Automatic sealing loader for button cell

A technology for automatic sealing and button batteries, which is applied in the direction of primary batteries, secondary batteries, battery pack components, etc., can solve the problems of disordered discharge, high manufacturing cost, unqualified sealing quality, etc., and eliminate the problem of product quality Influence, guarantee quality and stability, effect of improving quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited by the embodiments.

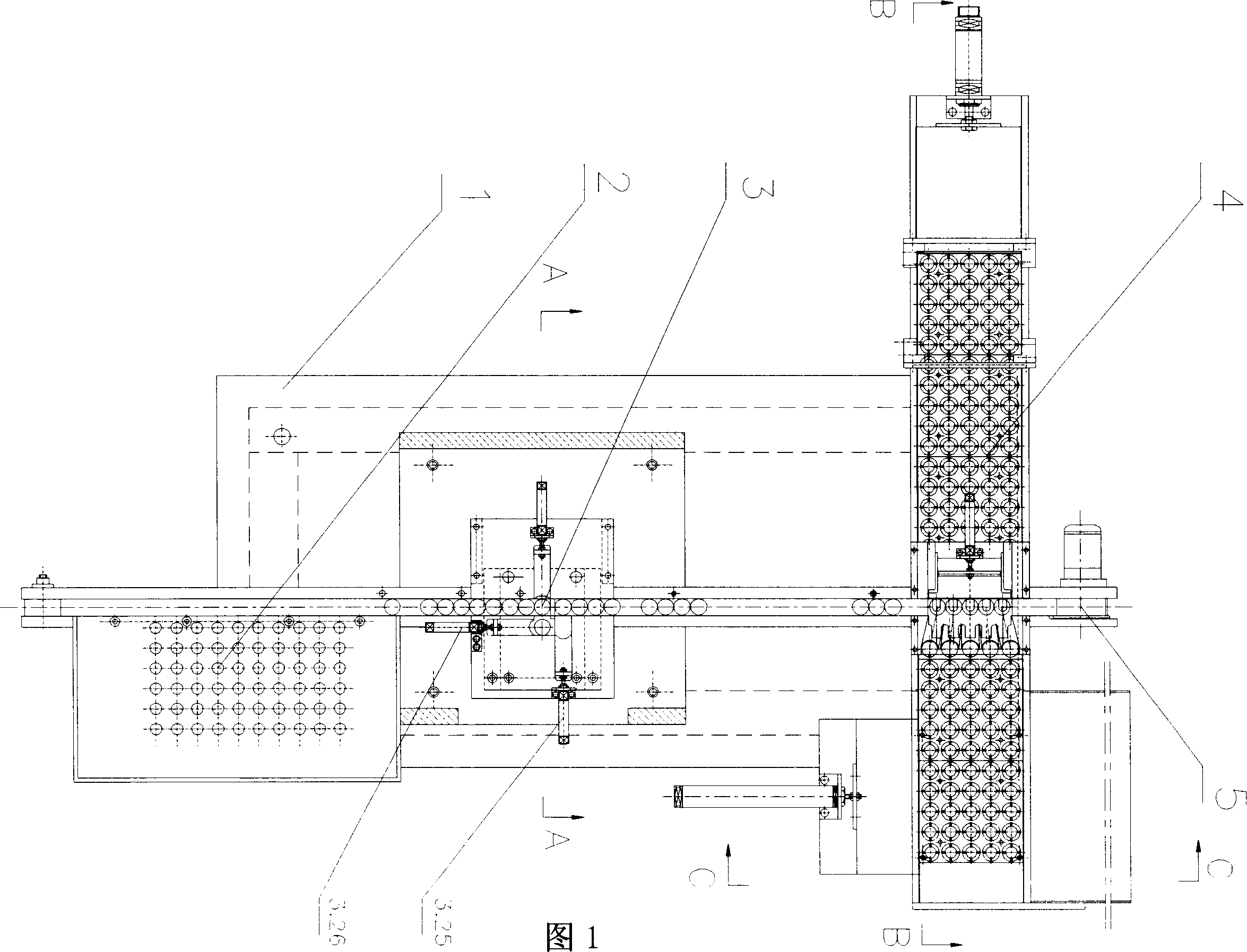

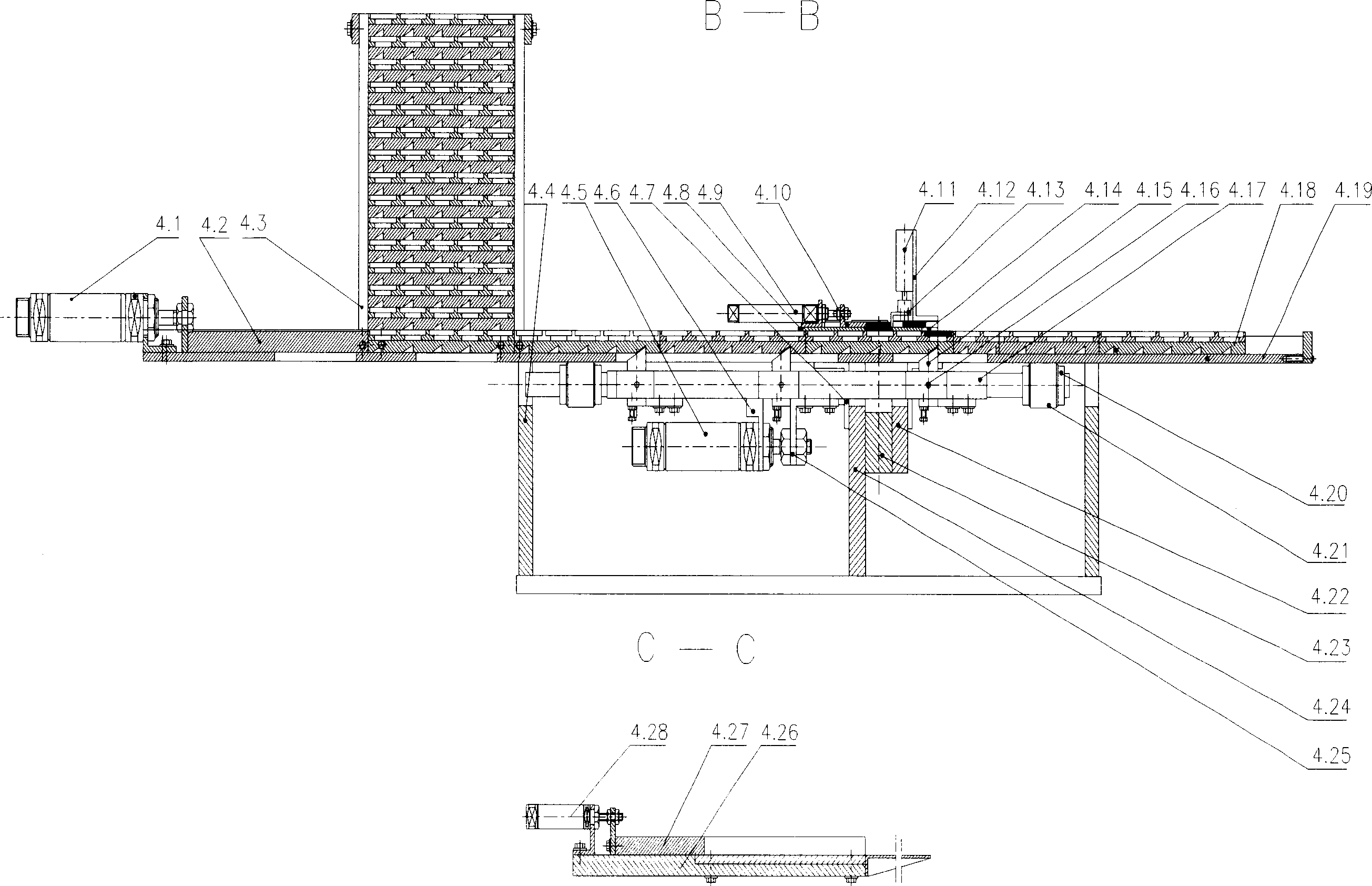

[0029] A button battery automatic sealing and loading machine (see Fig. 1) designed by the present invention includes a frame assembly 1, a feeding mechanism 2, a sealing mechanism 3, a loading mechanism 4, a transmission mechanism 5, a pneumatic control system and an electrical control system.

