Patents

Literature

802 results about "Volume content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

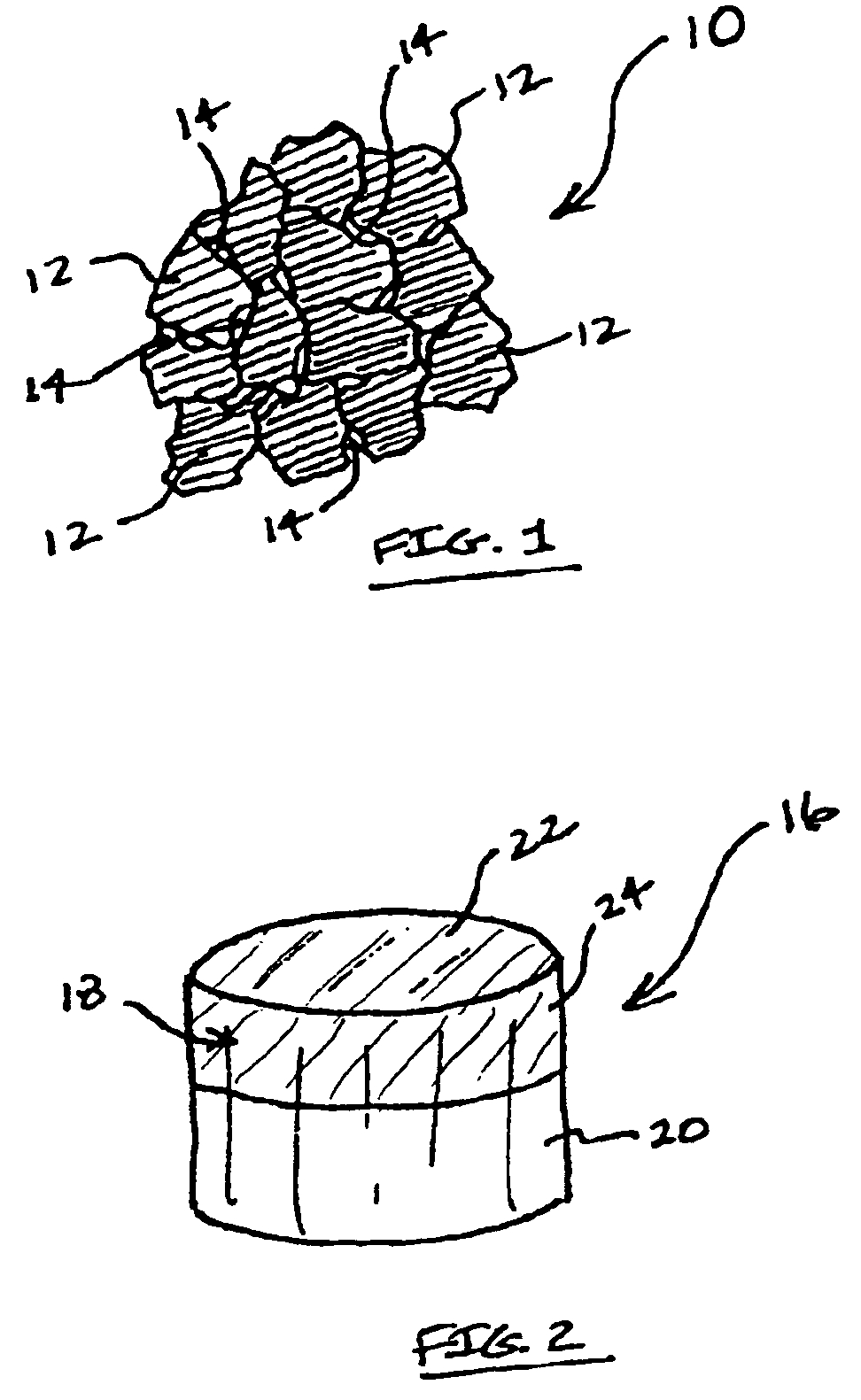

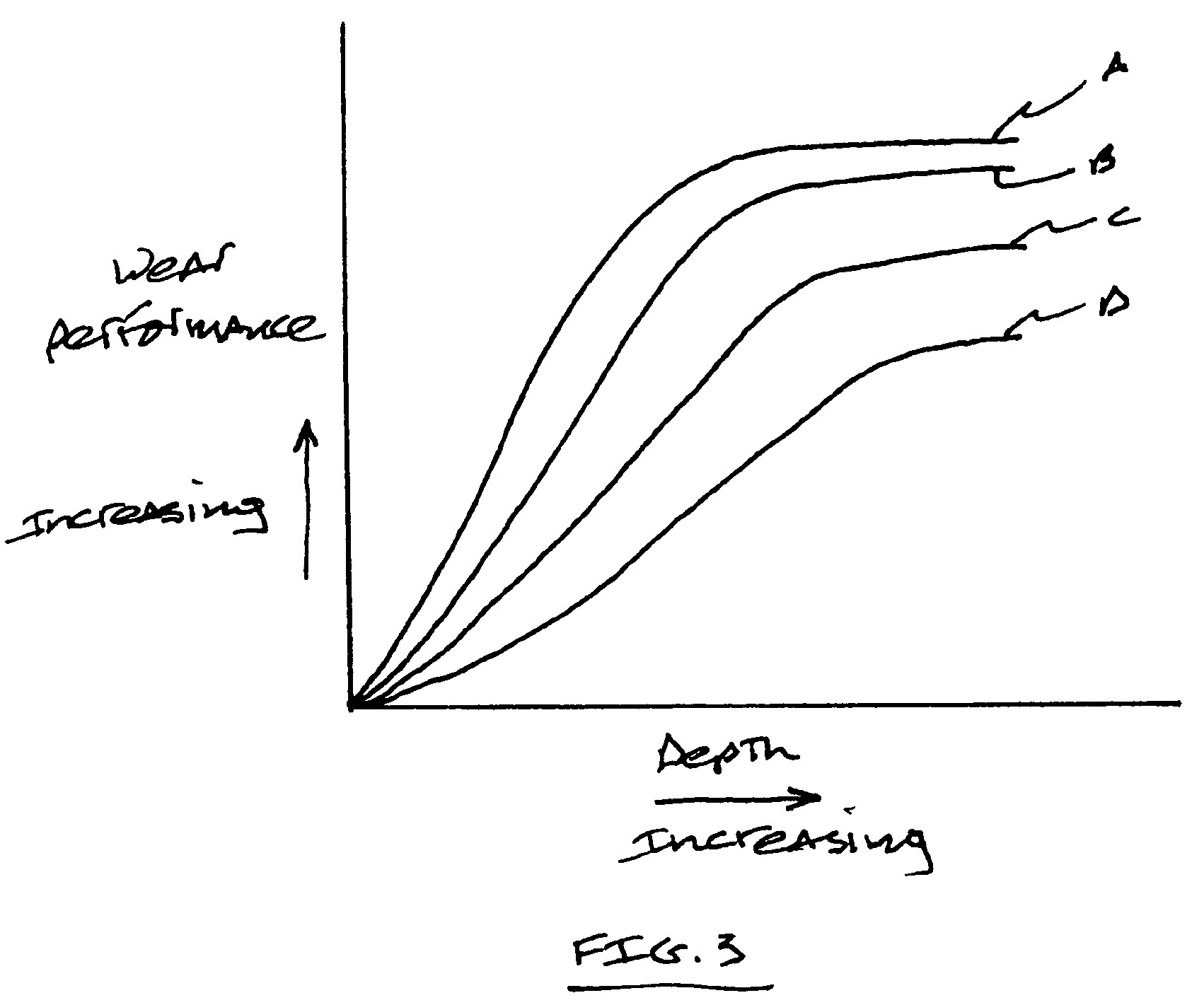

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

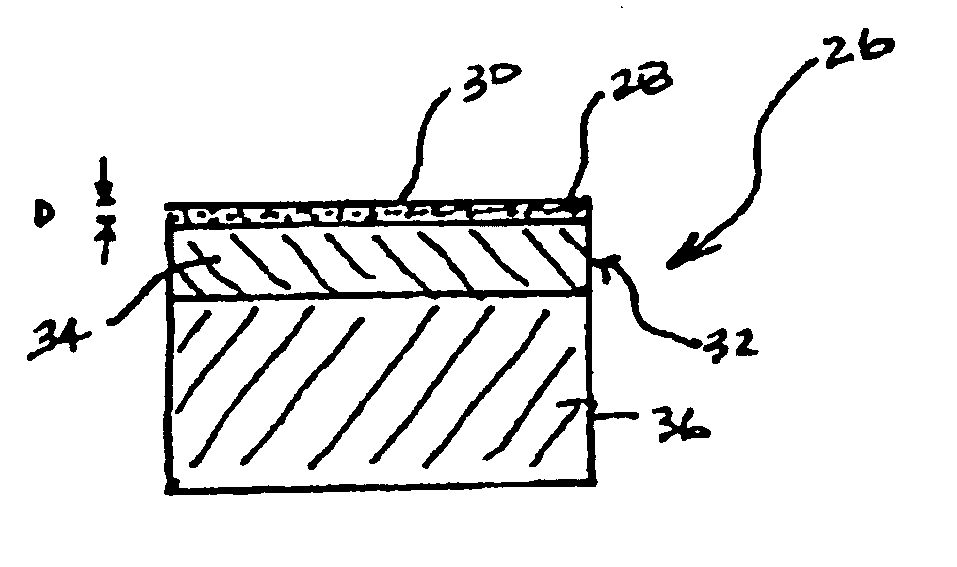

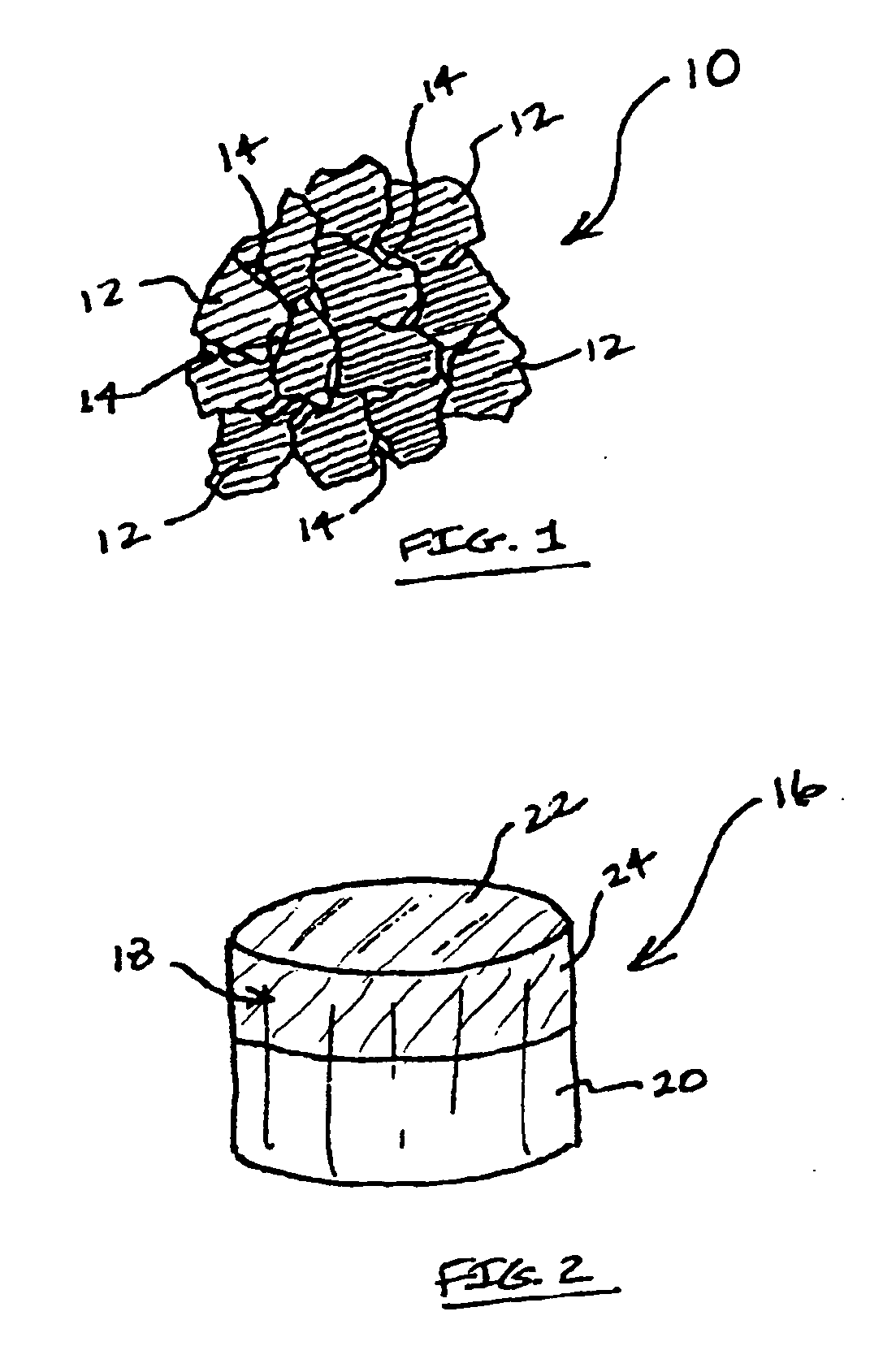

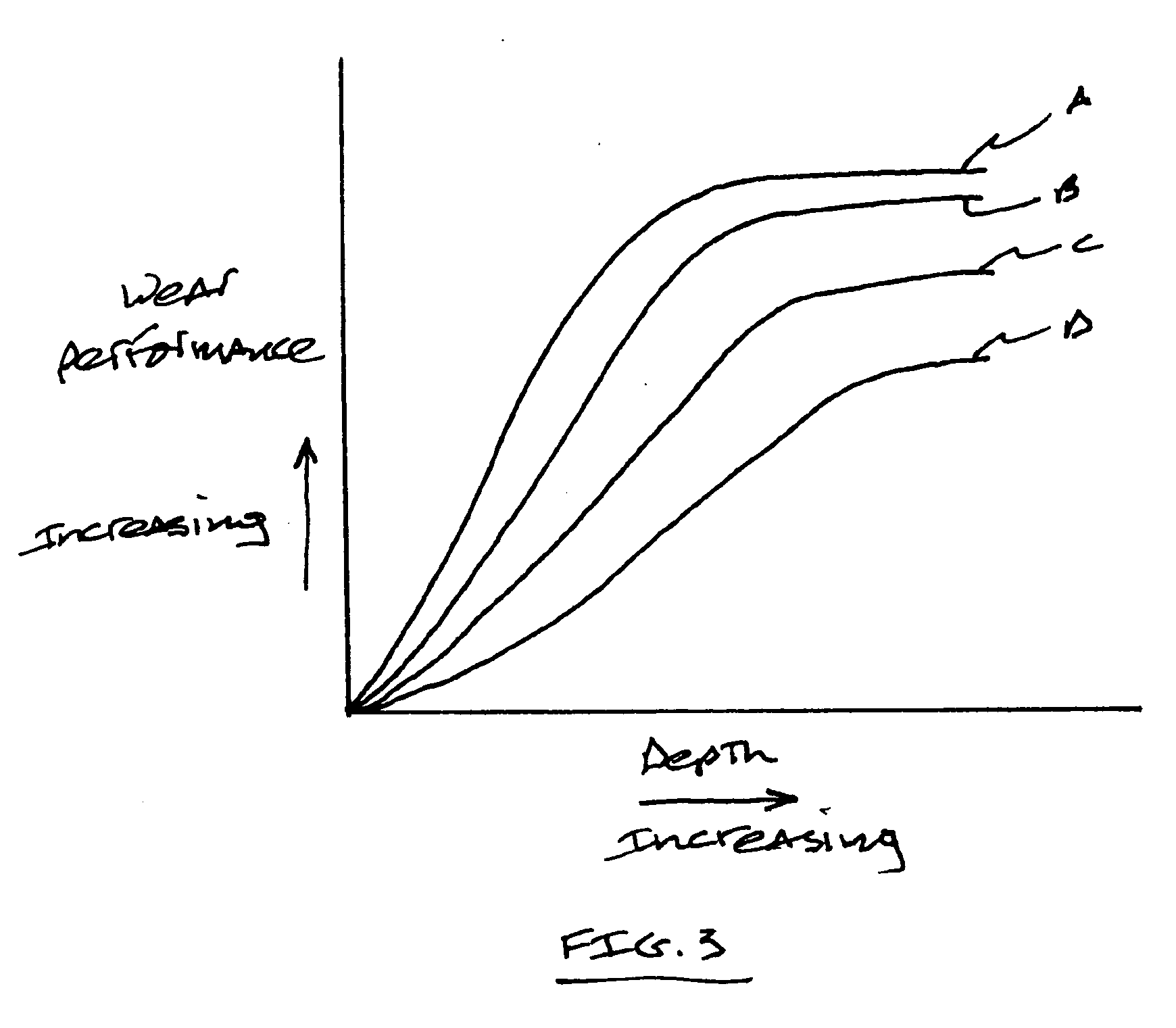

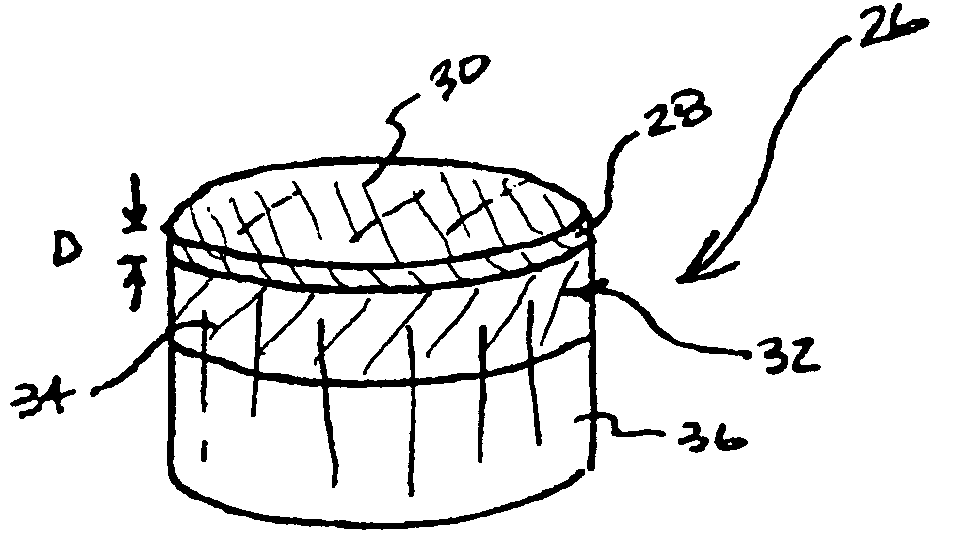

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Solid golf ball

InactiveUS6121357AImprove controllabilityImprove flight performanceAnti-corrosive paintsGolf ballsVulcanizationHardness

