Patents

Literature

127results about How to "Avoid rebound phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

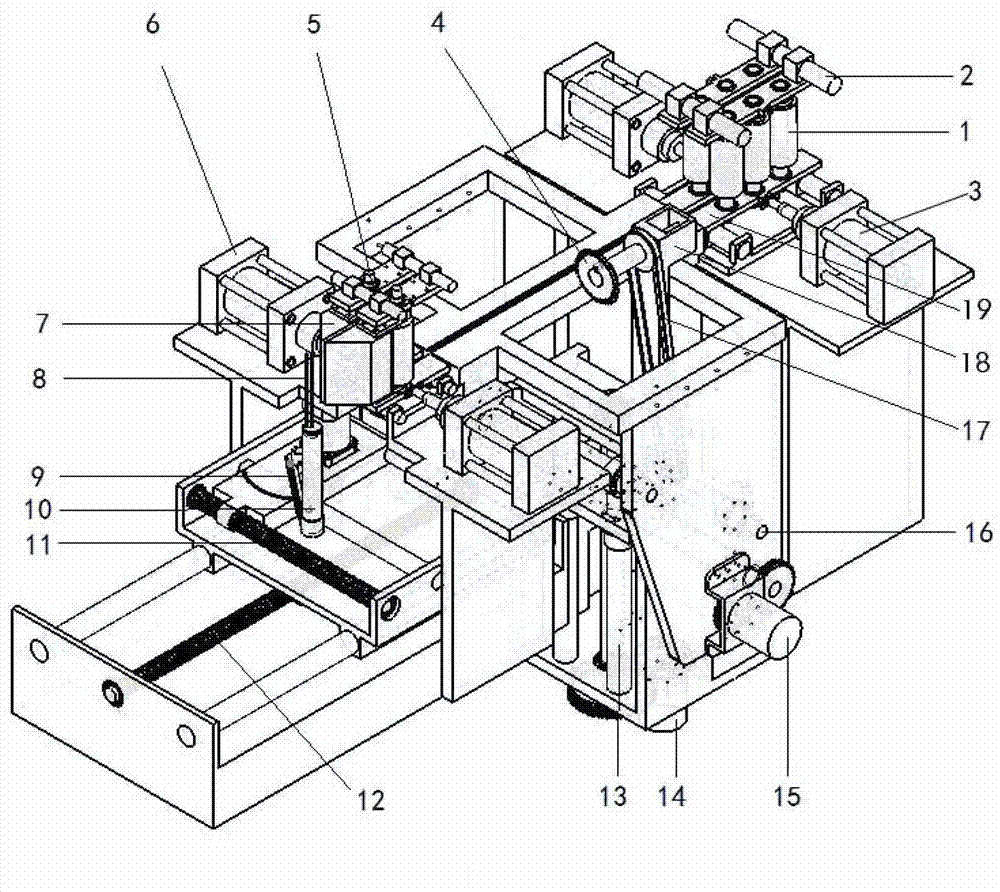

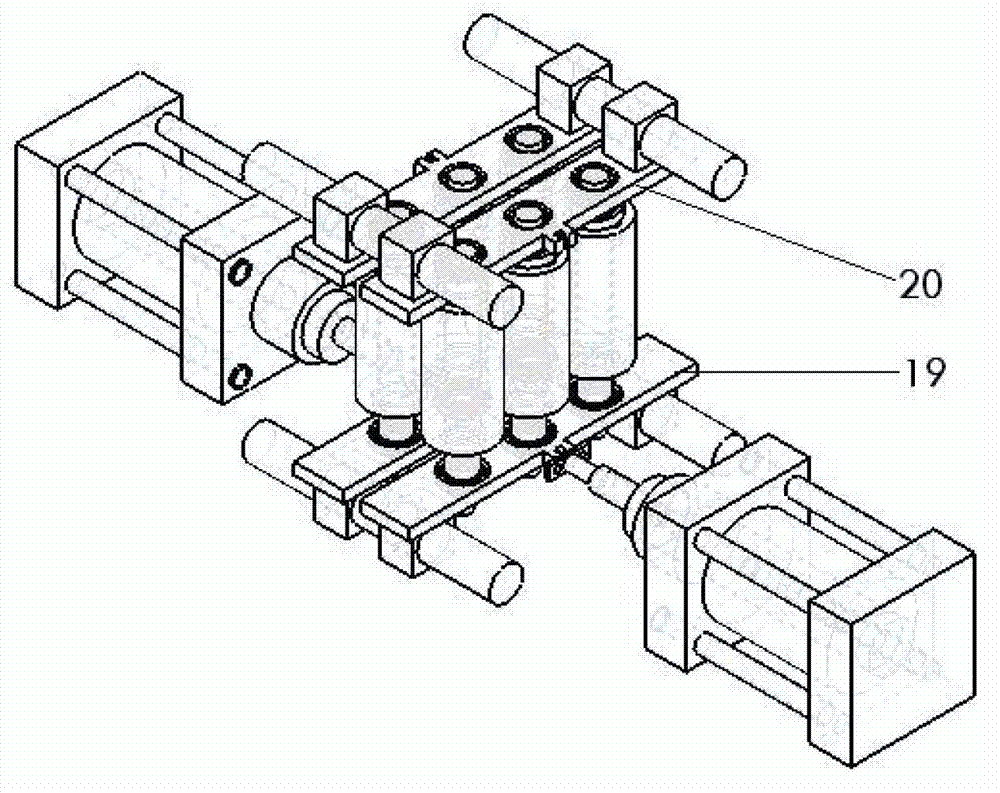

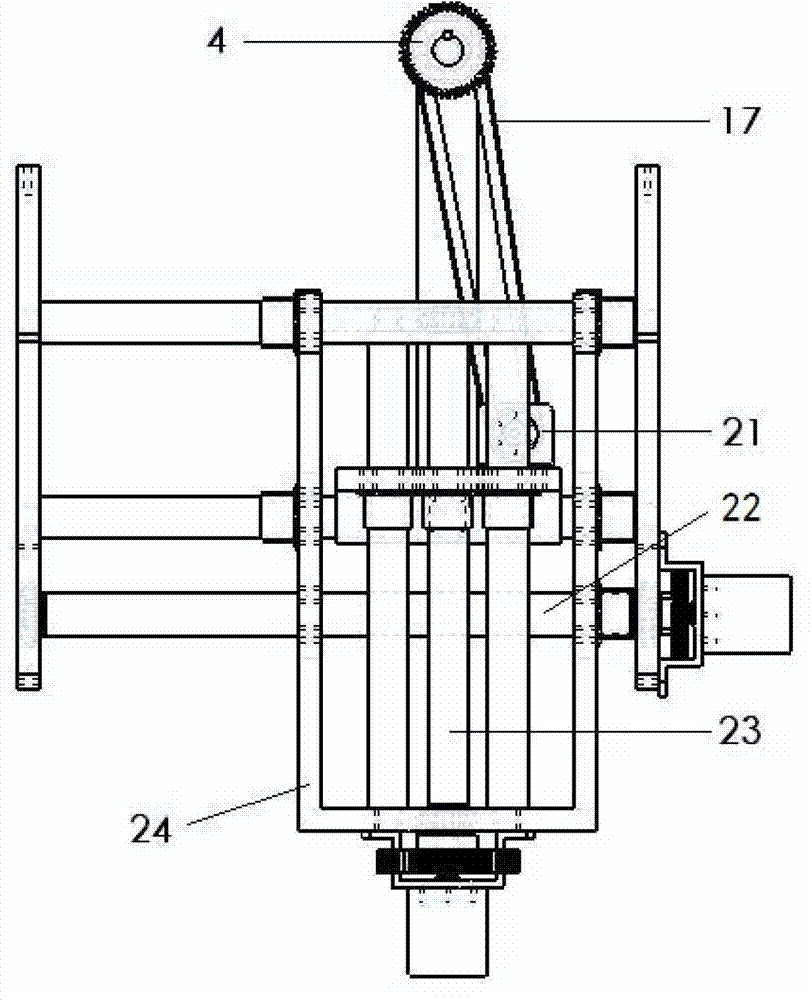

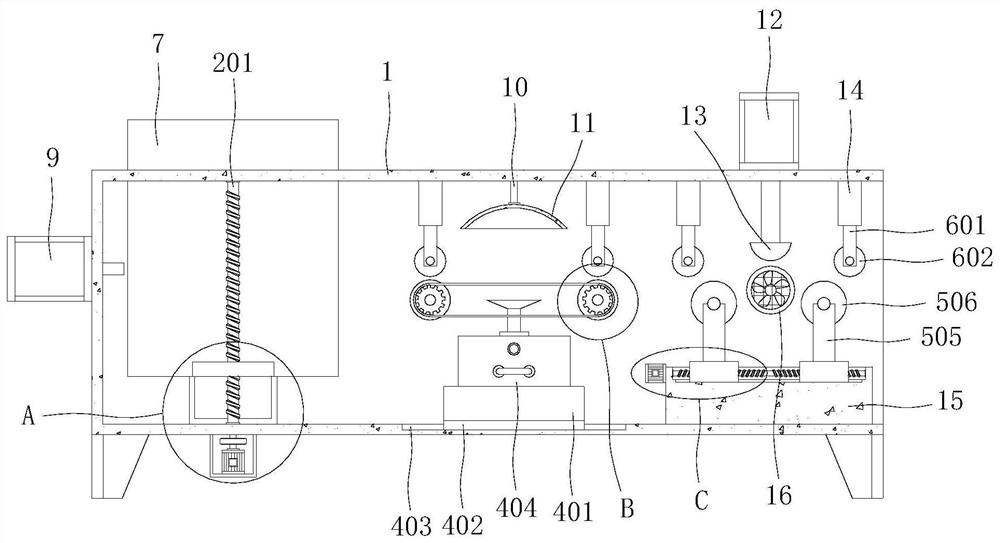

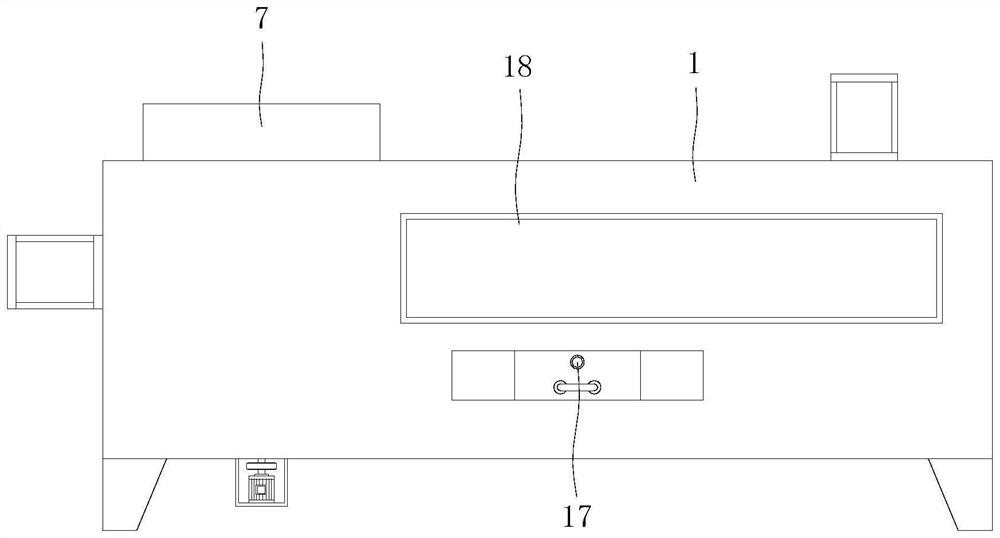

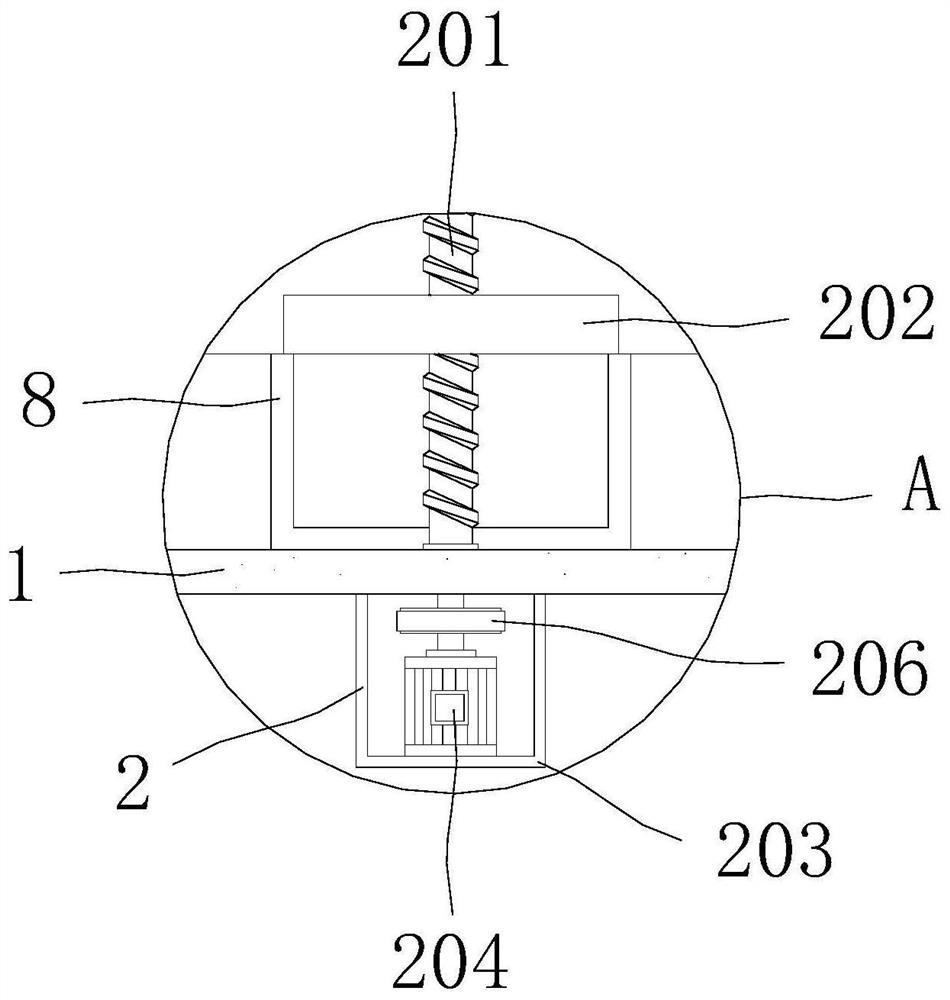

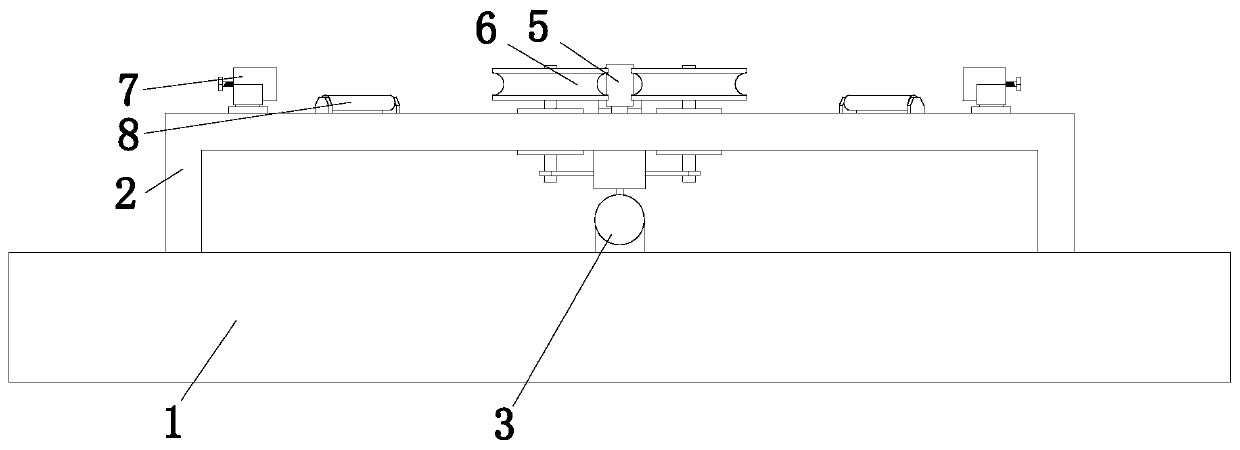

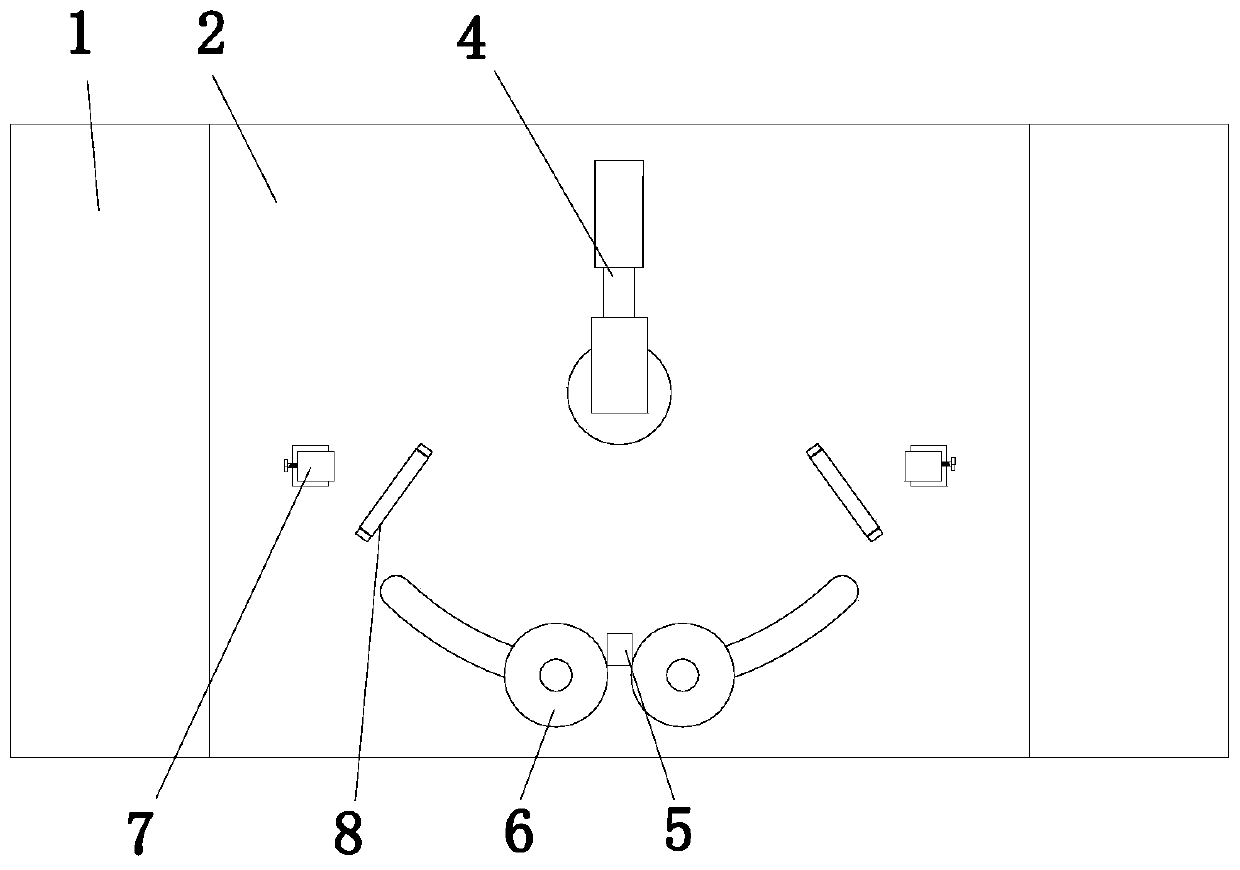

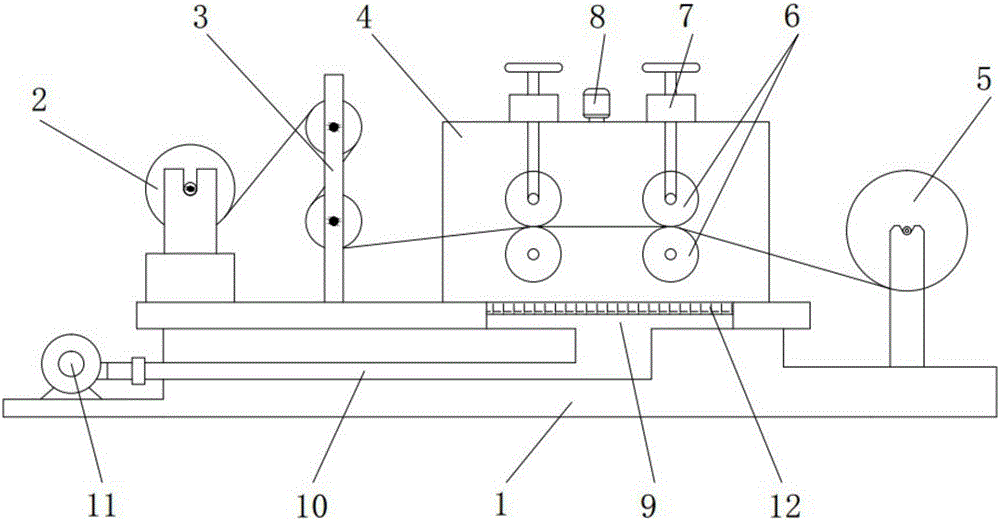

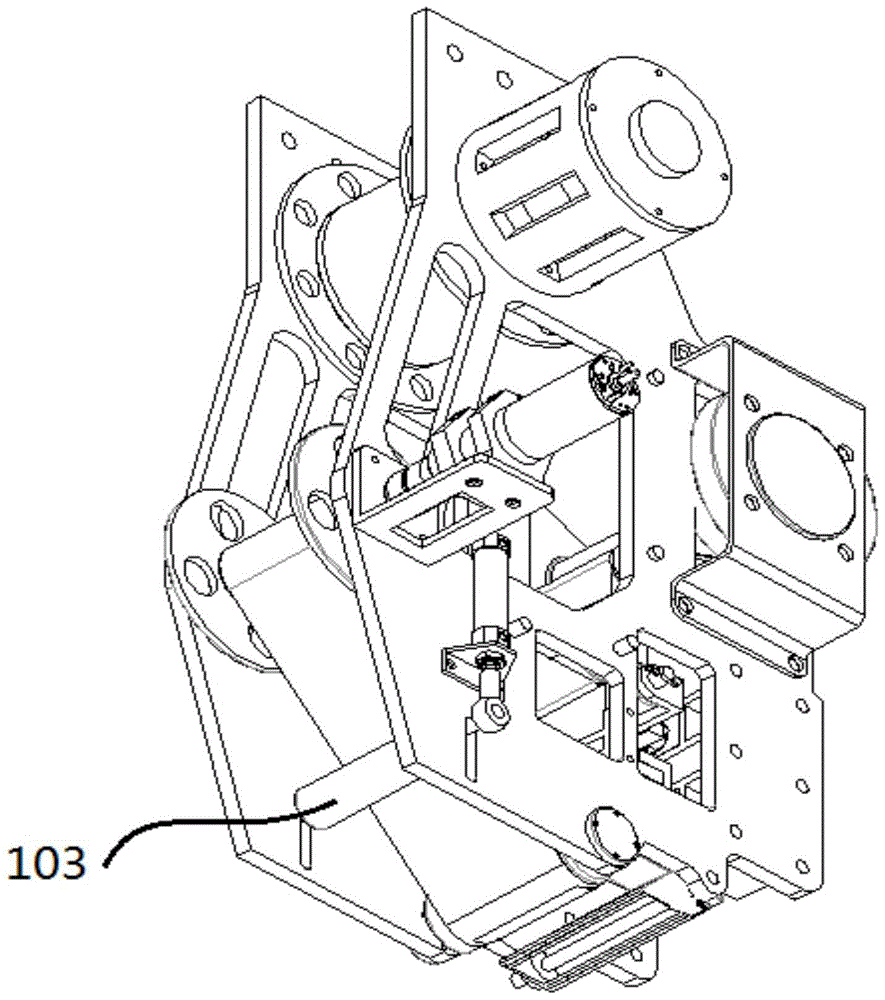

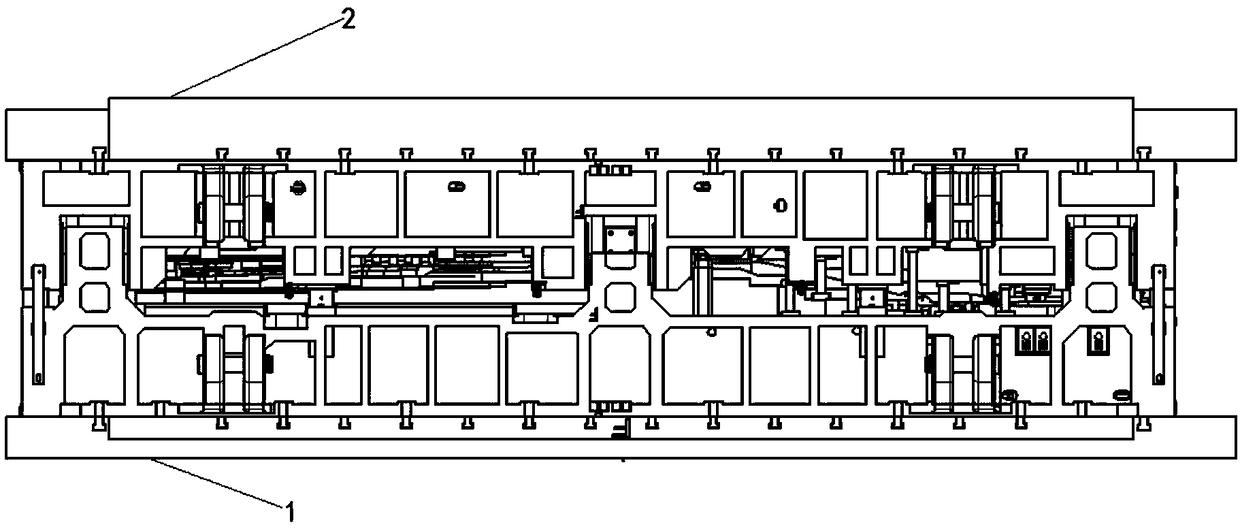

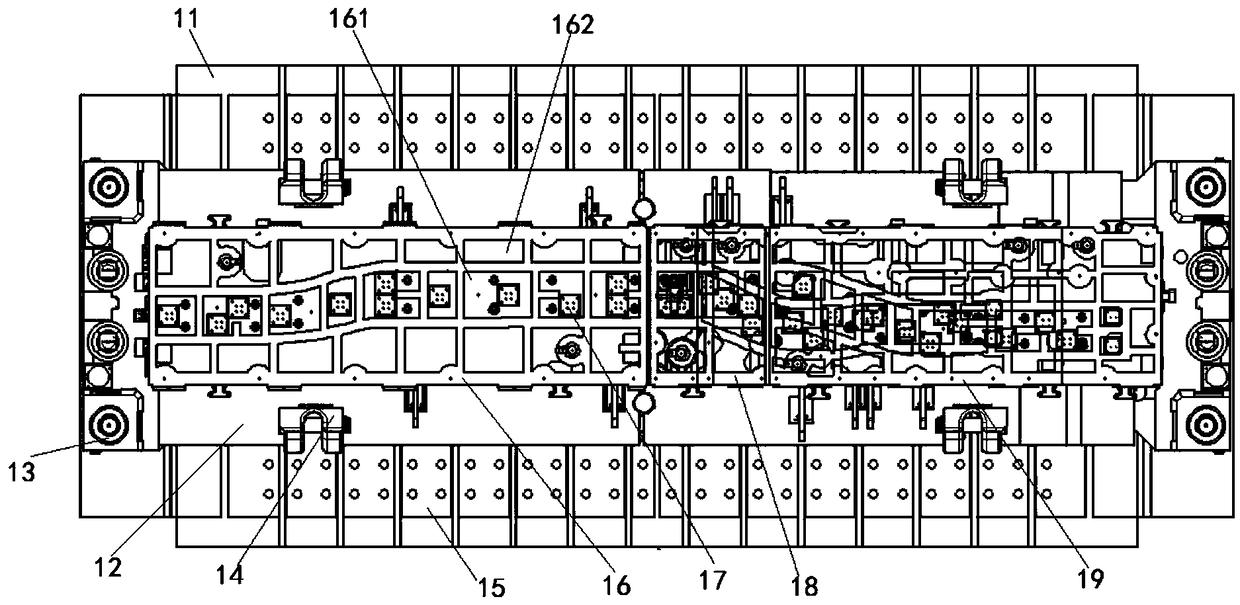

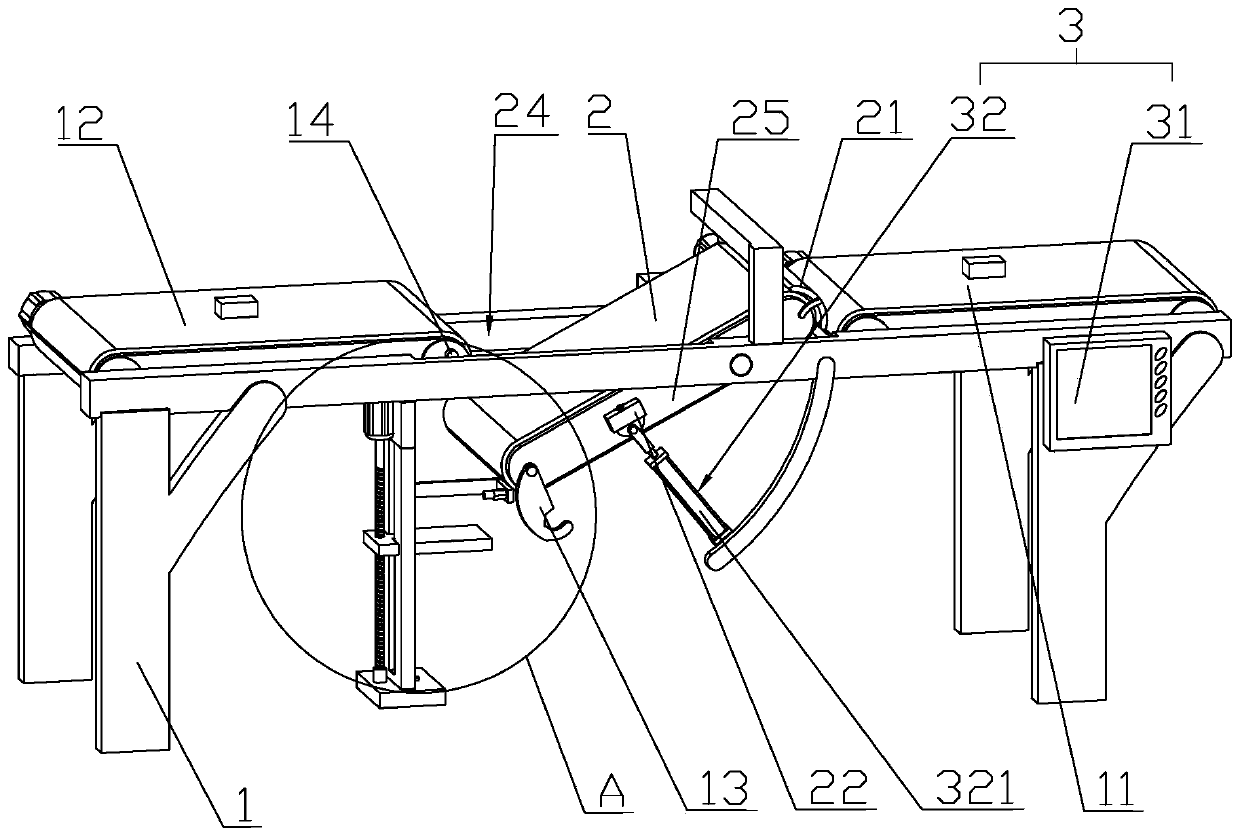

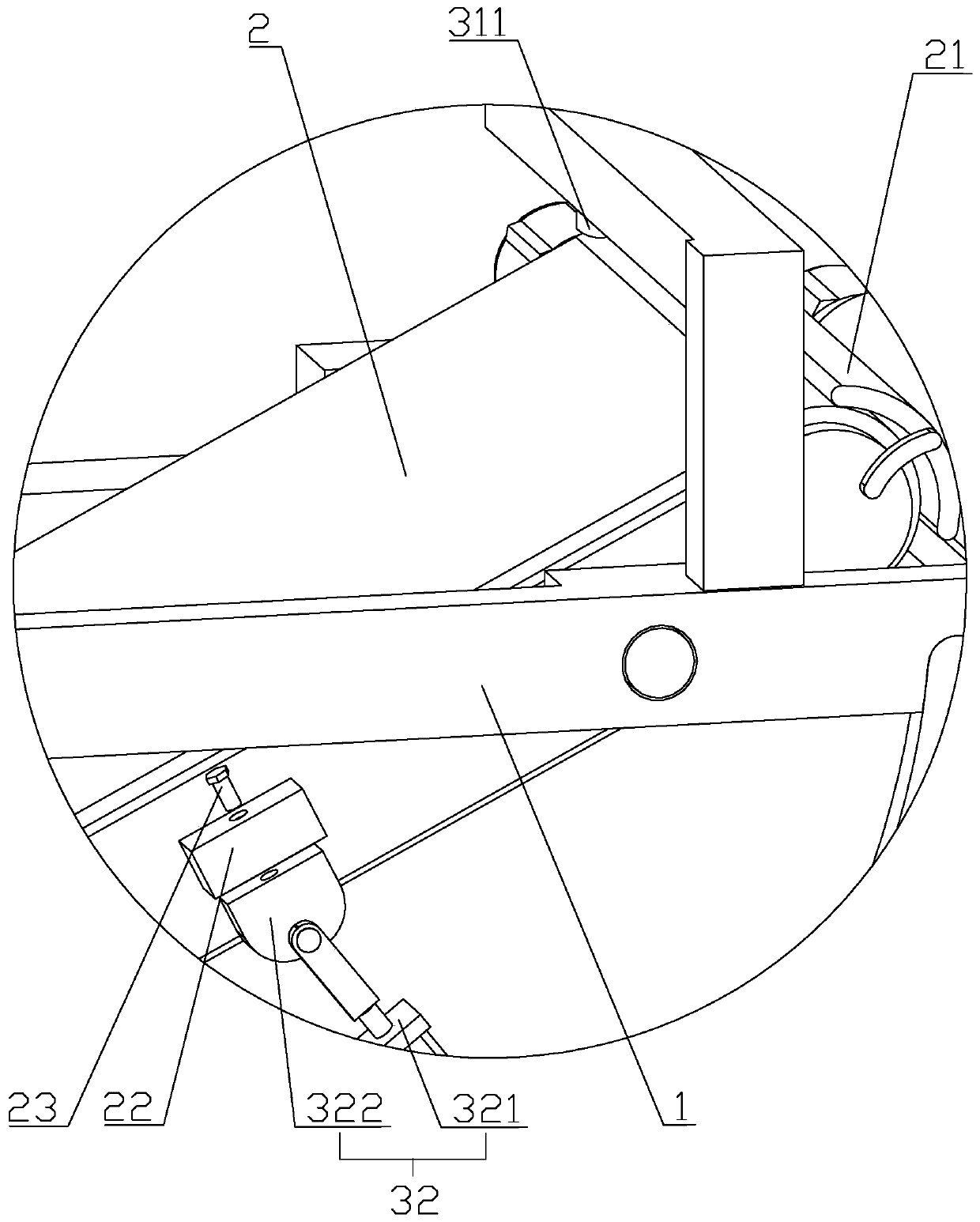

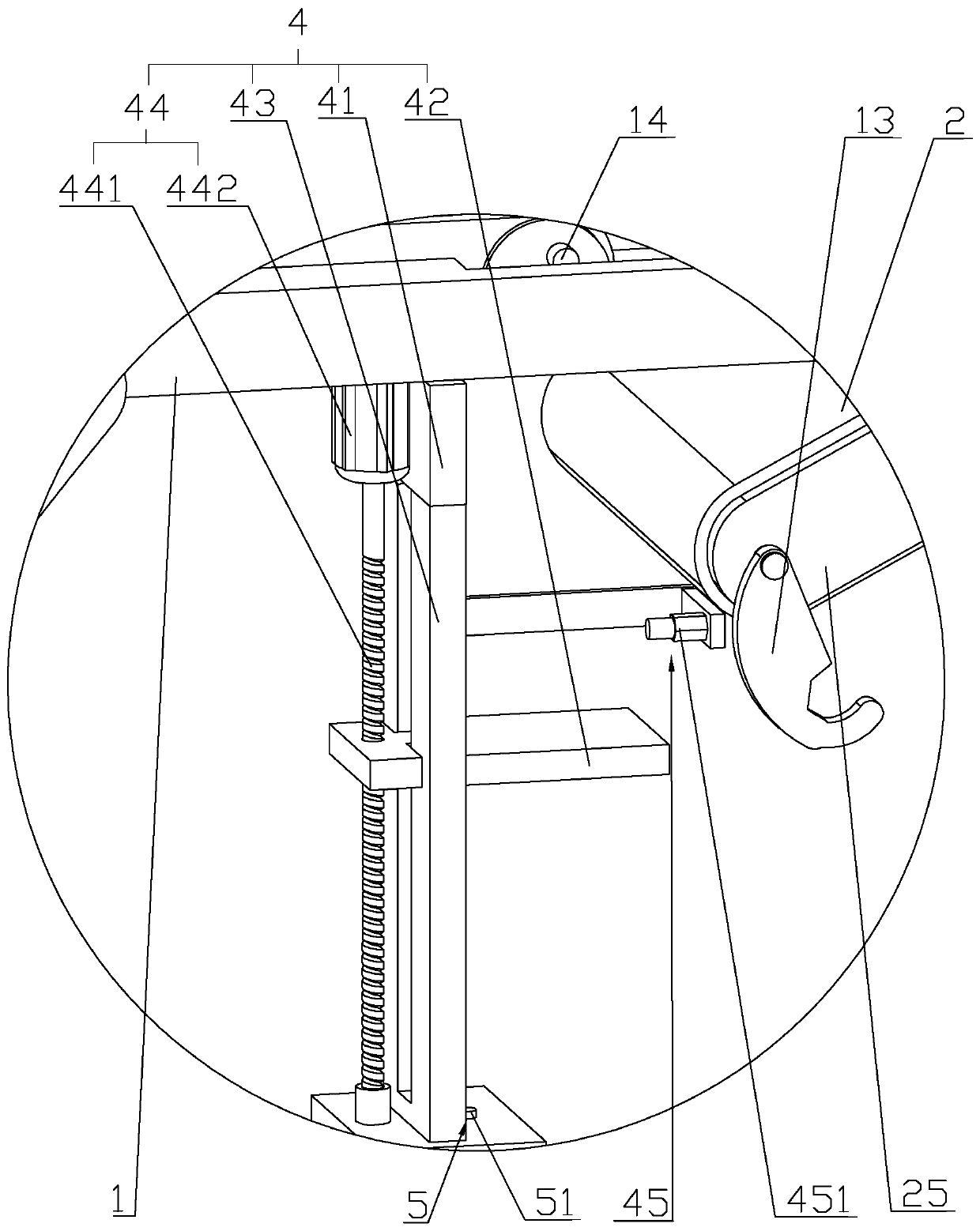

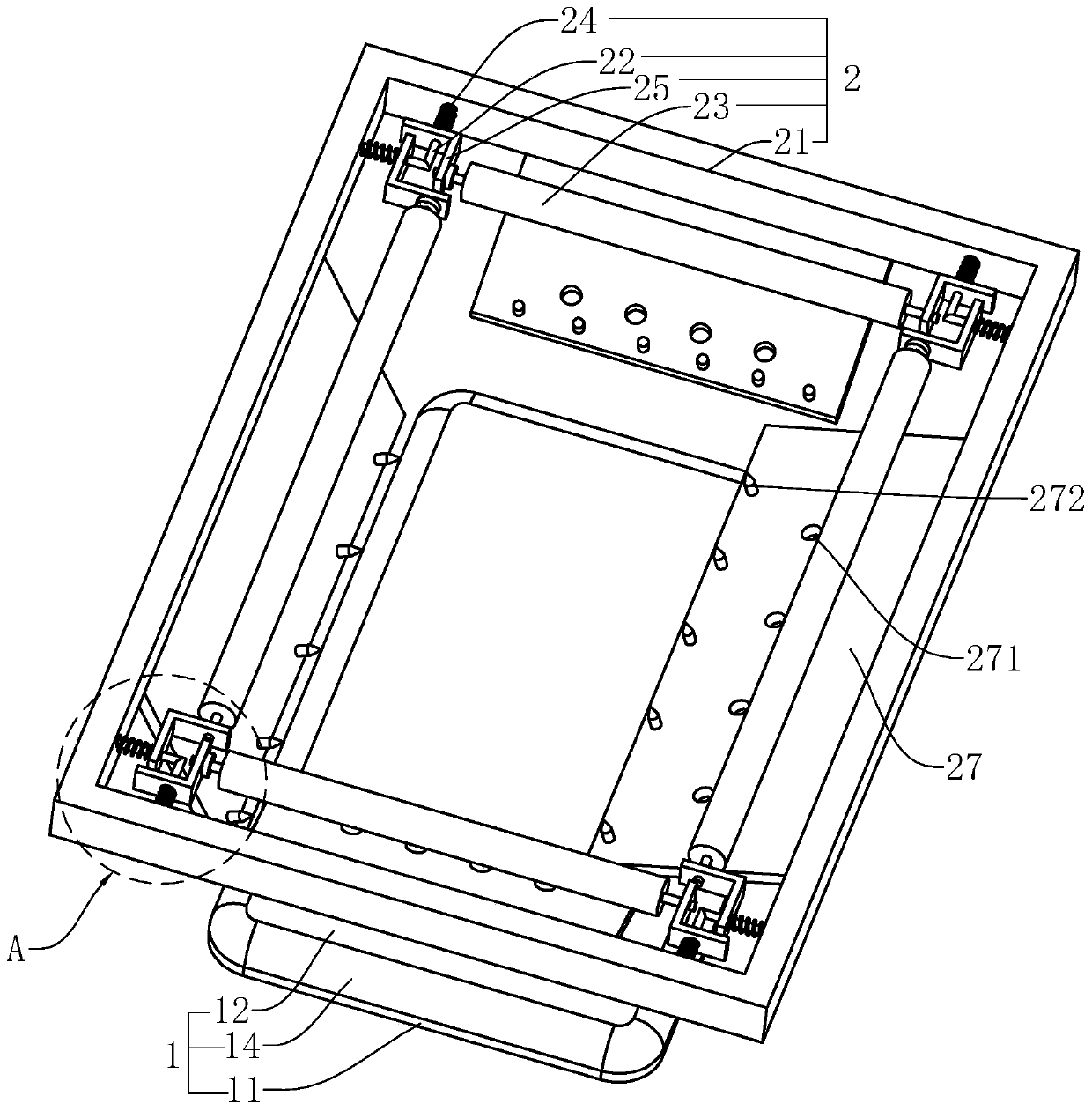

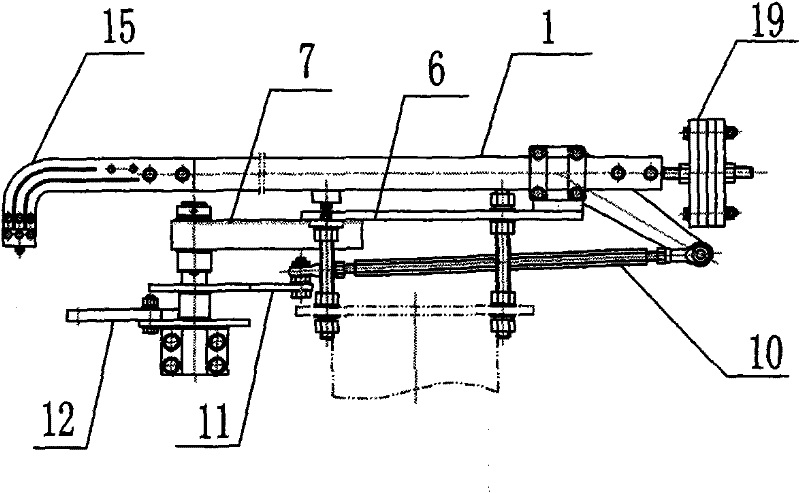

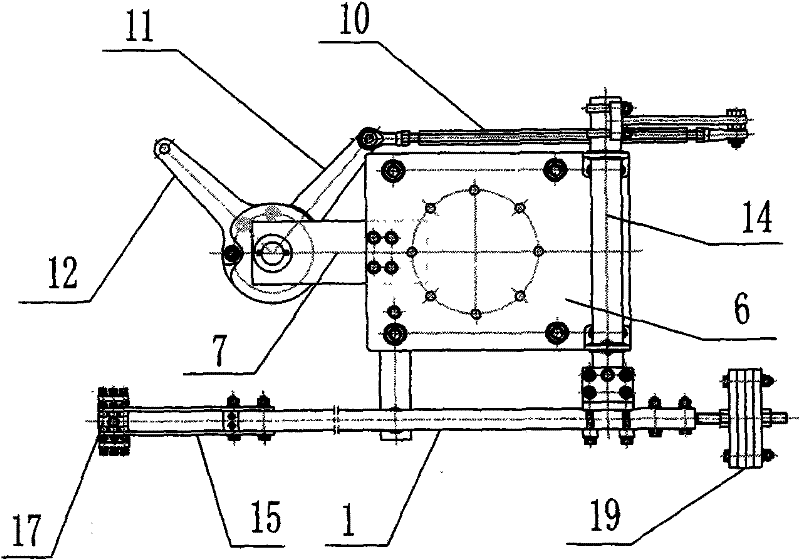

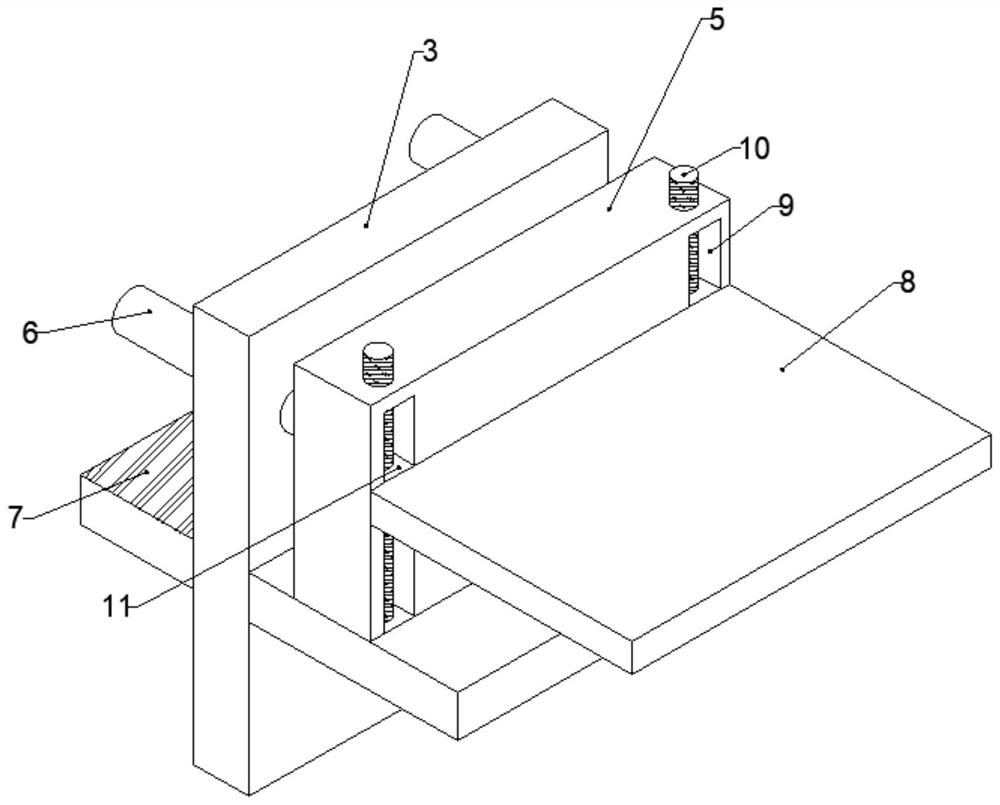

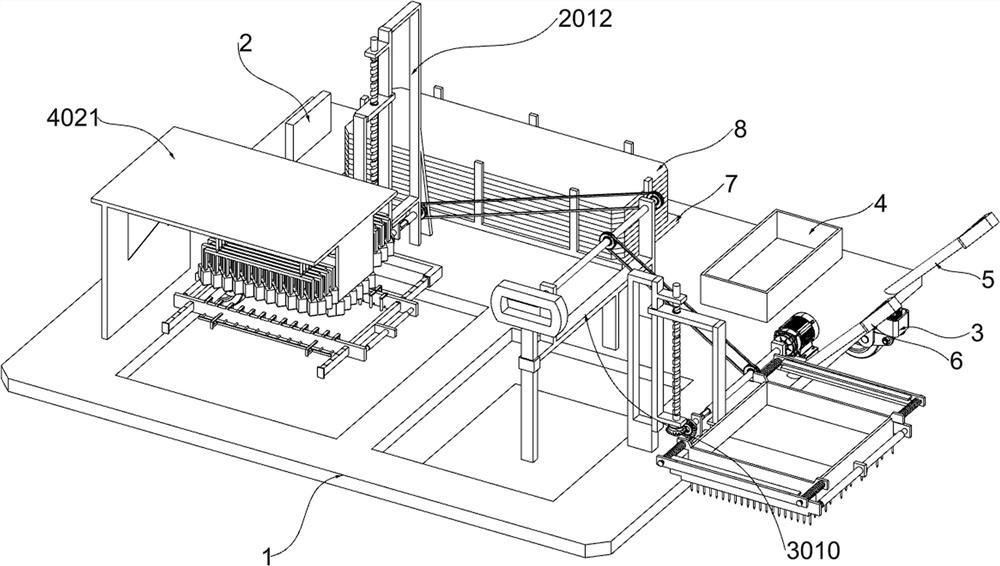

Full-automatic slotting bending machine

InactiveCN102862054ARealize automated productionAvoid rebound phenomenonMetal-working feeding devicesOther manufacturing equipments/toolsInterference phenomenonEngineering

The invention discloses a full-automatic slotting bending machine, comprising a base, and a feeding mechanism, a slotting mechanism and a bending mechanism which are sequentially arranged on the base, wherein the bending mechanism comprises a two-dimensional movement platform, a rotary bending device and a clamping mechanism, the two-dimensional movement platform is arranged on the base, the rotary bending device is arranged on the two-dimensional movement platform, and the clamping mechanism is arranged on the base and is used for clamping plates which are to be bent by the rotary bending device. The full-automatic slotting bending machine disclosed by the invention can continuously bend circular arcs or straight lines during machining, effectively avoids an interference phenomenon and a material resilience phenomenon, can realize full-automatic production of slotting and bending of the plates, can be applied to automatic production of LED (light-emitting diode) slotted characters and the like, and can ensure that the product machining efficiency is high and the product precision is good, thus having wide application prospect.

