Preparation method of ITO thin film

A thin film and coating technology, which is applied in the field of ITO thin film preparation, achieves the effects of high feasibility, low equipment cost and high work function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

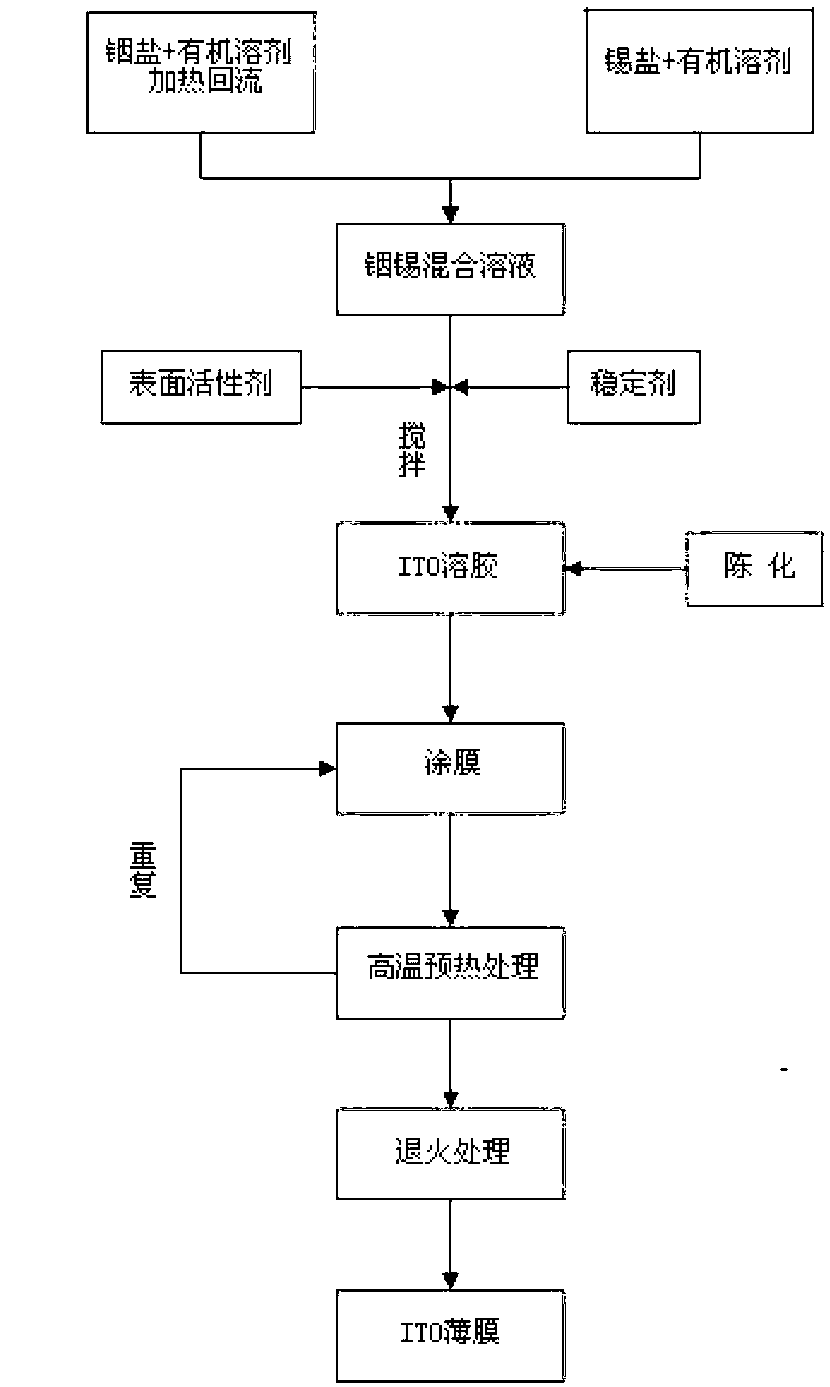

[0014] The embodiment of the present invention provides a kind of preparation method of ITO film, comprises the following steps:

[0015] S01. Prepare ITO sol: add stabilizer and surfactant to the mixed solution containing indium salt and tin salt for mixing and aging treatment to obtain ITO sol;

[0016] S02. Preparation of ITO thin film: the ITO sol is subjected to at least one post-coating drying treatment on the substrate, and then annealed to obtain an ITO thin film, wherein the annealing method is: dry the coated matrix in N 2 and H 2 Incubate at 450-700°C for 1-2h under a mixed atmosphere, wherein the N 2 and H 2 H in mixed atmosphere 2 The volume fraction is 1 to 4%.

