Patents

Literature

75results about How to "High cleanliness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

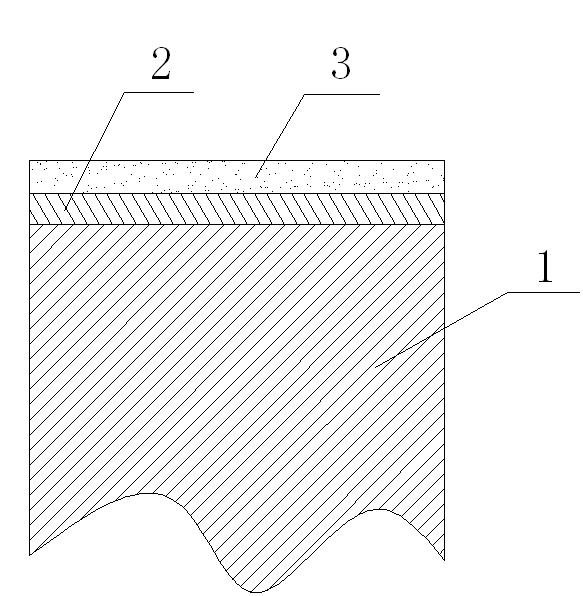

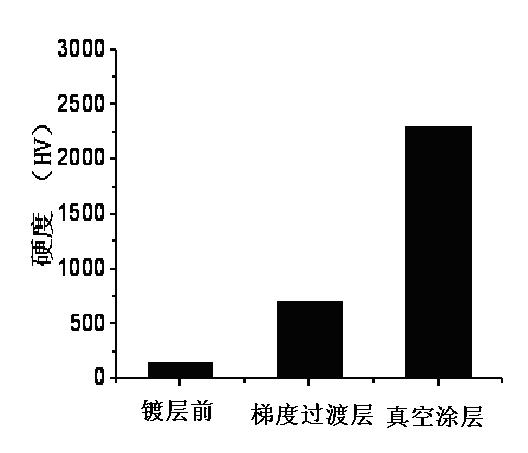

Surface compound strengthening process for aluminum alloy material

ActiveCN102115883AHigh bonding strengthHigh hardnessSuperimposed coating processDlc coatingChemical plating

The invention discloses a surface compound strengthening process for an aluminum alloy material, aiming to solve the problems that chemical plating of Ni, Ni-P and Ni-W-P or electroplating of Ni and Cr for aluminum and aluminum alloy has good bonding strength but low rigidity and poorer wear resistance, and vacuum coatings of CrN, TiN, TiAlN, TiCN or DLC for an aluminum alloy material have high rigidity and good wear resistance but poorer bonding strength with a substrate. The surface compound strengthening process disclosed by the invention comprises the following steps: firstly, plating a 2-10mu m thick gradient transition layer on the surface of an aluminum alloy substrate, then baking for 1-2 hours at constant temperature of 75-85 DEG C in a dry environment, and finally depositing oneor multiple coatings of CrN, TiN, TiAlN, TiCN or DLC on the aluminum alloy substrate by a vacuum coating technology. The surface compound strengthening process can improve the bonding strength between the vacuum coating and the aluminum alloy substrate, and simultaneously the surface of the aluminum alloy substrate has higher rigidity and wear resistance.

Owner:NAXAU NEW MATERIALS CORP

Bearing outer ring washing process

ActiveCN102069080AReduce noiseExtended service lifeCleaning using toolsCleaning using liquidsProcess engineeringGrinding wheel

The invention discloses a bearing outer ring washing process, which comprises the following steps of: washing by using a hairbrush so as to wash away heavy garbage such as grinding wheel dust, antirust oil dirt and the like generated in the polishing process of an outer ring; and washing tiny garbage away by using multi-slot channel type ultrasound so as to meet the requirement of high cleanliness. When observed under a microscope, a bearing washed by the washing process almost do not have the garbage with the diameter of more than 20mu m, so that the noise of the bearing is effectively reduced, and the service life of the bearing is prolonged.

Owner:南通山口精工机电有限公司

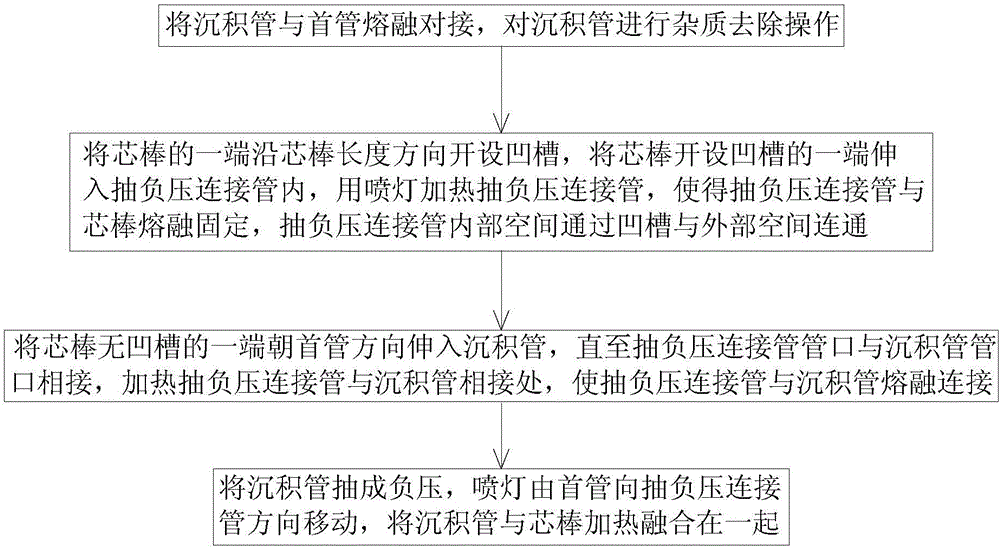

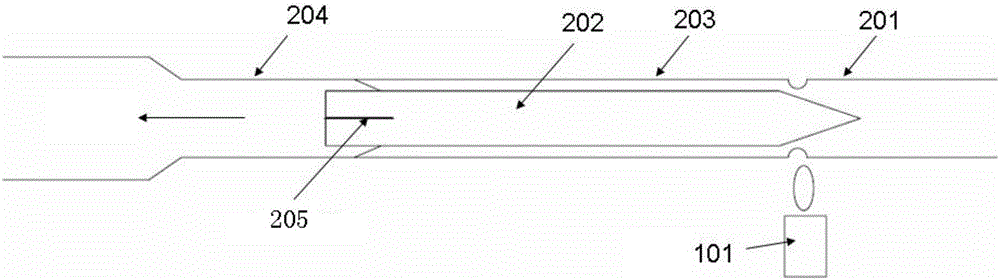

Method for preparing doped optical fiber outer cladding layer

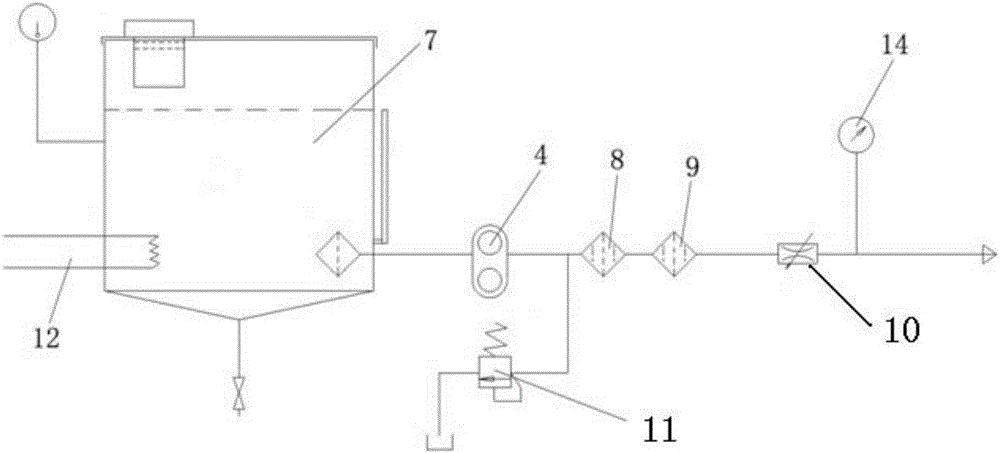

ActiveCN106242262AQuality assuranceImprove the effect of impurity removalGlass making apparatusPressure systemEngineering

The invention discloses a method for preparing a doped optical fiber outer cladding layer, and the method comprises the following steps: 1) a deposition tube and a head tube are butted by fusion, and impurities are removed; 2) one end of a core rod is provided with a groove along the length direction of the core rod, the end, which is provided with the groove, of the core rod stretches into a negative pressure suction connection pipe, and the negative pressure suction connection pipe is heated for fusion fixing with the core rod; 3) one end, which is not provided with the groove, of the core rod stretches into the deposition tube toward the direction of the head tube, and the opening of the deposition tube is heated for sealed connection of the negative pressure suction connection pipe and the deposition tube; 4) the pressure of the deposition tube is pumped to a negative pressure, a blast burner moves from the head tube to the direction of the negative pressure suction connection pipe for heating to fuse the deposition tube and the core rod together. Through arrangement of the groove on one end of the core rod, when air is pumped, the groove plays a key role, air between the deposition tube and the core rod enters the negative pressure suction connection pipe through the groove, and a negative pressure system is formed in the deposition tube, so that the deposition tube and the core rod can be reliably fused.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH +1

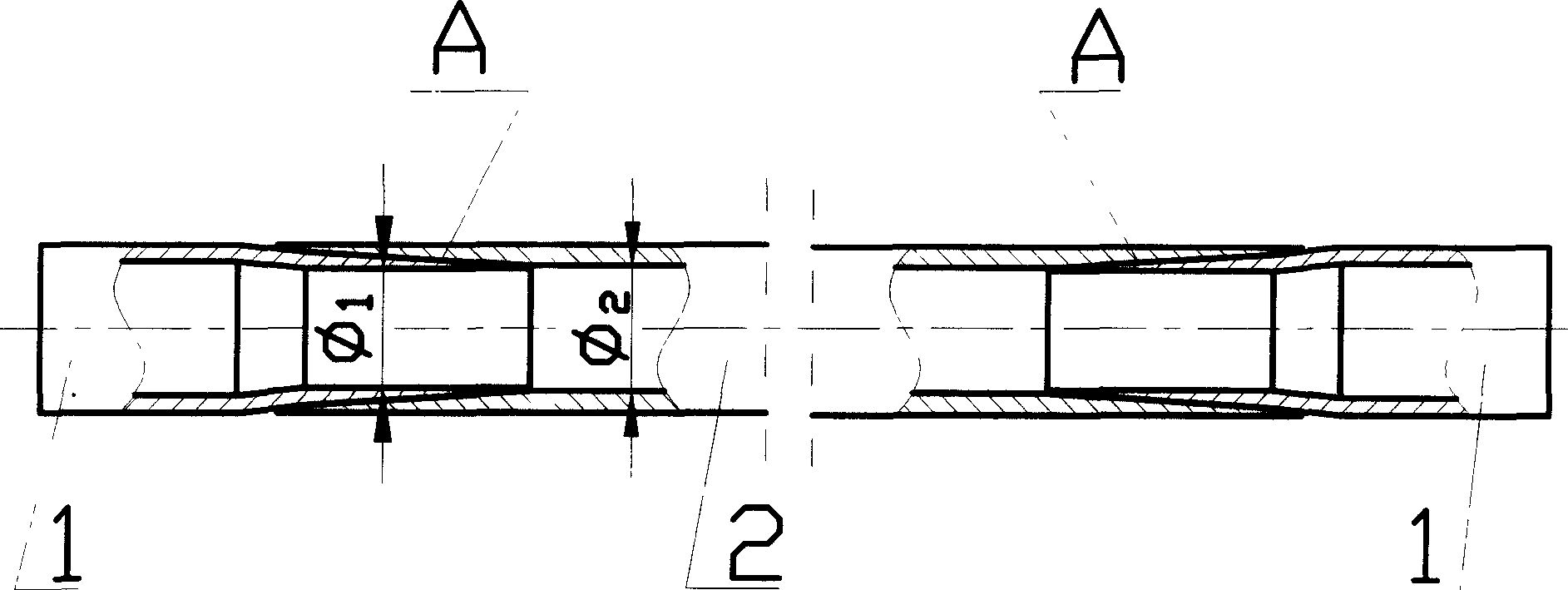

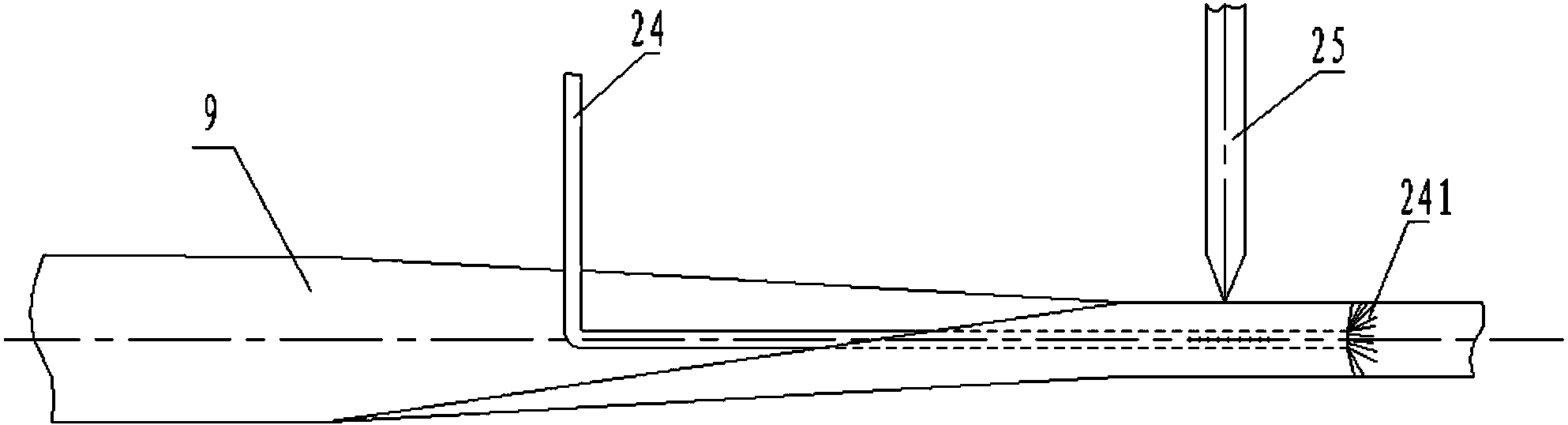

Copper-aluminium combined pipeline piece with identical joint diameter and aluminium pipe

ActiveCN1677024AImprove welding qualityFusion surface widthFluid circulation arrangementTubular elementsMaterials scienceTube diameter

The invention discloses a copper aluminum tube component of the same connecting terminal diameter, features that on one end or two end of the aluminum tube is welded with a copper tube and the contacting surface of the copper and aluminum tube with the same or nearly the same diameter, is the cone sleeve surface with copper tube inside and aluminum tube outside. The sleeved surface diameter phy 1 is equal or close to the diameter phy 2 of the aluminum tube. The invention is of fine welding quality and large welding surface area, the connecting terminal is of nearly the same size as aluminum tube although the sleeved terminal is adopted, which, ensures the product refrigerating requirement and following process structural requirement. Thus, the invention can be applied to refrigerating pipes which has a high requirement on compaction, cleanness and special requirement on flow volume, inner and outer diameter, to products such as air conditioner, refrigerator, show chest, drinking machine, drying machine, and other refrigerating products.

Owner:左铁军 +1

Method for detecting fluid flow and fluid heat quantity by thermal flow and its application device

InactiveCN1749717AThe detection link is clearEasy to detectIndirect mass flowmetersCalorimeterHeat flowTemperature difference

The present invention provides method and device of detecting fluid flow rate and heat quantity by means of heat flow. The method is to utilize heat flow sensor in detecting the heat quantity Q of the fluid and conducted through pipe or wall. Under certain physical property condition and determined heat exchange shape parameters, the heat quantity Q is related only to the fluid flow rate and the temperature difference across the pipe or wall. Based on the mathematic model, the function relation of heat quantity Q to the fluid flow rate and the temperature difference is first determined and the flow rate and the heat quantity are measured. Compared with available other fluid flow rate and heat quantity detecting method and instrument, the present invention has the advantages of high precision, low cost, high stability, etc.

