Patents

Literature

506results about How to "Improve braking performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

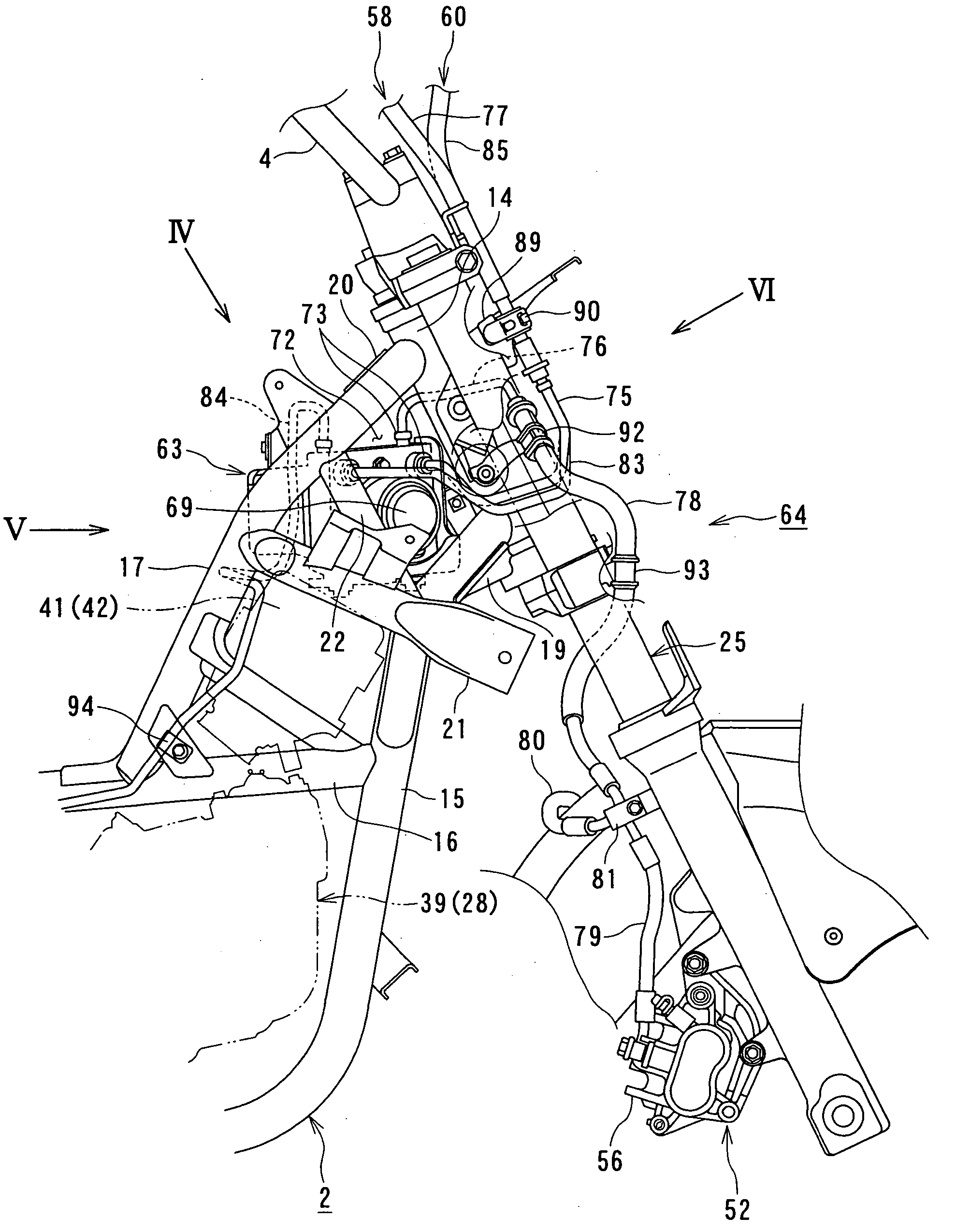

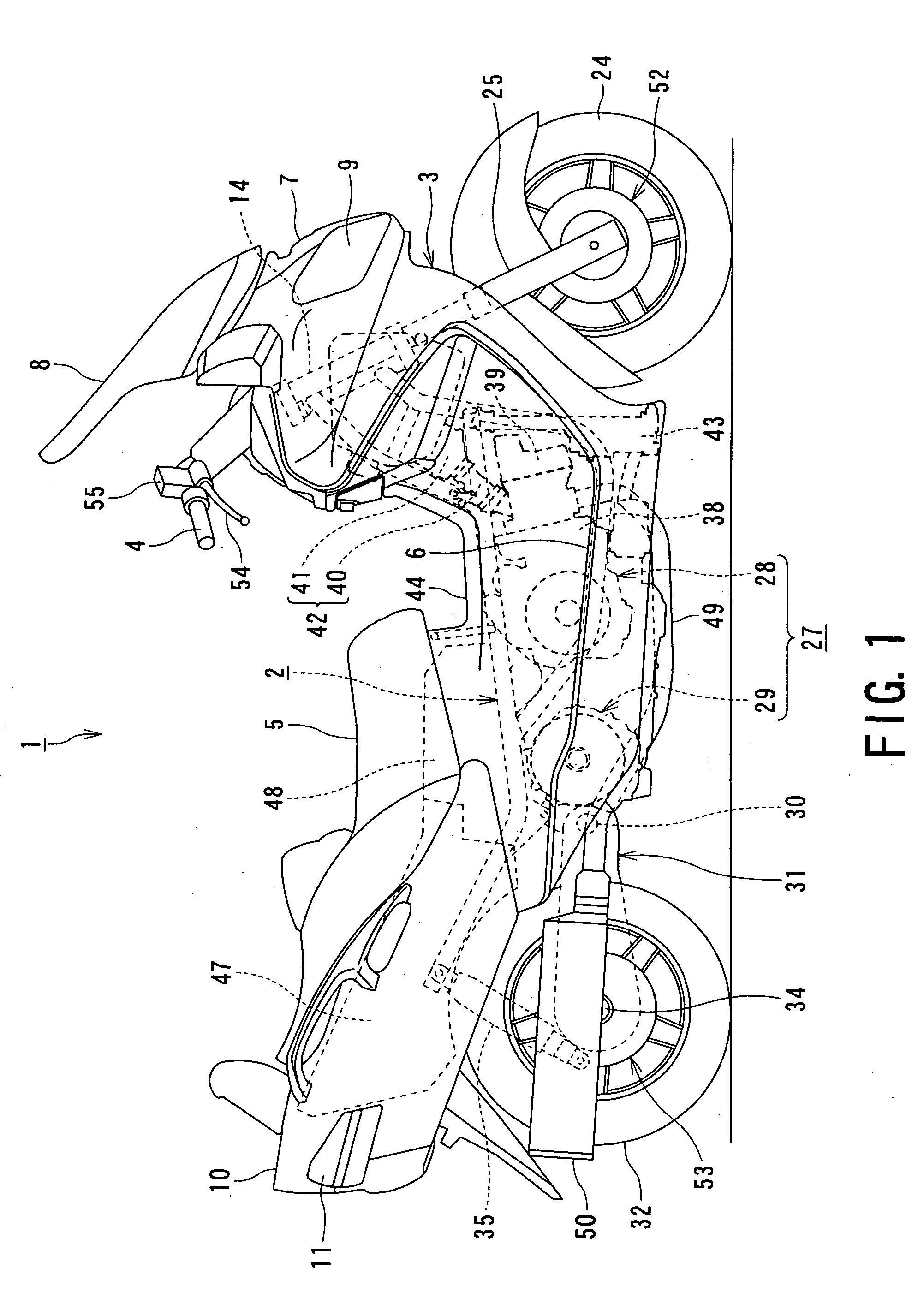

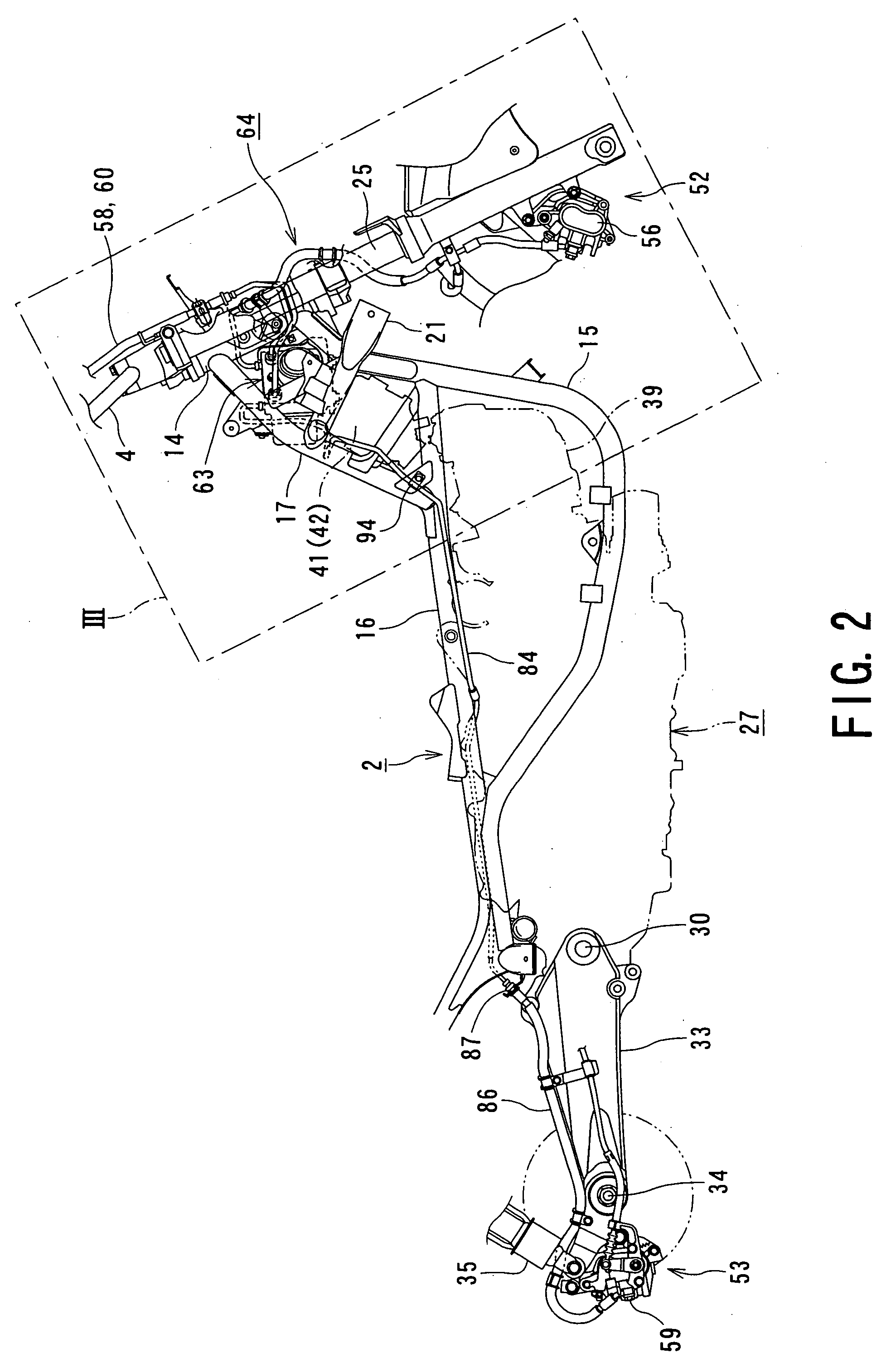

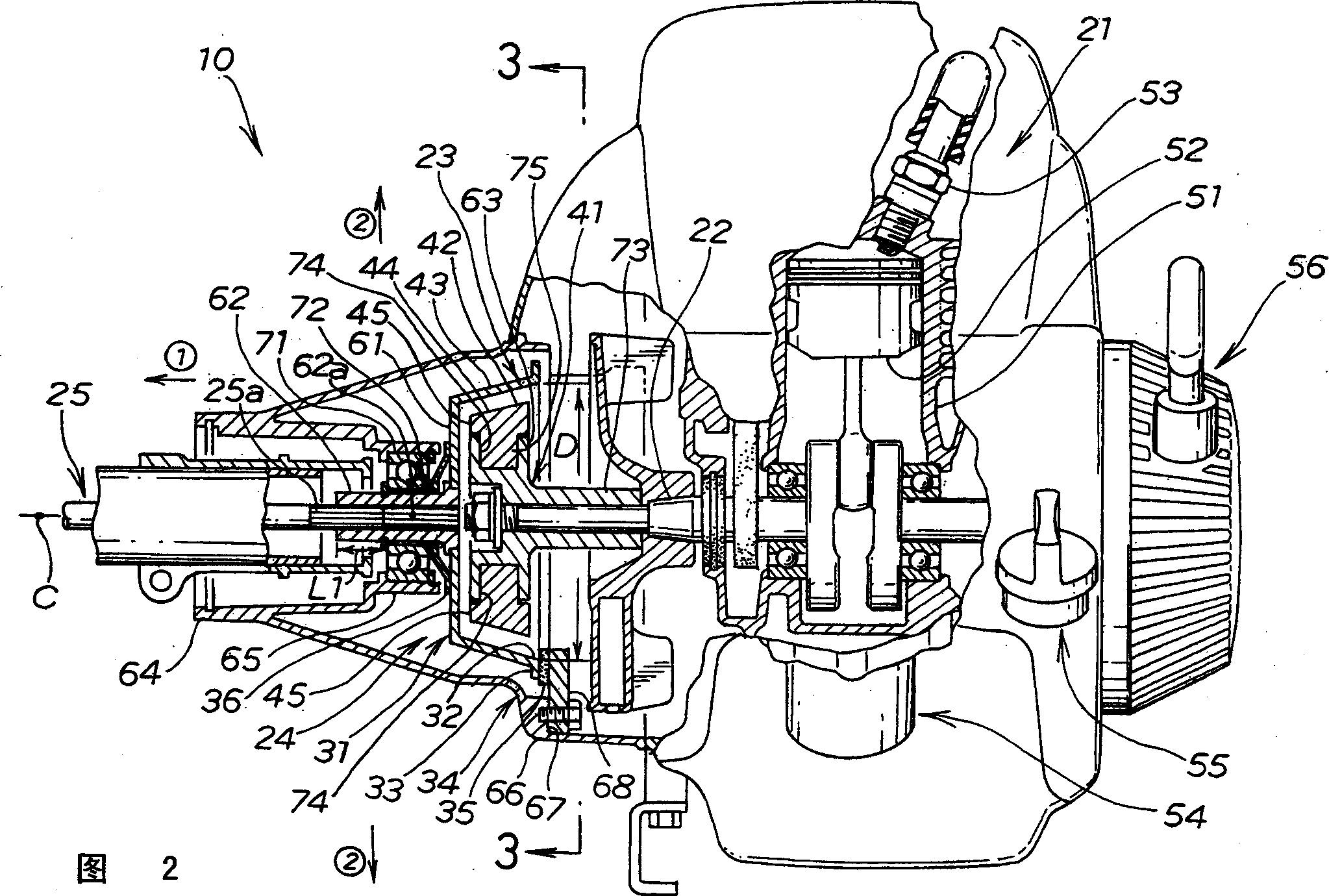

Motorcycle with antilock brake system

ActiveUS20050134114A1Improve braking performanceImprove engine performanceElectric propulsion mountingGas pressure propulsion mountingMaster cylinderEngineering

In a motorcycle provided with an antilock brake system, a front fork supporting a front wheel of a motorcycle is supported to be rotatable by a head pipe which is located at the front end portion of a body frame of a motorcycle, a handle-bar is secured to an upper end portion of the head pipe, master cylinders attached to the handle-bar are connected to hydraulic wheel brakes, respectively, via brake pipes. An antilock brake system includes an ABS-unit for antilock control disposed in an intermediate portion of the brake pipes. The ABS-unit is disposed immediately behind the head pipe and between a pair of body frame components disposed on both lateral sides of the motorcycle body and extending, from the head pipe, obliquely downward and backward, while extending outward in directions opposite to each other in the width direction of the motorcycle body.

Owner:SUZUKI MOTOR CORP

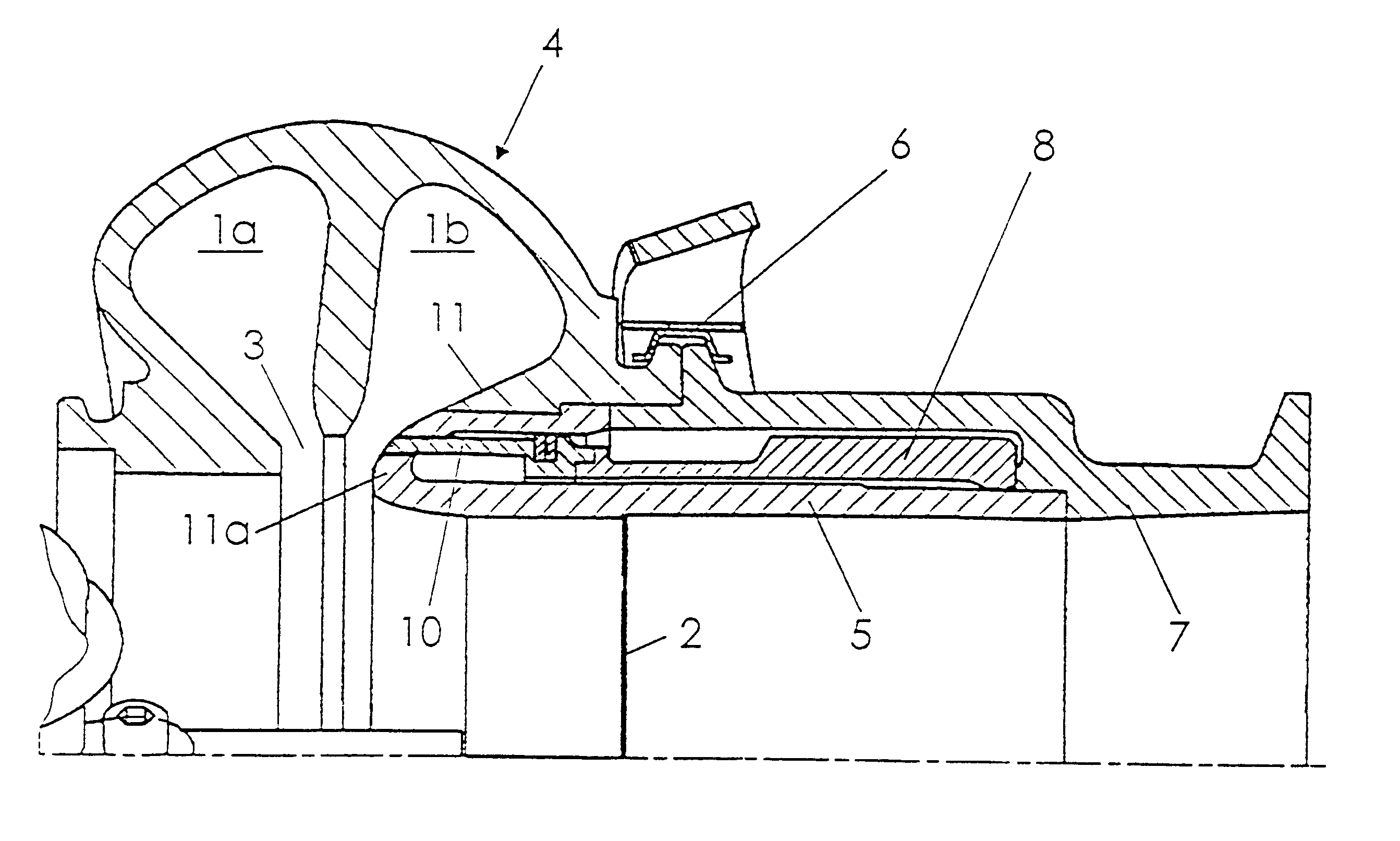

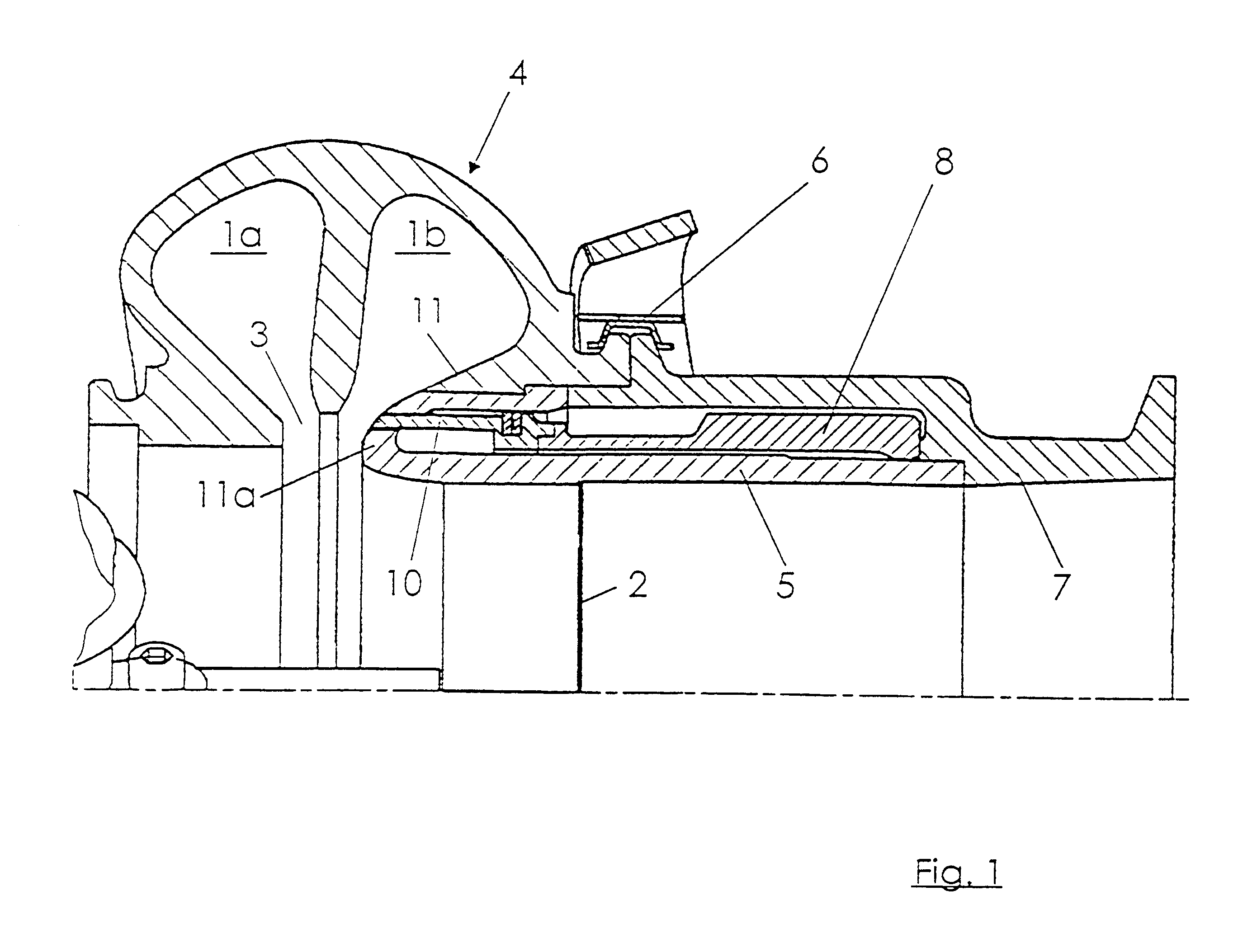

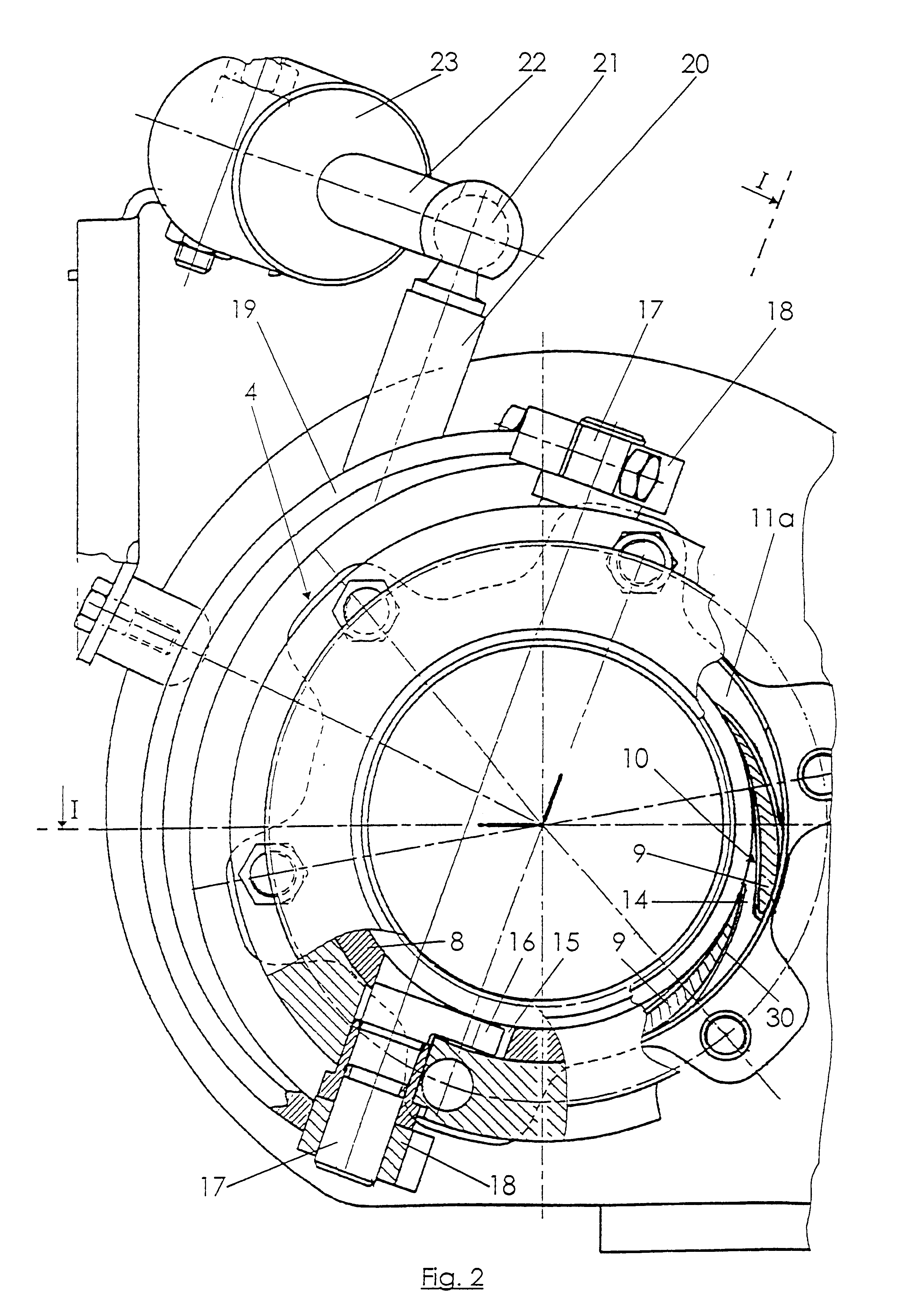

Exhaust gas turbocharger turbine

InactiveUS6443696B1Simple processIncrease back pressurePump componentsWind motor controlImpellerAxial displacement

An exhaust-gas turbocharger turbine of an internal combustion engine is provided with a spiral guide passage arranged in a turbine housing, a turbine impeller, a flow gap be ween the guide passage and the turbine impeller, and guide blades forming a guide cascade. The guide cascade with the guide blades projects axially from a support, arranged so as to be displaceable in the axial direction in the turbine housing, in such a way that the guide blades, in normal operation, are mounted in recesses of a housing wall part of the turbine housing, the recesses, in the form of a female piece, forming a mating profile shape for the guide blades. In braking operation of the internal combustion engine, the guide blades project into the flow gap during an axial displacement of the support. The device with actuation for the braking operation can be fitted as a complete module into the turbine spiral.

Owner:DAIMLER AG

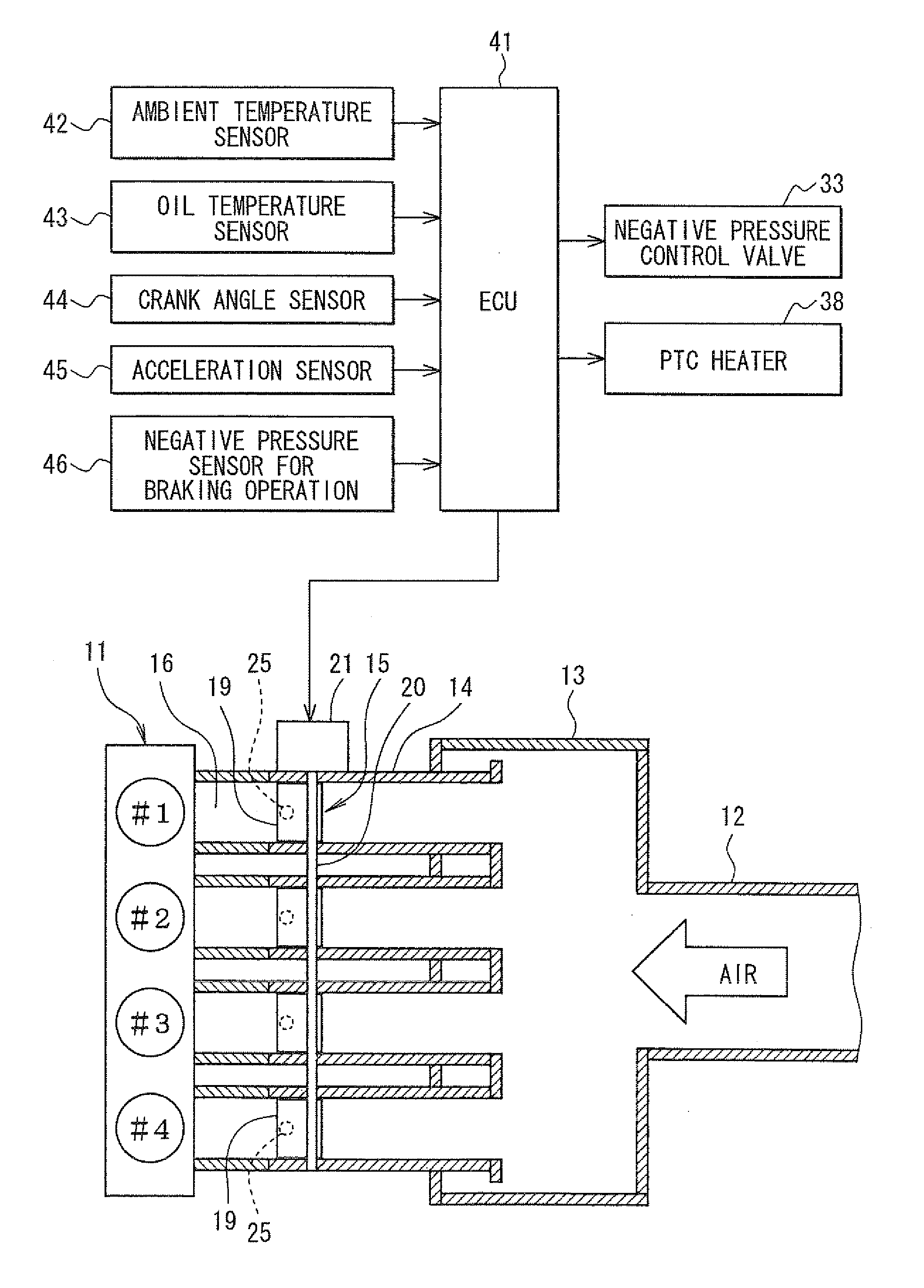

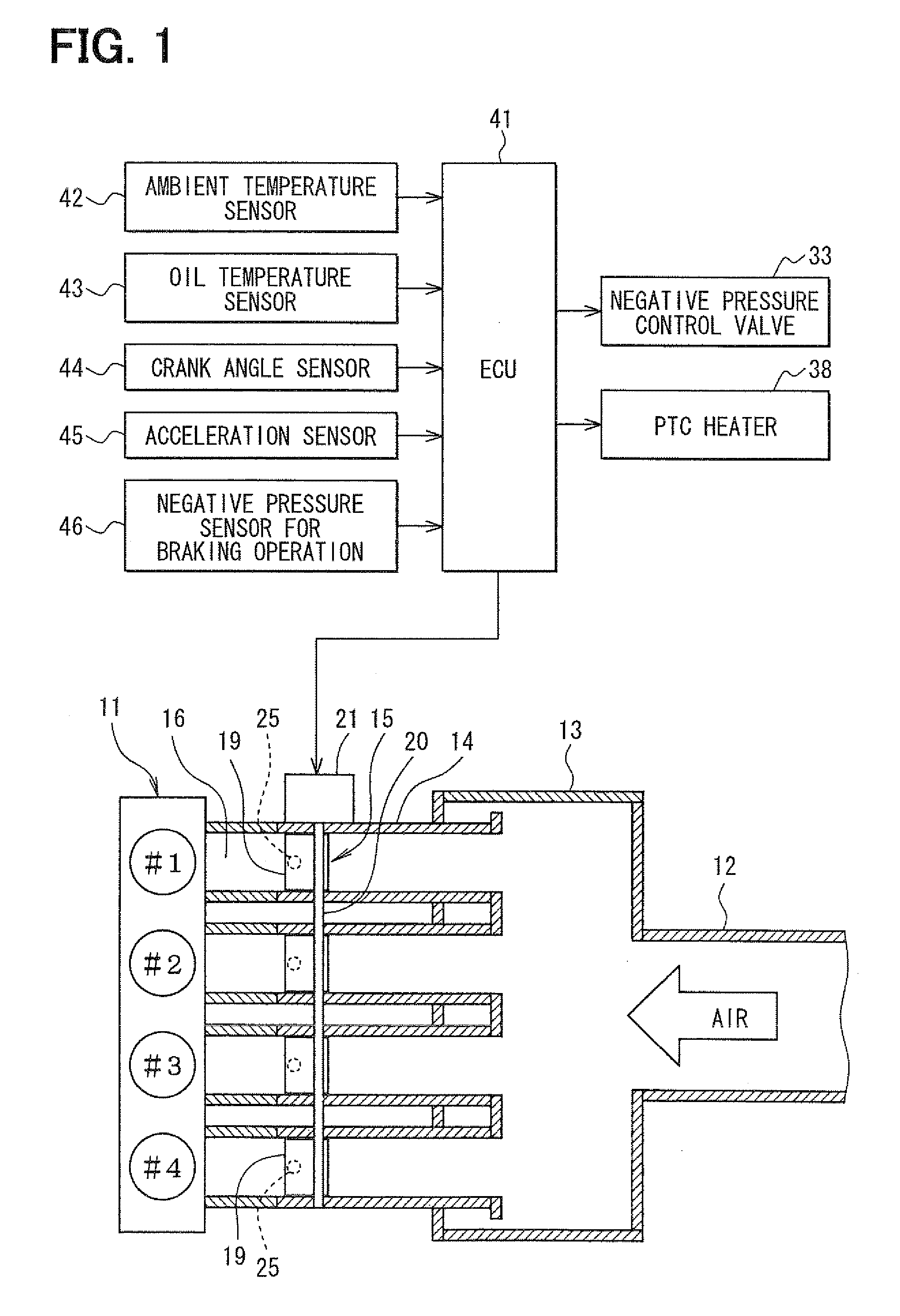

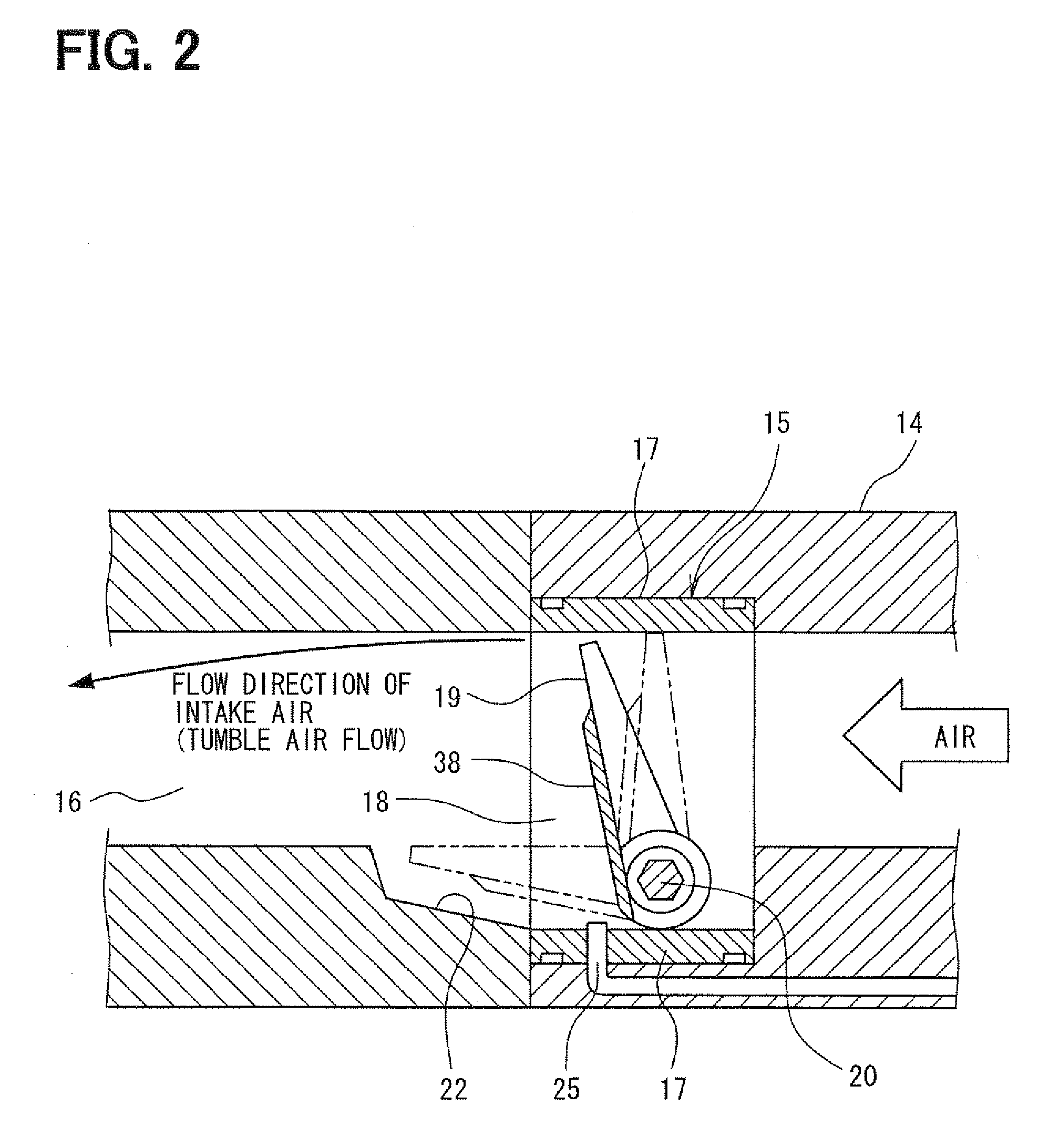

Negative pressure control apparatus for vehicle breaking operation

InactiveUS20080103667A1Reduce negative pressureImprove braking performanceAnalogue computers for trafficCombustion enginesEngineeringCheck valve

A communication passage for generating braking negative pressure is connected to an air passage for respective cylinders at a downstream side of a throttle valve. An air ejector is provided in a negative pressure pipe, to which communication passages for the respective cylinders are converged. A negative pressure passage for a brake booster is connected to the air ejector at a side of suction gas via a check valve. A passage for PCV gas and an intake air branched passage for bifurcating a part of the intake air from a surge tank at an upstream side of the throttle valve are connected to a driving gas side of the air ejector, wherein a negative pressure control valve is provided in the intake air branched passage. The PCV gas and the part of the intake air are forced to flow into the driving gas side of the air ejector, so that the air ejector functions as a vacuum pump. As a result, the braking negative pressure for the brake booster can be surely reduced to a target negative pressure.

