Patents

Literature

46results about How to "Overcoming toxicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination of slow released anticancer medication

InactiveCN1660437AAddress sensitivityOvercoming toxicityAntineoplastic agentsPharmaceutical active ingredientsWhole bodyTherapeutic effect

A slowly-releasing anticancer composite medicine is composed of the hormone-kind anticancer medicine chosen from steroid-type hormone and hormone antagon for regulating the cell reproduction of hormone dependent tumor and the medicinal additive chosen from biocompatible and biodegradable high-molecular polymer for slowly releasing said anticanser medicine toward tumor.

Owner:SHANDONG LANJIN PHARMA +1

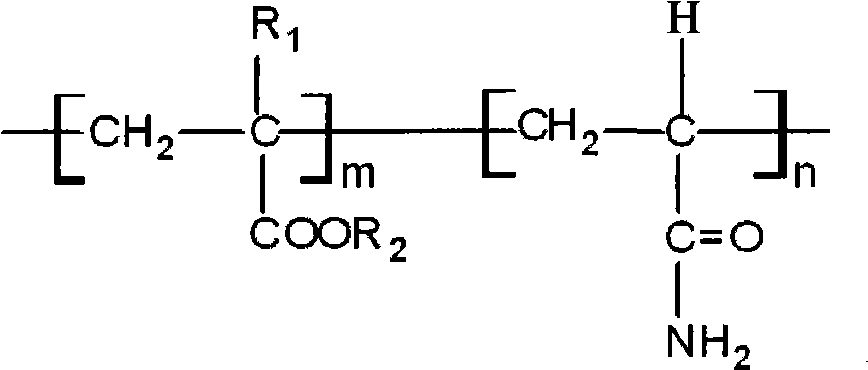

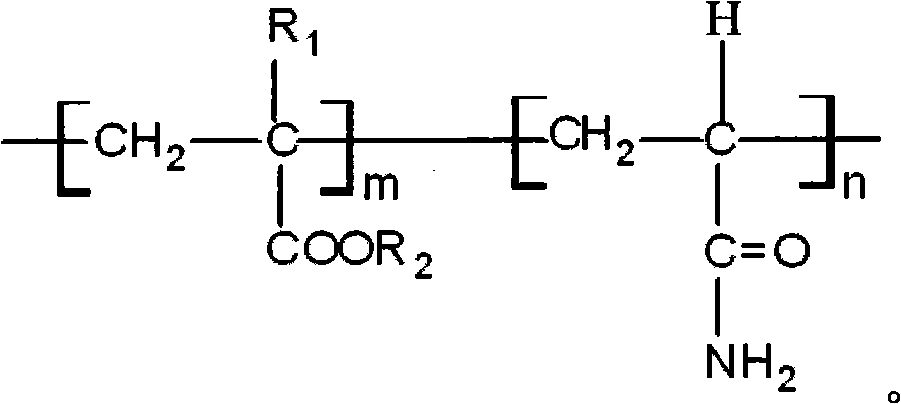

Low surface energy liquid control release type marine anti-fouling paint

InactiveCN101845262AOvercoming effectOvercoming toxicityAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

The invention discloses a low surface energy liquid control release type marine anti-fouling paint, comprising the following components in parts by weight: 30.0-55.0 parts of film-forming resin, 7.0-18.0 parts of lamella cross-linking silicone oil microcapsule, 1.0-10.0 parts of plasticizer, 1.0-3.0 parts of defoaming agent, 15.0-35.0 parts of added pigment and 5.3-22.7 parts of solvent. The lamella cross-linking silicone oil microcapsule is obtained by polymerizing an oil-in-water system in situ; the core material of the lamella cross-linking silicone oil microcapsule is one or several of methyl silicone oil, hydroxy silicone oil, amino silicon oil and alkoxy silicone oil; and the wall material of the lamella cross-linking silicone oil microcapsule can be one of polyacrylamide, polyacrylic acid, polymaleic anhydride and the like which can be swelled in the water. The anti-fouling paint has the advantages of remarkable anti-fouling effects, no pollution to a marine environment, low cost and applicability for industrial application production. The film-forming resin is acrylic resin, the structural general formula of which is shown in the specification of the invention.

Owner:NINGBO HAITENG NEW MATERIALS CO LTD

Anticancer combination of medication

InactiveCN1660436AAddress sensitivityOvercoming toxicityAntineoplastic agentsPharmaceutical active ingredientsWhole bodyTherapeutic effect

An anticancer composition medicine is composed of the antimitosis medicine for suppressing the reproduction of tumor cells and the medicinal additive chosen from the biocompatible and biodegradable high-molecular polymer for slowly releasing said antimitosis medicine toward the tumor.

Owner:DASEN BIOLOGICAL PHARMA CO LTD

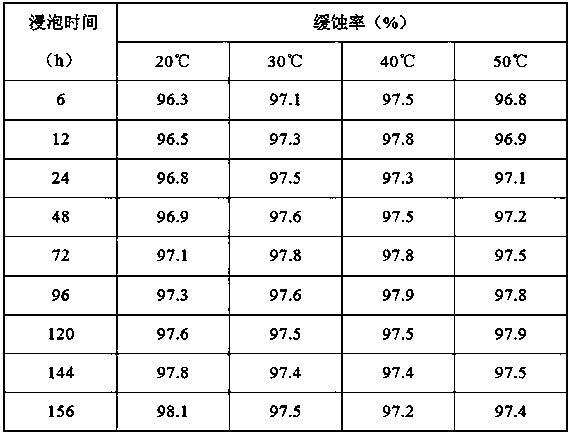

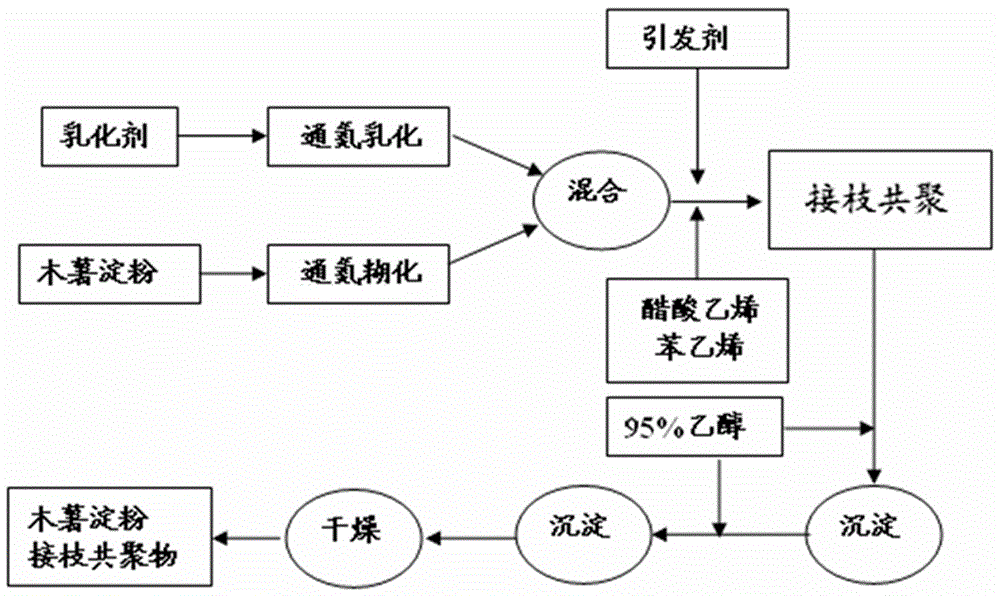

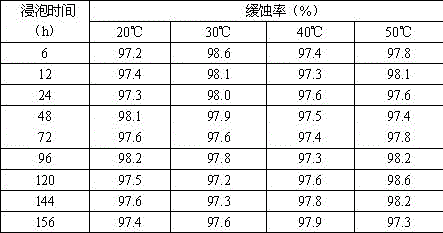

Modified macromolecular combined corrosion inhibitor and preparation method and application thereof

The invention discloses a modified macromolecular combined corrosion inhibitor and a preparation method and application thereof. The modified macromolecular combined corrosion inhibitor comprises cassava starch-vinyl acetate-styrene grafted copolymer of 0.1-1.0 g / L, sodium lignin sulfonate of 0.05-0.1 g / L, potassium sorbate of 0.05-0.1 g / L, glycol of 0.01-0.1 g / L and the balance pickling solutions. The preparation method comprises the steps of raw material preparation and preparation. According to the application, the modified macromolecular combined corrosion inhibitor can be applied to preparation of cleaning agents for steel, aluminum, petrochemical equipment, boilers and pipelines. The modified macromolecular combined corrosion inhibitor has the advantages of being free of poisons, low in cost and high in adaptability, obviously inhibiting the corrosion effect of various kinds of organic acid and inorganic acid to metal material, being suitable for acid pickling of the steel and the aluminum in the organic acid and the inorganic acid, being suitable for cleaning of the petrochemical equipment, the boilers and the pipelines, being free of pollution after being used and being safe and convenient to use.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Metasilicate cleaning inactivating process

InactiveCN101135050AImprove corrosion resistanceRealize cleaner productionMetallic material coating processesPotassium silicateRoom temperature

The present invention is clean silicate deactivating process for the post-treatment of steel part after plating zinc or ferrozinc alloy electrically, and belongs to the field of metal material surface treating technology. The process includes compounding brightening liquid comprising HNO3 and H2O and deactivating liquid comprising sodium or potassium silicate, boric acid, H2O2, HNO3, H2SO4 and H2O in the pH 1.5-3; washing steel part after plating zinc or ferrozinc alloy electrically; brightening treatment in the brightening liquid and water washing; deactivating in the deactivating liquid at room temperature and water washing; and blowing to dry. The process can raise the corrosion resistance of the steel part obviously and is environment friendly.

Owner:KUNMING UNIV OF SCI & TECH

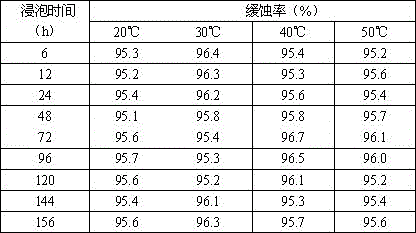

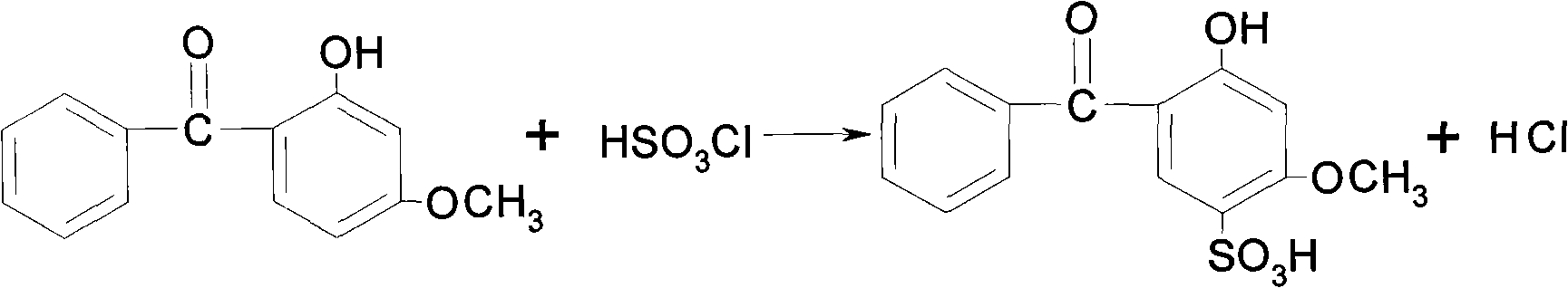

Method for producing 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid

ActiveCN101624357AResidue reductionOvercoming toxicityCosmetic preparationsOrganic compound preparationMethyl carbonateUltraviolet

The invention provides a method for producing benzophenone ultraviolet absorbent 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid (BP-4). The invention uses a BP-3 refined product and chlorsulfonic acid to synthesize and prepare the BP-4 in methyl carbonate, and is characterized in that the method comprises the following steps: adding BP-3 refined product, chlorsulfonic acid, methyl carbonate andwater according to a production ratio into a crude product reaction kettle, controlling the temperature to be 23-38 DEG C, keeping temperature and reacting for 18-20 hours to obtain a BP-4 crude product; dissolving the BP-4 crude product in the mixed solvent of the methyl carbonate and a latent solvent, recrystallizing, separating solid phase from liquid phase to obtain the solid phase BP-4 refined product; refining and drying the BP-4 refined product to obtain a finished product. The invention reduces the harmful solvent residue of the product, decreases production cost, and has notable economic benefit and environmental benefit. The product yield reaches 92% and the product purity is increased to 99.5% from 99%.

