Patents

Literature

616 results about "Axial piston pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

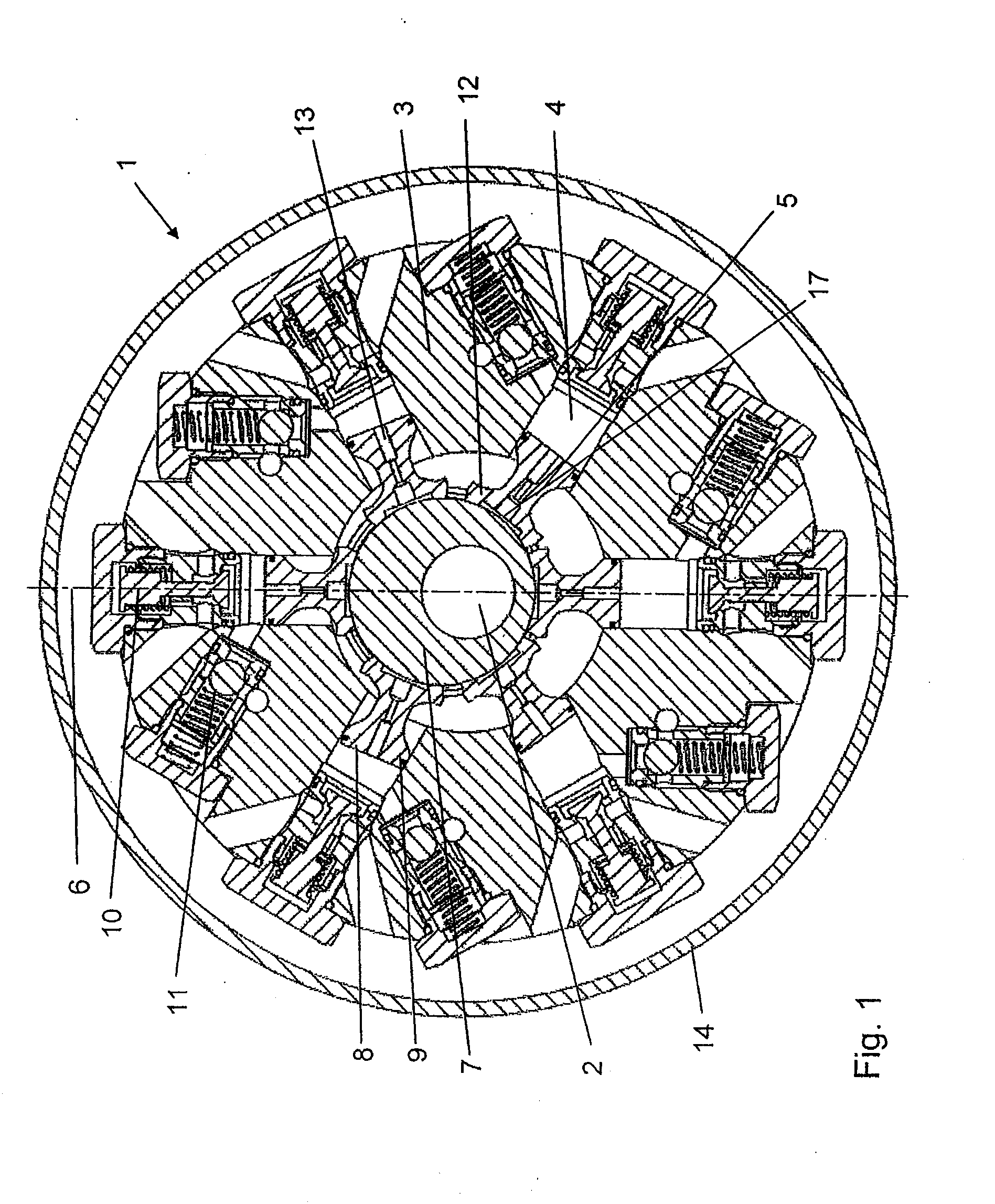

An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a cylinder block. It can be used as a stand-alone pump, a hydraulic motor or an automotive air conditioning compressor.

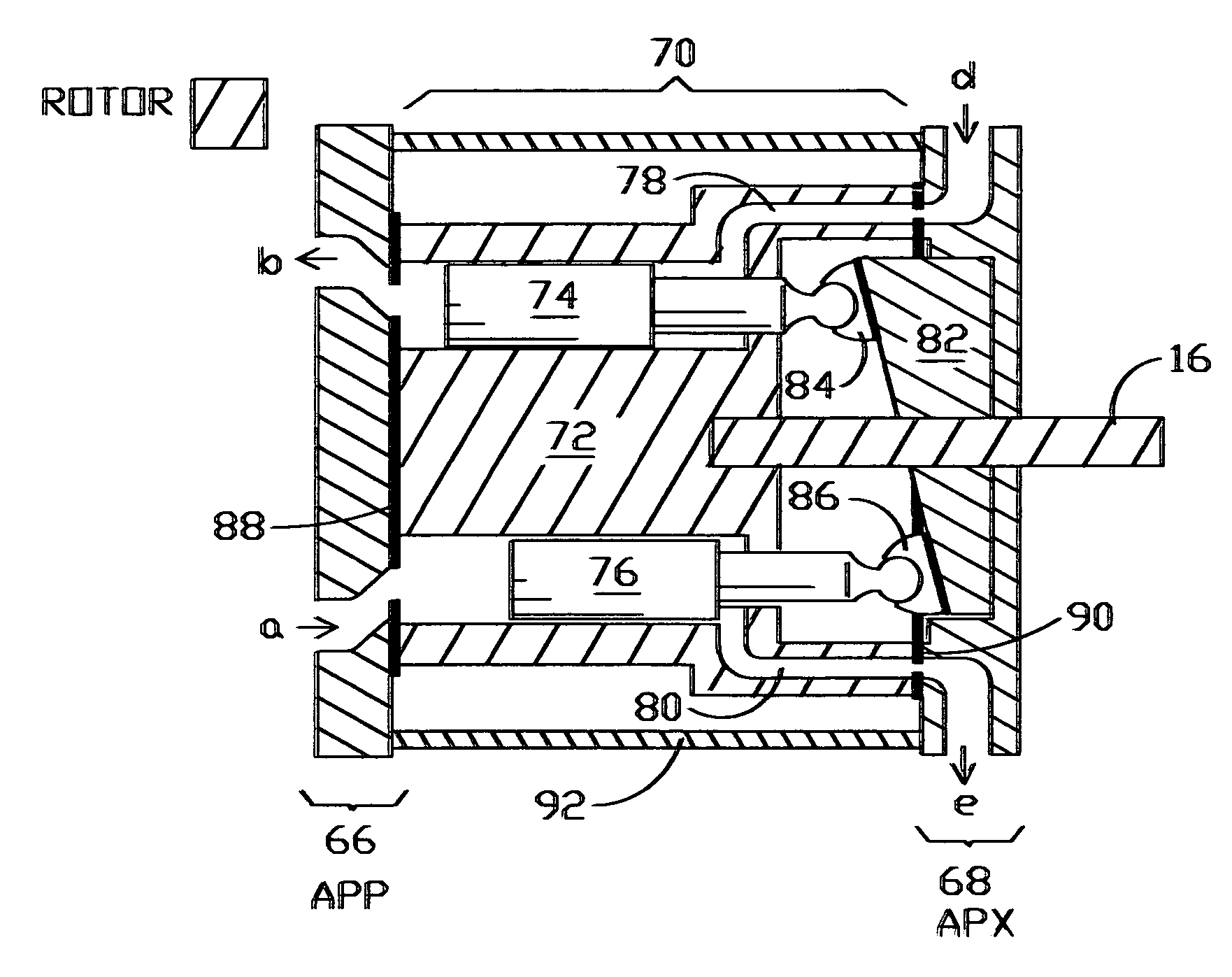

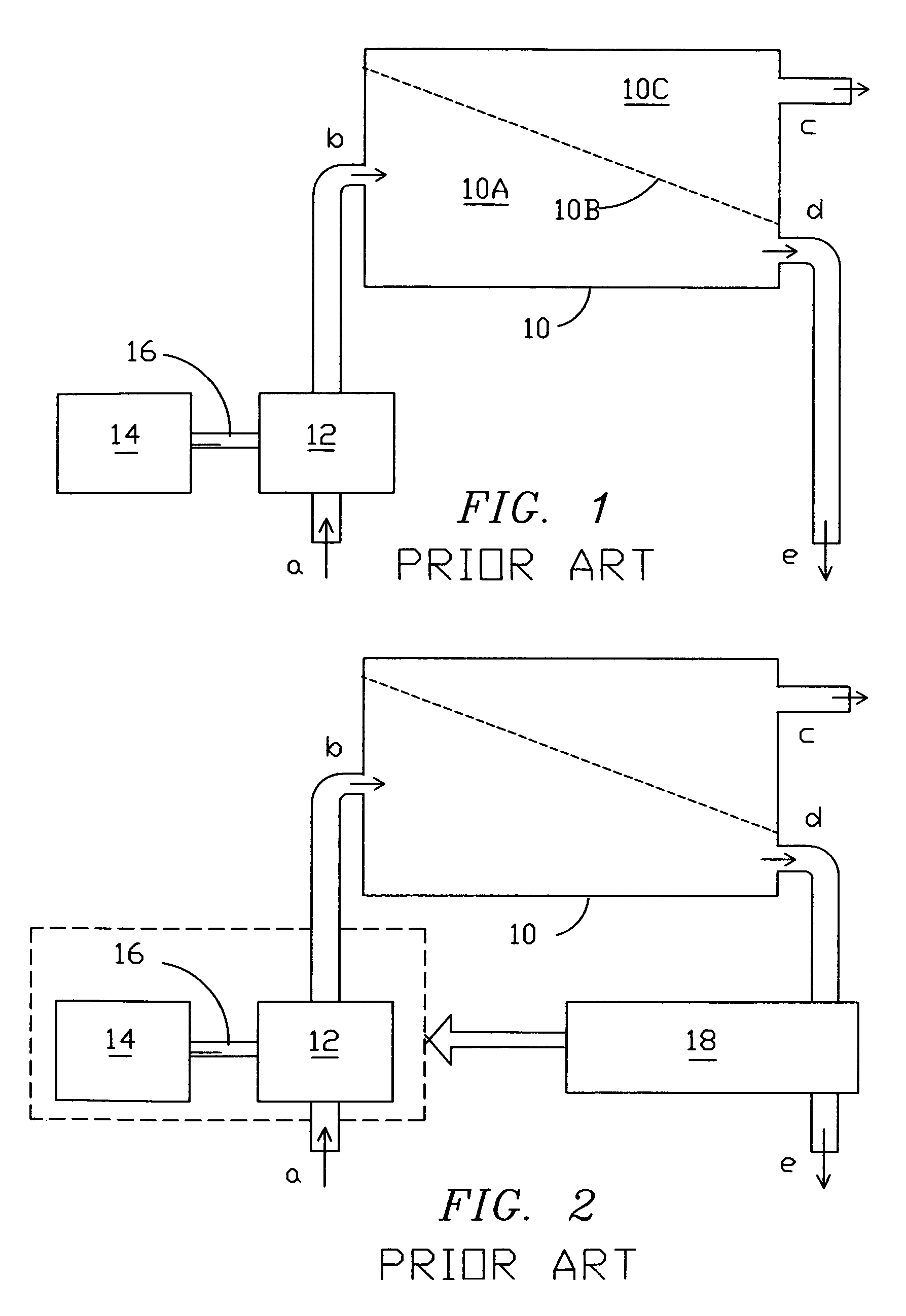

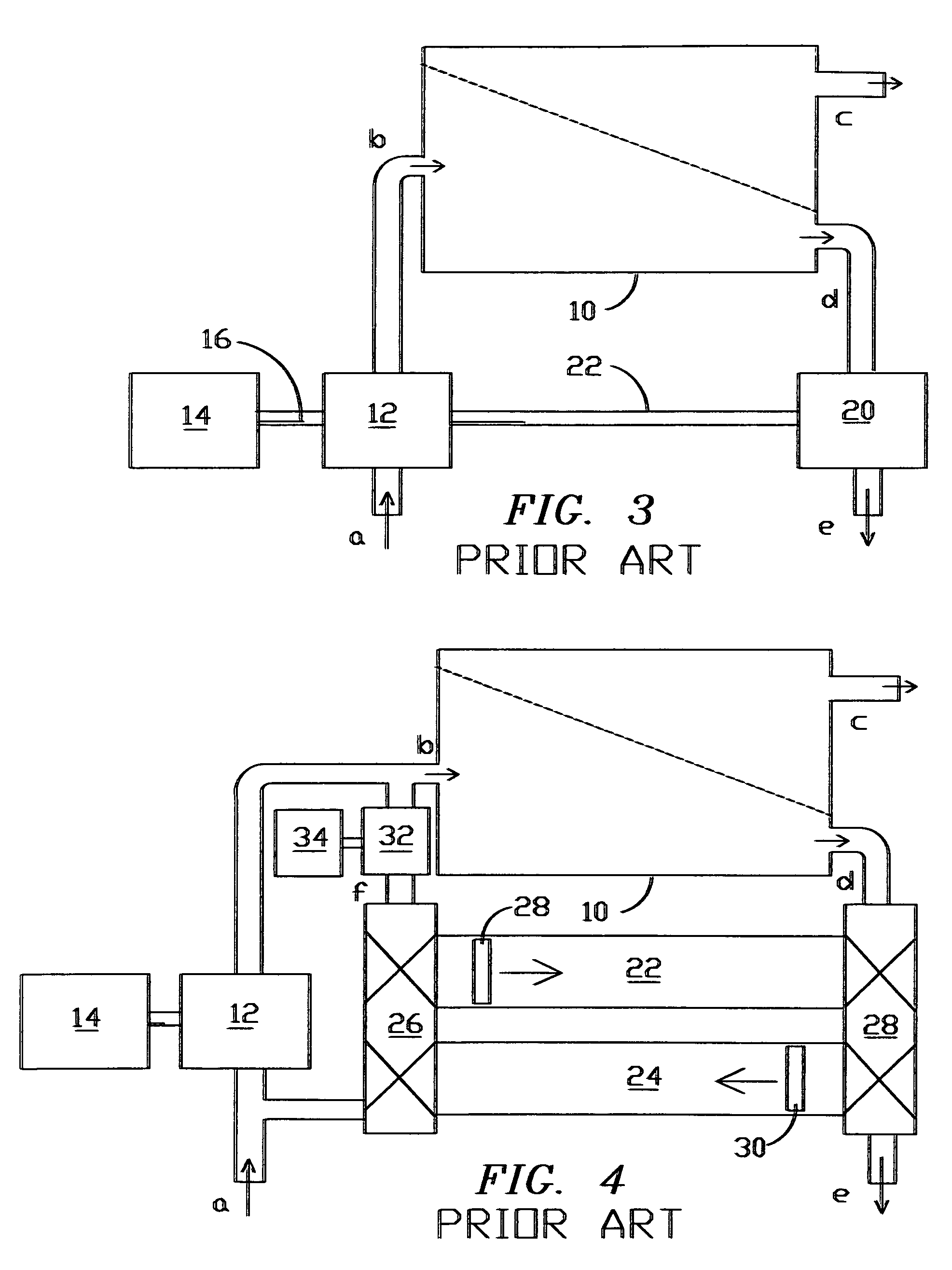

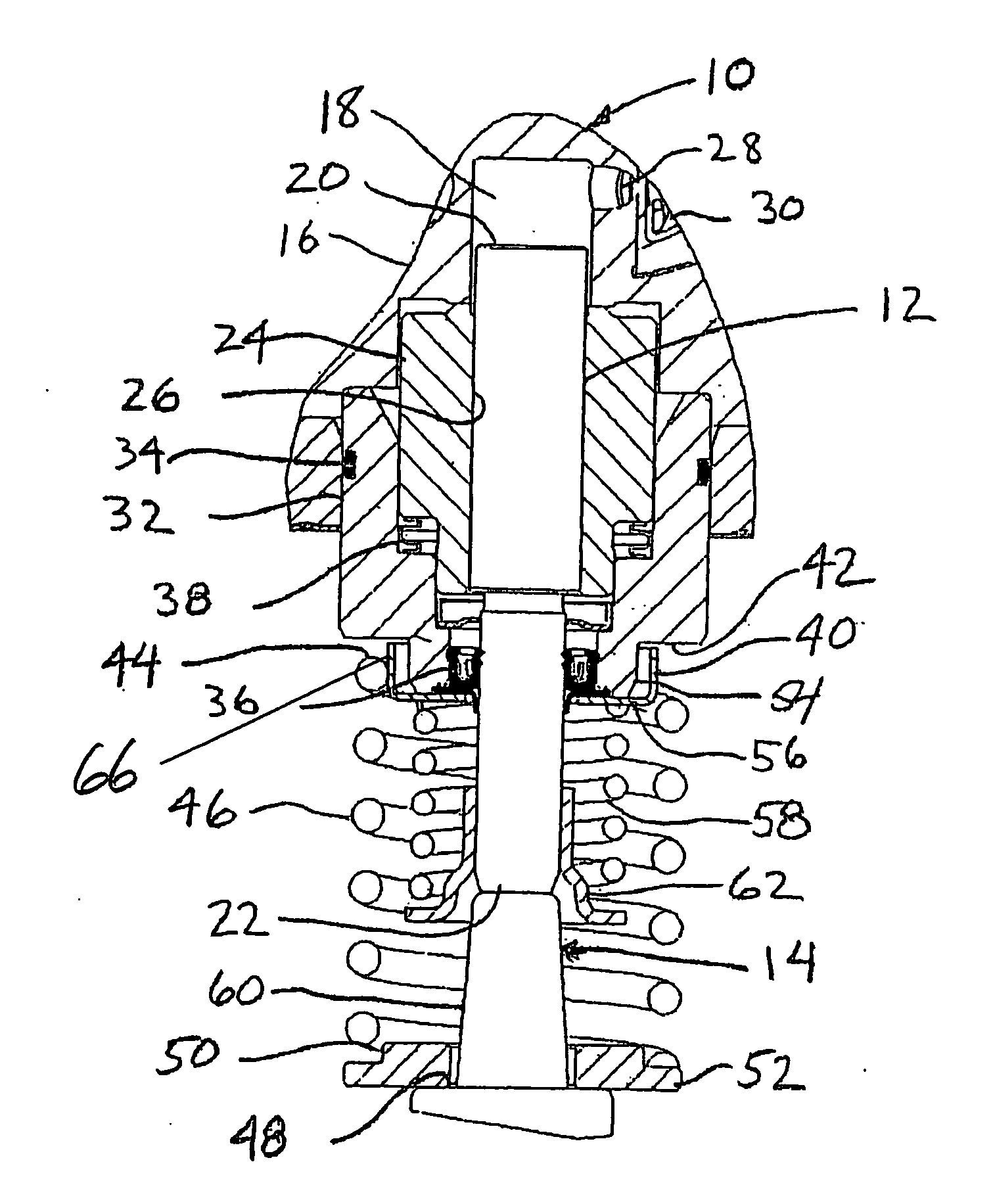

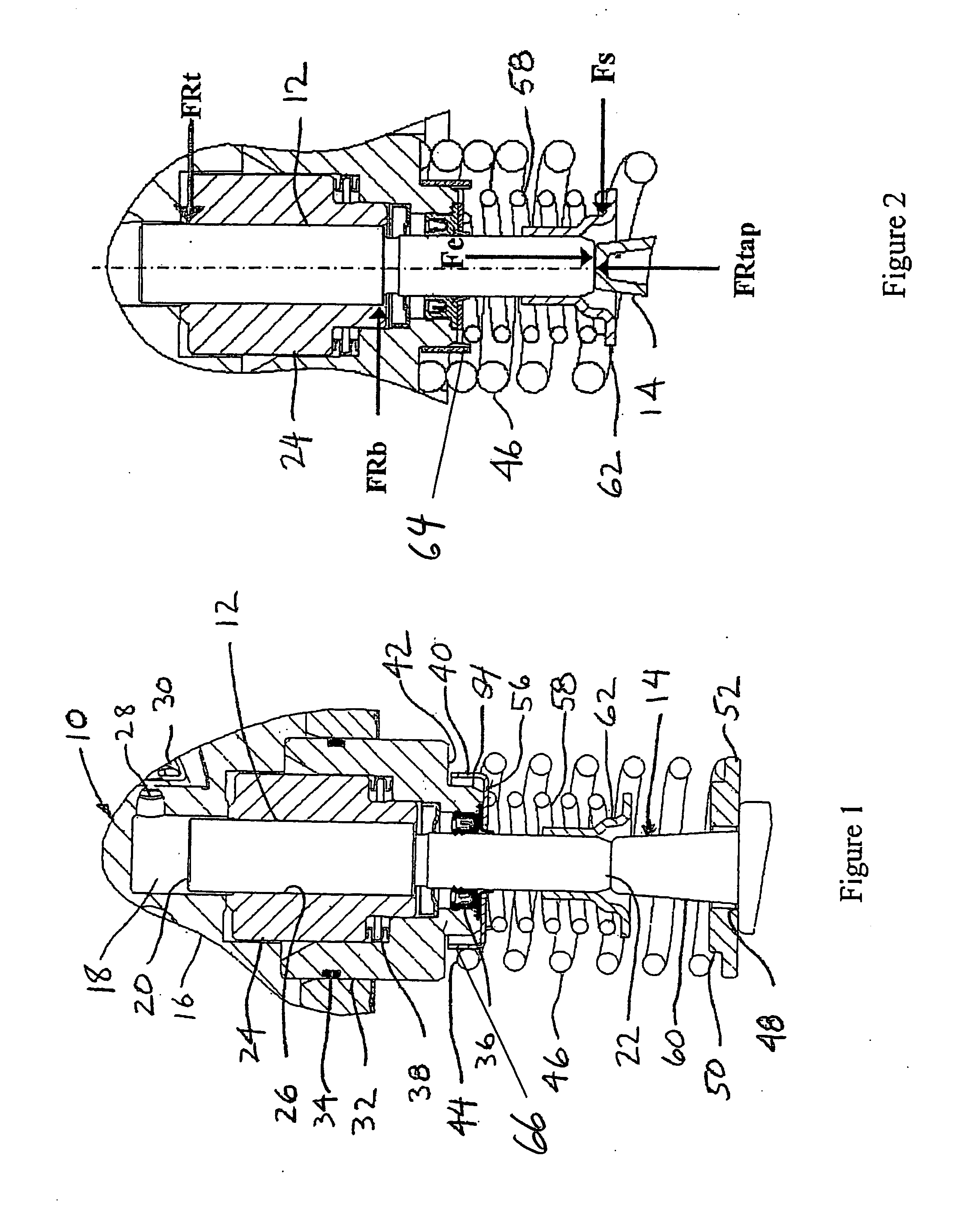

Combined axial piston liquid pump and energy recovery pressure exchanger

InactiveUS7799221B1Improve welfareMinimize the numberMembranesGeneral water supply conservationReciprocating motionEnergy recovery

A pumping machine, that can serve a system as the sole main pump for pressurizing a primary liquid flow, incorporates, in a single machine, a rotor-drum type AP (axial piston) pump and a PX (pressure exchanger) that recovers energy from a secondary liquid flow such as the brine discharge from an RO seawater desalination system, with benefits including fewer moving parts and small machine size along with lower capital and operating costs. A single rotor-drum containing the cylinders and pistons is located between two end blocks, one or both configured with manifold passageways, ports and sliding valves. A swash-plate at one end reciprocates the pistons axially when the rotor-drum is rotated. Two working chambers, primary and secondary, are formed at opposite ends of a single piston in each cylinder, thus enabling the single rotor-drum to function as a primary liquid-pressurizing axial pump (AP) with sliding valves at the primary end enabling primary liquid pumping, and as a secondary outflow-driven pressure exchanger (PX) recovering energy from pressure drop in the secondary liquid flow and thus contributing work to primary pumping, saving energy and reducing operating costs.

