Patents

Literature

329results about How to "Reduce negative pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

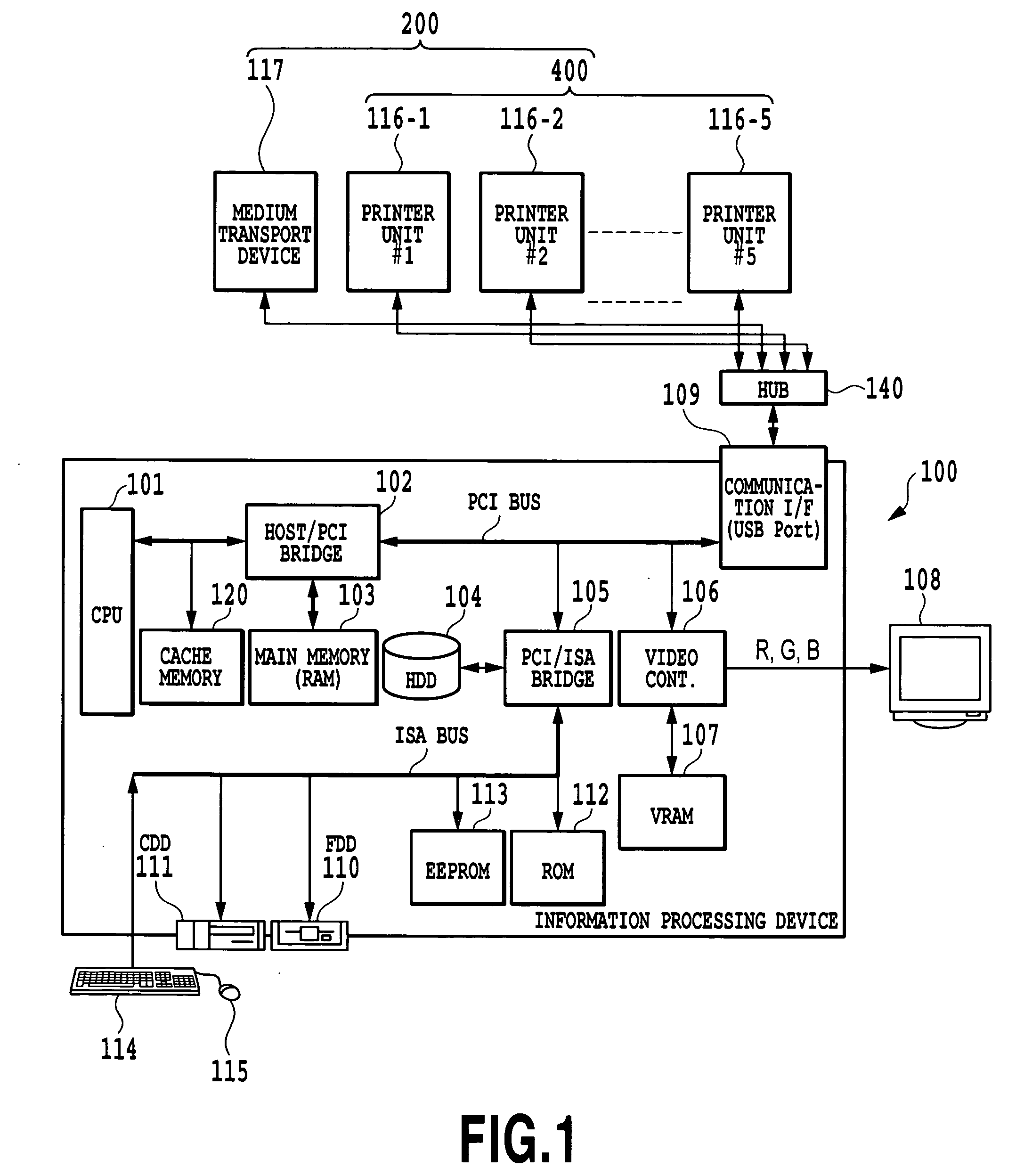

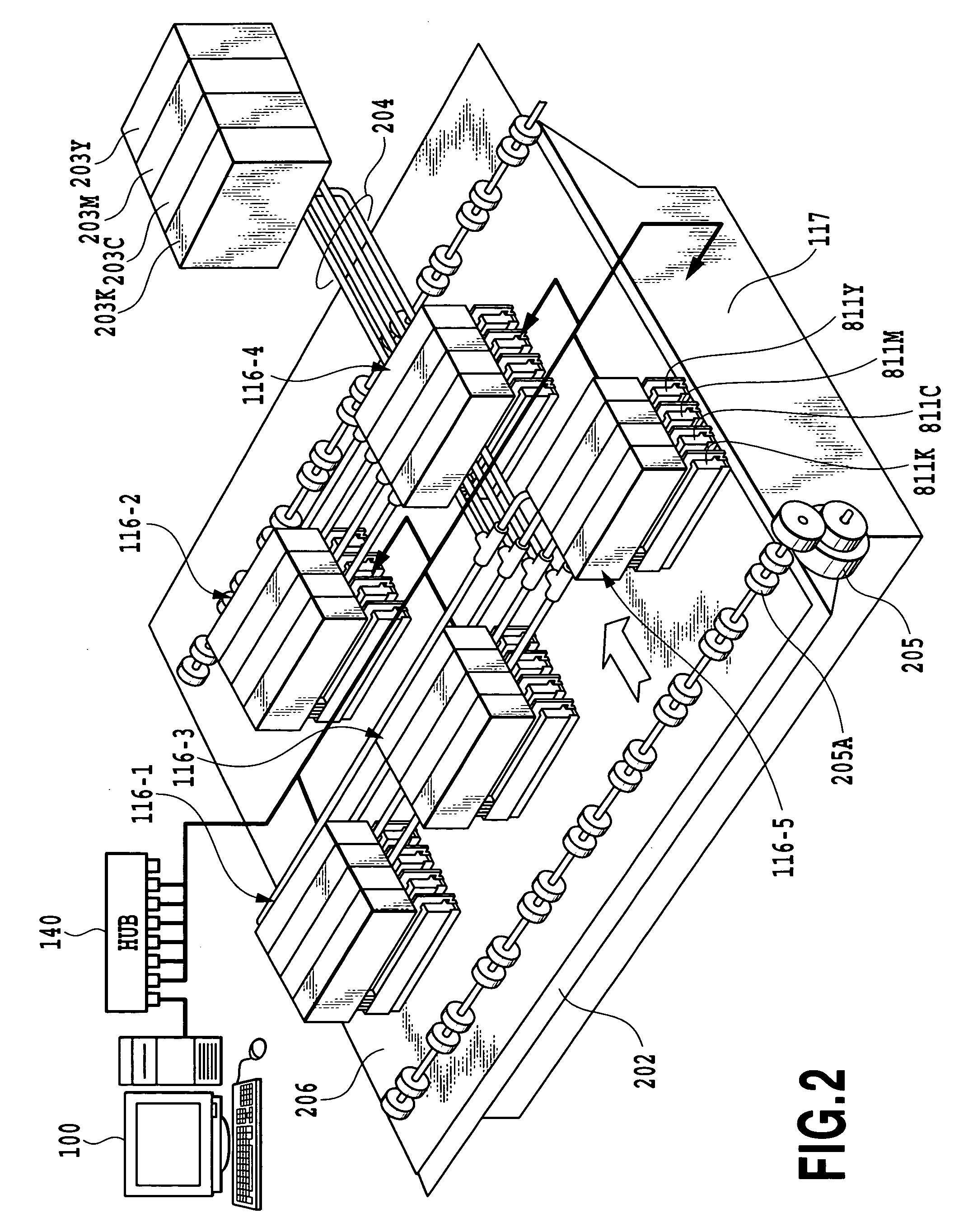

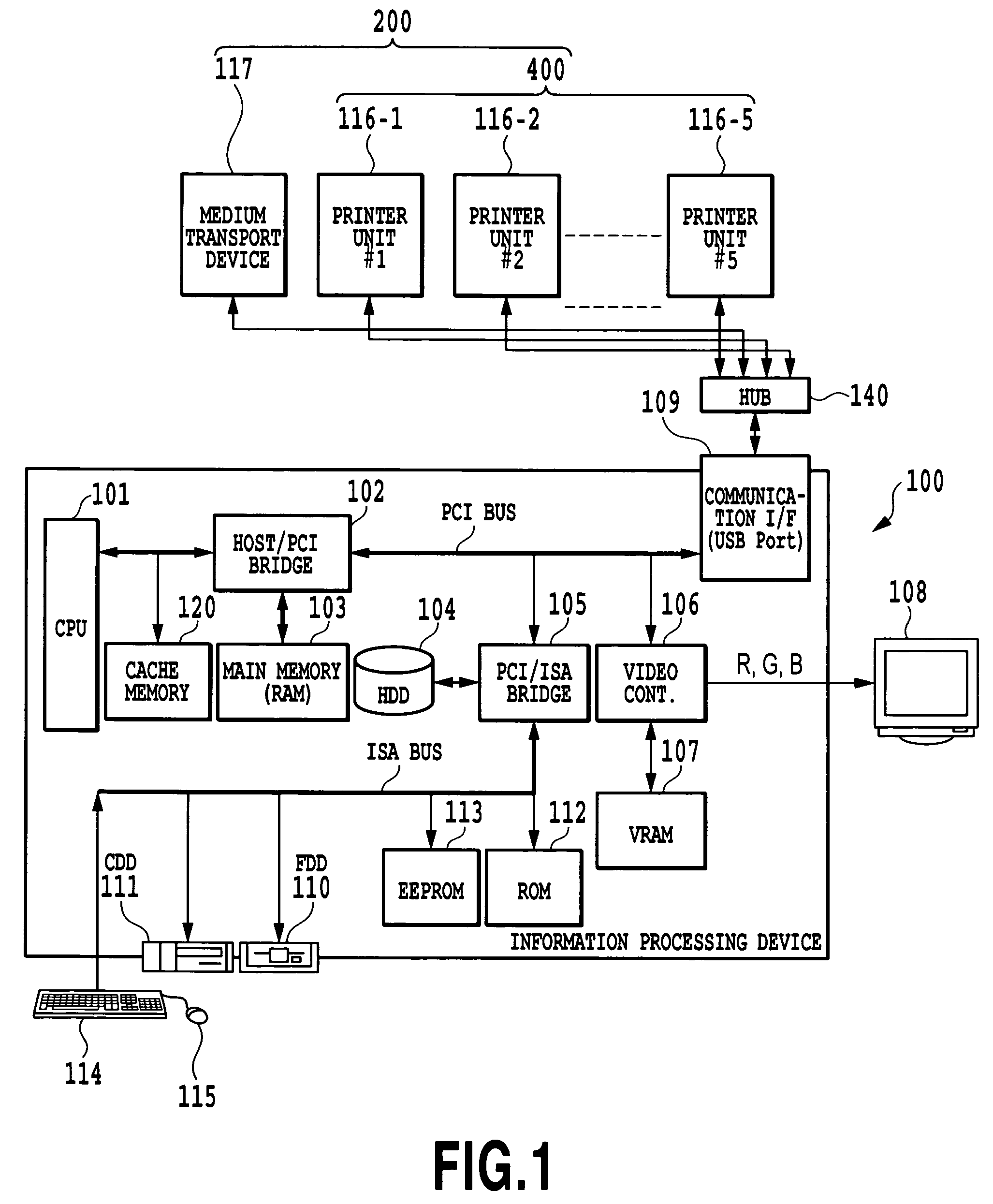

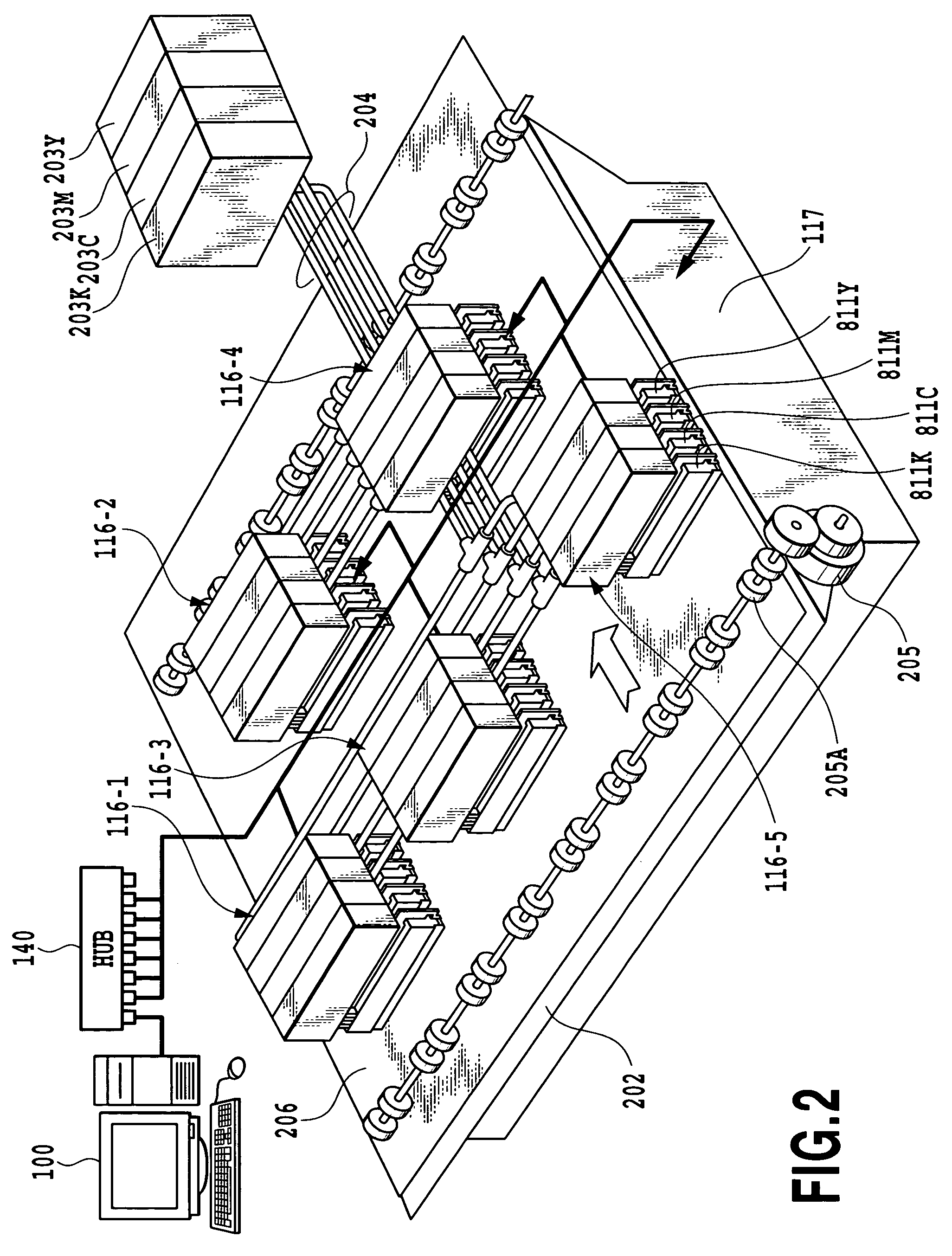

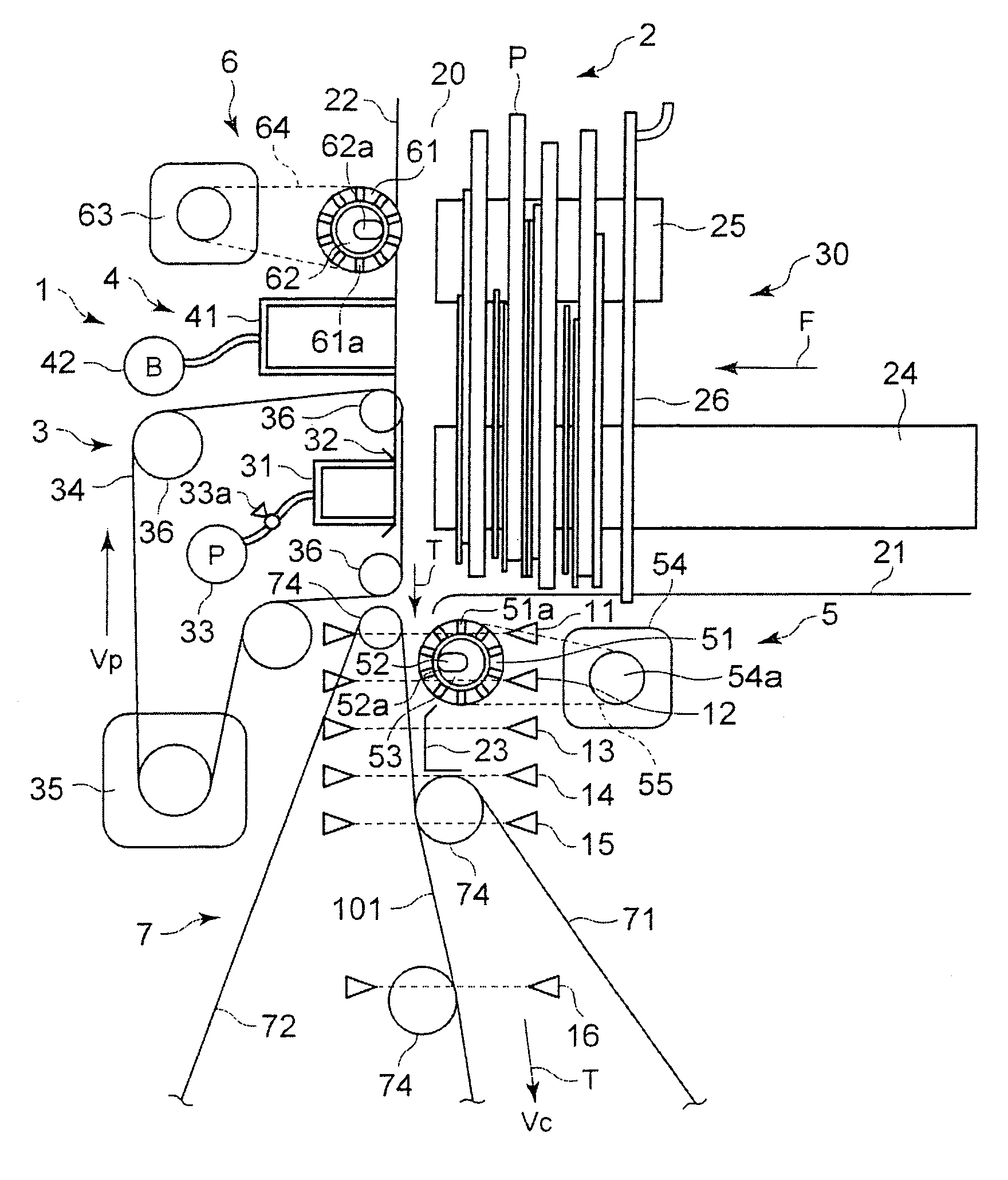

Ink Supplying Device, Recording Device, Ink Supplying Method and Recording Method

InactiveUS20080273046A1Easy to changeMinimize negative pressure variationOther printing apparatusEngineeringMechanical engineering

Owner:COPYER

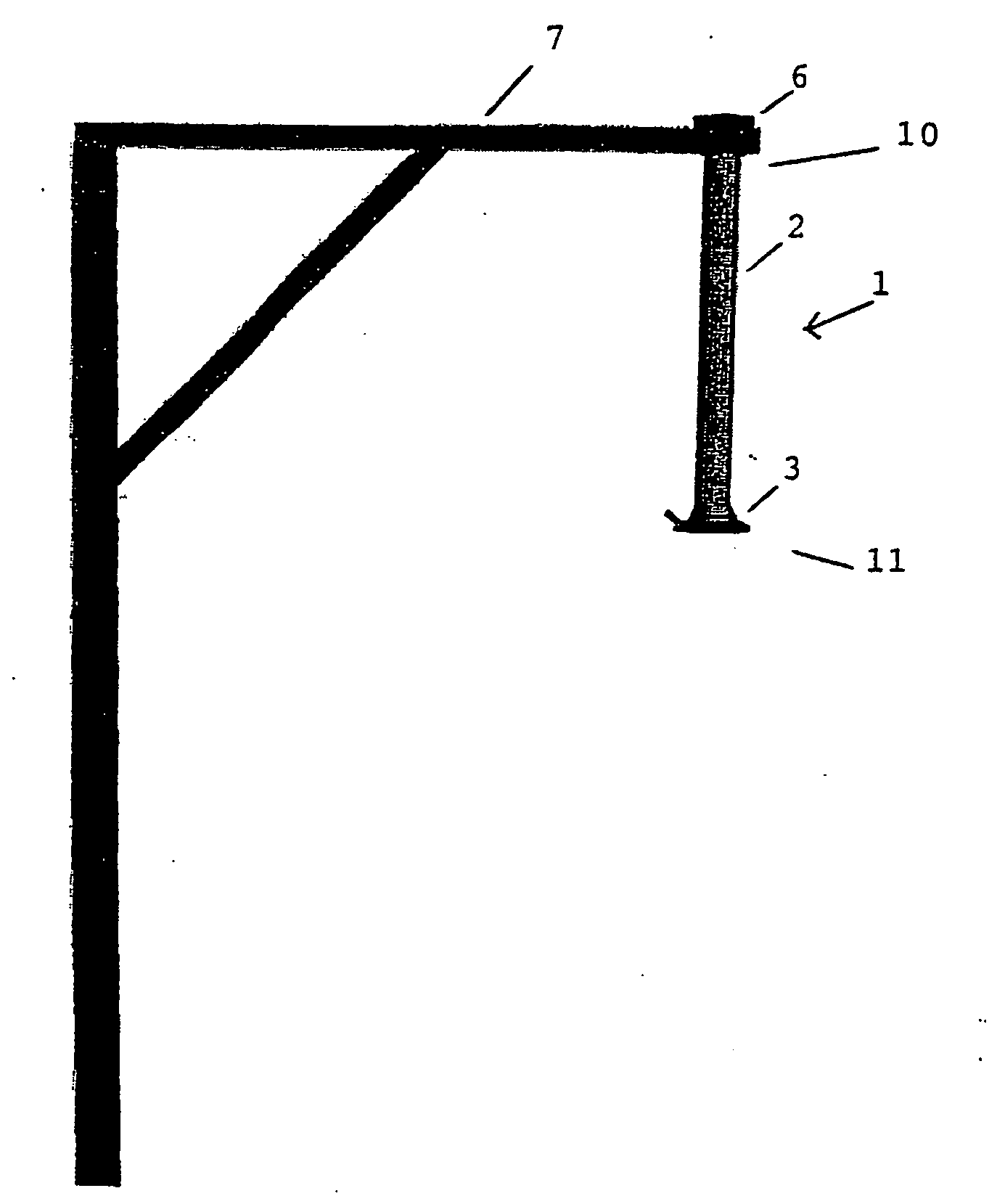

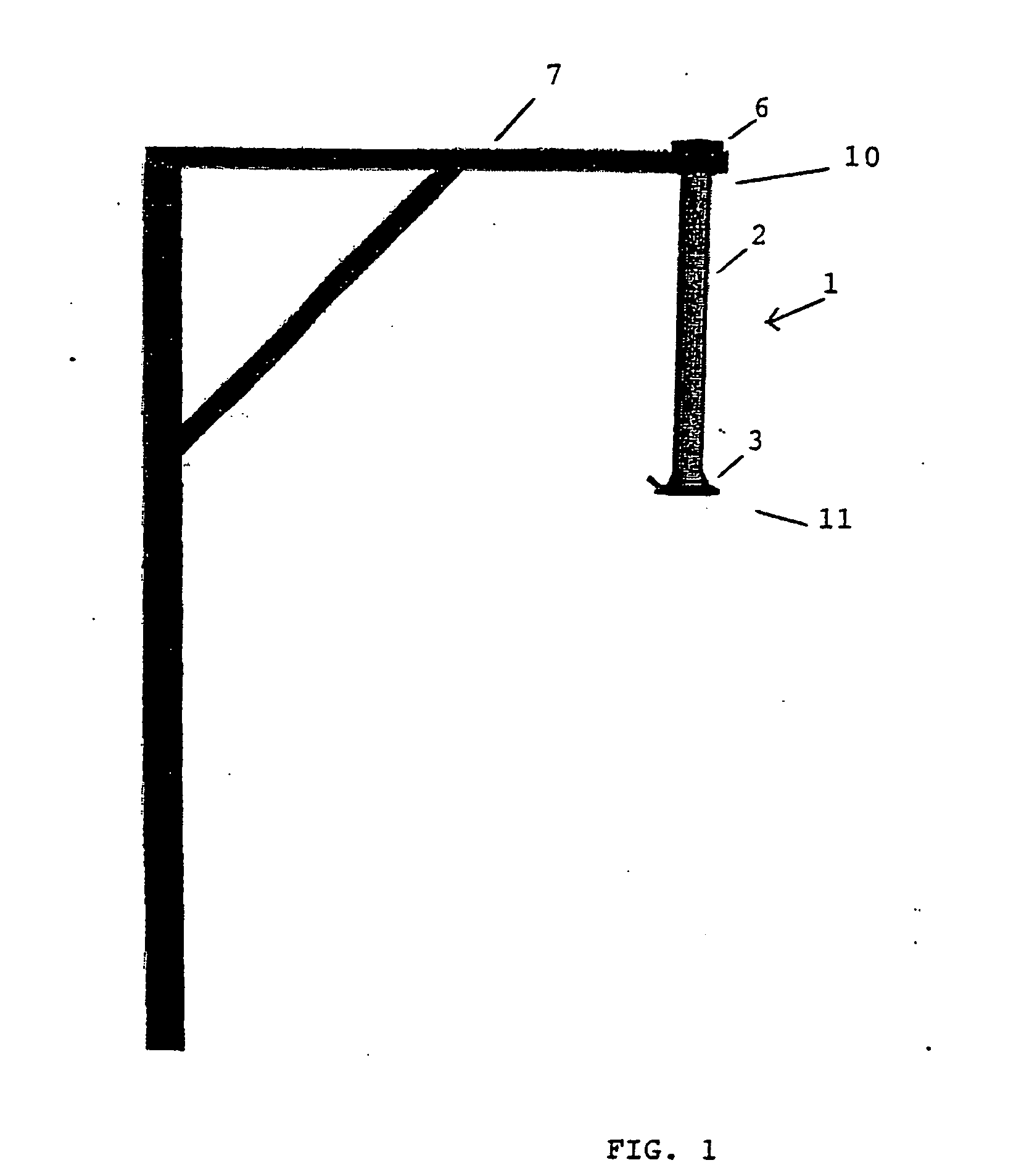

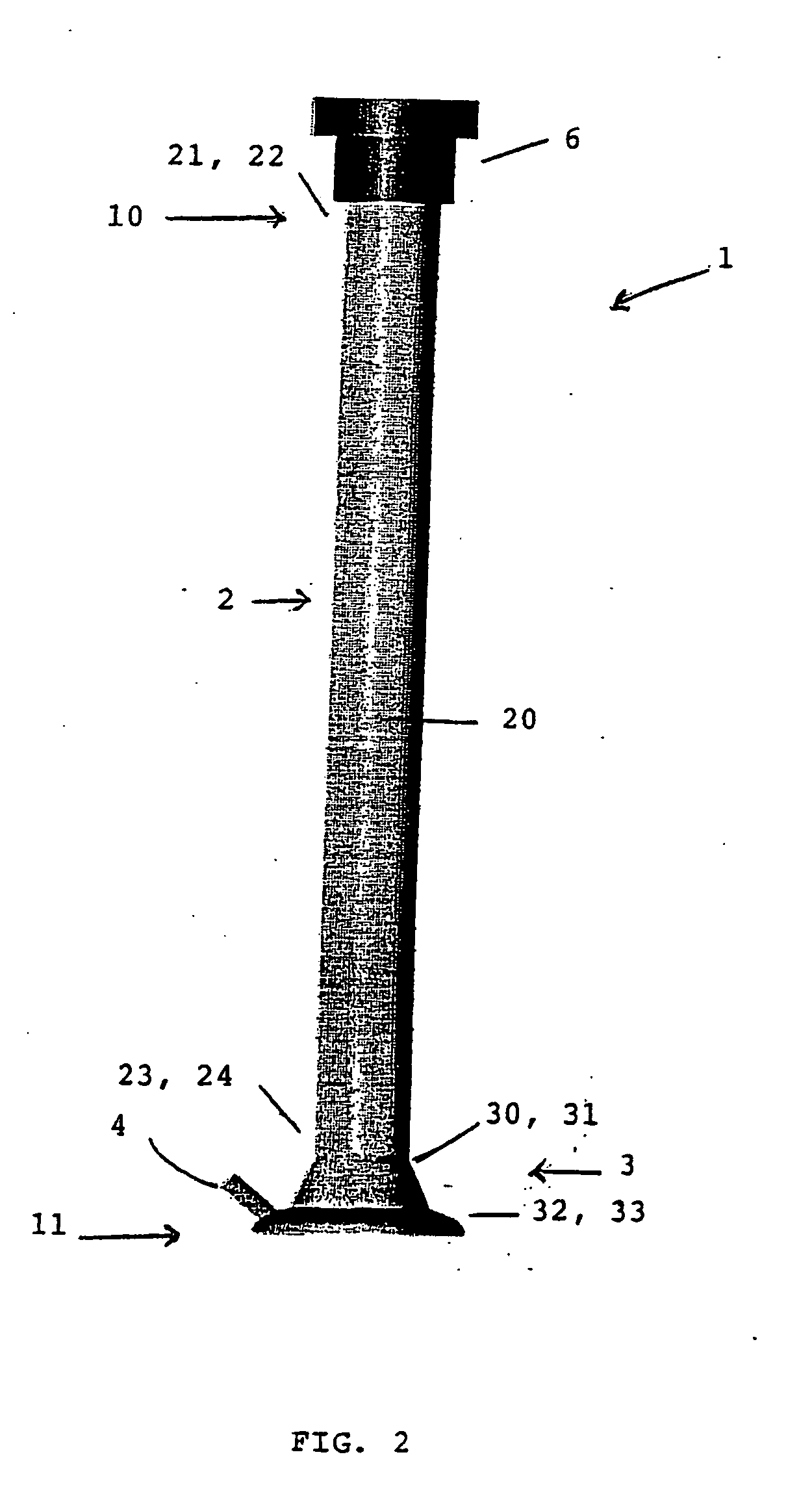

Guiding member for surgical instruments, surgical instruments, coupling and uses thereof

InactiveUS20060069383A1Reduce riskMinimize traumaEar treatmentDiagnosticsEngineeringHepatic operation

The present invention is related to a guiding member for guiding surgical instruments to a target volume inside a patient. The present invention also concerns surgical instruments specifically adapted for cardiac or hepatic surgery as well as a surgical assembly coupling said guiding member and said surgical instruments.

Owner:BOGAERTS GEORGES +1

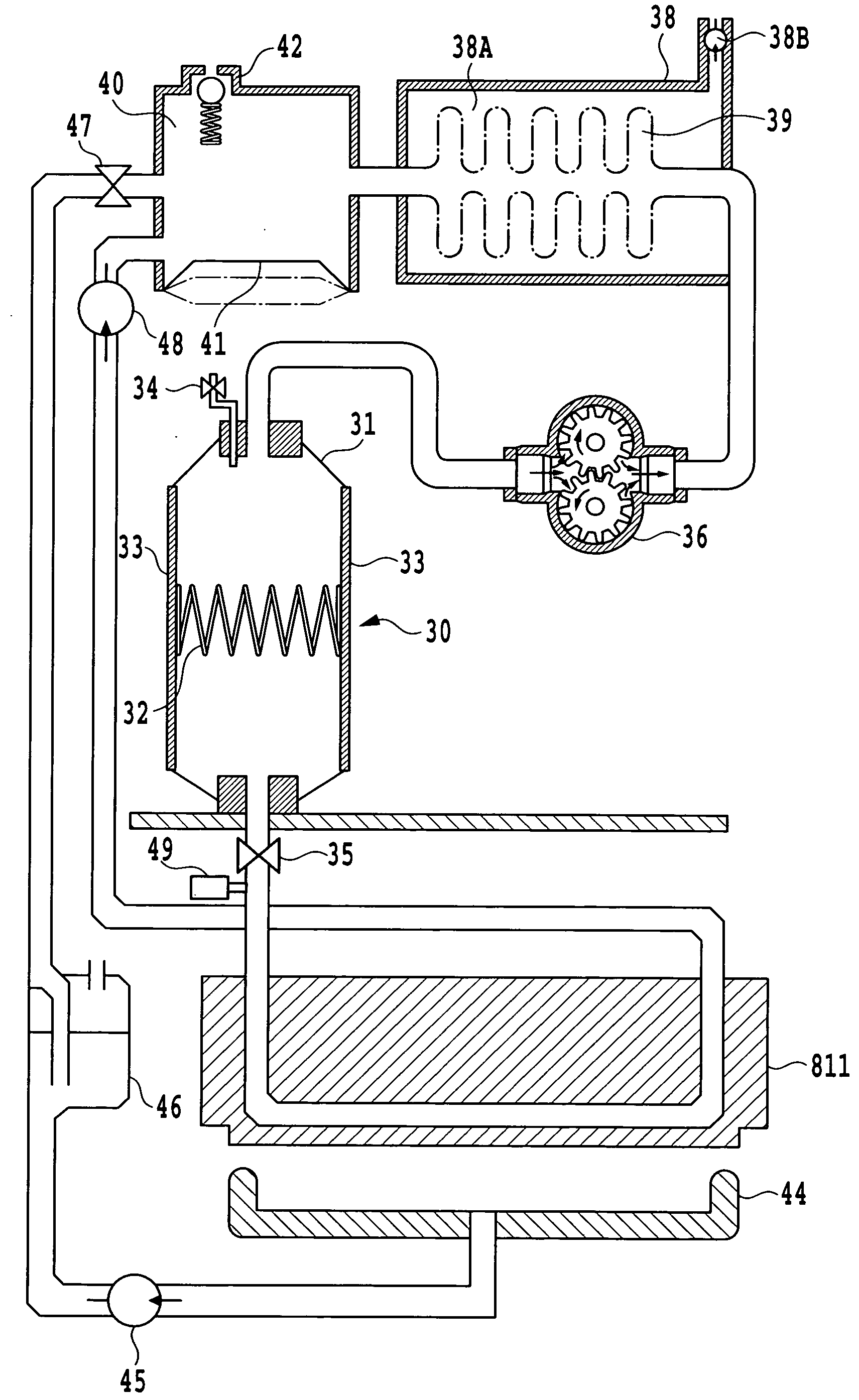

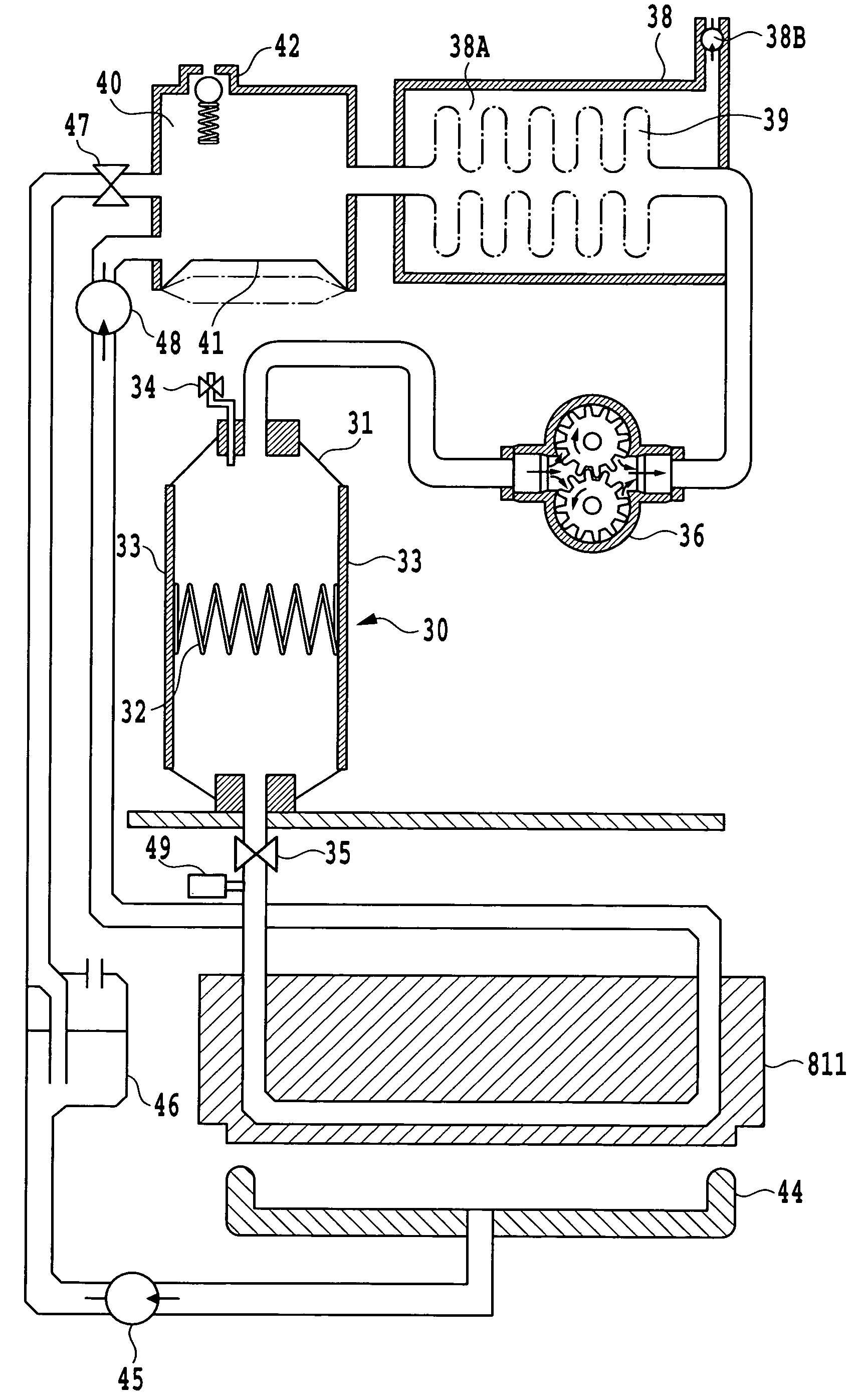

Ink supply apparatus and method for controlling the ink pressure in a print head

InactiveUS7841706B2Easy to changeMinimize negative pressure variationOther printing apparatusMechanical engineering

