Patents

Literature

184 results about "Anti-fouling paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-fouling paint - a category of commercially available underwater hull paints (also known as bottom paints) - is a specialized category of coatings applied as the outer (outboard) layer to the hull of a ship or boat, to slow the growth and/or facilitate detachment of subaquatic organisms that attach to the hull and can affect a vessel's performance and durability (see also biofouling). Anti-fouling paints are often applied as one component of multi-layer coating systems which may have other functions in addition to their antifouling properties, such as acting as a barrier against corrosion on metal hulls that will degrade and weaken the metal, or improving the flow of water past the hull of a fishing vessel or high-performance racing yachts.

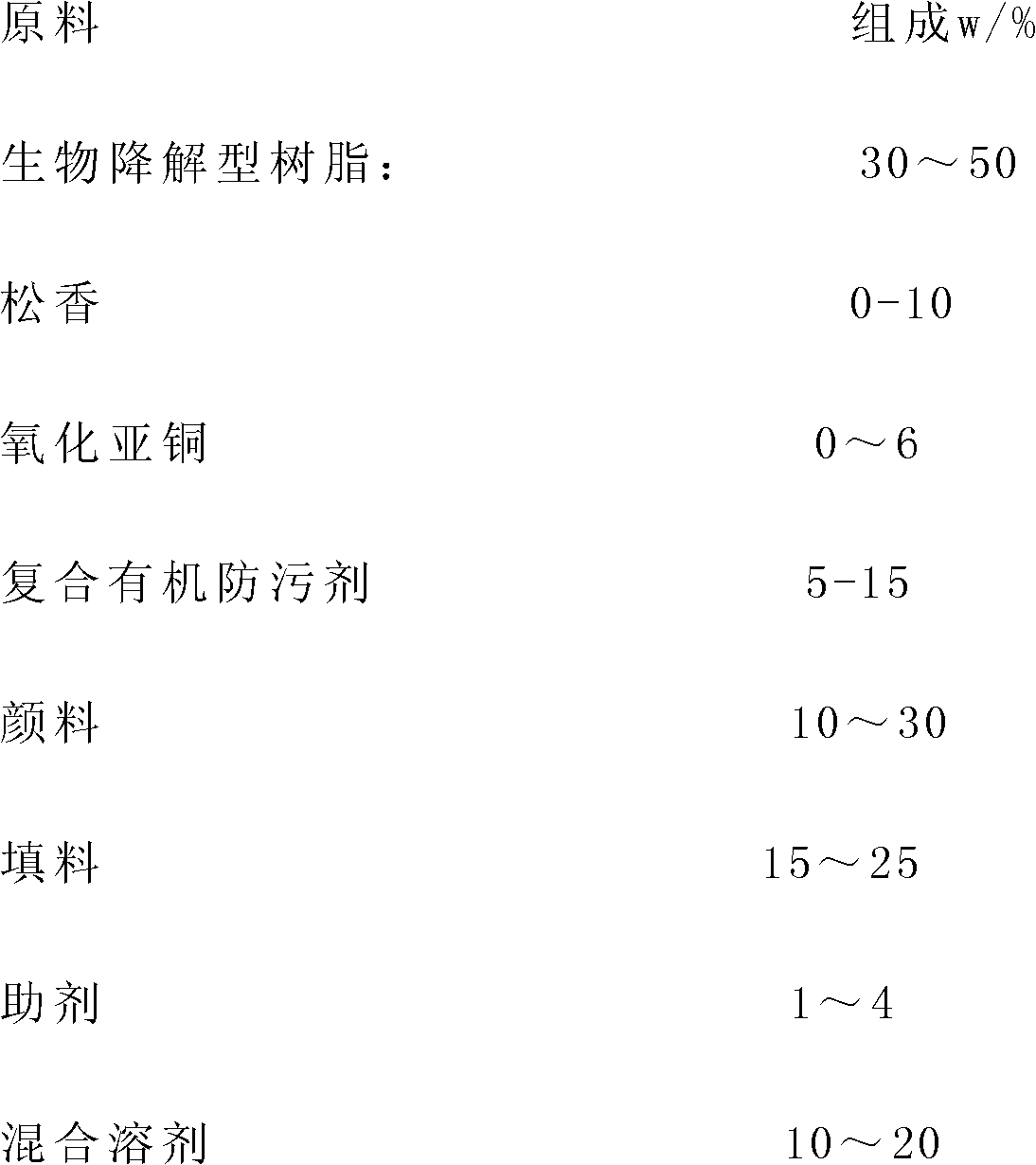

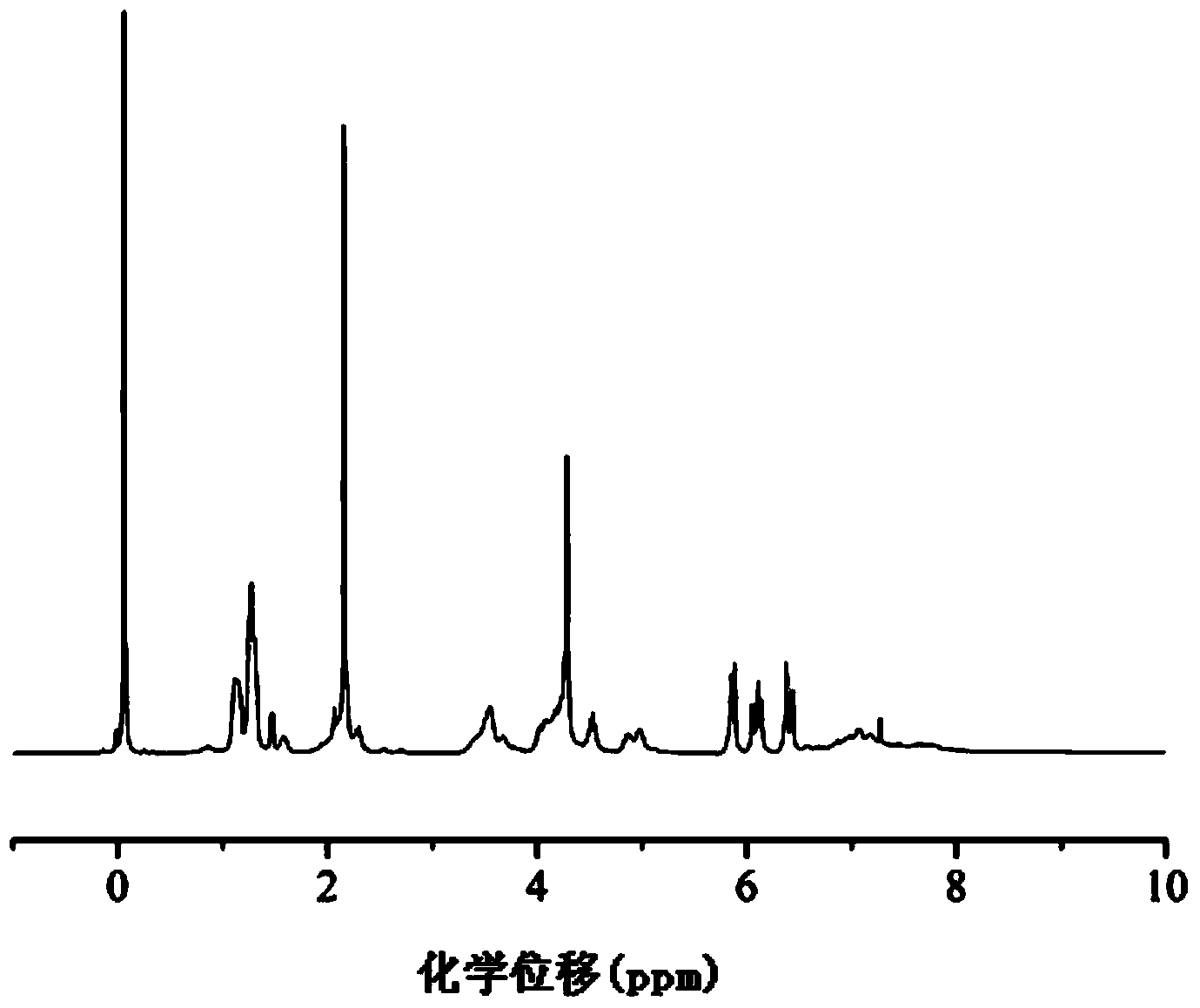

Resin for biodegradable anti-fouling paint, synthetic method of the same, and anti-fouling paint composition containing the same

ActiveCN102432802AReduce dosageHigh requirements for reaction conditionsAntifouling/underwater paintsPaints with biocidesCompound organicEnvironmental resistance

The invention provides a resin for a biodegradable anti-fouling paint. The resin for the biodegradable anti-fouling paint is a polymer containing a multi-block structure, characterized in that: the resin is prepared by polymerizing by polylactic acid oligomer, flexible segments, polyisocyanates under the effect of catalysts, wherein, the polylactic acid oligomer is prepared by carrying out reflux reaction on lactic acid having a monomer content of 80-85 % and aromatic solvents under negative pressure or normal pressure until no water generates; the flexible segments comprises polyols or / and polyester polyols; and the amount of the flexible segments accounts for 5-30 % of the weight percentage of the lactic acid raw material; and the amount of polyisocyanates accounts for 10-30 % of the weight percentage of the lactic acid raw material. The invention further provides a biodegradable anti-fouling paint composition containing the resin as a matrix resin. The anti-fouling paint contains composite organic antifouling agent and contains no or little cuprous oxide, and has the advantages of low toxicity, environmental protection, and good anti-fouling effect.

Owner:MARINE CHEM RES INST CO LTD

Ultraviolet light curing anti-fouling paint and preparation method thereof

ActiveCN103642382AImprove mechanical propertiesImprove hydrolysis resistanceAntifouling/underwater paintsPaints with biocidesUltraviolet lightsDiluent

The invention discloses an ultraviolet light curing anti-fouling paint and a preparation method thereof to solve the technical problems of high cost, poor anti-fouling effect and endurance of an ultraviolet light curing anti-fouling paint in the prior art. The curing anti-fouling paint provided by the invention comprises by weight 38-116 parts of multifunctional fluorine-containing fluorosilicone containing polyurethane acrylate, 3-8 parts of multifunctional polyurethane acrylate, 12-18 parts of a multifunctional acrylate diluent, 0.4-1.5 parts of a photoinitiator, 0.15-0.55 part of a leveling agent and 0.1-0.7 part of a defoaming agent. The film of the anti-fouling paint provided by the invention has excellent compactness, fungal resistance and low surface energy, strong stain resistance and good anti-fouling endurance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Low surface energy nano polyurethane anti-fouling paint and preparation method thereof

ActiveCN102433062AUniform micro-nanostructureEvenly dispersedAntifouling/underwater paintsPaints with biocidesToxicantAcrylic resin

The invention, belonging to the field of paints, discloses a low surface energy nano polyurethane anti-fouling paint and a preparation method thereof. The paint is mainly applied in preventing fouling for ships. The low surface energy nano polyurethane anti-fouling paint comprises 20-60 wt% of organosilicon modified acrylic resin, 0.5-10 wt% of polydimethylsiloxane resin, 0.5-10 wt% of fluoroal kylsilane modified nano silicon dioxide, 20-40 wt% of extender pigment, 5-15 wt% of auxiliary agent, and 10-30 wt% of organic solvent. The preparation method comprises the following steps: 1) carrying out surface treatment with fluoroal kylsilane on nano silicon dioxide; 2) preparing the treated fluoroal kylsilane modified nano silicon dioxide into a concentrated slurry; and 3) mixing the fluoroal kylsilane modified nano silicon dioxide concentrated slurry with other raw materials to obtain a component A of the anti-fouling paint; dissolving a curing agent to obtain a component B, adding the component A in the component B, curing 30 min-15 day at a temperature of 10-30 DEG C to form the low surface energy nano polyurethane anti-fouling paint. The anti-fouling paint prepared by using a new technique of nanoparticle treatment has the advantages of low surface energy, no toxicant release, safety, and environmental protection.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

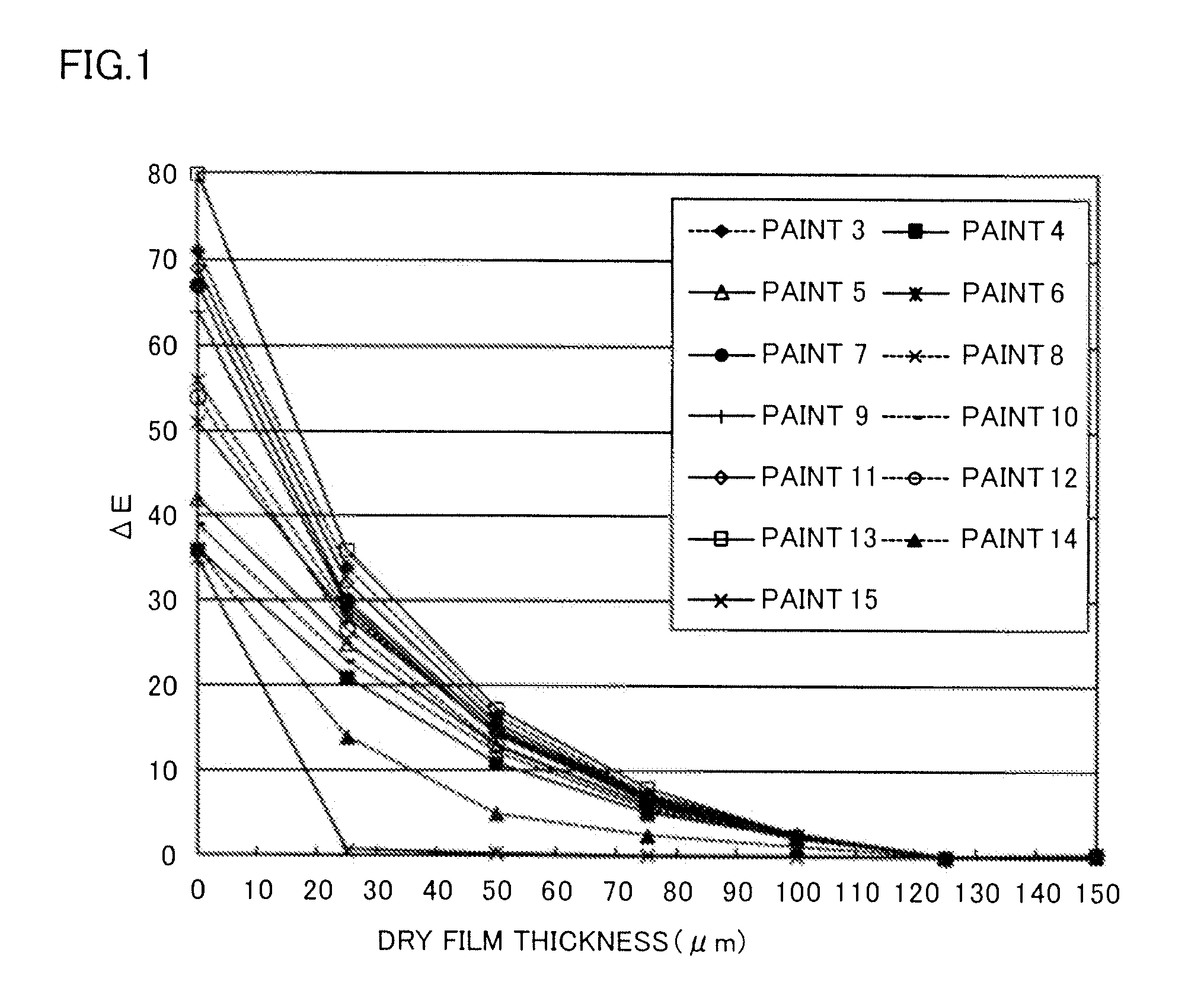

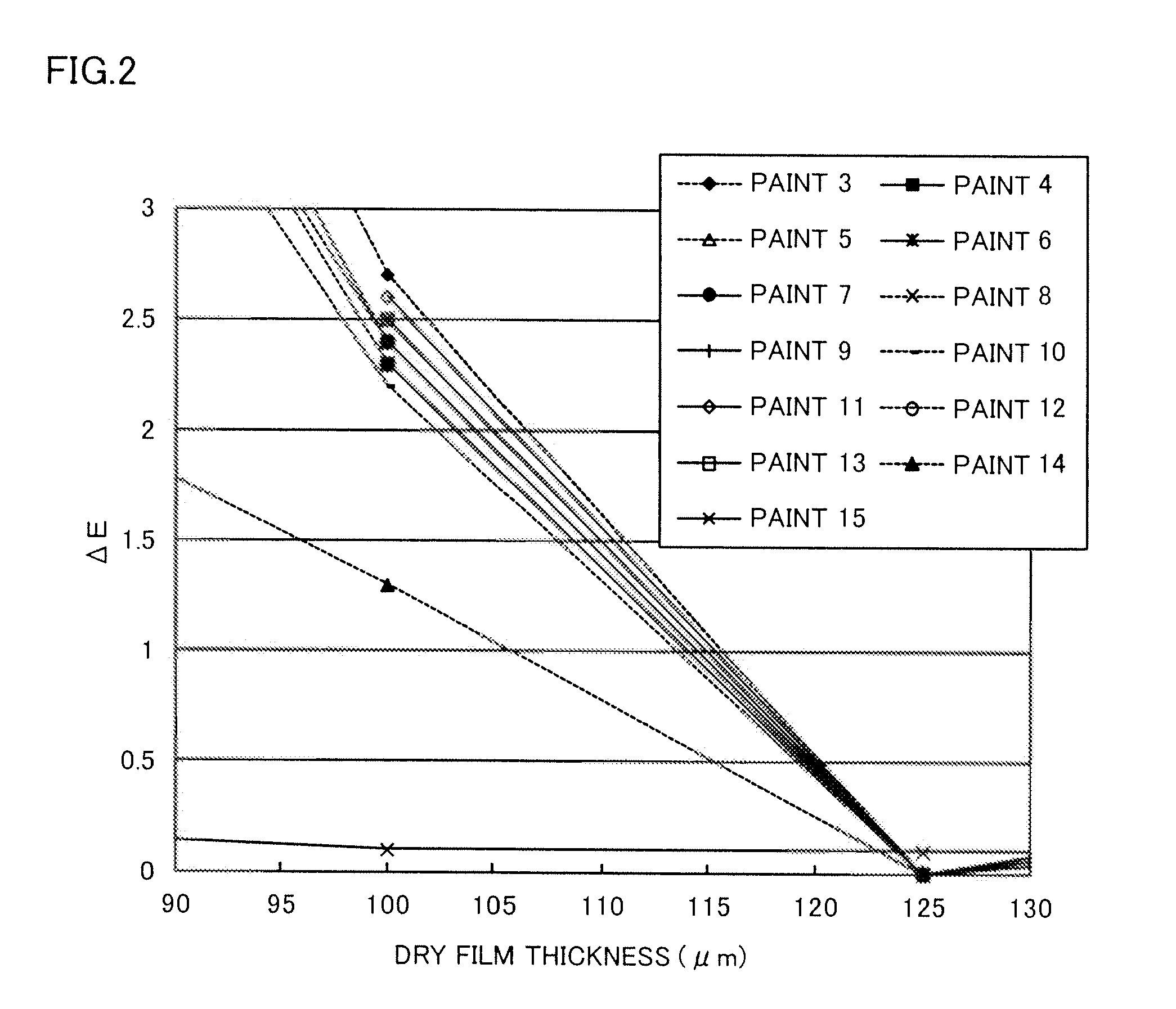

Method of forming antifouling coating film

ActiveUS20120294825A1Paint be saveResistant to crackAntifouling/underwater paintsPaints with biocidesColor differencePolymer chemistry

