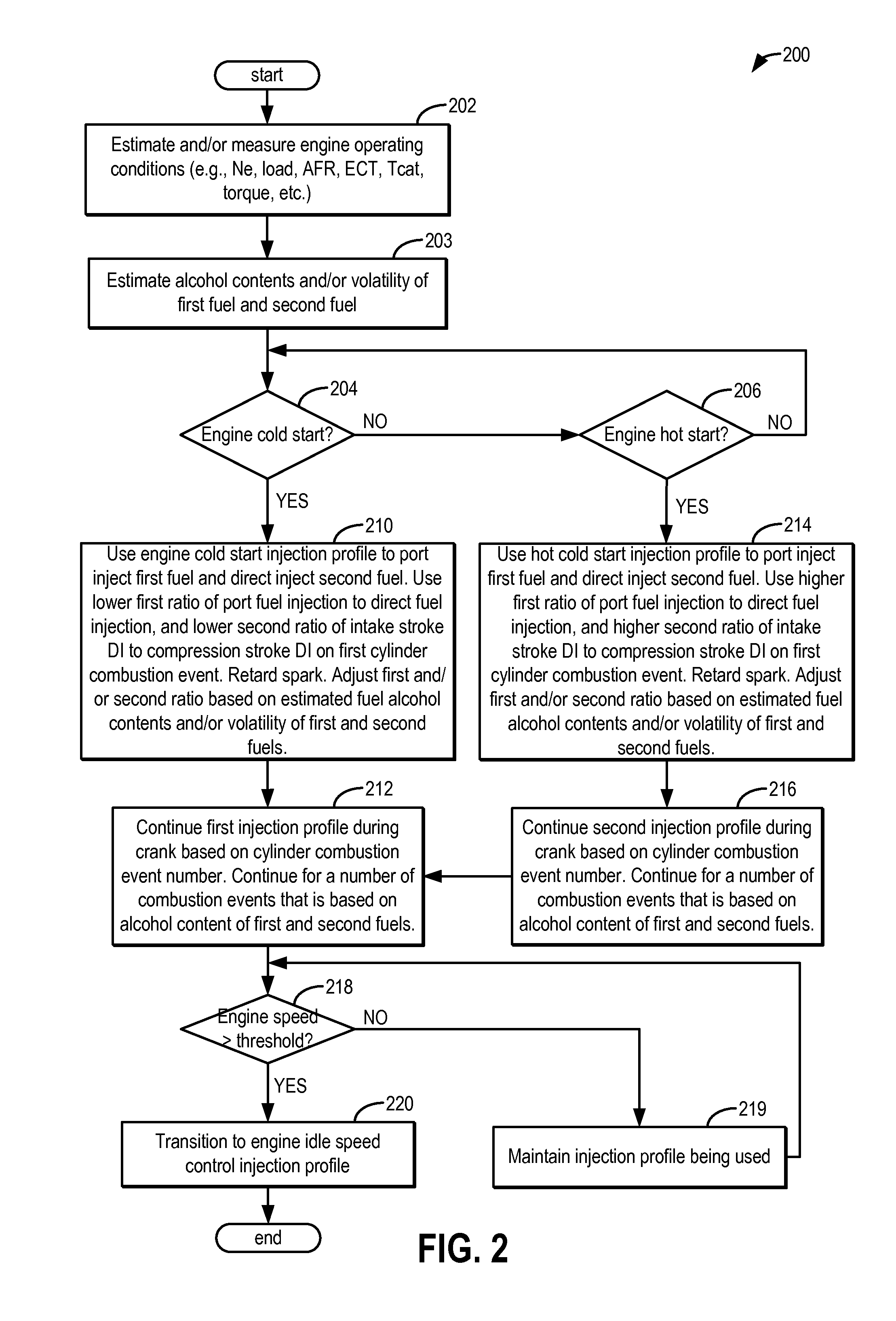

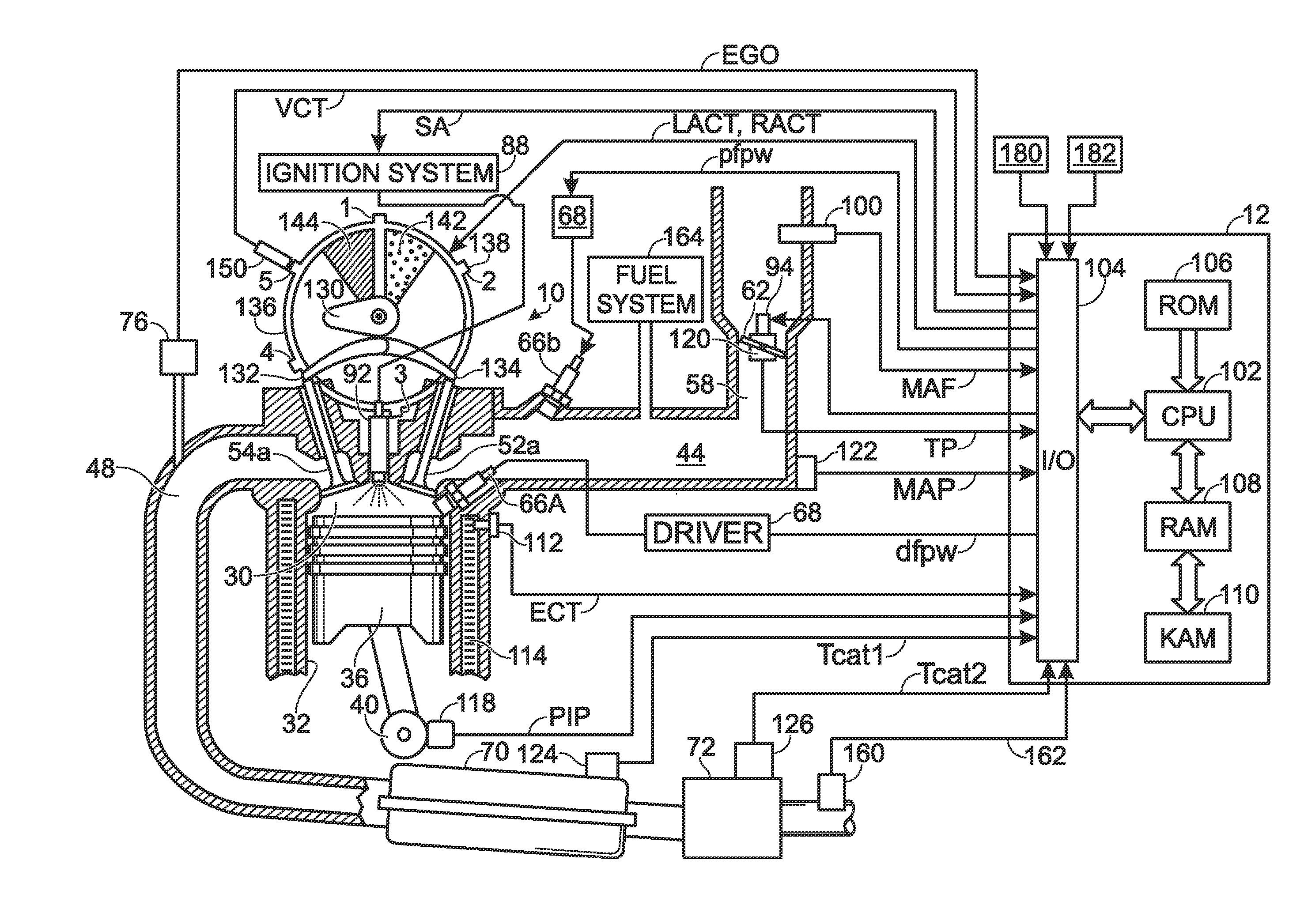

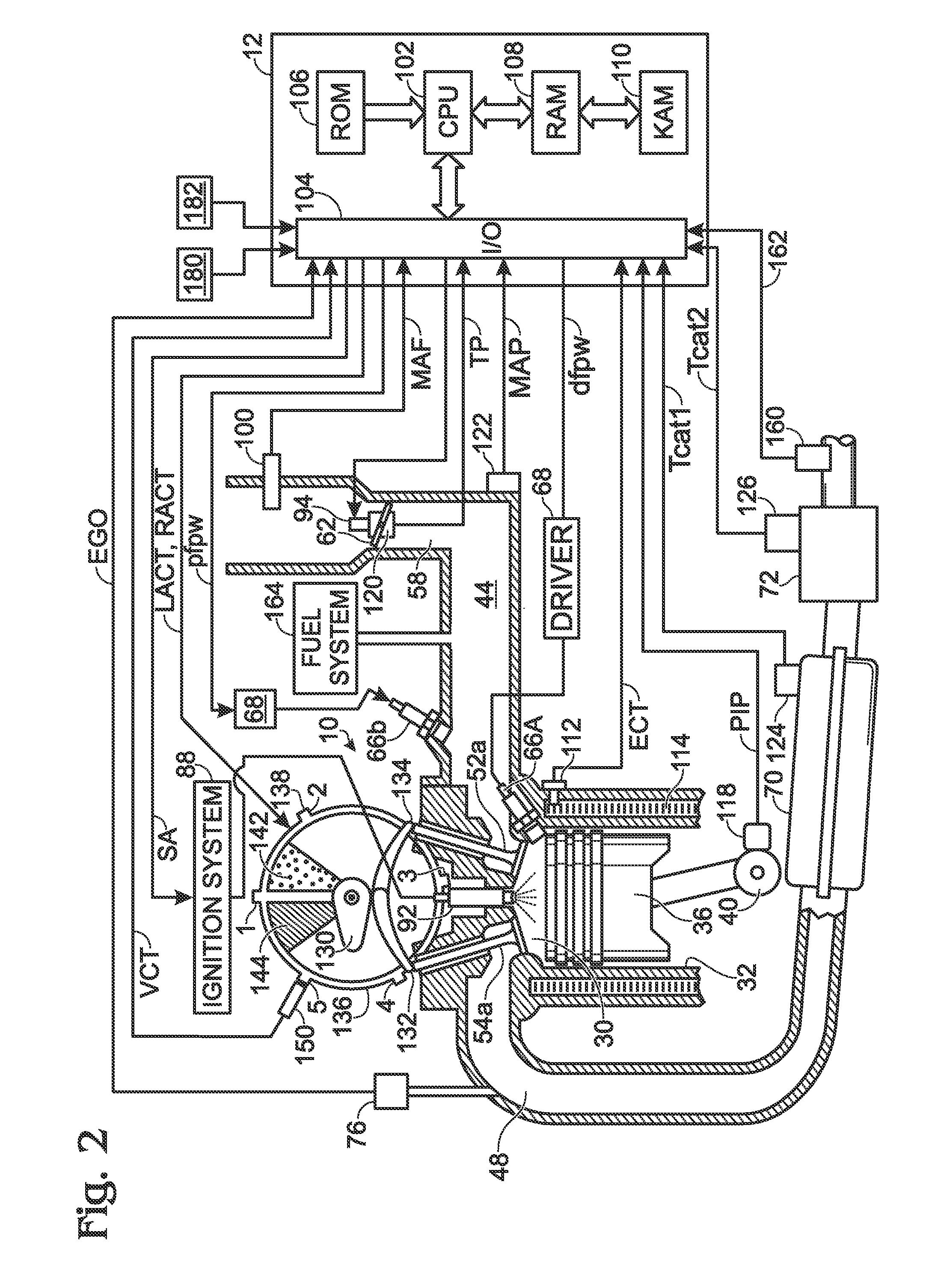

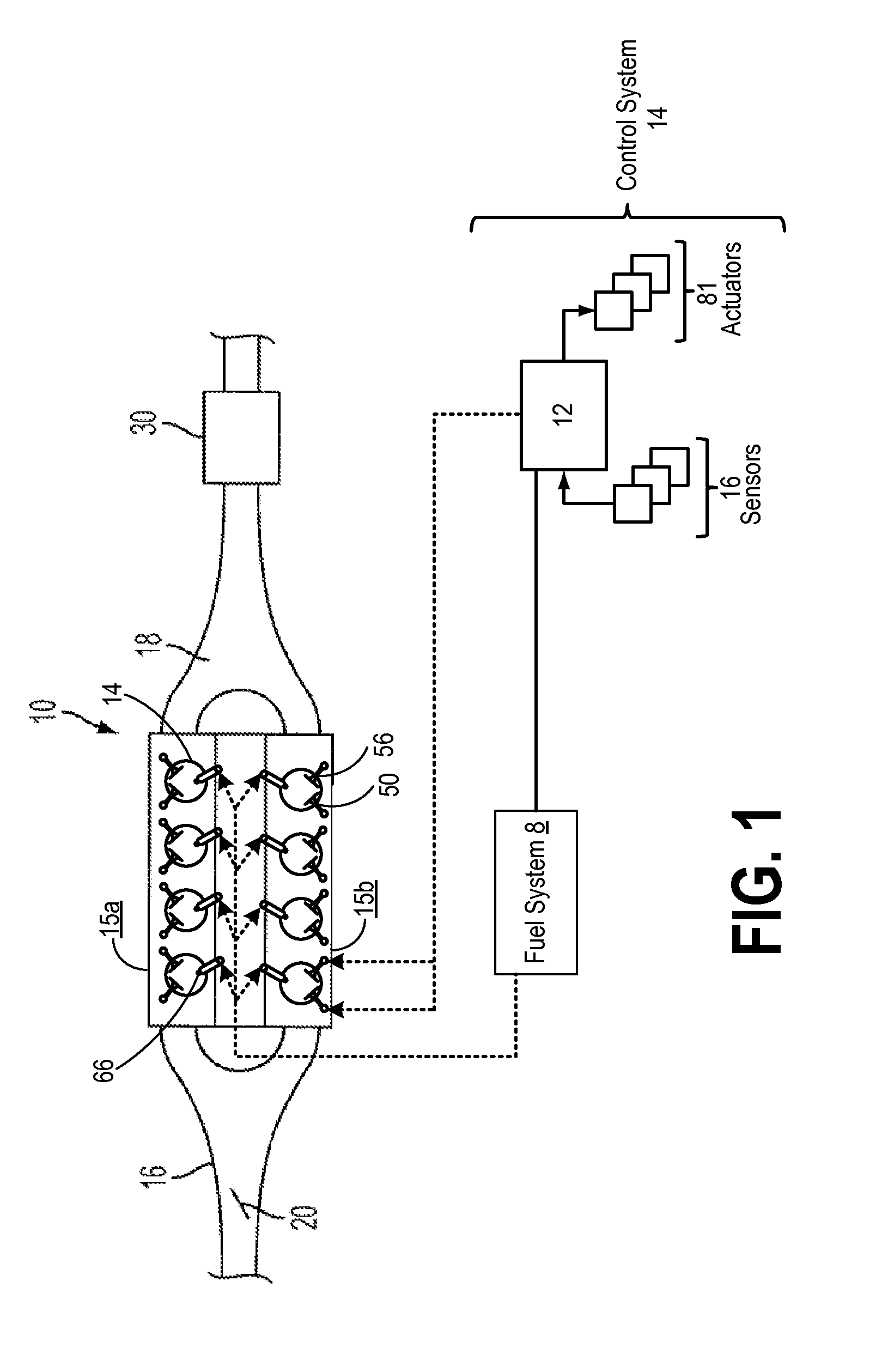

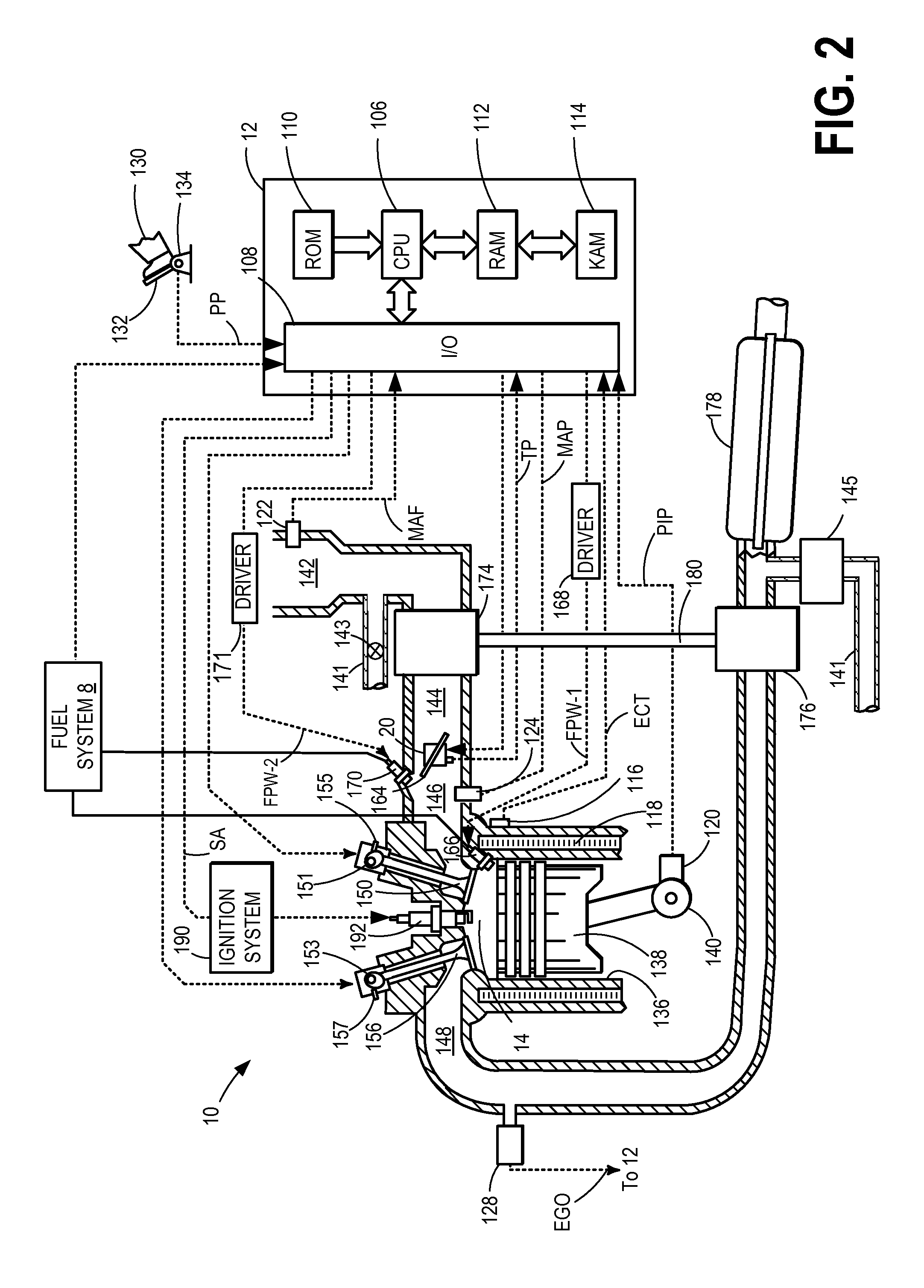

Method and system for engine control

ActiveUS20140297159A1Improve cooling effectIncrease heatValve arrangementsElectrical controlAlcohol contentMultiple injection

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for different fuels injected into an engine cylinder from different fuel injectors during engine start and crank. By splitting fuel injection during start and cranking so that fuel of lower alcohol content is port injected and fuel of higher alcohol content is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved.

