Heat transmission ceramic matrix composite material and preparation method thereof

A composite material and ceramic-based technology, which is applied in the field of preparation of thermally conductive ceramic-based composite materials, can solve the problems that the application effect of domestic high thermal conductivity carbon fiber has yet to be evaluated, and the research on high thermal conductivity carbon fiber toughened composite materials lags behind and starts late. Improve high temperature anti-oxidation and ablation performance, good mechanical properties and weavable performance, and improve thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a thermally conductive ceramic matrix composite material, such as figure 1 shown, including the following steps:

[0041] (1) Preparation of carbon fiber preform

[0042] The carbon fiber prefabricated body is woven by mixing mesophase pitch-based high thermal conductivity carbon fiber and polyacrylonitrile-based carbon fiber.

[0043] The mesophase high thermal conductivity carbon fibers used in this step can be selected from domestic or imported materials, and can also be prepared according to existing preparation methods (for example, using a preparation method comprising the following preparation steps: mesophase pitch synthesis, porous continuous melt spinning, Fiber continuous non-melting treatment, low / high temperature carbonization and graphitization treatment).

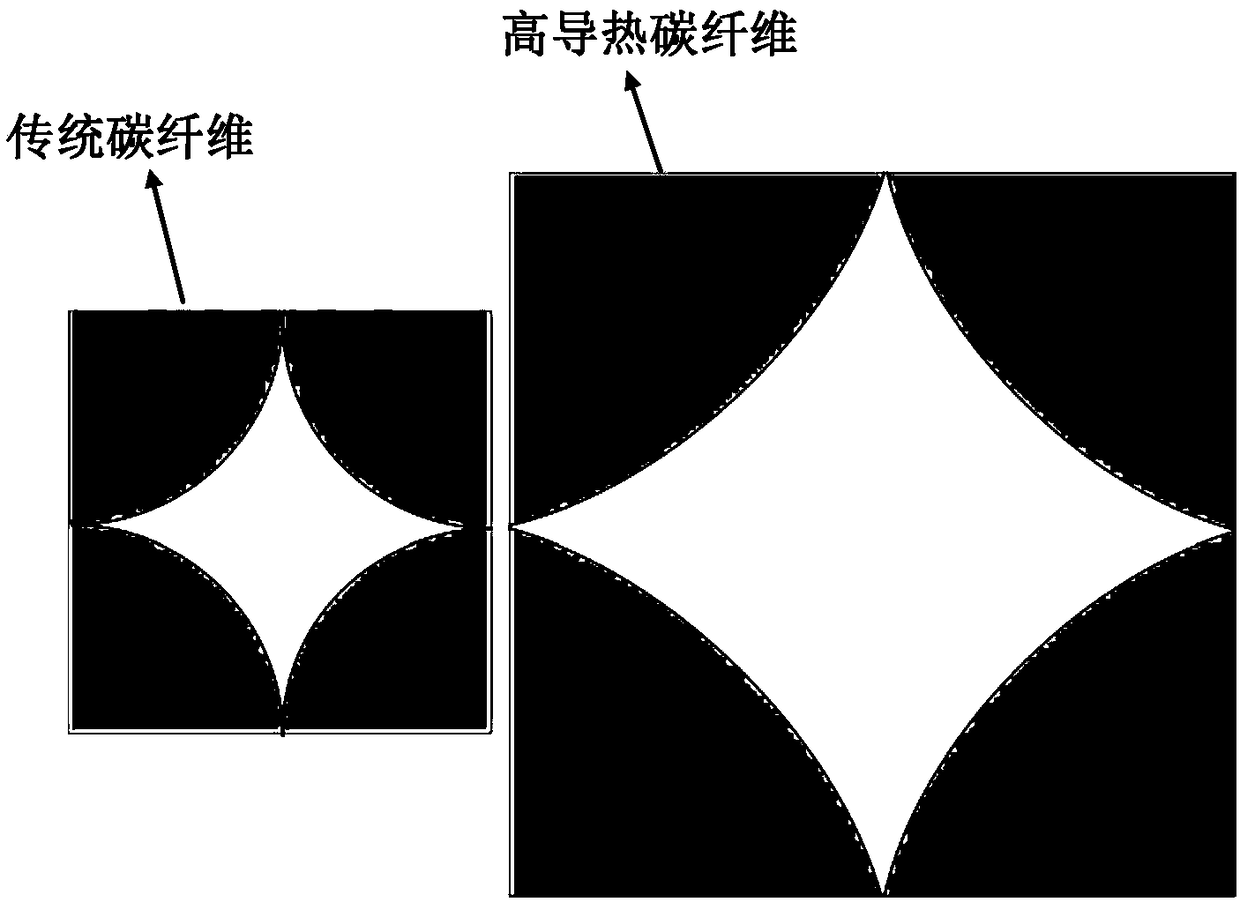

[0044] Due to the high tensile modulus of mesophase pitch-based high thermal conductivity carbon fibers, it is difficult to meet the requirements for mec...

