Method for separating and extracting feldspar ore with complex impurity components

An extraction method and technology of feldspar ore, which is applied in the field of separation and extraction of feldspar ore, can solve the problems of unmined and single, and achieve the effects of improving production capacity, simple process, and improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

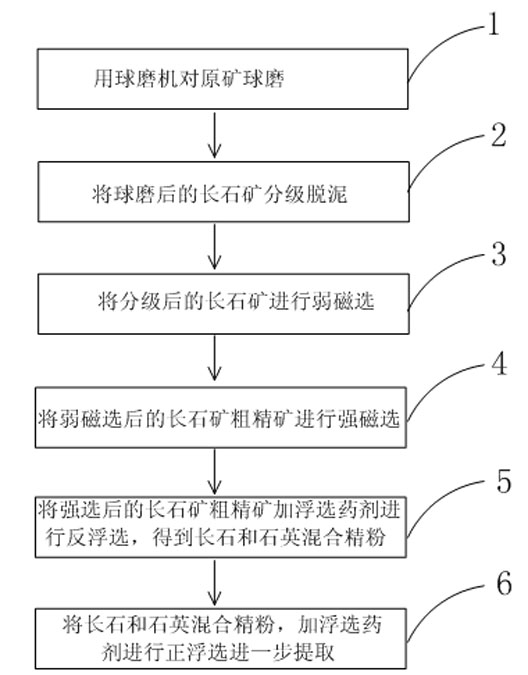

Method used

Image

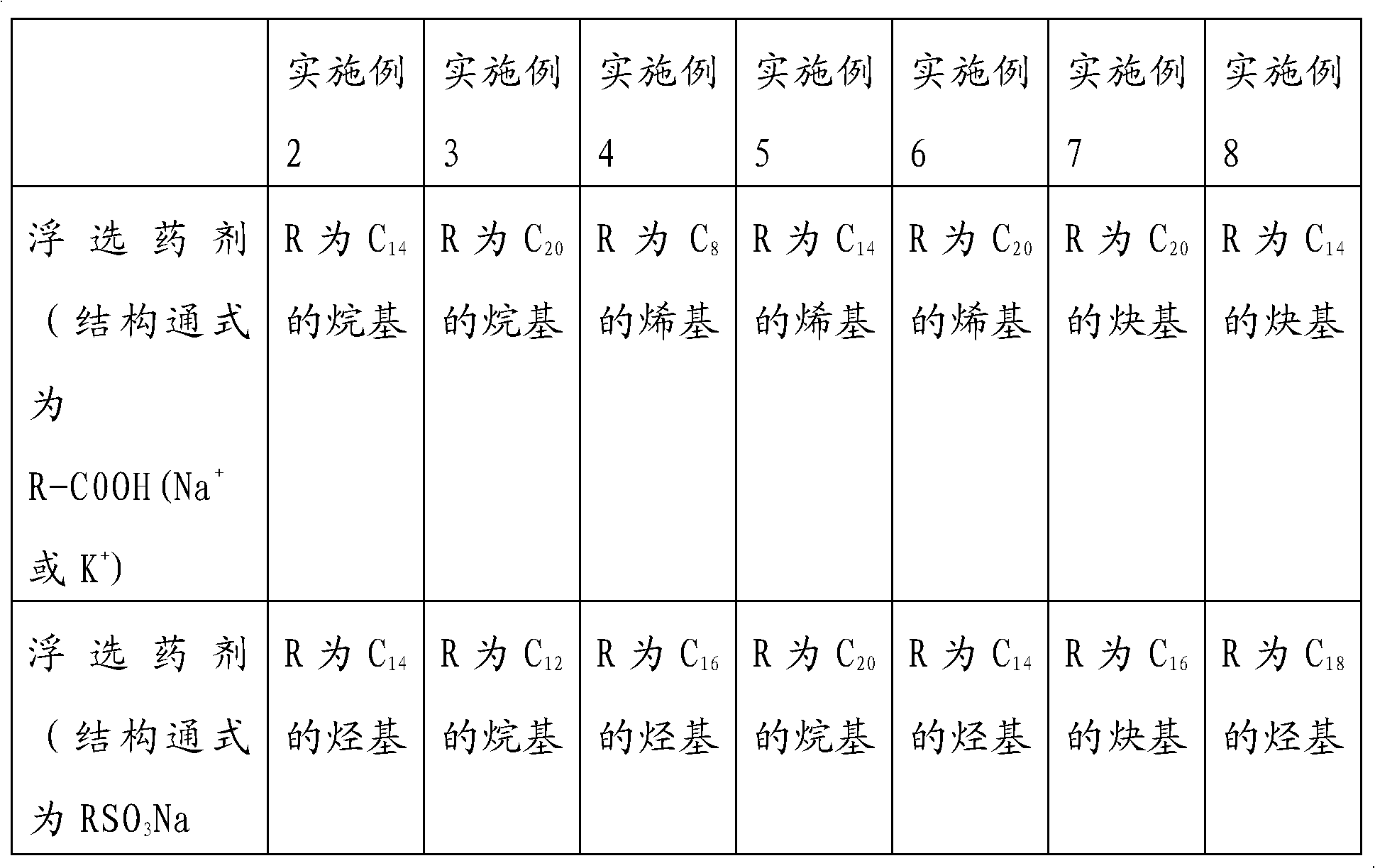

Examples

Embodiment 1

[0048] Experiments were carried out on the Laiyang feldspar mine in Shandong, the chemical composition of the raw ore: K 2 O: 8.24%, Na 2 O: 2.50%, Fe 2 o 3 : 0.30%, mica: 1.2%, and build a feldspar processing plant with a daily processing capacity of 2,500 tons.

[0049] Firstly, the raw ore is ground through a ball mill; the ground feldspar ore is classified and deslimed with an improved hydraulic classifier to obtain feldspar ore with a grinding particle size of -200 mesh accounting for 68%; the classified feldspar ore is Weak magnetic separation with a magnetic field strength of 1000Oe is carried out through a weak magnetic separator to separate the strong magnetic substances and the feldspar coarse concentrate into the strong magnetic separation; then the feldspar coarse concentrate obtained after the weak magnetic separation is passed through the strong magnetic separator Carry out strong magnetic separation with a magnetic field strength of 8000Oe, separate and obtai...

Embodiment 9

[0056] Conducted experiments on Hengyang feldspar mine in Hunan, and built a feldspar ore dressing plant with a daily processing capacity of 1,200 tons. The operation effect is very good. The chemical composition of the raw ore: K 2 O: 6.98%, Na 2 O: 3.88%, Fe 2 o 3 : 0.39% Mica: 1.8%, Tourmaline: 1.2%.