Owner:COPYER

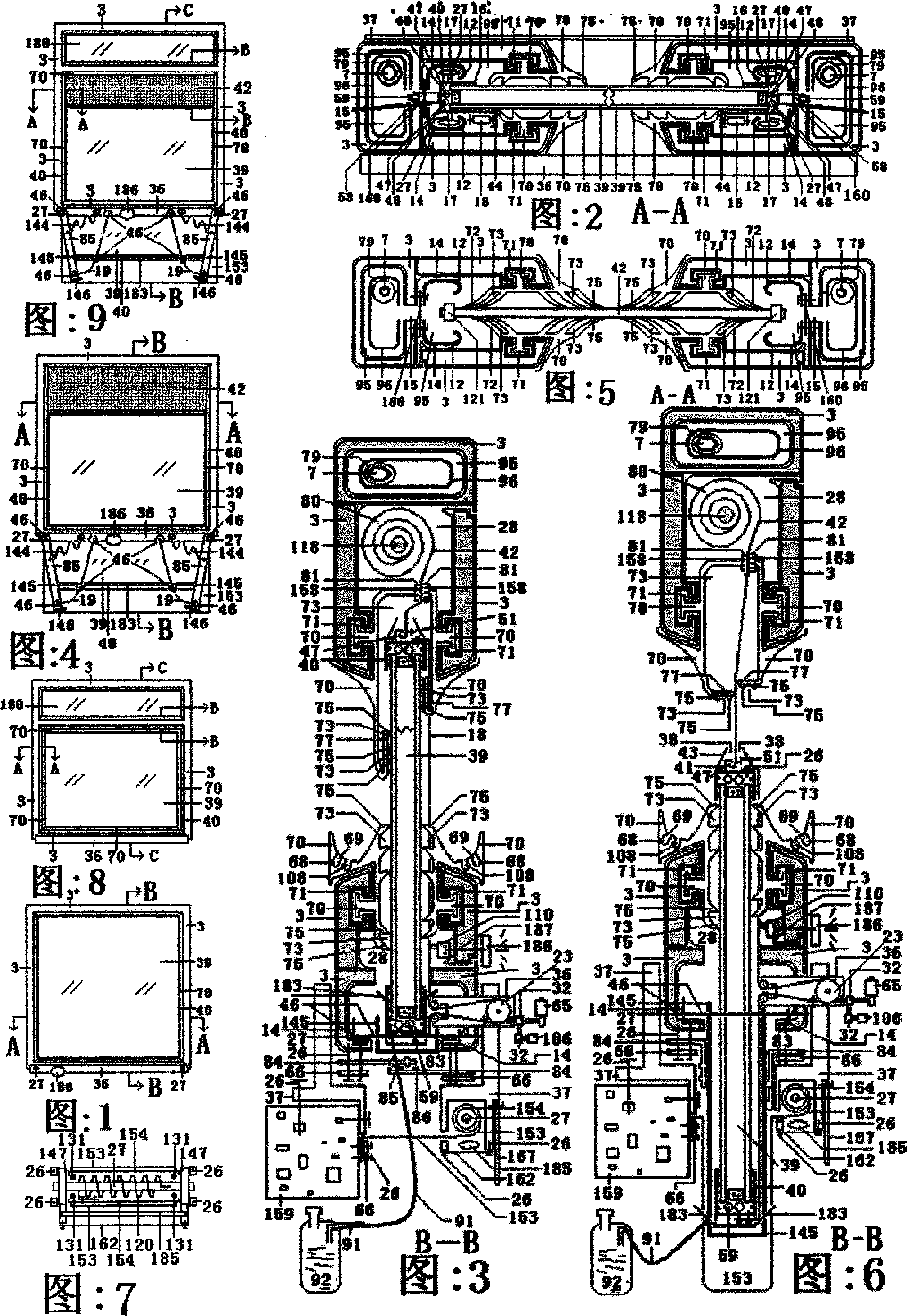

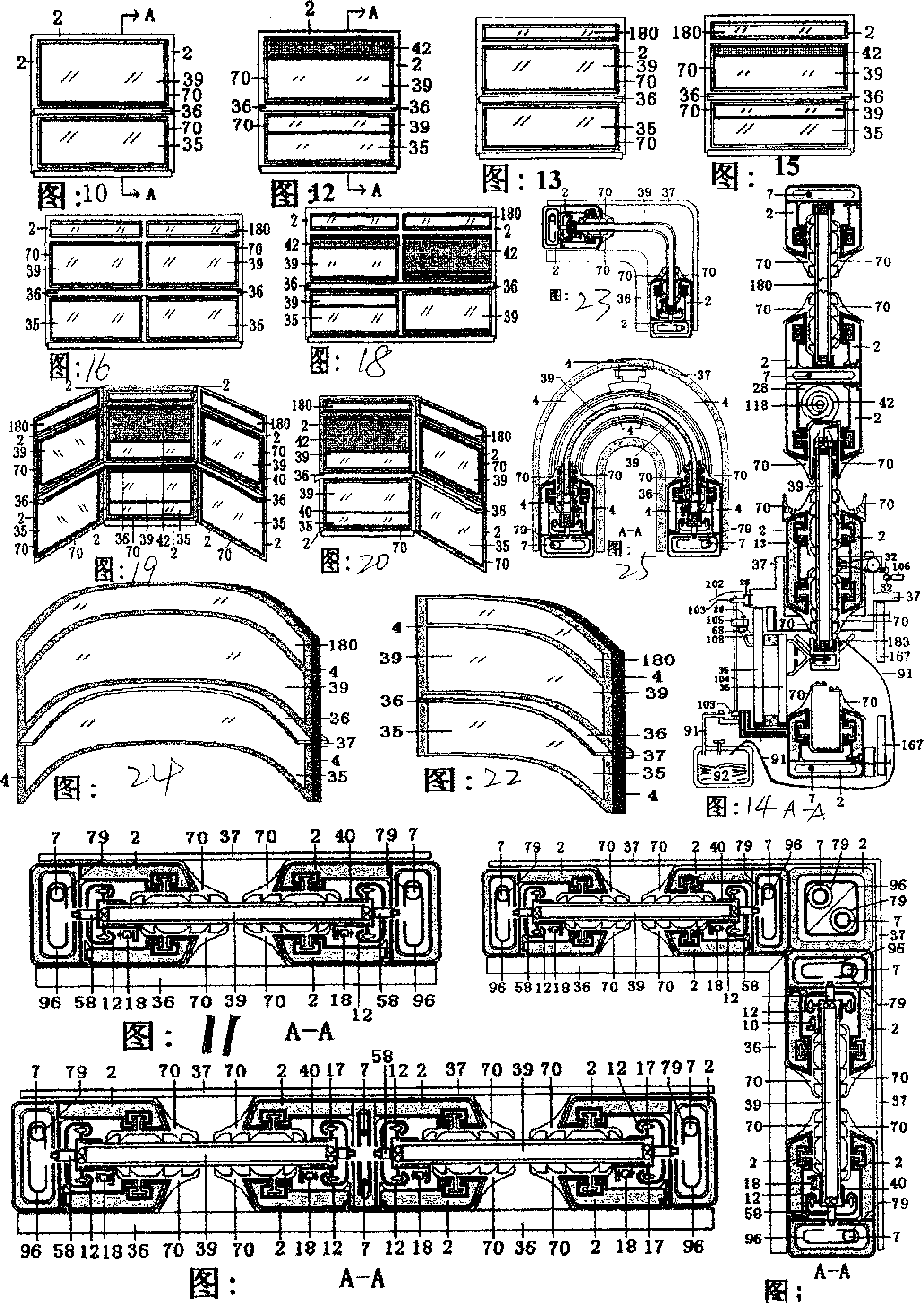

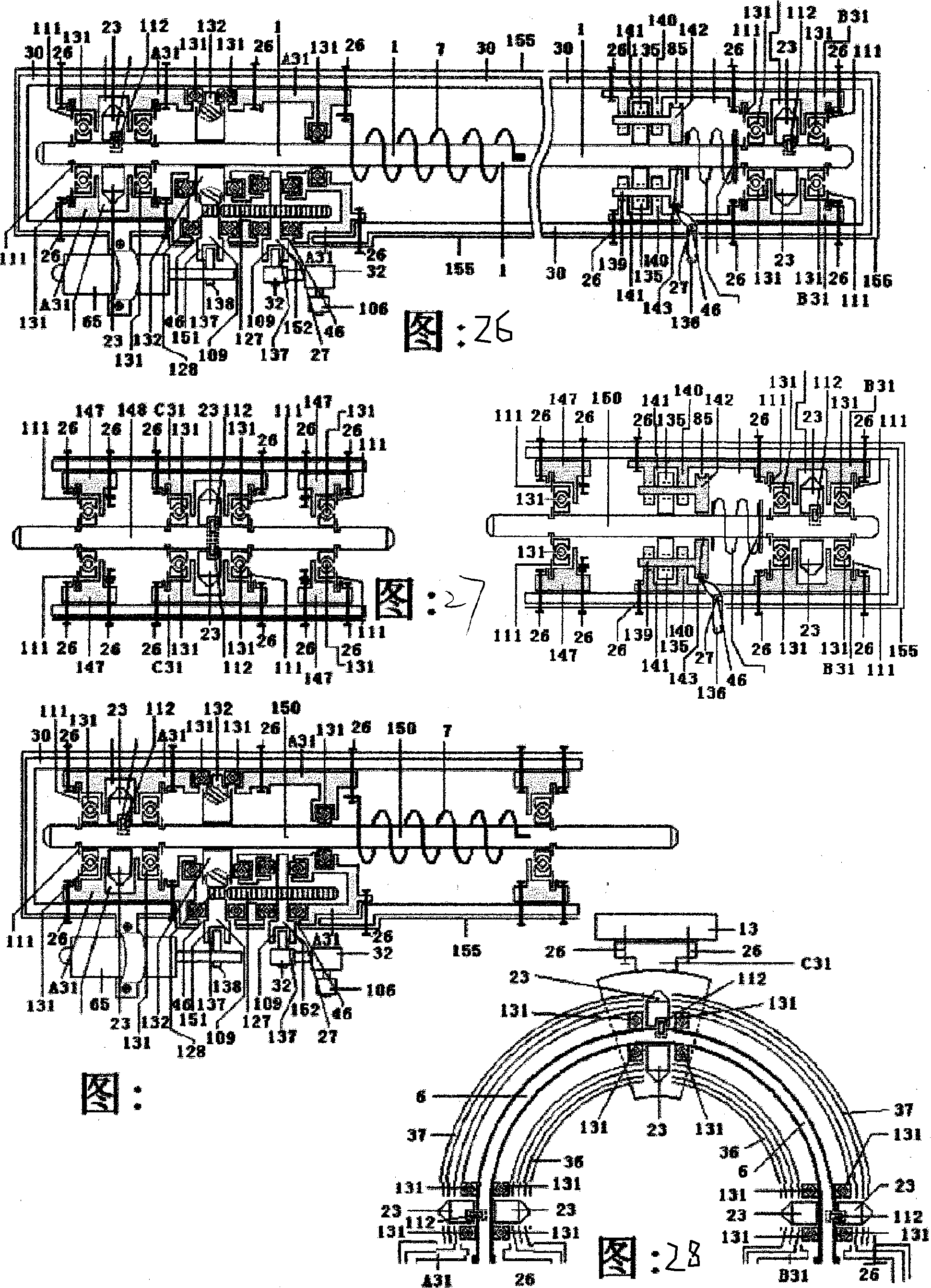

Multi-functional window structure

ActiveCN101298821ASolve potential safety hazardsImprove insurance coverage measuresMan-operated mechanismInsect protectionWindow screenMultiple function

A multifunctional window structure is composed of a window frame sectional material, a primary shaft main body, glass and a protective frame, a clean-free window screen, a primary shaft system, glass for cleaning indoors and outdoors automatically, an electric / manual switching mechanism locking state, an air filtering decompression device, a transparent, insulting, soundproof flexible rolling window which can be rolled up, double-layer flexible transparent curtain, a theft-proof telescopic guard rail, separated glass of the transparent insulating curtain, a transparent, insulating and soundproof flexible rolling door which can be rolled up. Glass (39) with the glass protective frame (40), a gland strip (70), a window sill bracket (36), a music promoting alarm (186) for opening and closingwindow, and a decorative cover (153) are installed in the separated window frame (3). The fully invisible window screen (42) and the glass (39) are connected actively. The steel cable (19) is installed on the glass protective frame (40). The upper bright band (180) is installed on the window frame sectional material (13).

Owner:李京岐

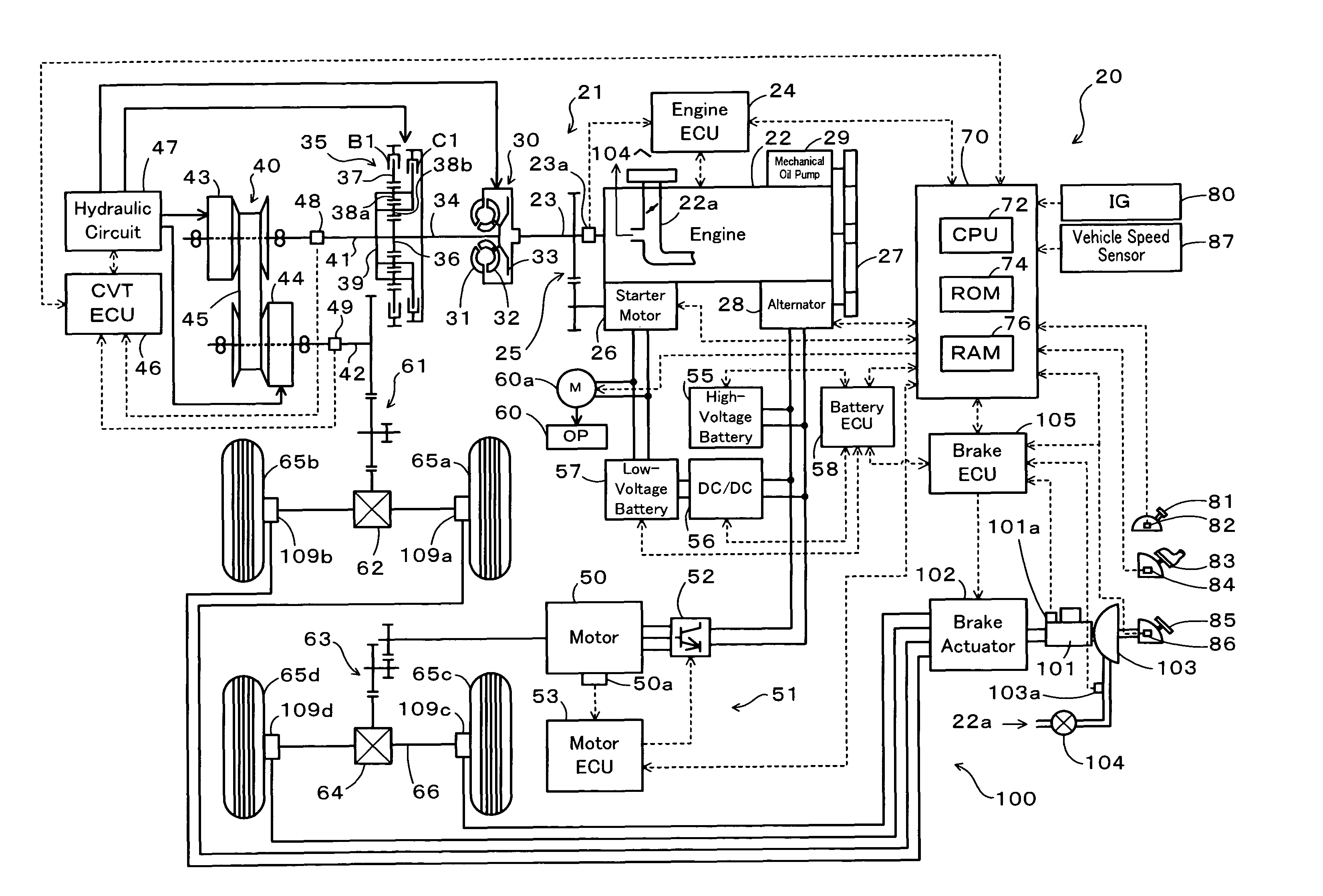

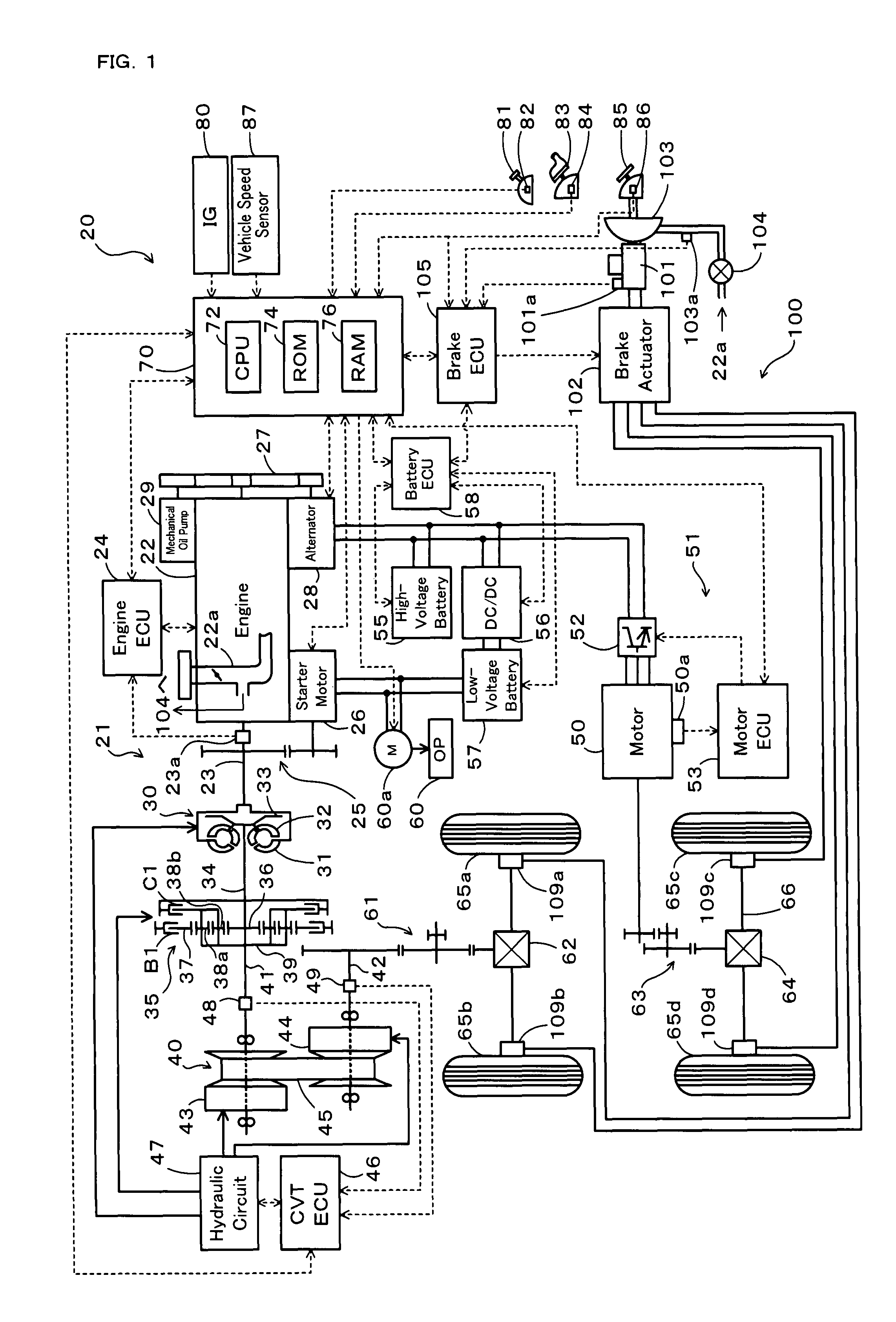

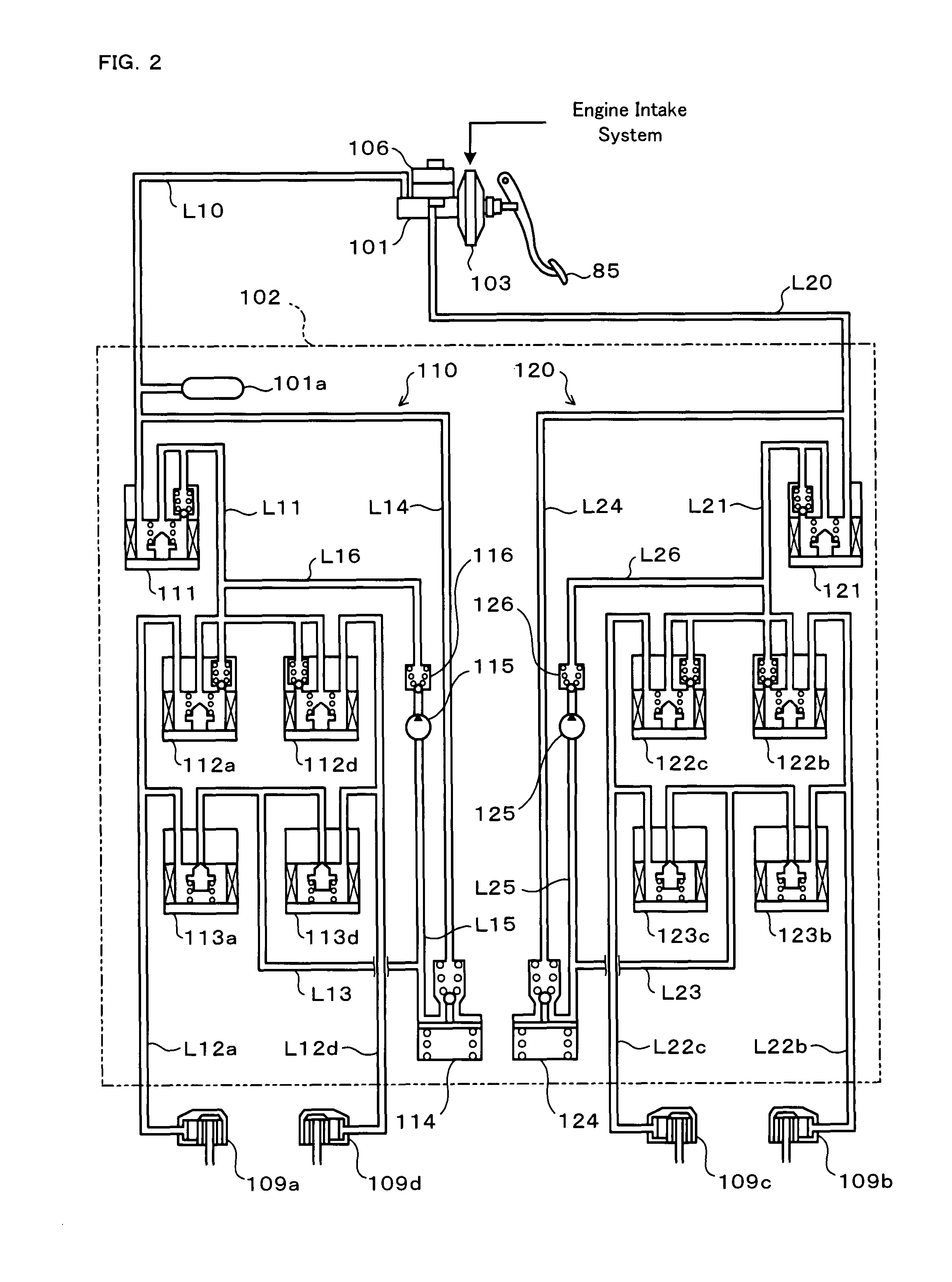

Vehicle and control method of vehicle

InactiveUS20070272457A1Reduce negative pressureAccurate settingAuxillary drivesBraking element arrangementsRegenerative brakeMaster cylinder

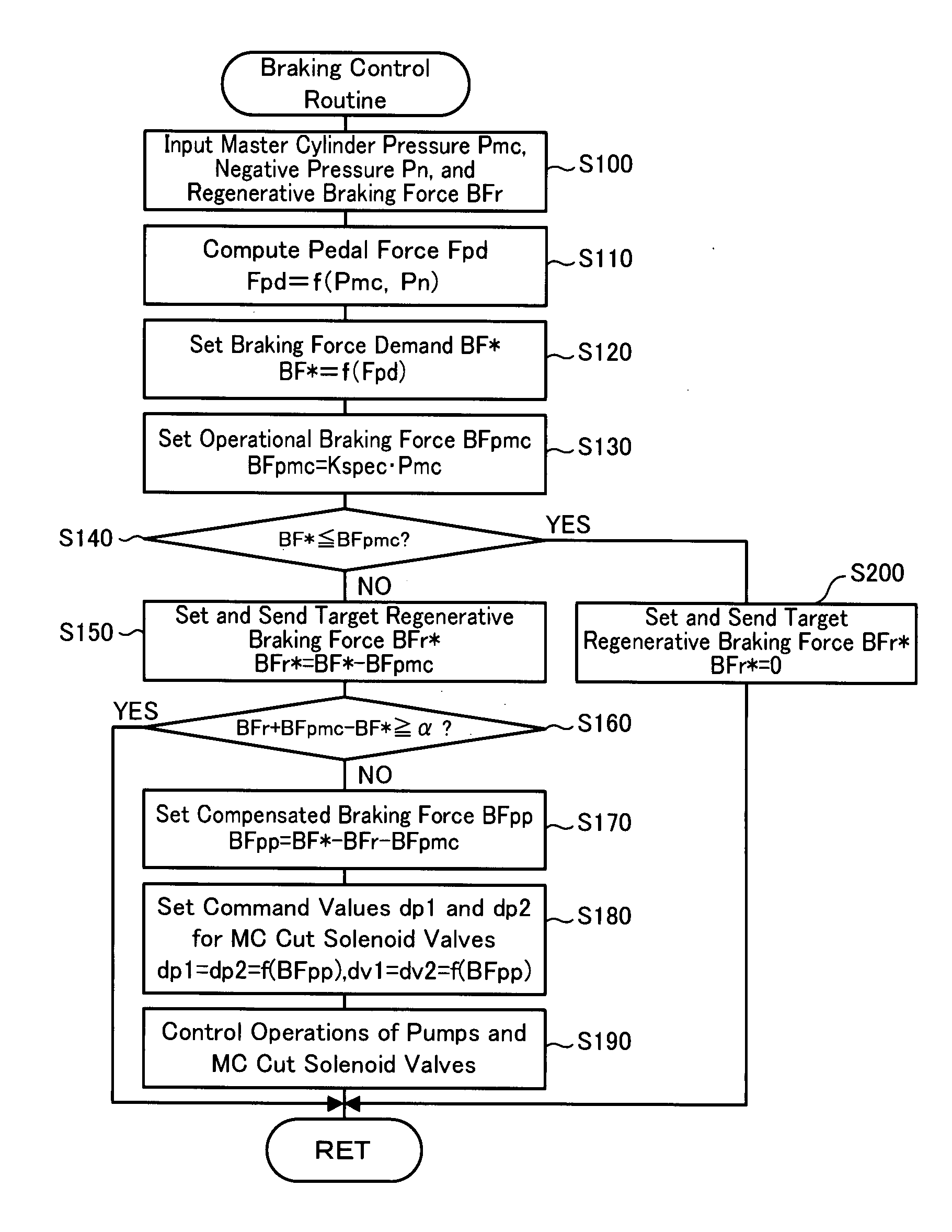

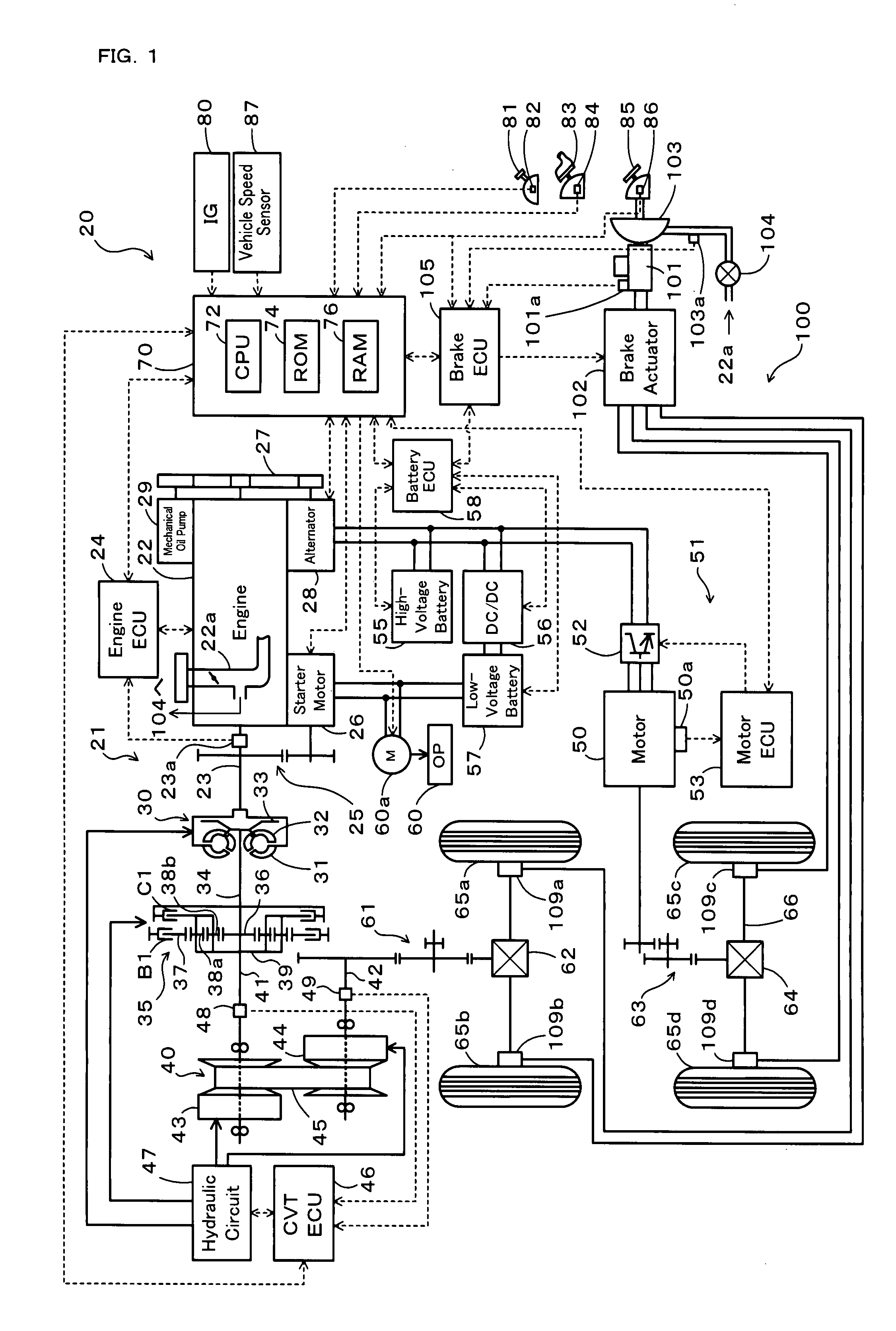

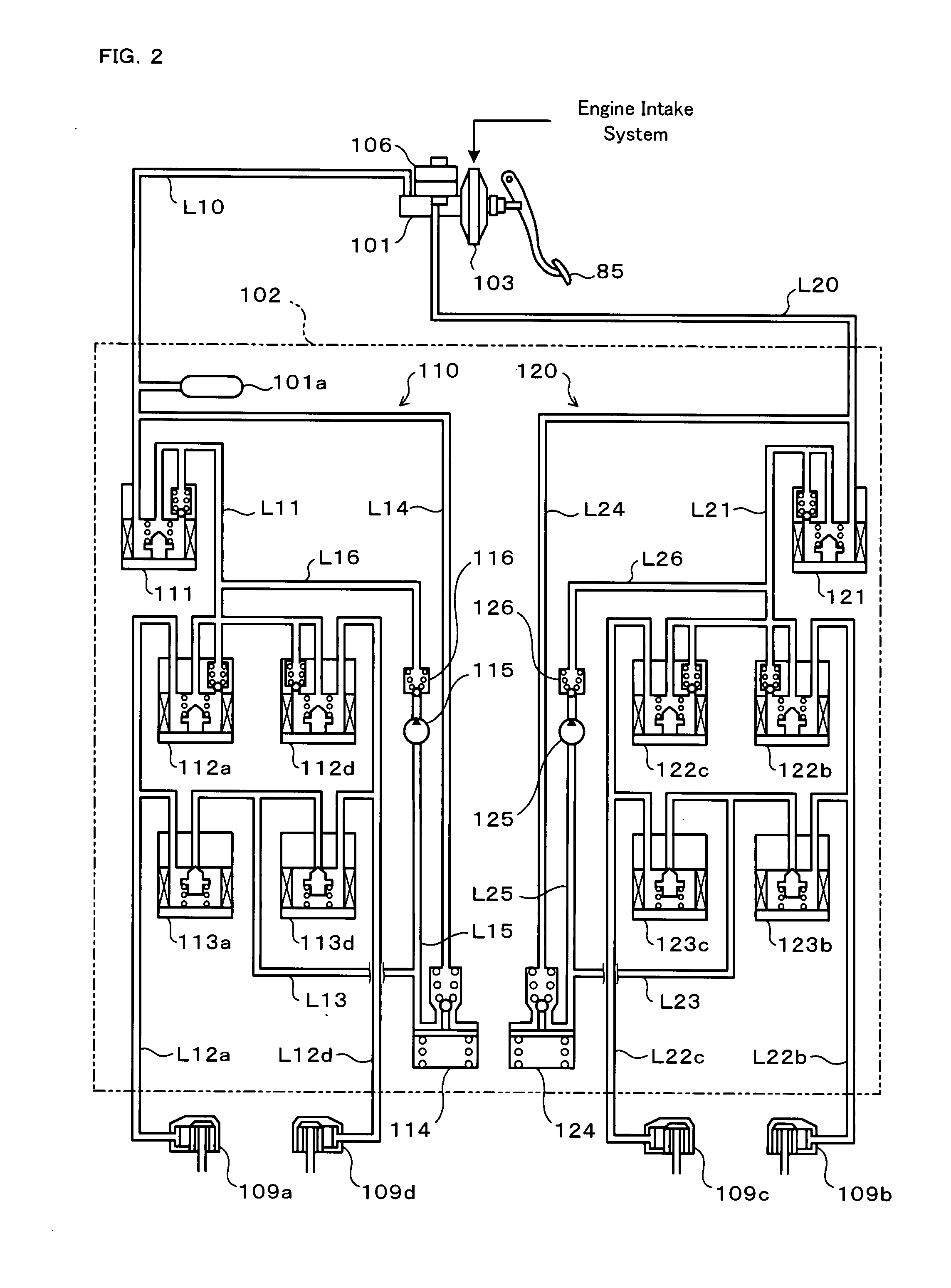

In the hybrid vehicle of the invention, when the sum of a regenerative braking force BFr produced by a motor and an operational braking force BFpmc based on a master cylinder pressure Pmc is insufficient for a braking force demand BF* required by the driver in response to the driver's depression of a brake pedal, the motor and a brake actuator of an HBS are controlled to satisfy the braking force demand BF* by the total of the regenerative braking force BFr of the motor, the master cylinder pressure Pmc-based operational braking force BFpmc, and a compensated braking force BFpp based on a pressure increase by two pumps included in the brake actuator (steps S170 through S190).