Owner:OCEAN PACIFIC TECH

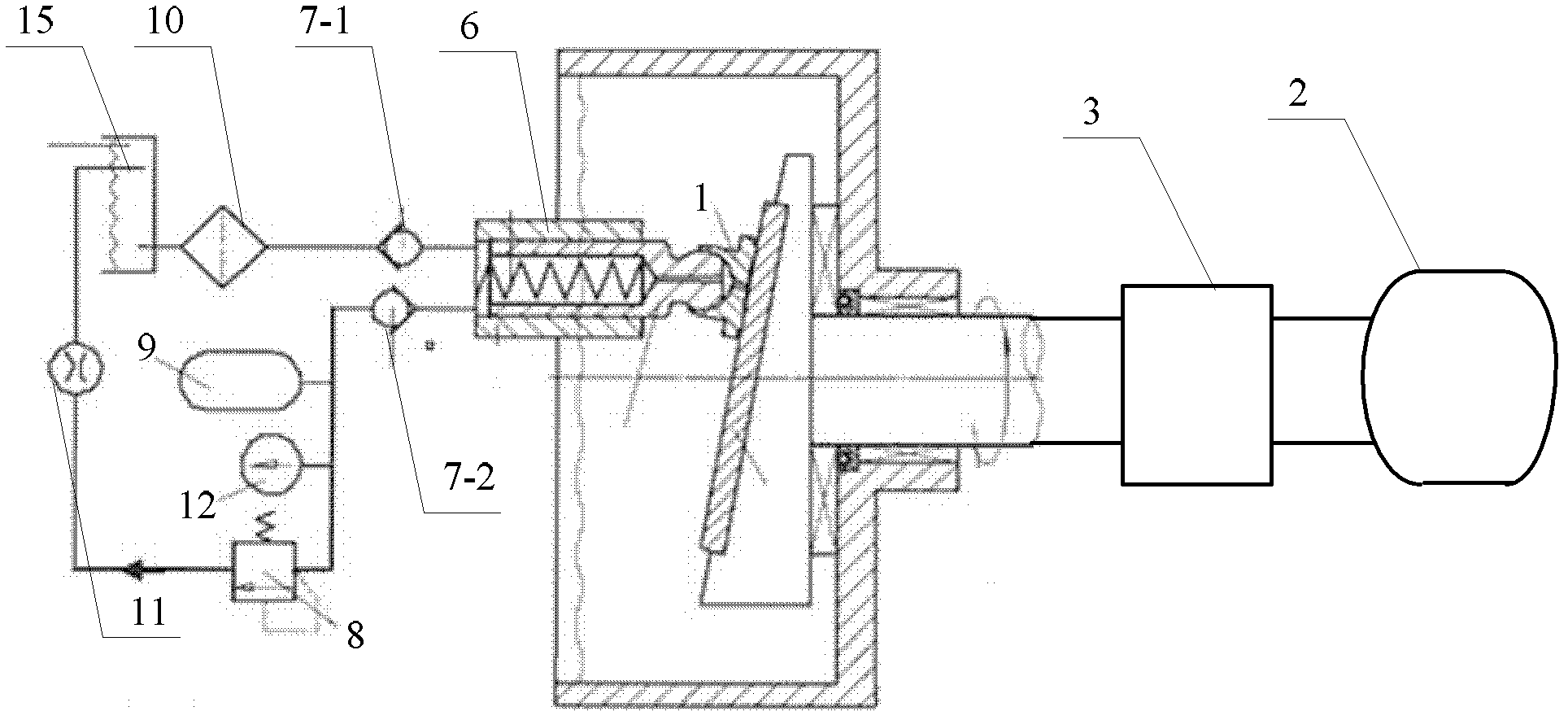

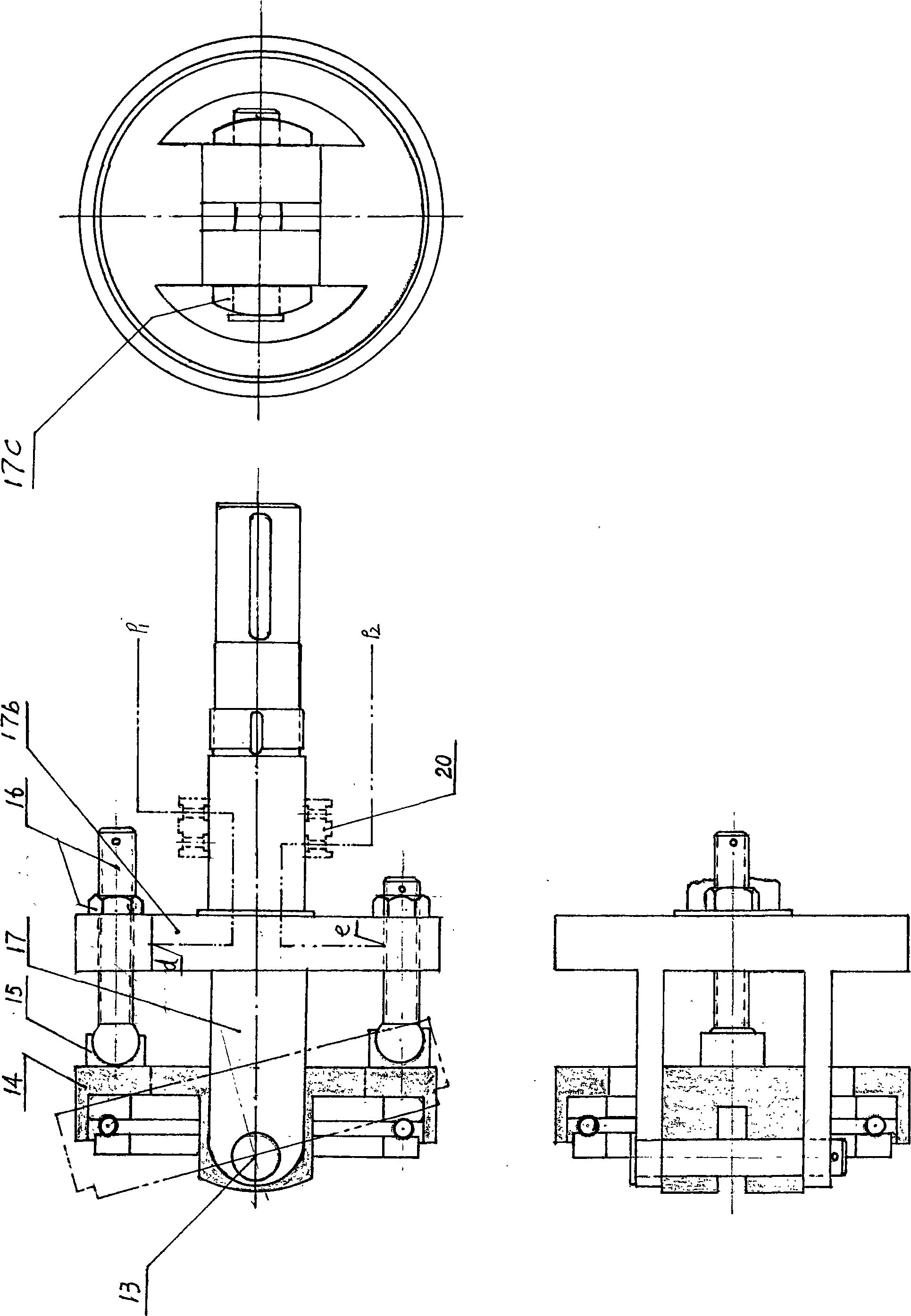

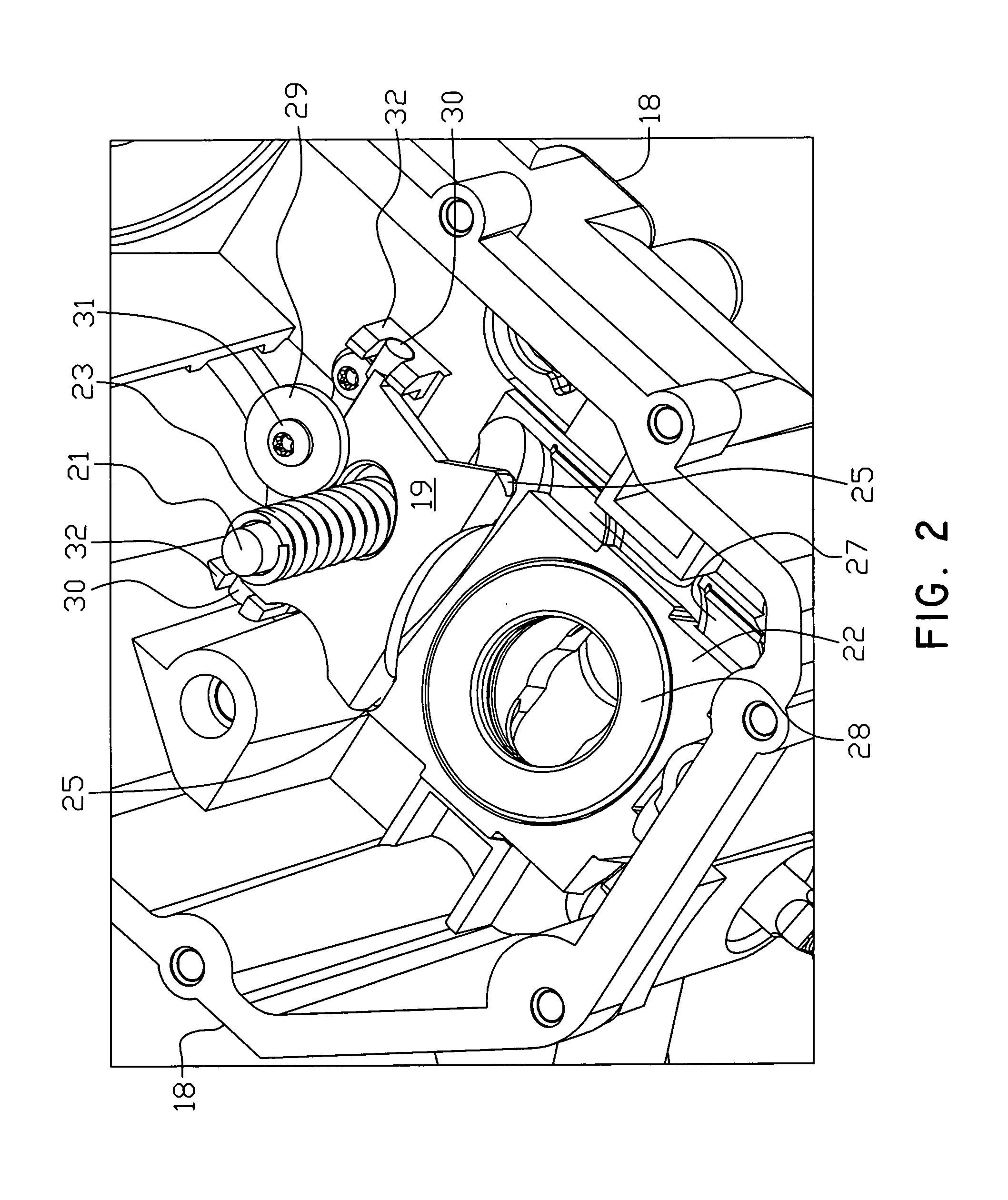

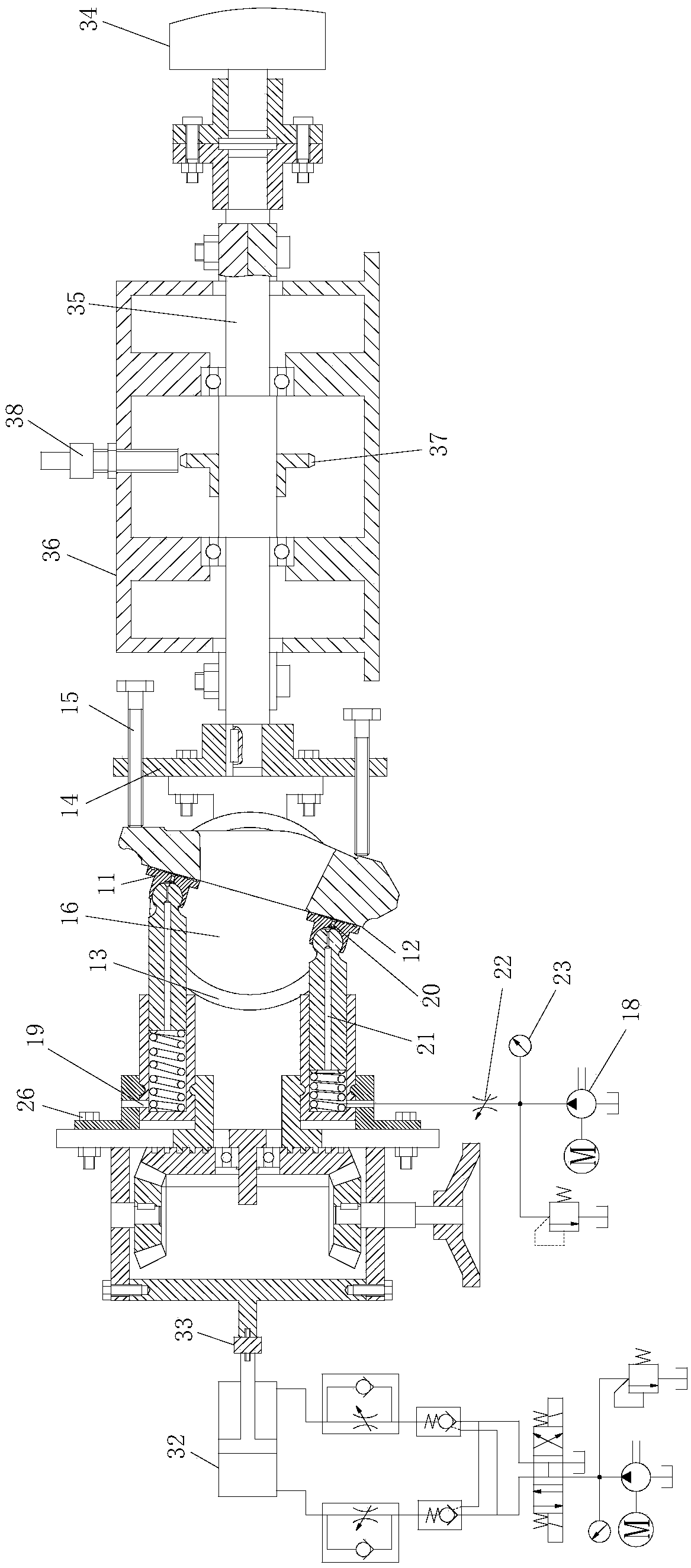

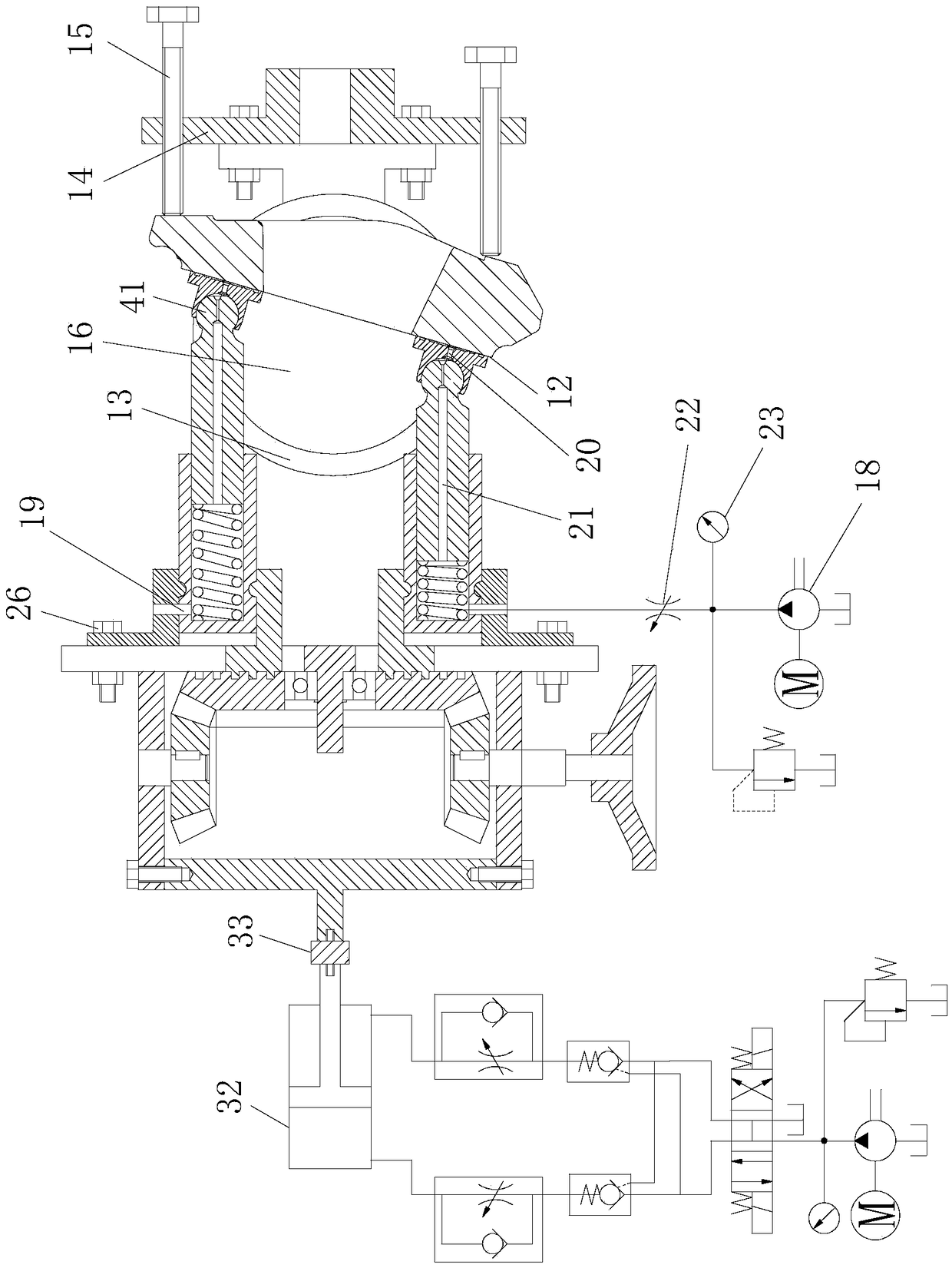

Performance testing device for piston shoe in axial plunger pump

InactiveCN102312830AImprove performanceImprove work performancePump testingPositive-displacement liquid enginesHydraulic cylinderCoupling

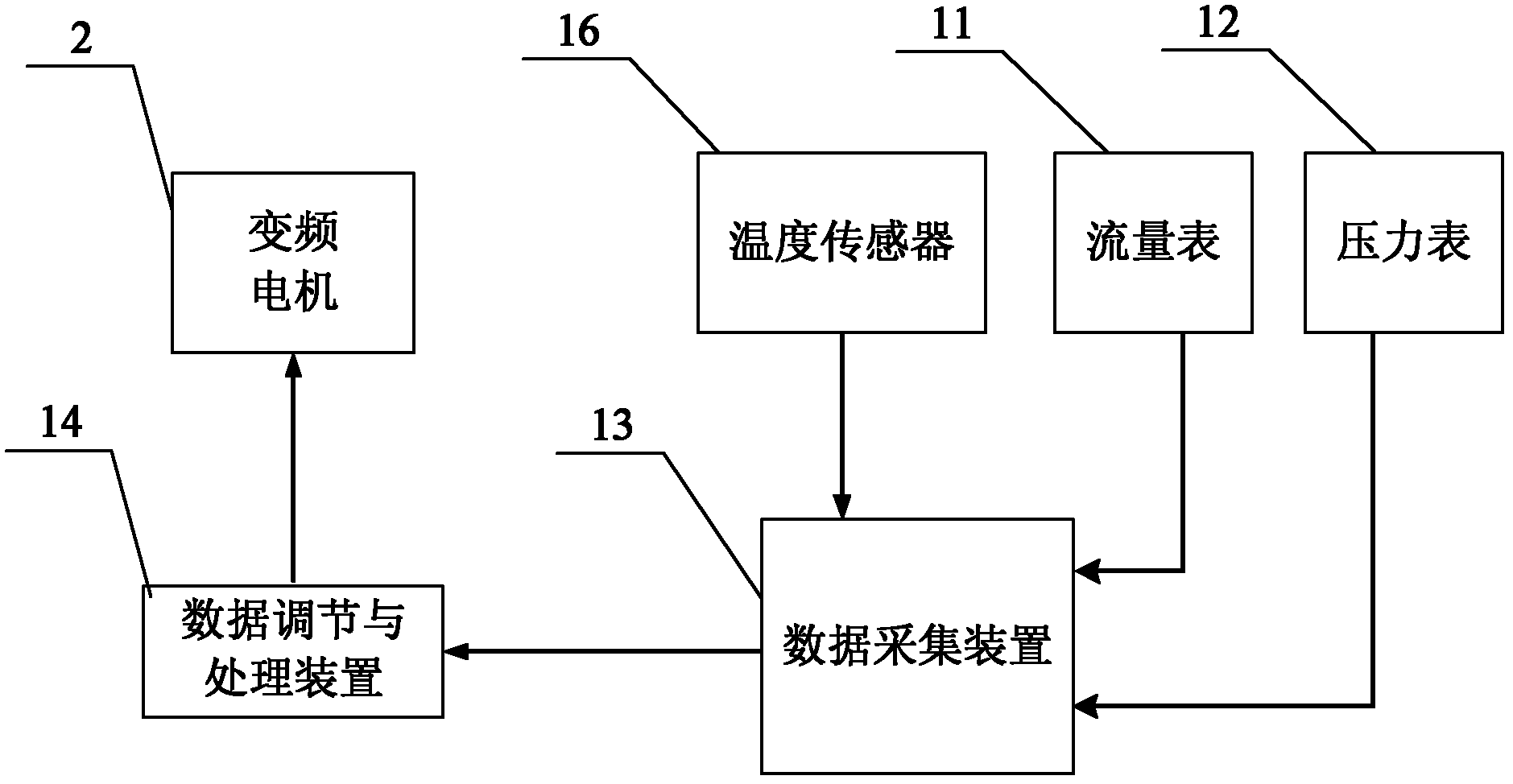

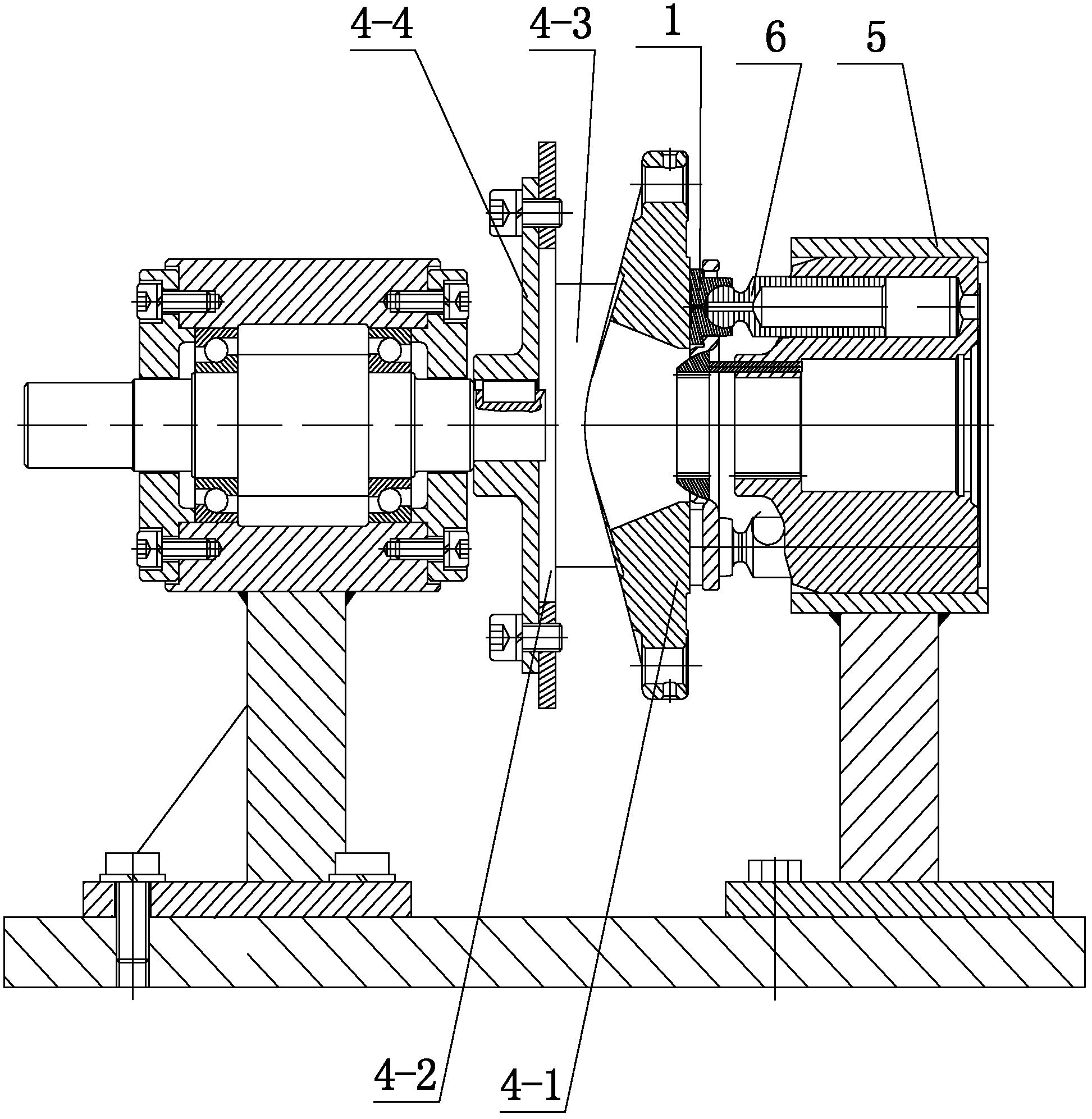

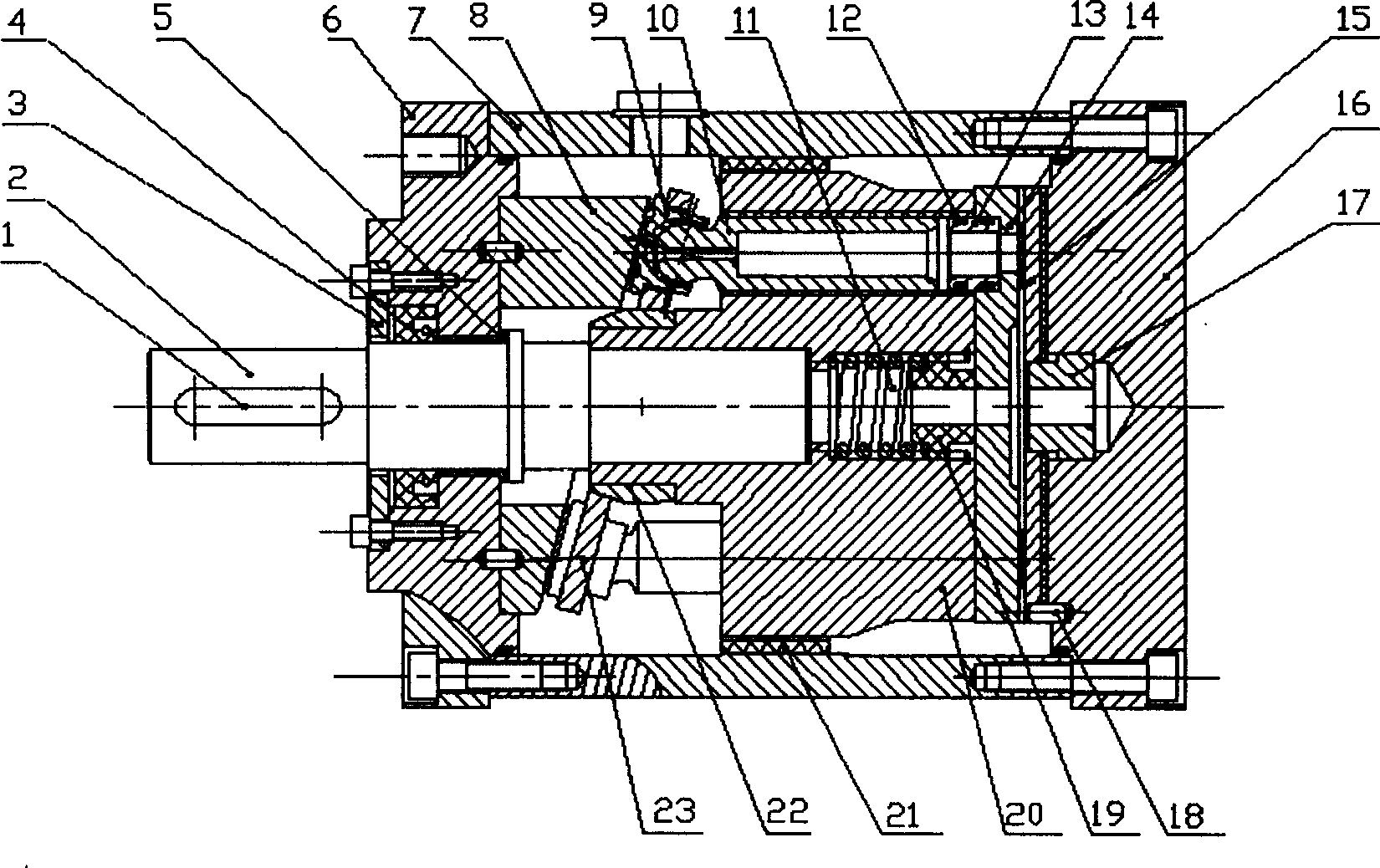

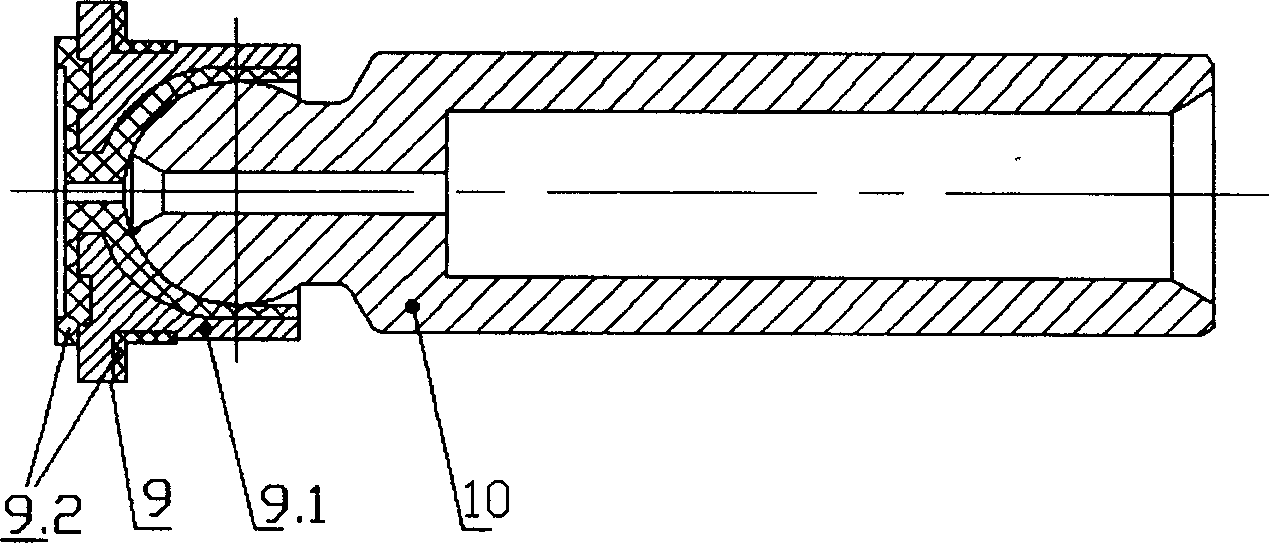

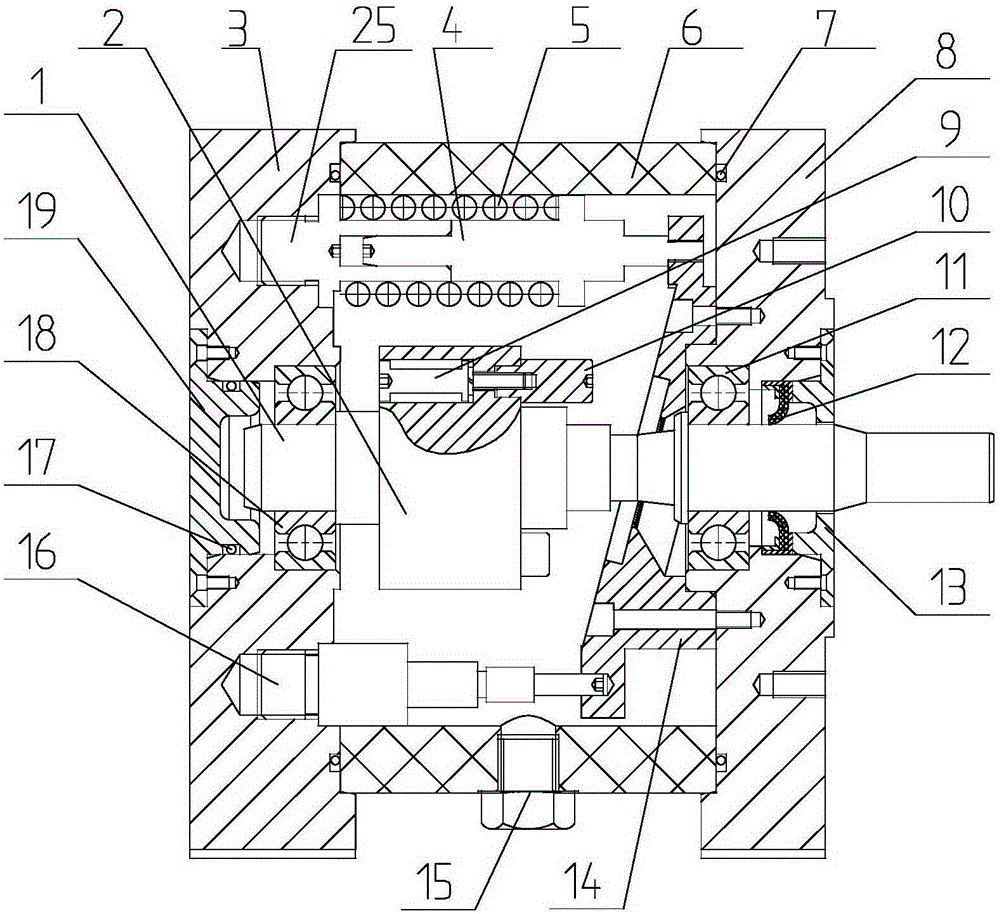

A performance testing device for a piston shoe in an axial plunger pump belongs to the technical field of hydraulic elements, and solves the problems that in the prior art a simulator is adopted to carry out the simulation test on the performance parameter of the piston shoe in the plunger pump, the test result has errors, and a piston shoe pair is difficult to be isolated from other friction component pairs when the performance parameter test is carried out in the piston shoe in a practical pump. The performance testing device for the piston shoe in the axial plunger pump comprises a piston shoe, and further comprises a variable frequency motor, a rotating speed and torque sensor, a variable device, a hydraulic cylinder body, a plunger, a flowmeter, a pressure gauge, an oil box and a temperature sensor, wherein the coupling plate of the variable device is fixedly connected with a bottom plate of a support tile of a swash plate through a bolt, the swash plate is supported by the support tile of the swash plate, three screwed holes on each fastening splint are connected with three corresponding screwed holes on one side of the swash plate through the bolts, a waist-shaped slot on each fastening splint corresponds to and is connected with the screwed hole on the side wall of the support tile of the swash plate through bolts, so the swash plate can swing in the support tile of the swash plate. The performance testing device for the piston shoe in the axial plunger pump is used for testing the performance of the piston shoe in the axial plunger pump.

