Patents

Literature

230results about How to "Precise content control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

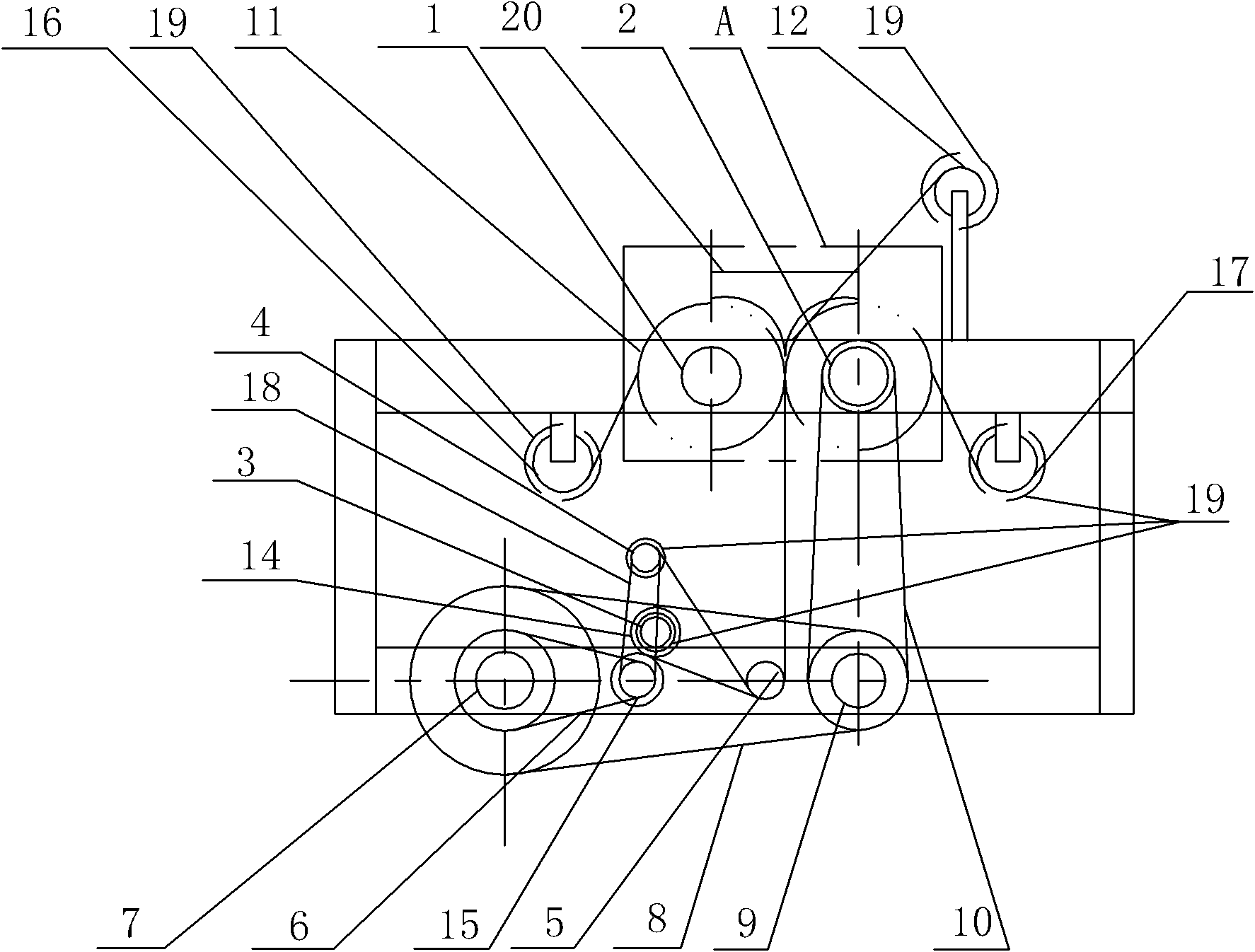

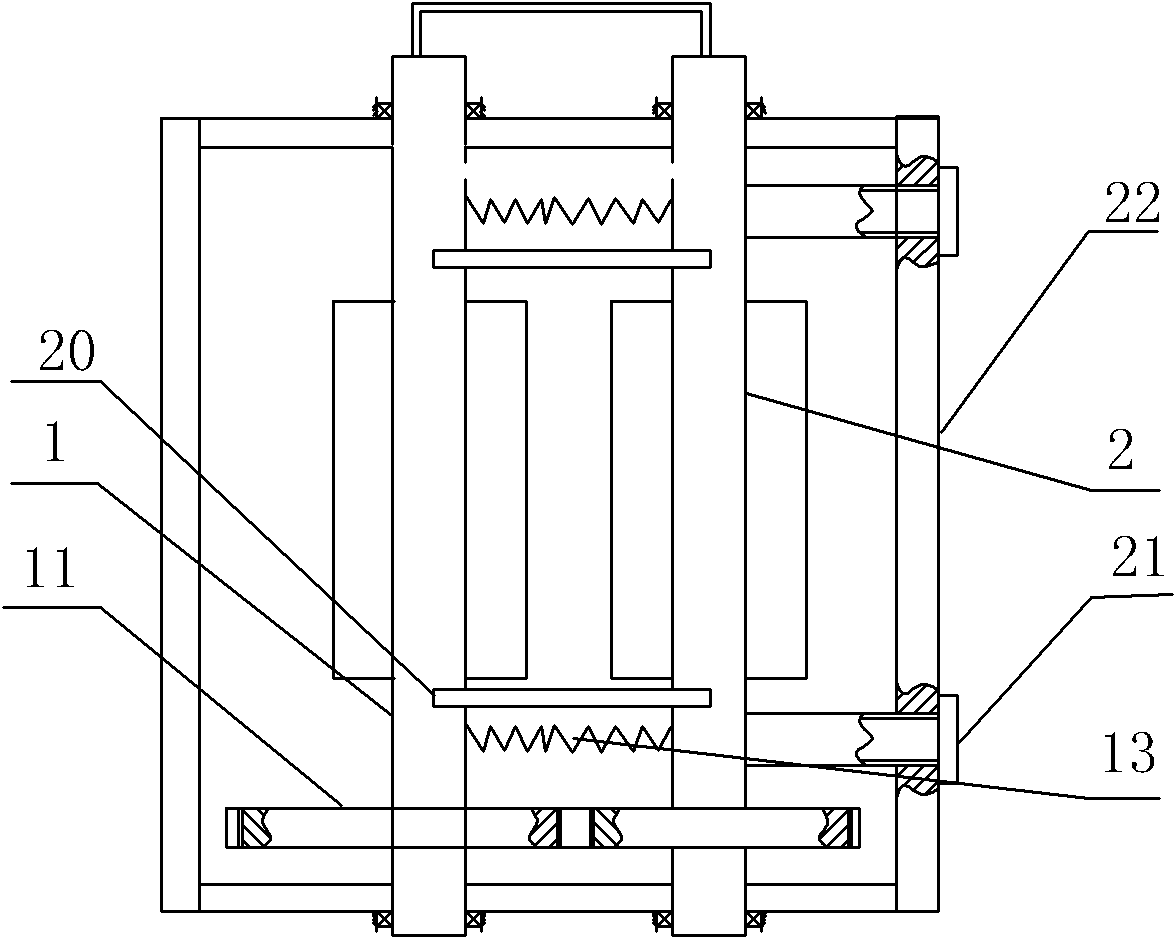

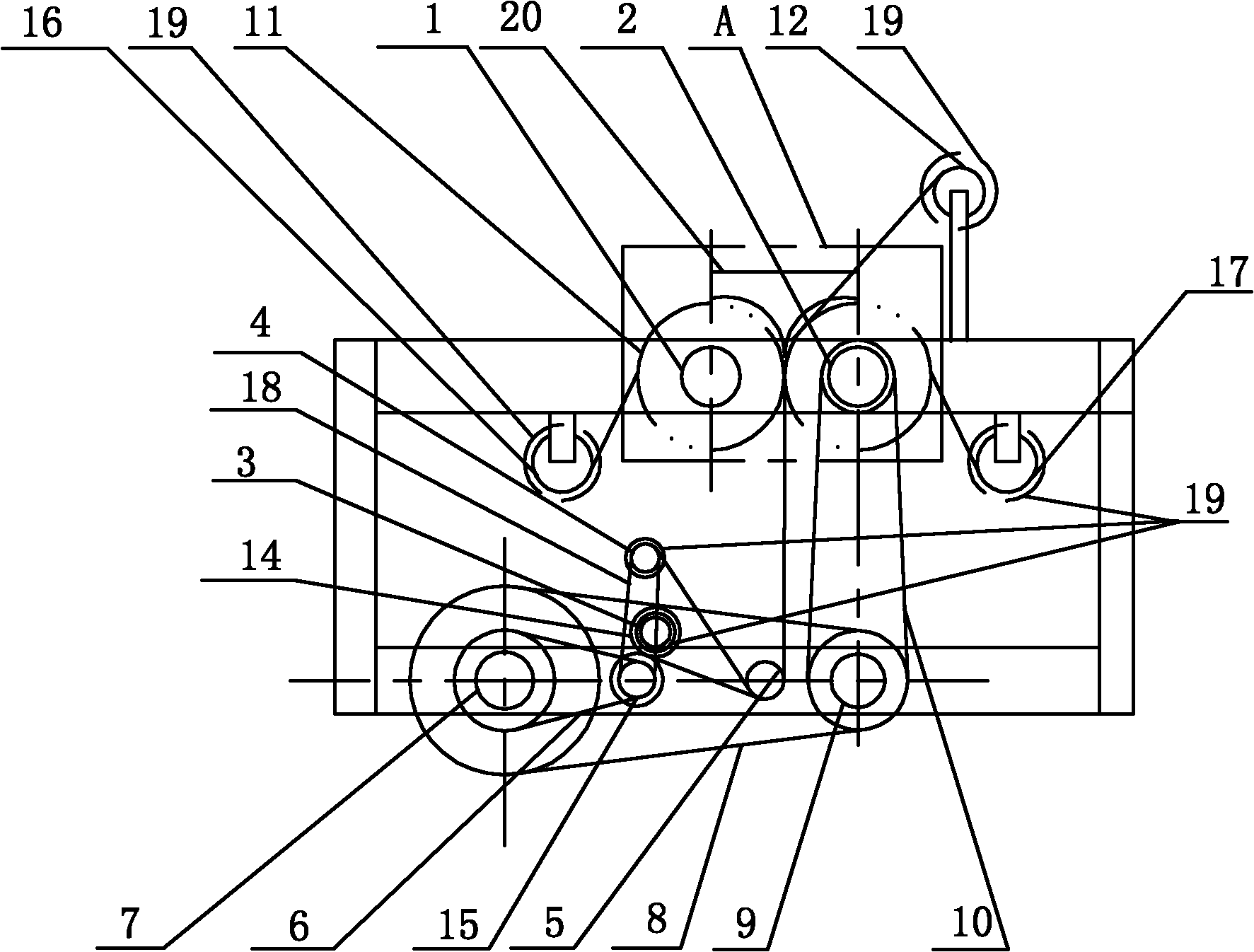

Epoxy matrix resin and prepreg and preparation method thereof and device for preparation thereof

The invention discloses an epoxy matrix resin, a prepreg, a preparation method of the prepreg and a device for preparation of the prepreg, in order to solve the problem of poor performance of an epoxy matrix resin curing substance caused by uneven toughening phase state even no phase separation in the traditional epoxy matrix resin curing product, the problem of complex technique of the traditional preparation method of the prepreg and relatively imprecise control on the resin content in the prepreg, and the problem of high manufacturing cost of the traditional device for preparing the prepreg. The epoxy matrix resin is prepared from a phenolic epoxy resin, a bisphenol A epoxy resin, a core shell polymer, a curing agent and a curing accelerator; the prepreg is prepared from the epoxy matrix resin and fiber woven cloth; and the prepreg is prepared through the device for producing the prepreg by a heat fusion method. After and before the resin is cured, the toughening phase state is not changed and is uniformly dispersed; and the toughening phase state effect is good and stable. The mechanical property of the composite material obtained by curing with the prepreg is high.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

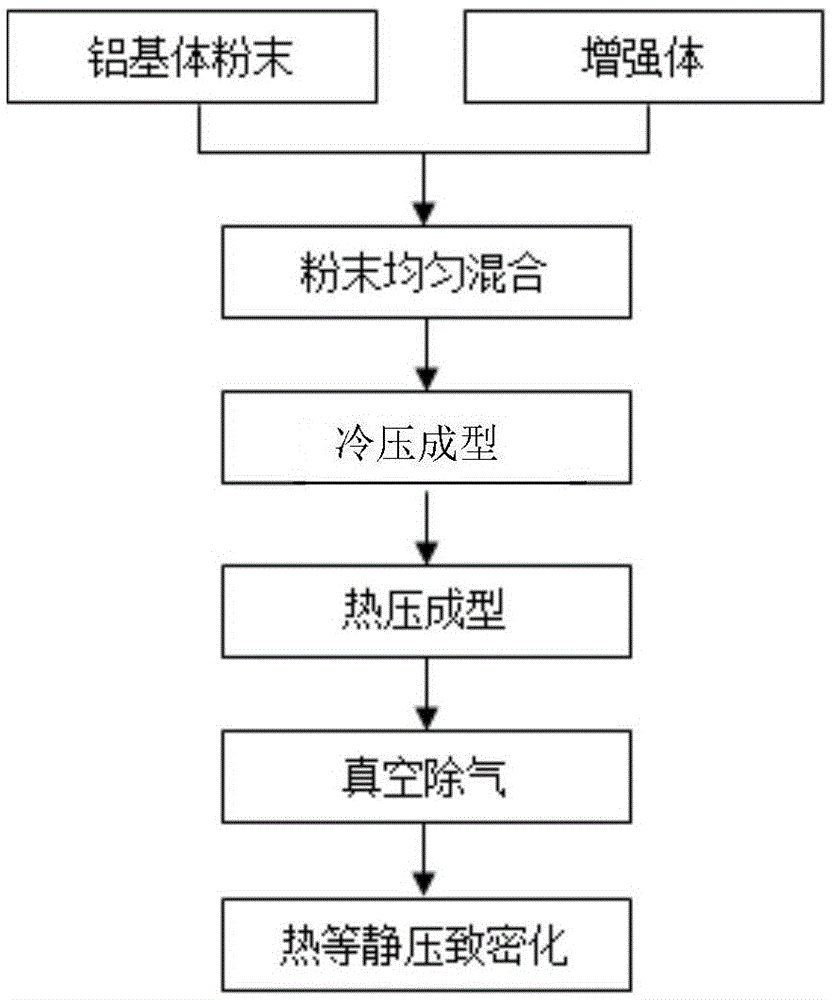

Manufacturing method of laminated aluminum matrix composite for electronic packaging

ActiveCN105483454AWill not oxidizePrecise content controlElectronic packagingCeramic matrix composite

The invention relates to a manufacturing method of a laminated aluminum matrix composite for electronic packaging. The method includes the steps that reinforcement powder and aluminum matrix powder are evenly mixed according to different proportions, obtained composite powder with different reinforcement contents is sequentially packaged to cylindrical steel dies to be subjected to cold press molding, and cold press billets are subjected to hot press molding in the inert gas atmosphere, so that the density of the billets is increased, the hot press billets are degassed in a high-temperature vacuum manner and then subjected to hot isostatic pressing densification, and the completely-dense billets are manufactured. The manufacturing method is simple and low in cost, the quality is stable, and the composite has the characteristics of being high in strength and tenacity and good in welding performance and can be applied to the electronic packaging field.

Owner:有研金属复材技术有限公司

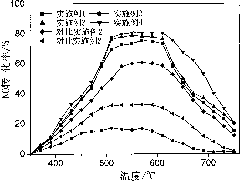

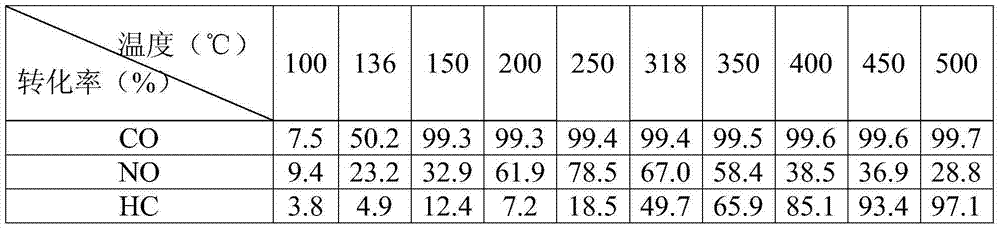

Method for preparing monolithic catalyst for purification of diesel exhaust

InactiveCN101797518AGood dispersionDrain controlMolecular sieve catalystsDispersed particle separationPhosphoric acidCordierite

The invention discloses a method for preparing a monolithic catalyst for the purification of diesel exhaust, which is to synthesize metal active ingredients and SAPO-34 molecular sieves directly by an assisted hydrothermal synthesis method and load the metal active ingredients and the SAPO-34 molecular sieves on honeycomb carriers. The method comprises the following steps of: treating cordierite honeycomb ceramic carriers with a dilute nitric acid, eluting the mixture with distilled water and drying the mixture; adding a metal oxide into a phosphoric acid, stirring the solution to dissolve the metal oxide, adding an aluminum source, a silicon source and organic template into the solution and stirring the solution to obtain the mother liquor of molecular sieves; putting the cordierite honeycomb ceramic carriers and the mother liquor of molecular sieves in a reaction kettle for hydrothermal synthesis; rinsing and drying the mixture after crystallization; and preparing the catalyst by roasting crystals in an oxygen-containing atmosphere. Compared with the conventional methods for preparing catalysts, the method of the invention has a simple preparation process and can accurately control the content of the metal active ingredients. The prepared monolithic catalyst has high NOx removal activity and high recycling stability.

Owner:TAIYUAN UNIV OF TECH

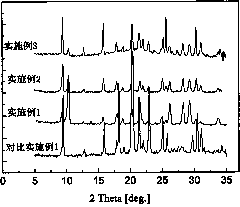

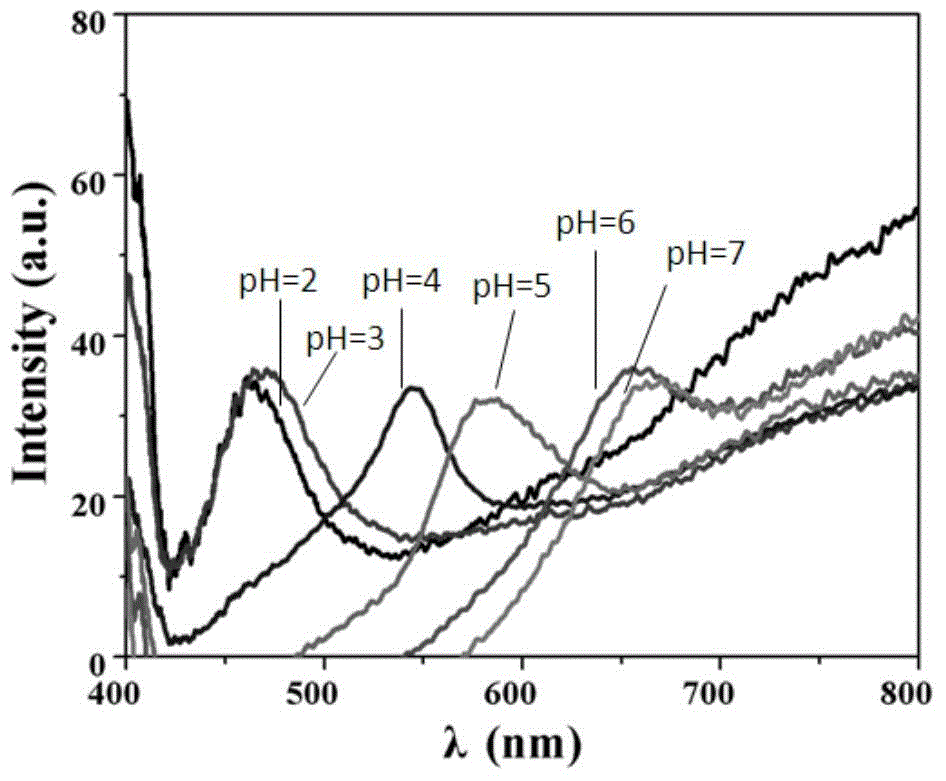

Photonic crystal hydrogel membrane with pH value and ionic strength response, preparation method and application thereof

ActiveCN104961906ABoth pHBoth strengthMaterial analysis by observing effect on chemical indicatorFerroso-ferric oxidesUltraviolet lightsColor changes

The invention discloses a photonic crystal hydrogel membrane with pH value and ionic strength response, a preparation method and an application thereof. The photonic crystal hydrogel membrane comprises Fe3O4 nano particles and polyacrylamide-methacrylate acetic acid hydrogel, wherein the Fe3O4 nano particles are uniformly dispersed in the hydrogel and are arranged in a one-dimensional chain shape, and the concentration of the nano particles in the membrane is 1 to 50 mg / mL. The preparation method of the photonic crystal hydrogel membrane comprises the steps of uniformly mixing the Fe3O4 nano particles and hydrogel monomers, so as to generate curing reaction through ultraviolet light, and soaking in a soluble carbonate aqueous solution at last, so as to obtain the required membrane. The preparation method has the advantages of simplicity in operation, strong repeatability and convenience in large-scale preparation, the carboxyl quantity of the obtained membrane is controllable, the membrane is monochromatic, obvious color change occurs under the stimulation of pH value or ionic strength, and naked-eye detection is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