Owner:CHONGQING UNIV

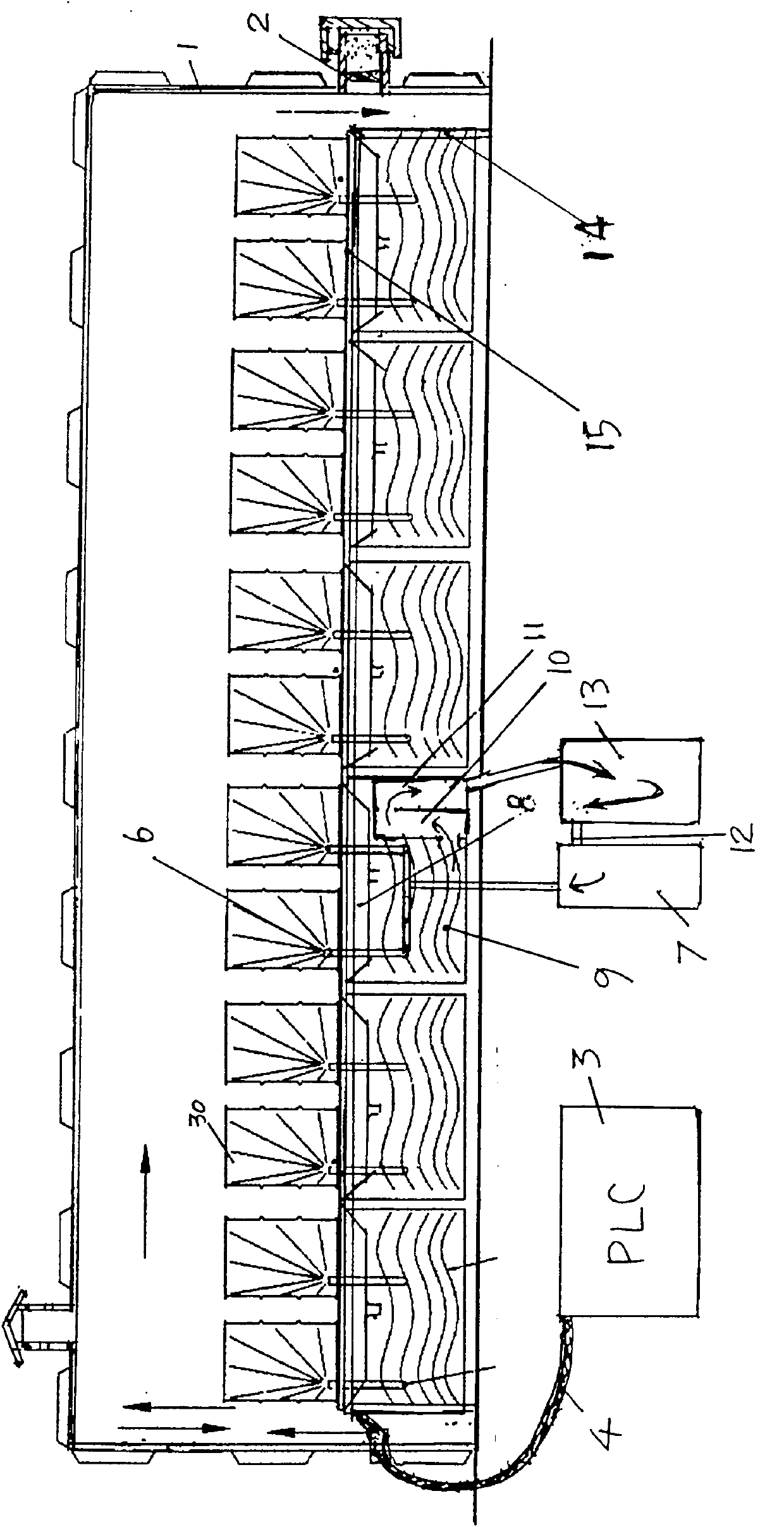

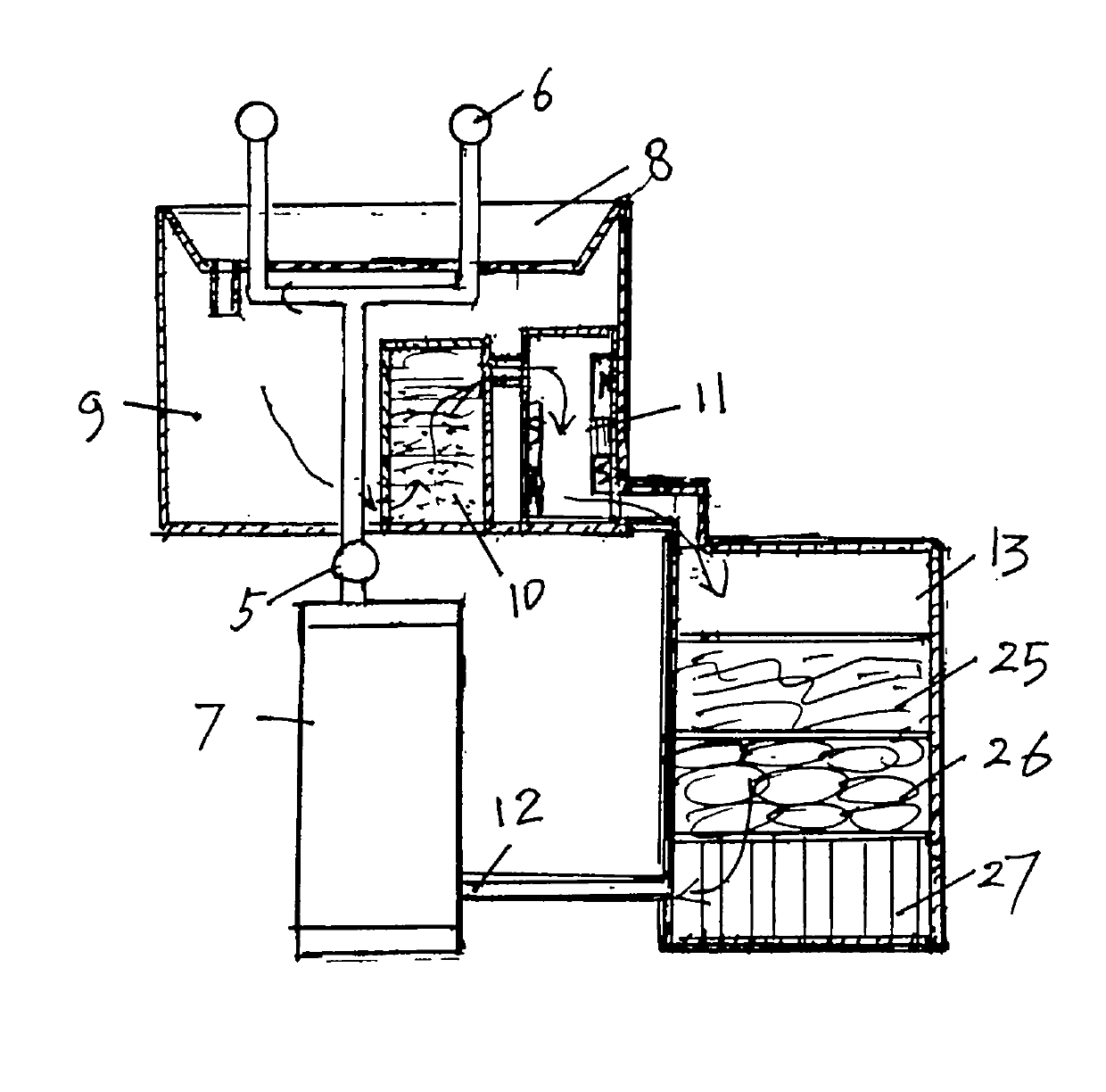

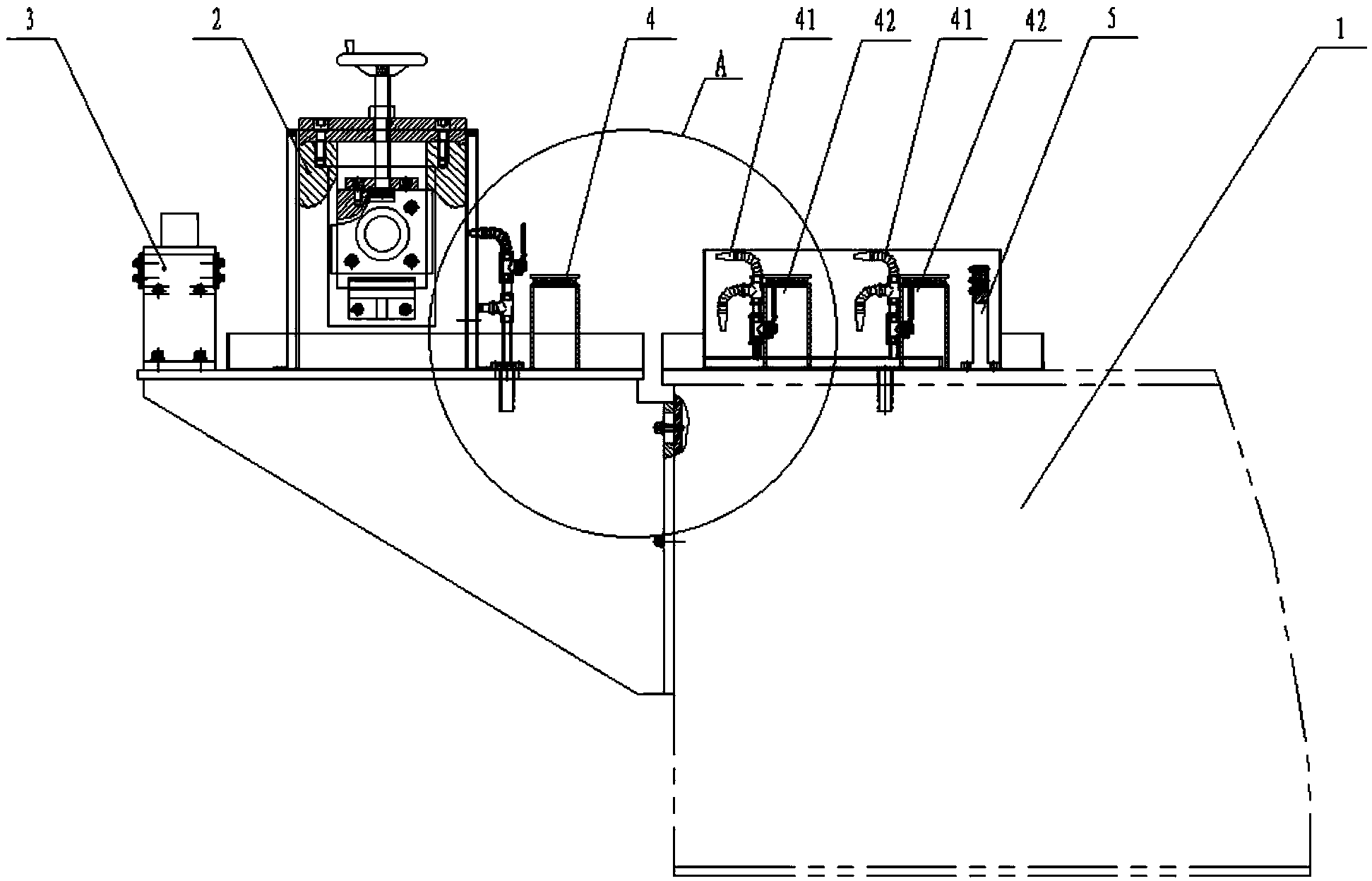

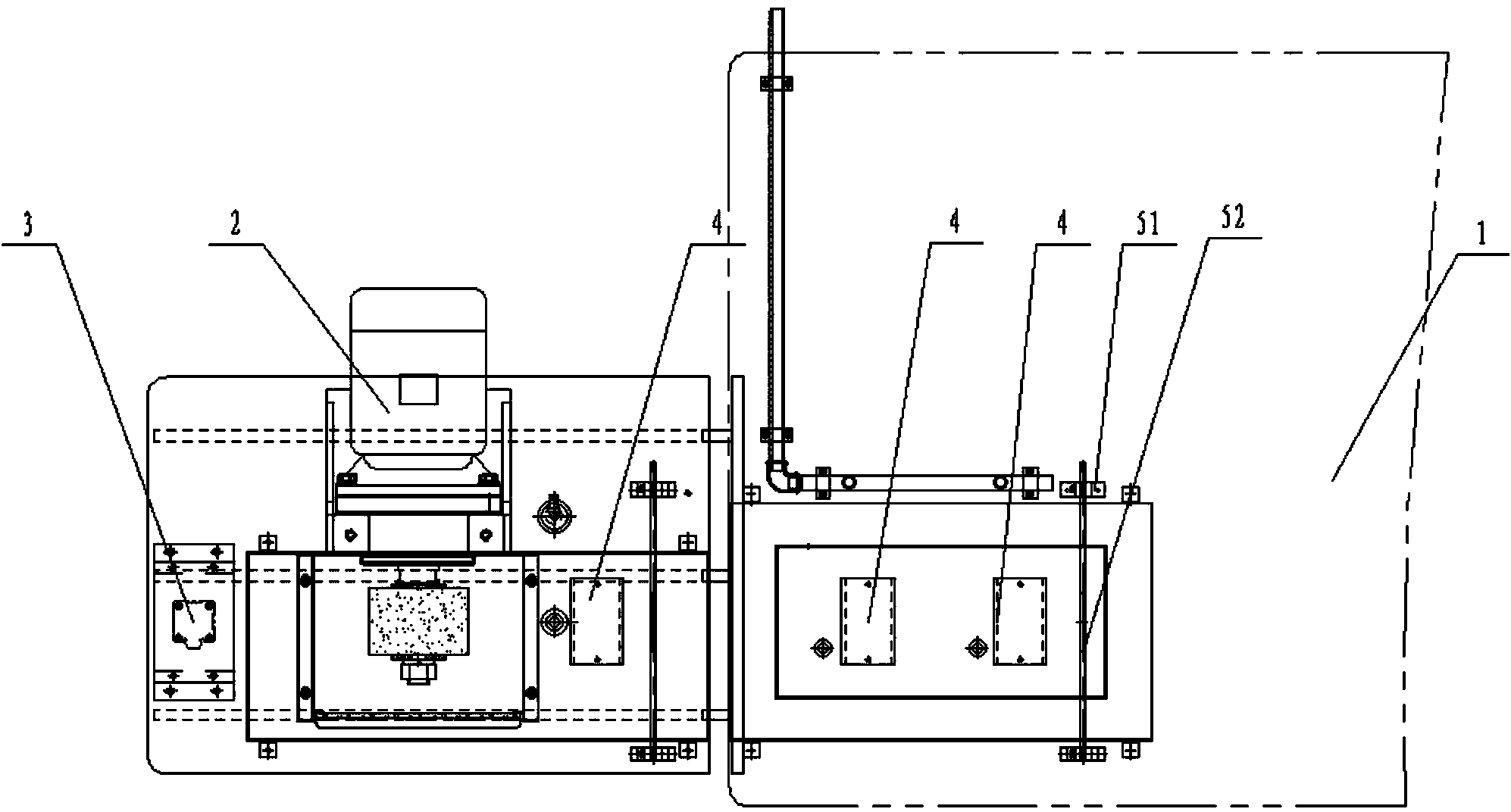

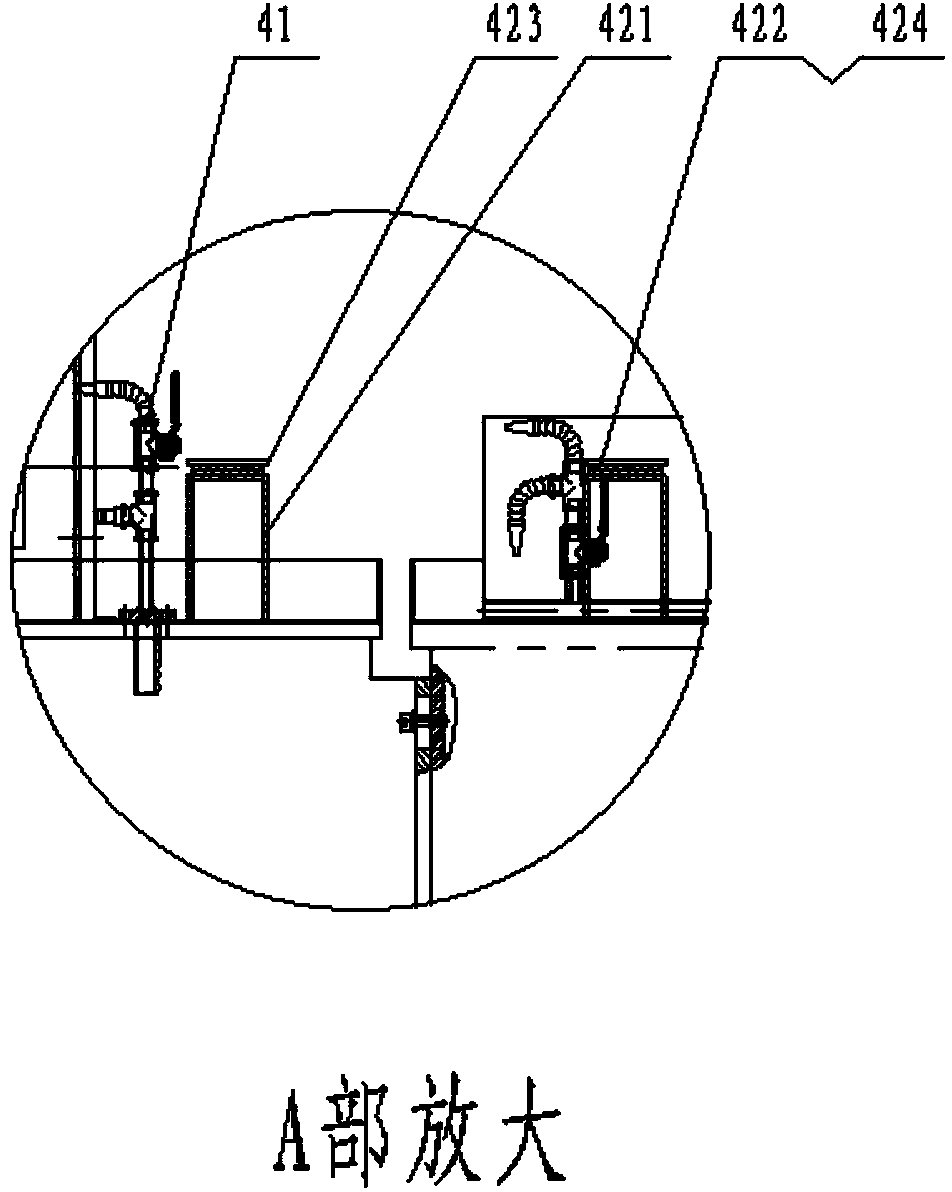

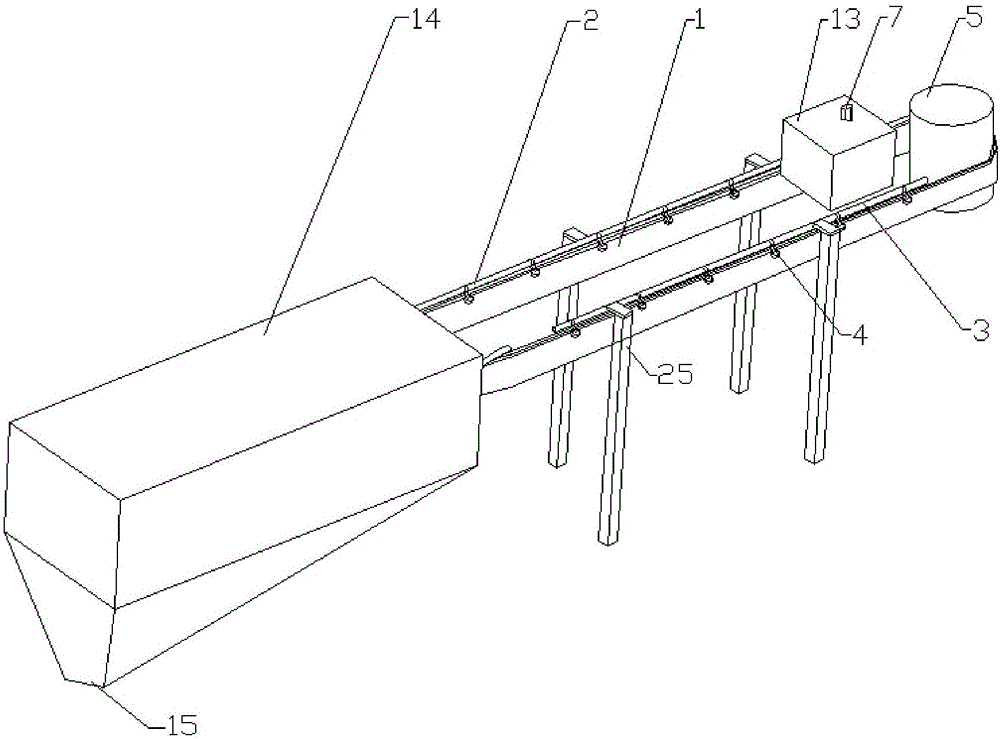

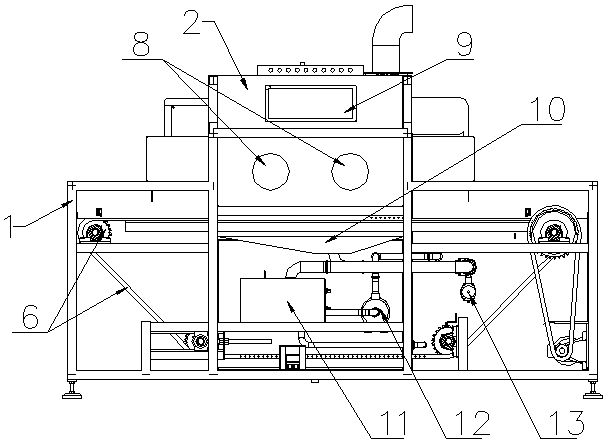

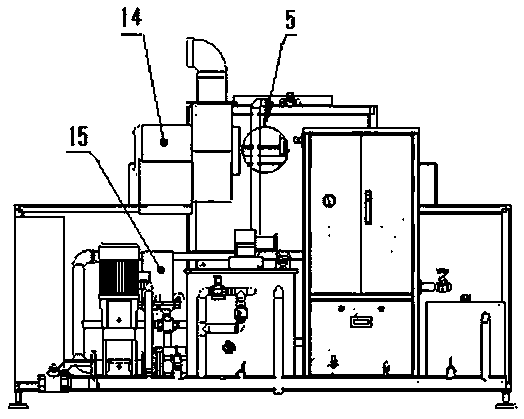

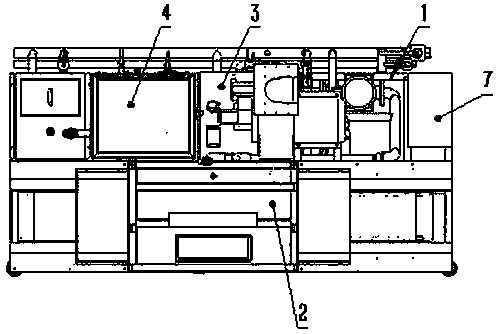

High-purification-treatment automatic production line of steel drum

InactiveCN102029277AHigh cleanliness requirementsHollow article cleaningProduction lineDiaphragm pump

The invention relates to a high-purification-treatment automatic production line of a steel drum, which comprises a plurality of continuous cleaning stations and a steel drum transmission device, wherein each station is respectively provided with a rotating nozzle cleaning device with a control valve; each nozzle is respectively connected with the output end of an anticorrosive 3-inch diaphragm pump; a cleaning liquid collecting disk is arranged between every two adjacent stations; each collecting disk is connected with a set of cleaning liquid recovering and separating box device with a primary filtering device and a magnetic pollutant intercepting device; the liquid separating box device is connected with a stainless steel fine filtering tank device; and the stainless steel fine filtering tank device is connected with the input end of the anticorrosive 3-inch diaphragm pump. The production line provided by the invention has the advantages of realizing the operation of mechanically, automatically and successively cleaning the inside of the steel drum, and achieving the effect of cleaning the inside of the steel drum through high purification treatment; and the treated steel drum meets the extremely-high cleanliness requirements of paints and chemical products for the inside of the packaged steel drum.

