A kind of heat-resistant modified bamboo fiber and its method for automobile brake friction material

A heat-resistant modification and automobile braking technology, applied in the field of materials science, can solve the problems of friction plate breakage, brake lock, scratch duality, etc., and achieve the advantages of reducing production costs, stabilizing braking performance, and stabilizing friction performance at room temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

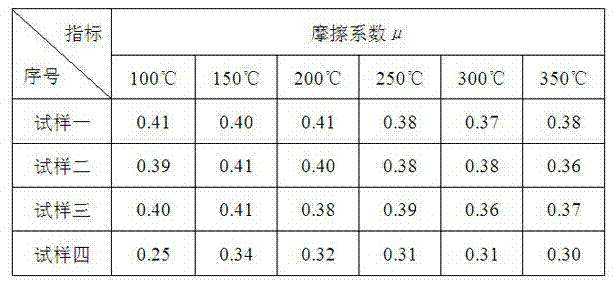

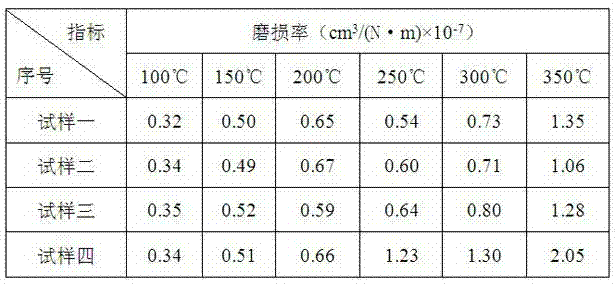

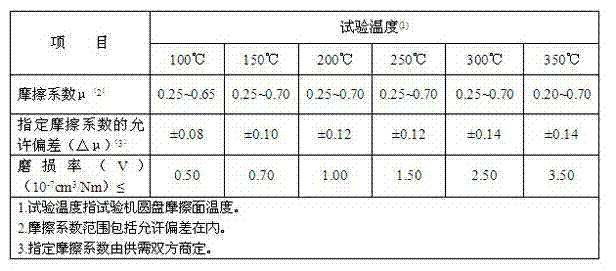

[0021] Embodiment one (preferred embodiment)

[0022] Add 290 ml of aqueous solution in a 500 ml beaker, add 10 grams of borax, start stirring and heat to 80°C to completely dissolve borax. Immerse 5 grams of bamboo fiber in the borax solution, take it out after 20 minutes, and dry it at 80° C. for 1 hour to obtain heat-resistant modified bamboo fiber. Take the following ingredients and proportions to make friction materials: 7 parts of heat-resistant modified bamboo fiber, 7 parts of anhydrous calcium sulfate whisker, 13 parts of basic magnesium sulfate whisker, 17 parts of phenolic resin, 10 parts of copper powder, and 3 parts of graphite powder , 15 parts of barite powder, 10 parts of alumina powder, 8 parts of cast iron powder, 12 parts of feldspar powder, and 3 parts of tire powder. Then put the phenolic resin on 60 DEG C and dry for 0.5 hour, place the other raw materials except the modified bamboo fiber in the baking oven and dry at 120 DEG C for 1 hour; Stir and bl...

Embodiment 2

[0023] Embodiment 2 (preferred embodiment)

[0024] Add 300 ml of aqueous solution in a 500 ml beaker, add 12 grams of borax, start stirring and heat to 100°C to completely dissolve borax. Immerse 5 grams of bamboo fiber in the borax solution, take it out after 26 minutes, and dry it at 100°C for 40 minutes to obtain heat-resistant modified bamboo fiber. Take the following composition proportions and make friction materials according to the above process steps: 13 parts of heat-resistant modified bamboo fiber, 8 parts of anhydrous calcium sulfate whisker, 10 parts of basic magnesium sulfate whisker, 20 parts of phenolic resin, and 8 parts of copper powder , 3 parts of graphite powder, 15 parts of barite powder, 10 parts of alumina powder, 10 parts of cast iron powder, 12 parts of pyrophyllite powder, 4 parts of tire powder. Then put the phenolic resin to dry at 50°C for 1 hour, place the other raw materials except the heat-resistant modified bamboo fiber in the oven and dry...

Embodiment 3

[0025] Embodiment three (preferred embodiment)

[0026]Add 250 ml of aqueous solution in a 500 ml beaker, add 9 grams of borax, start stirring and heat to 40°C to completely dissolve borax. Immerse 4.5 grams of bamboo fiber in the borax solution, take it out after 12 minutes, and dry it at 120° C. for 20 minutes to obtain heat-resistant modified bamboo fiber. The following composition ratios are taken and the friction material is produced according to the above process steps. 4 parts of heat-resistant modified bamboo fiber, 16 parts of anhydrous calcium sulfate whisker, 10 parts of basic magnesium sulfate whisker, 16 parts of phenolic resin, 10 parts of copper powder, 2 parts of graphite powder, 12 parts of barite powder, aluminum oxide 15 parts of powder, 9 parts of cast iron powder, 14 parts of feldspar powder, and 2 parts of tire powder. Then put the resin on 55 ℃ and dry for 40 minutes, put the other raw materials except the heat-resistant modified bamboo fiber in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com