Owner:DENSO CORP +1

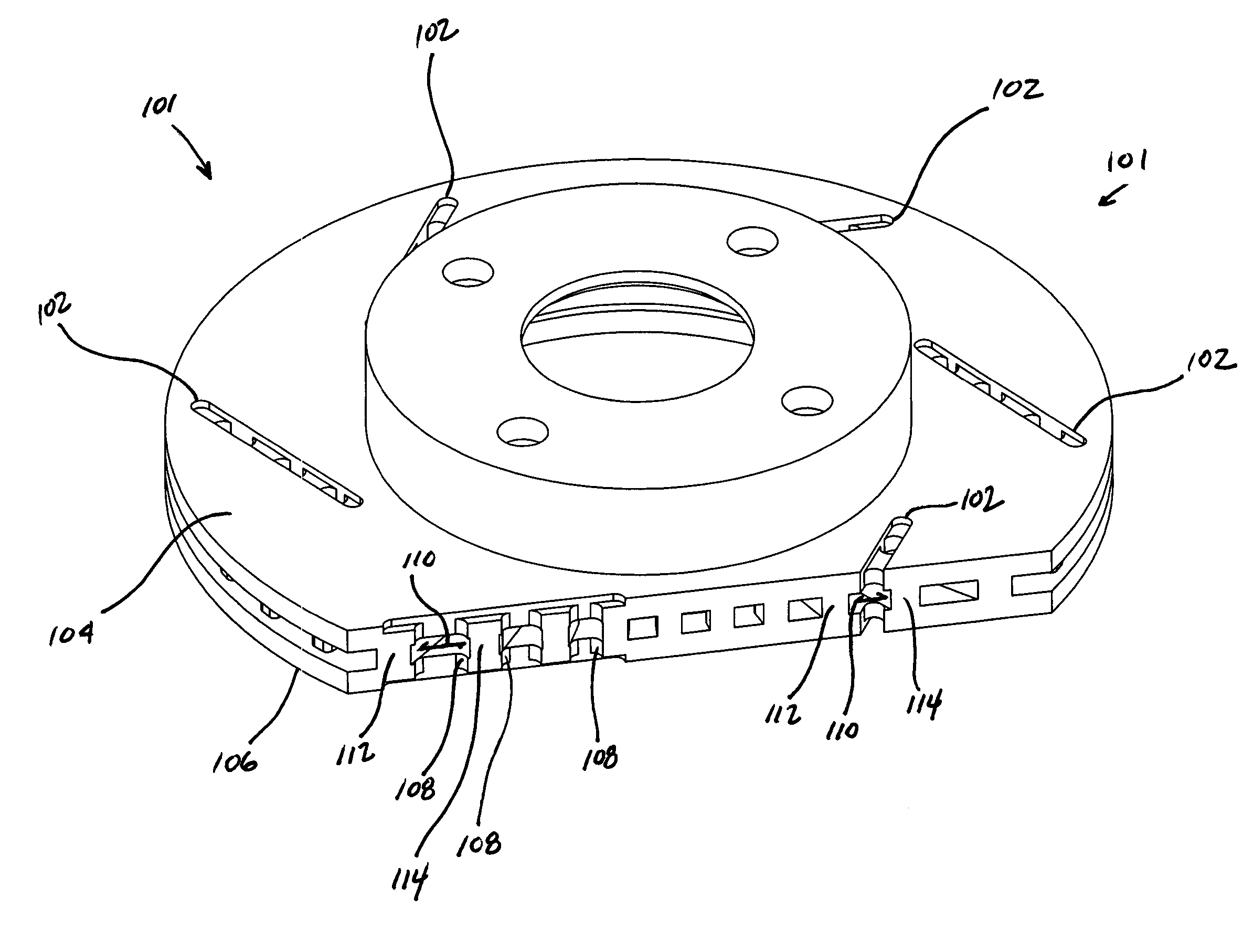

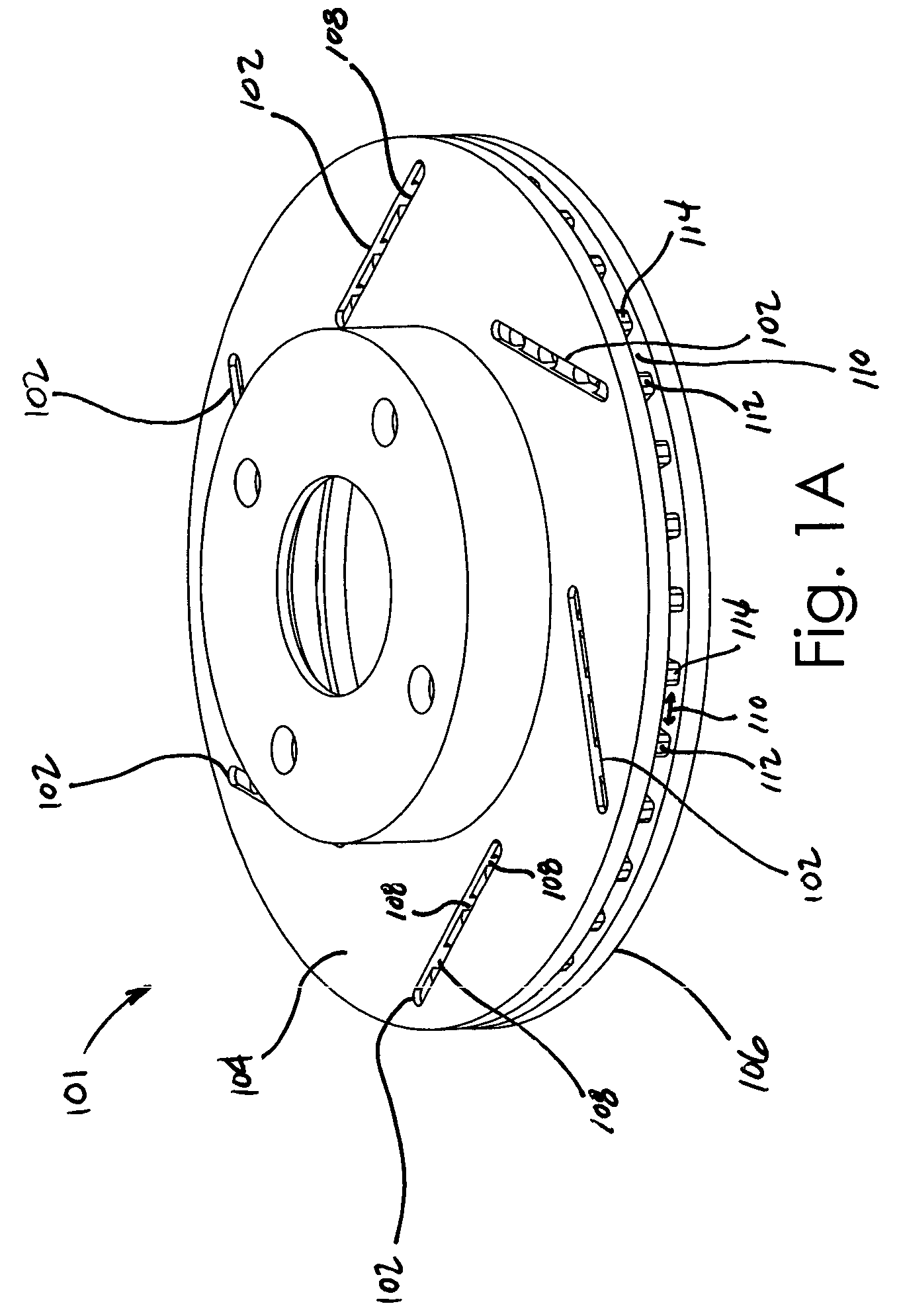

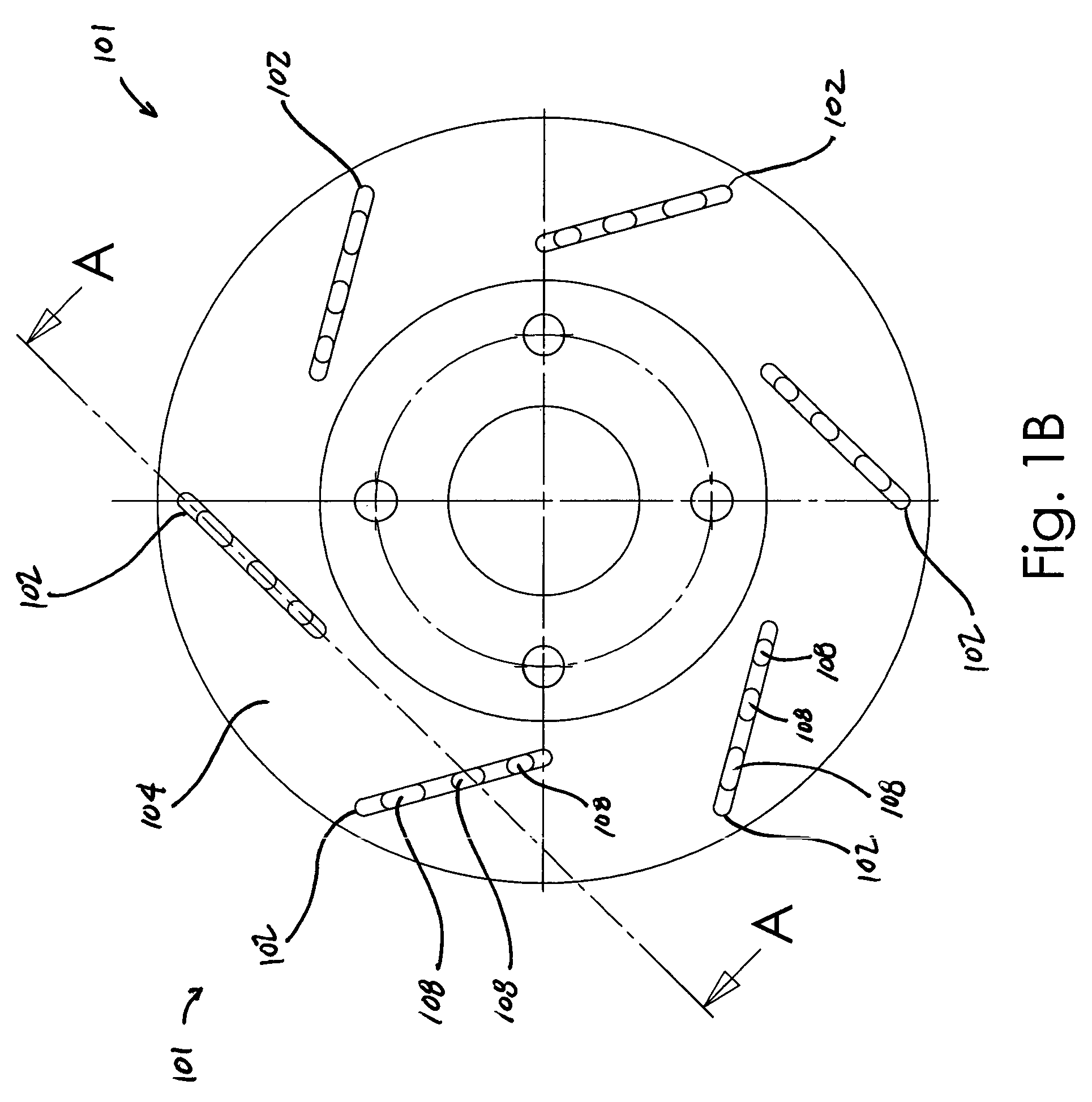

Vented slot brake rotor

InactiveUS7097007B2Improve braking performanceImprove cooling efficiencyBraking discsFriction liningMechanical engineeringCentral region

A brake rotor and methods for cooling and / or removing debris from a brake rotor are provided. The brake rotor may include a first and second annular braking surfaces jointly defining inner and outer circumferential surfaces and a central portion and a hat portion disposed in the central portion and adapted for mounting the rotor to a vehicle. The rotor may also include a plurality of vanes provided between the inner and outer circumferential surfaces, which may define a plurality of corresponding flow channels between at least a pair of vanes. Each flow channel may include a first flow channel opening (e.g., inlet) provided near the central region and a second flow channel opening (e.g., outlet) provided near a periphery of the brake rotor. The rotor and methods also may include a plurality of first slots provided on the first annular braking surface and a plurality of second slots provided on the second annular braking surface corresponding to the plurality of first slots. At least one first opening may be included within one or more slots. Similarly, at least one second opening may be provided within each second slot. Each second opening of each second slot may correspond substantially to and fluid communicate with a first opening of a first slot.

Owner:LIN WARREN

Rubber Composition and Use Thereof

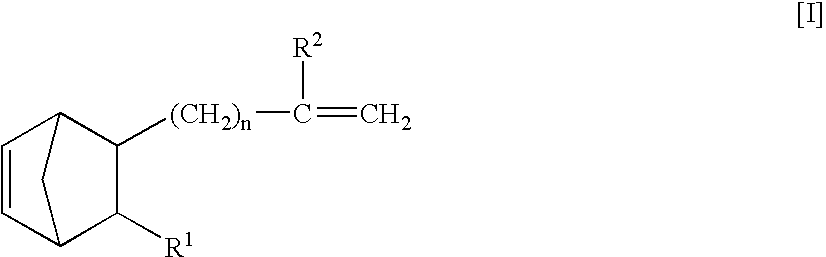

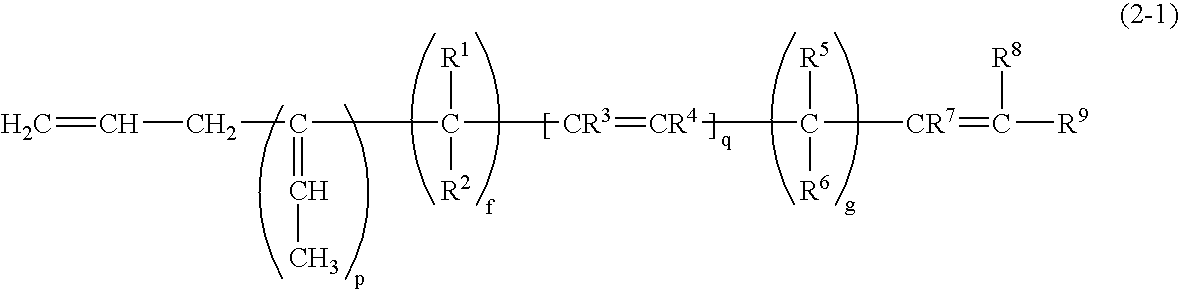

InactiveUS20080188621A1Improve braking performanceIncrease fuel consumptionSpecial tyresPolymer scienceAlpha-olefin

Provided is a rubber composition which can give a tire excellent in braking performance and fuel consumption and which is excellent in mechanical strength and fatigue resistance, and a use thereof.The rubber composition of the present invention contains a (A) 60 to 0.1 parts by weight of a nonconjugated polyene copolymer, which is a random copolymer containing 96 to 70 mol % of the structural units derived from α-olefin (A1) and 4 to 30 mol % of the structural units derived from a nonconjugated polyene (A2), and has a glass transition temperature (Tg) of −25 to 20° C.,(B) 40 to 99.9 parts by weight of a diene rubber and(C) at least one selected from the group consisting of specific polymers.

Owner:MITSUI CHEM INC +1

Method for preparing brake pad friction material by using rice and wheat straws

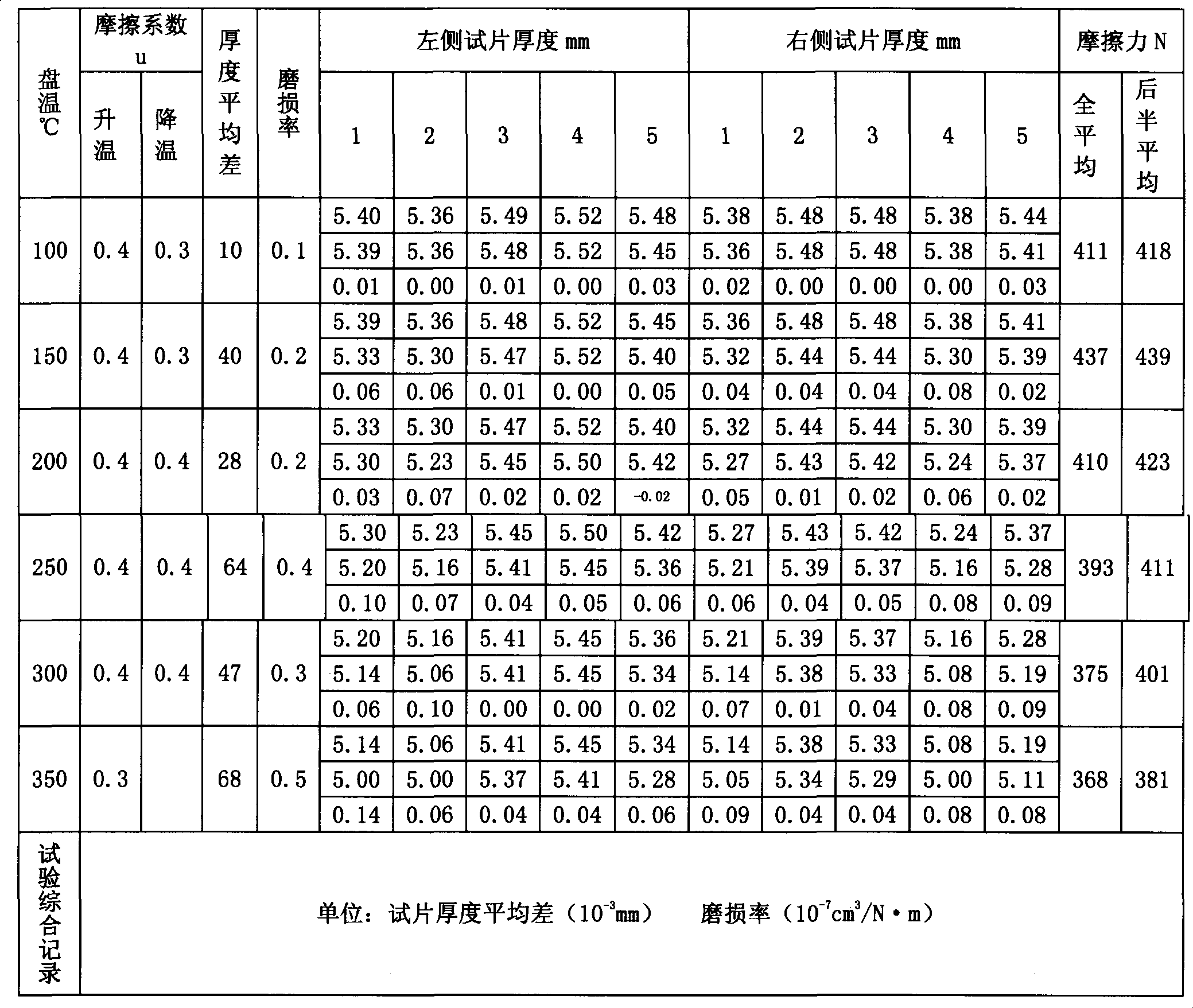

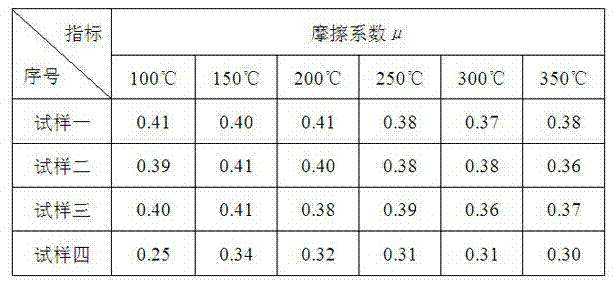

InactiveCN103820078AAbundant resourcesReduce recycling costsOther chemical processesFriction liningFiberAtmospheric pollution

The invention discloses a method for preparing a brake pad friction material by using rice and wheat straws and relates to the technical field of composite materials. The brake pad friction material has the following formula: 15 percent of toughened fibers, 16 percent of modified resin, 14 percent of a friction increase agent, 9 percent of sulfur and tin powder, 1.6 percent of carbon black, 2.5 percent of zinc oxide, 8.9 percent of barium sulfate, 10 percent of rice and wheat straw carbon powder, 6 percent of aluminum hydroxide, 14 percent of modified li beads and 3 percent of zinc stearate. The materials are uniformly mixed and stirred, pressed in a mold and subjected to machining such as grinding and chamfering according to a technical requirement to obtain a braking pad. According to the method, the rice and wheat straws are used as raw materials to prepare carbon powder which replaces graphite in a friction material formula, so that the atmospheric pollution caused by severe combustion of straws in each year is alleviated, the production cost of the brake pad is reduced, and the brake performance and the braking effect are enhanced; the friction coefficient is stable; the brake pad is simple in structure, low in brake noise, environment-friendly and pollution-free.