Owner:天津大田包装容器有限公司

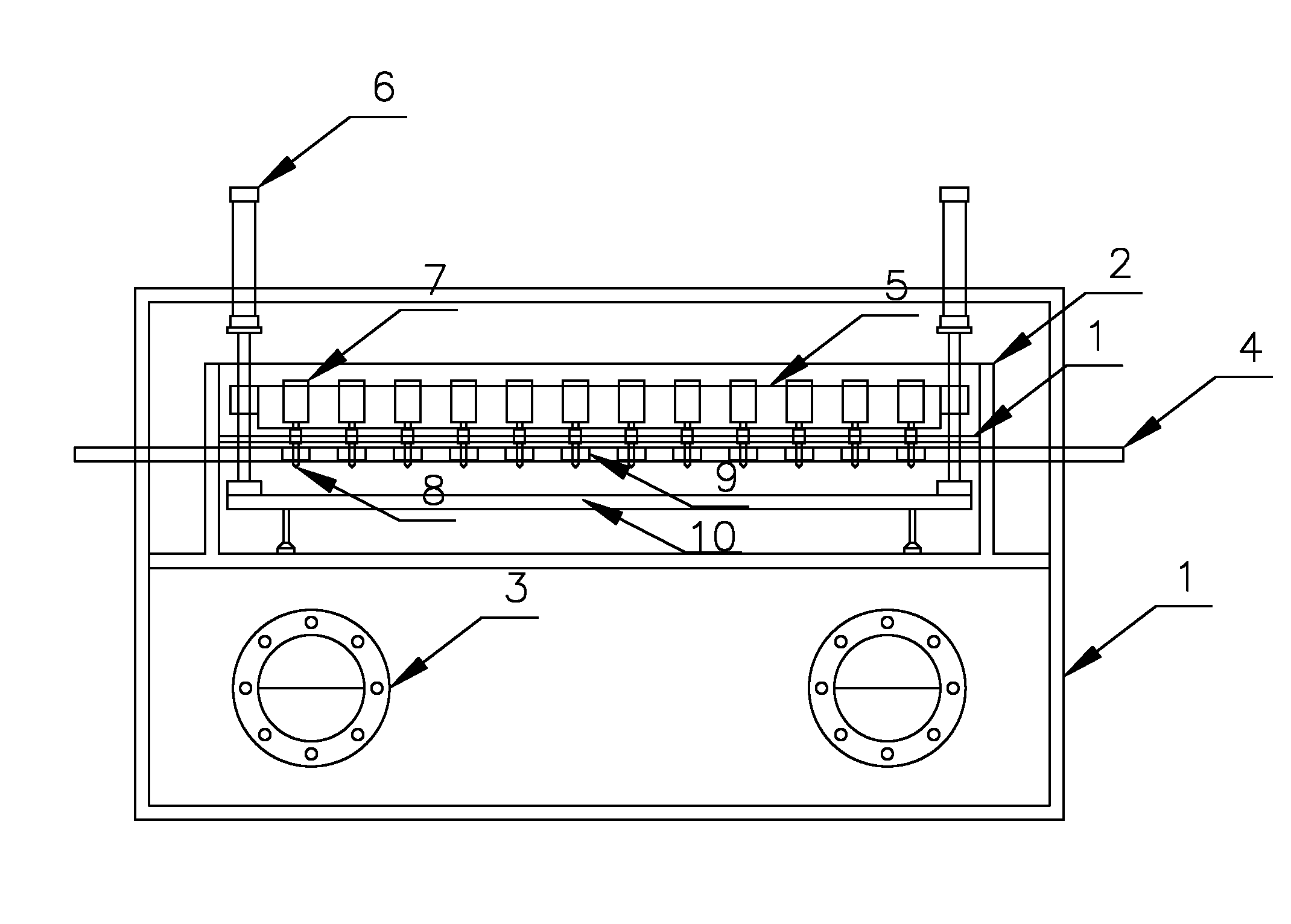

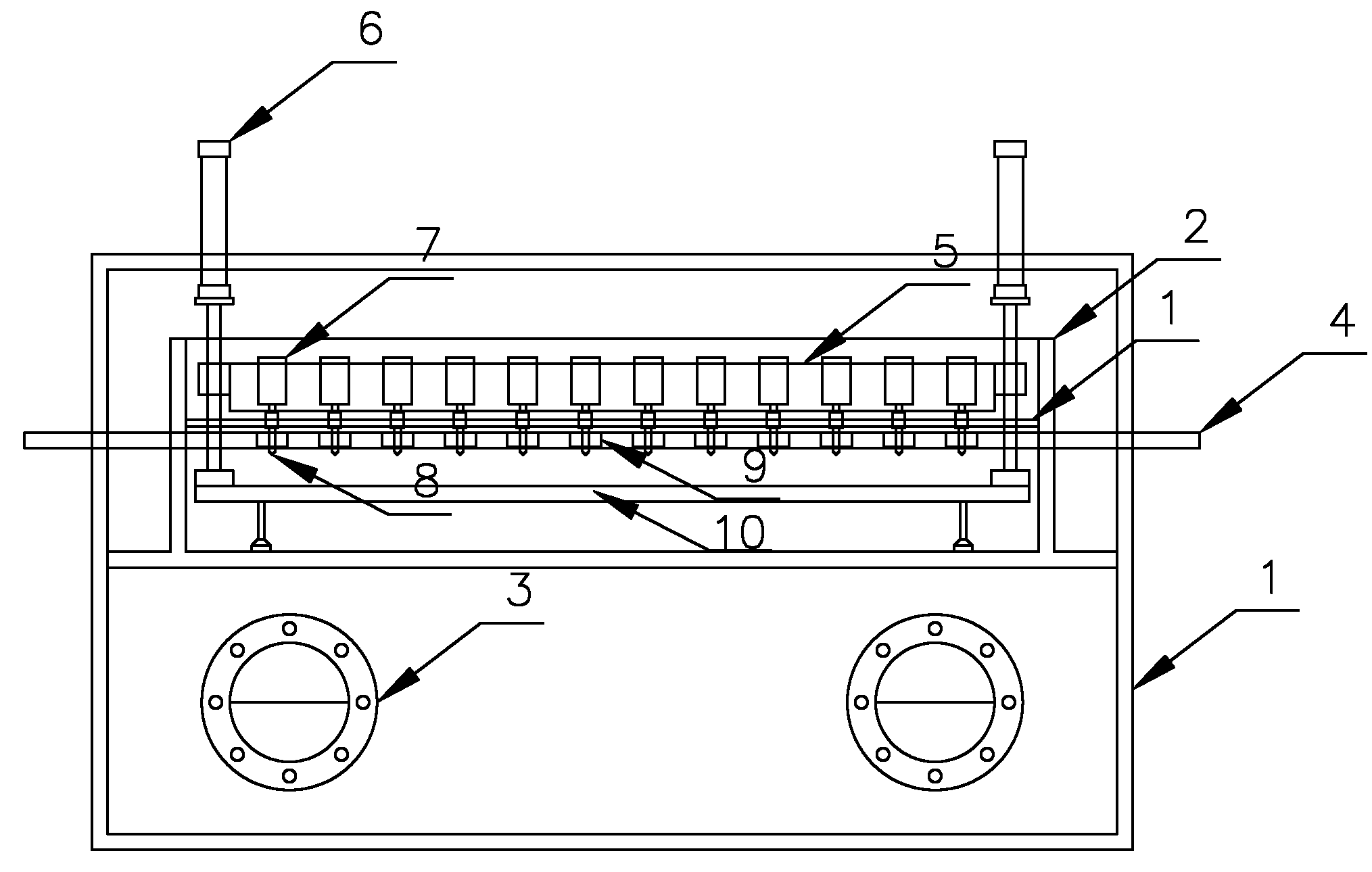

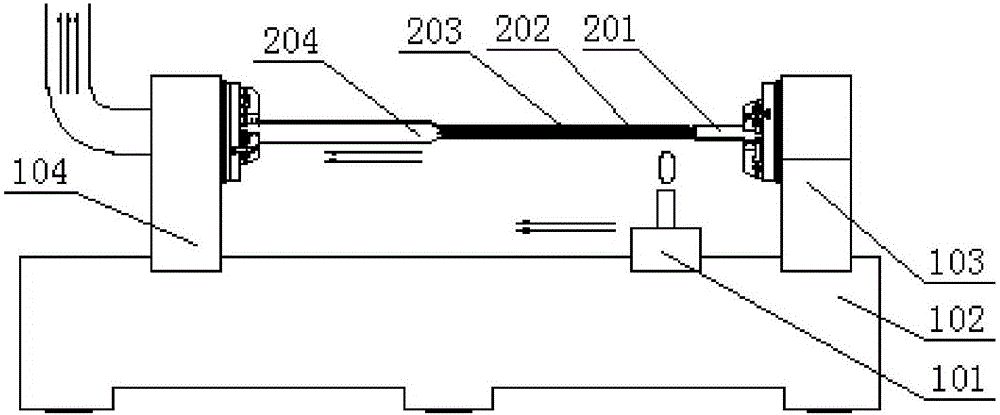

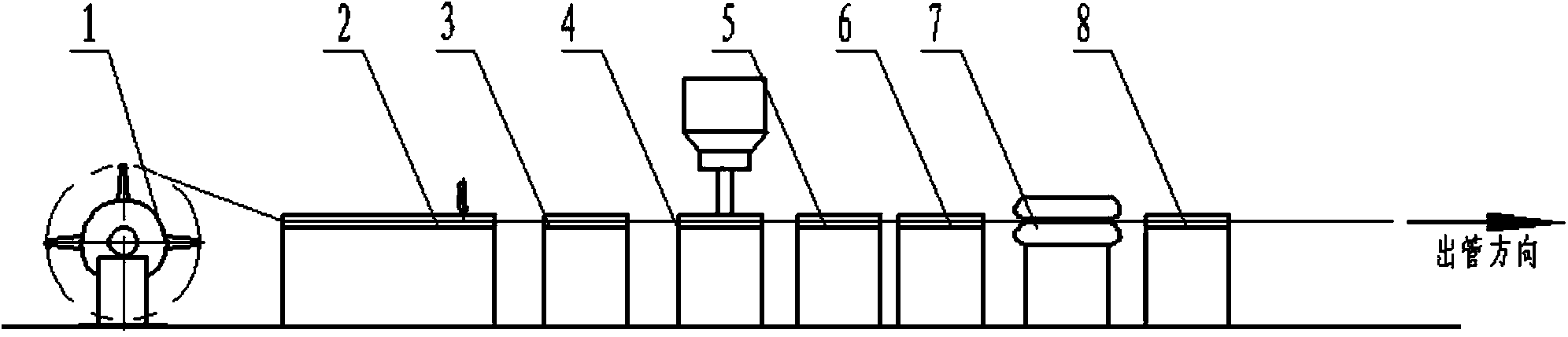

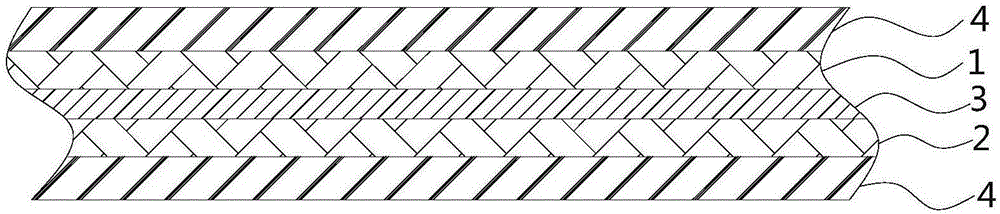

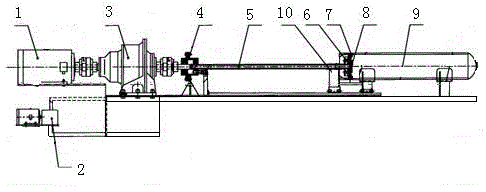

Continuous production device of plastic coated stainless steel pipeline

ActiveCN103921078AIncrease productivityLow costFurnace typesGrinding machinesSolid solutionSteel pipeline

The invention discloses a continuous production device of a double-layer plastic coated stainless steel pipeline. The continuous production device is low in production cost, high in production efficiency and high in pipeline internal cleanness and comprises a stainless steel band unreeling machine, a pipeline welding machine, a welding bead solid solution tempering device, a plastic coating extruding machine, a composite pipeline sizing device, a cooling device, a crawler-type dragger and a cut-off machine. A machine frame at the feeding end of the pipeline welding machine is sequentially provided with a band cleaning and dirt-removing device, a grinding and polishing mechanism and a plurality of washing and water-removing mechanisms.

Owner:江苏薪泽奇机械股份有限公司

Modified method for semi-glue die-cut product processing technique

InactiveCN101186787AAvoid secondary pollutionImprove cleanlinessFilm/foil adhesivesManufacturing technologyAdhesive

Disclosed is an improved process of the manufacture technology of semi-colloid die-cutting products. 1, in the procedure of compounding materials, a protective paper of which the size is wider than a double sticky tape via certain specification is chosen to proceed the double-faced compounding, which enables an upper layer protective paper and a lower layer protective paper of the double sticky tape to be equal in width, but to be a little bit wider than the double sticky tape via certain specification.2, the shape of the products is cut by the die-cutting of a machine from the front surface in the manner of semi-cutting, the key point is that a handle portion is enabled to be cut on the adhesive-free protective paper, the left-right position of the material should be concentrated at any time, simultaneously, the machine can automatically proceed arranging waste edges and cutting single sheet.3, finished products are produced after the machine cuts sheet, inspectors check the positions of the semi-adhesive, and the qualified products can be packed, consequently the procedure is finished. Take an ordinary semi-adhesive product for example, 40,000 times of die-cutting can be finished in eight hours, and then 40,000 products can be produced by the calculation of one product by one time. The subsequent work of boding products by hand of 40,000 products cut by the conventional technical process demands 15 persons and eight hours to accomplish. Compared with the conventional technical process, 40,000 products cut by the improved technology only demand one person and four hours to check and pack, thereby greatly saving labor resource and reducing cost.

Owner:TIANJIN NIUSIDA PACKAGE NEW TECH

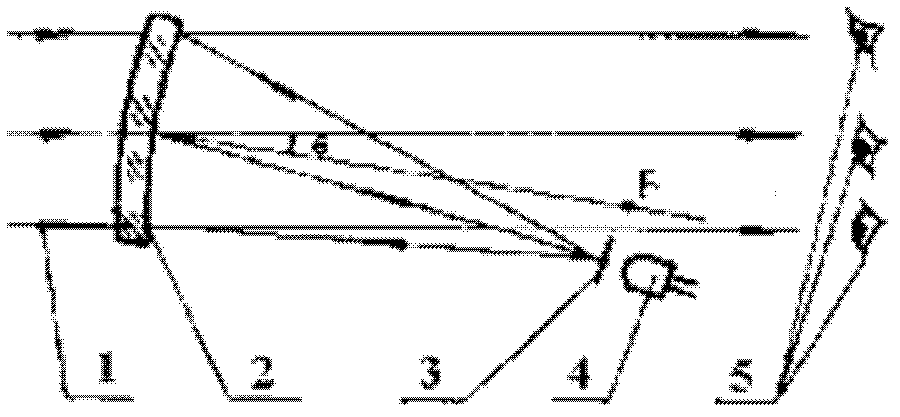

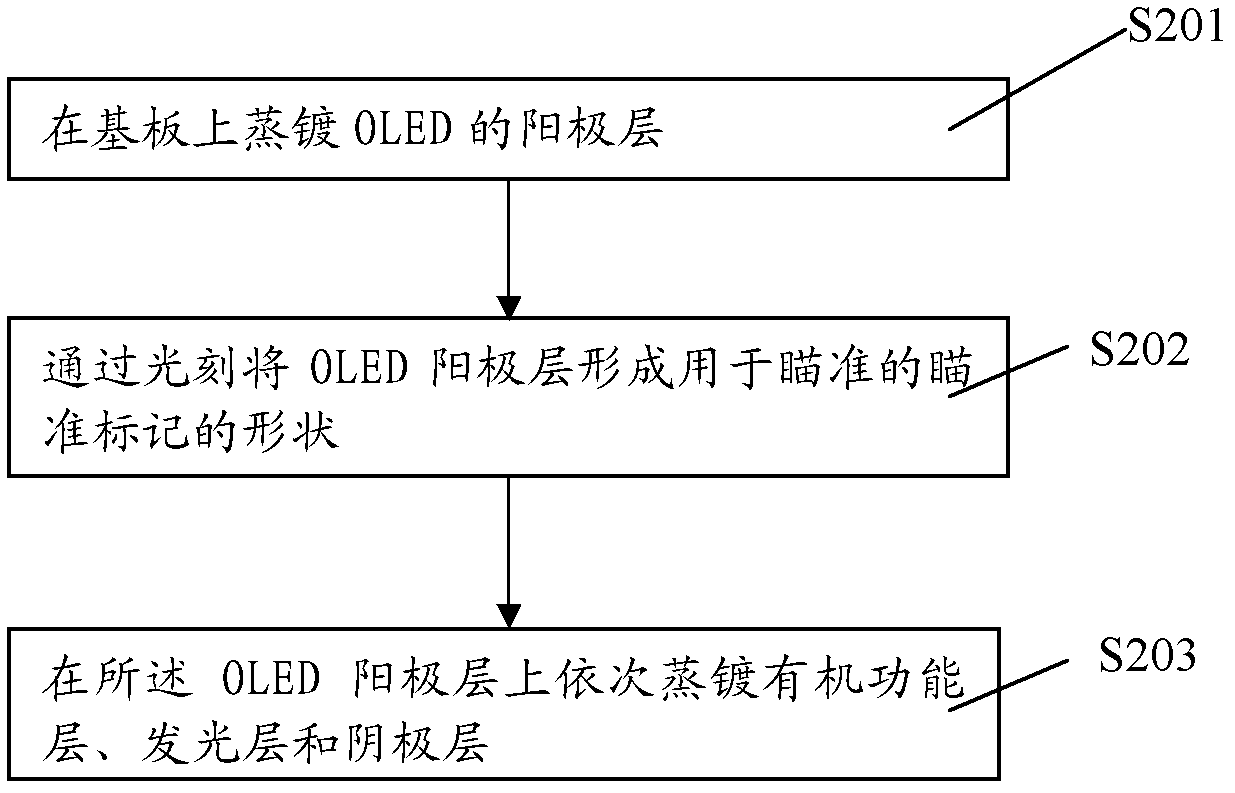

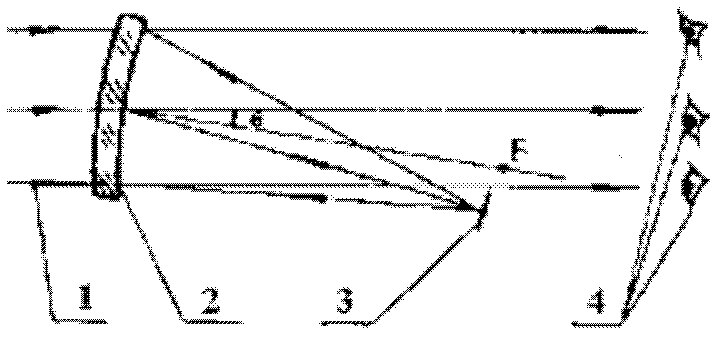

OLED (Organic Light Emitting Diode) reticle, manufacturing method thereof and reflecting type sighting telescope

ActiveCN102456850ASave spaceLow costSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeTelescope

The invention provides a manufacturing method of an OLED (Organic Light Emitting Diode) reticle, comprising the following steps: evaporating an anode layer of an OLED on a substrate, and enabling the anode layer to form a sighted and marked shape; and sequentially evaporating an organic functional layer, a light emitting layer and a cathode layer on the anode layer of the OLED. The invention also provides an OLED reticle comprising the OLED, wherein the OLED comprises the substrate as well as the anode layer, the organic functional layer, the light emitting layer and the cathode layer which are sequentially overlapped on the substrate, wherein the anode layer of the OLED is in the sighted and marked shape. In addition, the invention provides a reflecting type sighting telescope with the OLED reticle provided by the invention. By using the OLED reticle, the manufacturing method thereof and the reflecting type sighting telescope, the space occupied by the reticle in the reflecting type sighting telescope and a lamp optical system can be greatly reduced.

Owner:GUAN YEOLIGHT TECH CO LTD +1

Method for treating inner surface of steel drum

ActiveCN101956189AHigh cleanliness requirementsSuitable for mass productionMetallic material coating processesEngineeringSolvent

The invention relates to a method for treating the inner surface of a steel drum, which is characterized by comprising the following steps of: pre-degreasing: adding a degreasing agent solution A into a pre-degreasing solvent tank and placing the steel drum into the pre-degreasing solvent tank for pre-degreasing; degreasing: adding a degreasing agent solution B into a degreasing solvent tank and placing the steel drum into the degreasing solvent tank for degreasing: water washing: carrying out first water washing and second water washing on the degreased steel drum in a water washing tank at normal temperature; phosphating: adding a phosphating ion series film agent and water into a phosphating tank to obtain phosphating liquid and placing the steel drum into the phosphating liquid for phosphating; third and fourth water washing: carrying out third and fourth water washing on the phosphate steel drum in the water washing tank at normal temperature; and drying: drying the steel drum subjected to the fourth water washing in a suspension chain drying channel. The invention can meet the high cleanness requirement of high-grade lubricating oil and is suitable for mass production on the industrial production flow line.

