Patents

Literature

1053results about How to "Realize large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aprepitant microemulsion for injection and preparation method thereof

InactiveCN102379845ARealize large-scale industrial productionLow costOrganic active ingredientsDigestive systemSocial benefitsOrganic solvent

The invention discloses an aprepitant microemulsion for injection. The aprepitant microemulsion consists of the following components in percentage by mass: 0.05 to 2 percent of aprepitant, 5 to 30 percent of oil for injection, 0.5 to 10 percent of emulsifier, 1 to 10 percent of co-emulsifier, 5 to 20 percent of protective agent and 60 to 80 percent of water for injection. Compared with the conventional oral aprepitant, the aprepitant microemulsion for the injection has the outstanding advantage that: the aprepitant is insoluble in the water and an organic solvent, in order to realize the aprepitant injection, the aprepitant microemulsion and aprepitant micro emulsion freeze-drying powder are prepared successfully and can be subjected to large-scale industrial production; and compared with a fosaprepitant dimethyl-meglumine injection, the aprepitant microemulsion has the advantages that: the cost is reduced greatly, the practicality is extremely high, and economic and social benefits are relatively good.

Owner:NANJING YOKO PHARMA GRP CO LTD

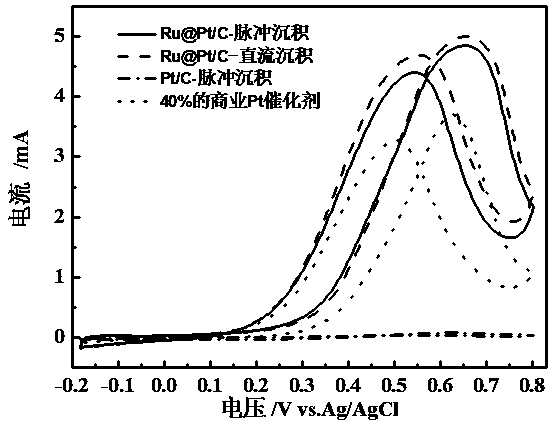

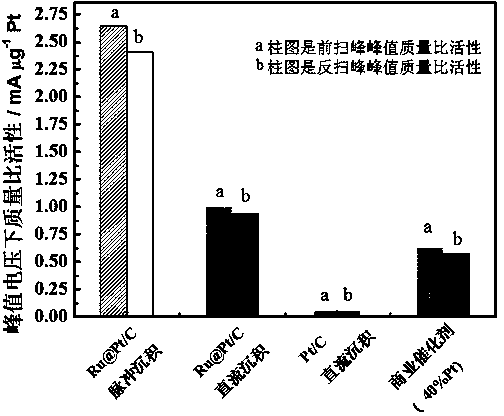

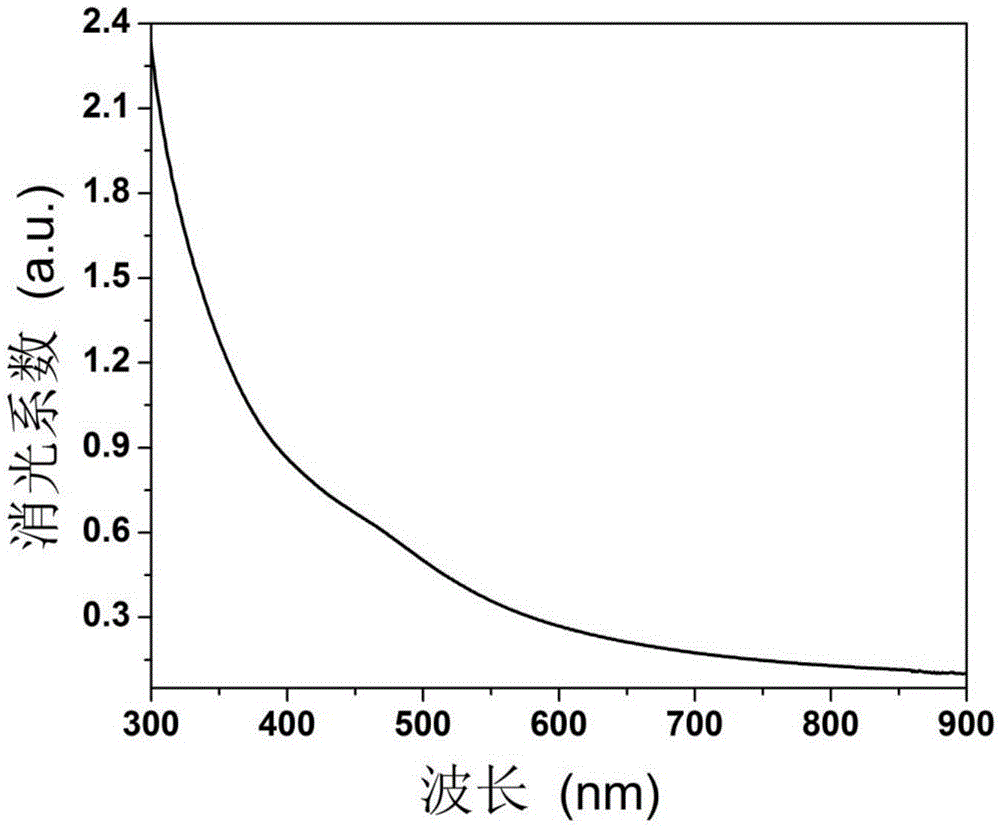

Core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method

ActiveCN103638925AIncrease profitReduce usageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlatinumPtru catalyst

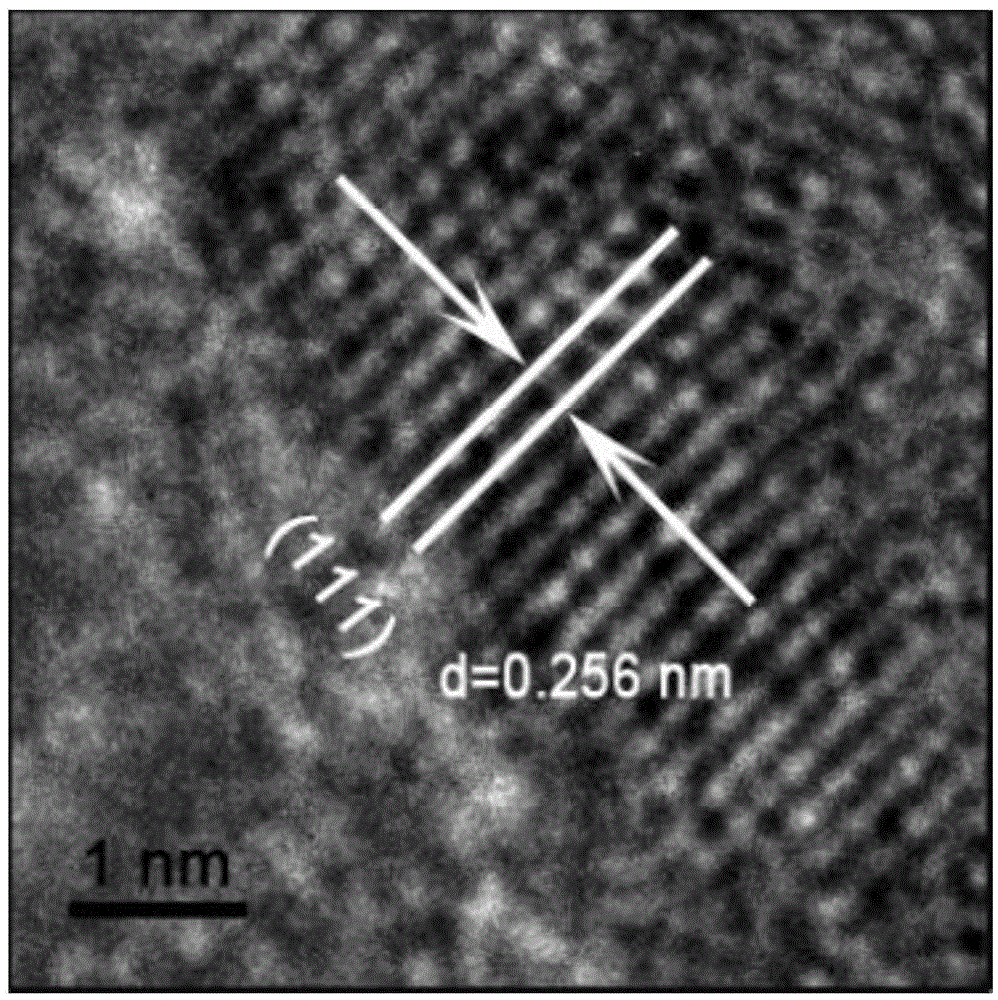

The invention discloses a core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method. The active component of the catalyst is a nanoparticle with a core-shell structure, and an active metal is cladded in the form of an ultrathin shell on the surface of a carbon carrier loaded metal or alloy nanoparticle serving as a core. The catalyst takes a non-platinum noble metal or transition metal as the core, and adopts more than one of Pt, Ir or Au as the shell. The preparation method includes: preparation of the nanoparticle serving as the core, making of a working electrode for pulse electrodeposition, and preparation of the catalyst by pulse electrodeposition. The catalyst can be used as an anode or cathode catalyst of a low temperature fuel cell. The obtained catalyst has very high stability. Compared with underpotential deposition, the method is simple to operate, has no need for inert atmosphere protection, and is more suitable for large-scale industrial production, also can greatly reduce the noble metal consumption of fuel cells, and greatly reduce the cost of fuel cells, thus having great significance in promoting the commercialization process of fuel cells.

Owner:SOUTH CHINA UNIV OF TECH

Surface protection of neodymium iron boron permanent-magnet material

ActiveCN101029389AImprove bindingUniform surfaceMetallic material coating processesTectorial membraneBoron

A surface protection technology of neodymium-ferrous-boron permanent magnetic material is carried out by grinding for neodymium-ferrous-boron permanent magnetic material, degreasing while removing oil, removing rust while acid cleaning, activating acid liquid, putting it into black liquid or blue liquid, chemically coating and forming into blue-black or dark blue protection film. It has excellent combination and anti-corrosion performances.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

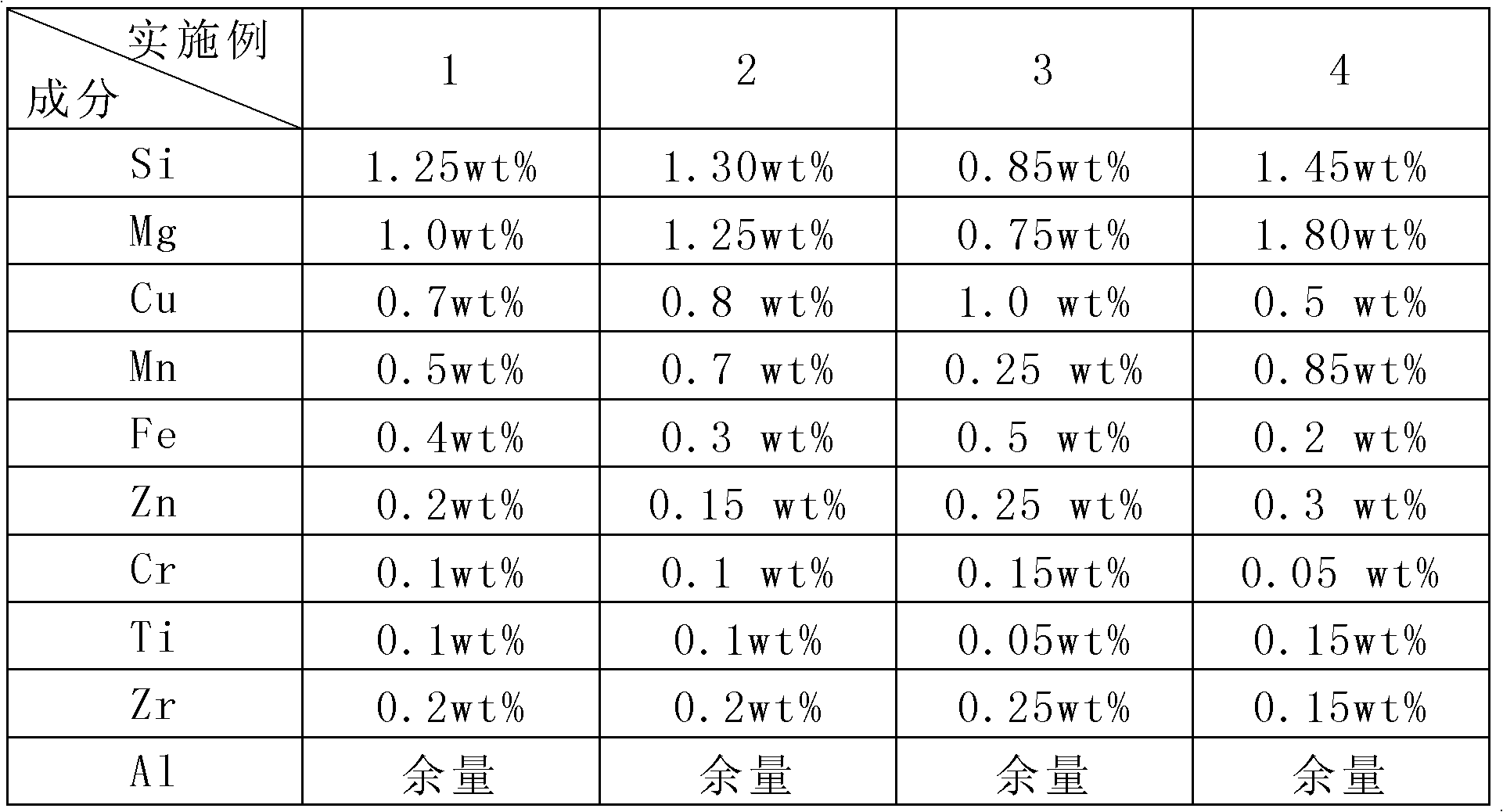

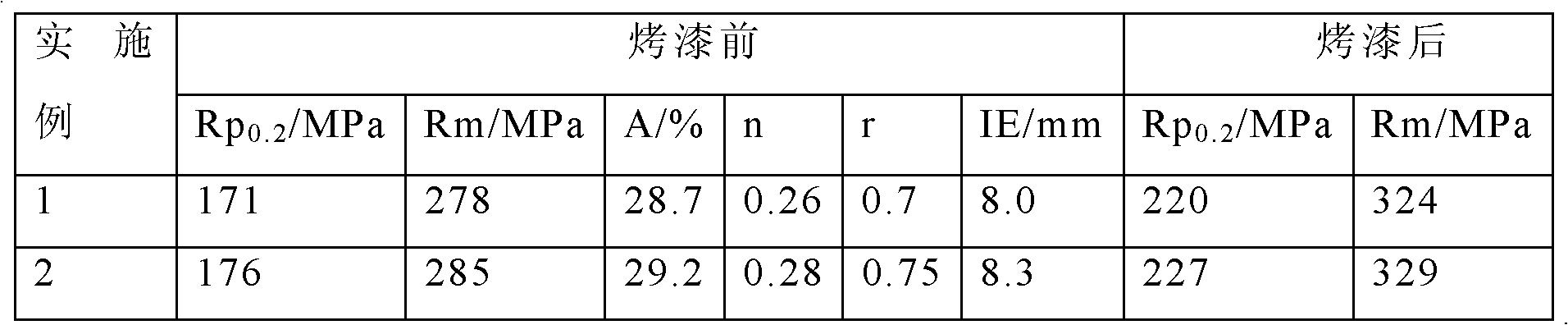

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

Nucleocapsid energizing agent for propelling agent and method for preparing same

InactiveCN101549289ASimple ingredientsLow priceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive agentVacuum drying

The present invention discloses a nucleocapsid energizing agent for propelling agent and a method for preparing same, the energizing agent is a nucleocapsid structure energizing agent that carbon is encapsulated on a metallic oxide surfaced. The preparing method includes steps as follows: selecting one or some raw materials: address sugar, diose or soluble polysaccharide to mix according with random weight rate for confecting water solution 50-1500g / L, adding the surfactant or dispersant into the water solution, then adding the metallic oxide powder, the metallic oxide weight is 1-60% of the raw material total weight, the surfactants or dispersants weight is 0-4.5% of the metallic oxide weight, ultrasounding or stirring to distribute evenly, heating in 100-260 DEG C during 1-72 hours; reducing the product temperature to a room temperature, washing, centrifuging, removing the water-soluble impurity again and again, then vacuum drying for obtaining the nucleocapsid energizing agent. The nucleocapsid energizing agent has better compatibility with other component of the propelling agent, and has simple preparing technique, low cost, green process and is easy to mass production.

