Rolling-forming manufacturing method for microstructure on curved surface

A technology of roll forming and manufacturing method, applied in the field of microstructure manufacturing, can solve problems such as high efficiency and low cost, and achieve the effect of cheap manufacturing method and low requirements for environmental cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

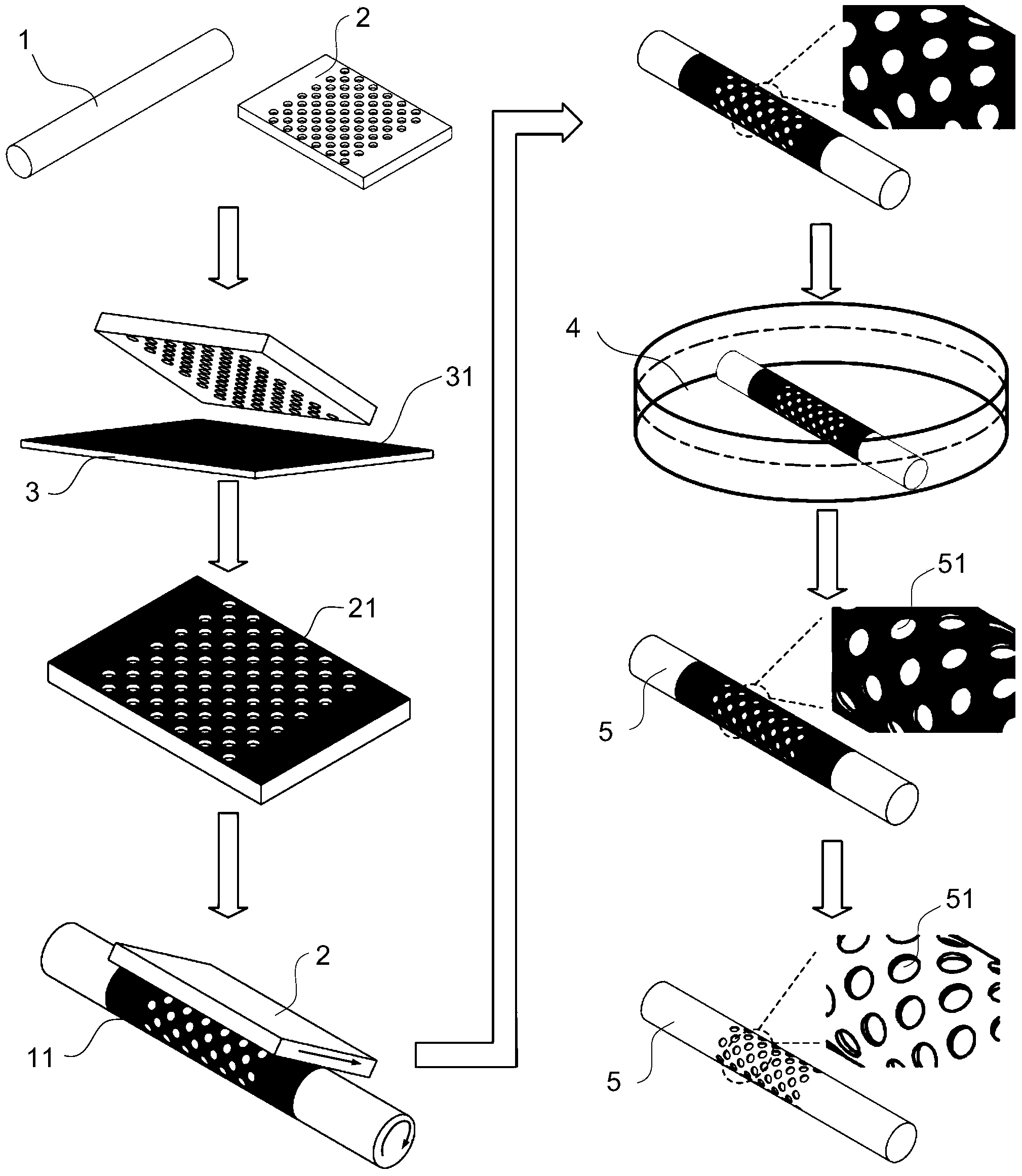

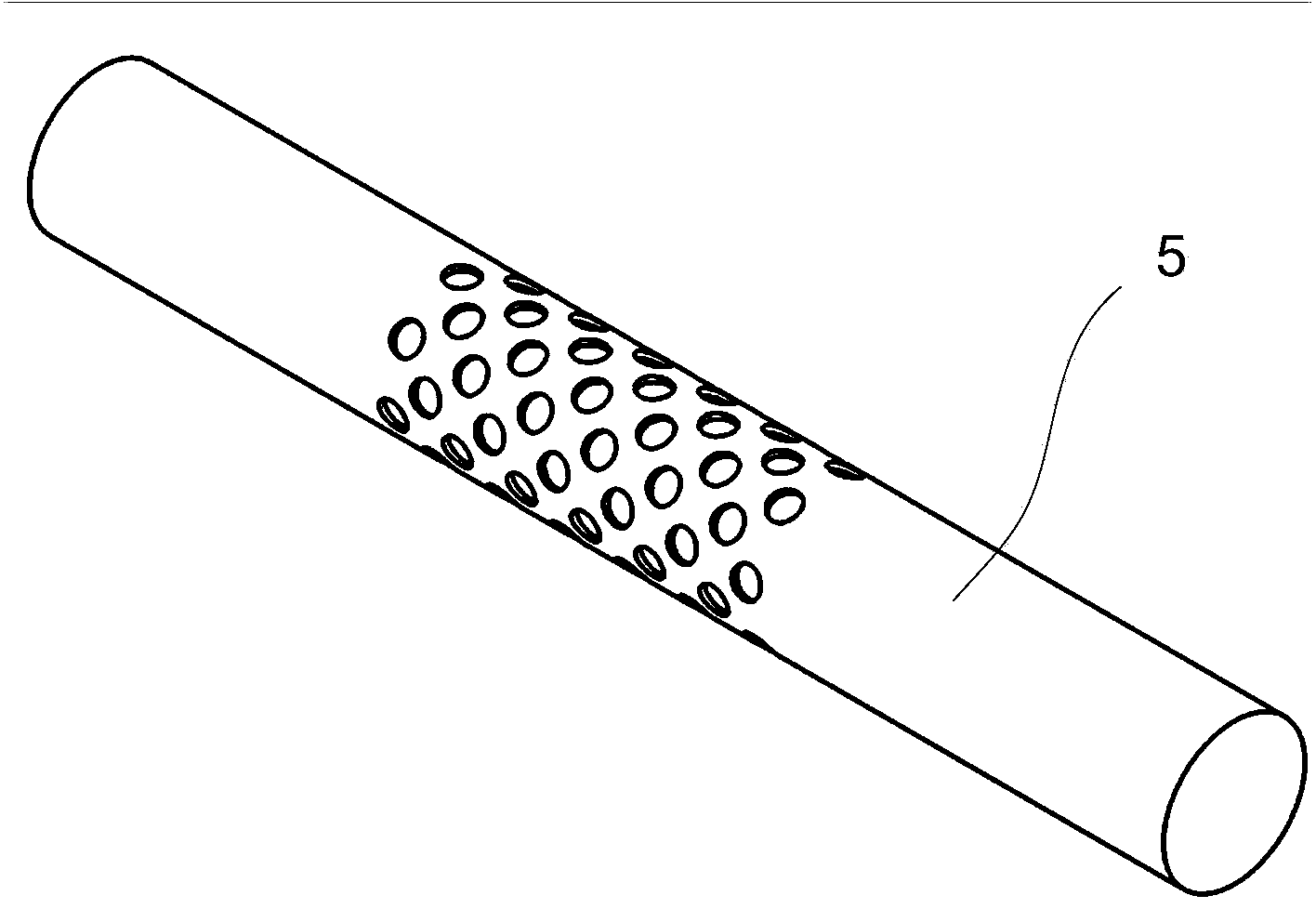