Owner:WUXI SIFANG YOUXIN

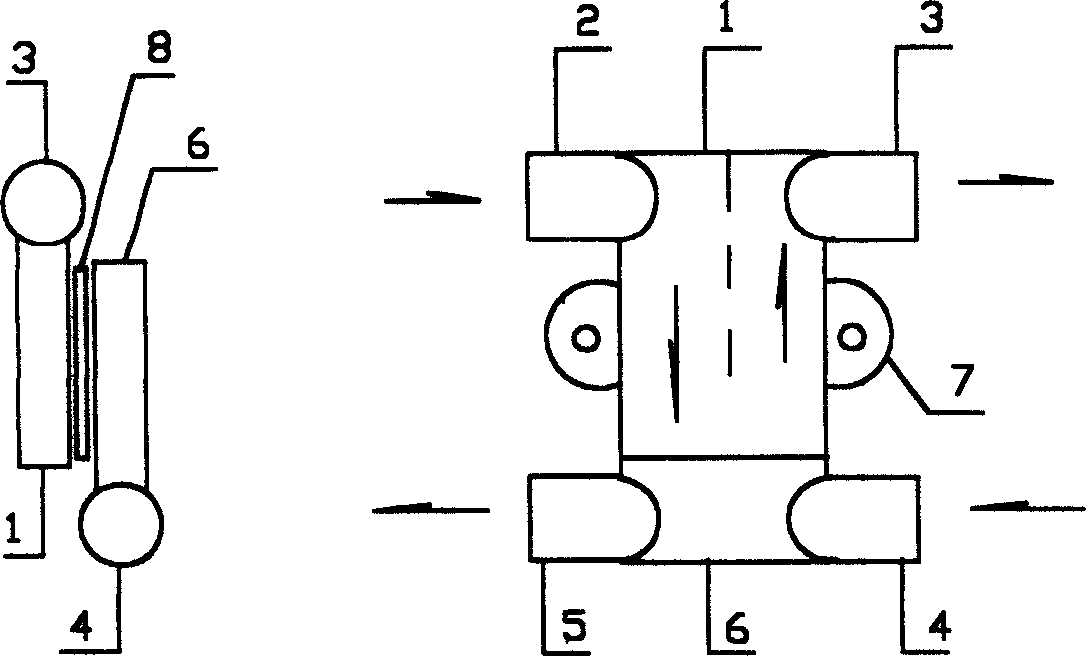

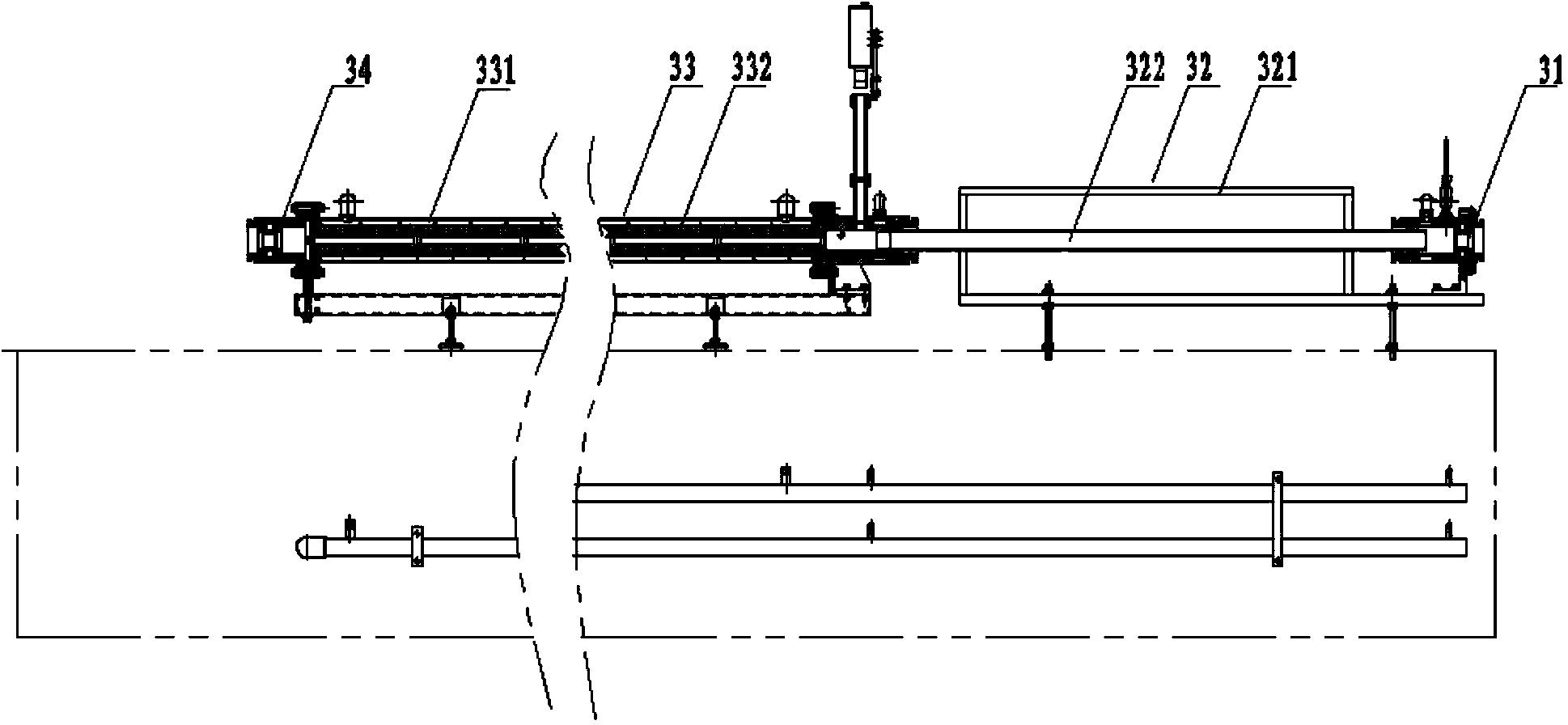

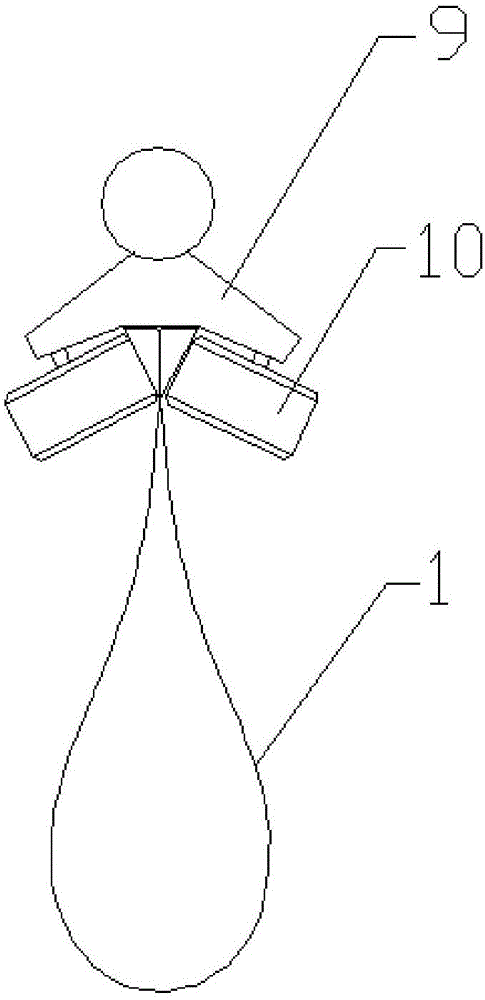

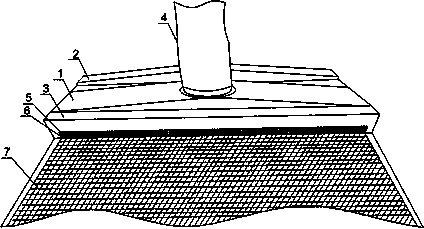

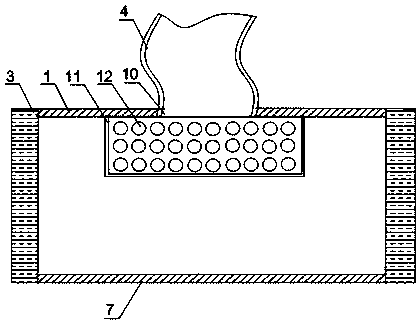

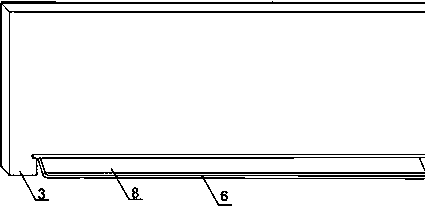

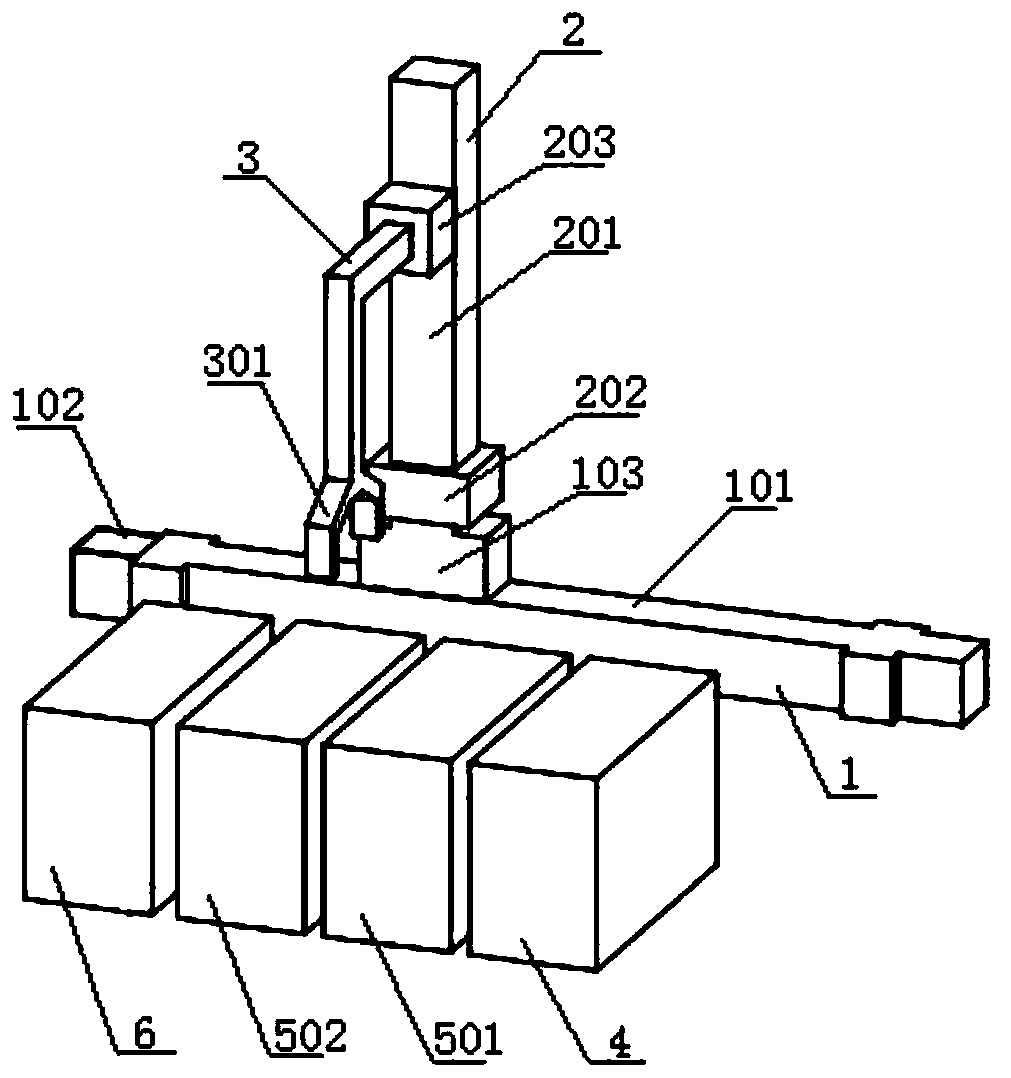

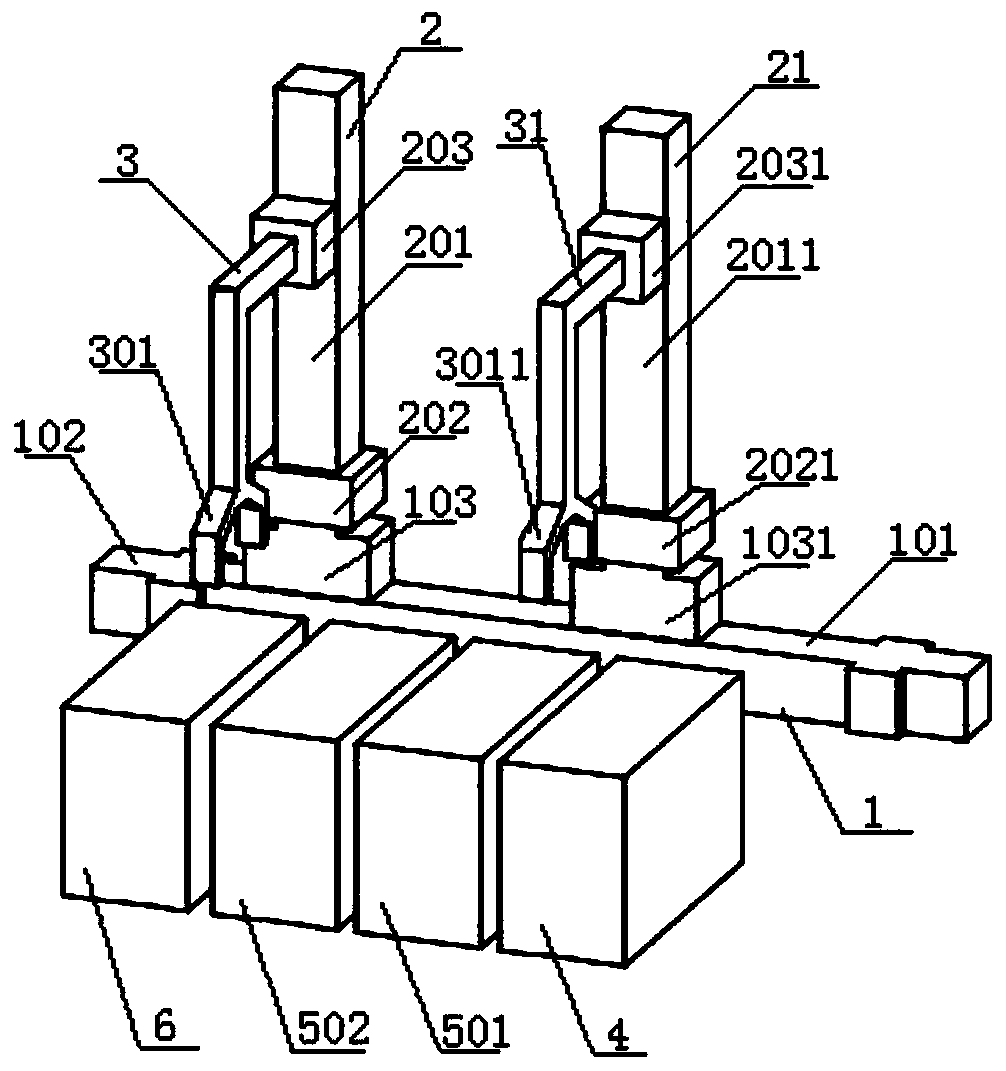

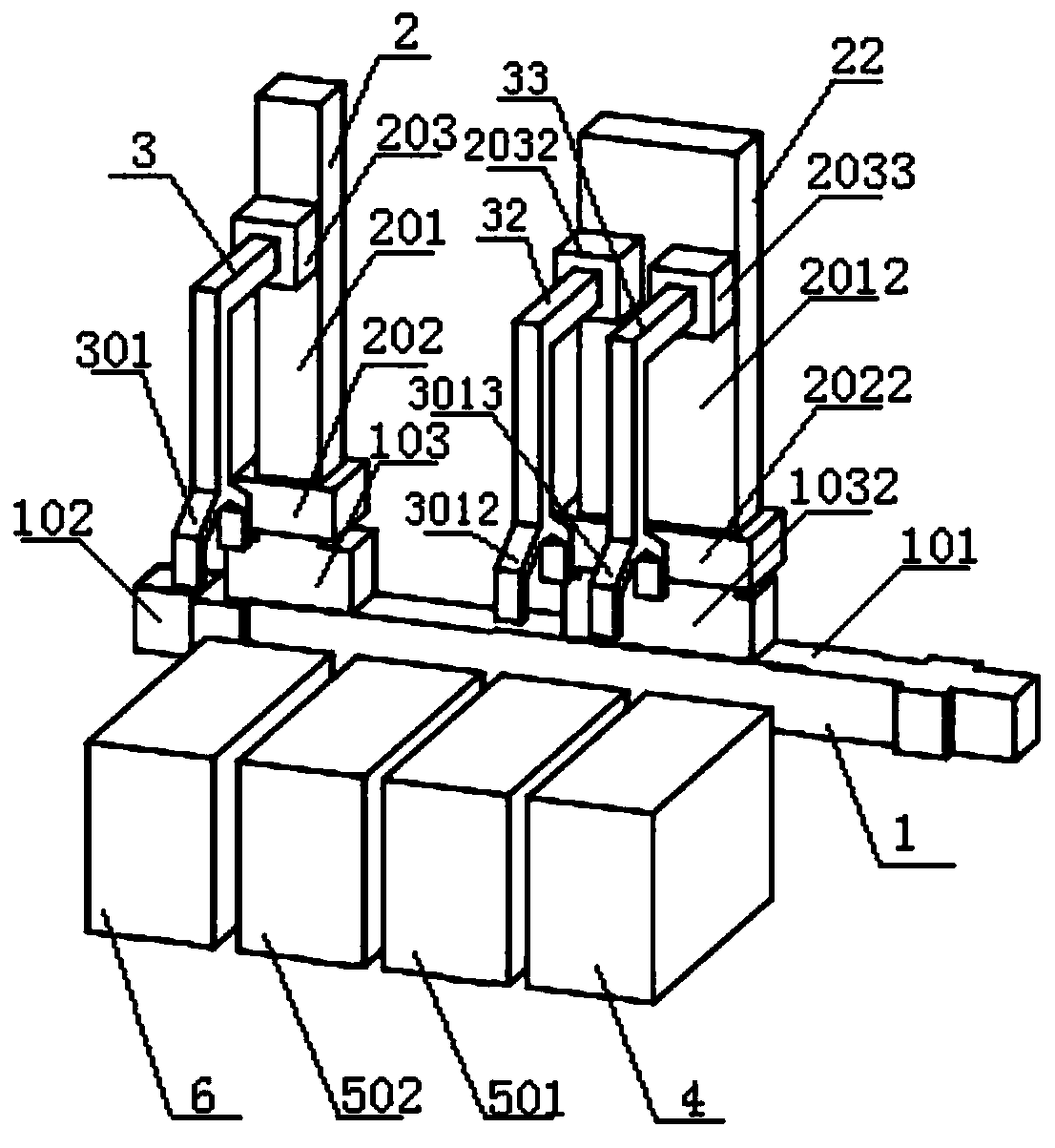

Material cleaning device of pipe welder

ActiveCN103949417AHigh cleanliness requirementsPass smoothlyDrying gas arrangementsCleaning using toolsMotor driveEngineering

The invention discloses a cleaning device capable of automatically removing oil stain on a to-be-processed strip on a pipe welder. The material cleaning device comprises a machine base, wherein a cleaning mechanism, a polishing mechanism, a plurality of washing mechanisms and a hot air drying mechanism are arranged sequentially on the machine base, the polishing mechanism comprises a gantry type installation rack arranged on the machine base, a lifting sliding block seat is arranged in the gantry type installation rack, a screw rod penetrates through the upper part of the gantry type installation rack, the bottom end of the screw rod is connected with the sliding block seat through a bearing, a core shaft and a motor driving the core shaft are arranged on the sliding block seat, a nylon grinding wheel is sleeved on the core shaft, a liner plate seat and a detachable liner plate are arranged below the nylon grinding wheel, and a polishing channel for the to-be-processed strip is formed between the nylon grinding wheel and the liner plate.

Owner:江苏薪泽奇机械股份有限公司

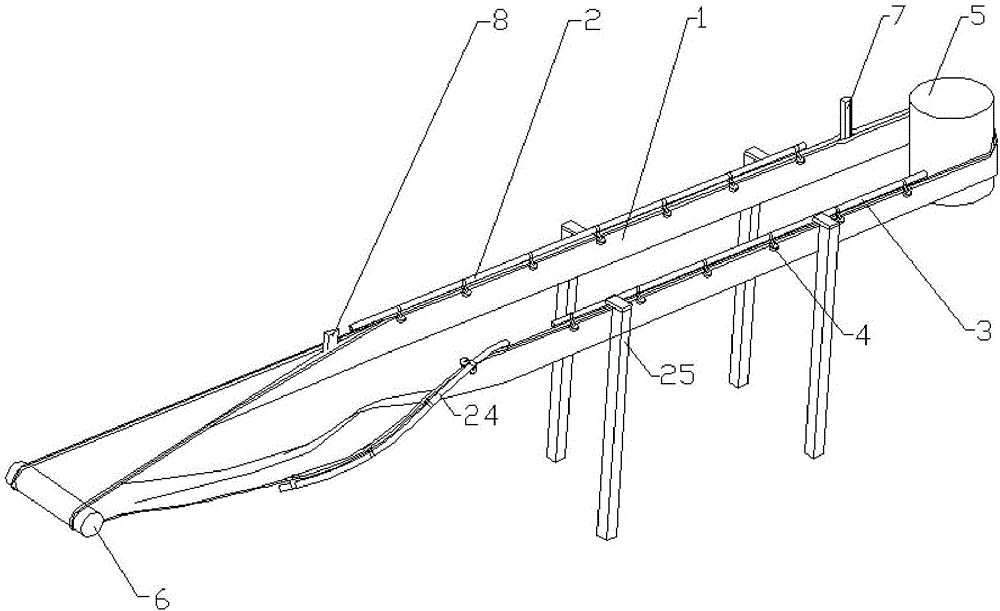

Closed conveyor

InactiveCN106743145ARealize unloadingRealize circular conveyingConveyorsConveyor partsSteering wheelButt joint

The invention discloses a closed conveyor, relates to a material conveyor, and aims to solve the problems of incapability of realizing closed conveying and incapability of changing the conveying direction in a traditional belt conveyor. Left and right mounting frames are arranged in parallel; left and right side edges of a conveying belt are upwards turned and tightly bonded to form a pipe shape or a cylinder shape; and after the conveying belt is matched and connected with a conveying mechanism on the right mounting frame in sequence, the conveying belt is bypassed through a steering wheel from right to left, then, is matched and connected with a conveying mechanism on the left mounting frame, is gradually unfolded to bypass through an unloading roller from top to bottom, and is overturned up and down to seal with the back end for butt joint to form a closed loop. The conveying belt is kept in a sealed state to realize closed material conveying; the conveying distance is changed through changing the lengths of the mounting frames and the conveying belt; and the direction of the conveying belt is changed through adding an auxiliary steering wheel and adjusting the extending directions of the mounting frames to realize turning conveying or high-height-fall conveying or even vertical conveying. The closed conveyor is used for material conveying.

Owner:NANO PHARM TECH MACHINERY EQUIP

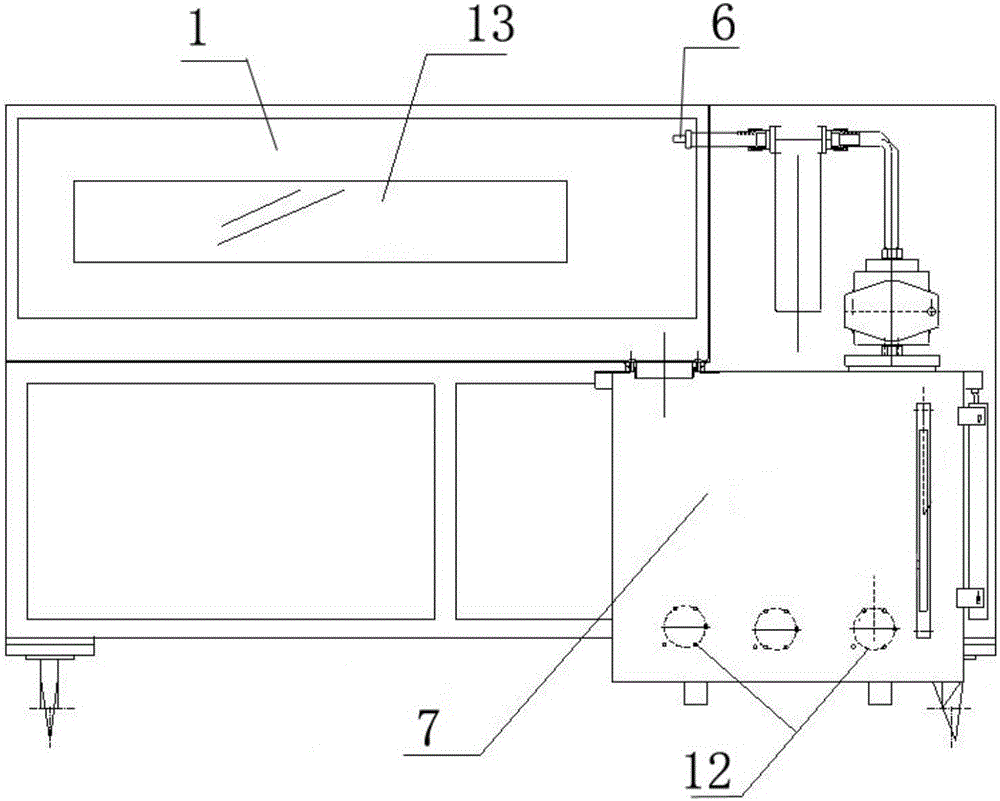

Cleaning equipment for clean aeroengine case

InactiveCN106623192AHighlight beneficial technical effectsImprove cleanlinessCleaning using liquidsAviationCavitation

The invention discloses cleaning equipment for a clean aeroengine case. The cleaning equipment comprises a cleaning chamber, a cleaning oil storage and transportation facility chamber and an oil injection gun, wherein a cleaning table for mounting a to-be-cleaned case is arranged in the cleaning chamber; an oil injection gun stretching window is formed in the chamber wall; an oil storage tank; an oil storage tank, an oil pump, a pressure-stabilizing overflow unit and an oil filter are arranged in the cleaning oil storage and transportation facility chamber; the inlet of the oil pump is connected with the interior of the oil storage tank through a connecting pipe, and the oil pump is driven by a motor; the pressure-stabilizing overflow unit and the oil filter are sequentially arranged on a pipeline behind the oil pump; and the oil injection gun is connected with the outlet end of the oil filter through a flexible connecting pipe. According to the cleaning equipment disclosed by the invention, the surface of the aeroengine case can be cleaned at high cleaning degree, metal debris remaining in the case can be cleaned, and the harm of the metal debris produced in the engine test and operation process is avoided. Moreover, because lubricating oil serves as a cleaning medium, the cleaning equipment disclosed by the invention has the advantage that the problem that cavitation corrosion is produced on the part surface is solved compared with ultrasonic cleaning.

