Patents

Literature

104 results about "Planform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

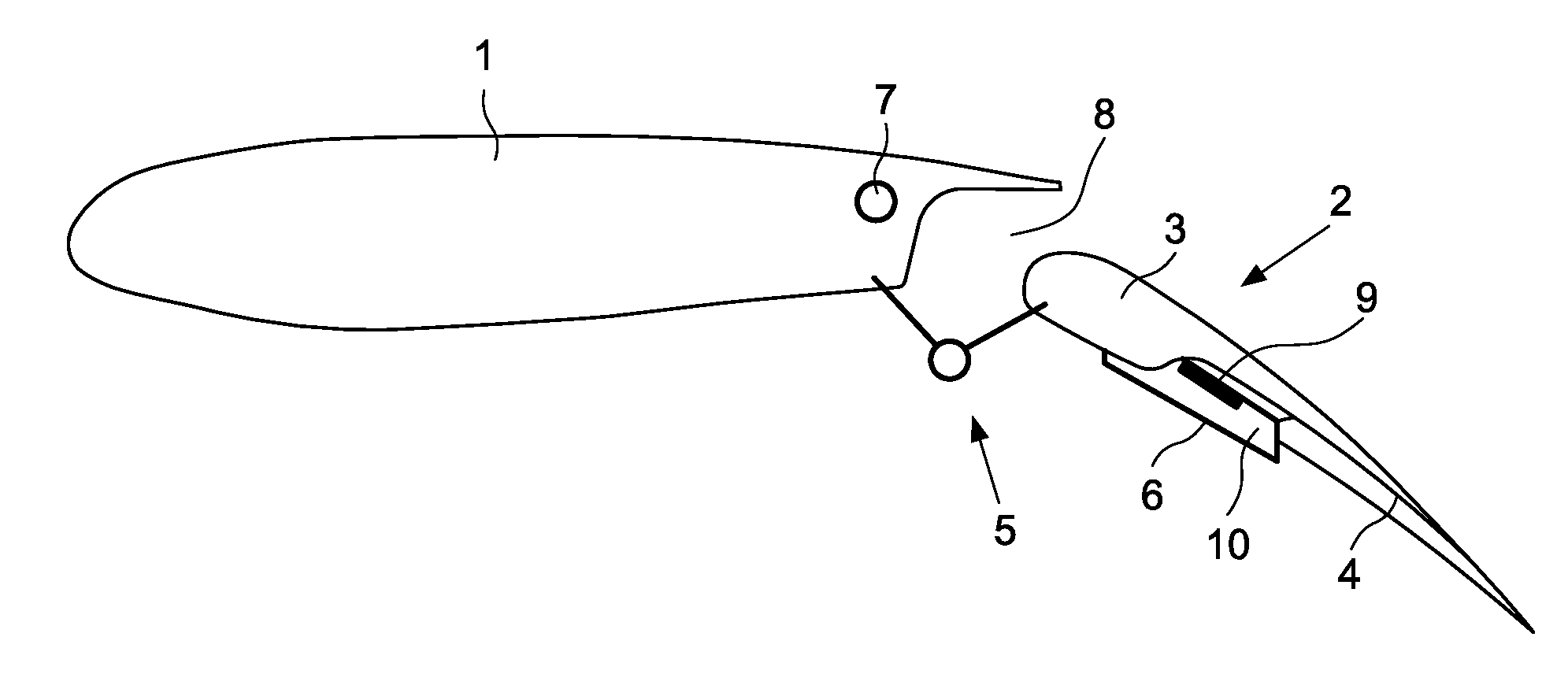

Application of conformal sub boundary layer vortex generators to a foil or aero/ hydrodynamic surface

InactiveUS20110006165A1Easy to liftImproving drag ratioInfluencers by generating vorticesWingsStream flowEngineering

A method of improving aerodynamic performance of foils by the application of conformal, low drag vortex generators. A film of erosion protection material or other conformal material is placed on the foil to provide a medium for the incorporation of planform edge vortex generators. The form edge is shaped to achieve submerged vortex generating shapes of chevron or ogival planforms, extending primarily chordwise on the foil surface. The vortex generators promote improved boundary layer dynamics by mixing free stream flow into the boundary layer while minimising separation and fluid losses. At the trailing edge, the shape formed with the chevrons applied apex forward, acts as a vented gurney tab series and additionally as disruptors to the Von Karman Street wake, delaying sheet rollup into the tip vortice.

Owner:IRELAND PETER

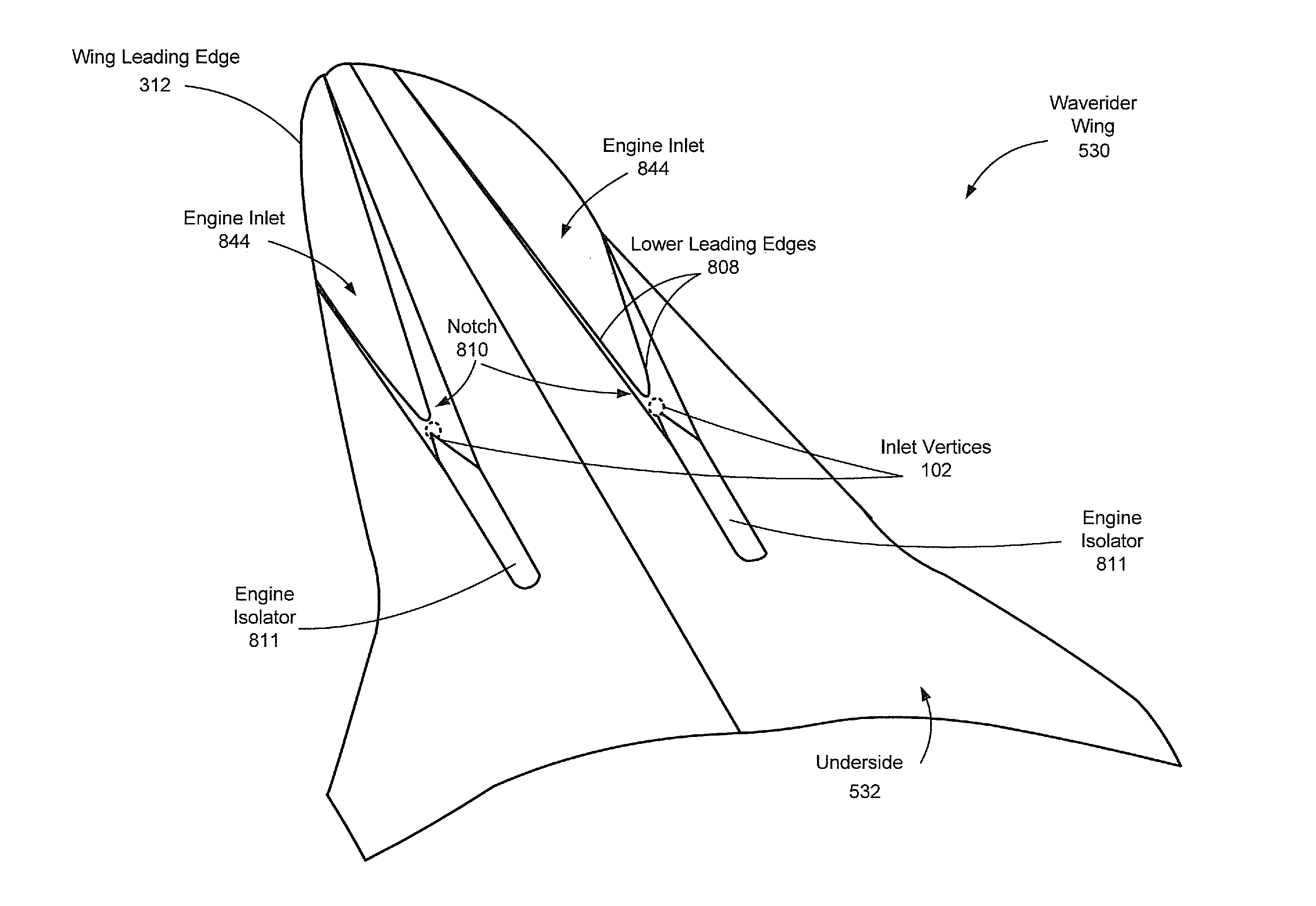

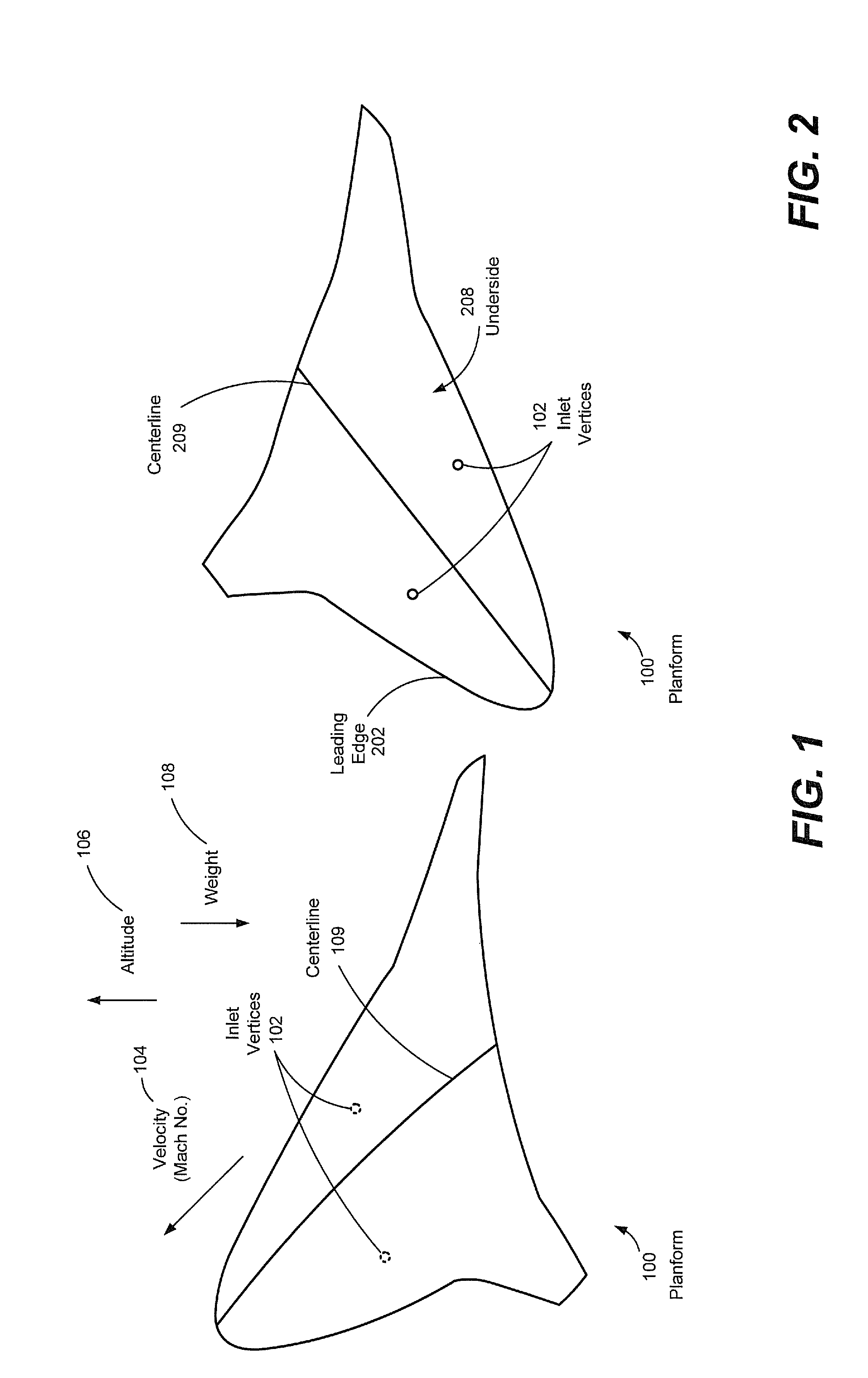

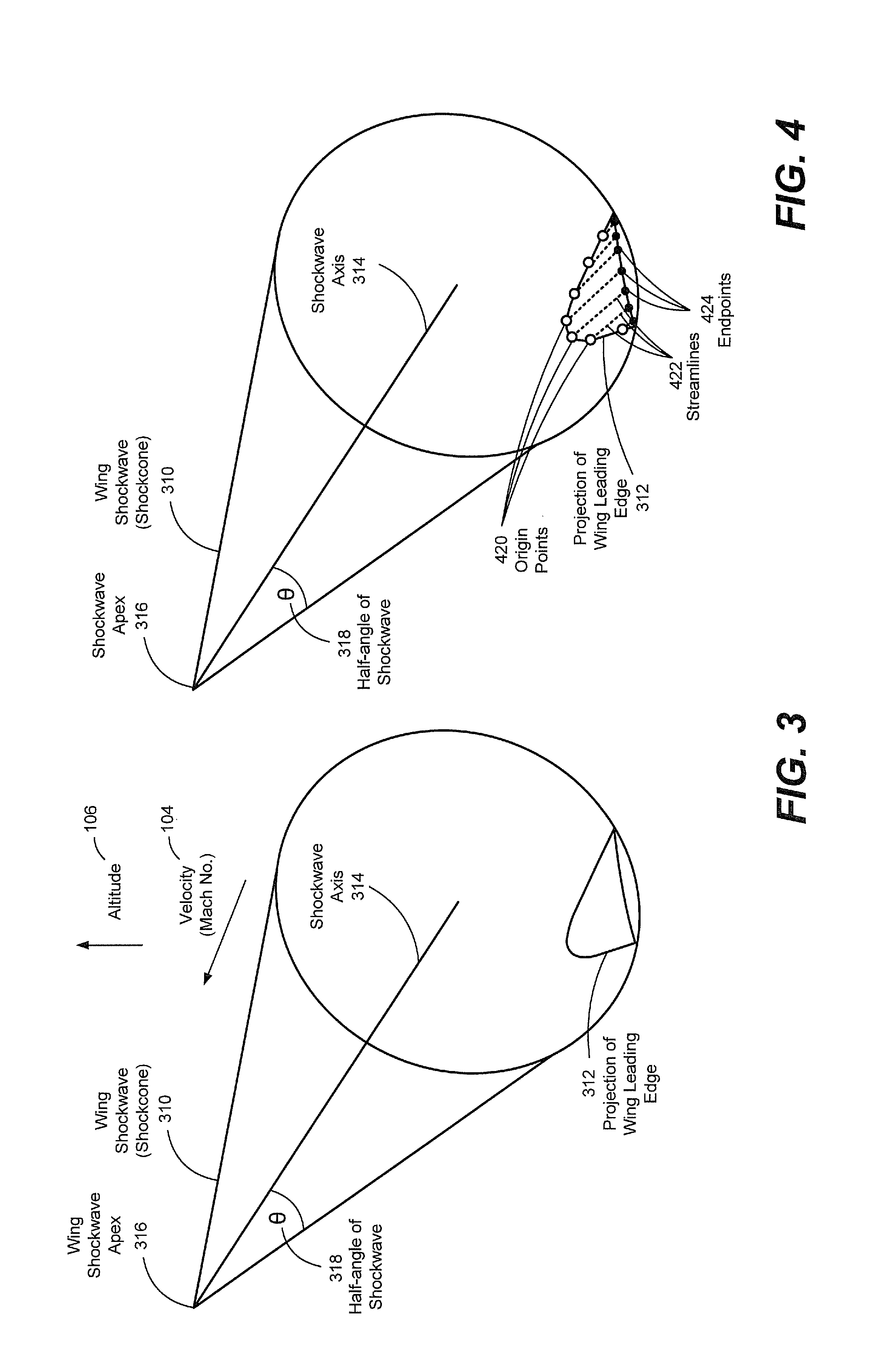

Integrated hypersonic inlet design

ActiveUS8256706B1Improve efficiencyImprove engine performanceAircraft navigation controlCombustion enginesLeading edgeNacelle

Methods, aircraft, and engine nacelles are disclosed. A wing leading edge of a planform is superimposed on a wing shockwave that extends in a first direction from a shockwave apex toward the wing leading edge. A waverider shape is streamline traced between the wing leading edge and a trailing edge of the planform to form a waverider wing. A position of an engine inlet vertex relative to the waverider wing is identified. An inlet shockwave is projected from the inlet vertex in a second direction generally opposed to the first direction. The inlet shockwave intersects the wing shockwave. An inlet leading edge of an engine inlet includes a lower leading edge including a plurality of points where the inlet shockwave intersects the wing shockwave.

Owner:THE BOEING CO

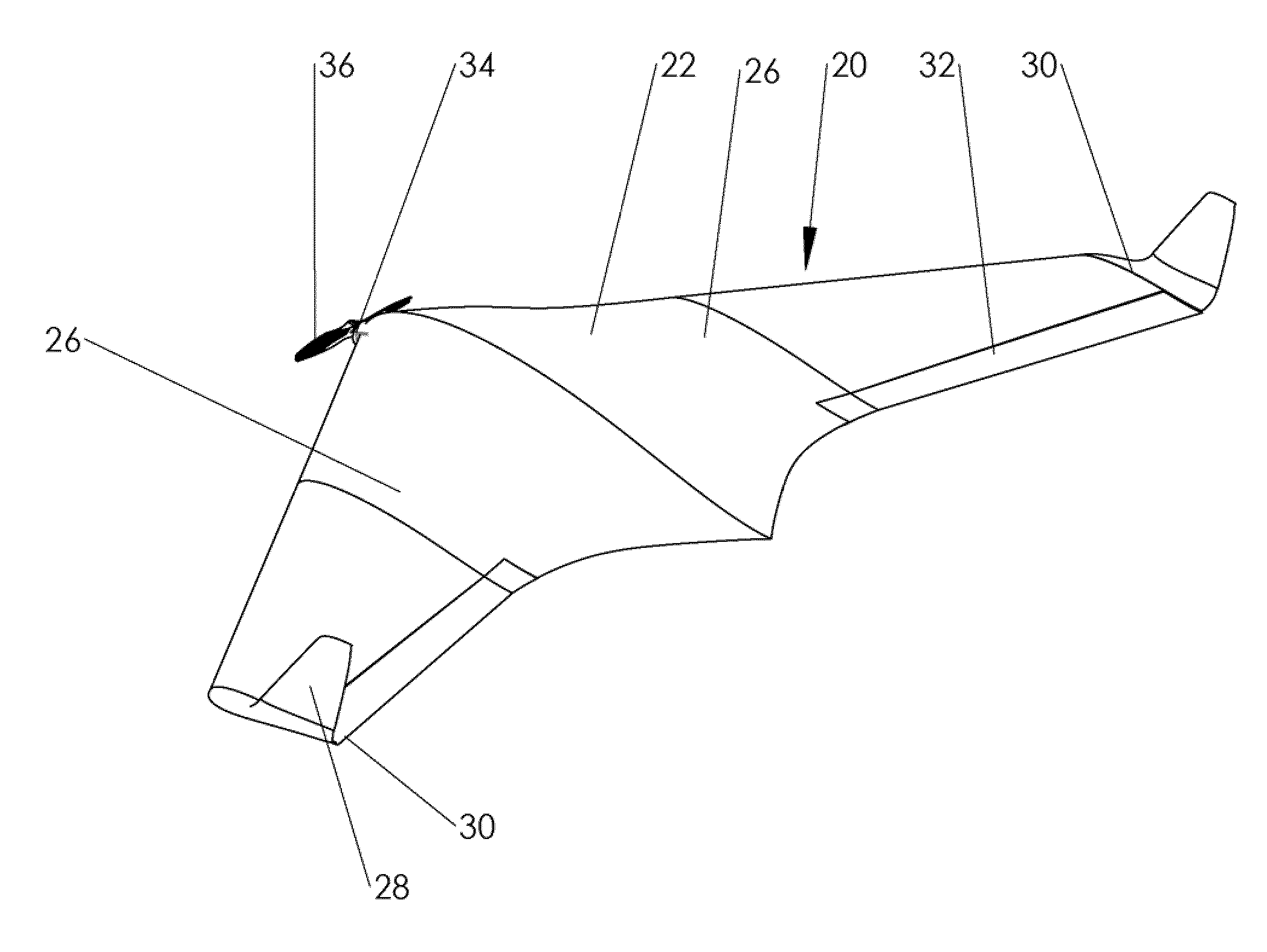

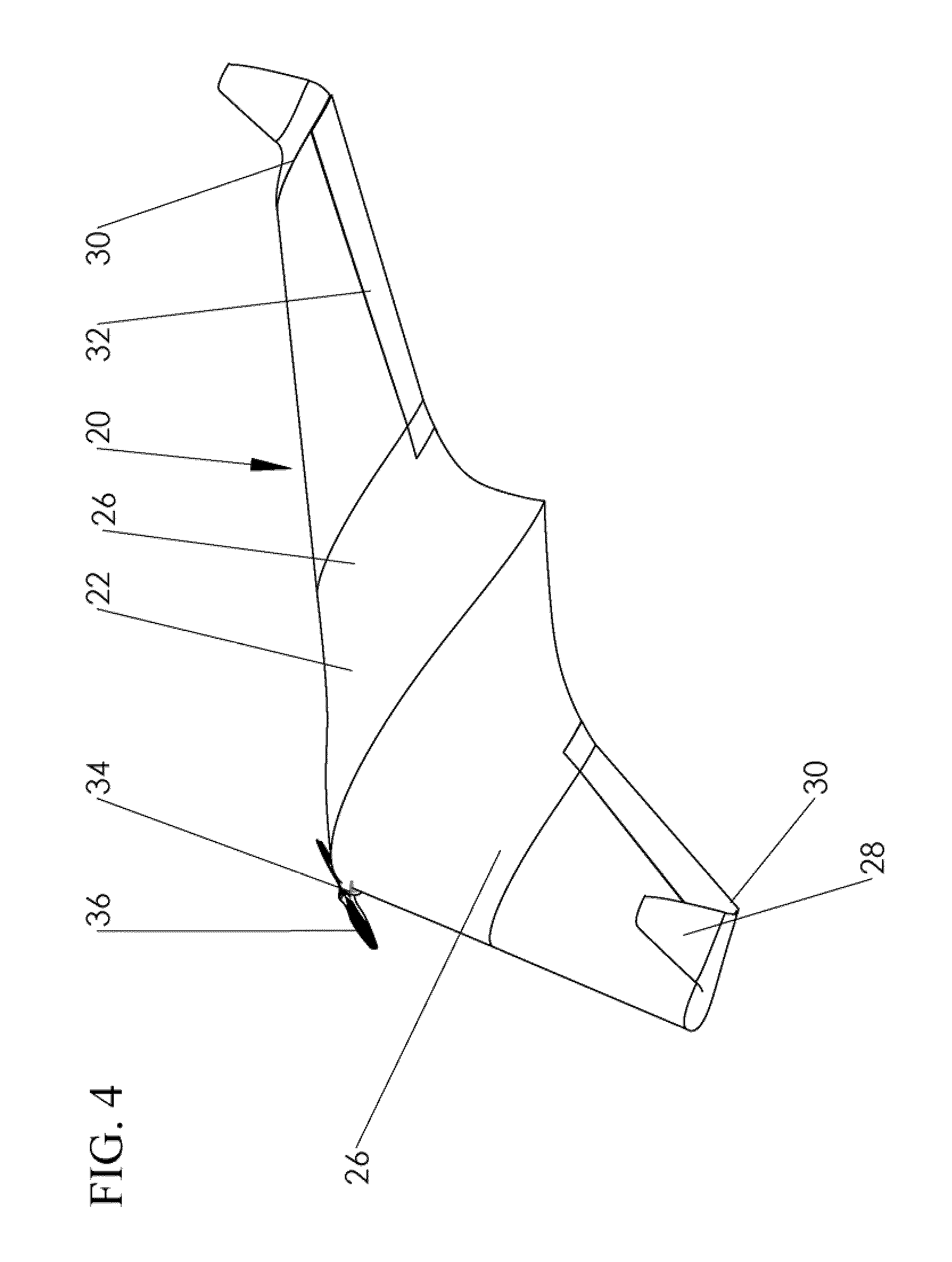

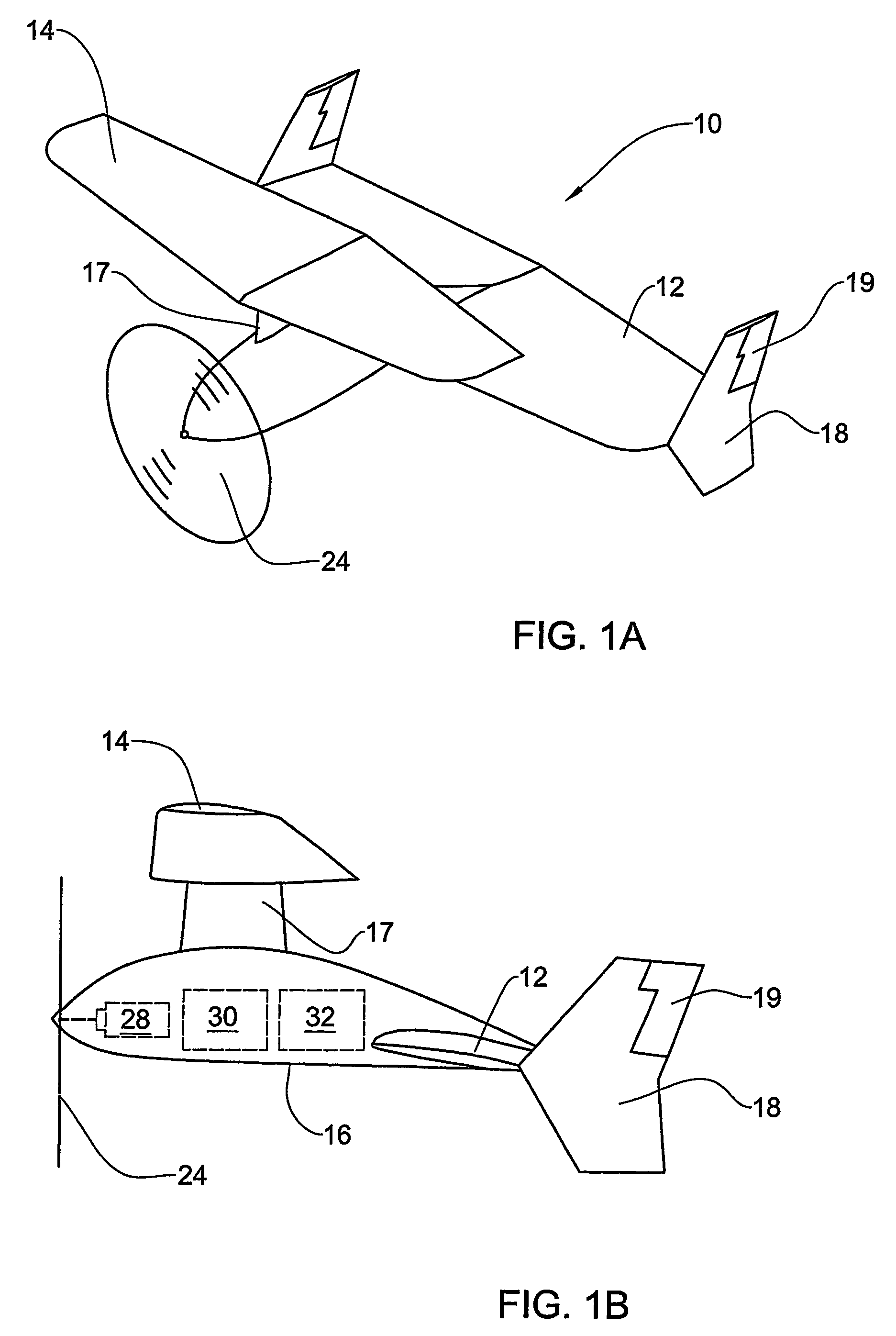

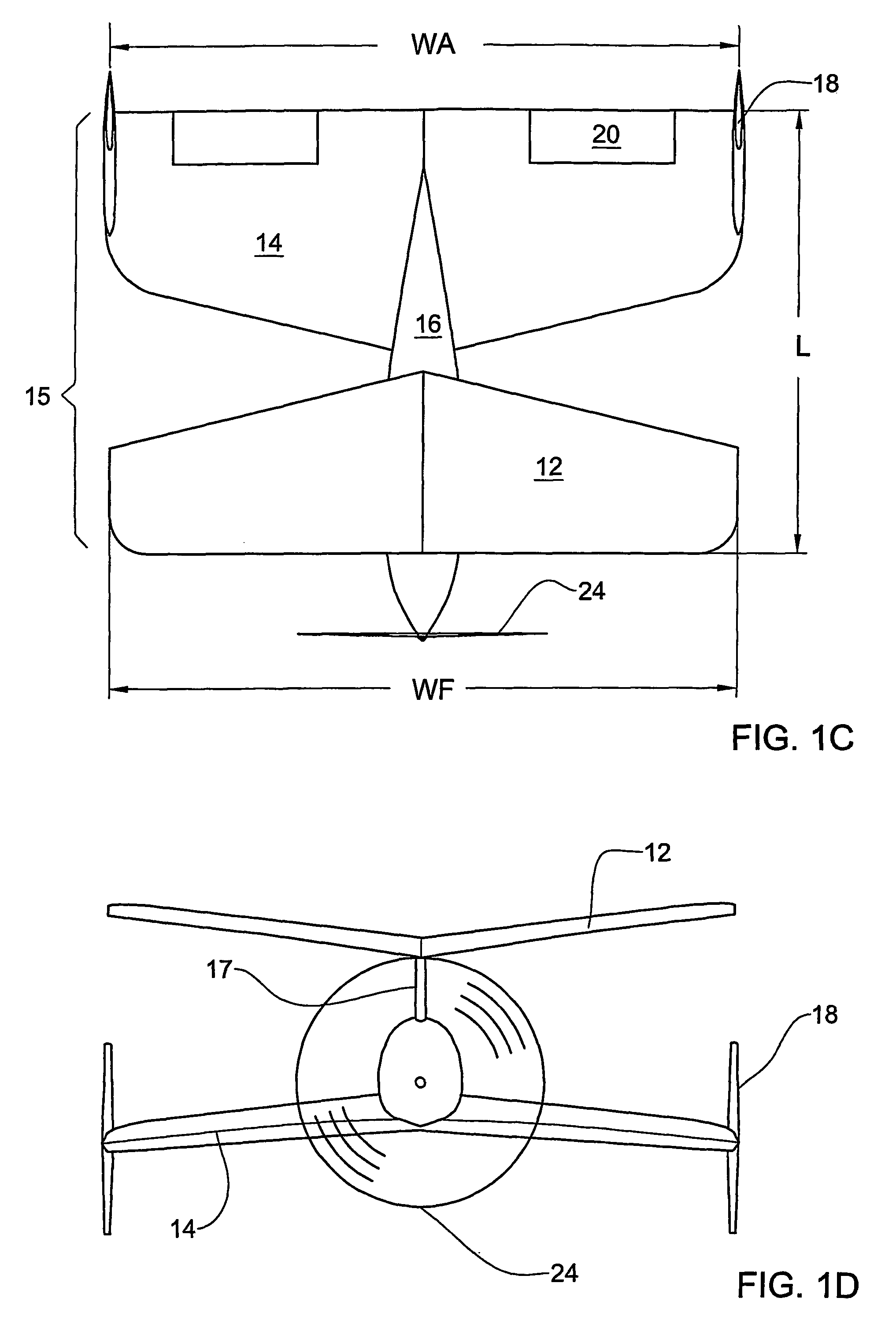

Blended Wing Body Unmanned Aerial Vehicle

InactiveUS20100123047A1Improve stabilityImproved safety characteristicUnmanned aerial vehiclesWing shapesComparable sizePropeller

A Blended Wing Body SUAV and MUAV is disclosed having a novel airfoil profile, wing configuration, rigging and tractor pull propeller placement that provide improved stability and safety characteristics over prior art SUAVs and MUAVs of comparable size and weight. This unique blended wing design includes wing twist on the outboard wing and an inverted “W” shaped planform to provide lateral and longitudinal stability, and smooth, even flight characteristics throughout the range of the expected flight envelope. These flight characteristics are crucial to providing a stable reconnaissance platform with favorable stall speeds, an increased payload and the ability to hand launch without the danger of exposing ones hands or wrist to a propeller.

Owner:WILLIAMS AEROSPACE

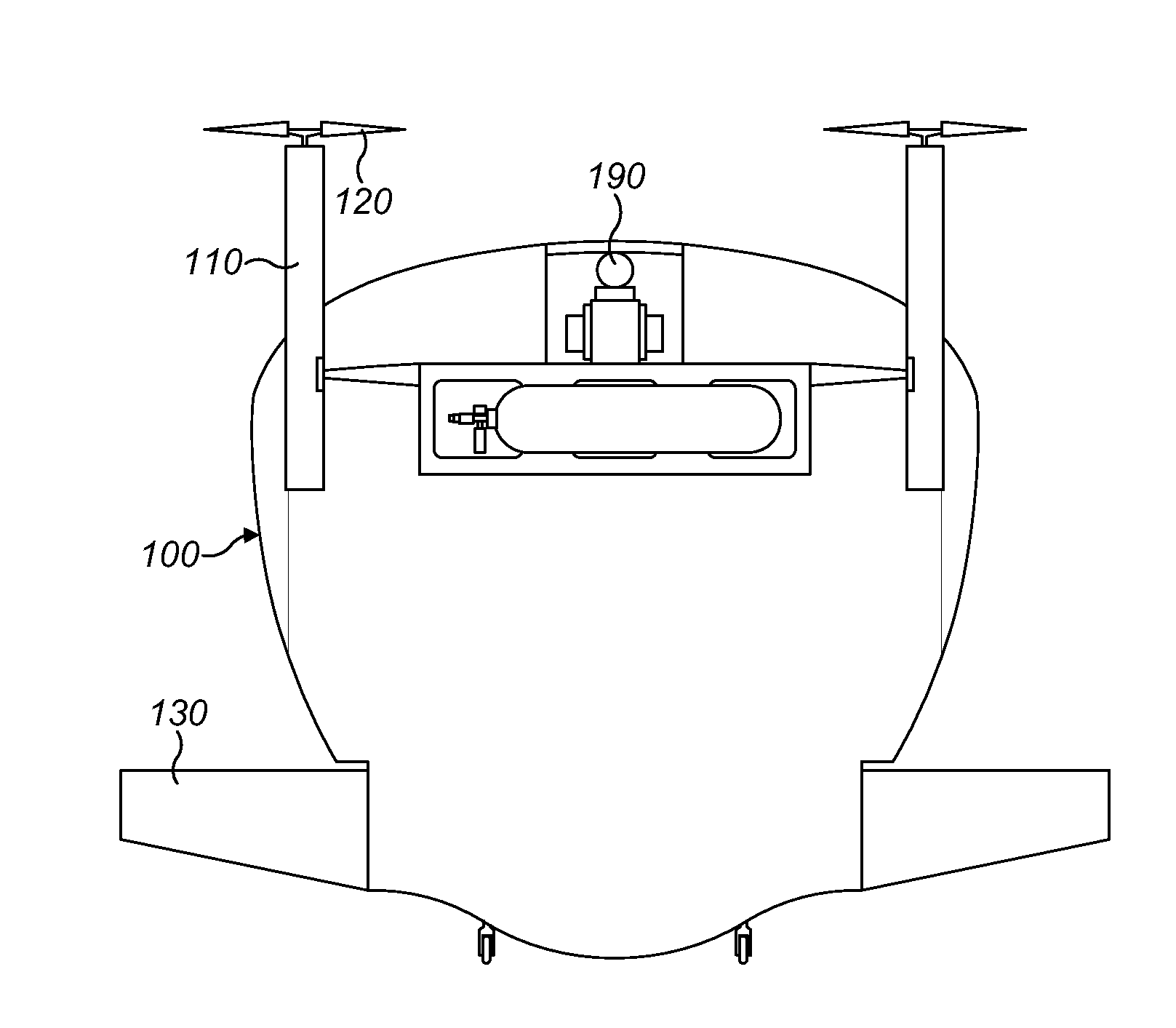

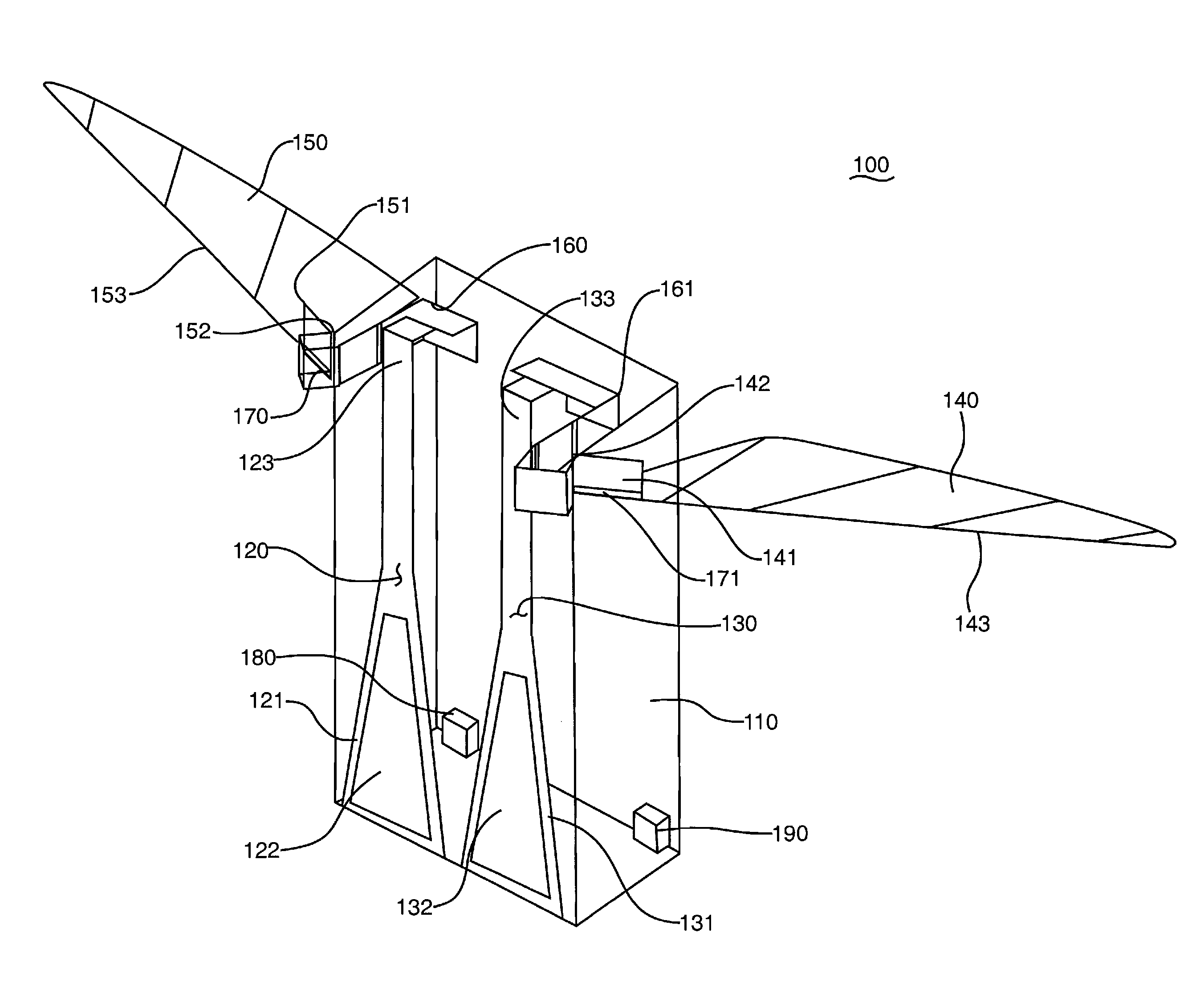

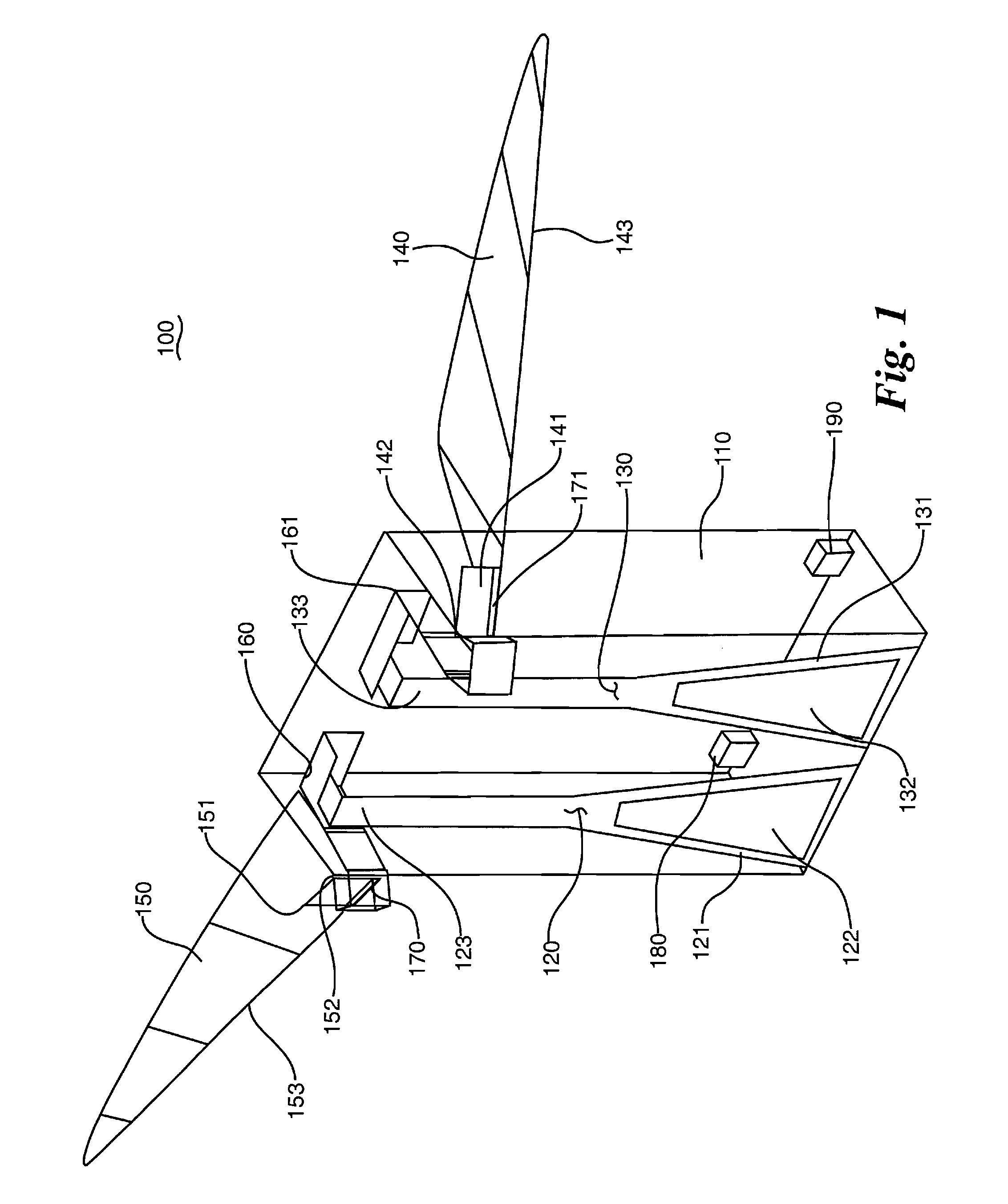

Unmanned Aerial Vehicle

ActiveUS20150210388A1Reduce noiseReduce vibrationDigital data processing detailsElectrical testingJet aeroplaneLarge distance

An unmanned aerial vehicle adapted for hover and short / vertical take-off and landing (S / VTOL) is disclosed. The vehicle comprises: a body having an aspect-ratio less than two and having therein a payload volume, at least one propeller located forward of the body, at least one rudder. The body may have an inverse Zimmerman planform which provides lift as air flows across the body in horizontal flight / fixed wing mode, and further adapted such that during hover and / or short / vertical take-off and landing (S / VTOL) the vehicle operates as a rotorcraft with the body oriented with the at least one propeller substantially above the body. The vehicle is suited to a method of inspection, such as power line inspection where large distances can be analysed efficiently by flying in fixed wing mode, but by transitioning to hover mode allows detailed inspection of selected areas.