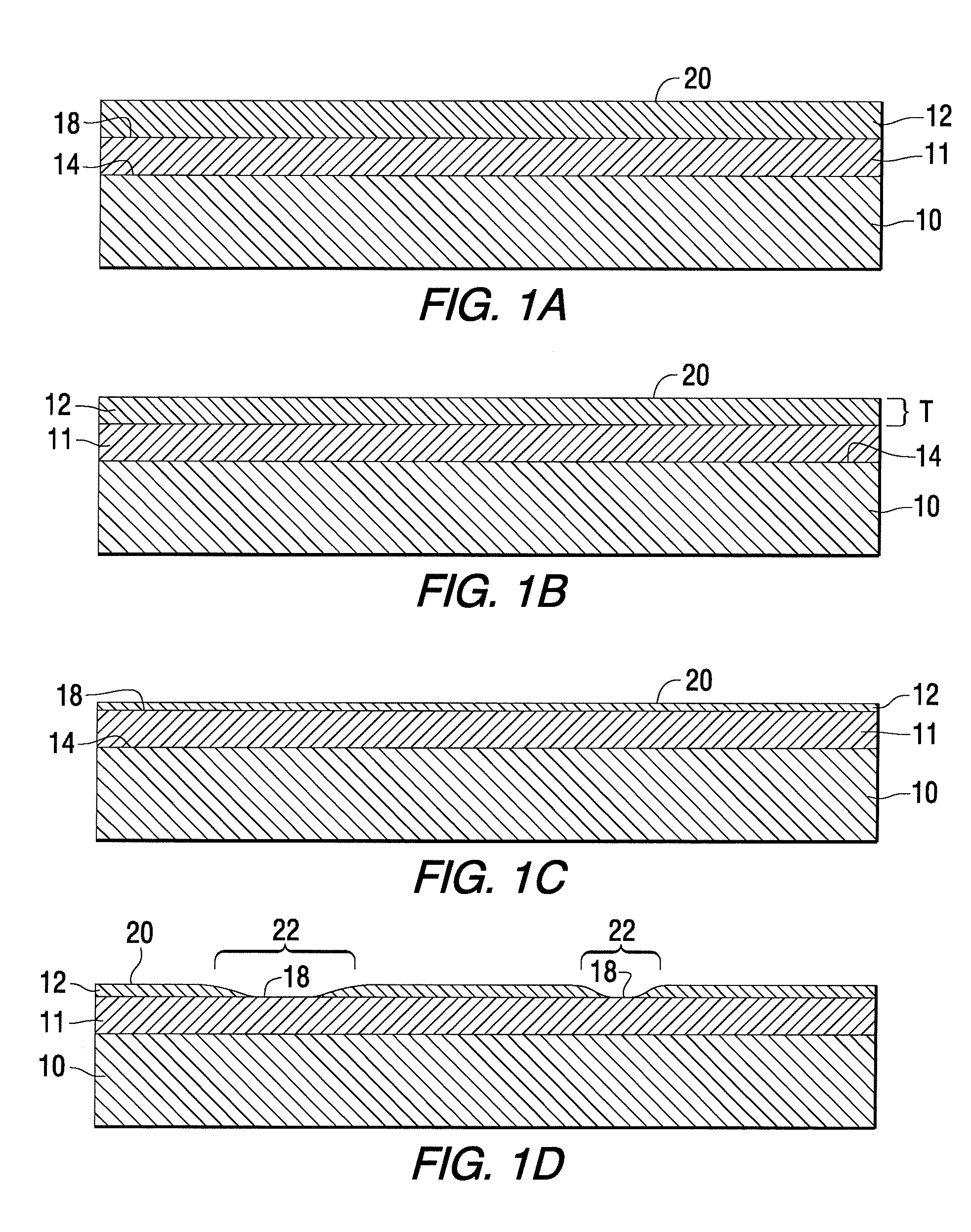

Provided is a method of forming an antifouling coating film including the steps of [1] preparing a colored antifouling paint containing a prescribed Si-containing hydrolyzable resin and a color pigment such that a coating film having a target dry film thickness T completely hides a surface of an object to be coated, the colored antifouling paint has a color difference ΔE1 between the coating film having the thickness T and a coating film having a dry film thickness of 0.8 T, at least 2.0, and preferably the colored antifouling paint has a color difference ΔE2 between the coating film having the thickness T and a coating film having a dry film thickness of 1.2 T, less than 1, and [2] coating a surface of the object with the colored antifouling paint until the surface of the object is completely hidden by the coating film formed from the colored antifouling paint.

Owner:NIPPON PAINT MARINE COATINGS

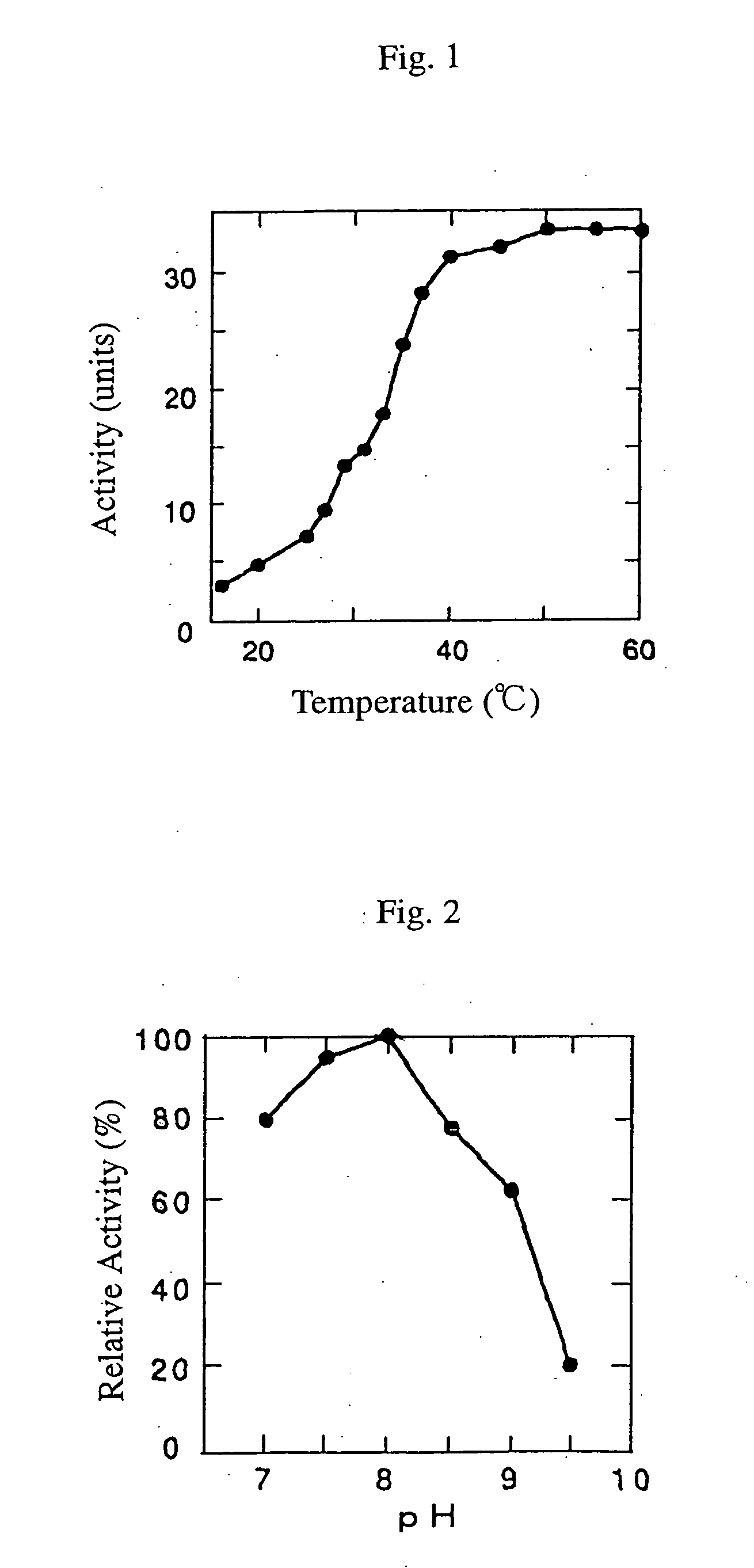

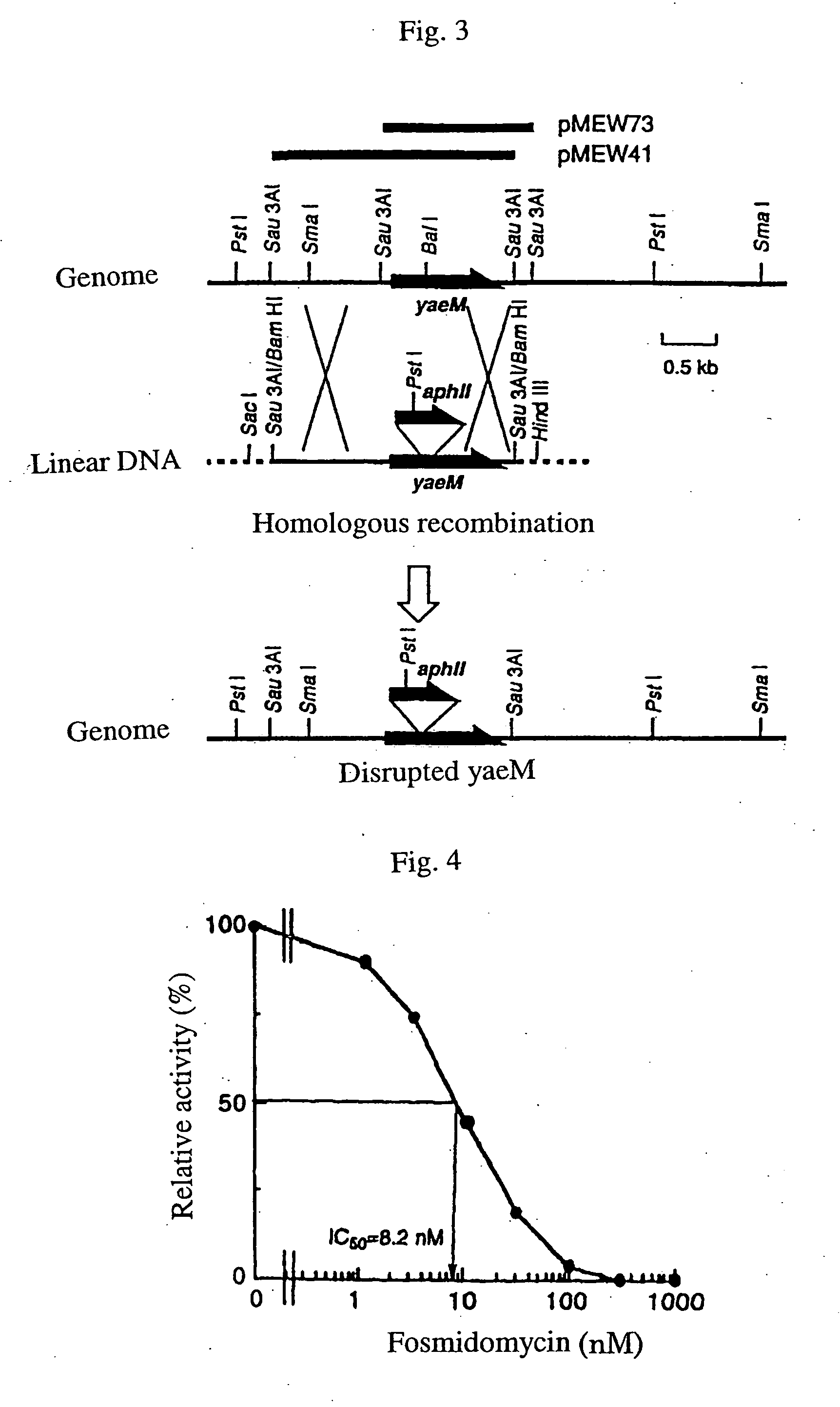

Process for producing isoprenoid compounds by microorganisms and a method for screening compounds with antibiotic or weeding activity

InactiveUS20070004000A1Improve efficiencyImprove productivityBiocideBacteriaPrenylationAnti-fouling paint

The present invention provides a process for producing isoprenoid compounds or proteins encoded by DNA using DNA that contains one or more of the DNA encoding proteins having activity to improve efficiency in the biosynthesis of isoprenoid compounds effective in pharmaceuticals for cardiac diseases, osteoporosis, homeostasis, prevention of cancer, and immunopotentiation, health food and anti-fouling paint products against barnacles; the DNA; the protein; and a method for screening a substance with antibiotic and weeding activities comprising screening a substance inhibiting enzymatic reaction on the non-mevalonate pathway.