Owner:AECC AERO SCI & TECH CO LTD

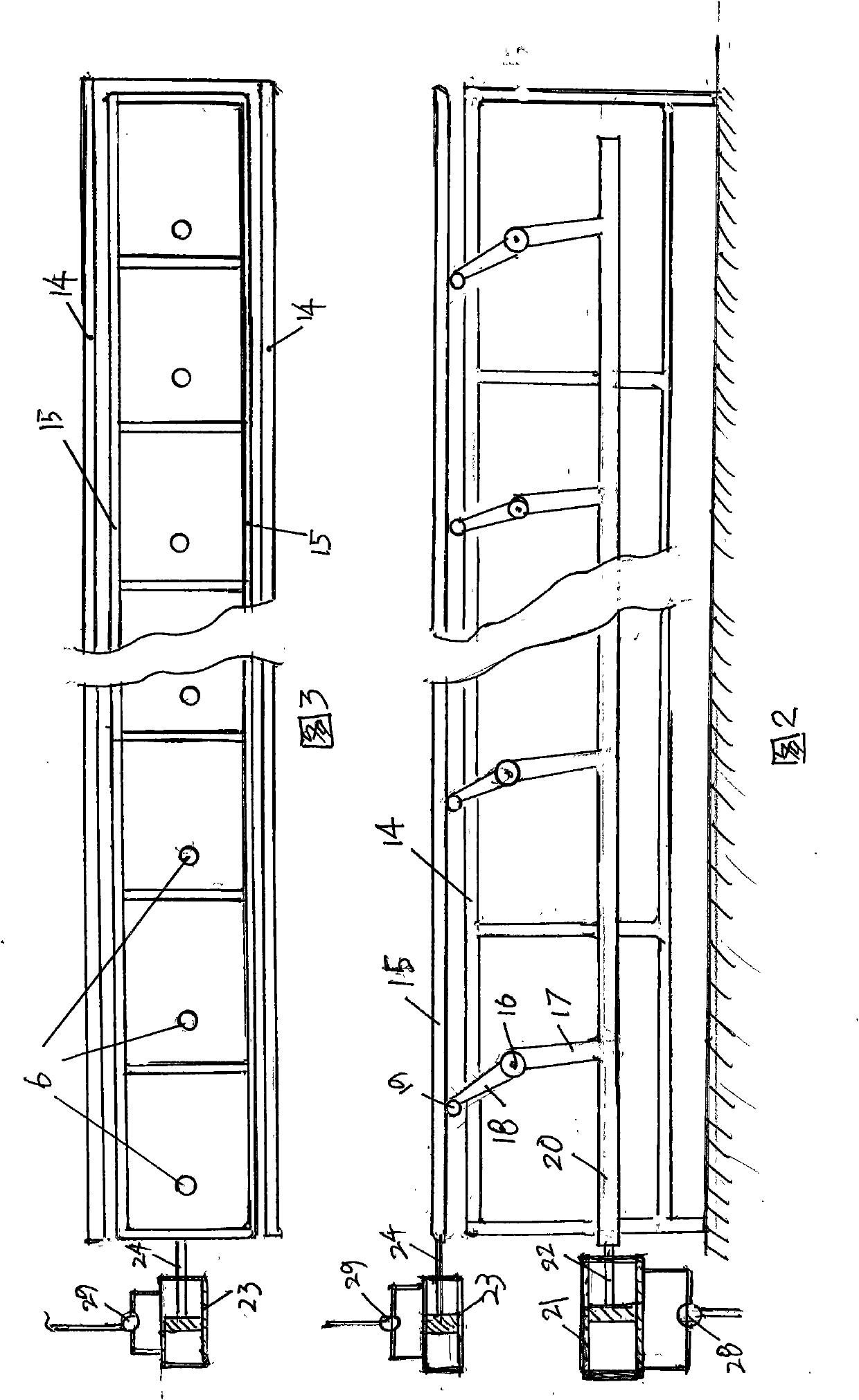

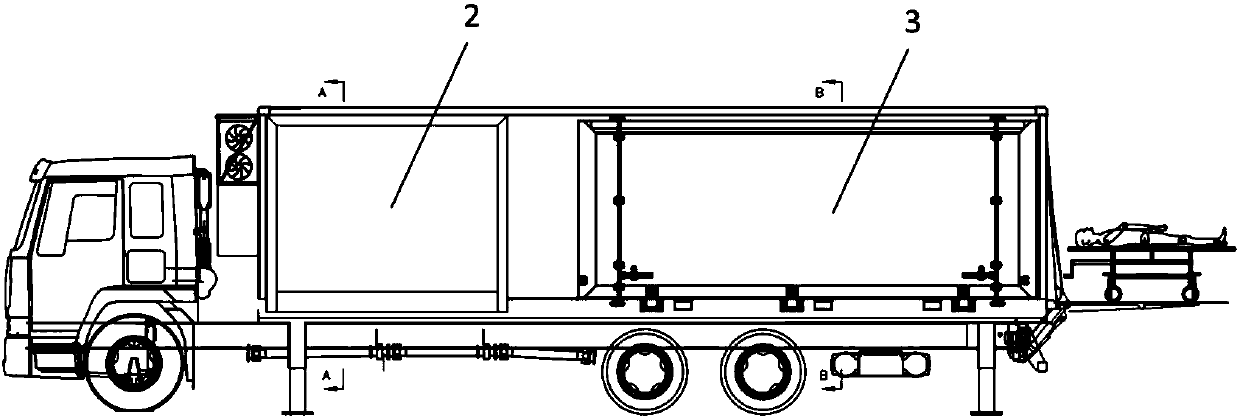

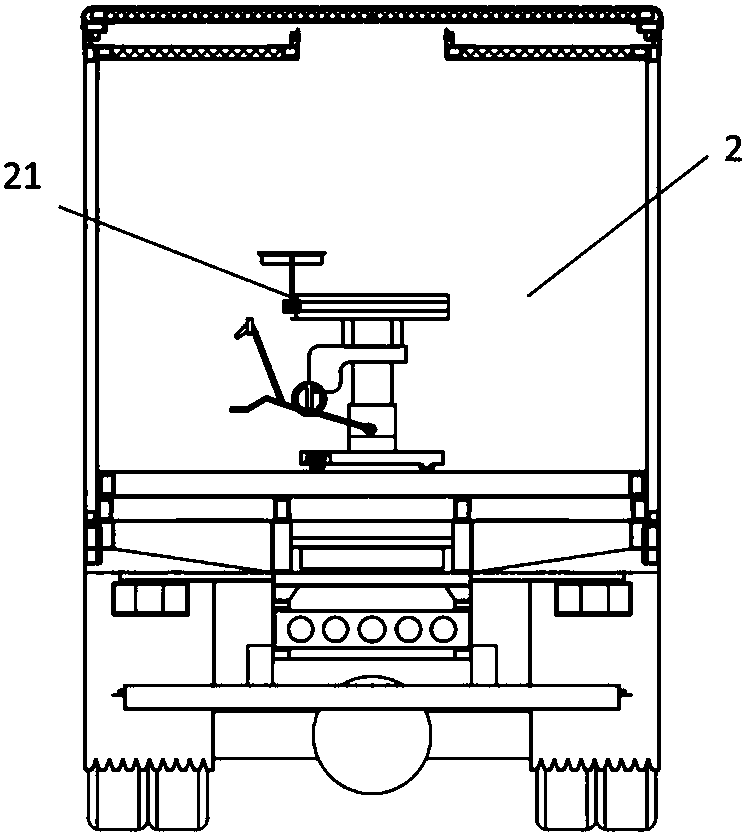

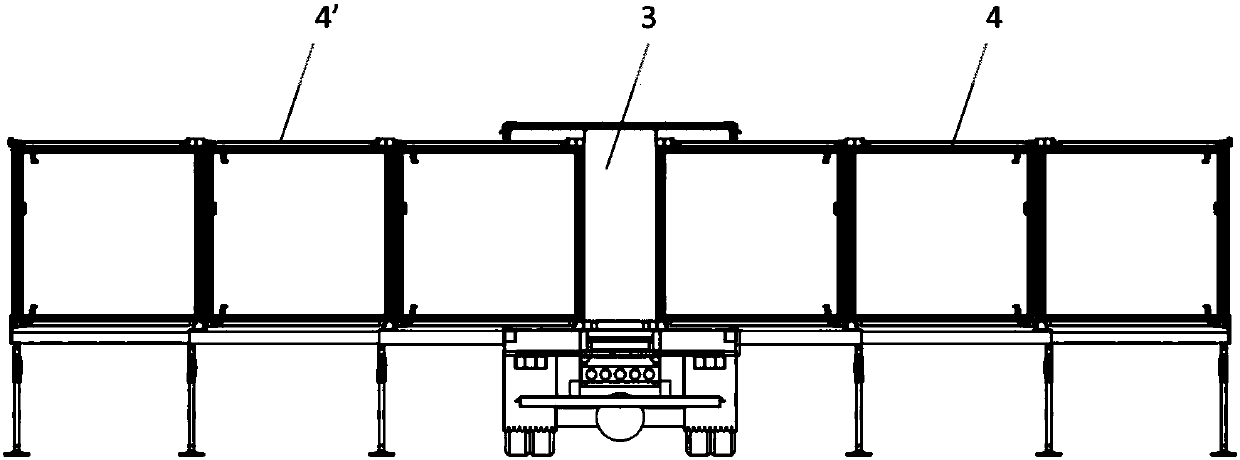

Partition extension operation square cabin

PendingCN107939085AImprove surgical safetyHigh cleanliness requirementsHospitalsBuilding constructionsClassical mechanicsMechanical engineering

The invention relates to a partition extension operation square cabin which comprises a square cabin body. The square cabin body comprises an operation cabin and a function cabin which are separated by an isolation door and longitudinally parallelly arranged. The operation cabin is provided with an operation table, and at least one side of the function cabin comprises an extension cabin capable oftransversely extending. The function cabin and the extension cabin mutually communicate to form a function extension area jointly. Separation of an operation area from the function extension area isachieved, and subsequent arrangement of devices in the operation cabin and pollution of the operation area are avoided while spatial extension is achieved. In addition, the extension cabin extends through electric extension devices such as electric push rods, a shear-type mechanism, a movement frame and a fixed frame, the shear-type mechanism serves as a gathering and extension movement mechanism,and the structural strength of the extension cabin is improved; and the shear-type mechanism is pushed to horizontally move through vertical movement of the electric push rods which are arranged correspondingly, and quick extension and on-demand extension are achieved.

Owner:THE THIRD MEDICAL CENT OF THE CHINESE PEOPLES LIBERATION ARMY GENERAL HOSPITAL

Preprocessing and cleaning device for glass

InactiveCN104043629AImprove efficiency during cleaningImprove efficiencyFlexible article cleaningCleaning using gasesPulp and paper industrySolid particle

The invention discloses a preprocessing and cleaning device for glass. The device comprises an adsorption plate, an adsorption hose, a conveyor and an exhaust fan, wherein the adsorption plate is arranged on the conveyor; an air outlet is arranged on the adsorption plate; one end of the adsorption hose is connected with the air outlet; the other end of the adsorption hose is connected with the exhaust fan; a first baffle and a second baffle are arranged on two ends of the adsorption plate; the first baffle, the second baffle and the adsorption plate form an adsorption cavity; a rectangular groove is arranged on the lower end of the second baffle; a feed board is rotatably arranged on the inner wall of the second baffle, and covers the rectangular groove; a U-shaped groove is arranged on the first baffle; the adsorption cavity is connected with an ultrasound spraying device through the U-shaped groove. The device also comprises a filter, wherein the filter is arranged on the air outlet; the adsorption cavity can thoroughly absorb more solid particles or dust on the surface of the glass, so that higher tidiness on the surface of the glass before cleaning the glass through ultrasound spraying is ensured, and the efficiency of cleaning the plain glass through ultrasound spraying is improved.

Owner:CHENGDU HAILINGDA MACHINERY

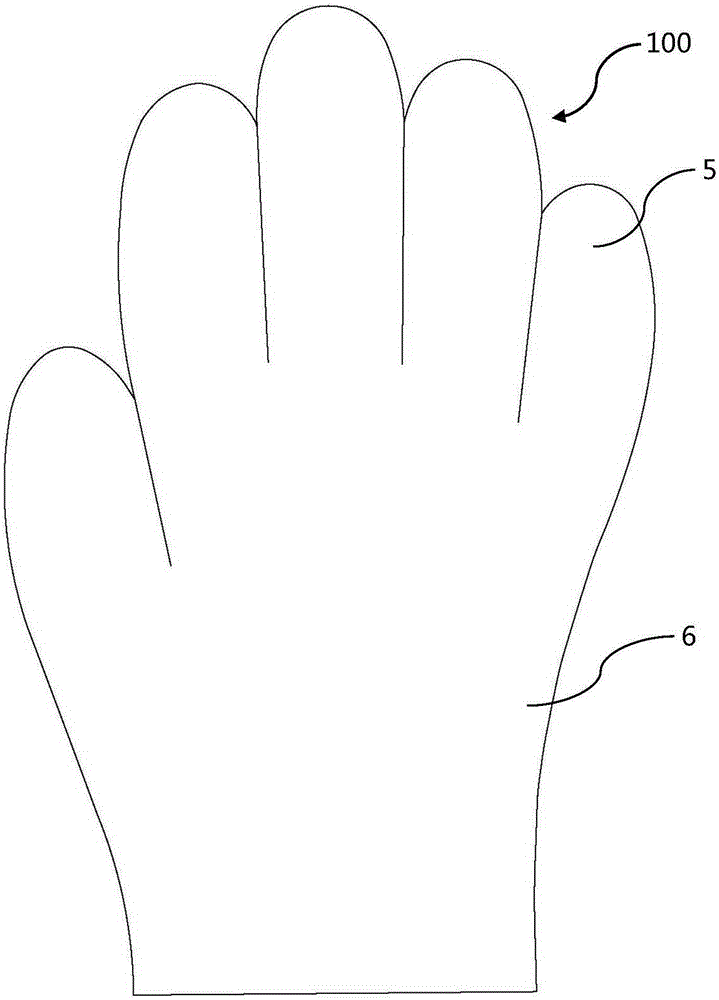

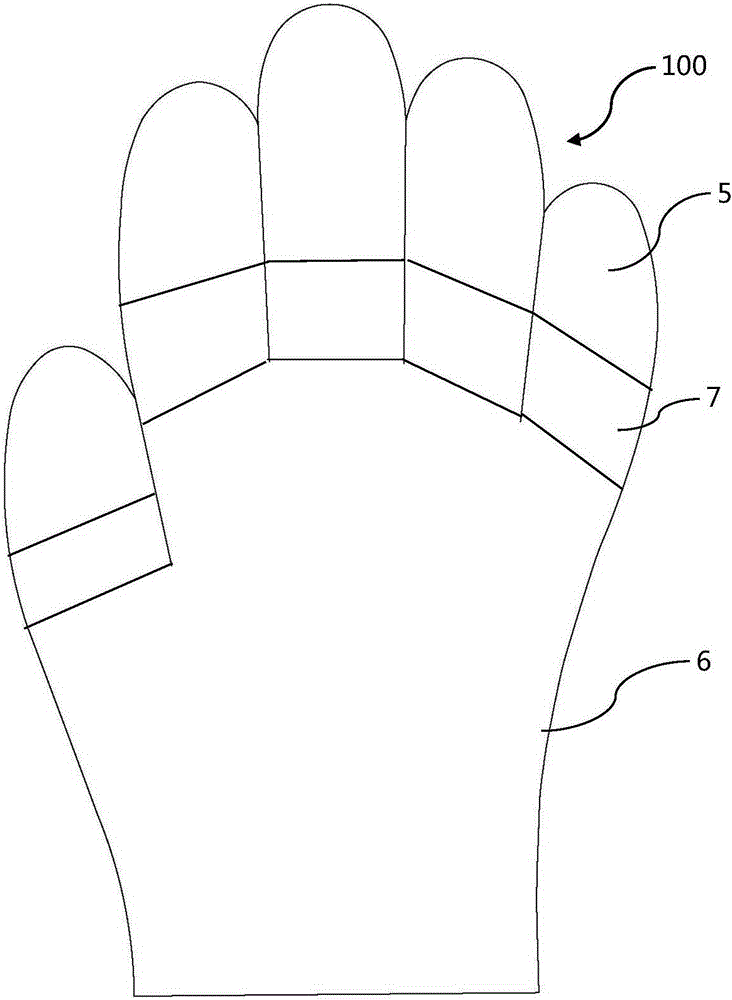

Dust-free glove

ActiveCN105212376AHigh cleanliness requirementsImprove sealingProtective garmentSpecial outerwear garmentsEngineeringWear resistance

The invention provides a dust-free glove. The dust-free glove comprises an inner layer, an outer layer, sealant and a sewing thread, wherein the inner layer adopts a palm-shaped sheet containing a finger part and a palm part, the outer layer has the same shape as that of the inner layer, the sealant is coated on the side edge of the face where the inner layer makes contact with the outer layer after the inner layer is overlapped with the outer layer, the sealant is used for bonding the inner layer with the outer layer through the side edge, and the sewing thread sews the inner layer and the outer layer together along the sealant from the faces, not coated with the sealant, of the inner layer and the outer layer. The dust-free glove which reaches high cleanliness requirements, wear resistance and high temperature resistance can be obtained, and the problem that secondary pollution of the glove is caused to the purification products can be solved. In addition, by means of the sealant layer, the sealing property of the dust-free glove can be improved, and dust entering is reduced. By means of an elastic part, the dust-free glove can be better attached to fingers, and operation is more convenient.

Owner:JIANGSU EMP TECH ELECTRONICS MATERIAL CO LTD

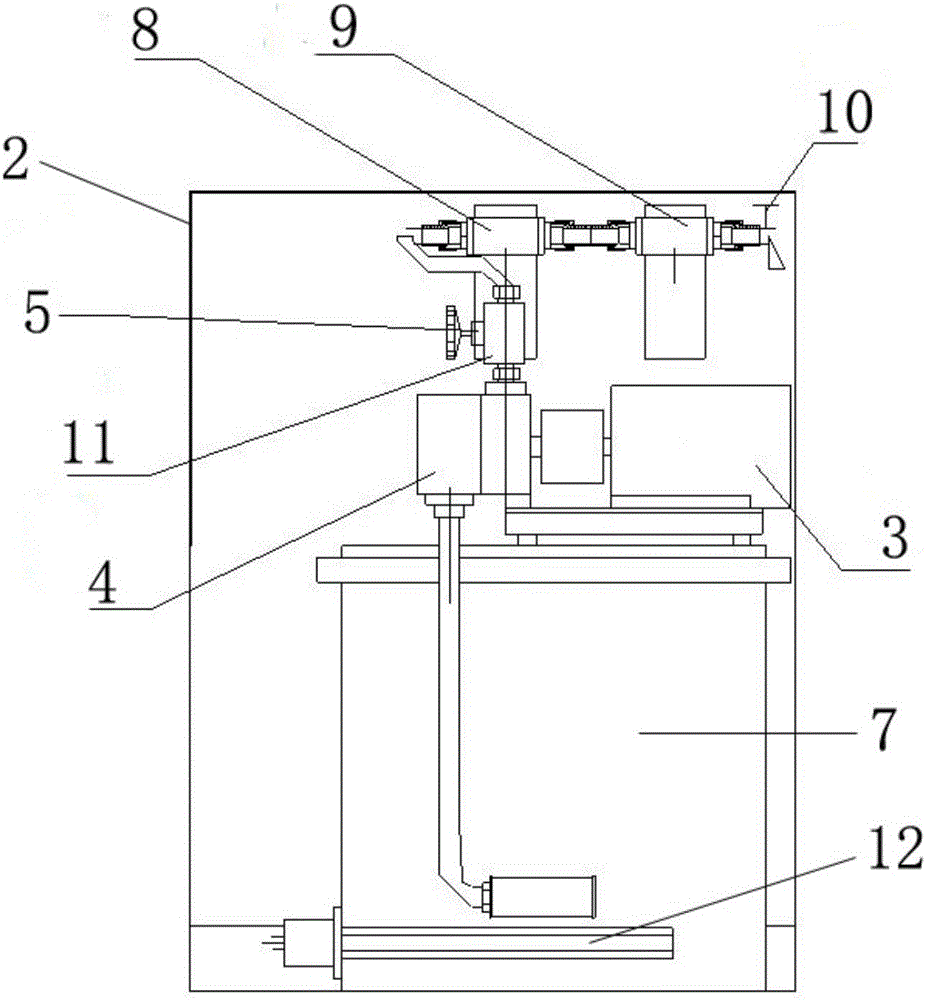

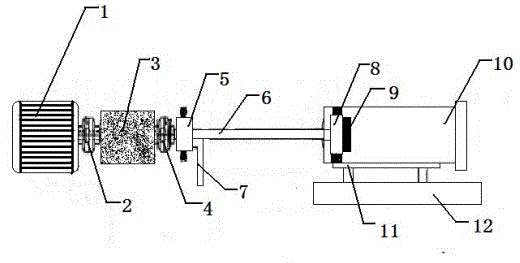

Special mechanical cleaning device for oil cylinder

InactiveCN105583209AImprove assembly qualityHigh cleanliness requirementsHollow article cleaningCouplingReduction drive

A special mechanical cleaning device for an oil cylinder is characterized in that the special mechanical cleaning device for the oil cylinder comprises a motor, a first coupler, a speed reducer, a second coupler, a water distribution pump, a water supply pipe, a liquid returning port, a brush head, a cleaning brush, the oil cylinder, a bracket and a base, wherein the motor is arranged on one side of the device and is a servo motor; a power output end of the motor is connected with the first coupler which is connected with the speed reducer; the second coupler is arranged at the other end of the speed reducer; the water distribution pump is connected with the other end of the second coupler; the water distribution pump is connected with the water supply pipe and the liquid returning port; a cleaning assembly is fixedly installed at the other end of the water supply pipe and comprises the brush head and the cleaning brush; a radial through hole is formed in the brush head; the cleaning assembly stretches into the oil cylinder which is movably installed on the bracket; and the bracket is fixedly installed on the base. The special mechanical cleaning device for the oil cylinder has the beneficial effects of being specialized, automatic, convenient to operate, capable of replacing manual operation, good in cleaning effect, high in work efficiency and capable of improving oil cylinder assembling quality and meeting the requirement of an electro-hydraulic control system for high cleanness of the oil cylinder.

