Method for preparing monolithic catalyst for purification of diesel exhaust

A monolithic catalyst and exhaust gas purification technology, applied in catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., to achieve the effect of simple preparation process, good cycle stability and high NOx removal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

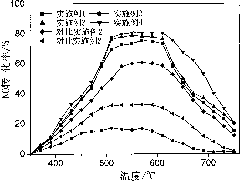

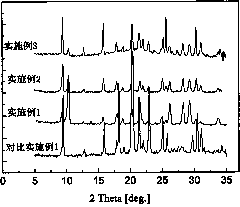

Examples

Embodiment 1

[0025] Step A: Vector pretreatment

[0026] The honeycomb cordierite support was treated with 15% dilute nitric acid solution at 80°C for 2h. After washing with distilled water, dry at 110°C for 3 hours to obtain a cordierite carrier;

[0027] Step B: Preparation of Molecular Sieve Mother Liquor

[0028] Add 12.32ml of phosphoric acid to 180ml of distilled water to obtain a phosphoric acid solution, add 1.2728g of copper oxide to the phosphoric acid solution, stir for 30min in a constant temperature water bath at 80°C, and cool to room temperature to obtain a solution (a); add 14.3520g of aluminum hydroxide to the solution In (a), stir vigorously for 30 minutes, then add 30% 6.52ml of silica sol and 21.79ml of morpholine, keep stirring evenly to obtain the molecular sieve mother liquor;

[0029] Step C: Synthesis of Monolithic Catalysts

[0030] Put the cordierite carrier obtained in step A into the bottom bracket of the reactor, then add the mother liquid of molecular siev...

Embodiment 2

[0034] Step A: Vector pretreatment

[0035] The honeycomb cordierite support was treated with 15% dilute nitric acid solution at 80°C for 2.5h. After washing with distilled water, dry at 110°C for 3 hours to obtain a cordierite carrier;

[0036] Step B: Preparation of Molecular Sieve Mother Liquor

[0037] Add 10.95ml of phosphoric acid to 180ml of distilled water to obtain a phosphoric acid solution; add 12.4462g of aluminum hydroxide to phosphoric acid, stir vigorously for 30min, then add 30% of 4.89ml of silica sol and 20.00ml of morpholine, keep stirring evenly to obtain a molecular sieve mother liquor;

[0038] Step C: Synthesis of Monolithic Catalysts

[0039] Put the cordierite carrier obtained in step A into the bottom bracket of the reactor, then add the mother liquid of molecular sieve obtained in step B into the reactor, and crystallize at 180° C. for 7 days. After the formed catalyst was rinsed with distilled water, it was dried at 110° C. for 3 hours, and then ...

Embodiment 3

[0043] Step A: Vector pretreatment

[0044] The honeycomb cordierite support was treated with 15% dilute nitric acid solution at 80°C for 2h. After washing with distilled water, dry at 110°C for 3 hours to obtain a cordierite carrier;

[0045] Step B: Preparation of Molecular Sieve Mother Liquor

[0046] Add 13.69ml of phosphoric acid to 180ml of distilled water to obtain a phosphoric acid solution, add 1.9092g of copper oxide to the phosphoric acid solution, stir for 30min in a constant temperature water bath at 80°C, and cool to room temperature to obtain a solution (a); add 15.6000g of aluminum hydroxide to the solution In (a), stir vigorously for 30min, then add 30% of 8.15ml silica sol and 22.66ml morpholine, keep stirring evenly to obtain molecular sieve mother liquor;

[0047] Step C: Synthesis of Monolithic Catalysts

[0048] Put the cordierite carrier obtained in step A into the bottom bracket of the reactor, then add the mother liquor of molecular sieve obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com