Owner:KYOWA HAKKO KOGYO CO LTD

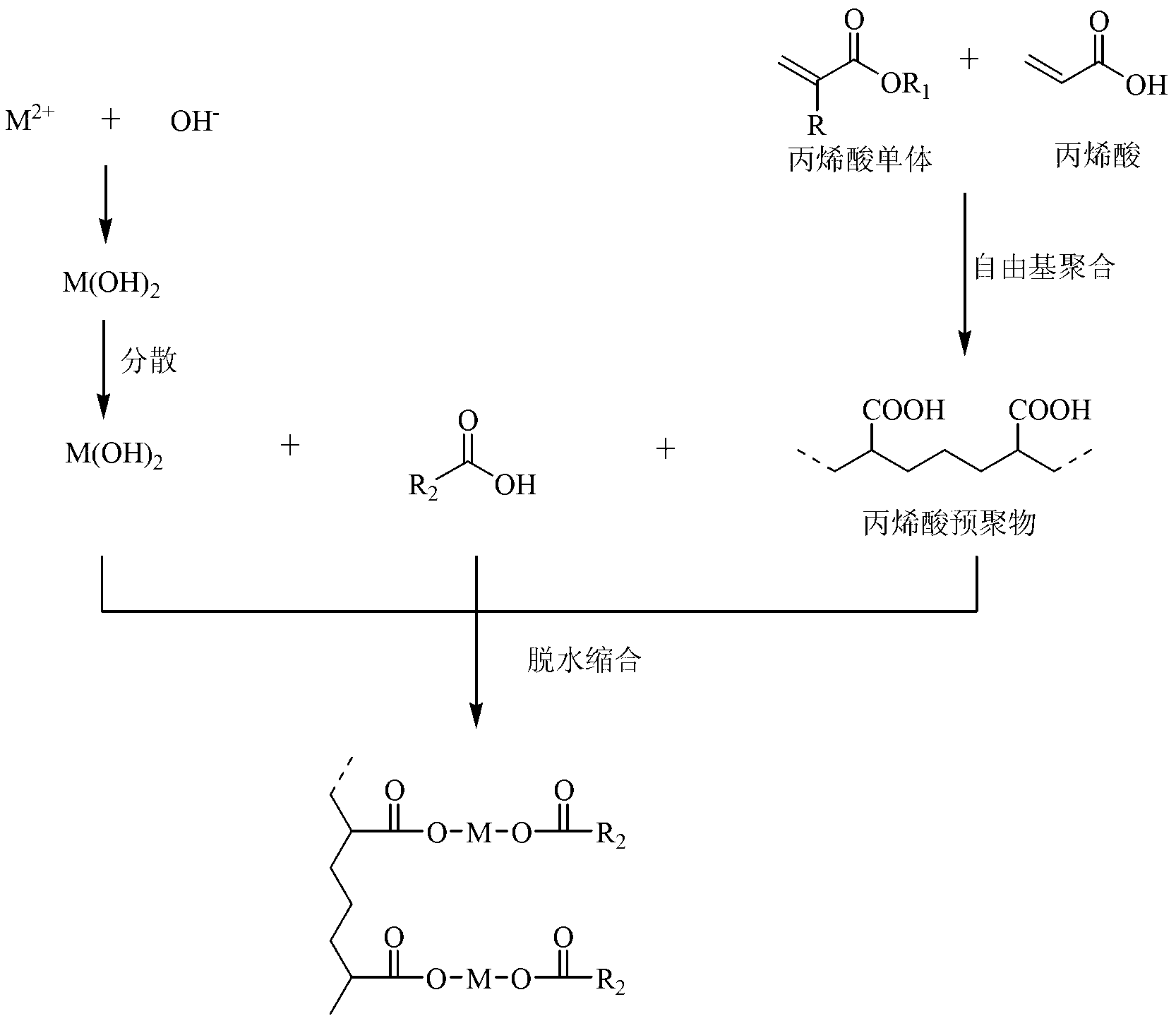

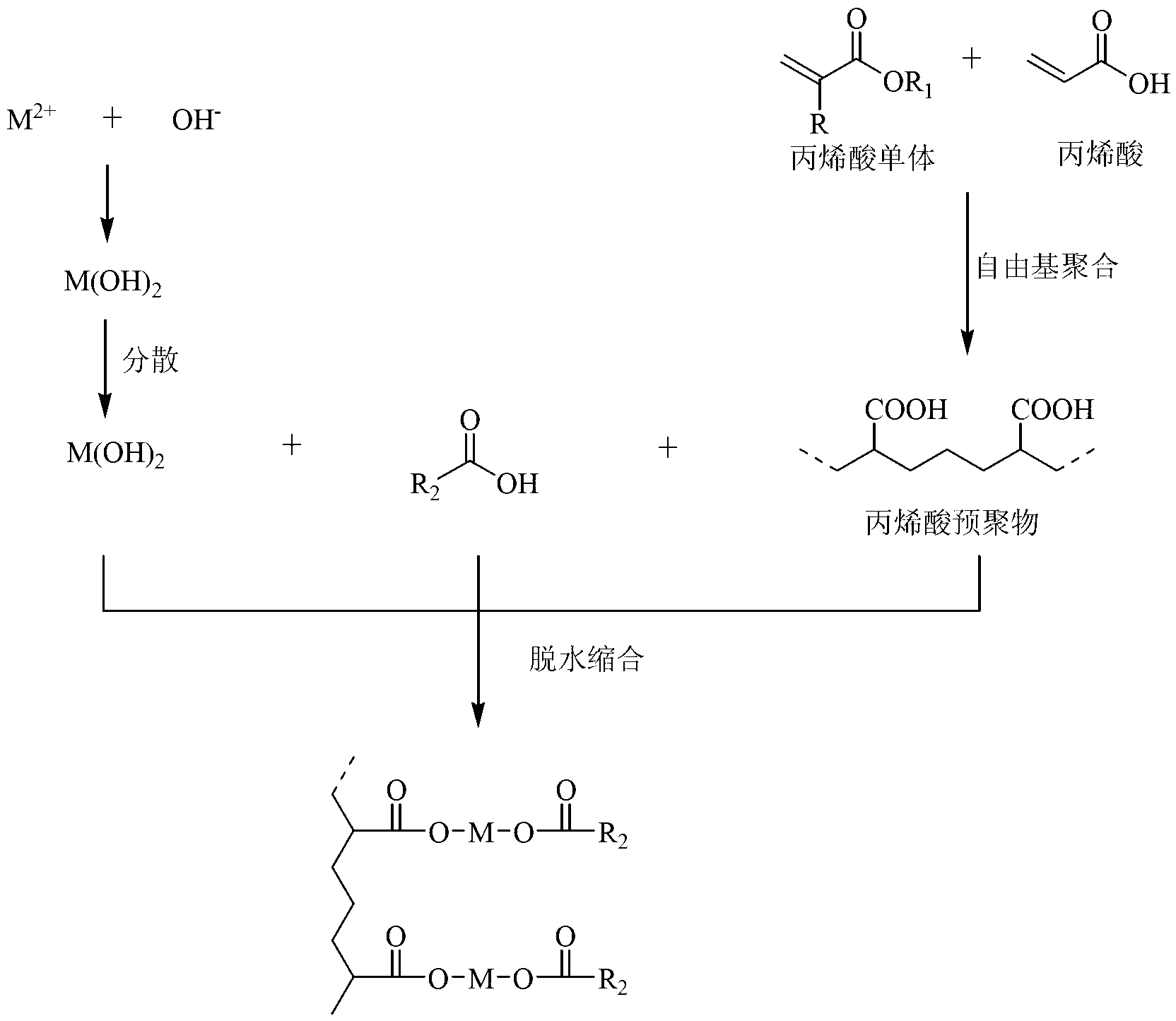

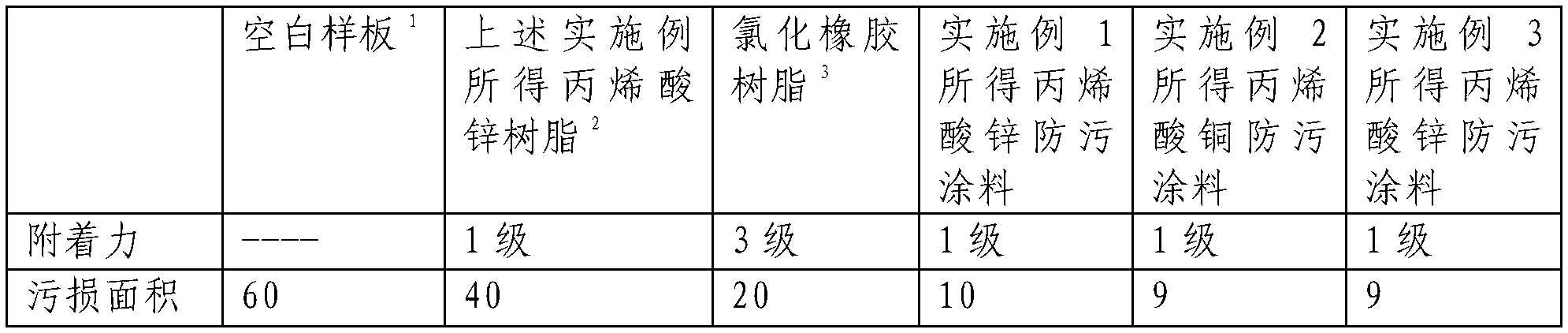

Improved preparation method for zinc/copper acrylate resin

ActiveCN103289007AGood dispersionNo additional costAntifouling/underwater paintsPaints with biocidesHydrolysisAnti-fouling paint

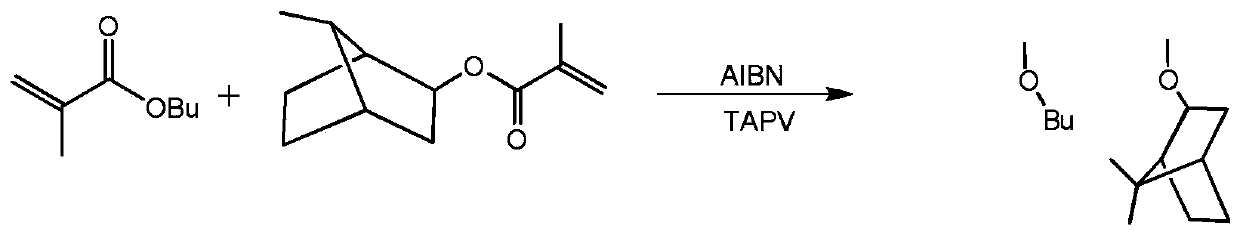

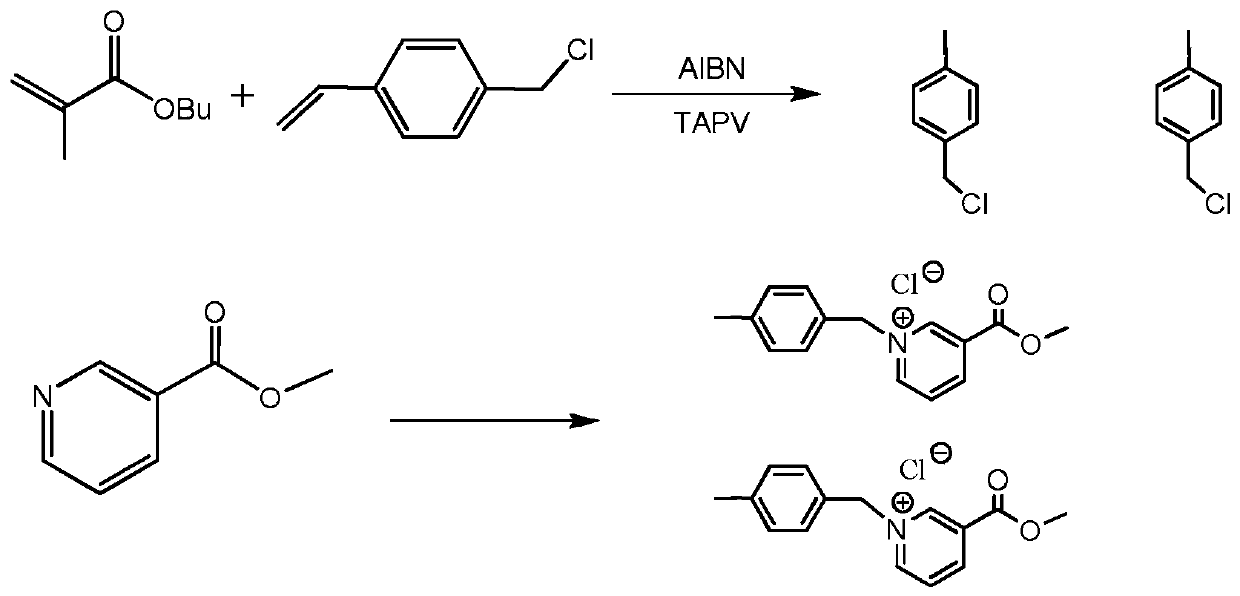

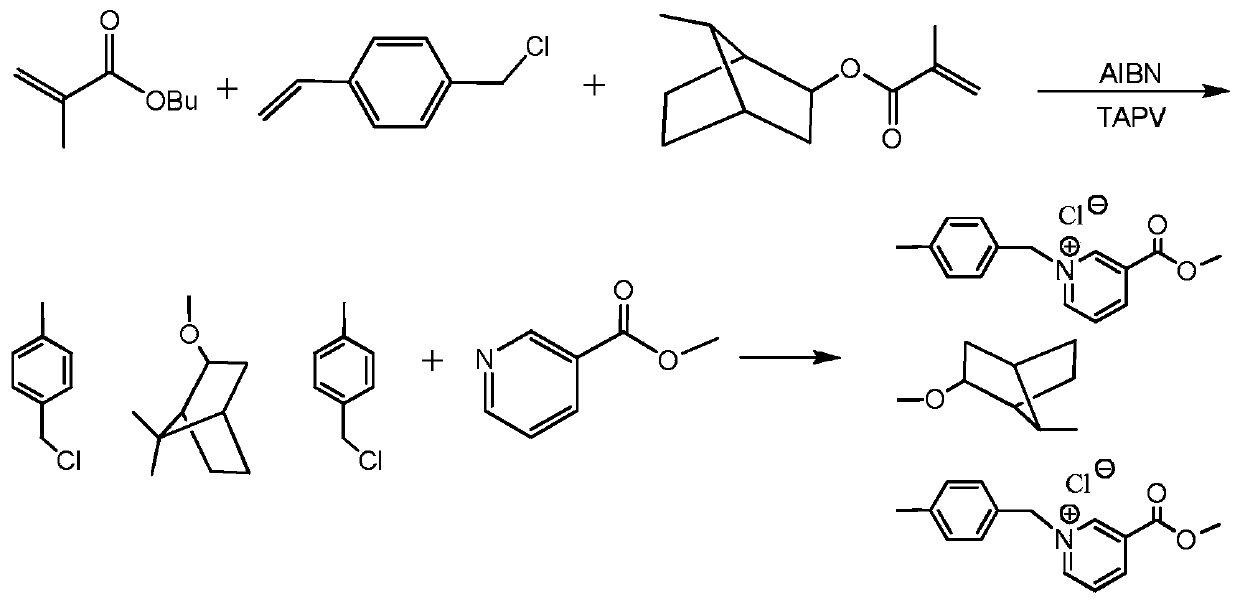

The invention specifically relates to an improved preparation method for a zinc / copper acrylate resin, which belongs to the technical field of marine anti-fouling paints. The preparation method comprises the following steps: with a mixed system of water and an organic solvent as a disperse medium, reacting a metal salt solution with aqueous alkali to produce zinc / copper hydroxide, fully dispersing the zinc / copper hydroxide in a dispersant and then carrying out filtering and drying so as to obtain high-dispersibility zinc / copper hydroxide; subjecting soft and hard monomers of acrylic acid to free radical polymerization under the action of an initiator at a constant temperature so as to produce an acrylic prepolymer containing a carboxyl group; and reacting the acrylic prepolymer obtained in the previous step with the dispersed zinc / copper hydroxide under the action of an organic acid at a constant temperature so as to prepare the zinc / copper acrylate resin with hydrolysis characteristics. According to the invention, the zinc / copper hydroxide prepared in the invention has good dispersibility and no agglomeration and needs short reaction time during reaction with the acrylic prepolymer, so cost is low, and original equipment does not need to be improved.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

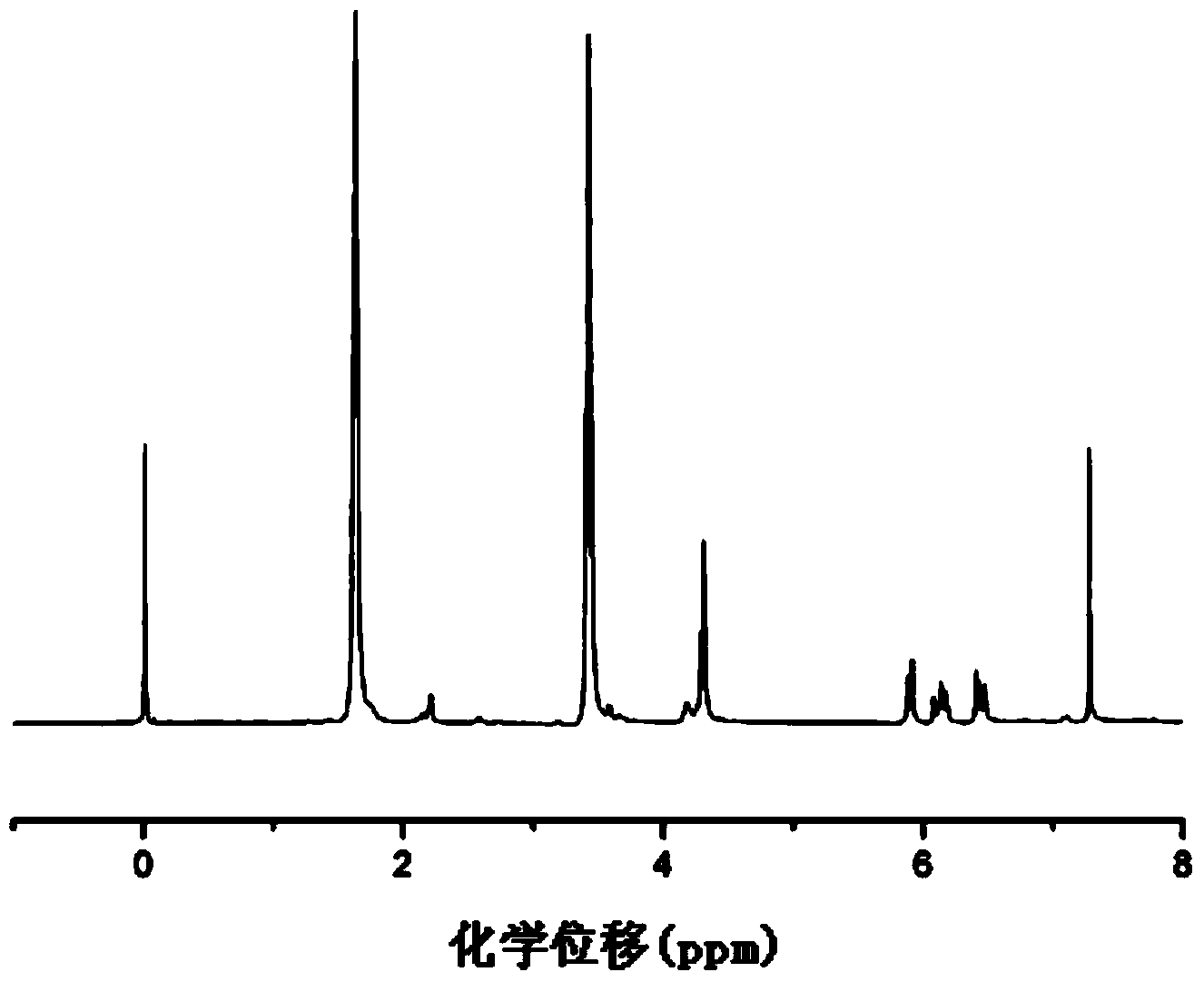

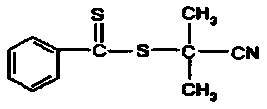

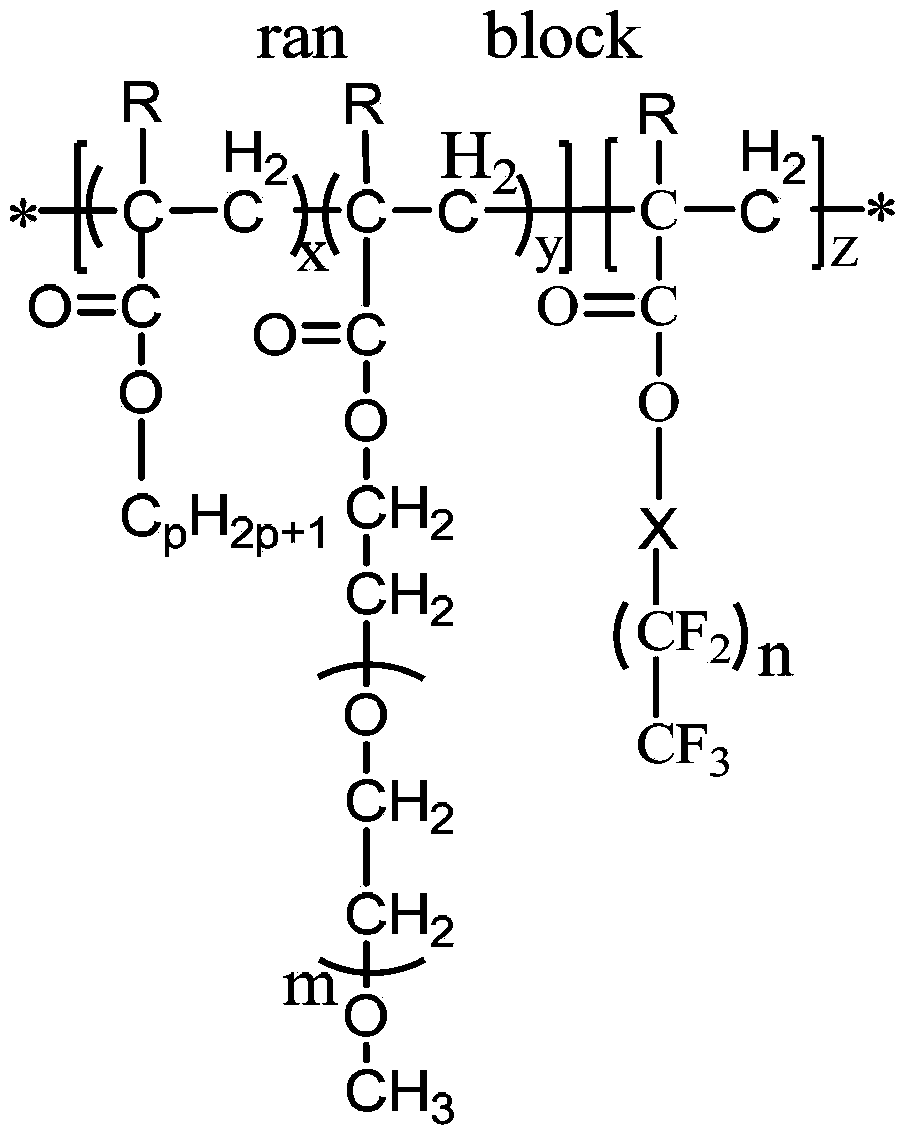

Amphiphilic fluorine-containing block copolymer resin, and preparation method and application thereof

InactiveCN103450419ASimple preparation processGood antifoulingAntifouling/underwater paintsPaints with biocidesHydrophilic monomerPolymer science

The invention relates to an amphiphilic fluorine-containing block copolymer resin, and a preparation method and application thereof. The structural general formula of the amphiphilic fluorine-containing block copolymer resin is as shown in formula (1). In the formula, R=CH3 or H; x=15.0-50.0, y=3.0-20.0, z=3.0-10.0, p=1 or 4, m=3.0-25.0, and n=3 or 5; and X is -(CH2)k- or -(CH2)k-N(ChH2h+1)-SO2-. The amphiphilic fluorine-containing block copolymer resin is prepared through a two-step reversible addition-fragmentation chain transfer-free radical polymerization (RAFT) method. The method comprises the following steps: preparing a random copolymer from a hydrophilic monomer and a hydrophobic monomer, and adding fluorine-containing components into the random copolymer serving as a macromolecular chain transfer agent to generate the amphiphilic fluorine-containing block copolymer. The amphiphilic fluorine-containing block copolymer resin is simple in preparation process, non-toxic, harmless and favorable in anti-fouling effect, and can be used for preparation of base materials of marine anti-fouling paint. Formula (1) is shown in the specification.