Owner:YANCHENG XINHAO MACHINERY

Pneumatic Tire

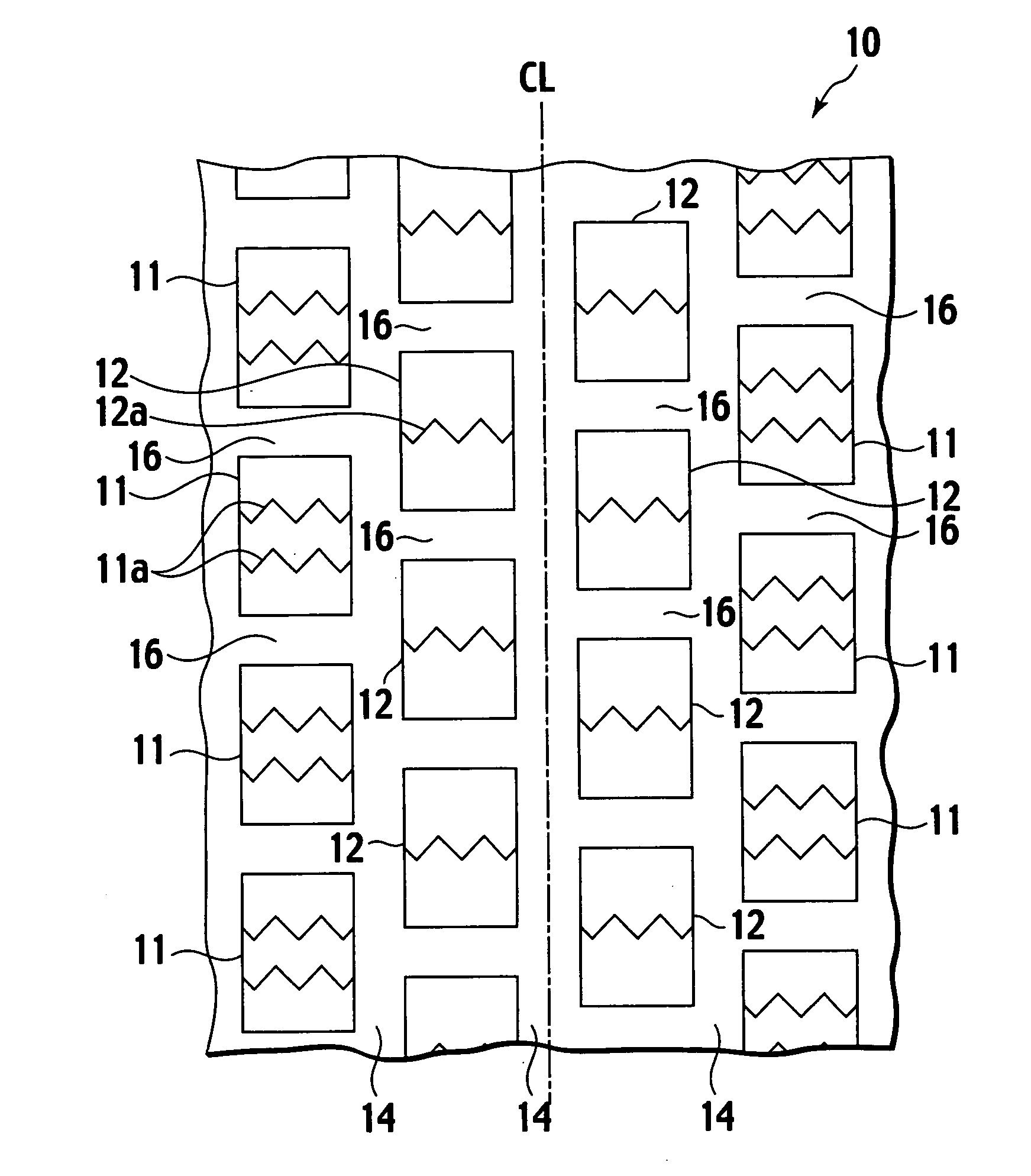

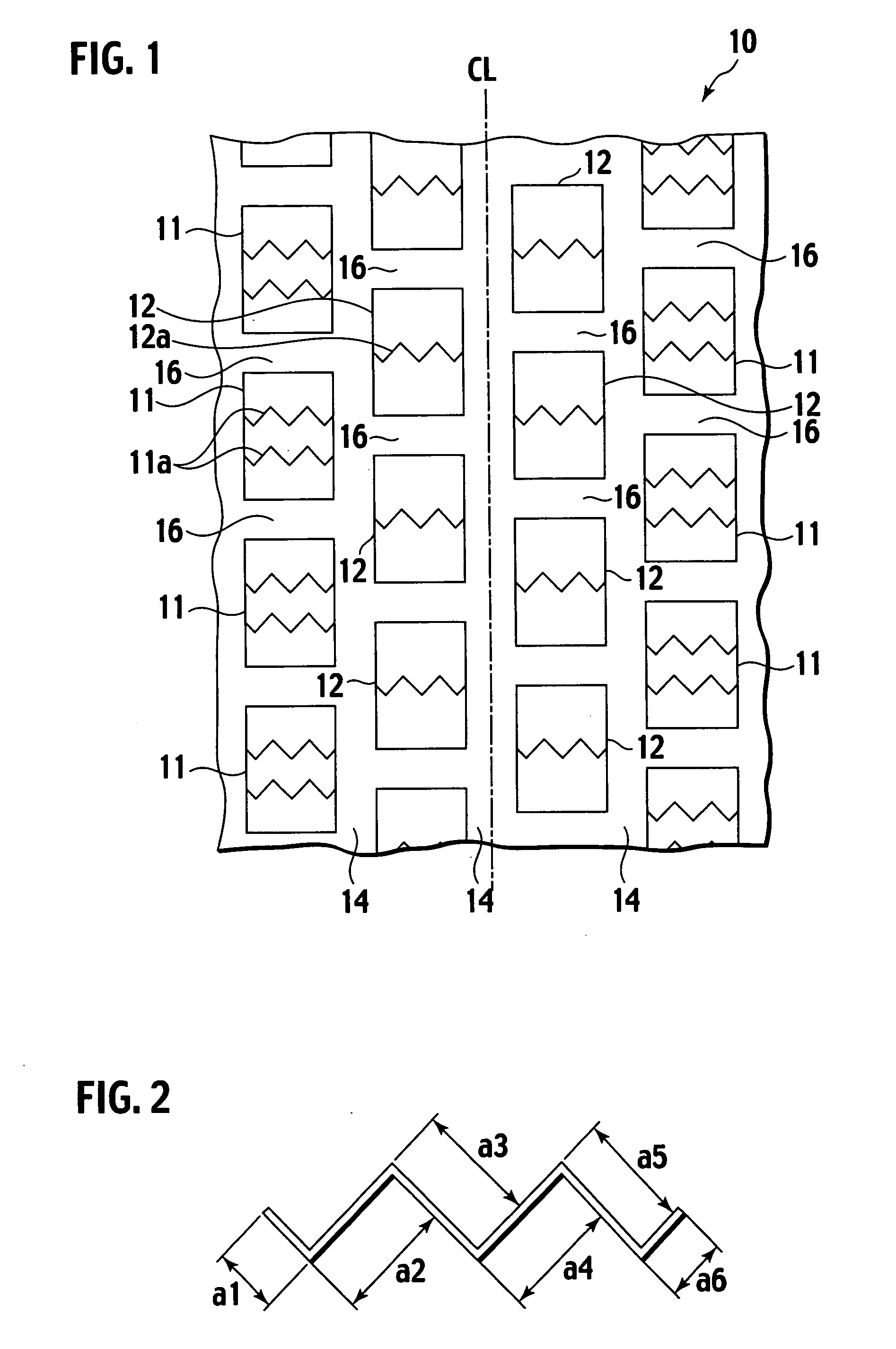

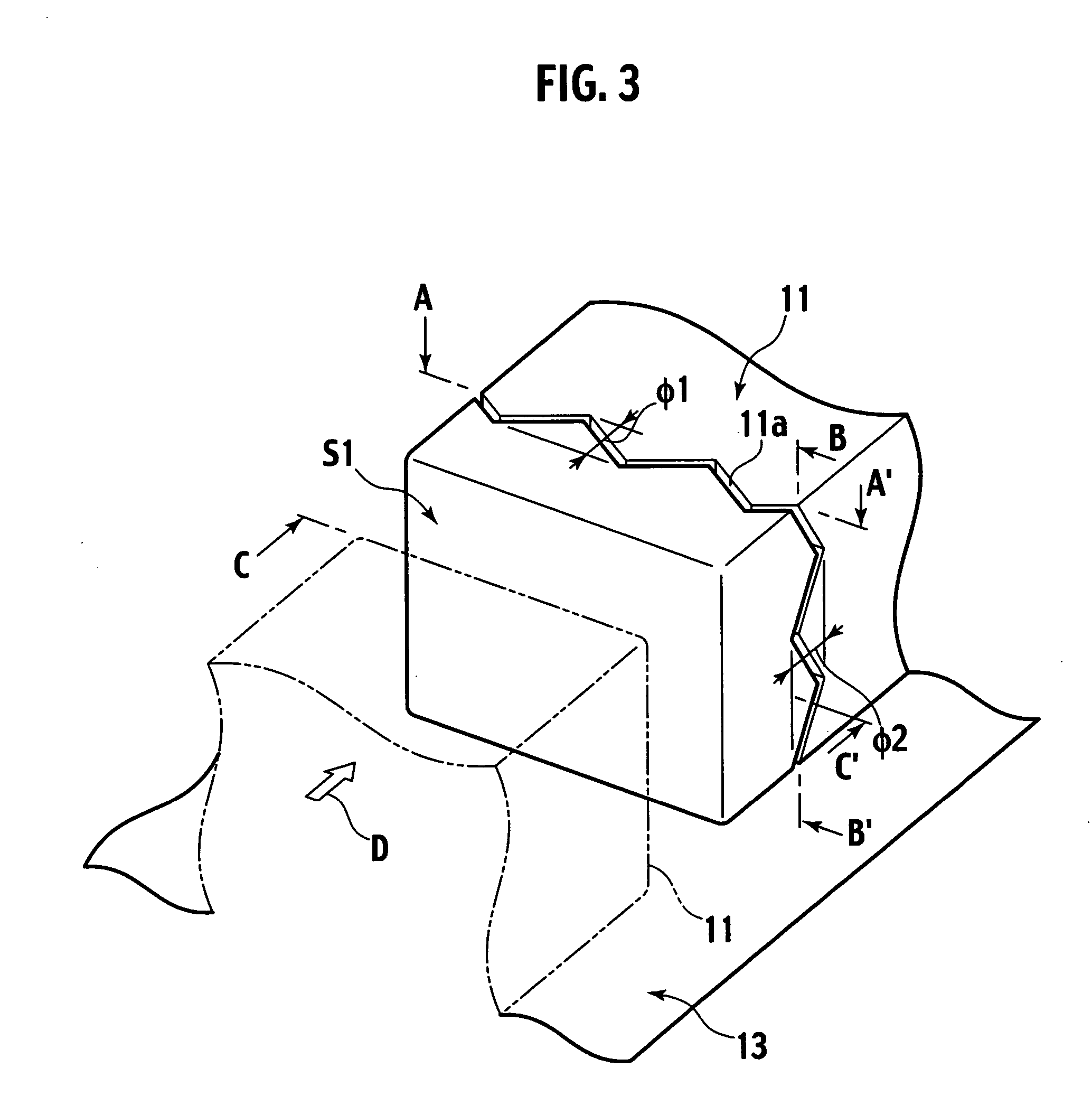

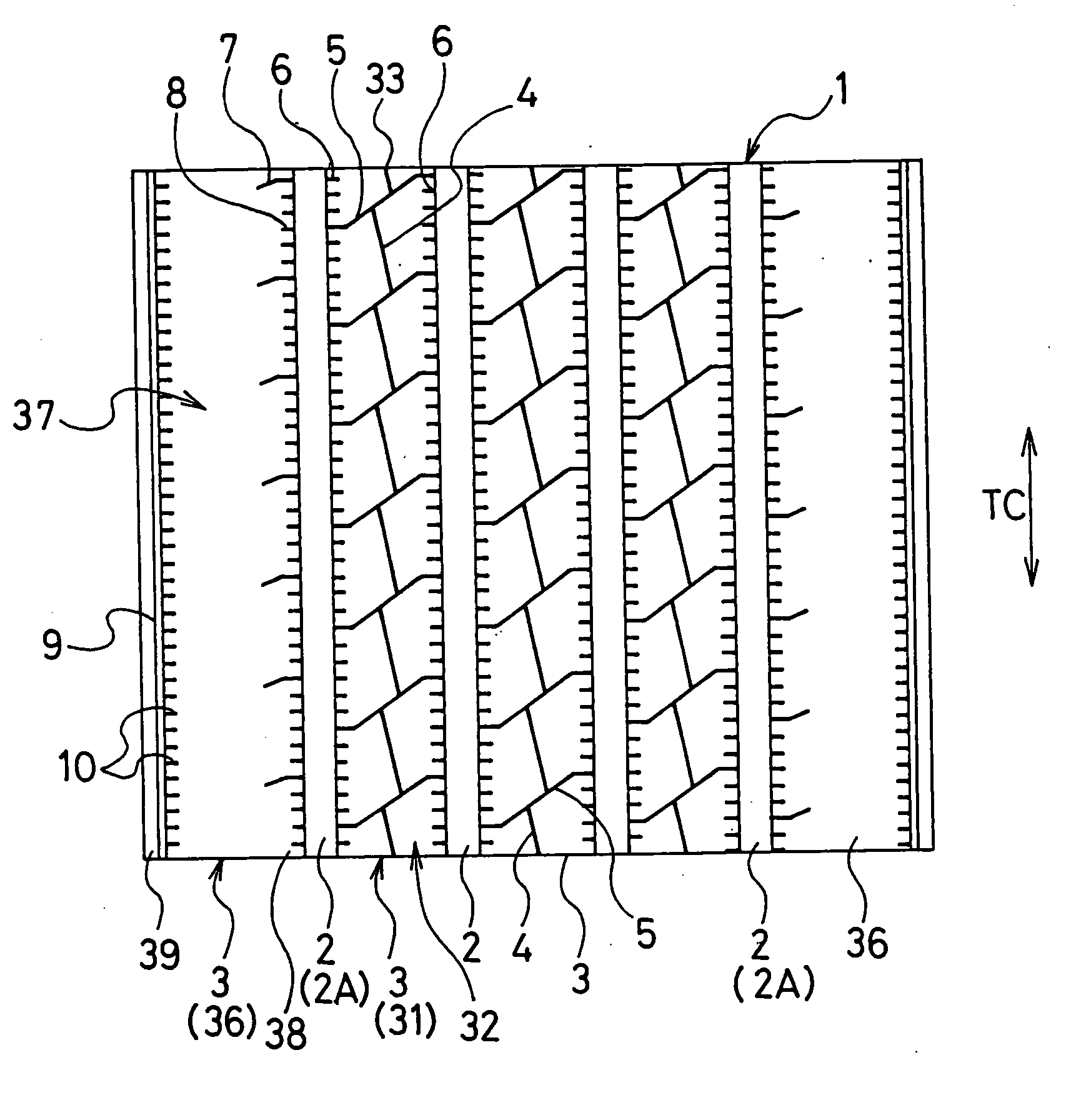

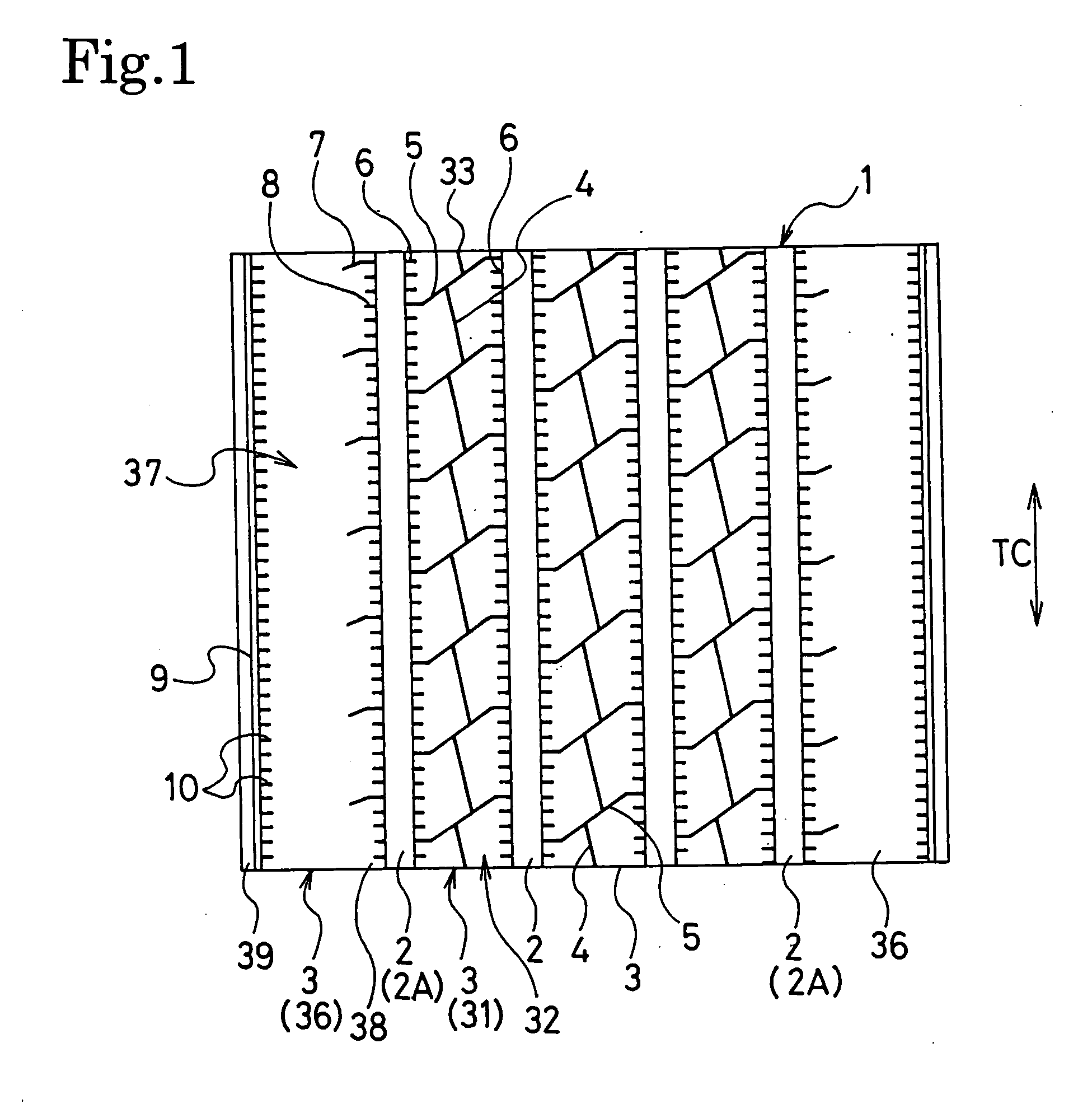

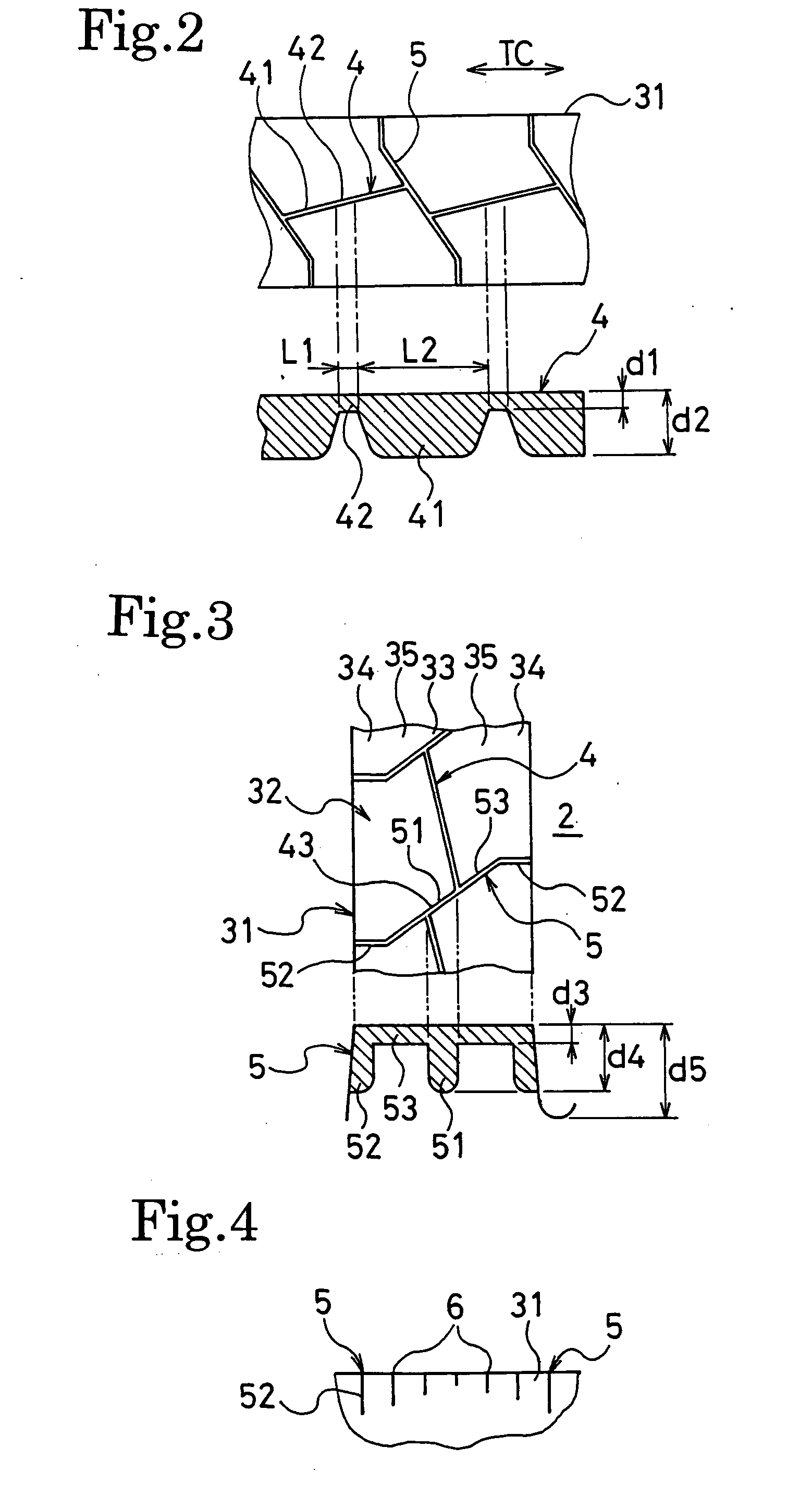

InactiveUS20070199634A1Improve rigidityImprove braking performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

A pneumatic tire includes, on a tread 10, a plurality of block rows 11 and 12 defined by circumferential main grooves 14 extended in a tire circumferential direction and by lateral grooves 16 intersecting the circumferential main grooves. Each tread-end-region block 11 has two zigzag sipes 11a, and each tread-center-region block 12 has one zigzag sipe 12a. Here, a total length of each sipe owned by one block on a tread surface, the number of sipes, and a sipe rigidity index (F) are larger in the tread-end-region block 11 than in the tread-center-region block 12.

Owner:BRIDGESTONE CORP

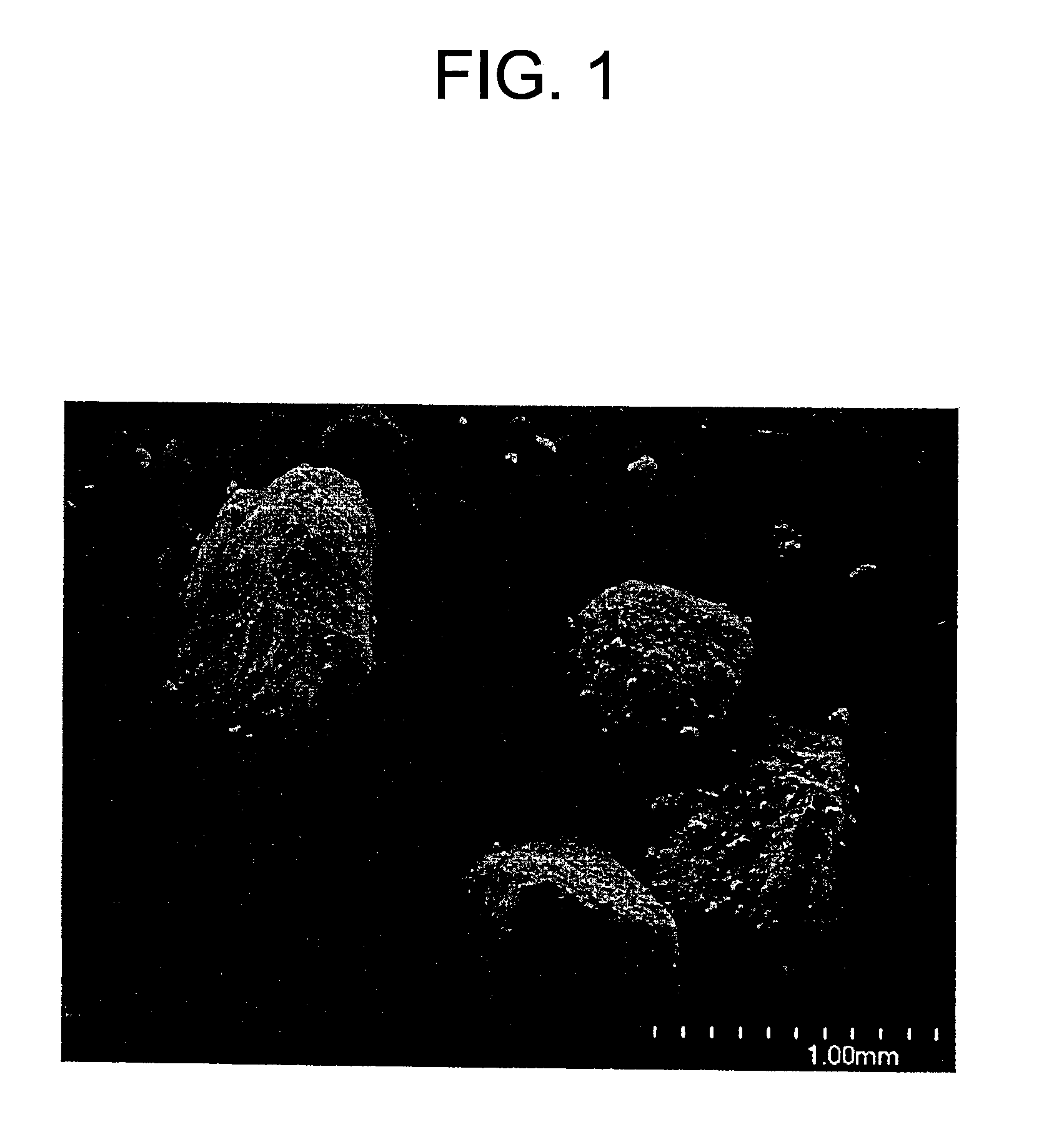

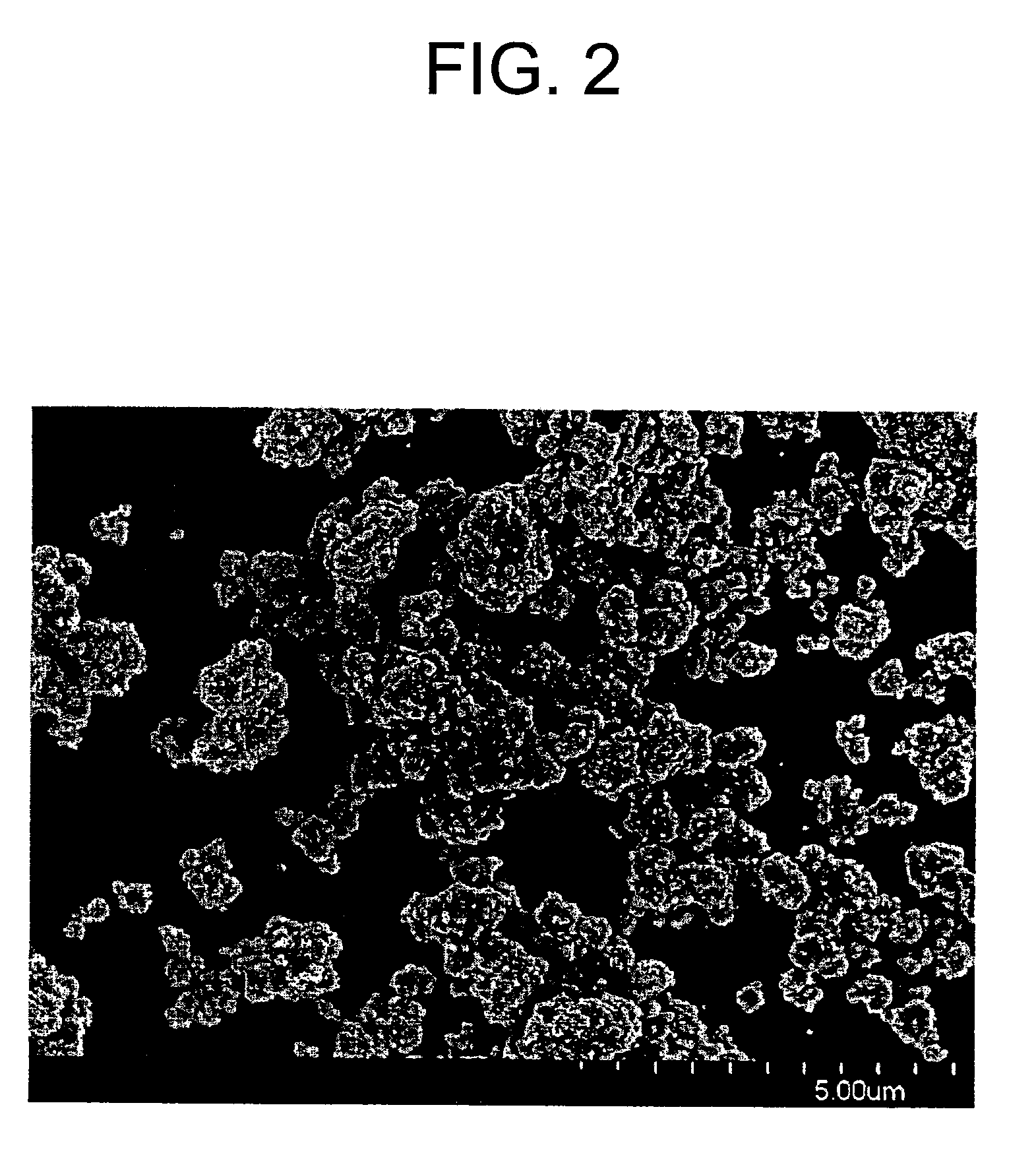

Method of manufacturing alkali metal titanate and hollow body particle thereof, product thereof, and friction material containing the product

ActiveUS20100112350A1Improve braking performanceImproved braking stabilityAlkali titanatesZirconium compoundsPotassiumTitanium

The present invention is to provide a method of manufacturing a potassium titanate adapted for a friction material of a friction slide member. The present invention includes the steps of uniformly mixing an aggregate or a granulation of a titanium compound and a potassium compound with a vibration rod mill to form a mixture and sintering the mixture for reaction one another in order to manufacture a desired potassium titanate with ease and low cost.

Owner:TOHO TITANIUM CO LTD

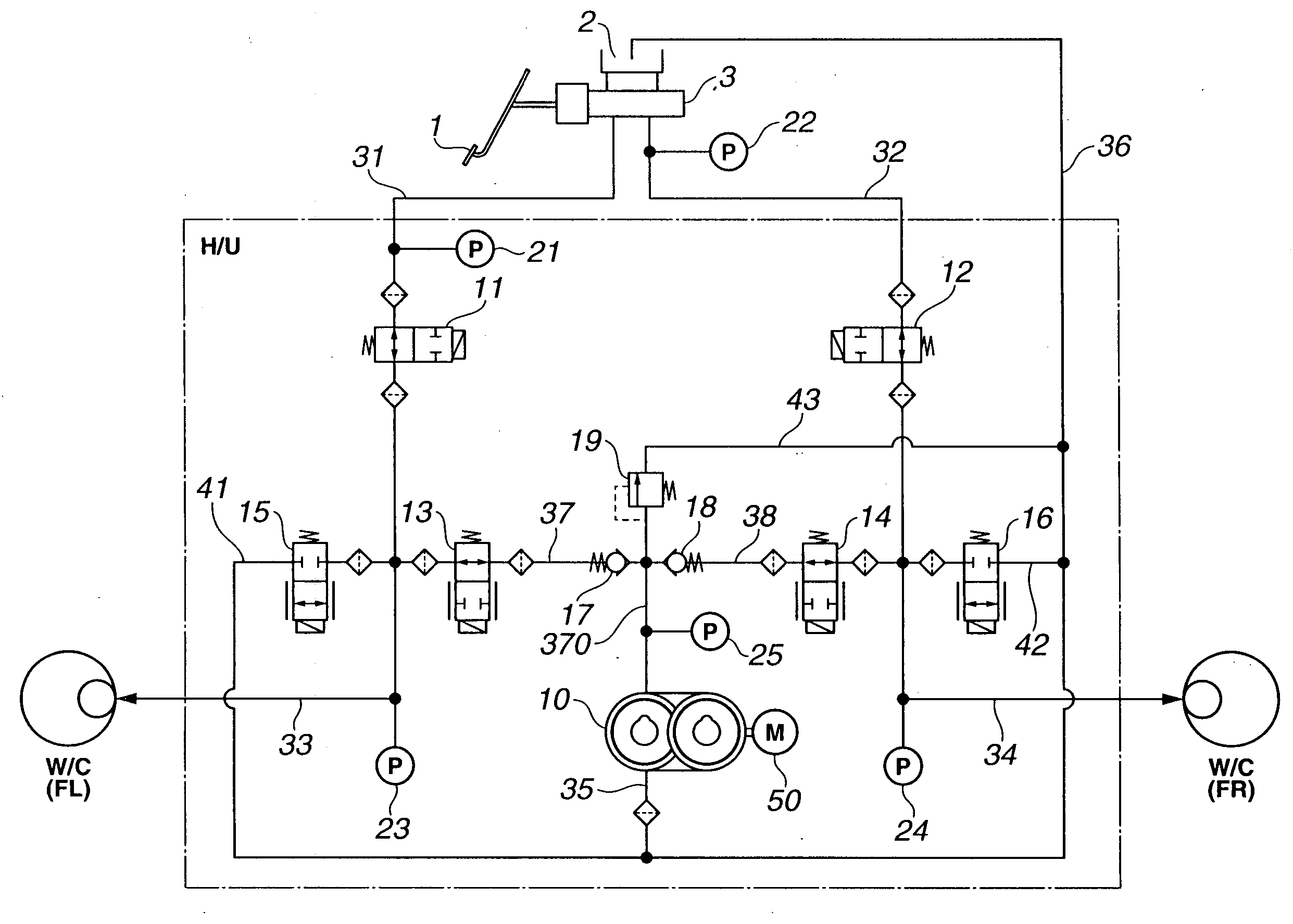

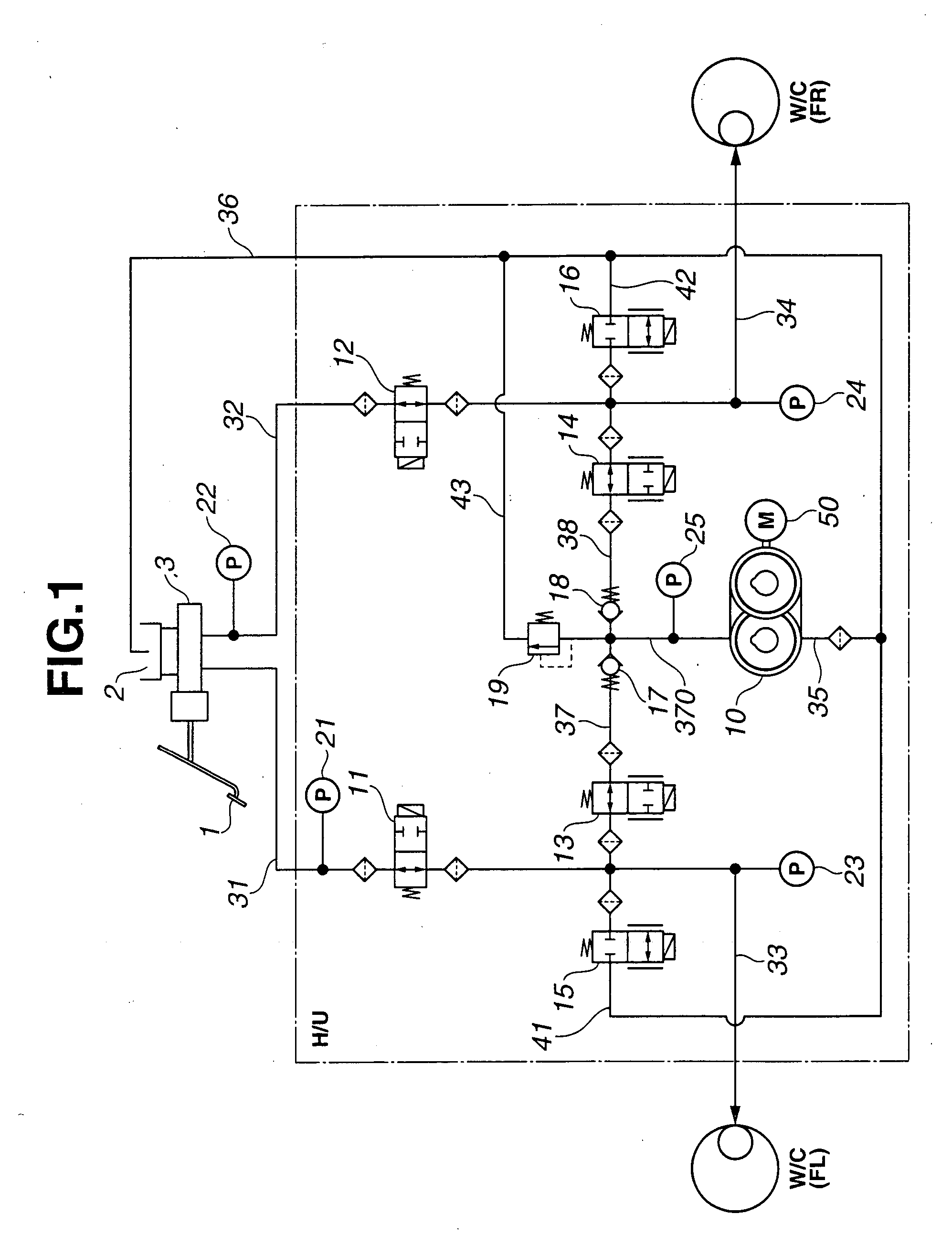

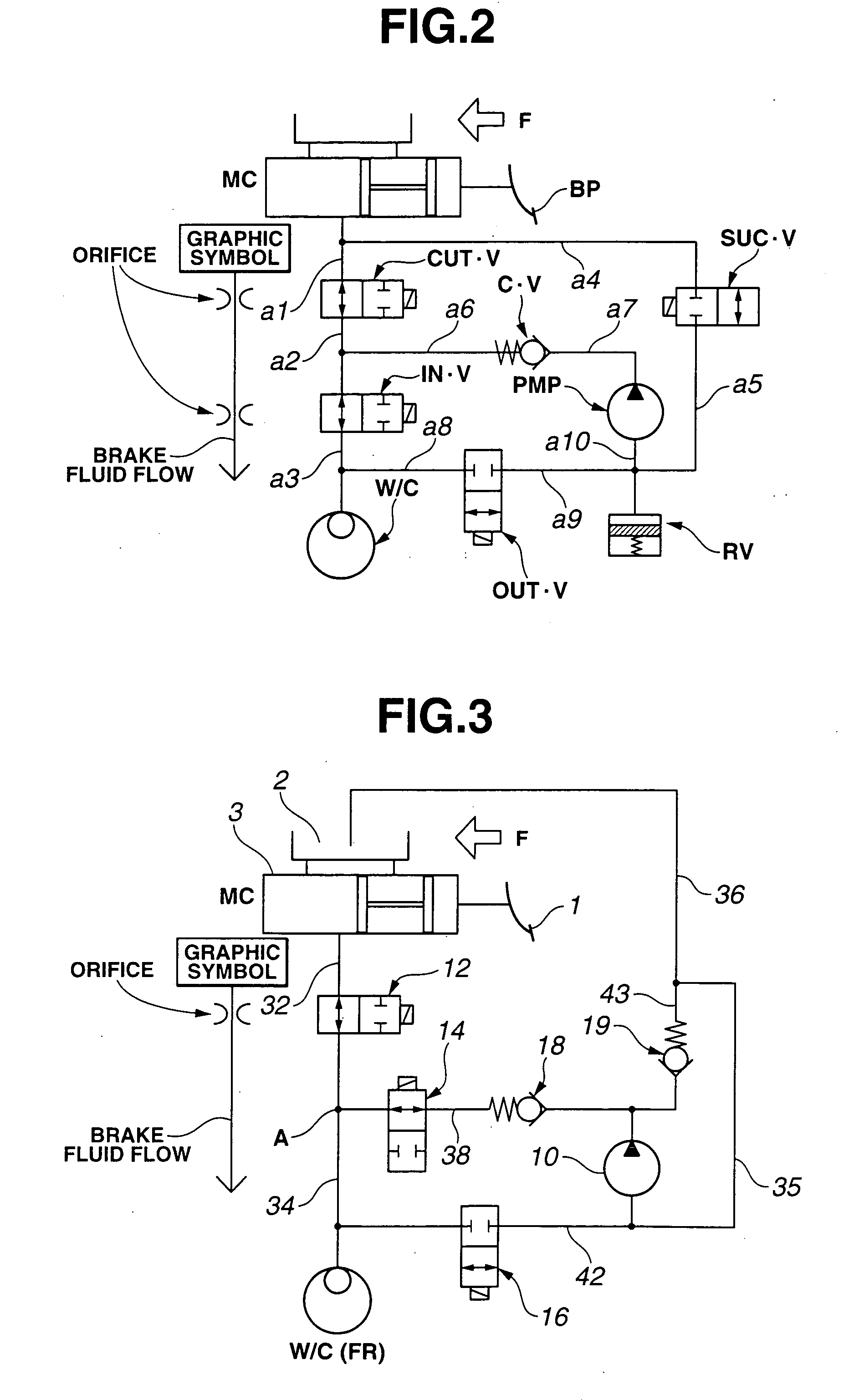

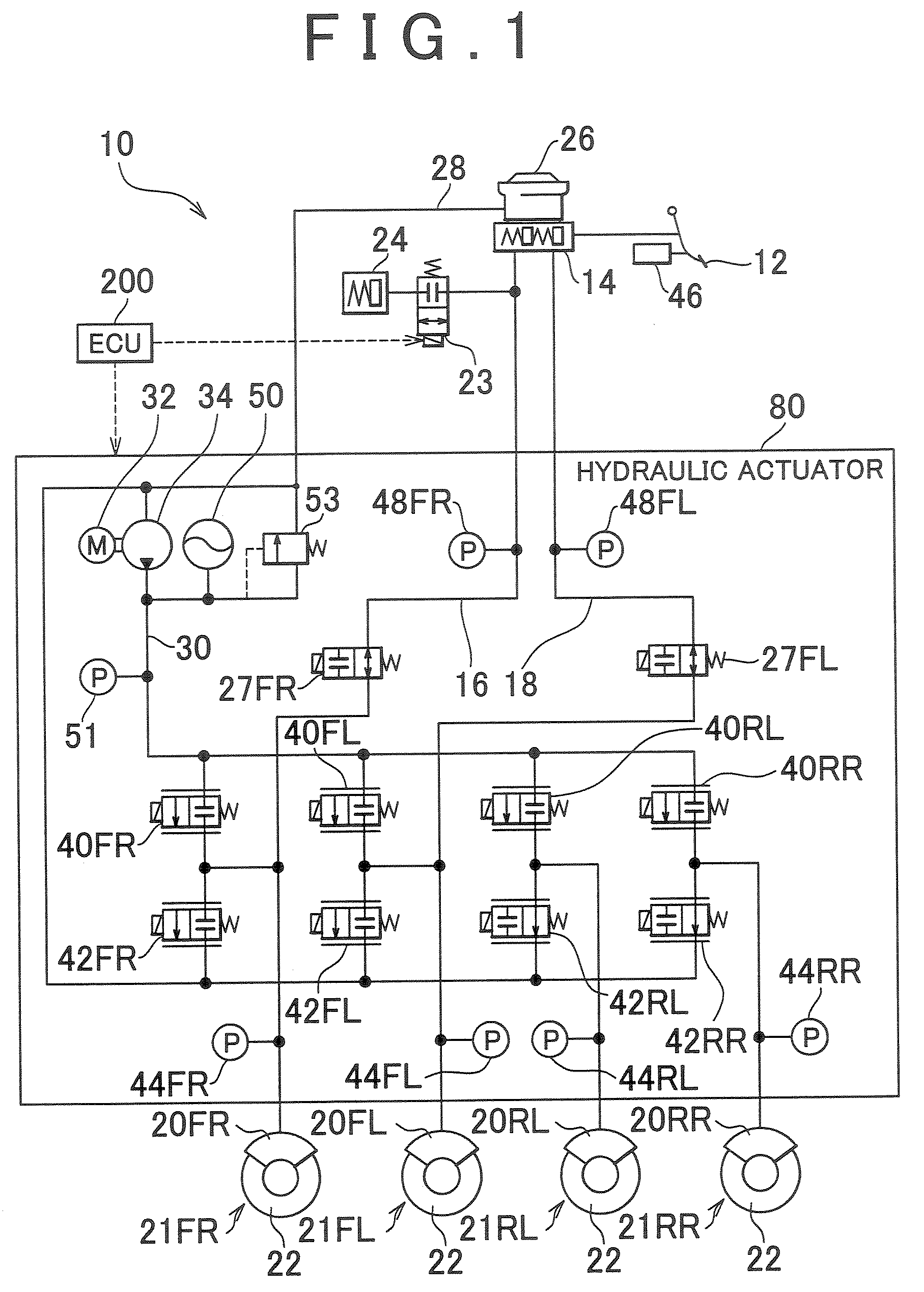

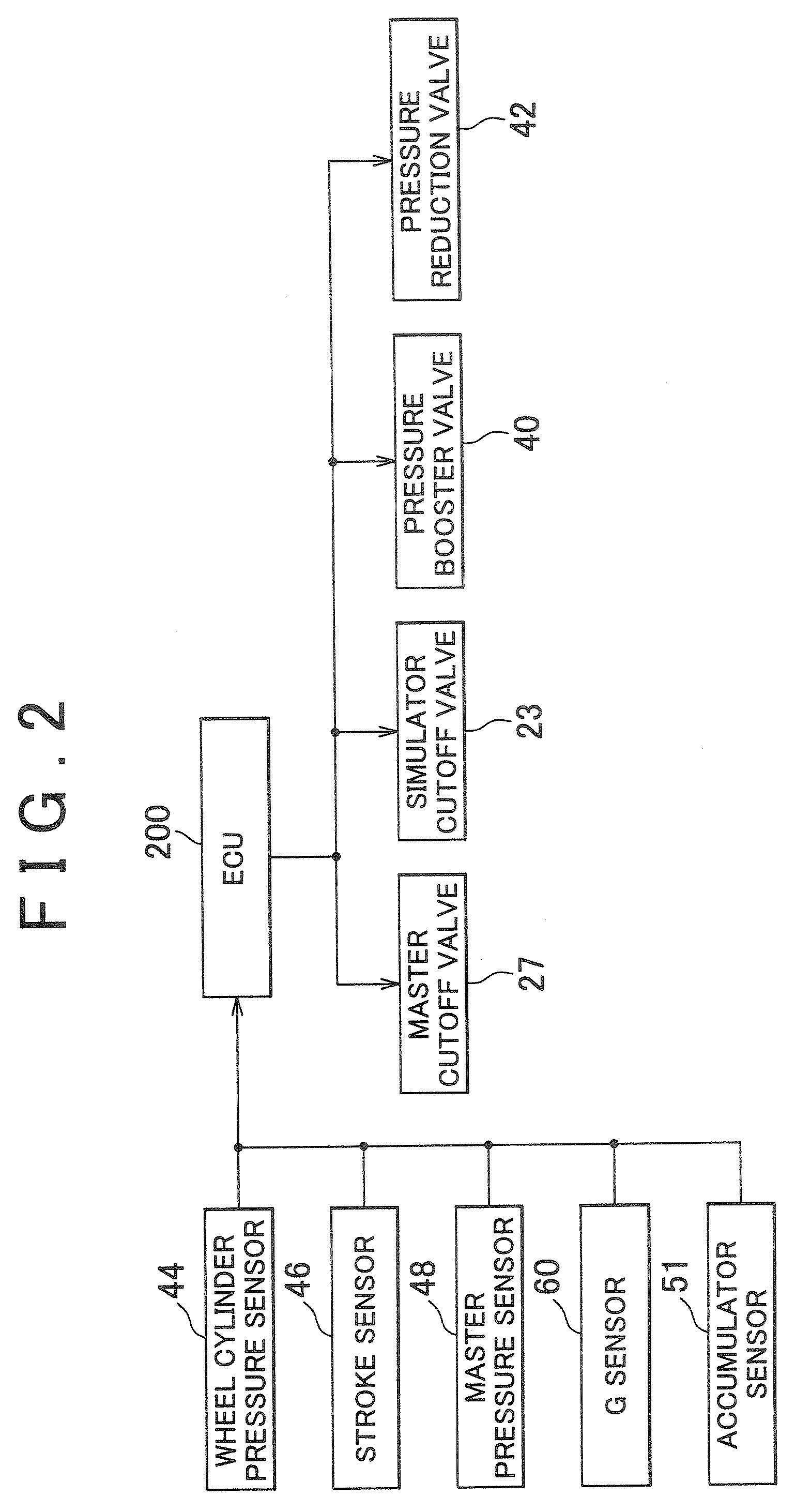

Brake control system

InactiveUS20060087173A1Stable brake performanceReduce energy consumptionBraking action transmissionHydraulic control unitBrake control