Owner:HARBIN INST OF TECH

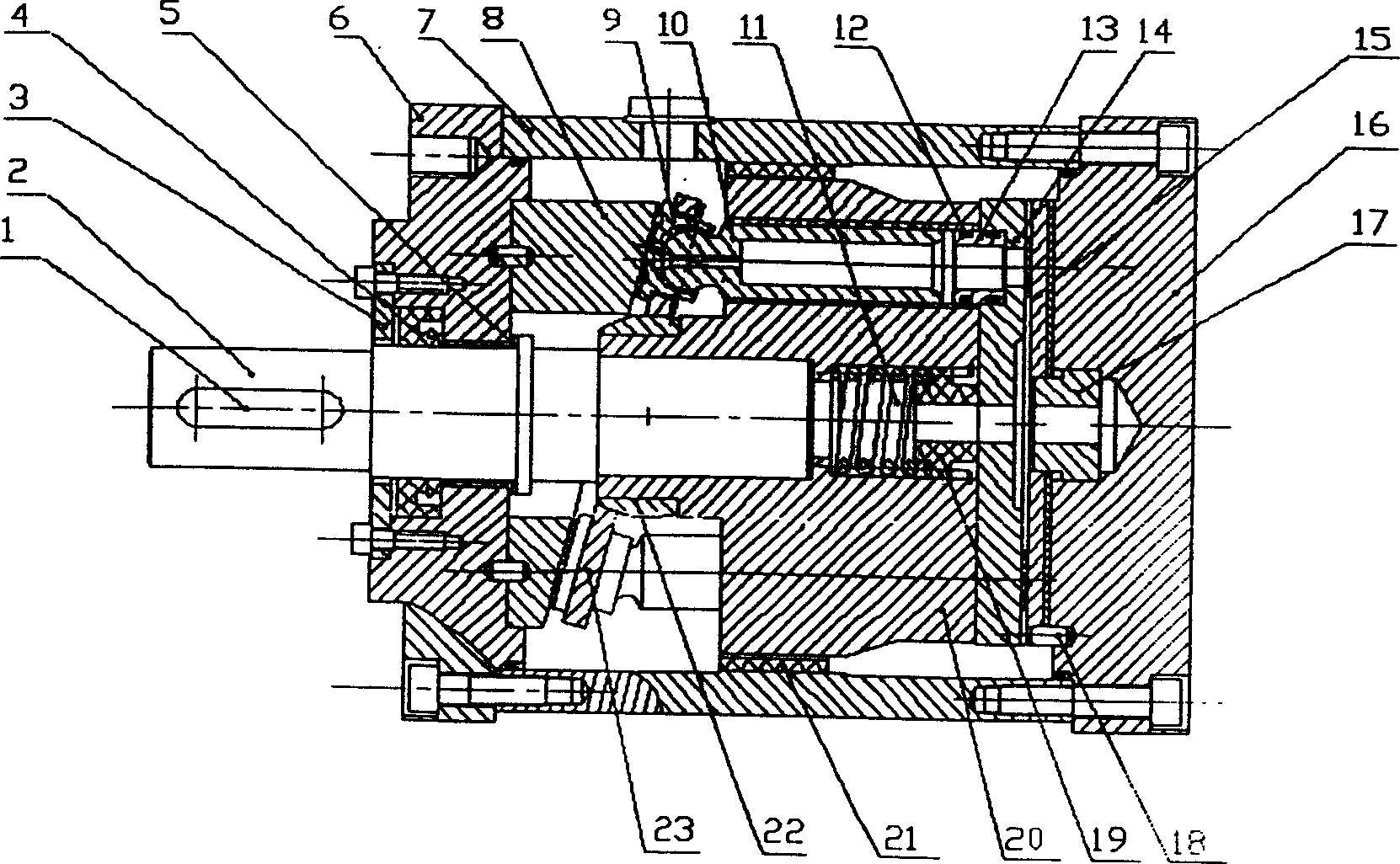

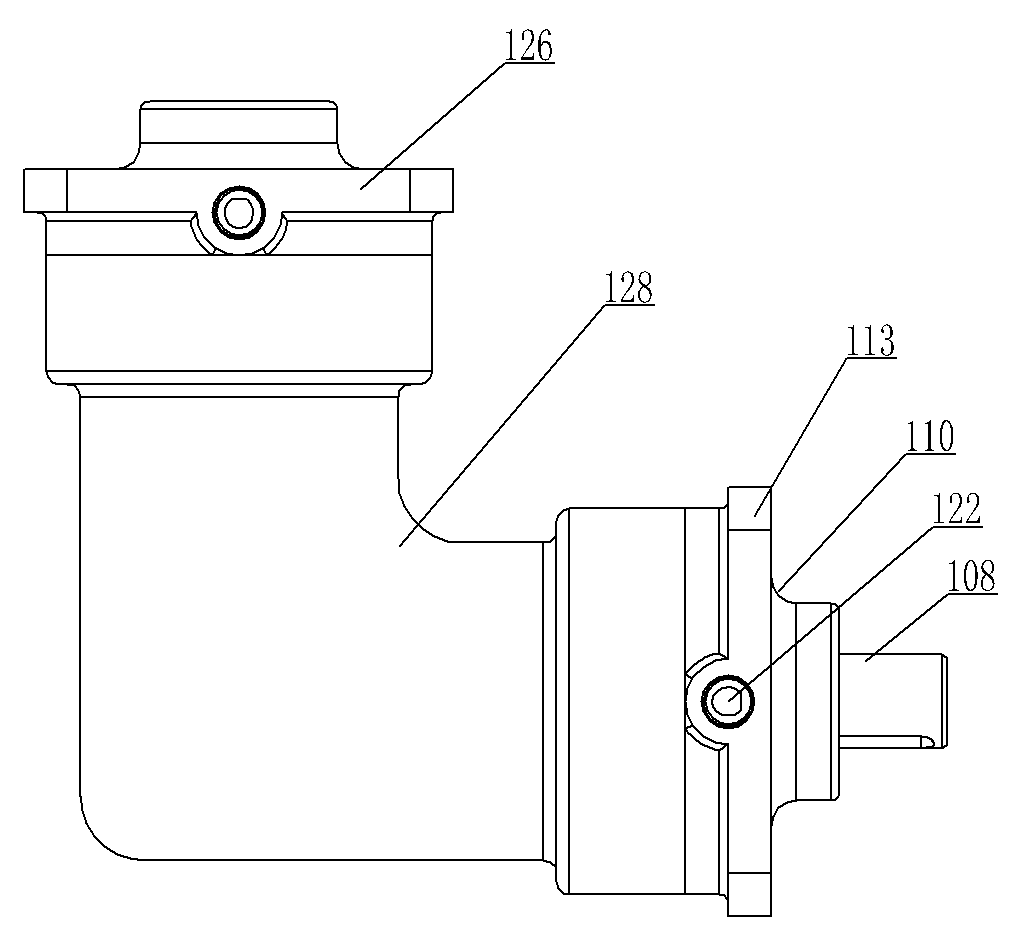

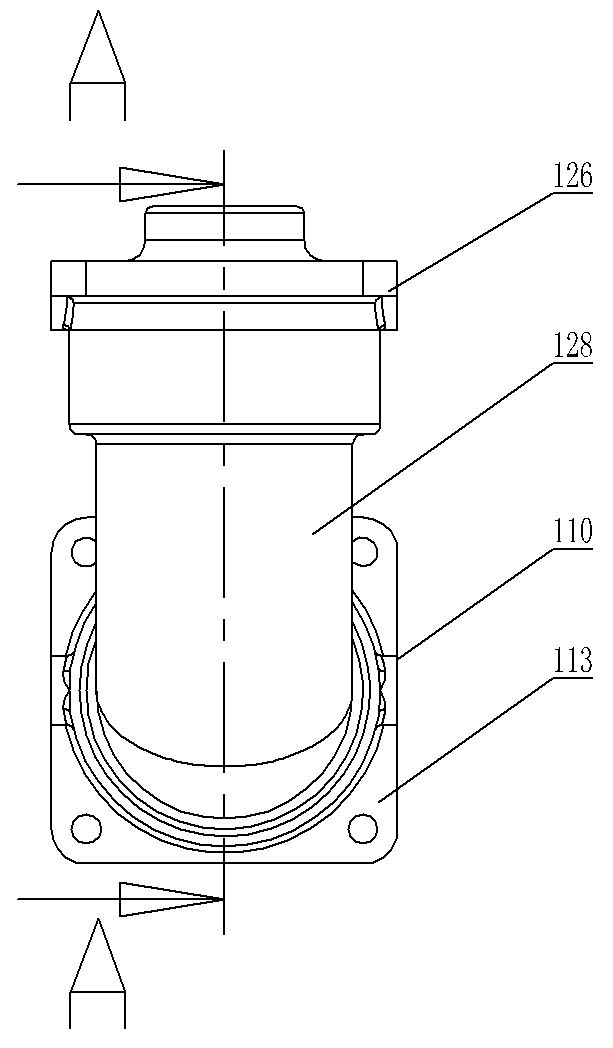

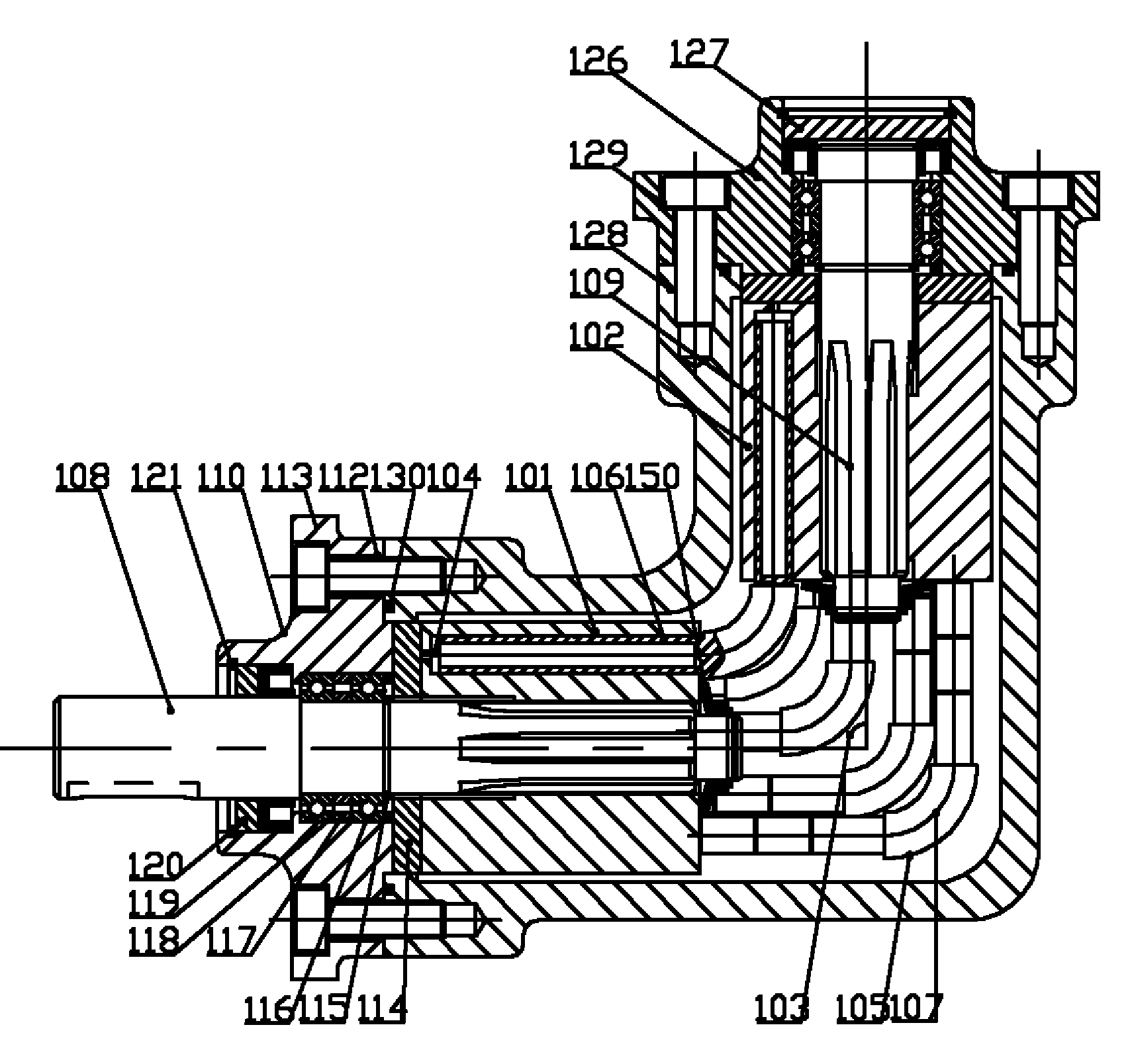

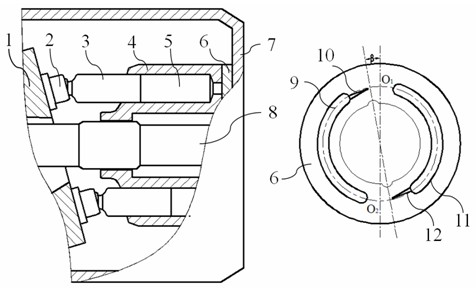

Fully water lubricating and end flow distributing pure water hydraulic axial plunger pump or motor

InactiveCN1554869AReduce radial sizeReduce volumePositive displacement pump componentsFluid-pressure actuatorsFresh waterEngineering

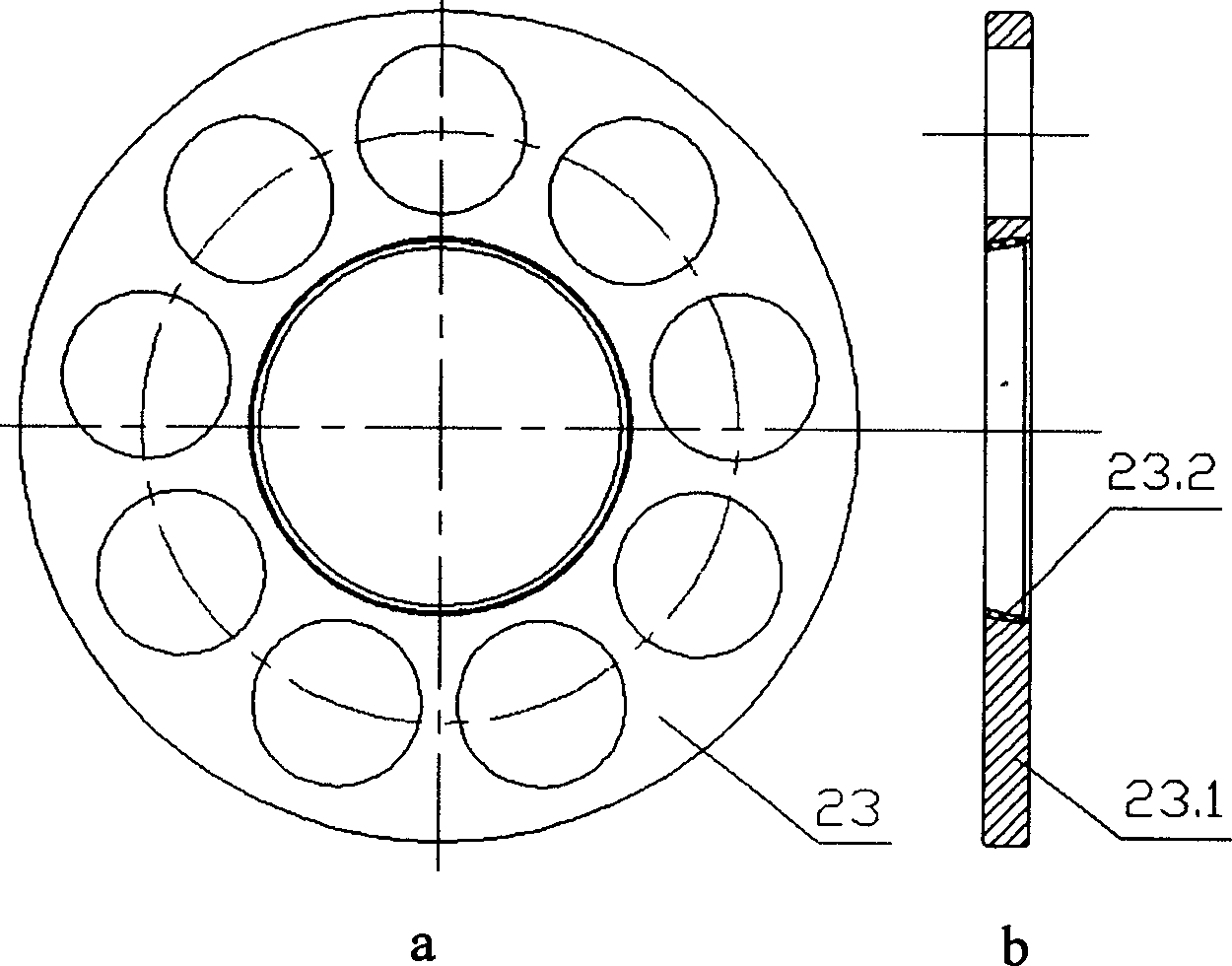

The fully water lubricating and end flow distributing water hydraulic axial plunger pump or motor operates with filtered natural water as work medium and consists of mainly one casing and one rotating cylinder inside the casing. The cylinder has odd holes distributed homogeneously in the same circumference and parallel to the driving or output shaft, plungers of the plunger-sliding shoe assembly are set inside the holes, and the flow distributing sleeve has one end installed in the other end of the holes and the other end set in the holes of the push stopping disc. The push stopping disc floats to the cylinder to compensate the error of parts in machining and installation. The central spring has one end pressing the push stopping disc to the flow distributing disc via plastic rod and the other end pressing the sliding shoe to the inclined disc via the cylinder, ball pivot and backstroke disc, and the driving or output shaft is combined firmly to the cylinder.

Owner:ZHEJIANG UNIV

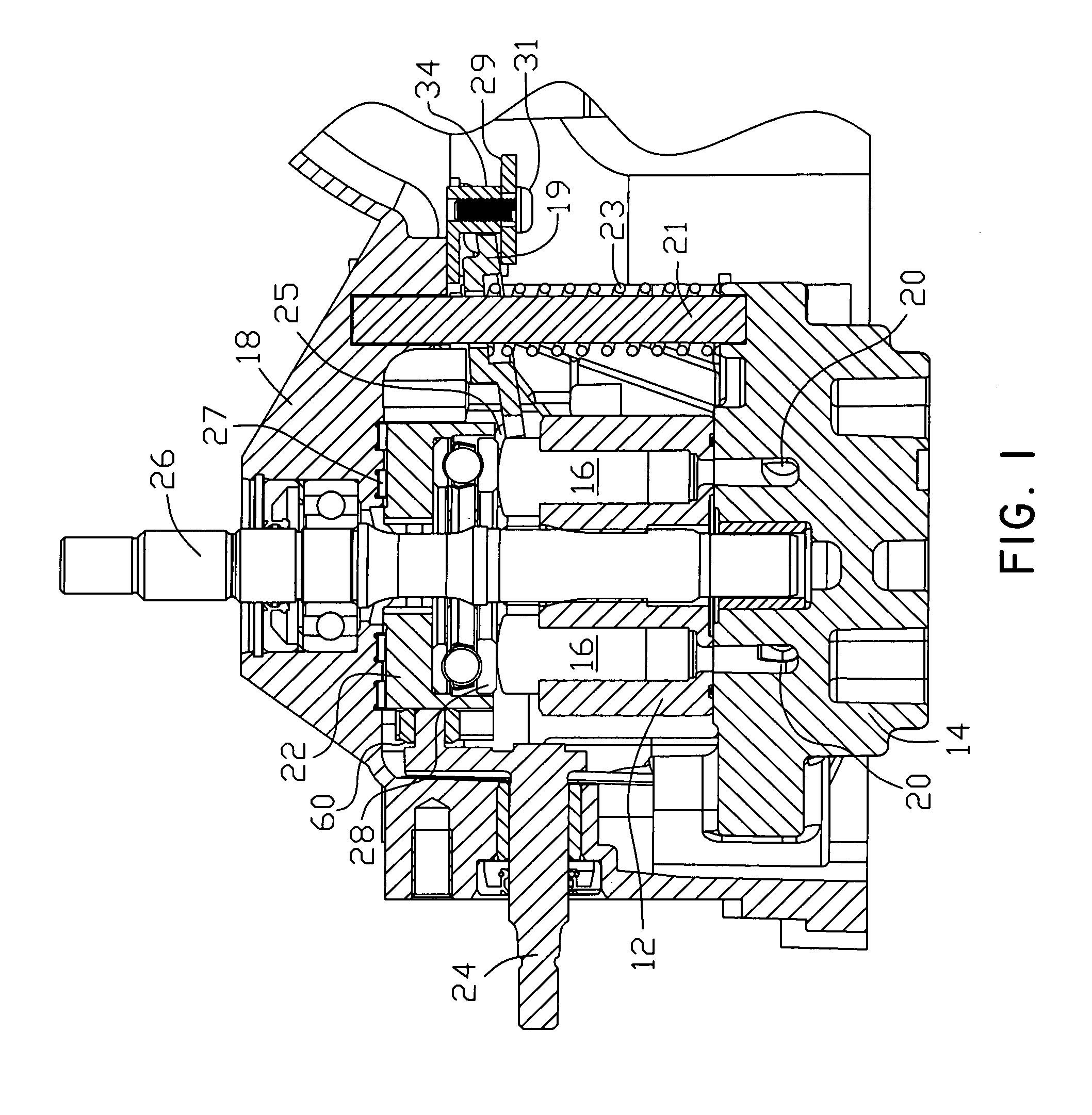

Hydrostatic transmission

InactiveUS6986406B1Reduce the overall heightAvoid less flexibilityFluid couplingsGearboxesThrust bearingEngineering

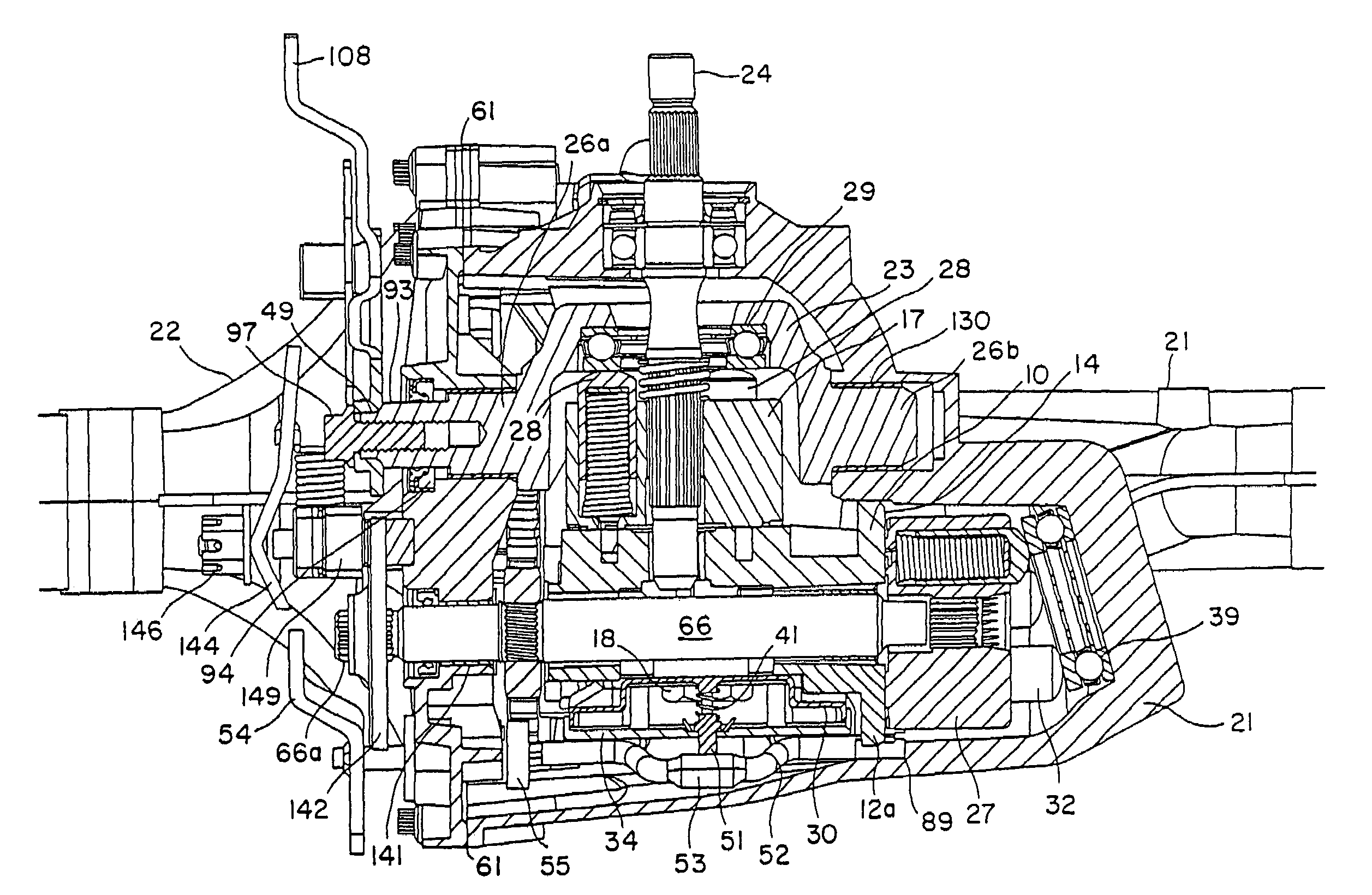

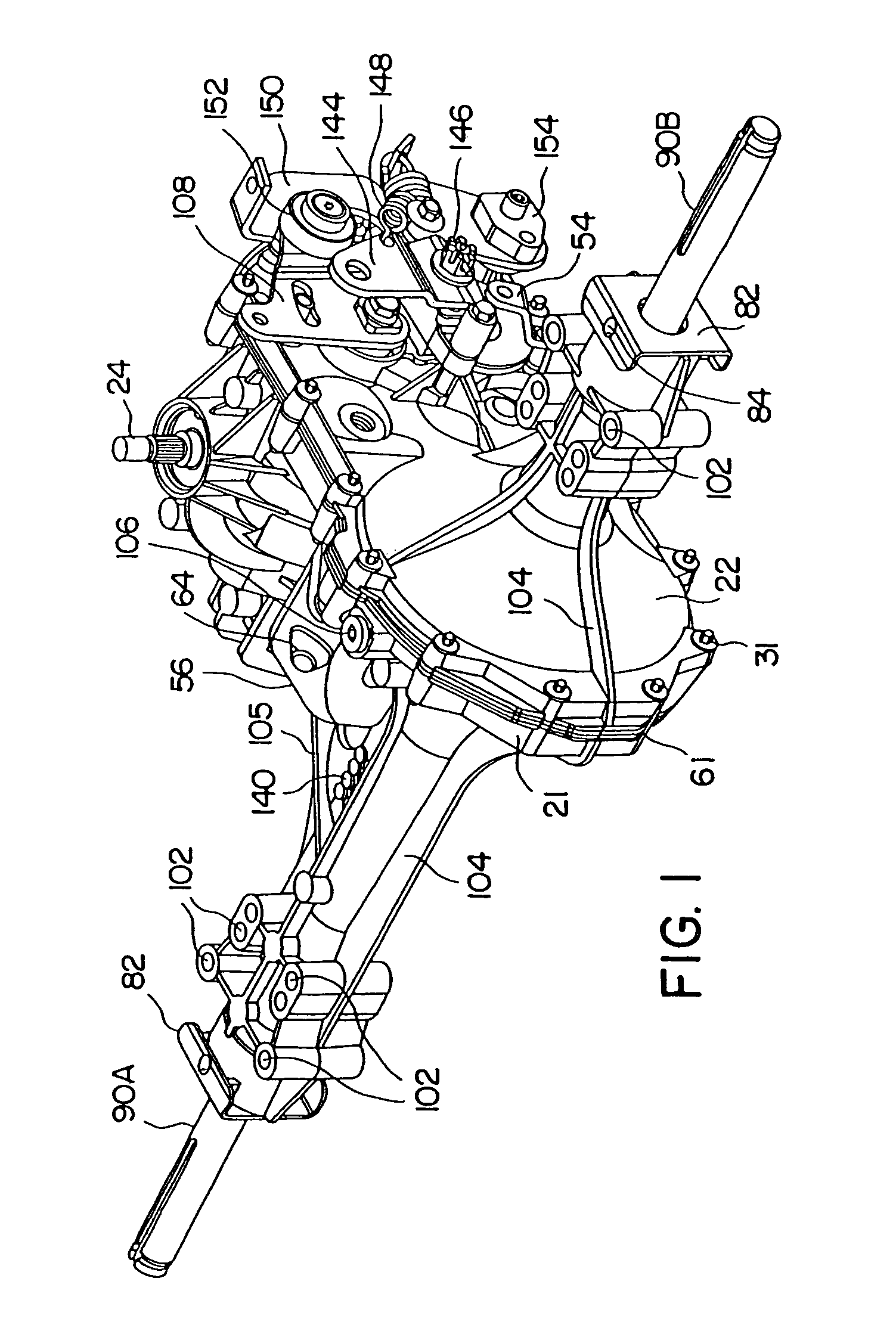

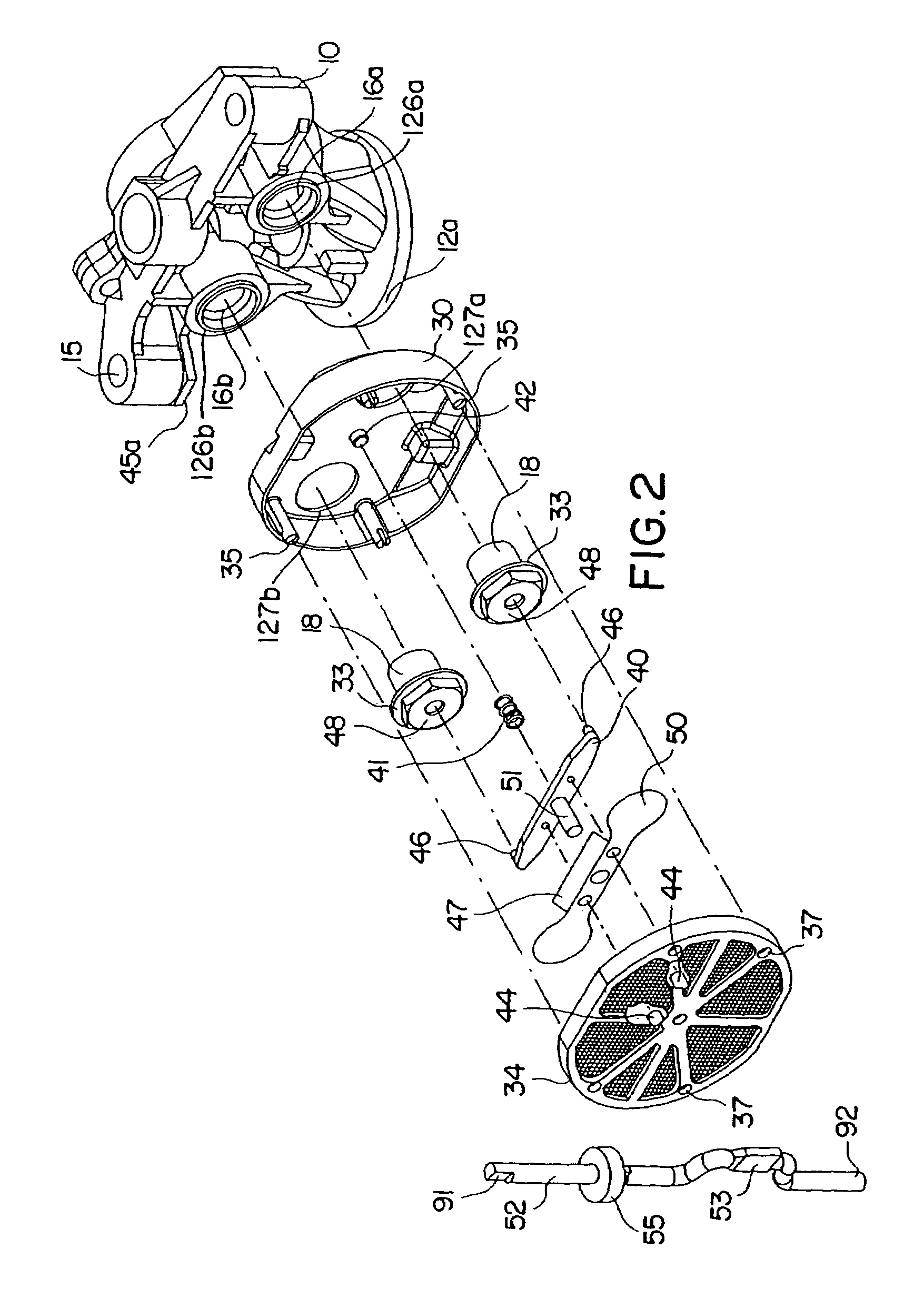

An axle driving apparatus having a housing having two members joined along a joint surface and a hydraulic axial piston pump and motor mounted on a center section located in the housing, wherein the pump and motor are mounted perpendicular to one another. The motor is engaged to a fixed thrust bearing located in the housing and the center section is located entirely between the joint surface and the thrust bearing.

Owner:HYDR0 GEAR

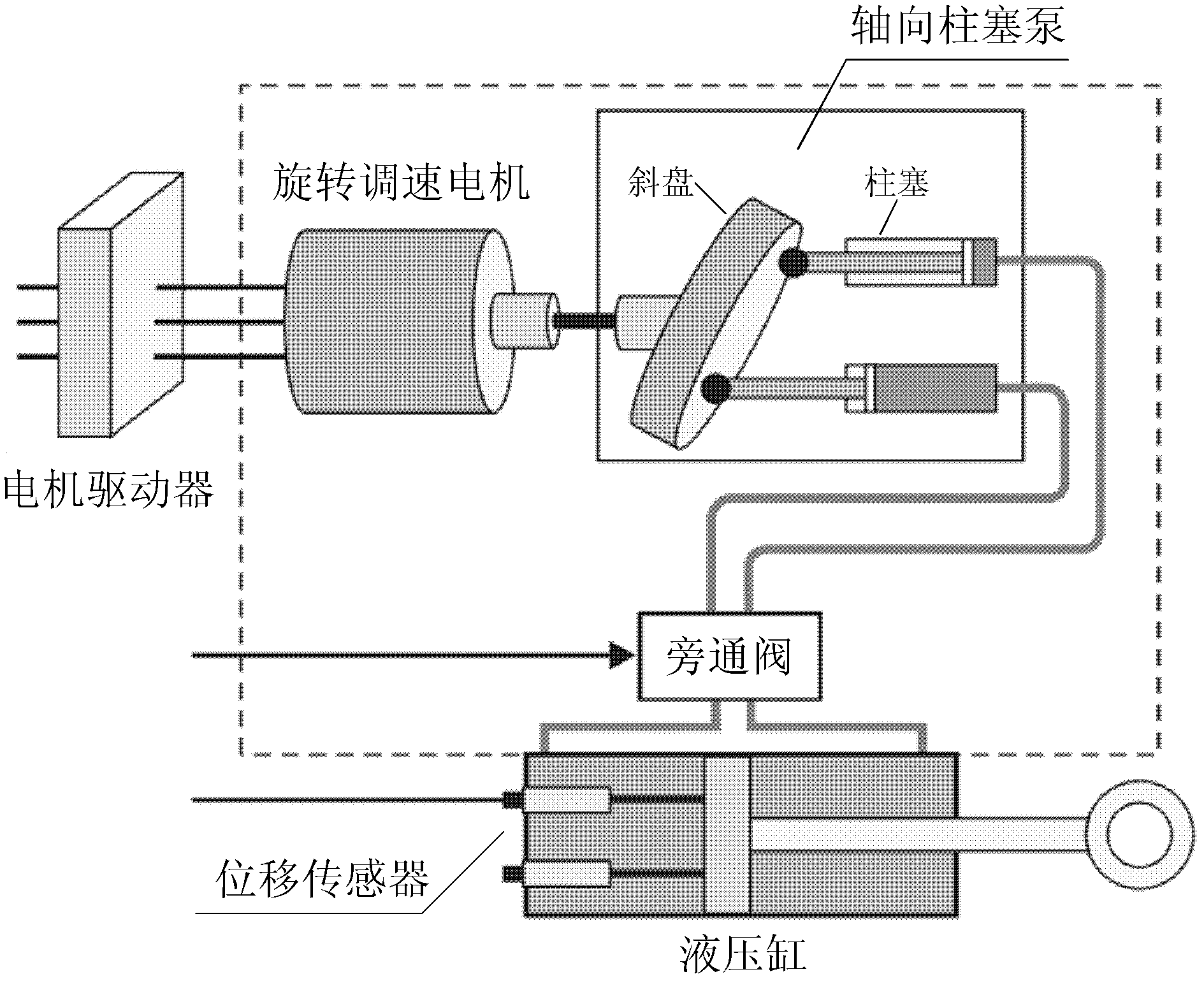

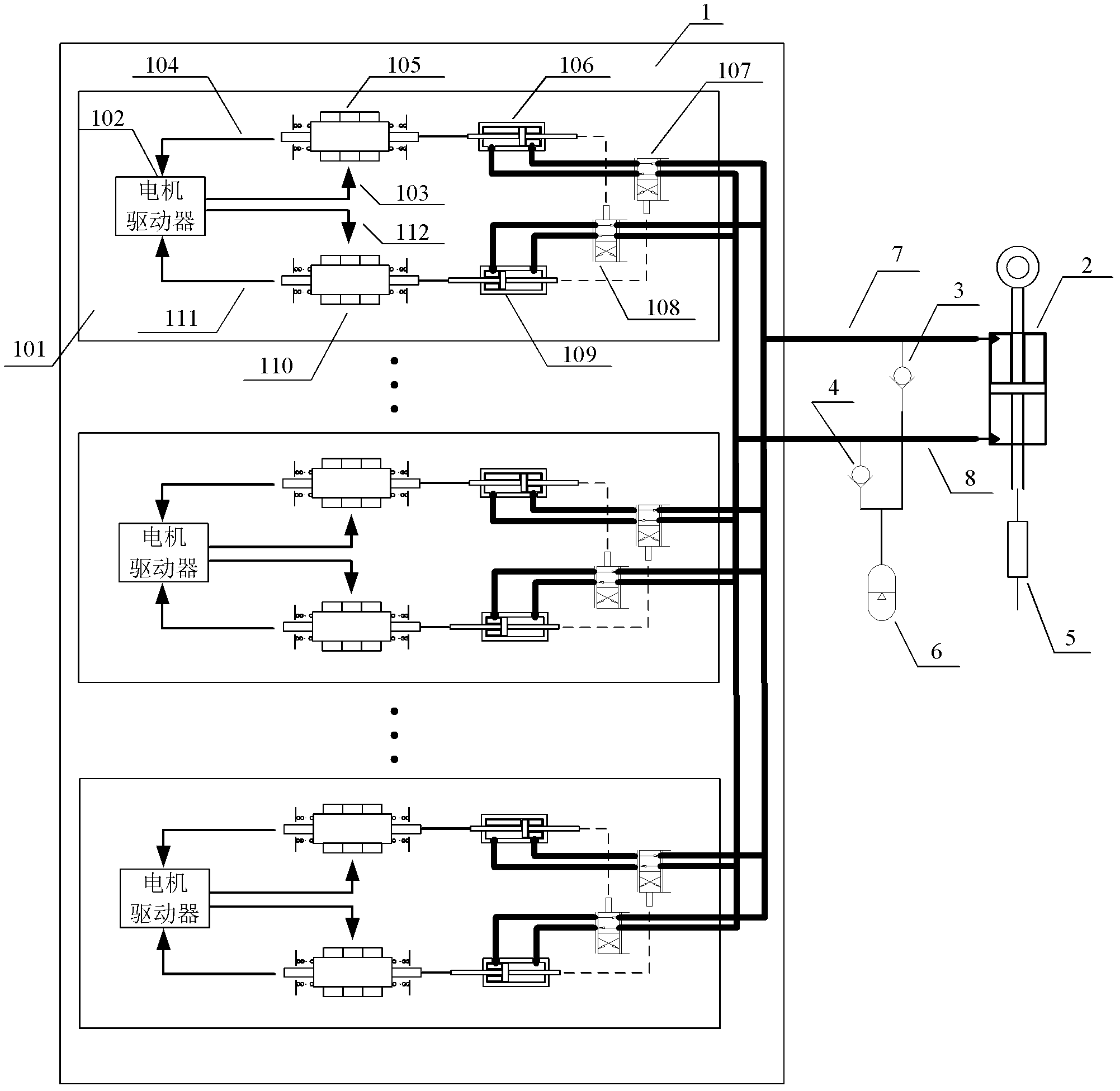

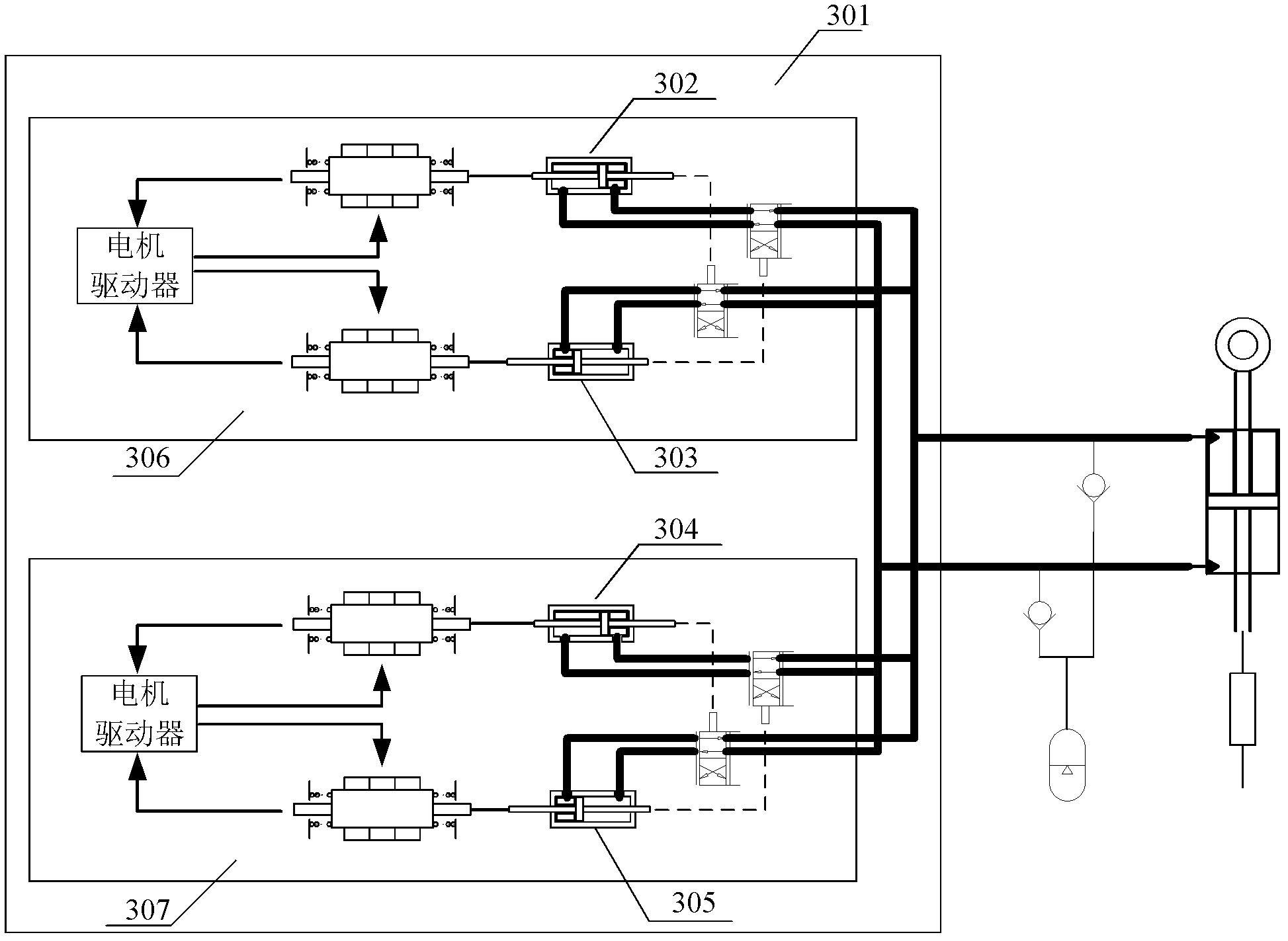

Direct-drive electro-hydraulic actuator

ActiveCN102588382AImprove flexibilityImprove reliabilityFluid-pressure actuator componentsFuel tankElectro hydraulic

The invention discloses a direct-drive electro-hydraulic actuator which comprises a direct-drive electro-hydraulic servo pump, a pressurizing oil tank, a first oil compensation check valve, a second oil compensation check valve and a hydraulic cylinder; according to the direct-drive electro-hydraulic actuator, a plurality of oil supply units are combined for use, so that the direct-drive electro-hydraulic servo pump system can be combined for construction according to the power requirement of an integrated hydraulic system; and parts do not need to be designed independently, so that the system has higher flexibility. According to the direct-drive electro-hydraulic actuator, the plurality of oil supply units work simultaneously so as to form a heat backup of the direct-drive electro-hydraulic servo pump system, particularly, redundant configuration is carried out to the pump system; when one or a quantity of oil supply units fail, the other oil supply units can lead the pump system to degrade to work, and compared with the condition that the whole pump fails when a plunger of an axial plunger pump is pulled away or tightly clamped, the direct-drive electro-hydraulic servo pump system has higher reliability.