Owner:宜都市华阳化工有限责任公司

Slow released anticancer combination of medication embedded the interior of the body

InactiveCN1660438AAddress sensitivityOvercoming toxicityPharmaceutical delivery mechanismAntineoplastic agentsDNA repairTreatment effect

A slowly-releasing anticanser composite medicine implanted in human body is composed of the anticancer medicine prepared from implantation agent, slowly releasing agent and dichloroethane-kind medicine for suppressing the growth of tumor cells and the medicinal additive chosen from biocompatible and biodegradable polymer for slowly releasing said anticancer medicine toward tumor.

Owner:DASEN BIOLOGICAL PHARMA CO LTD

Environment-friendly composite colorful passivating solution and preparation method thereof

ActiveCN107740085AColorfulUniform film formationMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite colorful passivating solution and a preparation method thereof and belongs to the technical field of surface treatment of metal materials. Thepassivating solution comprises the components of 17-22 g / L of sodium silicate, 4-8 g / L of sodium molybdate, 6-10 g / L of sodium nitrate, 3-7 mL / L of hydrogen peroxide, 1-3 g / L of potassium fluoride, 2-6 mL / L of nitrilotrimethylene triphosphonic acid, 2-4 g / L of sodium gluconate, 2-4 mL / L of tartaric acid and the balance water, wherein the pH value of the passivating solution is 2.0-2.5. The preparation method of the passivating solution comprises the steps that the sodium silicate, the sodium molybdate, the sodium nitrate, the potassium fluoride, the nitrilotrimethylene triphosphonic acid, thesodium gluconate, the tartaric acid and the hydrogen peroxide are sequentially added into deionized water to be evenly mixed; the water with the constant volume is added to the needed volume; and sulfuric acid is used for adjusting the pH value to be 2.0-2.5, and thus environment-friendly composite colorful passivating solution is obtained. A galvanized layer passivated film treated by the passivating solution is colorful, bright in color, even in film forming and excellent in corrosion resistant performance; the passivating solution does not contain trivalent chromium, hexavalent chromium and other harmful substances and is environmentally friendly, free of pollution, simple in passivating process and high in passivating efficiency, and the corrosion resistance of a film layer is good.

Owner:KUNMING UNIV OF SCI & TECH

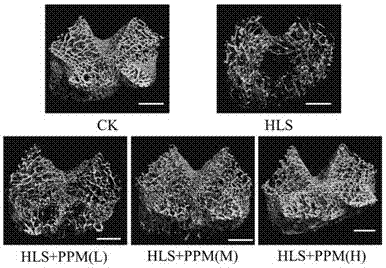

Chinese medicinal herbal compound preparation for killing ichthyophthirius multifiliis and preparation method and application

InactiveCN101926910AOvercoming high residualOvercoming toxicityAntiparasitic agentsPlant ingredientsIchthyophthiriasisPapaya family

The invention provides a Chinese medicinal herbal compound preparation for killing ichthyophthirius multifiliis and a preparation method and application thereof. The Chinese medicinal herbal compound preparation consists of the following raw material medicaments in percentage by weight: 30 to 40 percent of papaya, 20 to 34 percent of areca seed, 10 to 14 percent of thinleaf milkwort root-bark, 10 to 13 percent of cassia bark, 10 to 12 percent of pokeberry root and 6 to 10 percent of eucalyptus leaf. The preparation method of the Chinese medicinal herbal compound preparation comprises the following steps of: drying and crushing each raw material medicament respectively, and sieving to obtain dry powder of each raw material medicament; mixing the dry powder of each raw material medicament, adding water for soaking, decocting for two times, filtering, and combining two-time filtrate to obtain filtrate a; and boiling the filtrate a for concentrating to make each liter of filtrate contain 100g of raw material medicaments so as to obtain the Chinese medicinal herbal compound preparation. The Chinese medicinal herbal compound preparation is safe, effective and environmental-friendly and can be used for preventing and treating ichthyophthiriasis of fishes.

Owner:JINAN UNIVERSITY

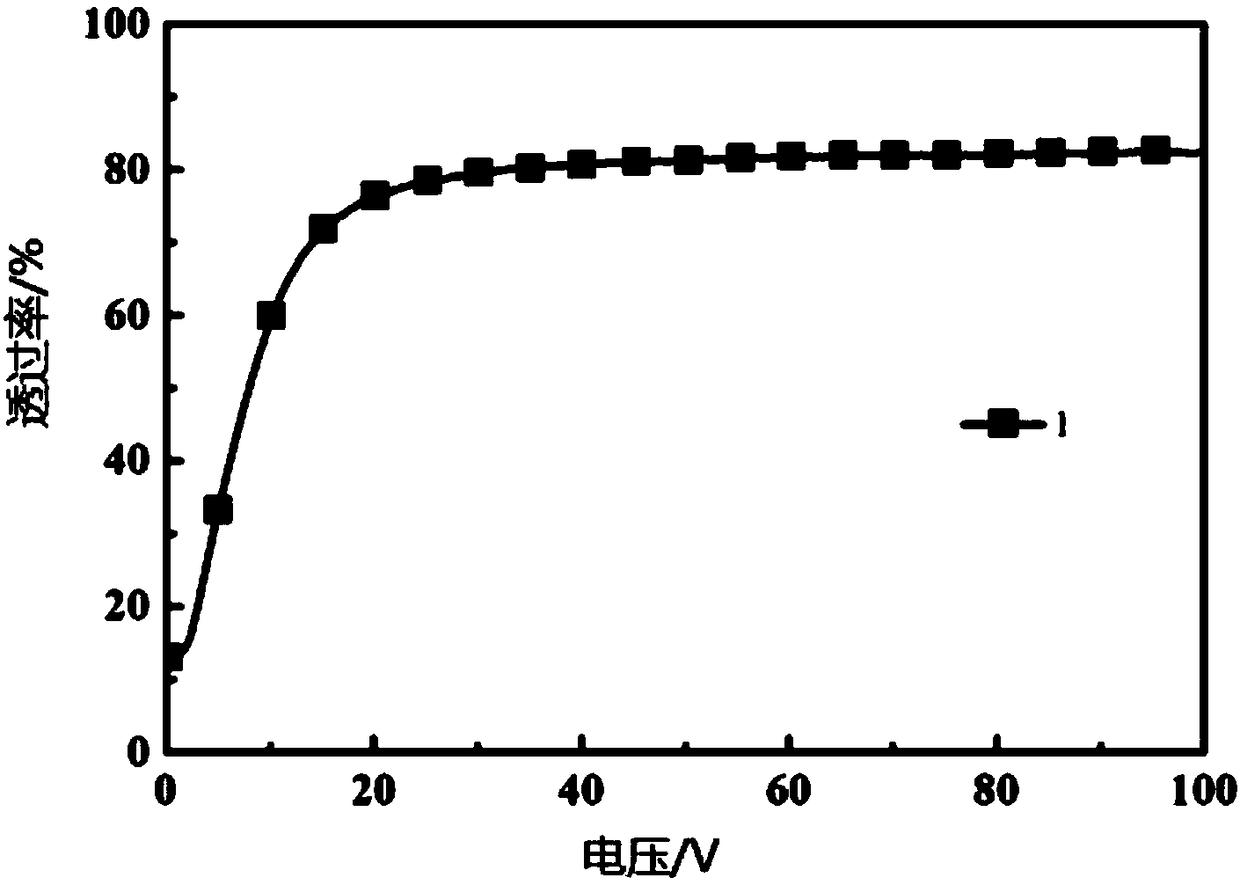

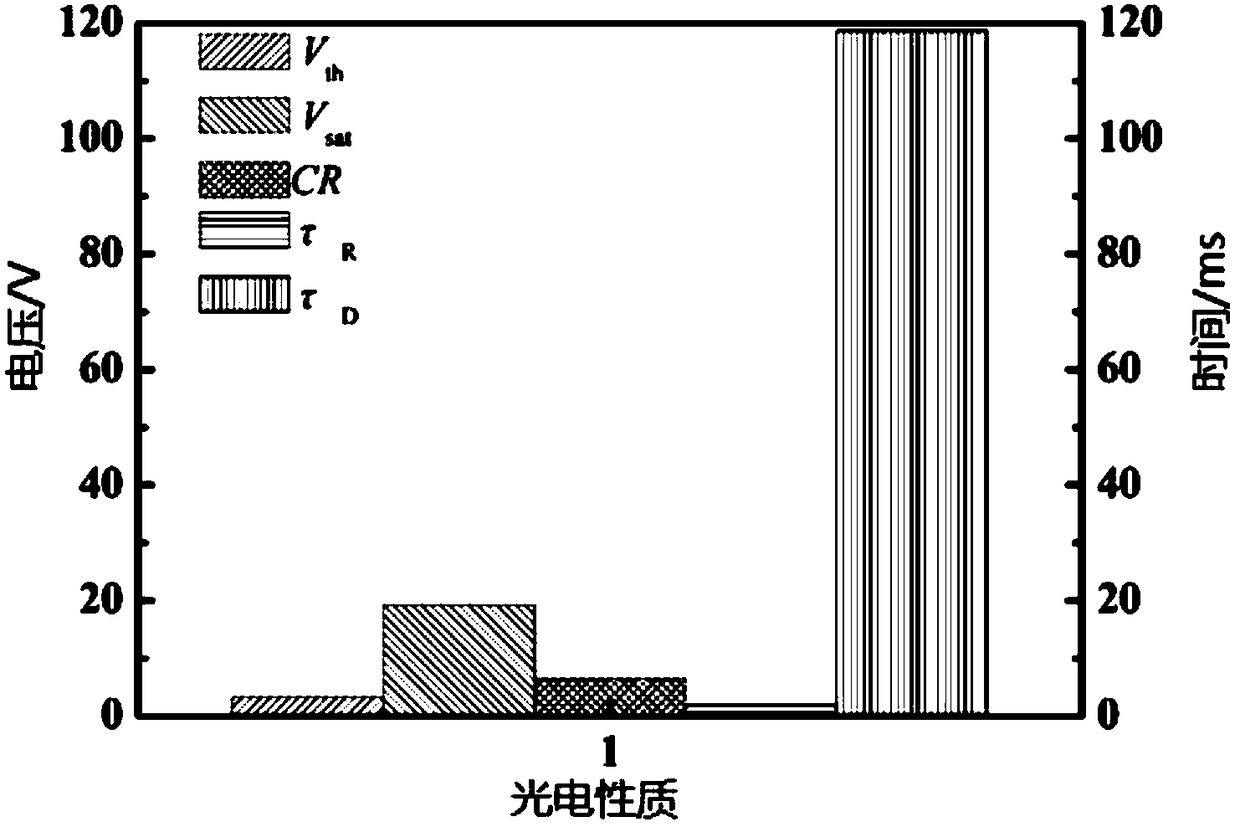

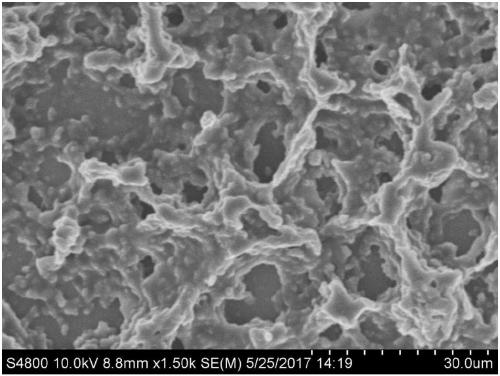

Polymer dispersed liquid crystal (PDLC) membrane preparation method and PDLC membrane