Owner:SUMITOMO RUBBER IND LTD

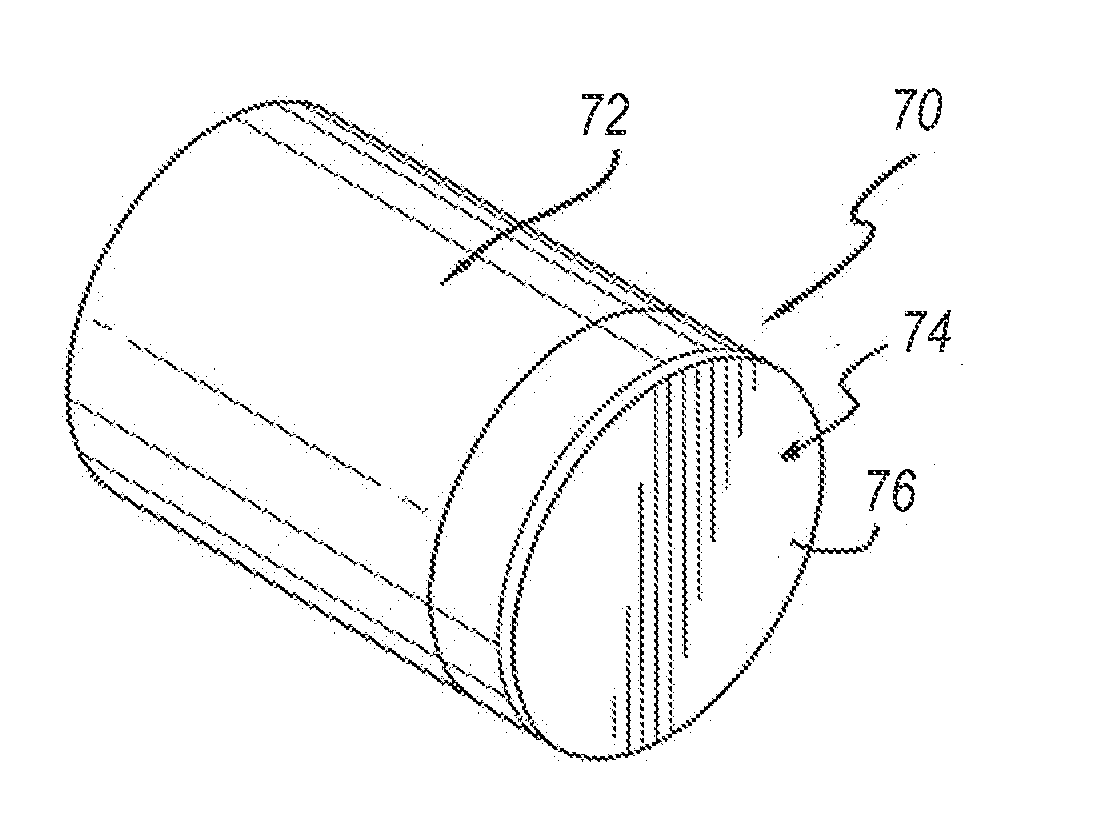

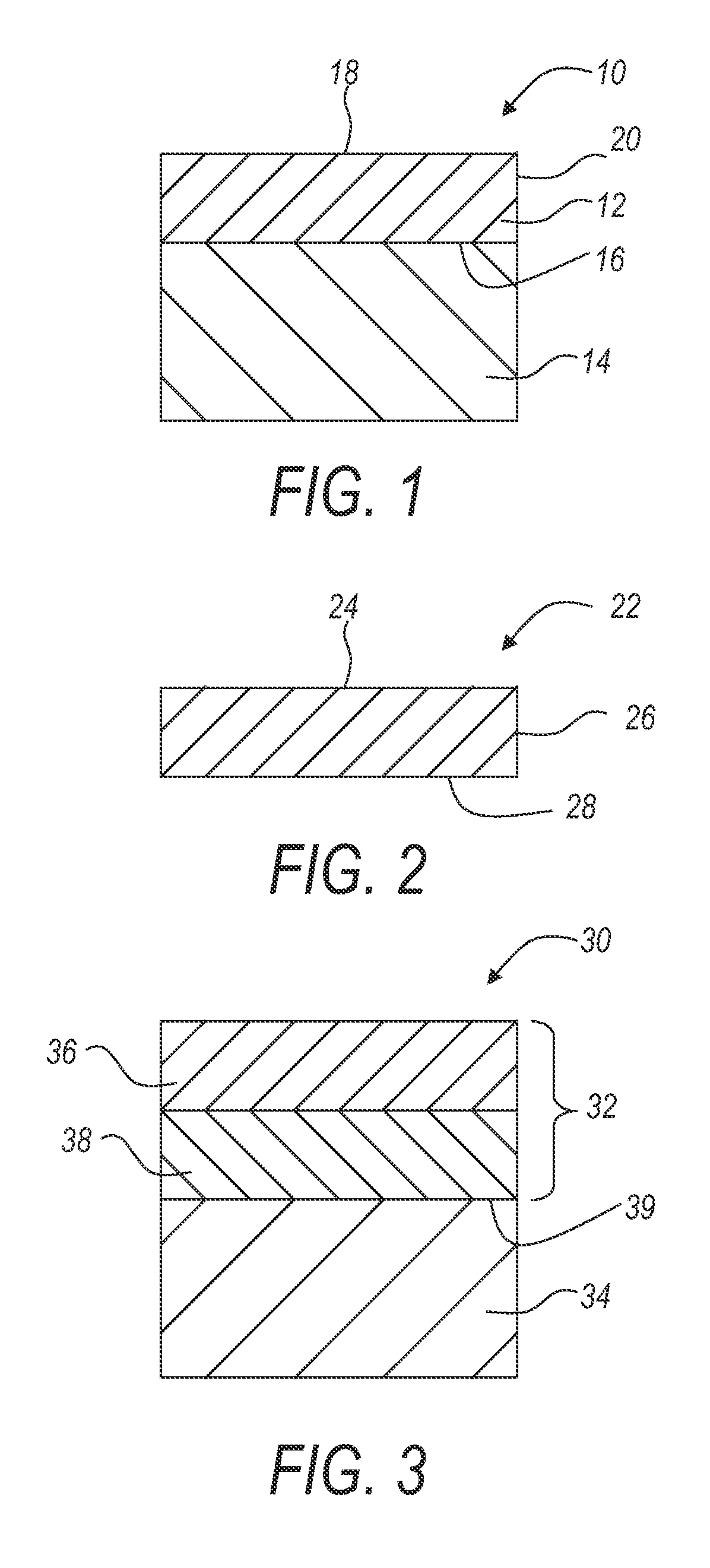

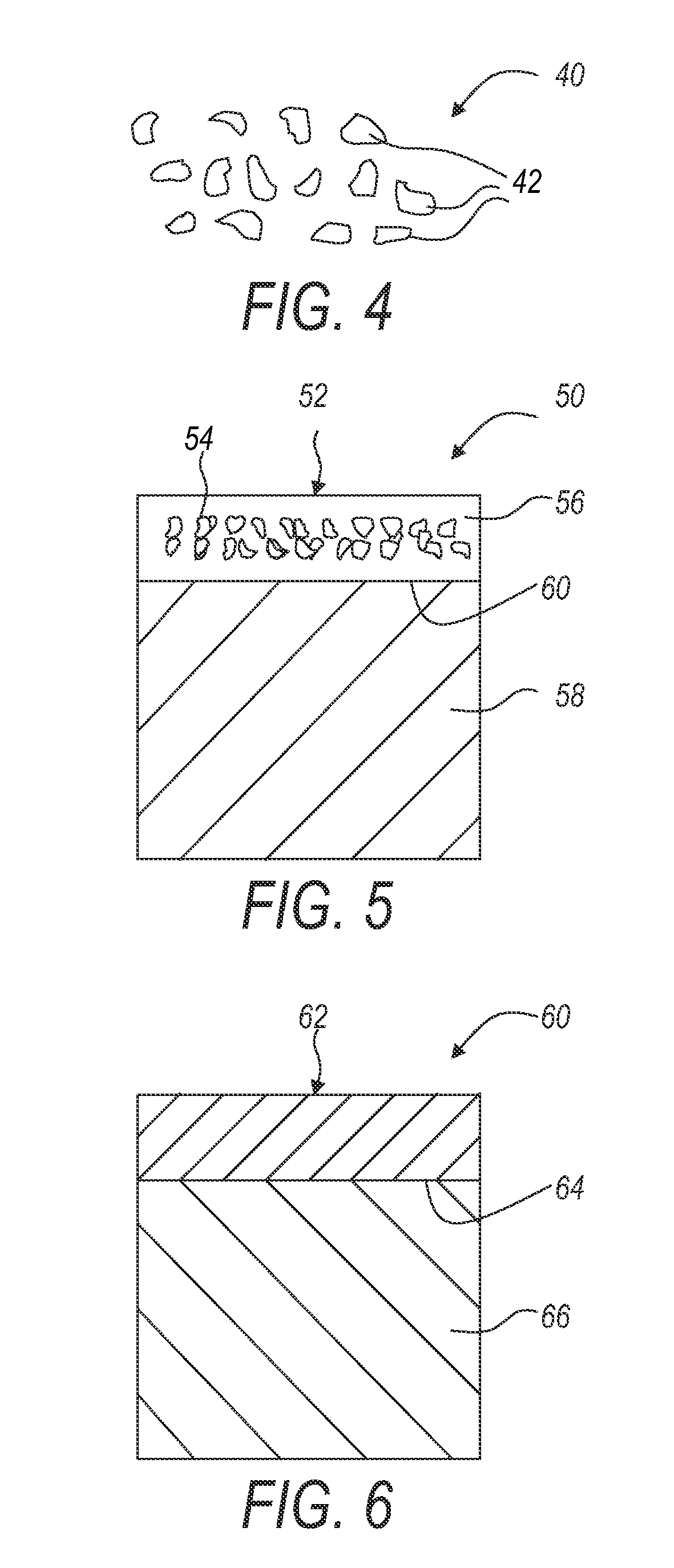

Diamond Bonded Construction Comprising Multi-Sintered Polycrystalline Diamond

InactiveUS20110083908A1Lower Level RequirementsImprove sintering performancePigmenting treatmentDrill bitsPolycrystalline diamondVolume content

Diamond bonded constructions comprise a diamond body attached to a substrate, wherein the body includes a first diamond bonded volume, and a second diamond bonded volume attached thereto. The second volume may be provided in the form of a powder or a presintered mass prior to attachment, and the first volume may be provided in the form of presintered pieces when combined with the second volume. The first volume diamond volume content is greater than about 94 percent, and is the same or greater than that of the second volume. The first volume is sintered during a first HPHT process, and the second volume is sintered and / or attached to the first volume during a second HPHT process. The first HPHT pressure is greater than the second HPHT pressure. The substrate is not an infiltration substrate used to form the first diamond volume. The diamond body may be thermally stable.

Owner:SMITH INT INC

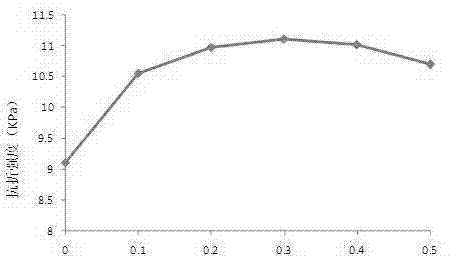

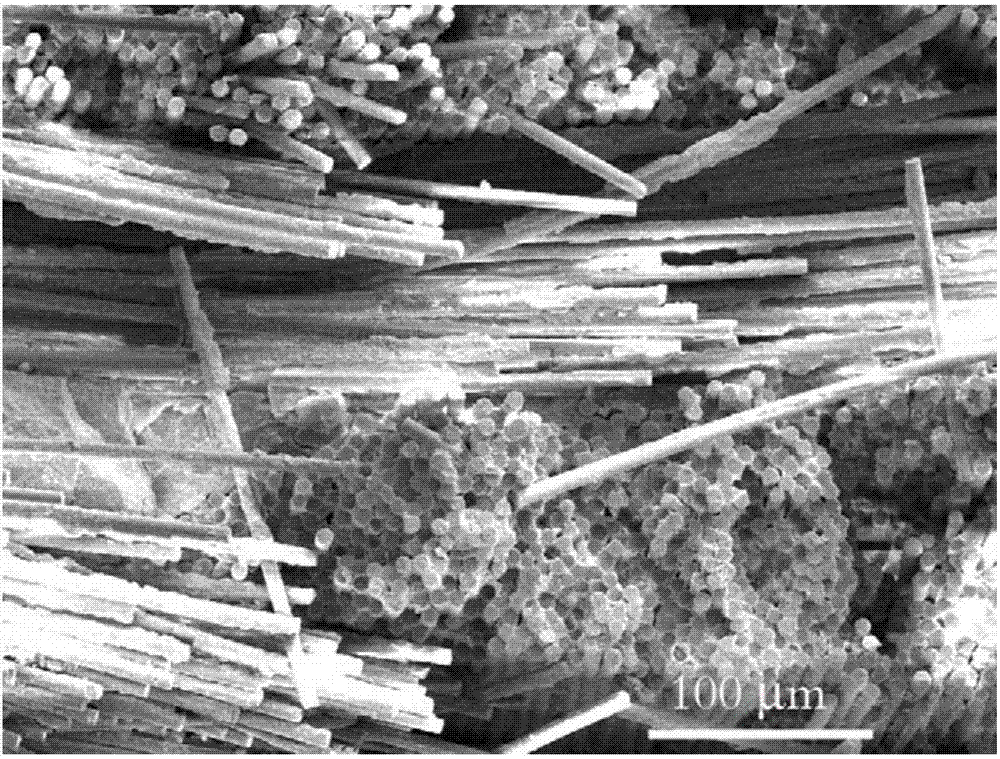

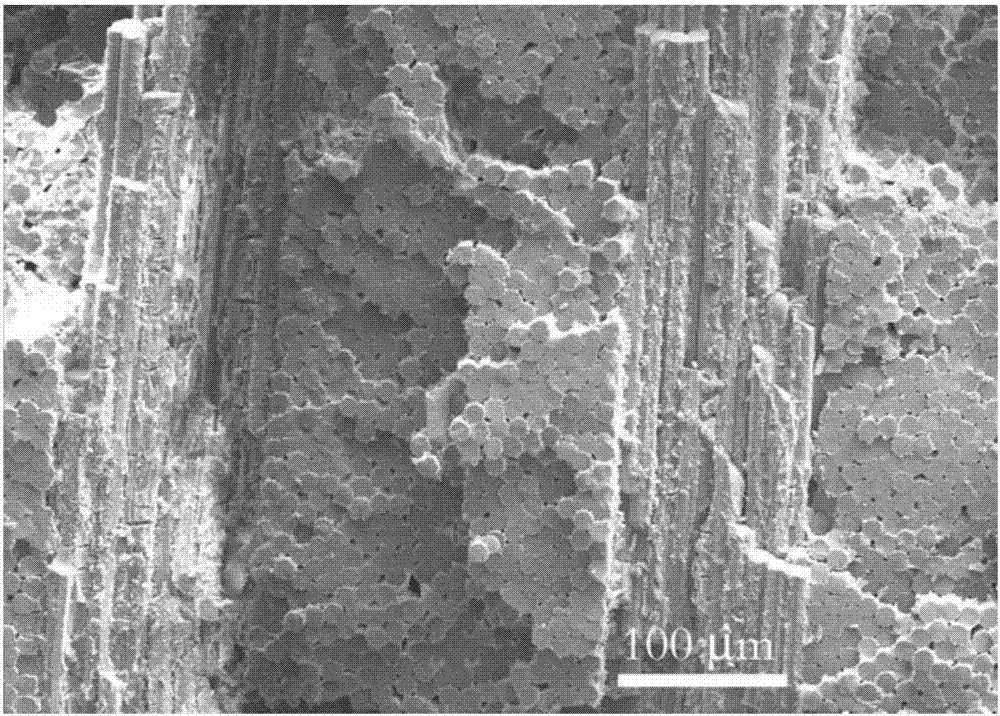

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

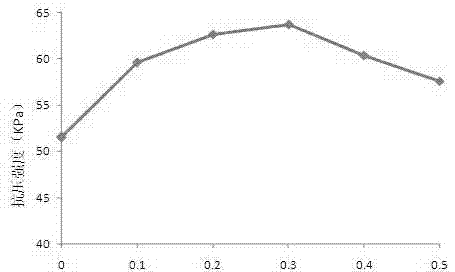

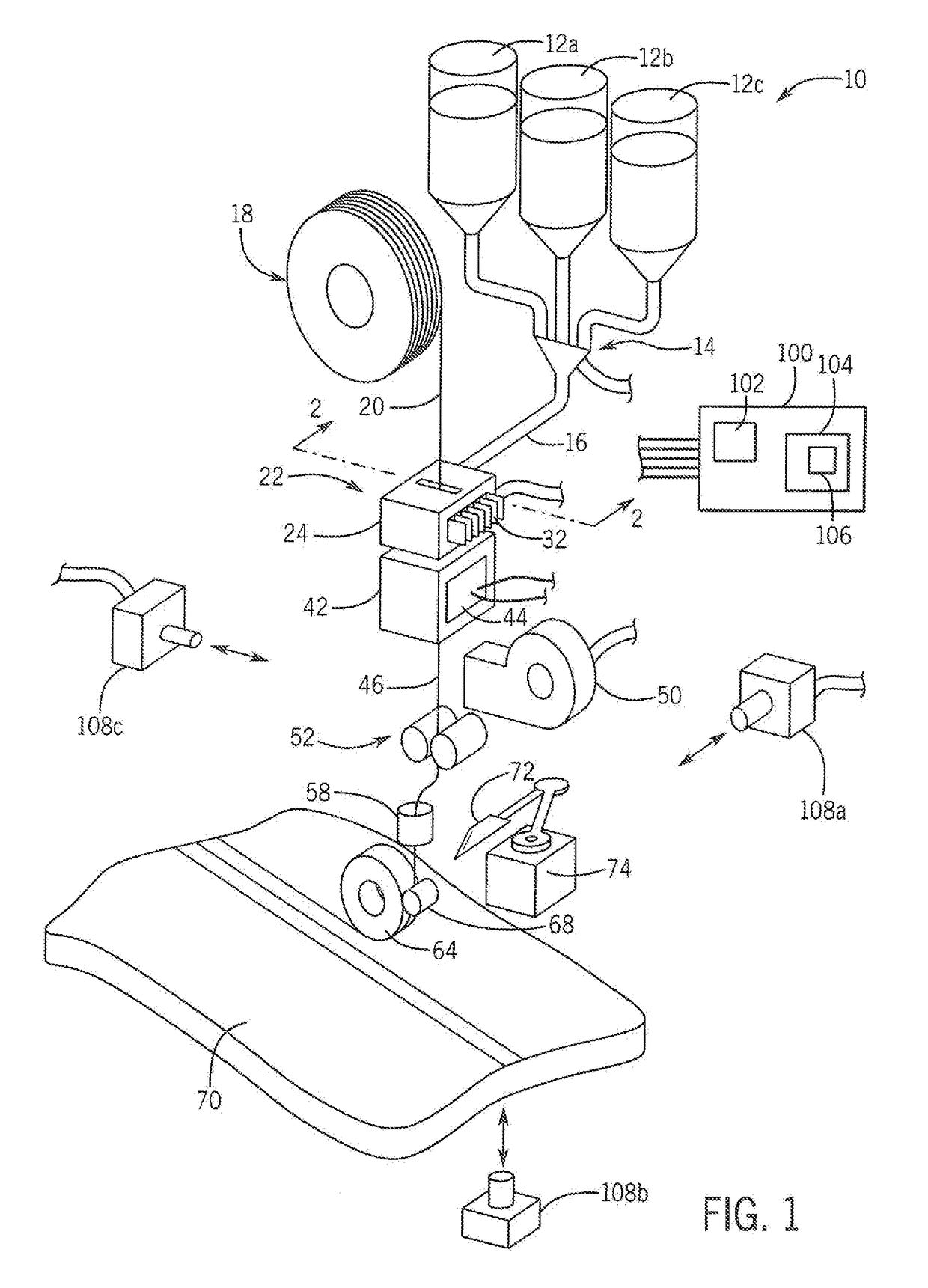

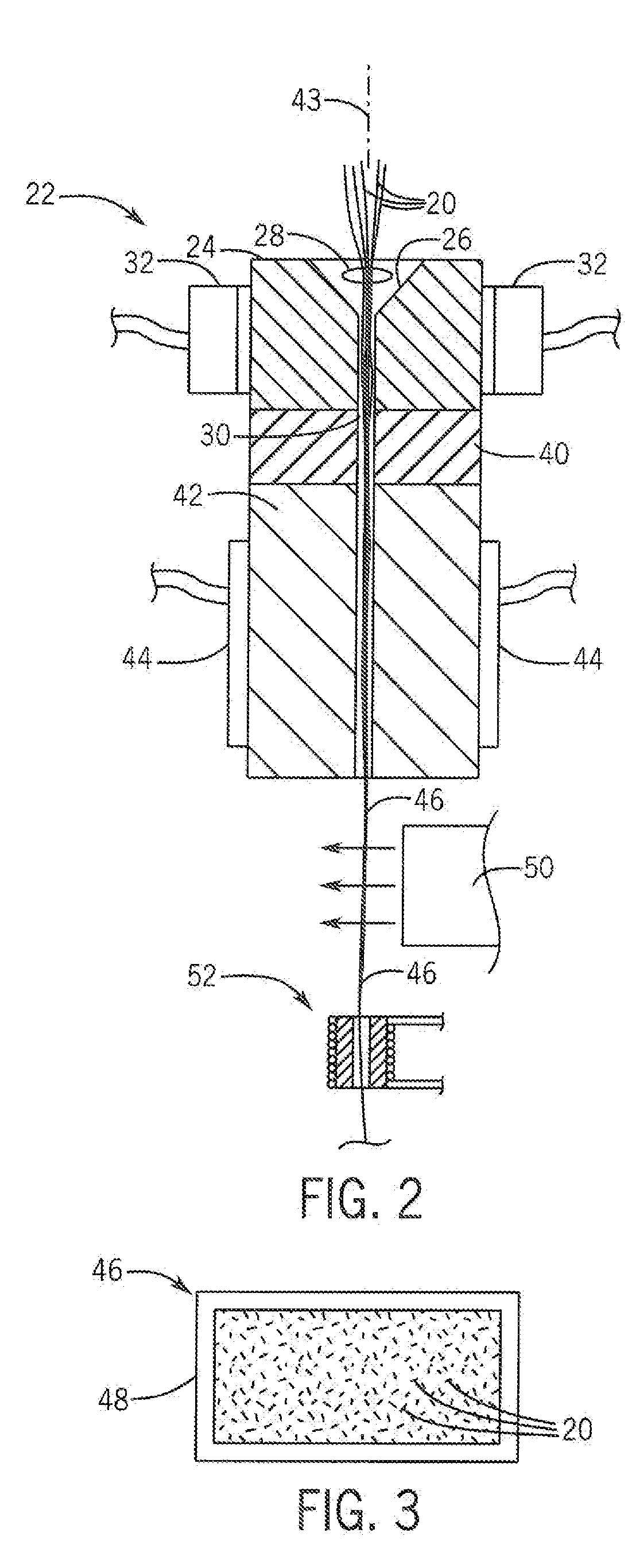

Additive Manufacturing Process Continuous Reinforcement Fibers And High Fiber Volume Content

PendingUS20170341300A1Easy to adaptIncreased fiber volume content3D object support structuresCoatingsHigh densityMechanical integrity

An additive printer dispenses filament having high volume content of axial reinforcing fibers impregnated with a partially cured thermoset material. Partial curing provides sufficient mechanical integrity for high-density fiber support and retention while maintaining tackiness necessary to allow layer by layer additive construction. The complete construction may then be heated to provide complete curing.

