Patents

Literature

80results about How to "Expand product range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

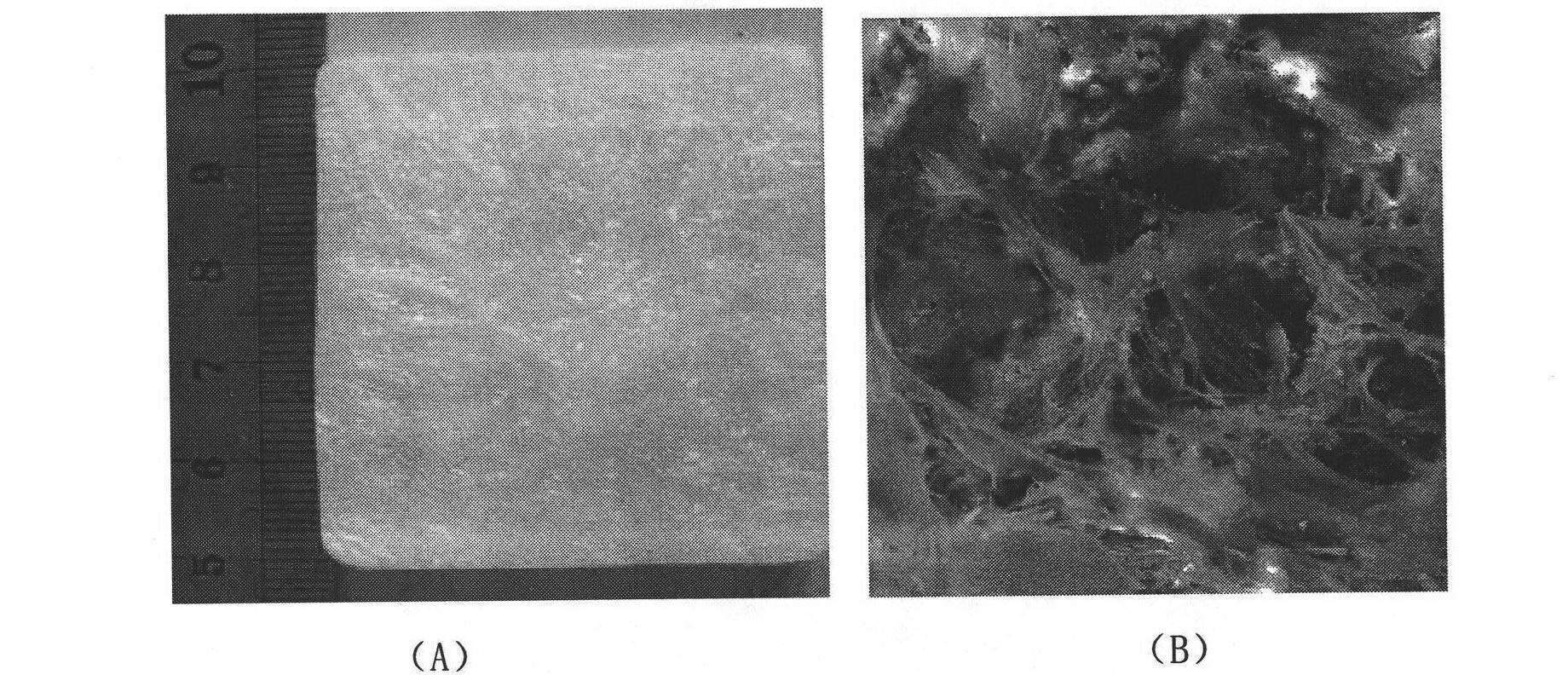

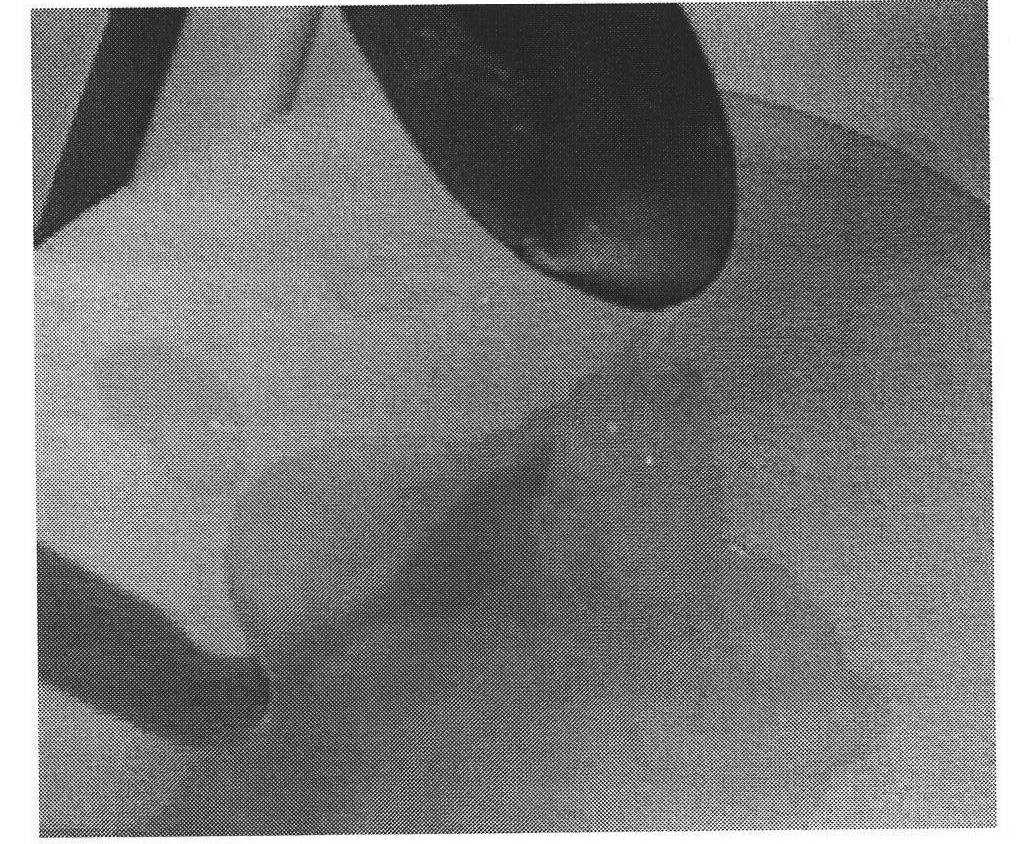

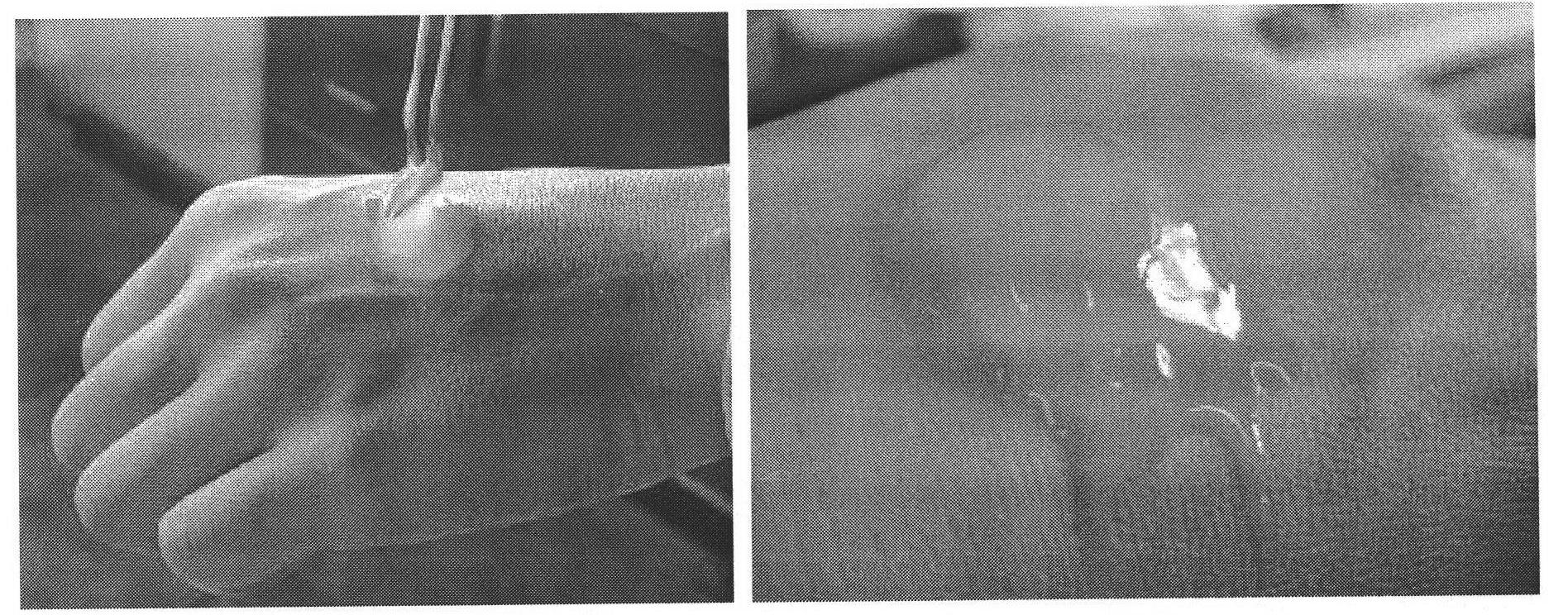

Human-body absorbable trauma dressing containing Yunnan white drug powder or Yunnan white drug powder extractive

InactiveCN101804218AIncrease usageImprove usabilityAbsorbent padsBandagesDressing changeCurative effect

The invention discloses a human-body absorbable trauma dressing containing Yunnan white drug powder or Yunnan white drug powder extractive, which is a novel medicine-carried dressing or a novel formulation of Yunnan white drug powder. The invention has the following remarkable characteristics: (1) the dressing can be absorbed by human bodies to lessen the pain added by dressing change and reduce the treatment cost; (2) the dressing can be made into a film solid dressing or an aquagel dressing so as to expand the use modes, the scope of applications and the drug effect of the Yunnan white drug powder; and (3) the curative effect of the dressing is enhanced by selecting a carrier material, auxiliary medicaments and functional accessories and adjusting the microstructure structure. The novel absorbable Yunnan white drug powder dressing overcomes the defects of the traditional Yunnan white drug powder in use and has economic and social values.

Owner:王艳

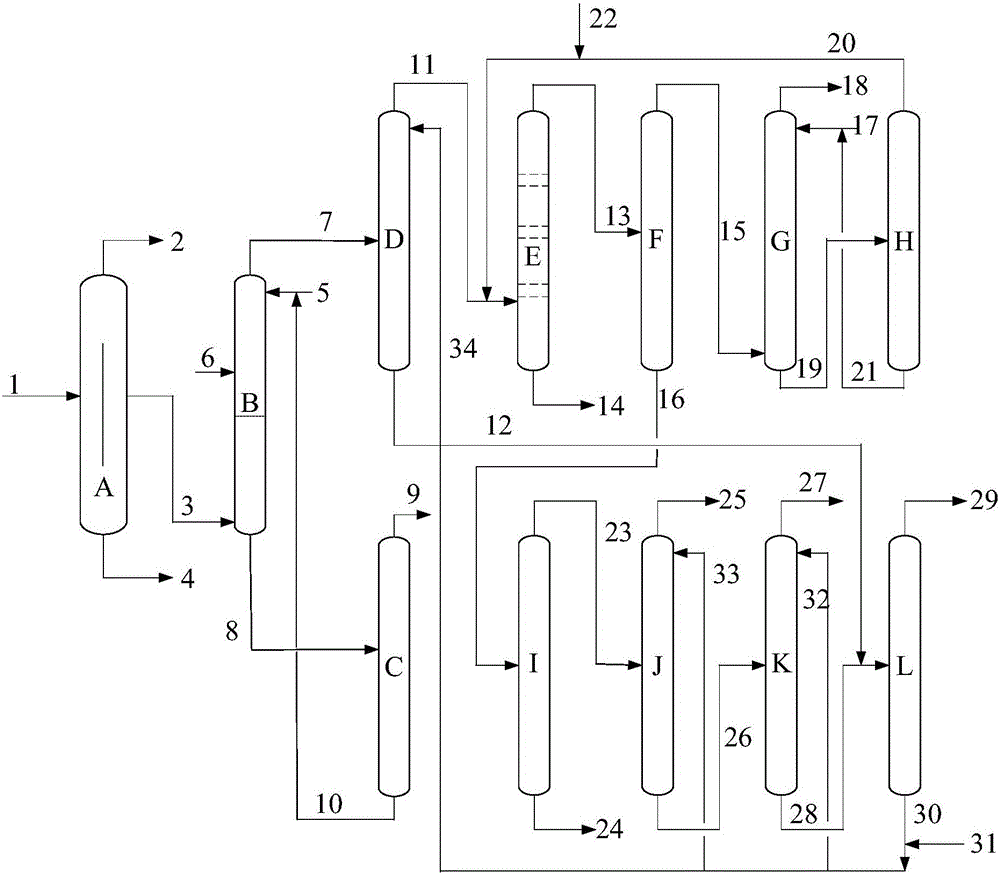

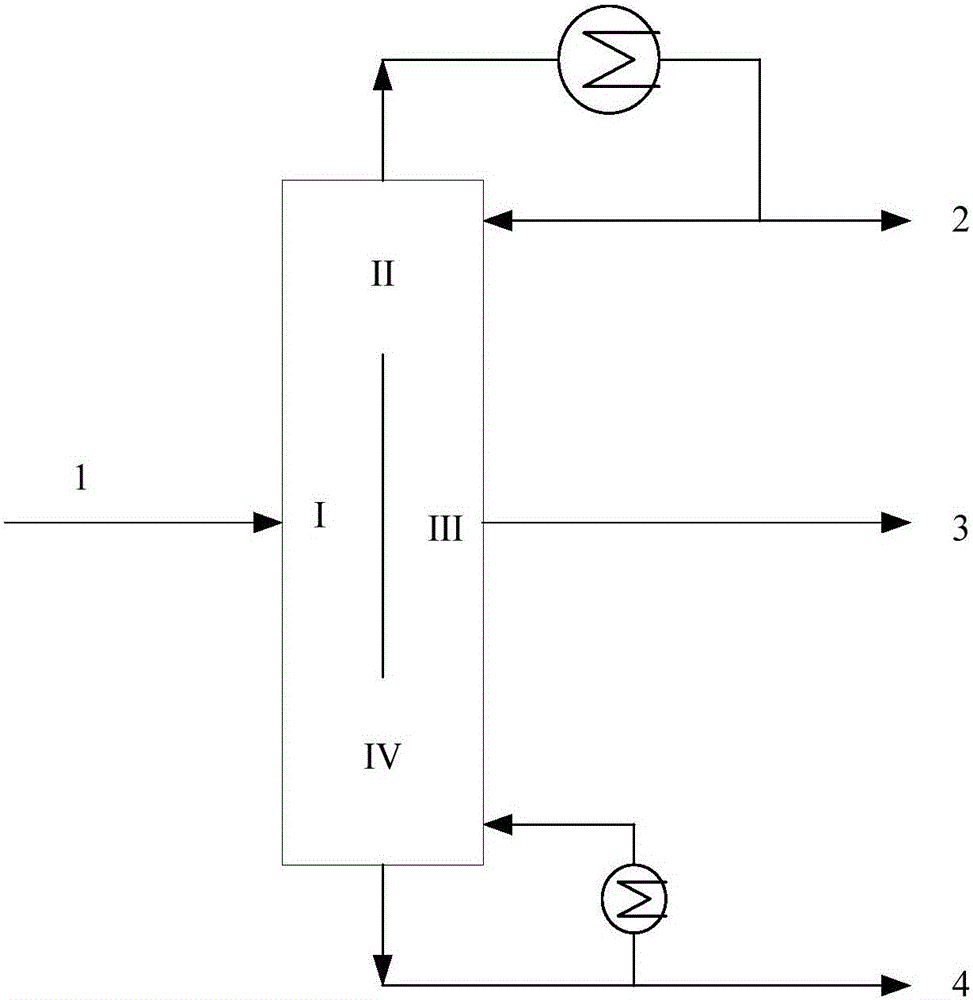

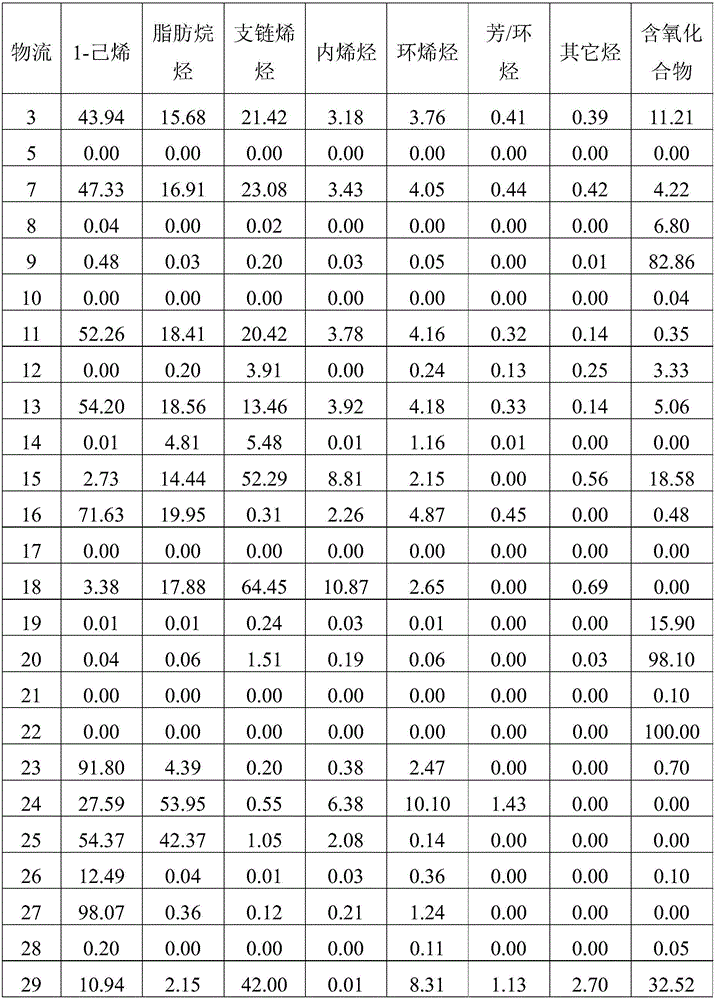

Method for separating oxygenated chemicals and 1-hexene from Fischer-Tropsch synthesis oil product

ActiveCN105777467AIncrease productionExpand product rangeOrganic compound preparationDistillation purification/separationAlkaneAlcohol

The invention relates to a method for separating oxygenated chemicals and 1-hexene from a Fischer-Tropsch synthesis oil product.The method comprises the steps that C6 fraction material flow is obtained through distillation in a predistillation tower by taking the Fischer-Tropsch synthesis oil product as a raw material, and two streams of extraction agents are fed to remove oxygenated chemicals in an extraction tower to obtain material flow rich in the oxygenated chemicals and crude C6 hydrocarbon material flow; the oxygenated chemicals contained in the crude C6 hydrocarbon material flow are further removed through a third extraction agent, tertiary olefins are converted into corresponding ethers through methyl alcohol under the action of an etherification catalyst to be removed, further purification is performed through rectification, and then C6 isoparaffin components and cycloolefin components are removed sequentially through a fourth extraction agent and a fifth extraction agent respectively to obtain 1-hexene product material flow.Compared with the prior art, the method has the advantages of being simple in technological process, low in cost and the like, and not only is 1-hexene separated and purified from the Fischer-Tropsch synthesis oil, but also the oxygenated chemicals can be separated.