Owner:THE BOEING CO

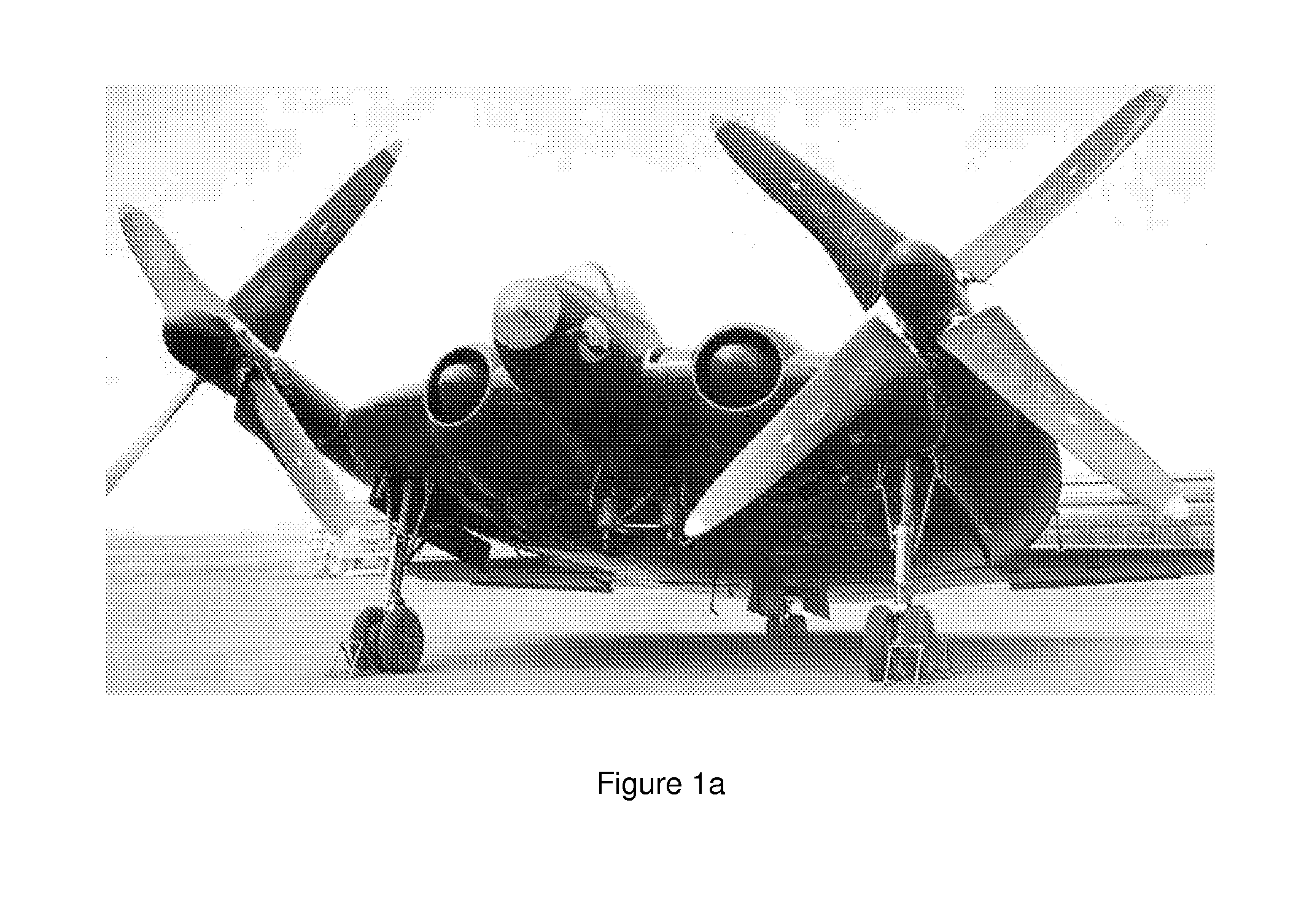

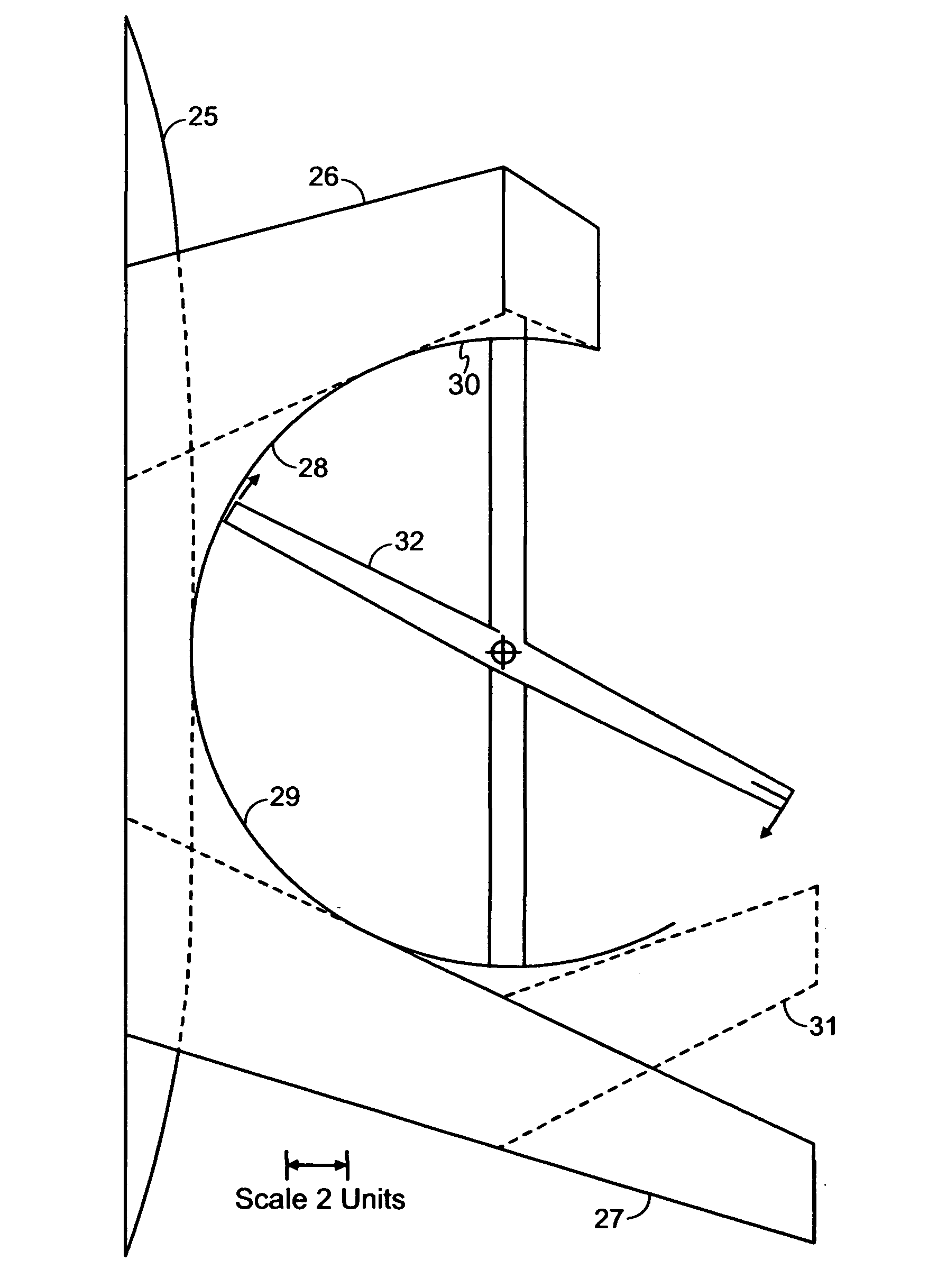

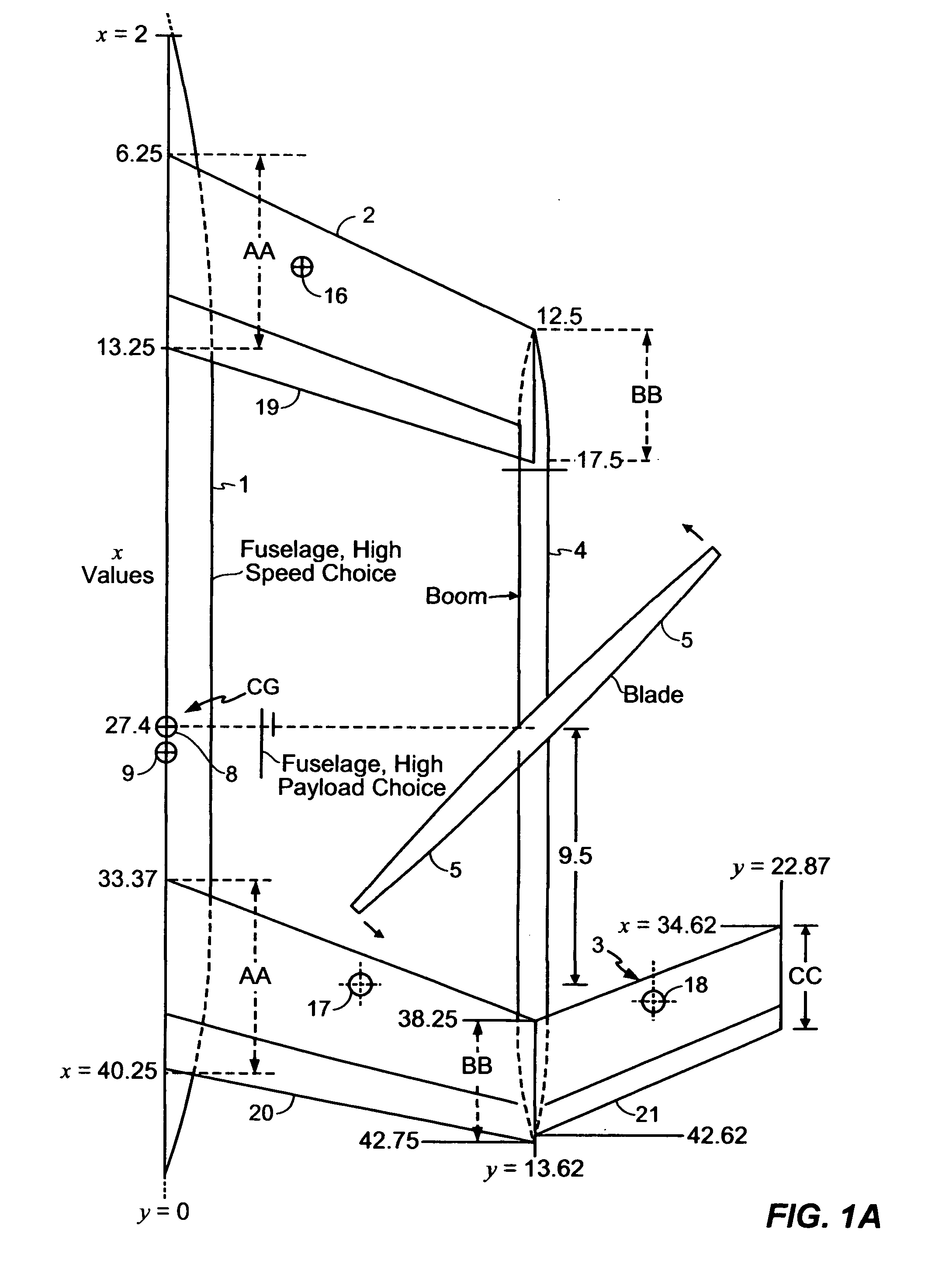

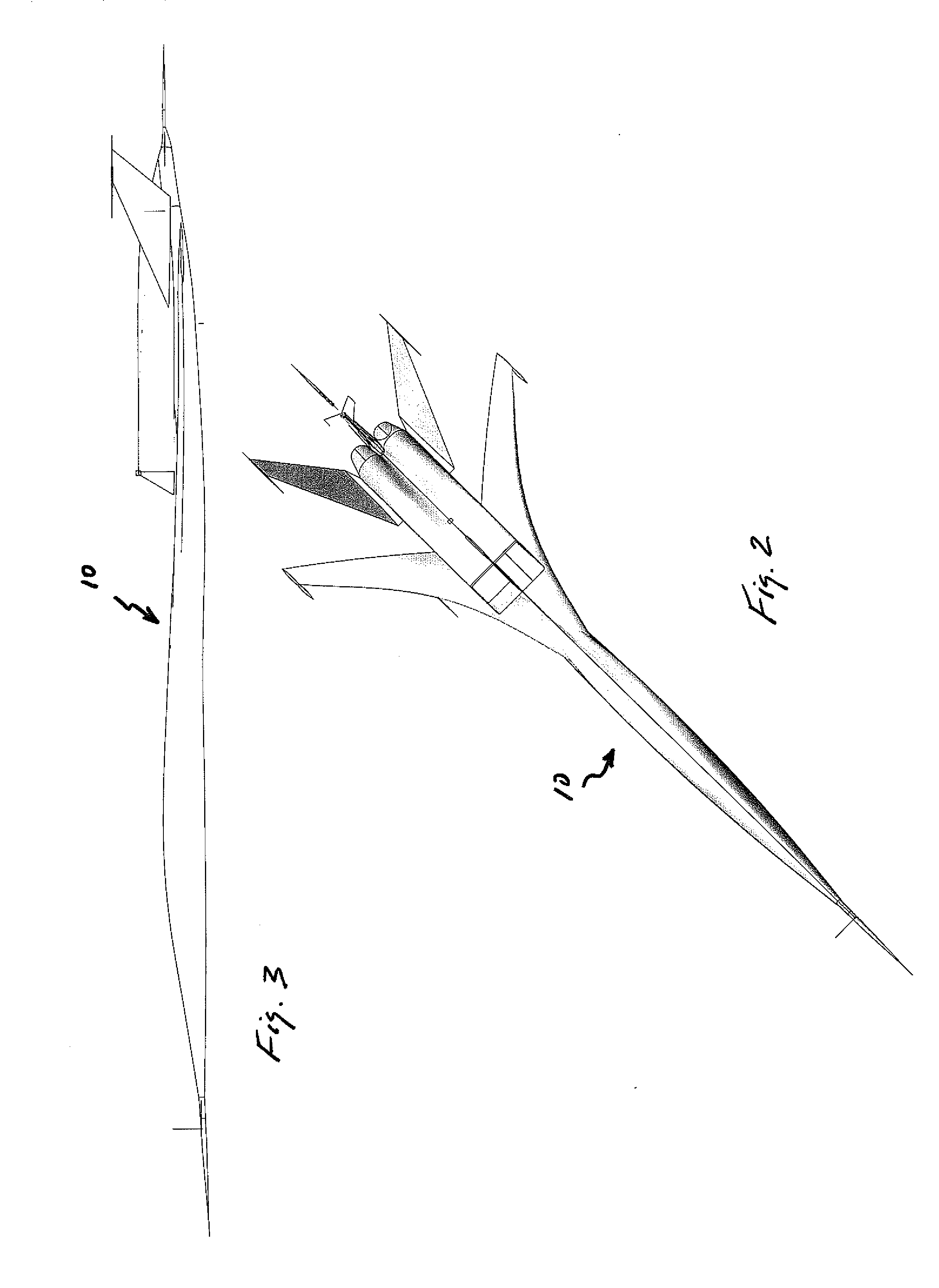

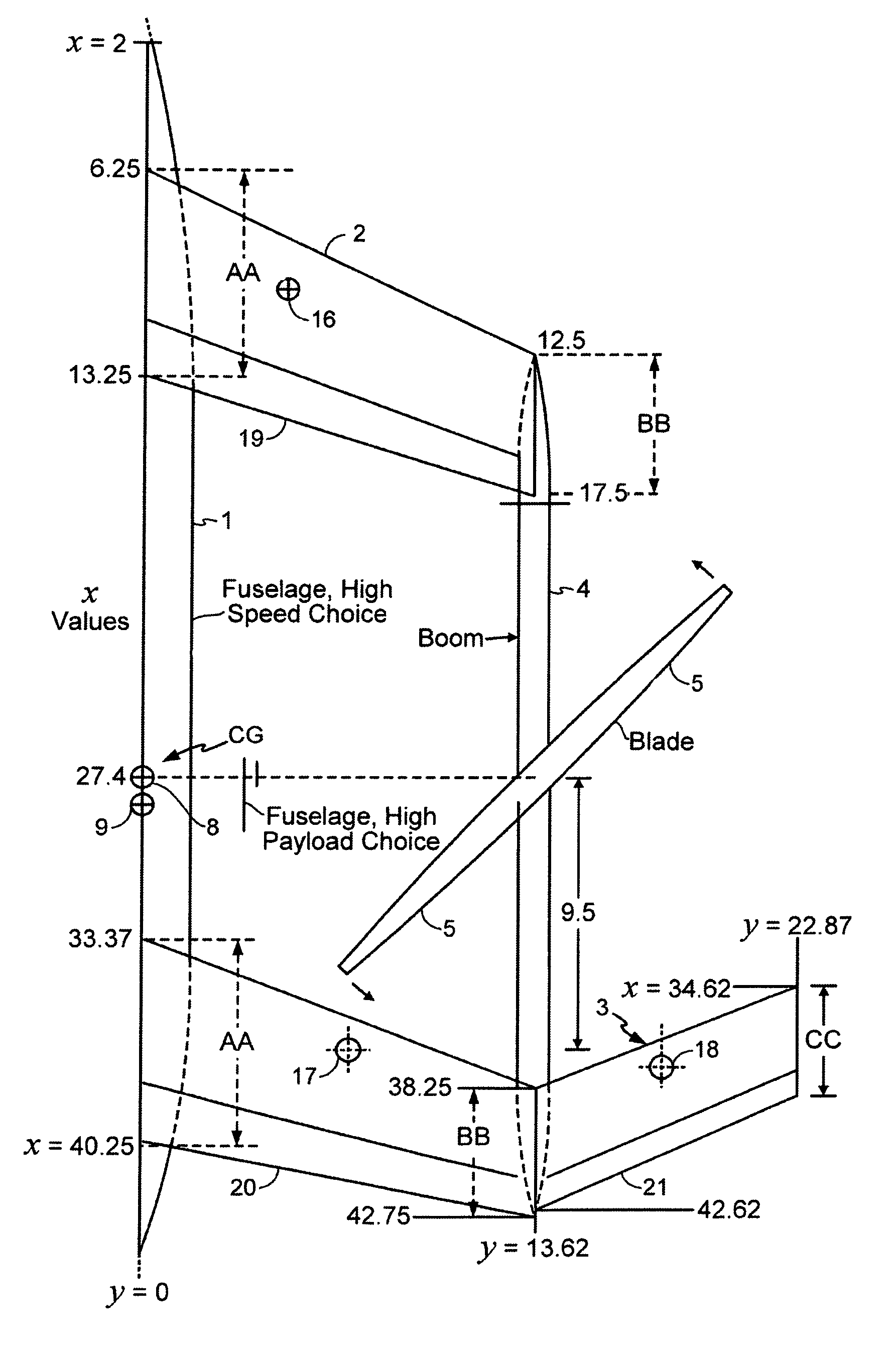

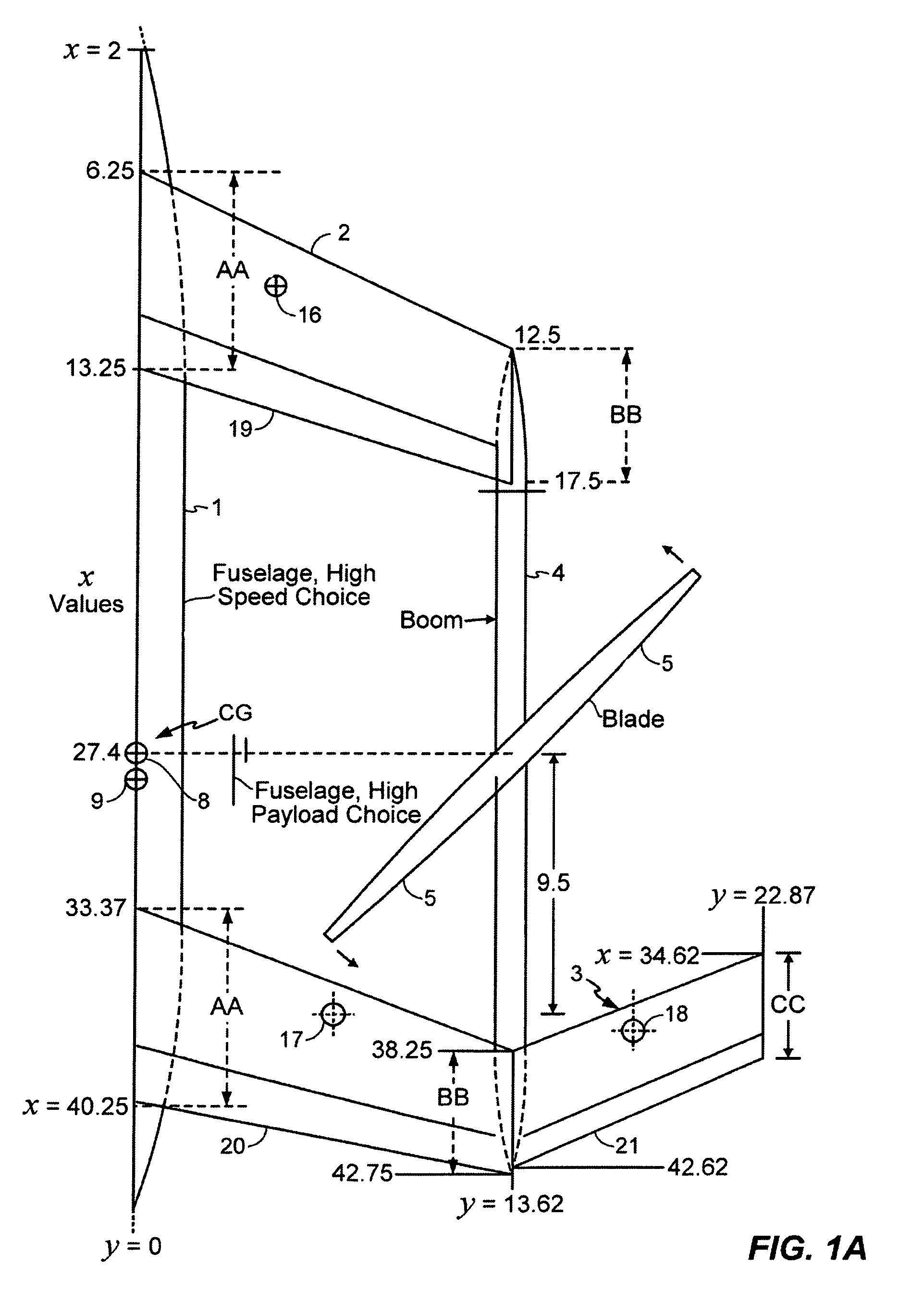

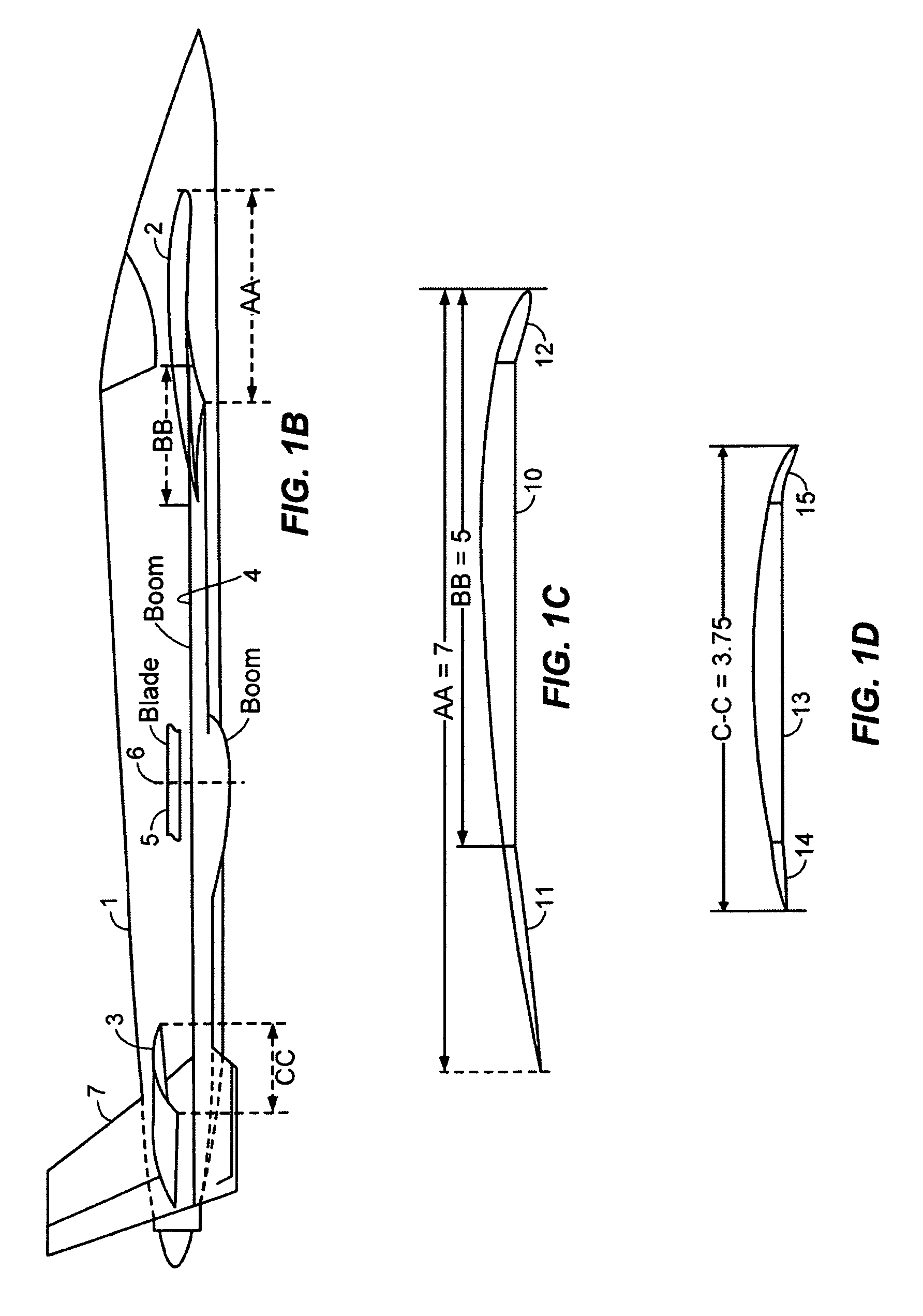

Aircraft with dual flight regimes

InactiveUS20110031355A1Eliminating asymmetric forceDrag minimizationPropellersPump componentsCenter of gravity of an aircraftPlanform

The aircraft is capable of two distinct fuel-efficient flight regimes: one is a vertical flight regime supported by two large two-bladed rotors with low disc loading located on right and left longitudinal booms. The booms extend between outboard regions of a front wing and inboard regions of a rear wing that has a larger span an area. The other flight regime is high speed up to high subsonic Mach number with the aircraft supported by wing lift with high wing loading, and with the rotors stopped and faired with minimal local drag contiguous to the booms. The longitudinal location of the aircrafts center of gravity, aerodynamic center and the center of the rotors are in close proximity. The front wing is preferably swept back, and the rear wing is preferably of W planform.

