A/B sirospun bunchy yarn blended with cotton fiber, viscose fiber and polyester fiber and blending technology

A technology of viscose fiber and polyester fiber, which is applied in the field of A/B siro spinning slub yarn and its blending process, which can solve the problems of large difference in blending ratio, unacceptable yarn, and difficult production, etc., and achieve the blending ratio precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

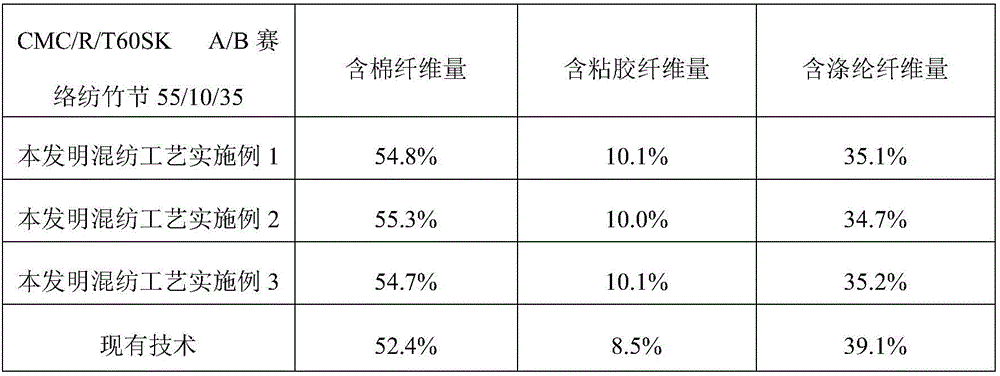

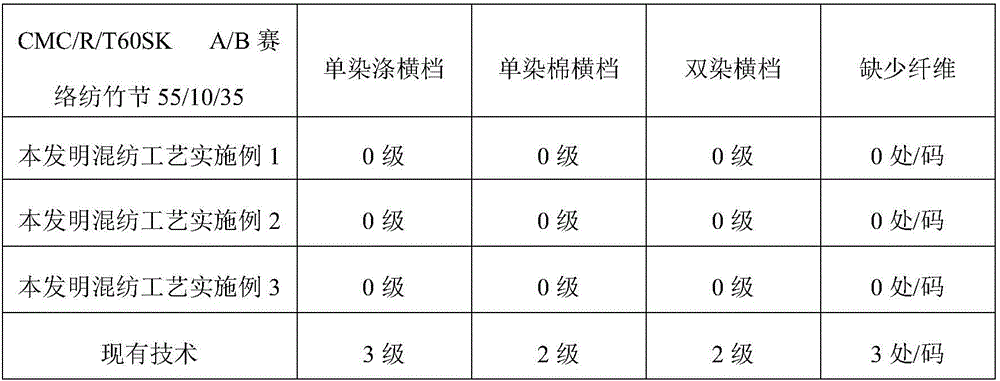

[0034] Embodiment 1: the present invention provides a kind of A / B siro spinning slub yarn and its blending process produced by cotton fiber, viscose fiber and polyester fiber, in this A / B siro spinning slub yarn, Cotton fiber is 54.8%, viscose fiber is 10.1%, polyester fiber is 35.1%.

[0035] The method for controlling the blending ratio of A / B siro spinning slub yarns includes: cotton fibers are pre-drawn after cleaning, carding, pre-drawing, sliver winding, combing, and one pre-combination; After the viscose fiber is cleaned, carded, pre-drawn in one pass, and pre-drawn in the second pass, the viscose fiber pre-drawing is obtained; the cotton fiber pre-drawing is mixed with the viscose fiber pre-drawing, and the two fibers are mixed evenly The cooked sliver is then fed into the roving frame to produce A roving; the polyester fiber is fed into the roving frame to produce B roving after cleaning, carding, one-stage drawing, and two-stage drawing; the A roving is combined with...

Embodiment 2

[0044] Embodiment 2: the present invention provides a kind of A / B siro spinning slub yarn and its blending process produced by cotton fiber, viscose fiber and polyester fiber, in this A / B siro spinning slub yarn, Cotton fiber is 55.3%, viscose fiber is 10.0%, and polyester fiber is 34.7%.

[0045] The method for controlling the blending ratio of A / B siro spinning slub yarns includes: cotton fibers are pre-drawn after cleaning, carding, pre-drawing, sliver winding, combing, and one pre-combination; After the viscose fiber is cleaned, carded, pre-drawn in one pass, and pre-drawn in the second pass, the viscose fiber pre-drawing is obtained; the cotton fiber pre-drawing is mixed with the viscose fiber pre-drawing, and the two fibers are mixed evenly The cooked sliver is then fed into the roving frame to produce A roving; the polyester fiber is fed into the roving frame to produce B roving after cleaning, carding, one-stage drawing, and two-stage drawing; the A roving is combined ...

Embodiment 3

[0054] Embodiment 3: the present invention provides a kind of A / B siro spinning slub yarn and its blending process produced by cotton fiber, viscose fiber and polyester fiber, in this A / B siro spinning slub yarn, Cotton fiber is 54.7%, viscose fiber is 10.1%, and polyester fiber is 35.2%.

[0055] The method for controlling the blending ratio of A / B siro spinning slub yarns includes: cotton fibers are pre-drawn after cleaning, carding, pre-drawing, sliver winding, combing, and one pre-combination; After the viscose fiber is cleaned, carded, pre-drawn in one pass, and pre-drawn in the second pass, the viscose fiber pre-drawing is obtained; the cotton fiber pre-drawing is mixed with the viscose fiber pre-drawing, and the two fibers are mixed evenly The cooked sliver is then fed into the roving frame to produce A roving; the polyester fiber is fed into the roving frame to produce B roving after cleaning, carding, one-stage drawing, and two-stage drawing; the A roving is combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com