Owner:FORD GLOBAL TECH LLC

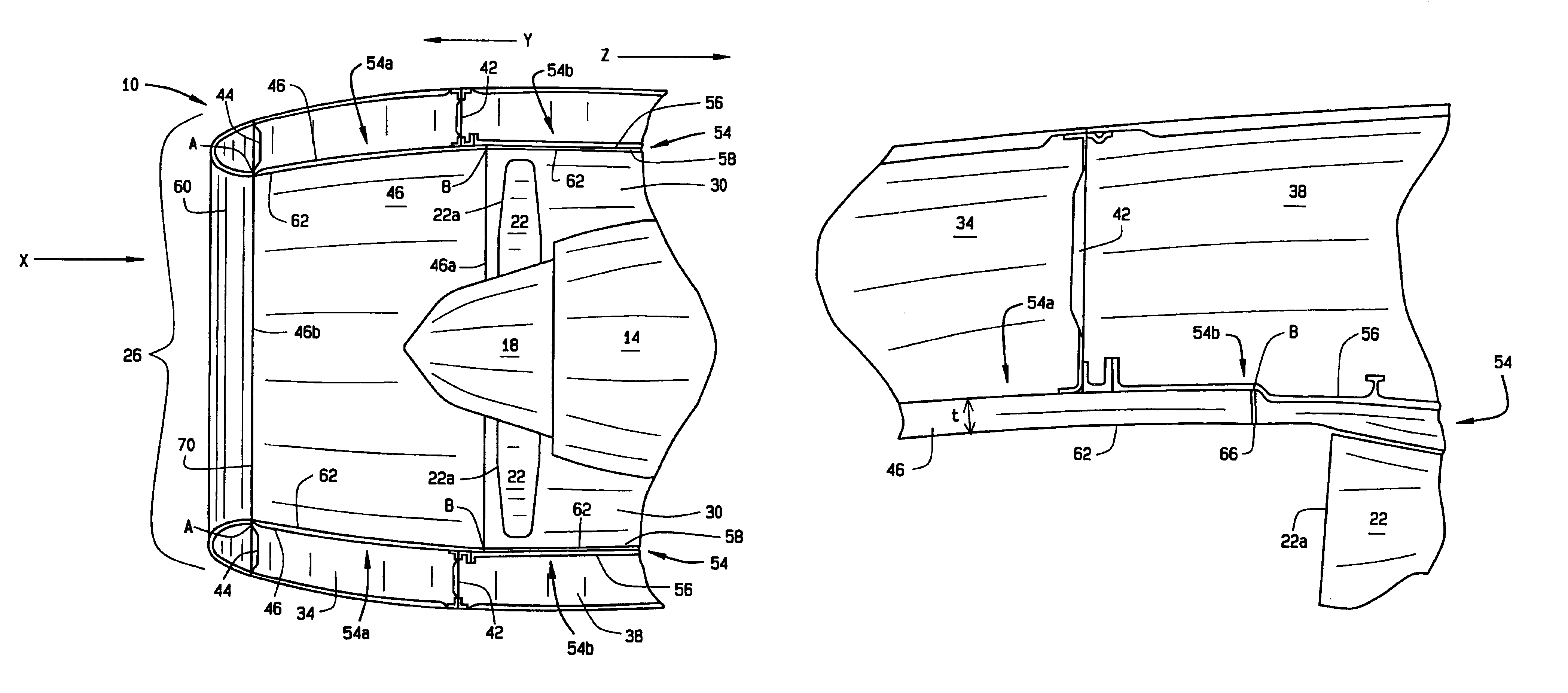

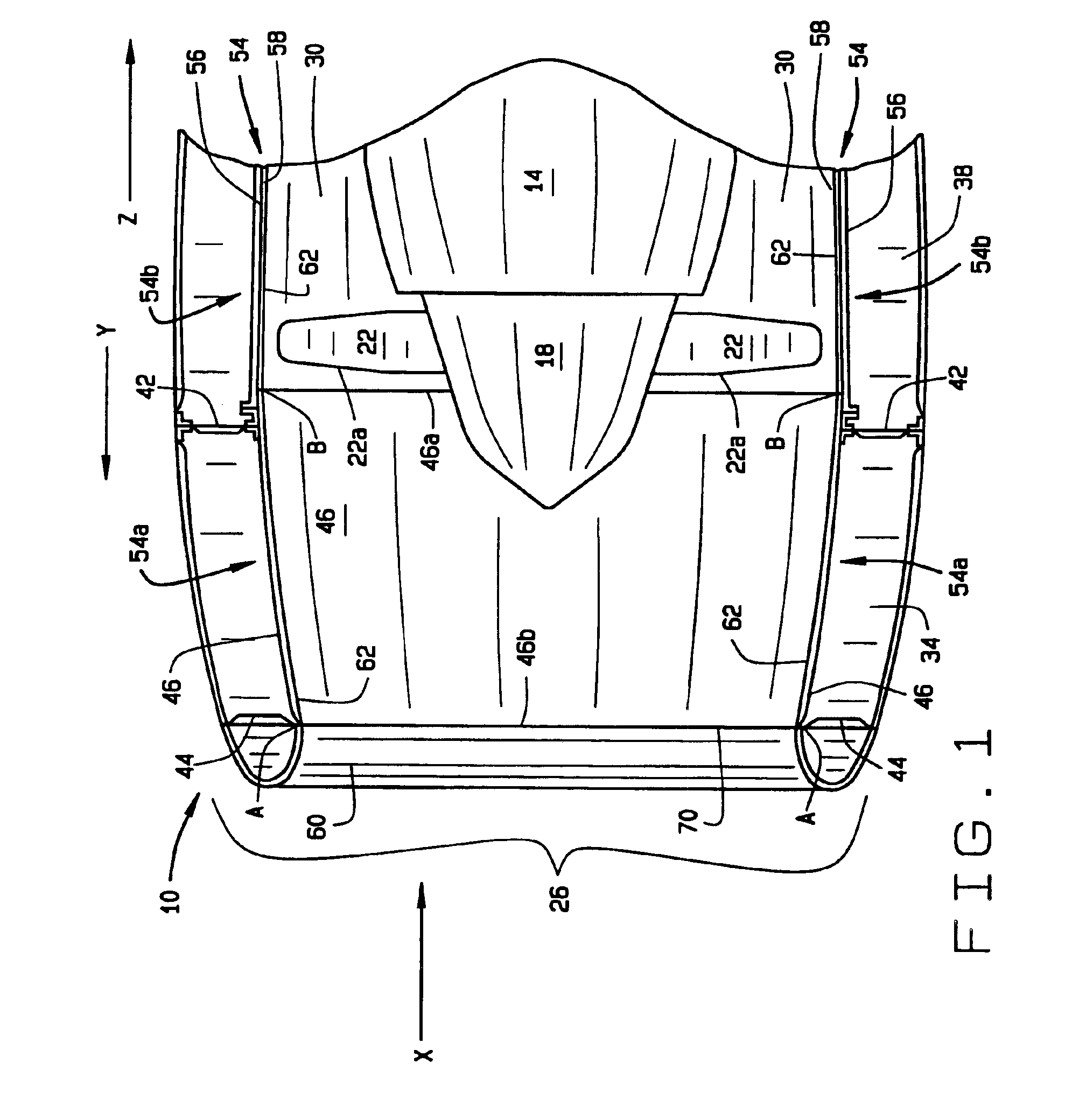

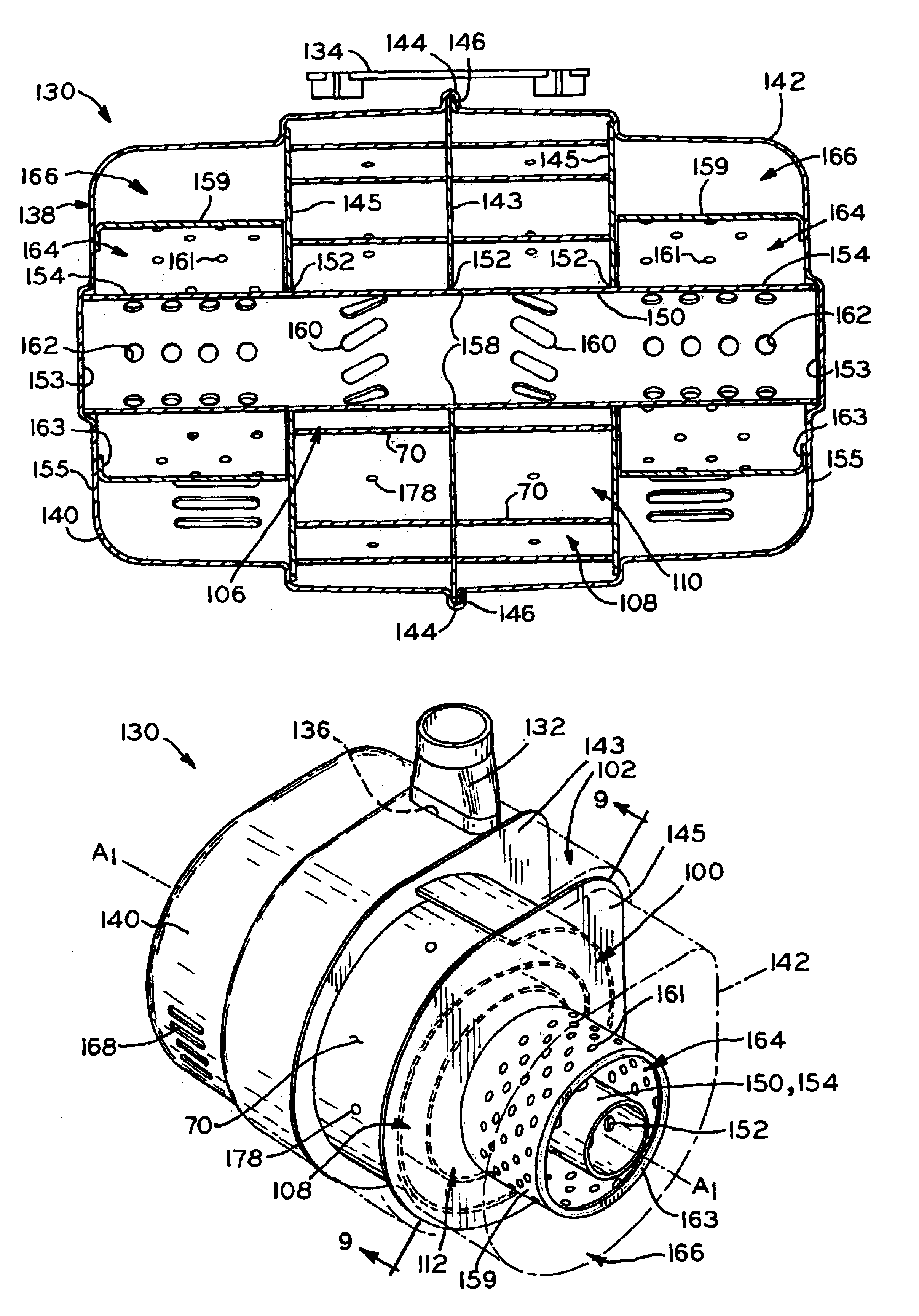

Annular acoustic panel

InactiveUS6920958B2Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

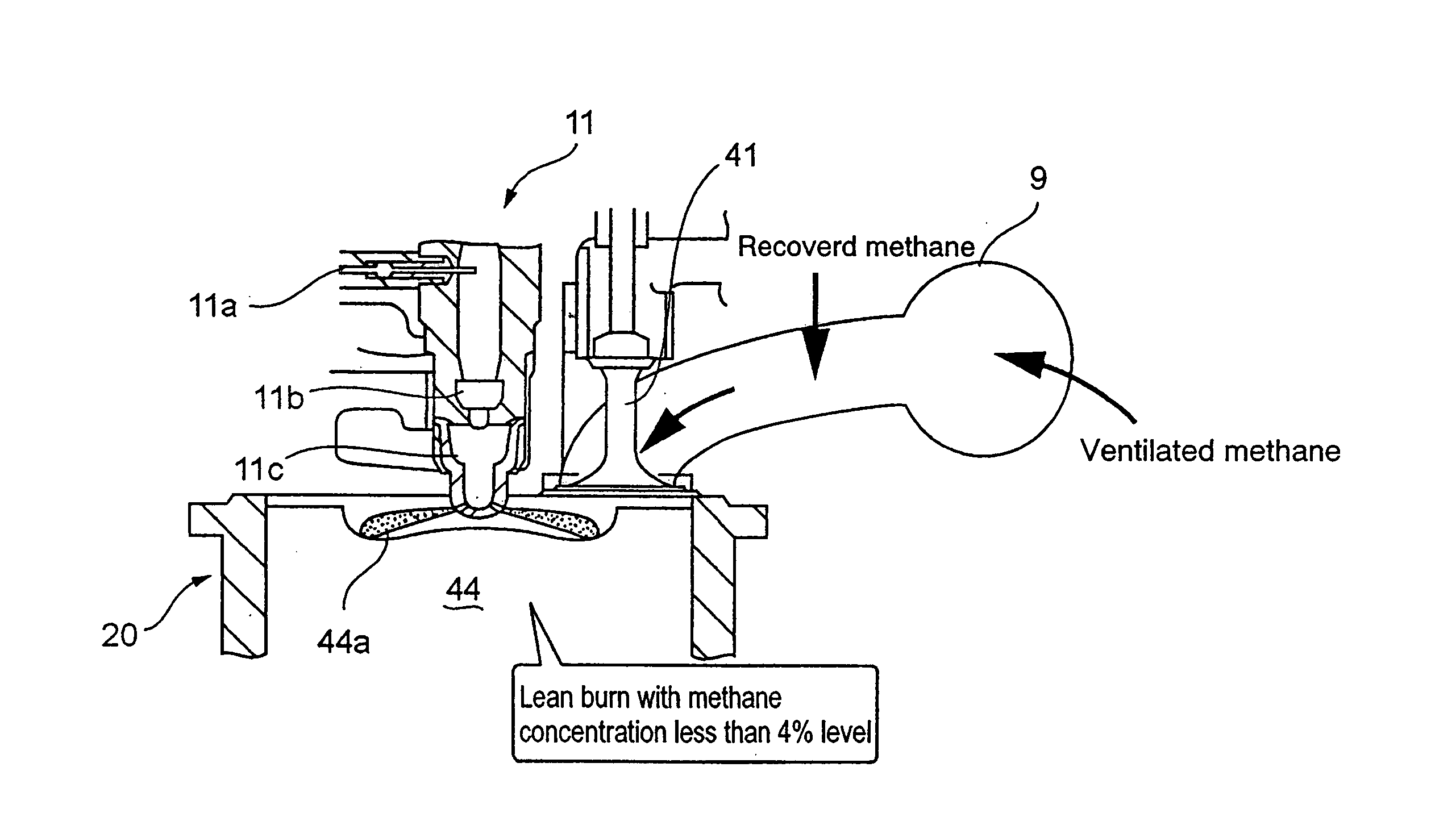

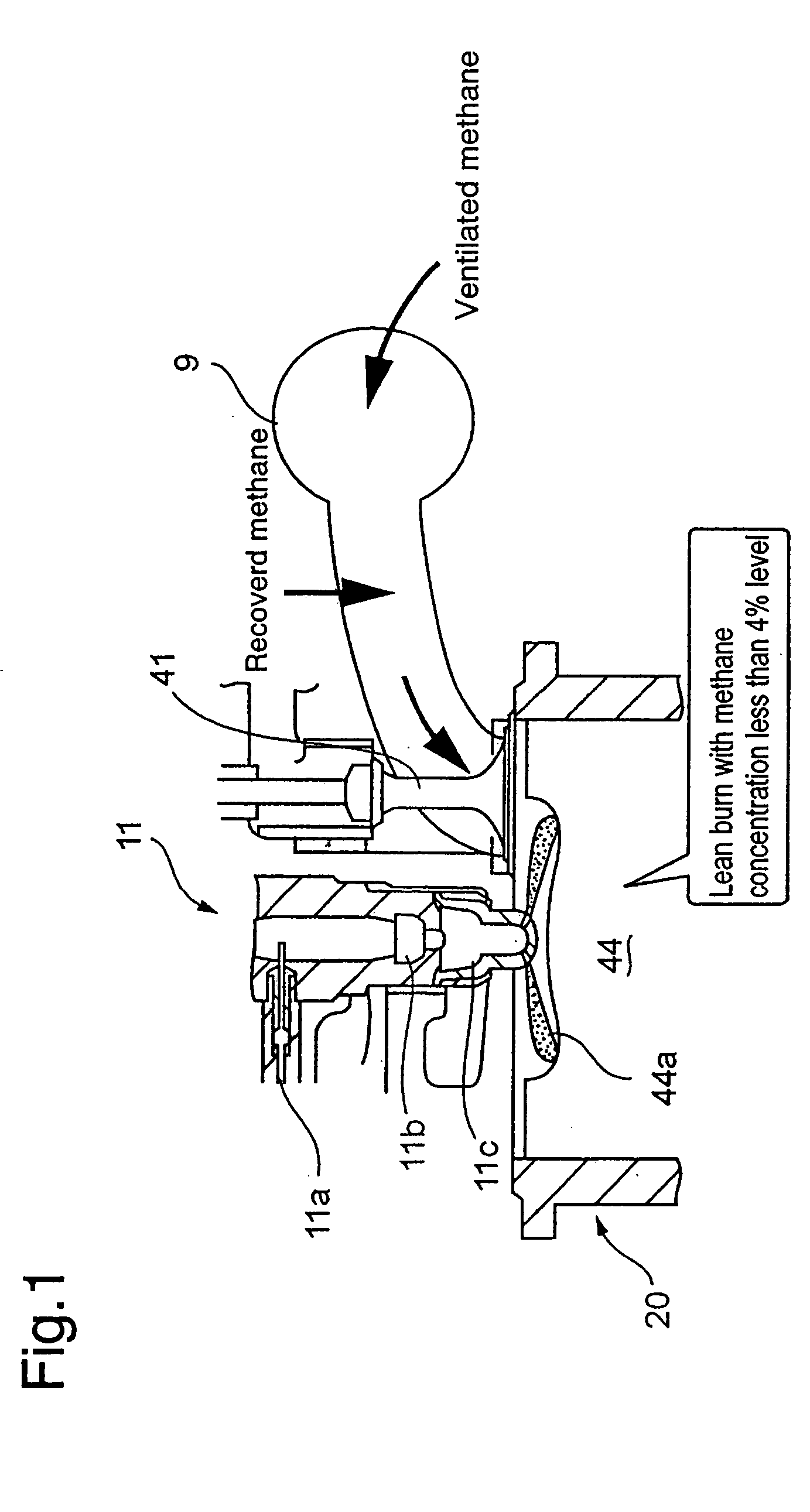

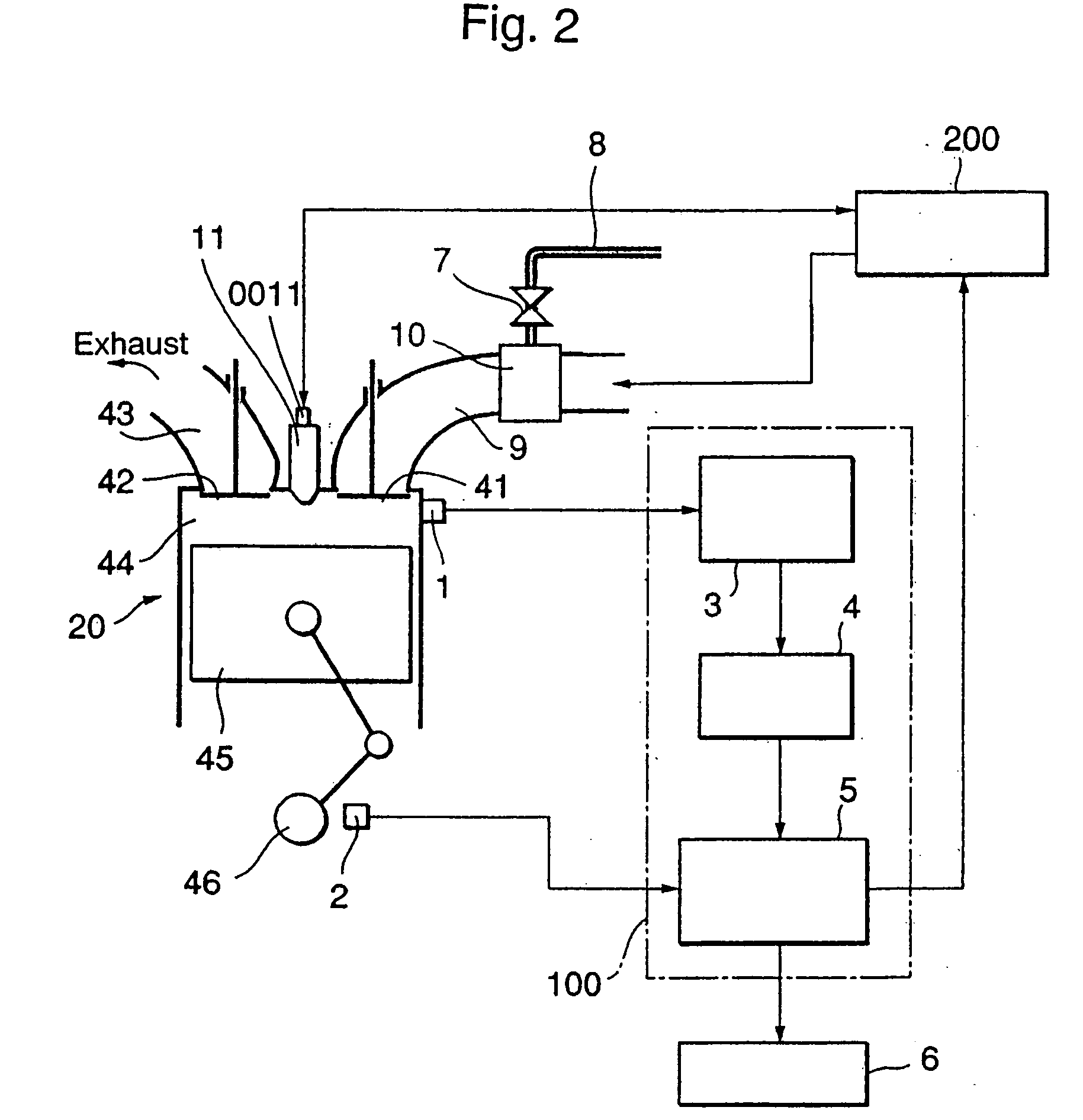

Gas engine electric power generating system effectively utilizing greenhouse gas emission credit

ActiveUS20050205022A1Promote economic developmentGuaranteed smooth progressInternal combustion piston enginesFinanceGreenhouse gasCarbon dioxide

The gas engine electric power generating system in which the electric power generating apparatus composed of an electric power generator connected with a gas engine of a pilot fuel oil ignition type is installed near a coal mine and the recovered methane gas and ventilated methane gas taken out of the mine shaft are introduced into the cylinder of the gas engine while being adjusted to be introduced as a lean methane / air mixture to operate the engine to produce electric power, is established near coal mine in developing country including China, the carbon dioxide emission credit produced by the difference in greenhouse effect index between the case where coal mine methane gas is released to the atmosphere and where said methane gas is utilized by the gas engine electric power generating system to be released to the atmosphere as carbon dioxide, is registered on a emission credit market to be traded with credit surcharge payment obligators(or those who want to purchase the emission credit). The invention also includes the affiliated system of mutual patronage relation constituted by one or a plurality of the systems and nearby power generating system or systems using coal bed methane or pre-mining gas as fuel.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

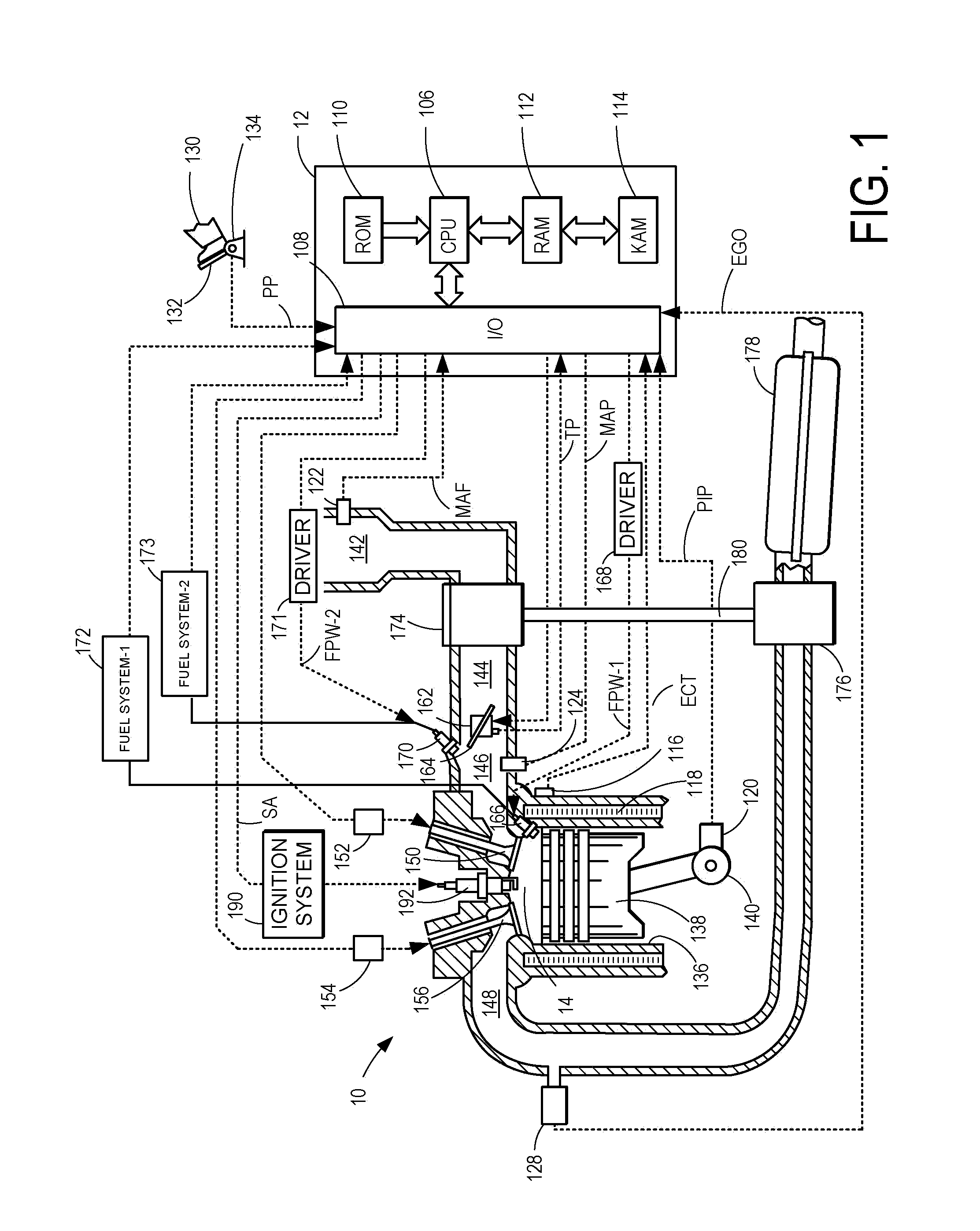

Warm Up Strategy for Ethanol Direct Injection Plus Gasoline Port Fuel Injection

InactiveUS20070289573A1Improve engine performanceLow costElectrical controlNon-fuel substance addition to fuelPort fuel injectionEngineering