Owner:ALVAREZ CALDERON F ALBERTO

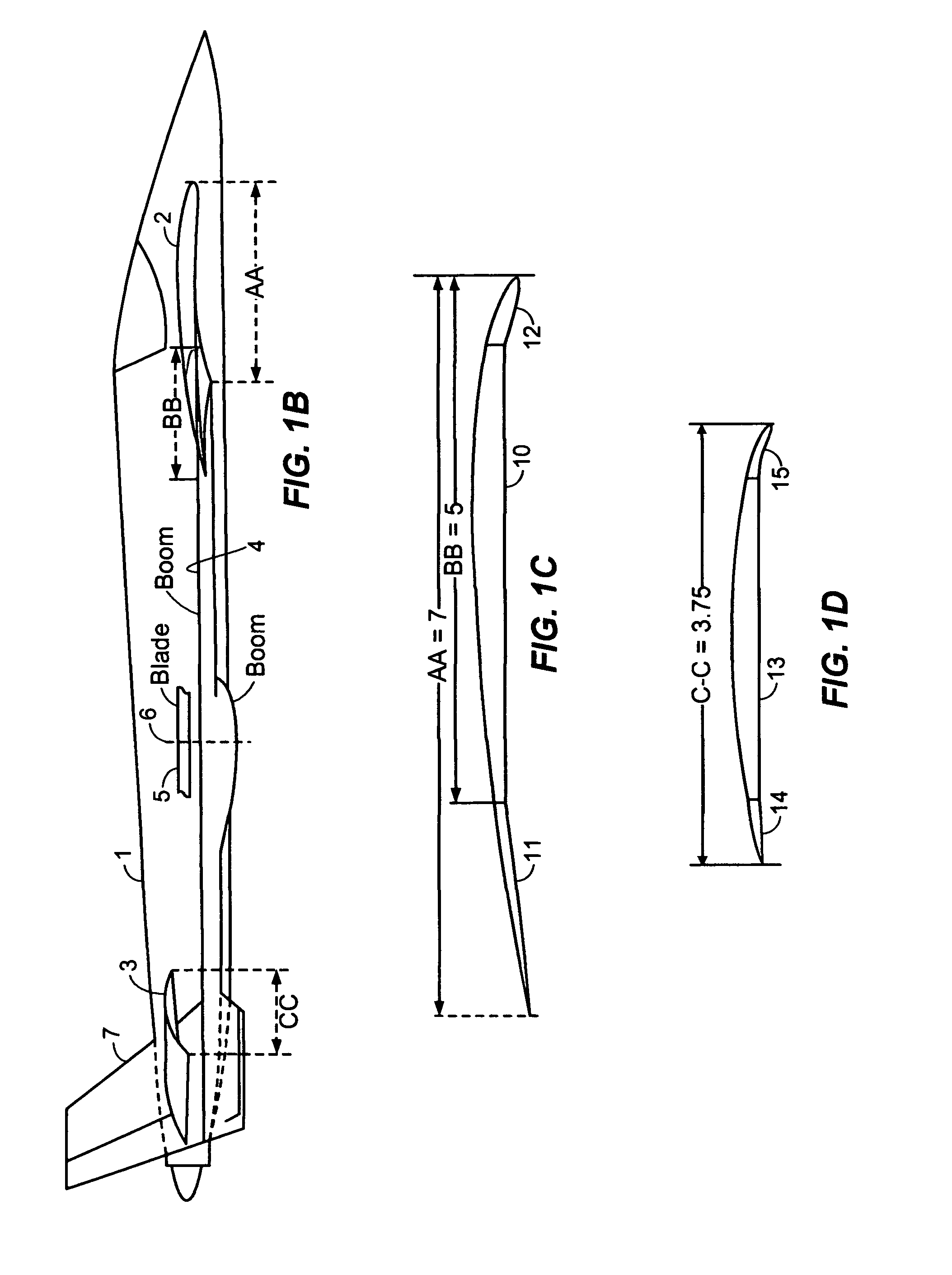

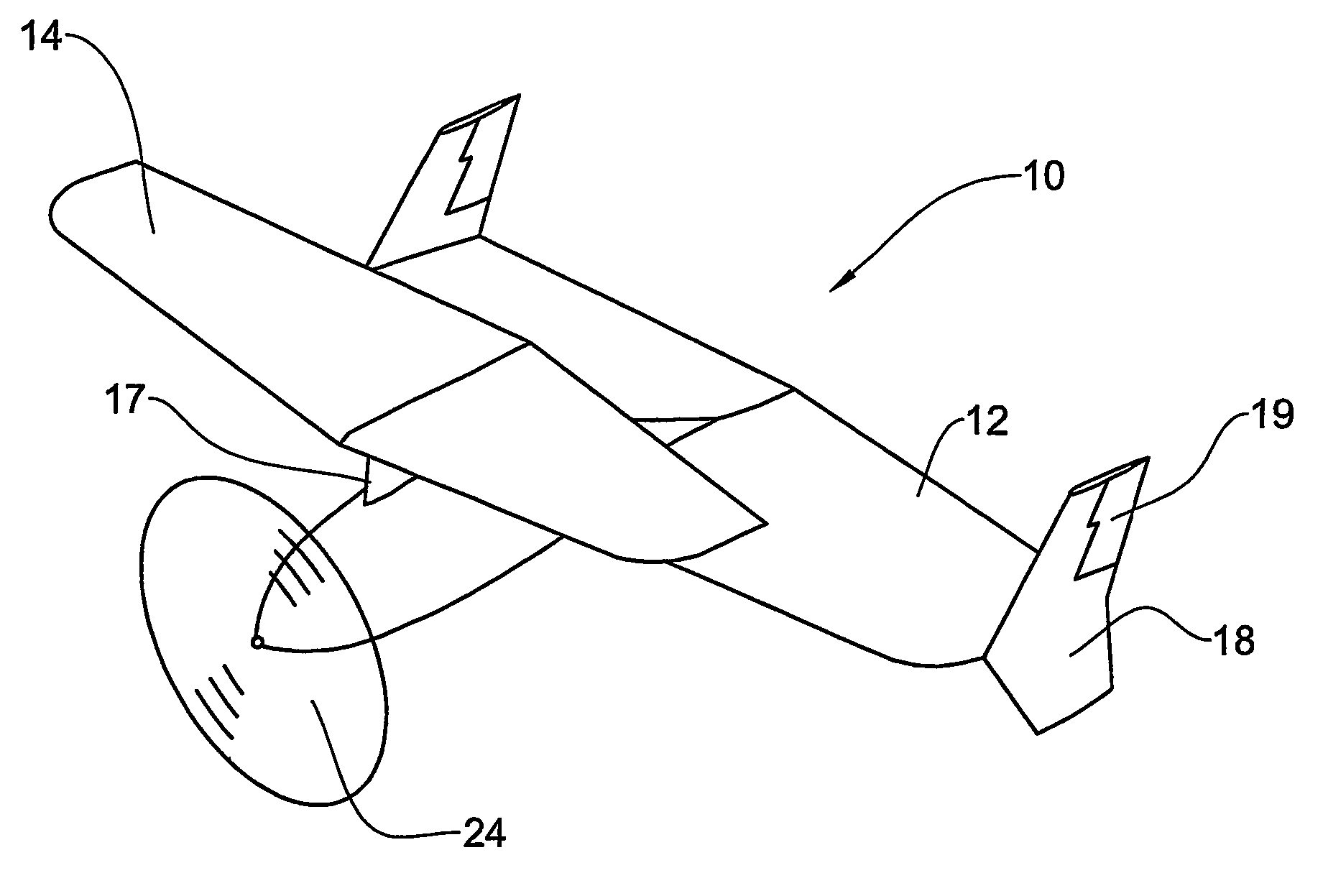

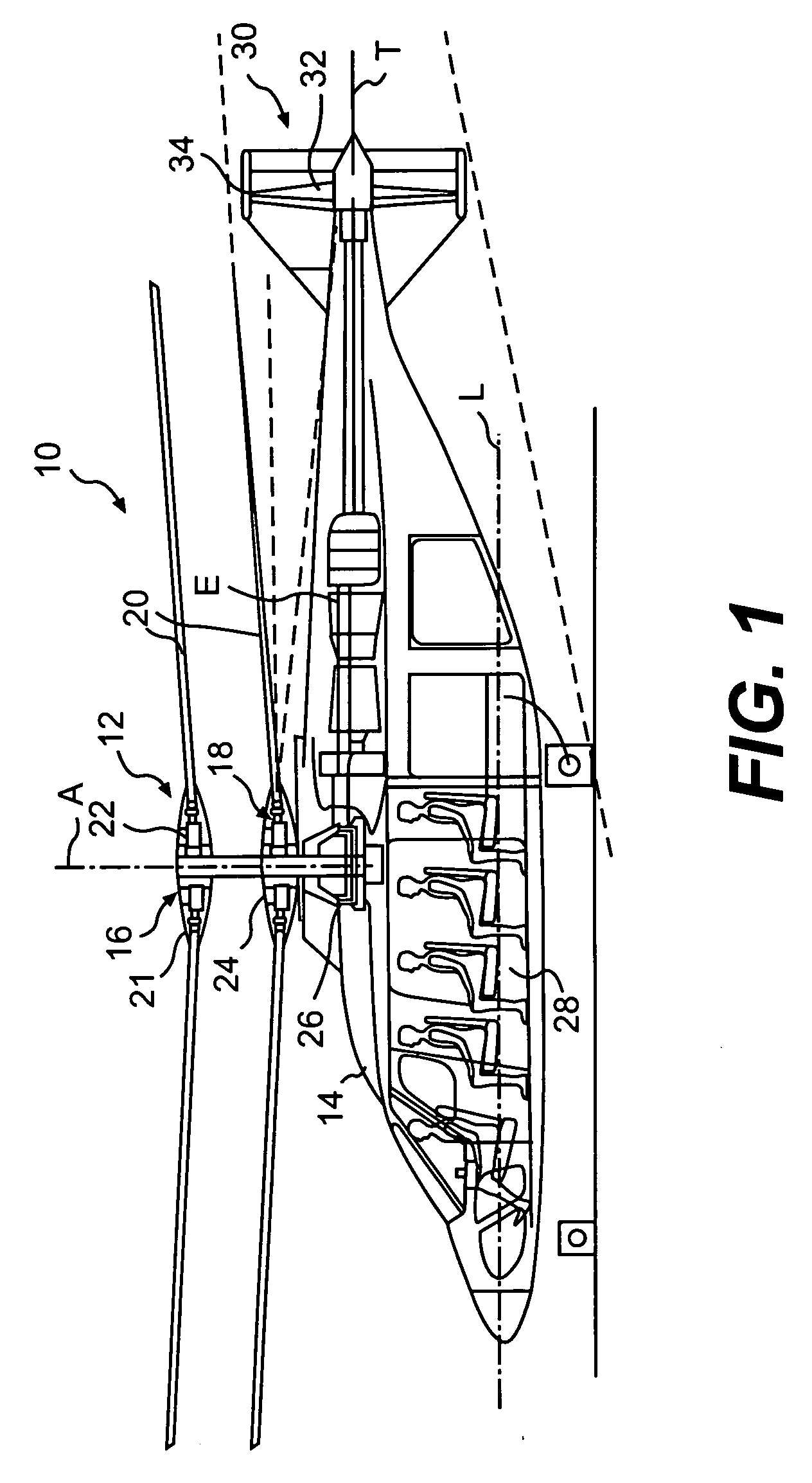

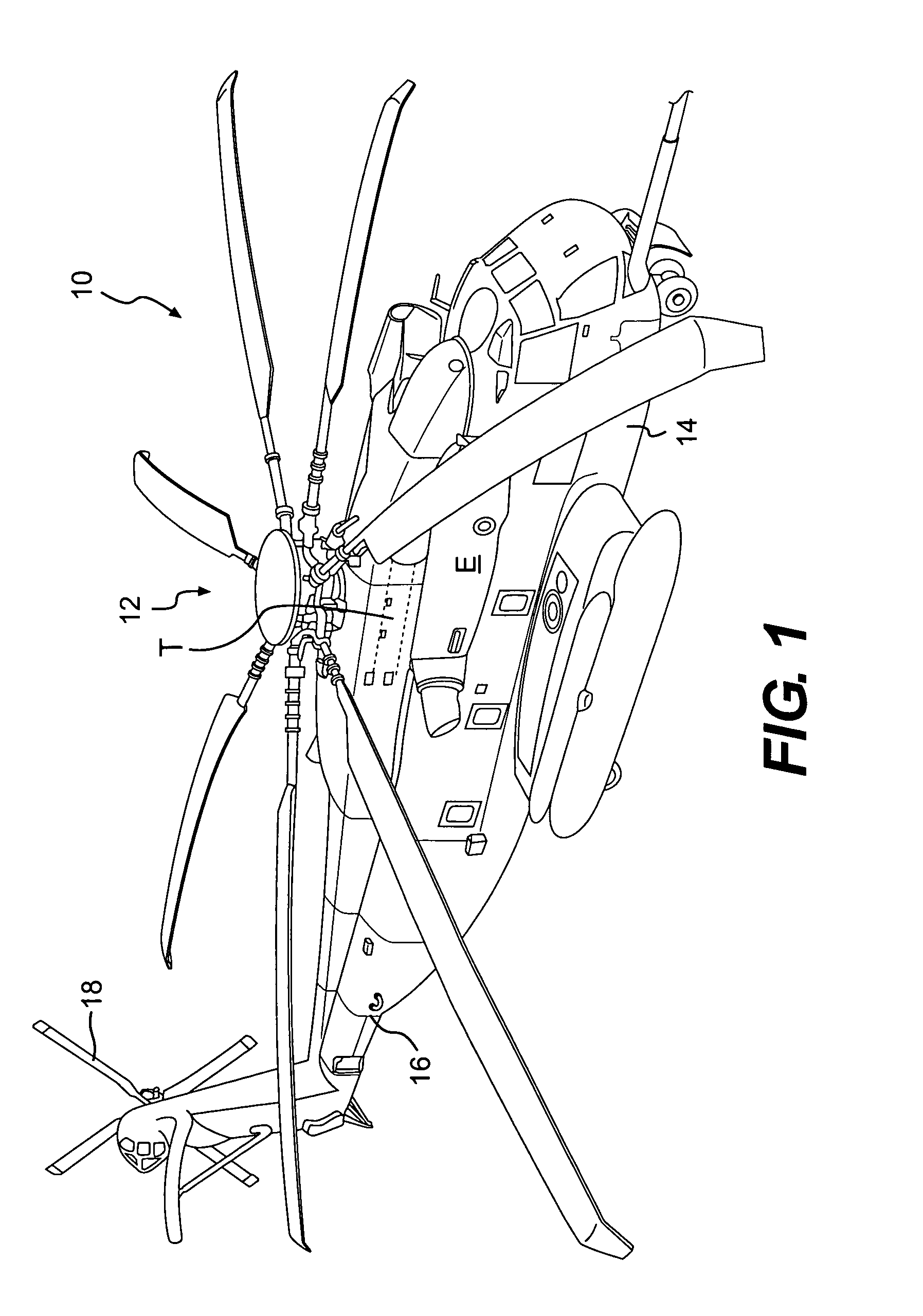

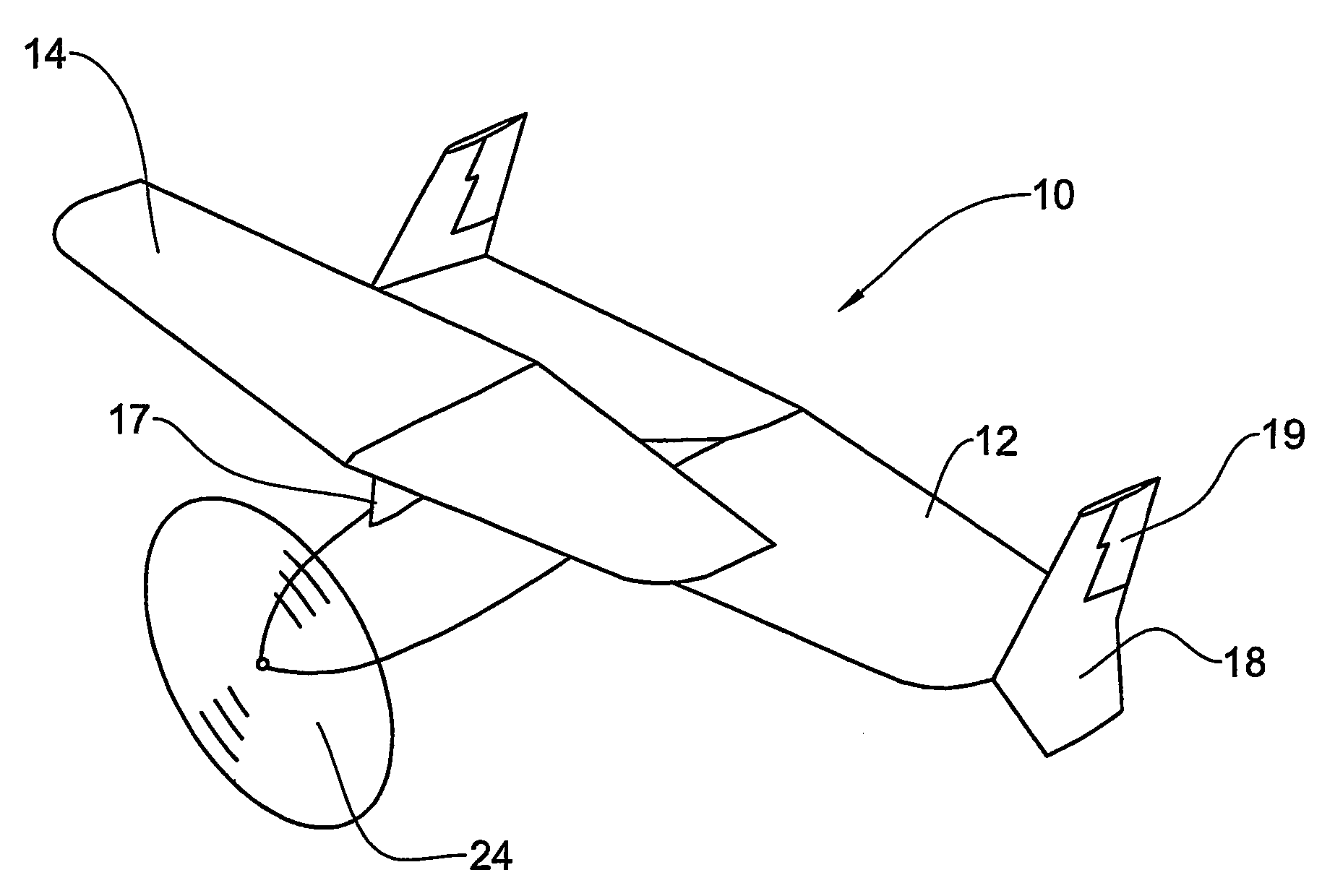

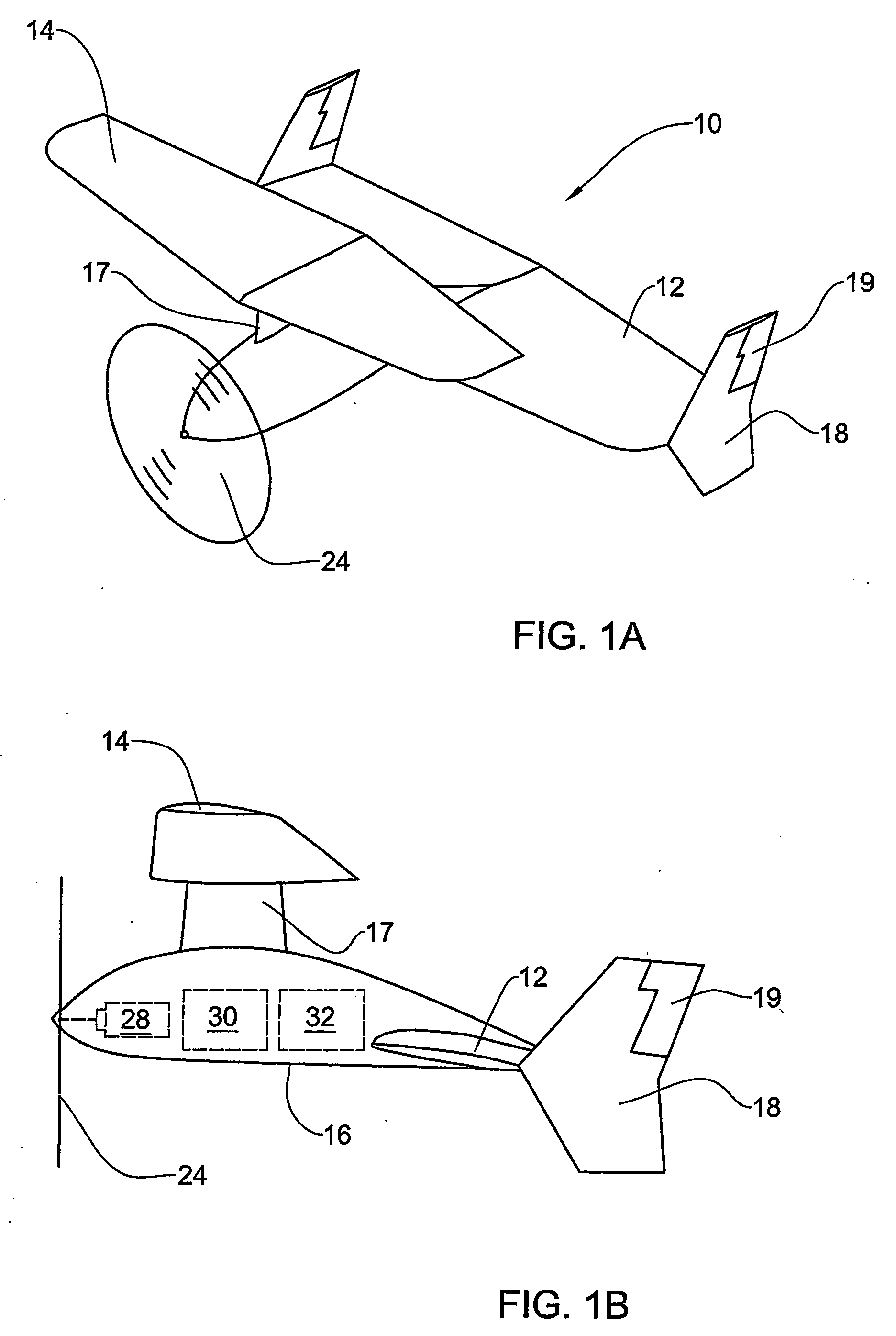

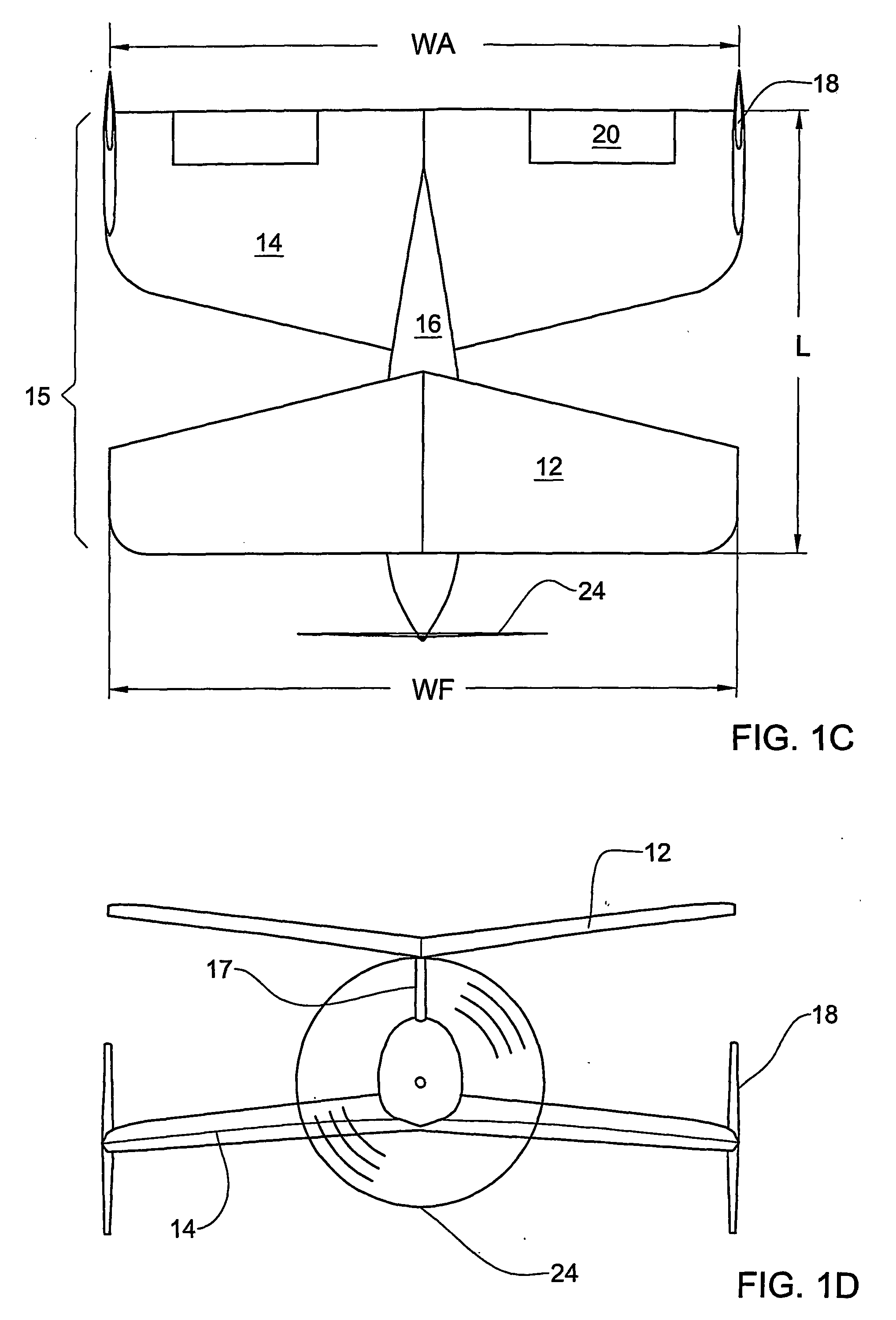

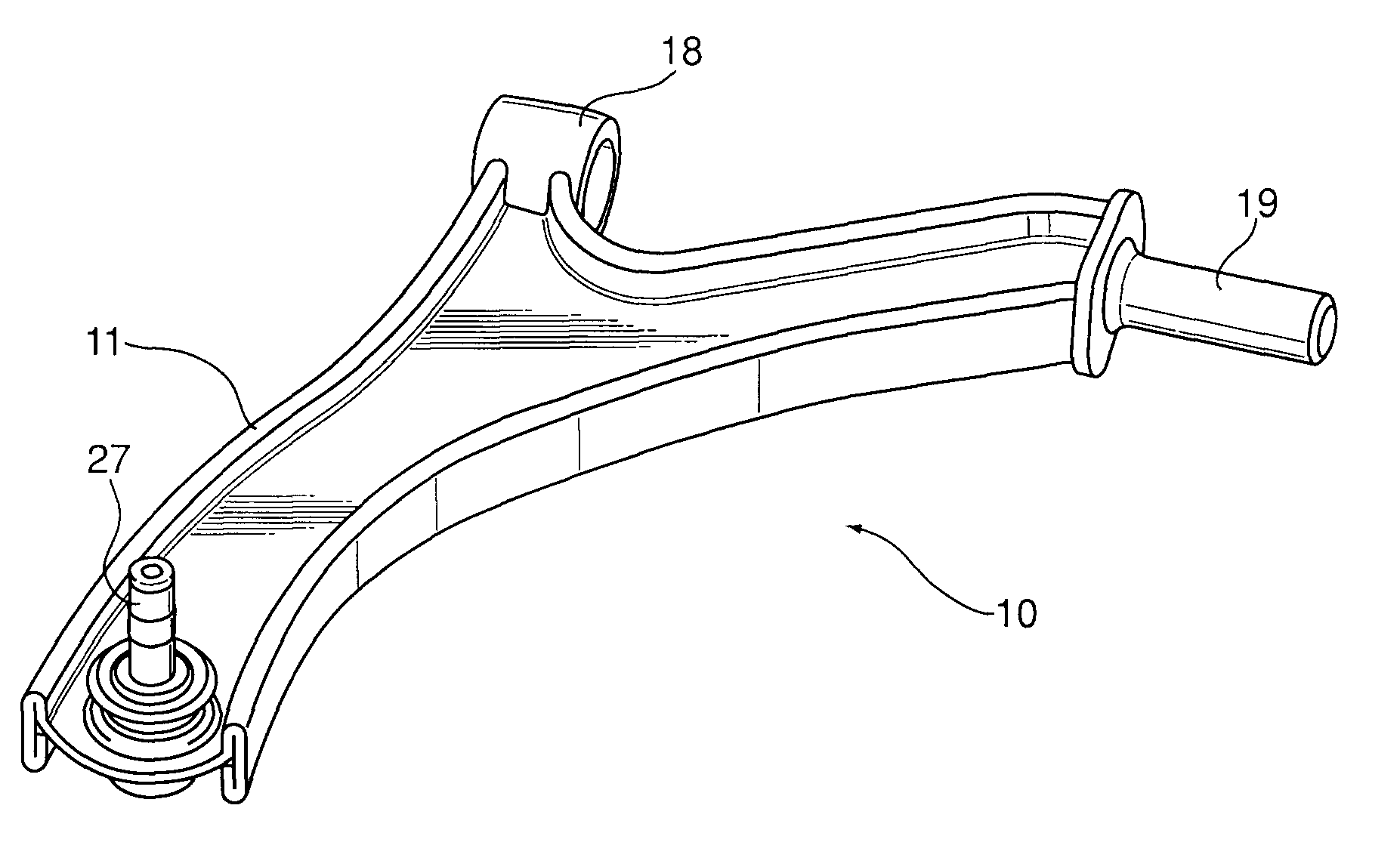

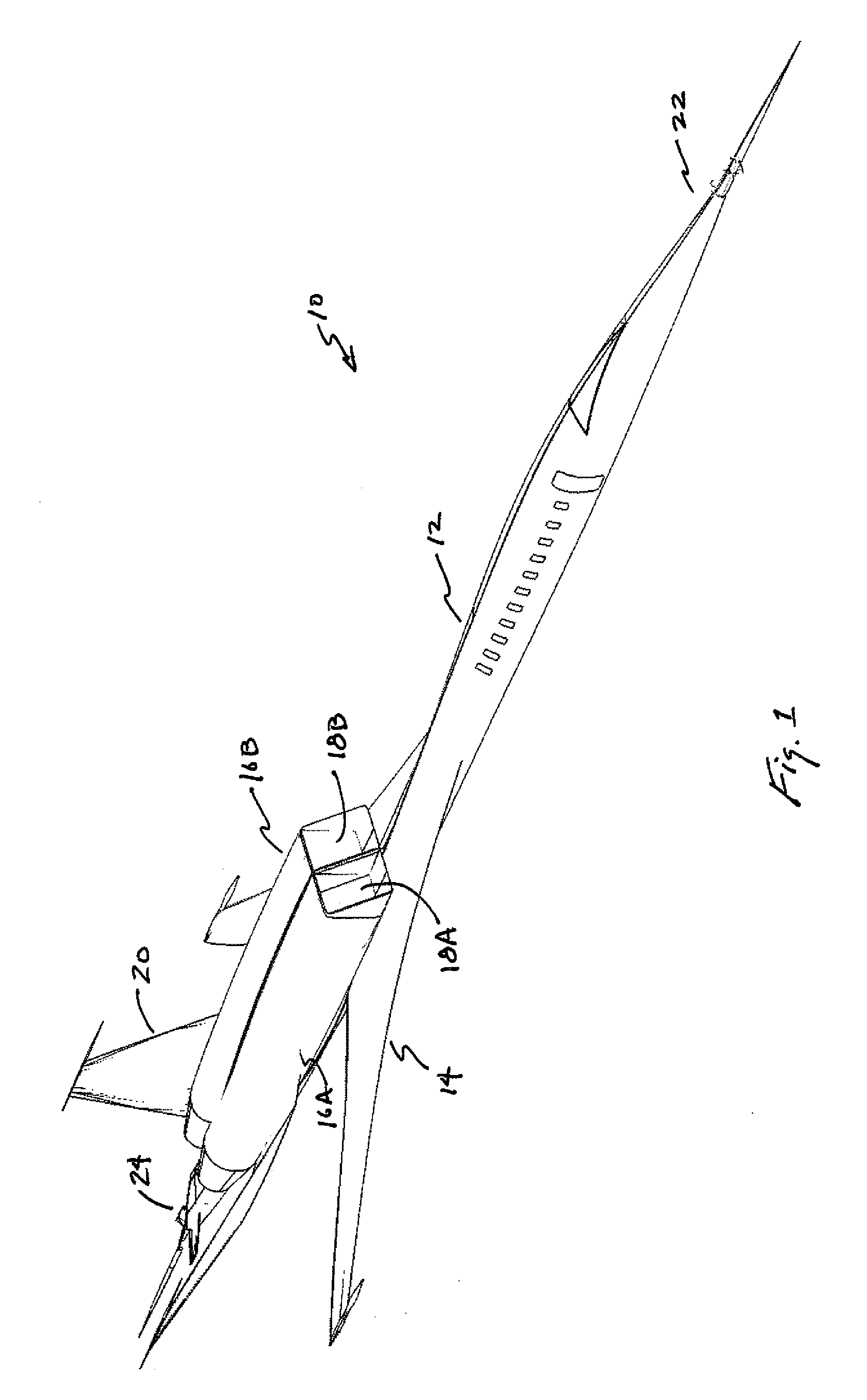

Aircraft configuration for micro and mini UAV

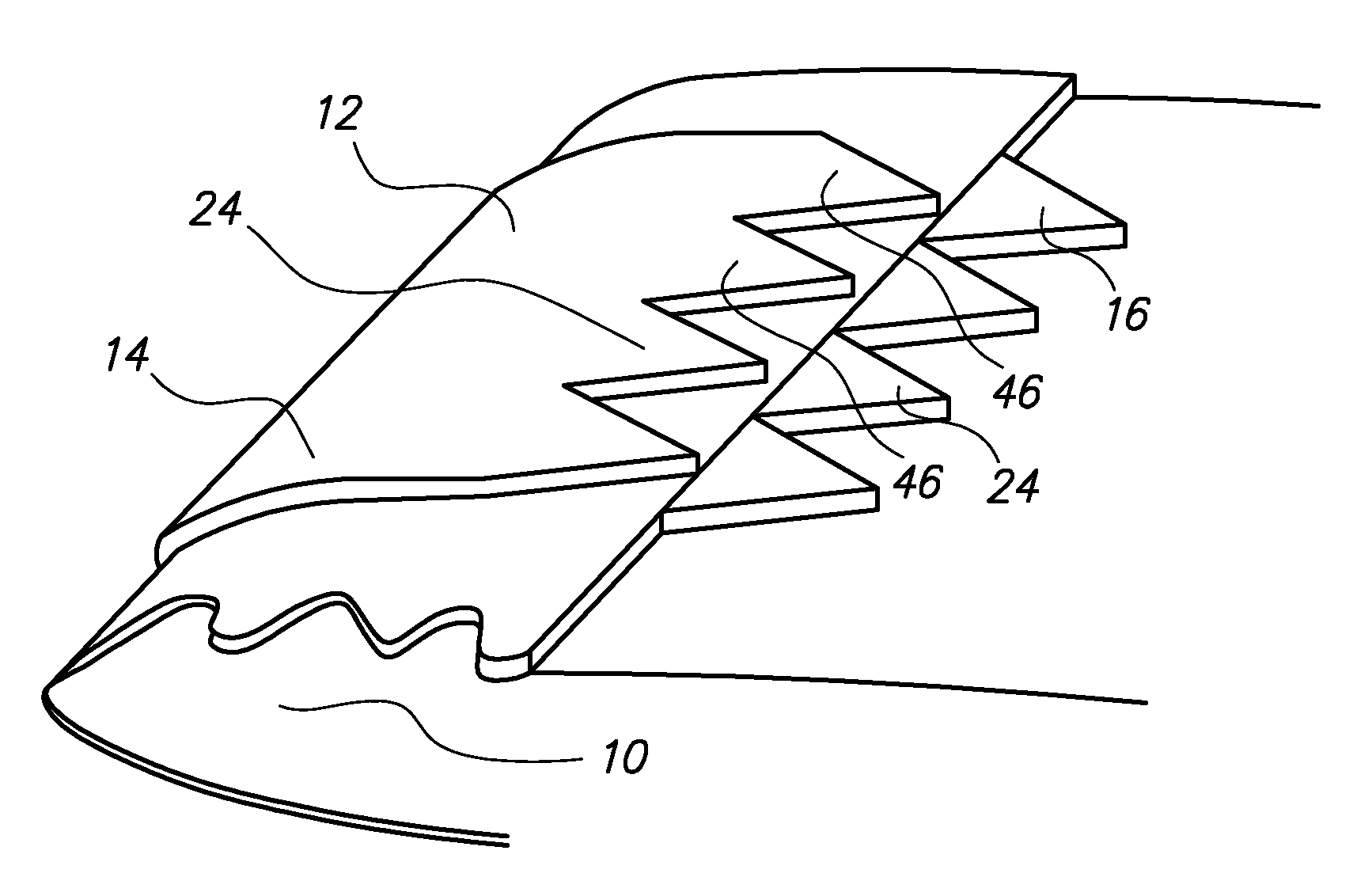

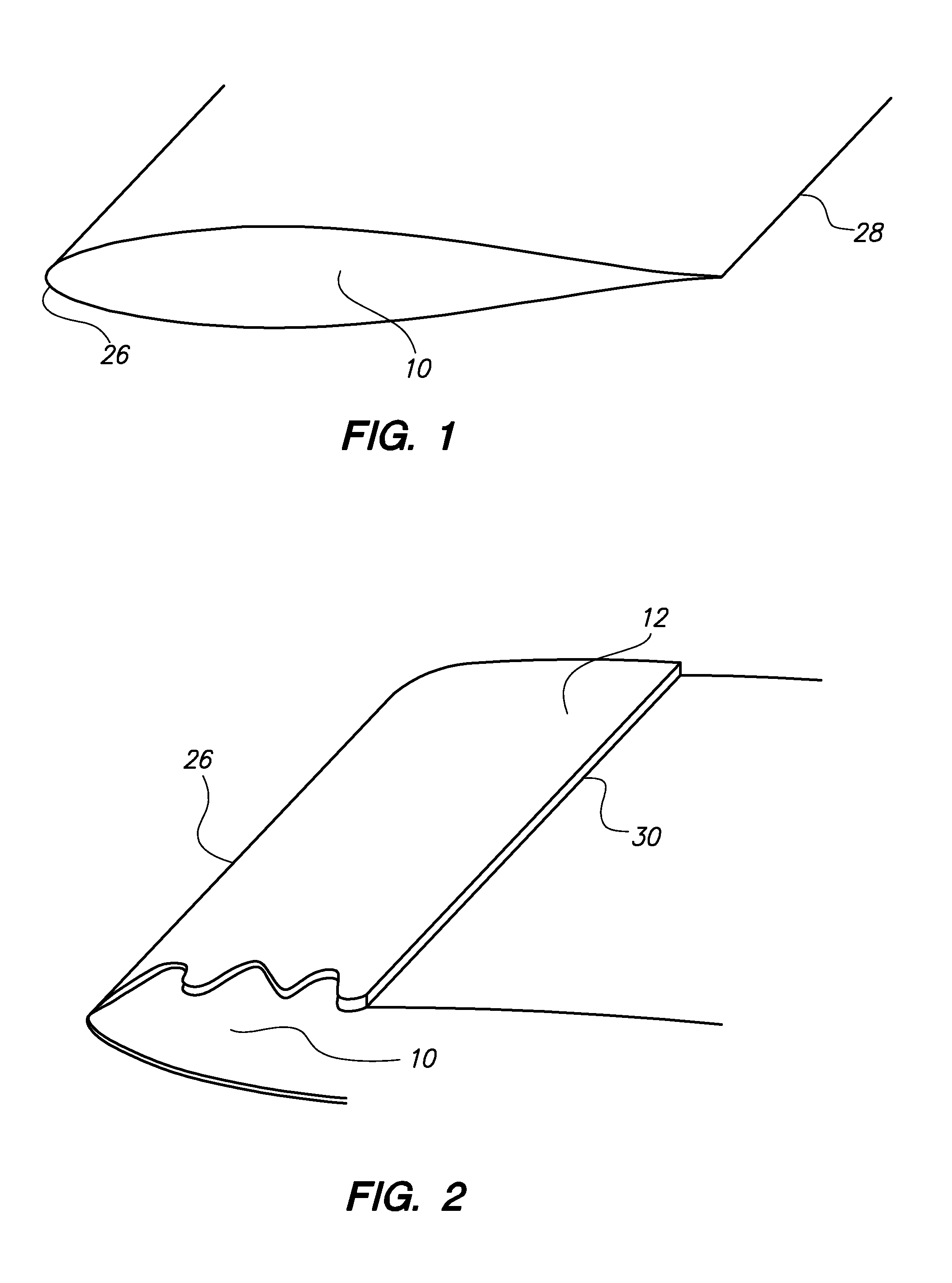

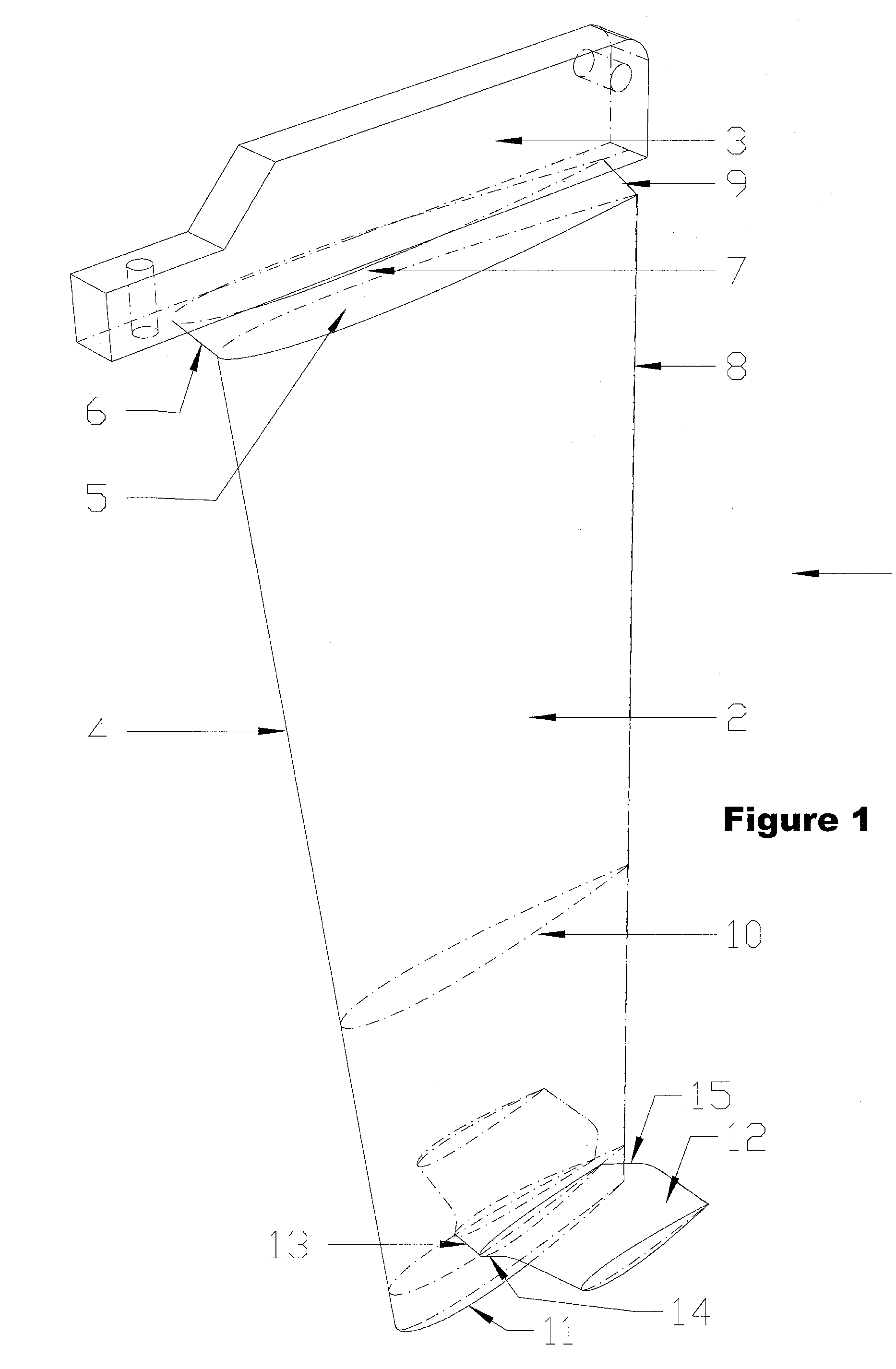

An aircraft arrangement for Mini or Micro UAV comprising a fore wing (14) and an aft wing (12) in tandem closed-coupled arrangement. The aft wing (12) has side panels (18) and control surfaces (19), and tapered planform with positive sweep, while the fore wing (14) has non-positive trailing edge sweep. The fore wing (14) and the aft wing (12) are disposed at different height, and the aircraft arrangement has no other wings or tail arrangements.

Owner:ISRAEL AEROSPACE IND

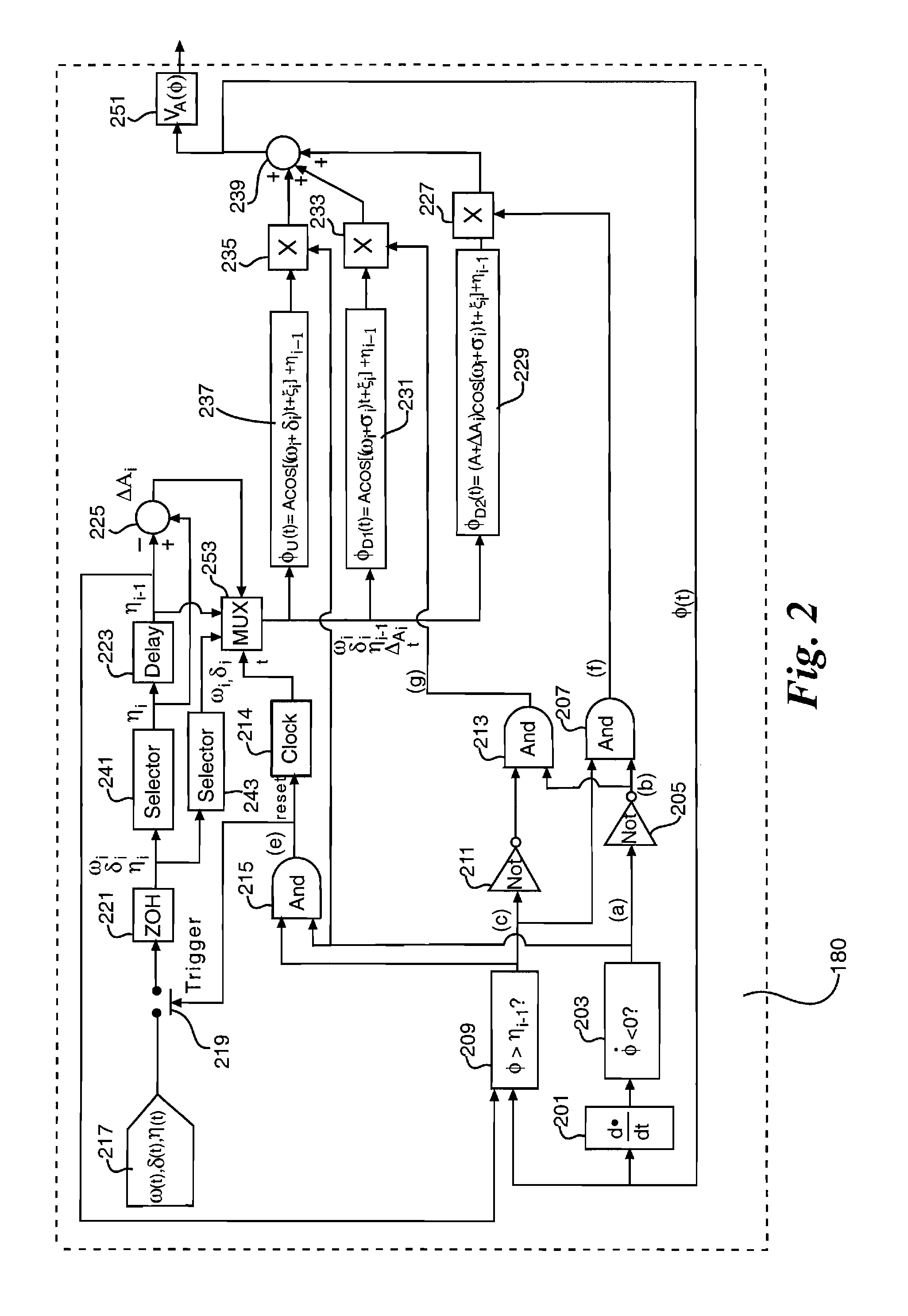

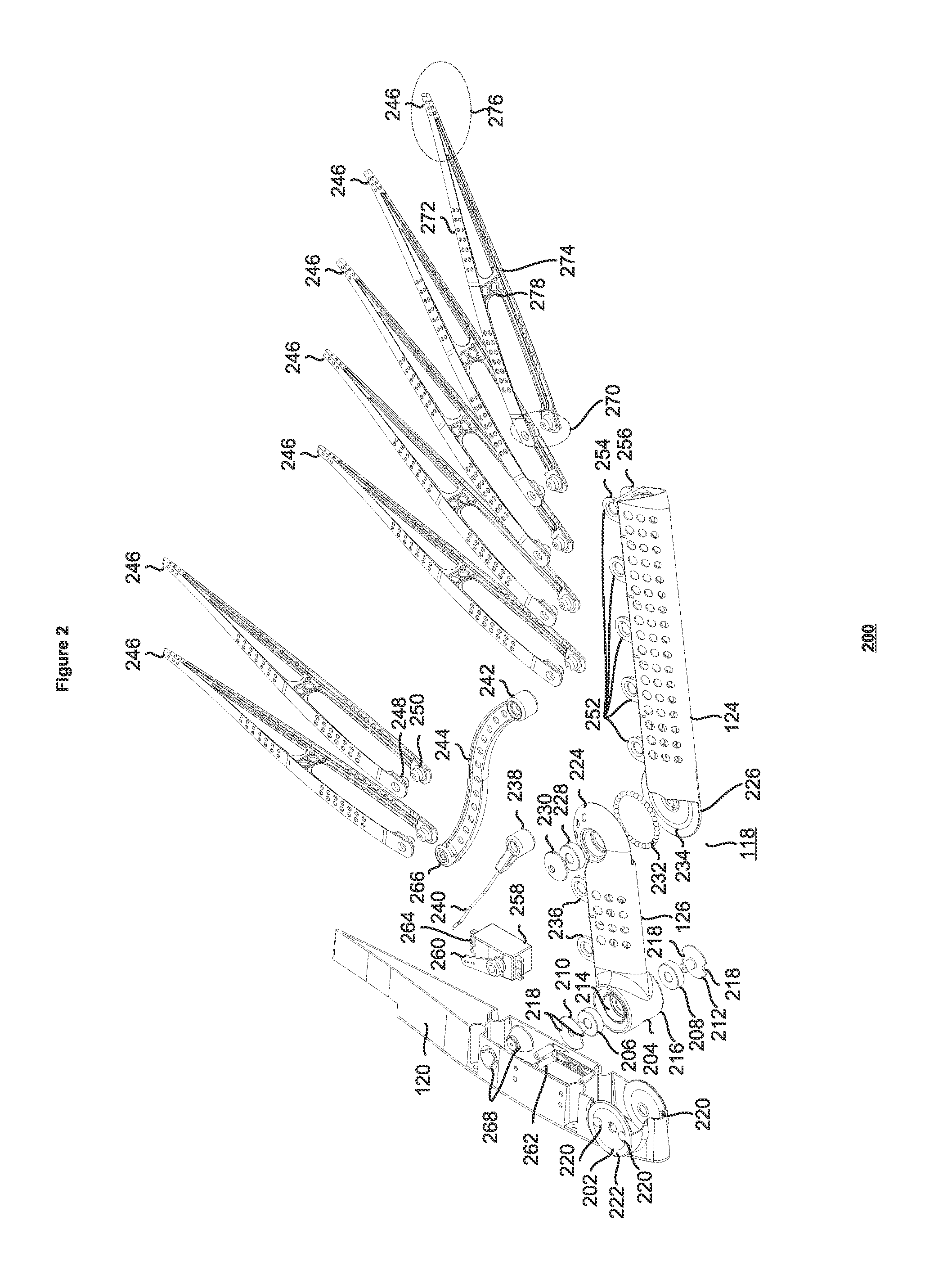

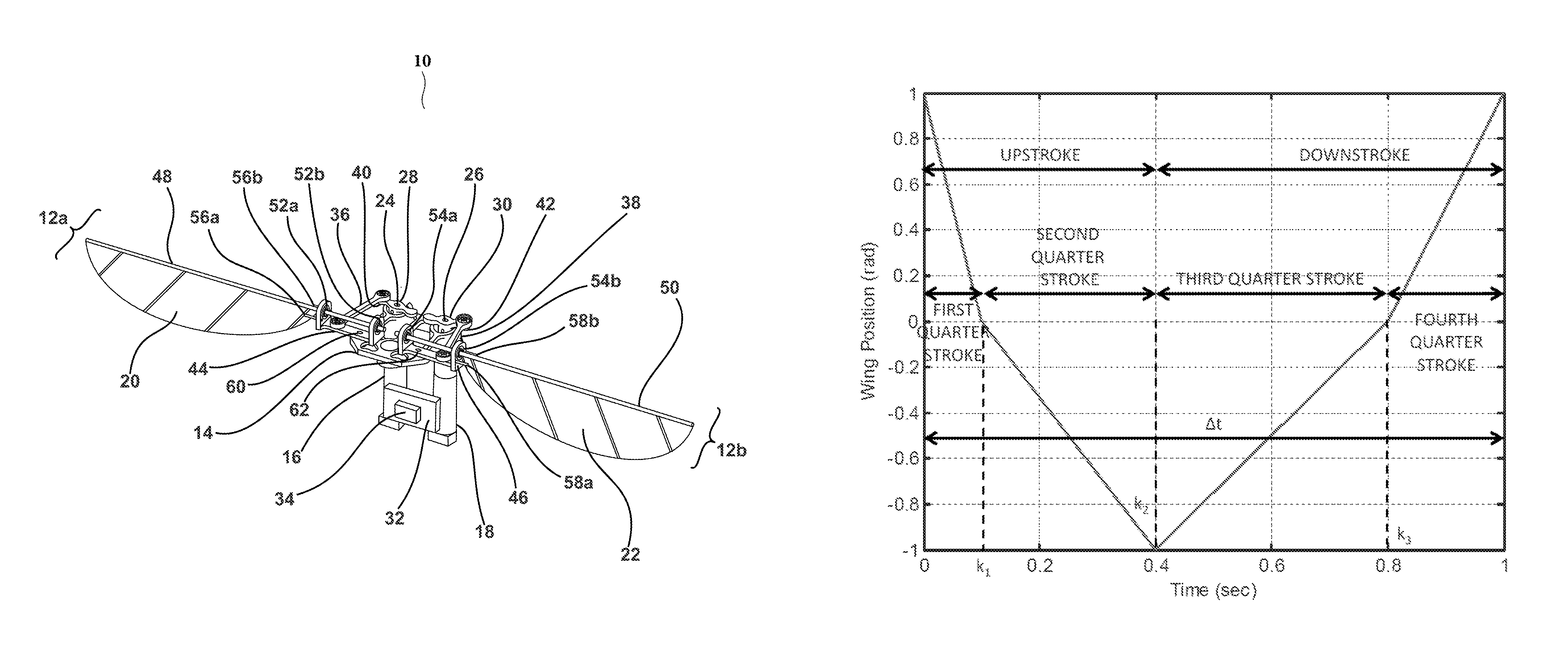

Method for shaping wing velocity profiles for control of flapping wing micro air vehicles

ActiveUS8700233B1Reduce weightReduce complexityUnmanned aerial vehiclesDigital data processing detailsFlapping wingGravity center

A method of controlling wing position and velocity for a flapping wing air vehicle provides six-degrees-of-freedom movement for the aircraft through a split-cycle constant-period frequency modulation with wing bias method that generates time-varying upstroke and downstroke wing position commands for wing planforms to produce nonharmonic wing flapping trajectories that generate non-zero, cycle averaged wing drag and alter the location of the cycle-averaged center of pressure of the wings relative to the center of gravity of the aircraft to cause horizontal translation forces, rolling moments and pitching moments of the aircraft.

