Patents

Literature

179results about How to "Low cleanliness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

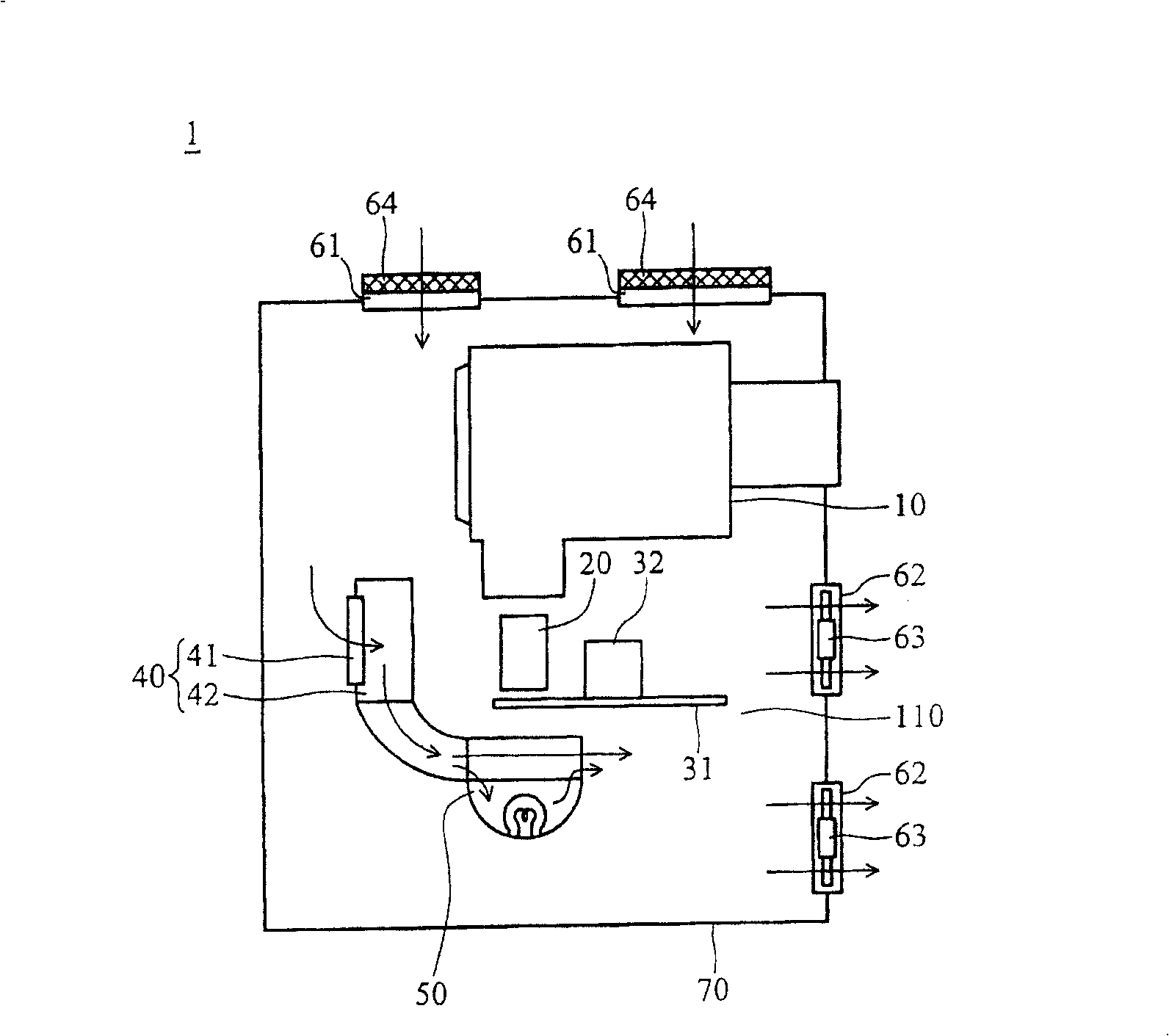

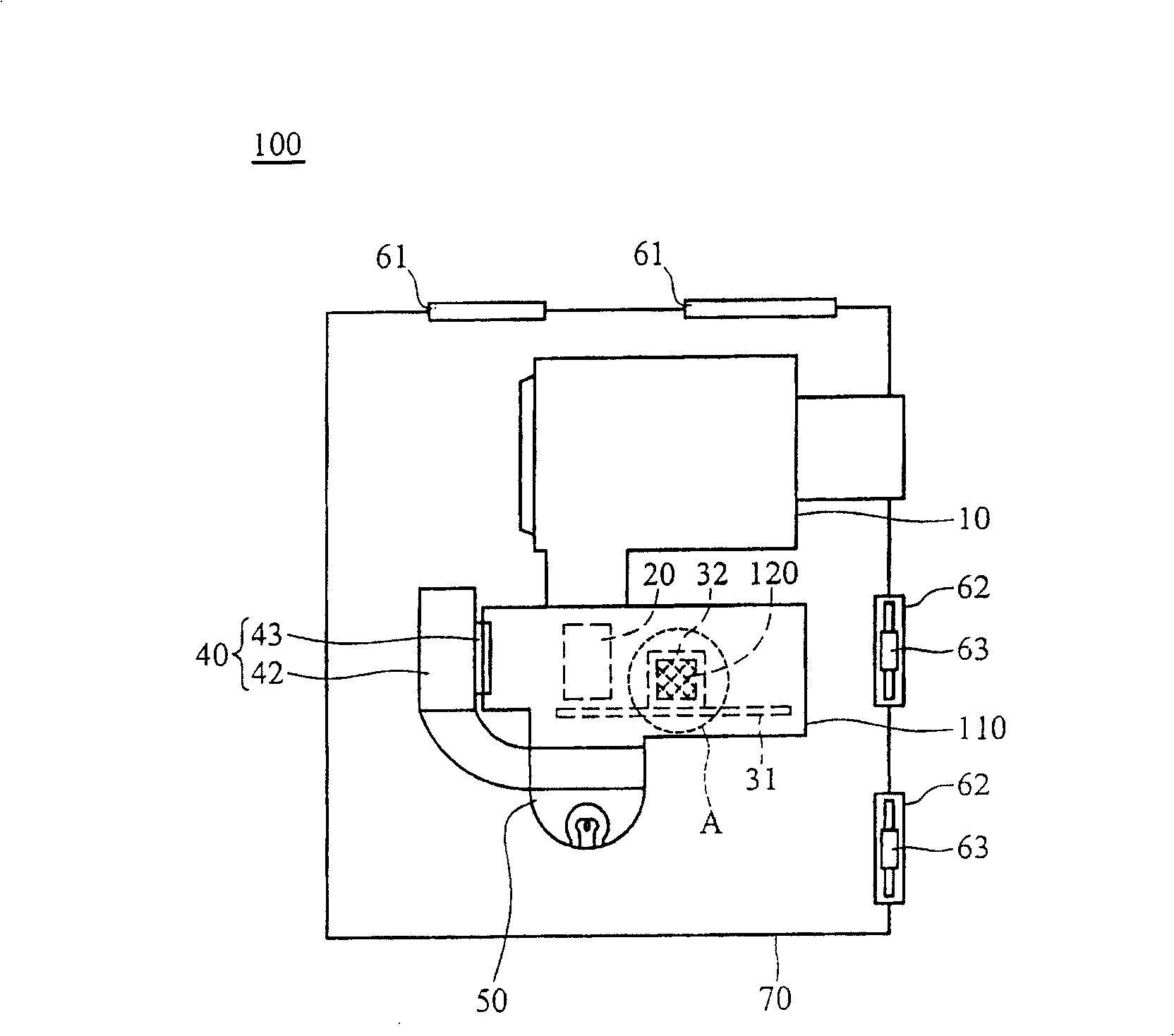

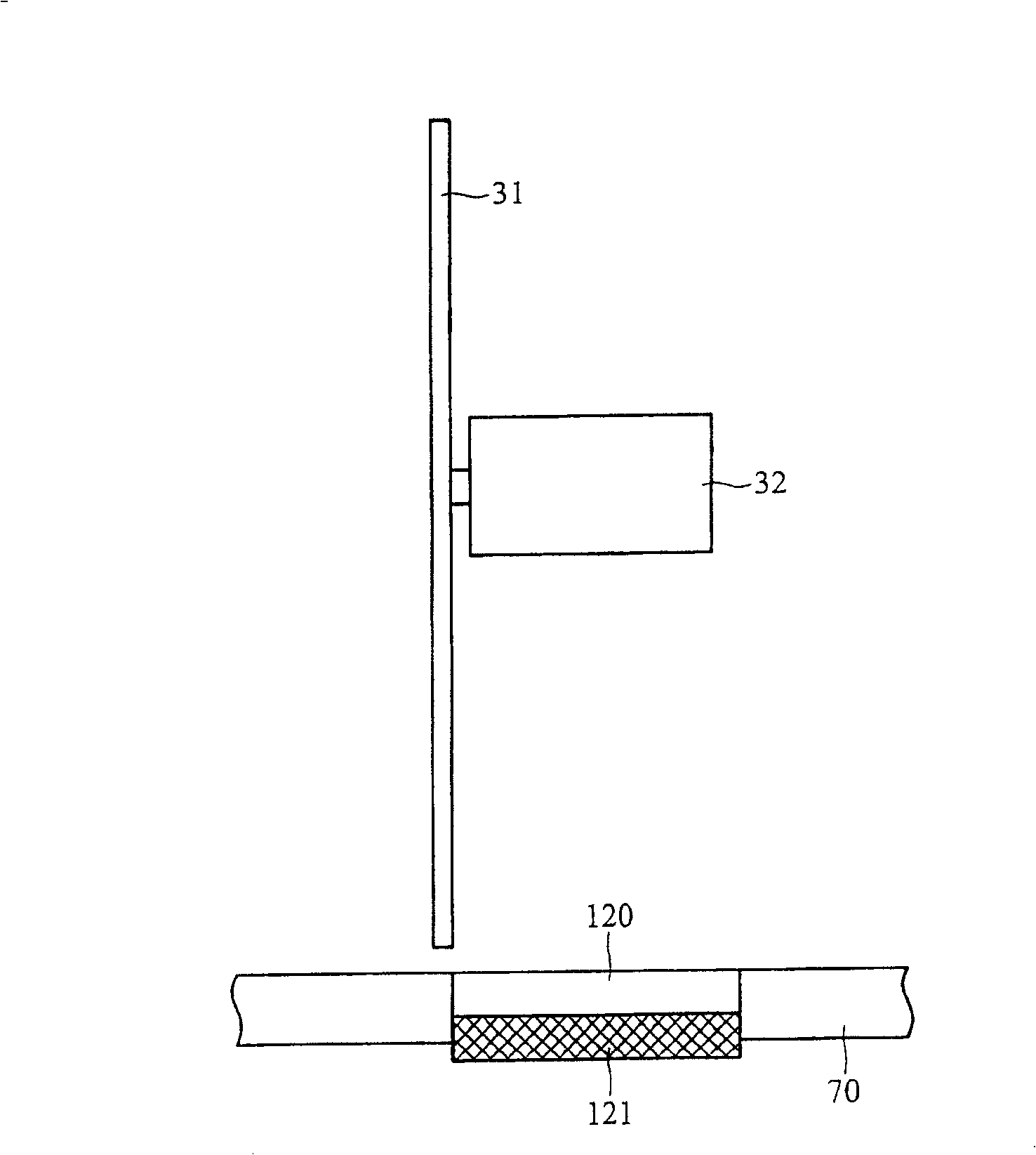

Projector

InactiveCN101256342AEfficient take awayTemperature controlProjectorsCooling/ventilation/heating modificationsLight pipeEngineering

The invention discloses a projector, comprising a wind scooper, a color wheel, a motor of color wheel, a light pipe and a first air inlet. The color wheel is set in the wind scooper. The motor of color wheel is connected with the color wheel and in the wind scooper. The light pipe is in the wind scooper and corresponds with the color wheel. The first air flow enters into the wind scooper from the first air inlet and passes through the motor of the color wheel and light pipe and flows out the wind scooper.

Owner:BENQ CORP

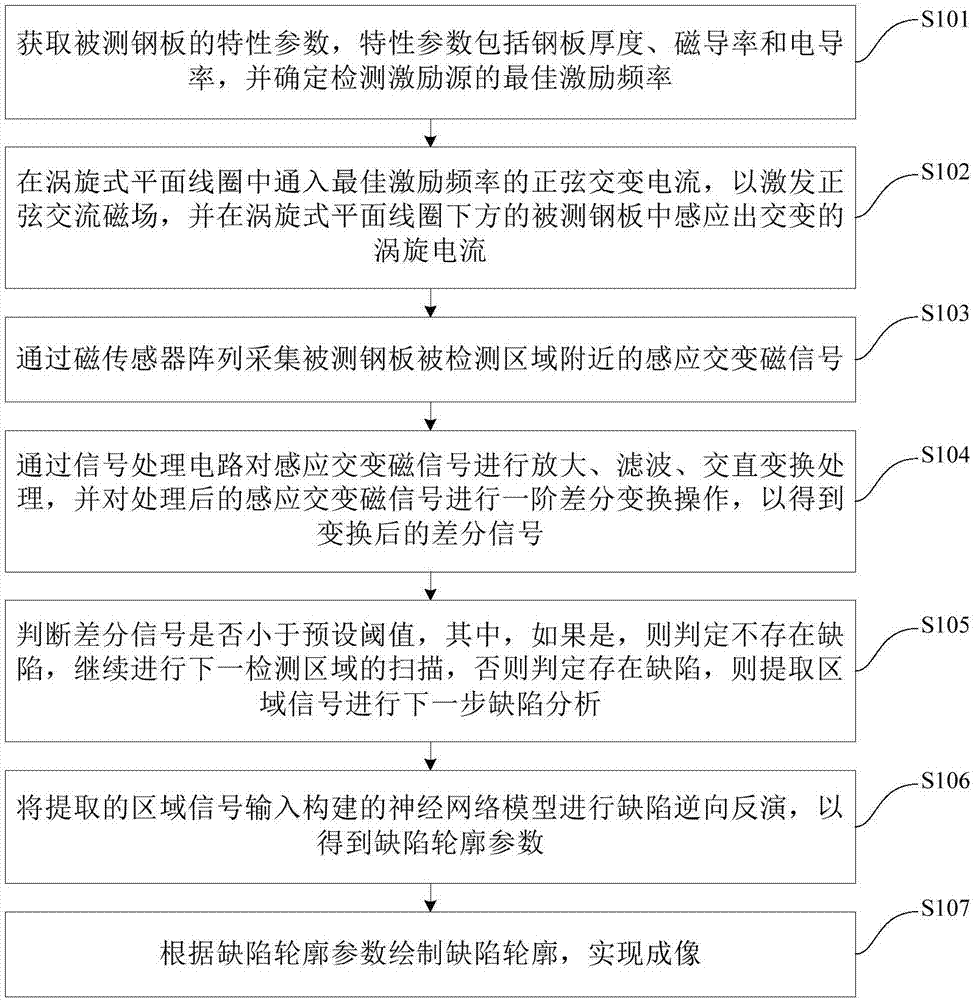

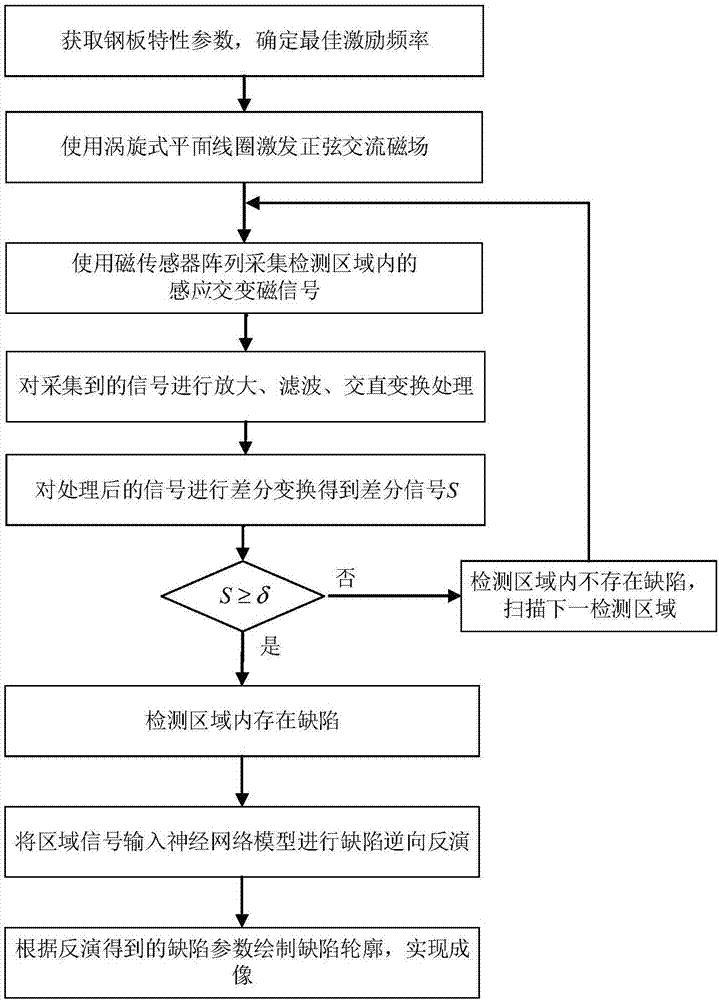

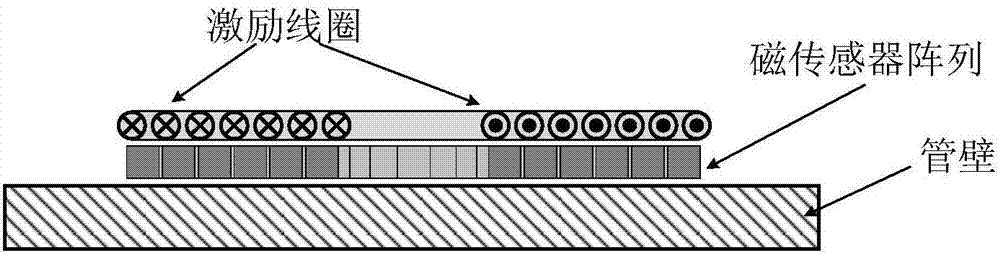

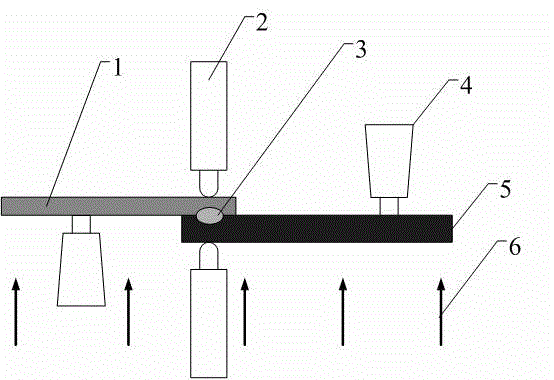

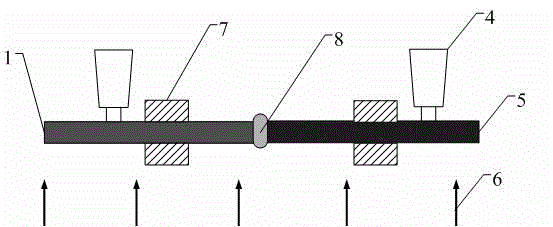

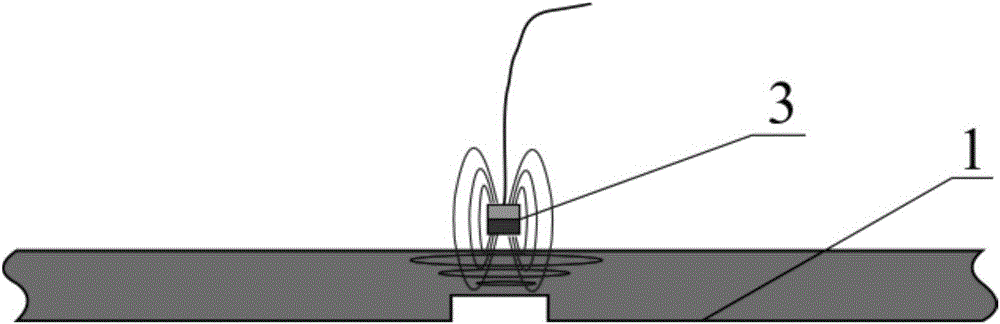

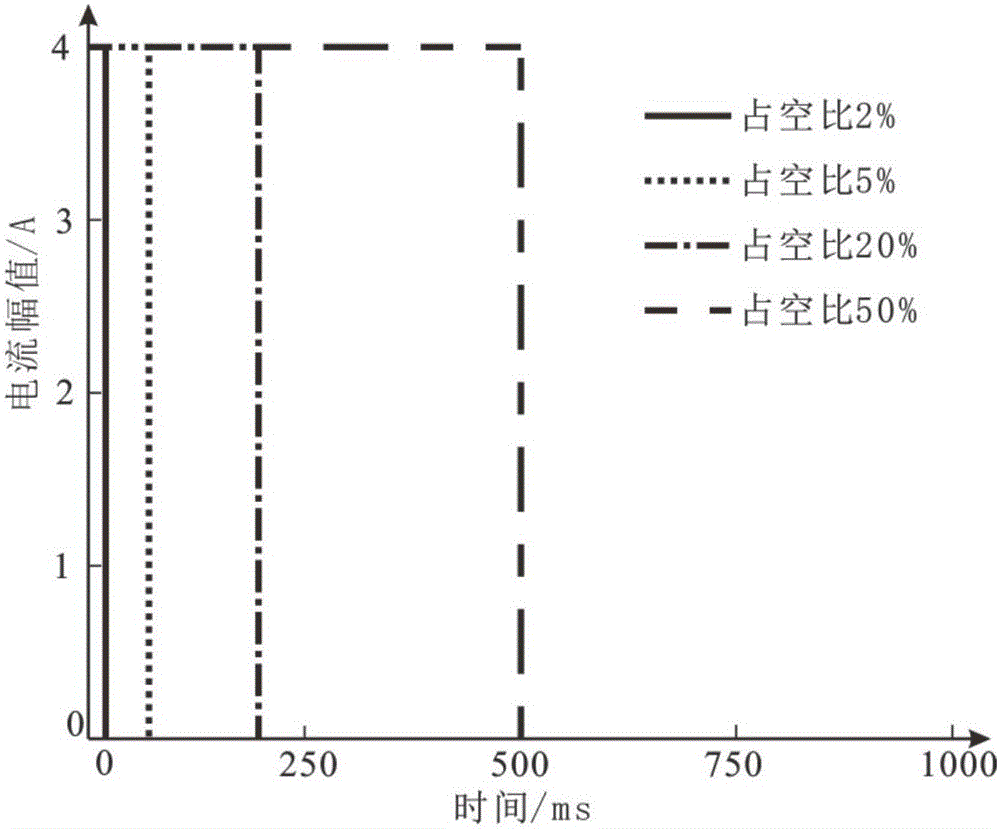

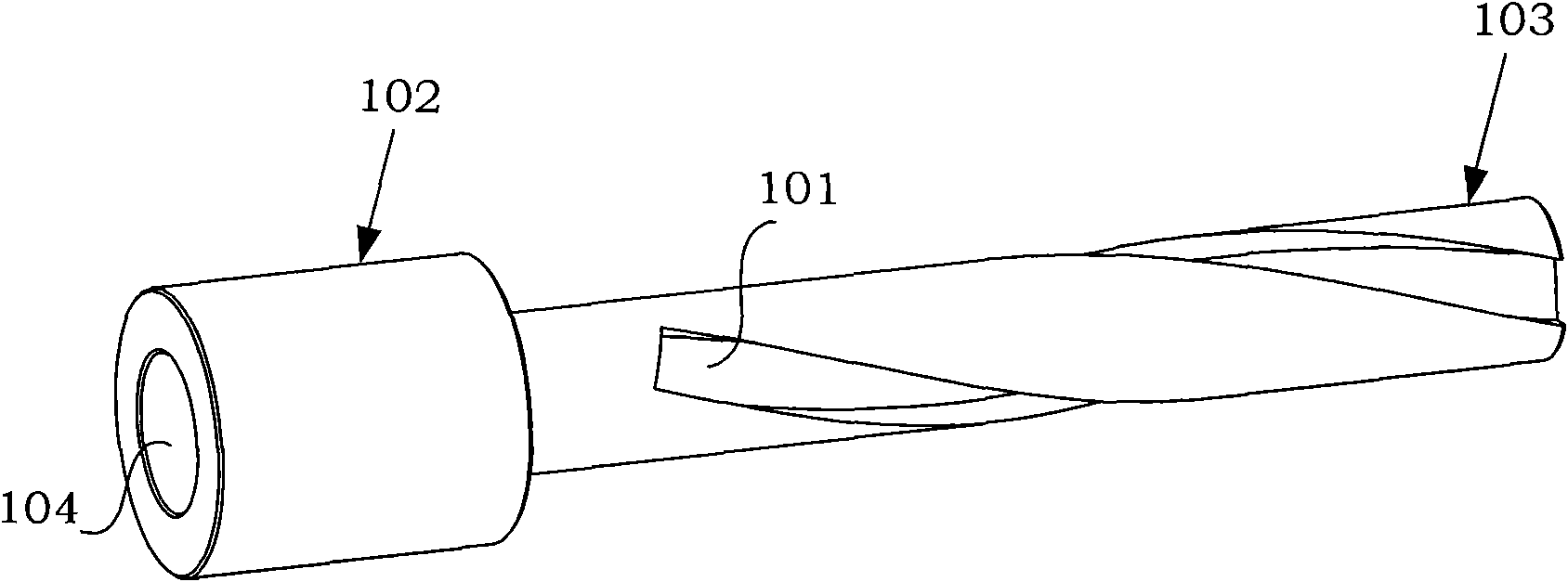

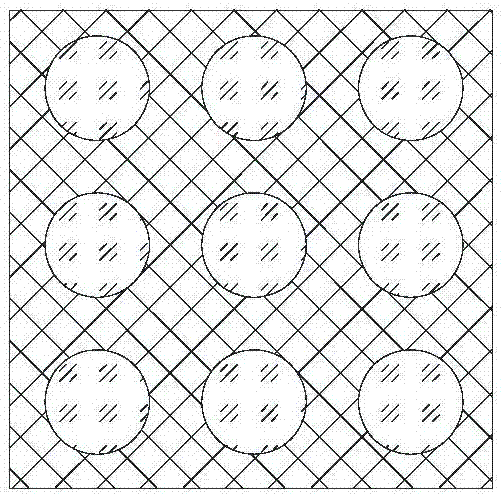

Magnetic vortex array imaging detection method and detection device for detecting defect of steel plate

ActiveCN107255671AEasy to achieve high-precision detectionLow cleanliness requirementsMaterial magnetic variablesMagnetic vortexDifferential signaling

The invention discloses a magnetic vortex array imaging detection method and a magnetic vortex array imaging detection device for detecting the defect of a steel plate, wherein the method comprises the following steps: acquiring a characteristic parameter and determining an optimal excitation frequency; exciting a sinusoidal alternating current magnetic field and inducing an alternating vortex current; acquiring an induction alternating magnetic signal near a detected area of the detected steel plate; processing the induction alternating magnetic signal and conducting the first differential transformation operation to obtain a transformed differential signal; judging whether the differential signal is less than the preset threshold, if so, judging that no defect exists, otherwise, judging that the defect exists, and extracting an area signal; inputting the area signal into a constructed neural network model to implement defect reverse inversion to obtain a defect profile parameter; and drawing a defect profile according to the defect profile parameter to realize imaging. The method uses a concentric ring type magnetic vortex array detection array to detect the defect, so that the defect of the steel plate is detected at the high accuracy, the detection accuracy is improved, and the defect imaging effect is improved.