InactiveCN109324434AImprove toughnessImprove stabilityLiquid crystal compositionsNon-linear opticsMicrosphereIrritation

The invention discloses a preparation method of a polymer dispersed liquid crystal (PDLC) membrane material and the prepared PDLC membrane. The preparation method comprises the steps that polymerizable monomers and a liquid crystal material are mixed according to the mass ratio of (3:7) to (7:3), and an ultraviolet initiating agent is added, wherein the ultraviolet initiating agent accounts for 3-5% of the total mass of the polymerizable monomers, and the adopted liquid crystal material is matched with the selected polymerizable monomers in refractive index; and a mixture is poured into a liquid crystal cell and irradiated under ultraviolet light, and thus the PDLC membrane is prepared. The adopted polymerizable monomers are not prone to volatizing, low in toxicity and small in irritation;a system is high in stability and easy to preserve; through a polymerization crosslinking reaction of ultraviolet light and acrylate and mercaptan monomers, a formed polymer matrix has a unique composite structure, namely, the composite structure is provided with the dense surface and a hole-type internal structure with attached microspheres, the polymer matrix is good in toughness, fast in deformation recovery and good in stability, the electro-optical performance of the PDLC membrane is greatly improved, and thus the PDLC membrane has the lower driving voltage, the high response speed and the high contrast.

Owner:PEKING UNIV +1

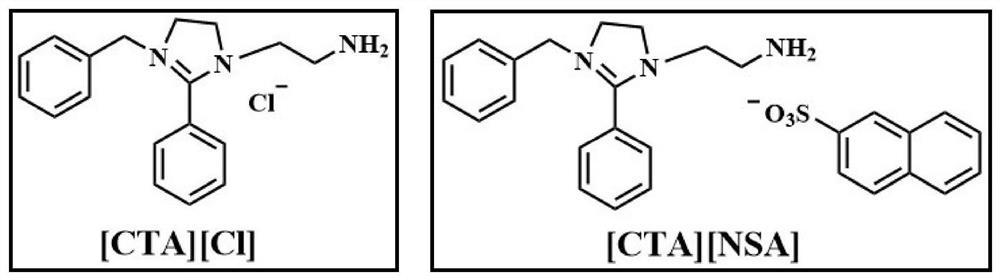

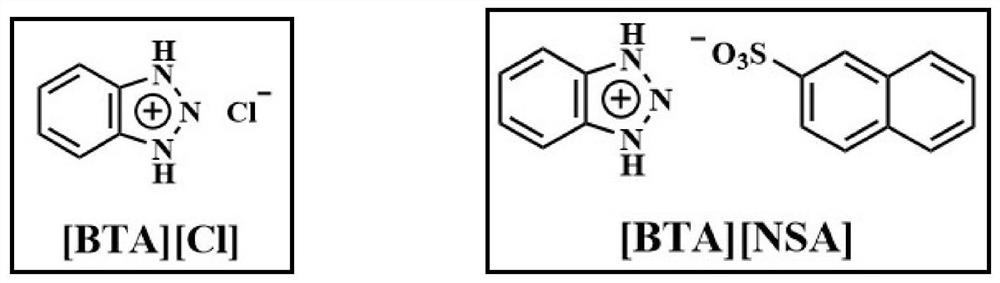

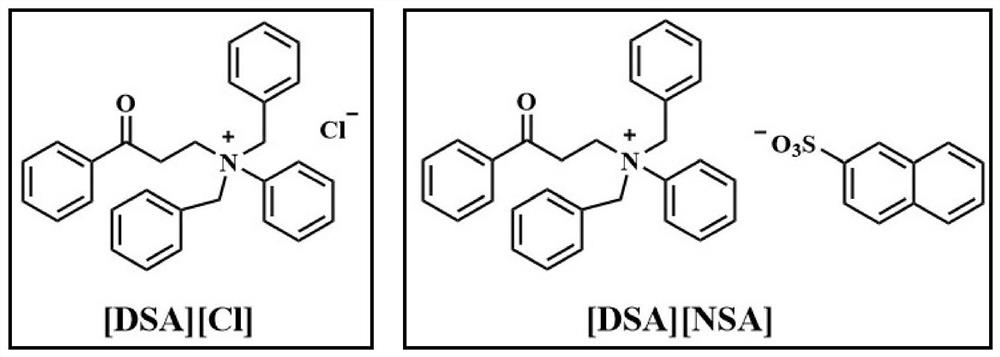

Anti-flash-rust agent for water-based paint and preparation method thereof

ActiveCN111876006AOvercoming toxicityOvercome environmental problemsAnti-corrosive paintsPolyurea/polyurethane coatingsAdsorptive membranePhosphate

The invention discloses an anti-flash-rust agent for water-based paint and a preparation method of the anti-flash-rust agent. The anti-flash-rust agent is formed by compounding imidazoline ionic liquid, triazole ionic liquid, quaternary ammonium salt ionic liquid, organic phosphate, alkynol and deionized water according to the mass ratio of 20-60 : 20-60 : 20-60 : 4-25 : 4-25 : 1000. According tothe method, a uniform and compact adsorption film is easily formed on the metal surface, electrochemical corrosion on the metal surface is effectively prevented, and the effect of inhibiting corrosionis achieved. The anti-flash-rust agent is applied to the water-based paint, the anti-flash-rust performance is good, the use amount is small, and it can be guaranteed that rust spots do not appear onthe metal surface only by adding 0.7 to 1.2 wt% of the anti-flash-rust agent.

Owner:HUAQIAO UNIVERSITY

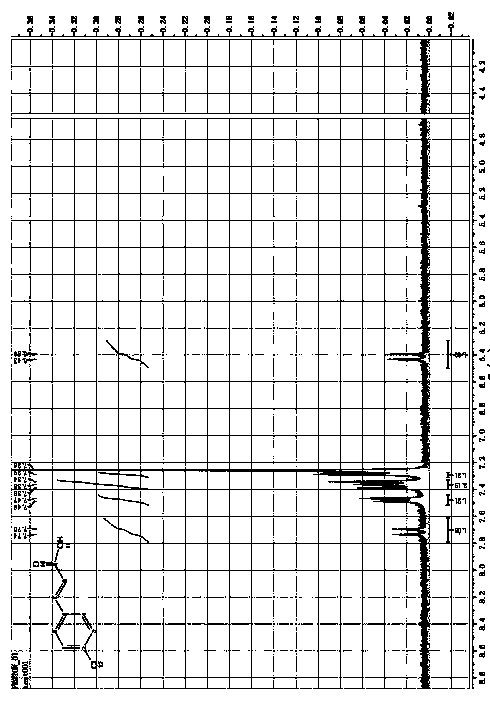

Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione

InactiveCN103086852AOvercoming toxicityImprove production safetyCarbonyl compound preparation by oxidationSolventChemistry

The invention discloses a novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione. According to the method, through taking beta-pinene as a raw material, taking acetone as a solvent and taking acidic potassium permanganate as an oxidant, beta-pinene is subjected to selective oxidation so as to generate nopinone; through taking KOH as a catalyst, 37% formaldehyde solution as a hydroxymethylation reagent is subjected to continuous hydroxymethylation-digestion reaction with nopinone so as to generate 3-methylene nopinone; and through taking potassium permanganate as an oxidant and adopting an acetone-water mixed solvent, 3-methylene nopinone is subjected to selective oxidation so as to generate 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione. The method has the outstanding advantages that the synthetic process of 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione is simplified, the defects of the traditional method that used reagents such as SeO2 and ozone are large in toxicity, explosion is easily caused, reaction time is long, energy consumption is large due to too low reaction temperature and the like are overcome, the production cost of 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione is reduced, and the production safety is improved, therefore, the method has good practicability.

Owner:NANJING FORESTRY UNIV

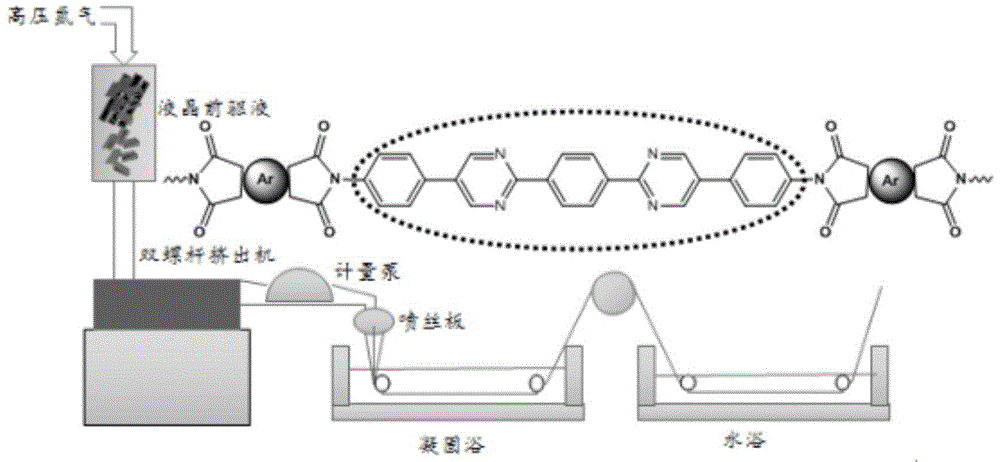

Preparation method of polyimide fibers containing symmetric bispyrimidine structures

ActiveCN105671671AImprove mechanical propertiesOvercoming toxicitySpinnerette packsArtificial filament washing/dryingThree levelFiber

The invention relates to a preparation method of polyimide fibers containing symmetric bispyrimidine structures. The preparation method comprises steps as follows: 2,2'-(1,4-phenylene)bis(5-(4-aminophenyl)) pyrimidine and anhydrous stannous chloride are added to polyphosphoric acid, aromatic dianhydride monomers and P2O5 are sequentially added, the mixture reacts at the temperature of 170-200 DEG C for 4-6 h, then, the mixture is heated to 200-240 DEG C and reacts for 3-6 h, and a liquid crystal type polyimide spinning solution is obtained; a twin-screw extruder is adopted, and polyimide nascent fibers are obtained from the liquid crystal type polyimide spinning solution through spinning, multi-coagulation bath forming, water washing and winding; three-level hot drafting is performed on the polyimide nascent fibers under the protection of nitrogen after the polyimide nascent fibers are dried, and the polyimide fibers are obtained. The polyimide fibers prepared with the method have excellent mechanical performance and have wide application prospect, and the synthesis and processing problems that conventional phenol and phenyl polyhalide type solvents have high toxicity, aprotic solvents are difficult to remove with a two-step processing method and the like are solved.