Owner:ZHEJIANG UNIV +1

Method for preparation of zinc or copper containing acrylic acid resin

A process for preparing acrylic resin containing zinc or copper characterized in that zinc or copper basic salt of organic acid is first synthesized, and acrylic resin containing carboxyl is then synthesized, thus obtaining the acrylic resin containing zinc or copper through the reaction between the zinc or copper basic salt of organic acid with the acrylic resin containing carboxyl. The acrylic resin containing zinc or copper can act as film forming article to be used in self-polishing anti-fouling paint containing no organotin, so as to prevent the adhesion of sea creatures on vessels and coastal facilities.

Owner:OCEAN UNIV OF CHINA

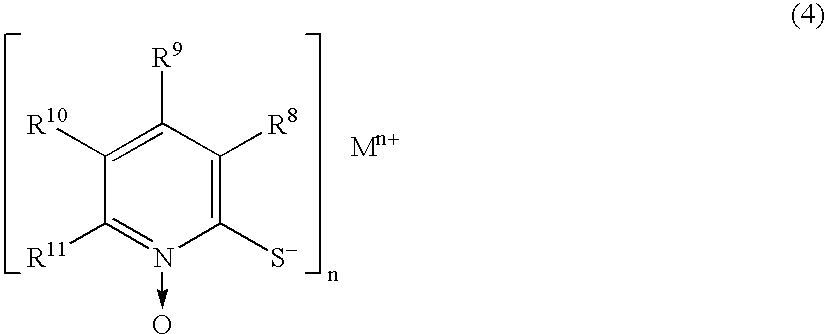

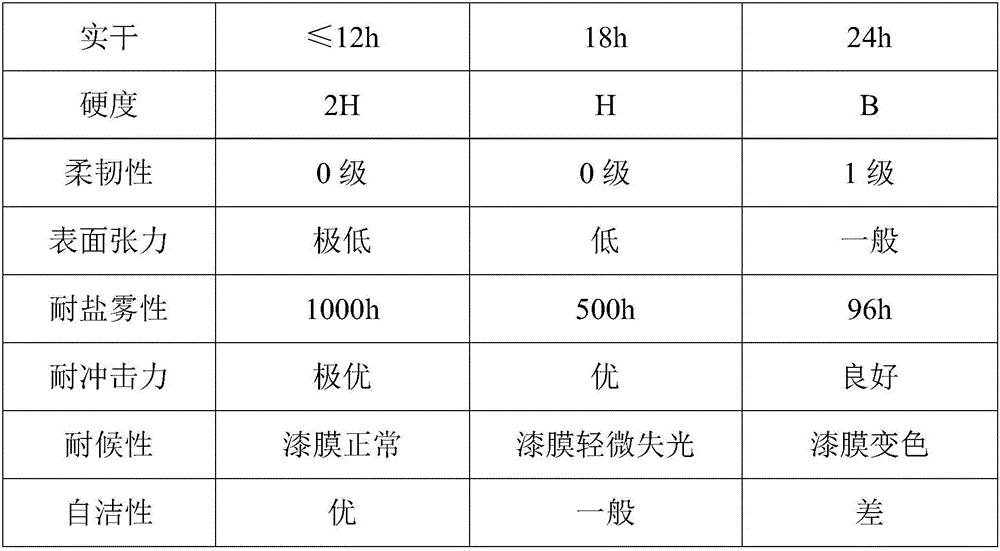

Antifouling paint composition, antifouling paint films, and, ships, underwater underwater structures, fishing gear and fishing nets covered with the films

An antifouling coating composition substantially not containing cuprous oxide and organotins, characterized by comprising (A) a metal-containing copolymer obtained by copolymerization of a polymerizable unsaturated monomer (a1) containing a metal and an unsaturated monomer (a2) capable of radical polymerization containing no metals; (B) 4,5-dichloro-2-n-octyl-4-isothiazolin-3-one; and (C) a metal pyrithione compound. There are provided an antifouling coating composition, antifouling coating film and, covered with the antifouling coating film, marine vessel, underwater structure and fishing gear or fishing net, which can reduce burdens on the environment, exhibiting excellent antifouling performance, and which excel in not only uniform wasting of coating film but also capability of maintaining antifouling performance of coating film for a prolonged period of time.

Owner:CHUGOKU MARINE PAINTS

Organic-polymer-coated nano cuprous oxide and its preparation process and use

InactiveCN1702120ASimple production processEasy to industrializeAntifouling/underwater paintsPaints with biocidesDispersityReaction temperature

A nanometer copper-protoxide coated with organic polymer, characterized in that the grain diameter of copper-protoxide particles is from 1 to 100nm, and that the surface is coated with organic polymer, range of weight ratio of copper-protoxide particle to organic polymer being 60-90: 0.1-18. In the water solution of organic polymer, and with alkali halide and alkali weak acid salt, deoxidize divalent nantokite with reducer, and separate the resultant, the reaction temperature of said reaction being from 10 to 100 Deg. C, reaction time from 1 to 8 hours, and PH of the reaction liquid from 5 to 7. The advantage of the nanometer copper-protoxide coated with organic polymer is that, manufacturing technique is simple, and facilitated to industrialization, at the same time, the easily-reuniting problem of nanometer particulars is settled; it has a good dispersity in anti-fouling paint, a strong power of oxidation resistance, extensive and strong antifouling ability, and cohesion to paint filming material to make perfect mechanical property of paint.

Owner:OCEAN UNIV OF CHINA

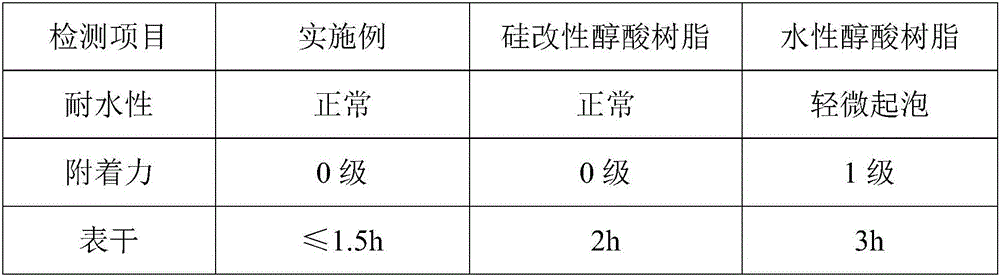

Fluorine-silicon modified waterborne alkyd resin and preparing method thereof

ActiveCN106117449AWith shielding protectionImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesAcid anhydride formationStain

The invention relates to a fluorine-silicon modified waterborne alkyd resin and a preparing method thereof. The fluorine-silicon modified waterborne alkyd resin is prepared from vegetable oil fatty acid, organic acid anhydride, polyol, fluorinated allyl monomers, isocyanate, hydroxyl-terminated organic silicon, acrylic monomers and deionized water. Single-component waterborne paint, double-component waterborne paint and room-temperature curing paint can be blended with the fluorine-silicon modified waterborne alkyd resin prepared through the method. The prepared fluorine-silicon modified waterborne alkyd resin has the performance such as high adhesion, stain resistance, high hardness, water resistance, durability, hydrophobicity and self-cleaning performance, and can be widely applied to waterborne wood paint, waterborne industrial paint, waterborne anti-fouling paint, waterborne corrosion resistance paint, waterborne special engineering paint such as radar dome materials, wind power generation, nuclear power and vessel paint and the like.

Owner:湖南大禹防水建材科技有限公司

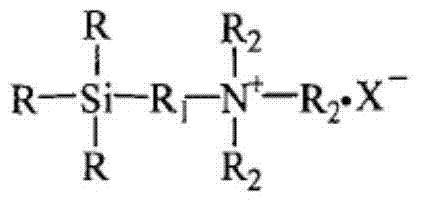

Nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint and preparation method thereof

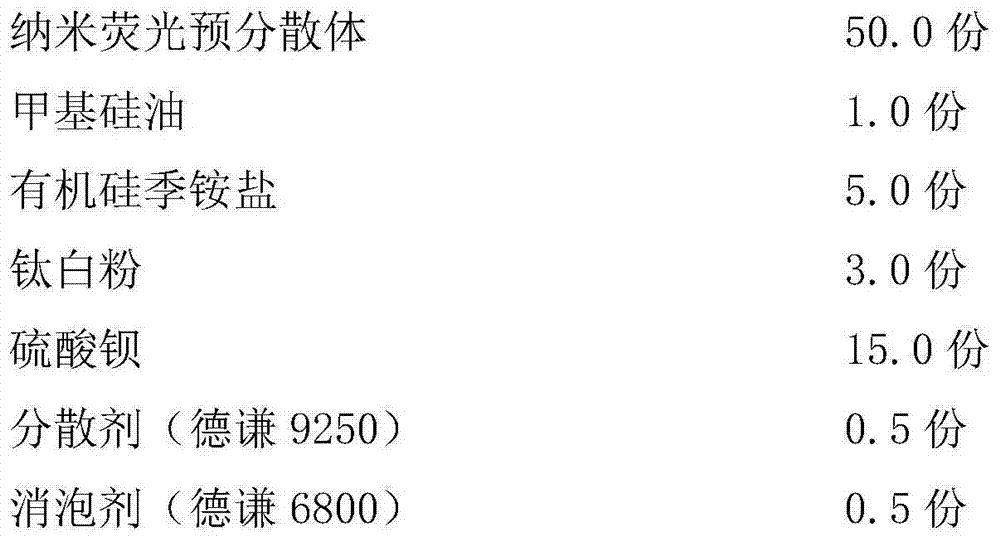

ActiveCN104327721AEasy to buyEasy to synthesizeAntifouling/underwater paintsLuminescent paintsMarine aquacultureFluorescence

The invention discloses a nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint, which comprises the following components by weight: 25-35 parts of component A, 2-5 parts of component B and 1 part of component C; the component A comprises 25.0-50.0 parts of nano fluorescence pre-dispersion, 5-25.0 parts of organosilicon quaternary ammonium salt and 0.5-5.0 parts of silicone oil; the component B comprises 3.0-50.0 parts of crosslinking curing agent and 1.0-10.0 parts of silane coupling agent; The component C comprises 0.1-3.0 parts of catalyst; and the catalyst is at least one of stannous octoate, dibutyl tin diacetate and dibutyltin dilaurate. The paint has long persistence luminescent performance, has can prevent pollution by depending on fluorescence and enables contact sterilization, and has advantages of excellent antifouling performance, high strength and high adhesive force, can be used for various ships, sea petroleum platforms, marine structure and facility, marine aquaculture nets.

Owner:DALIAN MARITIME UNIVERSITY

Slow release type biological anti-fouling paint

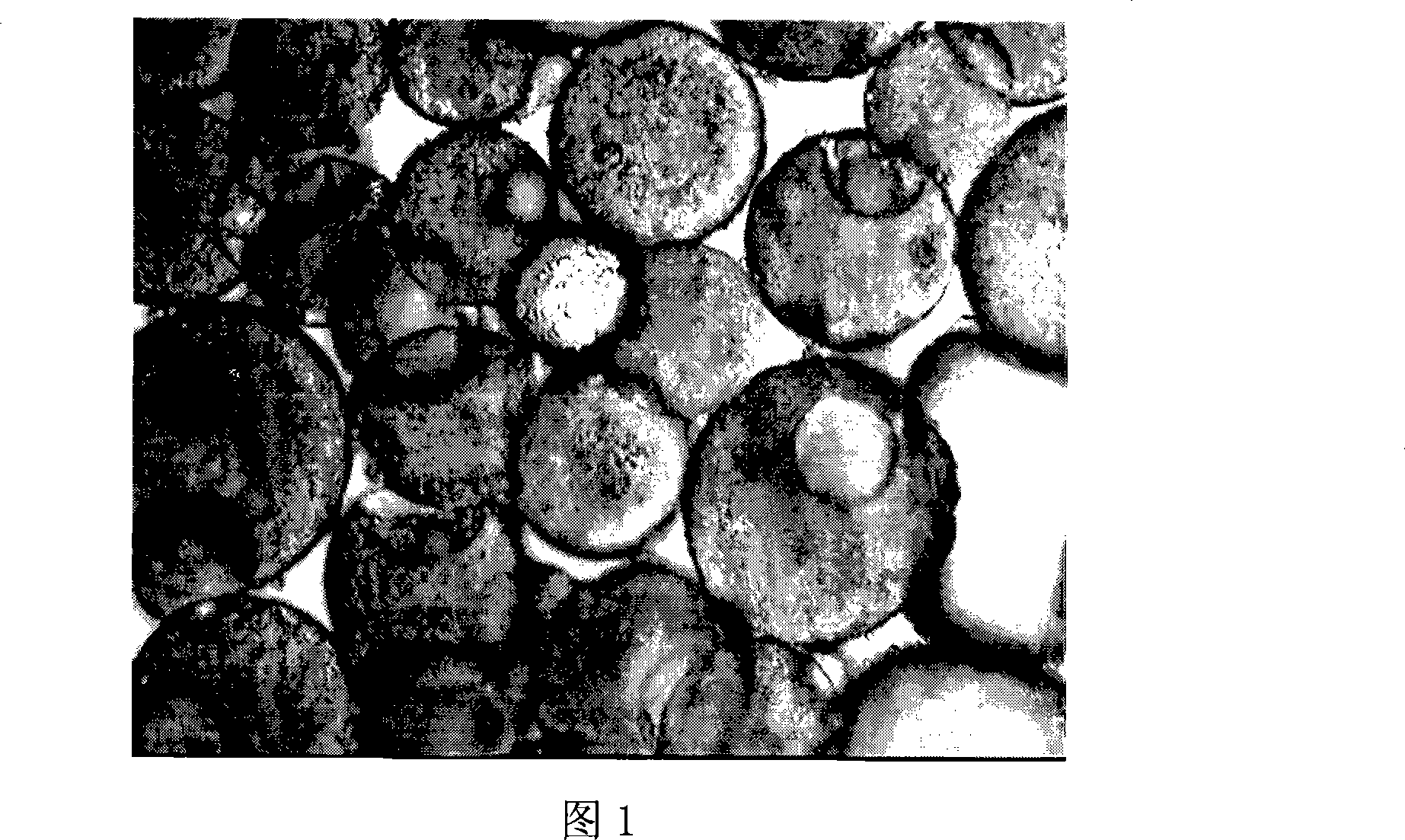

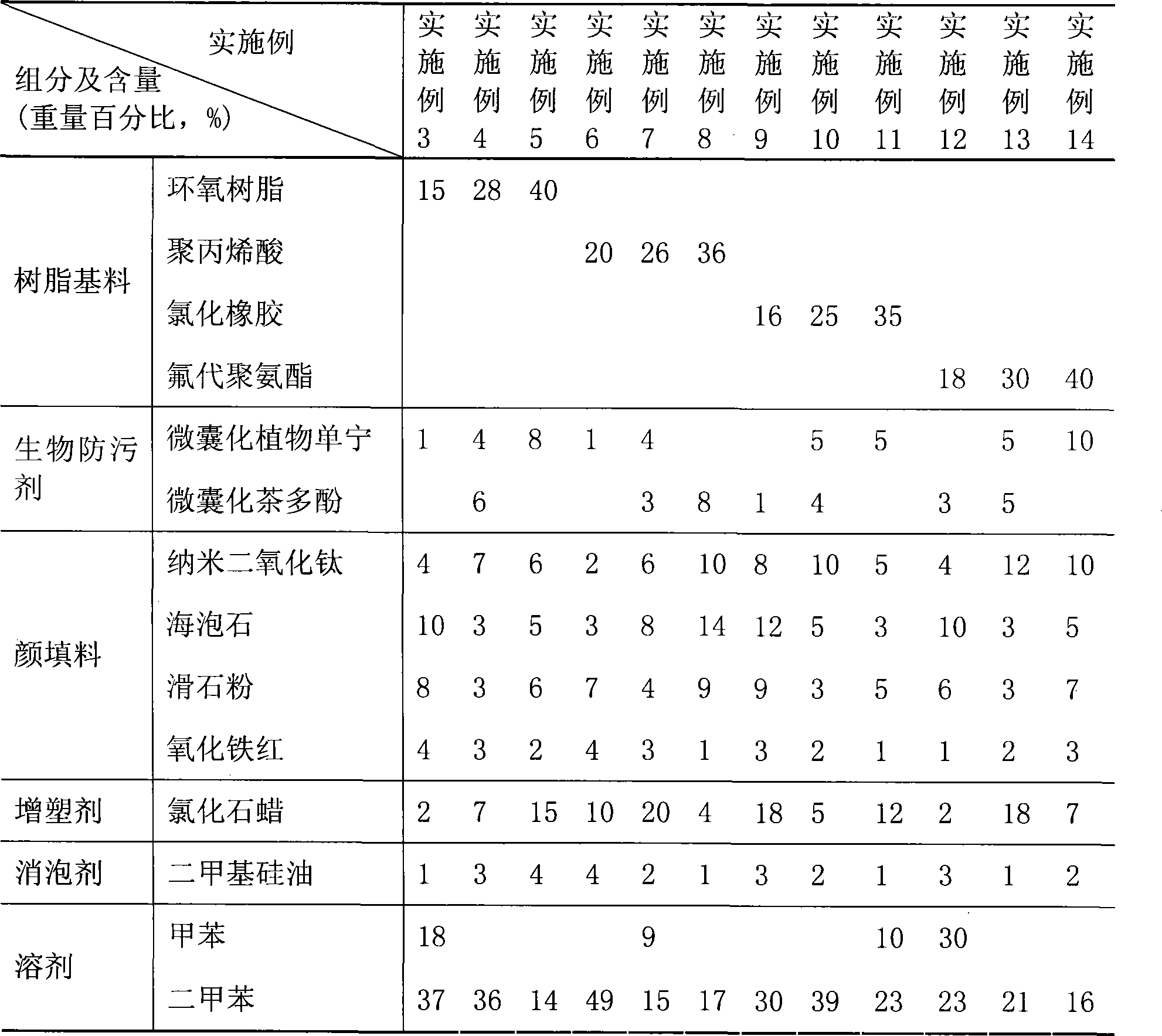

InactiveCN101186767ALow priceOvercome the disadvantage of high costRubber derivative coatingsAntifouling/underwater paintsTanninSolvent