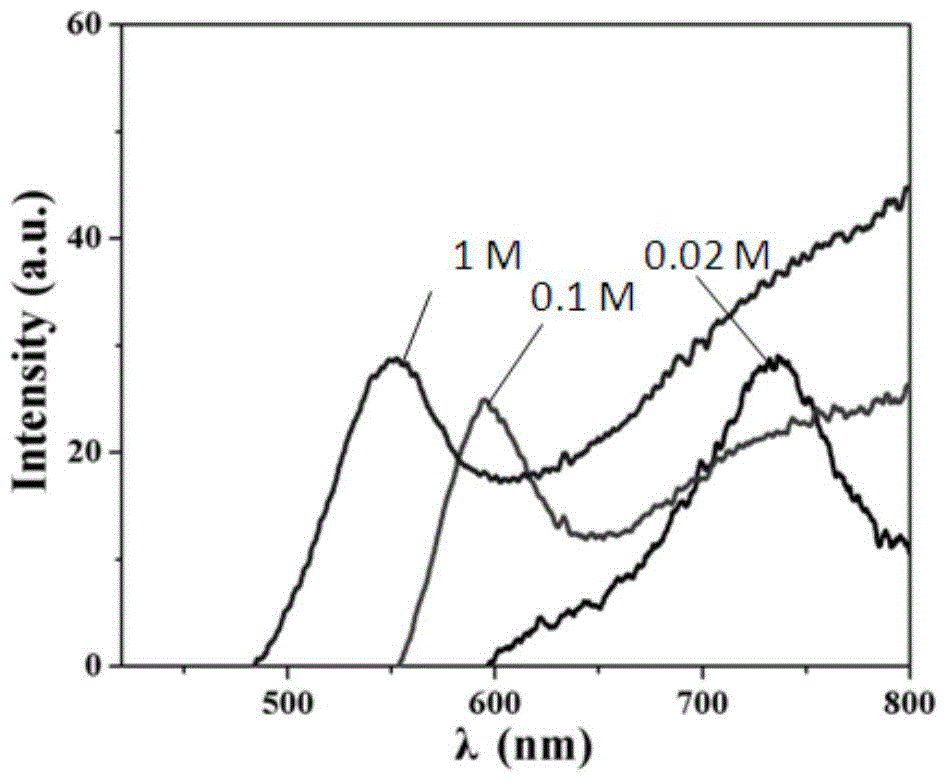

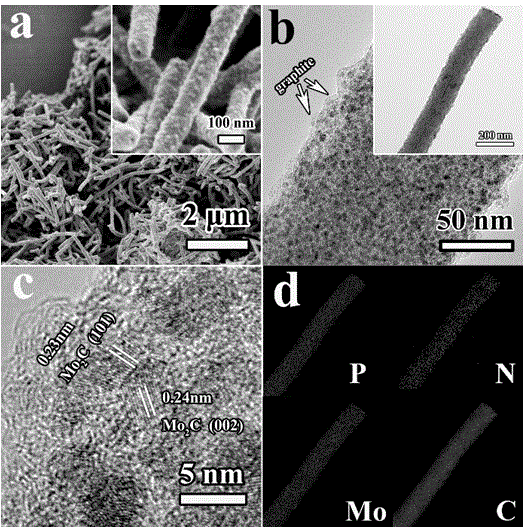

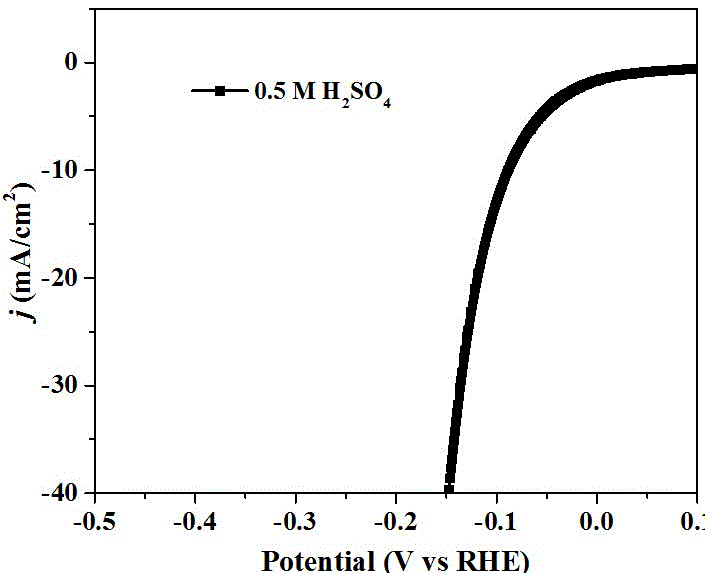

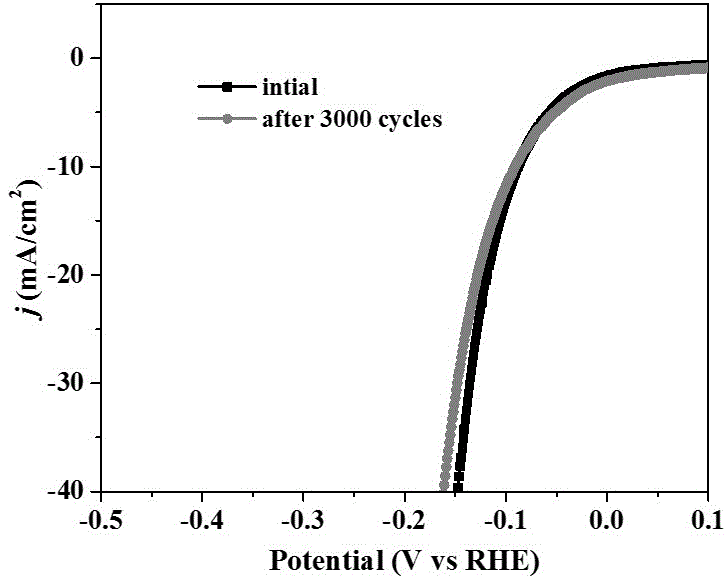

Nitrogen-doped graphite-loaded phosphorus-doped molybdenum carbide nanowire electrocatalytic hydrogen production catalyst and preparation method thereof

The invention belongs to the technical field of electrocatalytic hydrogen production, and in particular relates to a nitrogen-doped graphite-loaded phosphorus-doped molybdenum carbide nanowire electrocatalytic hydrogen production catalyst and a preparation method thereof. The catalyst has a rough-surface nanowire structure with a diameter of 100-200nm on the whole, the particle size distribution of an active centre beta-Mo2C is 2-10nm, and beta-Mo2C particles are closely embedded on the surface of nitrogen-doped graphite, phosphorus is evenly doped into a beta-Mo2C structure by means of a phosphorus-molybdenum bond. The nitrogen-doped graphite is generated in place in a high-temperature carbonation process of polyaniline in MoOx-phytic acid-polyaniline hybrid precursor. The catalyst has very high electrocatalytic hydrogen production activity and stability under the acidic condition; the preparation method of the catalyst is simple in operation, high in adjustability, low in raw material price and low in production process risk, thus being suitable for large scale production and industrial hydrogen production by using electrolysis of water.

Owner:FUDAN UNIV

Preparation method of solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding

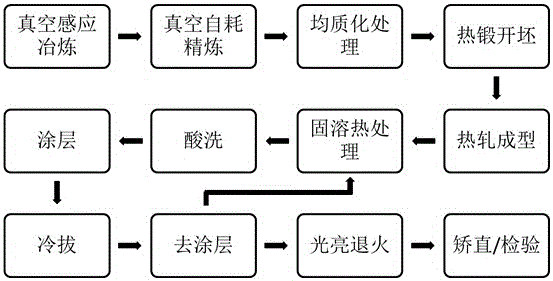

ActiveCN106181131APrecise content controlReduce lossWelding/cutting media/materialsSoldering mediaSolution treatmentVacuum arc remelting

The invention discloses a preparation method of a solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding, and belongs to the technical field of metal welding. The method includes the technological processes of vacuum smelting, vacuum arc remelting, homogenization, hot forging cogging, hot rolling, solution treatment, acid pickling, coating, cold drawing, coating removal and bright annealing. The invention further discloses the solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding. The solid cored welding wire is prepared through the method. Compared with the prior art, by the adoption of the method, high-quality solid cored welding wires of various diameters for molten-salt corrosion resistance nickel-base superalloy welding can be produced with the extremely-high rolling yield in a batch mode, and the prepared solid cored welding wire can meet the requirement for welding molten-salt reactor structural materials.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Preparation method of rare earth-iron intermediate alloy for low-oxygen rare earth steel

The invention discloses a preparation method of a rare earth-iron intermediate alloy for low-oxygen rare earth steel. The preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel comprises the steps that a vacuum smelting furnace is adopted, and rare earth metal and pure iron are placed in a crucible of the vacuum furnace at the mass ratio of 1-5:5-9; vacuumizing is conducted on the vacuum furnace until the pressure of the vacuum furnace is below 20 Pa, inert gas is fed for shielding, and the process of high-temperature melting-refining and electromagnetic stirring alloying is executed, wherein the high-temperature melting temperature is 1000-1500 DEG C, the temperature of the refining process is 1400-1500 DEG C, and the time is 5-15 minutes; molten metal is poured into an ingot mold, and then the rare earth-iron intermediate alloy is obtained. By the adoption of the preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel, the rare earth yield can be significantly improved, the content of the rare earth in the steel can be accurately controlled, the adding cost of the rare earth is reduced, and the plasticity, the low-temperature impact toughness, the thickness-direction property and the corrosion resistance of the steel are improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Process for co-producing sulphuric acid and cement by using gypsum

ActiveCN101830442AAffect qualityReduce drying and dehydration stepsSulfur compoundsCement productionGranularitySulfur

The invention discloses a process for co-producing sulphuric acid and cement by using gypsum. The process is characterized by comprising the step of: grinding raw materials, wherein the raw materials comprise the gypsum, a carbonaceous reducer, a silica raw material and an aluminum raw material; and the step of grinding the raw materials specifically comprises the step of grinding the carbonaceous reducer to make the carbonaceous reducer have a granularity of 0.2mm and screen residues of below 20 weight percent. The process has the advantages of obviously reducing loss caused by easily-burnt coke in the raw materials before the subsequent reduction reaction of the coke for producing the sulphuric acid and the cement, effectively reducing production cost and effectively avoiding reaction between CO generated by burning the coke and SO2 generated by decomposing the coke before the reduction reaction of the coke generating the condensation of sublimed sulfur in a purification system of a sulphuric acid device to cause system blockage so as to effectively eliminate potential safety hazard in the production at the same time.

Owner:CHONGQING SANSHENG IND CO LTD

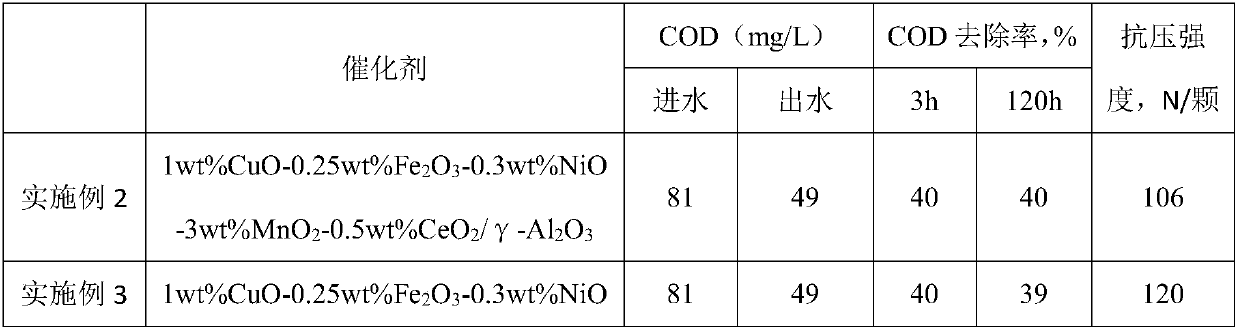

Catalyst for ozone catalytic oxidation treatment of chemical wastewater and preparation method of catalyst

InactiveCN110116007ARapid responseEasy to prepareWater treatment compoundsWater contaminantsCeriumCatalytic oxidation

The invention discloses a catalyst for ozone catalytic oxidation treatment of chemical wastewater and a preparation method of the catalyst. The catalyst comprises a carrier and active components, wherein the active components are metallic copper, iron, nickel, manganese and cerium oxides. The catalyst has good catalytic activity for the ozone catalytic oxidation treatment of high-salt and high-chlorine chemical wastewater with high TDS content and high chloridion content, and the removal rate of wastewater COD reaches 40% or above. The catalyst is applied to deep treatment of biochemical effluents containing high salt and high chlorine in sewage treatment plants.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

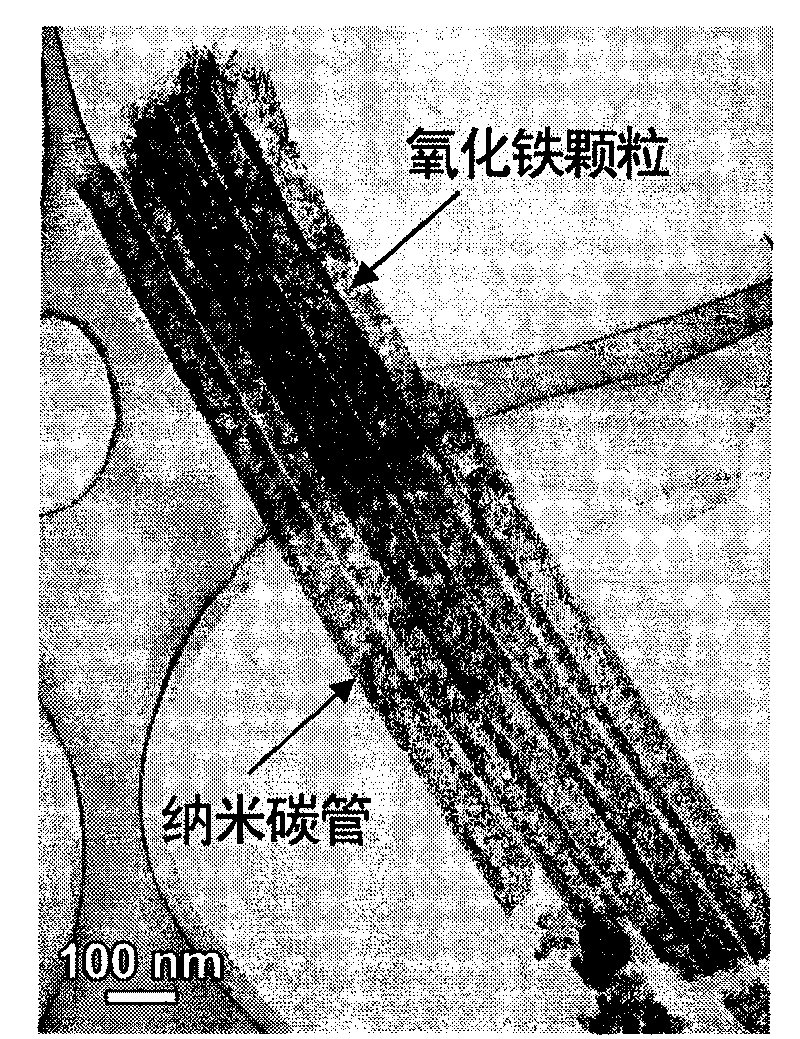

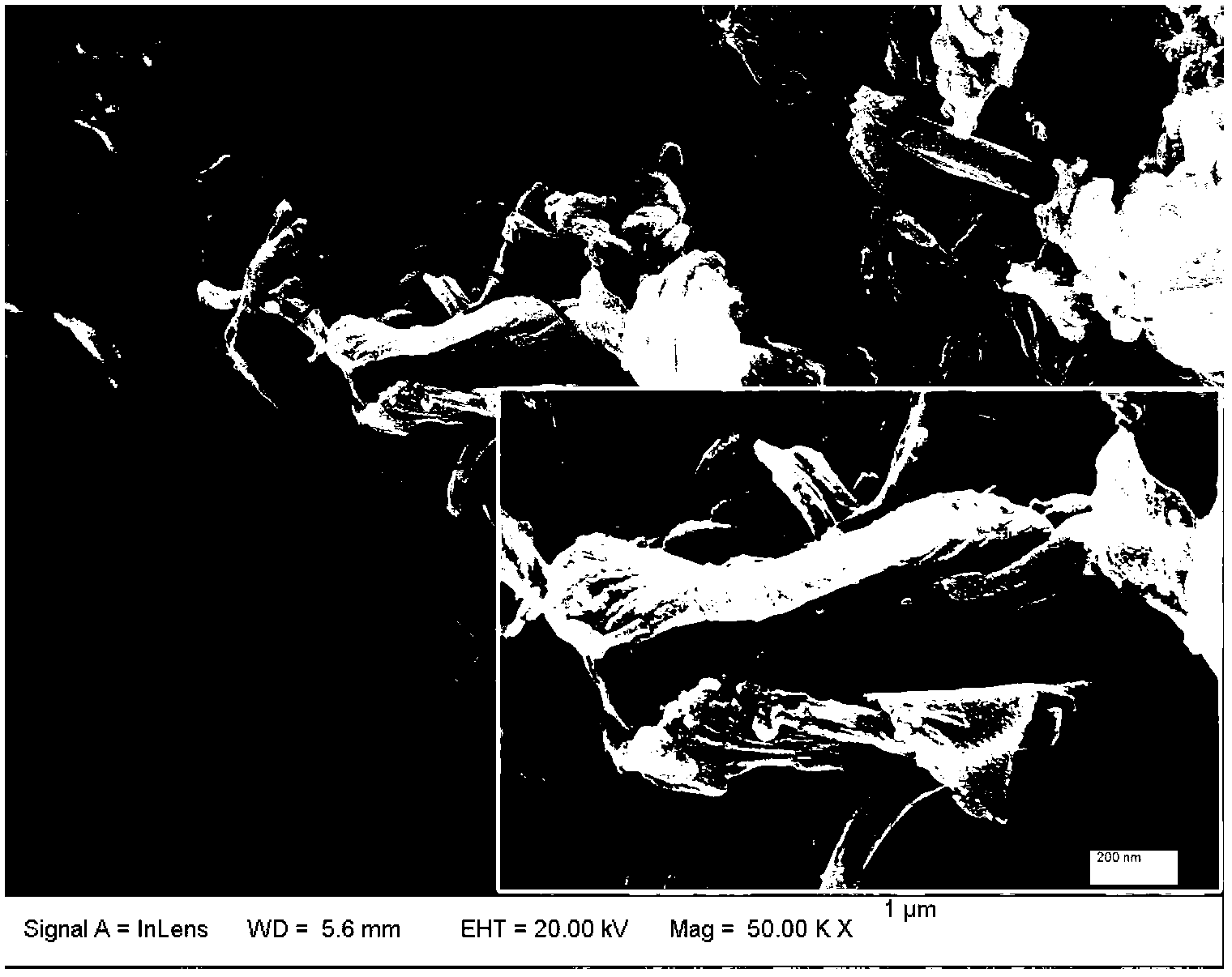

Method for selectively filling ferric oxide particles in hollow cavity of carbon nanotube

InactiveCN101745434APrecise content controlPrecise size controlCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon layerCarbon nanotube

The invention relates to the selectively filling of ferric oxide particles in the hollow cavity of a carbon nanotube, in particular to a method for selectively filling ferric oxide particles in the hollow cavity of a carbon nanotube, with accurate and controllable ferric oxide particle filling amount and size, and the application of a filling compound. An anodic alumina membrane with a regular pore structure is taken as a template, and a carbon layer is evenly deposited on the template by a chemical vaporous deposition method, and then an anodic alumina membrane / carbon compound is obtained; the compound is put in a ferric nitrate solution and then is ultrasonically shaken at room temperature; the anodic alumina membrane / carbon compound is taken out and then is treated under the protective atmosphere after being dried; ferric nitrate is decomposed into ferric oxide; then the anodic alumina template is removed; and finally, a carbon nanotube that the ferric oxide particles are selectively filled in the hollow cavity of the carbon nanotube is obtained. The ferric oxide particles are selectively filled in the hollow cavity of the carbon nanotube, the content by weight of the ferric oxide particles is between 5 percent and 70 percent and is accurate, even and controllable, and the sizes of the ferric oxide particles are between 1nm and 10nm and is controllable.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