Owner:DONGHUA UNIV

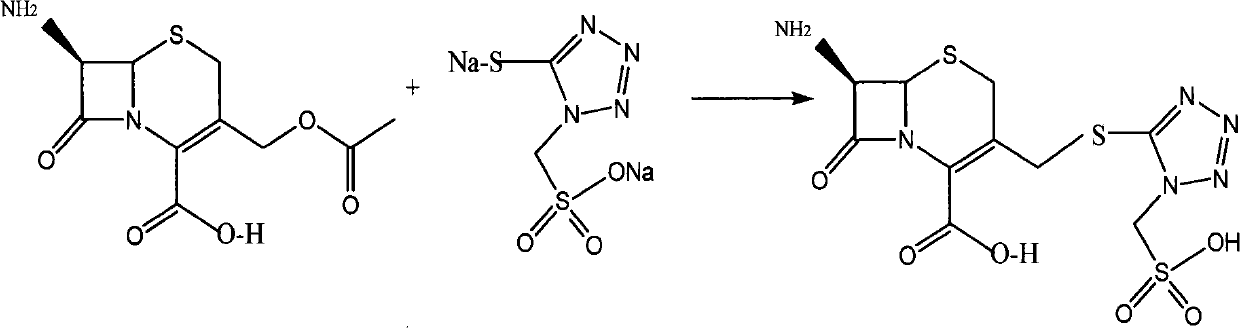

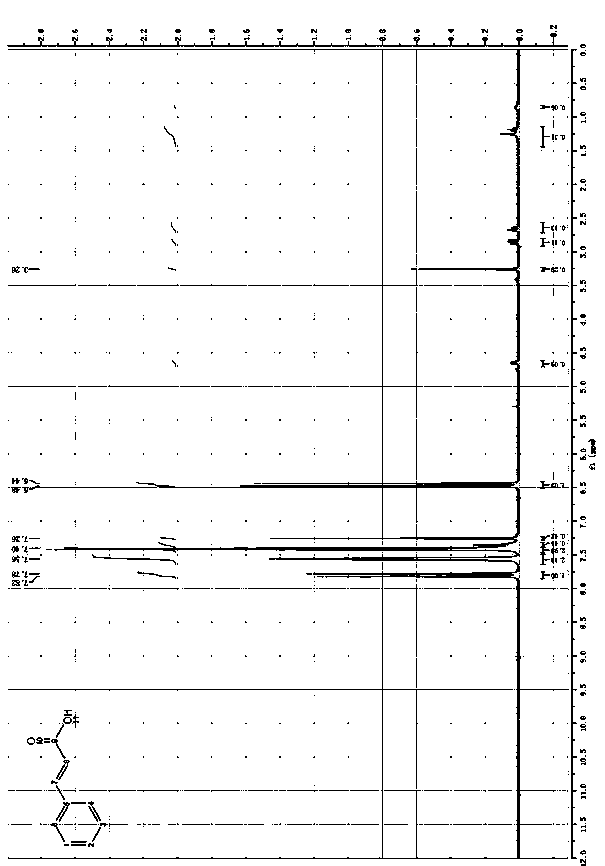

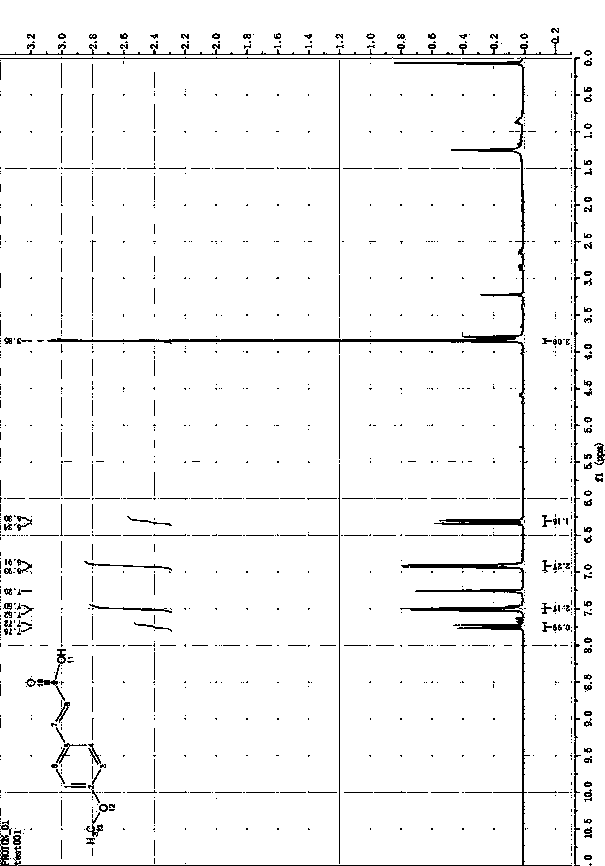

Method for preparing 7-amino-3-sulfotetrazolthiomethylcephalosporanic acid

InactiveCN101792453AConvenient storage and transportationSimple and mild reaction conditionsOrganic chemistryFiltrationSolvent

The invention discloses a method for preparing 7-amino-3-sulfotetrazolthiomethylcephalosporanic acid, which comprises: adding solution of boron trifluoride and dimethyl carbonate in a dimethyl carbonate solvent, stirring the solution, adding 7-aminocephalosporanic acid and 5-mercapto-1H-tetrazole-1-methanesulfonic acid disodium salt in turn to perform an reaction; when reactant residue is less than or equal to 0.5 percent, adding purified water to continue the reaction; cooling the reaction solution, filtering the reaction solution, and washing the product obtained by filtration to obtain a coarse crystal product; and dissolving the coarse crystal product, adding an organic solvent, adjusting the pH value, stirring the solution, cooling and standing the solution, filtering the solution, washing the product obtained after filtration and drying the product to obtain the finished product. Compared with the traditional process, the method has the advantages of mild and simple reaction conditions, easy solvent recovery and recycling, reaction yield up to 90 to 91.2 percent, purity up to 98.0 percent and light color as the solution of boron trifluoride and dimethyl carbonate is used as a catalyst. The method is suitable for large-scale production and overcomes the drawbacks of high price, difficult recovery, low yield, low purity and high production cost of the process using solution of boron trifluoride and acetonitrile as a catalyst.

Owner:河北九派制药股份有限公司

Preparation method of cinnamic acid or derivatives thereof

InactiveCN104003839AOvercome yieldOvercome temperatureOxygen-containing compound preparationOrganic compound preparationDistillationReaction temperature

The invention discloses a preparation method of cinnamic acid or derivatives thereof. The method comprises the following steps: adding a dichloromethane solution of triethyl phosphonoacetate, sodium chloride and raw material aldehyde into a reaction container, performing room-temperature reaction, adding a saturated water solution of ammonium chloride, stirring, performing organic phase washing, performing reduced pressure treatment to remove a solvent, and performing column chromatography purification to obtain a light yellow oily product; adding a mixed solution of dichloromethane and methanol into a reaction product, stirring, dropwise adding a methanol solution of sodium hydroxide to generate a large quantity of turbid materials, performing reduced pressure distillation on a reaction solution until the reaction solution is dry, removing impurities, extracting, combining organic phases, drying, performing reduced pressure treatment to remove the solvent, and drying in vacuum to obtain a white or light yellow product. According to the method, triethyl phosphonoacetate is adopted as an activating reagent for condensation esterification with aldehyde and then the product is conveniently prepared through alkaline hydrolysis; the reaction can be carried out at room temperature, and the shortcomings of low yield, high reaction temperature, high toxicity and serious pollution in a conventional process are overcome.

Owner:褚朝森

Silicate blue-white passivation solution and preparation method thereof

InactiveCN107574430AColorfulUniform film formationMetallic material coating processesHazardous substanceMetallic materials

The invention discloses a silicate blue-white passivation solution and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The silicate blue-white passivation solution consists of 26-34g / L of sodium silicate, 2-4g / L malic acid, 8-12g / L sodium fluoride, 9-14mL / L hydrogen peroxide, 8-13mL / L amino trimethylene phosphonic acid and the balance water, and the pH of the silicate blue-white passivation solution is 3.0-3.5. The preparation method of the silicate blue-white passivation solution comprises the steps that sodium silicate, malic acid, sodiumfluoride, amino trimethylene phosphonic acid and hydrogen peroxide are sequentially added to deionized water and are mixed uniformly, water is added for constant volume treatment till the required volume is reached, and the pH is adjusted to 3.0-3.5 by adopting sulfuric acid, thus the silicate blue-white passivation solution is obtained. A zinc coating passivation film after the treatment by thesilicate blue-white passivation solution is blue-white, and is bright in color, the film forming is uniform, and the corrosion resistance is excellent; the silicate blue-white passivation solution isfree of trivalent chromium, sexavalent chrome and other hazardous materials, so that the silicate blue-white passivation solution is environment-friendly and pollution-free; a passivation technology is simple; the passivation efficiency is high; and the film layer corrosion resistance is good.

Owner:KUNMING UNIV OF SCI & TECH

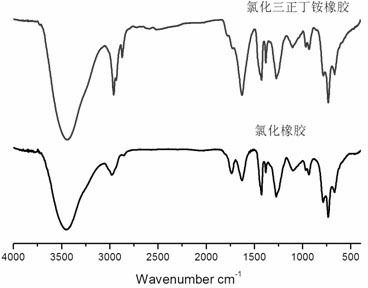

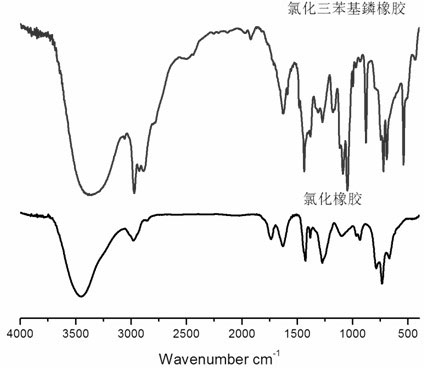

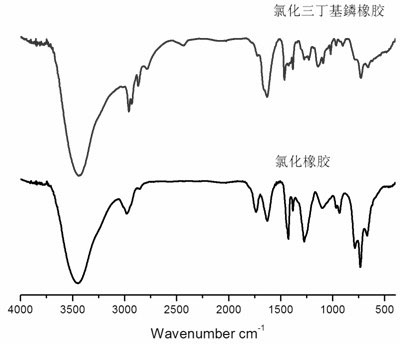

Preparation method for quaternary ammonium or quaternary phosphonium modified chlorinated natural rubber

ActiveCN102633912AOvercome toleranceGood antibacterial effectBiocideDisinfectantsTumor targetAntibiosis

The invention discloses a preparation method for quaternary ammonium or quaternary phosphonium modified chlorinated natural rubber, which includes the steps: dissolving the chlorinated natural rubber by organic solvent, then adding an organic amine compound or organic phosphine compound for reaction, and obtaining the quaternary ammonium or quaternary phosphonium modified chlorinated natural rubber after extraction, suction filtration, drying and the like. The quaternary ammonium or quaternary phosphonium modified chlorinated natural rubber prepared by the method is efficient, low in toxicity and broad-spectrum in antibiosis, can be applied to preparation of antibiotic rubber or plastic products, can also be applied to the fields such as water pollution microbiological treatment, agriculture or tumor targeting medicines and the like, and is wide in application prospect.