Owner:BEIHANG UNIV

Radial piston pump

ActiveUS20090155095A1Sufficient degree of sealingReduce overall outer diameterPump controlPressure lubricationRadial piston pumpCylinder block

The invention relates to a radial piston pump having external loading. Said radial piston pump has an inner eccentric which is attached to a rotatable driveshaft, a cylinder block which has positionally fixed cylinder bores aligned radially with respect to the driveshaft, and displacement pistons which are mounted in a longitudinally movable manner in the cylinder bores, with the displacement pistons having a piston head with a short casing height, and being mounted with their piston base on the eccentric, in such a way that the piston head, during its longitudinal movement, pivots in a predetermined angle range &r about the longitudinal central axis of the associated cylinder bore.

Owner:DANFOSS POWER SOLUTIONS INC

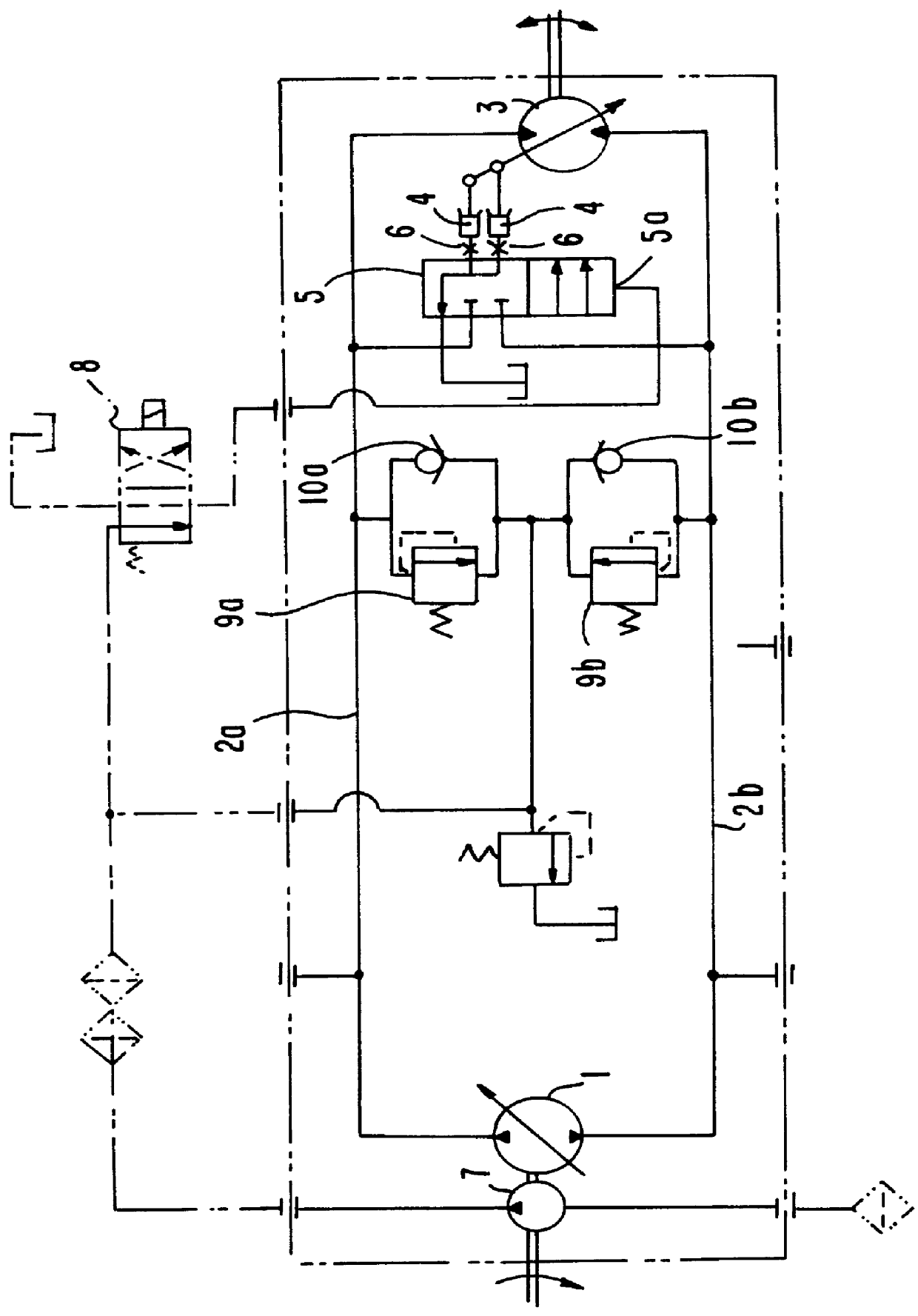

Hydrostatic transmission system

An object of the present invention is to provide a hydrostatic transmission system integrally constructed without being large-sized while incorporating a variable displacement motor therein. In order to accomplish the object, a casing 11 has a variable displacement pump 1 and a variable displacement motor 3 incorporated therein in a manner to be juxtaposed to each other. The pump 1 is constituted by a cam plate type axial plunger pump which is constructed so as to render a tilting angle of a cam plate 18 variable and render a discharge rate of hydraulic fluid zero when the tilting angle is within a range set near 0 degree. The motor 3 is constituted by a cam plate type axial plunger motor including a cam plate 33 of which a tilting angle is variable. A cover 48 is provided with a pair of passages 2a and 2b, relief valves 9a and 9b, check valves 10a and 10b, and a change-over valve 5.

Owner:KYB CORP

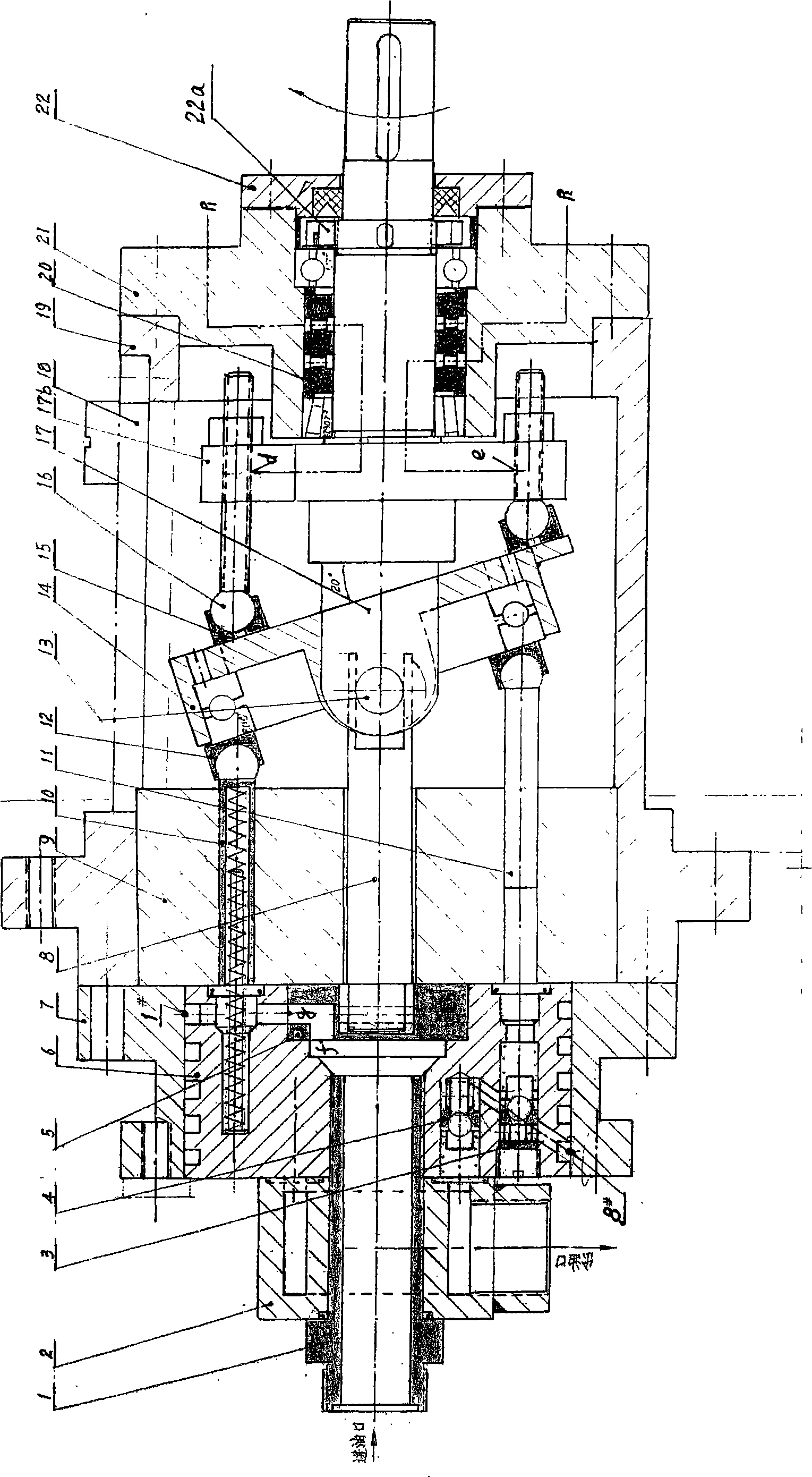

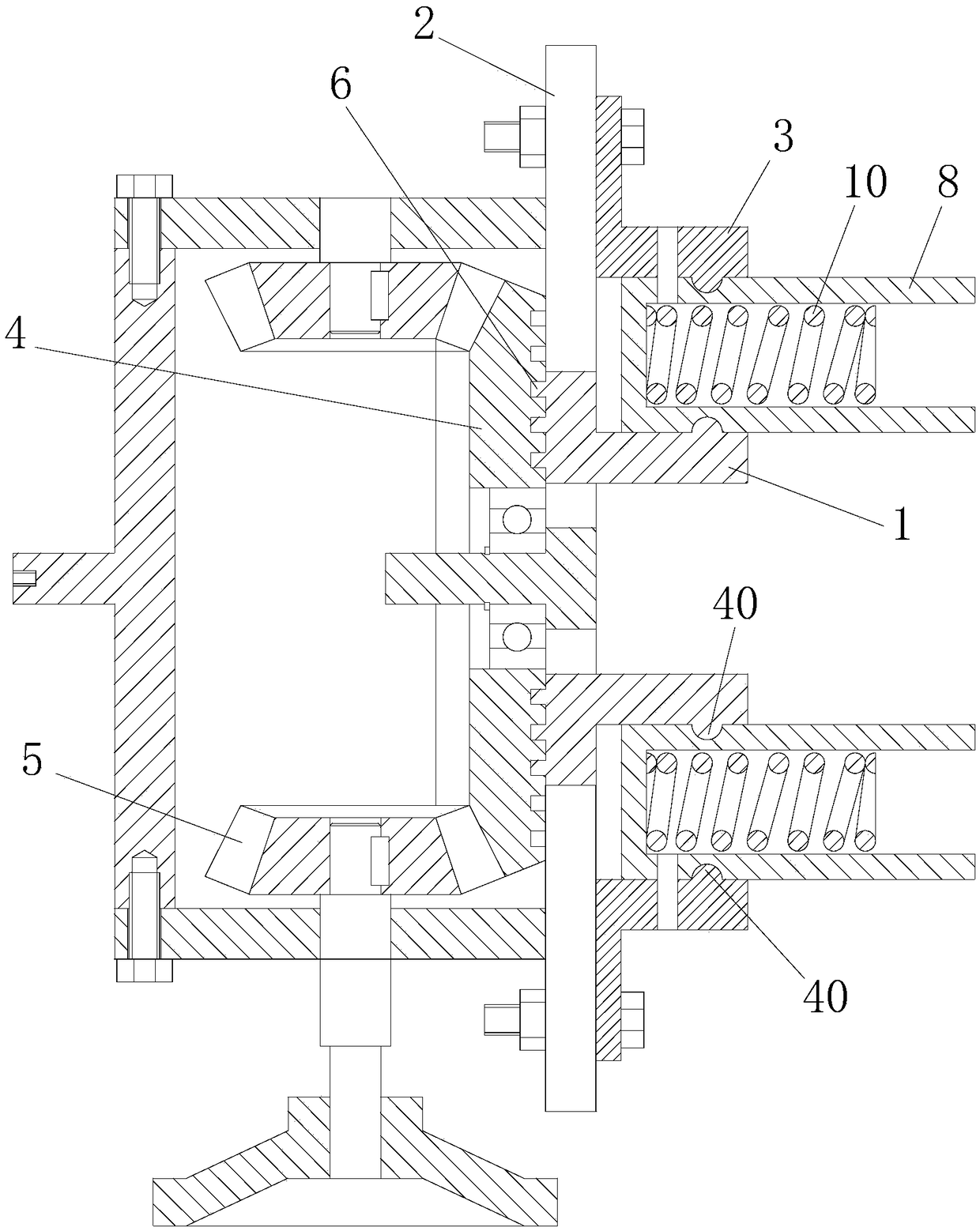

Lubricating property testing device for port plate pair of axial plunger pump

InactiveCN1570605AImplement Feedback ControlReal-time monitoring of experiment statusUsing mechanical meansMaterial analysisTest fixtureFeedback control

This invention discloses an apparatus for measuring the lubrication of axial plunger pump auxiliary. Its hydraulic power system is composed of main oil line and loading oil line, wherein main oil line serves to provide hydraulic oil to test bench of lubricant film, and loading oil line serves to provide relevant pressing force to auxiliary to balance hydraulic backward thrust from seal band; test bench of lubricant film is to test auxiliary lubrication under various working situations; monitoring and controlling system is to monitor the experiment status in real time and to collect multiple working parameters during the experiment to accomplish the analysis and process of the datum in measuring experiment. Computer is employed to accomplish the on-line monitoring of various working situations to ensure high safety and stability.

Owner:ZHEJIANG UNIV

Axial variable displacement plunger pump of swash plate

InactiveCN101487458APositive-displacement liquid enginesMulti-cylinder pumpsEngineeringHigh pressure

The invention provides a power element used in a hydraulic transmission system. A swash plate variable axial plunger pump consists of a swash plate, a plunger cylinder body and a port plate. The angle-variable swash plate rotates with a drive rotating shaft which is connected by a hinge, and the swash plate drives the plunger to only have reciprocating motion in a fixed cylinder barrel, thus avoiding the disadvantages of large rotating inertia, large friction surface of port surface and easy leakage of a common swash plate axial plunger pump. The swash plate can be divided into a manual swash plate, a hydraulic-control swash plate and a hydraulic-control and spring combined variable swash plate. The swash plate can be conveniently adjusted by a window above a variable shell. The plunger pump has various uses and advantages of small rotating inertia, little friction surface, and high mechanical efficiency and volumetric efficiency, and being insensitive to pollution, generating little heat, being capable of taking as an economical combination pump with 'low pressure and large flow or high pressure and small flow' and the like. Besides as a common pump, the axial plunger pump can also be used in the superhigh pressure and synchronous cylinder field. The axial plunger pump has the advantages of general working accuracy and low production cost.

Owner:张全根

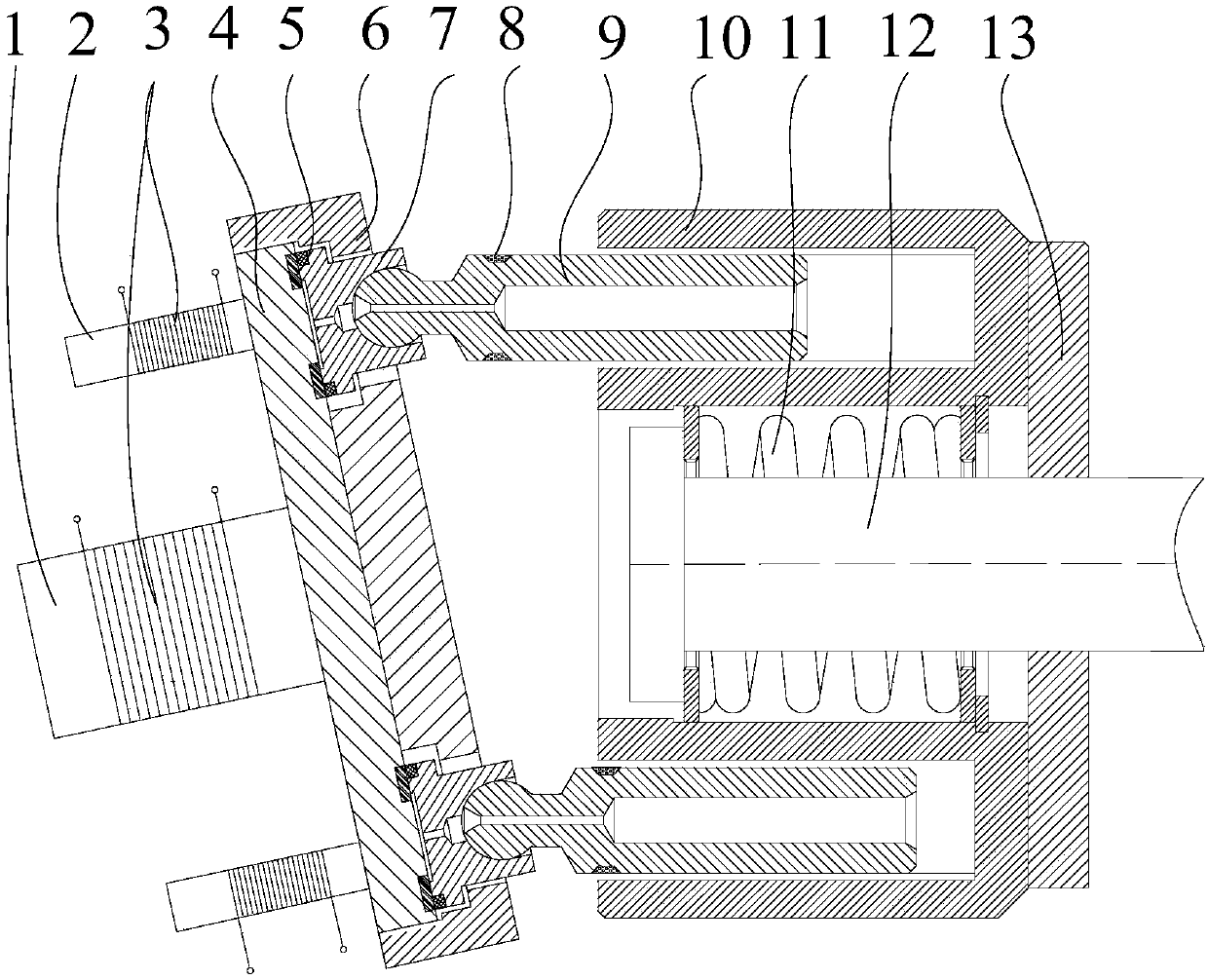

Device for measuring stirring loss caused by high-speed rotating element of axial plunger pump/motor

ActiveCN105201814AThe overall structure is simple and reliableReduce processing costsPump testingFluid-pressure actuator testingDynamic balanceEngineering

The invention discloses a device for measuring stirring loss caused by a high-speed rotating element of an axial plunger pump / motor. The device mainly comprises a main shaft, a cylinder, a torque rotation speed sensor, screws, plungers, a swash plate, a variable rod, a variable piston, a compression spring, a front end cap, a rear end cap, a casing and the like. According to the device for measuring the stirring loss, almost all factors influencing the stirring loss in the pump / motor are taken into consideration, interference of other power loss sources in the pump / motor to measurement of the stirring loss is eliminated through application of proper enlargement of a fit clearance, fastening of a mounting structure and grease lubrication of a bearing, dynamic balance of the rotating element is realized through the designed screw structure, and the stirring loss is measured according to a torque difference measured when a casing is full of oil or devoid of oil under the same work condition. The device is simple and reliable in overall structure, parts are convenient to replace, and the machining and detection costs are low.

