Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

A zipper tooth, zinc alloy technology, applied in applications, clothing, sliding fastener components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

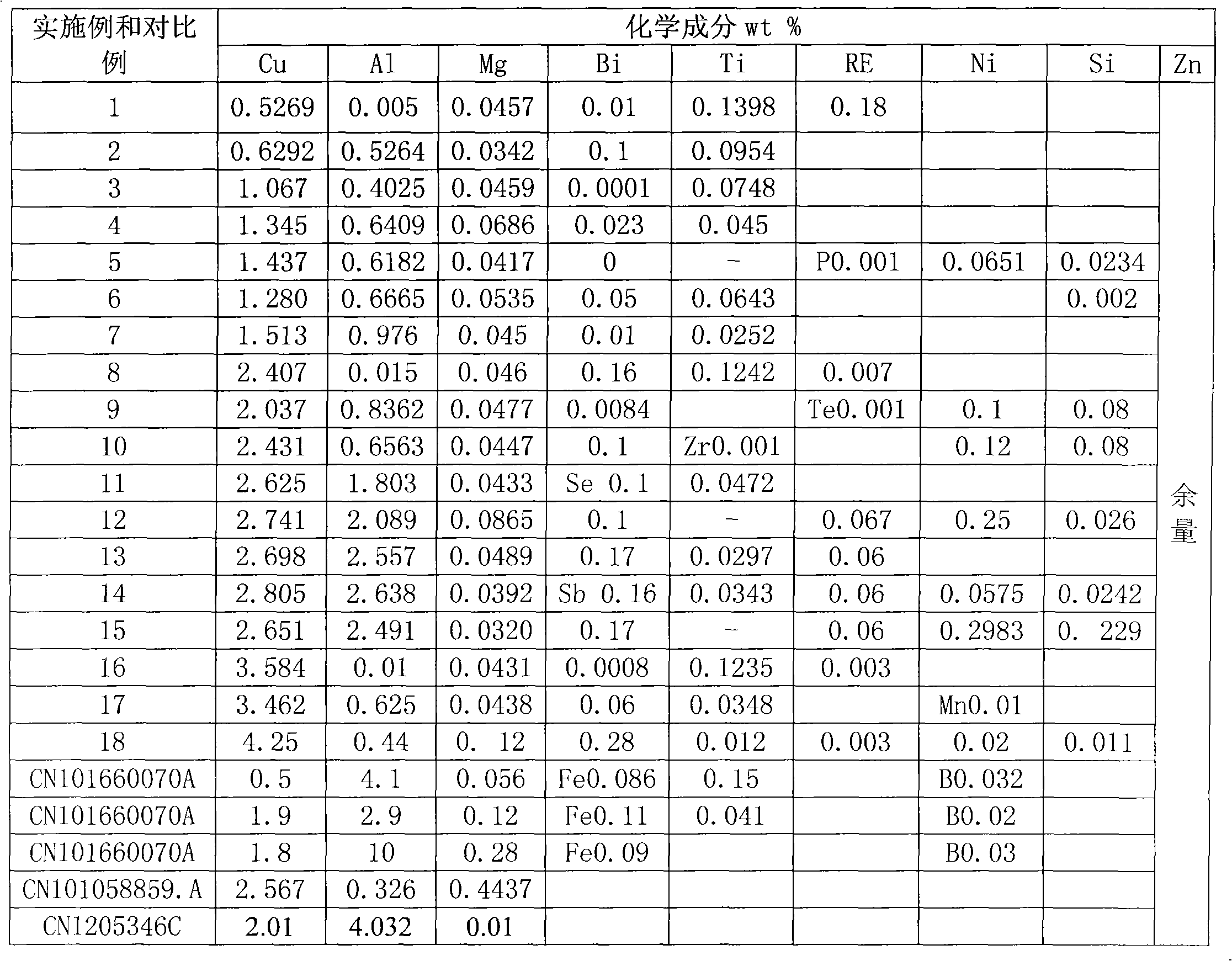

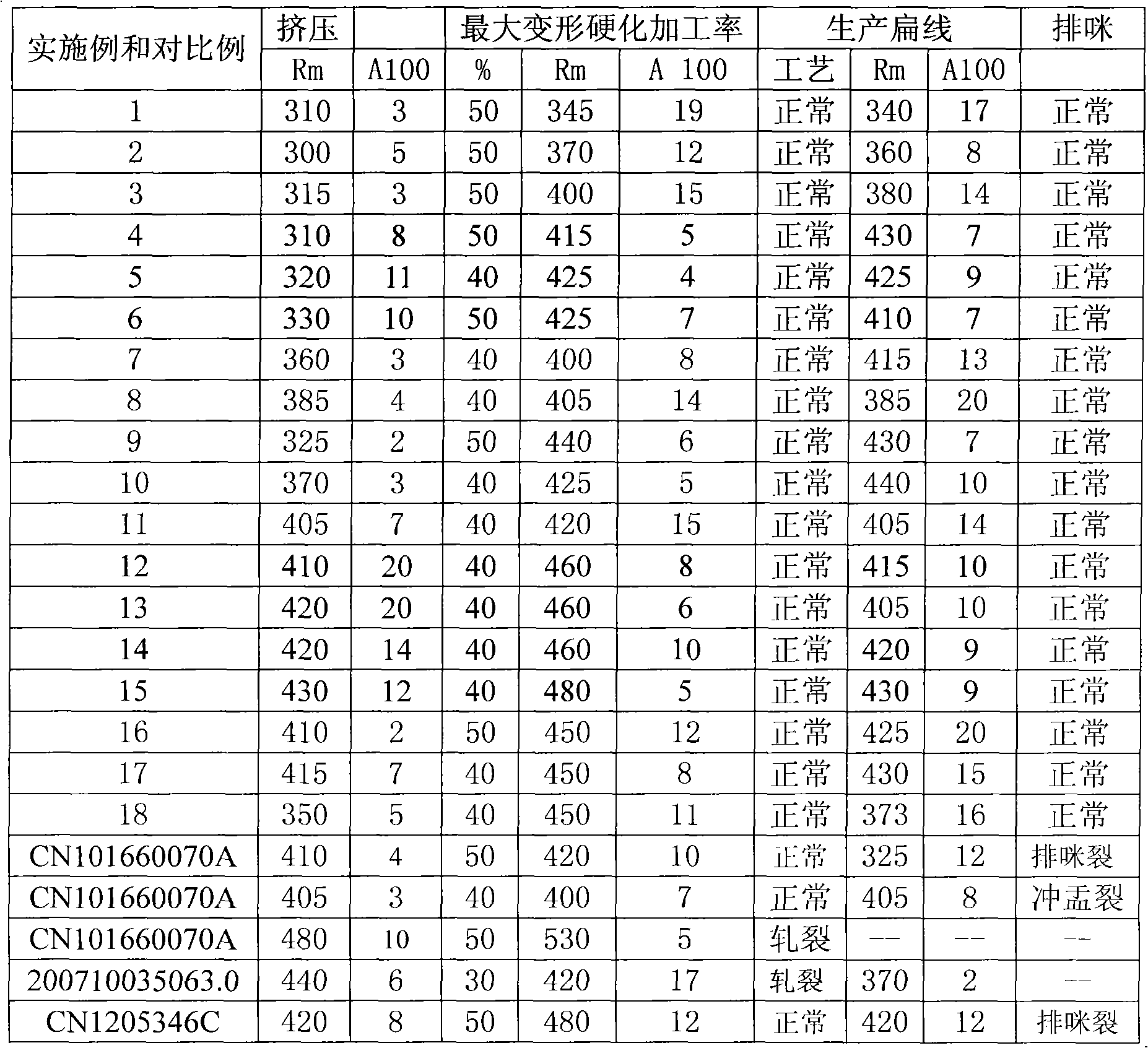

Examples

Embodiment 19

[0070] According to the design ratio, it is melted in an induction furnace with a melting temperature of 500-600°C and a refining temperature of 600-750°C. It is refined with a commercially available refining agent. After the refining is completed, a φ50 casting rod is continuously cast horizontally.