Owner:YANKUANG ENERGY R&D CO LTD

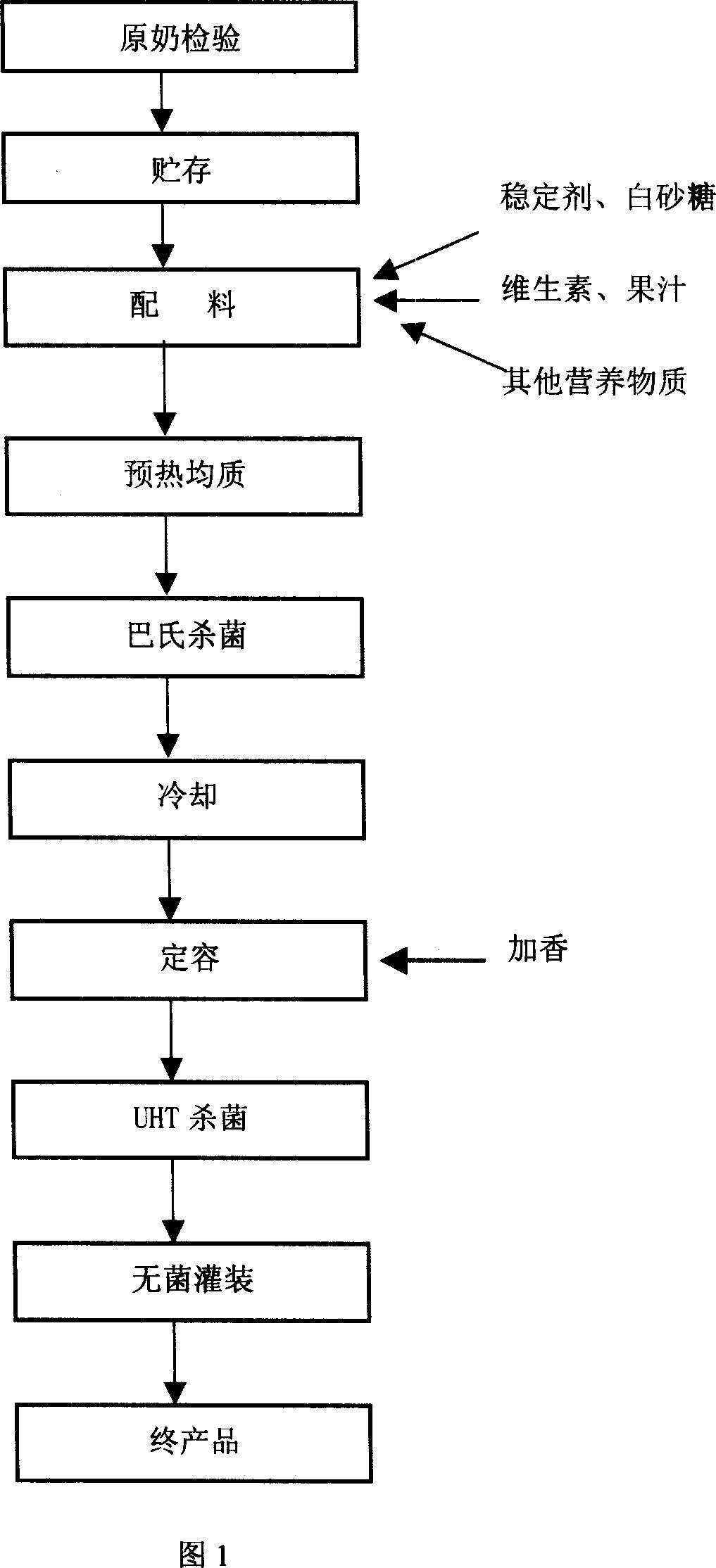

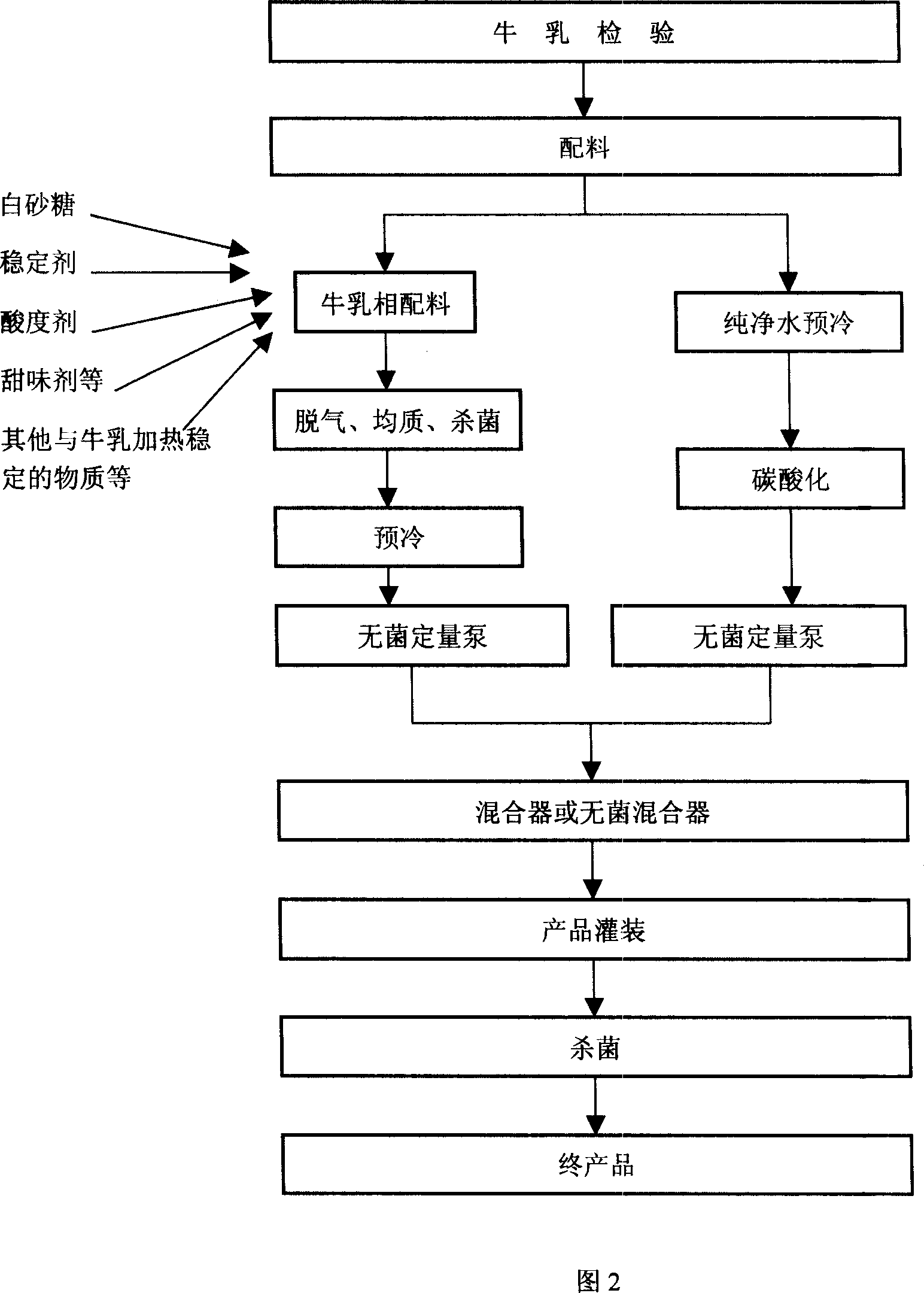

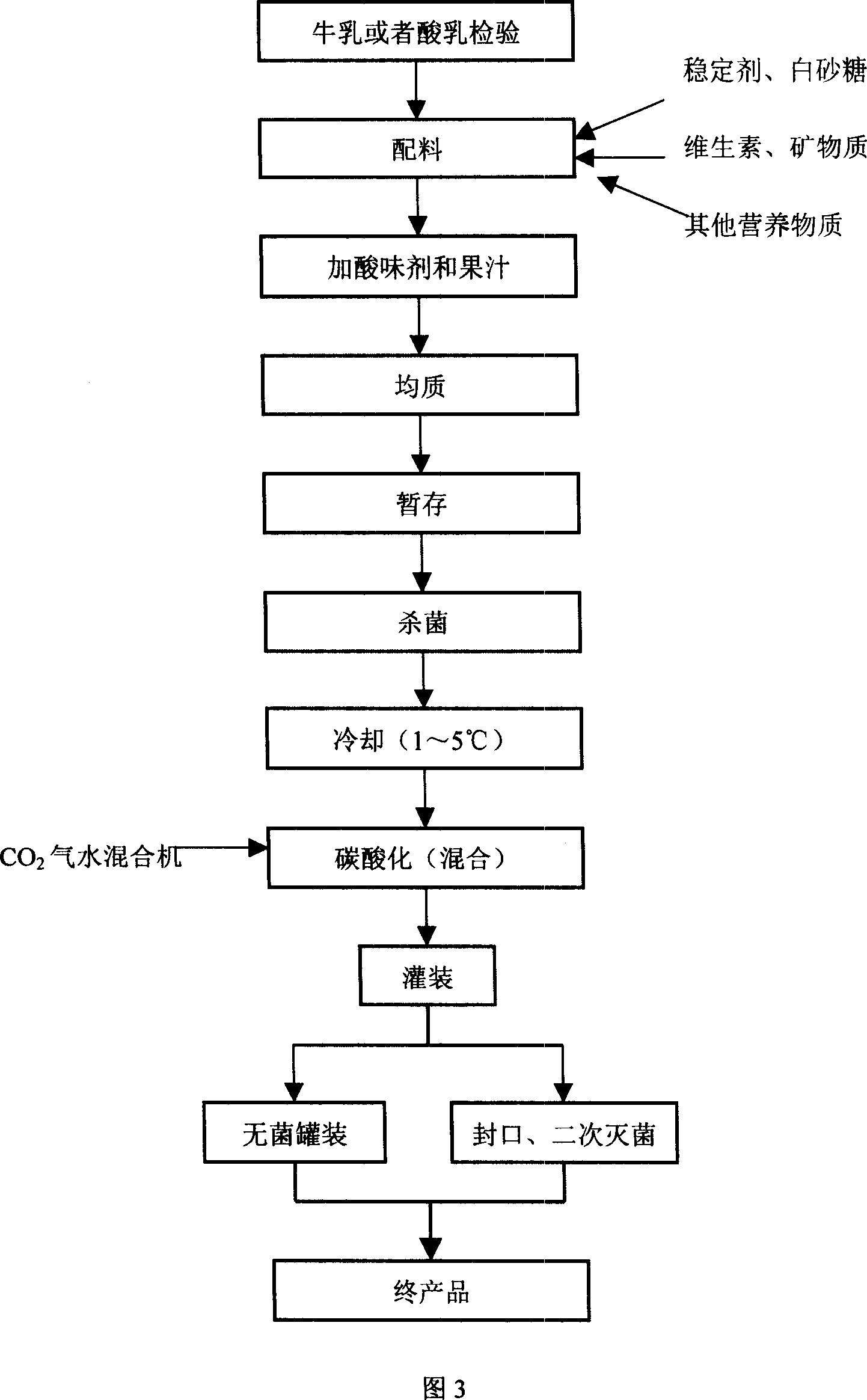

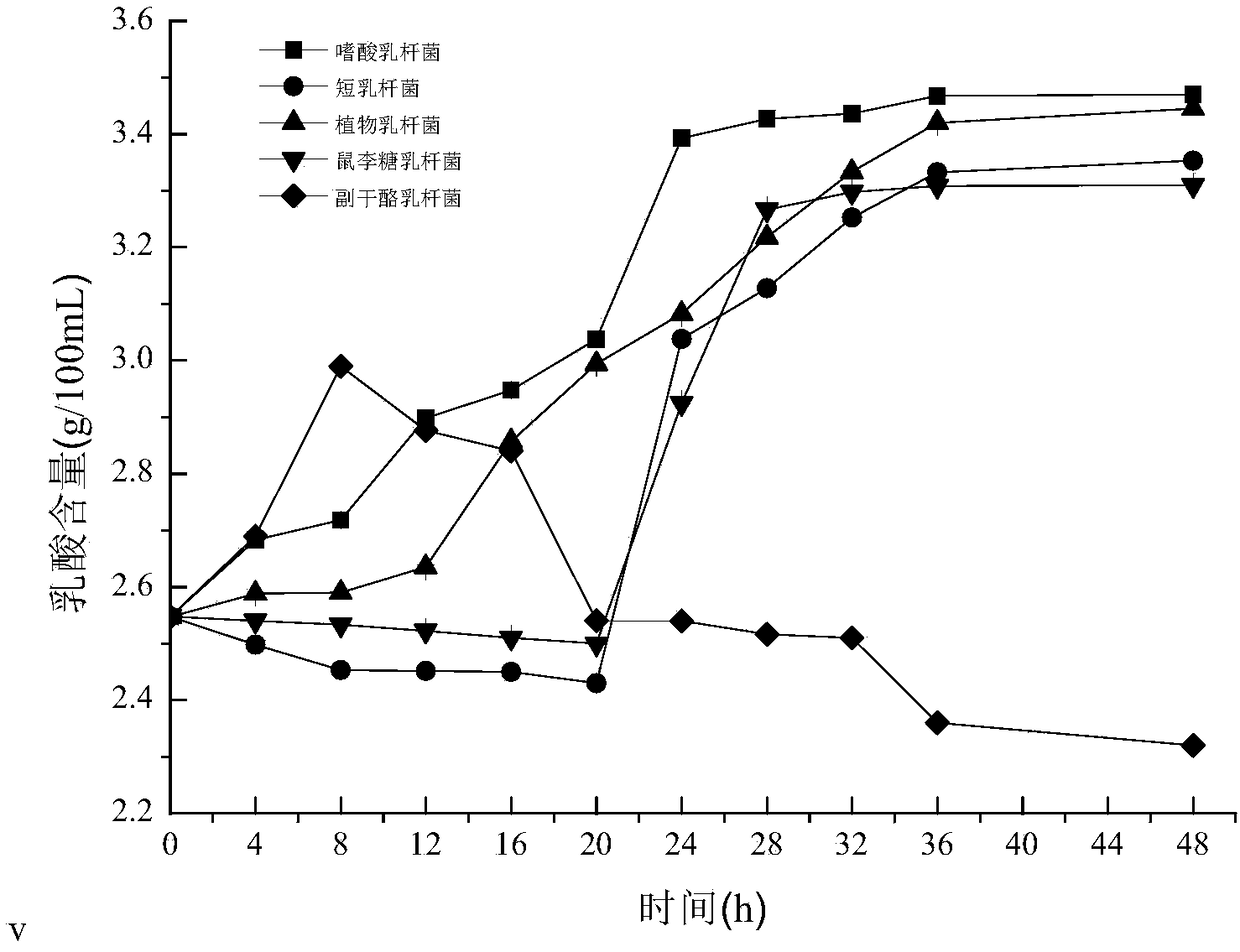

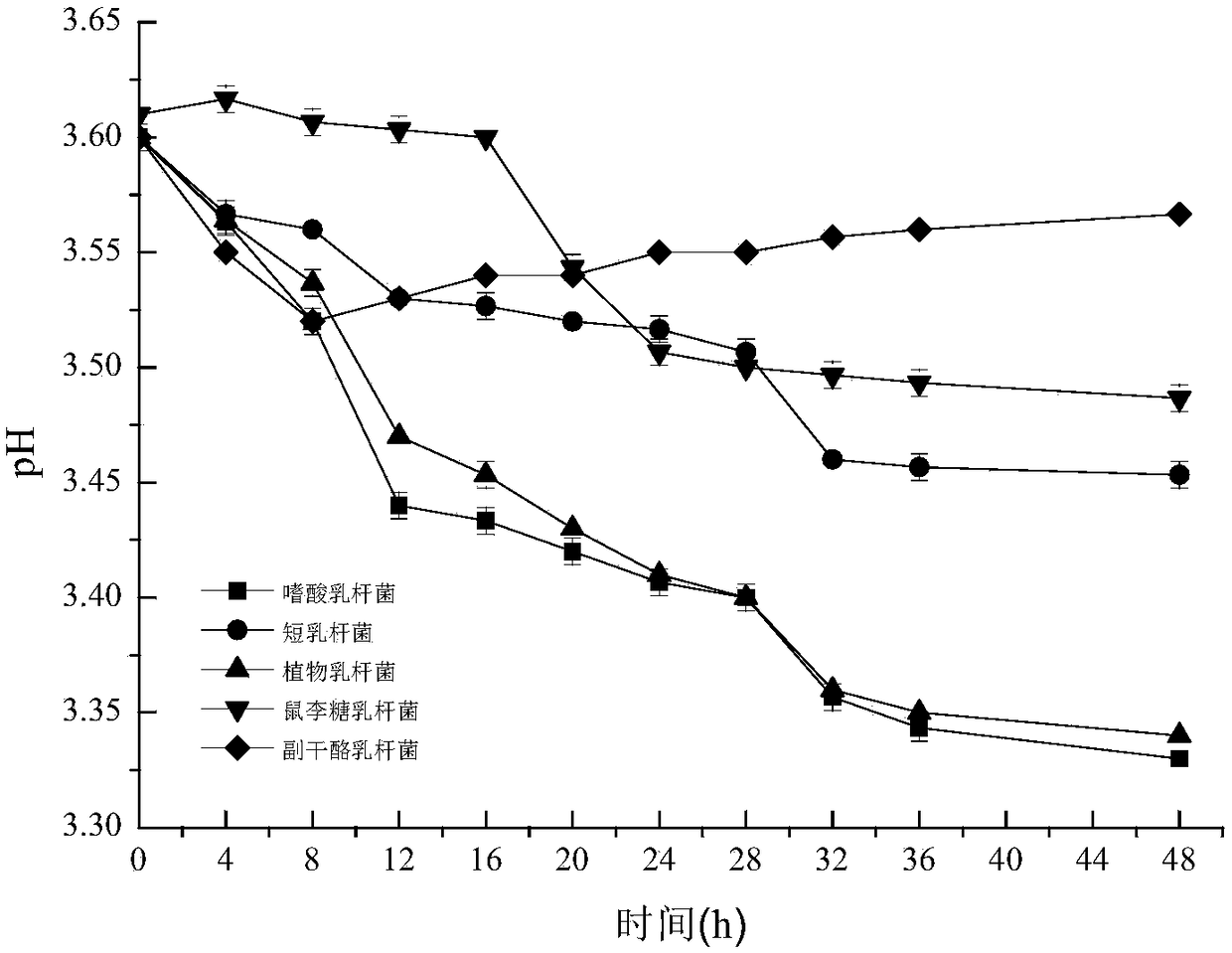

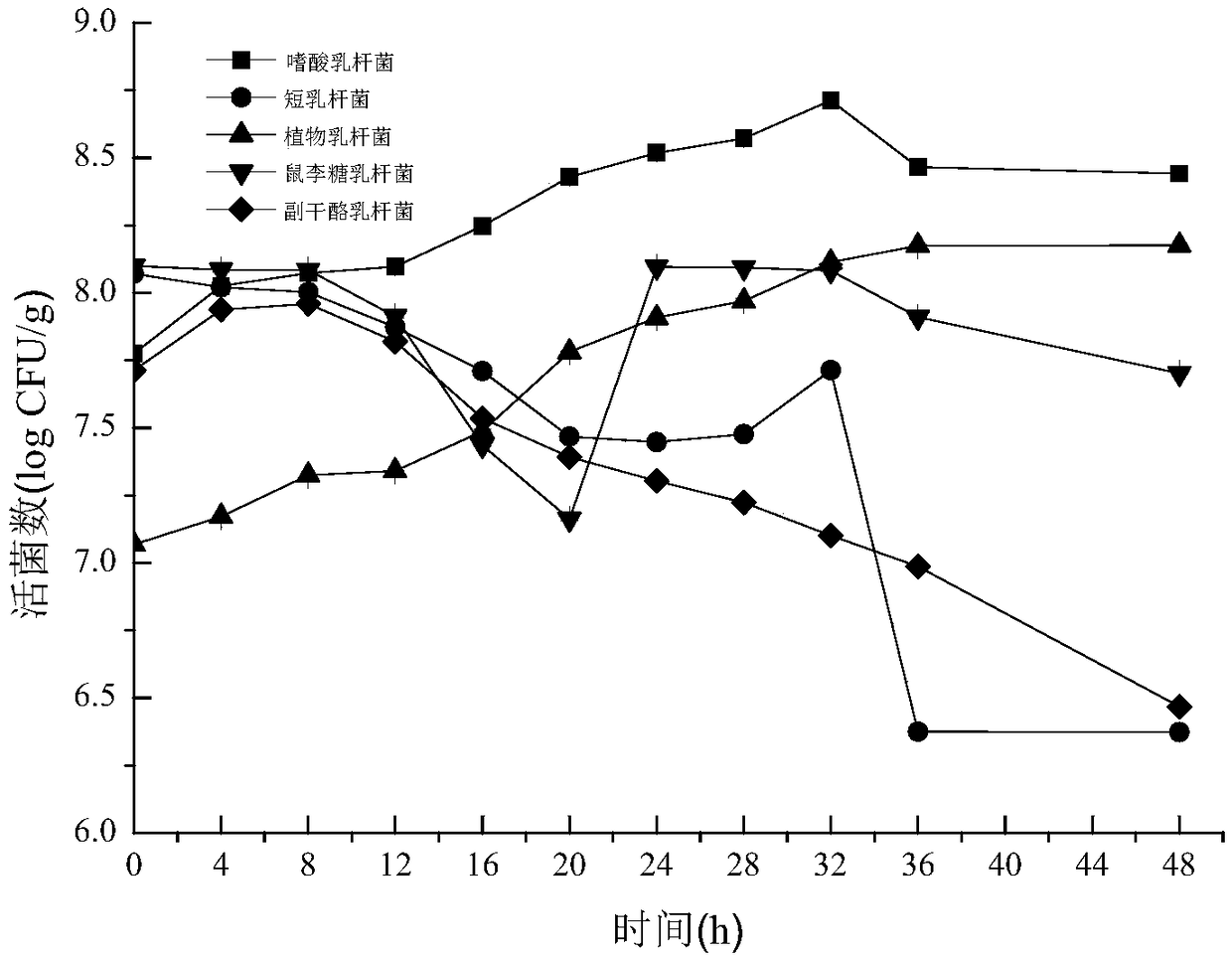

Method for producing air-containing acidic milk-like beverage

InactiveCN101011082AAchieve innovationExpand product rangeMilk preparationFood preparationProduct gasRegular Production

The invention relates to a method for producing lactic acid drink, which comprises that 1, preparing milk phase; 2, adding carbon dioxide gas; 3, packing, disinfecting to obtain the lactic acid drink. Compared with general method, the invention can reduce the pollution of microbe, improve the quality and widen the application.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

