Low surface energy liquid control release type marine anti-fouling paint

A liquid control and marine antifouling technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc., can solve the problem of increasing the surface roughness and weight of the hull, increasing the number of maintenance times on the ship's dock, and greatly toxic Pollutants and other issues, to achieve significant anti-marine biofouling, good anti-marine biofouling, and simple preparation process

Inactive Publication Date: 2010-09-29

NINGBO HAITENG NEW MATERIALS CO LTD

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Once marine organisms attach to the bottom surface of the ship, it will cause serious harm, mainly in the following aspects: ① Increase the surface roughness and weight of the hull, increase resistance, slow down the speed of the ship, lose maneuverability, and increase fuel consumption. Increased release of harmful gases; ②Increasing the number of docking repairs on ships, wasting time and resources, and at the same time producing a large amount of toxic pollutants; ③Accelerating the corrosion of substrates (steel, aluminum, etc.) under attached organisms

The traditional antifouling coatings used to prevent the adhesion of marine fouling organisms include tributyltin self-polishing antifouling coatings, cuprous oxide antifouling coatings, etc. Banned for environmental pollution [Claude Alzieu.Impact of tributyltin on marine invertebrates[J].Ecotoxicology, 2000, (9): 71-76; F.Garaventa, F.Pellizzato, M.Faimali et al, Imposexin Hexaplex trunculus at some sites on the North Mediterranean Coast as a base-line future evaluation of the effectiveness of the total ban on organotin based antifouling paints[J]. Hydrobiologia, 2006(555): 281-287; Li Zhengyan, Zhou Mingjiang, Li Jun, etc. Effects of triphenyltin chloride on physiological functions of Isochrysis [J], Marine Science Collection, 1996, (37): 115-120; Wang Yongfang, Pollution and toxicity of organotin compounds [J], China Food Hygienic impurities, 2003, 15 (3): 244-247], and cuprous oxide antifouling coatings, the antifouling effect is not very ideal, the use process needs a lot of use to achieve a certain effect, and a large amount of use of cuprous oxide On the one hand, it will increase pollution, on the other hand, it will increase the cost of use

Especially at present, with the increasing calls for environmental protection, countries have legislated to restrict the use of organotin. The International Maritime Organization (IMO) proposed to completely ban the use of organotin in antifouling coatings by 2008, while cuprous oxide antifouling The use of paint will also be further restricted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