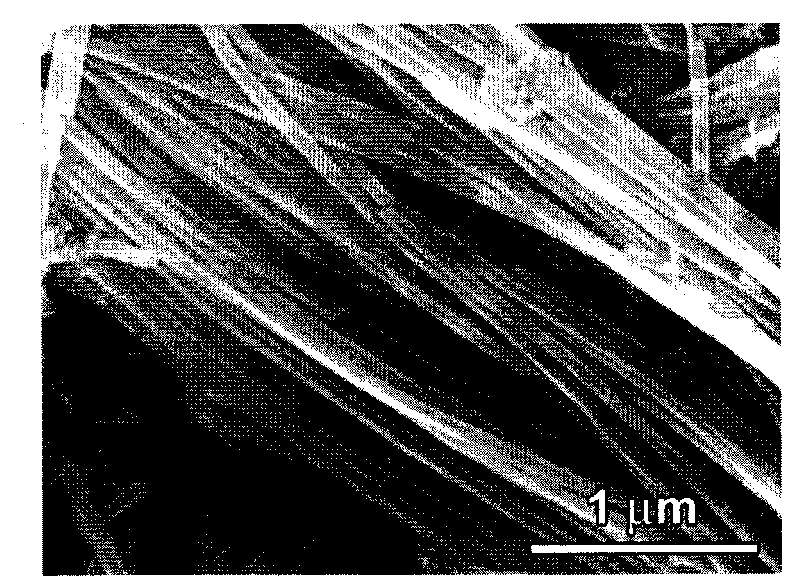

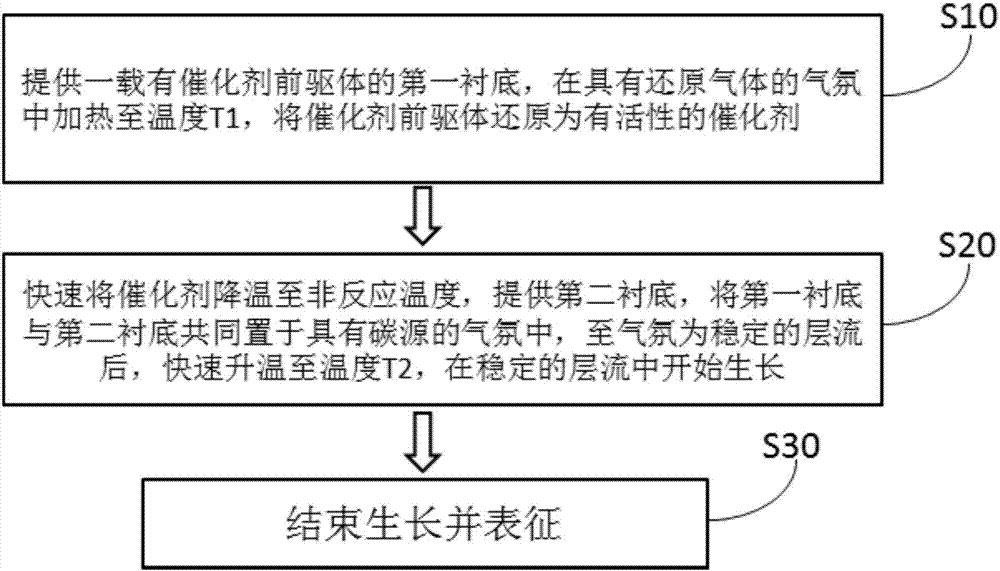

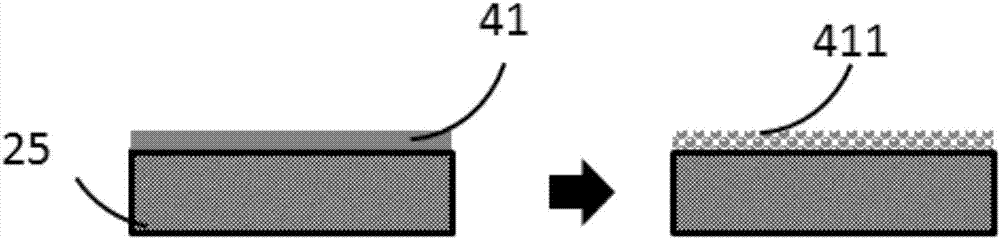

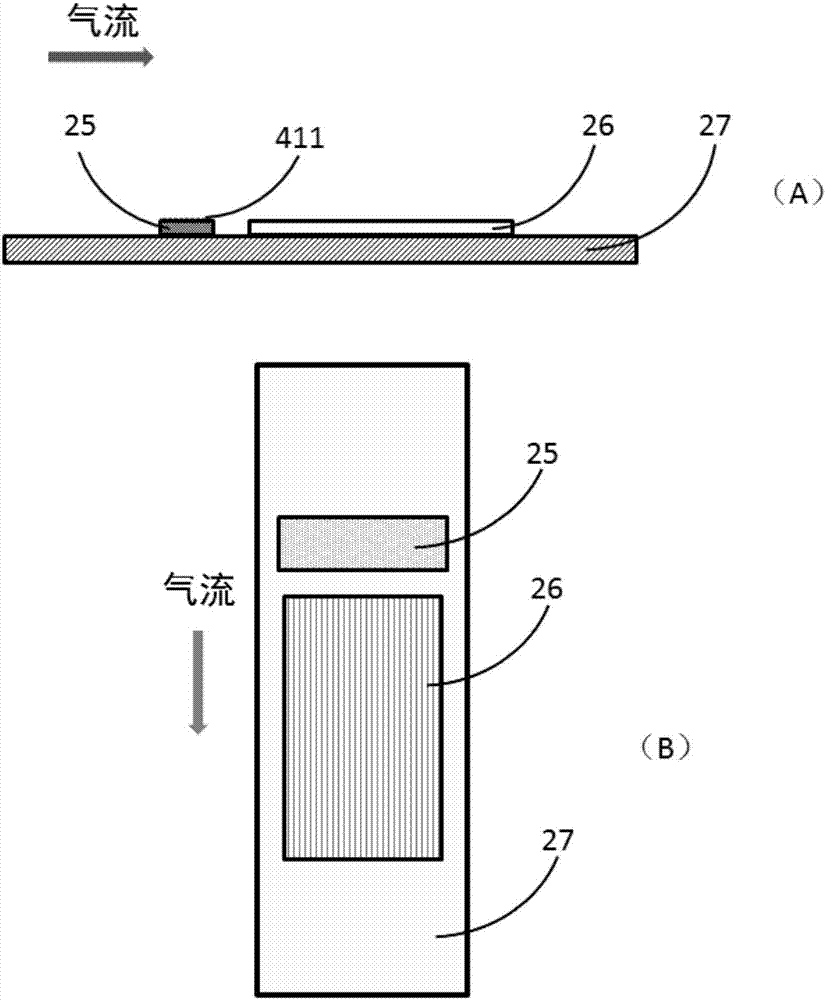

Horizontal array for overlong single-wall carbon nano-tube, preparation method and reaction device

ActiveCN106957051AGood collimationImprove parallelismSingle-walled nanotubesAligned nanotubesHigh densityReaction temperature

The invention provides a preparation method for preparing a uniform-nature horizontal array for an overlong single-wall carbon nano-tube by utilizing a stable airflow and a reaction device and relates to the field of nano-material research. The preparation method comprises the following steps: reducing a catalyst precursor in a reducing atmosphere into a catalyst with an activity and then quickly reducing the temperature to non-reaction temperature; placing both a second substrate and a first substrate loaded with the catalyst with the activity into a stable laminar flow atmosphere with a carbon source; quickly increasing the temperature to the growth temperature and reacting, thus obtaining the horizontal array for the overlong single-wall carbon nano-tube. The reaction device at least comprises a reaction chamber and a heating device. The reaction chamber can quickly increase temperature and reduce temperature so as to meet the temperature requirement required by the reaction. The method and the device provided by the invention can guarantee the aligned parallel array of the acquired overlong single-wall carbon nano-tube in stable laminar flow and can effectively controllable prepare the horizontal array for the overlong single-wall carbon nano-tube with flawless surface, uniform nature, high collimation, high parallel property and high density.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

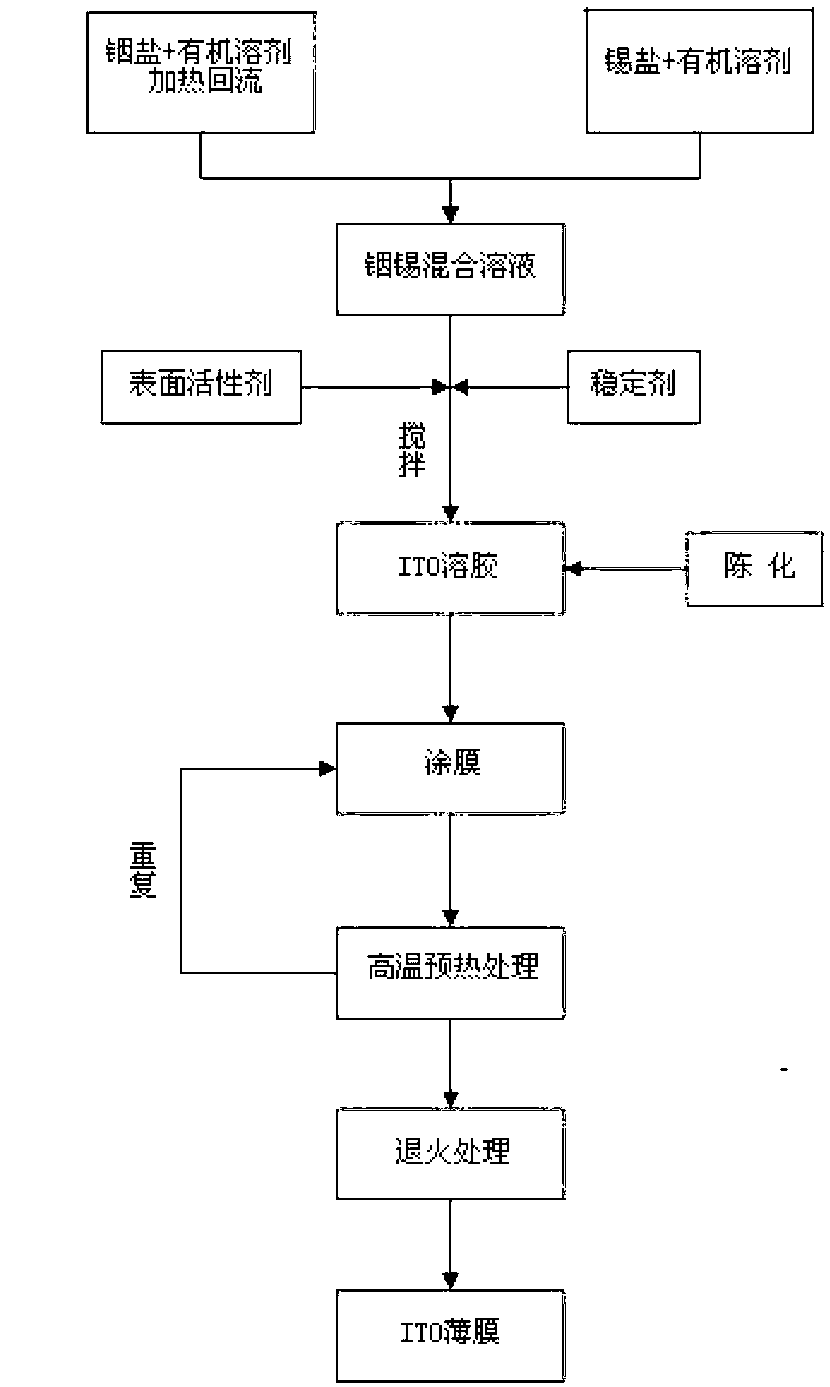

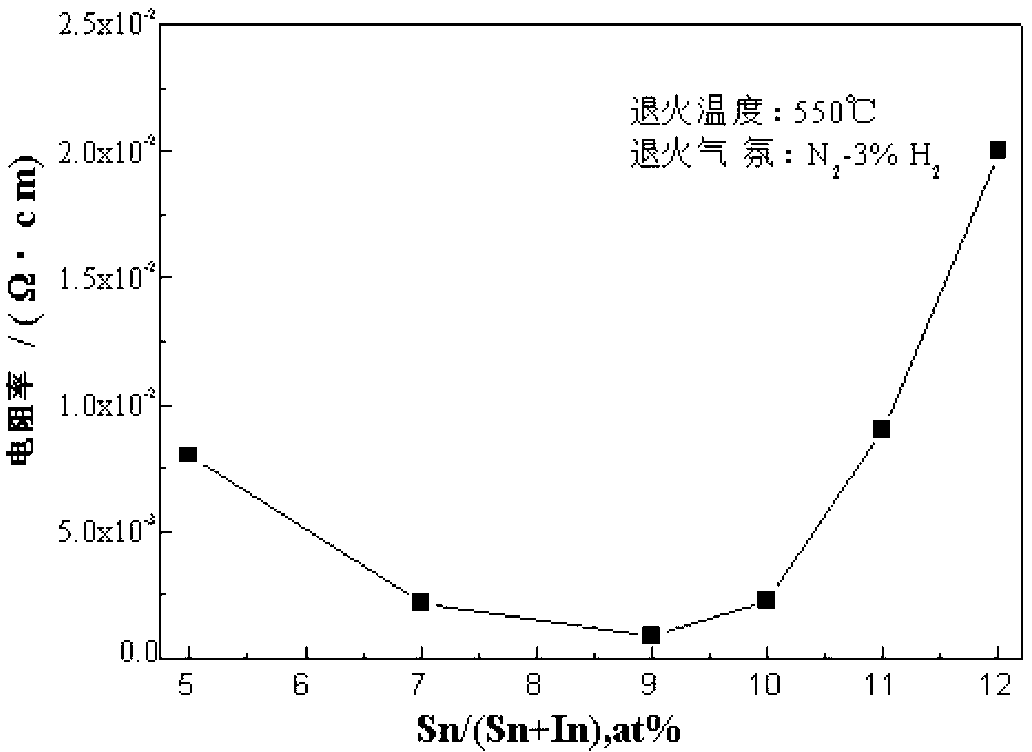

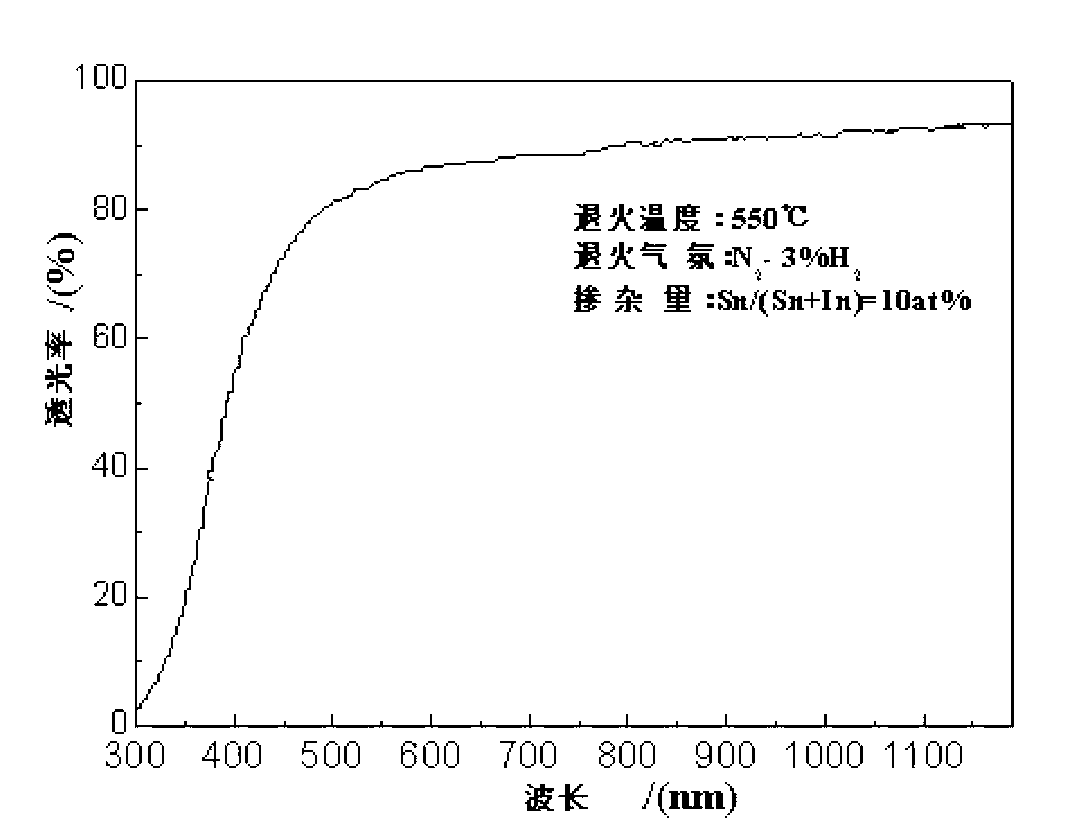

Preparation method of ITO thin film

ActiveCN103325859AHigh purityLow resistivityFinal product manufactureSemiconductor devicesWork functionTransmittance

The invention belongs to the field of photoelectric materials, and provides a preparation method of an ITO thin film. The method comprises the following steps of preparing ITO colloidal sol and preparing the ITO thin film. The ITO thin film prepared through the mentioned method is smooth in surface and compact in particle, average transmittance in a visible light region reaches up to 90%, electrical resistivity reaches grade10 to grade4, work function reaches 4.9eV, and the ITO thin film can meet application in the field of LCDs, solar thin film batteries and the like.

Owner:徐东

Preparation process for high-silicon super-hard PVD coating

InactiveCN104593737AWon't breakPrecise control of ingredientsVacuum evaporation coatingSputtering coatingVacuum pumpingPower flow

The invention provides a preparation process for a high-silicon super-hard PVD coating. The preparation process comprises the following steps: I, pre-processing a workpiece surface; II, clamping and loading a workpiece; III, performing vacuum-pumping on a furnace chamber; IV, heating the workpiece; V, etching and cleaning a target material and the workpiece; VI, preparing a high-silicon coating; VII, cooling the workpiece. The preparation process is used for obtaining the high-silicon super-hard PVD coating by controlling vacuum degree of a film-coating furnace chamber, bias voltage of a base body, a flow rate of nitrogen gas, target current and the like, wherein the flow rate of the reaction gas nitrogen gas (N2) ranges from 130 sccm to 210 sccm, the bias voltage of the base body ranges from 40 V to 120 V, and the vacuum degree of the furnace chamber ranges from 0.005 mbar to 0.060 mbar. By changing the element components of the coating, high silicon element content is obtained, so that the coating has characteristics of relatively high strength, hardness, wear resistance, high-temperature stability and corrosion resistance. A coating tool prepared by the process can be used for cutting a material with hardness of HRC65, and has relatively good using performances in comparison with a conventional coating.

