Preparation method and application of transition metal and its compound-anchored nitrogen-doped carbon catalyst

A transition metal and carbon catalyst technology, applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of complicated procedures, waste of metal ligands, and metal particle agglomeration, and achieve simple production methods, good stability, and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

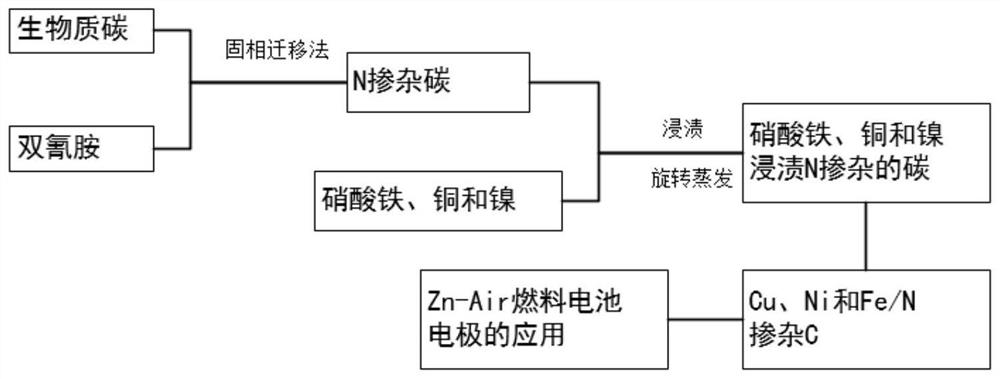

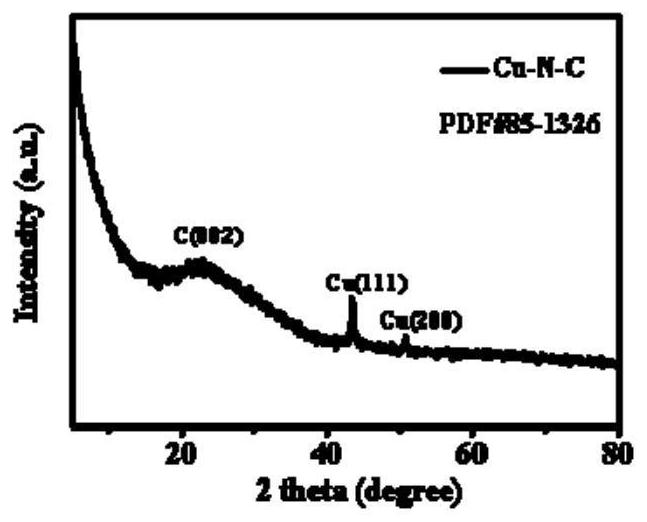

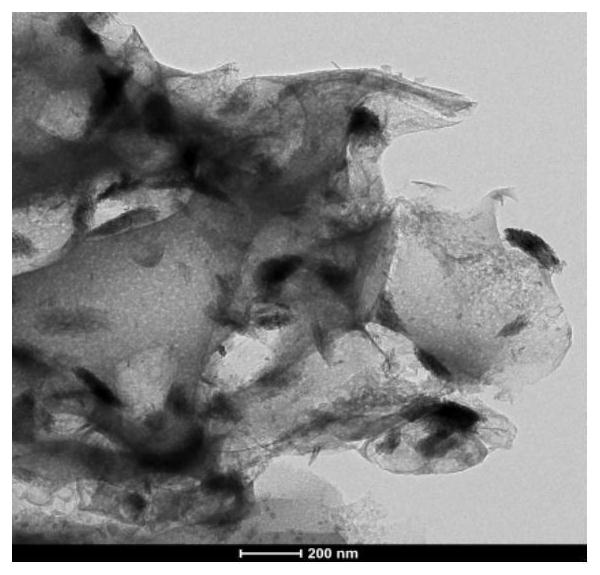

[0046] The present embodiment prepares a transition metal Cu-anchored N-doped carbon catalyst, which is specifically implemented according to the following steps:

[0047] Step 1. Place the treated corn stalk and dicyandiamide on both ends of the porcelain boat. The mass ratio of corn stalk and dicyandiamide was 1:2. The porcelain boat was placed in a tube furnace, the heating rate was 5°C / min, the temperature was 800°C, and the holding time was 1.5h. During the heating process, dicyandiamide is decomposed into CN x The active material reacts with biomass carbon, and the obtained product is N-doped biomass carbon.

[0048] Step 2, under stirring, mix the copper nitrate and the N-doped biomass carbon in a ratio of 0.1:1, the solvent is water and ethanol, the volume ratio of water and ethanol is 1:1, and the mixed solution is obtained by ultrasonicating for 3 hours. , the mixed solution was subjected to rotary evaporation and dried in an oven at 80°C to obtain the precursor o...

Embodiment 2

[0053] The present embodiment prepares a transition metal Ni-anchored N-doped carbon catalyst, which is specifically implemented according to the following steps:

[0054] Step 1. The treated corn stalk and dicyandiamide are placed on both ends of the porcelain boat respectively, the mass ratio of corn stalk and dicyandiamide is 1:5, the porcelain boat is placed in a tube furnace, the heating rate is 5°C / min, and the temperature 8 ℃, the holding time is 2h. During the heating process, dicyandiamide is decomposed into CN x The active material reacts with biomass carbon, and the obtained product is N-doped biomass carbon.

[0055] Step 2. Under stirring, mix nickel nitrate and N-doped biomass carbon in a ratio of 0.05:1, the solvent is water and ethanol, the volume ratio of water and ethanol is 1:1, and the mixture is obtained by ultrasonicating for 4 hours. , the mixed solution was subjected to rotary evaporation and dried in an oven at 80° C. to obtain the precursor of N-dop...

Embodiment 3

[0060] The present embodiment prepares a transition metal compound FeN-anchored N-doped carbon catalyst, which is specifically implemented according to the following steps:

[0061] Step 1. The treated corn stalk and dicyandiamide are placed on both ends of the porcelain boat respectively, the mass ratio of corn stalk and dicyandiamide is 1:6, the porcelain boat is placed in a tube furnace, the heating rate is 5°C / min, and the temperature 700 ℃, the holding time is 2h. During the heating process, dicyandiamide is decomposed into CN x The active material reacts with biomass carbon, and the obtained product is N-doped biomass carbon.

[0062] Step 2. Under stirring, mix according to the mass ratio of ferric nitrate and N-doped biomass carbon to 0.2:1, the solvent is water and ethanol, the volume ratio of water and ethanol is 1:1, and the first mixing is obtained by ultrasonic for 2h. The first mixed solution was subjected to rotary evaporation, and then dried in an oven at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com