Owner:ZHEJIANG UNIV

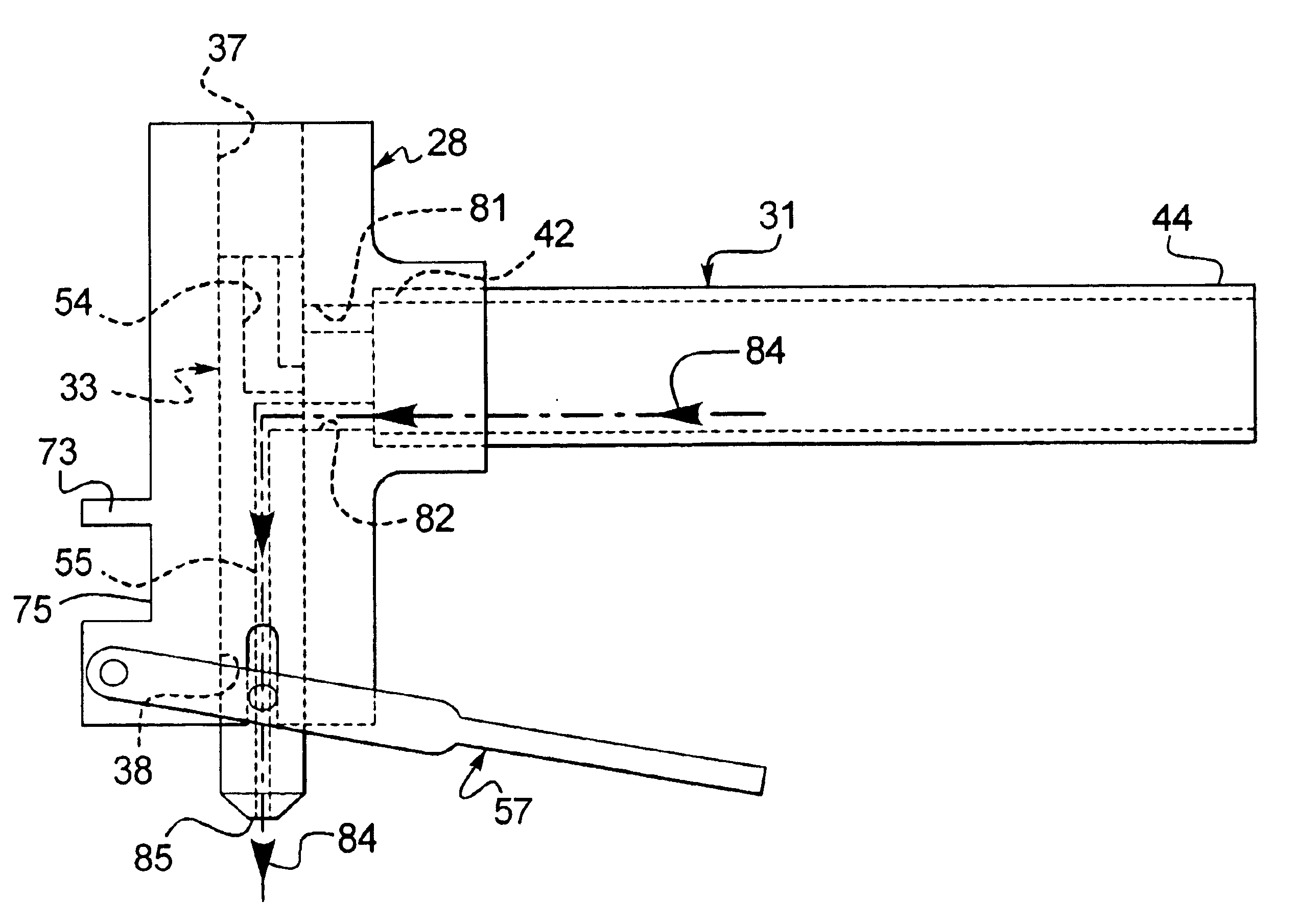

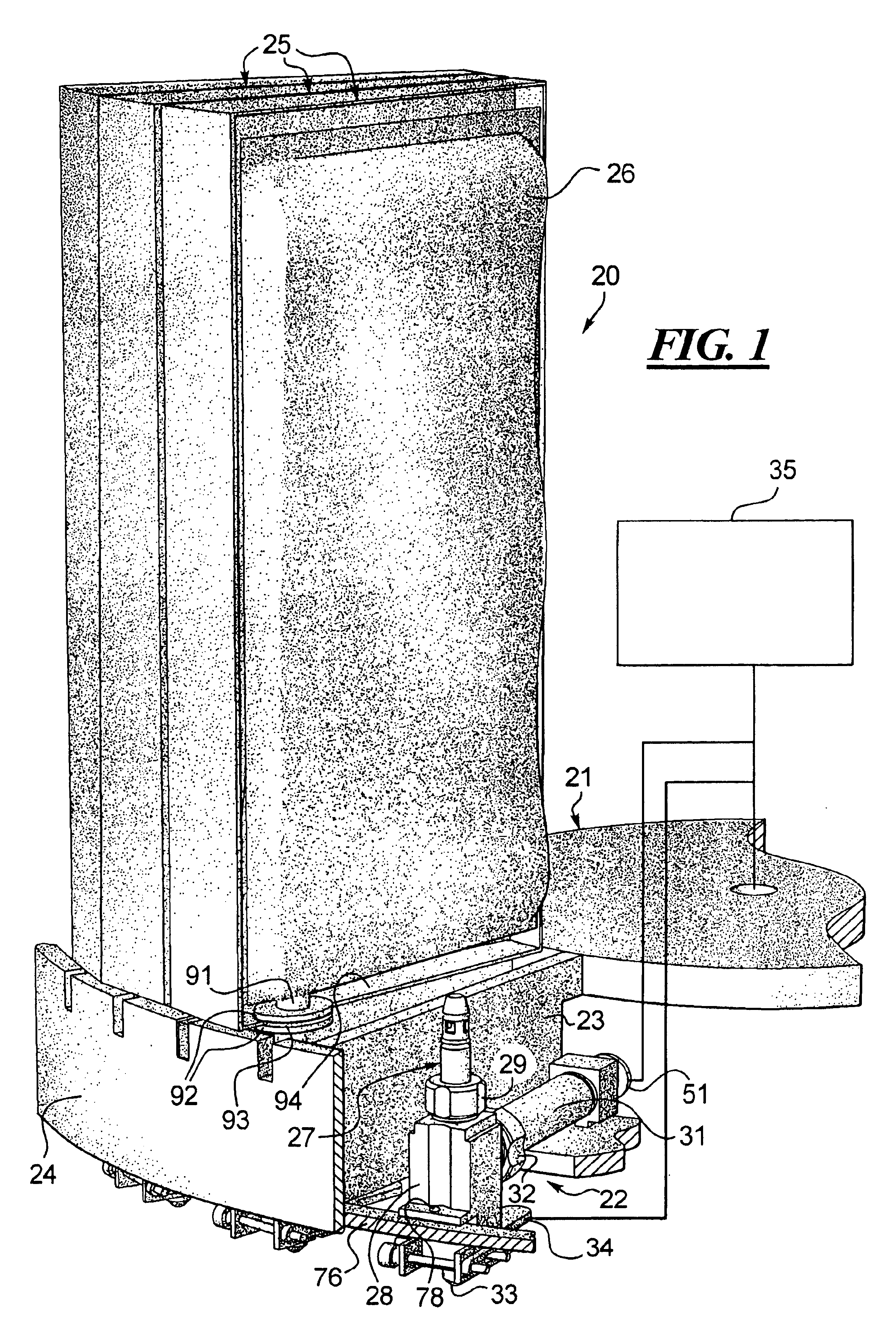

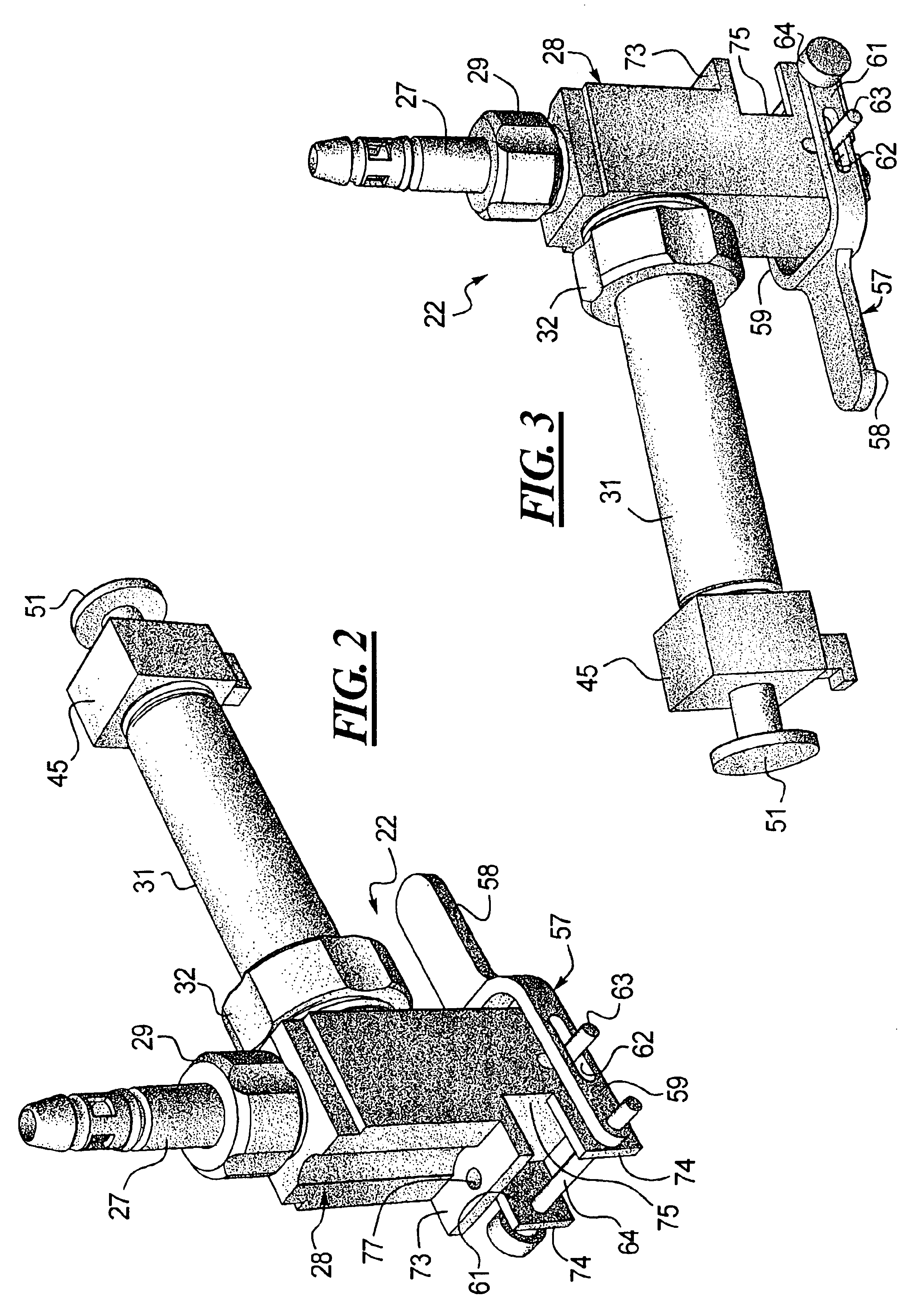

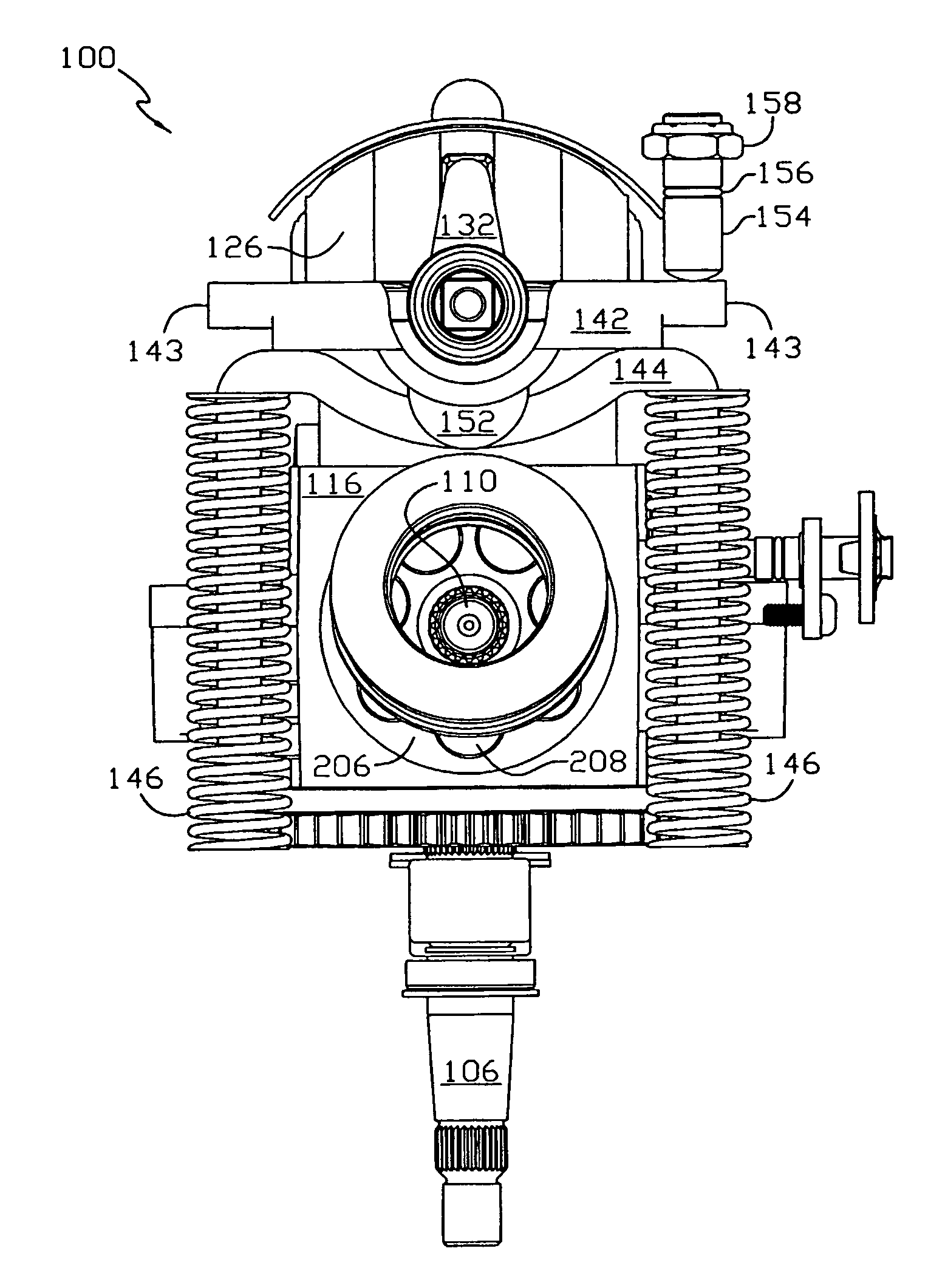

Return to neutral device for a hydraulic apparatus

In a hydrostatic device using an axial piston pump, a return plate is mounted so that it contacts the movable swash plate of the hydrostatic transmission. The plate is biased by a spring-type mechanism to force the swash plate to return to neutral, and the set position of the plate may be externally adjusted. A bias arm comprising a generally U-shaped member having spring mounted on either leg thereof may be engaged to the return plate.

Owner:HYDRO GEAR PARTNERSHIP

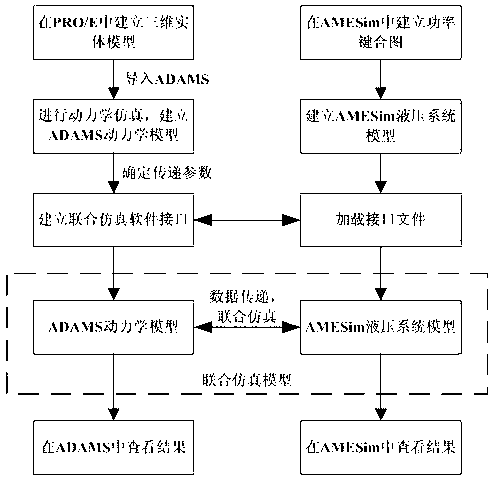

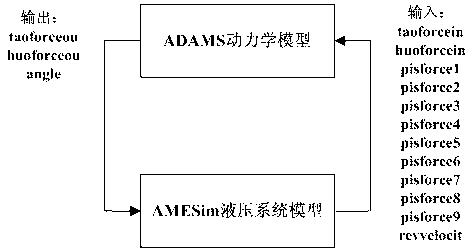

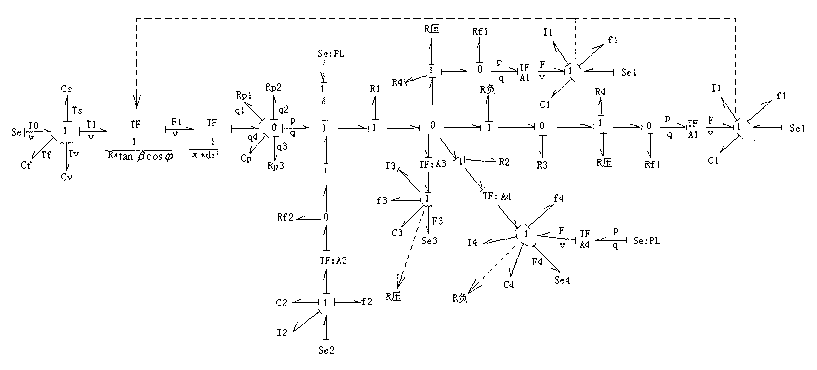

Method for establishing load sensitivity controlled axial plunger pump virtual prototype

InactiveCN102799705AComputational targetingSimplify the modeling processSpecial data processing applicationsEngineeringPlunger pump

The invention relates to a method for establishing a load sensitivity controlled axial plunger pump virtual prototype. The method comprises the following steps of: 1, establishing a kinetic model of an axial plunger pump in kinetic simulation software, and establishing a hydraulic system model of the axial plunger pump in hydraulic system simulation software; 2, establishing a software interface by using correlated condition variants and parameters associated with each other in the simulation process of the kinetic model and the hydraulic system model as transfer parameters between the two models; and 3, performing real-time data transmission and united simulation by using the software interface between the kinetic model and the hydraulic system model. By using a hydraulic-mechanical coupling united simulation technology in the method, advantages of the kinetic simulation software on the simulation aspect of a mechanical system and the hydraulic system simulation software on the simulation aspect of a control system are fully exerted; and by united simulation, accuracy of the simulation result of the axial plunger pump virtual prototype is improved, the experiment cost is reduced, the experiment efficiency is improved, and the design time is shortened.

Owner:FUZHOU UNIV

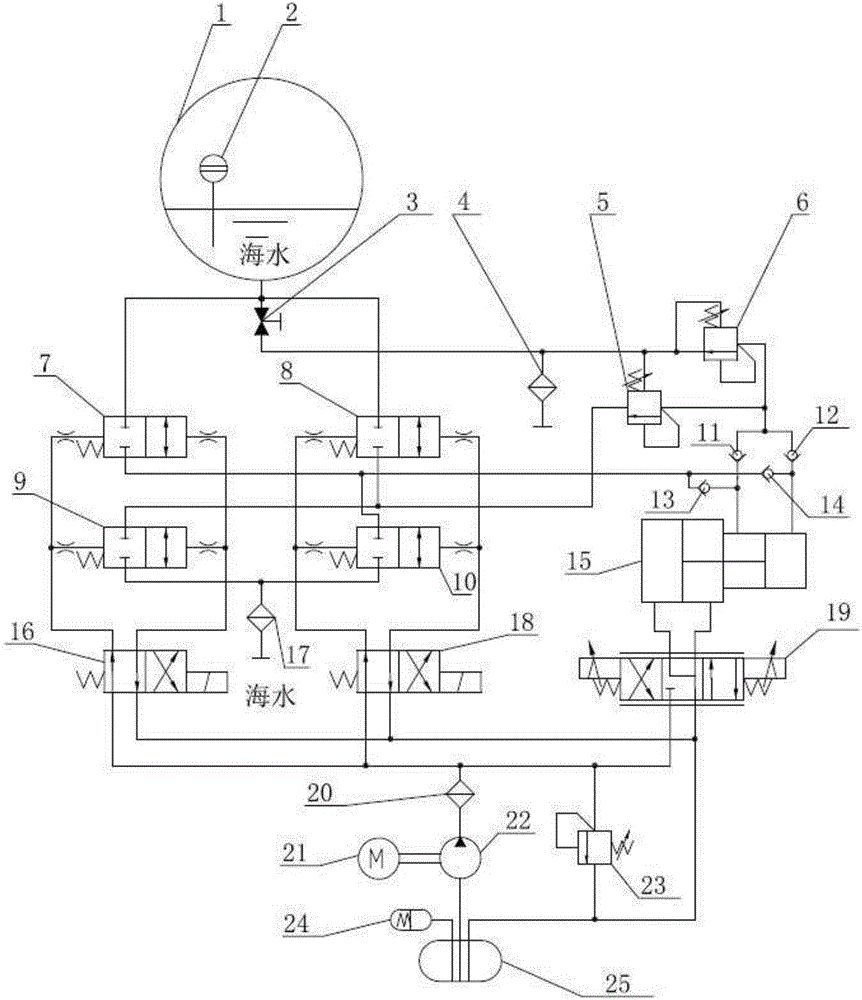

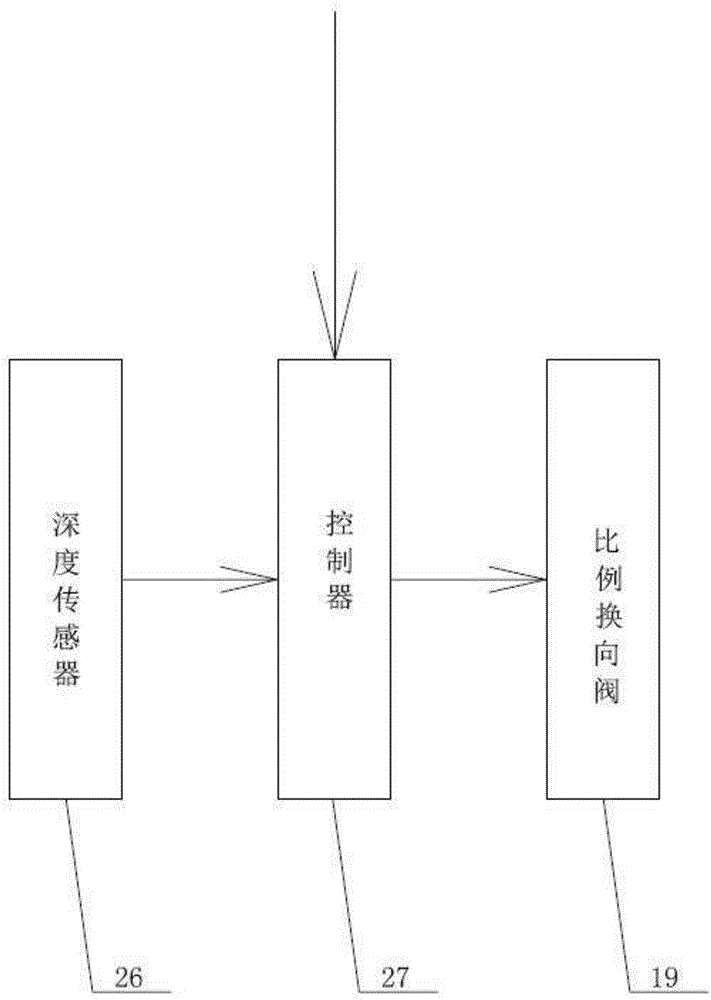

Hydraulic system used for adjusting buoyancy of full-ocean-depth submersible

ActiveCN106516057AImprove reliabilityReduce or even eliminate pressure spikesUnderwater vesselsUnderwater equipmentEngineeringControl valves

The invention relates to a hydraulic system used for adjusting the buoyancy of a full-ocean-depth submersible. The hydraulic system comprises a hydraulic power source, a seawater hydraulic power source, a water ballast space and a water ballast space control valve set. The hydraulic power source drives the seawater hydraulic power source to work, and water injection or water drainage of the interior of the water ballast space is controlled through switching of the water ballast space control valve set, and thus adjusting of the buoyancy of the full-ocean-depth submersible is achieved. The hydraulic system is simple in structure and convenient to use; and a pressure cylinder of the hydraulic system is driven by oil pressure and outputs aqueous media, compared with traditional axial plunger type seawater pumps, the machining cost of the hydraulic system is low, and the flow is larger, the service life is long, the reliability is good and the volume efficiency is high with the same volume. The submersible buoyancy adjusting working condition of the hydraulic system has quite low requirements for pumping flow pulsation, the hydraulic system is better agree with the submersible buoyancy adjusting working condition than the axial plunger pumps, and the outlet pressure of the pressure cylinder can meet the full-ocean-depth application requirements by adjusting the pressure ratio of the pressure cylinder.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

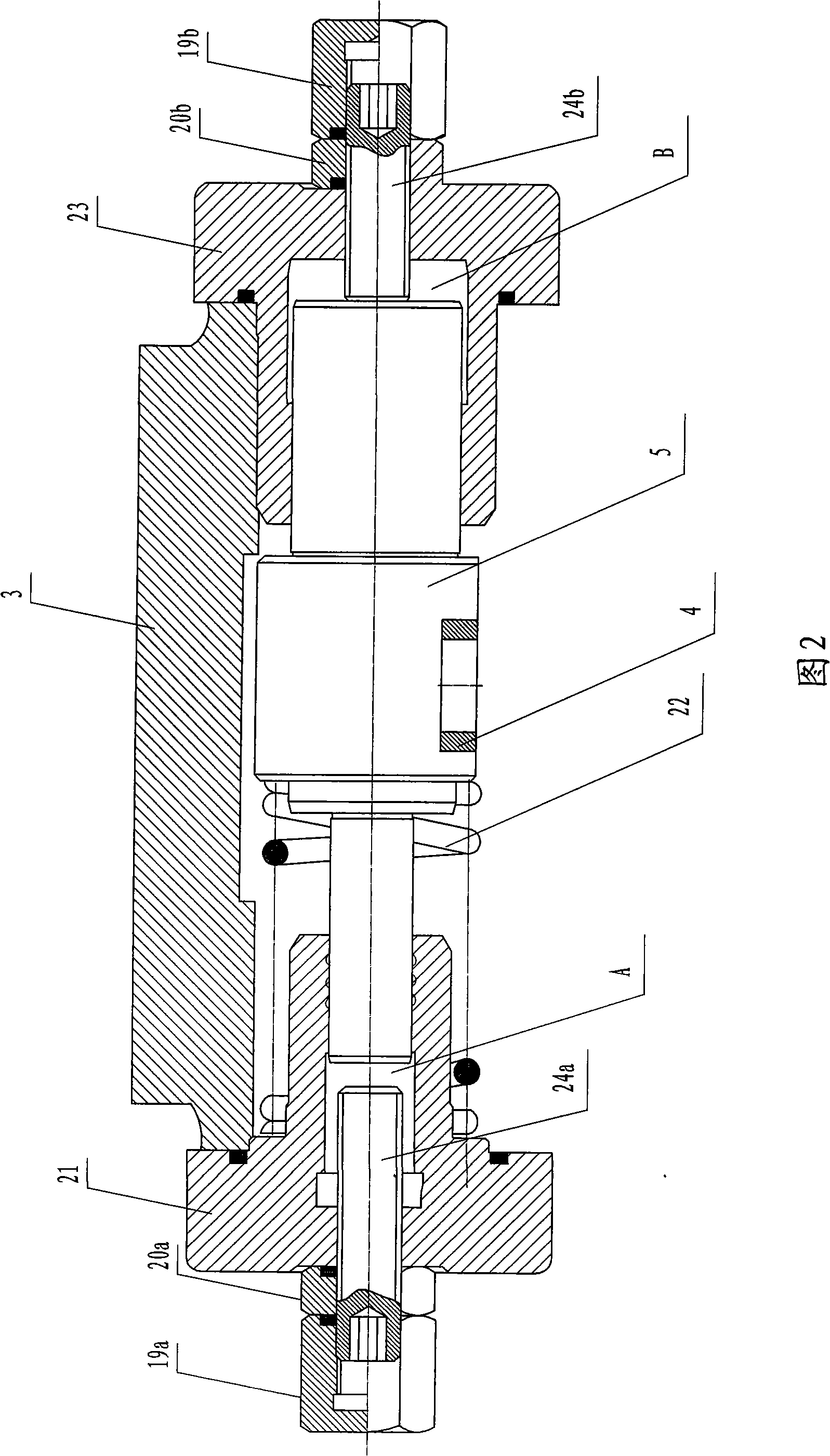

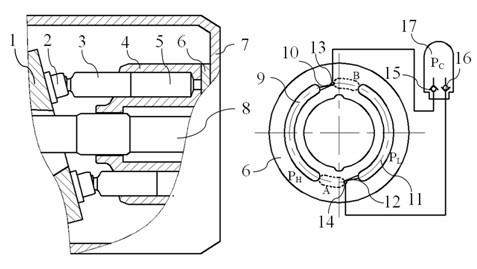

Unidirectional hydraulic axial variable displacement plunger pump

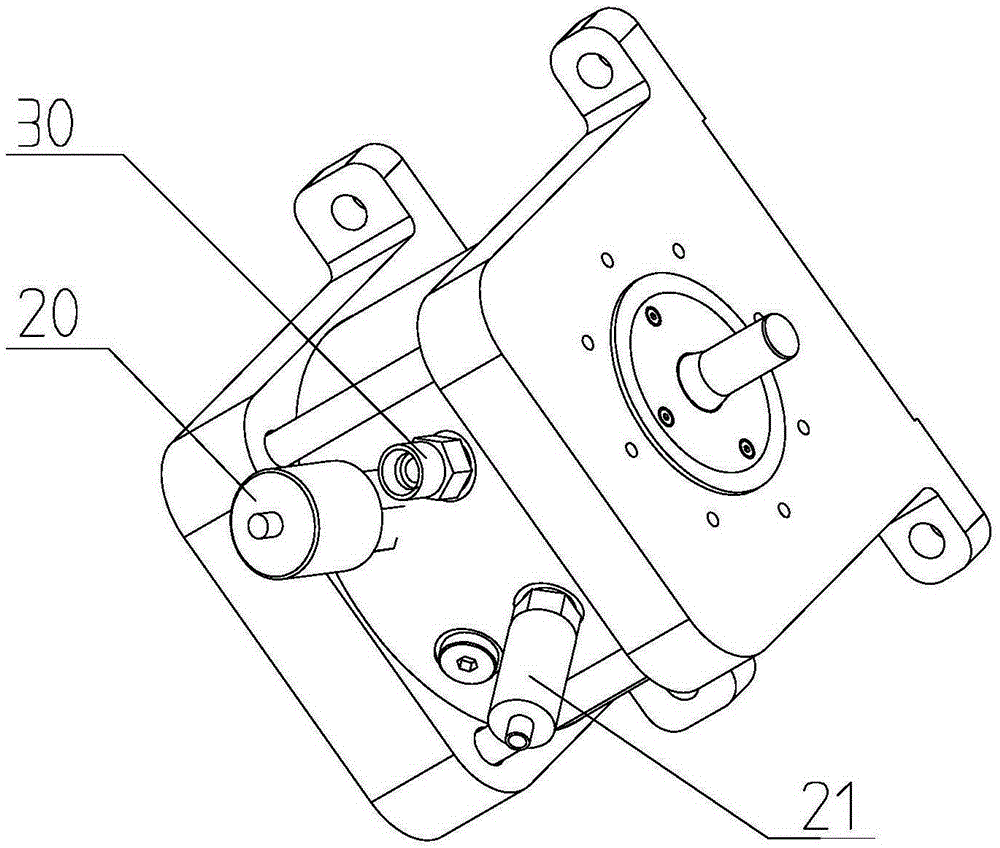

InactiveCN101319666AMeet the action requirementsEasy to controlPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringAxial piston pump

The invention relates to a one-way hydraulic variable axial piston pump which comprises a piston pump and a variable mechanism arranged on one side of the piston pump; the piston pump is characterized in that the variable mechanism comprises a first flange (21), a second flange (23), a variable piston (5), a reset spring (22), a transitional plate (2) and an electromagnetic directional valve (1). Both ends of the variable piston (5) are sealed and connected with the first flange (21) and the second flange (23), to respectively form a first oil reservoir (A) and a second oil reservoir (B), and the bottom of the variable piston (5) is connected with a variable disk (6) in the piston pump; the transitional plate (2) is arranged on the outer side of the pump (3) of the piston pump. Compared with the prior art, the piston pump has the advantages that the electromagnetic directional valve is used to adjust and control the flowing direction of the oil so as to adjust the displacement of the piston pump; control is simple, the motion is relatively quick, the reliability is good, and the motion requirements of a glass steel hydraulic press are met.

Owner:宁波恒力液压股份有限公司

Single piston pump with dual return springs

ActiveUS20110303195A1Eliminate pump piston seizuresSpring force can be minimizedPositive displacement pump componentsFuel injecting pumpsReturn functionSpring force

Pump piston seizures caused by excessive side loads produced by the uneven loading of a large piston return spring are prevented by separating the tappet return function from the piston return function, thereby minimizing the spring force acting on the piston. Separate and distinct biasing means perform the respective functions. Preferably, a stronger, heavier load outer spring is mounted between the pump body and the tappet, such that it imparts no load and therefore no side loads to the pumping piston. A weaker, lighter load inner spring imparts less side load to the pumping piston than a conventional piston return spring, because the inner spring need not carry any tappet load. During both the pumping and charging strokes of the piston, the piston return spring can assist the tappet return spring, but the tappet return spring does not assist the piston return spring.

Owner:STANADYNE OPERATING CO LLC (

Pure water hydraulic axial plunger pump / motor by total water lubrication

InactiveCN1542295AGuaranteed self-lubricationGuaranteed wear resistanceOscillating piston enginesFluid-pressure actuatorsInterference fitFresh water

The present invention discloses one kind of completely water lubricated pure water hydraulic axial plunger pump / motor, which adopts filtered natural water, including fresh water and sea water, as work medium and consists of mainly one casing and one rotary cylinder inside the casing. The cylinder has odd holes parallel to the driving / outputting shaft and distributed in the same circle; plunger sliding shoe assembly with plunger inside the cylinder holes, flow distributing sleeve and floating thrust disc inside corresponding hole, center spring with one end holding the flow distributing disc and the other end holding the sliding shoe to the inclined disc, and driving / outputting shaft interference fitted to the cylinder. The device of the present invention has all the friction pairs lubricated and cooled with water, and has small radial size, small volume, light weight and great specific power.

Owner:ZHEJIANG UNIV

Double-cylinder plunger pump

ActiveCN102162434ASolve the problem of small flowSolve efficiency problemsPositive displacement pump componentsPositive-displacement liquid enginesEngineeringCylinder block

The invention relates to a double-cylinder plunger pump which comprises a first cylinder body, a second cylinder body and a thrust plate which is respectively corresponding to the first cylinder body and the second cylinder body; the axis of the first cylinder body and the axis of the second cylinder body intersect outside the first cylinder body and the second cylinder body and form a first included angle, and an angle bisection plane of the first included angle is a second plane; the first cylinder body is provided with a first cylinder holes; the second cylinder body is provided with a second cylinder hole corresponding to the first cylinder hole; the crossing point of the central lines of the corresponding first cylinder hole and second cylinder hole is positioned on the second plane; the first cylinder body and the second cylinder body are connected in a transmission mode through a plunger assembly; the plunger assembly comprises two plungers which are slidingly inserted in the corresponding firs cylinder hole and second cylinder hole; and the adjacent ends of the two plungers extend out of the respective cylinder holes and are connected in a transmission mode through a connecting piece which is used for enabling the two plungers to stretch out or draw back in the respective cylinder holes in the rotation process of the two cylinder bodies. Through the double-cylinder plunger pump provided by the invention, the problems of low flow rate and low efficiency of the traditional axial plunger pump are solved.

Owner:庄森

Sanitizable piston pumps and dispensing systems incorporating the same

A sanitizable piston pump for dispensing ingredients of cosmetic preparations and other sanitary mixtures is shown and described. The pump includes a valve block including an inlet port threadably connected to a nipple which is detachably connected to an outlet port of a flexible package. The valve block further includes a piston port threadably connected to cylinder and an outlet port that sealably receives a valve stem. The inlet port, the outlet port and the piston port are in fluid communication with one another upon removal of the valve stem from the valve block. The valve stem includes an intake passage and an output passage. The cylinder slidably receives a piston. Both the piston and valve stem are connected to separate actuators. The actuator connected to the valve stem moves the valve stem into one of either an intake position for withdrawing fluid into the cylinder or a dispense position for pumping fluid out of the cylinder and out the outlet of the valve stem. A disposable plastic piston pump is also disclosed. Further, a lever mechanism for quickly and easily releasing a flexible package from the nipple connected to the valve block of the disclosed piston pumps is also shown and described.

Owner:FLUID MANAGEMENT LLC

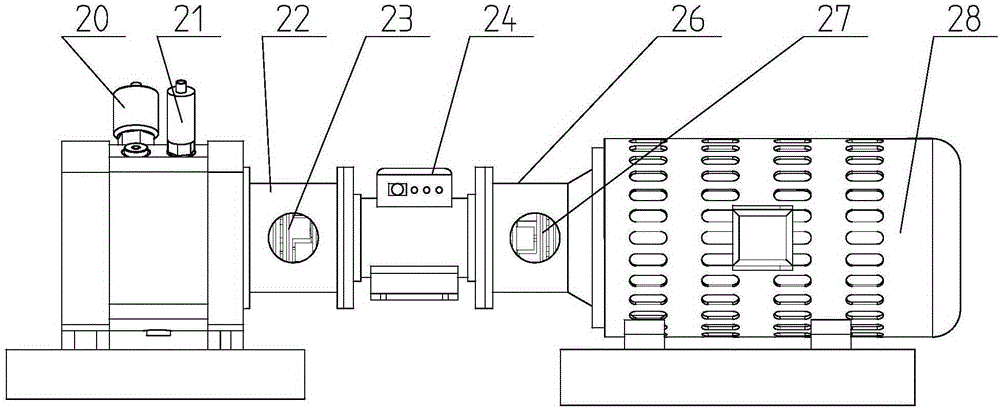

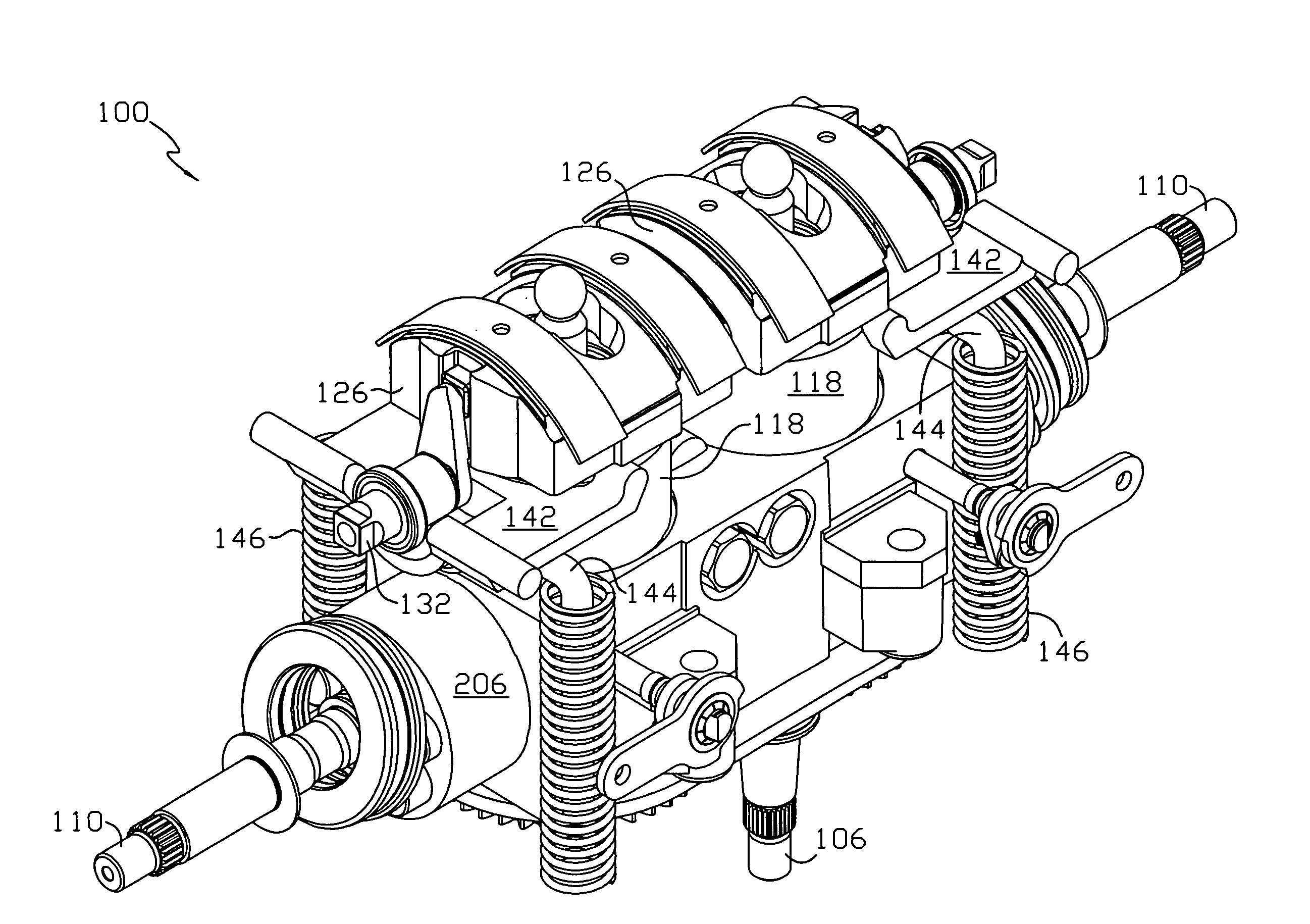

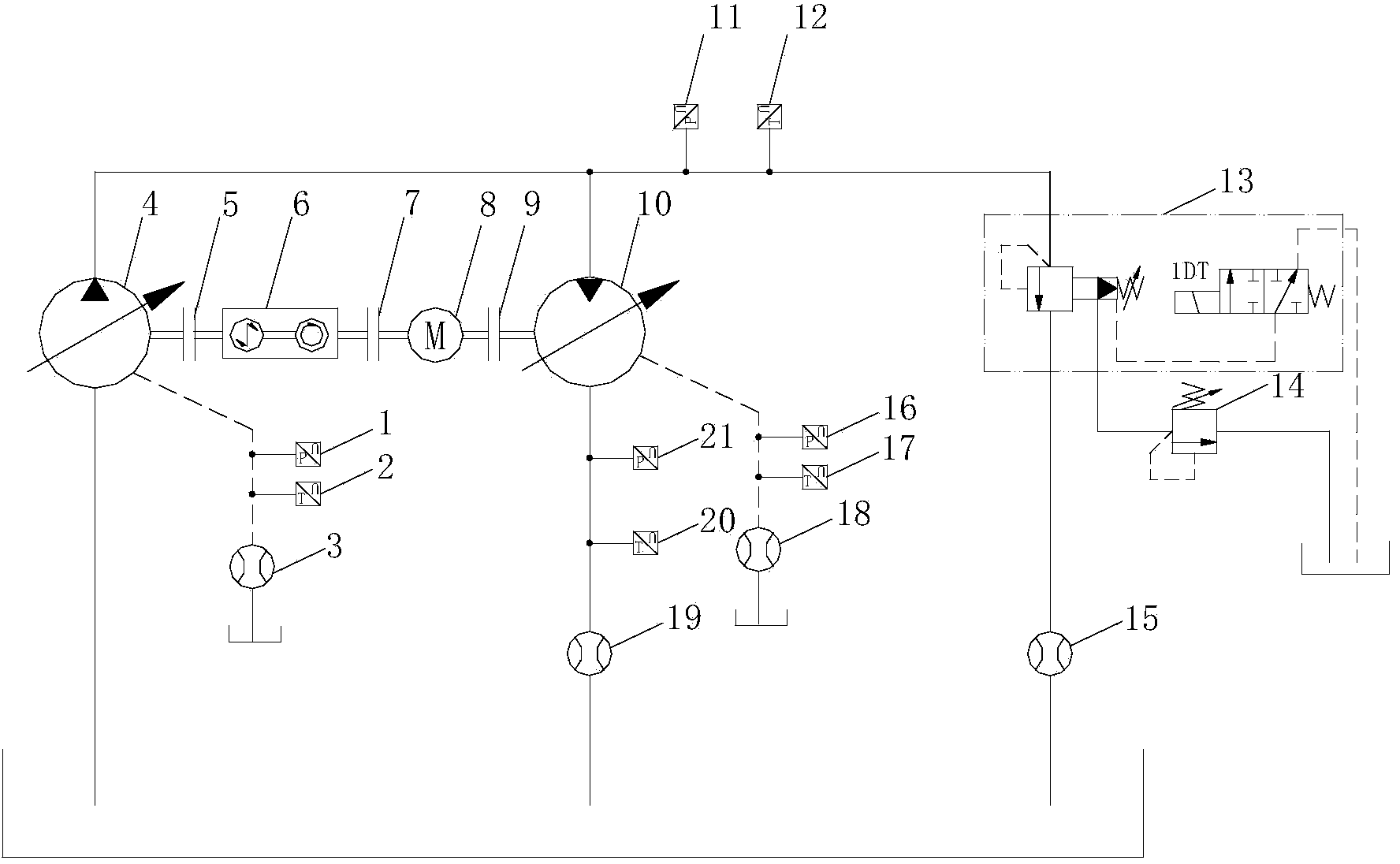

Reliability test method and device for axial plunger pump and axial plunger motor

InactiveCN103511397AIncrease speedAdvance the test progressFluid-pressure actuator testingFrequency conversionTest sample

The invention discloses a reliability test method and device for an axial plunger pump and an axial plunger motor. According to a test system, the first shaft of a variable-frequency motor is connected with a torque rotational speed meter in an extension mode, and the torque rotational speed meter is connected with the tested axial plunger pump. The tested axial plunger motor is connected with the second shaft of the variable-frequency motor in an extension mode. An oil outlet of the tested axial plunger pump is connected with an oil inlet of the tested axial plunger motor. A pressure sensor, a temperature sensor, an electromagnetic relief valve and a flow meter are arranged on a pipeline connecting the oil inlet of the tested axial plunger motor and an oil tank. Pressure sensors, temperature sensors and flow meters are arranged on the tested axial plunger pump, a motor leakage oil circuit and an oil outlet circuit of the tested axial plunger motor. According to the reliability test method and device for the axial plunger pump and the axial plunger motor, a frequency conversion and power recovery technology is used, reliability test time is shortened, reliability test samples are increased, and electric energy losses are reduced.