Owner:SHANGHAI INST OF TECH

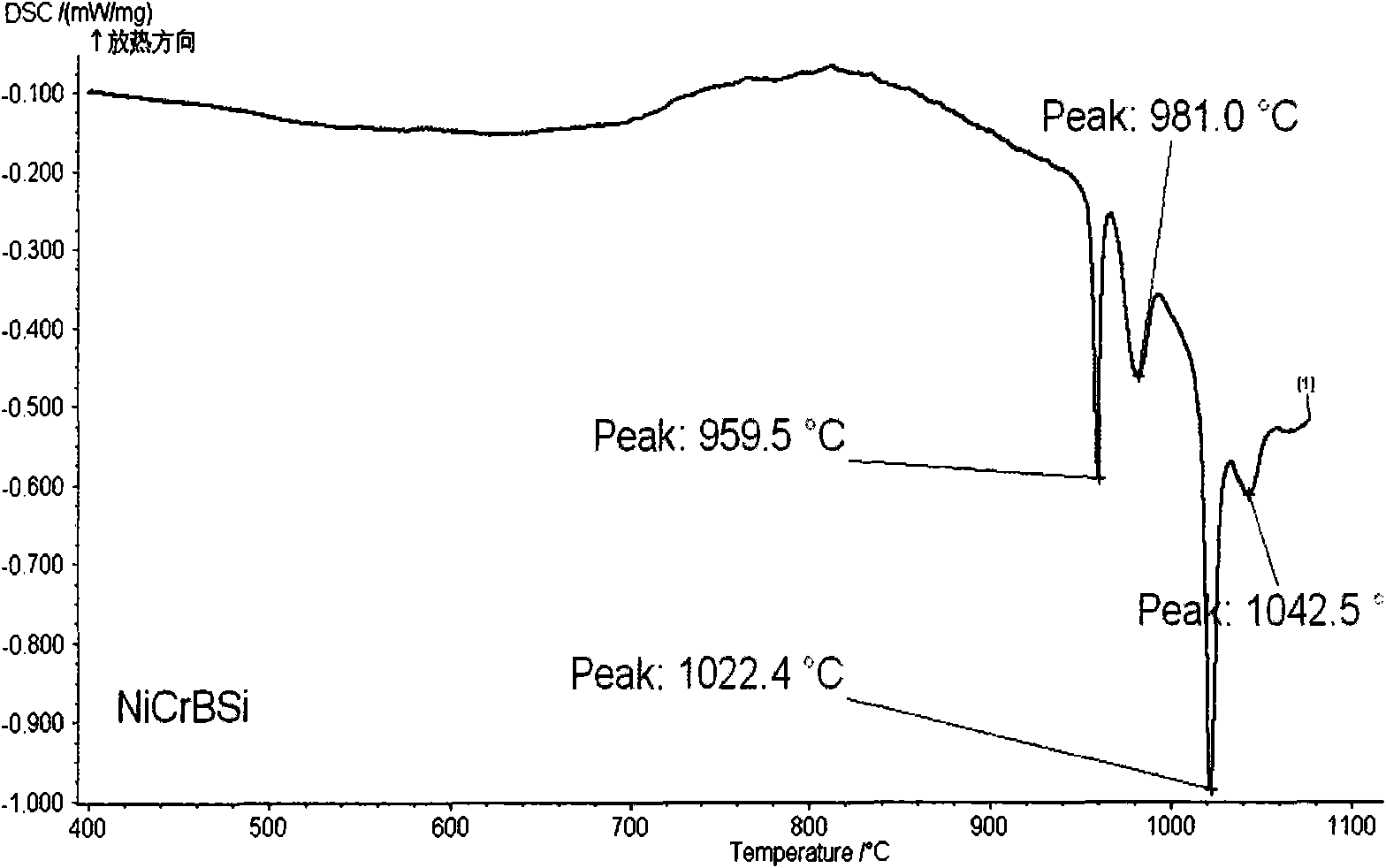

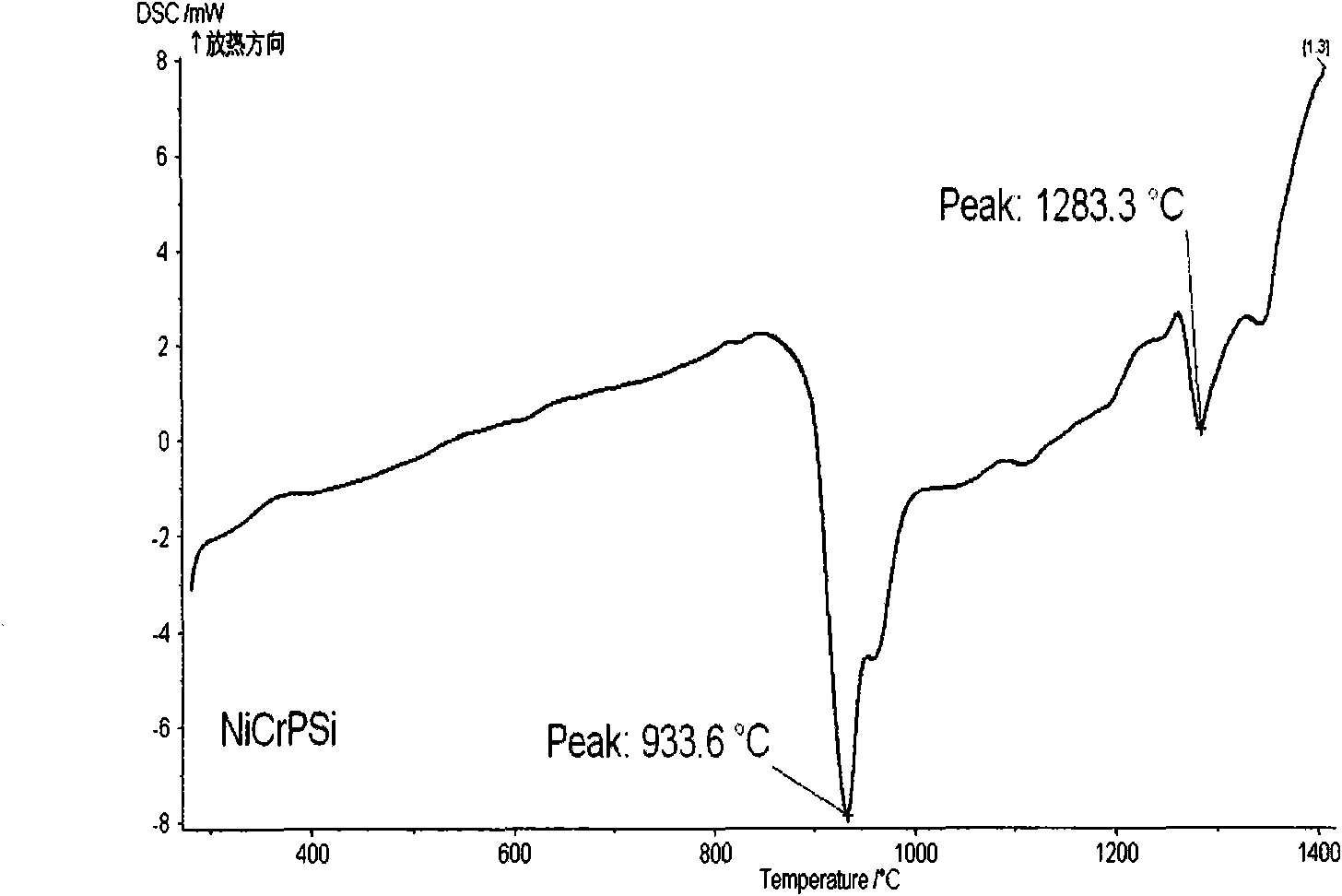

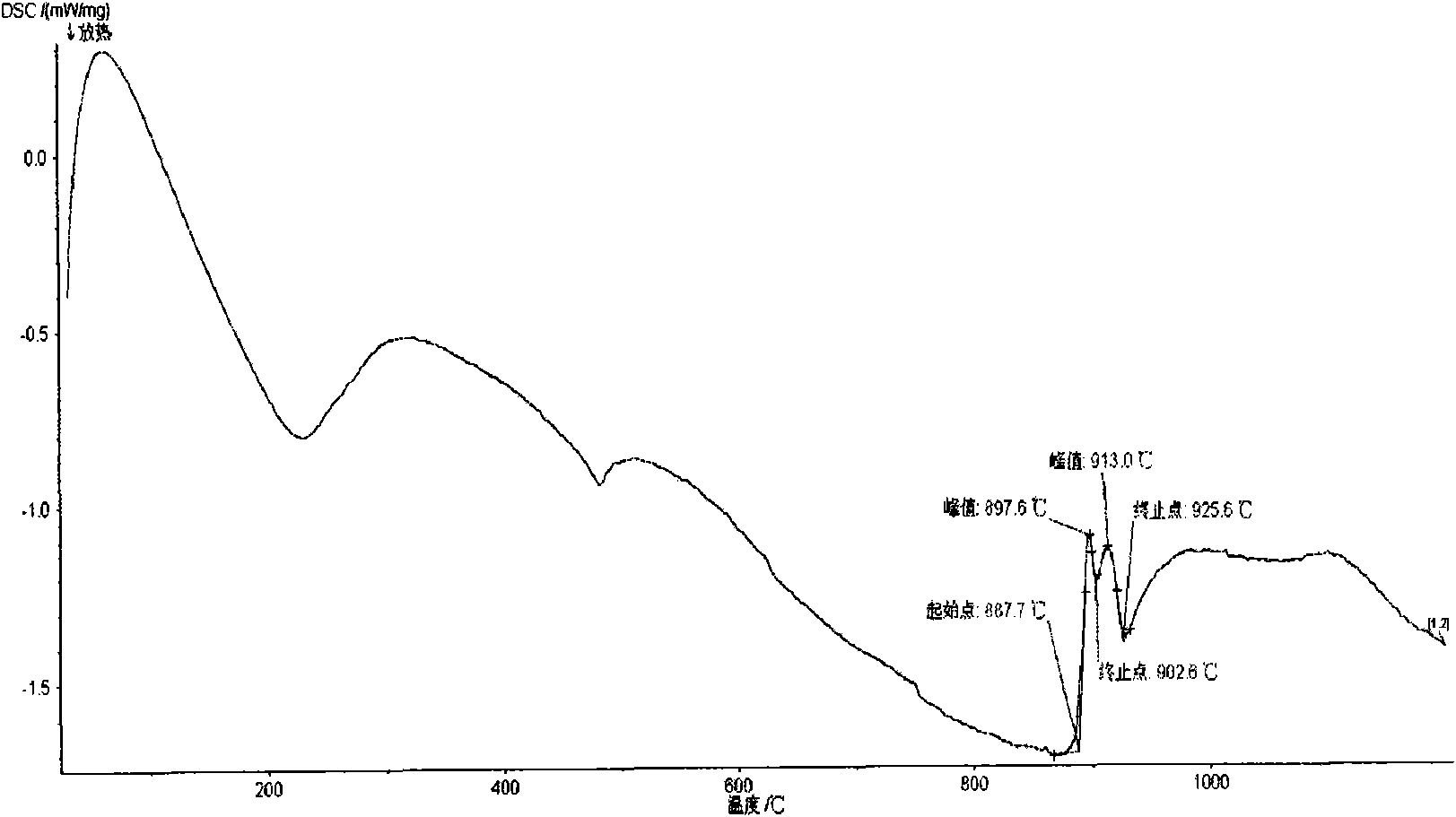

Nickel-based brazing material for brazed diamond tool and preparation method thereof

ActiveCN101890593APrecise content controlReduce contentWelding/cutting media/materialsSoldering mediaChemical compositionNickel based

The invention discloses a nickel-based brazing material for a brazed diamond tool and a preparation method thereof, and belongs to the technical field of brazing. The brazing material is high-medium temperature Ni-Cr brazing material alloy powder used for the brazed diamond tool, and comprises the following chemical compositions in percentage by weight: 2.0 to 2.5 percent of Si, 4.0 to 4.5 percent of Cr, less than or equal to 0.7 percent of C, 2.0 to 20.0 percent of Fe, 2.0 to 2.5 percent of P, 1.0 to 1.5 percent of B, and the balance of Ni. By accurately controlling the content of B, Si, P and C on the basis of a Ni-Cr series and properly reducing the content of Cr, the brazing material has the advantages of good brazing performance, excellent holding force on the diamond and narrower sold-liquid phase range, namely the liquid phase temperature does not exceed 950 DEG C, the brazing temperature does not exceed 1,000 DEG C; and the diamond tool brazed by the brazing material has satisfied cutting efficiency and service life.

Owner:ADVANCED TECH BAZHOU SPECIAL POWDER CO LTD

Method for preparing compact yttria ceramics

The invention relates to technology for preparing ceramics, in particular to a method for preparing compact yttria ceramics. The method comprises the following steps: adding 0 to 20 mol percent of a sintering auxiliary agent; and heating at a temperature of between 1,100 and 1,800 DEG C to obtain the compact yttria ceramics with the relative density over 92 percent. The technology is characterized in that a small amount of sintering auxiliary agent is added to obtain a compact yttria ceramics material at a lower heating temperature.

Owner:NORTHEASTERN UNIV

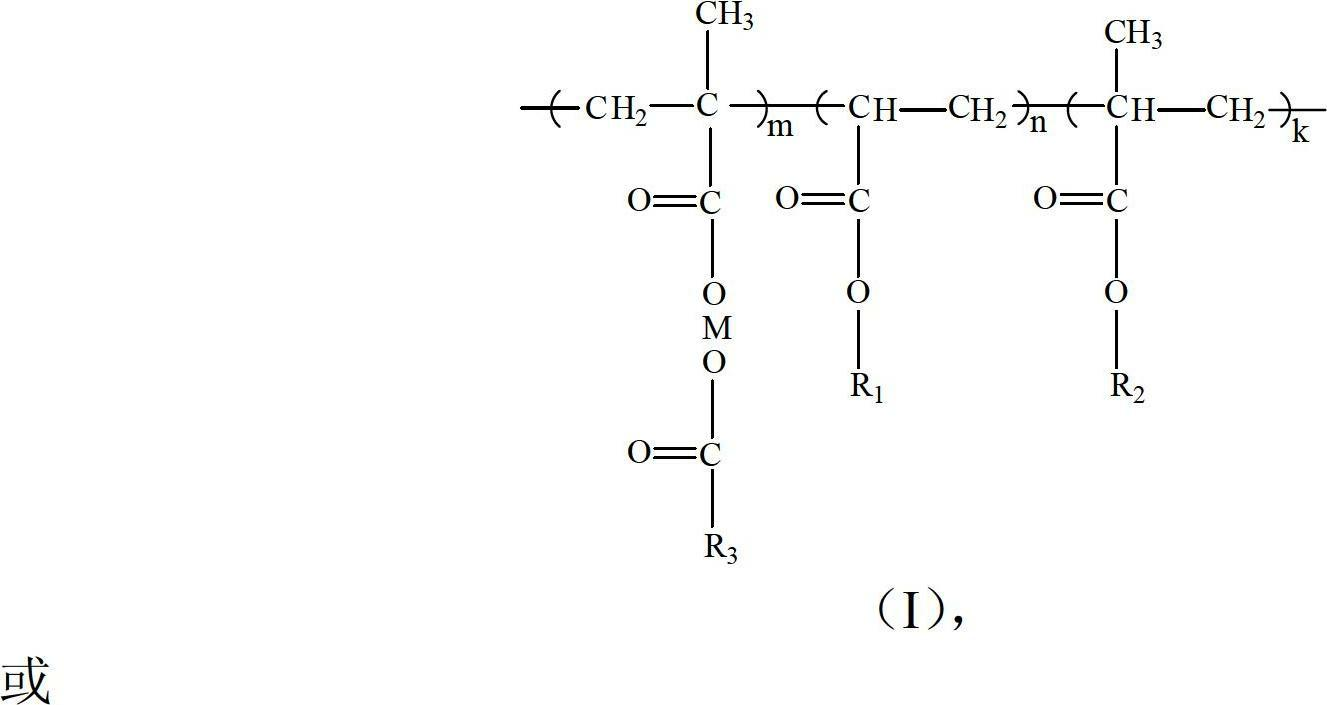

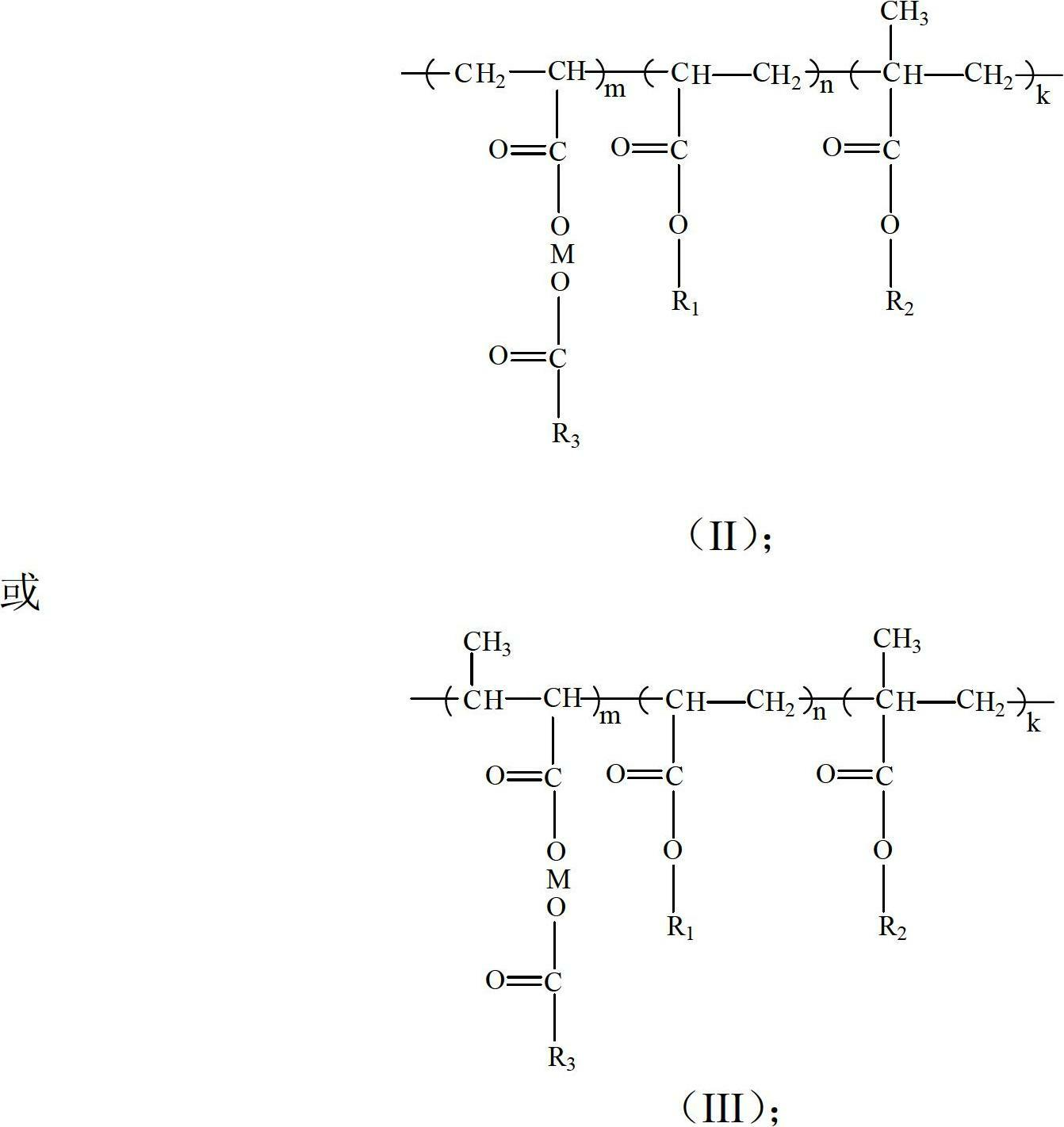

Self-polishing anti-fouling resin and preparation method thereof

InactiveCN102675524AImprove the shortcomings of low grafting ratePrecise content controlAntifouling/underwater paintsPaints with biocidesOrganic acidDivalent metal ions

The invention discloses a self-polishing anti-fouling resin and a preparation method thereof. The self-polishing anti-fouling resin disclosed by the invention has better fluidity and adhesion and a definite self-polishing rate, and can be used as the main resin of self-polishing anti-fouling paint for ship bottoms. The preparation method of the self-polishing resin comprises the following steps: reacting unsaturated organic acid with basic divalent metal-ion complex salt, and then reacting with other acrylic monomers under the effect of an initiator to synthesize the self-polishing anti-fouling resin. Thus, the invention improves the disadvantage of low grafting ratio in the tin-free self-polishing resin synthesis, shortens the reaction time and makes the product more stable.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

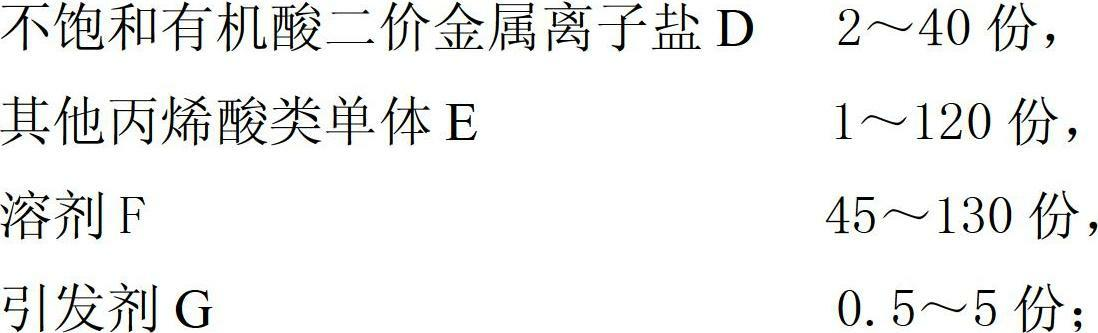

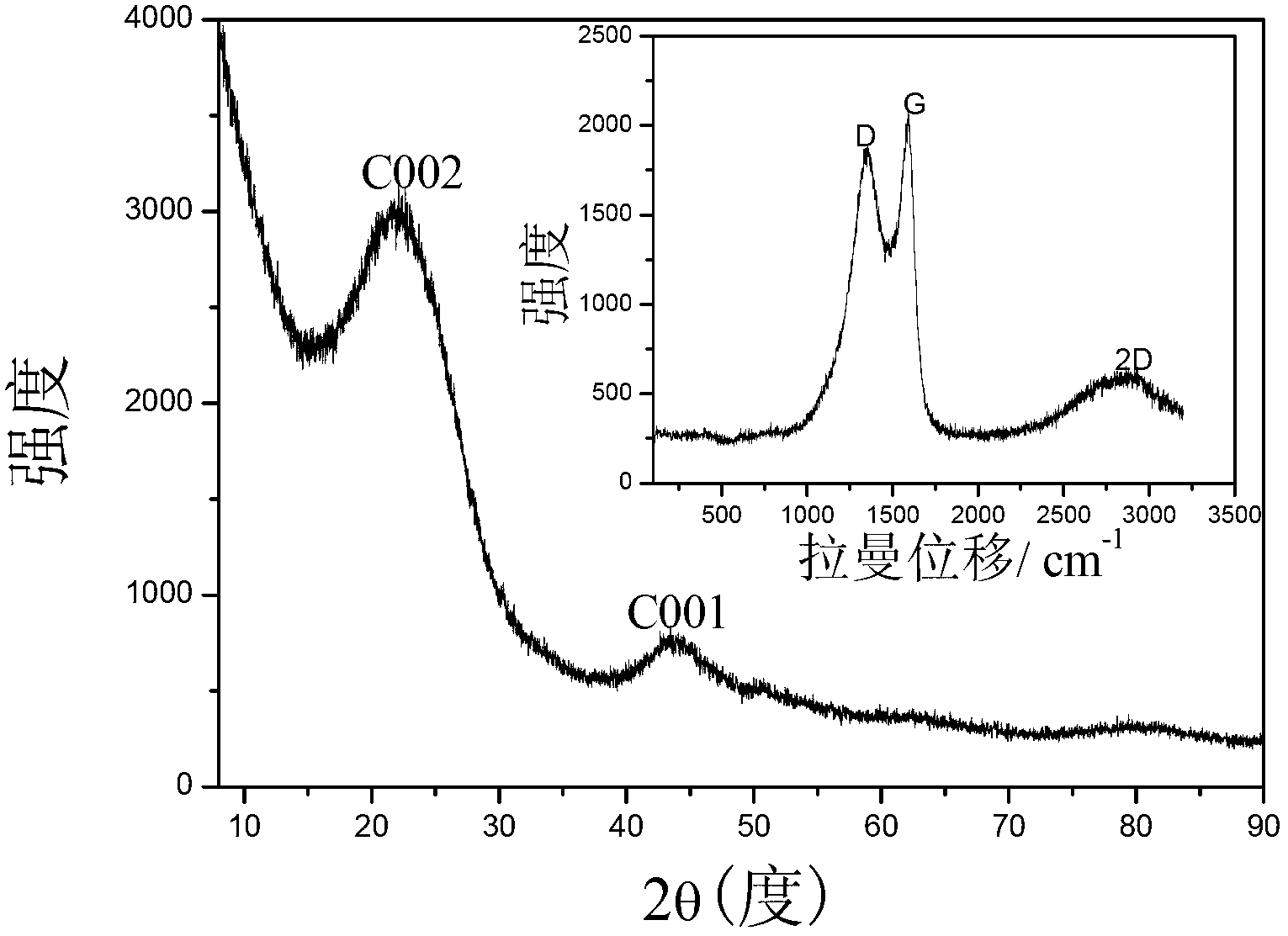

New method for preparing nitrogen doped graphene

ActiveCN103159210AImprove electrochemical performanceElectrochemical performance can be adjustedMaterial nanotechnologyGrapheneNitrogen sourceNitrogen doped graphene

A method for preparing nitrogen doped graphene belongs to the technical field of graphene. An appropriate organic compound is selected and a covalent organic polymer material is prepared through nickel-catalytic Yamamoto coupled reaction; in a programmed heating tubular furnace, the material is used as a carbon source and also a template, and carbonized at a high temperature to prepare a high-performance nitrogen-doped graphene powder material. The method is simple in preparation process, convenient for operation, easy to implement and free of extra nitrogen source; and the content and the distribution of the nitrogen element can be accurately controlled by screening the matrix.