A system for an engine, comprising of a cylinder of the engine, a first injector configured to inject a first substance to said cylinder, a second injector configured to inject a second substance to said cylinder; and a controller configured to commence combustion in the engine by injecting fuel into said cylinder, where said fuel is injected by both said first and second injectors during said start.

Owner:FORD GLOBAL TECH LLC

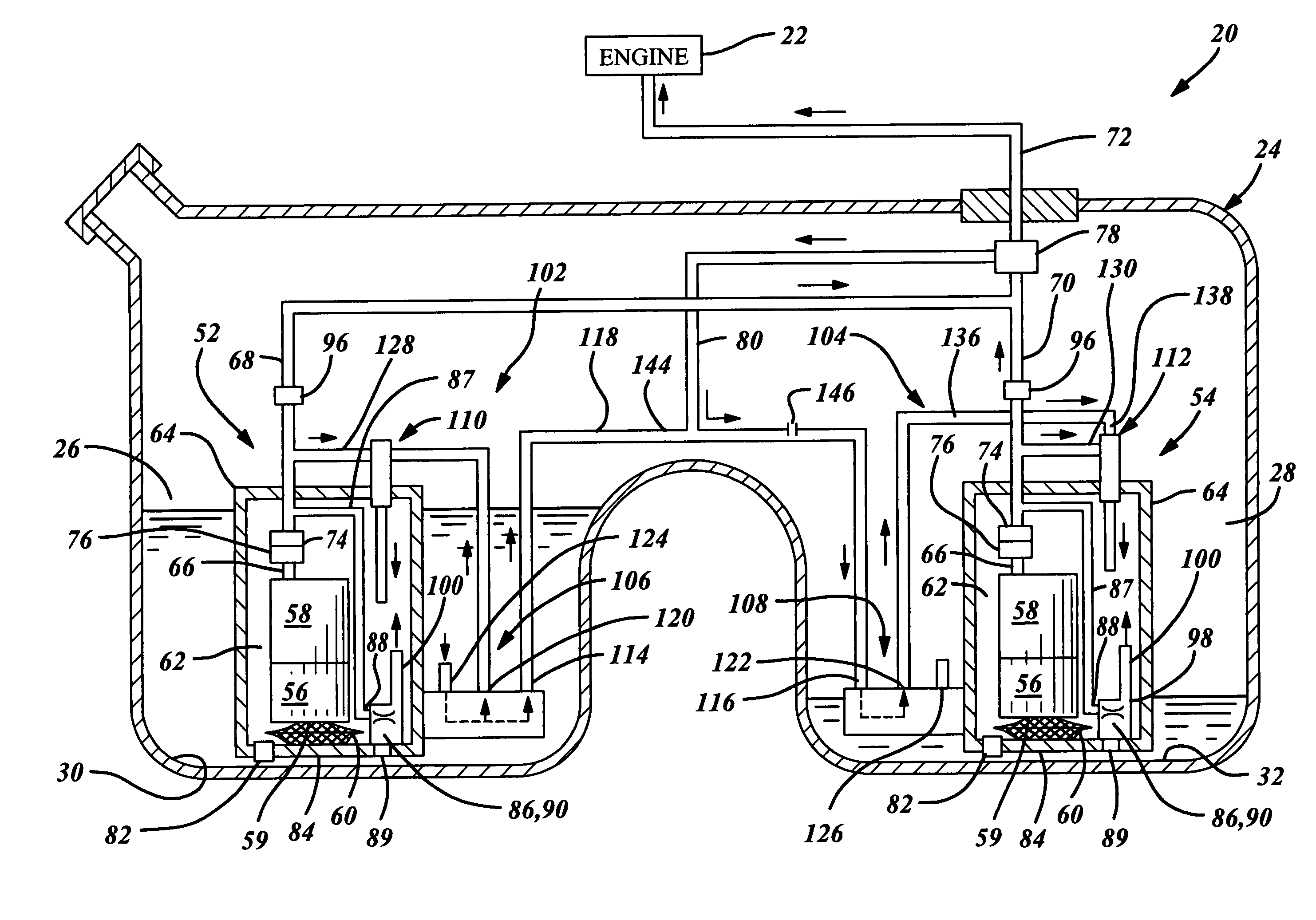

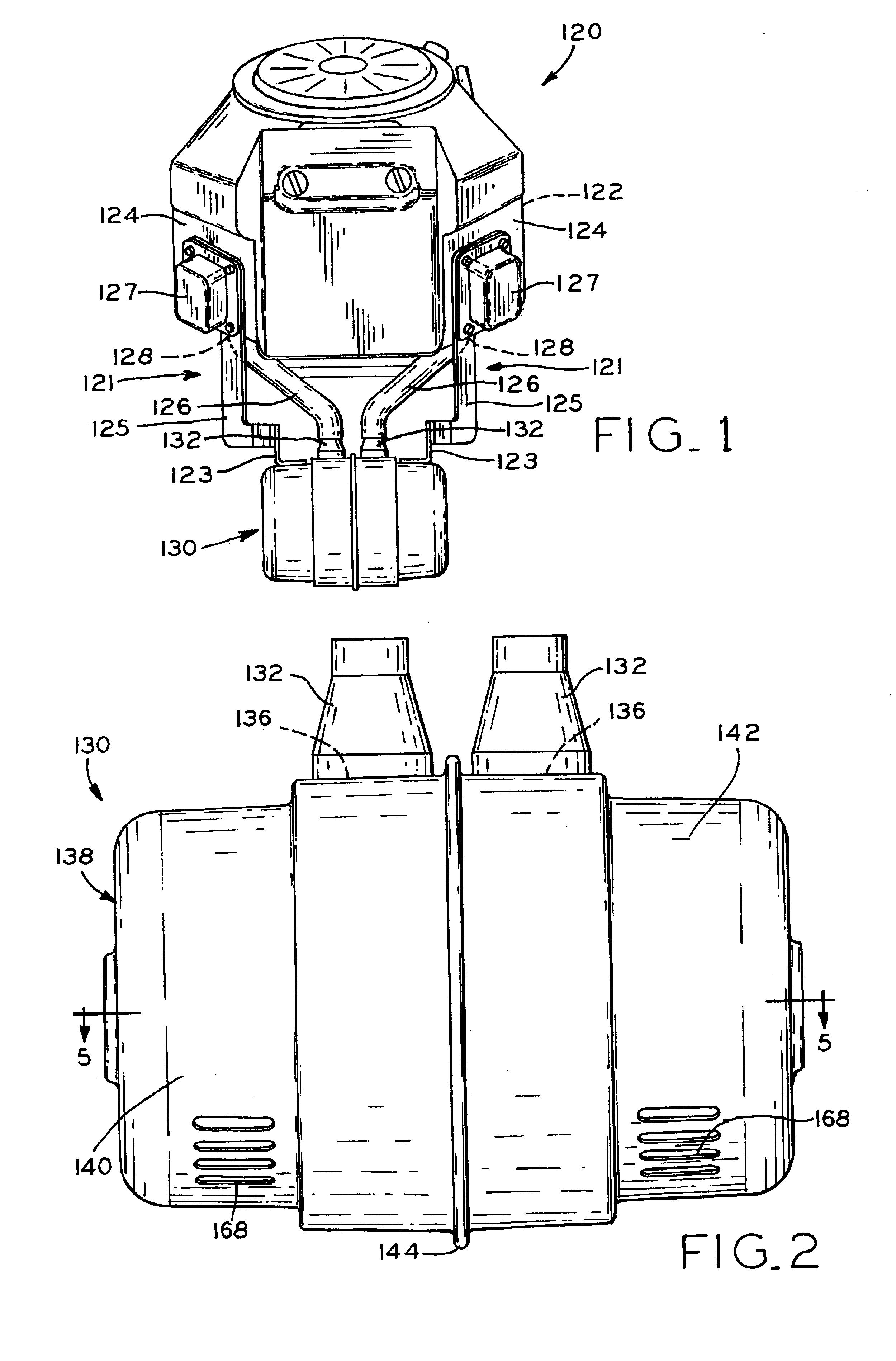

Fuel delivery system for a combustion engine

InactiveUS7069913B1Increase fuel consumptionEconomical and robust fuel deliveryMachines/enginesLiquid fuel feedersCombustionFuel tank

A fuel delivery system with at least one fuel tank and at least two fuel chambers has a fuel transfer assembly preferably integrated into an in-tank fuel pump module for controlling fuel levels between the at least two fuel chambers. The fuel transfer assembly has a transfer jet which receives pressurized fuel from a fuel pump of the module and at least two control valves for dictating the source of low pressure fuel flowing into the transfer jet and discharged therefrom preferably into a fuel reservoir of the module. Preferably, one control valve is located in each fuel chamber. The control valve opens upon a pre-established high fuel level and closes upon low fuel level. The fuel chamber containing the open control valve is generally the source of fuel for the fuel pump module.

Owner:TI GRP AUTOMOTIVE SYST LLC

Method and system for particulate matter control

ActiveUS20160115878A1Extending cylinder deactivation benefitImprovement in PM emissionElectrical controlSpeed sensing governorsParticulatesCoolant temperature

Methods and systems are provided for particulate matter control in an engine configured for skip-fire operation. A cylinder pattern selected for selective cylinder deactivation, including a total number of deactivated / active cylinders as well as individual deactivated cylinder identities, may be adjusted based on an engine soot load, or a parameter indicative of engine soot load such as engine coolant temperature. In addition, reactivated engine cylinders may be transiently operated with split fuel injection to raise combustion surface temperatures.