Owner:ZHEJIANG UNIV

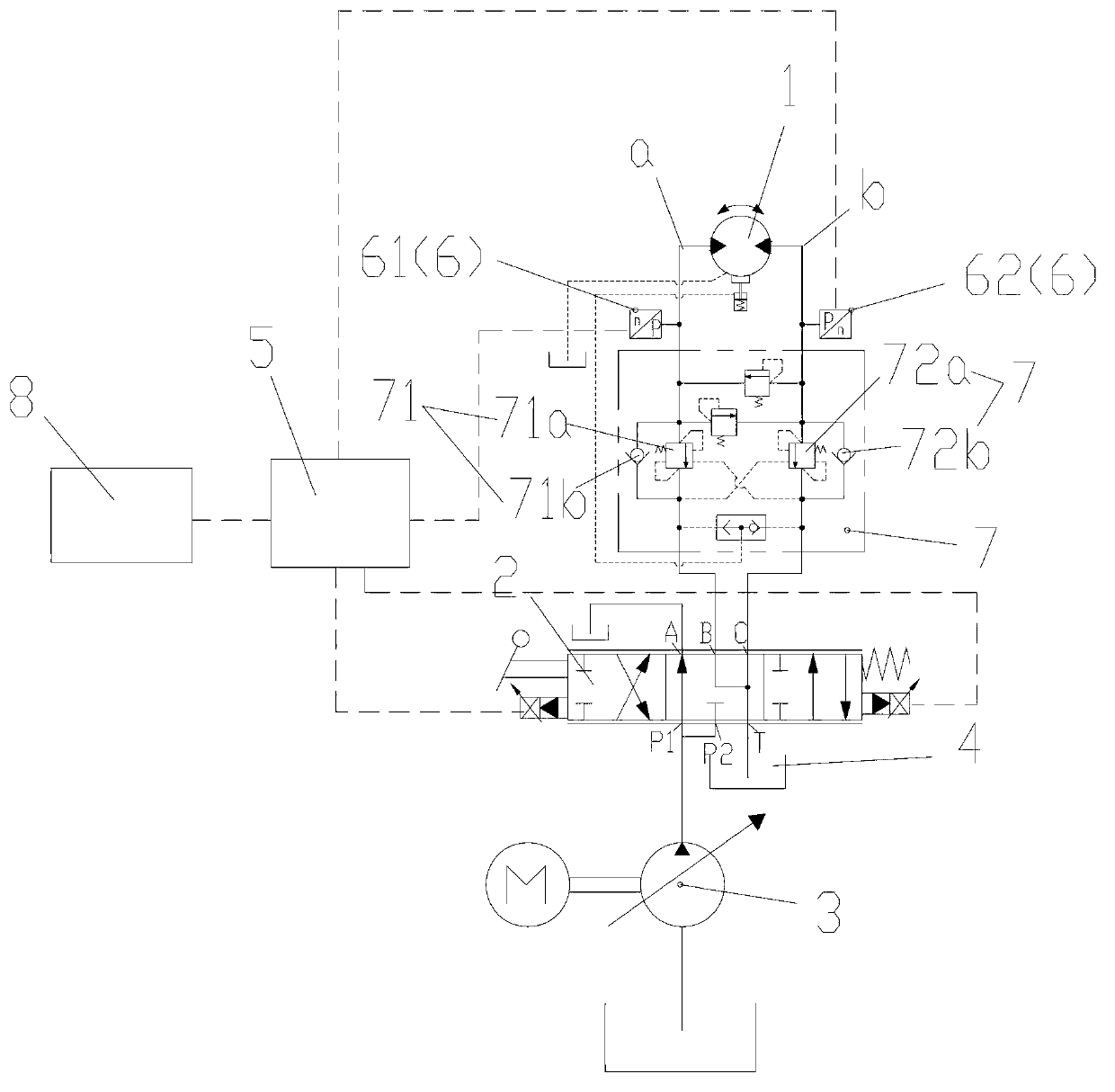

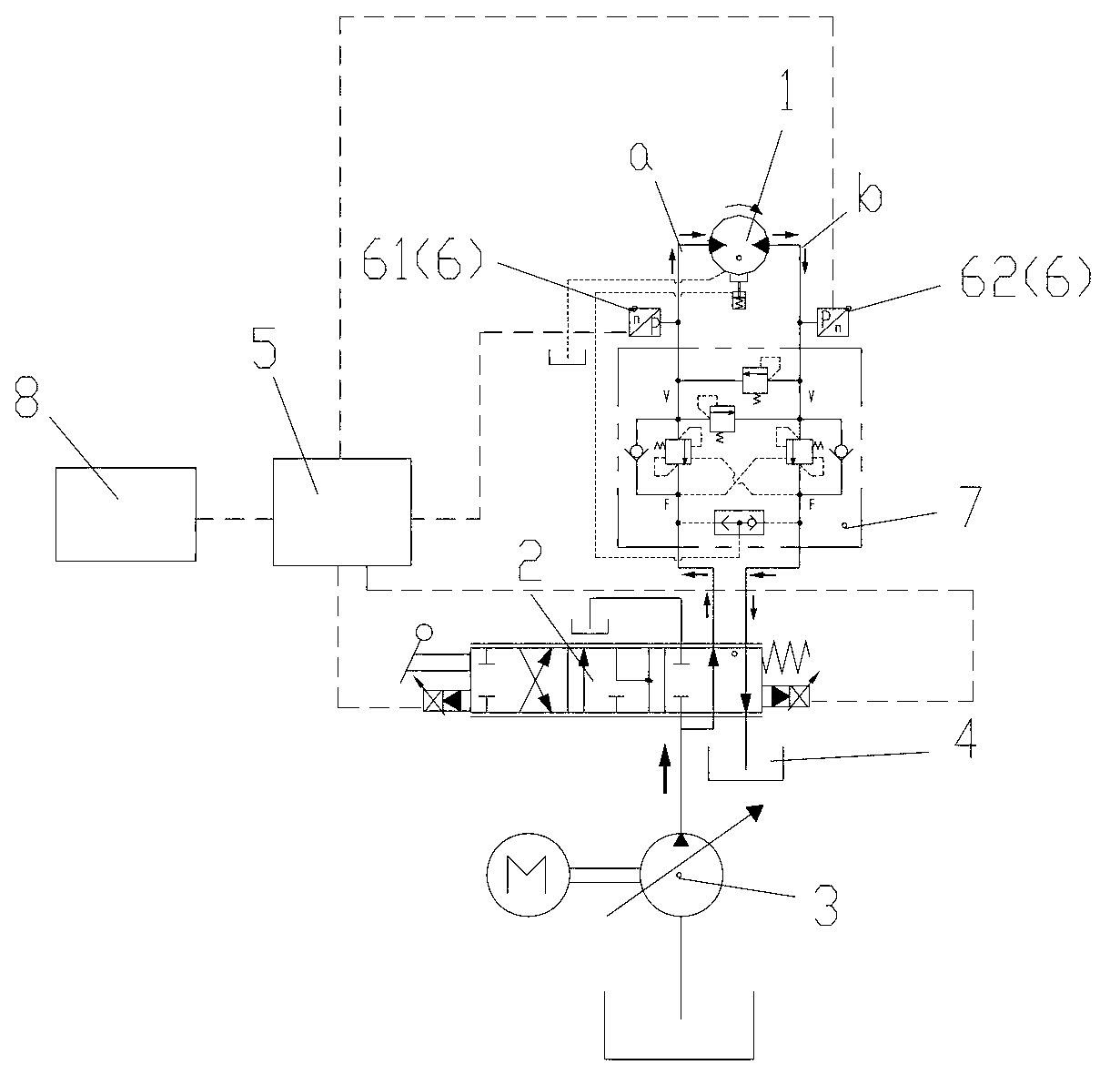

Hydraulic system for controlling rotation of boom, control method thereof and concrete pumping equipment

ActiveCN103122894AAvoid rebound phenomenonProvides positioning accuracy and securityFluid-pressure actuator safetyServomotor componentsFuel tankHydraulic pump

The invention discloses a hydraulic system for controlling rotation of a boom and a control method thereof. The hydraulic system comprises a hydraulic motor, a main valve, a hydraulic pump and an oil tank. When the main valve controls the hydraulic motor to rotate, an oil inlet passage of the hydraulic motor is communicated with the hydraulic pump, and an oil return passage is communicated with the oil tank. After the main valve controls the hydraulic motor to stop rotating, the oil inlet passage and the oil return passage are both locked. The hydraulic system comprises a controller and a detection device. After the main valve controls the hydraulic motor to stop rotating, the detection device is capable of detecting pressure value of the oil return passage, and the controller controls the degree of opening of the main valve based on the pressure value so as to enable the oil return passage to be communicated with the oil tank. Therefore, when the boom starts to stop rotating and the oil inlet passage and the oil return passage are locked, the degree of opening of the main valve is controlled based on the pressure changes of the oil return passage so that the oil return passage can be communicated with the oil tank again, pressure cannot be accumulated in the oil return passage, and thus rebounding occurring after the boom stops rotating is avoided. The invention further discloses concrete pumping equipment provided with the hydraulic system for controlling rotation of the boom.

Owner:ZOOMLION HEAVY IND CO LTD

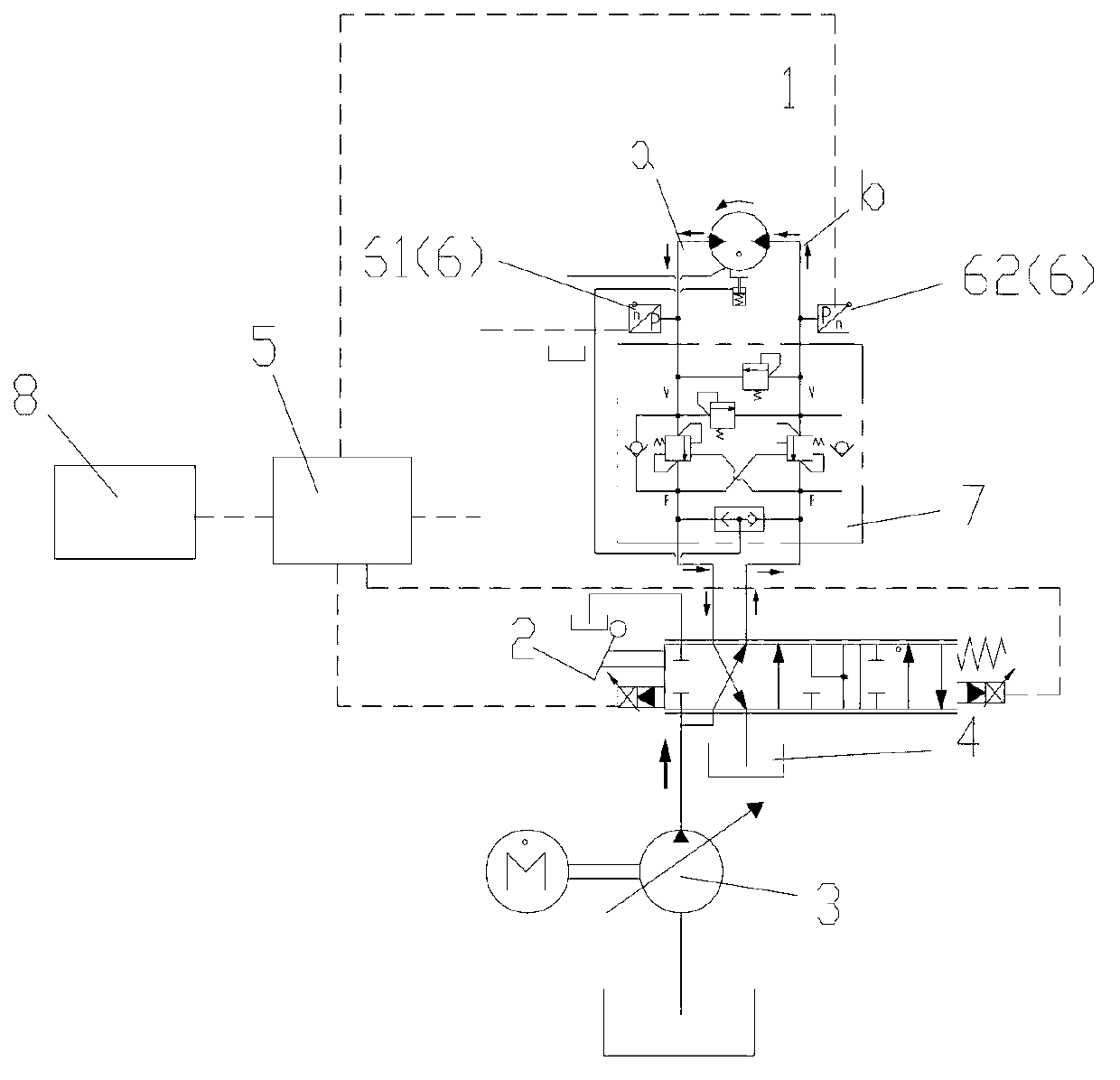

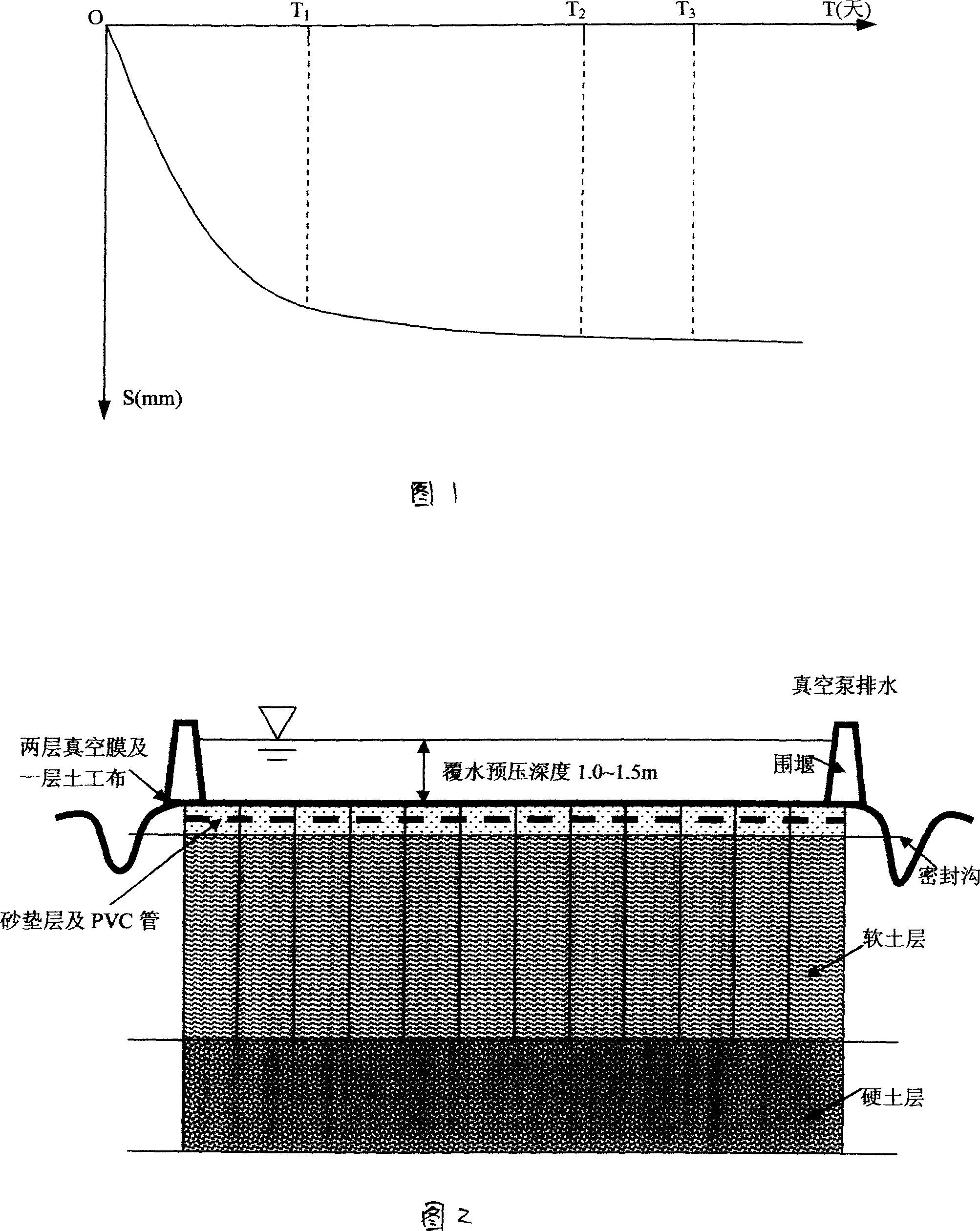

'Short-distance overload vacuum precompression and dynamic water-drainage consolidation united method' soft foundation processing method

ActiveCN1963038AReduce moisture contentImprove soil consolidationIn situ soil foundationSoil preservationCushionEngineering

A ''short-range overloading vacuum prepressing---dynamic discharging consolidation combination method'' to dealing with the soft soil ground foundation, its features are : overloading prepressing the vacuum membranes of conventional vacuum prepressing method with covering water; proceeding the settlement observation to each settlement observation points according the vacuum prepressing operating rules, continuing prepressing 5~10 days after the prepressing settlement above 80% of calculate settlement, then stopping the water overloading vacuum prepressing after ensuring stable completely; removing the vacuum membrane and sun-curing 1~2 days, then proceeding the dynamic dewatering consolidation to eliminating the stored water in sand cushions which is leaved when overloading vacuum prepressing rapidly, then dynamic consolidation or roller compaction after the water level below 1.5m. Its beneficial effects are: it can eliminate the water in muck soil during a short time and enhance the consolidation degree; it makes the skin soil layer get the greatest density, meets the requirements of load bearing capacity and rigidity rapidly and prevents rebound phenomenon; it shortens the construction period and lowers the costs and applies to large area project filling soil recently which has large thickness saturated soft soil particularly.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

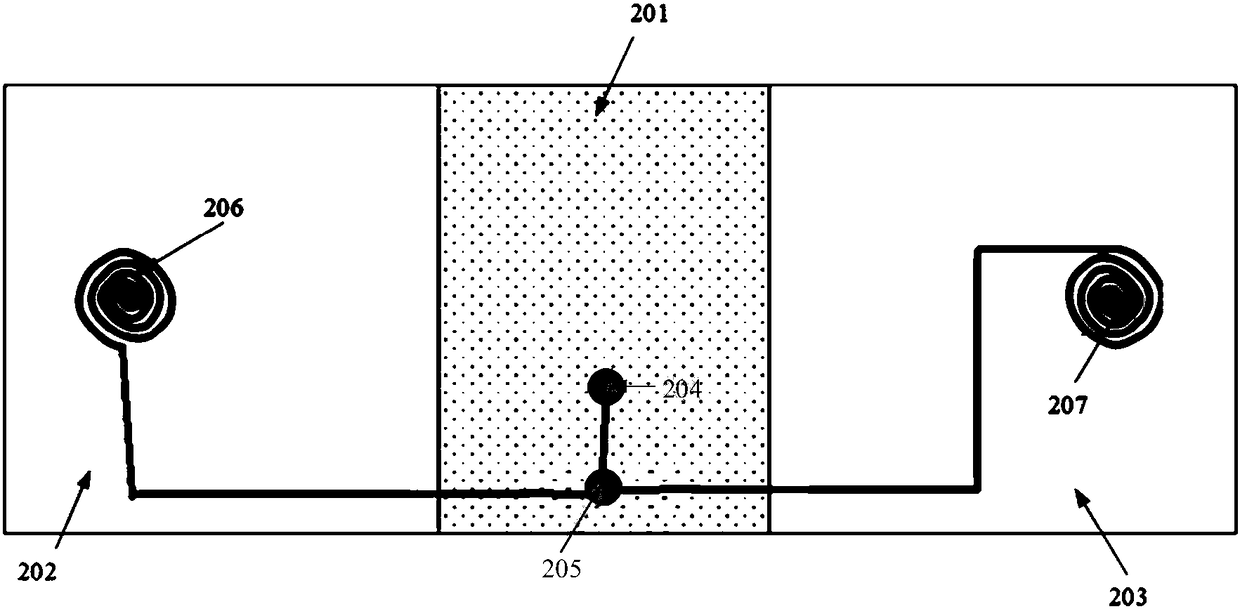

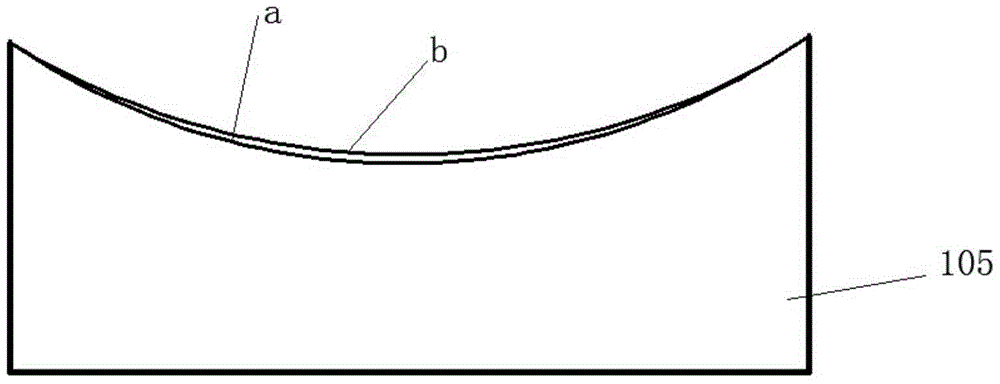

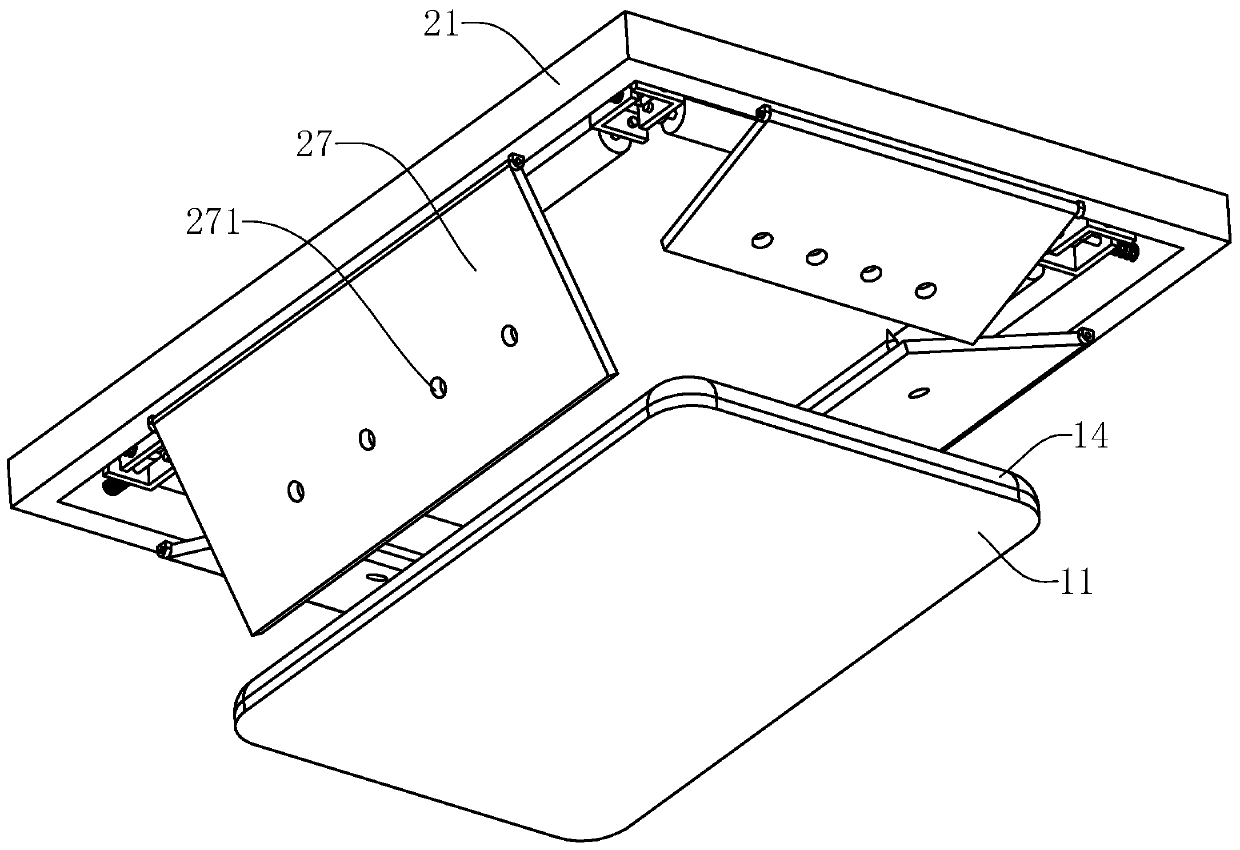

Flexible display screen and display device

The invention discloses a flexible display screen and a display device. The flexible display screen comprises a bending area, a first display area, a second display area, a chip and a power source. The chip is used for monitoring a curvature radius of the bending area and sending power supply instructions to the power source when the curvature radius is smaller than or equal to a threshold. A first metal coil and a second metal coil are arranged in the first display area and the second display area respectively. The power source is used for providing currents in opposite directions for the first metal coil and the second metal coil to enable the first metal coil and the second metal coil to generate electromagnetic force enabling mutual attraction of the first display area and the second area when the power supply instructions are received. The flexible display screen and the display device have the advantage that resilience of two sides of the folded flexible display screen can be effectively avoided.