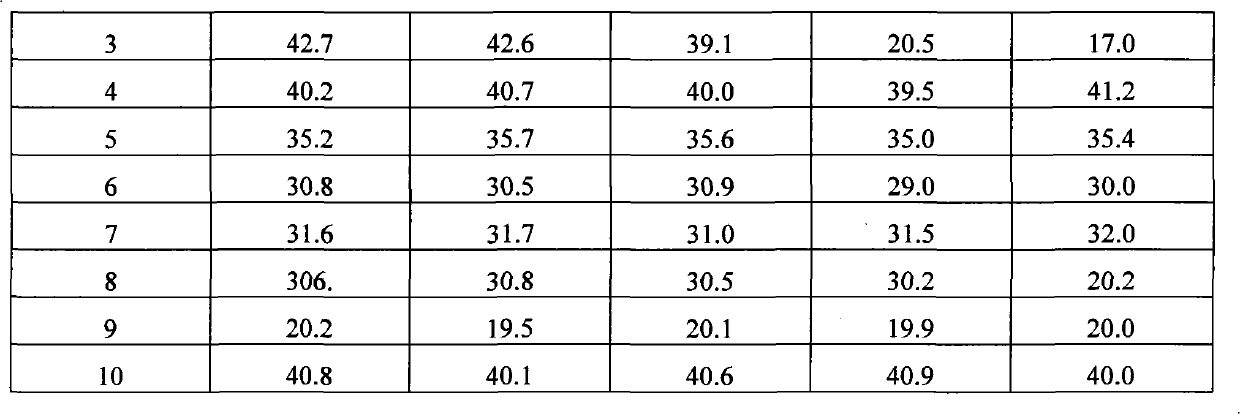

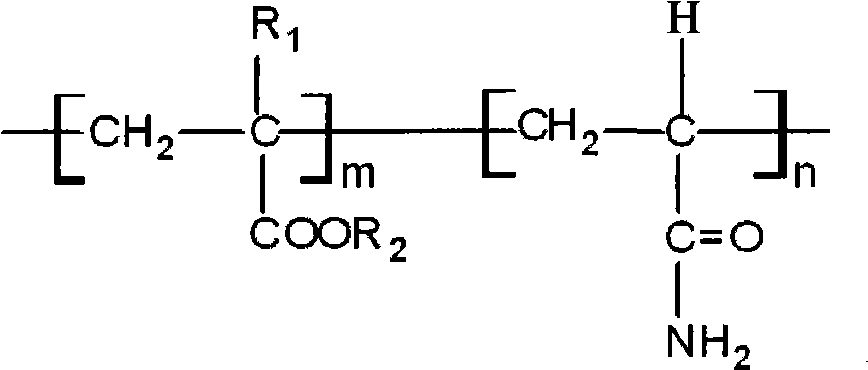

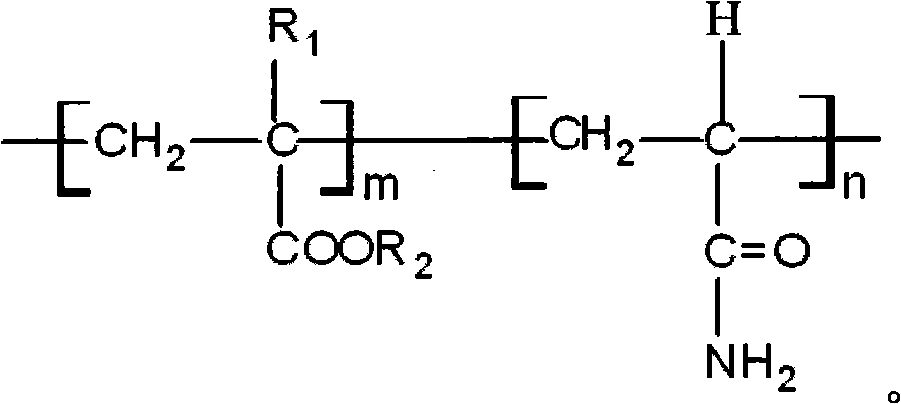

The invention discloses a low surface energy liquid control release type marine anti-fouling paint, comprising the following components in parts by weight: 30.0-55.0 parts of film-forming resin, 7.0-18.0 parts of lamella cross-linking silicone oil microcapsule, 1.0-10.0 parts of plasticizer, 1.0-3.0 parts of defoaming agent, 15.0-35.0 parts of added pigment and 5.3-22.7 parts of solvent. The lamella cross-linking silicone oil microcapsule is obtained by polymerizing an oil-in-water system in situ; the core material of the lamella cross-linking silicone oil microcapsule is one or several of methyl silicone oil, hydroxy silicone oil, amino silicon oil and alkoxy silicone oil; and the wall material of the lamella cross-linking silicone oil microcapsule can be one of polyacrylamide, polyacrylic acid, polymaleic anhydride and the like which can be swelled in the water. The anti-fouling paint has the advantages of remarkable anti-fouling effects, no pollution to a marine environment, low cost and applicability for industrial application production. The film-forming resin is acrylic resin, the structural general formula of which is shown in the specification of the invention.

Description

technical field The invention relates to the field of anti-marine biofouling coatings, in particular to a marine anti-fouling coating with controlled release of low surface energy liquid. Background technique Any facility exposed to seawater for a long time, such as the bottom of a ship, aquaculture cages, etc., is very easy to be adhered to the surface by various marine fouling organisms and grow and reproduce, causing great damage to appearance and function, and bringing huge economic benefits loss. These marine fouling organisms include animals such as barnacles, hydra, and sea squirts, algae such as diatoms and green algae, and fungi such as bacteria and fungi. Once marine organisms attach to the bottom surface of the ship, it will cause serious harm, mainly in the following aspects: ① Increase the surface roughness and weight of the hull, increase resistance, slow down the speed of the ship, lose maneuverability, and increase fuel consumption. The release of harmful g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D133/12C09D133/10C09D133/08C09D151/08C09D5/16

Inventor 龙宇华徐坚王中善苏联刘剑洪郑德

Owner NINGBO HAITENG NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com