Owner:FORD GLOBAL TECH LLC

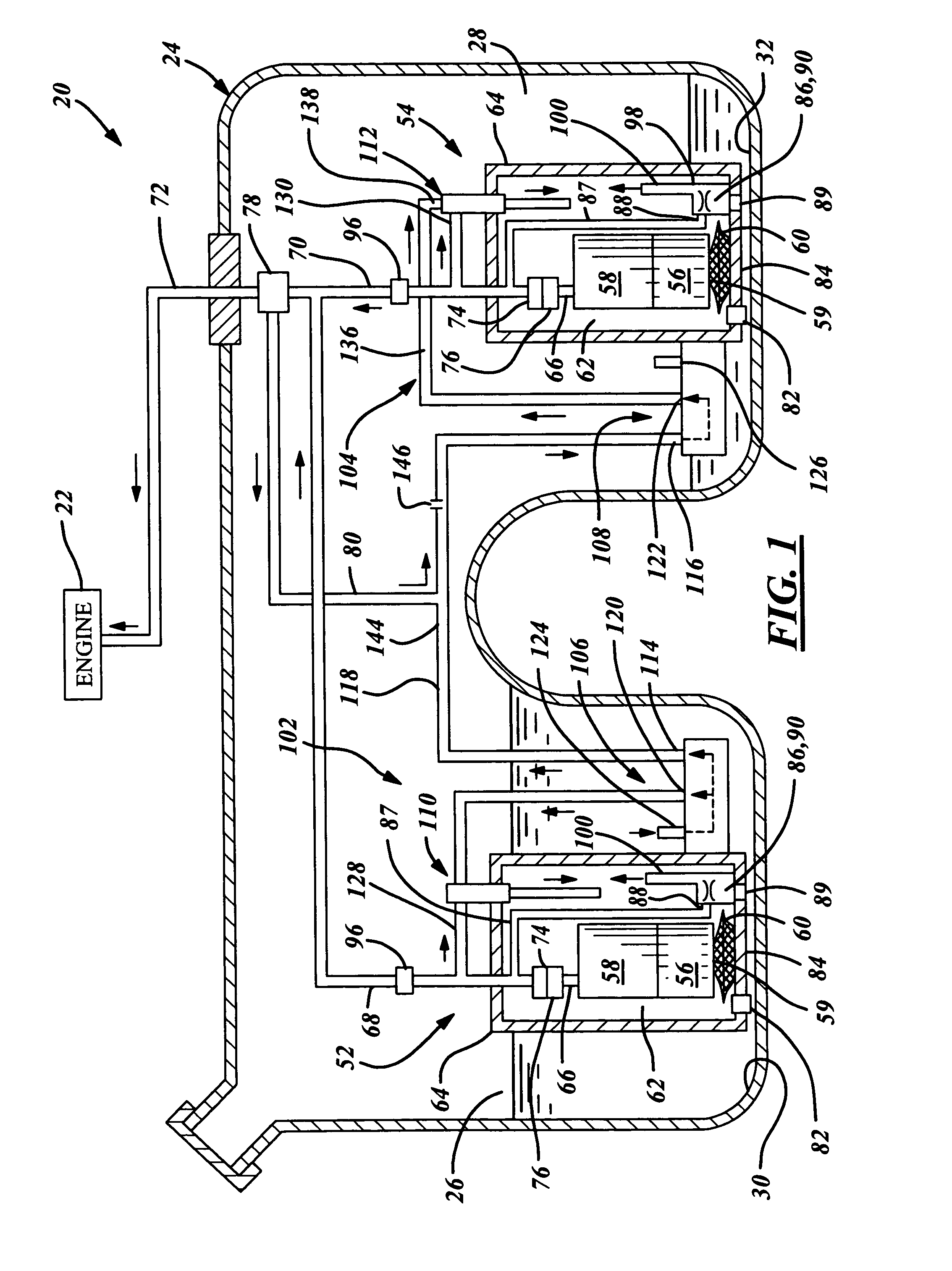

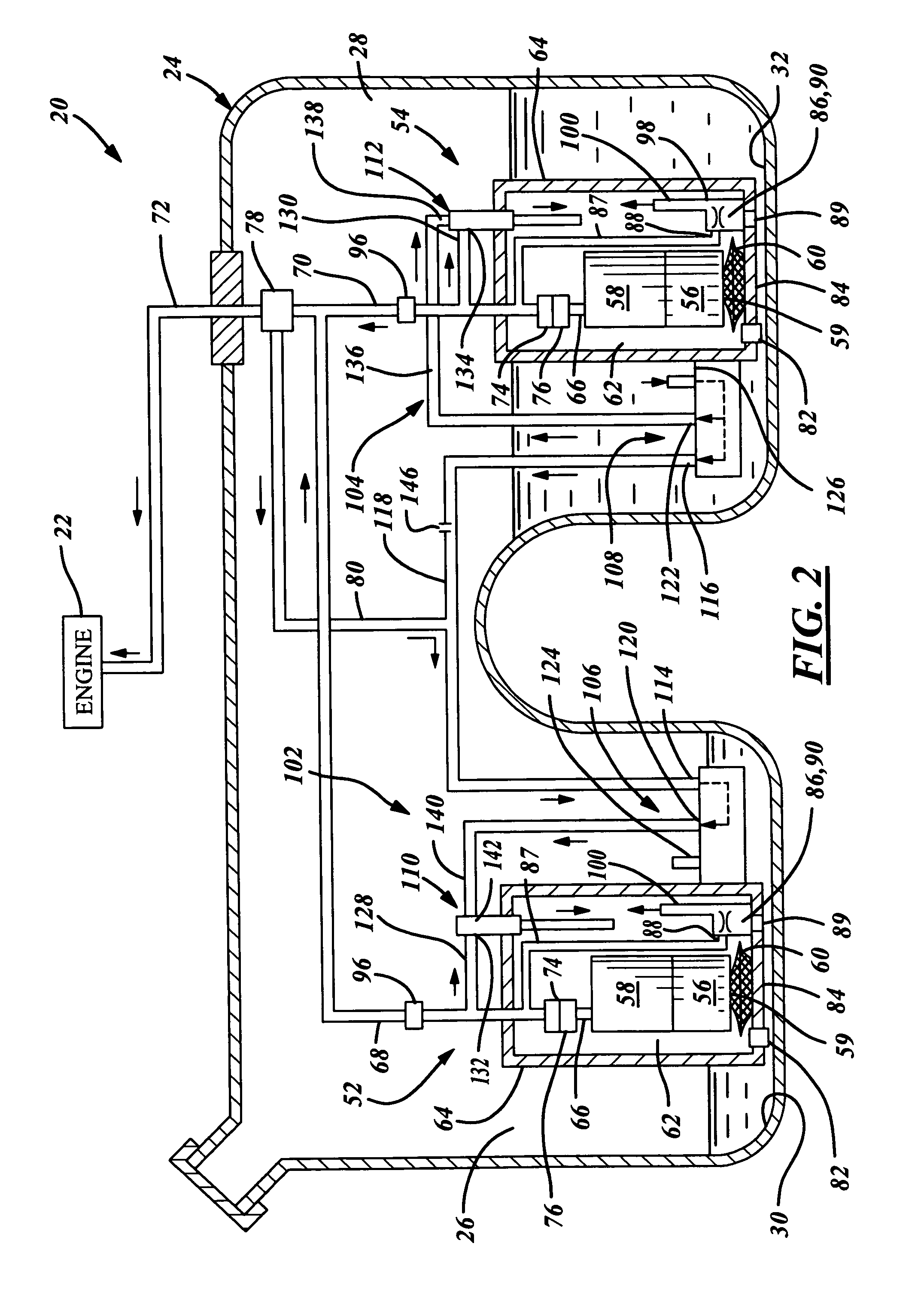

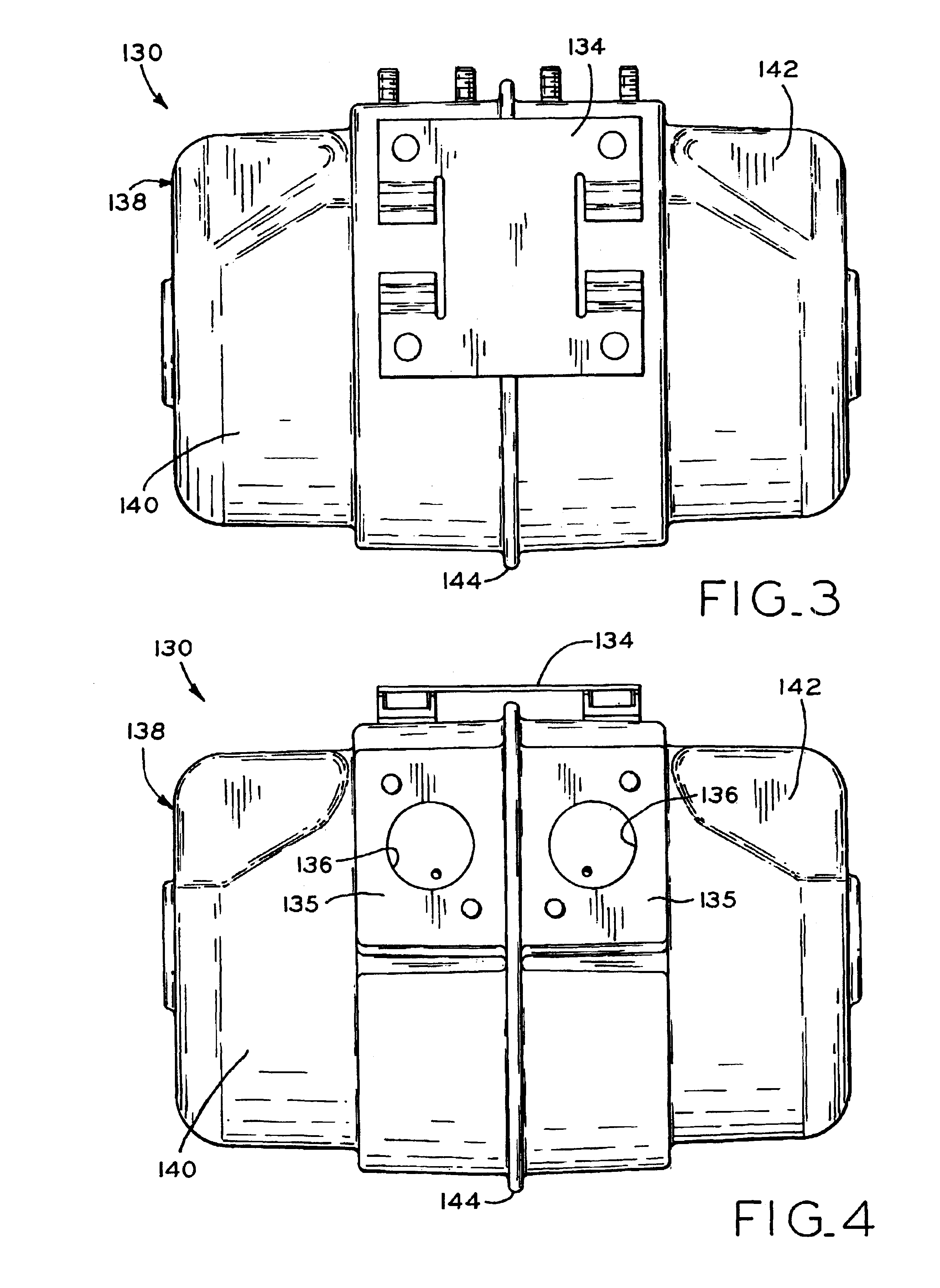

Tuned exhaust system for small engines

InactiveUS6959782B2Reduced overall size and profileImprove engine performanceCombustion enginesSilencing apparatusExhaust fumesPulp and paper industry

A tuned exhaust system for small two cylinder engines, the exhaust system including a pair of exhaust passage through which exhaust gasses pass. The exhaust passages are dimensioned to providing a tuning effect to the exhaust gasses for enhanced engine performance. The exhaust passages are not straight and elongated, but rather are sprialed, scrolled, coiled, or otherwise folded upon themselves at least twice. In this manner, the exhaust passages may be housed at least in part within a muffler having a significantly reduced overall size or profile, such that the muffler may be used in small engines.

Owner:TECUMSEH POWER

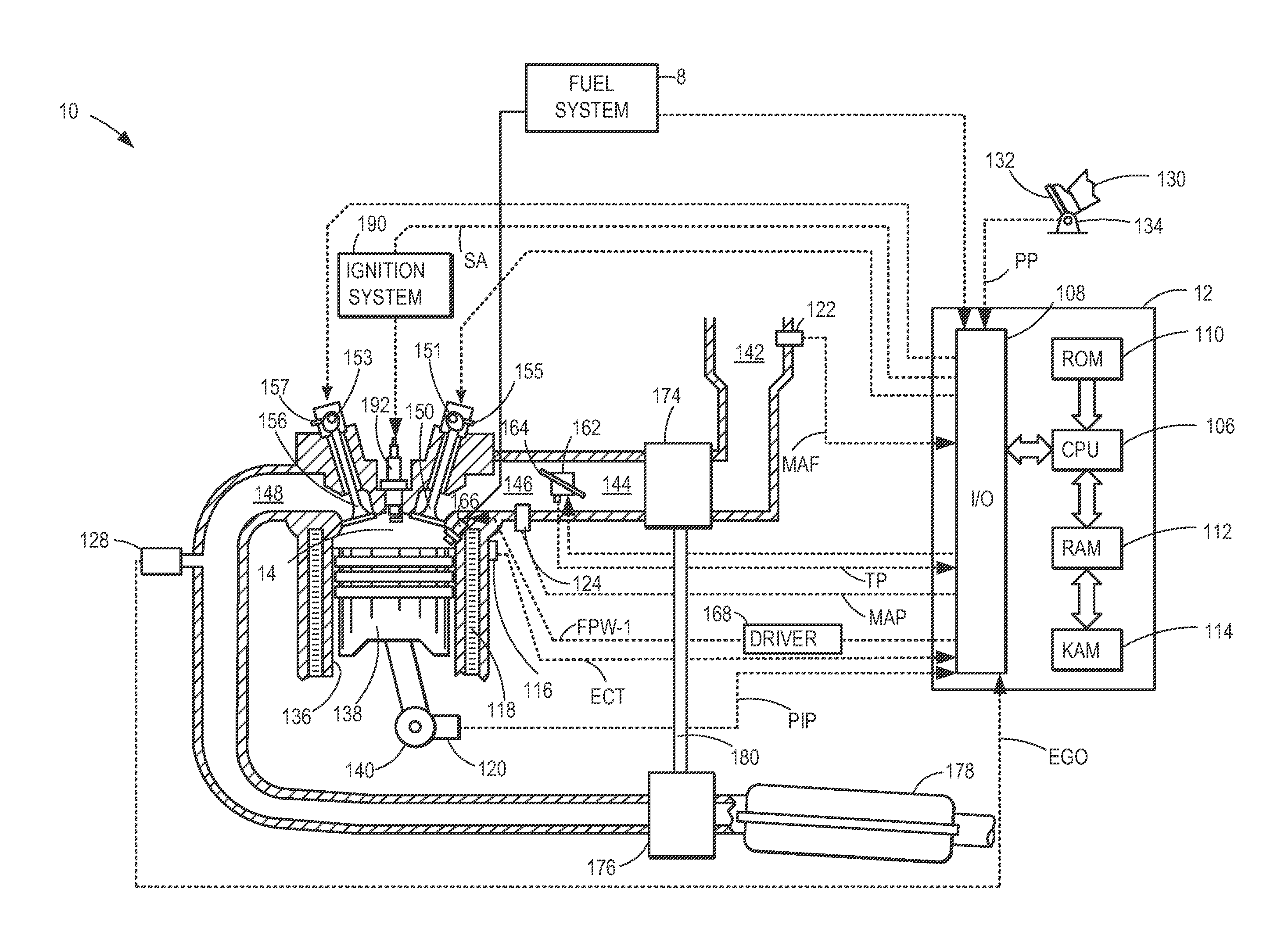

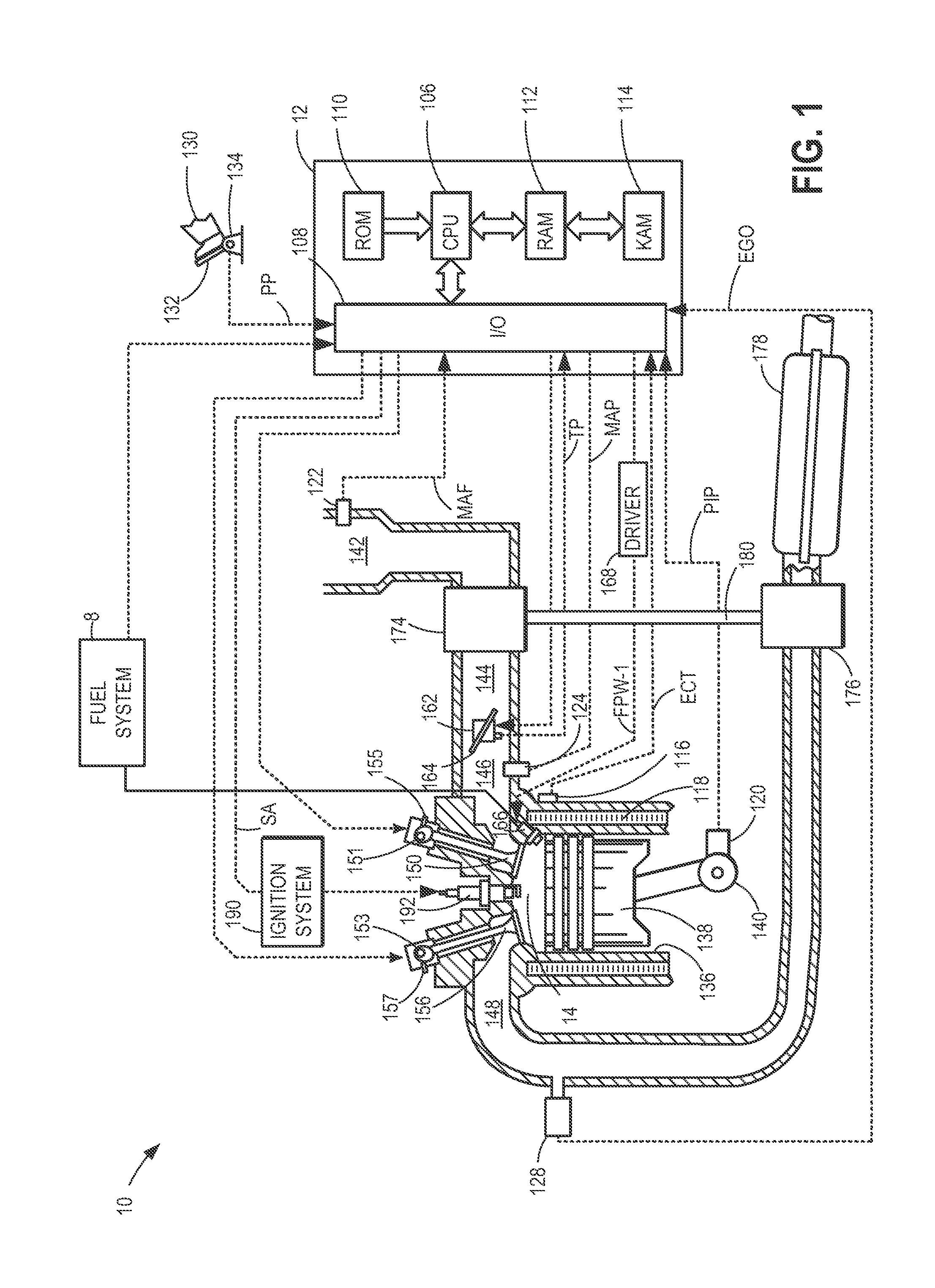

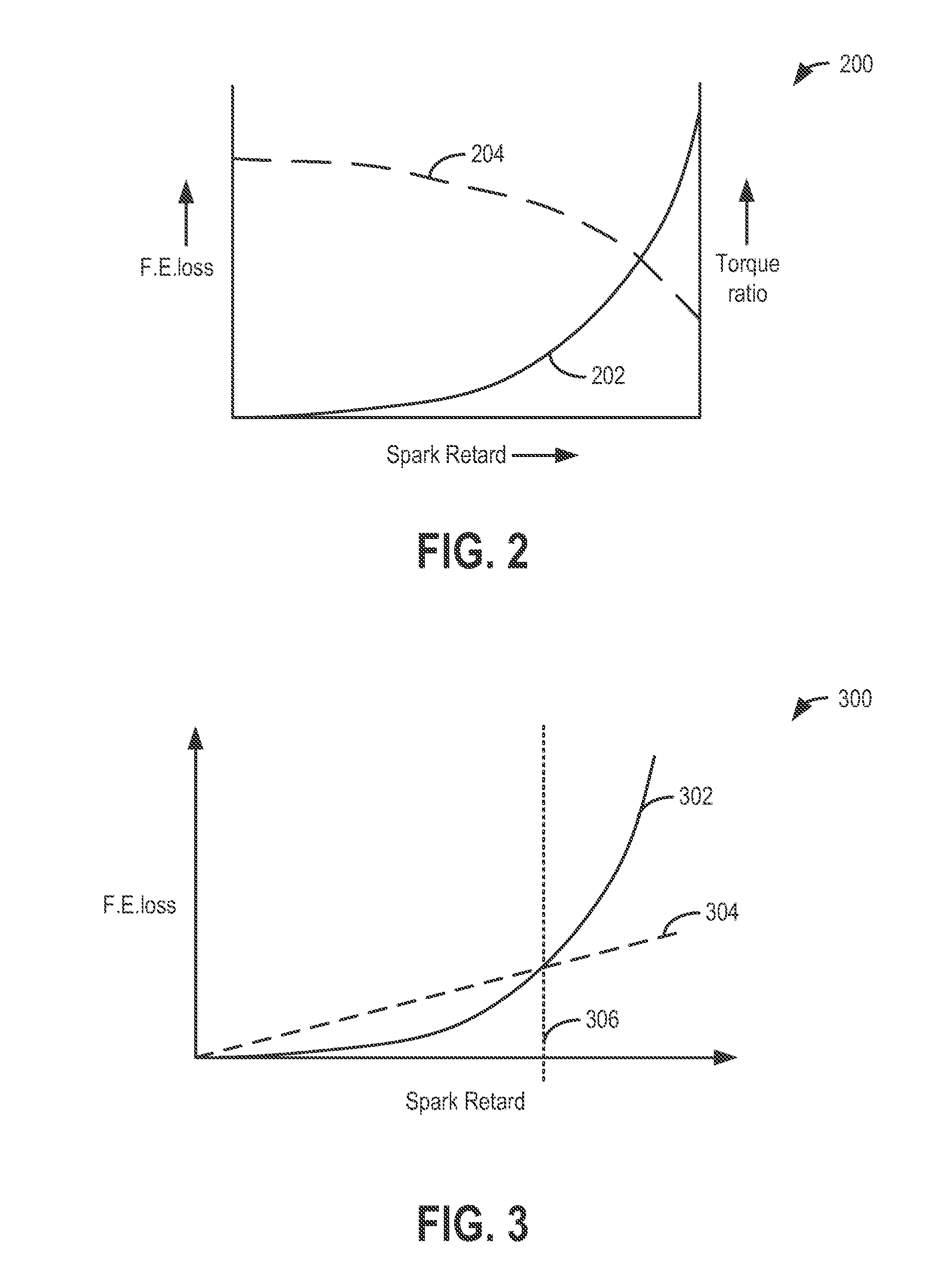

Method and system for controlling fuel usage

ActiveUS20120029795A1Reduce exhaust emissionsHigh priceAnalogue computers for vehiclesElectrical controlOperant conditioningThrottle

Methods and systems are provided for improving fuel usage while addressing knock by adjusting the use of spark retard and direct injection of a fluid based on engine operating conditions and the composition of the injected fluid. One or more engine parameters, such as EGR, VCT, boost, throttle position, are coordinated with the direct injection to reduce torque and EGR transients.