Owner:TSINGHUA UNIV

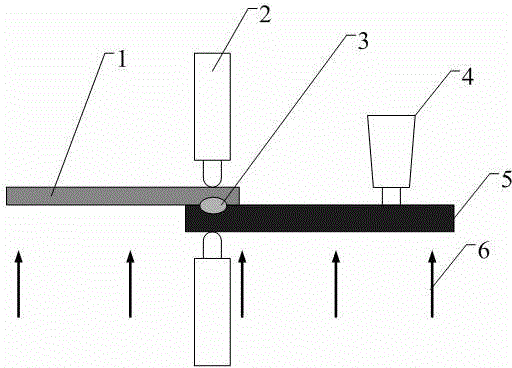

Multi-physics field-assisted electric resistance welding method for dissimilar metal material

InactiveCN104384698ARefinement sizeSmall sizeResistance welding apparatusElastic vibrationElectric resistance welding

The invention discloses a multi-physics field-assisted electric resistance welding method for dissimilar metal material. The multi-physics field-assisted electric resistance welding method for the dissimilar metal material includes steps that exerting a magnetic-sound composite field to a piece to be welded after performing oil removing and acid pickling so as to activate the surface of the piece to be welded, carrying out electric resistance welding on the dissimilar metal under the magnetic-sound composite field environment till solidifying the metal at the weld joint, cooling to a room temperature, and stopping exerting the composite field to finish welding the dissimilar metal. The multi-physics field-assisted electric resistance welding method for the dissimilar metal material has advantages that by means of the stirring and shock excitation effects of the magnetic-sound composite field for the melt metal at the weld joint in the welding process, the primary crystal size is effectively reduced, the dislocation density in the crystal is increased, the size of the crystal grain tissue at the weld joint is refined, and the mechanical performance of the weld joint is improved; by means of the magnetic field and high-frequency vibration, the energy generated by elastic vibration is converted into the plastic flow energy of the metal material, the friction power of the welding interface and heat energy, the energy needed for melting base metal for the electric resistance welding can be lowered, and the energy is saved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

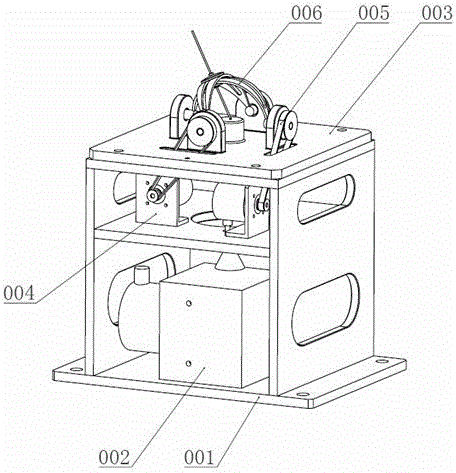

Feeding mechanism of stamping equipment for motor rotor piece

InactiveCN103949558AReduce size requirementsReduced precision requirementsMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention particularly relates to a feeding mechanism of stamping equipment for a motor rotor piece, and belongs to the technical field of stamping equipment. The feeding mechanism comprises a frame, wherein a material storage bucket and a material distribution device are arranged on the frame; the material distribution device is arranged above the material storage bucket through a support frame, and comprises a material suction disk and a power component for driving the material suction disk to perform reciprocating straight line movement; a magnetic device is arranged at the discharge end of the material storage bucket; a push device is arranged on one side of the material suction disk; a material guide groove is formed in the other side, opposite to the push device, of the material suction disk. The feeding mechanism has low requirements on the size and the precision or the cleanliness of blank and has a wide application range, is simple in structure, low in manufacturing cost, simple and convenient to maintain, and long in service life; materials are distributed accurately, and one piece is distributed for each time; the phenomena of piece clamping and material blocking are avoided; the production efficiency is high; 90-95 pieces of blank can be machined per minute averagely when the feeding mechanism is matched with a stamping mechanism; manpower is saved; one person can control a plurality of machines.