In a brake control system for a vehicle employing a brake-by-wire (BBW) hydraulic control unit, a master cylinder serves as a first fluid pressure source and a pump serves as a second fluid pressure source operated during a BBW system normal brake operating mode. Also provided is a manual-brake hydraulic circuit capable of supplying hydraulic pressure from the master cylinder to the wheel-brake cylinder during a fail-safe operating mode. A back-flow prevention device is disposed in a pump outlet passage, intercommunicating the manual-brake hydraulic circuit and the pump outlet, for permitting free flow in one direction from the pump to the wheel cylinder. A normally-open inflow valve is disposed in the pump outlet passage downstream of the back-flow prevention device. A normally-open shutoff valve is disposed in the manual-brake hydraulic circuit upstream of the normally-open inflow valve, and unactuated and opened during the fail-safe operating mode.

Owner:HITACHI LTD

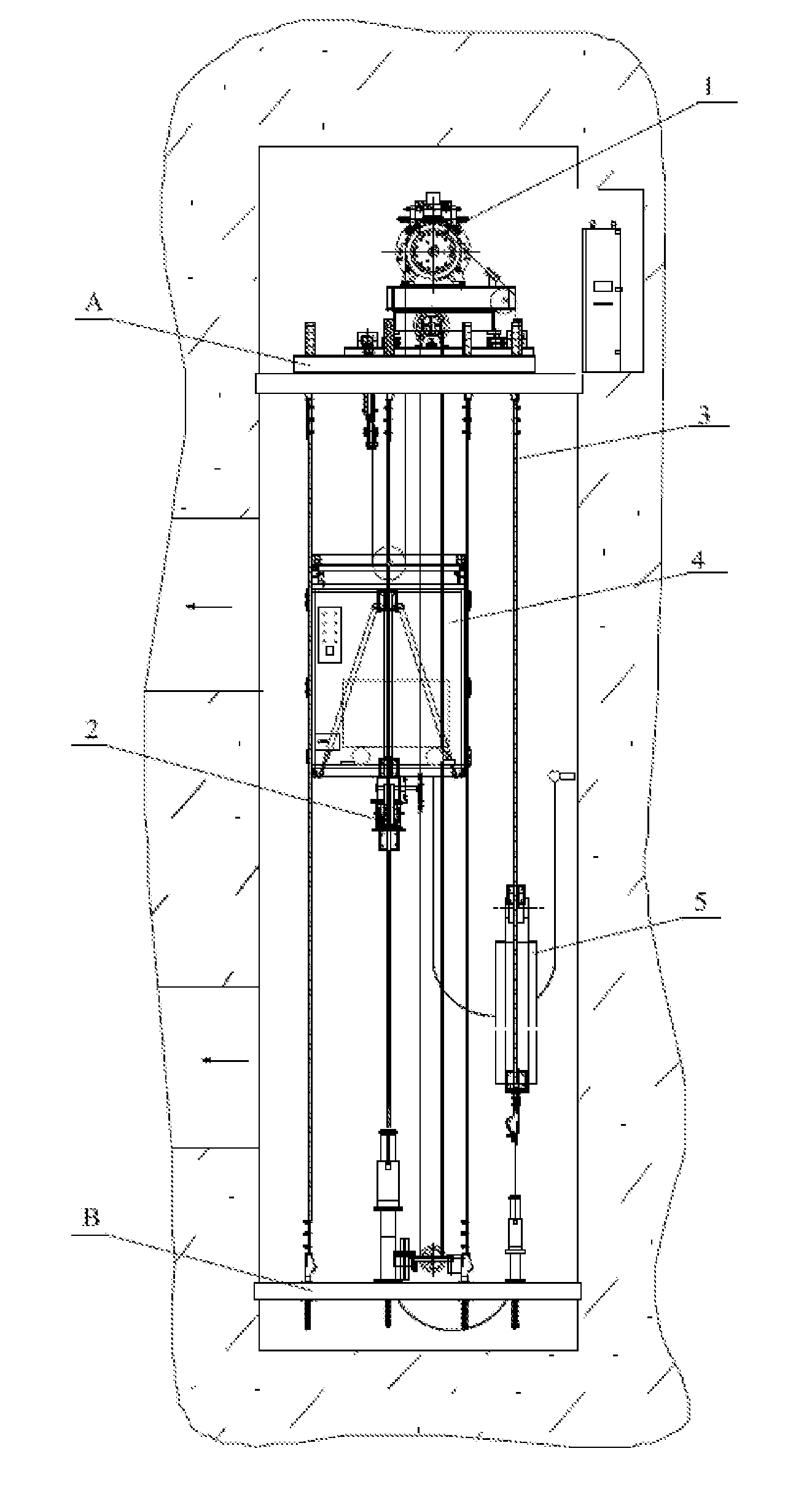

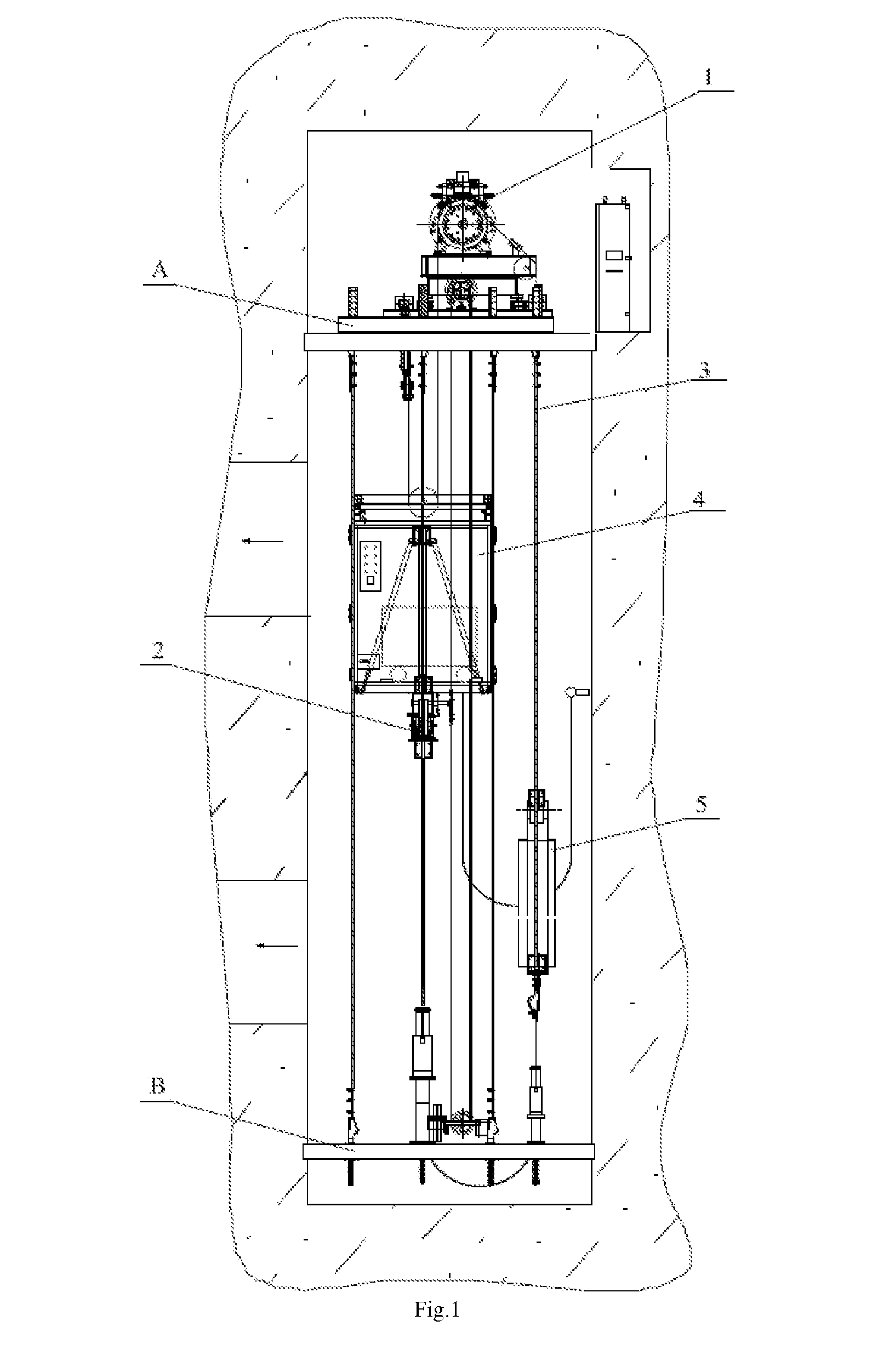

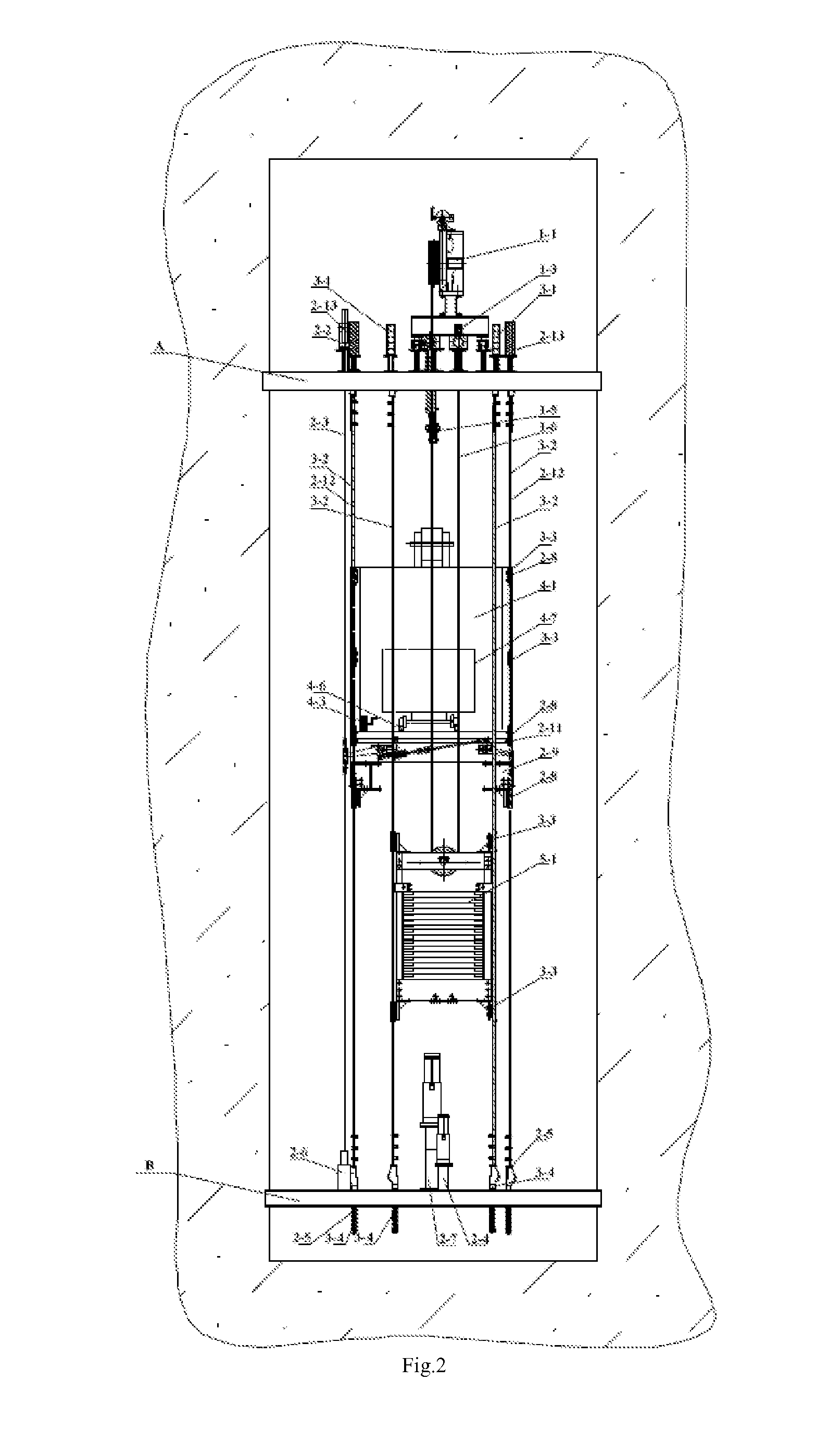

Mining elevator

ActiveUS20140110194A1Compact structureReliable braking capabilityElevatorsBuilding liftsTraction systemAutomotive engineering

A mine elevator is provided having an anti-explosion traction system, an anti-explosion lift car protection system, a flexible guide rail guiding system, a compound lift car, and a counterweight system. The anti-explosion traction system comprises a traction rope tension regulating device, an anti-explosion traction machine, and an anti-explosion control cabinet. The anti-explosion lift car protection system comprises a rope holder, a speed limiter, two hydraulic buffers, a safety clamp, a brake rope, and a brake rope tension buffer device. The flexible guide rail guiding system comprises a steel wire rope guide rail, a guide rail tension device connected to the steel wire rope guide rail and fixed to the an upper platform, a guide rail connection device connected to the steel wire rope guide rail and fixed to a lower platform, and a flexible guide rail guide sleeve fixed to the compound lift car and the counterweight system.

Owner:DONGNAN ELEVATOR +1

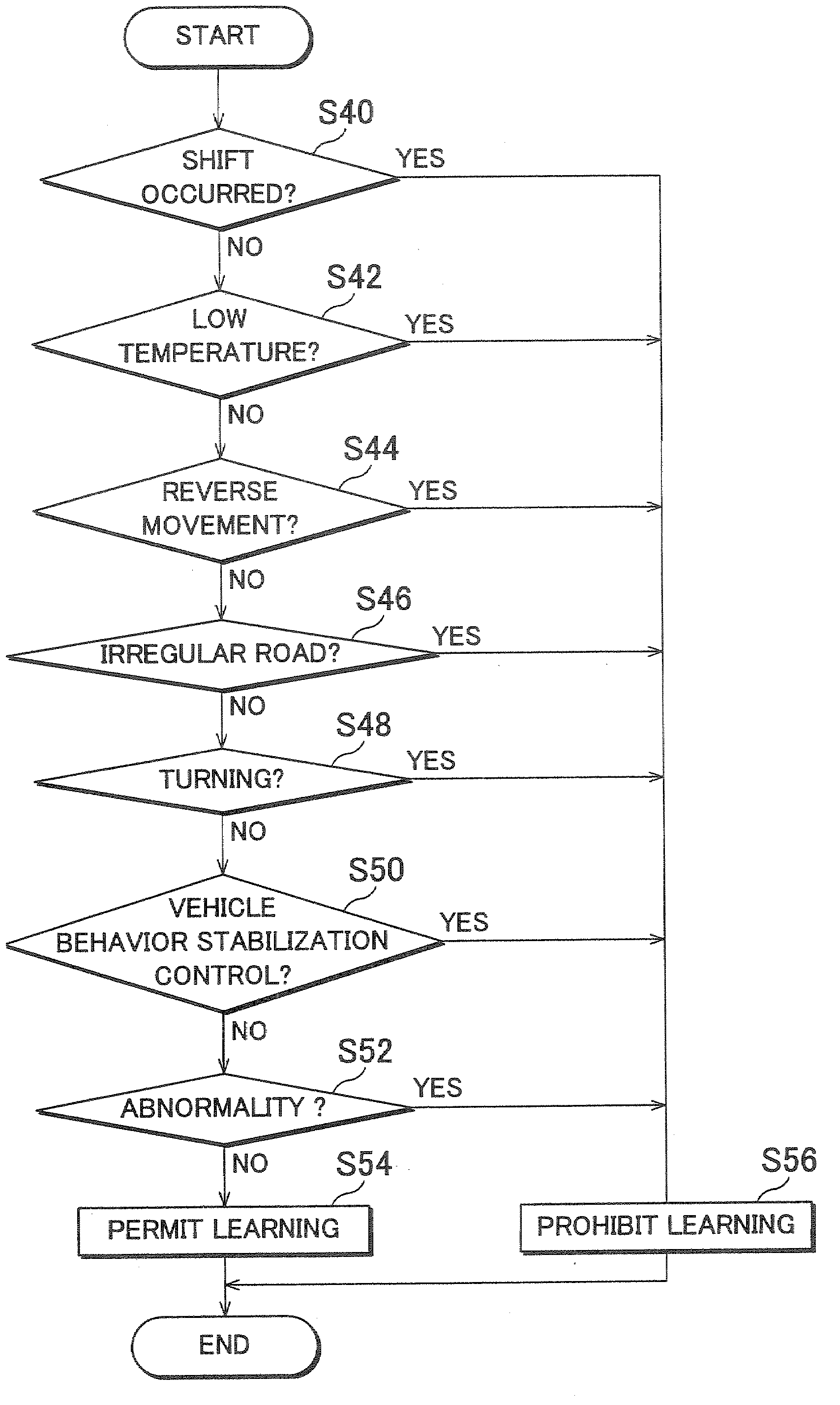

Brake controller and method for controlling brakes

InactiveUS20070216222A1Stabilizing braking effectivenessImprove braking performanceBrake safety systemsEngineeringBrake force

A brake controller is provided, having a braking force application mechanism that presses a friction member against a braked member so as to apply a braking force to a wheel of a vehicle; and a control unit that calculates an index indicating the difference between an estimated braking effectiveness and an actual braking effectiveness, and calculates a correction amount using the index, determines that the index is inaccurate. The control unit further limits the change in the correction amount calculated using the index, if it is determined that the index is inaccurate, and corrects a target value, which is set to control a pressing force of the friction member, based on the correction amount to reduce a variation in a braking effectiveness of the vehicle.