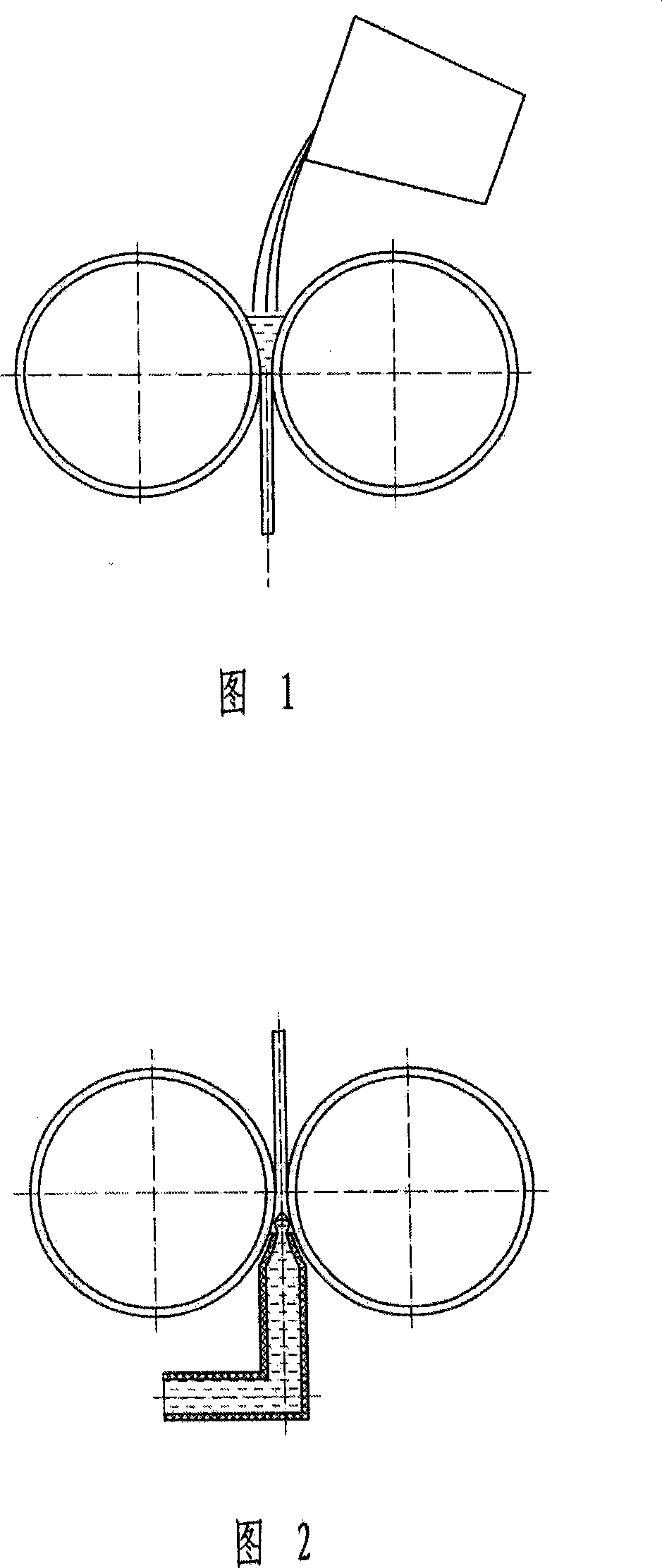

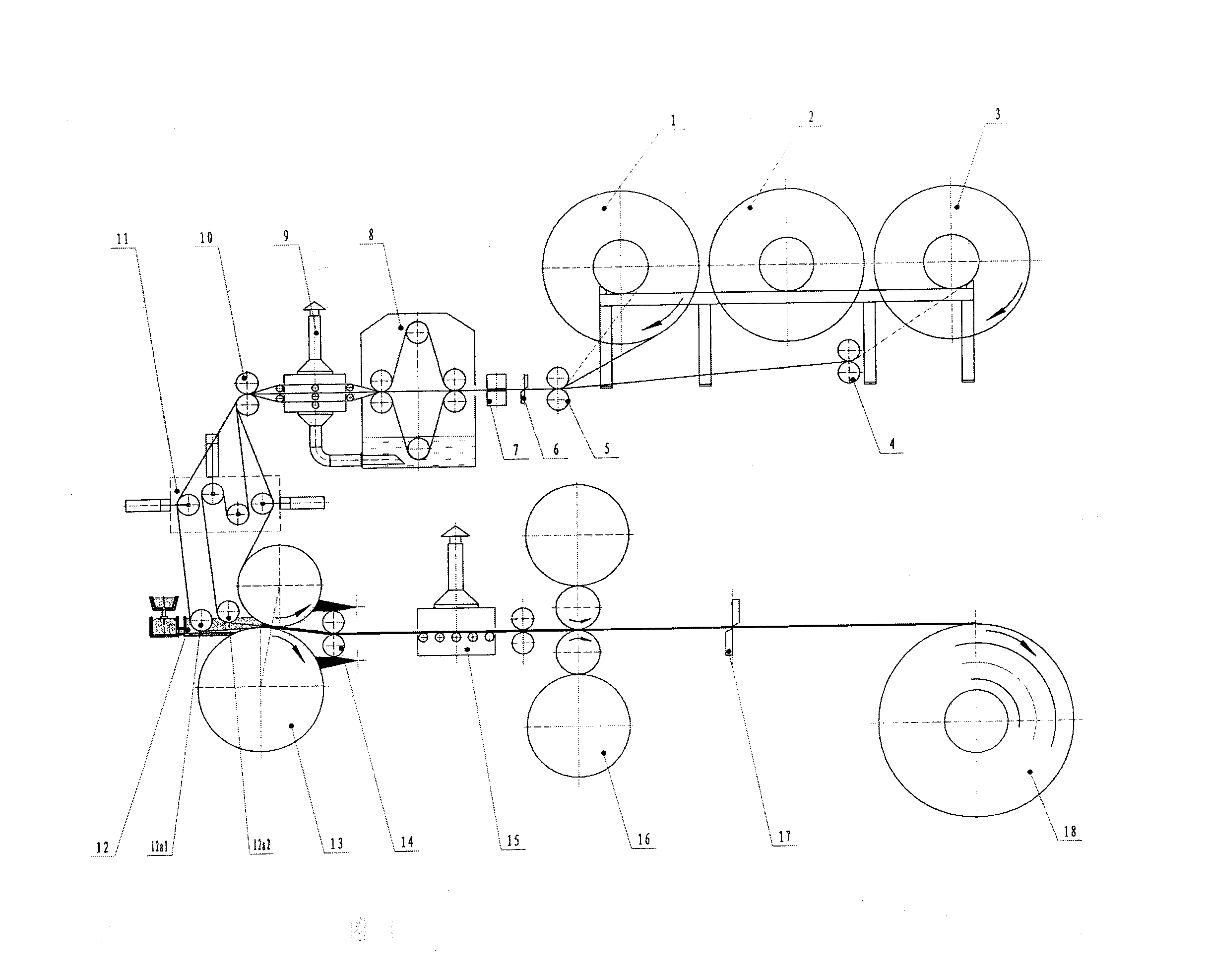

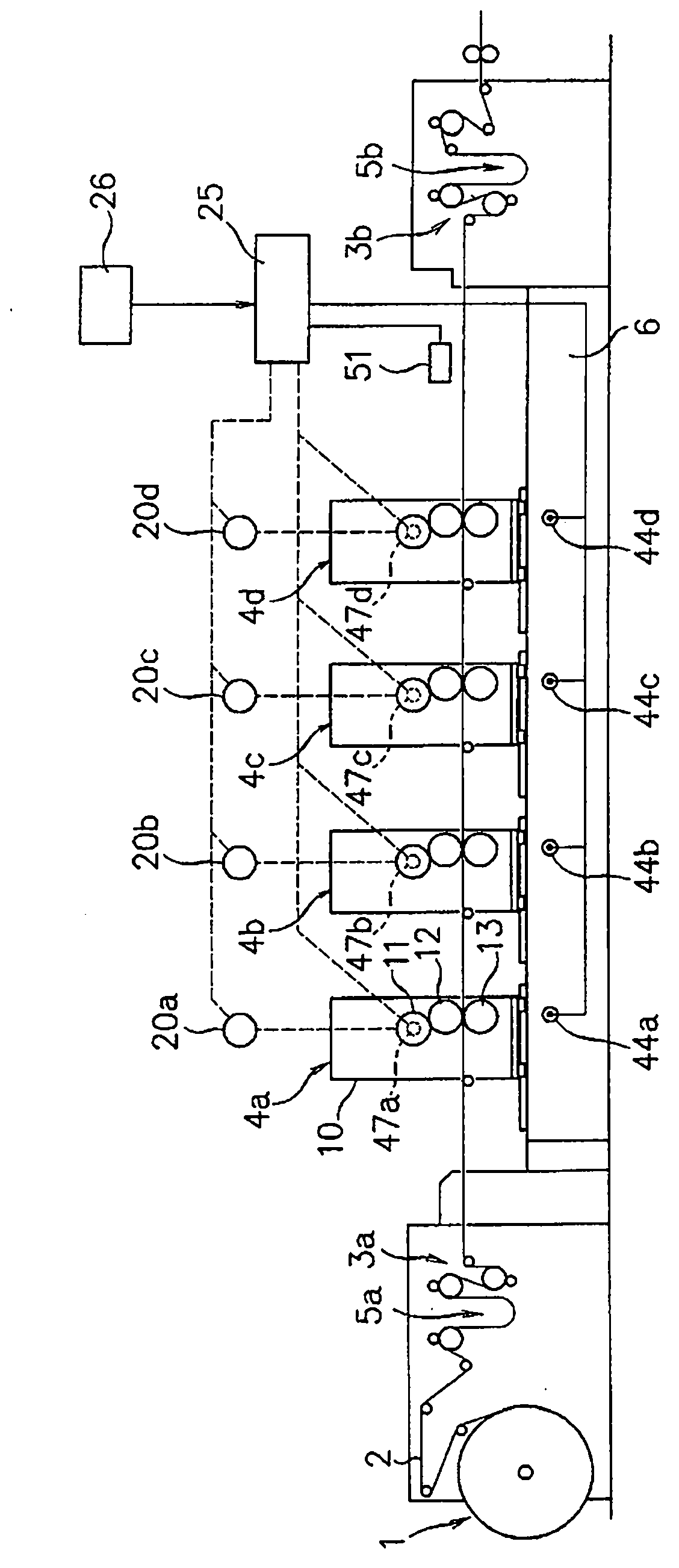

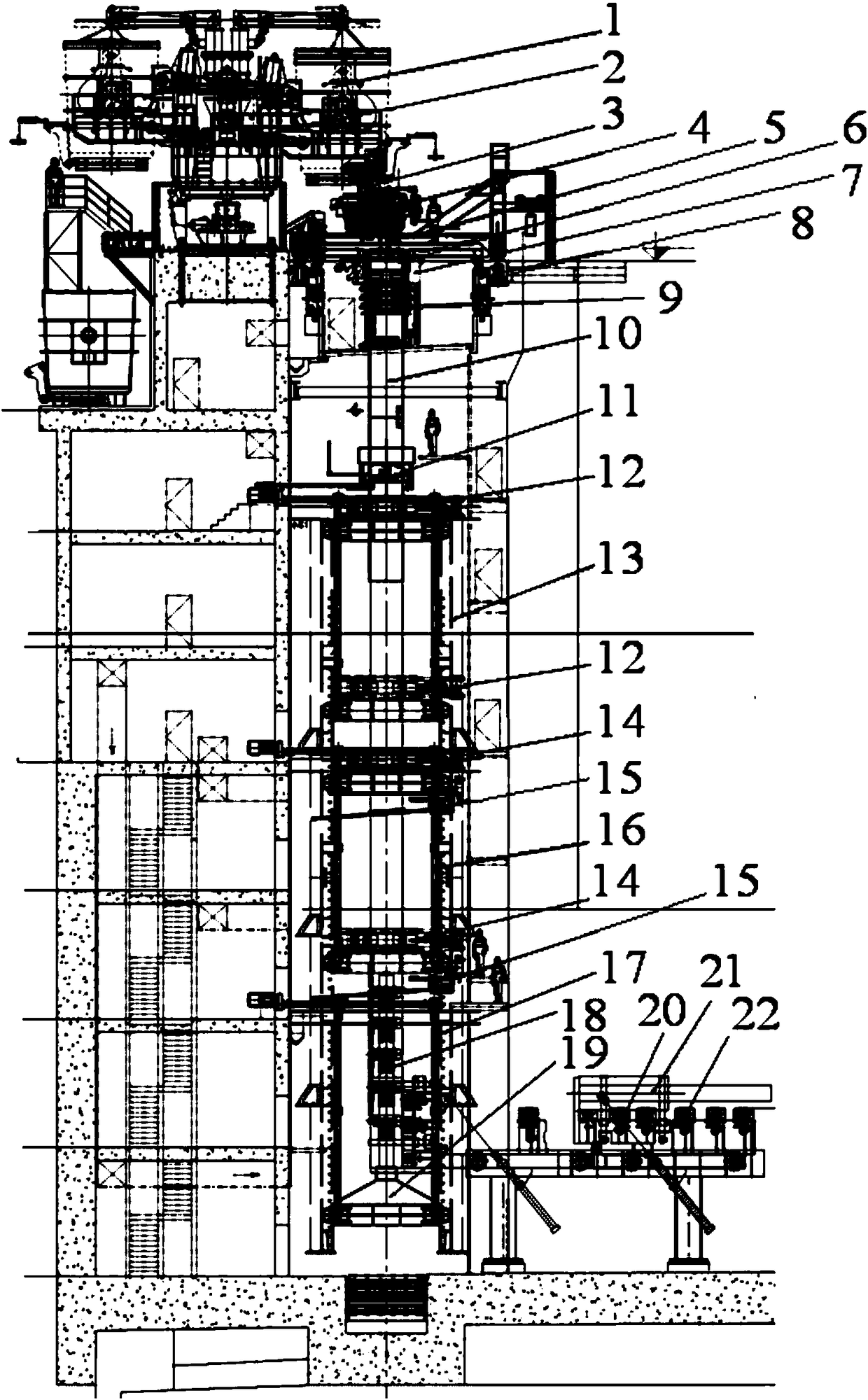

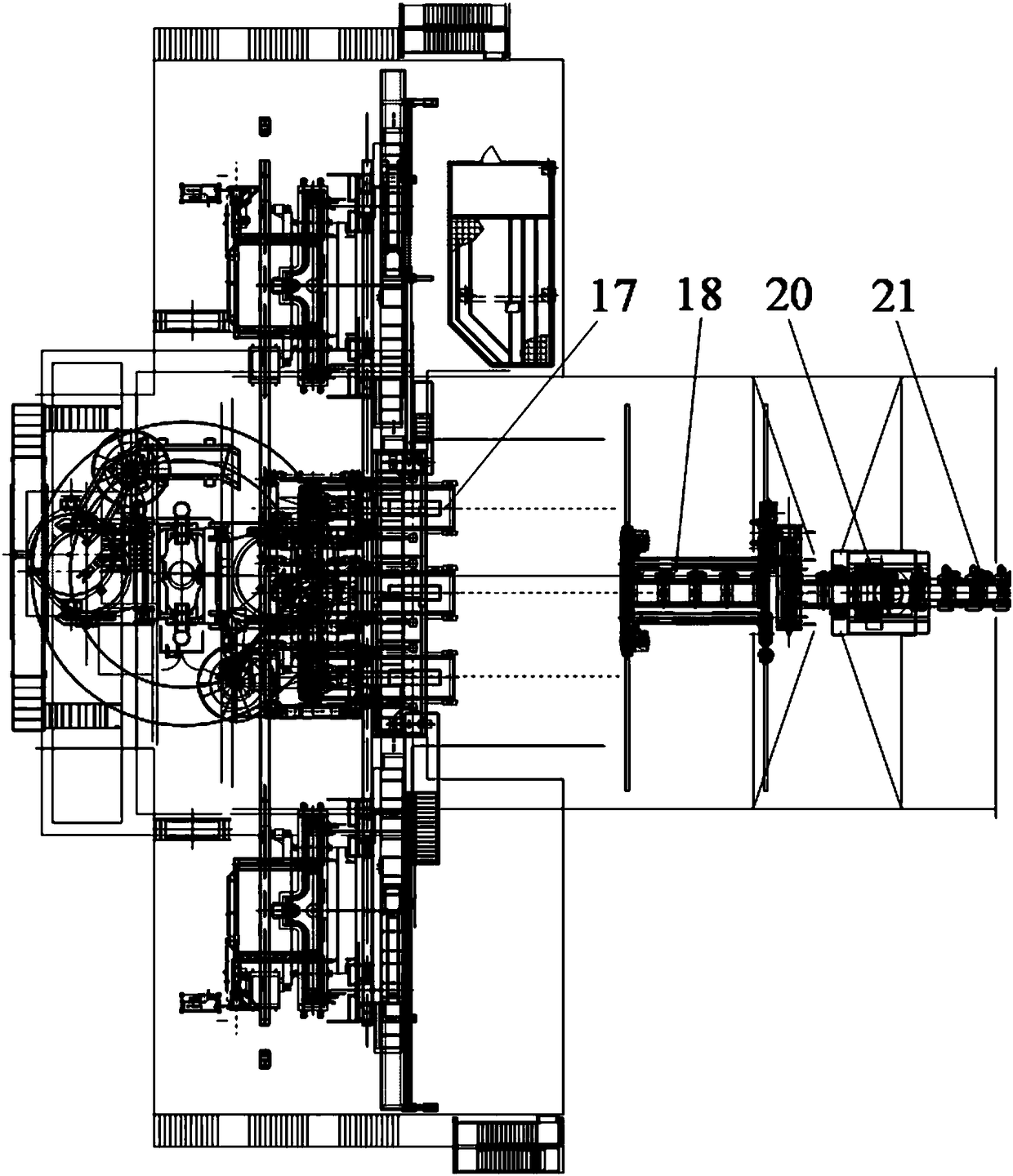

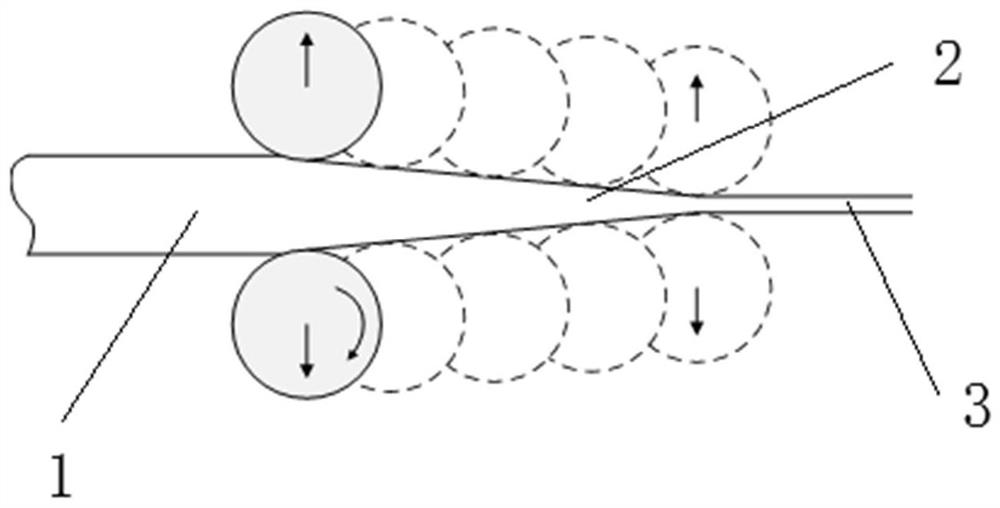

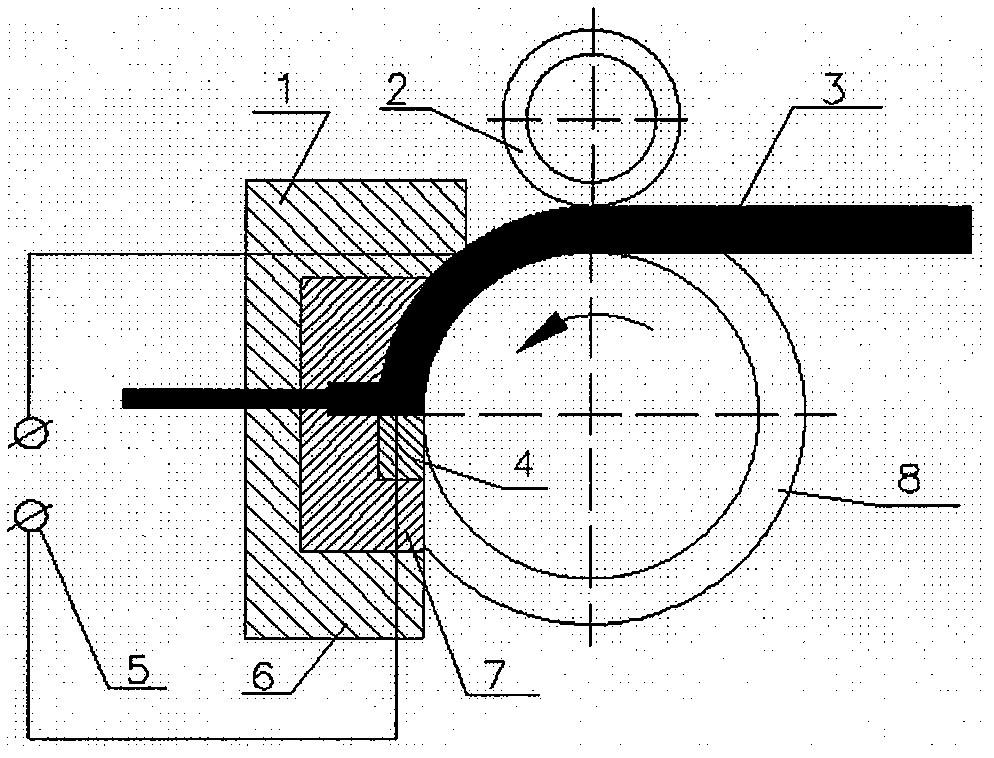

Double-roller casting rolling-hot continuous rolling method and equipment

ActiveCN101239358AIncrease productionHigh dimensional accuracyTemperature control deviceMetal rolling stand detailsProduction lineUltimate tensile strength

The invention provides a method and device for double-roller cast rolling-thermal tandem rolling, which are a method and device for producing aluminum and aluminum alloy plate blank. By using the method, thick cast rolling plate blank can be produced, and coiled material with quality corresponding to that of thermal rolling plate is produced by large rolling amount of thermal rolling, transmitting and coiling. The invention provides a method and device for producing aluminum and aluminum alloy coiled material with high efficiency and greatly improved property by modification aiming at shortcoming of limited cooling space and cooling intensity of the double-roller cast rolling mill in prior art. The invented device enlarges the cast rolling space of the cast rolling mill in prior art with 1.8-4.0 times, enlarges the roller gap thereof with 1.5-2.5 times, enhances the cast rolling speed thereof with 1.5-3.0 times, cast rolls the casting blank continuously with a temperature ranging from 310 DEC C to 510 DEG C, and the integral processing amount is controlled in the range of 40-85, thereby the yield, size accuracy and mechanical property are greatly improved, and the product range is enlarged. The invented device is: inclination angle adjustable off-centering reducing double-roller cast rolling-thermal tandem rolling- cutting-coiling production line.

Owner:张明

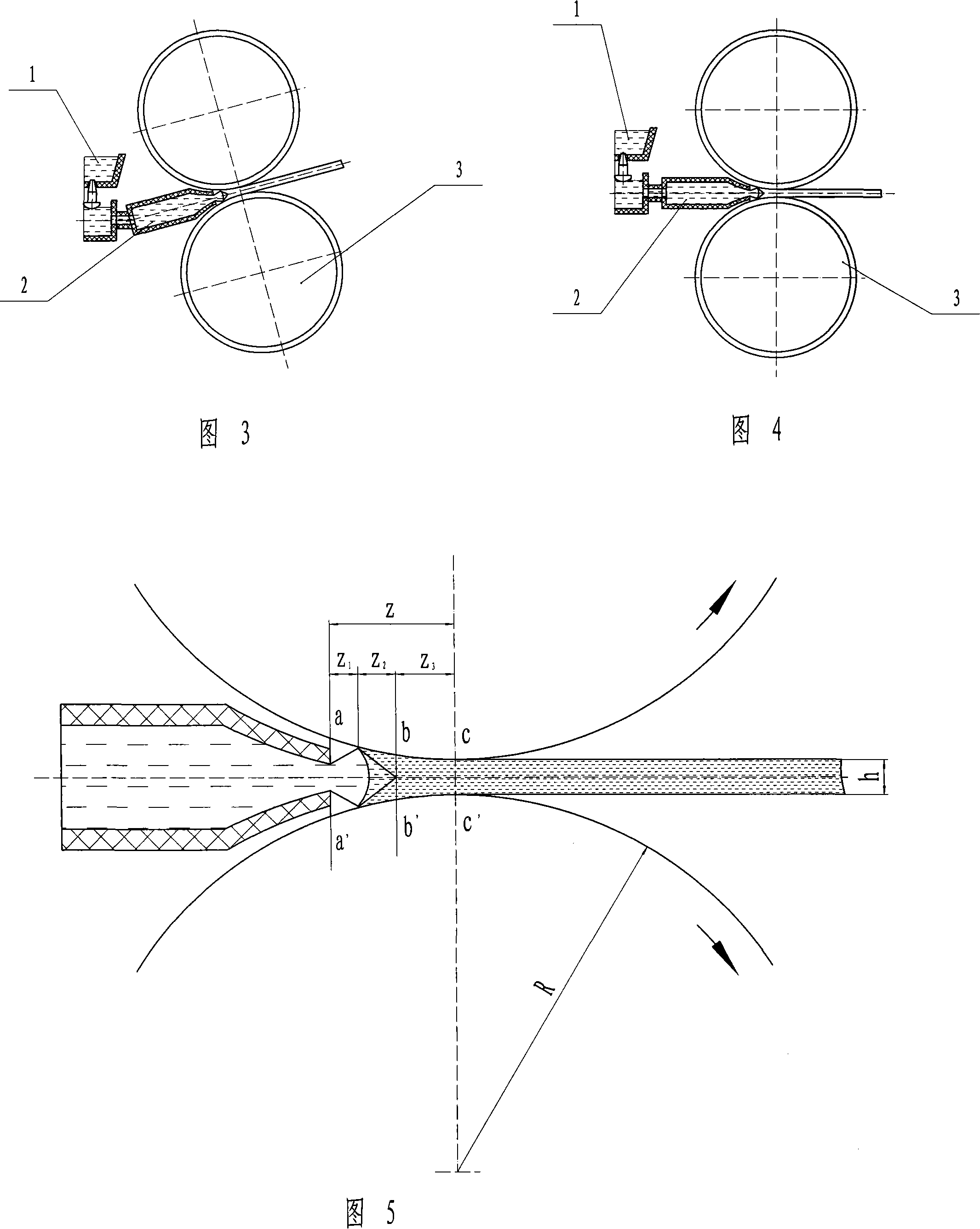

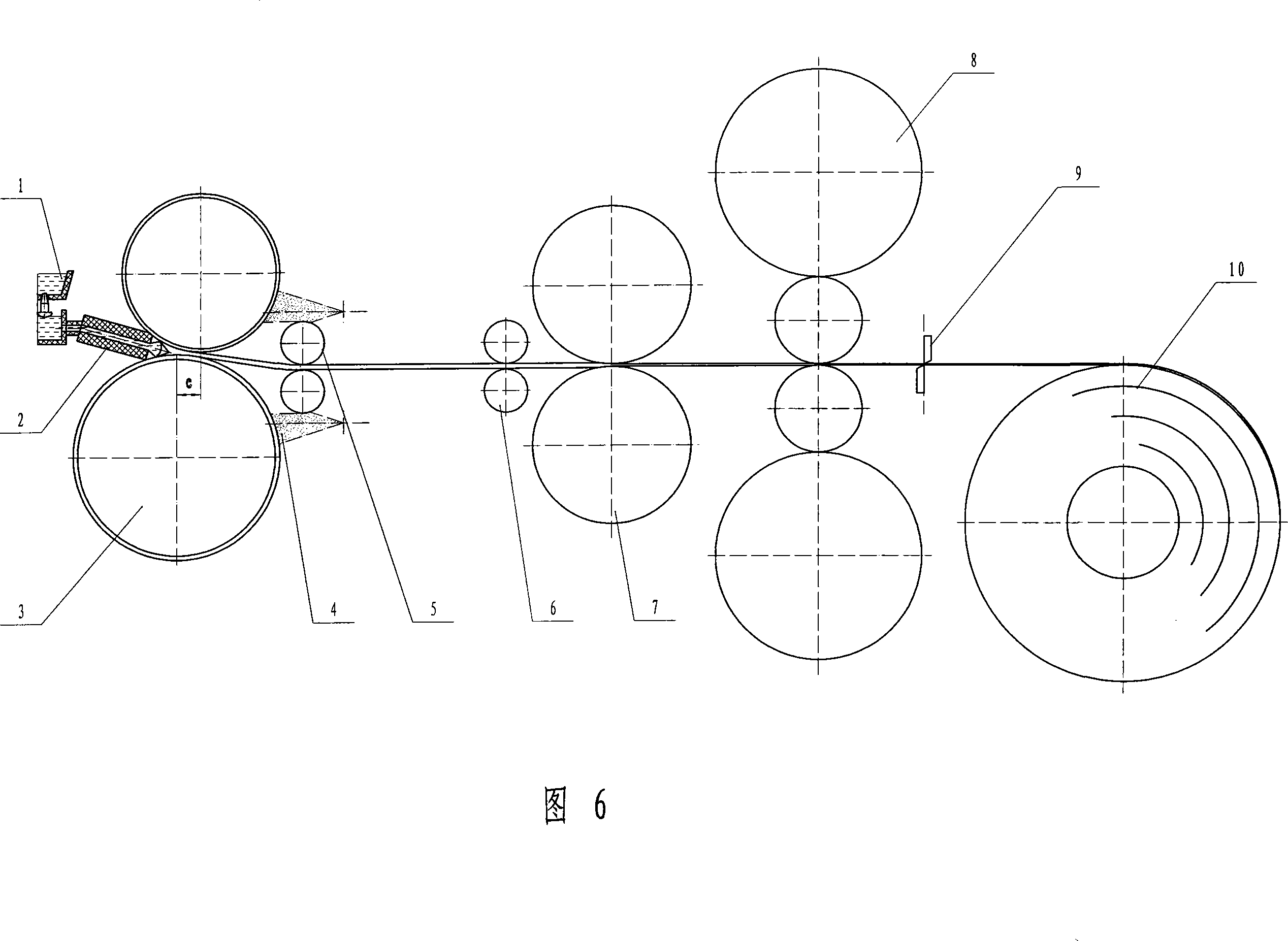

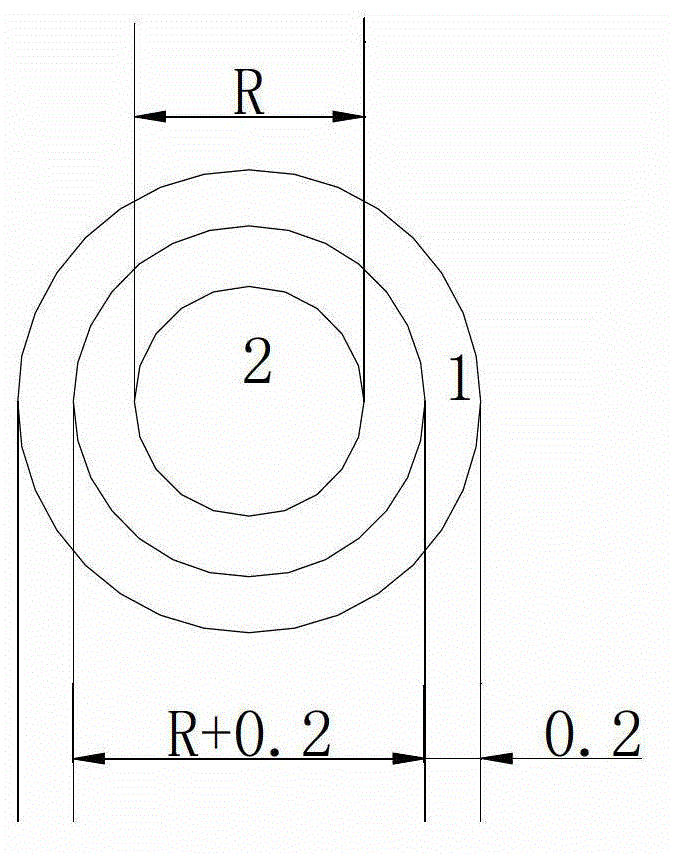

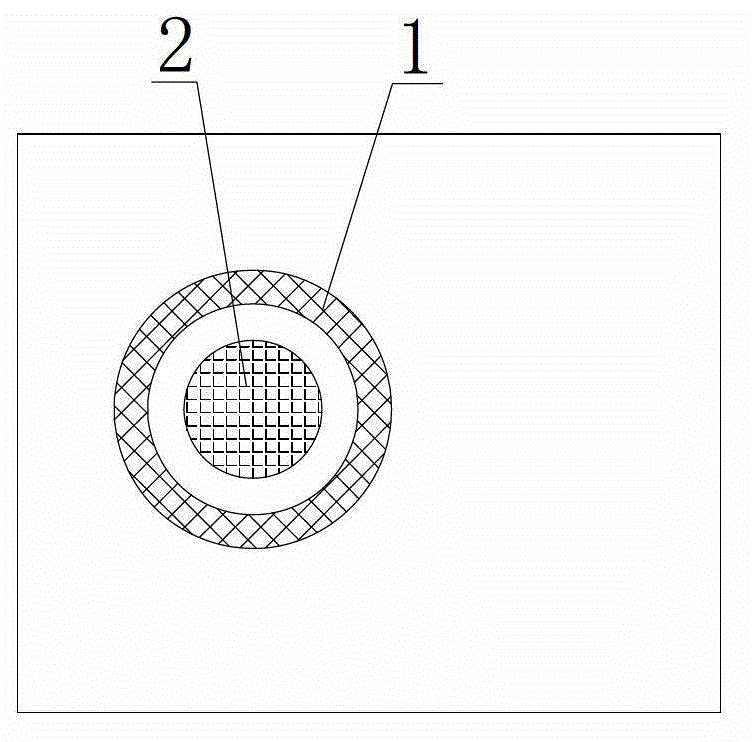

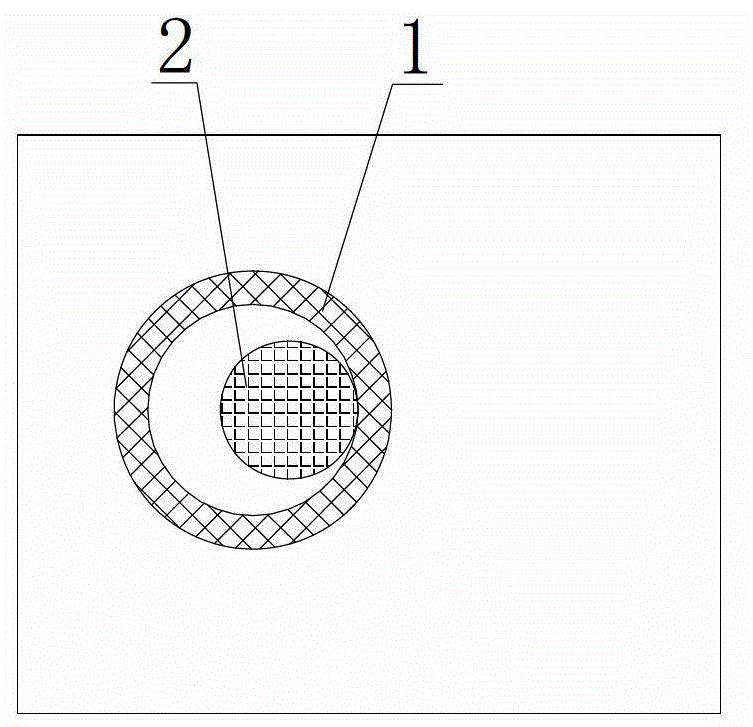

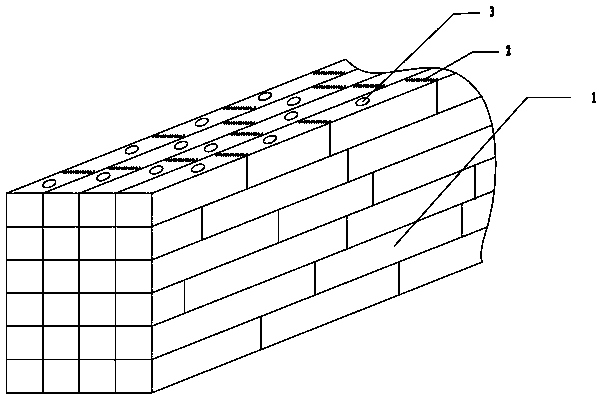

Solid-liquid phase metal cast rolling compounding method and device

ActiveCN103252369AIncrease productionHigh dimensional accuracyAuxillary arrangementsMetal rolling arrangementsProduction lineMetal strips

The invention provides a solid-liquid phase metal cast rolling compounding method and device capable of producing a novel metal composite strip through one time continuously by using multi-layer and various metal plates through liquid metal. On the basis of a plate strip cast rolling process, an open feeding nozzle is adopted, a pre-processed multi-layer metal strip penetrates through a cast rolling machine roll gap after soaking in metal melt in the feeding nozzle, the metal strip and the metal melt cooled to be in a semi-solid state and a solid state in a cast rolling area are rolled together, the metal melt is cured and attached to the metal strip, metallurgical bonding of two or more than two types of metal is formed, and the metal composite strip with the preset thickness is produced. The solid-liquid phase metal cast rolling compounding method and device has the advantages of being less in investment, low in production cost and energy consumption, good in product performance and wide in product range. The device comprises an uncoiling unit, a first dragging machine, a second dragging machine, an end shear, a splicer, a washing machine, a drying machine, a third dragging machine, a strip length and tension adjusting device, a cast rolling machine, (a heat preservation heating device, a hot continuous rolling machine), a shearing machine and a coiling machine production line.