Owner:FORD GLOBAL TECH LLC

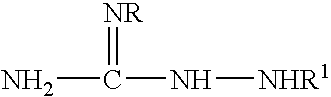

Fuel additive for improved performance in fuel injected engines

ActiveUS20130333649A1Maximize driveabilityMaximize economyOrganic chemistryNon-fuel substance addition to fuelCarboxylic acidDiesel engine

A fuel composition for a fuel injected diesel engine, a method for improving performance of fuel injectors and a method for cleaning fuel injectors for a diesel engine. The fuel composition includes a major amount of fuel and a minor effective amount of a reaction product of (i) a hydrocarbyl substituted compound containing at least one tertiary amino group and (ii) a halogen substituted C2-C8 carboxylic acid, ester, amide, or salt thereof, wherein the reaction product as made is substantially devoid of free anion species.

Owner:AFTON CHEMICAL

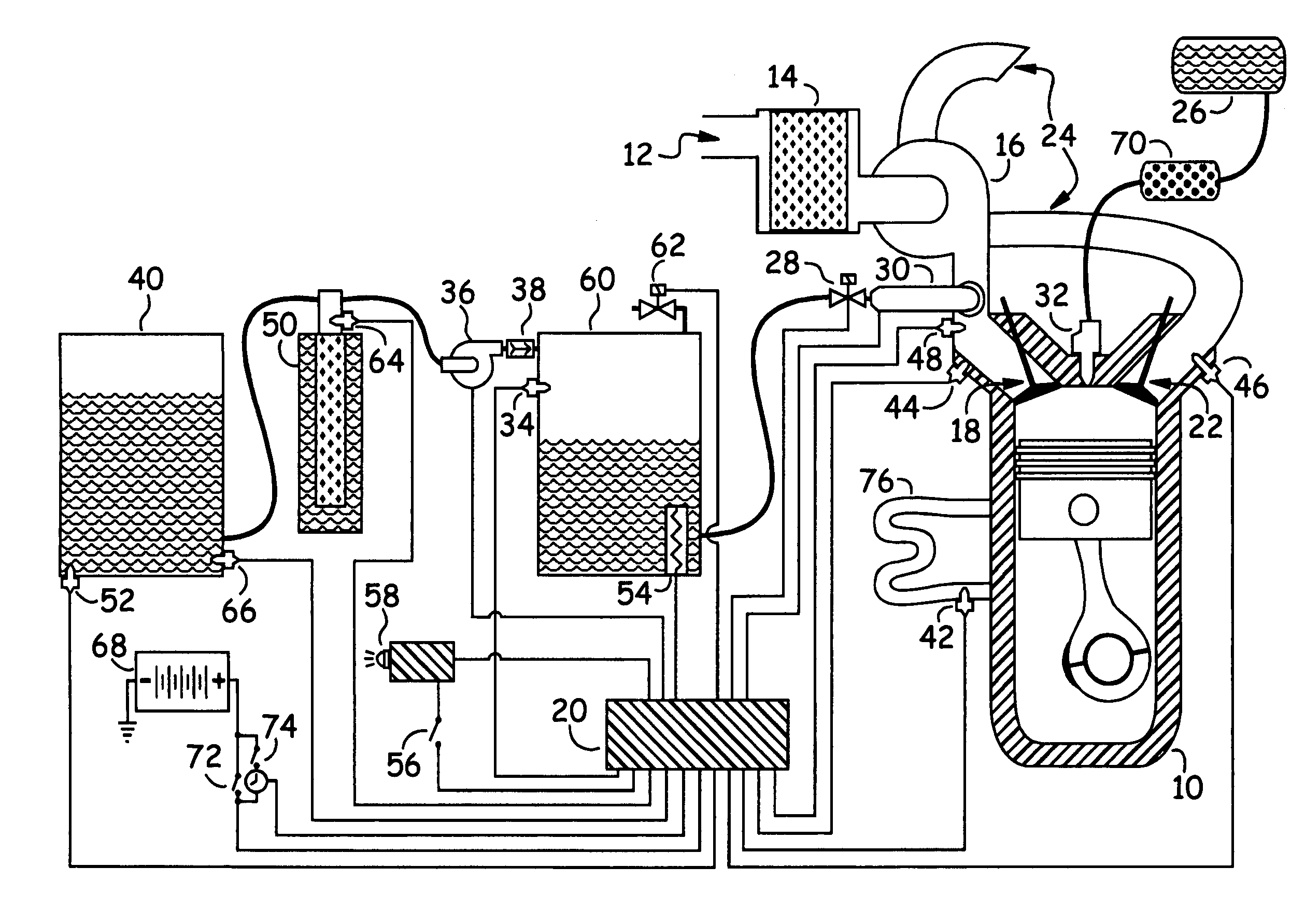

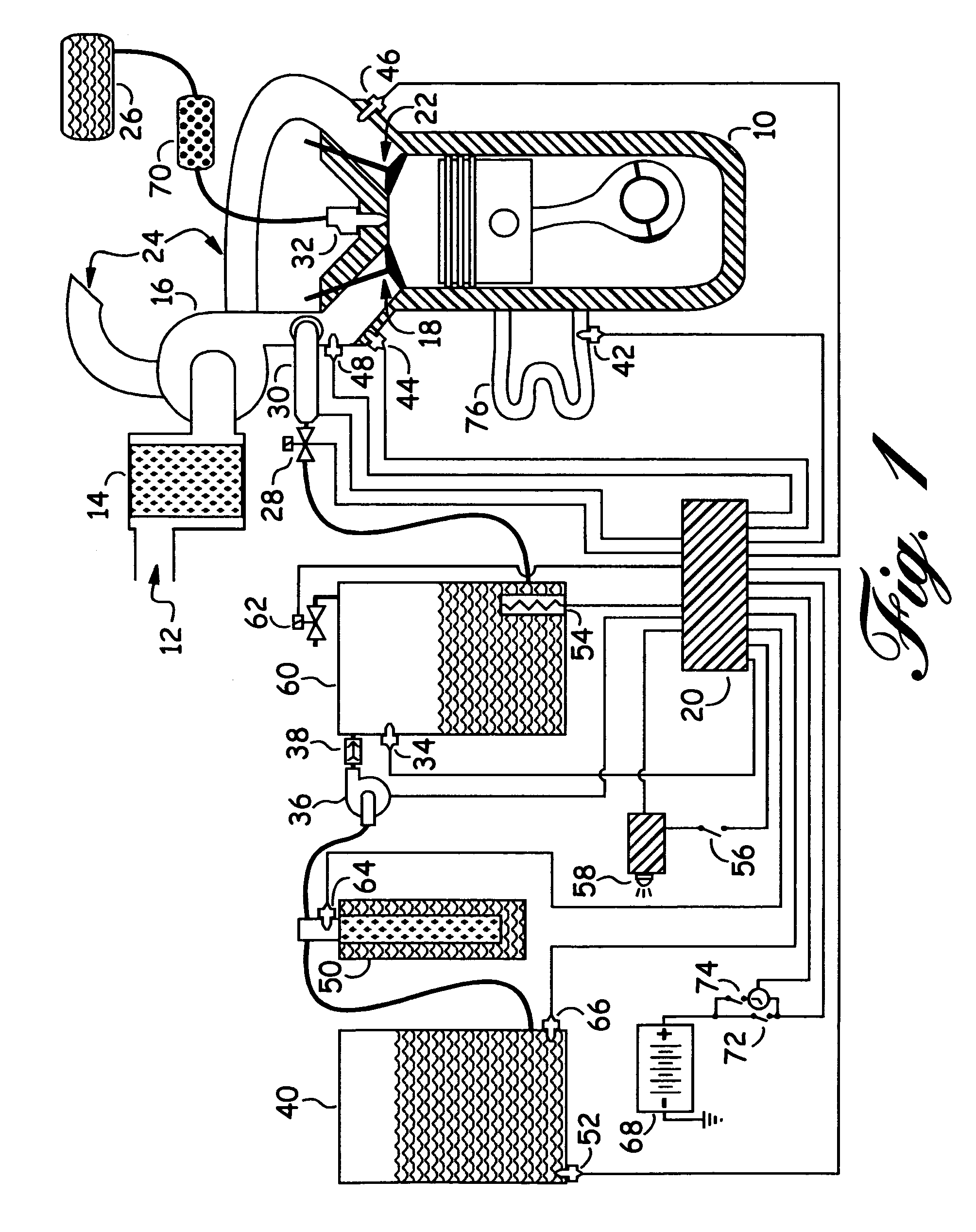

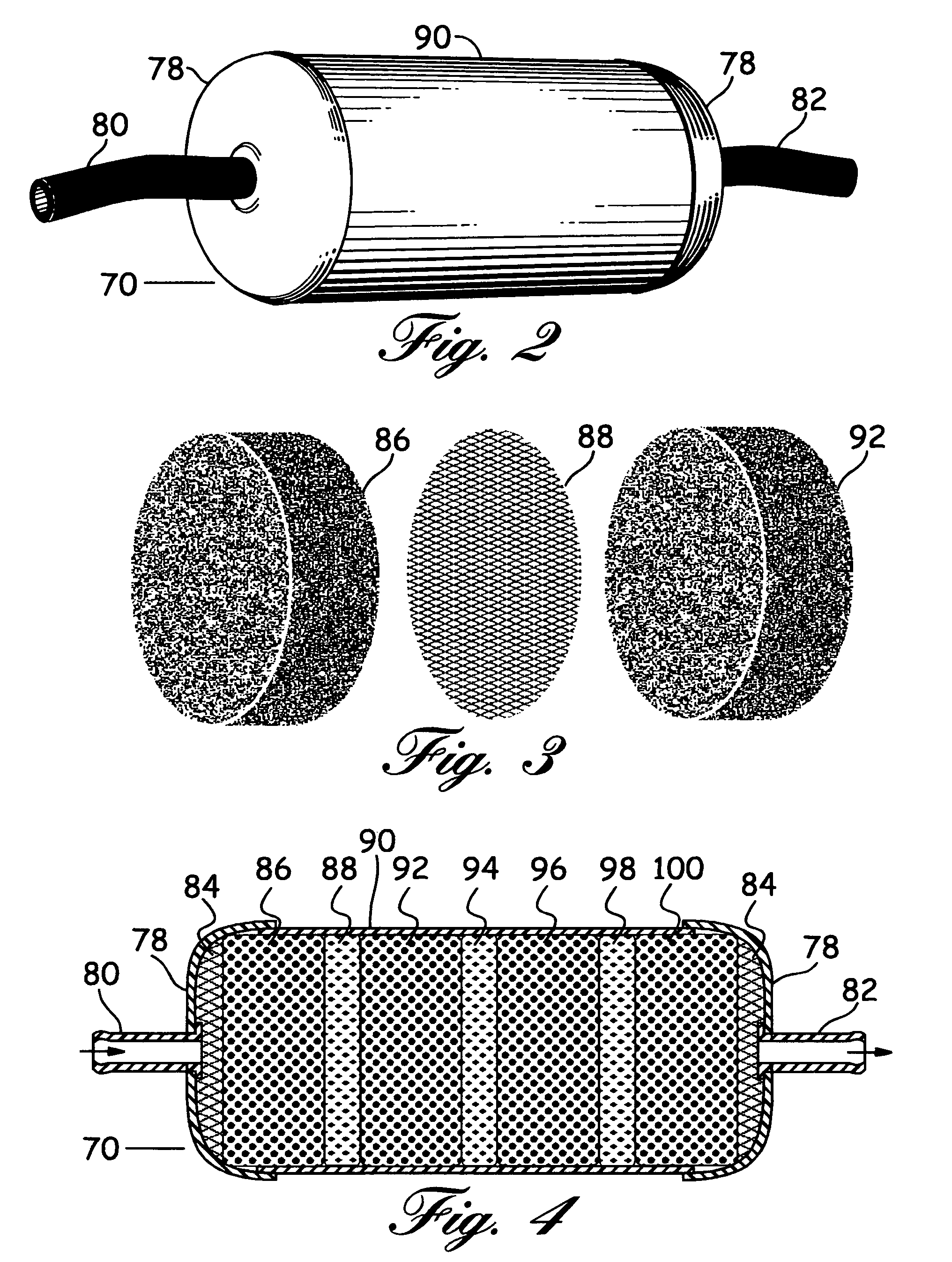

Emissions reduction system for an internal combustion engine

InactiveUS7013845B1Reduce harmful emissionsImprove performanceInternal combustion piston enginesNon-fuel substance addition to fuelPrime moverNitrogen oxides

A dual system for overall engine emissions control, including prevention of excessive formation of nitrogen oxides and carbon compounds 1) by cooling and humidifying intake air and 2) by restructuring and modifying hydrocarbon fuels, resulting in a more complete combustion, a significant reduction of the latent heat of combustion and increased combustion potency. The invention utilizes one or more ultrasonic devices to create an aqueous vapor from an ultra-pure water supply, said vapor varying in quantity according to engine size and load, having electronic sensors and controls for precision switching, metering and delivery. Simultaneously, while humidifying the intake air, the hydrocarbon fuel is passed from a fuel supply through a catalytic reactor to restructure the hydrocarbon molecules into a more homogeneous, more combustible and cleaner-burning fuel. Thus equipped, said internal combustion engine can be run as a fuel conserving, low emissions prime mover.