The invention discloses a slow-soluble biological antifouling paint, which comprises binder resin, biological antifouling compositions, pigments, fillers, additives and solvents, wherein the biological antifouling compositions are vegetable tannin and tea polyphenols of biological extracts of plants. The vegetable tannin and the tea polyphenols are then encapsulated by employing the encapsulization technology, the encapsulated vegetable tannin and tea polyphenols are taken as the antifouling compositions, the antifouling paint of the invention is further composed by combining the binder resin, the pigments, the fillers, the additives and the solvent together with the vegetable tannin and the tea polyphenols, and the antifouling effect is achieved by the slow releasing of the vegetable tannin and the tea polyphenols from micro-capsules. The invention has the advantages that the invention coming from the biological extracts of plants is environment-friendly, the cost is low, the encapsulization technology is simple, the price of capsule materials is low and the large-scale production is easy to be achieved. Further, the invention is characterized by low surface energy, biological antifouling, long term slow releasing and environment protection, and is capable of being employed in antifouling treatment of ocean ships, ocean fixture and fittings, sewers, cable ducts, optical cable ducts and the like.

Owner:重庆丰博科技发展有限公司 +1

Marine life corrosion-resistant ceramic coating and preparation method thereof

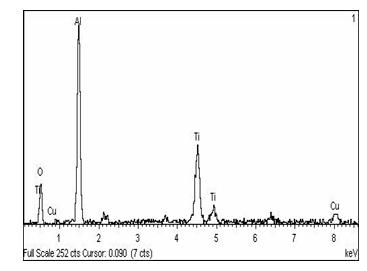

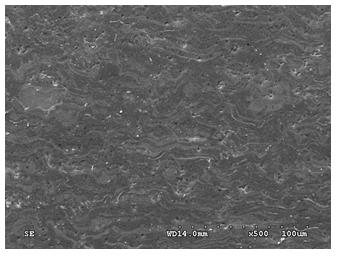

InactiveCN102181815AImprove the anti-corrosion performance of marine organismsGuaranteed high temperature performanceMolten spray coatingThermal sprayingComposite ceramic

The invention relates to a marine life corrosion-resistant ceramic coating and a preparation method thereof. The coating is characterized by being a composite ceramic coating formed by dispersively distributing copper oxide particles in a ceramic substrate, and the thickness is 0.2 to 1 mm. By adopting the novel composite ceramic coating with wear and friction resistance and marine life corrosion resistance, which is prepared by dispersively distributing the copper oxide particles in the wear- and corrosion-resistant ceramic substrate by using a thermal spraying method, the problems that the conventional ceramic coating is not resistant to the marine life corrosion, while an anti-fouling paint is not resistant to friction are solved. The marine life corrosion-resistant ceramic coating prepared by the method provided by the invention maintains the original characteristics, such as wear resistance, high-temperature resistance, oxidant resistance and the like of the ceramic coating; meanwhile, since the copper oxide particles are added, the marine life corrosion-resistant performance of the coating is remarkably improved, and the application of the ceramic coating in the ship parts is broadened. The marine life corrosion-resistant ceramic coating has the characteristics of low cost and high efficiency, and is suitable for industrialized production.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

