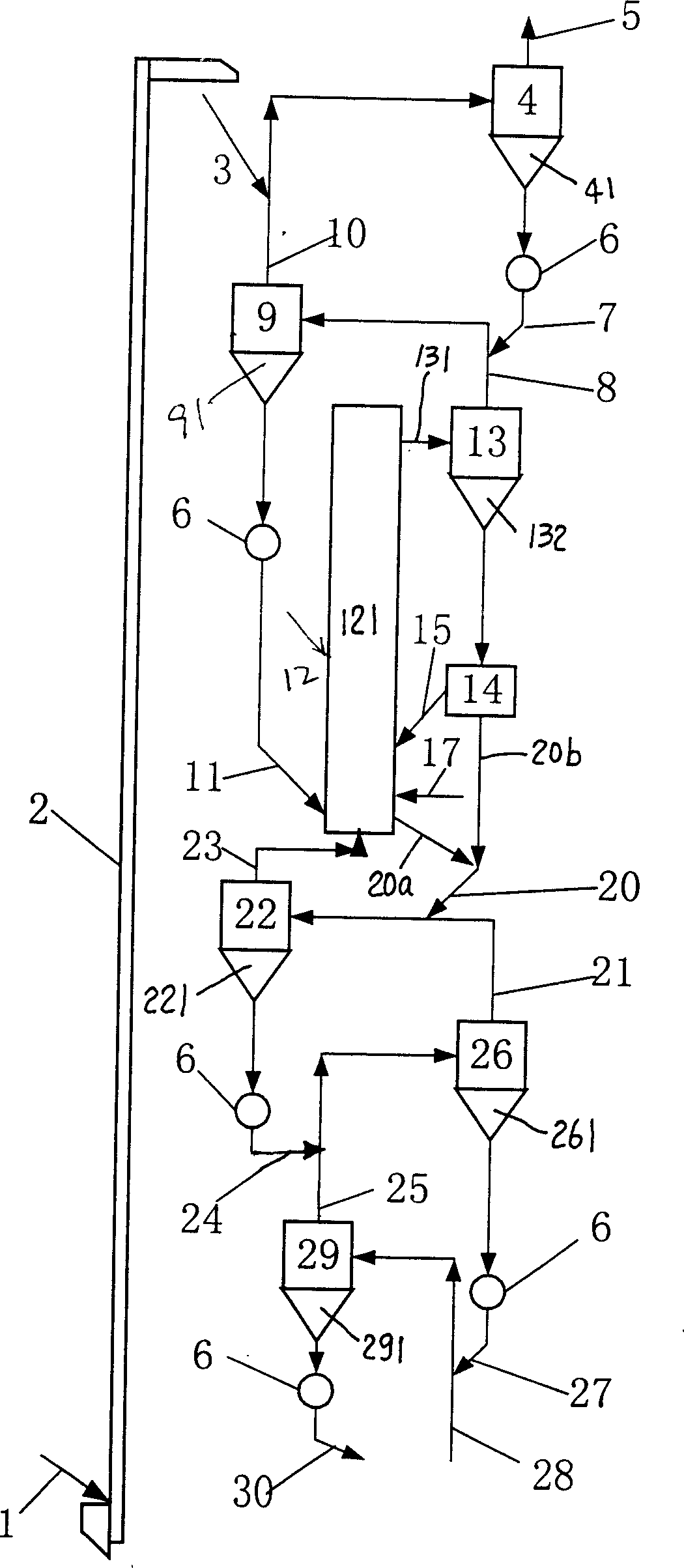

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

A technology of ultra-fine kaolin and rapid circulation, applied in clay products, other household utensils, aluminum silicate, etc., can solve the problems of high unit fuel consumption, uneven product quality, insufficient recovery of sensible heat, etc., and achieve calcination time. Adjustment, operation flexibility, complete response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