Owner:UNITED STATES OF AMERICAS AS REPRESENTED BY THE SEC OF THE AIR FORCE THE

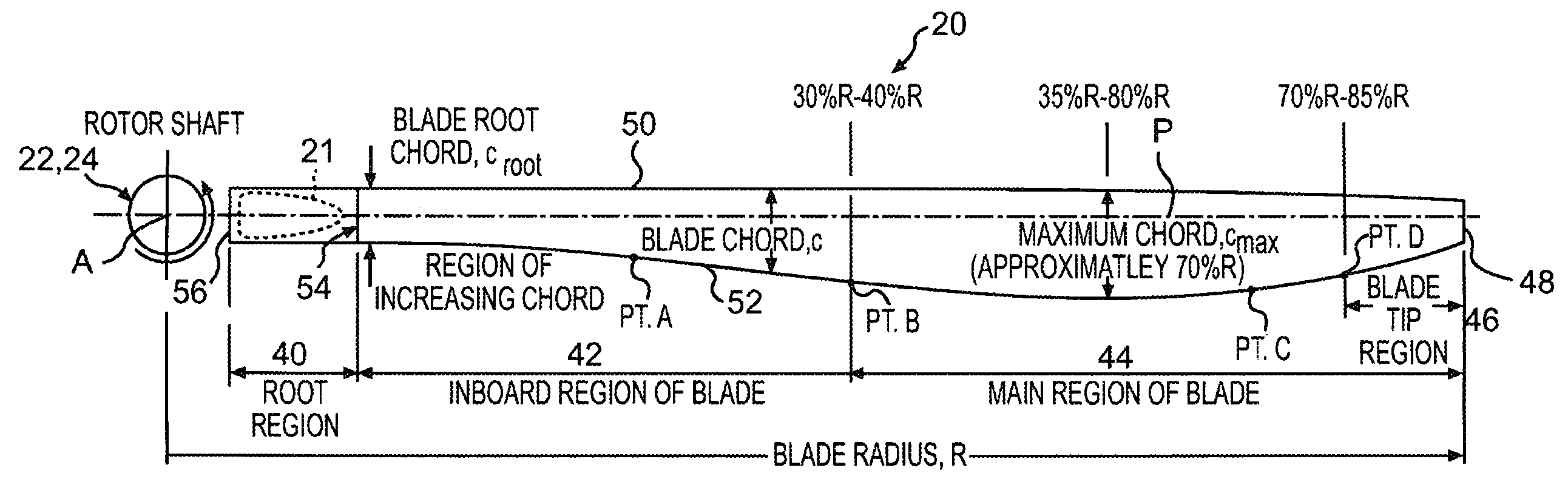

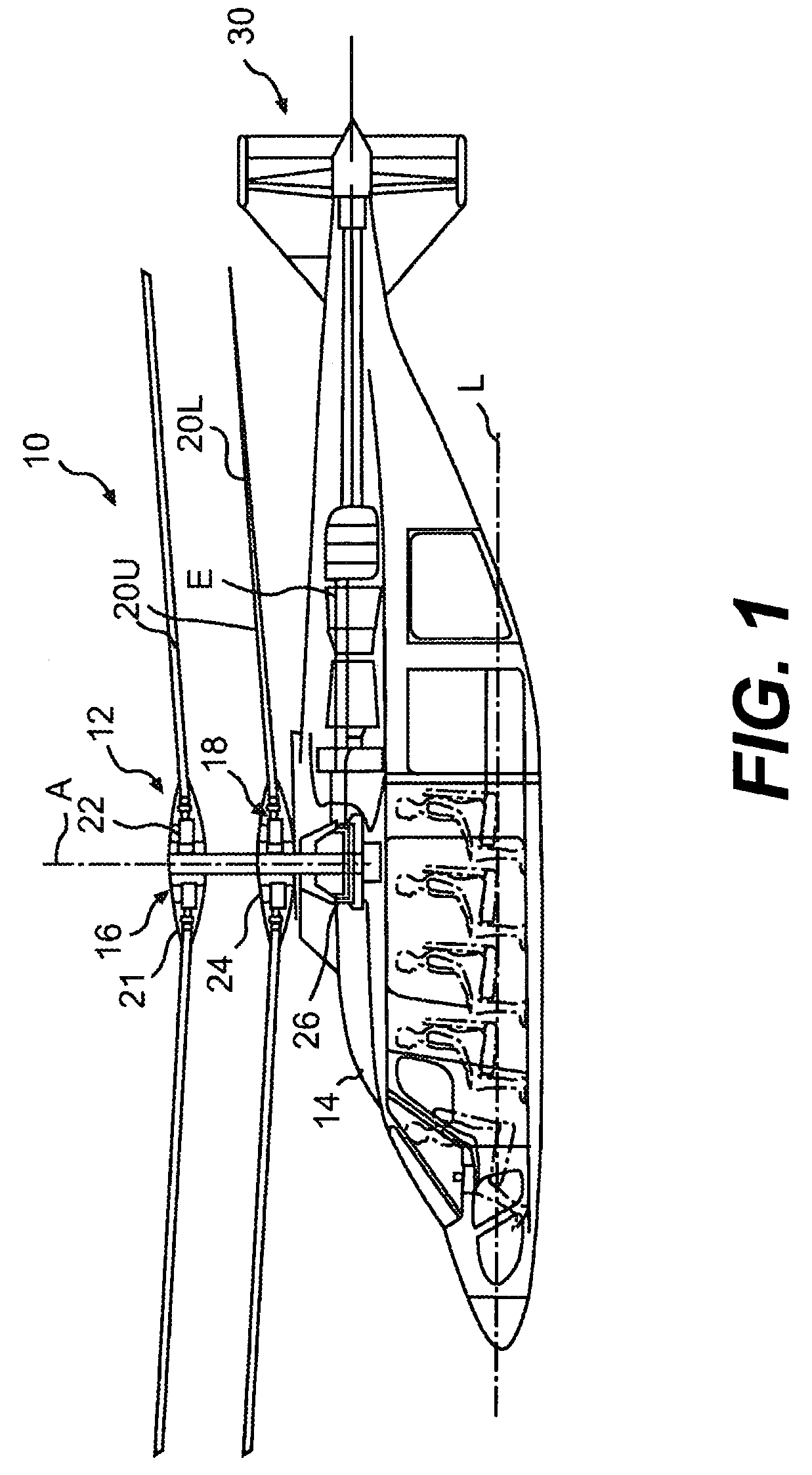

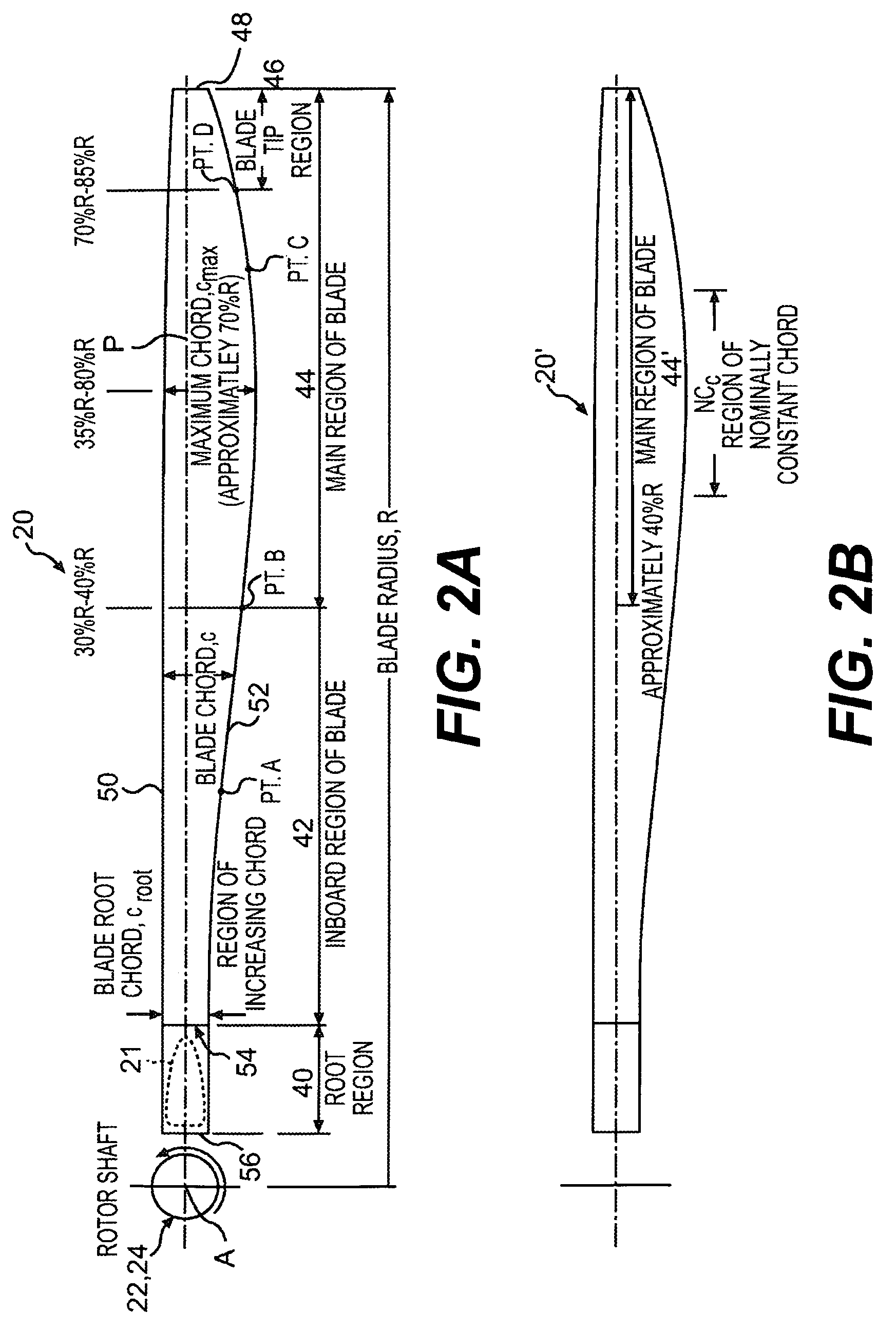

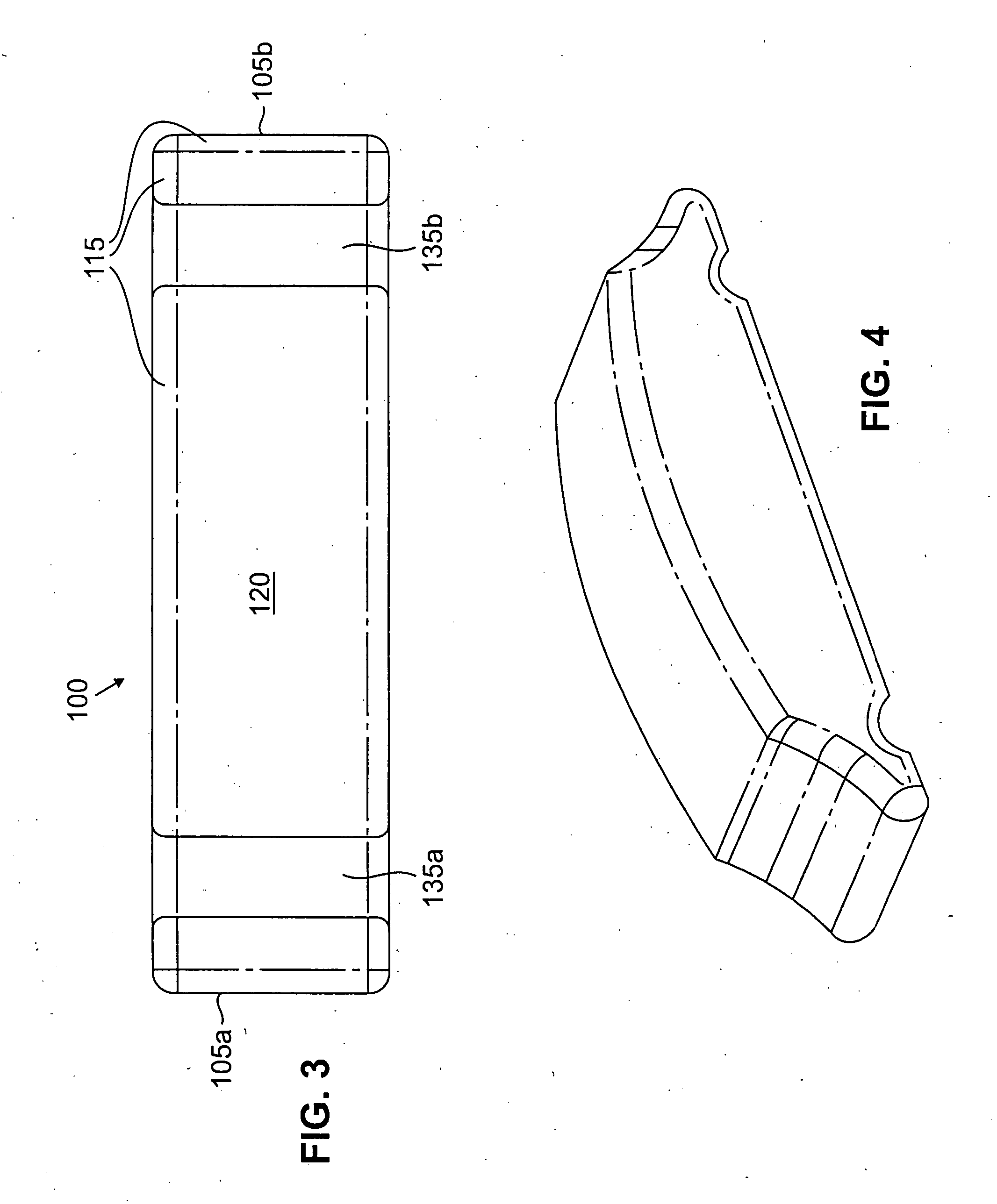

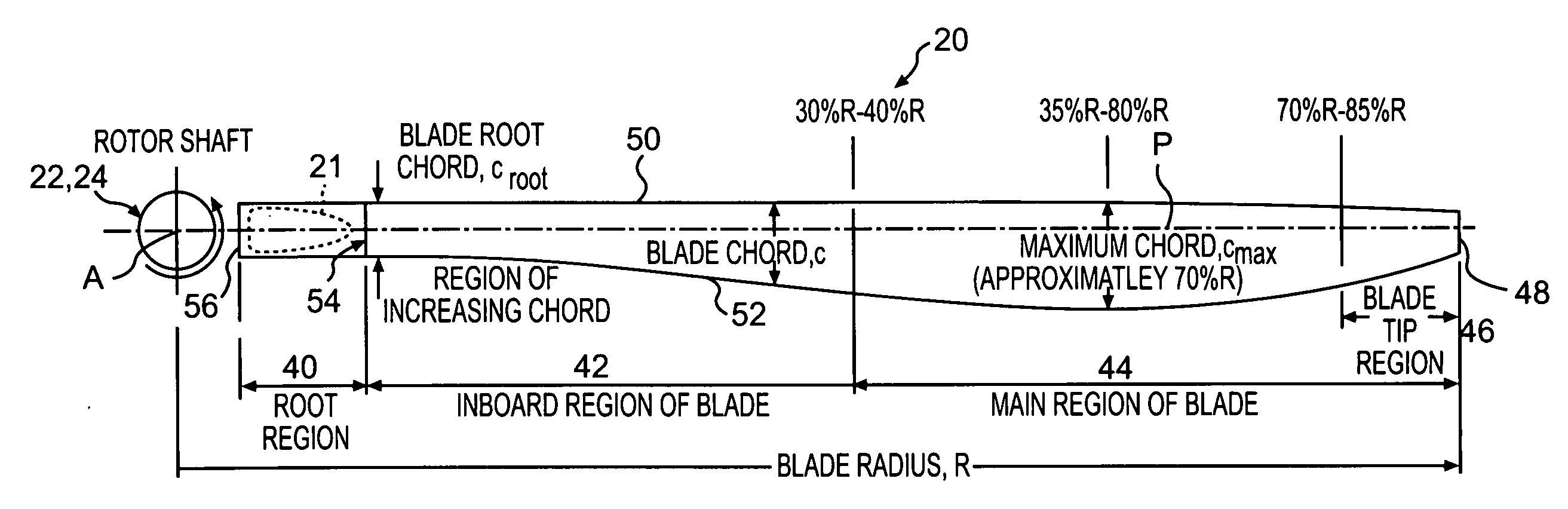

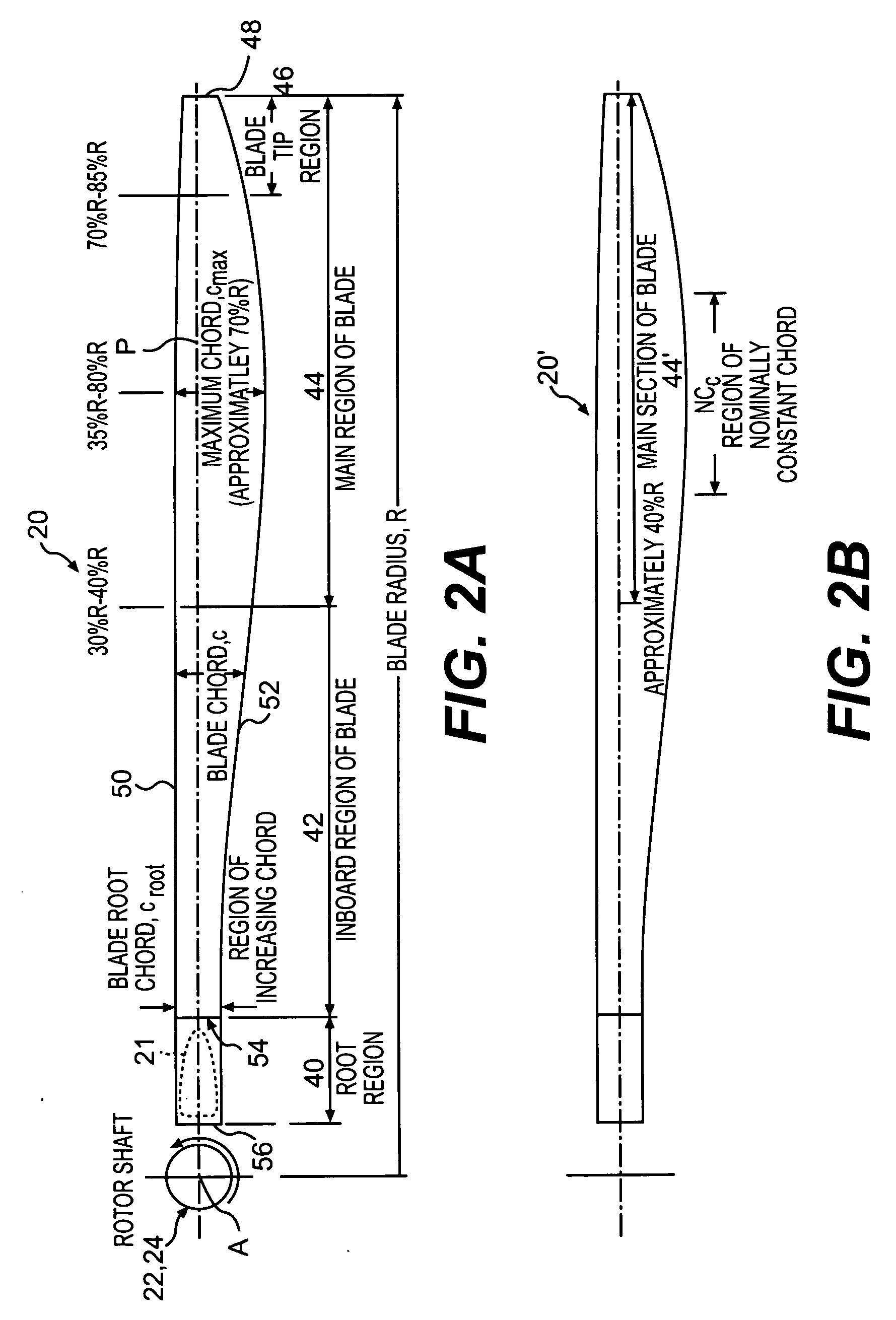

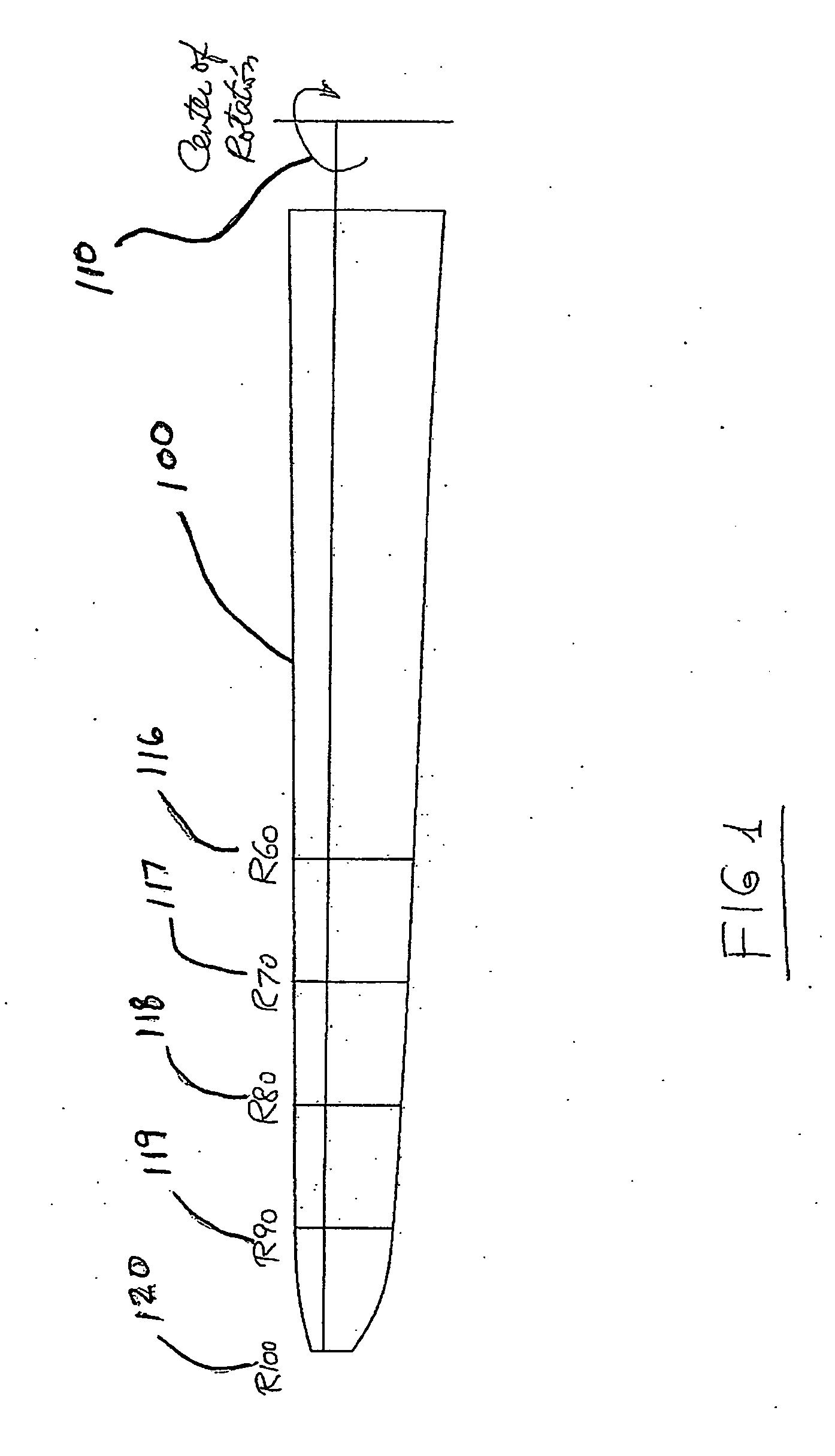

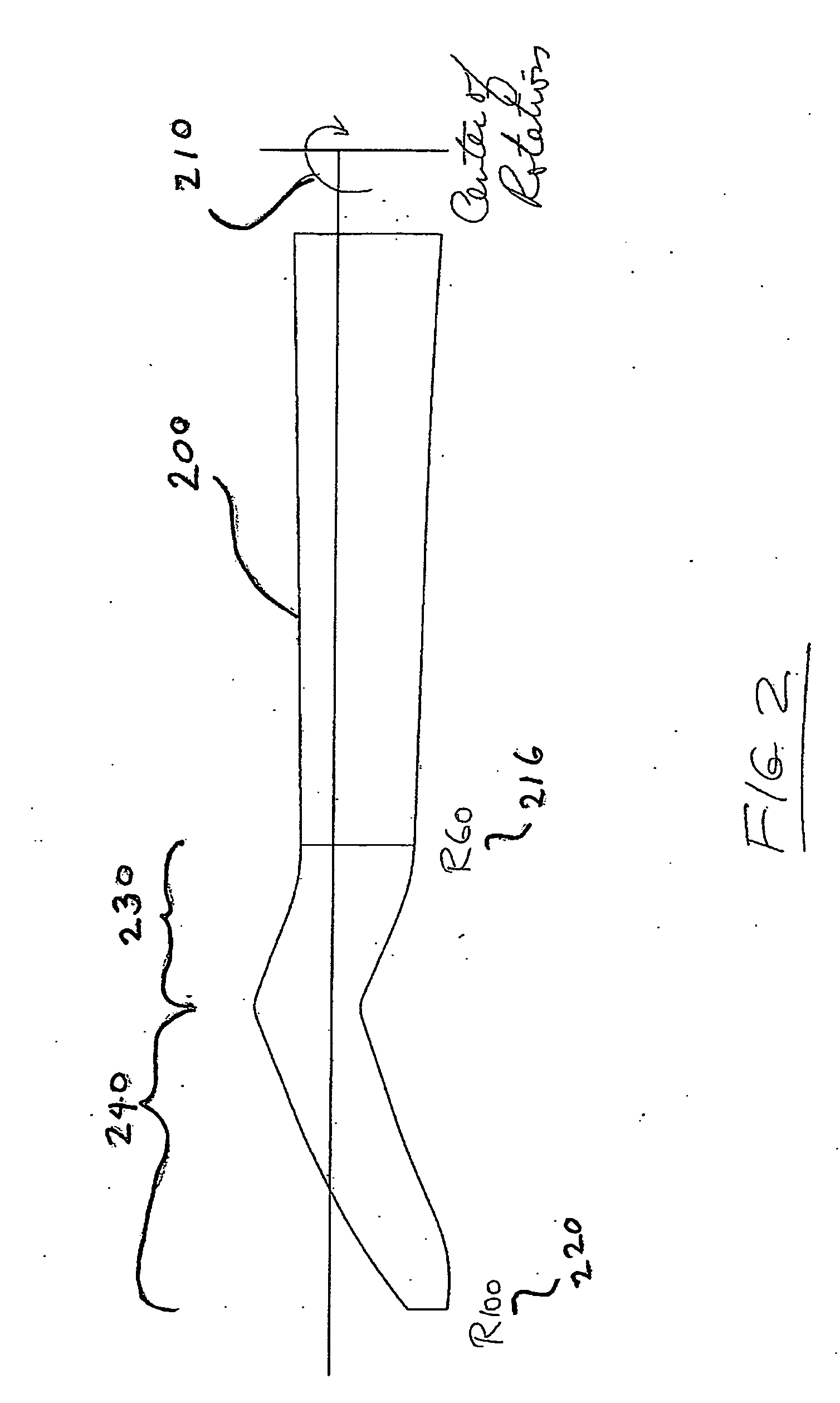

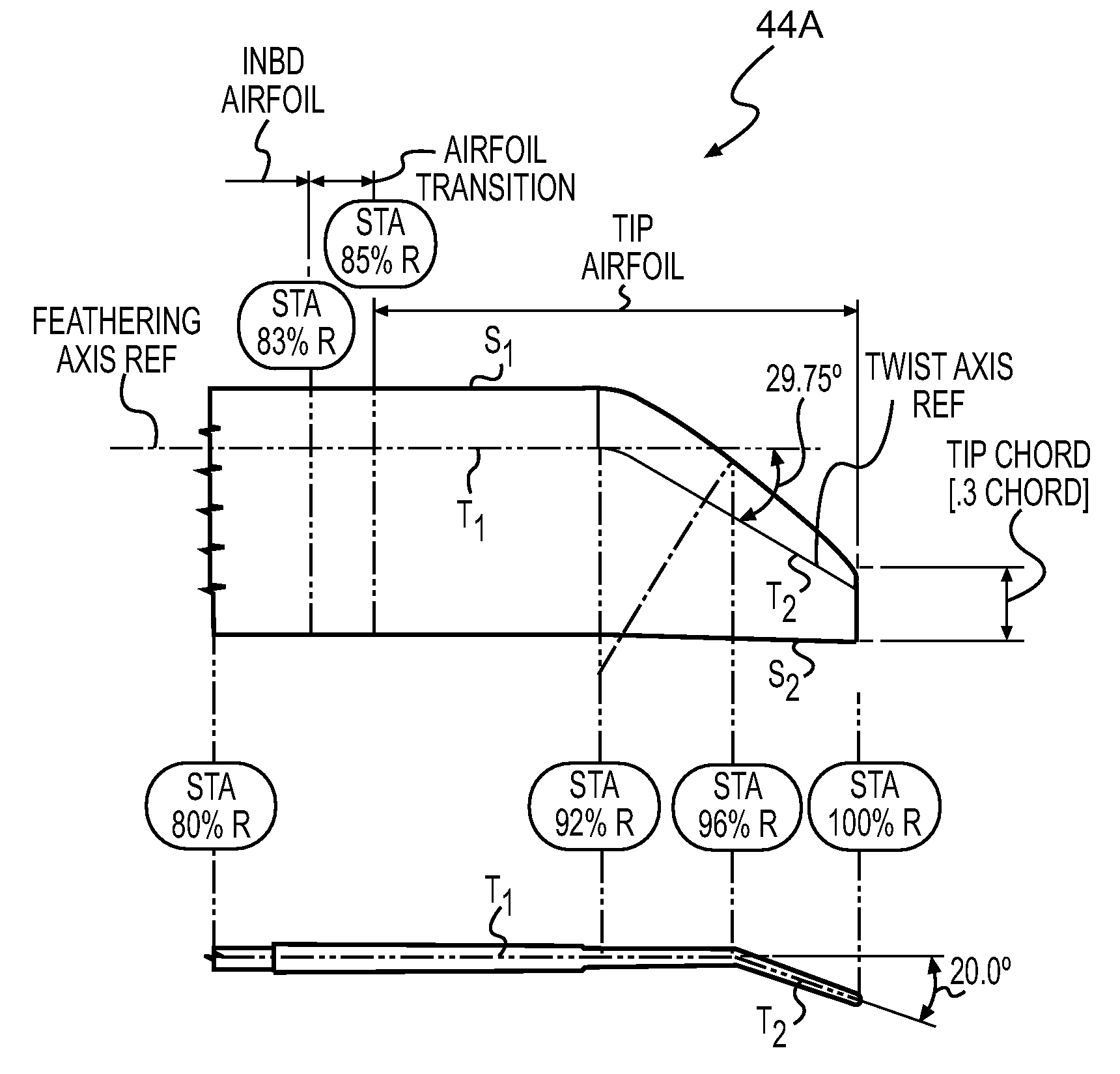

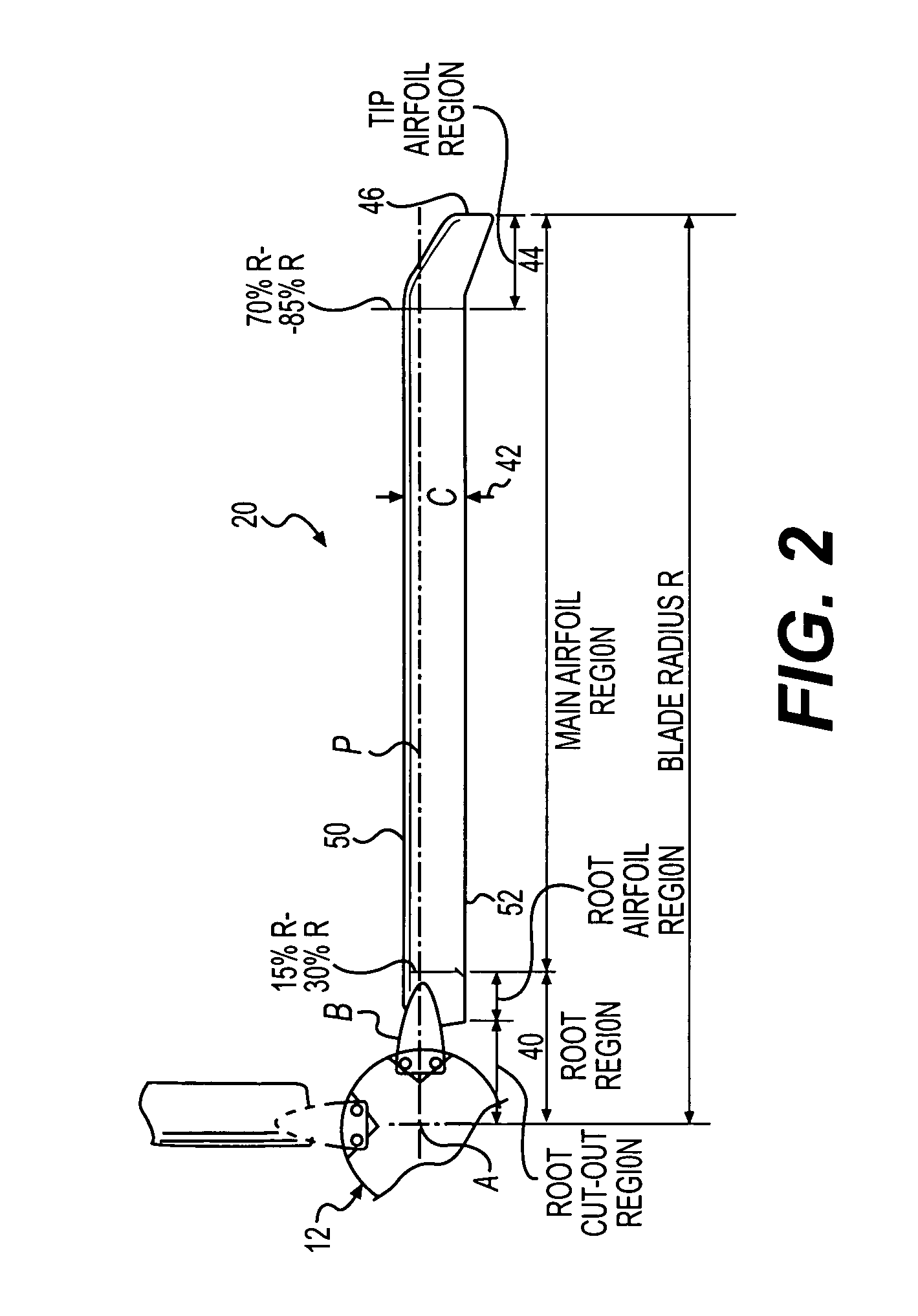

Rotor blade for a high speed rotary-wing aircraft

ActiveUS7252479B2Increase the areaHigh-speed efficiencyPropellersPump componentsLeading edgeTrailing edge

A main rotor blade exhibiting a unique planform shape in which the blade chord increases from the root end of the blade inboard region to the outer main region of the blade, where the blade chord achieves a maximum chord at a spanwise location within the main region, then decreases toward a distal tip end. The leading edge preferably is generally straight while the trailing edge is contoured to define the chord. Another characteristic feature of the rotor blade design is the location of the blade-feathering axis in which the feathering axis is located at a mid chord position over some inboard length of the rotor blade then transitions to a quarter chord location. Another characteristic feature is an airfoil distribution along the blade span that transitions from a blunt trailing edge to a sharp trailing edge airfoil suited for mid-range Mach number operation. The tip region preferably utilizes a transonic flow airfoil. Another characteristic feature of the rotor blade design is an unconventional combination of positive and negative twist gradients.

Owner:SIKORSKY AIRCRAFT CORP

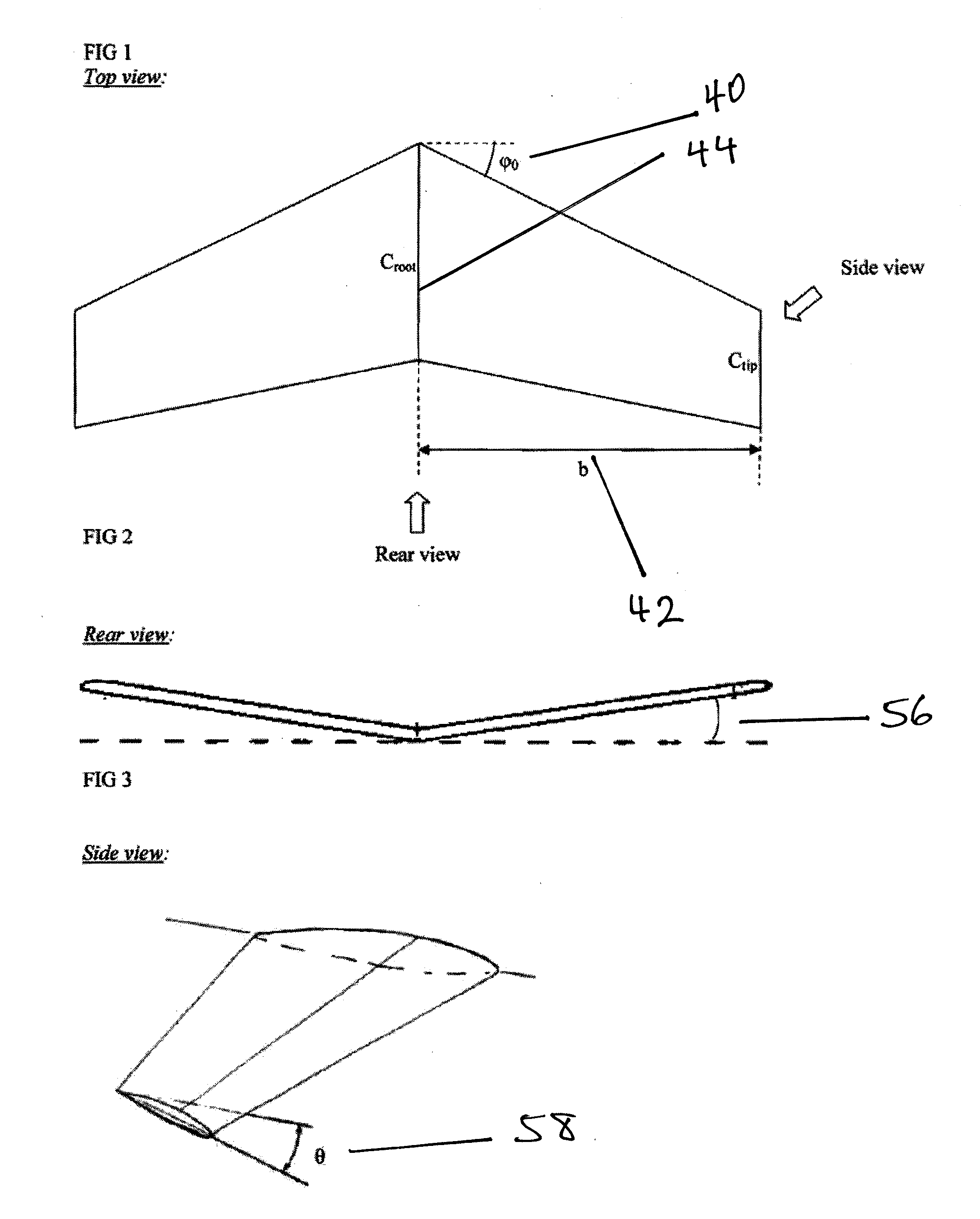

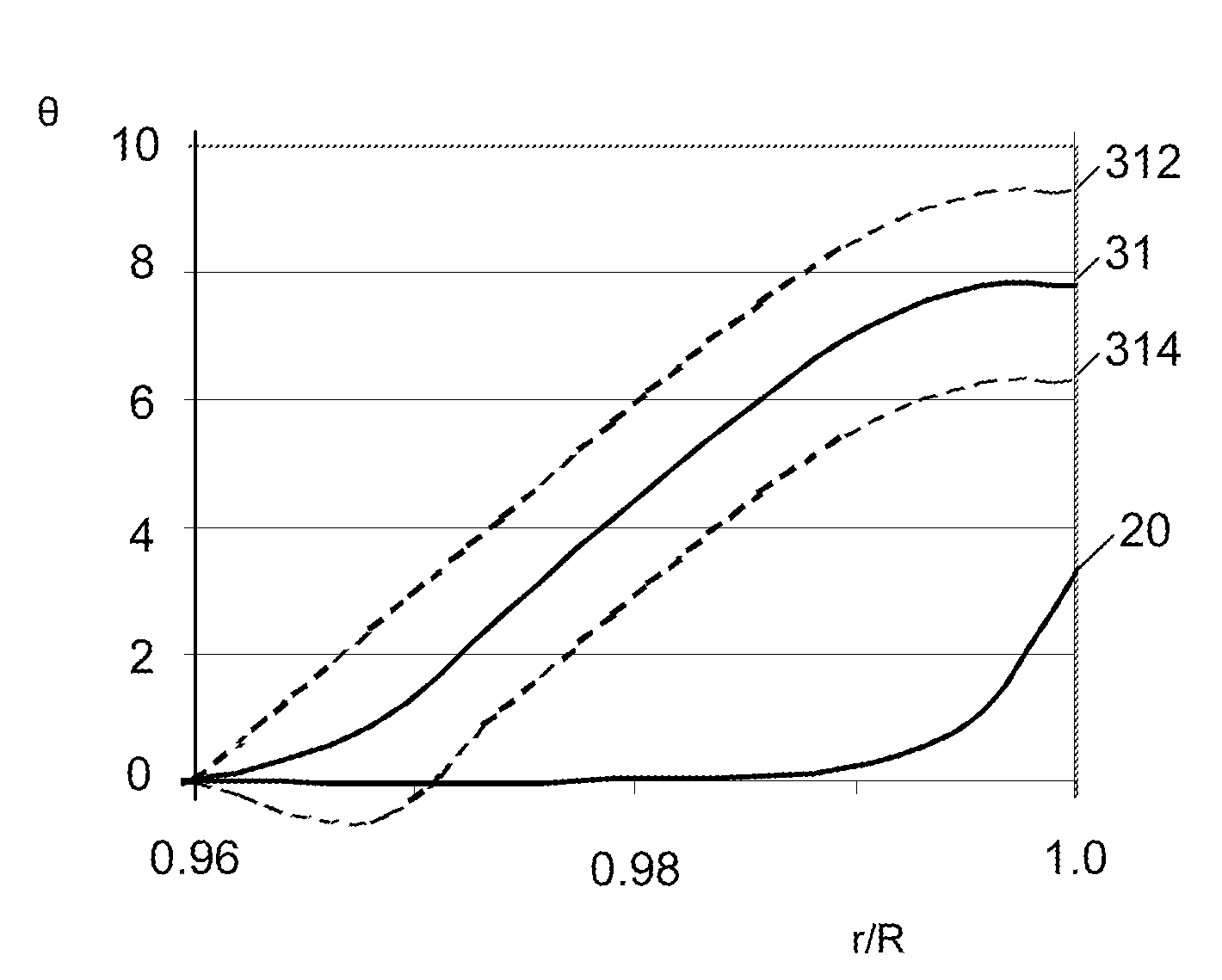

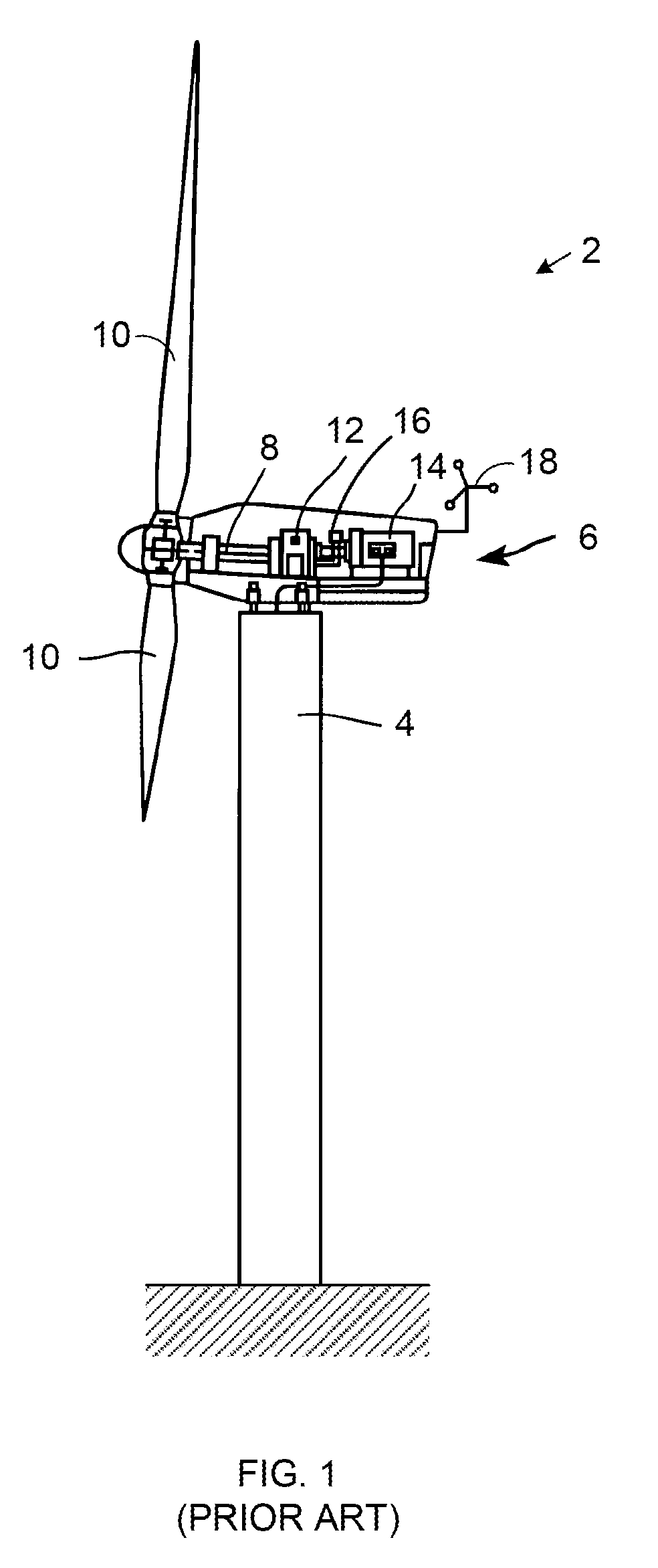

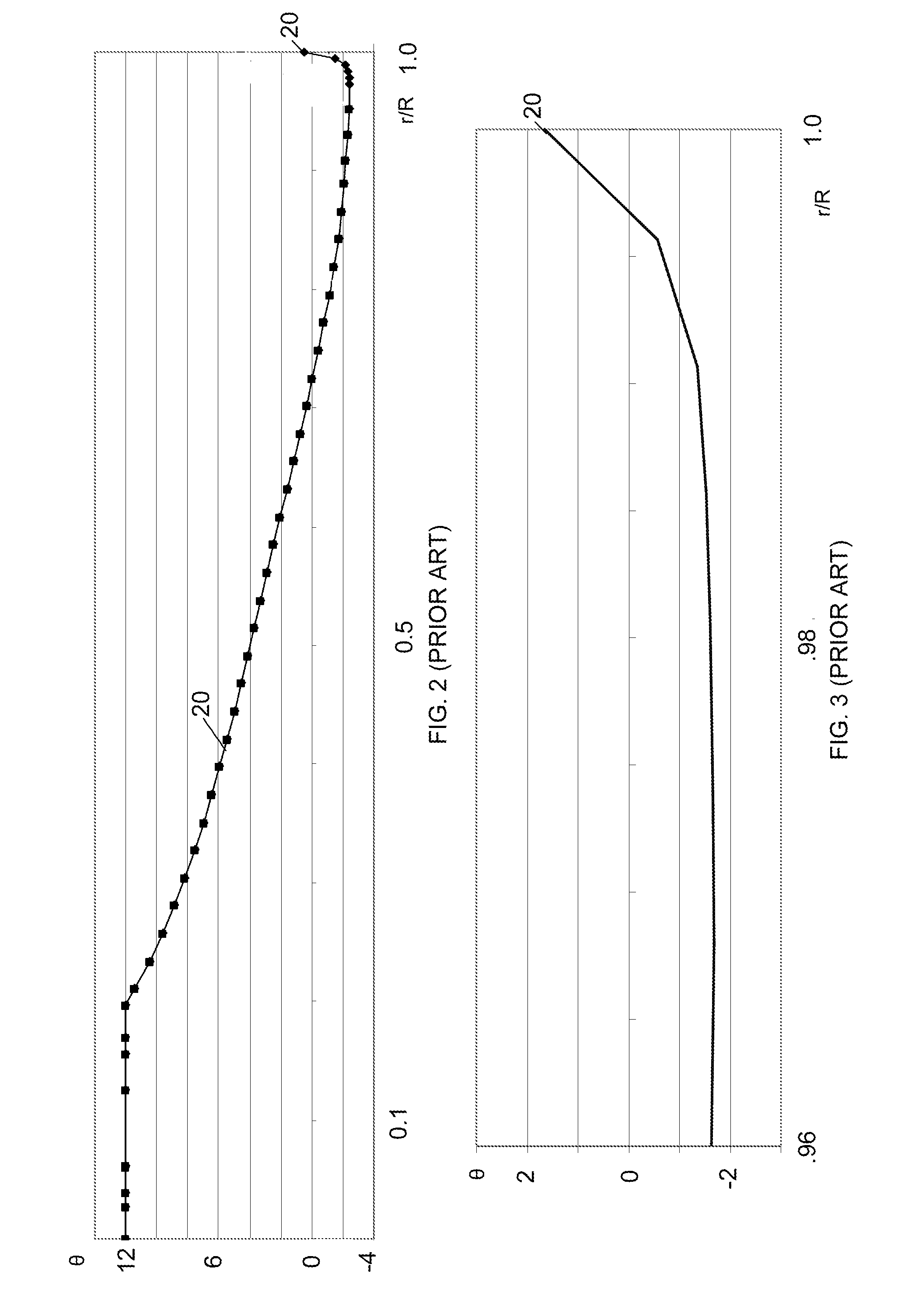

Wind turbine blade planforms with twisted and tapered tips

A blade for a wind turbine includes a total backward twist of between approximately 6 degrees and approximately 15 degrees between an outer approximately 1 percent to 10 percent of a rotor radius of the blade; and an approximate planform distribution within the following rangesr / Rc / R(LE)c / R(TE).960.60 to 0.65%−1.42 to −1.34%.9680.54 to 0.59%−1.31 to −1.34%.9740.39 to 0.58%−1.36 to −1.22%.98060.13 to 0.57%−1.45 to −1.06%.9856−0.23 to 0.56% −1.56 to −0.74%.9906−0.76 to 0.55% −1.74 to −0.24%.9956−1.44 to 0.54% −1.99 to 0.23% 1.00−2.17 to 0.54% −2.27 to 0.44% where “r / R” is an approximate normalized distance outward from a center of rotation of the blade along a span of the blade; and “c / R(LE)” and “c / R(TE)” are approximate relative positions of a leading (LE) and trailing edge (TE) of a chord “c” expressed as a percentage of a distance outward from the center of rotation at each r / R.