Owner:YANSHAN UNIV

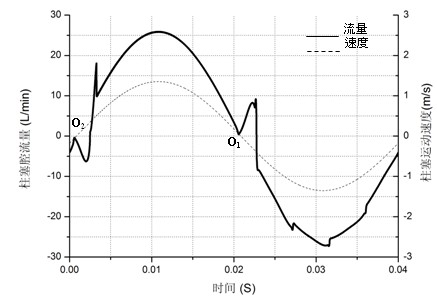

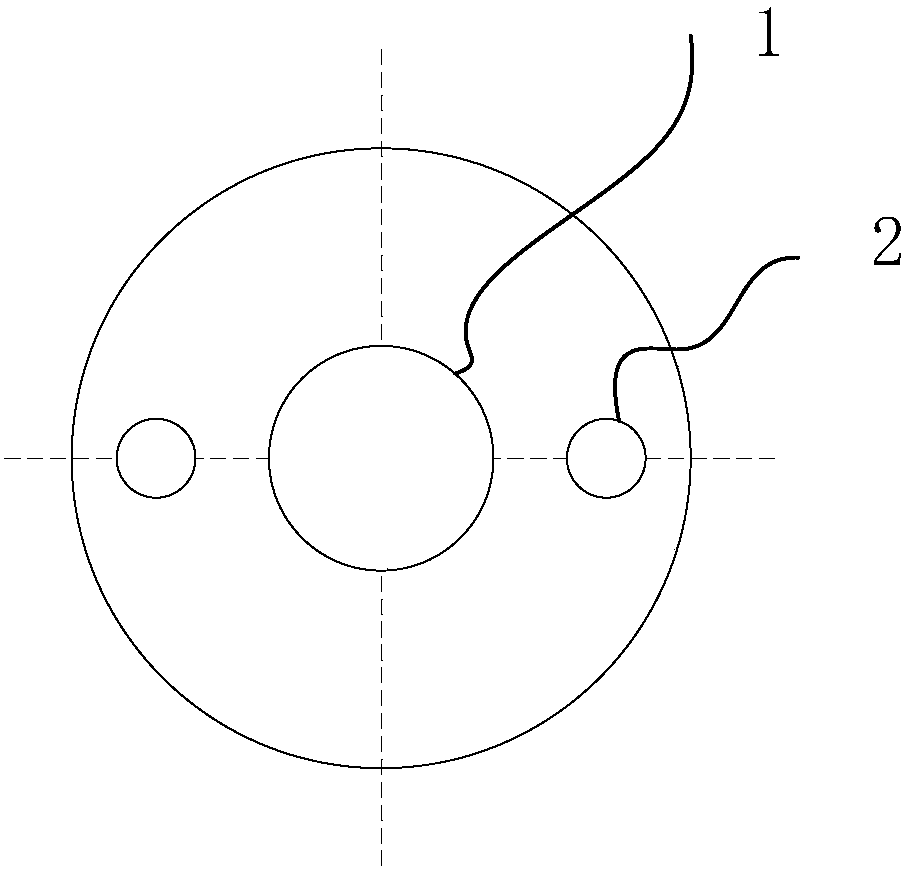

Low-noise axial plunger pump based on average pressure

ActiveCN102155372ASmall flow pulsationReduce noise levelPositive-displacement liquid enginesMulti-cylinder pumpsLow noiseDecreased pressure

The invention discloses an axial plunger pump based on average pressure. The axial plunger pump comprises an inclined disk, a plurality of piston shoes, a plurality of plungers, a cylinder body, a flow distributor, a shell, a main shaft, a rear check valve, a front check valve and a pressure recovery containing chamber; after a high-pressure plunger chamber finishes oil discharging and enters the transition region of the flow distributor, the high-pressure oil in the plunger chamber flows into a pressure recovery containing chamber through the front check valve; and the high-pressure plunger chamber reduces pressure in advance, the pressure of the pressure recovery containing chamber increases, while a low-pressure plunger chamber finishes the oil absorption and enters the transition region of the flow distributor, the high-pressure oil liquid stored in the pressure recovery containing chamber flows into the low-pressure plunger chamber through the rear check valve, the low-pressure plunger chamber increases the pressure in advance, and pressure of the pressure recovery containing chamber reduces. Under the effect of average pressure, the boost in advance and depressurization effect of the plunger chamber are approximately equal to half of the pressure difference of a high-pressure oil extraction kidney slot and a low-pressure oil absorption kidney slot of the axial plunger pump, the outlet flow rate pulsation of the axial plunger pump is reduced, the rotation torque of the inclined disk is reduced, and the average flow rate of the pump outlet is increased.

Owner:ZHEJIANG UNIV

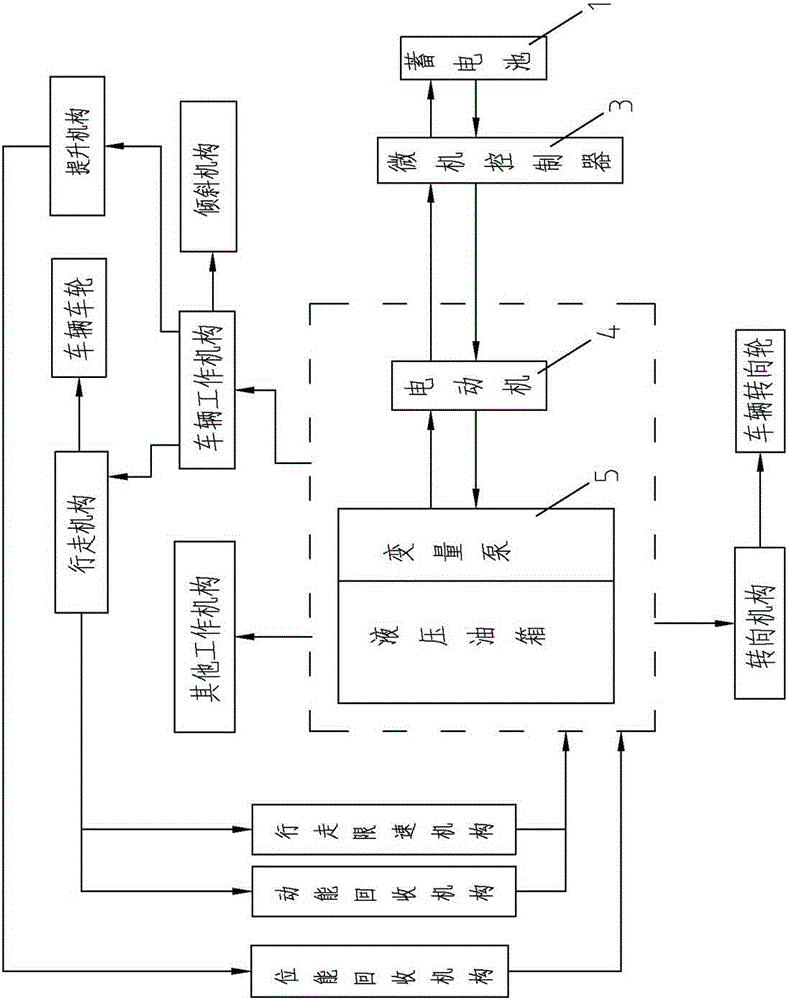

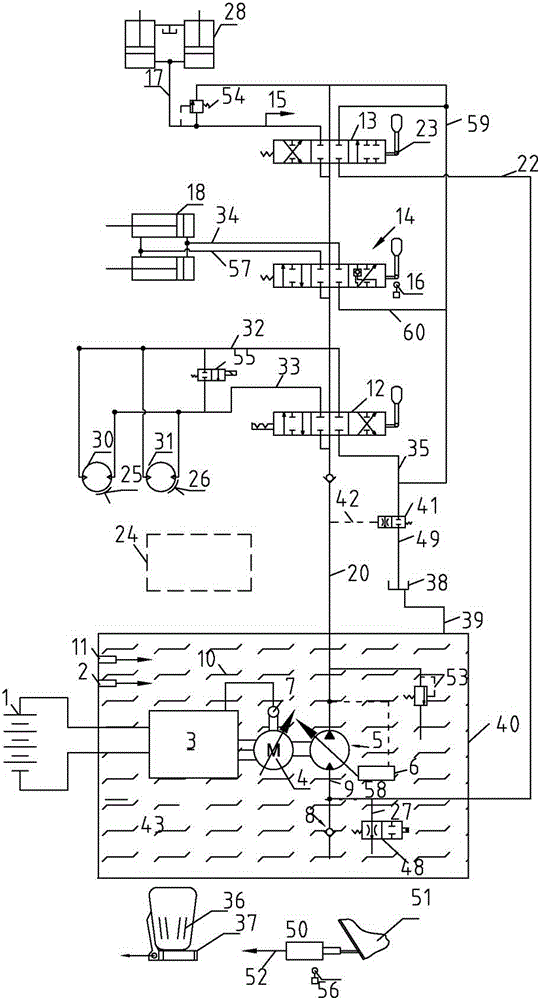

Electric control hydraulic driving system for industrial vehicle

ActiveCN105197840AAchieve recyclingSimple structureVehicle fittingsElectrodynamic brake systemsBrushless motorsRadial piston pump

The invention relates to an electric control hydraulic driving system for an industrial vehicle. Only one electromotor and one microcomputer controller are used for driving a variable pump to conduct frequency control so as to convey hydraulic oil in a hydraulic oil tank to a travelling mechanism, an inclining mechanism, a lifting mechanism, a steering mechanism, a kinetic energy recycling mechanism, a potential energy recycling mechanism and a travelling speed limiting mechanism; kinetic energy recycle, overload potential energy recycle, and no-load and light-load unloading can be realized while the vehicle realizes actions of travelling, inclining, lifting and steering; through the adoption of the travelling speed limiting mechanism, the vehicle speed can be limited, and the vehicle travelling can be stable; during slope sliding and braking, the hydraulic system can automatically supply oil; during slope climbing of the vehicle, the variable pump automatically varies according to the load pressure set value to achieve the low-speed large-torque slope climbing function, and the slope climbing current is low. The electromotor consists of a permanent-magnet brushless motor, an inverter controller and a variable piston pump; zero current start to a load current is realized, the starting time is within the millimeter-level range, large current starting can be avoided, and energy can be saved.

Owner:上海市闸北区物流工程技术研究所

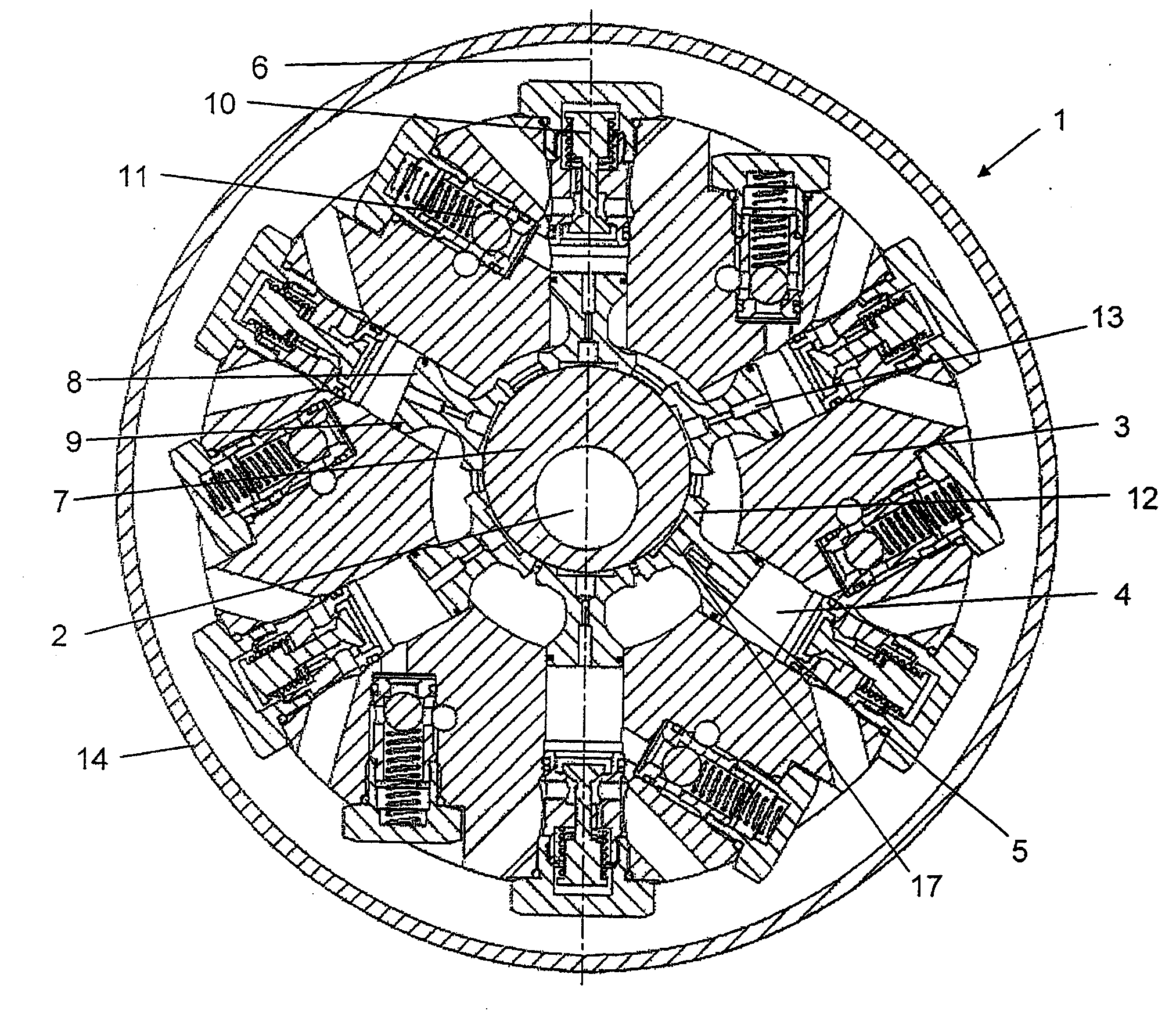

Magnetic sliding shoe pair for axial plunger pump and motor and control method

ActiveCN107725301APrevent too thinStable working condition at all timesPositive displacement pump componentsPositive-displacement liquid enginesStress conditionsSelf feedback

The invention discloses a magnetic sliding shoe pair for an axial plunger pump and a motor and a control method. The magnetic sliding shoe pair comprises plungers, coil sleeve pieces, sliding shoes and an inclined disc; closing coils are arranged in the coil sleeve pieces; micro modeling holes are formed in the bearing face, making contact with the sliding shoes, of the end face of the inclined disc and are in a semi-spherical shape; and the back face of the inclined disc is provided with a main iron core and two auxiliary iron cores, the iron cores are all wound with coils, and the coils areconnected with an external alternating current power supply. An electromagnetic force self feedback regulation mode is provided so that the stable working state of the sliding shoe pair can be ensured. When the axial plunger pump / motor works, the coils are powered on, a magnetic field is generated, accordingly, the sliding shoes are attracted to the inclined disc, meanwhile, the coil sleeve piecesgenerate an induced magnetic field, electromagnetic force applied to the sliding shoes is converted into attraction force or repulsive force along with moving of the sliding shoes, a hydrodynamic effect is formed when the sliding shoes are under a complex stressed condition, the bearing face of the inclined disc is subjected to micro modeling design, thus, the oil film rigidity is improved, and the friction coefficient is reduced.

Owner:ANHUI UNIV OF SCI & TECH

Return to neutral device for a hydraulic apparatus

InactiveUS7111545B1Maintain positionEliminate the problemFluid couplingsPositive-displacement liquid enginesHydraulic equipmentEngineering

In a hydrostatic device using an axial piston pump, a return plate is mounted so that it contacts the movable swash plate of the hydrostatic transmission. The plate is biased by a spring-type mechanism to force the swash plate to return to neutral, and the set position of the plate may be externally adjusted. A bias arm comprising a generally U-shaped member having spring mounted on either leg thereof may be engaged to the return plate.

Owner:HYDRO GEAR PARTNERSHIP

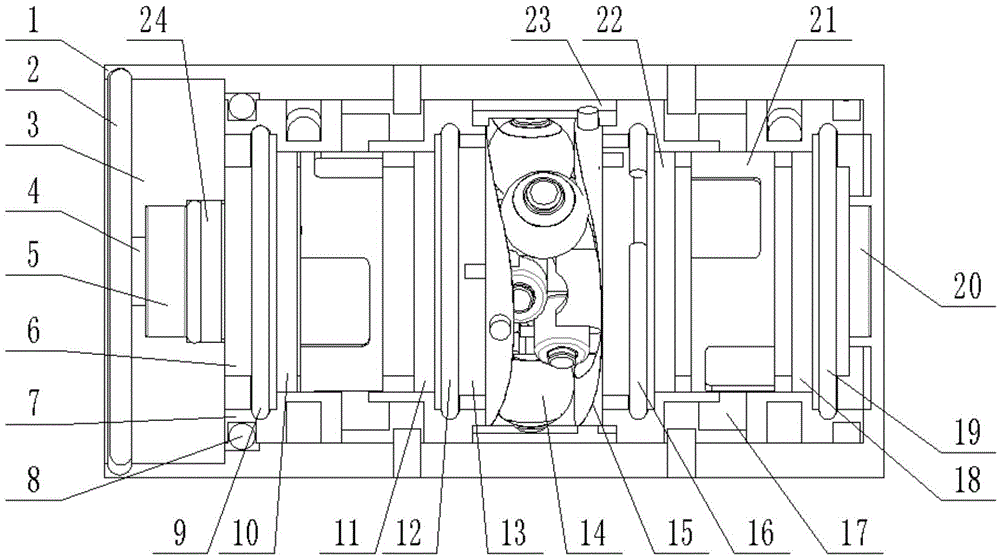

Axial plunger pump swash plate-piston shoe friction pair abrasion test device and test method thereof

PendingCN109026650ASolve complexityEnables evaluation of wear characteristicsPump testingPositive-displacement liquid enginesEngineeringMechanical engineering

The invention discloses an axial plunger pump swash plate-piston shoe friction pair abrasion test device and a test method thereof. The axial plunger pump swash plate-piston shoe friction pair abrasion test device comprises a loading mechanism, a driving mechanism, a swash plate angle adjusting device and a piston shoe positioning and clamping mechanism. The loading mechanism and the piston shoe positioning and clamping mechanism are connected. The swash plate angle adjusting device is mounted on the driving mechanism. By means of the axial plunger pump swash plate-piston shoe friction pair abrasion test device and the test method thereof, the problems that axial plunger pump overall rack experiments and practical engine comprehensive investigation are long in period and complex are solved, the abrasion characteristic evaluation on a swash plate-piston shoe friction pair can be completed in a short experiment period, and a reliable basis is provided for practical production.

Owner:SOUTH CHINA UNIV OF TECH

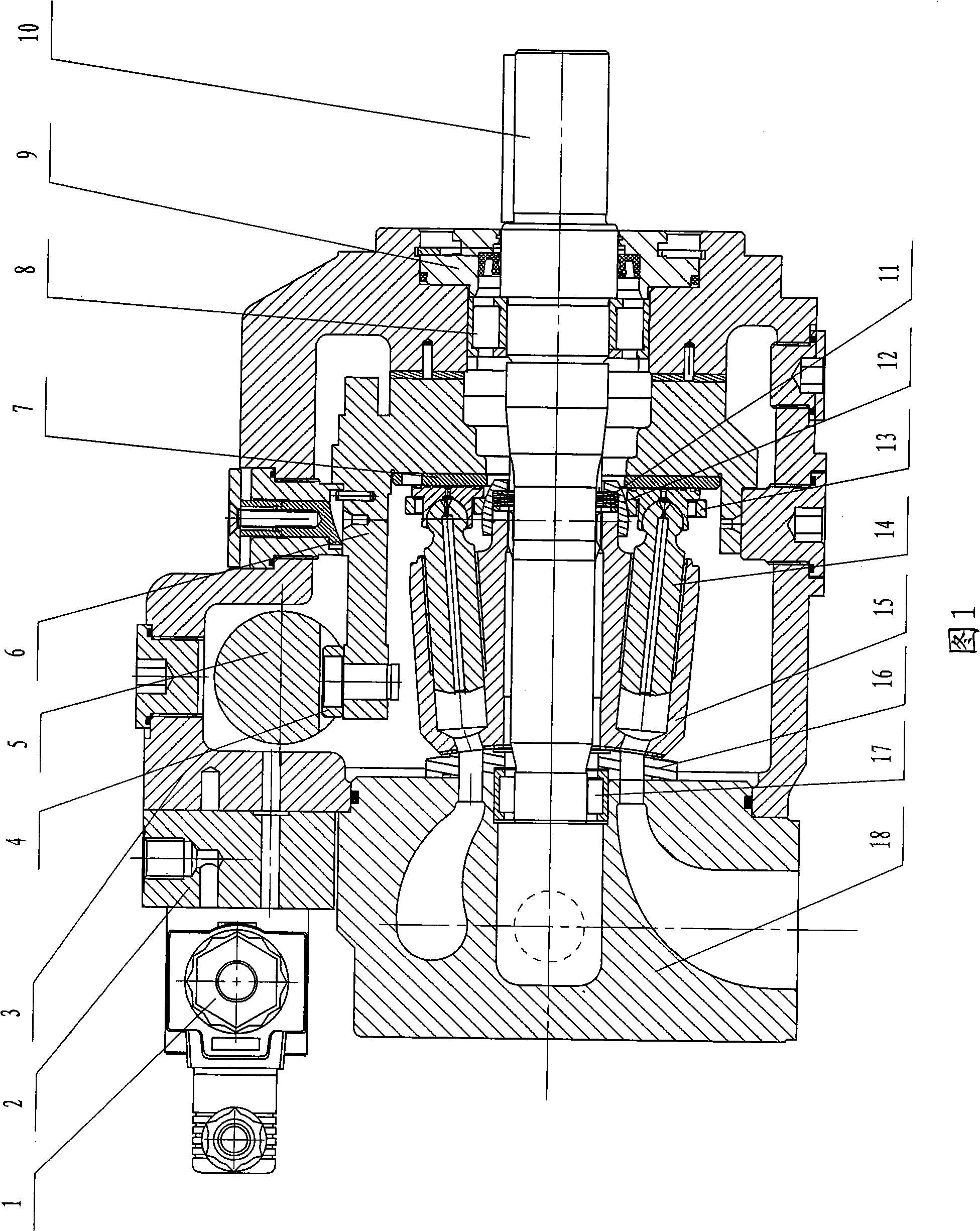

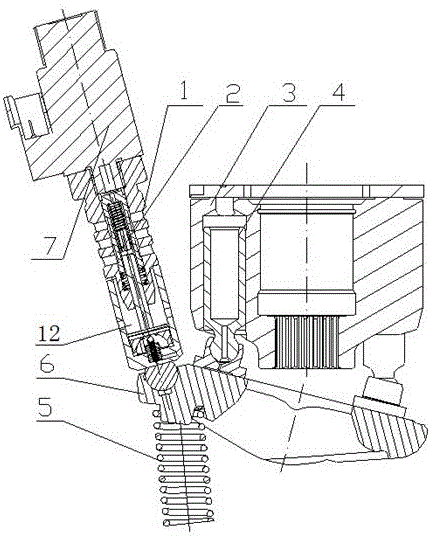

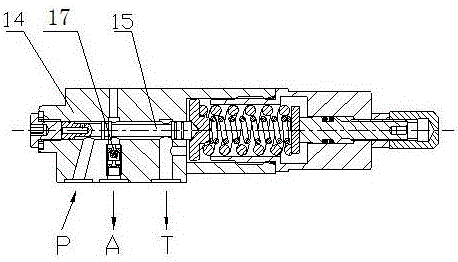

Compact swash plate type electric proportional axial plunger pump and control method thereof

ActiveCN106351813AShorten the lengthRealize intelligent controlPositive-displacement liquid enginesMulti-cylinder pumpsElectricityProportional control

The invention discloses a compact swash plate type electric proportional axial plunger pump, comprising an electric proportional control valve (1) and a pump body, wherein the electric proportional control valve (1) is connected with a proportional electromagnet (7), the pump body is connected with a swash plate (6), the electric proportional control valve (1) is arranged at one side of the swash plate (6), and a return spring (5) is arranged at the other side, relative to the electric proportional control valve (1), of the swash plate (6). The control method is as follows: when an electric signal is input to the proportional electromagnet, a thrust force from the proportional electromagnet and a feedback force produced by rotating of the swash plate are applied to left and right sides of a valve core of the electric proportional control valve respectively, so that the valve core of the electric proportional control valve keeps a dynamic equilibrium, and the swash plate is also located at a swing angle corresponding to the electric signal. According to the invention, the overall size of the plunger pump can be reduced, and high compactness is achieved; and all oil lines can be arranged in a pump shell, so that the size can be further reduced.

