Liquid film dynamic compensating device

A dynamic compensation and liquid film technology, applied in microscopes, optics, instruments, etc., can solve the problems of easy contamination of liquid, change of liquid properties, and influence on observation quality, so as to avoid disturbance and impact of flow field boundaries, reduce requirements, and improve The effect of observed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be described below in conjunction with the drawings and examples.

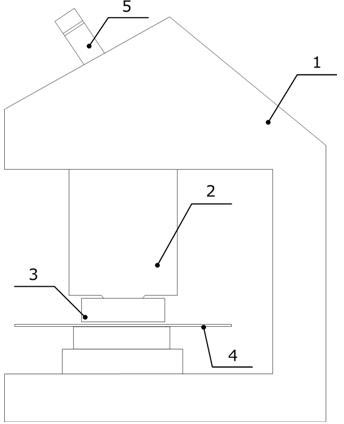

[0031] figure 1 Schematically shows the assembly of the liquid film dynamic compensation device and the lens group of the embodiment of the present invention, the liquid film dynamic compensation device 3 arranged between the lens group 2 and the substrate 4 can be used in microscopic equipment such as an immersion microscope 1 application. In actual observation, the light on the surface of the substrate 4 (silicon wafer or liquid crystal substrate, etc.) is captured by related equipment for microscopic analysis through the slit liquid film above the substrate 4 and the lens group 2 . For the consideration of equipment utilization and economy, immersion microscopic observation can have two modes: direct visual inspection and image analysis. If the wavelength of the observation light is visible light, it can be directly observed through the eyep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com