Owner:GENERAL ELECTRIC CO

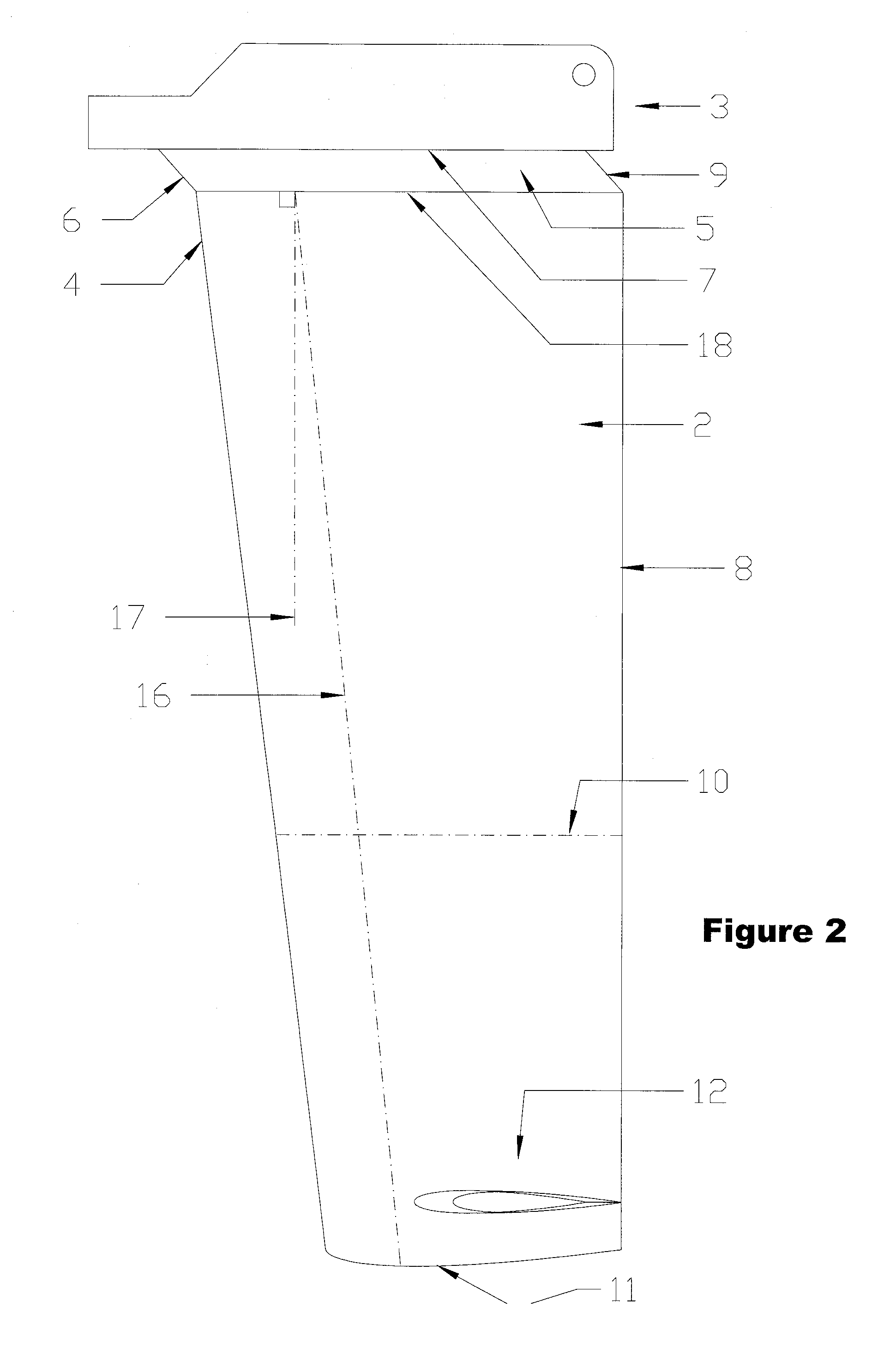

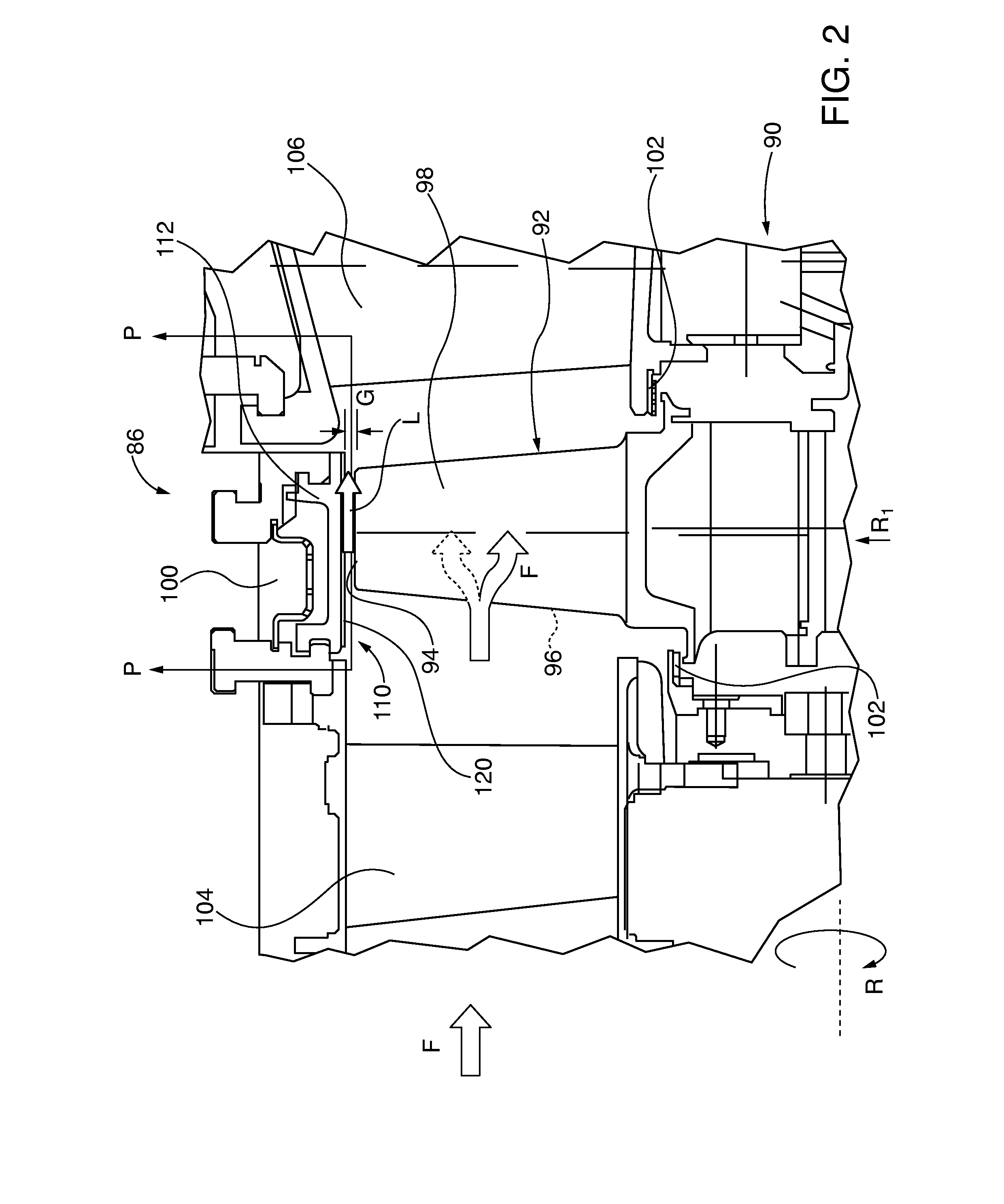

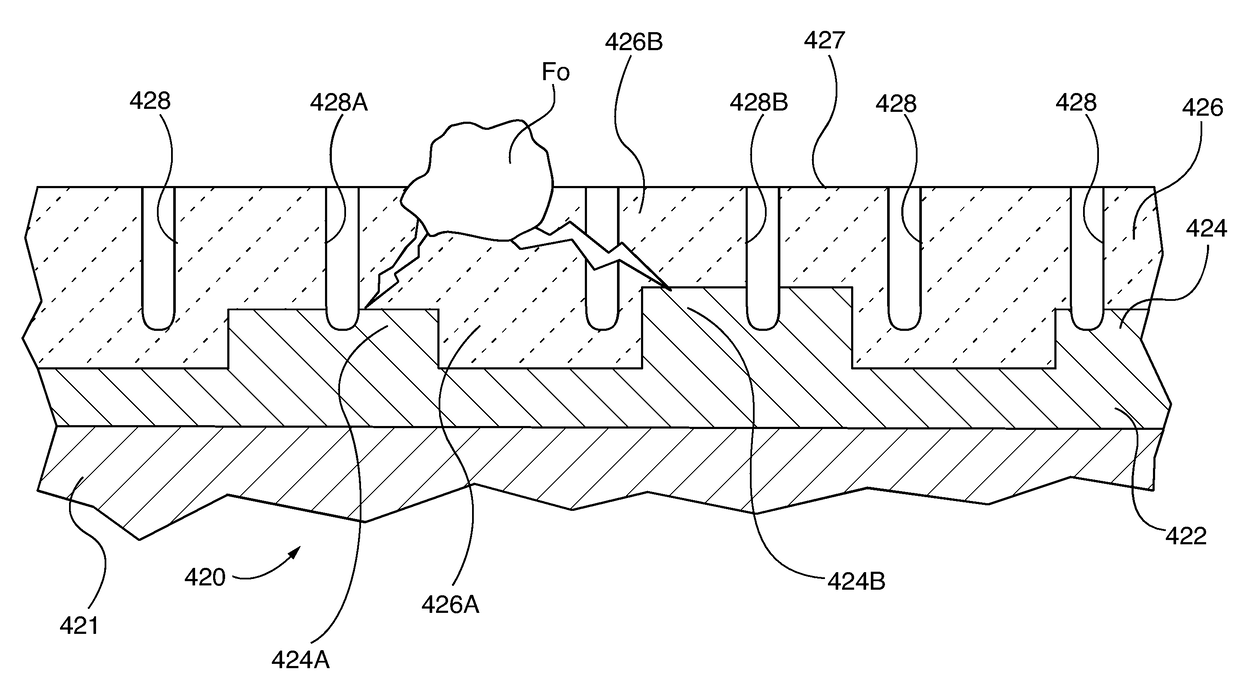

Turbine abradable layer with progressive wear zone terraced ridges

InactiveUS8939707B1Improve efficiencyControl and reduceEngine manufacturePump componentsTurbine bladeRidge

Turbine and compressor casing abradable component embodiments for turbine engines, with composite grooves and vertically projecting rows of stepped first ridges in planform patterns, to reduce, redirect and / or block blade tip airflow leakage downstream into the grooves rather than from turbine blade airfoil high to low pressure sides. Each stepped first ridge has a first portion proximal the substrate surface with a pair of first opposed lateral walls terminating in a plateau, and a second portion terminating in a ridge tip. These ridge or rib embodiments have first lower and second upper wear zones. The lower zone, which at and below first portion height, optimizes engine airflow characteristics, while the upper zone, between the plateau and the second portion ridge is optimized to minimize blade tip gap and wear by being more easily abradable than the lower zone.

Owner:SIEMENS ENERGY INC

Trailing edge flap

ActiveUS8714493B2Convenient ArrangementEasy to liftAircraft controlWing adjustmentsEngineeringTrailing edge

Owner:AIRBUS OPERATIONS LTD

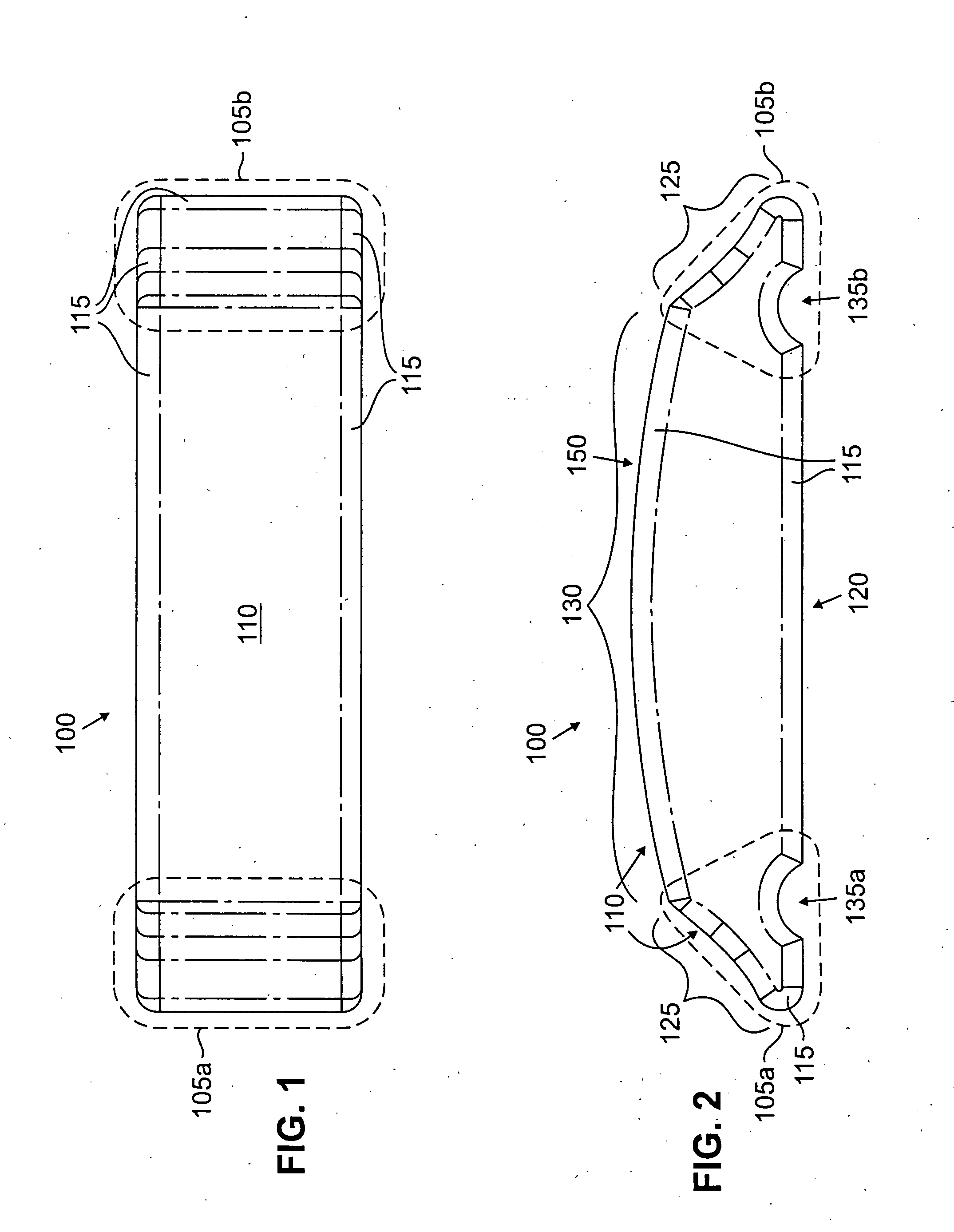

Scleral prosthesis for treatment of presbyopia and other eye disorders

InactiveUS20050283233A1Restores effective working distanceIncrease the adjustment rangeLaser surgeryEye implantsDiseaseCiliary epithelium

Presbyopia and other eye disorders are treated by implanting within a plurality of elongated pockets formed in the tissue of the sclera of the eye transverse to a meridian of the eye, a prosthesis having an elongated base member having an inward surface adapted to be placed against the inward wall of the pocket and having a ridge on the inward surface of the base extending along at least a major portion of the major dimension of the base. The combined effect of the implanted prostheses is to exert a radially outward traction on the sclera in the region overlying the ciliary body which expands the sclera in the affected region together with the underlying ciliary body. The expansion of the ciliary body restores the effective working distance of the ciliary muscle in the presbyopic eye and thereby increases the amplitude of accommodation. Introduced is an improved scleral prosthesis for the treatment of presbyopia and other eye disorders. An exemplary prosthesis is adapted for contact with the sclera of an eyeball, and comprises a body having a first end and a second end wherein the body has (i) a planform adapted to expand the contacted sclera to increase the effective working distance of the ciliary muscle of the eyeball, and (ii) means for stabilizing the prosthesis within the surgically formed pocket within the sclera of the eyeball.

Owner:REFOCUS GROUP

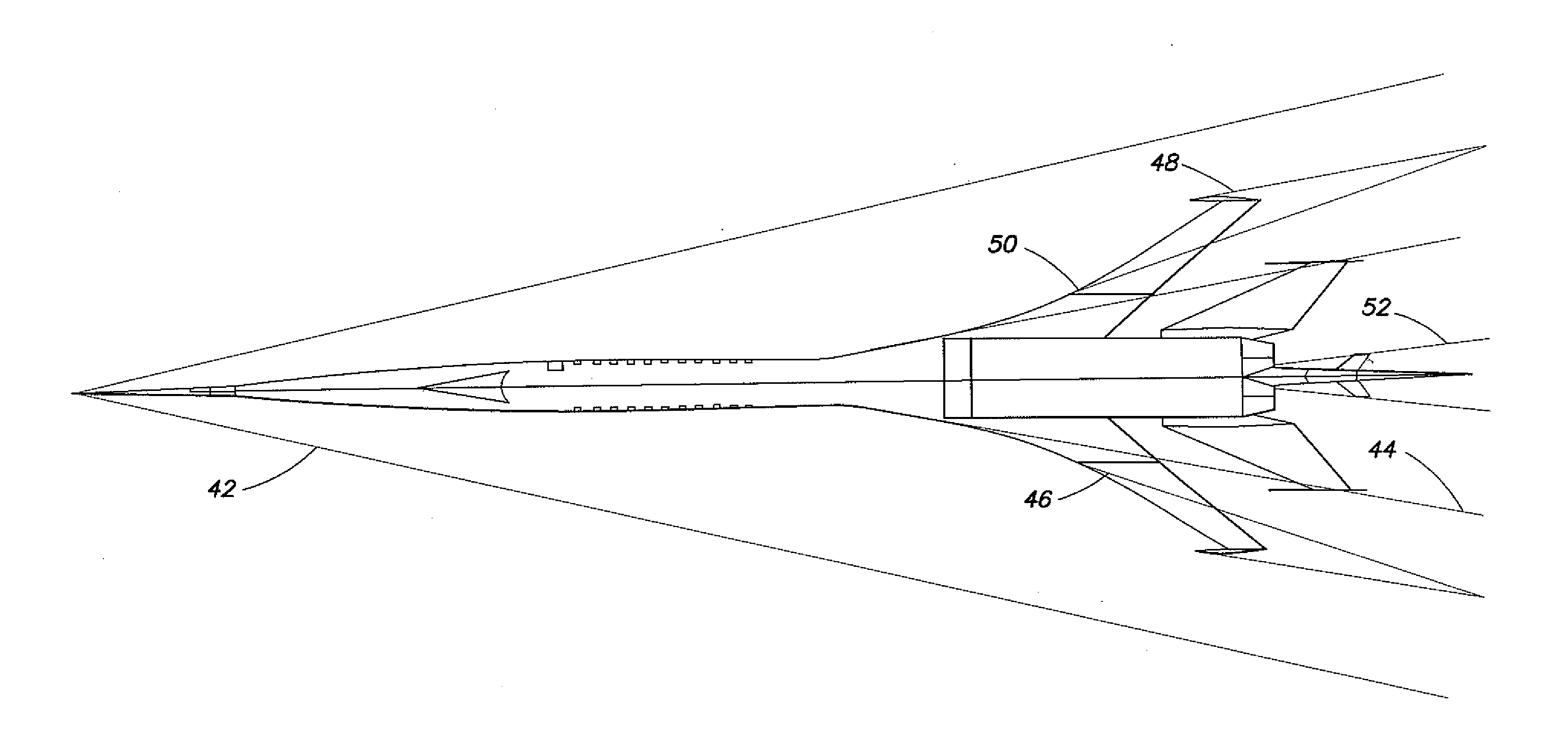

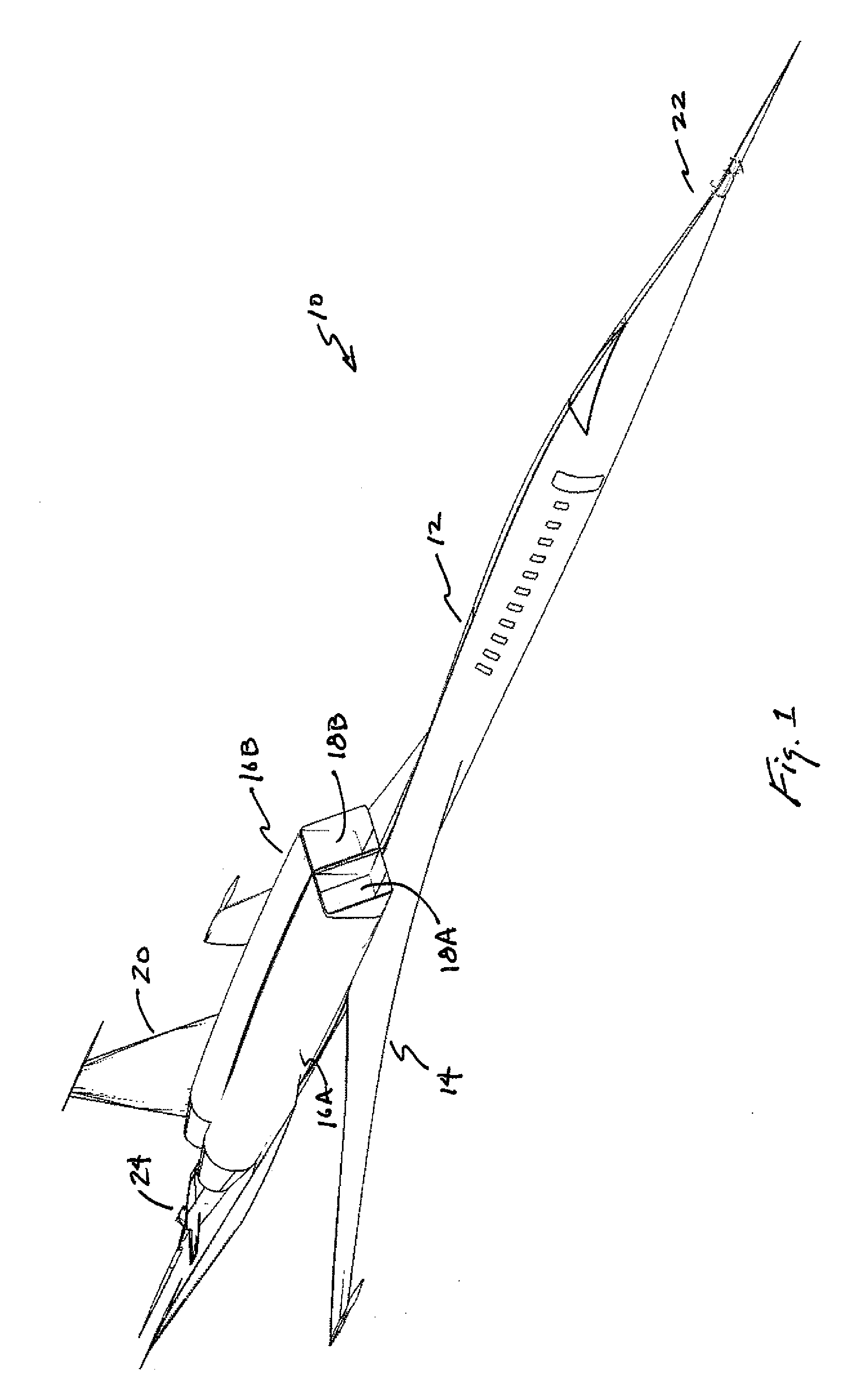

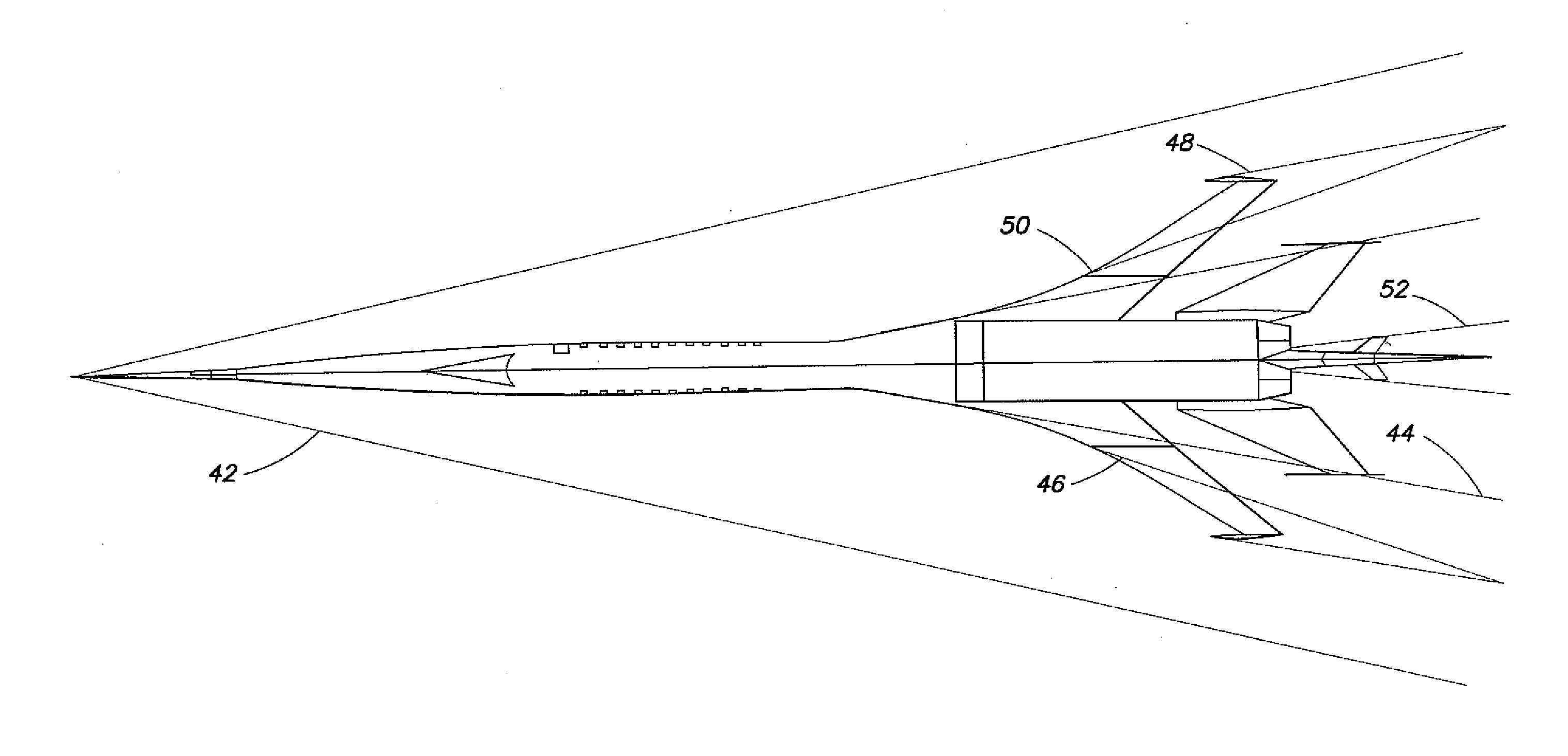

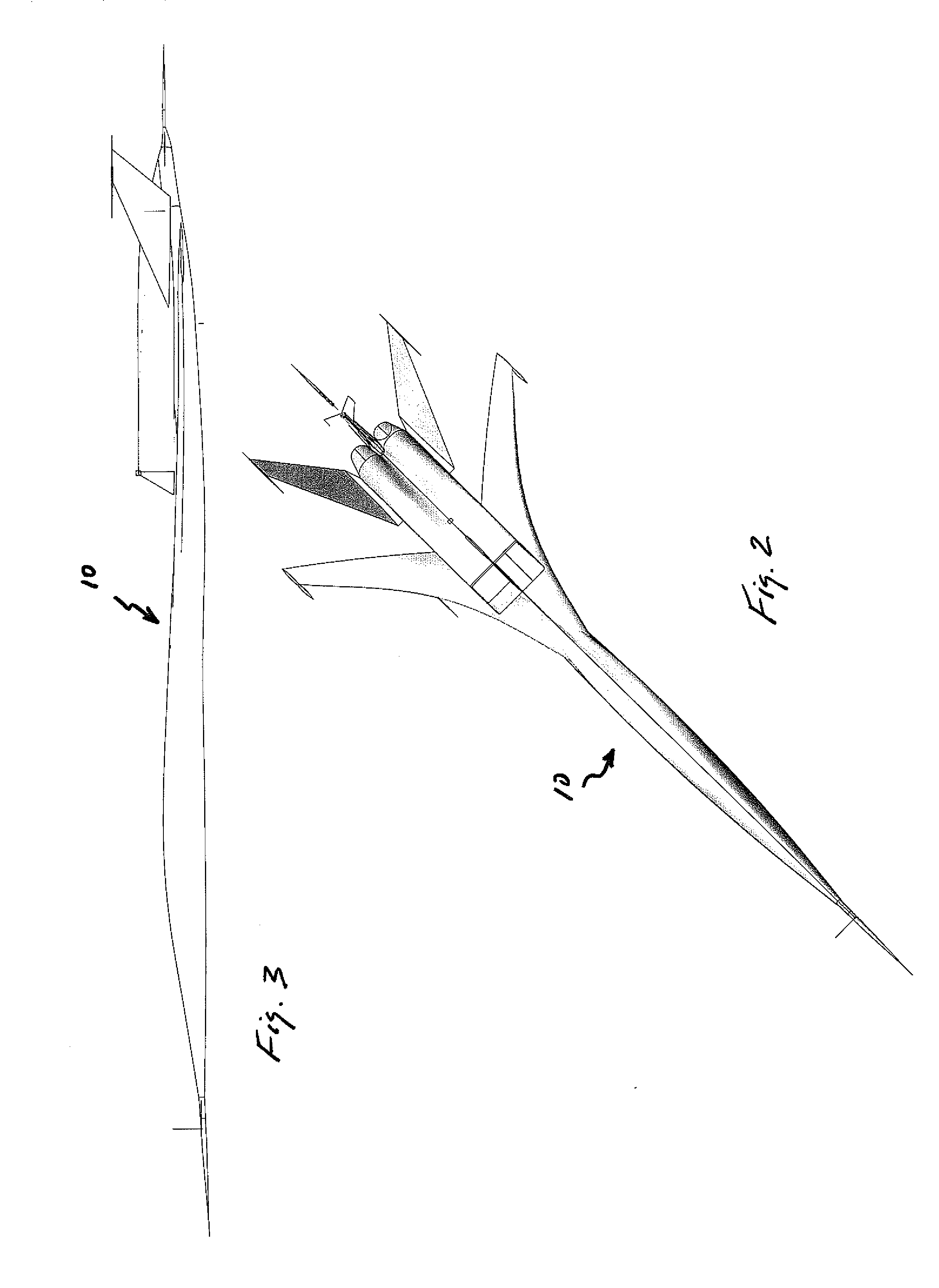

Supersonic aircraft with shockwave canceling aerodynamic configuration

ActiveUS20110133021A1Maximize aerodynamic performanceMaximize efficiencyAircraft stabilisationEnergy efficient board measuresPlanformAirplane

Disclosed is a supersonic aircraft design having a single structural component that simultaneously joins the wings to the aircraft fuselage, the engines to the aircraft fuselage, and the wings to the engines, resulting in an airframe planform, which, in combination aerodynamic shaping and structural morphing technologies within the aircraft fuselage, enables the aircraft to be optimized to reduce sonic boom.

Owner:HYPERMACH AEROSPACE INDS

Rotor blade for a high speed rotary-wing aircraft

ActiveUS20060269418A1Optimizing rotor performanceOptimizing high-speed flight efficiencyPropellersRotary propellersLeading edgeTrailing edge

A main rotor blade exhibiting a unique planform shape in which the blade chord increases from the root end of the blade inboard region to the outer main region of the blade, where the blade chord achieves a maximum chord at a spanwise location within the main region, then decreases toward a distal tip end. The leading edge preferably is generally straight while the trailing edge is contoured to define the chord. Another characteristic feature of the rotor blade design is the location of the blade-feathering axis in which the feathering axis is located at a mid chord position over some inboard length of the rotor blade then transitions to a quarter chord location. Another characteristic feature is an airfoil distribution along the blade span that transitions from a blunt trailing edge to a sharp trailing edge airfoil suited for mid-range Mach number operation. The tip region preferably utilizes a transonic flow airfoil. Another characteristic feature of the rotor blade design is an unconventional combination of positive and negative twist gradients.

Owner:SIKORSKY AIRCRAFT CORP

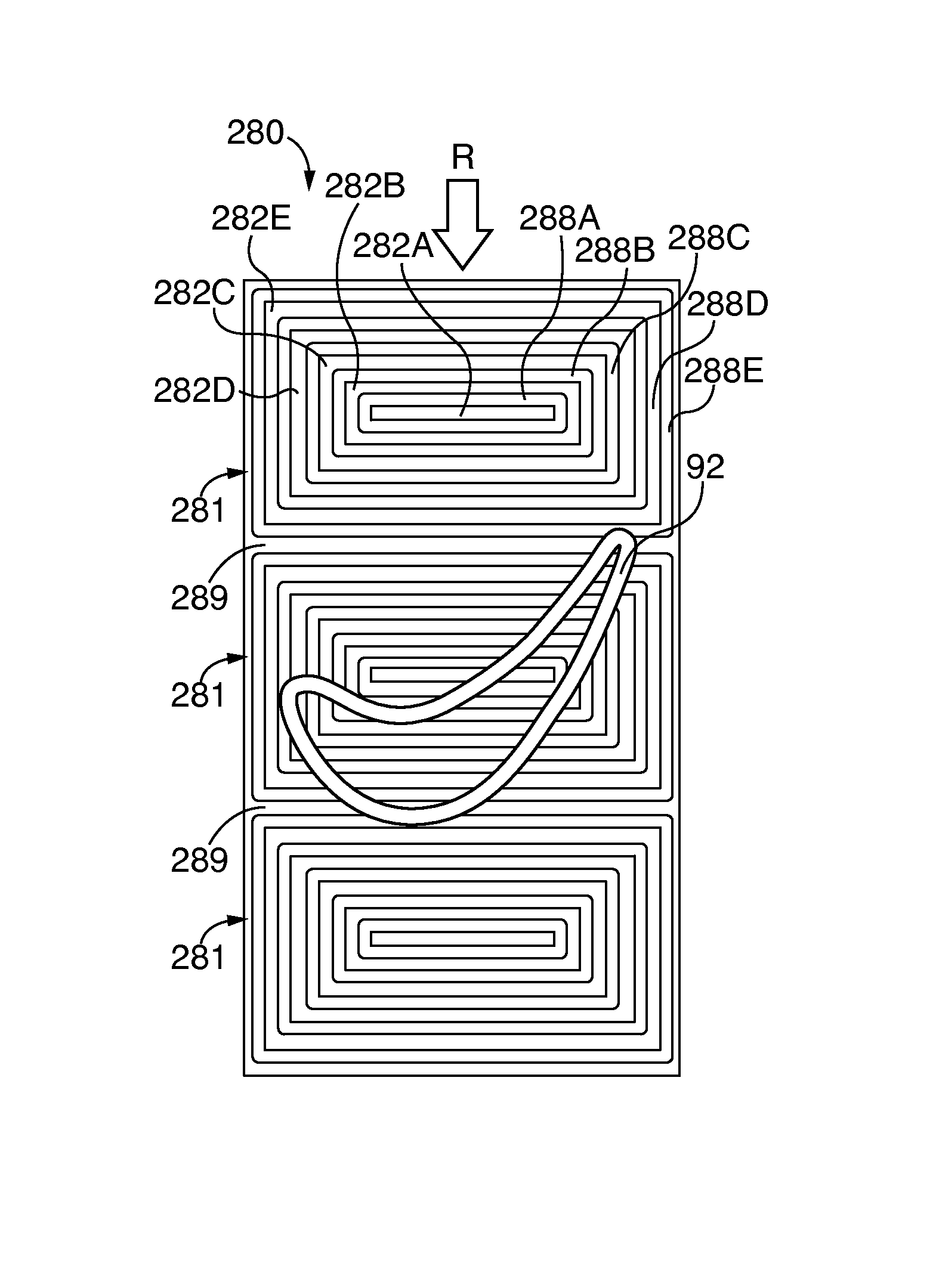

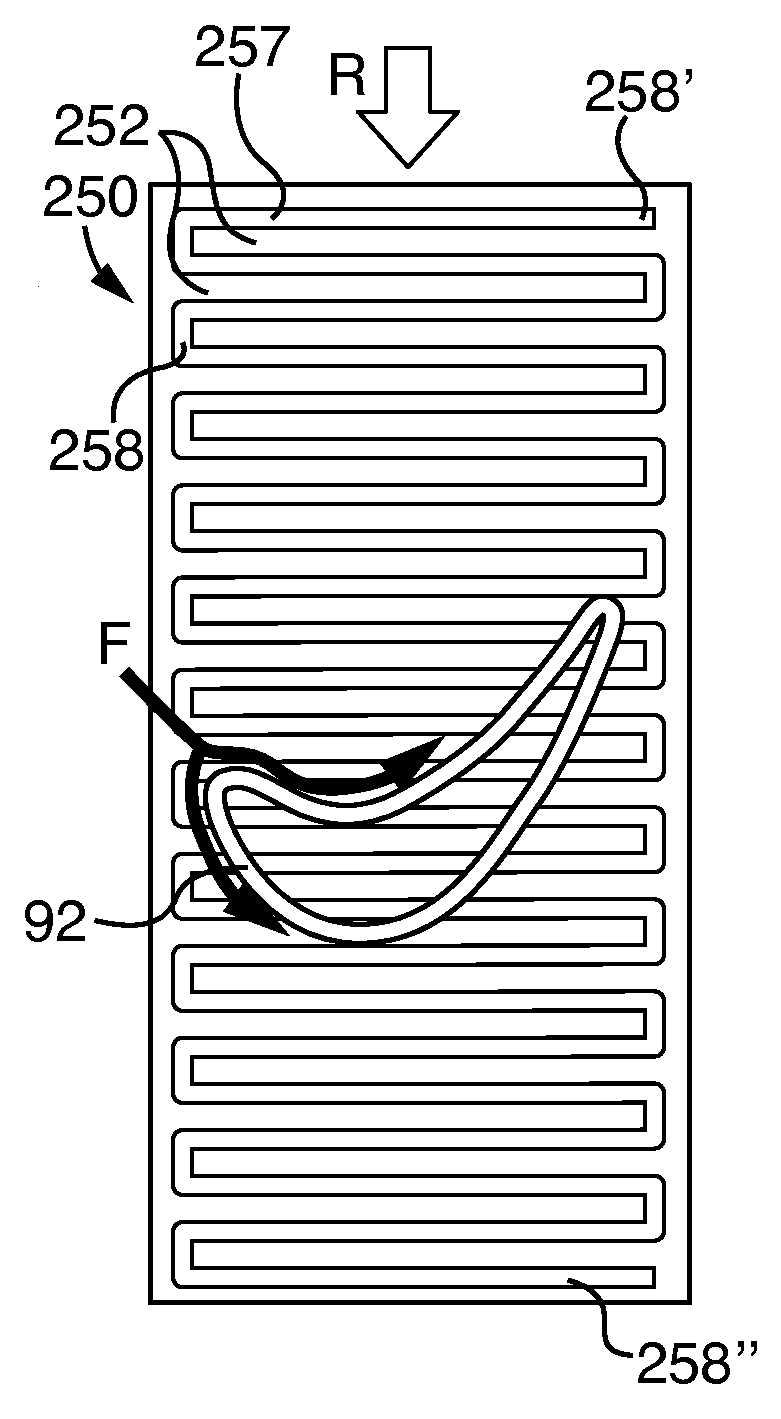

Turbine abradable layer with nested loop groove pattern

InactiveUS8939716B1Enhance engine efficiency performanceReducing and controlling blade tip gapEngine manufacturePump componentsTurbine bladeHigh pressure

Turbine and compressor casing abradable component embodiments for turbine engines, with nested loop pattern abradable surface ridges and grooves. The nested loops comprise nested fully closed loops or a spiraling maze pattern loop. Some embodiments include distinct forward upstream and aft downstream composite multi orientation groove and vertically projecting ridges planform patterns, to reduce, redirect and / or block blade tip airflow leakage downstream into the grooves rather than from turbine blade airfoil high to low pressure sides. Ridge or rib embodiments have first lower and second upper wear zones. The lower zone optimizes engine airflow characteristics while the upper zone is optimized to minimize blade tip gap and wear by being more easily abradable than the lower zone.