Owner:TOYOTA JIDOSHA KK

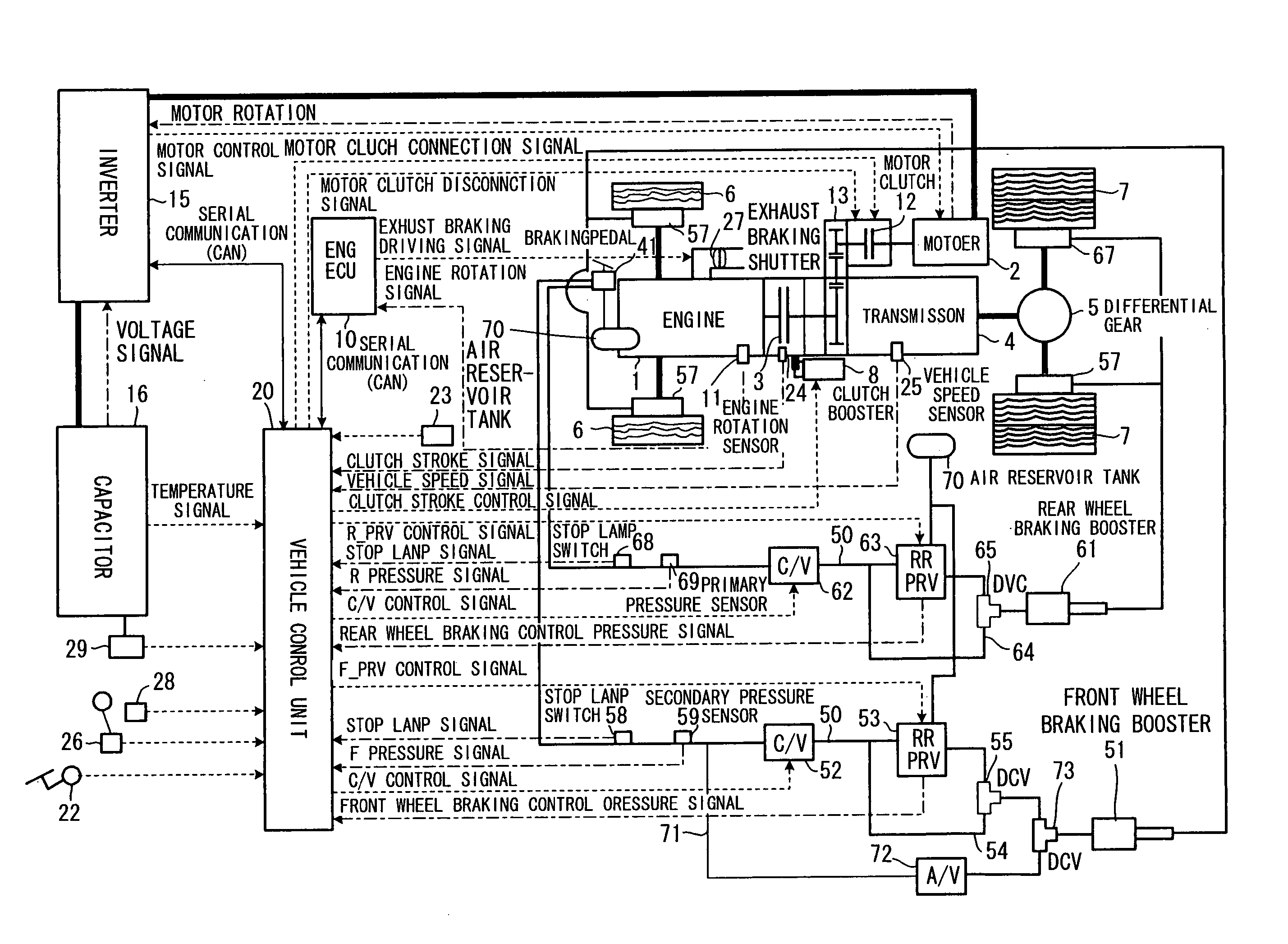

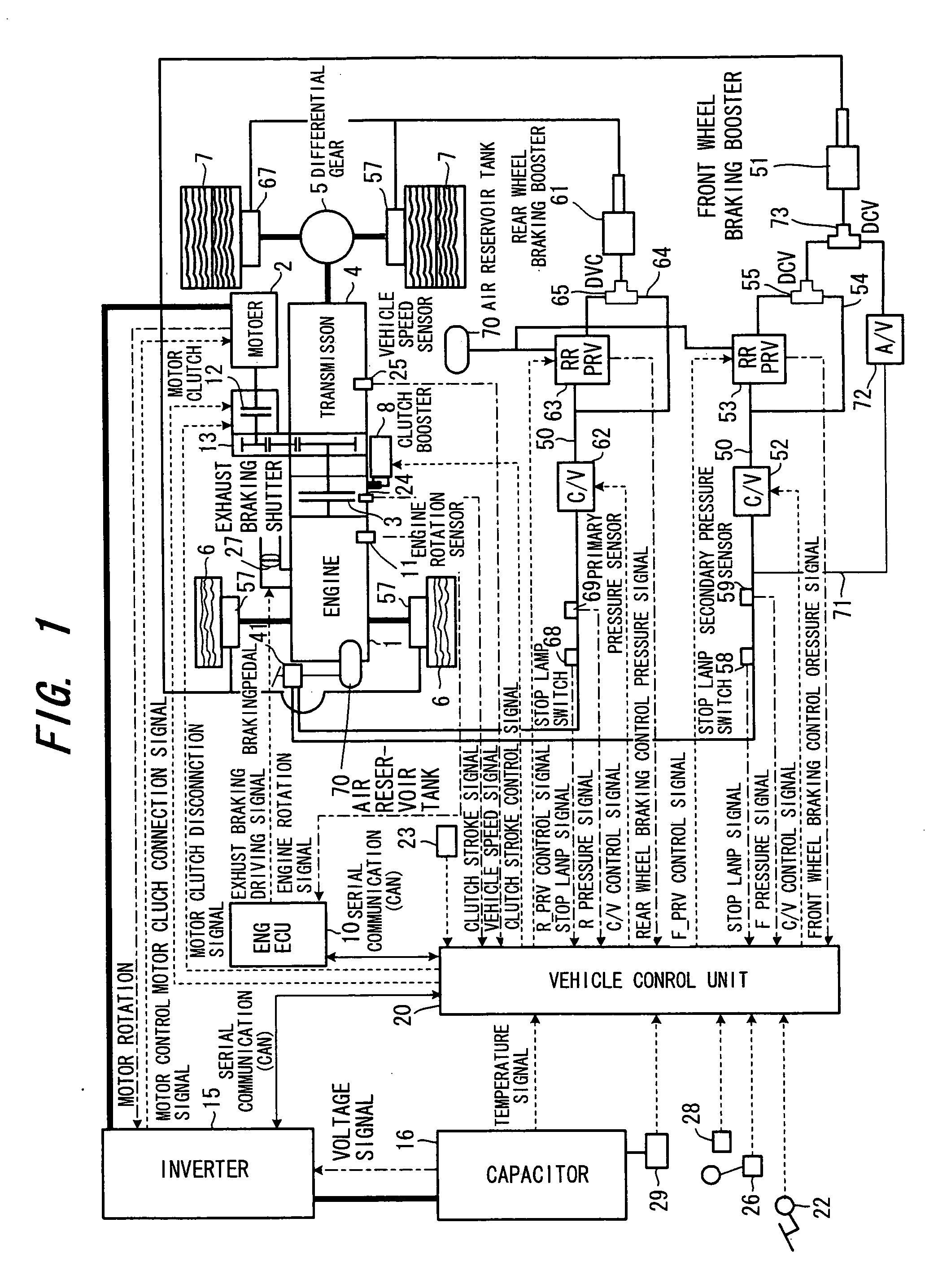

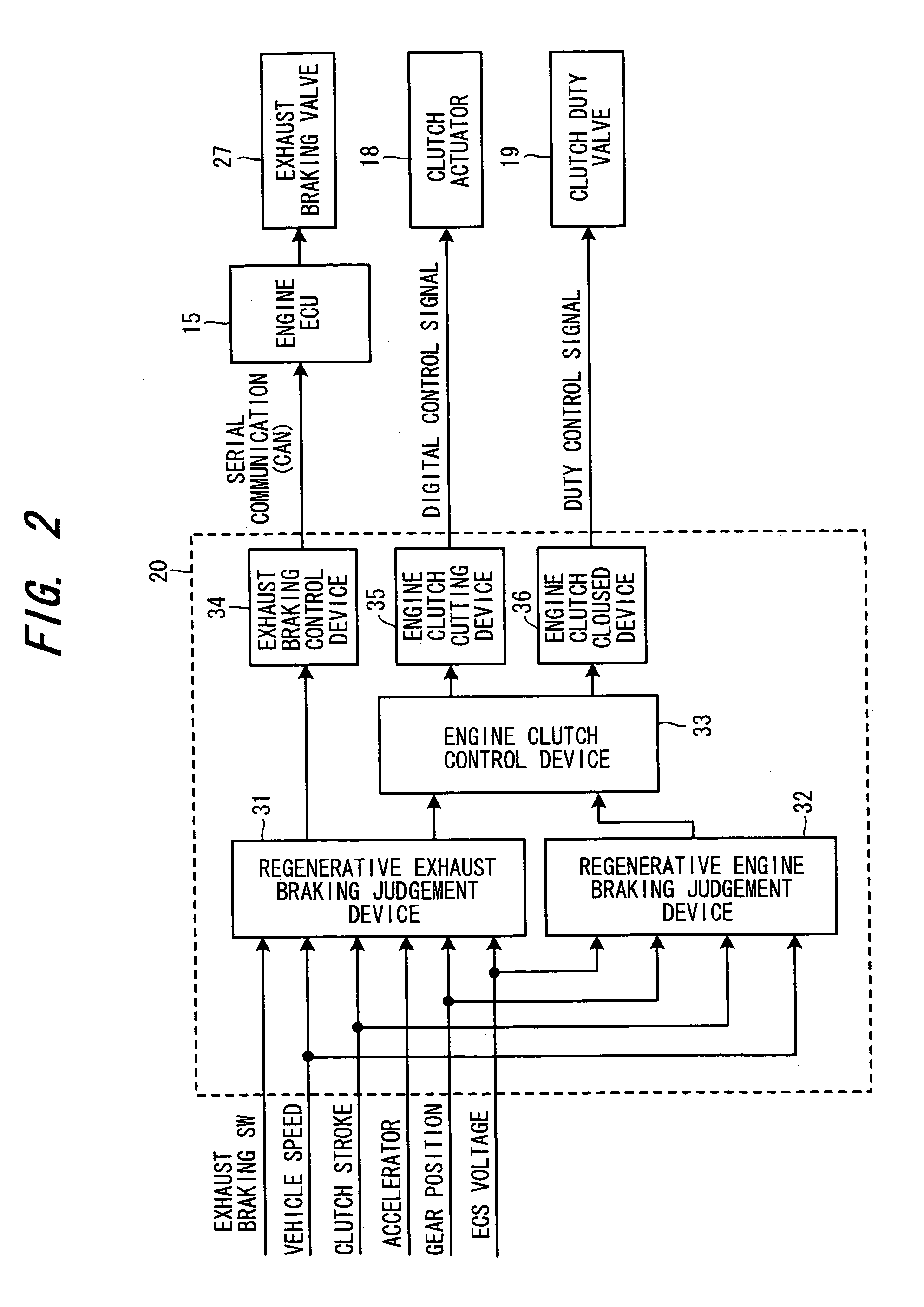

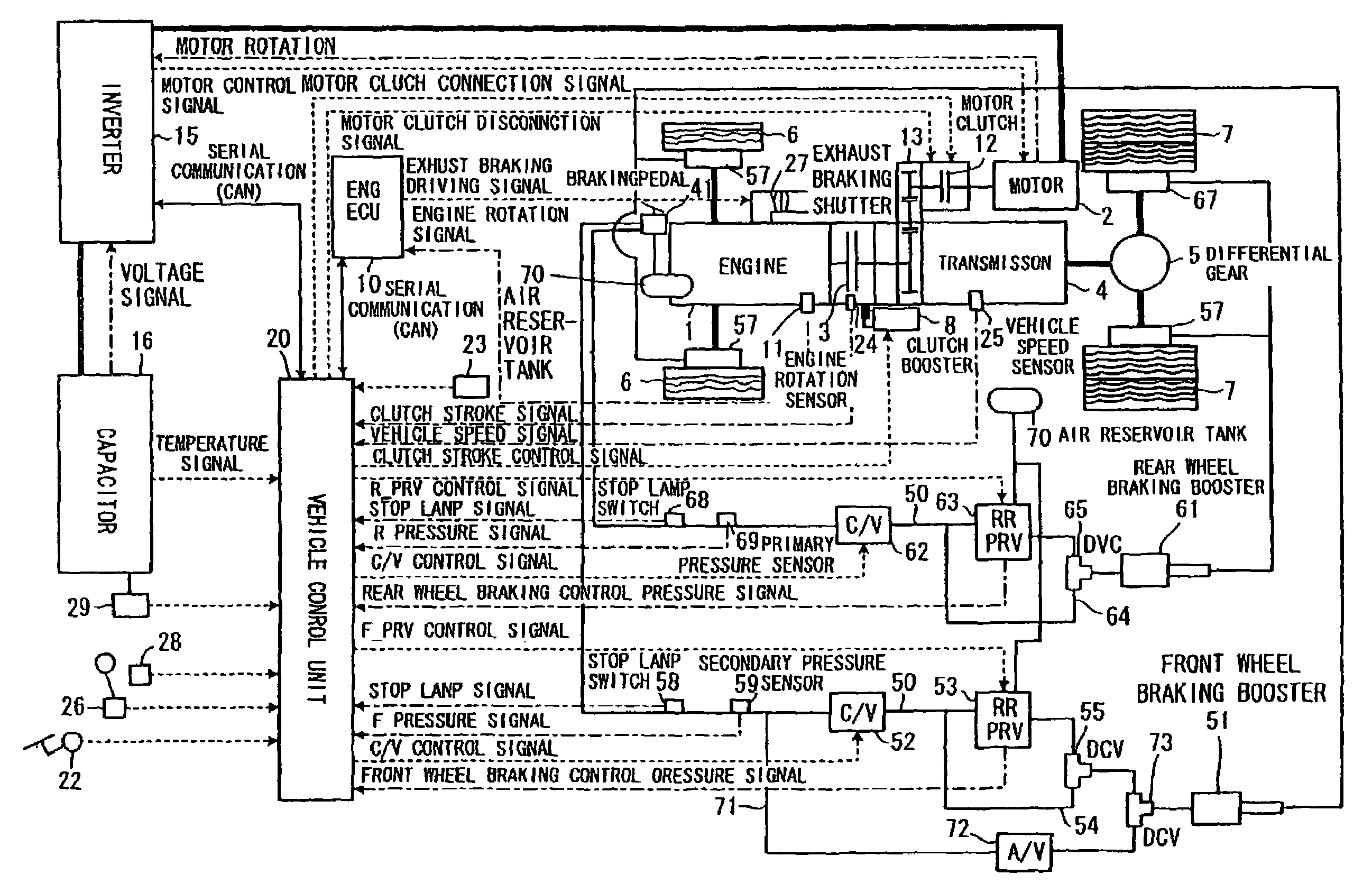

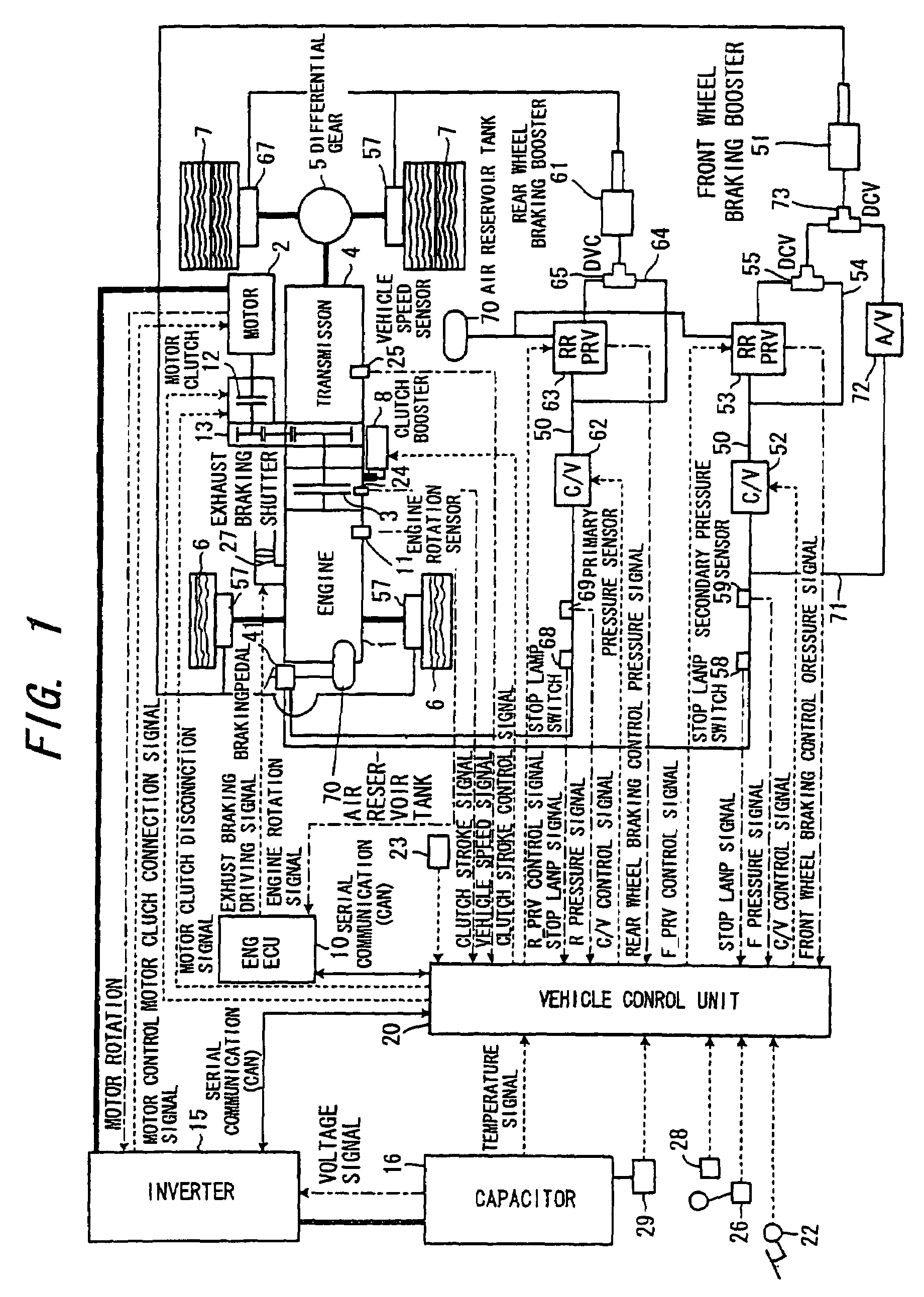

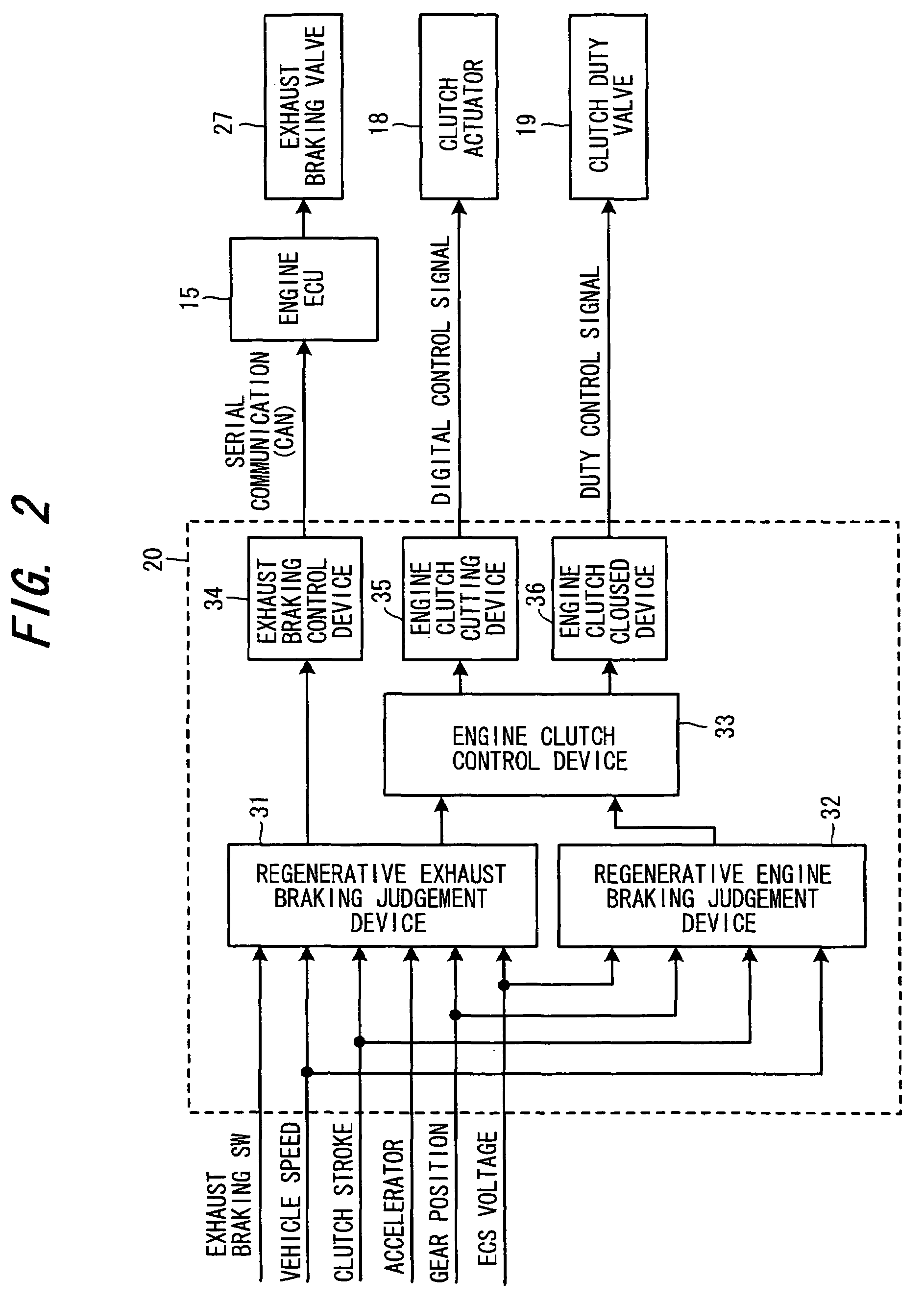

Braking system of hybrid vehicle

ActiveUS20050218717A1Improve braking performanceBraking element arrangementsBraking action transmissionHybrid systemEnergy based

A hybrid system for a vehicle which can ensure a braking stability on a slippery road is provided. Therefore, the system is provided with a motor 2 a rotation force of which is transmitted to a rear wheel 7, braking actuators 57, 67 which brake the front wheel 6 and the rear wheel 7, and proportional valves 53, 63 controlling a braking force introduced into each braking actuator 57, 67. A control unit 20 is so provided that the control unit 20 calculates a required braking energy based upon a vehicle operating condition in demanding a braking and operates the motor 2 as a power generator to generate a power so as to produce the calculated braking energy, as well as controls a braking force of the front wheel 6.

Owner:NISSAN DIESEL MOTOR CO

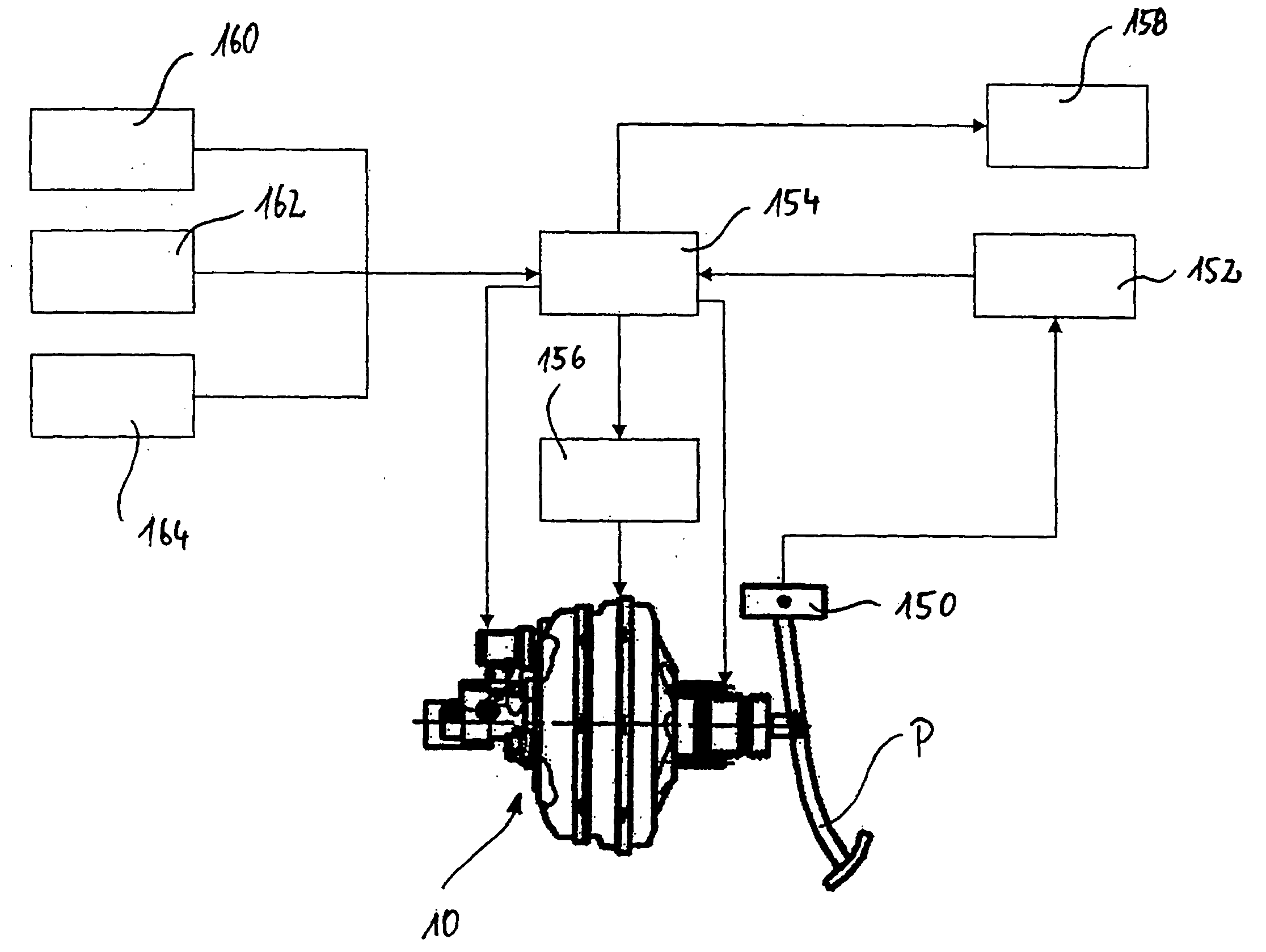

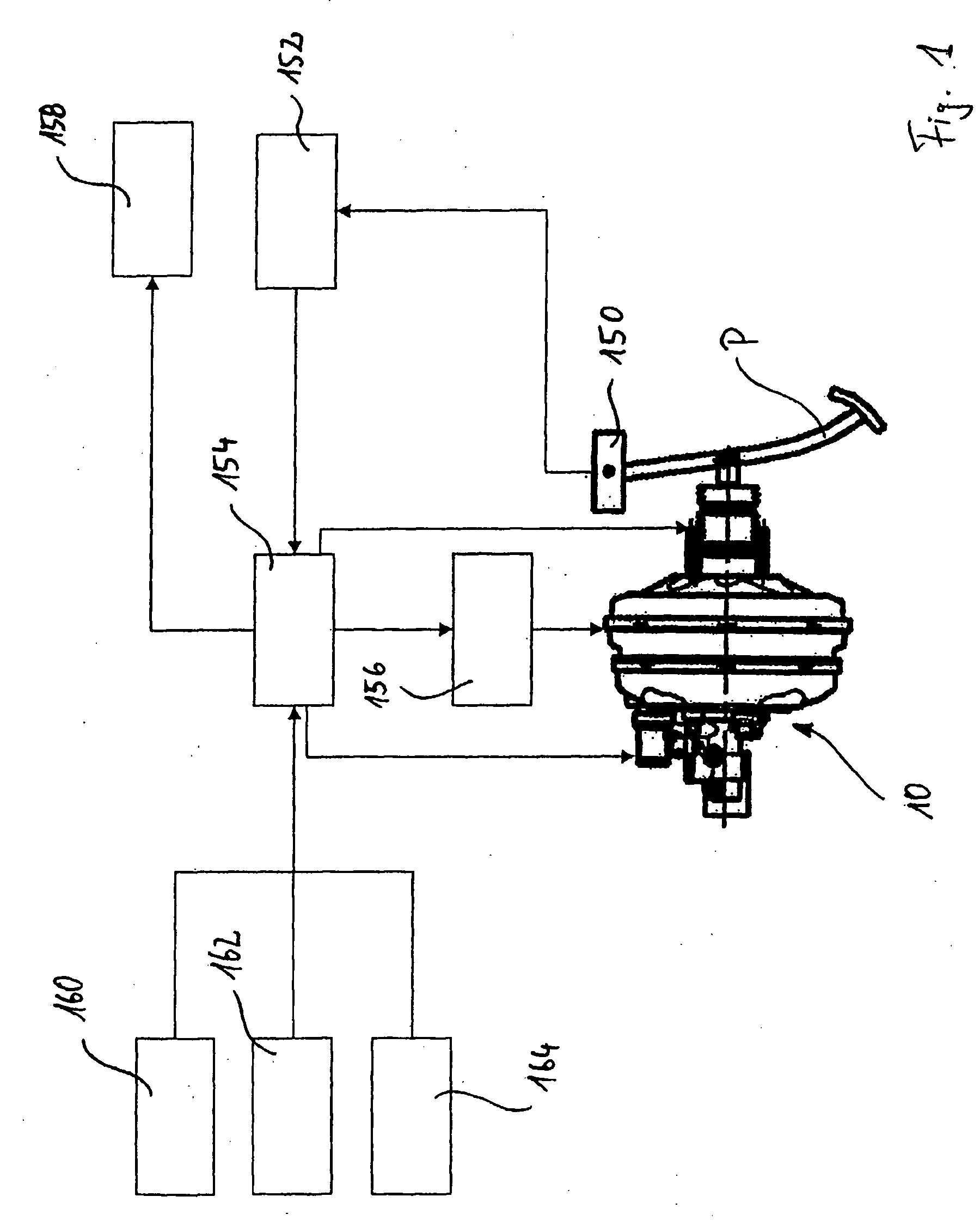

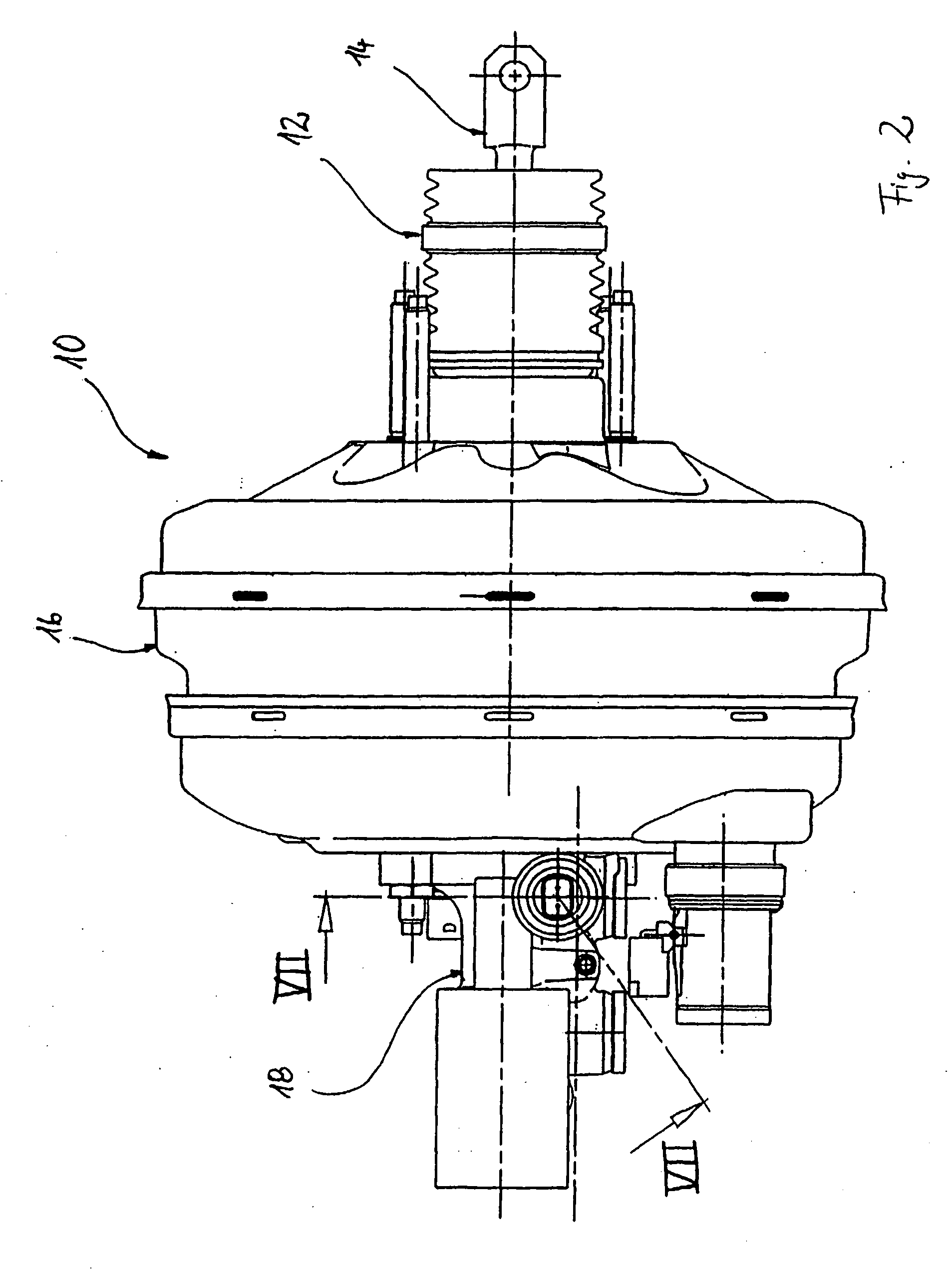

Braking force generator for a hydraulic vehicle braking system

InactiveUS20070001508A1Improve braking performanceSimple and economical and developmentBraking action transmissionFoot actuated initiationsMaster cylinderControl valves

In a brake force generator for a vehicle hydraulic brake system having a force input element, which is connectable or connected to a brake pedal and displaceable in a base housing of the brake force generator, a master cylinder, in which a primary piston is displaceably guided for generating a hydraulic brake pressure, a pedal counterforce simulating device connected to the force input element, a pedal actuation detecting device for detecting a pedal actuation, and an actuating force generating device for exerting an actuating force on the primary piston, it is provided that the actuating force generating device comprises a control valve, a chamber arrangement and an electromagnetic actuator, wherein the chamber arrangement is designed with a vacuum chamber and a working chamber, which is separated from the vacuum chamber by a movable wall and is fluidically connectable to the vacuum chamber by the control valve, and wherein the control valve may be activated in accordance with the detected pedal actuation.

Owner:LUCAS AUTOMOTIVE GMBH

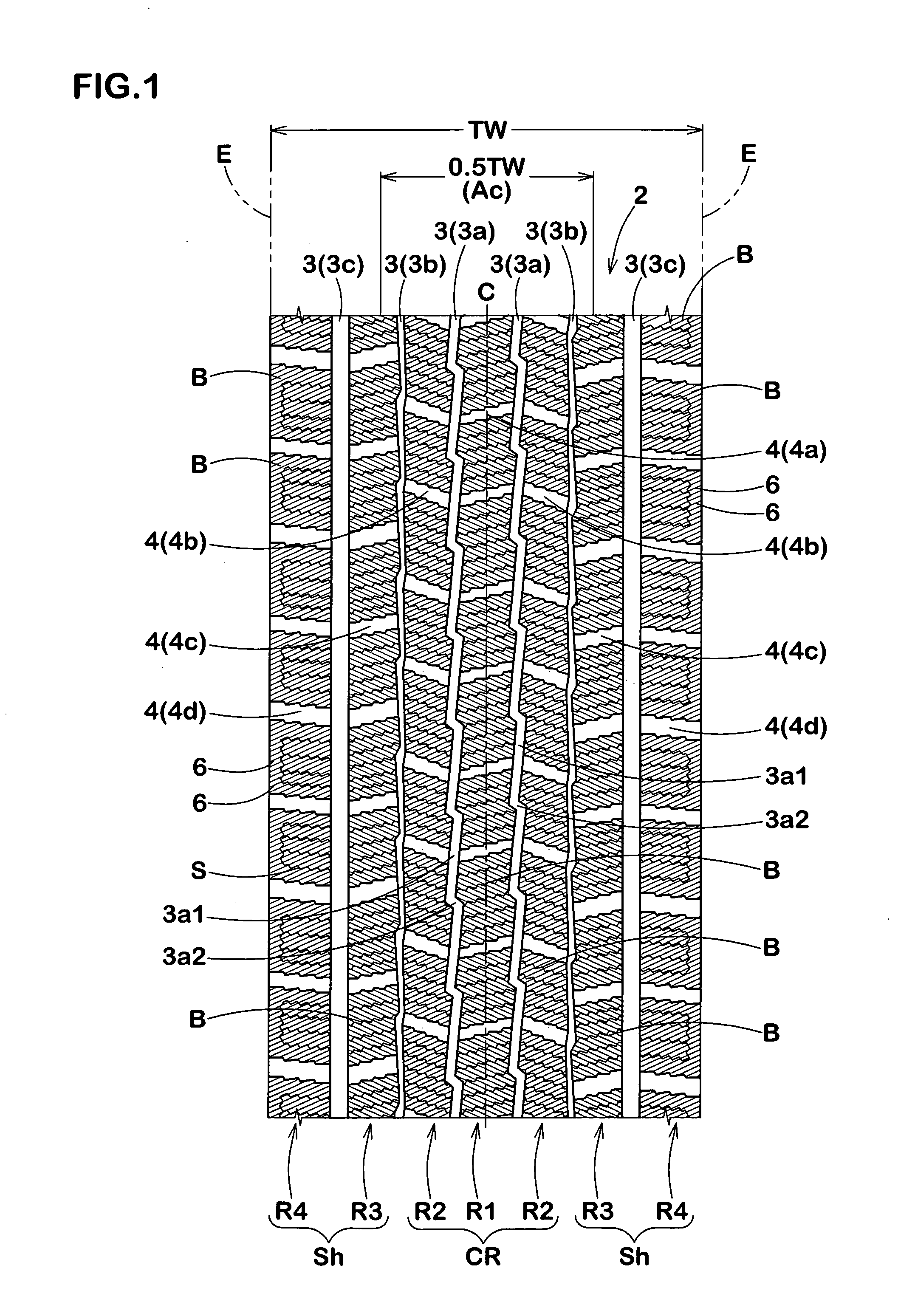

Pneumatic tire

ActiveUS20070284026A1Moderate shear strainUneven wearHeavy duty tyresHeavy duty vehicleEngineeringTread

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

A kind of heat-resistant modified bamboo fiber and its method for automobile brake friction material

InactiveCN102295783AReduce manufacturing costRich sourcesOther chemical processesFriction liningFiberPhenol formaldehyde resin

The invention relates to a heat-resisting modified bamboo fiber and a method for preparing an automotive brake friction material from the same. The heat-resisting modified bamboo fiber is prepared by modifying a bamboo fiber through borax. A composite friction material is prepared from the heat-resisting modified bamboo fiber, phenolic resin, inorganic whisker, a friction performance regulator and the like, so that the environmental-friendly automotive brake composite material with excellent friction coefficient, high stability, low wear rate and good heat fading resistance is obtained. Compared with an unmodified bamboo fiber, the bamboo fiber subjected to heat-resisting modification, which is disclosed by the invention, has the advantages that the heat resistance of the bamboo fiber is obviously improved; and the high temperature friction wear performance of the composite friction material prepared from the heat-resisting modified bamboo fiber is also obviously improved.

Owner:FUZHOU UNIVERSITY

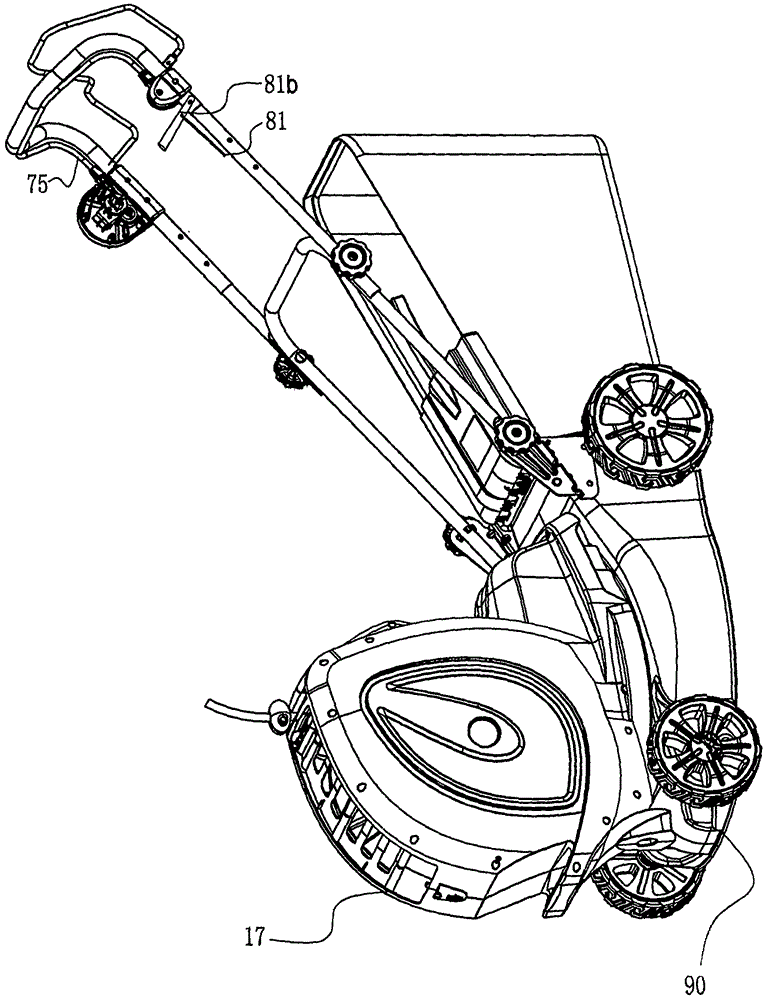

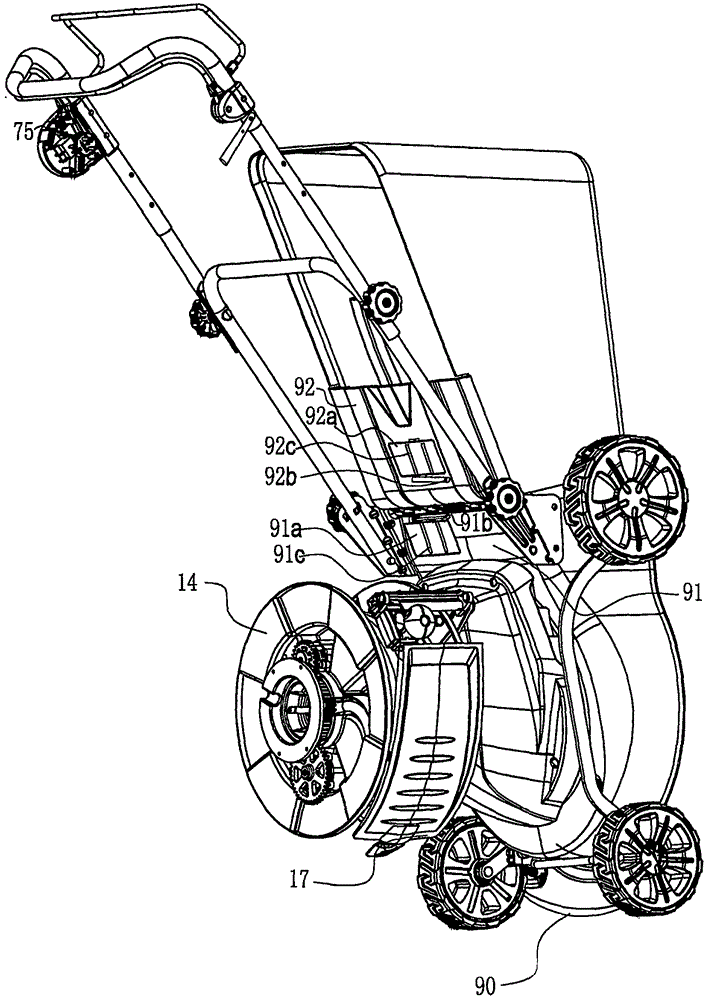

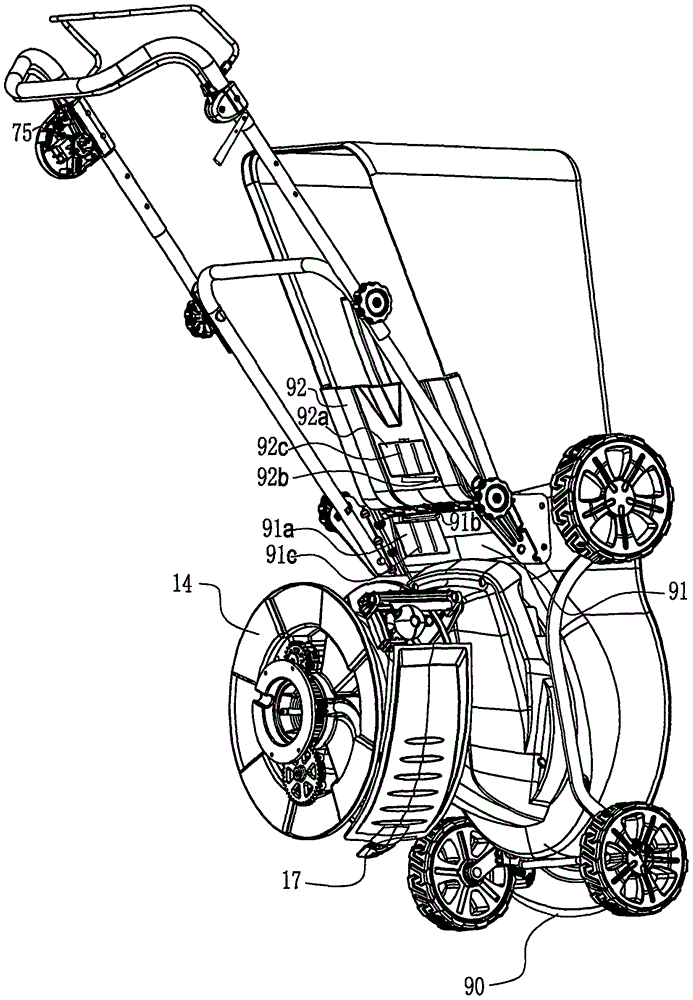

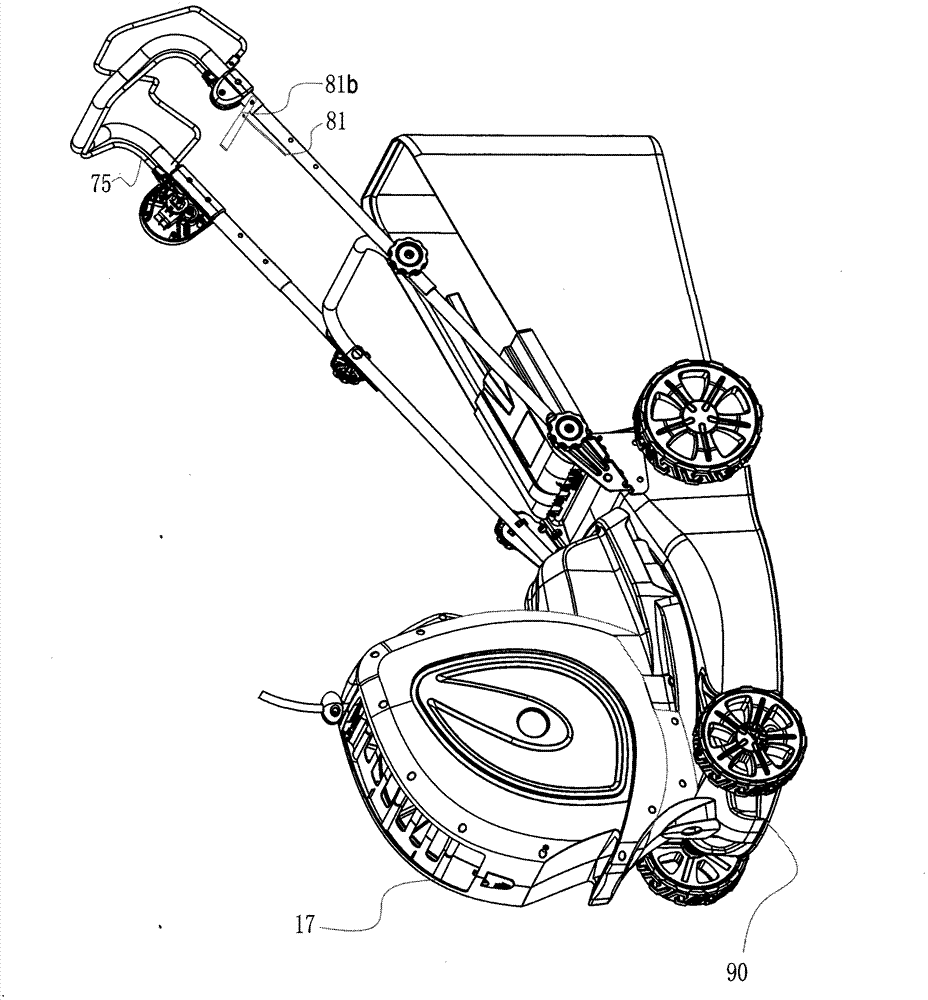

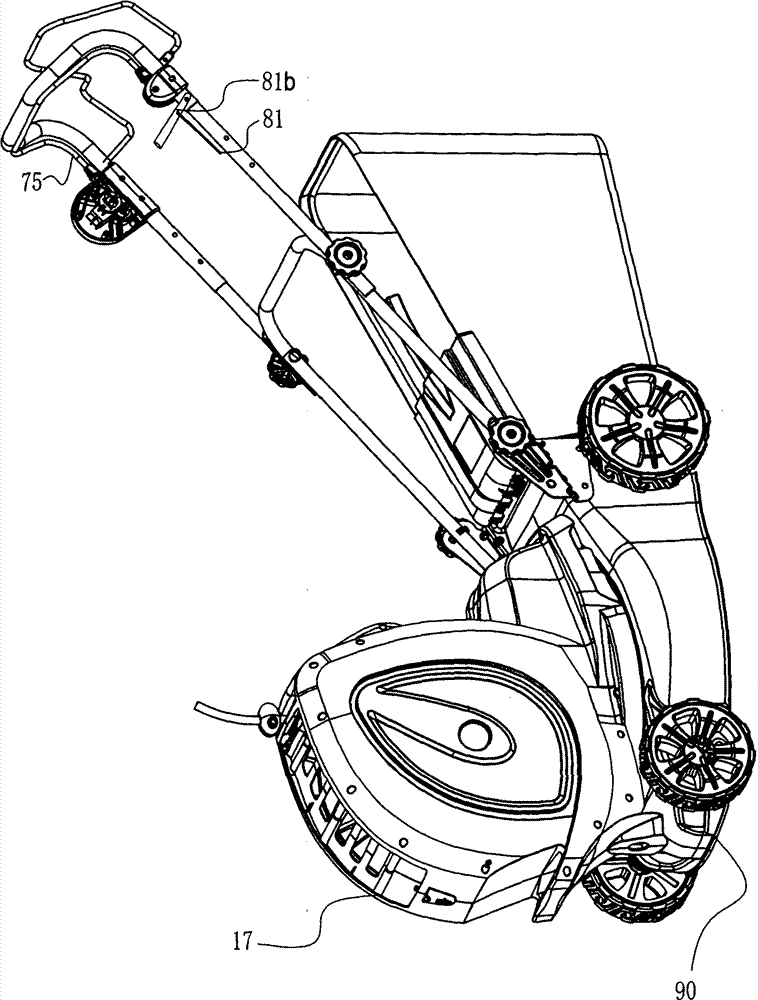

Blocked-grass lower-poking and upper-cutting mechanism for cleaning grass discharging passage of hand mower