Owner:WUHAN UNIV

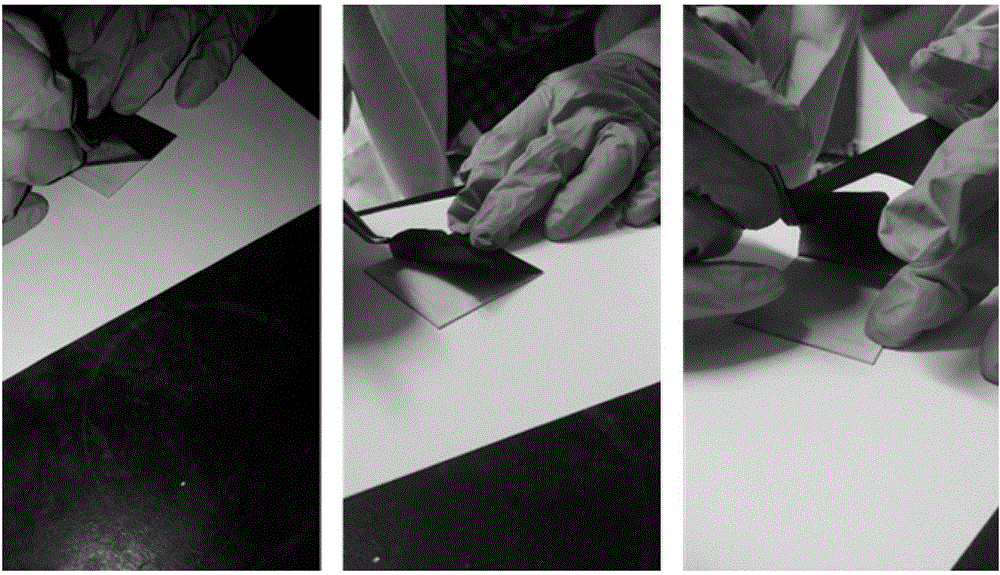

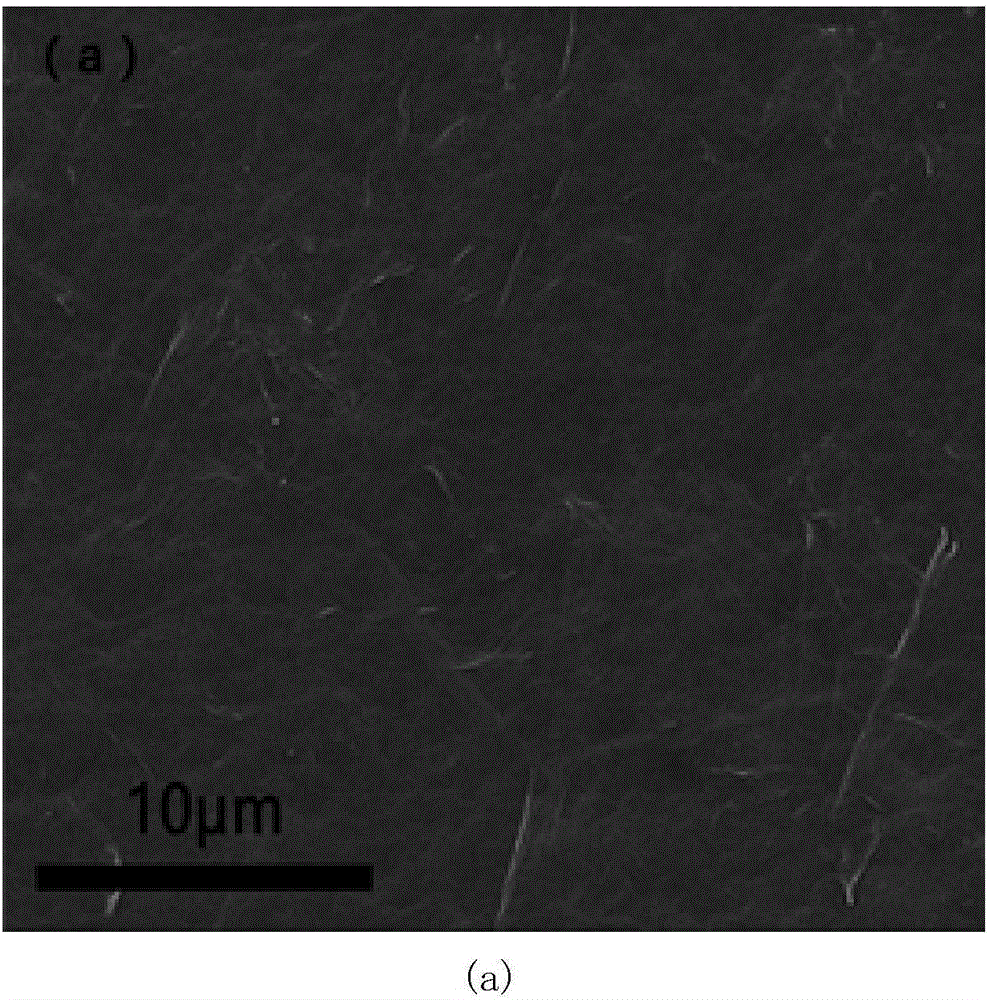

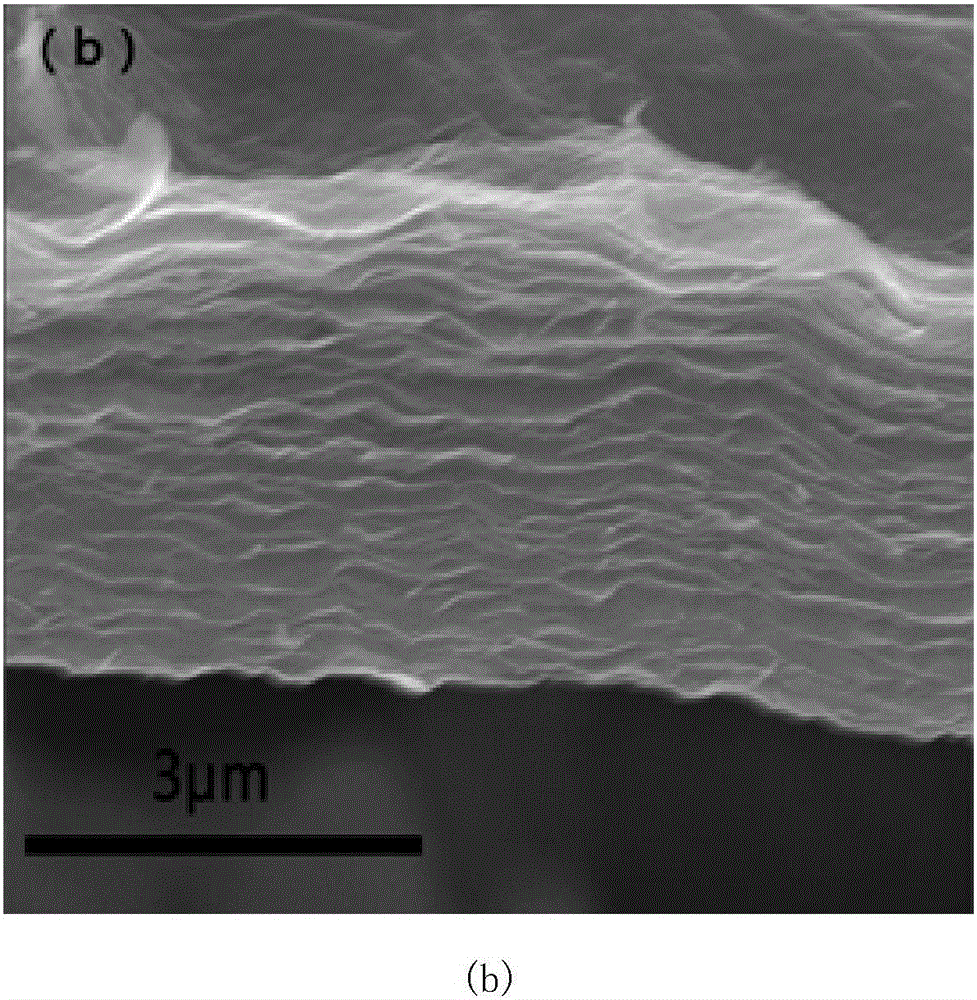

Preparation method of high-heat-conduction flexible graphene film

The invention provides a preparation method of a high-heat-conduction flexible graphene film. Oxidized graphene powder is frozen, dried and dispersed in a solvent, and an oxidized graphene dispersion liquid with the concentration being 0.1-10 mg / ml is obtained; the oxidized graphene dispersion liquid is added to a spraying device and sprayed on a substrate, the substrate is heated at the temperature of 50-150 DEG C for 0.5-5 h, and the oxidized graphene film is formed on the substrate after the dispersion liquid is evaporated; the oxidized graphene film is peeled off and rolled; hot-pressing carbonization and high-temperature graphitization are performed under the protection of a protective atmosphere, and the heat-conduction graphene film is obtained. With the adoption of the method, the high-heat-conduction flexible graphene film with the size and the thickness being controllable can be effectively prepared to meet requirements of different heat dissipation devices and can be applied to various wearable equipment, smart phones, smart televisions and LEDs on a large scale to improve the heat dissipation effect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

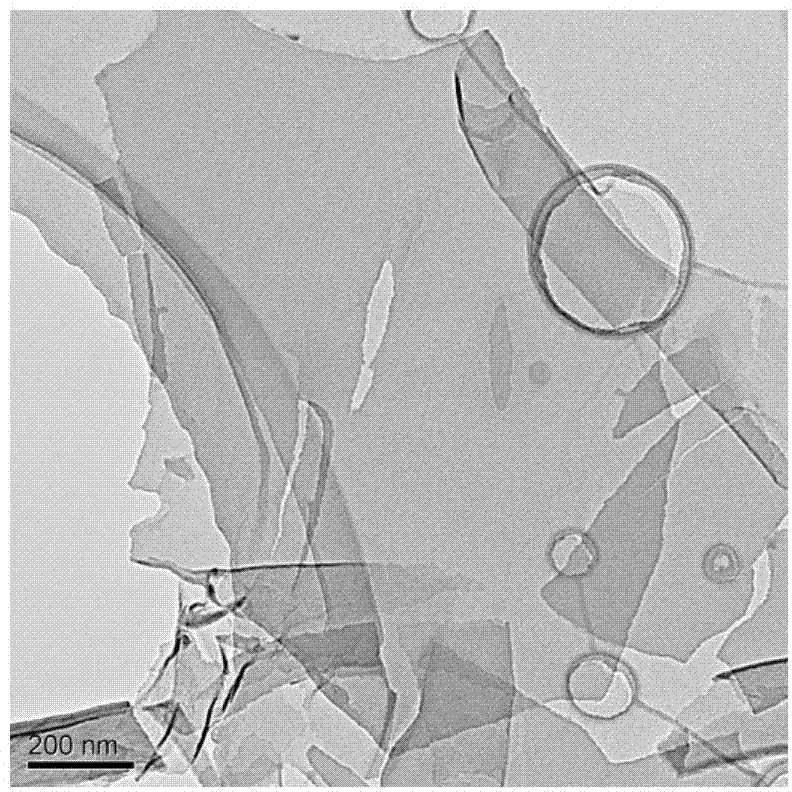

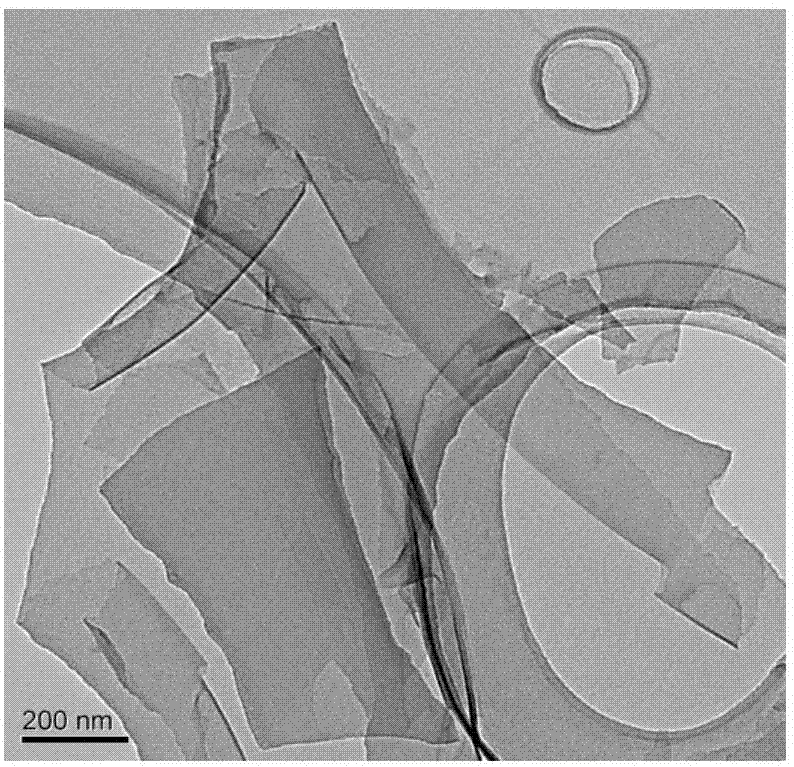

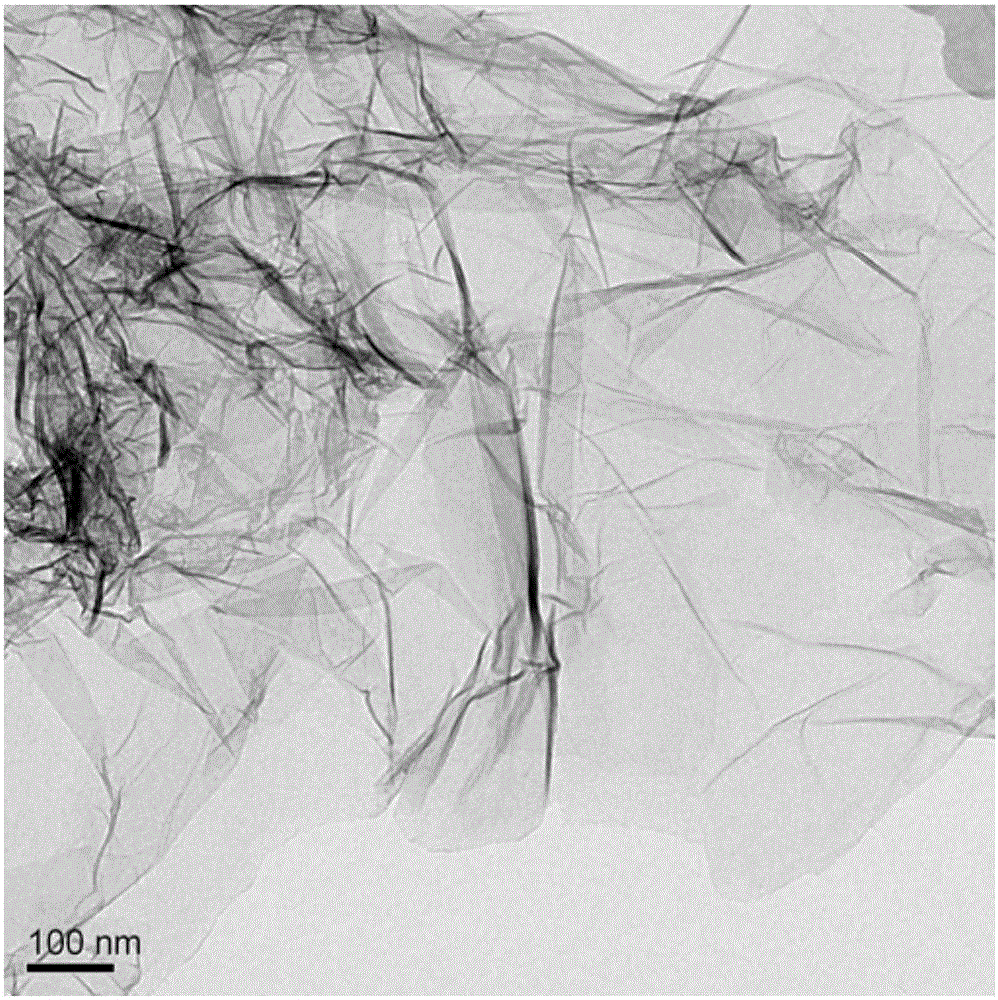

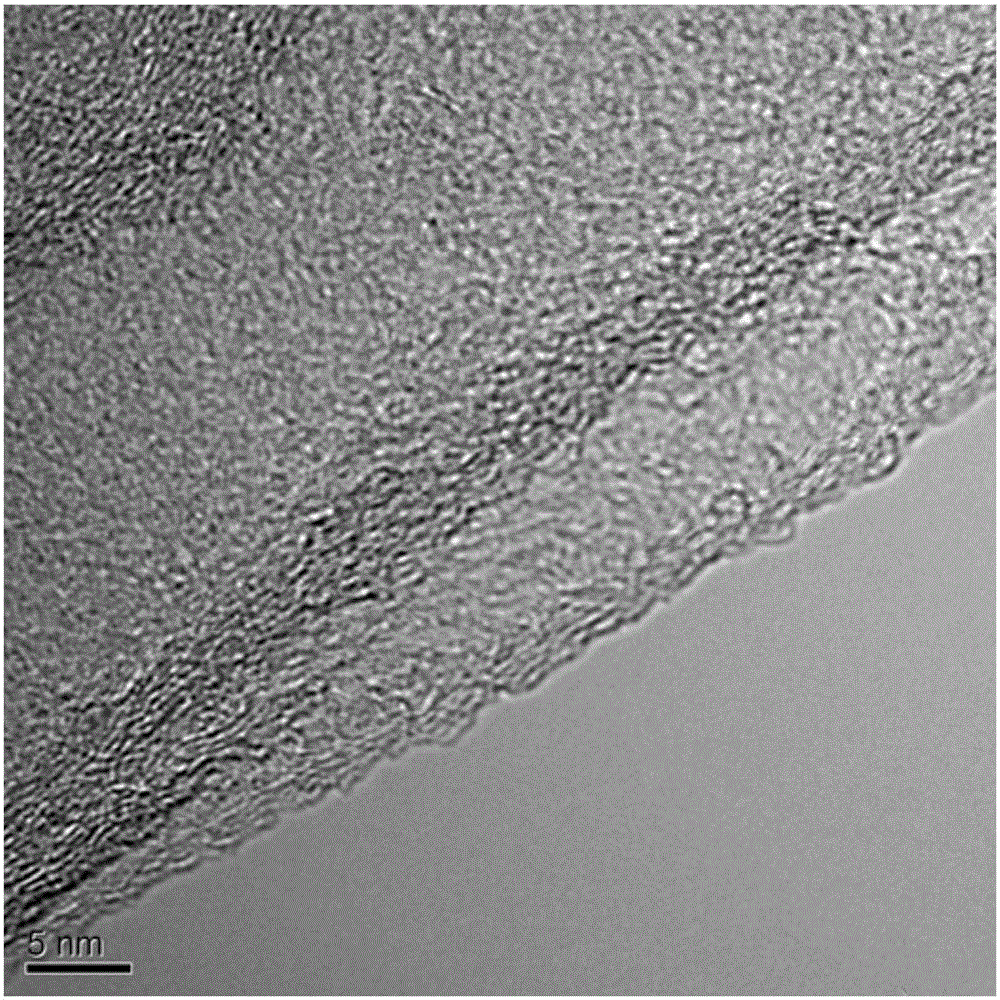

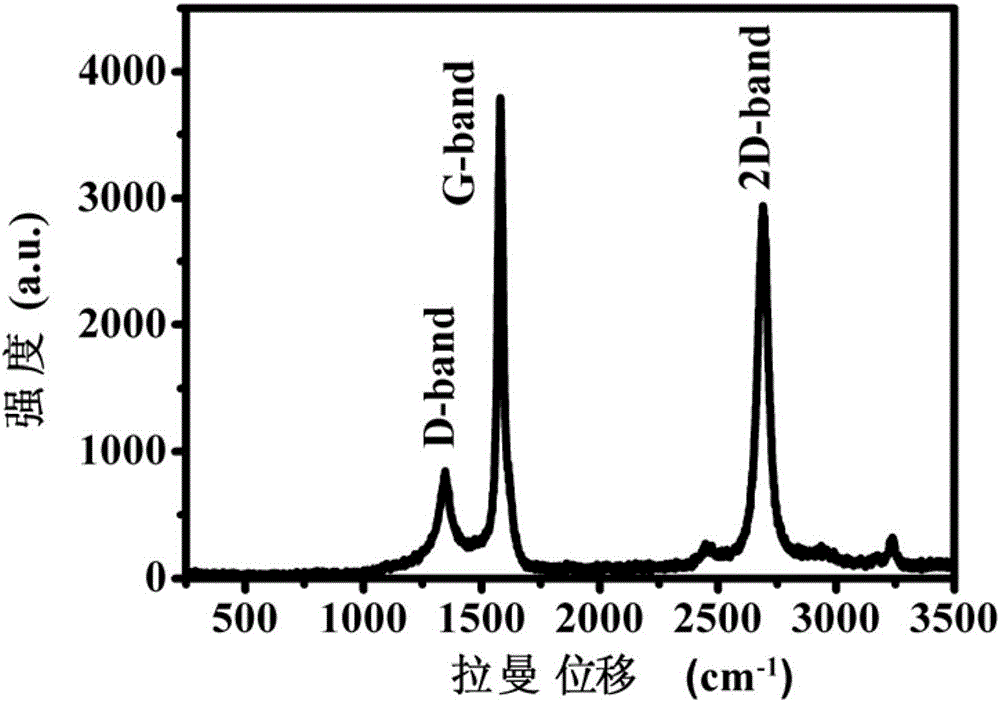

Method for high yield preparation of graphene by using biologic carbon source material

The invention discloses a method for the high yield preparation of graphene by using a biologic carbon source material. The method comprises the following steps: carrying out microwave treatment on the biologic carbon source material, adding to an acid solution, dipping for 1-24h, washing with water, and drying to obtain a preprocessed biologic carbon source material; and mixing the preprocessed biologic carbon source material with a catalyst, calcining at 600-1600DEG C in the presence of a protection gas for 1-2h, and cooling to obtain graphene, wherein the catalyst is at least one of platinum, palladium, rhodium and iron. The method for the high yield preparation of graphene by using the biologic carbon source material uses cellulose or lignin as a raw material, so the production cost is greatly reduced, and the large-scale industrial production of graphene is realized; and graphene prepared through the method has a lamellar thickness of 2-5nm, and the yield and the purity of graphene are improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High heat conducting nylon composite material and preparation method thereof

The invention discloses a high heat conducting nylon composite material and a preparation method thereof. The high heat conducting nylon composite material belongs to one of functional high molecules. The composite material is prepared from a thermoplastic nylon resin base body, heat conducting filler and other processing agents. The heat conducting coefficient is greater than 2.7W / m.K. The resin base body can be nylon 6 or a compound of nylon 6, nylon 9, nylon 66, nylon 610 and nylon 1010. The heat conducting filler can be one or more of magnesium oxide, aluminum oxide, aluminum nitride, boron nitride, silicon nitride, a multiwalled carbon nanotube and a graphite flake layer. The processing agents can be octadecanamide, polyethylene wax, liquid paraffin and the like. The method disclosed by the invention is simple to operate and low in cost, and can prepare the heat conducting composite material with excellent comprehensive performance by one step. The method is easy to realize industrialized production and can be widely applied to the fields of automobiles, household appliances, meter cases, circuit elements and the like.