Owner:BEIJING UNIV OF CHEM TECH

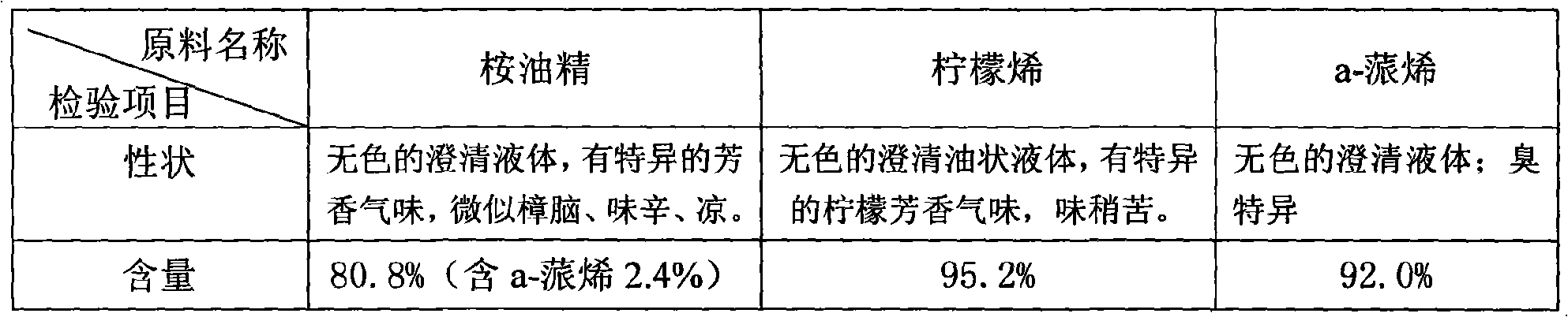

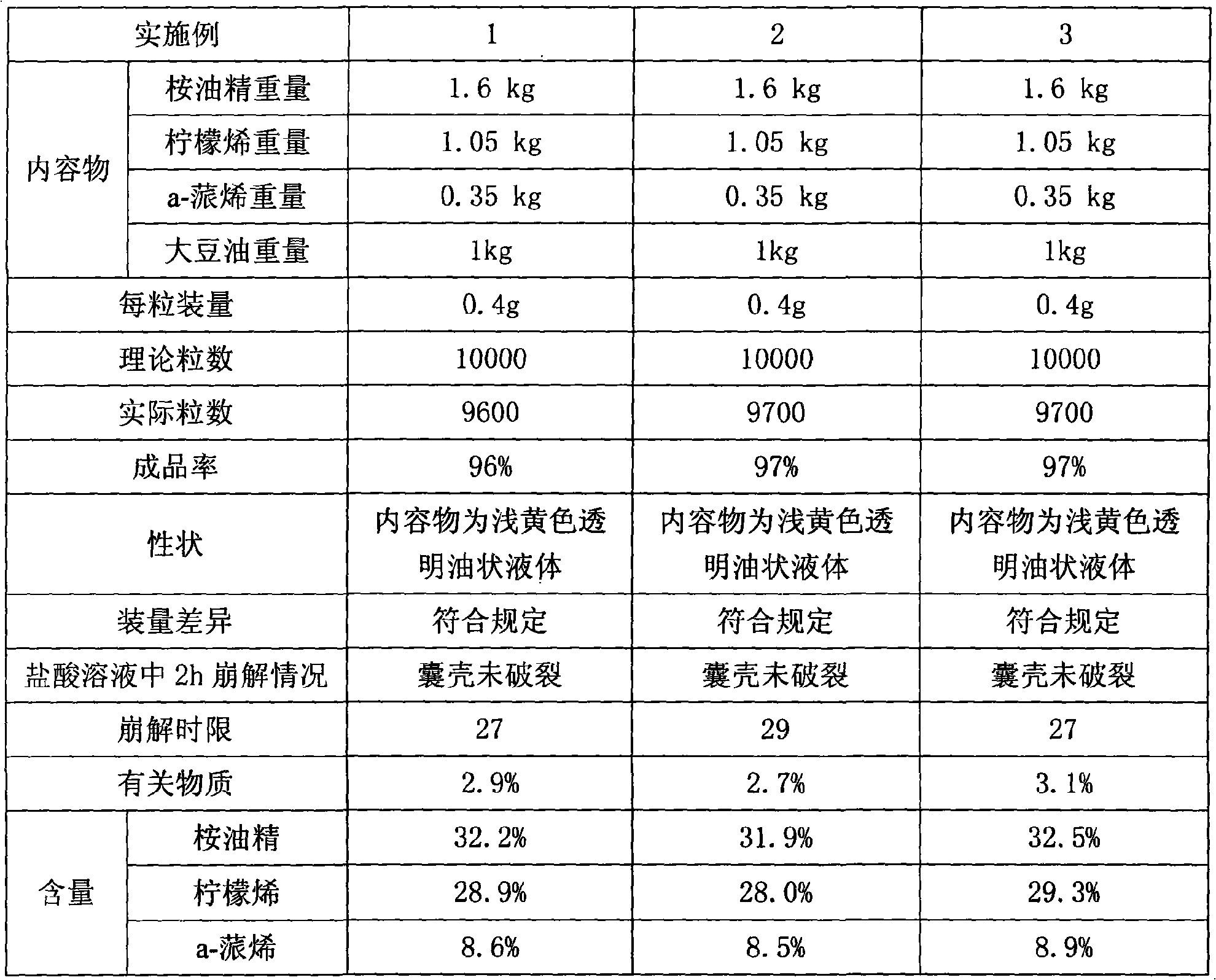

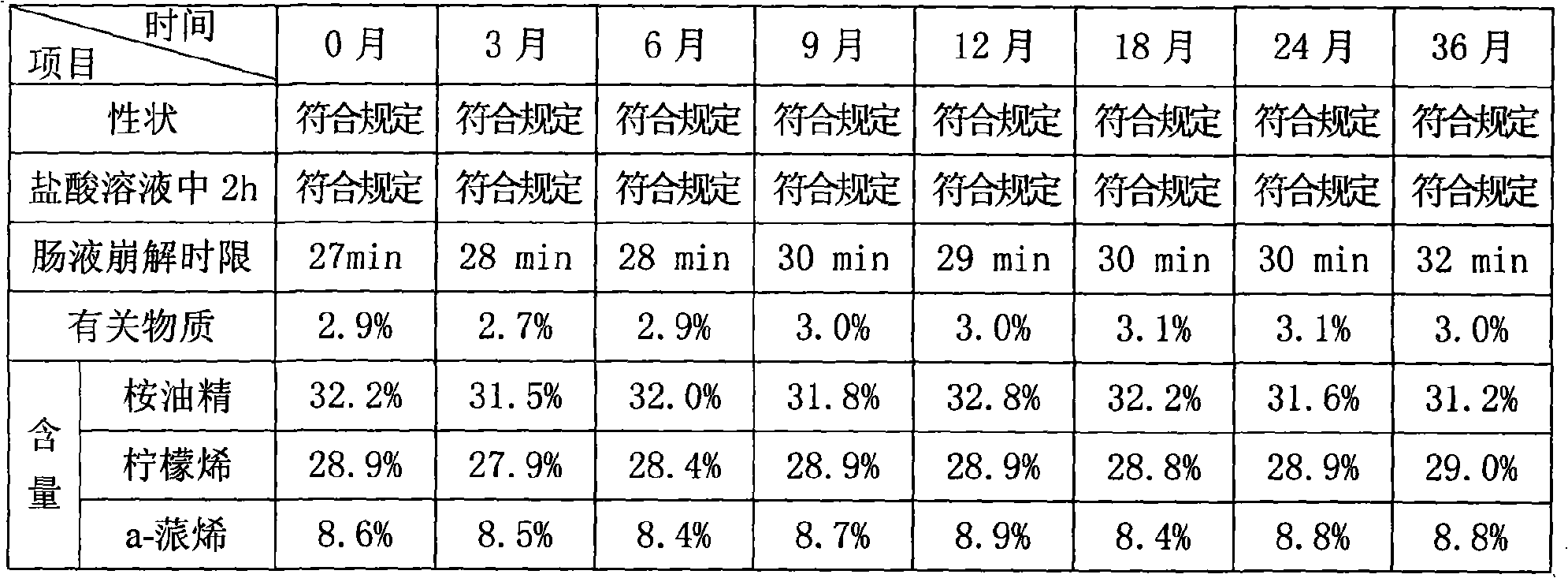

Preparation of pharmaceutical combination enteric soft capsules containing eucalyptol, limonene and a-pinene

InactiveCN101254237AWide variety of sourcesSimple processOrganic active ingredientsCapsule deliveryActive componentLimonene oxide

The invention provides a preparation method of a pharmaceutical composition Changrong Soft Capsule containing eucalyptol, limonene and Alpha-pinene, and relates particularly to a method for directly composing pharmaceutically active components eucalyptol, limonene and Alpha-pinene, a composition of the enteric coating of the Changrong Soft Capsule, and an one-step forming method.

Owner:BEIJING GRAND JOHAUM PHARMA CO LTD

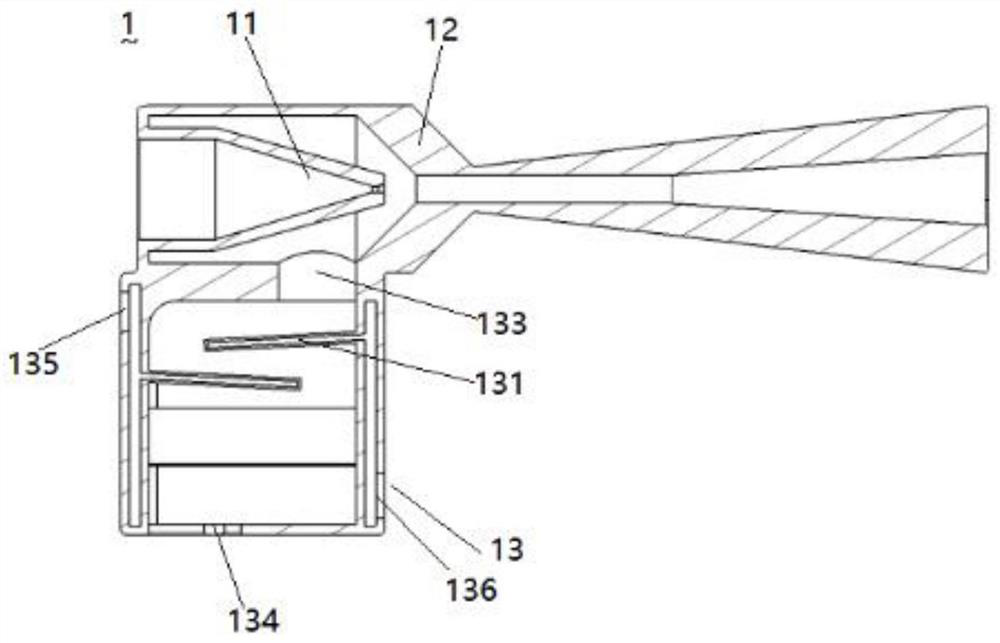

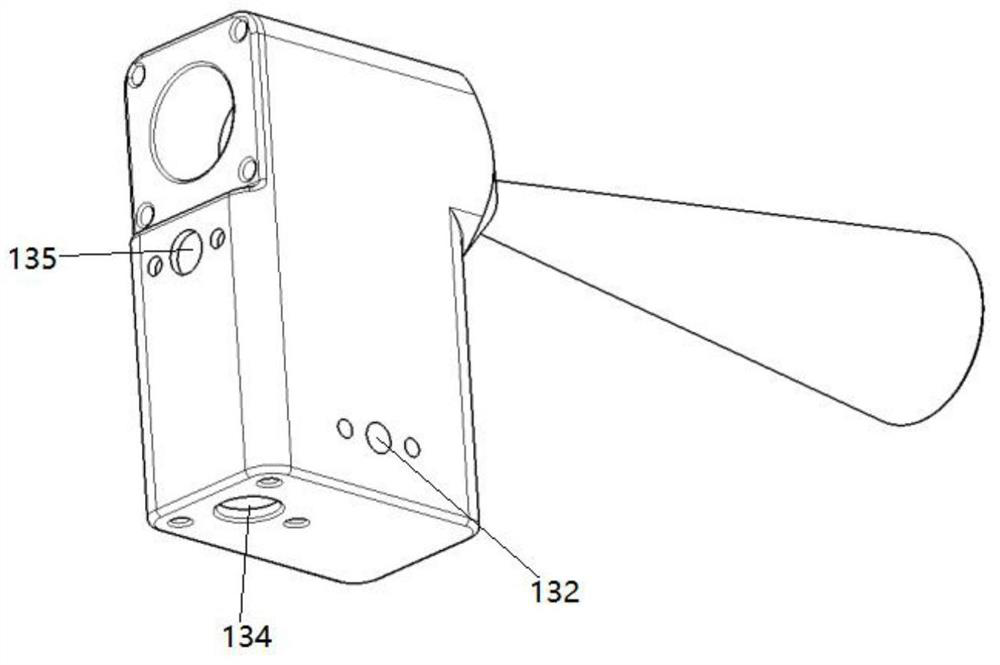

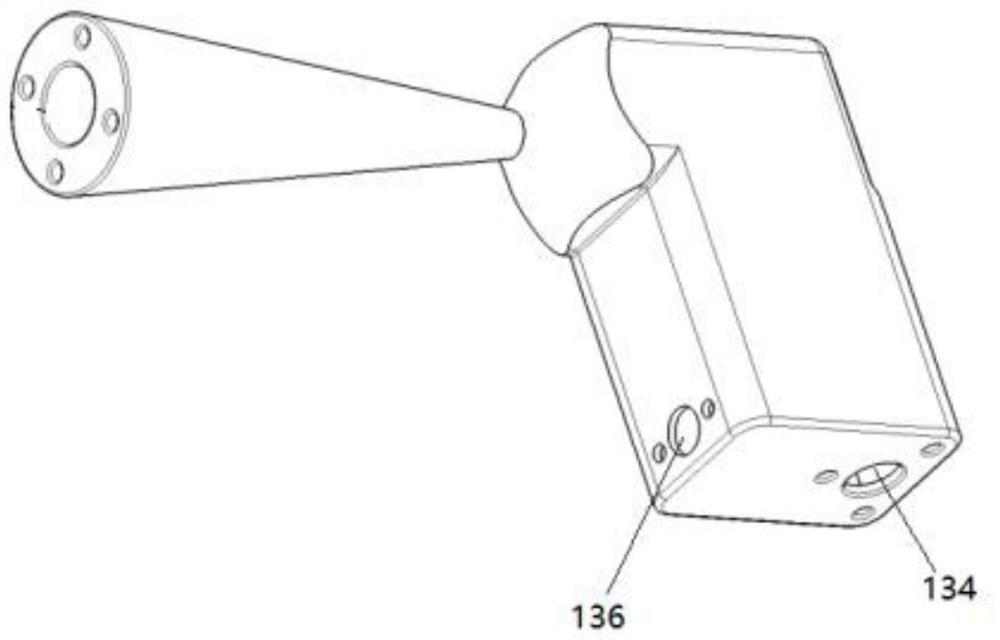

Fuel cell hydrogen ejector and hydrogen circulating system thereof

PendingCN111785994AIncrease the proportionEasy to controlReactant parameters controlThermodynamicsFuel cells

The invention belongs to the technical field of fuel cells, and discloses a fuel cell hydrogen ejector and a hydrogen circulating system thereof. The fuel cell hydrogen ejector comprises a nozzle, anejector main body and a regulation and control main body, wherein the ejector main body comprises a suction chamber, a mixing chamber and a diffusion chamber which are communicated in sequence; a primary flow inlet for high-pressure hydrogen to flow in is formed in one side of the suction chamber, and a mixed gas outlet for mixed gas to flow out is formed in one side of the diffusion chamber; thenozzle is arranged in the suction chamber; the regulation and control main body is provided with a refrigerant channel and a mixed cooling channel; the refrigerant channel is used for circulation of arefrigerant; the mixed cooling channel is used for carrying out heat exchange cooling on high-temperature hydrogen and water vapor mixed gas discharged from a galvanic pile and a refrigerant; and themixed cooling channel is communicated with the suction chamber. According to the fuel cell hydrogen ejector, the temperature difference and the flow of the refrigerant are regulated and controlled, so that the condensation amount of water vapor can be controlled, the hydrogen proportion is controlled, and the amount of the hydrogen ejector is increased from integrated drainage.