[0071] The chemical composition analysis results of the cast rod are as follows (% by weight): Cu 2.425 Al 2.072 Mg 0.100 Bi0.0001 Ni0.13%, Si 0.056%. The balance is Zn.

[0072] The cast rod is sawed and cut to the designed length, kept at 300°C for 2 hours, and then extruded into a billet of φ8.0. The extruded billet is stretched through multiple passes, stretched to a flattened round billet, and undergoes 2 times of annealing and rapid cooling in the middle. It is then flattened to a flat wire stock, with an annealing in between. The flat wire blank is rolled and drawn to make a flat wire with a specification of 0.9×3.95. The produced flat wire is discharged on the rice di...

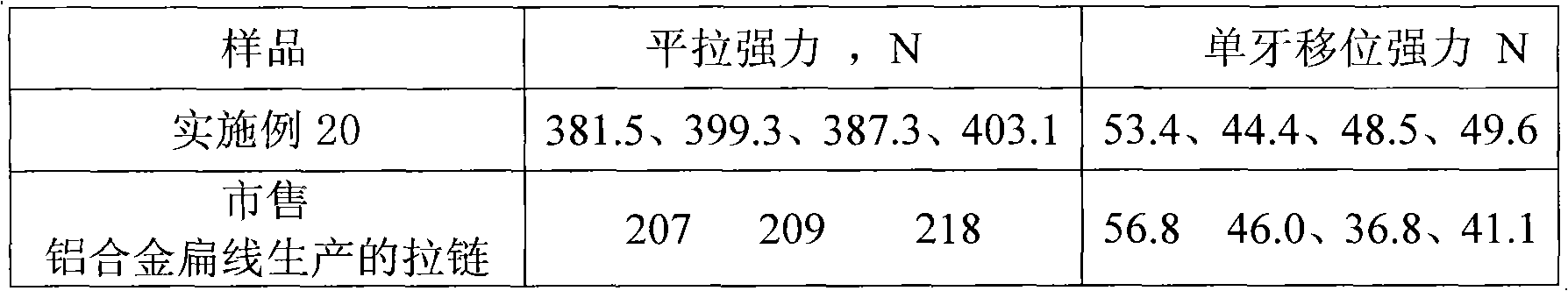

Embodiment 20

[0082] According to the proportion of ingredients designed, it is smelted in an induction furnace at a melting temperature of 500-600°C and a refining temperature of 600-750°C, refined with nitrogen, and cast in an iron mold. The chemical composition analysis results are listed in Table 3:

[0083] Table 3 embodiment 20 chemical composition (weight %)

[0084] Cu Al Mg Bi Ti RE Zn Example 20 1.62 0.47 0.047 0.011 0.0329 0.012 margin

[0085] After the ingot is wagoned, it is kept at 300°C for 2 hours, and then extruded into a billet with a diameter of φ8.0, and the extrusion ratio is not greater than 100. After 2 times of annealing and rapid cooling in the middle. It is then flattened to a flat wire stock, with an annealing in between. The flat wire blank is rolled and drawn to make a flat wire with a specification of 0.9×3.95. The produced flat wire is discharged on the rice discharge machine, and the zipper tape is s...

Embodiment 21

[0089] Example 21, Big Ingot Extrusion Drawing Example

[0090] The ingredients are melted in an induction furnace at a melting temperature of 500-600°C and a refining temperature of 600-750°C, using a refining agent for refining, and semi-continuous casting of φ200 ingots after refining. The chemical composition analysis results are listed in Table 5:

[0091] Table 5 embodiment 21 chemical composition (weight %):

[0092] Cu Al Mg Ti Ni Si Zn Example 21 2.327 0.8326 0.0461 0.0651 0.0216 0.0124 margin

[0093] The ingot is sawed and cut to the designed length, and the round wire billet is extruded in a 2500-ton reverse extrusion machine, induction heating, extrusion temperature 360 ℃, multi-head extrusion, extrusion ratio not greater than 100. The extruded billet is stretched through multiple passes, annealed and rapidly cooled at least twice in the middle, and then flattened to a flat wire billet, and annealed once d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com