Owner:WISCONSIN ALUMNI RES FOUND

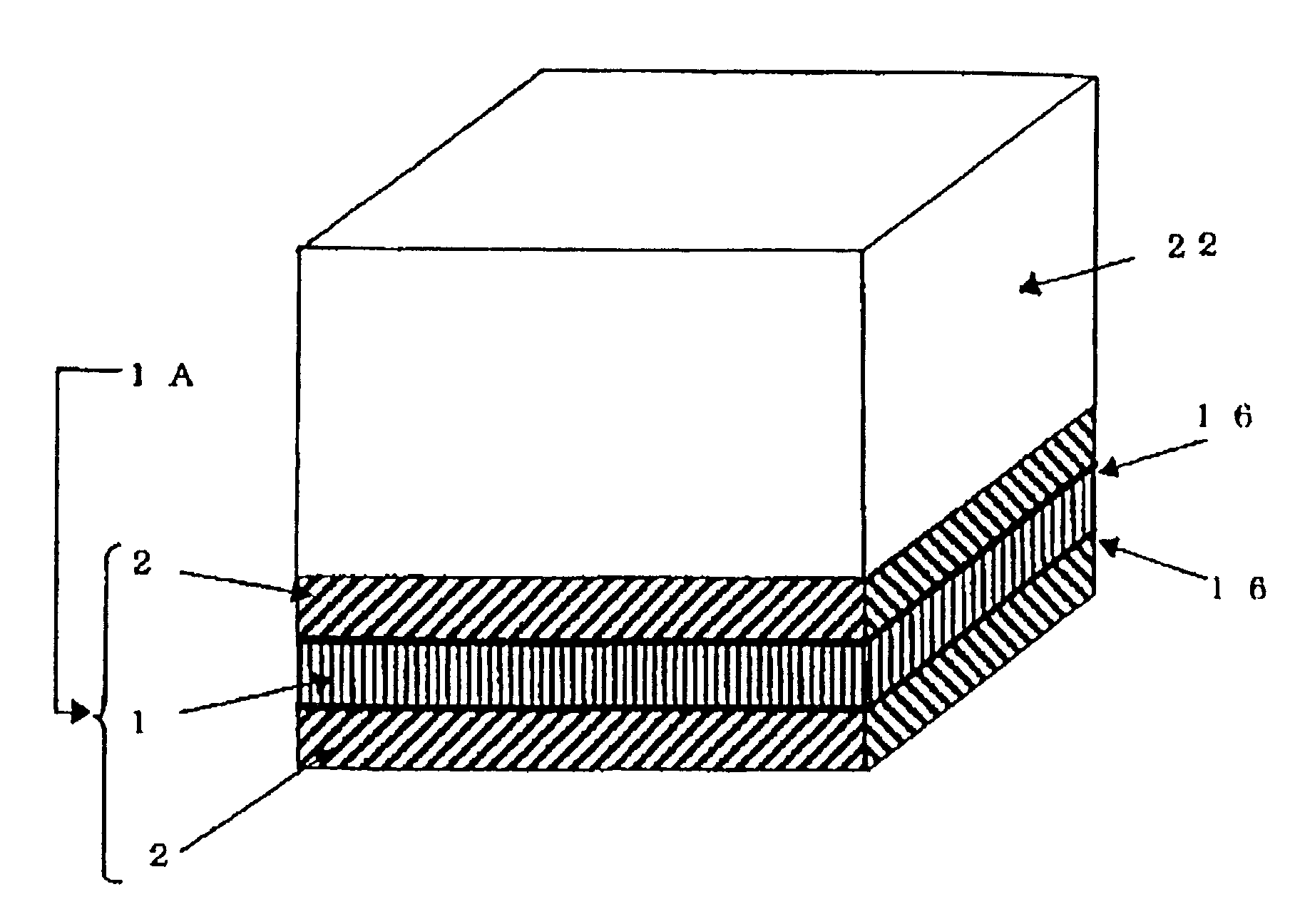

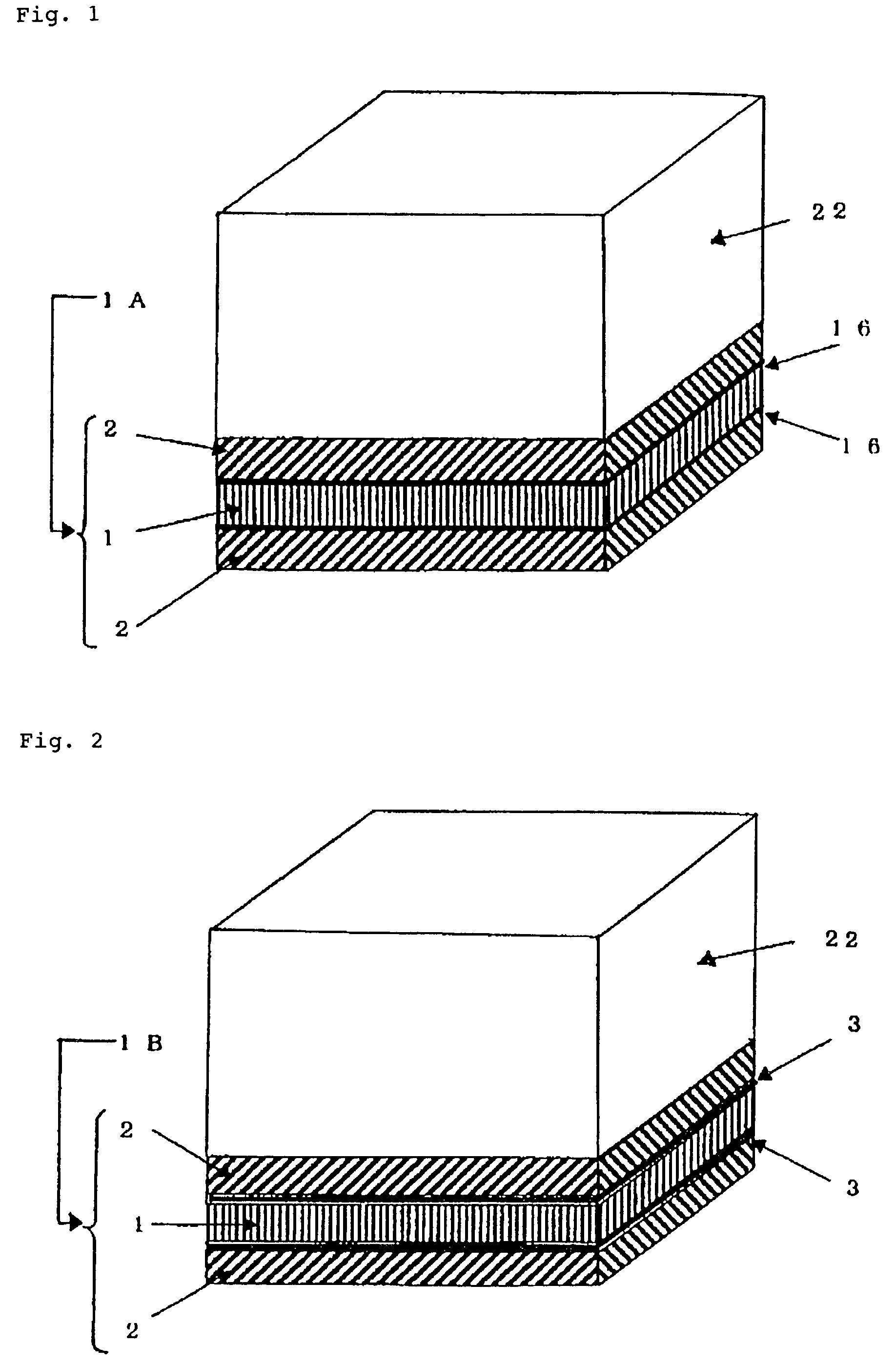

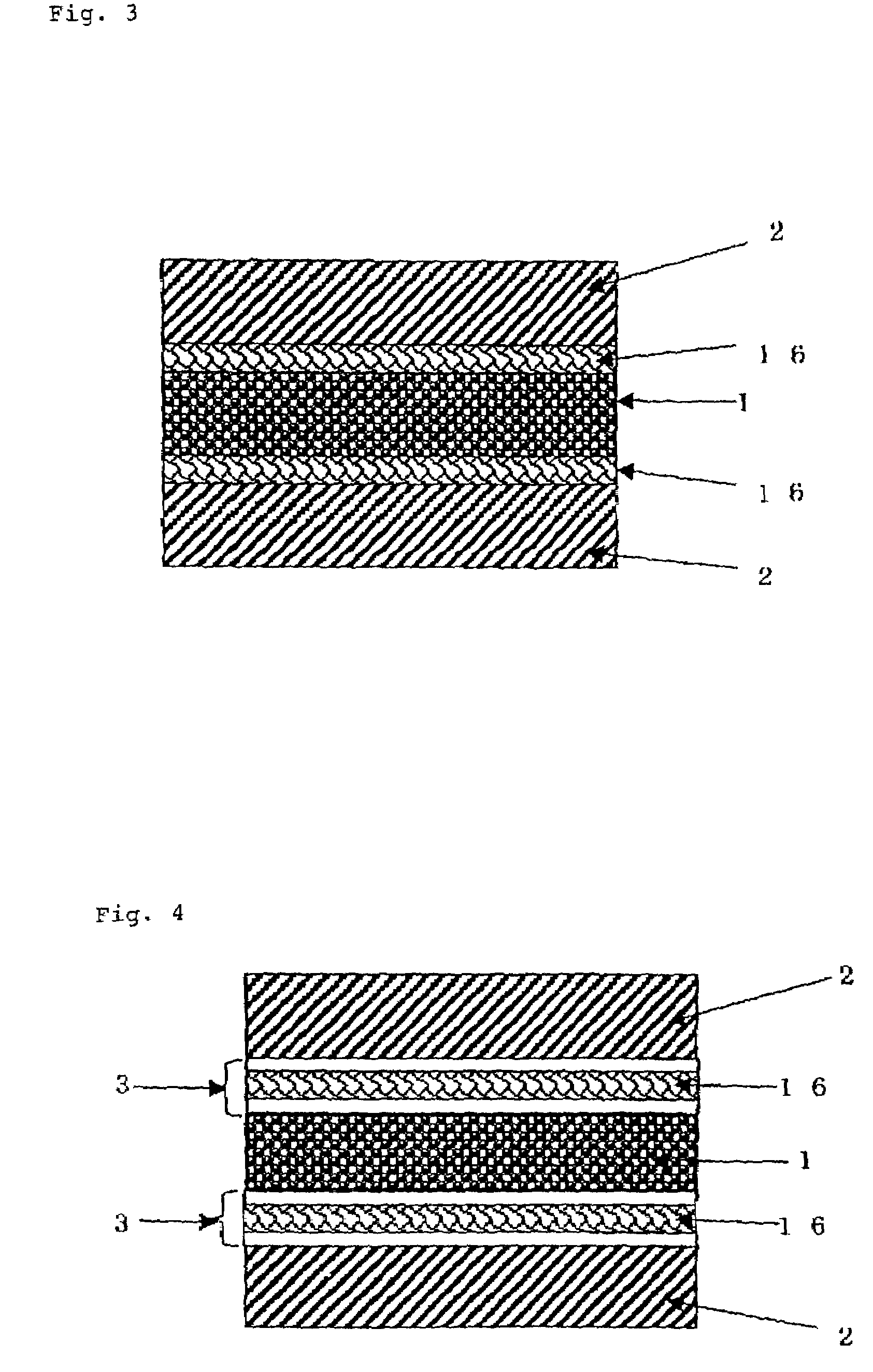

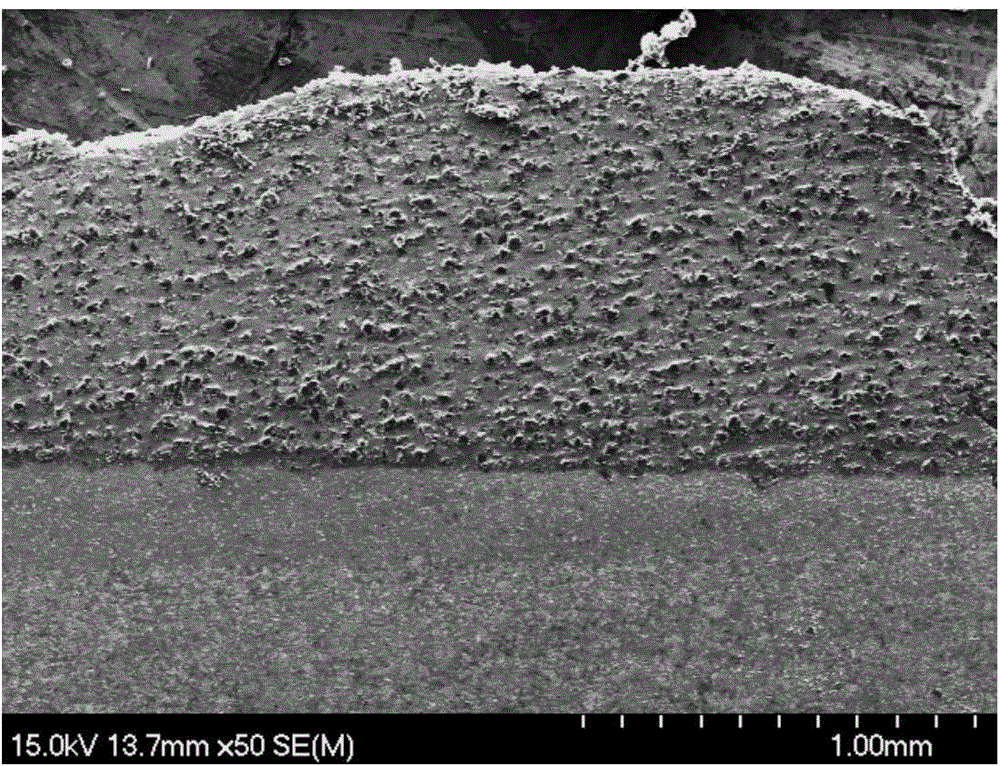

Road reinforcement sheet, structure of asphalt reinforced pavement and method for paving road

A paved road including a reinforcement sheet layer (1A) and a pavement layer (22), in which the reinforcement sheet layer (1A) includes an asphalt layer (2) laminated to at least one side of a reinforcement sheet (1) including a composite material that is impregnated with a thermoplastic resin to achieve a volume content of a continuous glass fiber, which is a reinforcement fiber, of not less than 30% and not moere than 85% is proved.

Owner:MITSUI CHEM INC

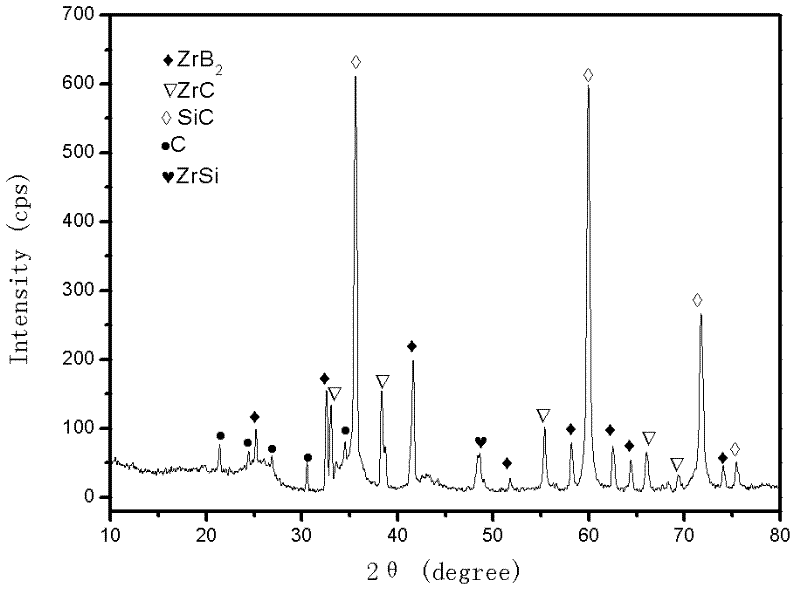

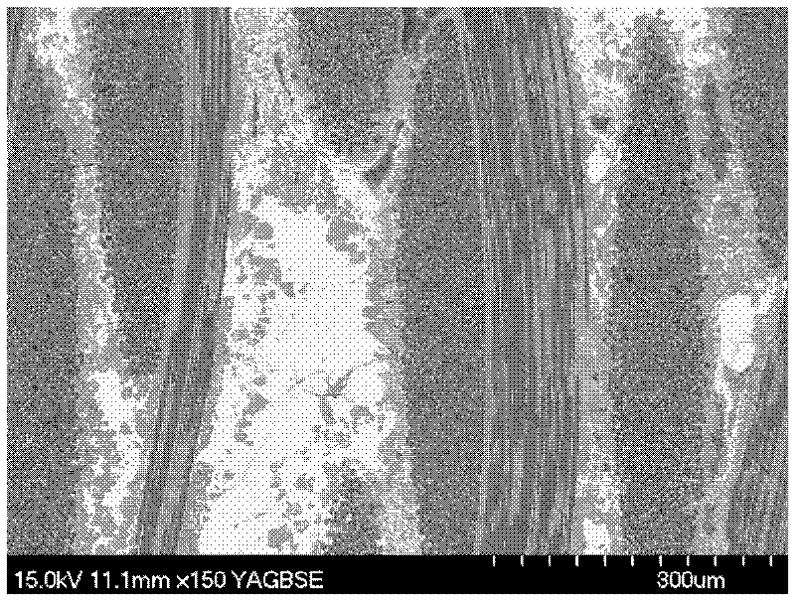

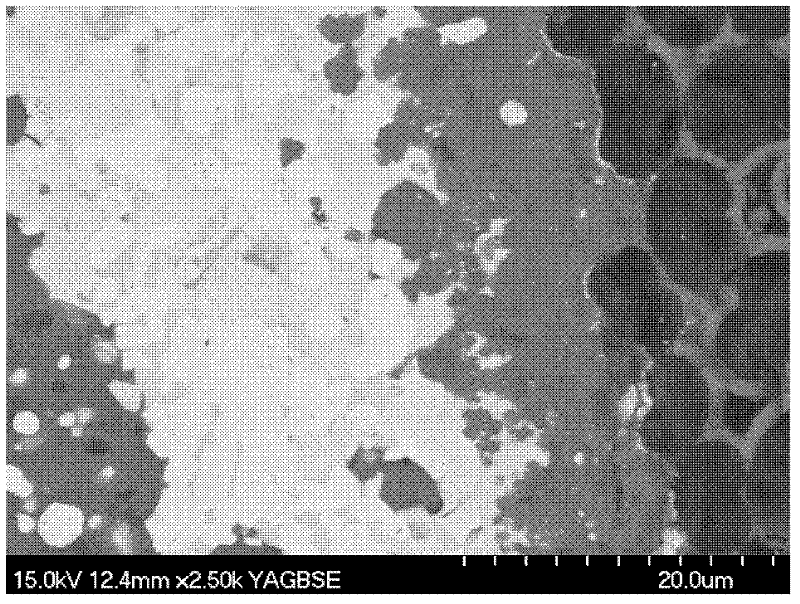

Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

ActiveCN102515870AGuaranteed mechanical propertiesHigh volume contentVacuum pressureUltrahigh temperature ceramics

The invention relates to a preparation method of a C / SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material. According to the invention, B4C and a C organic precursor are introduced into a C / SiC composite material with a vacuum pressure impregnation method; the obtained material is cured and is subject to a heat treatment, such that the C organic precursor is cracked, and pores sealed by the C organic precursor are opened; with a reactive melt infiltration method, under a condition that a temperature is higher than that of silicozirconium alloy, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized, and the C / SiC-ZrB2-ZrC composite material is prepared. According to the invention, with the vacuum pressure impregnation method, B4C and the C organic precursor are introduced into the C / SiC composite material; with the reactive melt infiltration method, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized. The produced ZrB2 and ZrC are advantaged in fine grains and high volume content. The ablation resistance and mechanical properties of the composite material are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

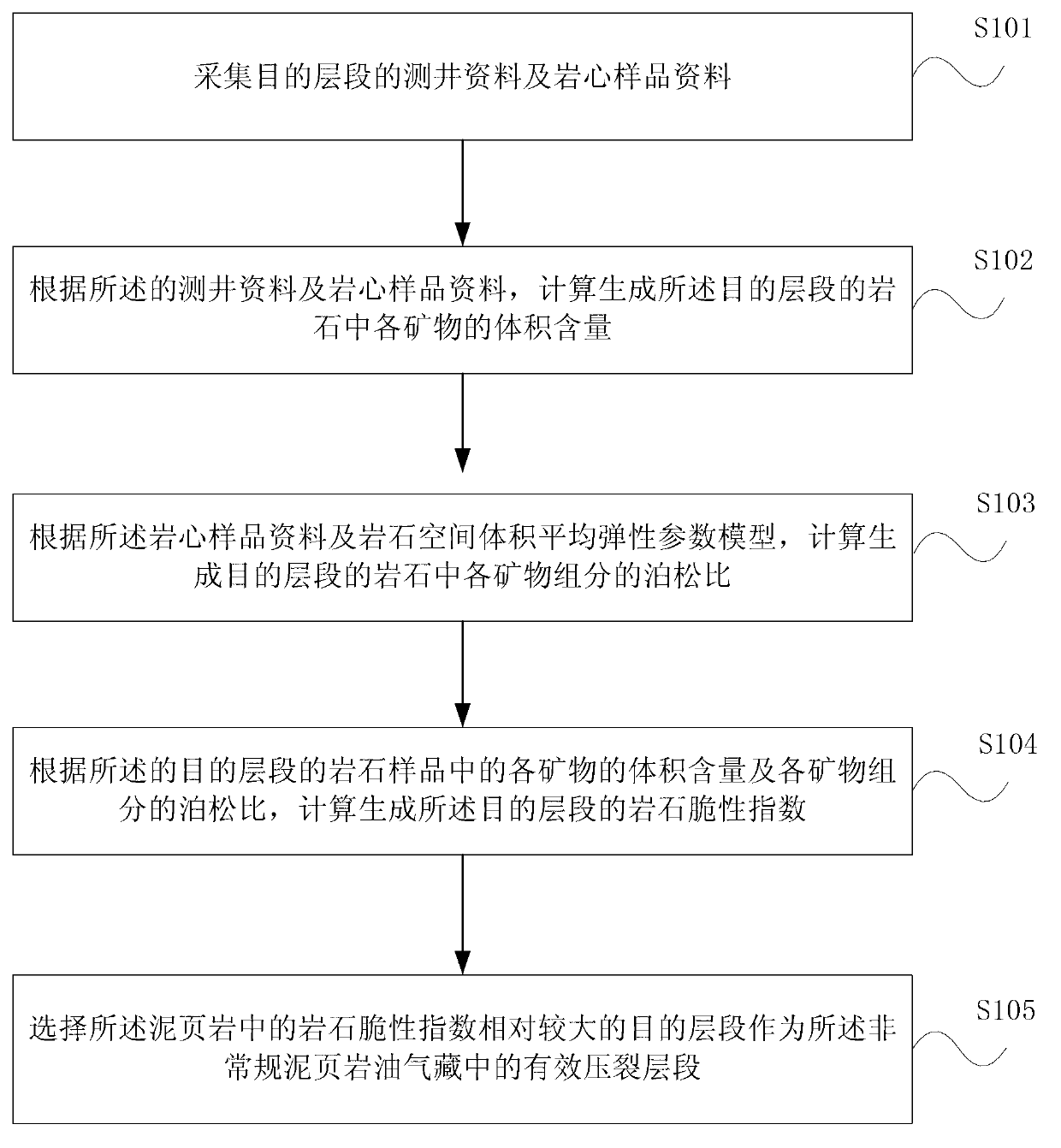

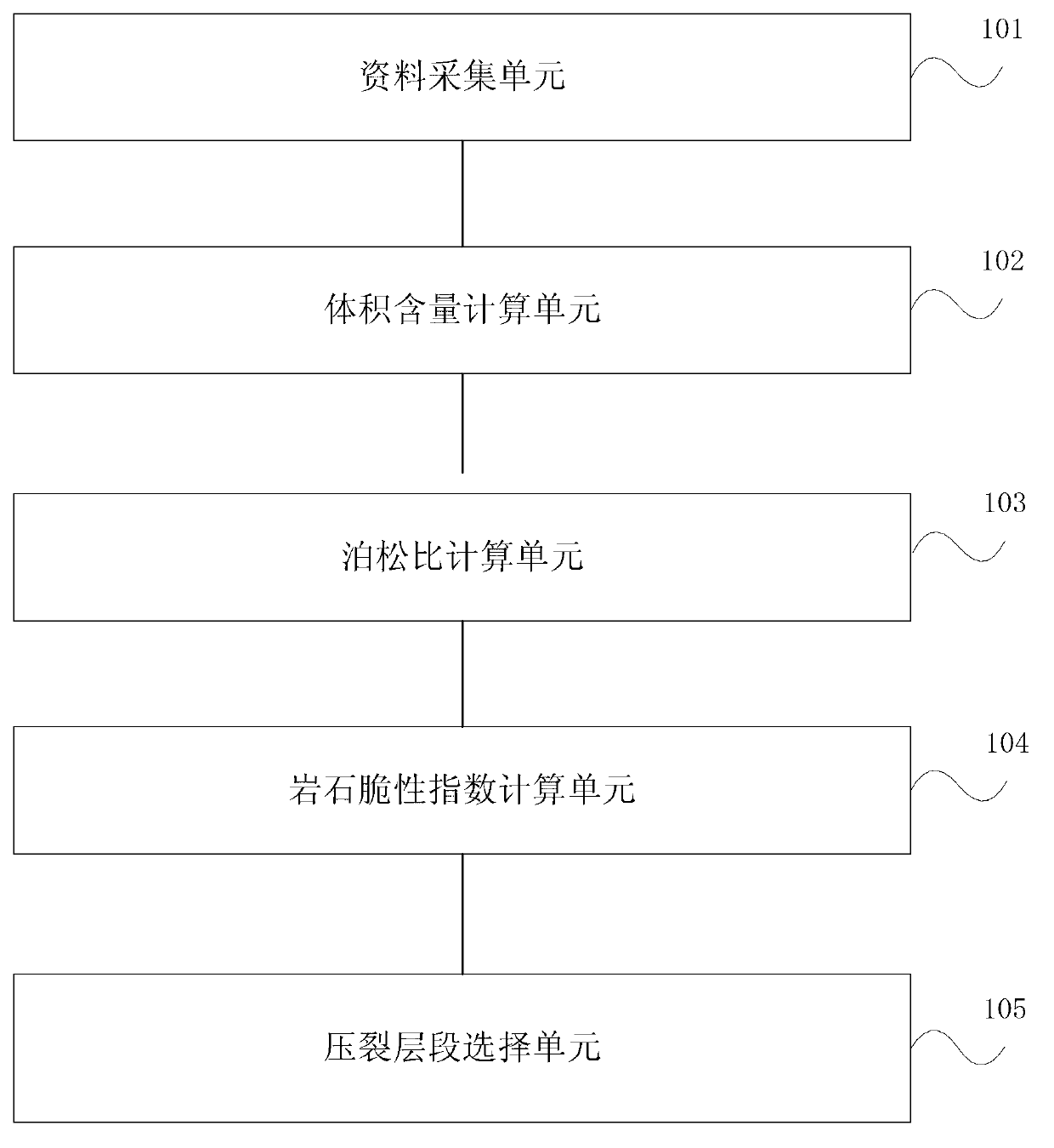

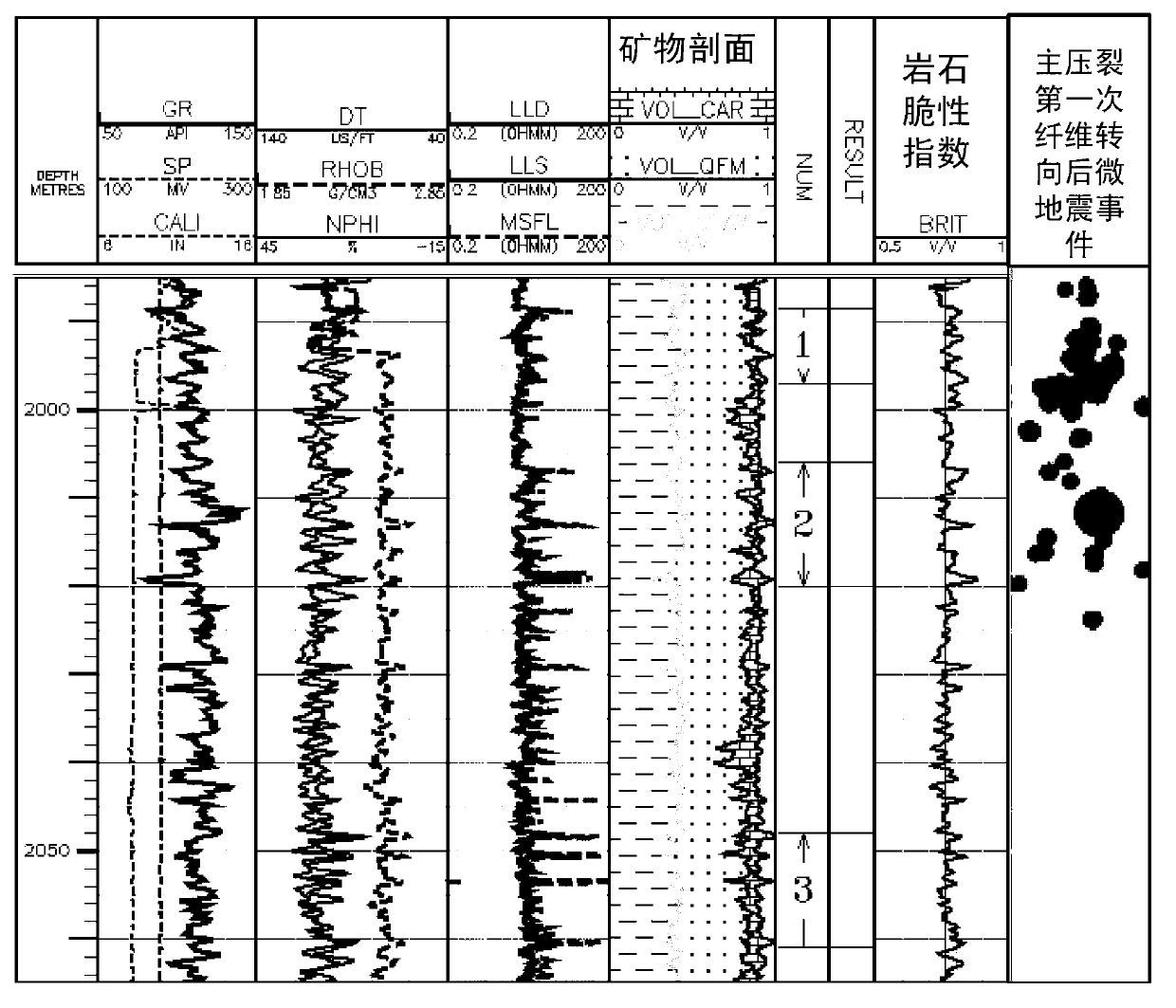

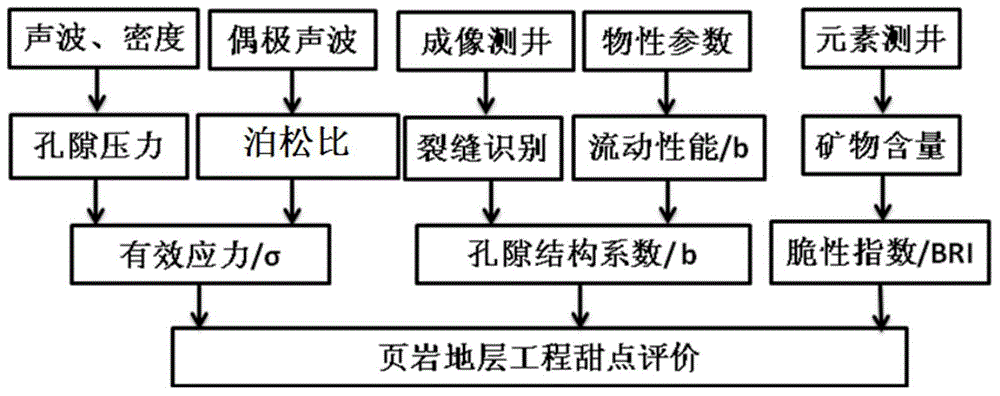

Detection method and device for effective fractured intervals in unconventional shale oil and gas reservoir

The invention discloses a detection method and a device for effective fractured intervals in an unconventional shale oil and gas reservoir. The method includes: collecting logging information and core sample information of intervals of interest; calculating volume contents of all minerals in rock generating the intervals of interest according to the collecting logging information and the core sample information; calculating the poisson ratio of all mineral constituents in the rock generating the intervals of interest according to the core sample information and rock space volume average elastic parameter models; calculating the fragility index of the rock generating the intervals of interest according to the volume contents of all the minerals and the poisson ratio of all the mineral constituents in the rock generating the intervals of interest; and selecting the intervals of interest with the high rock fragility index in the shale as the effective fractured intervals in the unconventional shale oil and gas reservoir. By means of the detection method and the device for the effective fractured intervals in the unconventional shale oil and gas reservoir, the actual production requirement for selecting the effective fractured intervals in exploration and development of the unconventional shale oil and gas reservoir can be met.