Owner:SHANGHAI FUEL CELL VEHICLE POWERTRAIN

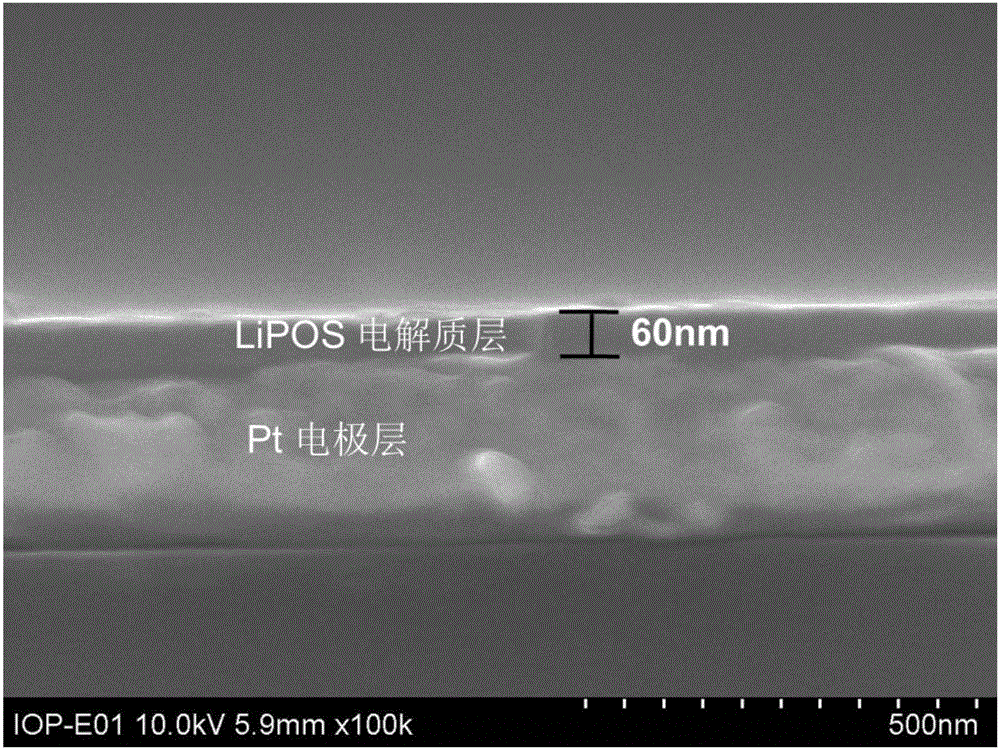

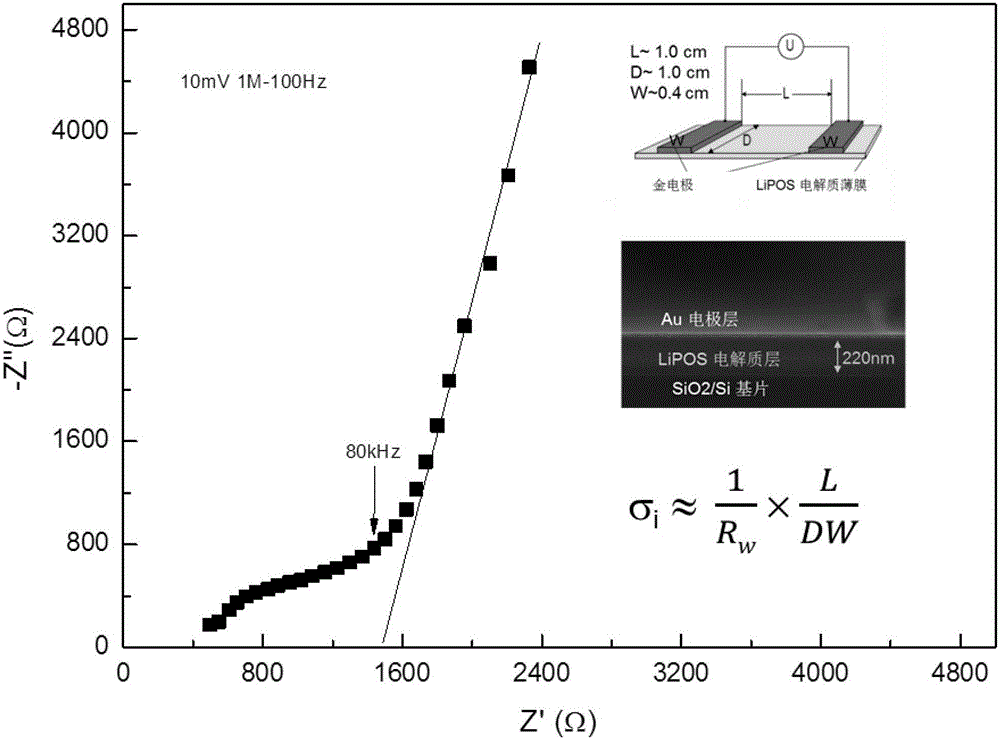

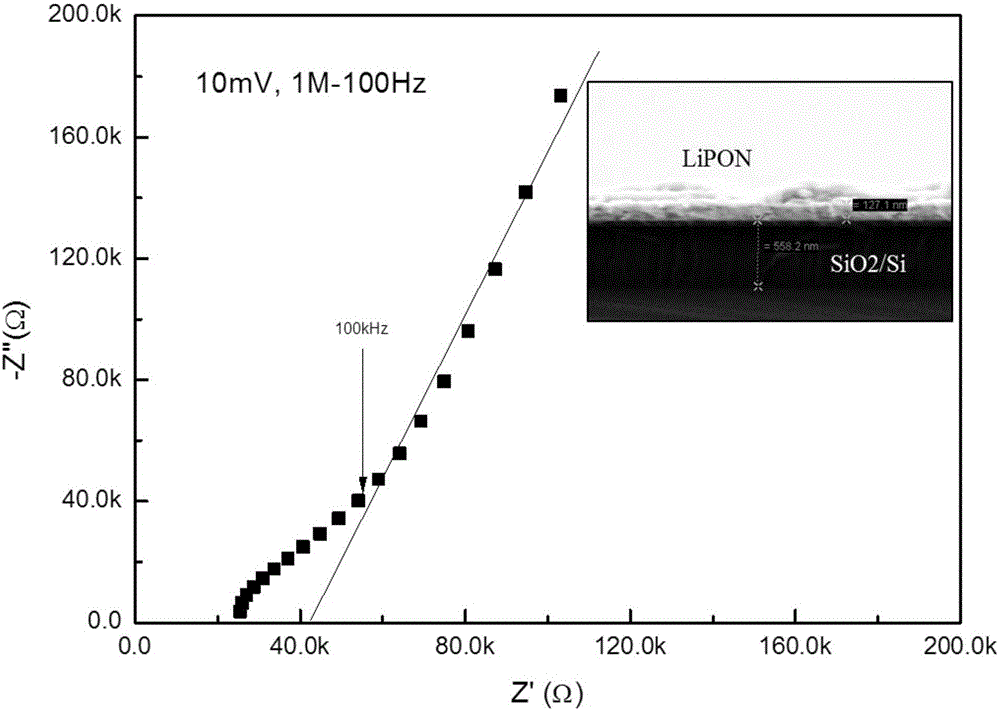

Solid electrolyte thin film and preparation method and ion device thereof

ActiveCN105862012AImprove conductivityStable performanceHybrid capacitor electrolytesHybrid capacitor electrodesMemristorElectrical resistivity and conductivity

The invention discloses a solid electrolyte thin film. The thin film is a composite thin film with Li3PO4 as a base and comprises Li3PO4-Li2S, Li3PO4-Li3N, Li3PO4-TiOx, Li3PO4-Li4SiO4 and other combination manners. The compositing manner of the composite thin film comprises mixed compositing and layered compositing. The ion conductivity of the composite thin film is 5.52*10<-5> mS / cm-1.82 mS / cm. According to the solid electrolyte thin film, Li3PO4 serves as the base and is composited with lithium-containing compounds or compounds where lithium can be embedded easily, and the conductivity of Li3PO4 is greatly improved. The invention further discloses an ion device using the solid electrolyte thin film. The ion device using the solid electrolyte thin film comprises an Au / LiPOS / Li3PO4 / Pt device structure with a diode effect of an ion one-way conducting characteristic, an Au / LiTiPO / LiPOS / Pt device structure which is an ion memristor with a memory characteristic, and an Au / Li / Li3PO4 / LiPOS / Li2S / Pt device structure which is a double-electric-layer capacitor with an energy storage characteristic.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing high performance yttrium oxide material

The invention relates to material preparation technology, in particular to a method for preparing a high-performance yttrium oxide material. The method prepares a rod, plate or cylindrical-shaped crystal strengthened yttrium oxide material by adding 0 to 40mol percent additives containing magnesium, strontium, calcium and other elements and adopting a proper sintering system at 1,000 to 1,800 DEG C. The technology has the characteristics of preparing the rod, plate or cylindrical-shaped crystal strengthened yttrium oxide material by adding the proper additives and adopting a proper sintering system. The content of the rod, plate or cylindrical-shaped crystals can be controlled by adjusting the factors such as the sintering system and the types and adding amount of the additives. The prepared yttrium oxide material has the advantages of high density, good heat and shock resistant performance, high strength and so on. In addition, the added additives can reduce the sintering temperature, save energy consumption and improve production efficiency. The method is simple in technical process, low in equipment investment and favorable for industrial large-scale production.

Owner:NORTHEASTERN UNIV

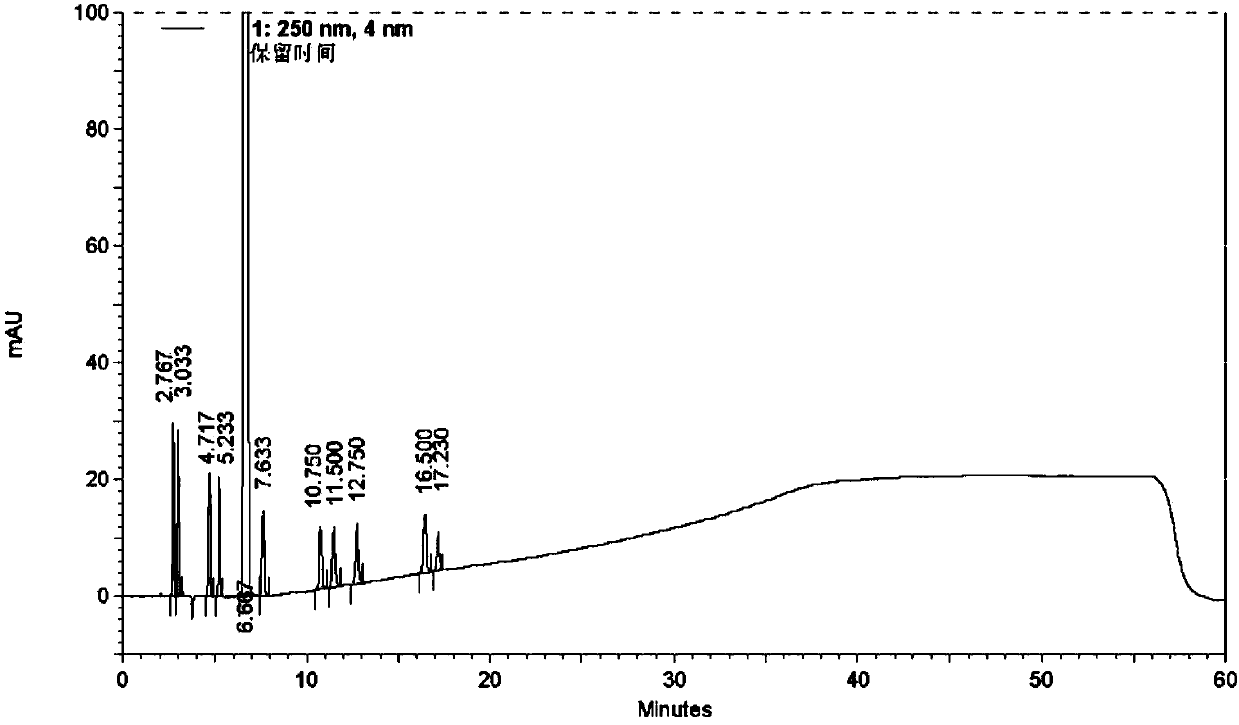

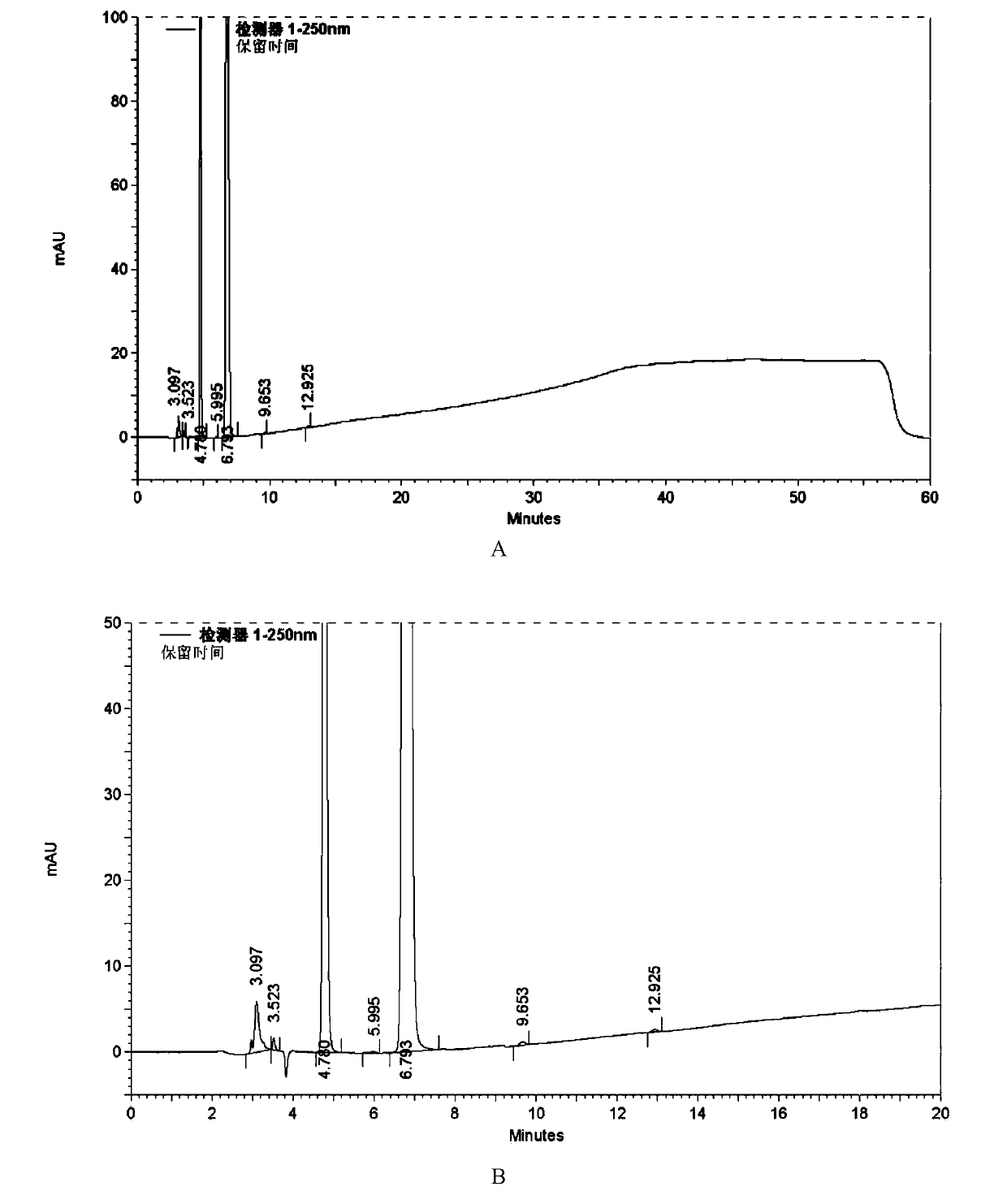

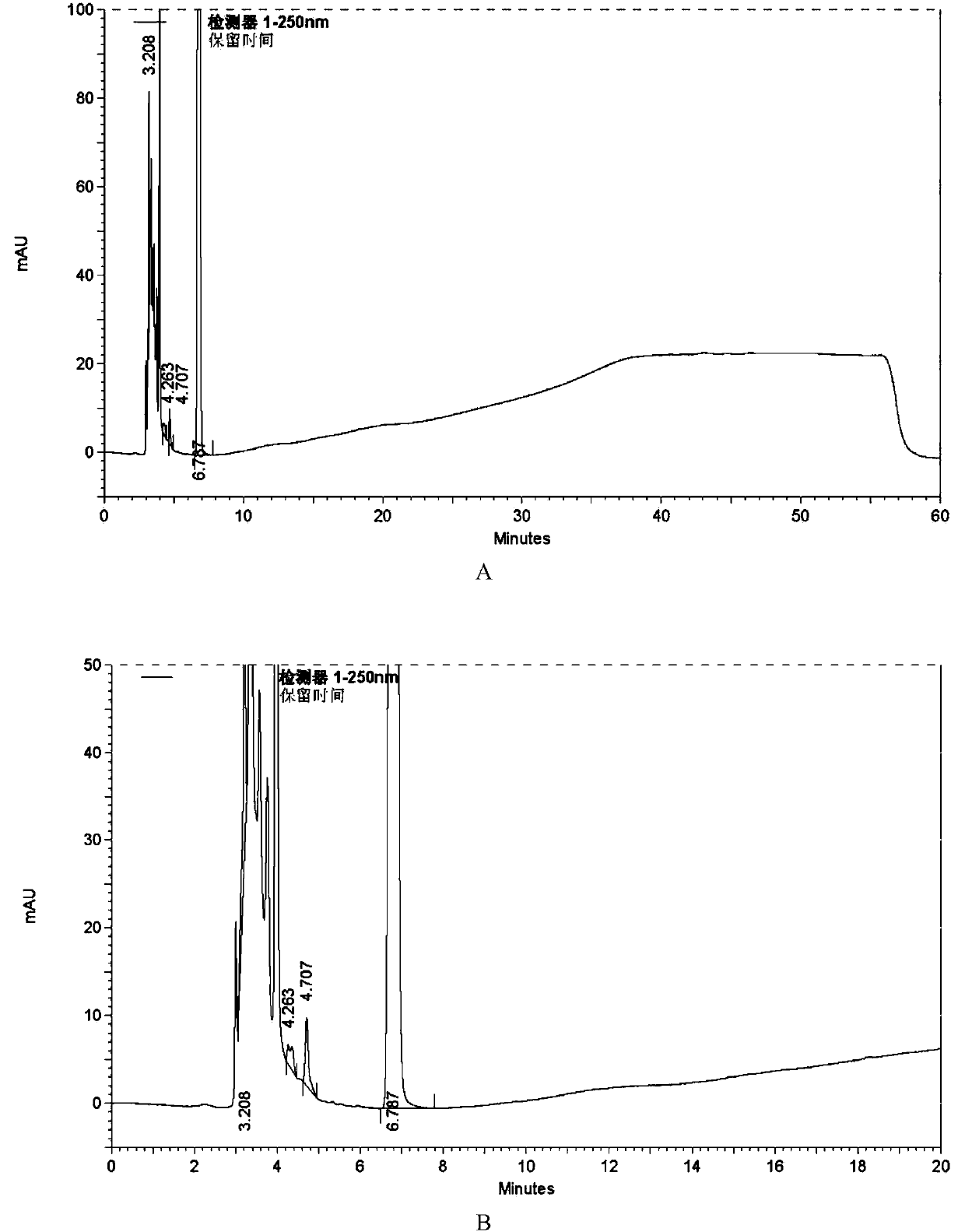

High performance liquid chromatography analysis method of azilsartan medoxomil

ActiveCN103743826AEffective controlStrong specificityComponent separationAzilsartan MedoxomilReversed-Phase Liquid Chromatography

The invention discloses a high performance liquid chromatography analysis method of azilsartan medoxomil. The method employs a reversed phase chromatography column and an ultraviolet detector, and an aqueous solution containing acetonitrile and acetic acid of low concentration is used as a mobile phase for gradient elution. The method can be used for simultaneously analyzing azilsartan medoxomil raw materials and all impurities in the preparation, and content of each known impurity can be effectively controlled by using a principle component self-contrasted method with correction factor added, and resolutions between each impurity peak, and resolutions between the main peak and adjacent impurity peaks are higher than 1.5, and purities of the main peak and each impurity peak are 1.0. The analysis method is simple with good repeatability and high specialization.

Owner:HEFEI JIUNUO MEDICAL TECH

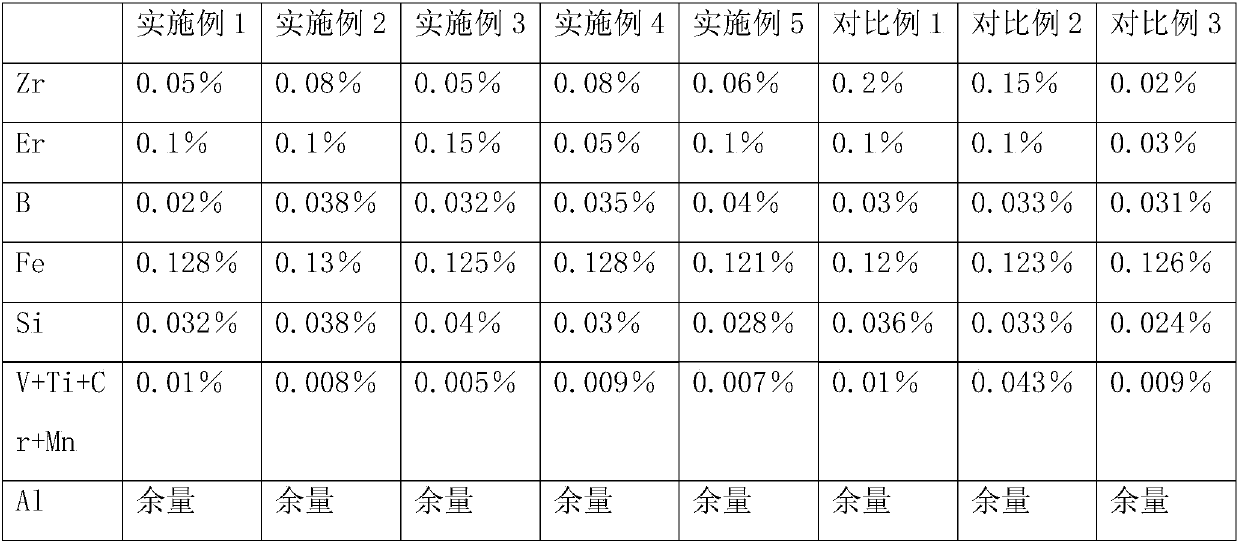

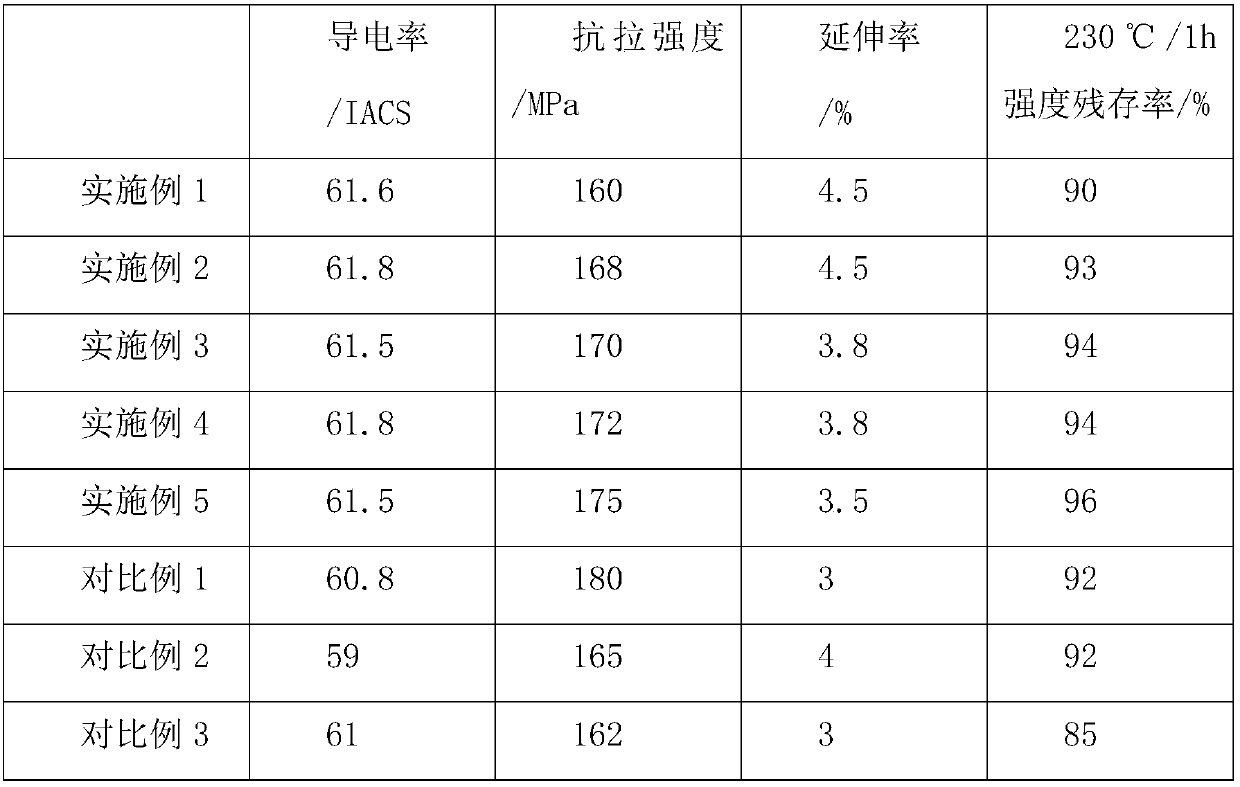

High-conductivity heat-resistant Al-Zr-Er alloy wire material and preparation method thereof