InactiveCN106034538ASolve the problem of weed blockingSolving Worldwide Problems of MalfunctionMowersAgricultural undercarriagesLogarithmic spiralMower

The invention relates to a blocked-grass lower-poking and upper-cutting mechanism for cleaning a grass discharging passage of a hand mower. According to the blocked-grass lower-poking and upper-cutting mechanism, a lower poking mechanism is mounted on a rear shaft of the bottom of the mower, and meanwhile, an upper cutting mechanism is mounted at a grass discharging port of the grass discharging passage of the mower; the lower poking mechanism contains grass discharging blades (j1) and direction-changing bevel gears (j2), the rotating direction of a third direction-changing bevel gear is reverse to that of a first direction-changing bevel gear and that of the rear shaft, and thus, the rotating and direction changing of the grass discharging blades (j1), which are connected with the third direction-changing bevel gear and sleeve the rear shaft, are achieved; and the upper cutting mechanism contains upper cutting blades (j3) and a belt-pulley belt (j4), and a rotating shaft of the upper cutting blades (j3) is driven by the belt-pulley belt (j4). The direction-changing bevel gears are Klingen-Berg cycloidal-tooth hypoid gears. At least one of the upper cutting blades (j3) of the upper cutting mechanism of the blocked-grass lower-poking and upper-cutting mechanism for cleaning the grass discharging passage of the hand mower has a bent segment, and a curve of the bent segment is a logarithmic spiral which has the characteristic that pressure angles are equal everywhere.

Owner:NINGBO DAYE GARDEN EQUIP

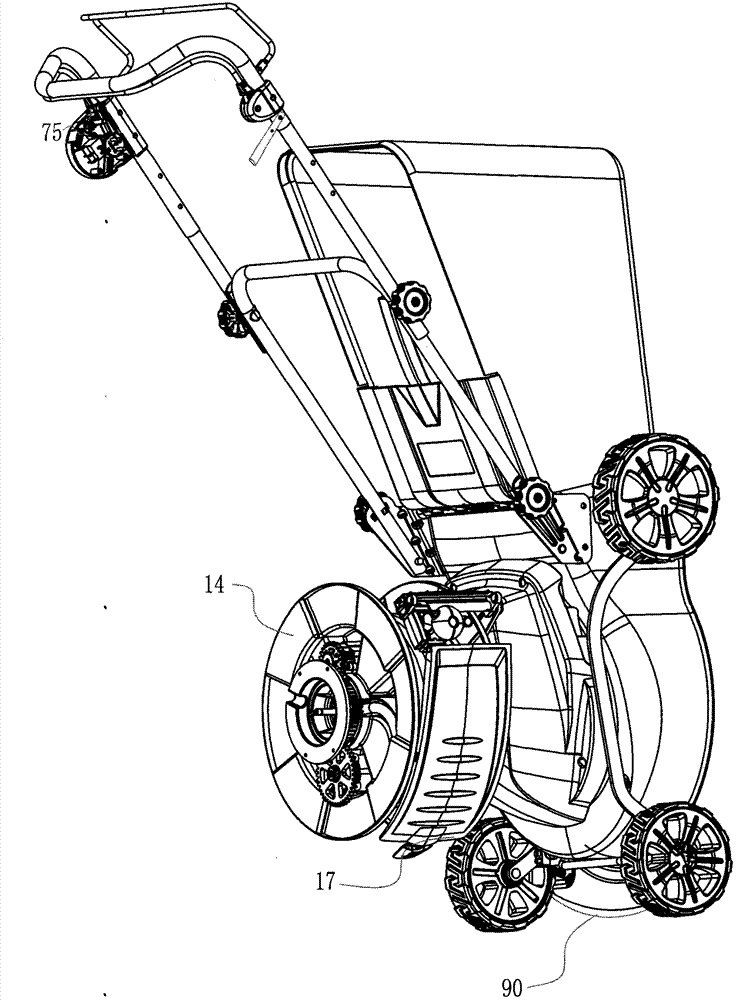

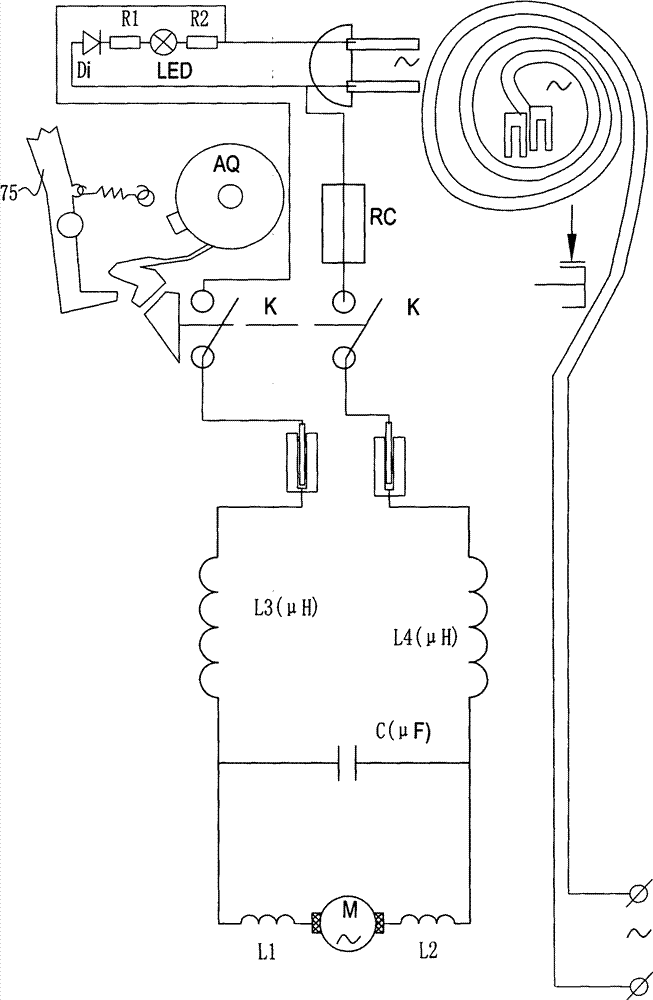

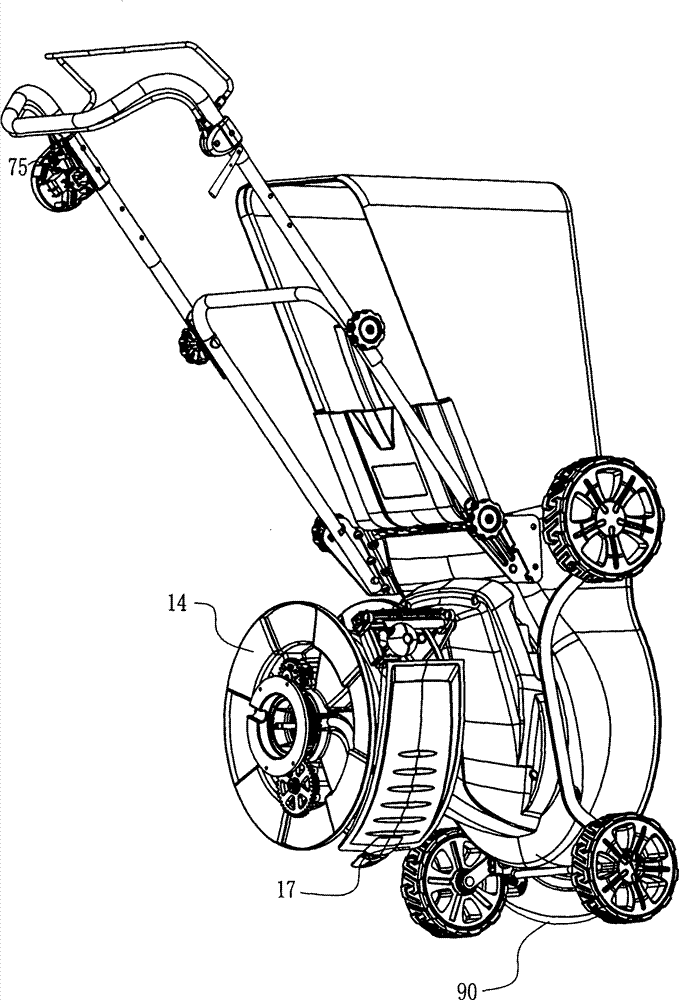

Automatic grass discharging passage cleaning mechanism of rear shaft of bottom of mower

InactiveCN106034537ASolve the problem of weed blockingSolve world problemsLawn-mowersGear wheelEngineering

The invention relates to an automatic grass discharging passage cleaning mechanism of a rear shaft of the bottom of a mower, i.e., a lawn mower which is applied to the lawn pruning of places such as courtyards, parks and road sides. The automatic grass discharging passage cleaning mechanism can be applied to multiple models such as a three-wheeled mower, a series-excited-machine electric mower and a lawn mower, wherein the three-wheeled mower is provided with a grass mowing head, and a front single wheel of the three-wheeled mower is adjusted upwards in a manner that gear engaging is carried out through turning an angle by a flat bar; the series-excited-machine electric mower is provided with a chassis, an anti-collision safeguard and a tape-function wave-disc brake; and the lawn mower comprises an anti-collision safeguard, a tape-function wave-disc brake, a grass blockage poking device and a grass crushing preventer, wherein the anti-collision safeguard is arranged at the front of a chassis of the mower, the tape-function wave-disc brake is arranged at the middle part of the chassis of the mower, and gears of the grass blockage poking device and the grass crushing preventer are driven by an electric motor. The automatic grass discharging passage cleaning mechanism is mounted on the rear shaft of the bottom of the mower. The automatic grass discharging passage cleaning mechanism of the rear shaft of the bottom of the mower comprises grass discharging blades (j1) and direction-changing bevel gears (j2), so that the rotating and direction changing of the grass discharging blades are facilitated.

Owner:NINGBO DAYE GARDEN EQUIP

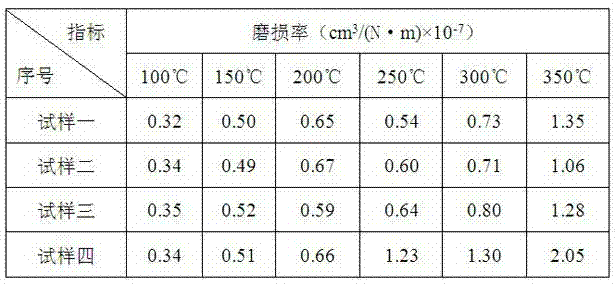

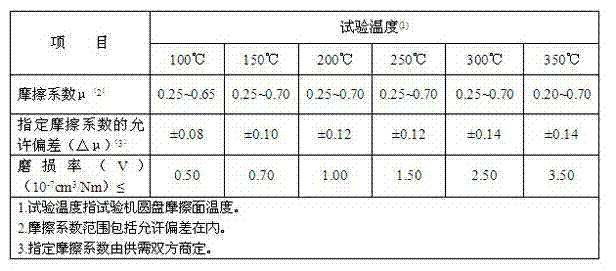

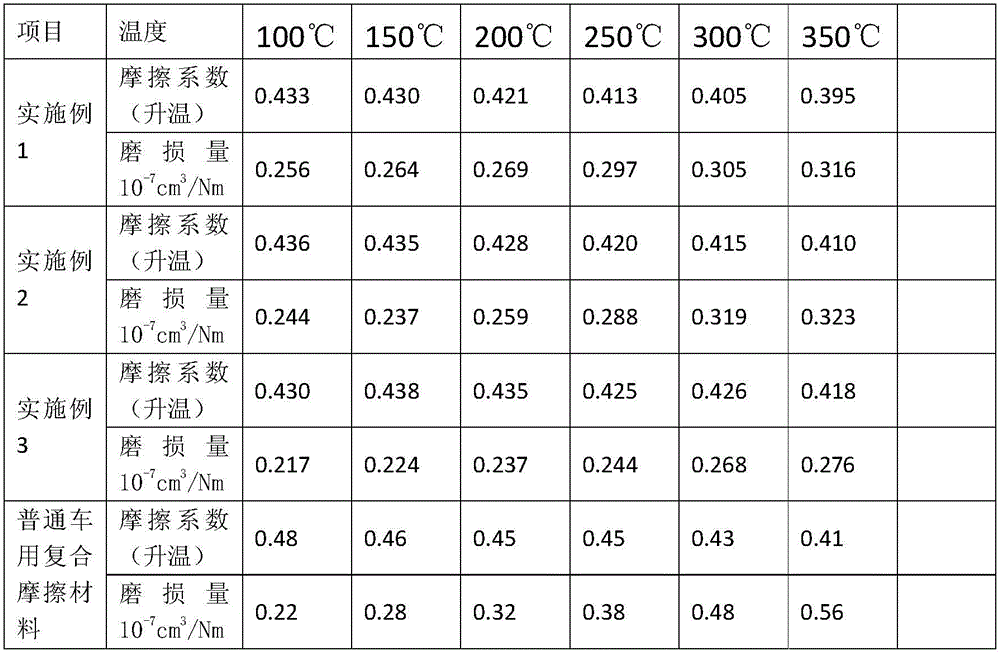

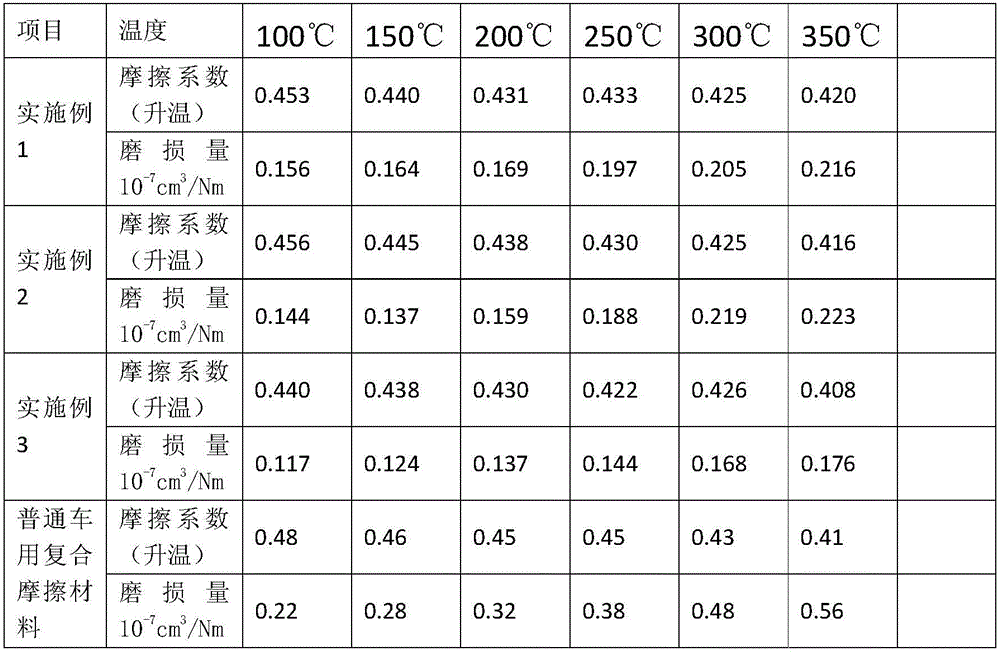

Automotive copper-based powder metallurgy composite friction material and manfuacturing method thereof

InactiveCN105778406AModerate modulus of elasticityStable coefficient of frictionPowder metallurgyPowder mixture

The invention discloses an automotive copper-based powder metallurgy composite friction material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that a copper-based powder metallurgy friction material is obtained; secondly, the copper-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the copper-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is cooled to the room temperature and then is discharged from the furnace. The automotive copper-based powder metallurgy composite frictional material has both advantages of high temperature resistance and low abrasion as the copper-based powder metallurgy friction material and high ductility and low hardness as the resin-based composite friction material.

Owner:SOUTH CHINA UNIV OF TECH

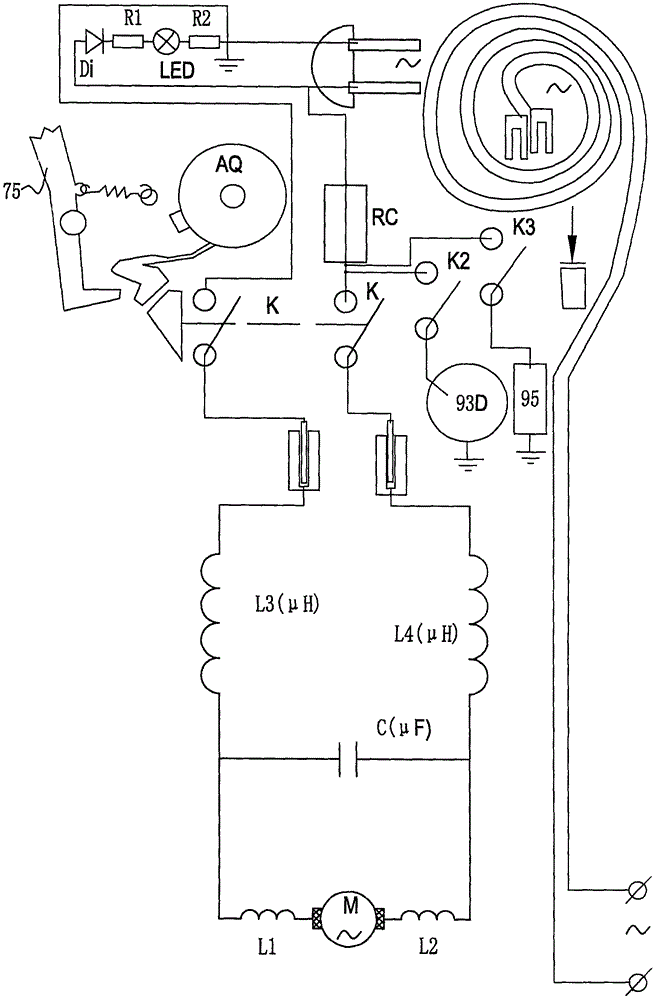

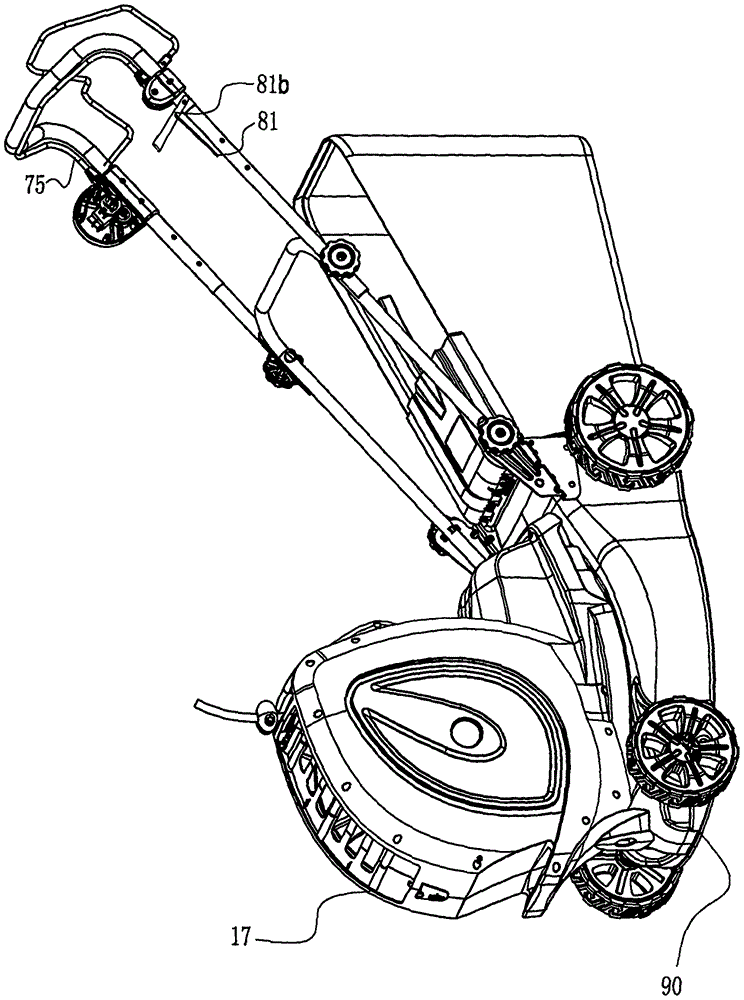

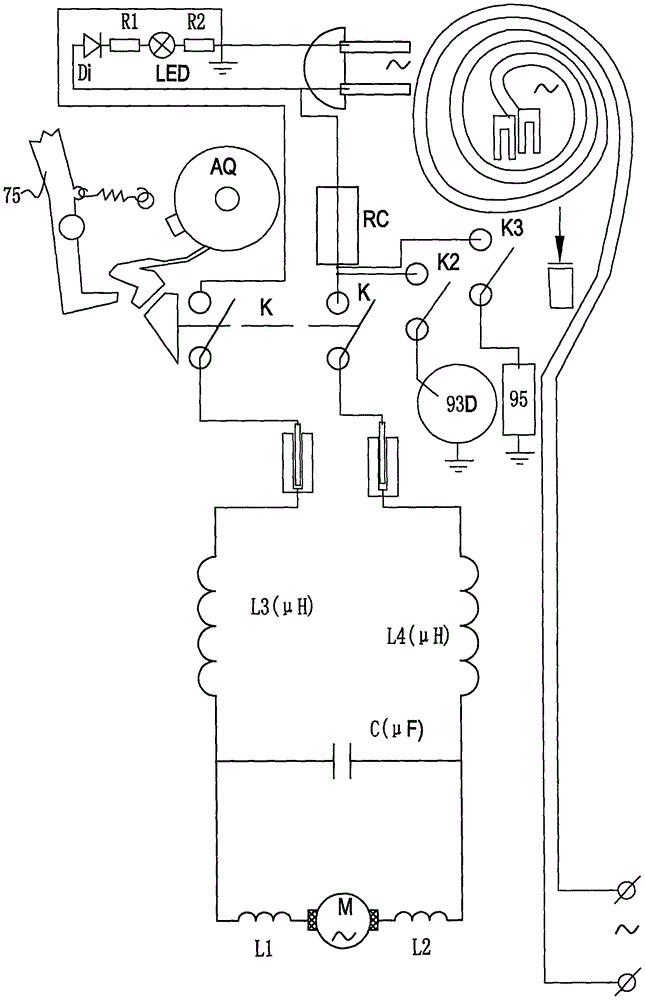

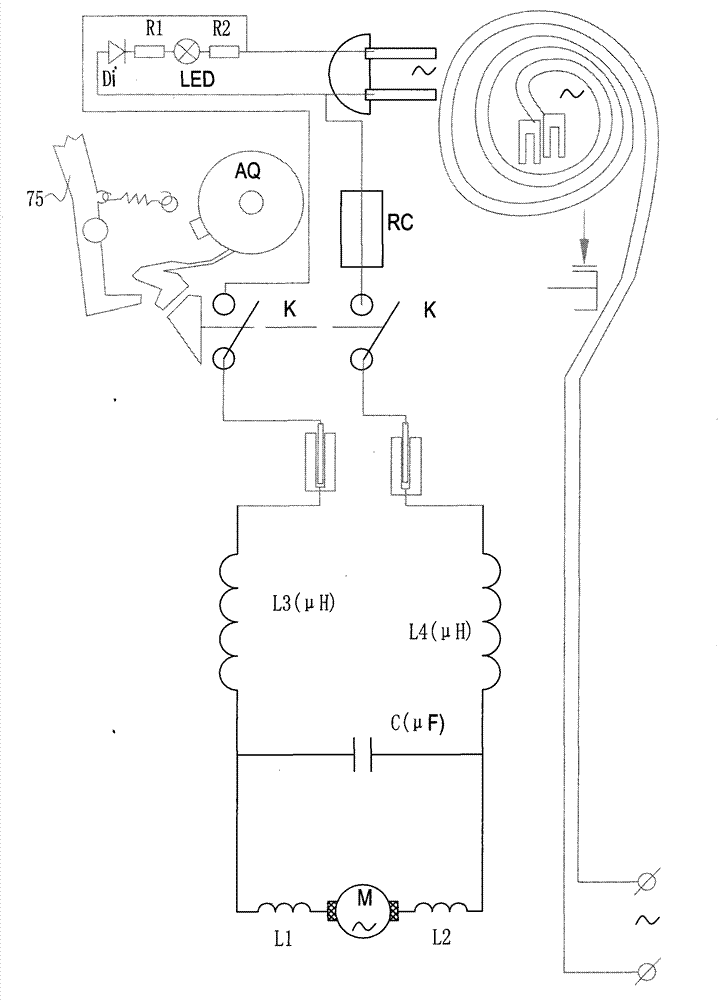

Series motor electric mower with chassis anti-colliding protector and function wave disc brake

ActiveCN102783307ASolving Worldwide Problems of MalfunctionSolve world problemsLawn-mowersDisc brakeMower

A series motor electric mower with a chassis anti-colliding protector and a function wave disc brake comprises the anti-colliding protector arranged on the front portion of a mower chassis, the brake arranged in the middle of the mower chassis, a grass beating head and a winder. When outer covering rubber skin of a movable support is collided at the front so that a sliding rod of the movable support is retracted, a limit switch is triggered so as to resist collision. The function wave disc brake comprises uneven disc pieces fluctuating according to wave-shape heights so as to be favorable for braking in alternate tension with relaxation, and parameters of the function wave disc brake are formed by computer molding. The brake is further provided with an axial shaft disc of a friction block gradually lifted according to functions, a belt pulley and a radial centrifugal throwing block, wherein the belt pulley is provided with internal multiple inner teeth, and the radial centrifugal throwing block is provided with multiple arc-shaped teeth. The series motor electric mower has the advantages that the anti-colliding safety and braking effect are reinforced, mowing and grass beating are selectable, and a moving area is large.

Owner:NINGBO DAYE GARDEN EQUIP

Winch brake device

InactiveCN102730591AImprove braking performanceIncrease the areaHoisting equipmentsWinchFriction force

The invention discloses a winch brake device which comprises a brake shaft, an outer brake cone plate, an inner brake cone plate, a brake hub, a spiral clutch mechanism and a brake coupling band, wherein the outer brake cone plate, the inner brake cone plate, the brake hub, the spiral clutch mechanism and the brake coupling band are arranged on the brake shaft; a brake drum is meshed with drum key teeth of the winch; the brake shaft drives the spiral clutch mechanism to separate; the outer brake cone plate and the inner brake cone plate respectively clamp the brake hub by the separating process of the spiral clutch mechanism; the outer brake cone plate and the inner brake cone plate are adopted to clamp the brake hub; and the brake hub and the cone plate are in conical contact, the area is larger, the friction force is increased, and brake is reliable. Compared with the existing conical drum tensioning brake, the brake hub is meshed with the drum key teeth of the winch, so the brake force loss is small, the brake response is effectively improved, and the brake performance of the winch is comprehensively improved.

