Electromagnetic direct-drive electro-hydraulic servo pump

An electro-hydraulic servo drive pump technology, applied in the field of hydraulic pumps, can solve the problems of inaccurate variable process adjustment, complex flow channel design, slow speed, etc., and achieve the effect of simple and efficient transmission, flexible control and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

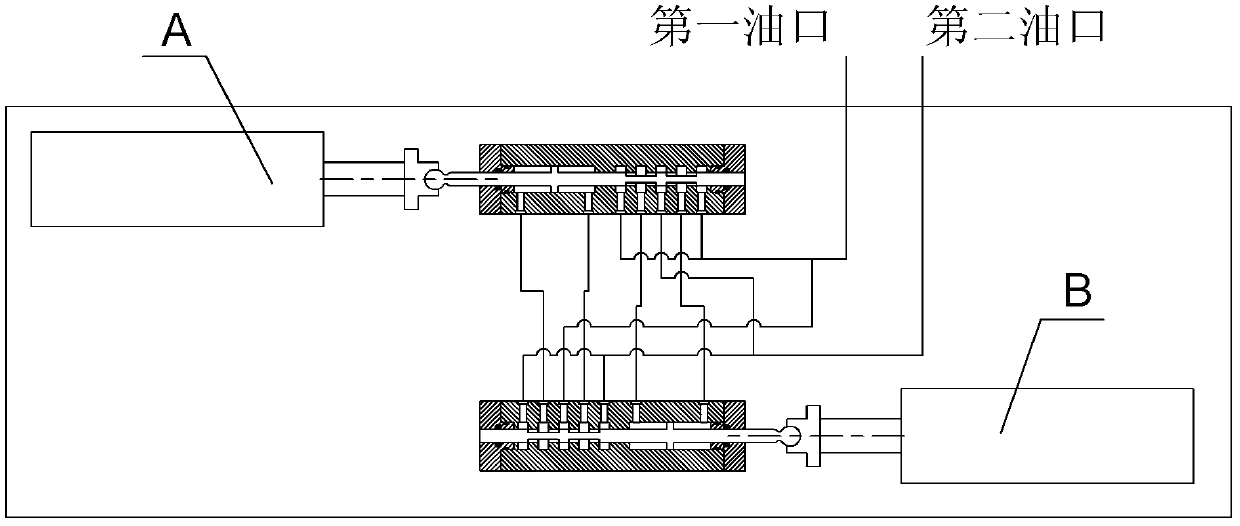

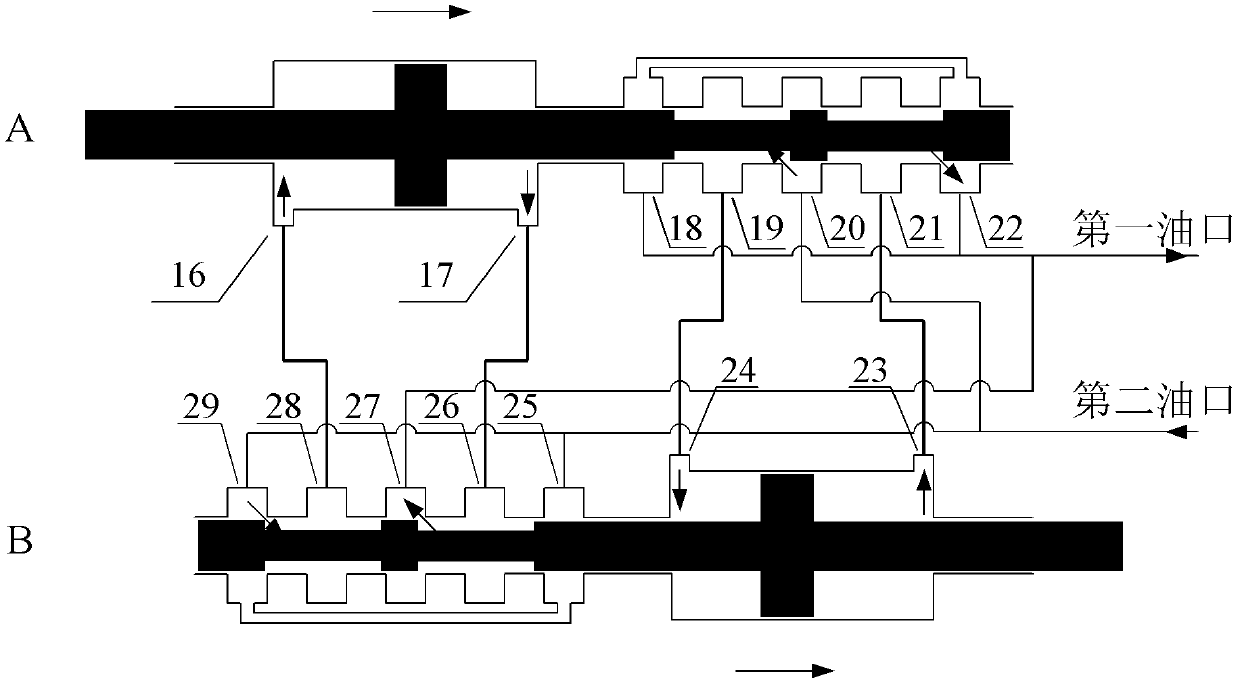

[0034] The present invention is an electromagnetic direct drive electro-hydraulic servo pump, such as figure 1 As shown, it includes an electromagnetic direct drive pump valve module A and an electromagnetic direct drive pump valve module B, and the electromagnetic direct drive pump valve module A and the electromagnetic direct drive pump valve module B have the same structure.

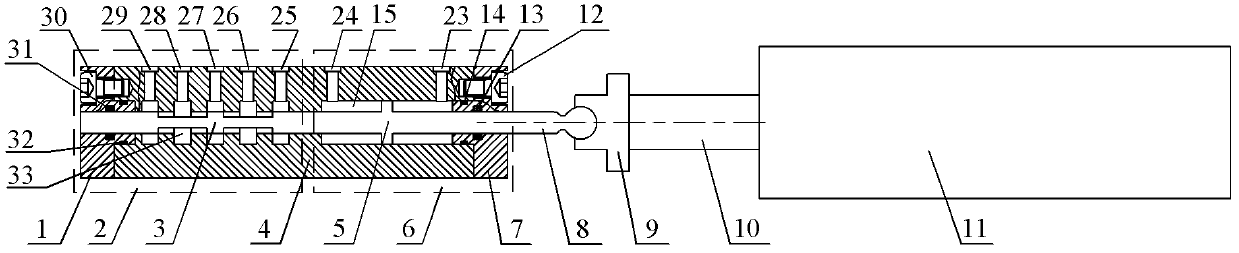

[0035] Among them, the electromagnetic direct drive pump valve module B such as figure 2As shown, it includes end cover 1, valve core 3, pump body 4, piston 5, end cover 7, pump shaft 8, ball joint sleeve 9, linear motor mover extension rod 10, linear motor 11, sealing ring 13, sealing Ring 14, piston cavity 15, sealing ring 31, sealing ring 32, valve chamber 33.

[0036] The linear motor 11 is equipped with a linear motor extension rod 10, and one end of the linear motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com