Owner:秋海滨

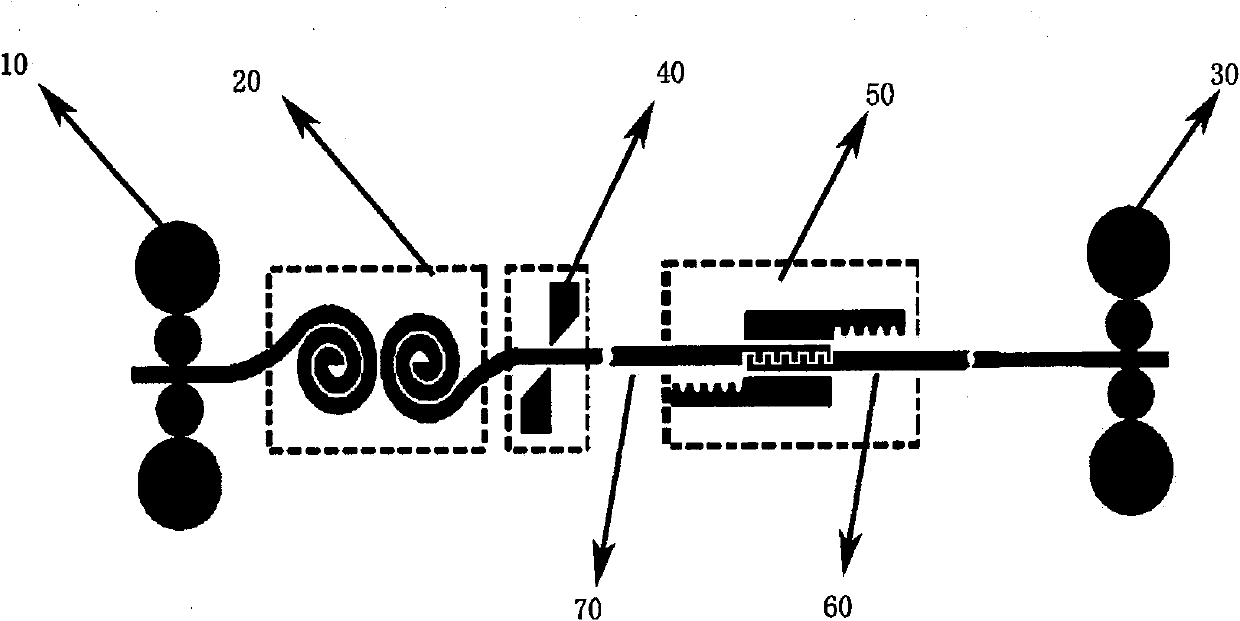

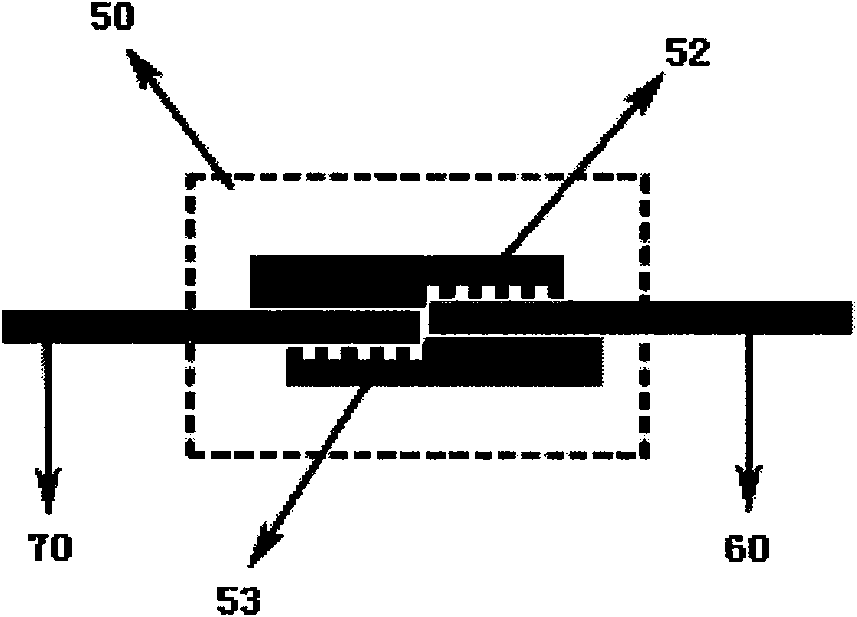

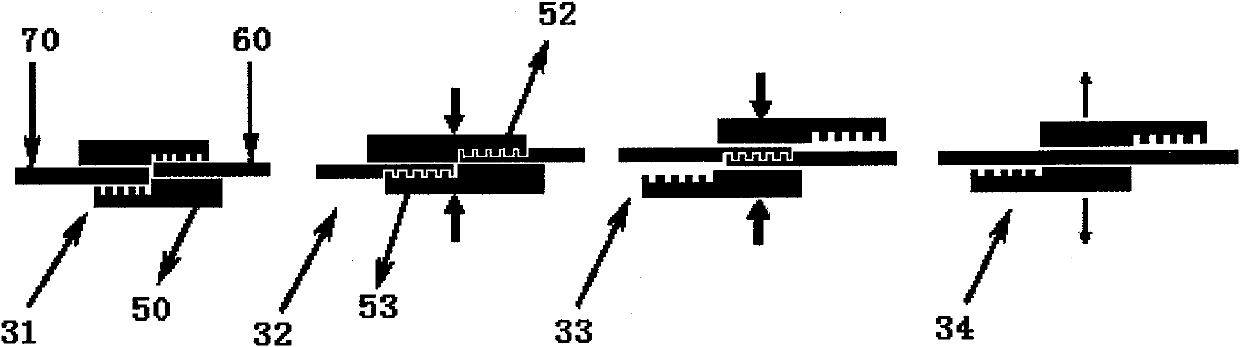

Connecting method for endless-rolled intermediate billets of hot-rolled strip steel

InactiveCN102019325ASimple process equipmentImprove connection strengthWelding/soldering/cutting articlesMetal working apparatusProduction lineProcess equipment

The invention discloses a connecting method for endless-rolled intermediate billets of hot-rolled strip steel, which belongs to the technical field of hot-rolled strip steel; and the connecting method comprises the following steps: cutting heads and tails: utilizing a shearing machine to cut the heads and tails of the intermediate billets after rough rolling, causing the intermediate billets to form straight end surfaces of the heads and the tails, and aligning the head and tail end parts of the front and back intermediate billets; pressing teeth: utilizing a pressing machine to press the teeth on the opposite surfaces of the end parts of the front and back intermediate billets, thus forming tooth-shaped regions on the opposite surfaces of the end parts of the front and back intermediate billets; lapping: oppositely lapping the tooth-shaped region at the tail of the front intermediate billet with the tooth-shaped region of the back intermediate billet together; and pressing: utilizingthe pressing machine to press the end parts of the front and back intermediate billets together. The method has the following advantages: process equipment is simple, the connection strength is high,the connection speed is fast, and the range of application is wide; and the method can not only be used for construction of newly-built continuous hot-rolled strip production lines, but also be used for transformation of the existing continuous hot-rolled strip production lines.

Owner:UNIV OF SCI & TECH BEIJING

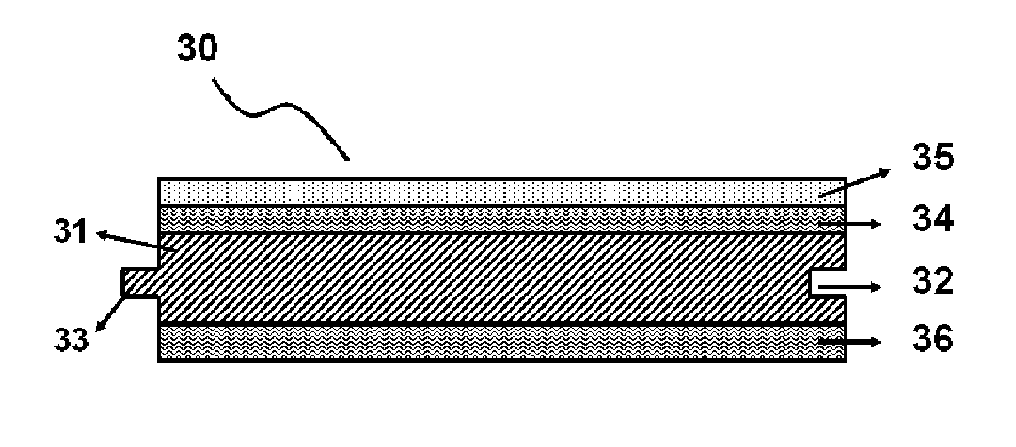

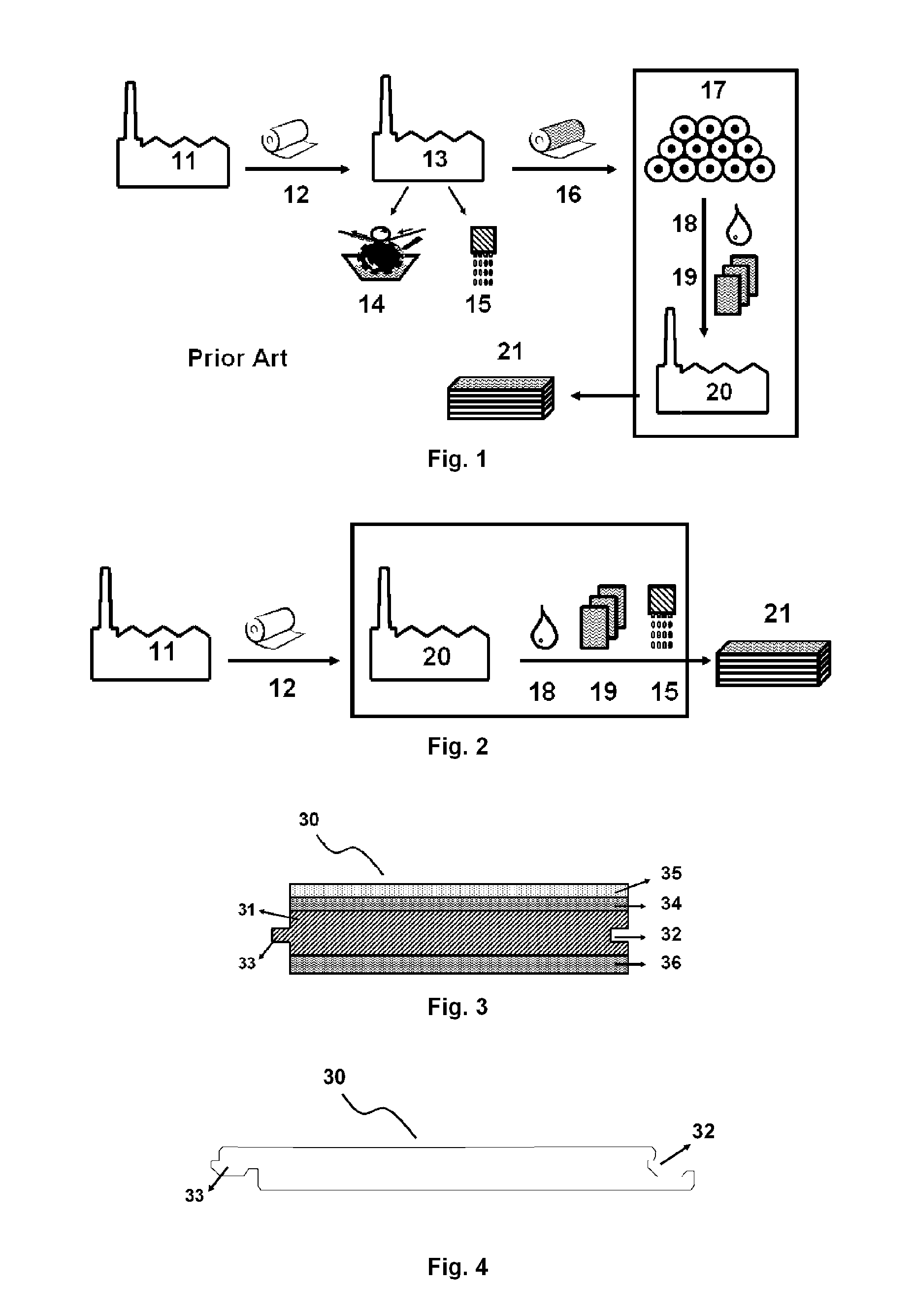

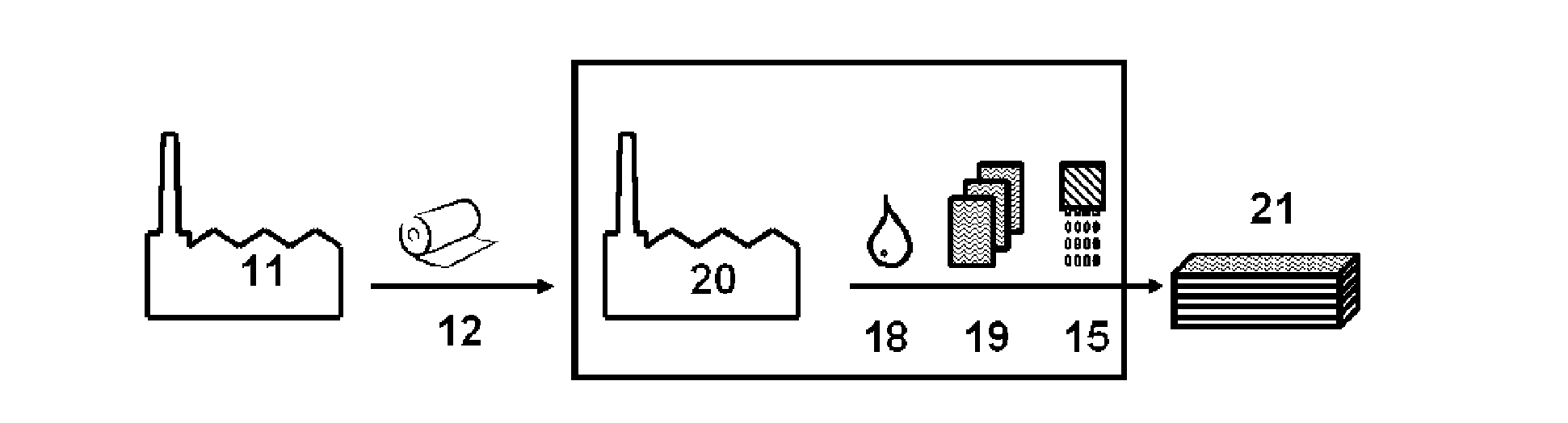

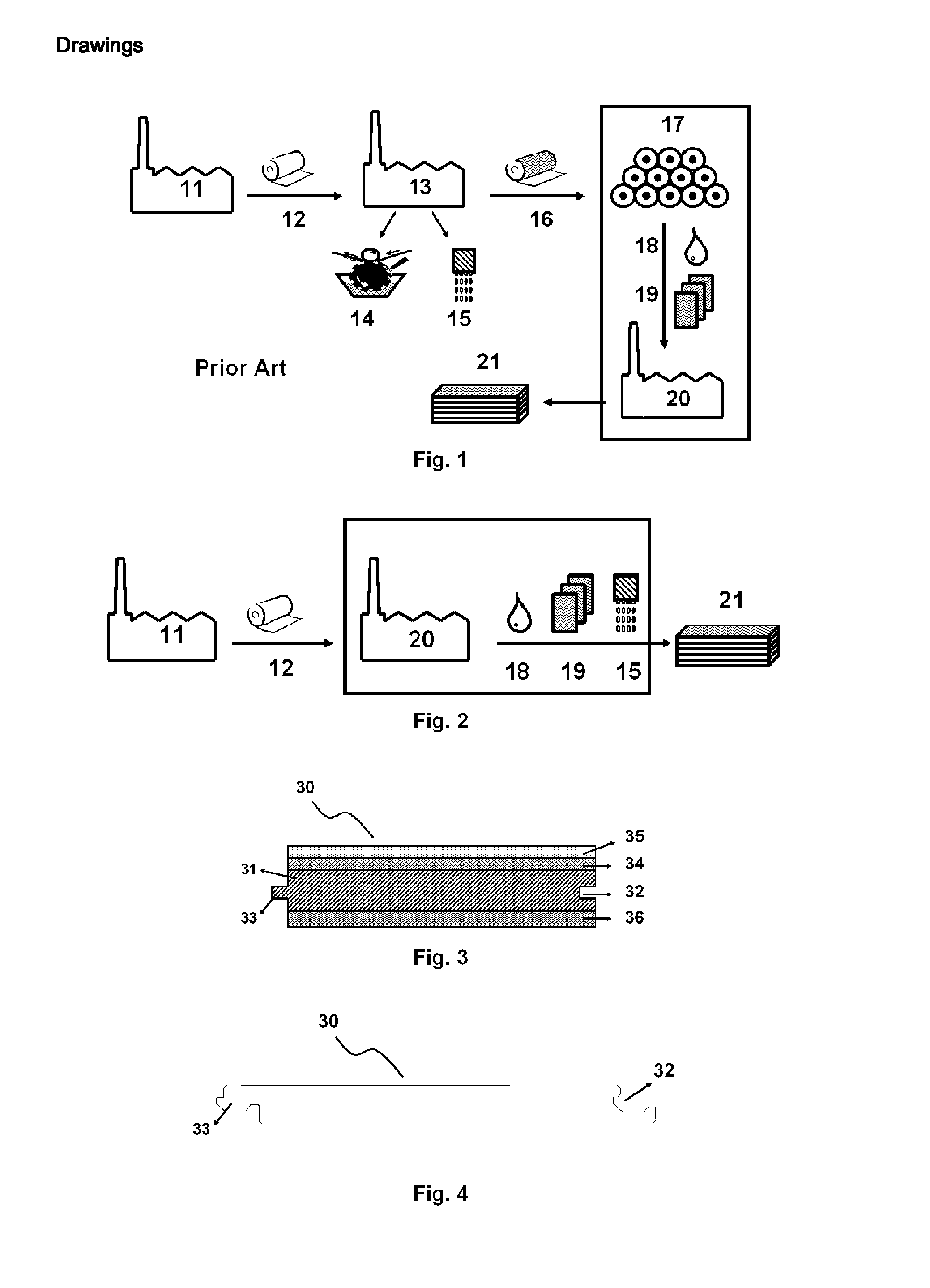

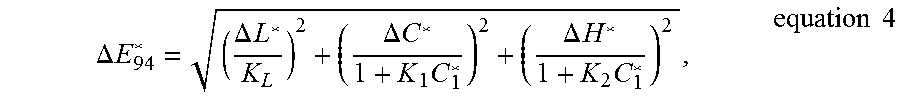

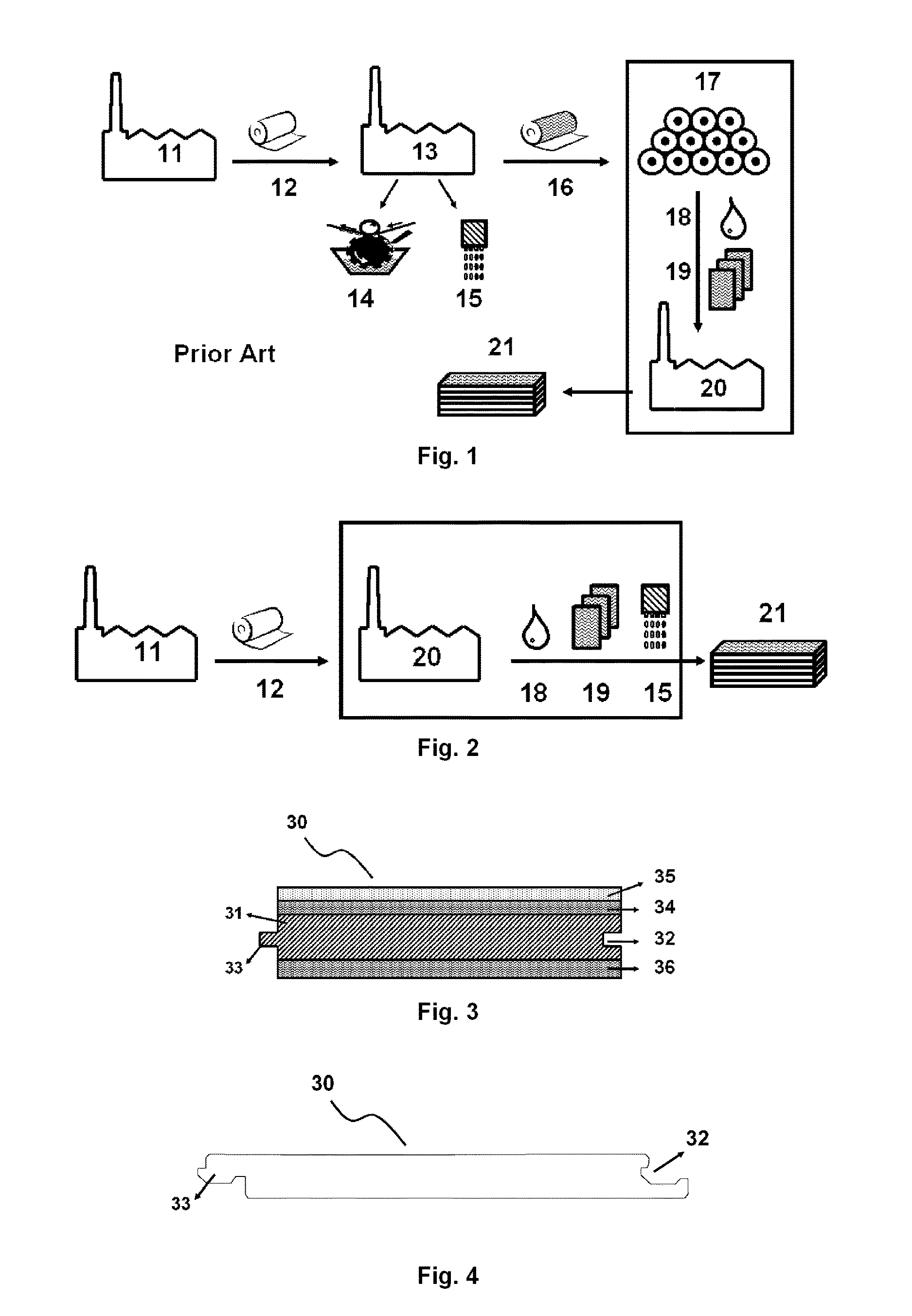

Manufacturing of decorative surfaces by inkjet

ActiveUS20160207307A1Simple manufacturing processMinimize dependenciesCovering/liningsLamination ancillary operationsPolymer sciencePolymer

A method of manufacturing a decorative surface includes the steps of a) impregnating a paper substrate with a thermosetting resin; b) jetting a colour pattern with one or more aqueous inkjet inks including a polymer latex binder on the thermosetting resin impregnated paper; c) drying the one or more aqueous inkjet inks; and d) heat pressing the thermosetting paper carrying the colour pattern into a decorative surface.