Owner:ZHEJIANG NOWVOW MECHANICAL & ELECTRICAL

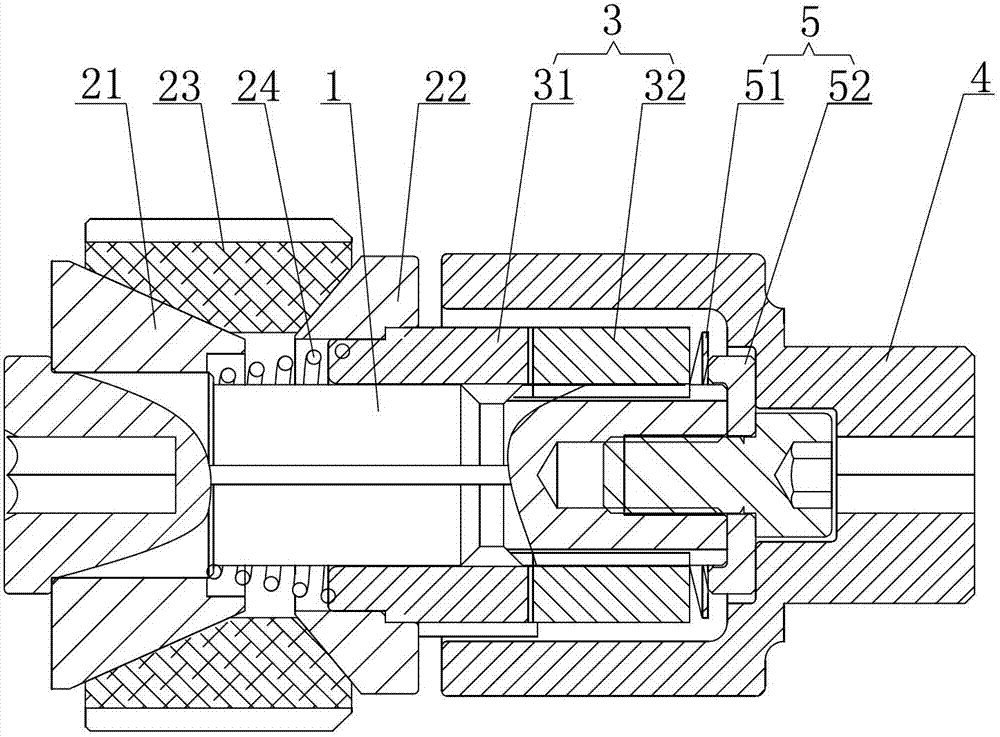

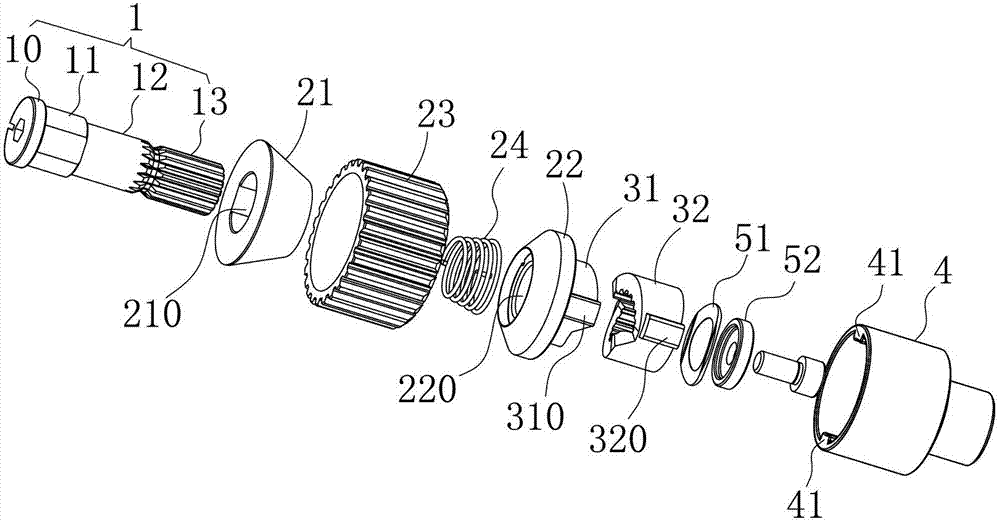

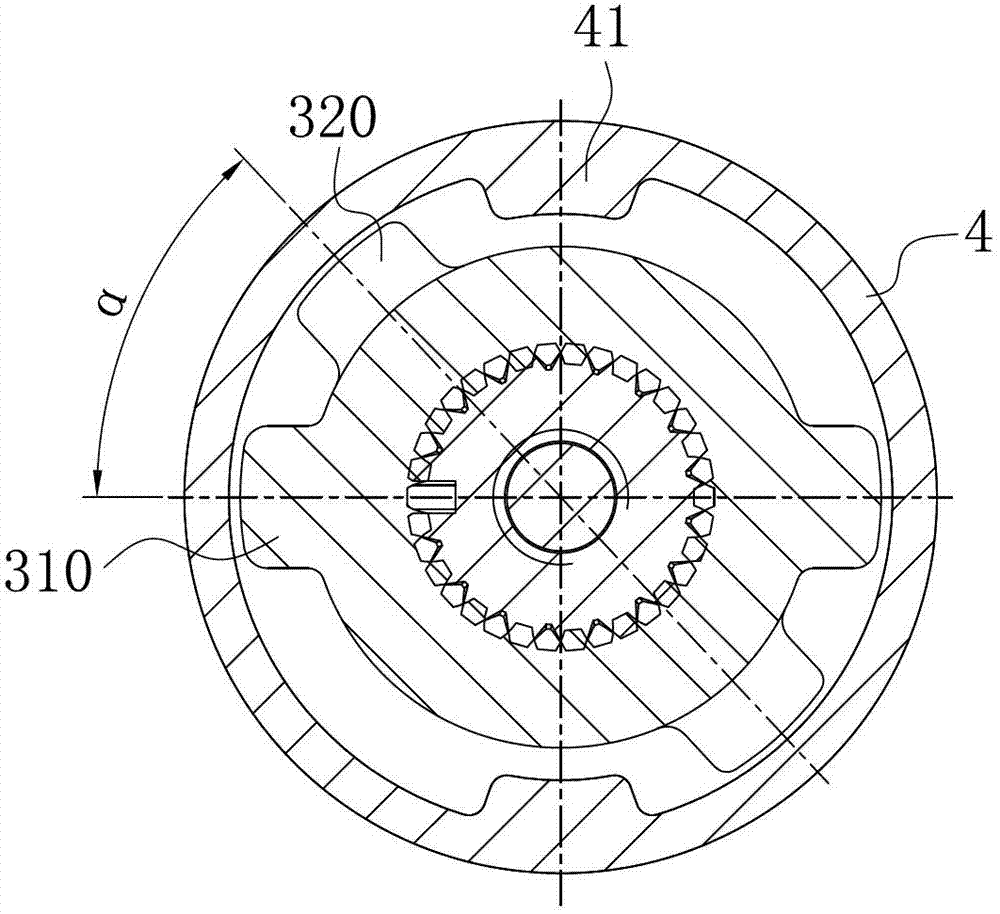

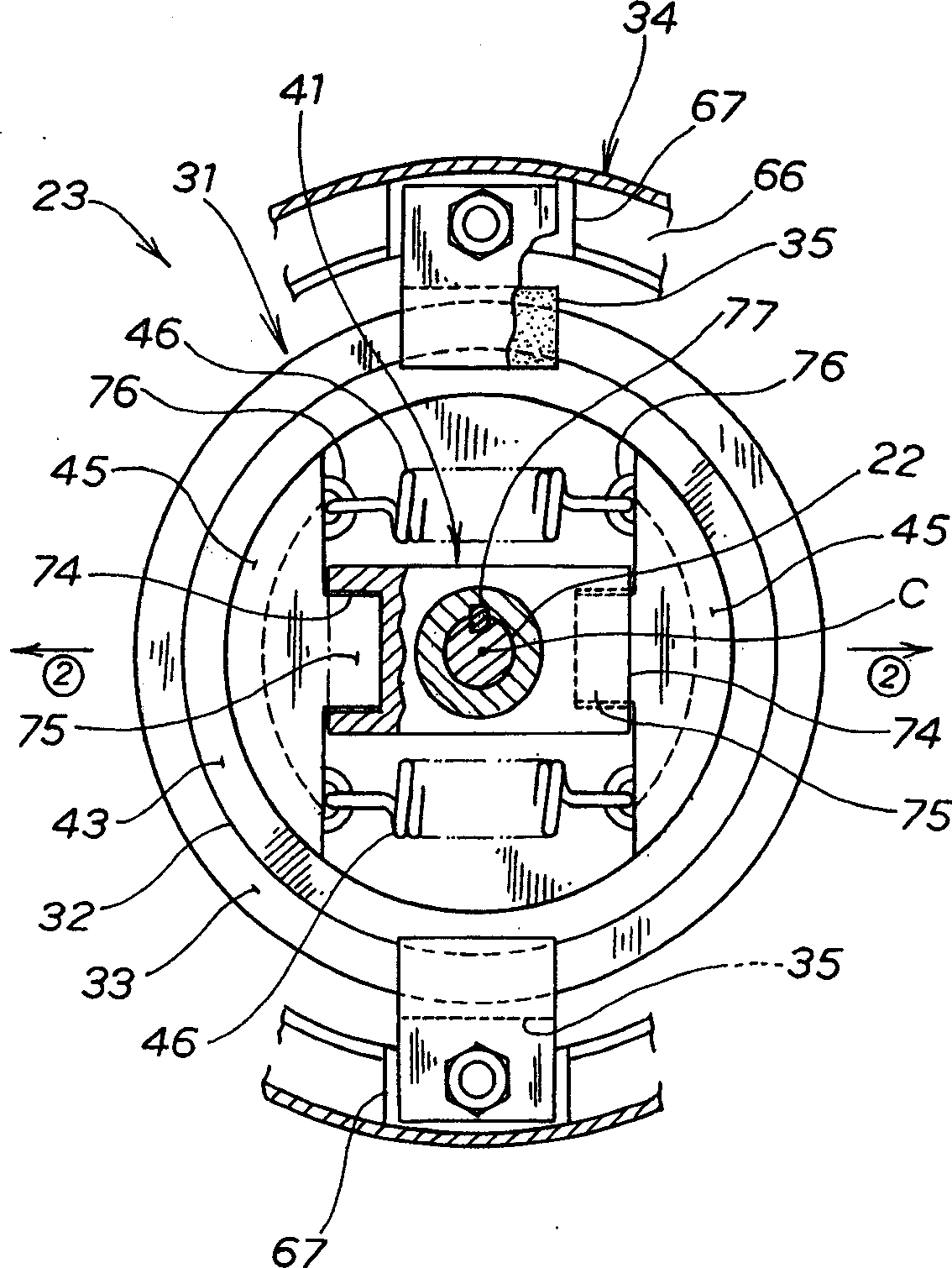

Cutting equipment for brush

When the rotation speed of the driving source (21) has been lower than a predetermined value, the clutch moving element (45; 85) is disengaged from the clutch drum (31; 81) under the action of the clutch elastic element (46), thus making the clutch drum (31; 81) elastically slides back to a predetermined braking position under the action of the braking elastic element (36), where the brake shoe (33; 83) presses against the brake pad (35) to apply Braking action. When the rotational speed of the source device (21) has increased beyond a predetermined value, the clutch moving element (45; 85) slides radially outwards under centrifugal force in such a way that the clutch moving element (45; 85) Overcoming the bias of the brake elastic element (36), applying pressure to the clutch drum (31; 81) and making the clutch drum (31; 81) axially slide to the non-braking position, so that the brake shoe (33; 83 ) is disengaged from the brake pad (35) to release the braking effect.

Owner:HONDA MOTOR CO LTD

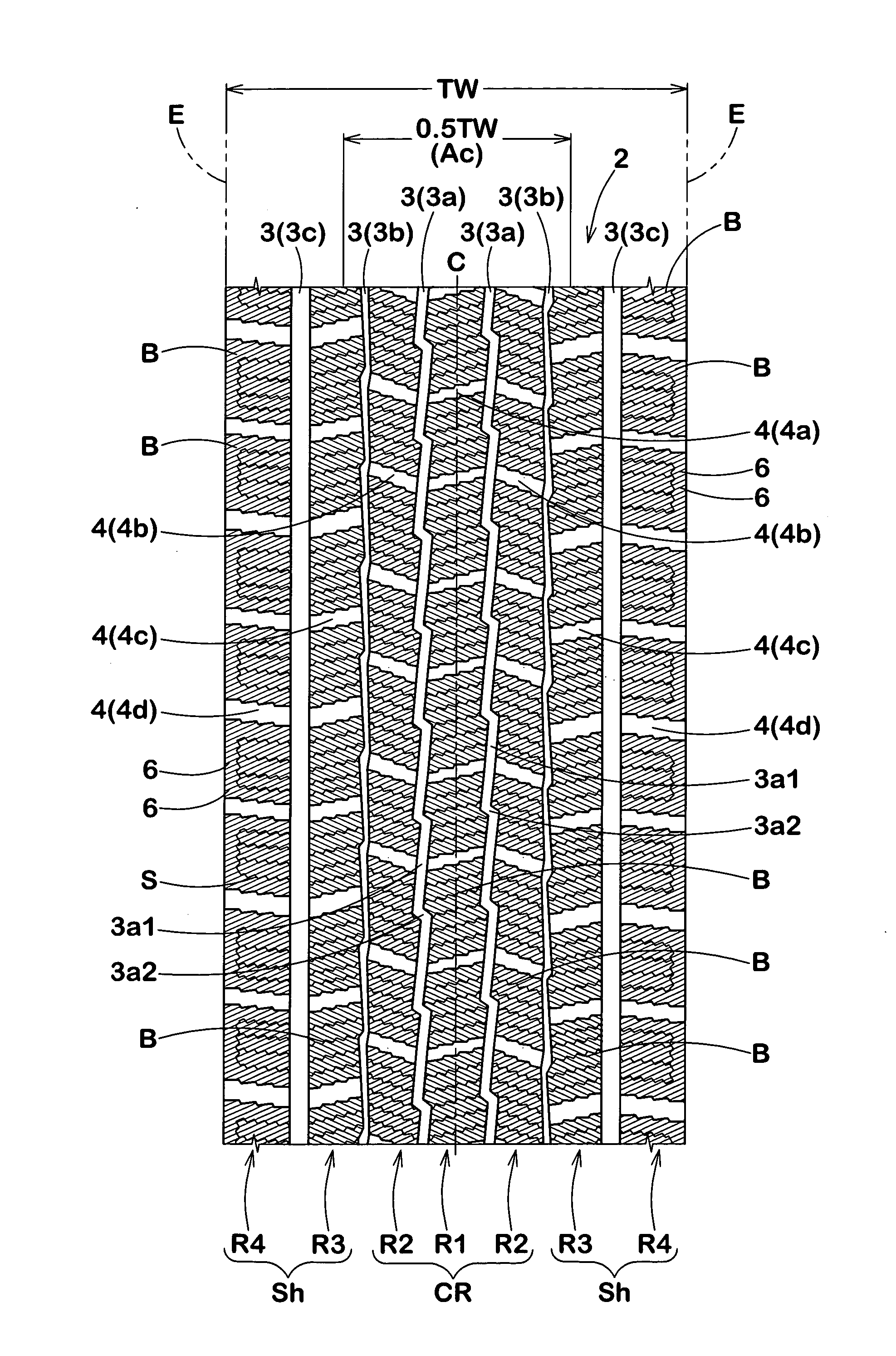

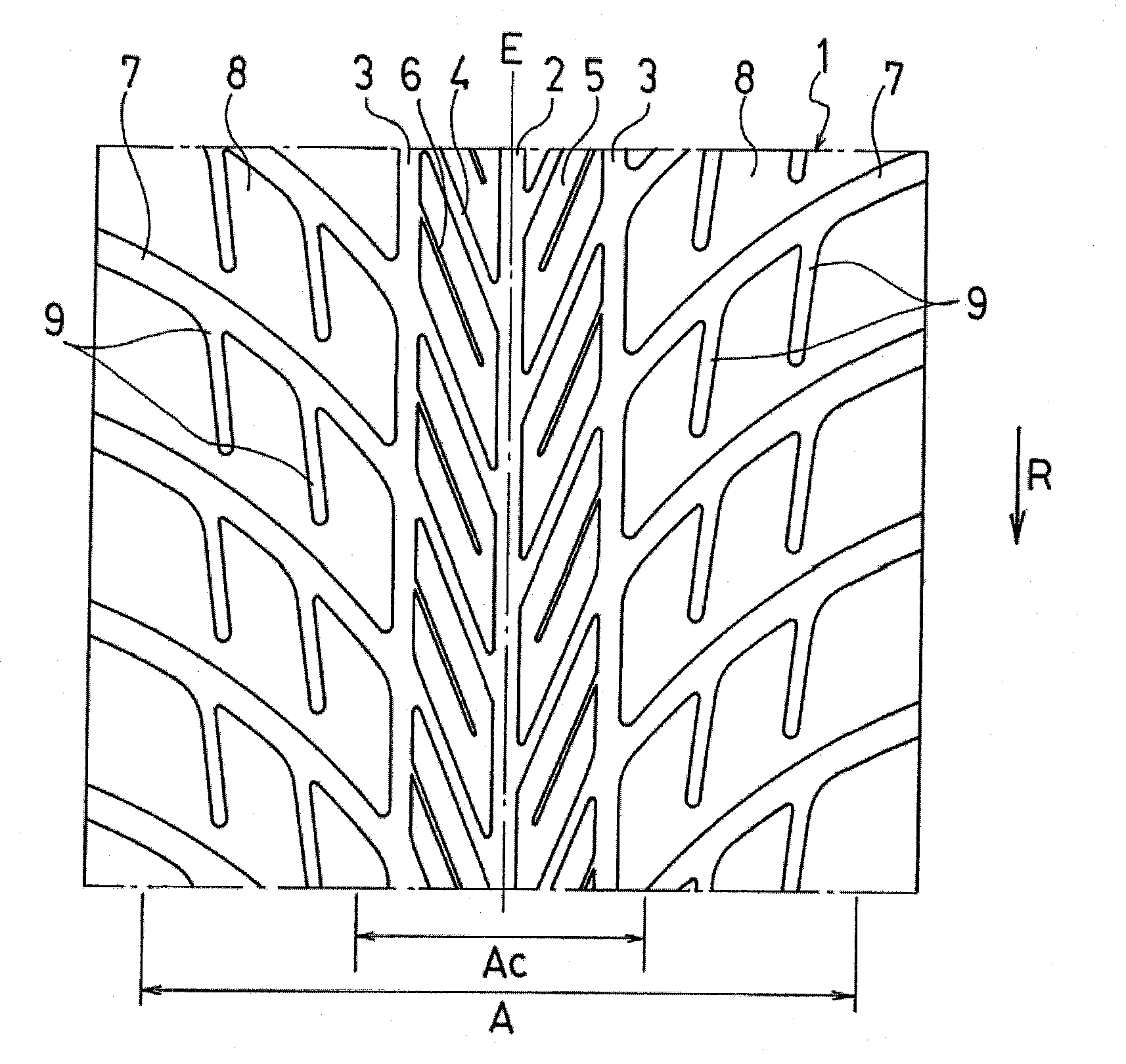

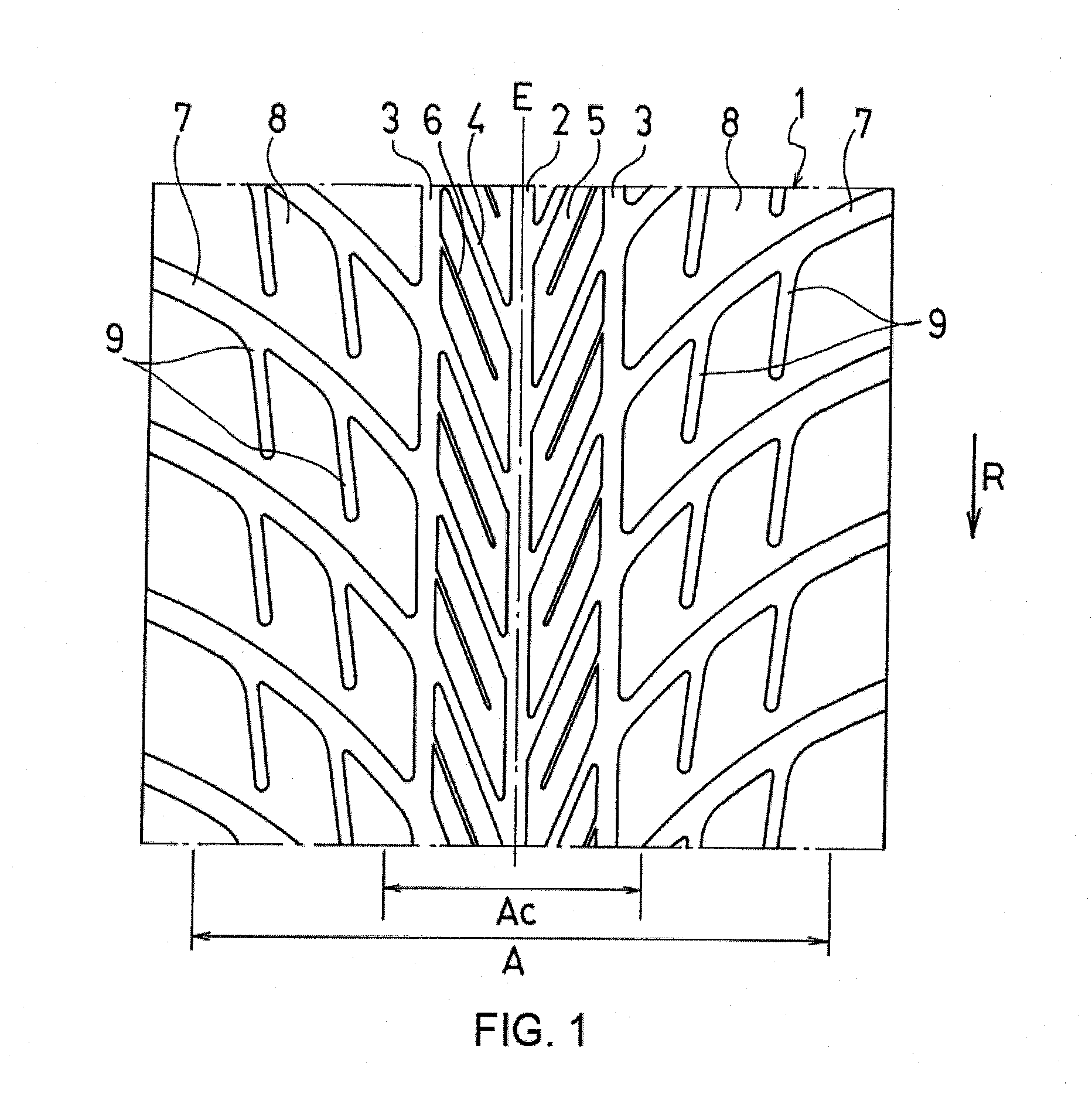

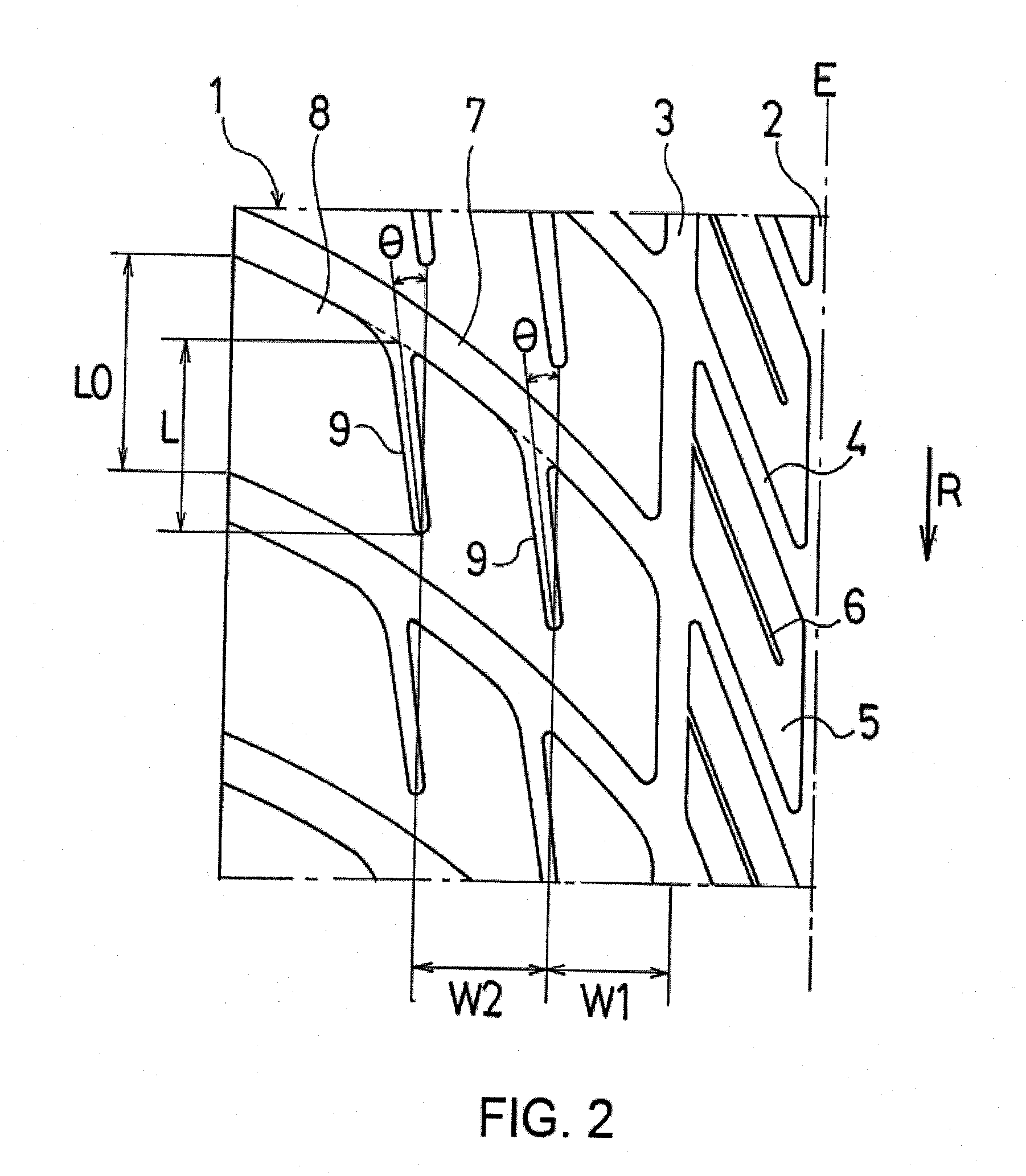

Studless tire

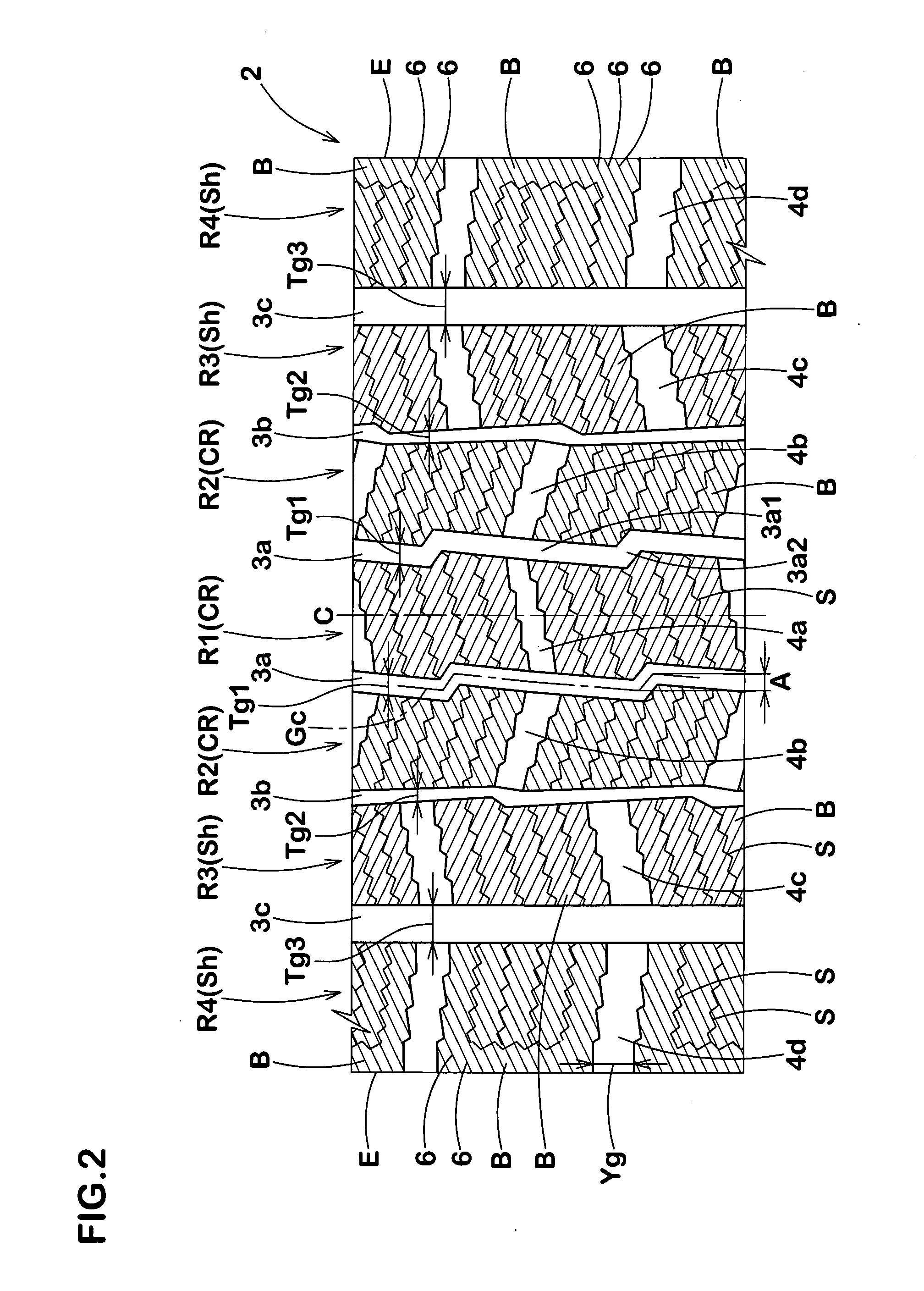

InactiveUS20080196808A1Improve braking performanceTimely brakingTyre tread bands/patternsNon-skid devicesMechanical engineeringEquator

A studless tire capable of suppressing a vehicle from staggering at the time of braking on icy and snow-covered roads, including a tread portion 2 provided with at least six block rows R1 to R4, wherein each block B is provided with sipes having a depth of at least 3.0 mm, and the block rows comprises at least two crown block rows CR disposed in a crown region Ac extending from the tire equator C as its center to have a width of 50% of the tread width TW, and at least two shoulder block rows Sh disposed on each axially outer side of the crown block rows CR, and wherein lateral grooves 4 provided in a block row are inclined in the opposite direction, with respect to the axial direction, to lateral grooves provided in an axially adjacent block row.

Owner:SUMITOMO RUBBER IND LTD

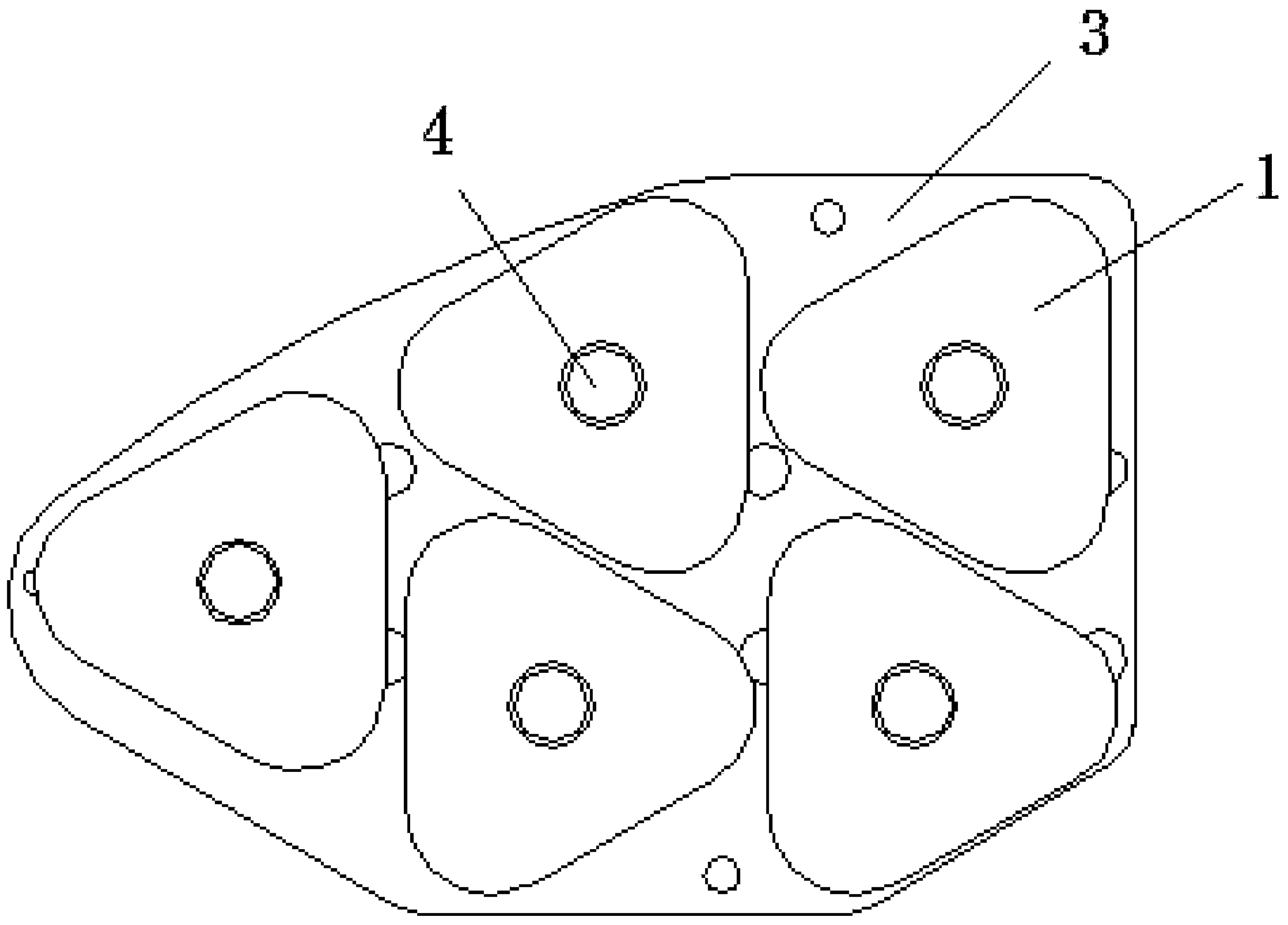

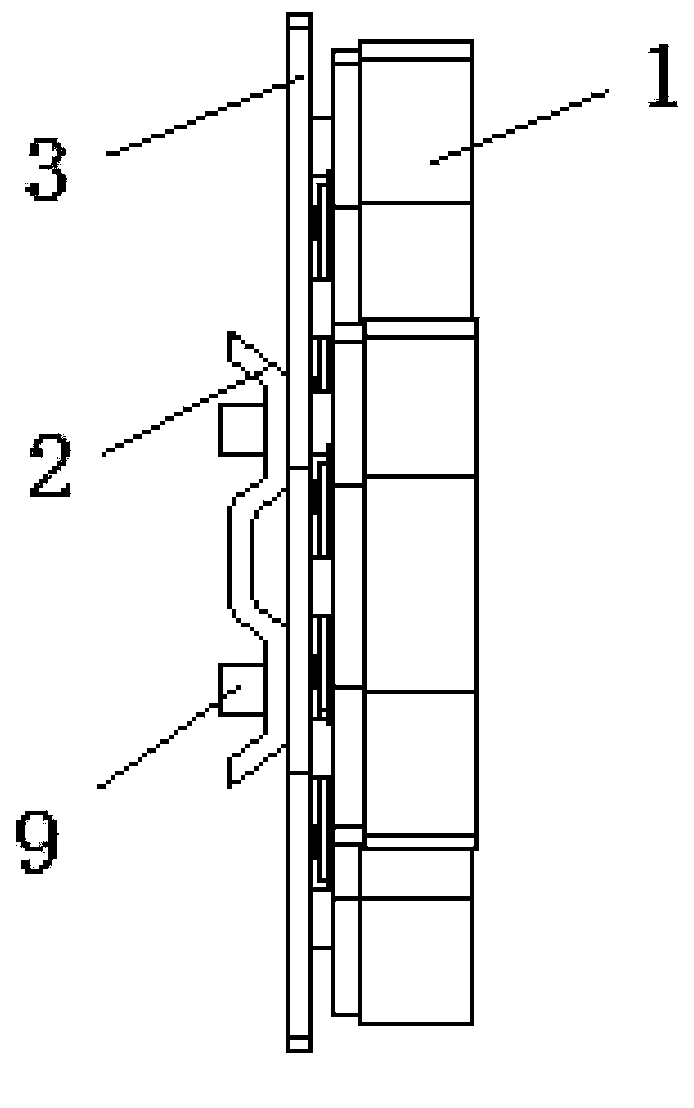

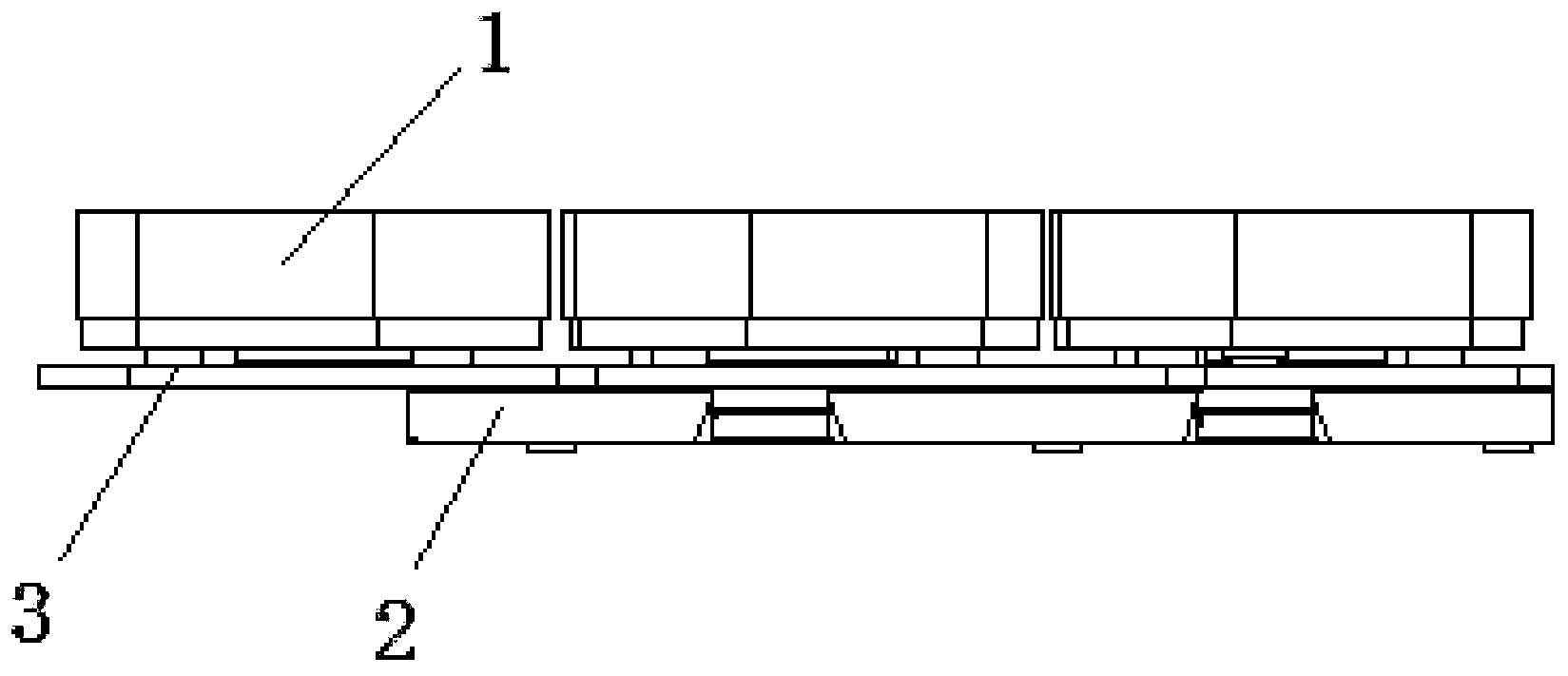

Powder metallurgy brake lining for CRH5 (China railway high-speed) motor train unit

ActiveCN103470665ATotally reliable brakingEasy to replaceFriction liningPowder metallurgyBrake lining

The invention relates to a powder metallurgy brake lining for the CRH5 (China railway high-speed) motor train unit. The powder metallurgy brake lining is characterized by comprising 5 brake lining friction bodies, 1 dovetail block, 1 steel back plate, 5 rivets, 5 large gaskets, 5 small gaskets, 5 butterfly-shaped shrapnels, 15 cotter pins and 6 flush head rivets; the 5 friction brake lining bodies are fastened at the front part of the steel back plate; each brake lining friction body is formed by an equilaterally triangular friction body skeleton with three arc chamfers and a friction body; the section of the dovetail block is in a W-shaped long plate structure; the steel back plate is in an irregular hexagonal plate structure; the back of the steel back plate is connected with the dovetail block; the front part of the steel back plate is riveted with the 5 brake lining friction bodies by the large gaskets, the small gaskets and the butterfly-shaped shrapnels at intervals; all pin joint holes in the steel back plate are respectively connected with one ends of the cotter pins; the other ends of the cotter pins are correspondingly suspended in guide holes in all friction body skeletons. Process holes are formed in the upper, lower and arc edges of the steel back plate.