Owner:CONTEGO MEDICAL INC

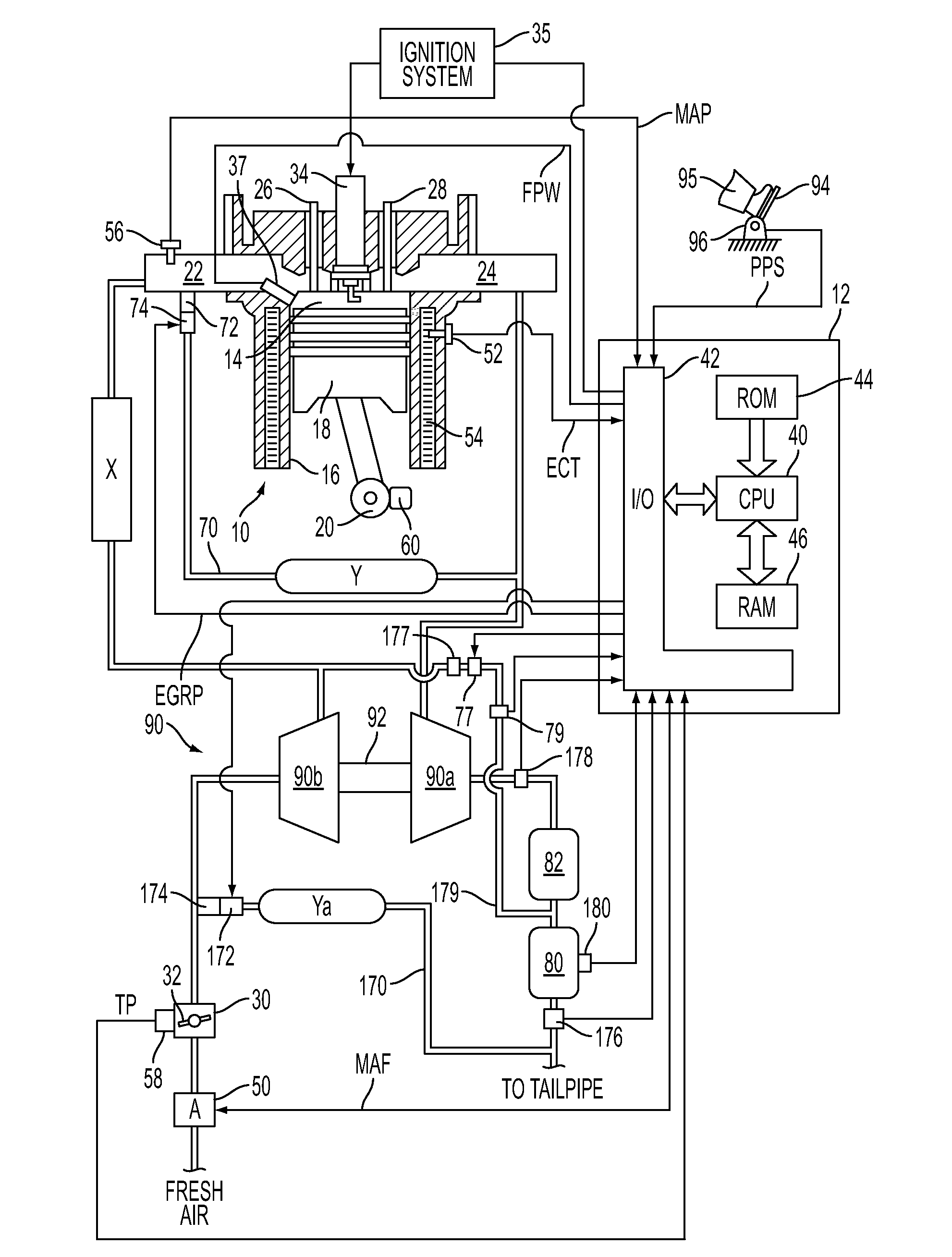

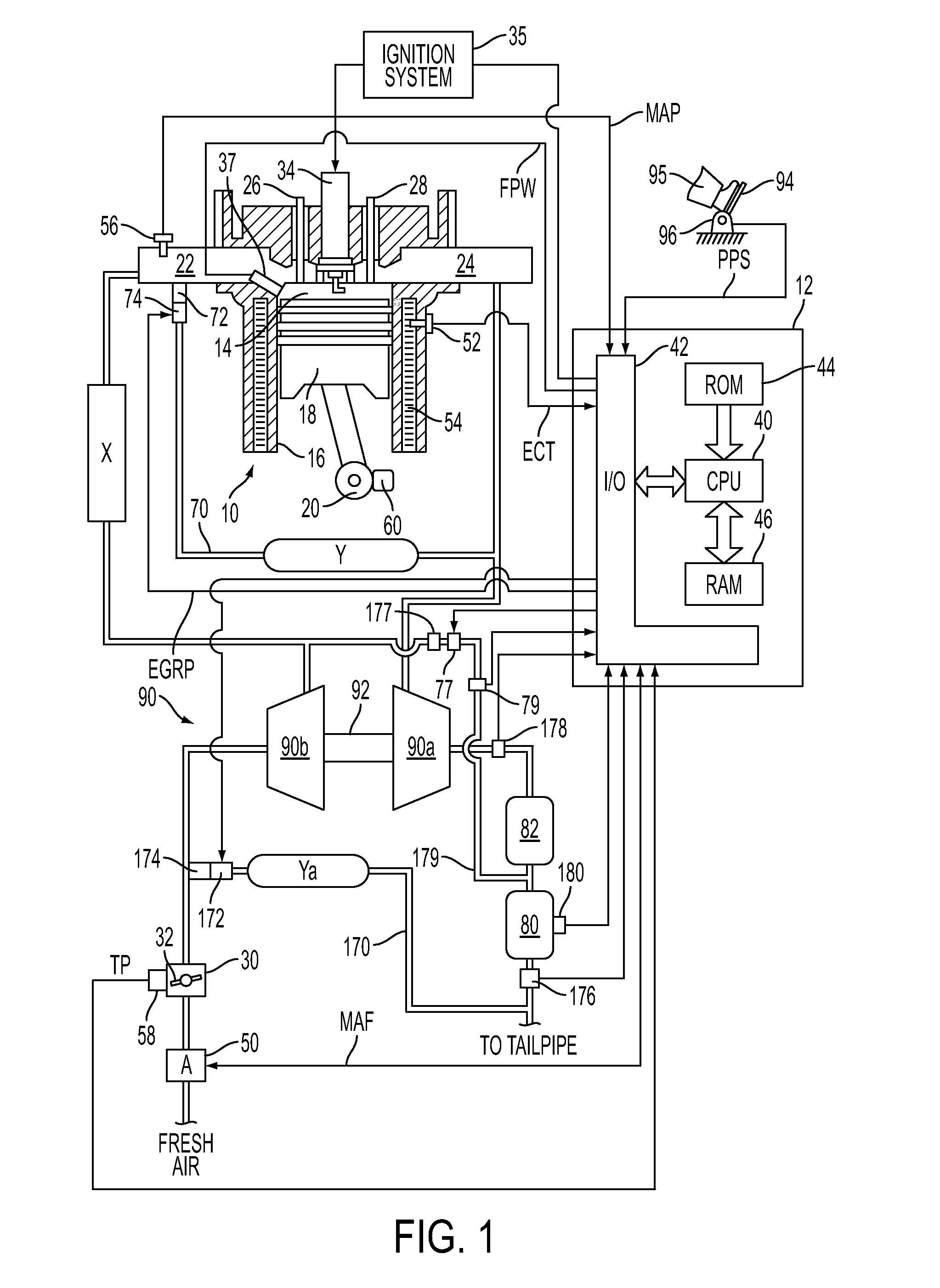

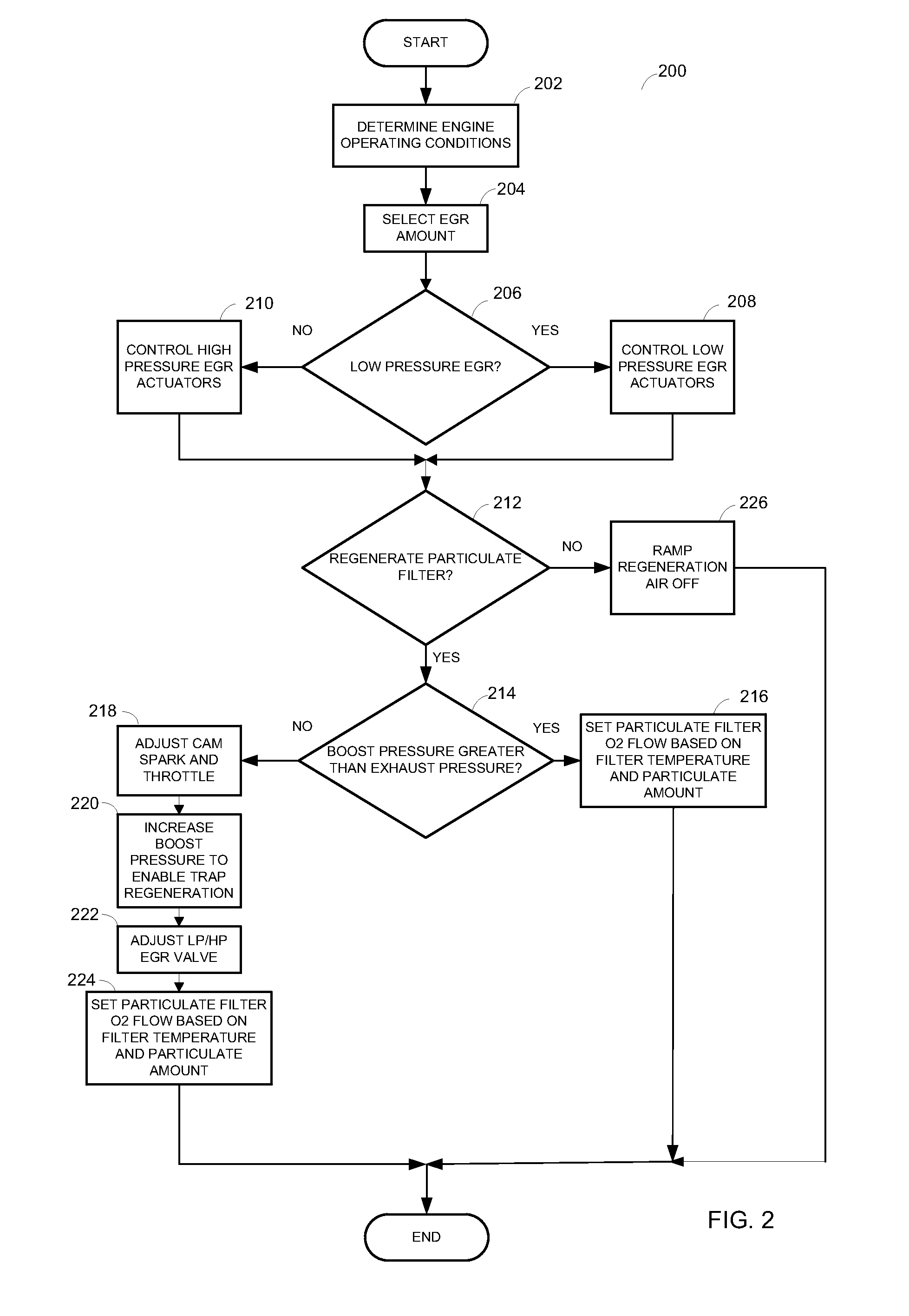

System and method for regenerating a particulate filter for a direct injection engine

ActiveUS20110072794A1Emission reductionReduce engine pumping lossesElectrical controlInternal combustion piston enginesGasolineEnvironmental engineering

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turobocharged gasoline engine to the exhaust system by a compressor. The oxygen is introduced to a particulate filter at a location upstream from the particulate filter. In this way, regeneration of a particulate filter may be accomplished without disturbing the chemistry of a three-way catalyst located in the exhaust system upstream of the particulate filter.

Owner:FORD GLOBAL TECH LLC

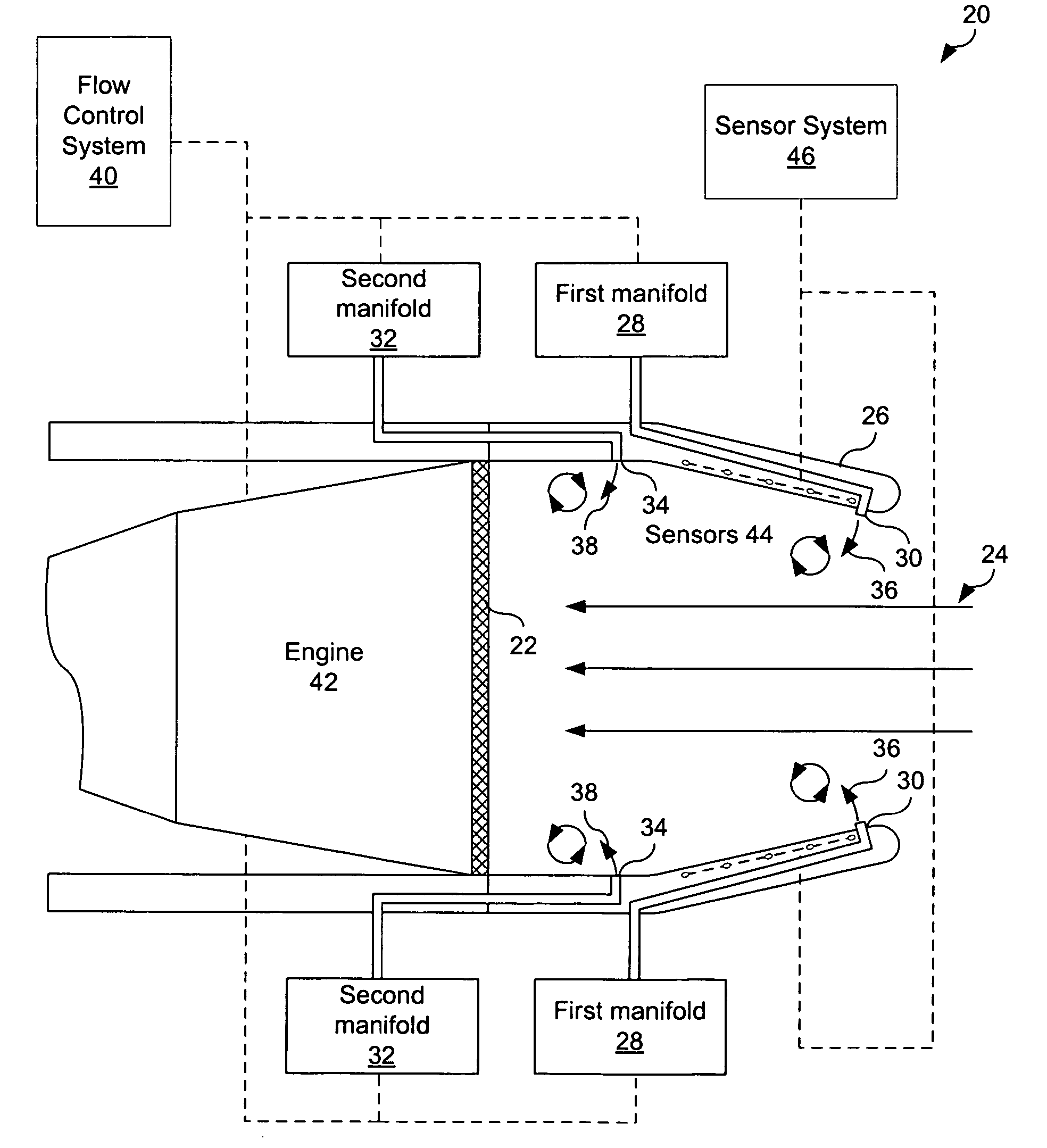

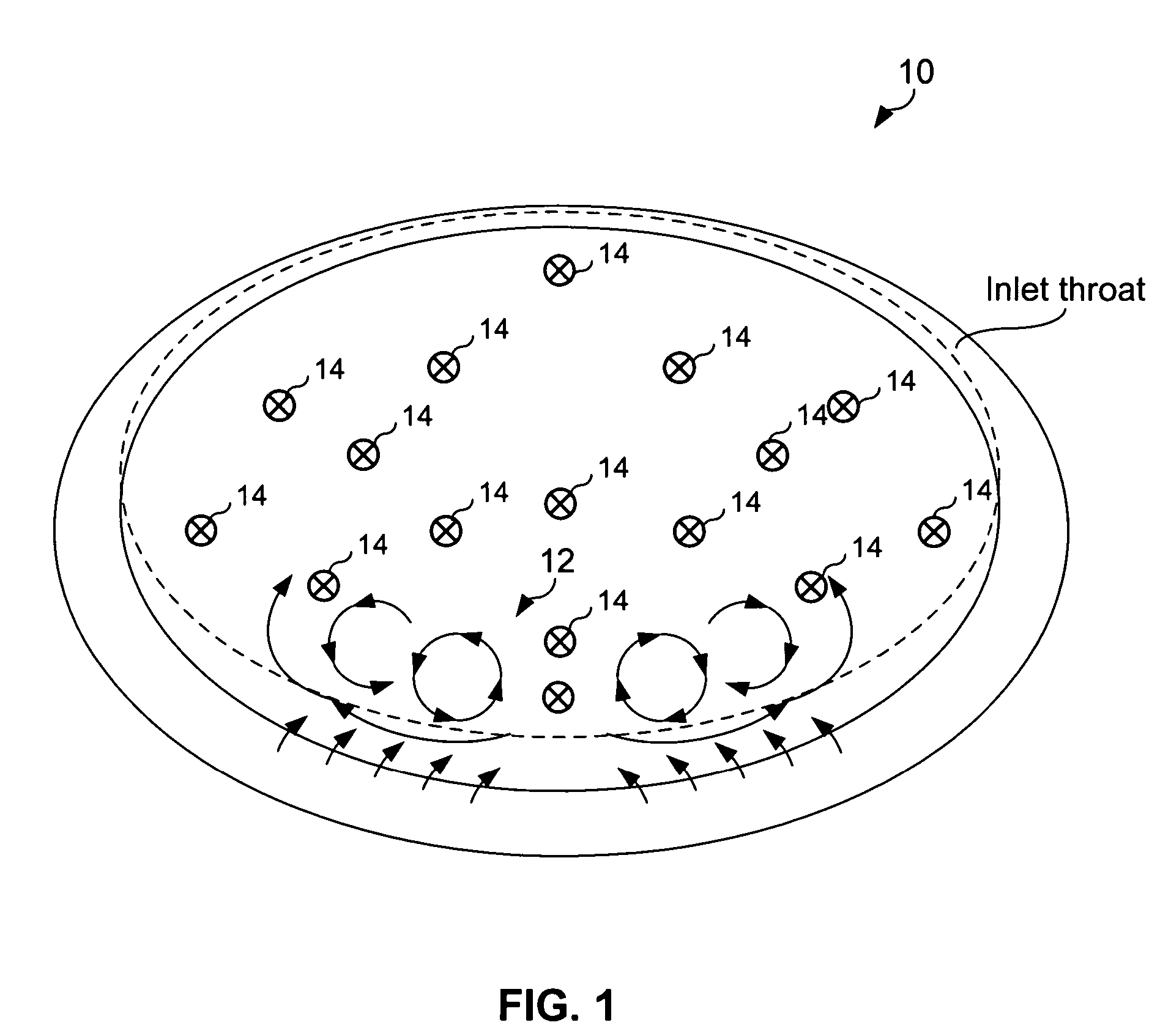

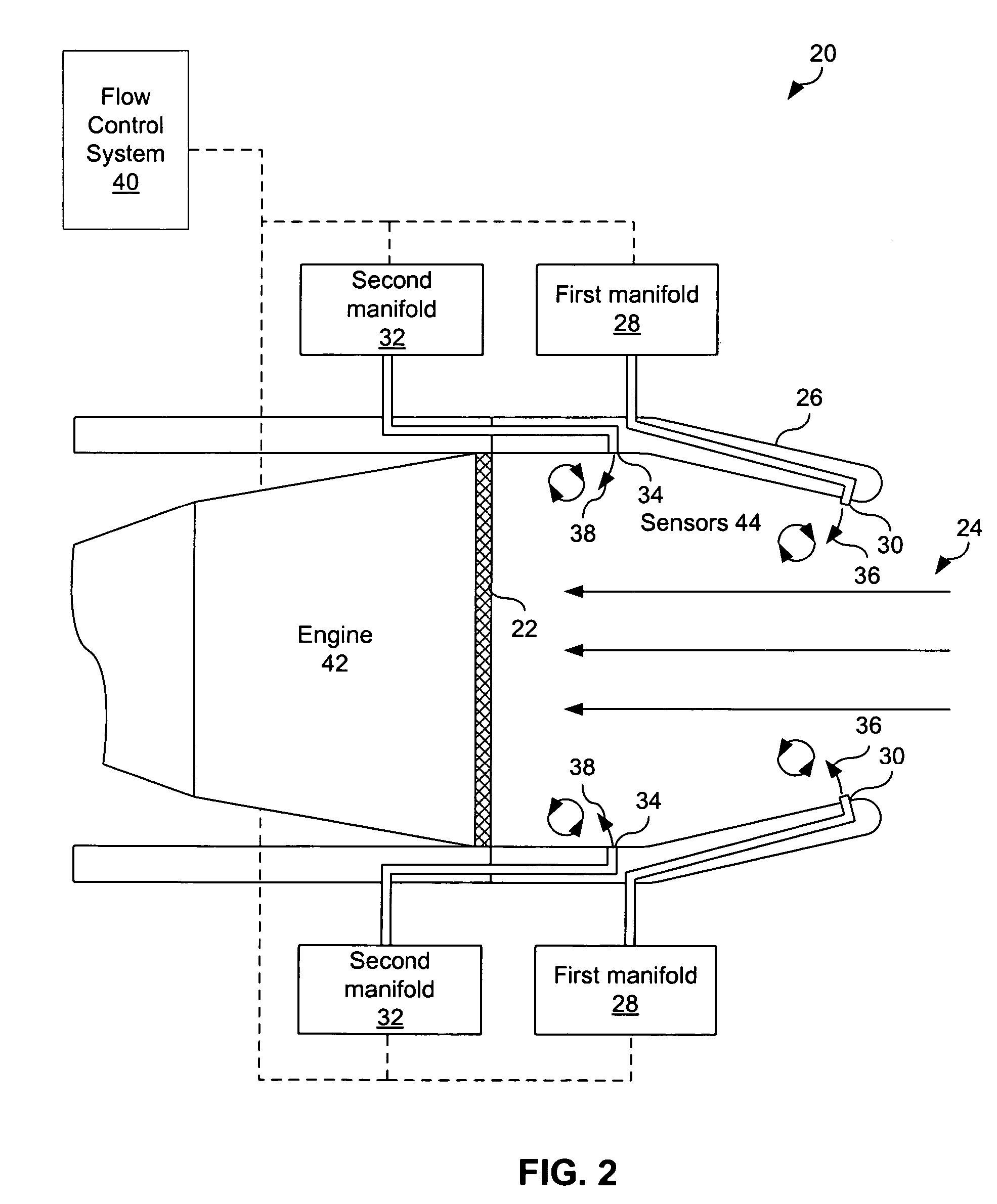

Flow control redistribution to mitigate high cycle fatigue

ActiveUS7617670B2Improve distortionPromote recoveryCombustion enginesGas turbine plantsEngineeringLow-cycle fatigue

A method operable to improve pressure recovery and / or distortion within engine inlet is disclosed. A first fluid flow is provided to primary jet vortex generator(s) operable to inject fluid at a first injection rate into a boundary layer of a primary fluid flow within the inlet. A secondary fluid flow is injected by secondary jet vortex generator(s) at a second injection rate into the boundary layer of the primary fluid flow, The fluid injected at the first injection rate and second injection rate is operable to induce secondary flow structures within the boundary layer. These secondary close structures are then operable to improve or manipulate the pressure recovery of the inlet. At specific engine conditions, this method may redistribute the ratio of the first injection rate and second injection rate in order to improve pressure recovery and / or distortion of the inlet when the particular engine conditions.