[0017] Specifically, in the above-mentioned step S01, the preparation method of the mixed solution is not limited, it may be to dissolve the indium salt in an organic solvent, reflux, stir and heat at 55-70°C for 1-3h, and wait for it to cool to room temperature, specifically 20 At -30°C, mix it wi...

Embodiment 1

[0031] Embodiment one kind of preparation method of ITO thin film

[0032] Preparation of ITO sol: Dissolve indium trichloride in acetylacetone at 55°C for 1 h under reflux, dissolve tin dichloride dihydrate in a small amount of absolute ethanol, and then mix the two solutions at room temperature, wherein the Sn / (Sn+In)=5%, add a small amount of monoethanolamine, monostearic fatty acid glyceride, continue to stir for 1 hour, and then obtain ITO sol after aging for 3 hours.

[0033] Substrate treatment: Ultrasonic cleaning of quartz glass for 10 minutes, rinsing with deionized water for several times, boiling in acetone for 10 minutes, finally rinsing with methanol and deionized water in turn, followed by nitrogen blowing and drying in an oven at 70°C.

[0034] Coating film pulling: ITO film was prepared by dipping and pulling, the quartz glass substrate was vertically immersed in the gel for 20s, and pulled at a constant speed of 5cm / min to obtain a uniform sol film.

[0035...