Owner:BEIJING UNIV OF CHEM TECH

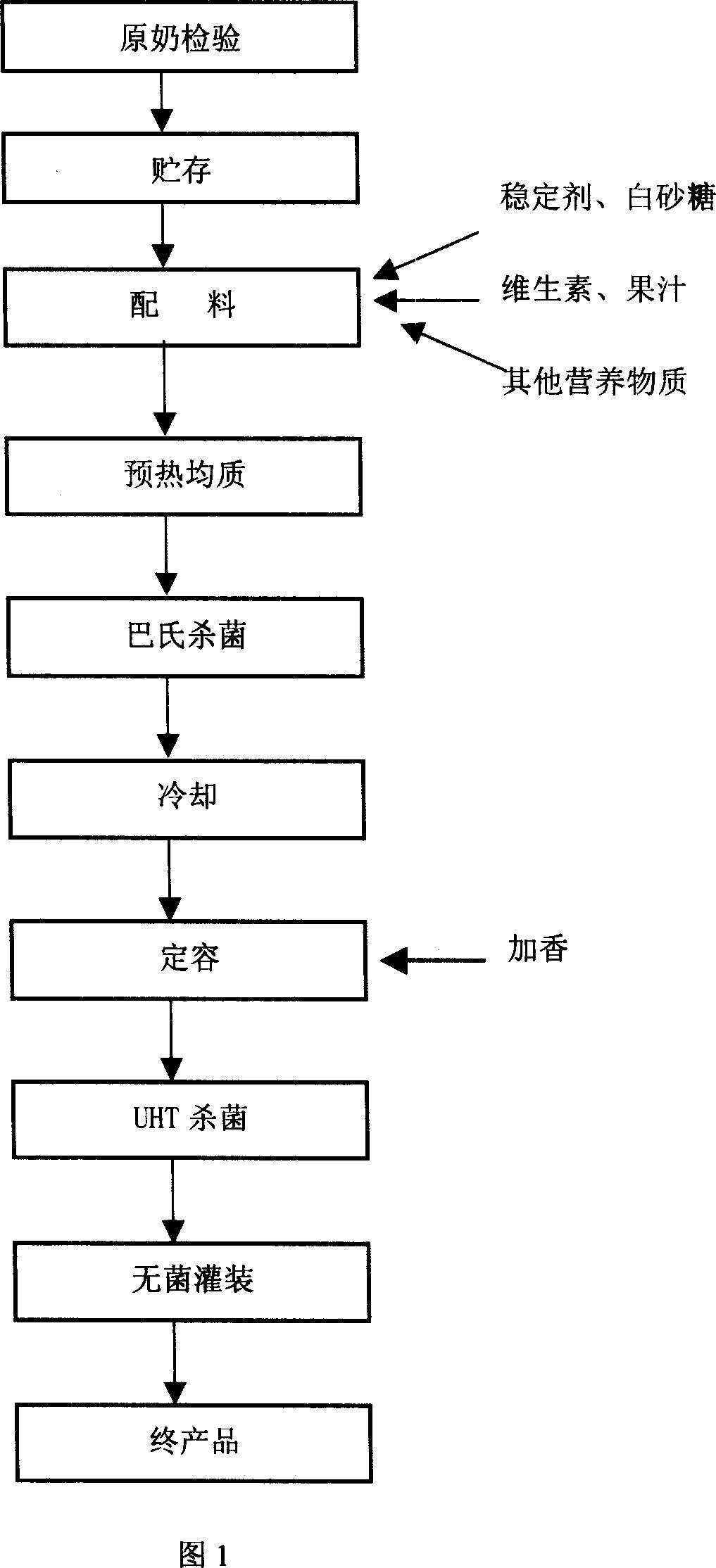

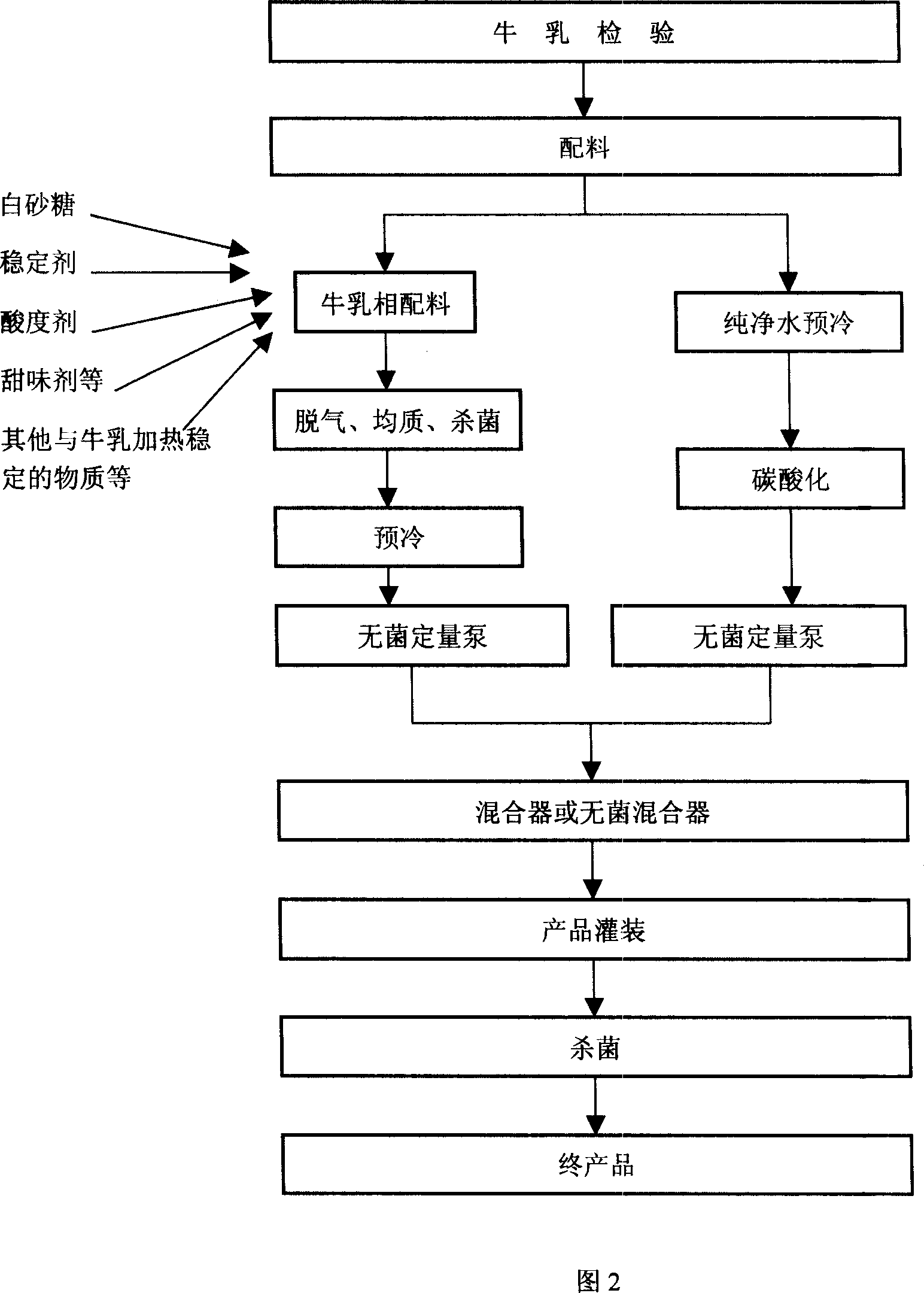

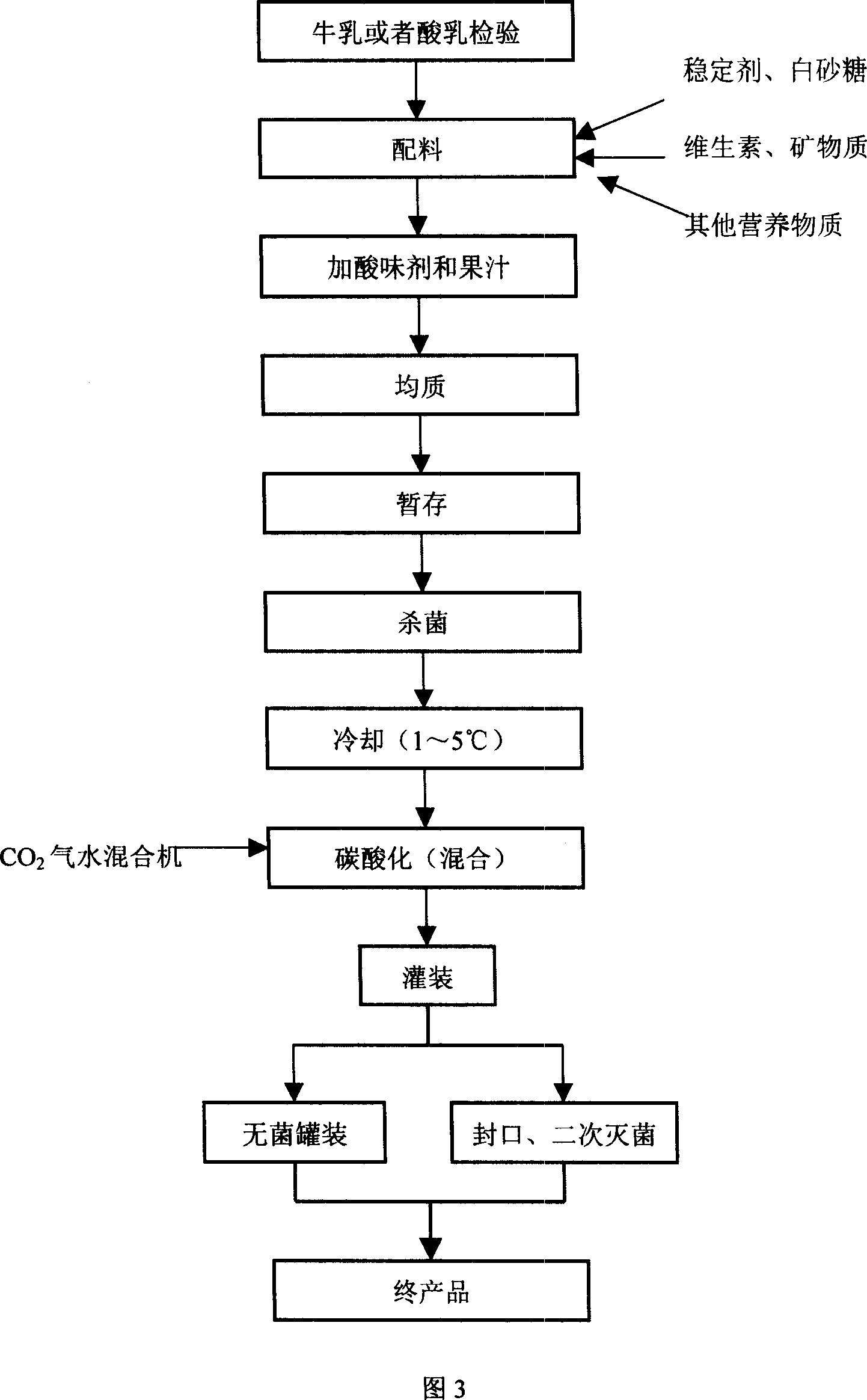

Method for producing air-containing acidic milk-like beverage

InactiveCN101011082AAchieve innovationExpand product rangeMilk preparationFood preparationProduct gasRegular Production

The invention relates to a method for producing lactic acid drink, which comprises that 1, preparing milk phase; 2, adding carbon dioxide gas; 3, packing, disinfecting to obtain the lactic acid drink. Compared with general method, the invention can reduce the pollution of microbe, improve the quality and widen the application.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

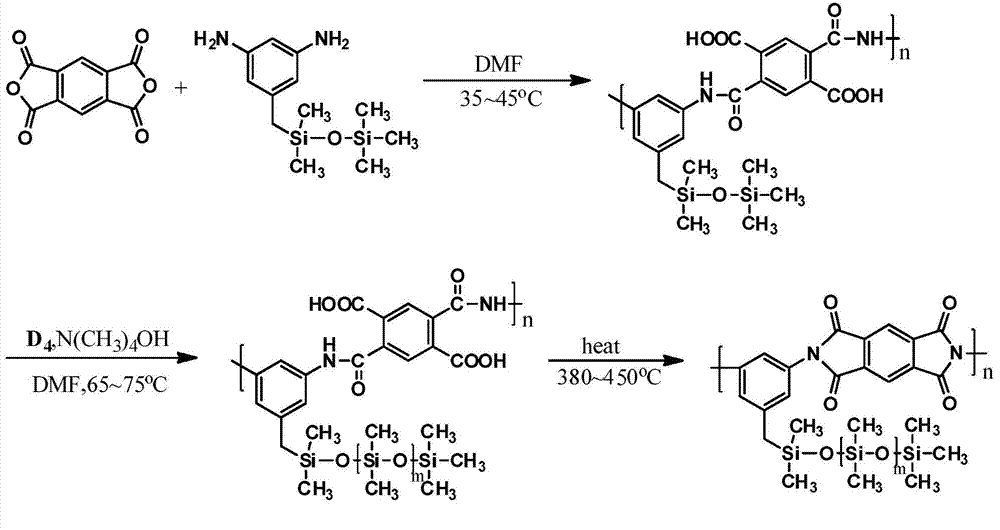

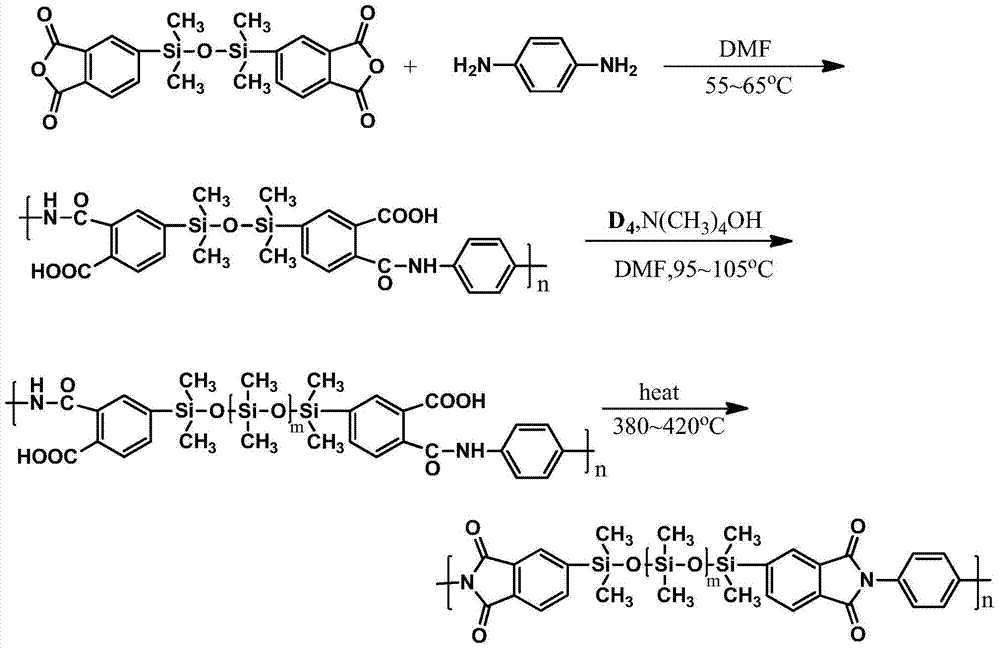

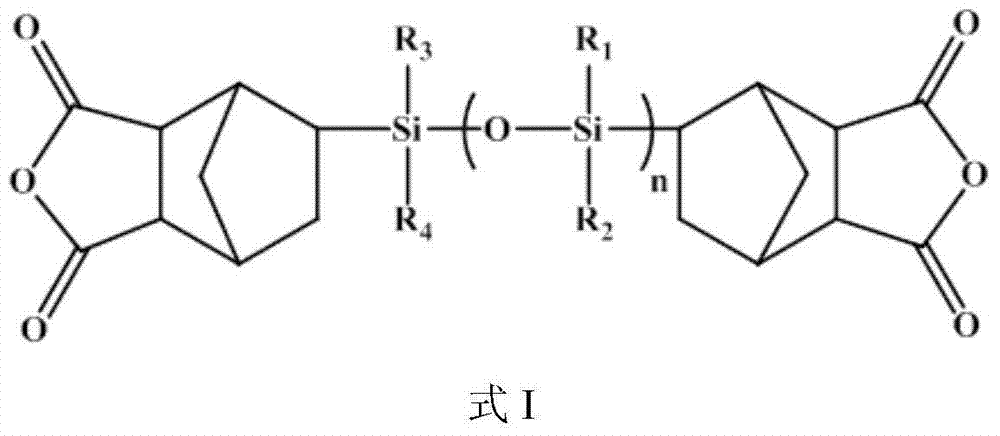

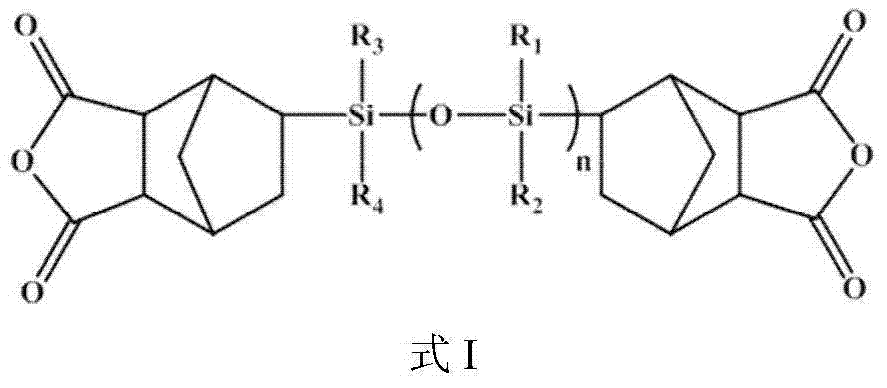

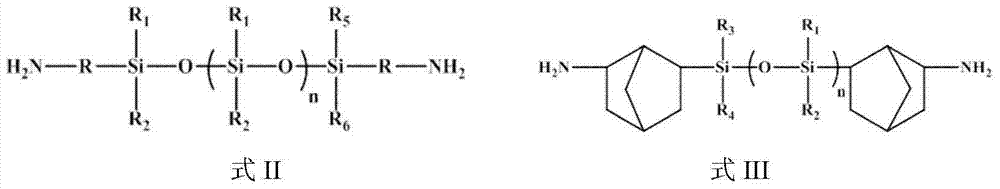

Novel electronic-grade polyimide film with low linear expansion coefficient and production method thereof