[0057] Firstly, the raw ore is ground through a ball mill; the ground feldspar is classified and deslimed with an improved hydraulic classifier to obtain a feldspar with a grinding fineness of -200 mesh accounting for 72%; the classified feldspar The ore is subjected to weak magnetic separation with a magnetic field strength of 1500Oe through a weak magnetic separator to separate the strong magnetic material and the feldspar coarse concentrate that is put into the strong magnetic separation; then the feldspar coarse concentrate obtained after the weak magnetic separation is passed through the strong magnetic separation The machine carries out strong magnetic separation wit...

Embodiment 19

[0064] Experiments were carried out on Albanian feldspar mines, the chemical composition of the raw ore: K 2 O: 4.37%, Na 2 O:, 3.38%, Fe 2 o 3 : 0.48%, Mica: 3.4%.

[0065] Firstly, the raw ore is ground through a ball mill; the ground feldspar is classified and deslimed with an improved hydraulic classifier to obtain feldspar with a grinding fineness of -200 mesh accounting for 70%; the classified feldspar The ore is subjected to weak magnetic separation with a magnetic field strength of 3000Oe through a weak magnetic separator to separate the strong magnetic material and the feldspar coarse concentrate into the strong magnetic separation; then the feldspar coarse concentrate obtained after the weak magnetic separation is passed through the strong magnetic separation The machine carries out strong magnetic separation with a magnetic field strength of 12000Oe, and separates weak magnetic substances and feldspar coarse concentrate into flotation; the feldspar coarse concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com