Owner:TOYOTA JIDOSHA KK

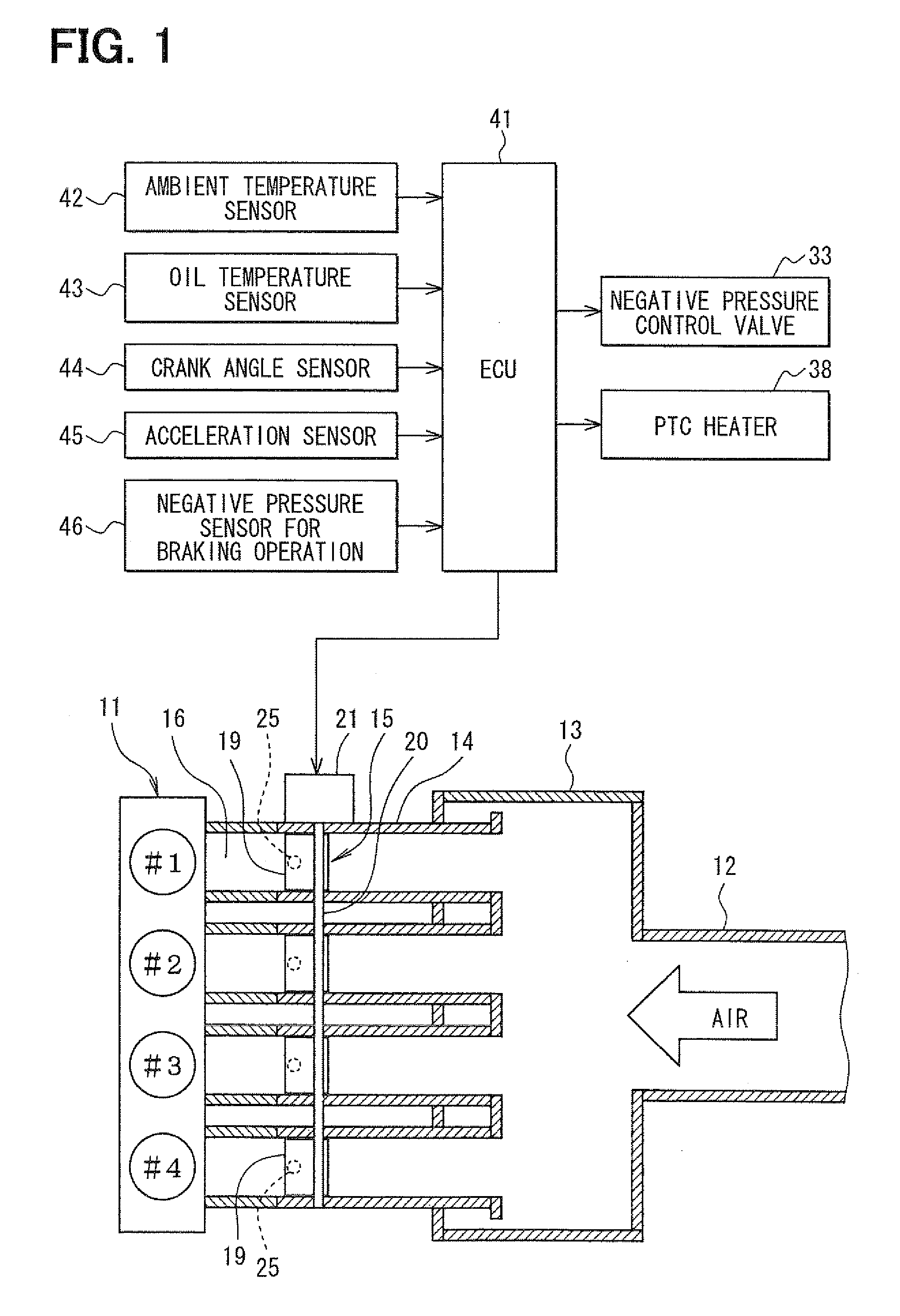

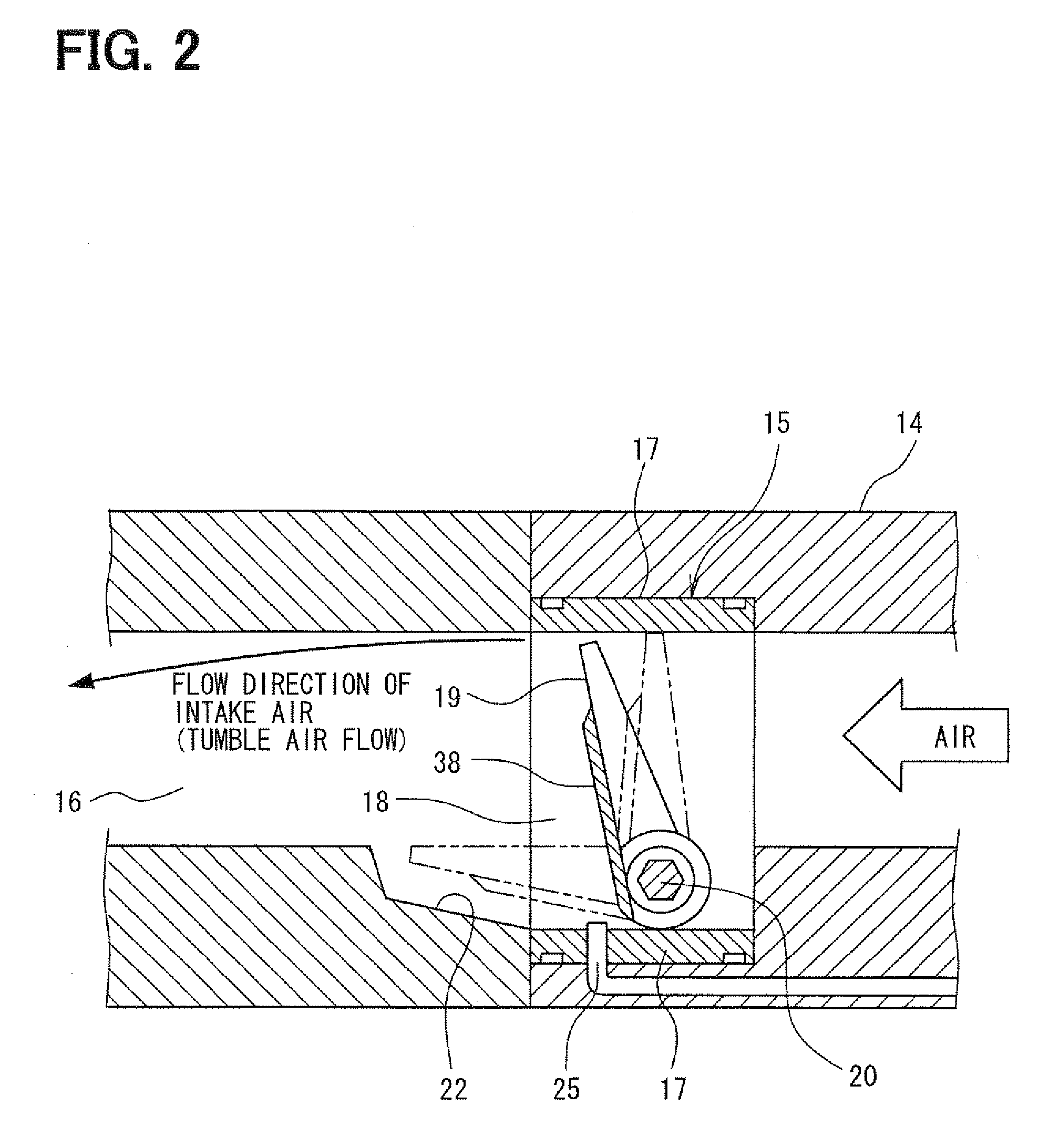

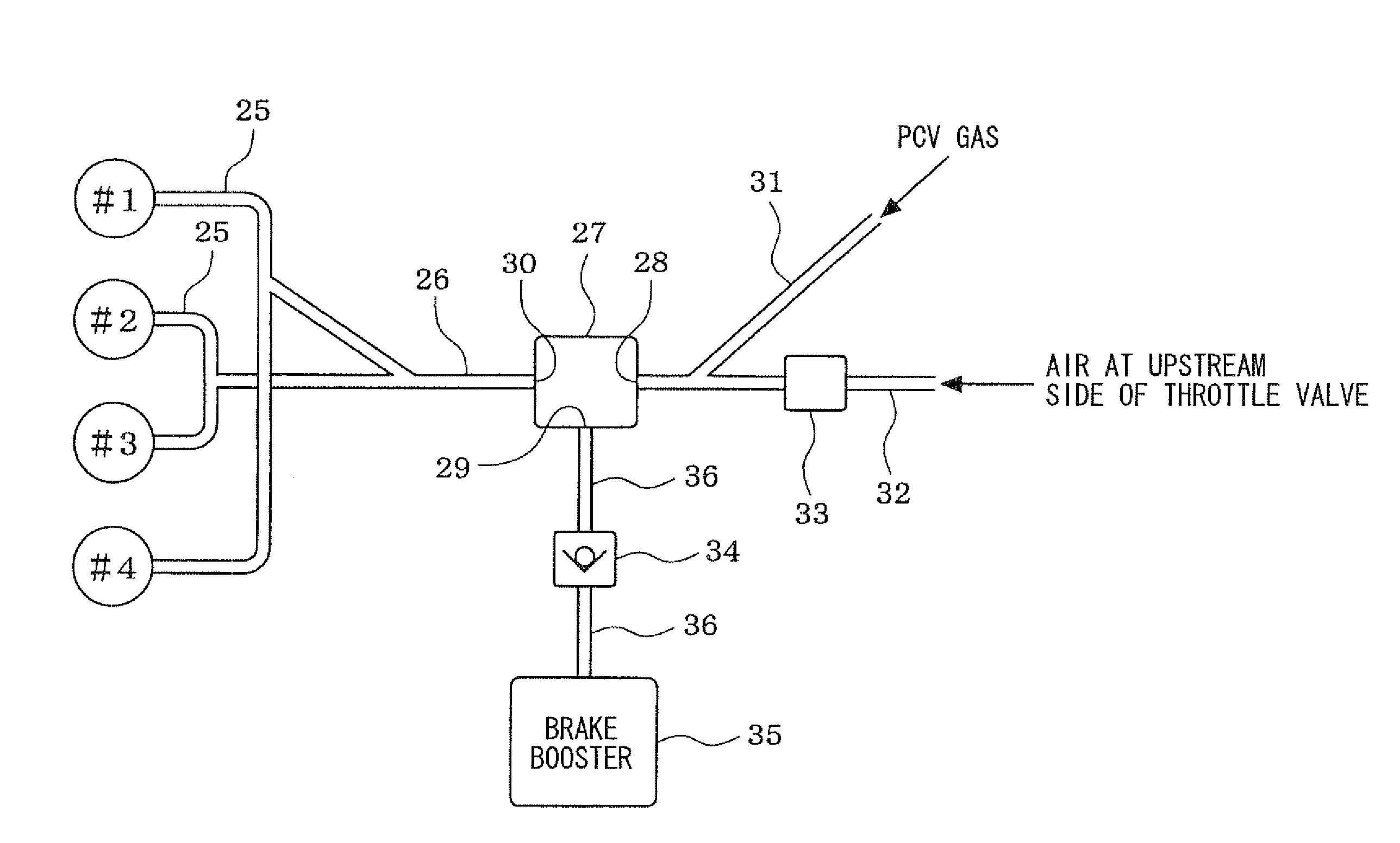

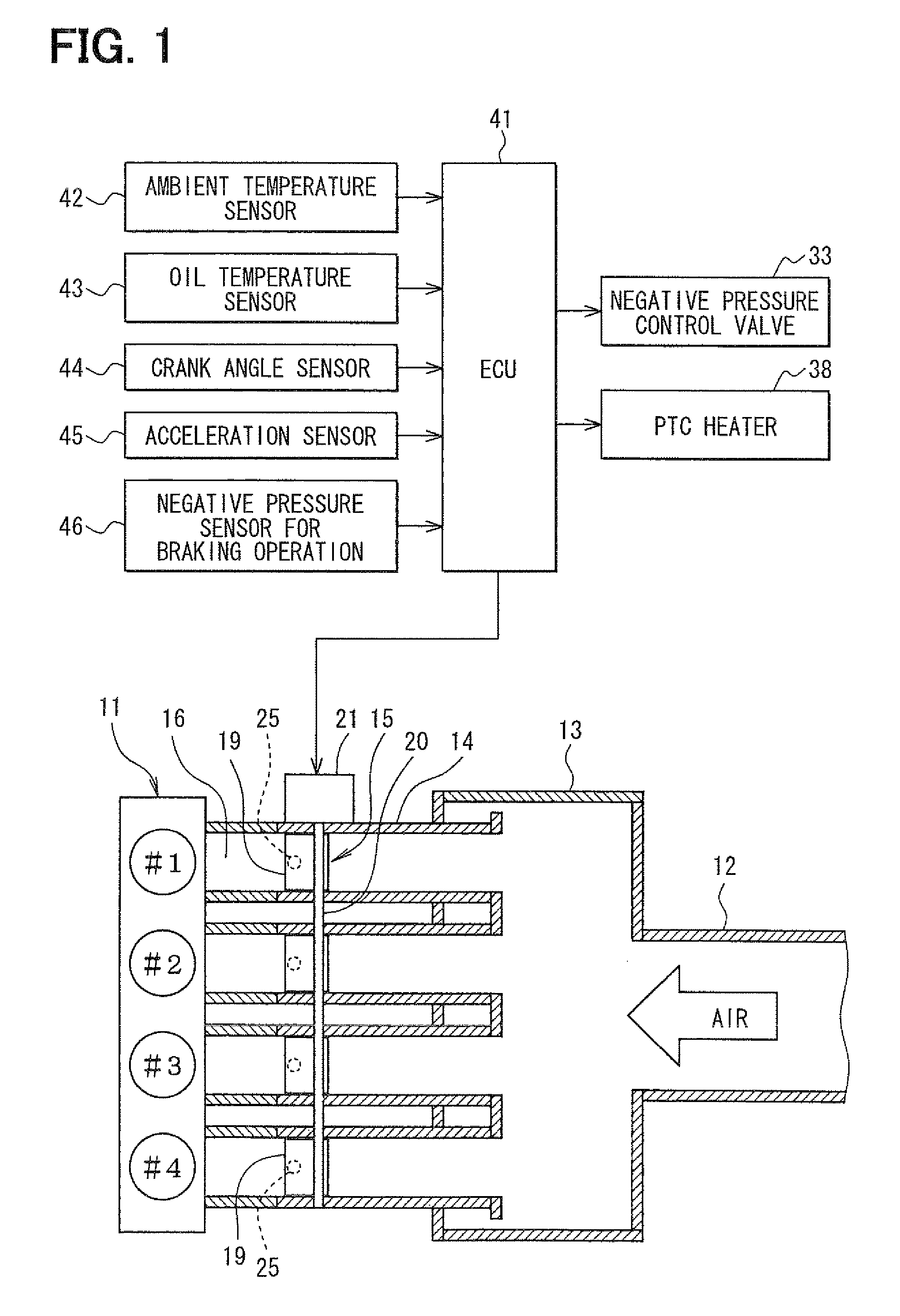

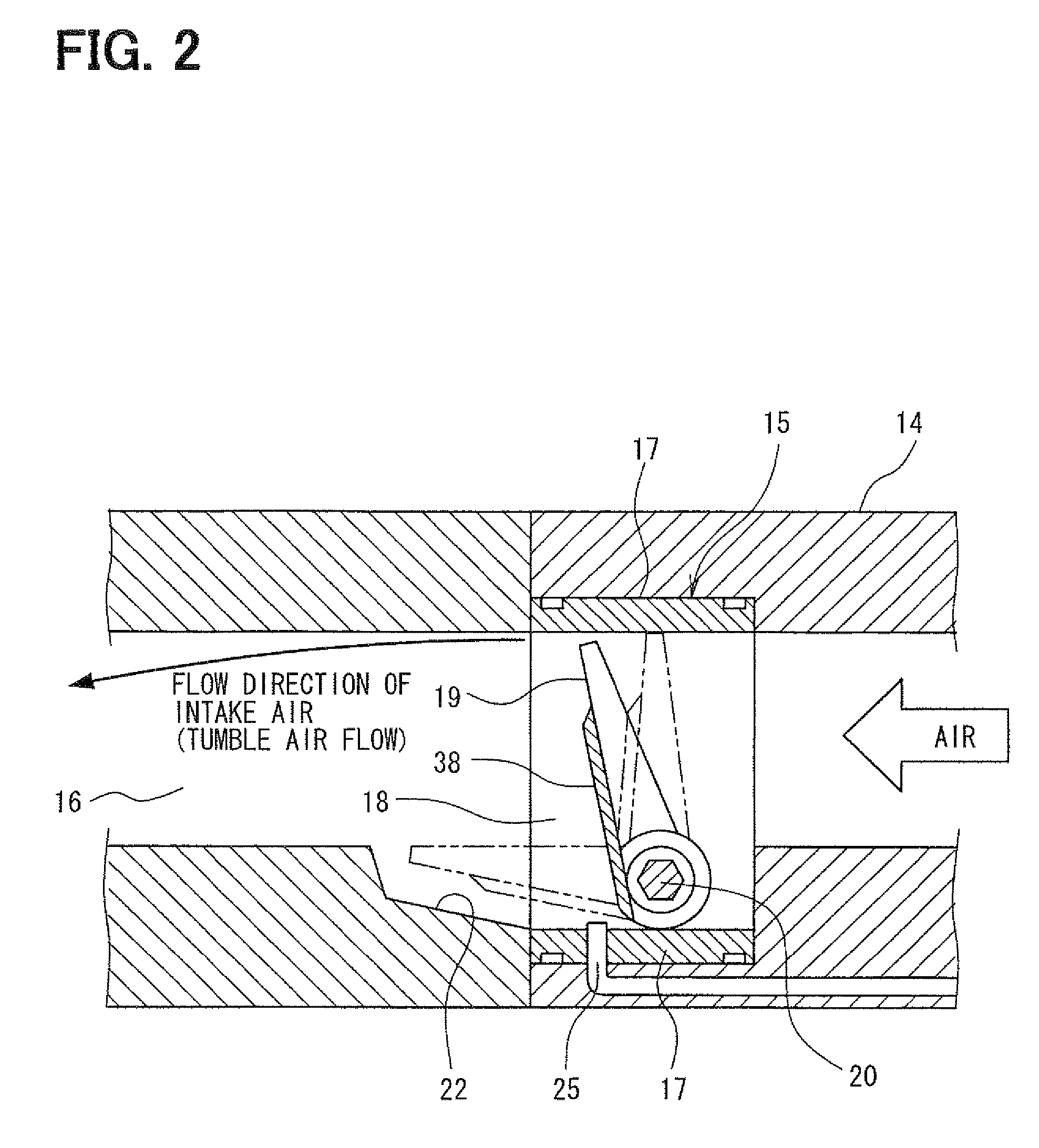

Negative pressure control apparatus for vehicle breaking operation

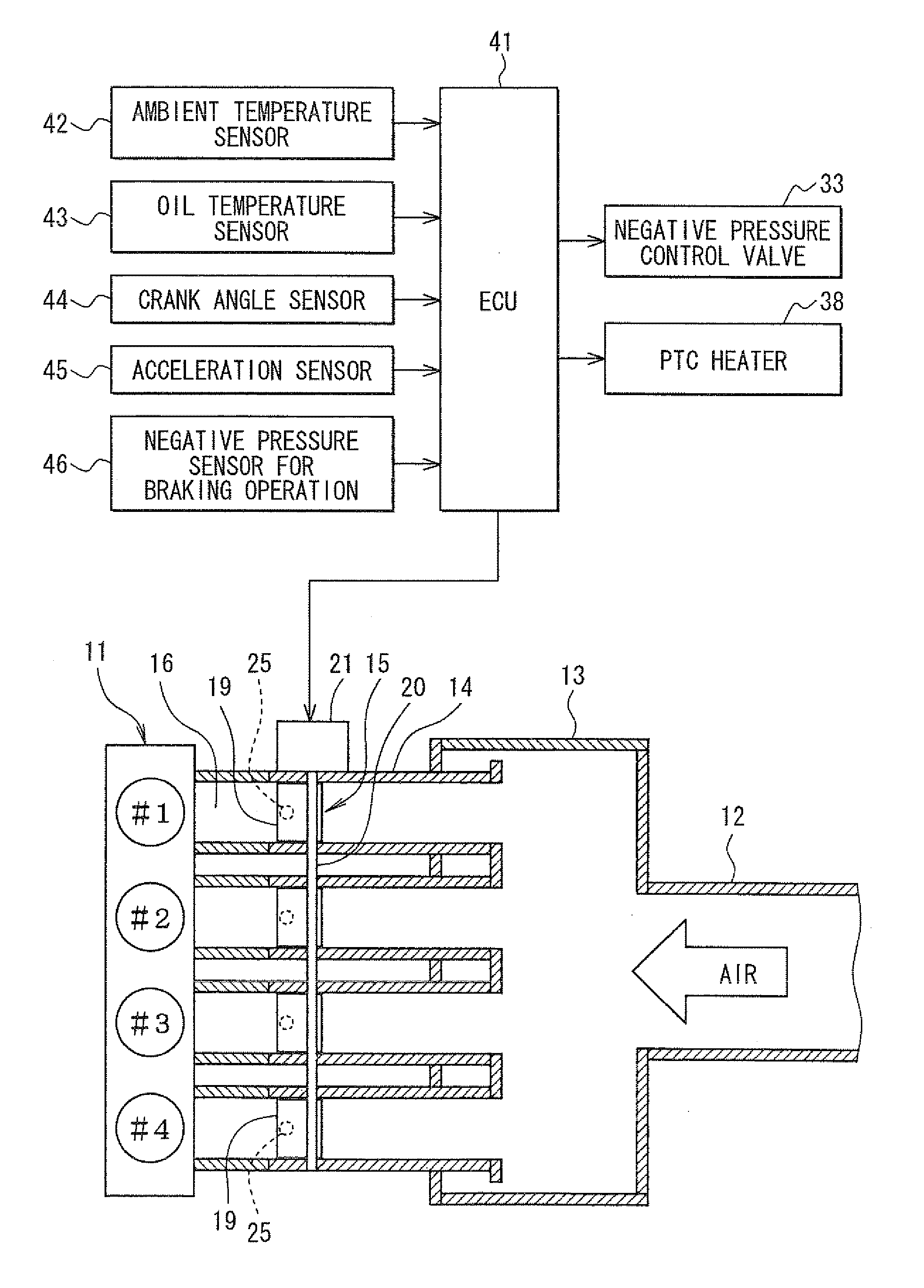

InactiveUS20080103667A1Reduce negative pressureImprove braking performanceAnalogue computers for trafficCombustion enginesEngineeringCheck valve

A communication passage for generating braking negative pressure is connected to an air passage for respective cylinders at a downstream side of a throttle valve. An air ejector is provided in a negative pressure pipe, to which communication passages for the respective cylinders are converged. A negative pressure passage for a brake booster is connected to the air ejector at a side of suction gas via a check valve. A passage for PCV gas and an intake air branched passage for bifurcating a part of the intake air from a surge tank at an upstream side of the throttle valve are connected to a driving gas side of the air ejector, wherein a negative pressure control valve is provided in the intake air branched passage. The PCV gas and the part of the intake air are forced to flow into the driving gas side of the air ejector, so that the air ejector functions as a vacuum pump. As a result, the braking negative pressure for the brake booster can be surely reduced to a target negative pressure.

Owner:DENSO CORP +1

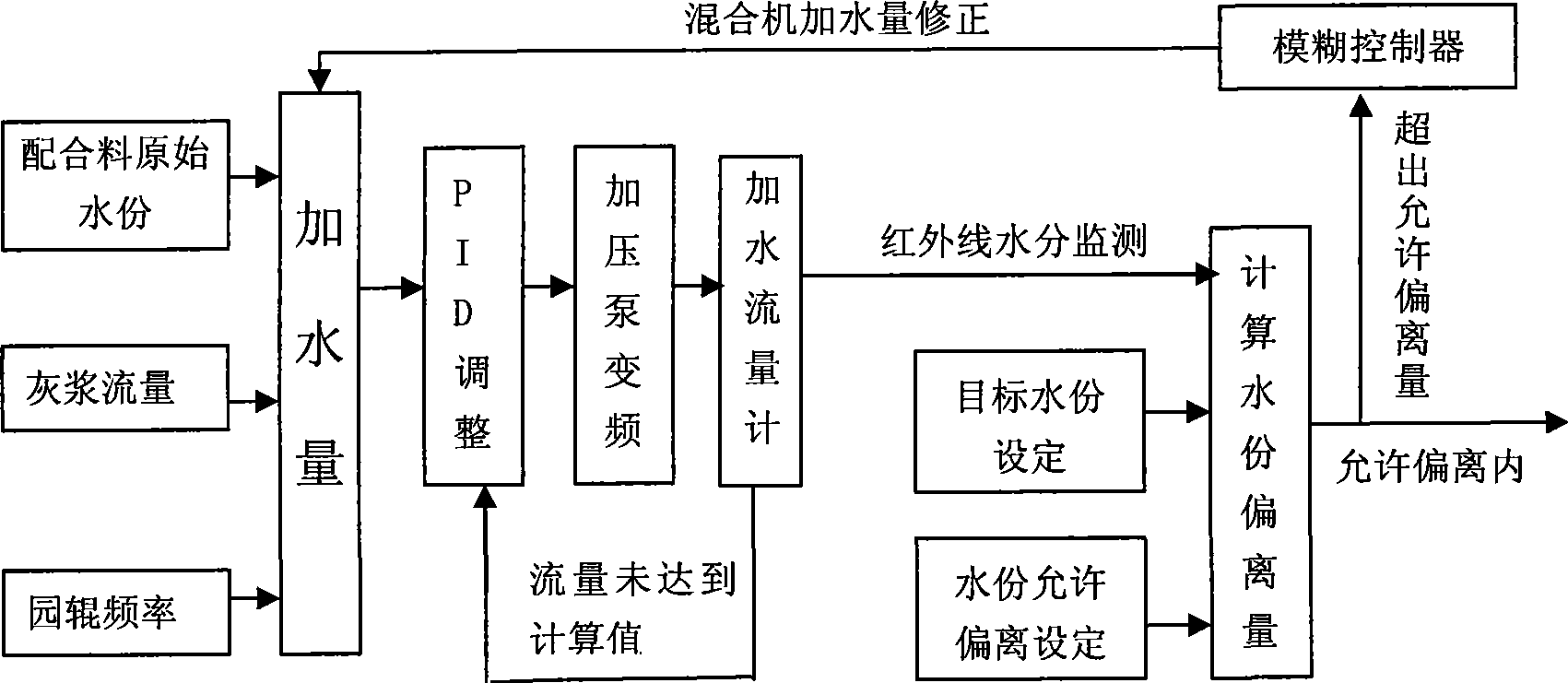

Humidity control method for mixture used in sintering production

ActiveCN101477378AReduce regulatory disturbancesMeet production requirementsControlling ratio of multiple fluid flowsAdaptive controlAutomatic controlData acquisition

The invention relates to a method for controlling moisture of a mixture for sintering production, and belongs to the technical field of automatic monitoring and intelligent control of mixture moisture. The method adopts a PLC system and a development tool. The control process comprises data acquisition, signal display, data processing, manual input of information, model operation and adjustment for fuzzy control, control quantity output, model self-adapting, and judgment and correction of manual intelligent mode. The method achieves automatic dynamic control of water adding amount of the sintered mixture to make the mixture moisture meet sintering production demand, displays data such as real-time moisture, water adding amount and the like of the material in the production process, and displays operation mode and the like. The method has the advantages that the method is suitable for control of the water adding amount in a mixing process using various sintering production process raw materials, can design an independent control system or can be realized by using the PLC control system based on automatic control of the production process, is limited little by field conditions, is suitable for new projects and reformed projects, and has low cost.

Owner:首钢股份公司迁安钢铁公司

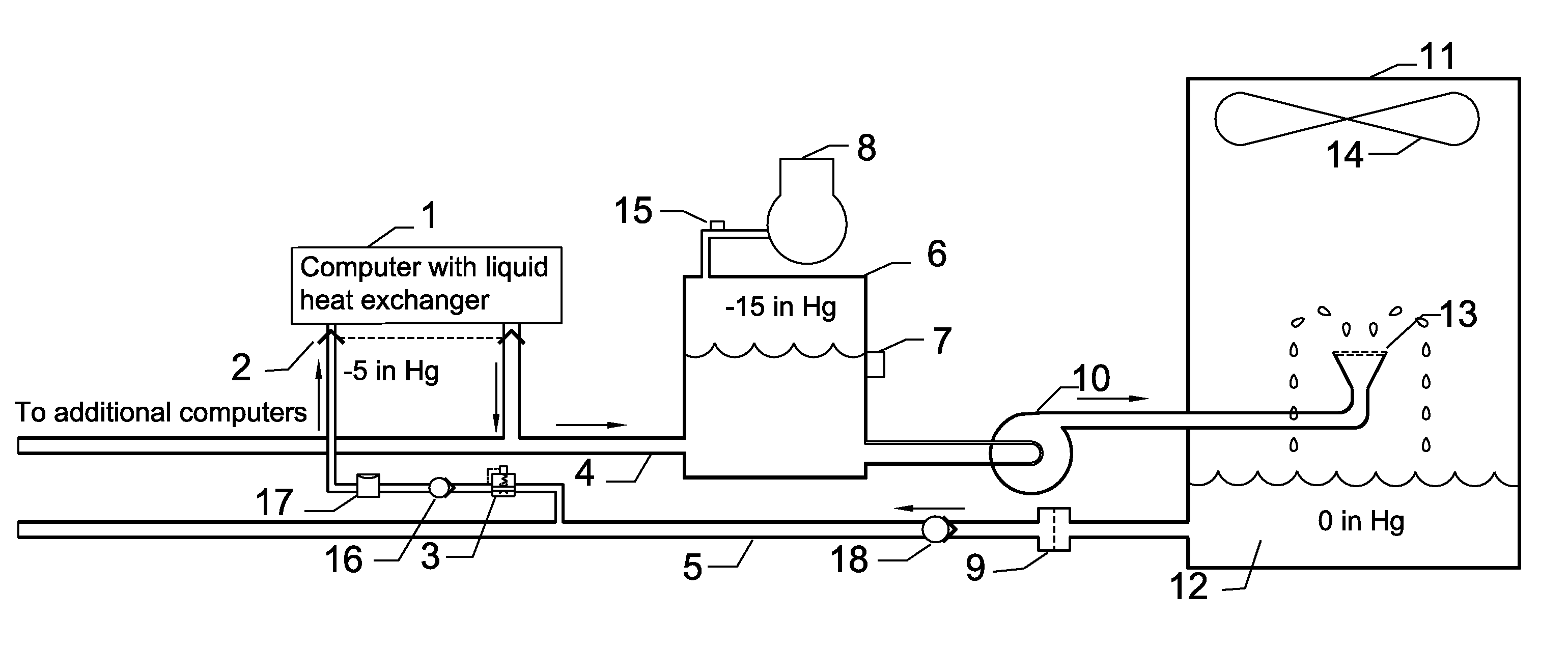

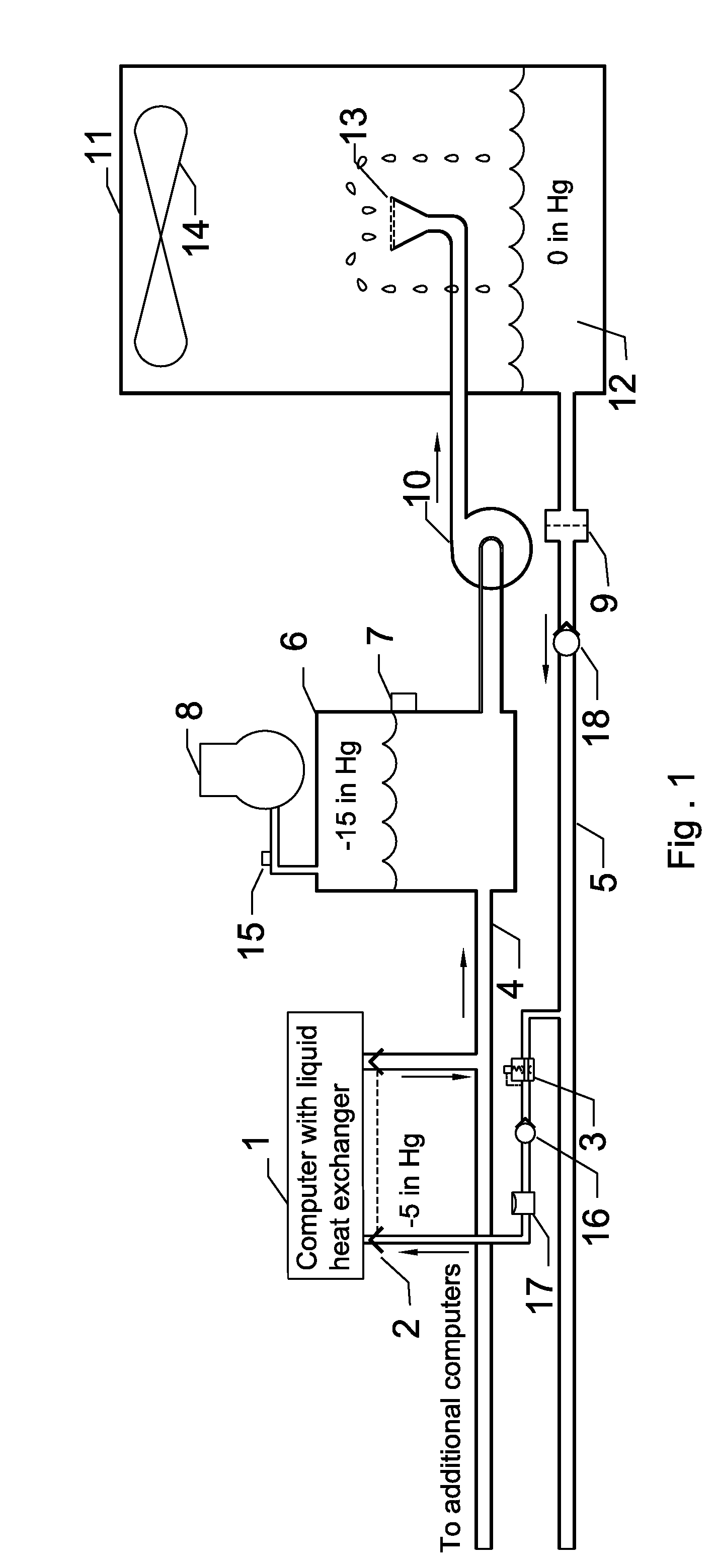

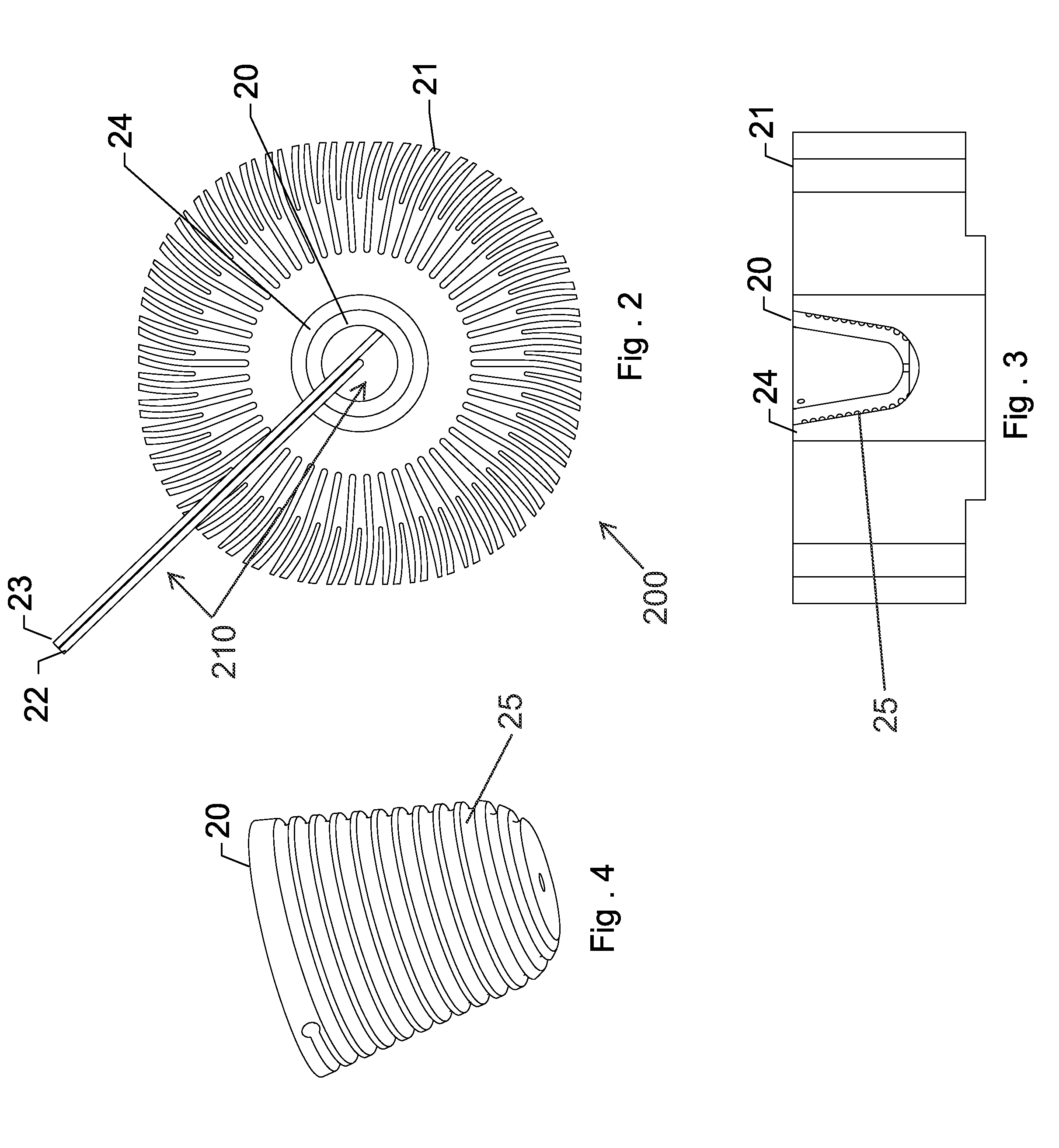

Vacuum Pumped Liquid Cooling System for Computers

InactiveUS20110253347A1Avoid cloggingAvoid heat exchangeDigital data processing detailsHeat exhanger finsLiquid cooling systemAir cooling system

A reliable, leak tolerant liquid cooling system with a backup air-cooling system for computers is provided. The system may use a vacuum pump and a liquid pump in combination to provide negative fluid pressure so that liquid does not leak out of the system near electrical components. The system distributes flow and pressure with a series of pressure regulating valves so that an array of computers can be serviced by a single cooling system. The system provides both air and liquid cooling so that if the liquid cooling system does not provide adequate cooling, the air cooling system will be automatically activated. A connector system is provided to automatically evacuate the liquid from the heat exchangers before they are disconnected.