Owner:SIEMENS AG

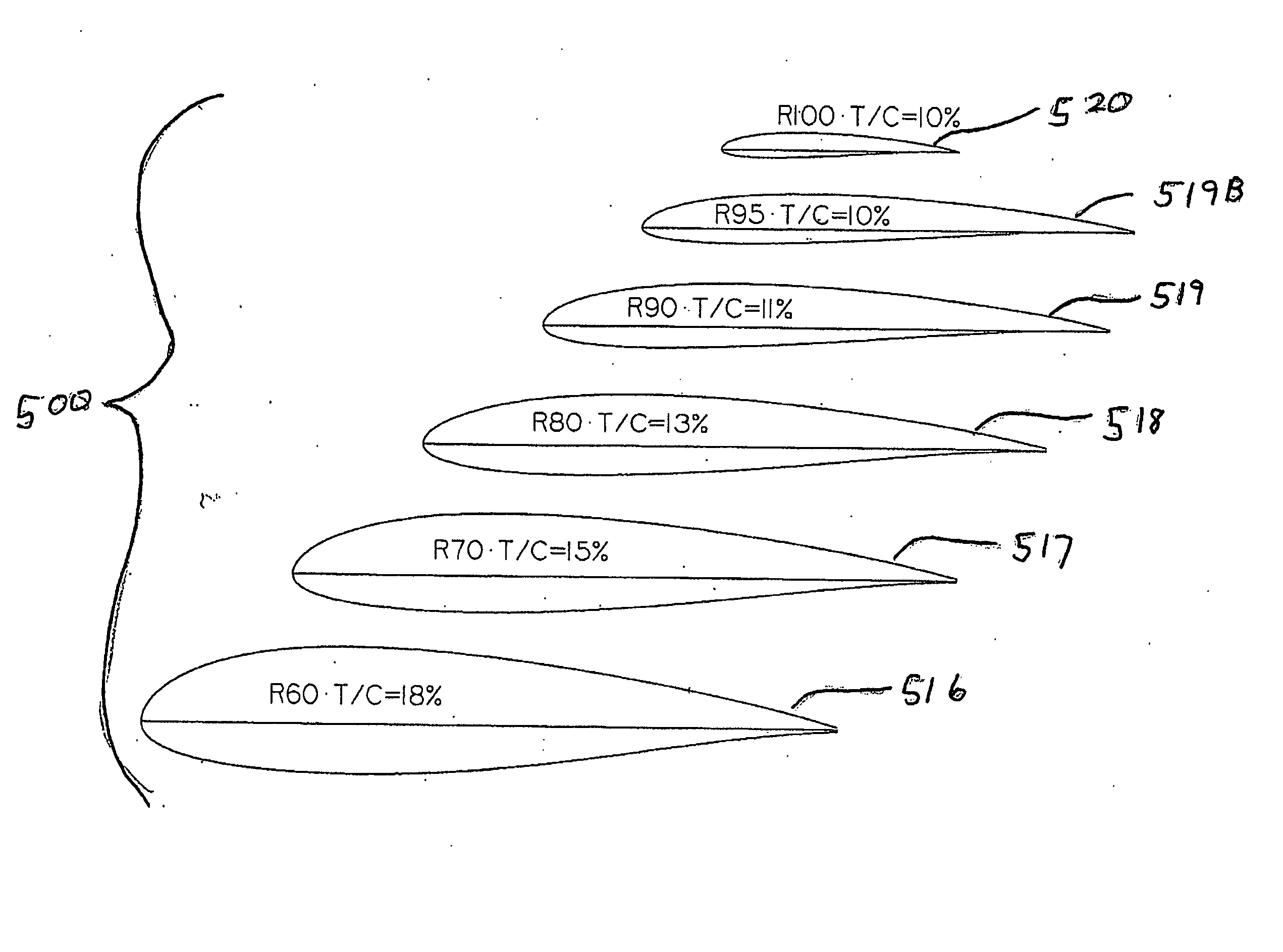

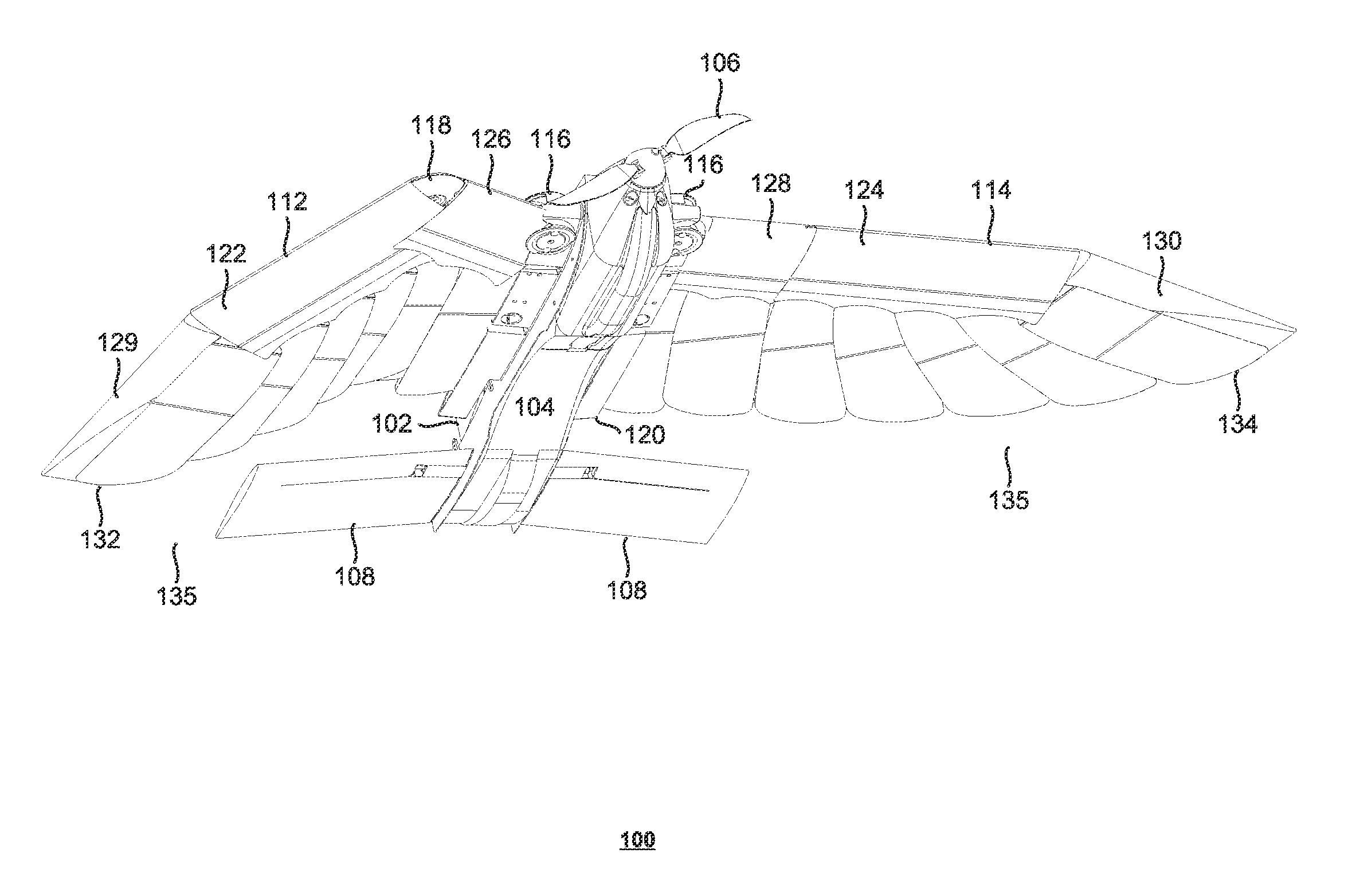

High performance outboard section for rotor blades

ActiveUS20100272576A1Increased maximum take-off weightReduced rotor loadPropellersPump componentsLow noiseRotary wing

Blades for rotorcraft are designed and / or implemented with rotor blades having a swept portion that occupies at least 20-40% of a length of the blade. Forward and aft sweeps are contemplated, with up to 20° or more of sweep. The swept portion preferably has a thickness ration of at least 10-20% at R80, and can have a tapered planform with a relatively outboard section having a smaller chord than a relatively inboard section. Contemplated design methods include optimizing or otherwise designing the rotor blade planform and lift distribution along the blade for efficiency in various flight conditions without taking into account the detrimental effects of high Mach numbers, and then using sweep angle, airfoil thickness and transonic airfoil shaping to maintain the lift distribution, low drag and low noise level at real Mach numbers at the various blade stations at the various flight conditions.

Owner:KAREM ABE

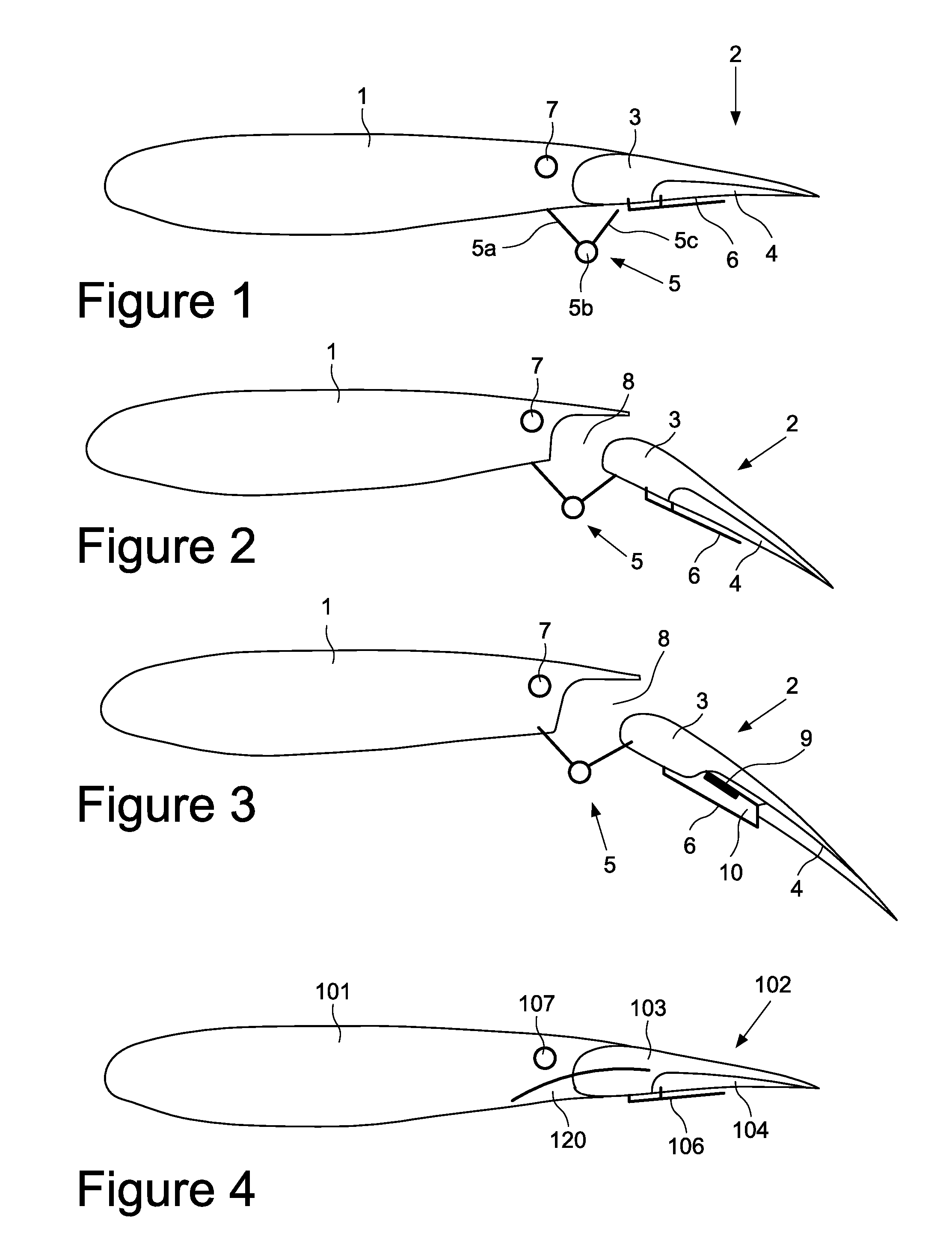

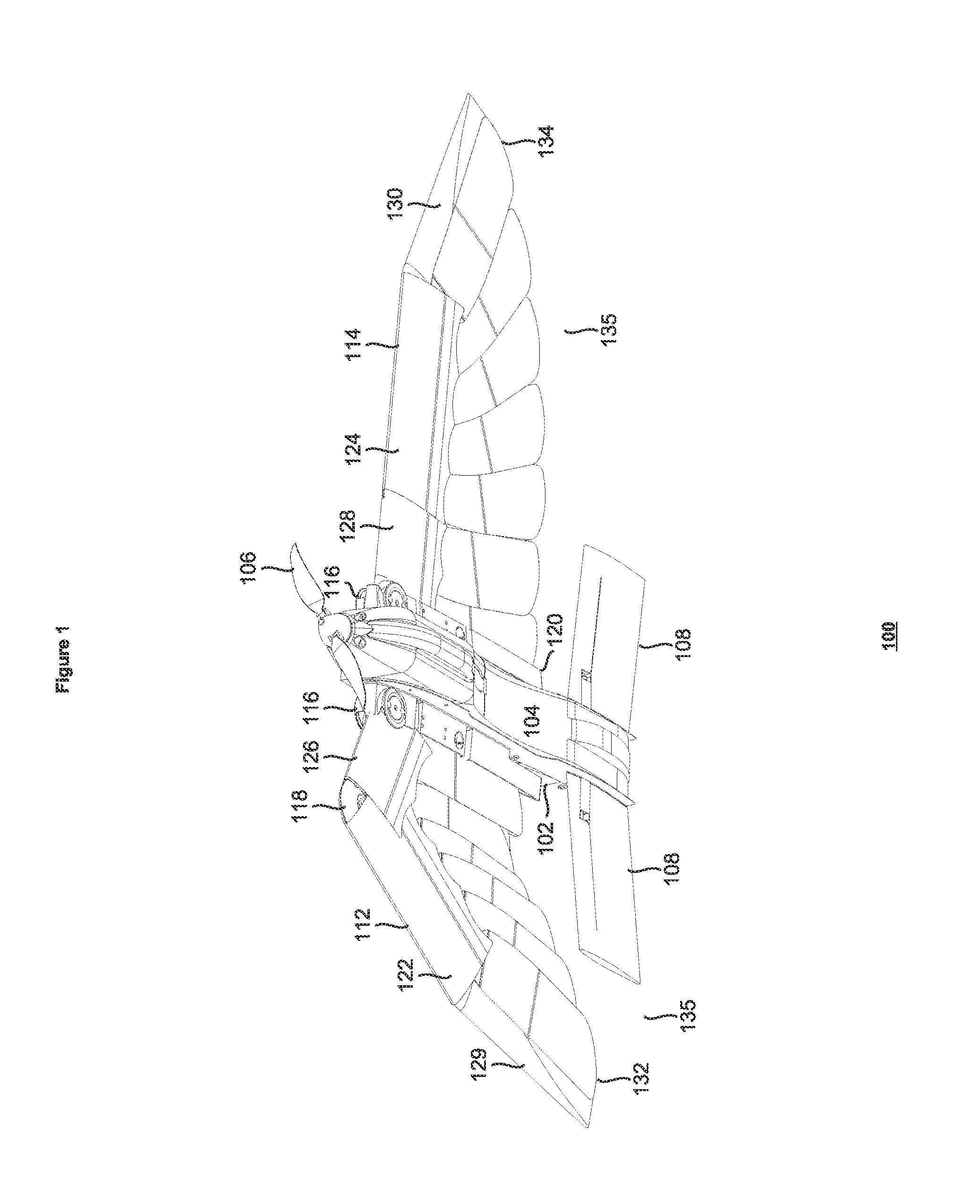

Morphing Foil or Wing

ActiveUS20160176502A1Unmanned aerial vehiclesRemote controlled aircraftLeading edgeVariable geometry

Embodiments of the present invention relate to an adaptable wing having a variable geometry for influencing aerodynamic performance, the wing comprising a jointed leading edge having a main pivot, and a wrist joint, with a wing arm therebetween, 5 and a distal wing hand depending from the wrist joint; the wing being reciprocally actuable, via the main pivot and wrist joint, between a first state having an extended wing planform and a second state having a tucked wing planform.

Owner:BLUE BEAR SYST RES

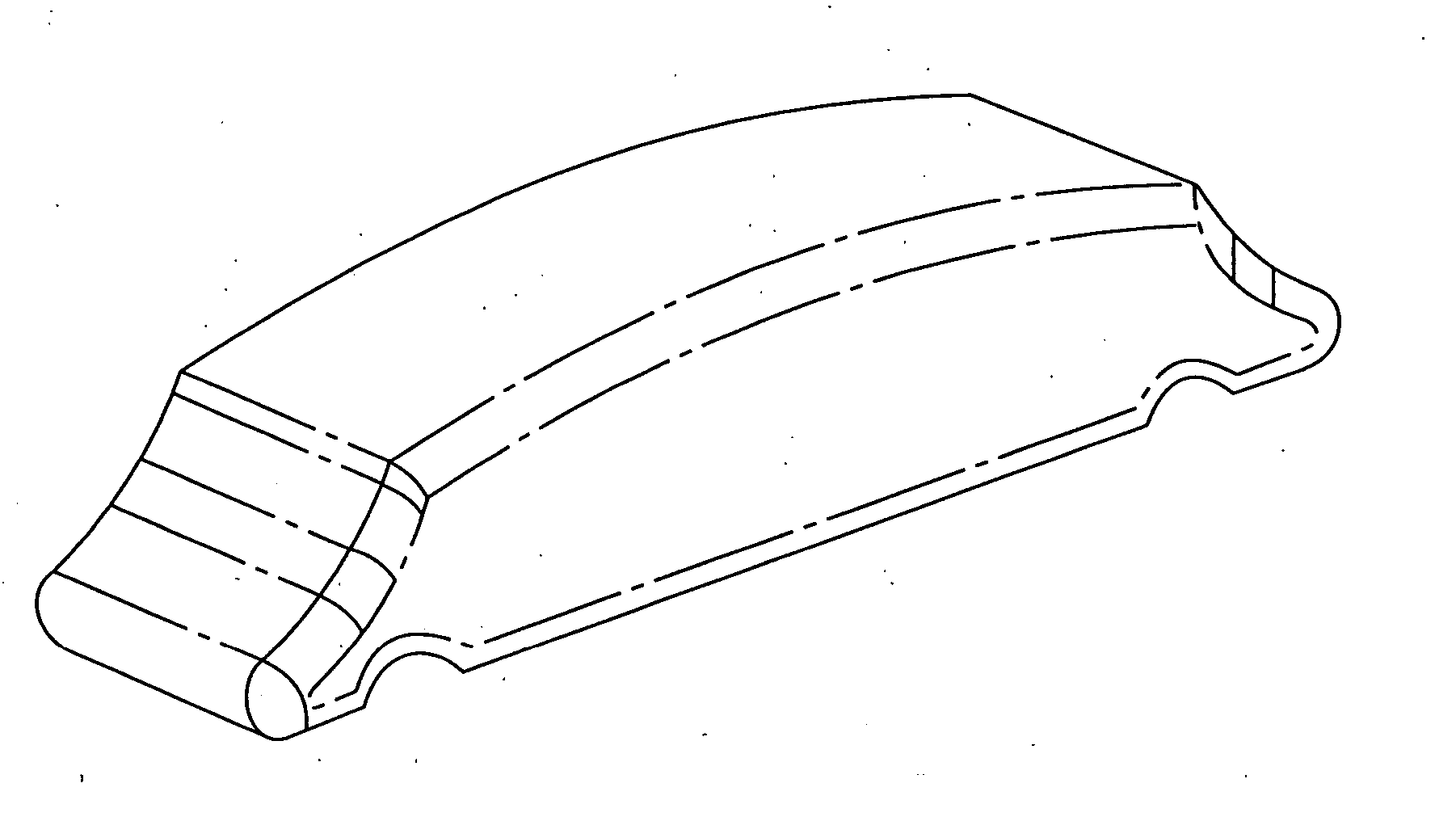

Rotor blade tip planform

ActiveUS7513750B2Improved lift and drag characteristicImprove efficiencyReaction enginesRotocraftEngineeringHigh lift

A main rotor blade incorporating a rotor blade tip region having a tip chord and a tip taper such that the ratio of the main rotor blade chord to the tip chord is approximately 0.30. The tip taper ratio preferably providing an approximately 28% area of reduction in said outer 10% of said blade span. The tip region preferably further including a hover optimized high lift airfoil and a tip sweep that reaches a constant value of approximately 30 degrees along the quarter chord line.

Owner:SIKORSKY AIRCRAFT CORP

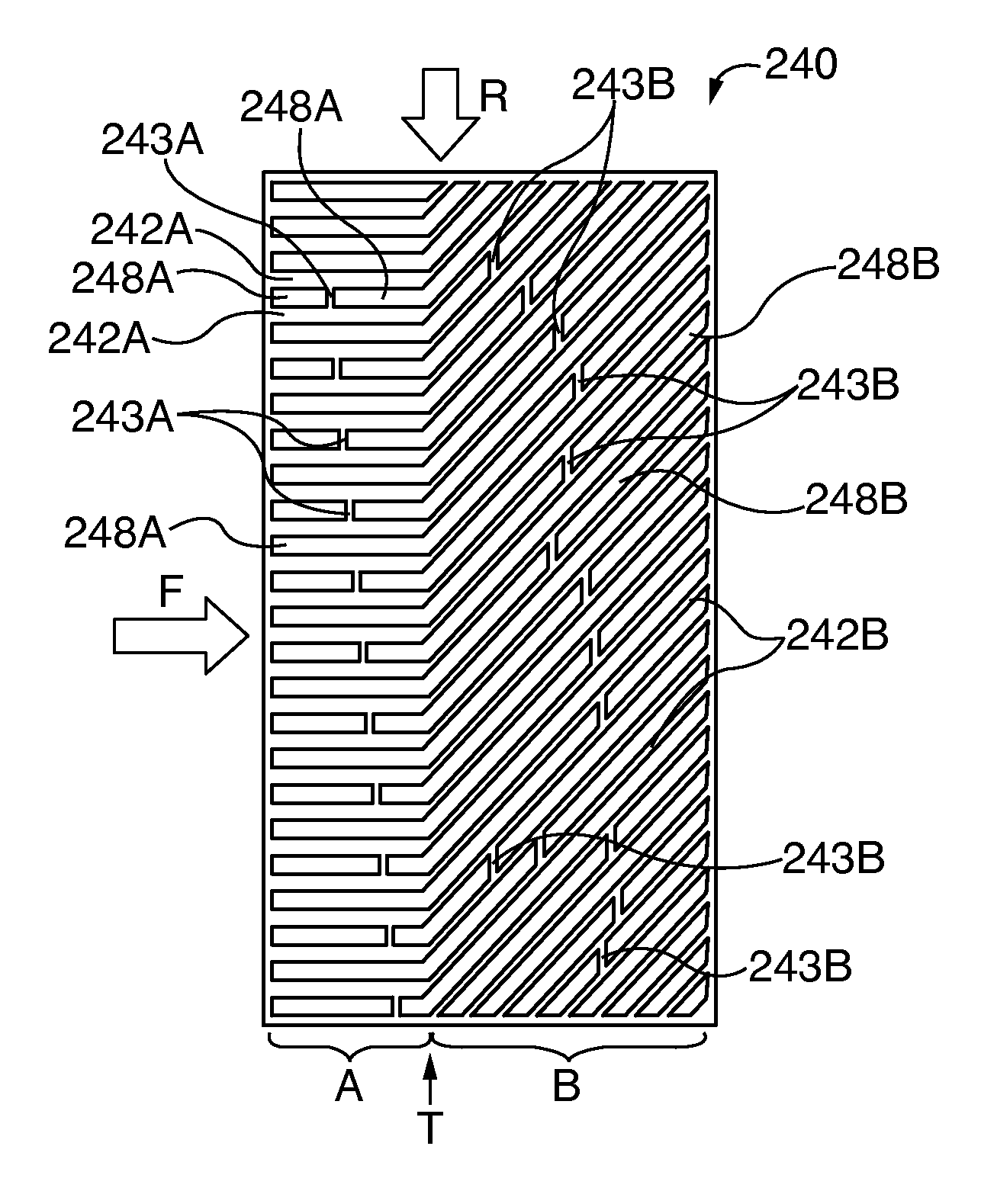

Turbine abradable layer with progressive wear zone multi level ridge arrays

ActiveUS9151175B2Improve efficiencyControl and reduceMolten spray coatingEngine manufactureTurbine bladeHigh pressure

Turbine and compressor casing abradable component embodiments for turbine engines, with composite grooves and vertically projecting alternating rows of first and second height ridges in planform patterns, to reduce, redirect and / or block blade tip airflow leakage downstream into the grooves rather than from turbine blade airfoil high to low pressure sides. The first ridges have a first ridge height greater than that of the second ridges. These ridge or rib embodiments have first lower and second upper wear zones. The lower zone, at and below the second ridge height, optimizes engine airflow characteristics, while the upper zone, between tips of the second and first ridges, is optimized to minimize blade tip gap and wear by being more easily abradable than the lower zone.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

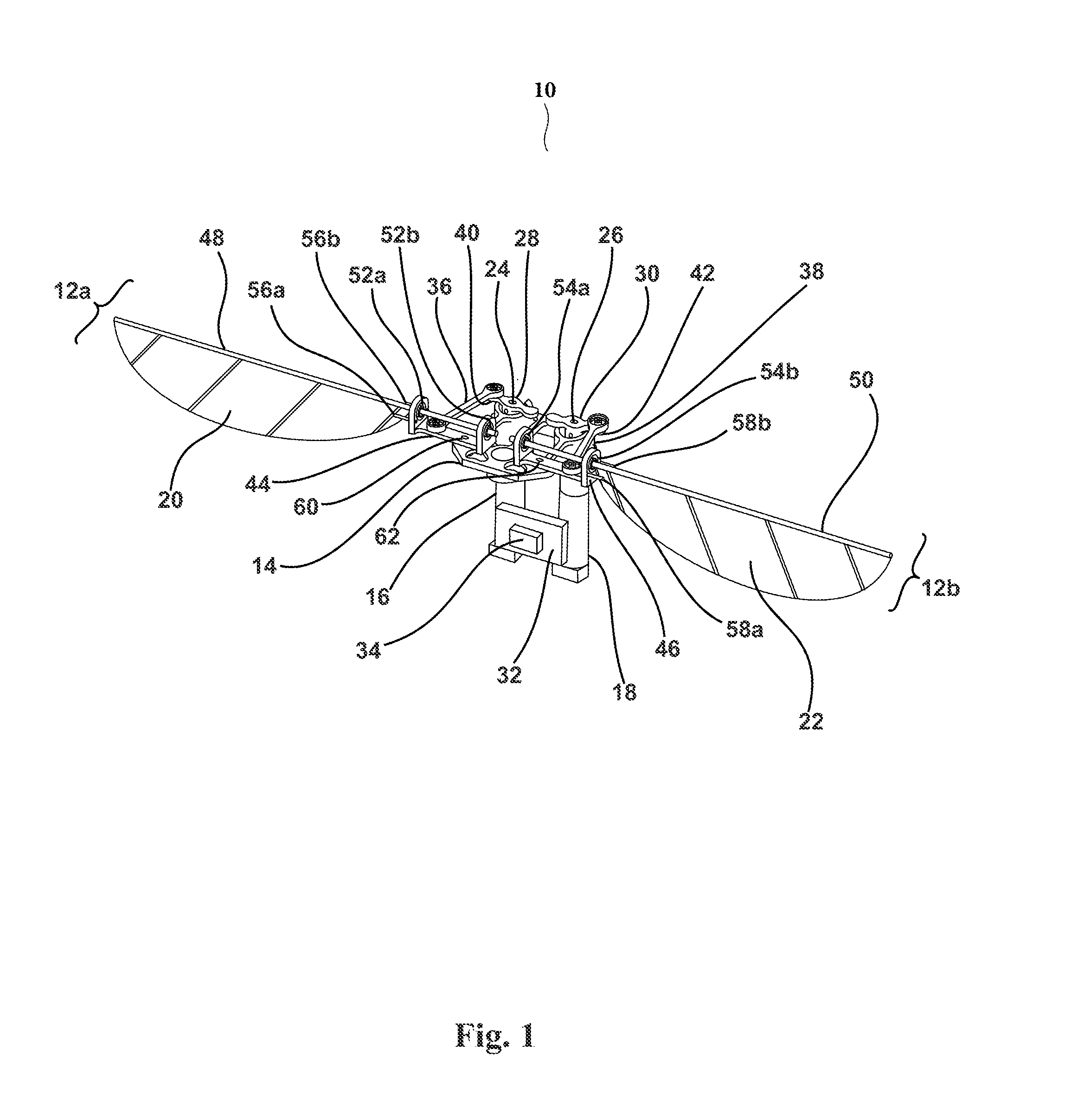

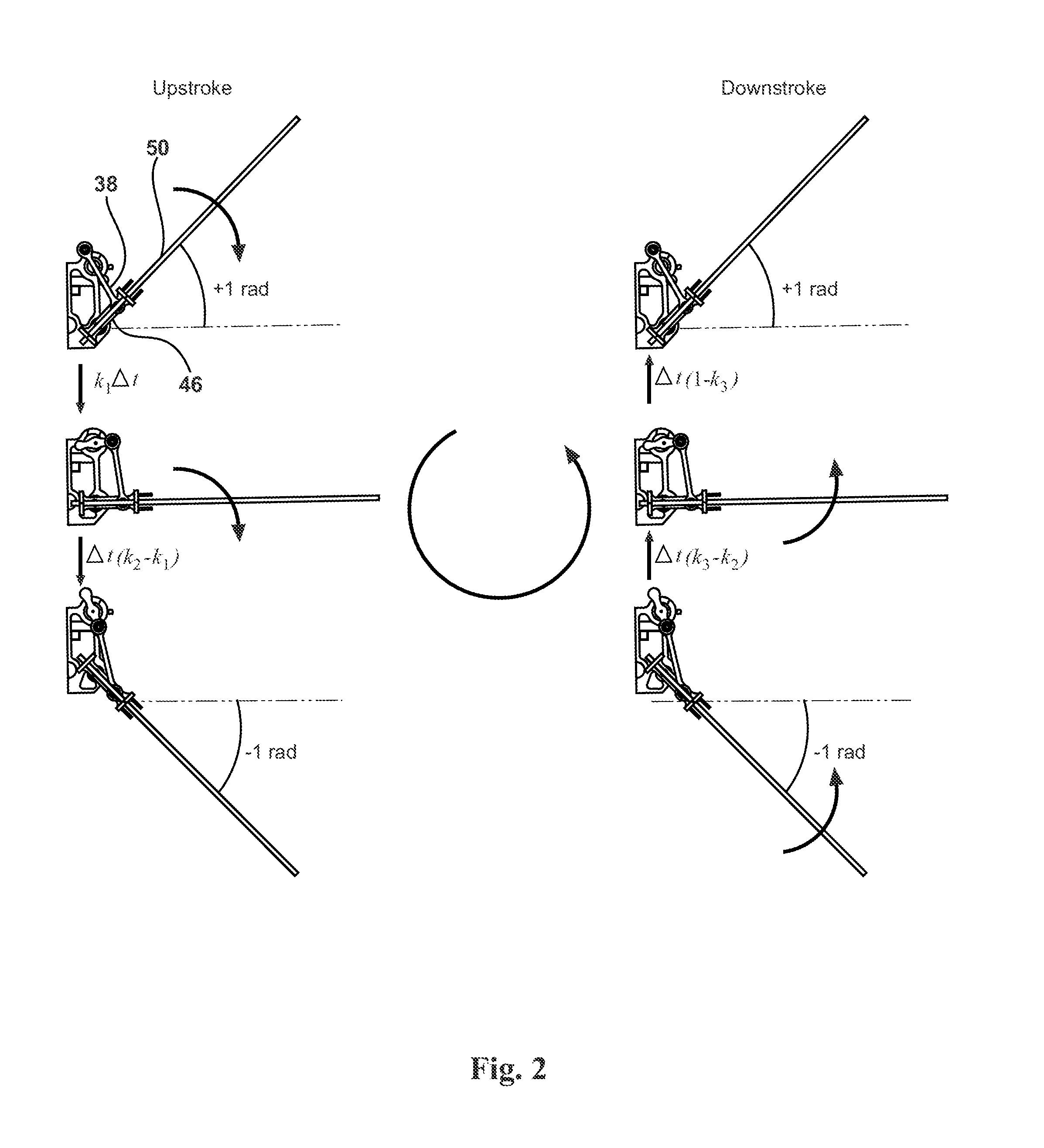

Methods and apparatus to achieve independent six degree control of flapping wing micro air vehicle

A method of configuring a wing velocity profile includes segmenting a complete wingbeat cycle into a set of quarter-strokes including a first quarter-stroke, a second quarter-stroke, a third quarter-stroke, and a fourth quarter-stroke. The method further includes generating time-varying quarter-stroke wing position commands for each of a first and second wing planforms to produce wing flapping trajectories that generate non-zero, cycle averaged wing lift and drag and alter a cycle average center of pressure of each of the first and the second wing planforms relative to the aircraft. The wing position commands include velocities and positions with temporally symmetric and asymmetric quarter-stroke components for the first wing planform and the second wing planform. The first wing planform and the second wing planform produce controlled six-degrees-of freedom vehicle motion without using actuators in excess of the first actuator and the second actuator.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