ActiveCN111349820ASolving ingredientsSolve the impurity contentConductive materialMetal/alloy conductorsRare-earth elementUltimate tensile strength

The invention provides a high-conductivity heat-resistant Al-Zr-Er alloy wire material. The alloy comprises the following components of, by mass, 0.02%-0.15% of Zr, 0.01%-0.2% of Er, 0.01%-0.04% of B,less than or equal to 0.20% of Fe, less than or equal to 0.05% of Si, less than or equal to 0.01% of (V+Ti+Cr+Mn) and the balance Al. According to the high-conductivity heat-resistant Al-Zr-Er alloywire material, the trace rare earth element Er is added while the element Zr is added into the alloy so as to modify the alloy and to optimize and adjust the content of the alloy elements, so that themechanical property of the alloy is guaranteed, and the electric conductivity is improved; and the electric conductivity of the prepared heat-resistant aluminum alloy monofilament material is largerthan or equal to 61.5% IACS, the tensile strength is larger than or equal to 160 MPa, the elongation rate is larger than 3.5%, the heat-resistant temperature is greater than or equal to 150 DEG C, andthe strength residual rate after heating at 230 DEG C for 1 hour is greater than 90%.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

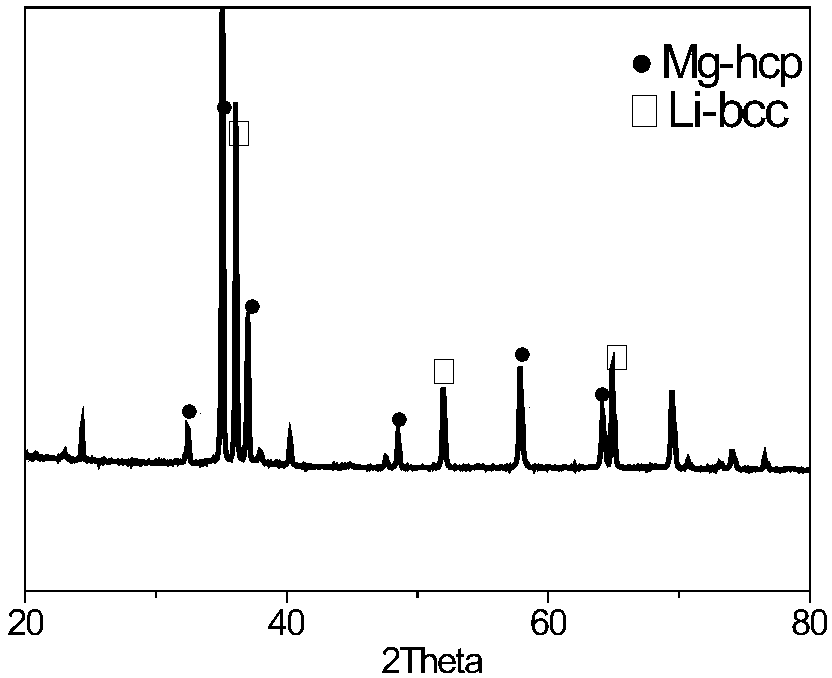

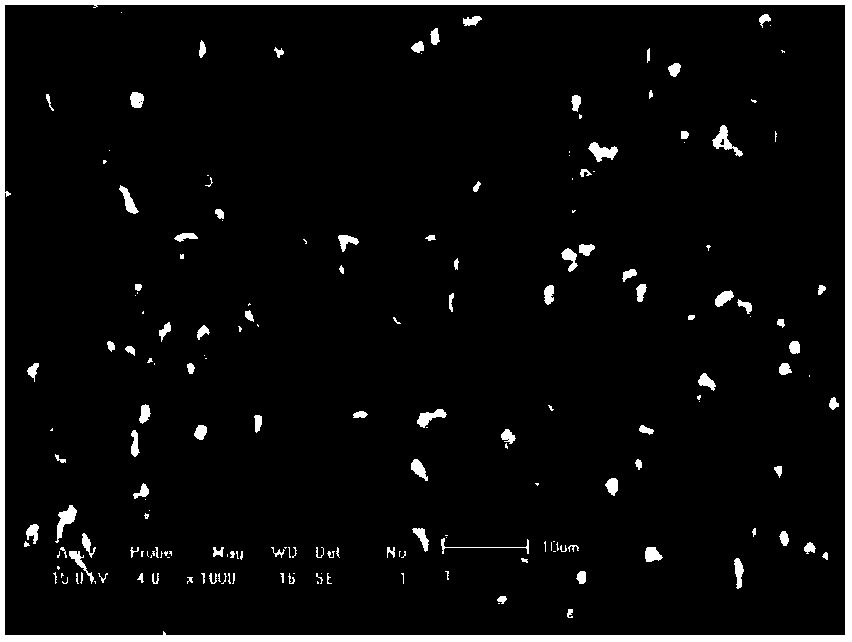

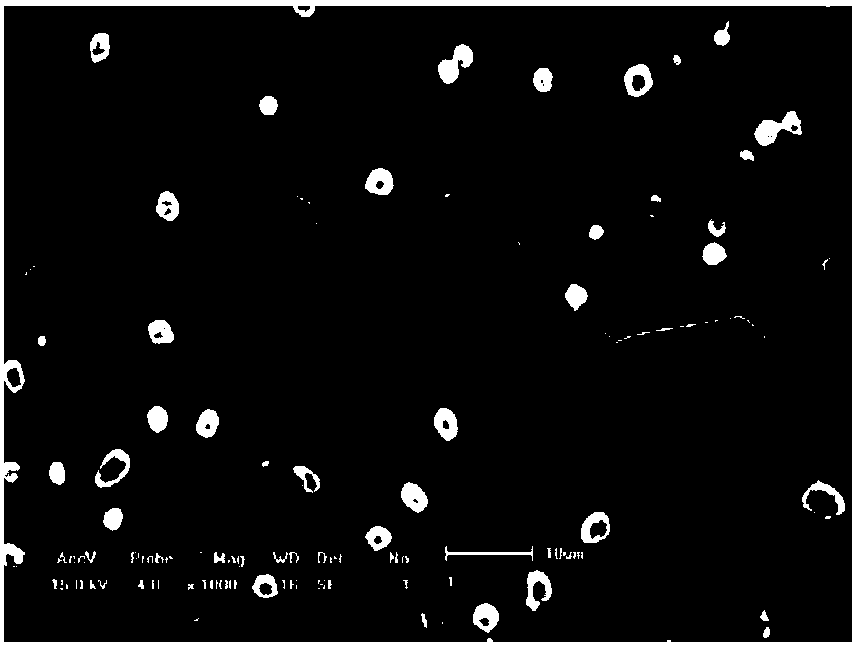

High-strength low-density hcp+bcc dual-structure magnesium-lithium alloy bar and preparation method thereof

The invention discloses a high-strength low-density hcp+bcc dual-structure magnesium-lithium alloy bar. The high-strength low-density hcp+bcc dual-structure magnesium-lithium alloy bar comprises the following raw materials of, by weight, 6.1%-10.2% of Li, 4.6%-5.8% of Al, 1.5%-2.3% of Zn, 0.1%-0.6% of Y, and the balance Mg and impurity elements thereof. The impurity elements comprise Ca, Fe, Cu and Ni, the total amount is smaller than 0.2%, wherein Fe is smaller than or equal to 0.04%, and Ca is smaller than or equal to 0.03%. According to the high-strength low-density hcp+bcc dual-structure magnesium-lithium alloy bar, through reasonable matching of the types and proportional relation of the alloy elements, the trace Y element is added, and the trace Y element and the matrix Mg element form an Al2Y strengthening phase so as to improve the strength of alloy. Mg-Y intermediate alloy is added into melt, smelting is conducted, alloy cost is lowered, and industrialized production is facilitated. A semicontinuous casting process is conducted under the non-vacuum condition, on the one hand, complexity of experimental operation is lowered, on the other hand, the melt purity degree and thealloy yield are improved, and the foundation is laid for later high-strength ultralight magnesium-lithium alloy.

Owner:D MAG KUNSHAN NEW MATERIAL TECH CO LTD +1

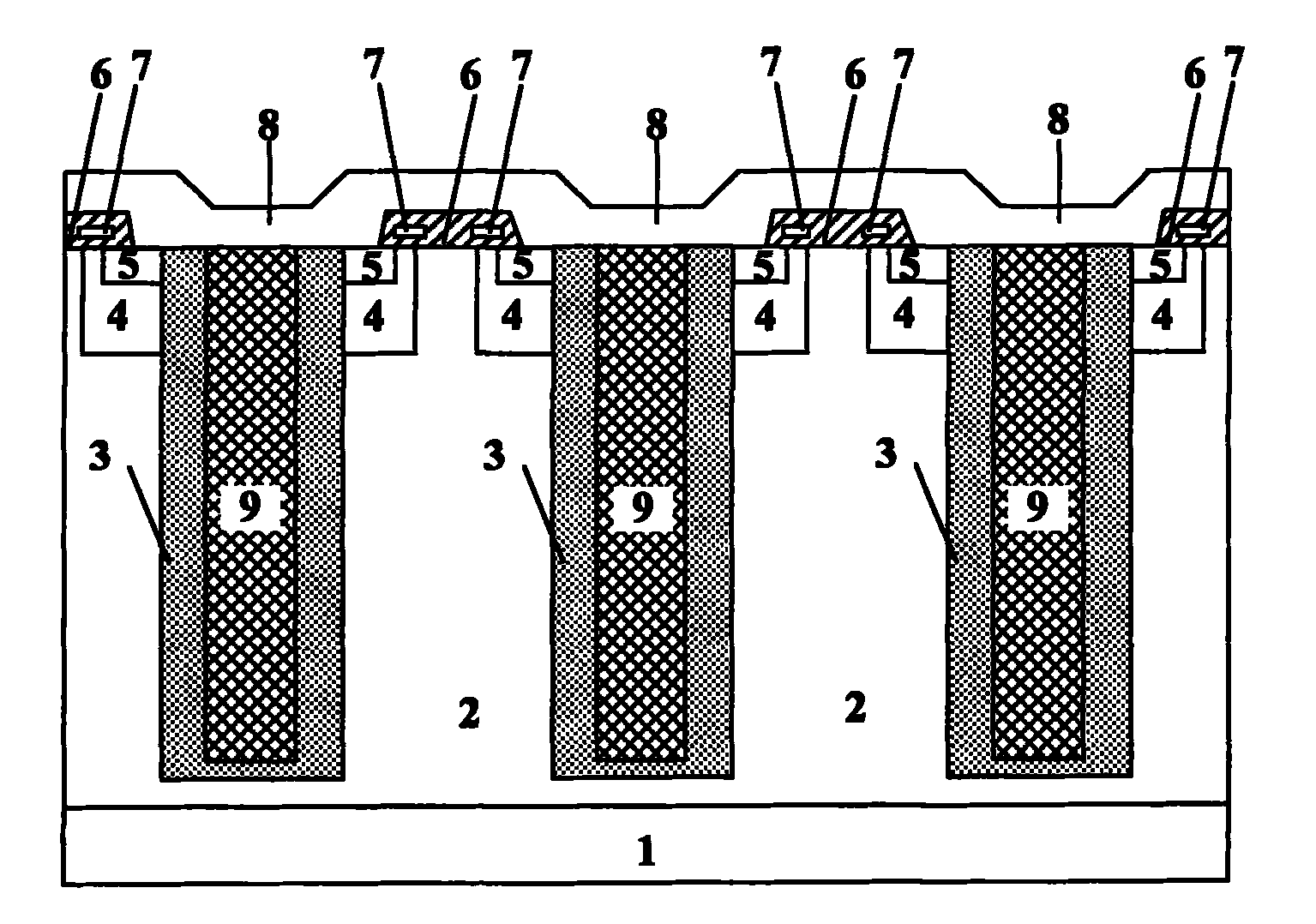

Method for preparing longitudinal high-pressure deep-slot transistor

InactiveCN101814436ALower on-resistanceOvercoming the serious problem of interdiffusionSemiconductor/solid-state device manufacturingHigh pressureControllability

The invention discloses a method for preparing a longitudinal high-pressure deep-slot transistor. P-type semiconductor regions and N-type semiconductor regions are alternatively arrayed in a drift region of a device. The P-type semiconductors in the drift region are prepared by the steps of: firstly, forming deep slots by using a deep-slot etching process; secondly, filling boron-phosphorosilicate glass into the deep slots; thirdly, removing the boron-phosphorosilicate glass from the surface by etching; and finally, diffusing boron impurities and phosphorus impurities in the boron-phosphorosilicate glass into silicon on the side walls and at the bottoms of the deep slots by using an annealing process, wherein the boron impurity content of the boron-phosphorosilicate glass is far more than the phosphorus impurity content, so that the semiconductor regions on the side walls and at the bottoms of the deep slots are changed into the P-type doped semiconductor regions. The method has high process controllability and low process cost, and the manufactured device has high performance.