Owner:CHILLDYNE

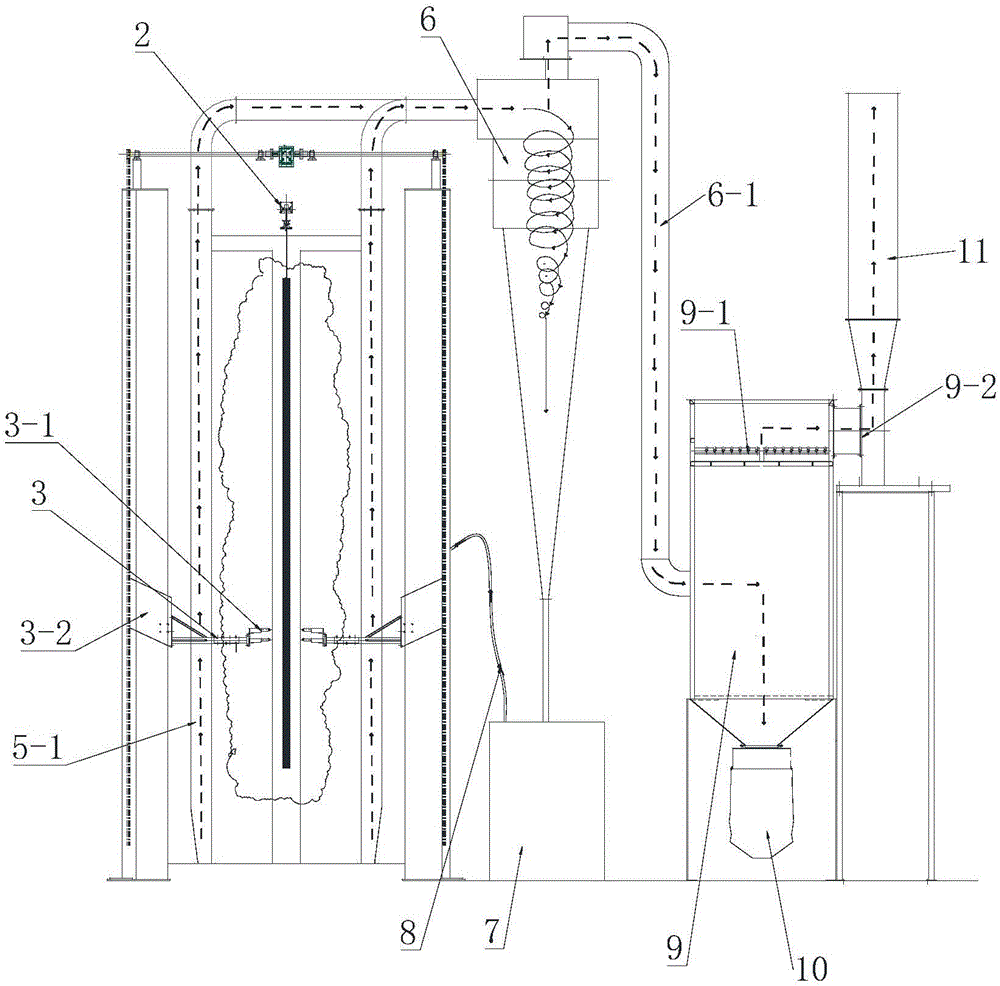

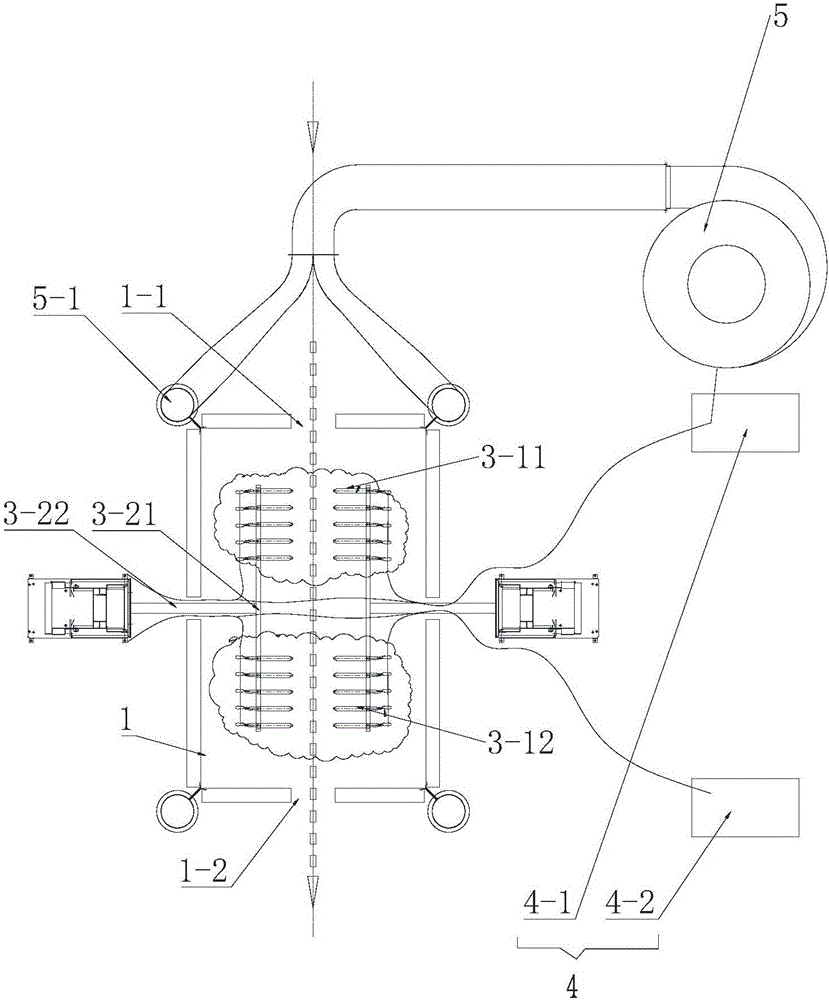

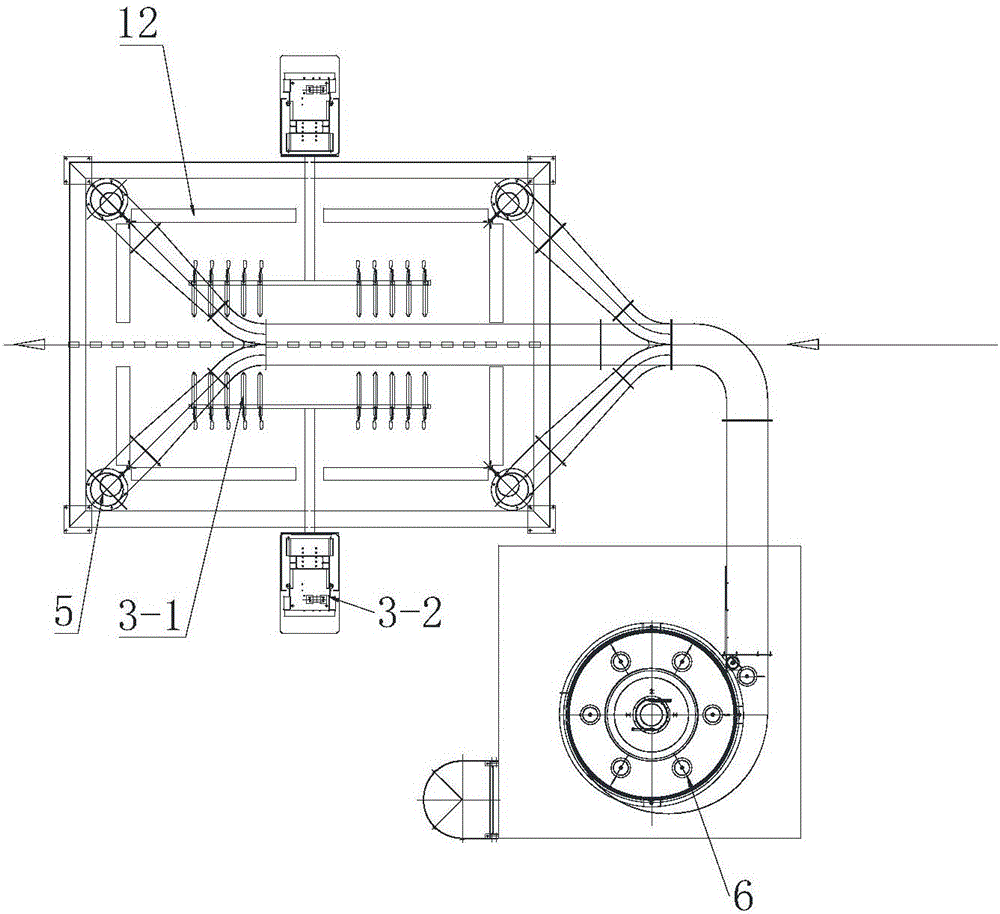

Electrostatic powder vertical type spraying device

ActiveCN105964435AEasy to closePrevent spillageLiquid spraying plantsLiquid surface applicatorsMetallurgyExhaust pipe

The invention discloses an electrostatic powder vertical type spraying device. The electrostatic powder vertical type spraying device comprises a powder spraying house, a conveying device for conveying workpieces, a powder spraying device, a powder supplying device and a powder recycling device. The powder spraying house is provided with a workpiece input port and a workpiece output port both of which correspond to the conveying device. The electrostatic powder vertical type spraying device is characterized in that the powder recycling device comprises exhaust pipes arranged at the four corners of the powder spraying house respectively, and each exhaust pipe is provided with a gap for exhausting air from bottom to top, so that air flow in the powder spraying house is uniform and the negative pressure of air needing to be exhausted is reduced; the powder spraying device comprises electrostatic spray gun sets oppositely arranged on the two sides of the conveying device and a lifting device driving the electrostatic spray guns on the two sides to synchronously ascend and descend. The electrostatic powder vertical type spraying device is simple in structure and convenient to use and install; in the powder spraying production process, powder consumption is low, the one-time powder coating rate is high, the time taken to clean the powder house and the time taken to change powder are shortened, electric energy is saved, fewer operating workers are needed, and the production cost is greatly reduced.

Owner:佛山市安邦得机械设备有限公司

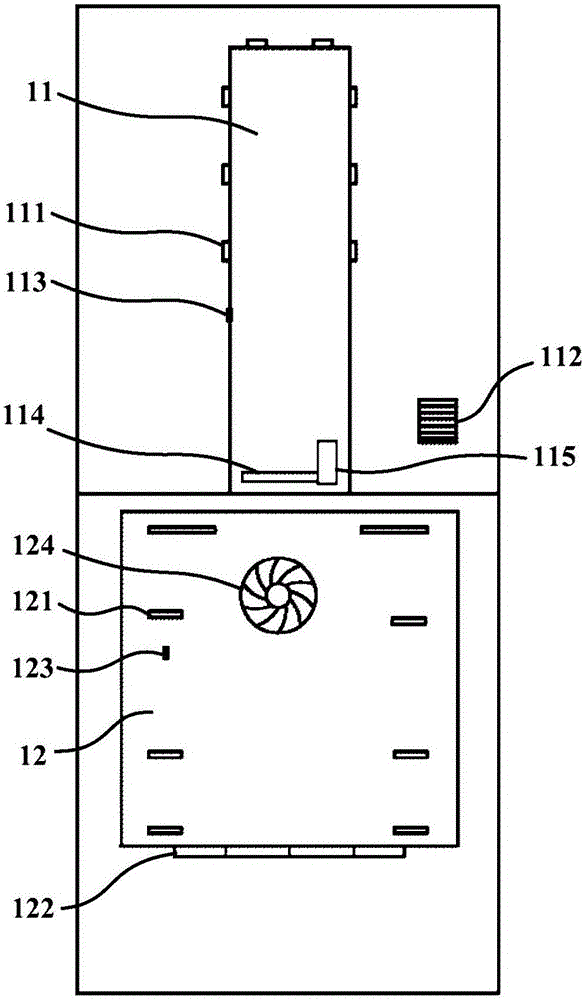

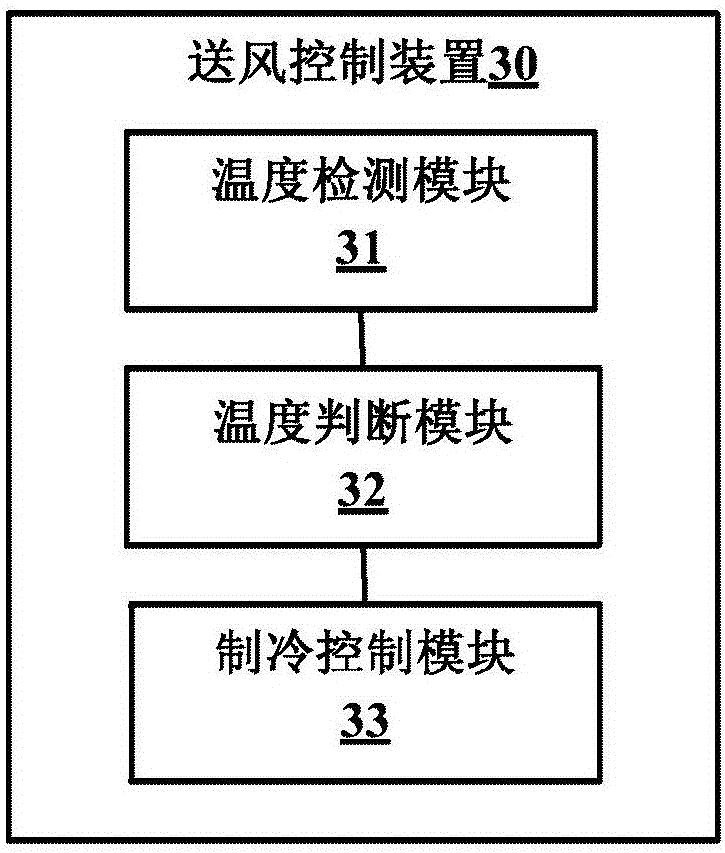

Air supply control method and device of air-cooled refrigerator

InactiveCN106595180AExtend cooling timeShorten cooling timeLighting and heating apparatusDomestic refrigeratorsRefrigerationAir door

The invention provides an air supply control method and device of an air-cooled refrigerator. The air supply control method of the air-cooled refrigerator comprises the steps that the actual temperature in a cold storage chamber and actual temperature in a freezing chamber are detected through a first temperature sensor and a second temperature sensor which are arranged in the cold storage chamber and the freezing chamber correspondingly; whether the actual temperature in the cold storage chamber is larger than or equal to the preset turn-on temperature is judged, and if yes, an air door is controlled to be opened at a preset angle, and a fan is controlled to operate at a first rotating speed; whether the actual temperature in the cold storage chamber is smaller than or equal to the first turn-off temperature is judged, the actual temperature in the freezing chamber is larger than the second shut-down temperature, and if yes, the air door is controlled to be closed and the fan is controlled to operate at a second rotating speed. According to the scheme, by shortening the negative pressure time of the cold storage chamber and reducing the negative pressure degree of the cold storage chamber, the condensation phenomenon in the cold storage chamber can be effectively relieved, and the problem that condensation affects the service life and the refrigeration effect of the refrigerator is avoided.

Owner:HAIER SMART HOME CO LTD

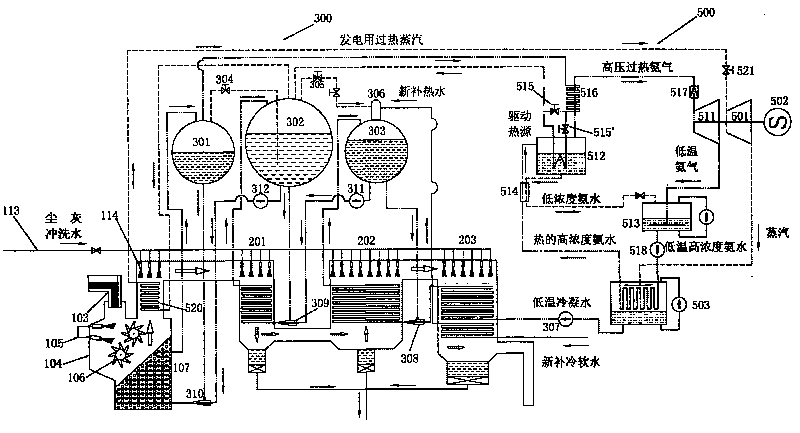

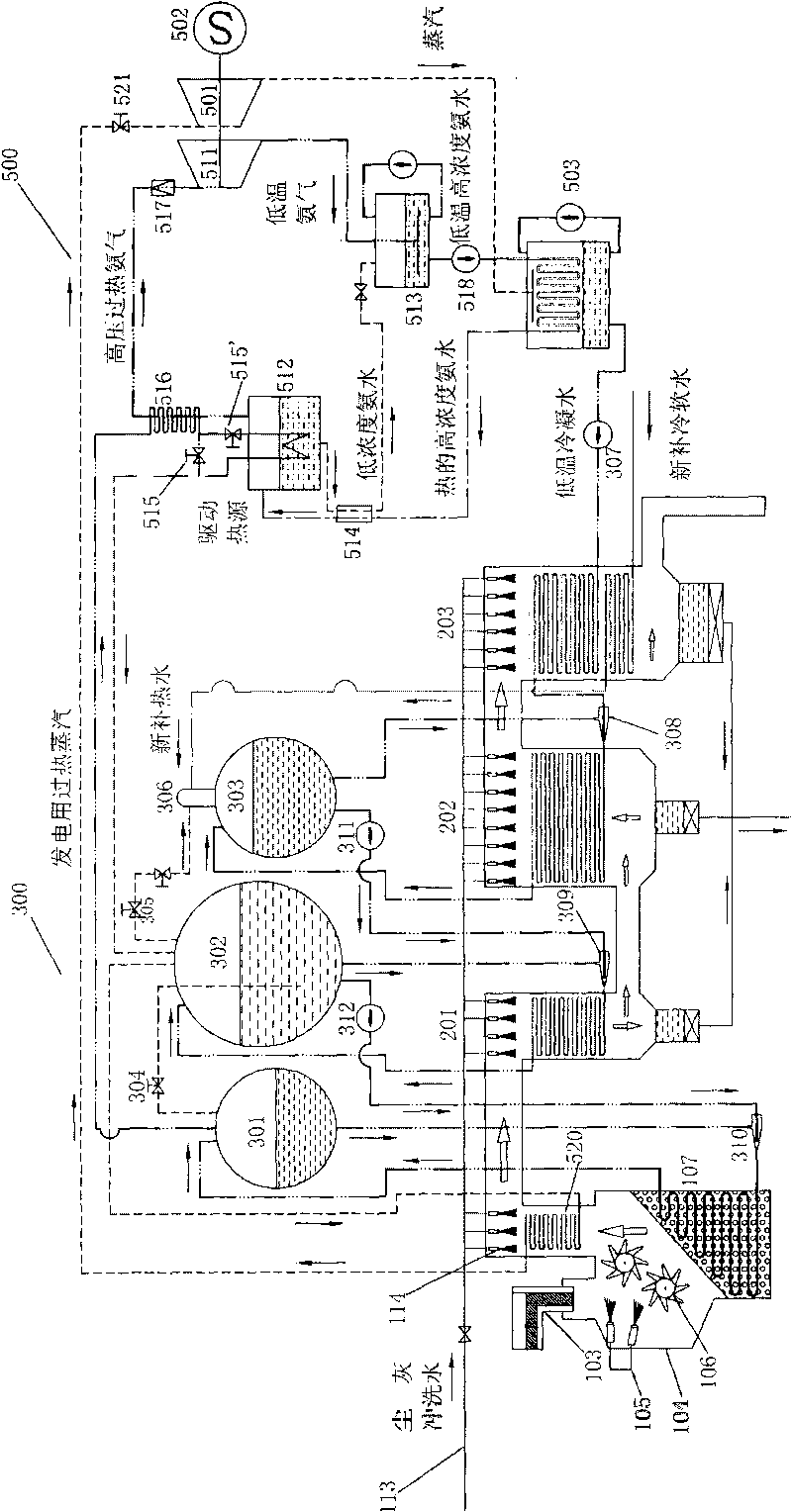

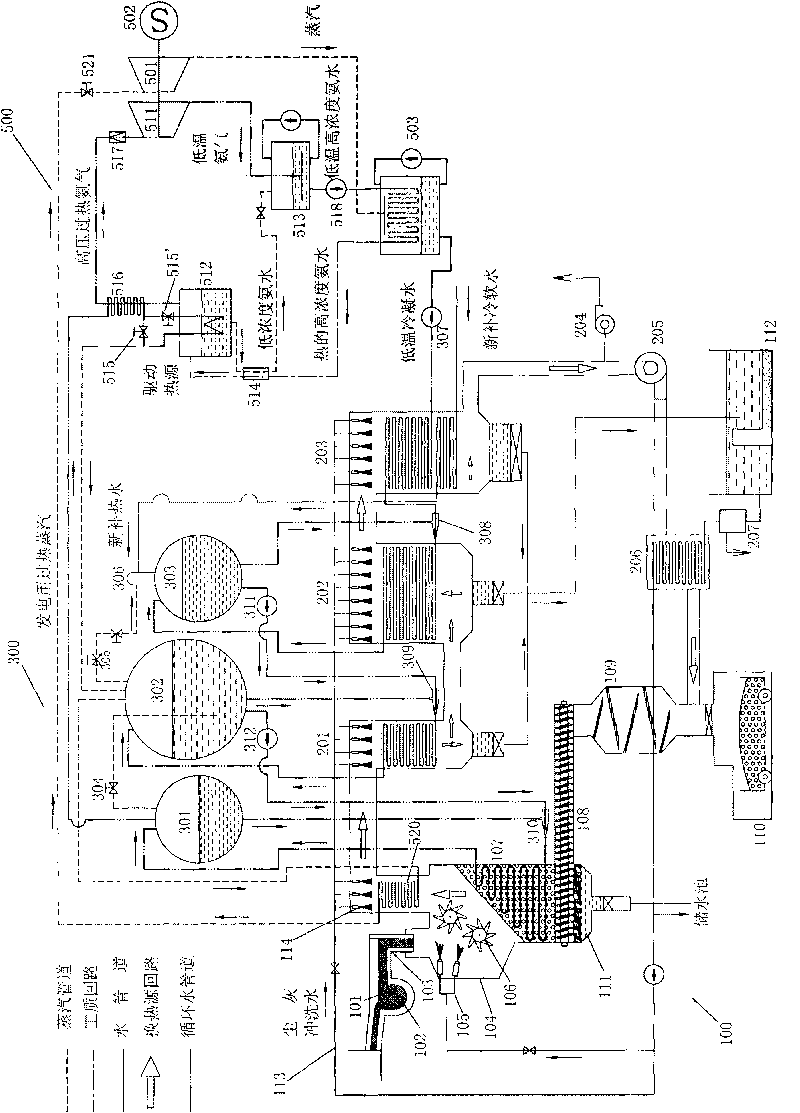

Waste heat generating system and generating method

ActiveCN101709661ASolve wasteReduce the temperatureEnergy industrySteam engine plantsThermal energyThermal energy storage

The invention discloses a waste heat generating system and a generating method. The generating system generates power by using the heat energy stage-stored in a multi-stage heat energy storage system; the generating system comprises a generator, a steam turbine, an ammonia turbine and an absorption heat pump; the multi-stage heat energy storage system delivers steam to the steam turbine, and the steam turbine converts the heat energy into dynamic mechanical energy and drives the generator to convert the mechanical energy into electrical energy; the absorption heat pump adopts ammonia-water as working medium, and converts the low-quality heat energy of the steam at the tail end of an output of the steam turbine into higher-quality heat energy; and the heat energy storage system provides a high-quality driving heat source for the heat pump so that a large amount of mixed solution of concentrated ammonia-water is evaporated under high pressure to form high-pressure saturated ammonia, and the high-pressure saturated ammonia drives the ammonia turbine to convert the pressure produced by the ammonia into mechanical energy, and delivers the mechanical energy to the generator. The generating system and the generating method overcome the defects that the heat-electricity conversion efficiency in the conventional waste heat generating process is low and the like, and achieve the purposes of high quality, high efficiency and low consumption.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

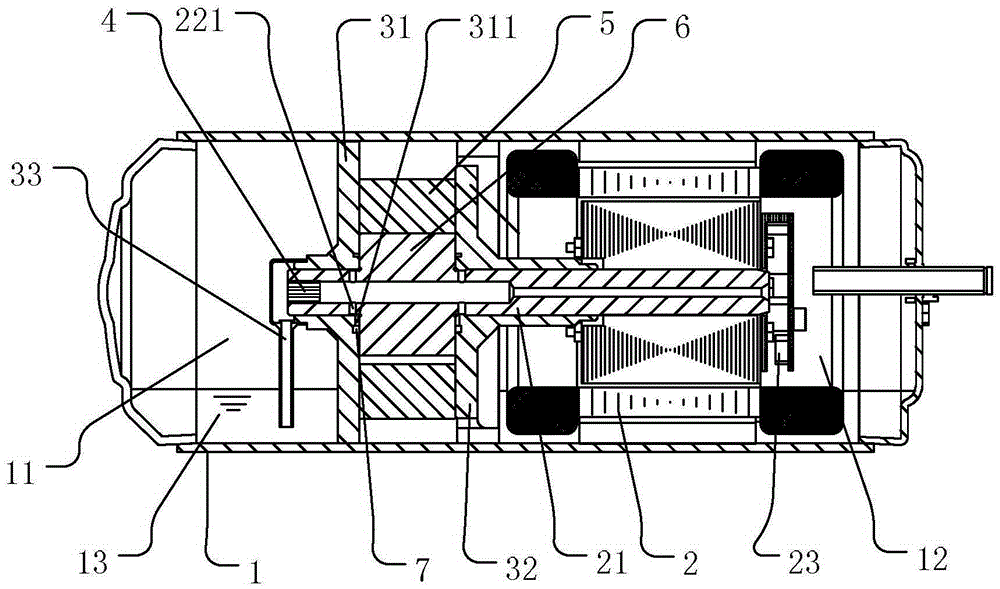

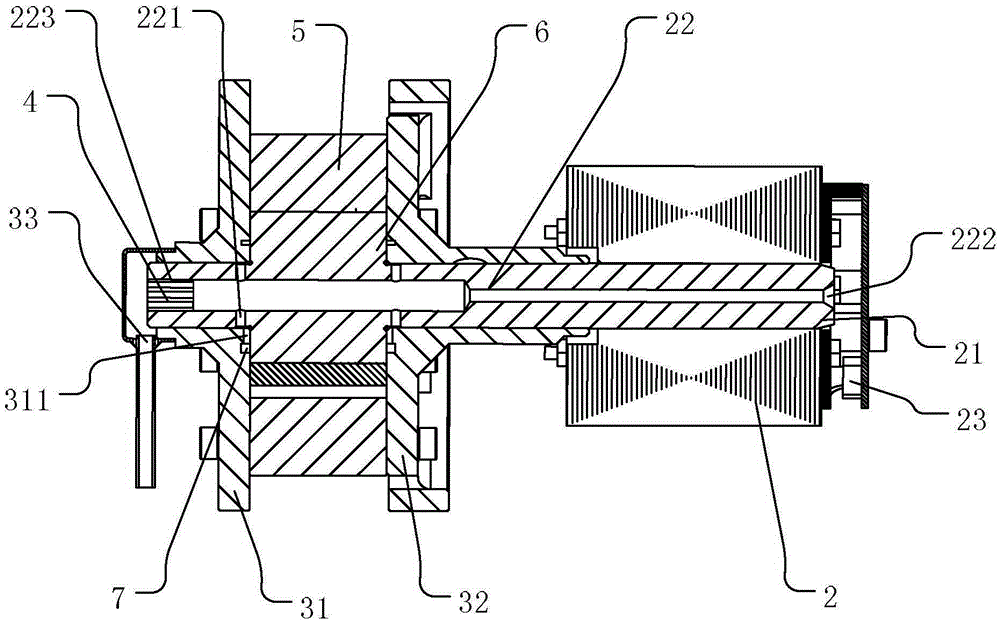

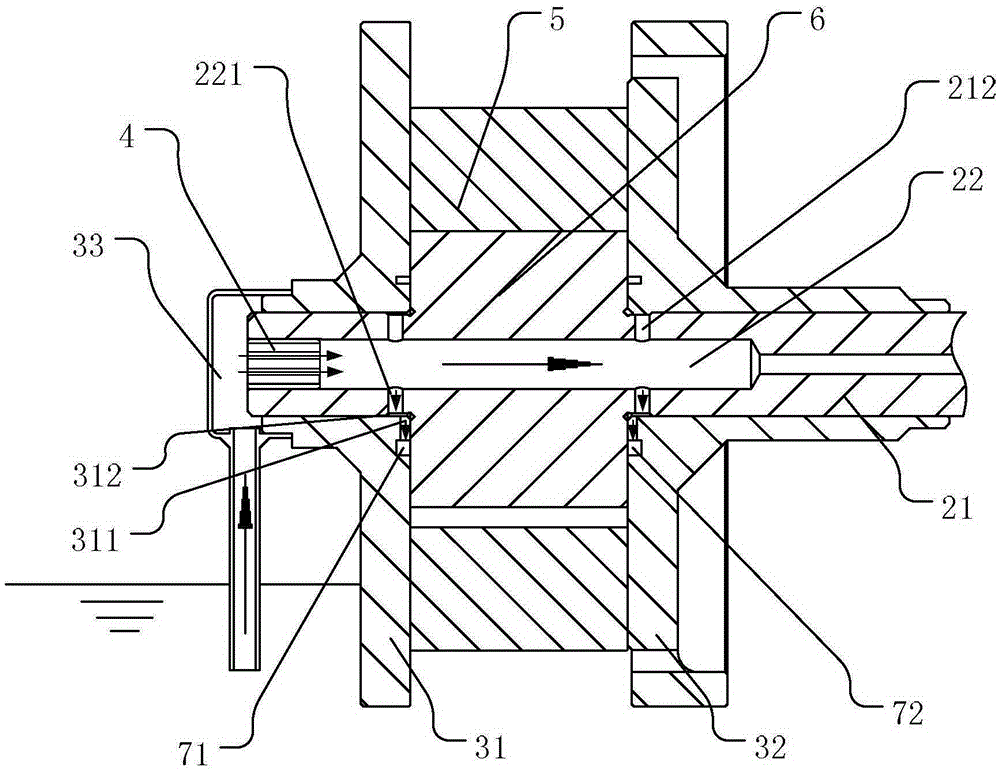

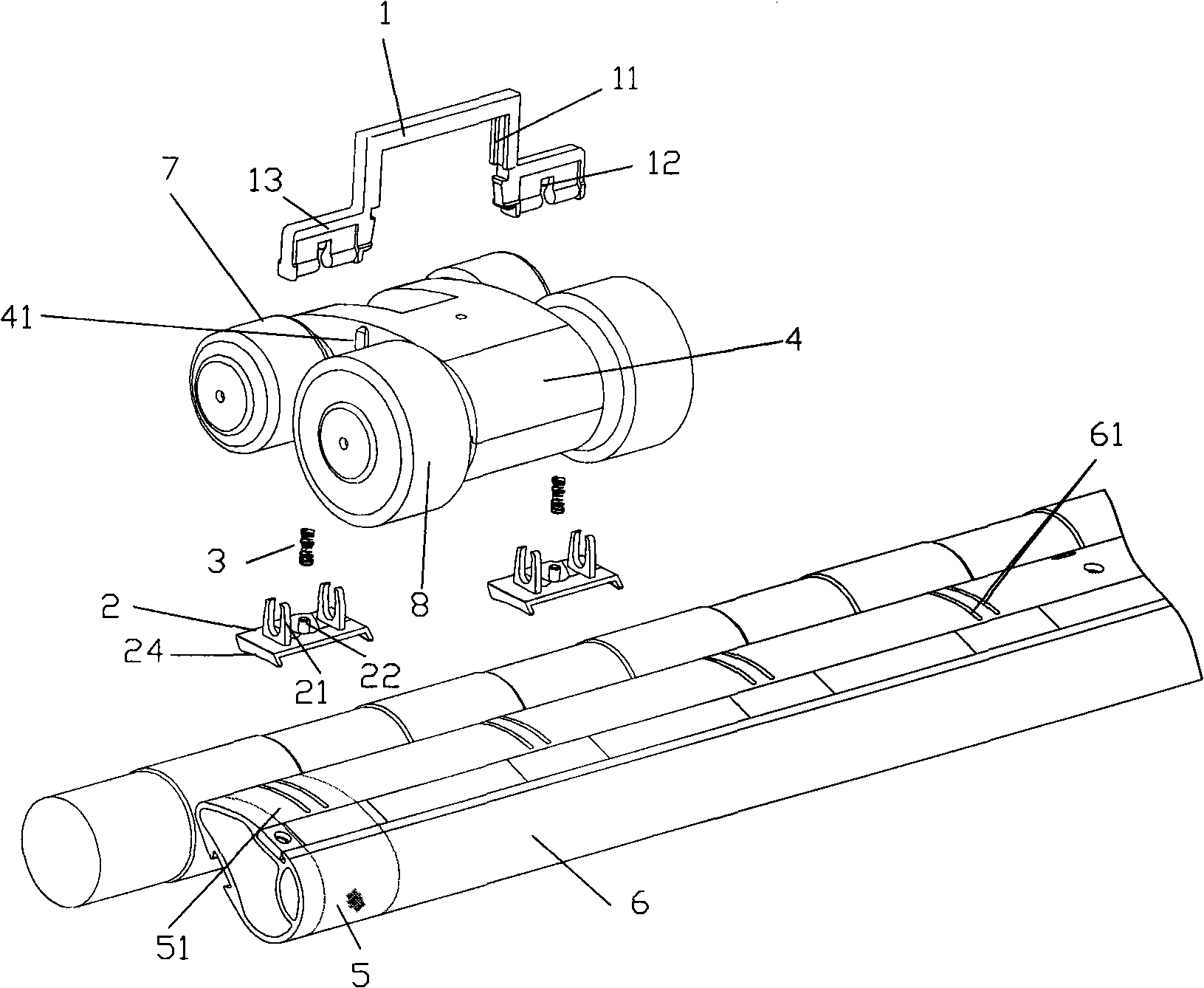

Slide vane compressor

ActiveCN105402125AStable back pressureReduce the cross-sectional areaRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPetroleum engineering

The invention aims at providing a slide vane compressor. The problem that backpressure oil supplying of an existing slide vane compressor is not stable is mainly solved. According to the technical scheme, negative pressure is generated in a main oil way in a spindle through a fan, and then an upper oil tube assembly is used for pumping oil from an oil pool; a backpressure oil tank is communicated with the main oil way, and the main oil way supplies pressure oil to the backpressure oil tank. Through the arrangement, oil supplying of the backpressure oil tank is more stable and reliable.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