Owner:YUNGU GUAN TECH CO LTD

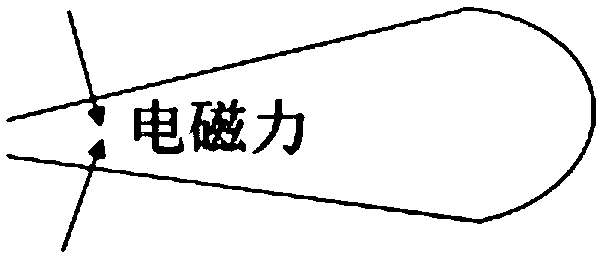

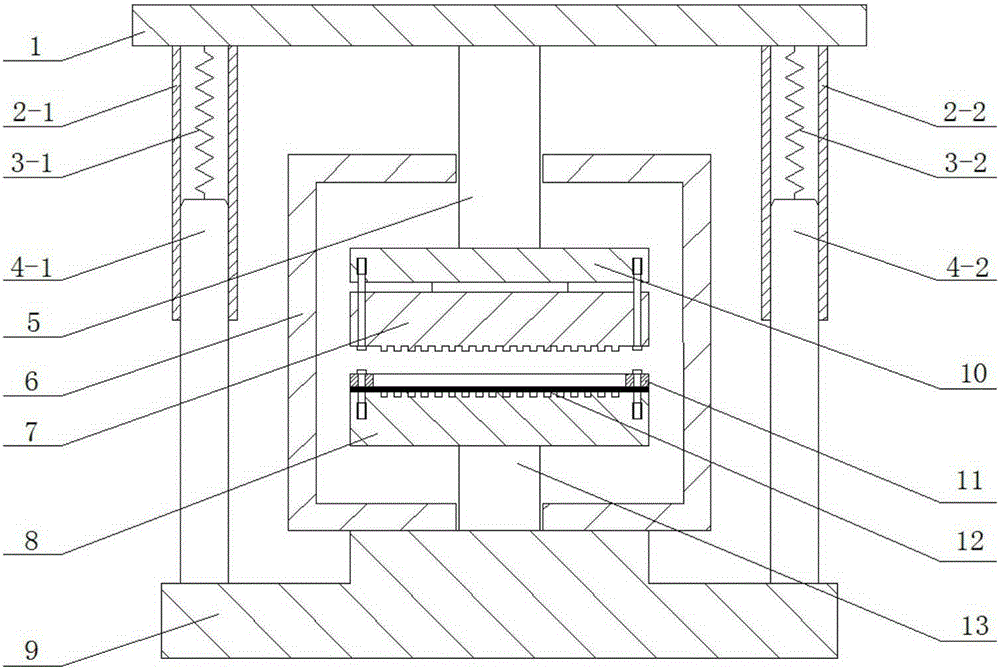

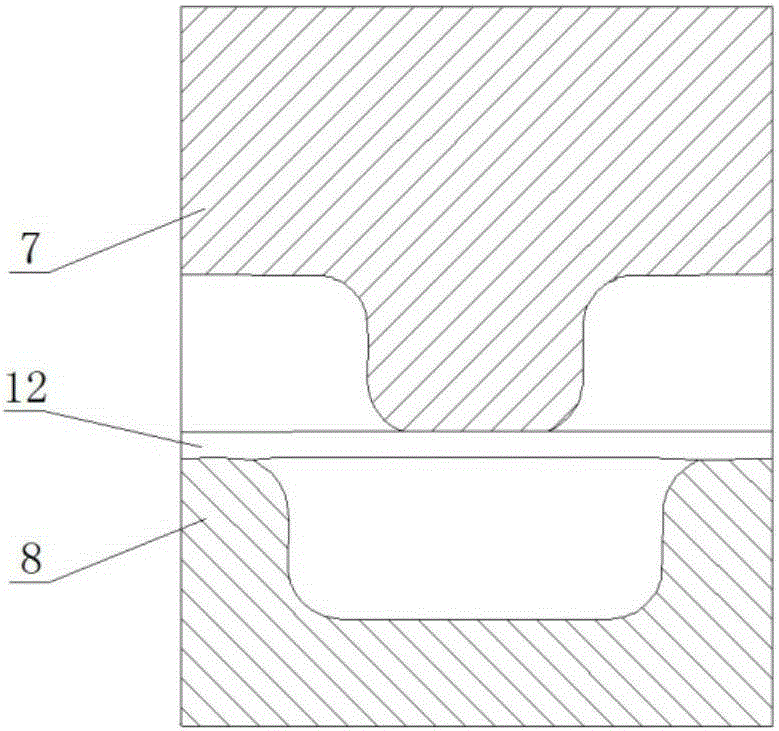

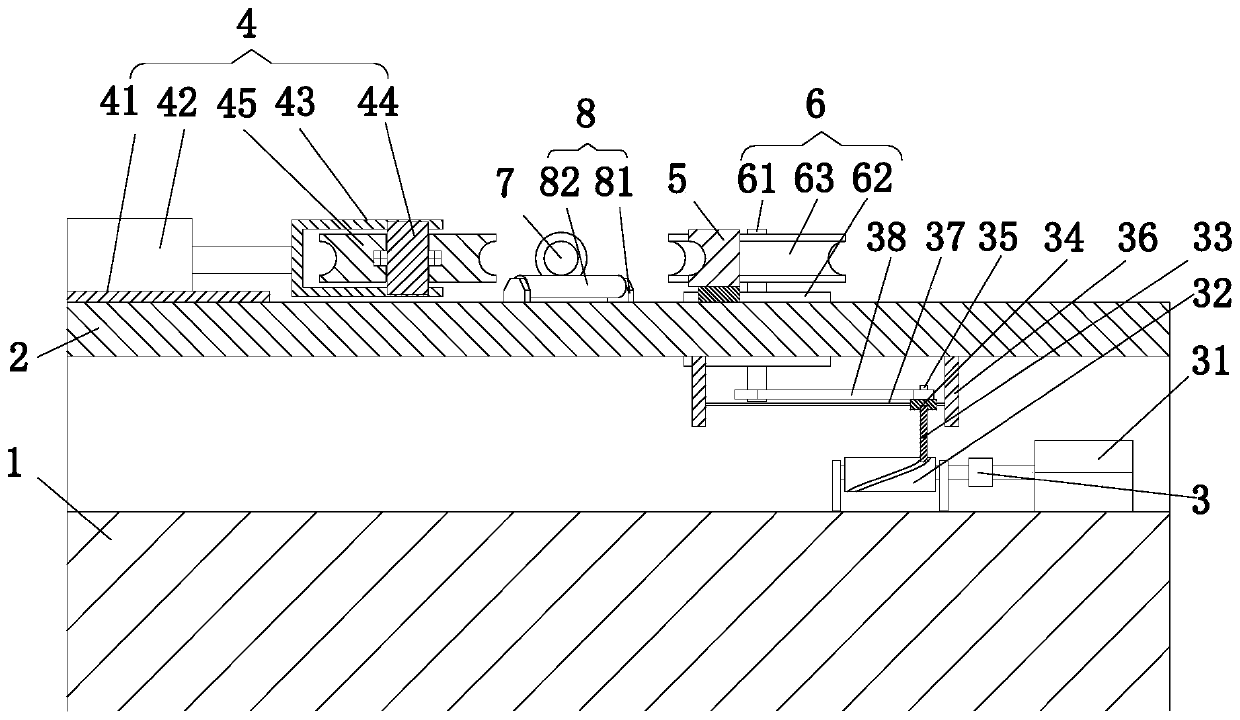

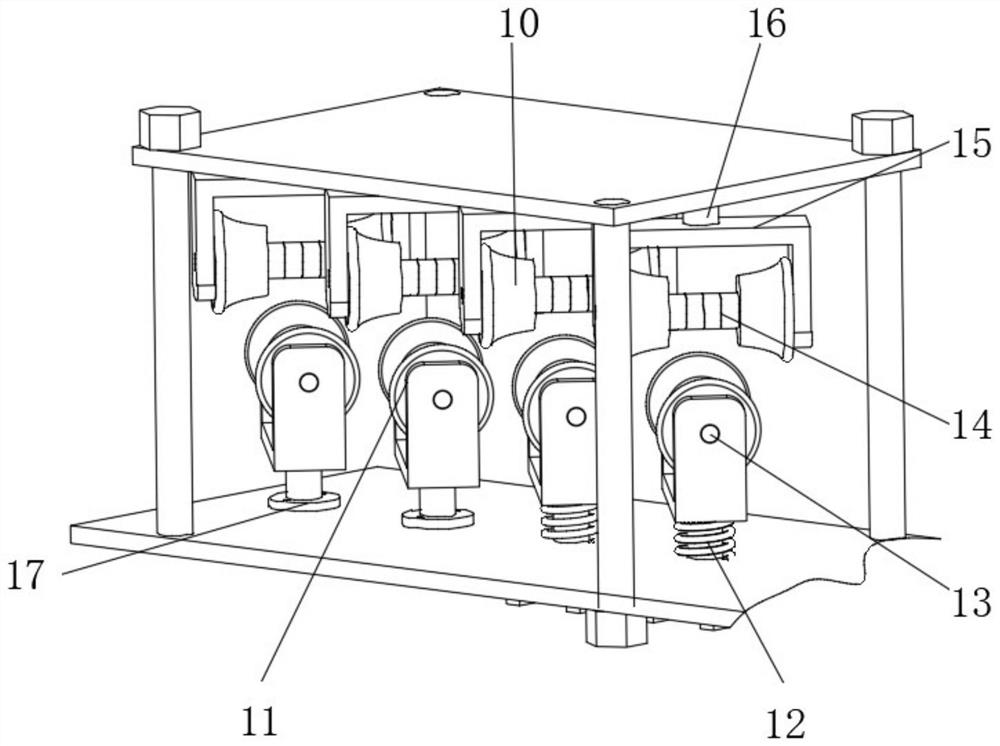

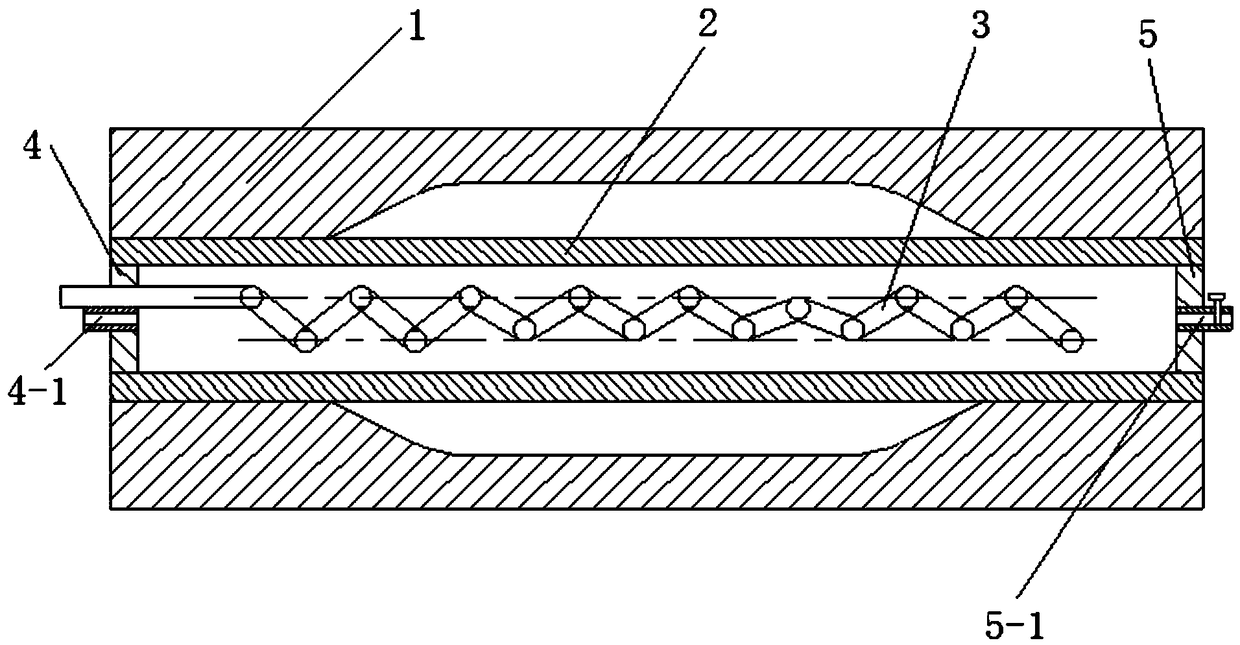

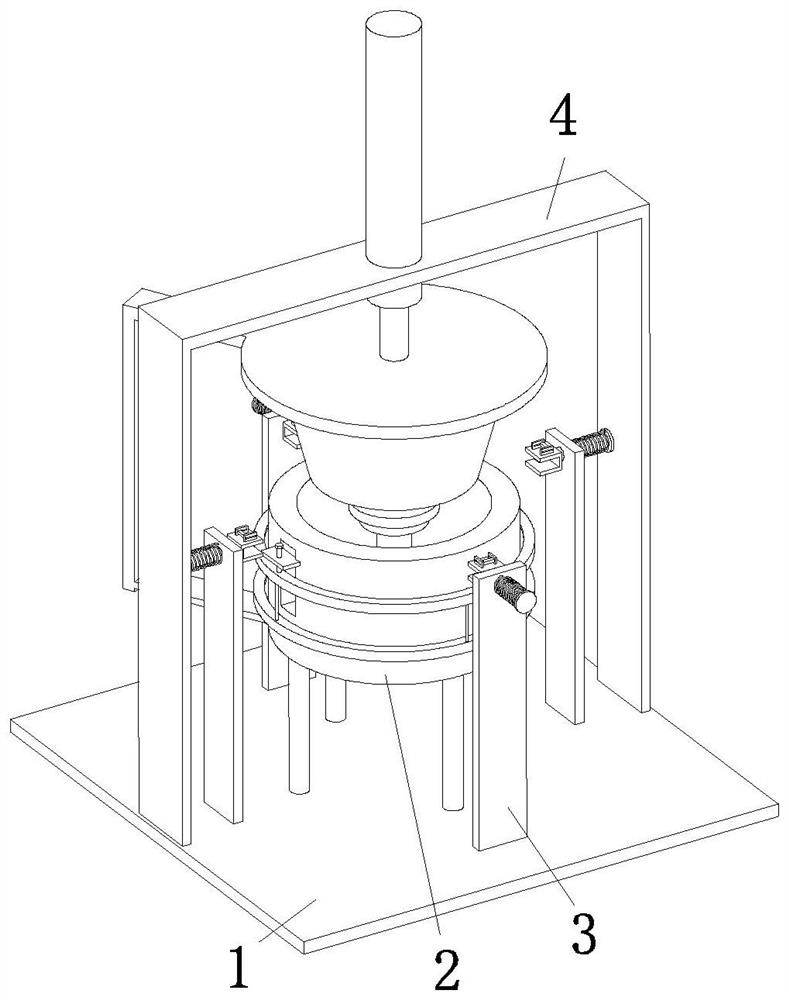

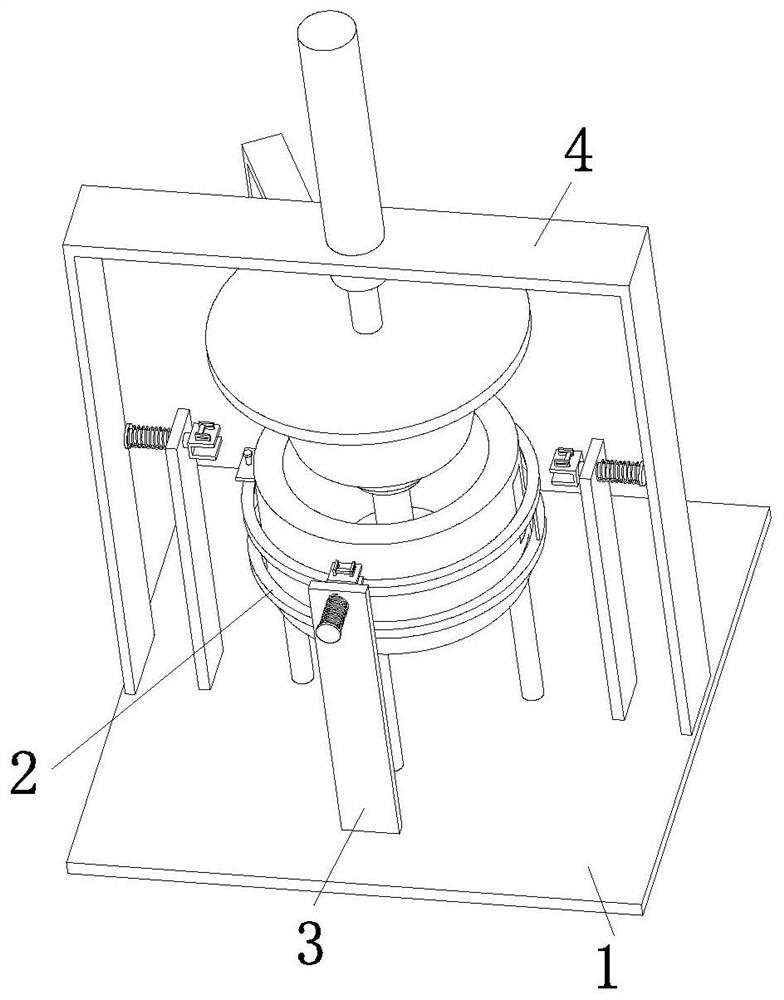

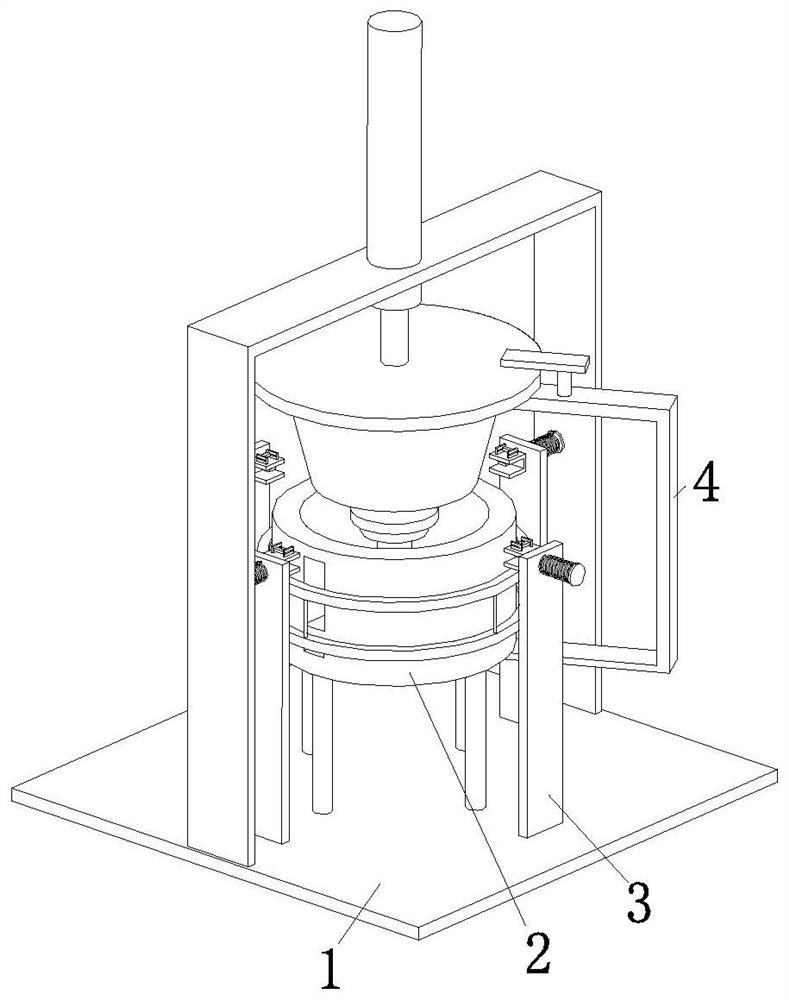

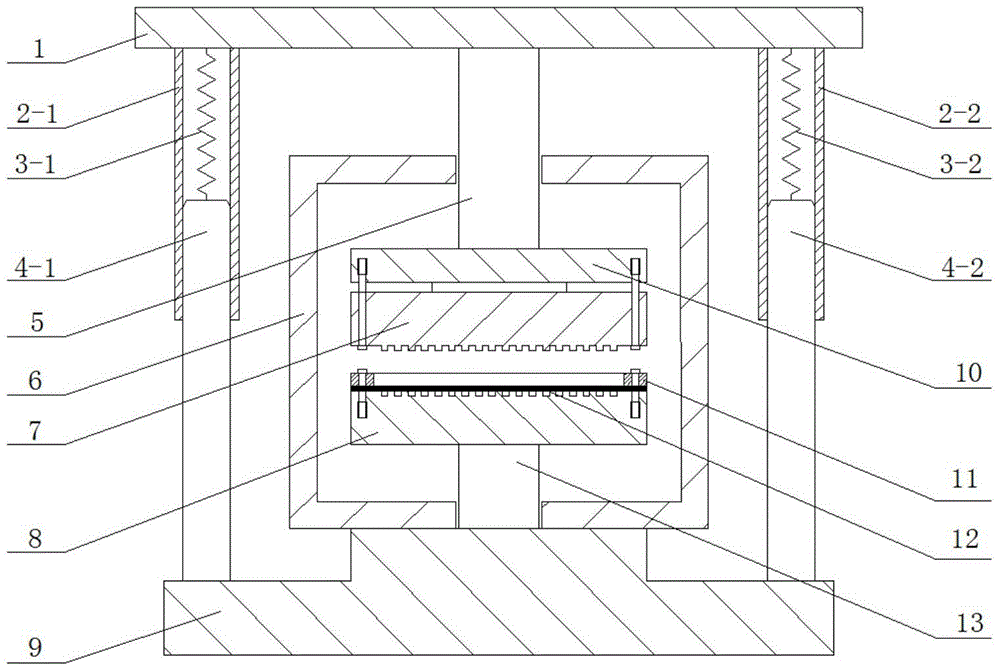

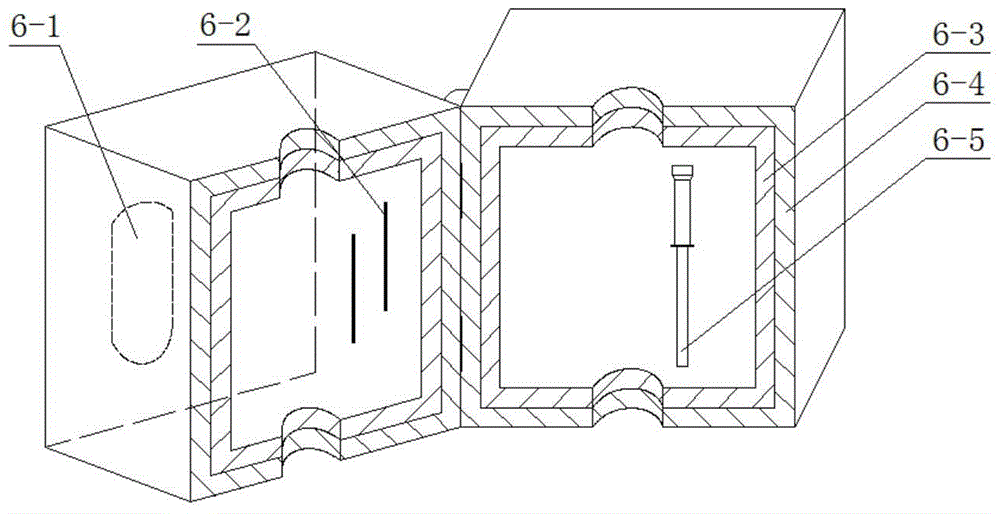

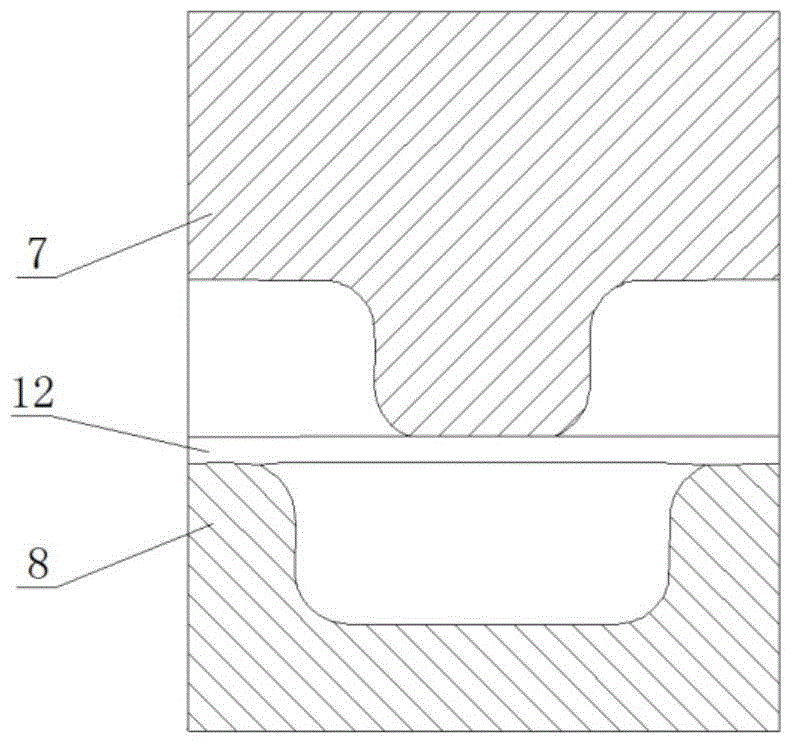

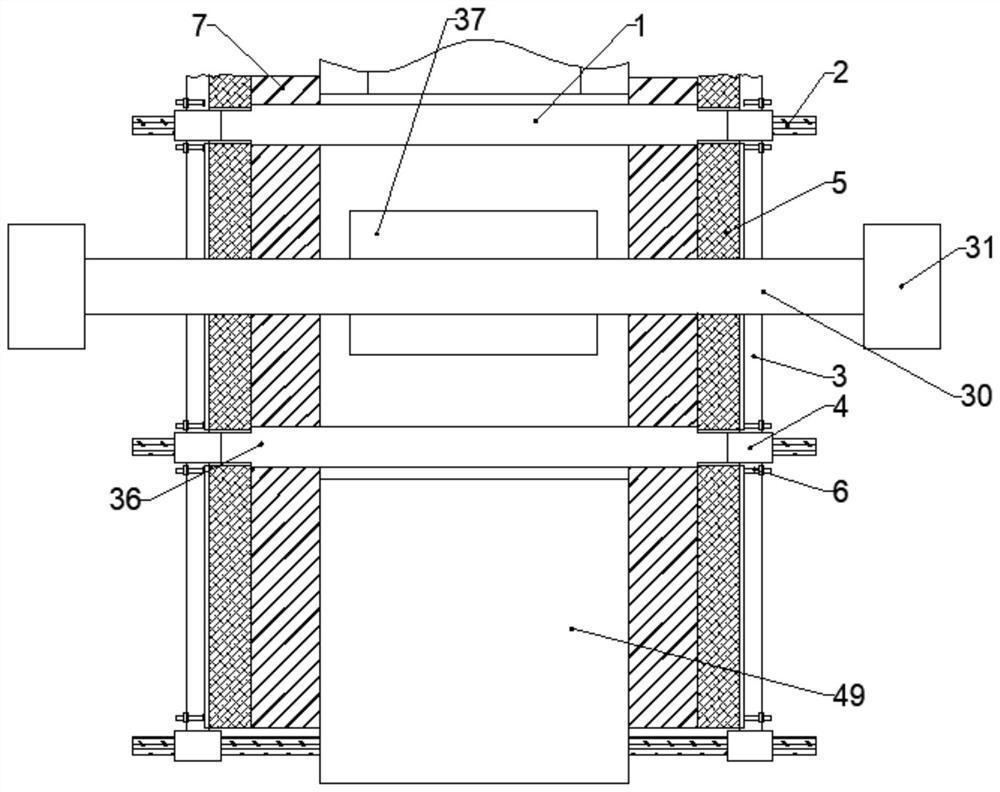

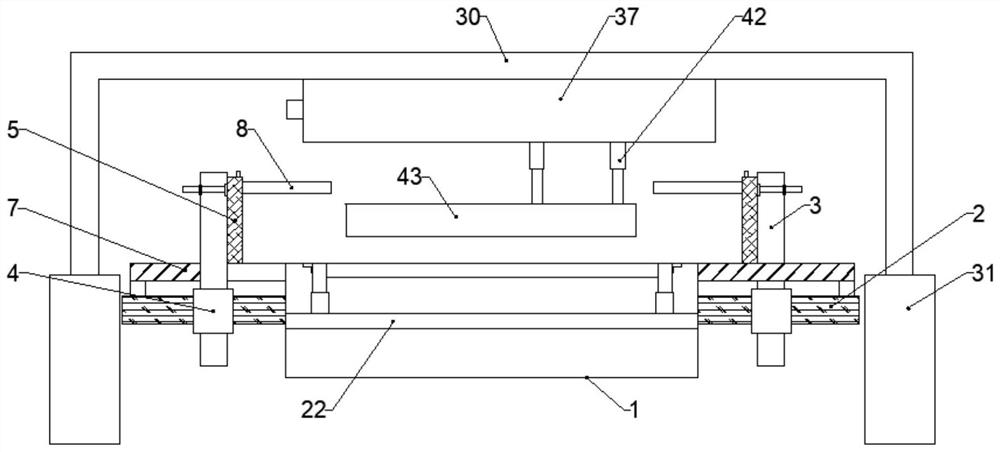

Super-plastic forming device and process of metal bipolar plate for proton exchange membrane fuel cell

InactiveCN105161731AAvoiding the disadvantages of cold formingReduce residual stressCell electrodesControl systemEngineering

The invention relates to a bipolar plate forming technology, in particular to super-plastic forming device and process of a metal bipolar plate for a proton exchange membrane fuel cell. The device comprises a pressure plate, guide sleeves, springs, guide posts, a pressing rod, an environmental box, an upper template, a lower template, a base, a connection plate, a blank pressing plate, a metal plate and a support rod. The process implemented by the device comprises the following steps: (1) opening the environmental box; (2) fixing a metal sheet of a processed part on the lower template; (3) closing the environmental box, determining the super-plastic forming temperature according to a processed plate and inputting the super-plastic forming temperature into a control system; (4) setting the stroke and the movement rate of the upper template according to the super-plastic strain rate and flow channel shape of the processed plate; (5) starting a circuit system and the environmental box, starting a pressure forming machine to move downwards, and finishing stamping; (6) starting the upper template of a press to reversely return back to the initial position; and (7) opening the environmental box, and cooing and taking out a formed part. According to the super-plastic forming device and process, the material is effectively prevented from rebounding, and the forming accuracy and the dimensional accuracy are ensured.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