Owner:UNILIN BVBA +1

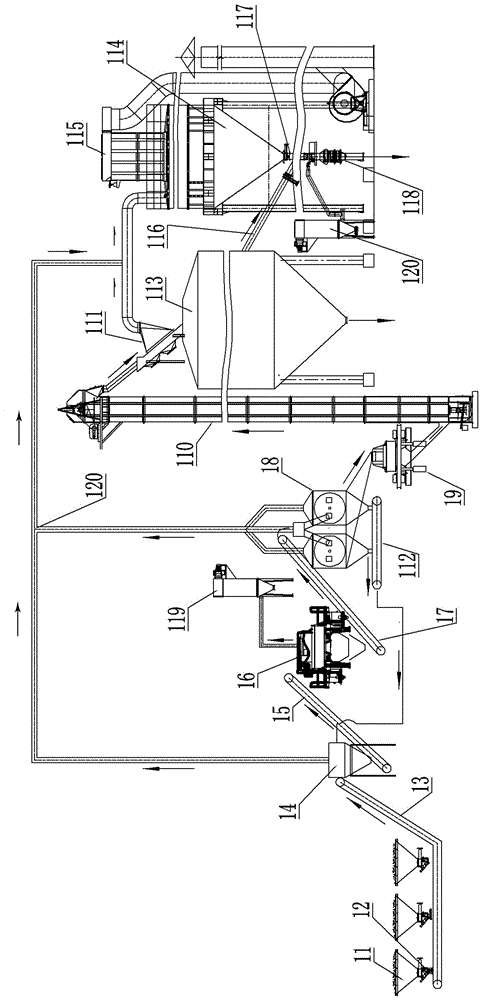

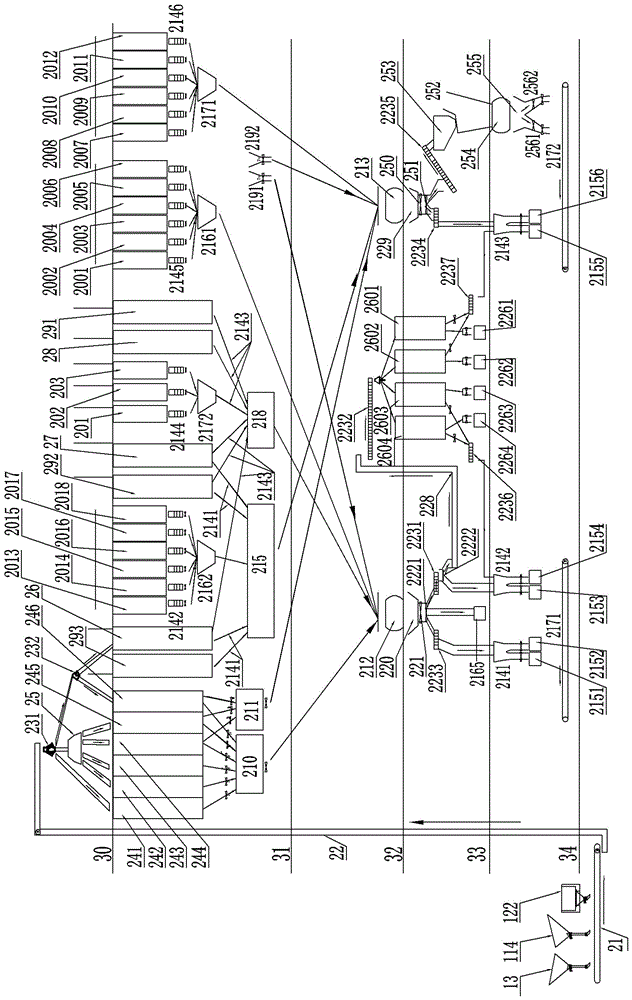

Dry-mixed mortar production method and production line

InactiveCN106113279ALow costReduce energy consumptionGrain treatmentsMixing operation plantProduction lineCrusher

The invention discloses a dry-mixed mortar production method and production line. The dry-mixed mortar production line comprises production equipment. The production equipment is provided with a sand silo used for storing sand and a powder silo used for storing powder. The production equipment further comprises a preparation device, and the preparation device comprises a crusher and a separating unit. An inlet of the separating unit is connected with an outlet of the crusher. A sand outlet of the separating device is connected with a sand conveying pipeline, and a powder outlet is connected with a powder conveying pipeline. According to the dry-mixed mortar production method and production line, the sand and powder required for preparation of dry-mixed mortar can be both obtained from broken materials after stone is broken, in other words, part of or all the sand and powder required for preparation of the dry-mixed mortar are separated from the broken materials after stone breaking, and it actually means that machine-made sand and machine-made powder are used for replacing part of natural sand and natural powder. Hence, dependence on the natural sand in dry-mixed mortar production process is reduced, production cost and energy consumption of the dry-mixed mortar are lowered, and production efficiency of the dry-mixed mortar is improved.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY

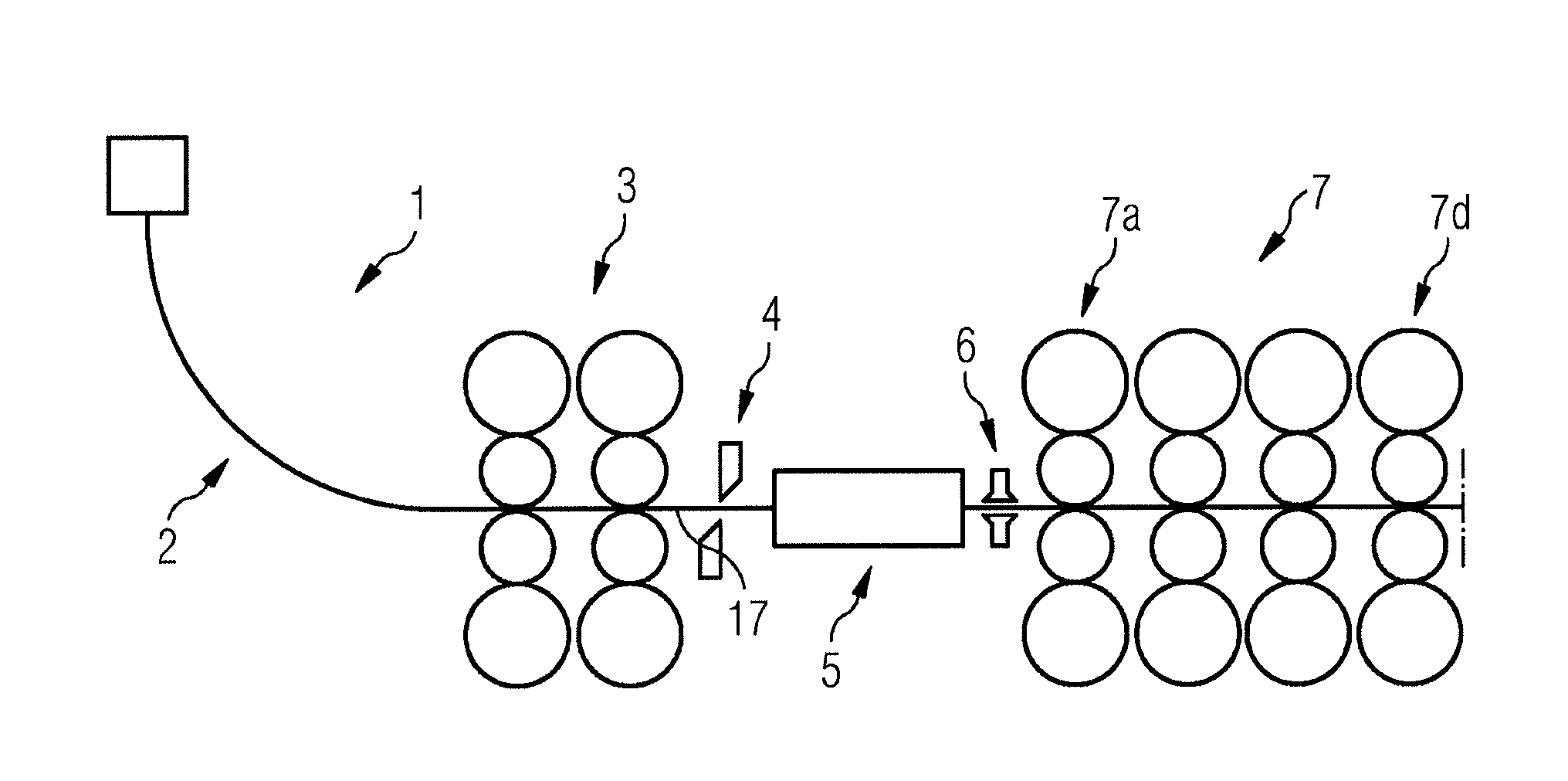

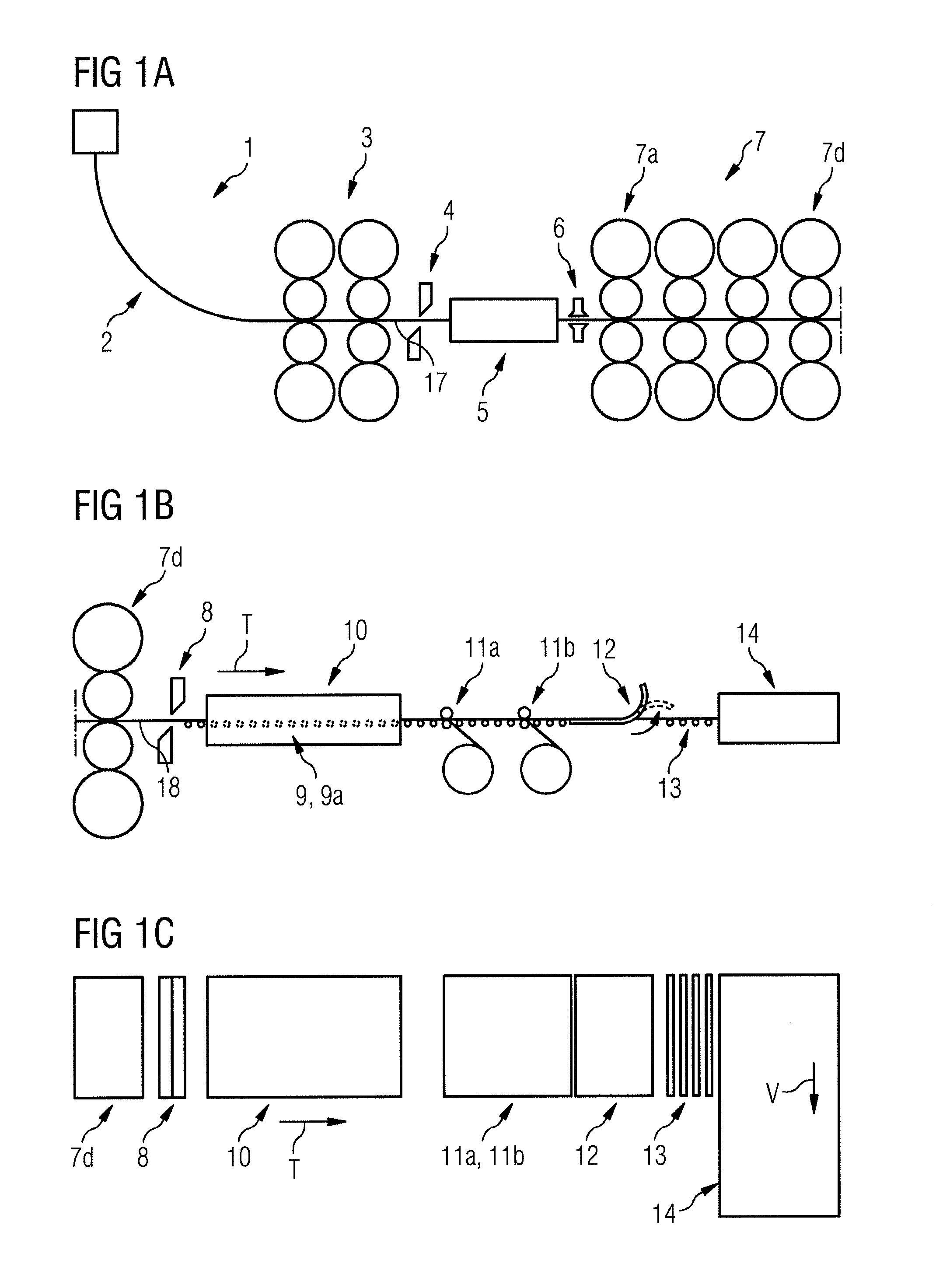

Method and apparatus for the rapid delivery of heavy plates from a rolling mill

InactiveUS20160101450A1Safe storageIncrease speedTemperature control deviceMetal rolling stand detailsThick plateStrip mill

A method and device for rapid discharging of metallic plates (21, 22) particularly thick plates, from a rolling mill, to enable secure discharge of relatively short plates (21, 22) from the rolling mill at high velocity and low cycle times by transporting a first plate (21) on a roller bed (9, 13) in the transport direction (T), and preferably the first plate (21) is accelerated in the transport direction (T); depositing the first plate (21) on the roller bed (9, 13); transporting a second plate (22) on the roller bed (9, 13) in the transport direction (T); depositing the second plate (22) in the transport direction before the first plate (21) on the roller bed (9, 13); and discharging the first and the second plates (21, 22) from the roller bed (9, 13) onto a storage (24), wherein the discharging occurs crosswise to the transport direction (T).

Owner:PRIMETALS TECH AUSTRIA GMBH

Method for preparing biogas by using peat as raw material

InactiveCN102994564AEasy to adjustIn line with industrial policyWaste based fuelFermentationActivated sludgePeat

The invention belongs to the field of peat reclamation application, and particularly relates to a method for preparing biogas by using peat as a raw material. The method is characterized in that enzyme liquid is added for enzymolysis after the peat is pretreated, activated sludge is mixed for fermenting the biomass, and the content of methane in the biogas is determined to reach 65%. The method has the advantages that energy contained in a peat organic matter is released through an appropriate treatment technology and is converted into biomass energy source biogas, so that the purpose of only using the peat as the raw material for preparing the biogas through anaerobic fermentation is achieved, a new path for comprehensive utilization of abundant peat is opened up, fossil energy can be partly replaced or saved, and the low-carbon cyclic economic development and clean energy substitution are realized in the end.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Inkjet printing methods for manufacturing of decorative surfaces

ActiveUS20160208121A1Simple manufacturing processMinimize dependenciesDuplicating/marking methodsSpecial ornamental structuresPolymer adhesiveEngineering

An inkjet printing method for manufacturing decorative surfaces includes the steps of a) jetting a colour pattern with one or more aqueous inkjet inks including a polymer latex binder on a thermosetting resin impregnated paper; and b) drying the one or more aqueous inkjet inks.

Owner:AGFA NV

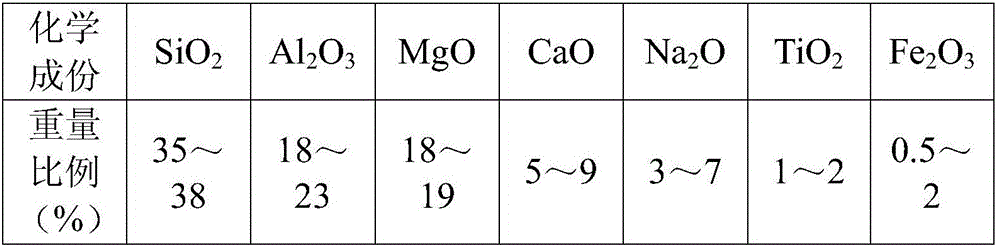

Microcrystalline glass produced from fly ash through all-electric melting calendaring process and production method thereof

ActiveCN105924014AMaintain healthTurn waste into treasureGlass rolling apparatusSlagGreen manufacturing

The invention discloses a microcrystalline glass produced from fly ash through an all-electric melting calendaring process, and a production method thereof. The microcrystalline glass is prepared from 320 to 350 parts by weight of fly ash used as a main raw material and accessory materials consisting of 98 to 115 parts by weight of light-burnt magnesia, 55 to 66 parts by weight of ground calcium carbonate, 42 to 44 parts of sodium carbonate and 2 to 3.5 parts by weight of titanium dioxide by using the all-electric melting calendaring process. The production method mainly comprises the following steps: mixing and melting of the raw materials; calendaring and molding; annealing; nucleation and crystallization; and surface treatment. The production method provided by the invention can consume a great amount of slag waste, turn the waste into the valuable, improve the environment and promote economic development; the production method also realizes green manufacturing, broadens the application space of the calendared microcrystalline glass as a base material and guides consumers to carry out green consumption; and the production method increases the varieties of microcrystalline glass products, improves market competitiveness of microcrystalline glass products and maximally meets consumption demands of different industries and different populations.

Owner:四川一名微晶科技股份有限公司

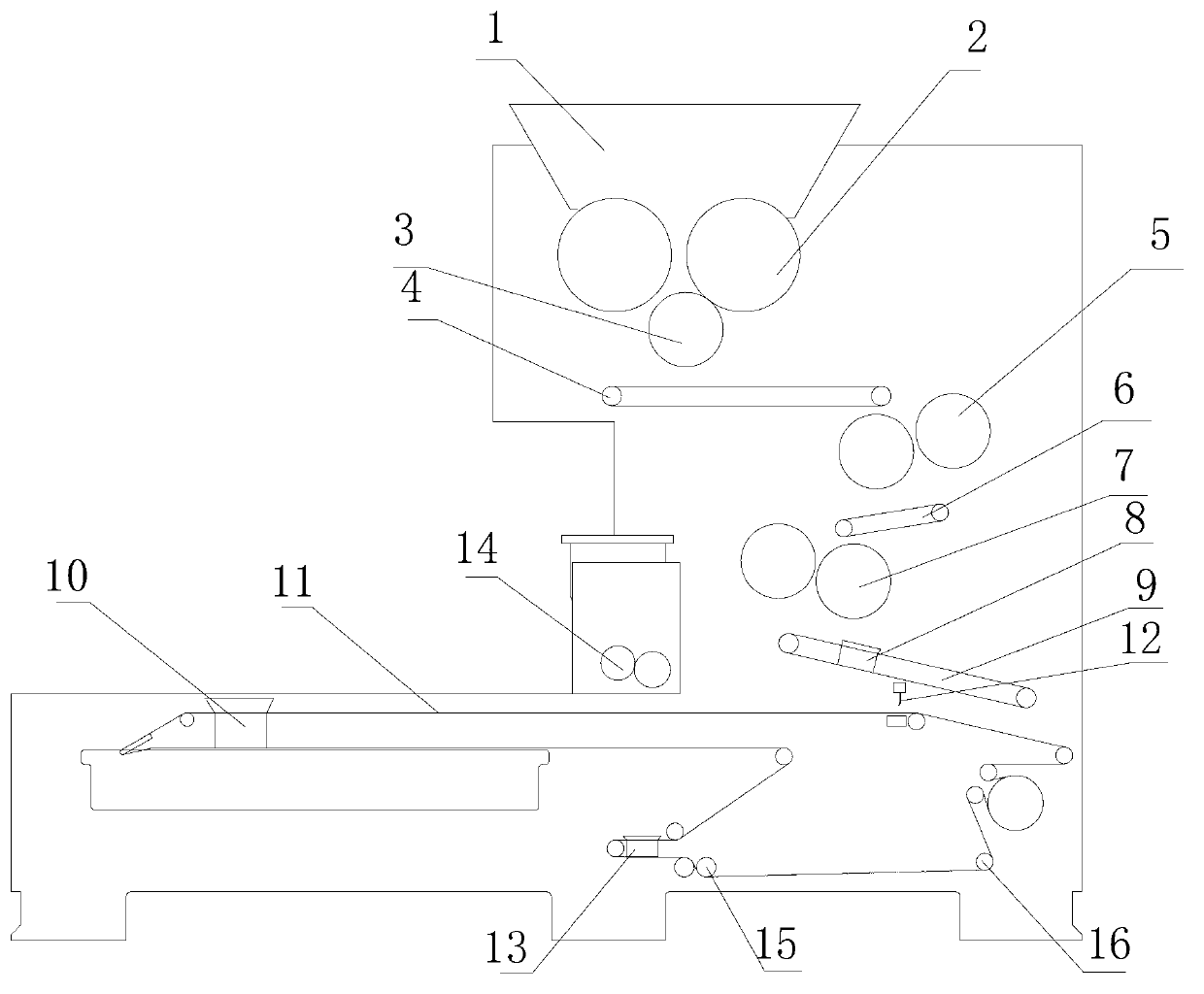

Laminating machine

ActiveCN103340222AResolve Fixed Chain RelationshipsExpand product rangeDough-sheeters/rolling-machines/rolling-pinsDough processingEngineeringMechanical engineering

The invention provides a laminating machine. The laminating machine comprises a mainframe, a surface rolling mechanism, a laminating mechanism and a conveying mechanism, wherein a hopper is arranged on the mainframe, the surface rolling mechanism consists of a first pressure roll and a first surface rolling roll which are arranged oppositely and used for rolling surfaces, first conveying transition belts arranged below a first pressure roll and a first surface rolling roll, a second pressure roll and a second surface rolling roll arranged at the tail ends of the first conveying transition belts oppositely, second conveying transition belts arranged below the second pressure roll and the second surface rolling roll, and a third pressure roll and a third surface rolling roll arranged at the tail ends of the second conveying transition belts oppositely; the laminating mechanism is arranged below the third pressure roll and the third surface rolling roll, the conveying mechanism is arranged below the laminating mechanism, and the laminating procedures can be completed through the connection relationship.

Owner:珠海市洪富食品机械制造有限公司

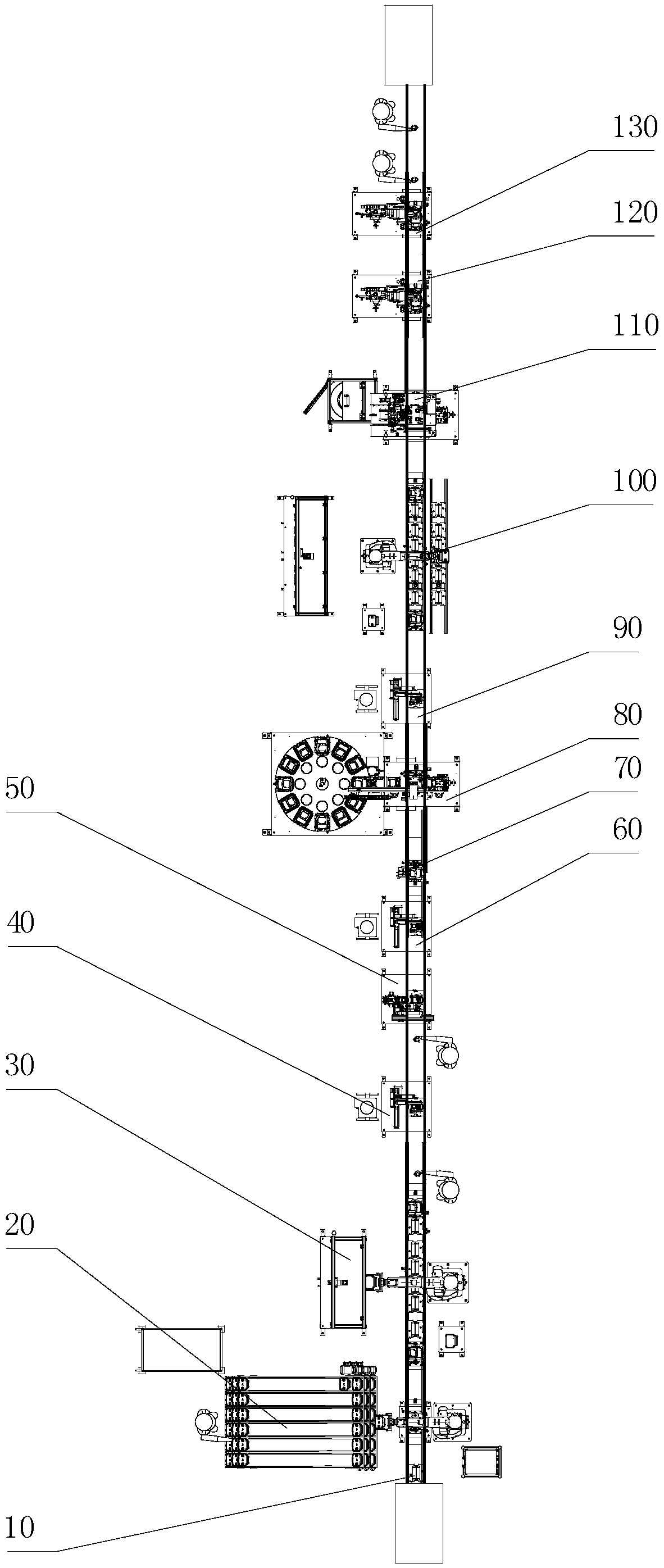

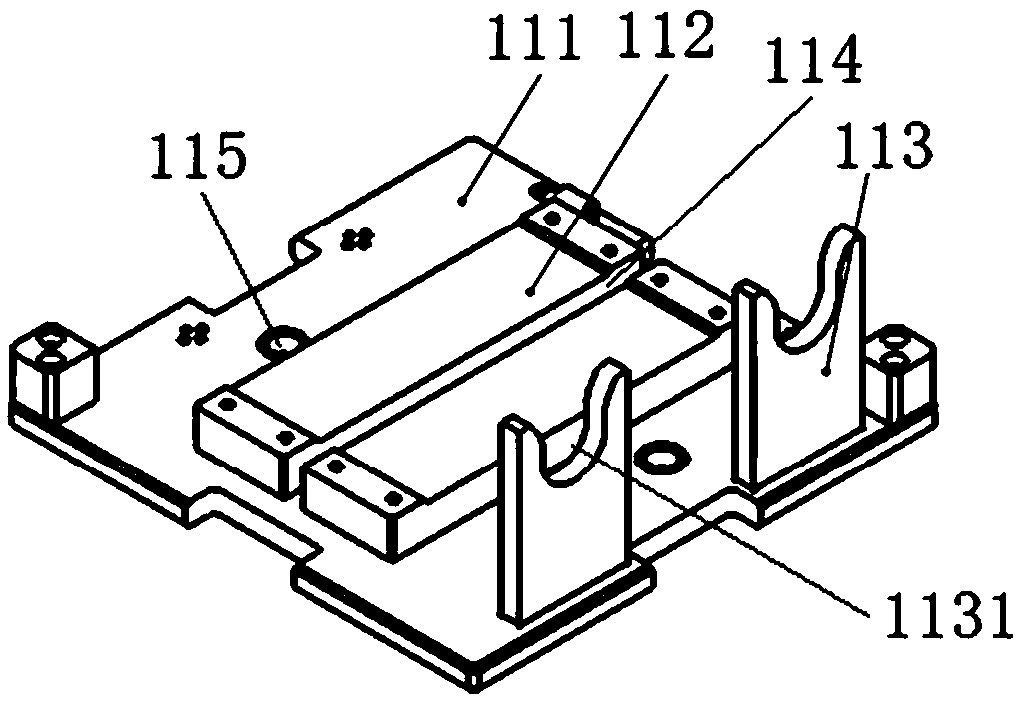

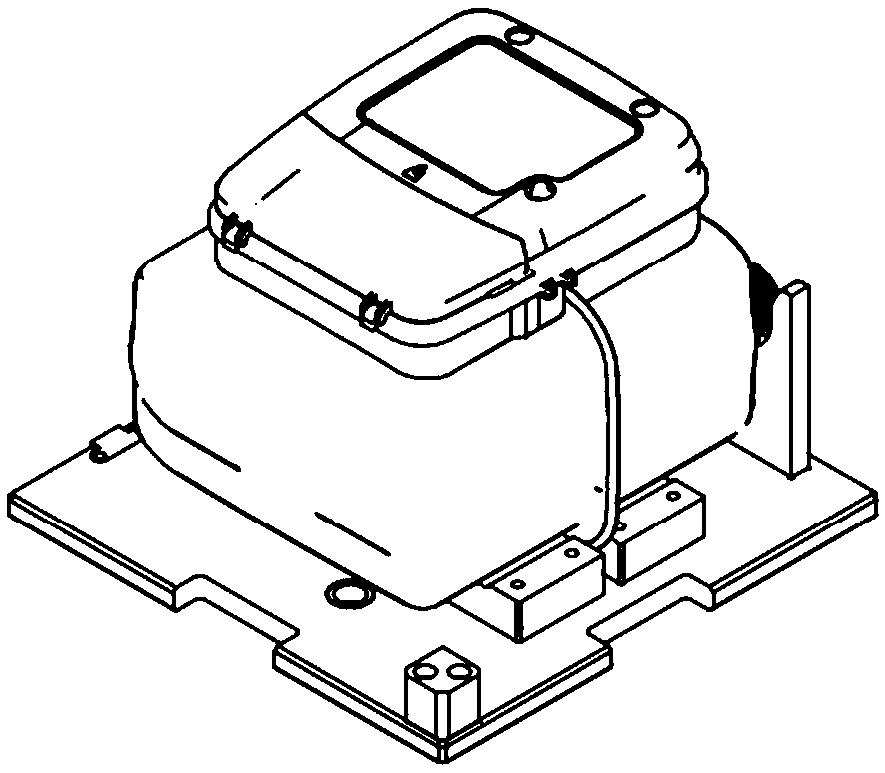

Intelligent final assembly production line for metering instrument

The invention discloses an intelligent final assembly production line for a metering instrument. The intelligent final assembly production line comprises a line body and further comprises an automaticbase meter feeding device, a ventilation tidying device, a master control board fixing device, a nameplate installing device, a nameplate fixing device, a final assembly information input device, a face cover installing device, a face cover fixing device, an automatic testing device, a plastic package installing device, a meter number pasting device and a qualification certificate pasting device,all of which are sequentially arranged in the conveying direction of the line body. The intelligent final assembly production line solves the problems that in the existing metering base meter (particularly a gas metering base meter) final assembly and testing process, the manual production efficiency is low, the assembling precision and the testing accuracy are hard to guarantee, and equipment compatibility is poor. The intelligent final assembly production line can meet the flexible production requirements of multiple kinds and multiple brands of products, assembling and testing informationis fed back in time, unified control is conducted, intelligent gas metering base meter final assembly and testing are achieved, the manual operation is greatly reduced, the production cost is reduced,and the production efficiency is improved.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

Production process for screen printed circuit board

InactiveCN103152989AFulfil requirementsSolve the amount of deformationConductive material chemical/electrolytical removalNon-metallic protective coating applicationScreen printingResist

The invention relates to a production process for a screen printed circuit board. The production process for the screen printed circuit board comprises the following steps of: performing substrate cutting, edging, performing numerical control (NC) drilling, deburring, performing graphic preprocessing, printing graphic photocurable anti-corrosion ink on a B-side screen, performing ultraviolet (UV) photocuring, printing the graphic photocurable anti-corrosion ink on an A-side screen, performing UV curing, etching and decoating, performing treatment before solder resist printing, printing photocurable solder resist ink on the A-side screen, performing the UV curing, printing the photocurable solder resist ink on the B-side screen, performing the UV curing, performing treatment before silver paste / copper paste through hole printing, performing silver paste / copper paste through hole screen printing, performing silver paste / copper paste hot air predrying and drying, performing treatment before printing, performing A / B-side silver paste / copper paste protective layer printing and the UV curing, curing characters on A / S sides by a printing machine, and performing follow-up production processes.