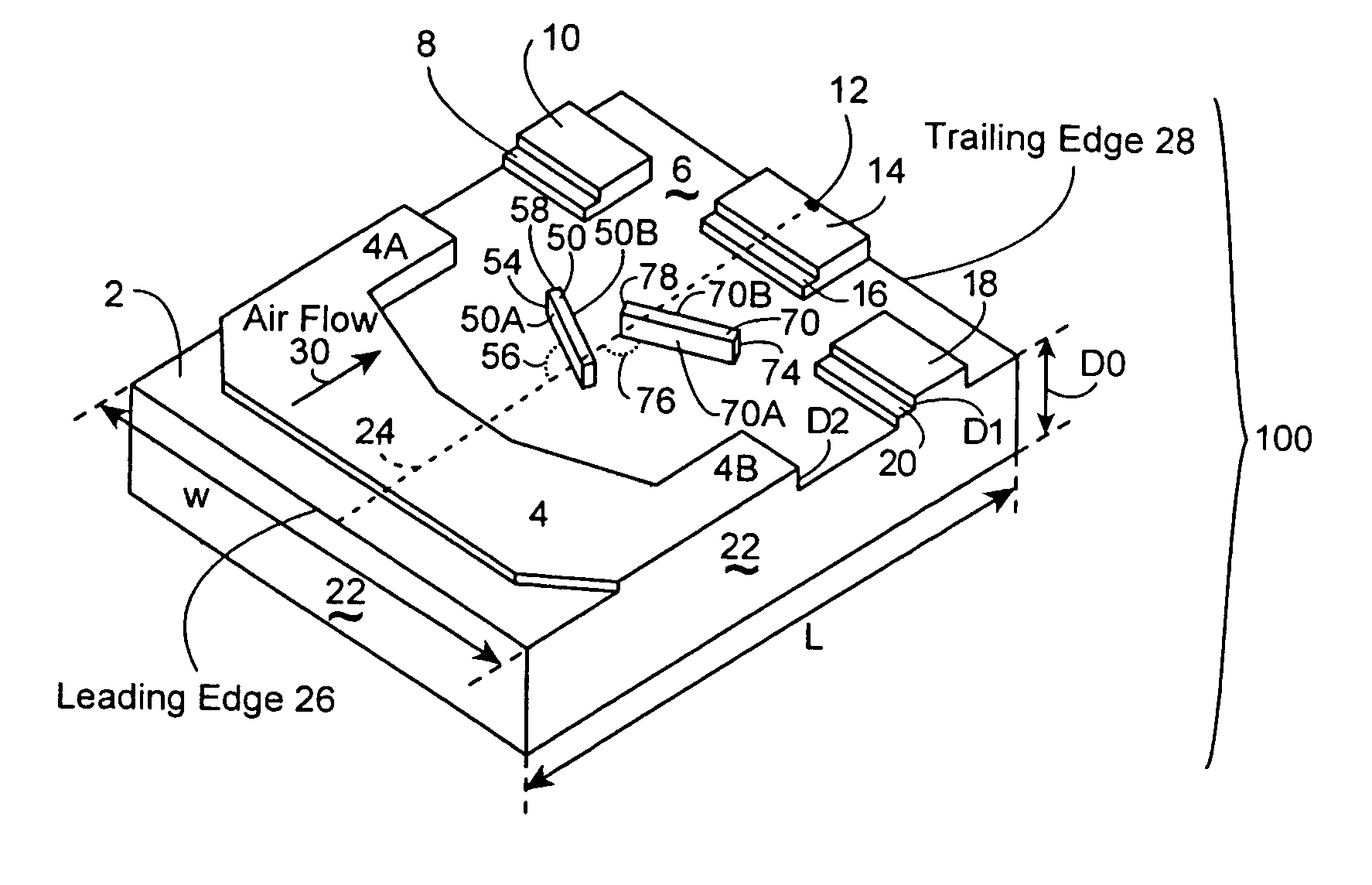

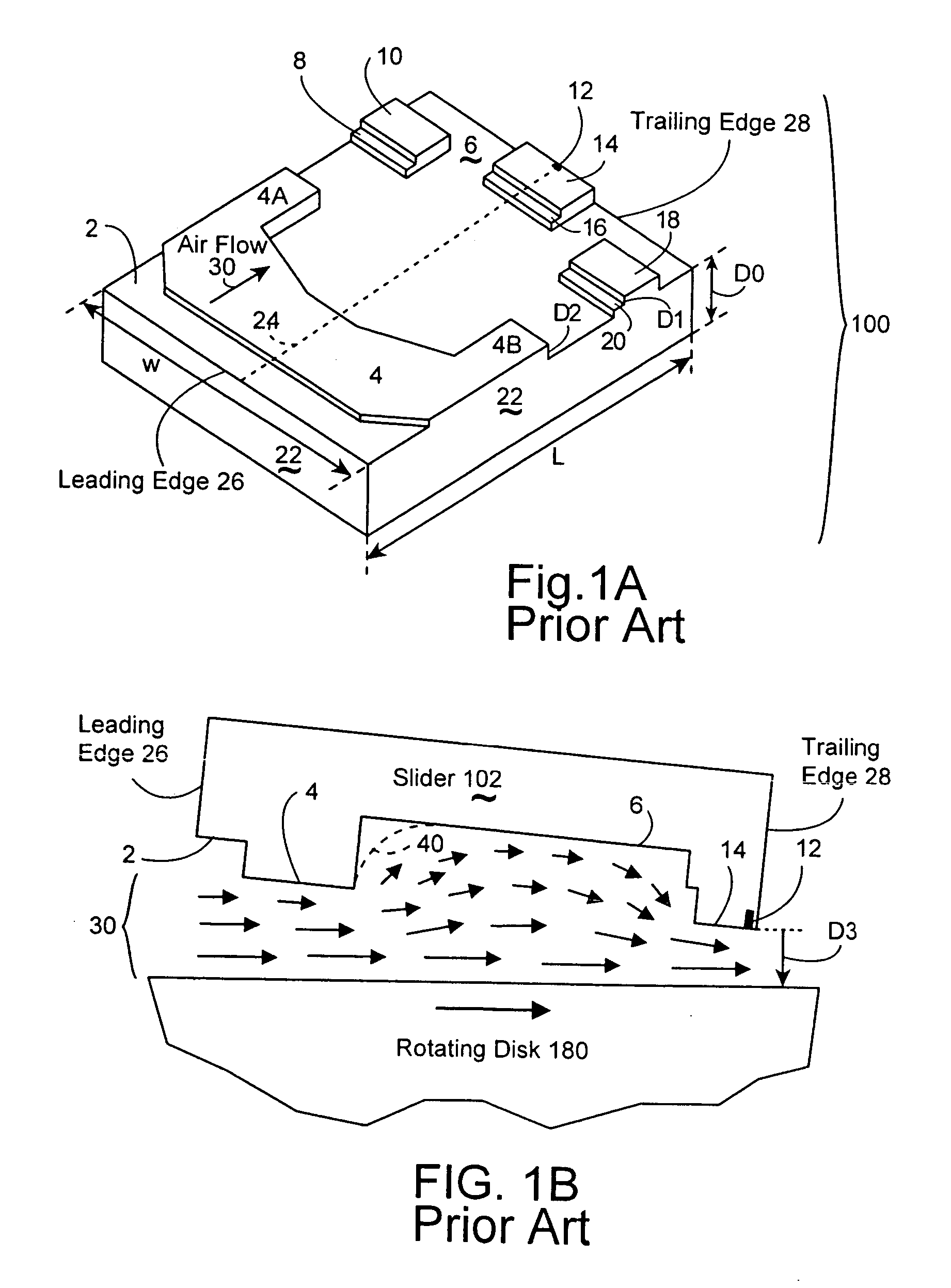

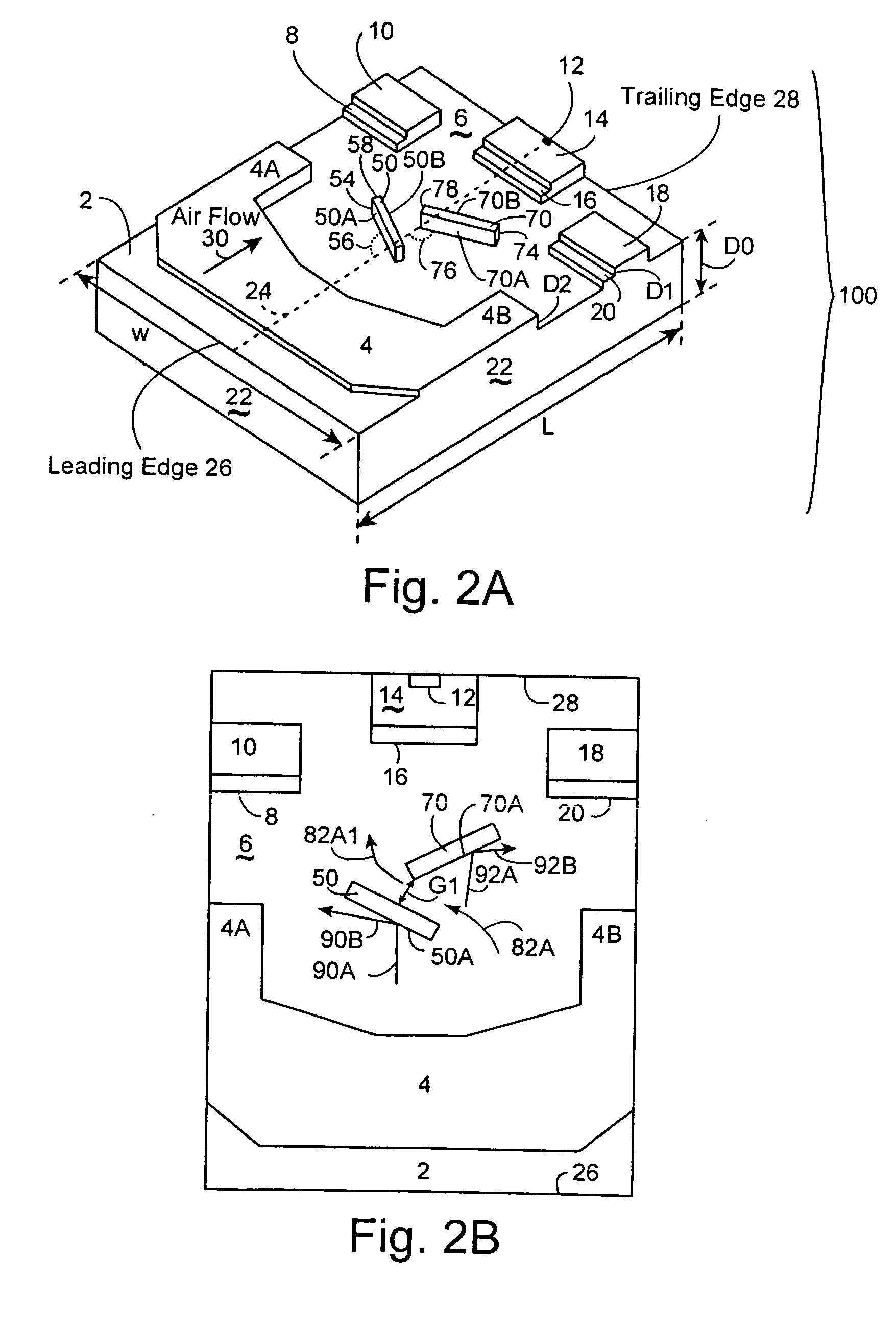

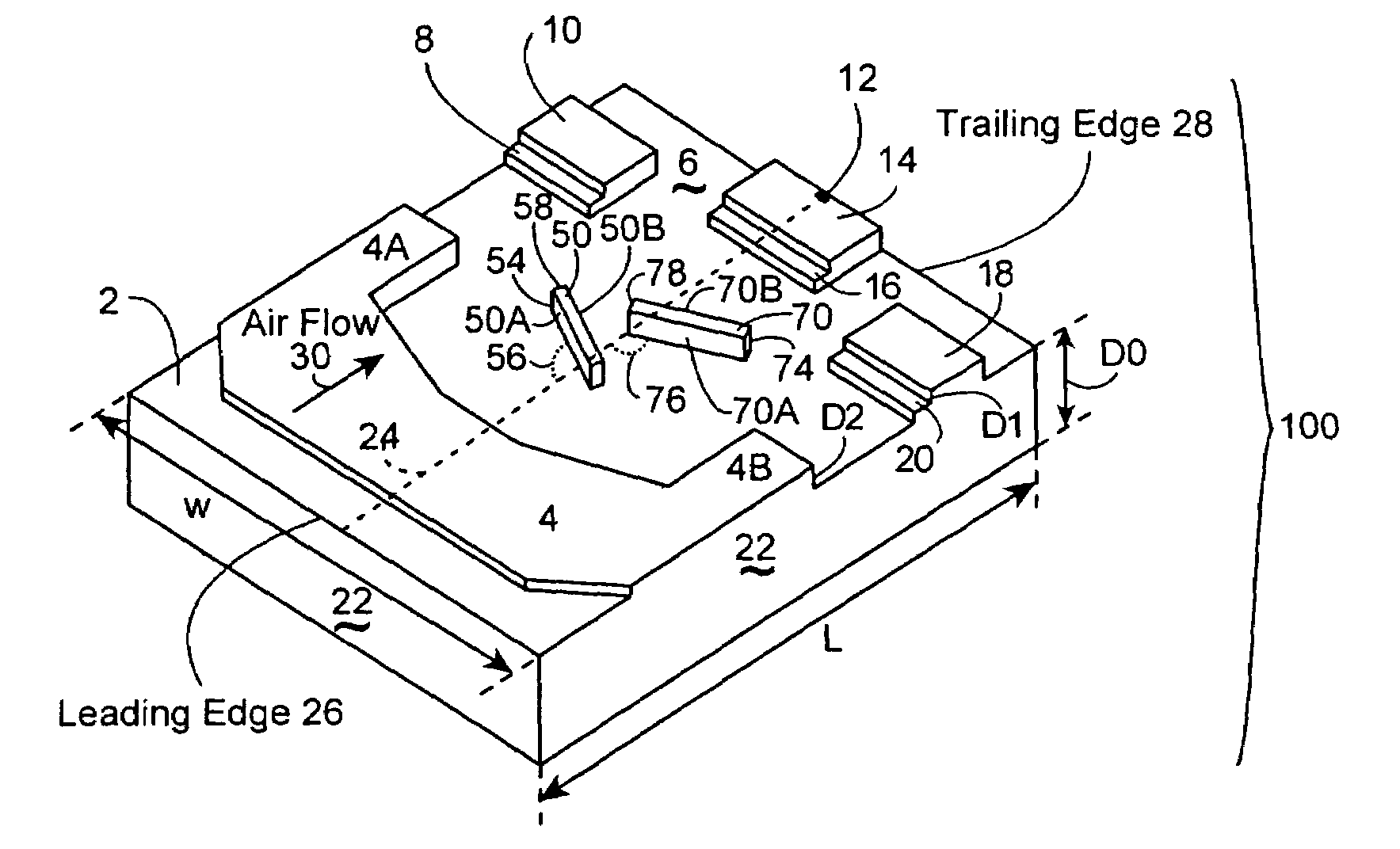

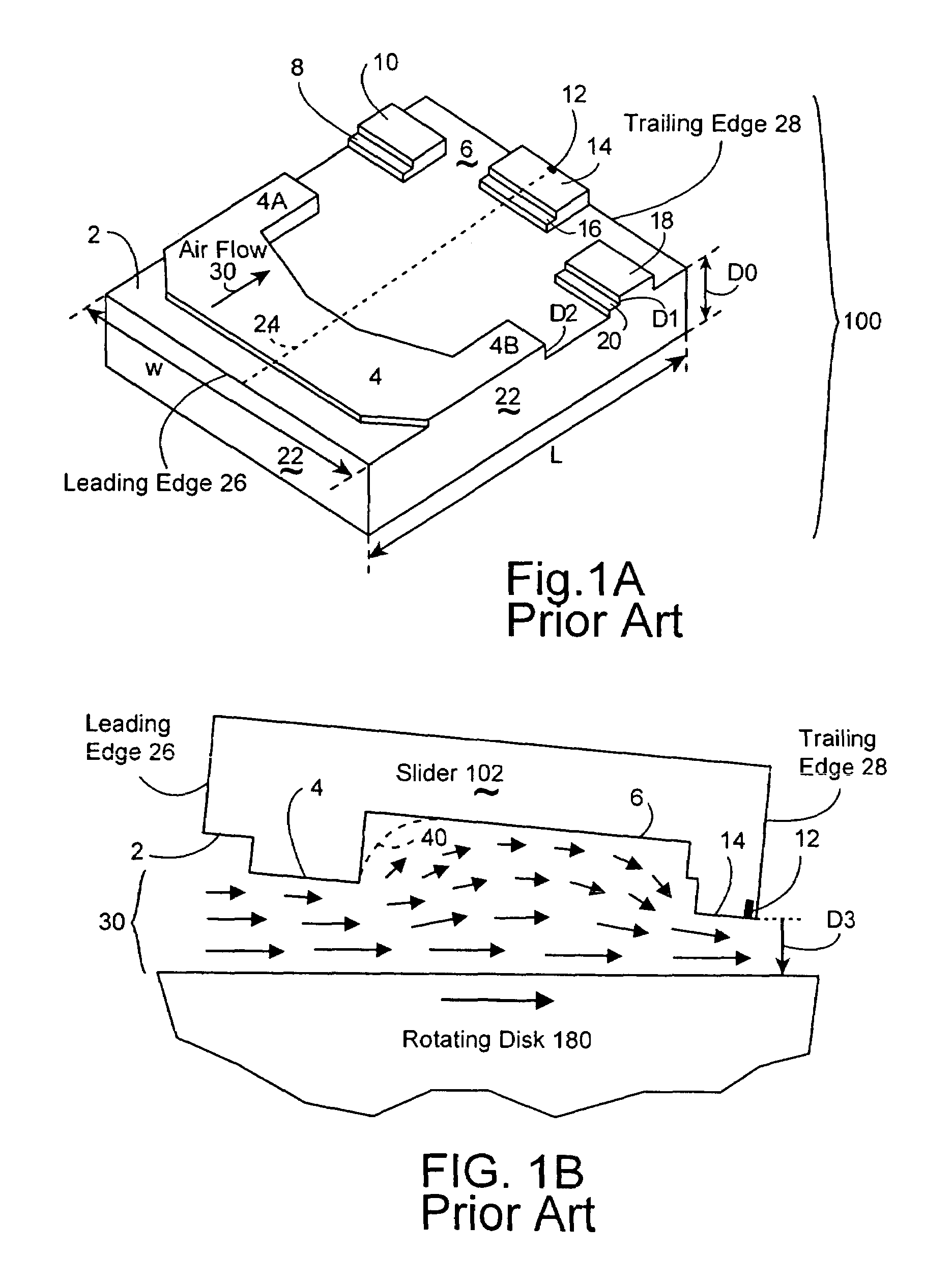

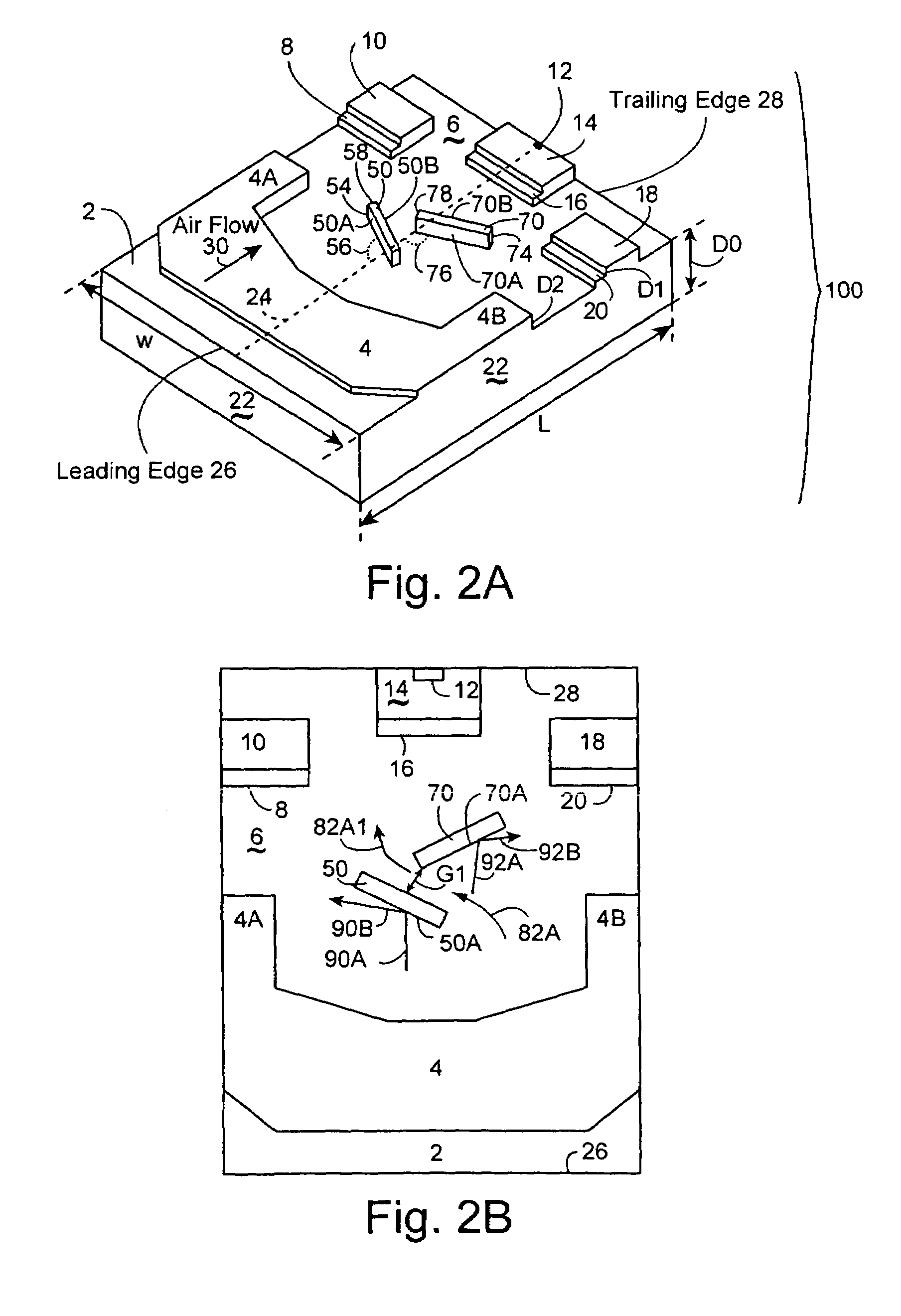

Method and apparatus supporting a slider having multiple deflection rails in a negative pressure pocket for a hard disk drive

InactiveUS20050213252A1Reduce decreaseReduce negative pressureDevices for pressing relfex pointsFluid-dynamic spacing of headsHard disc driveActuator

An air bearing surface, with multiple deflection rails in a negative pressure pocket, between a leading air bearing surface and a central island for the read-write head. A gap separates left and right deflection rails. During the slider's normal operation, incoming particles may collide with at least one of the deflection rails and deflect away from the central island and the read-write head. The gap supports diminishing additional negative pressure in the negative air pressure pocket. The gap may minimize the accumulation of debris behind the rejection rails. The invention includes head gimbal assemblies containing these sliders, actuator arms coupled to the head gimbal assemblies, actuator assemblies including at least one of the actuator arms, and hard disk drives whish include the actuator assemblies. The invention also includes methods for making sliders, actuator arms, actuator assemblies, and hard disk drives, as well as the products of these manufacturing methods.

Owner:SAMSUNG ELECTRONICS CO LTD

Vehicle and control method of vehicle

InactiveUS7934779B2Avoid discomfortReduce negative pressureAuxillary drivesBraking element arrangementsRegenerative brakeMaster cylinder

In the hybrid vehicle of the invention, when the sum of a regenerative braking force BFr produced by a motor and an operational braking force BFpmc based on a master cylinder pressure Pmc is insufficient for a braking force demand BF* required by the driver in response to the driver's depression of a brake pedal, the motor and a brake actuator of an HBS are controlled to satisfy the braking force demand BF* by the total of the regenerative braking force BFr of the motor, the master cylinder pressure Pmc-based operational braking force BFpmc, and a compensated braking force BFpp based on a pressure increase by two pumps included in the brake actuator (steps S170 through S190).

Owner:TOYOTA JIDOSHA KK

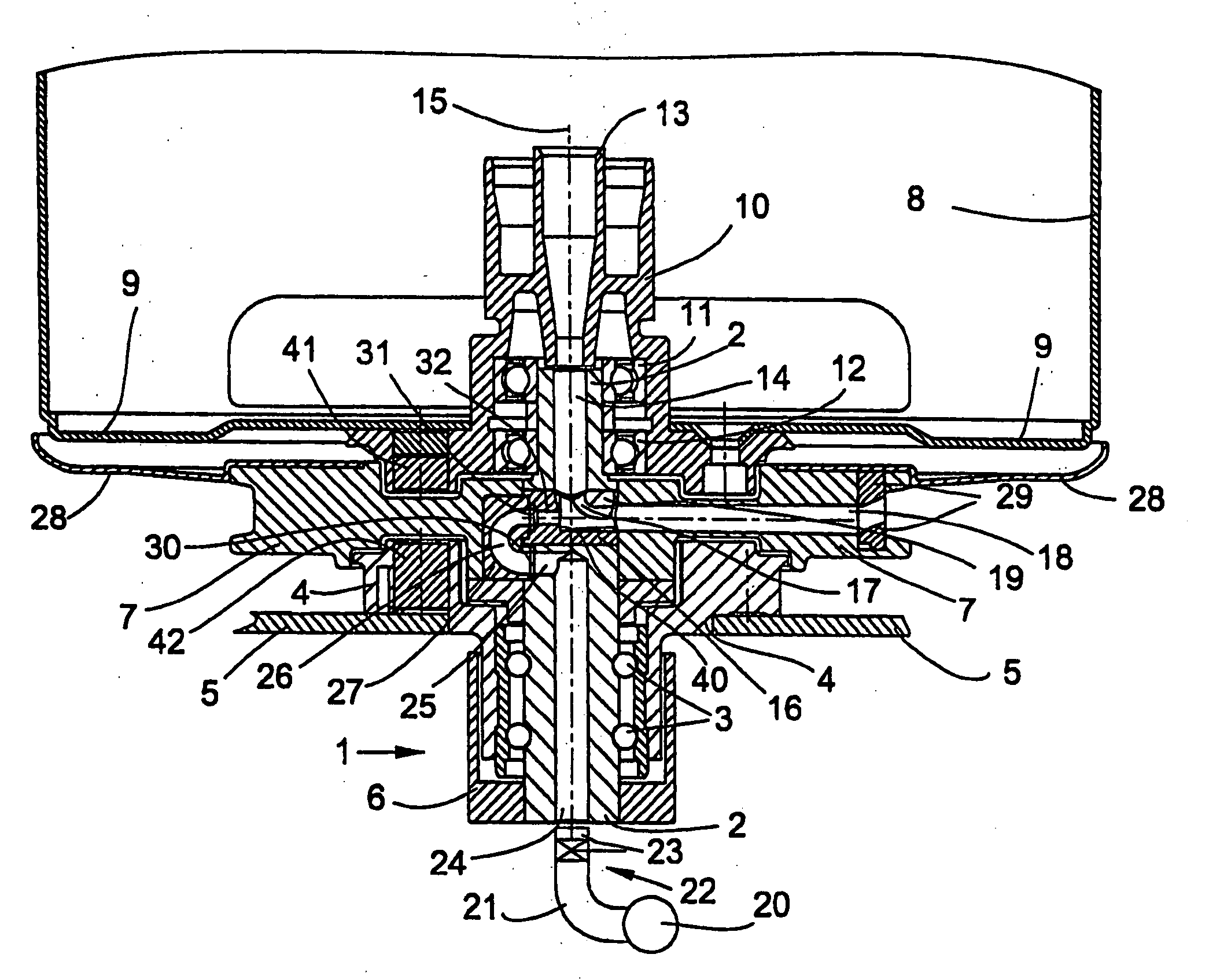

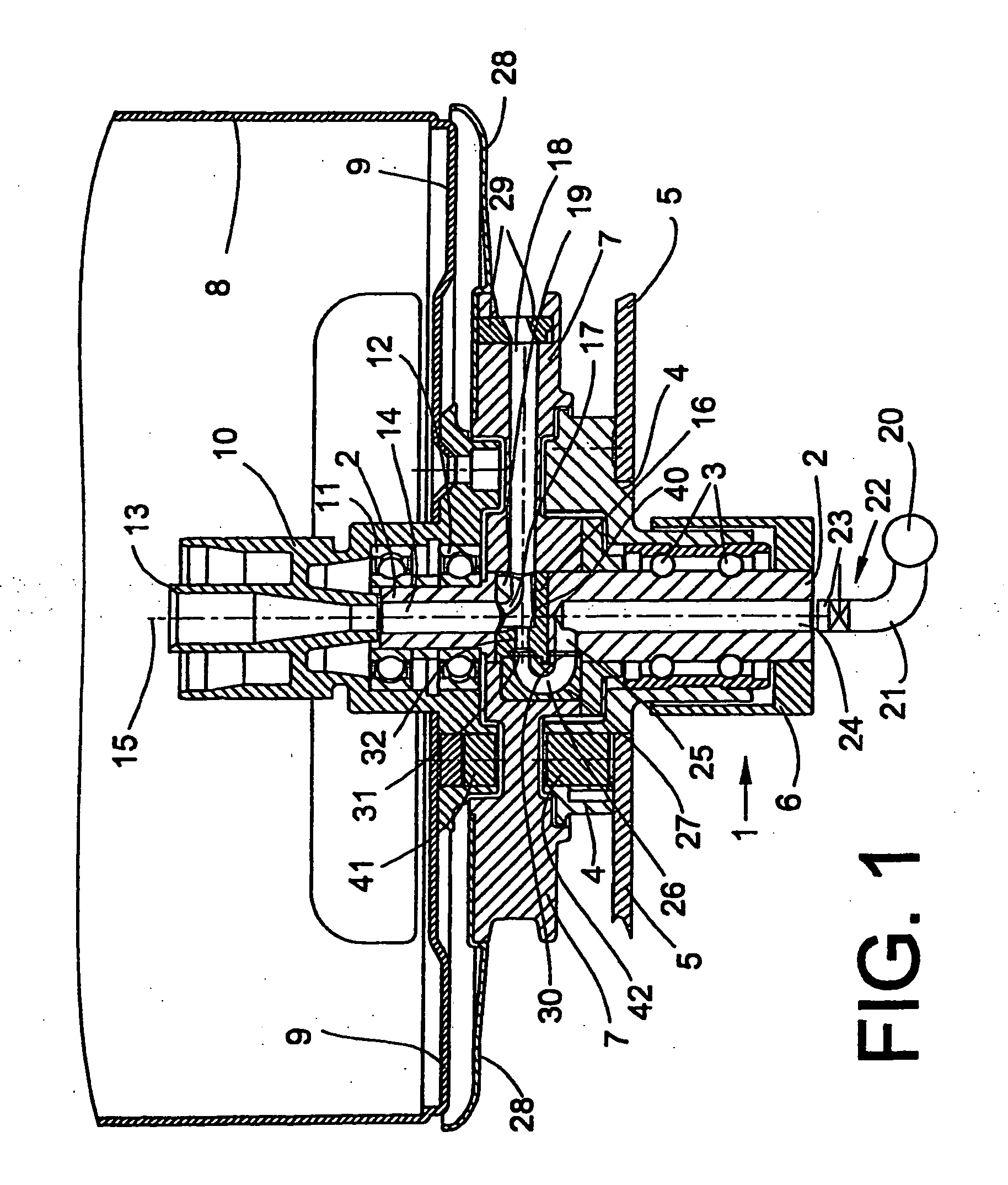

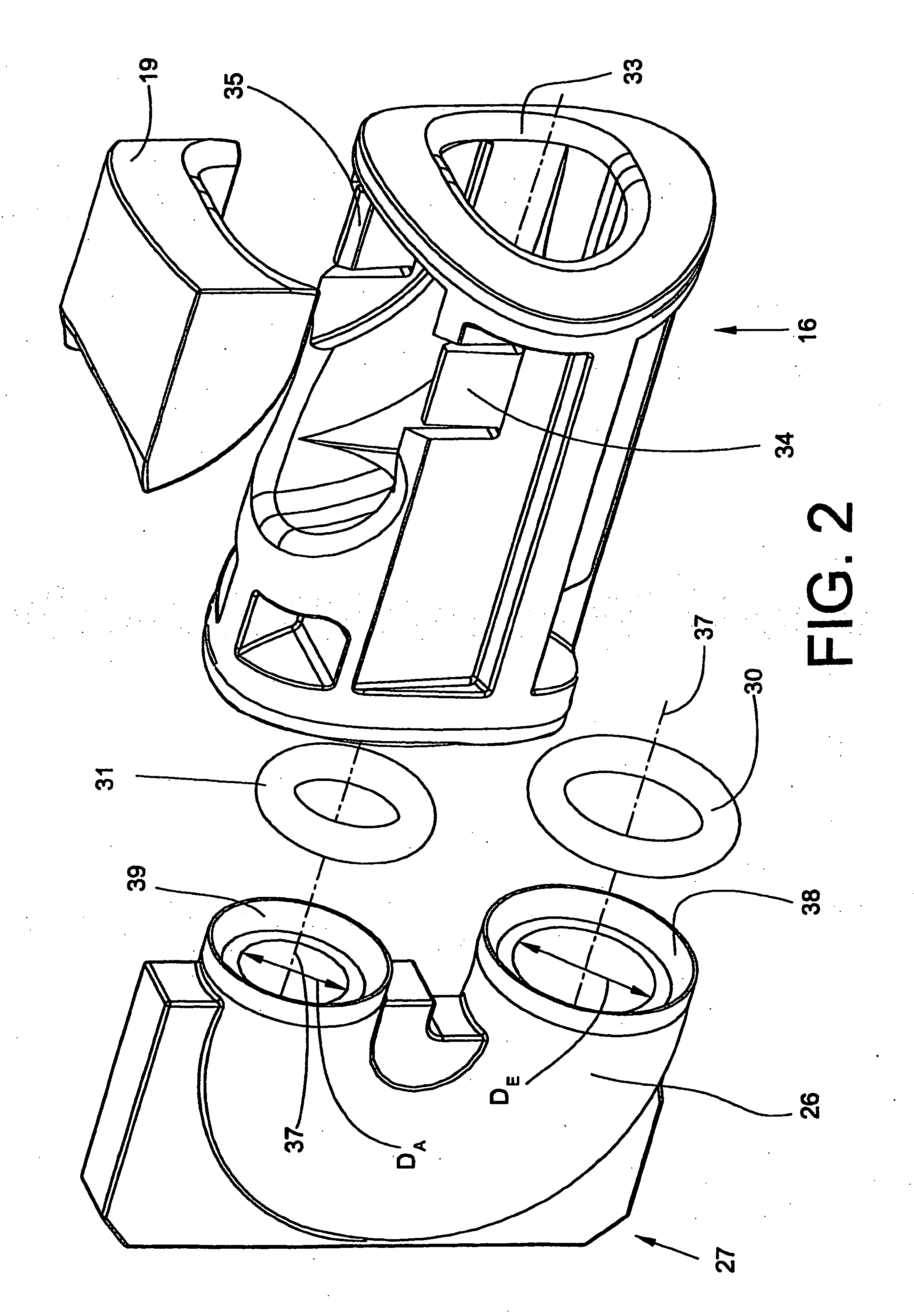

Two-For-One Twisting Spindle Having a Pneumatically Actuated Threading Device

InactiveUS20100018178A1Easy to produceReduce weightPiercing arrangementsDrafting machinesRotational axisEngineering

Two-for-one twisting spindle having a pneumatically actuated threading device, with a spindle shaft rotatable about a vertical axis partially configured as a hollow shaft with a lower feed bore extending coaxially to the rotational axis, and with an injector element opening into a thread guide channel of a thread guide ring temporarily connectable during threading to a compressed air source. Part of the compressed air feed to the injector element is formed by the feed bore. The compressed air feed comprises a connection element (27) with a curved air channel (26), which connects the feed bore (24) to the injector element (16). The connection element (27) is configured as a separate component and the air channel (26) is adapted to the flow requirements.

Owner:SAURER TECH GMBH & CO KG

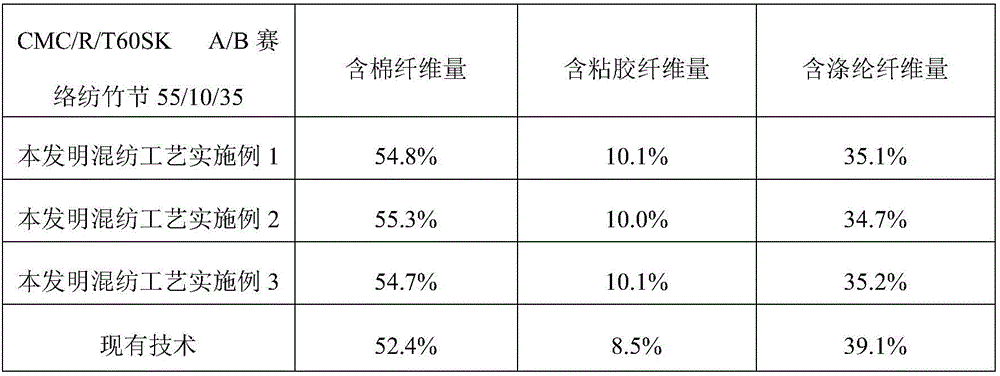

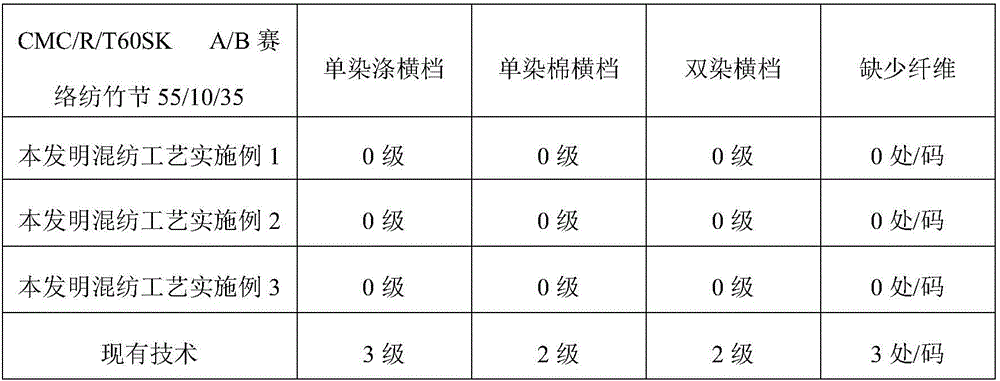

A/B sirospun bunchy yarn blended with cotton fiber, viscose fiber and polyester fiber and blending technology

The invention provides an A / B sirospun bunchy yarn blended with cotton fiber, viscose fiber and polyester fiber and blending technology, and the A / B sirospun bunchy yarn comprises 55+ / -1% cotton fiber, 10+ / -1% viscose fiber, and polyester fiber as the balance; the A / B sirospun bunchy yarn blending technology comprises the steps of obtaining a cotton fiber pre-merging strip by cotton fiber series operations; obtaining a viscose fiber pre-merging strip by viscose fiber series operations; processing the cotton fiber pre-merging strip and the viscose fiber pre-merging strip to produce an A rove; producing a B rove by polyester fiber series operations; feeding the A rove and the B rove into a spinning machine at the same time, and producing the A / B sirospun bunchy yarn through a CCZ-8 fancy yarn apparatus. According to the invention, the problems of unstable blending proportion, severe fiber loss, crosspiece caused by single dying or double dying are solved; and the product quality and class are raised greatly.