Owner:PETROCHINA CO LTD

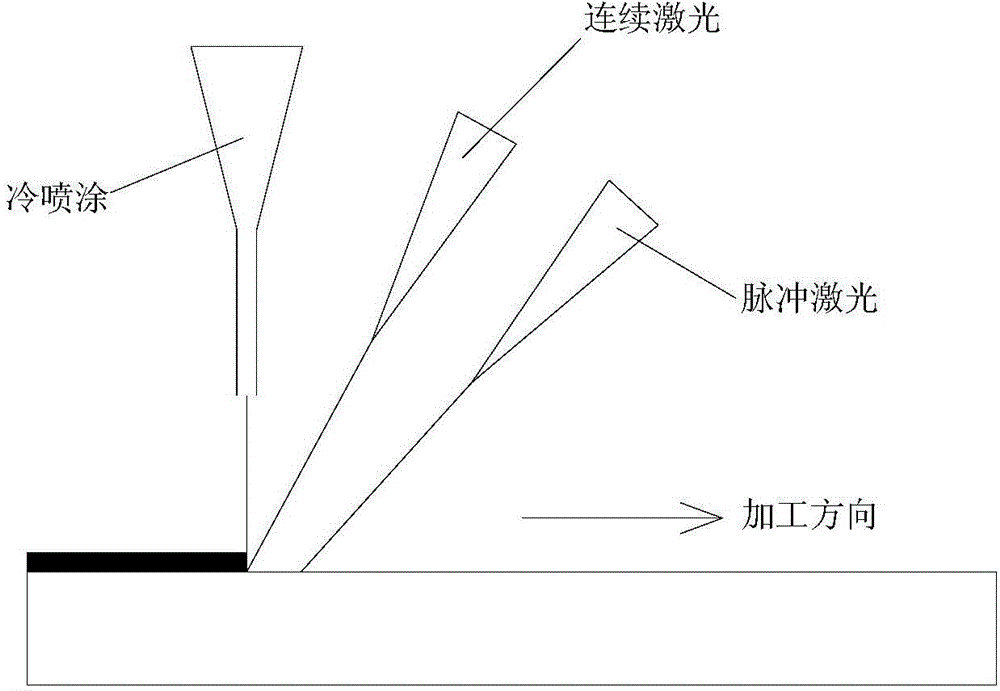

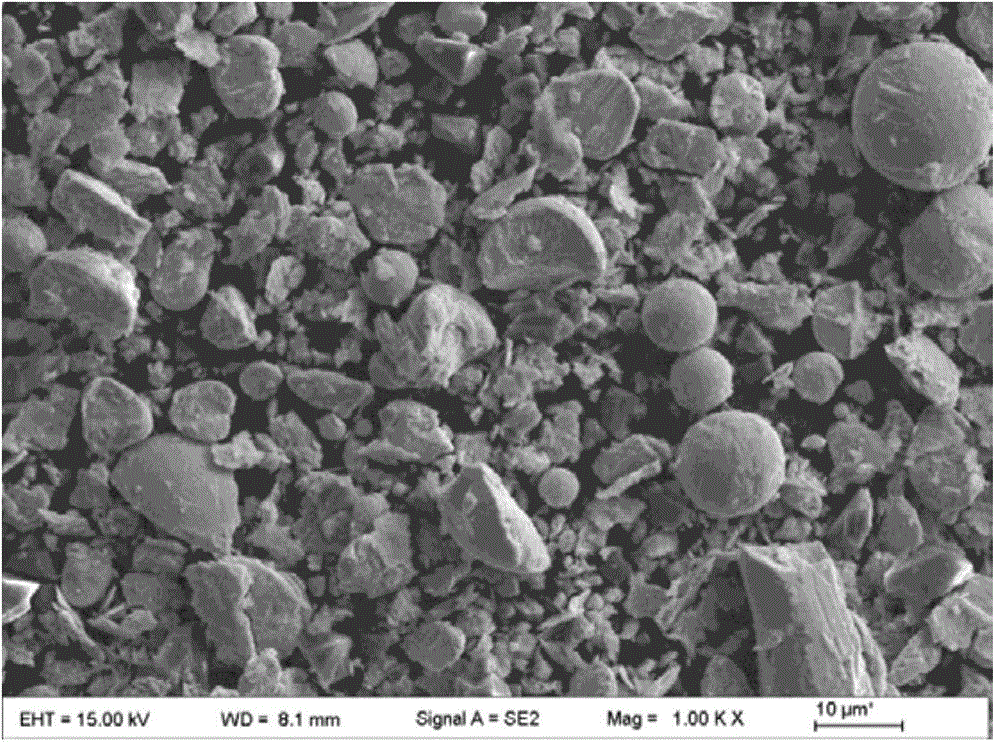

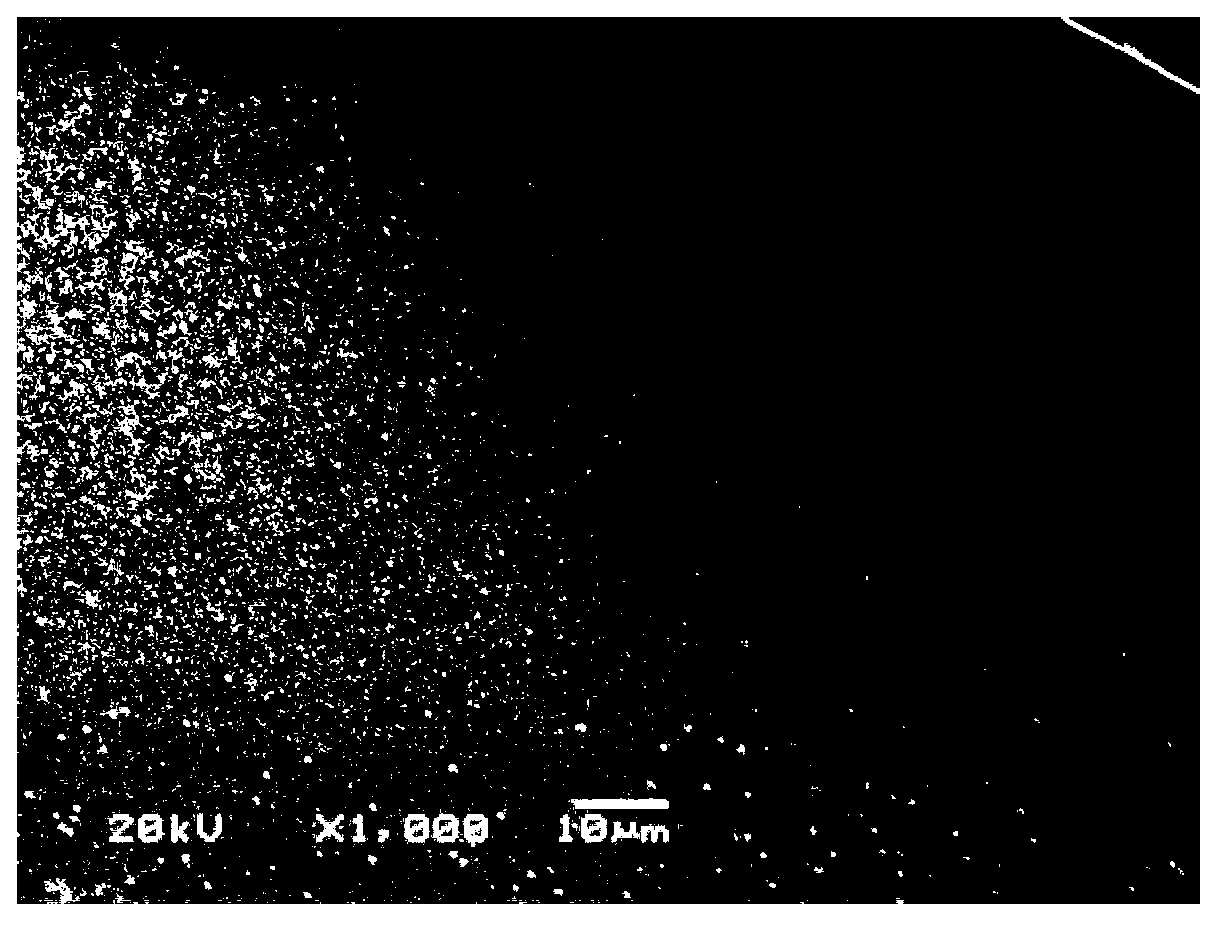

Metal-based/diamond laser composite coating and preparation method thereof

ActiveCN104018156AAvoid easy decompositionInhibition of dissolutionMovable spraying apparatusLaser beam welding apparatusCompound aHardness

The invention discloses a metal-based diamond laser composite coating and a preparation method thereof. The preparation method comprises the following steps: firstly selecting high-hardness metal powder and diamond powder with proper grain size and shape, uniformly mixing the high-hardness metal powder and the diamond powder by using a ball-milling method, and finally preparing the composite coating on a matrix by using a method of synchronously compounding a laser texturing technology, a laser heat treatment technology and a cold spraying technology. The thickness of the composite coating is over 1mm, and the diamond volume content in the coating is more than 45%. The preparation of the composite coating by using the high-hardness metal powder as the diamond binding phase is realized, and the binding strength of the composite coating and the matrix is improved through the pulse texturing treatment, and finally the stable and high-quality high-hardness metal-based / diamond composite high wear-resisting coating is prepared, and the integration, the automation and the efficiency of the matrix surface treatment and the coating deposition treatment are realized.

Owner:ZHEJIANG UNIV OF TECH +1

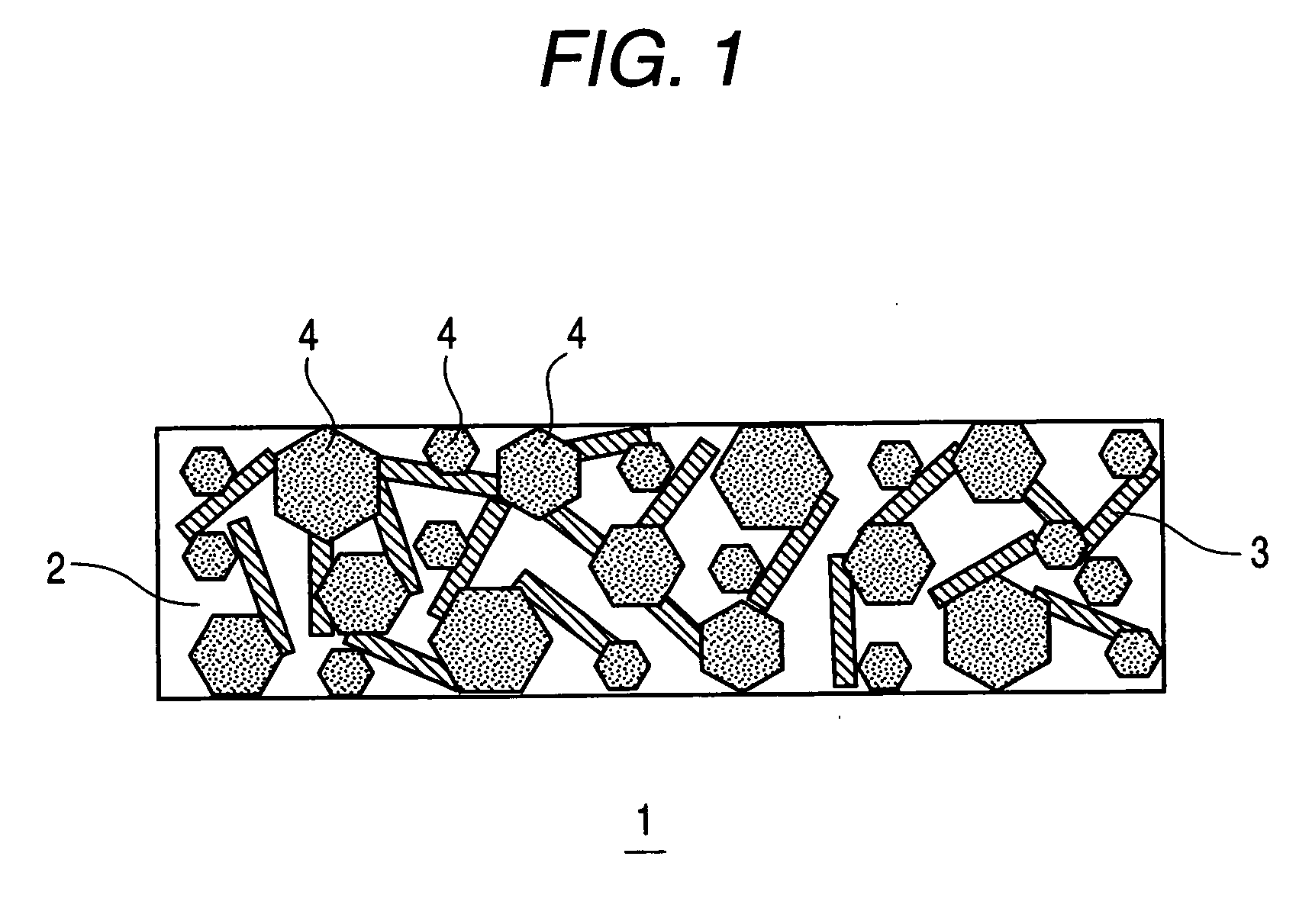

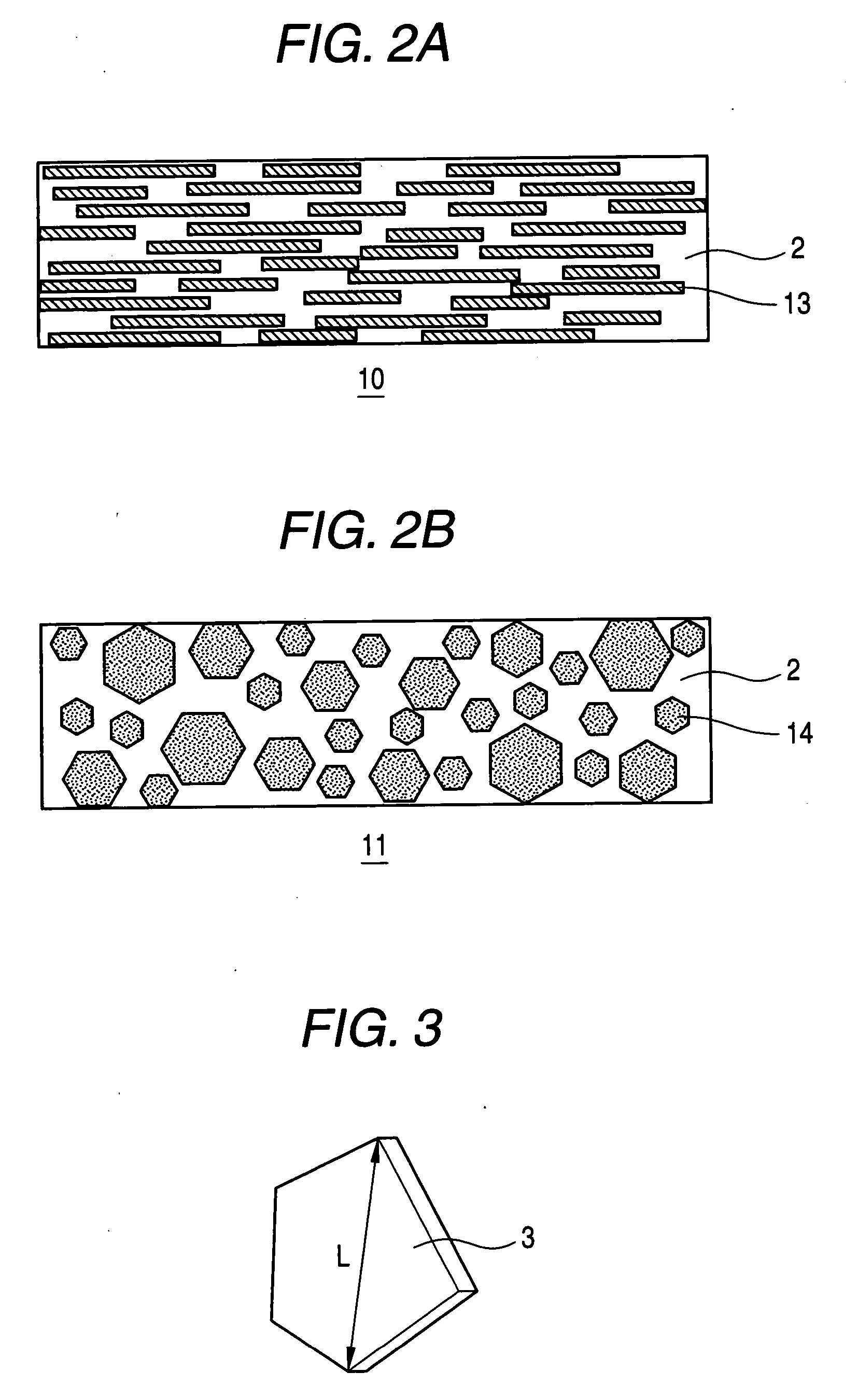

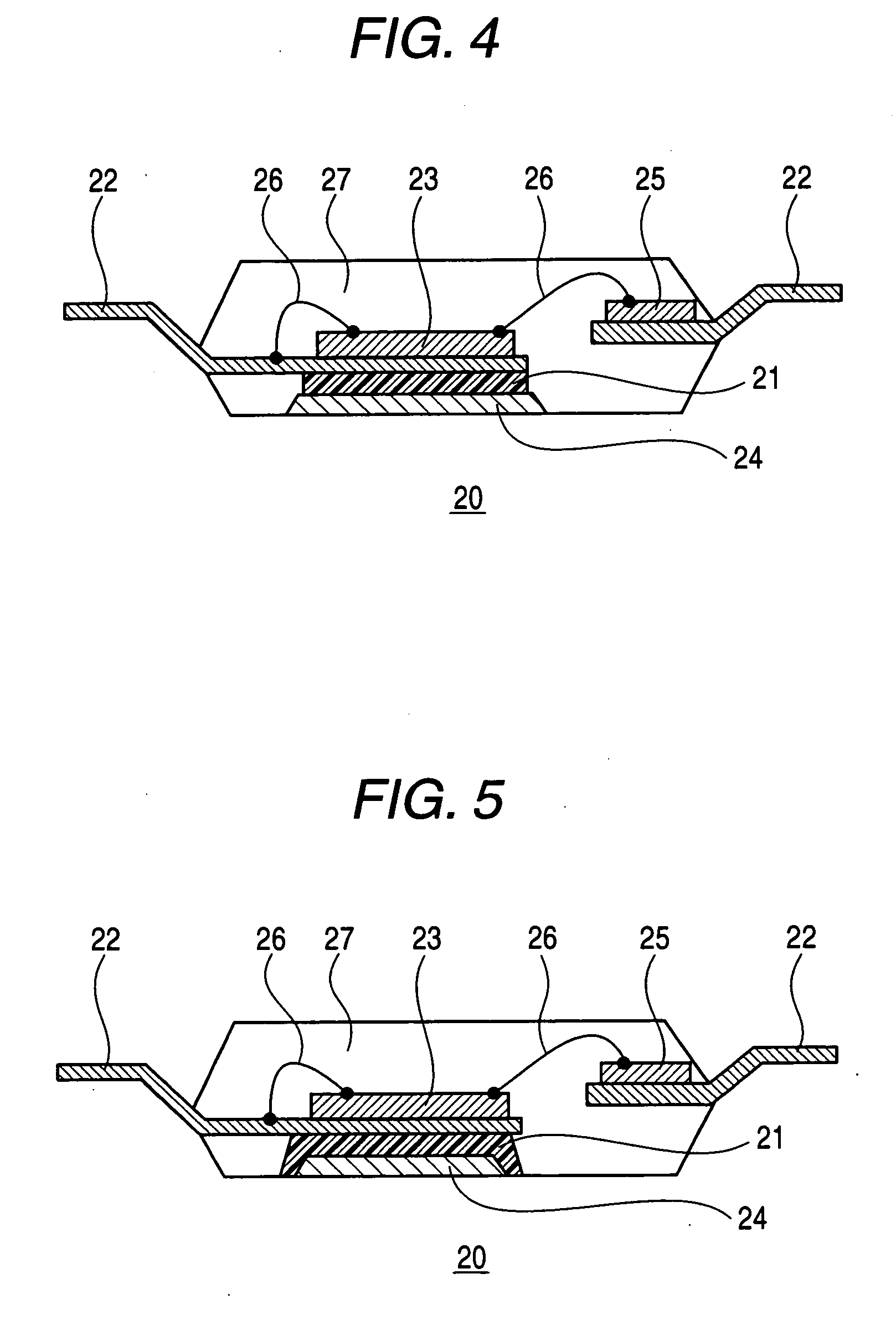

Thermally conductive resin sheet and power module using the same

ActiveUS20060188727A1Improve thermal conductivityHeat dissipationSemiconductor/solid-state device detailsSynthetic resin layered productsInorganic fillerPower module

A thermally conductive resin sheet includes a thermosetting resin, and a thermally conductive and electrically insulating inorganic filler. The inorganic filler is a mixture of a flat inorganic filler and a granular inorganic filler. The ratio of the volume content, VL, of the flat inorganic filler to volume content, VR, of the granular inorganic filler in the mixture is from 30 / 70 to 80 / 20, in terms of VL / VR.