Owner:JINAN UNIVERSITY

Special edible bone strengthening gelatin for astronauts and preparation method thereof

InactiveCN107048369ASolve the problem of bone lossOvercoming defensivenessOrganic active ingredientsSkeletal disorderFructus psoraleae extractSide effect

The invention discloses special edible bone strengthening gelatin for astronauts and a preparation method thereof. The special edible bone strengthening gelatin is prepared from 5-10wt% of Radix Morindae Officinalis extract, 5-10wt% of Rhizoma Drynariae extract, 5-10wt% of Herba Epimedii, 5-10wt% of Radix Rehmanniae Preparata extract, 10-15wt% of Fructus Psoraleae extract, 2-5wt% of Cortex Eucommiae extract, 2-5wt% of Radix Achyranthis Bidentatae extract, 2-5wt% of Radix Astragali extract, 2-5wt% of Radix Polygoni Multiflori extract, 2-5wt% of Radix Puerariae extract, 1-5wt% of Radix Salviae Miltiorrhizae extract and 15-30wt% of pine polyphenol nanoparticles. The problem of bone loss of the astronauts in a space flight process is solved while the defect of high toxicity or severe side effects of existing protective agents is overcome. By extraction of various active polyphenol components with protective effects on weightlessness bone loss from natural plants, the special edible bone strengthening gelatin has advantages of scientific and reasonable ratio, low cost, convenience in administration and high safety.

Owner:HARBIN INST OF TECH

In vivo slow-releasing anticancer medicinal composition

InactiveCN1676165AAddress sensitivityOvercoming toxicityUnknown materialsHeterocyclic compound active ingredientsWhole bodyTherapeutic effect

The present invention relates to an anti-cancer medicine composition which can be slowly-released in human body. Said composition comprises medicinal auxiliary material and plant alkaloids anti-cancer medicine, in white the plant alkaloids anti-cancer medicine can inhibit hyperplasia of tumor, and the medicinal auxiliary material mainly can be bio-compatible high-molecular polymer which can be degraded and absorbed, in the course of its degradation and absorption the plant alkaloid can be slowly released in tumor locality, so that at the same time of obviously reducing systematic toxic it can retain effective medicine concentration in tumor locality so as to obtain good therapeutic effect.