Owner:AVIC LIYUAN HYDRAULIC

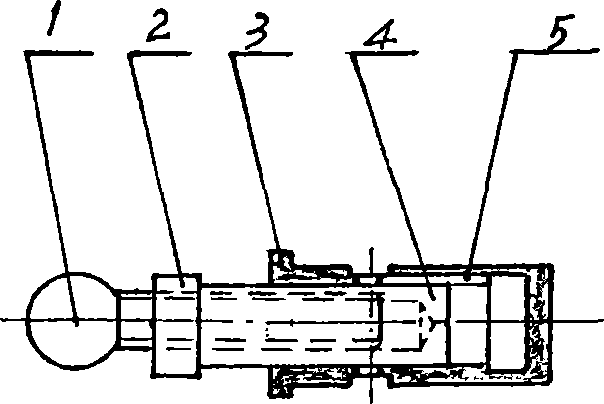

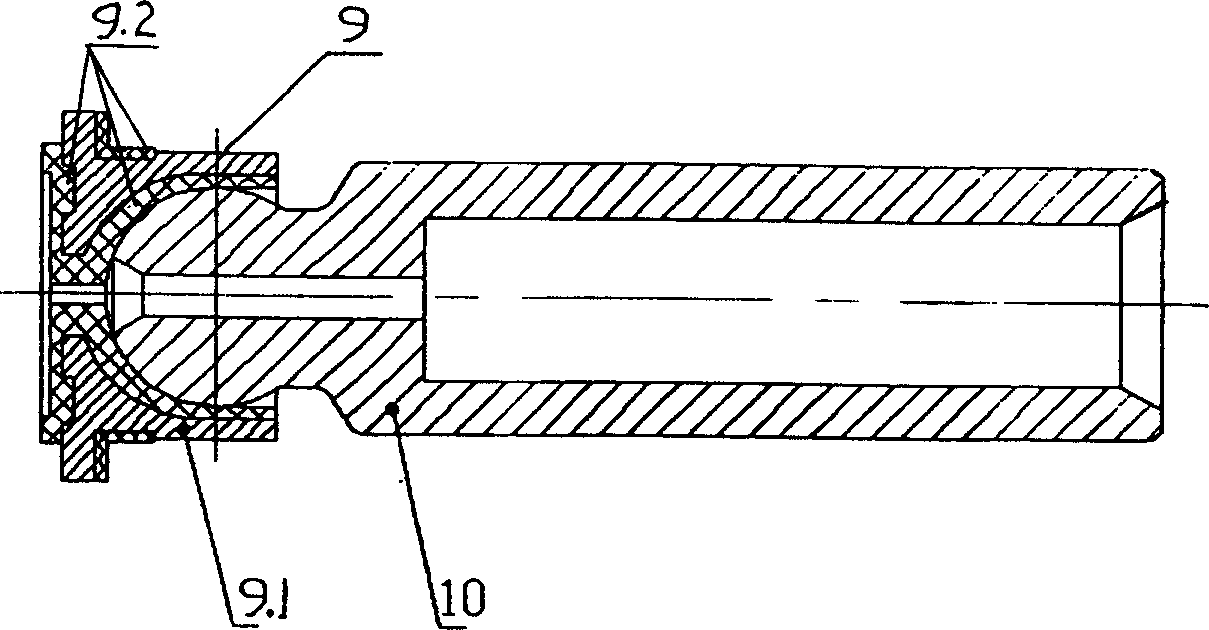

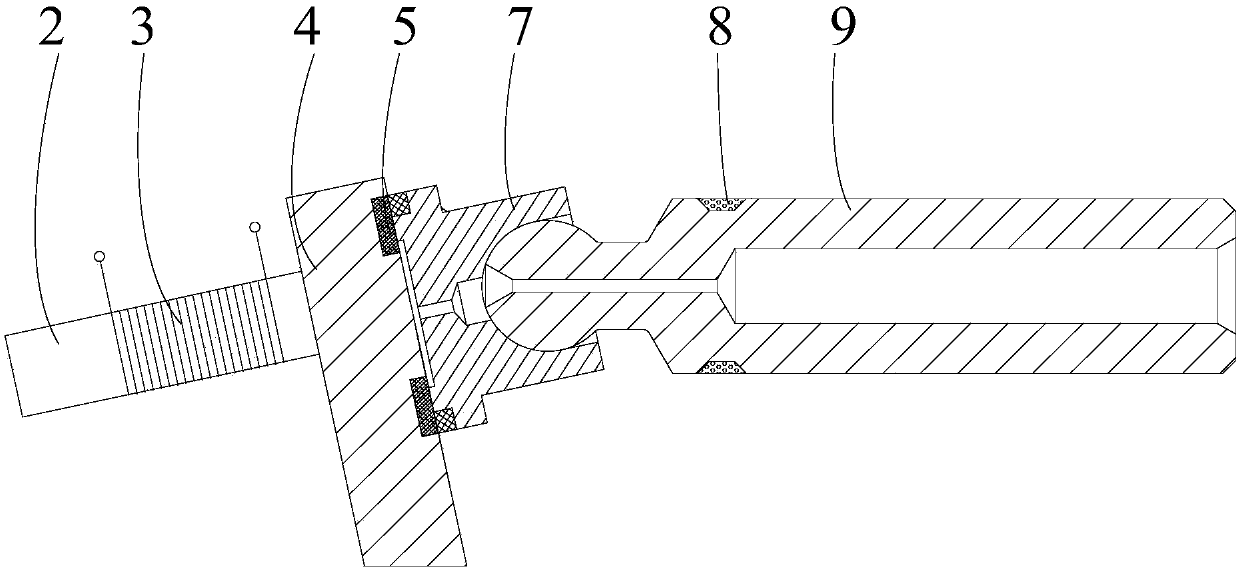

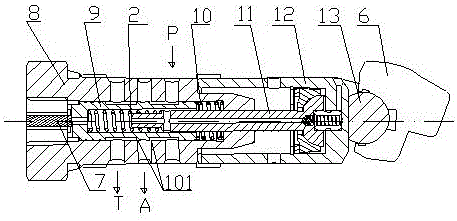

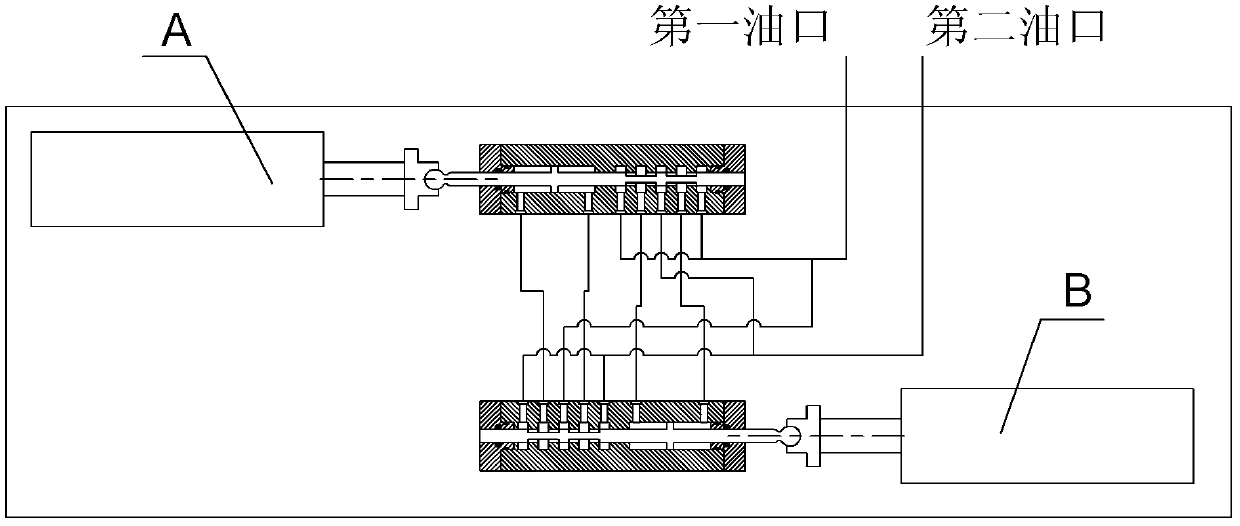

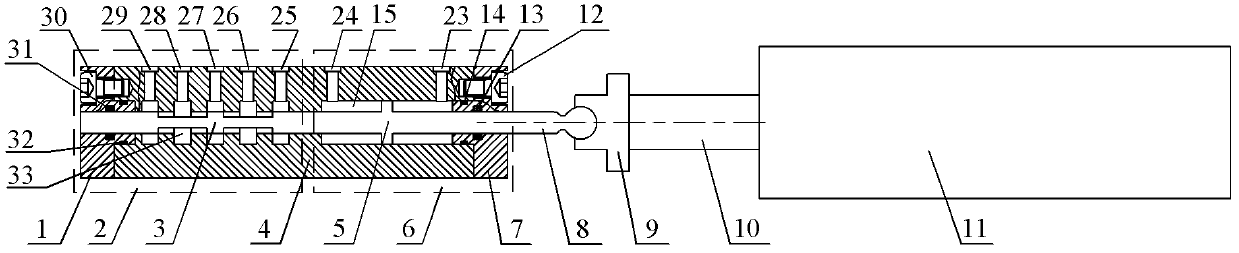

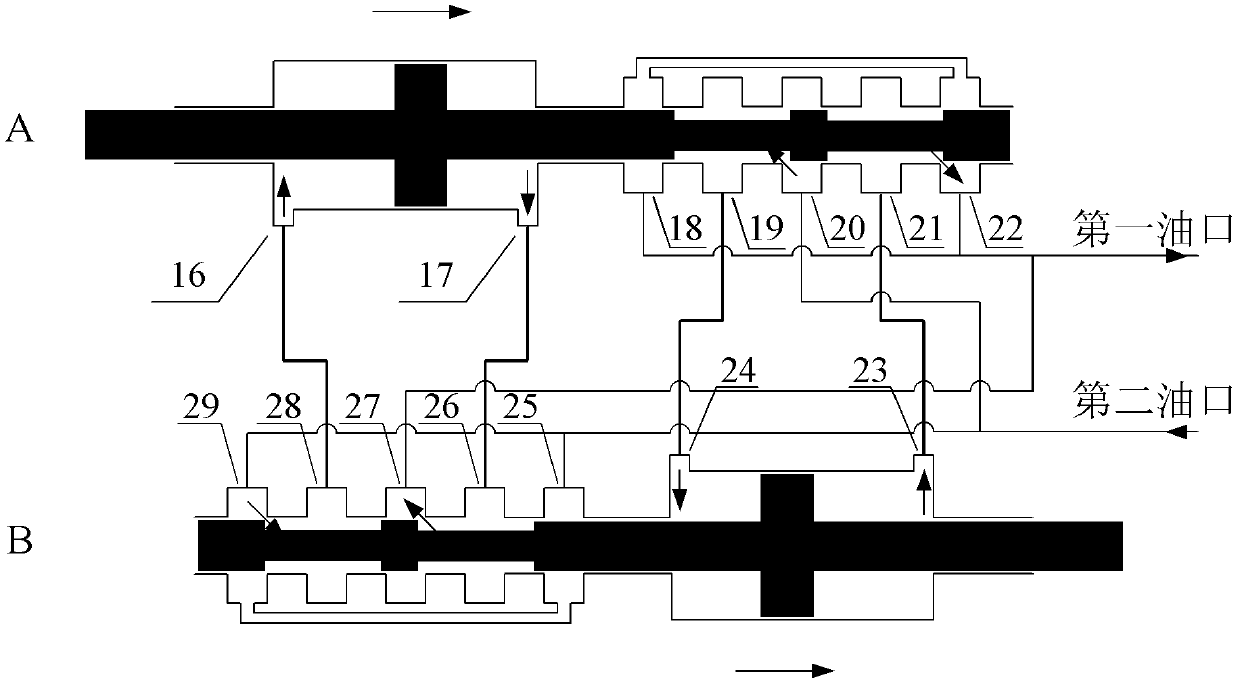

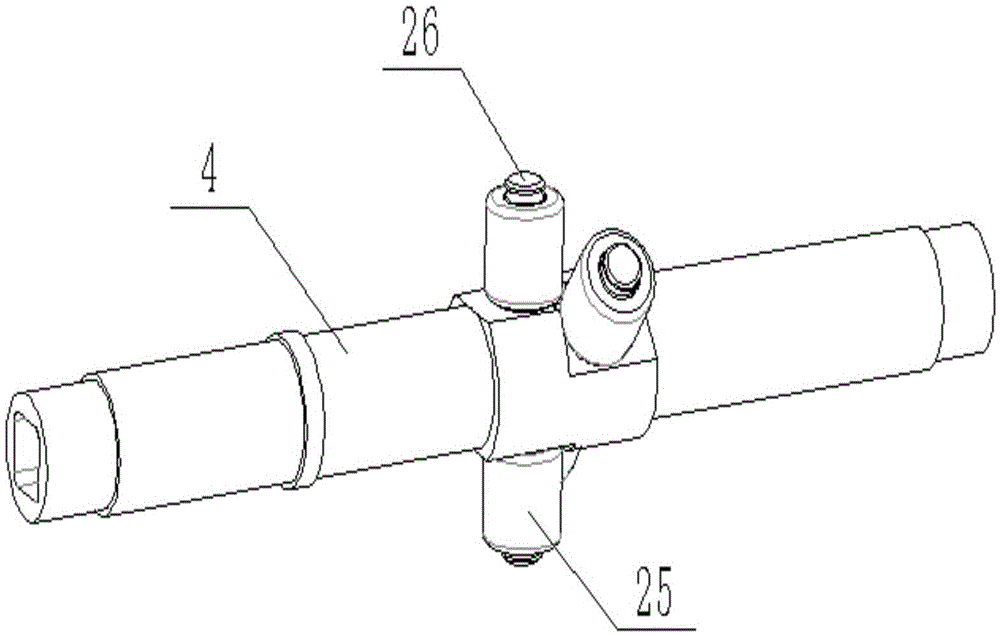

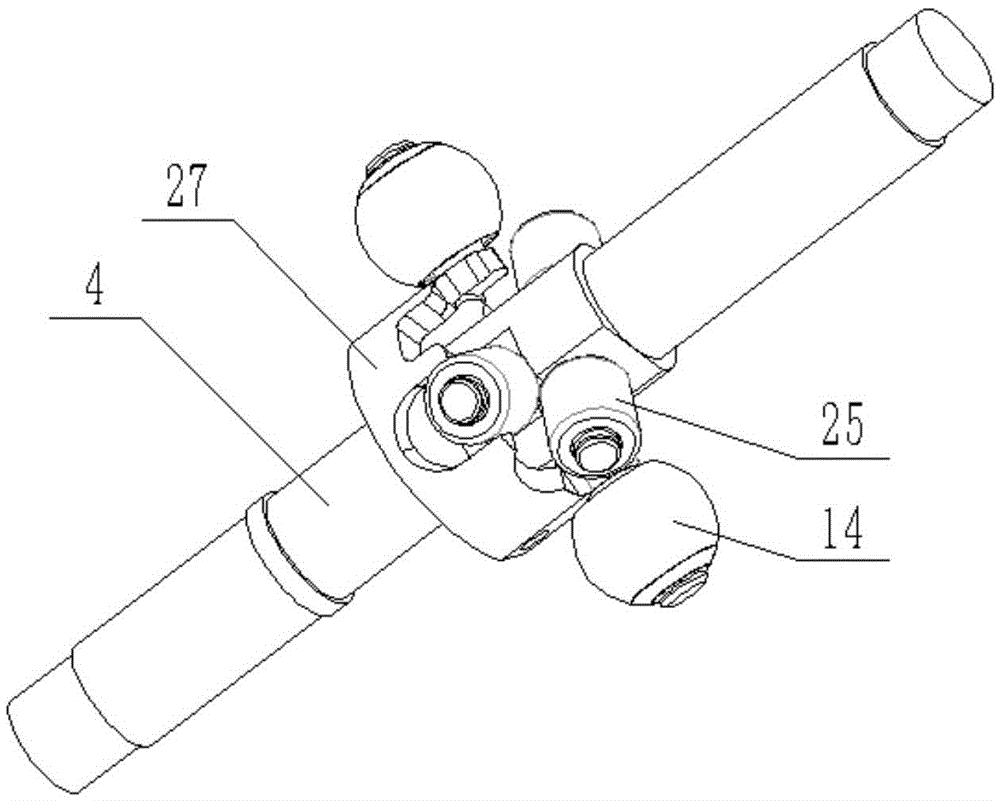

Electromagnetic direct-drive electro-hydraulic servo pump

ActiveCN102606443ASimple driveNo additional lateral forcePumpsPositive-displacement liquid enginesElectromagnetic interferenceElectro hydraulic

The invention discloses an electromagnetic direct-drive electro-hydraulic servo pump, which comprises an electromagnetic direct-drive pump valve module A and an electromagnetic direct-drive pump valve module B. The electromagnetic direct-drive pump valve module A and the electromagnetic direct-drive pump valve module B are identical, the electromagnetic direct-drive pump valve module B comprises an end cover (1), a valve spool (3), a pump body (4), a piston (5), an end cover (7), a pump shaft (8), a ball hinge sleeve (9), a linear motor rotor extending rod (10), a linear motor (11), a sealing ring (13), a sealing ring (14), a piston cavity (15), a sealing ring (31), a sealing ring (32) and a valve cavity (33). The piston is directly driven to suck and drain oil by the linear motor, transmission is simple and high-efficient, additional lateral force is avoided, internal friction loss is reduced, and the service life of the electromagnetic direct-drive electro-hydraulic servo pump is longer that that of an axial plunger pump on the same technologic level.

Owner:BEIHANG UNIV

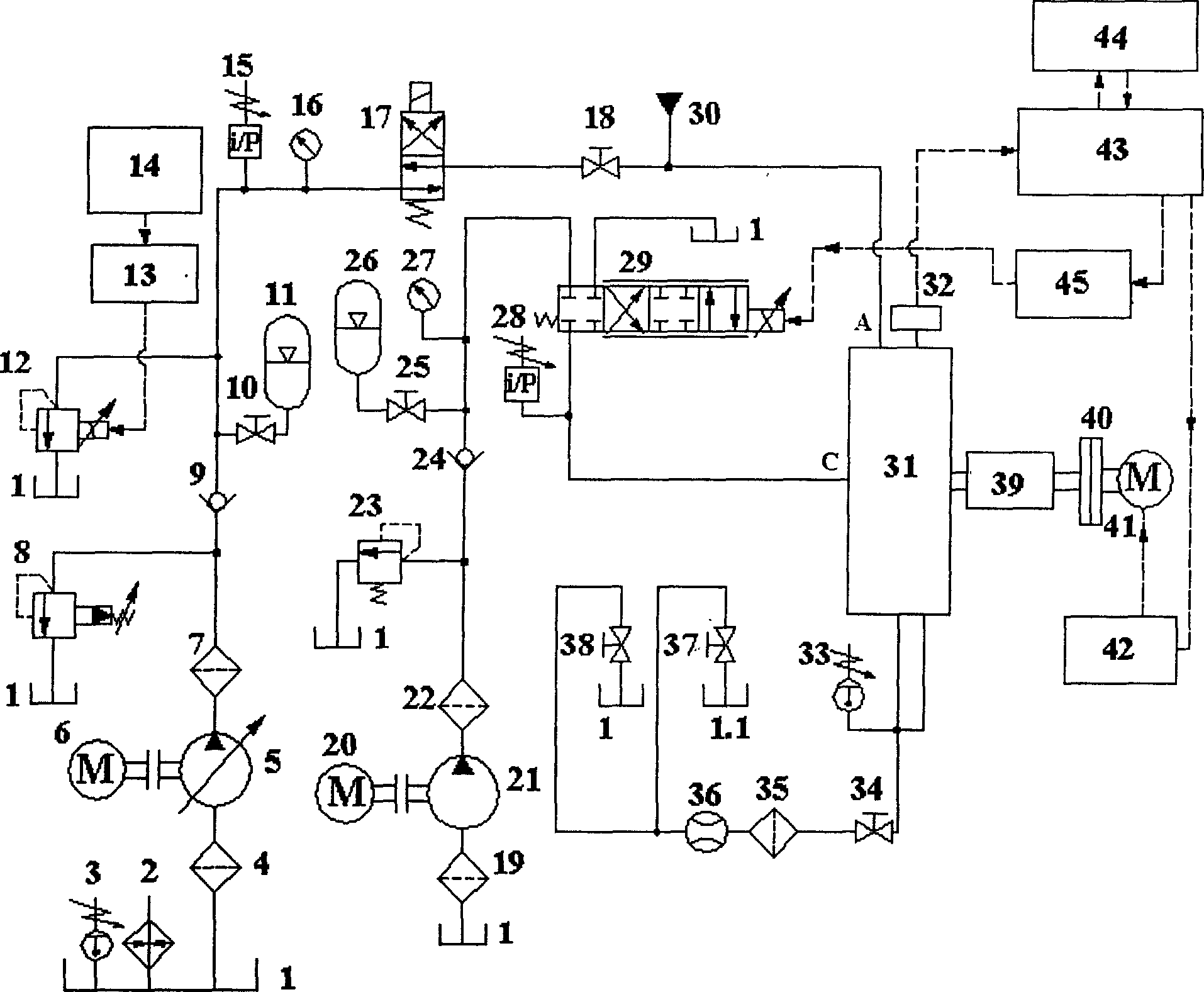

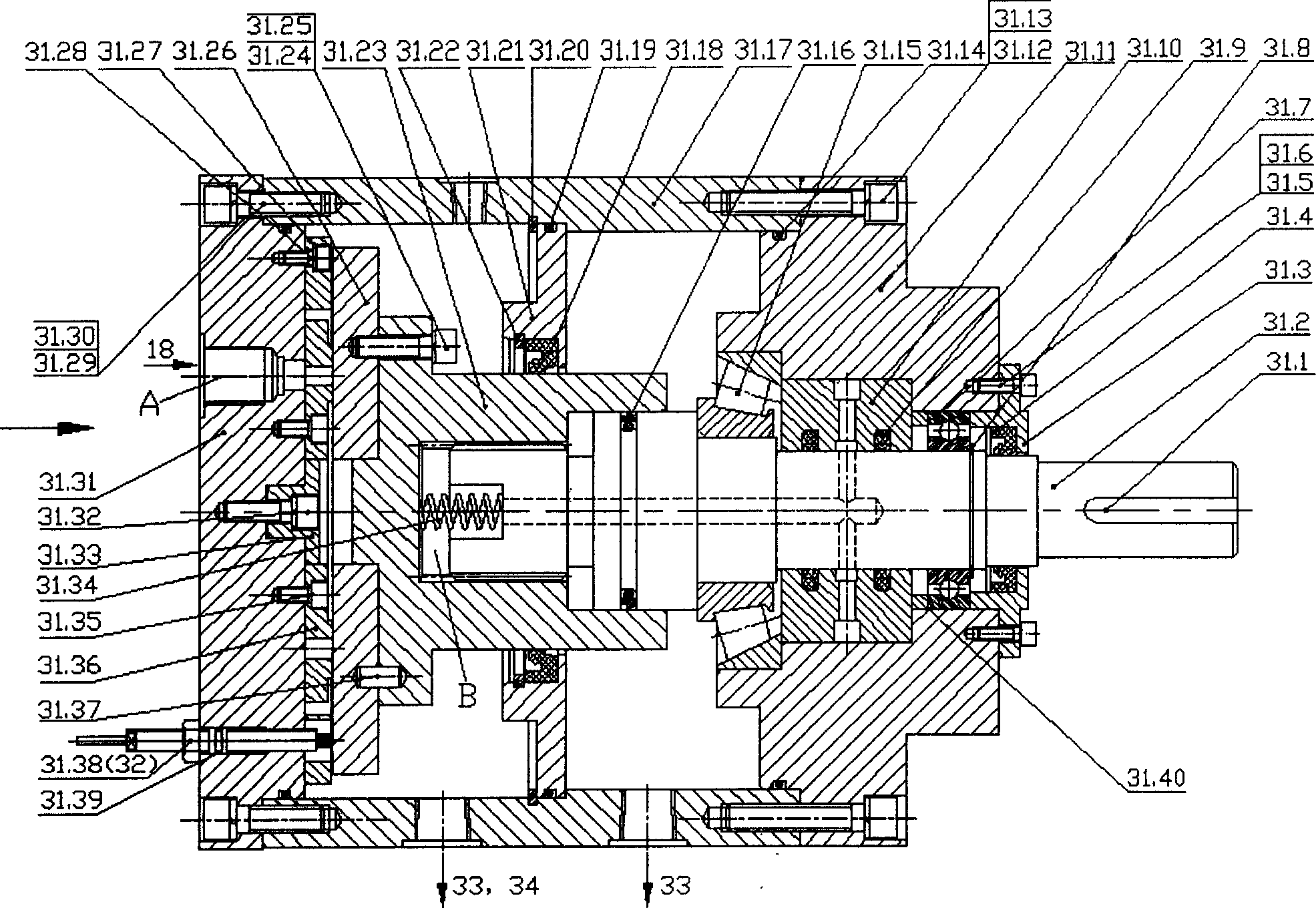

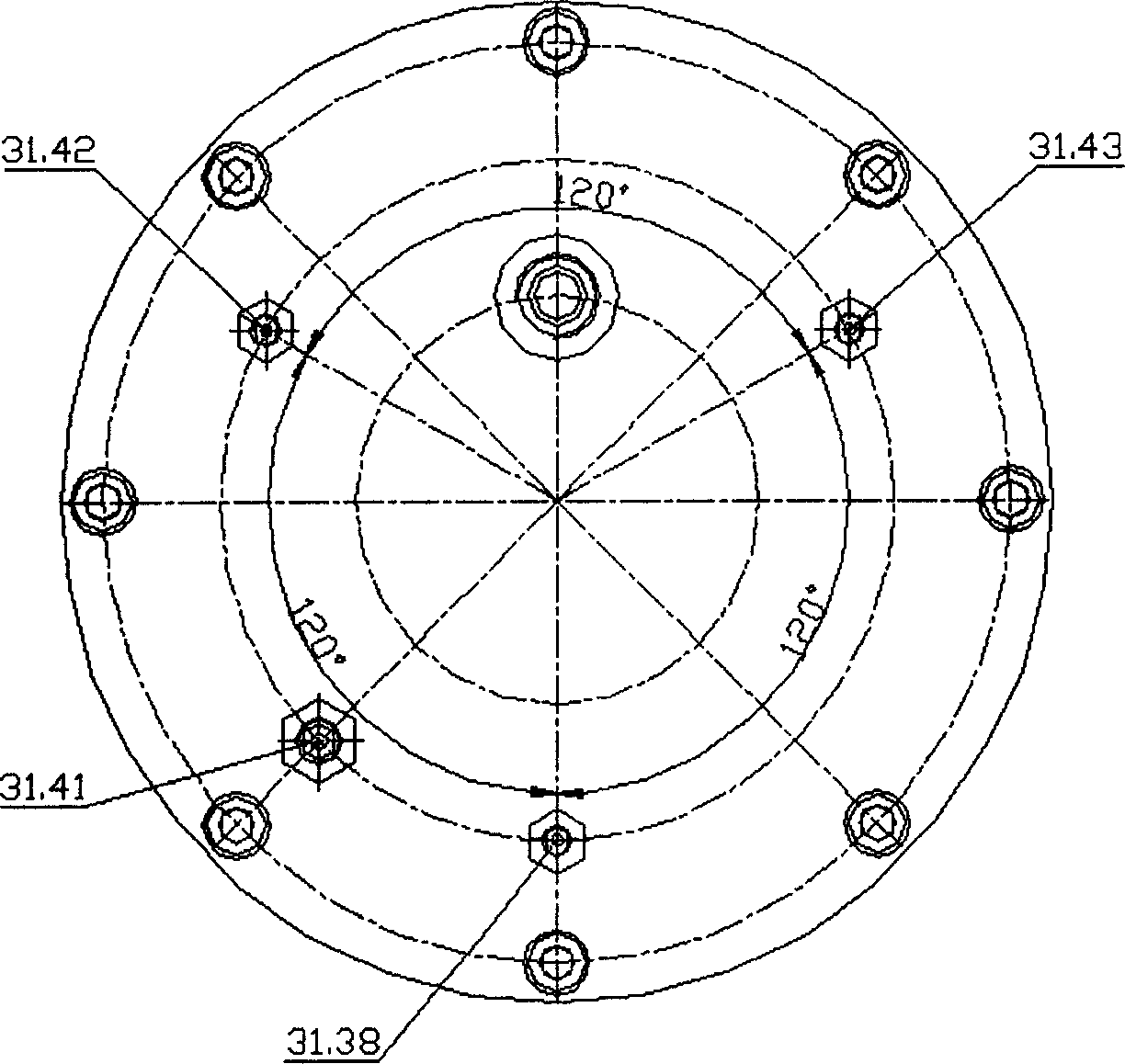

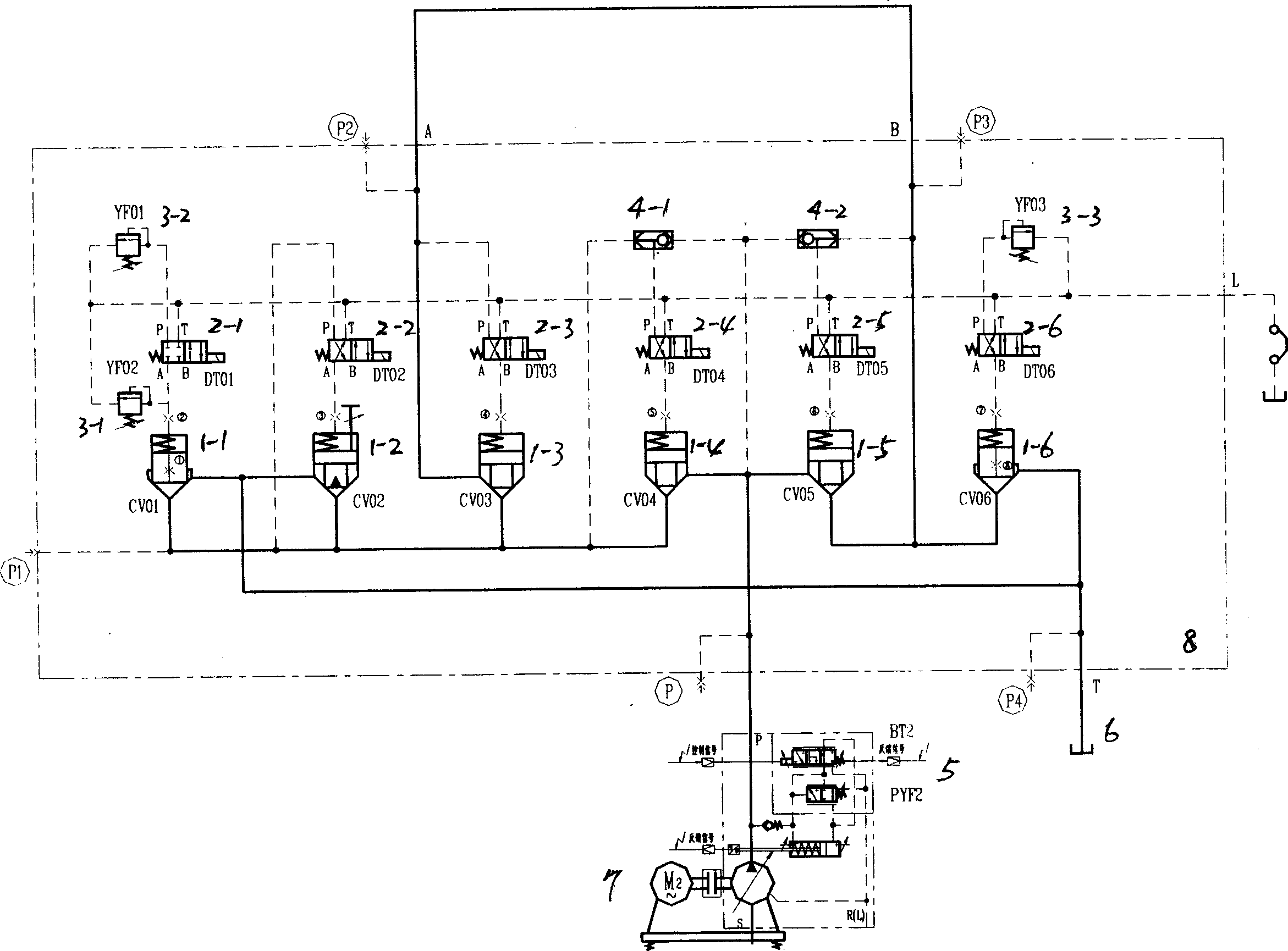

Stepless speed varying control method and system for hydraulic on/off machine with high pressure and great flow rate

InactiveCN1707033ARunning does not affectAvoid mutual interferenceBarrages/weirsStream flowControl system

The stepless speed varying control method for hydraulic on / off machine with high pressure and great flow rate in huge navigation lock, such as that in Yangtze Gorges hydro complex, is used mainly in controlling the water conveying valve, and features that one high pressure and great flow electro-hydraulic proportion plunger pump is used as the basic element combined with the integrated control structure of two-way inserted valve based on 'fluid lock theory' to constitute the stepless speed varying control on the water conveying valve and the A-shaped gate of the huge navigation lock. The control system has water conveying valve on / off machine hydraulic control loop comprising motor-pump combinations and two-way inserted valve. The present invention has accurate and reliable control and smooth running in controlling the great inertia load of the permanent navigation lock, and excellent steady and dynamic characteristics.

Owner:SHANGHAI HAIYUE HYDRAULIC ELECTROMECHANICAL ENG COOP

Two-dimensional dual axial piston pump

InactiveCN105484962ASimple structureRealize continuous oil suction and discharge functionPositive displacement pump componentsPositive-displacement liquid enginesSteel ballCylinder block

The invention discloses a two-dimensional dual axial piston pump which comprises a shell, a left cylinder, a right cylinder, a left piston and a right piston. The left cylinder and the right cylinder are arranged in the shell through positioning steel balls and are fixedly connected with the shell through connecting sleeves. An oil sucking and draining hole and a leaking oil return channel are formed in the shell. A left end cover is fixedly installed at the left end of the shell. The right end of the left cylinder and the left end of the right cylinder are fixedly connected with a left constant-adding and constant-subtracting curved-surface rail and a right constant-adding and constant-subtracting curved-surface rail respectively, and rolling curved surfaces of the left constant-adding and constant-subtracting curved-surface rail and the right constant-adding and constant-subtracting curved-surface rail are the same. The left constant-adding and constant-subtracting curved-surface rail and the right constant-adding and constant-subtracting curved-surface rail are arranged in a 90-degree staggered manner, and the highest point and the lowest point of the left constant-adding and constant-subtracting curved-surface rail correspond to the lowest point and the highest point of the right constant-adding and constant-subtracting curved-surface rail respectively. The two-dimensional dual axial piston pump has the advantages that the structure is novel and compact, the size is small, weight is low, transmission is simple, torque pulsation is zero, the speed is easy to adjust, and displacement is high.