Owner:MITSUBISHI ELECTRIC CORP

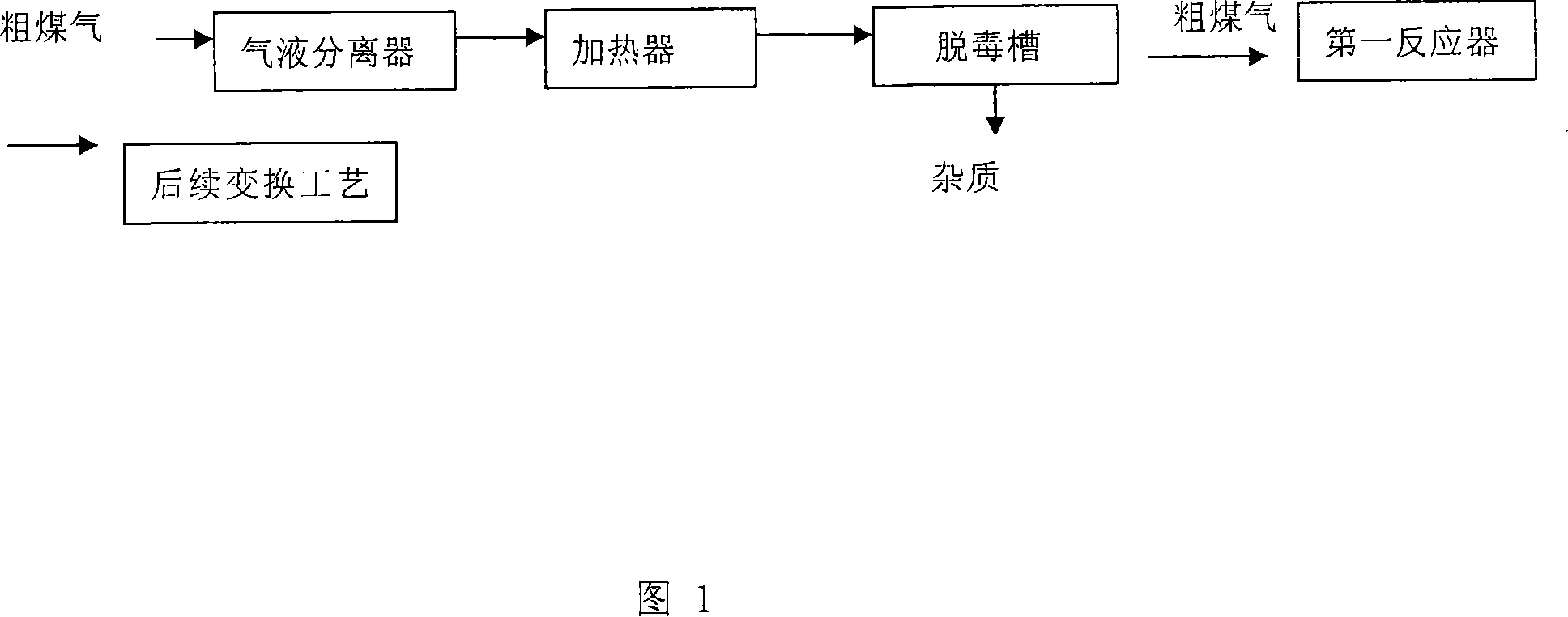

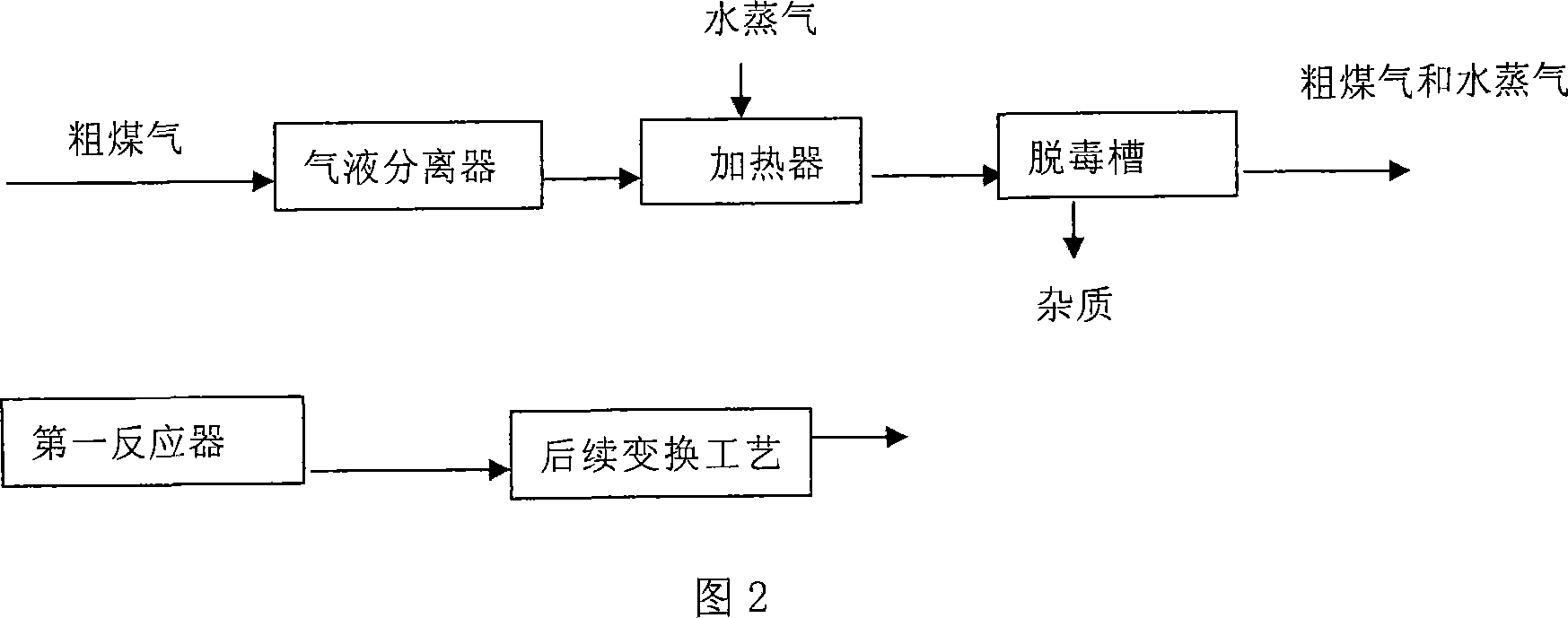

Sulfur resisting transform technique under low water / gas for gasifying powdered coal

ActiveCN101050391AExtended service lifeSmall volume content on dry basisCombustible gas catalytic treatmentVapor–liquid separatorSulfur

This invention relates to a process for gasifying pulverized coal at a low water / gas ratio by sulfur-tolerant conversion. The process comprises: introducing crude coal gas into a gas-liquid separator, heating the crude coal gas exhausted from the separator top to 180-220 deg.C, removing impurities, sending to a first reactor, and performing sulfur-tolerant conversion. In the first reactor, the water / gas volume ratio at the inlet is 0.15-0.20; the temperature at the inlet is 180-220 deg.C; the hot-point temperature of the bed layer is 330-400 deg.C; the space velocity is 6000-9000 h-1; the reaction pressure is 3.0-4.0 MPa; the CO volume content in the crude coal gas at the inlet is 55-70%. The process has such advantages as low water / gas ratio and low energy consumption.

Owner:青岛联信催化材料有限公司 +2

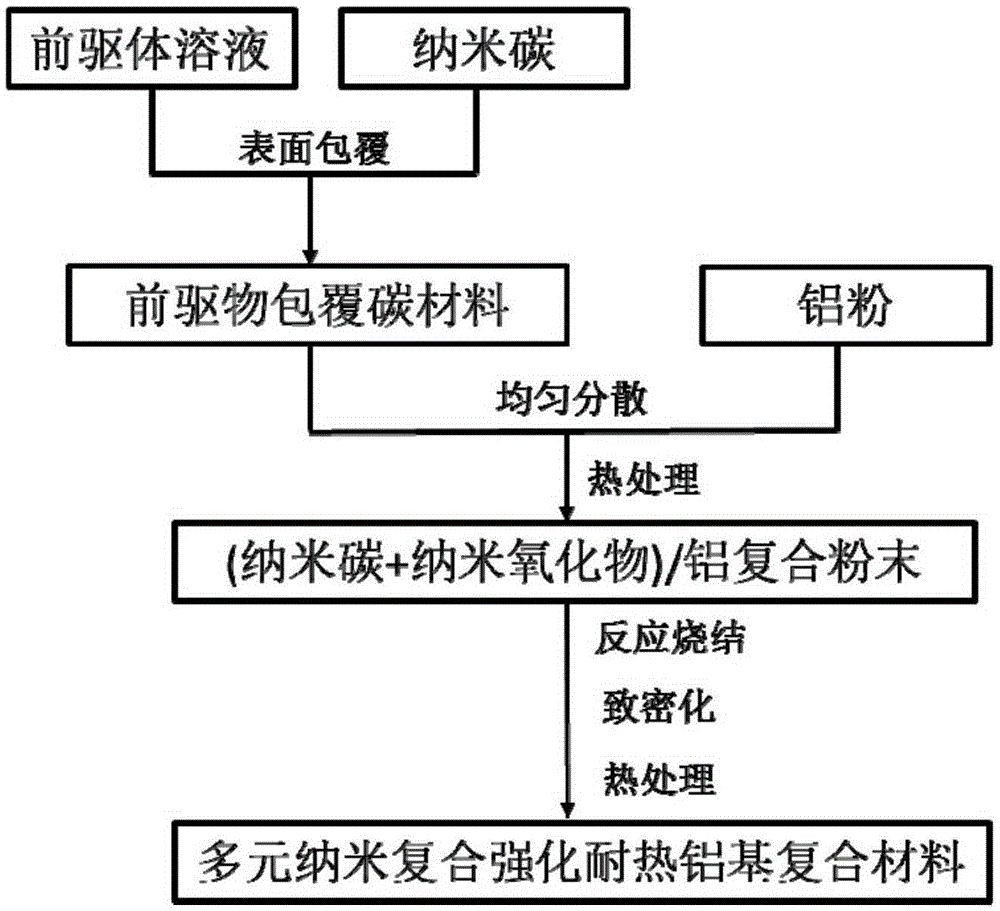

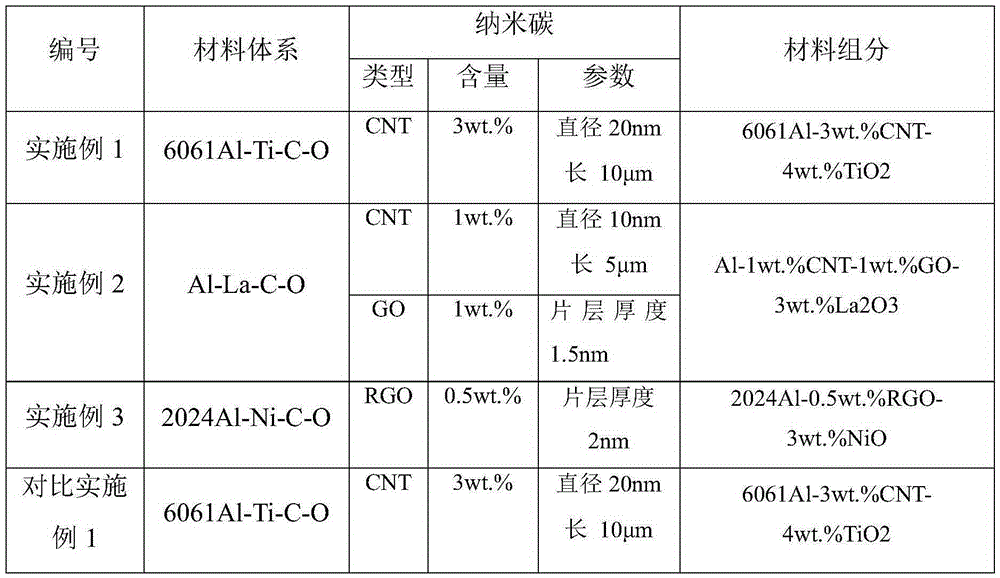

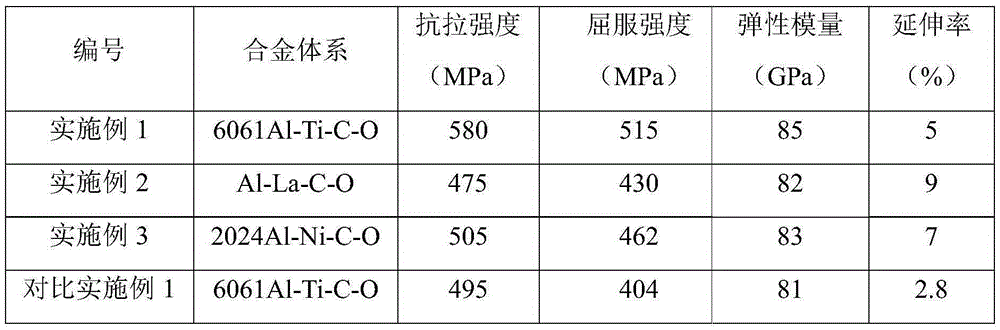

Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

The invention provides a preparing method of a multielement nanometer composite strengthening thermal-resisting aluminum matrix composite. The surface of nanocarbon is coated with a metal ion precursor in advance, the nanocarbon is evenly scattered in aluminum powder, the precursor is converted into oxide through thermal treatment, reactive sintering and densifying treatment are carried out on the obtained composite powder, and the multielement nanometer strengthening aluminum matrix composite is obtained. The nanocarbon has the high specific surface area, the feature size of the nanocarbon is far larger than that of the nanometer oxide, and therefore a proper amount of nanometer oxide can be loaded and evenly led into the aluminum powder, metallic oxide, carbide, an intermetallic compound and other multielement nanometer strengthening phases are generated through the in-situ reaction, and the tissue stability and the thermal resistance of the aluminum matrix composite are improved coordinately. The method achieves the purposes of even leading of high-volume-content multielement nanometer strengthening phases and the space occupation control, and the conventional powder metallurgy technology can be adopted for preparing the multielement nanometer composite strengthening thermal-resisting aluminum matrix composite.

Owner:SHANGHAI JIAO TONG UNIV

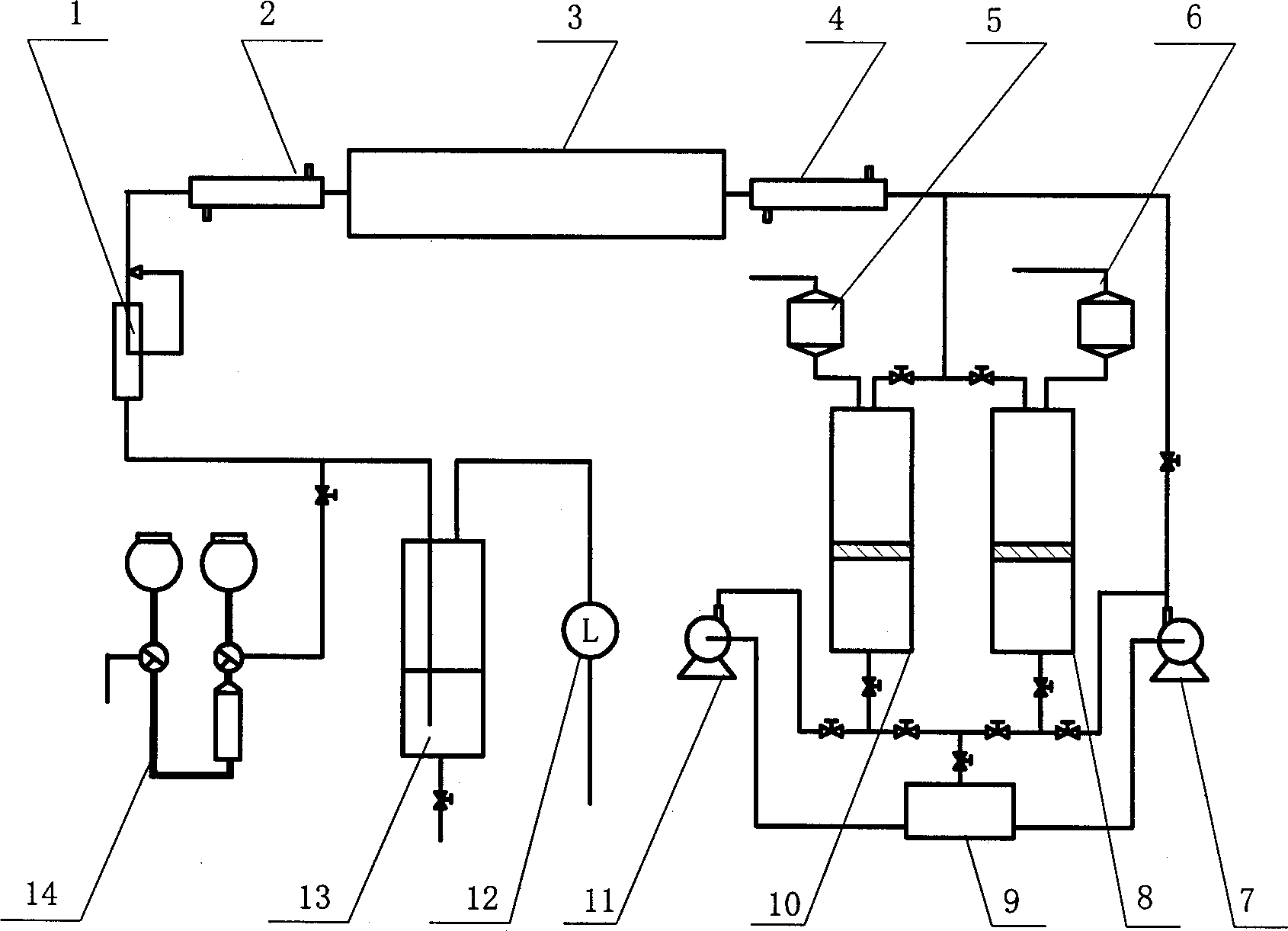

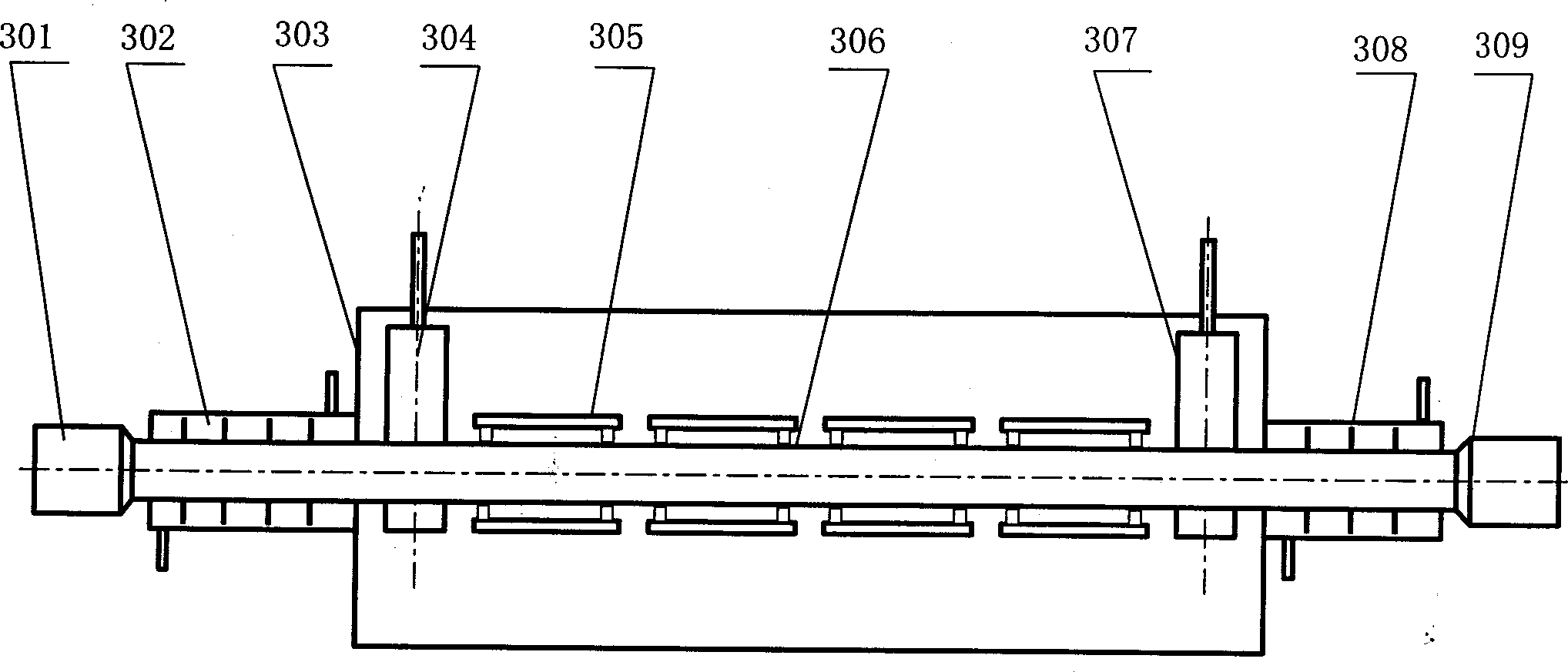

Continuous supercritical water gasifying hydrogen producing method and apparatus with organic solid matter

InactiveCN1375447AHeating up fastFast and efficient gasification reactionPlastic recyclingHydrogen productionHigh pressureSolid matter

The solid raw material has no need of drying treatment, can be pulverized and directly added into reaction system; said invention uses carboxymethyl-cellulose sodium as additive and implement high-pressure multiphase mixed continuous transmission of solid raw material; its reaction equipment is formed from double-pump, double feeding system, reactor, back pressure valve, gas-liquid separator, sampling device and wet gas flowmeter; it adopts the reactor with current heating mode and radiation heating mode, can implement quick heating and high-effective gasification reaction. The hydrogen-making and sampling device provided by said invention can product hydrogen gas and CO2 gas as main product, its CO volume content is less than 1%, and its gasification rate can be up to 100%.