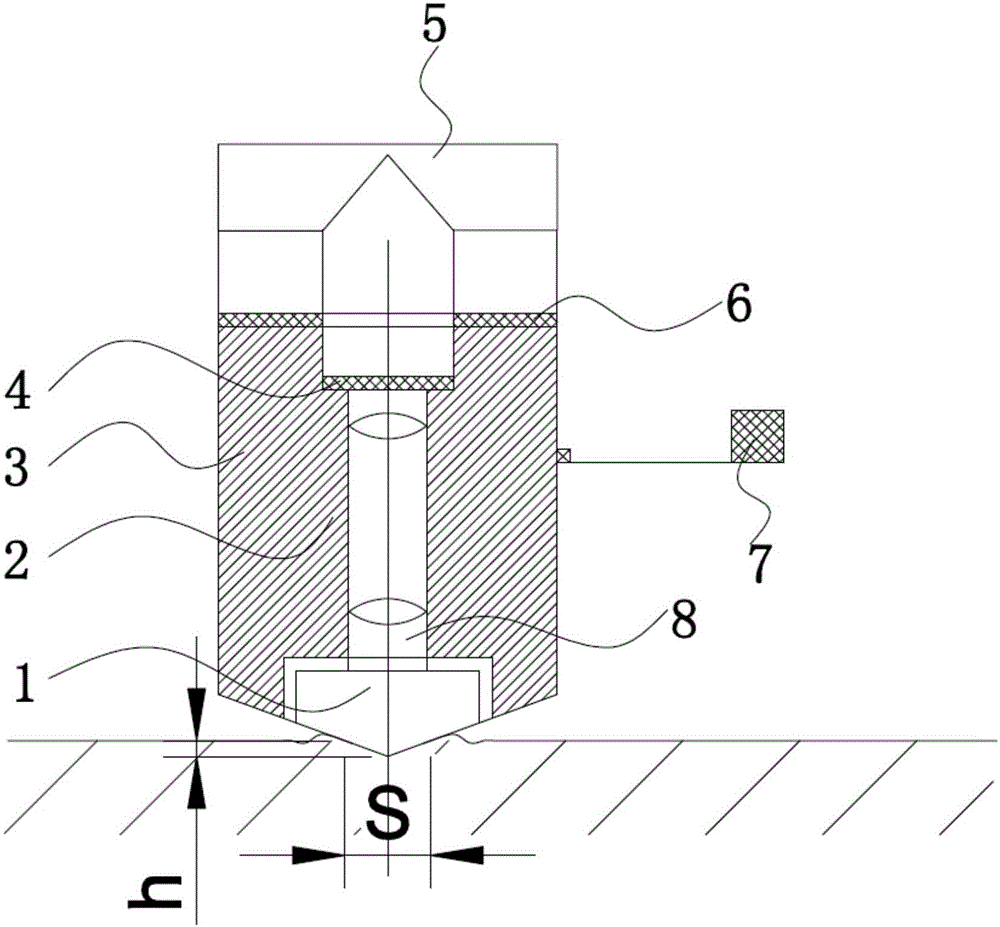

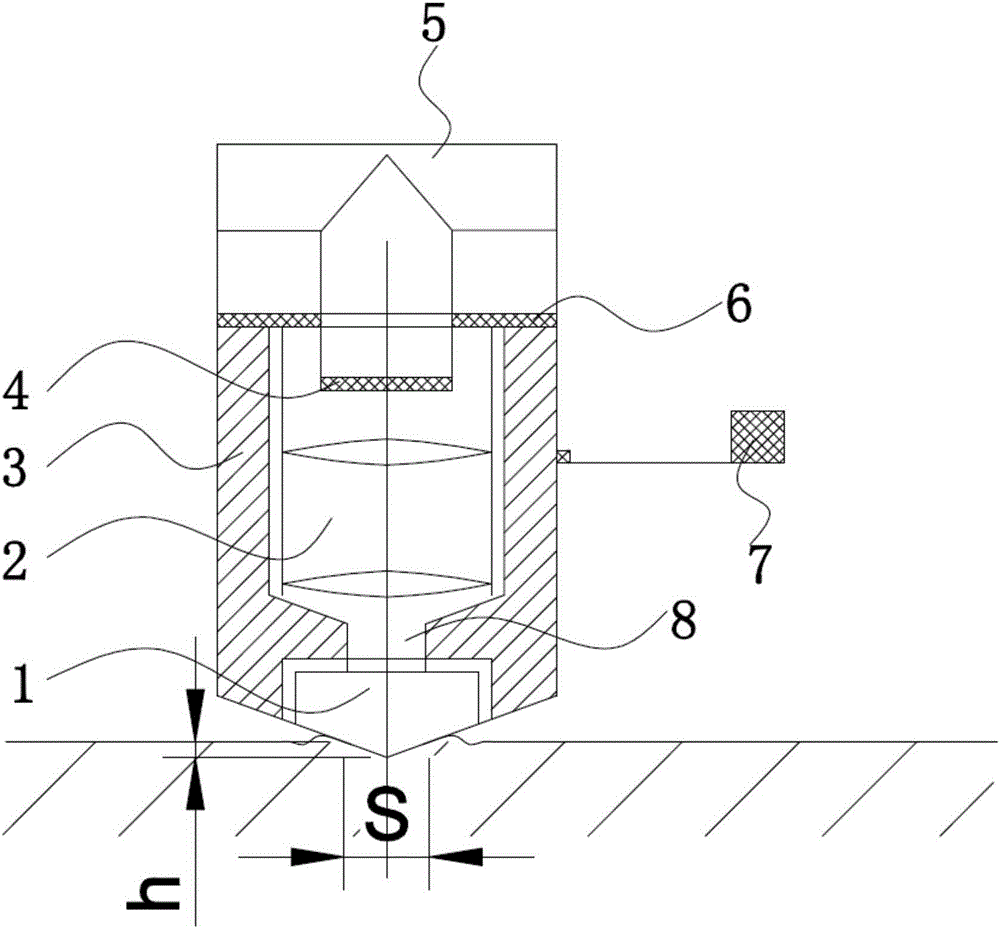

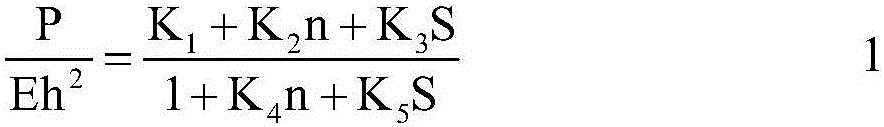

Material mechanical performance measurement device and pressing head assembly and measurement method thereof

InactiveCN105716975AHigh precisionAvoid rebound phenomenonInvestigating material hardnessReal-time dataBiomedical engineering

The invention discloses a material mechanical performance measurement device and a pressing head assembly and measurement method thereof. The pressing head comprises a pressing head body and a pressing head rod which are used for applying pressure on a measured object to obtain indentations, a sensor assembly used for obtaining the pressure and pressing depth of the pressing head body, and an optical assembly used for obtaining images of the indentations and deformation size data of the measured object. The pressing head rod is of a hollow structure. The optical assembly is arranged on the pressing head rod. The pressing head body is made of a transparent material and arranged at the end of the pressing head rod. The light imaging route of the optical assembly is consistent with the pressure applying direction of the pressing head body. Collection of real-time data of the optical assembly is achieved, real-time measurement data of multiple times can be achieved through the combination of the sensor assembly and the optical assembly, two characterization factors can be added to characterization of material mechanical performance, and the accuracy of mechanical performance detection is improved.

Owner:金南辉

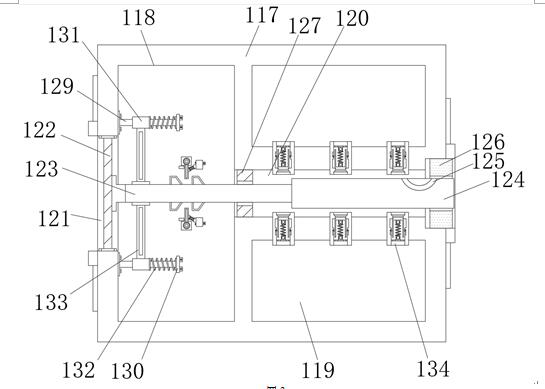

Wood product bending component forming device capable of locally softening

ActiveCN111906864AEasy to adjustEasy to collectWood stock bendingProcess engineeringMaterial resources

The invention discloses a wooden product bending component forming device capable of locally softening, and relates to the technical field of wooden product production and processing. The wood productbending component forming device capable of achieving local softening comprises a box body, and a feeding mechanism, a transmission mechanism, a cooking softening mechanism, an adjusting mechanism and a clamping limiting mechanism are arranged in the box body. According to the wood product bending component forming device capable of achieving local softening, one part of a wood product is heatedand softened in a water vapor spraying mode, the bending forming efficiency of the device is improved, and due to the structural design of a collection box installed in a sliding mode, and an operatorcan conveniently adjust a spraying part; and by means of an automatic lifting structural design of a stacking frame, waste of manpower and material resources due to the fact that wooden products areplaced into a heavy cooking pot is avoided, meanwhile, sprayed water vapor can be condensed and drop into the collection box again after meeting a backflow plate, water resources can be collected andfurther utilized conveniently, and the device is more environmentally friendly and efficient.

Owner:浙江金隆木业有限公司

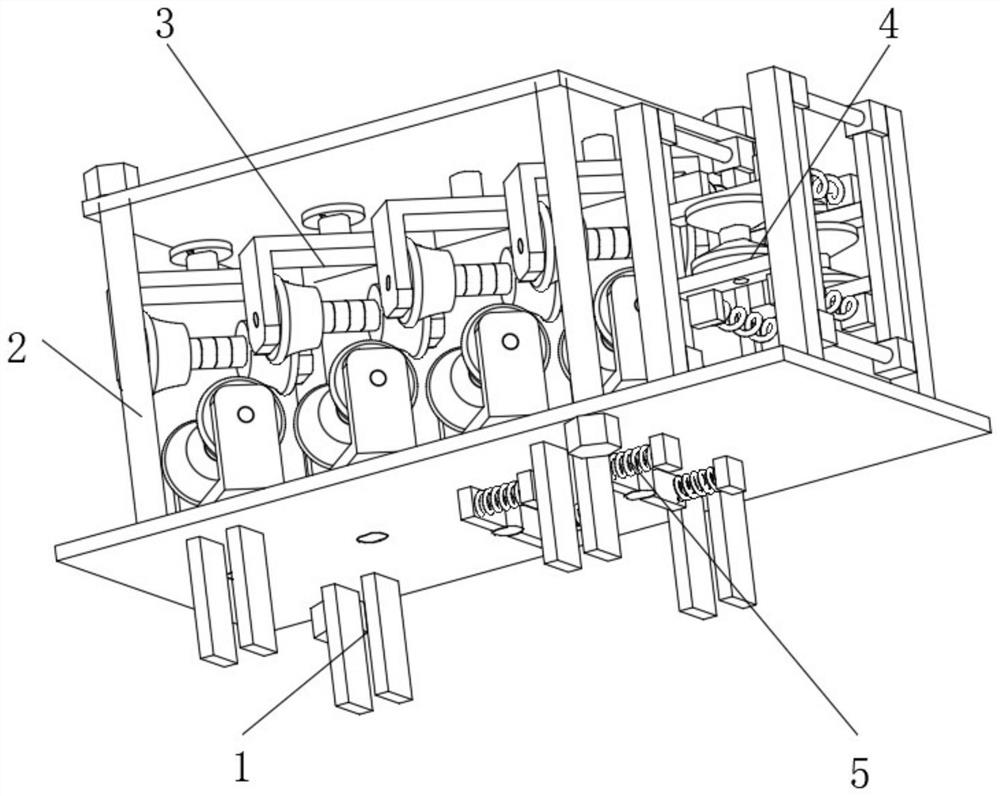

Roll bending machine for manufacturing of aluminum alloy profile

ActiveCN110434203ASolve the phenomenon of reboundRealize reprocessingMetal-working feeding devicesPositioning devicesFixed frameMachining

A roll bending machine for manufacturing of an aluminum alloy profile comprises a bottom plate, a fixed frame, a drive device, a bending device, a limiting block, rolling devices, clamping devices androll wheels. The fixed frame is mounted on the bottom plate and is of a U-shaped structure. Arc through holes are symmetrically formed in the front side of the upper end of the fixed frame. The problems that during existing roll bending machining of manufacturing of the aluminum alloy profile, machining of reducing the rebounding margin cannot be carried out on a round pipe profile subjected to roll bending molding machining, consequently, the rebounding phenomenon happens to the machined round pipe profile, meanwhile, when the round pipe profile is clamped, clamping marks are prone to beinggenerated on the clamped surface of the round pipe profile, consequently, the surface of a round pipe is not smooth, when roll bending machining is started no buffer function is achieved at the clamping position, the phenomena of cracks and bending are prone to being generated due to too large stress of the round pipe profile, and consequently roll bending machining fails can be solved.

Owner:江苏中航重工机床有限公司

Combined steel pipe straightening roller and straightening device thereof

InactiveCN112090997AExpand the scope ofEasy to process separatelyMetal-working feeding devicesPositioning devicesSteel tubePipe

The invention discloses a combined steel pipe straightening roller and a straightening device thereof, and relates to the technical field of steel pipe straightening. The invention aims to solve the problem of range adjustability. The combined type steel pipe straightening roller specifically comprises an adjustable frame structure fixed to the ground through supporting legs, the adjustable framestructure comprises a base and a top plate, first screws are connected to the inner walls of the opposite corners of the top plate through threads, and second screws are rotatably connected to the inner walls of the other opposite corners of the top plate; and the inner walls of the bottoms of the first screws make contact with the outer portion of the top of the base. According to the combined steel pipe straightening roller and the straightening device thereof, by hyperbolic surface structures of first roller blocks and second roller blocks, the range of the pipe diameter of a straightened steel pipe can be guaranteed; and adjusting cushion blocks are arranged between the first roller blocks and the second roller blocks, and the distances between the first roller blocks and the second roller blocks can be adjusted by adjusting the number of the adjusting cushion blocks between the first roller blocks and the second roller blocks, so that the pipe diameter range of the straightened steel pipe is changed, and the range of the straightened steel pipe is expanded.

Owner:杭州嘉威机械配件有限公司

Multiple hot pressing equipment for nonwoven fabric processing

PendingCN106757947AGuaranteed structural strengthReduce moisture contentTextile shapingNonwoven fabricVacuum pump

The invention discloses multiple hot pressing equipment for nonwoven fabric processing, and belongs to the field of nonwoven fabric machinery. The multiple hot pressing equipment comprises a base, a discharging roller, a leveling adjustment mechanism, a hot pressing chamber and a coil stock roller are arranged on the base from left to right; hot pressing roller groups are arranged in the hot pressing chamber side by side; the hot pressing roller groups are connected with a height adjustment mechanism arranged at the top of the hot pressing chamber; a draught fan is arranged at the top of the hot pressing chamber, and a dehumidification box integrally arranged with the base is arranged at the bottom of the hot pressing chamber; an air draft hole communicated with the dehumidification box is formed in the base; and a vacuum pump is arranged at an outer end of the air draft hole. According to the multiple hot pressing equipment disclosed by the invention, multiple hot pressing roller groups are arranged to ensure full hot pressing of the nonwoven fabrics, ensure the processing quality and avoid the restoration phenomenon; and meanwhile the multiple hot pressing equipment disclosed by the invention further has excellent drying and dehumidification functions, thereby avoiding the mildew phenomenon of the nonwoven fabrics.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

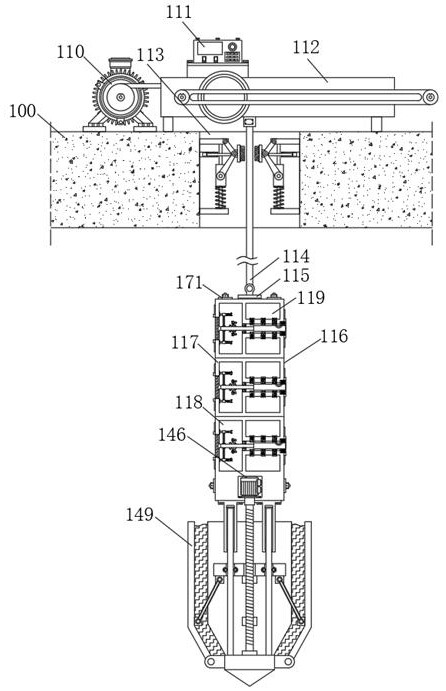

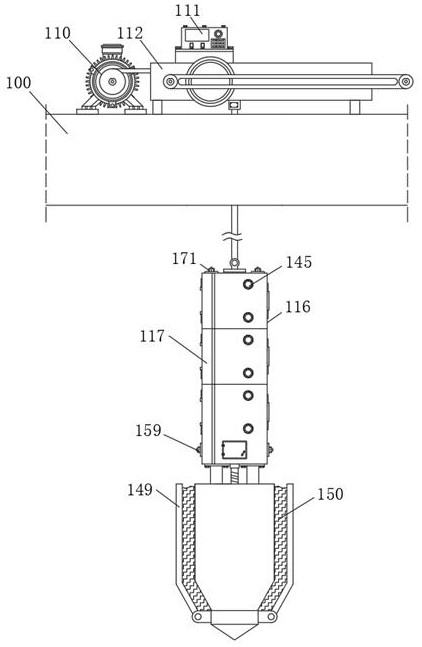

Automatic stratified sampling geological survey device

InactiveCN114486357AIncrease in sizeGuaranteed accuracyWithdrawing sample devicesSample waterGeological survey

The invention discloses an automatic stratified sampling geological survey device which comprises a device body, a first servo motor and a rope lowering rack are arranged at the top end of the device body, a control panel is fixedly mounted at the top end of the rope lowering rack, and a rope lowering groove is formed in the top end of the first servo motor; a rope body is arranged in the rope lowering rack, the sampling water tank is driven by a first servo motor to sink, and in the process that the sampling water tank gradually sinks, after an elastic extrusion pad at one end of the sampling water tank is extruded by the water pressure of underground water, the sampling water tank is stressed to move rightwards; and a sampling push rod is pushed away from the interior of a push cavity groove by utilizing the push rod body, and an arc-shaped through groove is exposed out of the interior of a first sealing sleeve gasket, so that underground water with different depths is collected into a sample storage cavity through connecting pipelines by utilizing the arc-shaped through groove.

Owner:王彦平

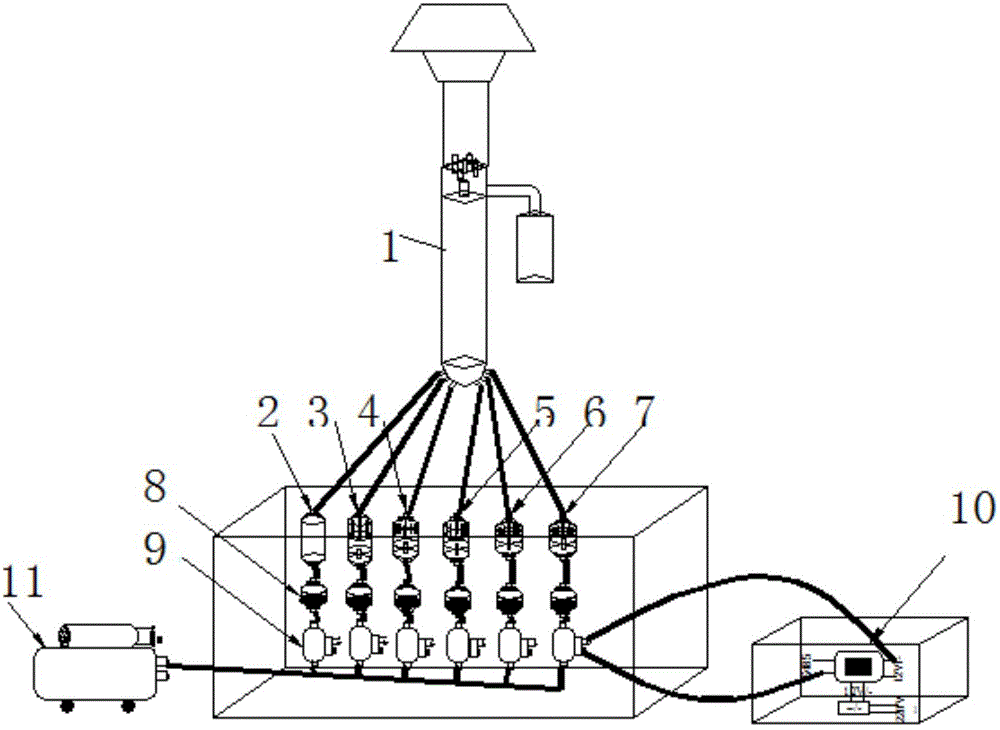

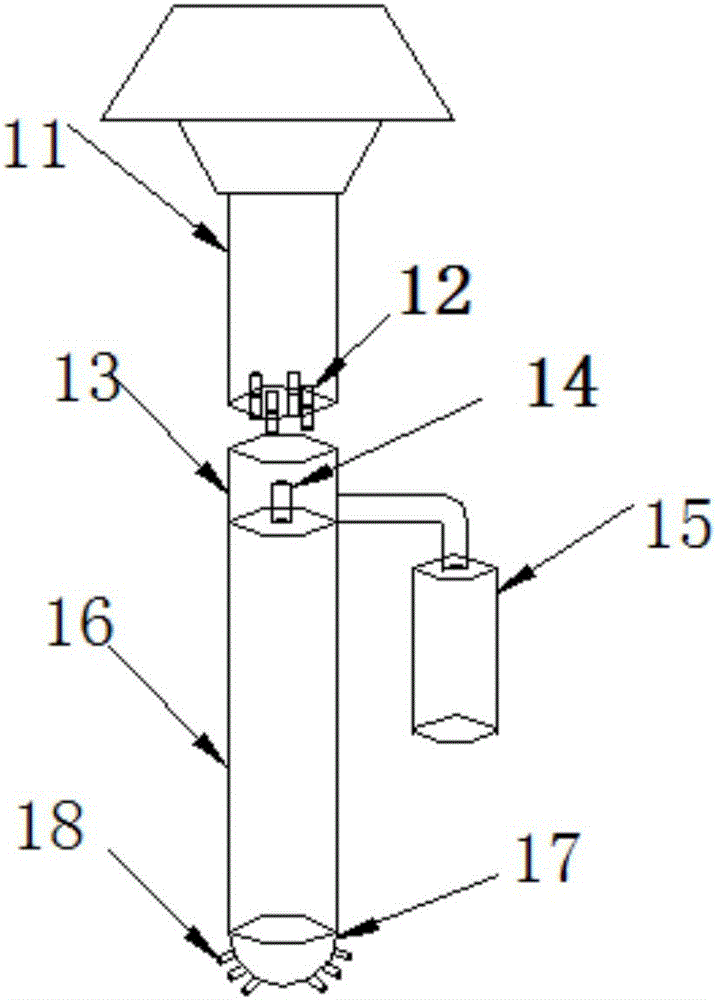

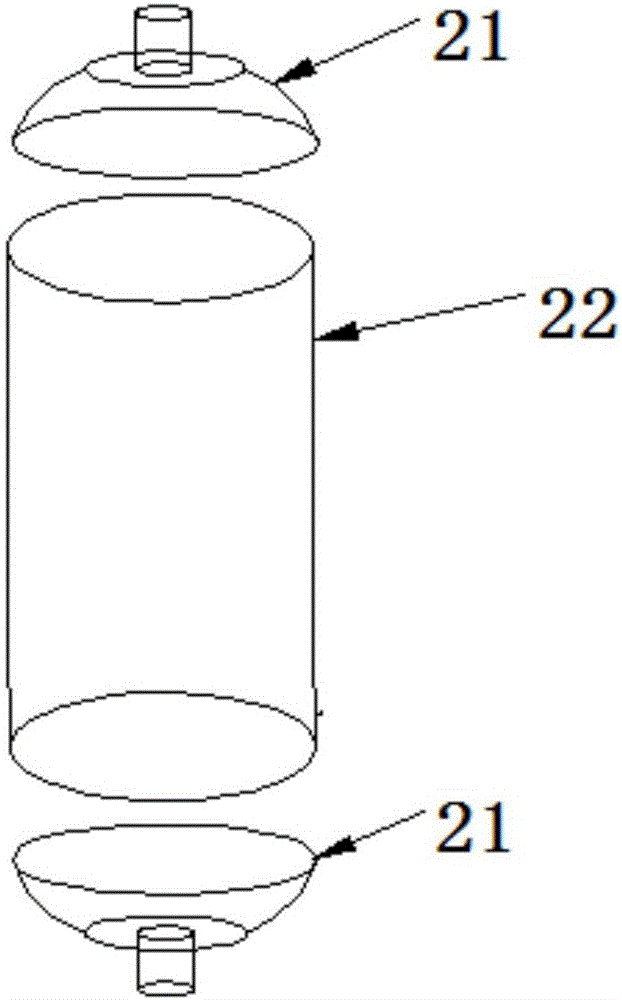

Wide-range multi-particle-size particulate matter parallel collection device

InactiveCN106226132ALow costEasy loading and unloadingWithdrawing sample devicesParticulatesElectronic control system

The invention relates to an atmospheric particulate matter collection device, in particular to a wide-range multi-particle-size particulate matter parallel collection device which comprises a PM10 sampling head, wherein a blank tube connector and five particle matter cutters, namely, PM2.5, PM1.0, PM0.7, PM0.44 and PM0.25 cutters, are respectively connected with the lower end of the PM10 sampling head; the blank tube connector and the five particle matter cutters are respectively connected with a filtering film clamp sampling unit; each filtering film clamp sampling unit is connected with a flow control system and a sampling air pump; the flow control system is connected with an intelligent economic control system. The atmospheric particulate matter collection device provided by the invention, has the characteristic that particulate matters of multiple particle sizes from micron to submicron can be simultaneously captured, and in addition, the parallel collection device with uniform collected sample distribution and high capturing efficiency can be applied to study on climate, environments and healthcare effects of particulate matters of different particle sizes.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