Owner:SHANDONG LANJIN PHARMA +1

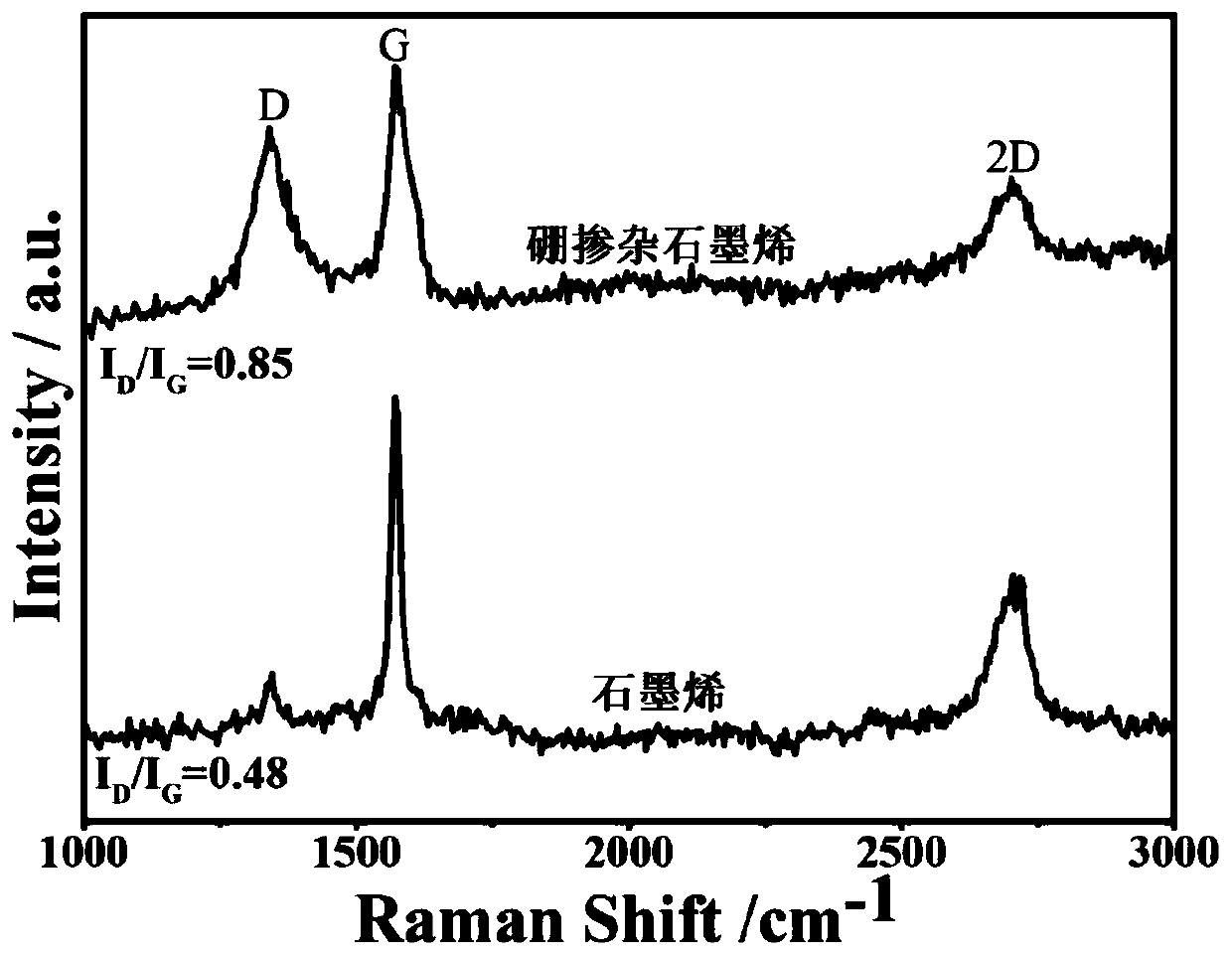

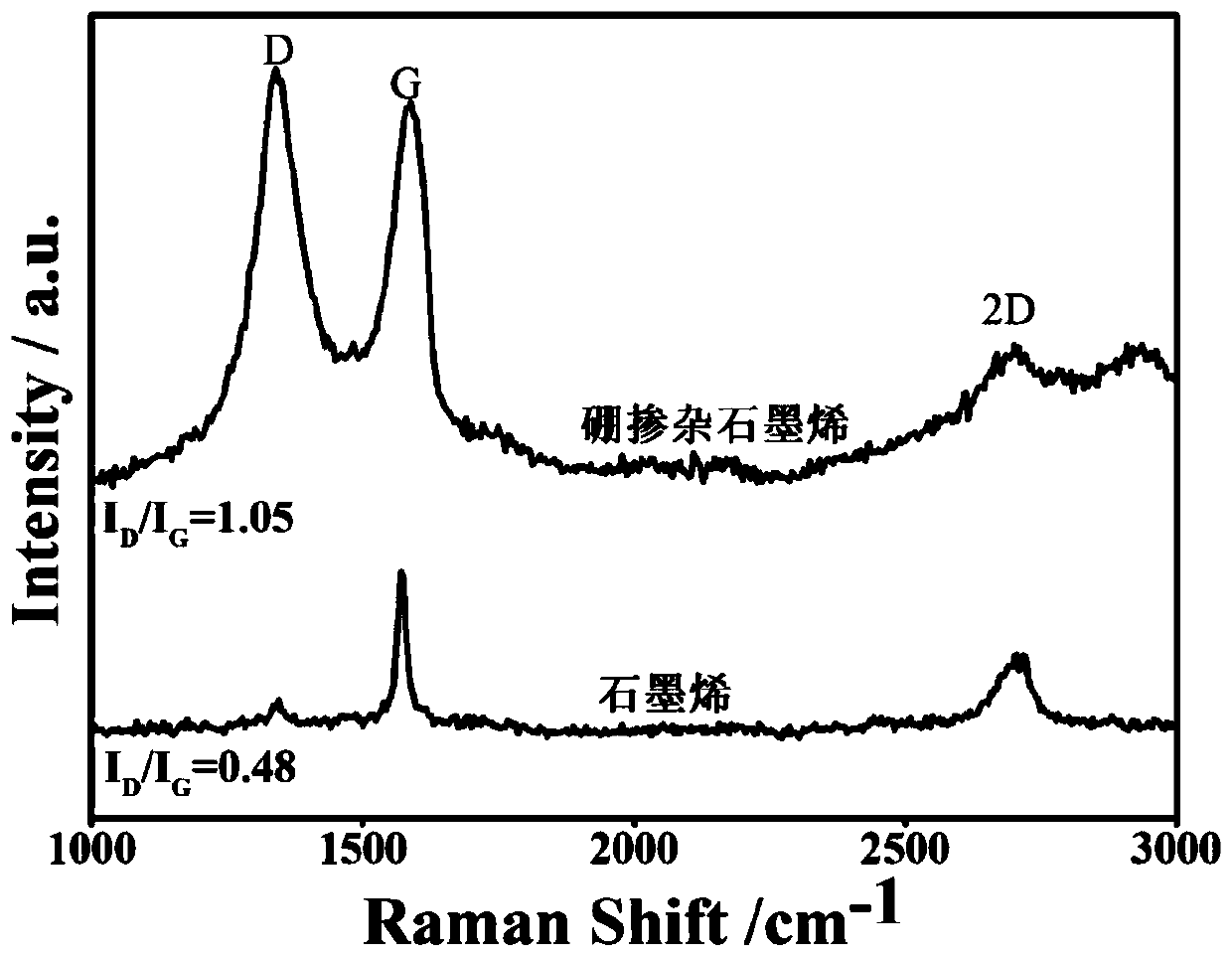

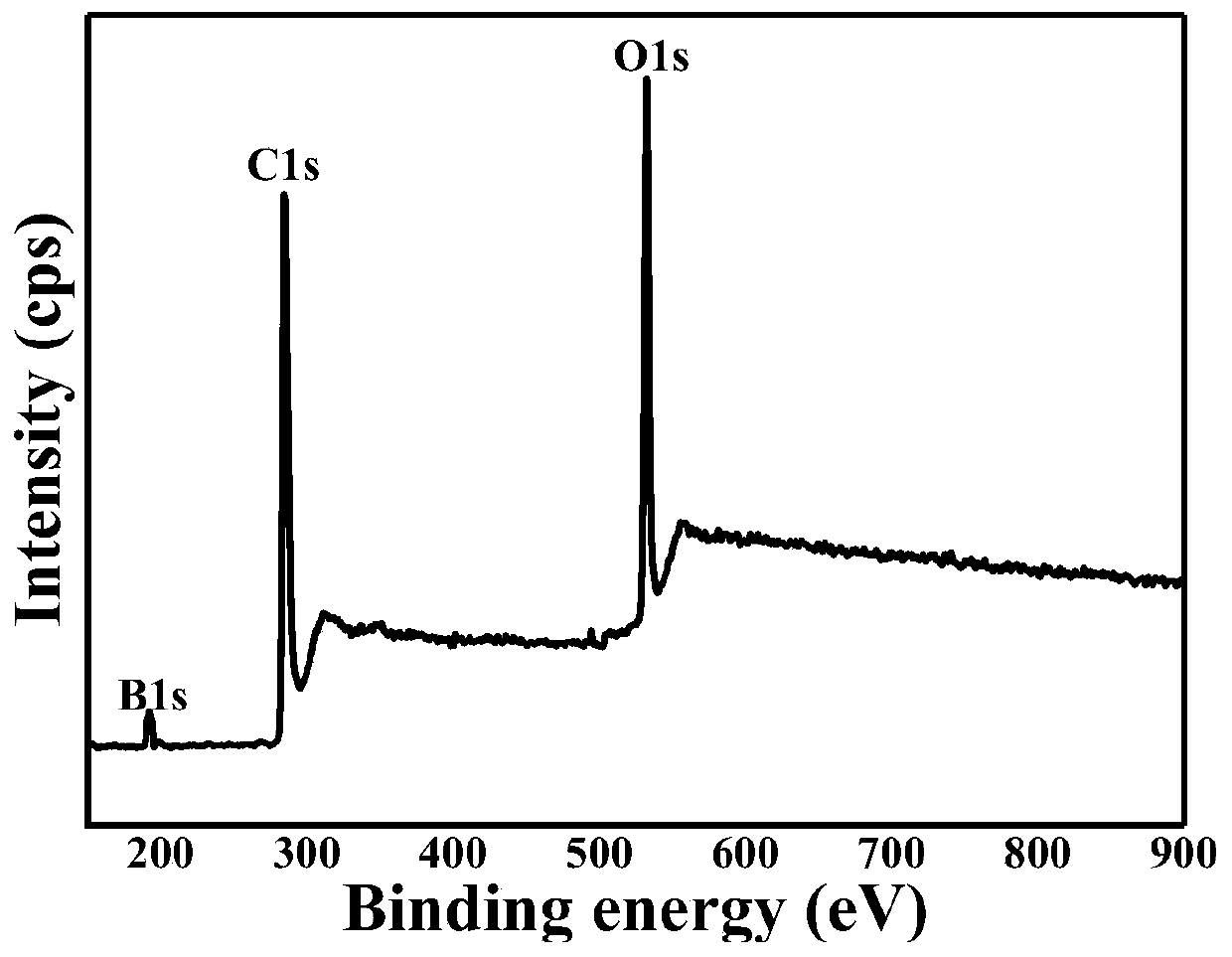

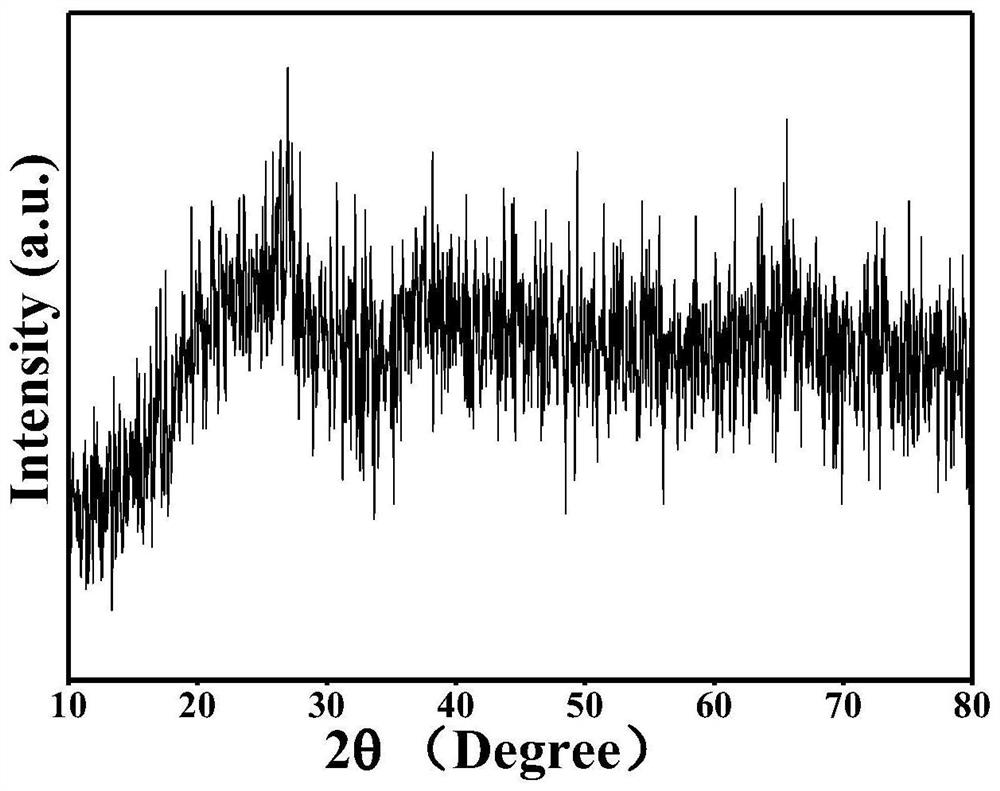

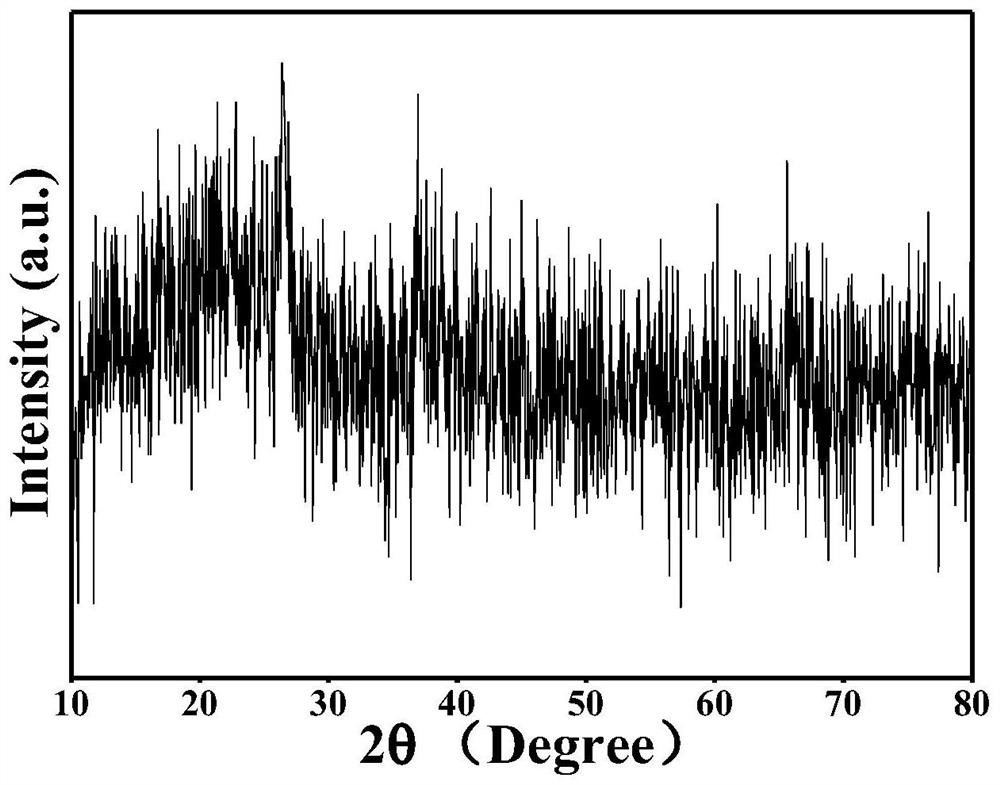

Method for preparing boron-doped graphene through electrochemical stripping of double graphite electrodes

PendingCN110980706AReduce usageThe process is easy to scale upGrapheneElectrolytic agentDoped graphene

The invention provides a method for electrochemically preparing boron-doped graphene through double graphite electrodes, and belongs to the technical field of controllable preparation of graphene materials and doping control of the graphene materials. The boron-doped graphene is prepared in one step by taking an aqueous solution of a soluble salt of which anions contain boron elements as an electrolyte and graphite foil as a raw material and adopting a double-graphite-foil electrochemical stripping method. As double graphite foils are used as positive and negative electrodes respectively, theuse of noble metal electrodes is reduced, and the cost is effectively reduced. The method can be simply implemented in a common beaker or glassware. The preparation method is green and environment-friendly, equipment is simple, operation time is short, operation is convenient, the process is simple and easy to amplify, and the prepared boron-doped graphene has the advantages of being high in quality, good in conductivity, excellent in dispersity in water and the like.