Owner:池海平

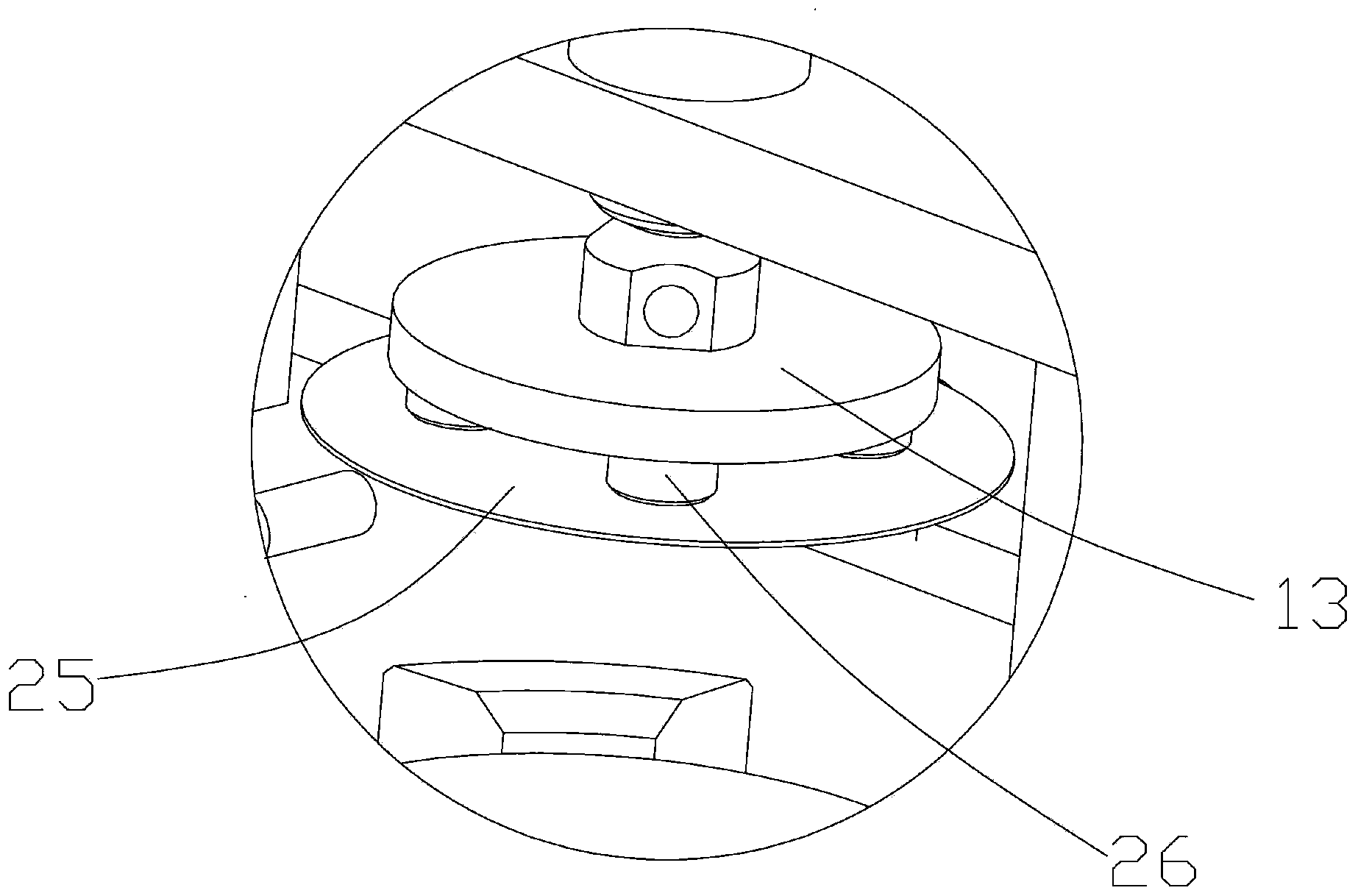

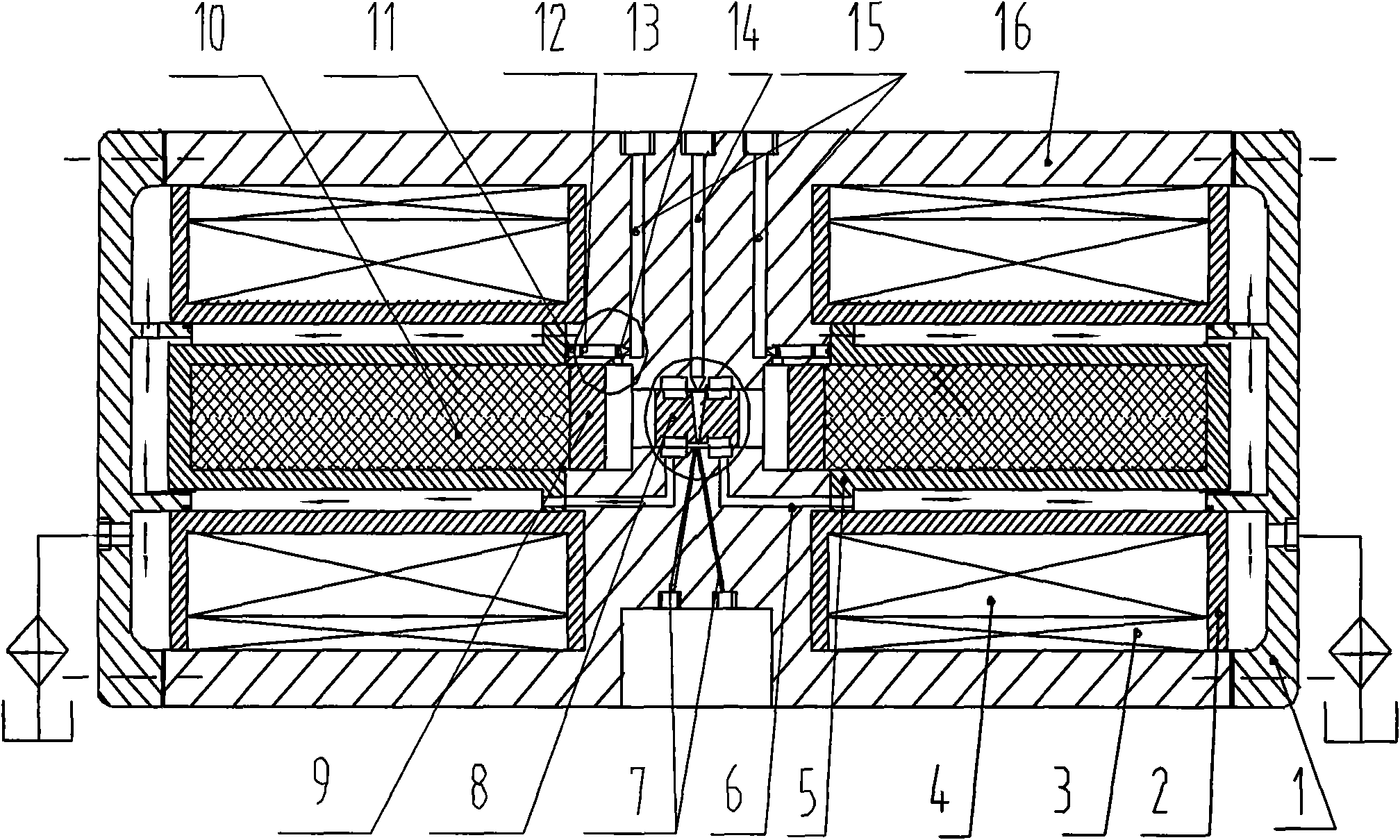

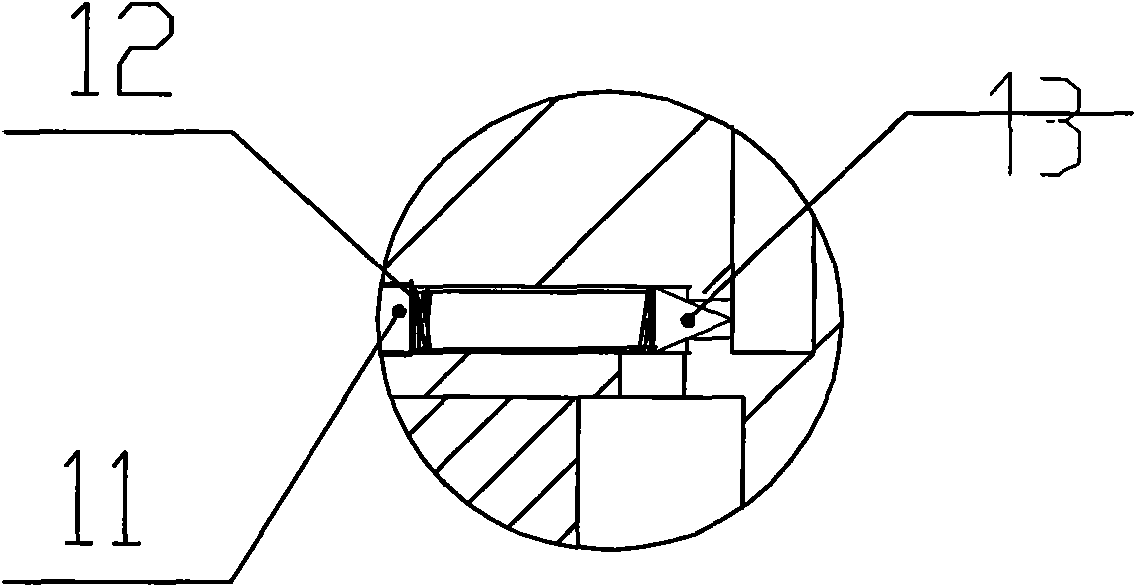

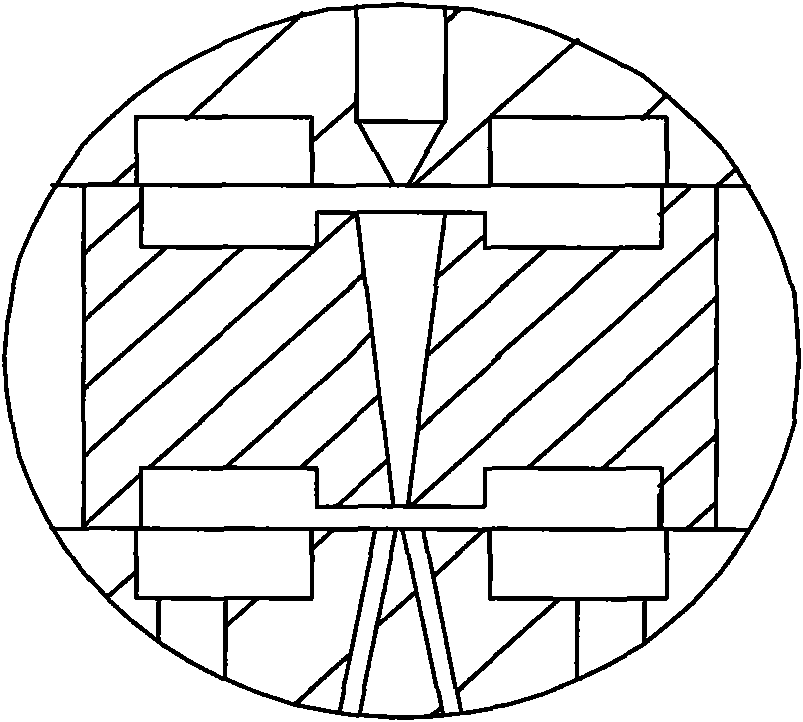

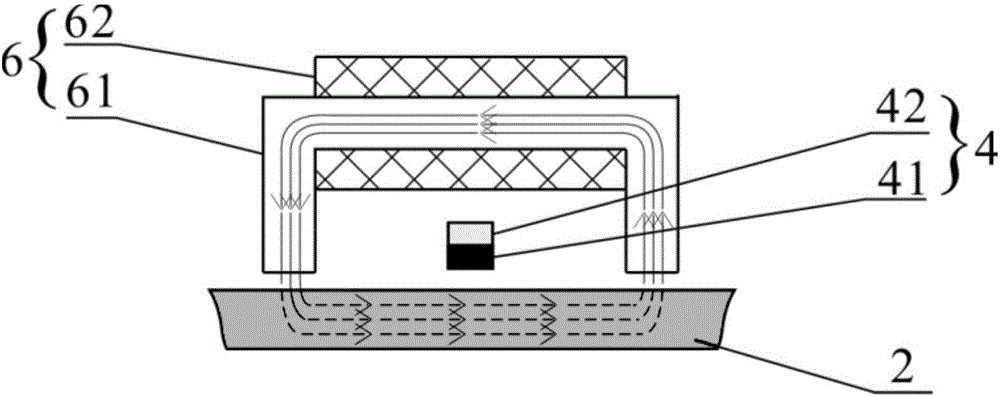

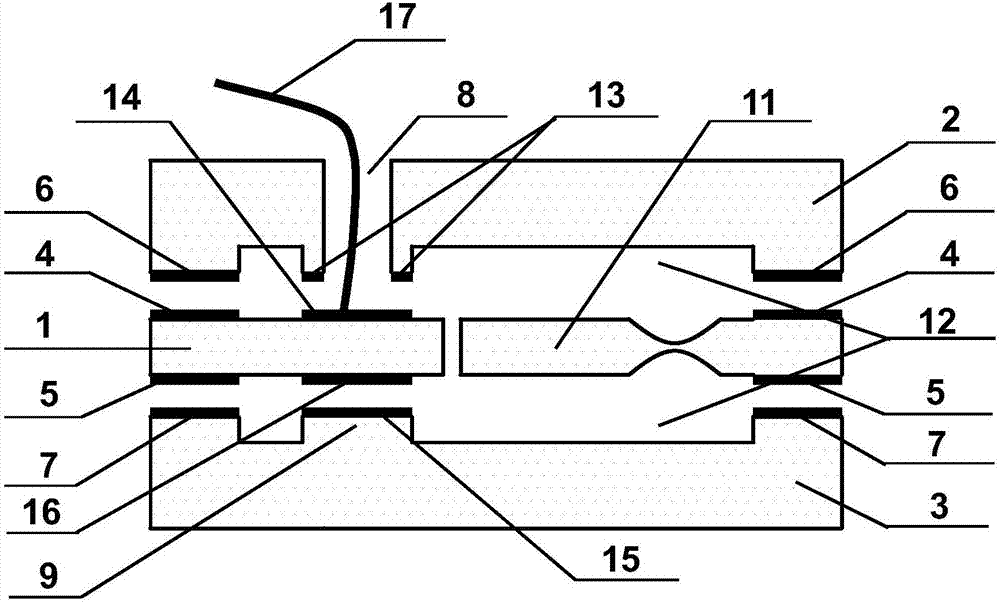

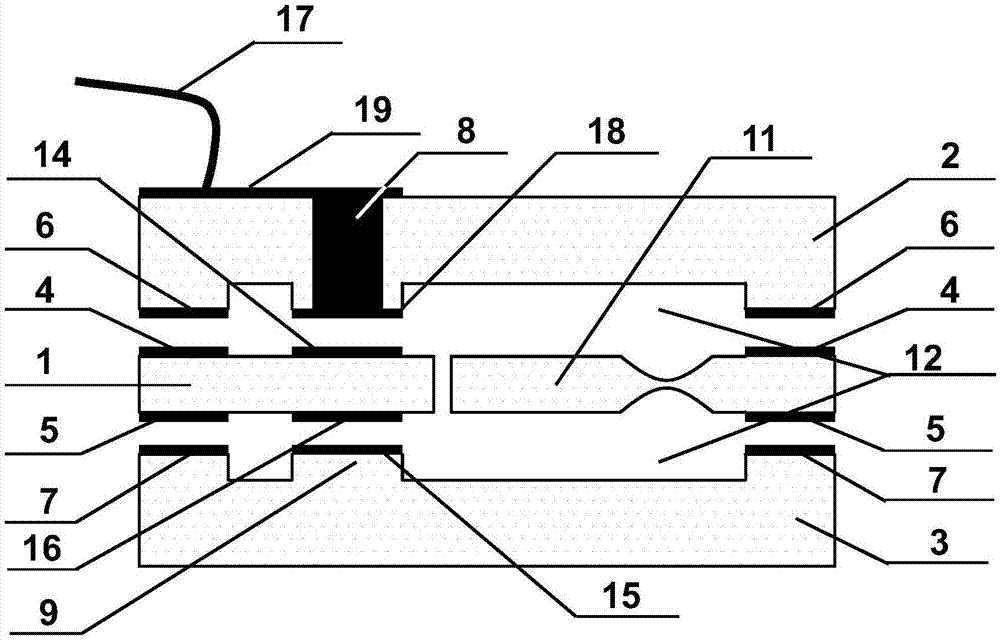

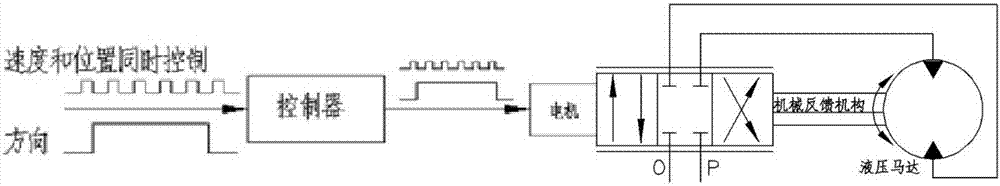

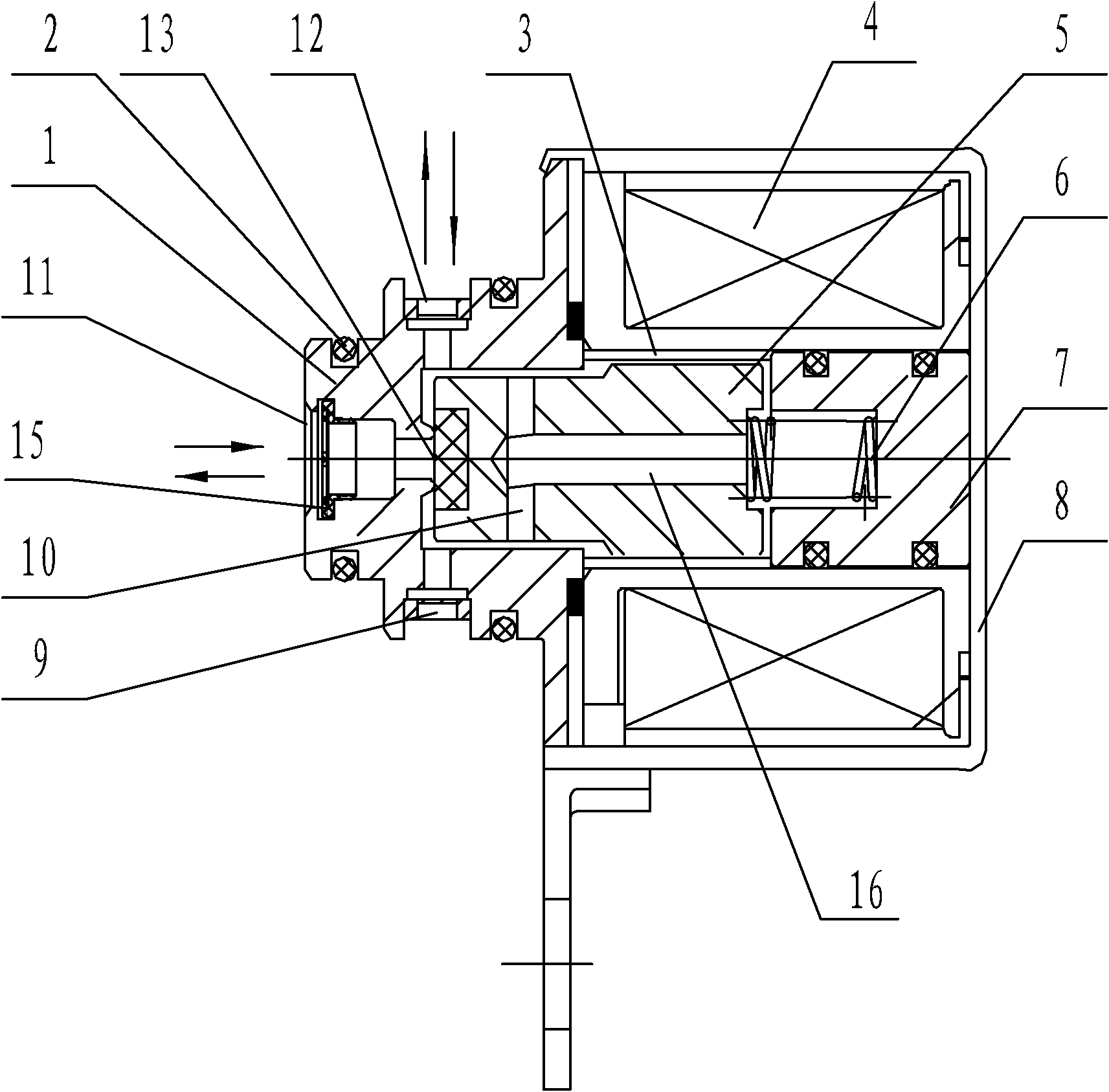

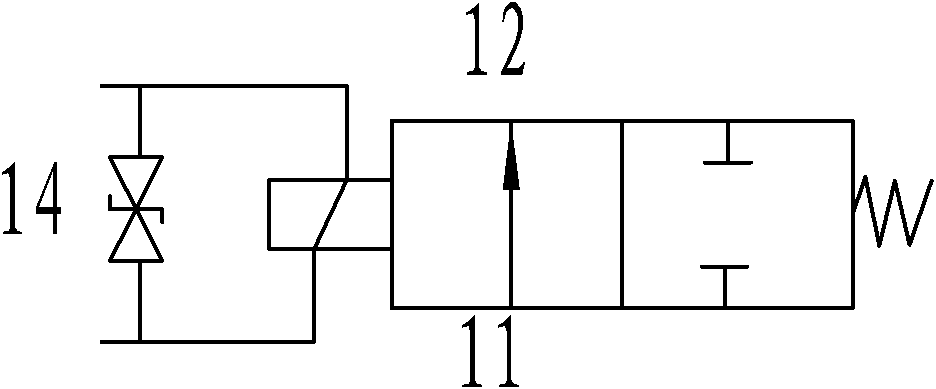

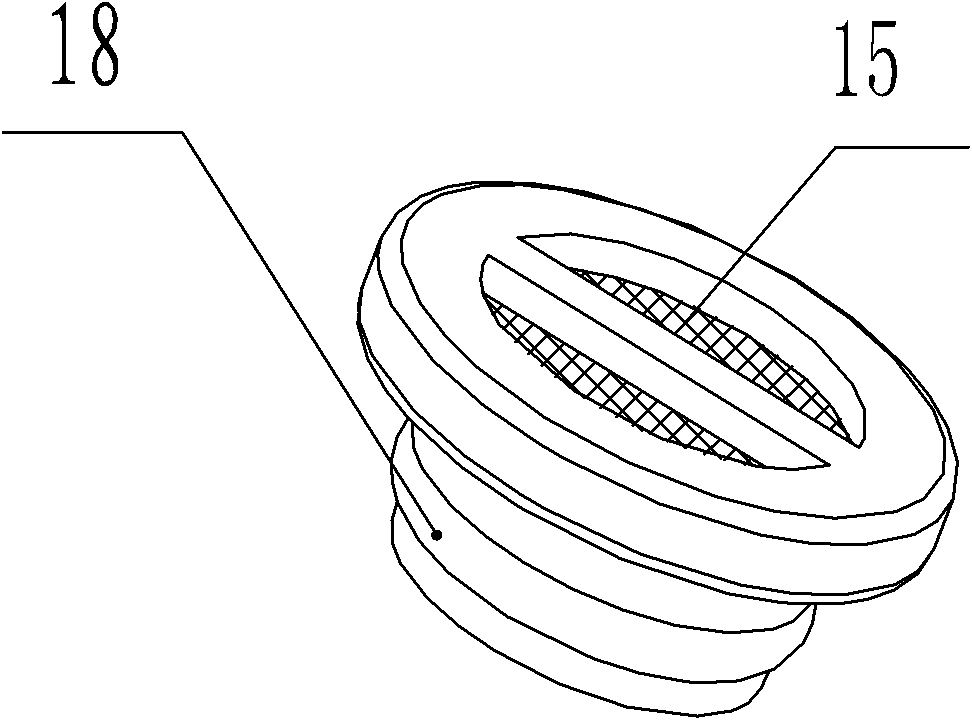

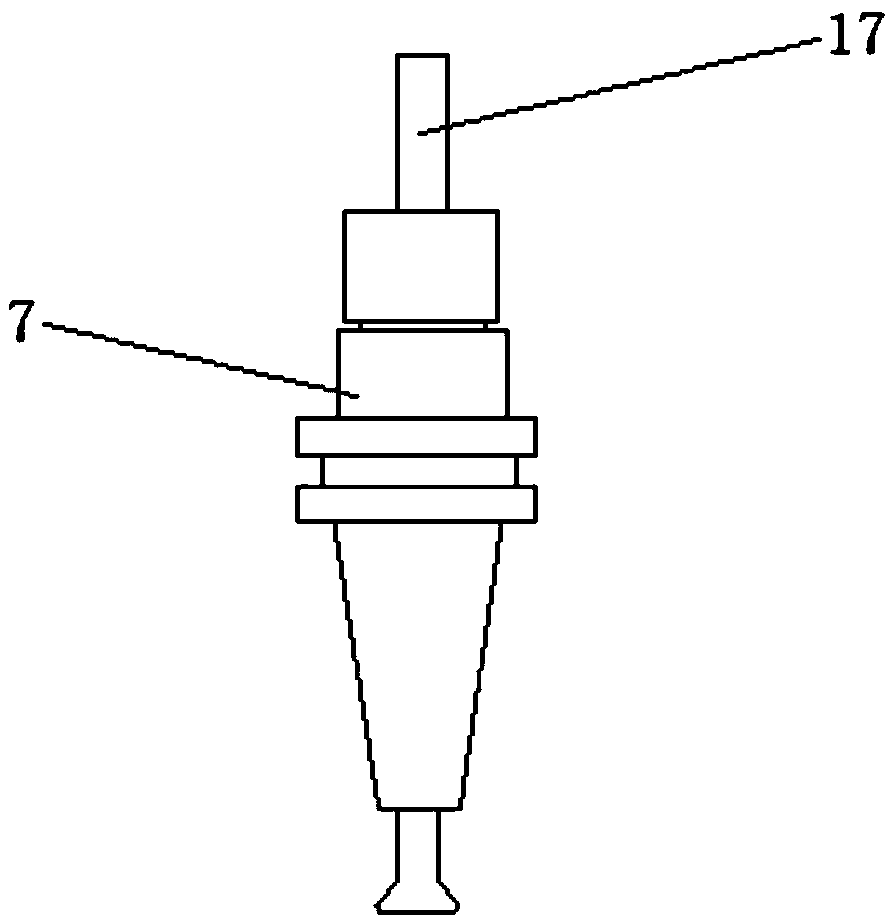

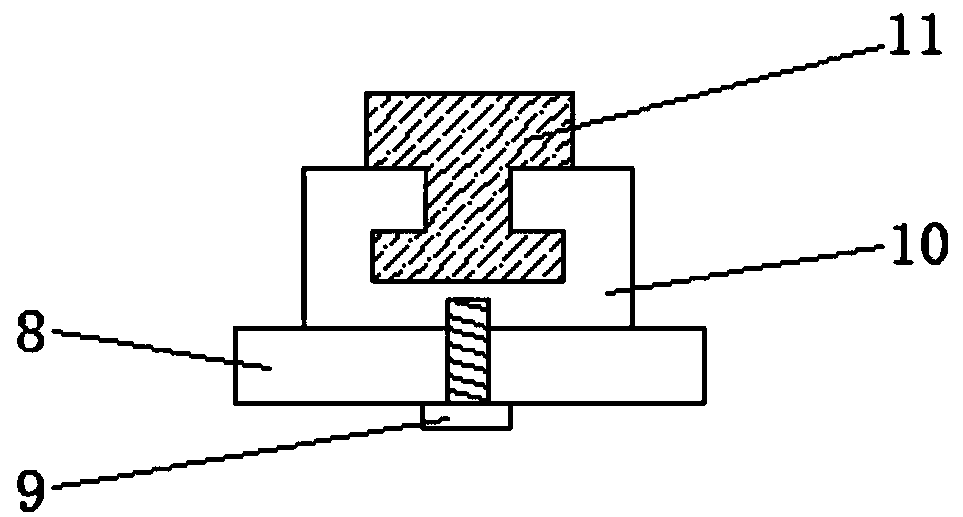

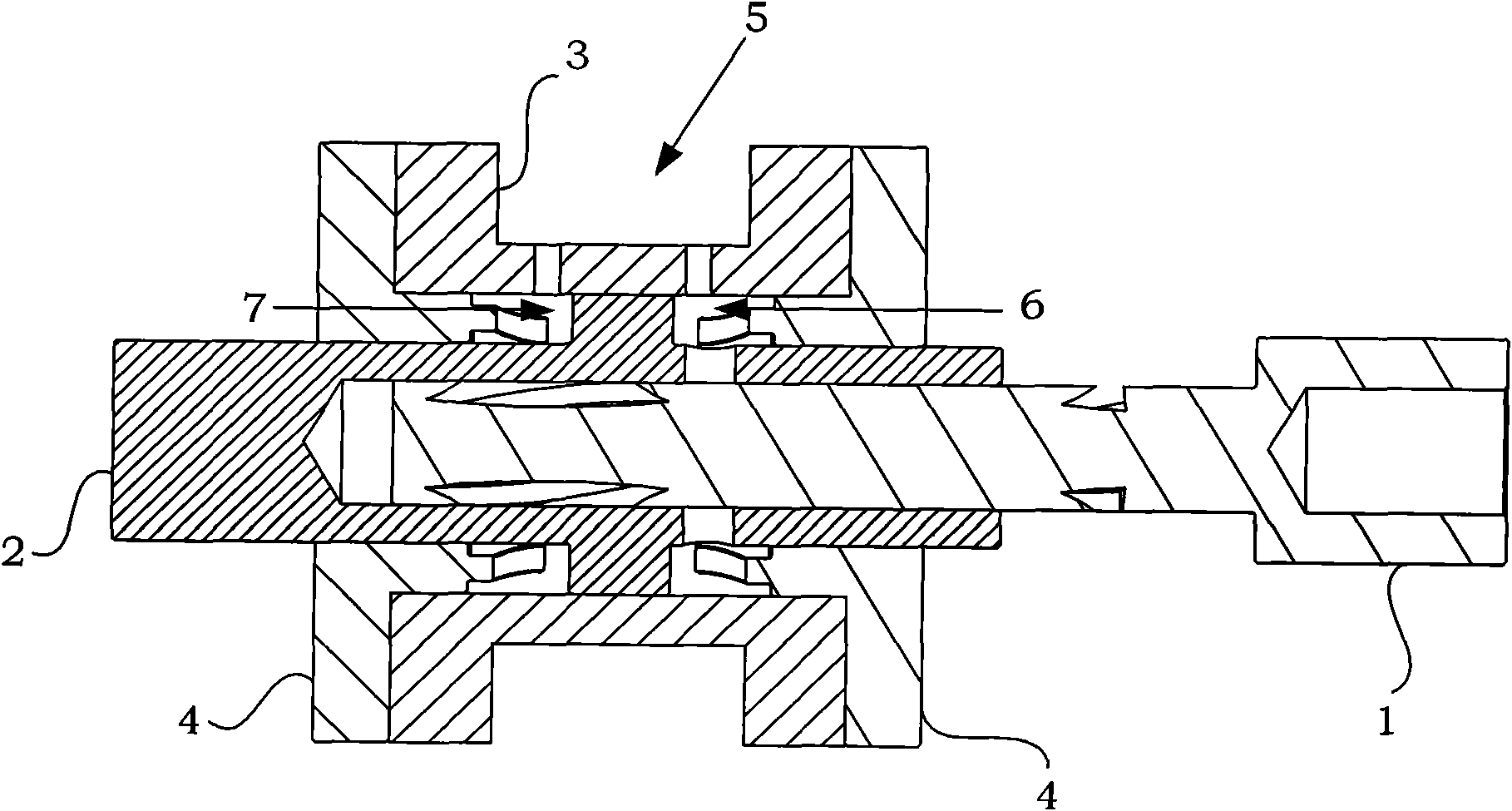

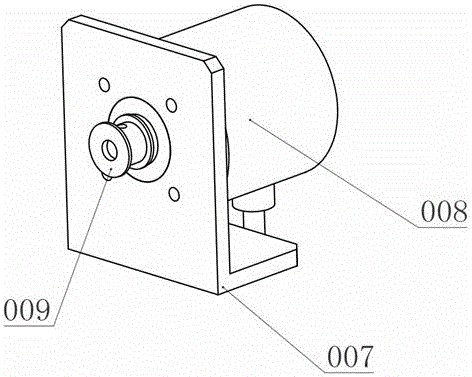

Super magnetostrictive actuator driving single-stage direct-acting jet pipe servo valve

The invention discloses a super magnetostrictive actuator driving single-stage direct-acting jet pipe servo valve, and belongs to the technical field of hydraulic servo control. The servo valve comprises a valve body (16), a flow distributor (8), a pair of electro-mechanical converters, and a pair of micrometric displacement amplifiers positioned between the electro-mechanical converters and the flow distributor (8), wherein each electro-mechanical converter comprises a thermal compensation hood (5), a super magnetostrictive rod (10) mounted in the thermal compensation hood, and a coil frame (2) positioned outside the thermal compensation hood (5), and also comprises a drive coil (4) and a bias coil (3) which are orderly wound outside the coil frame (2); each micrometric displacement amplifier comprises a cylinder, a big piston (9) arranged at one end of the cylinder and connected with the corresponding super magnetostrictive rod (10); and the other end of the cylinder is connected with the flow distributor (8). The jet pipe servo valve has obvious characteristics of quick response, big driving power and control flow, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

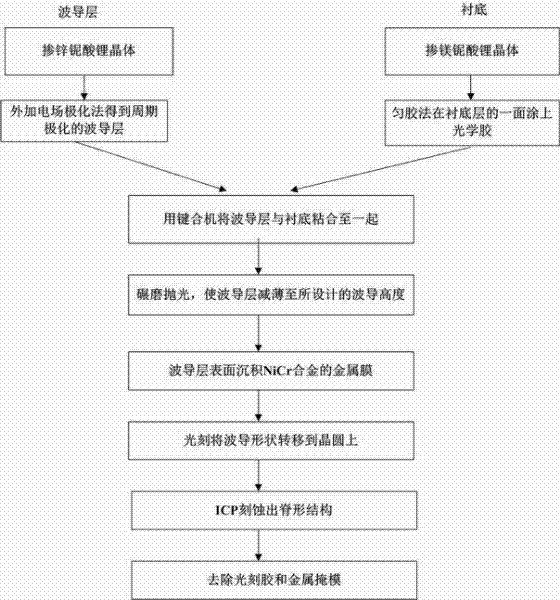

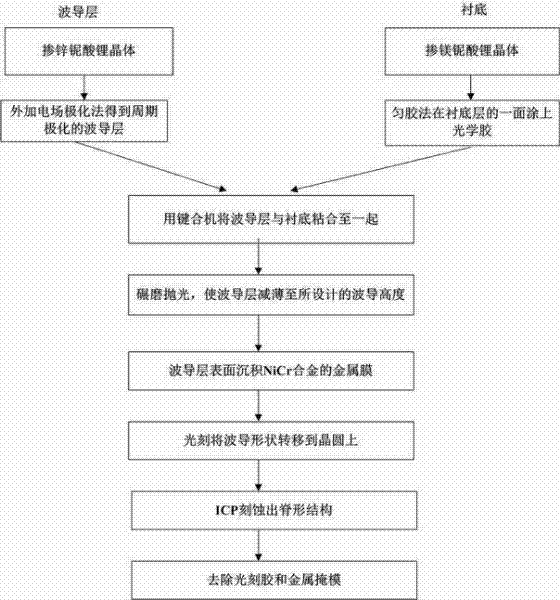

Preparation method of lithium niobate optical waveguide

InactiveCN102253451AStrong light field confinementImprove coupling efficiencyOptical waveguide light guideManufacturing technologyRefractive index

The invention provides a preparation method of a lithium niobate optical waveguide. The preparation method of the lithium niobate optical waveguide comprises the steps of: fabricating a periodical domain inversion structure on a doped lithium niobate crystal by adopting an applied electric field polarization method by selecting a zinc-doped or magnesium-doped lithium niobate crystal; bonding the periodical domain inversion structure as a waveguide layer with a lithium niobate substrate or a lithium tantalite substrate through optical cement the refractive index of which is lower than that of the waveguide layer; and etching to obtain a ridge waveguide structure by using an ICP (inductively coupled plasma) dry method to obtain the lithium niobate optical waveguide. The adhesive layer adopted by the invention has a reflective index more approaching that of air, therefore, in the waveguide, the optical field limiting function is stronger, the optical field is distributed symmetrically, and the coupling efficiency of single mode fibers is higher. By adopting adhesive bonding, the requirement on cleanness and roughness of the surface of a wafer is far lower than that of the surface of a directly bonded wafer, thus the preparation method is realized more easily in technology. The lithium niobate optical waveguide prepared by the method has more excellent performance in the aspects of improving the optical field limiting function, reducing the transmission loss of the waveguide, inhibiting the photorefractive effect, reducing the difficulty in manufacturing technology and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

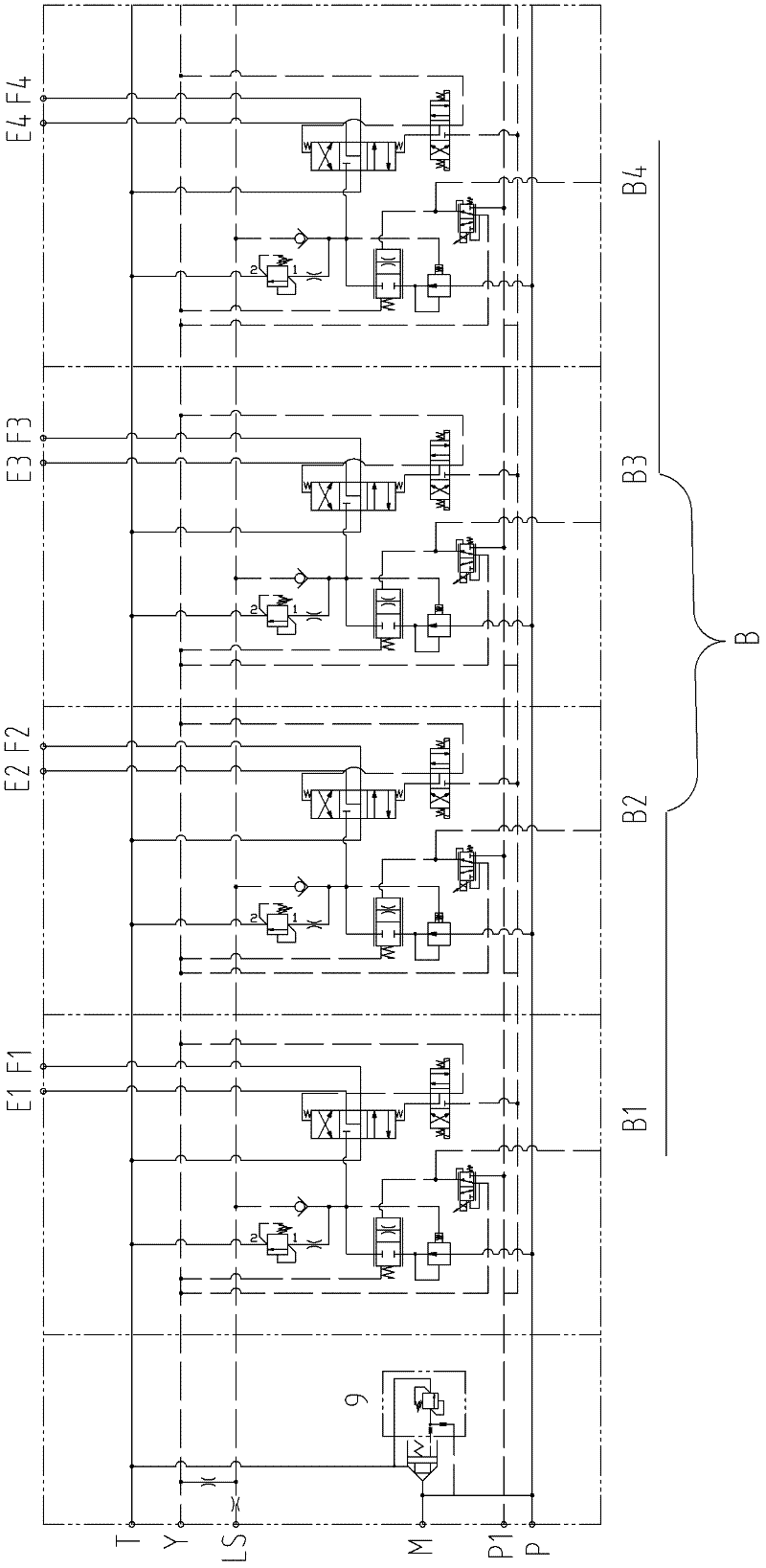

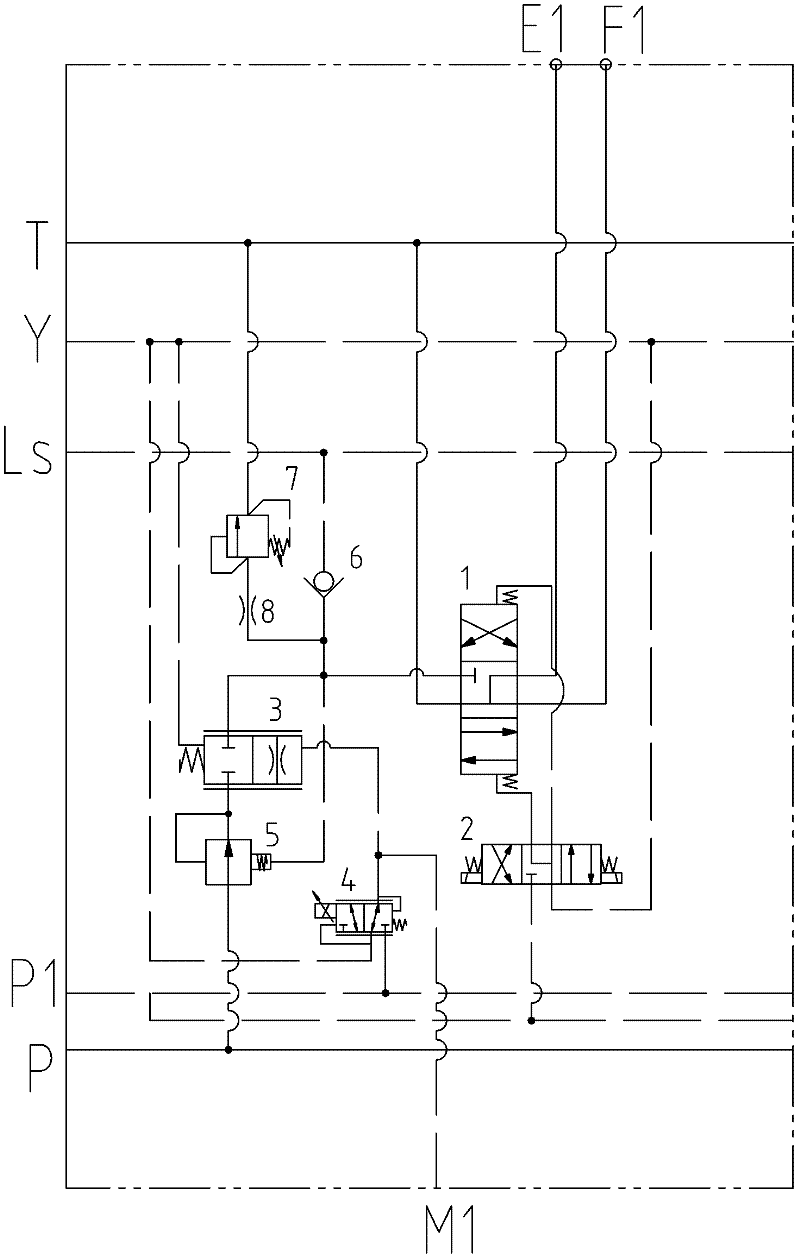

Multi-way valve and tunnel boring machine

ActiveCN102506030AAvoid enteringAvoid easy cloggingServomotor componentsAutomatic controlTunnel boring machine

The invention provides a multi-way valve and a tunnel boring machine. The multi-way valve comprises a main oil inlet, an oil inlet control port, a main oil return port, a main oil drainage port and a plurality of reversing valve groups, wherein the reversing valve groups are used for controlling actuating elements respectively. Each reversing valve group is provided with a pilot-operated reversing valve and an electromagnetic reversing valve. The pilot-operated reversing valve comprises a first oil inlet, a first oil return port and two first working ports, hydraulic oil pumped from the main oil inlet is led into the first oil inlet, and the first working ports are connected with the actuating elements. The electromagnetic reversing valve comprises a second oil inlet, a first oil drainage port and two second working ports, hydraulic oil pumped from the oil inlet control port is led into the second oil inlet, and the second working ports are connected to two ends of the pilot-operated reversing valve to realize reversing thereof. Compared with the prior art, the multi-way valve has the advantages that the requirement to cleanliness of hydraulic oil is low, feedback oil ways are not easy to be blocked, automatic control is easy to realize and the like.

Owner:SANY HEAVY EQUIP

Steel pipe wall thickness measuring method based on eddy current permeability measurement

InactiveCN106524892AGuaranteed magnetic inductionIncrease magnetic inductionUsing electrical meansElectrical/magnetic thickness measurementsSurface layerMetallurgy

The invention relates to a steel pipe wall thickness measuring method based on eddy current permeability measurement. Under a precondition of unchanged total magnetic flux, a steel pipe is magnetized, and thereafter magnetic flux density in the steel pipe is greater than the magnetic flux density corresponding to a maximum magnetic permeability point. The change of the local steel pipe wall thickness is capable of causing the change of the magnetic flux density of the same part in the steel pipe, and the magnetic permeability of the same part of the pipe body is changed, and the change is expressed on the surface layer of the steel pipe. Center lines of an excitation coil and a receiving coil of an eddy current measuring head face the surface of the steel pipe along a normal direction, and center lines of an excitation coil and a receiving coil of another eddy current measuring head face a surface of a reference steel plate along a normal direction. The reference steel plate is magnetized by adopting an independent magnetizer, and the differential motion of the output signals of the two eddy current measuring heads is carried out. When the steel pipe local wall thickness is changed, the amplitudes of the differentially-output eddy current detection signals are changed along with the change of the steel pipe local wall thickness, and therefore non-contact thickness measurement is realized. The steel pipe wall thickness measuring method is advantageous in that non-contact large lift-off measurement is realized without requiring coupling, and the measuring method is suitable for a high-speed thickness measuring requirement, and a requirement on the surface of the steel pipe is low.

