Fully water-lubricated valve distribution plunger pump

A water lubrication and flow distribution technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problem that it is difficult to improve the radial bearing capacity, increase the radial size of the hydraulic pump, and increase the radial size of the hydraulic pump. Increase the volume and mass and other problems to achieve the effect of solving serious friction and wear problems, solving environmental and product pollution, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the embodiments are only used to illustrate the present invention. For those of ordinary skill in the art, on the premise of not paying creative work, other variants can be obtained according to the technical solutions of these embodiments of the present invention All belong to the protection scope of the present invention.

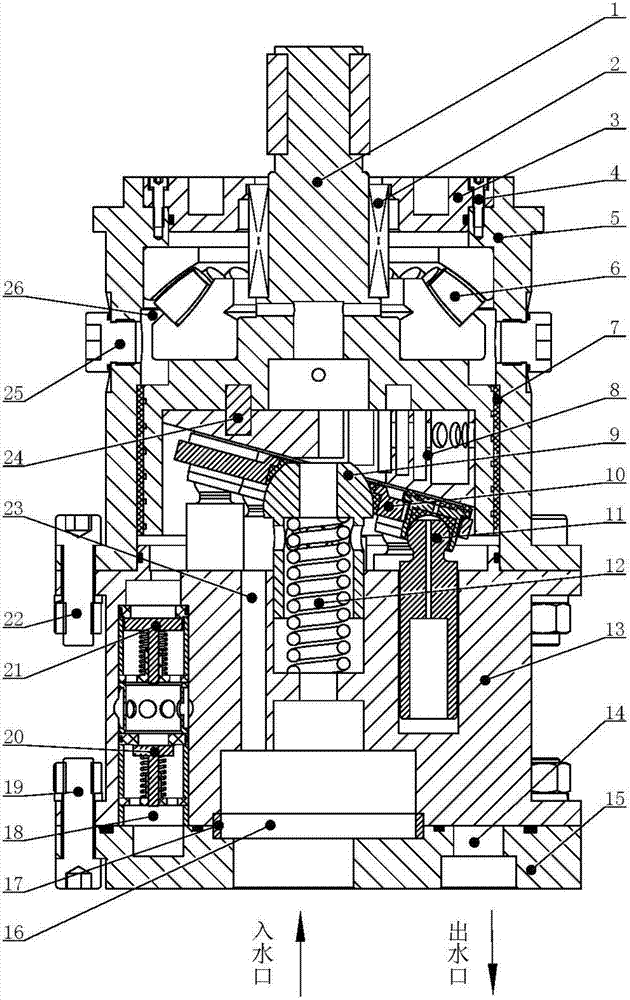

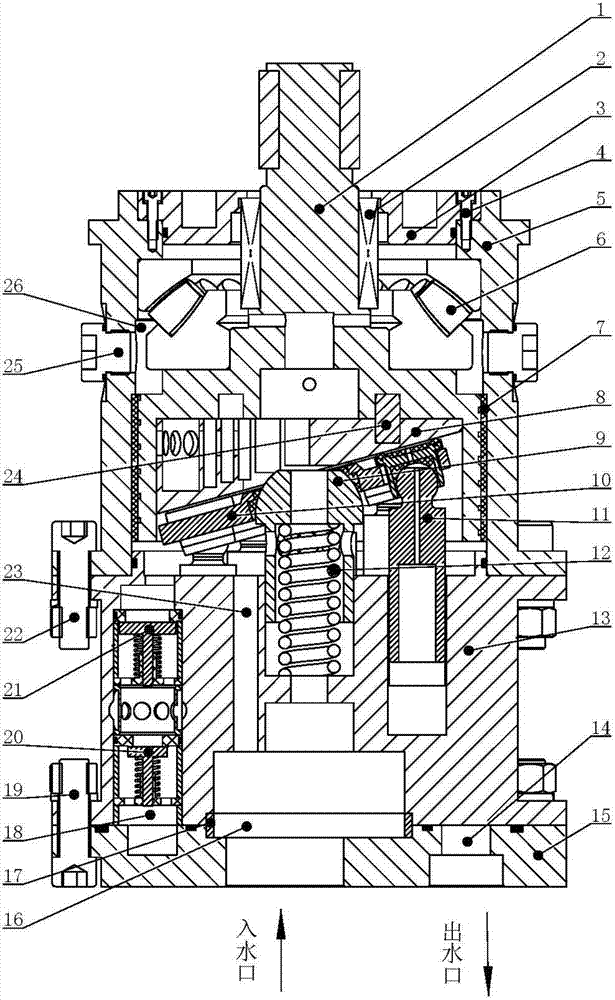

[0027] A schematic structural diagram of a valve-distributed plunger type all-water lubricated hydraulic pump according to an embodiment of the present invention is shown in FIG. 1 . The hydraulic pump includes a pump main body, a rotating unit, a supporting unit and a plunger flow distribution unit.

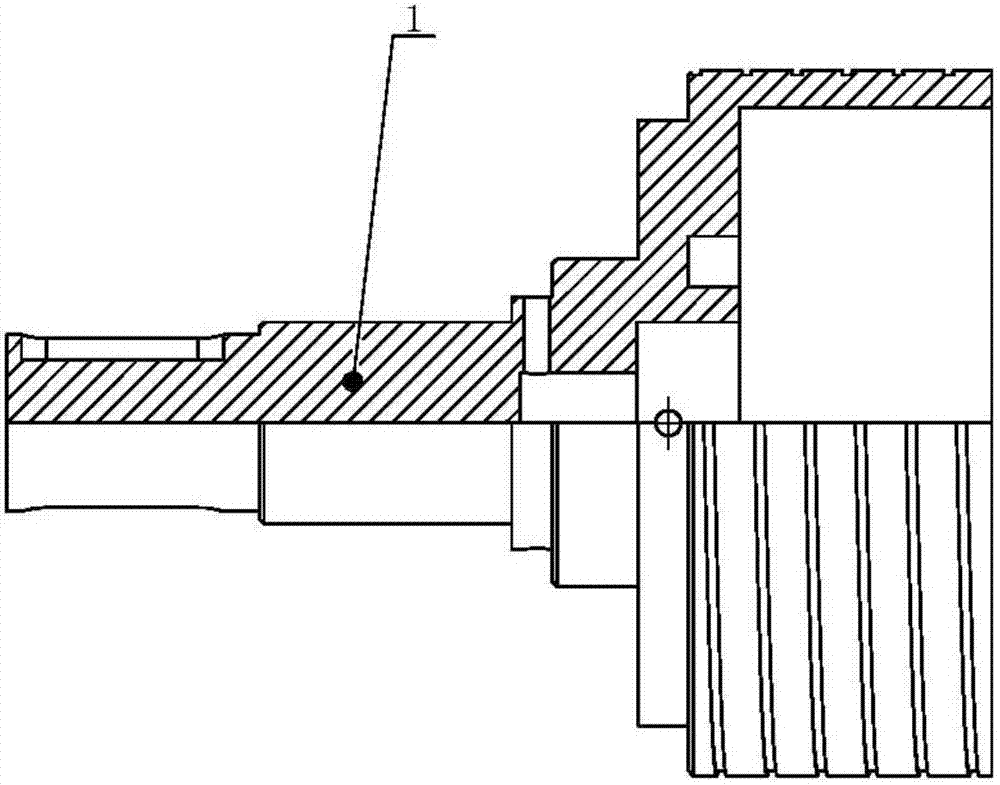

[0028] Wherein, the main body of the hydraulic pump includes a cavity, a water inlet of the hydraulic pump, and a water outlet of the hydraulic pump. The rotating unit includes a rotating main shaft 1 , a swas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com