The invention relates to a preparation method of an electronic-grade polyimide film with low linear expansion coefficient. The method comprises the following steps that (1) the step-by-step condensation polymerization technology is used for obtaining polybasic block copolymerization polyamide acid glue solutions comprising one or more bar-shaped rigid chain sections containing para-benzene or biphenyl and one or more soft chain sections containing ether bonds or silicon-oxygen bonds and the like; (2) polyamide acid comprising one or more bar-shaped rigid chain structures containing para-benzene or biphenyl and polyamide acid comprising one or more soft chain structures containing ether bonds or silicon-oxygen bonds are independently compounded, and the two or more polyamide acid glue solutions different in rigidity and softness are mixed and compounded; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, casting filming, bidirectional stretching, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

Method for preparing graphene from agriculture and forestry waste biomass as carbon source

The invention belongs to the technical field of graphene preparation, and discloses a method for preparing graphene by using agricultural and forestry waste biomass as a carbon source. The method specifically includes the following steps: (1) Take the pulverized agricultural and forestry waste biomass, add it to a reaction kettle filled with water, undergo a hydrothermal reaction, cool to room temperature after the reaction, and then filter, wash, and dry to obtain a solid biochar; (2) mix the alkali with the biochar obtained in step (1), grind it sufficiently to make it evenly mixed, and heat and calcinate in the presence of protective gas; (3) use acid to prepare the sample after calcining in step (2) Soaking in liquid to remove by-products in the reaction, and then filtering, washing the obtained solid with water until the washing liquid is neutral, and then drying to obtain few-layer graphene. The method has the advantages of simple process, high yield, mild reaction conditions, simple required instruments and equipment, no pollution to the environment, using agricultural and forestry waste biomass as raw materials, greatly reducing production costs, and easy to realize industrial production.

Owner:SOUTH CHINA AGRI UNIV

Novel electronic-grade polyimide film with low linear expansion coefficient and manufacturing method thereof

The invention relates to a manufacturing method of an electronic-grade polyimide film with low linear expansion coefficient. The method is characterized by comprising the steps that (1) the step-by-step condensation polymerization technology or the blending compounding technology is used for obtaining two or more polyamide acid glue solutions comprising rigid structures and soft structures at the same time and are different in rigidity and softness; (2) ultrafine inorganic whiskers, like zinc oxide whiskers, silicon carbide whiskers and zirconium tungstate whiskers, which are subjected to surface organic modification already and / or nanoparticle materials are smashed and cavitated through high-energy-density supersonic waves, and then the functional fillers are compounded with polybasic polyamide acid in an in-situ micro-nano mode; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, extrusion casting filming, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

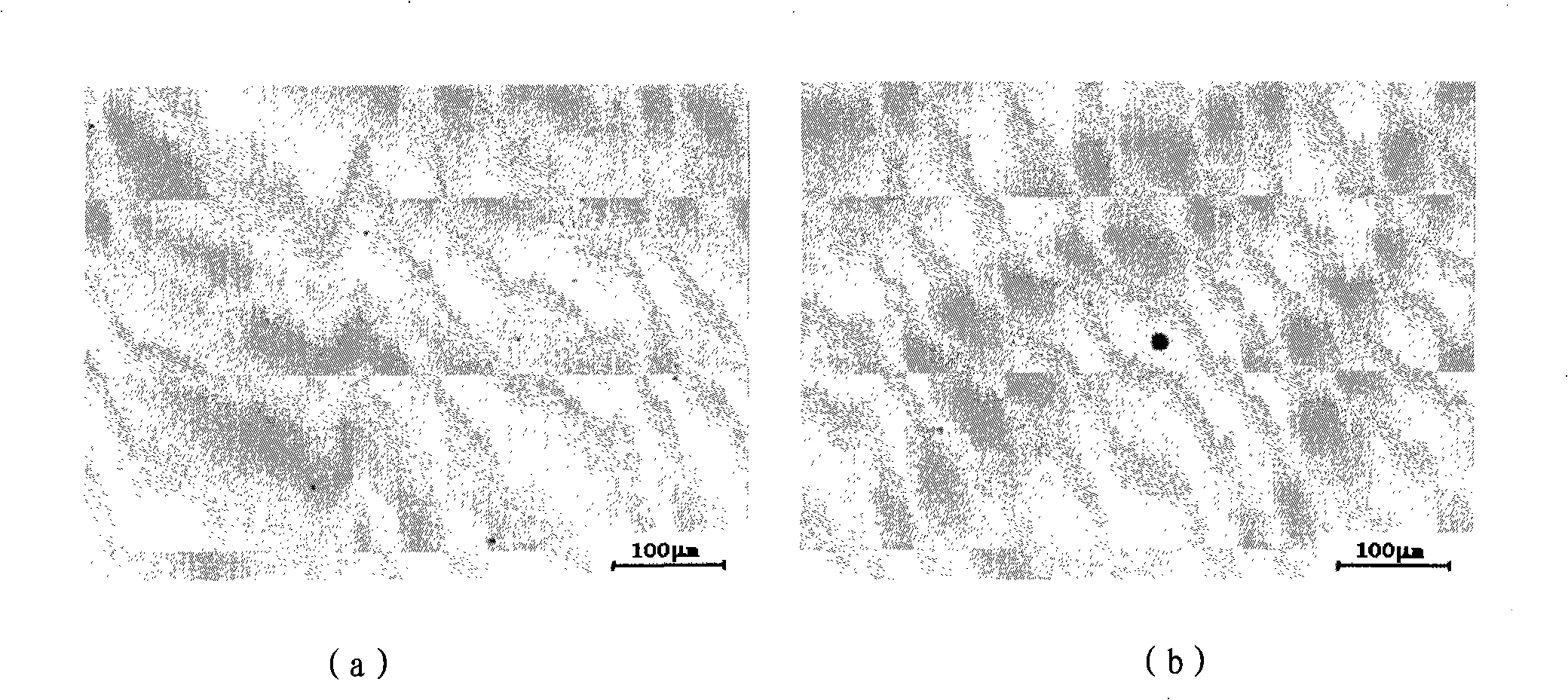

15MnNiDR low alloy steel plate for low temperature pressure vessel and production method thereof

ActiveCN102418036ARealize large-scale industrial productionMeet actual needsTemperature control deviceManufacturing convertersLaminar coolingPressure vessel

The invention discloses a 15MnNiDR low alloy steel plate for a low temperature pressure vessel. According to the invention, the 15MnNiDR low alloy steel plate is prepared by smelting and rolling nine alloy elements of Fe, C, Si, Mn, Ni, V, Nb, Ti and Als; through reasonable and strict control of the production processes of KR molten iron pretreatment, converter smelting, LF furnace refining, vacuum degassing treatment, continuous casting, heating, rolling, ACC laminar cooling, normalizing and the like, large scale industrial production of medium and heavy plates used for low temperature pressure vessels is realized, and all the performance of the medium and heavy plates reaches JB / T47030 standard, according with demands for low alloy steel plates in development of the industry of low temperature pressure vessels in China.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Method for extracting phospholipid-rich krill oil from Antarctic krill

ActiveCN102766530ASimple process operationProcess environmental protectionFatty-oils/fats productionEnzymeKrill oil

Owner:辽渔南极磷虾科技发展有限公司

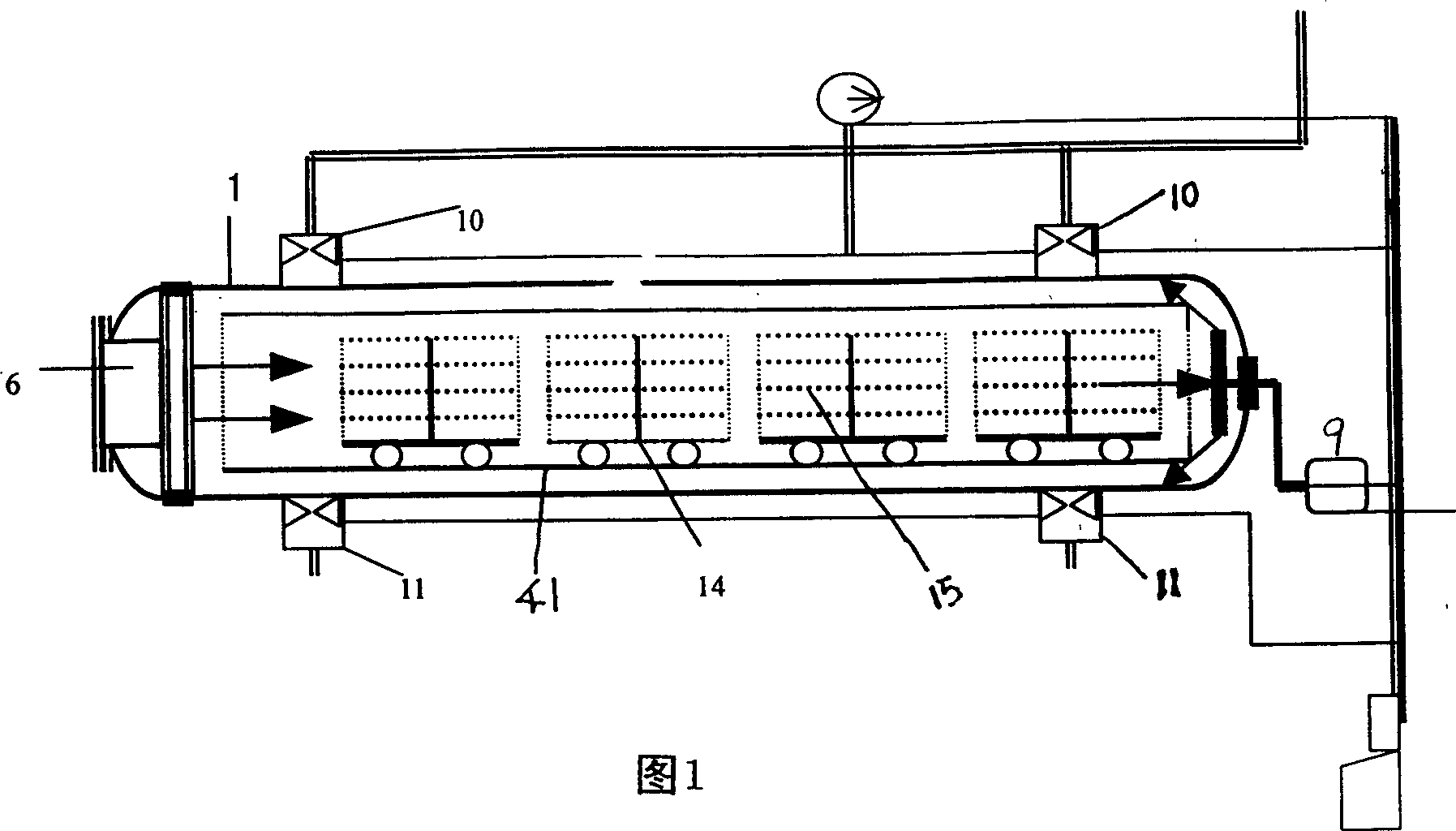

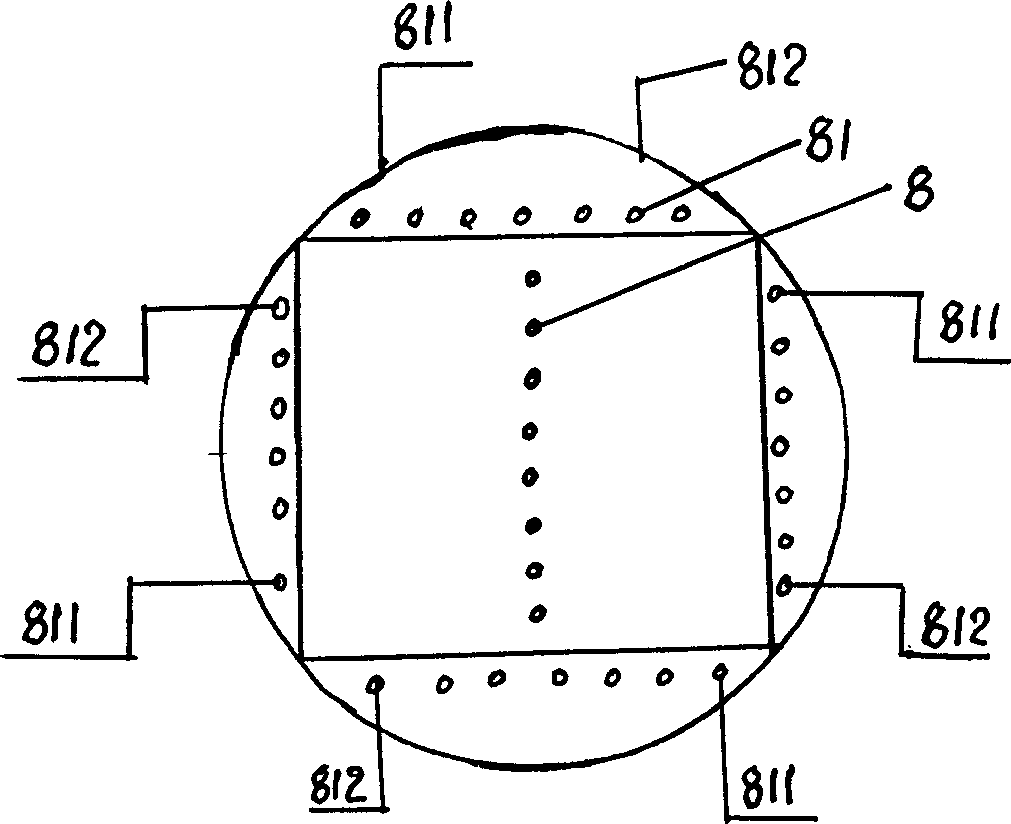

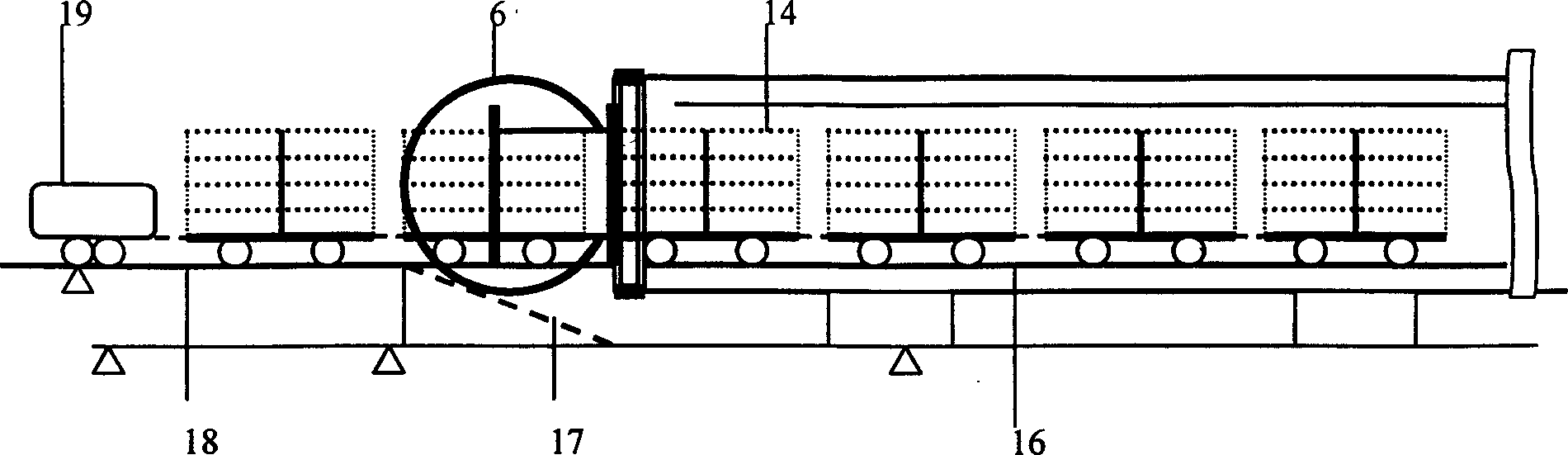

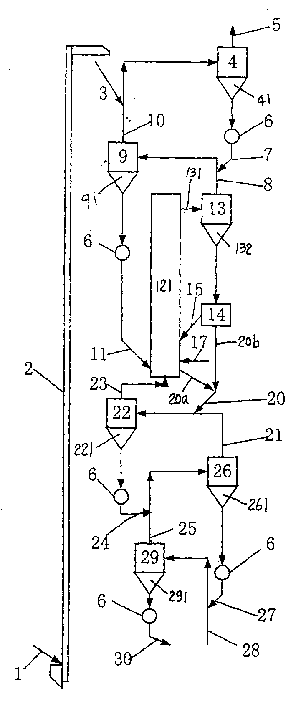

Gas-phase double-dynamic solid fermentation technology and fermentation apparatus