Owner:WUHAN HUAYUYIMU TESTING EQUIP CO LTD

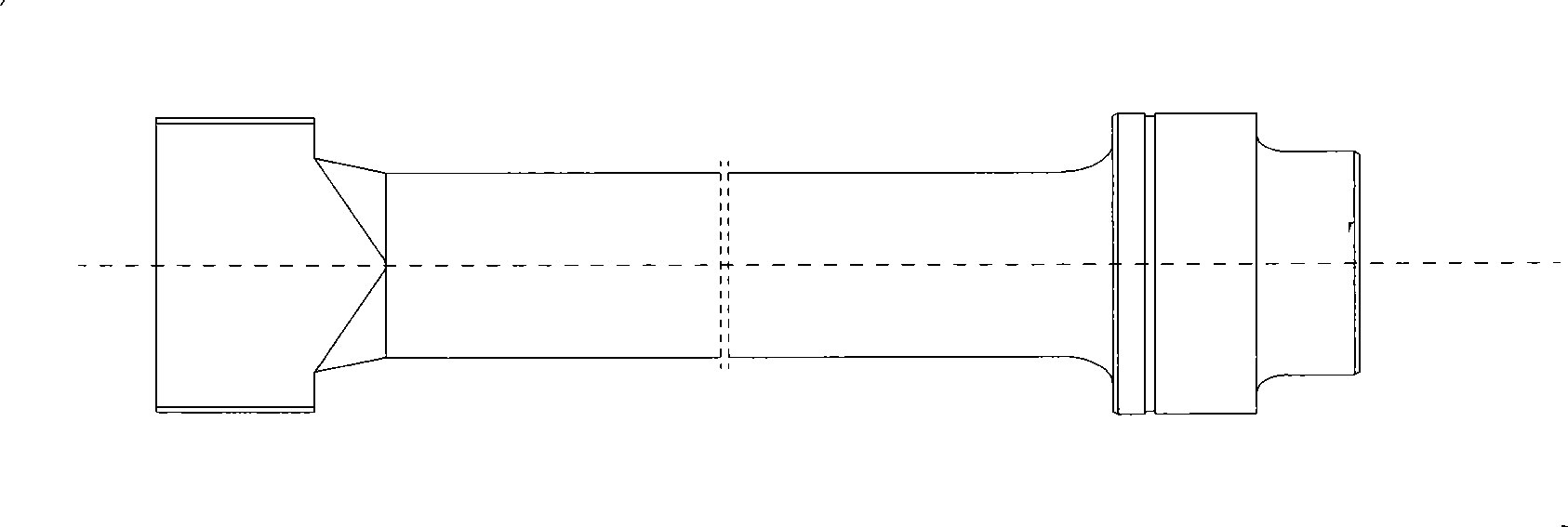

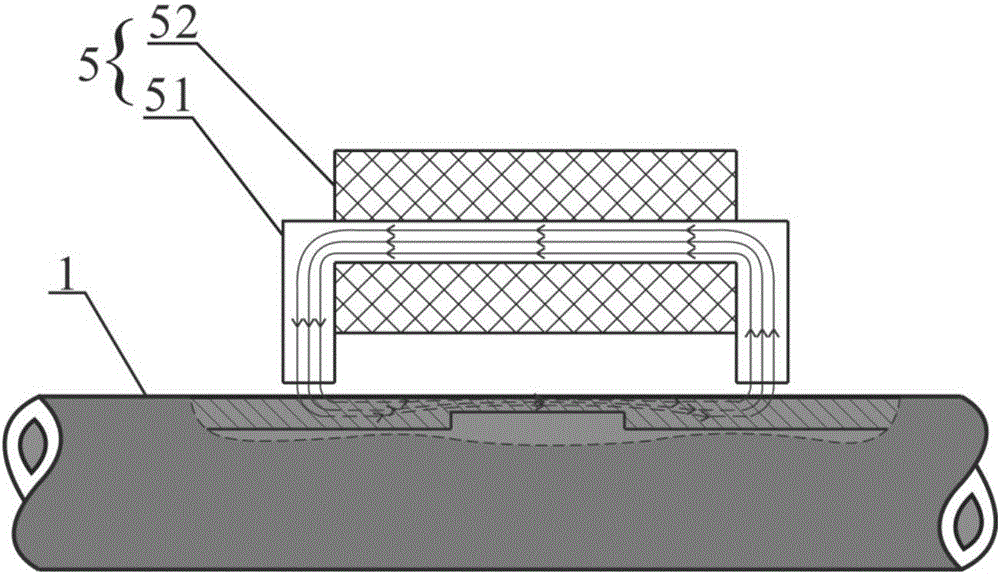

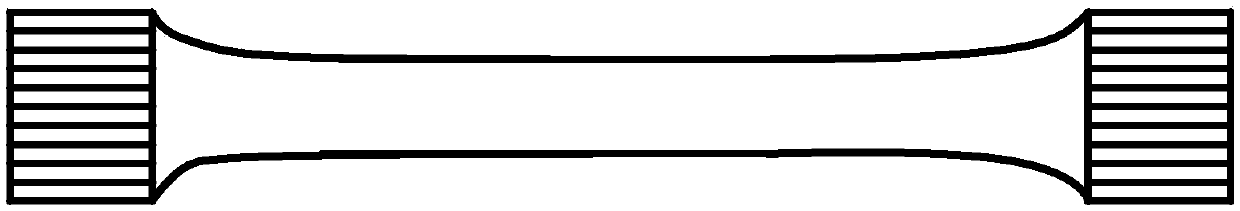

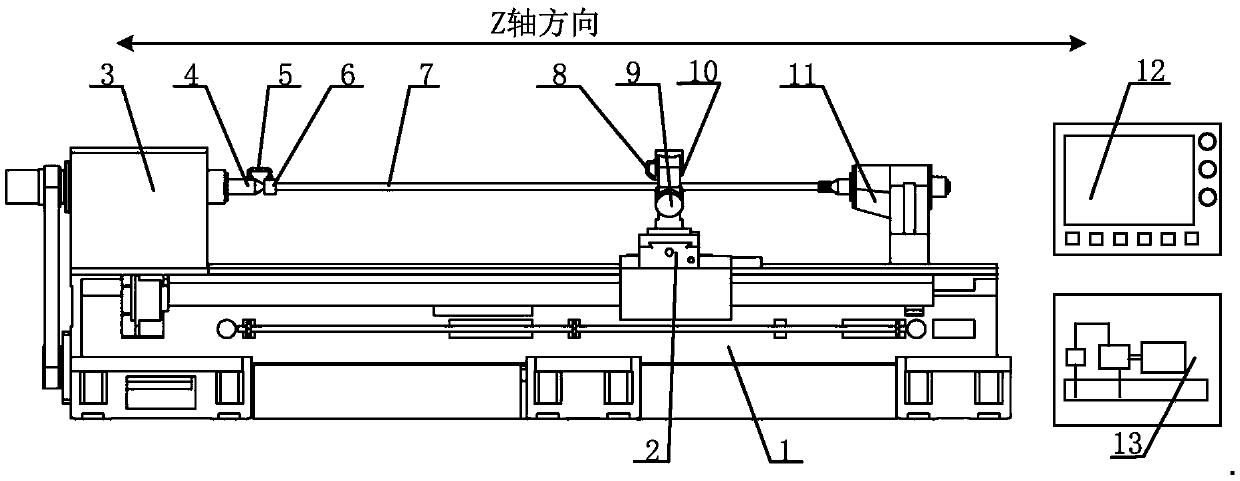

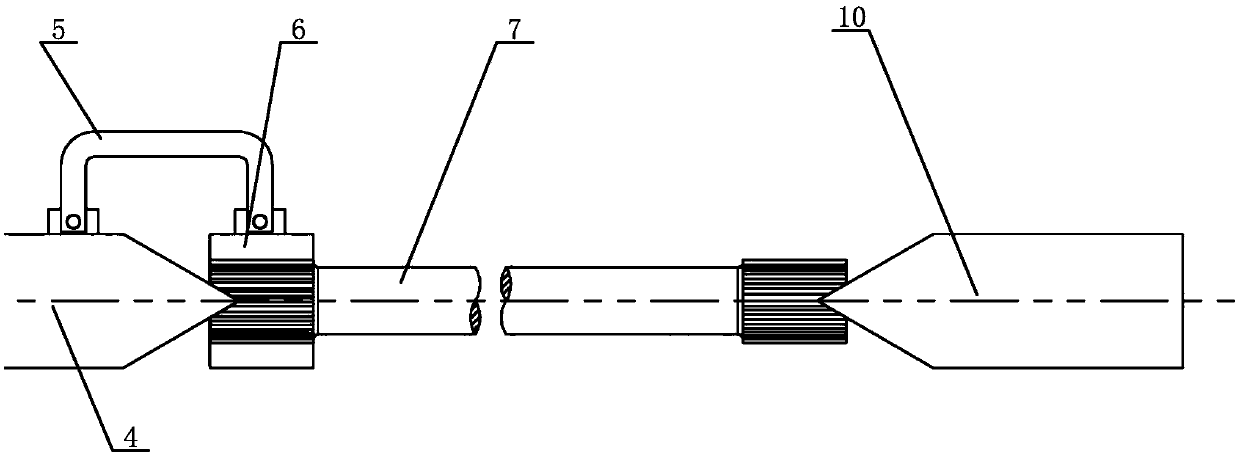

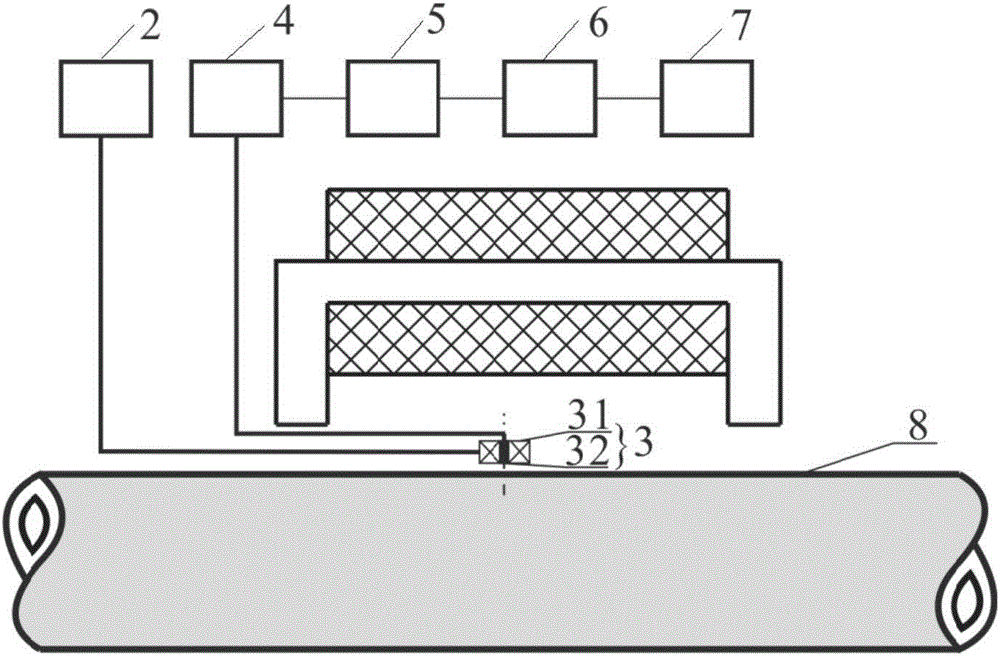

Numerical control rolling machine tool for outer circle rolling of torsion shaft

ActiveCN108673051AFastenedHigh speedWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention provides a numerical control rolling machine tool for outer circle rolling machining of a torsion shaft. The numerical control rolling machine tool comprises a machine tool body, an outer circle rolling head, a dual centre locating device, a shifting fork connecting part, an internal spline clamp sleeve, a full closed protection cover, a displacement measurement system, a precise oilmist cooling system, a numerical control system and a hydraulic system. The outer circle rolling head of the machine tool adopts a multi-rolling-wheel symmetric rolling device structure, and when outer circle rolling machining of the torsion shaft is carried out, a workpiece bears multiple equal pressures in the radiation direction; a displacement sensor is mounted in a hydraulic cylinder of theouter circle rolling head, the change value of the rolling diameter in the outer circle rolling process is worked out through the rolling cylinder displacement value fed back by the displacement sensor, and intelligent judgment on the limiting position of the outer circle rolling arc end can be achieved; and the shifting fork connecting part replaces a traditional chuck, a transmission structure is optimized, meanwhile, worker operation is more convenient, the machine tool is more suitable for streamlined production operation, and the rolling machining efficiency is higher.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing discharge plasma of metal laminated composite material

The invention provides a method preparing discharge plasma of a metal laminated composite material and belongs to the technical field of the preparation of metal laminated composite materials. In the method, two or more types of bulk metals, of which the surfaces are simply treated, are used as raw materials to be combined, under conditions of vacuum or inert atmosphere and reasonably matched discharge plasma preparation process parameters and under an action of inverted high-speed flow of discharge shock waves generated by impulsive discharge, electrons and ions in electric fields, the surfaces to be combined of the bulk metals are punctured to a certain degree to make the surfaces to be combined quickly purified and activated and the metallurgical combination performed between the interfaces to be combined of the laminated bulk metals to make the bulk metals quickly combined and formed at a smaller pressure and at the low temperature, so that the metal laminated composite material with flat and straight interface, high combined strength and accurately controlled shape and size of products can be directly obtained. The method has the advantages of low requirement on the surface cleanliness of the metals to be combined, energy conservation and environmental protection, easy operation, strong repeatability, short flow and cycle and low cost.

Owner:UNIV OF SCI & TECH BEIJING

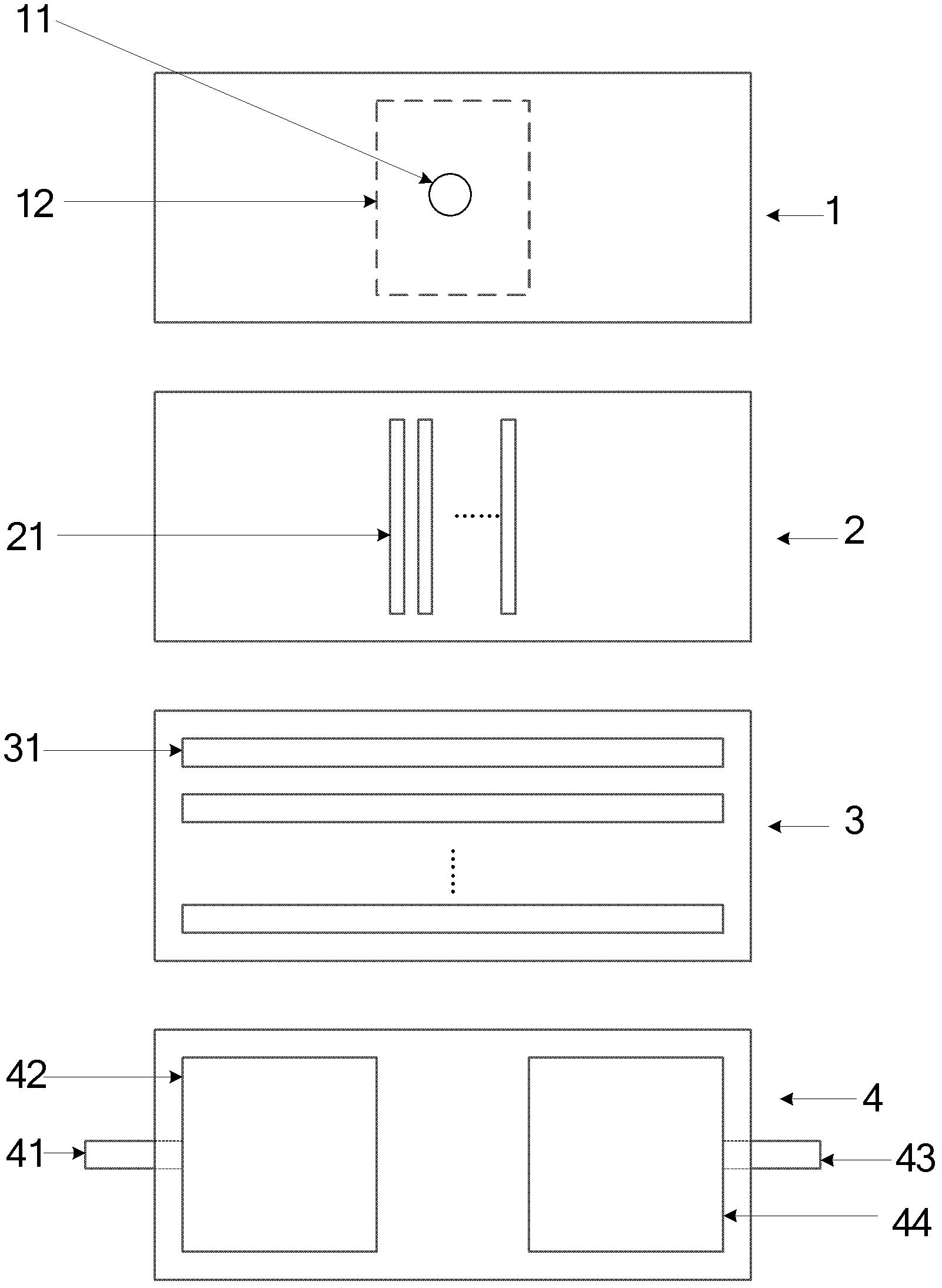

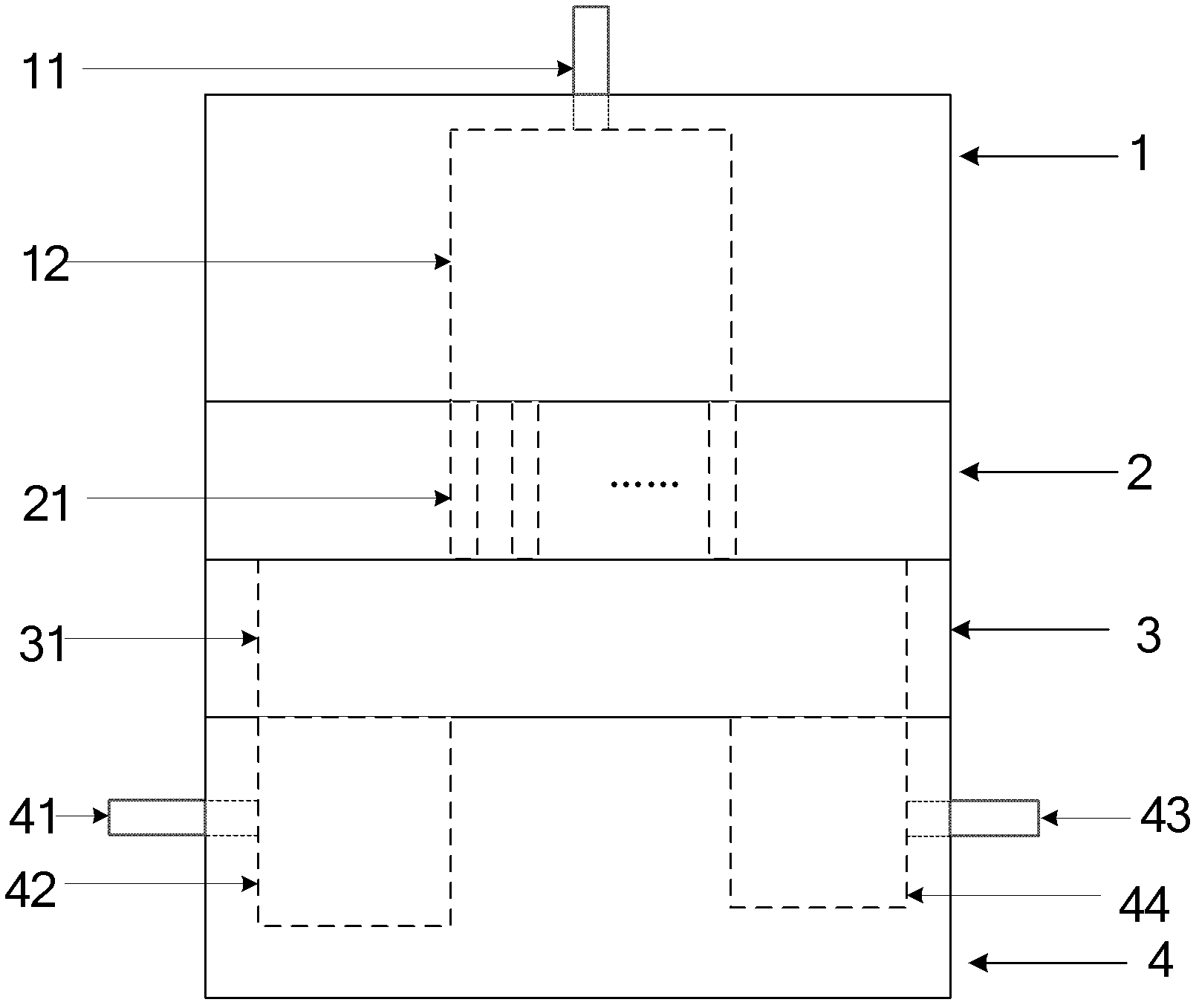

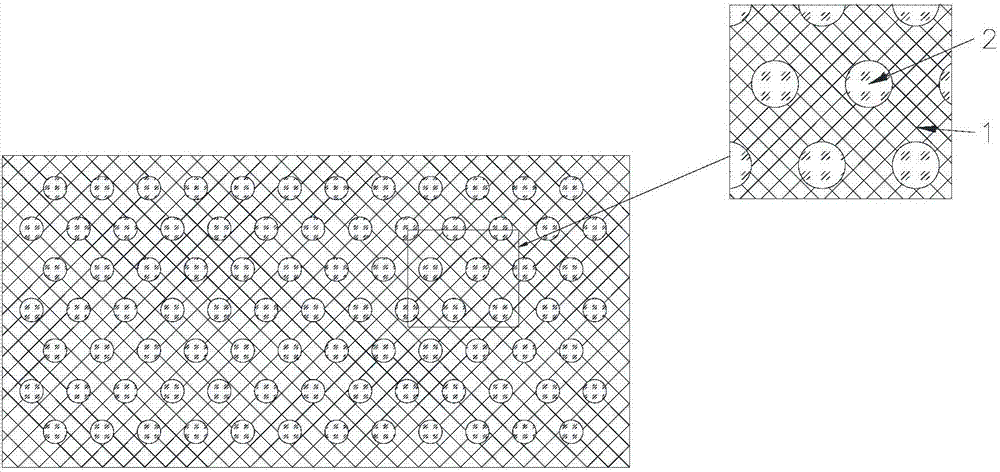

Quartz vibrating beam accelerometer sensitive chip based on gold-gold bonding

ActiveCN107478862ALow roughness requirementsLow cleanliness requirementsAcceleration measurementPhysicsQuartz

The invention relates to a quartz vibrating beam accelerometer sensitive chip based on gold-gold bonding and relates to the processing field of the quartz vibrating beam accelerometer sensitive chip. The sensitive chip comprises a sensitive unit layer, an upper protection unit layer and a lower protection unit layer, wherein the upper protection unit layer is arranged at an upper surface of the sensitive unit layer, the lower protection unit layer is arranged at the upper surface of the sensitive unit layer, the upper surface of the sensitive unit layer is equipped with a first sealing ring, a lower surface of the sensitive unit layer is fixedly equipped with a second sealing ring, a lower surface of the upper protection unit layer is fixedly equipped with a third sealing ring, an upper surface of the lower protection unit layer is fixedly equipped with a fourth sealing ring, one side of the upper protection unit layer is symmetrically provided with two square holes, and the upper surface of the lower protection unit layer is symmetrically provided with two bosses at the corresponding position. The sensitive chip is advantaged in that a problem of compatibility difficulty caused by airtight packaging and internal electrodes is effectively solved, excellent portability is realized, and the sensitive chip can be applied to the preparation process of MEMS devices taking quartz, silicon and glass materials as base materials.

Owner:BEIJING RES INST OF TELEMETRY +1

Method and device for measuring steel tube residual wall thickness magnetization pulse eddy current

InactiveCN106289042ASimple structureLow cleanliness requirementsUsing electrical meansElectrical/magnetic thickness measurementsSurface layerMagnetization

The invention relates to a method and device for measuring steel tube residual wall thickness magnetization pulse eddy current. After a steel tube is magnetized in the state that total magnetic flux is not changed, magnetic induction intensity in the steel tube is greater than magnetic induction intensity corresponding to a maximum permeability point; change of the magnetic induction intensity in a tube body at the position is produced due to change of a local steel tube wall thickness, then permeability of the tube body of the part is changed, the change expresses on the surface layer of the steel tube, and change of measurement waveforms is caused; and arrayed pulse eddy current measuring probes which are perpendicular to the axial lead of the steel tube are uniformly arranged in the peripheral direction at an angle of 360 degrees, and exciting coils of the pulse eddy current measuring probes and the center line of a receiving magnetic sensitive element face the surface of the steel tube in the normal direction. Therefore, when the local wall thickness of the steel tube is changed, the amplitude of outputted pulse eddy current detection signals is changed, the amplitude of the signals is corrected after ovality is measured, and non-contact measurement is realized.