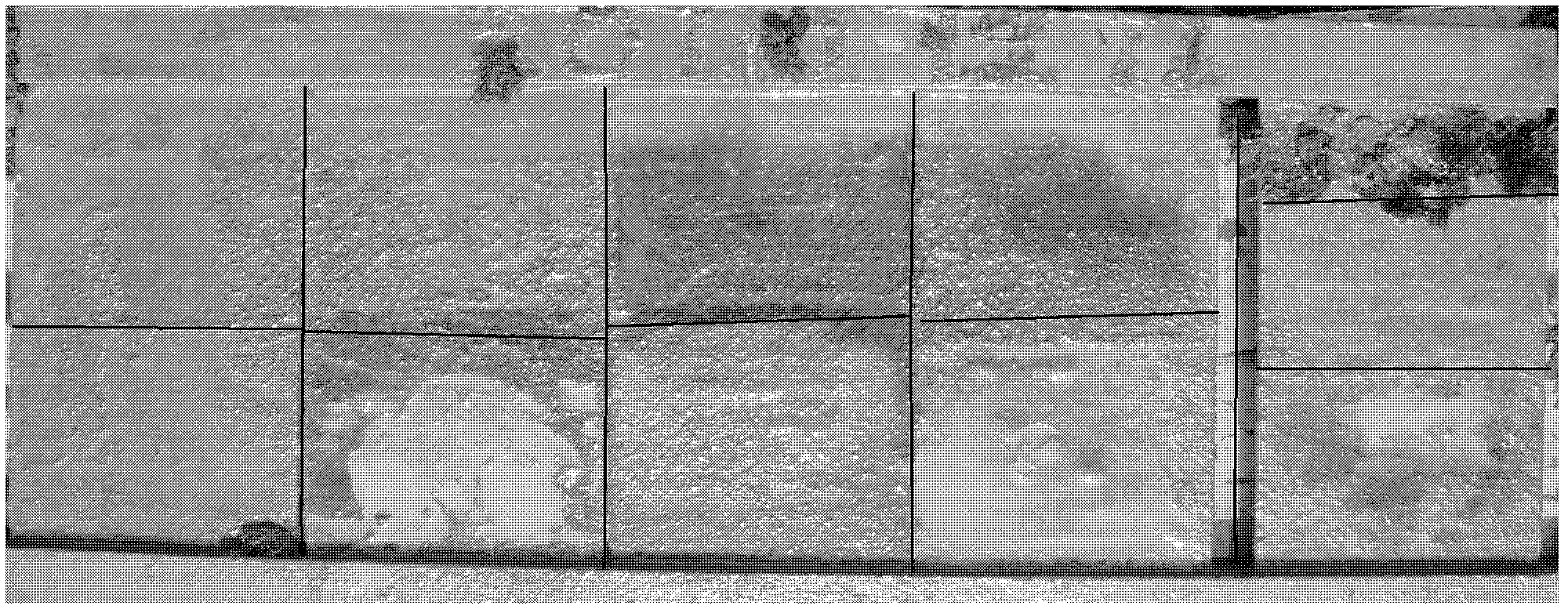

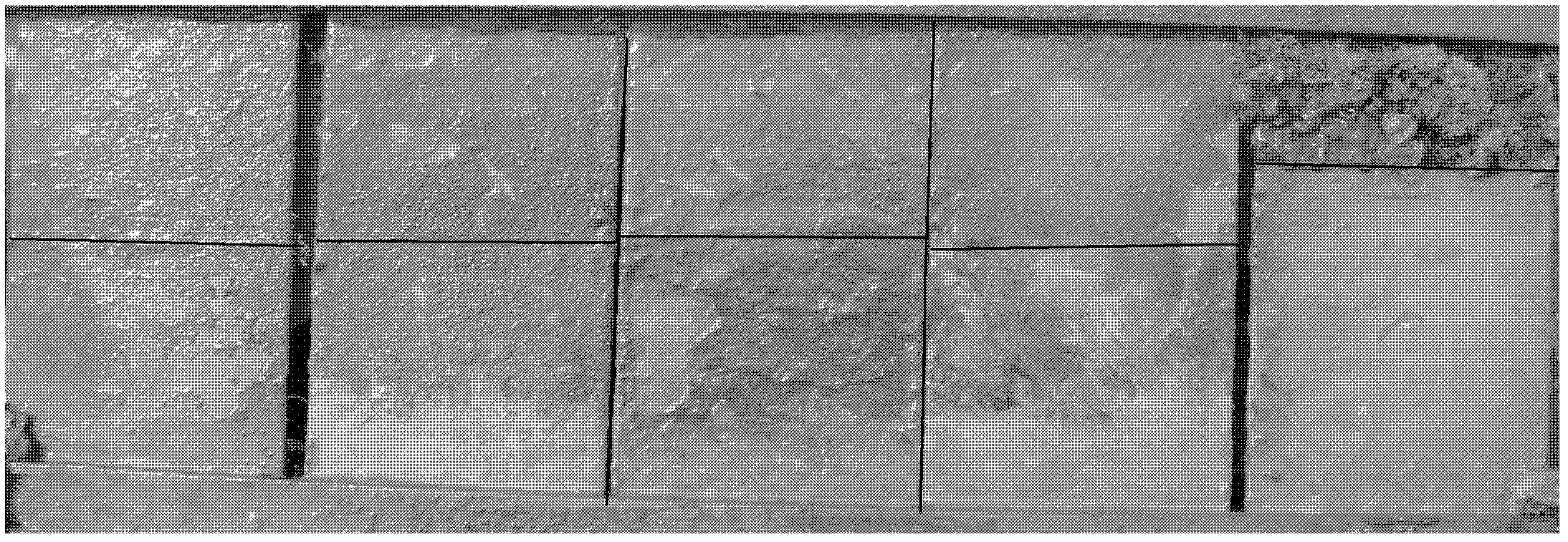

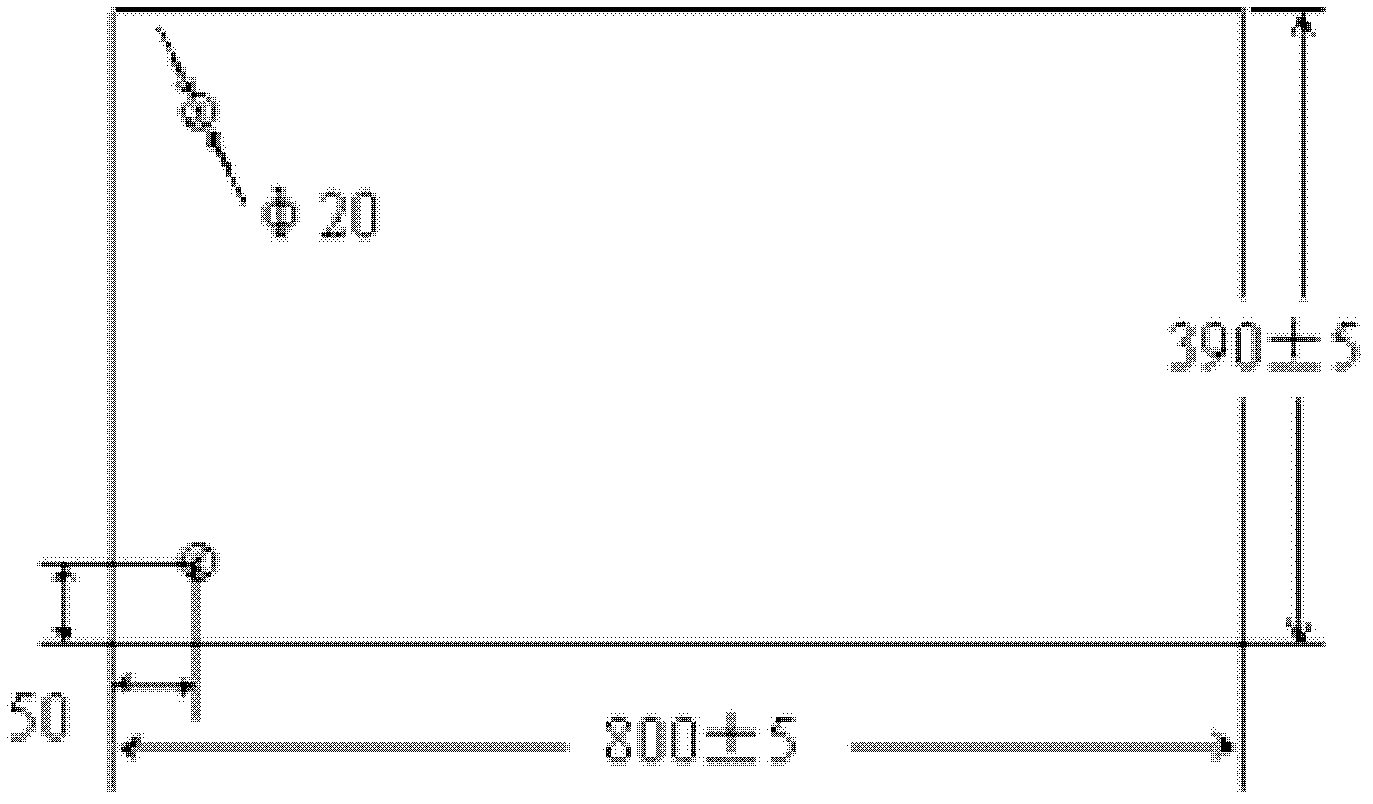

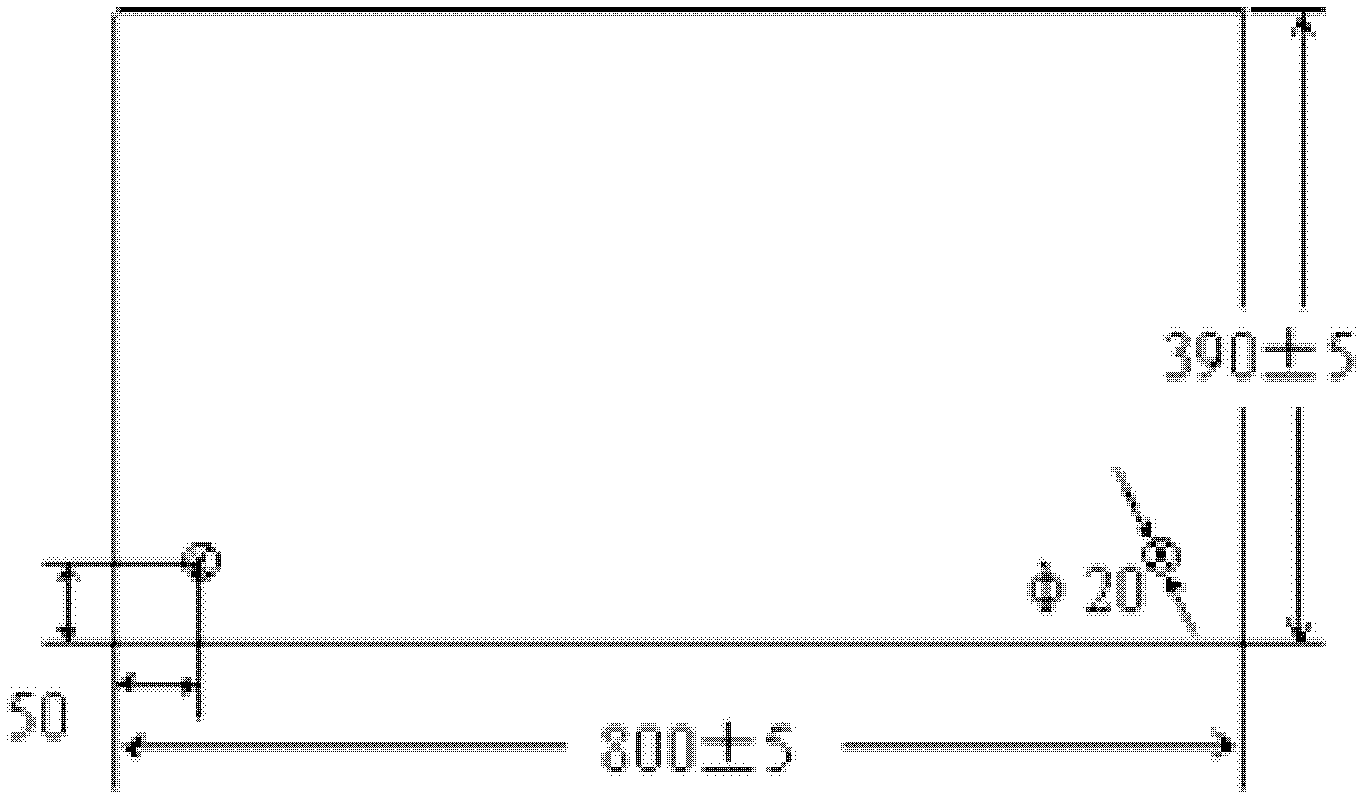

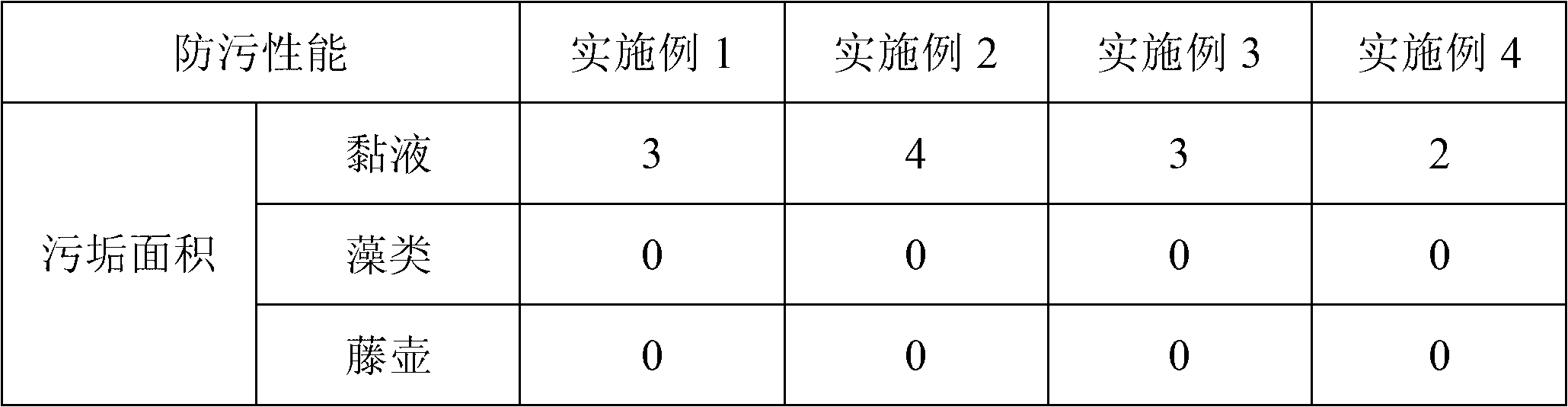

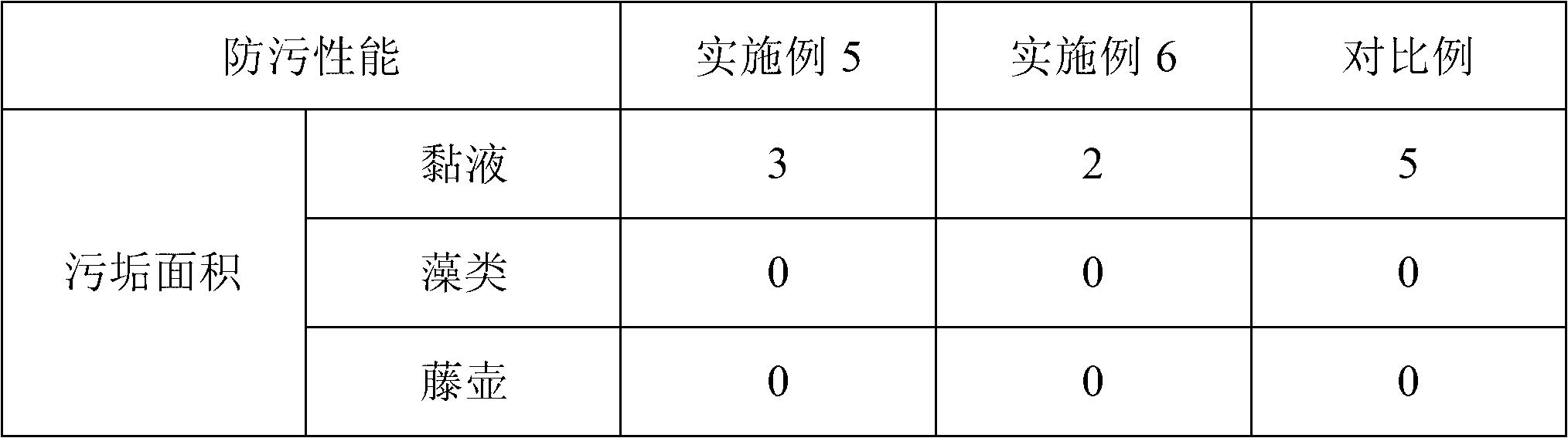

Green and environment-friendly antifouling paint for fishing boats, and fouling-panel testing method

The invention provides a green and environment-friendly antifouling paint for fishing boats. The antifouling paint is characterized in that in the green and environment-friendly antifouling paint, the content of a volatile organic compound (VOC) is less than or equal to 450 g / L, the mass fraction of benzene, toluene, dimethyl benzene and ethylbenzene is less than or equal to 25%, the total mass fraction of copper is less than or equal to 25%, and other toxic substances that are explicitly forbidden or restricted in the standard of Technical requirement for environmental labeling products Ship anti-fouling paints are not added initiatively; and the green and environment-friendly antifouling paint for the fishing boats adopts modified zinc acrylate resin, rosin, liquid bisphenol A epoxy resin and compound anti-soil agent, does not gel after being stored for a long time, and has excellent anti-cracking and anti-stripping performances. An antifouling paint sample shallow sea immersion testing method is characterized in that plastic boards such as PVC (polyvinyl chloride), coated or uncoated steel, stainless steel, copper, copper alloy, aluminium, aluminium alloy, titanium alloy anti-decaying paint or tie coat of the titanium alloy anti-decaying paint is adopted, and then the testing antifouling paint is applied to perform a shallow sea immersion test.

Owner:MARINE CHEM RES INST CO LTD

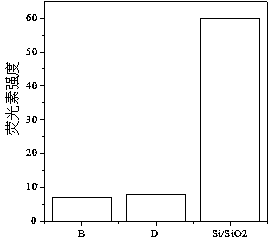

Organosilicon modified acrylate/nano SiO2 low surface energy anti-fouling paint and producing method thereof

InactiveCN101033358AThere is no release loss problemReduce manufacturing costAntifouling/underwater paintsPaints with biocidesPolymer scienceToxic material

The invention relates to a kind of coating and its preparation, which particularly raltes to a kind of modified silicone acrylate / nanosilica SiO2 antifouling coatings with low surface energy and its preparation which are primarily used for the ship's antifouling and others. The coationg includes following components by weight ratio: 12~50% of modified silicone acrylate, 5~20% of nano - silica, 20~35% of Physical pigments and fillers, 0.1~1% of promoter, 20~60% of organic solvent. The surface coating has no toxic substances released depletion.

Owner:DALIAN JIAOTONG UNIVERSITY +1

Water moistening type non-toxic antifouling paint and its preparation method

InactiveCN1618893ANo pollution in the processReduce resistanceAntifouling/underwater paintsPaints with biocidesWater solubleSurface-active agents

Owner:INST OF CHEM CHINESE ACAD OF SCI

Anti-fouling paint composition

InactiveCN102702880ANo harmImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesOrganic solventSilicon

The invention relates to an anti-fouling paint composition. Film-forming substances of the anti-fouling paint are fluororesin and organic silicon resin. The paint composition comprises the components in parts by weight: 5-25 parts of film-forming substance, 5-25 parts of organic solvent and 1-10 parts of pigment. The anti-fouling paint also contains a leveling agent. According to the invention, the fluororesin and organic silicon resin are used as the film-forming substances, the characteristic of low surface energy of the film-forming substances is utilized, and other auxiliary agents are matched to obtain the anti-fouling paint; and the obtained anti-fouling paint has no harm to human body and ocean environment, and has better anti-fouling action on biological dirt. The anti-fouling paint composition is suitable for antifouling of fishing nets, vessels, underwater equipment and other ocean equipment, and is free of mercury or organo-tin compounds capable of causing organic solvent pollution on the sea.

Owner:TIANCHANG YINHU PAINT

Anti-fouling paint containing micro-encapsulation capsaicin and preparation method thereof

InactiveCN101081950ASimple preparation processReduce manufacturing costAntifouling/underwater paintsPaints with biocidesSodium BentoniteGas phase

The present invention provides one kind of antifouling paint containing capsaicin microcapsule and its preparation process. The antifouling paint consists of adhesive of epichlorohydrin rein or vinyl resin 40-55 weight portions, organic solvent of toluene, xylene, etc. 11-33 weight portions, dispersant of sodium triphosphate, sodium or polyglycol 1.5-5.5 weight portions, anti-settling agent of organic bentonite, gas phase silica or polyethylene wax 0.5-3.5 weight portions, and antifoulant of capsaicin microcapsule 20-30 weight portions. The capsaicin microcapsule with covering of melamine resin is prepared through a in-situ polymerization process. The antifouling paint has simple preparation process and low production cost, and may be applied widely for sea ship, sea water cooling pipeline, etc.

Owner:SHANGHAI UNIV OF ENG SCI

Low surface energy liquid control release type marine anti-fouling paint

InactiveCN101845262AOvercoming effectOvercoming toxicityAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

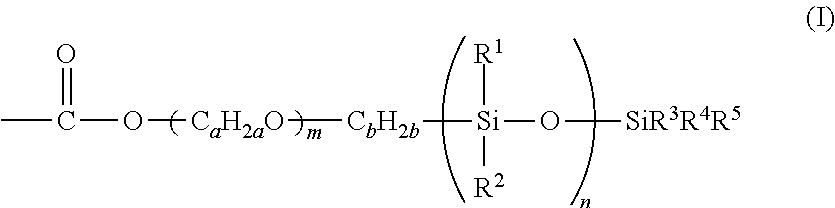

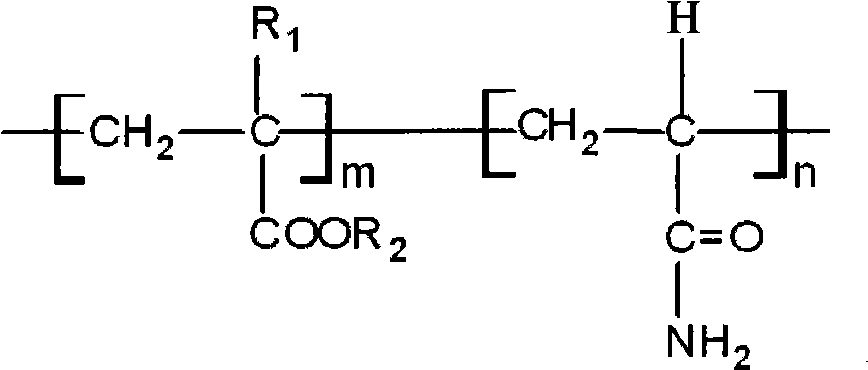

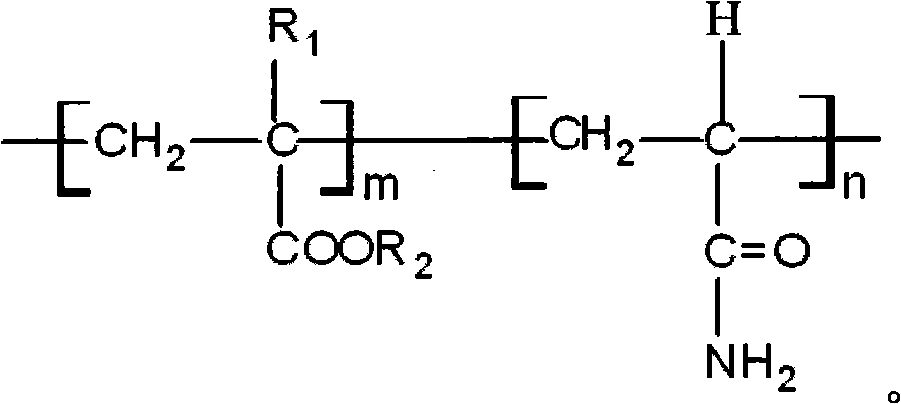

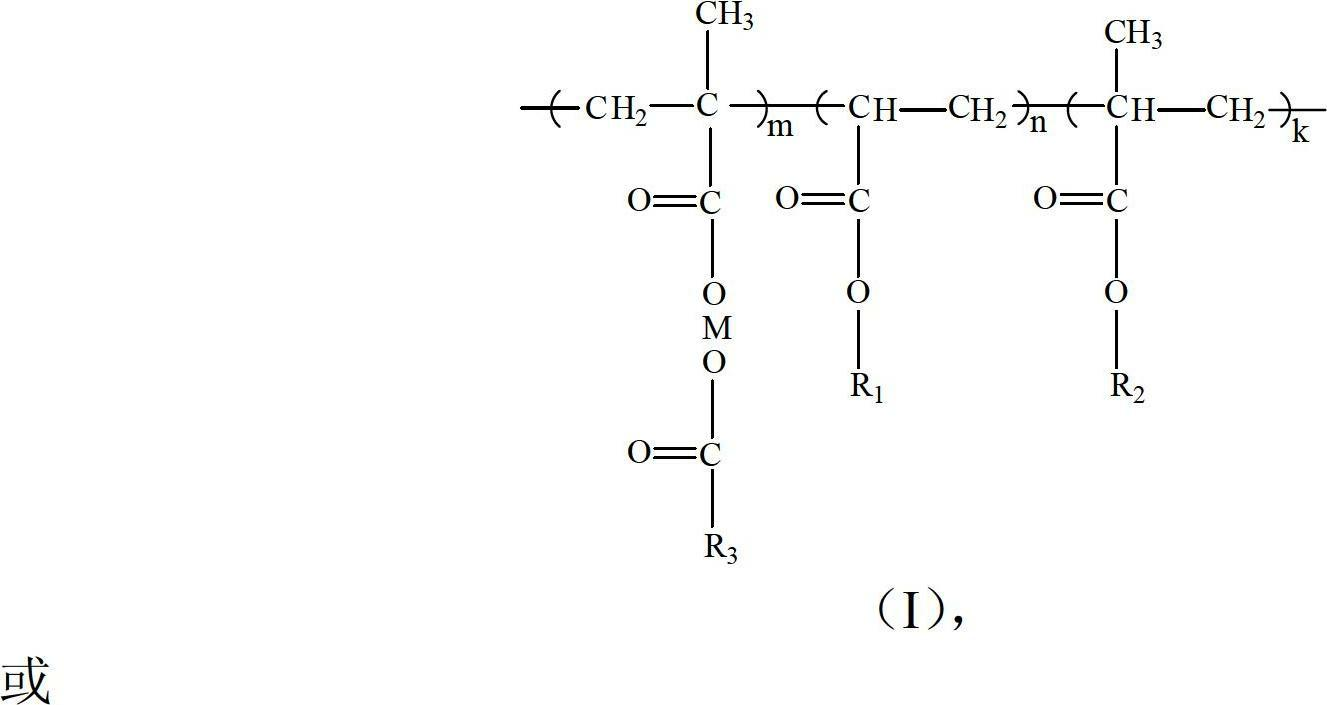

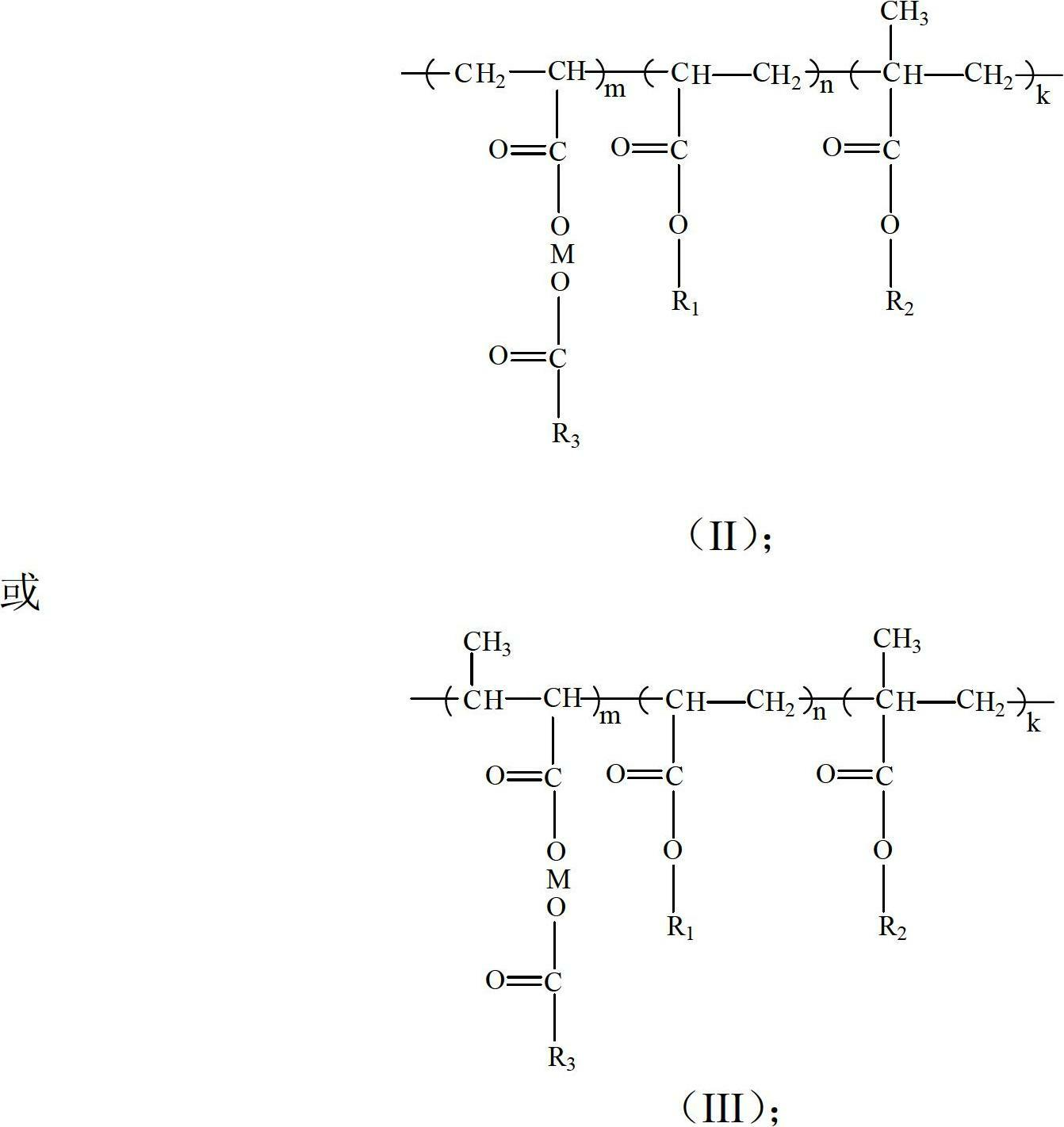

The invention discloses a low surface energy liquid control release type marine anti-fouling paint, comprising the following components in parts by weight: 30.0-55.0 parts of film-forming resin, 7.0-18.0 parts of lamella cross-linking silicone oil microcapsule, 1.0-10.0 parts of plasticizer, 1.0-3.0 parts of defoaming agent, 15.0-35.0 parts of added pigment and 5.3-22.7 parts of solvent. The lamella cross-linking silicone oil microcapsule is obtained by polymerizing an oil-in-water system in situ; the core material of the lamella cross-linking silicone oil microcapsule is one or several of methyl silicone oil, hydroxy silicone oil, amino silicon oil and alkoxy silicone oil; and the wall material of the lamella cross-linking silicone oil microcapsule can be one of polyacrylamide, polyacrylic acid, polymaleic anhydride and the like which can be swelled in the water. The anti-fouling paint has the advantages of remarkable anti-fouling effects, no pollution to a marine environment, low cost and applicability for industrial application production. The film-forming resin is acrylic resin, the structural general formula of which is shown in the specification of the invention.