InactiveCN1434113ASimple structureImprove sealingBioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseEngineering

The present invention relates to a gas-phase double-dynamic solid fermentation techinque, and is characterized by that the solid material to be fermented is placed into a double-dynamic environment with pressure pulsatino and circular flowing air to make solid fermentation. Its fermentation equipment includes a horizontal cylindrical tank with a quickly-opening door, in the interior of the tank arectangular spacing cylinder which is formed from four partition boards and whose section is quadratic is axially placed, and in the space of partition board and tank wall a cooling calandria parallel to the partition board is arranged, and the vertical centre of the spacing cylinder is equipped with horizontally-arranged several groups of cooling calandria.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

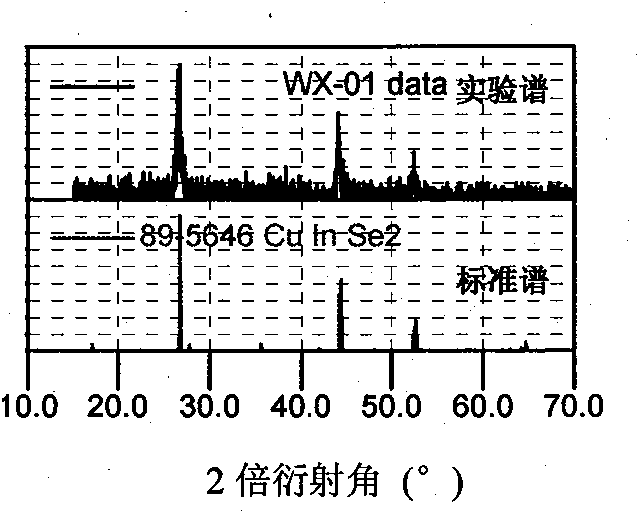

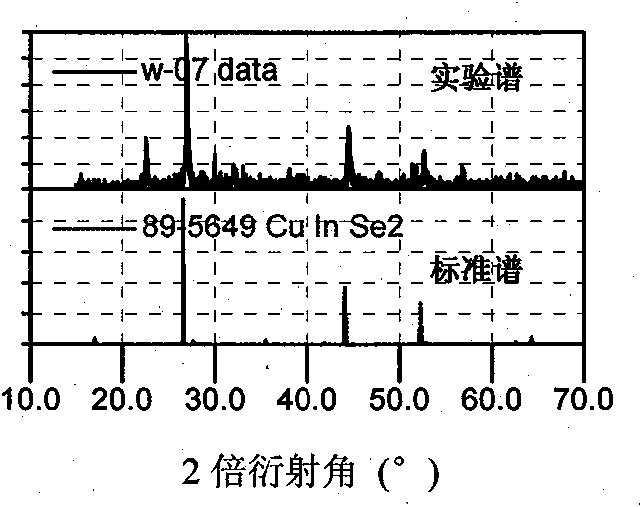

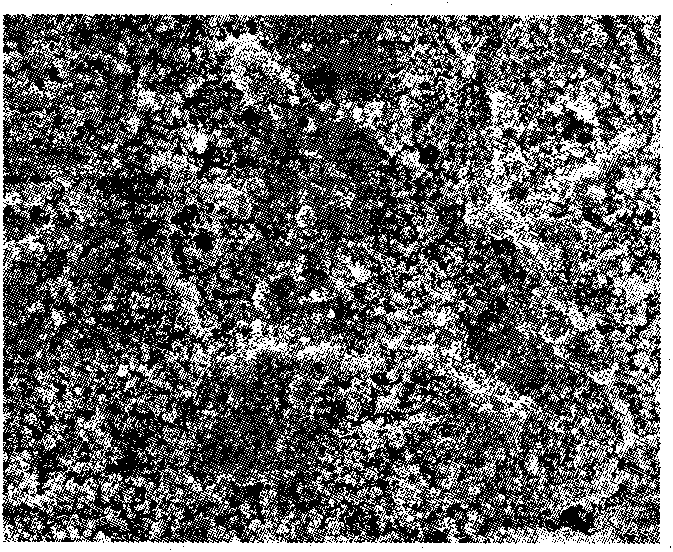

Method for preparing copper-indium-selenium optoelectronic thin film material of solar cell

InactiveCN101630701ALower requirementLow costFinal product manufactureSemiconductor devicesIndiumCopper

The invention discloses a method for preparing a copper-indium-selenium optoelectronic thin film material of a solar cell and belongs to the technical field of the preparation of optoelectronic thin films for solar cells. The method prepares the copper-indium-selenium optoelectronic thin film material of the solar cell by the following steps: firstly, cleaning a glass substrate; secondly, placing CuCl2.2H2O, InCl3.4H2O and SeO2 into a solvent; thirdly, adjusting the pH value of the solution to 7.5; fourthly, obtaining a precursor thin film by drying; fifthly, placing the precursor thin film sample into a closed reactor containing hydrazine hydrate and preventing the precursor thin film sample from contacting the hydrazine; and finally, obtaining a copper-indium-selenium optoelectronic thin film by drying. The method does not require high temperature and high vacuum conditions, has low requirements on instruments and is low in product cost, high in production efficiency and easy to operate. The obtained copper-indium-selenium optoelectronic thin film has excellent continuity and uniformity, and the main phase of the obtained copper-indium-selenium optoelectronic thin film is a CuInSe2 phase. The process allows for easily control of the components and structure of a target product and provides low cost and large-scale industrial production of high-performance copper-indium-selenium optoelectronic thin films.

Owner:SHANDONG JIANZHU UNIV

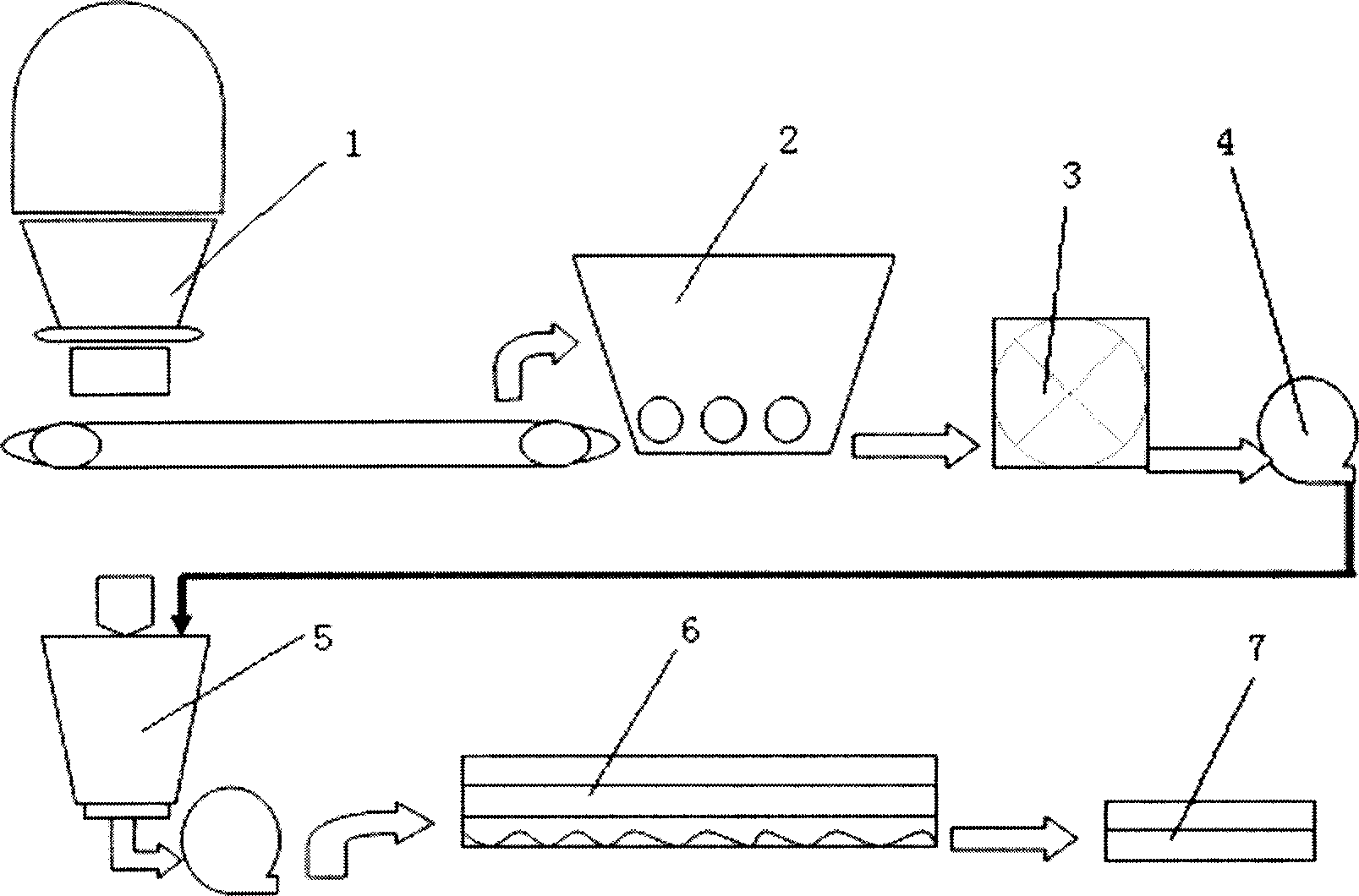

Preparation technology for slag foamed concrete block

InactiveCN102219546AGood early strengthShort initial setting timeCeramicwareFoam concreteFoaming agent

The invention discloses a preparation technology for a slag foamed concrete block. The preparation technology comprises: (1) preparing a slag early strength agent; (2) preparing a slag cementing material; (3) preparing a compound admixture; (4) preparing foam of a foaming agent; (5) preparing a mixed slurry; (6) mixing the mixed slurry and the foam of the foaming agent according to a volume ratio of 1:6, followed by carrying out stirring to prepare a foamed slurry having a volume weight of 20-130 mm; (7) conveying the foamed slurry in a standing room, and supplying saturated vapor to the standing room, wherein a heating rate on the standing room is 5-8 DEG C per hour, followed by standing for 3-6 hours at a temperature of 55-60 DEG C, then conveying the stood foamed slurry in a autoclave, wherein steam pressure in the autoclave is increased to 0.8-1.2 Mpa in 2-3 hours, then remaining a constant temperature for 4-6 hours, followed by decreasing the steam pressure to zero in 2-2.5 hours to prepare the finished product. Each technical index of the solid slag autoclaved foamed concrete block provided by the present invention is superior to or accords with standard requirements of JC / T1062-2007 foamed concrete block.

Owner:杜世永

Smelting production method of low activation martensitic steel for fusion reactor

InactiveCN101328522AReduce manufacturing costMeet the design requirementsIncreasing energy efficiencyQuality levelSteel bar

The invention relates to a method for producing a low-activation martensitic steel for a fusion reactor by melting. The method comprises: step one, a charging material is smelted in a vacuum induction furnace: (1) when a vacuum degree is between 0.1 and 10 Pa, argon gas is passed through the vacuum induction furnace till the vacuum degree is between 0.005 and 0.08MPa, and a smelting temperature is between 1450 and 1650 DEG C; (2) alloys are added in sequence: firstly, pure Fe is melted; Cr and W are added into the furnace; then Ta and V are added into the furnace, and finally C and Mn are added into the furnace; simultaneously, the level of an oxygen content in the pure Fe is observed; before Cr is added, a little of C is added into the furnace for carrying out deoxidation treatment; (3) on-line detection is carried out to the compositions of alloy elements; the alloy elements are added according to a detection result; and (4) after the compositions are qualified, a mixture is cast under the vacuum at a casting temperature of between 1450 and 1550 DEG C. Step two, according to the compositions and the inner quality level of a cast ingot which is obtained by vacuum induction and melting, whether the cast ingot is remelted and refined in a vacuum electroslag remelting furnace or a common electroslag remelting furnace with argon protection. Step three, a needed CLAM steel bar material is prepared by the production of forging, cogging and hot rolling. The method has the characteristics of simple smelting operation, stable process and low production cost; the compositions and impurities of the produced CLAM steel meet the design requirement; and the method has no aliquation of the compositions and tissues and high degree of purity and is suitable for the application of the fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