Owner:陕西中核交大超洁能源技术有限公司

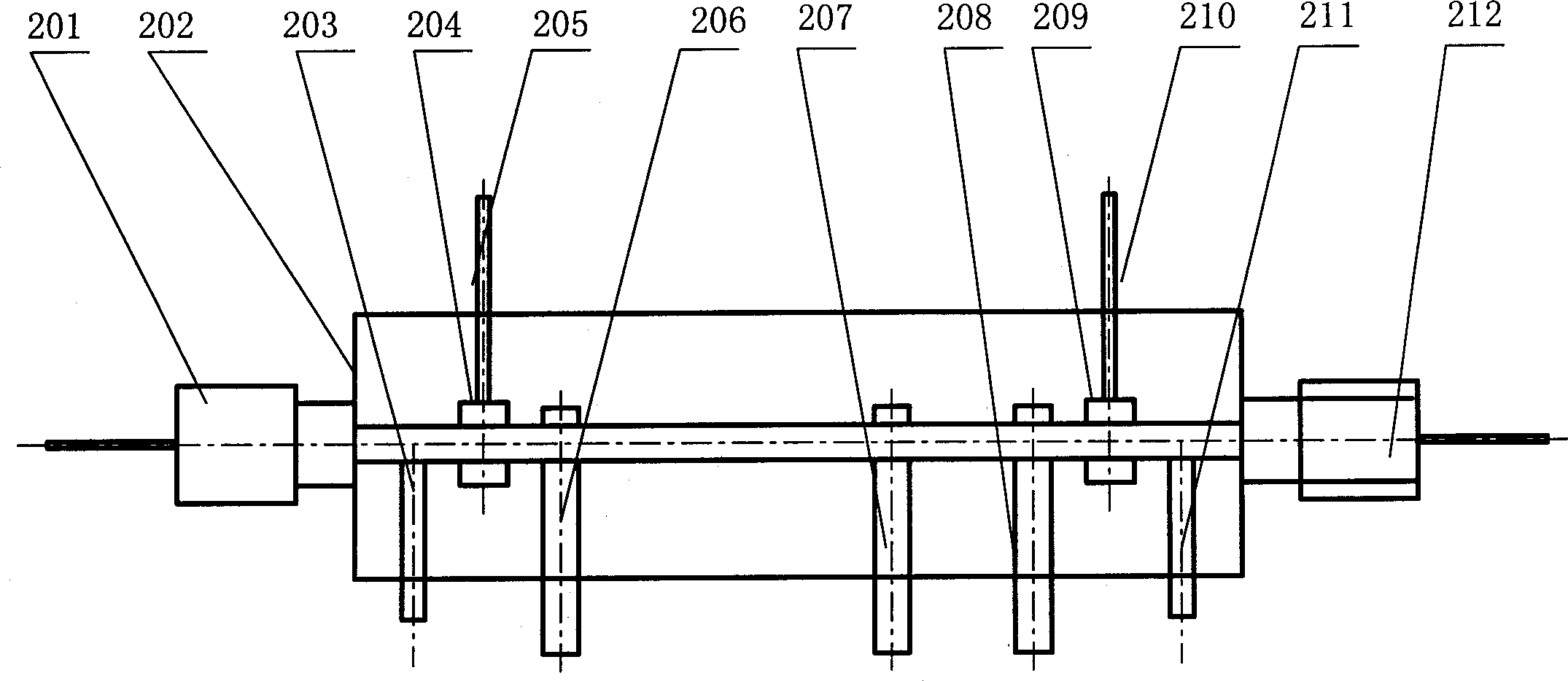

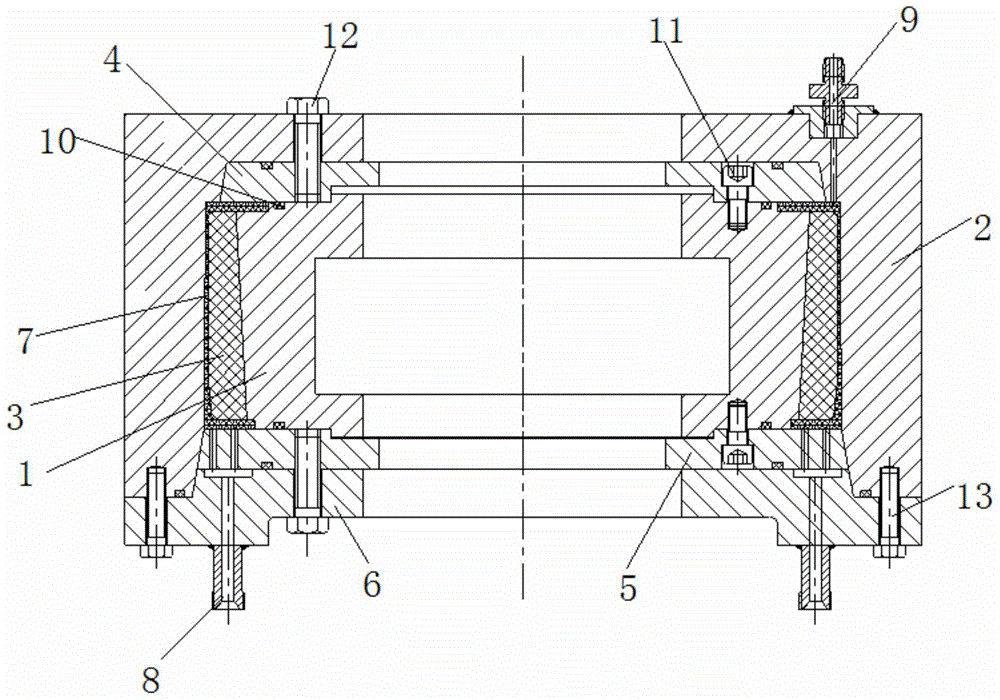

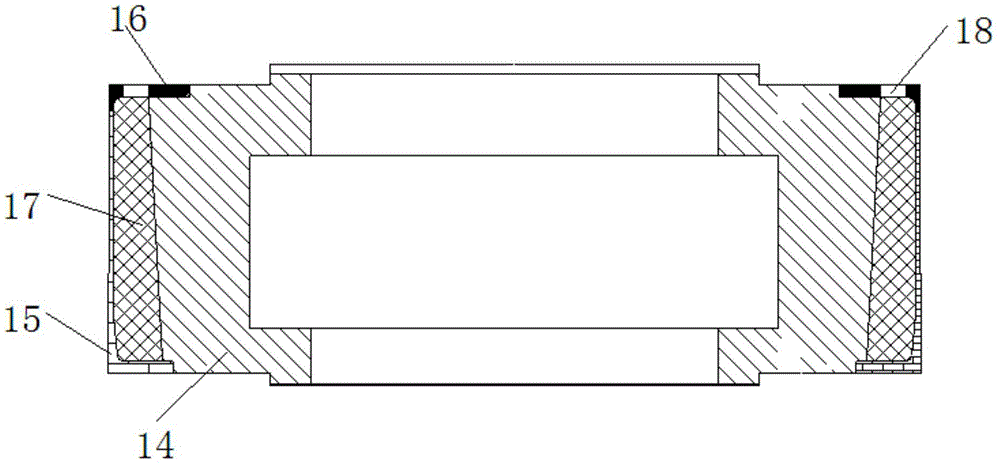

Composite material connecting skirt forming method and mold and inner rubber core mold forming mold

The invention discloses a composite material containing skirt forming method and mold and an inner rubber core mold forming mold. The method comprises the following steps: (1) manufacturing the forming mold, namely manufacturing an outer mold, an inner mold and the inner rubber core mold and sheathing the inner rubber core mold on the outer wall of the inner mold; (2) laying up; (3) preheating and vacuumizing the forming mold; (4) carrying out resin pretreatment; (5) injecting glue and solidifying, namely solidifying resin after glue injection, wherein the inner rubber core mold is expanded along with the increase of temperature to uniformly pressing a preform and enable the resin to fully infiltrate the preform; and (6) demolding and trimming. The forming mold structure adopts the inner rubber core mold; silicone rubber is adopted and a resin transfer molding (RTM) process is assisted to form the composite material containing skirt, and a double-sided mold is adopted, so that a product has the advantages of stable dimension, good quality consistence, controllable fiber and resin contents and the like; measures such as co-solidification and the adoption of the expandable core mold are adopted to reduce the porosity, increase the volume content of the fibers of the product and improve the mechanical property.

Owner:湖北三江航天江北机械工程有限公司

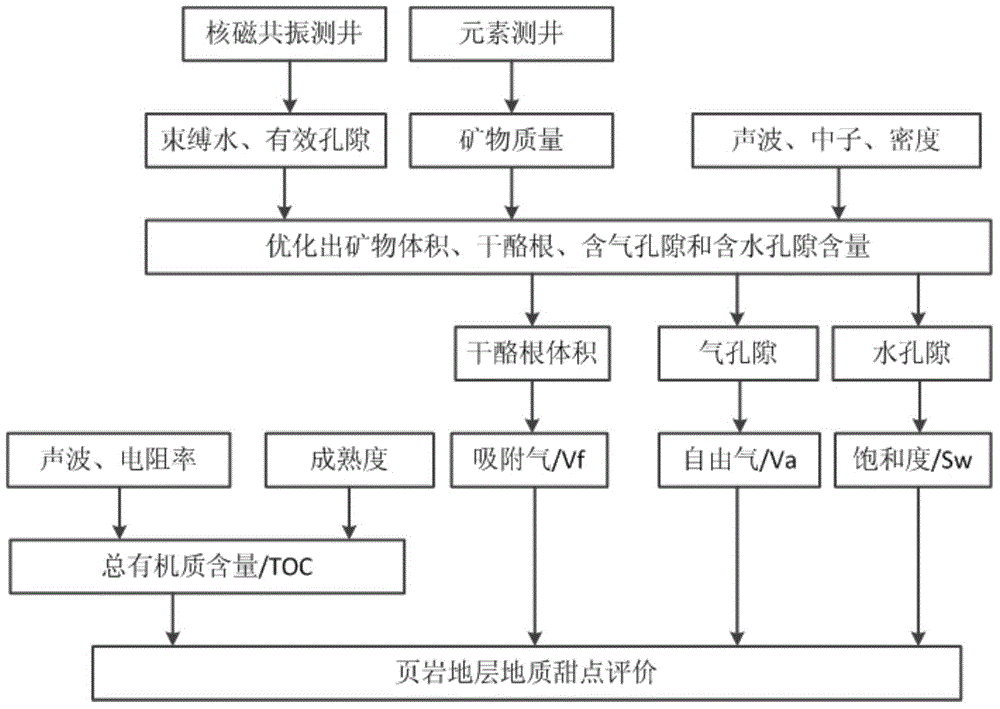

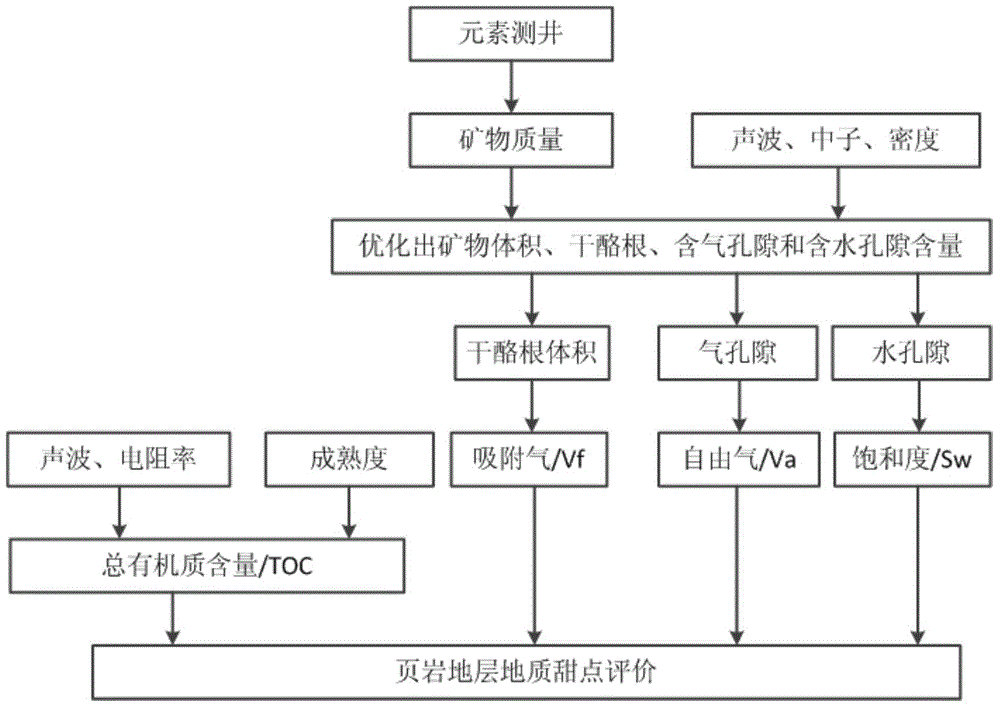

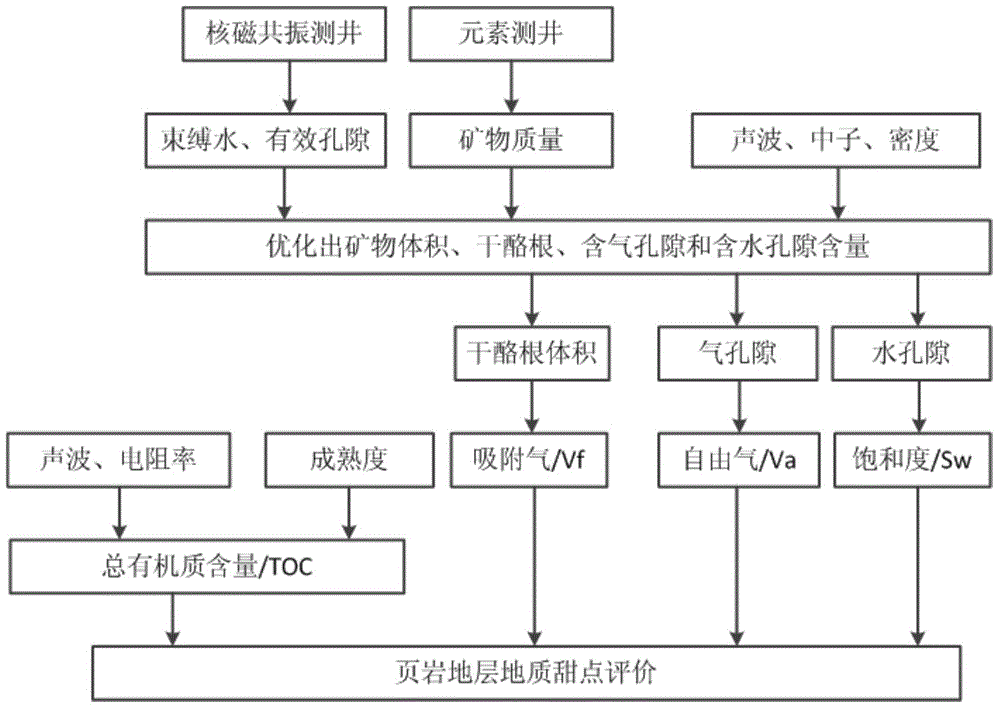

Method for recognizing sweet spots in shale stratum

ActiveCN105986816AFull consideration of integrityConsider completenessBorehole/well accessoriesPorosityKerogen

The invention discloses a method for recognizing sweet spots in a shale stratum. The method includes the following steps that the kerogen volume content, the gas-bearing porosity, the gas saturation and the total organic content of the shale stratum are determined according to logging information, and the geological sweet spot coefficient of the shale stratum is obtained through a radar map analyzing method; the maximum horizontal effective stress value, the pore structure index and the brittleness index of the shale stratum are determined according to the logging information, and the engineering sweet spot coefficient of the shale stratum is obtained through the radar map analyzing method; and the sweet spots in the shale stratum are recognized according to the geological sweet spot coefficient and the engineering sweet spot coefficient. According to the method, the geological sweet spots and the engineering sweet spots in the shale stratum are quantitatively represented according to the geological sweet spot coefficient and the engineering sweet spot coefficient, and the sweet spots in the shale stratum can be determined through comprehensive analysis of the two coefficients; and the development cost can be lowered by exploration and development in sweet spot areas, and the development efficiency of shale gas is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydroxyapatite nano pole

The invention discloses a preparation method of a hydroxyapatite nano-rod, which adopts an oleic acid-ethanol-water phase transfer system with low cost to prepare the hydroxyapatite nano-rod with uniform size, controllable appearance and nano-scale. The hydroxyapatite nano-rod is prepared by the steps as follows: a. firstly, the oleic acid, ethanol and an additive are mixed; b. secondly, a calcium salt aqueous solution is dispersed into the oleic acid-ethanol mixed medium; the volume content of the calcium salt aqueous solution in a final mixed solution is 5 percent to 15 percent; the mass volume concentration of the calcium salt is 0.1 percent to 10 percent; c. then,a phosphate aqueous solution is added and mixed at room temperature; the mass volume concentration of the phosphate is 0.1 percent to 10 percent; d. the mixture generated from step c reacts in a reactor between 80 DEG C and 200 DEG C; e. centrifugation is carried out to remove a supernatant fluid and the obtained object is washed by a cleaning solvent and then dried so as to obtain the hydroxyapatite nano-rod. The preparation method is characterized by low production cost and comparatively high product quality, thus being hopeful to be applied in the medical field.

Owner:SOUTHEAST UNIV

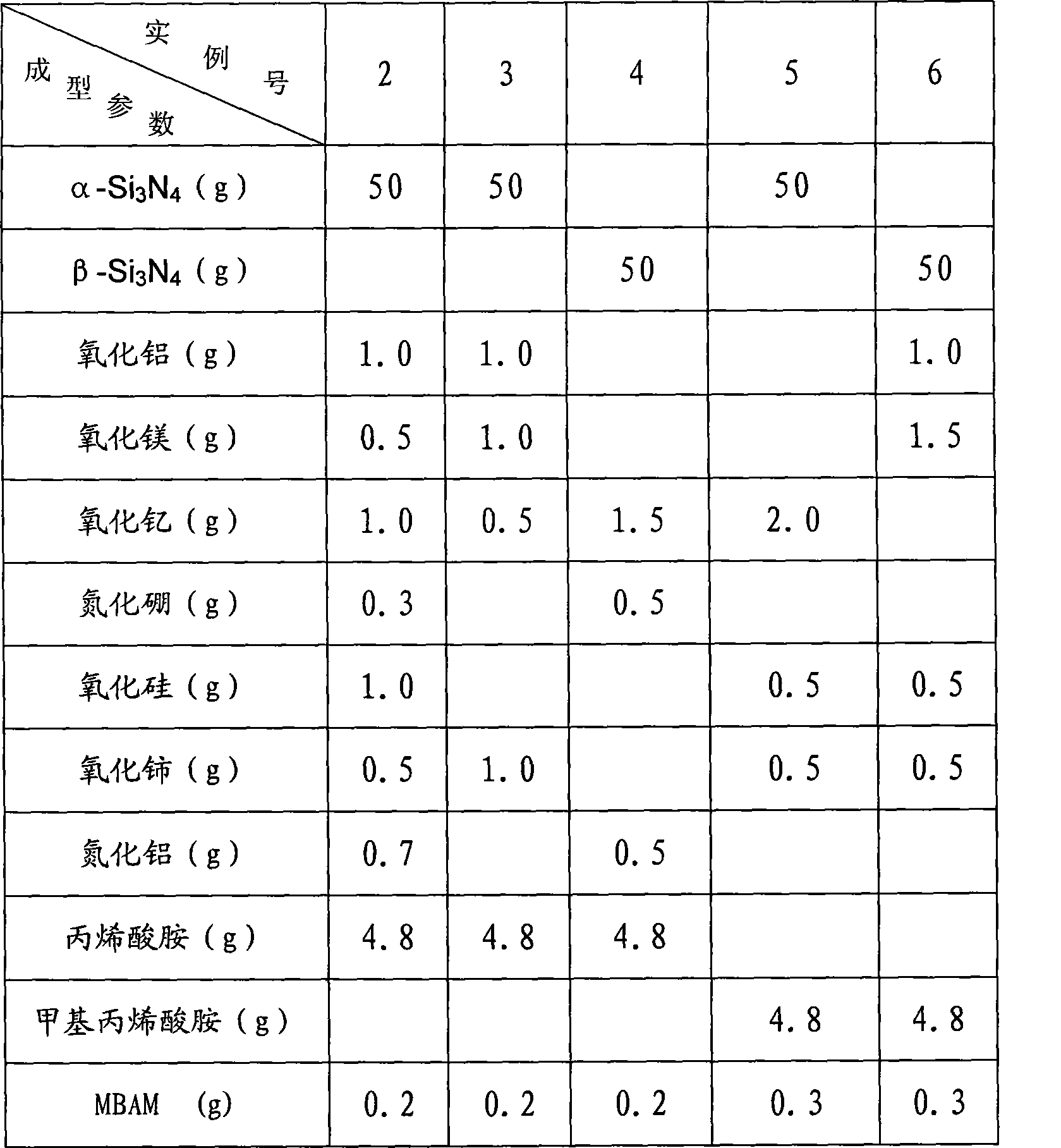

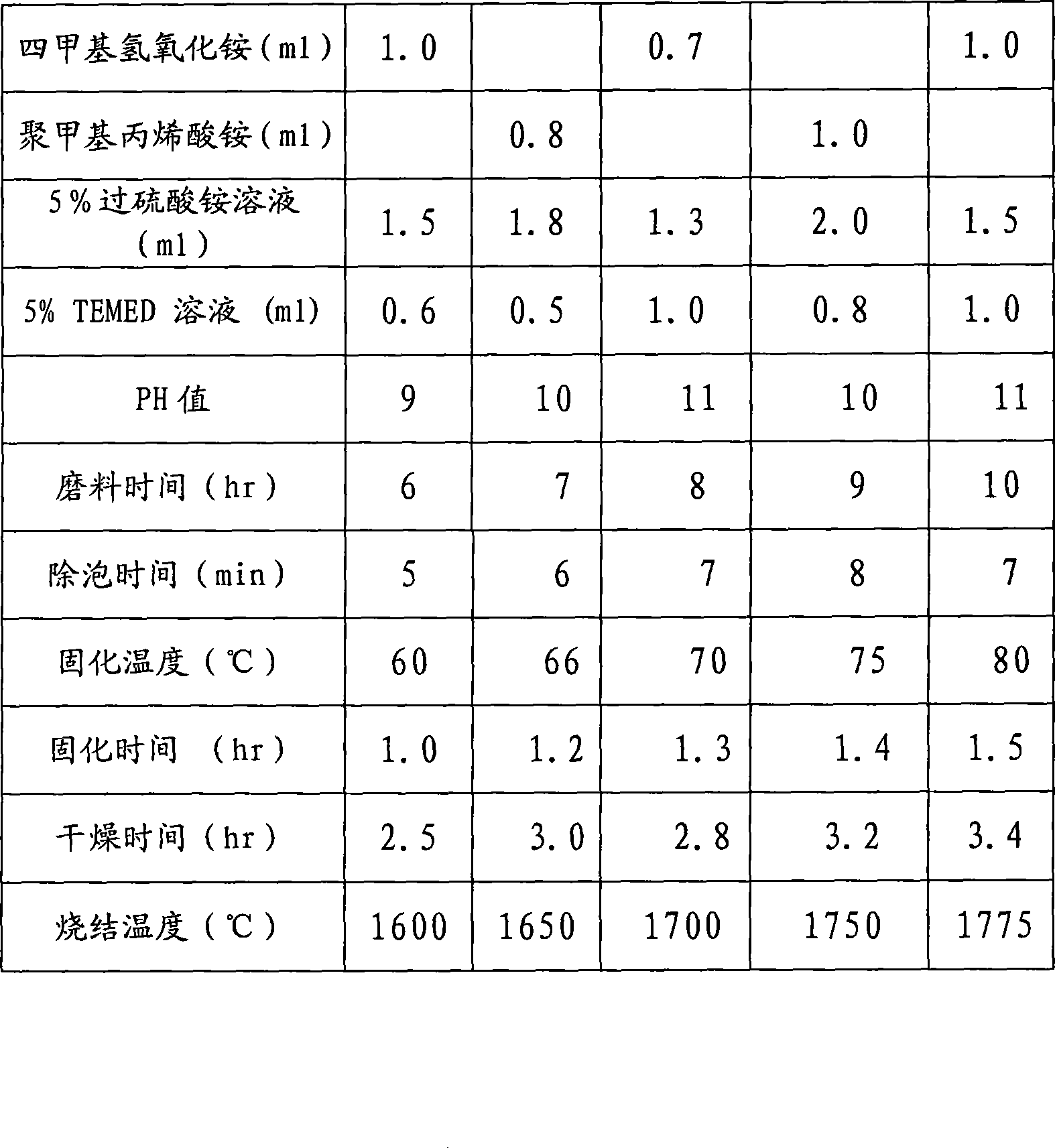

Gel-casting moulding technique for preparing silicon nitride ceramics heating element

InactiveCN101397210AUniform structureImprove dry strengthCeramic shaping apparatusMicrowave ovenCross linker

The invention relates to a gelatin injection molding-shaping method for preparing silicon nitride ceramics heating elements, pertains to the technical field of inorganic material composition and preparation, and is characterized in that the following steps are included: a monomer solution containing an organic monomer and a cross linker is confected, silicon nitride ceramics powder and 4-39% of sintering addition agent are added for preparing suspensoid slurry, and dispersing agent which accounts for 1-3% of the mass of solid-phase powder material is added; the pH value is adjusted to 9-11; the suspensoid slurry is ball-milled for 4-8 hours, and the ceramics slurry with 55-60% of solid phase volume content and 0.7-0.9 Pa.s of viscosity is obtained; 20-50% of initiator and 10-30% of catalyst are added and stirring is carried out in vacuum for 5-15 minutes to remove bubbles; then injection mold, solidification and dryness are carried out; finally the blanker is sintered in a microwave oven at 1550-1800 DEG C. The ceramics blanker obtained by the invention has even structure, the operation is simple, and the production cost is low.