Owner:田玥

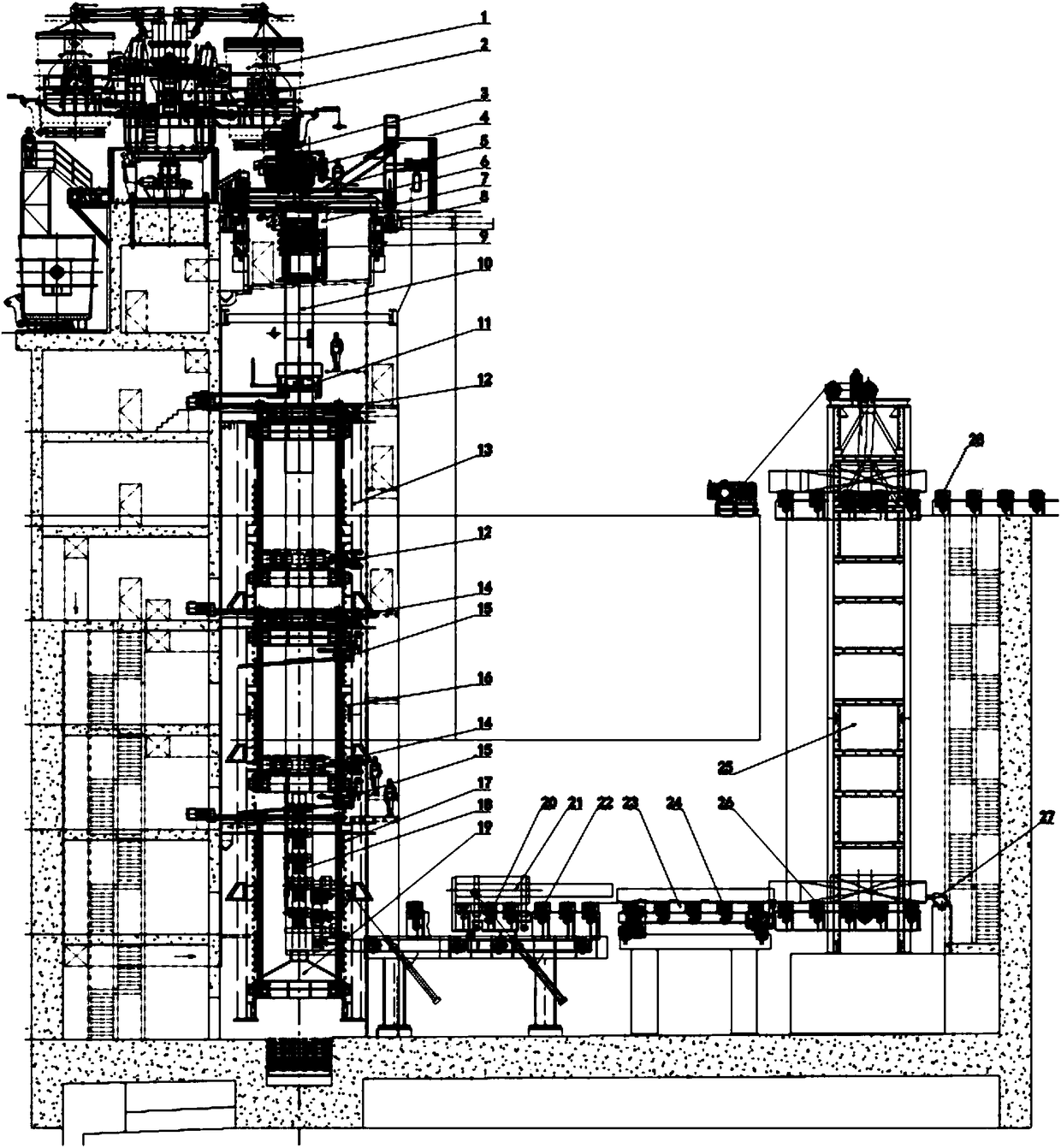

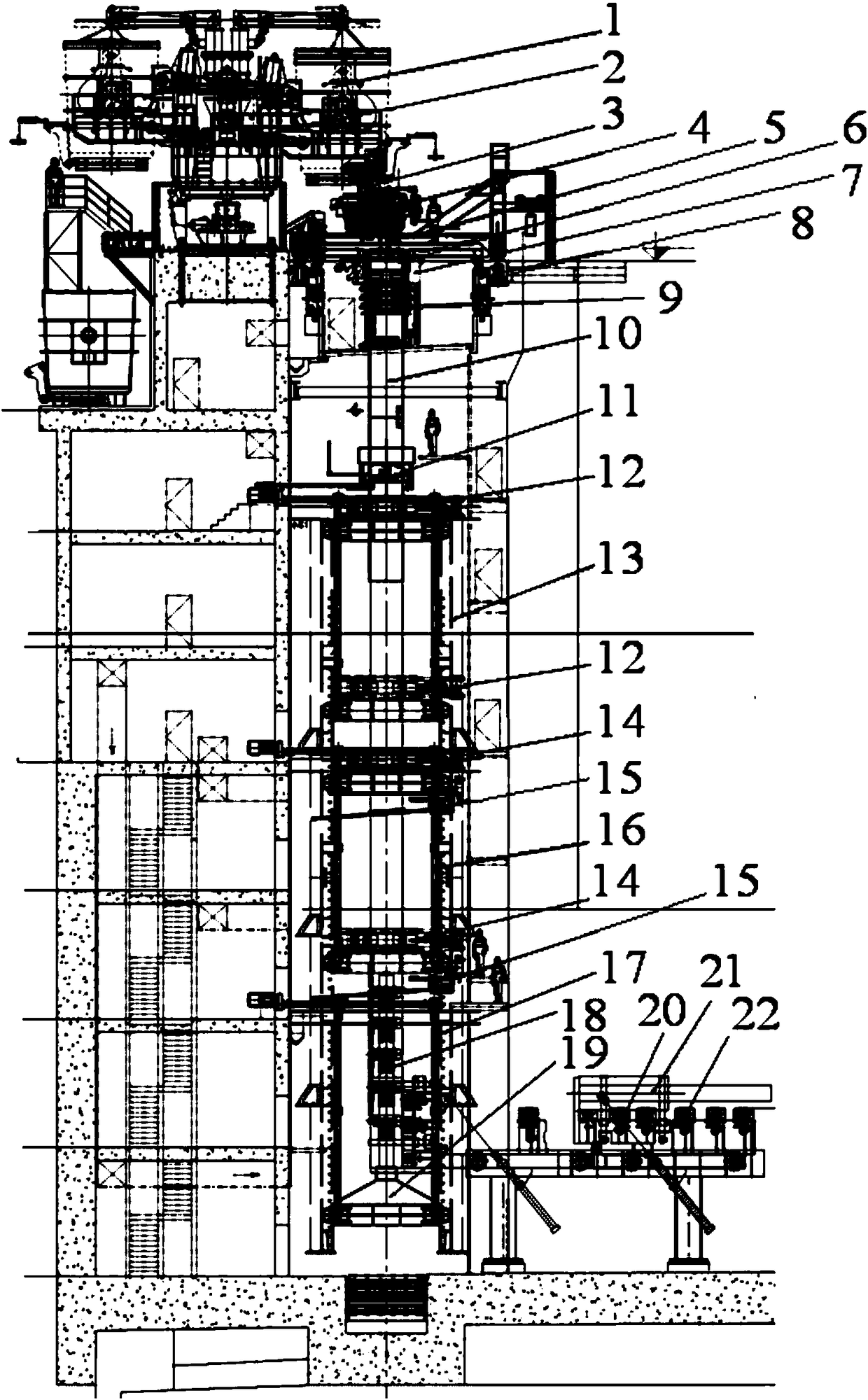

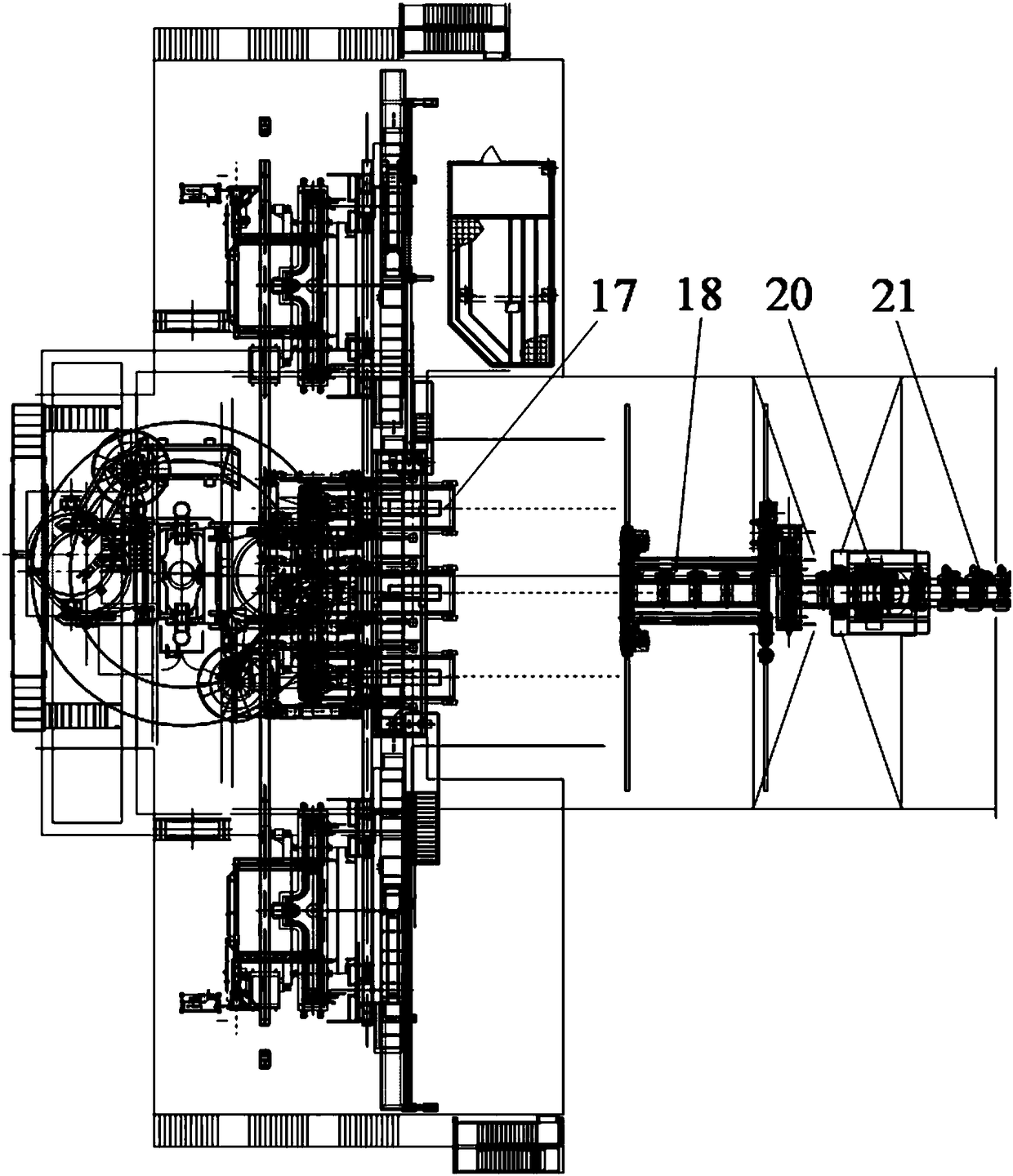

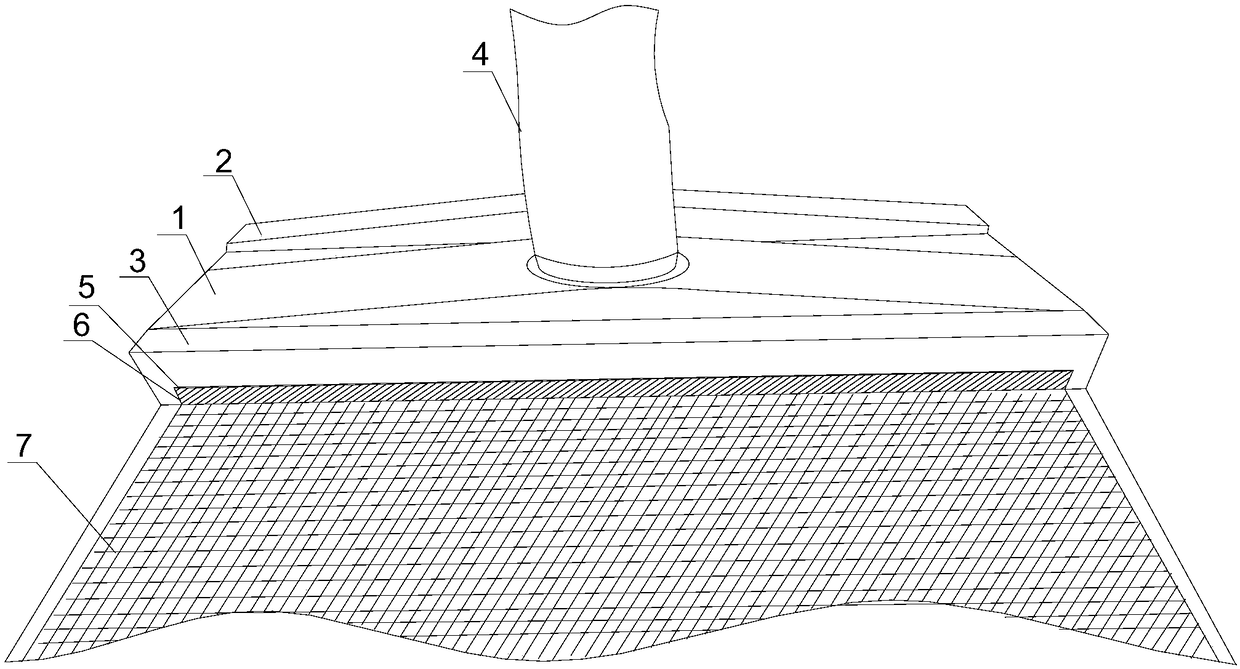

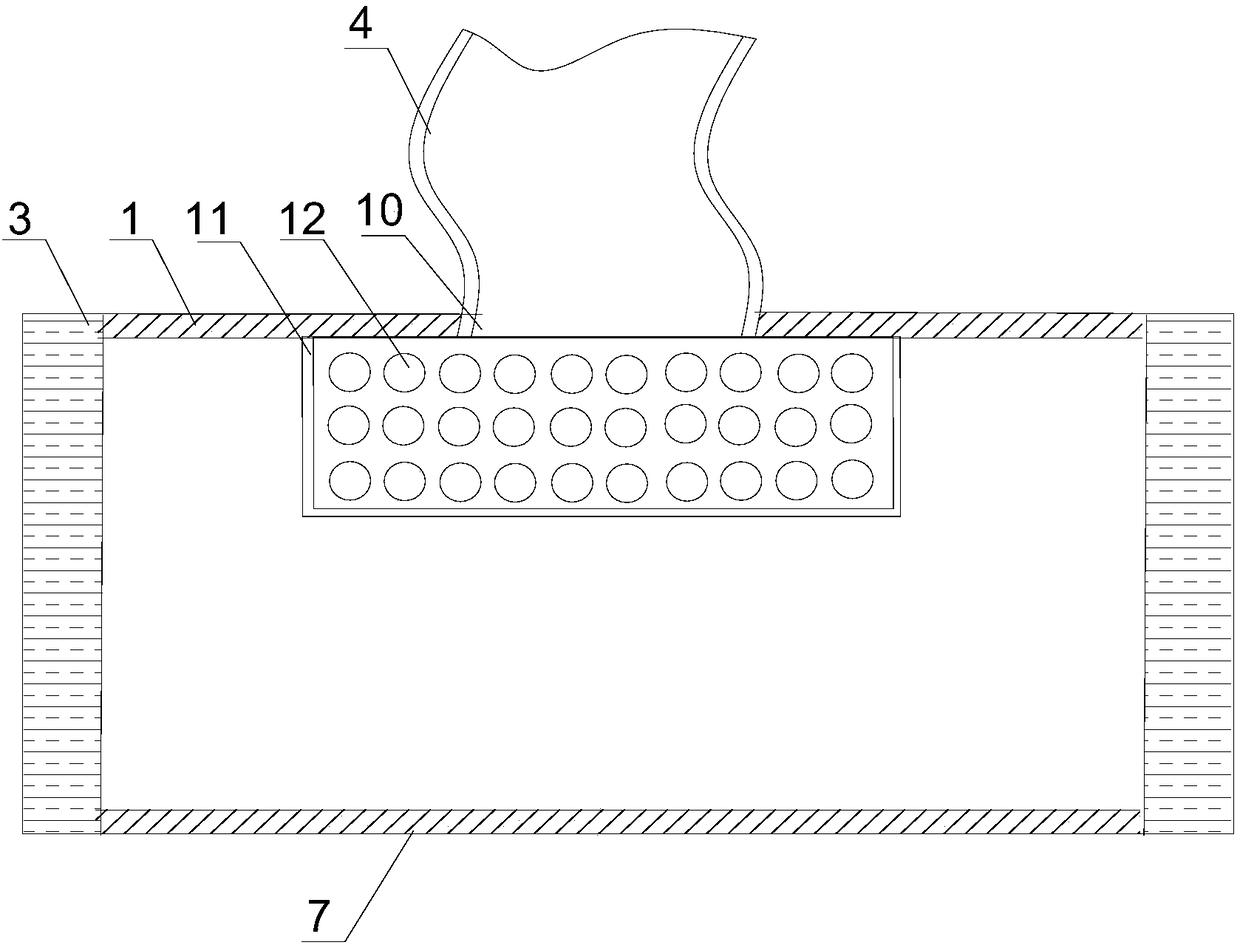

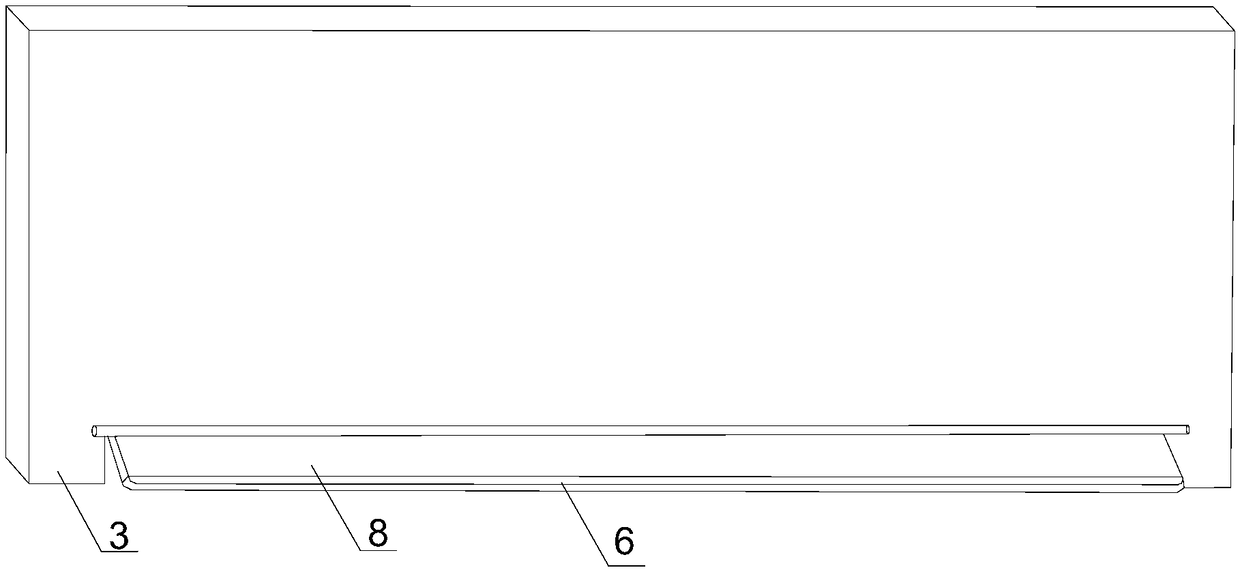

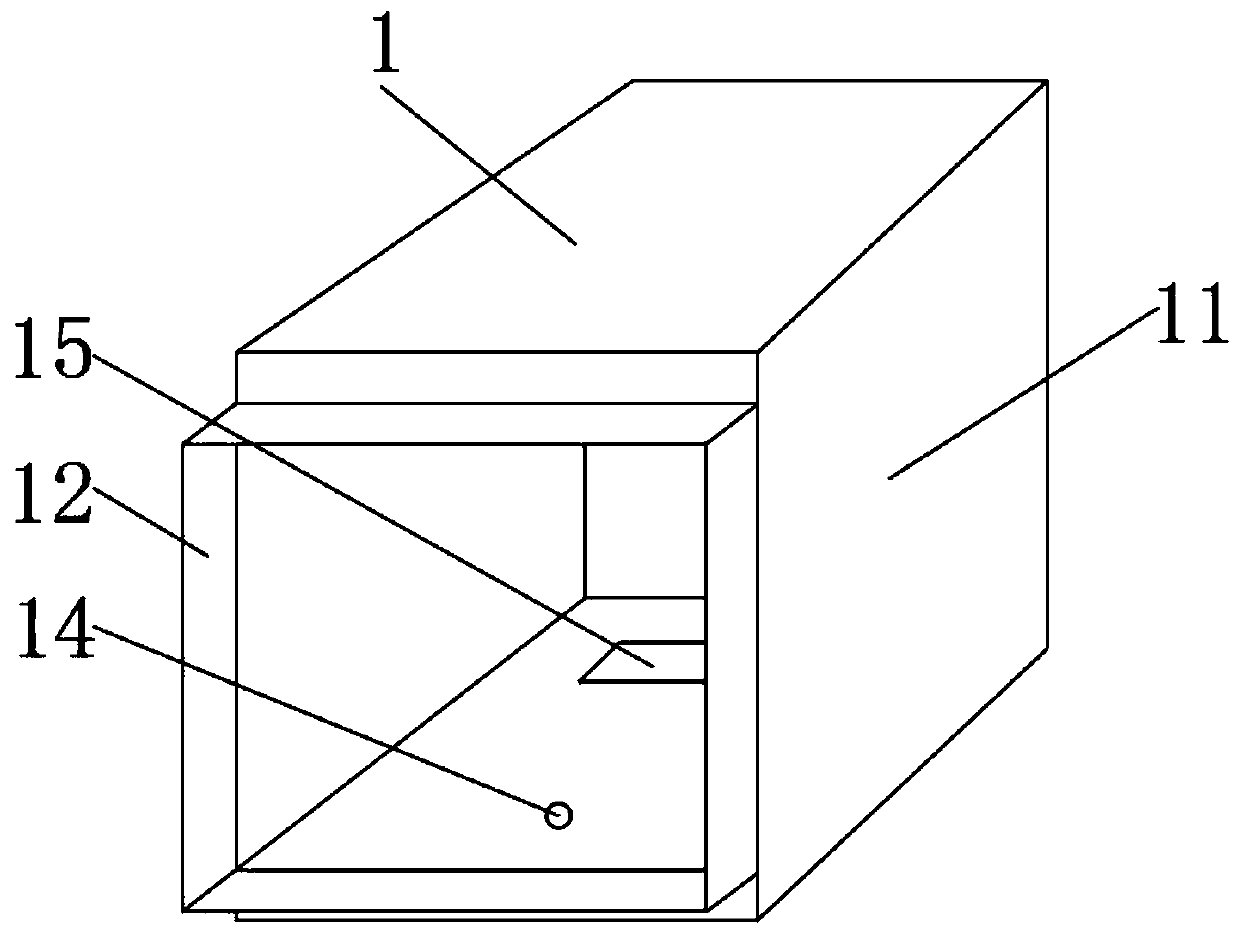

Vertical continuous casting production device and method for round billets of extra large specification

PendingCN108436046AHigh cleanliness requirementsHigh crack sensitivityIncreasing energy efficiencyCarbon steelContinuous casting

The invention discloses a vertical continuous casting production device and method for round billets of an extra large specification. The vertical continuous casting production device for the round billets of the extra large specification comprises a steel ladle (1), a middle tank (4), a crystallizer (6), a billet pulling system and a billet discharging system. The billet discharging system comprises a casting billet discharging device (20), a casting billet combining device (23), a casting billet lifting device (25) and an upper billet discharging roller bed (28). The vertical continuous casting production device and method for the round billets of the extra large specification are mainly applied to the round billets with the extra-large-specification sections with the diameter being 600mm-1300 mm, the brand new technologies of the billet pulling system, the billet discharging system and the like are adopted, multiple matched technological devices are adopted, and therefore the vertical continuous casting process method is suitable for producing a variety of steel like carbon steel and alloy steel, especially medium-and-high alloy clean steel and steel with high casting crack sensitivity, and continuous production of large-section high-quality billets is achieved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