Owner:ZHEJIANG UNIV OF TECH

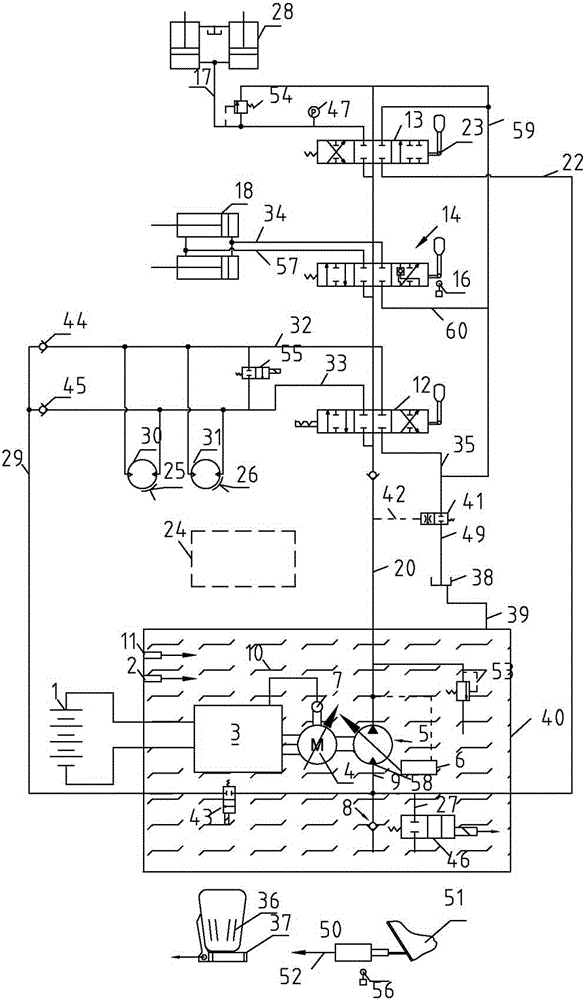

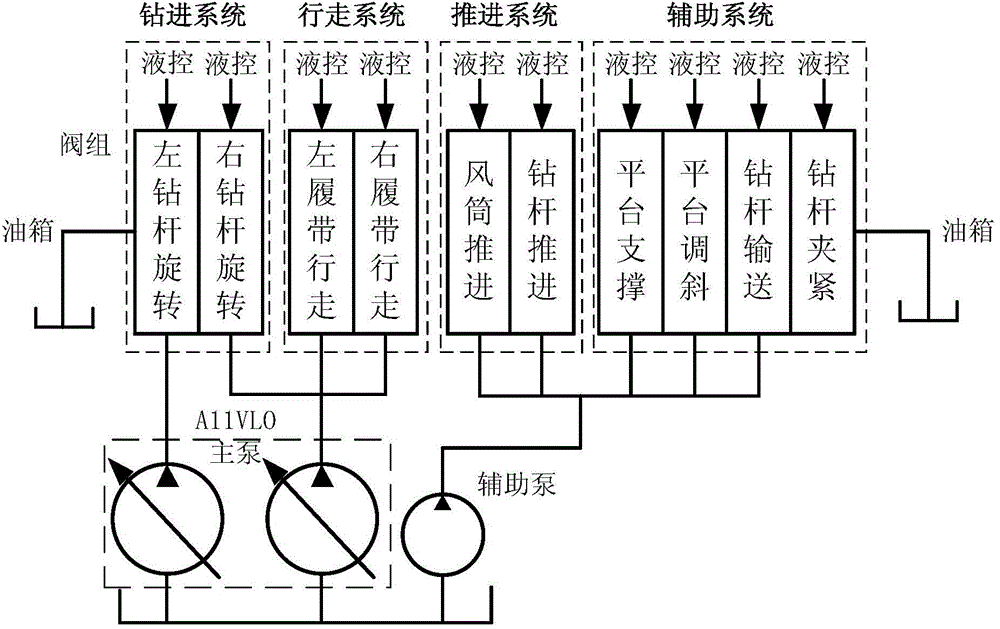

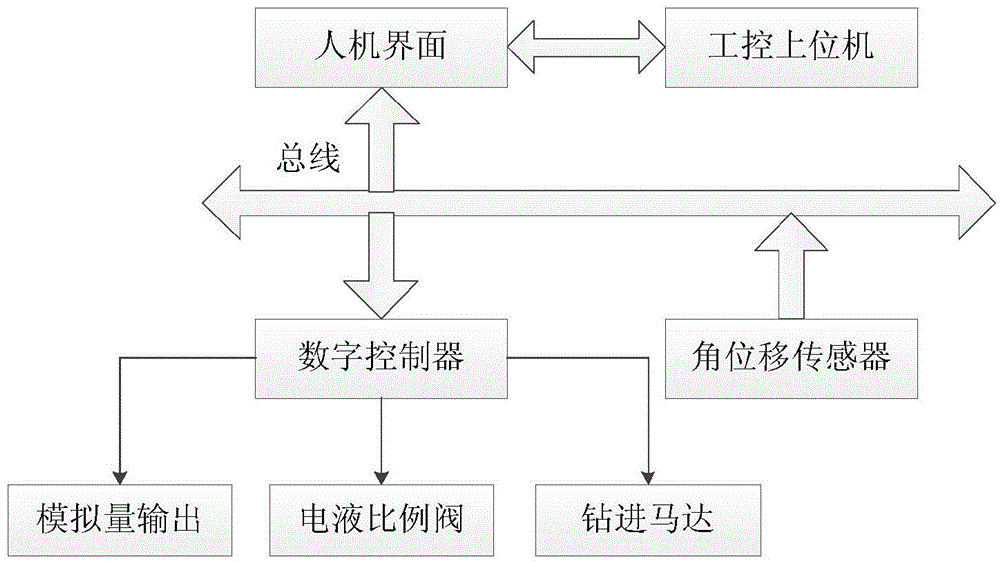

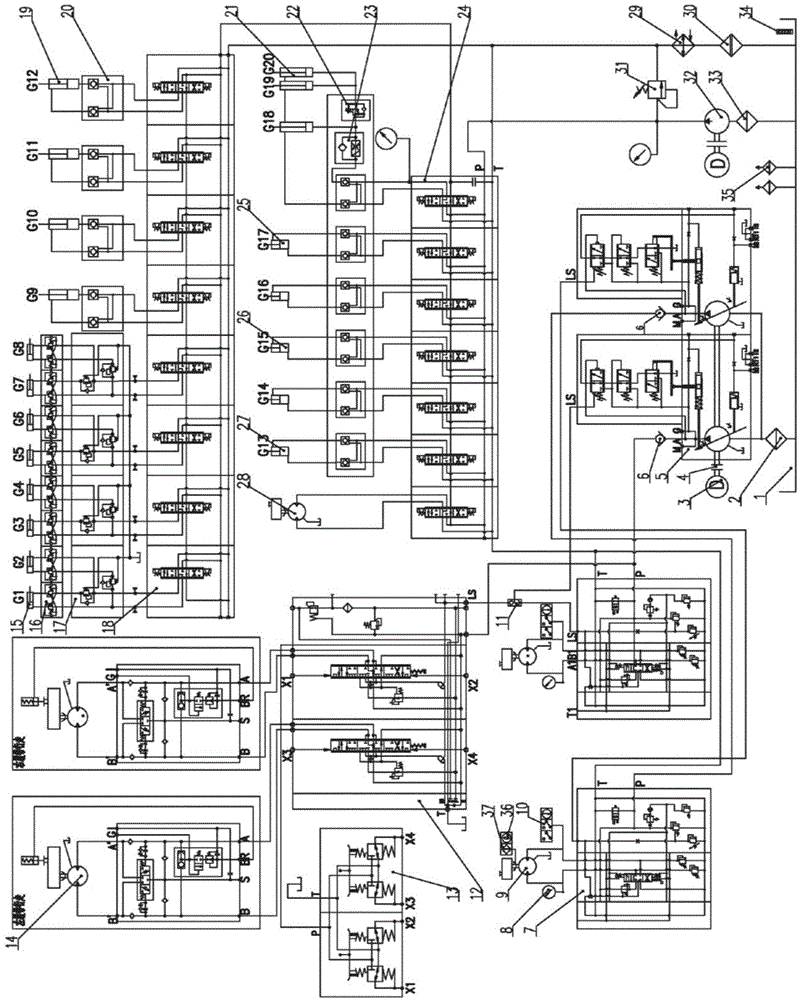

Hydraulic control system of full-hydraulic drill type coal miner

The invention discloses a hydraulic control system of a full-hydraulic drill type coal miner. The hydraulic control system comprises a drill system, a walking system, a propelling system and an auxiliary system. The drill system is controlled in a closed-loop manner by a load sensitive variable pump and an electro-hydraulic proportional valve, the pressure and the flow of the drill system can be automatically adjusted according to load changes; and the drilling speed and the position of a drill rod can be controlled in real time. The walking system and the drill system share one dual variable axial piston pump, and the complexity and space of the walking system can be effectively reduced; a speed regulating valve is adopted in the propelling system to adjust the speed, the propelling speed is adjusted according to the working condition, and cutting of a drill machine under the maximum power is achieved; and the auxiliary system can complete supporting and slope adjustment of a working platform of the drill machine, conveying and clamping of the drill rod and adjustment of the working angle of the drill machine, and positioning of the drill rod in the process of drill rod changing is completed. The problems that a hydraulic system of an existing hydraulic drill type coal miner is complex in oil way, the drill rod is difficultly controlled precisely, the system efficiency is low, and auxiliary work time and drill rod changing time are long are solved.

Owner:CHINA UNIV OF MINING & TECH

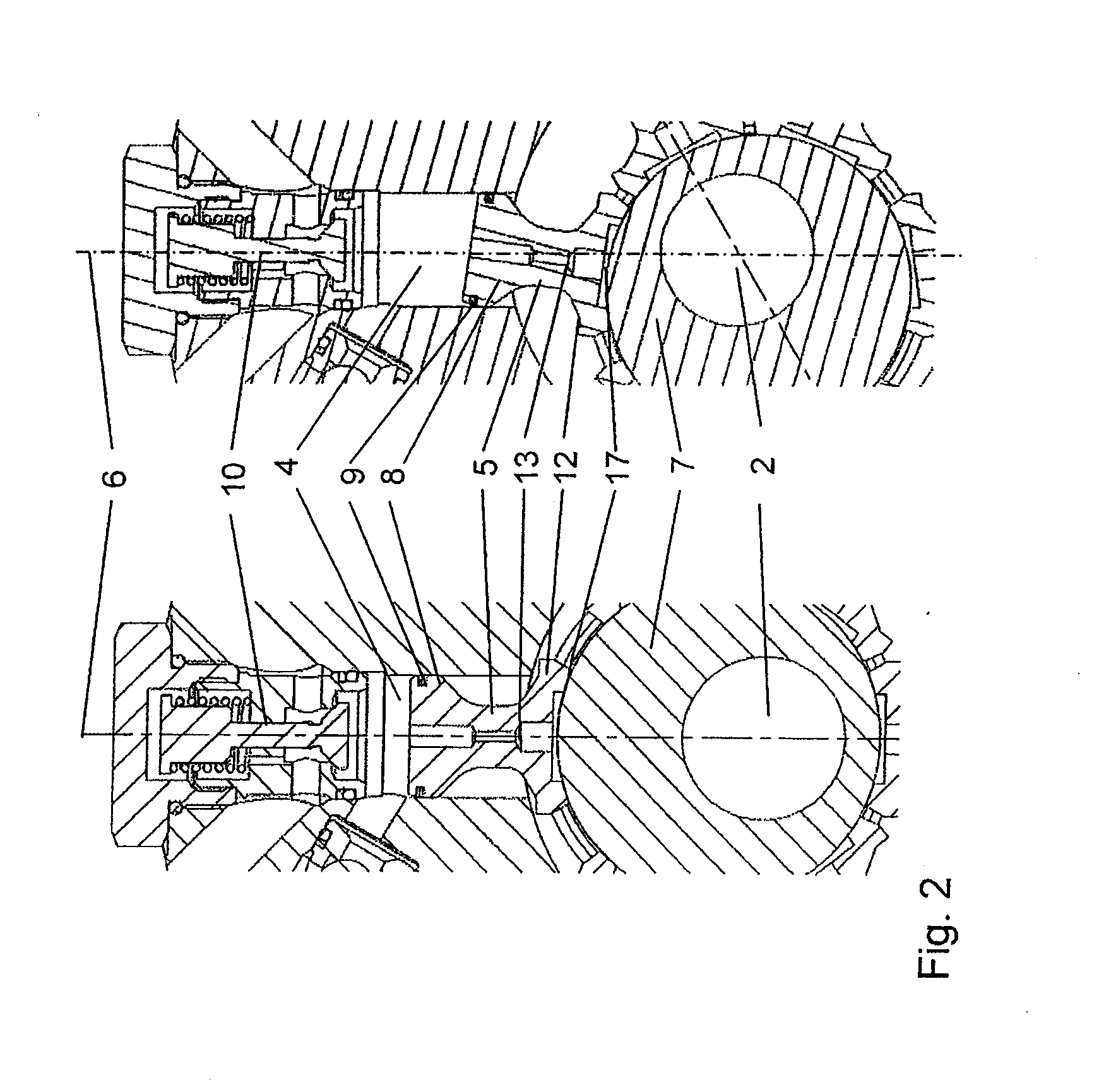

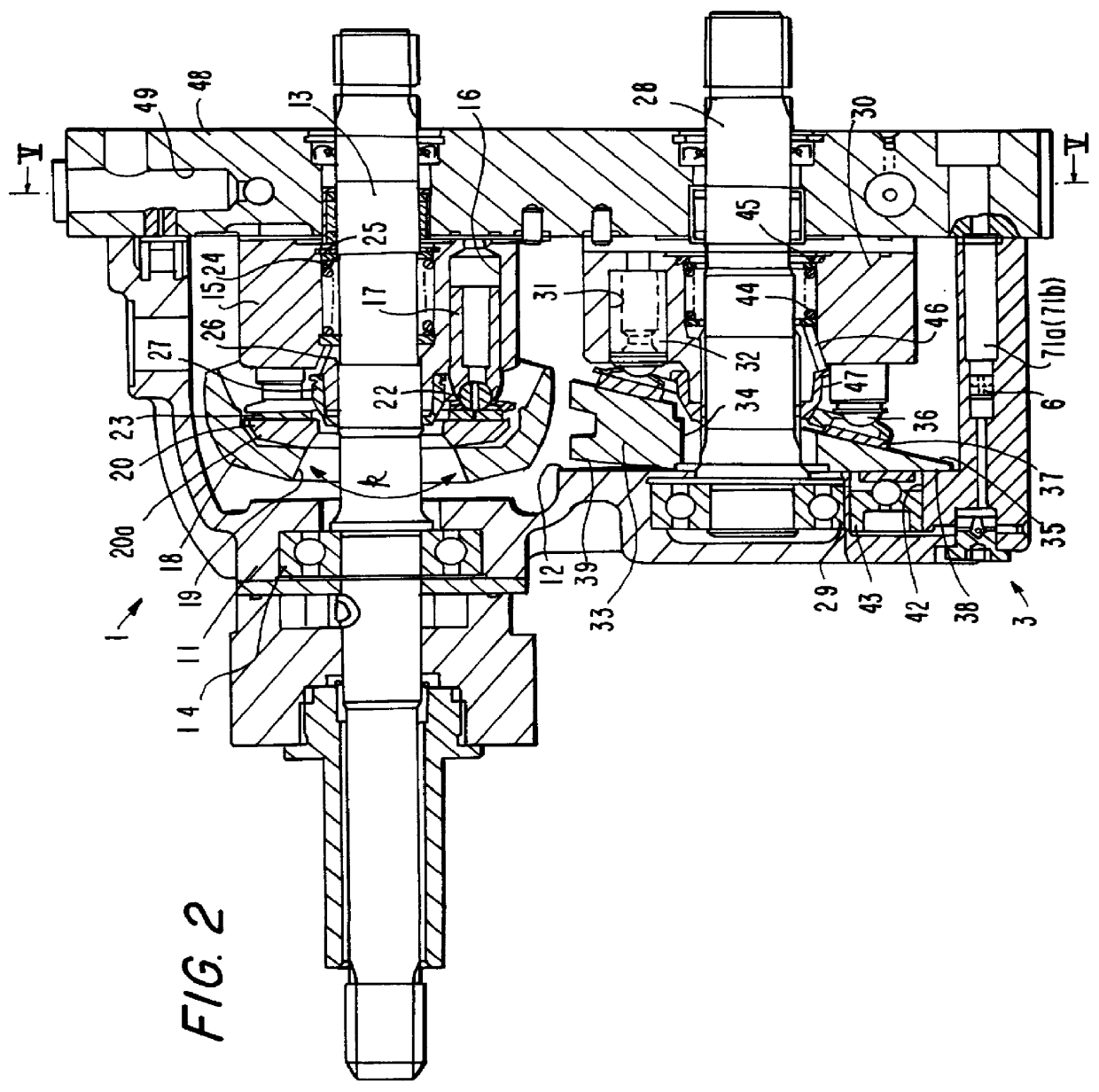

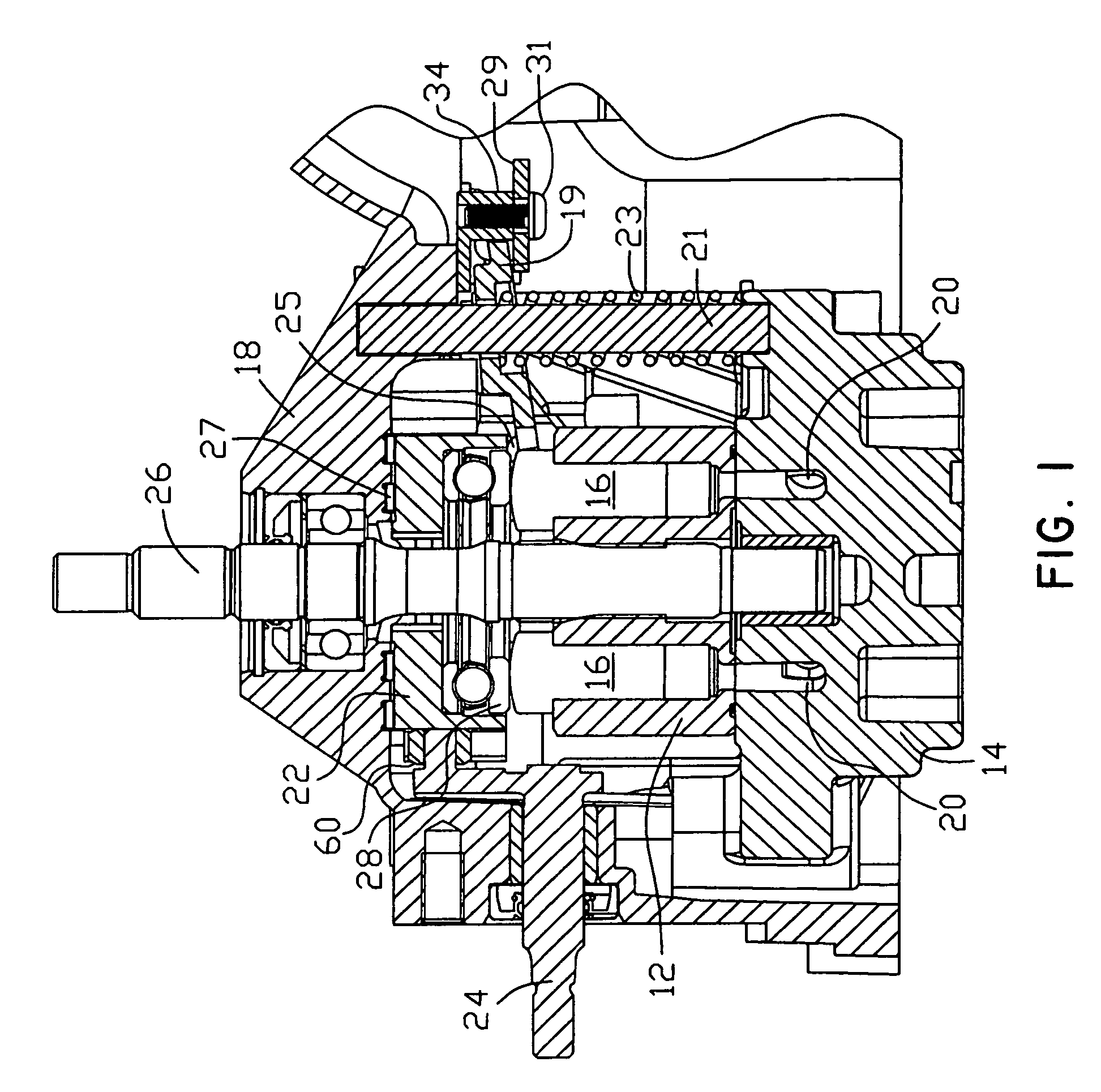

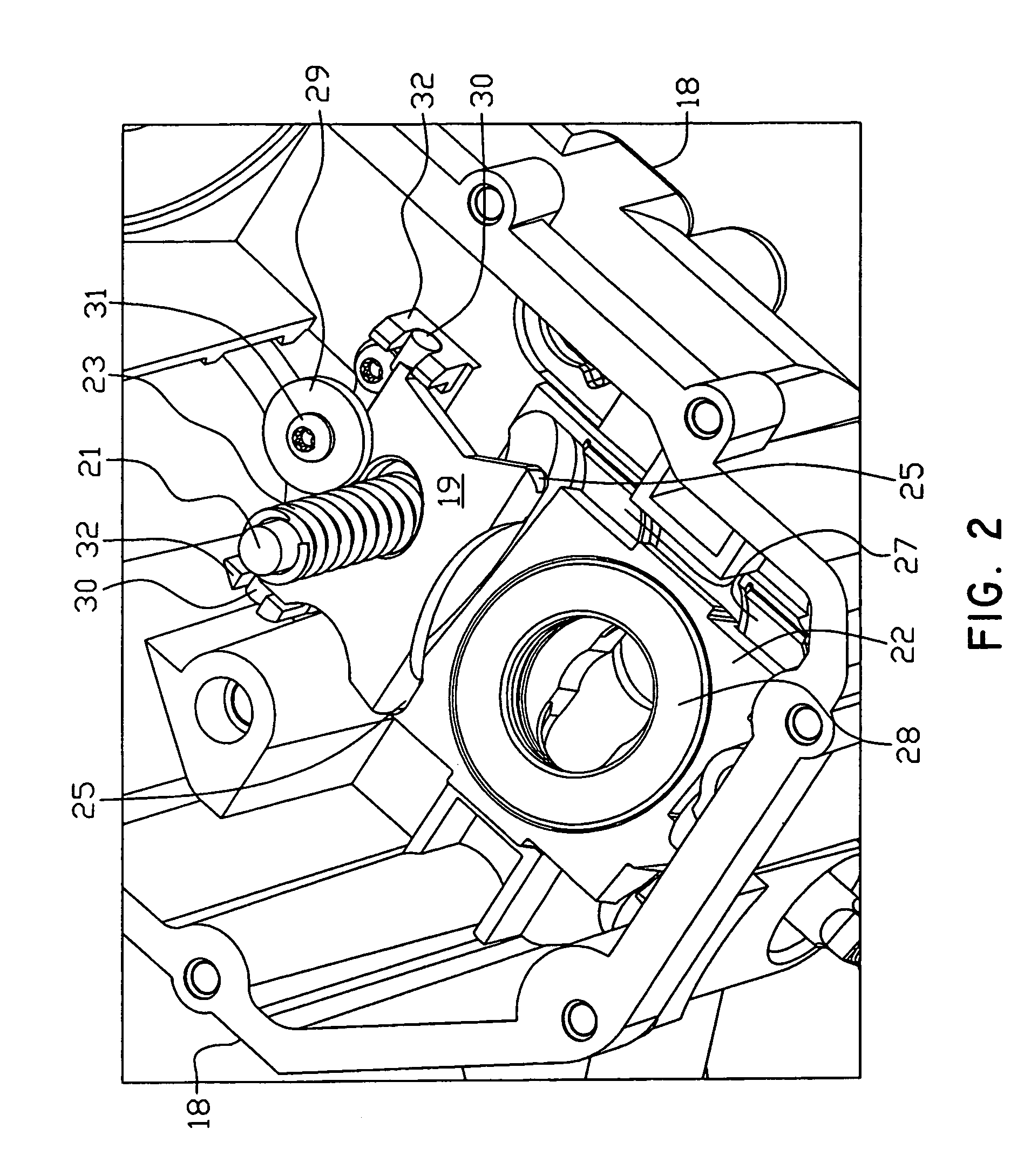

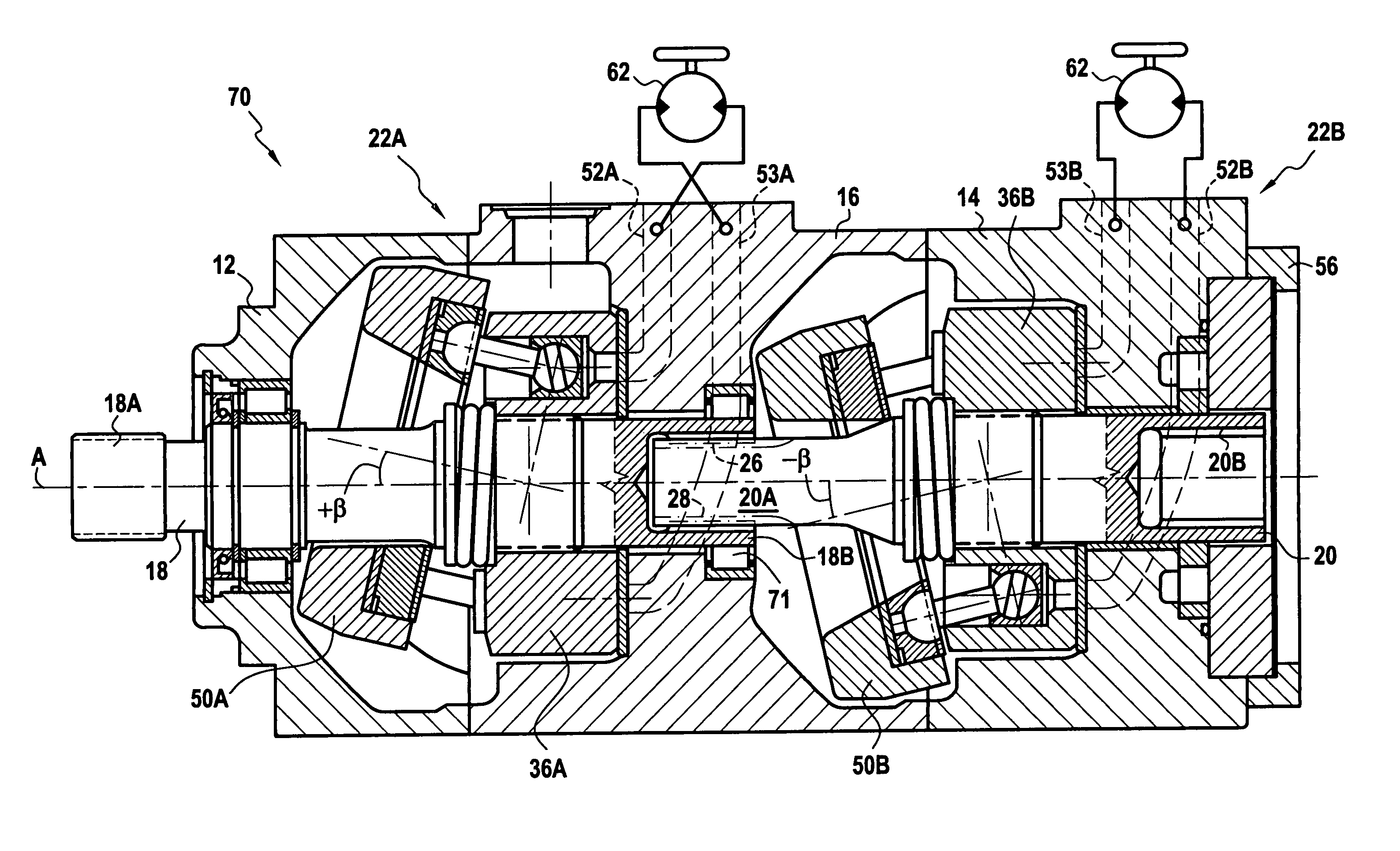

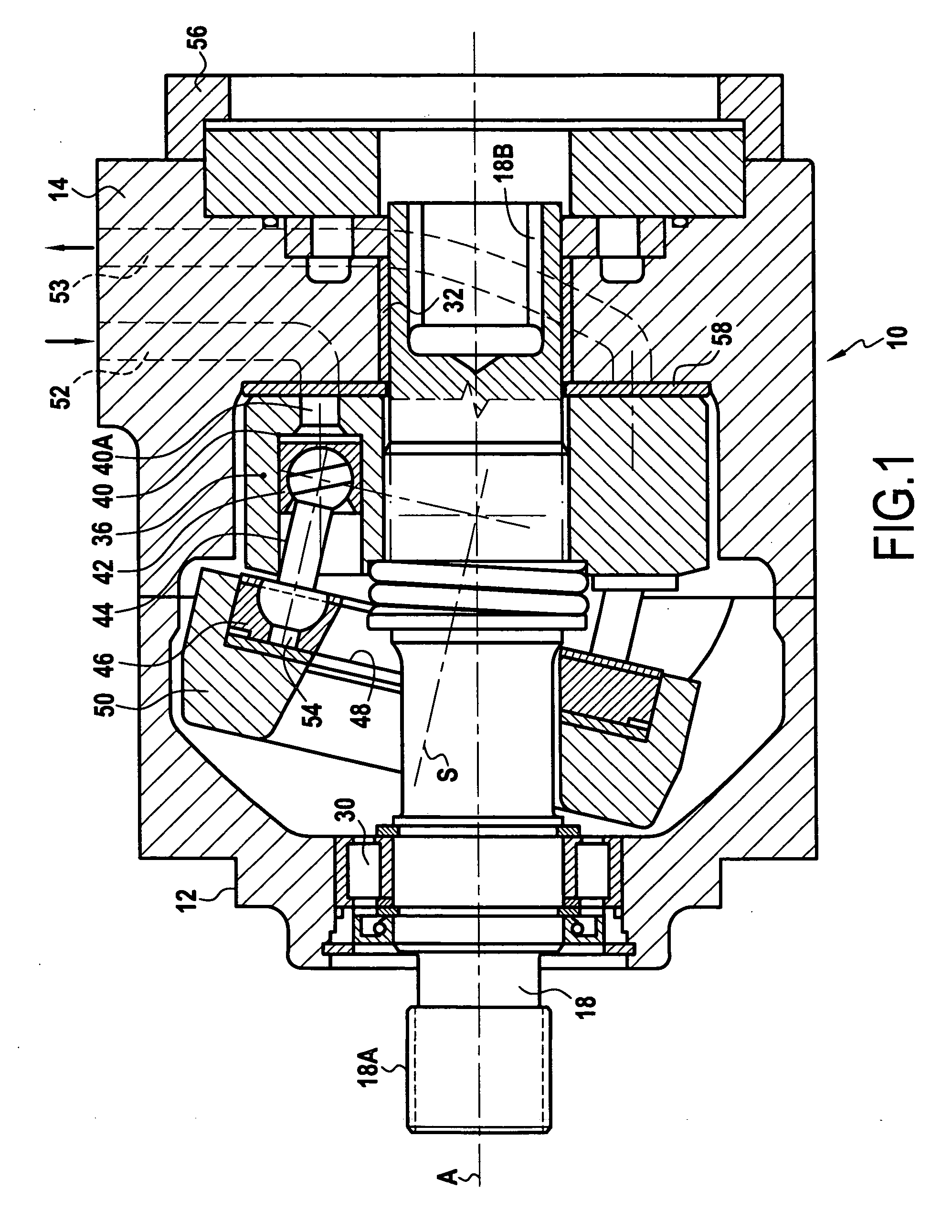

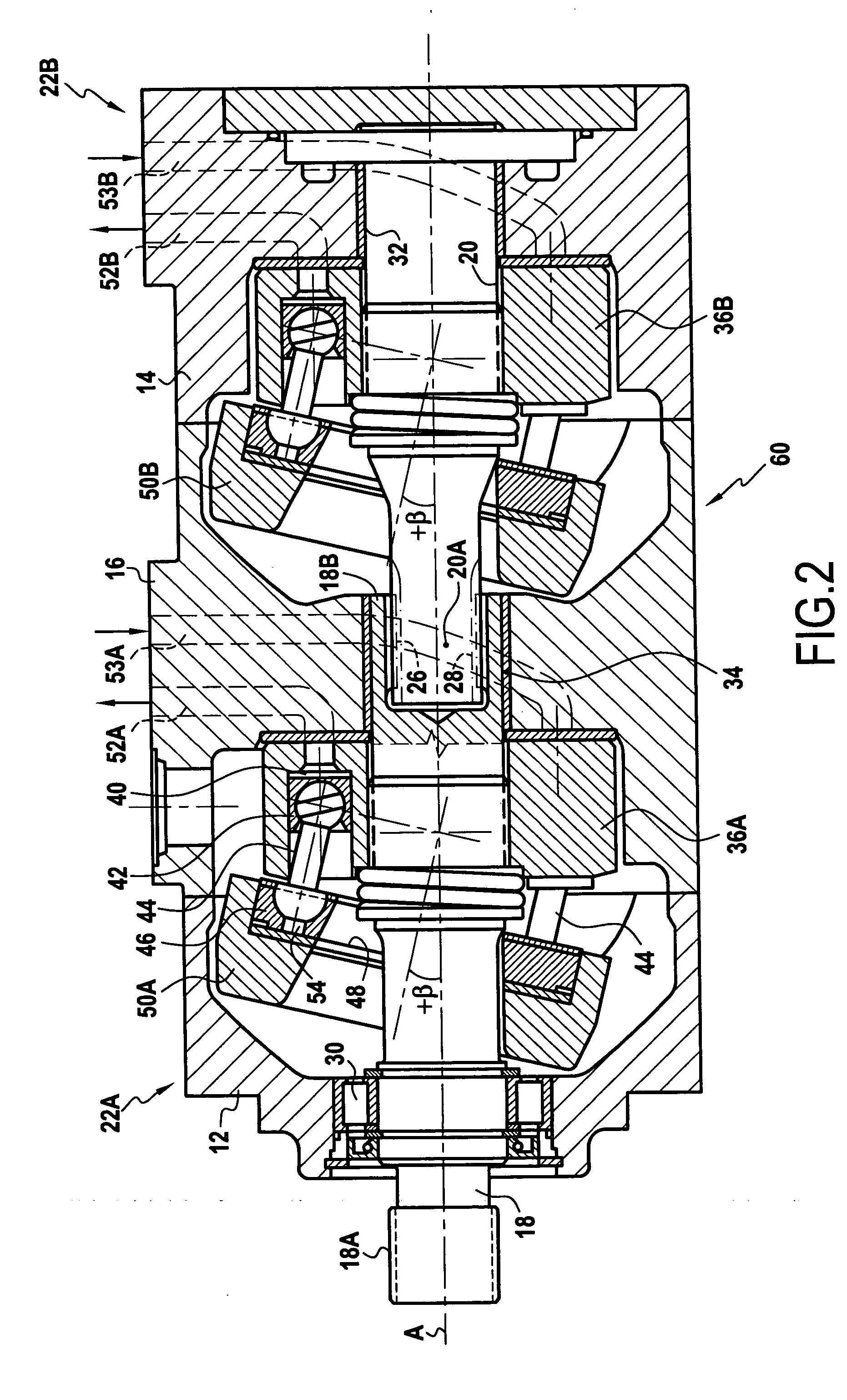

Tandem axial piston pump unit

ActiveUS20070022751A1Improvement of dynamic behaviorExtended service lifeFluid couplingsCouplings for rigid shaftsCylinder blockMechanical engineering

A hydraulic machine (60, 70) comprising a housing (12, 14, 16) and at least first and second hydraulic units. Each unit comprising a cylinder block (36A, 36B) located in the housing and having pistons (42), and a shaft (18, 20) in rotational engagement with the cylinder block (36A, 36B). The shafts (18, 20) being arranged coaxially and being coupled so as to rotate together. The machine (60, 70) further comprising bearings (30, 32, 34, 71) for supporting the shafts (18, 20) in the housing (12, 14, 16). The shafts (18, 20) are coupled by corresponding male and female splined end portions (18A, 20A) thereof engaged one in the other, and the bearings (30, 32, 34, 71) comprise first and second bearings (30, 32) for respectively supporting the shafts (18, 20) at portions thereof located on the other sides of the cylinder blocks (36A, 36B) with respect to said splined end portions (18A, 20A). A single third bearing arrangement (34, 71) engages one of the shafts (18, 20) at least in the vicinity of the splined end portion (18A, 20A) thereof thereby supporting the shafts (18, 20) between said cylinder blocks (36A, 36B).

Owner:SA POCLAIN HYDRAULICS B P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com