Owner:SHAANXI SCI TECH UNIV

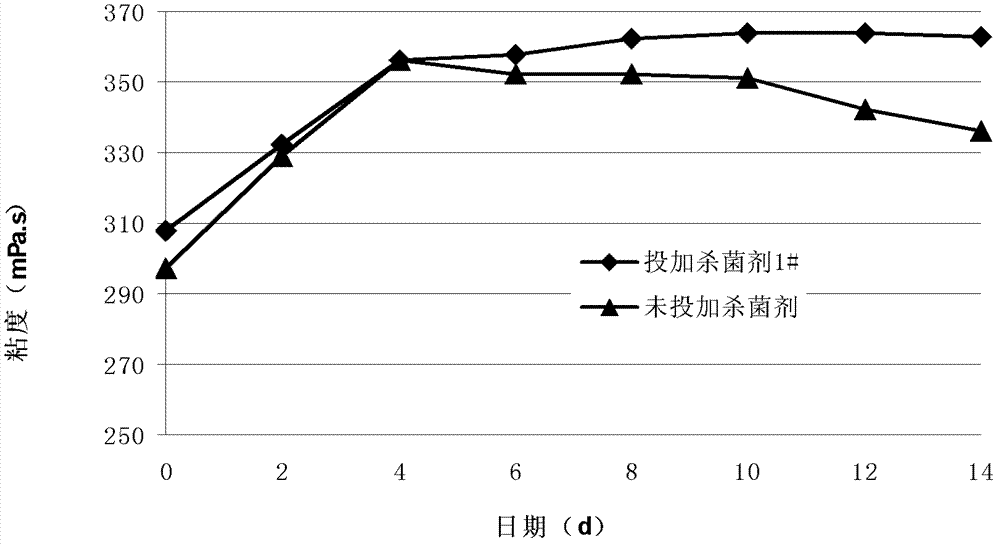

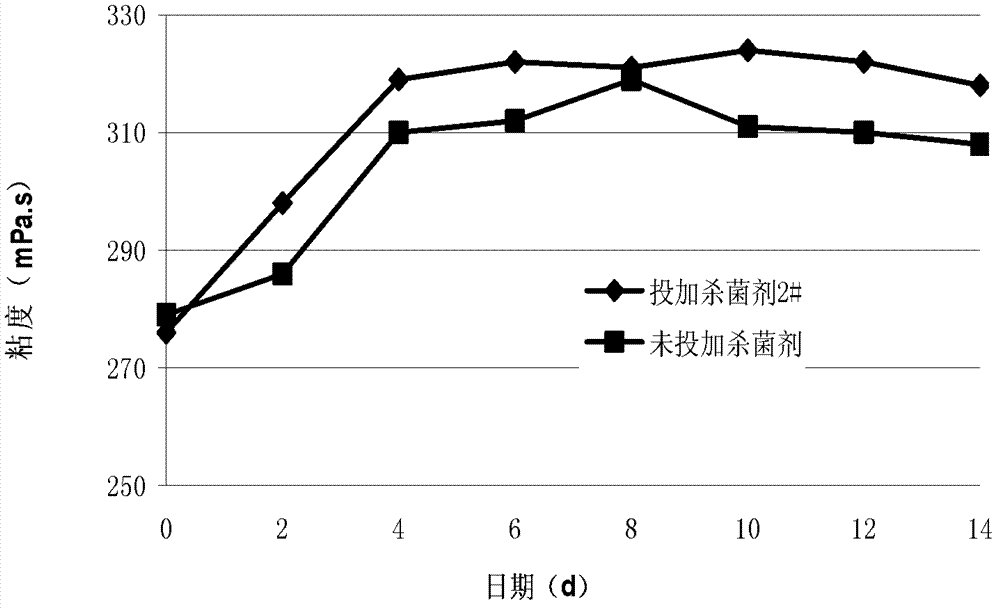

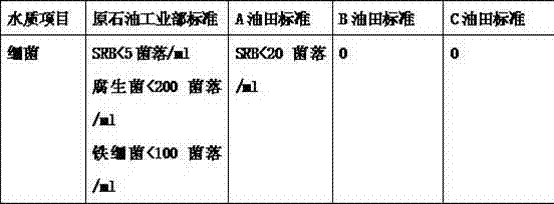

Oil recovery reinjection water bactericide and application thereof

ActiveCN103081914AReduce hydrolysisImprove stabilityBiocideDisinfectantsWater savingHydantoin derivatives

The invention discloses an oil recovery reinjection water bactericide and an application thereof. The bactericide comprises dibromo nitrilotriacetic propionamide and halogenated hydantoin with a weight ratio of 200:1-20:1. The bactericide can be used in polymer flooding reinjection water. According to the bactericide provided by the invention, with a synergetic effect between monomers, hydrolysis stability is improved, such that potency is increased and is maintained stable. Therefore, oil recovery pipeline and stratum corrosion, fouling and blocking caused by bacteria and algae can be greatly relieved. Because of the compatibility of bactericide components and oil recovery additives, polymer flooding reinjection water viscosity can be substantially improved, such that polymer dose during polymer flooding can be greatly reduced, and oil recovery production stability and efficiency improvement can be facilitated on a basis of water saving and emission reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

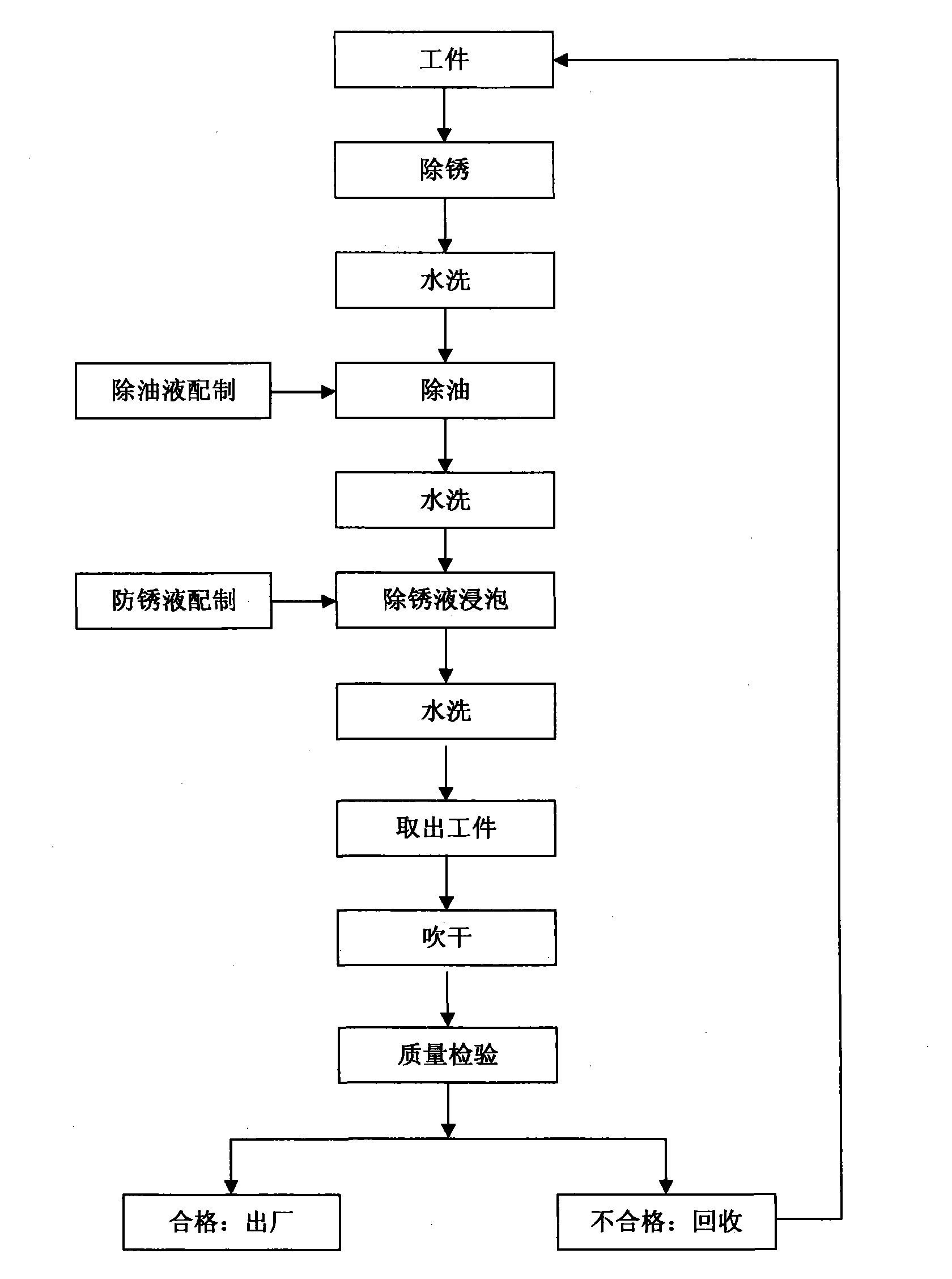

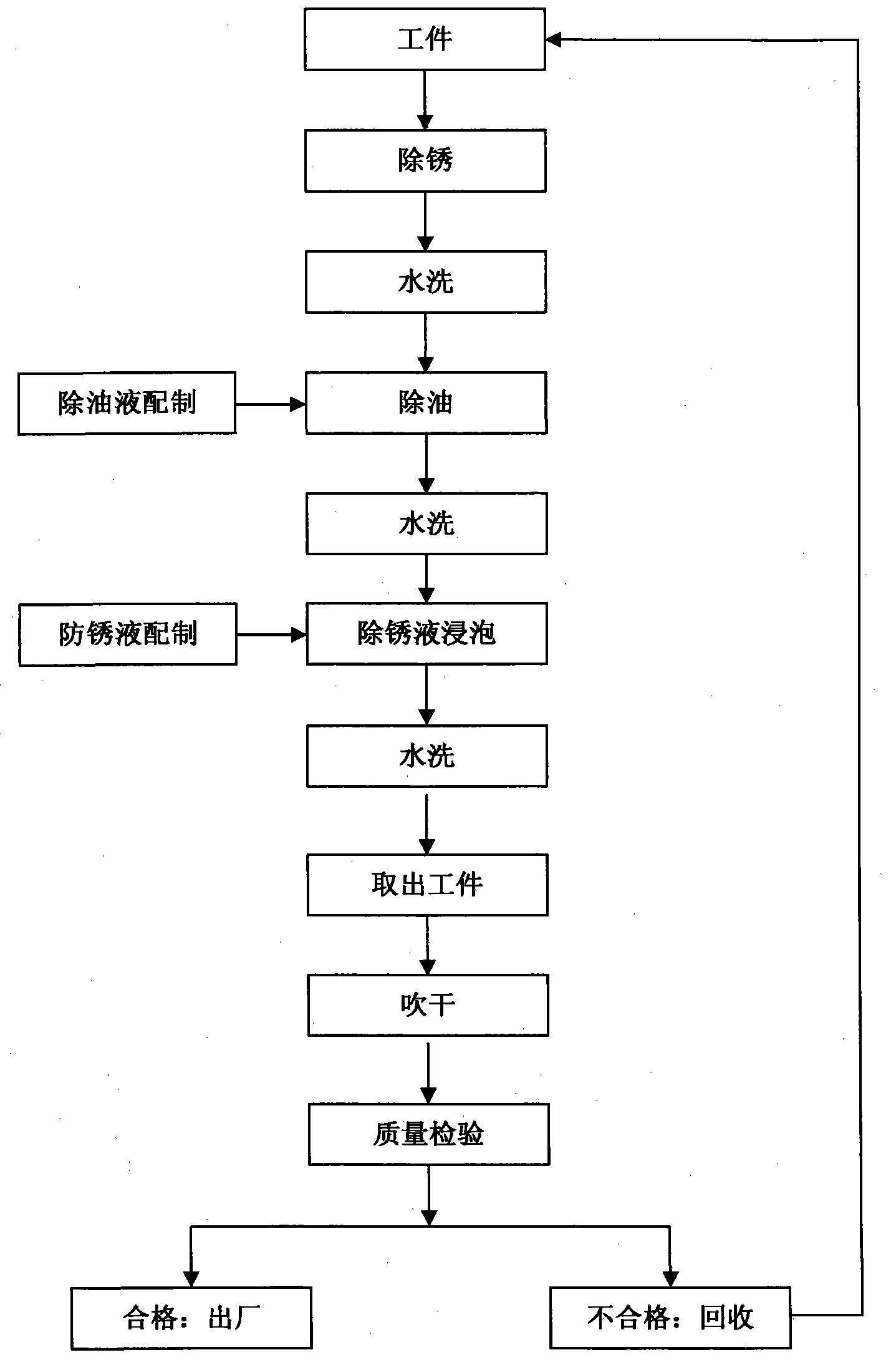

Rust-proof treatment process for steel fastener

InactiveCN104232280AImprove corrosion resistanceOvercoming toxicityLubricant compositionSodium bicarbonateSodium metasilicate

The invention discloses a rust-proof treatment process for a steel fastener. A rust-proof treatment fluid adopted by the process consists of the following components in percentage by weight: 6-8% of sodium silicate, 5-7% of sodium metasilicate, 3-5% of sodium bicarbonate, 1-3% of ammonium citrate, 0.8-1.2% of diethylamine, 0.3-0.5% of octadecyl amine, 0.05-0.07% of fatty alcohol-polyoxyethylene ether, 0.03-0.05% of tween-80, 0.2-0.4% of hydroquinone, 0.15-0.35% of an organic silicon wetting agent, 0.6-0.8% of texanol ester alcohol, 12-14% of alcohol and the balance of water. The treatment process comprises the following steps: firstly, mechanically removing rust for the steel fastener, then washing the steel fastener with clear water, removing oil by alkali wash water, flushing with clear water; and then, soaking the steel fastener in the treatment fluid with the components, flushing the steel fastener with clear water and drying the steel fastener, wherein the temperature of the treatment fluid is 25-45 DEG C, the pH value is 2.0-3.0, and the treatment time is 10-20 minutes.

