Dust-free glove

A technology for gloves and palms, applied in the field of gloves, can solve the problems of cleanliness, wear resistance, unsatisfactory high temperature resistance, etc., achieve high cleanliness requirements, reduce the entry of dust, and improve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

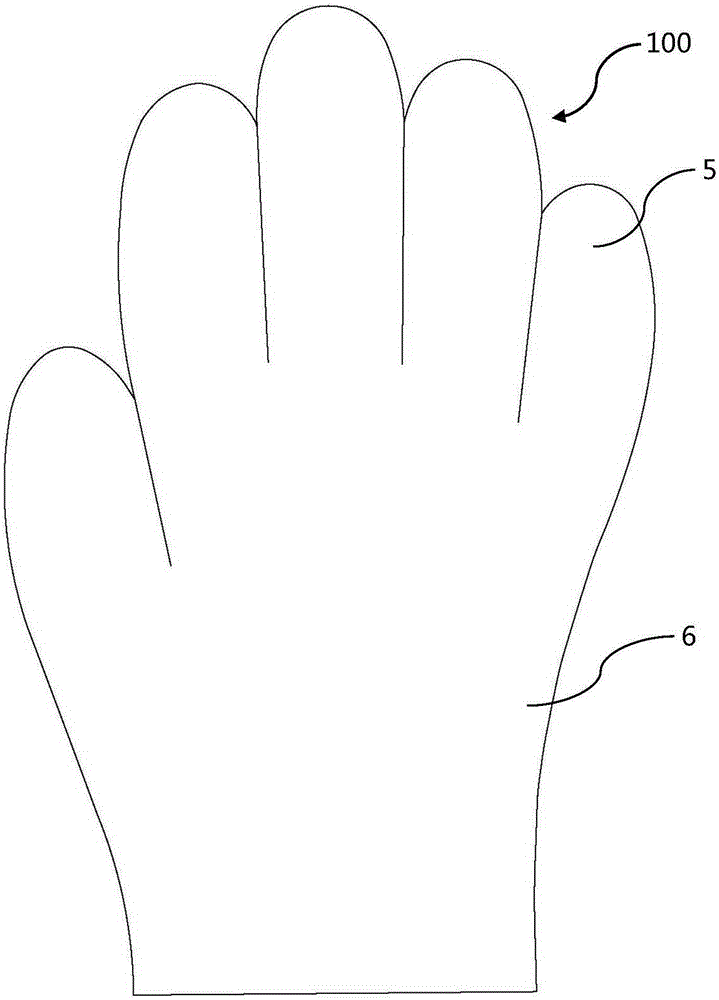

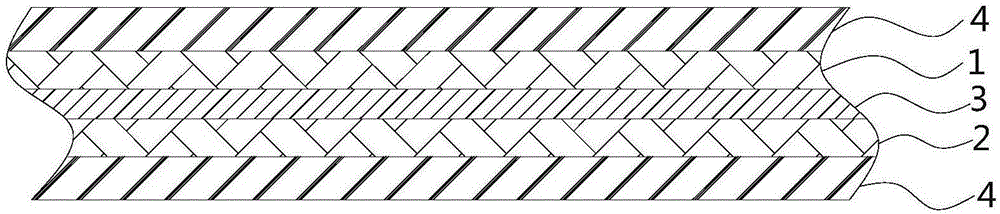

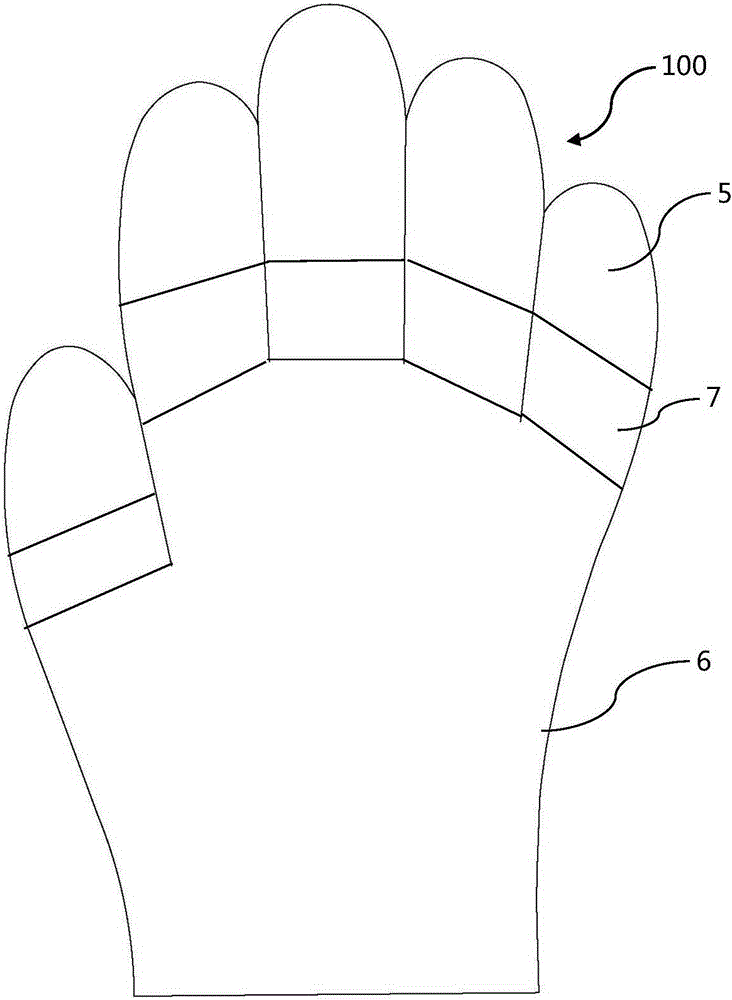

[0033] Such as figure 1 , 2 As shown, the dust-free glove 100 of the embodiment of the present invention generally includes: an inner layer 1 , an outer layer 2 , a sealant 3 and a sewing thread 4 . Wherein the inner layer 1 and the outer layer 2 are composed of the finger portion 5 and the palm portion 6 having five independent fingers, and the inner layer 1 and the outer layer 2 respectively constitute the upper and lower surfaces of the clean glove 100 . The sealant 3 is used to bond the inner layer 1 and the outer layer 2 together through the sides correspondingly. The sealant 3 can be applied only on the side of one layer, or on the sides of the two layers respectively. . The sewing line 4 is used to sew the inner layer 1 and the outer layer 2 together along the sealant 3 from any outer side of the bonded inner layer 1 and outer layer 2 .

[0034] In this embodiment, the materials of the inner layer 1 and the outer layer 2 are made of high-elastic polyester yarn, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com