Owner:北京浦然轨道交通科技股份有限公司 +1

Braking system of hybrid vehicle

InactiveUS7275795B2Improve braking performanceBraking element arrangementsBraking action transmissionEngineeringRoad surface

A hybrid system for a vehicle which can ensure a braking stability on a slippery road is provided. Therefore, the system is provided with a motor 2 a rotation force of which is transmitted to a rear wheel 7, braking actuators 57, 67 which brake the front wheel 6 and the rear wheel 7, and proportional valves 53, 63 controlling a braking force introduced into each braking actuator 57, 67. A control unit 20 is so provided that the control unit 20 calculates a required braking energy based upon a vehicle operating condition in demanding a braking and operates the motor 2 as a power generator to generate a power so as to produce the calculated braking energy, as well as controls a braking force of the front wheel 6.

Owner:NISSAN DIESEL MOTOR CO

Pneumatic tire

ActiveUS20110073230A1Sufficient hydroplaning prevention performanceReduce the amount of waterTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A pneumatic tire having a designated rotational direction is disclosed, wherein an entire area having a width 85% of a total tire width and a center area having a width 30% of the total tire width are defined in a tread portion. A center main groove is positioned on a tire equatorial line and extends in a tire circumferential direction. Subsidiary main grooves are positioned on two sides of the center main groove and extend in the tire circumferential direction. Angled and lateral grooves extend at an angle, in a direction opposite the rotational direction towards an outside in the tire width direction. Lateral grooves extend from each subsidiary main groove. Sub grooves extend from the lateral grooves towards the rotational direction. A total length of a block edge in the center area is from 40% to 60% of a total length of a block edge in the entire area.

Owner:YOKOHAMA RUBBER CO LTD

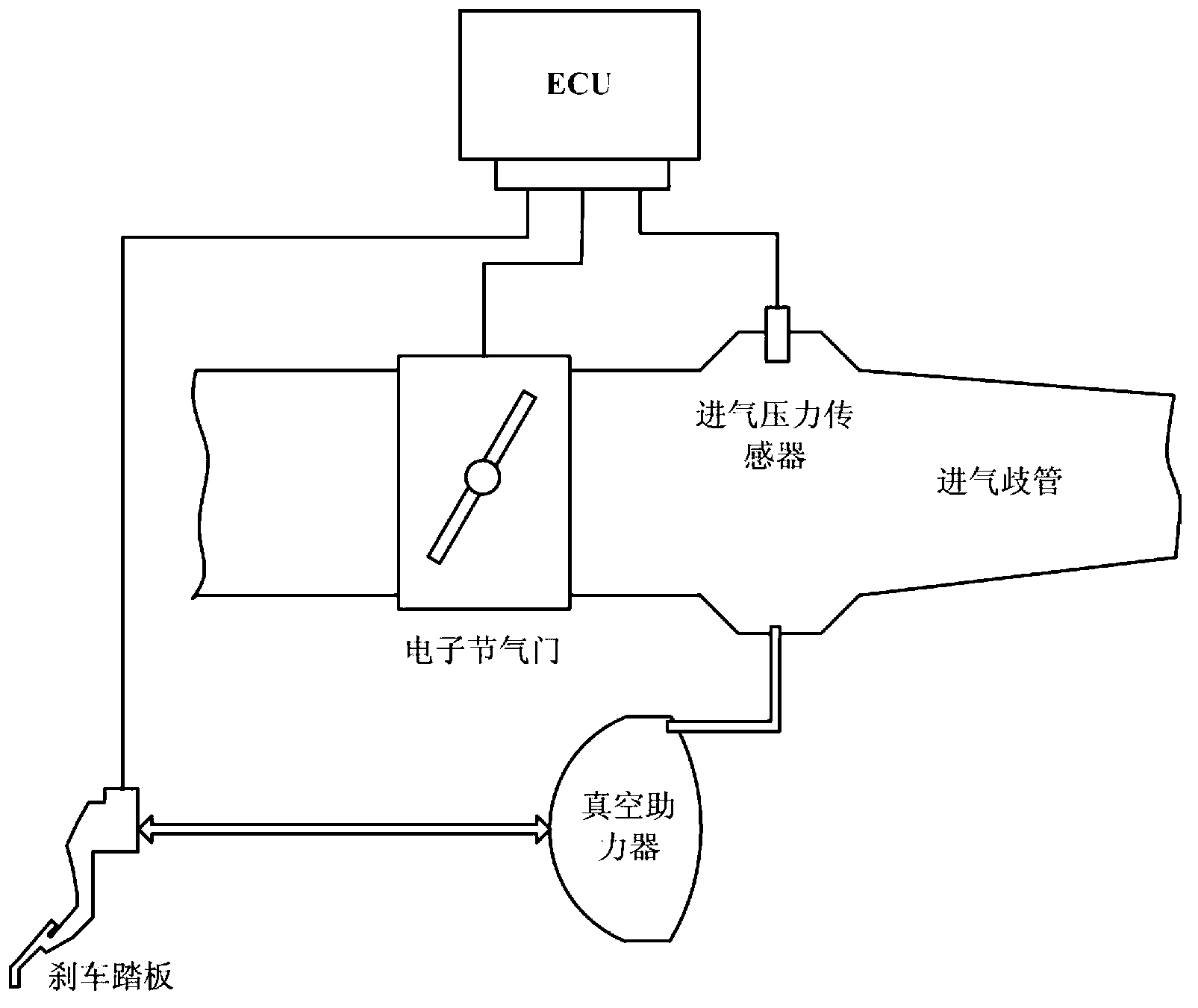

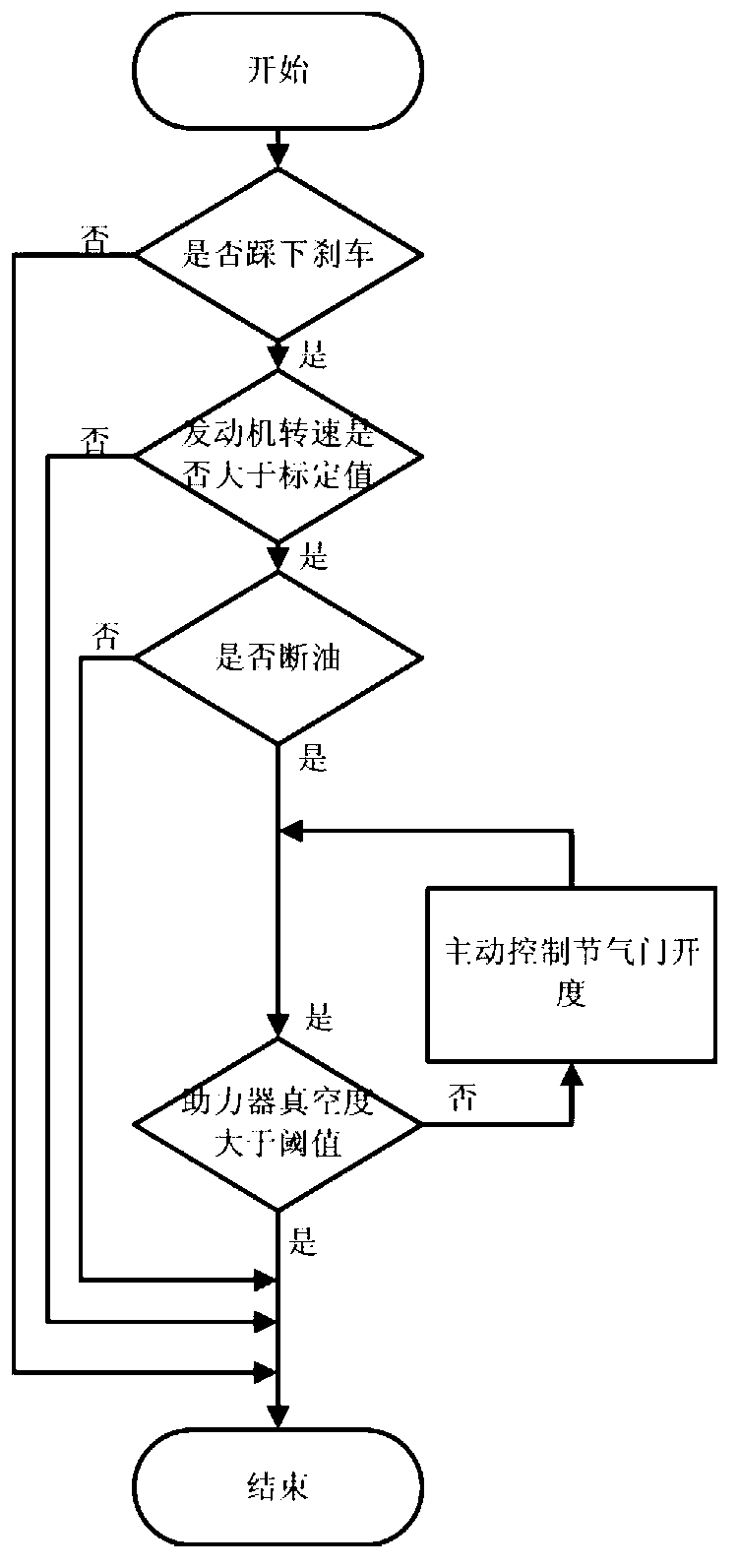

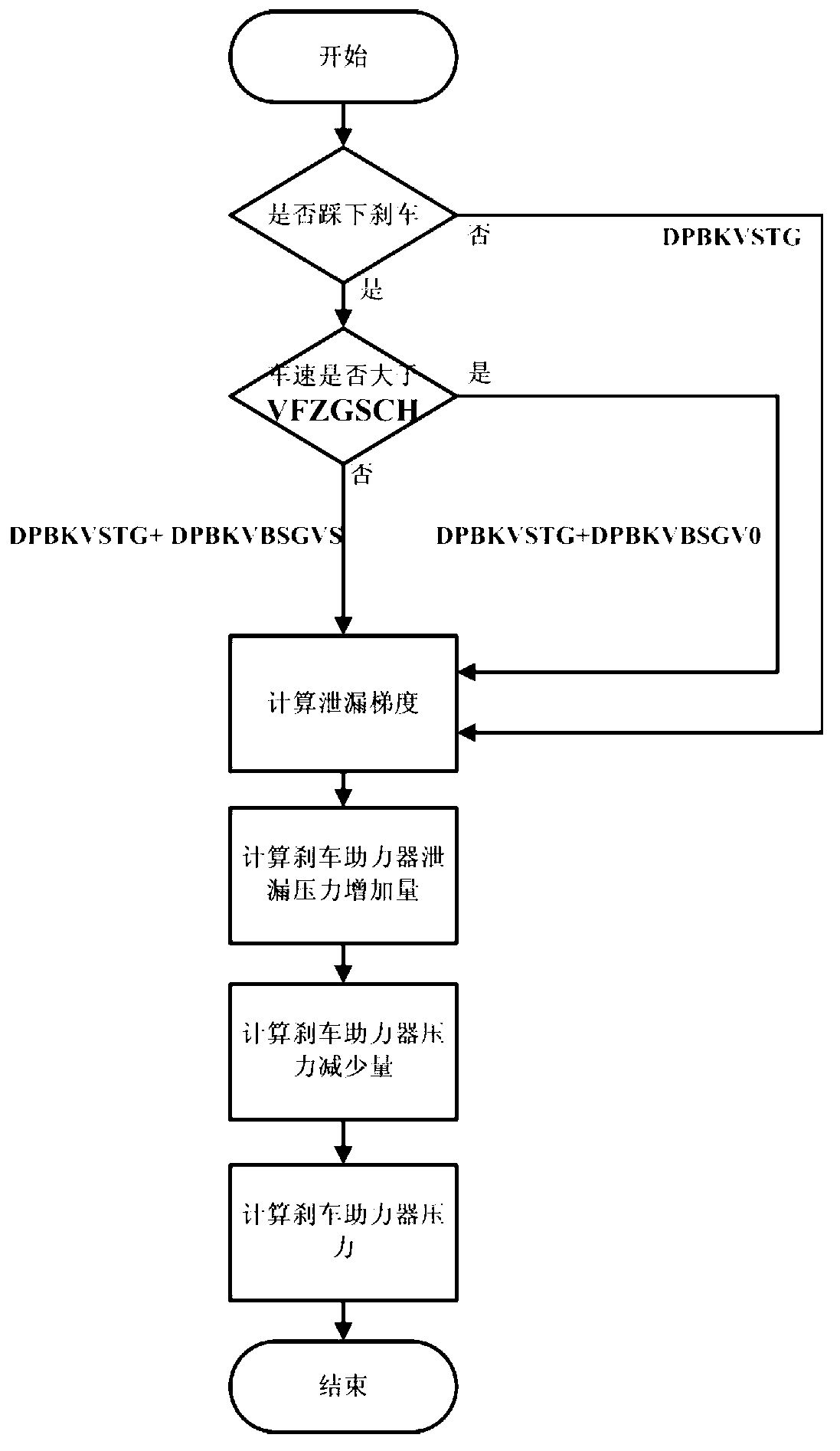

Control method for improving brake performance

ActiveCN102837693AIncrease vacuumLow costBraking action transmissionEngine controllersElectronic throttleEngineering

The invention discloses a control method for improving the brake performance, which comprises the following steps of: a step 1 of judging whether to meet the following conditions that a brake signal exists, the rotating speed of an engine is higher than the lowest operation rotating speed and fuel is cut off after braking is carried out; a step 2 of judging whether the vacuum degree of a vacuum booster is reduced to a certain threshold value if the conditions are met, and if yes, actively reducing the opening of a throttle valve by a system to improve the vacuum degree of an intake manifold so as to improve the vacuum degree of the booster; and a step 3 of continuously judging the current vacuum degree state of the brake booster and stopping the active control of the electronic throttle valve to improve the vacuum degree until the vacuum degree is improved to a threshold value. According to the invention, the vacuum degree of the vacuum booster can be improved, the promotion of the brake performance is implemented, other functions are also not influenced and the hardware cost is not increased.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

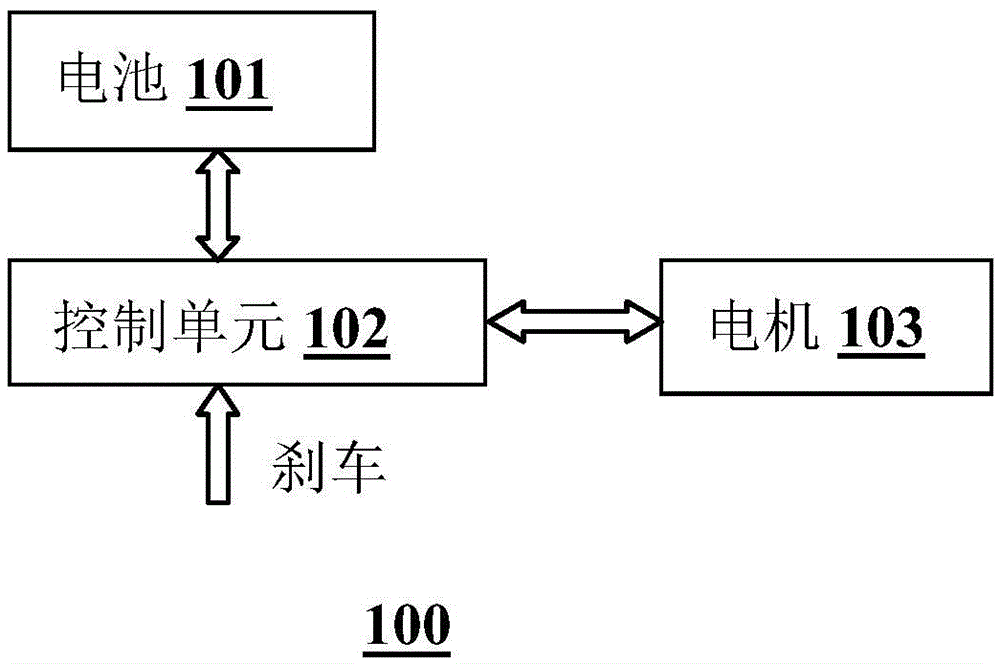

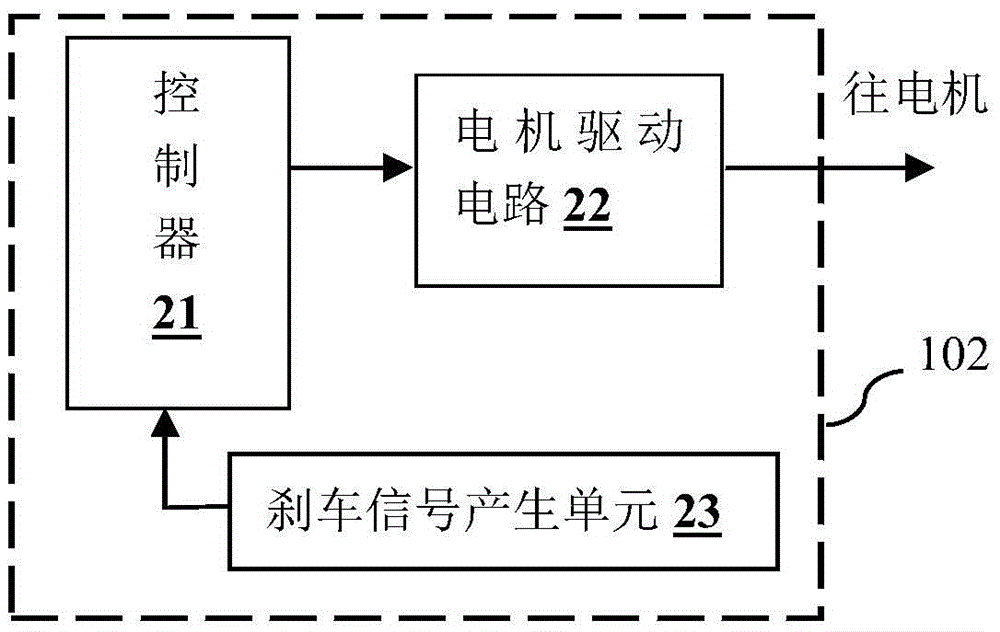

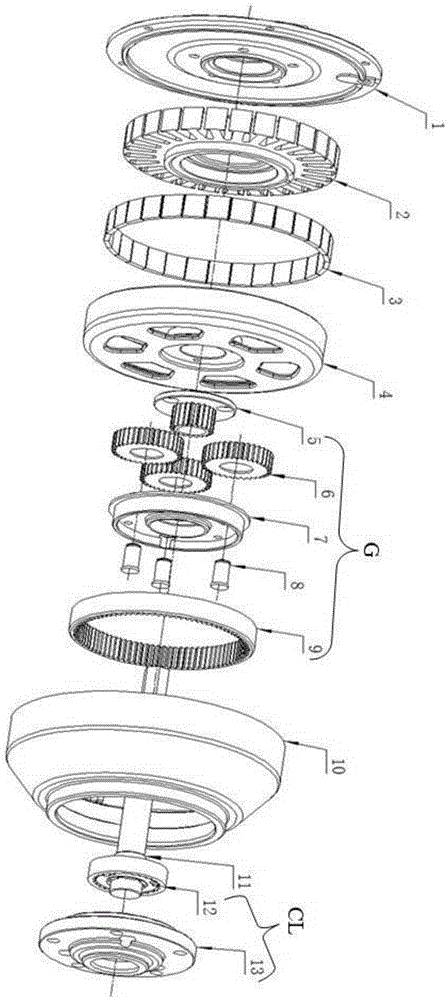

Motor, motor system and charging and braking method

ActiveCN105656243ACompact structureSmall sizeWheel based transmissionBatteries circuit arrangementsPower flowElectric machine

The invention relates to a motor used for a vehicle, a motor system comprising the motor and a charging and braking method adopting the motor system. The motor comprises a clutch unit, a planetary gear system, a rotor, magnetic steel and a stator fixedly connected with the magnetic steel, wherein the clutch unit is used for transmitting rotary moment between a wheel axle and the planetary gear system; the planetary gear system is arranged on the wheel axle in a sleeving manner, can utilize force transmitted by the clutch unit to drive the rotor to rotate, or can transmit rotation of the rotor to the clutch unit; when the vehicle travels normally, the motor charges a battery of the vehicle by utilizing induction current which is generated in a coil through relative motion of the stator and the rotor; when the vehicle receives a braking signal, the motor promotes the vehicle to brake by utilizing induction inverse potential which is generated in the coil through relative motion of the stator and the rotor. The motor has the characteristics of compact structure and simple maintenance.

Owner:HANHAI INFORMATION TECH SHANGHAI

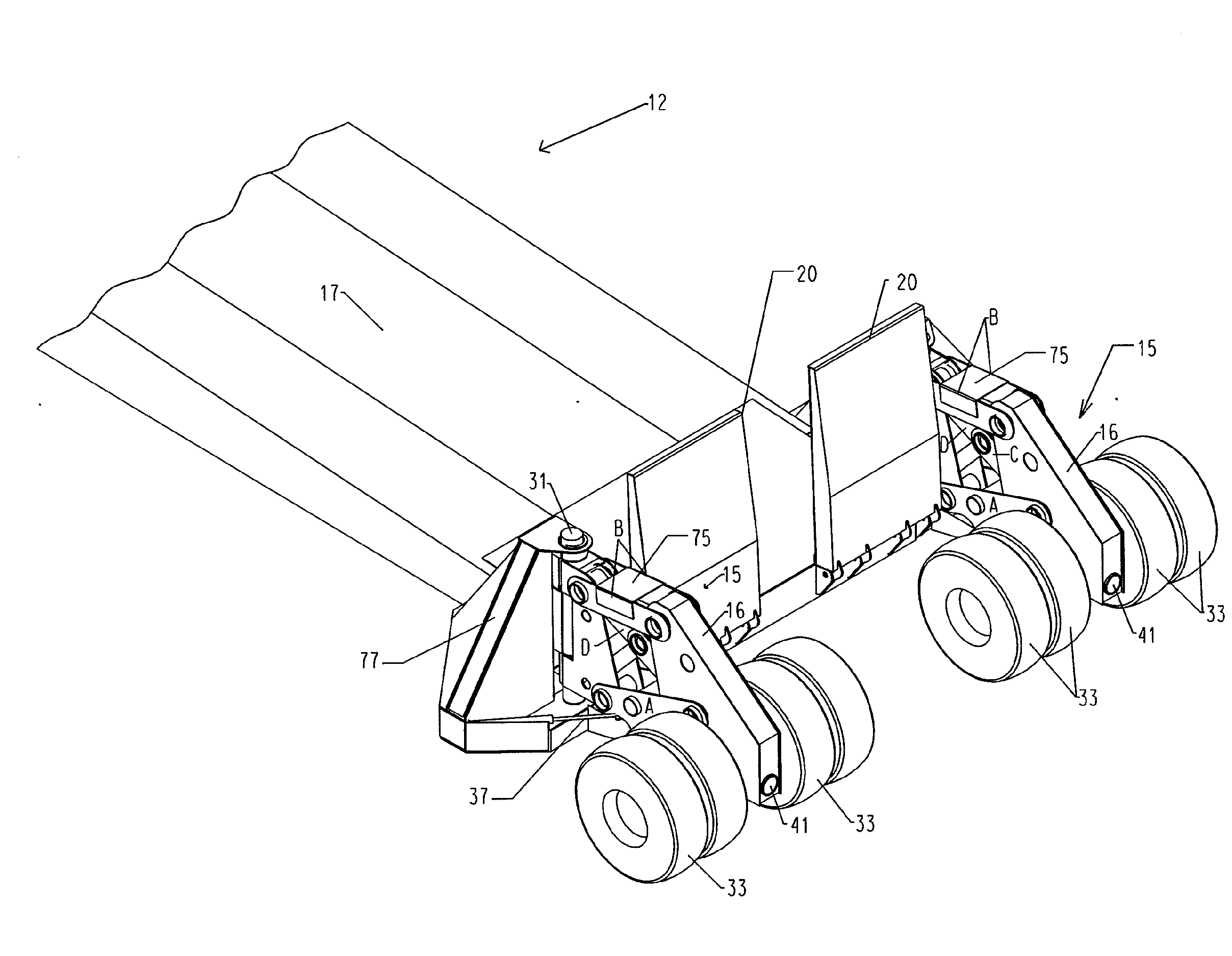

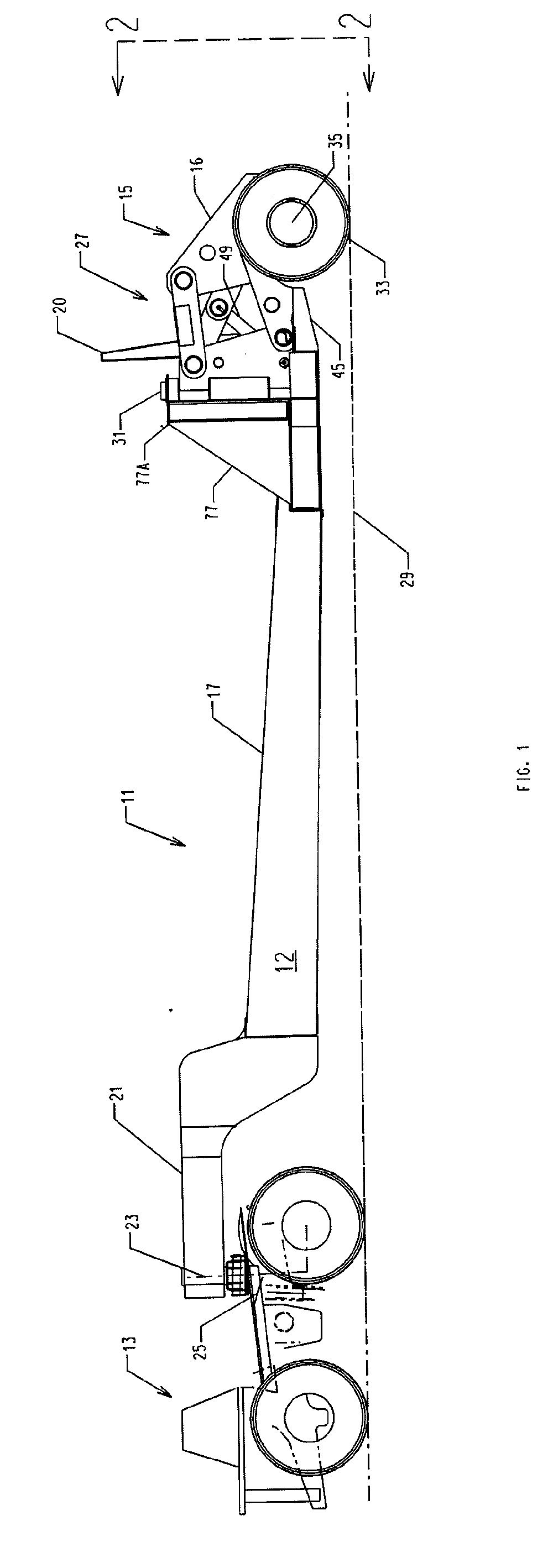

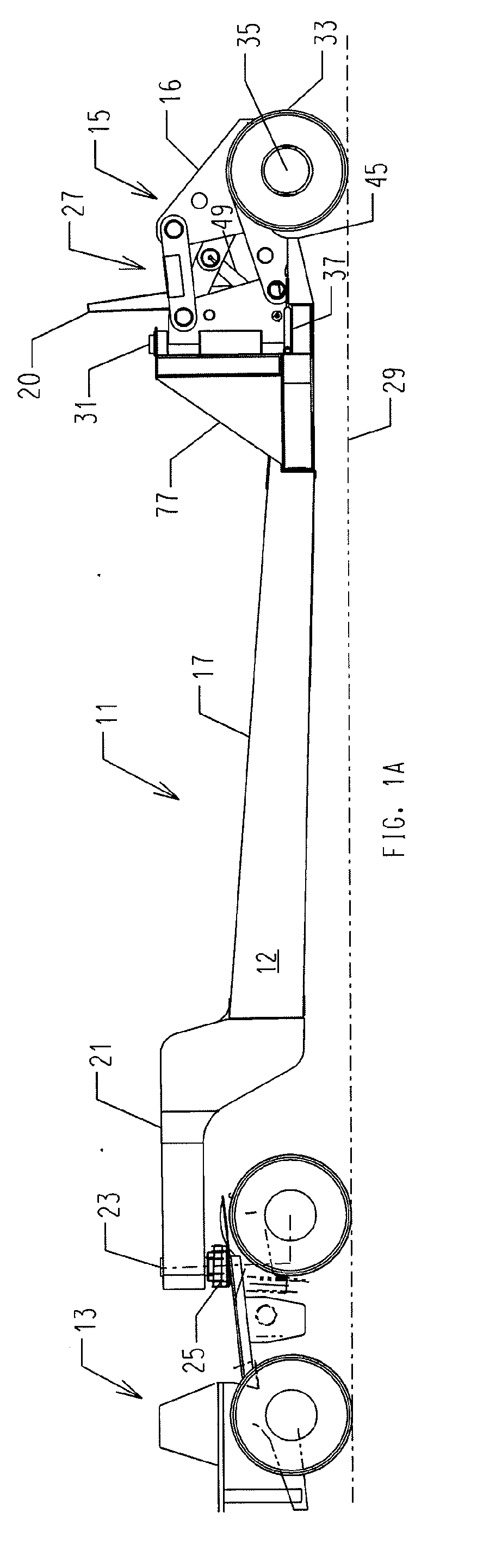

Method and apparatus for transitioning a heavy equipment hauling rear loading trailer between transport and loading positions

ActiveUS20090108562A1Minimize any apexMinimizes and eliminates any concentration of loadTractor-trailer combinationsHand carts with one axisHeavy equipmentVertical axis

A lowboy trailer is described having a pair of rear wheel assemblies mounted to a chassis of the trailer for movement between transport and loading positions such that the wheel assemblies are aligned across a back of the body when they are in the transport position and raised and positioned outwardly when the chassis is in the loading position. A linkage mechanism moves each of the wheel assemblies between the transport and loading positions. Each linkage mechanism automatically fastens the wheel assembly to the chassis of the trailer when the assembly is moved to its transport position. In operation, each of the wheel assemblies is moved from its transport position to the loading position by first moving to an intermediate raised position. By moving the wheel assemblies to the raised position they are automatically unfastened from the chassis and freed to move outwardly about a vertical pivot axis. Also, by raising the wheel assemblies, the back end of the chassis is lowered to the ground, which is the loading position for the trailer. To return the trailer to its transport position, the rear wheel assemblies are moved inwardly about the vertical axes so as to bring the assemblies back to their intermediate raised position. Then the wheel assemblies are lowered so that each of them automatically fastens to the body, thereby preventing lateral movement of the assemblies as the trailer moves into its transport position.

Owner:HAGENBUCH LEROY G

Automotive iron-based powder metallurgy composite frictional material and manufacturing method thereof

The invention discloses an automotive iron-based powder metallurgy composite frictional material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that an iron-based powder metallurgy friction material is obtained; secondly, the iron-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the iron-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is preserved at the temperature of 150-180 DEG C, cooled to the room temperature and then discharged from the furnace. The automotive iron-based powder metallurgy composite frictional material remains the stable friction coefficient and good abrasive resistance of the conventional powder metallurgy friction material, service life of the friction material is prolonged and its high-temperature stability is also improved.

Owner:SOUTH CHINA UNIV OF TECH

Mower comprising chassis blade broom and having blowing/suction, irrigation, fertilization, pesticide spreading and braking functions

PendingCN104838799ASolve the problem of double failureImprove braking performanceMowersEngineeringFan blade

The invention provides a mower comprising a chassis blade broom and having blowing / suction, irrigation, fertilization, pesticide spreading and braking functions. The mower is a multifunctional mower comprising a logarithmic spiral brake with an anti-corrosion guard and a pipe winder with liquid pipelines for irrigation, fertilization and pesticide spreading; four major assemblies, namely a support assembly with a charger and an inverter for a storage battery, a cutting device assembly dragged by a series excitation motor, a pipe winder assembly for irrigation, fertilization and pesticide spreading, and a brake assembly and a cutting device assembly, are additionally arranged on a common lawn mower; due to the addition of the irrigation, fertilization and pesticide spreading functions, the mower is wide in application range and large in movement area; a liquid fertilizer for fertilization in the pipe of the pipe winder is formed by adding a soluble fertilizer or pesticide to water in percentage. The dust collection bag support (35) of a blowing / suction unit arranged on the mower is connected with a dust collection bag (36) and a pipeline is connected with a grass collection arranged on the rear part of the mower. A blowing / suction fan blade (231) is arranged on a mowing cutter arranged on the chassis of the mower and a broom (232) is arranged to realize direct blowing, suction and sweeping.

Owner:NINGBO DAYE GARDEN EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com