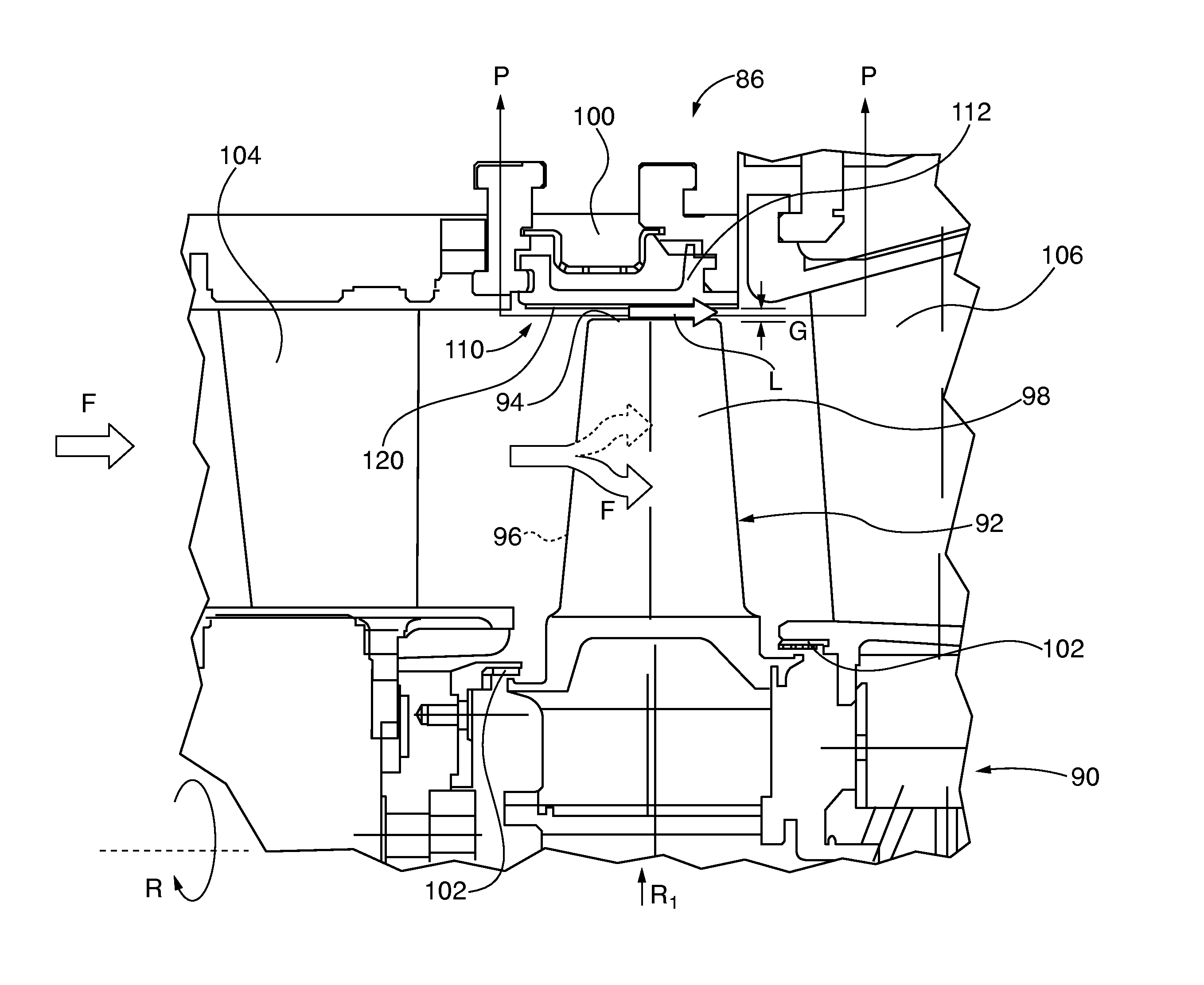

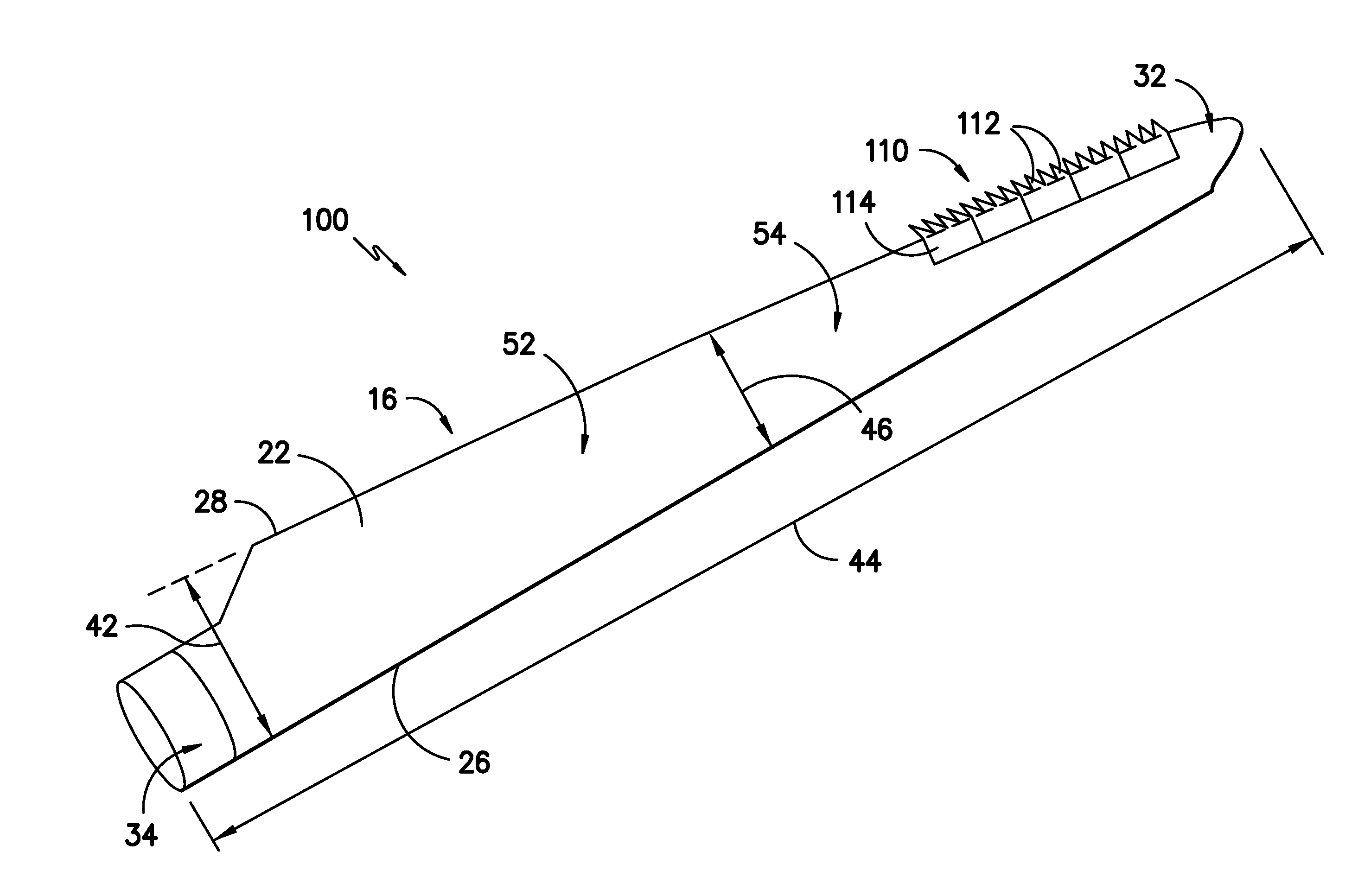

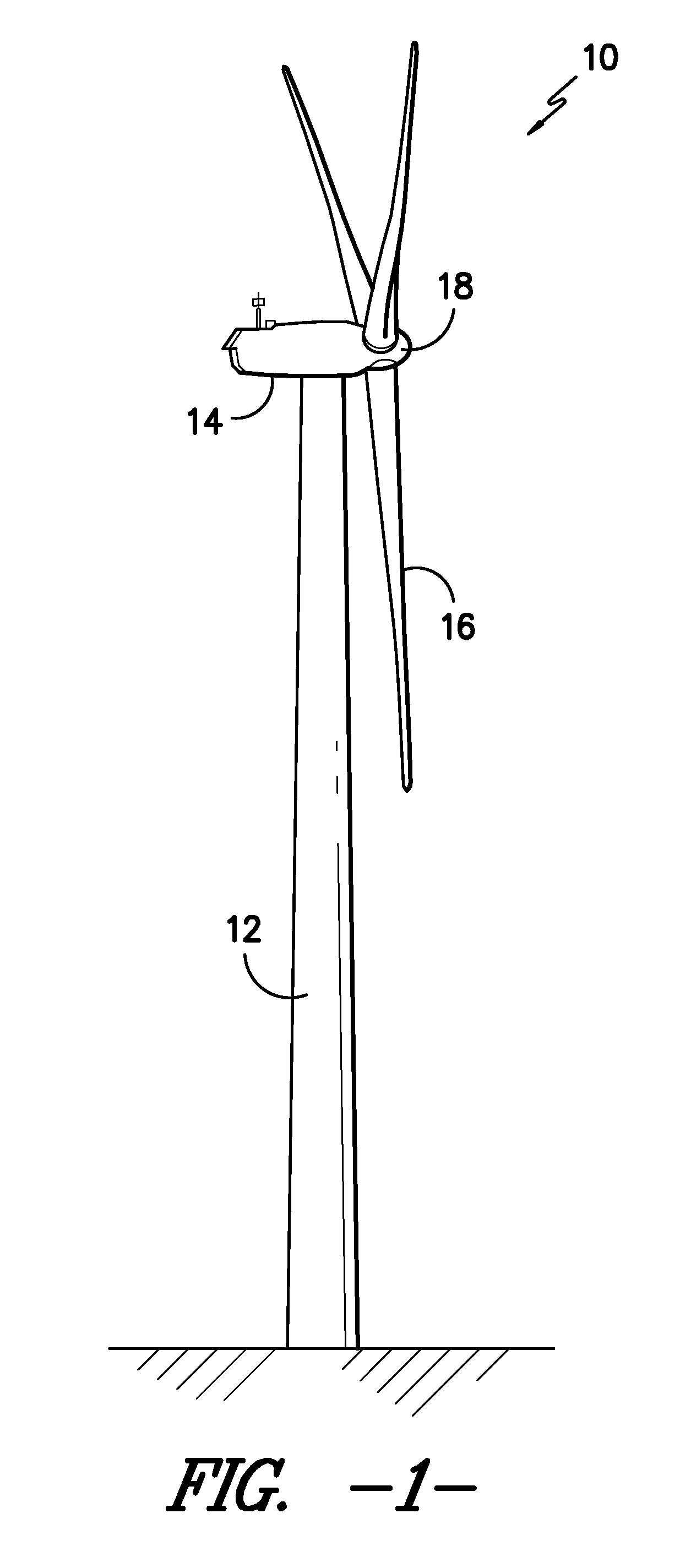

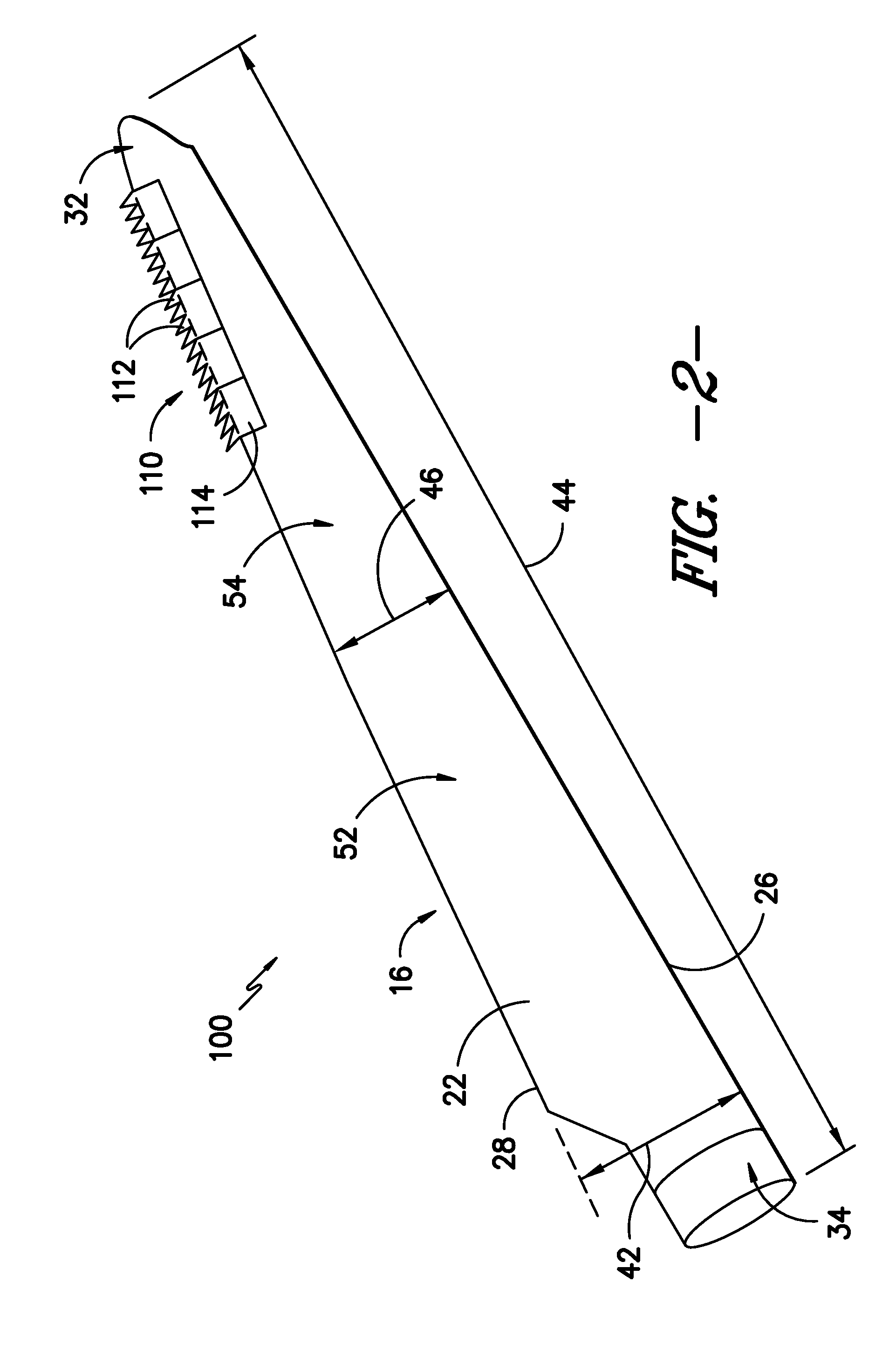

Flow modification device for rotor blade in wind turbine

A rotor blade assembly for a wind turbine is disclosed. In one embodiment, the rotor blade assembly includes a rotor blade having exterior surfaces defining a pressure side, a suction side, a leading edge, and a trailing edge extending between a tip and a root. The rotor blade further defines a span and a chord. The rotor blade assembly further includes a noise reducer configured on an exterior surface of the rotor blade. The noise reducer includes a plurality of noise reduction features. Each of the plurality of noise reduction features defines a centerline. In a planform view, the centerline of each of the plurality of noise reduction features is approximately parallel to a local flow streamline for that noise reduction feature at the trailing edge of the rotor blade.

Owner:GENERAL ELECTRIC CO

Aircraft with dual flight regimes

InactiveUS8690096B2Remove asymmetryLow aircraft dragPropellersPump componentsCircular discClassical mechanics

The aircraft is capable of two distinct fuel-efficient flight regimes: one is a vertical flight regime supported by two large two-bladed rotors with low disc loading located on right and left longitudinal booms. The booms extend between outboard regions of a front wing and inboard regions of a rear wing that has a larger span an area than the front wing. The other flight regime is high speed up to high subsonic Mach number with the aircraft supported by wing lift with high wing loading, and with the rotors stopped and faired with minimal local drag contiguous to the booms. The longitudinal location of the aircrafts center of gravity, aerodynamic center and the center of the rotors are in close proximity. The front wing is preferably swept back, and the rear wing is preferably of W planform.

Owner:ALVAREZ CALDERON F ALBERTO

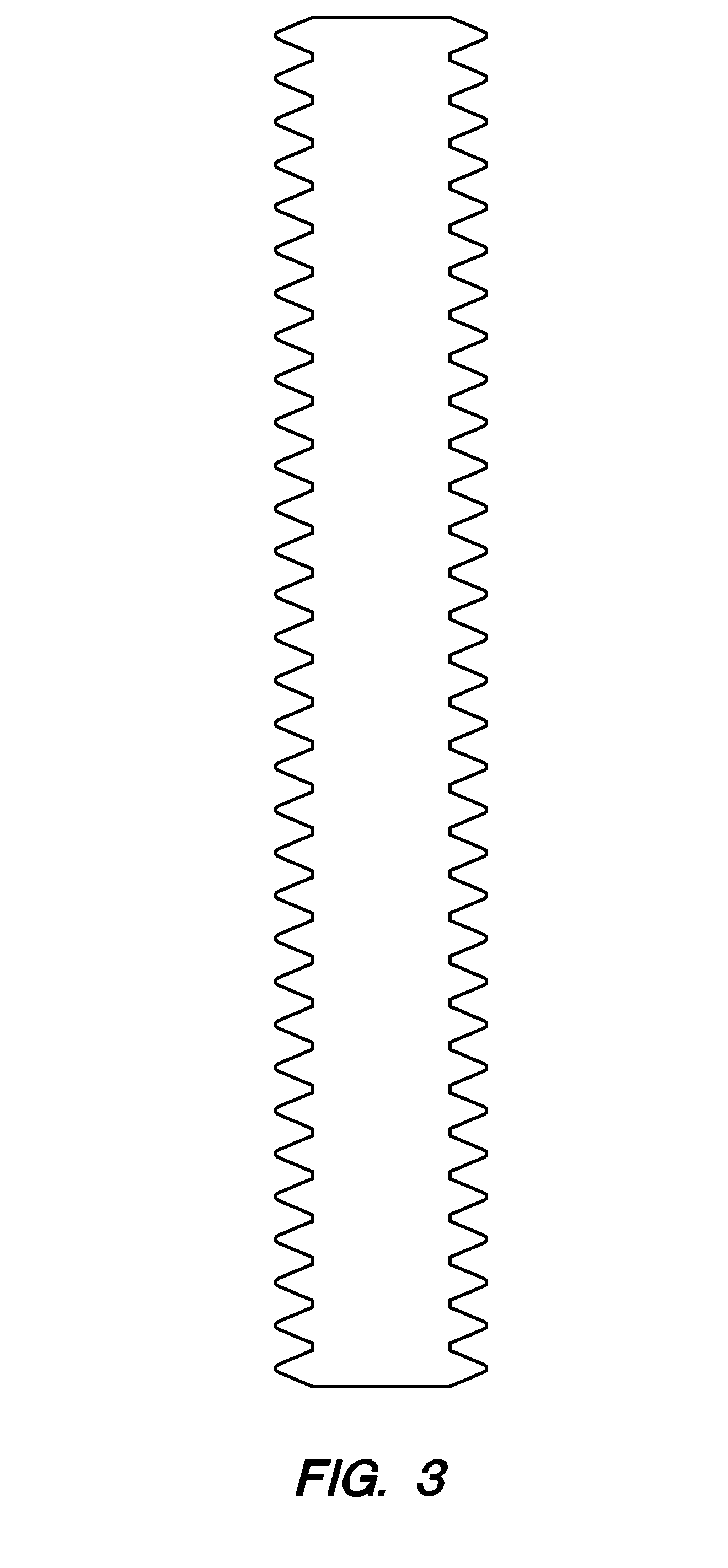

Turbine abradable layer with zig zag groove pattern

ActiveUS9243511B2Improve efficiencyControl and reduceEngine manufactureBlade accessoriesTurbine bladeHigh pressure

Turbine and compressor casing abradable component embodiments for turbine engines, with zig-zag pattern abradable surface ridges and grooves. Some embodiments include distinct forward upstream and aft downstream composite multi orientation groove and vertically projecting ridges planform patterns, to reduce, redirect and / or block blade tip airflow leakage downstream into the grooves rather than from turbine blade airfoil high to low pressure sides. Ridge or rib embodiments have first lower and second upper wear zones. The lower zone optimizes engine airflow characteristics while the upper zone is optimized to minimize blade tip gap and wear by being more easily abradable than the lower zone.

Owner:SIEMENS AG

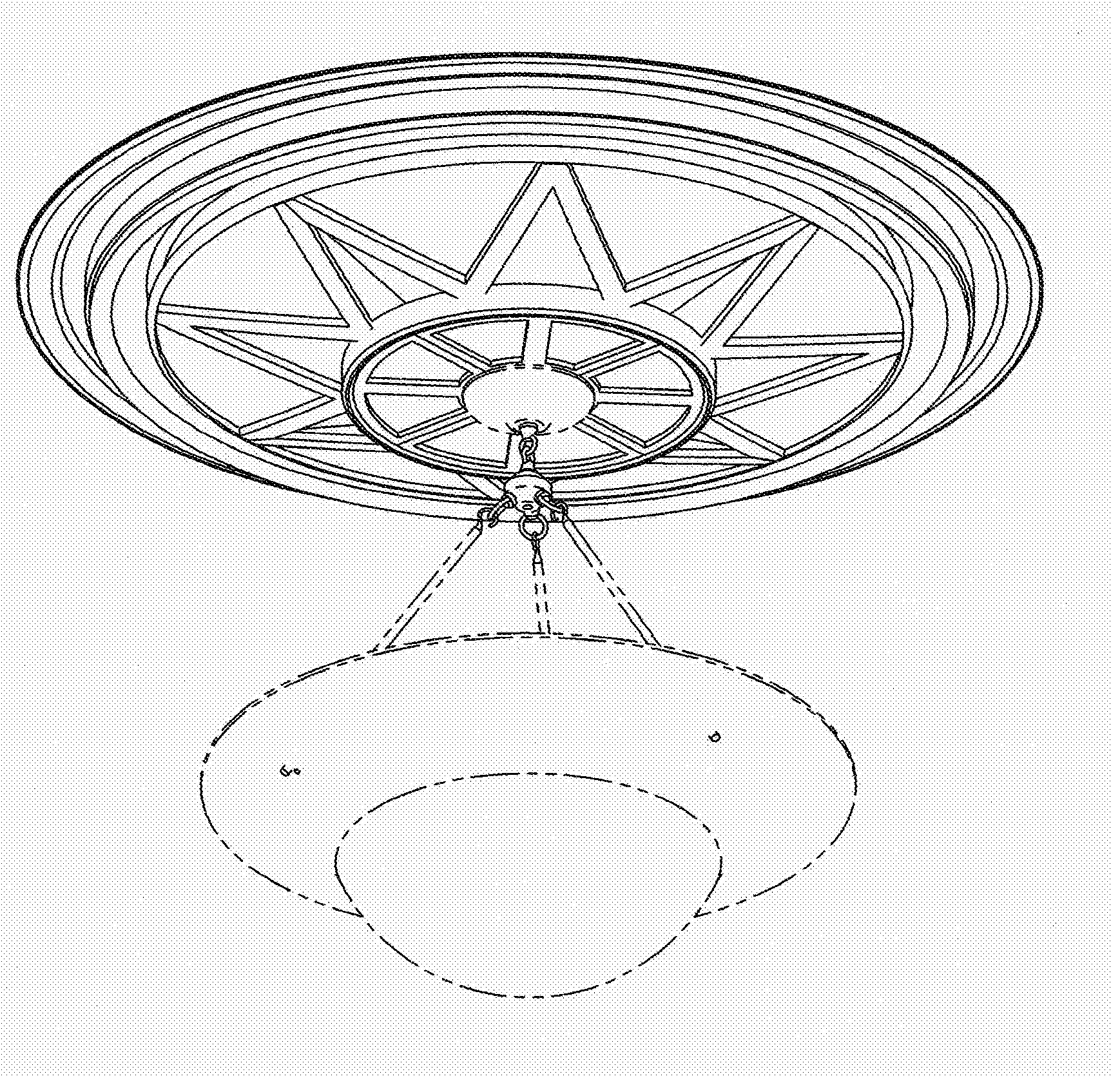

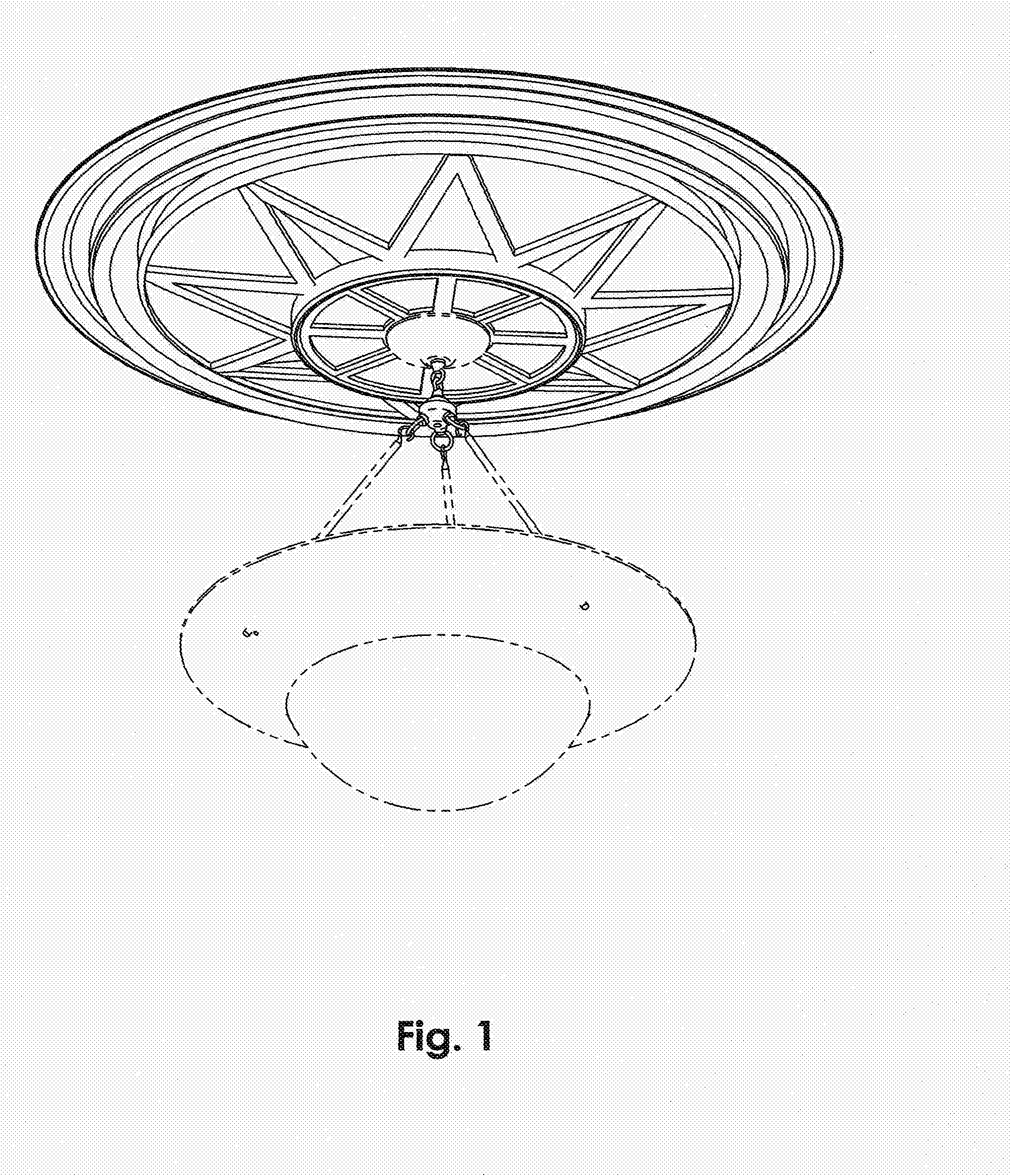

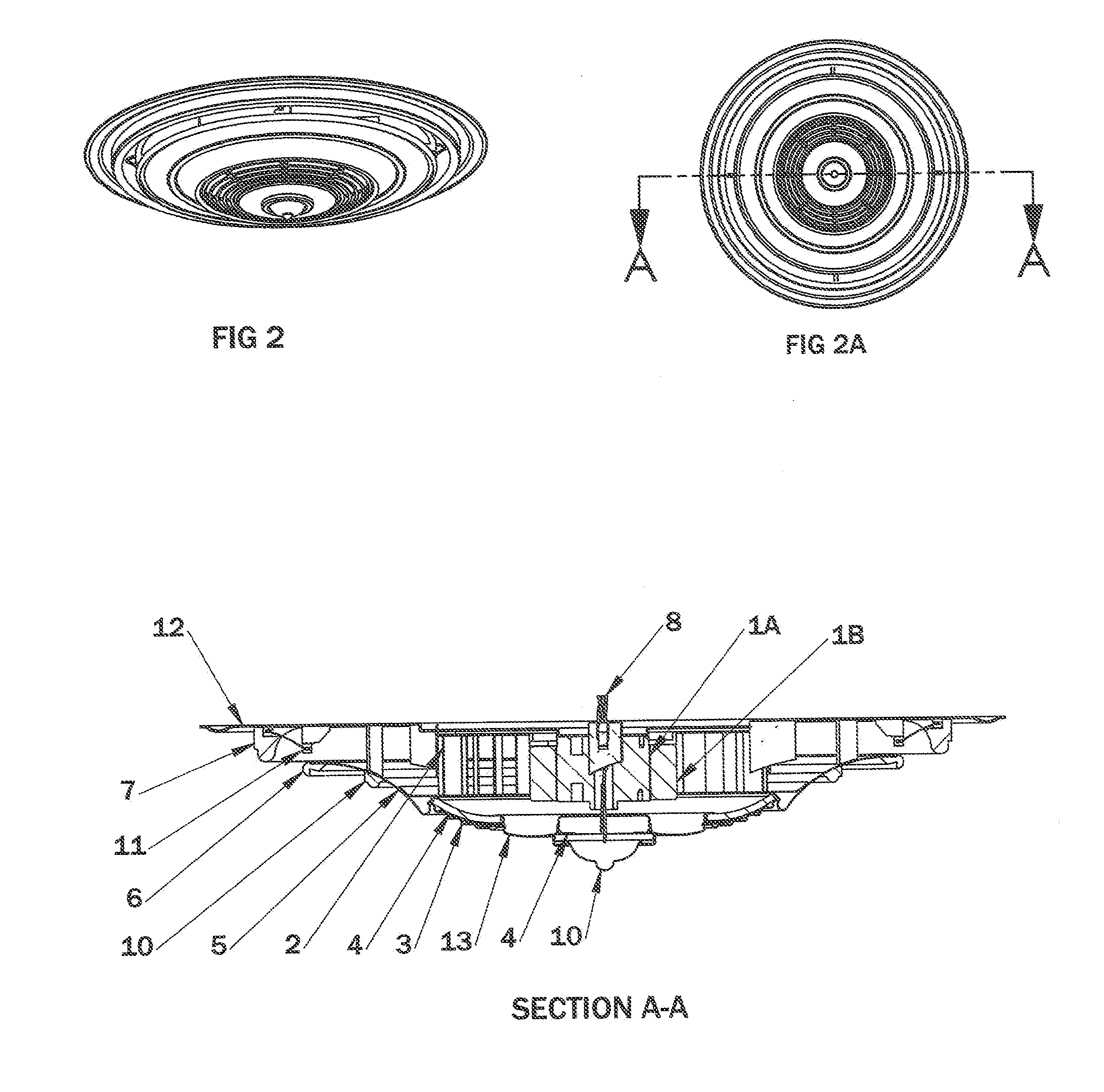

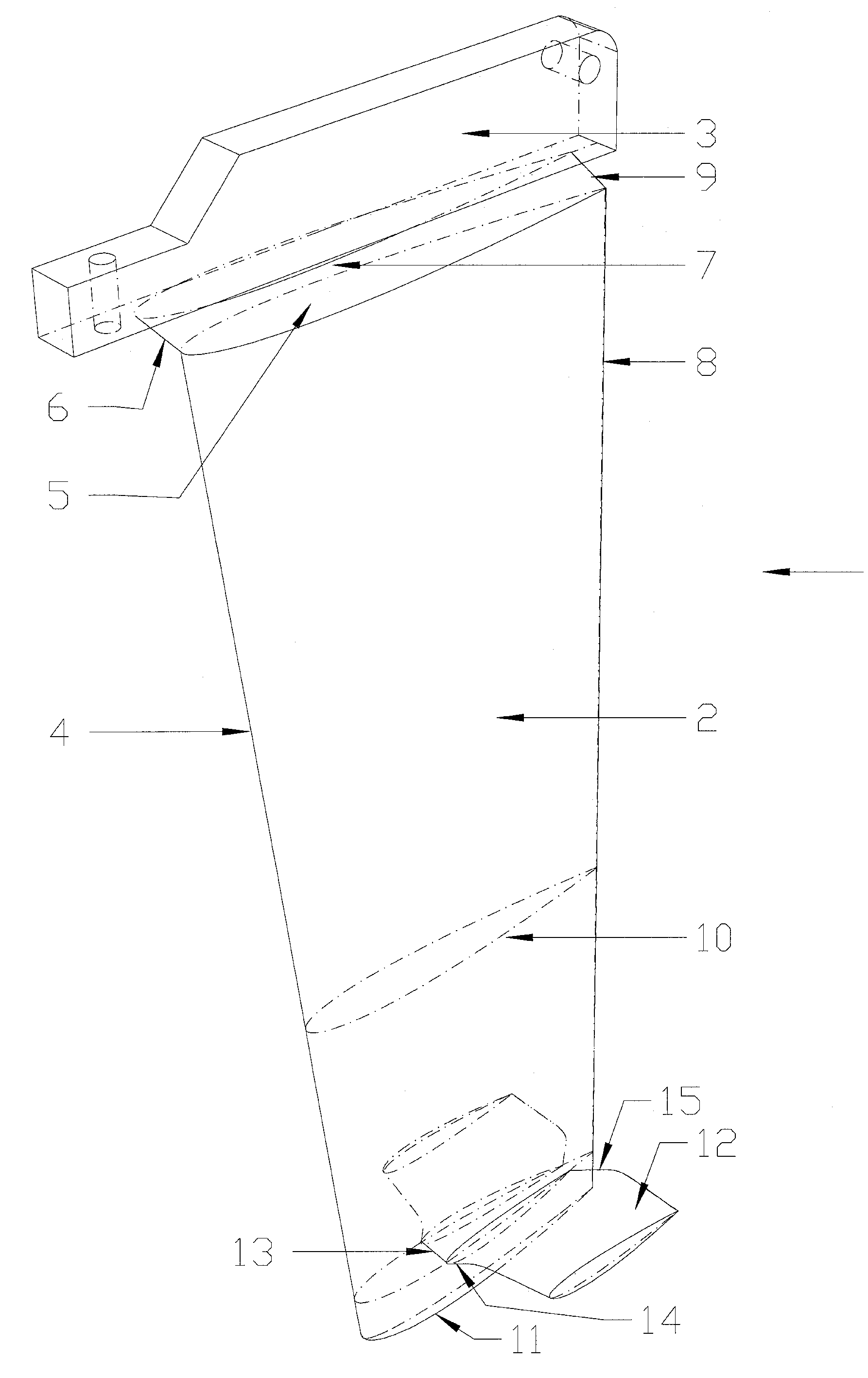

Medallion Fan

This invention relates to a ceiling mounted air circulating apparatus comprising, in combination: a motor; an essentially centrally located radial or axial air impeller; air guiding means; optional airflow enhancement by means of air amplification means; an optional centrally located wiring path from an electrical power source to a wiring enclosure suitable for hanging a lighting fixture or chandelier; and decorative embellishments, all of which are arranged to blend with the architectural style of a space in a manner similar to a decorative ceiling medallion, the planform of which, when viewed from below may be circular, rectangular, or polygonal. Optionally, the apparatus of the present invention may embody any of the following; heating, cooling, filtration means, positive ion generation means, and / or air sterilization means.

Owner:HUNTER FAN

High-lift, low drag fin for surfboard and other watercraft

ActiveUS7244157B2Easy to liftReduce resistanceWater sport boardsFloating buildingsLeading edgeEngineering

This invention discloses a fin, for use on a surfboard and other watercraft, of a low-drag, high-lift, high-aspect-ratio, low-sweepback-angle planform of symmetrical foil section, with a fit root section that has a forwardly projecting leading edge and cutaway at the trailing edge, alone or in combination with winglets placed on the vertical fin element so as to minimize tip-vortex drag, so as to make the surfboard or watercraft more maneuverable, easier to propel through the water, and to stabilize the surfboard or watercraft.

Owner:WAVEGRINDER

Turbine abradable layer with zig zag groove pattern

ActiveUS20150240653A1Enhance engine efficiency performanceReducing and controlling blade tip gapEngine manufacturePump componentsTurbine bladeHigh pressure

Turbine and compressor casing abradable component embodiments for turbine engines, with zig-zag pattern abradable surface ridges and grooves. Some embodiments include distinct forward upstream and aft downstream composite multi orientation groove and vertically projecting ridges planform patterns, to reduce, redirect and / or block blade tip airflow leakage downstream into the grooves rather than from turbine blade airfoil high to low pressure sides. Ridge or rib embodiments have first lower and second upper wear zones. The lower zone optimizes engine airflow characteristics while the upper zone is optimized to minimize blade tip gap and wear by being more easily abradable than the lower zone.

Owner:SIEMENS AG

Aircraft configuration for micro and mini uav

An aircraft arrangement for Mini or Micro UAV comprising a fore wing (14) and an aft wing (12) in tandem closed-coupled arrangement. The aft wing (12) has side panels (18) and control surfaces (19), and tapered planform with positive sweep, while the fore wing (14) has non-positive trailing edge sweep. The fore wing (14) and the aft wing (12) are disposed at different height, and the aircraft arrangement has no other wings or tail arrangements.

Owner:ISRAEL AEROSPACE IND

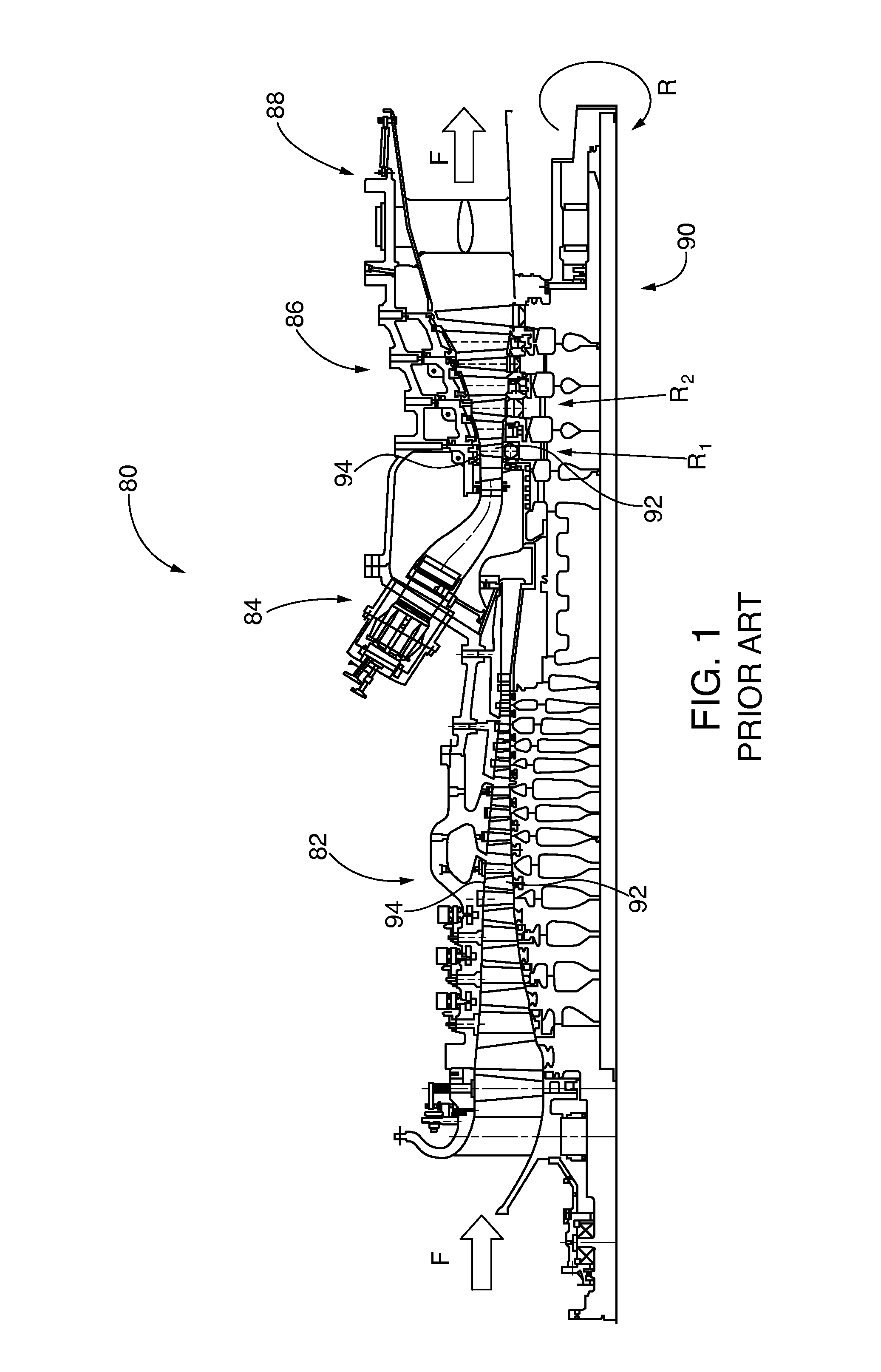

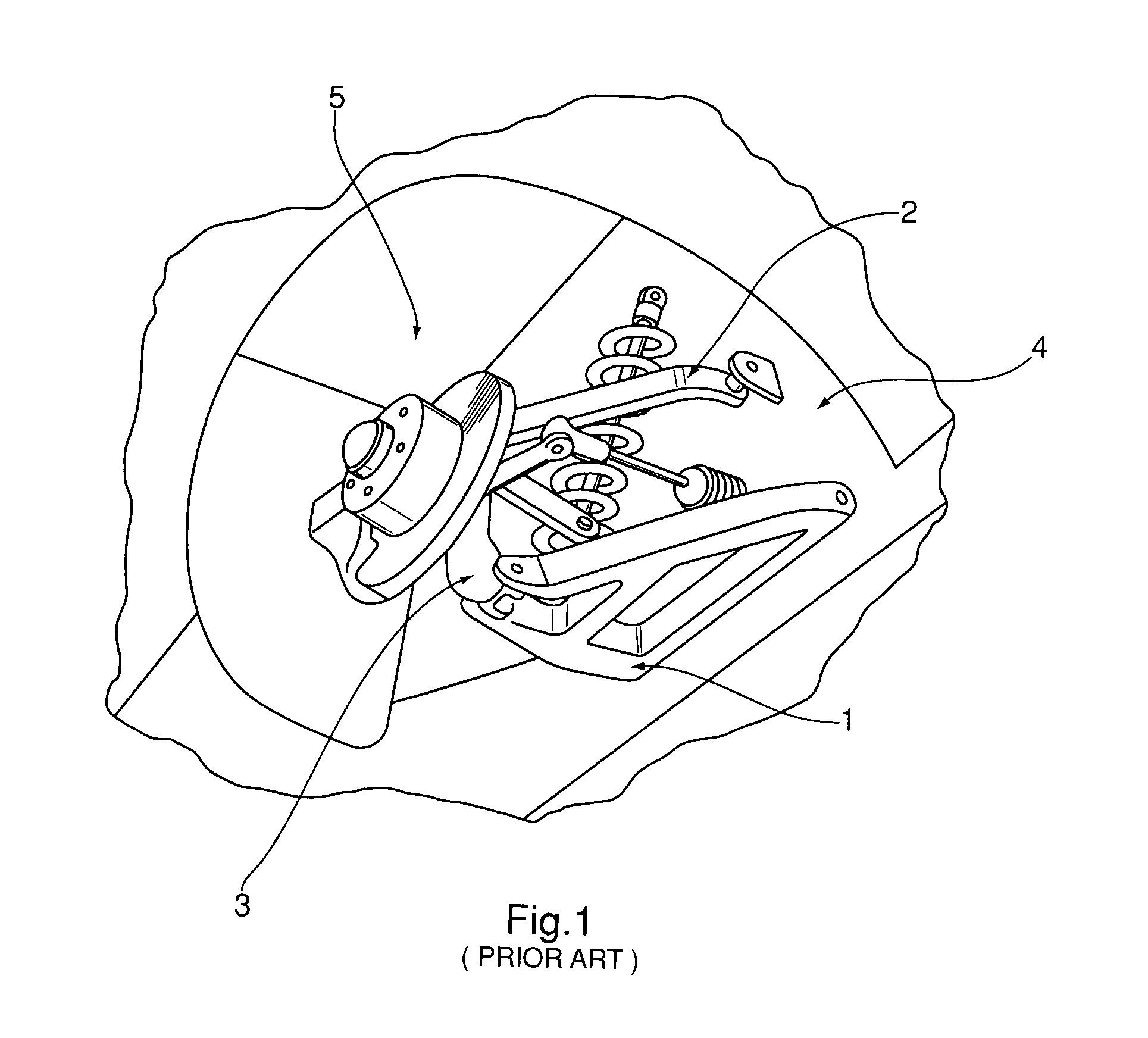

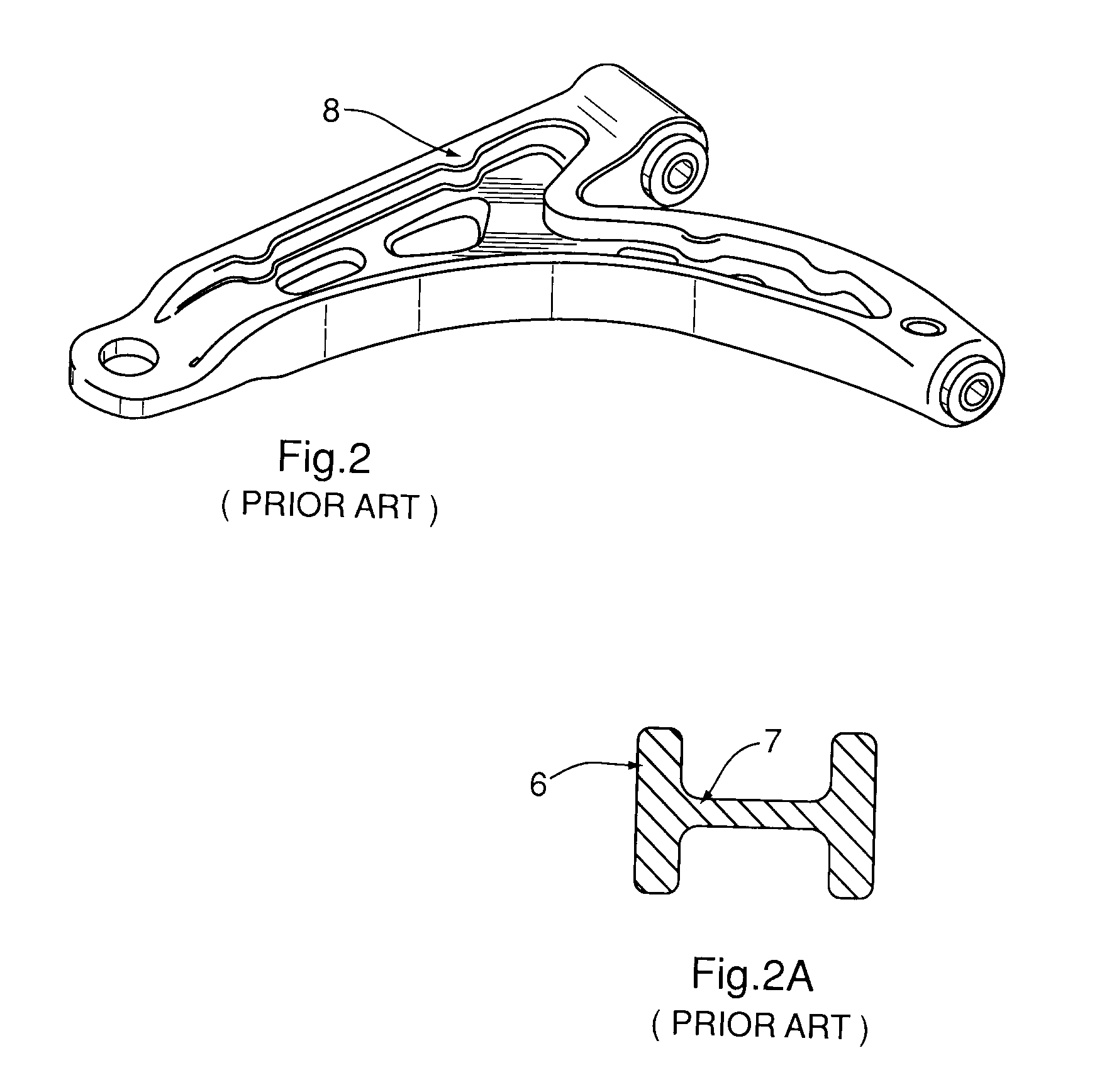

Structural i-beam automotive suspension arm

ActiveUS20100264615A1High inherent stiffness and strengthReduce quality problemsResilient suspensionsPivoted suspension armsControl armI-joist

A structural element comprising a vehicle suspension control arm is constructed from a complex, single piece, sheet metal stamped component formed from a material of uniform thickness. The stamping is configured with the correct plan view shape and formed into an I-beam cross-section comprising a central web portion and two flange portions. The central web portion is configured as a single material thickness and the flange portions comprise upstanding and downstanding closed sections with a continuous double returned segment. The open ends of the sheet metal terminate at or near the central web portion and are welded to the web portion, and in an alternative embodiment also to the continuous double returned segment, to create a favorable structural I-beam section with flange portions twice the thickness of the web portion.