Owner:无锡杨市表面处理科技有限公司

Environment-friendly composite color passivation solution and preparation method thereof

InactiveCN108531900ABright colorUniform thicknessMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite color passivation solution and a preparation method thereof, and belongs to the technical field of surface treatment of metal materials. The passivation solution comprises the components of 5-8g / L of tannic acid, 4-8mL / L of titanium trichloride, 4-7mL / L of nitric acid, 15-20mL / L hydrogen peroxide, 2-5mL / L concentrated sulfuric acid, 8-12mL / L of phosphoric acid, 2-7g / L of sodium silicate, 6-10g / L of potassium fluoride, 2-5mL / L of ascorbic acid, 4-7mL / L of aminotrimethylene fork phosphonic acid, and the balance water, and the pH value is1.5-2.0. A zinc plating coating passivation film treated by the passivation solution is bright in color, uniform in color and film thickness and excellent in corrosion resistance; and the passivationsolution has no trivalent chromium, hexavalent chromium and other harmful substances, environmental protection and no pollution are achieved, the passivation process is simple, the passivation efficiency is high, and corrosion resistance of the film is good.

Owner:KUNMING UNIV OF SCI & TECH

Anti-rust treatment process for steel surface

InactiveCN104233271AImprove corrosion resistanceOvercoming toxicityMetallic material coating processesWash waterPotassium silicate

The invention discloses an anti-rust treatment process for a steel surface. A treatment fluid adopted by the anti-rust treatment process comprises the following components by weight: 6-10 g / L of potassium silicate, 11-15 g / L of sodium silicate, 22-24 g / L of sodium nitrate, 7-11 g / L of zinc nitrate, 14-18 g / L of zinc oxide, 18-22 ml / L of sulfuric acid, 23-27 mL / L of hydrogen peroxide, 0.8-1.2 g / L of triethanolamine and the balance of water. The anti-rust treatment process comprises the following steps of: firstly mechanically derusting a steel part; then washing by using clear water; then deoiling by using alkali wash water; then washing by using clear water; then soaking into the treatment fluid which comprises the components for 30-60 minutes while keeping the treatment fluid at the temperature of 25-45 DEG C and the pH at 2.0-3.0; then washing by using clear water; finally blow-drying.

Owner:无锡杨市表面处理科技有限公司

Silicate antirust liquid

InactiveCN101857955AImprove corrosion resistanceOvercoming processingMetallic material coating processesBarium saltSalt spray test

The invention discloses a silicate antirust liquid. The antirust liquid consists of the following components: 5g / L to 20g / L of silicate, 5ml / L to 20ml / L of H2O2, 8g / L to 20g / L of NaNO3, 25g / L to 45g / L of Zn(NO3)2, 3ml / L to 15ml / L of H2SO4 and the balance of H2O; and in the process of preparation, after all the components in the antirust liquid are completely dissolved, concentrated H2SO4 or NaOH solution is used for regulating the pH value to 1.5 to 3.0. The silicate is one or the combination of sodium silicate and potassium silicate. The silicate antirust liquid can be used as a temporary means of protection when antirust oil cannot be used in the process of the transportation of steel parts, dense protective films can be formed on the surfaces of the processed steel parts, and thereby the corrosion resistance of the steel parts can be enhanced. The invention can remarkably enhances the corrosion resistance of steel parts, so that the rust formation time in a salt fog test can reach more than 50 to 80 hours, which is far longer than the national standard. Since the antirust liquid does not contain barium and even sulphonate, the antirust liquid overcomes the defects of the barium salt processing technique, such as high toxicity and unenvironment-friendliness, and thereby the clean production of steel parts can be implemented in a post-processing process.

Owner:KUNMING UNIV OF SCI & TECH

Slow released combination of anticancer drugs embedded in vivo

InactiveCN1660070AImprove anti-cancer effectAddress sensitivityOrganic active ingredientsUnknown materialsWhole bodyTherapeutic effect

A slowly-releasing anticancer medicine able to be implantated in human body is composed of the anticancer Duoxitasai and / or its derivative and the biosoluble and biodegradable high-molecular polymer for slowly releasing said medicine to the cancer position.

Owner:DASEN BIOLOGICAL PHARMA CO LTD

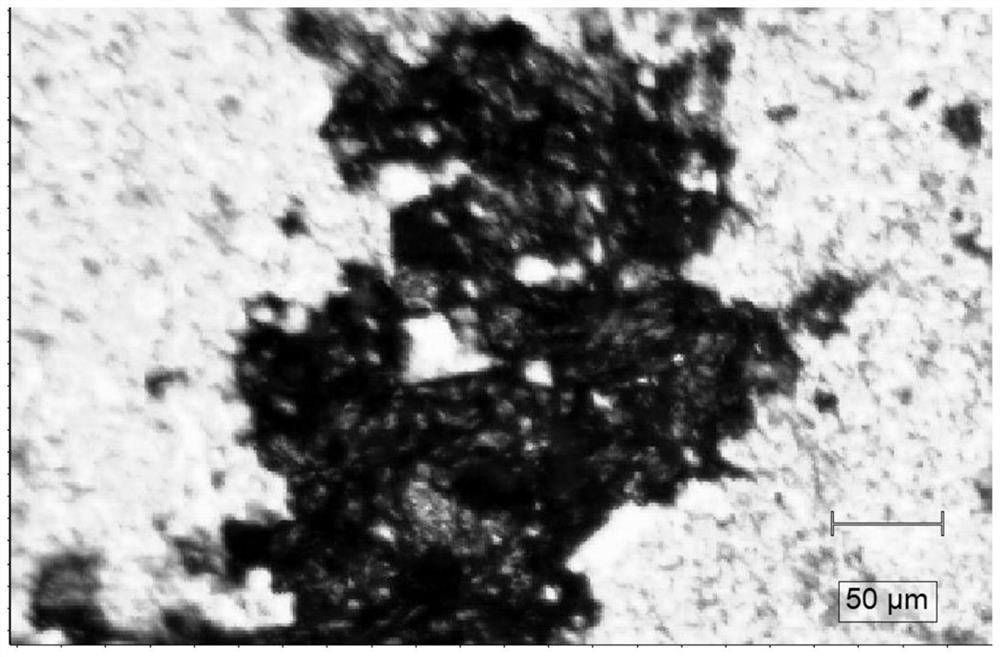

Method for electrochemically preparing manganese dioxide-graphene compound

PendingCN112225257AReduce usageLow costGrapheneManganese oxides/hydroxidesElectrolytic agentPermanganic acid

The invention provides a method for electrochemically preparing a manganese dioxide-graphene compound, and belongs to the technical field of controllable preparation of inorganic nano materials. Soluble salt containing ammonium, sulfate, peroxysulphate or halogen anions and soluble salt containing permanganate or manganate are used as electrolyte, graphite foils or graphite rods are used as electrodes, and the manganese dioxide-graphene compound is prepared in one step by adopting an electrochemical method. As two graphite foils are respectively used as the anode and the cathode, the use of noble metal electrodes is reduced, and the cost is effectively reduced. The method disclosed by the invention is simple and can be implemented in a general beaker or glassware. The preparation method isgreen, environment-friendly, simple in equipment, short in operation time, convenient to operate, simple in process and easy to amplify.

Owner:SHAANXI SCI TECH UNIV

Amygdalus pedunculata leaf extract and use thereof

InactiveCN101485750AOvercoming toxicityOvercome environmental problemsAntiparasitic agentsPlant ingredientsRefluxMedicine

The invention discloses an amygdalus pedunculata leaf extract, which is prepared through the following steps: drying and grinding amygdalus pedunculata leaves; performing hot reflux with 5 to 10 folds of distilled water to extract the powder for 1 to 3 times, each time for 0.5 to 2 hours; and putting the reflux extracts together and concentrating the extracts until the concentration of the raw drug is between 0.5 and 5 grams per milliliter. Amygdalus pedunculata leaf aqueous extract is used to develop and prepare insecticidal fishery medicines so as to overcome the disadvantages that chemical fishery medicines have high toxicity and cause environmental pollution, not influence aquatic livestock to take food and grow, and be safe to the aquatic livestock.

Owner:NORTHWEST UNIV(CN)

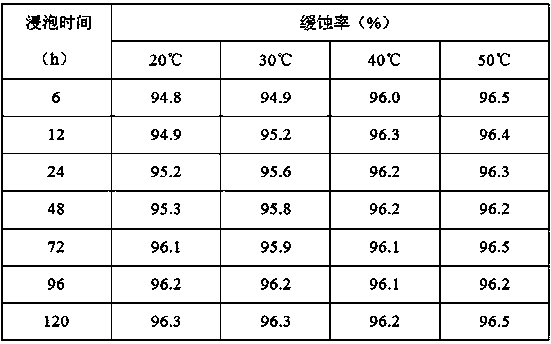

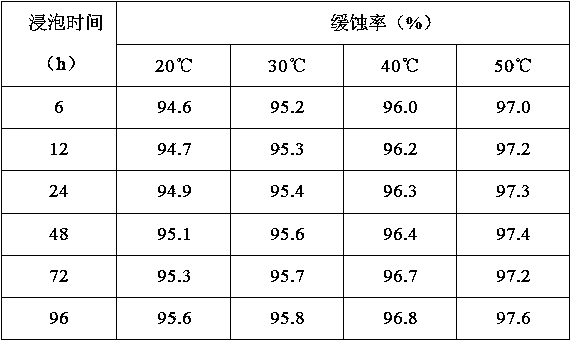

Rape seed cake compound corrosion inhibitor and preparation method and application thereof

The invention discloses a rape seed cake compound corrosion inhibitor and a preparation method and application thereof. The rape seed cake compound corrosion inhibitor comprises, by weight, 0.1-1.0g / Lof rape seed cake meal extract, 0.05-0.5g / L of high polymer, 0.1-0.5g / L of anionic surfactant, 0.01-0.1g / L of diethylamino pentyne diol, and the balance a pickling solution. The preparation method comprises the following steps: mixing and uniformly stirring raw materials according to the formula ratio to obtain the target rape seed cake compound corrosion inhibitor. The rape seed cake compound corrosion inhibitor is applied in acid pickling of iron and steel materials.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Slow released anticancer combination of medication embedded the interior of the body

InactiveCN1299774CAddress sensitivityOvercoming toxicityPharmaceutical delivery mechanismAntineoplastic agentsDNA repairWhole body

Owner:DASEN BIOLOGICAL PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione](https://images-eureka.patsnap.com/patent_img/928f03b1-60b3-4179-8760-b67680f0c3fa/BDA00002847331800011.PNG)

![Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione](https://images-eureka.patsnap.com/patent_img/928f03b1-60b3-4179-8760-b67680f0c3fa/BDA00002847331800021.PNG)

![Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione Novel method for preparing 6,6-dimethylbicycol[3.1.1]heptane-2, 3-dione](https://images-eureka.patsnap.com/patent_img/928f03b1-60b3-4179-8760-b67680f0c3fa/BDA00002847331800022.PNG)