Owner:WEIQIAO TEXTILE

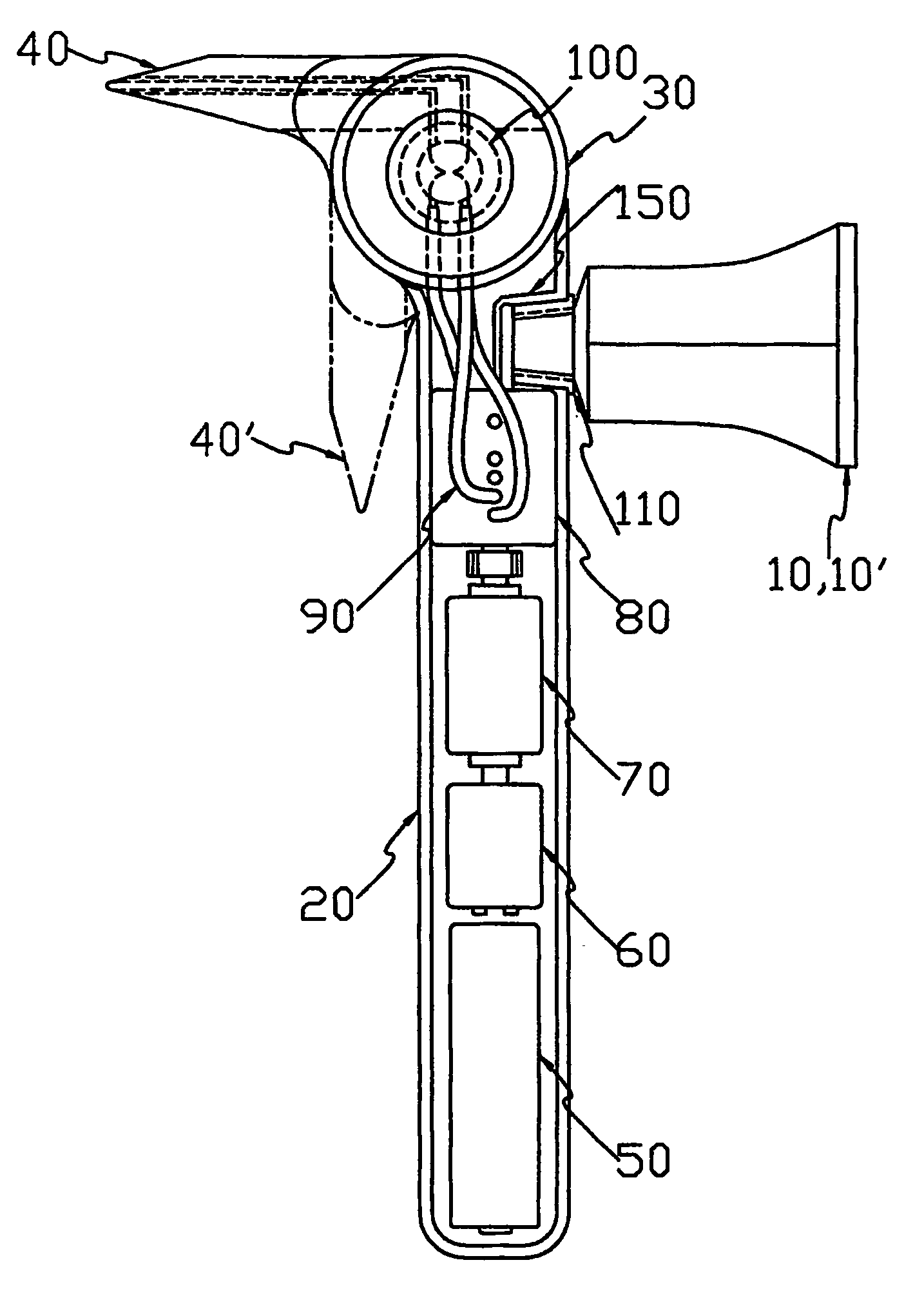

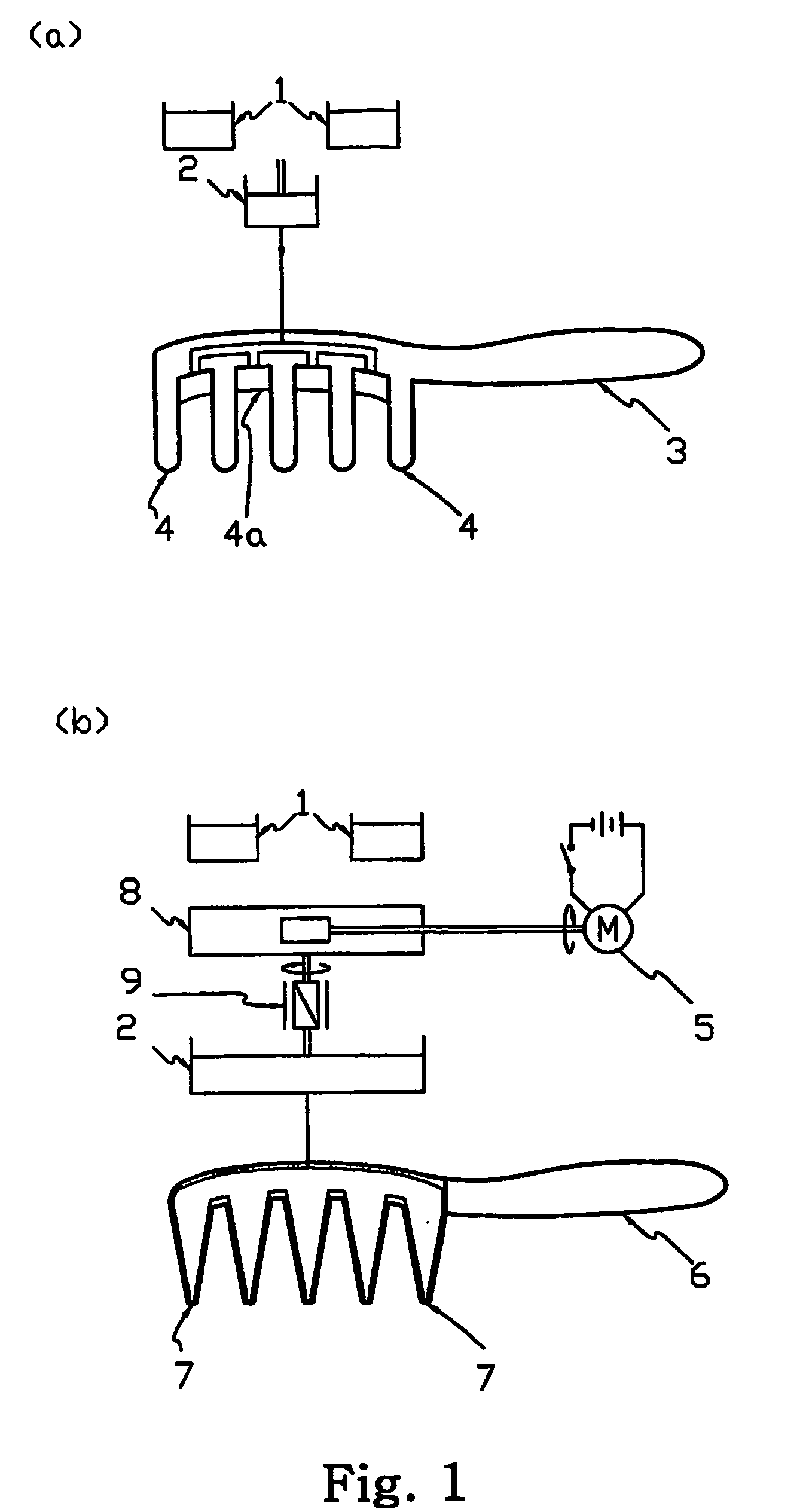

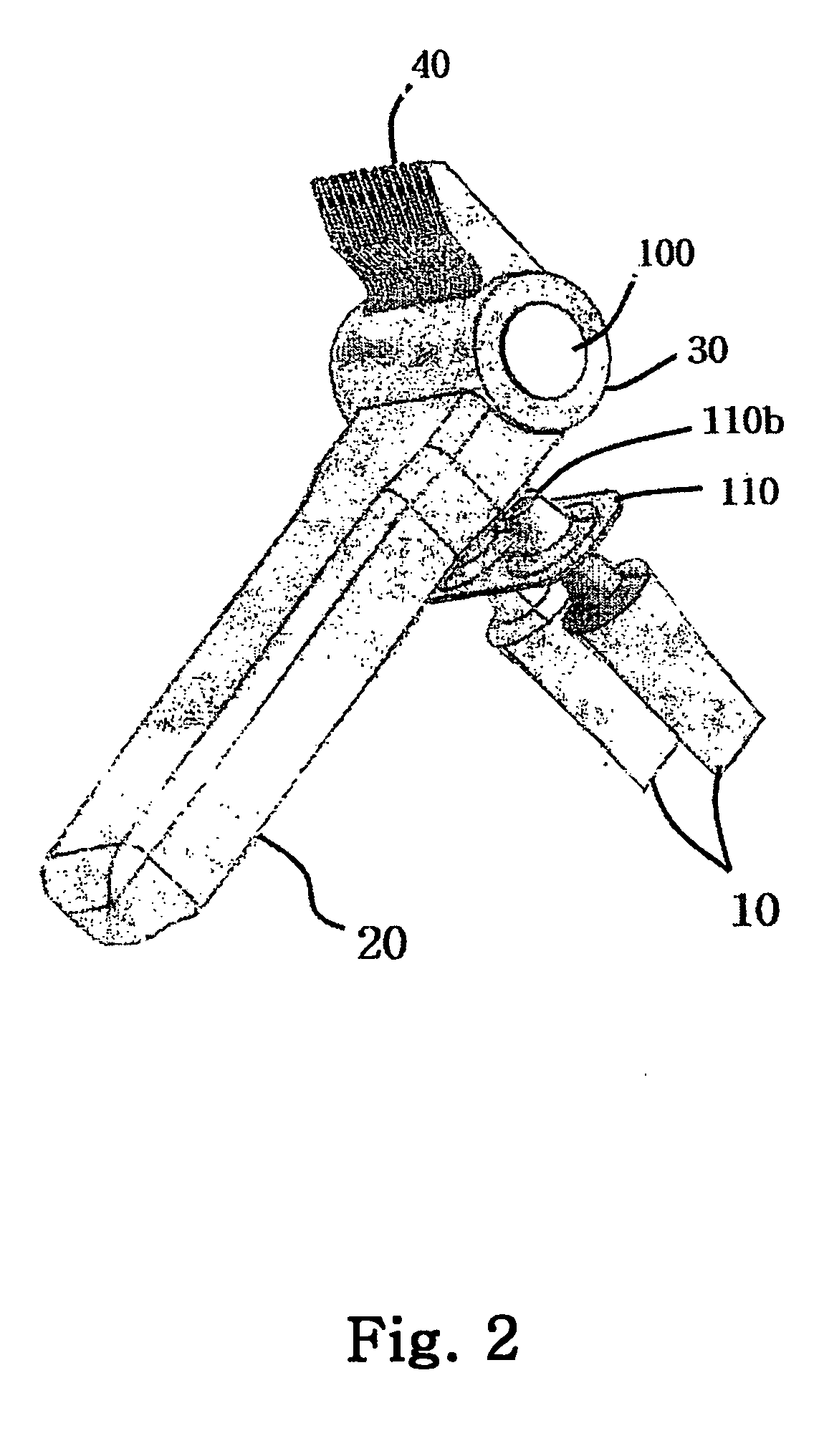

Dye container and hair dyeing device using the same

This invention relates to a device for performing dyeing operation such as bleaching, coloring, and coating using an electric power with a dye container attached. Main components of the invention are comprised of a body, a comb assembly, a pump and a piping member. The body composed of handle and head is equipped with a motor, battery and switch. The comb assembly composed of a plurality of teeth having respective conduits is rotatably fixed to the body. The pump is connected to the motor so as to feed the dye from the container attached to the body to the respective comb of the comb assembly with an enforced and uniform flow. The piping member is disposed at a flow path between the pump and the comb assembly so as to maintain a uniform flow of dye through the conduits of the comb assembly.

Owner:LEE JAE KUN

Method and apparatus supporting a slider having multiple deflection rails in a negative pressure pocket for a hard disk drive

InactiveUS7333297B2Reduce decreaseReduce negative pressureDevices for pressing relfex pointsRecord information storageHard disc driveEngineering

An air bearing surface, with multiple deflection rails in a negative pressure pocket, between a leading air bearing surface and a central island for the read-write head. A gap separates left and right deflection rails. During the slider's normal operation, incoming particles may collide with at least one of the deflection rails and deflect away from the central island and the read-write head. The gap supports diminishing additional negative pressure in the negative air pressure pocket. The gap may minimize the accumulation of debris behind the rejection rails. The invention includes head gimbal assemblies containing these sliders, actuator arms coupled to the head gimbal assemblies, actuator assemblies including at least one of the actuator arms, and hard disk drives whish include the actuator assemblies. The invention also includes methods for making sliders, actuator arms, actuator assemblies, and hard disk drives, as well as the products of these manufacturing methods.

Owner:SAMSUNG ELECTRONICS CO LTD

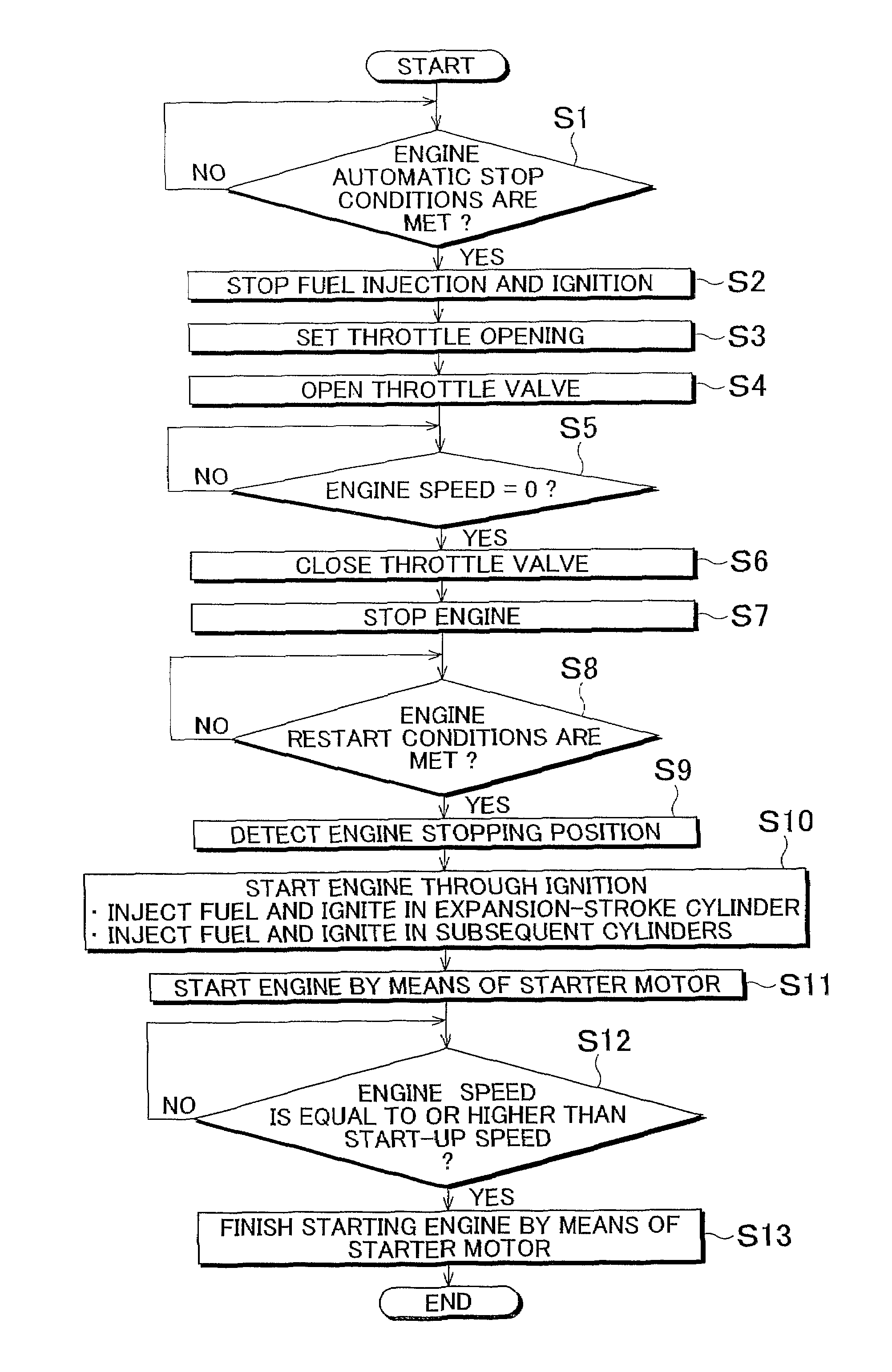

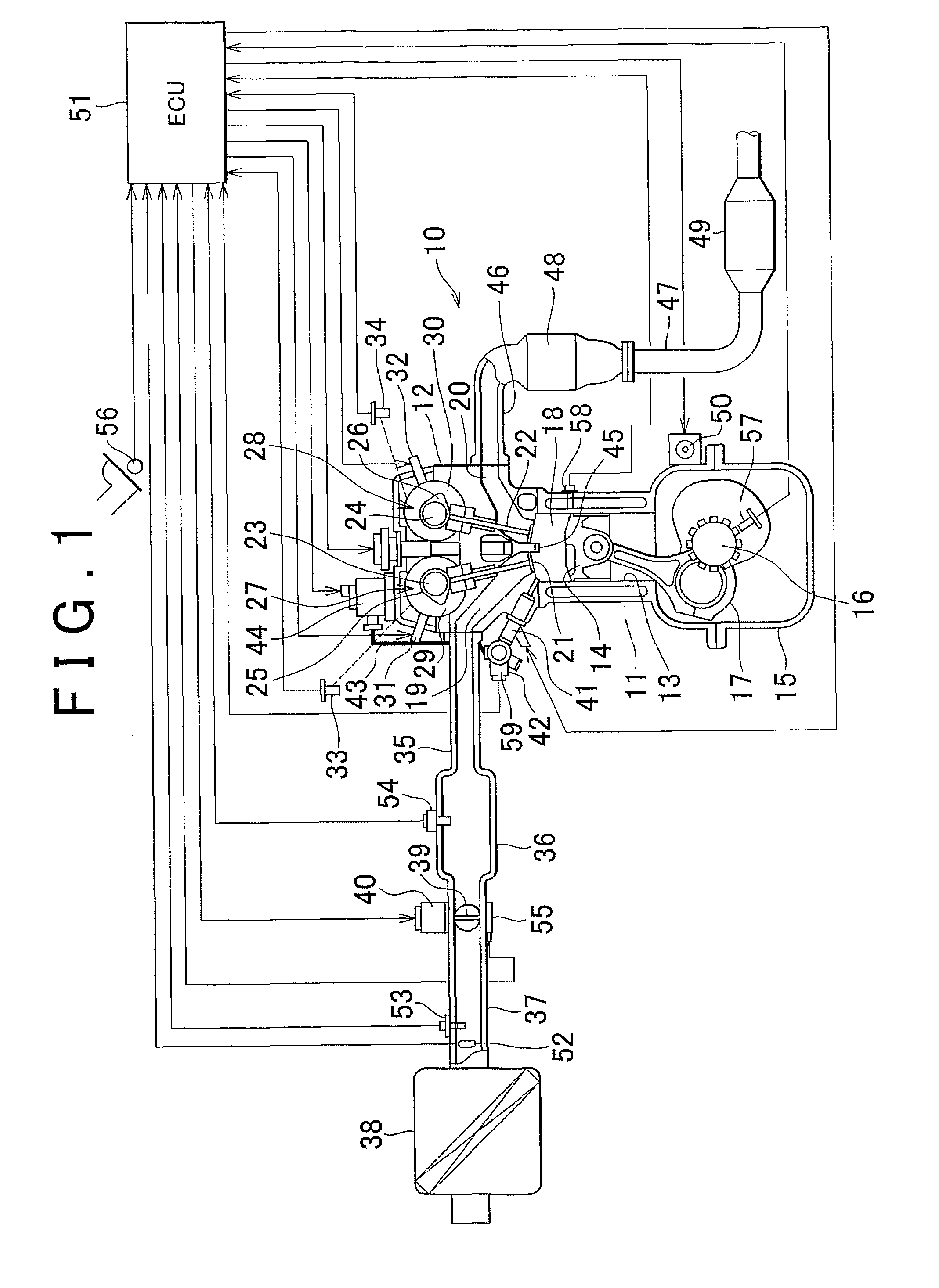

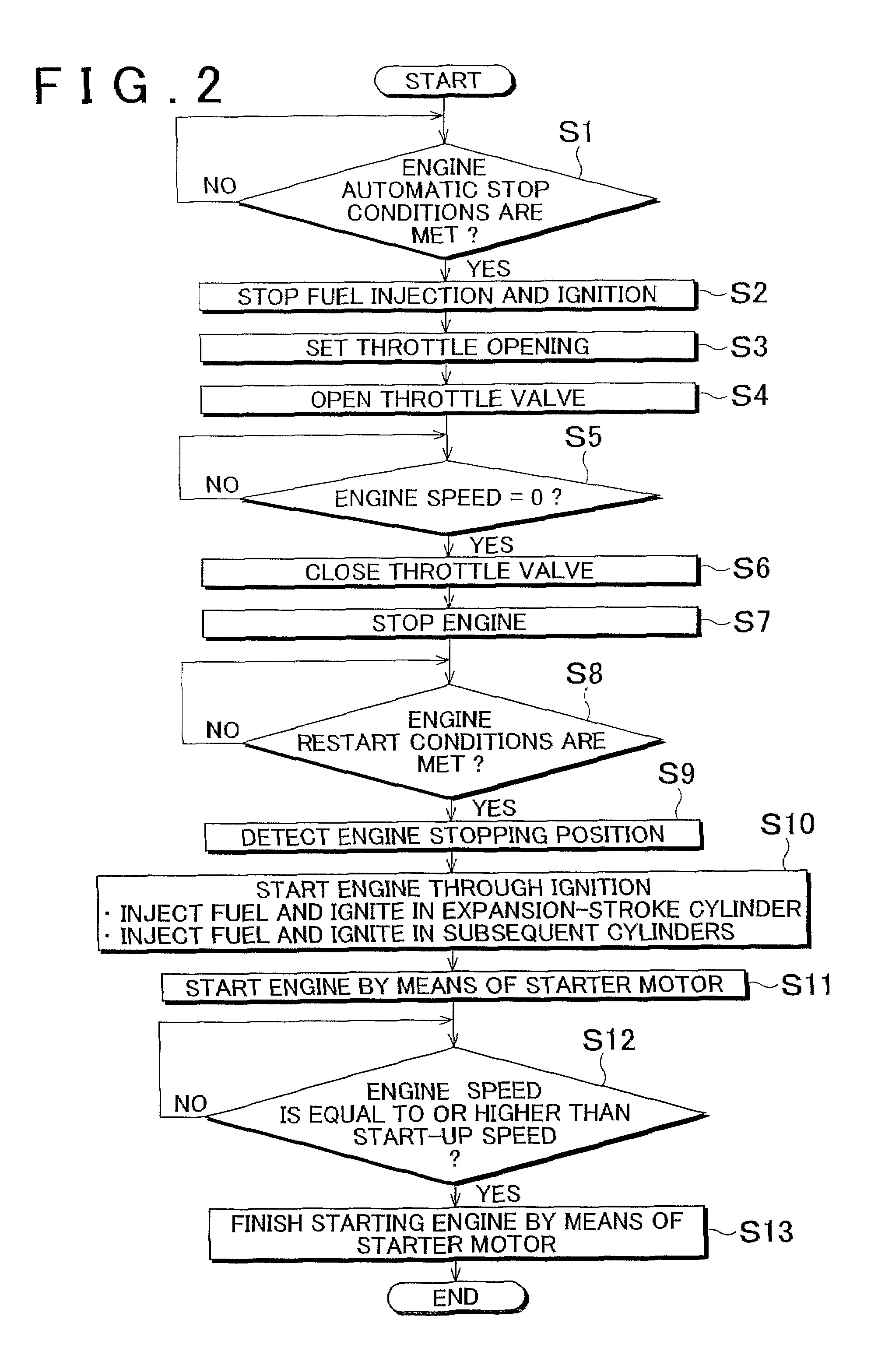

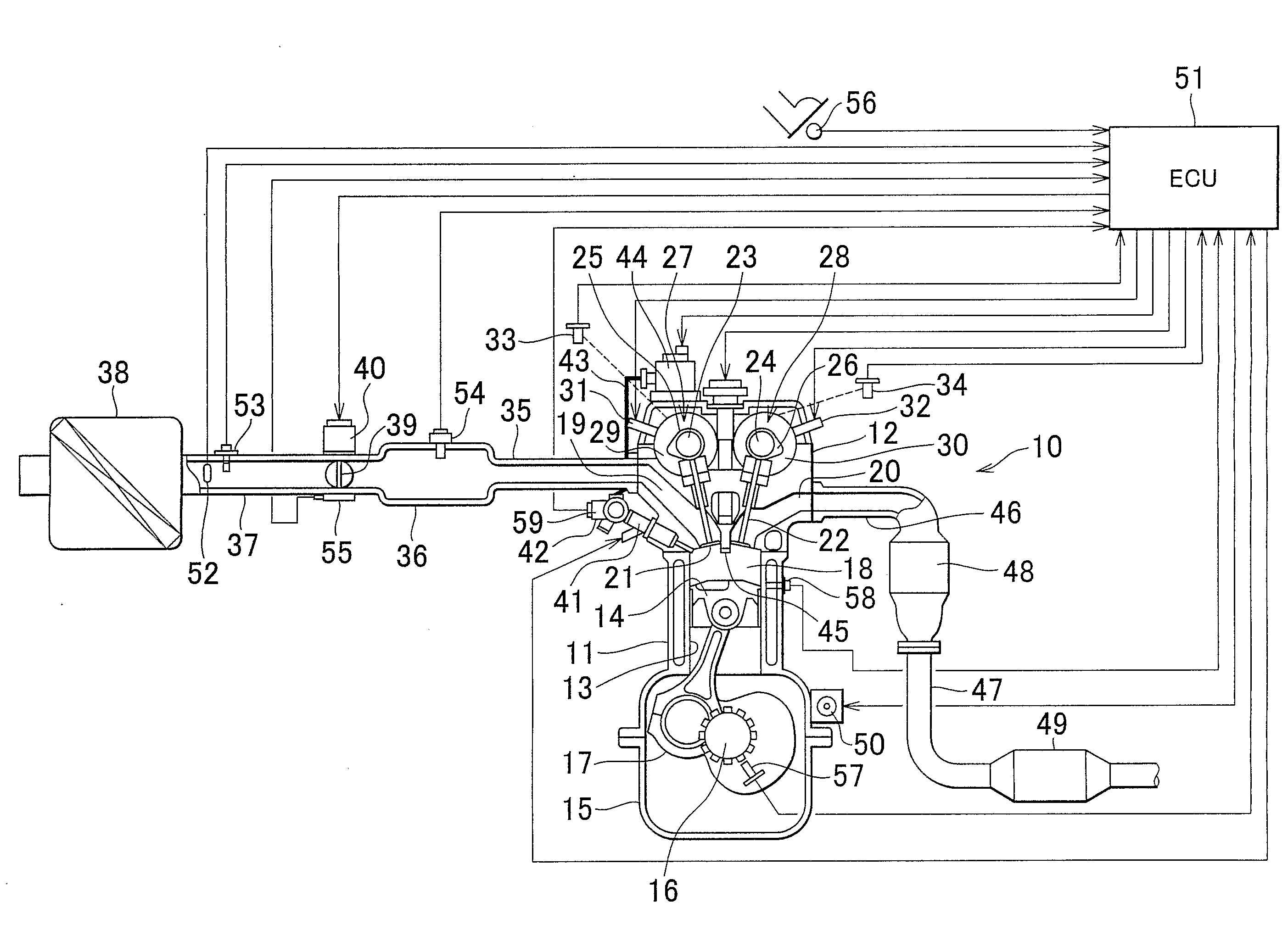

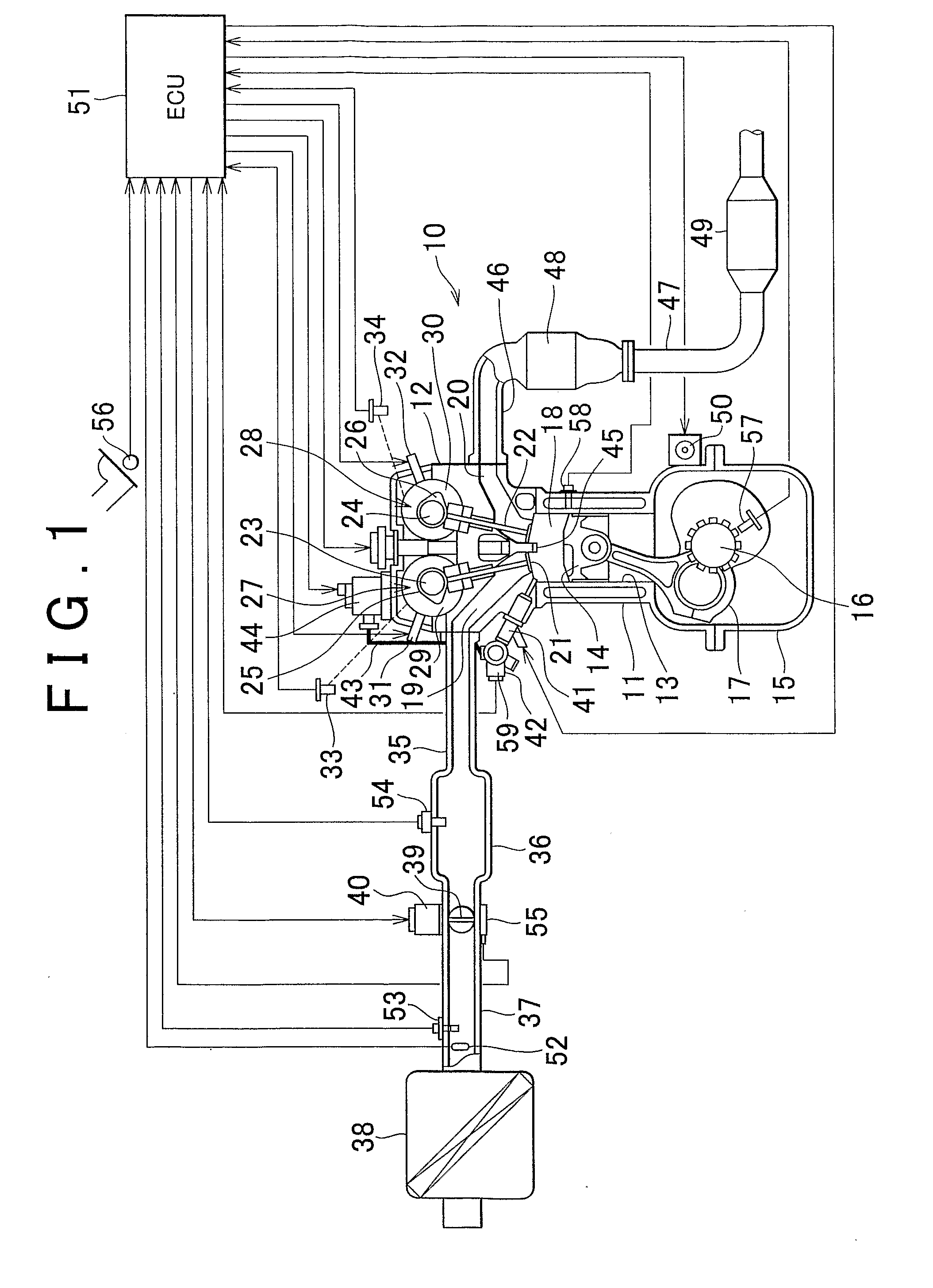

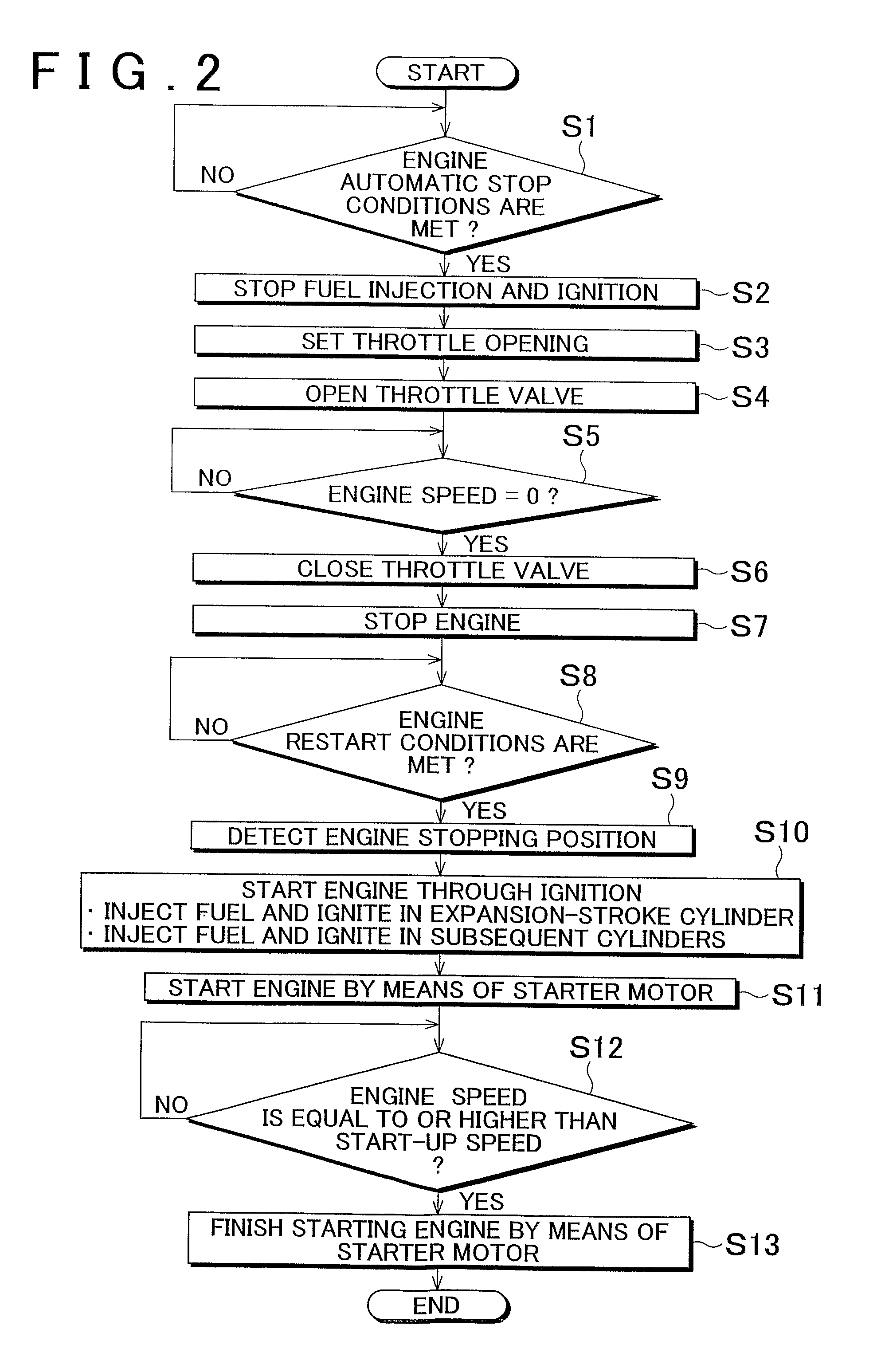

Starting system and method of internal combustion engine

InactiveUS7664594B2Improve efficiencyImprove reliabilityAnalogue computers for vehiclesPower operated startersExternal combustion engineThrottle opening

In a starting system of an internal combustion engine, an injector for injecting fuel directly into a combustion chamber and an ignition plug for igniting an air / fuel mixture in the combustion chamber are provided, and a throttle device is provided in an intake pipe. During stopping of the engine, the starting system operates the throttle device to open a throttle valve to a predetermined throttle opening at a throttle opening speed that is set based on the intake pressure. Upon a start of the engine, the starting system actuates the injector to inject the fuel into a cylinder that is in the expansion stroke, and actuates the ignition plug to ignite the mixture in the combustion chamber.