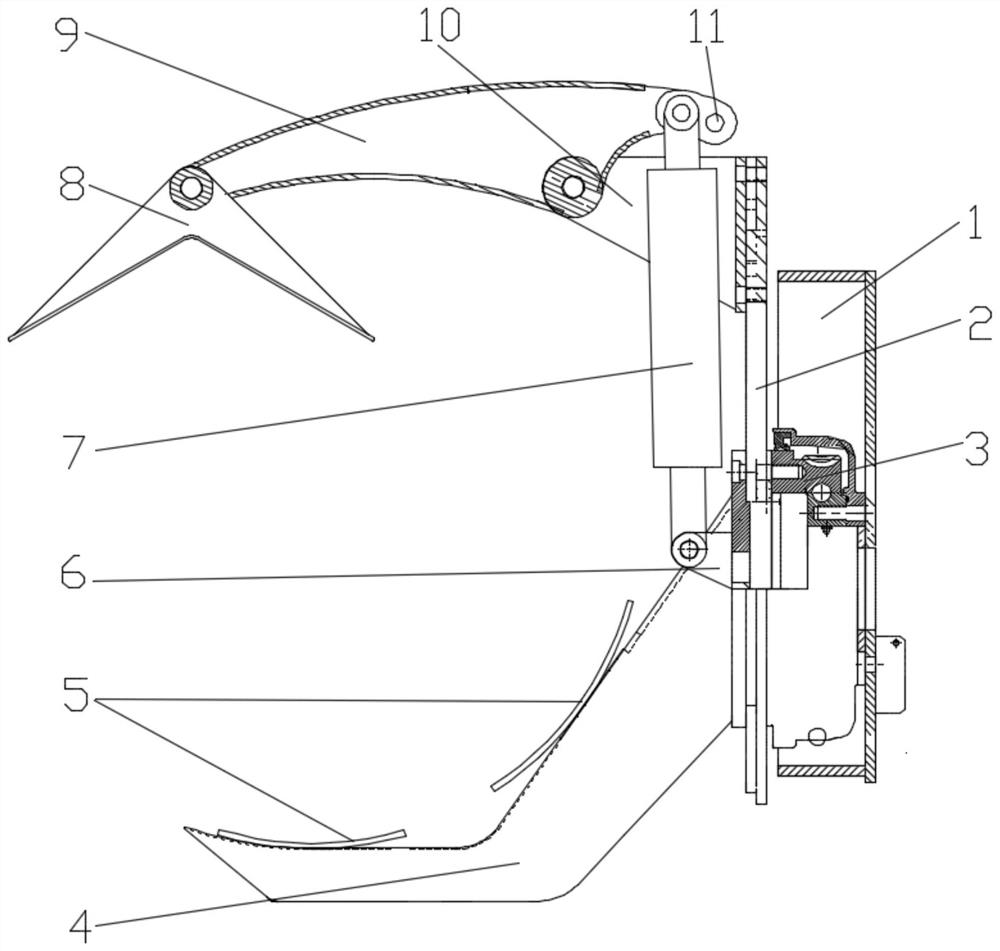

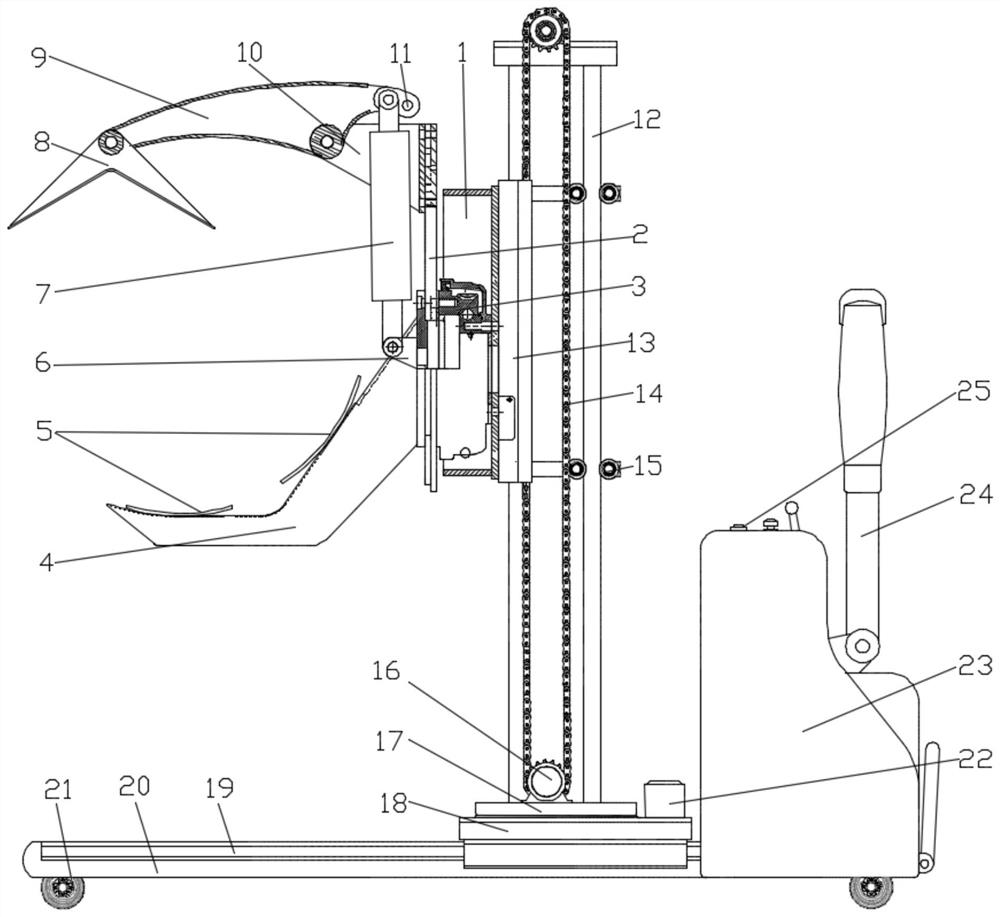

Rotary holding and clamping mechanism and rotary holding and clamping trolley

InactiveCN112591666AExtended service lifeGuaranteed rigidityLifting devicesVertical planeVehicle frame

The invention discloses a rotary holding and clamping mechanism and a rotary holding and clamping trolley, and relates to the technical field of mechanical carrying. The problems of high labor intensity and potential safety hazards of manual carrying of material coils in plastic printing are solved. The rotary holding and clamping trolley comprises a frame and a chassis, a rotary lifting mechanismand a rotary holding and clamping mechanism are arranged on the chassis, and the rotary holding and clamping mechanism comprises a base. A rotary disc and a rotation driving mechanism for driving therotary disc to rotate in a vertical plane are arranged on the base, and a fixed arm and a movable arm are oppositely arranged on the rotary disc. The movable arm comprises a hinged support fixedly connected with the rotary disc, a rotary arm is hinged to the hinged support, a V-shaped clamping plate is hinged to the end, away from the hinged support, of the rotary arm, and a holding and clampingoil cylinder for driving the rotary arm to swing up and down around the hinged support is arranged on the rotary disc. According to the rotary holding and clamping mechanism and the rotary holding andclamping trolley, integrity is high, the structure is small, exquisite and compact, operation is simple and convenient, turning and moving of the rotary holding and clamping trolley are convenient, limitation from the operation site area is small, flexible operation in the small space is facilitated, and the application requirements of the printing clean workshop with the high clean requirement,small space and high load requirement are met.

Owner:西安创力源工业科技有限公司

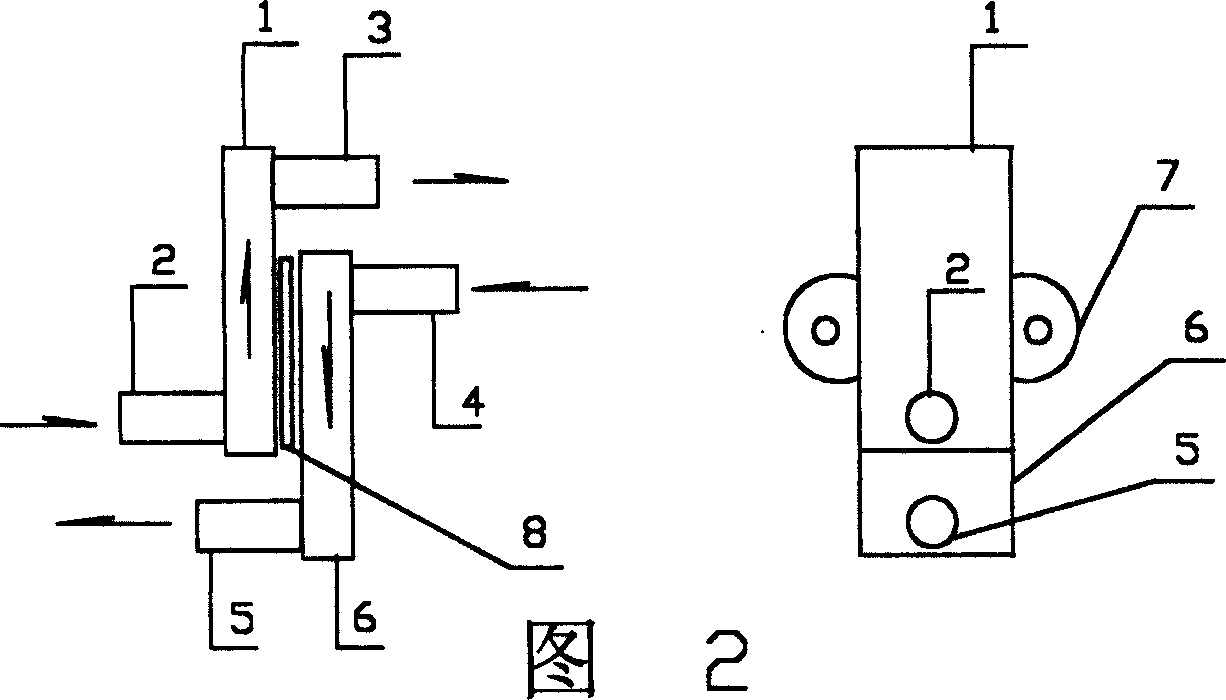

Portable saturated seam cleaning machine

PendingCN109277350AOptimize layoutCompact structureCleaning using liquidsProgrammable logic controllerSmall footprint

The invention provides a portable saturated seam cleaning machine. The portable saturated seam cleaning machine comprises a rack, a closed type cleaning bin, a spraying water tank, a saturated steam generator, a cleaning spray head assembly, a workpiece conveying mechanism and a PLC (Programmable Logic Controller) control cabinet, wherein the closed type cleaning bin, the spraying water tank, thesaturated steam generator, the cleaning spray head assembly, the workpiece conveying mechanism and the PLC control cabinet are fixed to the rack; the spraying water tank and the small-sized saturatedsteam generator are connected to the cleaning spray head assembly through respective pipelines; the cleaning spray head assembly is located in the cleaning bin; a negative pressure air sucking hole isformed in the cleaning pin and is connected to a negative pressure air sucking pipe; and the workpiece conveying mechanism passes through the cleaning pin. The portable saturated seam cleaning machine organically combines all parts, is compact in structure and small in size, has small floor space, can be carried through a forklift, facilitates the integrated layout of factories, realizes line production and is very practical.

Owner:湖南中航精工有限公司

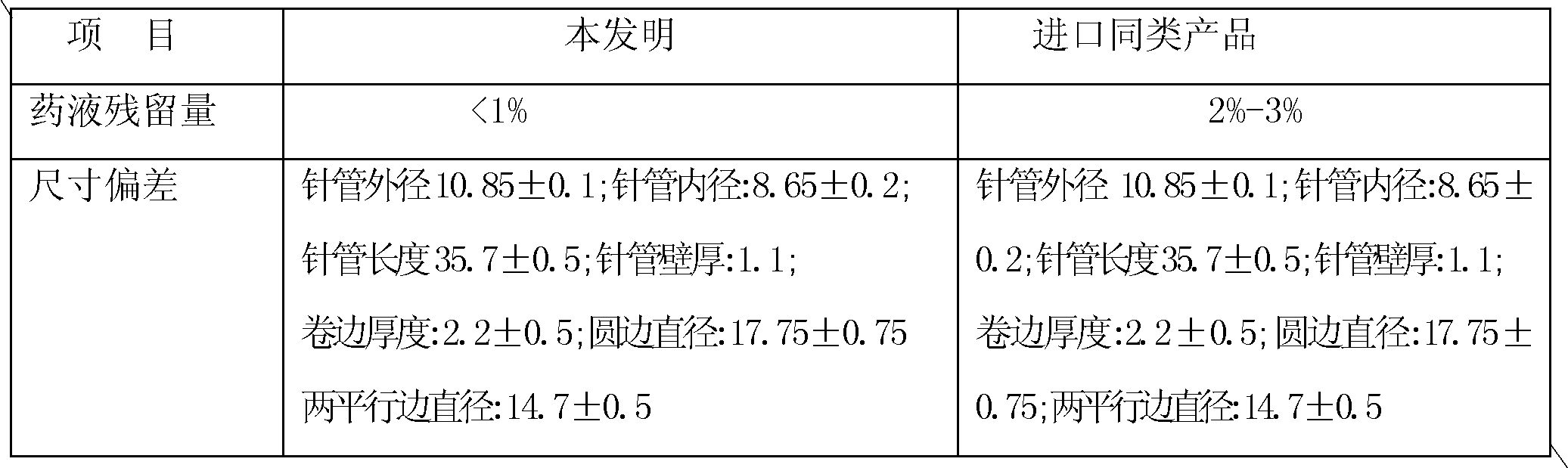

High-cleanness pre-filled syringe

ActiveCN102068733AResidue reductionGuaranteed dimensional accuracyInfusion syringesPharmaceutical containersEthylene oxideDrug product

The invention discloses a high-cleanness pre-filled syringe, which belongs to the field of production of medicinal packing materials. The syringe is characterized in that: a method for manufacturing the syringe comprises the following steps of: 1) producing the syringe; 2) performing rich text format (RTF) treatment; 3) performing ethylene oxide (ETO) sterilization; and 4) accepting, packing and warehousing. Through the syringe, the residue amount of liquid medicine of the prefilled syringe is effectively reduced and the utilization ratio of a medicament is improved while the dimensional accuracy is guaranteed. Particularly, the advantage of the syringe that waste of high-value medicaments is avoided is brought into full play in the fast-developing biological and immunologic preparation industry.

Owner:SHANDONG PHARMA GLASS

Mechanical equipment special for cleaning oil cylinder

InactiveCN105290065AGood cleaning effectImprove efficiencyHollow article cleaningElectric machineryEngineering

The invention discloses mechanical equipment special for cleaning an oil cylinder. The mechanical equipment special for cleaning the oil cylinder is characterized by comprising a motor, a pump, a speed reducer, a water distribution device, a water supply pipeline, an electromagnetic sucker, a cleaning brush, a cleaning head, the oil cylinder and a movable carrier; the motor and the pump are fixedly installed on the equipment; the motor is in transmission connection with the water supply pipeline; the cleaning brush and the cleaning head are installed at the other end of the water supply pipeline; the electromagnetic sucker is also installed at the other end of the water supply pipeline; the water distribution device is connected outside the water supply pipeline; the water distribution device is communicated with the water supply pipeline; the movable carrier is arranged on the lower portion of the equipment; the water distribution device and the water supply pipeline are slidably connected with the movable carrier; one end of the oil cylinder is installed on a fixing rack, and the other end of the oil cylinder is fixedly installed on the movable carrier; the oil cylinder is connected with the pump; the speed reducer is connected between the motor and the water supply pipeline in a transmission mode. The mechanical equipment special for cleaning the oil cylinder has the advantages of being professional, effective, good in cleaning effect, high in efficiency and capable of greatly relieving the labor intensity of personnel and meeting the requirement for high cleanliness of the oil cylinder.

Owner:蒋天虹

Wafer transmission device, wafer transmission method and CMP equipment cleaning module

InactiveCN111524847AEasy to cleanReduce fallsSemiconductor/solid-state device manufacturingConveyor partsWaferGravity center

The invention discloses a wafer transmission device, a wafer transmission method and a CMP equipment cleaning module, and the wafer transmission device comprises at least one clamping jaw clamping armmodule which is used for taking and placing a wafer; at least one Z-axis moving module, wherein the Z-axis moving modules are connected with the clamping jaw clamping arm modules and used for achieving movement of the clamping jaw clamping arm modules in the Z-axis direction; at least one X-axis moving module, wherein the X-axis moving modules are connected with the lower ends of the Z-axis moving modules and used for achieving movement of the clamping jaw clamping arm modules in the Z-axis direction. The X-axis moving modules are mounted at the lower ends of the Z-axis moving modules, the overall gravity center of the wafer conveying device is lowered, the possibility that impurity particles on the wafer conveying device fall onto a wafer is reduced, the cleaning effect of the wafer is improved, meanwhile, the number of the X-axis moving modules and the number of the Z-axis moving modules are increased, and the wafer conveying time is shortened.

Owner:HANGZHOU ZHONGGUI ELECTRONICS TECH CO LTD

Treatment device for pre-cleaning of tempered glass outer wall

InactiveCN108067476AImprove efficiency during cleaningImprove efficiencyElectrostatic separationCleaning using toolsPulp and paper industrySolid particle

The invention discloses a treatment device for pre-cleaning of a tempered glass outer wall. The treatment device comprises an adsorption plate, an adsorption hose, a conveyor and an exhaust fan, wherein the adsorption plate is arranged on the conveyor; the adsorption plate is provided with an air outlet; one end of the adsorption hose is connected with the air outlet; the other end of the adsorption hose is connected with the exhaust fan; a first baffle and a second baffle are arranged at the two ends of the adsorption plate; the first baffle, the second baffle and the adsorption plate form anadsorption cavity; a rectangular groove is formed in the lower end of the second baffle; a feeding plate is rotationally arranged on the inner wall of the second baffle and covers the rectangular groove; a U-shaped groove is formed in the first baffle; and the adsorption cavity is connected with an ultrasonic atomizing device through the U-shaped groove. The treatment device further comprises a filter which is arranged at the air outlet. The adsorption cavity can thoroughly adsorb most solid particles or dust on the surface of glass, high cleanness of the surface of the glass can be guaranteed before ultrasonic atomizing cleaning of the glass, and the ultrasonic atomizing cleaning efficiency of the planar glass is improved.

Owner:ZHONGJIANG ZHICHENG TEMPERING GLASS PROD

Annealing process of sealing welding flux

ActiveCN101864511AHigh vacuum requirementHigh cleanliness requirementsFurnace typesHeat treatment process controlVacuum pumpingFree cooling

The invention discloses an annealing process of sealing welding flux, which comprises the following steps: cleaning a furnace liner of an annealing furnace; placing alloy materials to be annealed into the furnace liner after the cleaning is completed; carrying out vacuum pumping on the annealing furnace; heating the annealing furnace at a temperature rise speed of 10 DEG C / min when the vacuum degree of the annealing furnace reaches 0.1 Pa; carrying out primary heat insulation for 20 to 60 minutes when the temperature reaches 420 to 600 DEG C; stopping the vacuum pumping; filling nitrogen gas; raising the temperature of the annealing furnace to 600 to 700 DEG C when the pressure intensity inside the annealing furnace reaches 0.1 to 0.3 Pa; carrying out secondary heat insulation for 120 to 240 minutes; and stopping the heating so that the alloy materials can be naturally cooled. The annealing process of the invention can overcome the defects of large hardness difference of batch products, poor product lustrousness, nonuniform fluxion property during product melting welding and the like in the prior art for realizing the goals of small hardness difference of the batch products, good product lustrousness and uniform fluxion property during the product melting welding.