Owner:WUHAN HUAYUYIMU TESTING EQUIP CO LTD

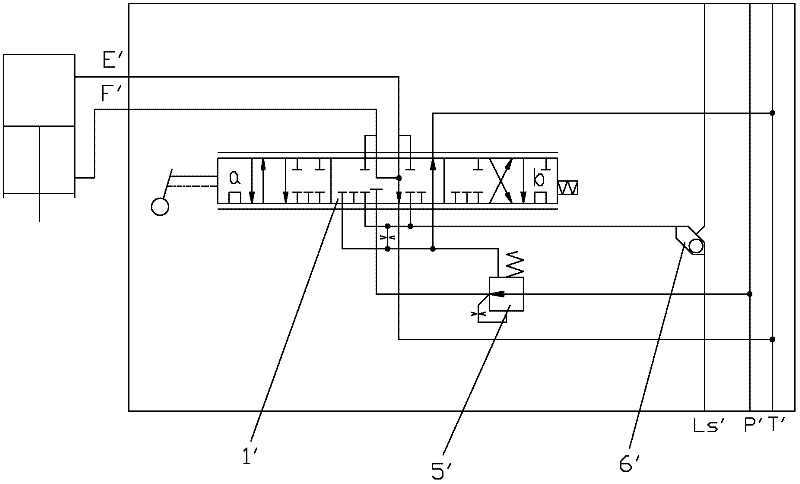

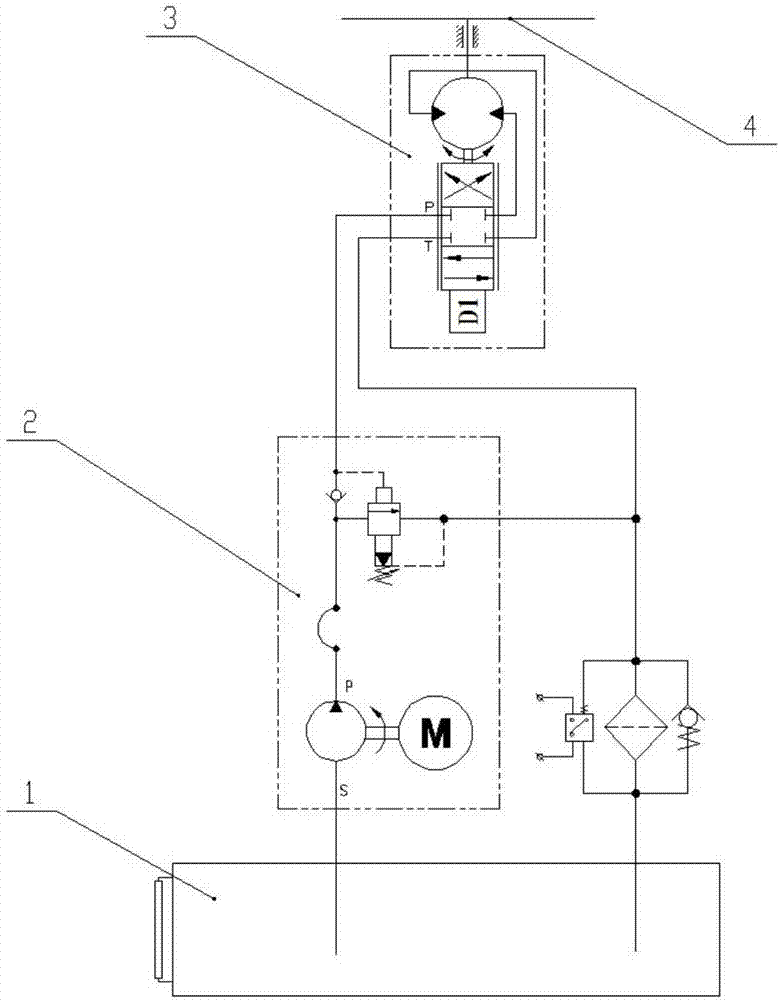

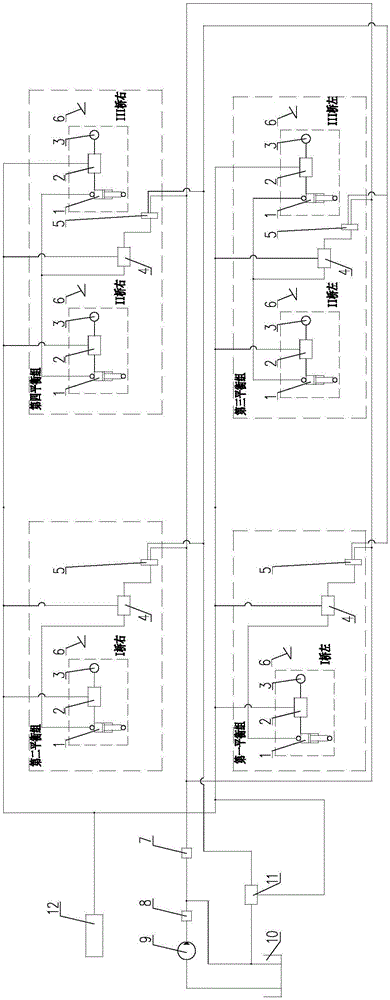

Heliostat azimuth angle digital hydraulic control system

ActiveCN107247467ALow cleanliness requirementsReduce the difficulty of debuggingControl using feedbackSolar thermal energy generationHydraulic motorHeliostat

The invention provides a heliostat azimuth angle digital hydraulic control system. The system comprises a hydraulic auxiliary element, a hydraulic power element, a digital hydraulic motor and a heliostat azimuth angle moving mechanism. Normal work of the digital hydraulic motor is guaranteed through the hydraulic auxiliary element. The hydraulic power element provides a high-pressure oil source for the digital hydraulic motor. The digital hydraulic motor is used for controlling movement of the heliostat azimuth angle moving mechanism. According to the system, the digital hydraulic motor is used for controlling the heliostat azimuth angle moving mechanism, the azimuth angle of a heliostat completely achieves vectorization and digitization, the debugging difficulty is reduced, the debugging period is shortened, the requirement on the cleanliness of hydraulic oil is reduced, system parameters do not need to be adjusted when the system is used for a long time, and high positioning precision is achieved.

Owner:AEMETEC +1

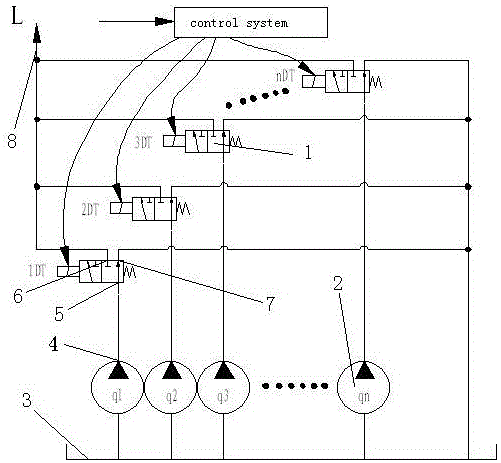

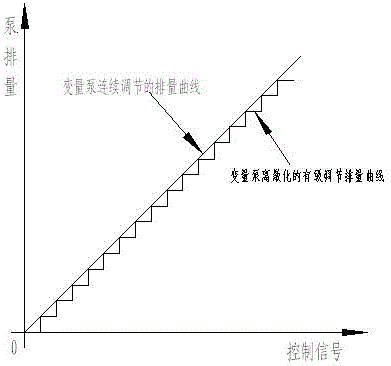

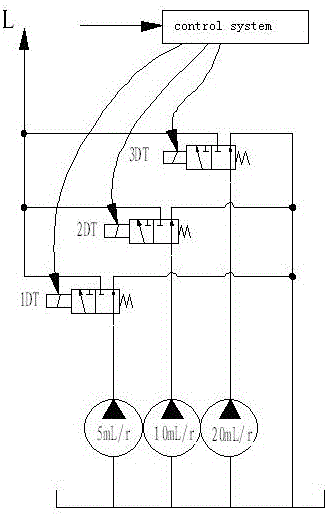

Multi-gear pump with step variable system

InactiveCN102141040BDisplacement has step changeSimple structureRotary/oscillating piston combinationsMachines/enginesMicrocontrollerGear pump

The utility model relates to a multi-gear pump with step variable system, which belongs to the field of pumps. The purpose of the present invention is to utilize the combination of a plurality of gear pumps with different displacements to realize a multi-gear pump variable system with step adjustment of displacement. The invention includes at least three gear pumps with different displacements and at least three electromagnetic reversing valves, each gear pump has a separate oil discharge port, and the oil discharge port of each gear pump is connected to the oil inlet of the electromagnetic reversing valve. The other two oil ports of the electromagnetic reversing valve communicate with the oil tank and the total oil discharge port respectively. The invention can control the on-off of the electromagnetic reversing valve through a single-chip microcomputer, PLC or computer, and then control whether each gear pump supplies oil to the system, so as to realize the flow control of the system with a small displacement gradient.

Owner:JILIN UNIV

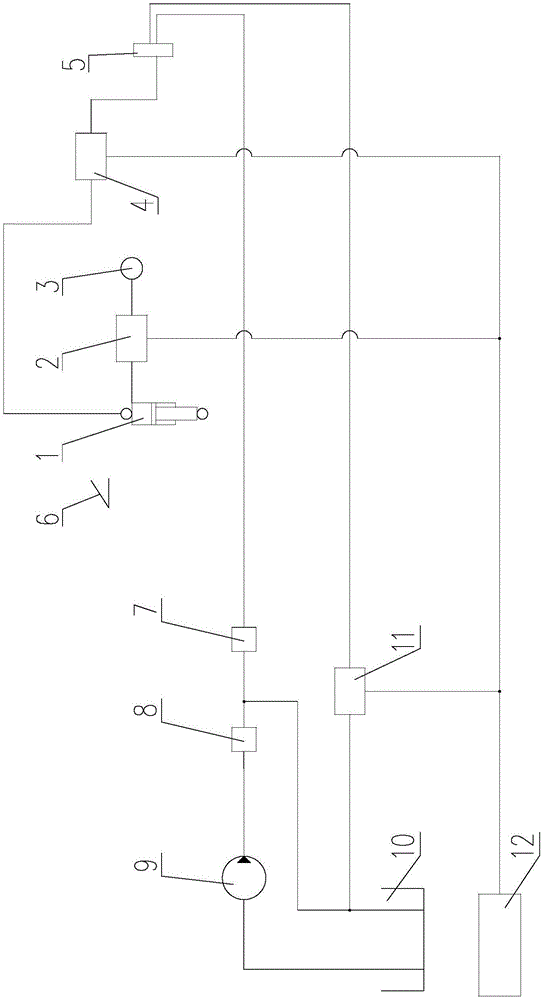

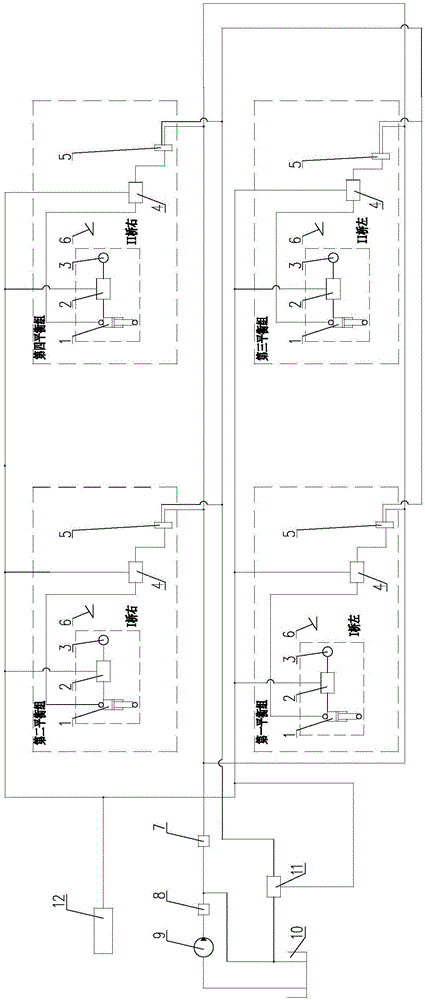

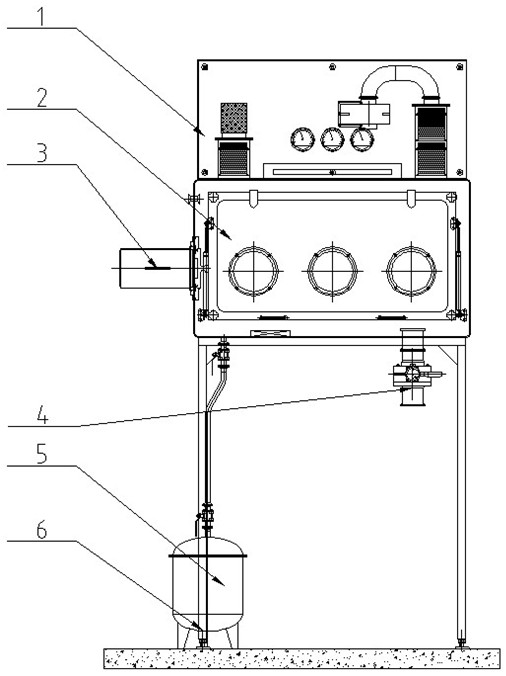

Lifting hydro-pneumatic suspension hydraulic system

ActiveCN106567904AMeet the automation level requirementsImprove reliabilityVibration dampersServomotor componentsHydropneumatic suspensionFuel tank

The invention discloses a lifting hydro-pneumatic suspension hydraulic system and relates to a hydraulic system applied to an automobile hydro-pneumatic suspension. According to the lifting hydro-pneumatic suspension hydraulic system, the automation level requirements of the lifting hydro-pneumatic suspension hydraulic system are met, and meanwhile the reliability is improved. The lifting hydro-pneumatic suspension hydraulic system comprises an oil tank (10), an oil supply pump (9), a safety valve (8), a one-way valve (7), an electromagnetic reversing valve (5), a grouping oil returning stopping valve (4), a rigidity stopping valve (2), an oil gas spring (1), an energy accumulator (3), a gas storage cylinder (12), an angle transducer (6), a pneumatic pipeline and a hydraulic pipeline. The oil conveying end of the electromagnetic reversing valve is connected with one oil end of the grouping oil returning stopping valve, and the other oil end of the grouping oil returning stopping valve is connected with the hydraulic oil opening of the oil gas spring. The rigidity stopping valve is arranged between the oil gas spring and the energy accumulator communicating with the oil gas spring. The grouping oil returning stopping valve and the rigidity stopping valve both are pneumatic ball valves.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

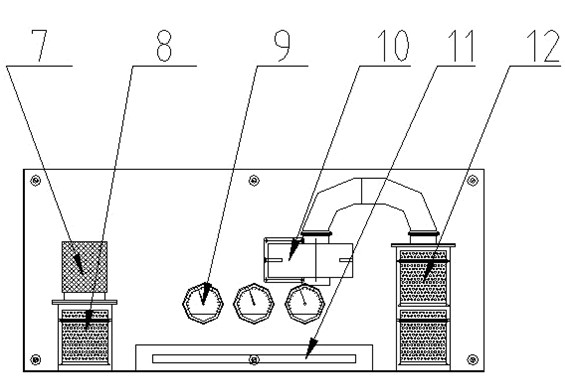

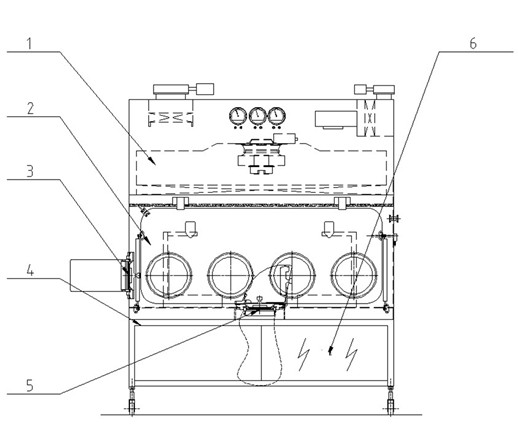

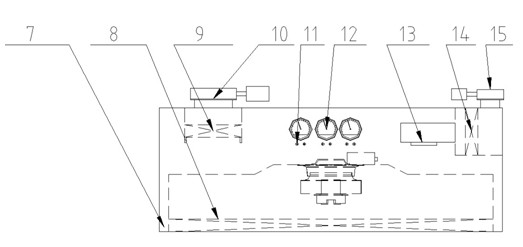

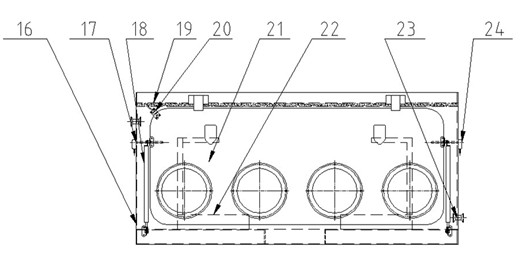

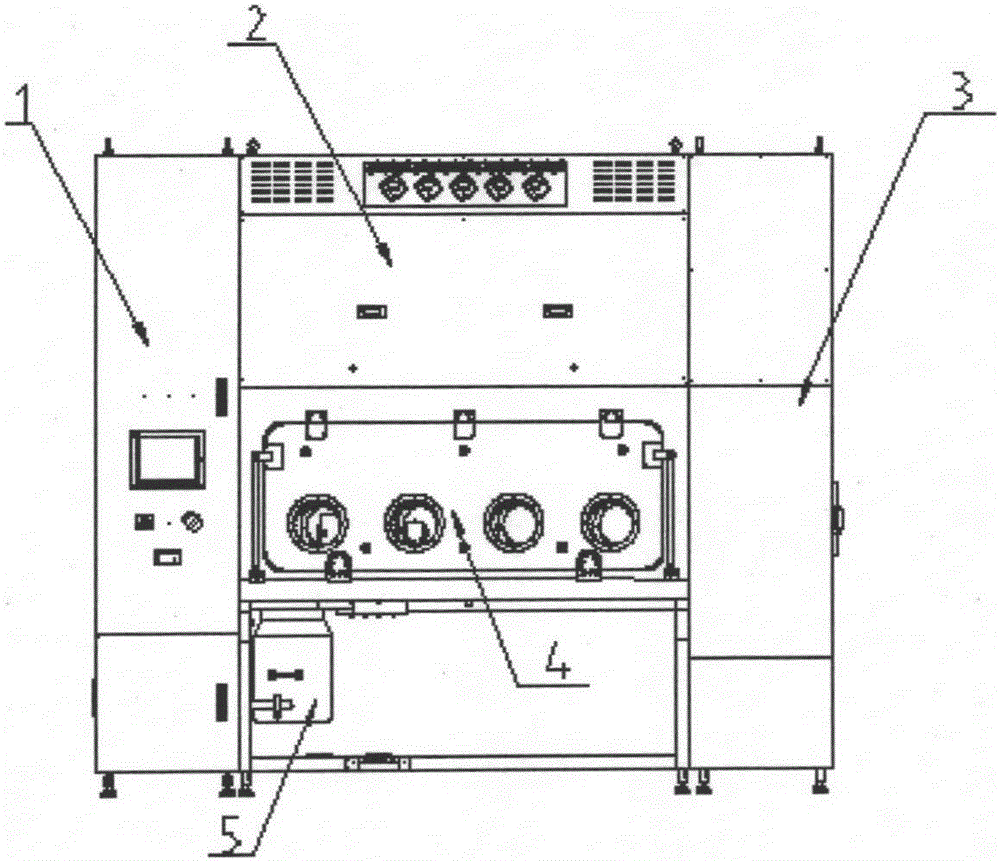

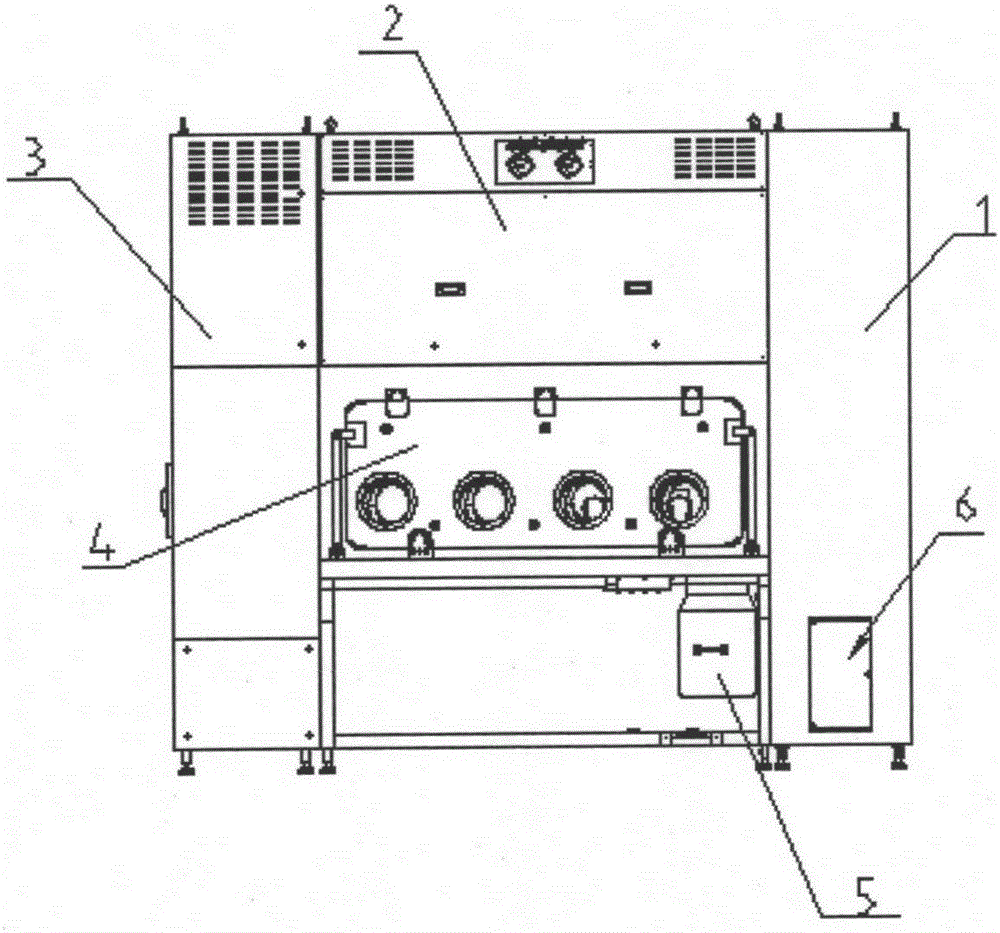

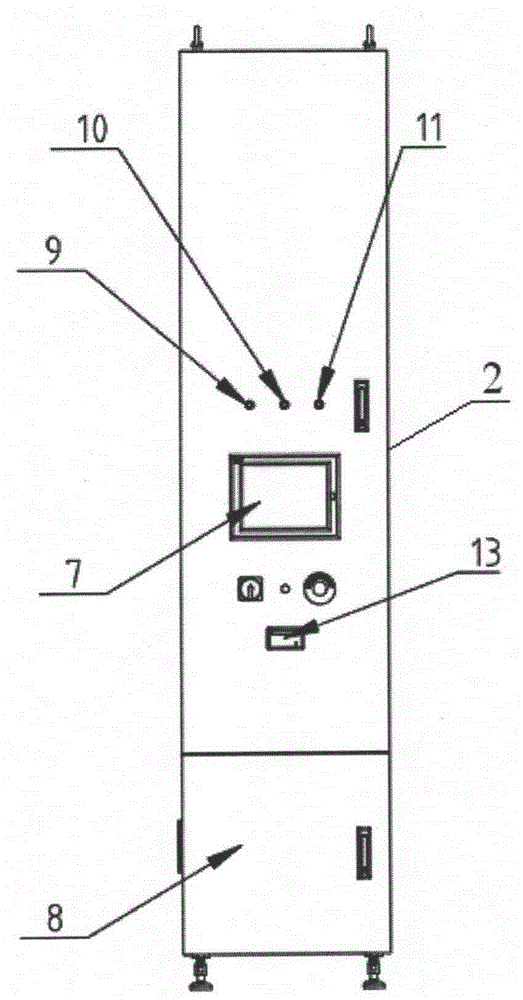

Isolator for sterile weighing and burdening process

The invention provides an isolator for a sterile weighing and burdening process. The isolator is characterized by comprising a glove operation box assembly, wherein the glove operation box assembly is provided with a sterile delivery interface; an air treating system is arranged on the top of the glove operation box assembly; the bottom of the glove operation box assembly is connected with a sterile butt joint valve assembly; and the glove operation box assembly is connected with a drainage system. The invention has the advantages that: the internal production environment is fully isolated from operators and the external environment, the risk of artificial contamination is lowered, the pollution of products on the operators and the external environment is lowered simultaneously, the cleanproduction region is reduced, the controllability of a production region is enhanced greatly, and the running cost and the maintenance cost are reduced.