Owner:TOYOTA JIDOSHA KK

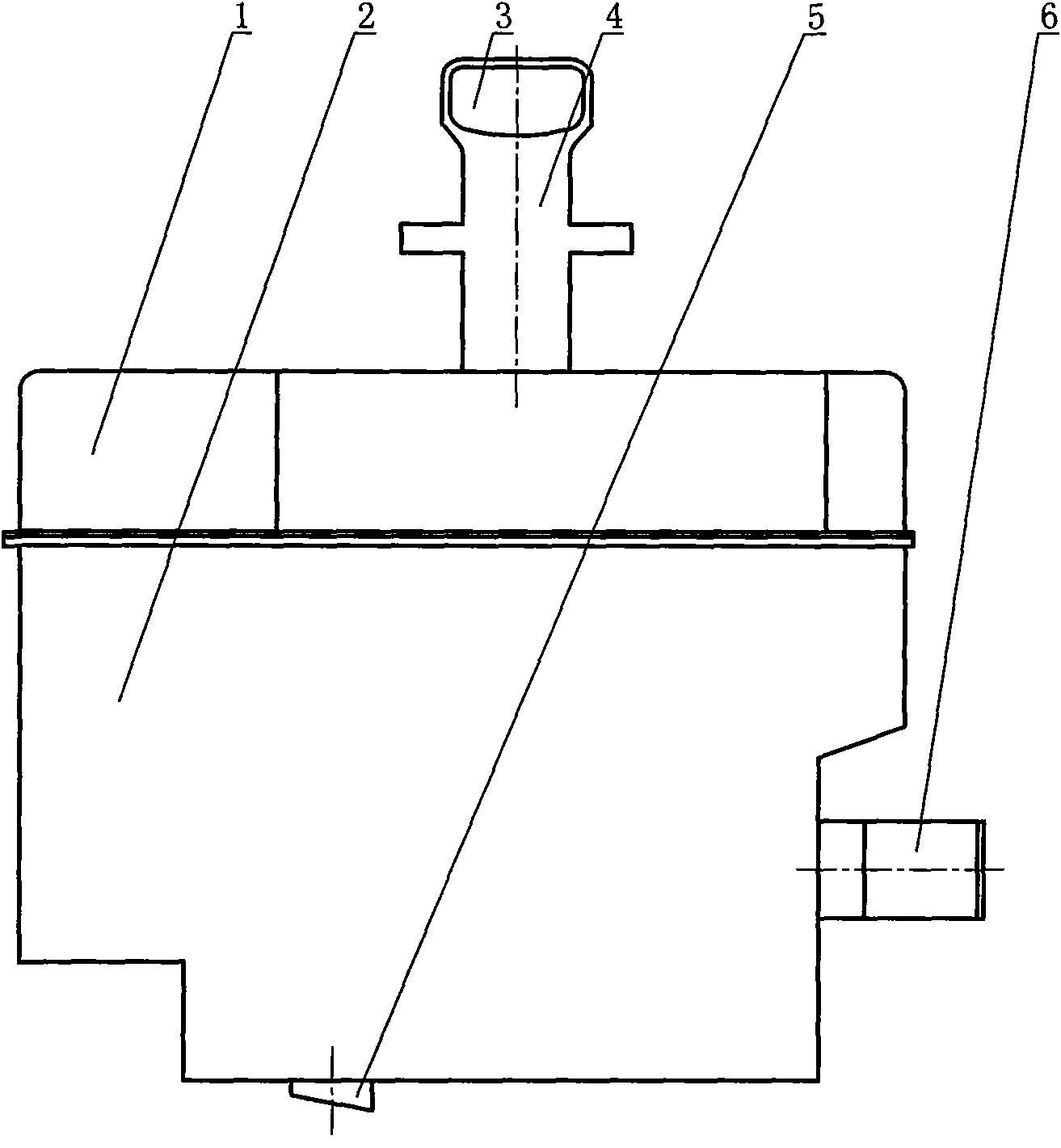

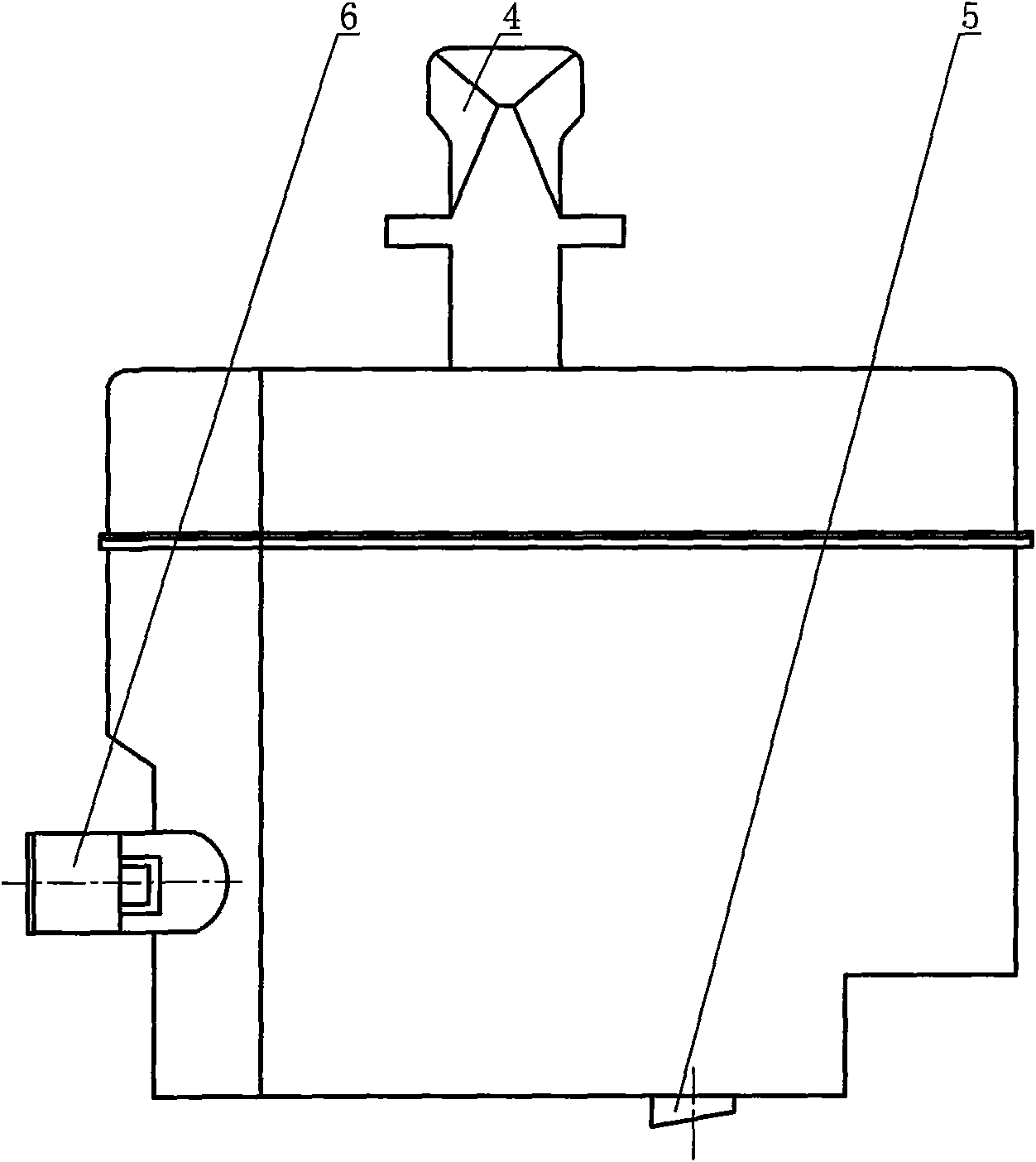

Silencer with balancing chamber

InactiveCN101629563AImprove stabilityReduce pressure differencePositive displacement pump componentsPositive-displacement liquid enginesEngineeringMuffler

The invention relates to a silencer with a balancing chamber, which consists of a silencer cavity, a cavity sealing cover, and an internal communicating pipe. The cavity sealing cover is fixed on the silencer cavity; the internal communicating pipe is clamped in a cavity formed after the fixation of the silencer cavity and the cavity sealing cover; one side of the silencer cavity is provided with an air suction port; the lower bottom of the silencer cavity is provided with an oil leakage hole; the cavity sealing cover is provided with an air outlet; and one end of the internal communicating pipe is communicated with the air suction port, while the other end is communicated with the air outlet, wherein the balancing chamber is separated in the silencer cavity on the other side of the air suction port of the silencer cavity through a partition, a lower bottom plate in the balancing chamber is provided with a balancing hole, and the balancing chamber is communicated with the silencer cavity. The silencer has a simple integral structure as well as scientific and reasonable design, can effectively reduce the negative pressure in the silencer cavity during the air suction of a compressor, reduce the whole noise of the compressor, and improve the stability of the compressor, and has higher novelty and is provided with the balancing chamber.

Owner:扎努西电气机械天津压缩机有限公司

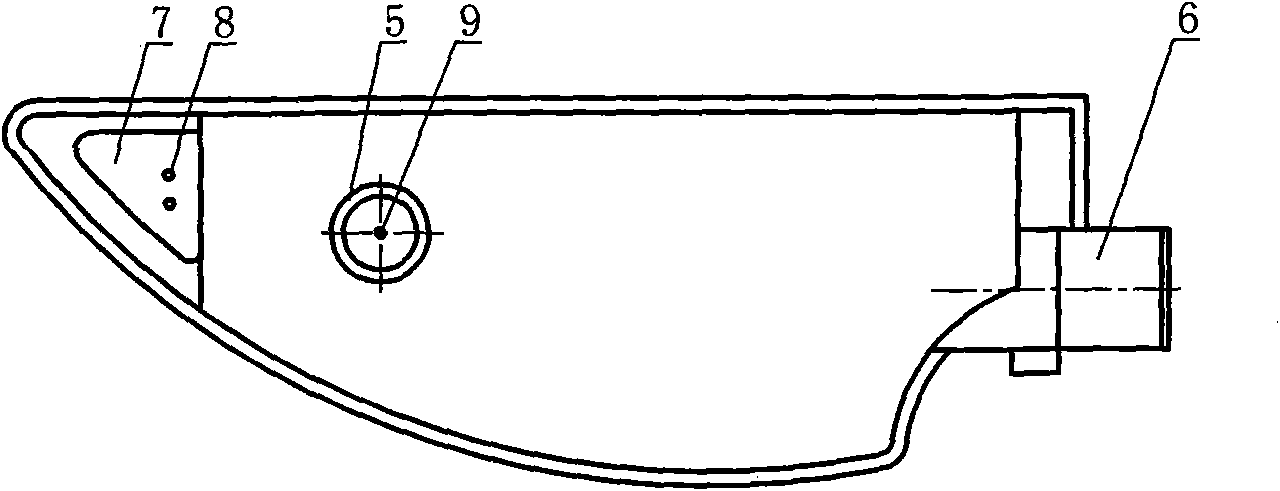

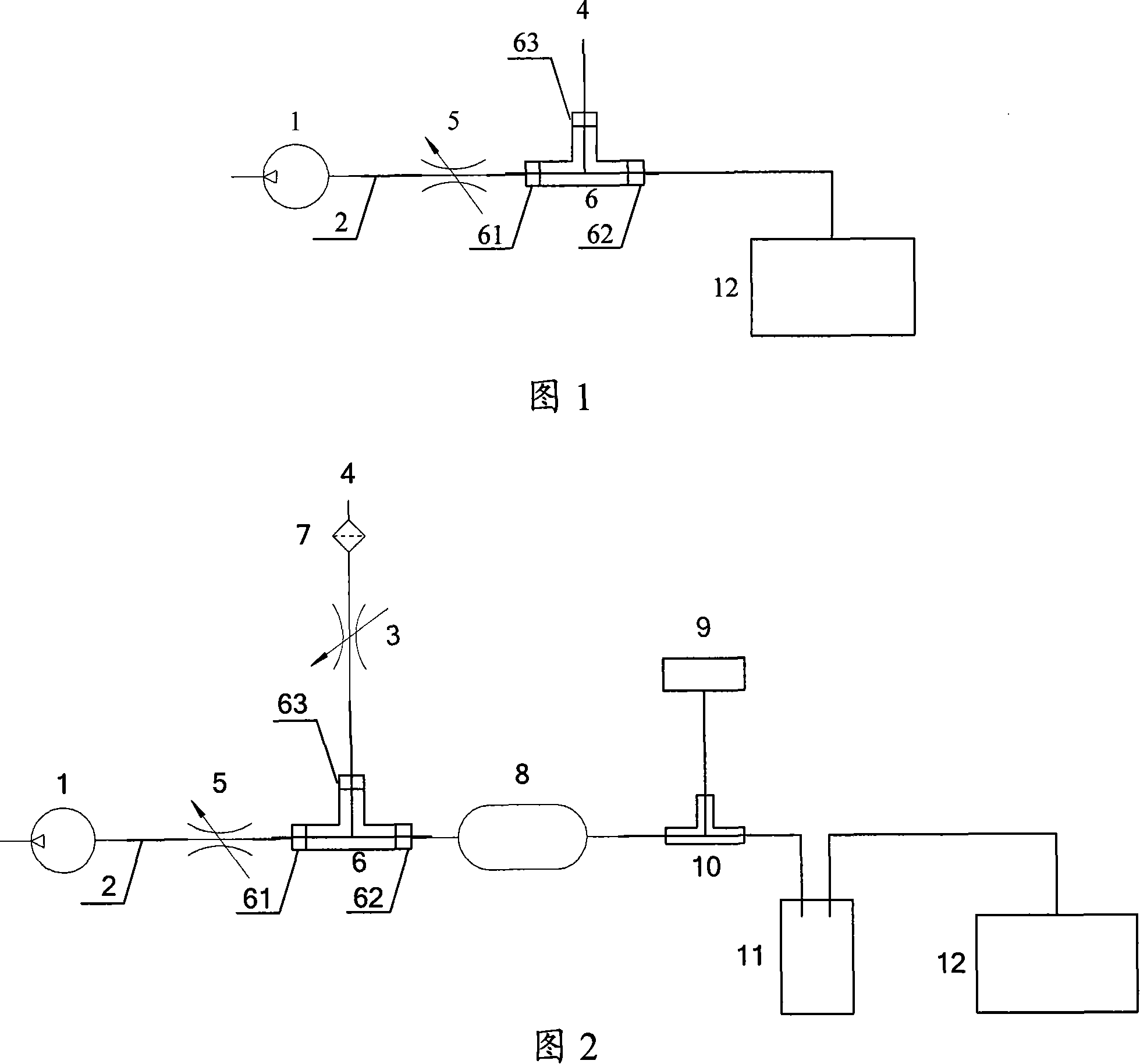

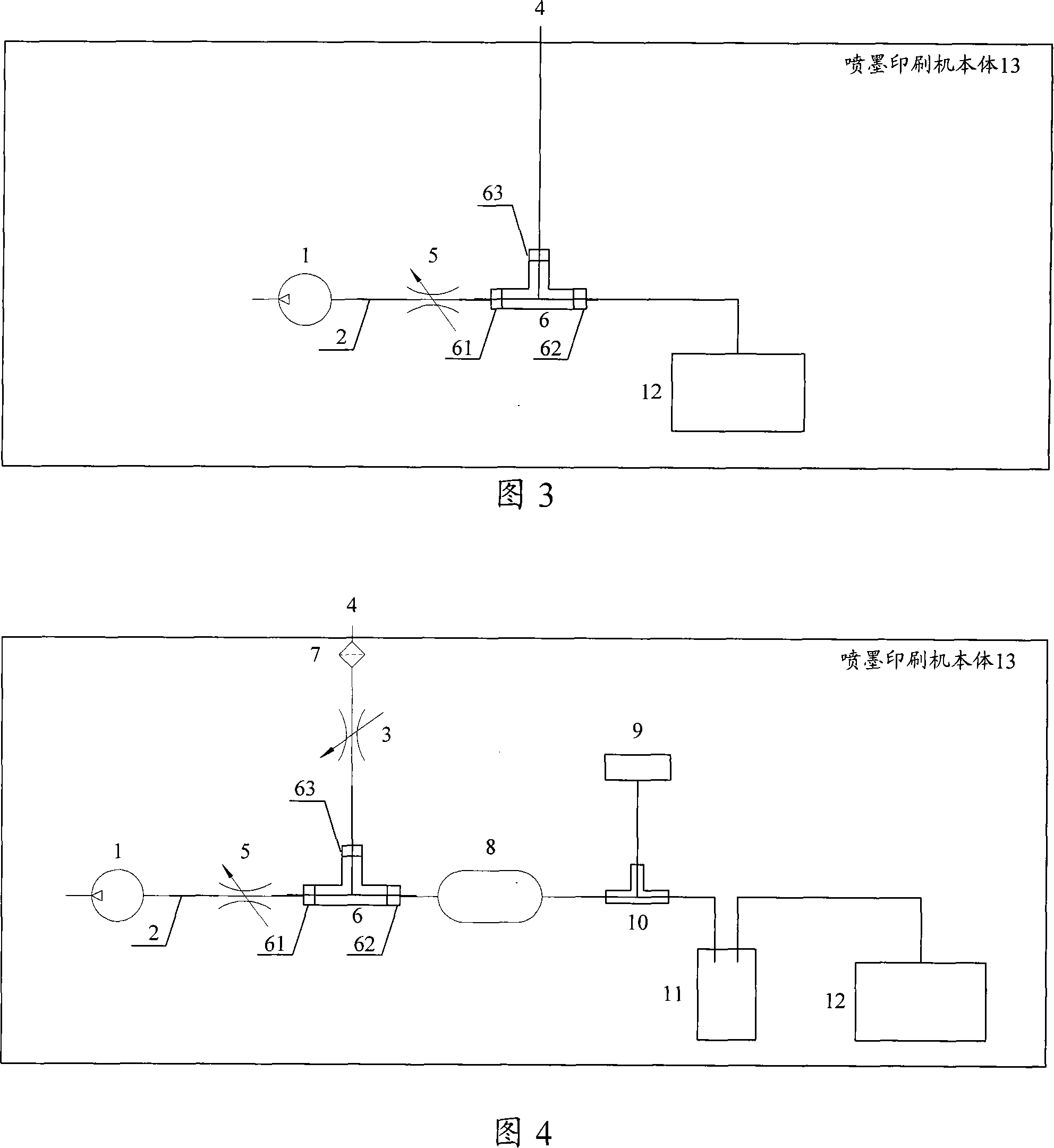

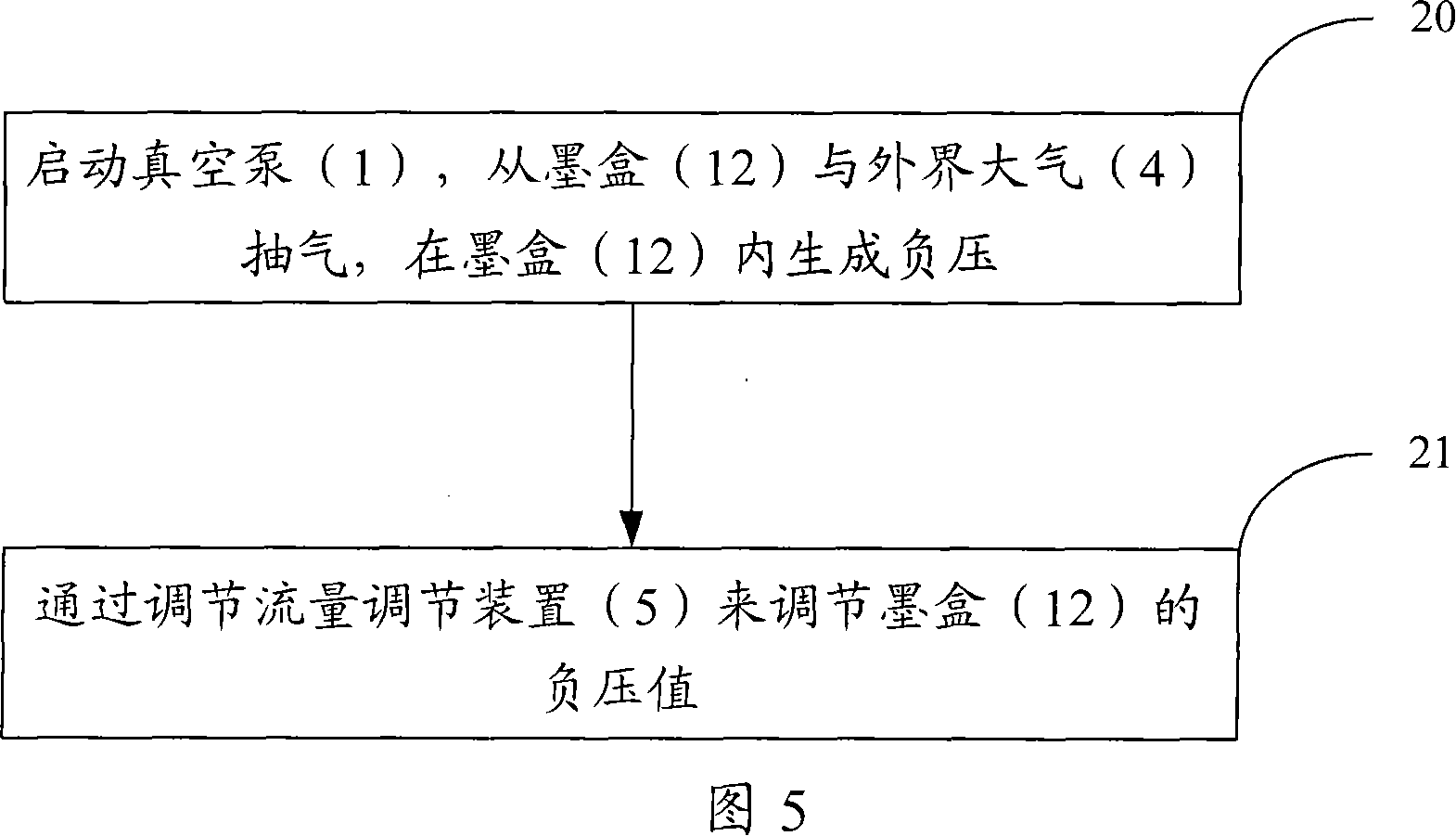

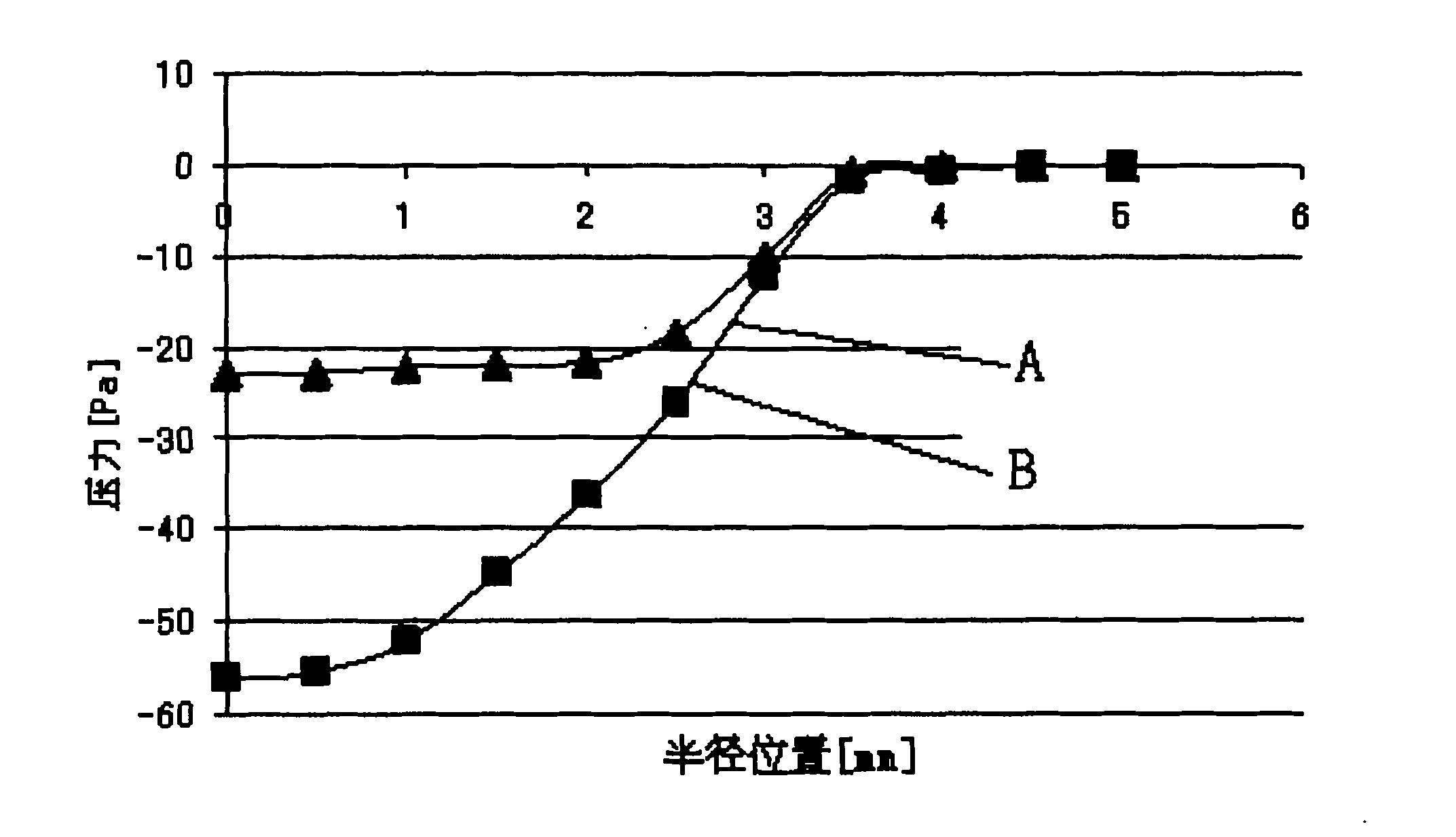

Negative pressure generating device, method and ink-jet printer

InactiveCN101138908AReduce negative pressureImprove anti-interference abilityPrintingEngineeringAtmospheric pressure

An embodiment of the present invention discloses a subpressure generating device. In order to solve the problem that the prior subpressure generating device can not produce lower stable subpressure and does not have better capacity of resisting disturbance at the same time. The device is provided with a vacuum pump (1), a pumping end of which is connected with a first flow rate adjusting device (5), another end of which is connected with an air outlet end (61) of a tee junction (6), and a port (62) of the tee junction (6) is connected with an ink cartridge (12), and an air inlet end (63) of the tee junction (6) is connected with atmosphere (4). Because the flow rate adjusting device (5) has certain function of resisting towards the undulation of a pumping velocity of the vacuum pump (1), and the pumping function of the air outlet end (61) inside the tee junction (6) and the air entering function of the air inlet end (63) have certain self-regulating ability towards the air pressure of the port (62), the device can produce lower stable subpressure and at the same time has better capacity of resisting disturbance.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

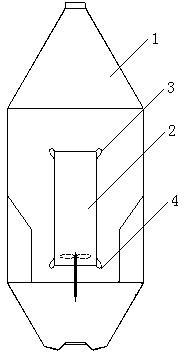

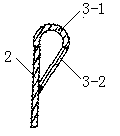

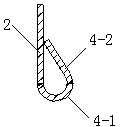

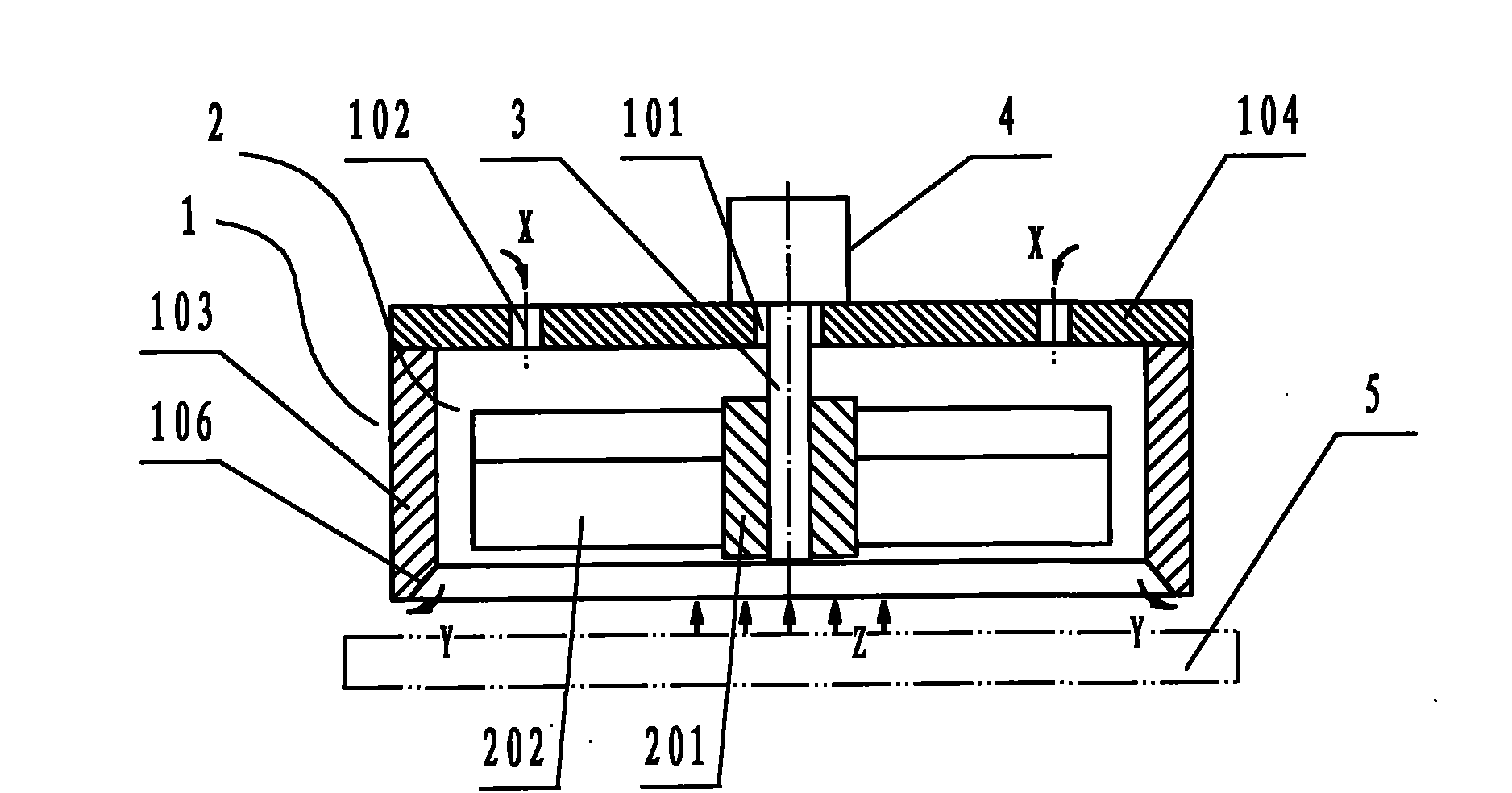

Crystallizer

InactiveCN104722098AReduce the negative pressure areaReduce wasteSolution crystallizationEngineeringMechanical engineering

A crystallizer comprises a crystallizer body. A guide cylinder is disposed in the crystallizer body. A streamline structure with a section similar to a water drop shape is disposed at the edge of each of the upper portion and the lower portion of the guide cylinder or at the edge of the lower portion of the guide cylinder. The crystallizer has the advantages that crystalline grain breaking is reduced, granularity of crystallized products is increased, the service life of the guide cylinder is prolonged, equipment maintenance rate is lowered, stirrer power is lowered, energy consumption is reduced, and the like.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

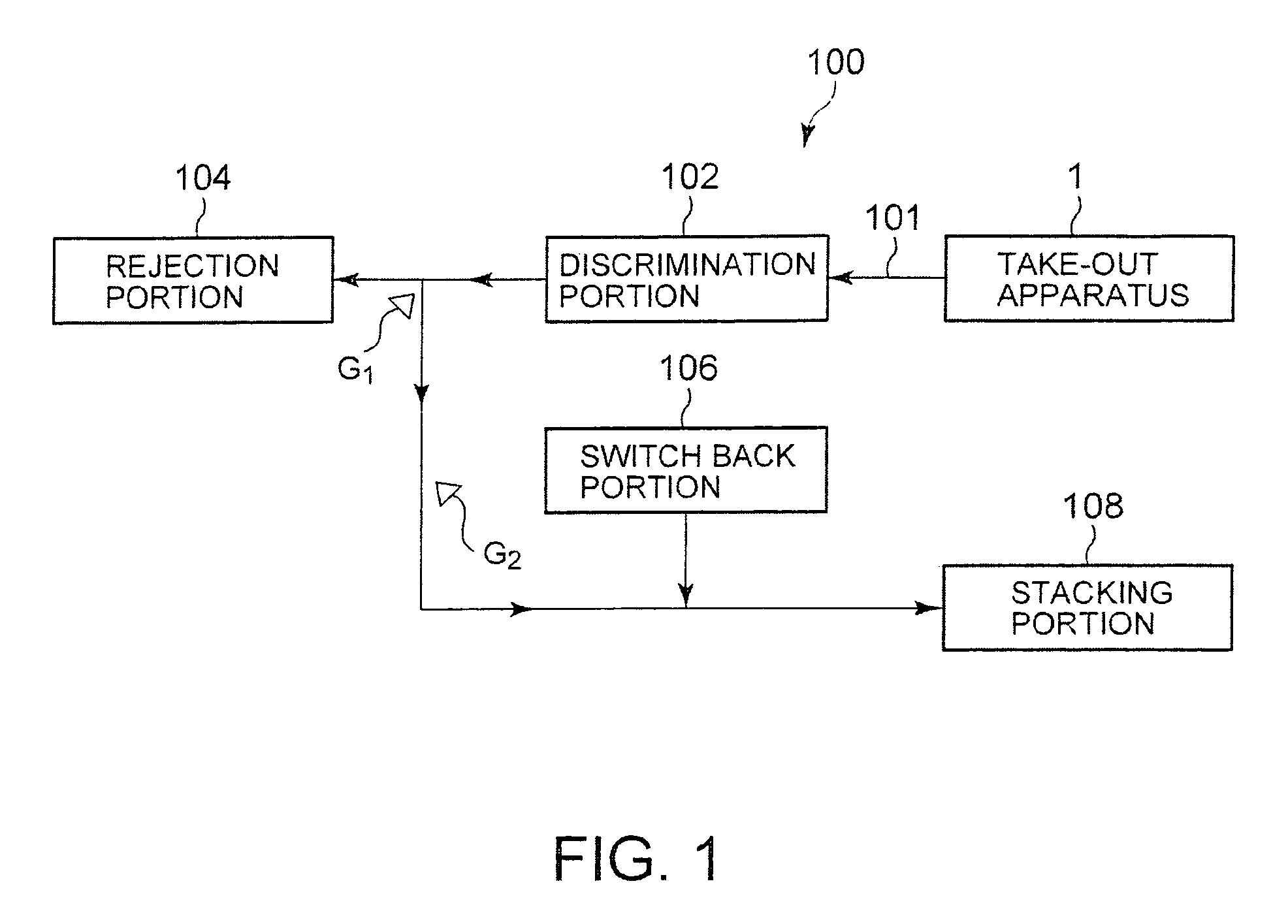

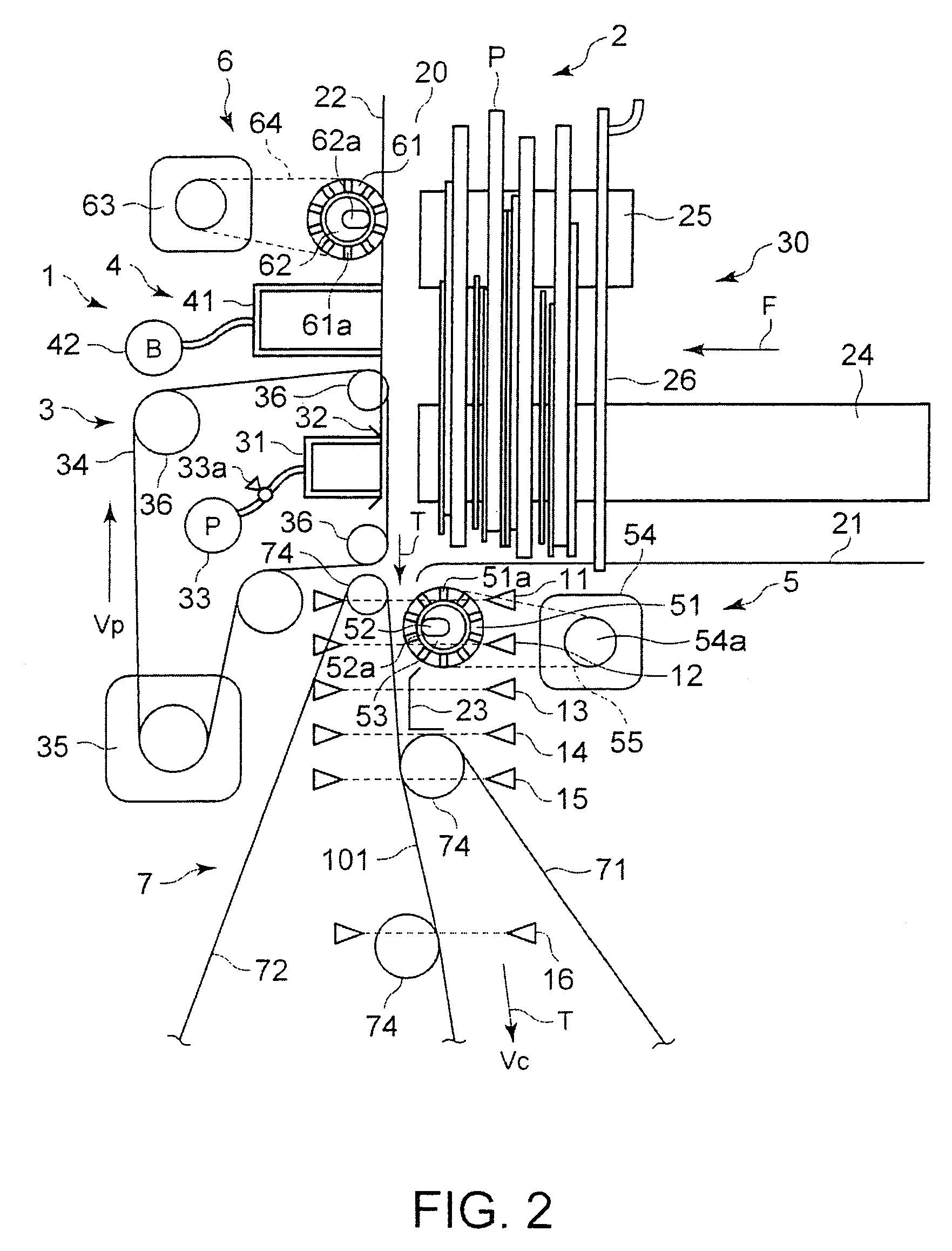

Sheet take-out apparatus, sheet processing apparatus, and sheet take-out method

ActiveUS7845629B2Reduce speedRotational speedFunction indicatorsArticle feedersLeading edgeEngineering

To provide a sheet take-out apparatus for preventing double feed of sheets and controlling gaps to a desired value, a sheet processing apparatus, and a sheet take-out method. A take-out apparatus includes a supply structure for supplying postal matter to a take-out position, a take-out structure for taking out the postal matter from the take-out position, and a conveying structure for receiving and conveying the postal matter taken out on a conveying path. When a leading edge of the postal matter is held by the conveying structure, an absorbing operation of a vacuum pump is stopped and a moving speed of a take-out belt is reduced. Furthermore, when the postal matter is detected by a sensor, the take-out belt is stopped.