Owner:杭州新三联电子有限公司

Method for manufacturing parquet decorative wood veneers

ActiveCN103878856AIncrease profitProtect and conserve resourcesOther plywood/veneer working apparatusWood compressionWood veneerPolymer science

The invention relates to a method for manufacturing parquet decorative wood veneers. The method for manufacturing the parquet decorative wood veneers is characterized by comprising steps of 1), preparing materials; 2), manufacturing elongated wood sections; 3), punching the elongated wood sections and inlaying columns in holes; 4), manufacturing wide wood boards; 5), soaking the wide wood boards; 6), manufacturing battens; 7), maintaining the battens; 8), slicing veneers; 9), leveling and drying the veneers. The method has the advantages that dyed and treated decorative wood chips are inlaid in the wide wood boards, and accordingly decorative and parquet effects can be realized.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Manufacturing of decorative laminates by inkjet

InactiveUS20170058456A1Simple manufacturing processMaximum flexibilityCovering/liningsSpecial paperPaper sheetHeat press

A method for manufacturing decorative laminates includes the steps of a) impregnating a paper substrate with a thermosetting resin by submersion of the paper substrate in a bath of thermosetting resin; b) applying on the thermosetting resin impregnated paper substrate an ink acceptance layer containing an inorganic pigment P and a polymeric binder B having a weight ratio P / B of inorganic pigment to polymeric binder of larger than 1.5; c) jetting on the ink acceptance layer a colour pattern with one or more aqueous pigmented inkjet inks and / or organic solvent based pigmented inkjet inks containing a colour pigment C; and d) heat pressing the thermosetting paper into a decorative laminate, wherein the weight ratio P / C of the inorganic pigment of the ink acceptance layer to the jetted colour pigment in the colour pattern is larger than 4.0.

Owner:AGFA NV +1

Wintercherry fermentation fruit juice and preparation method thereof

ActiveCN108902594AExpand product rangeRetain nutrientsNatural extract food ingredientsFood ingredient functionsFlavorFruit juice

The invention relates to wintercherry fermentation fruit juice and preparation method thereof. The preparation method of the wintercherry fermentation fruit juice comprises the following steps, crushing, performing enzymolysis, performing enzyme deactivation, performing filtration to prepare original wintercherry fruit juice; S2, inoculating a fermentation agent of which the weight is 5% to 12% ofthe weight of the original wintercherry fruit juice in the original wintercherry fruit juice and fermenting at constant temperature of 33 DEG C to 39 DEG C for 16h to 24h, obtaining original wintercherry fermentation fruit juice; S3, performing flavor blending on the original wintercherry fermentation fruit juice obtained from the S2, obtaining the wintercherry fermentation fruit juice. The wintercherry fermentation fruit juice prepared by lactobacillus fermentation of original wintercherry fruit juice, not only is the bitterness of the original acid reduced, but also can be widely accepted and absorbed more effectively by people. The wintercherry fermentation fruit juice integrates good characteristics of wintercherries and lactobacillus, has characteristics of high nutritional value, easy operation, wide adaptability on the basis of satisfying the requirements of general beverage, and has higher popularization value.

Owner:SHANXI AGRI UNIV

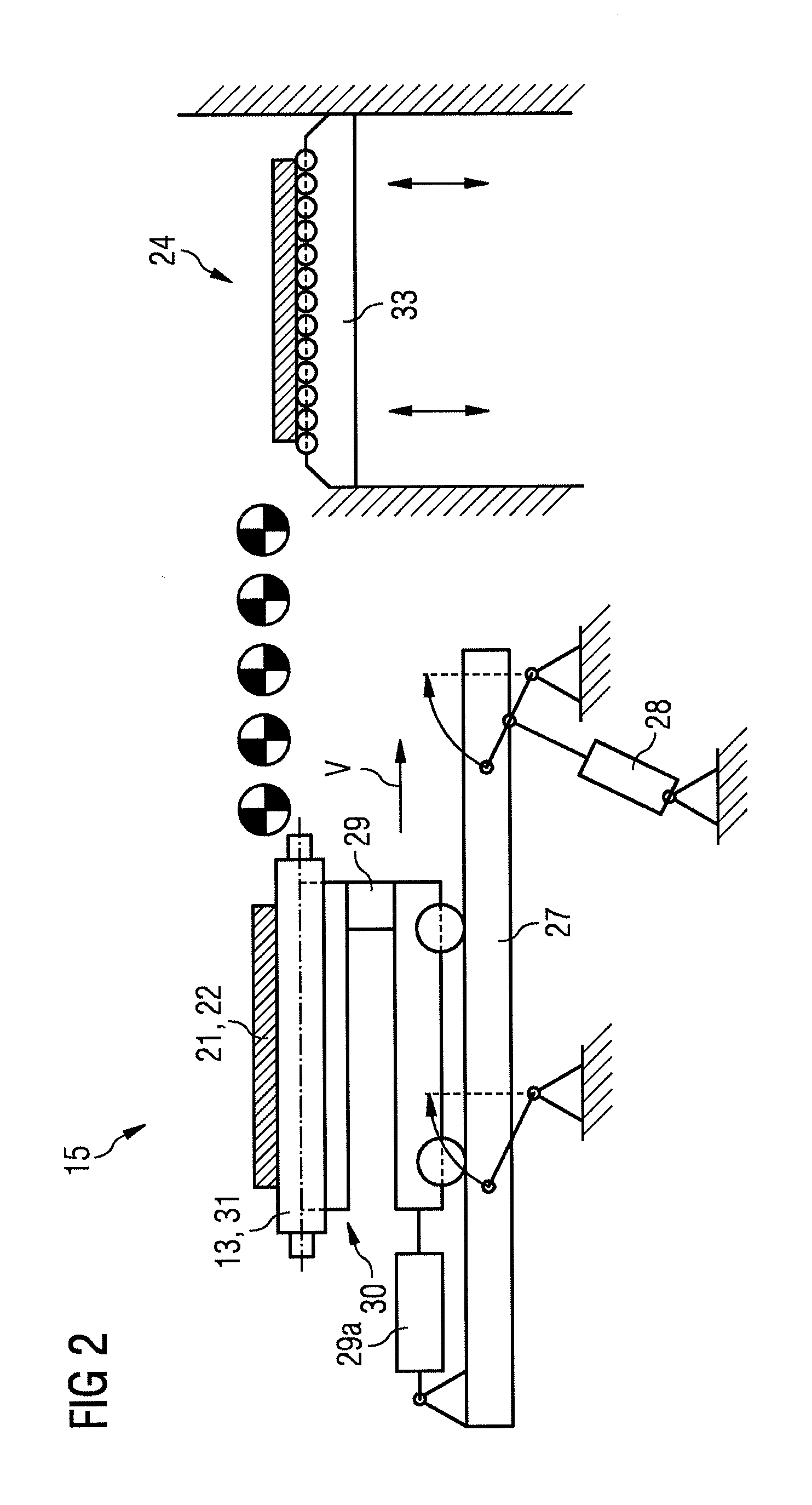

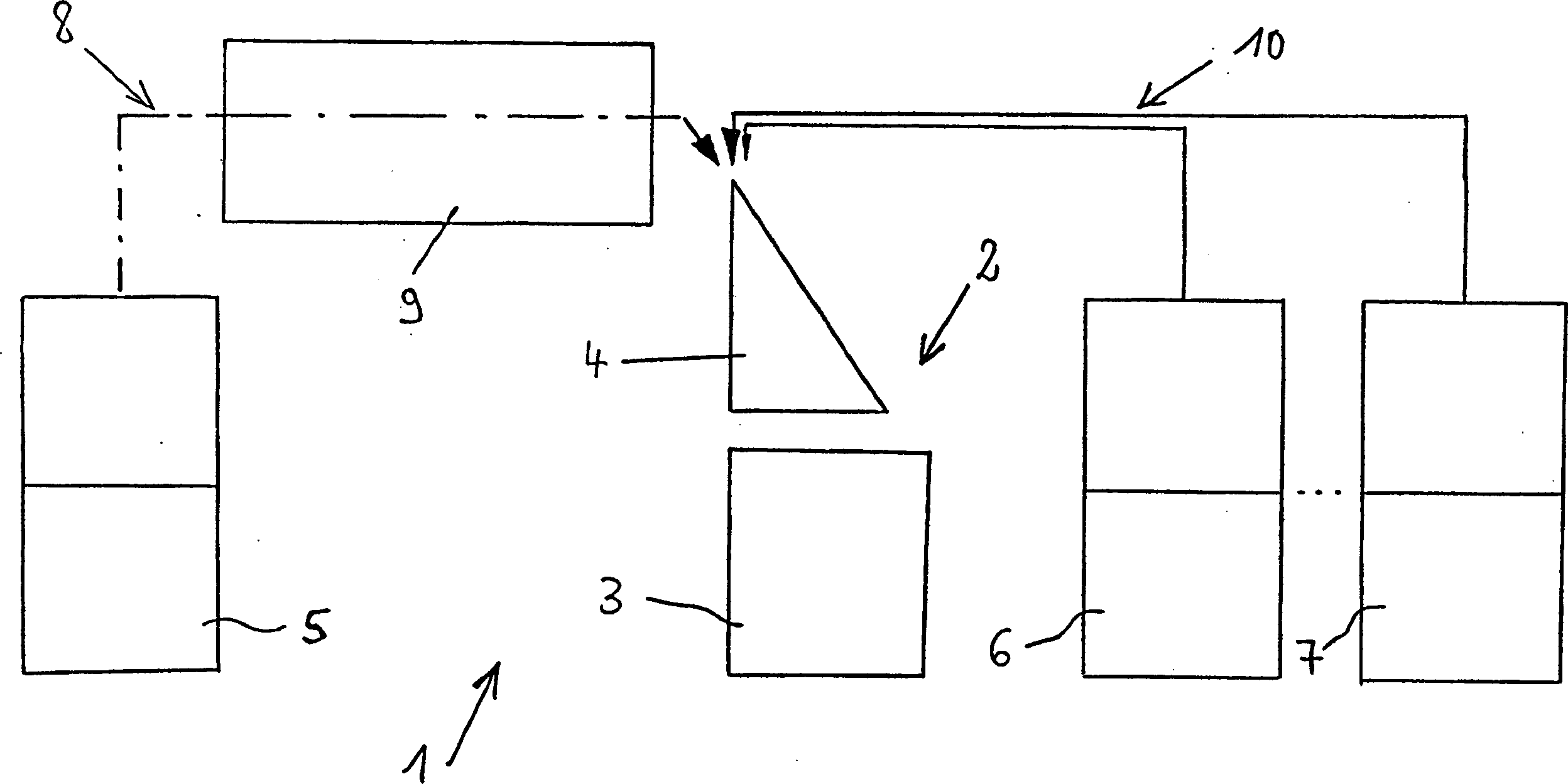

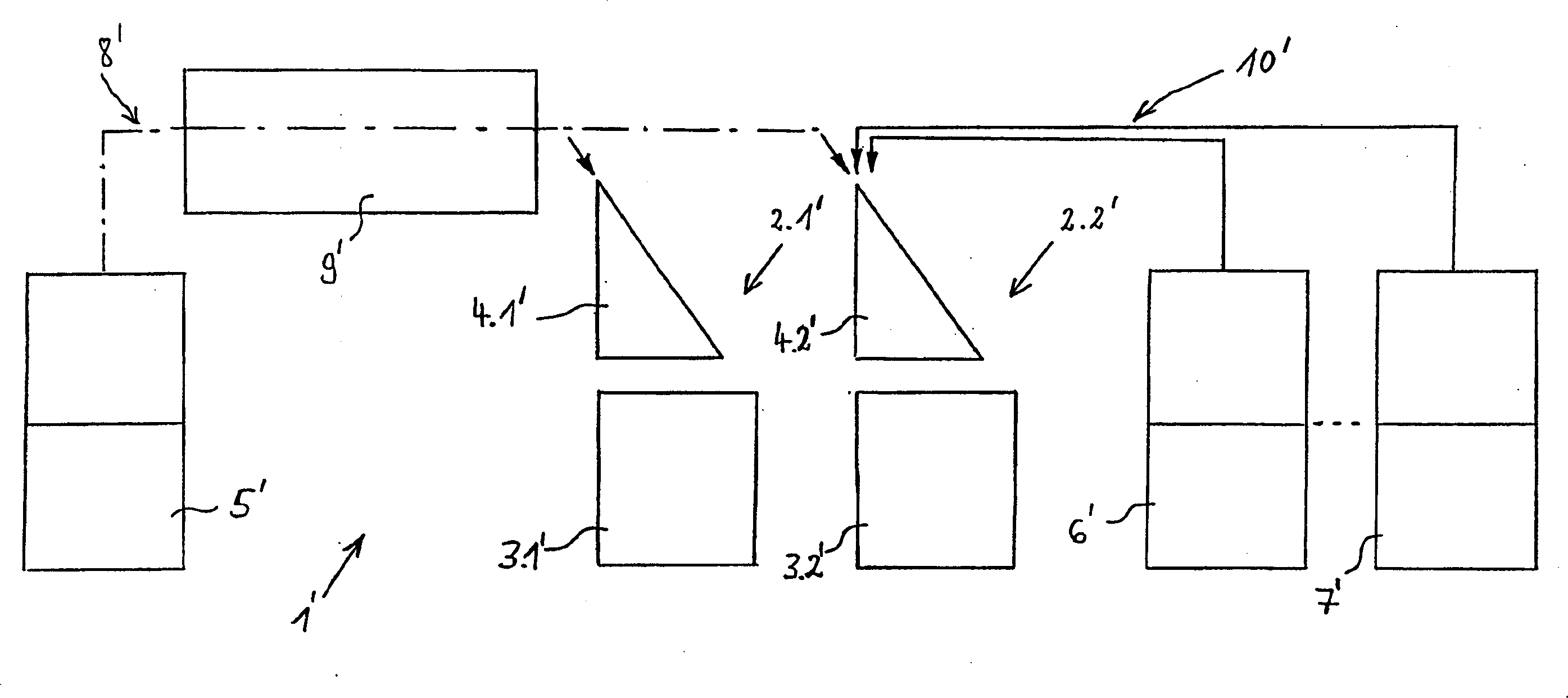

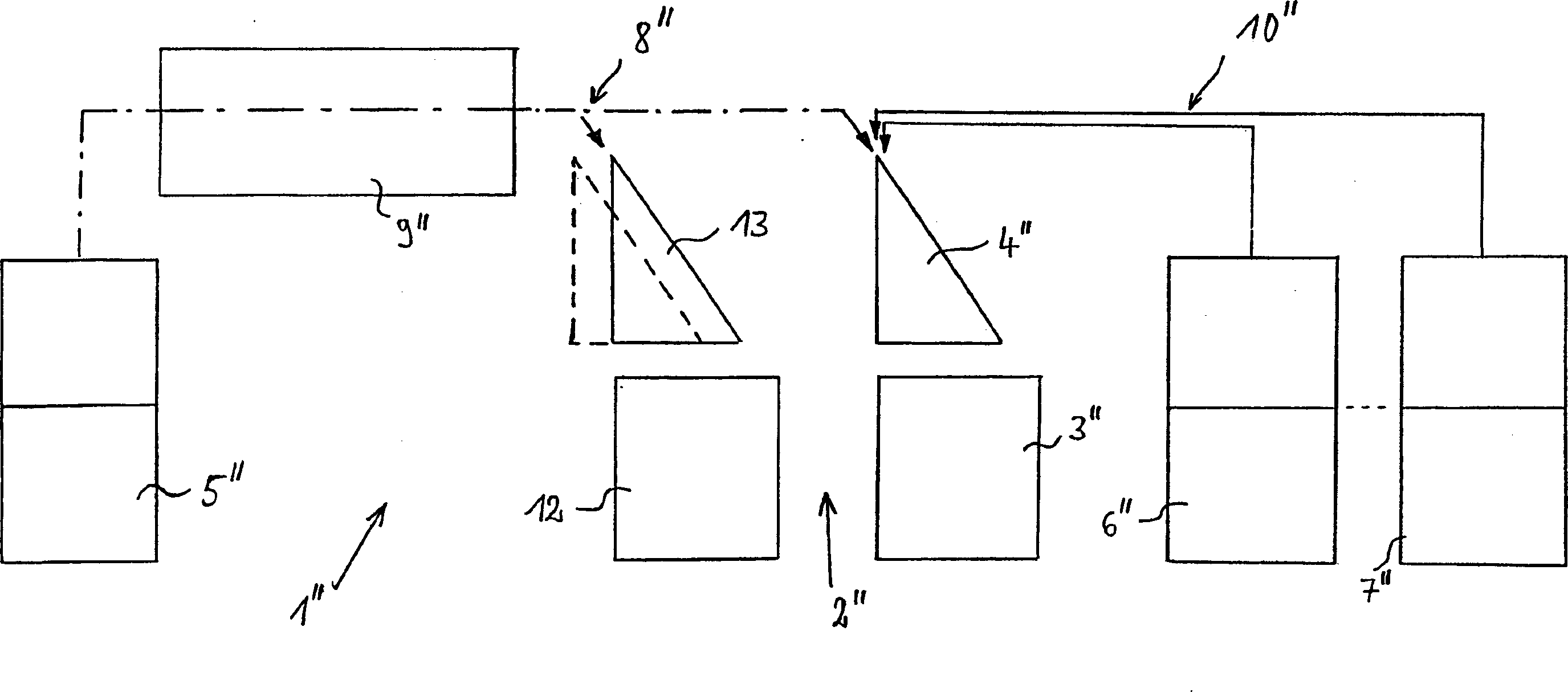

Folding sheets unit of rotary press used for union newspaper and selective commercial products production

InactiveCN1486843AExpand product rangeEfficient use ofFolding thin materialsRotary pressesPrinting pressMechanical engineering

The roller rotation printing machine enables sheets to be printed in both newsprint and commercial quality with printing units of the roller rotation printing machine. The folding unit consists of at least one newspaper folding mechanism and at least one illustration folding mechanism and the relevant printed sheets can be fed to the newspaper folding mechanism and to the illustration folding mechanism according to the required folding quality. The roller rotation printing machine (1) enables sheets to be printed in both newsprint and commercial quality with printing units (5-7) of the roller rotation printing machine. The folding unit (2) consists of at least one newspaper folding mechanism (3) and at least one illustration folding mechanism (12) and the relevant printed sheets can be fed to the newspaper folding mechanism and to the illustration folding mechanism according to the required folding quality.