Owner:SHENZHEN JINKE SPECIAL MATERIALS CO LTD

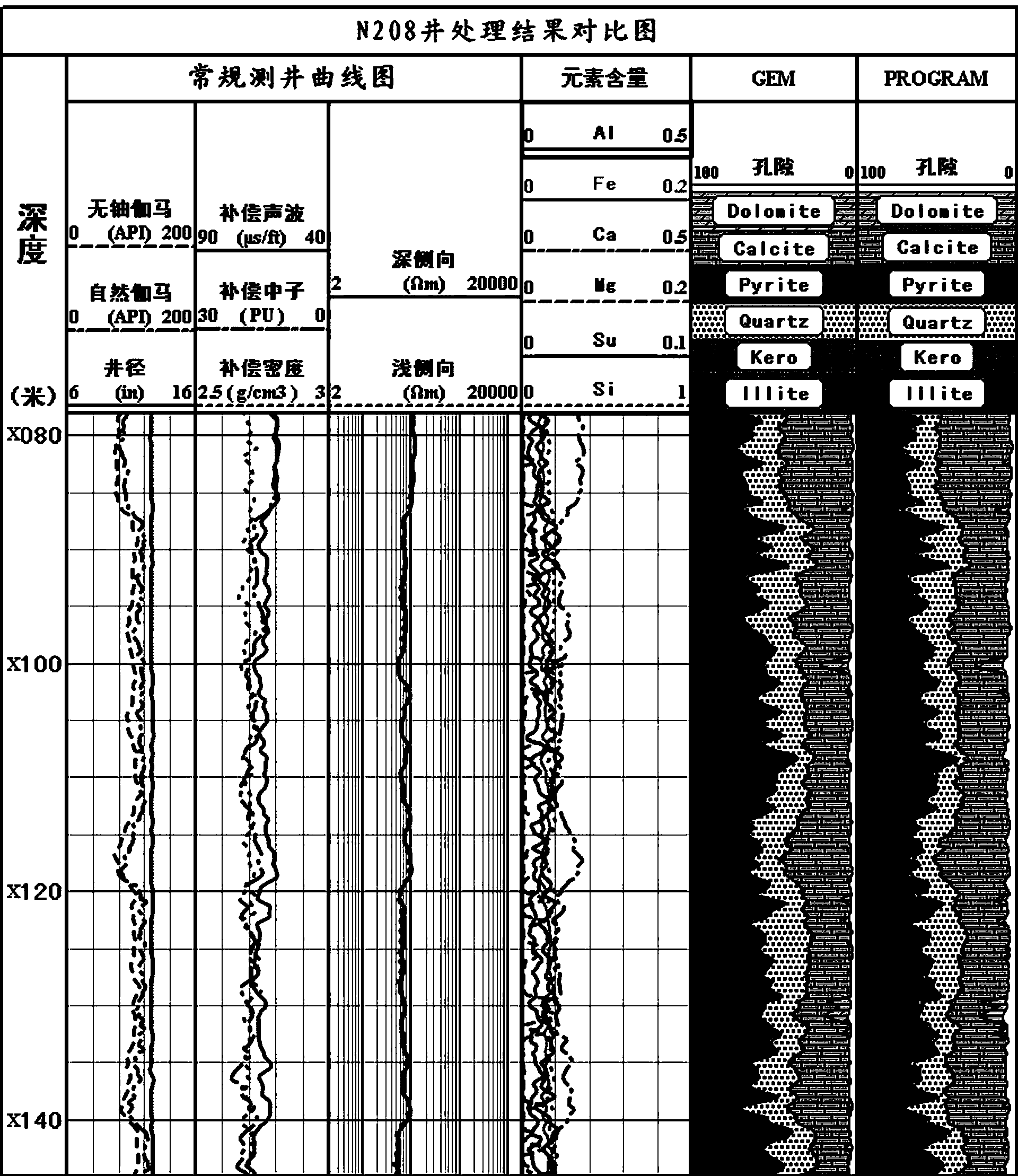

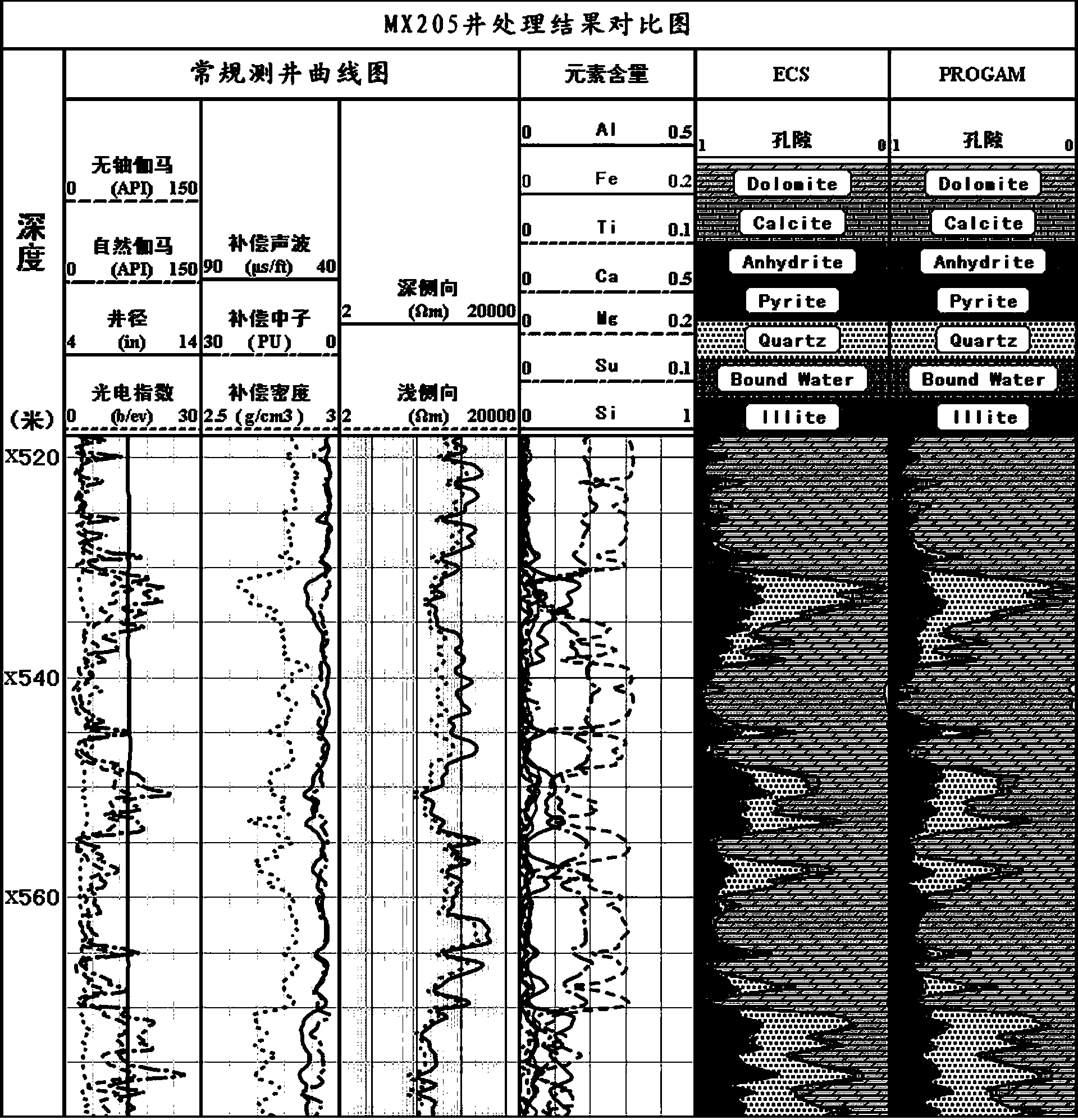

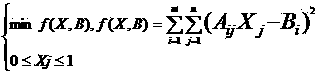

Method of calculating mineral components of rock in formations through element contents

InactiveCN103617345AEasy to implementImprove calculation accuracySpecial data processing applicationsBorehole/well accessoriesPorosityLithology

The invention discloses a method of calculating mineral components of rock in formations through element contents. According to the method, formation element content curves obtained by element logging and conventional logging curves are used as input information; the volume contents of rock mineral contents in complex lithological formations are calculated according to the input information and areal geological parameter. The method is applicable to the determination on rock mineral components in various complex lithological formations, and rock mineral components and porosity thereof can be calculated more accurately.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

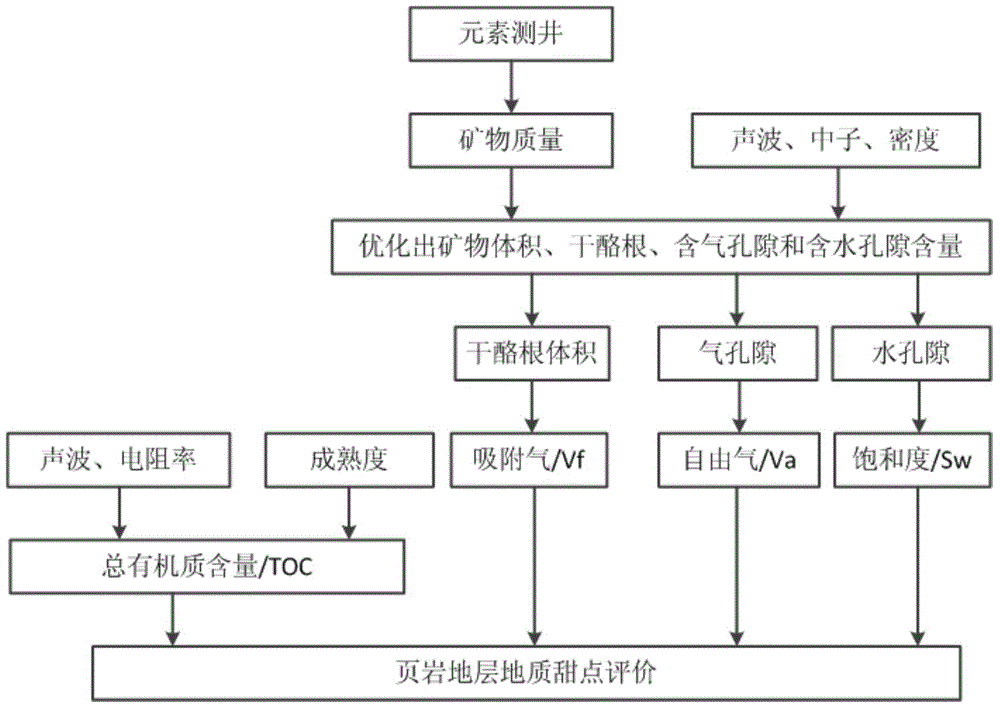

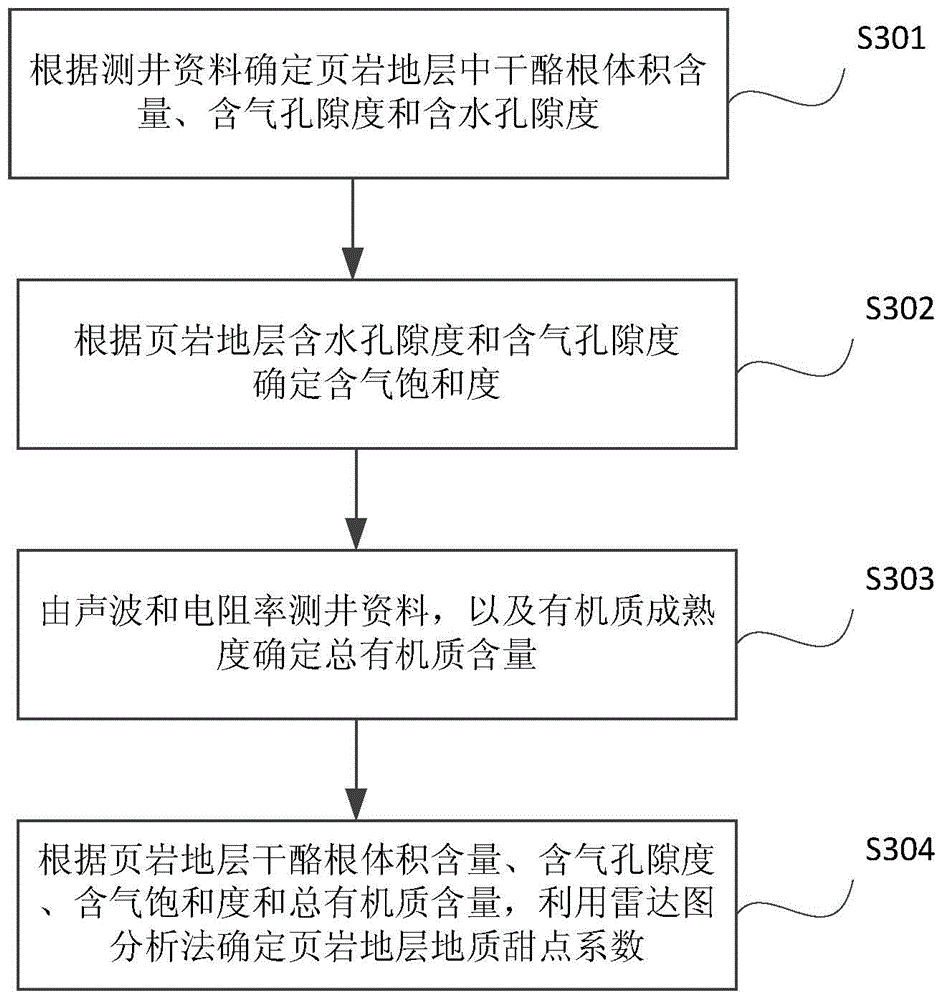

Method for recognizing geological sweet spots in shale stratum

The invention discloses a method for recognizing geological sweet spots in a shale stratum. The method includes the following steps that the kerogen volume content, the gas-bearing porosity and the water-filled porosity in the shale stratum are determined according to logging information; the gas saturation is determined according to the water-filled porosity and the gas-bearing porosity of the shale stratum; the total organic content is determined according to sound wave and resistivity logging information and the organic matter maturity; and according to the kerogen volume content, the gas-bearing porosity, the gas saturation and the total organic content of the shale stratum, the geological sweet spot coefficient of the shale stratum is determined through a radar map analyzing method, and the geological sweet spot coefficient is used for recognizing the geological sweet spots in the shale stratum. According to the method, the geological sweet spots in the shale stratum are represented through the four parameters of the organic content, the kerogen volume content, the gas-bearing porosity and the gas saturation, recognition completeness of the geological sweet spots in the shale stratum is fully considered, the quality of the geological sweet spots in the shale stratum is quantitatively represented through the geological sweet spot coefficient, and quantitative reference is provided for mining engineering of the shale stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

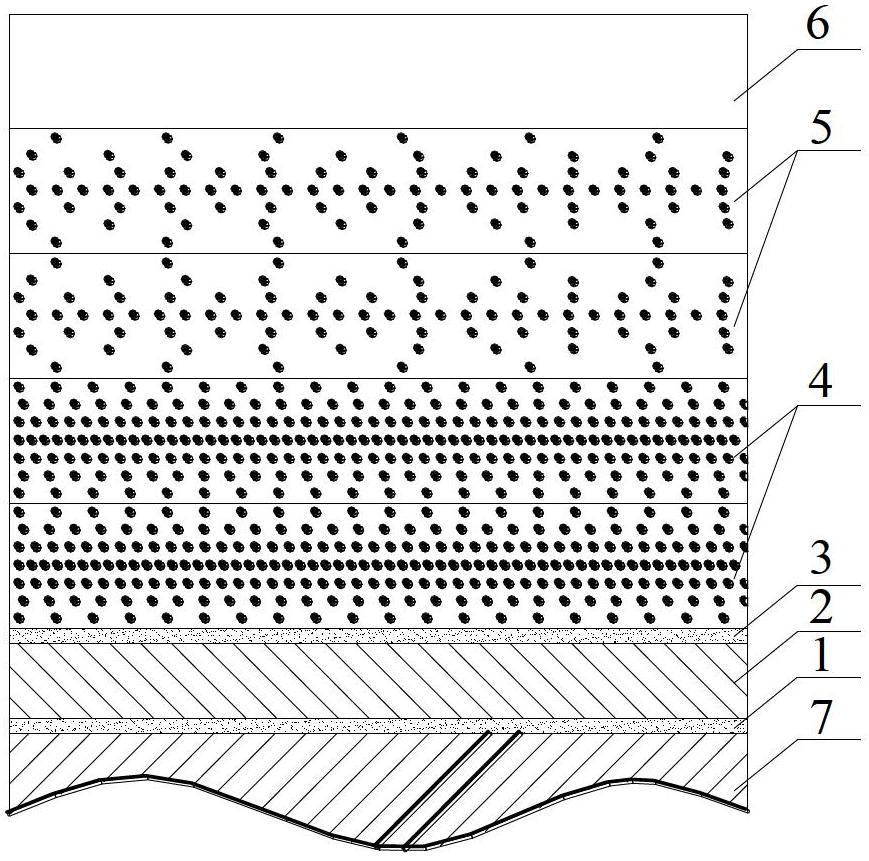

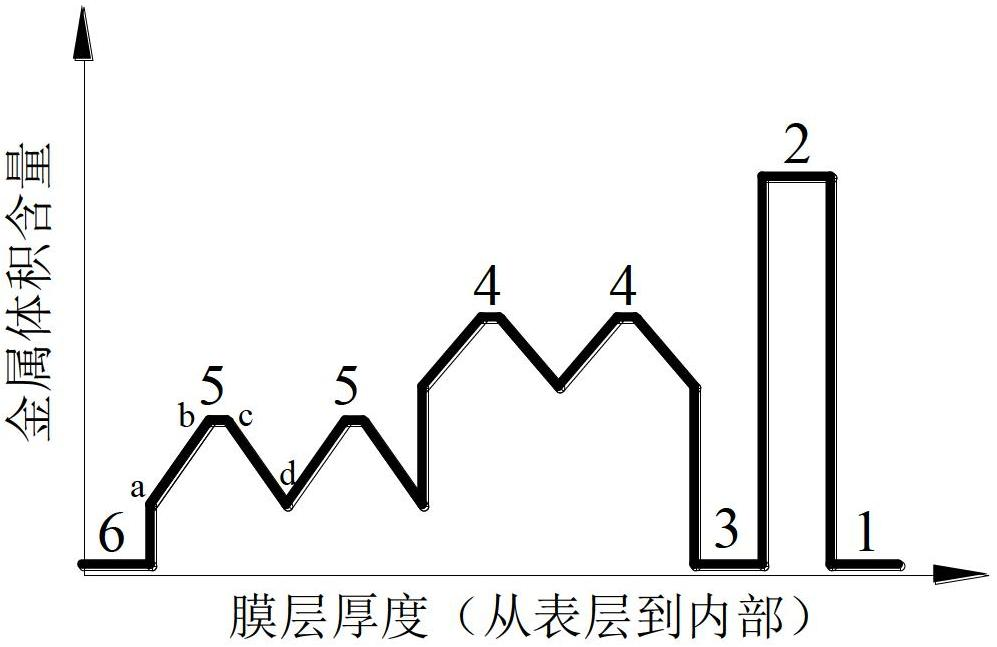

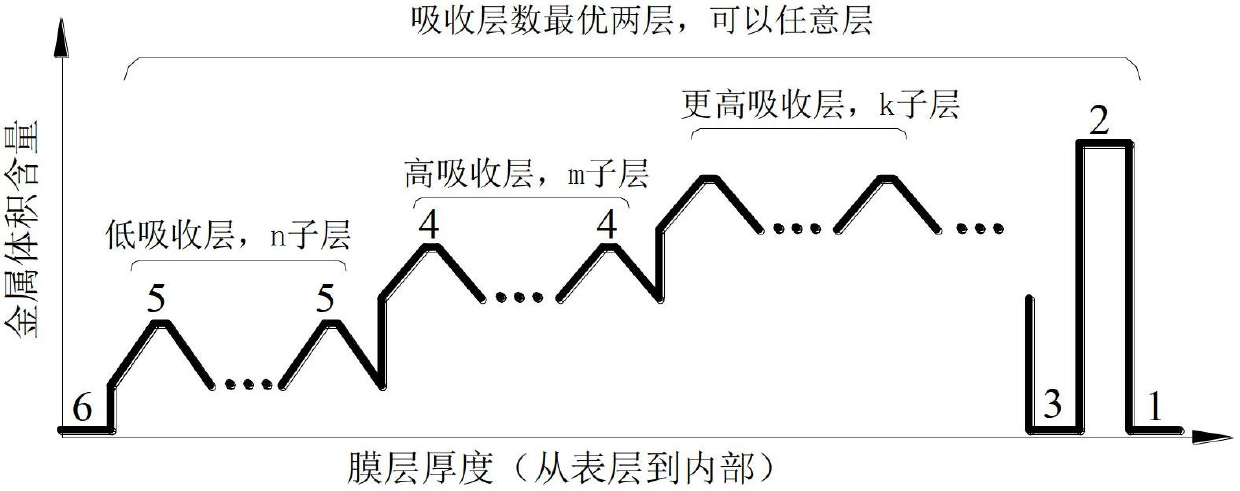

Solar selective absorption coating

ActiveCN102653151APromote absorptionExcellent Absorption RatioSolar heat devicesCeramic layered productsChange TypeAbsorption layer

The invention discloses a solar selective absorption coating comprising a bonding layer, an infrared reflection layer, a diffusion stopping layer, an absorption layer and an antireflection layer, wherein the absorption layer is formed by at least two layers of metal ceramic absorption layers; the at least two layers of metal ceramic absorption layers are composite material thin films formed by doping metal atoms in ceramic; the middle metal volume content in a film layer is the highest and the metal volume content is gradually reduced from middle to two boundary directions; and the metal volume content between the adjacent two metal ceramic absorption layers with different average metal volume contents has an obvious interface. Compared with gradually-changed type and interference type solar selective absorption coatings, the metal volumes of the absorption layers are gradually changed and have the characteristic that the gradually-changed type solar selective absorption coating can easily absorb a solar spectrum; and meanwhile, the obvious interface exists between the absorption layers, the absorption layers have phase interference of lights, and the sunlight absorption is increased.