Owner:KK TOSHIBA

Non-contact handling device

The invention discloses a non-contact handling device and relates to a handling device. The device comprises a cover body with a cylindrical inner hole, gyratory fan blades arranged in the cover body and a power input shaft for driving the gyratory fan blades to rotate, wherein the central position of the top end of the cover body is provided with a power input shaft mounting hole and air sucking ports distributed on the periphery of the power input shaft mounting hole; each gyratory fan blade consists of a shaft sleeve and blades distributed on the shaft sleeve; the lower parts of the blades are vertical, the upper parts are bent, and the bending directions of the blades are consistent with the rotation directions of the gyratory fan blades; and one end of the power input shaft passes through the power input shaft mounting hole and is connected with the shaft sleeve of the gyratory fan blades in the cover body, while the other end is connected with a rotary drive device arranged outside the cover body. The device has the characteristics of low energy consumption and strong suspension force, can be driven by adopting a motor, has the advantages of low cost, wide application range, large motion range, and the like, conforms to the development trends of energy saving and high efficiency in the semiconductor industry at present and is easy to popularize and apply.

Owner:杭州孚亚科技有限公司

Negative pressure control apparatus for vehicle braking operation

InactiveUS8095289B2Reduce negative pressureImprove braking performanceAnalogue computers for trafficCombustion enginesSurge tankEngineering

A communication passage for generating braking negative pressure is connected to an air passage for respective cylinders at a downstream side of a throttle valve. An air ejector is provided in a negative pressure pipe, to which communication passages for the respective cylinders are converged. A negative pressure passage for a brake booster is connected to the air ejector at a side of suction gas via a check valve. A passage for PCV gas and an intake air branched passage for bifurcating a part of the intake air from a surge tank at an upstream side of the throttle valve are connected to a driving gas side of the air ejector, wherein a negative pressure control valve is provided in the intake air branched passage. The PCV gas and the part of the intake air are forced to flow into the driving gas side of the air ejector, so that the air ejector functions as a vacuum pump. As a result, the braking negative pressure for the brake booster can be surely reduced to a target negative pressure.

Owner:DENSO CORP +1

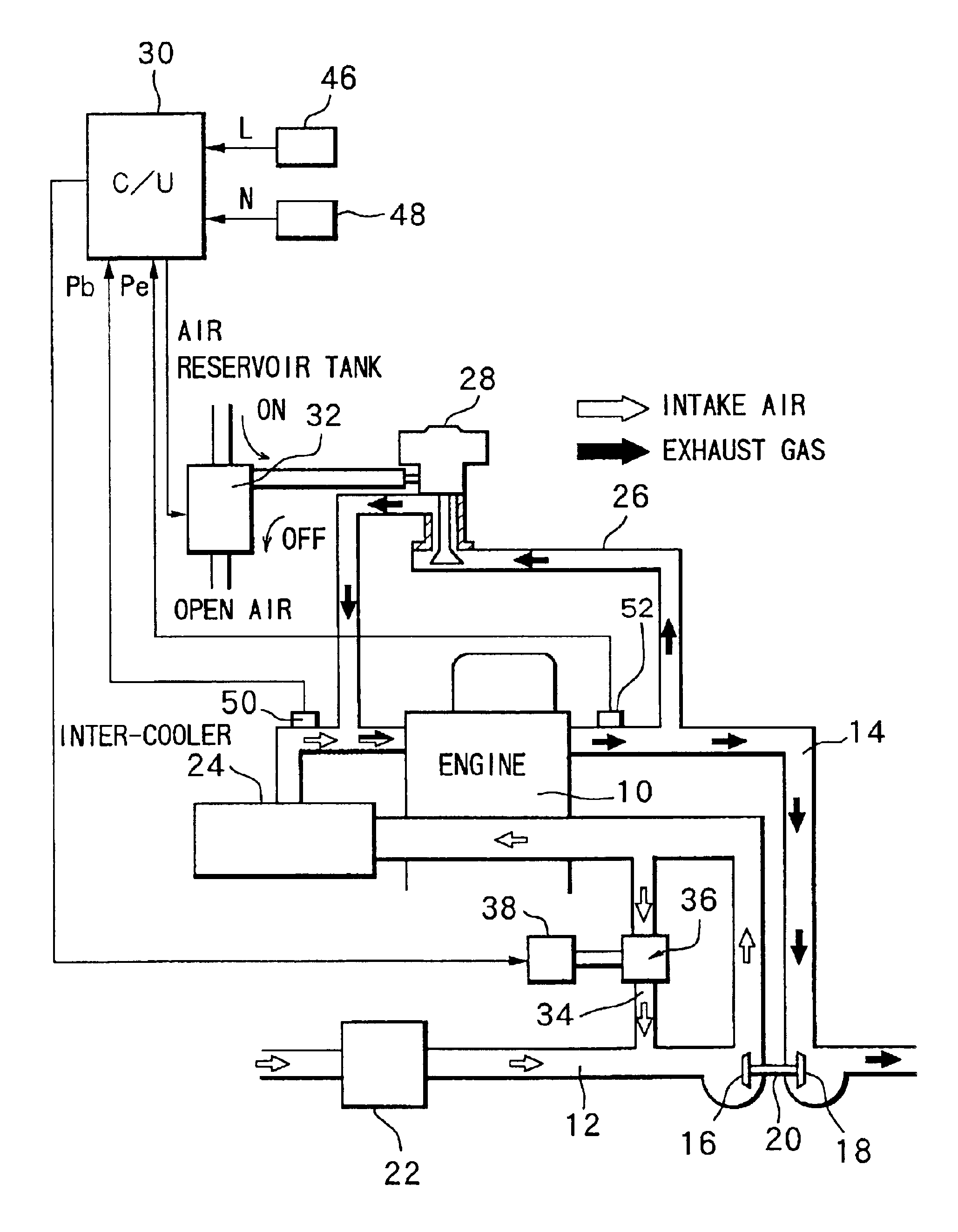

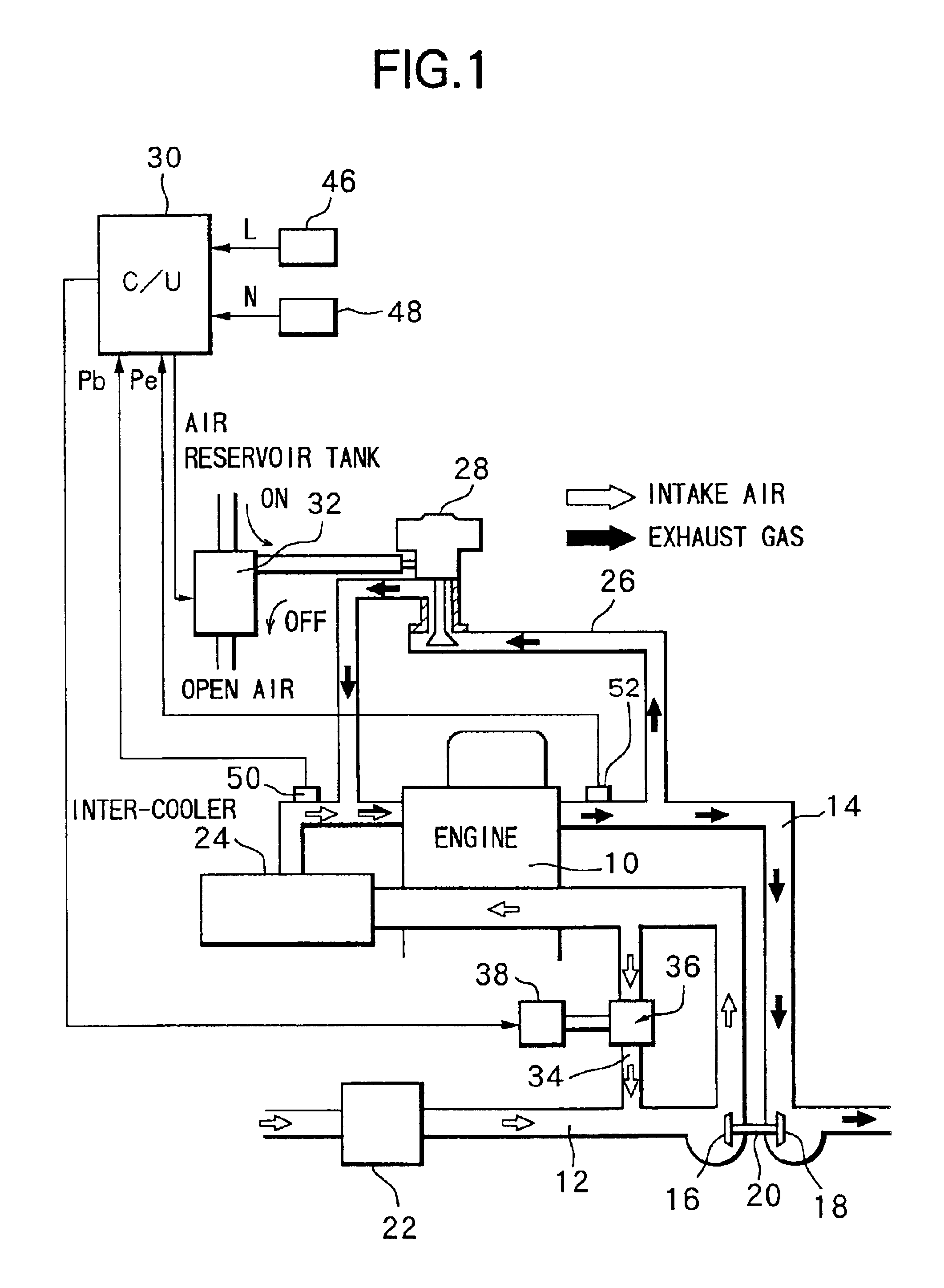

Device and method for exhaust gas circulation of internal combustion engine

InactiveUS6945240B2Reduce negative pressureIncrease negative pressureElectrical controlNon-fuel substance addition to fuelTurbochargerDifferential pressure

In an exhaust gas recirculation apparatus for an internal combustion engine mounted with a turbocharger in which a turbine is disposed in an exhaust passage and a compressor is disposed in an intake passage, when the exhaust gas recirculation is carried out, a port formed at the intake passage on the downstream side of the compressor is opened. As a result, since an intake air on the downstream side of the compressor is released to the atmosphere and a negative pressure in the exhaust passage is lowered, a differential pressure between an exhaust pressure in the intake passage and the negative pressure in the intake passage is increased, to improve an exhaust gas recirculation rate, so that a NOx discharge amount can be reduced.

Owner:NISSAN DIESEL MOTOR CO

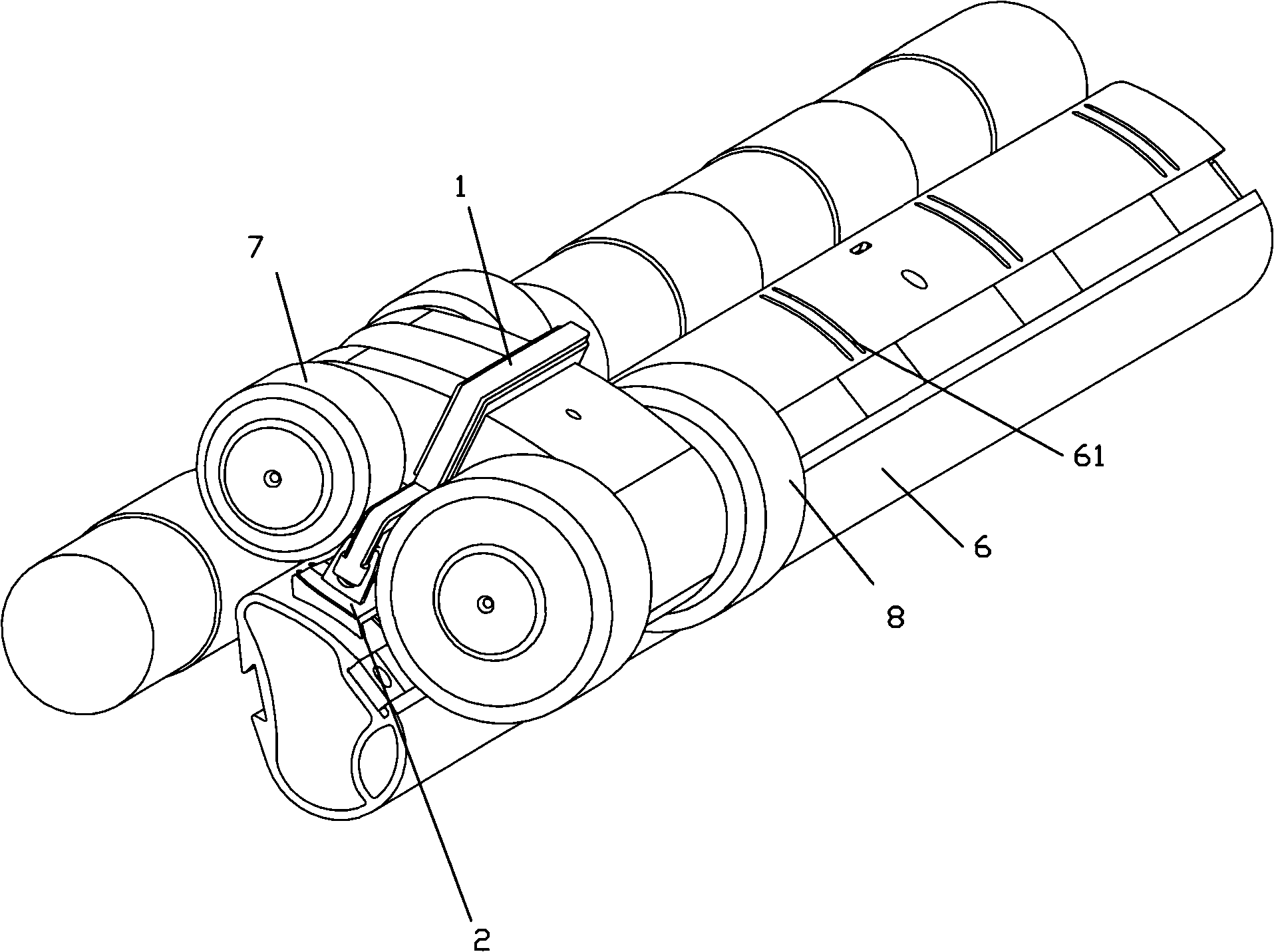

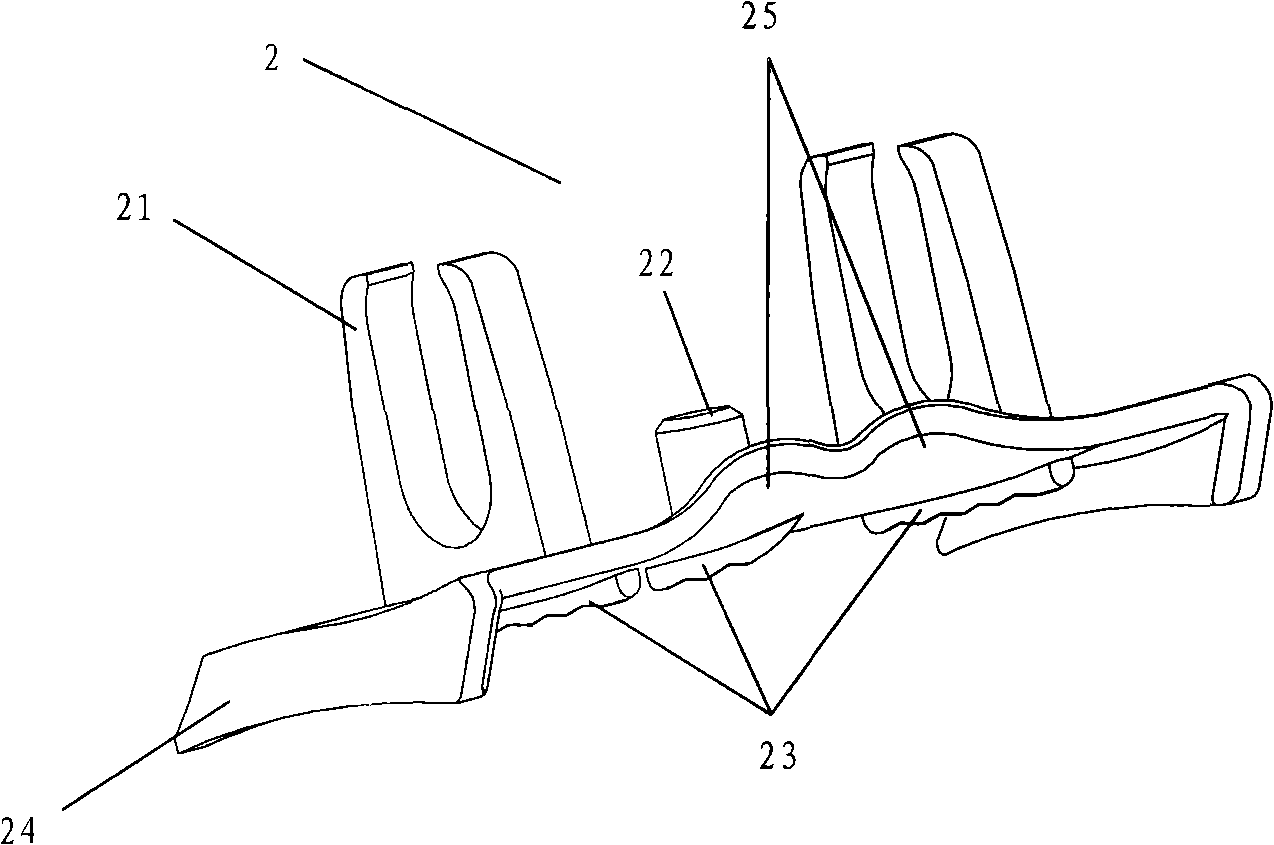

Yarn-collecting device for compact spinning

A yarn assembling apparatus for tight spin includes a bracket and a yarn assembling plate, wherein, a couple of protuberances are provided on both sides of the bracket, the protuberance and bracket center are in mirror symmetry, a groove is provided on the bracket for snapping with a boss on a wheel box, a couple of grippers are provided on the yarn assembling plate and are snapped with the corresponding protuberance on the bracket, a couple of feet are provided on the lower part of the yarn assembling plate, yarn assembling airflow guide tendons are provided in the feet, the height of the yarn assembling airflow guide tendons is lower than that of the feet, and the height difference is larger than the thickness of the conveyer band. The invention has advantages that a yarn assembling apparatus is between a drawing roller and a gripping roller, spans the conveyer band and elastically supports on a slide surface; the airflow before entering the suction duct can implement orienting and effective press to the strand of fibers by guiding of the guide tendon on the yarn assembling plate, thereby the airflow is effectively utilized above the strand of fibers, the negative-pressure is reduced and the energy consumption is saved. The yarn assembling apparatus allows the two strands of fibers to be not easy to unite and wind, by guiding of three airflow guide tendon on the yarn assembling plate when the yarn assembling apparatus spins the compound yarn, thereby improving the compound yarn quality.

Owner:YUNSHENG HLDG GRP

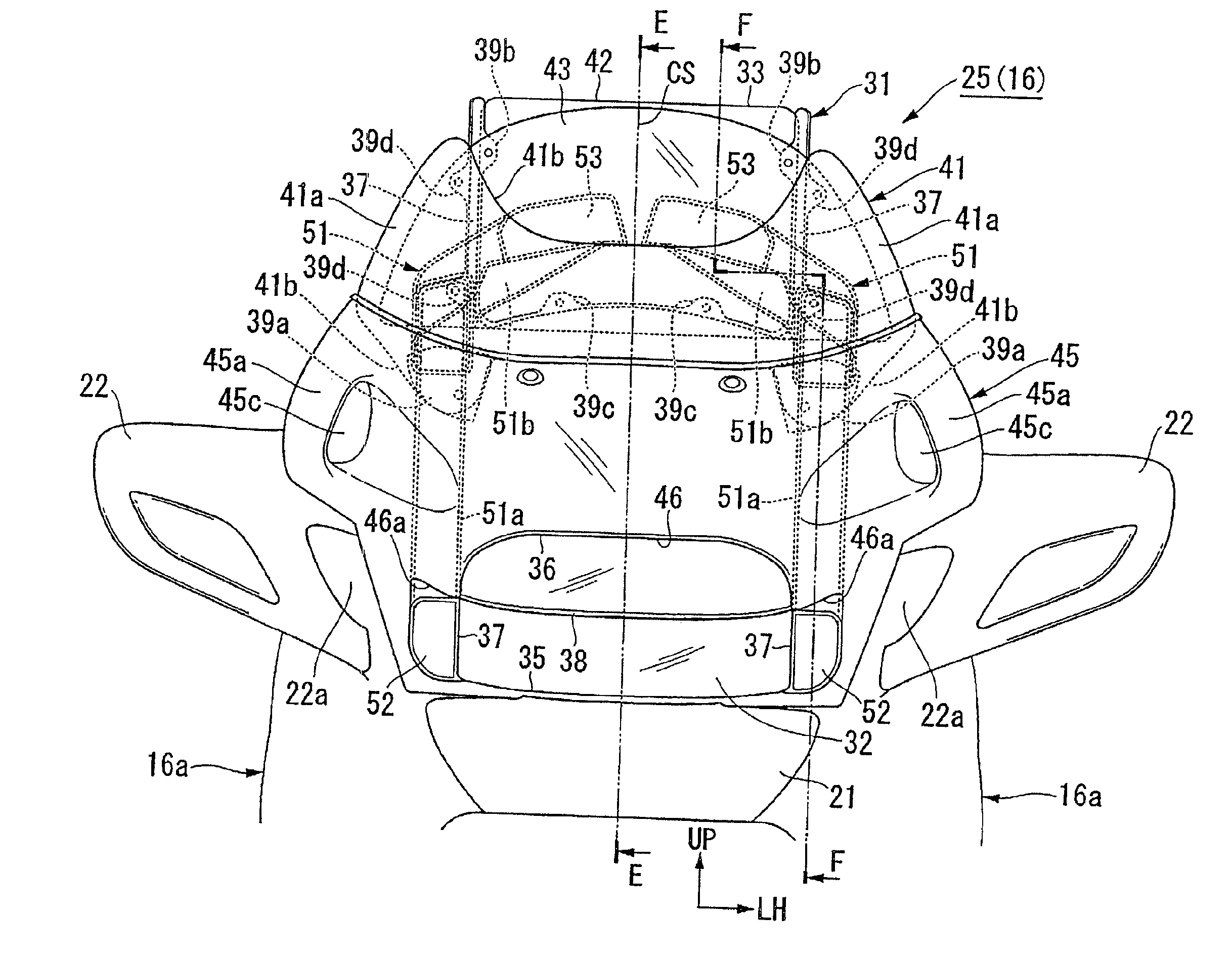

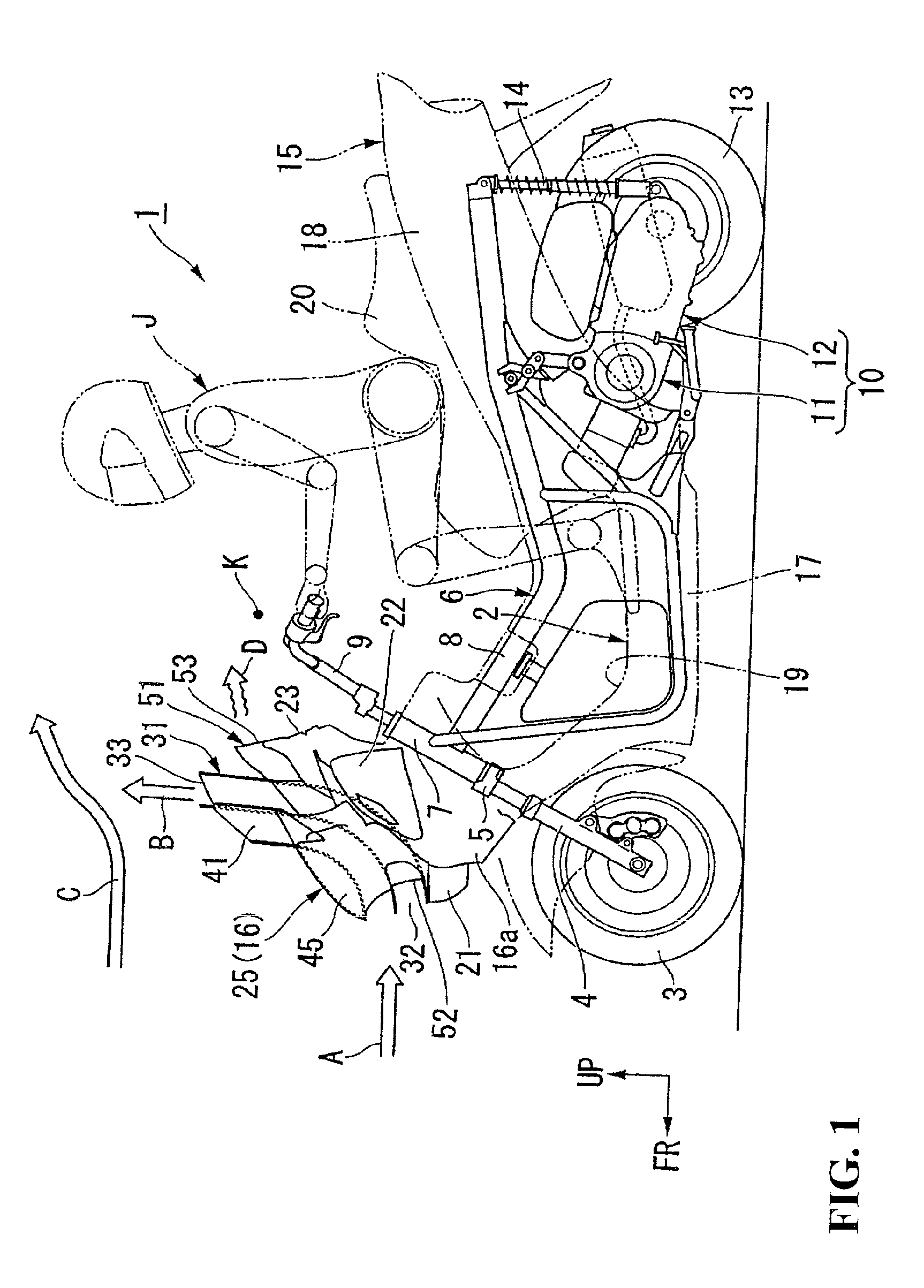

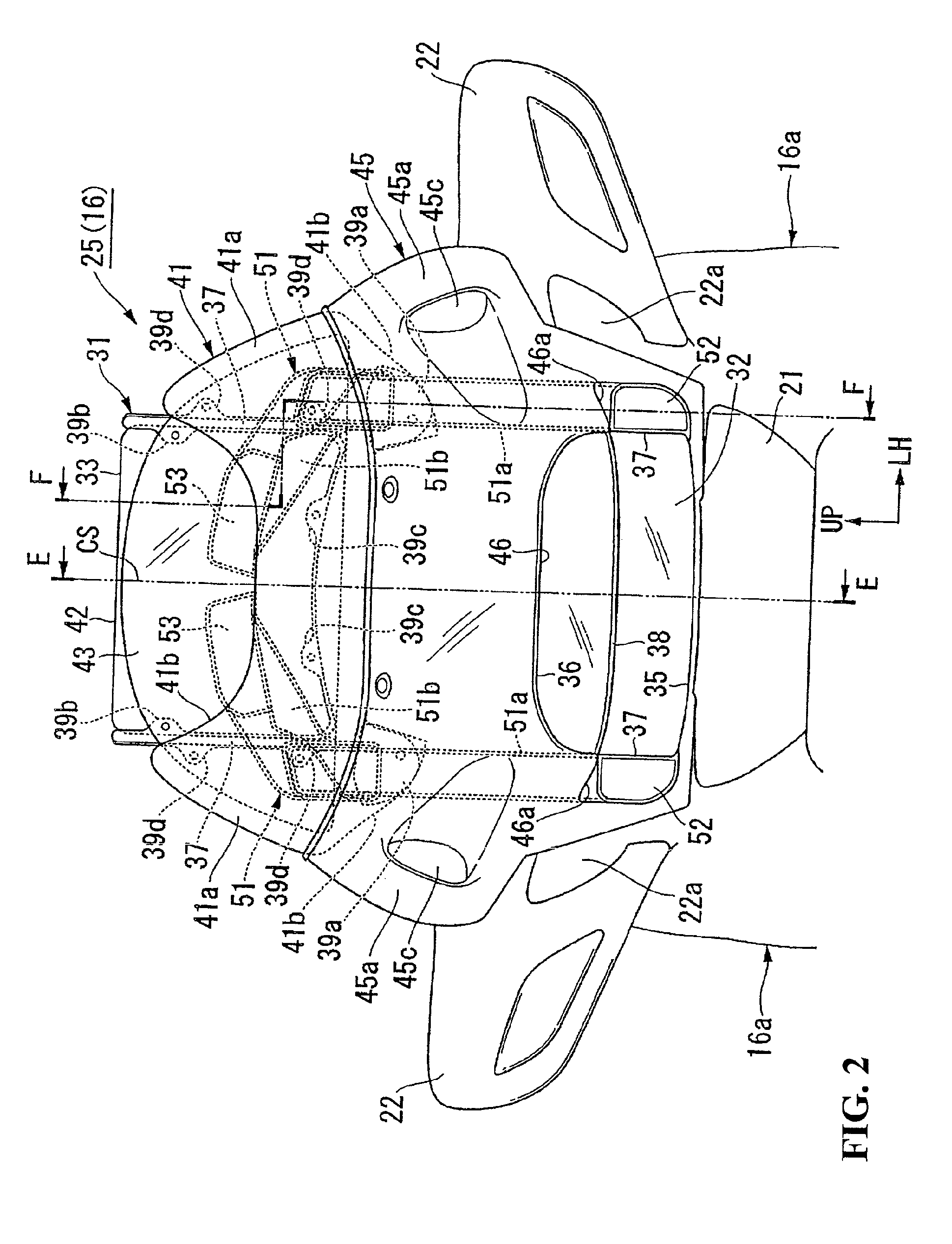

Windshield unit for saddle-ride type vehicle

InactiveUS7703831B2Effective correctionInhibition heightWindowsLighting and heating apparatusPressure differenceWindshield

A pressure difference rearward of a windshield is efficiently corrected in a windshield unit for a saddle-ride type vehicle provided with two types of air ducts for directing the air flow from the front of the vehicle to the upside of the vehicle and to the rear of the windshield. A windshield unit includes an air duct for allowing an air introduction port opening toward the front of the vehicle to communicate with an air blowout port opening toward the upside of the vehicle and a second air duct for allowing a second air introduction port opening toward the front of the vehicle to communicate with a second air blowout port disposed rearward of the air duct to open toward the rear of the vehicle. The second air blowout port is disposed within the left-right width of the air blowout port of the air duct.

Owner:HONDA MOTOR CO LTD

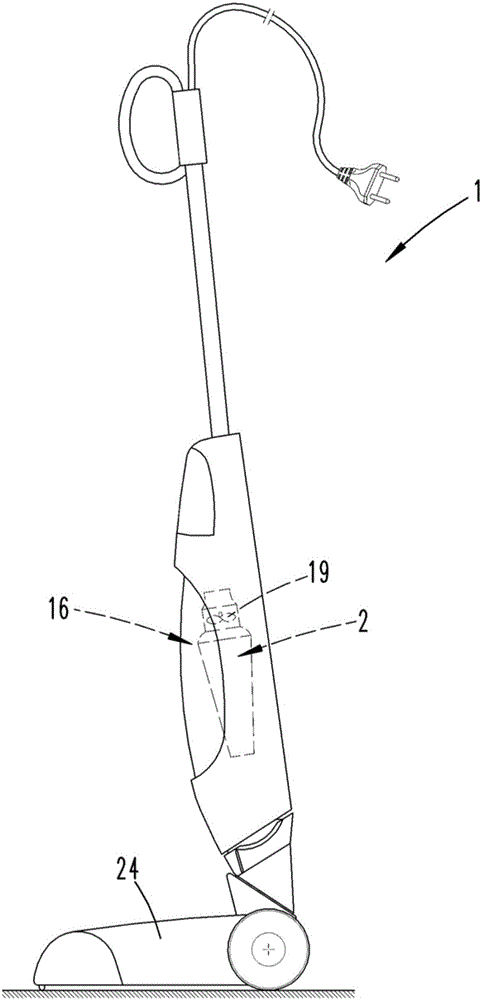

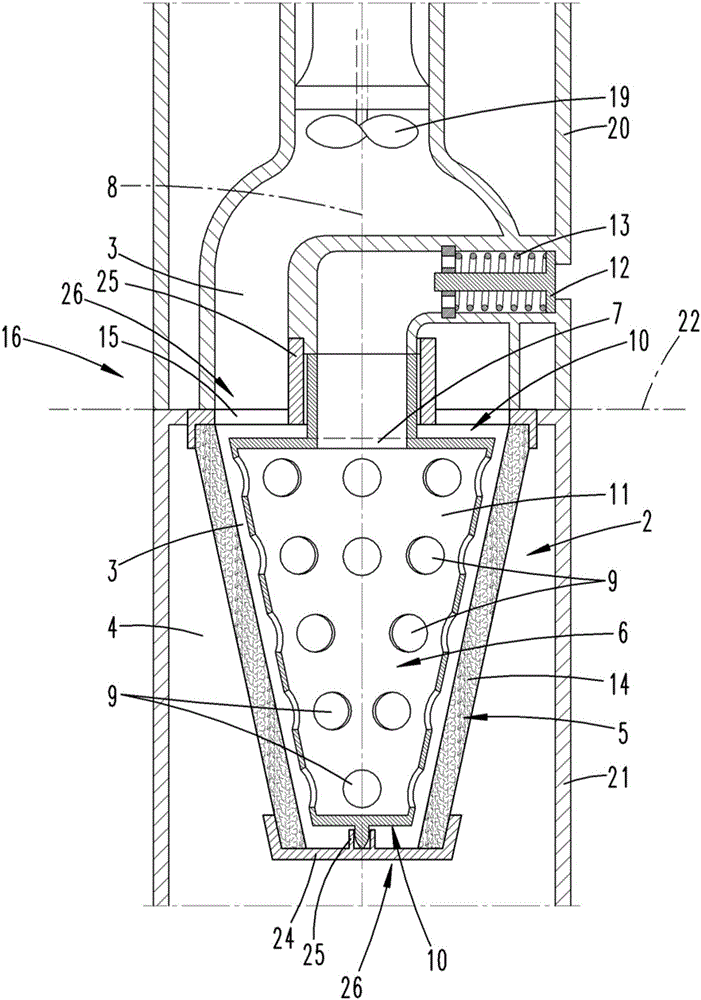

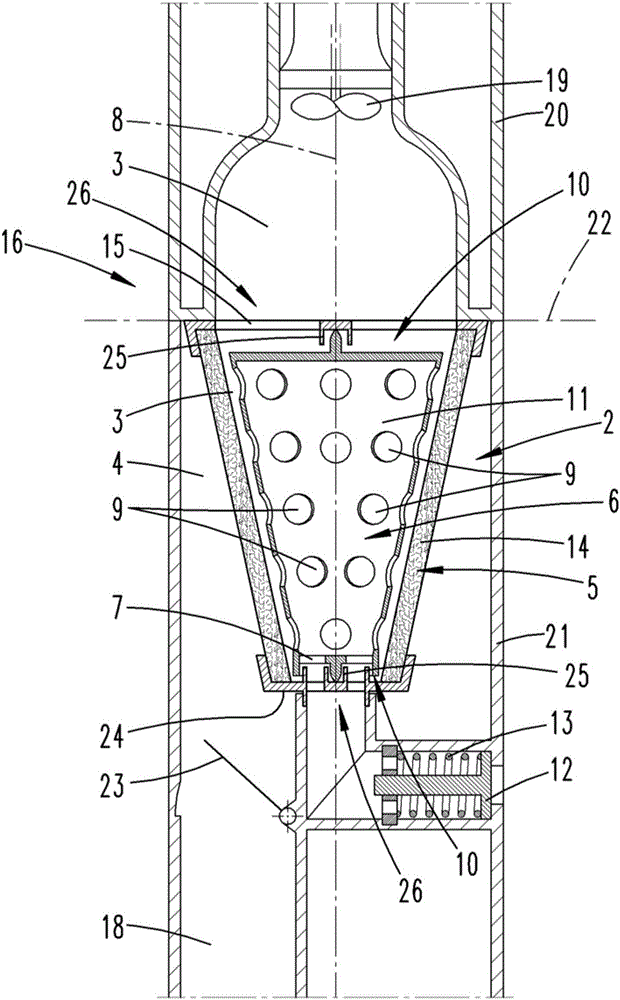

Air filter

ActiveCN106175592AReduce negative pressureRealize coaxial arrangementCleaning filter meansSuction filtersAir filterPressure controlled ventilation

The invention relates to an air filter (2), which is especially used for a household dust collector (1). The air filter (2) is provided with a filter element (5) which separates a clean-air space (3) from a suction space (4), and the filter element (5) is operated in a filter operation of air to be cleaned from the direction of the suction chamber (1), and the air filter (2), in particular for a household vacuum cleaner (4) in the direction of the clean-air space (3) and with an action element (6) designed to act on the filter element (5) on the clean-air side. In order to provide an air filter (2), which allows a longer filter operation over a longer period of time and whose function is not hindered by the suction material, it is proposed that, with the flow through the filter element (5), the filter element (6) is moved from the suction space (4) (3) can be activated on the filter element (5) by virtue of an air flow which can be triggered under the influence of pressure control and acts on the influencing element (6).

Owner:VORWERK & CO INTERHOLDING GMBH

Starting system and method of internal combustion engine

InactiveUS20090132155A1Improve efficiencyImprove reliabilityAnalogue computers for vehiclesPower operated startersExternal combustion engineThrottle opening

In a starting system of an internal combustion engine, an injector for injecting fuel directly into a combustion chamber and an ignition plug for igniting an air / fuel mixture in the combustion chamber are provided, and a throttle device is provided in an intake pipe. During stopping of the engine, the starting system operates the throttle device to open a throttle valve to a predetermined throttle opening at a throttle opening speed that is set based on the intake pressure. Upon a start of the engine, the starting system actuates the injector to inject the fuel into a cylinder that is in the expansion stroke, and actuates the ignition plug to ignite the mixture in the combustion chamber.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com