Owner:NINGBO HAITENG NEW MATERIALS CO LTD

Nano-coated waterproof and anti-fouling corrugated carton

ActiveCN106882468APrevent penetrationSuperhydrophilicCoatings with pigmentsWater-repelling agents additionEpoxyCardboard

The invention discloses a nano-coated waterproof and anti-fouling corrugated carton. The nano-coated waterproof and anti-fouling corrugated carton comprises a corrugated paperboard. The corrugated paperboard is sequentially composed of surface paper, corrugated paper and inner paper from outside to inside. The surface of the surface paper and the surface of the inner paper are coated with nano waterproof and anti-fouling paint. The paint is prepared from, by weight, 50-60 parts of epoxy resin, 10-20 parts of nano titanium dioxide, 20-30 parts of curing agents, 5-10 parts of active diluents, 1-2 parts of dispersing agents and 10-15 parts of organic solvents. Gaps of V-shaped structures of the corrugated paper are filled with drying agents. According to the nano-coated waterproof and anti-fouling corrugated carton, a plurality of waterproof layers are adopted, the surface paper and the inner paper are both coated with the nano waterproof and anti-fouling paint, and the nano titanium dioxide which is highly hydrophilic and oleophylic is added into the paint, so that the waterproof and anti-fouling capacity of the paperboard can be improved; and the V-shaped wavy structures of the corrugated paper are filled with the molecular sieve drying agents, and thus the waterproof capacity of the paperboard is further improved.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Grafted resin with hydrolysis and low surface energy characteristic and anti-fouling paint prepared by the same

A grafted resin and an anti-fouling paint produced by this resin, is to prepare monomers mixture with methyl methacrylate, ethyl acrylate, butyl acrylate, acrylic acid, hema, chain transfer agent and initiator. The monomers mixture and mixed solvent are used to prepare the acrylic containing hydroxyl. Then ethyl silicate, anhydrous ethanol, deionized water and dilute hydrochloric acid are used to prepare polysiloxane. The hydroxyl acrylic, polysiloxane, catalysts, and mixed solvents are prepared the grafted resins with hydrolysis and low surface energy. The grafted resins, anti-fouling paint, color filler, additives, and mixed solvent are prepared the anti-fouling paint.

Owner:DALIAN JIAOTONG UNIVERSITY +1

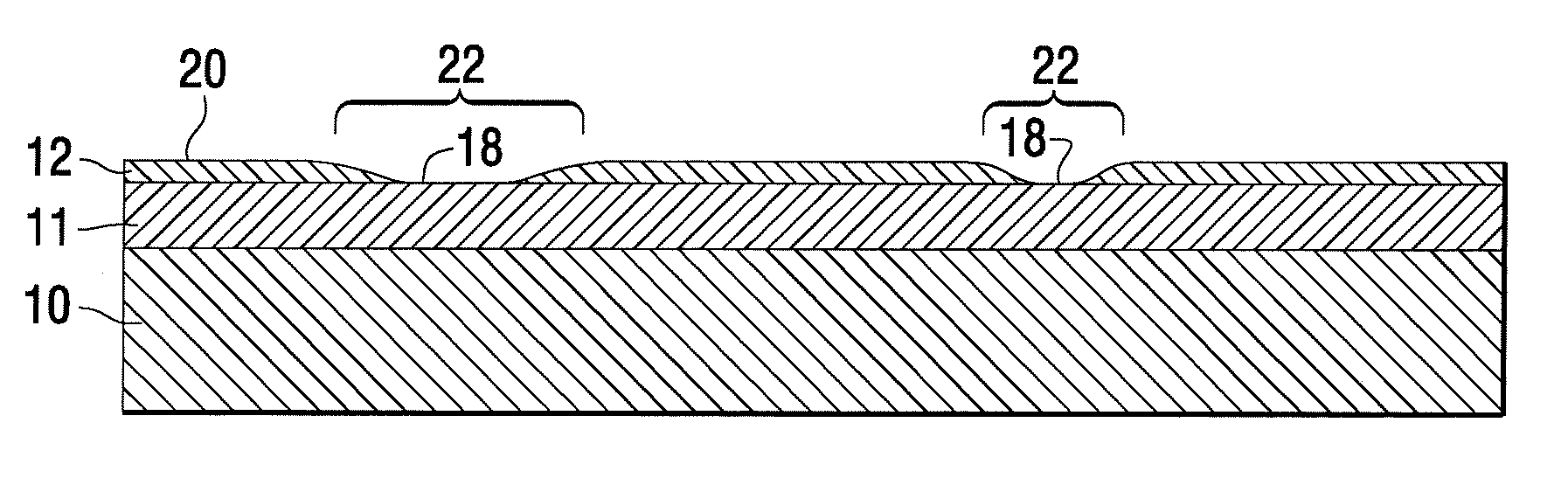

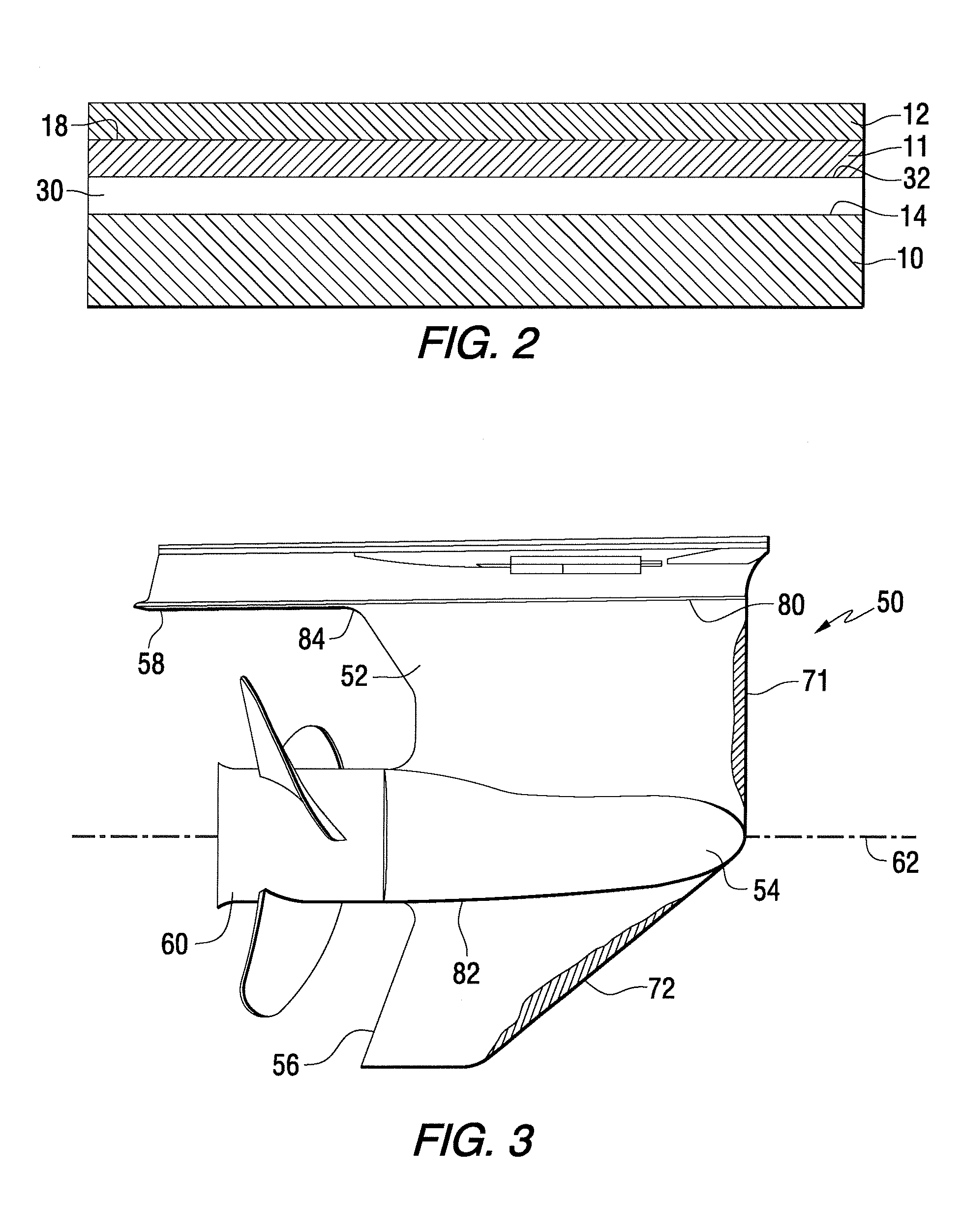

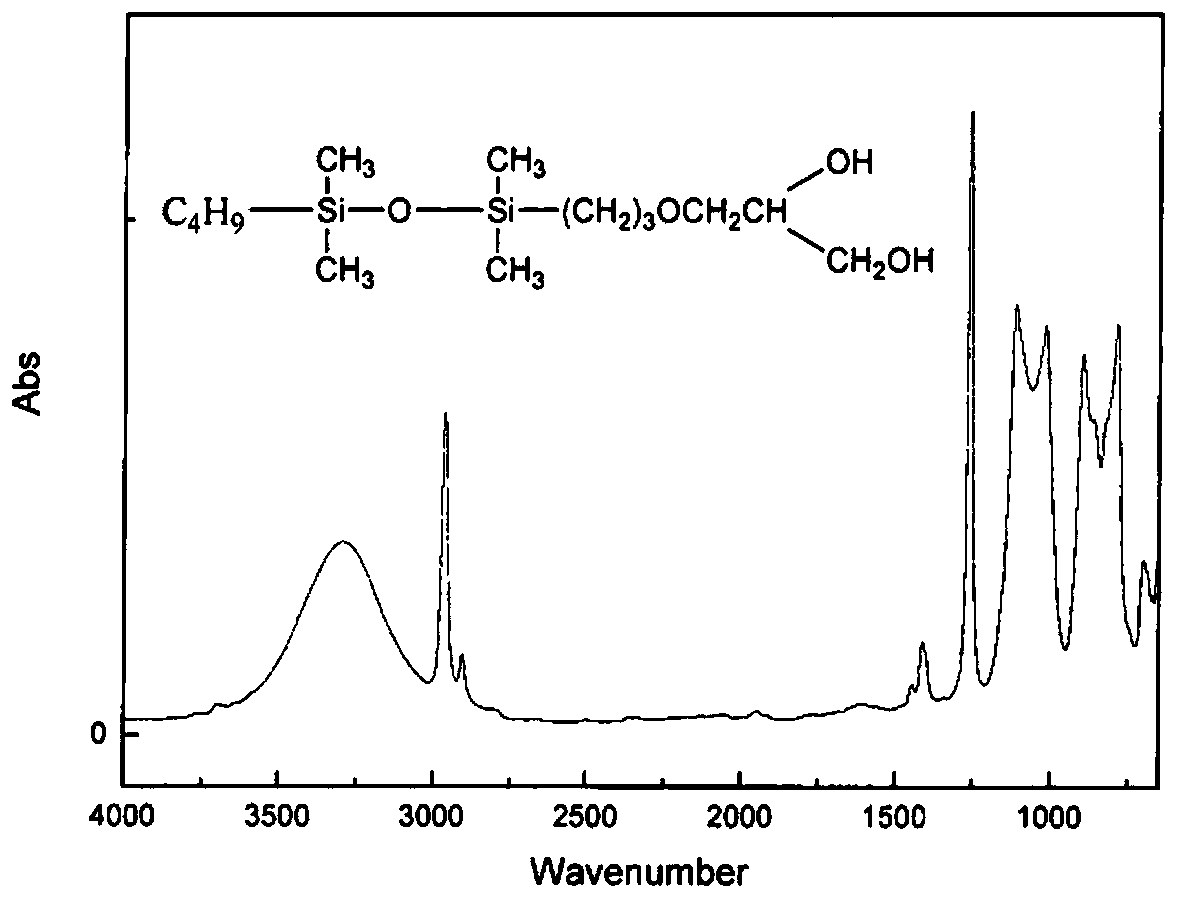

Submersible object with antifouling paint configuration

Antifouling materials are used to provide first and second layers or coatings on a submersible object. The first and second layers are visually distinct from each other, such as being made of two distinct colors, so that the ablation of an outer layer will be evident when an inner layer is exposed to show a different color in the regions of ablation. The materials for the first and second layers can be chemically active to cause the antifouling nature of the materials or can be electrically conductive to permit their use in the creation of either chlorine bubbles on the wetted surface or a change in ionic characteristic of water in contact with the wetted surface.

Owner:BRUNSWICK CORPORATION

Method for preparing ocean anti-fouling paint

InactiveCN101096491ASimple production processImprove antioxidant capacityWax coatingsAntifouling/underwater paintsGas phaseOxidation resistant

The invention discloses a method for preparing a marine pollution prevention paint. The paint comprises the resin solution, the elasticizer, the filler and the copper-protoxide. The method comprises the following steps: adding carboxymethyl cellulose, copper acetate, potassium bromide, water in the three-hole flask; mixing and heating; dissolving potasium carbonate and hydrazine hydrate in the water; mixing; dropping in the copper acetate solution; dropping caustic soda solution in three-hole flask; adjusting pH value of the system; keeping the temperature; mixing; stewing; producing a good deal of yellow particles; filtering; cleaning; drying; getting cuprous oxide; vibrating the mixture of 40% elastic acrylic aqueous emulsion, chlorcosane, iron oxide red, gas phase silica dioxide and cuprous oxide in the oil paint oscillator; filtering with filter. The invention is provided with the simple production technology, the high oxidation resistance and the high pollution resistibility.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

