Self-polishing anti-fouling resin and preparation method thereof

An antifouling resin and self-polishing technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of long time, low energy consumption, and difficult to achieve 100% grafting rate, etc. Achieve good fluidity, product stability, and shorten reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

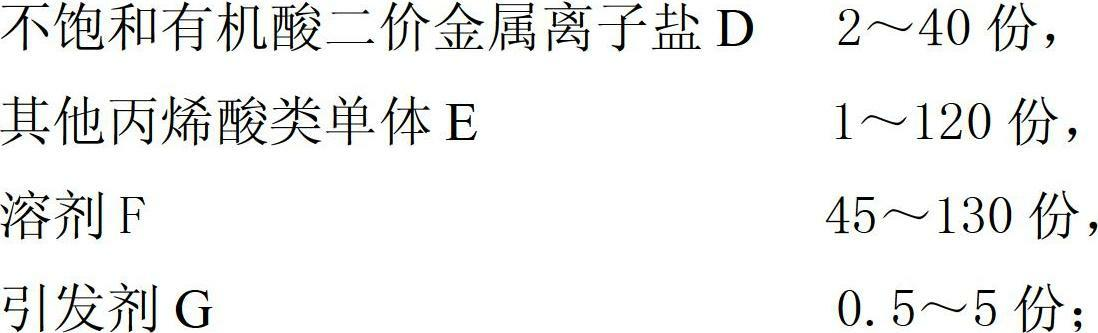

Method used

Image

Examples

Embodiment 1

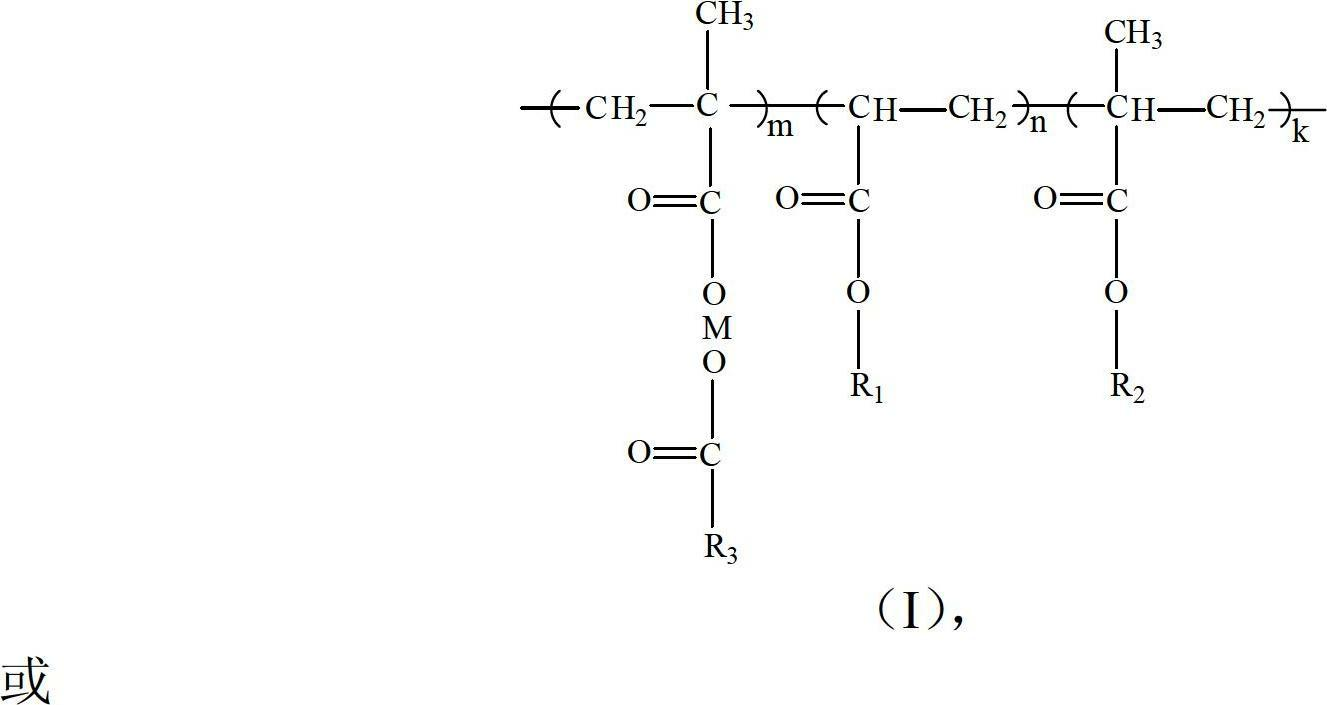

[0043] A self-polishing antifouling resin with the molecular formula:

[0044]

[0045] In the formula, M is Zn; R 1 , R 2 Both are methyl; R 3 is a methyl group; m, n, and k are respectively integers greater than 1; the number average molecular weight of the self-polishing antifouling resin is 7000-9000, and the polydispersity coefficient is ≤5.