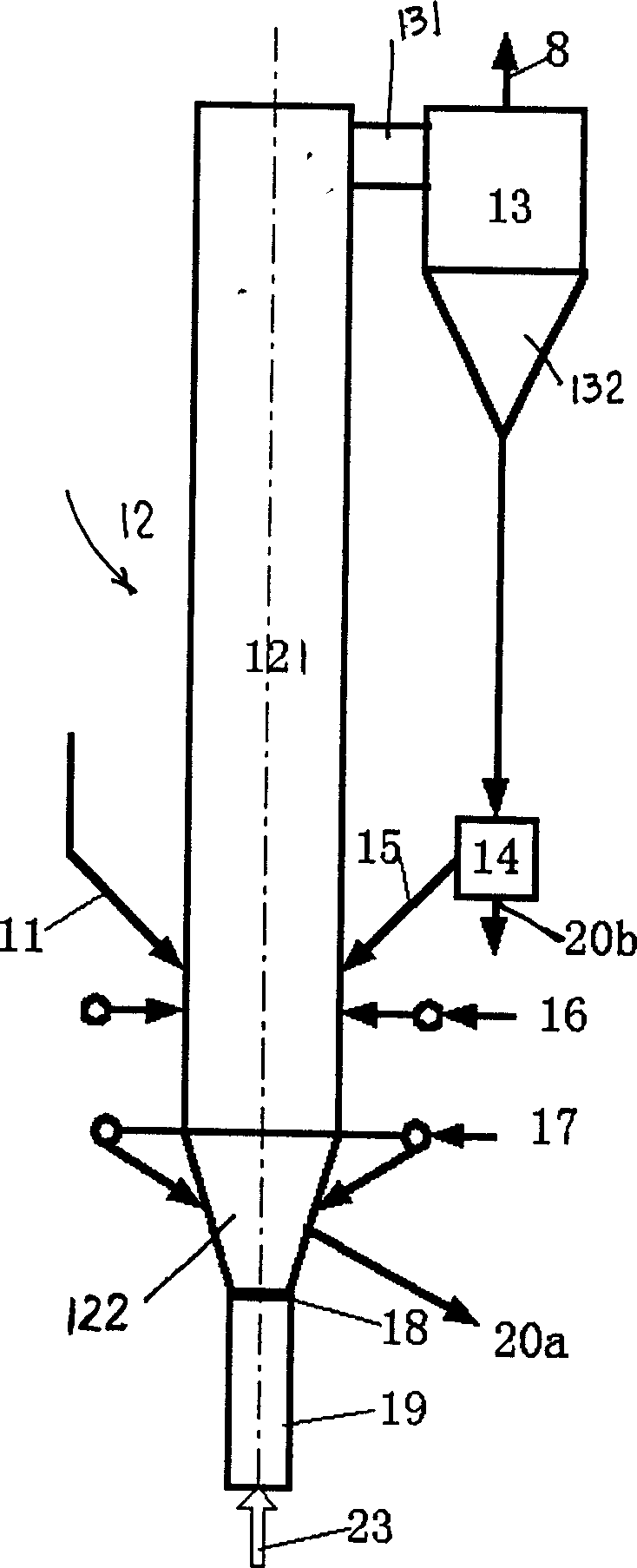

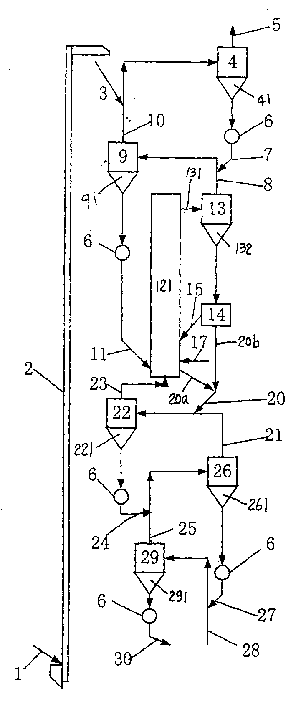

Method used

Image

Examples

Embodiment 1

[0048] A coal-measure kaolinite (soil) sample in a certain place in China, code-named DN, has a kaolinite (soil) content of 91% and a natural whiteness of 45.3%. Mineral samples of different particle sizes made by grinding are about 0.05-45μm, 0.05-15μm, 0.05-8μm and 0.05-4μm, respectively recorded as codes DN-1, DN-2, DN-3, and DN- 4. The weight percentages of each ore sample with particle sizes smaller than 2 μm are 16%, 28%, 32% and 91% respectively.

[0049]A, (1) the ore sample with a particle size of about 0.05-45 μm (wherein the weight percentage of the ore sample less than 2 μm is 16%) is promoted with a pneumatic lift feeder and sent to a cyclone preheater ( see figure 1 Preheat to about 500°C in subscripts 4 and 9);

[0050] (2) Send the ore sample preheated to 500°C into the calciner from the lower part of the rapid circulation fluidized calciner provided by the present invention, and simultaneously feed synthetic gas into the calciner; send primary air from the b...

Embodiment 2

[0068] The coal series kaolinite (soil) ore sample in a certain place in China in Example 1, code-named DN, has a kaolinite (soil) content of 95% and a natural whiteness of 55.3%. Mineral samples of different particle sizes of about 0.05-45μm, 0.05-15μm, 0.05-8μm and 0.05-4μm are made after grinding, which are respectively coded as DN-11, DN-22, DN-33, and DN- 44. The weight percentages of each ore sample smaller than 2 μm are 18%, 30%, 35% and 92% respectively.

[0069] Sample code

Embodiment 3

[0071] A kaolinite (soil) ore sample from a certain place in China, code-named DN, has a kaolinite (soil) content of 88% and a natural whiteness of 65.8%. Mineral samples of different particle sizes made by grinding are about 0.05-45μm, 0.05-15μm, 0.05-8μm and 0.05-4μm, respectively recorded as codes DN-111, DN-222, DN-333, and DN- 444, the weight percentages of each ore sample smaller than 2μm are 20%, 29%, 33% and 91% respectively.

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com