Piston type diesel engine

A diesel engine, piston type technology, applied in the direction of mechanical equipment, machine/engine, etc., can solve the problem of the difficult deformation effect of the trembling elimination part, and achieve the effect of overcoming the poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below by specific embodiment:

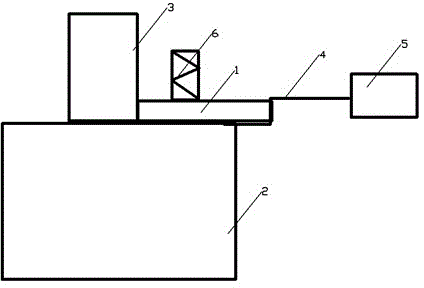

[0010] Such as figure 1 As shown, the piston diesel engine includes an elastic body 1, which contains a single number of setting parts 3 arranged on the surface of the piston top seal 2 and a buckling part that is convex against the curved roller 4 to buckle the belt drive part 5 6. The elastic body 1 is a powerful spring.

[0011] The working principle of the present invention is that the elastic body 1 contains a singular set part 3 arranged on the surface of the piston top seal 2 and a fastening part 6 that protrudes from the curved roller 4 to fasten the belt drive part 5 . In this way, the fastening part can overcome the problem that the chatter eliminating part is difficult to deform and has poor effect.

[0012] The above description is only a preferred embodiment of the present invention, and does not limit the present invention in any form. Although the present invention has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com