Owner:LOCKHEED MARTIN CORP

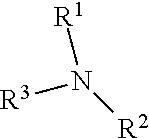

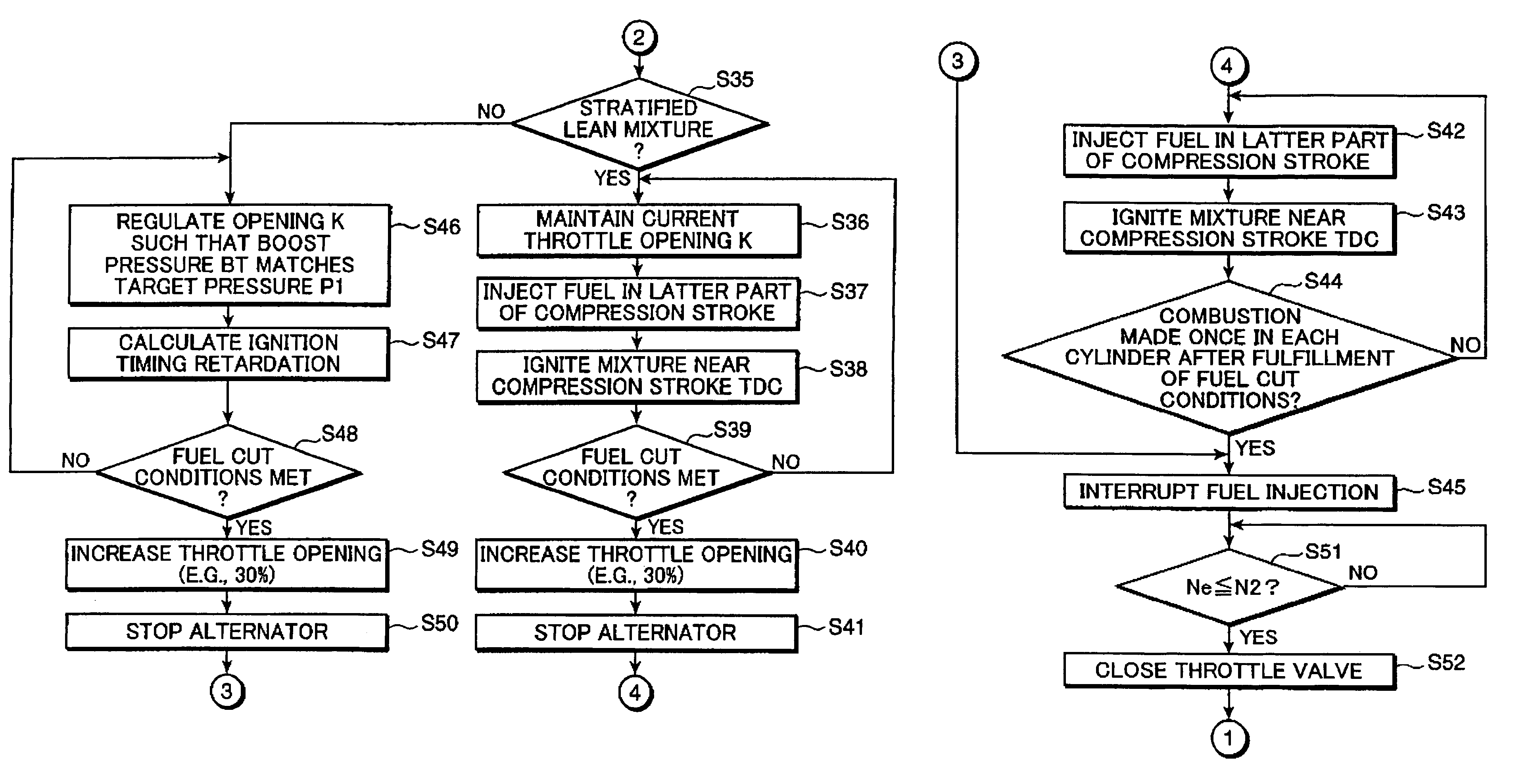

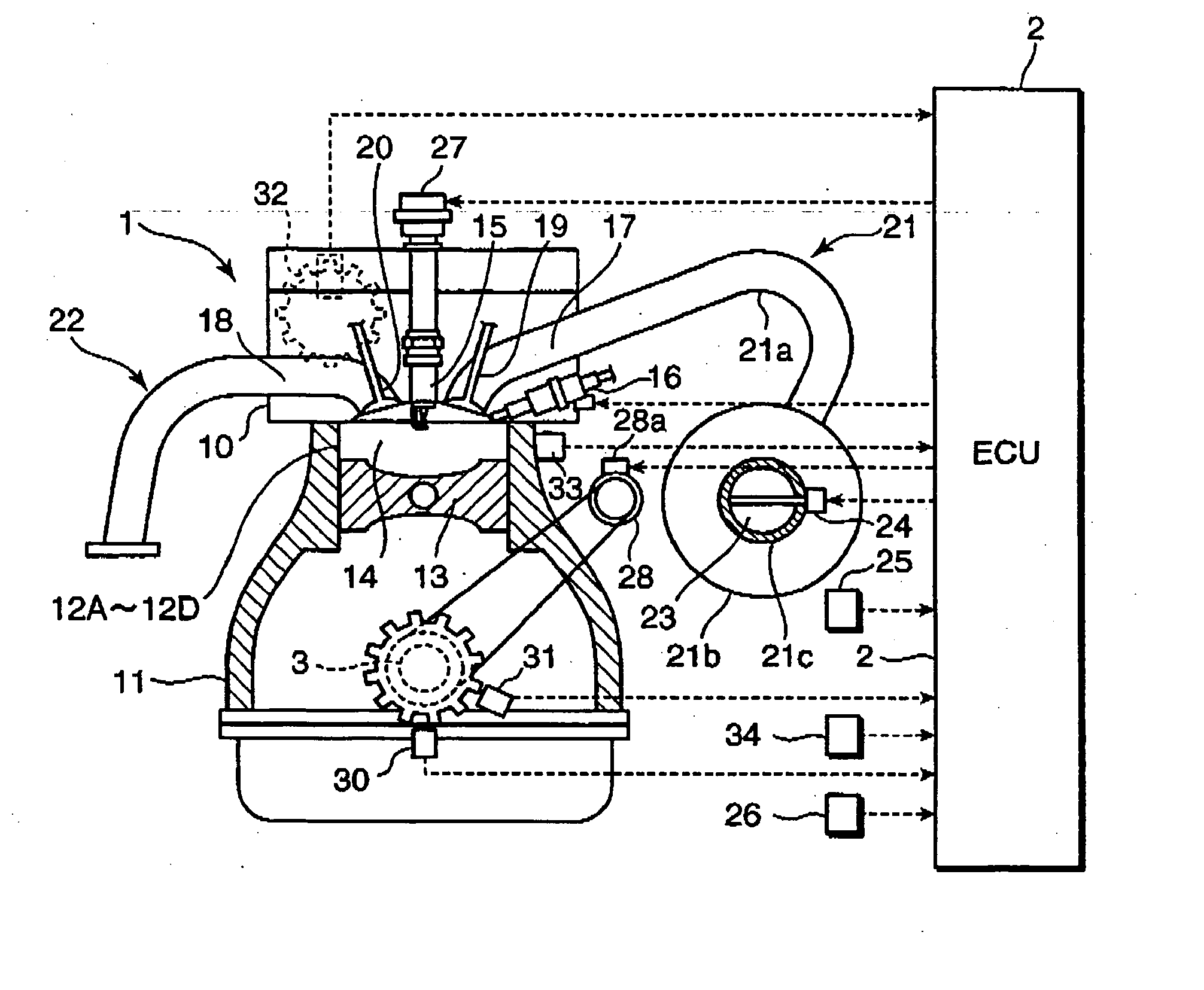

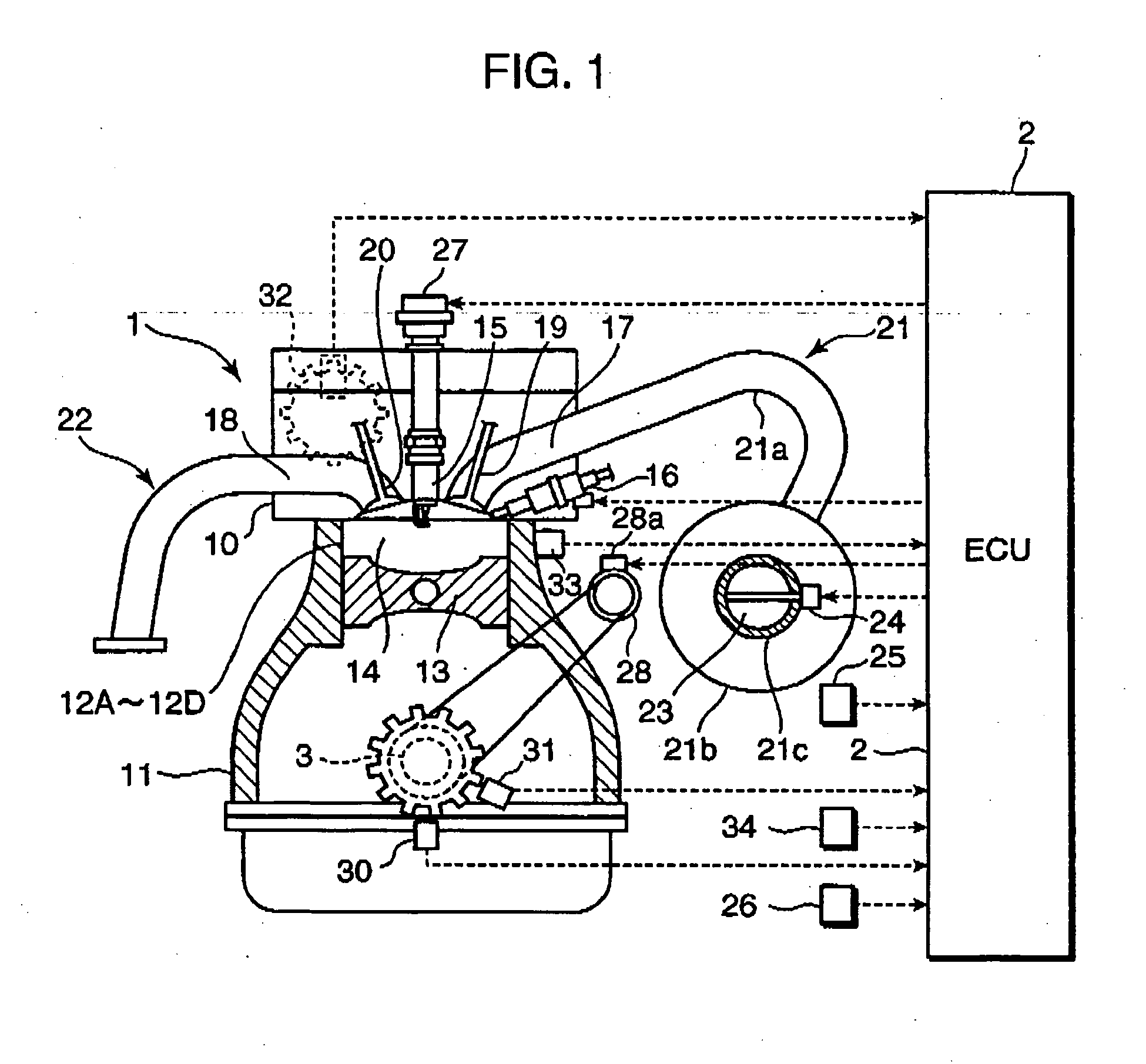

Engine starting system

ActiveUS20050221952A1Improve engine performanceImprove rendering capabilitiesAnalogue computers for vehiclesElectrical controlAlternatorElectric power

An engine starting system includes a throttle valve, an alternator, an engine speed sensor and an electronic control unit (ECU). The ECU functionally includes an automatic engine stop controller for automatically stopping the engine by interrupting fuel injection when predefined automatic engine stop conditions are satisfied, and an automatic engine restart controller for automatically restarting the engine when predefined engine restart conditions are satisfied. The automatic engine stop controller sets the quantity of intake air at a level higher than a minimum quantity of intake air necessary for keeping the engine running, decreases the amount of electric power generated by the alternator in an early part of automatic engine stop control operation, and decreases the quantity of intake air and causes the alternator to once decrease the amount of electric power generated thereby at a point in time when the engine speed drops down to a predetermined reference engine speed, and causes the alternator to later increase the amount of electric power generated thereby.

Owner:MAZDA MOTOR CORP

System for actively controlling compressor clearances

InactiveUS7434402B2Compressor clearances can beReduce gapPump componentsEngine fuctionsEngineeringBleed air

Aspects of the invention relate to a system and method for actively controlling compressor clearances in a turbine engine by passing a thermal fluid in heat exchanging relation through a compressor vane carrier. During some operational conditions, such as hot restart or spin cool, it may be desirable to heat the vane carrier to enlarge or at least prevent a decrease in compressor clearances. In such cases, a heated thermal fluid can be provided by reclaiming residual exhaust energy from a heat recovery steam generator. At any condition where improved performance is desired, such as at base load operation, the vane carrier can be cooled to minimize compressor clearances. A cooled thermal fluid can be bleed air from an upstream portion of the compressor, water-cooled high pressure bleed air from a downstream portion of the compressor, or feed water from the bottoming cycle in a combined cycle engine.

Owner:SIEMENS ENERGY INC

Methods and systems for egr control

ActiveUS20150047618A1Improving peak power outputImprove exhaust emissionsElectrical controlNon-fuel substance addition to fuelEngineeringStreamflow

Methods and systems are provided for using compressor recirculation flow via a venturi to enhance low pressure EGR flow. The opening of a compressor recirculation valve can be adjusted based on EGR flow demand to recirculate cooled compressed air through a venturi while generating vacuum for drawing EGR. The approach allows for concurrent EGR control and surge control.

