Picture fixation device and circulation film for picture fixation

A technology for image fixing and film application in the direction of shafts and bearings, electric recording technology using charge patterns, and equipment for electric recording technology using charge patterns, which can solve problems such as film instability or bending transmission characteristics, deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

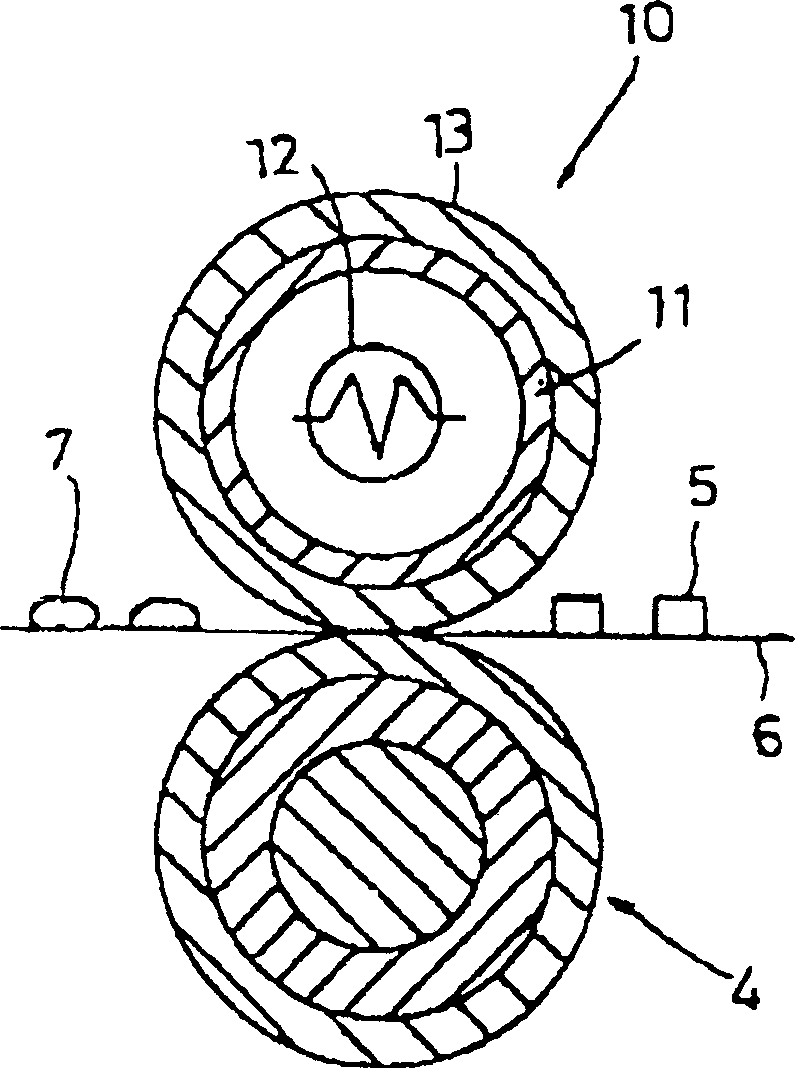

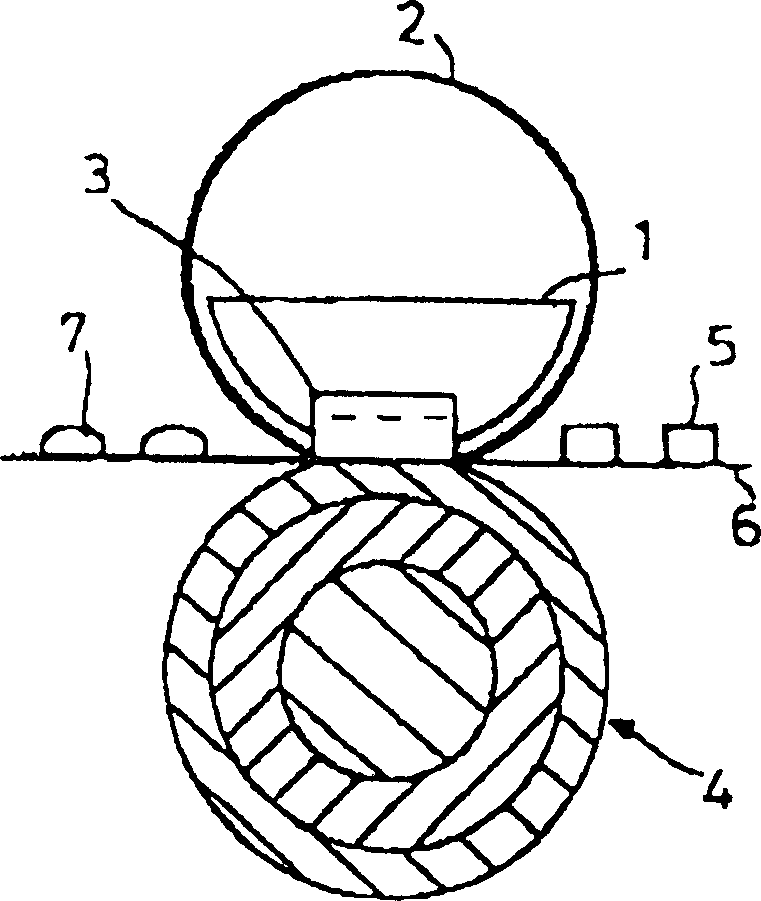

Image

Examples

example 1

[0035] In 791.6 g of N-methyl-2-pyrrolidone, 100 parts by weight of polyimide resin solid content and 30 parts by weight (49.4 g) of hexagonal boron nitride were put and mixed and stirred. Then put in 117.6 grams of 3,3',4,4'-biphenyltetracarboxylic dianhydride, 21.6 grams of P-phenylene diamine and 40.0 grams of 4,4'-diaminobenzidine to continue together mix. The mixture was stirred at room temperature under a nitrogen atmosphere for 7 hours to complete the polymerization. In this way, the polyamic acid solution has been prepared. In the above introduction, the molar ratio of p-phenylenediamine (diamine exhibiting rigidity) to 4,4'-diaminobenzidine (diamine exhibiting flexibility) is 5 to 5.

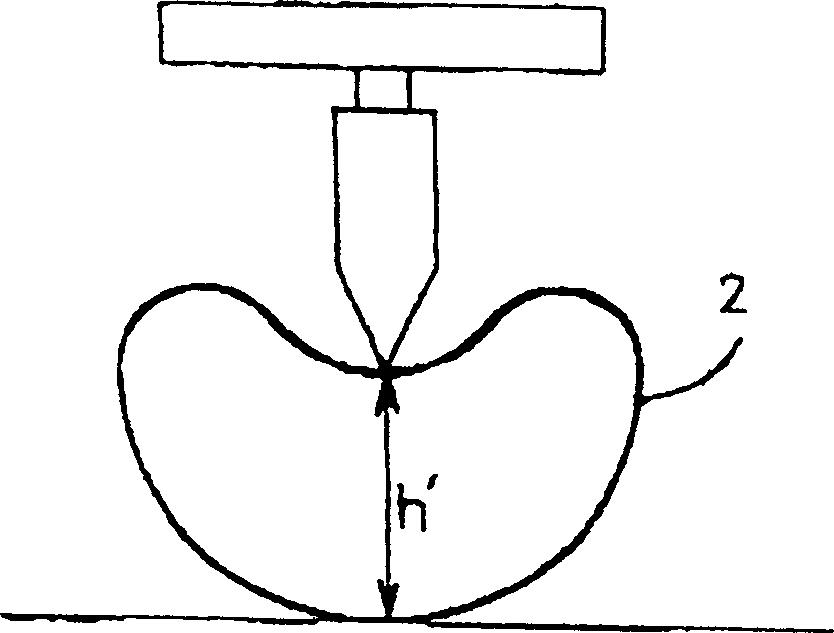

[0036] The polyamic acid solution was placed on the inner peripheral surface of a cylindrical mold having an inner diameter of 30 mm and a length of 500 nm. A bullet-shaped moving body moves down by its own weight and rotates at 1500 rpm for 10 minutes, thereby obtaining a uniform co...

example 2

[0039] A thin tubular material was fabricated in the same manner as in Example 1, except that after spraying, the soak time at 350°C was 40 minutes. That is, a thin tubular material was produced with a combined polyimide layer of about 50 microns and a fluororesin layer of about 12 microns. The tensile elastic modulus of the tubular material is measured in accordance with Japanese Industrial Standard JISK-7127 (1999). As a result, the average tensile modulus of elasticity was 6500 N / mm2. On the other hand, the compressive load of the tubular material is 3.5 grams, and its Vickers hardness is 16 Hv. The copying test was carried out with the same method as in Example 1 under the condition of continuous operation of the device. The results showed that even after 3 weeks, no wear was seen on the surface of the releasable resin. Also, the image after fusing was so clear, indicating that the fusing characteristics of the device are excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com