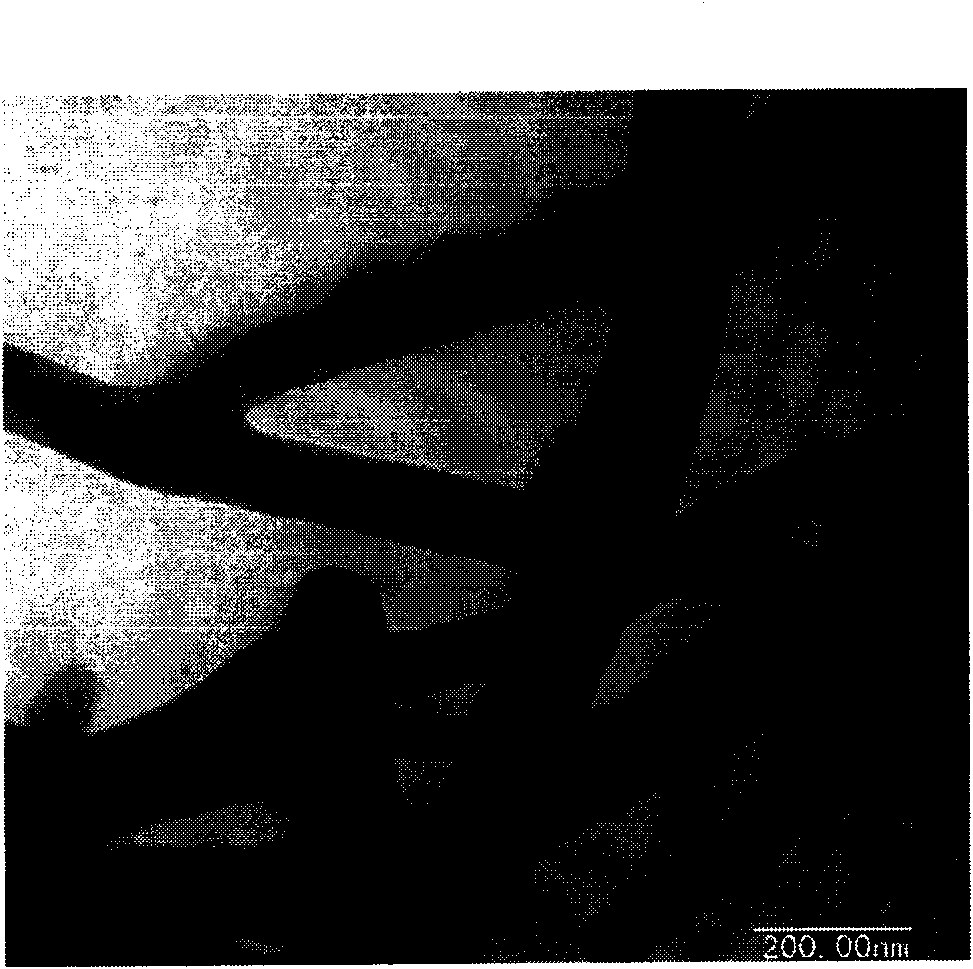

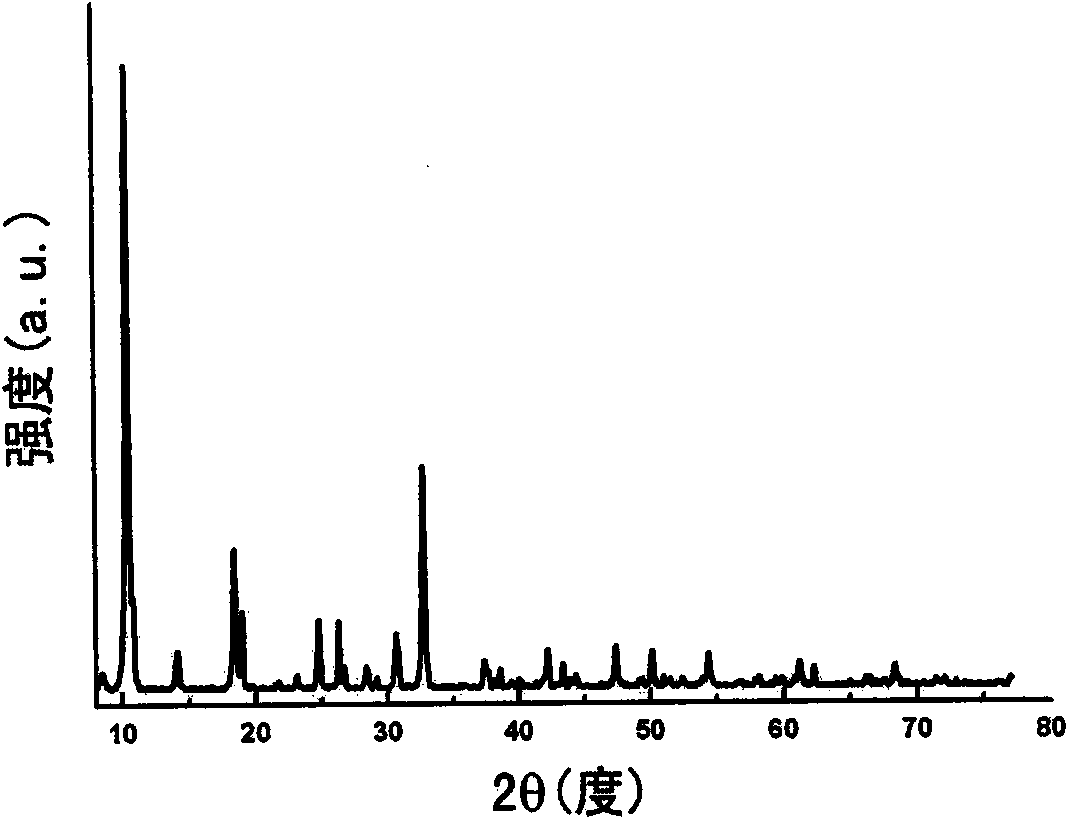

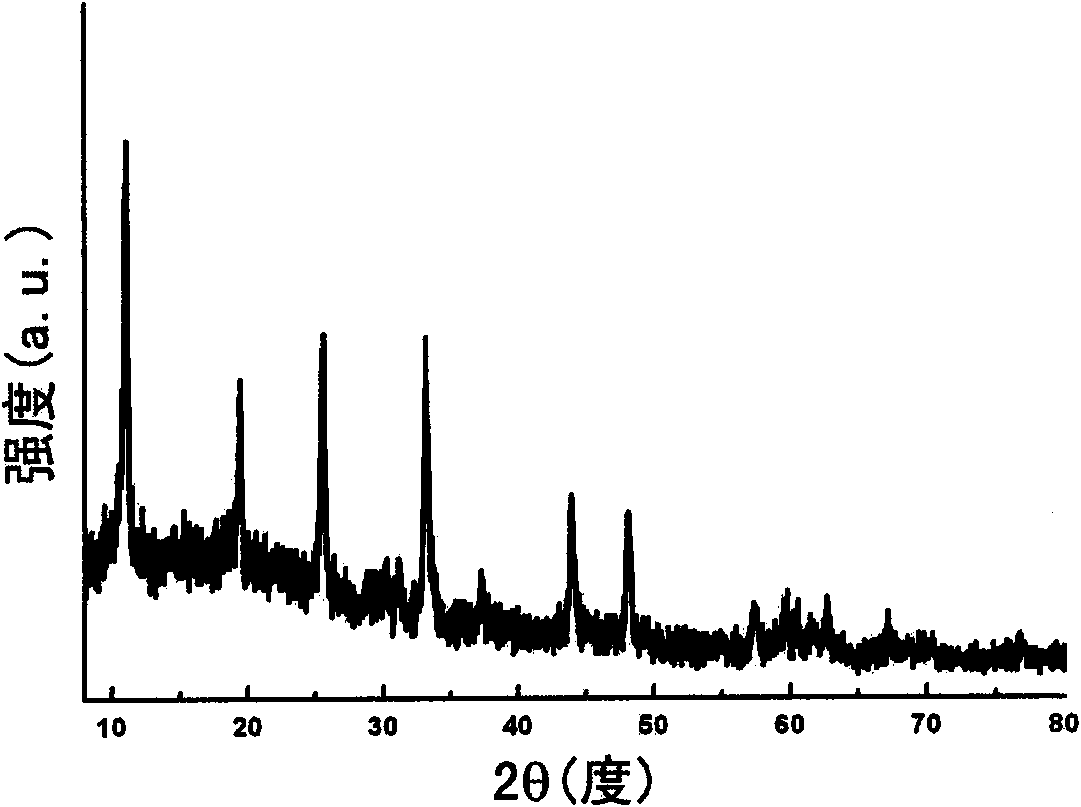

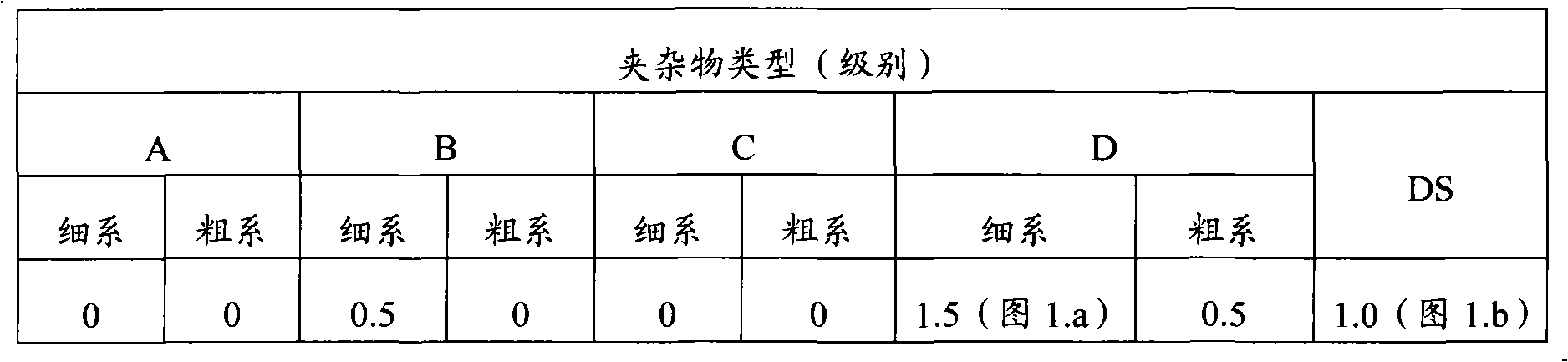

Small-sized black phosphorus flakes and preparation method thereof

ActiveCN105600760ARealize large-scale industrial productionMaterial nanotechnologyPhosphorus preparationWater bathsOrganic solvent

The invention provides a preparation method of small-sized black phosphorus flakes. The preparation method comprises the following steps: under the condition that air is isolated, grinding black phosphorus, and dispersing the ground black phosphorus into a first organic solvent to obtain a dispersion at the concentration of 0.6-1.2mg / mL; performing probe-type ultrasonic treatment to the dispersion for 2-4h under the power of 1000-1400W first and then performing water-bath ultrasonic treatment for 8-12h under the power of 200-400W; after the ultrasonic treatment, centrifuging and collecting a supernatant, namely the stripped small-sized black phosphorus flakes. The preparation method is simple in process, easy to operate, relatively high in yield, good in reproducibility, easy to realize low-cost industrial production of the small-sized black phosphorus flakes, and free of secondary pollution to the environment. The invention further provides the small-sized black phosphorus flakes.

Owner:HUBEI MOPHOS TECH CO LTD

Super high molecular weight polyacrylamide industrialized production process

InactiveCN1865299AHigh molecular weightRealize large-scale industrial productionManufacturing technologyFunctional monomer

The invention discloses an industrial manufacturing technology of polyacrylamide (over 25,000 thousand molecular weights), which is characterized by the following: introducing functional monomer under insulation condition; finishing polymerization reaction through synergic action of three-segmented composite initiator; grinding; graining; hydrolyzing; drying; breaking; screening; improving polymerization molecular weight to polymerize block kettle-typed polyacrylamide; fitting for large scale producing; making the product quality, volume of production, energy consumption and using scope satisfy domestic leading level.

Owner:PETROCHINA CO LTD

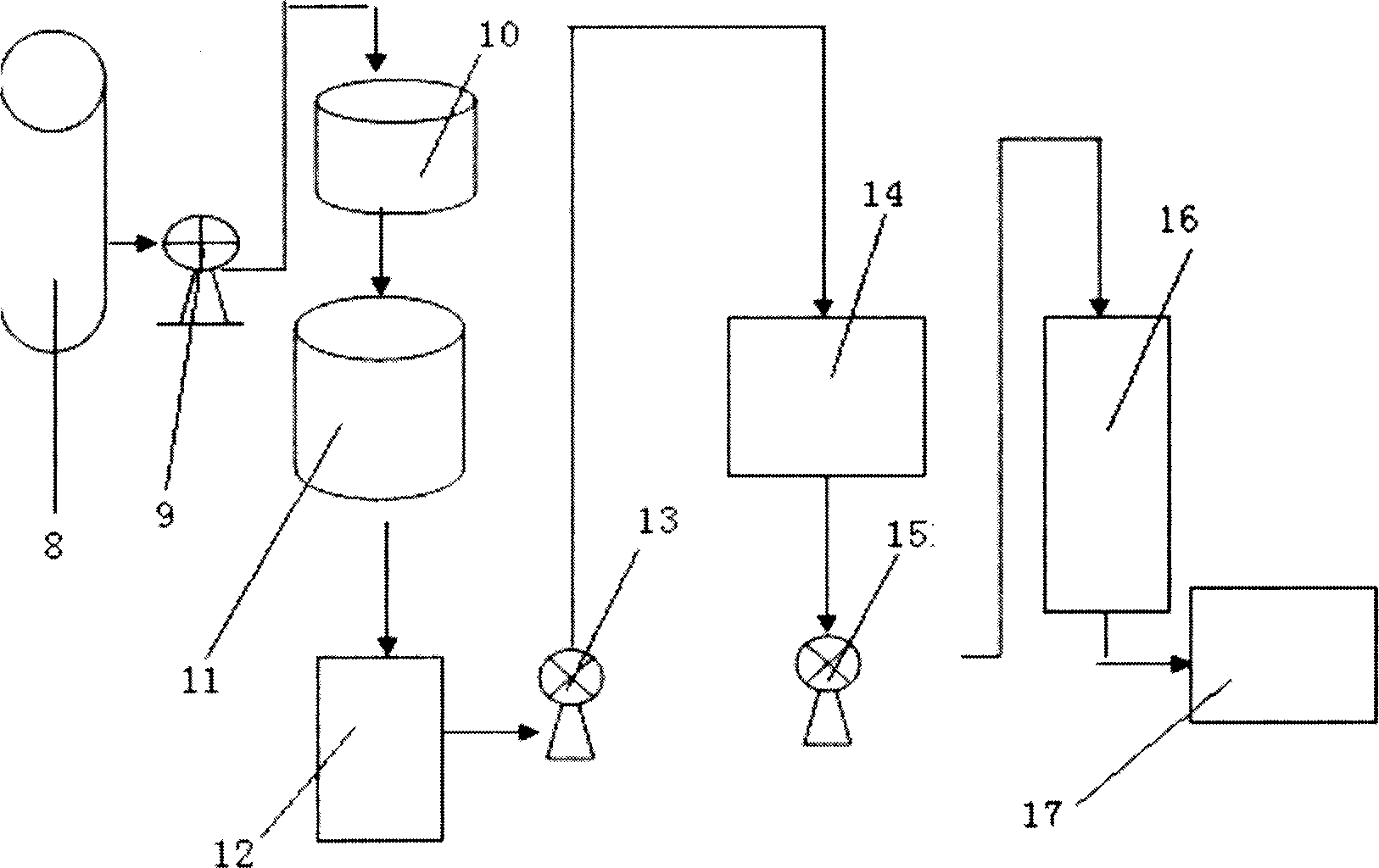

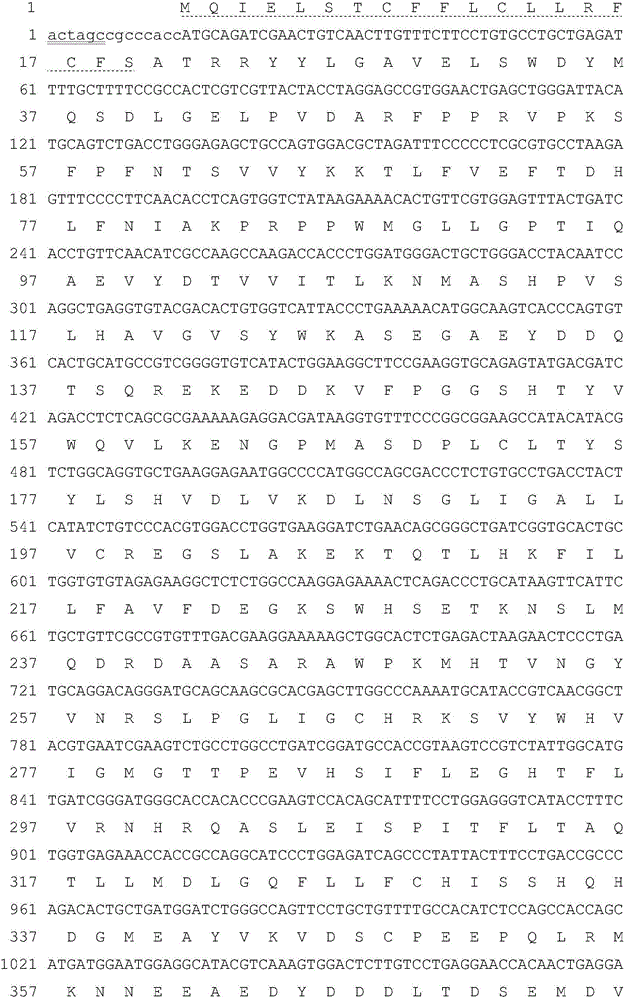

Hyperglycosylatedhuman coagulation factor VIII fusion protein and preparation method and application thereof

ActiveCN106279437AIncrease productionExtended half-life of activity in vivoFactor VIIPeptide/protein ingredientsHuman Chorionic Gonadotropin Beta SubunitHalf-life

The invention discloses a hyperglycosylated human coagulation factor VIII (FVIII) fusion protein and a preparation method and application thereof. The fusion protein successively contains human FVIII, a soft peptide connector, at least one human chorionic gonadotropin betasubunitcarboxyl terminal peptide rigid unit and prolonged half-life period portion (preferably ahumanIgG Fc variant) from an end N to an end C. The fusion protein has biological activity similar to that of recombinant FVIII and prolonged in-vivo activity half-life period, thereby improving the pharmacokinetics and drug efficacy.

Owner:AMPSOURCE BIOPHARMA (SHANGHAI) INC +3

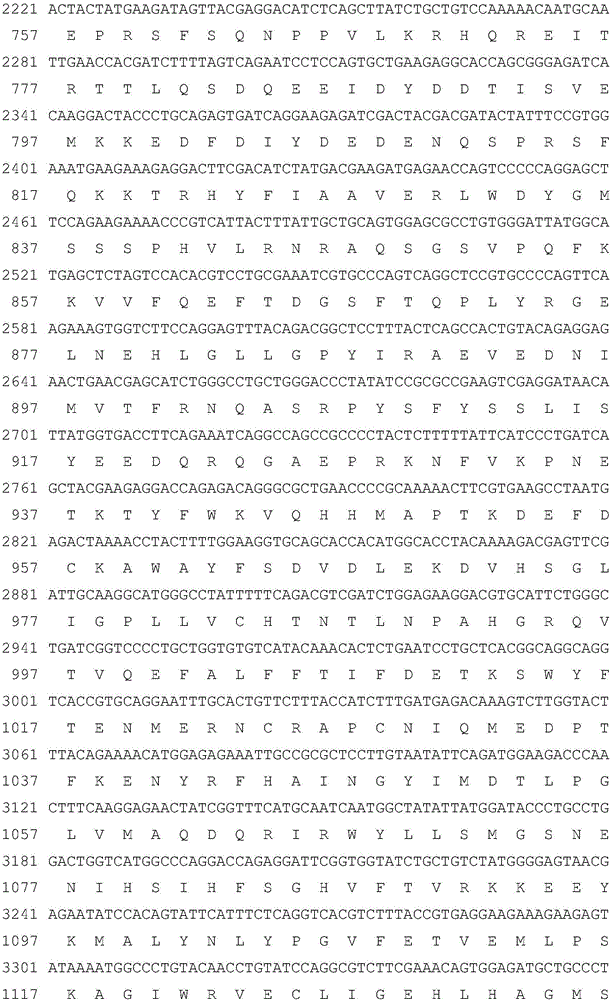

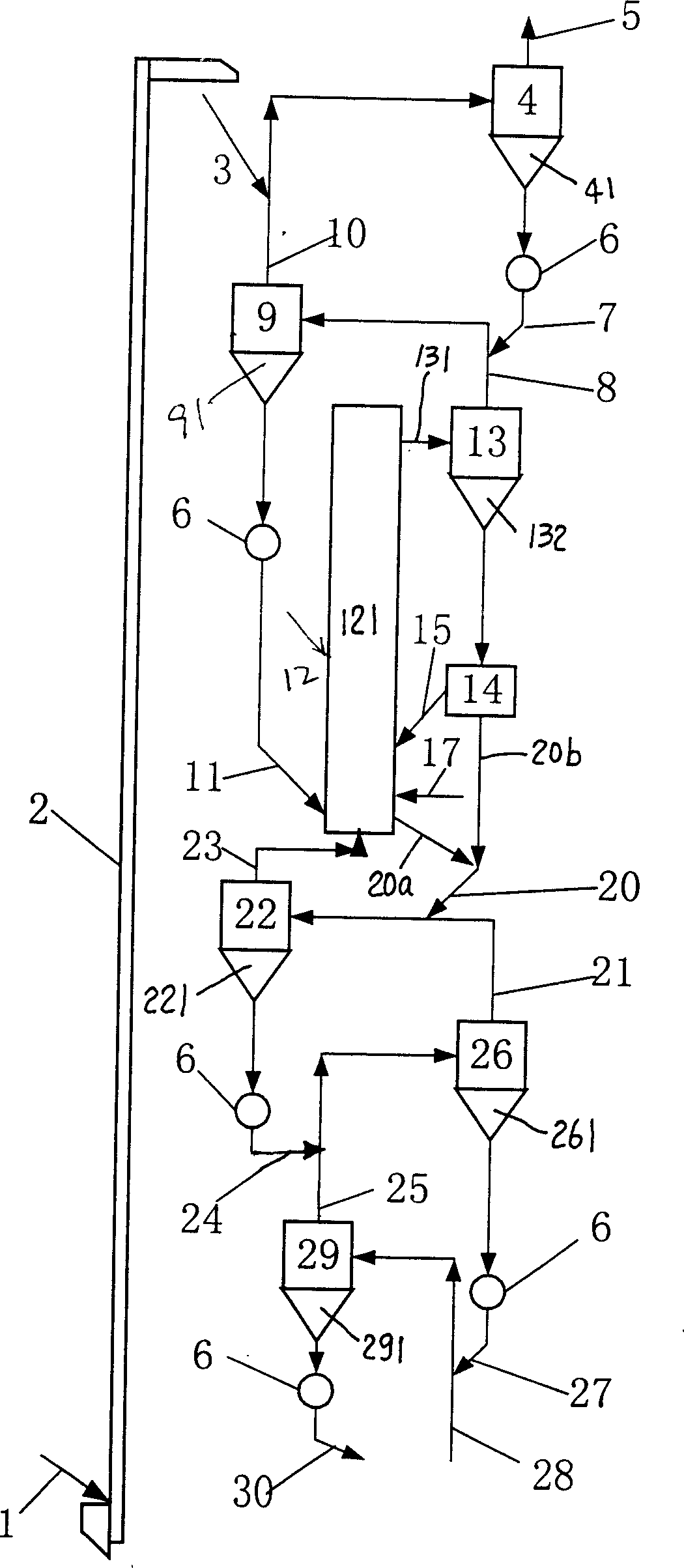

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

InactiveCN1600687AIncrease productivityImprove thermal efficiencyPigmenting treatmentAluminium silicatesCycloneEngineering

The invention relates to superfine Kaolin calcining process and device, the prodn, method includes; preheating kaolin raw powder material, then putting it in fluidization calcining furnace from the bottom, at same time, sending fuel into the furnace, preheated primary air is sent from plenum under the furnace burns with the fuel and to form a reducibility atmosphere calcining area in the lower section, the volume content of CO+H2 in reduction area is 0-10 percent, secondary air is sent from top of the reduction area to burn residual CO+H2 completely, airflow speed is 1-6m / s in the furnace, raw powder material is in fluidization, kaolin is circularly burned for 0.3-3 hours in temp. 700-1100 deg.C, then is sent into cyclone cooling system to be cooled to obtain superfine kaolin by mixer-grinding and depolymerizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of preserved rice noodles

InactiveCN102178179ASolve the problem of resurrectionSolve cohesionFood preparationWater bathsFiltration

The invention relates to a preparation method of preserved rice noodles. The preparation method includes the steps of rice machining and sand filtration, smashing, humidity adjustment, extrusion for gelatinization, extrusion for emerging of silk noodles, cutting off, checking and packaging. The preparation method is characterized by taking the rice noodles before extrusion for emerging of silk noodle and drying as materials, wherein the water content of the rice noodles at the moment is 25wt%-30wt% and the temperature is 40-60 DEG C; cutting the rice noodles to 17-19cm; soaking the rice noodles for 60-100min in Didazuril bactericide solution with concentration of 50%-60% and temperature of 35-45 DEG C, wherein the ratio of material to liquid is 1wt%:5wt%; conducting vacuum packaging, wherein the vacuum degree is 0.09MPa-0.092Mpa; thermally sterilizing the rice noodles for 0.5h-1h in a water bath maintained at the temperature of 90-95 DEG C; cooling packaging bags with circulating cold water so as to fast reduce the temperature in the center of the packaged material to 30-35 5 DEG C; blowing the water at the outer surfaces of the packaging bags to dry; checking whether the packaging bags bulge and break and conducing metal detection; putting the rice noodles together with auxiliary materials such as matched sauce bags in a packaging box; and sealing the packaging box, thus obtaining a finished product. For the preserved rice noodles produced according to the preparation method, the water content is higher than 60% and the quality guarantee period is longer than 6 months; the infusing and dispersing performance is good; caking does not happen and undesirable odor does not emerge; the dissolving starch rate of the rice noodles is low; after culture for 1 month at the temperature of 37 DEG C, the rice noodles achieve 1426g of hardness, 26.14gs of crisp performance, 512 of viscosity, 0.513s of viscoelasticity.