Owner:FORD GLOBAL TECH LLC

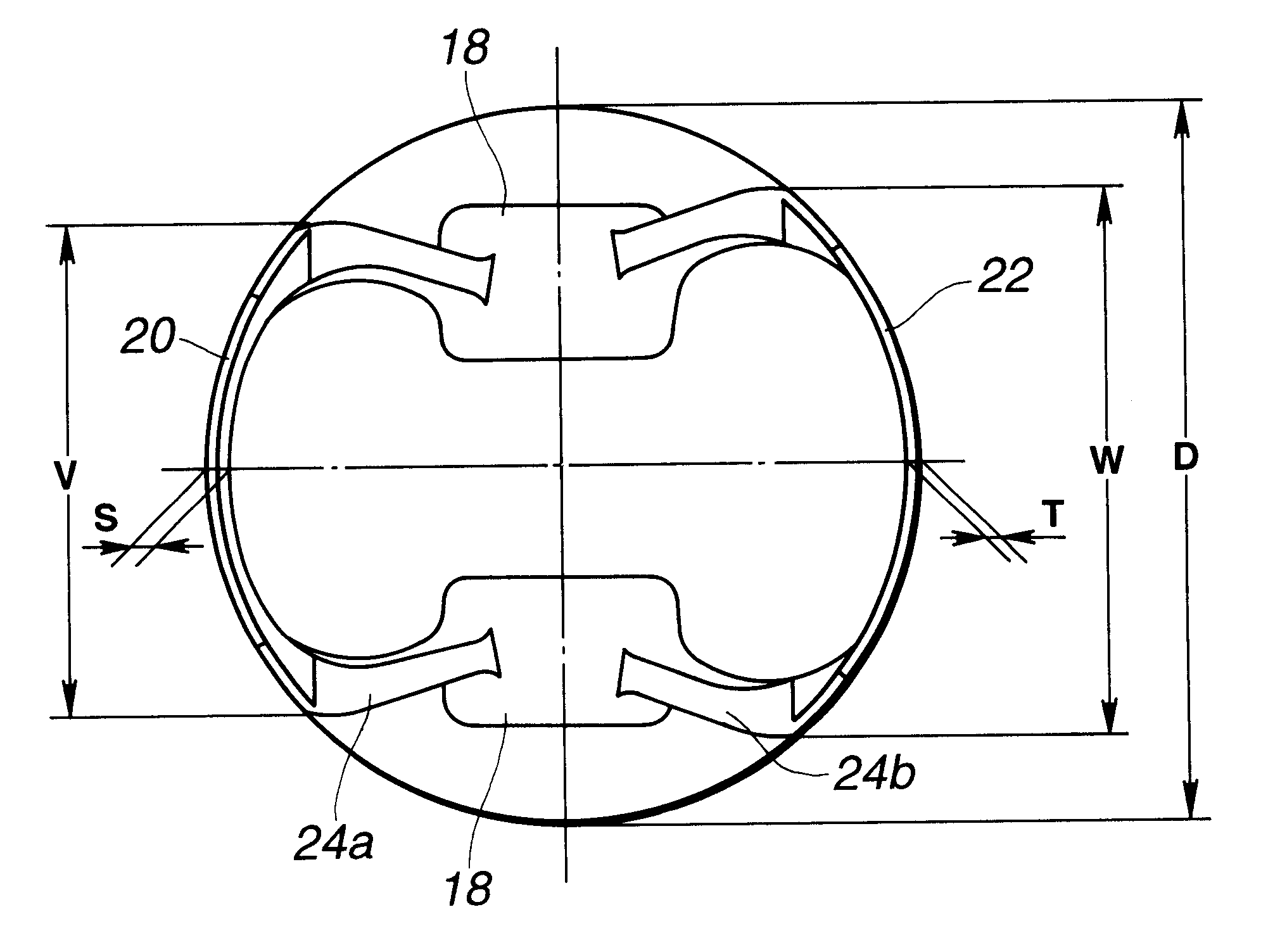

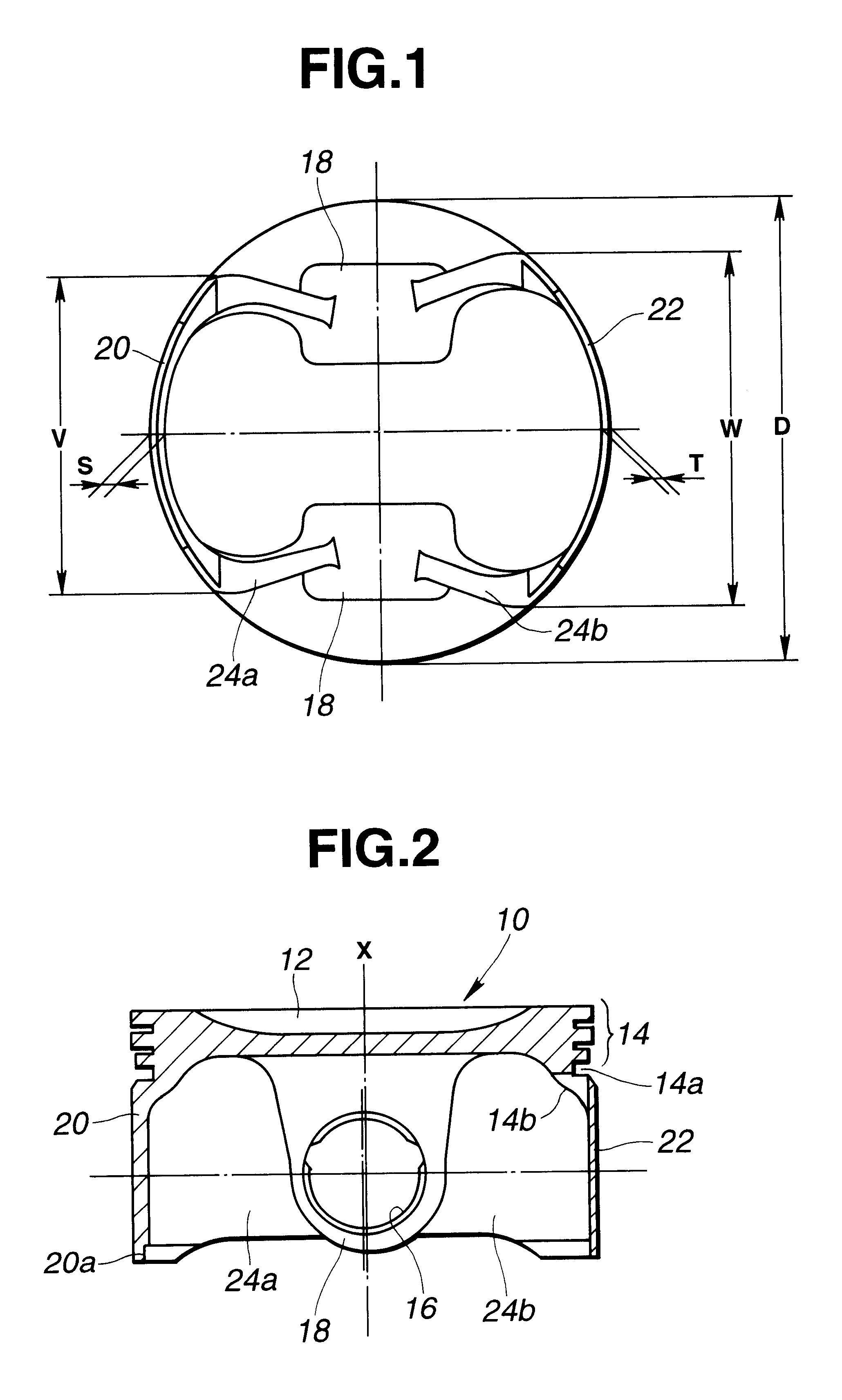

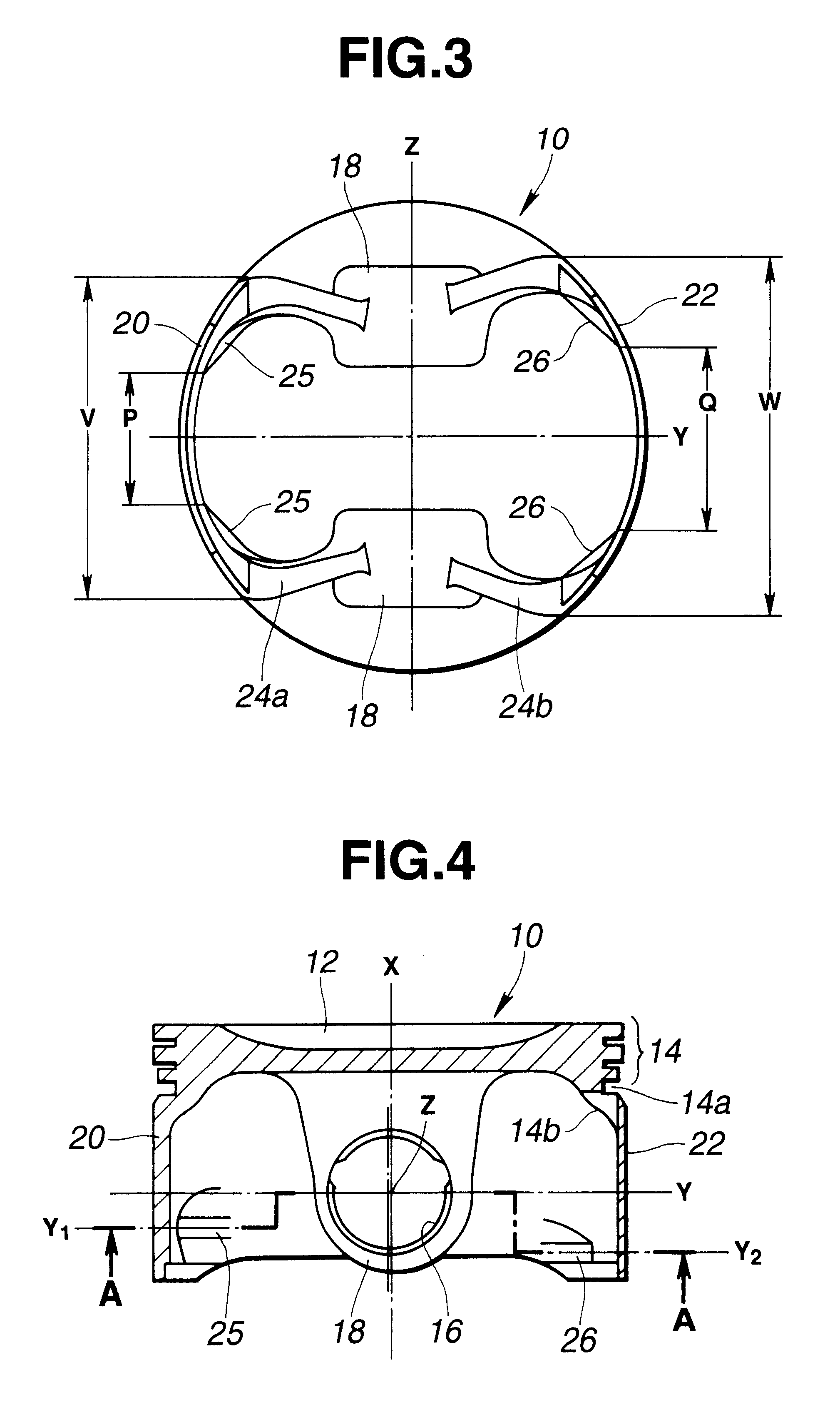

Piston of internal combustion engine

InactiveUS6357341B1Reduce frictional resistanceReduce coefficient of frictionPlungersMachines/enginesEngineeringInternal combustion engine

In a reciprocating piston of an internal combustion engine comprising a piston skirt having a major-thrust-side skirt portion and a minor-thrust-side skirt portion, a projected circumferential width of the minor-thrust-side skirt portion is greater than a projected circumferential width of the major-thrust-side skirt portion. Additionally, the piston skirt is dimensioned so that the minimum thickness of the minor-thrust-side skirt portion is less than the minimum thickness of the major-thrust-side skirt portion.

Owner:UNISIA JECS CORP

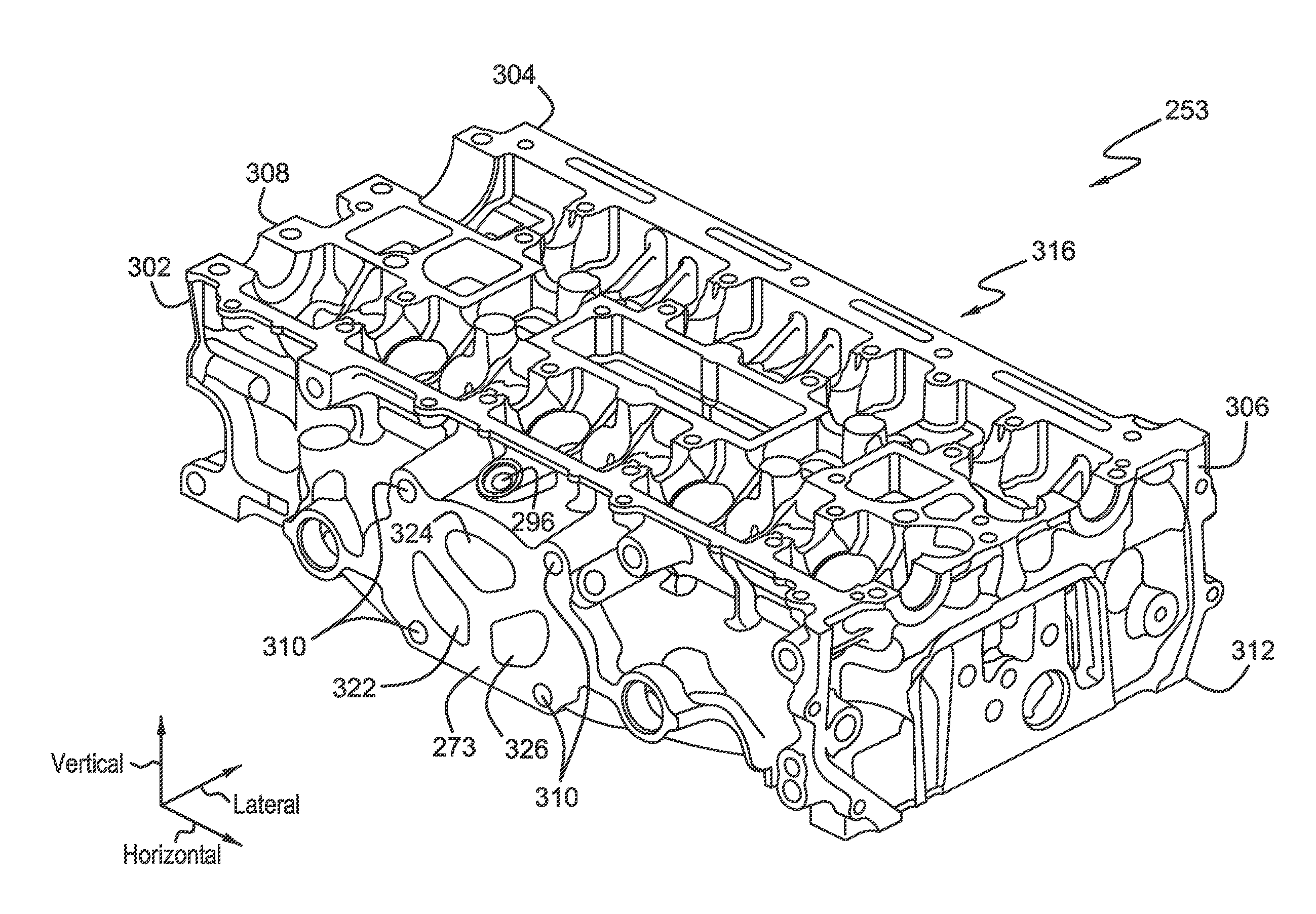

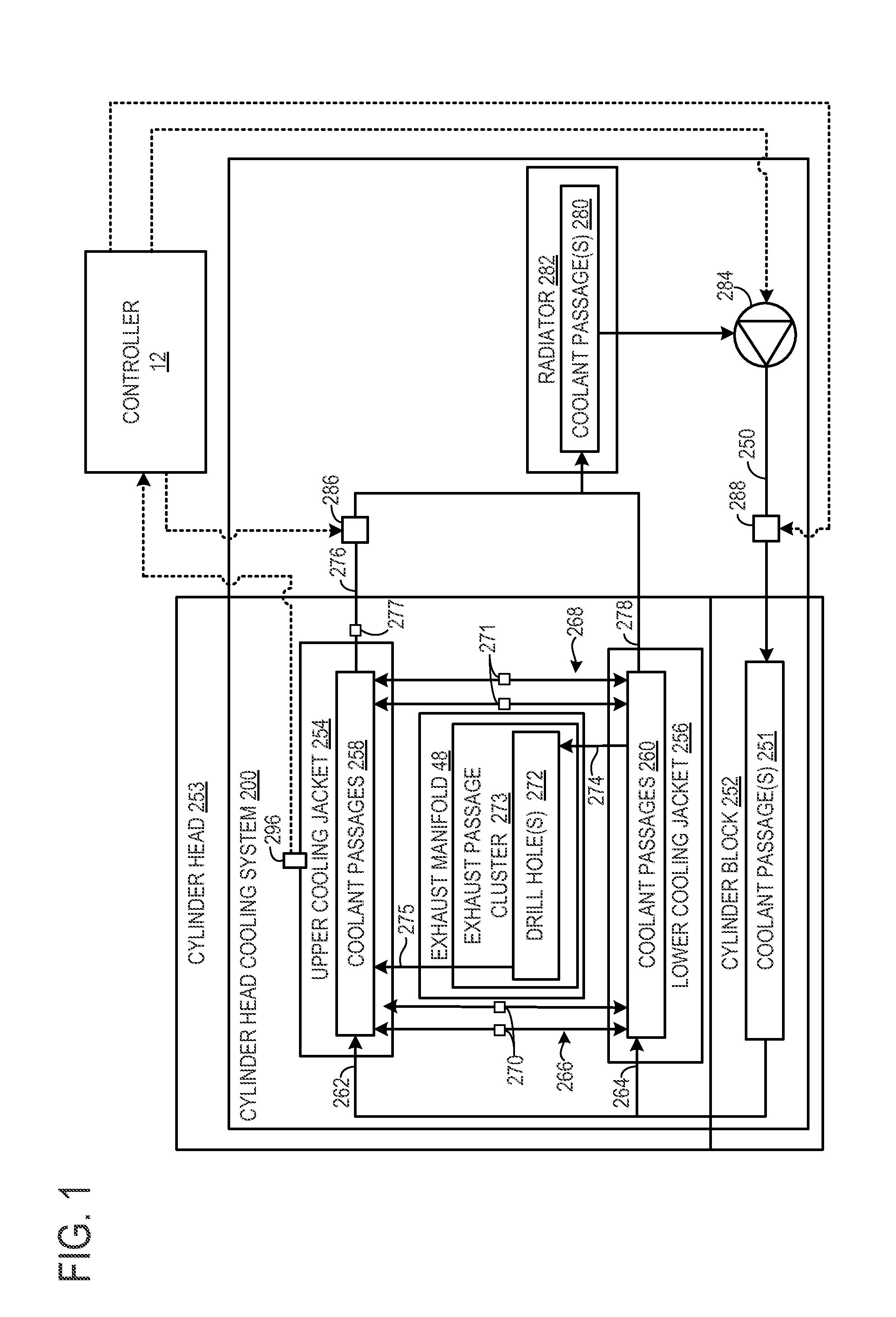

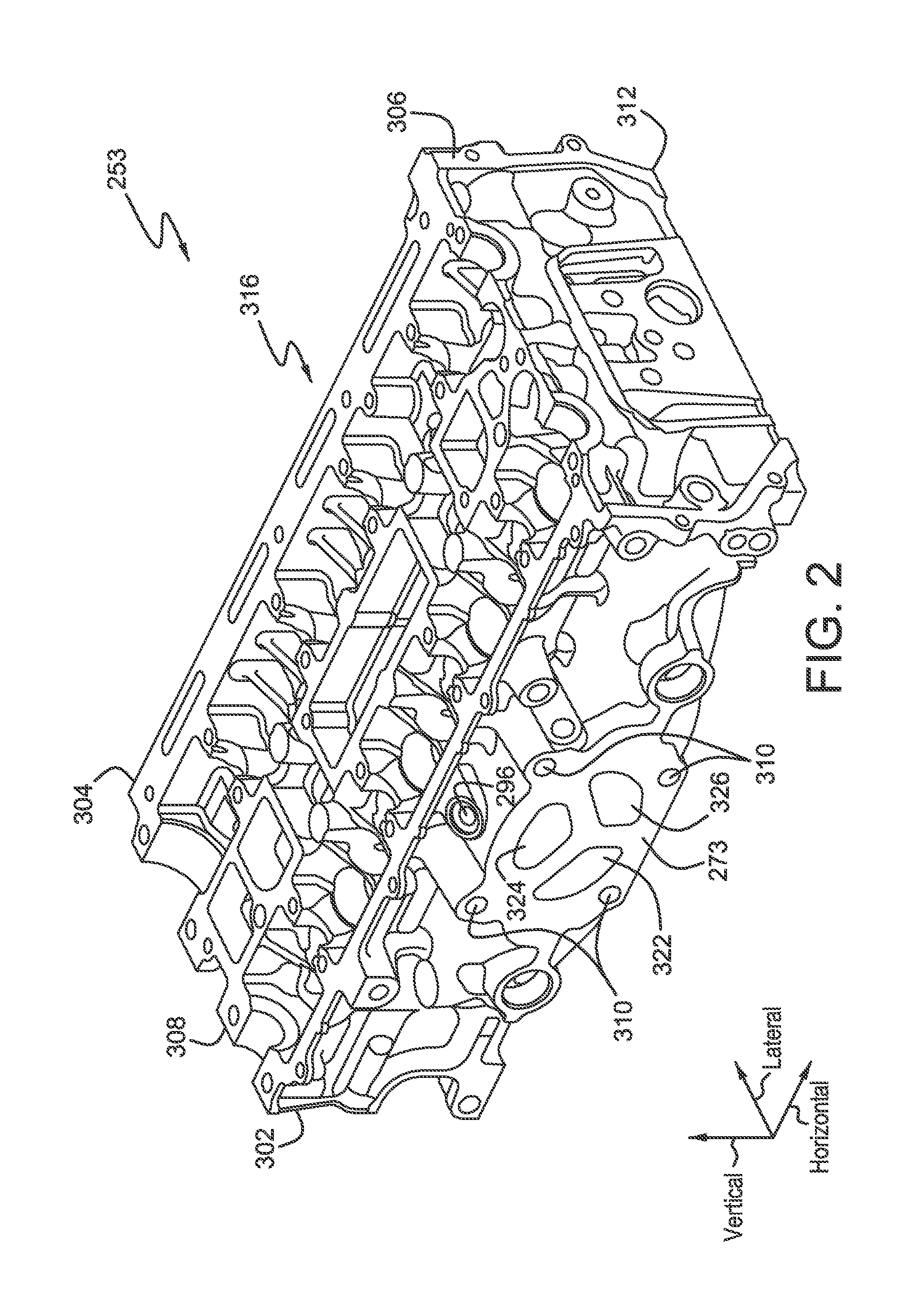

Integrated exhaust cylinder head

ActiveUS20130055971A1Reduce componentsReduce thermal stressLiquid coolingInternal combustion piston enginesCylinder headEngineering

An engine cooling system is provided. The engine cooling system includes a cylinder head including an integrated exhaust manifold that directs exhaust gases to an exhaust outlet port and a coolant passage surrounding the exhaust manifold. The engine cooling system further includes a cluster of separated exhaust passages for directing exhaust gases to the exhaust outlet port, the cluster including a drill hole disposed within material between the exhaust passages, the drill hole fluidically coupled to the coolant passage.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com