Embodiment 1

[0078] (1) Preparation of carbon fiber preform

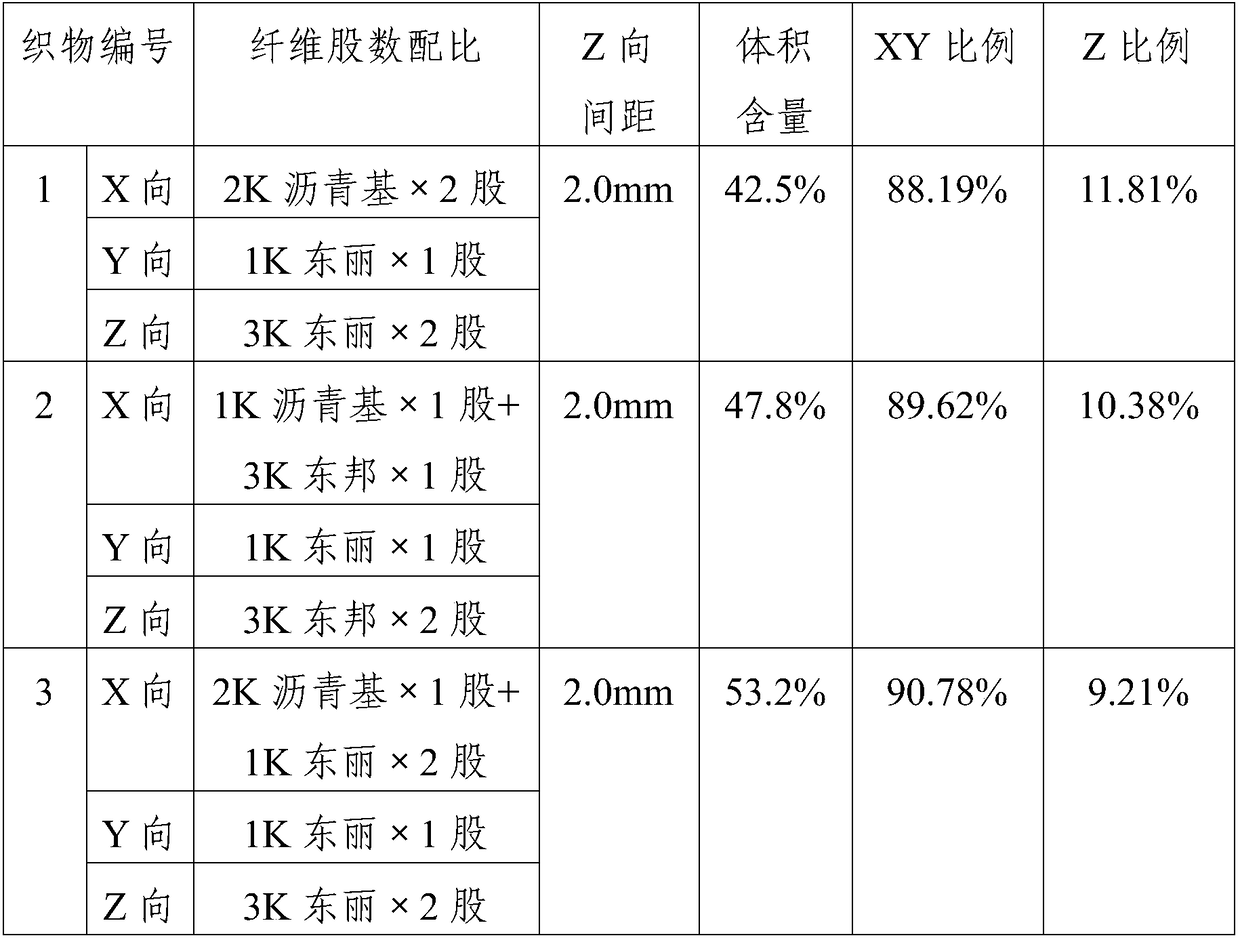

[0079] Mitsubishi Chemical K13D2U pitch-based high thermal conductivity carbon fiber is used for mixed weaving with Japan's Toray and Toho T300 traditional polyacrylonitrile-based carbon fiber. The weaving method is a three-way orthogonal method, and mesophase pitch-based high thermal conductivity carbon fiber is used in the flow direction. Carry out weaving, see Table 1 for other weaving requirements, and weave according to fabric number 1 in Table 1 to obtain a carbon fiber prefabricated body. The fiber volume content and XY ratio of the fiber preform are shown in Table 1.

[0080] (2) Preparation of C / C body

[0081] Put the carbon fiber prefabricated body into the CVI-C furnace, the carbon source gas is propane, the carrier gas is argon, the deposition temperature is 1020°C, and the chemical vapor infiltration method is used for deposition, and the obtained density is 1.0g / cm 3 The C / C green body.

[0082] (3) impregnatio...

Embodiment 2

[0089] The preparation method is basically the same as that of Example 1, except that the weaving is carried out according to the fabric number 2 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com