Owner:江西华达昌食品有限公司

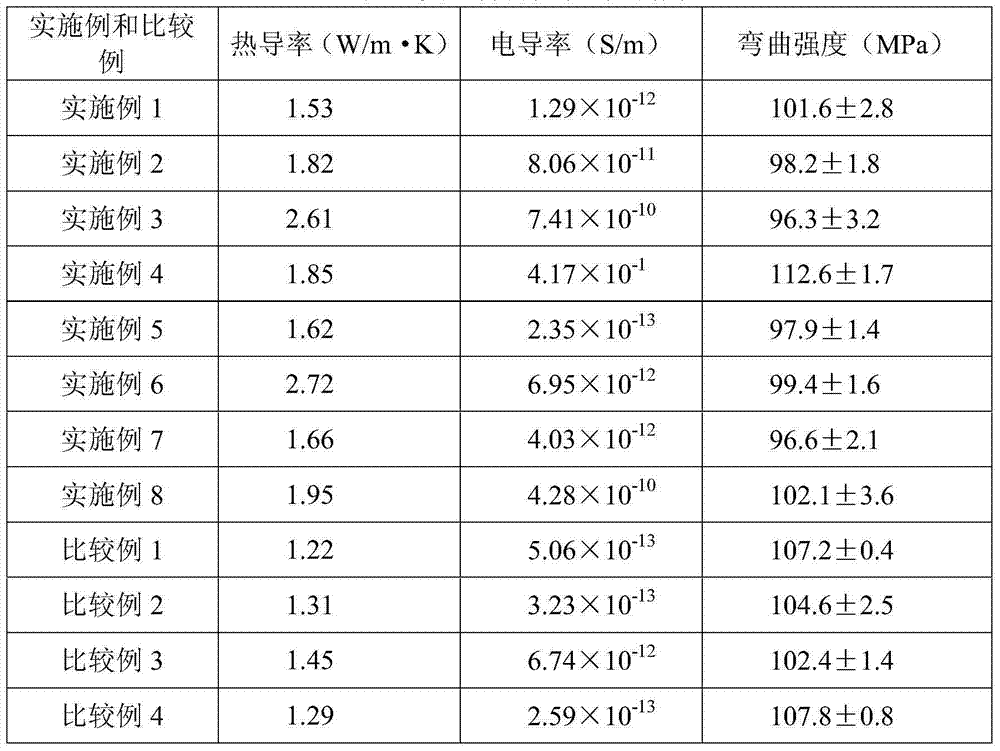

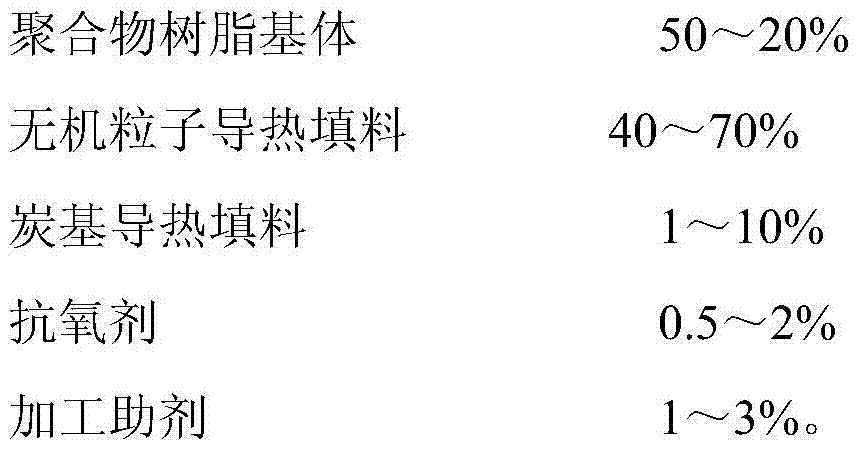

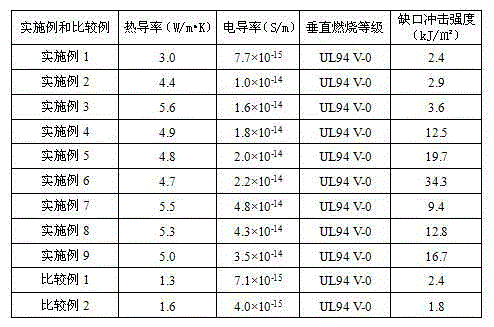

Multifunctional polypropylene composite material and preparation method thereof

ActiveCN104629187AGood mechanical propertiesGuaranteed flame retardant performancePolypropylene compositesProcedure Agents

The invention relates to a multifunctional polypropylene composite material and a preparation method thereof. The composite material is prepared from a thermoplastic polypropylene resin matrix, inorganic particles, thermal conducting fillers or a halogen-free flame retardant, carbon-based thermal conducting fillers, toughening fillers and other processing additives, the highest heat conductivity coefficient of the composite material is larger than 5.0 W / m.K, the insulating property is excellent, the vertical flammability is UL94 V-0, and the mechanical properties are excellent. The operation is simple, the cost is low, the multifunctional composite material with excellent comprehensive performance can be prepared in one step, industrialized production is easy to achieve, and the multifunctional polypropylene composite material can be widely used in such fields as heat exchangers, instrument shells, circuit components, automobiles, chemical energy and aviation, etc.

Owner:BEIJING UNIV OF CHEM TECH

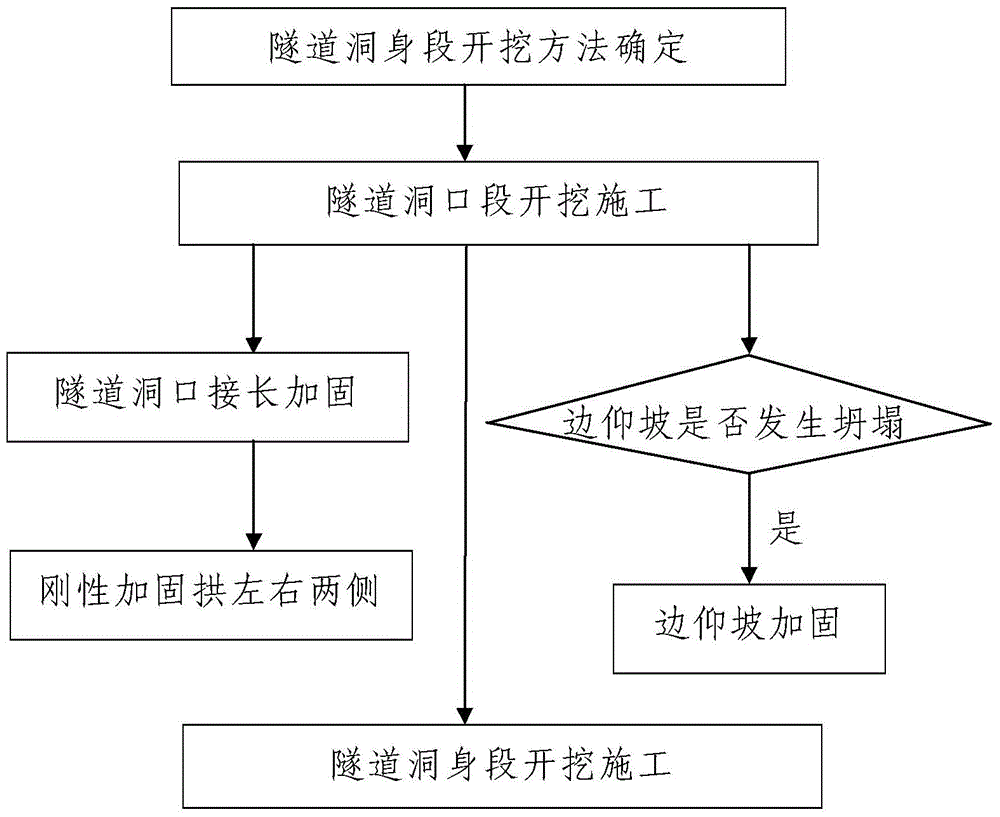

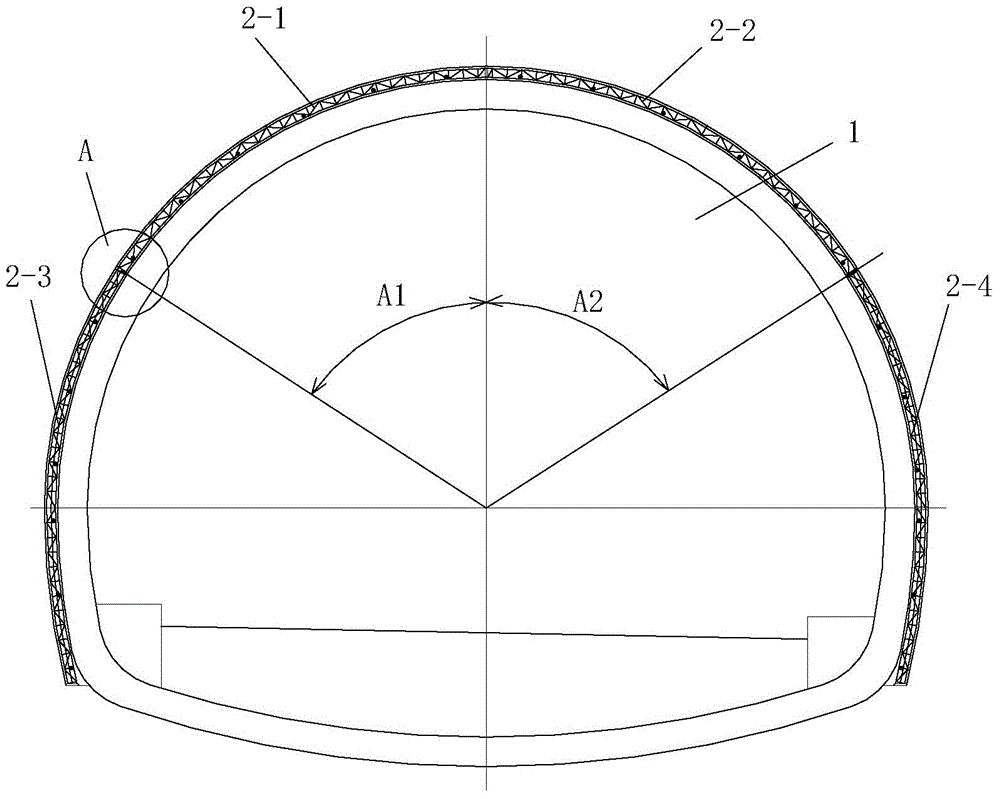

Process for excavating and constructing soft rock tunnels

ActiveCN104453921AThe process steps are simpleReasonable designTunnel liningStructural engineeringRock tunnel

The invention discloses a process for excavating and constructing soft rock tunnels. Each constructed soft rock tunnel comprises two tunnel portal sections and a tunnel trunk section. Each tunnel trunk section is arranged between the two corresponding tunnel portal sections in a connected manner, surrounding rock level of two tunnel portals of each constructed soft rock tunnel is V level, surrounding rock level of each tunnel trunk section is IV level, and entrances and exits of the constructed soft rock tunnels simultaneously start to be constructed and are constructed in opposite directions. The process includes constructing procedures of firstly, determining methods for excavating the tunnel trunk sections, to be more specific, simulating excavating and constructing procedures by the aid of tunnel excavating and constructing simulation software, and determining the methods for excavating and constructing the tunnel trunk sections according to simulation results; secondly, excavating and constructing the tunnels, to be more specific, dividing each soft rock tunnel to be constructed into a plurality of sections from the rear of the corresponding tunnel portal to the front and starting to excavate and construct the multiple sections. The tunnel trunk sections are excavated in the excavating and constructing procedures by the aid of full-section techniques. The process has the advantages of simple steps, reasonable design, convenience in construction, good service effects, safe constructing procedures and capabilities of easily and conveniently completing the soft rock tunnel excavating and constructing procedures and guaranteeing the construction periods.