Owner:SUZHOU POWERON IC DESIGN

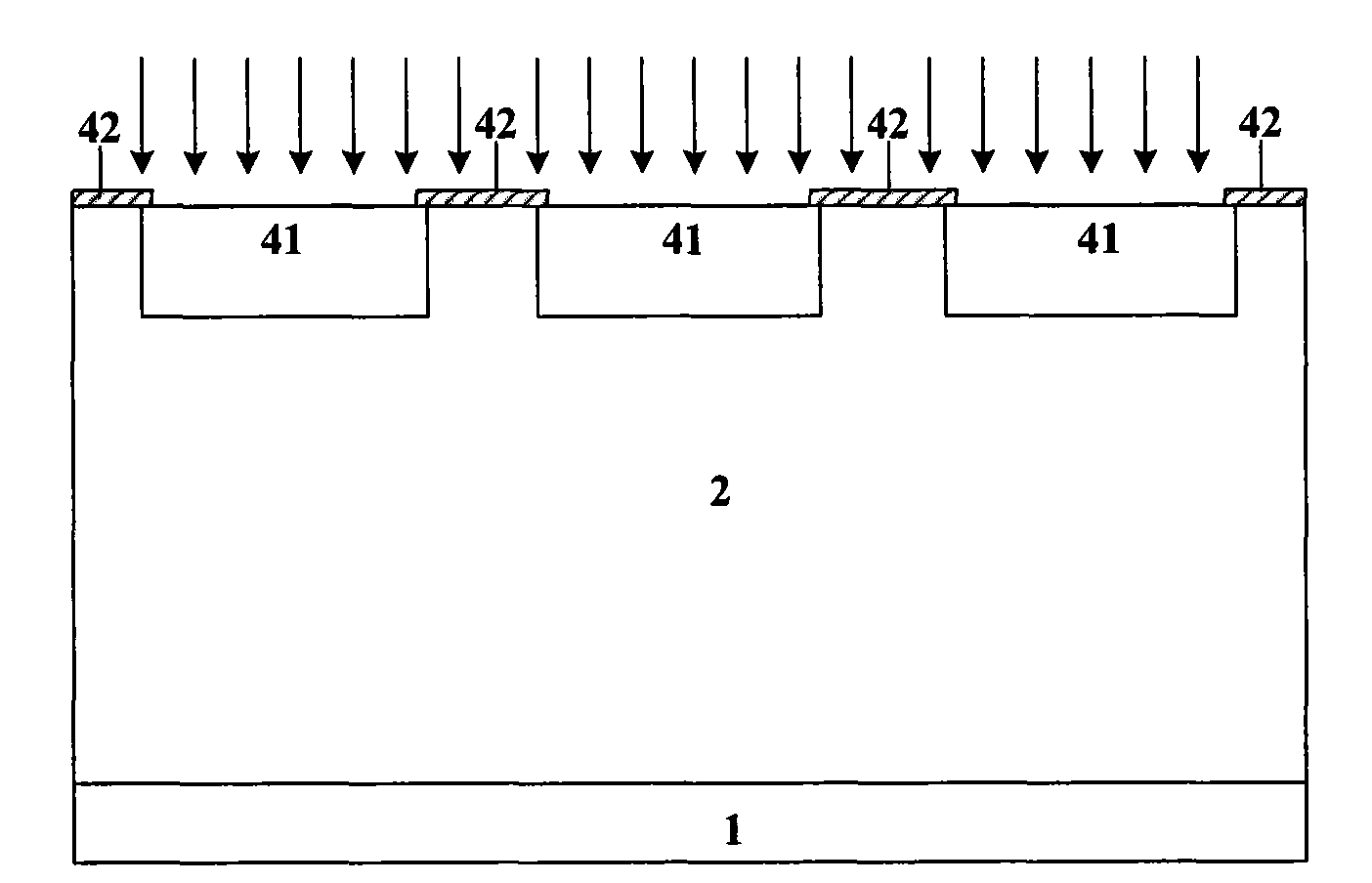

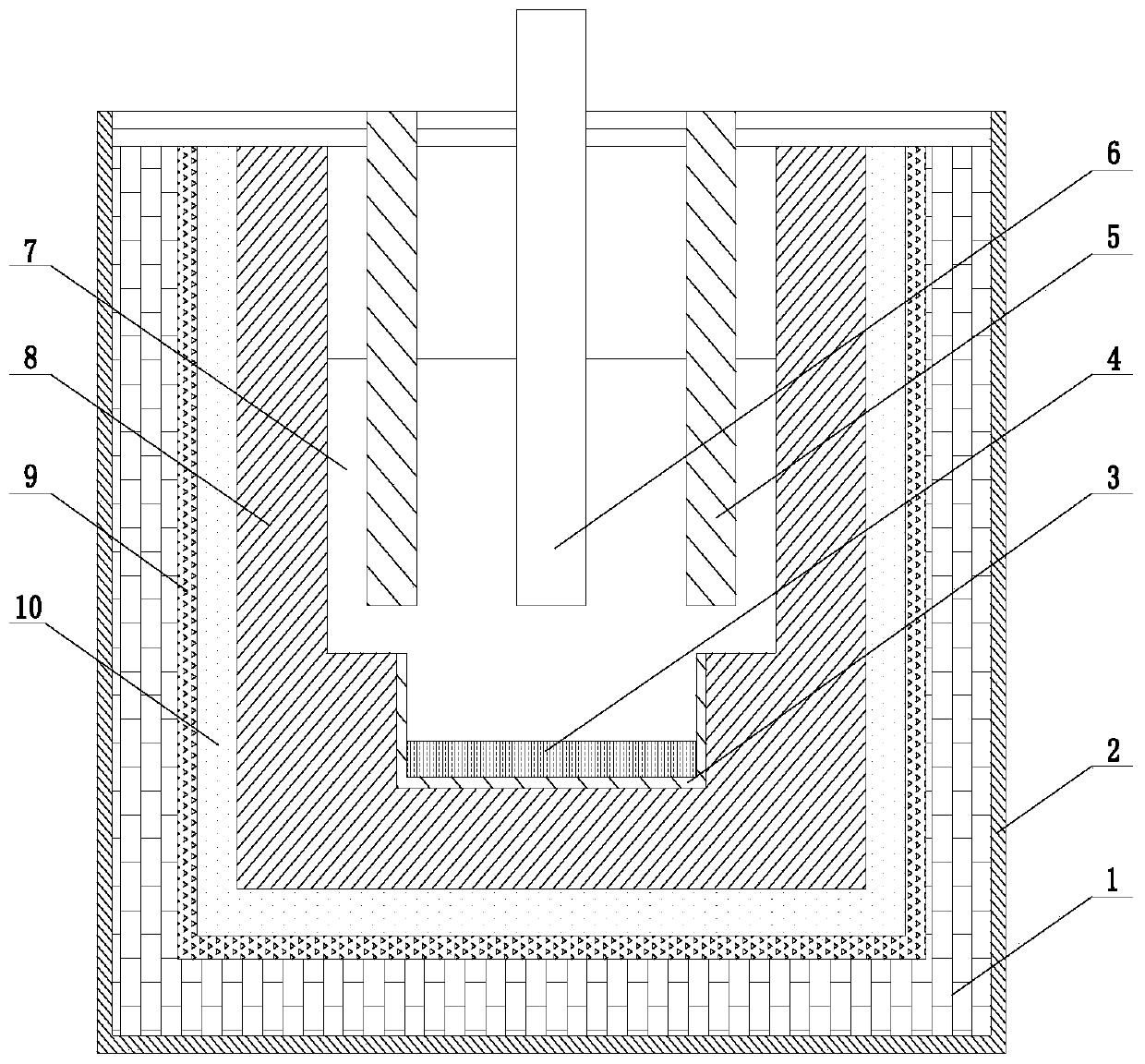

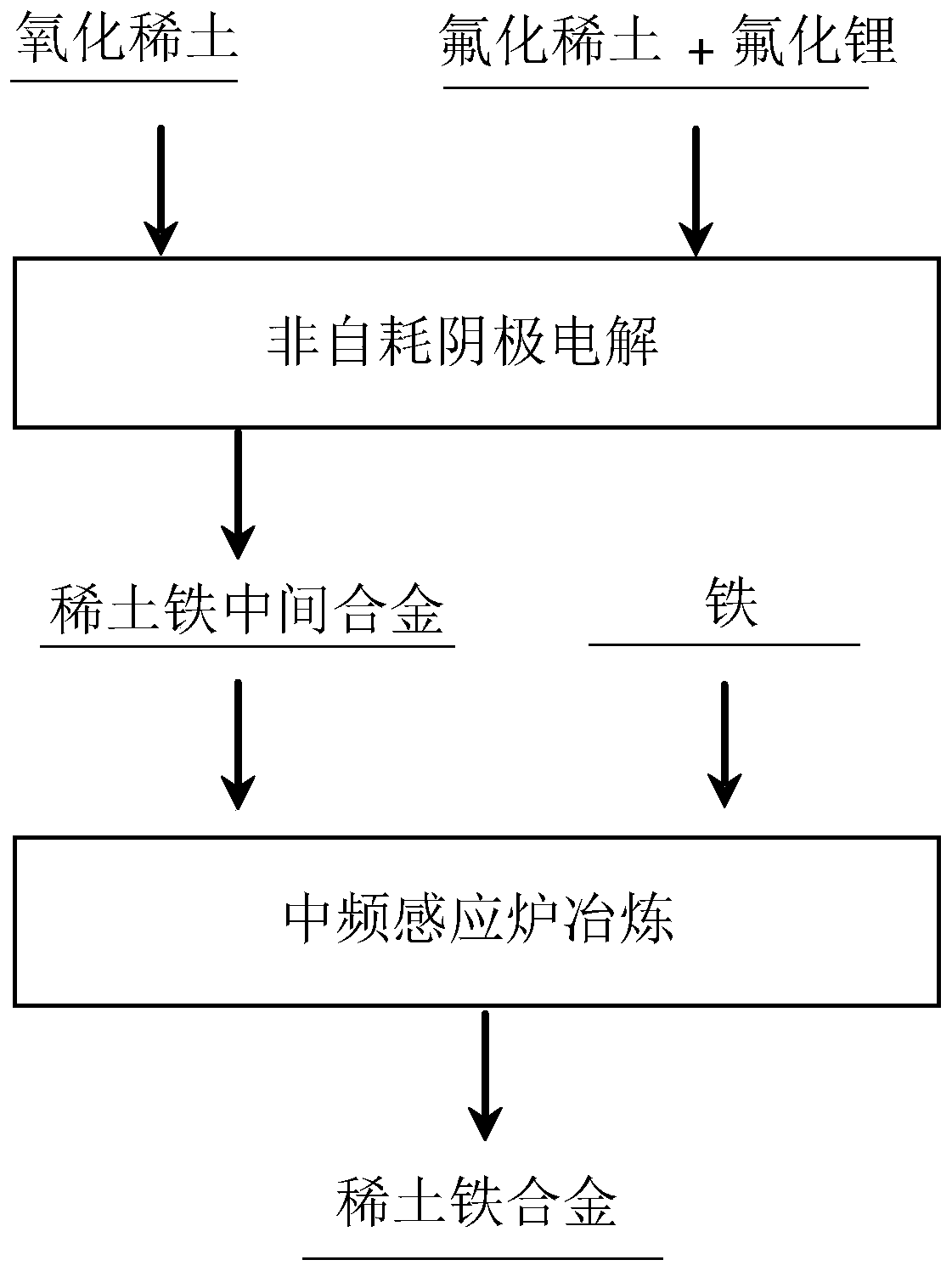

Preparation method of rare earth ferroalloy

ActiveCN111411372AThe composition is uniform and stableReduce segregationInduction furnaceLithium fluoride

The invention discloses a preparation method of a rare earth ferroalloy. The preparation method of the rare earth ferroalloy comprises the steps that a rare earth iron immediate alloy is prepared by non-self-consuming cathode electrolysis; an electrolyte is loaded in an electrolytic cell, a graphite carbon plate is used as an anode, a tungsten or molybdenum material is used as an cathode, and a crucible under the tungsten and molybdenum cathode is used as a receiver; in an electrolyte system of rare earth fluoride and lithium fluoride molten salt, rare earth oxide and iron are used as raw materials, then a direct current is passed for electrolysis, and the rare earth iron immediate alloy is obtained in the receiver; and the rare earth iron immediate alloy and iron are put into the crucibleas the raw materials, and the rare earth iron immediate alloy is further smelted by a melting and mixing method in a medium frequency induction furnace to obtain the rare earth ferroalloy. The rare earth ferroalloy obtained by the preparation method has uniform and stable composition, low impurity element content and close density and melting point to the density and melting point of steel, and the rare earth ferroalloy is easy to be added to the steel; and the rare earth ferroalloy can fundamentally solve the problem of effective addition of rare earth in the steel and can accurately controlthe content of the rare earth in the steel.

Owner:BAOTOU RES INST OF RARE EARTHS +1

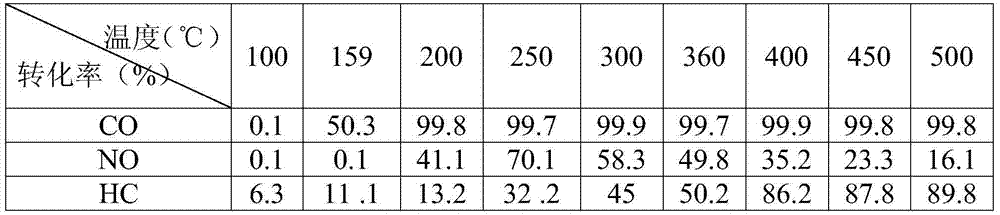

Diesel vehicle oxidation catalyst containing Al-Si-Ti composite oxide

ActiveCN104117381APrecise content controlEvenly distributedMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention relates to a diesel vehicle oxidation catalyst containing Al-Si-Ti composite oxide. The diesel vehicle oxidation catalyst is prepared by taking cordierite honeycomb ceramics as a carrier, TiO2 and Al-Ti-Si composite oxide as a dispersing agent, a molecular sieve as adsorbing material, zirconium nitrate as a thermal stabilizing auxiliary agent, citric acid as a binding agent and precious metals Pt and Pd as active components; the feeding amount of the precious metals is 5-200g / ft<3>. The preparation method is simple; the prepared catalyst are coated by the precious metal active components by a mixed coating method, so that the content of the precious metals can be accurately controlled, the precious metals are evenly distributed, and the effect of the catalyst is better.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

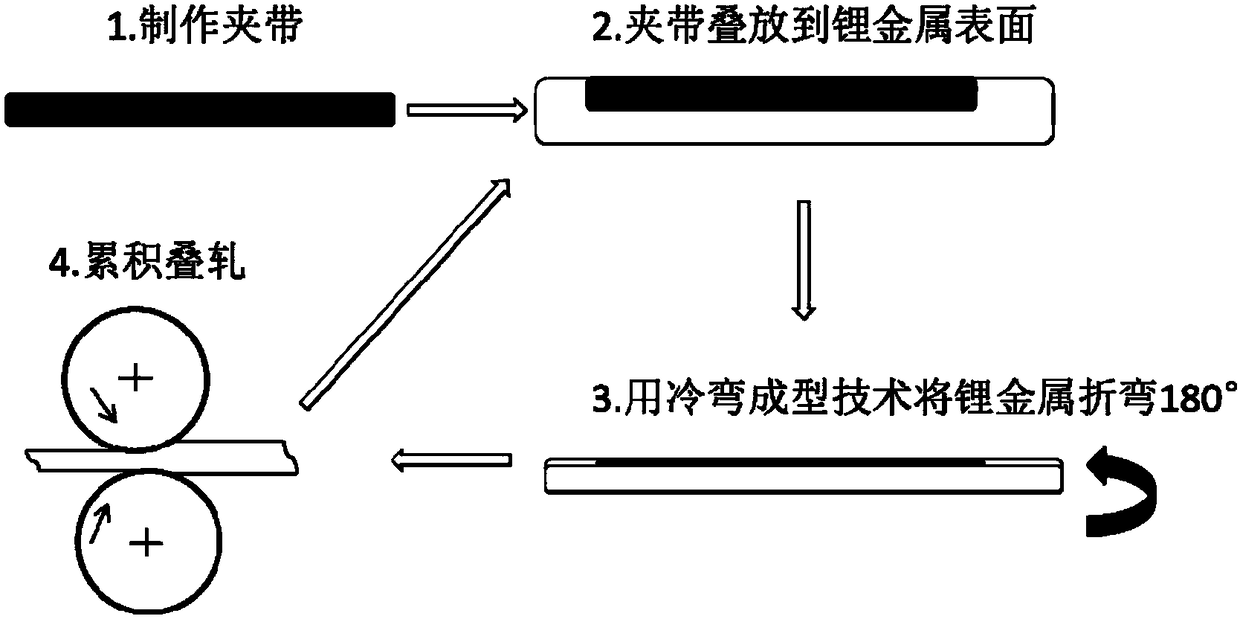

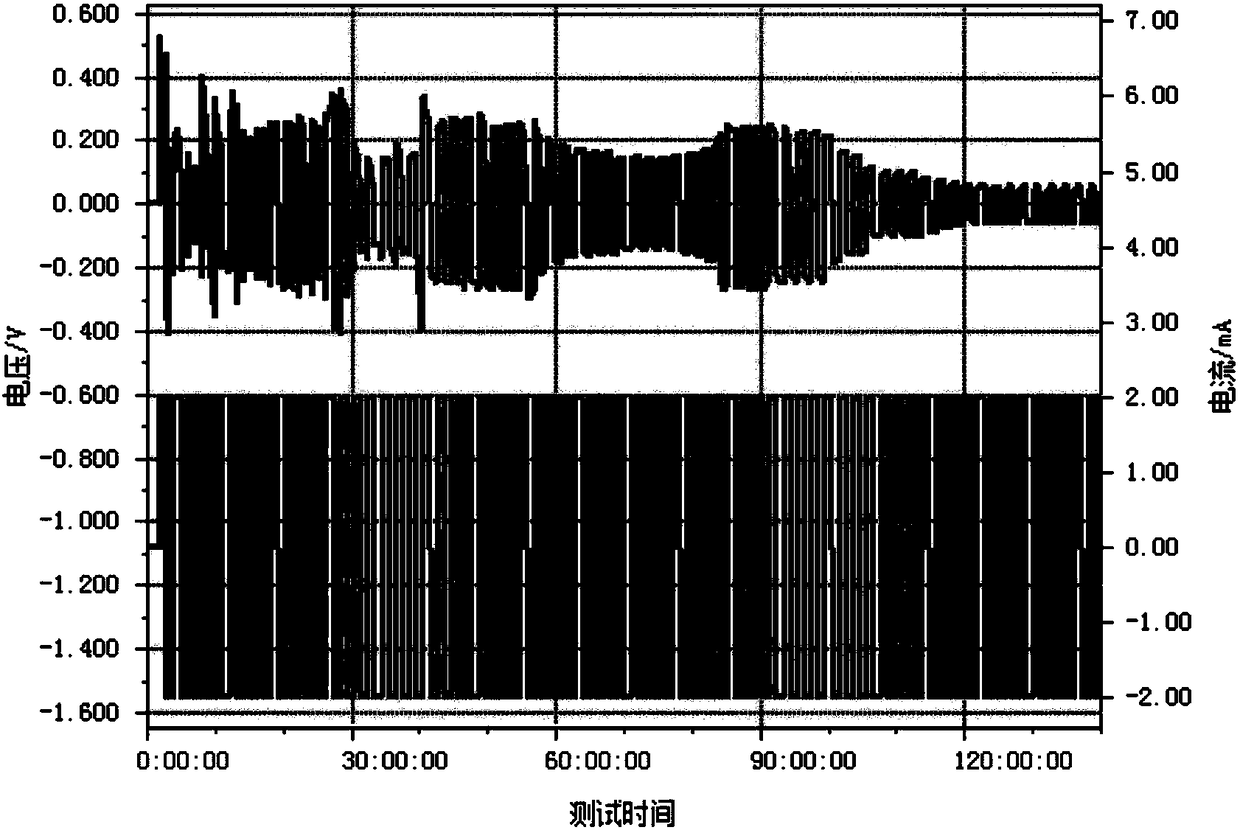

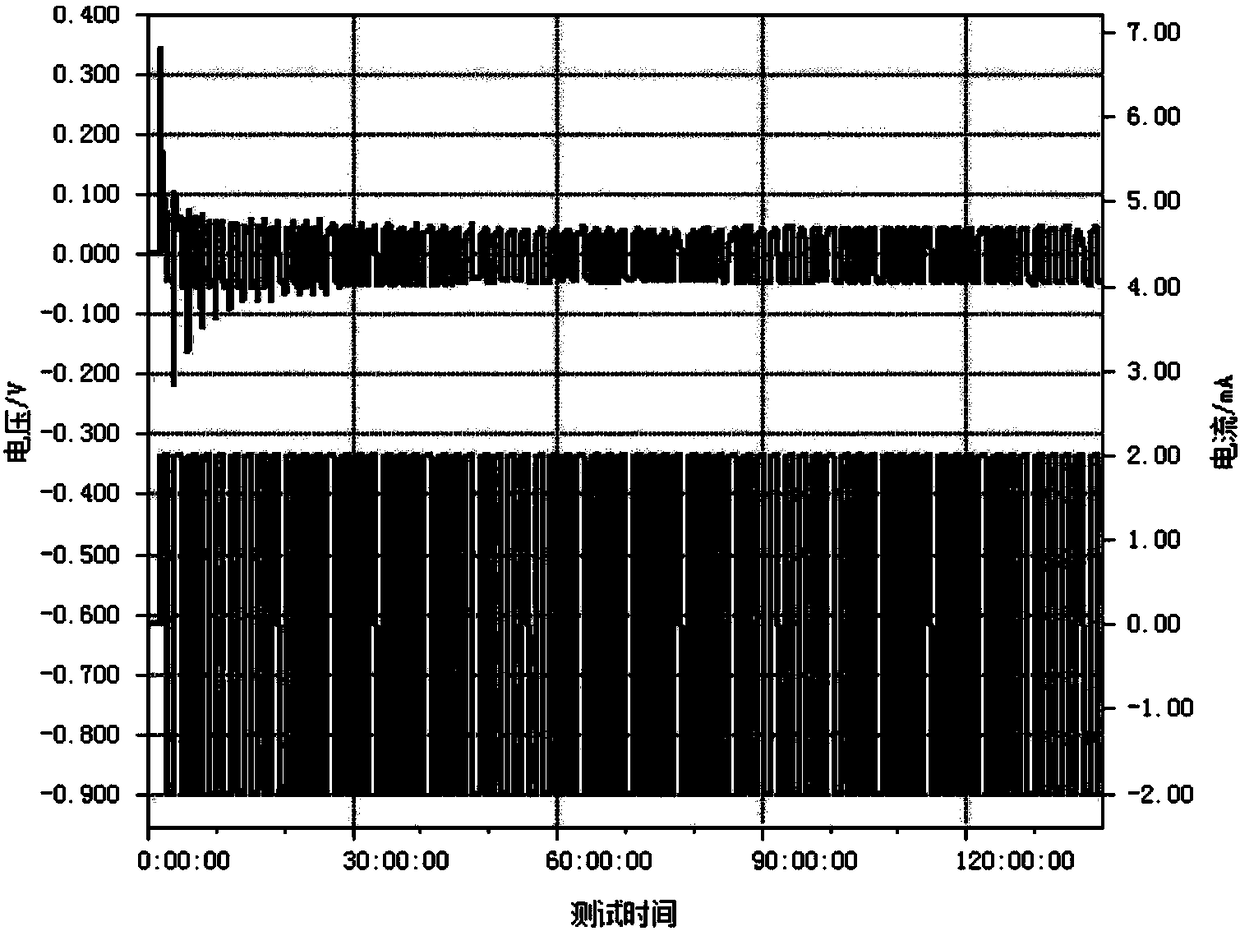

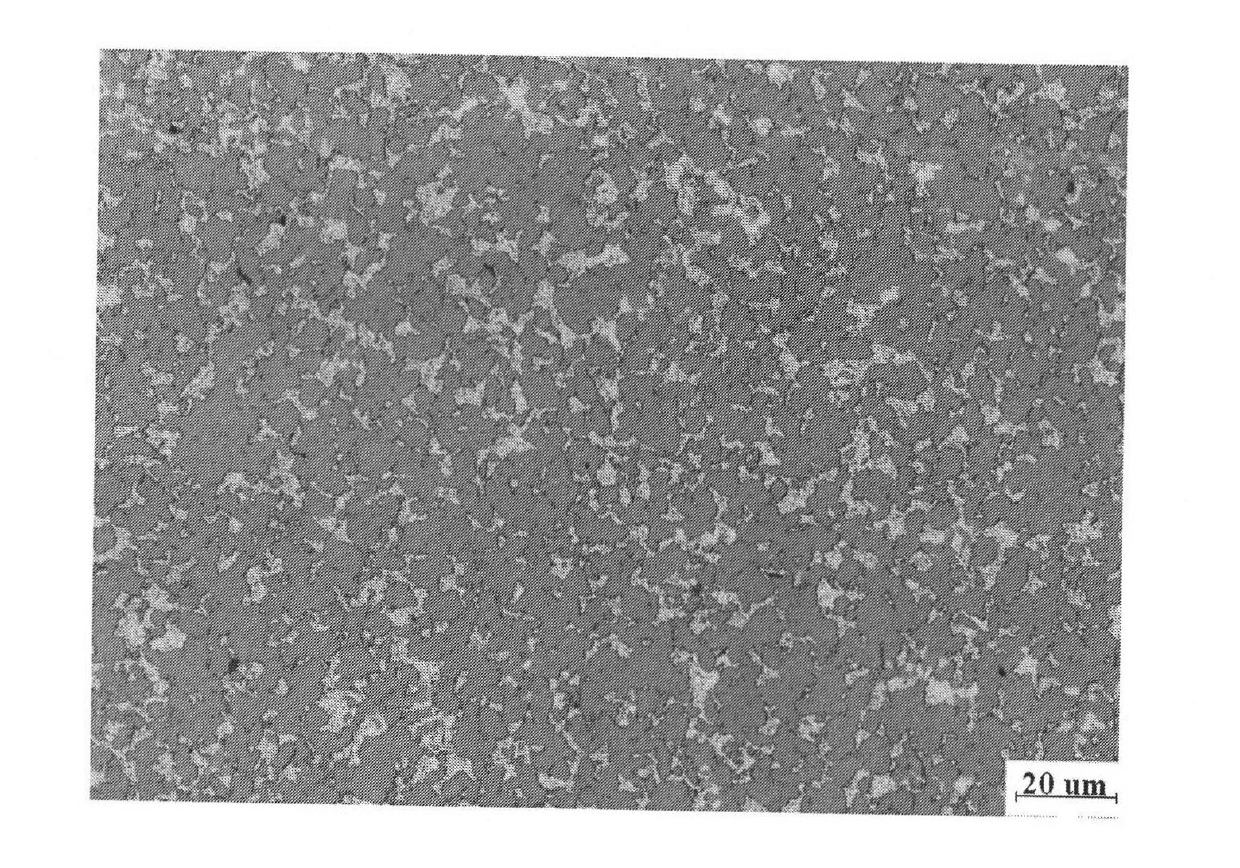

Preparation method of composite metal lithium negative electrode

InactiveCN108598358AEvenly distributedEnsure consistencyElectrode rolling/calenderingSecondary cellsPolymer adhesiveInorganic materials

The invention provides a preparation method of a composite metal lithium negative electrode. The preparation method comprises the steps of pasting an inorganic material with a polymer adhesive to forma layered clamping tape; laying the clamping tape on a surface of lithium metal, bending the lithium metal for 180 degrees in a width direction by a cold roll formation technology to form a lithium / clamping tape / lithium composite structure; and performing rolling, pressing with deformation quantity by 20-50% to obtain a composite material rolled in one time, and repeating the step for 3-20 timesto obtain the composite metal lithium negative electrode material with a multi-layer structure. By the method, the lithium deposition morphology is improved, lithium dendrites growth is suppressed, sothat the cycle property and the safety of the battery are improved, and industrial and continuous production of the composite metal lithium negative electrode can be achieved.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

Silicon-aluminum bicontinuous composite material and preparation method thereof

The invention relates to a bicontinuous composite material which has excellent comprehensive properties due to the special interpenetrating network structure. Aiming at the silicon aluminum material having wide application prospects, the invention implements a silicon-aluminum bicontinuous composite material and a powder metallurgy preparation technique thereof. The technique overcomes the defects of overgrowth of silicon, and material nonuniformity and noncompactness in the casting method and liquid phase impregnation method, and prepares the bicontinuous composite material with controllable composition, phase dimensions and microstructure. The invention implements uniform mixing of the two phases silicon and aluminum by selecting reasonable composition and powder size; and the alloy elements of the aluminum alloy are added by an element powder direct mixing method. The billet is completely compacted within a proper temperature range; and silicon atoms are diffused, so that the silicon powder particles are connected with each other and interpenetrate with the aluminum alloy to form the bicontinuous composite material. The silicon content in the composite material is 40-80 vol.%; and the composite material is completely compact and has a uniform structure. The composite material has excellent comprehensive properties, and is applicable to various conventional machining means.

Owner:有研金属复材技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com