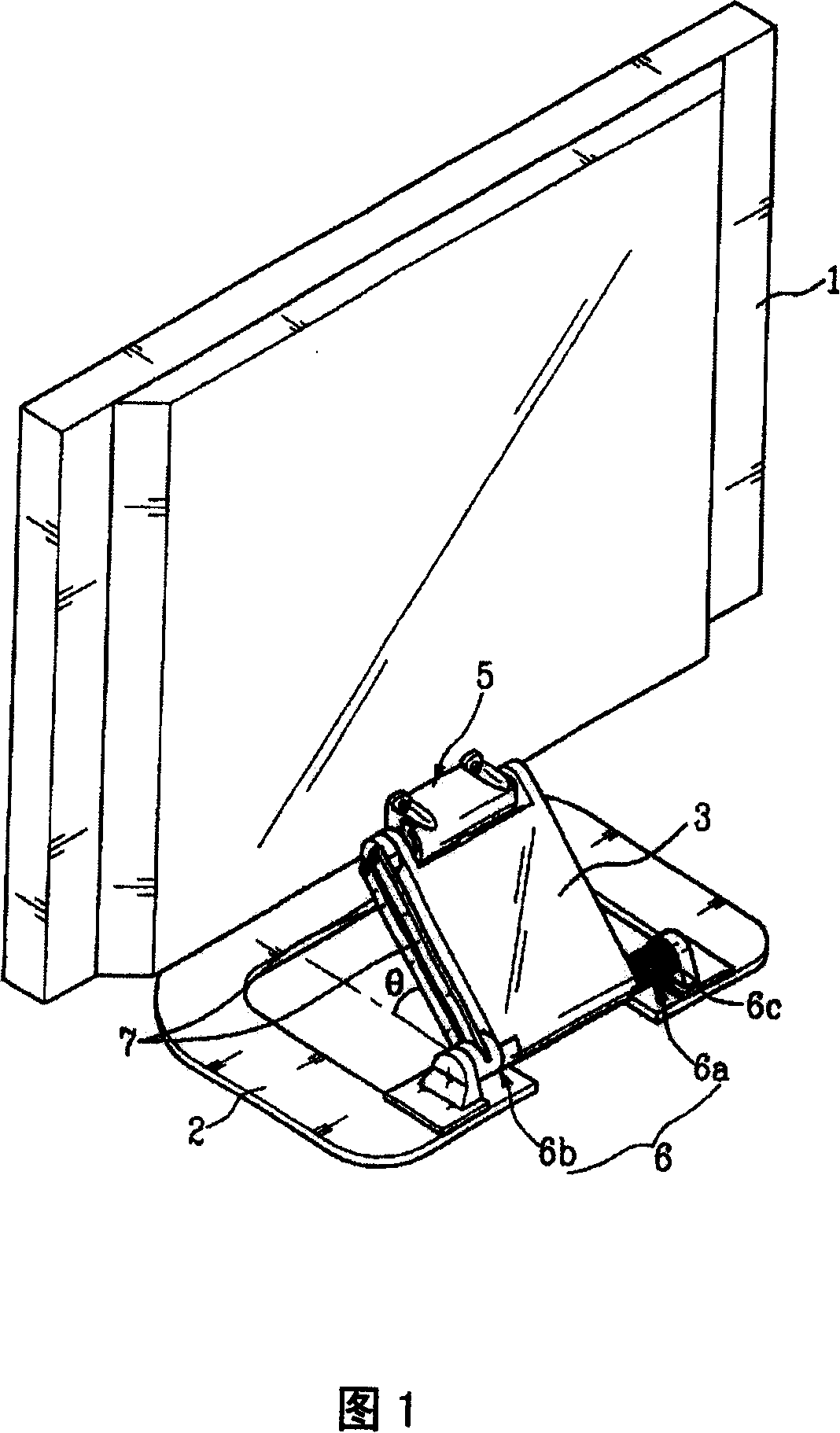

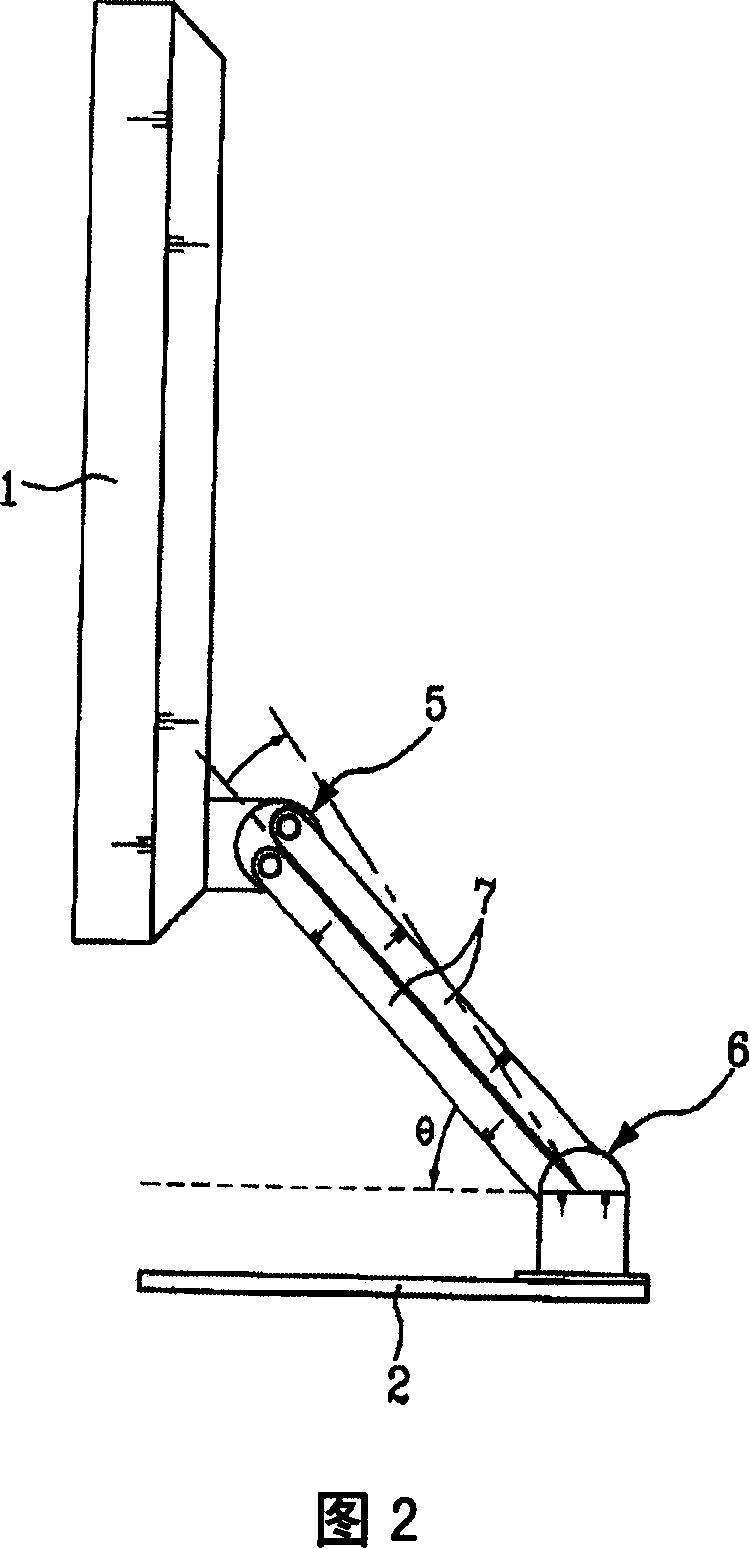

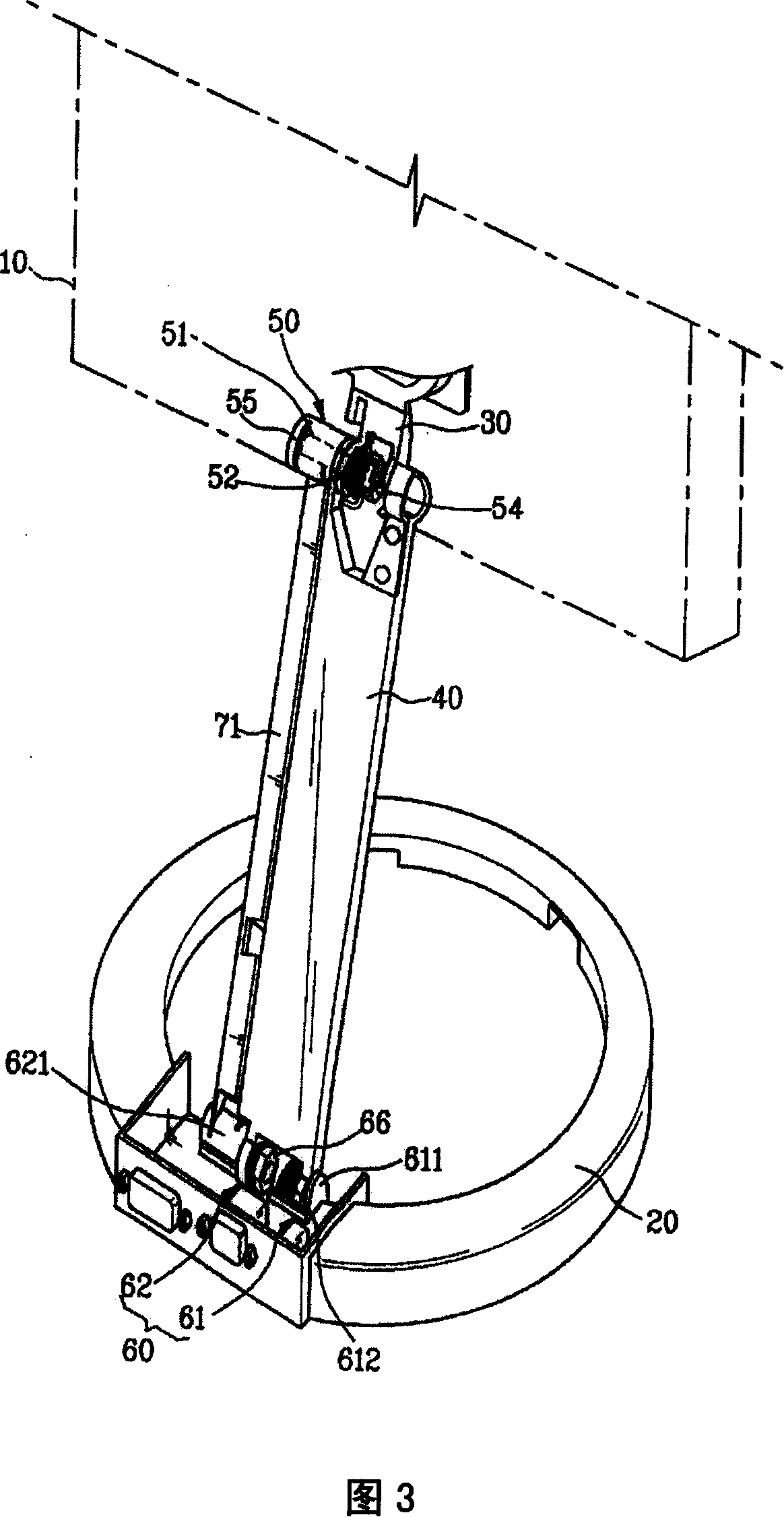

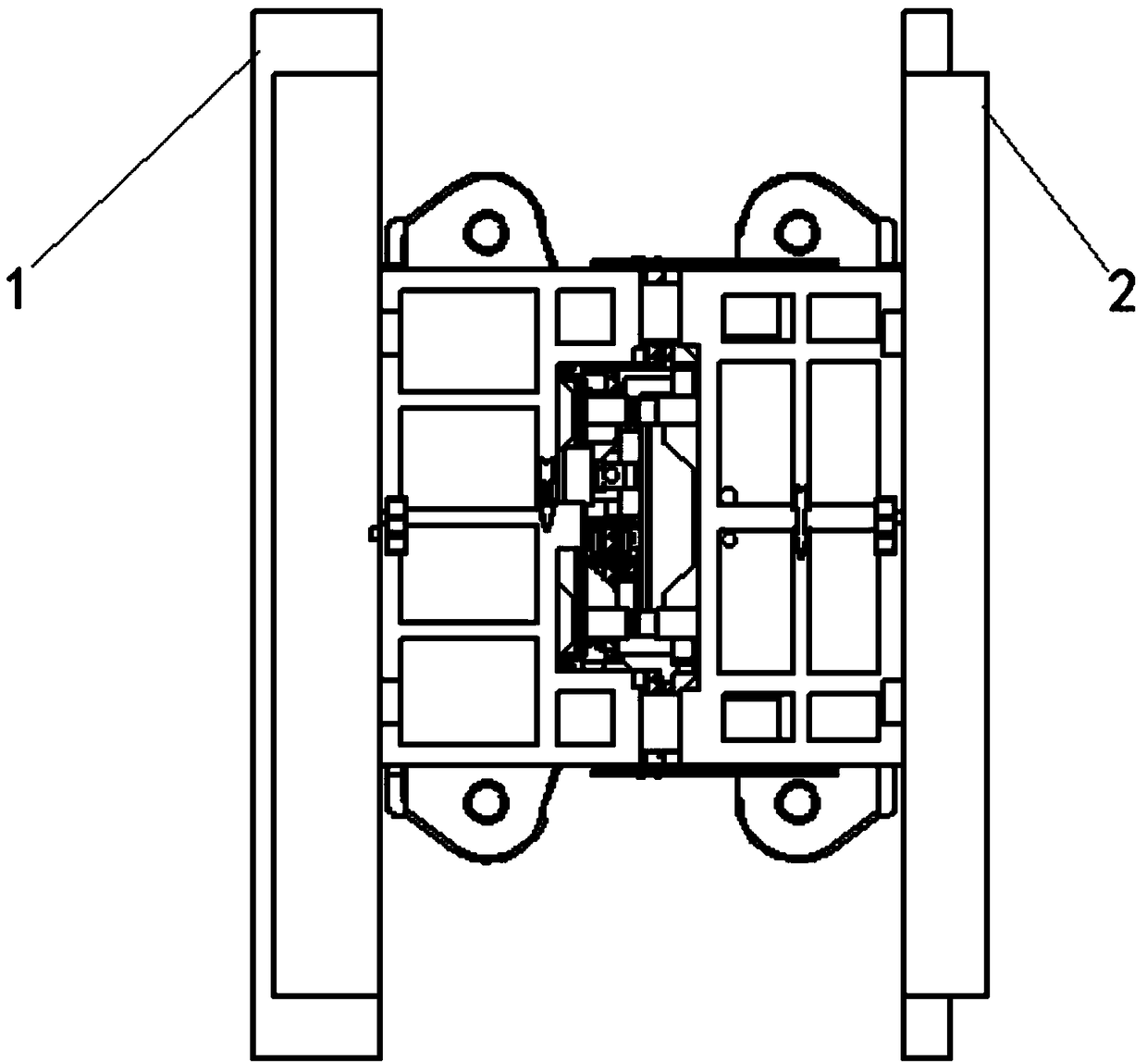

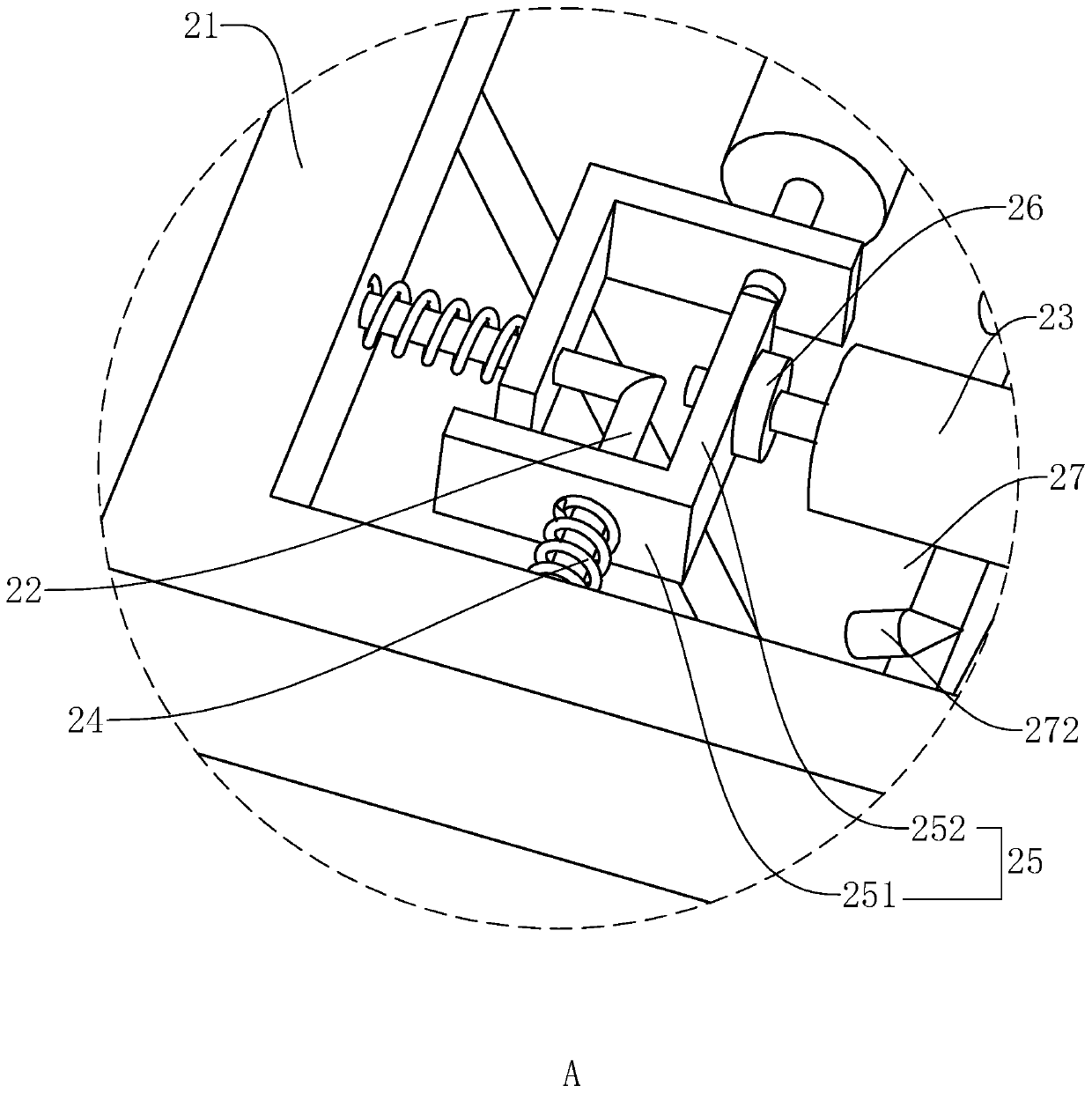

Display hinge device

InactiveCN101149981AEasy to moveEliminate external forceInstrument housingPivotal connectionsDisplay deviceEngineering

The disclosed display comprises a display main body for outputting image, a base fitted on level and supporting the said display main body, a bracket capable rotating whose upper end is connected onto the display main body and its lower end is connected onto the base by using a hinge. It also comprises a rotating shaft which is fixedly connected on the base and used for connecting the lower end throughout the bracket and the base, multiple friction-force-producing components which are fixedly connected onto the rotating shaft and close fit the lower end of the bracket, and a friction-force-changing device for increasing the friction force between the bracket and the friction-force-producing component in a defined angle range while the bracket rotating, with the rotating shaft as center, relative to the base.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

Bendable organic imitation steel fiber

InactiveCN102051704AImprove toughnessImprove impact resistanceMonocomponent polyolefin artificial filamentFiberHardness

The invention relates to a bendable organic imitation steel fiber for building concrete. The preparation method of the bendable organic imitation steel fiber comprises the following steps of: adding a stiffness enhancing agent, a reinforcing agent, a lubricating agent, and the like to polypropylene used as a main raw material for blending; and then carrying out wire drawing with high multiplying power to manufacture a coarse fiber with teeth. The fiber can be used for suppressing a plastic shrinkage microcrack of cement mortar and concrete and improving the strength and the toughness of a cement product, and because the added stiffness enhancing agent forms a structure coupling hardness with softness together with the polypropylene, the fiber overcomes the defects of large elasticity and difficult bending of a pure polypropylene organic imitation steel fiber.

Owner:李群胜

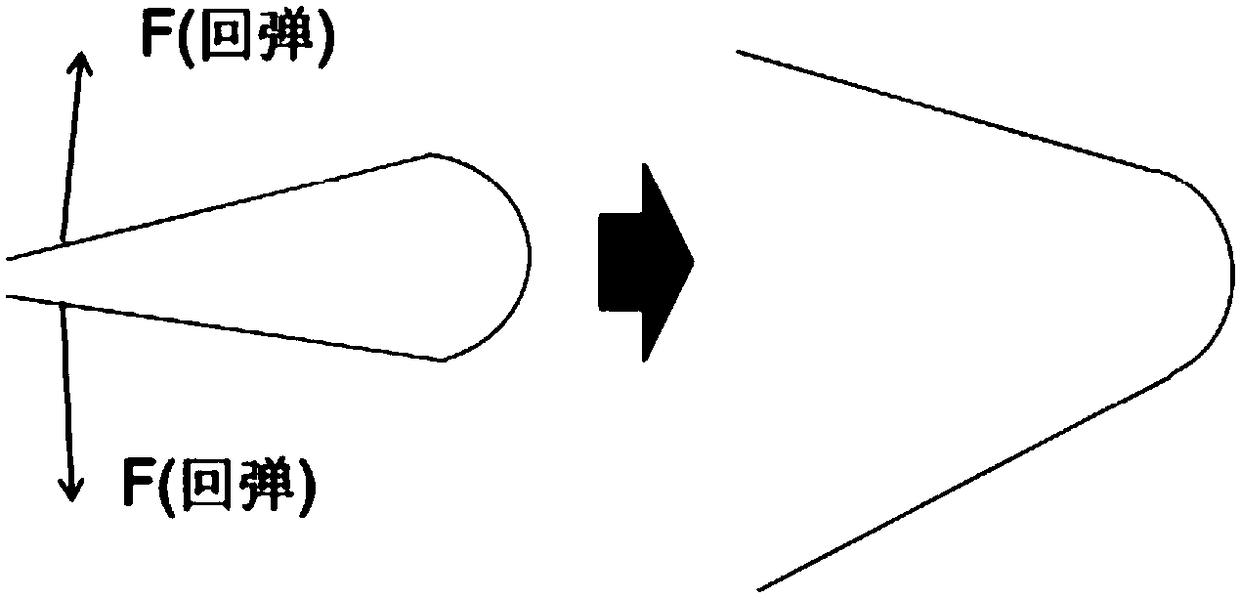

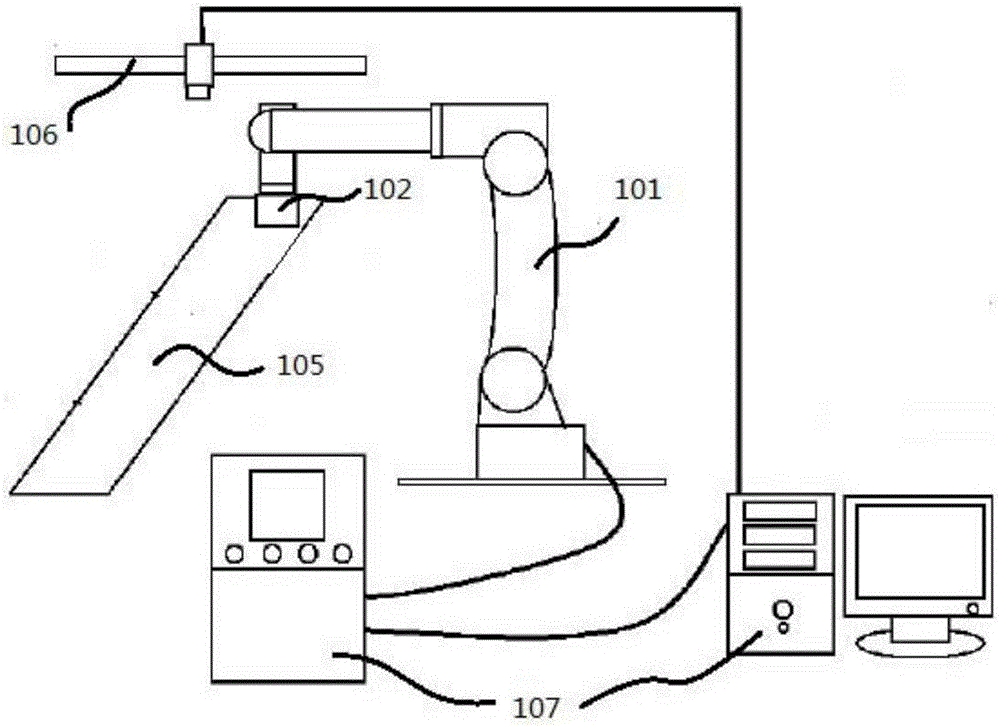

A system to solve the springback phenomenon in the process of laying up composite materials

ActiveCN105128363BQuality assuranceAvoid rebound phenomenonThree dimensional morphologyQuality control

The invention relates to a system for solving a springback phenomenon in a composite material laying process, and the system based on a torque / force sensor and a three-dimensional morphology measurement system is used for solving the springback phenomenon of a prepreg tape in the composite material laying process. Based on six-axis robot platform, motion control on a tape laying head is achieved easily; a joint of the tail end of a robot and the tape laying head is provided with the torque / force sensor, the pressure of a main press roller of the tape laying head is detected real-timely, and constant-pressure laying is ensured as far as possible to be used for preventing generation of the springback phenomenon; the three-dimensional morpography measurement system is equipped, a workpiece contour is reconstructed, and a video detection technology is used for quality control of the composite material laying process; the original tape laying head is equipped with an auxiliary compaction device and an auxiliary heating system, under heating of the auxiliary heating system, the auxiliary compaction device can recompact the prepreg tape of regions generating the springback phenomenon, and the probability of springback phenomenon generation is reduced to the minimum, so as to realize full-automatic laying with high quality and high efficiency.

Owner:WUHAN UNIV

Pipe semi-solid air pressure contact forming method

The invention relates to a pipe semi-solid air pressure contact forming method, and relates to a metal pipe internal bulging process method. The invention aims to solve problems that due to the fact that the existing pipe machining method requires that yield strength and thickness of the pipe can not be too high, and thus the existing pipe machining method can not be applied to materials with poorplasticity; the existing pipe machining method is not suitable for forming parts with complex shapes, and forming equipment is large in tonnage. The method comprises the step 1 of placing the pipe ina mold cavity of a forming mold, closing the forming mold and sealing the pipe; the step 2 of heating the pipe to a semi-solid temperature and preserving heat; the step 3 of continuously feeding airinto the inner of the pipe until the outer wall of the pipe is attached to the mold cavity of the forming mold; the step 4 of stopping the heating of the pipe and discharging the air; and step 5 of opening the forming mold, taking out the formed pipe from the mold cavity, and namely the pipe semi-solid air pressure contact forming method is completed. The invention is used for the pipe semi-solidair pressure contact forming.