Owner:CHINA RAILWAY 20 BUREAU GRP

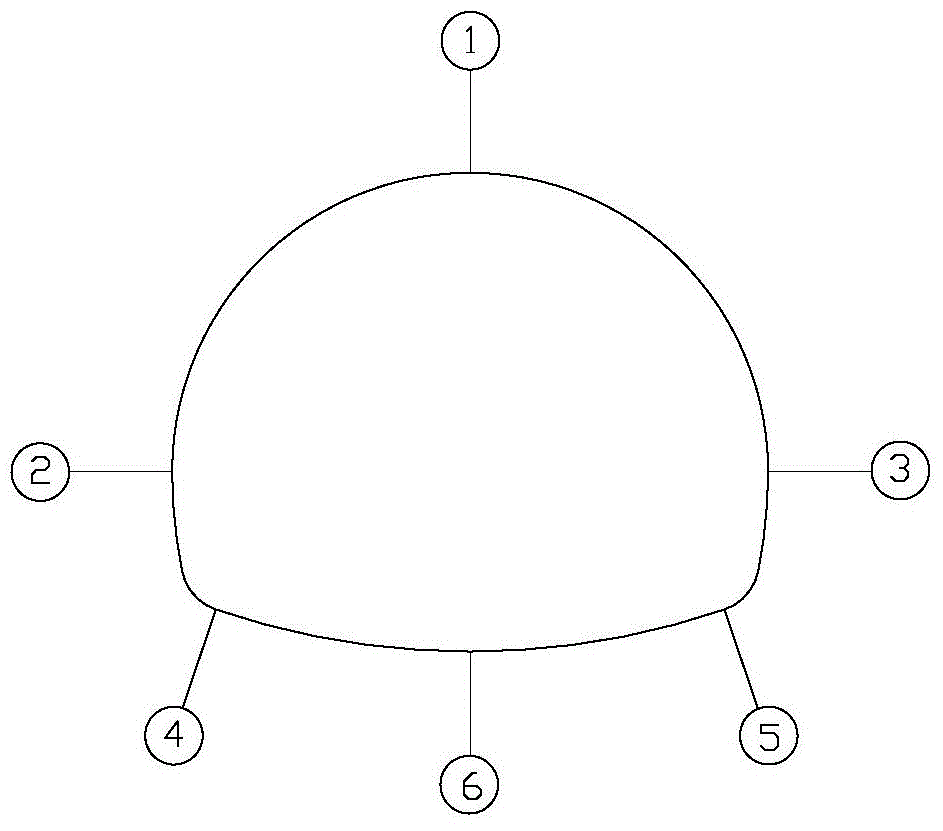

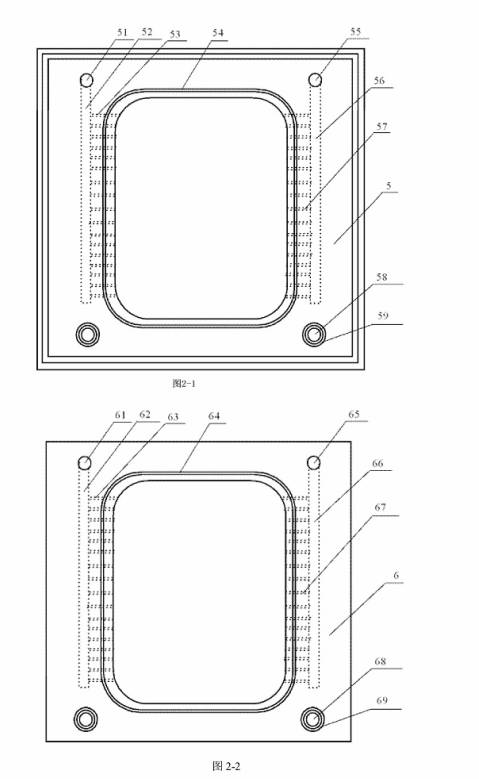

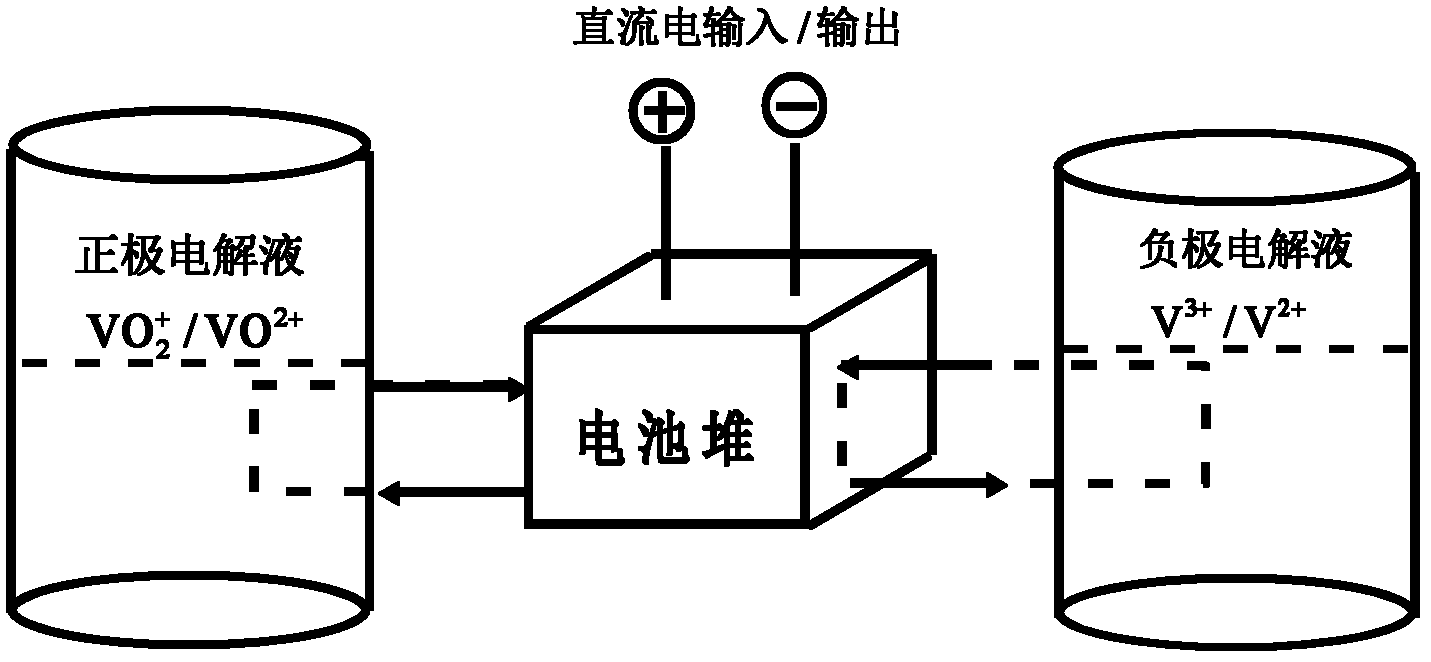

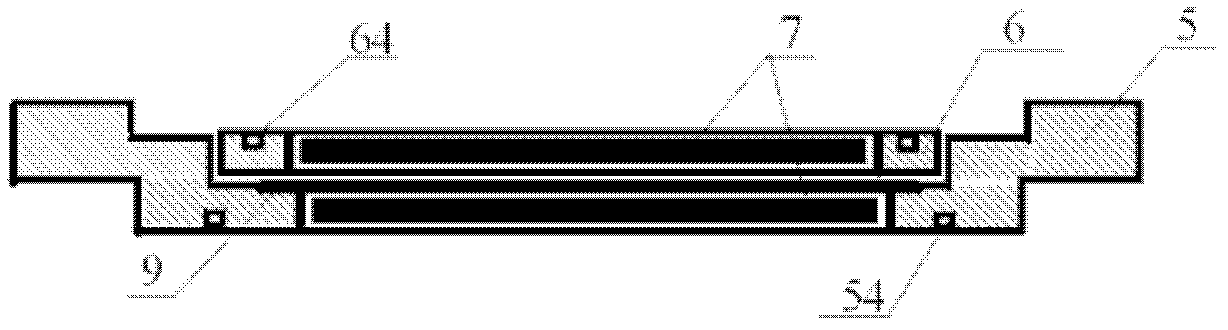

Embedded electrode frame of flow cell pile

ActiveCN102569843AImprove reliabilityEasy to assembleFinal product manufactureFuel cell detailsClamp connectionEngineering

An embedded electrode frame of a flow cell pile belongs to the technical field of flow cell manufacturing. The embedded electrode frame is characterized in that a first bipolar plate frame (5) used as a positive pole half-cell of a single cell, a second bipolar plate frame (6) used as a negative pole half-cell of another adjacent single cell and a bipolar plate (9) clamped between the first bipolar plate frame (5) and the second bipolar plate frame (6) are connected sequentially to form an electrode frame (4). The first bipolar plate frame (5) and the second bipolar plate frame (6) achieve accurate location by means of a mutually embedded structure formed by a boss and a groove. A sealing ring groove provided with a sealing ring is arranged on the surface of the electrode frame which are formed by the first bipolar plate frame and the second bipolar plate frame, the sealing ring groove locates on the combined surface where the boss and the groove are in clamping connection to facilitate installation and sealing, and the flow cell pile is formed by connecting a plurality of electrode board frames.

Owner:TSINGHUA UNIV +1

Mobile phone curved glass panel and forming method thereof

ActiveCN104023099AFit tightlyComfortable fitGlass reforming apparatusTelephone set constructionsEngineeringGraphite

The invention discloses a mobile phone curved glass panel and a manufacturing method of the mobile phone curved glass panel. A curved glass panel body is formed by bending a mobile phone panel body toward the same side in an arc shape with the center line of the mobile phone panel body in the X-axis direction or the Y-axis direction as a center, or bending the periphery of the mobile phone panel body toward the same side in an arc shape with the center point of the mobile phone panel as the center, or the mobile phone curved glass panel comprises a main panel and curved panels. The curved panels are formed by bending one or more side edges of the main panel. The multiple curved panels are bent toward the same side relative to the main panel. The forming method includes the three steps of manufacturing a planar glass panel, manufacturing a graphite die and forming the curved glass panel. The good lubricating performance of graphite is used, through exerting certain pressure for deformation, heat deformation is achieved at the temperature below a glass softening point, the manufactured product is high in precision, the designing requirements of a 3D mobile phone glass panel are met, large-scale industrial production can be achieved, production cost can be reduced, and the requirement for personalized and fashionable mobile phones can be met for people.

Owner:LENS TECH

Method for preparing high-performance magnesium alloy sheet

InactiveCN101462123AEasy to organizeRealize large-scale industrial productionRoll force/gap control deviceTemperature control deviceRolling millHot rolled

The invention relates to a method for preparing a high performance magnesium alloy sheet, which belongs to the technical field of magnesium alloy preparation. The method is characterized by comprising: firstly, smelting out a magnesium alloy fused mass conforming to the requirements on components and then, adopting a double-roller rolling mill to produce rolling sheet blanks; heating the rolling sheet blanks to a set temperature so as to carry out hot rolling and matching with intermediate annealing in the hot rolling process so as to ensure that the sheets have perfect recrystallization and eliminate processing hardening; and subsequently, thermally rolling the hot rolled sheets to the needed thickness and carrying out final annealing on the magnesium alloy sheets so as to obtain the high performance magnesium alloy sheets with fine and uniform crystal grains. The prepared magnesium alloy sheets have the advantages of higher tensile strength, yield strength and elongation.

Owner:TSINGHUA UNIV

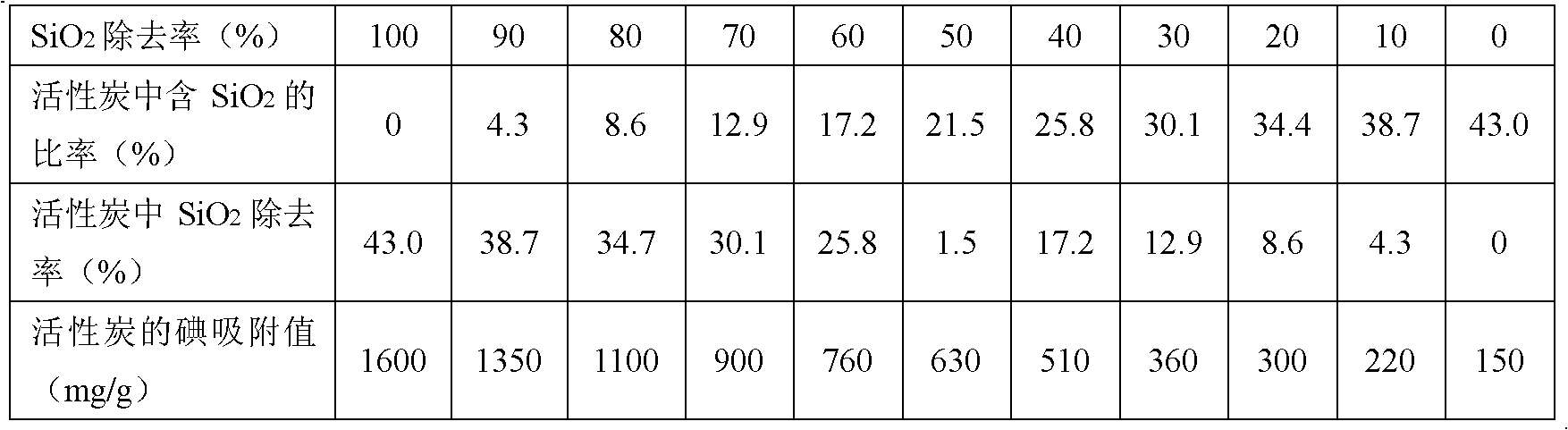

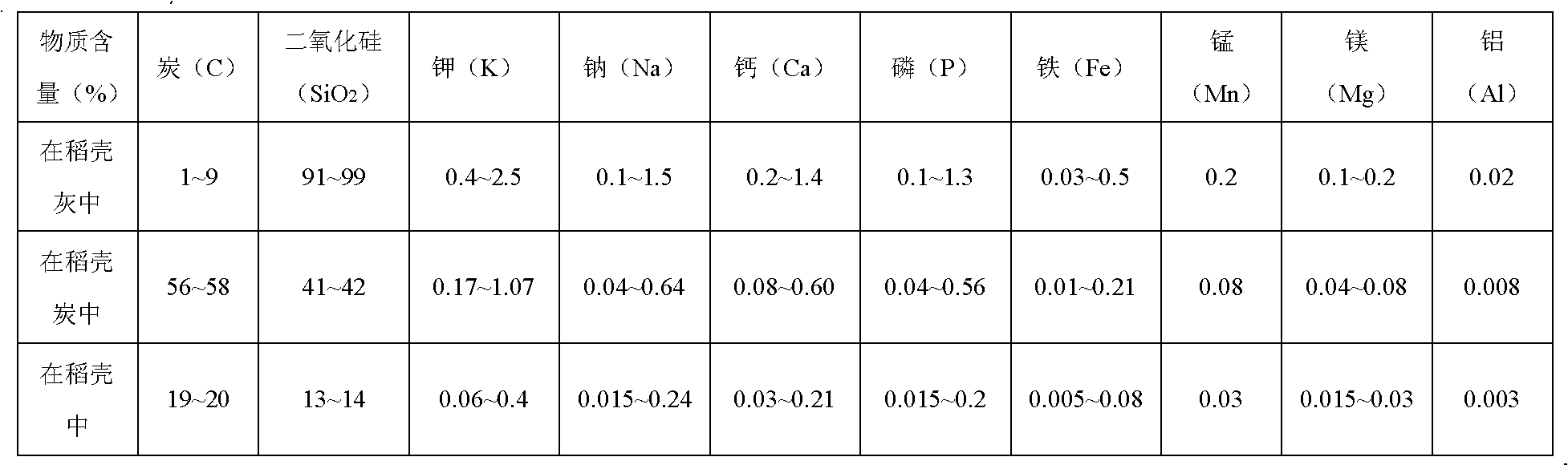

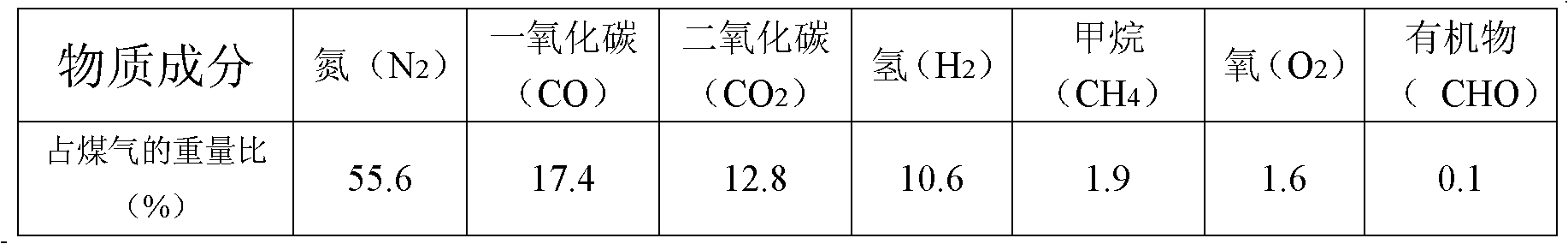

Method for preparing coal gas, top-grade active carbon, water glass and silicate phosphate from rice hulls

ActiveCN101891189AImprove qualityOvercome absorbencyPhosphatesAlkali metal silicatesPhosphateBiological activation

The invention relates to a method for preparing coal gas, high-grade active carbon, water glass and silicate phosphate from rice hulls, which comprises the following steps of: smouldering, carbonizing and activating the rice hulls to produce the coal gas for power generation and to obtain rice hull carbon; activating the rice hull carbon with acid and alkaline to obtain low-grade active carbon, packaging the low-grade active carbon in a dust-proof explosion-proof sealed mode, and activating at moderate temperature, secondary high temperature and high temperature to finally obtain the high-grade active carbon and produce the water glass and the silicate phosphate simultaneously. The defect of low-grade active carbon prepared from the rice hull carbon in the prior art is overcome. The invention has reasonable technological method and technological process, and solves the technical obstacles on moderate temperature and high temperature activation of the rice hull carbon. The rice hull carbon obtained after preparing the coal gas from the rice hulls can be directly used for producing the high-grade active carbon, the water glass and the silicate phosphate, and the economical benefits and the social benefits of the rice hulls are effectively increased. Large-scale industrial production can be realized, and a new approach is provided for realizing a complete industrial chain of agriculture industrialization and rice processing.

Owner:长沙稻香农业科技有限公司

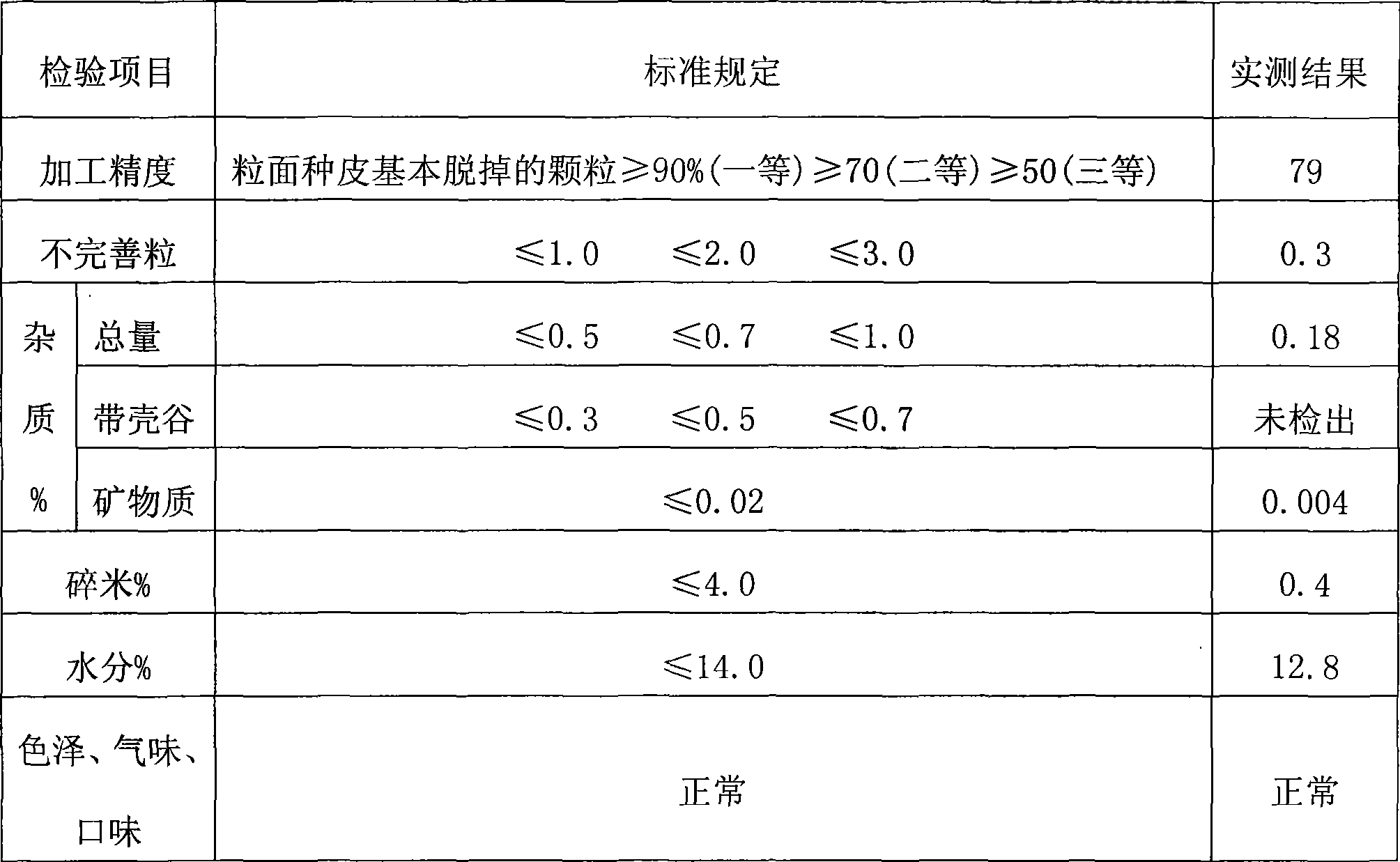

Technique for processing millet with remained germ

InactiveCN101486005AEmbryo intactHigh embryonic rateGrain huskingGrain polishingAir volumeAdditive ingredient

The invention provides technology for processing millet rice with remained germ. In the technology, unpolished rice which is screened through husked rice separation with husking yield and serviceability rate of rice germ more than or equal to 97 percent, moisture content of between 12.5 and 14 weight percent is adopted as a raw material for processing the rice with remained germ; four ranges of rice milling machines are arranged, wherein two parallel machines are arranged in each range; four-placer four-iron combined rollers are adopted in first milling and second milling; an additional air jetting device is arranged in the range of third milling to form a wind packing auger, so that air-jet capacity can reach 120 to 170m / h; the rice milling machine of the fourth range is connected with a set of negative pressure air nets, with air quantity of between 15,000 and 18,000 cubic meters / hour; and the millet rice with remained germ with complete germ and germ content of between 80 and 85 percent can be finally obtained through rice grading screen and color selection. The technology has the advantages of scientific and reasonable design and mature implementing technology; and by the technology, the millet rice with remained germ with complete germ, high germ content and rich nutrient ingredients can be produced, thereby realizing large-scale industrial production of the millet rice with remained germ for the first time.

Owner:辽宁兴诺米业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com