Owner:上海东富龙爱瑞思科技有限公司 +1

Isolator for sterility detection process

The invention relates to an isolator for a sterility detection process, which is characterized by comprising an air processing system positioned at a top part, wherein a glove operating box assembly is positioned under the air processing system, a sterility deliver bin is arranged on an isolation wall of the glove operating box assembly so as to realize sterile material transfer, the glove operating box assembly can be fixed and supported by a movable bottom frame assembly, and a bag output device which is used for collecting waste gas produced during the sterility detection process is arranged at the bottom of the glove operating box assembly. The invention has the advantages that the inside growth environment is completely isolated from the outside environment, so that risk of artificial pollution is reduced, and simultaneously, the pollution of a product to operators and the outside environment is reduced; and the production clean area is reduced, the operability of the production area is greatly increased, and further, the running cost and the maintenance cost are reduced.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

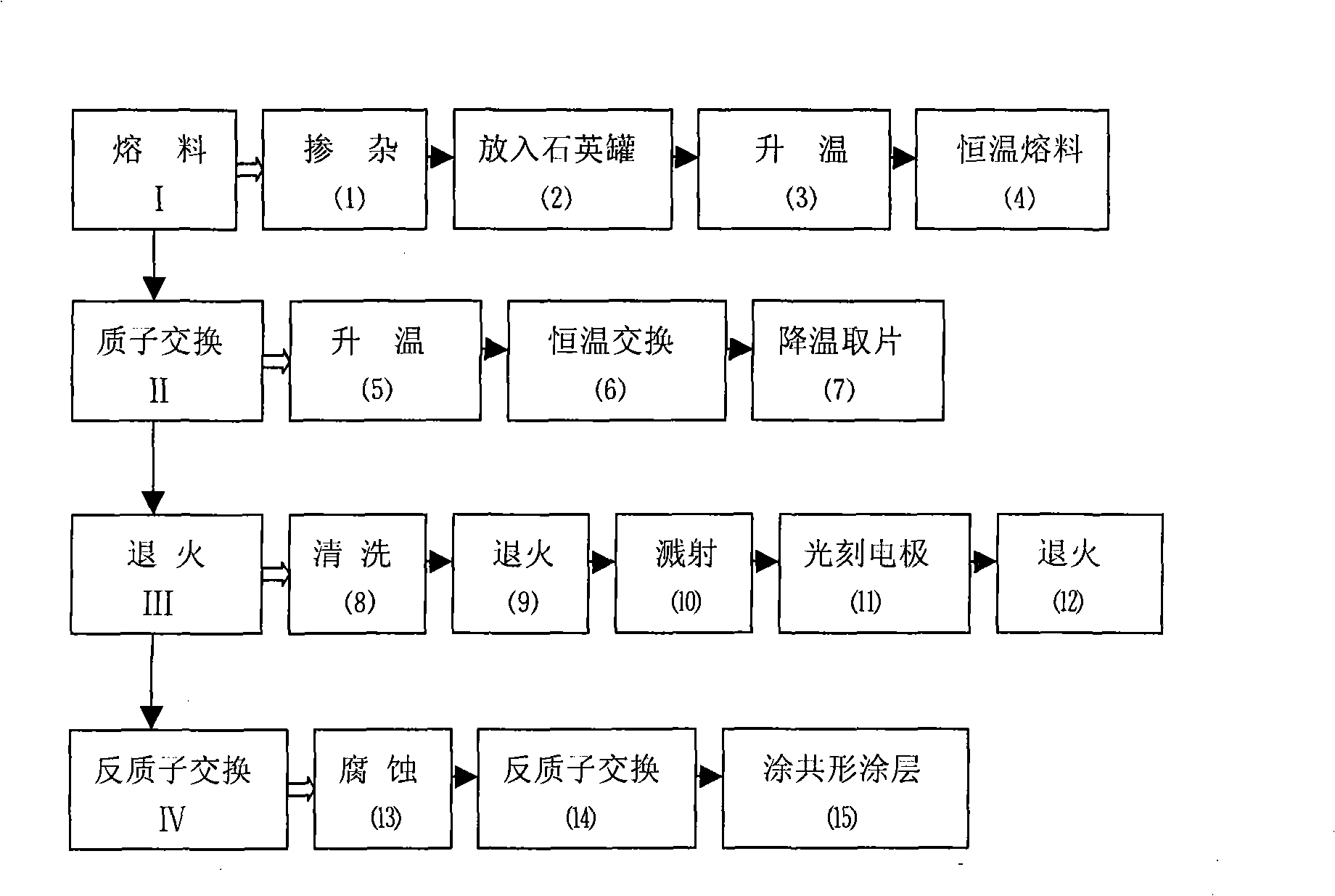

Method for manufacturing high temperature uron commutative LiNbO3 optical waveguide

ActiveCN101256253AImprove stabilityGuaranteed physical propertiesOptical waveguide light guideFiberGyroscope

The invention relates to an integrated optics waveguide producing domain, especially a LiNbO3 optical waveguide producing method of high temperature proton exchange. The waveguide with no phase change is produced on the lithium niobate substrate and the waveguide is mainly used for multiple-function chip of optic fiber gyroscope. The producing method comprises melting step, proton exchanging step, annealing step and antiproton exchanging step, wherein the proton exchanging step is performed at the temperature of 350 plus or minus 3 degree. In the method, the waveguide is composed of alpha phase of pure HxLi1-xNbO3. The said method has features of even and simple structure, good stability of waveguide, increased rate of finished products, induced impact of temperature contrast to substrate, prevention of pollution to the environment, reduced loss of device and reduced production cost.

Owner:上海傲世控制科技股份有限公司 +1

Two-way multifunctional electromagnetic valve

InactiveCN102588612AReduce volumeQuickly control on-offOperating means/releasing devices for valvesLift valveLiquid mediumEngineering

The invention belongs to a two-way multifunctional electromagnetic valve which comprises a valve body and an electromagnet part. The electromagnet part adopts a coil injection-molding assembly; and a TVS (transient voltage suppressor) pipe is arranged in the coil injection-molding assembly. The valve adopts a valve core structure that springs are embedded in a static magnetic core and a dynamic magnetic core and a structure that the static magnetic core is combined with a metal sleeve, has the structure characteristics that a rubber sealing layer at the front end of the dynamic magnetic core simultaneously separates a medium inlet and a medium outlet of the valve body and the medium inlet and the medium outlet are exchangeable, and is an electromagnetic valve which can simultaneously controlled by a direct current signal and a direct current pulse electric signal and further can be simultaneously applicable to a gas medium or a liquid medium, and the medium inlet and the medium outlet of the valve can be used in an exchangeable way.

Owner:WUHAN DONGJIANG FEITE SCI & TECH CO LTD

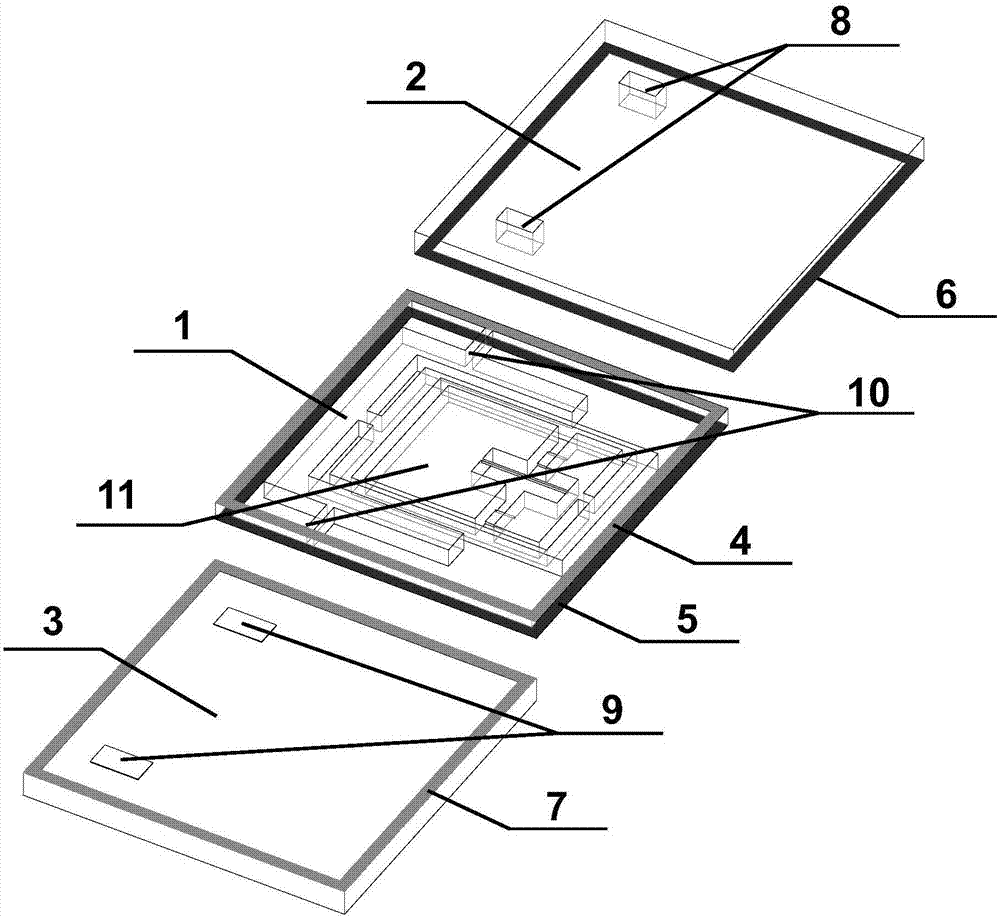

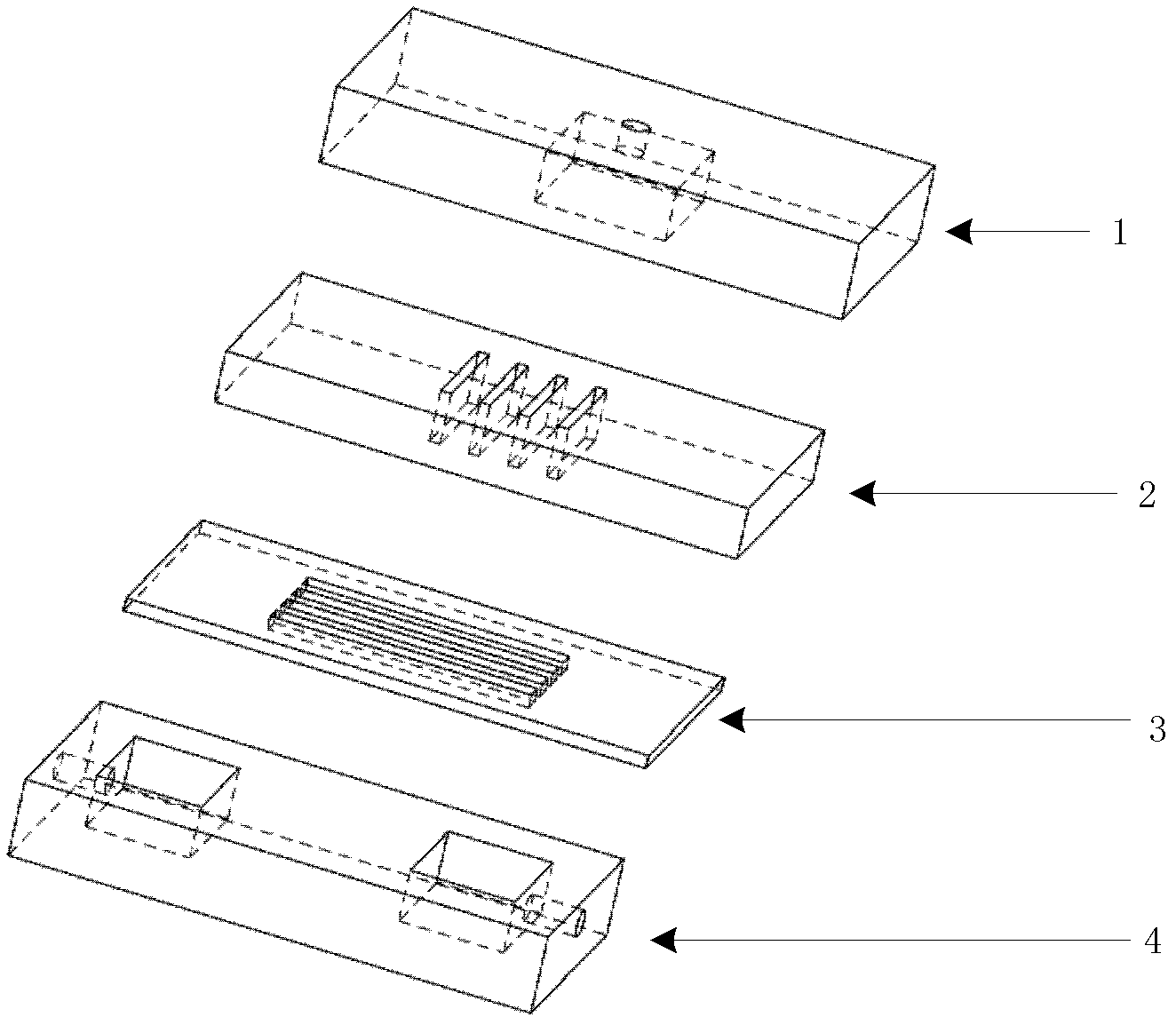

Micro-structured mixer

ActiveCN102847455AAvoid easy-to-block problemsGuaranteed mixing effectFlow mixersEngineeringPetrochemical

The invention discloses a micro-structured mixer, which belongs to the technical field of chemical and chemical engineering. The micro-structured mixer is formed by stacking a first interface board, a first fluid distributing plate, a fluid mixing plate and a second interface board in sequence, wherein the first interface board is provided thereon with a first fluid inlet pipe and a first fluid buffer chamber, the first fluid distributing plate is provided thereon with at least one through slot, the fluid mixing plate is provided thereon with at least one through slot, the second interface board is provided thereon with a second fluid inlet pipe, a second fluid buffer chamber, a mixed fluid buffer chamber and a mixed fluid outlet pipe, when the number of the through slots arranged on the first fluid distributing plate is larger than one, the arranged through slots are parallel through slots, when the number of the through slots arranged on the fluid mixing plate is larger than one, the arranged through slots are parallel through slots. The treatment capacity of unit volume of the micro-structured mixer is larger, the micro-structured mixer is easy to store and enlarge, has low requirement for material cleanliness, and can be used in chemical, chemical engineering, petrochemical, medicine and food industries.

Owner:TSINGHUA UNIV

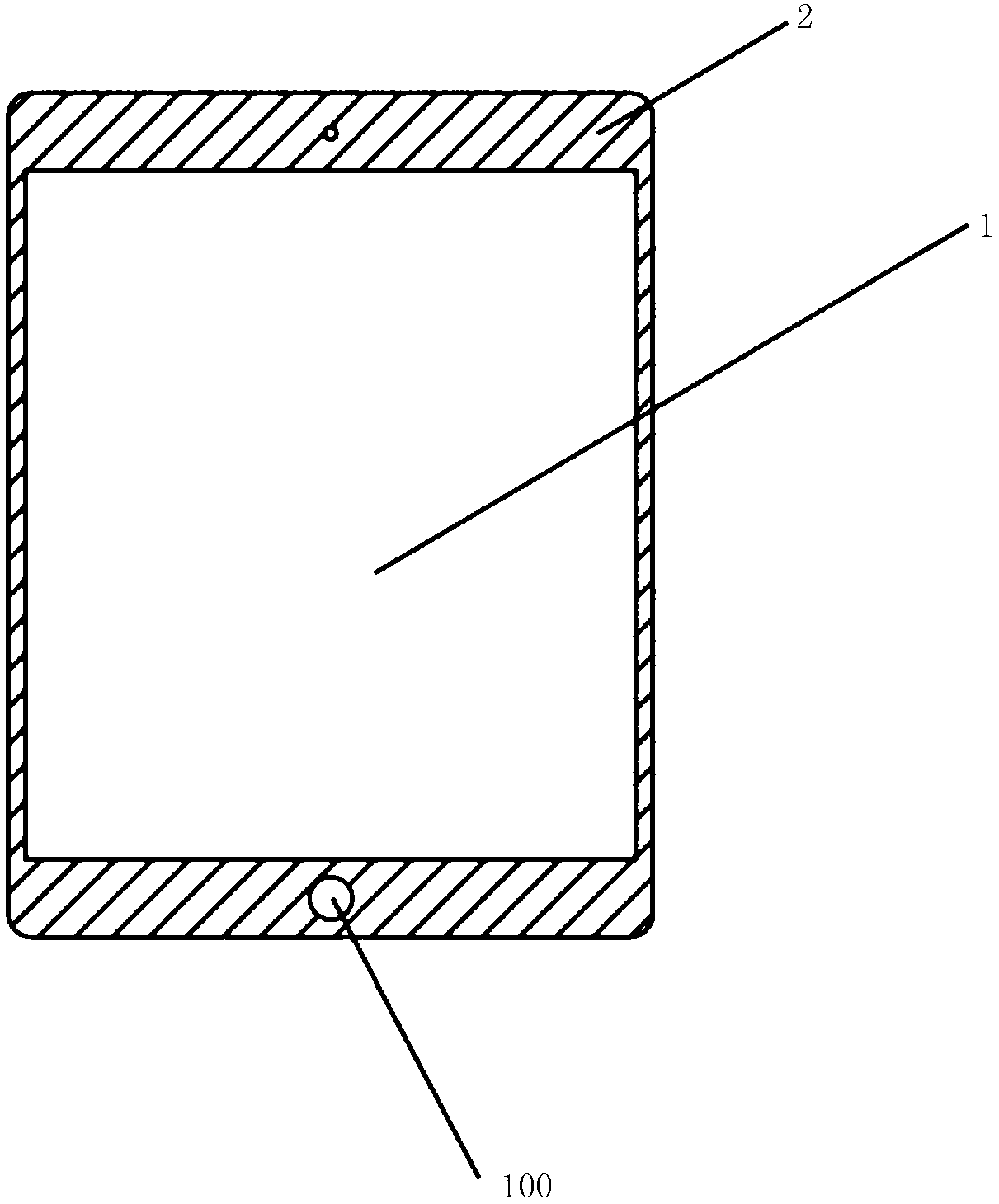

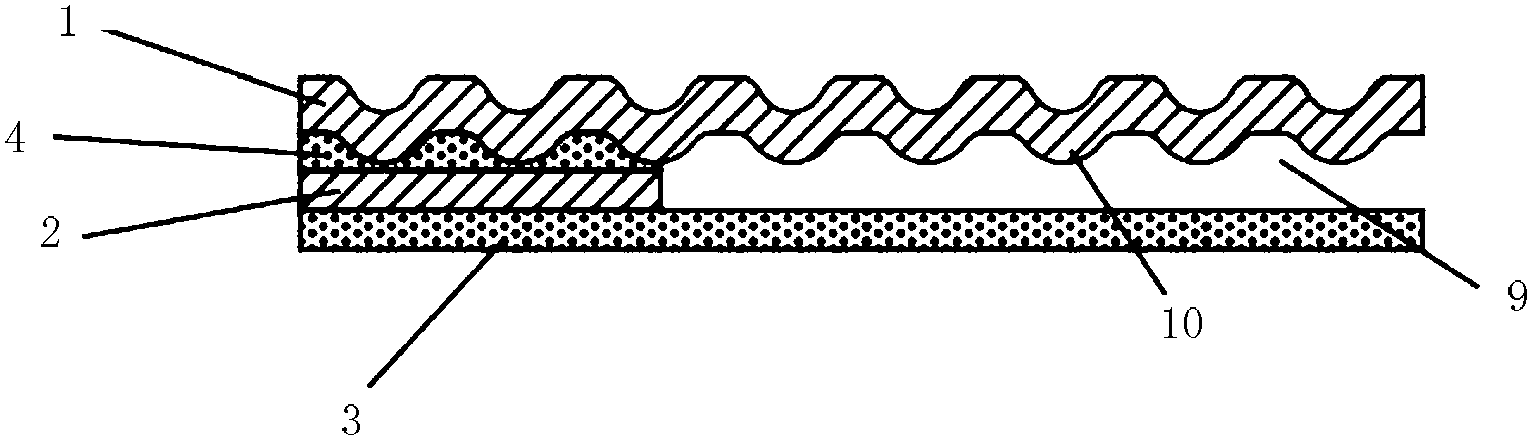

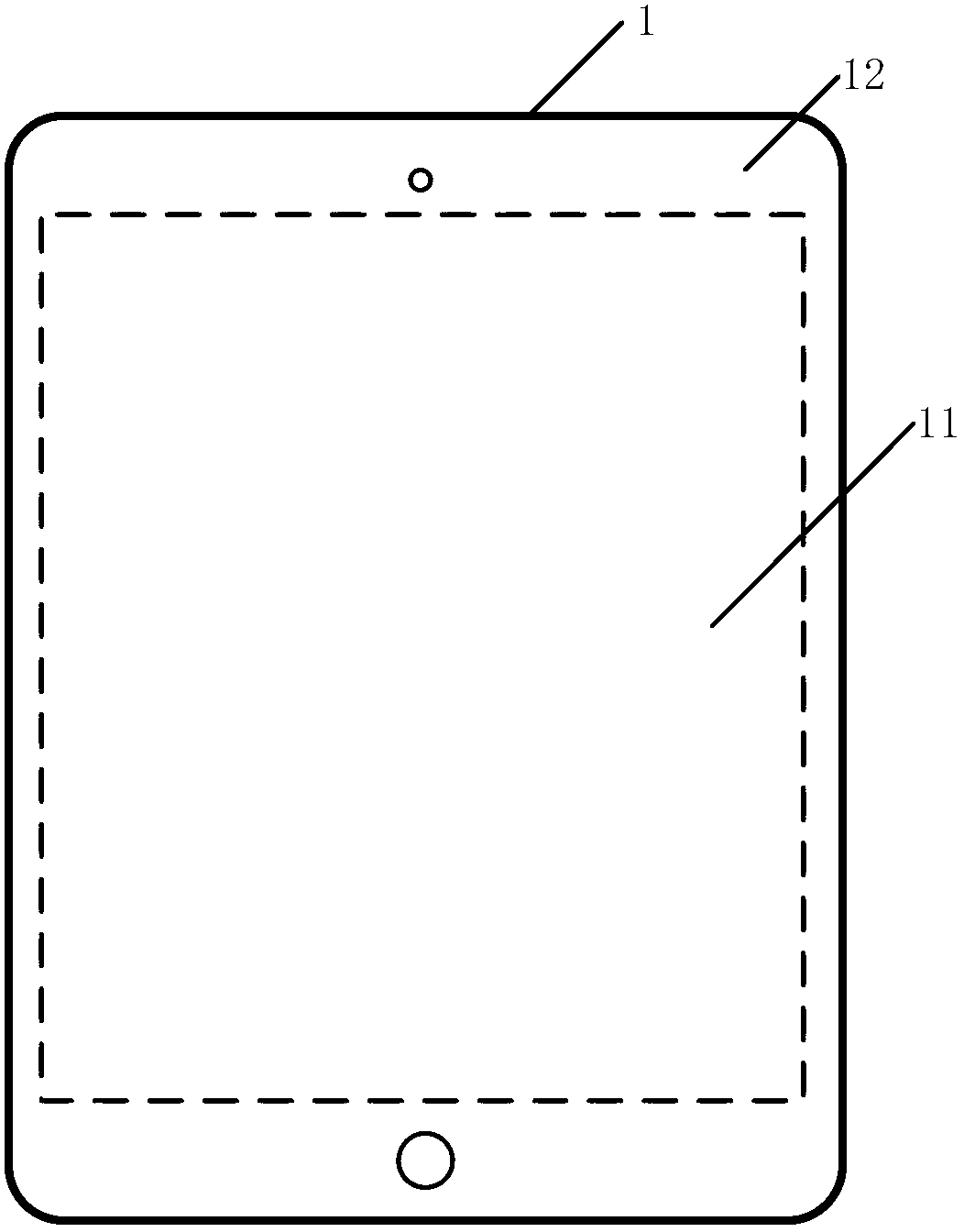

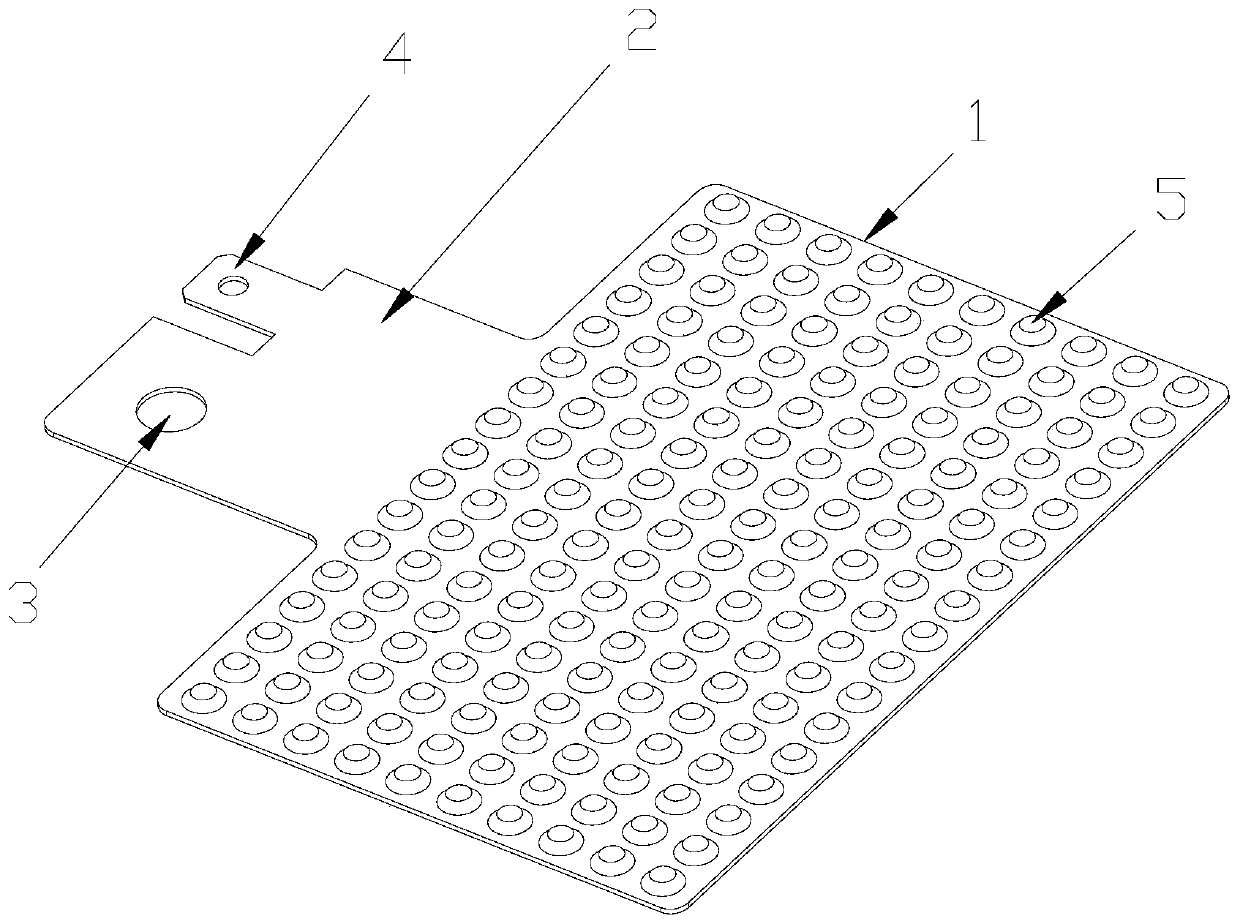

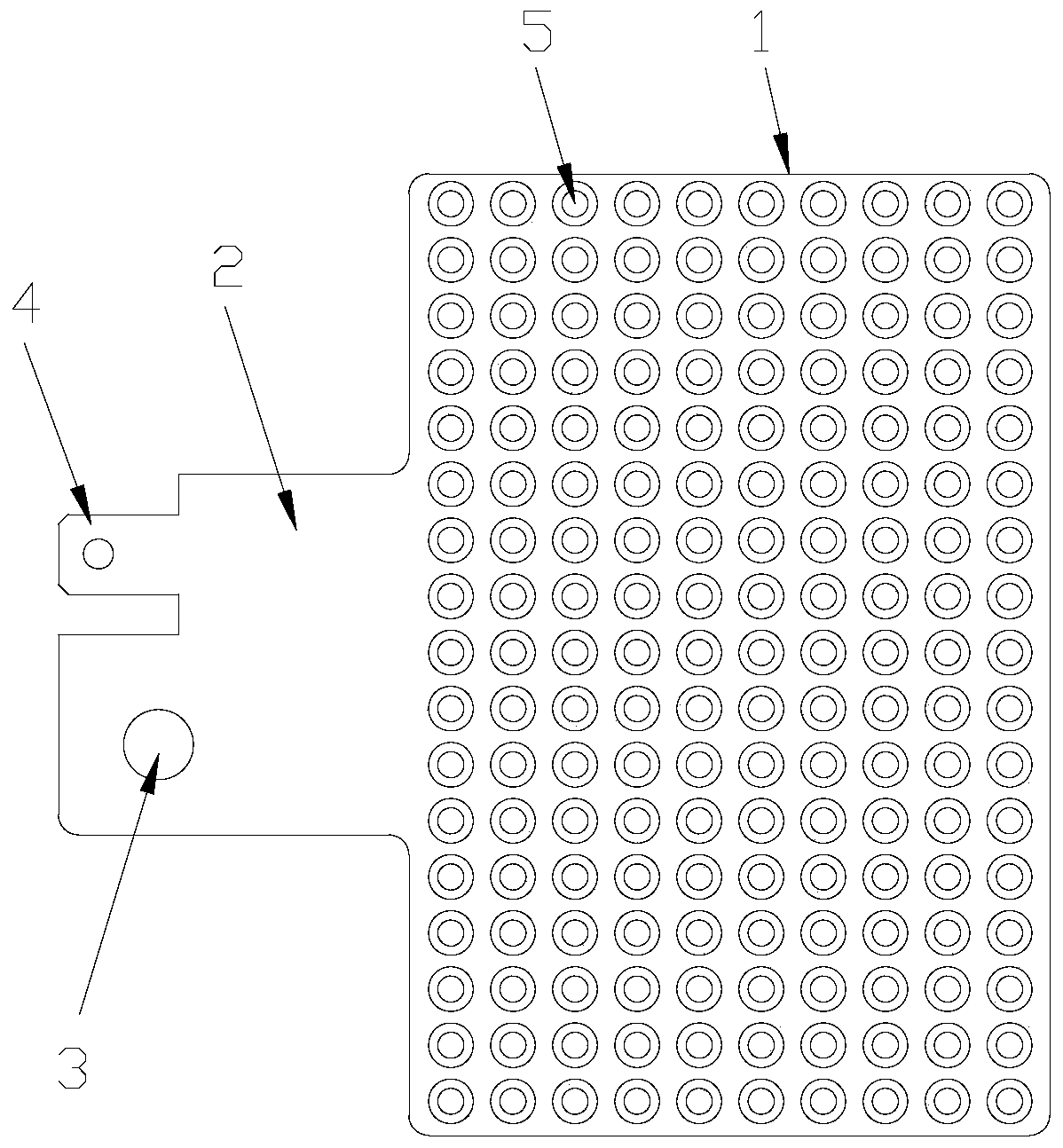

Screen protection paste

ActiveCN103024104AEliminate static electricityAvoid pollutionFlexible coversWrappersTectorial membraneDie casting