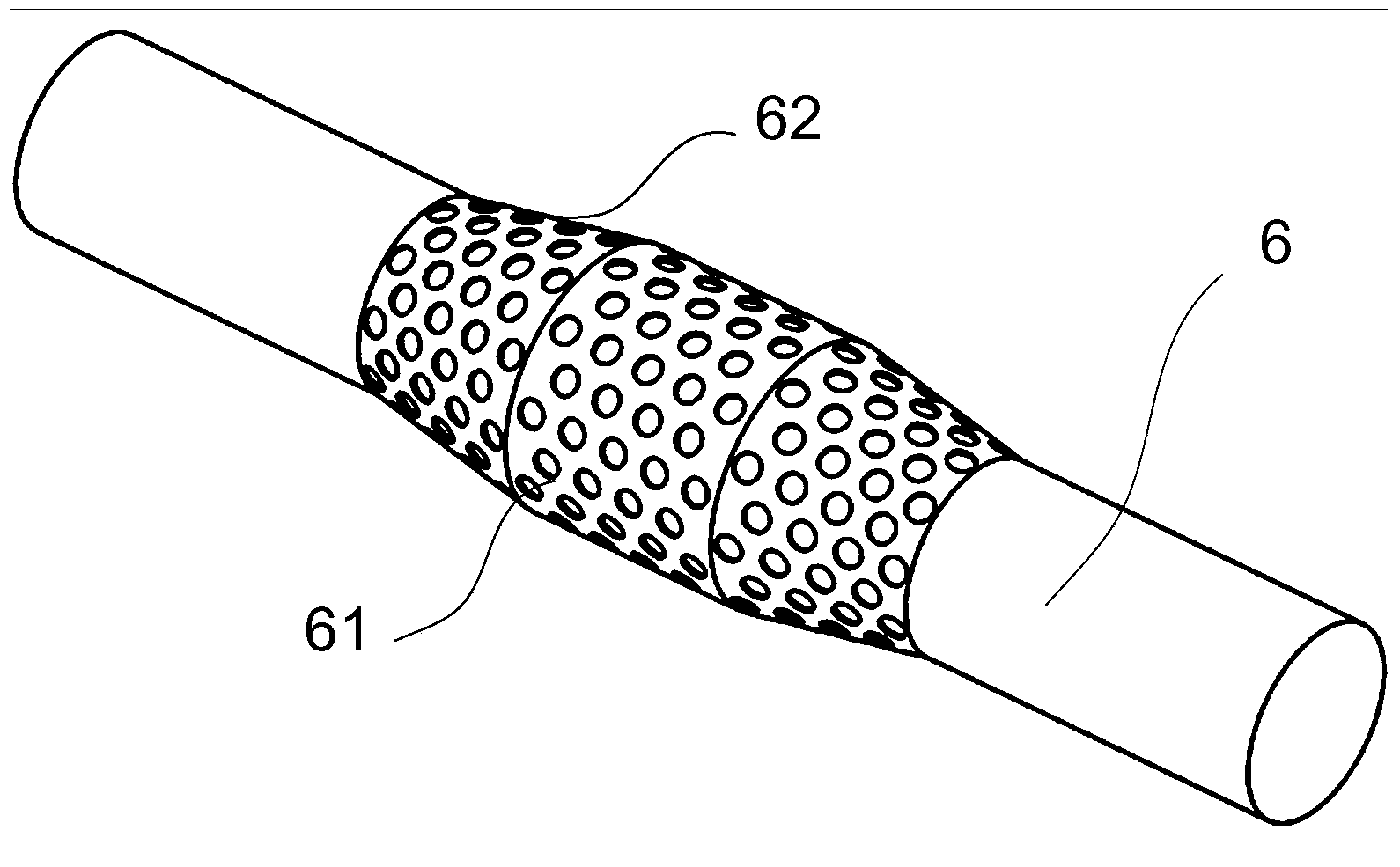

[0028] Such as figure 1 In the process shown, the substrate (3) is evenly covered with a transfer medium (31), here is a photoresist. The obtained imprint template (2) is brought into contact with the substrate (3), so that the transfer medium (31) is evenly transferred from the substrate (3) to the imprint template (2). The transfer medium (21) on the embossing template is rolled onto the bar (1), so as to realize the transfer of graphics. Then the rod (1) is etched, here, the etching solution (4) is put in, and the etching depth is controlled. Finally a final bar (5) is obtained which contains microstructures (51) on the bar. After the template is cleaned up, the next production can be carried out.

[0029] See figure 1 — Figure 5 , the present invention is a microstructure roll forming manufacturing method on a curved surface, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com