Owner:HARBIN INST OF TECH

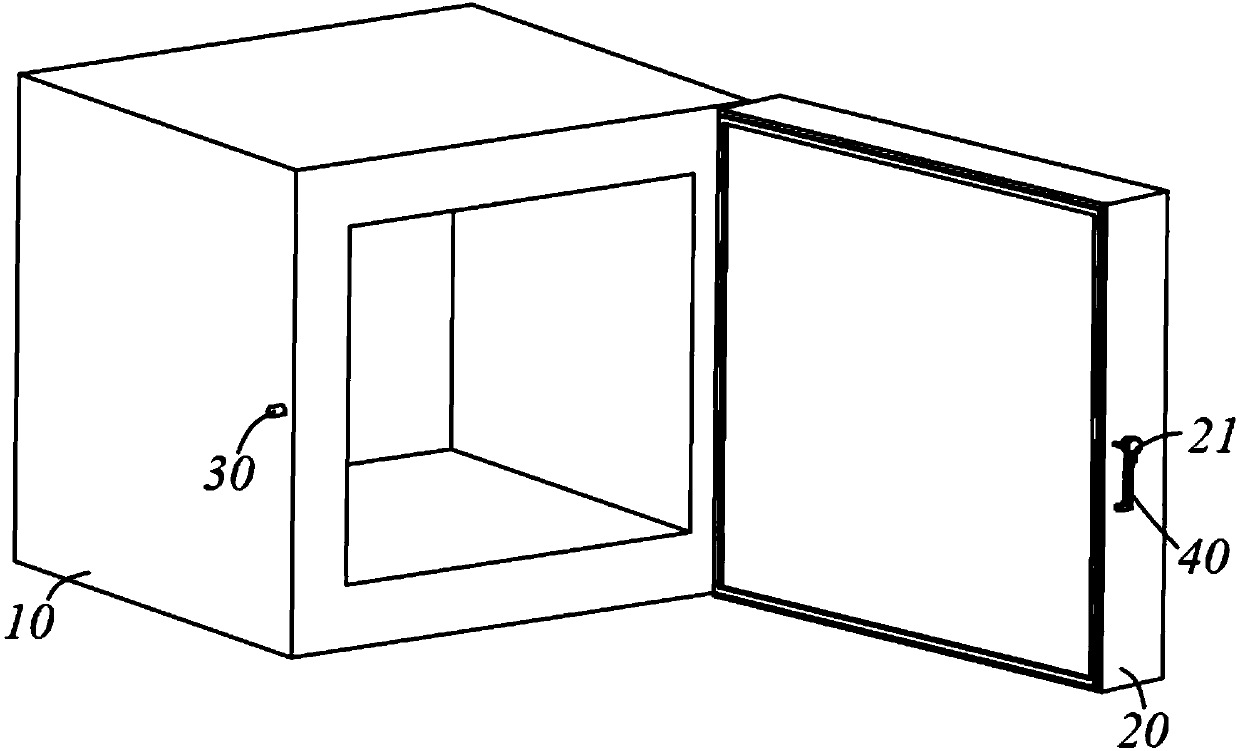

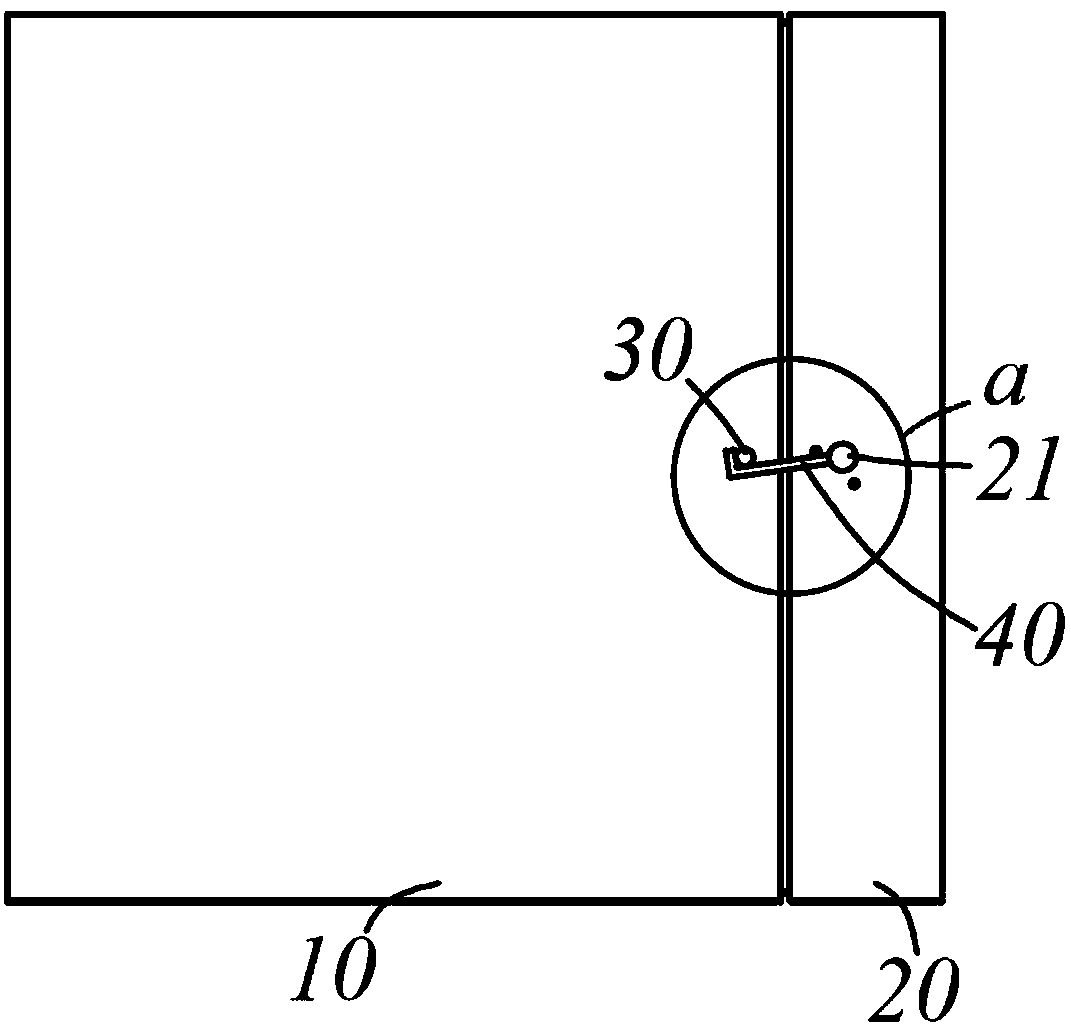

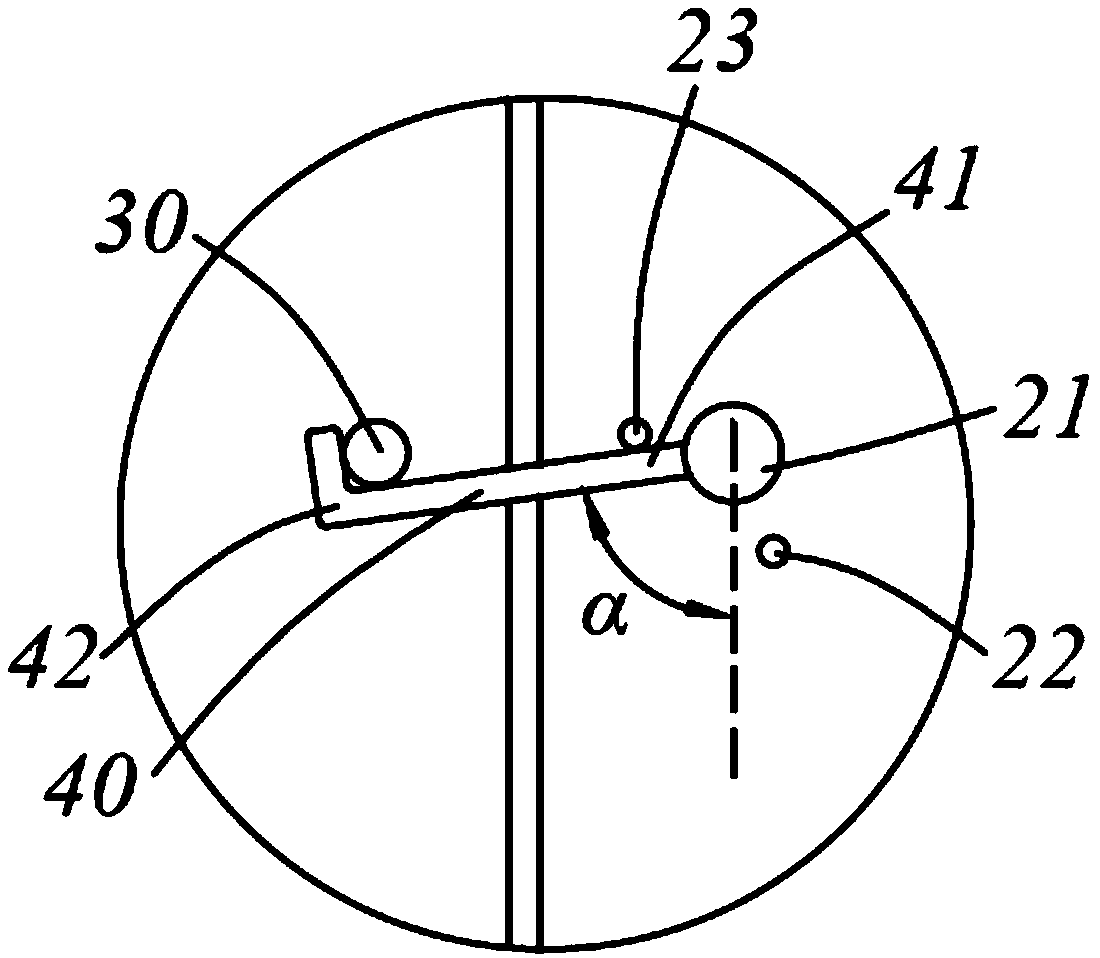

Door body locking device and refrigerator with same

ActiveCN107700988ACompact structureLow costDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a door body locking device. The door body locking device comprises a limiting piece installed on a refrigerator body and a positioning piece installed on a refrigerator door body, the positioning piece can pivot relative to the refrigerator door body, at the moment that the refrigerator door body is closed, the positioning piece pivot in the first direction under the inertia effect to be connected with the limiting piece in a clamped manner, and the refrigerator door body is in the locking state relative to the refrigerator body; and after the refrigerator door body isclosed, the positioning piece pivots in the second direction opposite to the first direction under the inertia effect to break away from the limiting piece, and the refrigerator door body is in the unlocking state relative to the refrigerator body. The invention further discloses a refrigerator with the above door body locking device. According to the embodiment manner, the door body locking device can prevent the rebounding phenomenon generated when the refrigerator door body is closed, the refrigerator door body is smooth and free of resistance when being opened or closed, and the user experience is not influenced.

Owner:HAIER SMART HOME CO LTD

Die forming process for automobile frame longitudinal girders

InactiveCN108856483AAvoid rebound phenomenonImprove pass rateLoad-supporting pillarsVehicle componentsCompression moldingPunching

The invention discloses a die forming process for automobile frame longitudinal girders. The process includes the following steps that mounting of a lower die is finished; mounting of an upper die isfinished; matched mounting of the upper die and the lower die is finished; blanking-punching is performed; pre-bending is performed; flanging forming is performed; and finally, side shaping, punchingand side punching machining are performed on a sheet metal part. By means of the die forming process for the automobile frame longitudinal girder, the rebound phenomenon is prevented from occurring during upper die and lower die compression molding, the qualified rate of products is improved, the service life of the products is prolonged, zero deflection exists in the forming positions of the formed longitudinal girders, gaps of girder combining operation and between a front transverse girder and a rear transverse girder are very small, the quality requirement is met, the production efficiencyis improved, the assembling time is shortened, and the working difficulty is lowered.

Owner:CHUZHOU UNIV +1

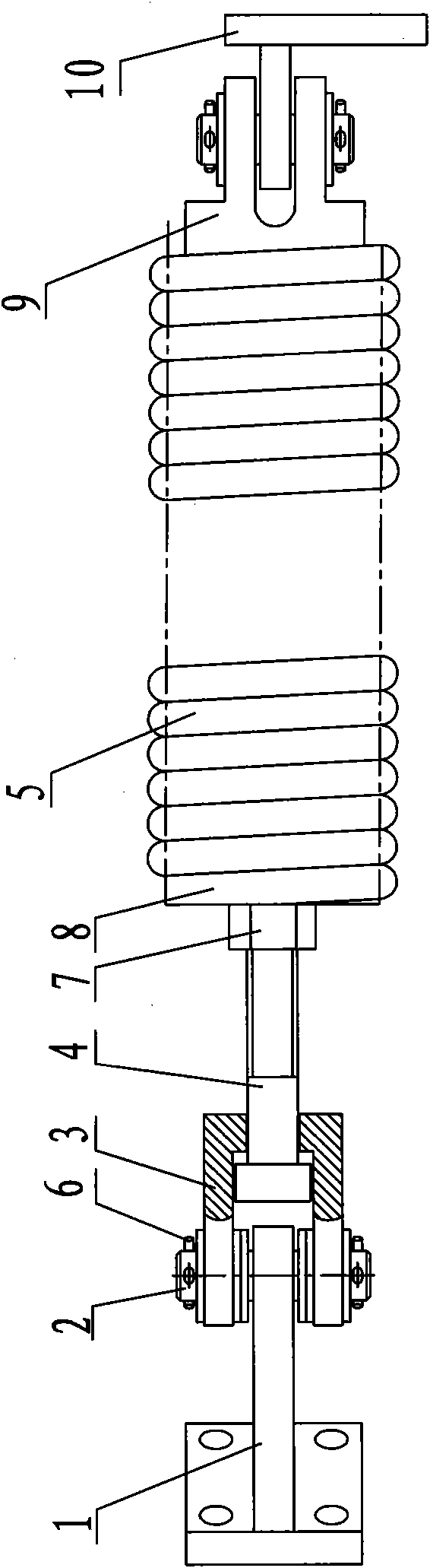

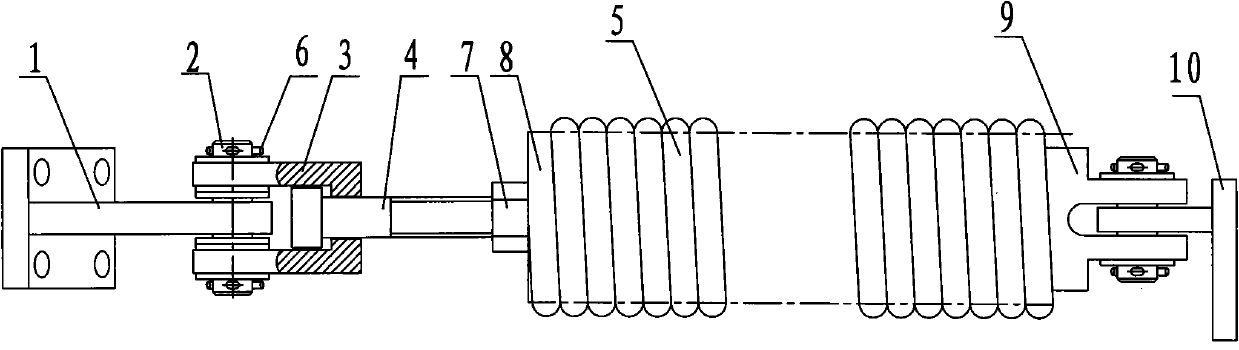

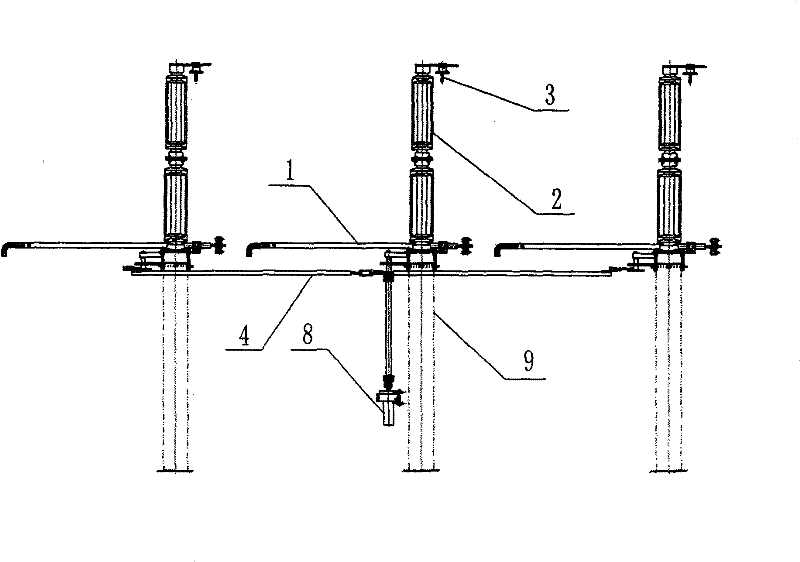

Connection structure of tension spring type balance spring of double-arm folding type high-voltage alternating current isolating switch

InactiveCN102005329AForce balanceGuaranteed synchronicityHigh-tension/heavy-dress switchesAir-break switchesArm foldingAC - Alternating current

The invention relates to a connection structure of a tension spring type balance spring of a double-arm folding type high-voltage alternating current isolating switch. The connection structure comprises a crank arm, a tension spring, an adjusting joint, an adjusting screw rod and the like, wherein the adjusting joint is an 'n'-shaped frame; the opening end of the adjusting joint is hinged with the crank arm through an axle pin; a through hole for the rod part of the adjusting screw rod to pass through is formed at the other end, opposite to the opening end, of the adjusting joint; the head part of the adjusting screw rod is positioned in the 'n'-shaped frame; an axial gap is reserved between the head part of the adjusting screw rod and the adjusting joint; the rod part of the adjusting screw rod extends out of the through hole of the adjusting joint to be spirally connected with the tension spring; and the other end of the tension spring is hinged with a fixed support. The connection structure effectively avoids the rebound phenomenon in the on / off process of a main knife switch, balances the applied force of the tension spring and is stretched stably. The connection structure hasthe characteristics of reasonable structure, good balance effect of the tension spring, stable action, high reliability and the like.

Owner:山东泰开隔离开关有限公司

Punch forming machine for metal mesh enclosure of range hood

InactiveCN112808830AAvoid driftingAvoid wastingMetal-working feeding devicesPositioning devicesPunchingStructural engineering

The invention relates to a punch forming machine for a metal mesh enclosure of a range hood. The punch forming machine for the metal mesh enclosure of the range hood comprises a placing plate, a forming device, clamping devices and a profiling device, wherein the forming device is installed in the middle of the upper end of the placing plate; and the multiple clamping devices are evenly arranged on the outer side of the forming device and installed on the placing plate. The punch forming machine for the metal mesh enclosure of the range hood provided by the invention can solve the problems that when existing equipment conducts punch forming on a stainless steel sheet, the position of the stainless steel sheet cannot be ensured in the punching process, and the stainless steel sheet is likely to deviate due to uneven stress, so that the punching success rate is reduced, material waste is increased, the punching cost is increased; meanwhile, secondary re-pressing cannot be carried out on the metal mesh enclosure subjected to punch forming, so that the punch forming effect is reduced, and the metal mesh enclosure is prone to springback; and in addition, the formed metal mesh enclosure cannot be ejected out, so that manual taking-out is not facilitated, and the punching efficiency is reduced.

Owner:伍晓明

Packing belt and manufacturing process for producing same

The invention discloses a packing belt. The packing belt comprises the compositions of, by weight, 1.4-2.0% of Si, 0.2-0.4% of Fe, 0.15- 0.48% of Cu, 0.55-1.15% of Mn, 0.15-0.45% of Zn, and the balance Al. The invention further discloses a manufacturing process for producing the packing belt. The manufacturing process comprises the following steps that an aluminum alloy with the composition ratiois melt into aluminum liquid, and the aluminum liquid is filtered through a filter plate in multiple layers; the aluminum liquid is cast into an aluminum alloy ingot through a casting machine; segregation inclusions on the surface of the aluminum alloy ingot are milled by using a milling machine; the milled aluminum alloy ingot is placed in an environment with a heat preservation temperature of 500-600 DEG C for heat preservation, and the heat preservation time is 2 to 4 hours; an insulated aluminum alloy ingot is hot rolled into an aluminum alloy coil with a thickness of 4mm to 5mm; the aluminum alloy coil is cold rolled to a thickness of 0.65mm + / - 0.02 mm after multiple cold rolling; and the aluminum alloy coil is cut into packing belts by a slitting machine. The strength of the packingbelts is higher than the strength of adhesive tapes and canvas tapes, and at the same time, the packing belts have good toughness, and can effectively avoid the rebound phenomenon when in use.

Owner:ALCOA KUNSHAN ALUMINUM PROD COMPANY

Screening device for sponge sand production

The invention relates to a screening device for sponge sand production and relates to the technical field of sponge sand production equipment. The device comprises a machine body, an adjusting guide belt which is arranged on the machine body and connected with a conveying belt used for conveying sponge sand, an output guide belt arranged on the machine body and a recognition assembly arranged on the machine body, wherein the adjusting guide belt is rotationally connected with the machine body, when the adjusting guide belt rotates, a shunting opening allowing inferior-quality products to penetrate through is formed between the adjusting guide belt and the output guide belt, a driving assembly is arranged on the machine body, when the recognition assembly recognizes that inferior-quality products pass through the adjusting guide belt, shunting signals are outputted, a controller used for receiving and responding to the shunting signals and controlling the driving assembly to act so as to open the shunting opening is arranged on the machine body, and a recycling assembly used for receiving the inferior-quality products is arranged on the machine body and located below the adjusting guide belt. The device is advantaged in that the workload of operators is reduced so as to reduce labor intensity of the operators.

Owner:深圳市东研磨料磨具有限公司

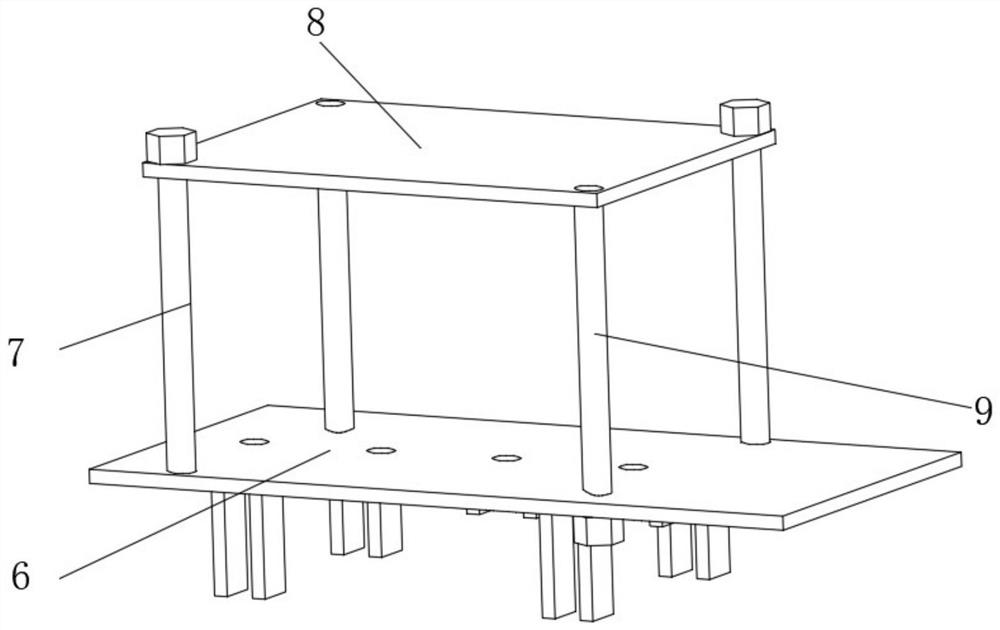

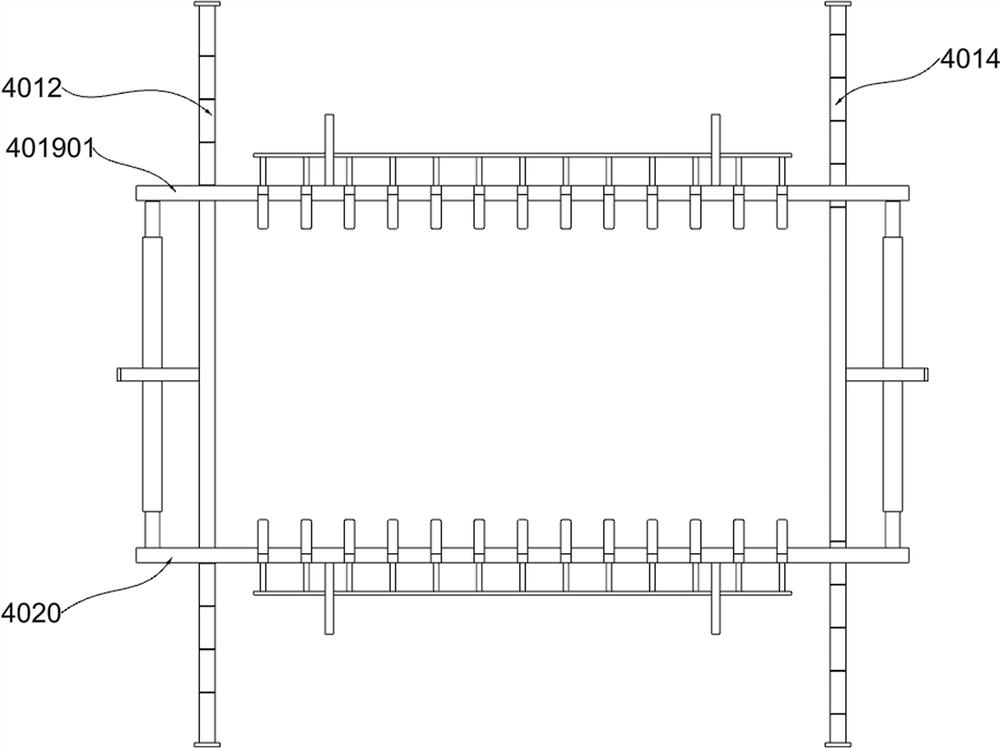

Installation structure of wall surface soft roll and construction method for installing wall surface soft roll

ActiveCN109853884ALow proficiency requirementShorten production timeCovering/liningsFixed frameEngineering

The invention relates to an installation structure of a wall surface soft roll. The installation structure comprises a soft roll panel and a frame-shaped auxiliary tool, wherein the auxiliary tool includes a fixed frame, guide rods, pressing rollers, springs and sliding blocks. The guide rods are fixed to the inner side of the fixed frame, corresponding two guide rods are fixed to each frame edgeof the fixed frame, the sliding blocks sleeve the outer sides of the guide rods and are slidably connected with the guide rods, the pressing rollers are parallel to the frame edges of the fixed frame,and the two ends of the pressing rollers are rotatably connected with the sliding blocks. The springs sleeve the guide rods and the two ends of the springs abut against the fixed frame and the sliding blocks correspondingly, limiting parts are fixed to the ends, away from the fixed frame, of the guide rods, and the springs are in a compressed state. According to the installation structure of thewall surface soft roll, the compression effect of the pressing rollers of the auxiliary tool and edge sealing strips on fabric is adopted, and as the frame gradually moves downwards, the pressing rollers gradually tighten and flatten the fabric, so that the effect of quickly and conveniently tensioning the fabric to enable the fabric to keep flat is achieved; and in addition, the manufacturing method is easy and convenient and easy to operate, the proficiency requirements for installation workers are less, and the manufacturing time of the soft roll can be greatly shortened.