Owner:WUXI RIYUE ALLOY MATERIALS

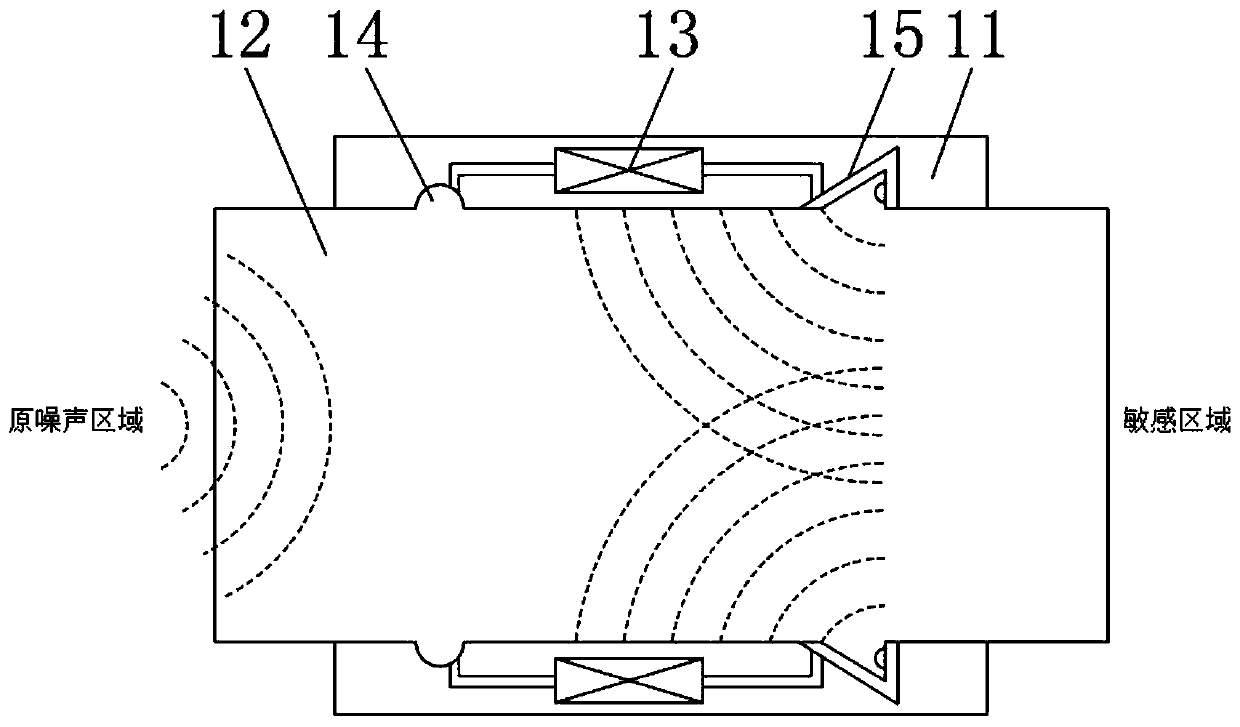

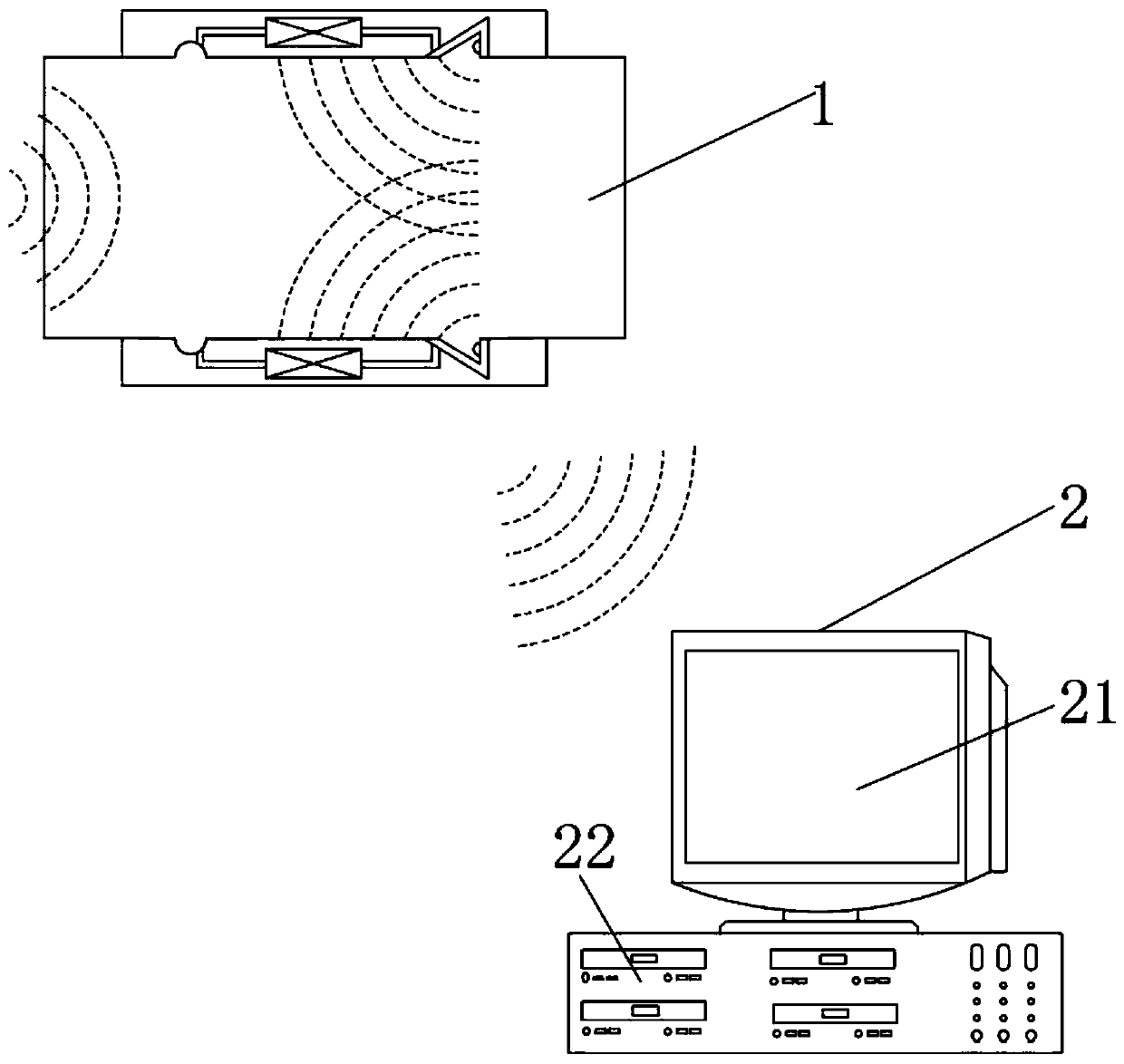

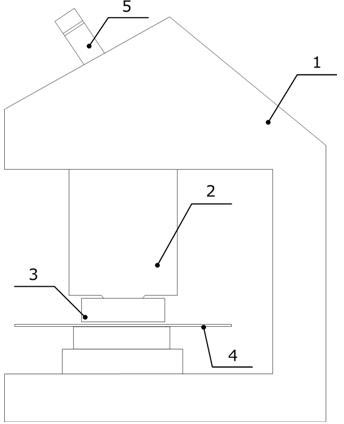

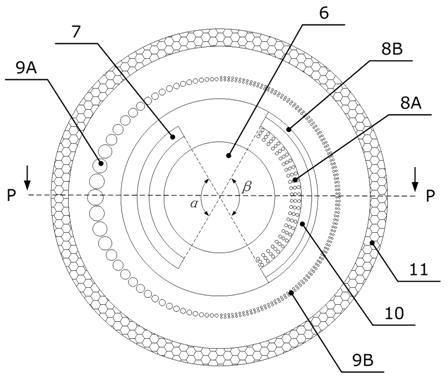

Electronic phase silencer

InactiveCN110530003ASmall sizeReduce weightMechanical apparatusNoise suppressionPhase noiseFilling materials

The invention discloses an electronic phase silencer. The silencer comprises a silencer device body, wherein the silencer device body comprises a silencer outer shell; a silencer inner shell is arranged in the silencer outer shell. Central processing units are installed in the middle of the upper end and the middle of the lower end of the silencer inner shell. One side of each central processing unit is connected with an original noise collector, the original noise collectors are installed on the silencer inner shell, the other side of each central processing unit is connected with a phase noise generator, the phase noise generators are installed on the silencer inner shell, and a Bluetooth module is integrated in the central processing units. The electronic phase silencer is small in size, light in weight, capable of being customized according to actual conditions, easy to install, convenient to maintain, free of ventilation resistance, capable of meeting system ventilation, free of filling materials and volatile organic pollutants, clean, safe, sanitary and environment-friendly, is used for soundproof rooms with high cleaning requirements in the medical industry, the health industry and the like, is easy to clean, resists high temperature and fire, and is suitable for humid special environments and the like.

Owner:SHENZHEN XRD ENVIRONMENTAL PROTECTION ENGCO LTD

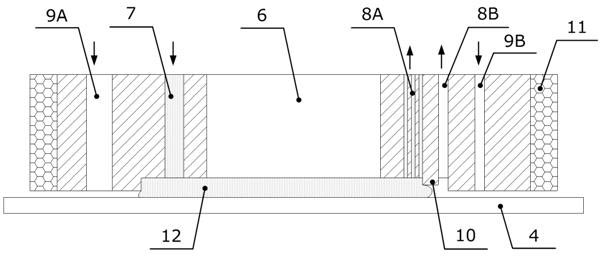

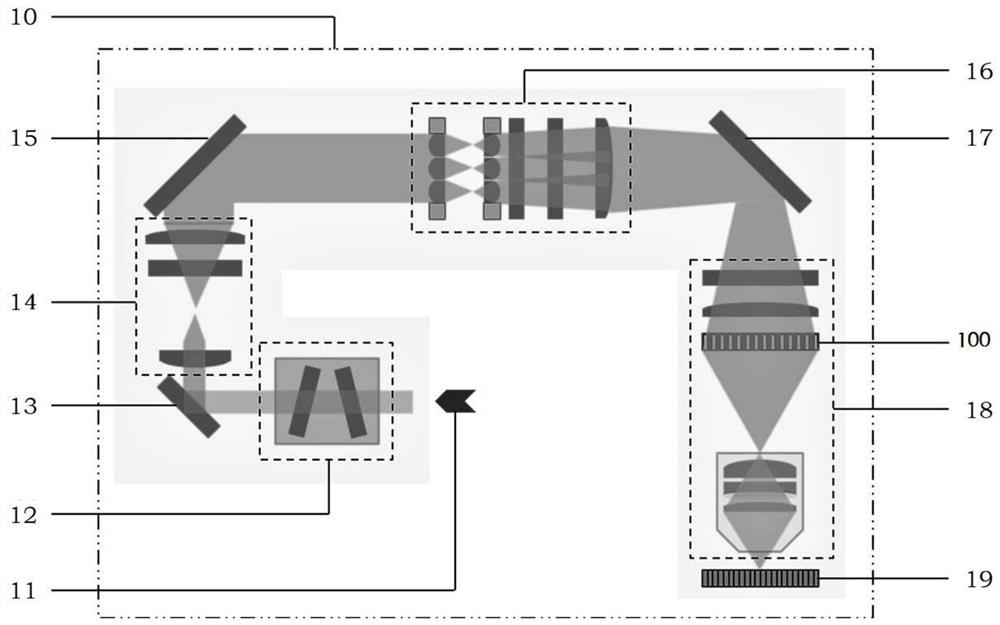

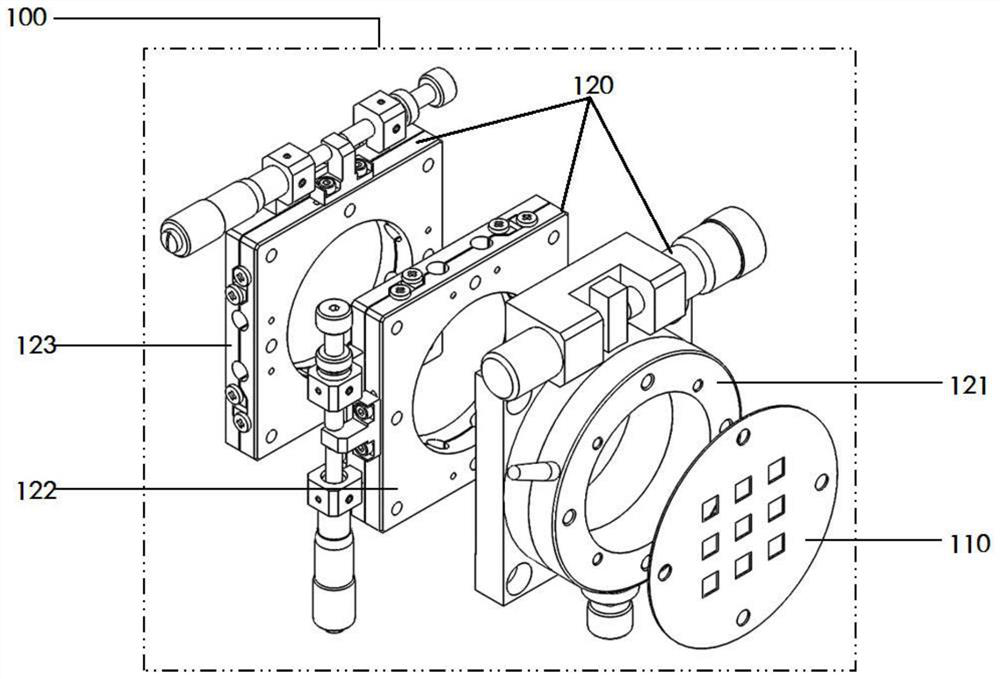

Liquid film dynamic compensating device

InactiveCN102566030AImprove cleanlinessImprove reliabilityMicroscopesDistribution characteristicEngineering

The invention discloses a liquid film dynamic compensation device. The liquid film dynamic compensation device is arranged between an optical lens and a substrate, a self-adaptive gas sealing belt is arranged at the periphery of a liquid injecting cavity, an isolation belt, a gas releasing cavity and a recovery end sealing belt are arranged at the periphery of a row of recovery holes, and thus the long-term stability of a flow field boundary under the dynamic update of the liquid is facilitated. Based on the pressure distribution characteristic of the flow field, non-uniform energy is applied to the boundary so that the liquid is facilitated to gather towards the center, and thus the impact at a low-pressure position of the flow field, caused by overlarge sealing energy, and the leakage at a high-pressure position of the flow field, caused by the shortage of the sealing energy, are avoided; and due to a corresponding structure at the periphery of the recovery holes, the sealing is reliable, the recovery gas-liquid two-phase flow is simultaneously restrained, and the stability of a system is enhanced. According to the liquid film dynamic compensation device disclosed by the invention, the flow updating of the liquid can be realized, thus the improvement of the cleanliness of the liquid at an observation area is facilitated, the reliability of observation imaging is enhanced, and the requirement for the cleanliness of the environment is lowered.

Owner:FUZHOU UNIV

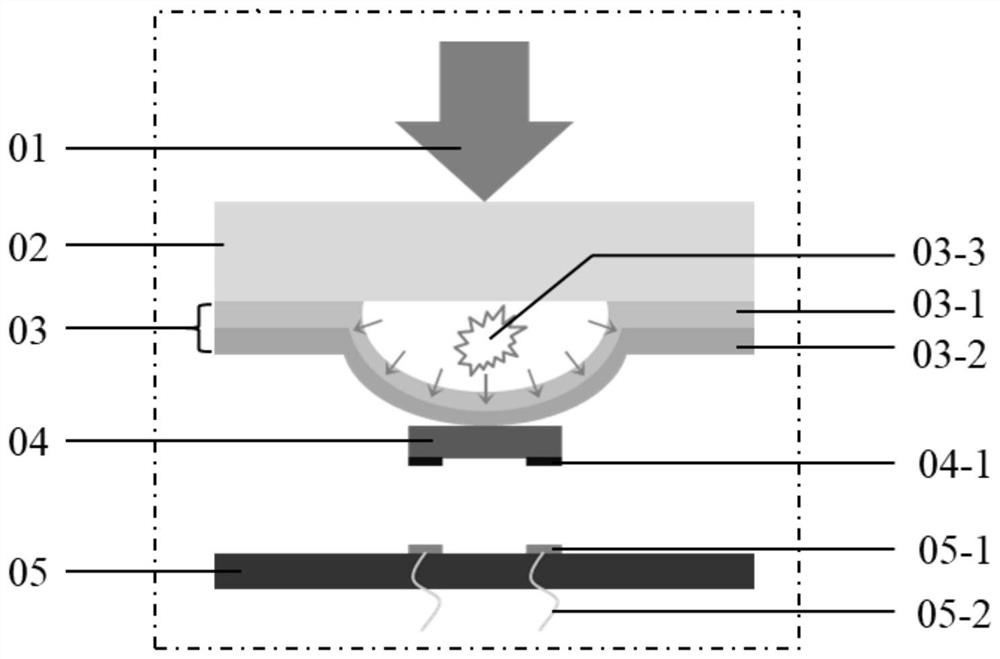

Alignment device and alignment method for mass transfer of micro LED through laser assistance

PendingCN113921439AAchieve precise alignmentSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention belongs to the related technical field of micro LED mass transfer, and discloses an alignment device and an alignment method for mass transfer of a micro LED through laser assistance, and the device comprises a mask projection assembly which comprises a self-defined mask plate and a mask plate fine adjustment device; the self-defined mask plate is provided with a hollow pattern; the mask plate fine adjustment device comprises a manual rotary table, a Z-direction displacement table and an X-direction displacement table which are connected in sequence; the self-defined mask plate is connected to the end part of the manual turntable; a camera alignment system comprises at least two cameras, a cross wire is arranged in the view center of each camera, and each camera is arranged on the corresponding Y-direction displacement table; and a motion platform system comprises a chip motion module and a drive circuit motion module, and alignment and positioning of a light spot, a chip and a drive circuit are achieved through a cross wire of a camera. According to the invention, accurate calibration and alignment of the laser spot, the chip and the driving circuit can be realized, the structure is simple, and the application value is great.

Owner:HUAZHONG UNIV OF SCI & TECH

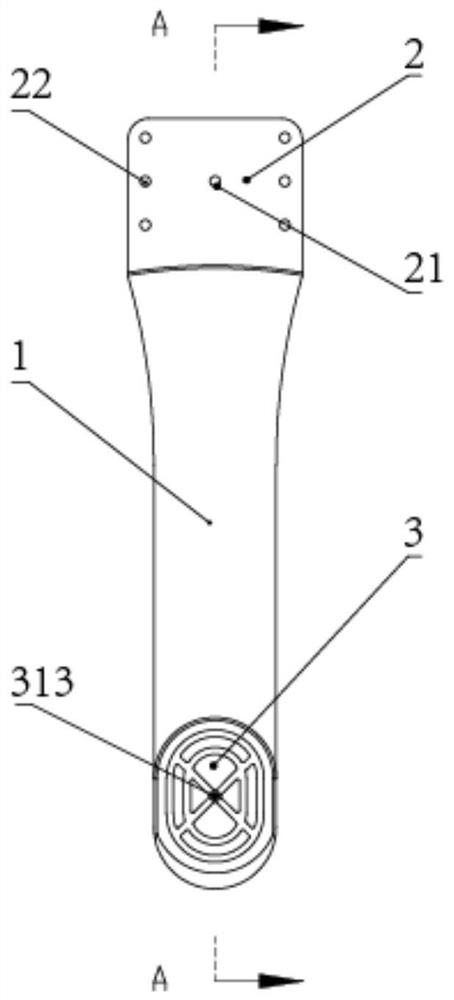

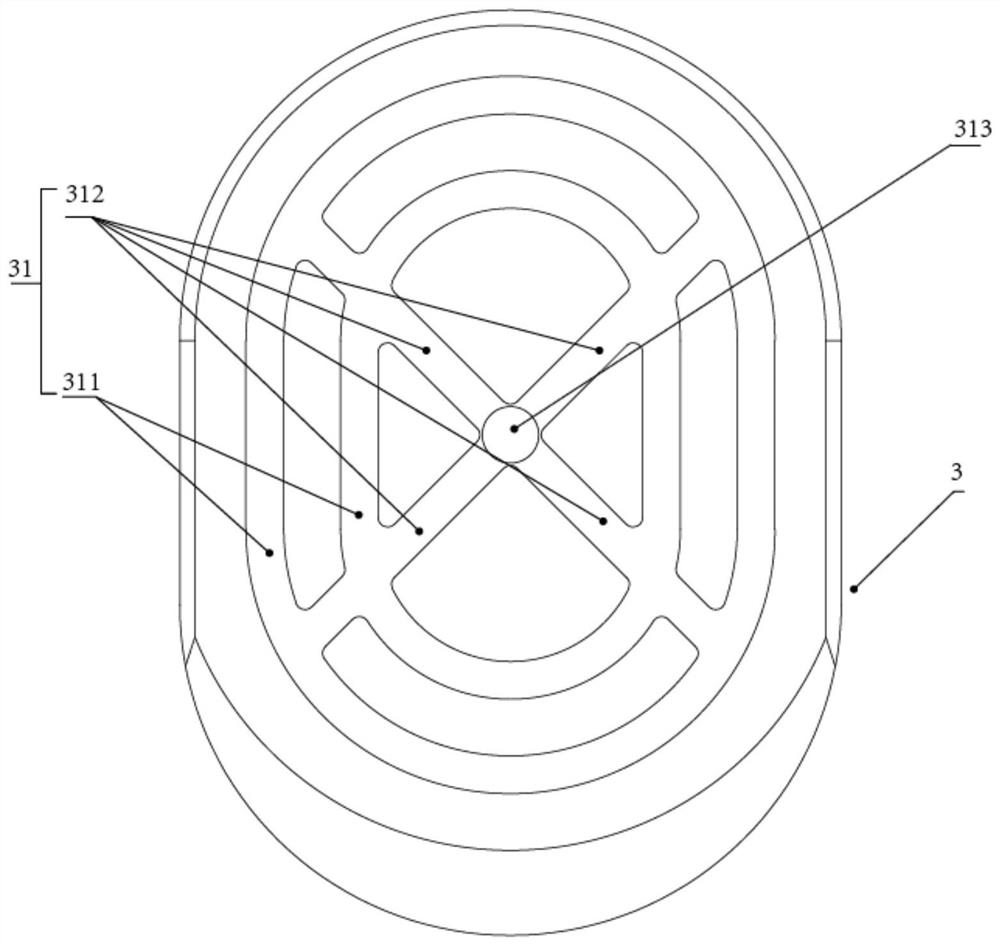

Vacuum adsorption type circular tail end holder

PendingCN111668152AStrong adsorptionReduce contact areaSemiconductor/solid-state device manufacturingFlangePhysics

The invention discloses a vacuum adsorption type circular tail end holder which comprises a body, a flange which is positioned at one end of the body, and a suction cup which is located at the other end of the body, wherein the suction cup and the flange form an integrated structure through the body, radial grooves are formed in the suction cup, the grooves comprise the first groove which is in aradial annular radial shape and the second groove which is in a radial linear radial shape, and the second groove intersects with the first groove. An existing holder has the problems that the clamping force is not easy to control and a wafer is easy to deform and even break, but by implementing the technical scheme of the invention, air between the suction cup at the tail end of the holder and the wafer is pumped out to form a negative pressure space, and the wafer is stably adsorbed on the suction cup by utilizing atmospheric pressure. The grooves and lines in the suction cup can effectivelyenlarge the contact range of an air chamber and the wafer, improve the stress area and stability of the wafer, reduce the direct contact area with the wafer and meet the requirement for high cleanliness.

Owner:昀智科技(北京)有限责任公司

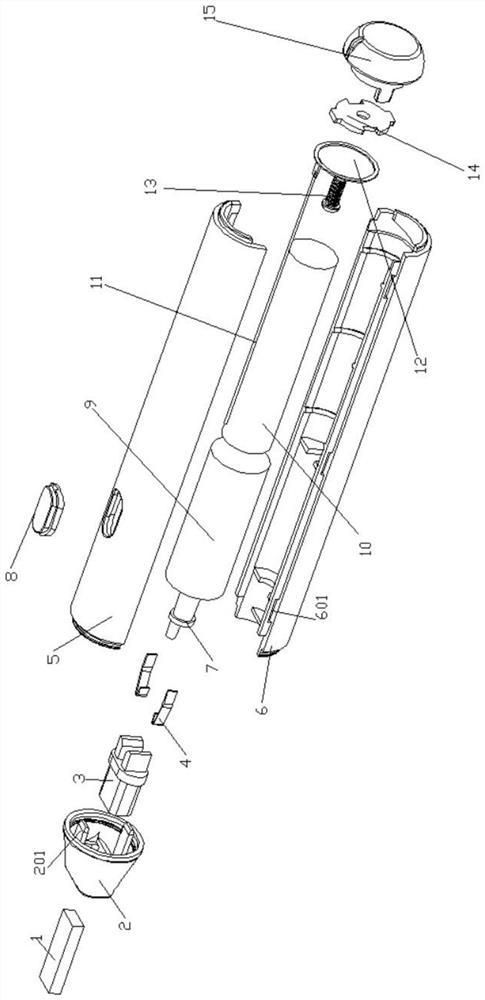

Reciprocating type electric eraser

PendingCN113547863AAchieve wiping effectIncrease contact areaErasing devicesElectric machineElectrical battery

Owner:谷晓川 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com