The invention provides a screen protection paste. The screen protection paste comprises a protection paste (1), a back-adhesive layer (2) and a backing paper (3), wherein a screen protection area (11) and a panel protection area (12) are formed on the back of the protection paste (1); the front surface of the back-adhesive layer (2) is clung to the back of the protection paste (1); the front surface of the backing paper (3) is connected to the back of the protection paste (1) by the back-adhesive layer (2); an expanding surface of the back-adhesive layer (2) is only limited to the panel protection area (12); a plurality of lug bosses (10) extend from the protection paste (1) to the back direction; and a clearance (9) is formed between the screen protection area (11) and the backing paper (3). According to the screen protecting paste, the static electricity can be removed by the lug bosses, thus the paste is easier to be coated; and the lug bosses are manufactured by means of die casting, the process is simple and stable, and the yield is high.

Owner:SHANGHAI BENPU TECH DEV

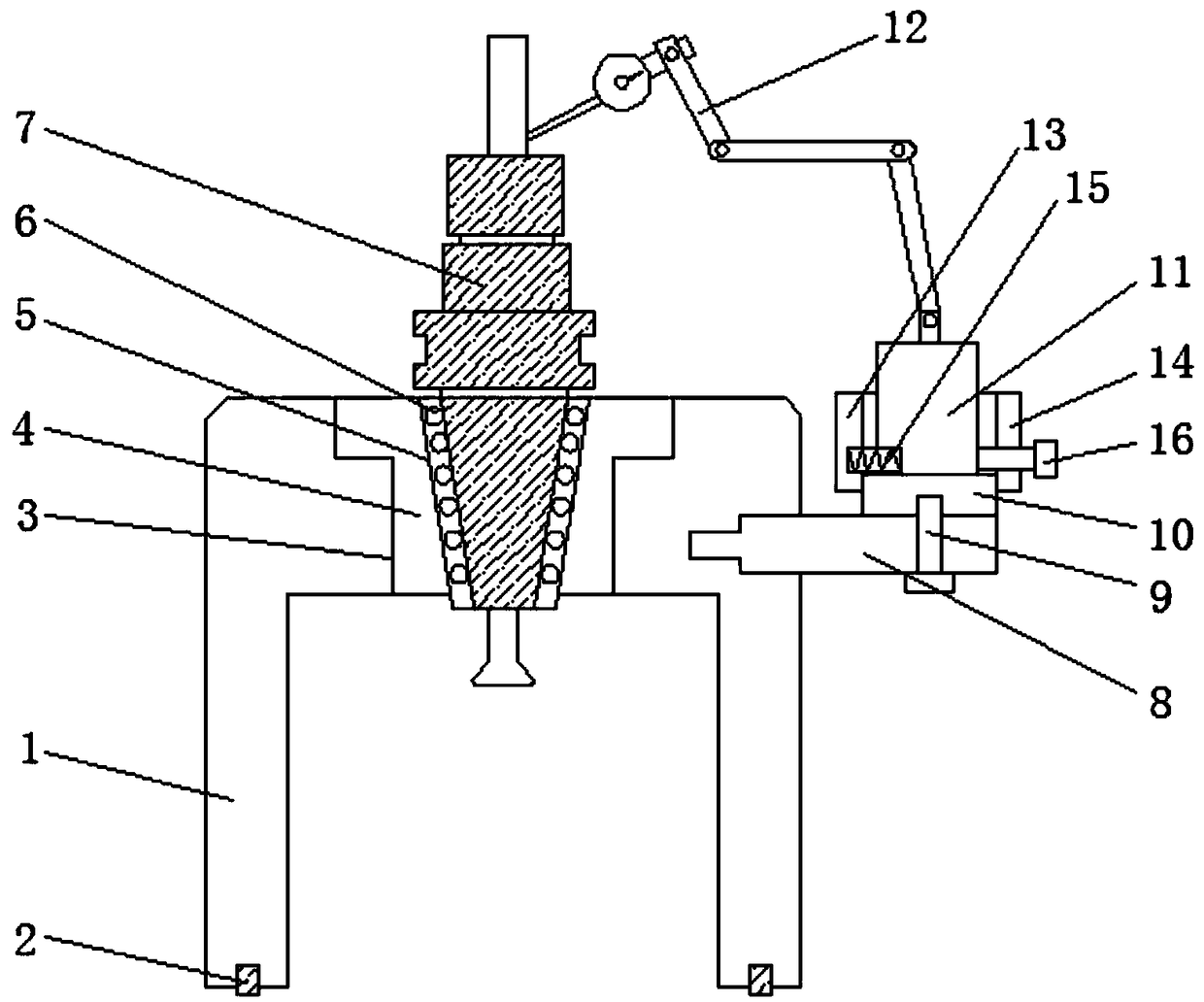

Device for detecting outer cutter swing of CNC cutter machine

PendingCN109084655ASimple structureSimple and fast operationMachine part testingMechanical measuring arrangementsSteel ballEngineering

The invention discloses a device for detecting outer cutter swings of a CNC cutter machine, which comprises a base. An annular sealing ring is embedded in the bottom of the base; a mounting groove isarranged through the center of the top of the base; a taper block is embedded in the mounting groove; the inner side of the taper block is sleeved with a bushing; steel balls are evenly distributed inthe inner side of the bushing; the inner side of the bushing is rotationally sleeved with a knife handle system; and a supporting block is embedded in one side of the top of the base. The device fordetecting outer cutter swings of a CNC cutter machine is simple in structure and convenient to manufacture. Multi-point contact is adopted to reduce a contact area between the knife handle and equipment, and reduce the requirement of a clean degree during use, which is convenient for quick use; a detachable steel ball bushing is adopted, the bushing is convenient for regular cleaning, and a worn bushing can be directly replaced, so that the interchangeability is strong; it is convenient to adjust the position of a scale when bouncing the cutter swing, and the position of the scale can be automatically reset; and the structure of the device is made of aluminum, the rubber sealing ring is anti-slip, the device is convenient to move, easy to carry, and has wide application prospects.

Owner:KUNSHAN XUZHENG PRECISION MACHINERY

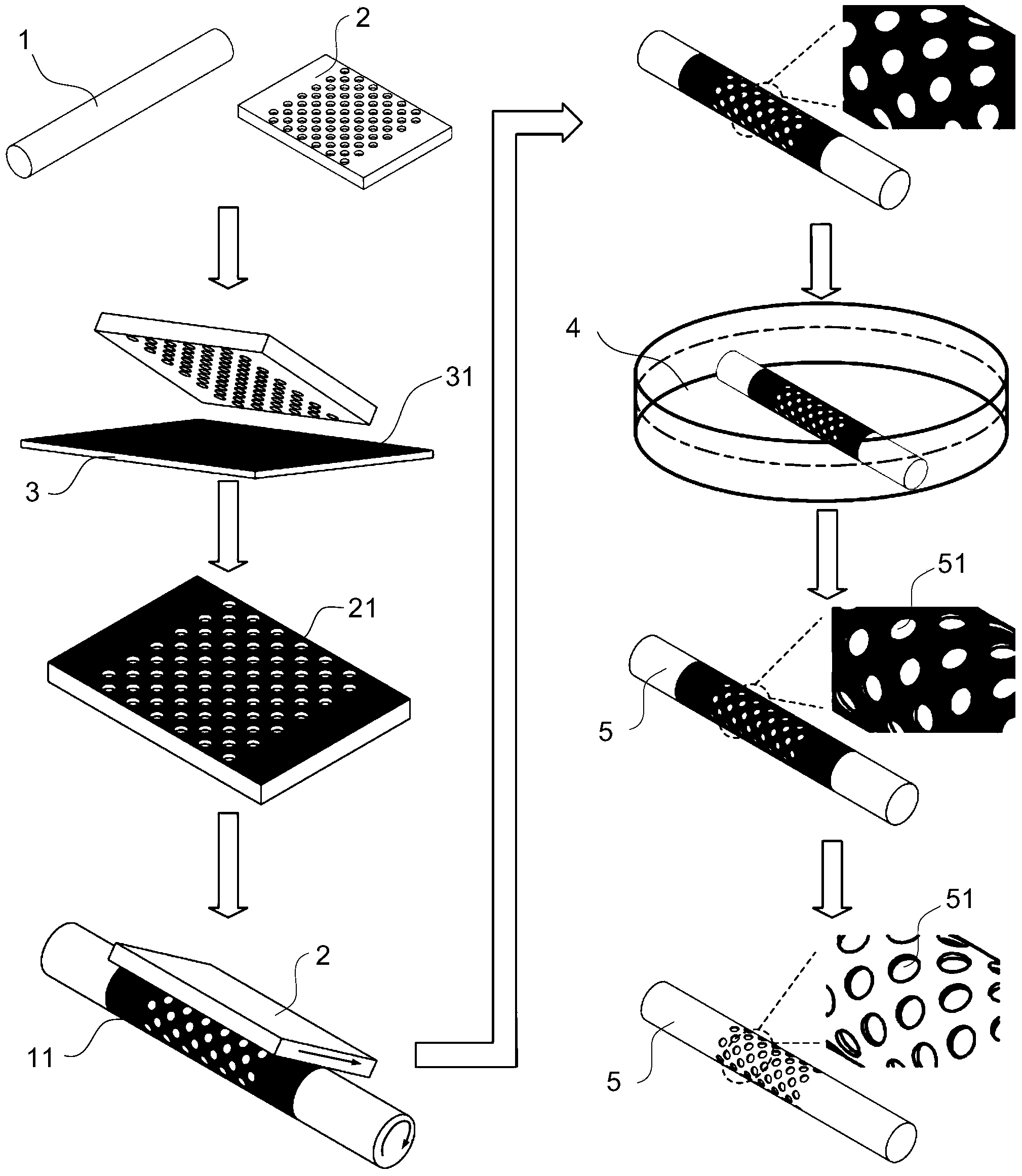

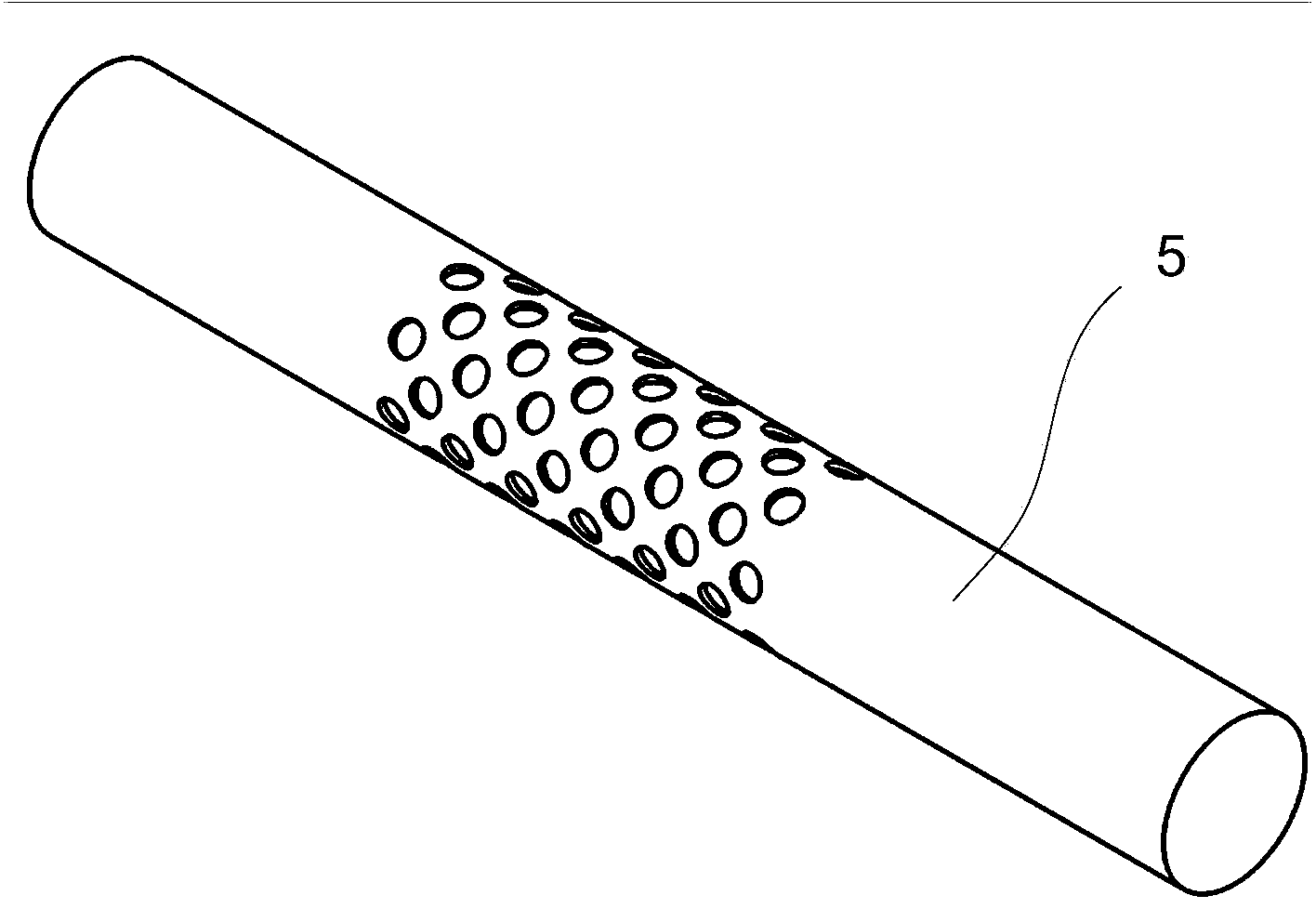

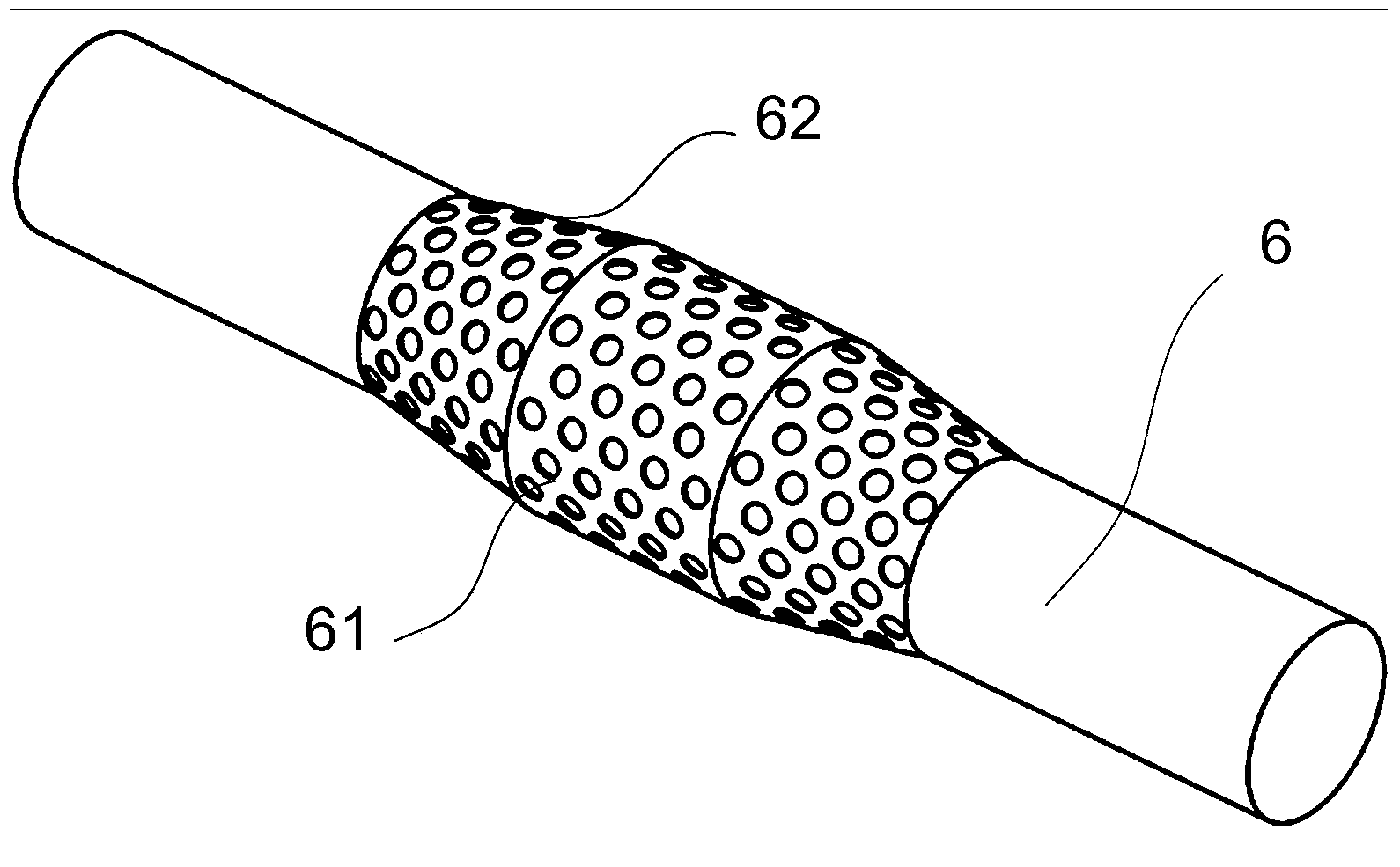

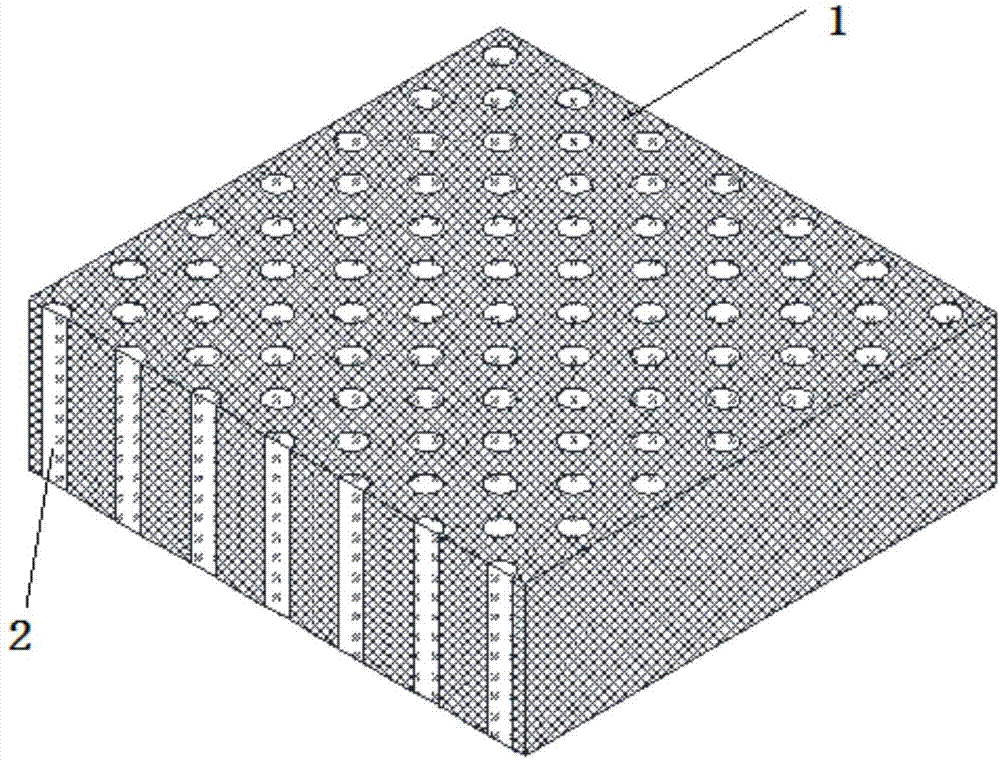

Rolling-forming manufacturing method for microstructure on curved surface

InactiveCN104360580ACheap manufacturing methodEnvironmental cleanliness requirements are lowPhotomechanical apparatusMicro nanoPhotolithography

The invention discloses a rolling-forming manufacturing method for a microstructure on a curved surface. The method comprises six steps. A template is rolled on the outer surface of a bar stock and then is etched, so that the manufacture of the microstructure on the curved surface is realized. Compared with the traditional method for only manufacturing the microstructure on a plane, the rolling-forming manufacturing method can adopt an easier way to break through the limitation that the traditional methods of photoetching and micro-contact printing can only manufacture the microstructure on the plane, and the method can manufacture the precise microstructure on the curved surface. The template subjected to impressing can be repeatedly used after being washed. Compared with other micro-nano impressing methods, the manufacturing method capable of realizing high efficiency and low cost has relatively low requirement for the environmental cleanliness.