Owner:MULTIMATIC INC

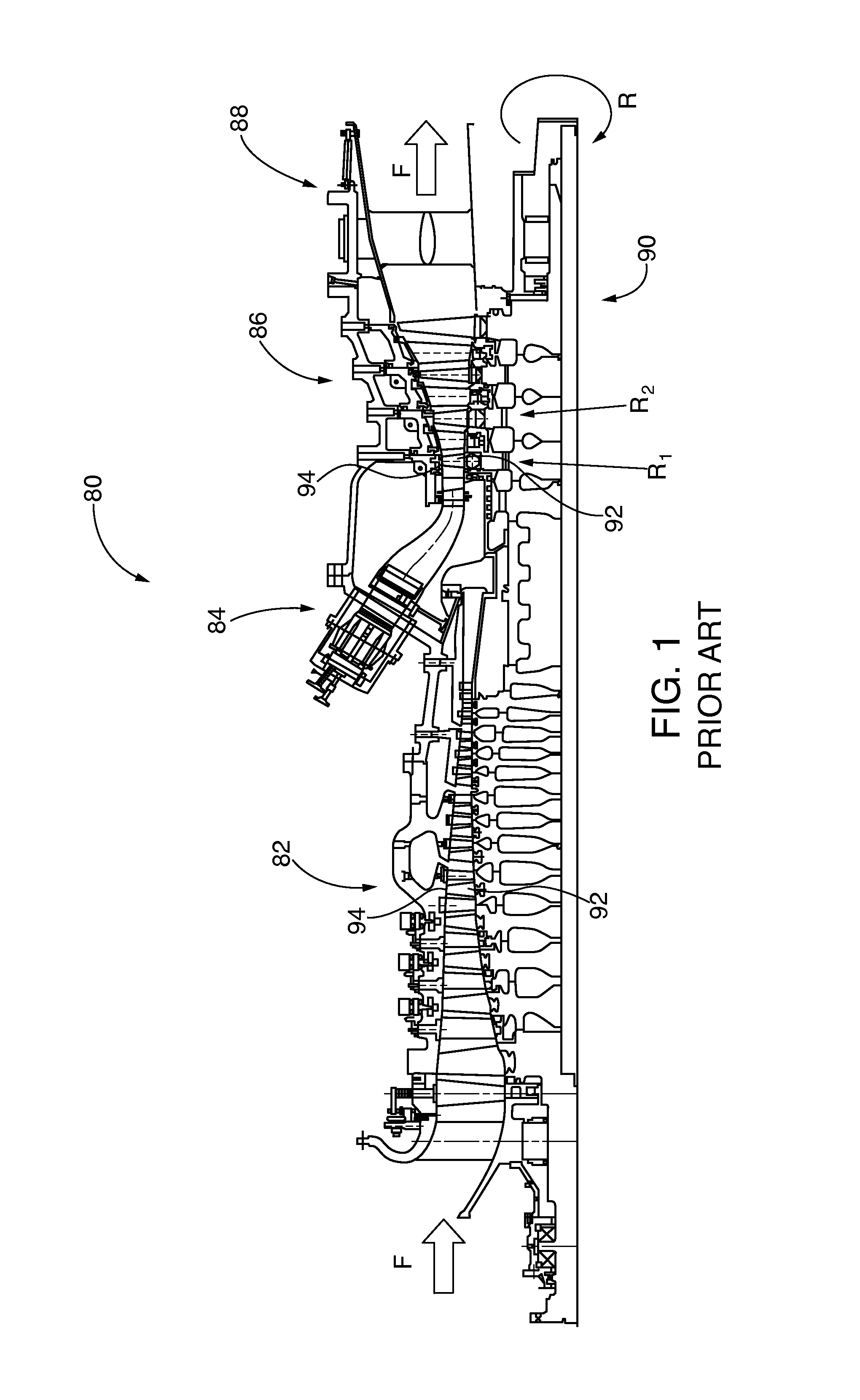

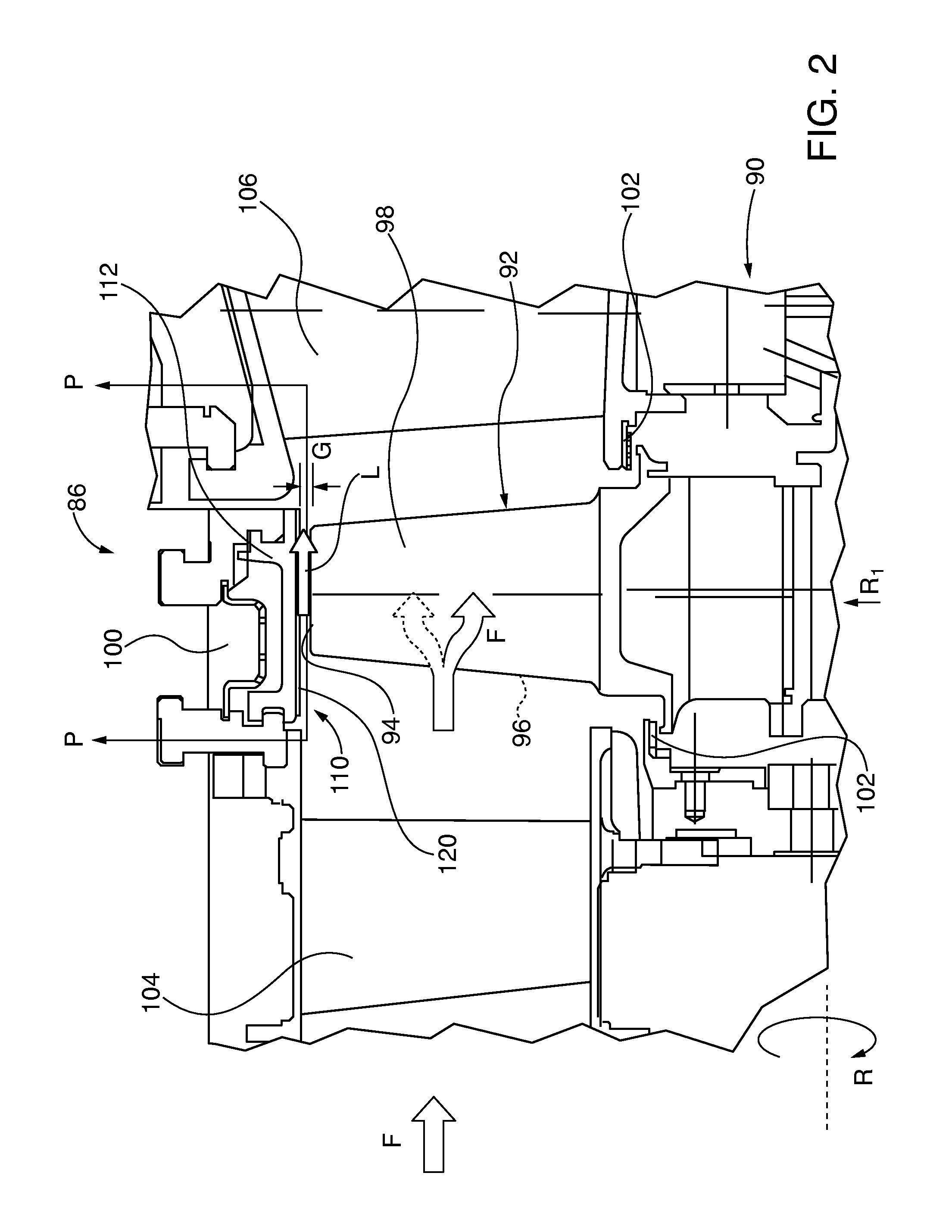

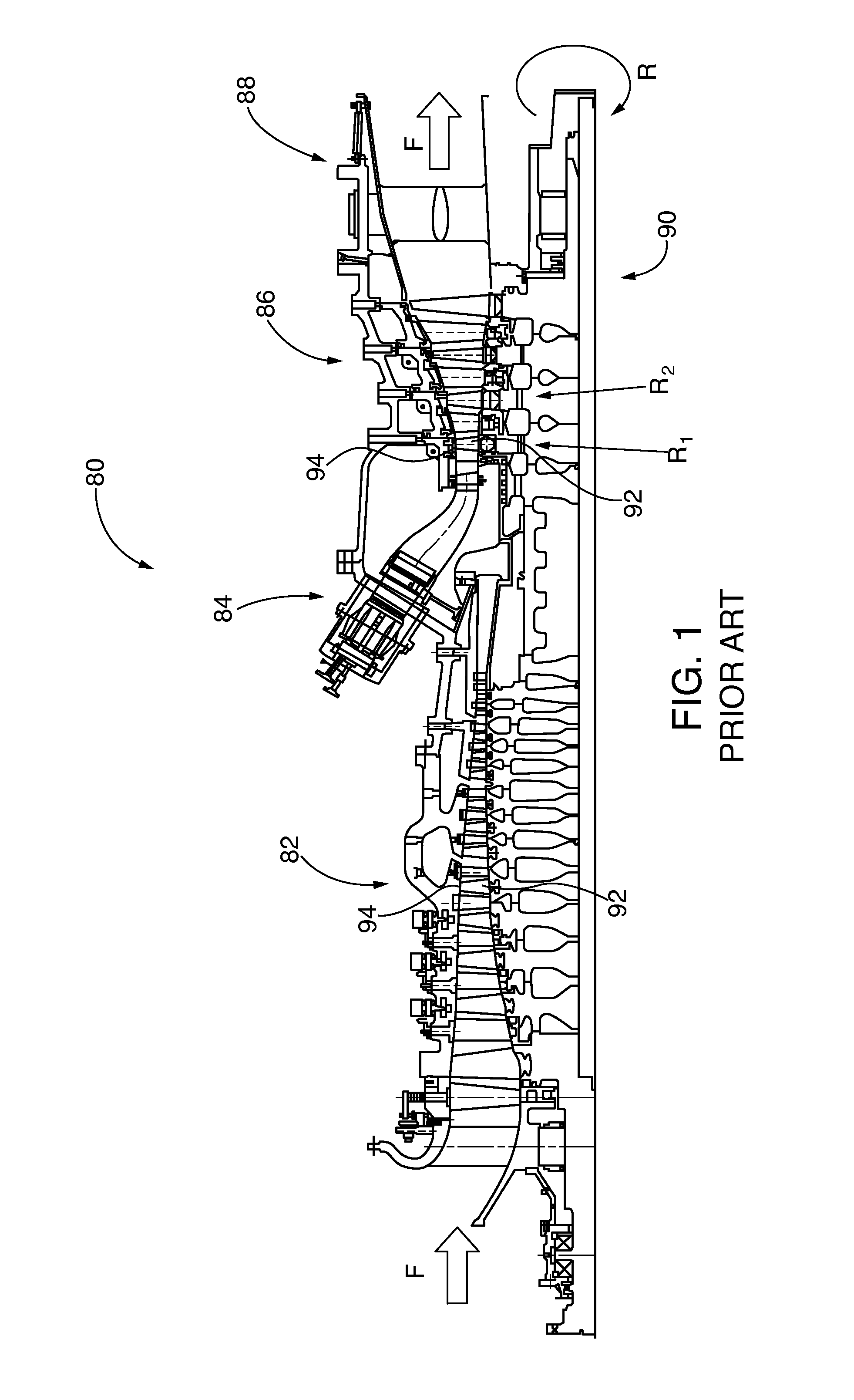

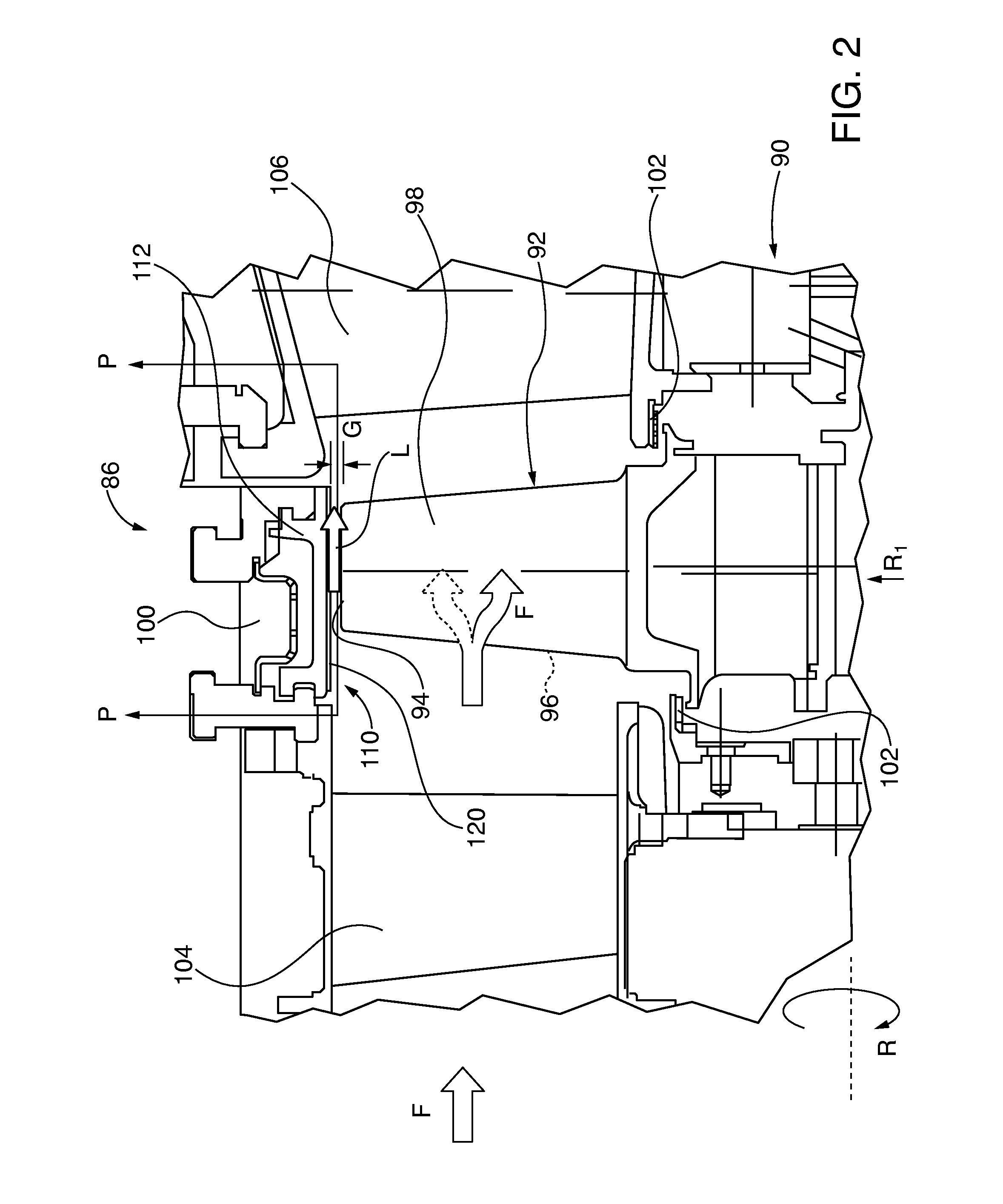

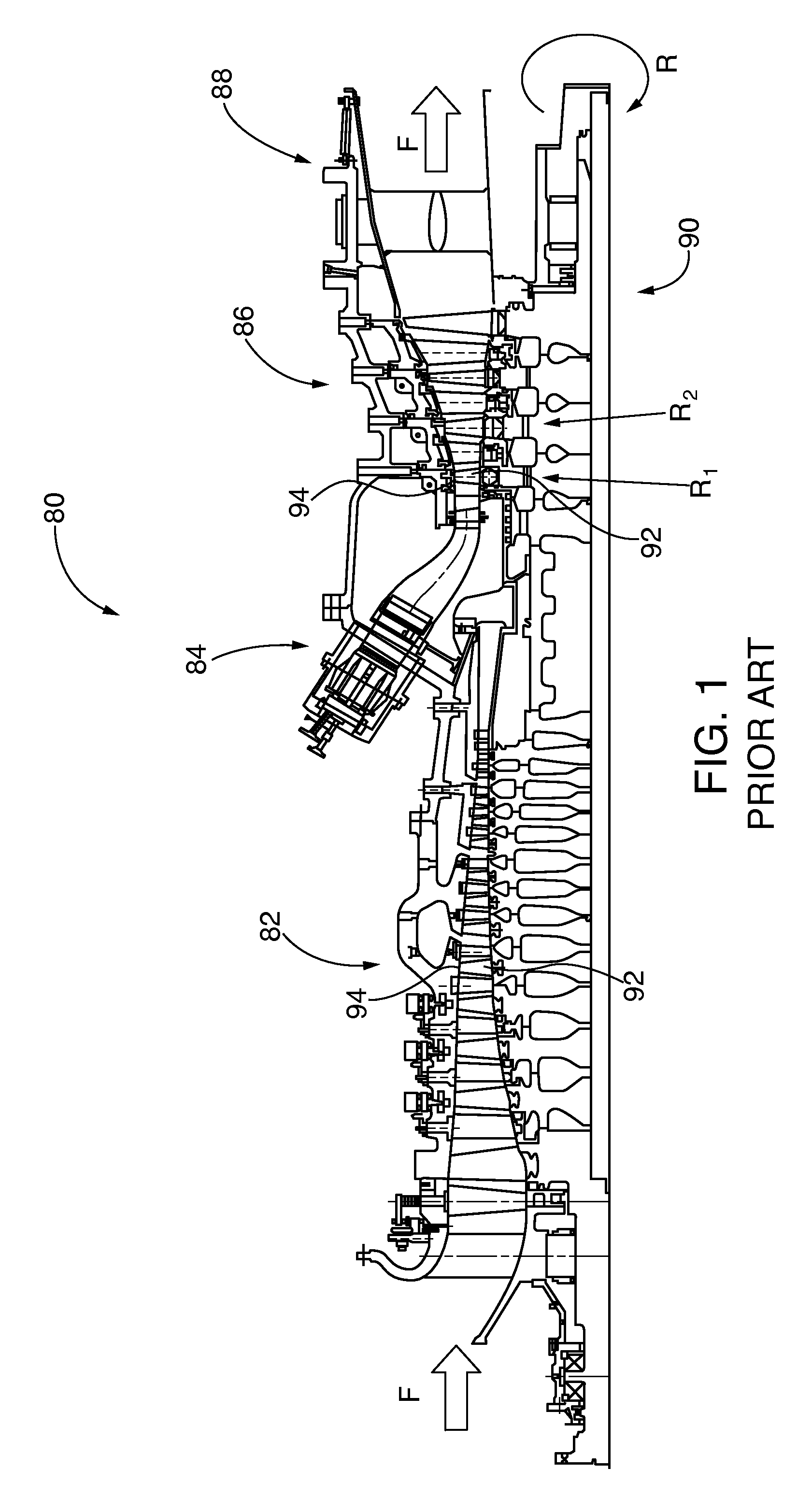

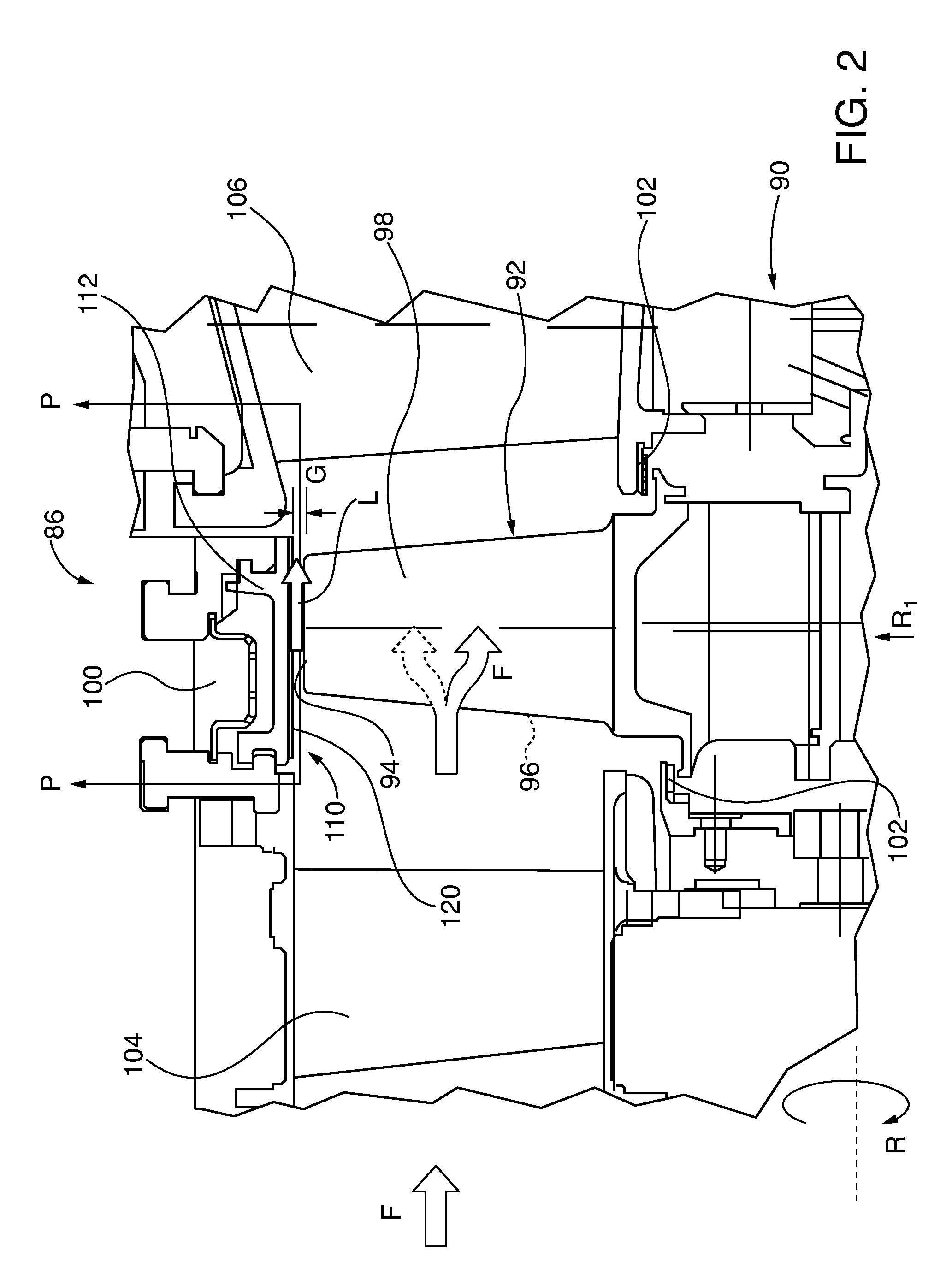

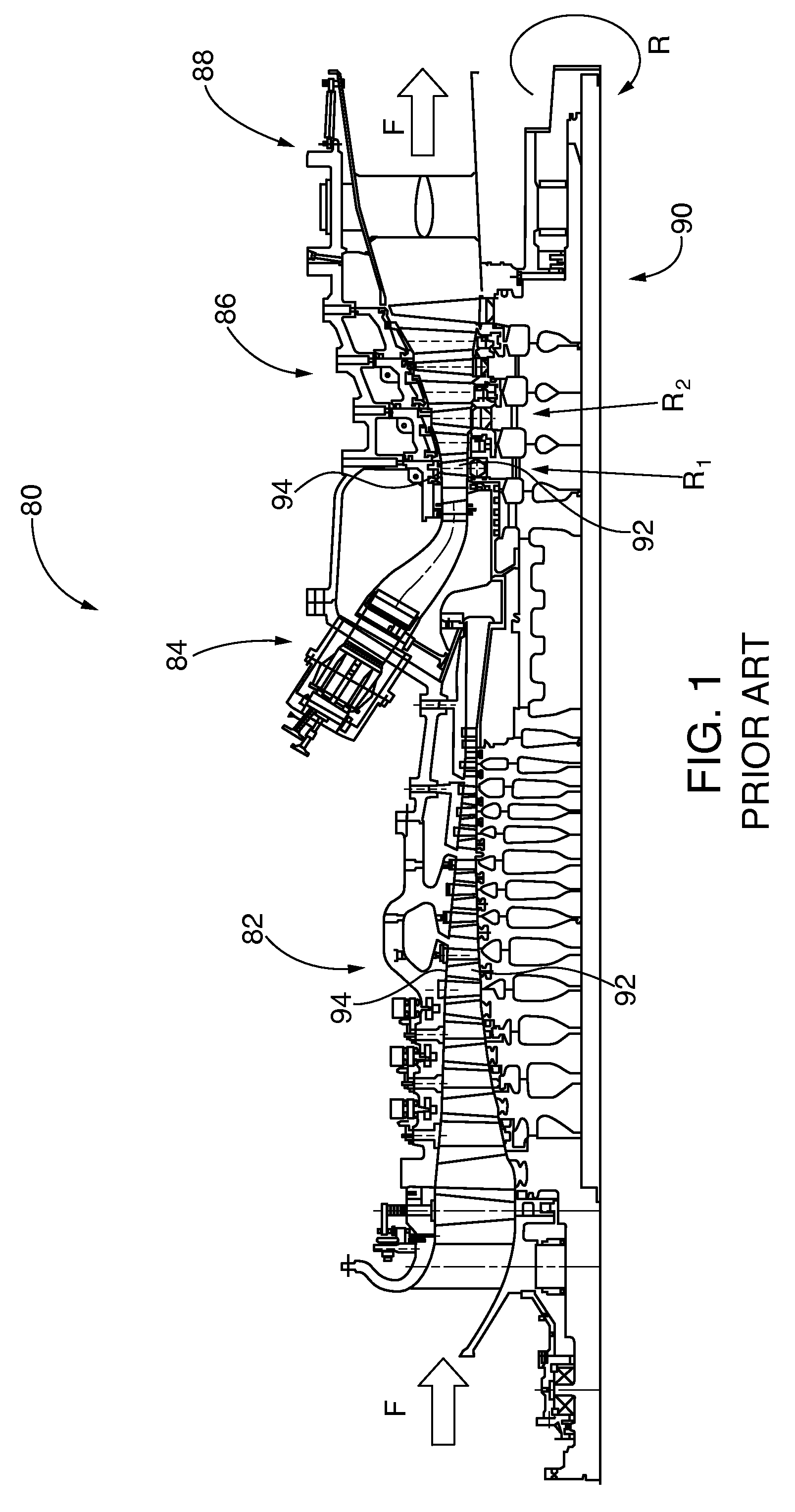

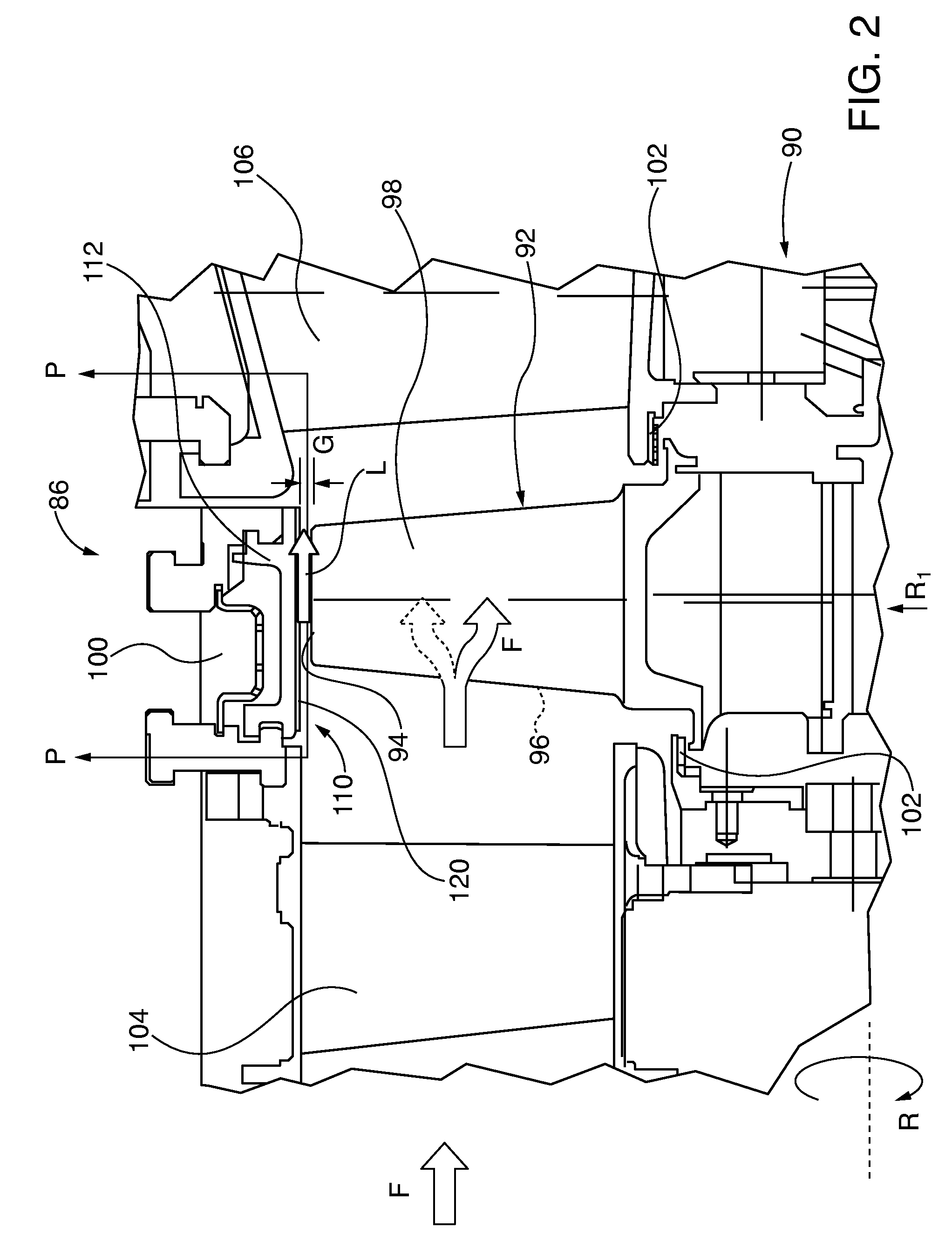

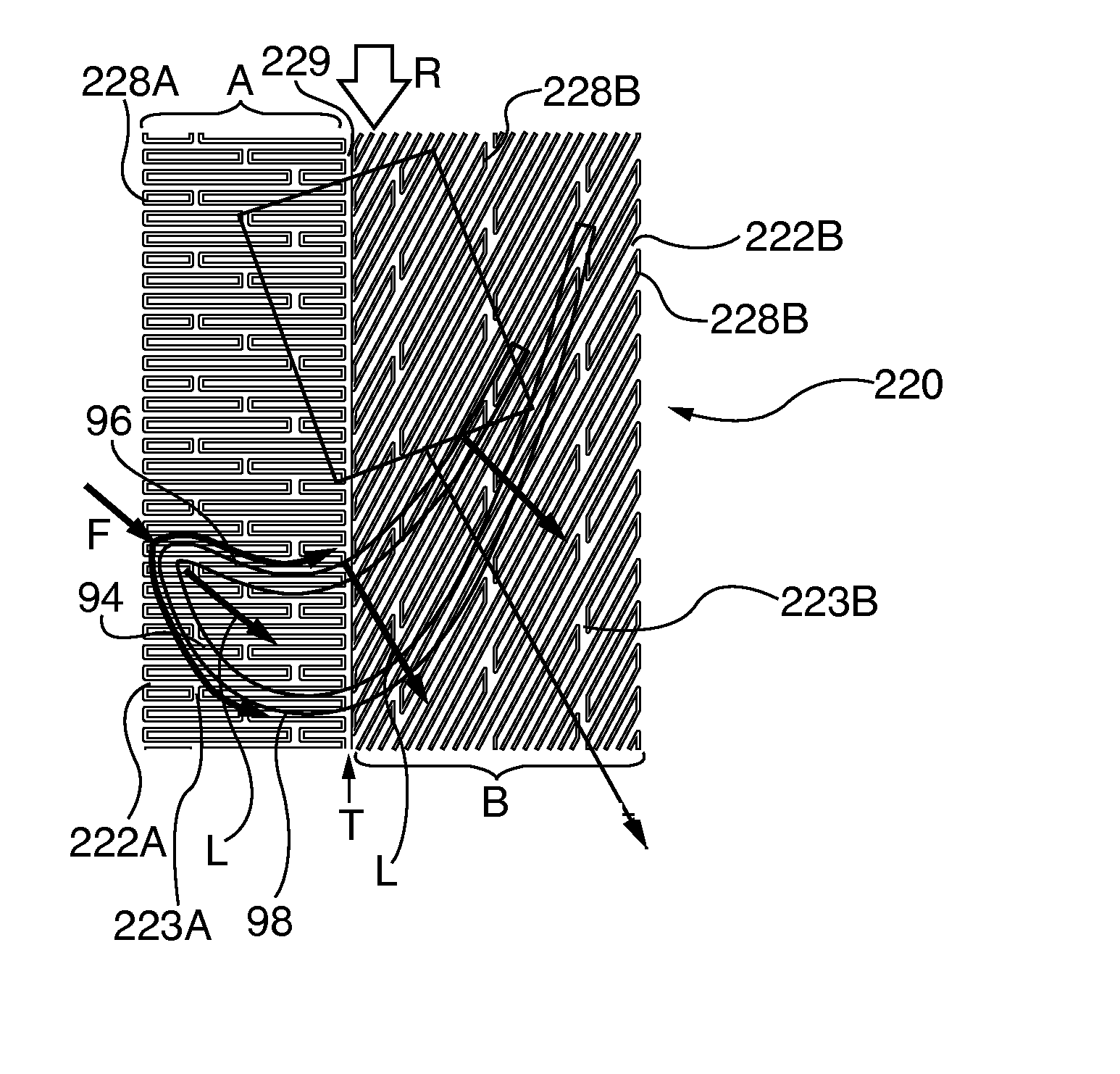

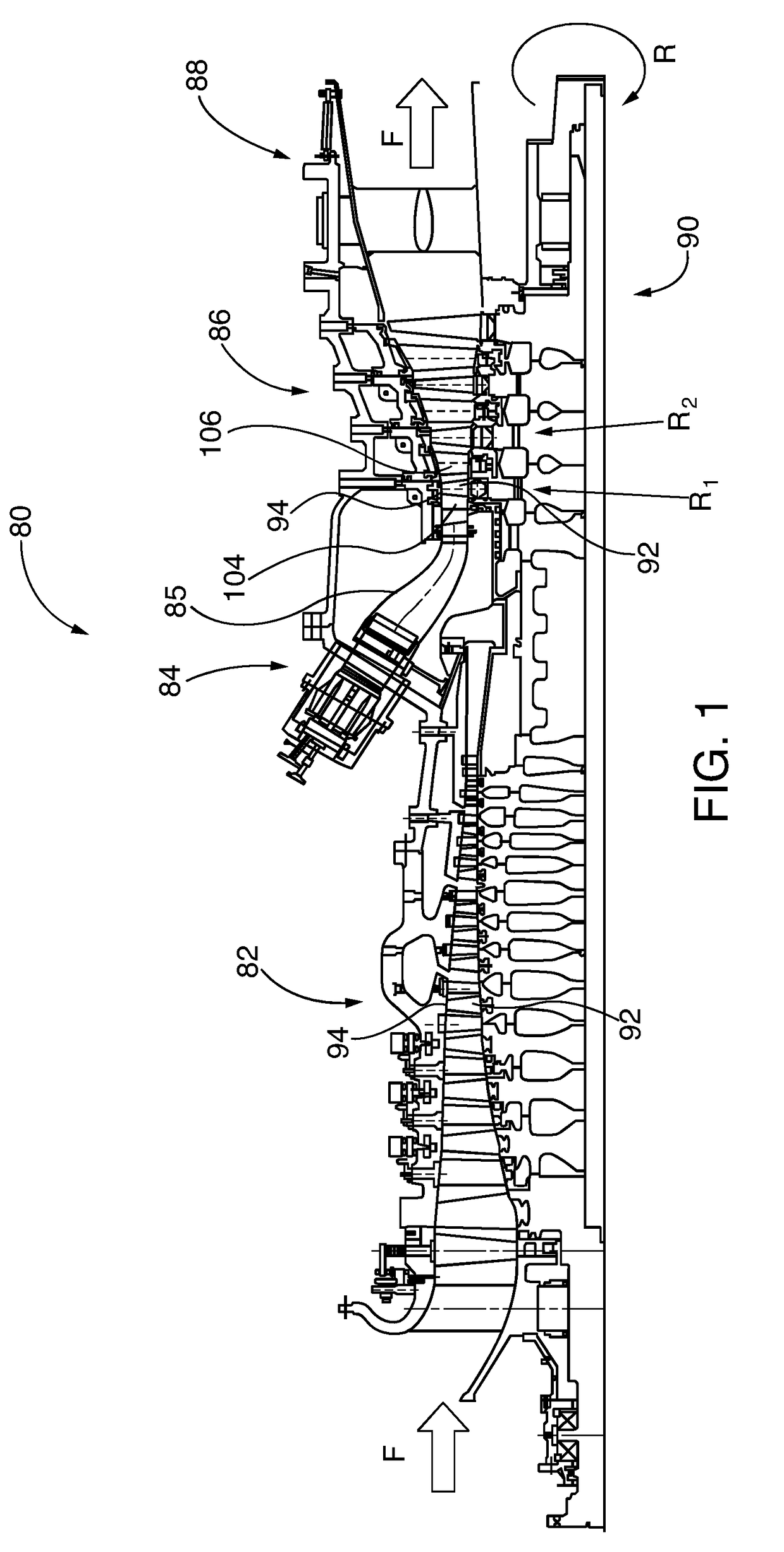

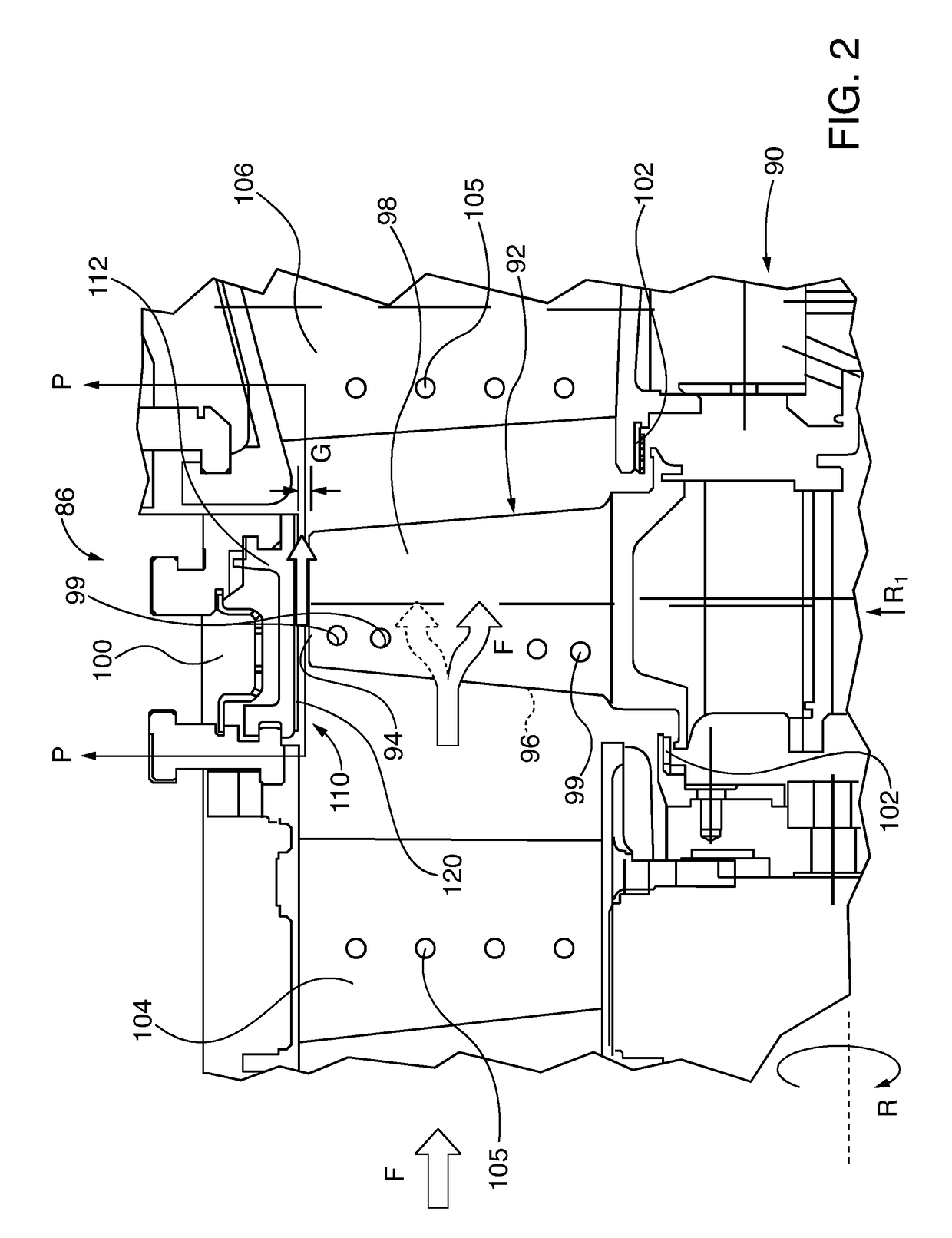

Turbine component thermal barrier coating with crack isolating, cascading, multifurcated engineered groove features

InactiveUS20180010469A1Enhance TBC layer adhesionMolten spray coatingEngine manufactureEngineeringTurbine

Turbine engine (80) components, such as blades (92), vanes (104, 106), ring segment 110 abradable surfaces 120, or transitions (85), have furcated engineered groove features (EGFs) (403, 404, 418, 509, 511, 512) that cut into the outer surface of the component's thermal barrier coating (TBC). In some embodiments, the EGF planform pattern defines adjoining outer hexagons (560, 640, 670, 690, 710). In some embodiments, the EGF pattern further defines within each outer hexagon (560, 640, 670, 690, 710) a planform pattern of adjoining inner polygons (570, 580, 590, 600, 610, 680, 682, 700, 702, 704, 705, 720). At least three respective groove segments (509, 511, 512) within the EGF pattern (506, 507, 508) converge at each respective outer hexagonal vertex (510, 564) or inner polygonal vertex (574, 564, 604, 614) in a multifurcated pattern, so that crack-inducing stresses are attenuated in cascading fashion, as the stress (σA) is furcated (σB, σC) at each successive vertex juncture.

Owner:SIEMENS AG

Supersonic aircraft with shockwave canceling aerodynamic configuration

ActiveUS8453961B2Maximize efficiencyPerformance maximizationAircraft stabilisationEnergy efficient board measuresJet aeroplaneFuselage

Disclosed is a supersonic aircraft design having a single structural component that simultaneously joins the wings to the aircraft fuselage, the engines to the aircraft fuselage, and the wings to the engines, resulting in an airframe planform, which, in combination aerodynamic shaping and structural morphing technologies within the aircraft fuselage, enables the aircraft to be optimized to reduce sonic boom.

Owner:HYPERMACH AEROSPACE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com