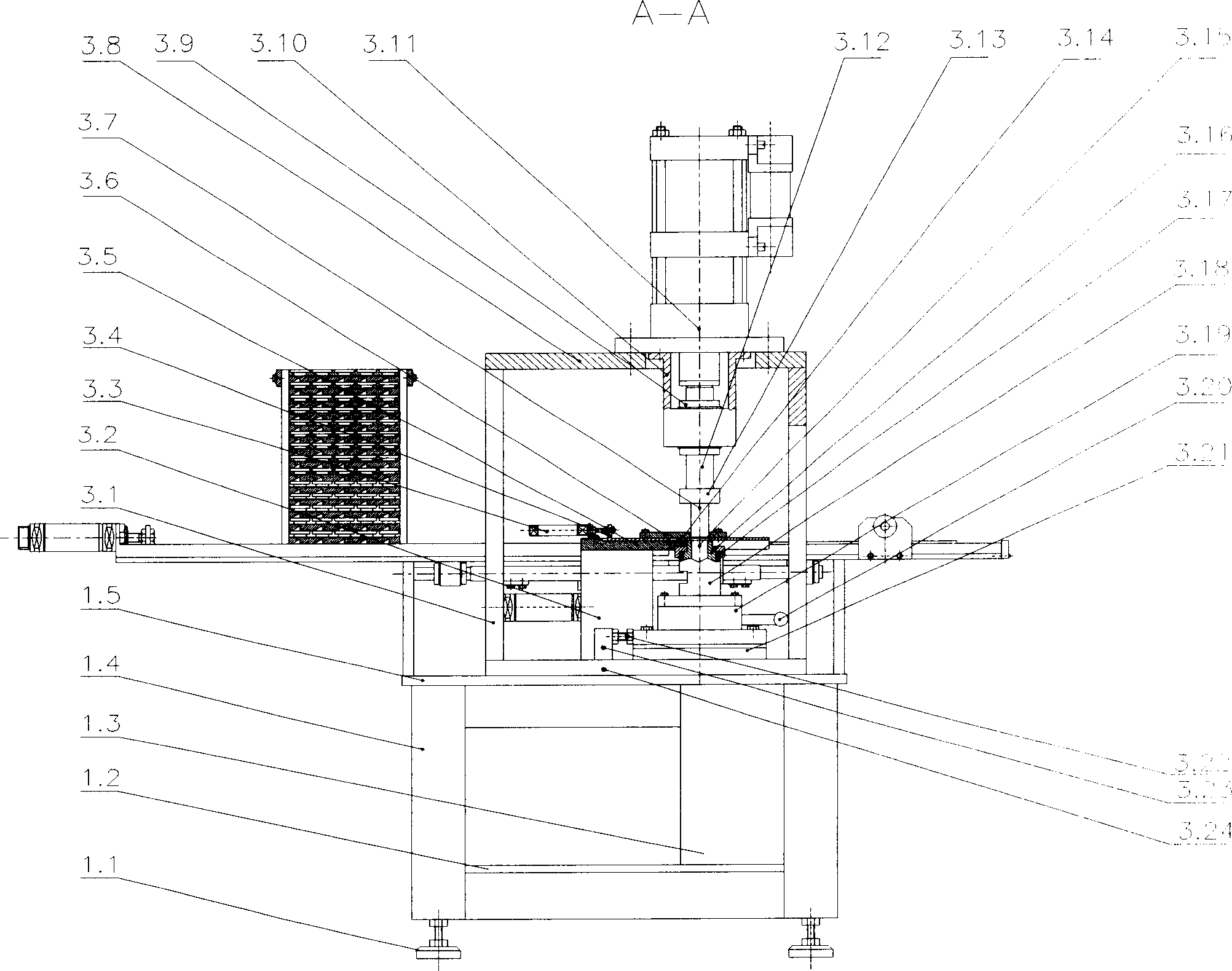

[0030] The frame assembly 1 (see figure 2 ) includes a workbench 1.5 and its support 1.4, a lower base plate 1.2 and an anchor 1.1, through which the levelness of the entire machine can be adjusted; the electrical control system and the pneumatic control system are installed on the lower base plate 1.2, and the rest of the feeding mechanism 2. The sealing mechanism 3, the loading mechanism 4 and the transmission mechanism 5 are all located on the working table 1.5;

[0031] The feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com