Owner:MANROLANAD AG

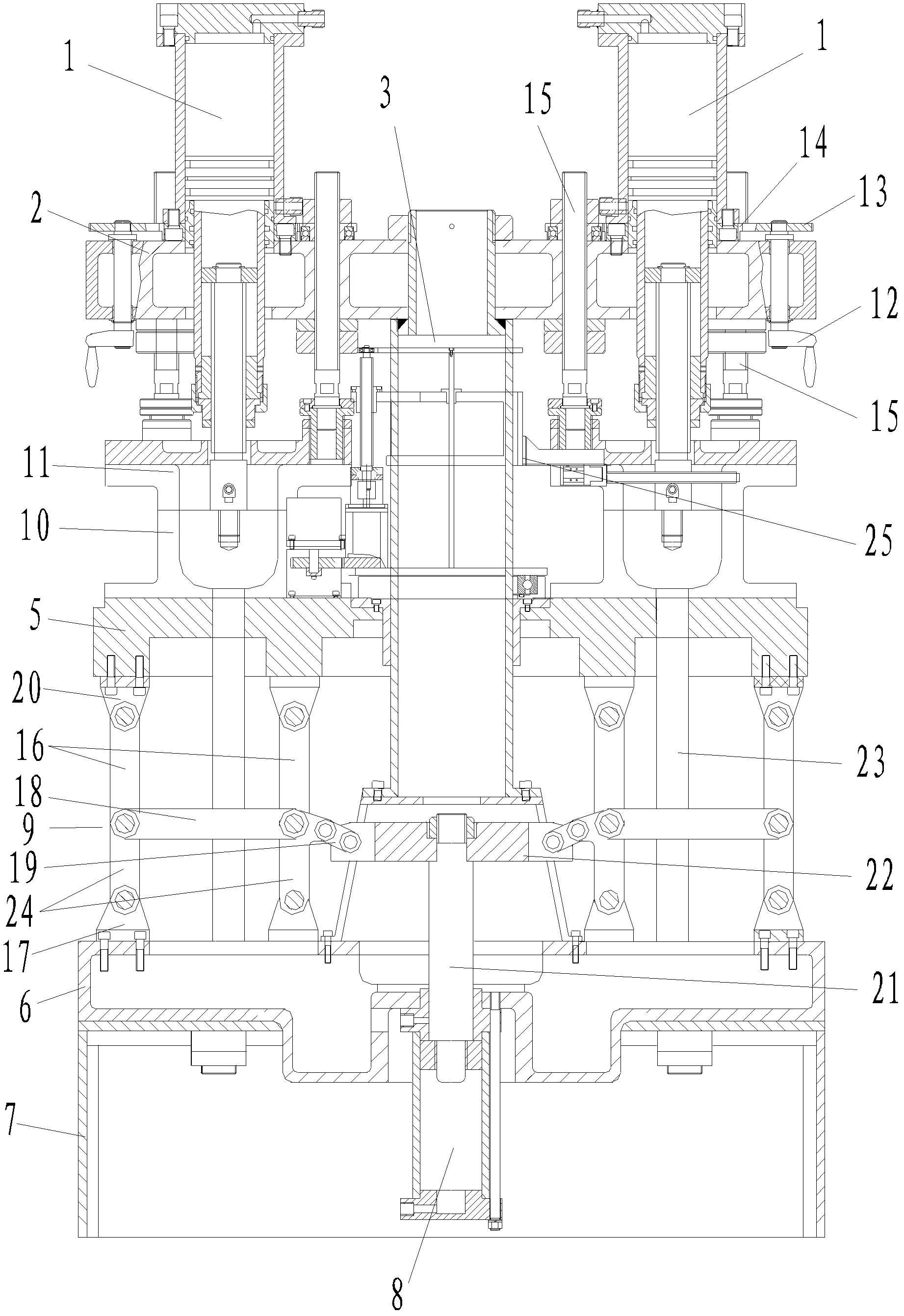

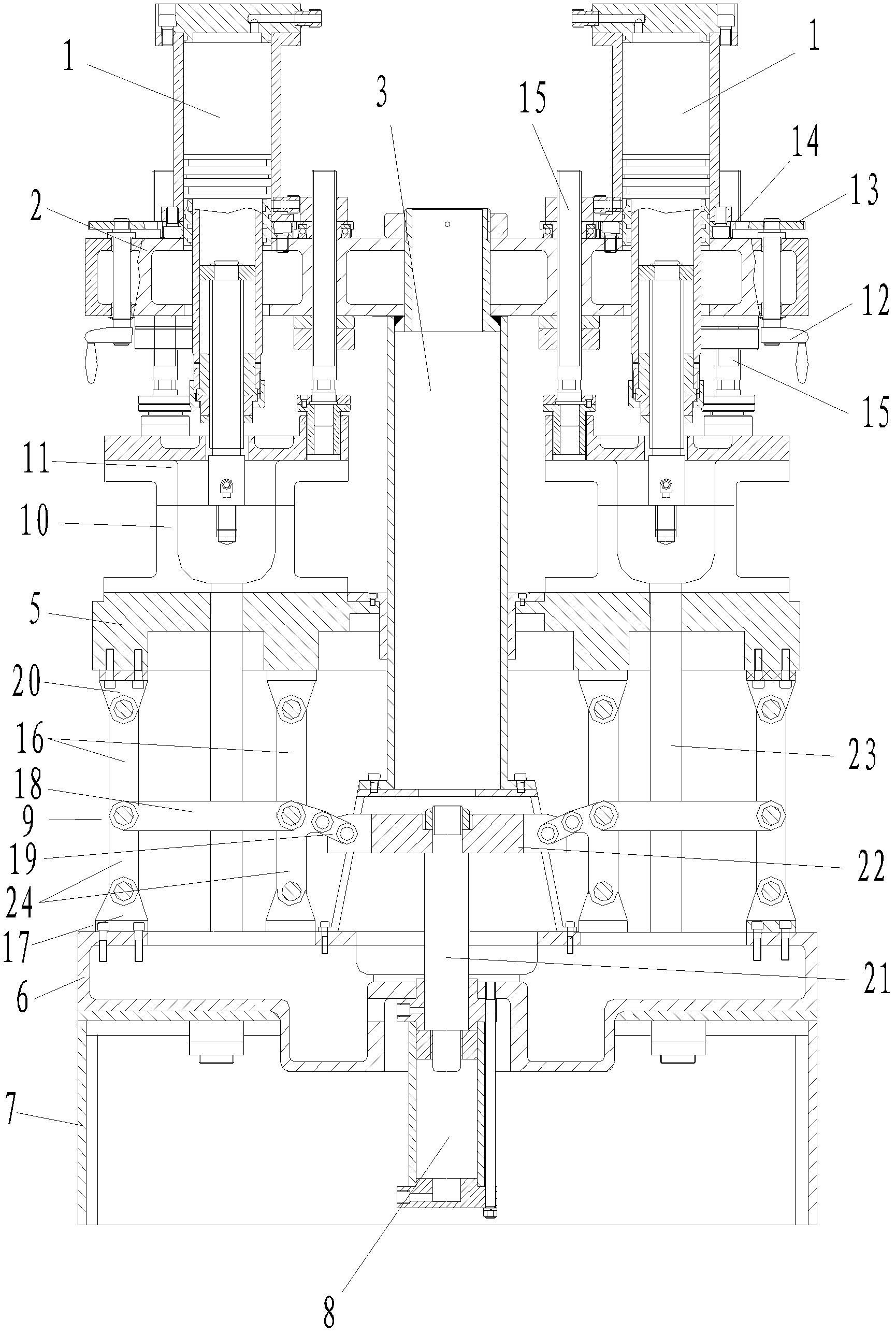

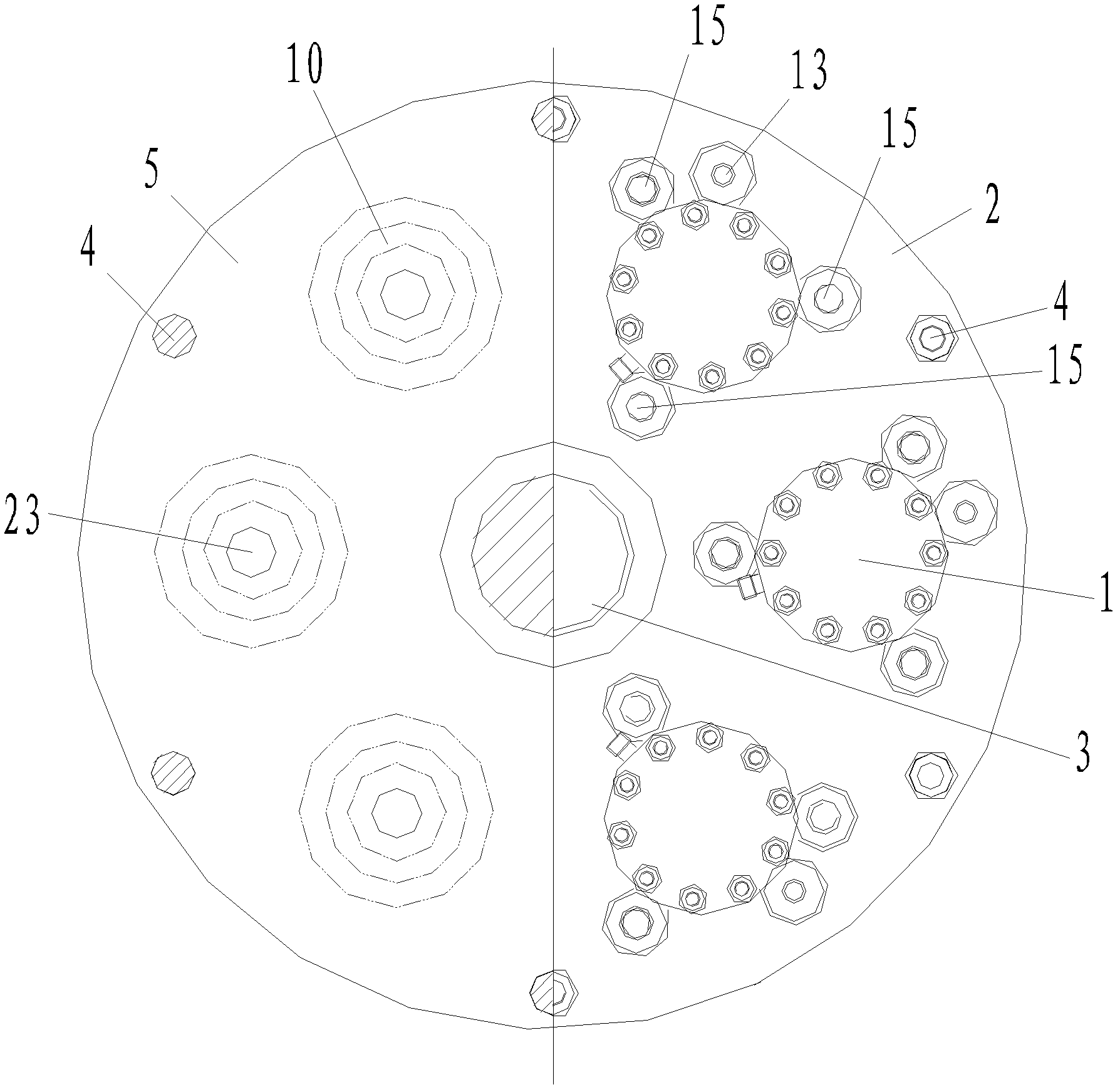

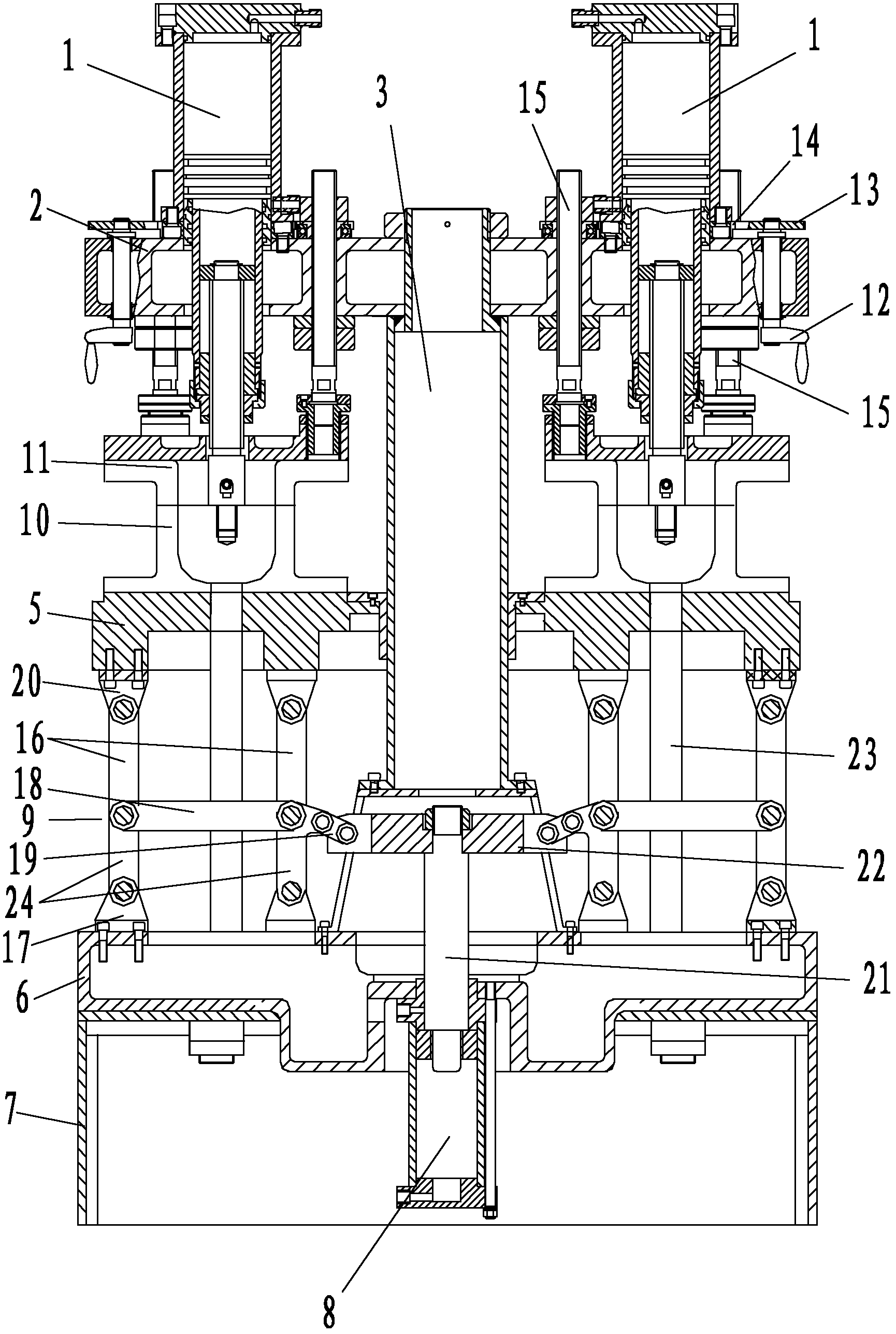

Multi-station hydraulic stretcher with transposition manipulator

InactiveCN102527807ARealize automatic ejectionImprove flexibilityProgramme-controlled manipulatorMetal-working feeding devicesHydraulic cylinderEngineering

The invention relates to a multi-station hydraulic stretcher with a transposition manipulator, which comprises a base, a bed bedplate, an upper oil cylinder bedplate, a middle upright, a peripheral upright and the transposition manipulator. The base is fixed on the ground; the bed bedplate is fixed on the base; the middle upright and the peripheral upright support the upper oil cylinder bedplate and a working bedplate between the upper oil cylinder bedplate and the bed bedplate; a plurality of upper hydraulic cylinders are distributed on the upper oil cylinder bedplate in the peripheral direction; a crankshaft mechanism is arranged between the bed bedplate and the working bedplate; the working bedplate is driven to move up and down by the crankshaft mechanism; the positions on the working bedplate, which correspond to the upper hydraulic cylinders, are provided with die stations; the transposition manipulator is arranged on the working bedplate and can rotate left and right to clamp and put down a workpiece; according to the invention, a plurality of independent die stations are arranged on the stretcher, so that the repeated stretching process on the same product on the same stretcher can be implemented; and meanwhile, the transposition manipulator can be used for carrying out automatic transposition on the workpiece.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

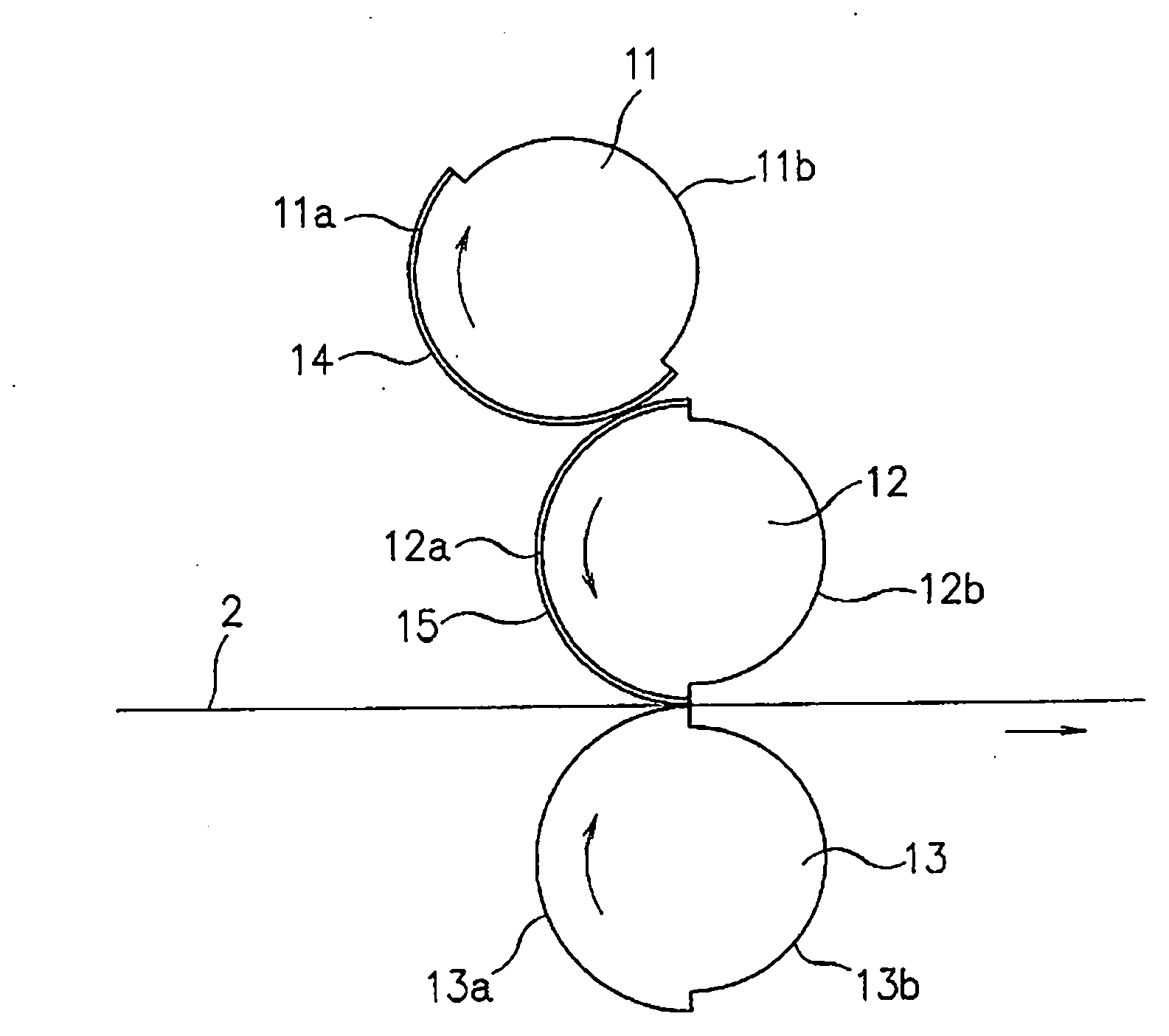

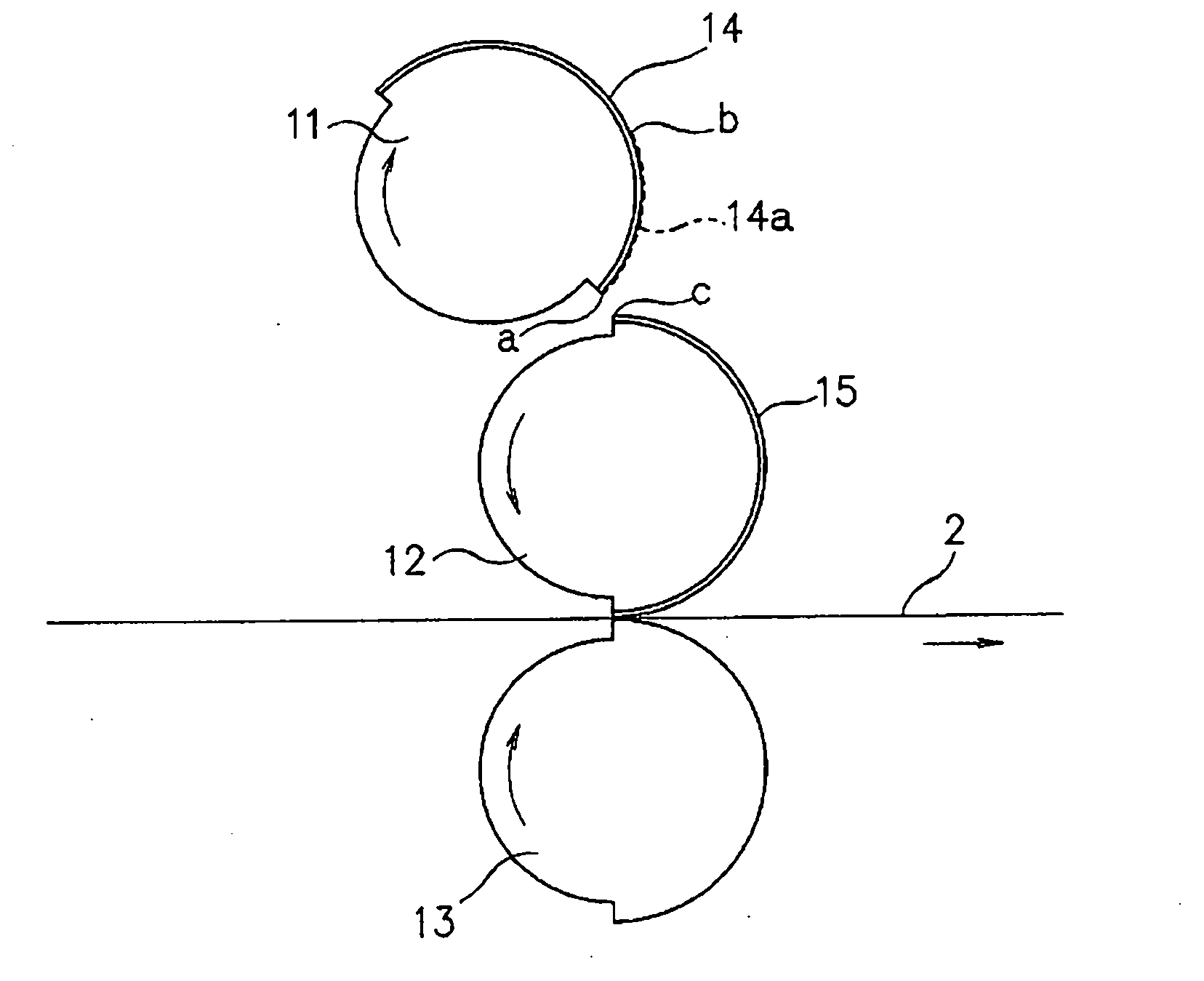

Variable printer

ActiveCN103252980AReduce replacement timeExpand product rangeRotary pressesEngineeringMechanical engineering

Provided is a variable printer which enables a printing plate of a printing unit to be replaced in a short time during printing. Moreover, blanket rollers 12 of a plurality of printing units (4a-4d) can be moved to be in positions of printing, so as to be in rotatable contact with a printing plate roller (11) and a pressing roller (13), and also to be in withdrawl positions, between the pressing roller (13) and the blanket rollers (12), of running gaps for paper, so as to be separated from the printing plate roller (11) and the pressing roller (13), such that the blanket rollers (12) of the printing units, used for replacement of printing plates, can become the withdrawl positions, and the blanket rollers (12) of other printing units can become the printing positions.

Owner:MIYAKOSHI PRINTING MACHINERY

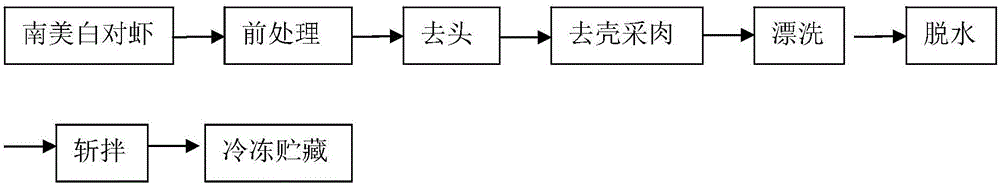

Minced penaeus vannamei preparation method

InactiveCN106262011AIncrease product varietyIncrease profitFood scienceSodium triphosphateGel strength

The invention provides a minced penaeus vannamei preparation method. The method includes the steps that fresh alive penaeus vannamei is cleaned with clean water of 0-10 DEG C, silt is removed, and penaeus vannamei is shocked; secondly, the head of the shocked penaeus vannamei is removed from the first urite, and the penaeus vannamei is cleaned with clean water of 0-10 DEG C; thirdly, meat is obtained from the penaeus vannamei without head, and shrimp shells are fully removed; fourthly, the obtained penaeus vannamei meat is washed 1-3 times with clean water of 0-10 DEG C; fifthly, the washed penaeus vannamei meat is centrifugally dewatered to obtain minced penaeus vannamei; sixthly, the centrifuged minced penaeus vannamei is chopped and stirred for 15-20 min by means of cane sugar, sorbitol, sodium pyrophosphate and sodium tripolyphosphate; seventhly, the chopped and mixed minced penaeus vannamei is packaged quantitatively and placed in the environment at temperature not higher than -20 DEG C to be stored. The prepared frozen minced penaeus vannamei is high in quality, gel strength is about 260g.cm after 6 months of storage, different minced penaeus vannamei products can be processed and manufactured according to needs, and consumption requirements of people are met.

Owner:SHANGHAI OCEAN UNIV

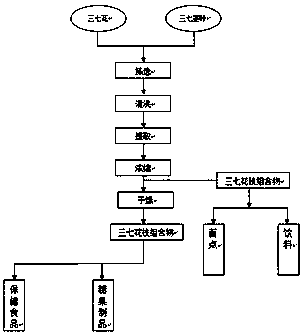

Panax notoginseng flower and branch composition as well as preparation method and application thereof

InactiveCN108835639ABalanced active ingredients of saponinsImprove immunityConfectionerySweetmeatsFood additiveFlavor

The invention discloses panax notoginseng flower and branch composition as well as a preparation method and an application thereof. The panax notoginseng flower and branch composition is prepared from30%-50% by weight of panax notoginseng flowers and 50%-70% by weight of panax notoginseng branches by pretreatment, extraction, concentration and drying or not. The prepared panax notoginseng flowerand branch composition has fresh fragrance of panax notoginseng and unique flavor, can solve the problems of constipation, internal fire and the like, has certain functions of adjusting hypertension and hyperlipaemia, can calm the liver, improve eyesight, lose weight, diminish inflammation, stop bleeding, relieve pain and strengthen human immunity, and can be taken as drinks for direct drinking, applied to food and cooking and used as a food additive to be added to various foods, thereby meeting requirements of the market for both nutrition and flavor.

Owner:YUXI WINHEY WEISHENGTANG HEALTH FOOD

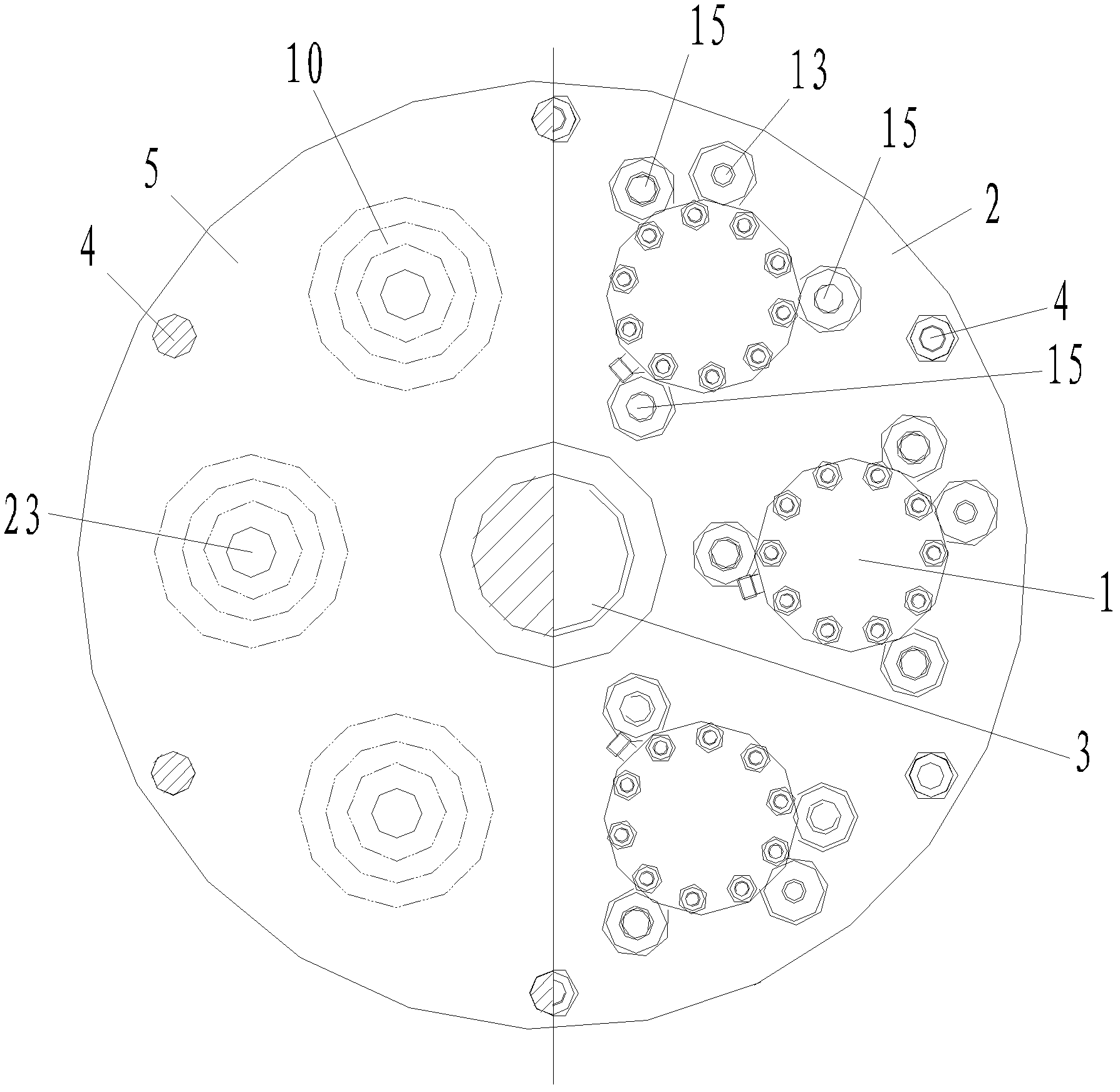

Multi-station hydraulic drawing machine

InactiveCN102554006AImprove flexibilityRealize automatic ejectionHydraulic cylinderPulp and paper industry

The invention relates to a hydraulic drawing device, in particular to a multi-station hydraulic drawing machine which comprises a base, a machine base bedplate, an upper oil cylinder bedplate, a middle column and columns, wherein the base is fixedly arranged on the ground, and the machine base bedplate is fixedly arranged on the base; the upper oil cylinder bedplate is supported between the upper oil cylinder bedplate and the machine base bedplate by the middle column and the columns, and a plurality of hydraulic cylinders are distributed on the upper oil cylinder bedplate in the circumferential direction; and a crank mechanism is arranged between the machine base bedplate and a working bedplate, and drives the working bedplate to move up and down, and mould stations are arranged on the working bedplate corresponding to the upper hydraulic cylinders. By arranging a plurality of independent mould stations on the drawing machine, the multiple drawing processes on the same product can be realized on the same drawing machine, so that the machining efficiency is improved.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

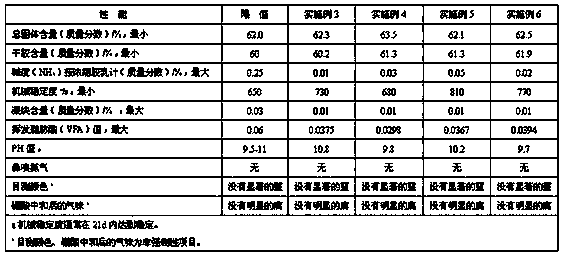

Green environment-friendly concentrated natural latex and preparation method thereof

ActiveCN108690147AReduce waste water and exhaust emissionsReduce manufacturing costSodium silicateWater soluble

The invention discloses green environment-friendly concentrated natural latex and a preparation method thereof. The preparation method includes the steps of: collecting, preserving and transporting fresh latex, processing and concentrating the fresh latex, and performing accumulation treatment. A non-ammonia preservative is employed in the method and includes sodium hydrogen sulfite, sodium tripolyphosphate, sodium carbonate, sodium silicate pentahydrate, citric acid and sodium benzoate; by using the sodium tripolyphosphate instead of butyl p-hydroxybenzoate, bacteria inhibition effect of thenon-ammonia preservative is maintained, and problems that the butyl p-hydroxybenzoate is poor in water solubility and the latex, after long preservation time, is liable to cake can be solved. In addition, by reducing usage amount of sodium carbonate, raw material cost is reduced largely. The green environment-friendly concentrated natural latex can satisfy related quality index requirements in terms of basicity, total solid content, dry latex content, volatile fatty acid number, mechanical stability and the like.

