Friction member for bicycle brake

A technology for friction components and bicycles, applied in the field of friction components, can solve the problems of high manufacturing cost of metal pads, low yield of metal plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

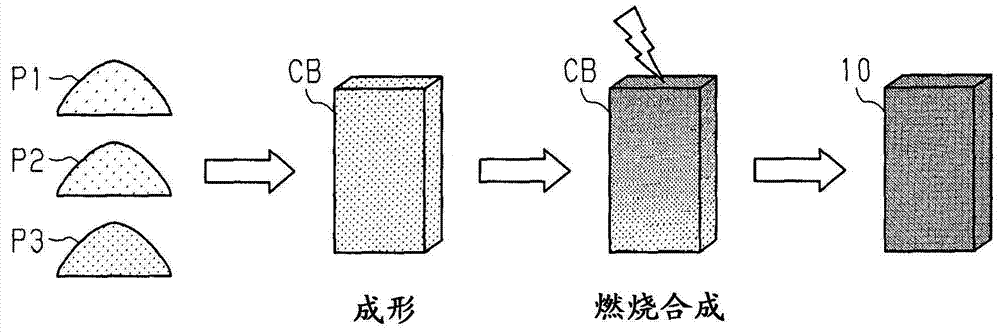

[0053]A method of manufacturing the friction member 10 of a bicycle brake as one example of a bicycle component will now be described. As shown in FIG. 1( a ), the manufacturing method of the friction member 10 includes forming a powder compact CB including at least three kinds of powders P1 , P2 and P3 , and subjecting the powder compact CB to combustion synthesis. Combustion synthesis can be called self-propagating high-temperature synthesis. The at least three powders P1, P2 and P3 are reactants in the combustion synthesis. The friction member 10 containing an intermetallic compound (for example, a Cu—Ti-based intermetallic compound) was manufactured by combustion synthesis. In the present embodiment, the friction member 10 contains TiCu, Ti 2 Cu, Ti 3 Cu 4 、Ti 2 Cu 3 and TiCu 4 At least one of them is an intermetallic compound. The friction member 10 may also contain TiC and Cu 3 Ti 3 at least one of O.

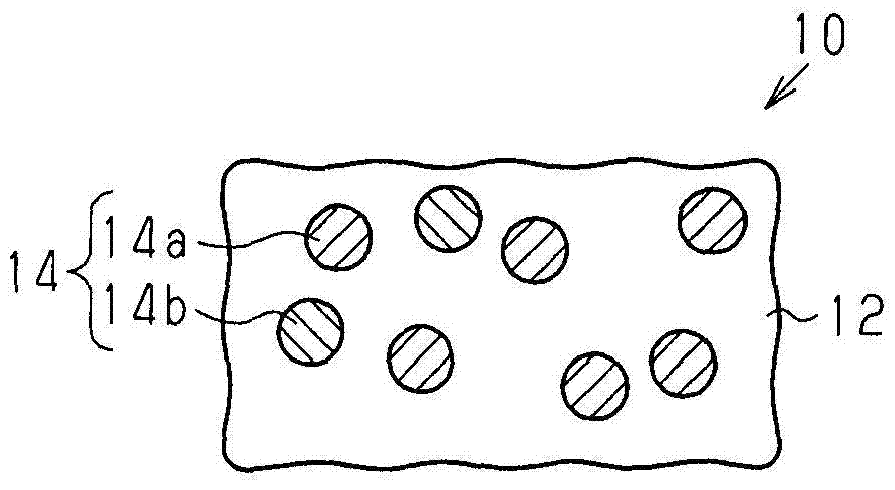

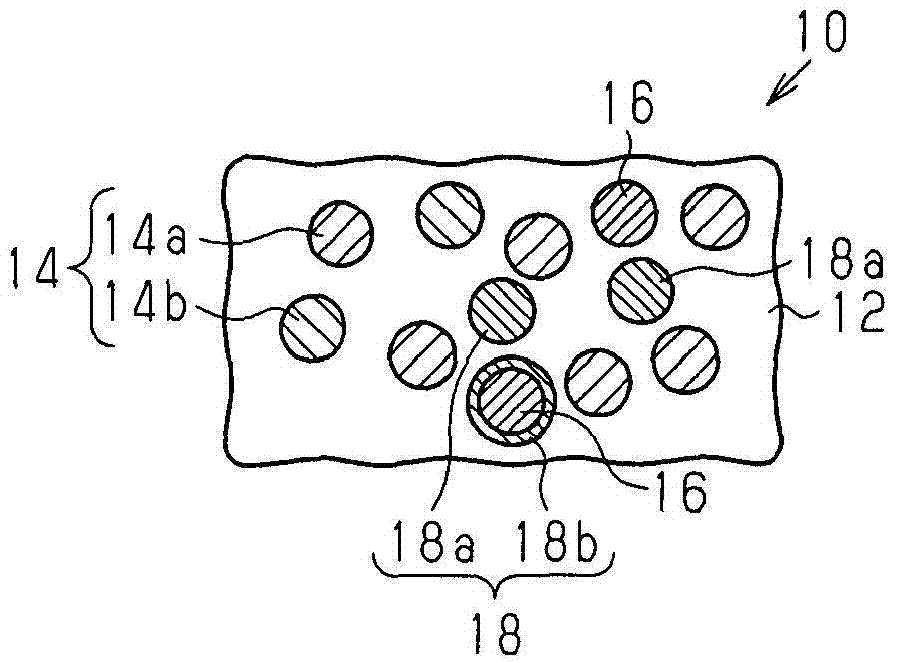

[0054] The friction member 10 produced by combustion synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com