Owner:HIMIN SOLAR

Preparation method for short carbon fiber/silicon carbide composites

The invention discloses a preparation method for short carbon fiber / silicon carbide composites by means of spark plasma sintering (SPS). The preparation method includes the steps: (1), pre-treating the short carbon fiber by placing the same in a heat-treatment furnace for heat preservation for 30 minutes under the temperature of 400 DEG C prior to soaking and coarsening the short carbon fibers in coarsening liquid composed of nitric acid, potassium dichromate, hydrogen peroxide and ammonium persulfate to be washed with deionized water and dried for standby; (2), placing the short carbon fiber, silicon carbide powder and sintering aids in a ball-milling pot to be ball-milled; (3), drying the materials in the step (2) through rotary evaporation prior to grinding the same to sieve the mixed powder; and (4), placing the mixed powder into a graphite mould and subjecting the mixed powder to the spark plasma sintering. The short carbon fiber / silicon carbide composites prepared by the method are good in performance, and volume content of the short carbon fibers can be controllable; and the short carbon fiber / silicon carbide composites have high specific modulus, high specific strength and excellent toughness, and can hopefully be applied to light weight armor field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

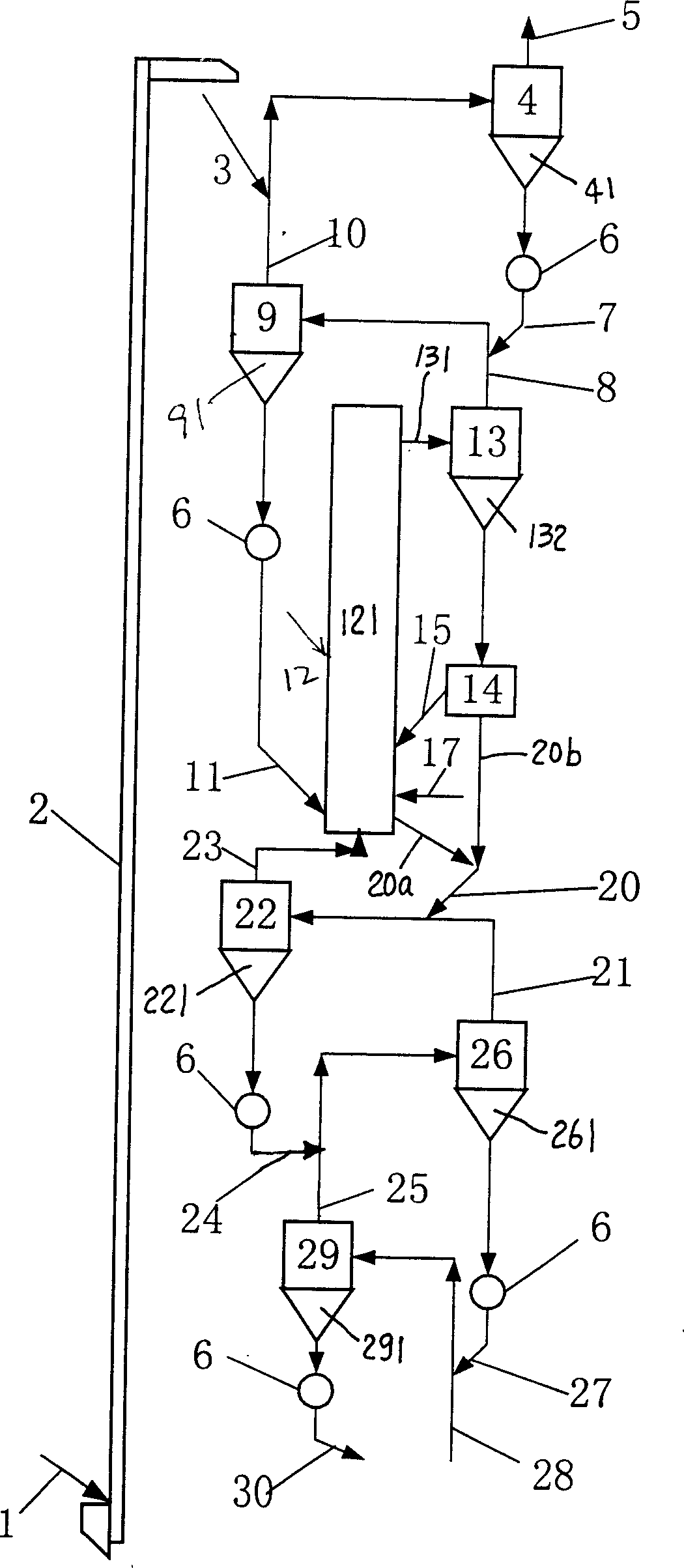

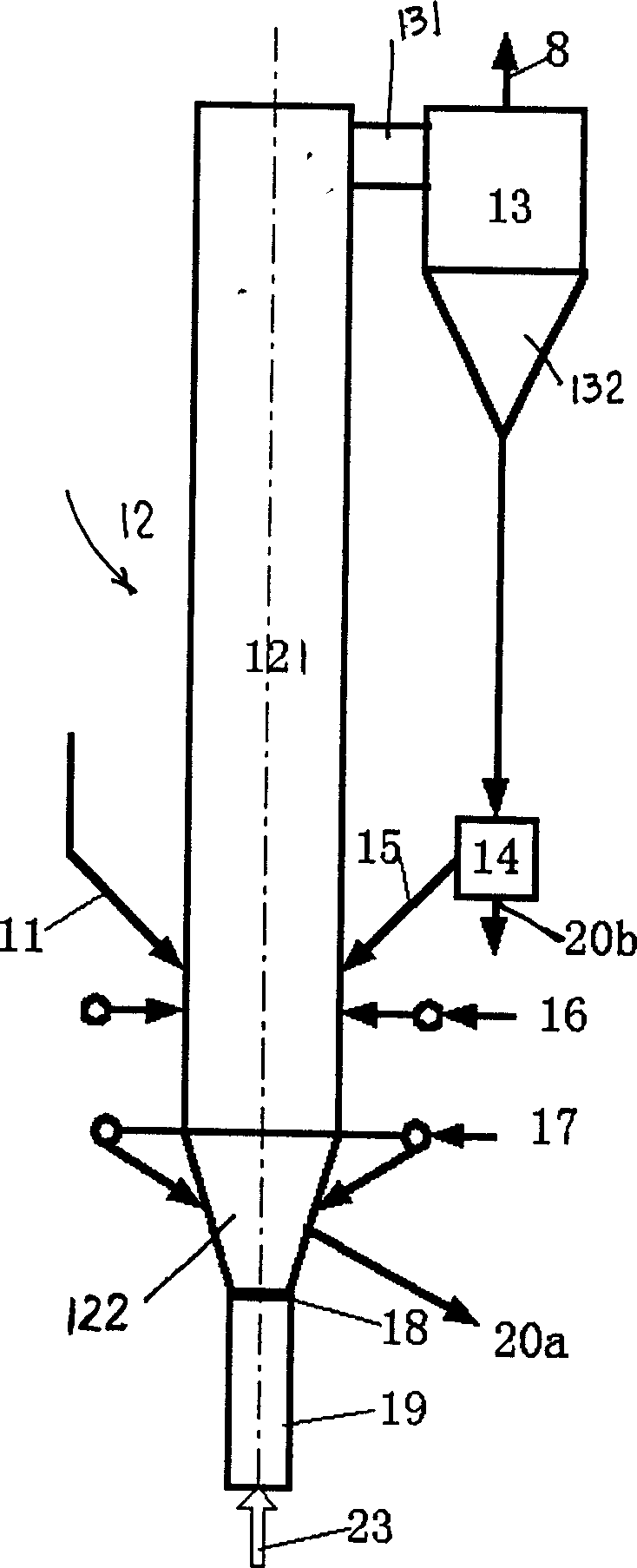

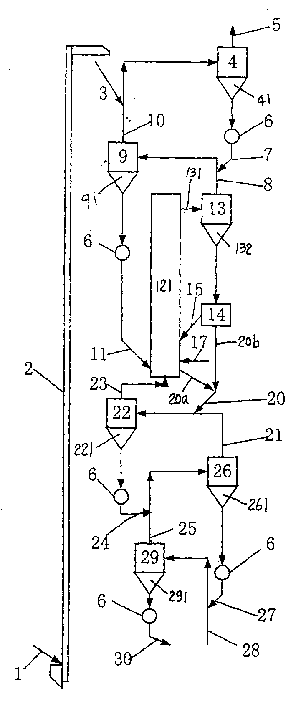

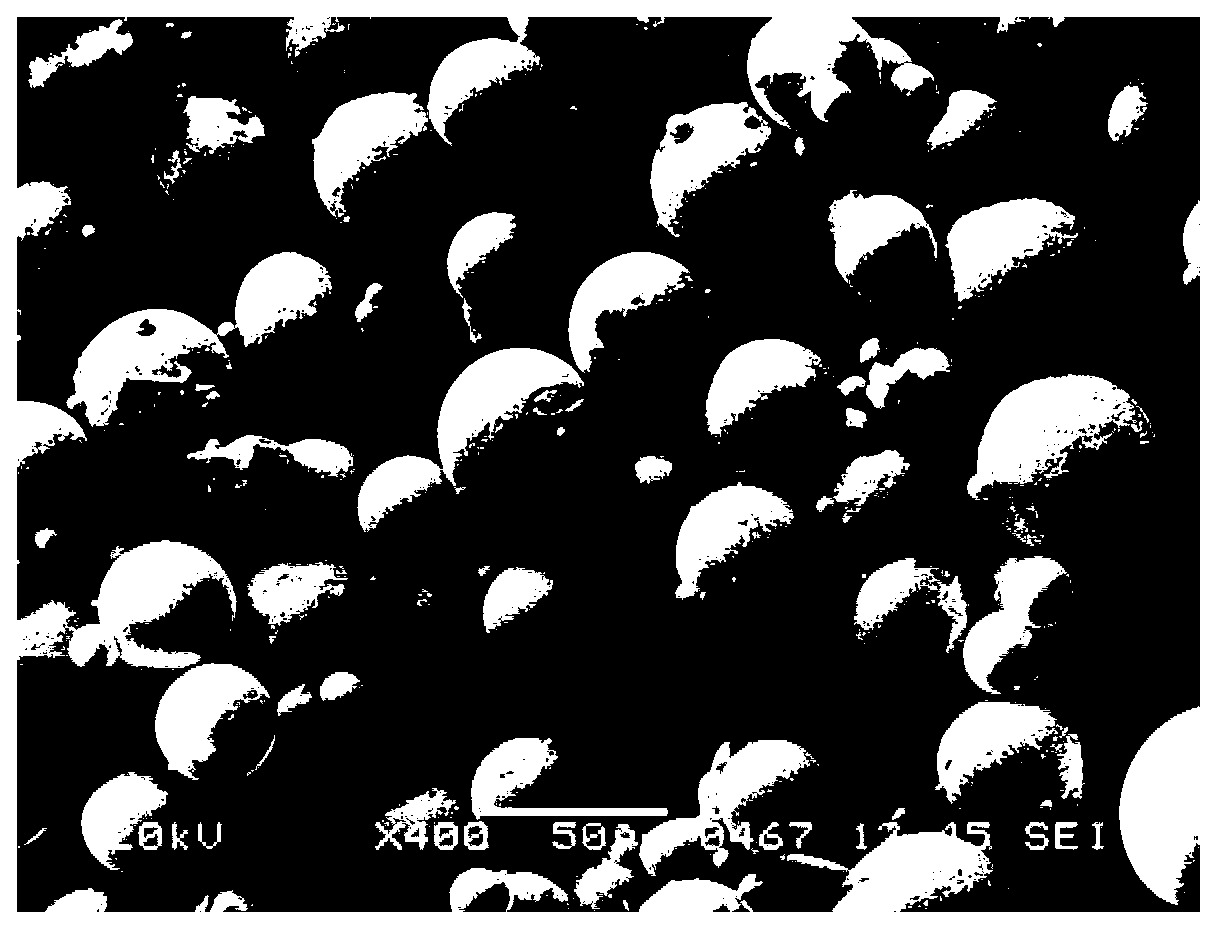

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

InactiveCN1600687AIncrease productivityImprove thermal efficiencyPigmenting treatmentAluminium silicatesCycloneEngineering

The invention relates to superfine Kaolin calcining process and device, the prodn, method includes; preheating kaolin raw powder material, then putting it in fluidization calcining furnace from the bottom, at same time, sending fuel into the furnace, preheated primary air is sent from plenum under the furnace burns with the fuel and to form a reducibility atmosphere calcining area in the lower section, the volume content of CO+H2 in reduction area is 0-10 percent, secondary air is sent from top of the reduction area to burn residual CO+H2 completely, airflow speed is 1-6m / s in the furnace, raw powder material is in fluidization, kaolin is circularly burned for 0.3-3 hours in temp. 700-1100 deg.C, then is sent into cyclone cooling system to be cooled to obtain superfine kaolin by mixer-grinding and depolymerizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Nano granule reinforced high-tough cast magnesium alloy and its preparing and shaping process

This invention provides a nano grain reinforcing high tenacity founding magnesium alloy and its preparation method, and belongs to magnesium alloy technology field. The components are: 5.0-10.0% Al, 0.1-1.0%Zn, 0.05-0.5%Mn, limiting element Si is less than or equal to 0.05%, Fe is less than or equal to 0.005%, Cu is less than or equal to 0.01%, Ni is less than or equal to 0.002%, and the rest is Mg. The grains are SiC grains with diameter less than 100nm, the adding amount is 0.1-3.0% of alloy volume content. Add pre-treated block nanometer grains in the melted liquid or half-solid magnesium alloy solution and make it dispersively distribute in the alloy and get the needed cast through gravity moulding and die casting. The strong points of this invention are: under the conditions of gravity moulding and die casting, the pulling resistance intension is more than 230MPa, and the extending ratio is more than 15%, and has good comprehensive performance. The magnesium alloy has good fluidity, and is suitable for the casting in cool chamber.

Owner:UNIV OF SCI & TECH BEIJING

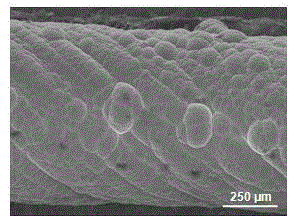

Method for manufacturing needle-punched carbon fiber pseudo-three-dimensional preform

InactiveCN101575766AImprove wear resistanceExtended service lifeNeedling machinesCarbon compositesCarbon fibers

The invention relates to a method for manufacturing a needle-punched carbon fiber pseudo-three-dimensional preform, which comprises the following steps: adopting alternating laminations of continuous carbon fibers and short carbon fiber mesh carcasses, wherein the laminations of the continuous carbon fibers are paved alternately with included angles between 0 and 30 degrees; and introducing longitudinal fortifying fibers through a needle-punching process in the axial direction of the short carbon fiber mesh carcasses and the continuous carbon fiber laminations, and controlling the needling density to between 36 to 44 needles / cm so as to manufacture a full carbon fiber pseudo-three-dimensional structural preform with the volume density of between 0.55 and 0.82g / cm. The preform manufactured by the method has the most important characteristics of high volume content of the carbon fibers, evener continuous carbon fiber laminations, high needling density, high mechanical property of a manufactured carbon / carbon composite material and good wear resistance, and is applicable to manufacturing aircraft carbon brake disc materials with high torque characteristics.

Owner:XIAN CHAOMA SCI TECH

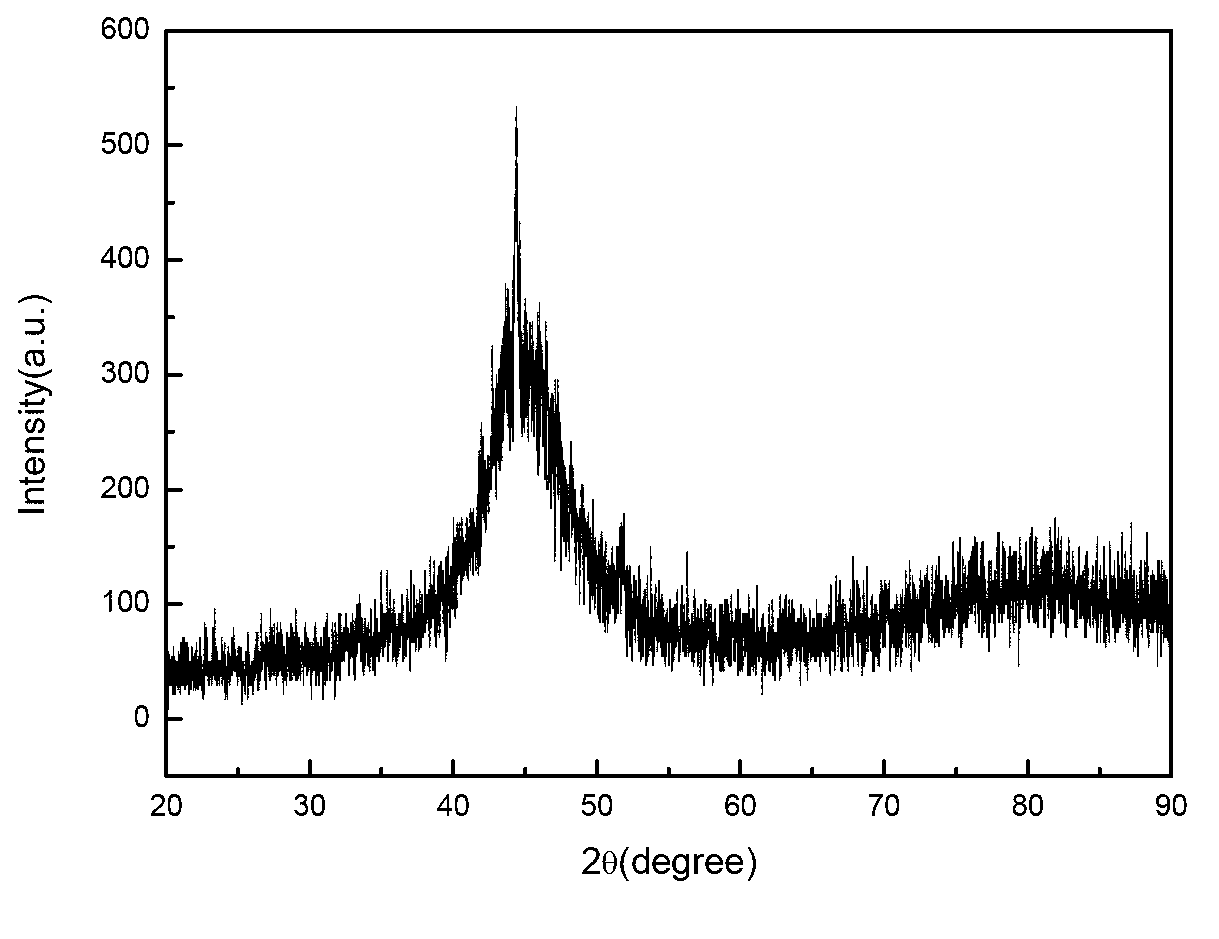

Nickel-base amorphous alloy powder as well as nickel-base amorphous composite coating and preparation method thereof

InactiveCN103060725AStrong Amorphous Formation AbilityIncrease in sizeMetallic material coating processesAlloyHardness

The invention discloses nickel-base amorphous alloy powder capable of obtaining an amorphous composite coating as well as a laser preparation method of the amorphous composite coating. The nickel-base amorphous alloy powder mainly consists of five elements, such as Fi, Fe, B, Si and Nb and has stronger amorphous forming ability; and meanwhile, the nickel-base amorphous alloy powder is prepared into a laser cladding coating on a low-carbon steel surface in a way of coaxially feeding powder, and then the amorphous composite coating is prepared through a high-speed laser re-melting way. The nickel-base amorphous composite coating provided by the invention is good in compactness, high in amorphous volume content and high in hardness number. The coating has good application foregrounds in the field of abrasion performance, corrosion resistance, radiation protection and the like.

Owner:SHANGHAI JIAO TONG UNIV

Detergent of adhesive

InactiveCN1796522AEasy to getRecipe with few ingredientsDetergent compounding agentsAcetic acidAdhesive

An adhesive cleaning agent, whose major adhesive-cleaning component is acetic ester with a volume content of 25% or higher,. The adhesive cleaning agent in this invention can rapidly and effectively clean a wide variety of sticky labels and greasy dirt. Usually the labels can be completely taken, and the paint or greasy dirt can be completely cleaned after immersion in the cleaning agent for 1min.

Owner:北京东方天甲科技发展有限公司

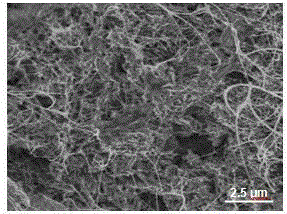

Composite material of silicon carbide and carbon nanotube and preparation method thereof

InactiveCN103061112ARapid depositionImprove thermal conductivityCarbon fibresCarbon nanotubeChemical vapor deposition

The invention relates to a composite material of silicon carbide and carbon nanotube and a preparation method thereof. Macroscopic bodies of the carbon nanotubes are used as performs, a chemical vapor deposition method is used for pyrolysis of a silicon-containing precursor, and then the silicon carbide is deposited on the carbon nanotube to prepared the composite material of the silicon carbide and the carbon nanotube, with a mass percent of the carbon nanotube being 0.5-90 %. By selecting the macroscopic bodies of the carbon nanotubes of various orientations and arrangements as performs, the composite material of the silicon carbide and the carbon nanotube with high dispersion, high volume content and various orientations and arrangements can be obtained. By designing fiber performs, the composite material of the silicon carbide and the carbon nanotube with various forms such as fibers and blocks and various sizes can be constructed and prepared. The composite material of the silicon carbide and the carbon nanotube with various mechanical and electrical properties can be obtained, and may be used as high-performance composite materials, conductive and thermal conductivity materials and functional materials in fields of aerospace, national defense equipment, functional material devices, etc.

Owner:TIANJIN UNIV

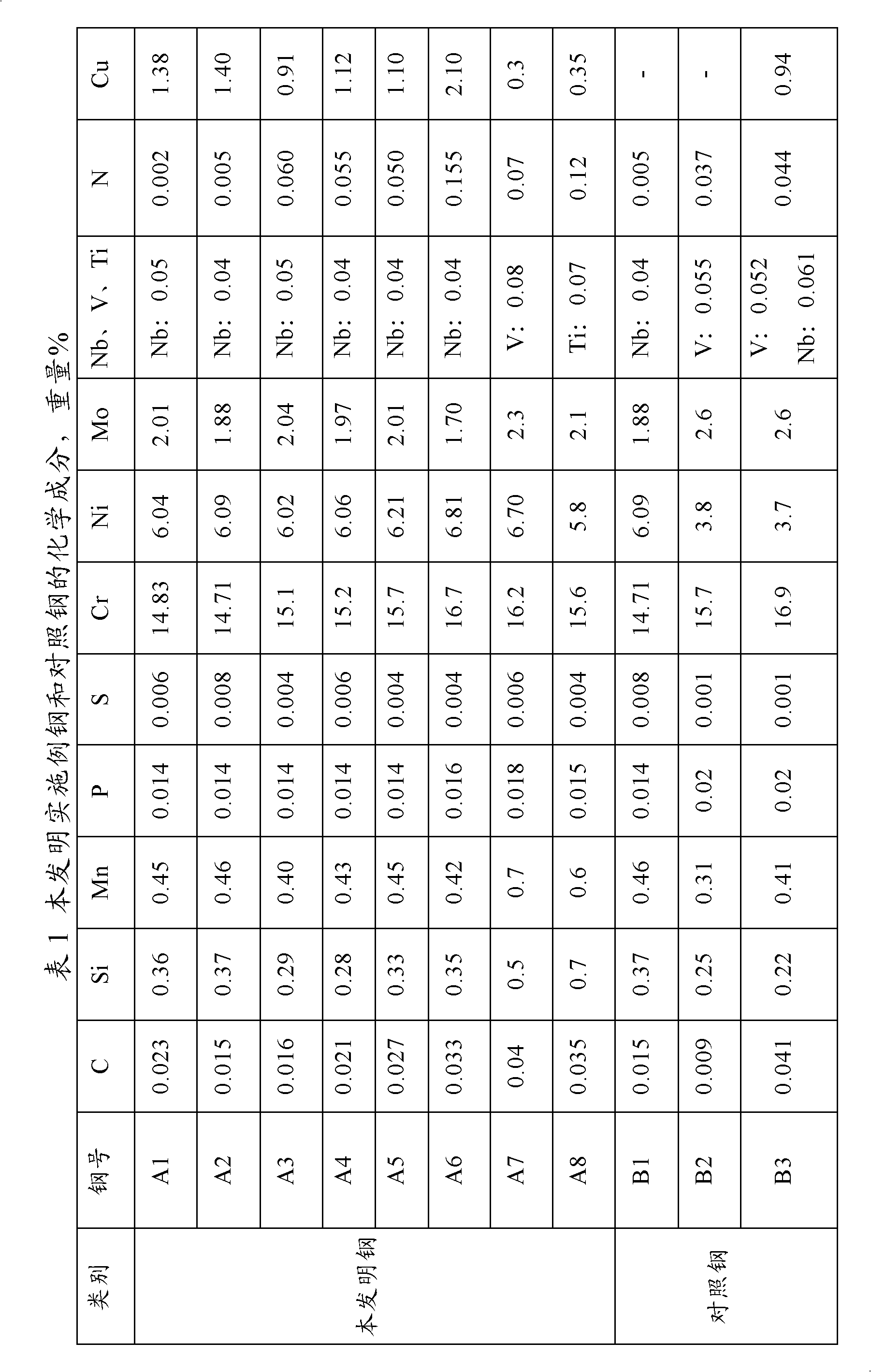

Martensitic stainless steel for oil casing and manufacturing method thereof

InactiveCN102534418AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesDouble phaseMartensitic stainless steel

The invention relates to a martensitic stainless steel for an oil casing and a production method thereof. The artensitic stainless steel comprises the following chemical components in percentage by weight: at most 0.04% of C, 0.20-1% of Si, 0.30-1% of Mn, at most 0.02% of P, at most 0.010% of S, 14-17% of Cr, less than 5% and at most 7% of Ni, 1.5-2.3% of Mo, 0-0.16% of N, 0.05-2.5% of Cu, one or more of 0.01-0.10% of Nb, 0.01-0.10% of V and 0.01-0.10% of Ti, and the balance of iron and inevitable trace impurity elements. The manufacturing method of the steel comprises the following steps: heating the oil casing to 950-1100 DEG C, cooling to below 200 DEG C by air cooling, oil cooling or water cooling, and heating to 550-650 DEG C to implement tempering. The steel has a microstructure which uses a tempered martensite phase as a base phase, and contains high-temperature ferrite (delta-ferrite), austenite and other second phases of which the volume contents are respectively below 10% or the total content is below 15%. The steel provided by the invention has the characteristics of high strength (the yield strength is up to Grade 110-150ksi), strong carbon dioxide / chloride ion corrosion resistance and the like, and can partially substitute double-phase stainless steel to be used in deep wells, superdeep wells and other severe well conditions.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com