Owner:北京天一瑞博科技发展有限公司

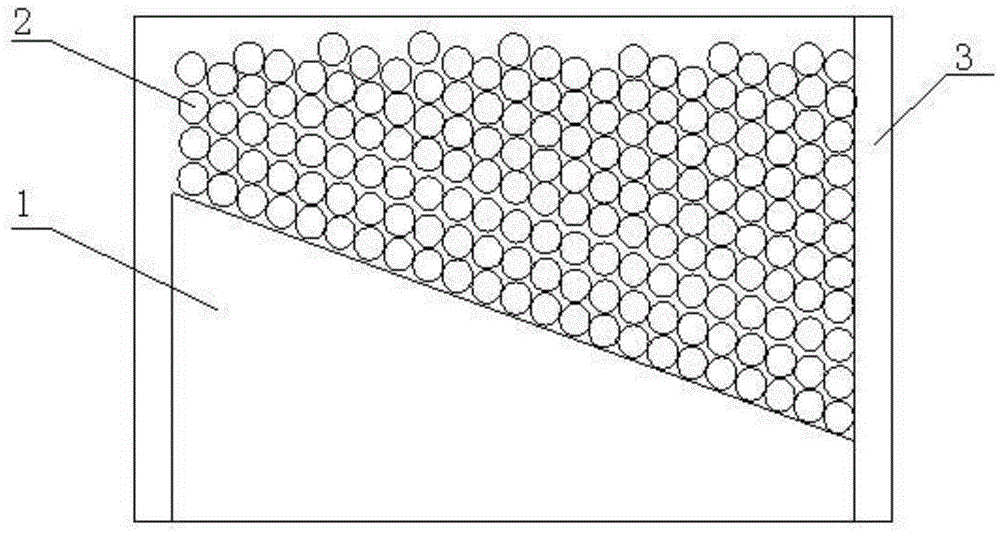

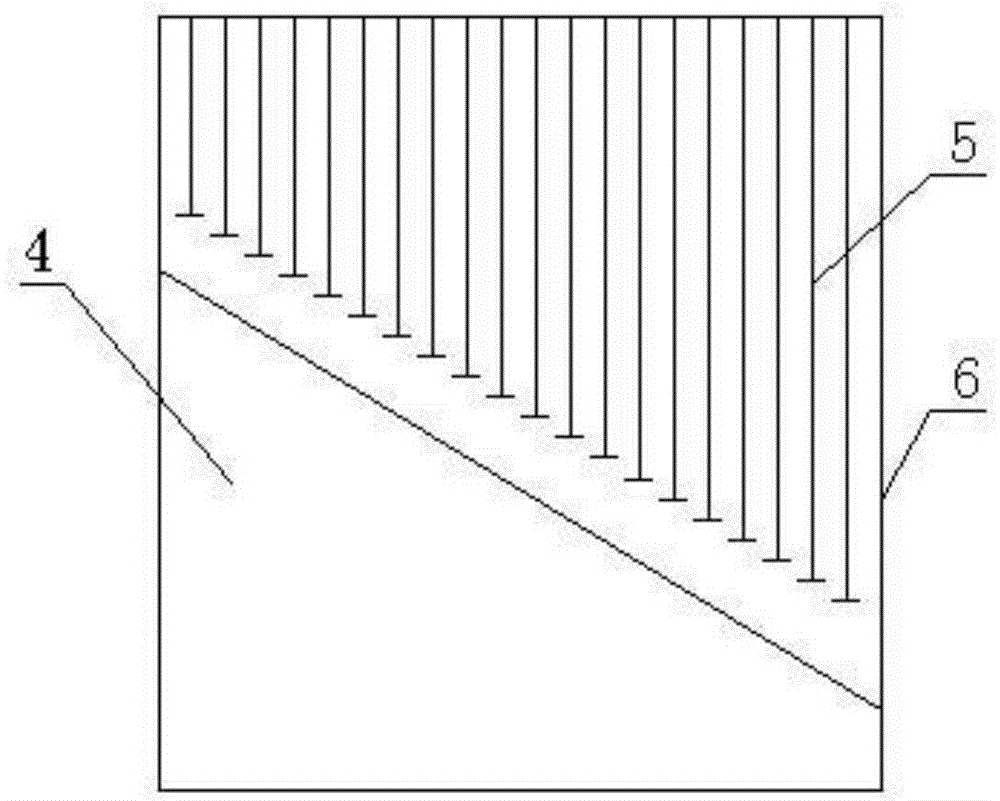

Process for simultaneously producing machine coke and molded coke by use of stamp-charging coke oven

InactiveCN104531190AExpand product rangeNo cost inputSpecial form destructive distillationCharging devicesCoke ovenHearth

The invention discloses a process for simultaneously producing machine coke and molded coke by use of a stamp-charging coke oven. The process comprises the following steps: a, tamping the charged mixing molded coal in the vertical direction in a coal charging car by use of a tamping hammer, thereby obtaining a mixing molded coal cake of which the upper surface is of a slope surface shape; b, pushing the mixing molded coal cake of which the upper surface is of the slope surface shape into a coking chamber, forming the structure of a sloping hearth furnace by use of the mixing molded coal cake and the inner wall of the coking chamber, charging the molded coal into the coking chamber from the top of the coking chamber and stacking the molded coal on the mixing molded coal cake; and c, when the coke is mature, opening a coke side furnace door to one side so that the molded coal coke rolls out of the coking chamber under the action of gravity and by use of the gradient of the upper surface of the mixing molded coal cake coke, and after the molded coal coke rolls out completely, pushing out the bottom mixing molded coal cake coke by use of a coke pusher. The process is used for simultaneously producing the machine coke and the molded coke by use of the traditional stamp-charging coke oven without modification; as a result, the product types of a coking plant are increased and a new idea is provided for the modification of the traditional coking plant.

Owner:CHINA UNIV OF MINING & TECH

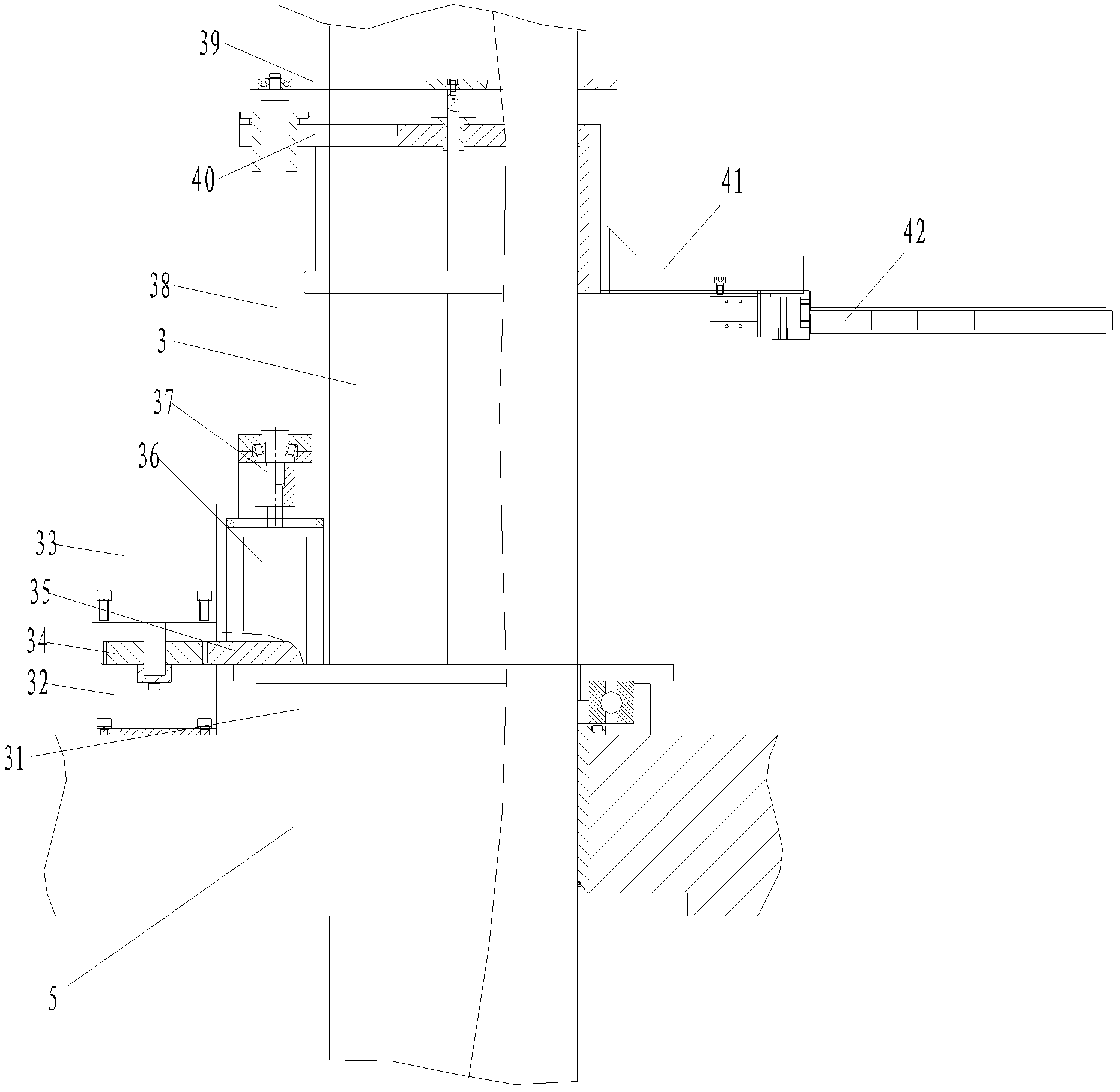

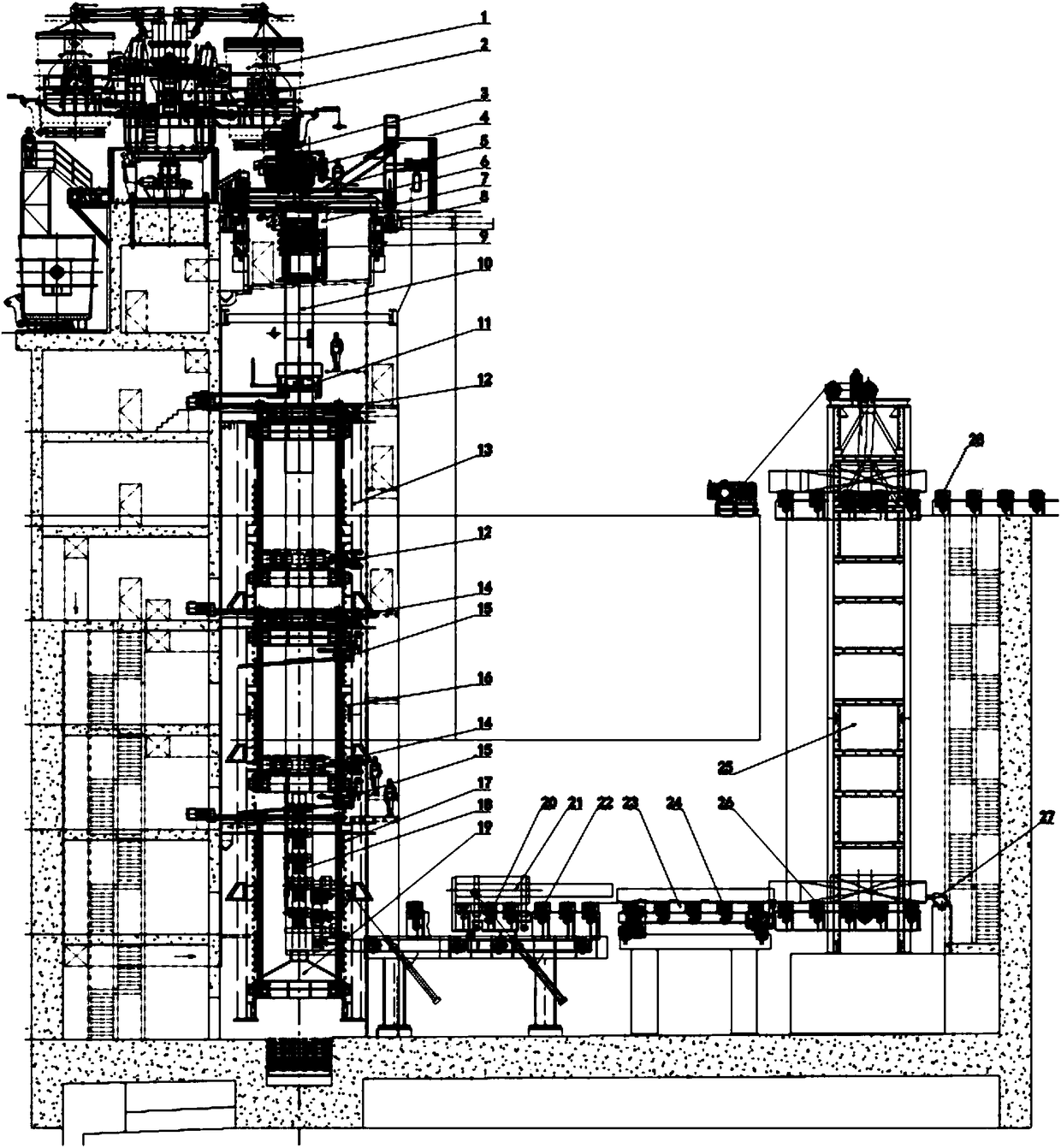

Vertical continuous casting production device and method for round billets of extra large specification

PendingCN108436046AHigh cleanliness requirementsHigh crack sensitivityIncreasing energy efficiencyCarbon steelContinuous casting

The invention discloses a vertical continuous casting production device and method for round billets of an extra large specification. The vertical continuous casting production device for the round billets of the extra large specification comprises a steel ladle (1), a middle tank (4), a crystallizer (6), a billet pulling system and a billet discharging system. The billet discharging system comprises a casting billet discharging device (20), a casting billet combining device (23), a casting billet lifting device (25) and an upper billet discharging roller bed (28). The vertical continuous casting production device and method for the round billets of the extra large specification are mainly applied to the round billets with the extra-large-specification sections with the diameter being 600mm-1300 mm, the brand new technologies of the billet pulling system, the billet discharging system and the like are adopted, multiple matched technological devices are adopted, and therefore the vertical continuous casting process method is suitable for producing a variety of steel like carbon steel and alloy steel, especially medium-and-high alloy clean steel and steel with high casting crack sensitivity, and continuous production of large-section high-quality billets is achieved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

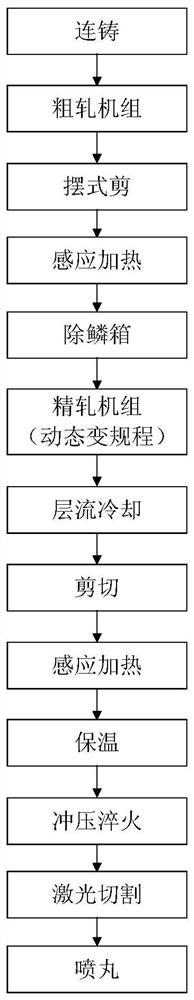

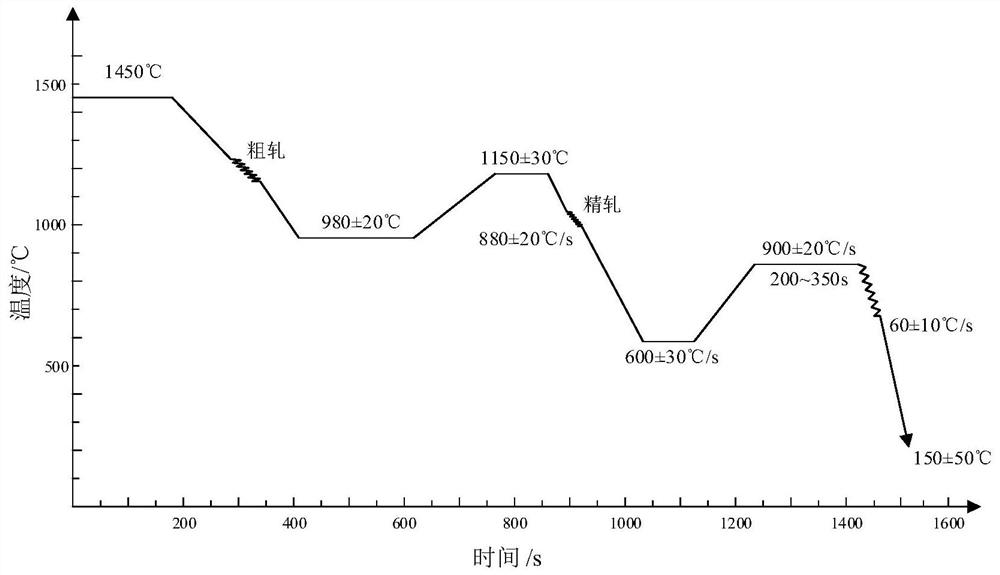

Plate blank performance gradient distribution forming method based on ESP dynamic variable regulation

ActiveCN111872149AAchieve integrationFully release the technical potential of continuous rolling equipmentFurnace typesMetal rolling arrangementsLaminar coolingProcess engineering

The invention relates to a plate blank performance gradient distribution forming method based on an ESP dynamic variable regulation, and belongs to the field of steel and iron material rolling and deep processing. The method achieves online non-stop roller changing rolling of a variable-thickness plate blank through a '5+1' dynamic variable regulation strategy of a finish rolling unit, cascading with a stamping quenching technology after a laminar cooling procedure is achieved, industry integration of upstream rolling and downstream deep processing is achieved, a short-flow compact productionflow combining rolling-deep processing is realized, and performance variable gradient characteristic stamping quenched parts can be produced; and the method realizes integrated production from metallurgical raw materials to products, the transportation cost of intermediate links is saved, besides, complementary energy resources of a rolling process can be effectively utilized, the overall manufacturing process of plate blank deep processing is remarkably shortened, high-quality development of the rolling and deep processing industry is promoted, and the method is of important significance in promoting green development of the rolling and deep processing industry field, expanding dominant supply, optimizing productivity layout and the like.

Owner:YANSHAN UNIV

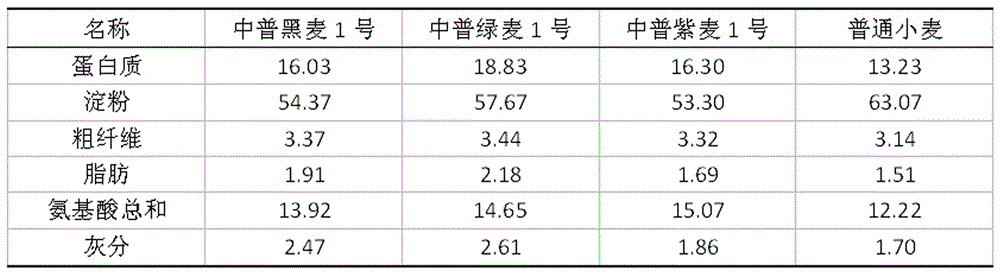

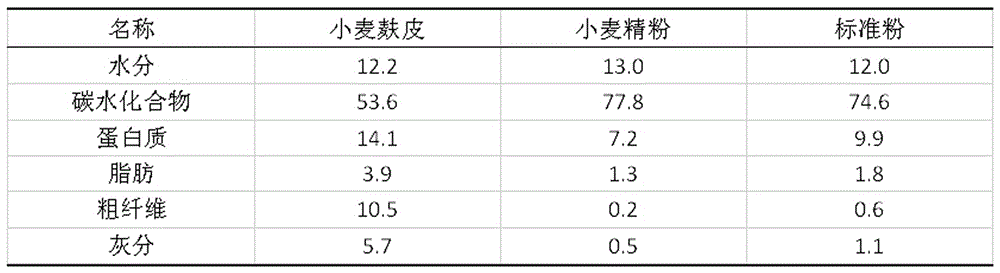

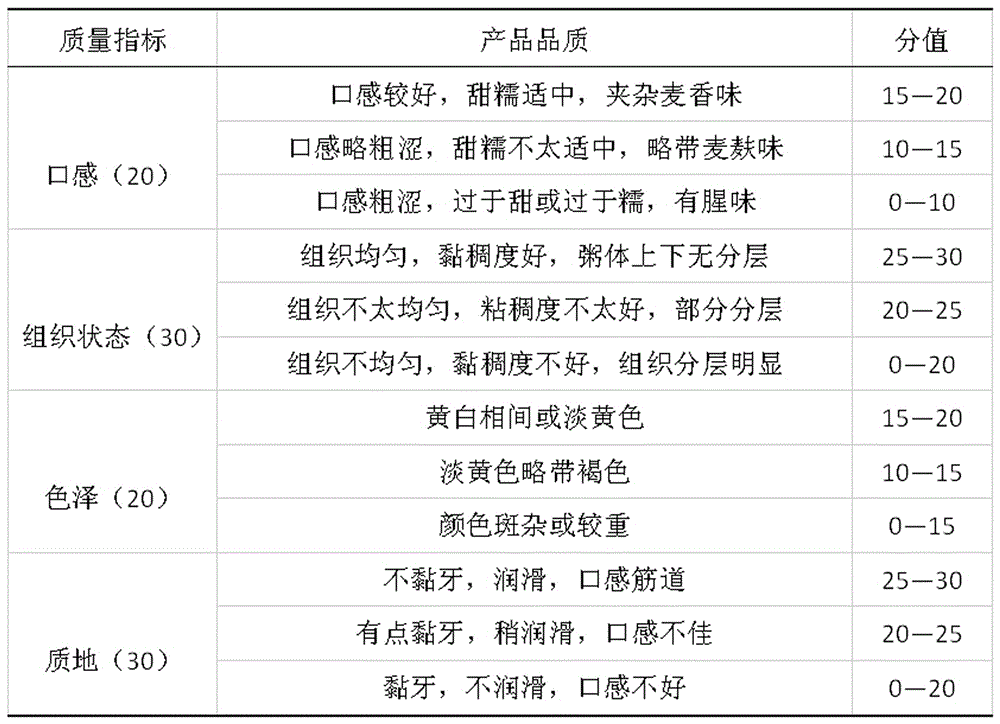

Nutritional instant congee rich in colored wheat bran dietary fibers, and production method thereof

The invention provides a nutritional instant congee rich in colored wheat bran dietary fibers, and a production method thereof. The instant congee is a finished product produced through adding an agriculture byproduct colored wheat bran to cereal raw materials, adding Chinese yam, small red beans and other medicinal and eatable plant components, and carrying out pretreatment and extrusion puffing. The instant congee comprises, by weight, 50-60 parts of mixed rice grains, 20-30 parts of mixed wheat grains, 10-20 parts of bean components and 1-2 parts of a seasoning assistant. The nutritional instant congee produced in the invention is instant after being boiled, is convenient to store, is rich in effective components of dietary fibers, can promote absorption of other nutrition elements and prevent rising of the in vivo blood sugar concentration, can dredge the intestine and strengthen the stomach, and is a good health care product used for opposing the three highs and modern urban ills.

Owner:HENAN UNIV OF SCI & TECH

Electro-plasticizing continuous extrusion molding processing technology of high-strength aluminum alloy

InactiveCN102814349AReduce residual stressReduced processing performanceElectricityWorking environment

The invention relates to a new method for molding processing of a high-strength aluminum alloy, and belongs to the plasticity processing field. The method enables a pulse current to be applied to a deformation zone in the high-strength aluminum alloy extruding process to promote the improvement of the plasticity of the high-strength aluminum alloy and reduce the deformation resistance of the high-strength aluminum alloy to make the difficult-deformation high-strength aluminum alloy deform at normal temperature, so the heat treatment operations comprising device heating, annealing and the like are omitted. The pulse current can be directly applied to dislocation structures to promote the dislocation motion, so the affections of residual stress and processing hardening are reduced under the action of the pulse current, thereby the product surface quality is improved and the annealing operation is omitted. The reduction of the deformation resistance can effectively reduce the load acted on a die and reduce the temperature of the cavity material baffle block, so the service life and the production efficiency of the die are greatly improved, thereby the production cost is reduced. The surface quality and the mechanical performances of products are improved because of the pulse current, so rigorous performance requirements of the high-strength aluminum alloy of aerospace vehicles, high-speed trains and the like because of bad working environments are satisfied.

Owner:陶艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com