Embodiment 2

[0037] Embodiment two a kind of preparation method of ITO thin film

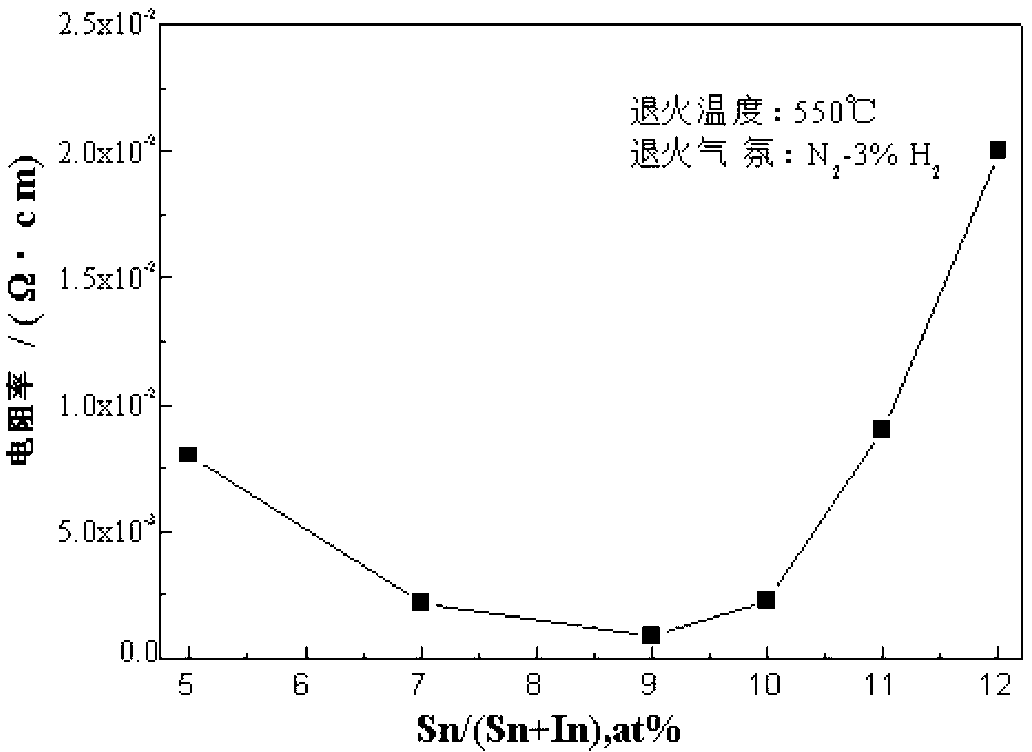

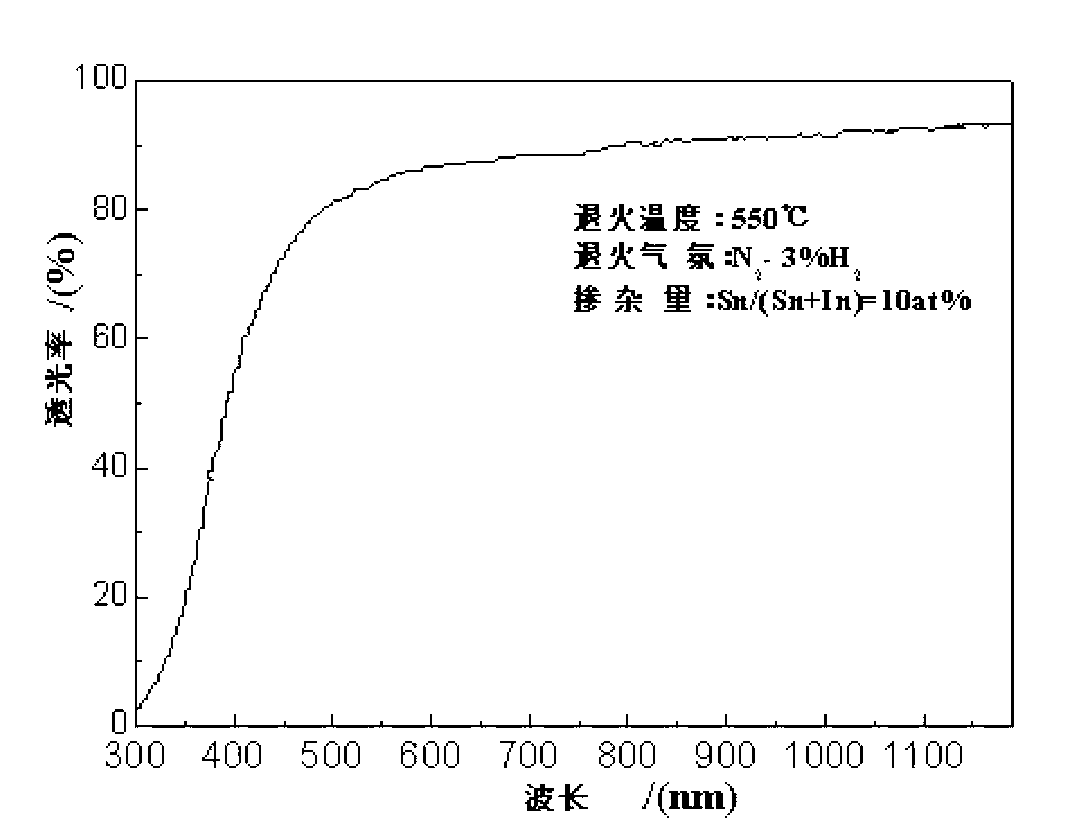

[0038] Sol preparation: dissolve indium chloride tetrahydrate in acetylacetone at 65°C and heat for 2 hours under reflux, anhydrous tin chloride is dissolved in a small amount of absolute ethanol, and then mix the two solutions at room temperature, in which the Sn / (Sn +In)=5-12%, add diethanolamine, polyoxyethylene sorbitan monooleate, continue to stir for 2 hours, and then age for 4 hours to obtain ITO sol.

[0039] Substrate treatment: Ultrasonic cleaning of quartz glass for 20 minutes, rinsing with deionized water for several times, boiling in acetone for 15 minutes, finally rinsing with methanol and deionized water in sequence, followed by nitrogen blowing and drying in an oven at 80°C.

[0040] Coating film pulling: ITO film was prepared by dipping and pulling, the quartz glass substrate was vertically immersed in the gel for 10s, and pulled at a constant speed of 10cm / min to obtain a uniform sol film. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com