Owner:WENZHOU ZHONGZE BUILDING DECORATION CO LTD

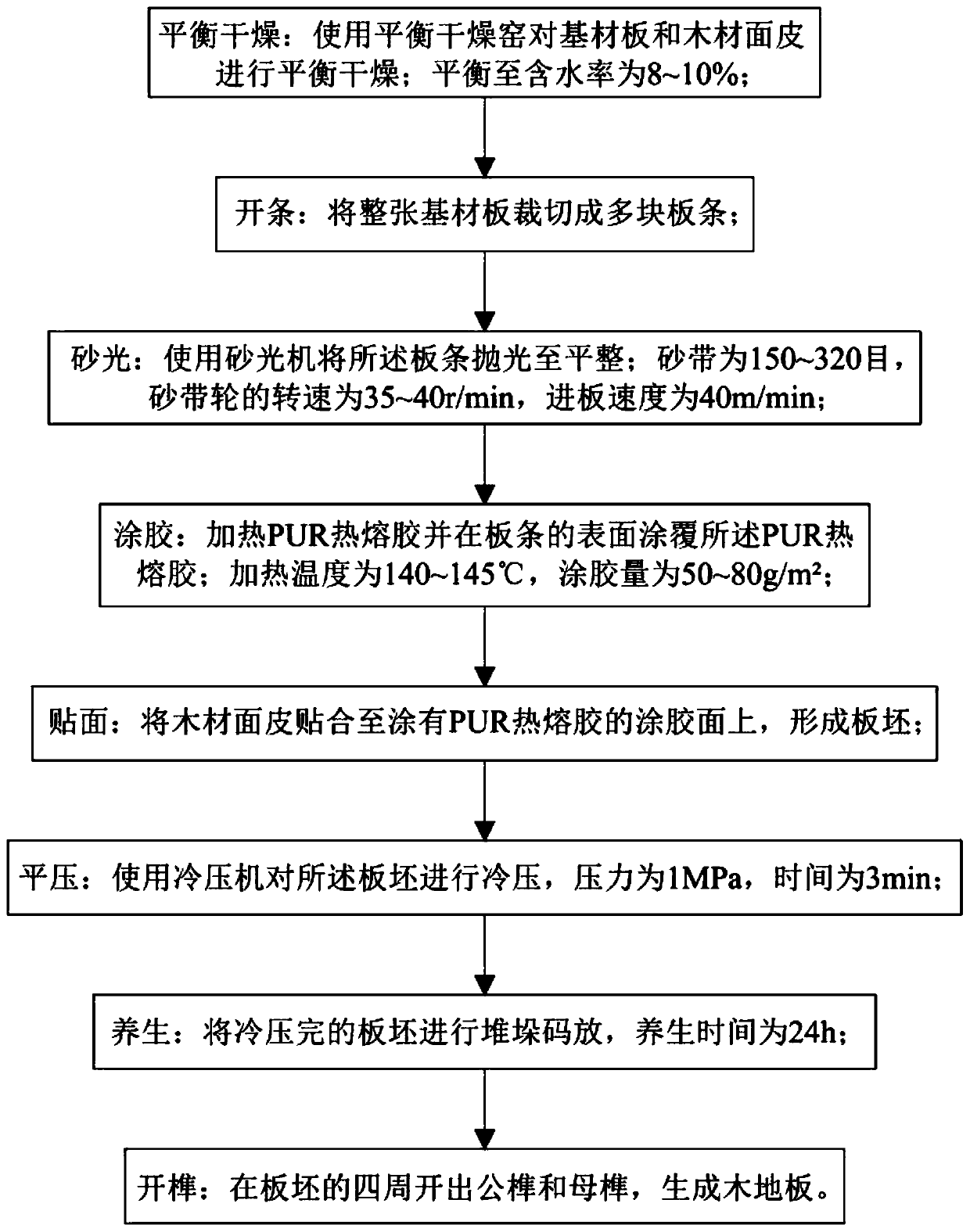

Veneering process suitable for PUR hot melt adhesives

InactiveCN110722646AAvoid deformationAvoid rebound phenomenonWood veneer joiningAdhesive application devicesAdhesive cementSander

The invention relates to the field of solid wood composite floors, in particular to a veneering process suitable for PUR hot melt adhesives. The veneering process comprises the following steps: slitting: whole substrates are cut into multiple battens; sanding: a sanding machine is used for polishing the battens smoothly; an abrasive belt is 150-320 meshes; the rotating speed of an abrasive belt wheel is 35-40 r / min; and the plate feeding speed is 40 m / min; gluing: the PUR hot melt adhesives are heated and coated on the surfaces of the battens; the heating temperature is 140-145 DEG C; and thegluing quantity is 50-80 g / m2; veneering: wood surfaces are bonded on glued surfaces with the PUR hot melt adhesives to form plate blanks; flat pressing: a cold press is used for cold pressing of theplate blanks; the pressure is 1 MPa; and the time is 3 min; and curing: the cold-pressed plate blanks are stacked; and the curing time is 24 h. The veneering process adopts the PUR hot melt adhesivesfor veneering, but not organic adhesives, so that such harmful substances as formaldehyde and benzene cannot be released, and higher environmental protectiveness and safety are achieved.

Owner:BAROQUE WOOD IND ZHONGSHAN CO LTD

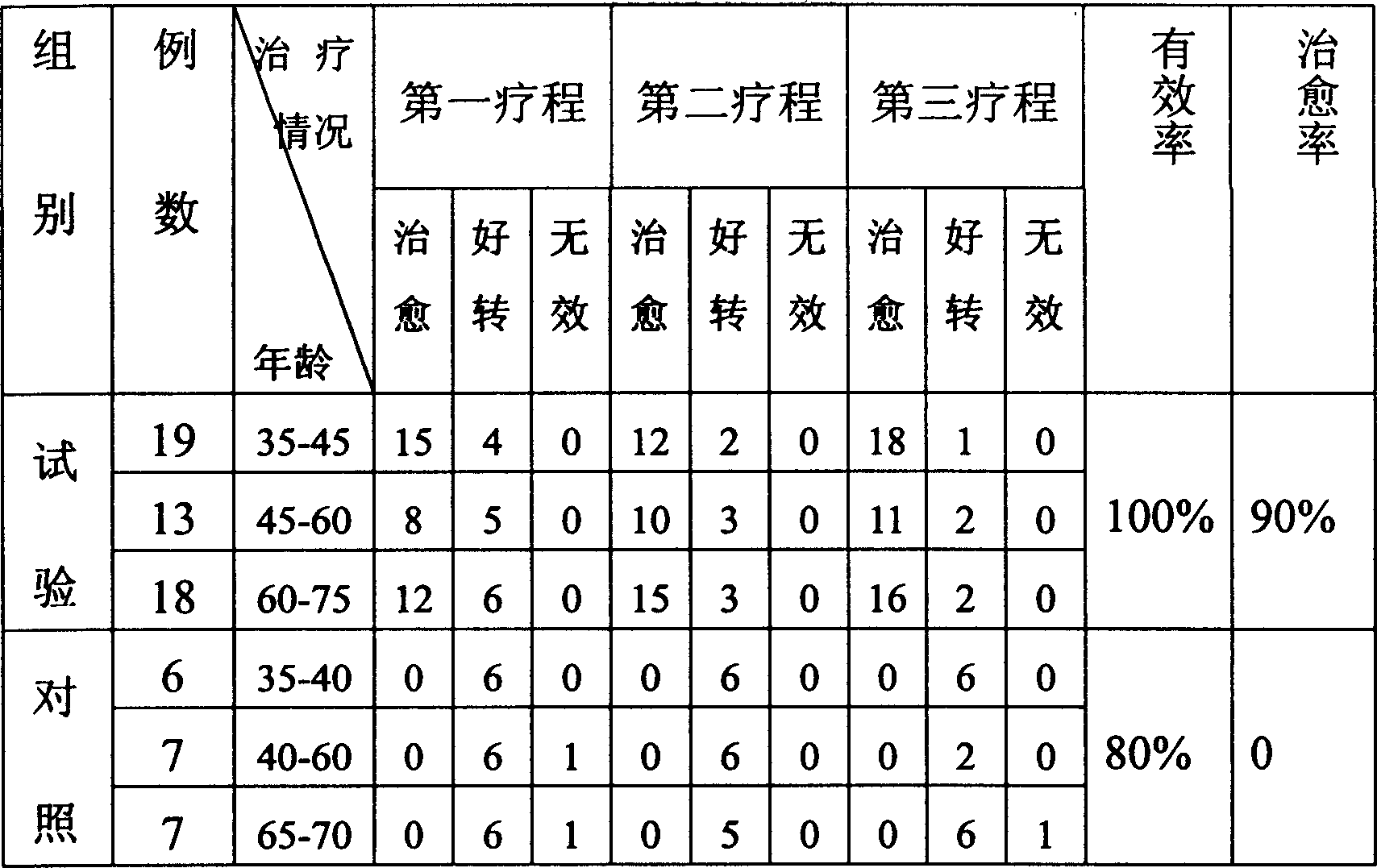

Oral administered medicated wine for treating cardiovascular and cerebrovascular diseases

InactiveCN1557371AGuaranteed ingredientsGood effectMetabolism disorderAlcoholic beverage preparationDiseaseCoronary heart disease

The present invention is medicated wine for treating coronary heart disease, hypertension, hyperlipemia, cerebral thrombosis and other cardiac and cerebral vascular diseases. It is prepared with angelica, prepared rhizome of rehmannia, white peony root, teasel root, malaytea scurfpea fruit and other 27 kinds of Chinese medicinal materials as well as white spirit with alcohol content of 30-60 %. The medicated wine has no high temperature treatment and thus the medicine components well maintained, has high treating effect and small taken amount and may be taken all the year around.

Owner:王根文

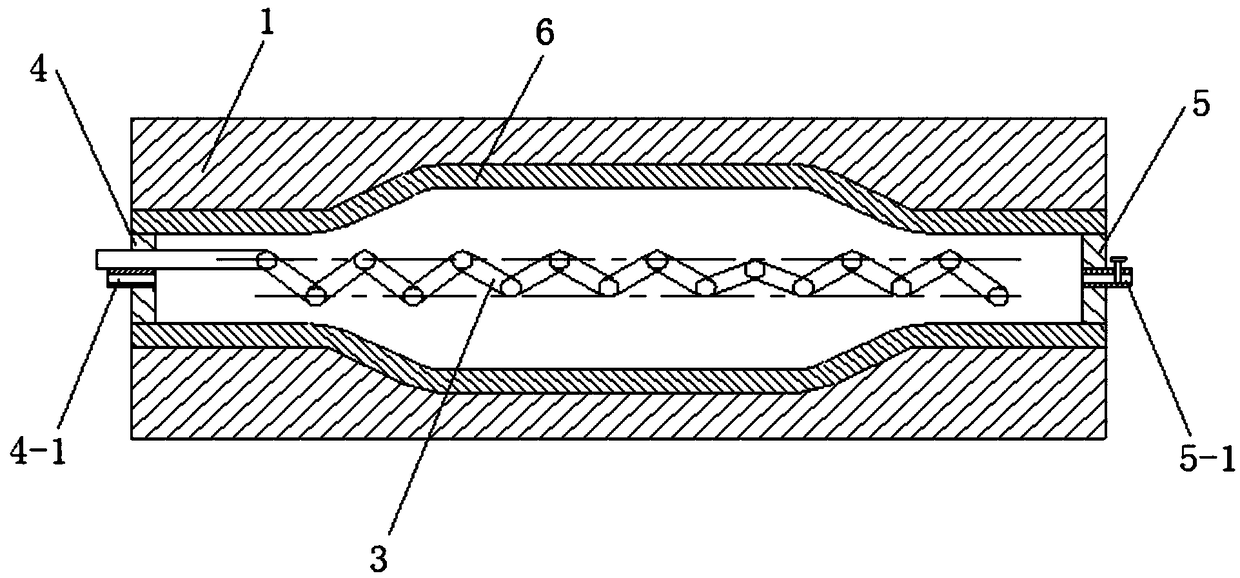

A superplastic forming device and process for a metal bipolar plate of a proton exchange membrane fuel cell

The invention relates to a bipolar plate forming technology, in particular to super-plastic forming device and process of a metal bipolar plate for a proton exchange membrane fuel cell. The device comprises a pressure plate, guide sleeves, springs, guide posts, a pressing rod, an environmental box, an upper template, a lower template, a base, a connection plate, a blank pressing plate, a metal plate and a support rod. The process implemented by the device comprises the following steps: (1) opening the environmental box; (2) fixing a metal sheet of a processed part on the lower template; (3) closing the environmental box, determining the super-plastic forming temperature according to a processed plate and inputting the super-plastic forming temperature into a control system; (4) setting the stroke and the movement rate of the upper template according to the super-plastic strain rate and flow channel shape of the processed plate; (5) starting a circuit system and the environmental box, starting a pressure forming machine to move downwards, and finishing stamping; (6) starting the upper template of a press to reversely return back to the initial position; and (7) opening the environmental box, and cooing and taking out a formed part. According to the super-plastic forming device and process, the material is effectively prevented from rebounding, and the forming accuracy and the dimensional accuracy are ensured.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

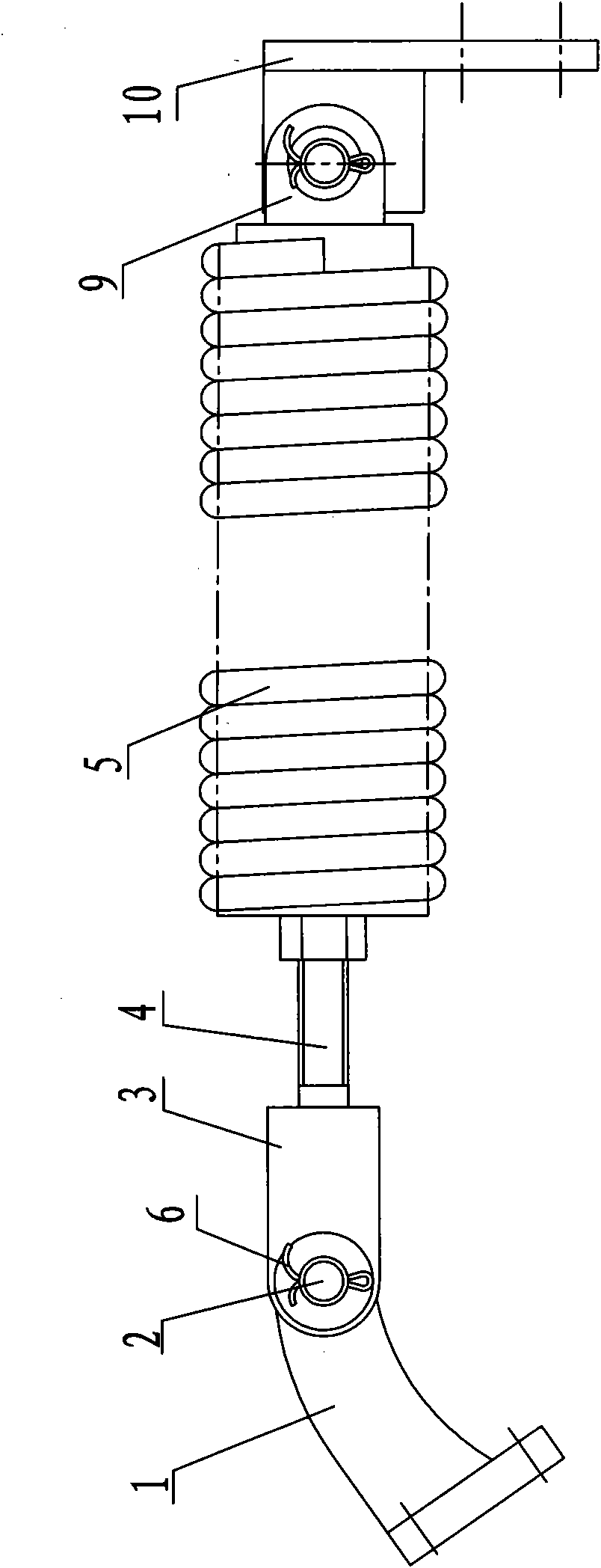

Single columns vertical straight-wheel outdoor high voltage AC earthing switch

InactiveCN101604593BAvoid rebound phenomenonIncrease cooling areaSwitches with movable electrical contactsHorizontal transmissionThree-phase

A straight-wheel outdoor high voltage AC earthing switch with single columns vertical relates to outdoor high voltage electrical apparatuses with three-phase AC of 50Hz and rated voltage of 252kV and below, is used for high voltage electrical apparatus earthing and comprises three single poles; wherein, the single poles are connected by a horizontal transmission rod (4); each single pole comprises a post insulator (2), a static contact (3), a bracket (9), a square board (6), an earthing switchgear rotating shaft (14), a transmission link (10) and an earthing switchgear tube (1); torque generated by an operating mechanism (8) of the mid-phase single pole is transmitted to the earthing switchgear tube (1) for switching closing via the transmission link (10) and the earthing switchgear rotating shaft (14); other two single poles carry out synchronous operation through the horizontal transmission rod (4); a dynamic contact of an earthing switchgear comprises bending boards (15), touch blocks (16) and guard boards (17); the touch blocks (16) are bolted at the inner sides of the bending boards (15); the two bending boards (15) are fixedly connected with the guard boards (17) through fixing bolts; adjustment of the clamping force of the dynamic contact of the earthing switchgear can be realized by adjusting nuts (20) at the outer sides of the bending boards (15). The earthing switch has the characteristics of reasonable structure, reliable and steady switching closing, excellent electrical property, safety, durability and convenient maintenance.

Owner:山东泰开隔离开关有限公司

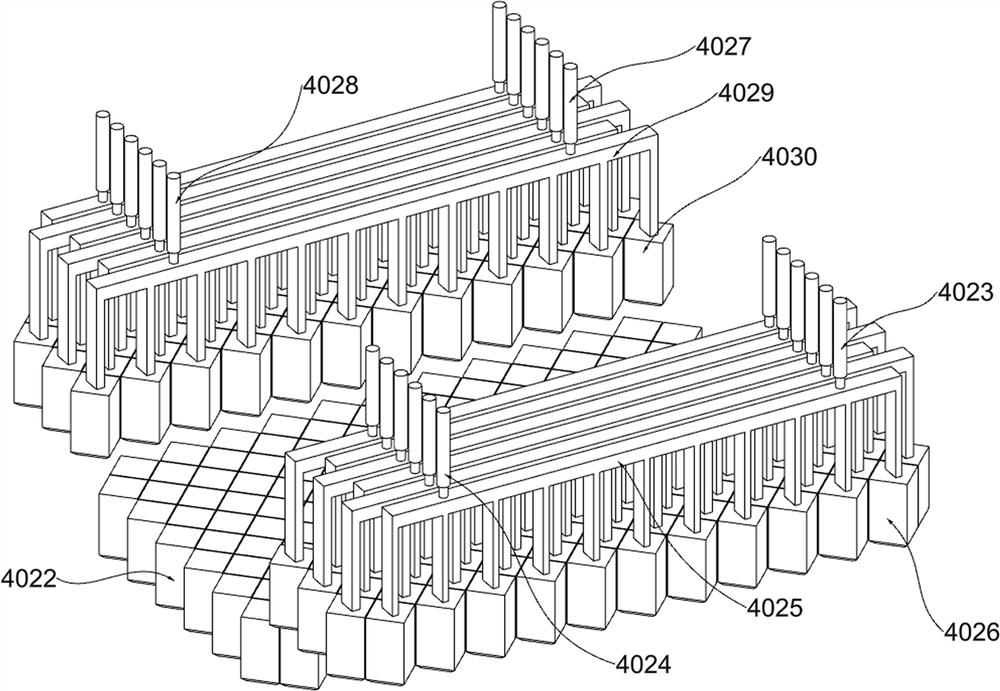

Aluminum alloy creep aging forming equipment

ActiveCN114101472AAvoid rebound phenomenonPrevent rebound phenomenonMetal-working feeding devicesProcess efficiency improvementScrew threadAge forming

The invention discloses aluminum alloy creep aging forming equipment which comprises a fixing mechanism, a mold mechanism and an adjusting mechanism. The mold mechanism is located in the fixing mechanism, and the adjusting mechanism is located on the top of the fixing mechanism. The fixing mechanism comprises a bottom box, the two ends of the bottom box are rotationally connected with first lead screws correspondingly, and the outer walls of the first lead screws are in threaded connection with first sliding blocks; according to the device, aluminum alloys with different widths can be supported and fixed, irreversible deformation of areas, not needing to be subjected to creep forming, of the aluminum alloys is prevented under the conditions of long-time gravity and heating during temperature rise creep deformation, and under the action of a pressing plate and a driving box, the deformation of the areas does not need to be subjected to creep forming. The outer surface of the aluminum alloy plate in the width direction and the length direction can be fixed, so that in the loading process of the aluminum alloy plate, the phenomenon that the loading deformation of the aluminum alloy plate is different from an expected curved surface due to infirm fixation in the width direction and the length direction is prevented.

Owner:INNER MONGOLIA UNIV OF TECH

Geocell laying device capable of adapting to multiple cell numbers and used for land treatment

InactiveCN113463612AAvoid wrinklesAvoid scratchesSoil preservationSoil scienceAgricultural engineering

Owner:王建军

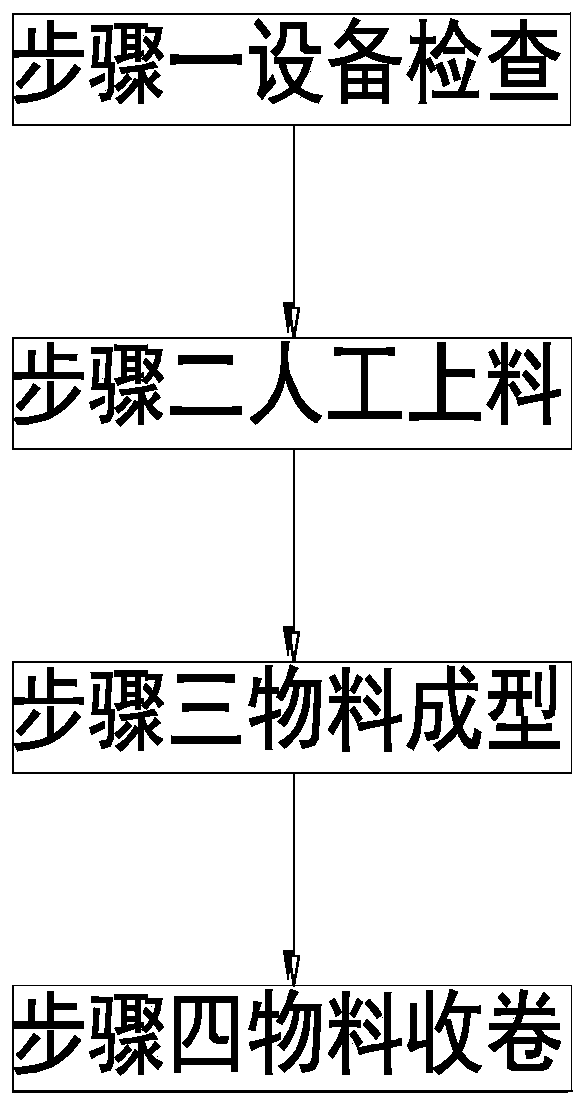

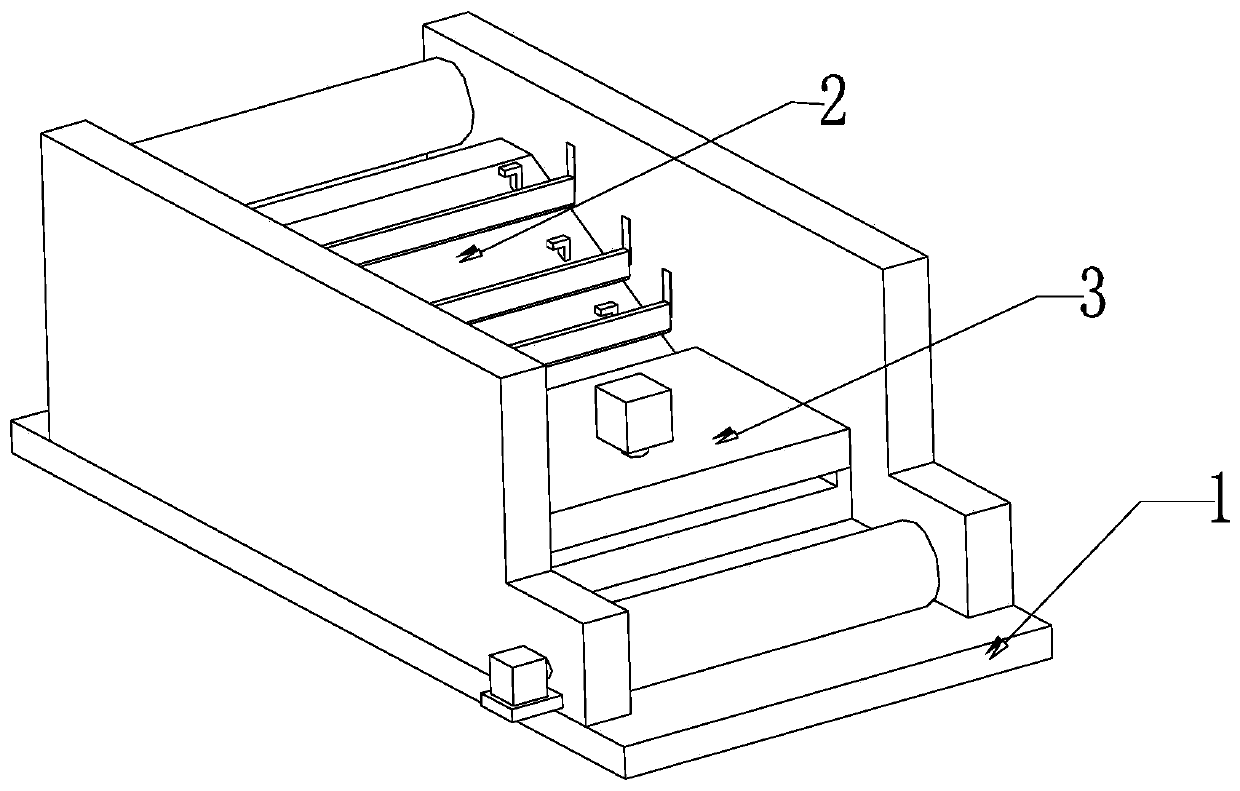

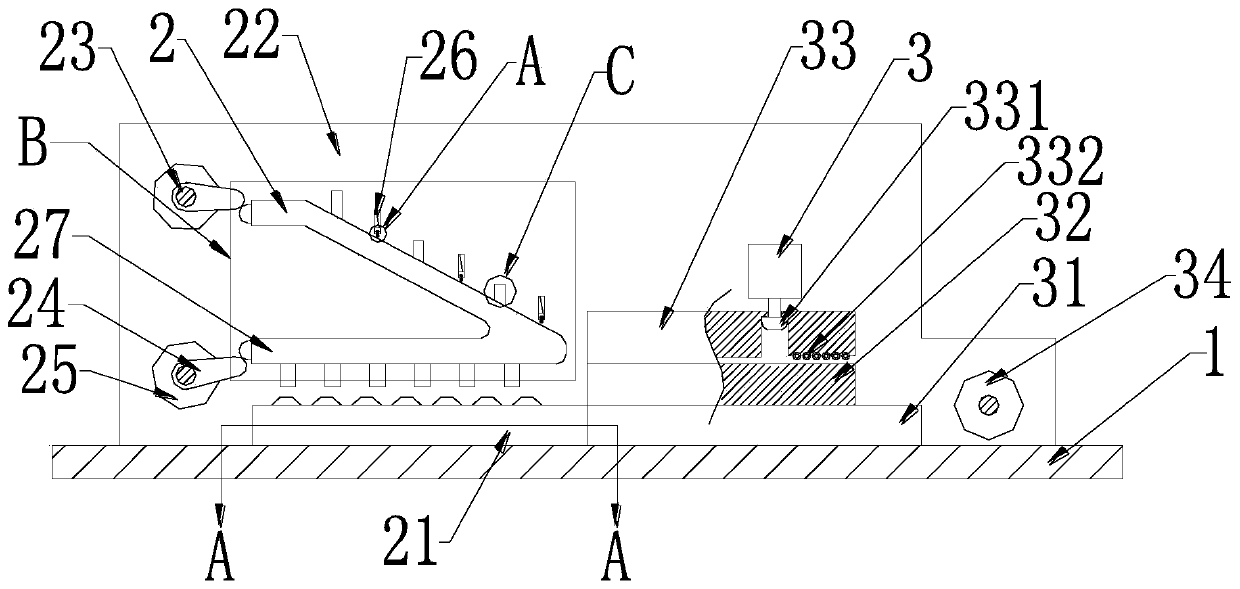

Plastic woven bag forming manufacturing method

The invention relates to a plastic woven bag forming and manufacturing method. The method mainly comprises the following steps of equipment detection, manual feeding, material forming and material rolling, a plastic woven bag forming device comprises a mounting frame, a guide suite and a material receiving suite, the guide suite is mounted on the mounting frame, the material receiving suite is mounted on the inner side of the guide suite, and the material receiving suite is mounted on the mounting frame. The method can solve the following problems existing when an existing plastic woven bag isformed and manufactured that a, when the existing woven bag is formed and manufactured, the phenomenon that the upper surface and the lower surface of the plastic woven bag are not aligned due to elastic resilience often occurs, therefore, the phenomenon of missing sewing of subsequently produced plastic bags occurs, a large number of defective products are produced, and the cost is increased; and b, when the existing woven bag is formed and manufactured, the phenomenon that the upper face and the lower face of a woven bag deform or overlap in the conveying process frequently occurs, productquality is seriously affected, and cost is wasted.

Owner:何欣悦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com