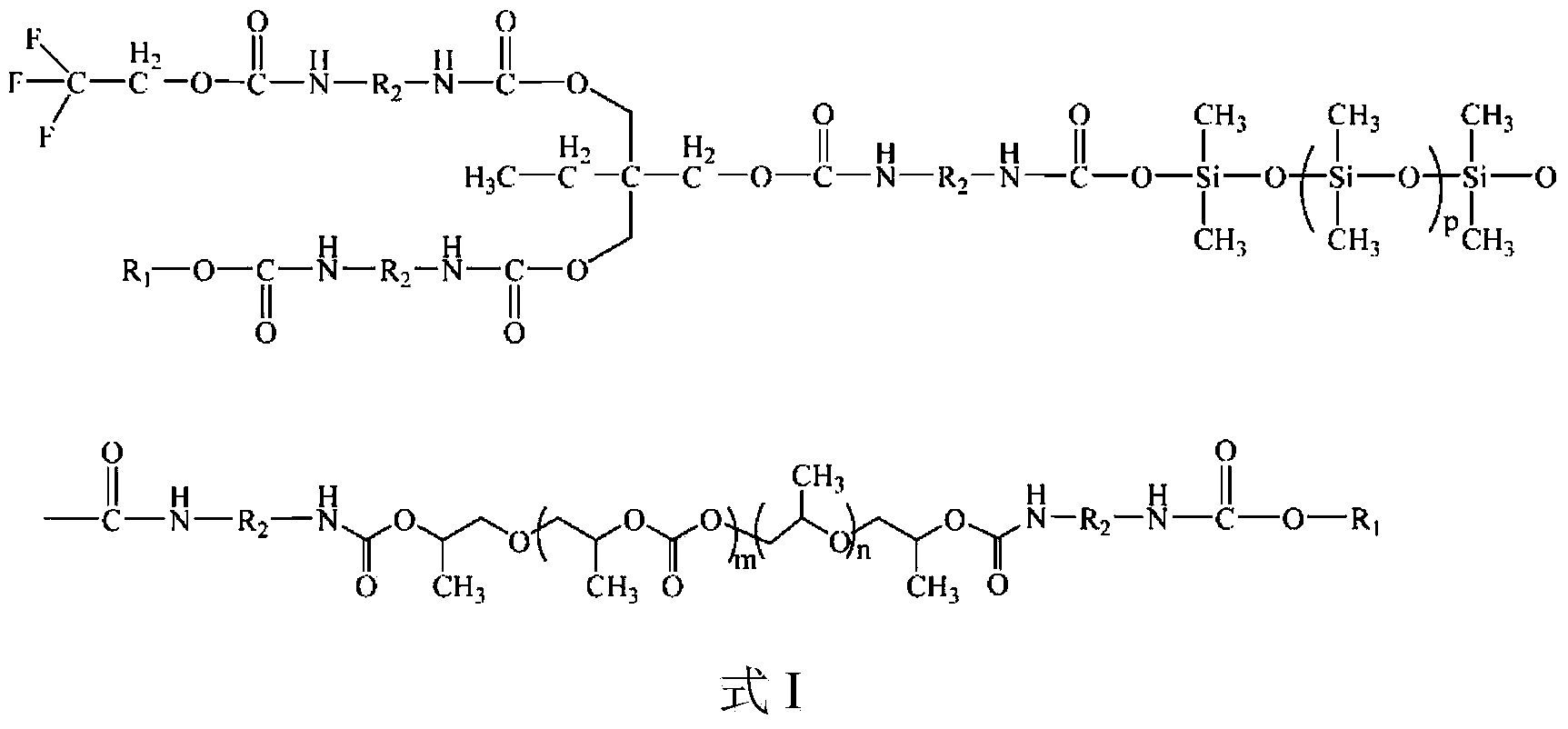

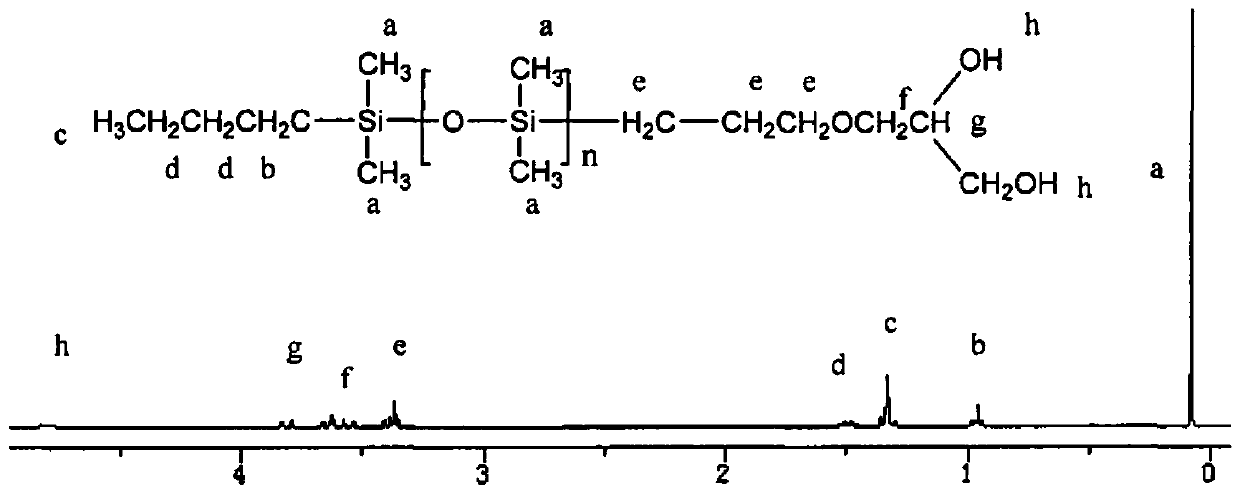

Organosilicone polyurethane anti-fouling material with low surface energy and hydrolyzed self-polishing function and application thereof

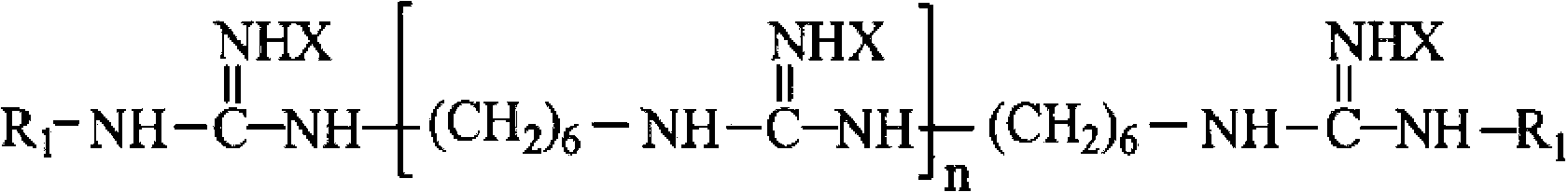

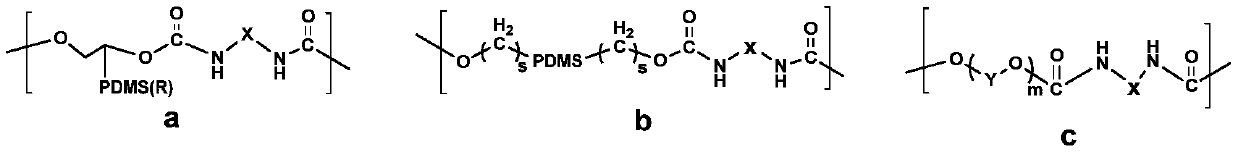

PendingCN109852225AReduce adhesionLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceBackbone chain

The invention discloses an organosilicone polyurethane anti-fouling material with low surface energy and a hydrolyzed self-polishing function and application thereof in the field of hydrolyzed self-polishing marine anti-fouling paint. The organosilicone polyurethane anti-fouling material is prepared through firstly synthesizing a single-terminal bishydroxyl siloxane polymer monomer, and polymerizing the single-terminal bishydroxyl siloxane polymer monomer, a double-terminal hydroxyl siloxane polymer monomer, a diol monomer for regulating softness and hardness and an isocyanate monomer throughfree radicals. According to the organosilicone polyurethane anti-fouling material and the application thereof, the material can have low surface energy through adding silicon groups to a principal chain and lateral chains; and an ammonia ester bond formed by silicon hydroxyl and isocyanate is prone to hydrolyzed breakage, so that the material can be decomposed in water to achieve a self-polishingeffect. The final obtained material has low surface energy and self-polishing capacity and has a relatively good application prospect in the field of marine anti-fouling.

Owner:ZHEJIANG UNIV

Copper-bearing linear self-polishing marine anti-fouling paint

ActiveCN109836951AStable antifoulingComprehensive antifouling effectAntifouling/underwater paintsPaints with biocidesCopperAntibacterial property

The invention relates to the field of paint and discloses a copper-bearing linear self-polishing marine anti-fouling paint. The paint of the invention contains eight different types of linear self-polishing anti-fouling resins. The synthetic process route of the resins is easier to control and the cost is lower. The resins have stable molecular weight and narrower molecular weight distribution, and have good linear polishing ability. After the resins are used to prepare the copper-bearing marine anti-fouling paint, antibacterial property, antifouling property, adhesion and weatherability are excellent. The paint of the invention is applicable to a long-acting antifouling coating system of ships.

Owner:ZHEJIANG MARINE DEV RES INST

Self-polishing anti-fouling resin and preparation method thereof

InactiveCN102675524AImprove the shortcomings of low grafting ratePrecise content controlAntifouling/underwater paintsPaints with biocidesOrganic acidDivalent metal ions

The invention discloses a self-polishing anti-fouling resin and a preparation method thereof. The self-polishing anti-fouling resin disclosed by the invention has better fluidity and adhesion and a definite self-polishing rate, and can be used as the main resin of self-polishing anti-fouling paint for ship bottoms. The preparation method of the self-polishing resin comprises the following steps: reacting unsaturated organic acid with basic divalent metal-ion complex salt, and then reacting with other acrylic monomers under the effect of an initiator to synthesize the self-polishing anti-fouling resin. Thus, the invention improves the disadvantage of low grafting ratio in the tin-free self-polishing resin synthesis, shortens the reaction time and makes the product more stable.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

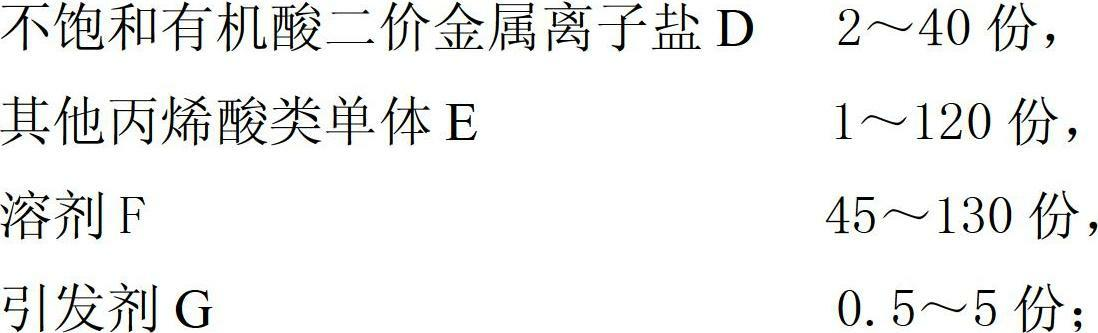

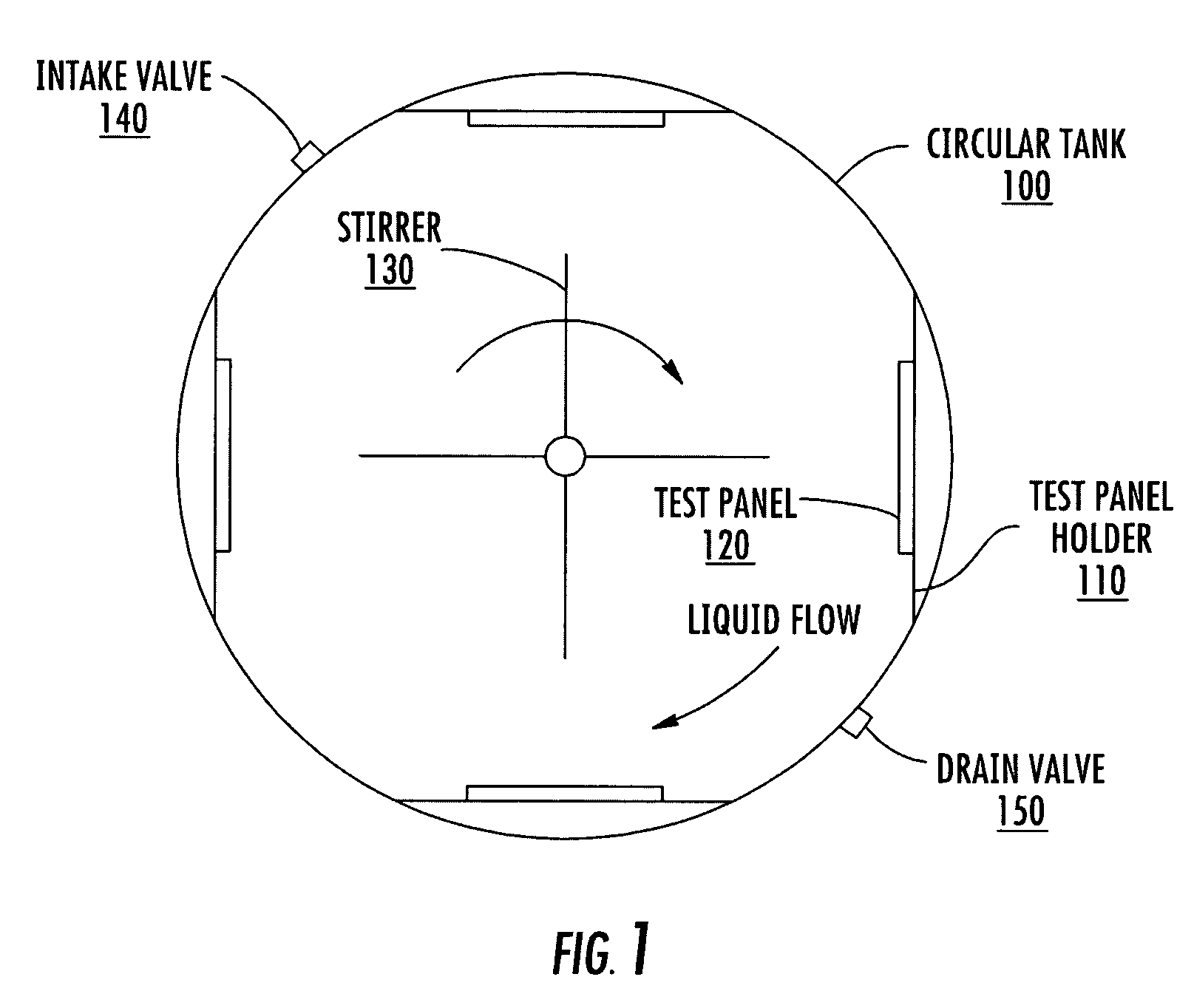

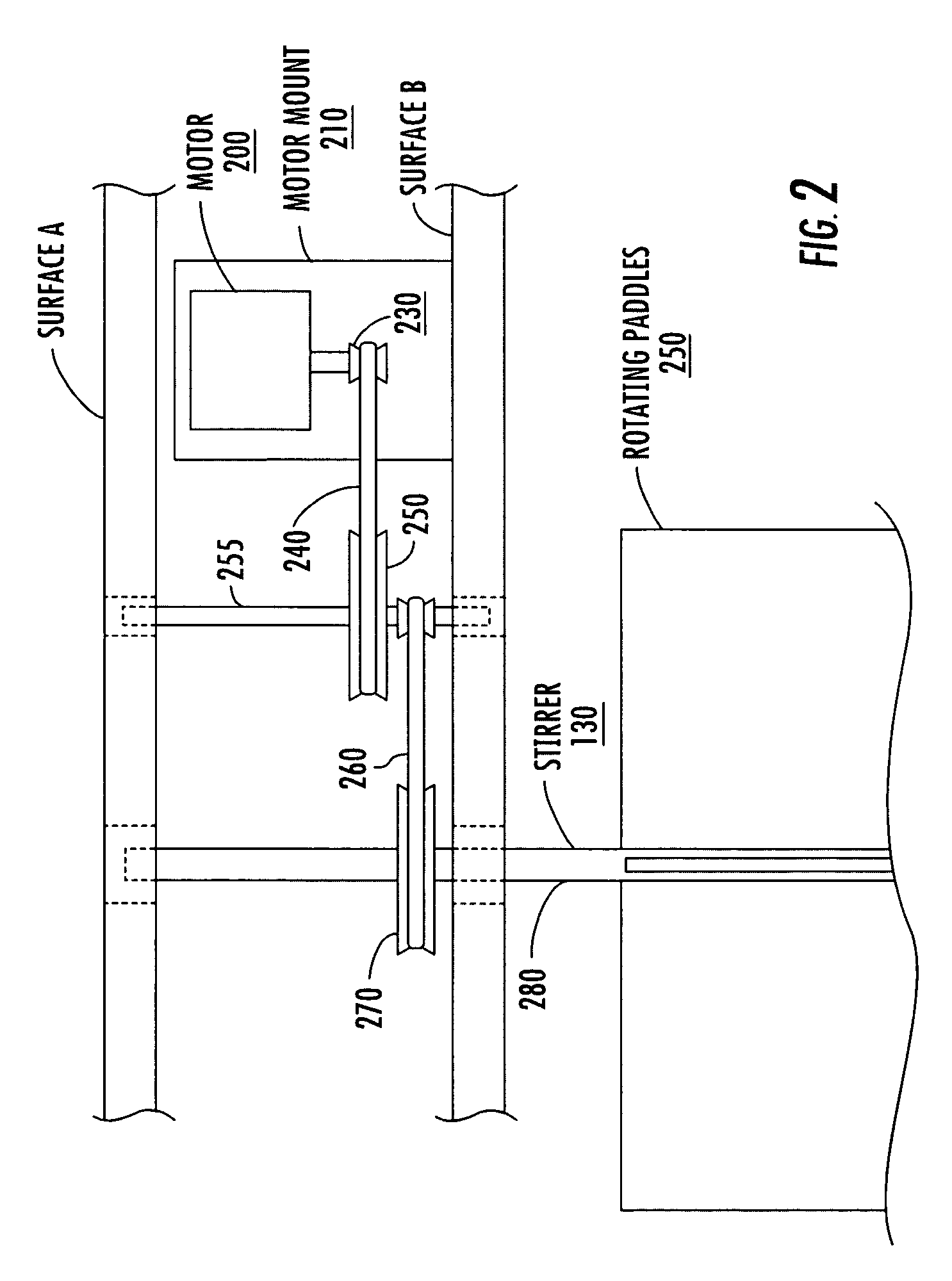

Techniques for dynamically testing and evaluating materials and coatings in moving solutions

The dynamic testing of materials in moving solutions, such as anti-fouling paint in seawater, is conducted in a cylindrical tank. A stirrer having a drive shaft and one or more paddles or blades is driven by a variable speed motor to rotate and to impart rotational velocity to a liquid, which passes over the test materials which are attached to the periphery of the tank. The flow conditions over the surface can be well characterized. The surface of the test materials may be instrumented to measure physical, chemical and hydrodynamic conditions. The energy required for testing is reduced over prior art techniques.

Owner:FLORIDA INST OF TECH

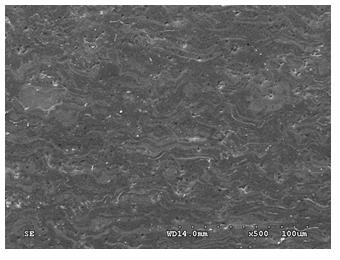

Epoxy anti-fouling material and preparation method and use of same

InactiveCN101544807AGood chemical stabilityImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesEpoxyUltimate tensile strength

The invention discloses an epoxy anti-fouling material and a preparation method and the use of the same. The method uses polyurethane prepolymer containing anti-fouling factors to modify epoxy resin and then forms a film through curing and cross-linking. A microphase separation surface structure is formed. The structure can give a full play of the anti-fouling function of the anti-fouling factors and take advantages of the characteristics of excellent adhesive force and high mechanical strength of the epoxy resin. The method for preparing the epoxy anti-fouling material has the advantages of simple process, readily available material, low cost and easy industrial production. The material has promising application prospect in the field of the preparation of anti-fouling paints and biological and medical material coatings.

Owner:UNIV OF SCI & TECH OF CHINA

Anti-fouling paint

The invention relates to a chemical coating, in particular to an anti-fouling paint which is used in marine facilities. The anti-fouling paint comprises the following components in parts by weight: 55-85 parts of rosin material, 20-60 parts of lactic acid polymer, 15-40 parts of linear addition polymer of olefin unsaturated acid, 5-20 parts of non-polymer plasticizer and 3-15 parts of aquatic organism killing agent. According to the anti-fouling paint, attachment of marine organisms can be effectively prevented without polluting water body, and meanwhile, the paint film has high strength and superior hydrolysis resistance and wear resistance performance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com