Owner:BEIHANG UNIV

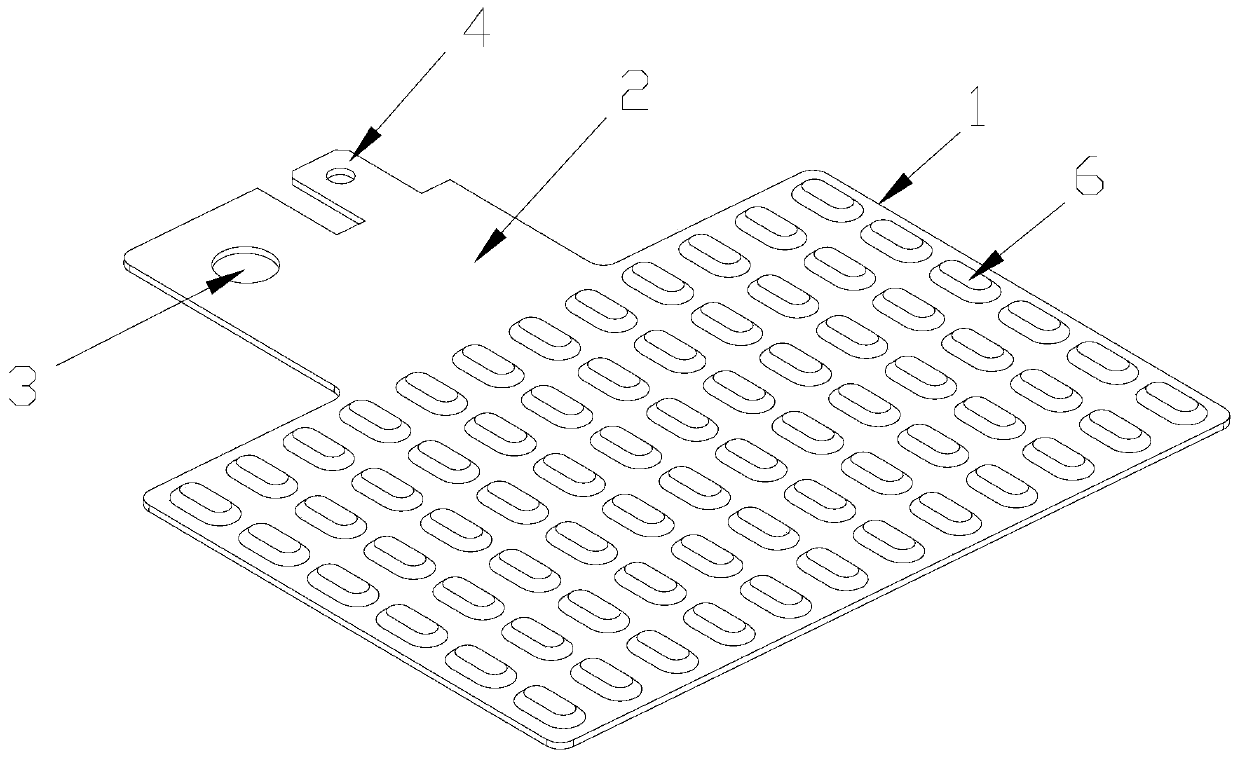

Current collector plate used for hydrogen fuel cell stack

ActiveCN110676478AResilience is simpleImprove impact resistanceFinal product manufactureCollectors/separatorsHydrogen fuel cellEngineering

The invention relates to a current collector plate for a hydrogen fuel cell stack. The current collector plate comprises a current collector plate body. The current collector plate body is in a metalplate shape. The current collector plate body is composed of a current collector surface and a terminal. The current collector surface is used for contacting with a graphite polar plate of an electricpile to collect a current of the electric pile. The terminal is used for connecting with a test lead, the current collector surface adopts a non-planar structure and is in contact with the graphite polar plate through a convex part of the non-planar structure, the terminal is provided with a screw hole and a quick plug structure, and the quick plug structure is matched with a quick plug connectoron the test lead so as to realize quick plug during testing. Compared with the prior art, large-area suspension caused by defects or sundries can be avoided to a great extent, an effective contact area is increased, requirements of the structure for materials, machining precision and cleanliness of an assembly workshop are greatly reduced, production cost is saved, meanwhile, rapid insertion andextraction during testing are achieved, and testing efficiency is improved.

Owner:上海亿氢科技有限公司

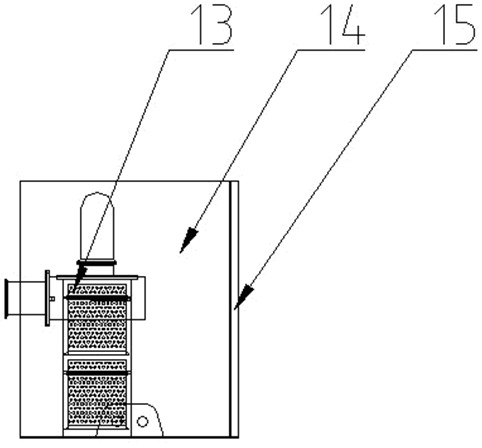

Sterility test process isolator for double-sided laminar flow operation

InactiveCN105196313AAchieve isolationNo harmGaseous substancesManipulatorAir treatmentProcess engineering

The invention discloses a double-sided sterility test process isolator. The isolator is characterized by comprising a glove bin system and an electrical cabinet system, wherein an air treatment system is arranged at the top of the glove bin system; the glove bin system comprises a bin body; a glove operation component is arranged on the bin body, and comprises operation window sealing glass; and gloves are connected with the operation window sealing glass by virtue of a glove connection component. The sterility test process of sterile medicines can be carried out under a controlled environment all the time by virtue of the sterility test isolator, so that toxic substances inside the sterile medicines cannot hurt operators, pollutants in the external environment are prevented from entering the operation space and polluting to-be-tested products, and the requirement of a production region for the cleanness of a background environment can be reduced. Changes of an arbitrary environment parameter inside the sterility test process isolator can be correspondingly regulated and controlled, so that isolation of the sterility test step after production of sterility medicines can be realized.

Owner:上海东富龙爱瑞思科技有限公司 +1

Screw full-bridge pilot structure

InactiveCN101598151AEasy to controlImprove dynamic characteristicsServomotor componentsCarrying capacityFull bridge

The invention belongs to the technical field of hydraulic pneumatic servo control and discloses a screw full-bridge pilot structure. The screw full-bridge pilot structure comprises pilot control rods, a secondary moving piston, a piston barrel and a piston end cap; in the structure, a smaller pilot control rod is driven by a motor to rotate or move in a straight line in the secondary moving piston to coordinate with the piston barrel and the piston end cap to change a hydraulic or pneumatic damping full-bridge to push the secondary moving piston to move, so as to achieve hydraulic or pneumatic amplification, and the structure can be widely used in two-stage proportion servo valve design. Compared with traditional nozzle baffle or jet pilot structure, the pilot structure has the following advantages: the amplification factor of the pilot is large, thus facilitating the manufacture of proportional valve and servo valve with large flow; the pilot control rods have very small rotary inertia and inertness, and extremely small loaded moment or carrying capacity, thus facilitating the control and improvement of dynamic performance; the pilot structure is simple and is convenient for processing; the pilot structure reduces the requirement on oil cleanliness and improves the work reliability of the pilot.

Owner:BEIHANG UNIV

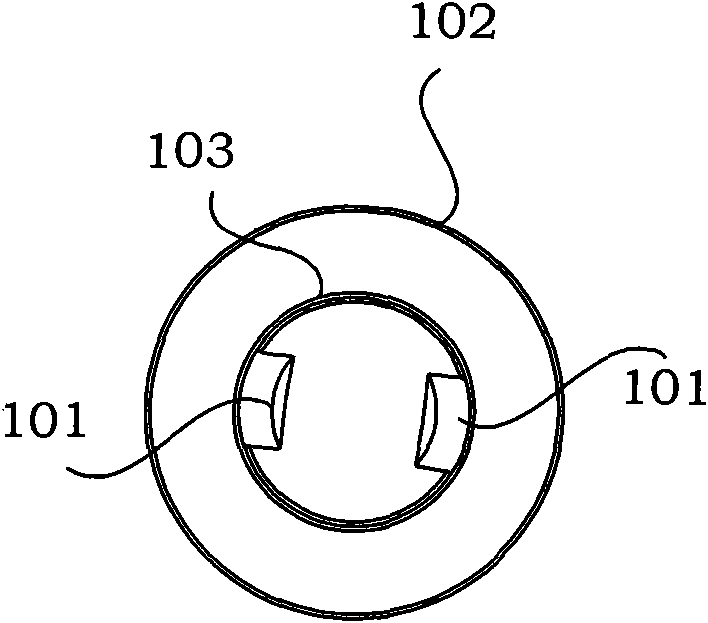

Solid light microchannel array panel and preparation method thereof

ActiveCN107285618ALarge aspect ratioOvercome the defect of strength dropGlass fibre drawing apparatusGlass fibre productsSolid lightFirst light

The invention discloses a solid light microchannel array panel and a preparation method thereof. The panel comprises a panel body, wherein the panel body comprises light-tight base bodies and multiple light-permeable channels; the light-tight base bodies are arranged among the light-permeable channels which are solid light channels. The preparation method comprises steps as follows: first light-permeable medium material bars and light-tight base body material bars are drawn into thin first light-permeable medium material bars and thin light-tight base body material bars; the thin first light-permeable medium material bars and the thin light-tight base body material bars are arranged and combined into primary composite bars; the primary composite bars are drawn into primary composite channel filaments; the primary composite channel filaments are made into blank composite filament bars; the blank composite filament bars are melt to form blank bars; the blank bars are subjected to follow-up processing, and the solid light microchannel array panel is obtained. The light channels have a large length-diameter ratio, the optical effect is good, requirements for environments in the packaging and use processes are low, and the panel is high in strength and efficiency, low in cost, flexible and capable of being widely applied to the field of optical elements.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

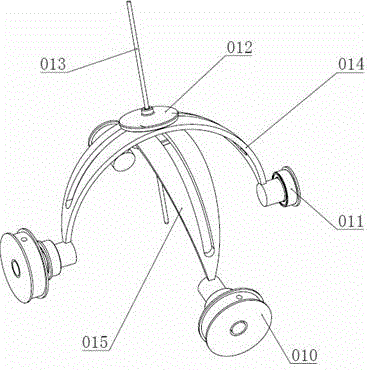

Measurement device for tail spatial position of robot

InactiveCN106042001AMeet measurement needsLow cleanliness requirementsManipulatorBall bearingMeasurement device

The invention relates to a measurement device for the tail spatial position of a robot. The measurement device comprises a base, a stay wire encoder, a transitional mounting plate, encoder assemblies, synchronous belts and follow-up pointing mechanisms, wherein the stay wire encoder is mounted on the bottom of the base through screws; the transitional mounting plate is mounted on the top of the base through screws; the two encoder assemblies are mounted in the middle of the base through screws; and the follow-up pointing mechanisms are mounted in four round holes of the transitional mounting plate through deep groove ball bearings and connected with the encoder assemblies through the synchronous belts. The measurement device is high in precision, convenient to operate and low in cost, and has a low requirement for the measurement environment.

Owner:SHANGHAI UNIV

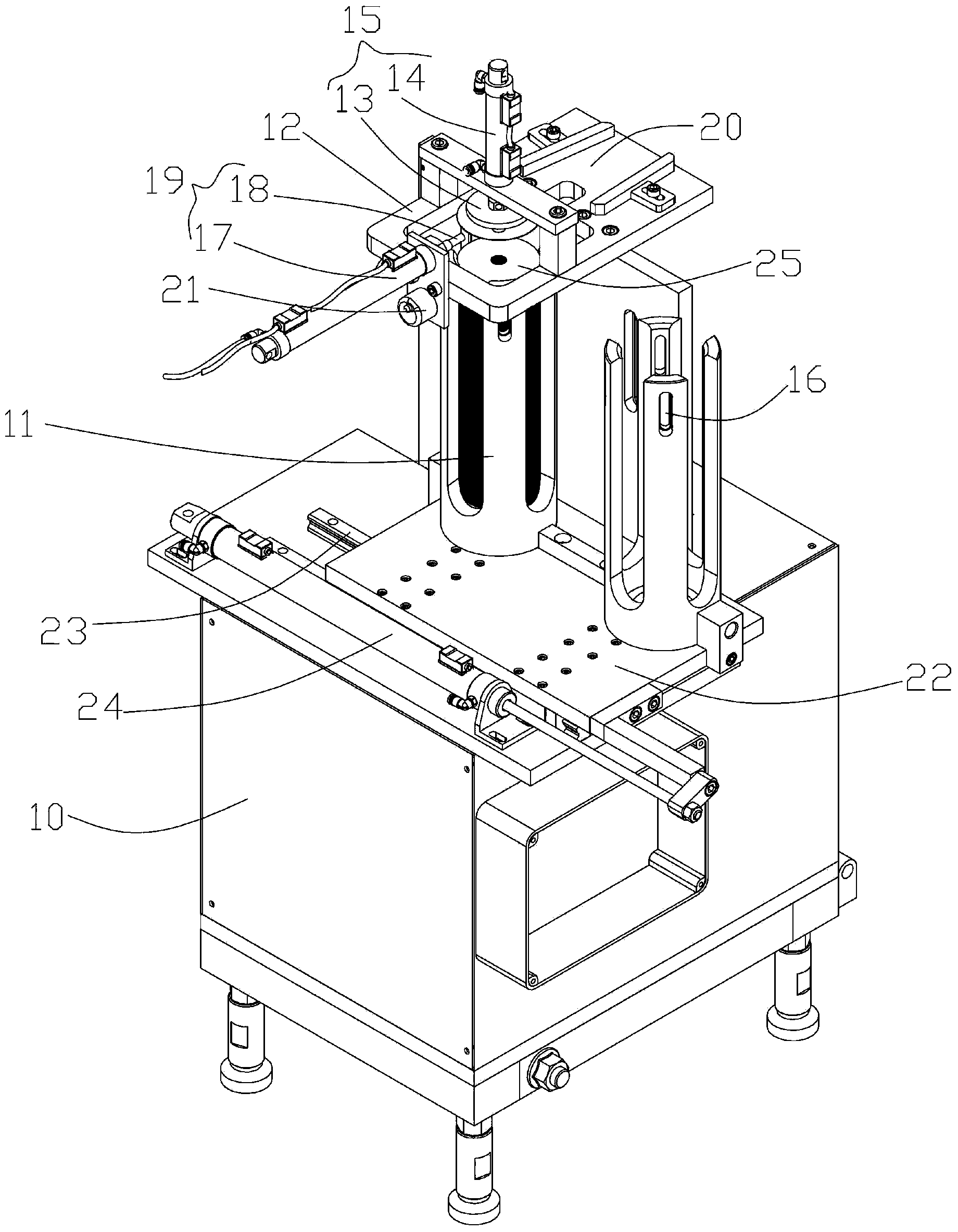

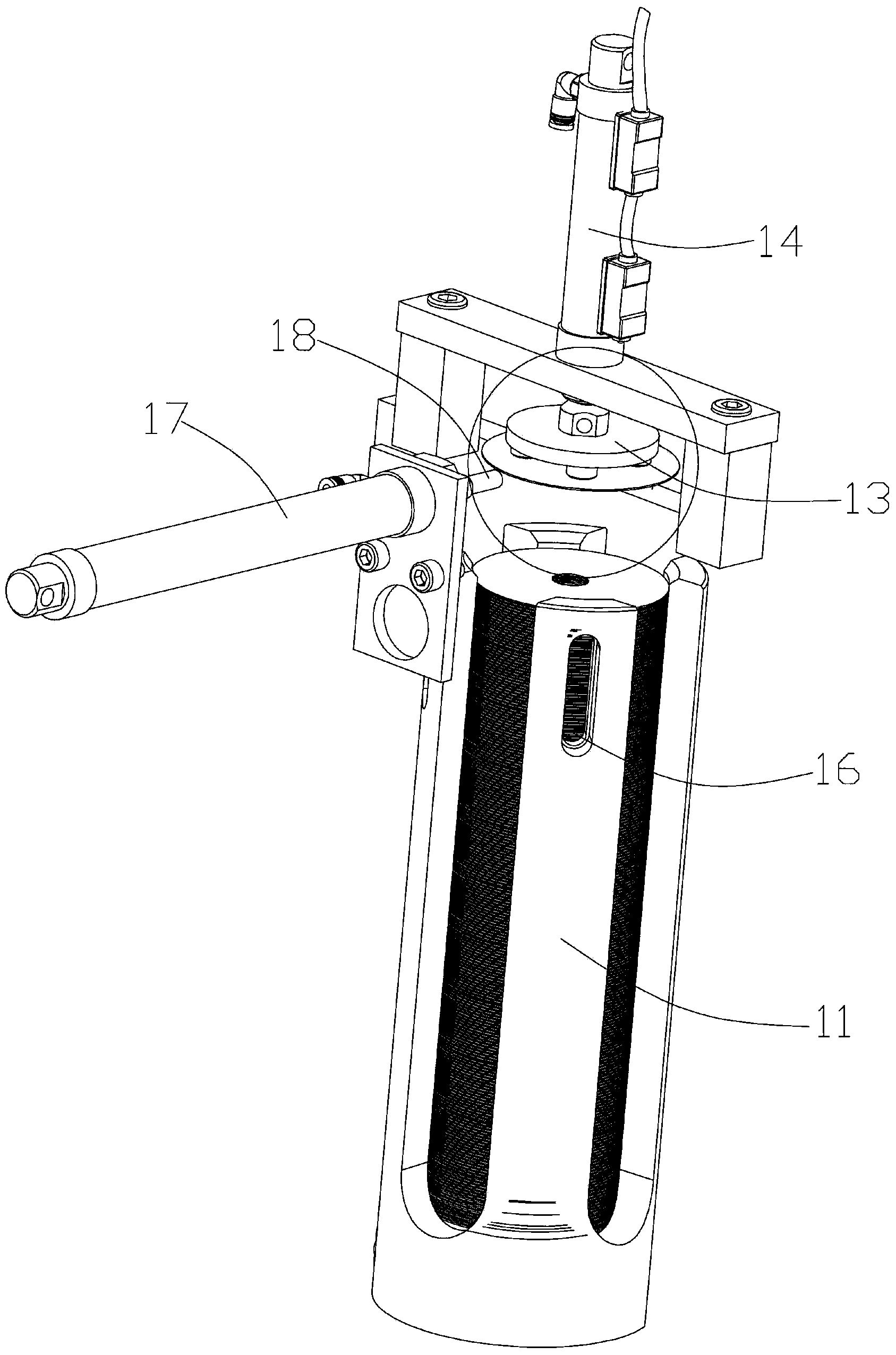

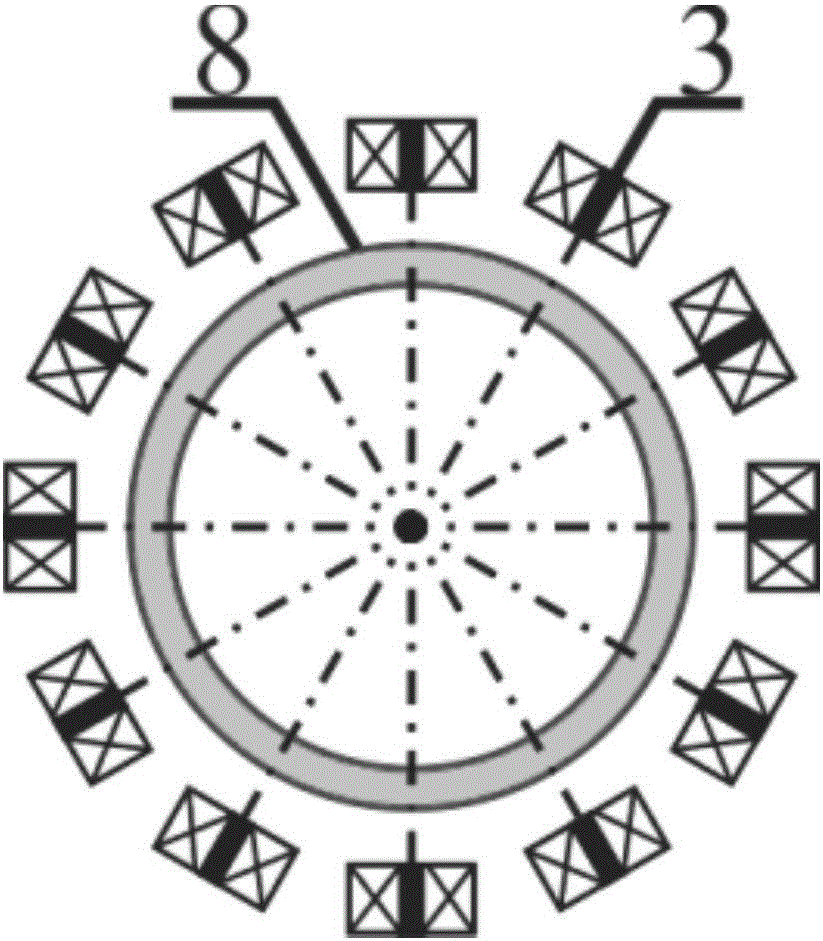

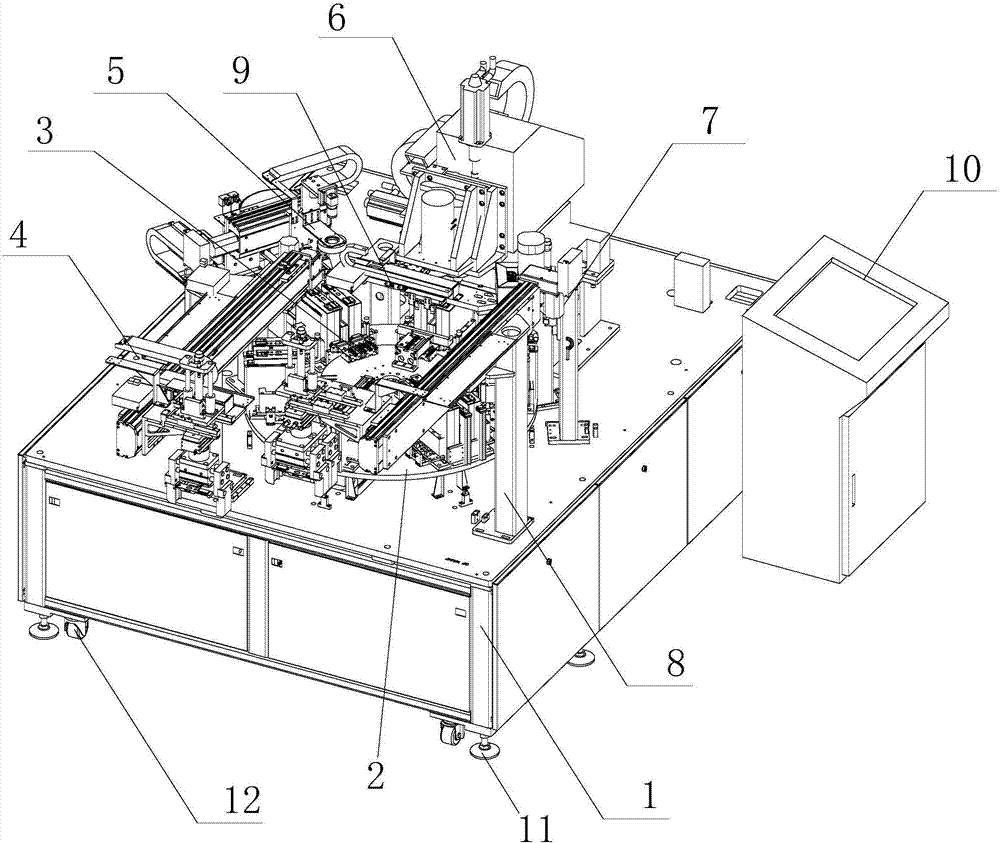

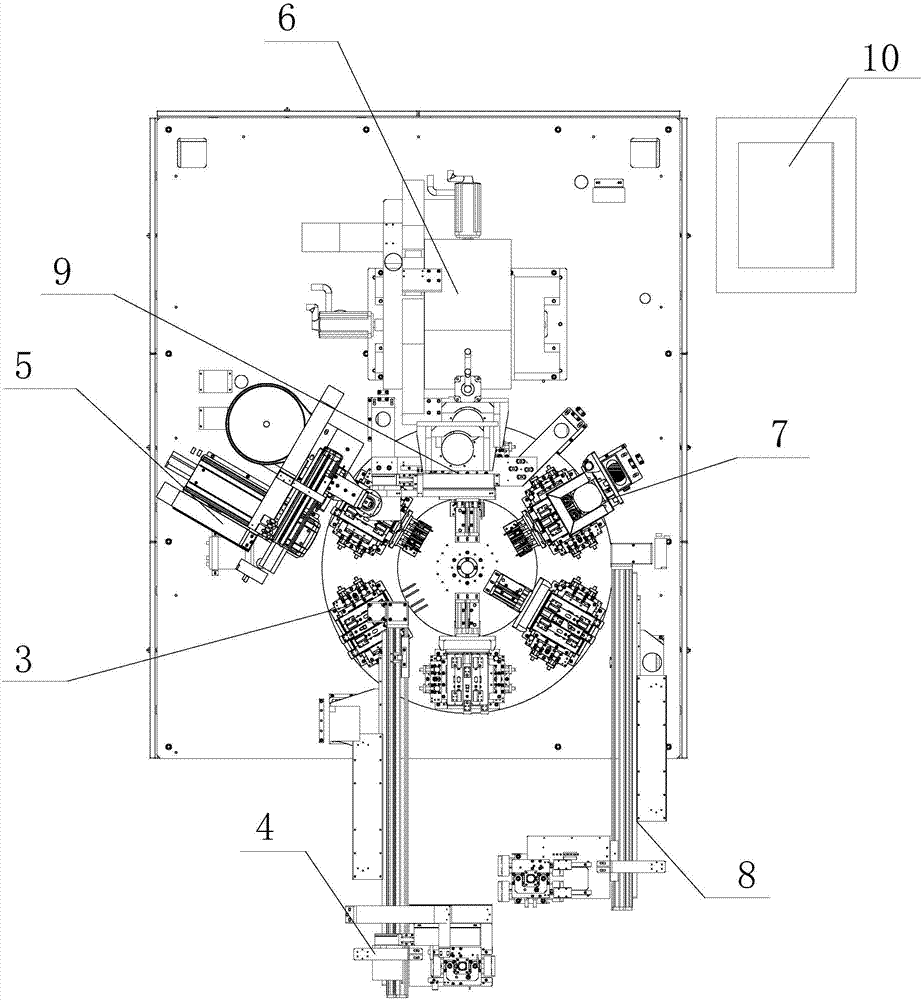

Battery liquid injection port sealing nail welding equipment

PendingCN107199393ALow cleanliness requirementsImprove pass rateWelding/soldering/cutting articlesMetal working apparatusManipulatorEngineering

The invention discloses battery liquid injection port sealing nail welding equipment. The equipment comprises a bed frame. The bed frame is provided with a horizontally-arranged rotary plate capable of doing pivoting motion around a vertical axis, a rotary plate pivoting driving device driving the rotary plate to do pivoting motion around the vertical axis, a battery charging manipulator, a sealing nail charging manipulator, a friction welding machine, a grinding dust collection assembly and a discharging manipulator, wherein the battery charging manipulator, the sealing nail charging manipulator, the friction welding machine, the grinding dust collection assembly and the discharging manipulator are located around the rotary plate and sequentially arranged in the circumferential direction; and at least five battery positioning clamps evenly distributed in the circumferential direction with the vertical axis as a center at intervals are mounted on the upper surface of the rotary plate. The welding equipment adopts a touch friction welding technology of spaceflight, various problems of laser welding are well solved, the product yield is increased, and the plant benefits are increased.

Owner:GEESUN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com