Embodiment 2

[0047] A kind of self-polishing antifouling resin, molecular formula is the same as embodiment 1, difference is: in formula, M is Cu; R 1 is ethyl; R 2 is propyl; R 3 is phenyl; m, n, k are respectively integers greater than 1; the number average molecular weight of the self-polishing antifouling resin is 10,000-12,000, and the polydispersity coefficient is ≤5.

Embodiment 3

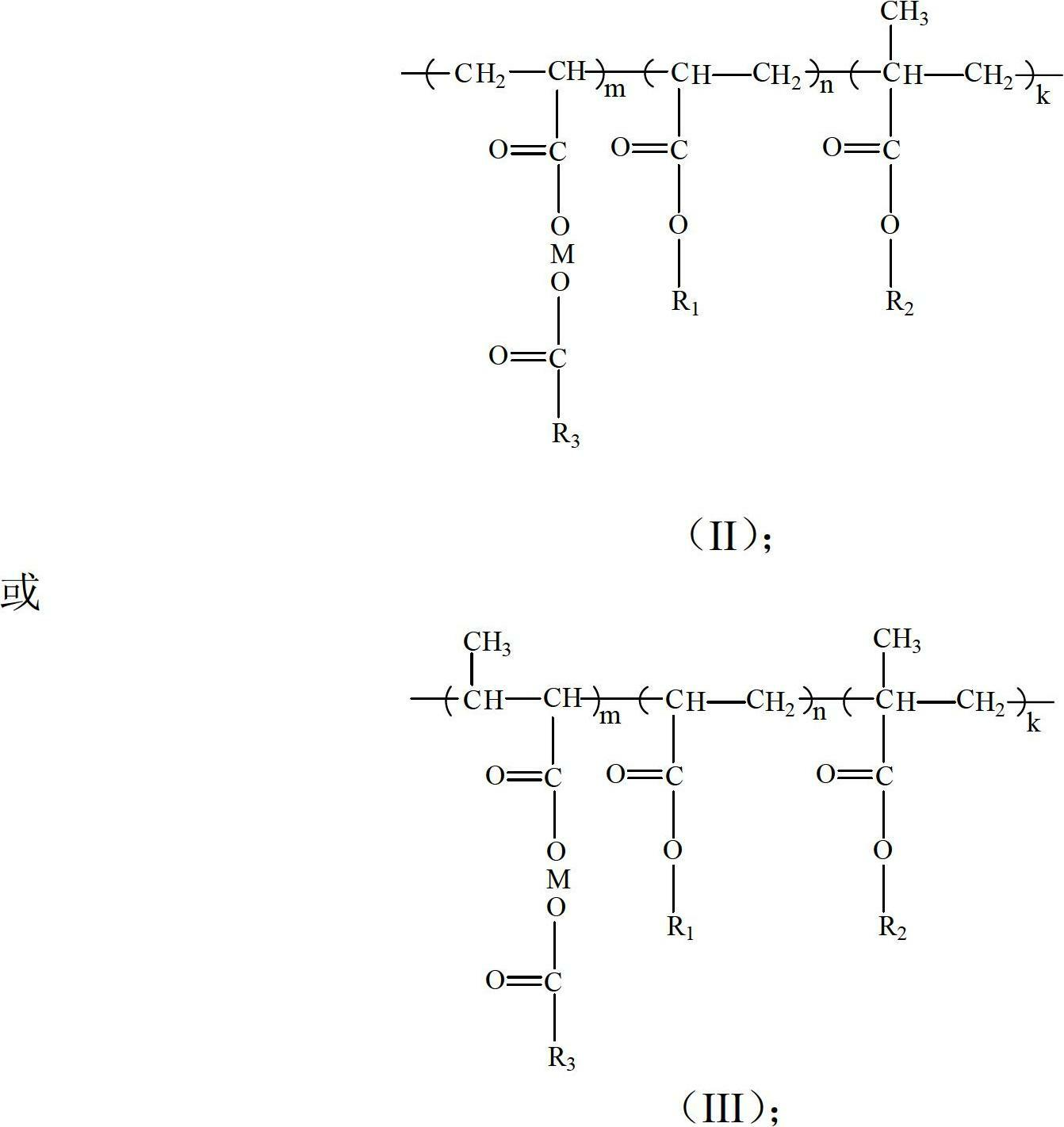

[0049] A self-polishing antifouling resin with the molecular formula:

[0050]

[0051] In the formula, M is Ca; R 1 is n-pentyl; R 2 is butyl; R 3 is phenyl; m, n, k are respectively integers greater than 1; the number average molecular weight of the self-polishing antifouling resin is 30,000-35,000, and the polydispersity coefficient is ≤5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com